Method for preparing low density polypropylene foam section or beads by two-step extrusion molding

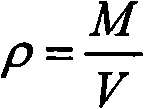

A low-density polypropylene, extrusion molding technology, used in the field of low-density polypropylene foam profiles and beads preparation, can solve the requirements of metering, sealing, mixing, pressure control, mixing equipment structure and process parameter control requirements are very high. High, gas foaming agent content control requirements are very high and other problems, to achieve the effect of easy molding process control, lower melt temperature, and lower special requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 30 parts of polypropylene copolymer (grade 8303), 10 parts of azodicarbonamide, 5 parts of ethyl silicone oil, and 1 part of superfine talc powder (particle size: 0.05-10um), and then add it to the double-roller plastic mixer , after kneading at 160-170°C for 7 minutes, feed the molten sheet into a single-screw extruder for extrusion and granulation to obtain 1# expandable masterbatch. The temperature of the single-screw extruder is 140-165°C, and the screw speed is 60r / min.

Embodiment 2

[0036] Mix 50 parts of random polypropylene, 25 parts of diisopropyl azodicarboxylate, 5 parts of zinc stearate, 3 parts of naphthenic oil, and 4 parts of superfine white carbon black (0.05-10um in particle size) , added to the twin-roller plastic mixer, and kneaded at 150-160°C for 10 minutes, then fed the molten sheet into a single-screw extruder for extrusion and granulation to obtain 2# expandable masterbatch. The temperature of the single-screw extruder is 140-160°C, and the screw speed is 40r / min.

Embodiment 3

[0038] Mix 60 parts of grafted polypropylene, 30 parts of p-toluenesulfonylsemicarbazide and 10 parts of zinc oxide evenly, then add them to the internal mixer, masticate at 140-155°C for 8 minutes, then add the molten mass To single-screw extruder extrusion granulation, prepared 3# expandable masterbatch. The temperature of the single-screw extruder is 160-195°C, and the screw speed is 80r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com