Patents

Literature

248 results about "Foamcore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foamcore, foam board, or paper-faced foam board is a lightweight and easily cut material used for mounting of photographic prints, as backing for picture framing, for making scale models, and in painting. It consists of a board of polystyrene foam clad with an outer facing of paper on either side, typically white clay-coated paper or brown kraft paper.

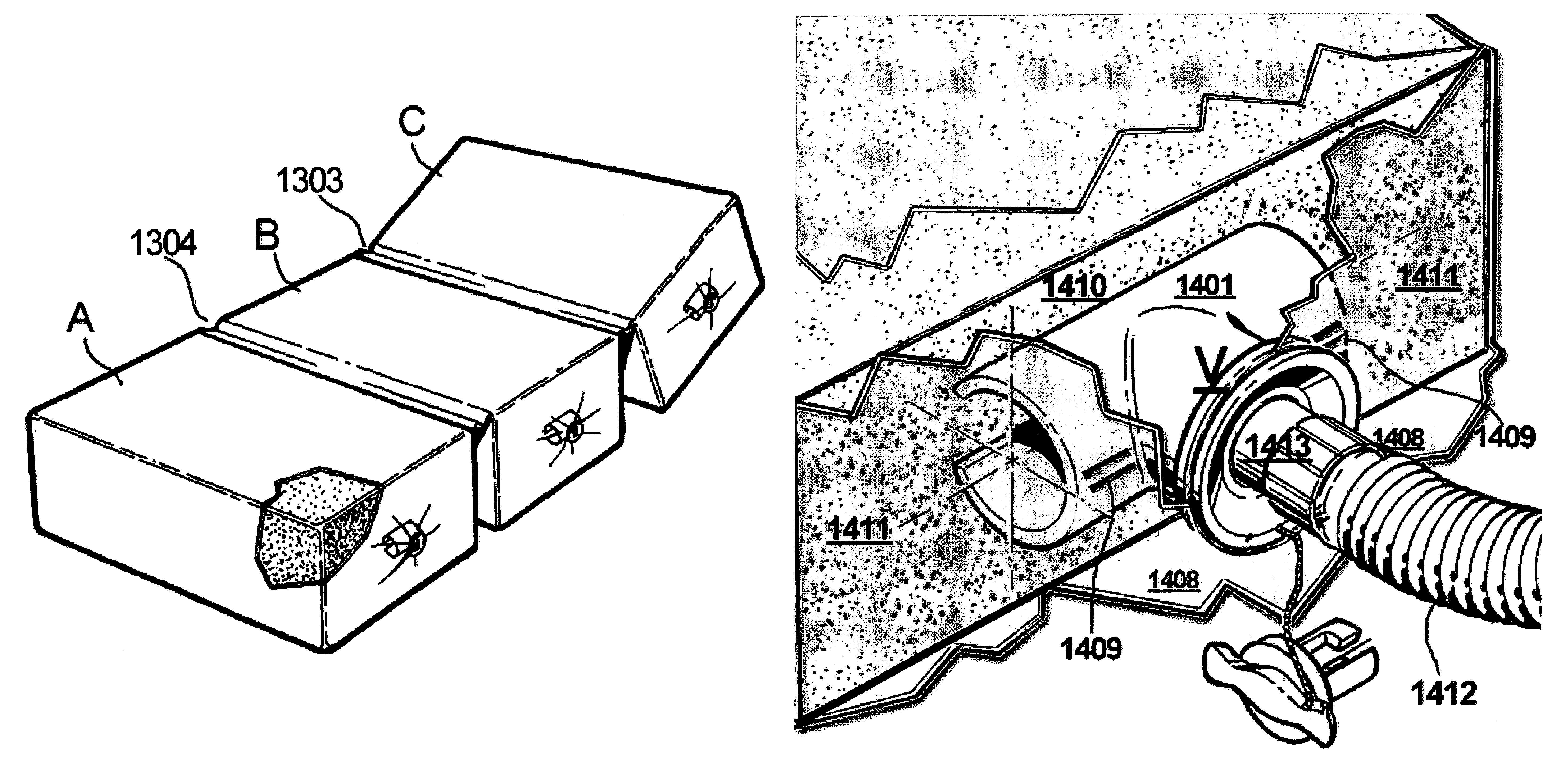

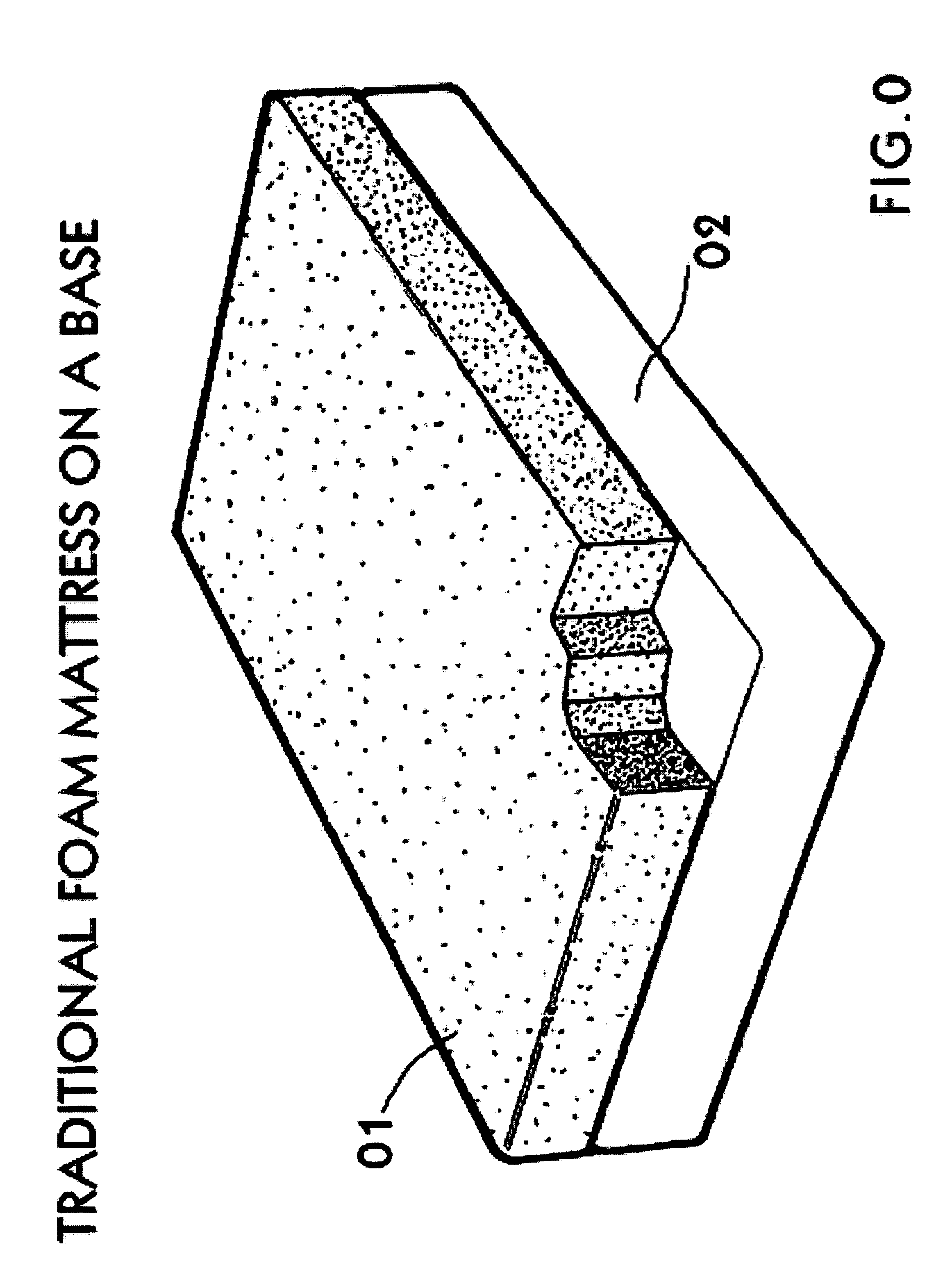

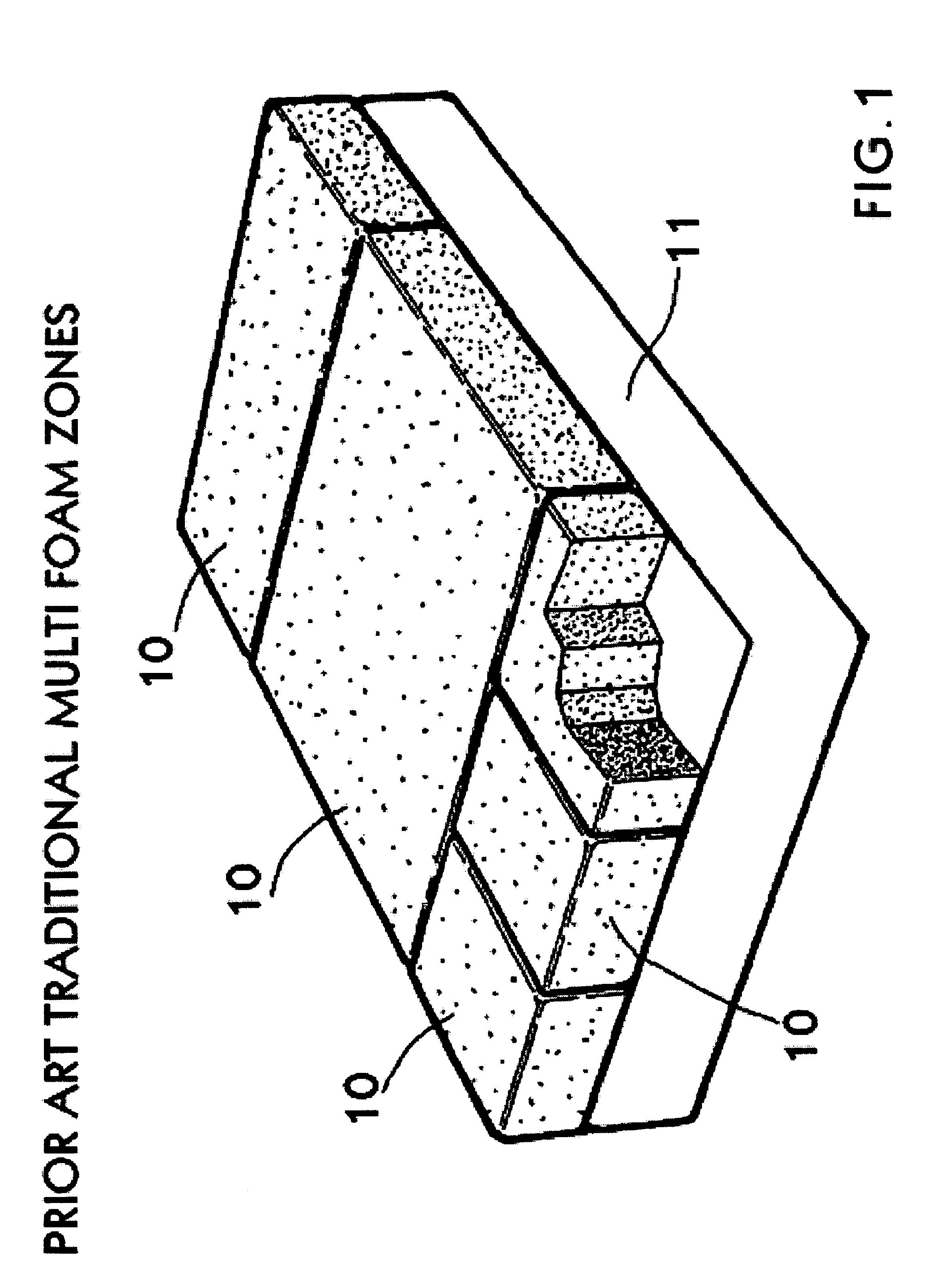

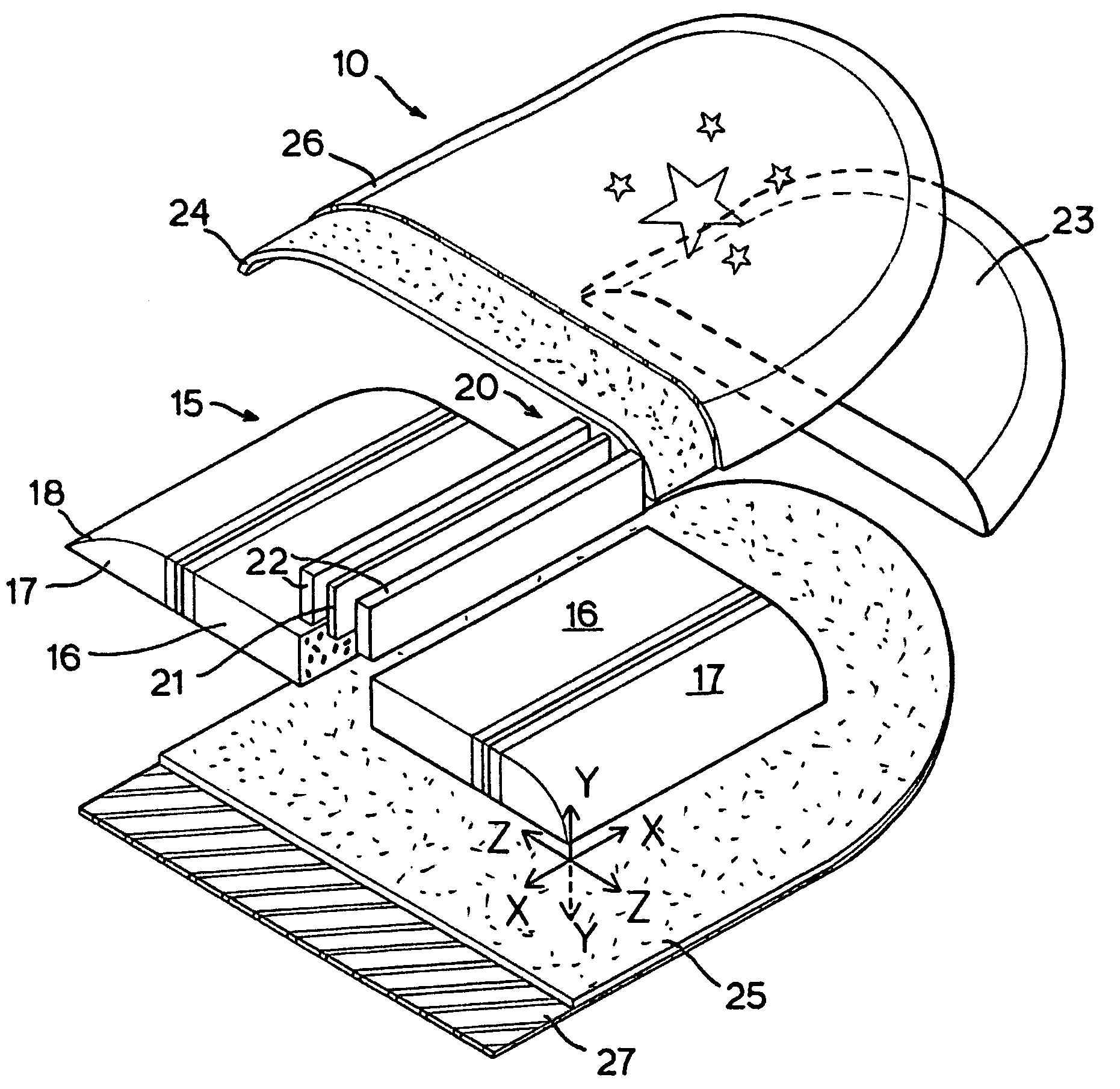

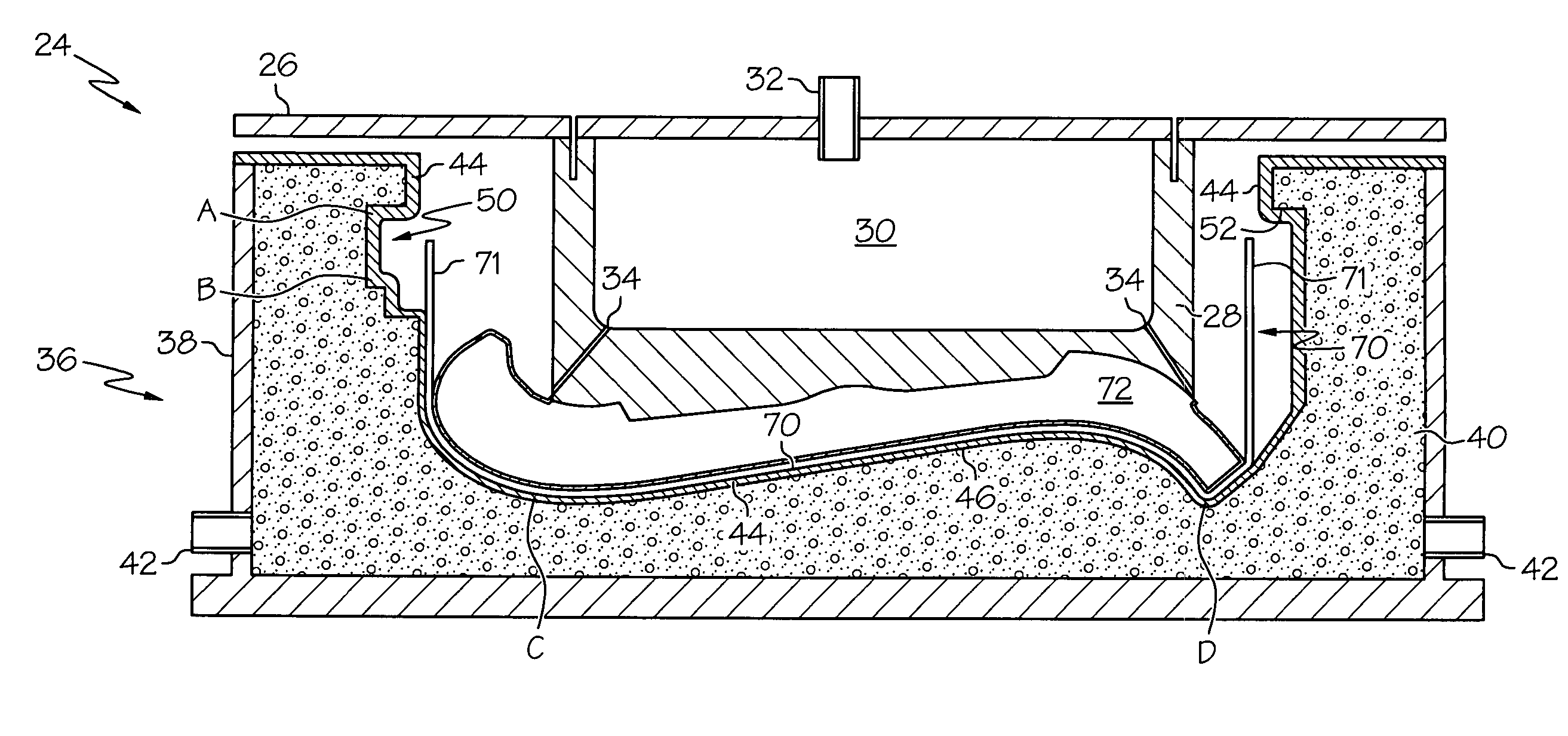

Adjustable foam mattress

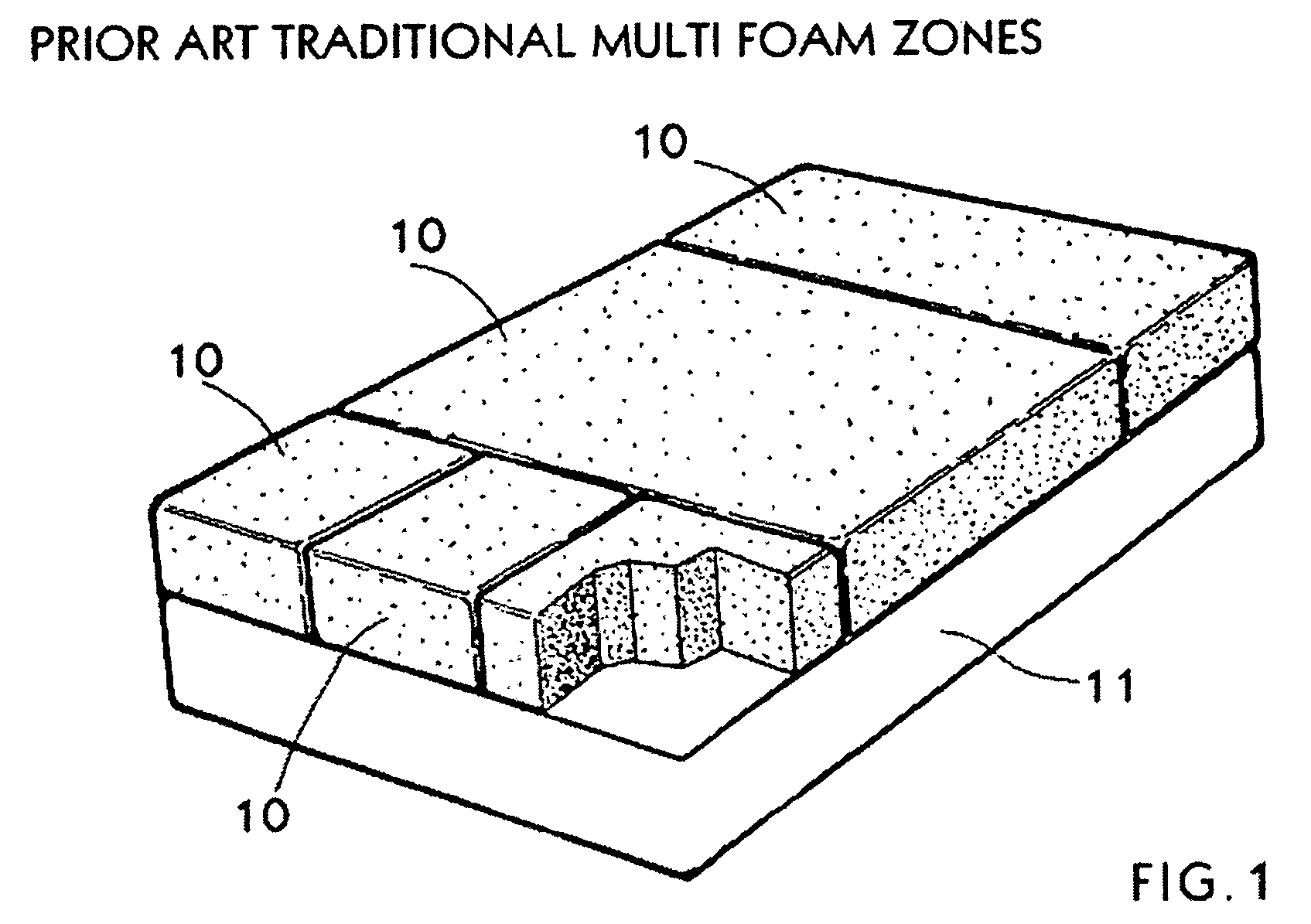

InactiveUS6922863B2Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeCoil spring

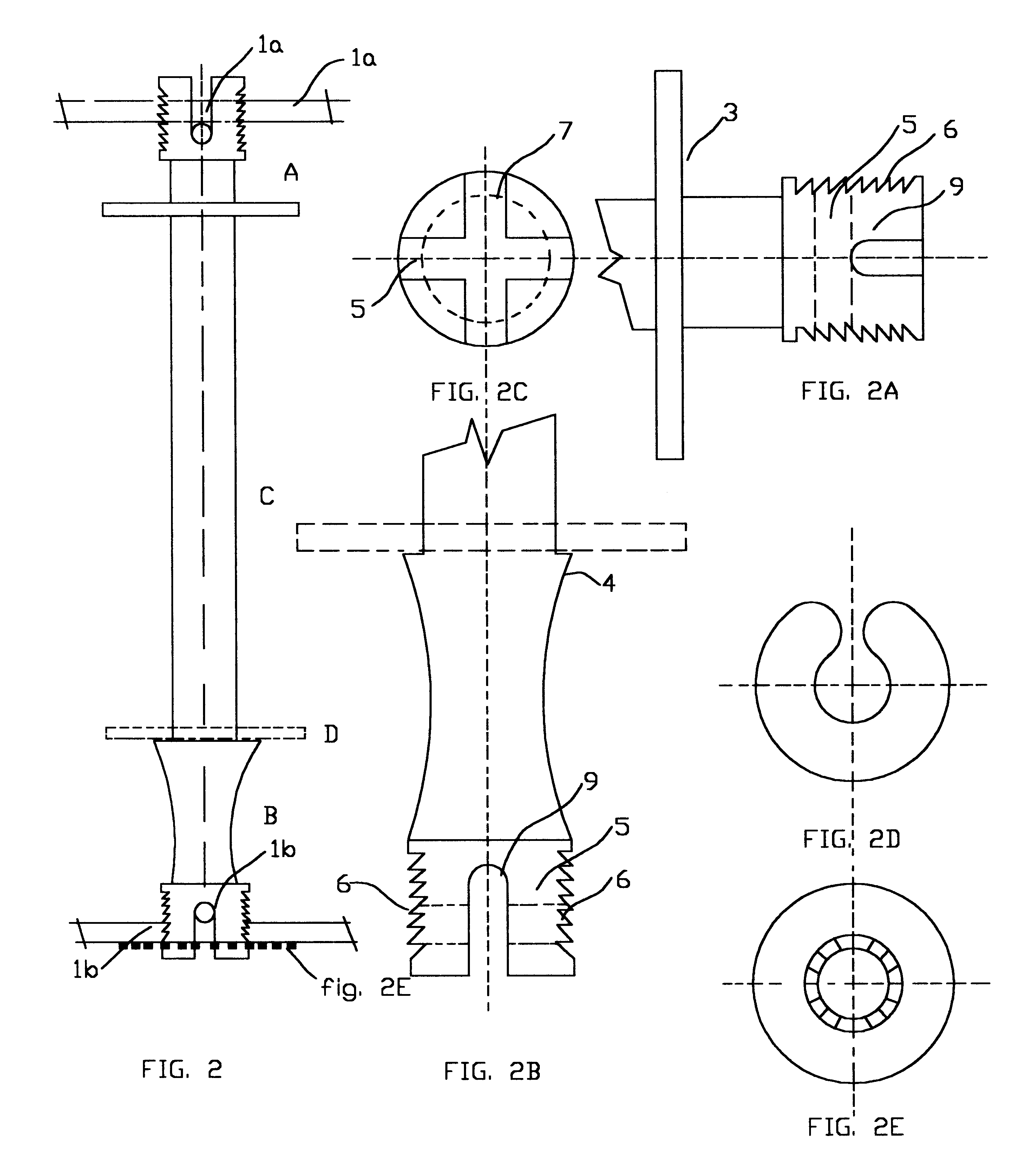

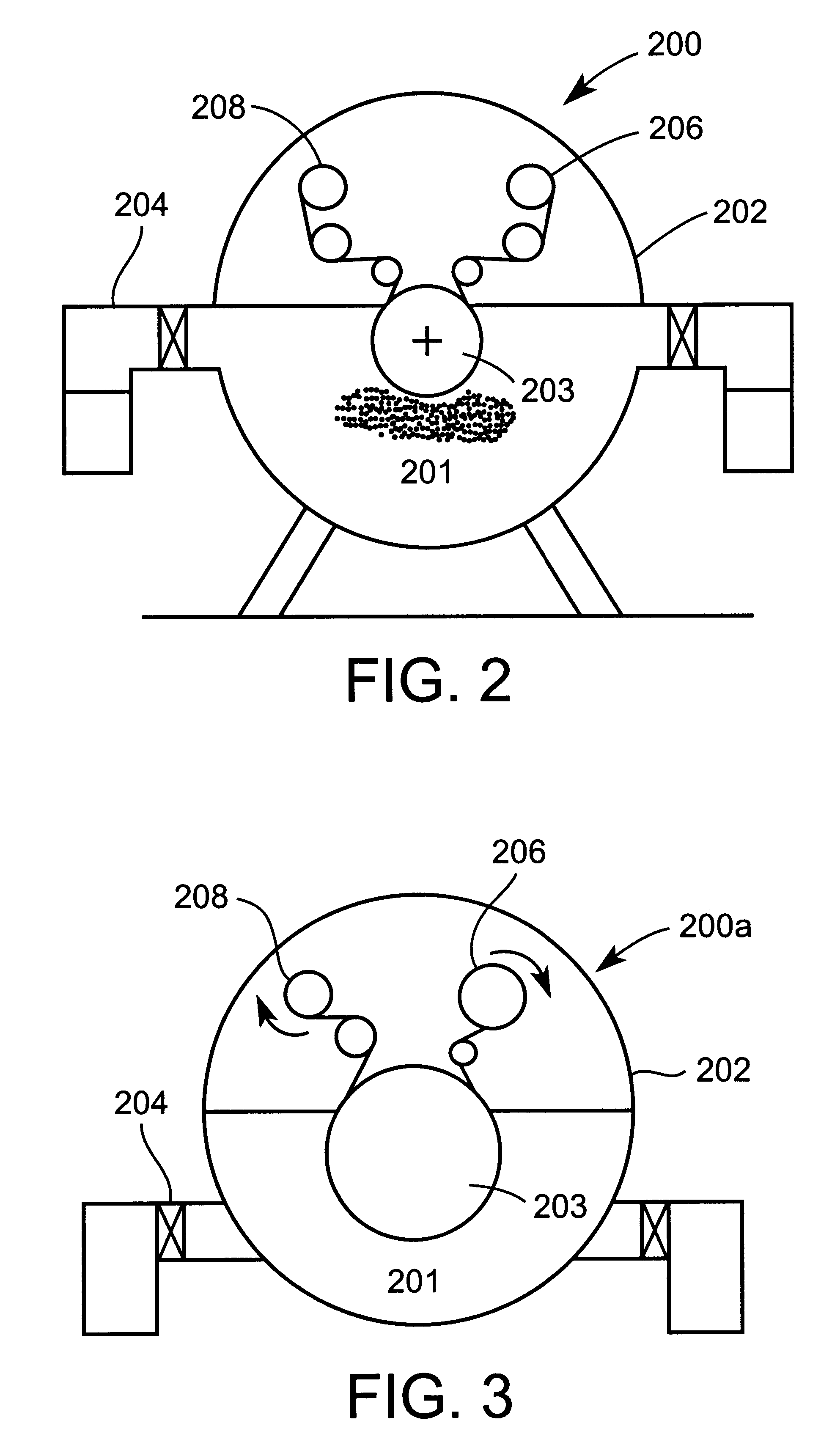

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GUALTIERO G +1

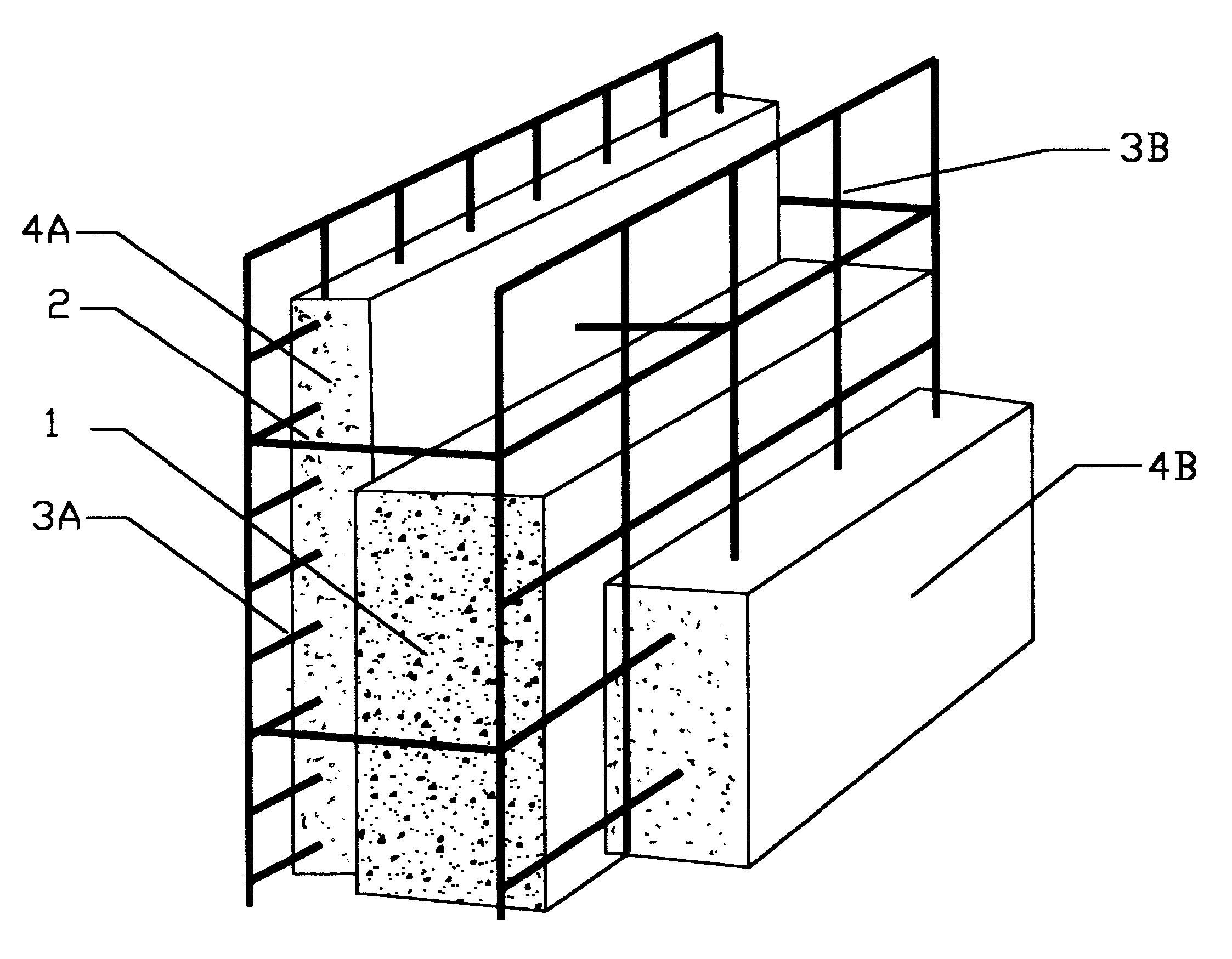

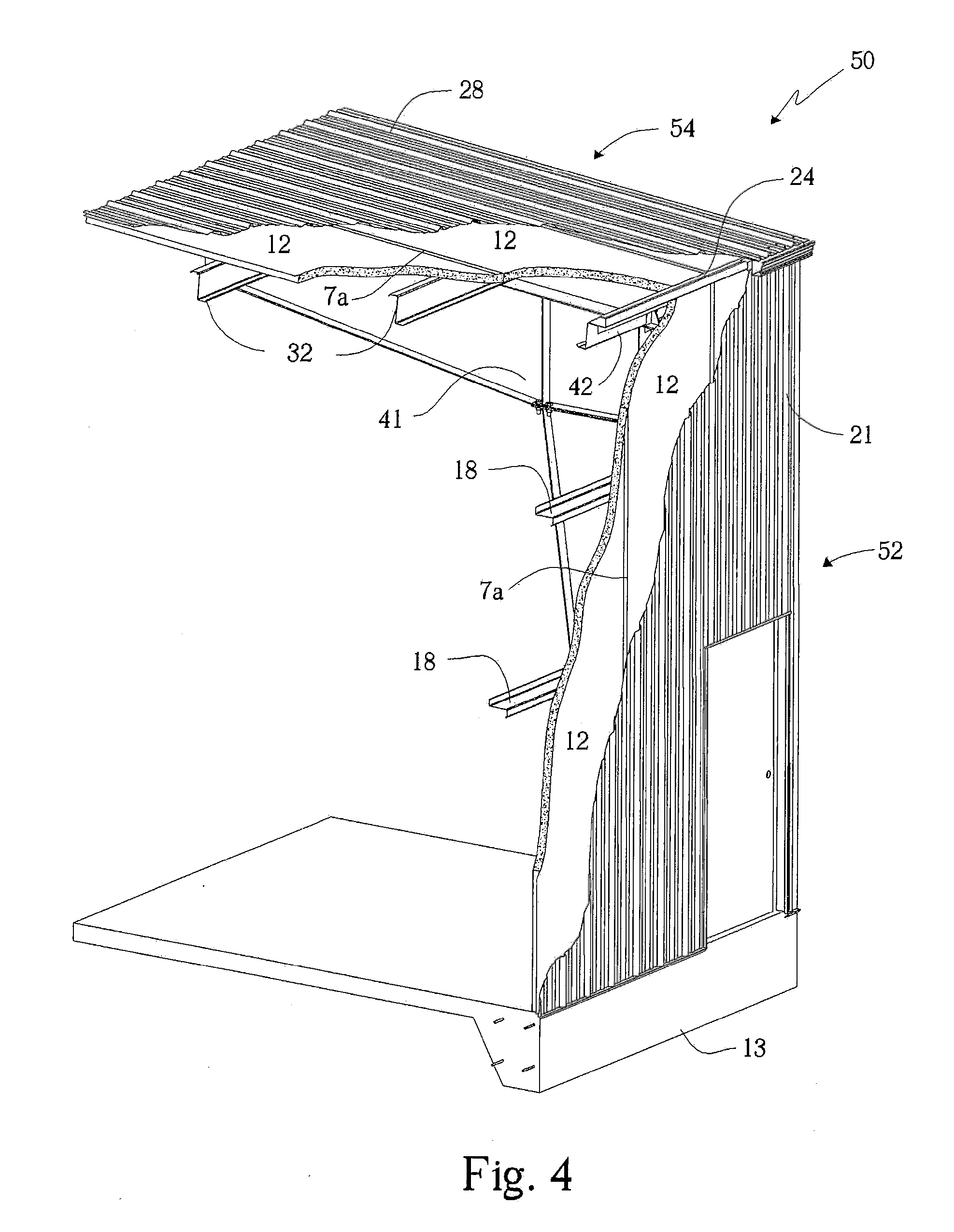

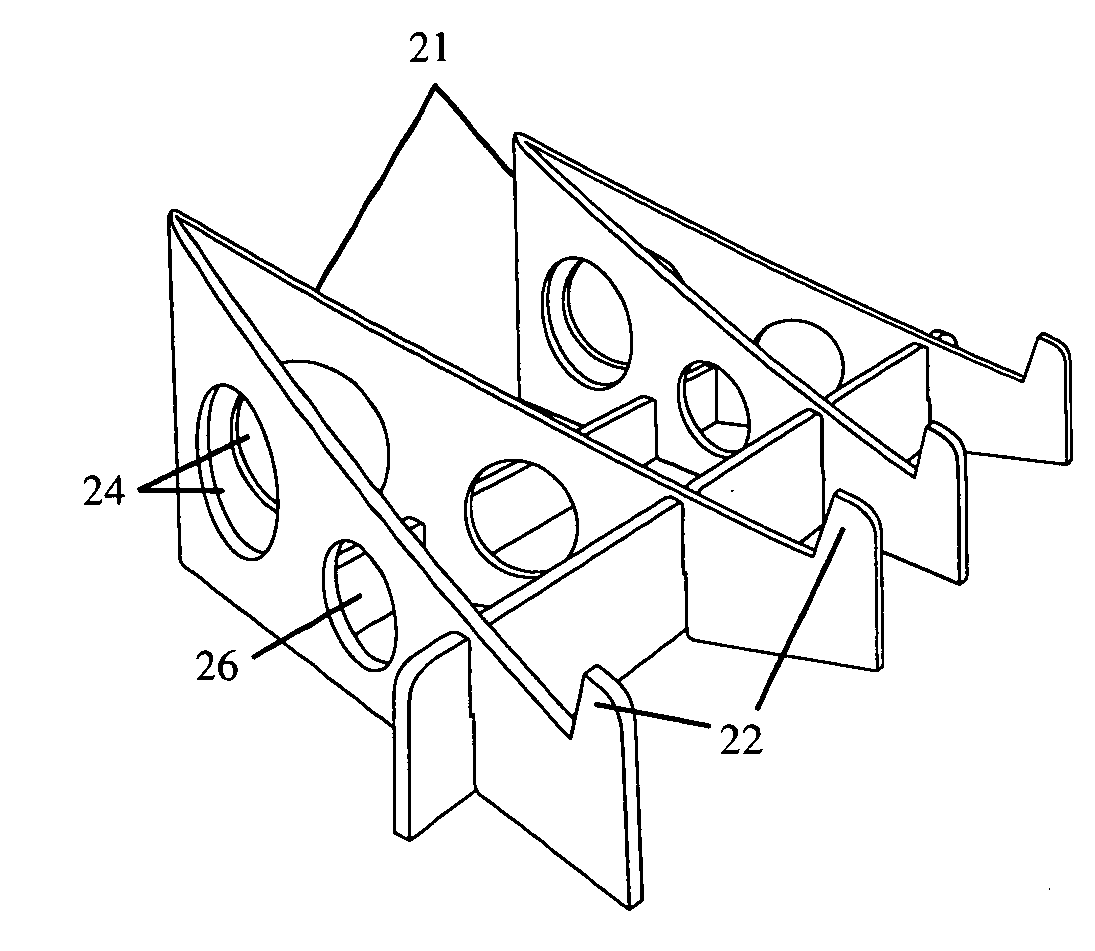

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

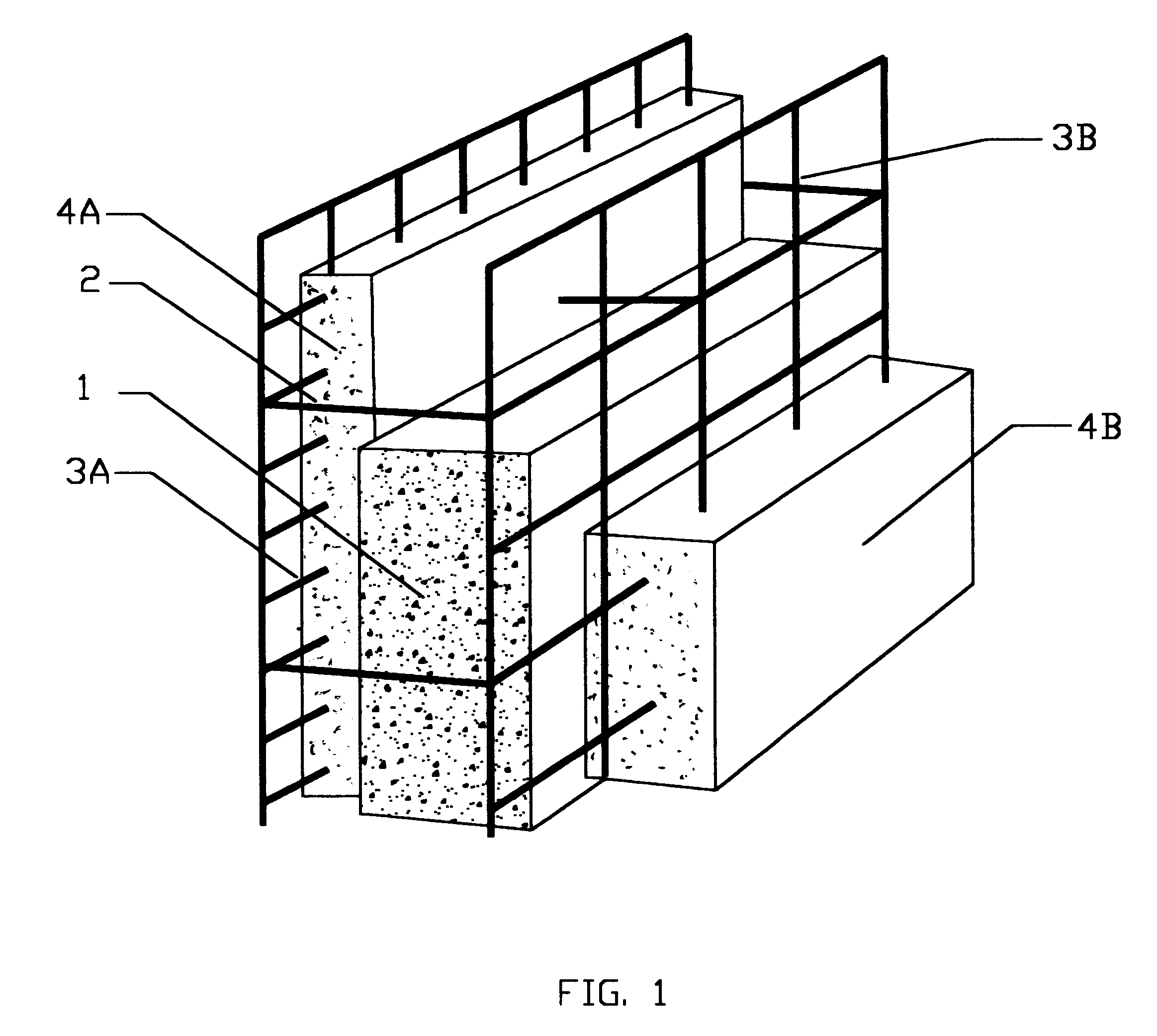

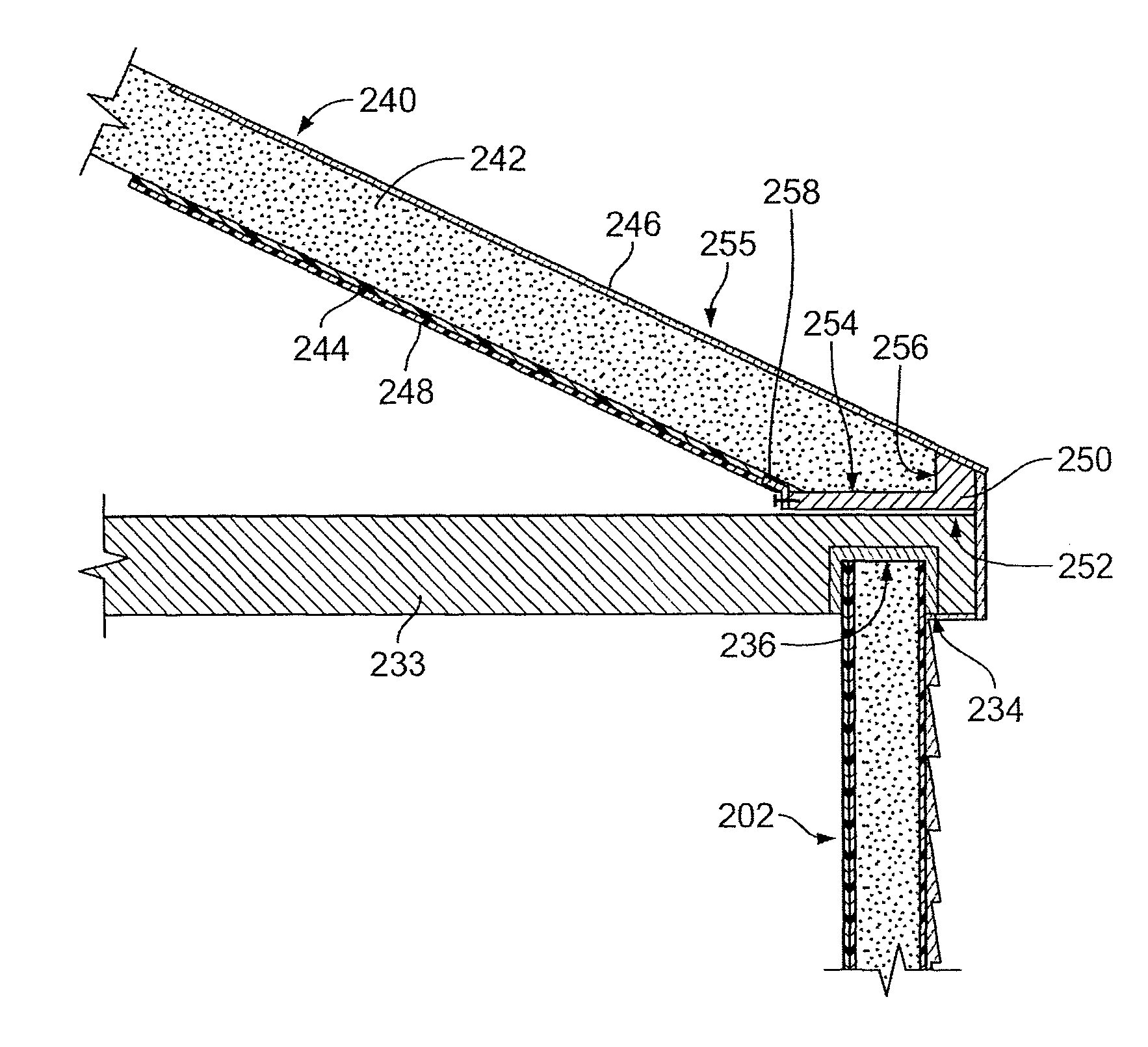

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

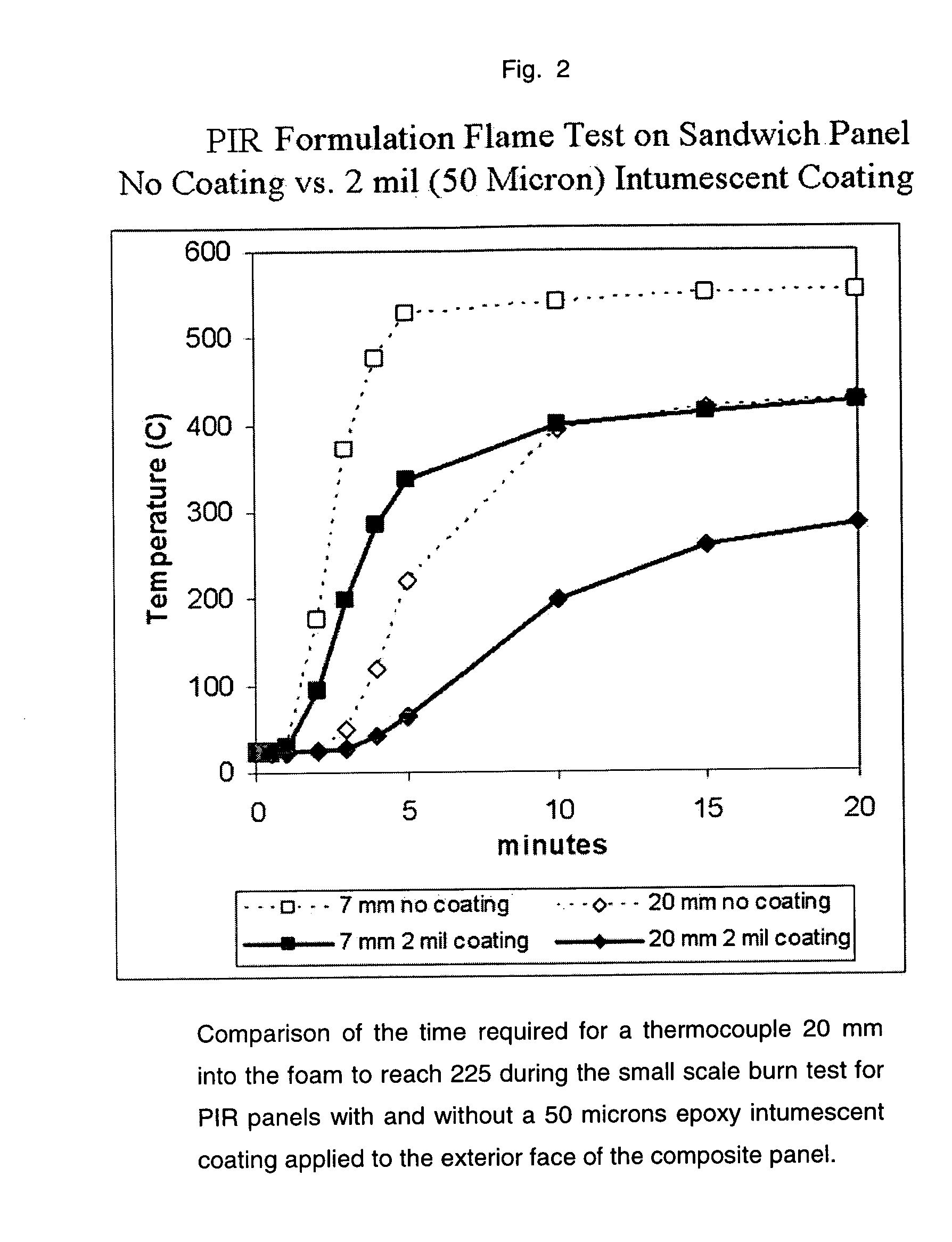

Fire resistant insulated building panels utilizing intumescent coatings

InactiveUS20070059516A1Reduce decompositionReduce transferLayered productsBuilding componentsFire resistanceFoamcore

This invention relates to an improvement in a process for producing a composite insulating panel comprised of at least one metal facer having an interior face and an exterior face and a foam core facing the interior face of at least one metal facer and to the resulting composite insulating panel. The improvement in the process for producing the composite insulating panel and improving the fire resistance thereof resides in the steps which comprise: applying an ultrathin intumescent coating composition to the exterior face of said metal facer in an amount to provide a coating thickness of 130 microns or less; and, subsequently providing said foam core facing the interior face of said metal facer.

Owner:AIR PROD & CHEM INC

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

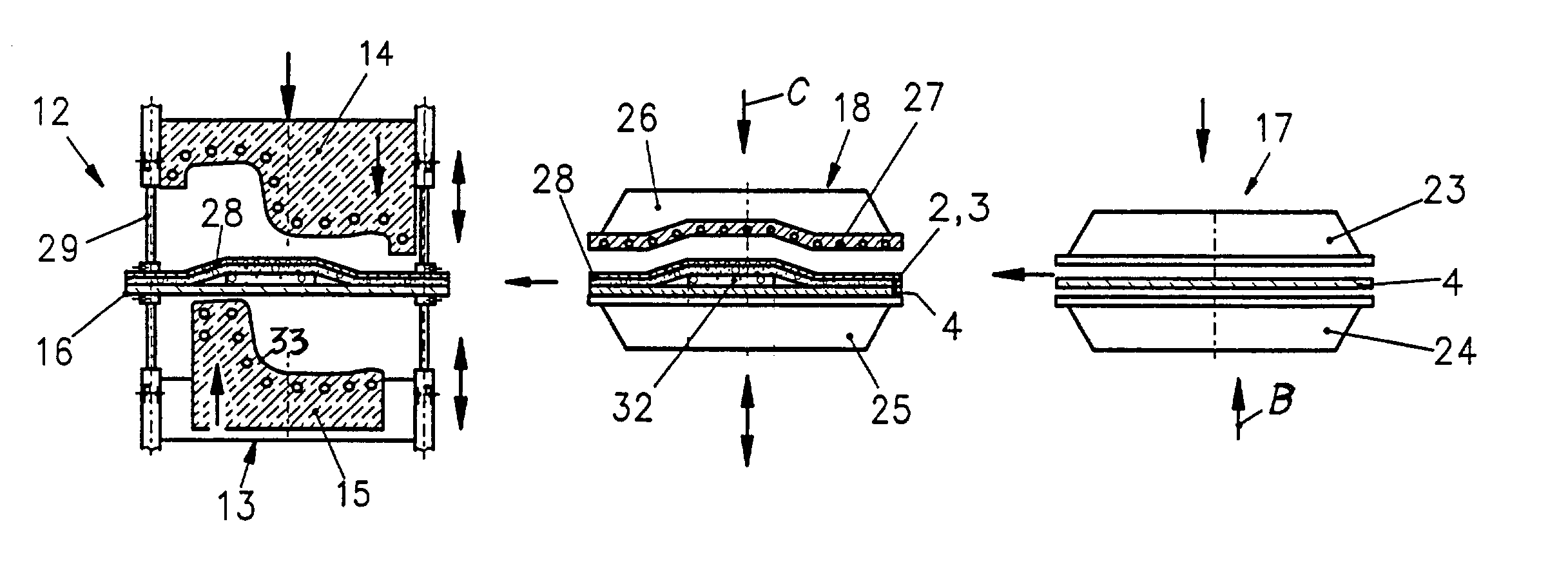

Method and apparatus for making a trim component with a foam core having a smoothly varying thickness

InactiveUS20030041955A1Guaranteed shock absorptionSoftness shockAdhesive processesEngine sealsThermoplasticPolymer science

A trim component includes a foam backing layer and a foam pad insert laminated between a cover material and a substrate. The foam pad insert provides an area of enhanced cushioning, and has smoothly tapered edges to ensure a smooth surface contour without a visible edge transition on the cover material. The foam pad insert has a lower melting temperature than the foam backing layer, both of which are thermoplastics. A foam pad insert is positioned and fixed on the back surface of the foam backing layer. A substrate material is heated and then laminated and molded with the foam and the cover material. The heat from the substrate partially softens and melts the foam backing layer and the foam pad insert. The partially melted foam pad insert is viscously deformed to form the tapered edges, as dictated by the smoothly varying mold gap spacing of the forming tools.

Owner:HERBERT OLBRICH

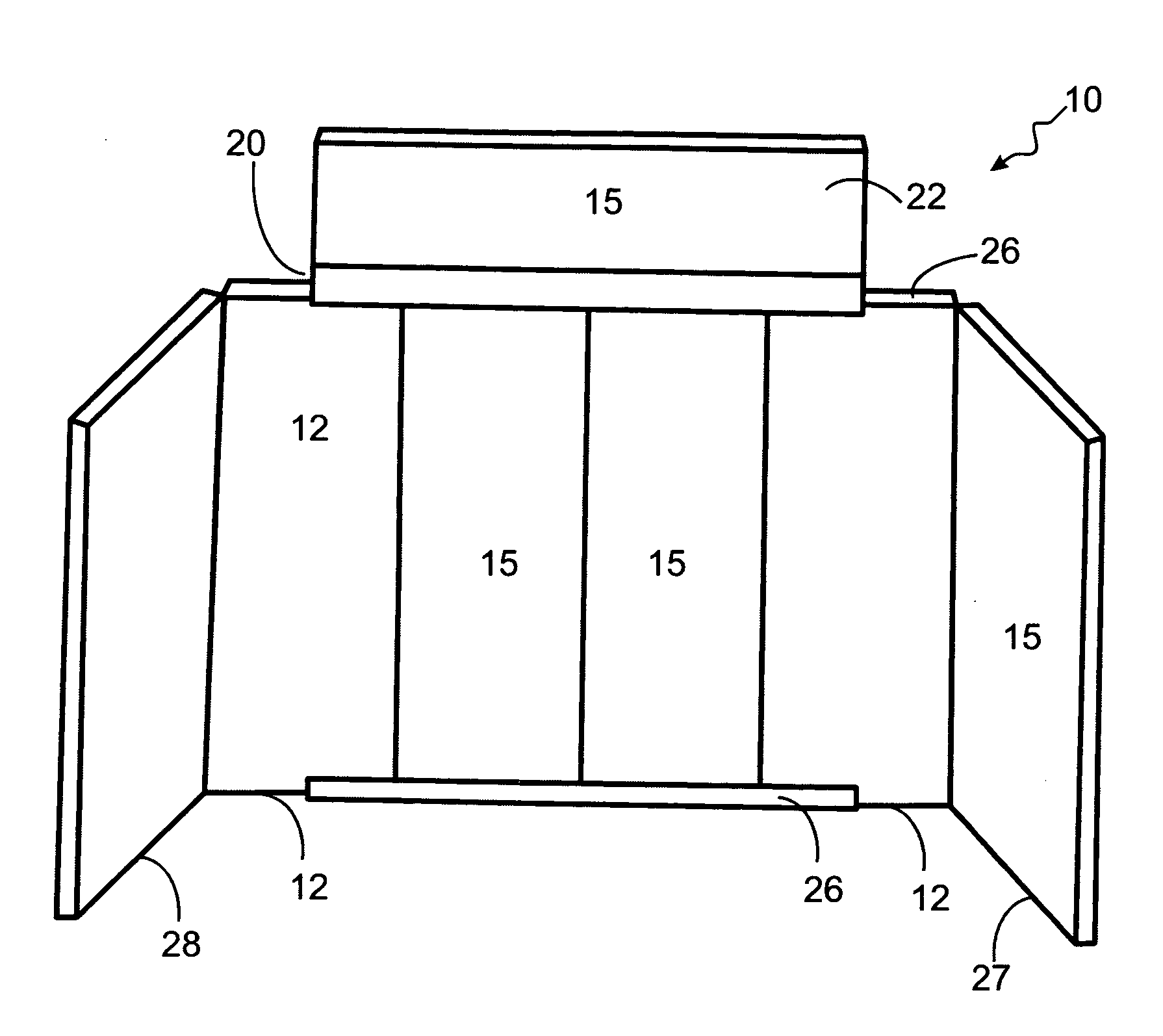

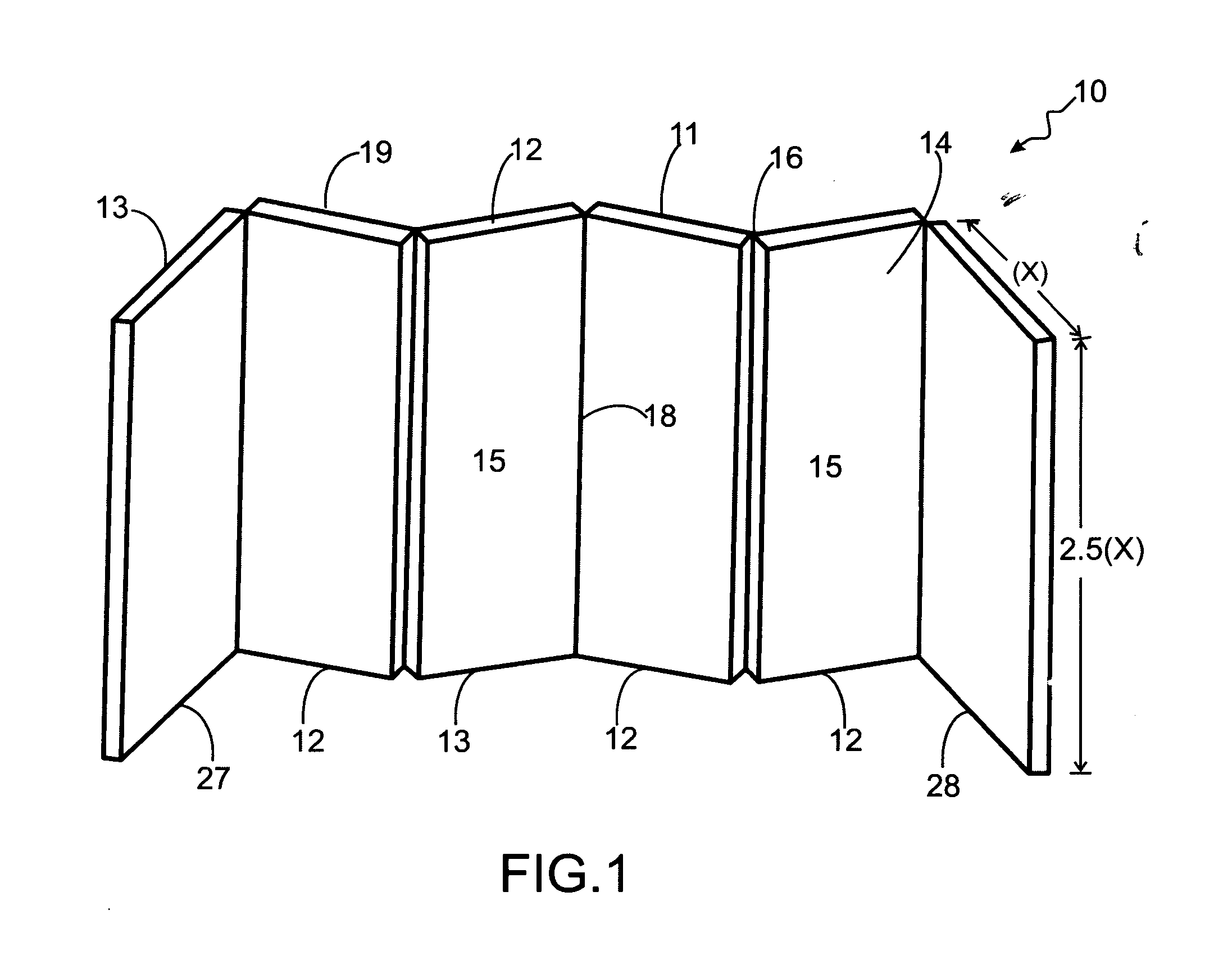

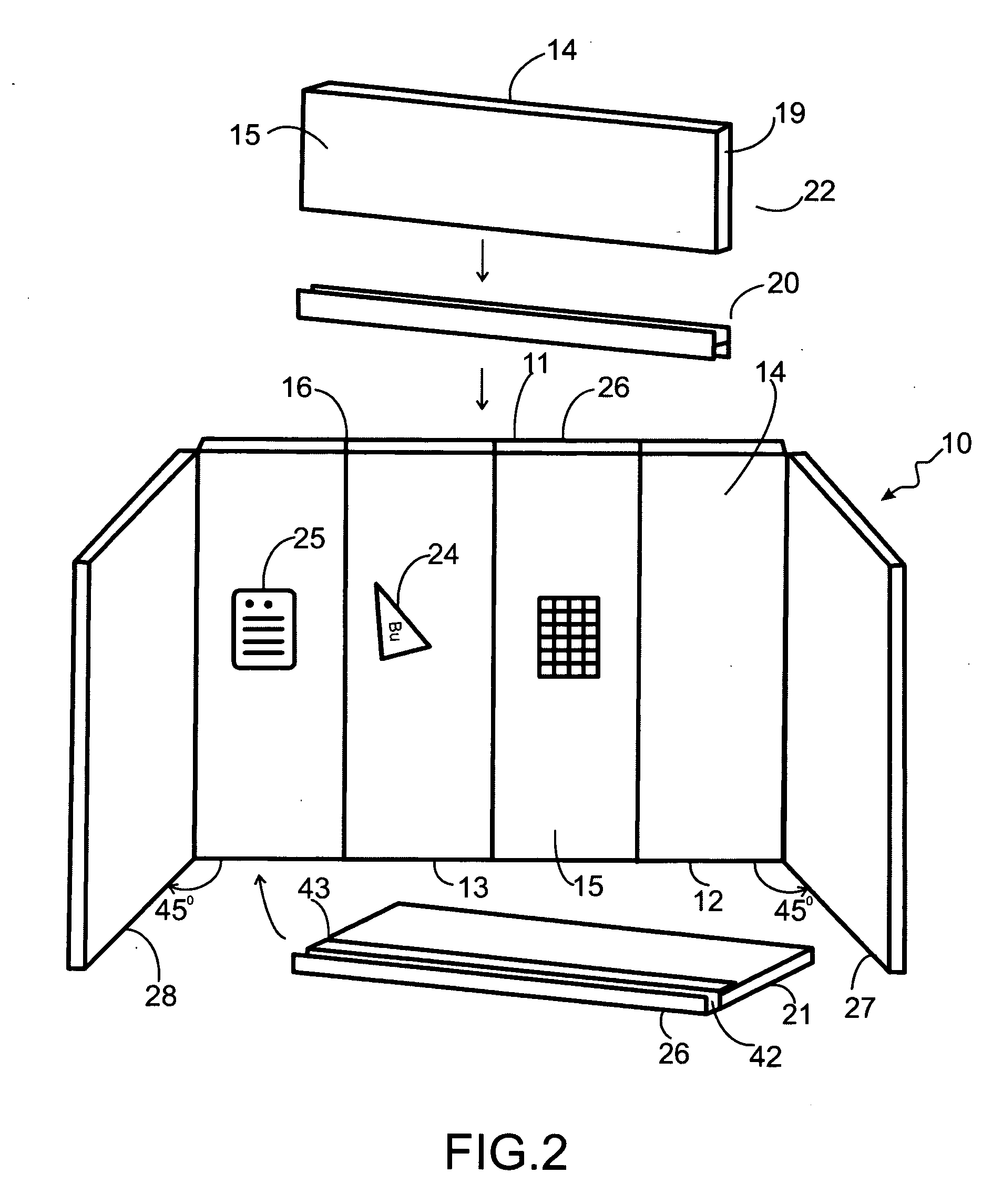

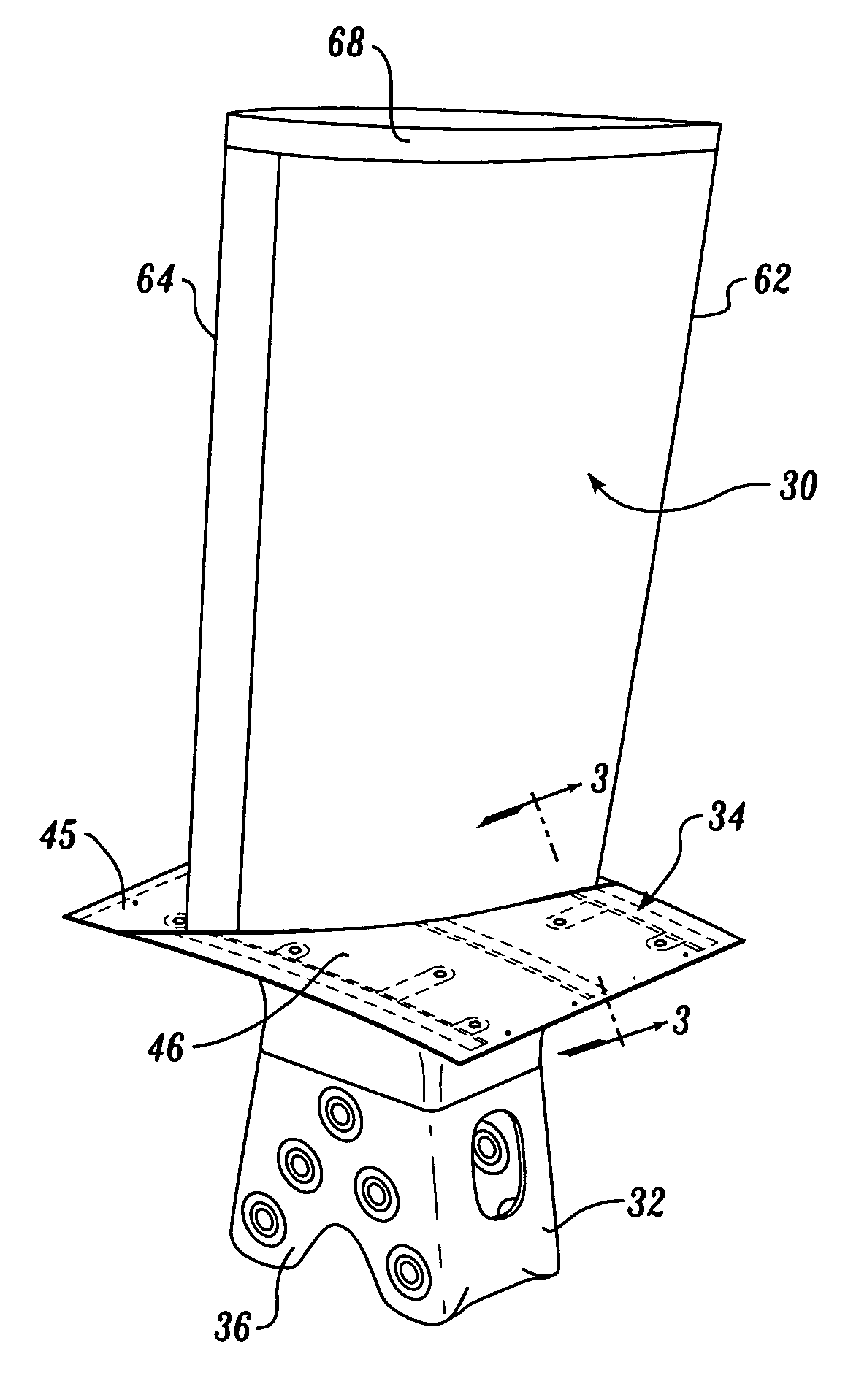

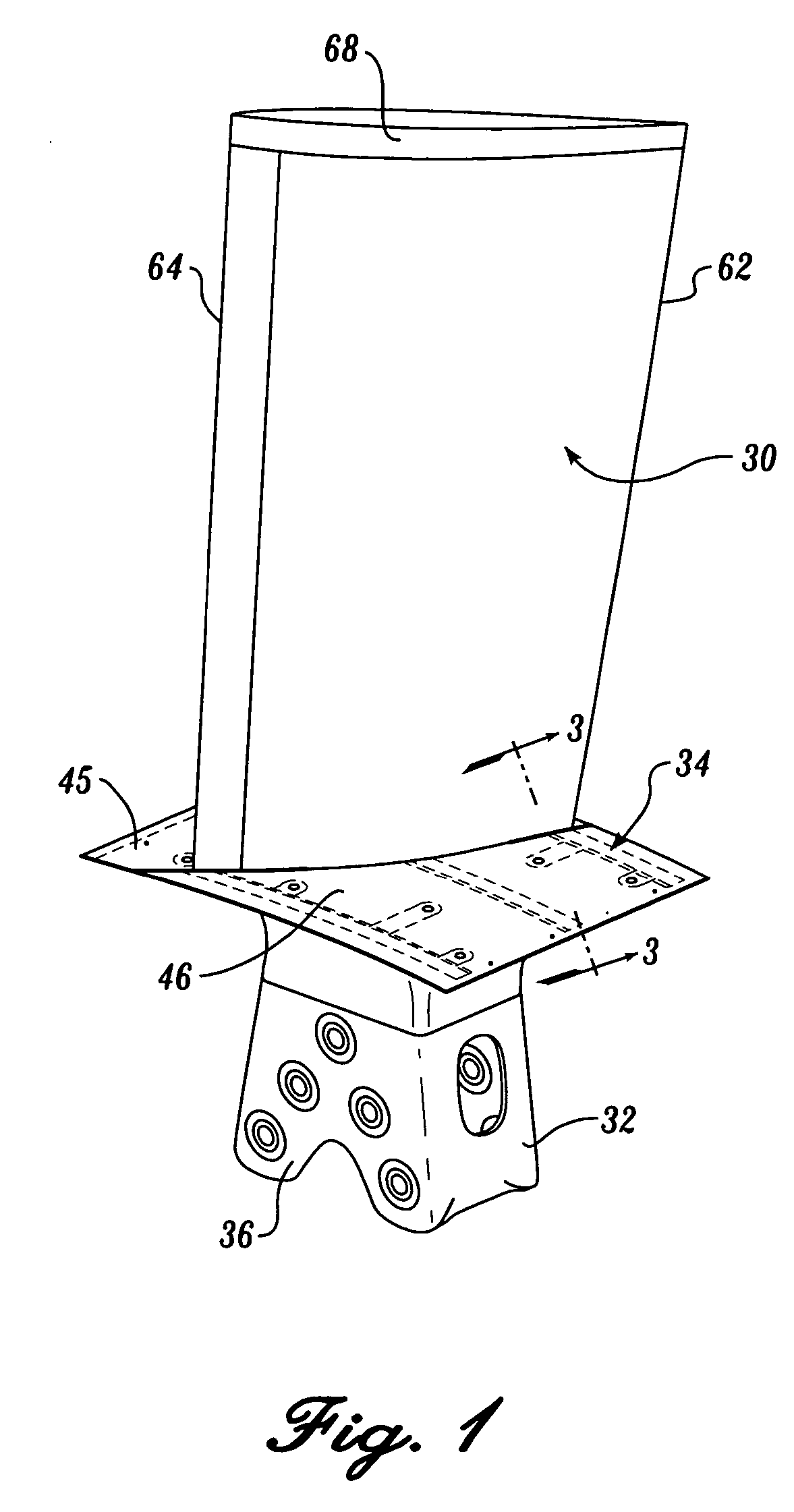

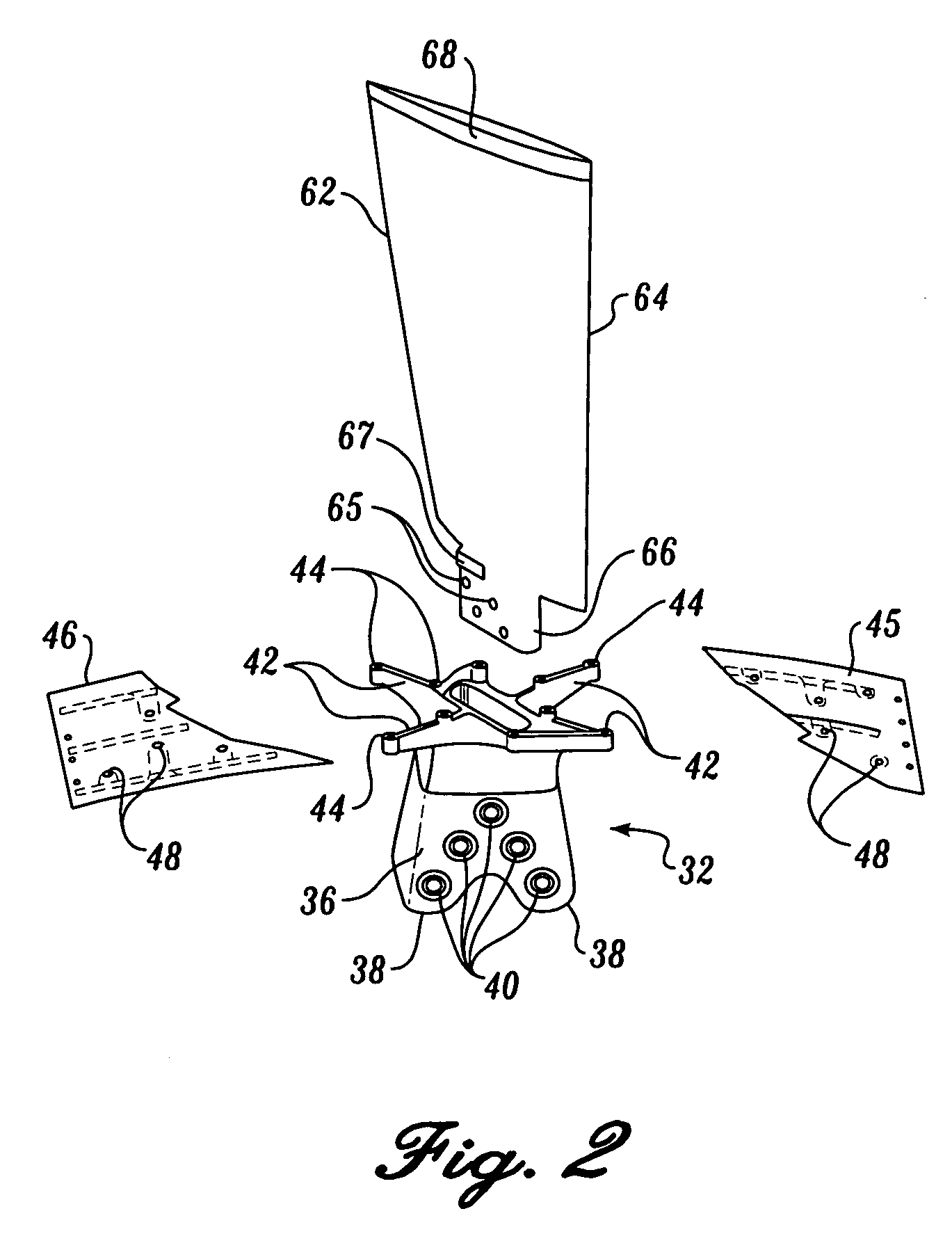

Portable presentation display device

The present invention comprises a presentation display device that is portable and easy to assemble and disassemble. The invention includes a plurality of movably hinged display panels as described. The display panels are composed of a foam core material coupled between two outer sheet layers made of foldable, tear resistant material. The invention also includes a connecting means comprising a removable connecting bracket which may be used to attach one or more display panels along the outer edges of the movable hinged panels thereby expanding the height and width of the display area of the device. The disclosure further includes a support means comprising a detachable support bracket used to vertically stabilize the device while it sits above a planar surface such as the floor, or a desktop.

Owner:HOUSSAIN VAZGEN +1

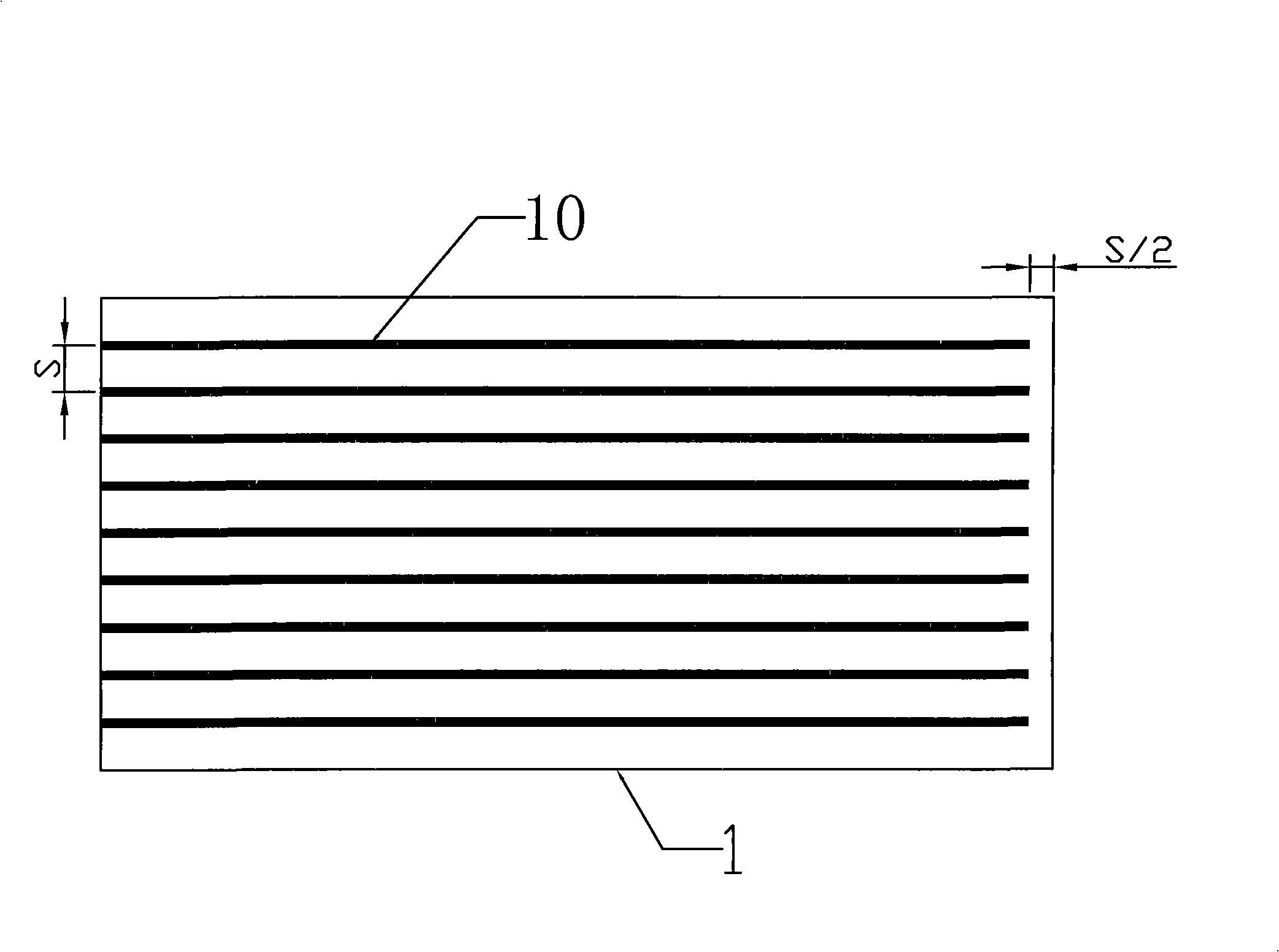

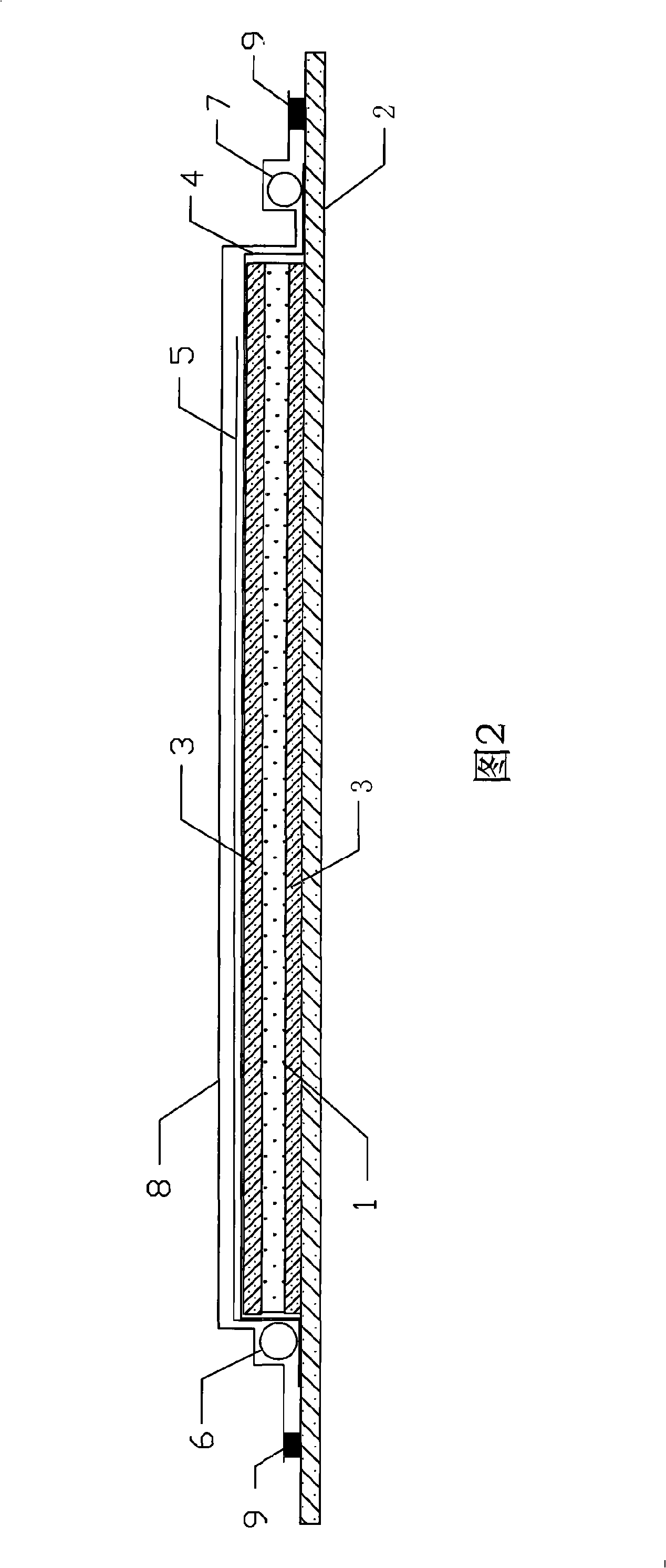

Vacuum auxiliary molding technique produced by large-sized sandwich composite material

The invention provides a vacuum assistant resin infused method for molding a large part of sandwich composite materials as follows: a set of grooves parallel to each other are arranged at the bottom of the foam core material; fiber fabrics are paved on a processed die according to the specified thickness, and then the grooved foam core material is arranged on the already-paved fiber fabrics, wherein, the machined surface of the grooves of foam core material contacts to the already-paved fiber fabrics, and then the fiber fabrics with a specified thickness are paved on the foam core material; a conduction pipe is arranged at one foam core material end with grooves and a vacuum pipe is arranged at the other end; sealed vacuum bag film and sealed adhesive tape are adopted to seal the fiber fabrics; when the vacuum pressure in the sealed bag film is equal to or less than negative 0.095Mpa, resin solution is inducted to the resin conduction system consisting of the conduction pipe and the conduction cloth after being poured with glue; after the resin immerses the fiber fabrics completely, glue pouring and evacuation are stopped; after the poured-in resin is heat-released and solidified, sandwich composite materials are obtained after 24 hours solidification under indoor temperature condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

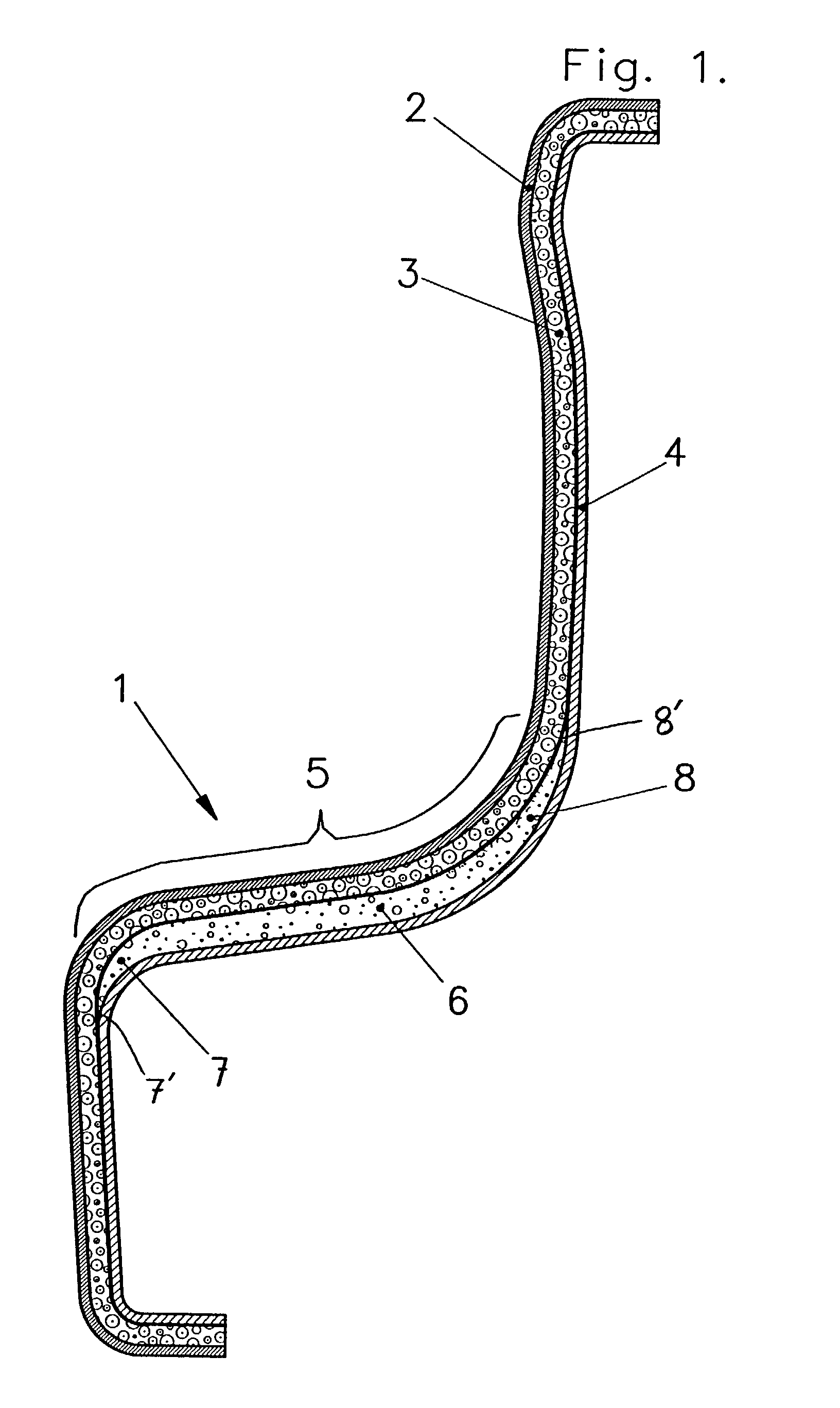

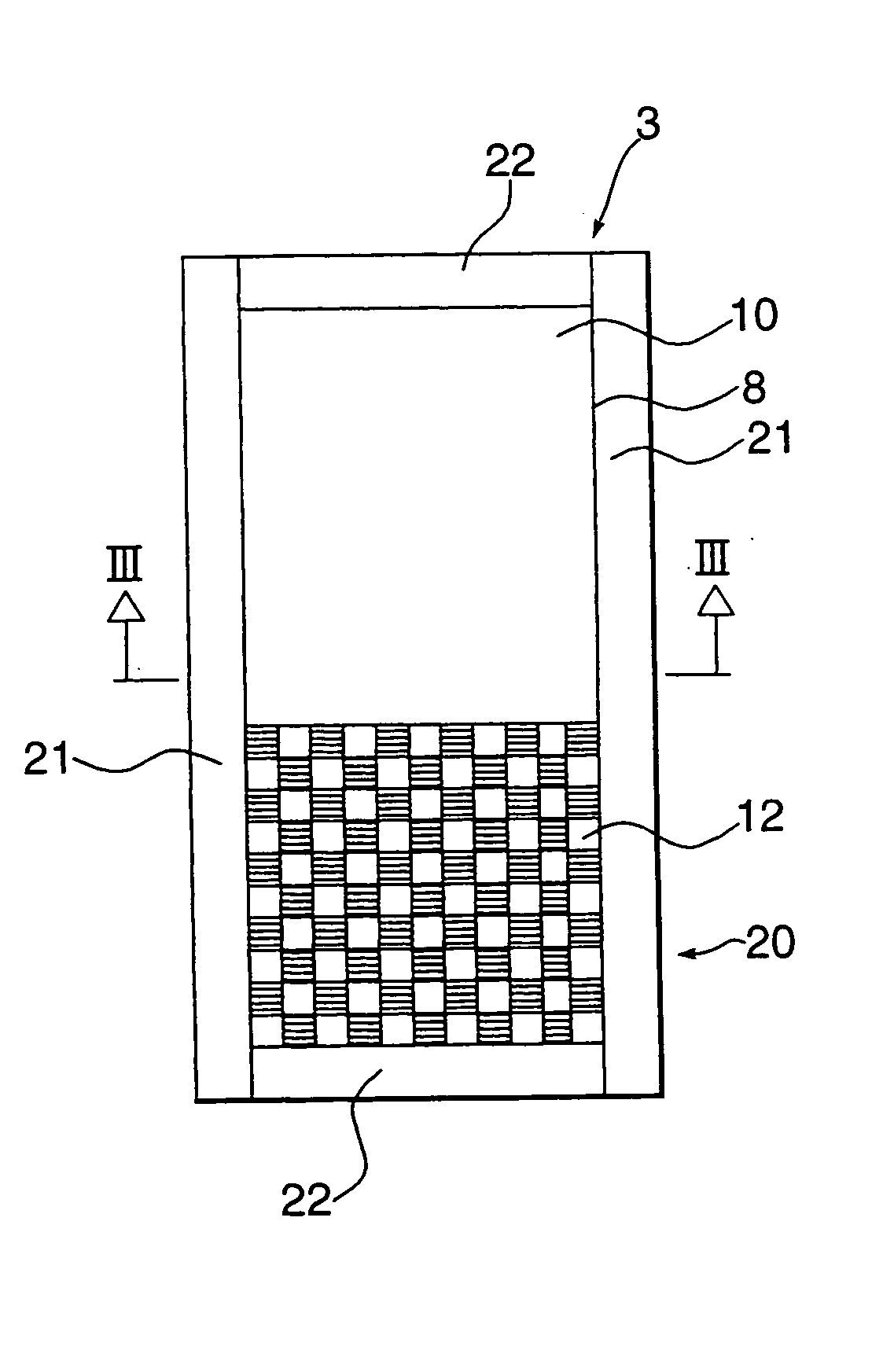

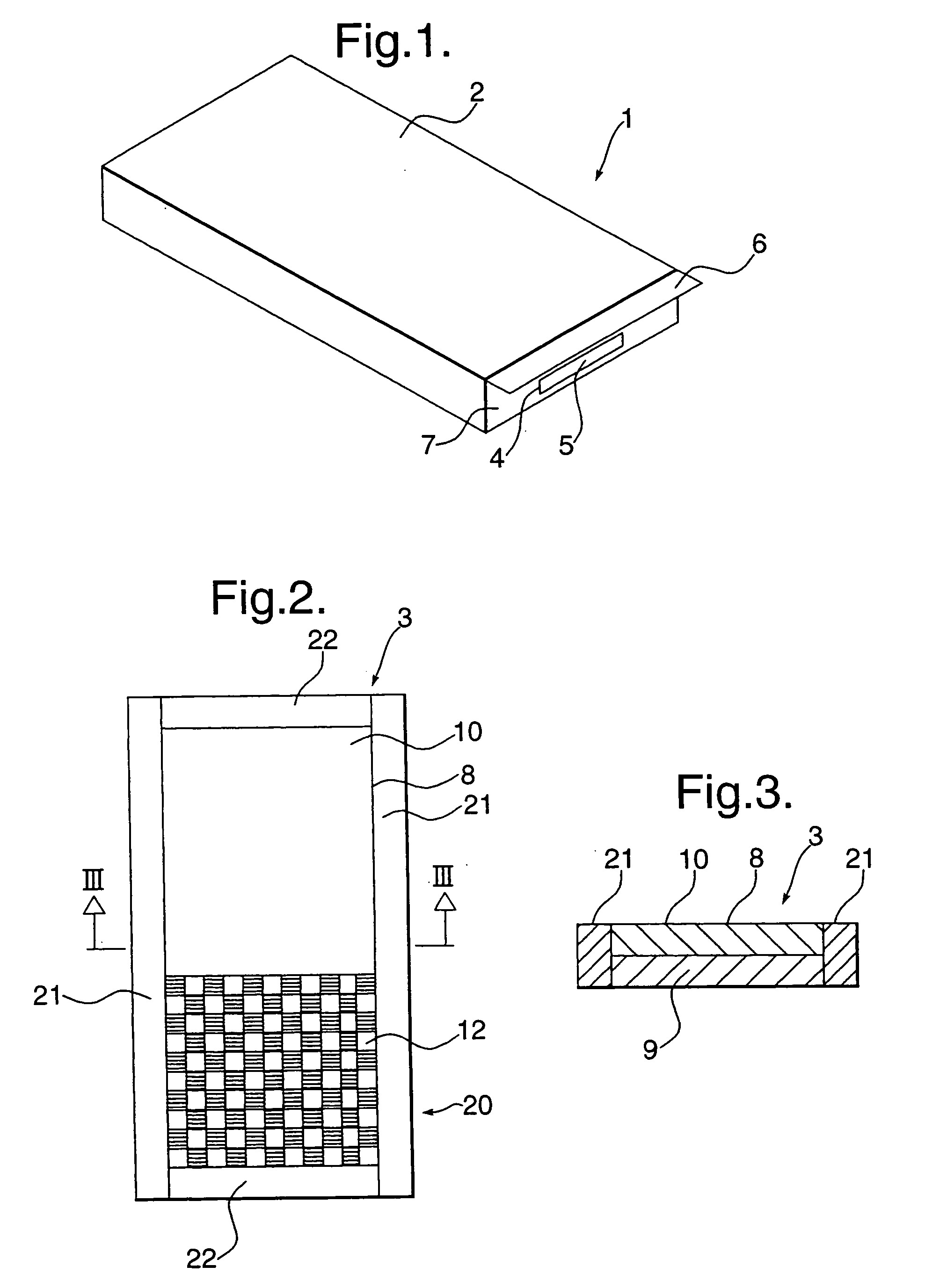

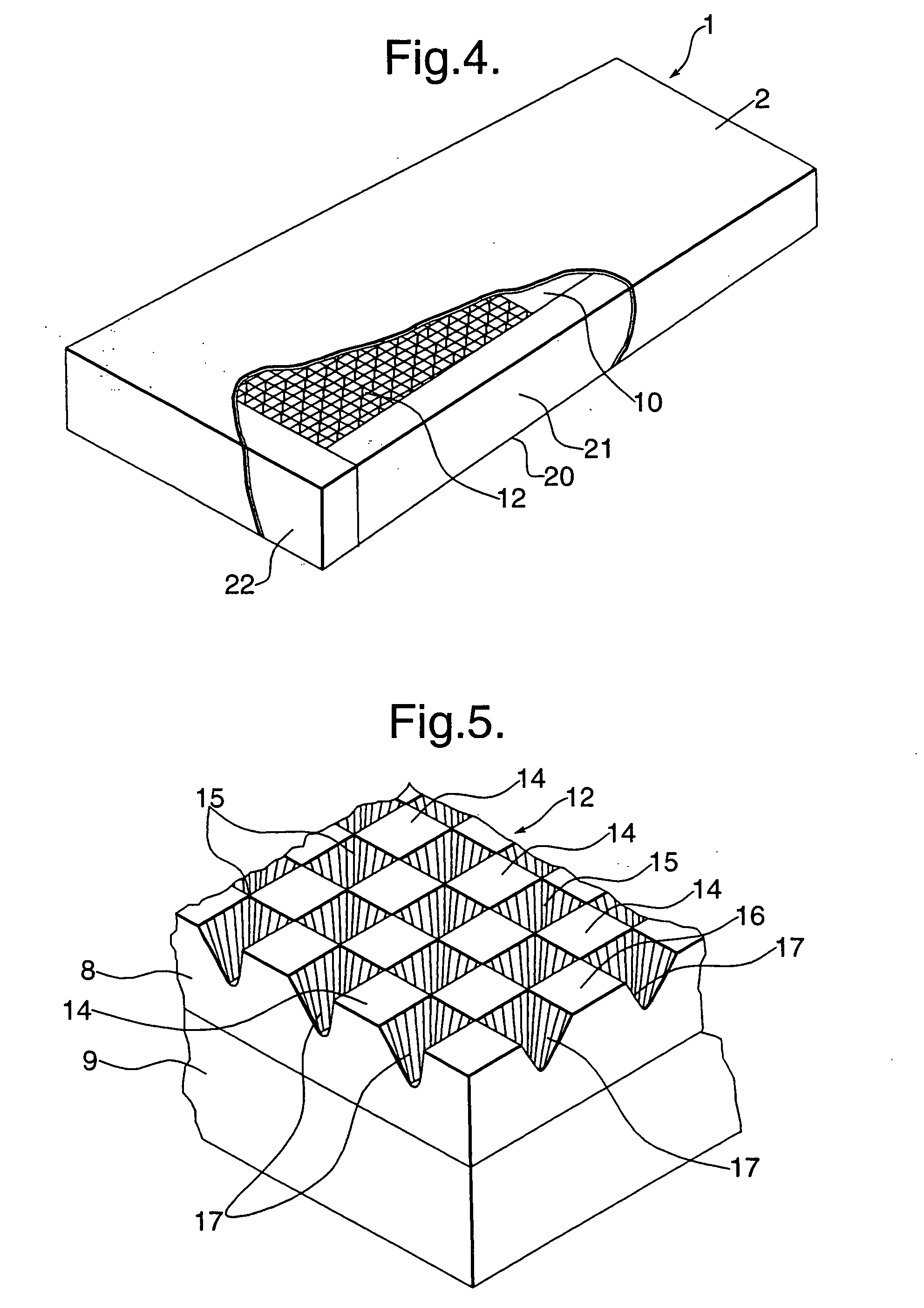

Mattress

InactiveUS20050188467A1Conveniently formedPoint becomes highStuffed mattressesSpring mattressesEngineeringMechanical engineering

A mattress comprises a sealed outer casing within which is mounted a resilient support formed by a composite foam core. At least an upper portion of the resilient support is formed by a visco-elastic foam. A vent is provided in a side wall of the casing and is covered by a filter which prevents ingress of bacteria into the cover. A flap is mounted on the cover and in use extends down over the vent to prevent the filter being damaged by fluids.

Owner:LANCASTRIA

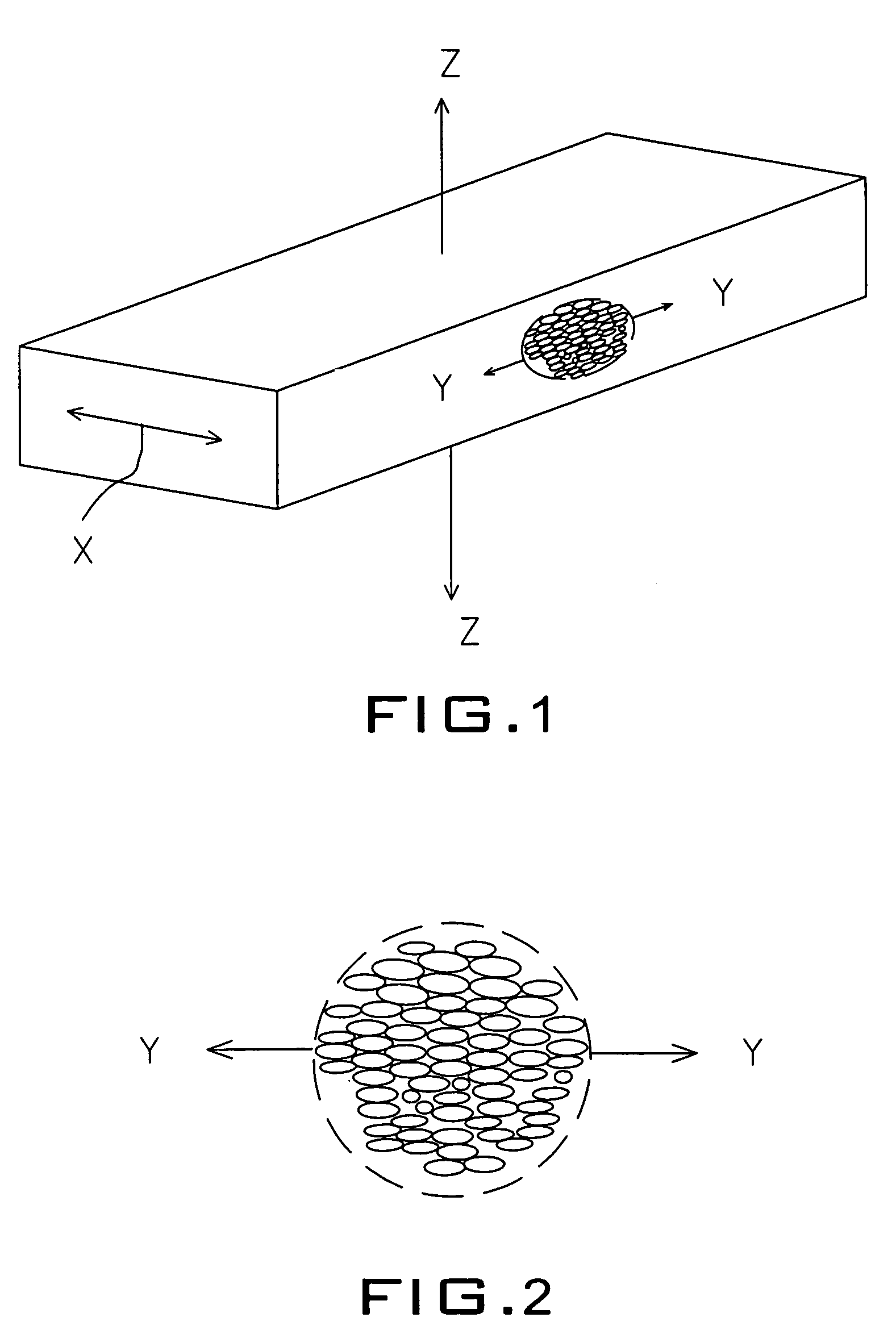

Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

The invention discloses a method for a preparing low density polypropylene foam section or beads by two-step extrusion molding, which comprises the following steps that: expandable master batch is prepared from 30 to 80 portions of polypropylene, 10 to 40 portions of foaming agent, 0 to 15 portions of foaming accelerant, 0 to15 portions of dispersant and 0 to 10 portions of nucleating agent at a temperature below the decomposition temperature of the foaming agent and above a viscous flow temperature of the polypropylene; 20 to 99 portions of polypropylene with high melt strength, 0 to 70 portions of common polypropylene and 1 to 10 portions of expandable master batch are plasticizated and extruded together; supercritical gas is added to perform the blending of the plasticizated and extruded mixture; and the product obtained is made to generate foamcores in a foaming nucleation apparatus to form the section or beads finally. A chemical foaming agent is partially decomposed and foamed during the plasticization and extrusion, so that the viscosity of fused mass is reduced, the dissolution and dispersion of the supercritical gas are facilitated, and a problem that a foam imploding is likely to happen in a secondary forming process so as to influence the quality and appearance of secondarily formed product is solved as the chemical foaming agent retained in molding beads can be decomposed and foamed again during the secondary processing.

Owner:SICHUAN UNIV

Faced foam insulation board and froth-foaming method for making same

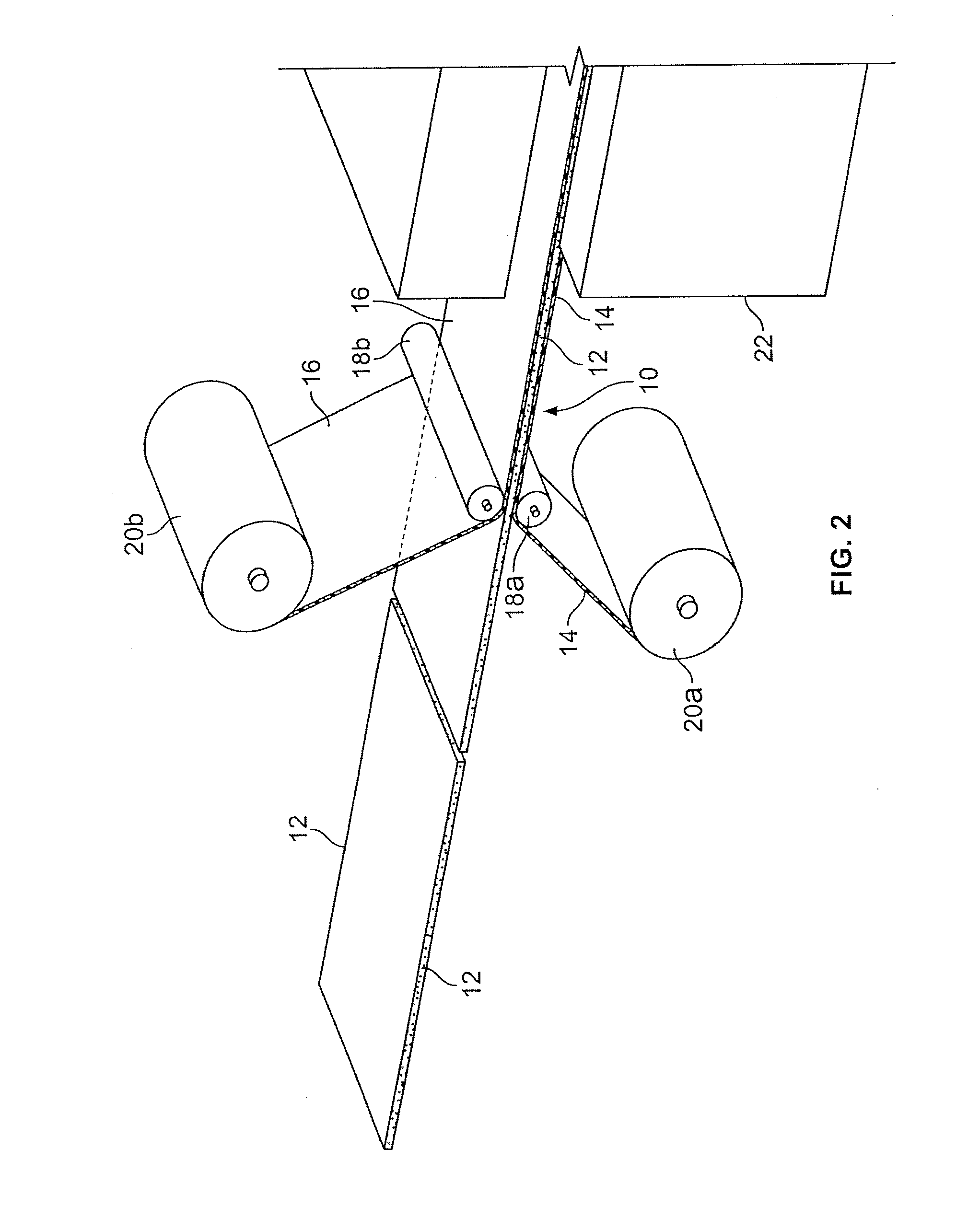

InactiveUSRE36674E1Big lossSimple and economical mannerConfectionerySweetmeatsProduction lineEngineering

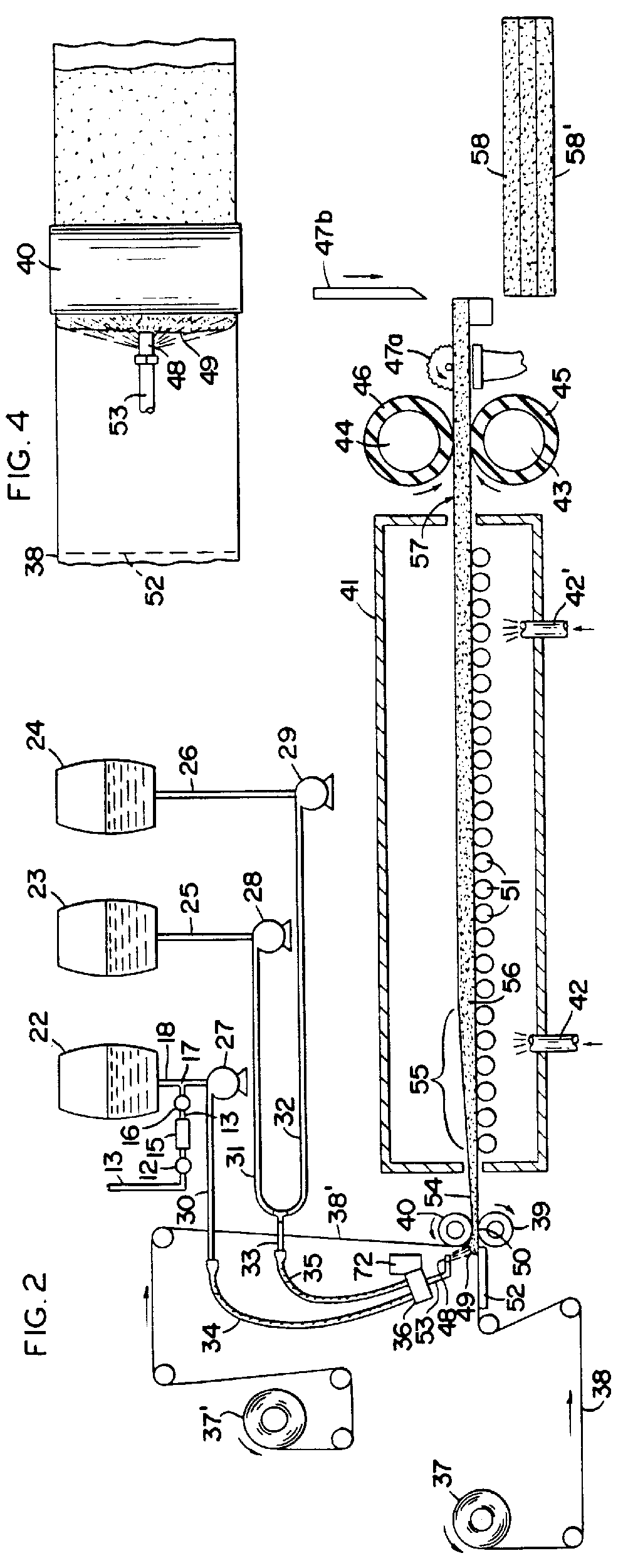

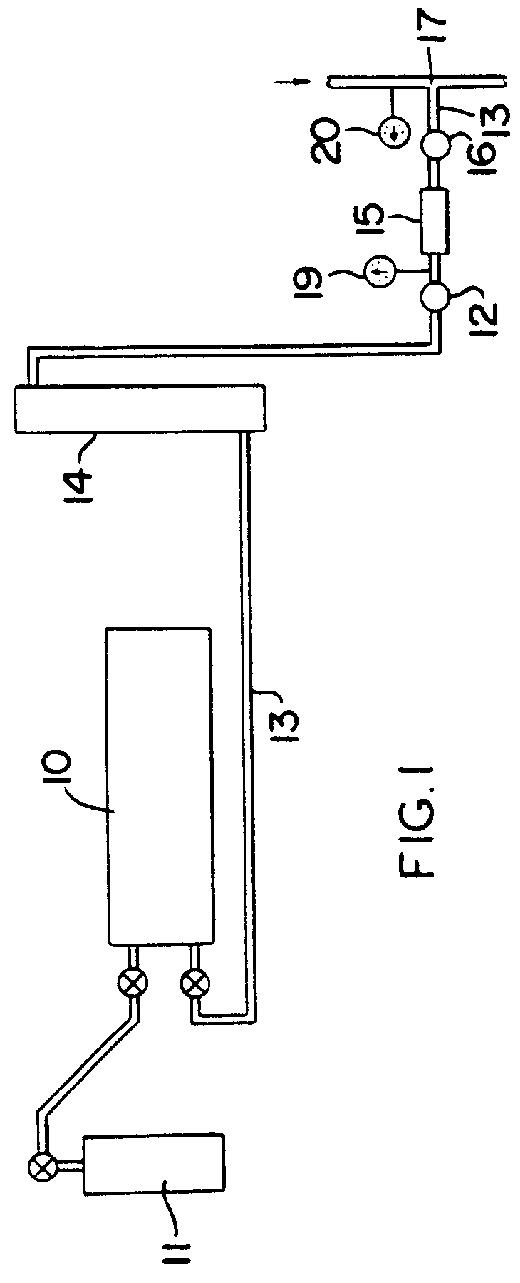

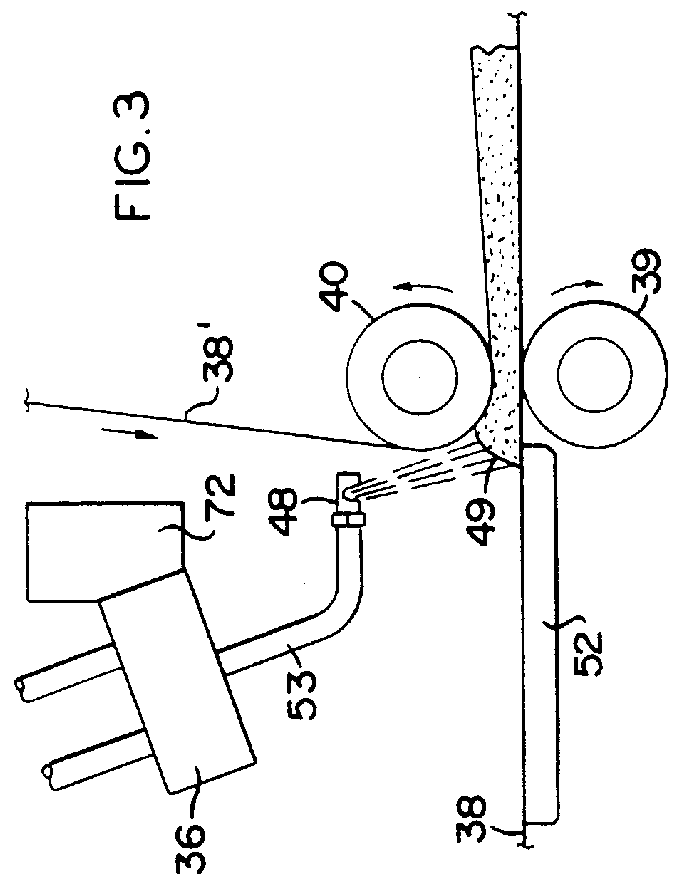

A method for continuously producing an insulation board comprising a rigid plastic foam core having two major surfaces and a facing material on one or both of the major surfaces, the method including conveying a facing material along a production line, depositing a partially expanded froth foam of a plastic mixture, which contains at least one frothing agent, on the facing material, and further expanding and curing the froth foam in contact wiht the facing material to form the insulation board. The board is particularly useful as roof insulation.

Owner:THE DOW CHEM CO

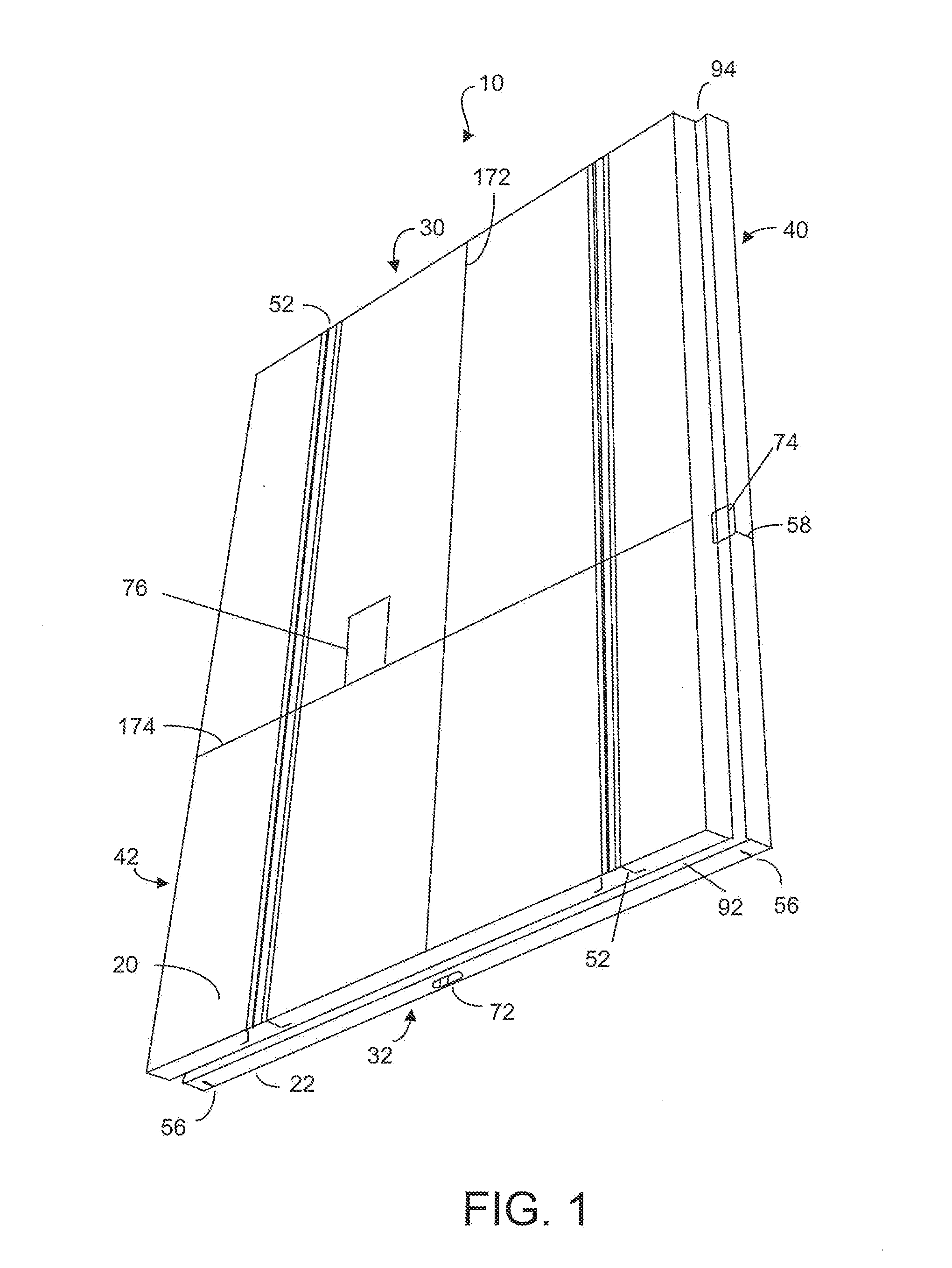

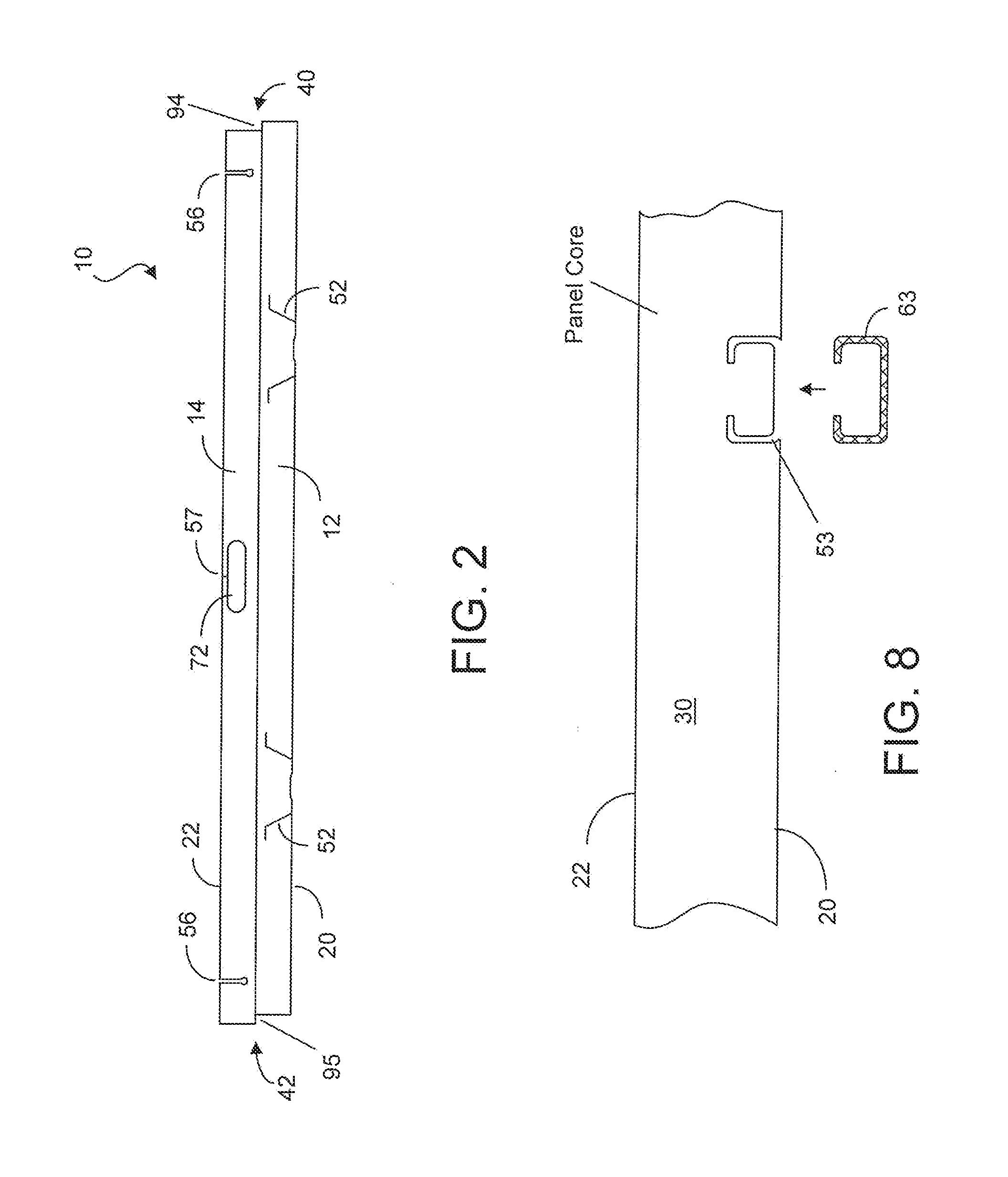

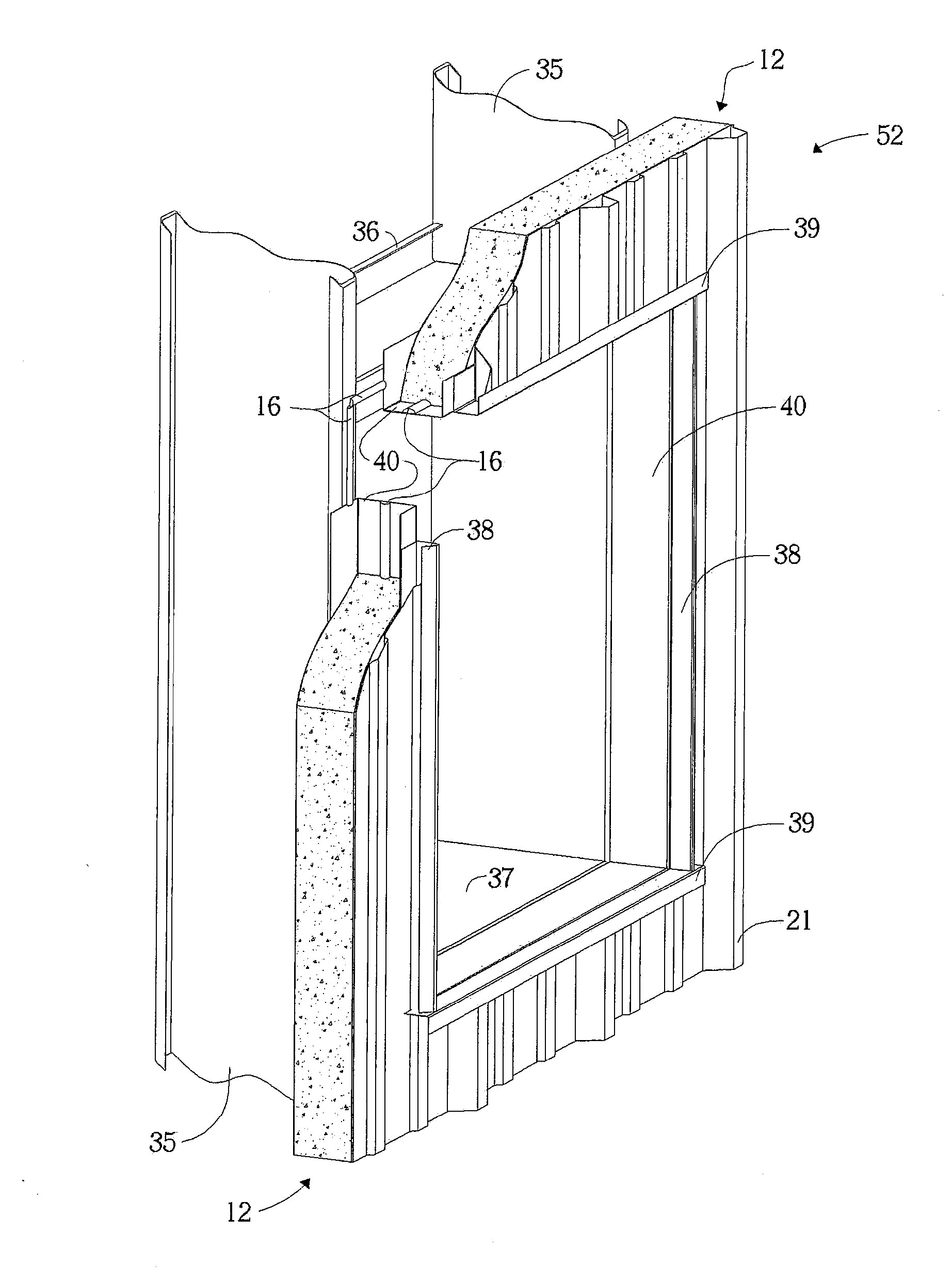

Insulating Wall Panel System

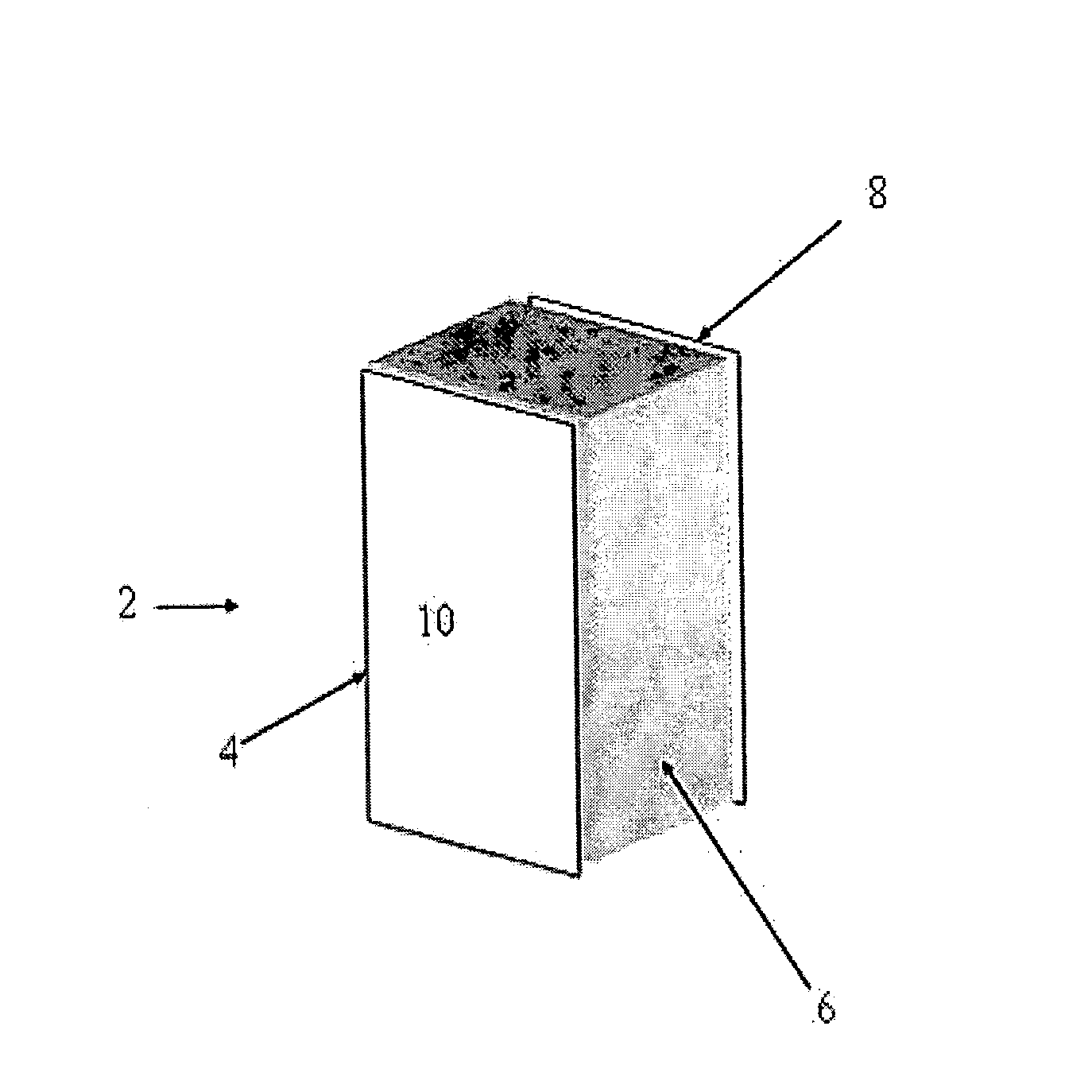

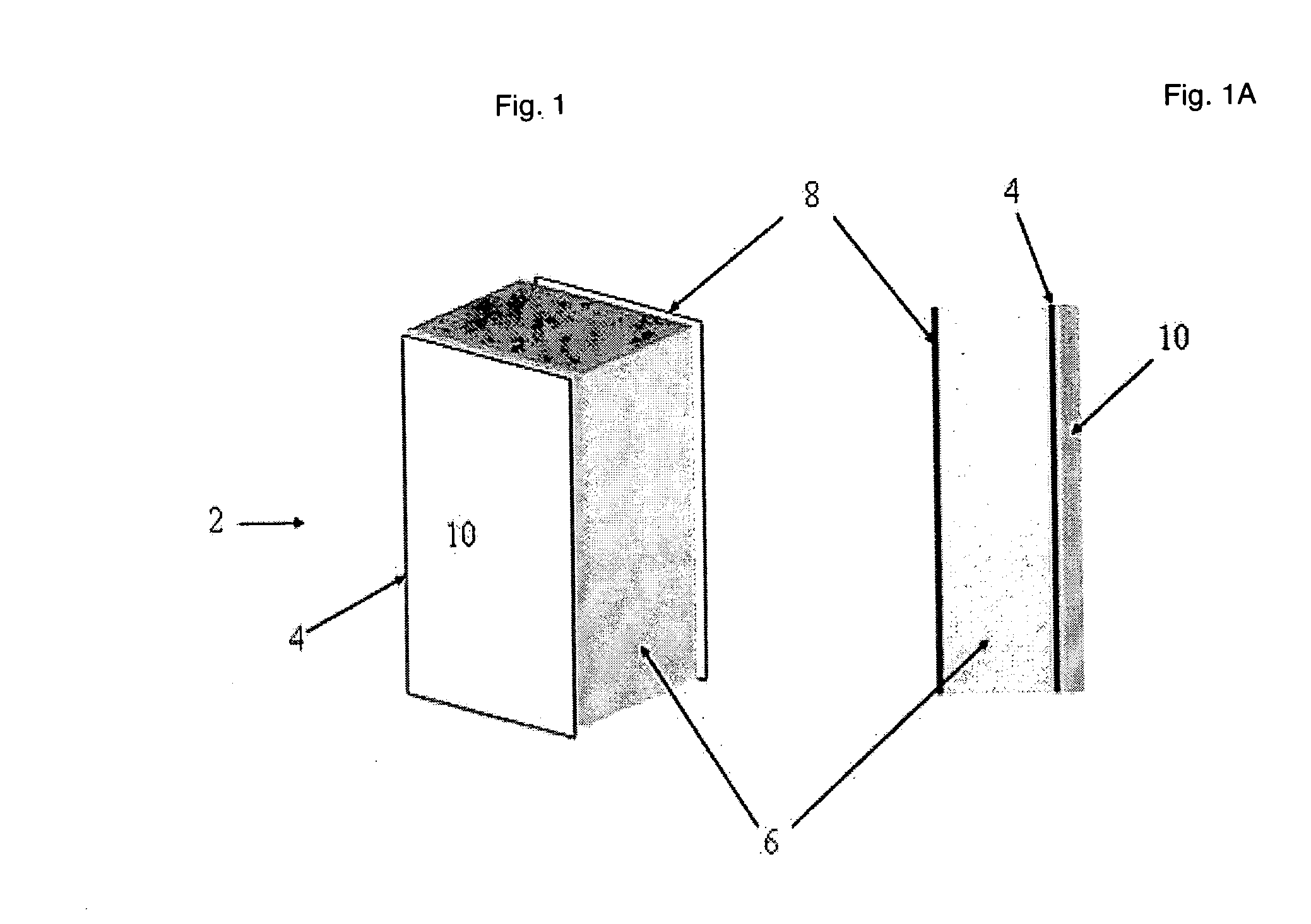

An insulating panel to be used in a panelized insulation system for insulating and finishing walls, including basement walls has a foam core made of inorganic materials. The system incorporates a capillary break, an integrated water drainage system and an electrical wire chase system within an insulating wall panel. Vertical slots are provided for insertion of metal studs for use in attaching the interior finish panel, such as inorganic fiber cement board with a vinyl laminate finish, onto the insulating panels. Embedding metal studs in the panel core reduces the sound transmission though the panel and eliminates thermal bridging between warm and cold surfaces. Steps on the edges and the top / bottom surfaces of the insulating panel allow more panels to join together with shiplap joints.

Owner:LEWIS DAVID L

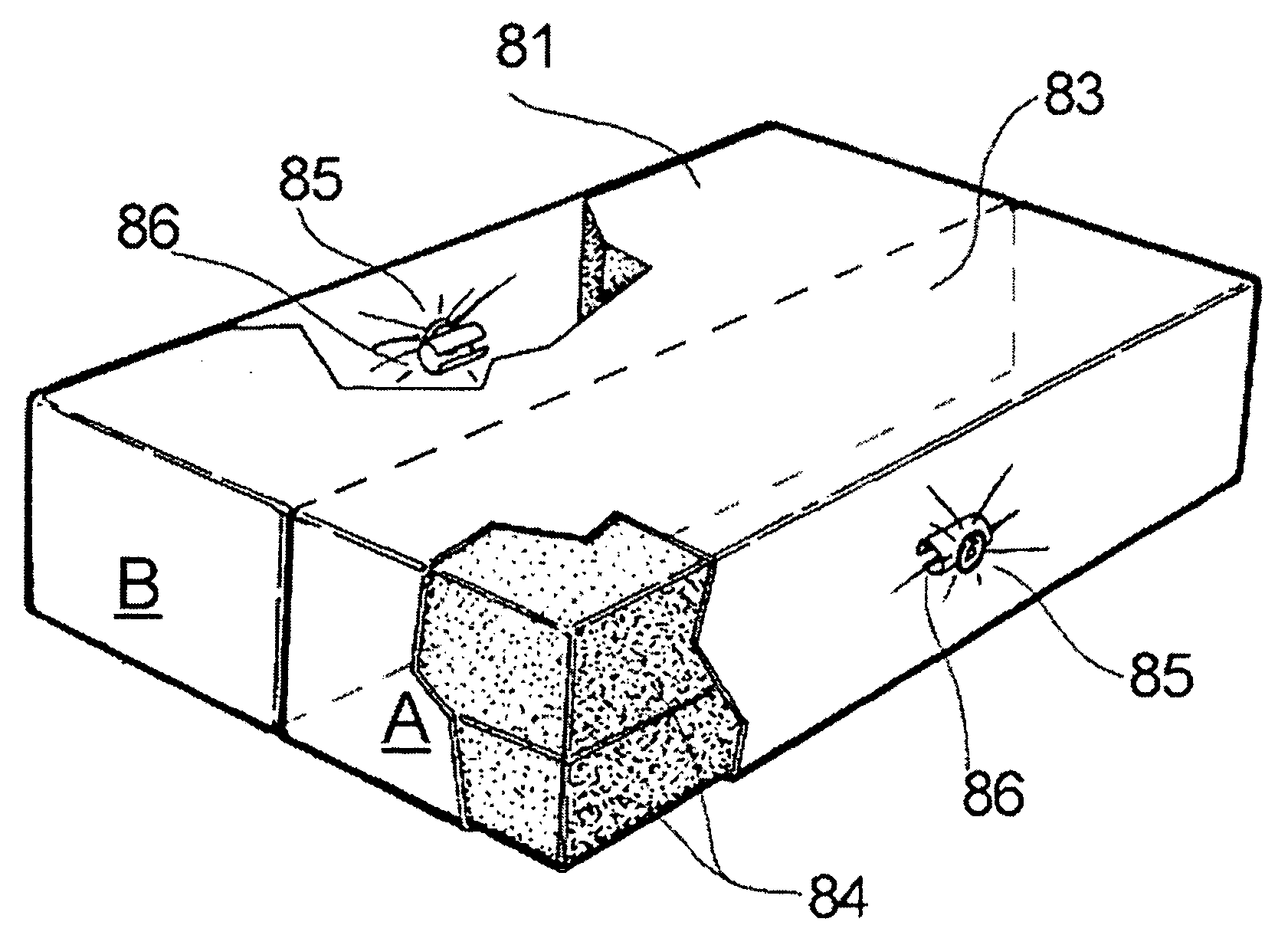

Adjustable foam mattress

InactiveUS20060075569A1Improve comfortLower comparable costStuffed mattressesSpring mattressesAir volumeEngineering

The invention modulates the air volume in foam cores of cushioning support devices and any other support apparatus using foam or similar materials. The foam core can be incrementally modulated to realize an infinite number of comfort levels as to softness and support firmness. The core consists of self-inflating open-cell flexible polyurethane foam and is completely sealed within an enclosure fitted over it, with one or more valves installed in the side walls which communicate with the outside air. Through the valves air is selectively withdrawn from the foam core, allowing the foam's density to increase. The invention uses relatively inexpensive foam, but through air volume modulation achieves a tactile feel of supreme softness for the user, without giving up the necessary firmness to support the body, as happens with very soft foam (bottoming-out or hammock-effect). When air is extracted from a self-inflating foam core, the surface of the core will soften uniformly while maintaining its support firmness. Contrary to this, when pressure is exerted on, for example, traditional coil spring core mattresses, their surface will harden. Integral part of the invention is a device using balanced springs in valve assemblies to avoid compression set, an irreversibly solid state of totally air-depleted foam.

Owner:GIORI GINO +1

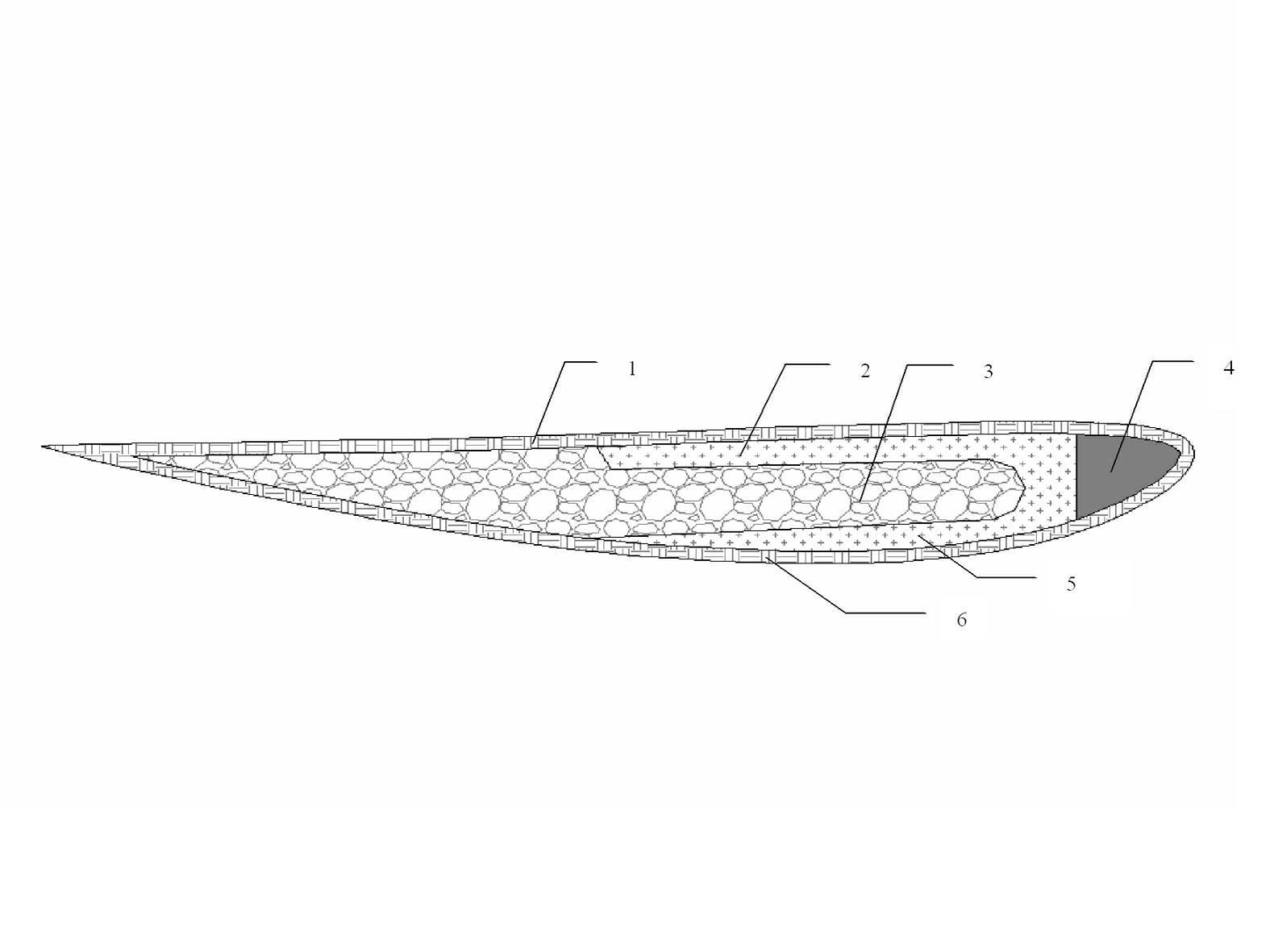

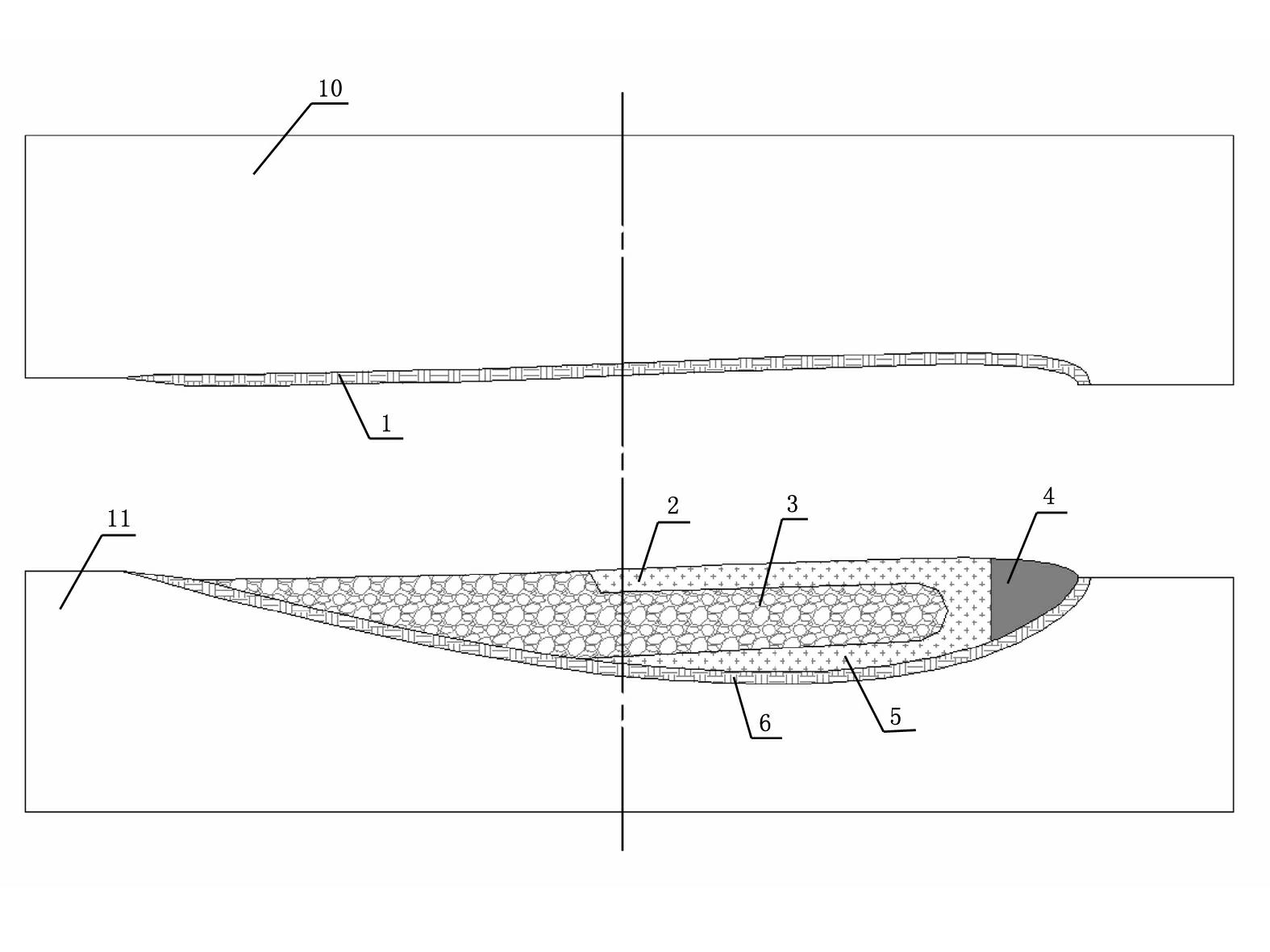

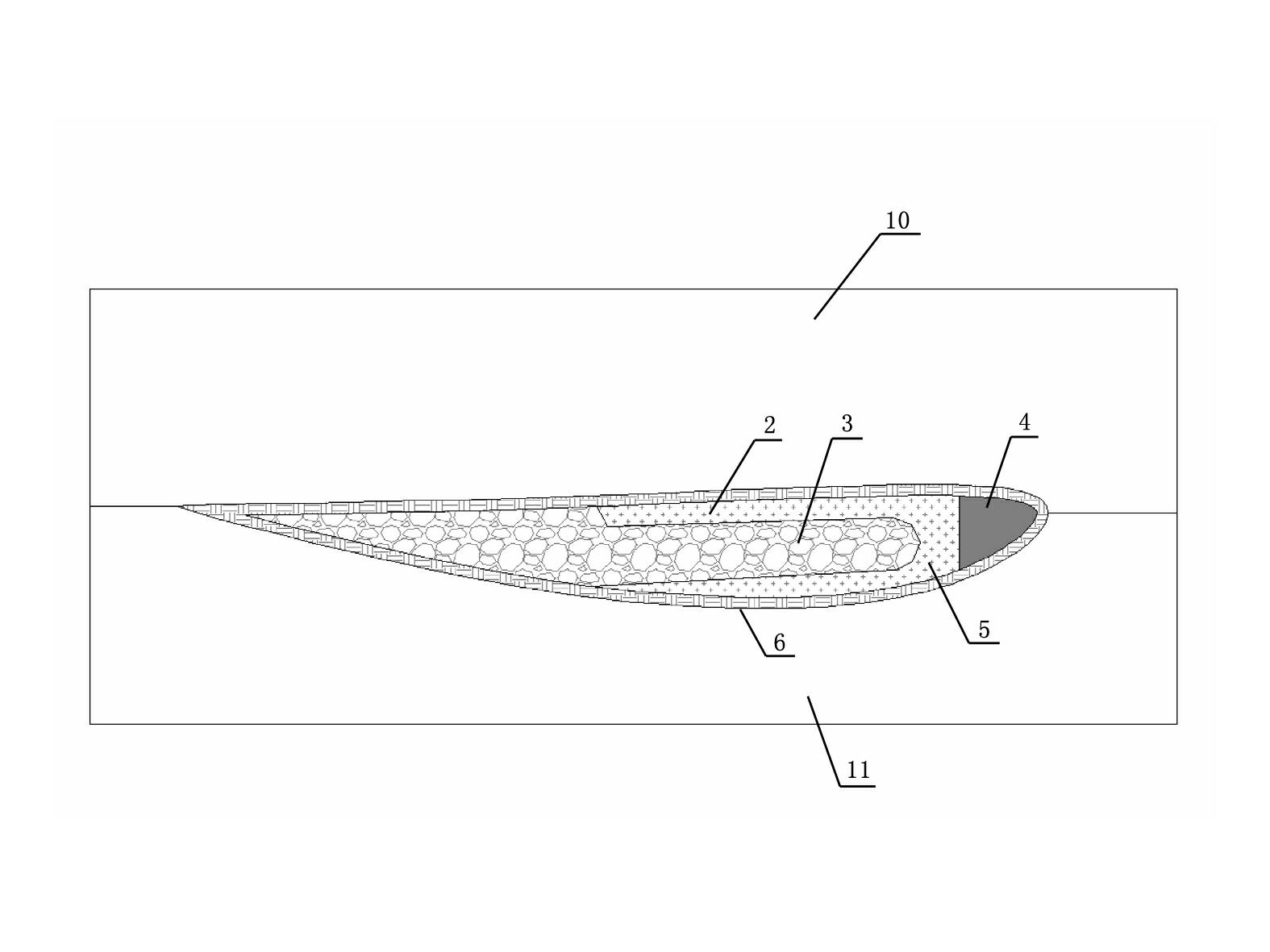

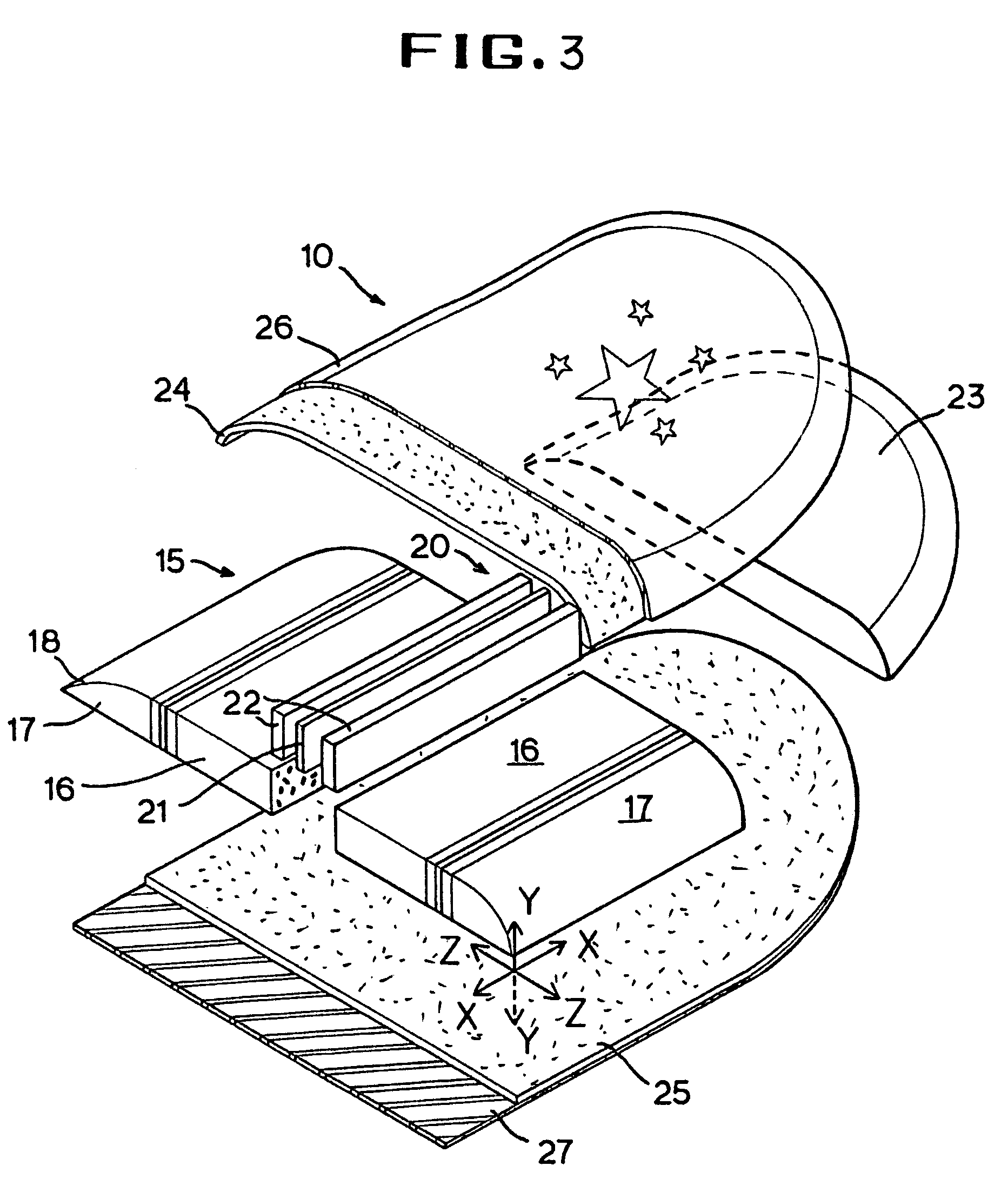

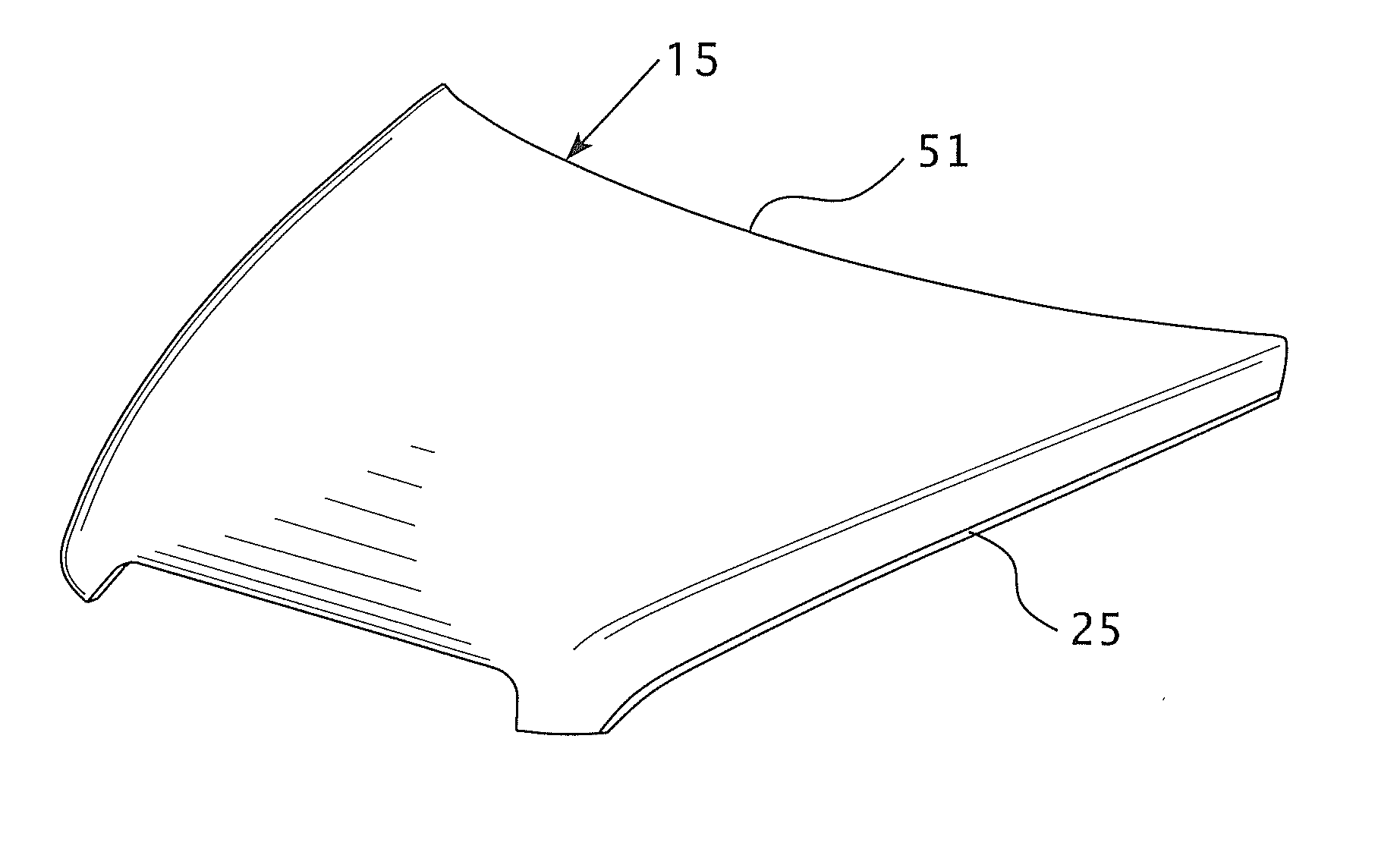

Composite rotor blade for unmanned helicopter and manufacturing method thereof

The invention relates to a composite rotor blade for an unmanned helicopter and a manufacturing method thereof. The composite rotor blade comprises an upper airfoil skin, a lower airfoil skin, an upper airfoil part of a C-shaped crossbeam, a lower airfoil part of the C-shaped crossbeam, a leading edge balance weight lead strip, a paddle root lining, a foam core, a paddle tip balance weight lead block and a balance weight pipe, wherein the upper airfoil skin and the lower airfoil skin are closed to form the profile of a blade; the leading edge balance weight lead strip is arranged on the leading edge of a blade airfoil profile; the upper airfoil part of the C-shaped crossbeam and the lower airfoil part of the C-shaped crossbeam are combined to form the C-shaped crossbeam; the C-shaped crossbeam is close to the leading edge balance weight lead strip; the foam core is filled into a trailing edge part of the C-shaped crossbeam; and in order to regulate balance, the paddle tip balance weight lead block and the paddle tip trailing edge balance weight pipe are cured on the front section of the blade, and the paddle root lining is arranged on the rear section of the blade.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

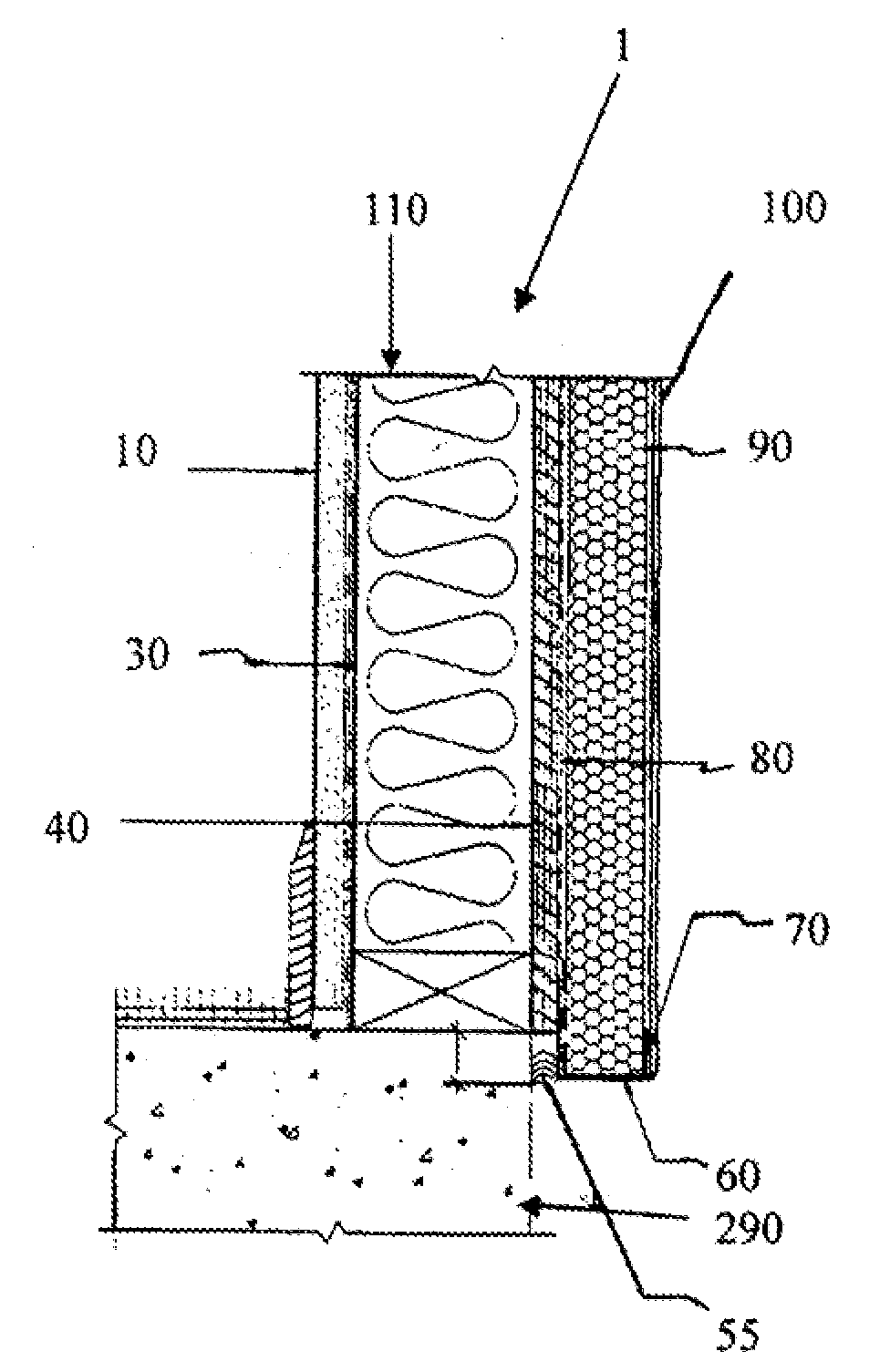

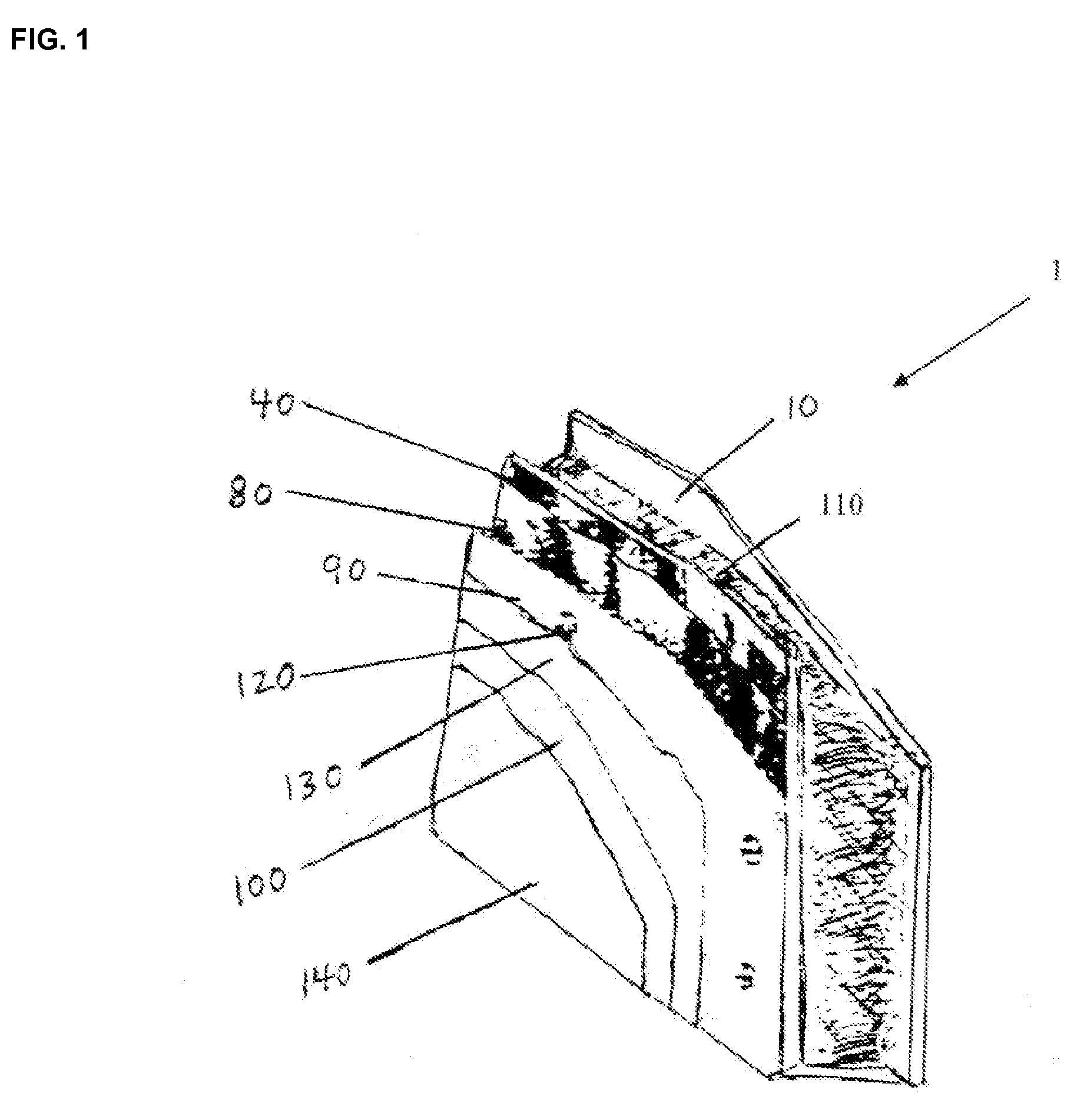

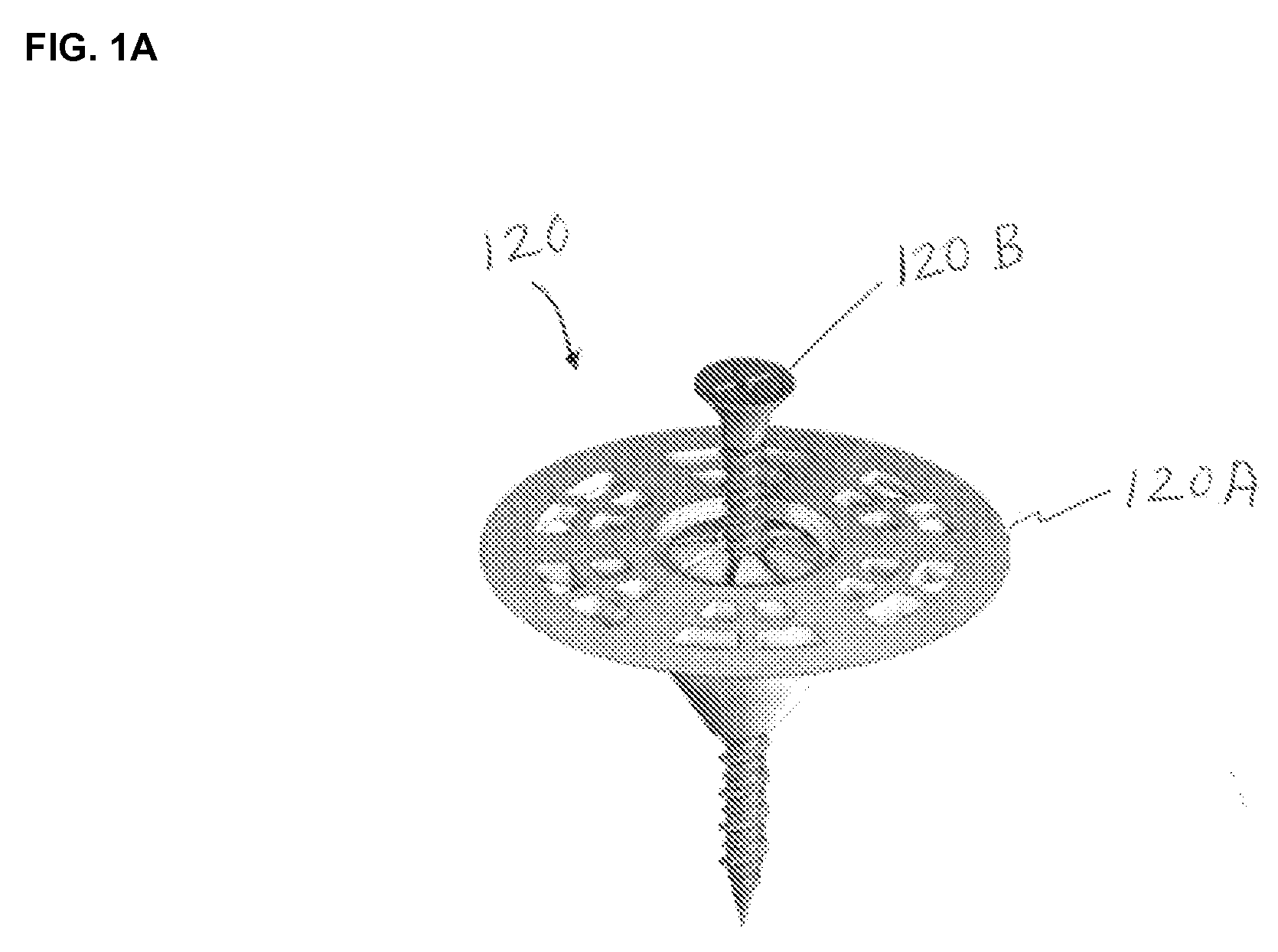

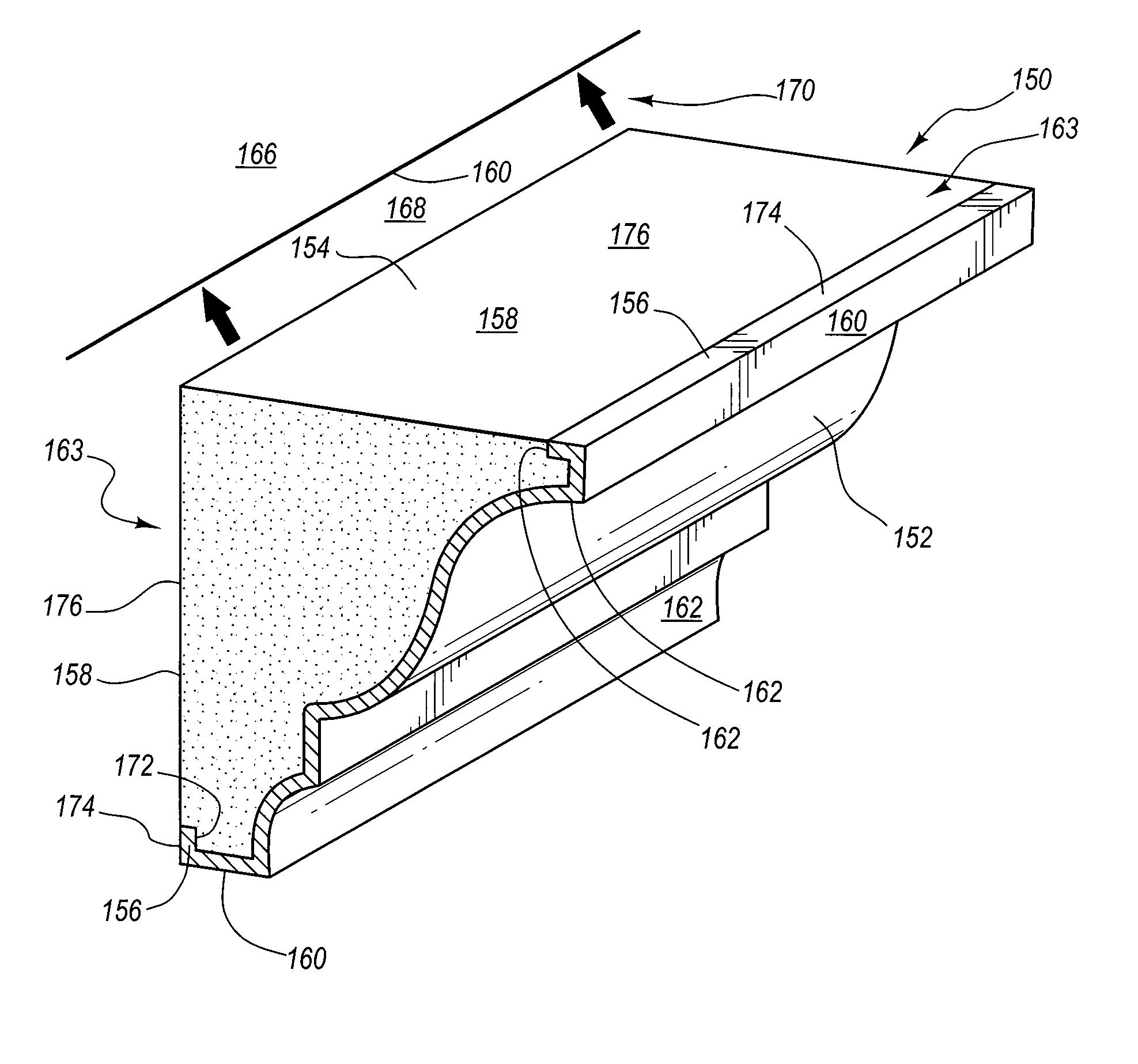

Composite insulating building panel and system and method for attaching building panels

An insulation panel includes a foam core with a reinforced and vapor-impervious facing disposed on one or both sides of the core. A portion of the facing extends beyond the core and has an adhesive so that the overhanging portion can be secured to an abutting panel to cover a seam between the abutting panels. A fixture for forming the panel includes two heated platens, preferably provided with a textured surface, held apart by a spacer and between which the facing is mechanically suspended. An installation of the insulation panel includes panel-securing elements attached to frame elements of the building and including first and second flanges spaced apart by the thickness of the panel. A portion of the insulation panel is disposed between the first and second flanges, the first flange is secured to the frame element, and a cover panel disposed over the insulation panel is secured to the second flange.

Owner:PACIFIC INSULATED PANEL

Structural insulated roof panels with rigid foam core

Owner:FUNFORM LLC

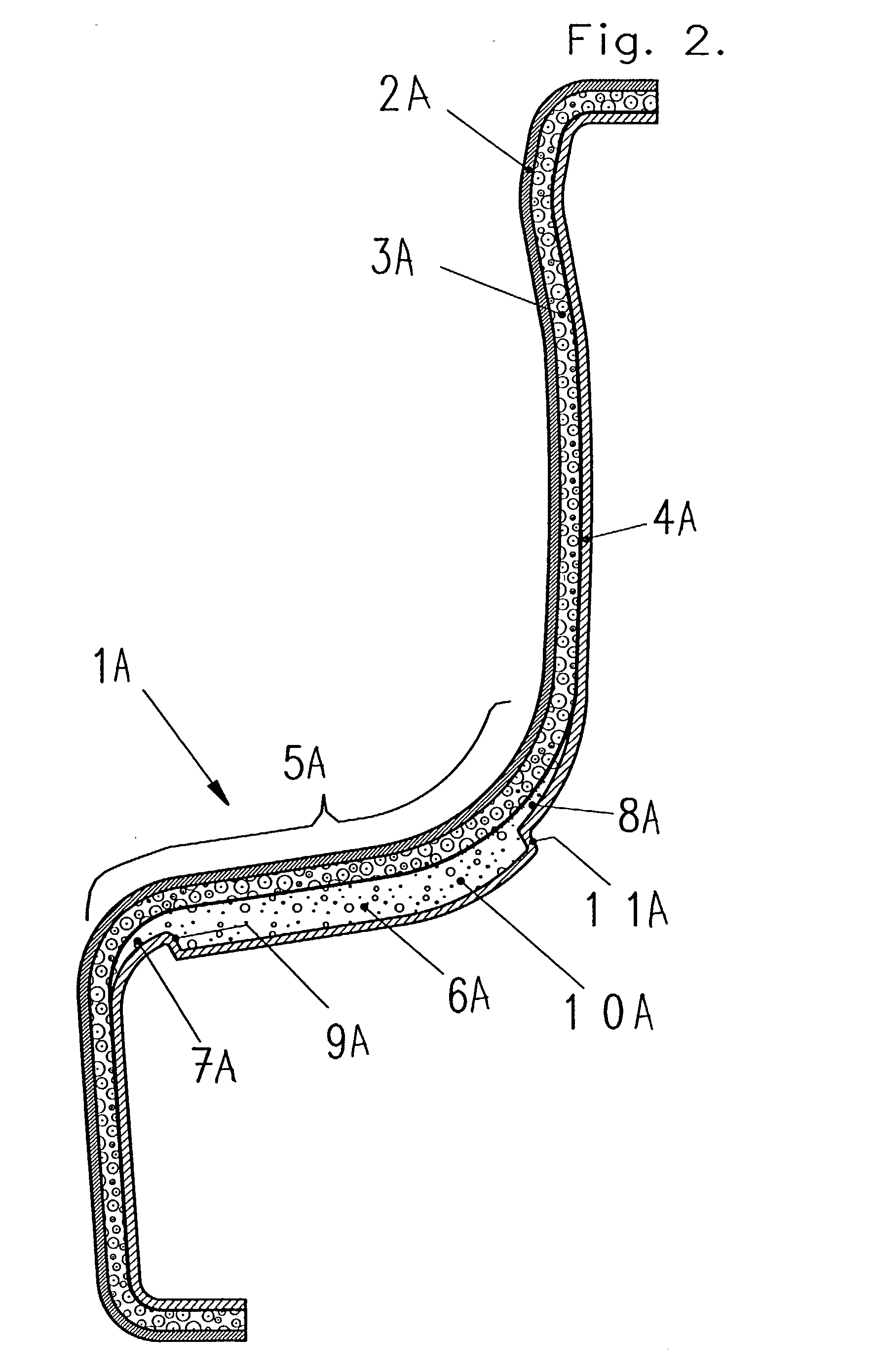

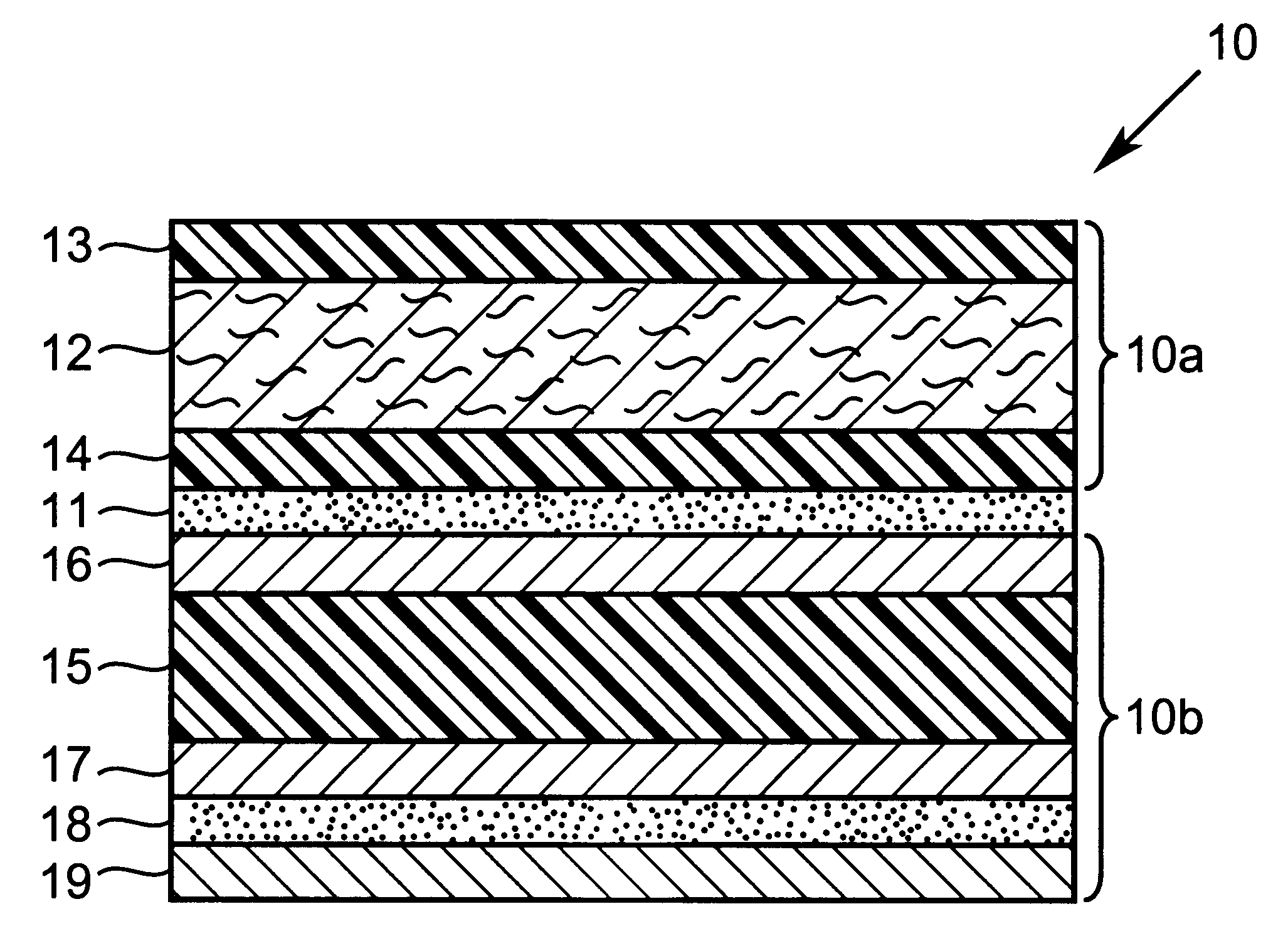

Packaging laminate with gas and aroma barrier properties

InactiveUS6338870B1Improved barrier and durability propertyWrappersMolten spray coatingThin oxidePaperboard

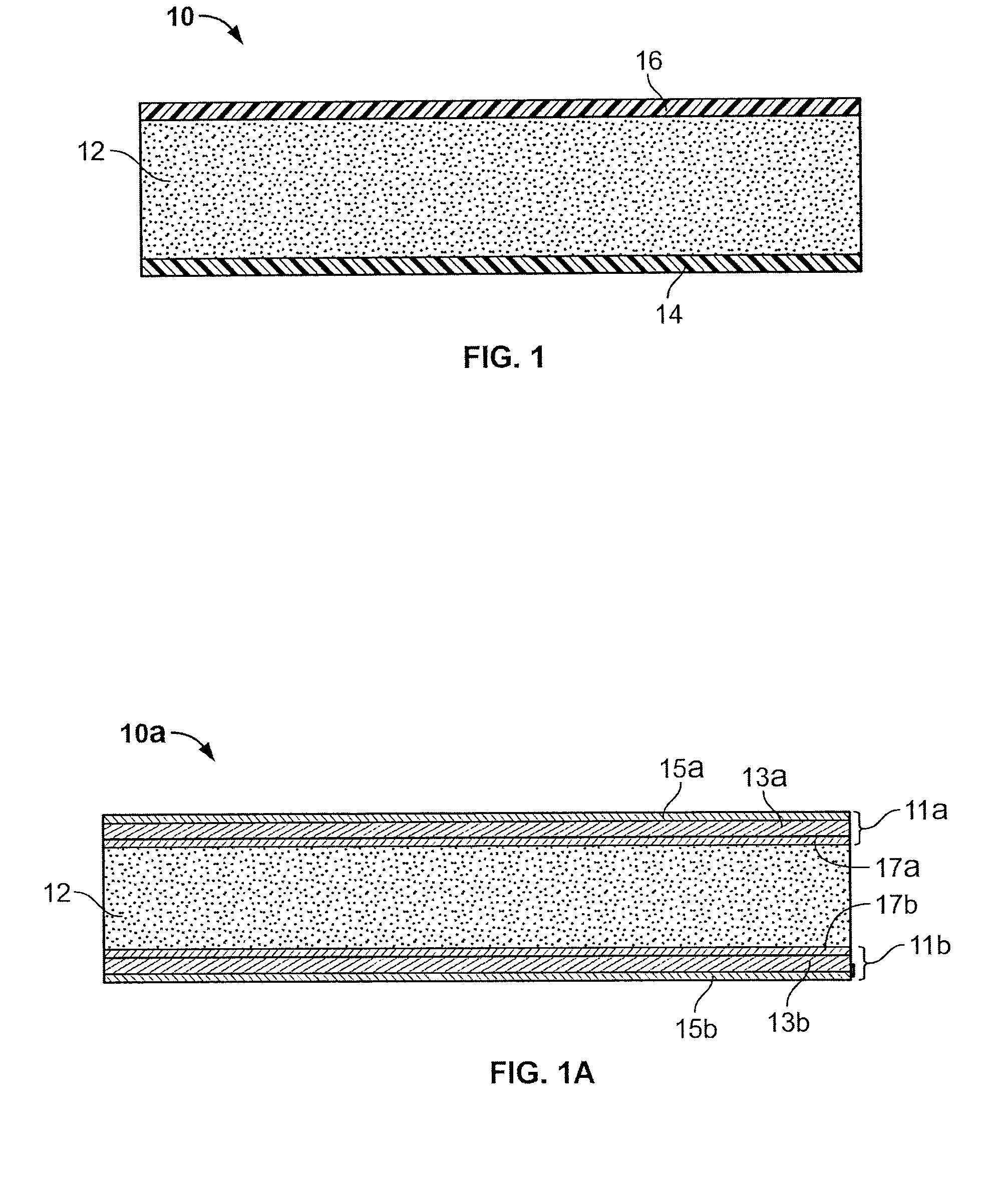

A packaging laminate (10) including a substrate film (15) coated with a carbon containing silicon oxide layer (16, 17) on both surfaces is disclosed herein. A method for producing the laminate (10), and blanks and packages fabricated from the laminate are also disclosed herein. The PECVD process of the present invention strains the substrate film (15) during deposition thereby creating a very thin oxide layer with superior durability, oxygen and aroma barrier properties. The carbon-containing silicon oxide coating (16, 17) has a stoichiometry of SiOxCy in which x is witin the range of 1.5-2.2 and y is within the range of 0.15-0.80. The substrate film (15) may include a core layer (12) of a material selected from the group consisting of paper, paperboard, a foamed core, polyethylene terephtalate, polyamide, polyethylene and polypropylene.

Owner:TETRA LAVAL HLDG & FINANCE SA

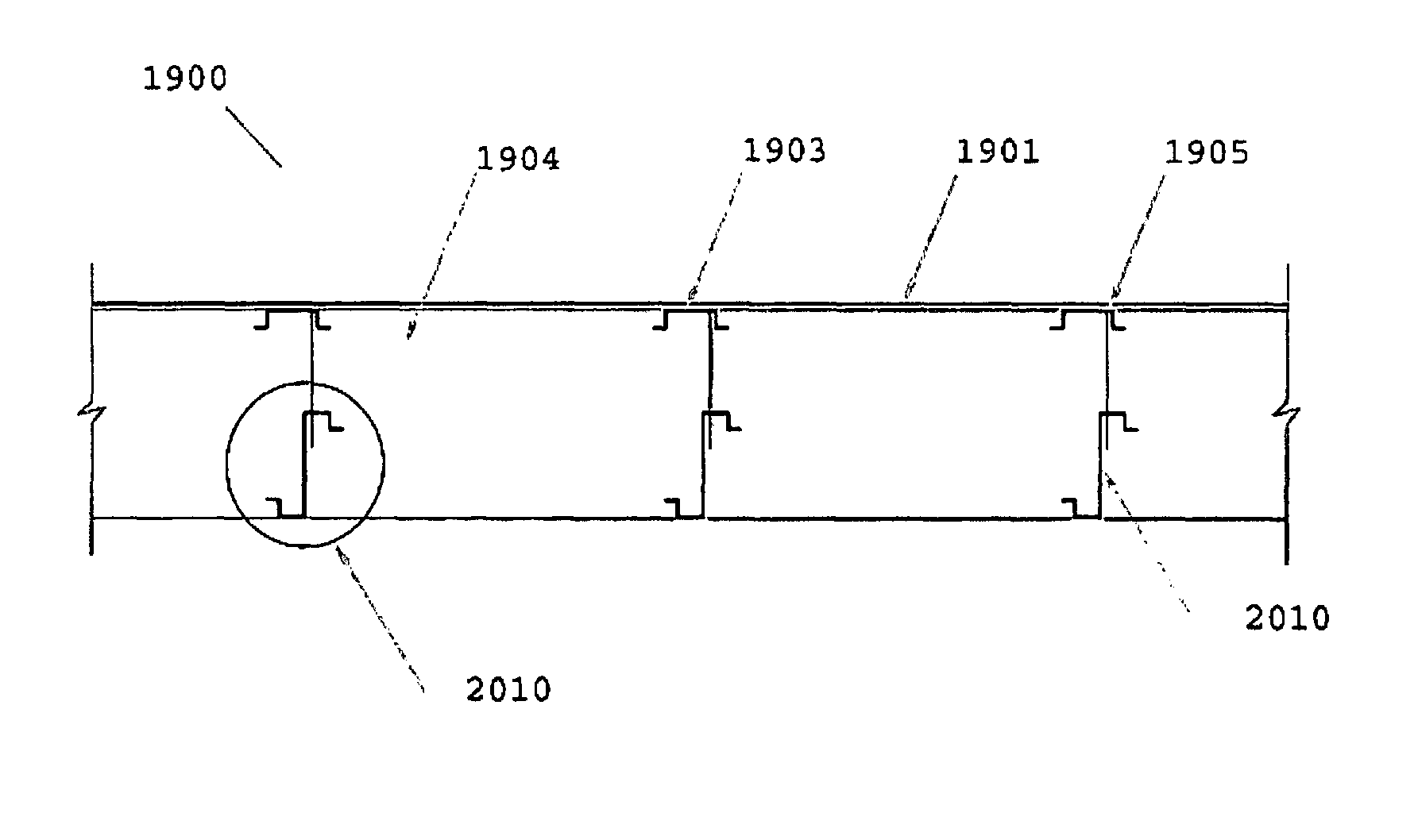

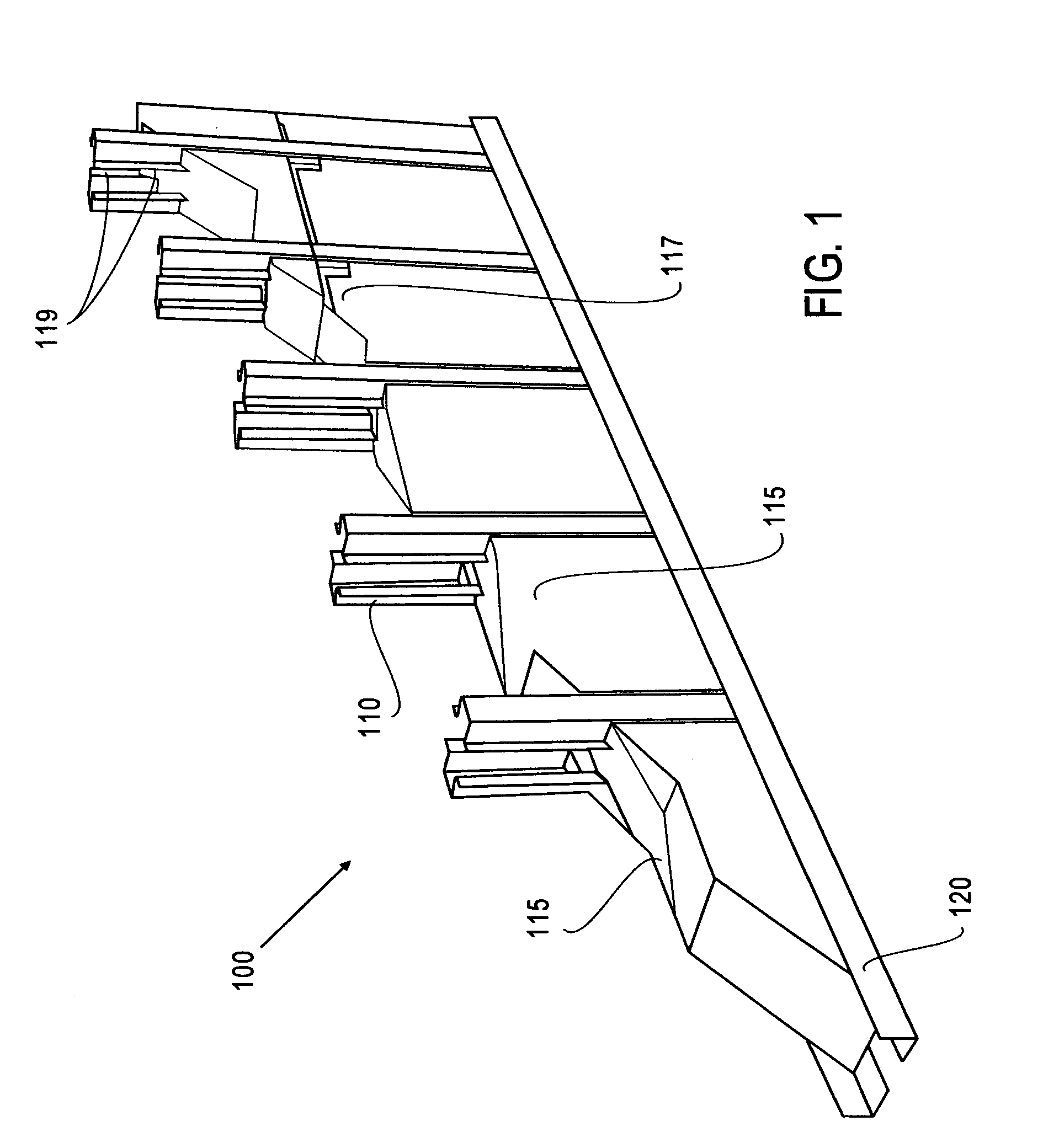

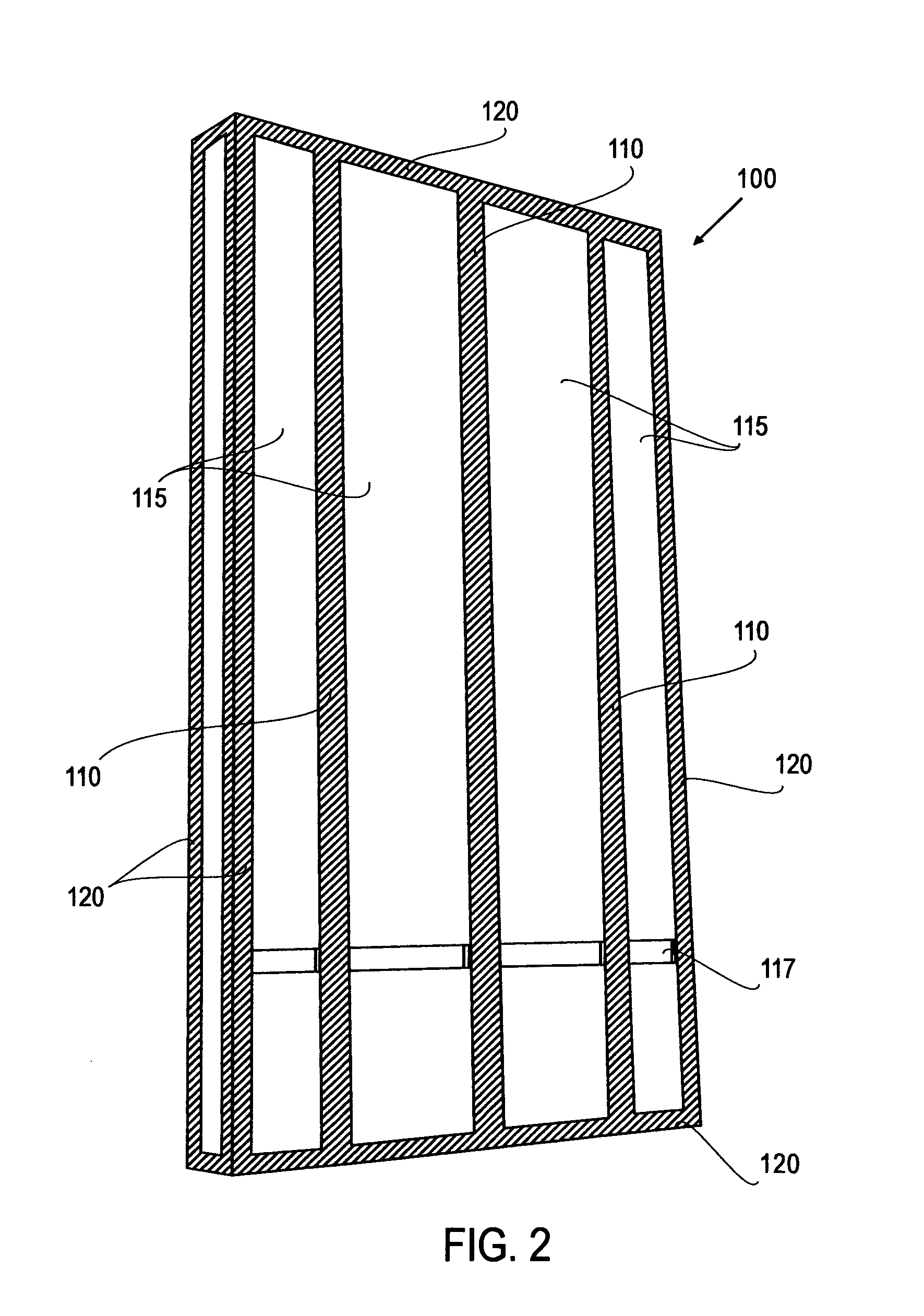

Modular building system utilizing composite, foam core panels

A system for constructing a structure comprises a plurality of composite panels having a laminate structure comprising a foam core to which are attached cover layers of the same or different material. One or both of the cover layers may be comprised of composite sub-layers. The system includes a number elongate and preferably extruded components for connecting the panels to form walls, roofs or floors for the structure. The system is modular, thereby allowing for a time and cost efficient means of erecting a structure.

Owner:INNOVATIVE COMPOSITES INT

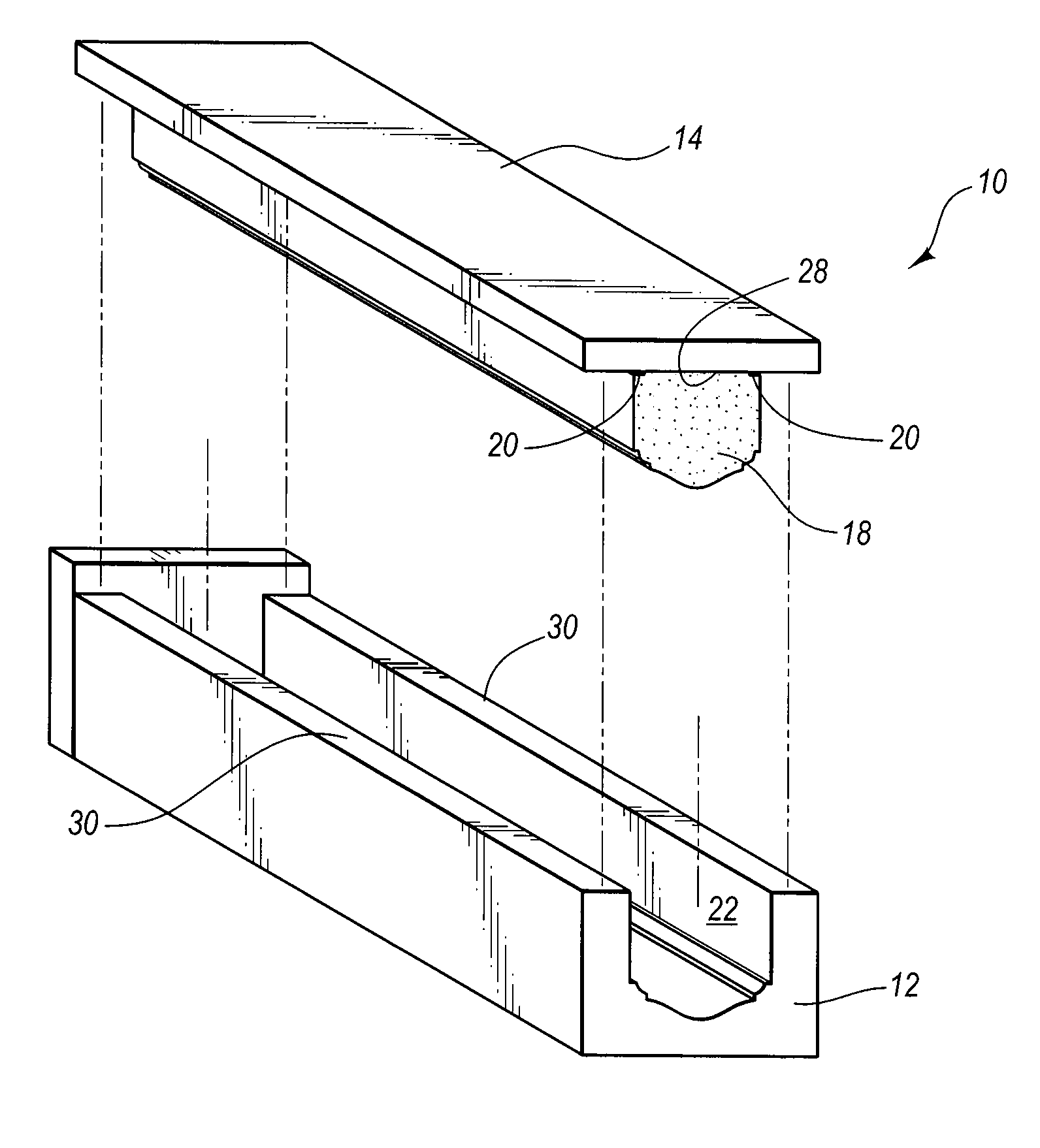

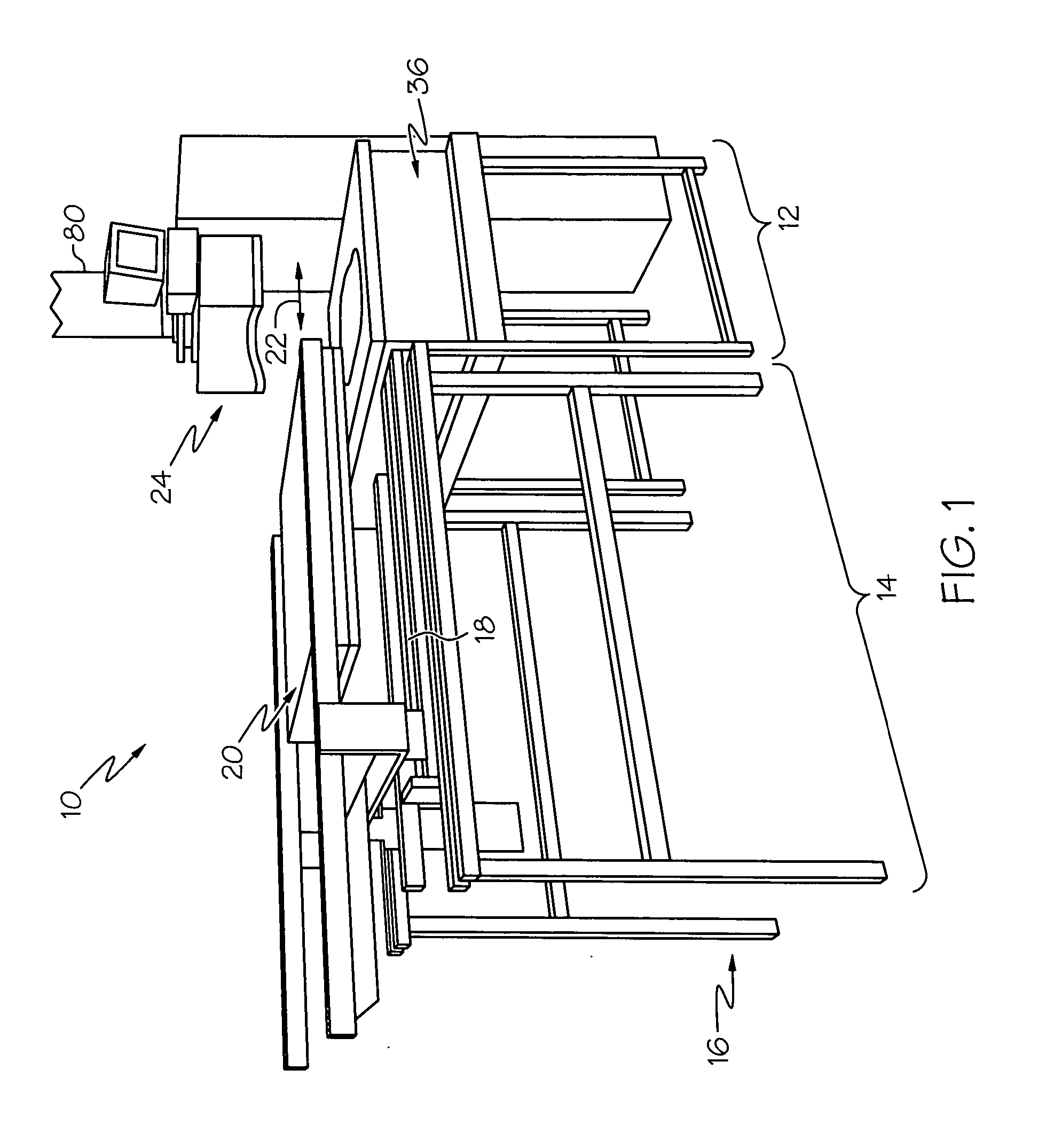

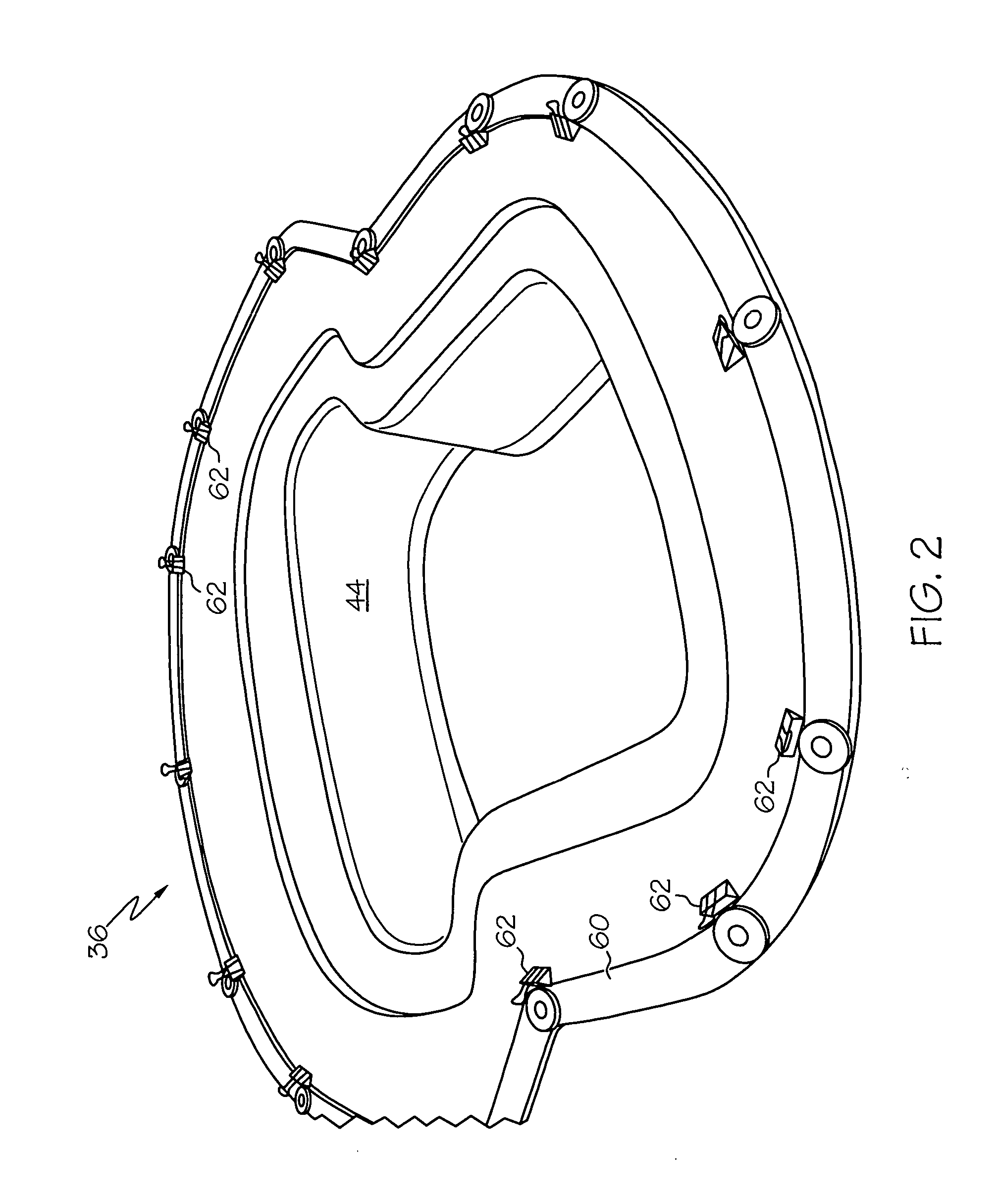

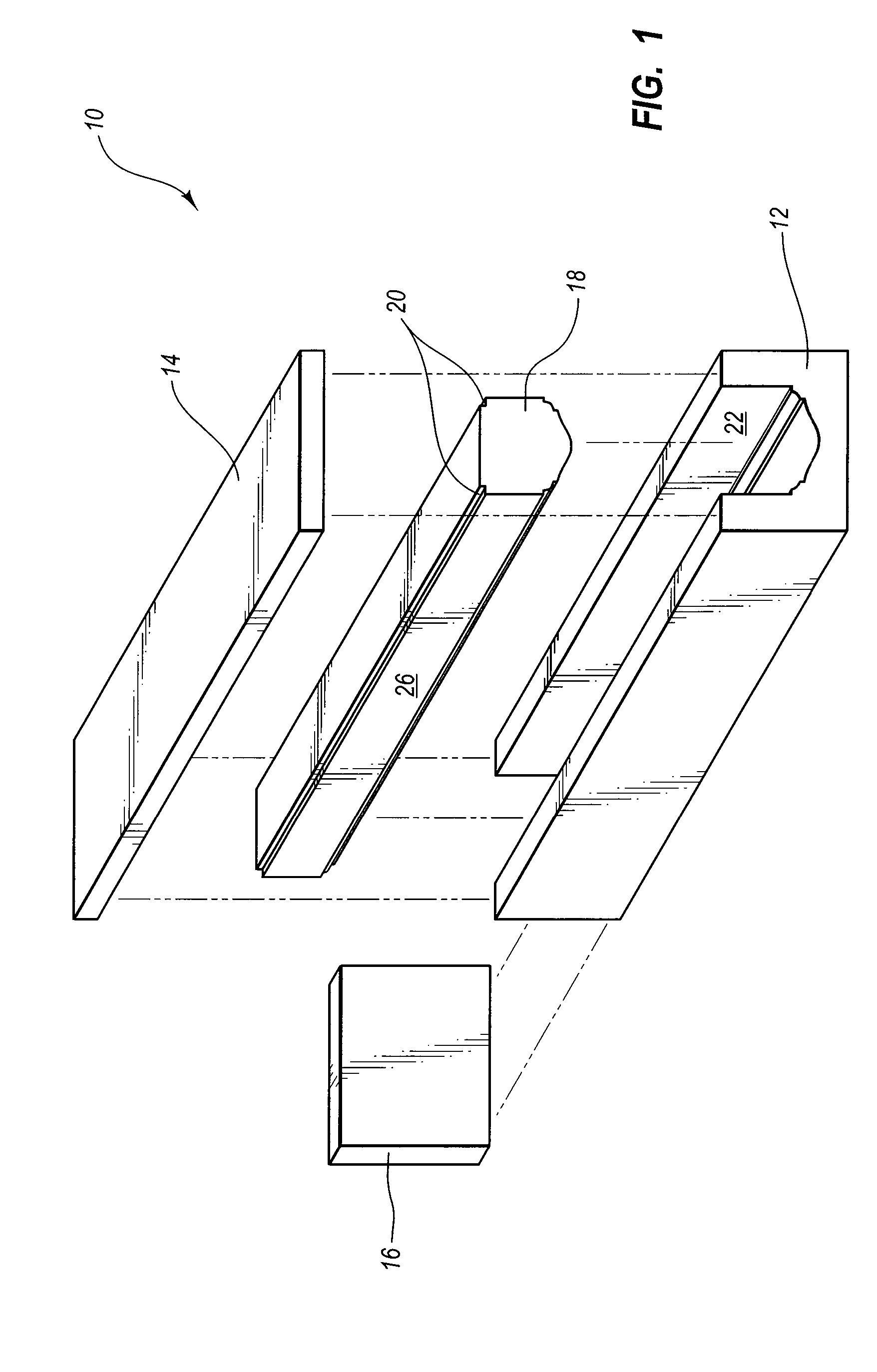

Resin transfer molding process

A wind tunnel blade (30) connected to a base (32) and held in position by a two-piece cuff (34). The wind tunnel blade (30) is formed in a resin transfer molding process in which central, fore, and aft foam core sections (70, 72, 74) are placed together to form the wind tunnel blade (30). Radius fillers (120) are used to fill the gaps between the outer edge of the foam core sections. The radius fillers (120) used in the wind tunnel blade (30) are formed by a braided sleeve (122) surrounding a number of unidirectional tows (124). A tip (68) is formed separately from the rest of the wind tunnel blade (30) and is glued to the top thereof. Stacked layers of braided fibers (100) are used to reinforce the central core section (70).

Owner:THE BOEING CO

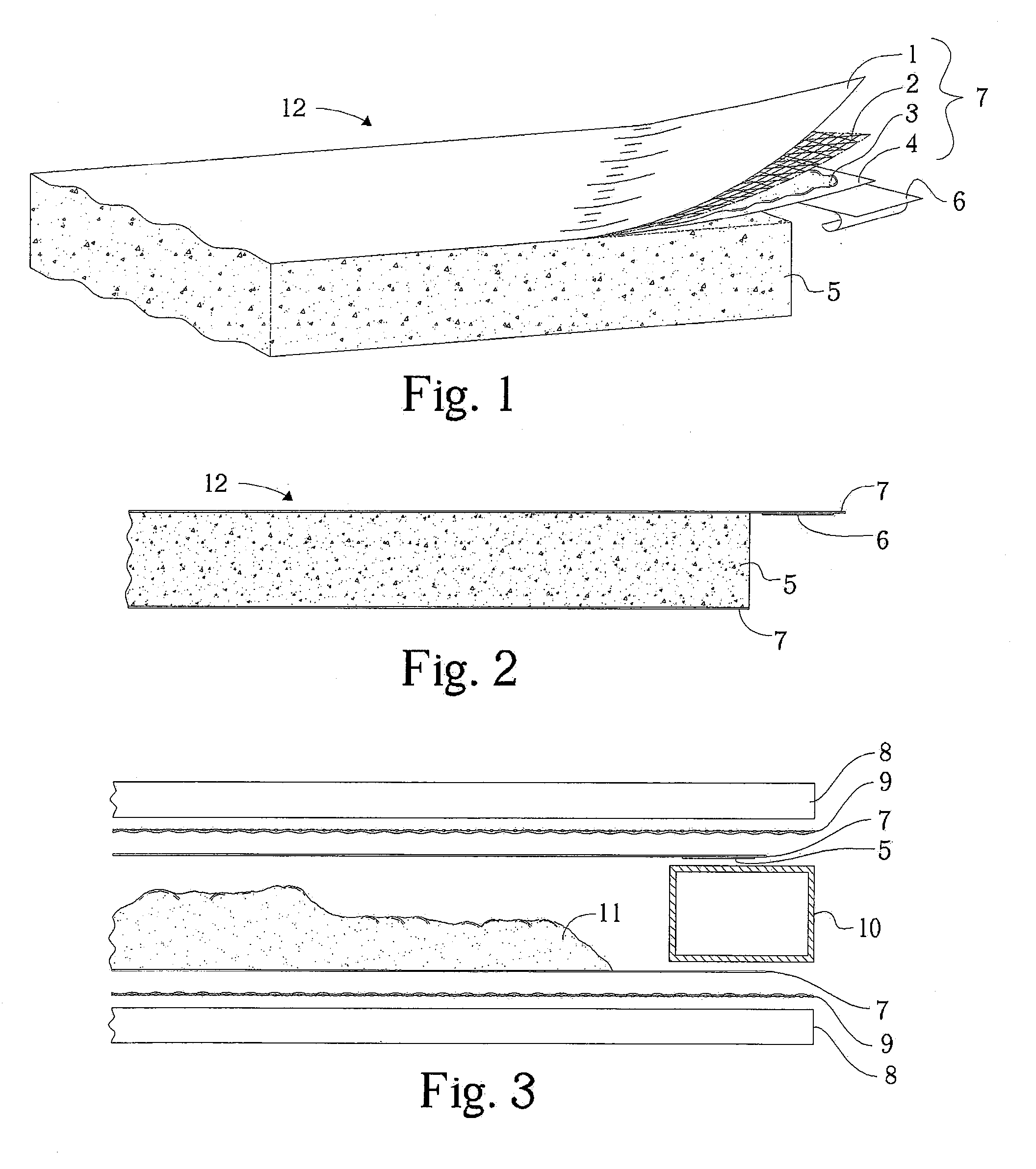

Molded stone architectural product having a foam core

InactiveUS20070157537A1Stable supportWeight controlConstruction materialFloorsBuilding productFoamcore

An architectural cast stone product for use in building construction, which has a unitary shell made of a molded cementitious material that partially surrounds and is affixed to a foam core. The architectural cast stone product has a mounting surface including an exposed surface of the foam core and an exposed surface of the shell. The architectural cast stone product is made by obtaining a front pattern having a desired surface configuration for the architectural cast stone product, obtaining a foam core, affixing the foam core to a backer, affixing the front pattern to the backer that together form a mold, pouring a cementitious material into the mold and into contact with the foam core, at least partially curing the cementitious material to form the architectural cast stone product, and removing the front pattern and backer from the architectural cast stone product.

Owner:E KHASHOGGI INDS +1

Advanced composite radome and method of manufacturing

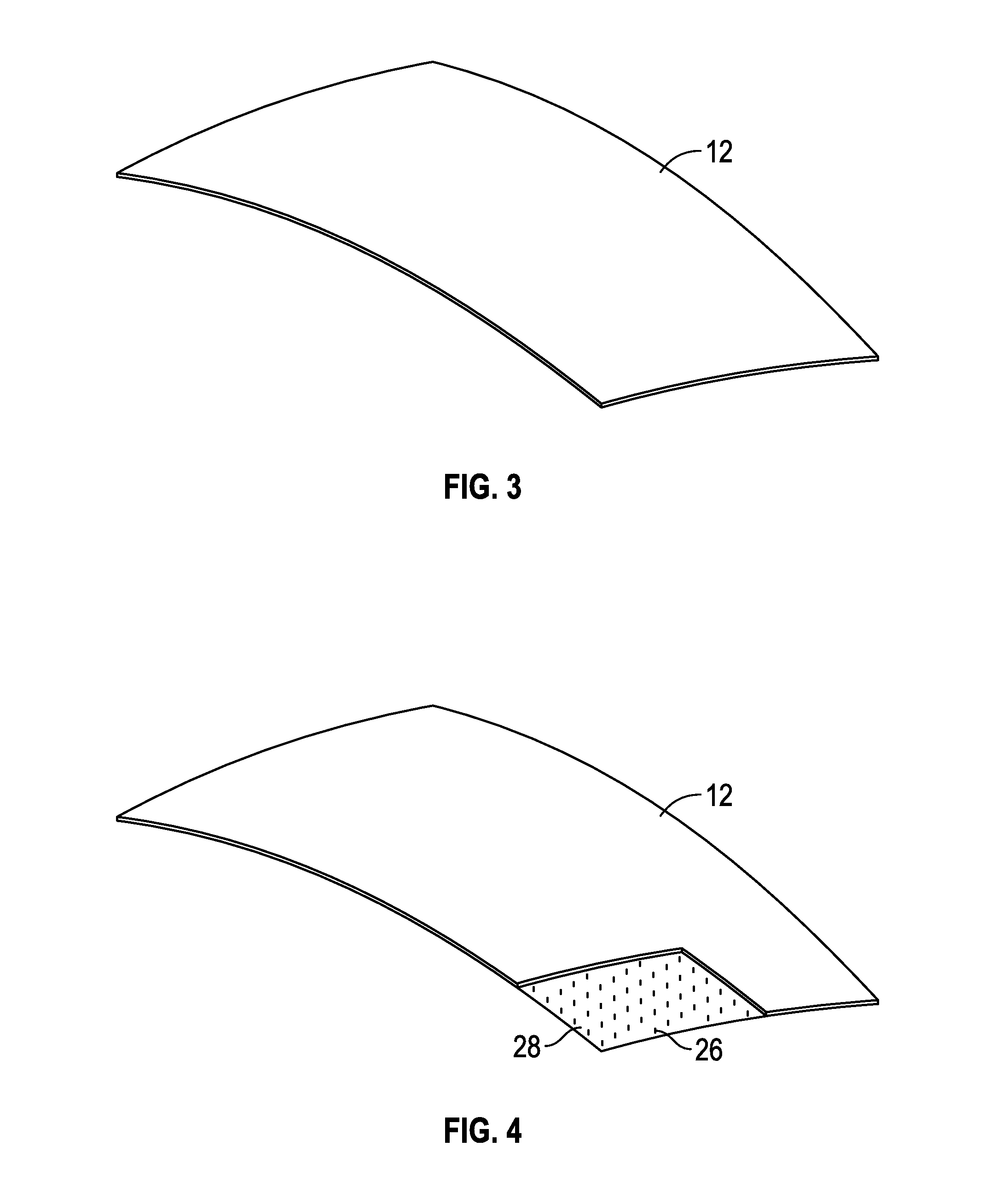

ActiveUS20150022423A1Superior weathering and hydrophobic propertyImproves UV resistanceMeasurement devicesLayered productsFiber bundleRadar systems

A radome for housing a radar system comprises a plurality of interconnected curved radome thermoplastic composite material panels, each curved radome thermoplastic composite material panel having a plurality of interconnecting edges, a foam core, an inner skin, an outer skin, and a plurality of three-dimensional fiber bundles tying the inner skin and the outer skin to each other through the foam core, inhibiting delamination. The radome includes a hydrophobic exterior surface that is self-cleaning and requires zero maintenance for 25 years.

Owner:EBERT COMPOSITES

Pet step and method

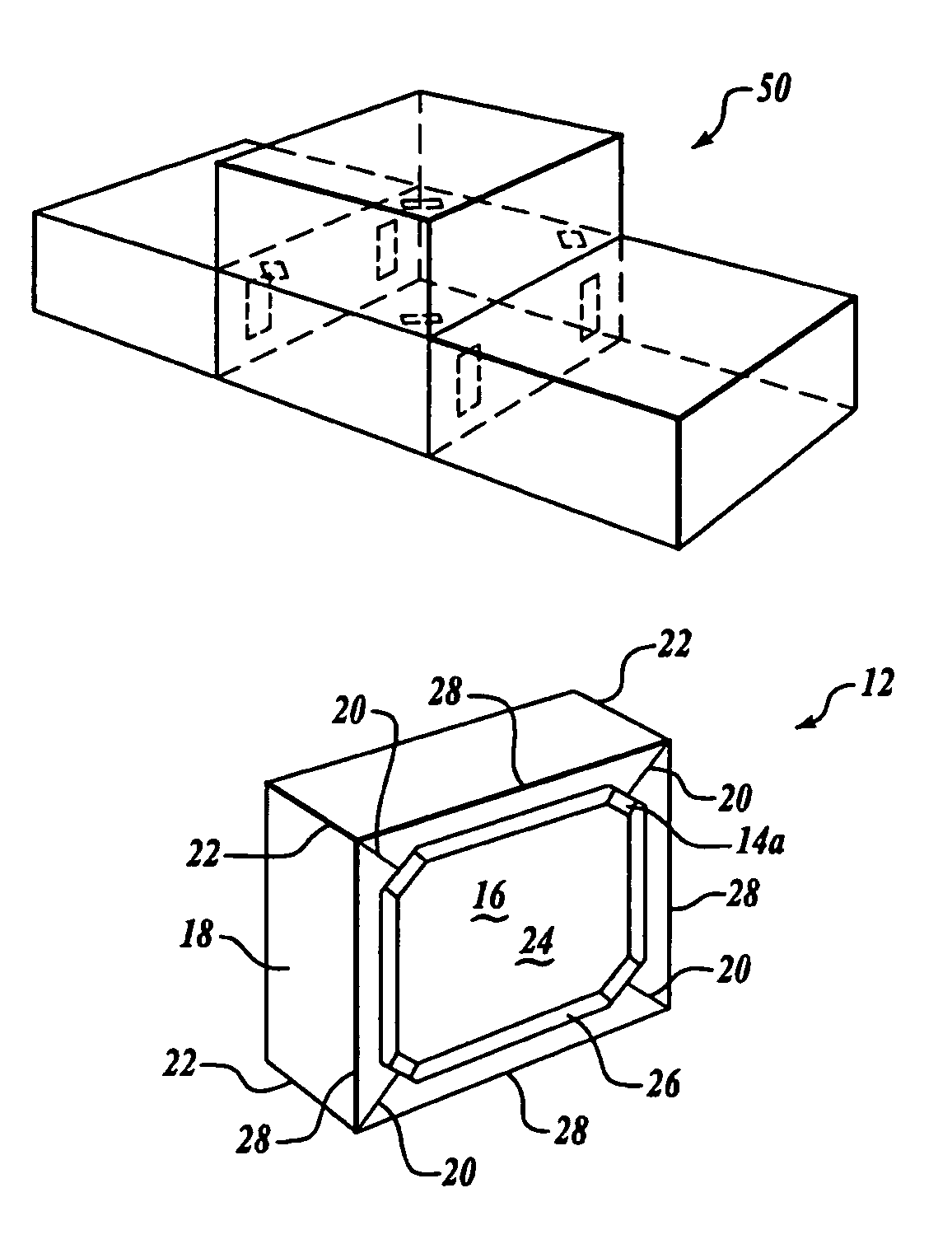

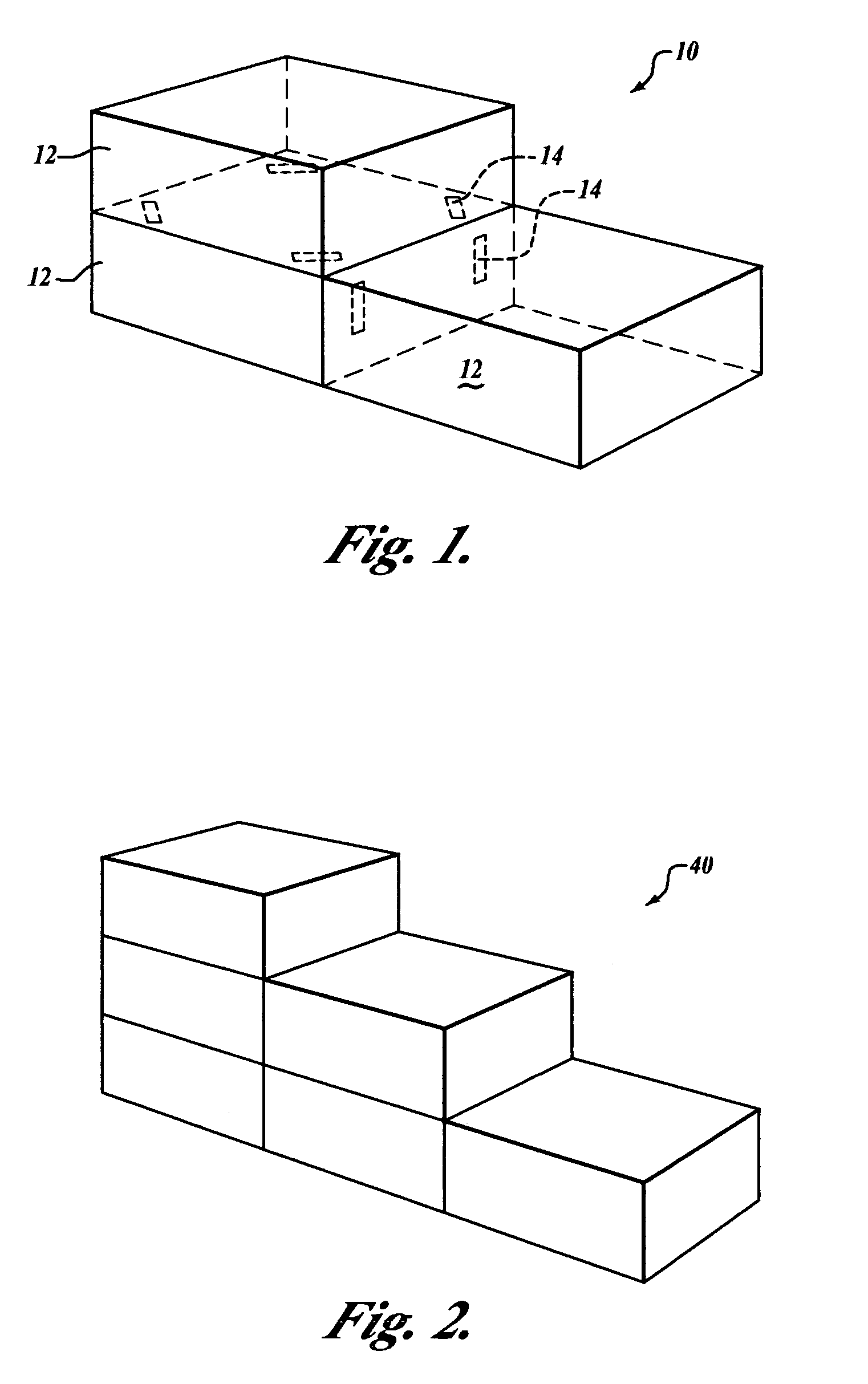

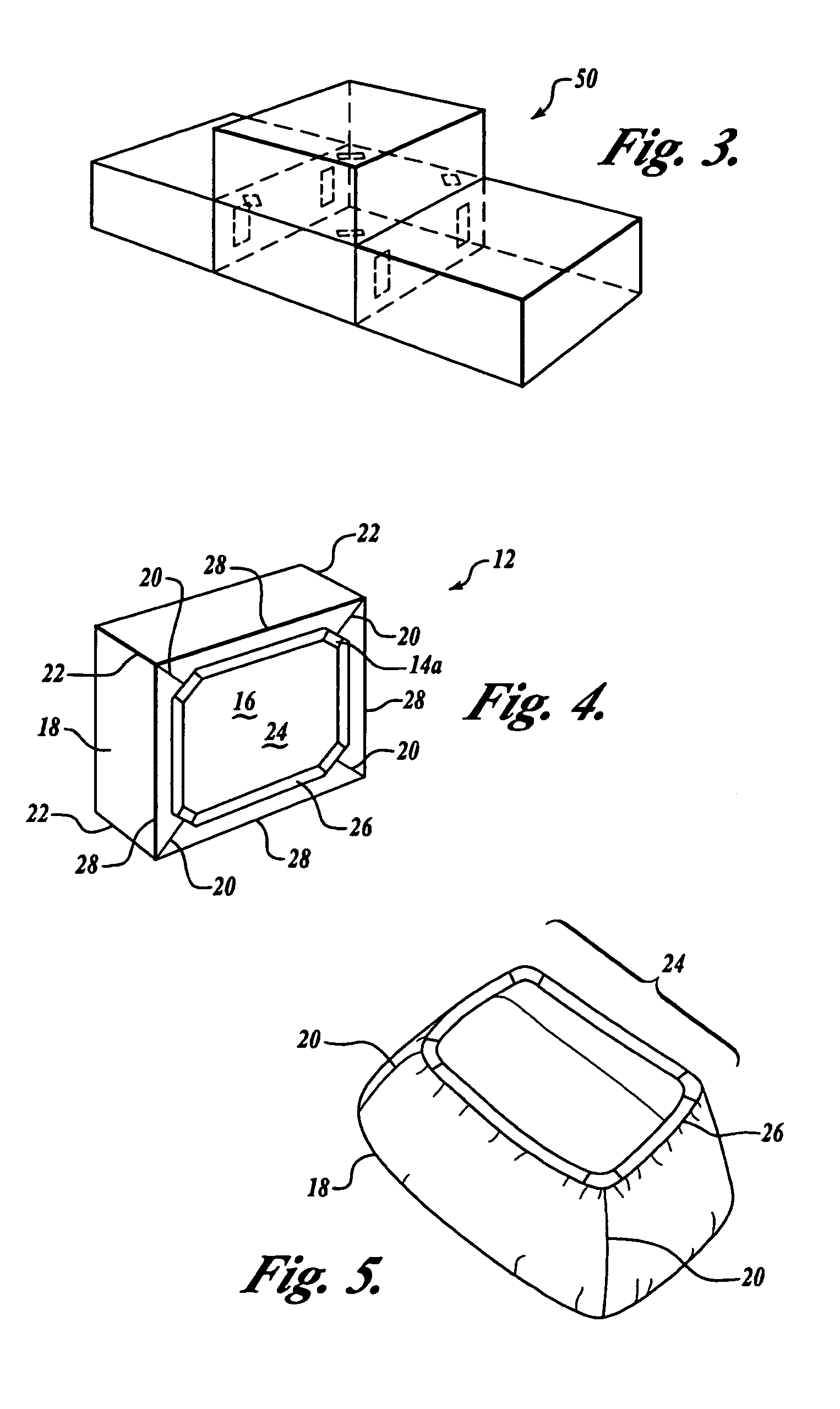

InactiveUS6964246B2Safely and comfortably climbIncrease coefficient of frictionAnimal housingLoading/unloadingHigh densityCompanion animal

A pet step is a modular foam core item which can be used alone or in an arrangement with other pet steps—referred to as cubes—to form a stair and offers a comfortable way for a pet that has been debilitated by age, surgery, illness, or injury to climb, e.g., from the floor to the couch and down, eliminating the impact of jumping. Each step is formed of a washable fabric cover stretched across a high-density foam core, the core being usually of regular block shape, but alternatively in the shape of a trapezoidal block, right wedge, or other. The cover may be made from various fabrics with different textures, colors, and designs, and is secured around the foam core using a band of elastic. Thus, the cover is easily removable and washable. The pet steps are intended to be used in a stair, formed by placing the steps adjacent one another with the elasticized opening of the cover on the bottom sides of the steps and mating and engaging the optional fasteners, such as hook-and-loop fasteners, which are mounted between the adjacent step surfaces.

Owner:STORE CHAIN INC

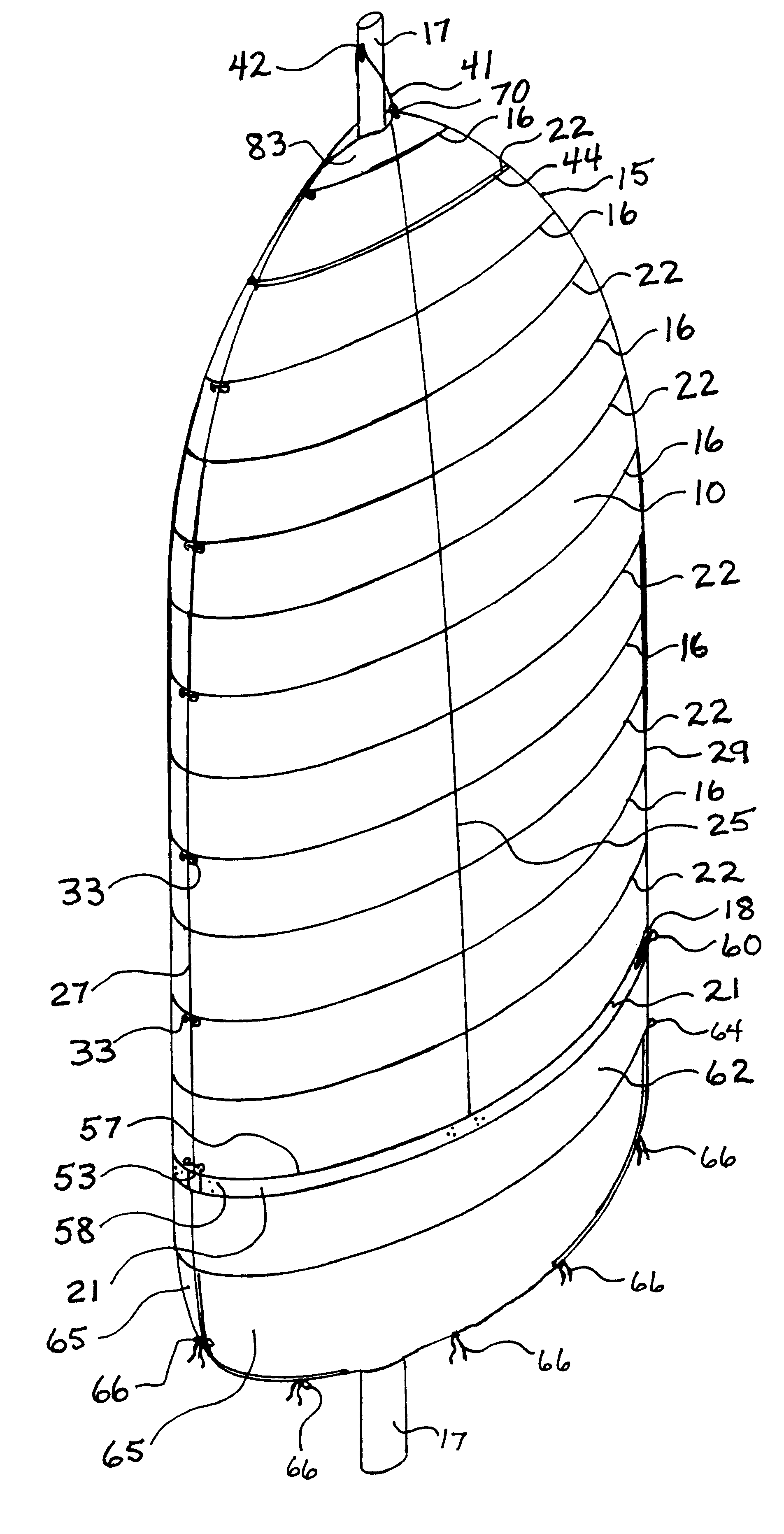

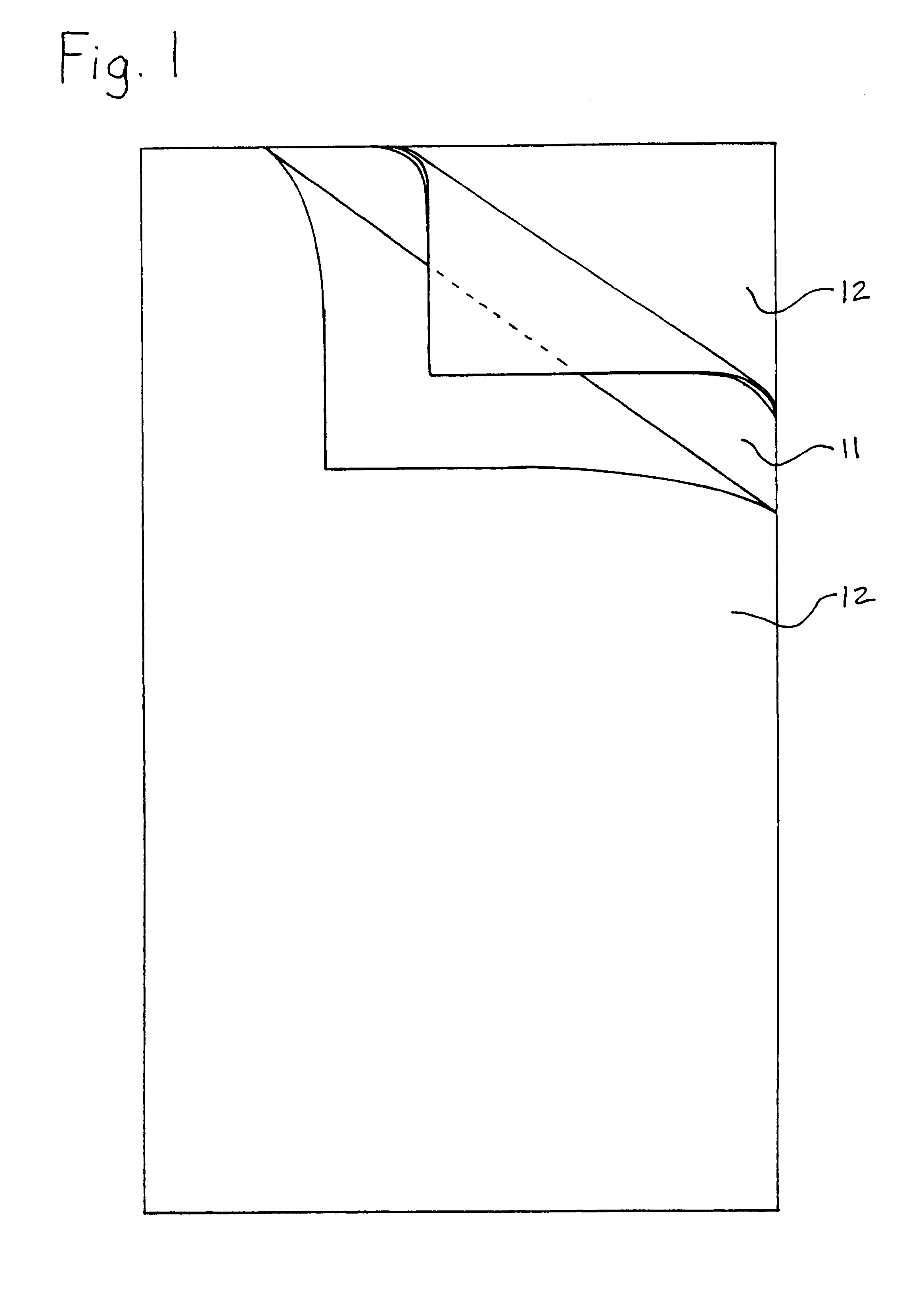

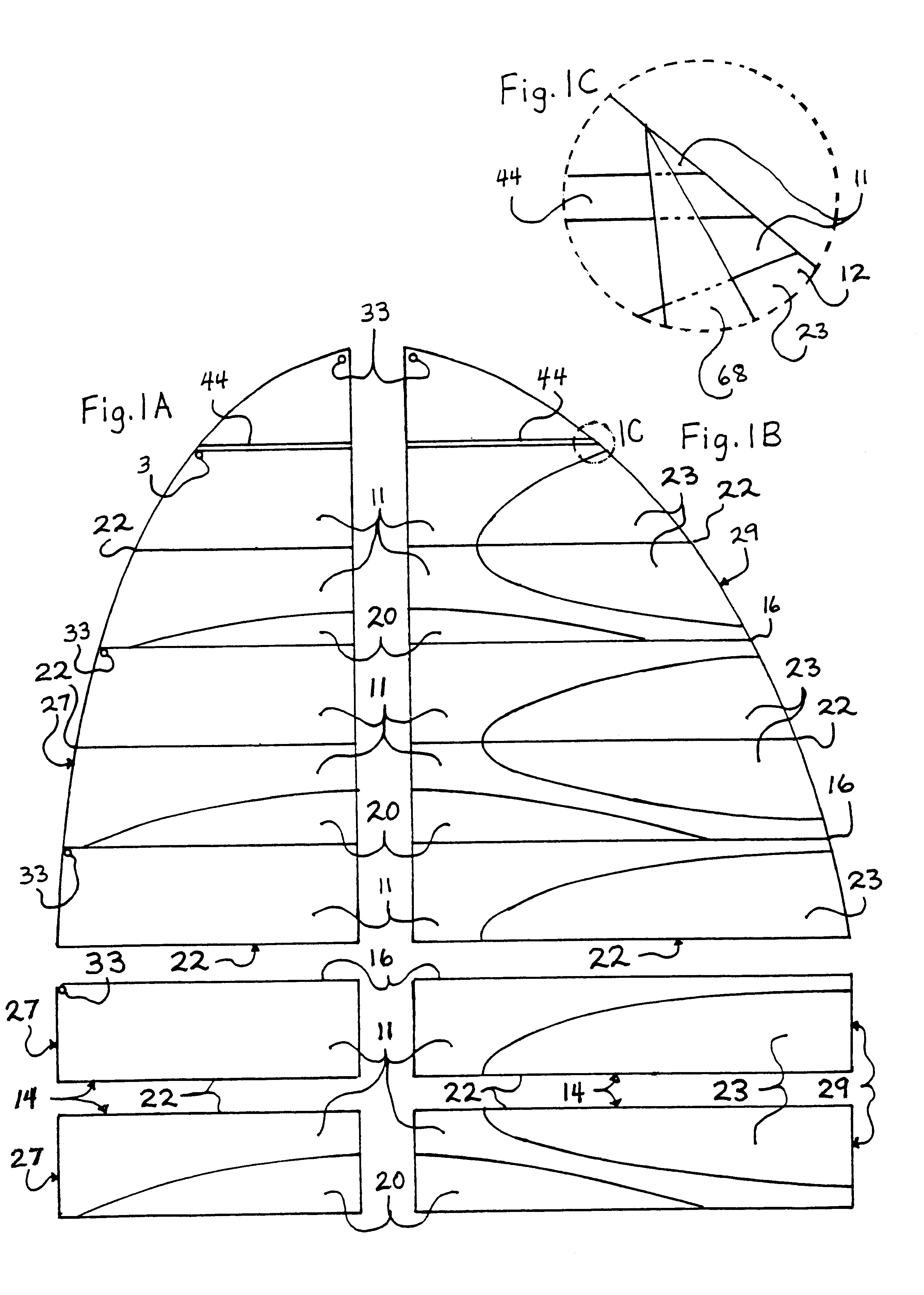

Stowable semi-rigid wing sail system

A stowable semi rigid airfoil assembly, functions automatically to airflow as a draft adjusting wing sail, or spinnaker sail (19), for use on a mast (17) with a halyard (41) on a wind powered craft. The halyard connected to the heads (83) of port and starboard sail panels (10) surrounding the mast vertically, elongates the airfoil from a "wing chord section shaped boom" (21) attached to the airfoils' foot (57). The sailcloth (12) panels are laminated with rigid foam cored (11) horizontal panel sections (13) set between flexible sailcloth spaces (14), for folding the rigid panels down over the wing shaped boom. The top of the panel sections above the boom are outward folding (22) spaces, and every other one of the spaces up the sail are outward folding, and every other one of the other spaces are inward folding (16) and are increased in separation (20) between the rigid panels. The leading edges (27) of the sail panels are joined at the inward folding spaces. The sail panels have shape control lines (34) along the inward folds for a wing chord section profile. Downhaul lines (31) reef and stow the sail panels. The leading edge of the boom pivots the trailing two sides of the boom from the mast. The flexible booms' pivotable leading edge is connected to a telescoping (48) fore boom (45) that is distally connected to the mast. Pivotable connections of the spinnaker (49) and draft control arms (50) between the foreboom and the inboard sides of the boom (55) adjust the draft of the wing sail.

Owner:ABSHIER CHARLES ALLEN

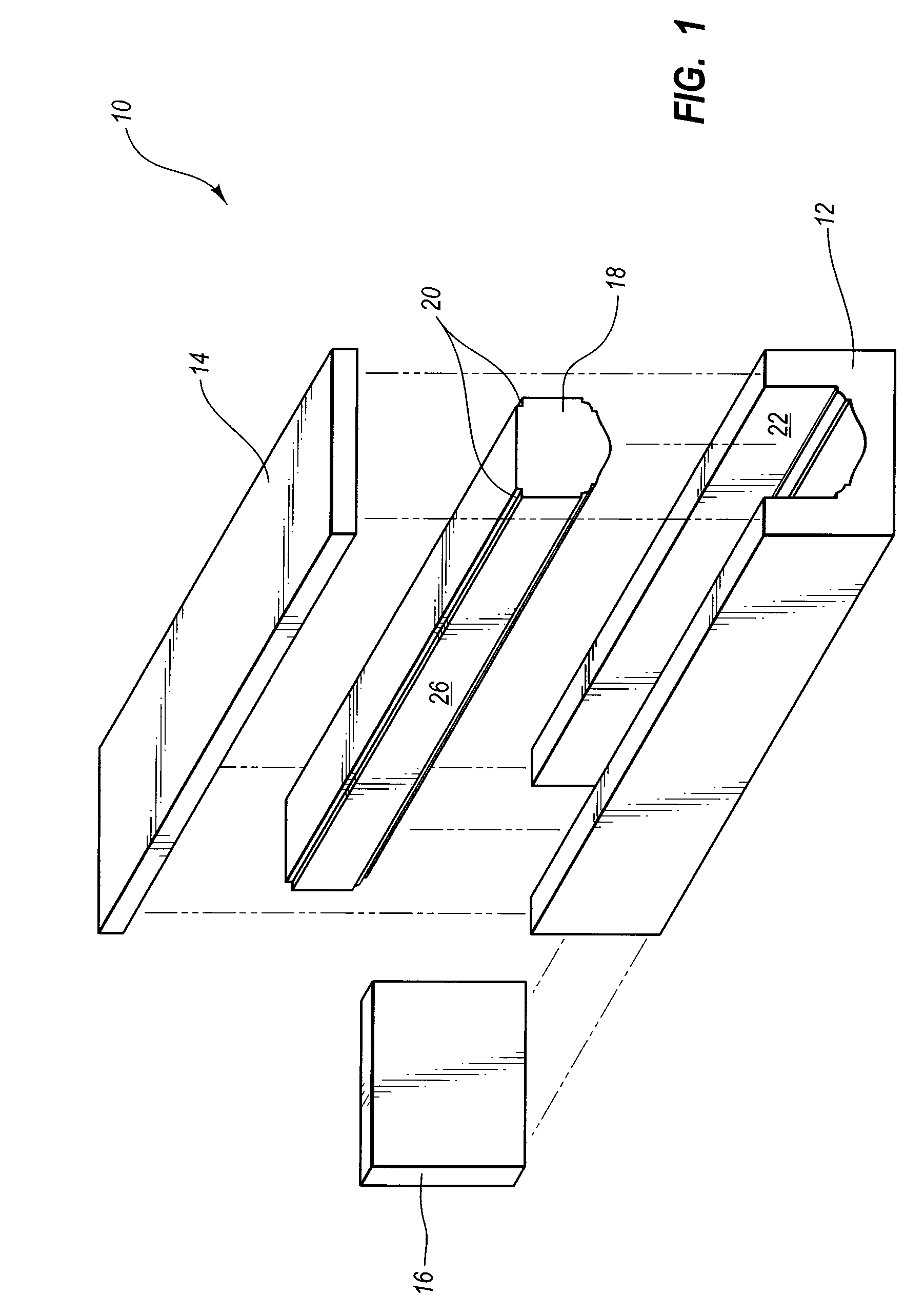

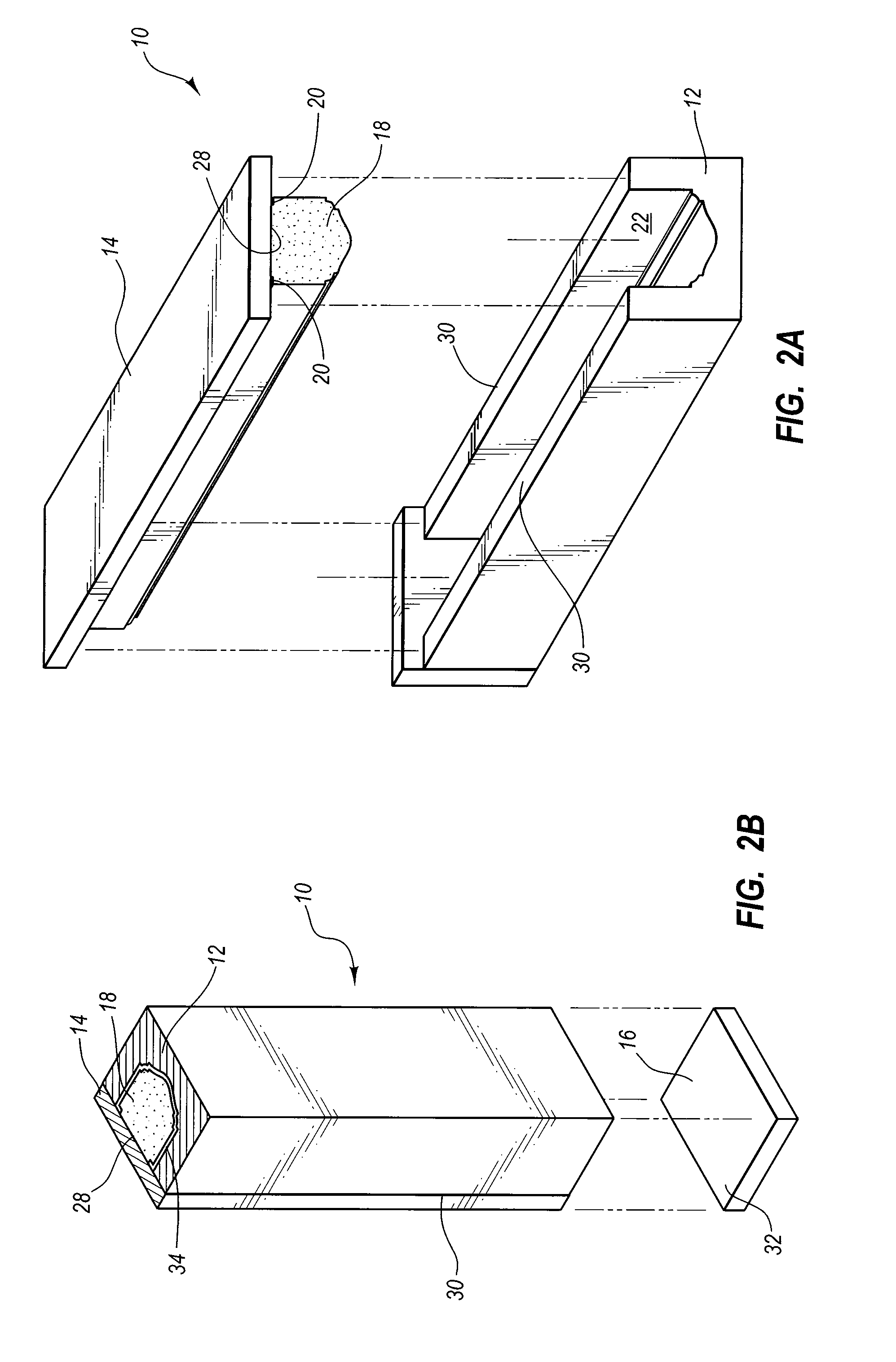

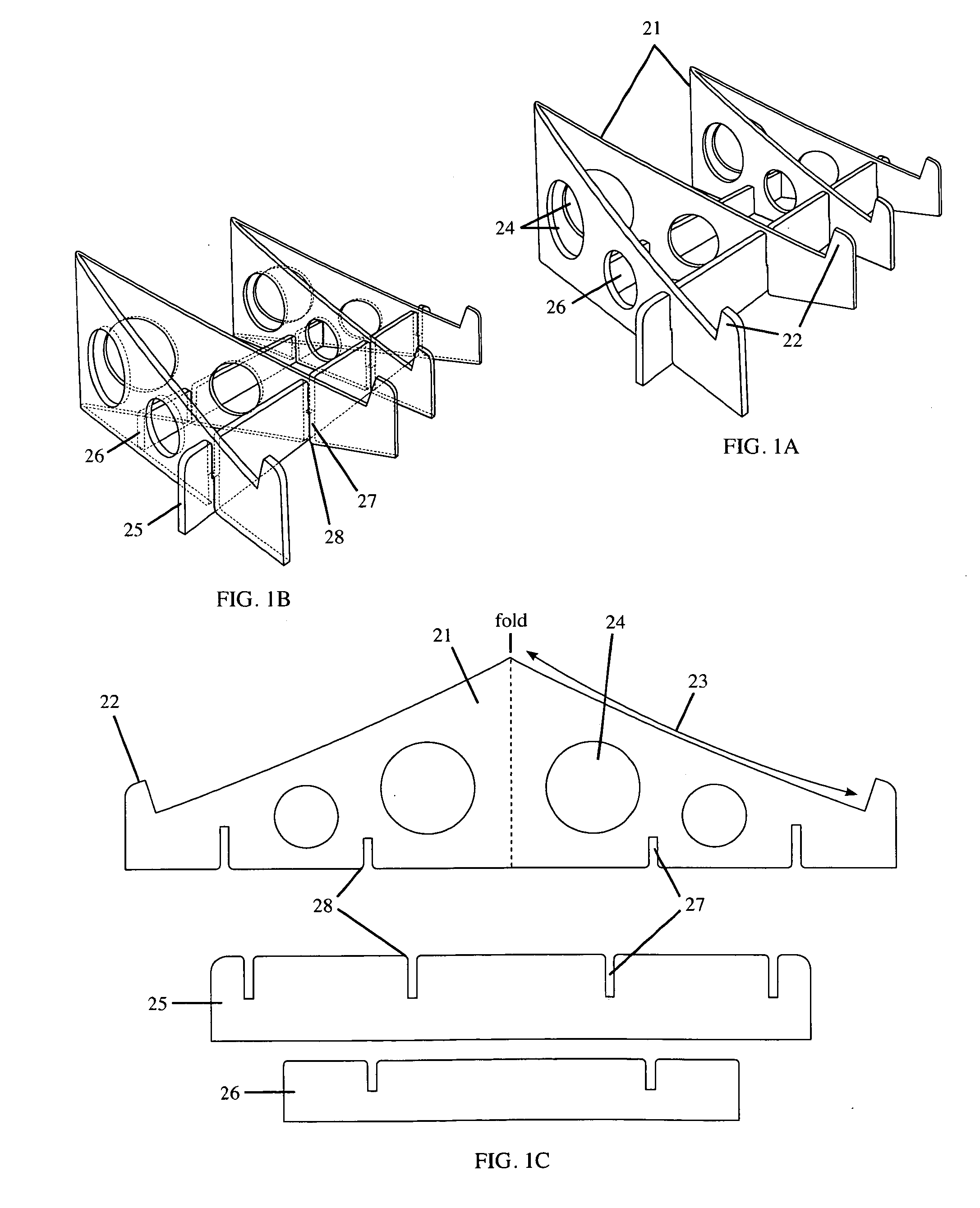

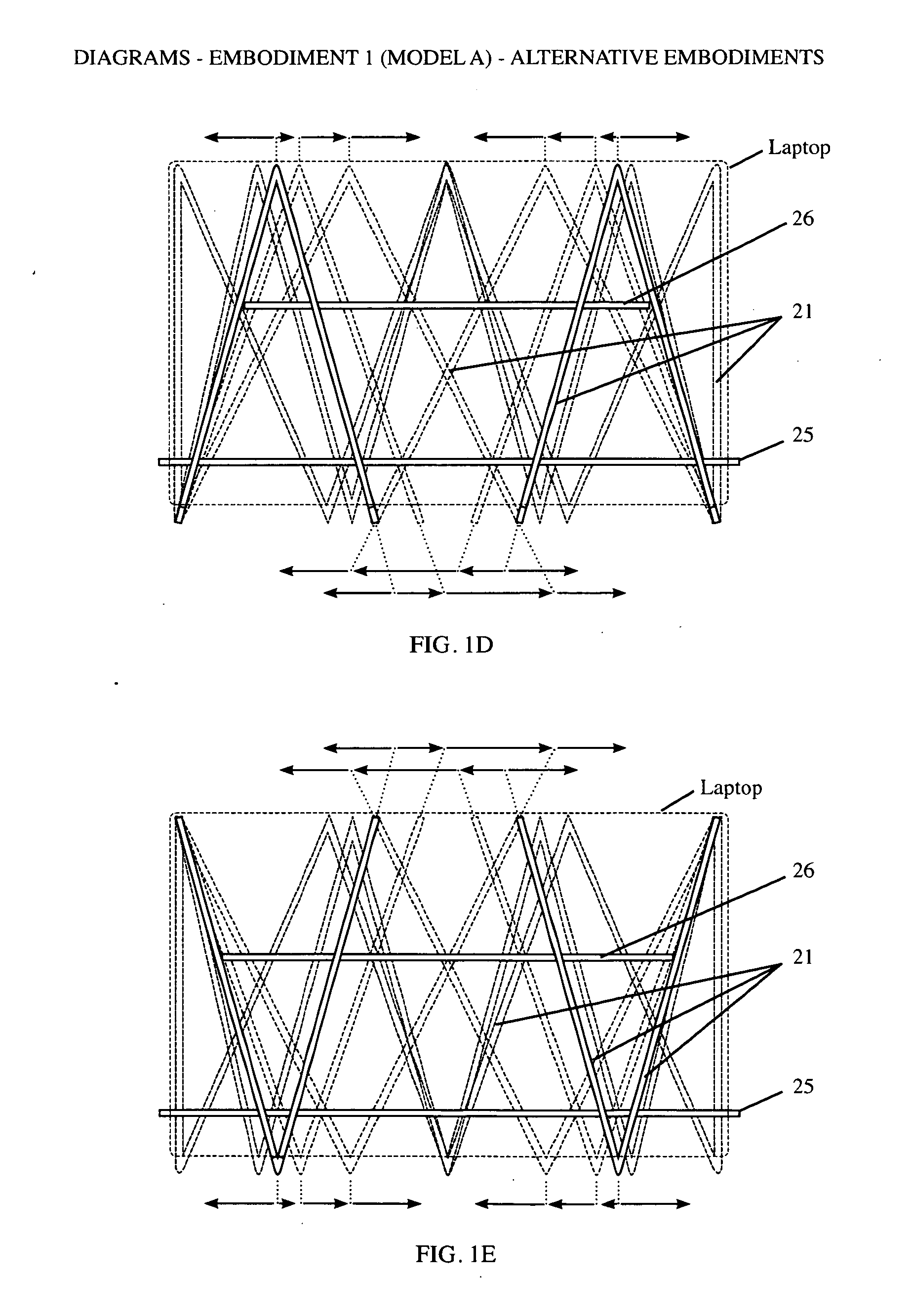

Laptop Stand

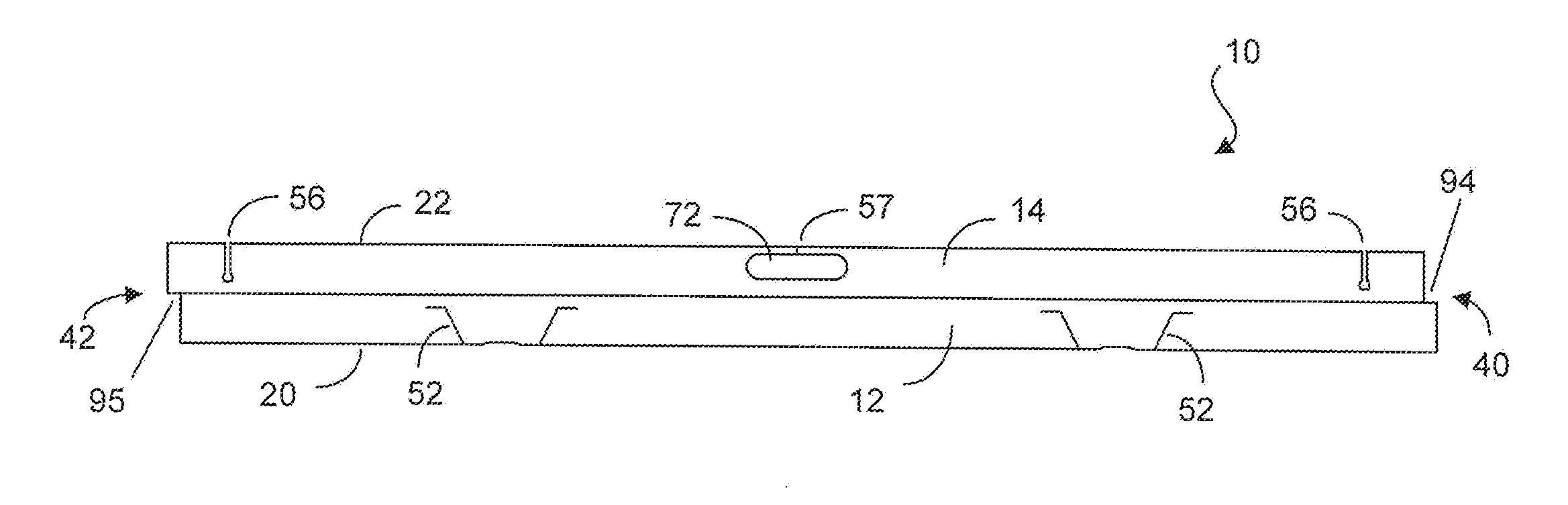

InactiveUS20090321605A1Comfortable to useAvoid disadvantagesFurniture partsStands/trestlesCost effectivenessAcute angle

The EZ Laptop Stand® is a stand for a laptop computer that is very inexpensive, extremely lightweight, easy to assemble and disassemble and folds flat for portability. It is made from foamcore for its light weight, inexpensive material cost, and strength and durability when designed in the manner that it is. Manufacturing is done by laser cutting or die cutting, both methods being cost effective and practical for use with foamcore. There are three models of the EZ Laptop Stand®, the main feature of all three consisting of primary support members, which when folded or hinged at an acute angle at their mid point, create two strong triangular sloped surfaces tapered to a narrower dimension towards the bottom, front edge (the side closest to the user), where feet protrude upward for the laptop computer to rest against. These two primary support members are connected by two smaller cross-members that slide onto them along slots that keep all the pieces of the EZ Laptop Stand® fixed, in a rigid, upright formation on which the laptop computer rests. The EZ Laptop Stand® raises the laptop computer high enough to achieve proper ergonomics for the user while allowing comfortable use of onboard keyboard, high enough to allow adequate ventilation for heat dissipation from under the computer, high enough to provide protection from spilled of beverages, and is inexpensive to buy and simple to disassemble and reassemble for easy portability.The EZ Laptop Stand® is made in 3 different designs called Model A, Model X, and Model U. Model A and Model X are for use on a desktop surface, under any laptop computer, but each one is designed to better accommodate slightly different configurations of laptop computers. Model U is for using a laptop computer while sitting or lying down when the user wishes to use it directly on their lap.

Owner:PETRIE SCOTT

Sports board with integral laminated stiffening element

InactiveUS7246568B1Uniform stiffnessImproves compression resistanceNon-magnetic metal hullsWater sport boardsPolyolefinPliability

A sport board for snow sledding or surf body boarding comprises a multi-layered laminated composite foam core coupled with stiffening elements for mechanical strengthening of the board. The composite foam core comprises laminates of polyolefin foam base and stiffening elements composed of substantially polymer foam and has substantial higher compressive strength and flexural strength than the foam base. A front section may be made of the same blank material as the low density polyolefin foam base and is bonded to the front end of the foam core complex to give a full frontal flexibility for a higher directional control by the rider and improved shock absorbing property. Upper and lower polyethylene foam sheets wrap the foam core complex subassembly and head section for sled integrity and graphic film finishes the sled top, the bottom is also finished with a polyethylene sheet for slickness.

Owner:CHEUNG WAH KAN

Rotational moulding

A method of producing a plastics article having solid skin and a foam core by a rotational moulding process, comprises charging a mold with a skin-forming component and substantially simultaneously with a foam core-forming component of bulk density greater than 0.5 g / cc, providing a first heating stage in which the mold is heated to a first temperature and is rotated for a first predetermined time to form a substantially impervious skin within the mold, and providing a second heating stage in which the mold is heated to a higher second temperature and is rotated for a second predetermined time to cause foaming of said foam core-forming component, thereby forming a foam core within said substantially impervious skin.

Owner:ROTEC CHEM

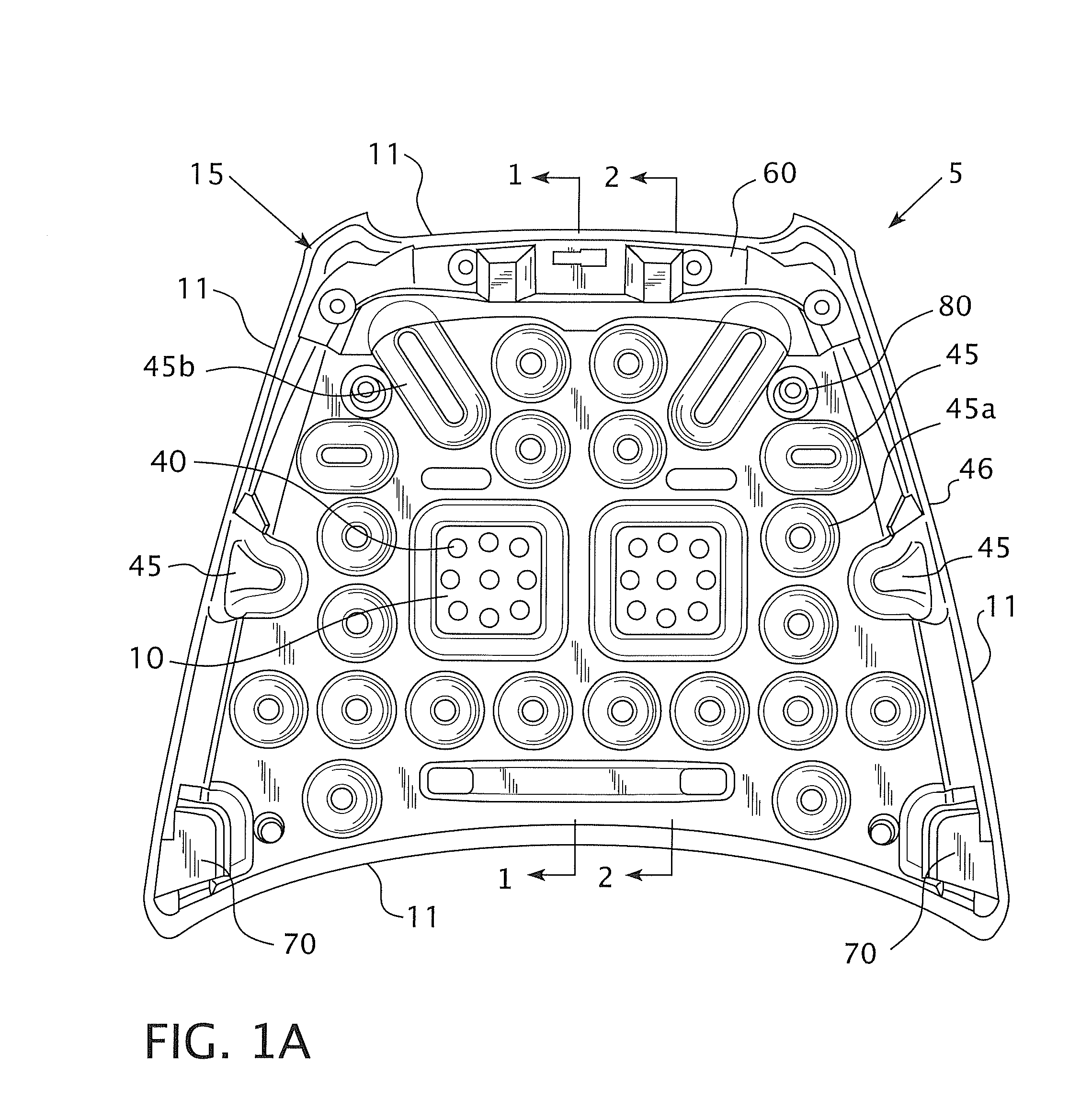

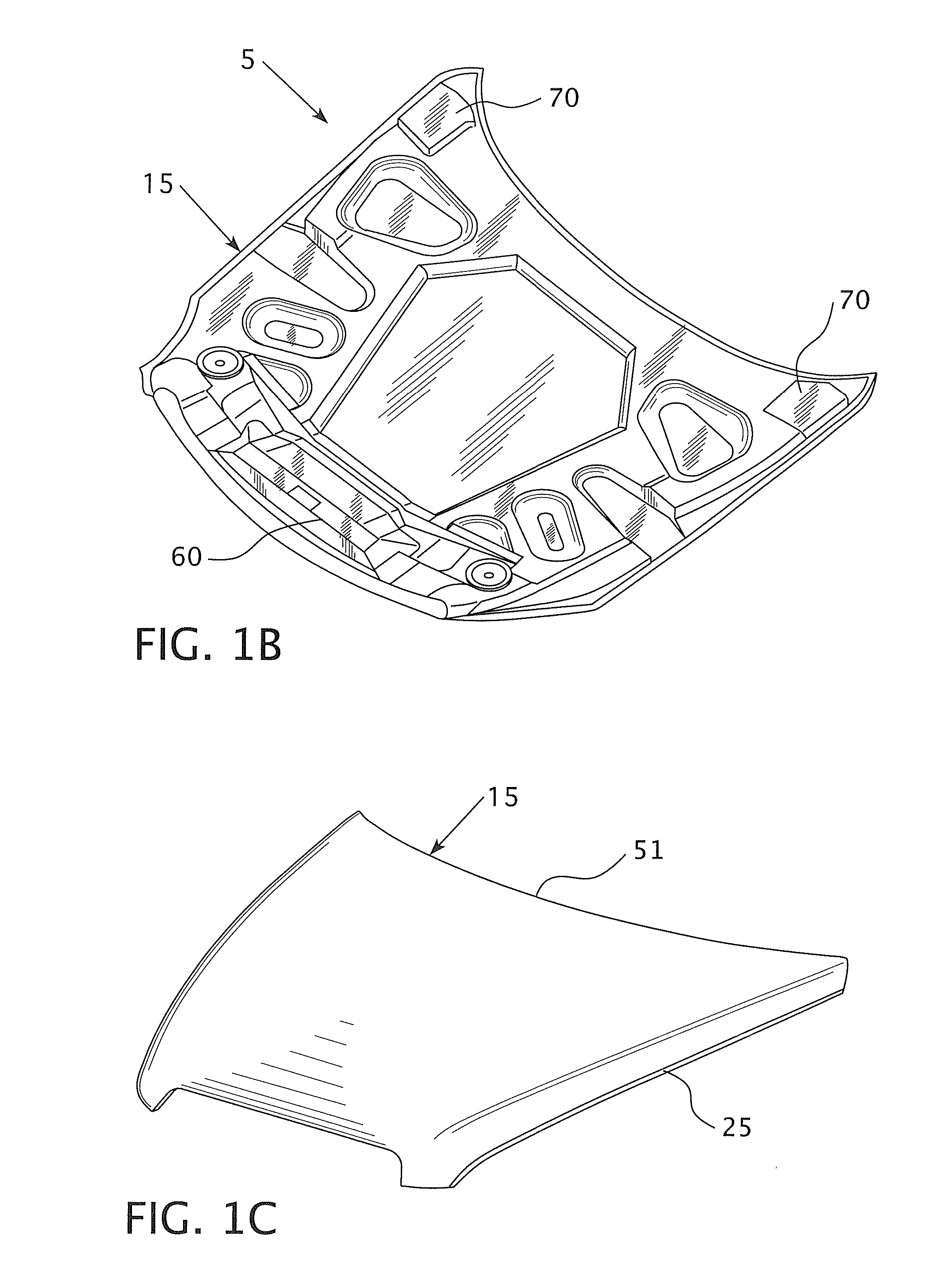

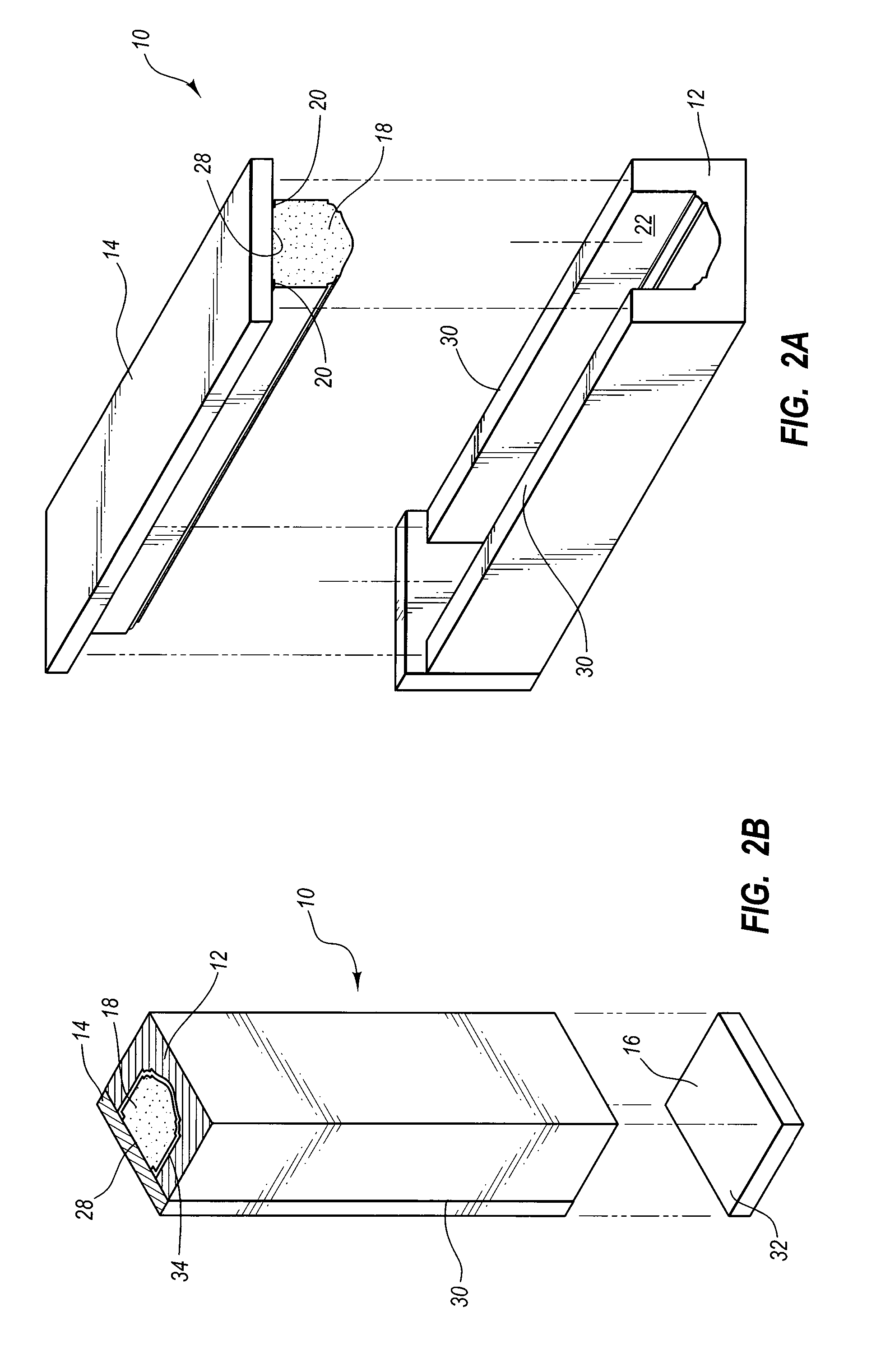

Pedestrian safe automotive hood having reinforcing foam

InactiveUS20100140979A1Keep distanceVehicle seatsPedestrian/occupant safety arrangementMobile vehicleEngineering

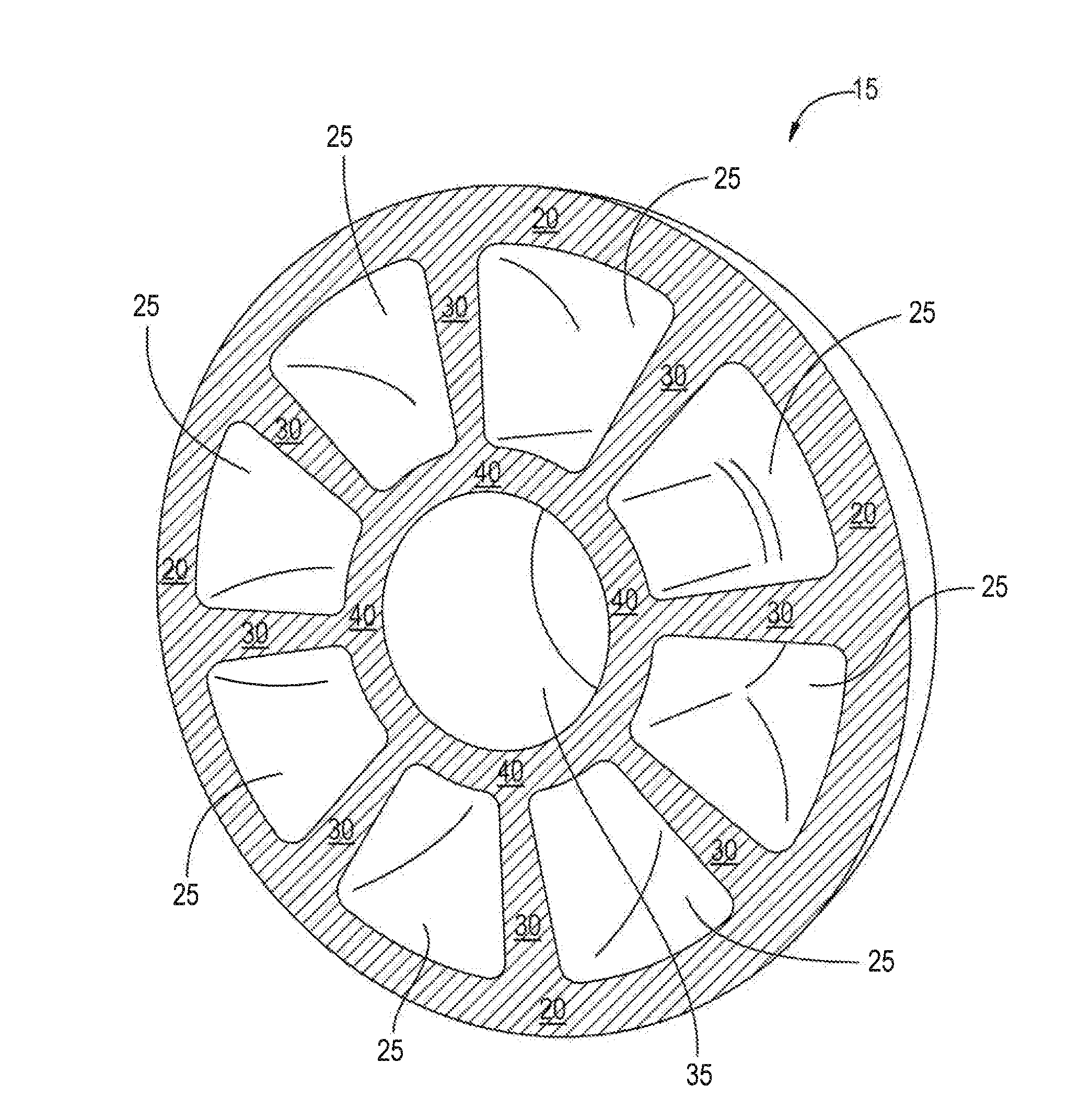

The present invention provides a thin vehicle closure panel design that substantially reduces a thickness (panel gauge plus the perpendicular distance or depth between the panels) of a vehicle hood (5) and the impact effect on the head of a pedestrian struck by a motor vehicle. In one embodiment, the vehicle hood (5) includes a hood shell (15) including an outer panel (25) and an inner panel (20); a unitary foam core (100) positioned between and bonded to the outer (25) and / or the inner panel (20) of the hood shell (15); and at least one recess (10) that corresponds to an underhood component (42). In another aspect of the invention, a vehicle hood (5) is provided in which a latch attachment member (60) and / or hinge members (70) are attached to inner surface (50) of the inner panel (20) of the hood shell (15).

Owner:ARCONIC INC

Method for making cushioned product with integral cover

InactiveUS20070151656A1Reduces time and laborEliminates the carpal tunnel syndrome (CTS)LaminationLamination apparatusAdhesiveEngineering

A process for producing an upholstered article in a bladder mold. A cover sheet with adhesive is positioned over the opened bladder mold. A foam core is inserted into the bladder mold, carrying the cover sheet into engagement with the bladder. The bladder mold is then closed so that the bladder wraps the marginal portion of the cover sheet around the foam core. After the adhesive cures to bond the cover sheet to the foam core, the mold is opened; and the article is removed.

Owner:ROYAL PLASTIC

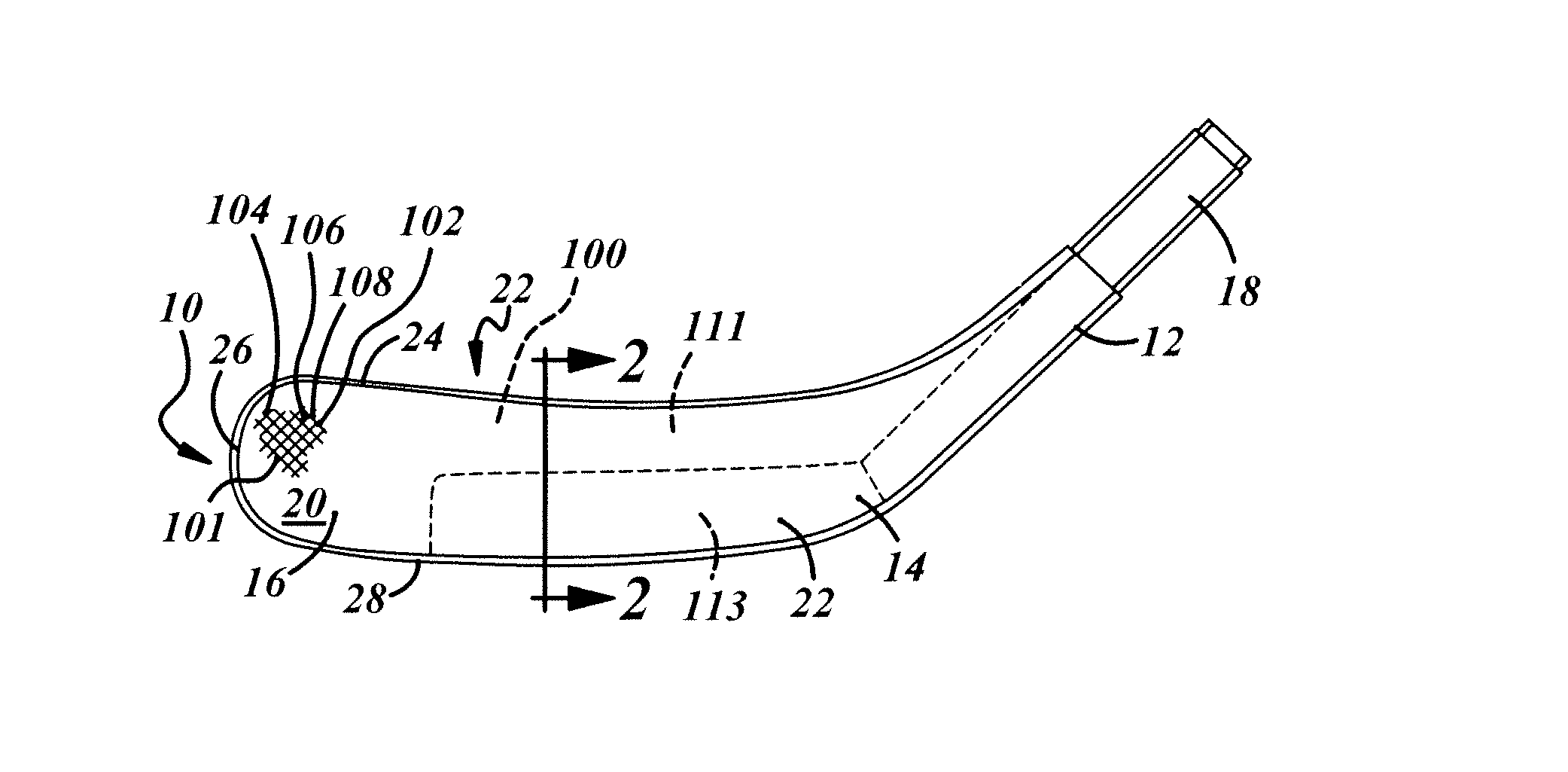

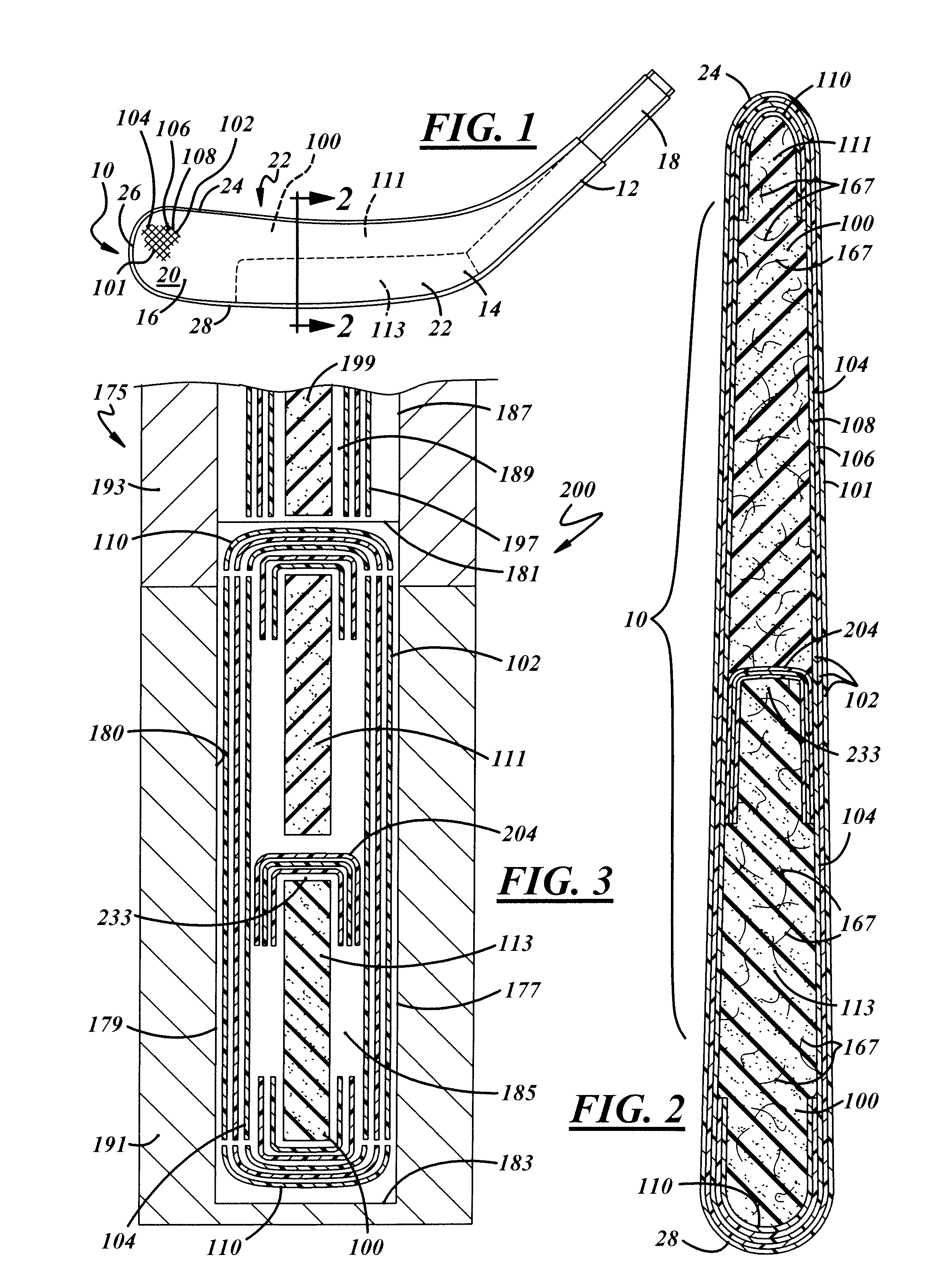

Split Core Hockey Stick Blade

A composite hockey stick blade having a paddle portion that includes an inner foam core overlaid, or sandwiched, with a plastic wrap. The inner foam core is formed having an upper section of a first foamed material and a lower section of a second foamed material, wherein the density of the upper foam core section is substantially less than the lower foam core section. More preferably, the upper foam core section has a density of about 3-5 pounds per cubic foot, while the lower foam core section has a density of greater than about 30 pounds per square foot. In addition, one or both of the foam core sections may be fiber reinforced. The location of the upper foam core section relative to lower foam core section within the paddle region may be varied to provide a hockey stick blade having different twisting and flexing characteristics.

Owner:WARRIOR SPORTS INC

Molded stone architectural product having a foam core

InactiveUS20070175139A1Weight controlStable supportBuilding componentsSurface layering apparatusSurface finishBuilding product

An architectural cast stone product for use in building construction has a unitary shell made of a molded cementitious material that partially surrounds and is affixed to a foam core. The architectural cast stone product has a mounting surface including an exposed surface of the foam core and an exposed surface of the shell. The architectural cast stone product is made by obtaining a front pattern having a desired surface configuration for the architectural cast stone product, obtaining a foam core, affixing the foam core to a backer, affixing the front pattern to the backer that together form a mold, pouring a cementitious material into the mold and into contact with the foam core, at least partially curing the cementitious material to form the architectural cast stone product, and removing the front pattern and backer from the architectural cast stone product. The architectural cast stone product may optionally be surface finished, such as by sanding or polishing, to yield a desired surface finish.

Owner:E KHASHOGGI INDS

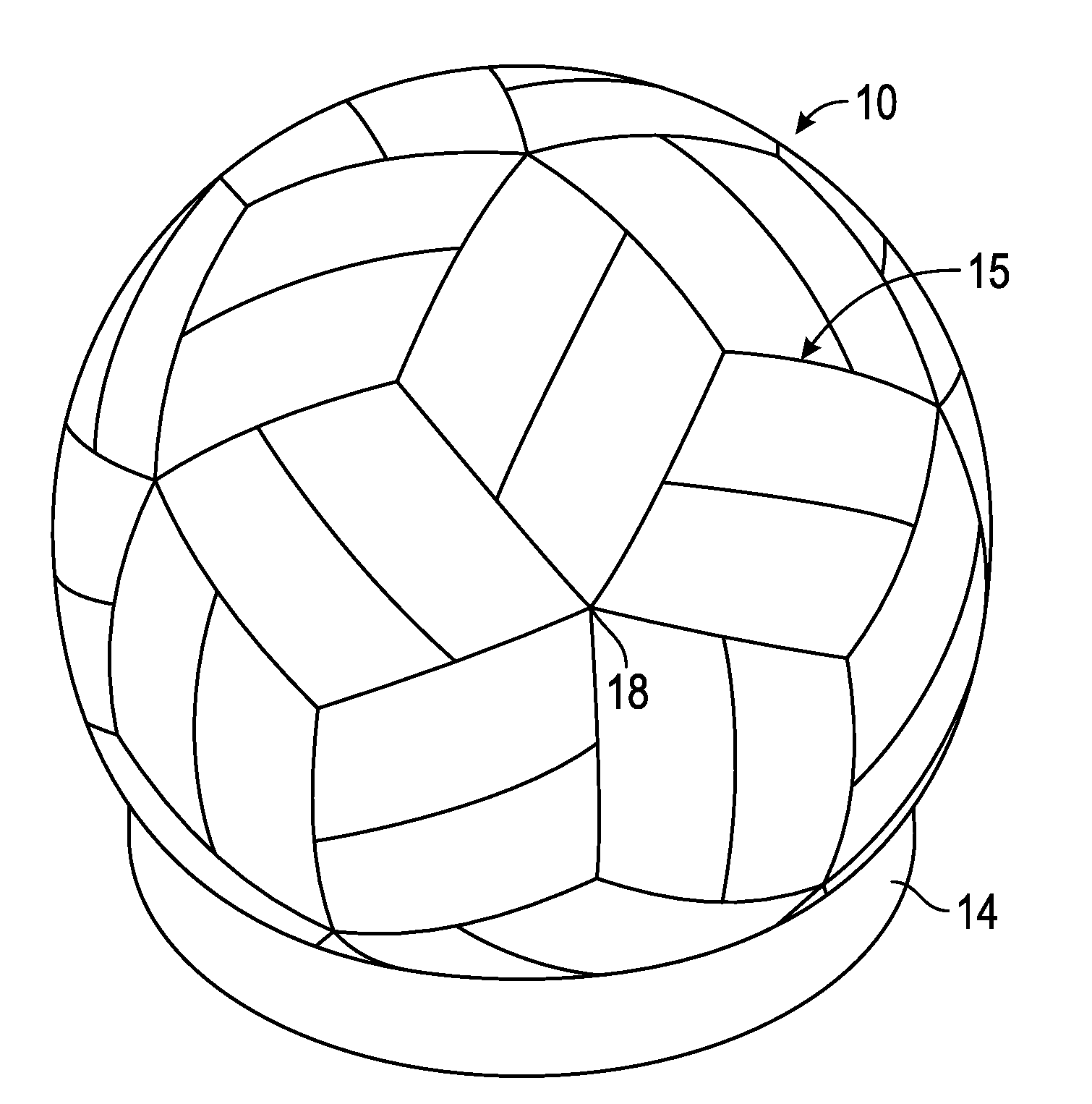

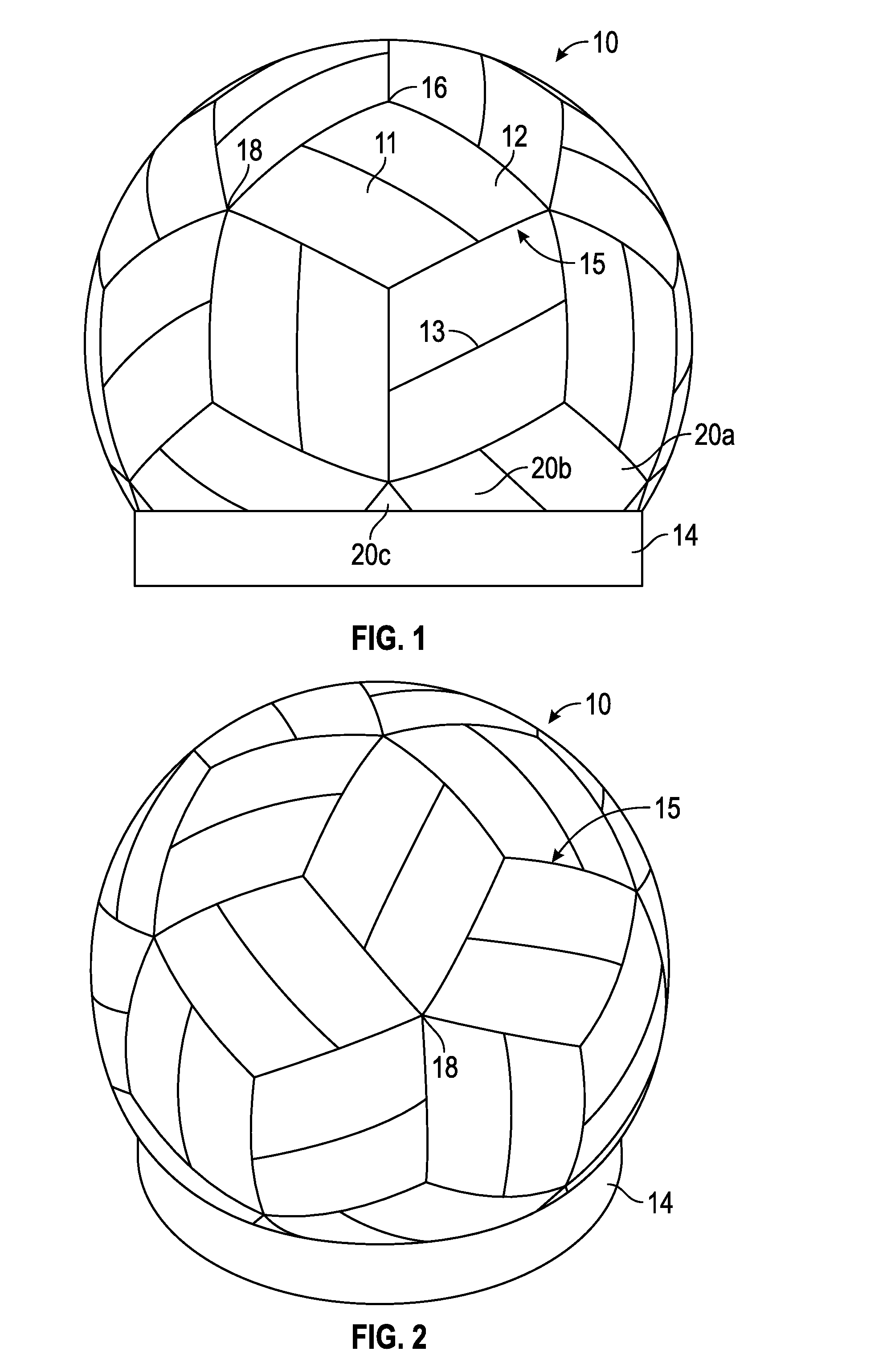

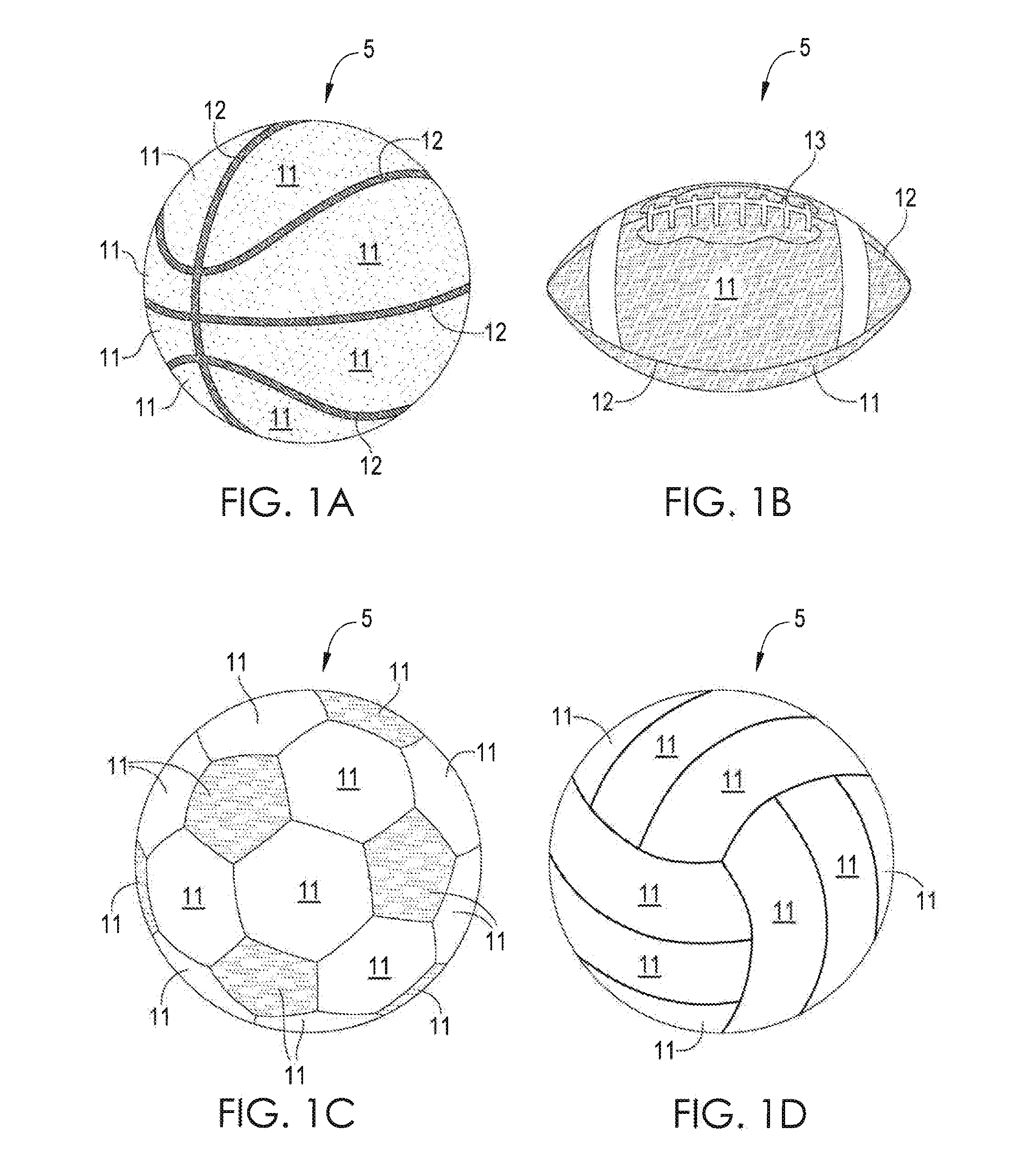

Inflation-Independent Ball with Cover

In some aspects, the invention relates to a inflation independent sports ball comprising a foam core 15 and an outer covering 10, wherein the sports ball is selected from the group consisting of a football, a basketball, a volleyball and a soccer ball, wherein the sports ball 5 is devoid of an inflatable air bladder. In other aspects, the invention relates to a sports ball having a diameter and comprising a synthetic leather outer covering 10 at least partially covering a polyurethane foam core 15, wherein the foam core further comprises at least one internal compartment and a cylindrical body spanning at least part of the length of the diameter of the sports ball. In other aspects, the invention relates to a sports ball having an outer covering and a foam core, wherein the foam core 15 is not filled with foam entirely throughout its internal volume, but rather includes space for air.

Owner:RUSSELL BRANDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com