Patents

Literature

5292 results about "Extrusion Granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The use of a series of integrated steps whereby a dry powder is conditioned to form a plasticized mass that is forced through a screen and cut into sections, ultimately to yield granules possessing characteristic dimensions and density.

Irradiation crosslinking halogen-free high flame-retardant cable material and preparation method thereof

InactiveCN101914236AFast self-extinguishingImprove performancePlastic/resin/waxes insulatorsInorganic insulatorsPolyolefinPolymer science

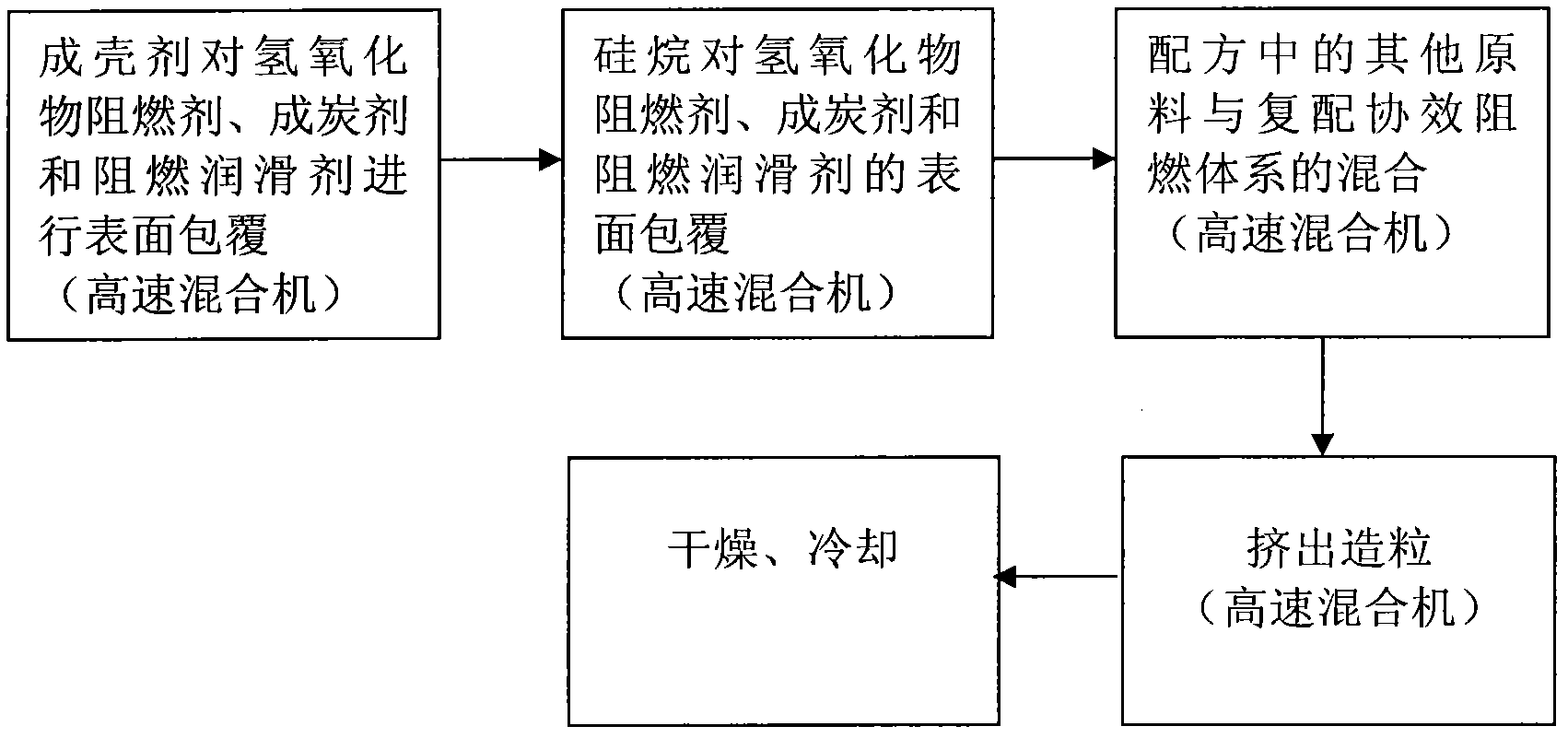

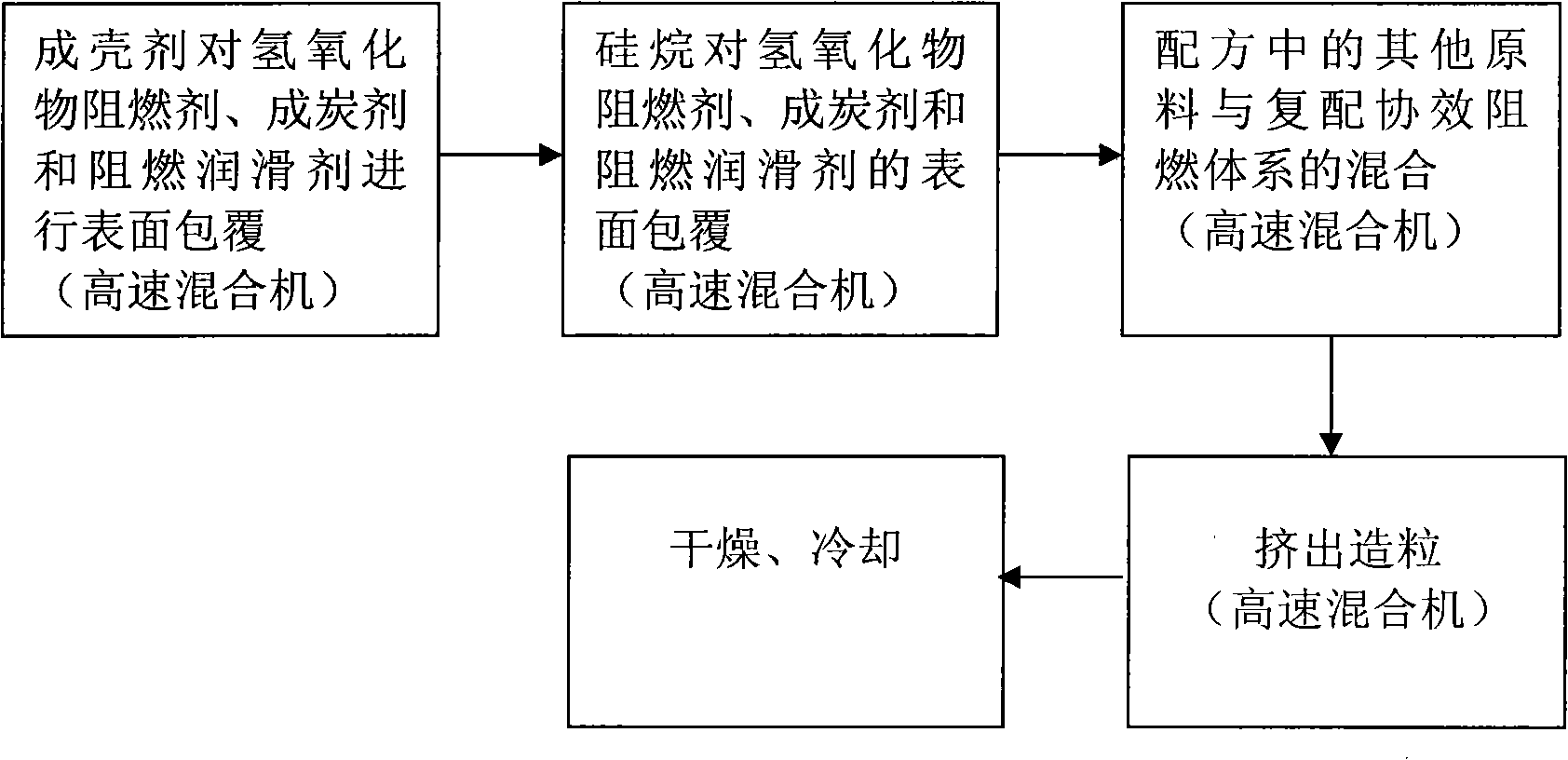

The invention relates to an irradiation crosslinking halogen-free high flame-retardant cable material and a preparation method thereof. The cable materials comprise the following compositions: 45-90 parts of basic resin, 10-55 parts of functional polyolefine resin, 45-125 parts of carbonate hydroxide flame retardant, 30-50 parts of charing agent, 30-50 parts of flame-retardant lubricant, 0.3-3 parts of methyl silicone rubber shell forming agent, 0.5-2 parts of silane surface modifier, 2-5 parts of crosslinking sensitizing agent, 0.2-2 parts of antioxidant, 1-4 parts of lubricant and 0.1-1.0 parts of initiator. The preparation method of the cable material comprises the following steps of: stirring the carbonate hydroxide flame retardant, the charing agent and the flame-retardant lubricant at a high speed for 2 min; and then adding the shell forming agent and continuously stirring at a high speed until the temperature rises to above 100 DEG C, coating the surface of the mixture with the shell forming agent; adding silane coupling agent and stirring for 5-8 min, and carrying out secondary surface treatment; adding initiator-alcohol solution, and discharging after mixing; extruding and pelletizing; finally drying and cooling to obtain the finished cable material product. The flame retardant performance of the product is obviously enhanced, and the product has good shell forming performance in conbustion without droplets.

Owner:王进

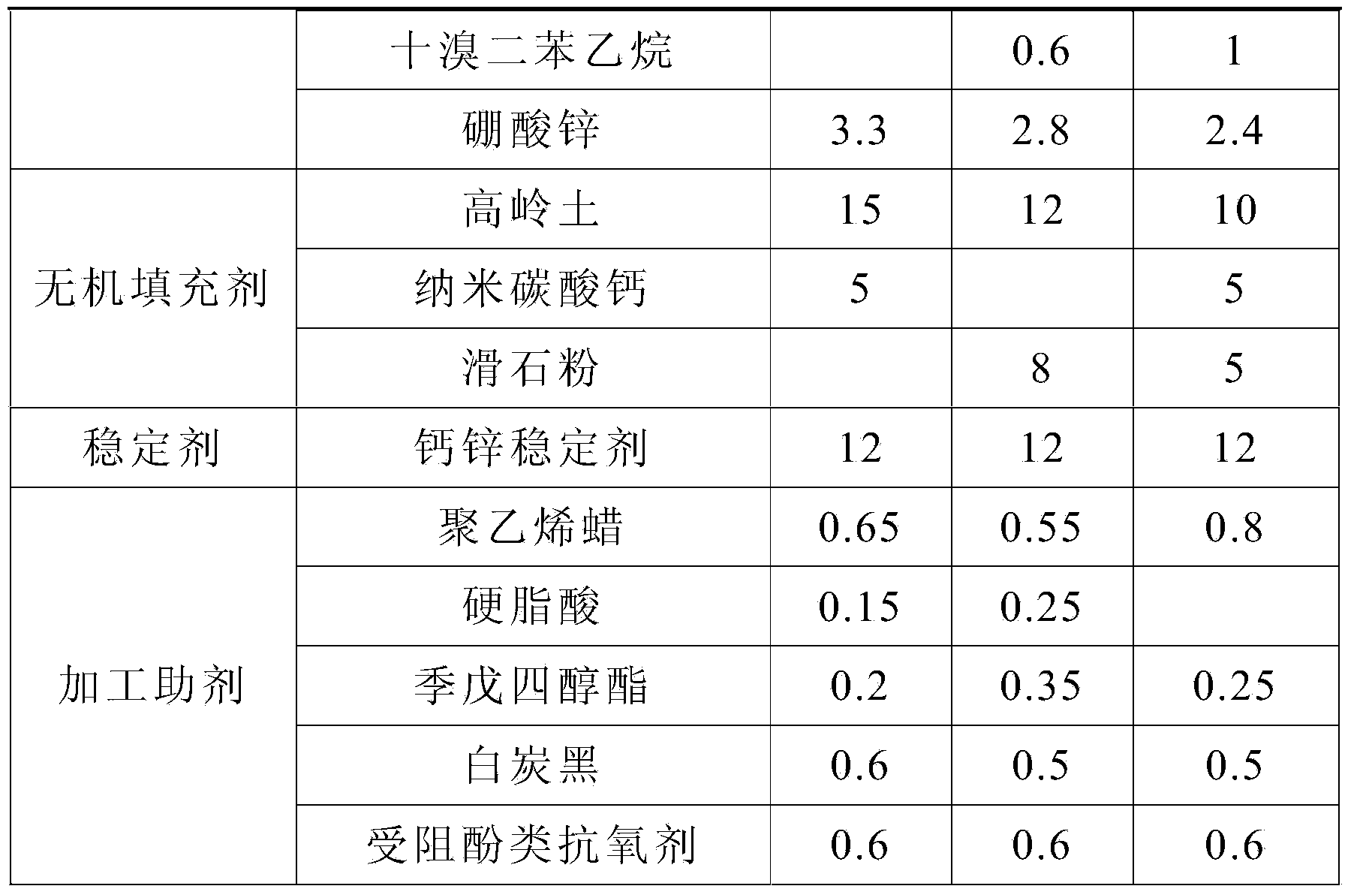

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

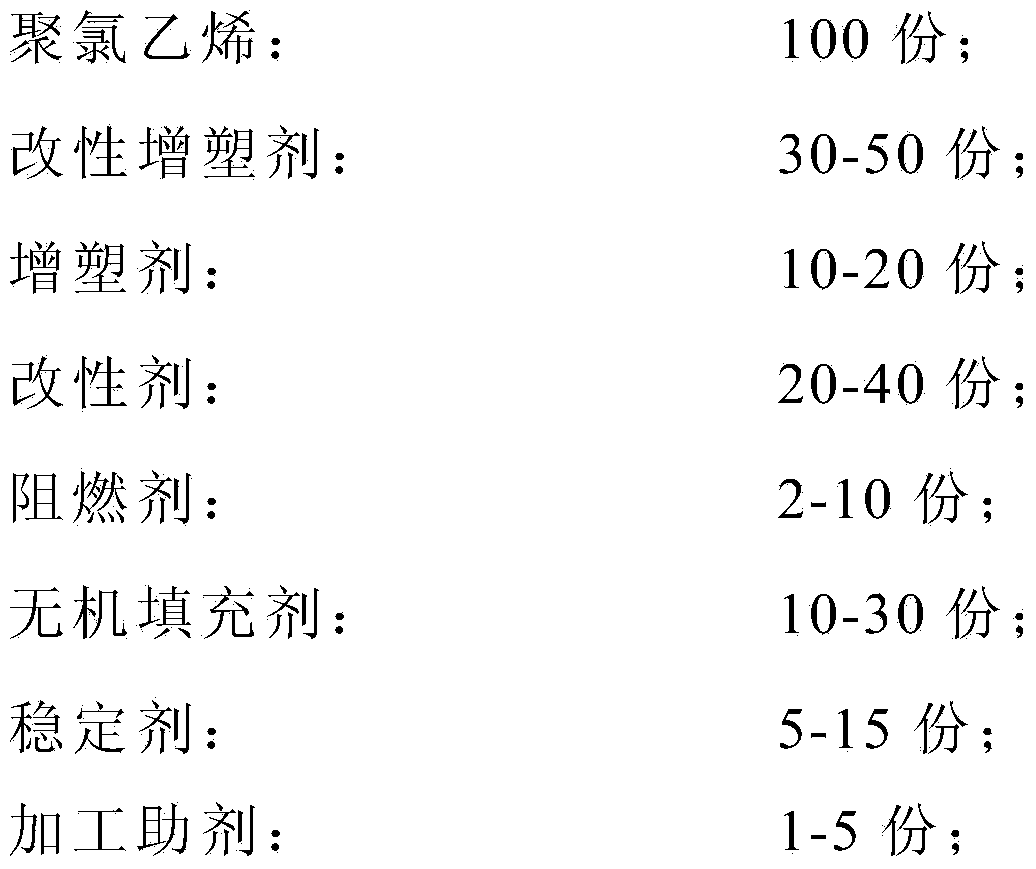

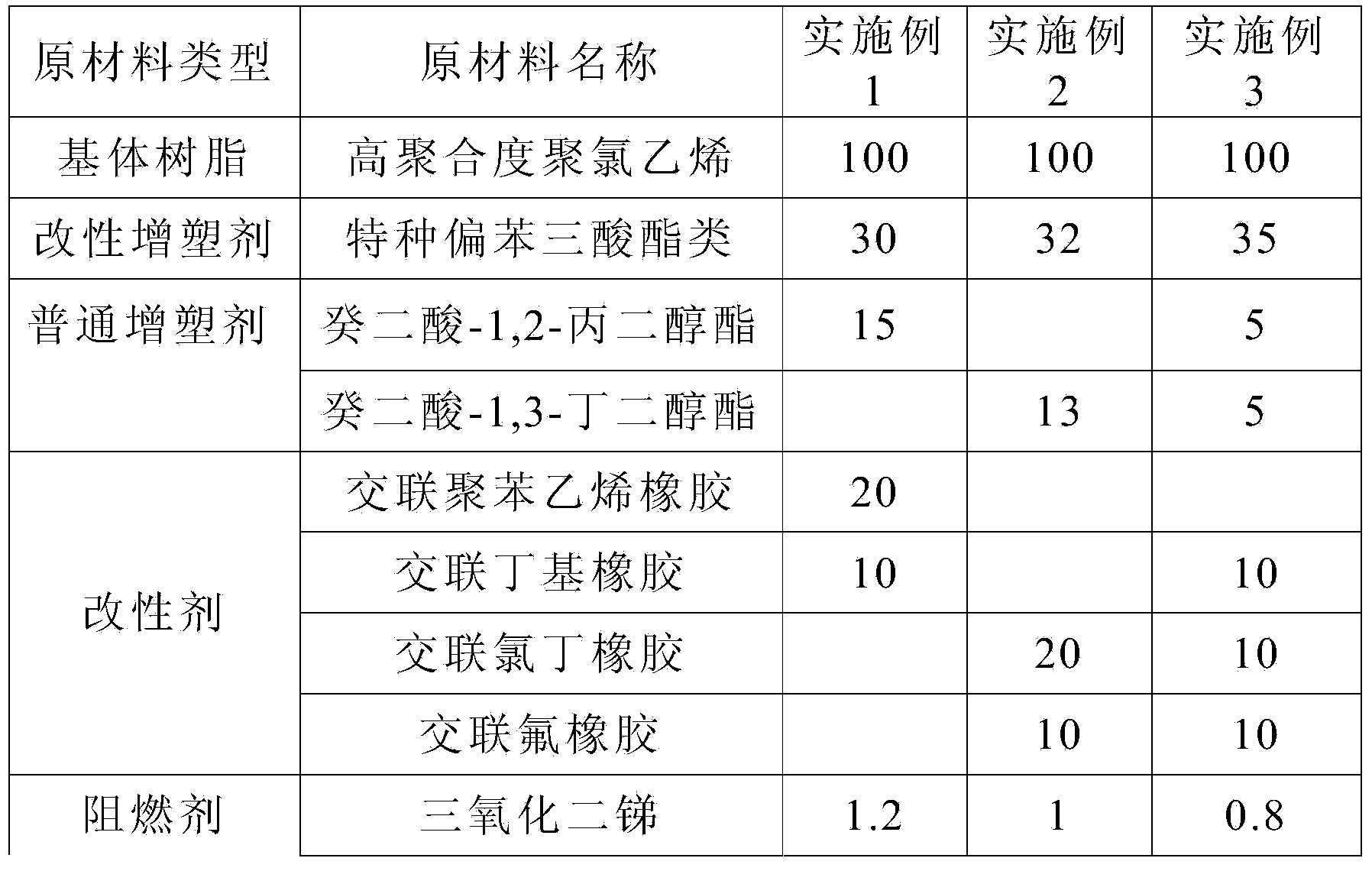

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

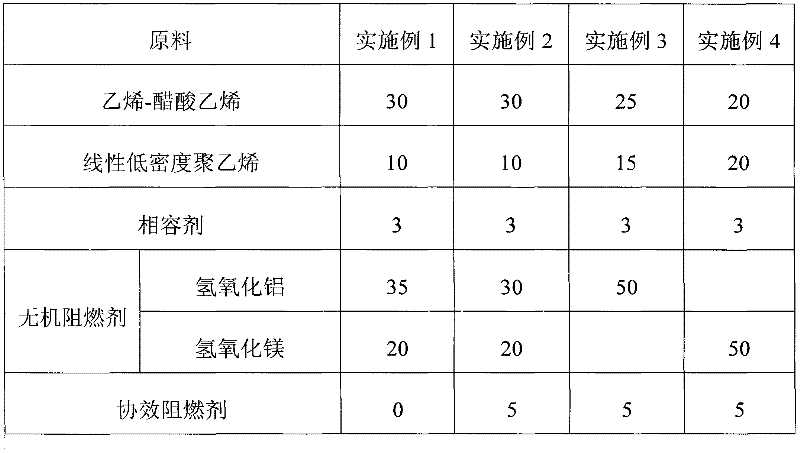

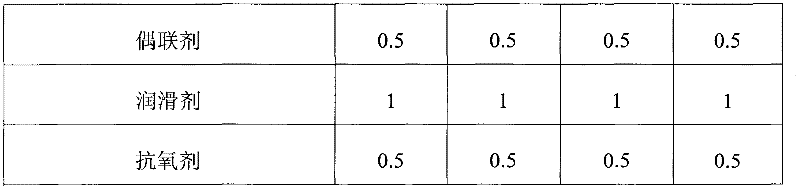

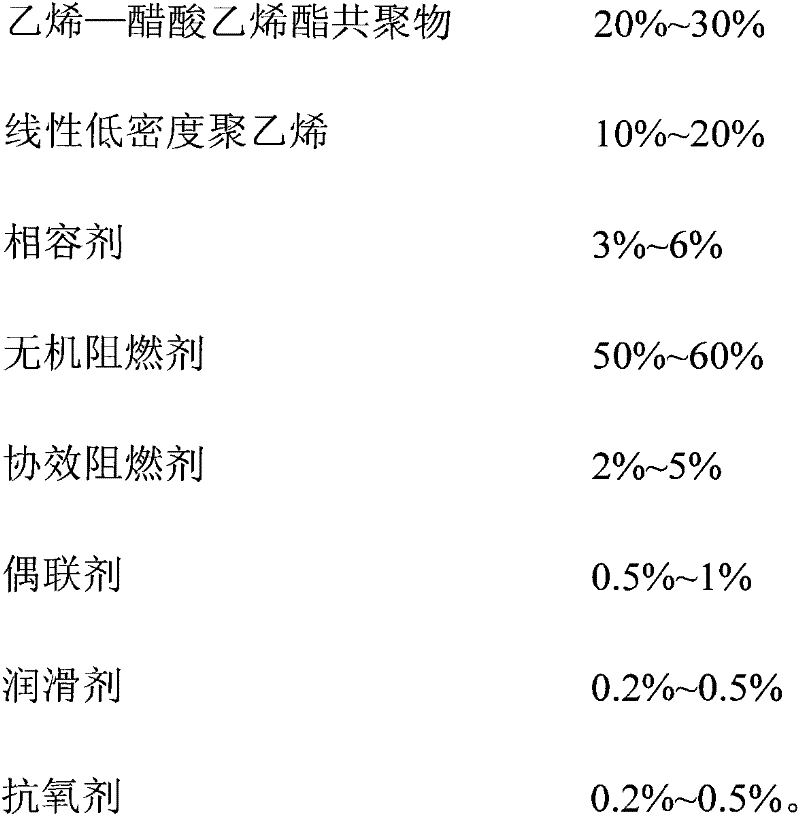

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:NANJING JINSHAN AUTOMOBILE ENG PLASTIC

Thermoplastic elastomer micropore foaming material and preparation method thereof

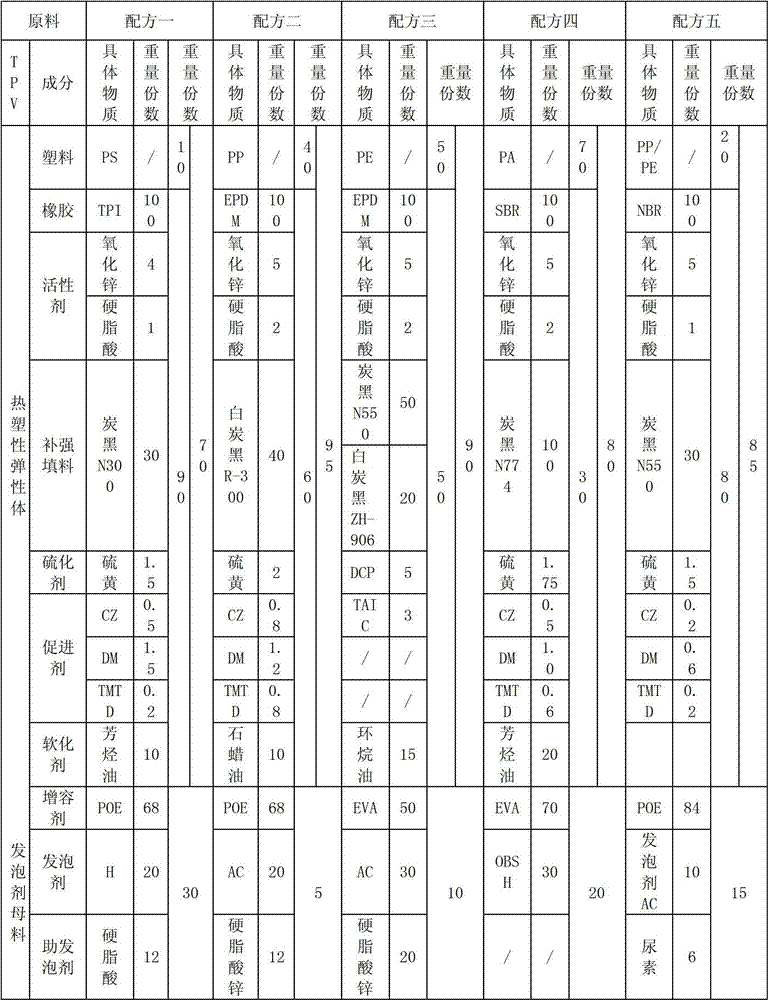

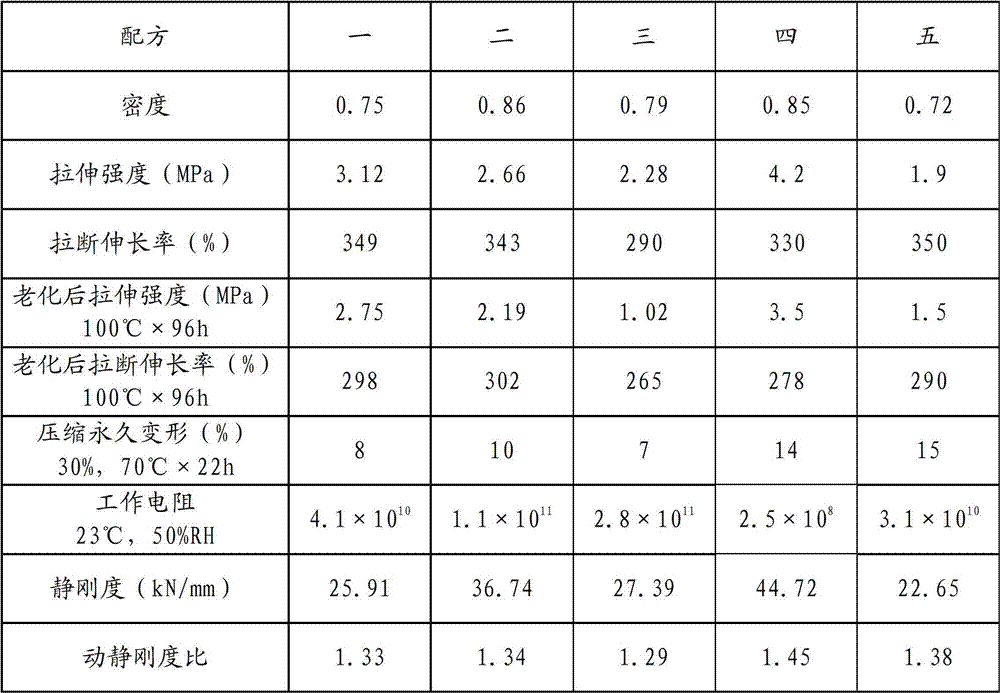

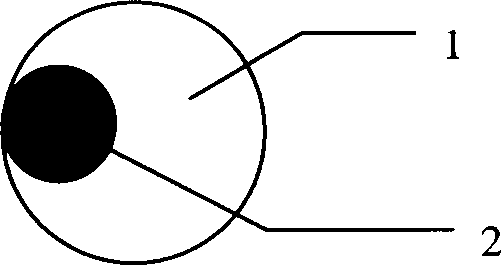

The invention discloses a thermoplastic elastomer micropore foaming material and a preparation method thereof. The material comprises the following componnets in parts by weight: 70-95 parts of thermoplastic elastomer and 5-30 parts of foaming agent master batch. The preparation method comprises the following steps of: based on weight parts, placing 50-90 parts of compatibilizers, 6-30 parts of foaming agent and 4-20 parts of auxiliary foaming agents into a double-roller open mill for mixing to prepare foaming agent master batch; sequentially adding 100 parts of matrix rubber, 5-10 parts of active agent, 20-100 parts of reinforced fillers, 0-20 parts of softening agents, 0.5-5 parts of vulcanizing agents and 1-10 parts of accelerating agents into the open mill or an internal mixer for uniformly mixing to prepare a rubber compound; chopping the rubber compound and uniformly mixing the chopped rubber compound with 10-70 parts of plastics by a high-speed mixer; and extruding and pelleting the mixture to prepare thermoplastic vulcanizate (TPV) aggregates; and uniformly mixing the foaming agent master batch with the TPV aggregates to extrude and form again to prepare a high-performance micropore foaming material for vibration attenuation. The TPV foaming material is high in physical and mechanical properties and thermal ageing performance, is simple in process, can be widely popularized, and is suitable for being used in the field of rail transit.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Method for preparing functional chips for manufacturing antibacterial fibers and plastics

InactiveCN102336957AOvercoming Difficult Difficulties in DiffusionEvenly dispersedArtifical filament manufactureFiberPolyresin

The invention relates to a method for manufacturing functional resin chips, in particular to a method for preparing antibacterial chips used for manufacturing antibacterial fibers and plastics, which has the advantages of high dispersibility, low energy consumption and simple process. The method comprises the following steps of: 1) stirring and dispersing organic antibacterial agent powder at the concentration of 10-50,000ppm in 0.01 to 5 weight percent of dispersing agent; 2) selecting proper original resin chips, and fully stirring and mixing with blend obtained in the step 1); and 3) drying, and performing extrusion granulation by using a twin-screw extruder. The prepared chips can serve as antibacterial resin masterbatches and also can be directly used for manufacturing the antibacterial fibers and plastics.

Owner:上海亿金纳米科技有限公司

Electrically conductive composite fibre containing carbon nanotube and method for making same

InactiveCN1840750AGood electrical propertiesIncreased durabilityFilament/thread formingArtifical filament manufactureFiberConductive polymer

The disclosed conductive composite fiber with carbon nano tube comprises a conductive core layer with 60~99.5wt% thermoplastic polymer, 0~5% carbon nano tube, 0~15% conductive carbon black, and 0.5~20% dispersant; and a shin layer with fiber-forming polymer. Wherein, the preparation method comprises mixing, extruding for granulation, and mixed spinning. This invention improves product performance.

Owner:DONGHUA UNIV

Metal-like engineering plastic composite material and preparation method thereof

The invention discloses a metal-like engineering plastic composite material and a preparation method thereof, and relates to a polymer composite material. The invention provides the metal-like engineering plastic composite material which combines plastic with metal and simultaneously keeps the advantages of the two and the preparation method thereof. The composite material comprises thermoplastic engineering plastic, high-density packing, mineral powder, glass fiber, toughener, coupling agent, lubricant and antioxidant. The metal-like engineering plastic composite material has high density, high mechanical properties, excellent thermal deformation temperature and good injection molding property. The preparation method adopts the method of being combined with the coupling agent and the optimized granulation conditions, the process is simple and easy to operate, extrusion and granulation can be carried out by adopting an ordinary twin-screw granulator, and injection molding can be carried out by adopting an ordinary injection machine.

Owner:XIAMEN RUNNER IND CORP

Graphene/carbon black thermoplastic resin master batch with high dispersibility and preparation method thereof

The invention discloses a graphene / carbon black thermoplastic resin master batch with high dispersibility and a preparation method thereof. The graphene / carbon black compound in the master batch is formed in an electrostatic self-assembly manner, and comprises 10-50% of graphene, 5-20% of carbon black, 0.5-10% of surfactant, 10-65% of carrier resin and 2-10% of assistant. The preparation method comprises the following steps: (1) compounding and dispersing graphene by adopting the surfactant to control the positive electricity of the graphene surface; (2) forming a stable graphene / carbon black compound from the modified graphene and carbon black with positive electricity through electrostatic incorporation in a self-assembly manner; (3) preparing the graphene / carbon black thermoplastic resin master batch with high dispersibility by matching with a solution blended process, a melt-blending method and an in-situ polymerization method; (4) adding the assistant to extrude and pelletize, so as to prepare the graphene / carbon black / thermoplastic resin master batch particles after processing the master batch. By adopting the obtained master batch, the problems of difficult charging of graphene powder, uneven dispersion, dust pollution, unstable product performance and the like are solved.

Owner:XIAMEN KNANO GRAPHENE TECH CORP

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Ultrahigh heat-resistant and flame-retardant ABS (acrylonitrile butadiene styrene) composition and preparation method thereof

Owner:KINGFA SCI & TECH CO LTD +2

Method for preparing low-contraction high-fluidity high-toughness polypropylene

InactiveCN101148528AInjection shrinkage reducedMeet the needs of industrial developmentElastomerPolyolefin

The present invention is one kind of low shrinkage high flowability and high toughness polypropylene composition and its preparation process and use. The polypropylene composition consists of high flowability polypropylene 35-65 weight portions, thermoplastic polyolefin elastomer 10-40 weight portions, toughening agent 6-20 weight portions, inorganic stuffing 10-25 weight portions, antioxidant 0.2-1.0 weight portion, weather resisting agent 0.2-1.0 weight portion and machining assistant 0.1-1.0 weight portion. The toughening agent is one or composition of ethylene-octene copolymer, ethylene propylene diene copolymer, styrene-butadiene-styrene block copolymer and hydrogenated styrene-butadiene-styrene block copolymer. The polypropylene composition is prepared through the following steps: 1. mixing all the materials and 0-50 wt% of inorganic stuffing for 3-8 min to obtain mixture; and 2. smelting and mixing the rest inorganic stuffing and mixture at 180-235 deg.c, and pelletizing.

Owner:SHANGHAI KINGFA SCI & TECH +1

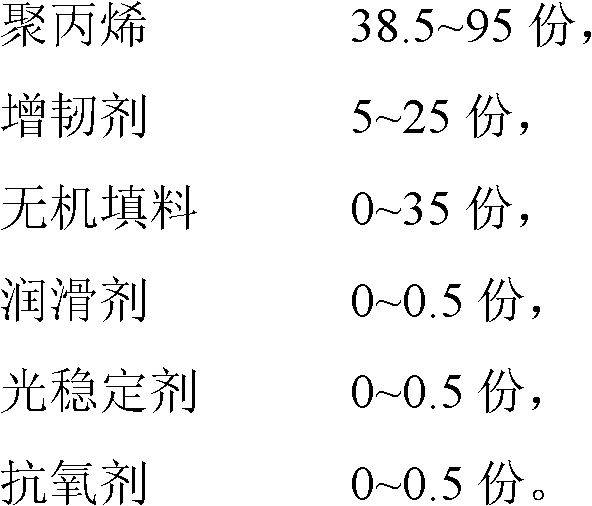

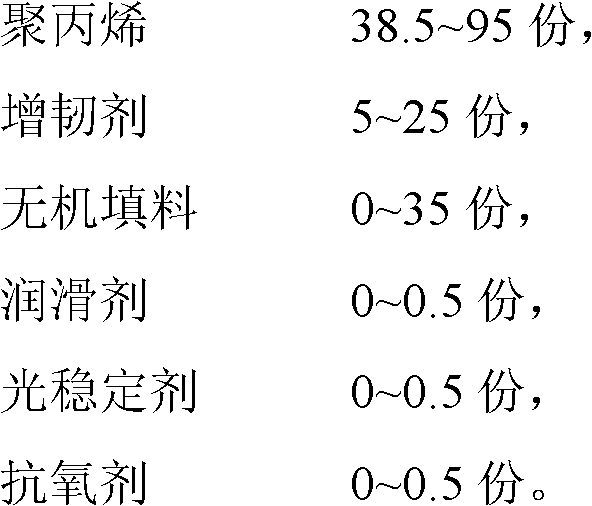

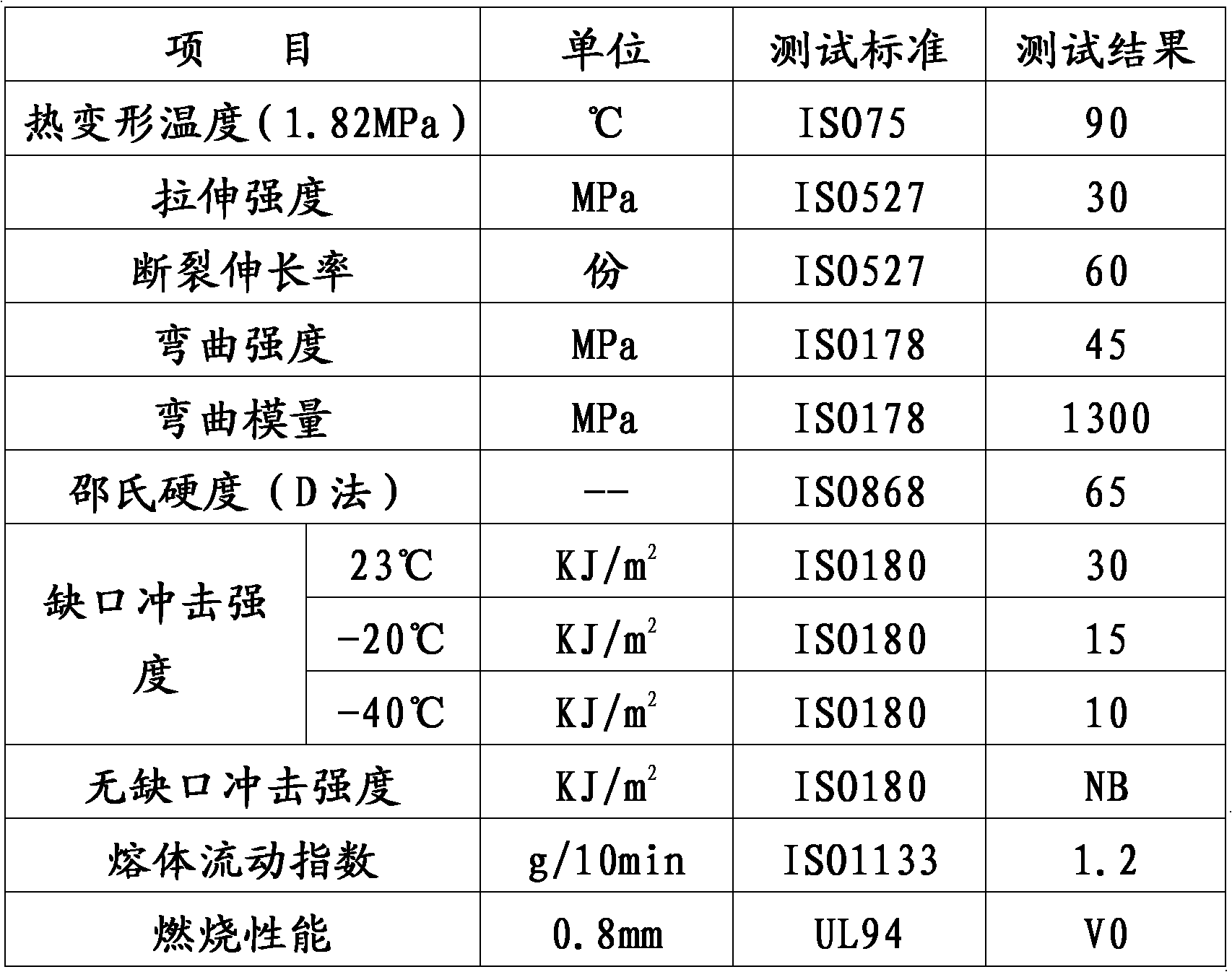

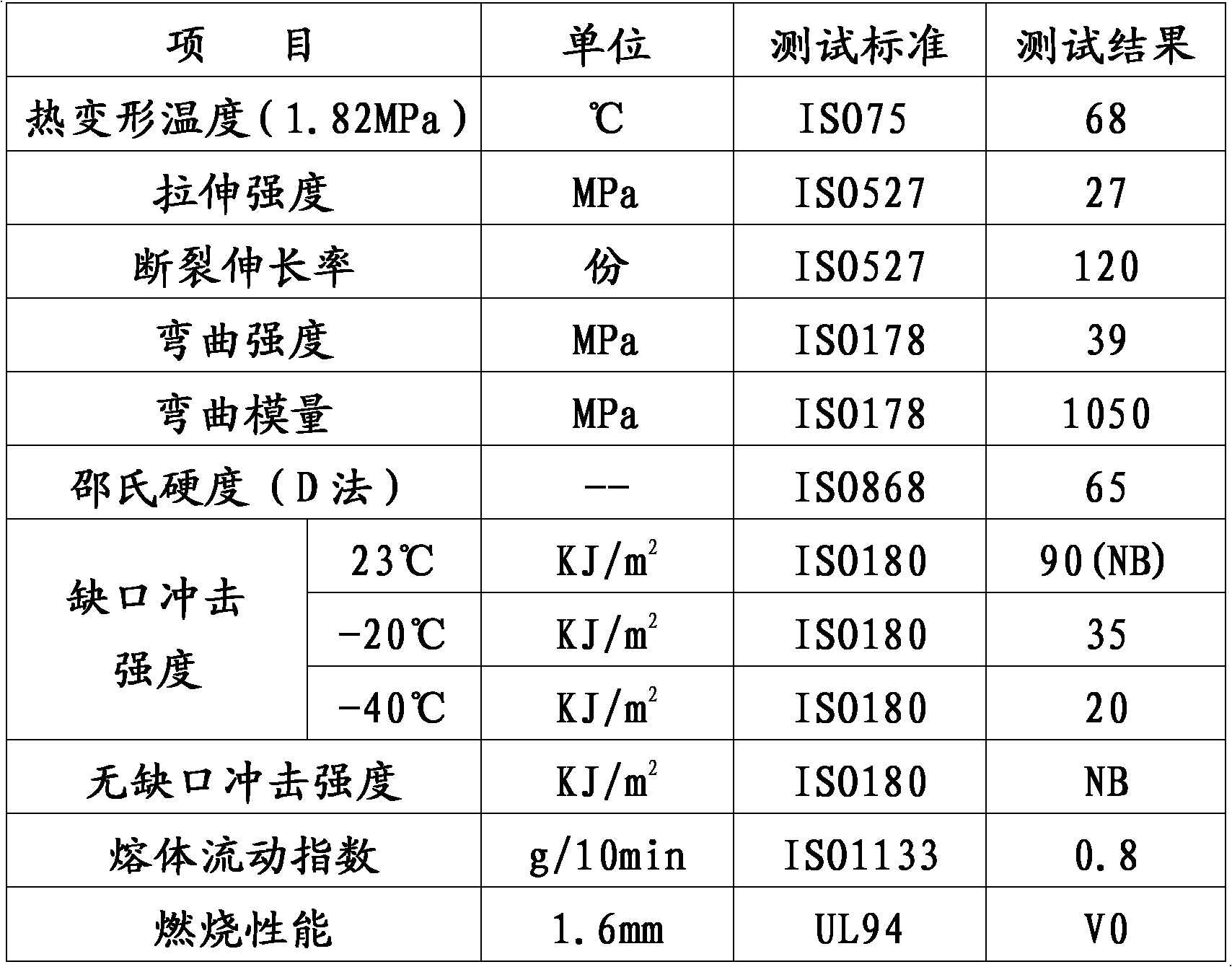

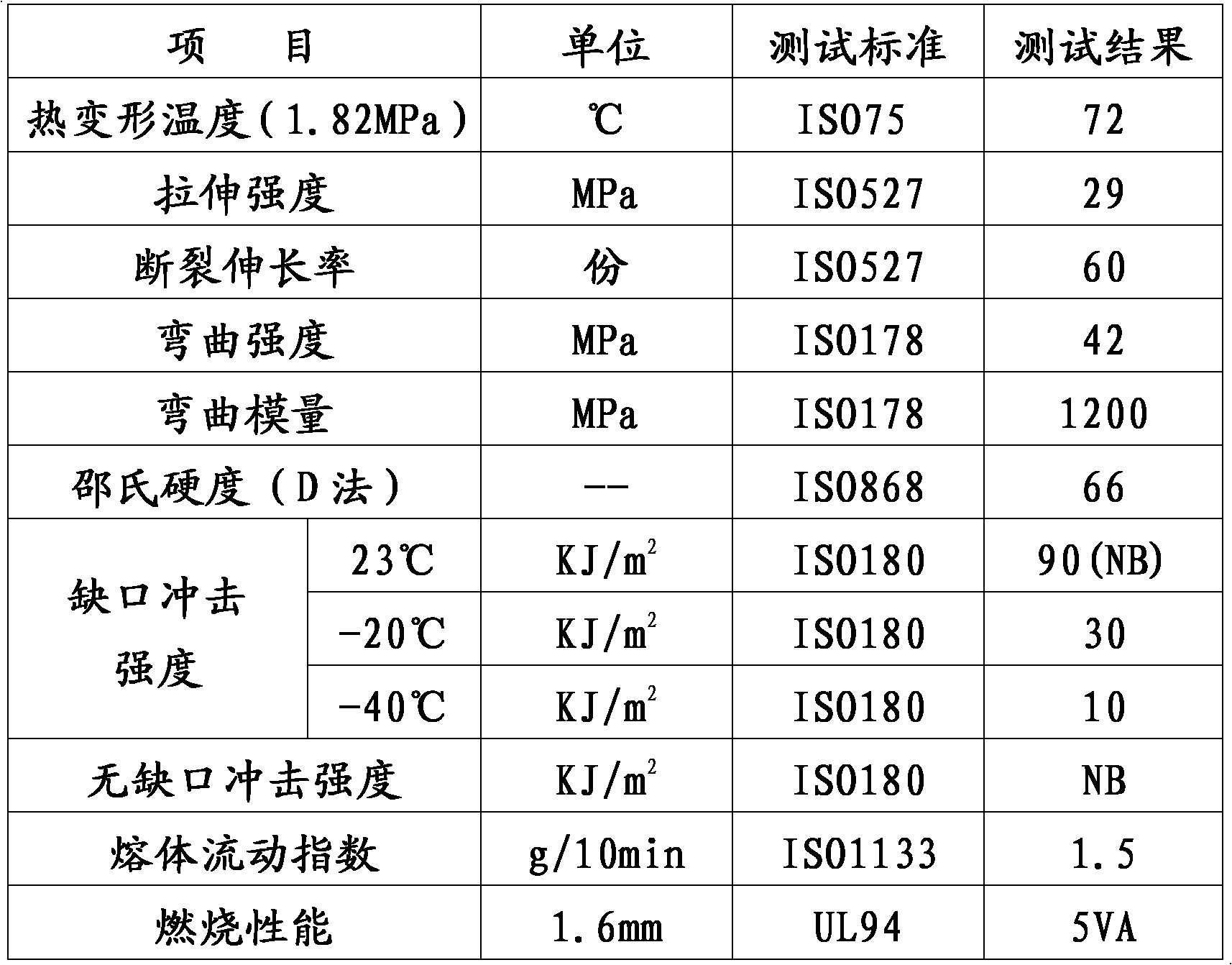

Polypropylene composition and preparation method thereof

The invention, belonging to the technical field of universal plastics modification, discloses a polypropylene composition and a preparation method thereof. The polypropylene composition disclosed herein comprises the following ingredients: 38.5-95 weight parts of polypropylene, 5-25 weight parts of toughening agent, 0-35 weight parts of inorganic filler, 0-0.5 weight parts of lubricant, 0-0.5 weight parts of light stabilizer, and 0-0.5 weight parts of antioxidant. The preparation method disclosed herein comprises the following steps: adding 38.5-95 weight parts of polypropylene, 5-25 weight parts of toughening agent, 0-35 weight parts of pretreated inorganic filler, 0-0.5 weight parts of lubricant, 0-0.5 weight parts of light stabilizer, and 0-0.5 weight parts of antioxidant in a high mixing machine to mix for 5-10 min; adding the mixture in a double-screw extruder from the charging hole, and granulating. According to the invention, under the condition of keeping excellent comprehensive performances, the polypropylene composition disclosed herein has low production cost, high cost performance, and strong competitive power on the market, and can be widely applied in the material fields of auto-inner ornaments, door sheets, bumpers, liners and shells of household appliances, etc.

Owner:HEFEI GENIUS NEW MATERIALS

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

High-impact polystyrene blend and preparation thereof

InactiveCN101372548AFlame-retardant high-impact polystyrene blend, environmentally friendlyEnvironmentally friendlyAntioxidantMechanical property

The invention relates to a synthetic material, in particular to a halogen-free flame retardant high impact polystyrene blend and a preparation method thereof. The high impact polystyrene blend comprises high impact polystyrene resin with the mass percent of 35-75%, an inorganic flame retardant with the mass percent of 7-45%, an intumescent flame retardant with the mass percent of 5-20%, a flame retardant synergist with the mass percent of 1-5%, a toughening agent with the mass percent of 10-20%, a coupling agent with the mass percent of 0.5-2.0%, a lubricant with the mass percent of 0.5-3.0% and an antioxidant with the mass percent of 0.2-3.0%. The halogen-free flame retardant high impact polystyrene blend is produced by high-speed premixing and extrusion prilling, and has the advantages of environmental protection, flame retardation, low smoke, weather resistance, good thermal stability and mechanical property, easy machine shaping, etc.

Owner:珠海市远康企业有限公司

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-smoke halogen-free flame retardant PC/ABS alloy and preparation method thereof

InactiveCN101591468AImprove flame retardant performanceImprove mechanical propertiesAcrylonitrileAlloy

The invention relates to a low-smoke halogen-free flame retardant PC / ABS alloy and a preparation method thereof. 40-75 polycarbonate (PC), 10-40 acrylonitrile-butadiene-styrol copolymer (ABS), 10-15 compound flame retardant, 0.2-2 compound smoke suppression agent, 2-16 compatilizer, 1-6 low-smoke promoter, 0.1-0.5 stabilizer and 0.1-0.6 lubricant are taken in percentage by weight and are put in a high-speed mixer for mixing for 1-15min, and then the mixture is put in a screw extruder for extrusion granulation. Compared with the prior art, the invention has the advantages of low smoke, halogen-free flaming retardation, excellent comprehensive performance, and the like.

Owner:SHANGHAI KELING INDS

High electrical property and low corrosion flame retardant reinforcing nylon material and preparation method thereof

The invention discloses a high electrical property and low corrosion flame retardant reinforcing nylon material and a preparation method thereof, aiming at solving the defects of low electrical property and high corrosion caused by red phosphorus based flame retardant added into flame retardant reinforcing nylon in the prior art. The invention adopts the technical scheme that the high electrical property and low corrosion flame retardant reinforcing nylon material disclosed by the invention has the formulation (by weight percent): (1) 40-65% of nylon 66 resin, (2) 10-20% of red phosphorus based flame retardant masterbatch, (3) 1-5% of compatilizer, (4) 3-10% of synergistic compound flame retardant system, (5) 0.5-5% of acid absorbent, (6) 0.1-0.5% of antioxidant, (7) 0.2-0.8% of lubricating agent and (8) 10-30% of glass fiber; and the reinforcing nylon material can be prepared by mixing all the components in a high-speed mixing machine for 1-2min and then putting into a twin-screw extruder for extrusion and pelleting. The flame retardant reinforcing nylon material is excellent in the electrical property, low in corrosion (extremely low in corrosion for equipment and a mould) as well as high in fluidity, heat resistance and cost performance, and is capable of meeting the requirements of electrical and electronic appliances such as a temperature controller, a contactor, a circuit breaker and the like as well as domestic appliance products.

Owner:GUANGDONG WAYLAM ENG PLASTICS

Soft low-smoke halogen-free flame-retardant polyolefin cable material and preparation method thereof

InactiveCN101817952ABright surfaceImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesLinear low-density polyethylenePolyolefin

The invention discloses a soft low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The cable material comprises the following components (based on by mass part ratio): 80-90 parts of copolymer of ethylene-vinylacetate, 10-20 parts of linear low-density polyethylene, 65-130 parts of an inorganic fire retardant through surface treatment, 10-30 parts of high-effective flame retardant synergist, 10-20 parts of high molecular compatilizer, 0.9-1.5 parts of antioxidant and 1-2 parts of processing aid. The preparation method comprises the steps of resin blending extrusion; surface treatment of the inorganic fire retardant; batching, mixing, extrusion, granulation and the like. Compared with the prior art, the invention has the characteristics of predominant flame retardation (an oxygen index up to 36), excellent toughness, excellent bending resistance, low density (density is only 1.28g / cm<3>), low smoke, low corrosion, low toxicity, environmental protection, good processability, bright surface of extrudates and the like.

Owner:XI AN JIAOTONG UNIV +1

Preparation method of polylactic acid material for 3D (three-dimensional) printing

Owner:ZHONGSHAN GREATSIMPLE TECH CO LTD

Starch-based edible film and preparation method thereof

InactiveCN101906220ARich sourcesReduce manufacturing costFlexible coversWrappersPliabilityStabilizing Agents

The invention relates to a starch-based edible film and a preparation method thereof. The starch-based edible film is a starch-based edible packaging film with favorable flexibility, barrier property, ageing-resistance property and heat sealing property, which is prepared by adopting the preparation method comprising the following steps of: adding a food-grade plasticizer, a lubricating agent, a reinforcing agent, a stabilizing agent and other accessories by taking stably-degraded composite modified starch as a main film-forming raw material, stirring and mixing at high speed, carrying out double-screw extrusion granulation and then carrying out single-screw extrusion casting to obtain the finished product. The invention has the characteristics of low energy consumption and high production efficiency and is suitable for industrial continuous production. The prepared film in the invention has edibility and full degradability, can be widely applied to inner packaging of foods, and avoids non-degradable food packages from polluting the environment.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

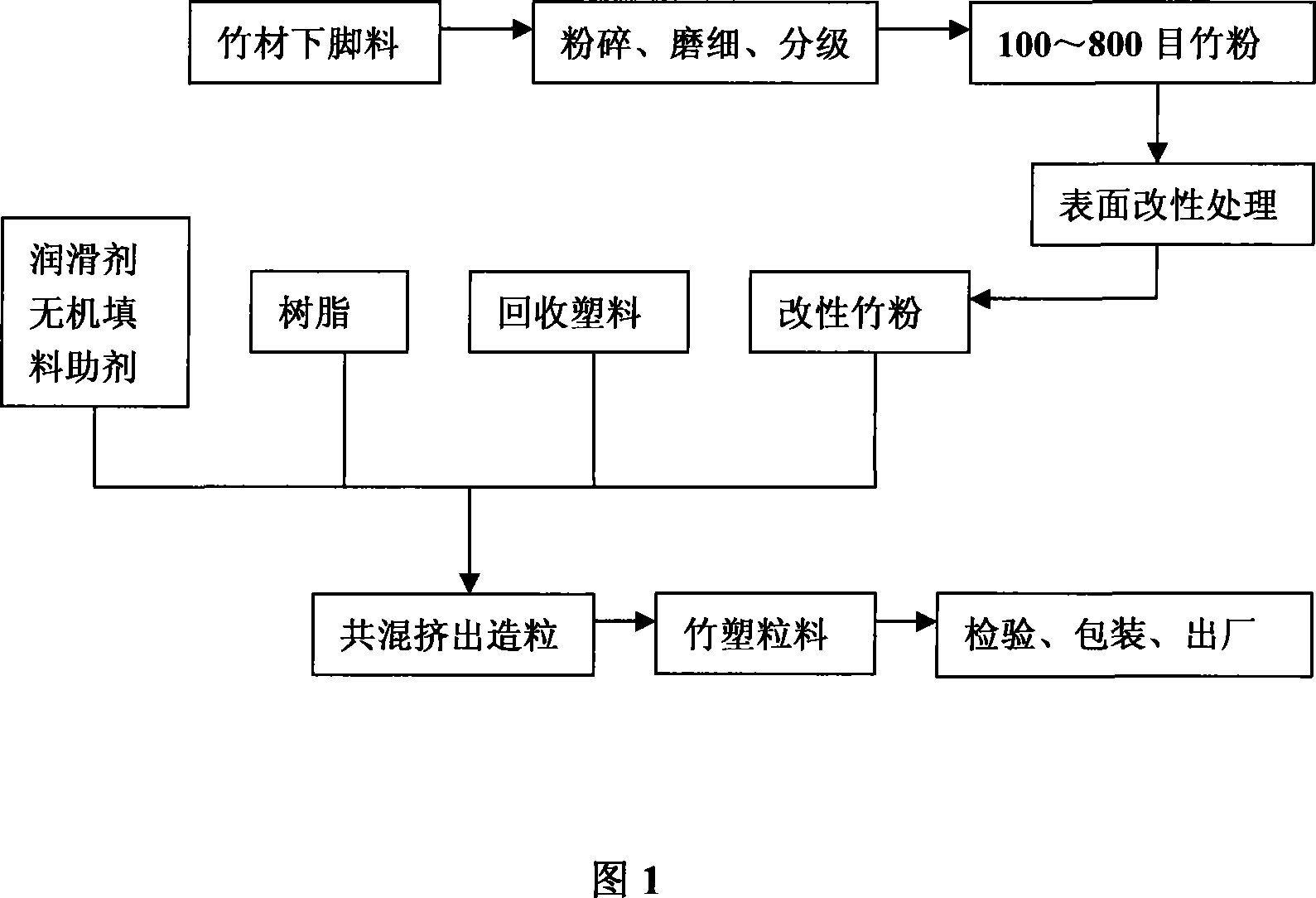

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

Preparation method of toughness enhanced and reinforced polybutanediol terephthalate nanometer composition

InactiveCN1537891AHigh surface finishImprove heat resistanceSurface finishPolytetramethylene terephthalate

A nano-class toughened and strengthened butanediol polyterephthalate composition is prepared through proportionally mixing butanediol polyterephthalate, inorganic nanoparticles, reaction compatibilizer, antioxidizing agent, and lubricant, high-speed stirring, loading it along with glass fibres in dual-screw extruder, reactive mixing and granulating. Its advantage is high high-temp resistance, strength, toughness and surface polished.

Owner:SHANGHAI JIAO TONG UNIV +1

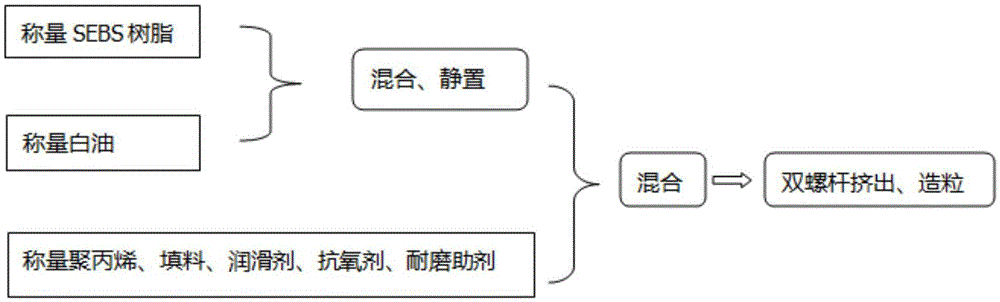

Wear-resistant SEBS thermoplastic elastomer material and preparation method thereof

InactiveCN105566924AGood mechanical propertiesImprove friction resistanceSocial benefitsThermoplastic elastomer

The invention discloses a wear-resistant SEBS thermoplastic elastomer material and a preparation method thereof. The wear-resistant SEBS thermoplastic elastomer material is prepared from the following raw materials in parts by weight: 100 parts of SEBS resin, 100-150 parts of white oil, 100-400 parts of polypropylene, 200-400 parts of a packing, 1-3 parts of a lubricant, 0.2-1 part of an antioxidant auxiliary agent, and 25-50 parts of a wear-resistant auxiliary agent. The preparation method comprises the following steps: 1) mixing the SEBS resin and the white oil evenly, and allowing to stand; and 2) adding polypropylene, the packing, the lubricant, the antioxidant auxiliary agent and the wear-resistant auxiliary agent, and mixing evenly; 3) adding the mixed material into a double-screw extruder, extruding, and granulating to obtain the wear-resisting SEBS thermoplastic elastomer material. The wear-resistant SEBS thermoplastic elastomer material has the advantages of excellent mechanical properties, excellent friction resistance, high content of the packing, low cost and green and environmental protection. The preparation method has the advantages of simple process, low investment, low energy consumption, high efficiency and remarkable economic and social benefits.

Owner:广州合成材料研究院有限公司

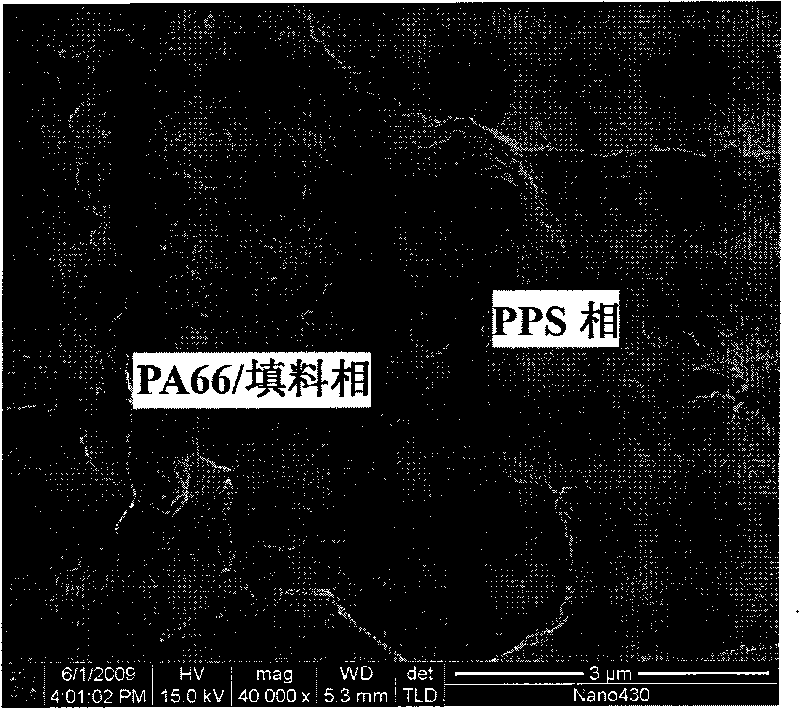

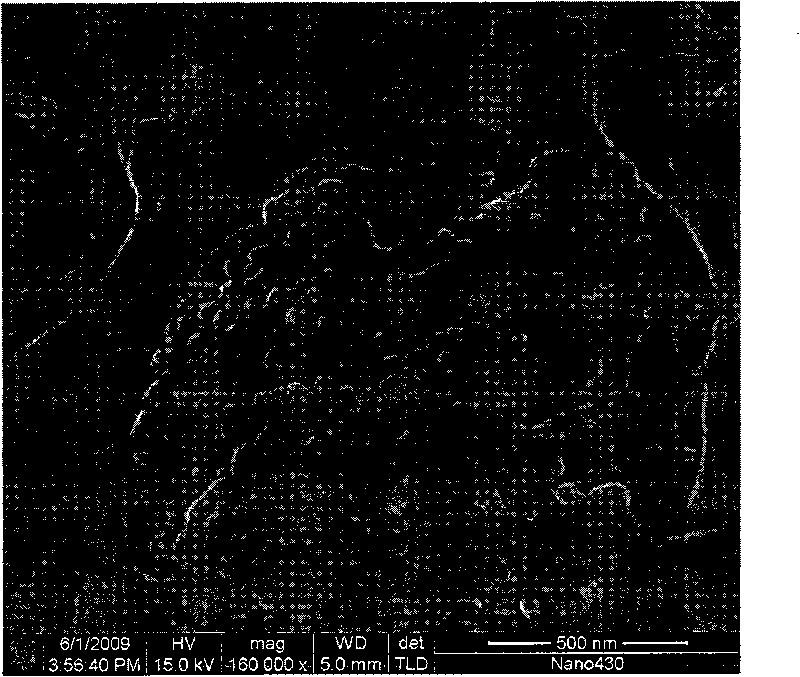

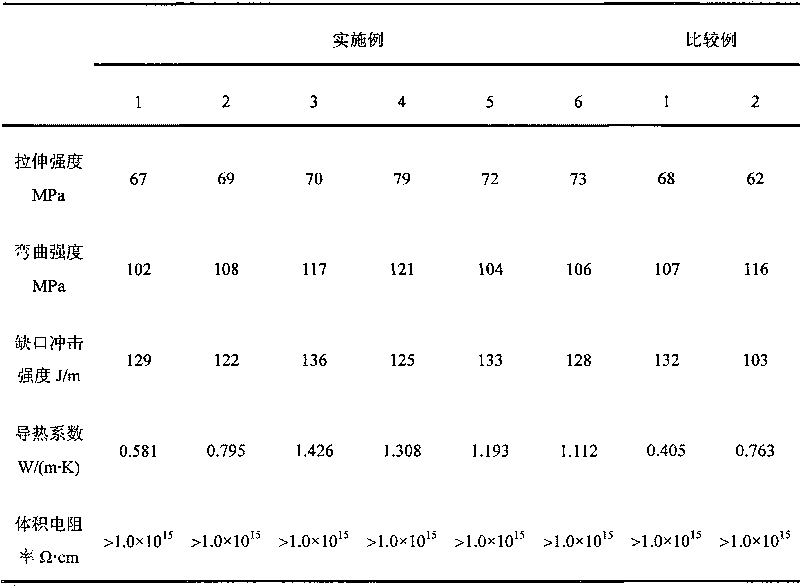

Filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and preparation method thereof

The invention discloses a filling-type thermal-conducting electric-insulating polyphenyl thioether and polyamide blended alloy and a preparation method thereof. The blended alloy comprises polyphenyl thioether, polyamide, an inorganic thermal-conducting filler, a surface modifier and processing assistants, wherein the polyamide and the polyphenyl thioether form a bicontinuous phase structure, and the inorganic thermal-conducting filler is distributed in the polyamide phase and forms a continuous thermal-conducting network. The preparation method comprises the following three steps: step 1: carrying out the surface modification on the inorganic thermal-conducting filler by using the surface modifier; step 2: mixing the inorganic thermal-conducting filler, the polyamide and the processing assistants by using a high-speed mixer, and extruding the mixture by using a double screw extruder to obtain the thermal-conducting master batch; and step 3: extruding the thermal-conducting master batch, the polyphenyl thioether and the processing assistants for the second time to make granules. The composite material of the invention has good thermal conduction, electrical insulation, mechanical properties and processability. Under the condition of the same amount of the inorganic thermal-conducting filler, compared with the blended alloy phase in which the continuous phase is not formed, the coefficient of thermal conductivity of the composite material in the invention is obviously enhanced.

Owner:SOUTH CHINA UNIV OF TECH

Friction material and method for manufacturing friction plate by using friction material

InactiveCN103012876AImprove wear resistanceReduce hardnessOther chemical processesFriction liningNitrile rubberVulcanization

The invention provides a friction material comprising an adhesive, a reinforcing material, a friction-enhancing material, a lubricant, and a filling material. The adhesive is a mixture of liquid nitrile rubber and phenolic resin. The invention also provides a method for manufacturing a friction plate by using the friction material. According to the invention, liquid nitrile rubber is adopted as a substrate of the friction material, and the friction plate with a required shape is manufactured through extrusion granulation and vulcanization molding. The friction plate has the advantages of high abrasion resistance and low hardness. When the friction plate is used in mine hoisting machinery and agricultural working machinery, the friction plate can be processed into special shapes, and another special requirement of good weather resistance can be satisfied.

Owner:BYD CO LTD

Preparation method for high-strength heat-proof polythene composite material

InactiveCN101367973AHigh strengthGood strength, heat resistanceHeat resistanceUltimate tensile strength

The invention relates to a method for preparing high heat-resisting polyethylene composite materials. The method takes advantage of the feature that thermosetting resin has sound rigidity and strength under high temperature after curing, and by adding reaction compatibilizing agent to act with thermosetting resin to form a semi-interpenetrating network of polyethylene and thermosetting resin, and thereby preparing novel polyethylene composite materials. The polyethylene, thermosetting resin, curing agent, accelerating agent, reaction compatibilizing agent and antioxidant which are premixed evenly in a high-speed agitator are added into a double screw extruder, and reactively blended at a proper temperature and rotation speed, the produced granules are extruded out, and the desired high heat-resisting polyethylene composite materials are achieved. Compared with the common polyethylene, the heat resistance and the strength of the materials under normal temperature and high temperature are improved remarkably, and the materials can be applied to the fields of civil buildings, auto parts, household electrical appliances as well as wires and cables, and the like.

Owner:SHANGHAI JIAO TONG UNIV

Full biological degradable composition and its preparing method and use

InactiveCN1683446ADoes not affect basic physical propertiesGood mechanical propertiesPlasticizerPolyresin

The fully biodegradable composition consists of modified starch, biodegradable polymer, nanometer reinforcer, plasticizer, lubricant, reactive bulking agent, crosslinking agent and biodegradation promoter. The preparation process includes drying starch and fining modification and plasticizing treatment, mixing with supplementary material, and extrusion and pelletizing in reciprocating single-screw extruder and electric mixer. The composition is completely biodegradable, has high adaptability, easy use, wide use range and low cost, and may be used directly as resin or mixed with other resin.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material and preparation method thereof

InactiveCN104403190AIncrease productivitySimple processPlastic/resin/waxes insulatorsCross-linkPolyolefin

The invention discloses an ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material and a preparation method thereof, and relates to a flame retardant polyolefin cable material and a preparation method thereof, for solving the problems that a conventional flame retardant polyolefin cable material is complex in process, high in cost of cross-linking equipment and poor in oil resistance. The ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material is prepared from a base material, a halogen-free flame retardant, a cation initiator, a free radical initiator, a multi-functional cross-linking agent, a flame retardant synergist, an antismoke agent, a composite antioxidant and a lubricant in parts by weight. The preparation method comprises the following steps: feeding the raw materials into an internal mixer according to the parts by weight, uniformly mixing, feeding the mixture into a double-screw extruder, further mixing and plastifying uniformly, and feeding into a single-screw extruder for extrusion pelleting, thereby obtaining the ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material. The invention aims at preparing the ultraviolet cross-linking oil-resistant low-smoke halogen-free flame retardant polyolefin cable material.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Nylon engineering plastic for high-speed railway rail fastening and method for manufacturing same

InactiveCN101250322AHigh anti-climbing resistanceHigh precisionRail fastenersEngineering plasticNylon 66

Polyamide engineering plastic for rail fasteners of high speed railway and a preparation process are disclosed. The plastic belongs to organic material, which is characterized in that the plastic is formed through conducting mixture extrusion pelleting for the following components: material substrate material with 48-88% percentage by weight, wherein the substrate material is polyamide 6 resin, or is polyamide 66 resin, or is the mixture of polyamide 6 resin and polyamide 66 resin, addition agent with 0-15% percentage by weight, wherein the addition agent is toughening agent and compatilizer, intensifier with 10-50% percentage by weight, wherein the surface of intensifier is treated with silane coupling agent with 0.2-5% percentage by weight relative to additive matters. Polyamide engineering plastic provides raw material for producing first-grade railway rail fasteners. The fastener which is produced by the plastic has the advantages of light weight, high strength and high impact, large loading, easy machine shaping and dyeing and reasonable cost.

Owner:NANJING JULONG SCI&TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com