Wear-resistant SEBS thermoplastic elastomer material and preparation method thereof

A thermoplastic elastomer and wear-resistant additive technology, which is applied in the field of wear-resistant SEBS thermoplastic elastomer material and its preparation, can solve the problems of reduced wear resistance and increased material wear, and achieves low cost, excellent friction resistance, The effect of high filler content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

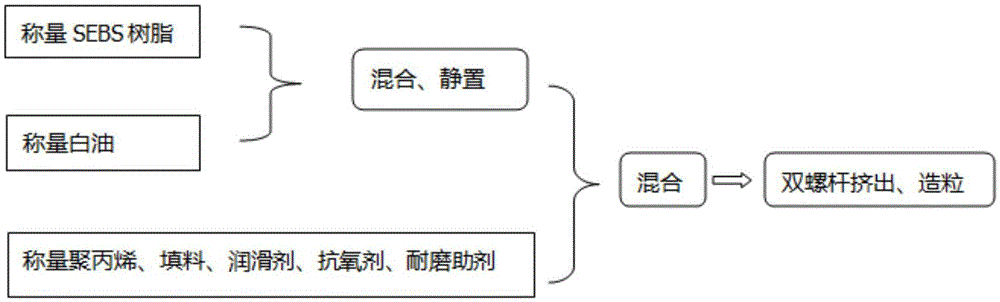

[0046] The preparation method of the wear-resistant SEBS thermoplastic elastomer material corresponding to above-mentioned formula or preferred formula, comprises the following steps:

[0047] 1) Mix SEBS resin and white oil evenly and let stand;

[0048] 2) Add polypropylene, fillers, lubricants, antioxidant additives and wear-resistant additives, and mix well;

[0049] 3) Put the mixed material into a twin-screw extruder, extrude and granulate to obtain a wear-resistant SEBS thermoplastic elastomer material.

[0050] Preferably, the mixing time of step 1) and step 2) is 30-50 minutes.

[0051] Preferably, the standing time in step 1) is 12-15 hours.

[0052] Preferably, during the granulation process described in step 3), the temperature of the first zone of the twin-screw extruder is 150-170°C, and the temperature of the head and other zones is 180-220°C.

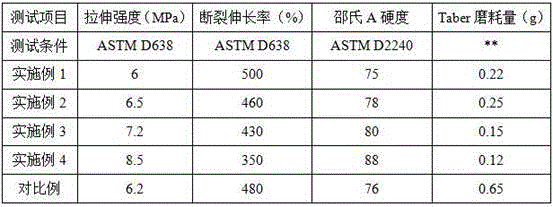

Embodiment 1

[0056] 1) Add 100 parts by mass of linear SEBS resin (weight average molecular weight 1.5×10 5 Da), 140 parts by mass of paraffin-based white oil were added to a high-speed mixer, mixed for 30 minutes, and then left to stand for 12 hours;

[0057] 2) Add 120 parts by mass of polypropylene copolymer, 200 parts by mass of talc powder, 1 part by mass of calcium stearate, 1 part by mass of PE wax, 0.1 part by mass of N,N'-bis-[3-(3 , 5-di-tert-butyl-4-hydroxyphenyl)propionyl]hexamethylenediamine, 0.1 parts by mass of tris(2,4-di-tert-butylphenyl)phosphite and 25 parts by mass of polytetrafluoroethylene powder, mixed for 50 minutes;

[0058] 3) Put the mixed material into a twin-screw extruder, extrude and granulate to obtain a wear-resistant SEBS thermoplastic elastomer material.

[0059] Step 3) During the granulation process, the temperature in the first zone of the twin-screw extruder is 150-170°C, and the temperature in the head and other zones is 180-220°C.

[0060]The per...

Embodiment 2

[0062] 1) Add 100 parts by mass of star SEBS resin (weight average molecular weight 1.5×10 5 Da), 100 parts by mass of paraffin-based white oil was added to a high-speed mixer, mixed for 40 minutes, and then left to stand for 15 hours;

[0063] 2) Add 100 parts by mass of polypropylene copolymer, 300 parts by mass of talc, 2 parts by mass of calcium stearate, 1 part by mass of N,N'-ethylene bisstearamide, 0.2 parts by mass of tetrakis [β -(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid]pentaerythritol ester, 0.5 parts by mass of tris(2,4-di-tert-butylphenyl)phosphite and 35 parts by mass of polytetrafluoroethylene Vinyl fluoride powder, mixed for 40 minutes;

[0064] 3) Put the mixed material into a twin-screw extruder, extrude and granulate to obtain a wear-resistant SEBS thermoplastic elastomer material.

[0065] Step 3) During the granulation process, the temperature in the first zone of the twin-screw extruder is 150-170°C, and the temperature in the head and other zon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com