Patents

Literature

1638 results about "Vinyl fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vinyl fluoride is an organic halide with the chemical formula C₂H₃F. It is a colorless gas with a faint etherlike odor. It is used as the monomeric precursor to the fluoropolymer polyvinylfluoride.

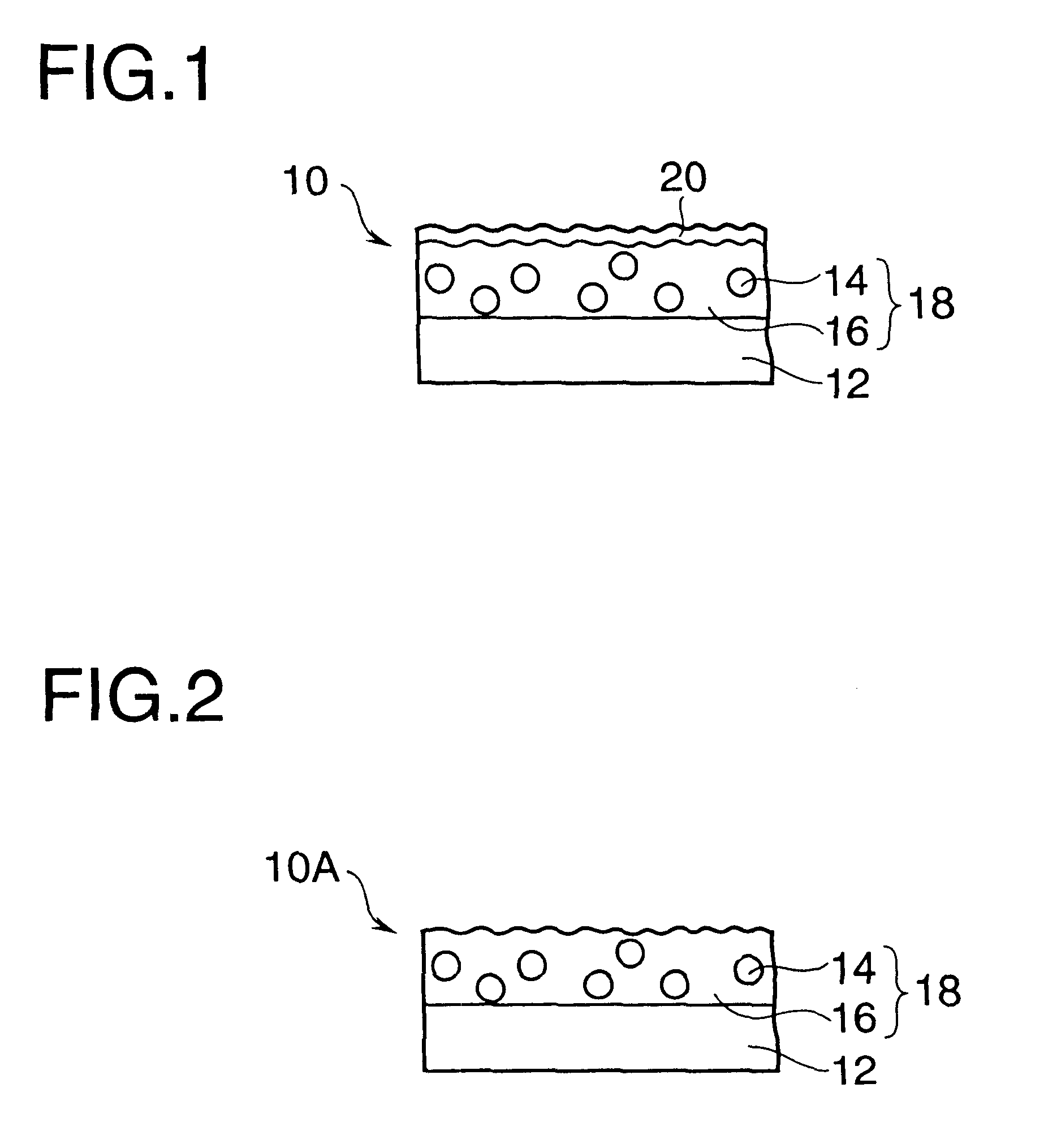

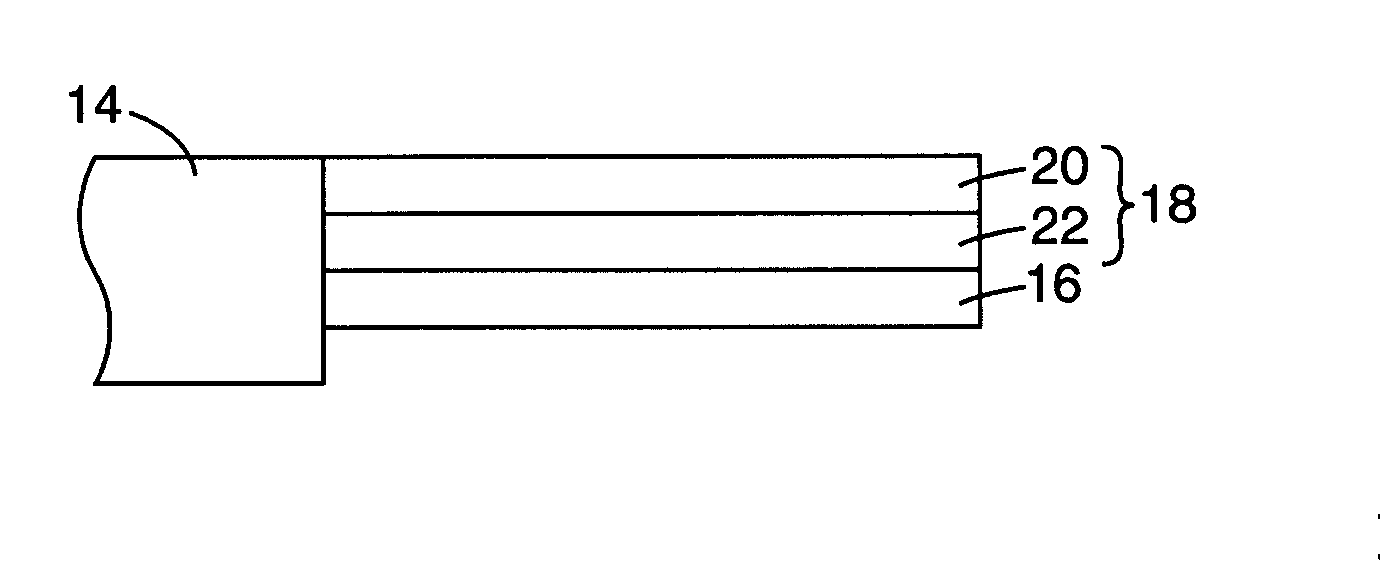

Non-glare film, polarizing device and display device

InactiveUS6343865B1Small particle sizeImprove display qualityMirrorsDiffusing elementsRefractive indexDisplay device

A non-glare film 10 is composed of a non-glare layer 18 formed by coating a transparent base film 12 of TAC or the like with a coating material obtained by mixing a light transmissive diffusing material 14 of resin beads and the like in a light transmissive resin 16, and a low refractive index layer 20 composed of a silicon-containing vinylidene fluoride copolymer, said low refractive index layer 20 being laminated onto the surface of the non-glare layer, in which the haze value on the surface of the non-glare layer 18 is 7 to 30 and the haze value inside the non-glare layer 18 is 1 to 15, and when the non-glare film is attached onto the surface of a display panel, it suppresses degradation in contrast and furthermore prevents face-glare, reflecting-in and whitening.

Owner:DAI NIPPON PRINTING CO LTD

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS20070154704A1Strong adhesionIncreased durabilitySynthetic resin layered productsRecord information storageEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

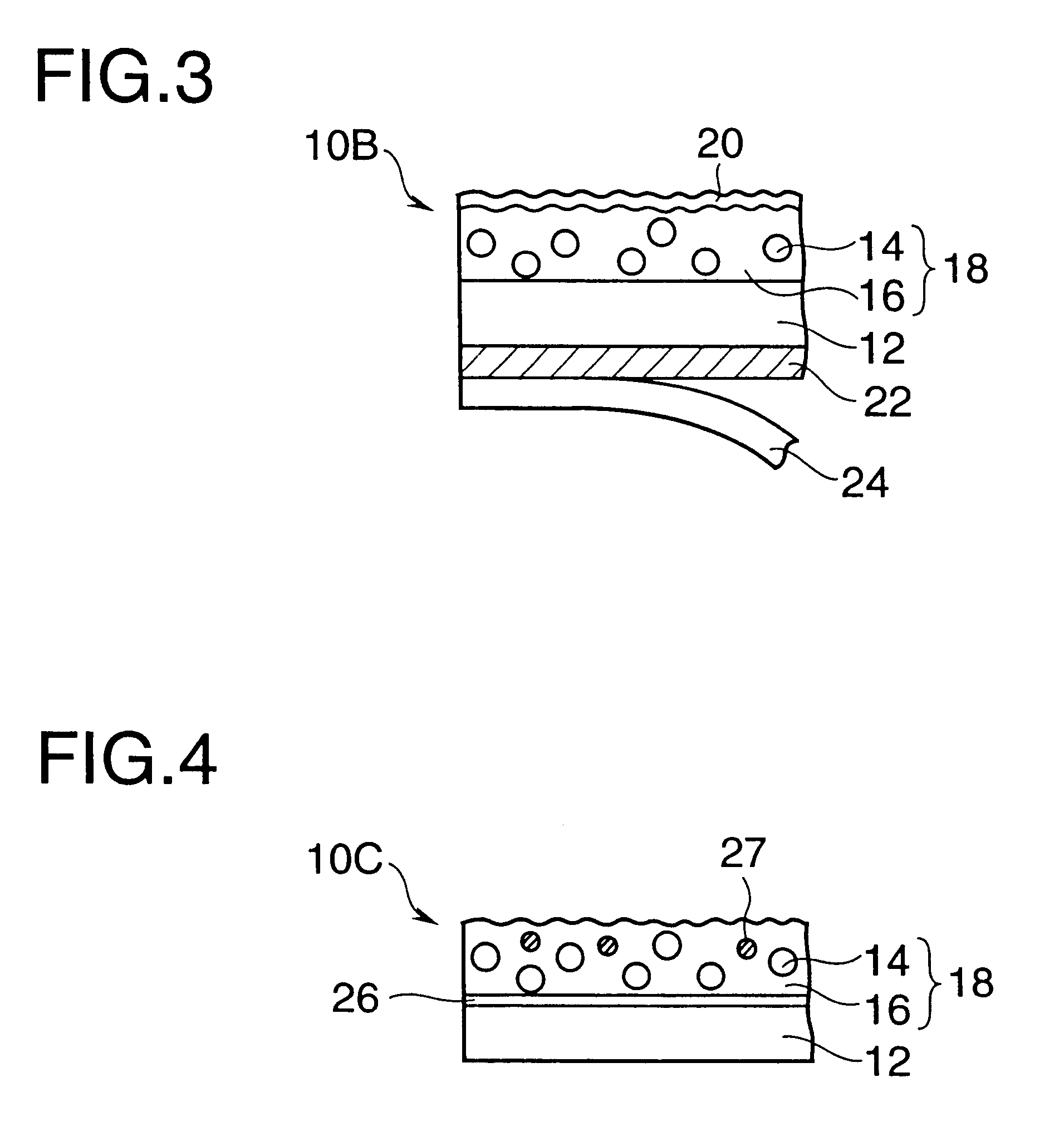

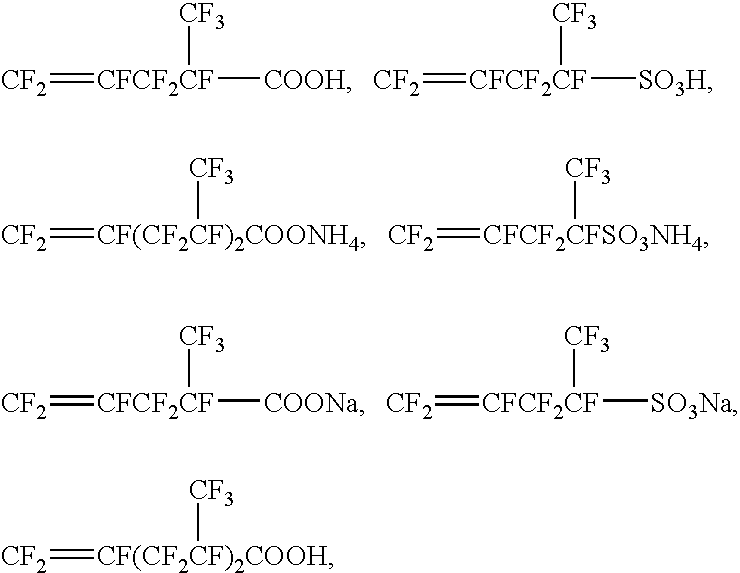

Aqueous tetrafluoroethylene polymer dispersion,process for producing the same, tetrafluoroethylene polymer powder,and molded tetrafluoroethylene polymer

InactiveUS20070060699A1Excellent in moldability/processabilityIncrease concentrationFibre treatmentTetrafluoroethylenePolymer science

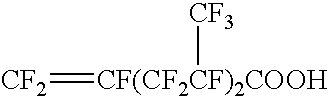

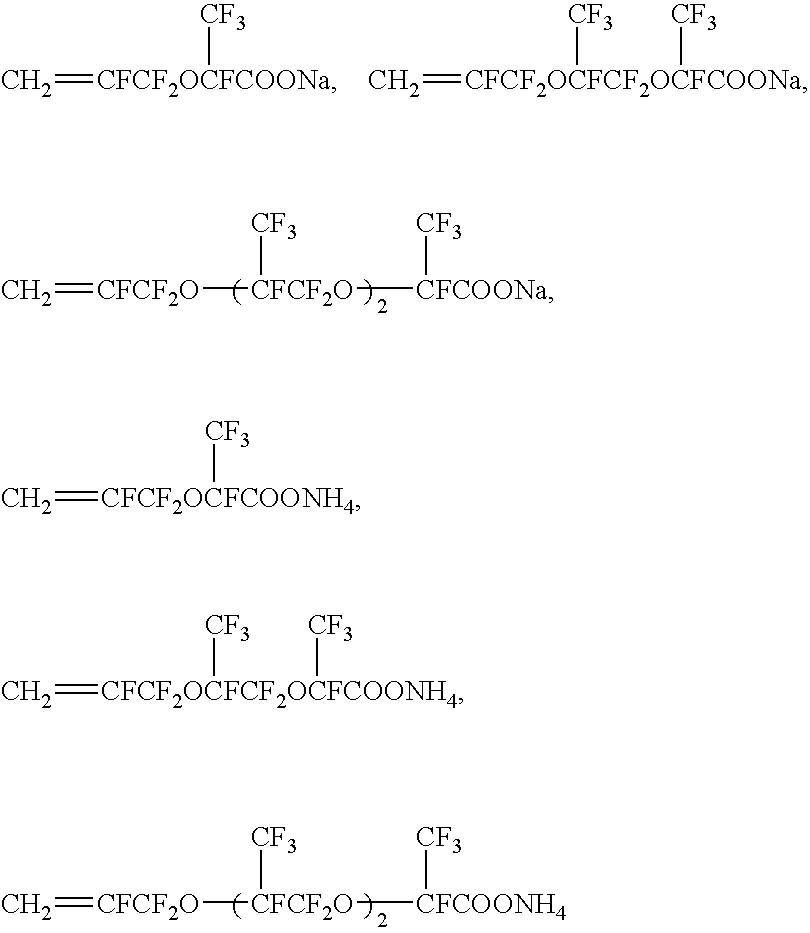

The present invention provides a tetrafluoroethylene polymer aqueous dispersion obtained by carrying out a TFE polymerization in an aqueous medium in the presence of a fluorovinyl group-containing emulsifier, wherein the TFE polymer aqueous dispersion contains a particle comprising a TFE polymer dispersed in the aqueous medium, the fluorovinyl group-containing emulsifier comprises a fluorovinyl group-containing compound, and the TFE polymer aqueous dispersion has a fluorine-containing surfactant content of not higher than 1000 ppm by mass.

Owner:DAIKIN IND LTD

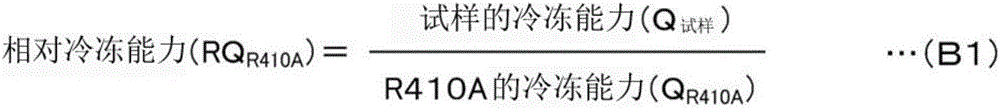

Working medium for heat cycle, composition for heat cycle system, and heat cycle system

InactiveCN106414654AImprove stabilityInhibition of the effects of global warmingCompressorCompression machines with non-reversible cycleEngineeringDouble bond

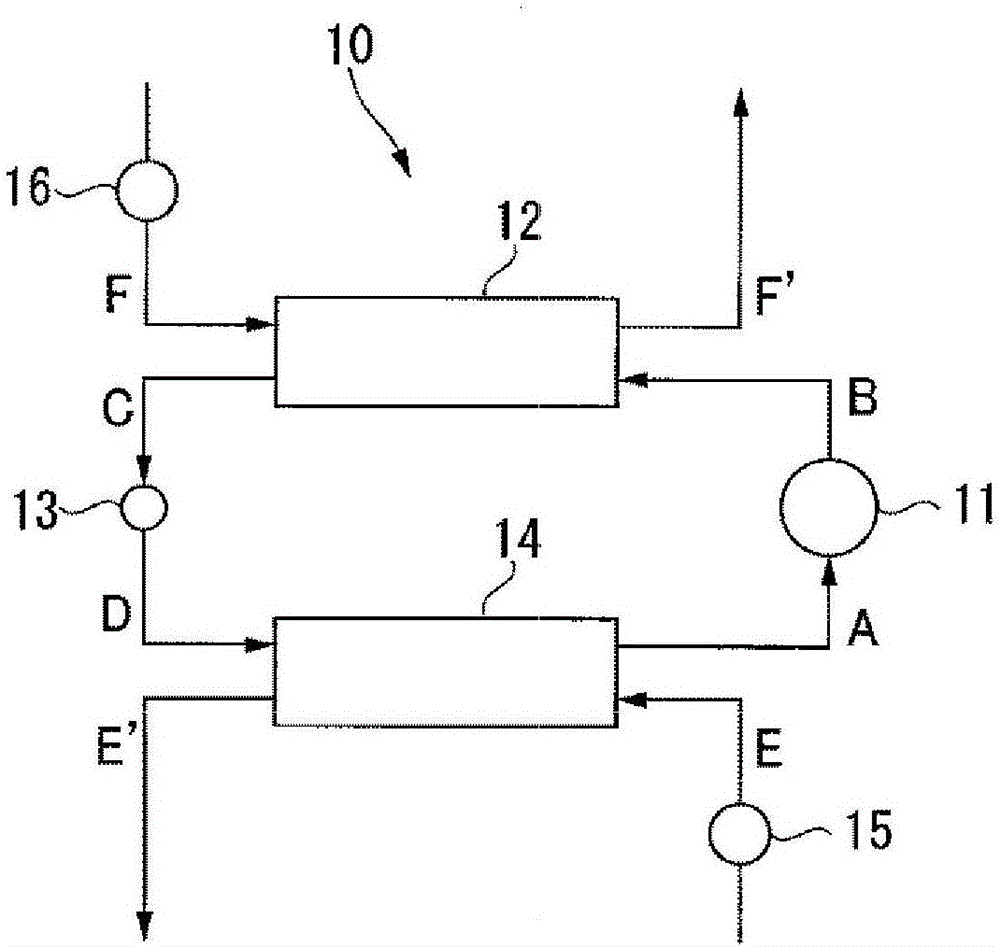

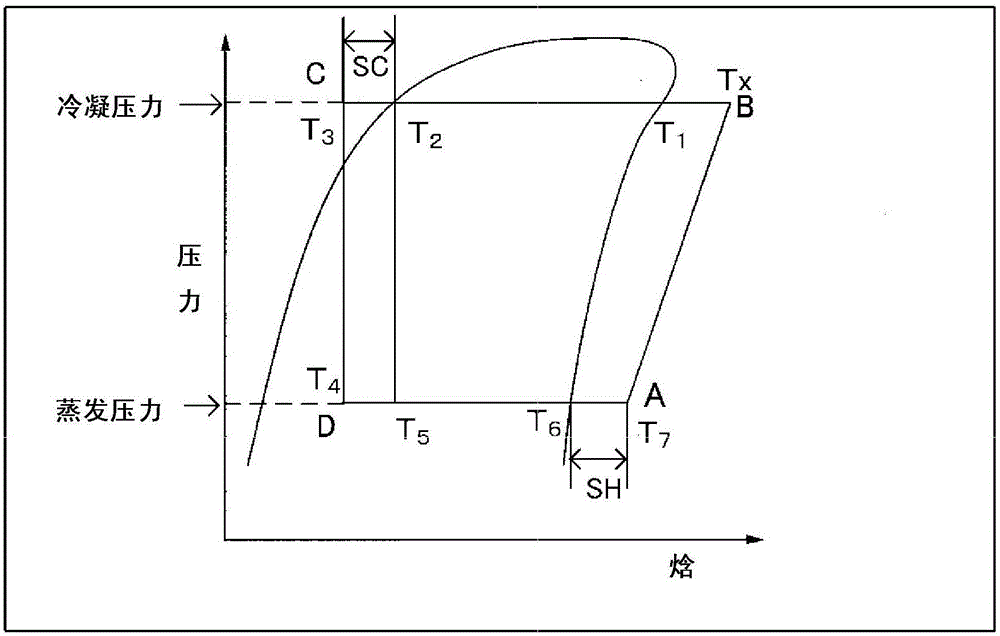

Provided are: a working medium for a heat cycle, said working medium containing 1,2-difluoroethylene and exhibiting high stability, reduced environmental impact, and cycle performance that can replace that of R410A (a pseudo-azeotropic mixed refrigerant including difluoromethane and pentafluoroethane at a mass ratio of 1:1) and 1,1,1,2-tetrafluoroethane; a composition for heat cycle system, said composition using the medium; and a heat cycle system using the composition. The working medium for a heat cycle is characterized by the inclusion of 1,2-difluoroethylene and at least two types of hydrofluorocarbon selected from the group of hydrofluorocarbons that include a carbon-carbon double bond other than a saturated hydrofluorocarbon and 1,2-difluoroethylene.

Owner:ASAHI GLASS CO LTD

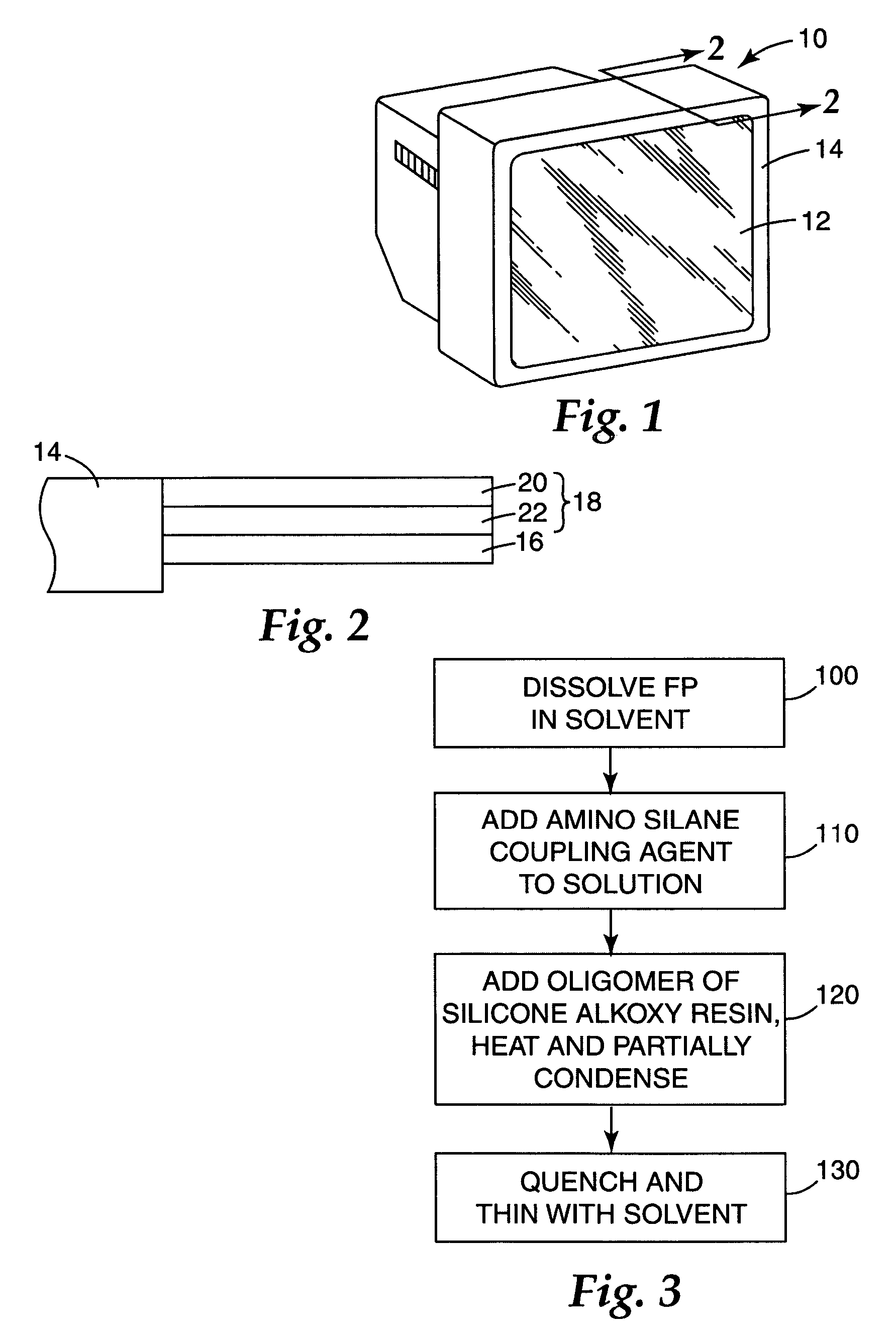

Low refractive index coating composition for use in antireflection polymer film coatings and manufacturing method

InactiveUS7374812B2Easy to manufactureImprove wettabilitySynthetic resin layered productsThin material handlingPolymer scienceSilanes

A silicone-modified fluoropolymer is formed by first dissolving a fluoropolymer in an organic solvent, the fluoropolymer having at least one monomer of vinylidene fluoride coupled to a hexafluoropropylene monomer unit, and subsequently reacting the mixture with an amino silane coupling agent to form an aminosilane-modified fluoropolymer. The aminosilane fluoropolymer is subsequently heated and partially condensed with an oligomer of a silane compound including alkoxy silane. The resultant composition is suitable for use as a low refractive index layer in an antireflection coating on an optical substrate.

Owner:3M INNOVATIVE PROPERTIES CO

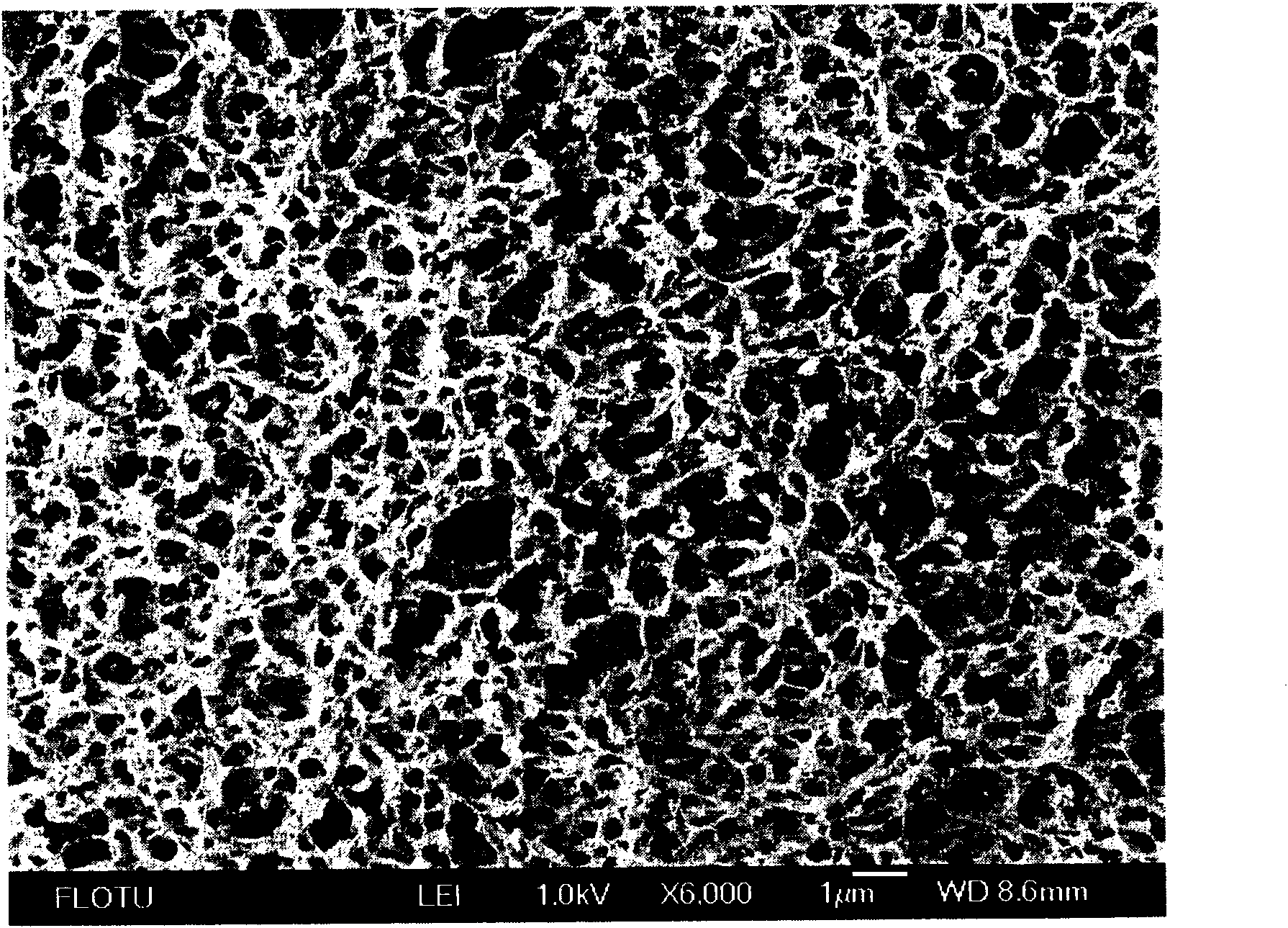

Separator having binder layer, and electrochemical device comprising the separator and method of preparing the separator

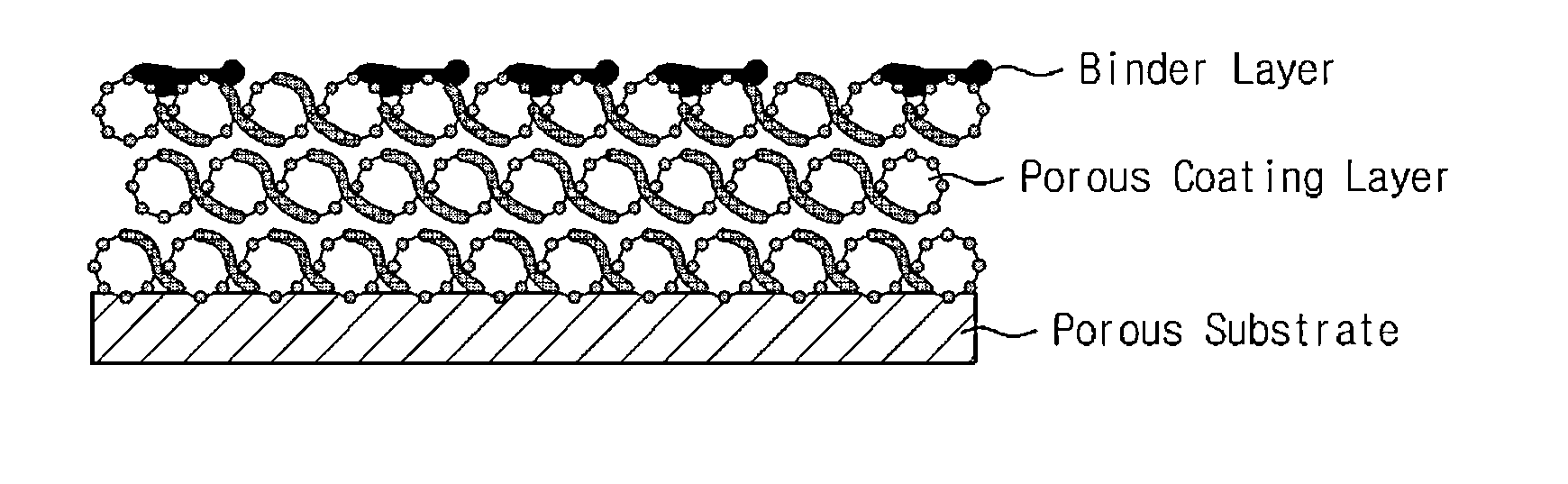

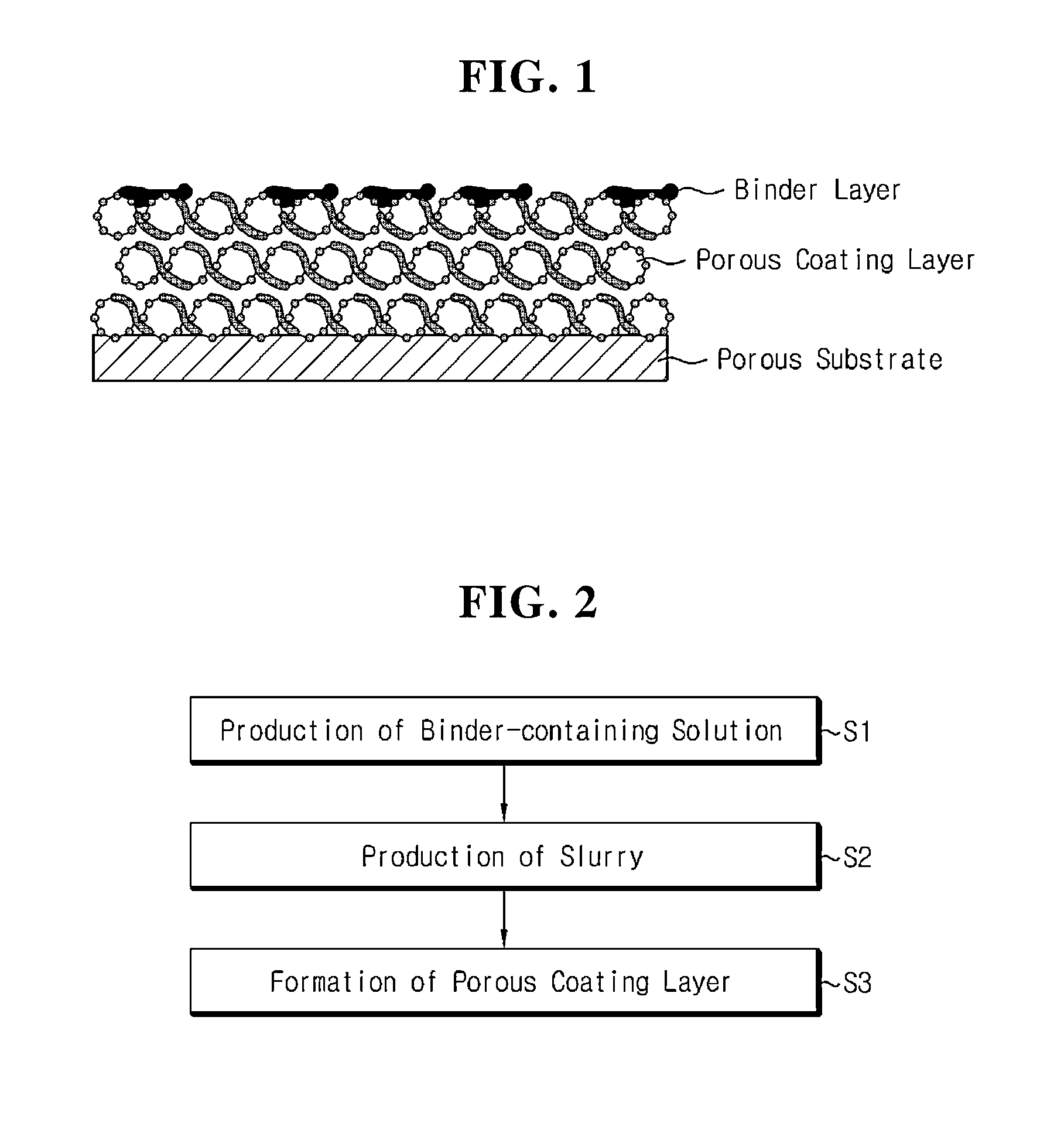

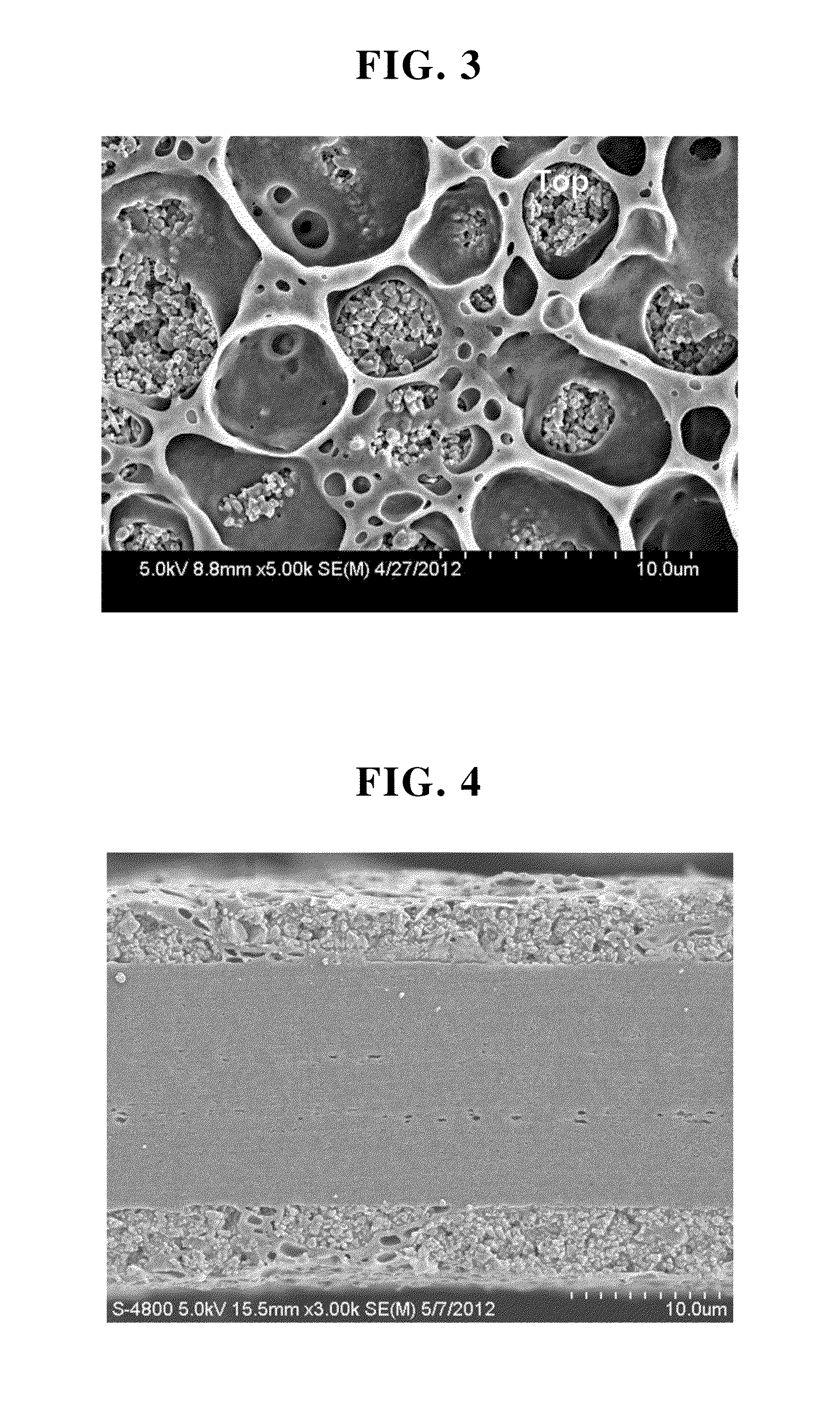

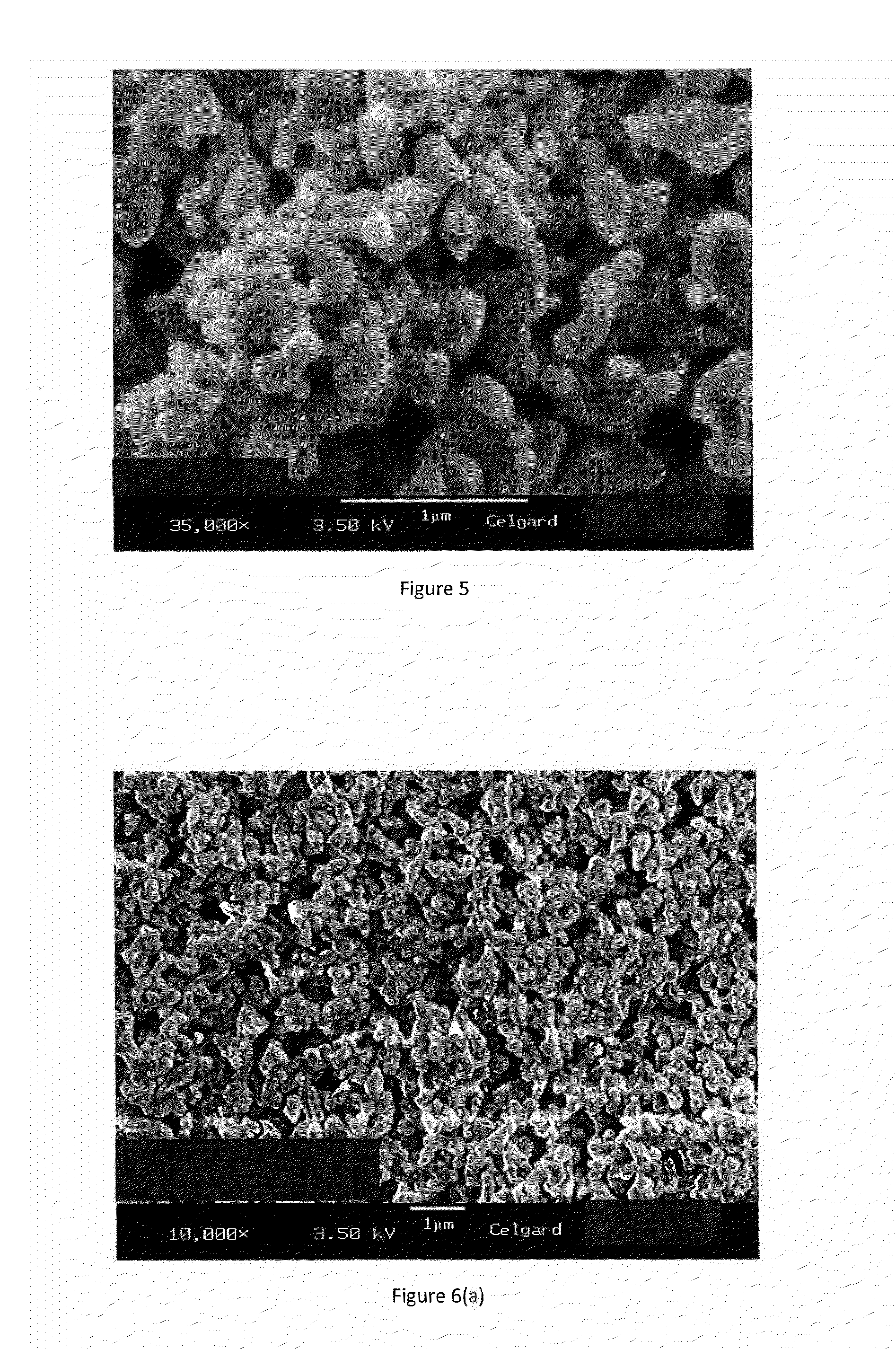

ActiveUS20150303003A1Excellent adhesivenessIncrease resistanceHybrid capacitor separatorsLight-sensitive devicesPolyvinylidene fluoridePorous coating

The present disclosure provides a separator comprising a porous substrate, a porous coating layer and a binder layer, the binder comprising at least one homopolylmer of polyvinylidene fluoride and at least one copolymer of polyvinylidene fluoride (PVDF)-co-hexafluoropropylene (HFP) so that a content difference of hexafluoropropylene (HFP) present in the two compounds is about 3 wt % or higher.

Owner:LG ENERGY SOLUTION LTD +1

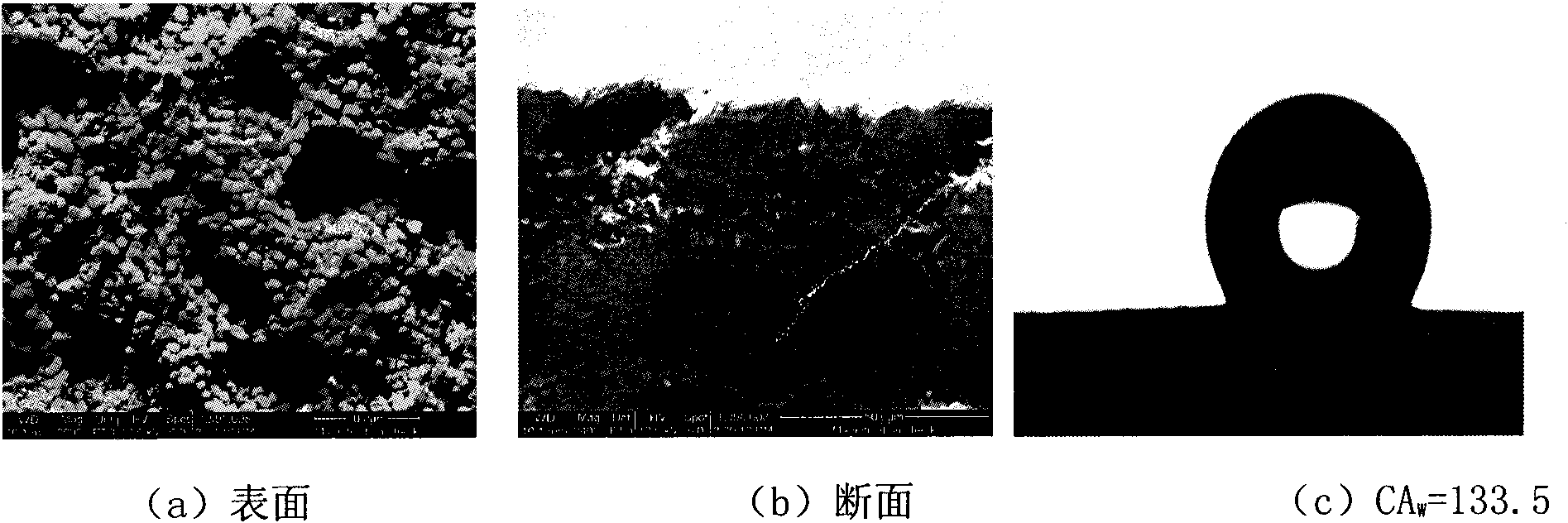

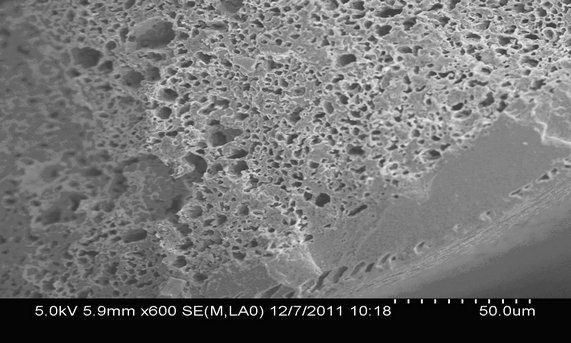

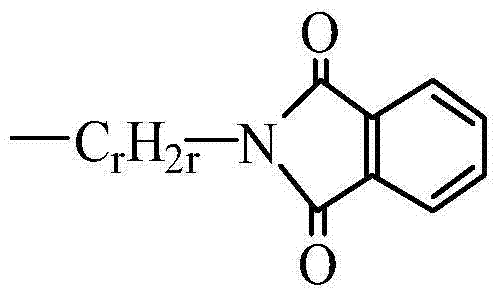

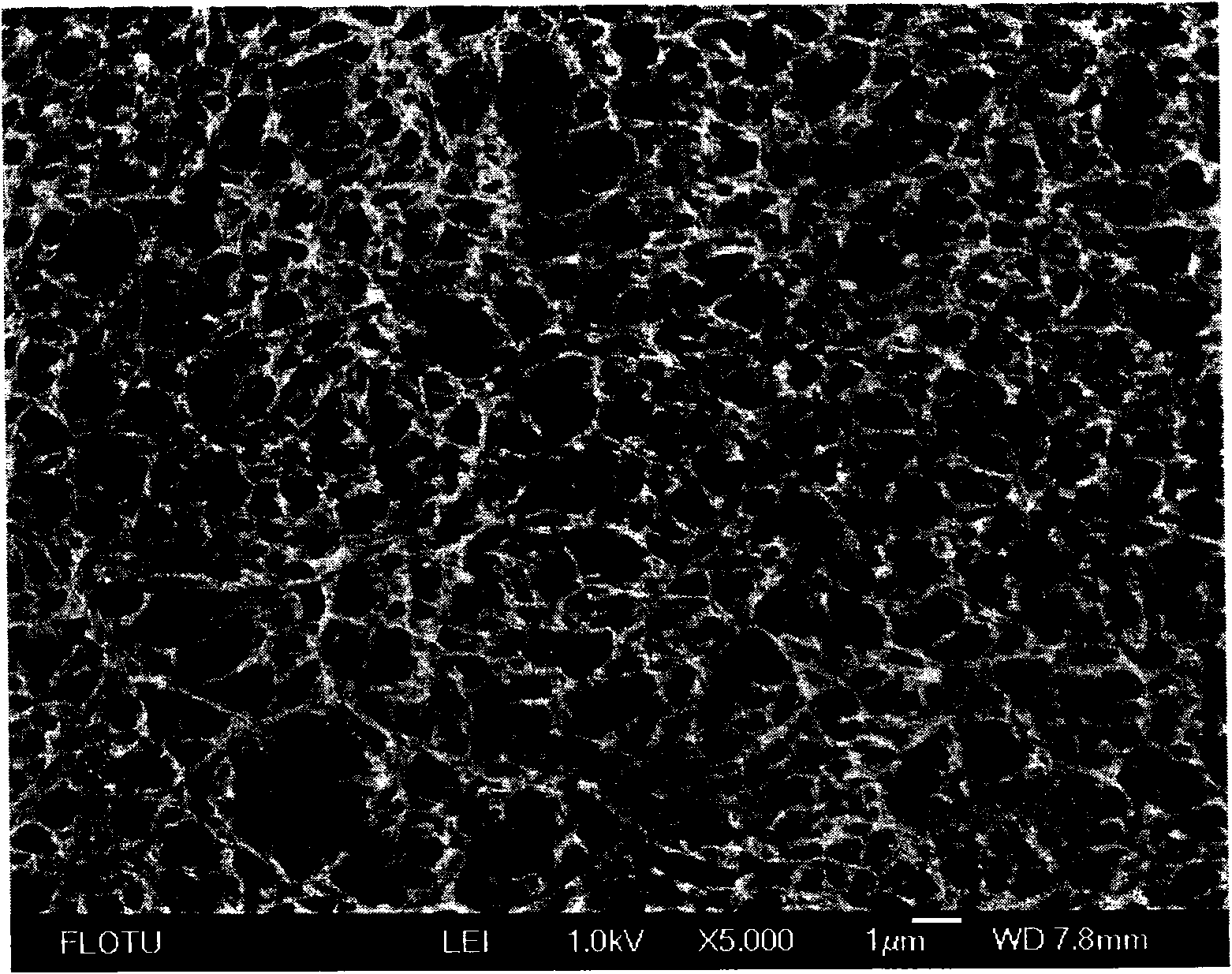

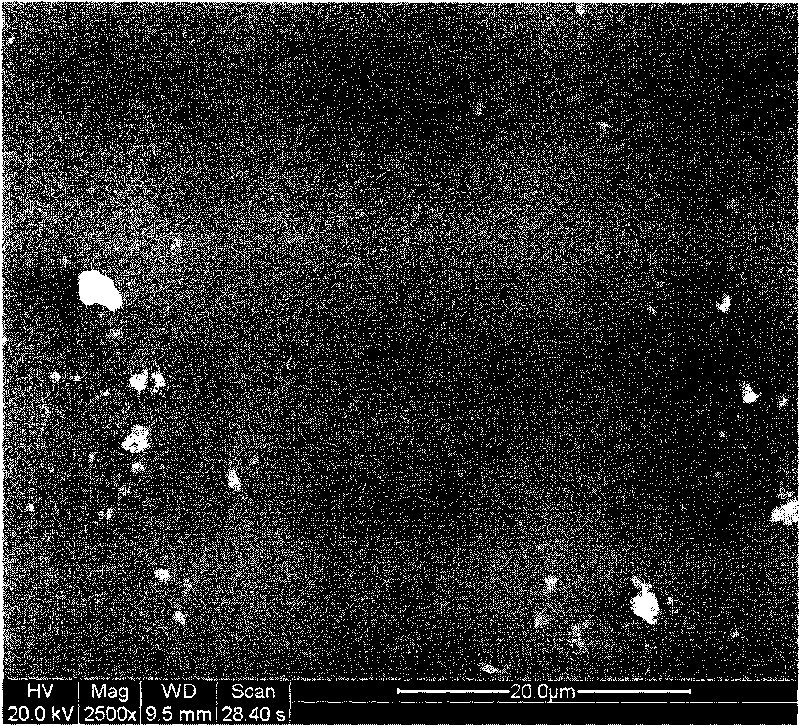

Polyvinylidene fluoride microporous film and preparation method

InactiveCN101632903AWith nanoscale dimensionsImprove hydrophobicitySemi-permeable membranesDistillationFatty alcohol

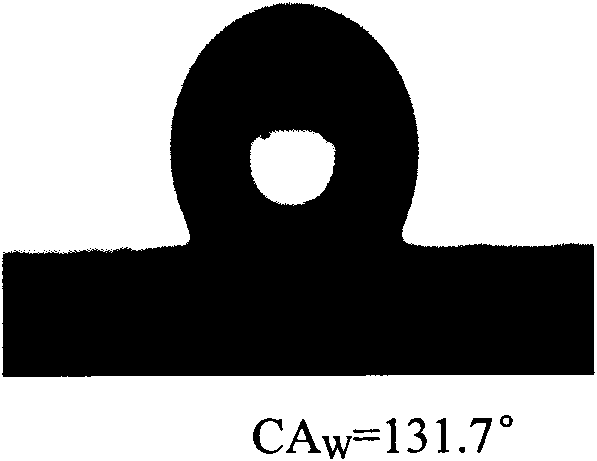

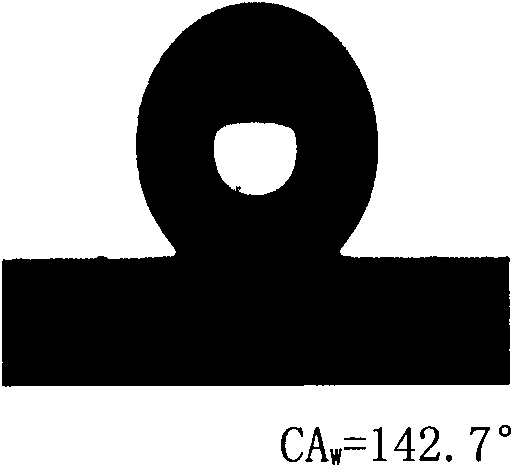

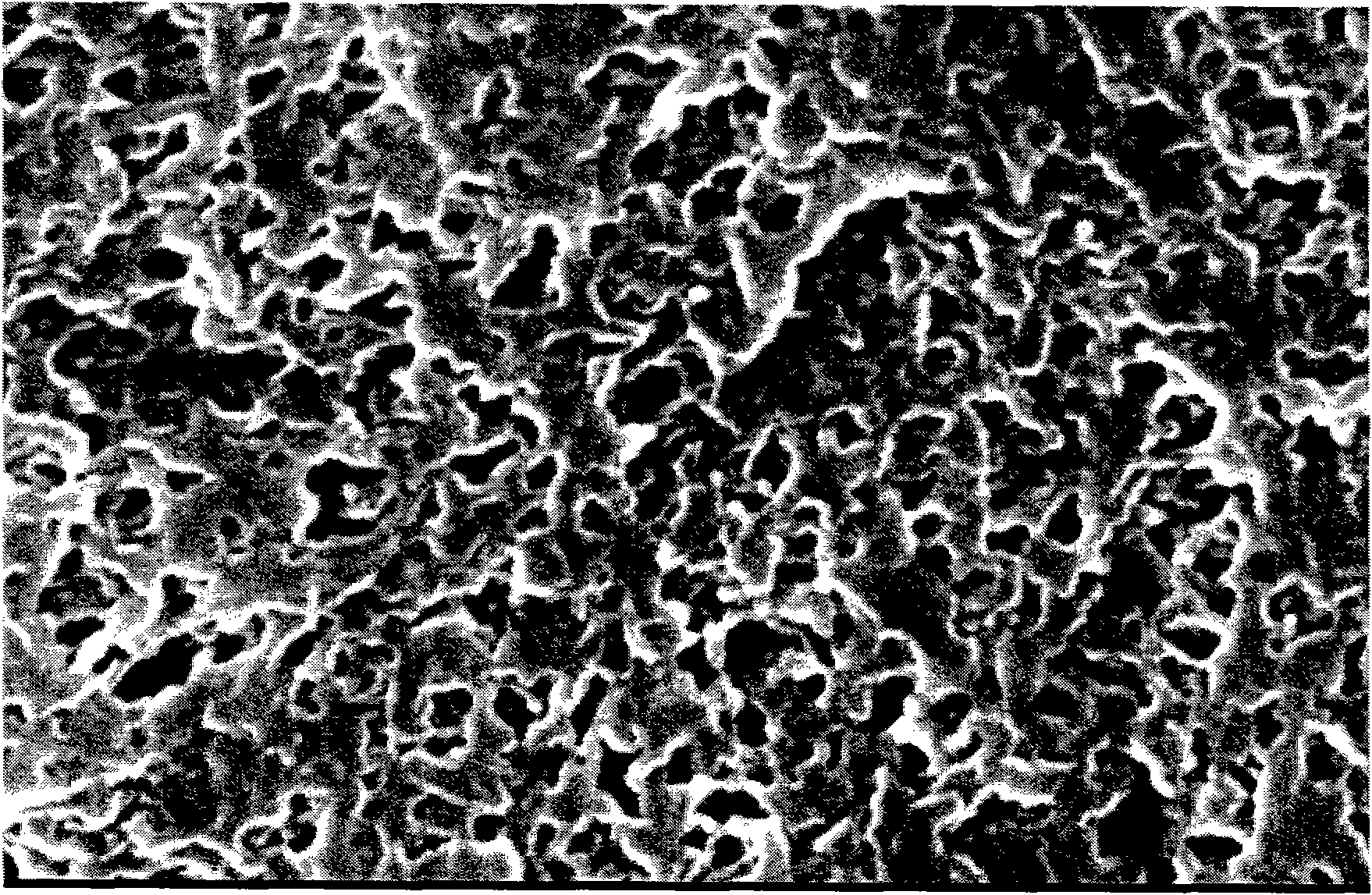

The invention provides a polyvinylidene fluoride microporous film and a preparation method; the polyvinylidene fluoride microporous film is prepared by using polyvinylidene fluoride, fatty alcohol (non solvent) and polar organic solvent as raw materials, the proportioning of which is as follows: the mass content of polyvinylidene fluoride is 10%-15%, and the content of non solvent is 6-12%; the specific steps are as follows: polyvinylidene fluoride, polar organic solvent and non solvent are mixed, dissolved and filtered, set aside and are deaerated to obtain clear casting film liquid which is struck on a coarse structure template substrate and placed in air; gel forms film in a coagulating bath, is processed by hot water, and then soaked in water and absolute ethyl alcohol to obtain high hydrophobic polyvinylidene fluoride microporous film; the contact angle between the surface of high hydrophobic polyvinylidene fluoride microporous film and water reaches 130 degrees to 140 degrees, air flux of the film reaches 6.0m<3> / (m<2>-h-kPa) under 60kPa, the maximum bore diameter is less than 0.5 mum, tensile strength reaches breaking strength which is larger than 5Mpa, and the elongation at break is larger than 50%. The invention is the polyvinylidene fluoride microporous film with high hydrophobicity, high flux and good mechanical strength and the preparation method, which is mainly applied to the film distillation and associated film process.

Owner:HEBEI UNIV OF TECH

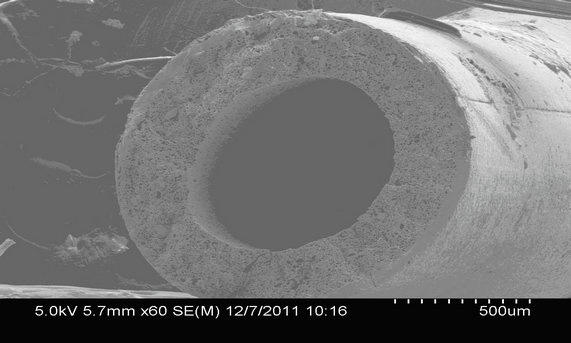

Coated separators for lithium batteries and related methods

PendingUS20160164060A1Desirable level of porosityImprove thermal stabilityCell seperators/membranes/diaphragms/spacersFinal product manufacturePolymer scienceHexafluoropropylene

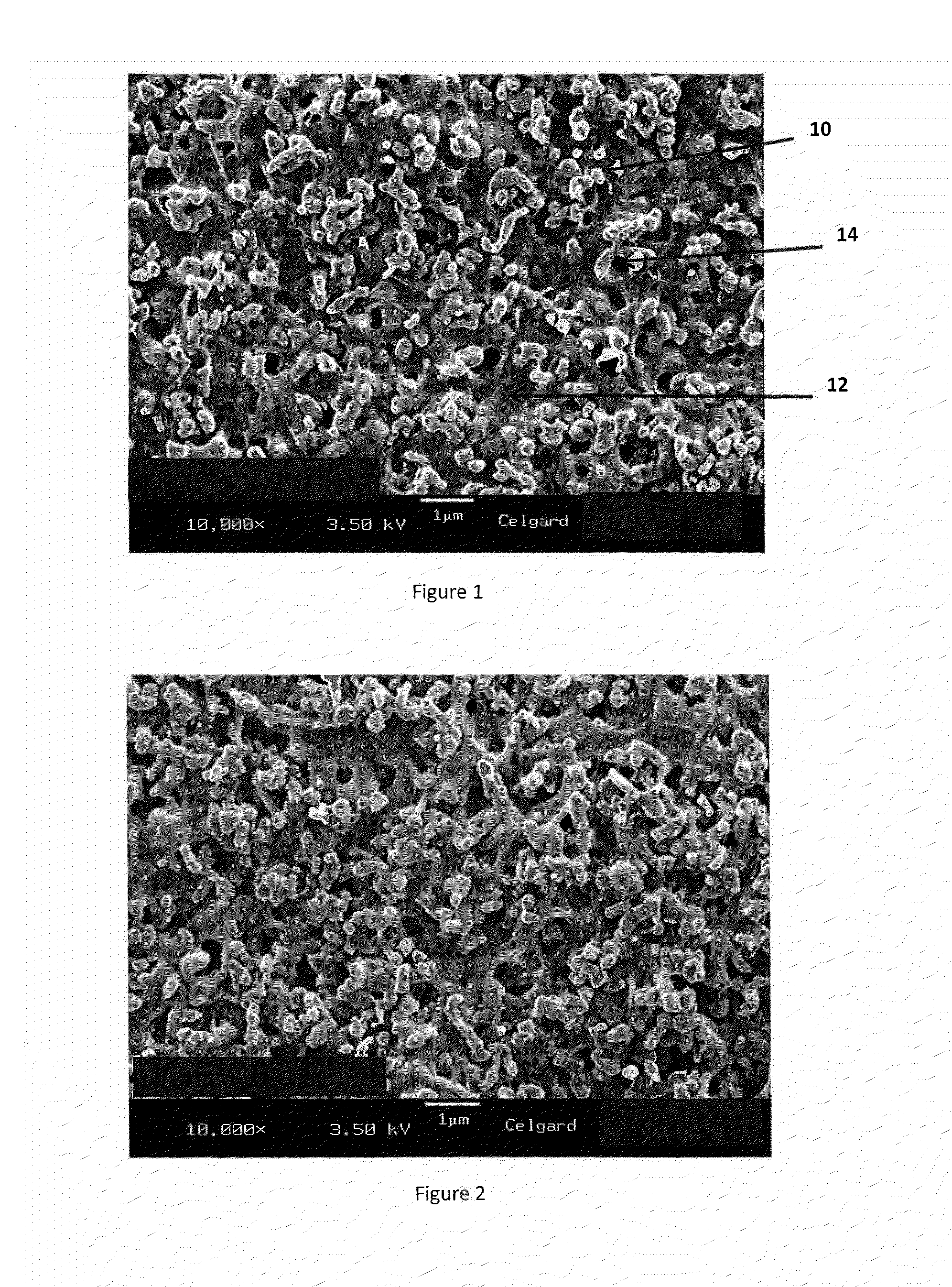

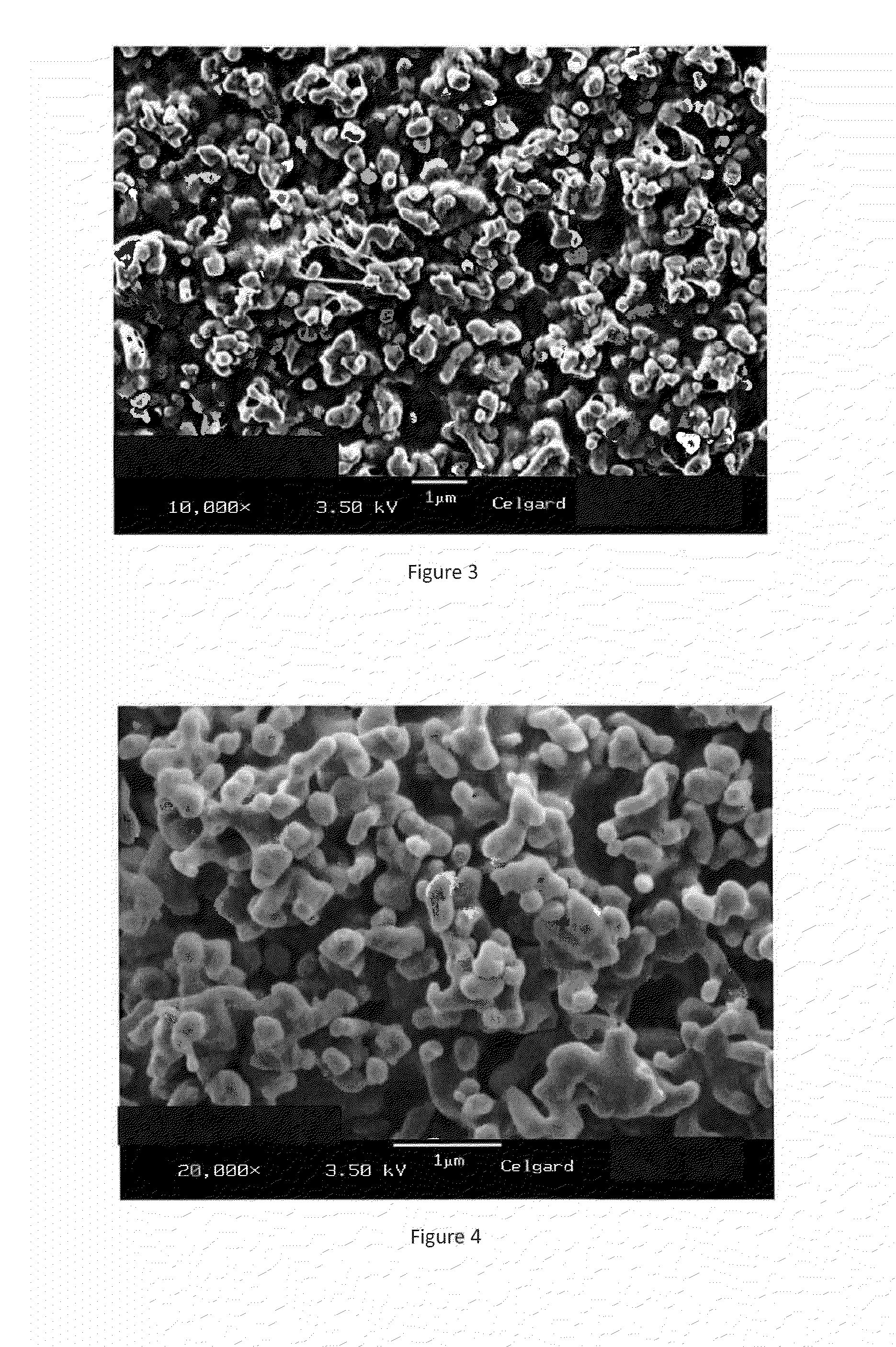

In accordance with at least selected embodiments, new or improved ceramic coated separators, membranes, films, or the like for use in lithium batteries, new or improved batteries including such ceramic coated separators, membranes, films, or the like, and methods of making or using such ceramic coated separators, membranes, films or the like are disclosed. In accordance with at least certain embodiments, new or improved aqueous or water-based polymeric coated separators, membranes, films, or the like are disclosed. In accordance with at least particular embodiments, new or improved aqueous or water-based polyvinylidene fluoride (PVDF) or polyvinylidene difluoride (PVDF) homopolymer or co-polymers of PVDF with hexafluoropropylene (HFP or [—CF(CF3)—CF2—]), chlorotrifluoroethylene (CTFE), vinylidene fluoride (VF2.HFP), tetrafluoroethylene (TFE), and / or the like, blends and / or mixtures thereof, coated separators, membranes, films or the like, new or improved porous separators for use in lithium batteries, new or improved coating or application methods for applying a coating or ceramic coating to a separator for use in a lithium battery, new or improved PVDF or PVDF:HFP films or membranes, and / or the like are disclosed.

Owner:CELGARD LLC

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS7553540B2Strong adhesionIncreased durabilityFilm/foil adhesivesSynthetic resin layered productsEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

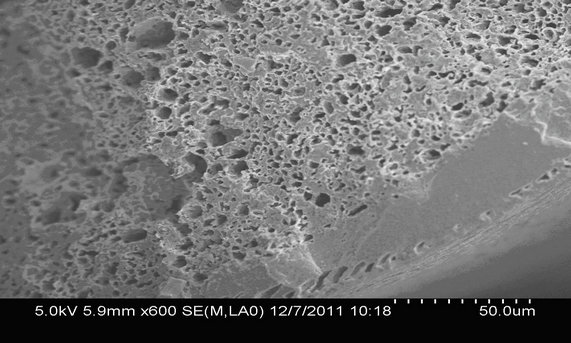

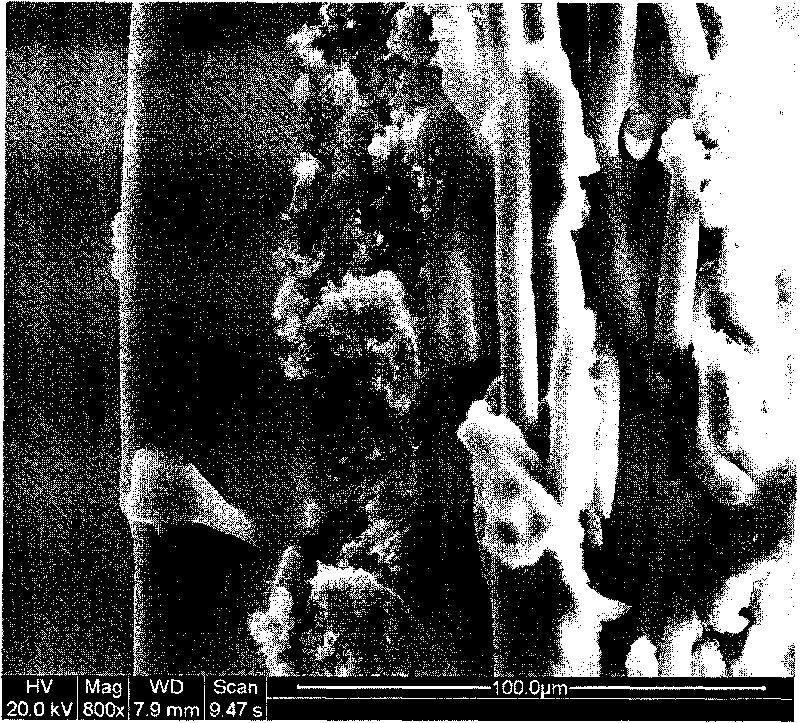

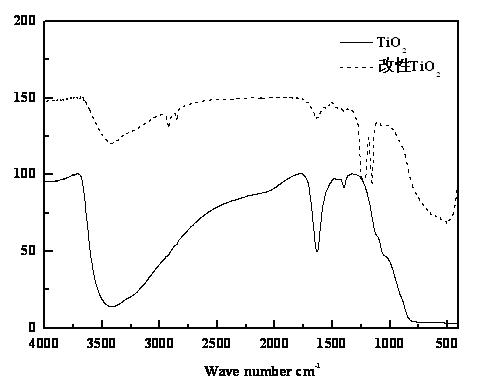

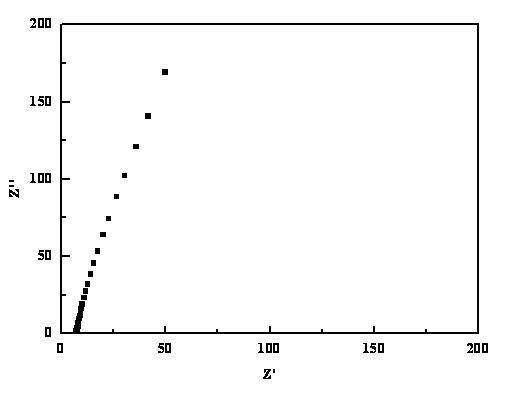

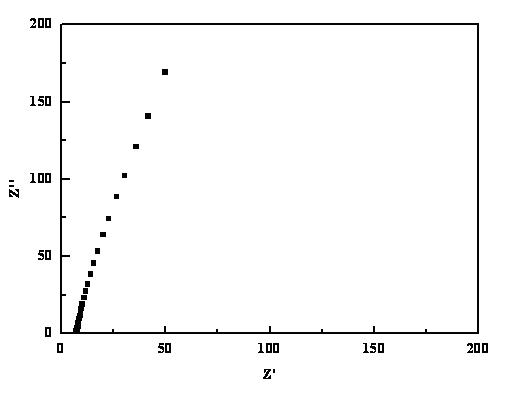

Preparation method for homogeneously-enhanced polyvinylidene fluoride hollow fiber membrane

ActiveCN102600733AImprove hydrophilicityImprove interfacial bond strengthMembranesSemi-permeable membranesPolymer scienceSpinning

Owner:TIANJIN POLYTECHNIC UNIV

Binder solution and electrode-forming composition for non-aqueous-type battery

InactiveUS6200703B1Good gelHigh affinityNon-aqueous electrolyte cellsNon-aqueous electrolyte accumulator electrodesOrganic acidOrganic solvent

A vinylidene fluoride polymer binder solution for forming an electrode for a non-aqueous-type battery is formed by adding an acid, preferably an organic acid, as a stabilizer to a solution of a vinylidene fluoride polymer in an organic solvent. The acid is preferably added in an amount sufficient to ensure a pH of at most 9 when measured with respect to a 10-times dilution of the binder solution with deionized water. The acid addition is effective for preventing a problematic viscosity increase in the binder solution and also gelling of an electrode-forming composition formed by adding a powdery electrode material in the binder solution.

Owner:KUREHA KAGAKU KOGYO KK

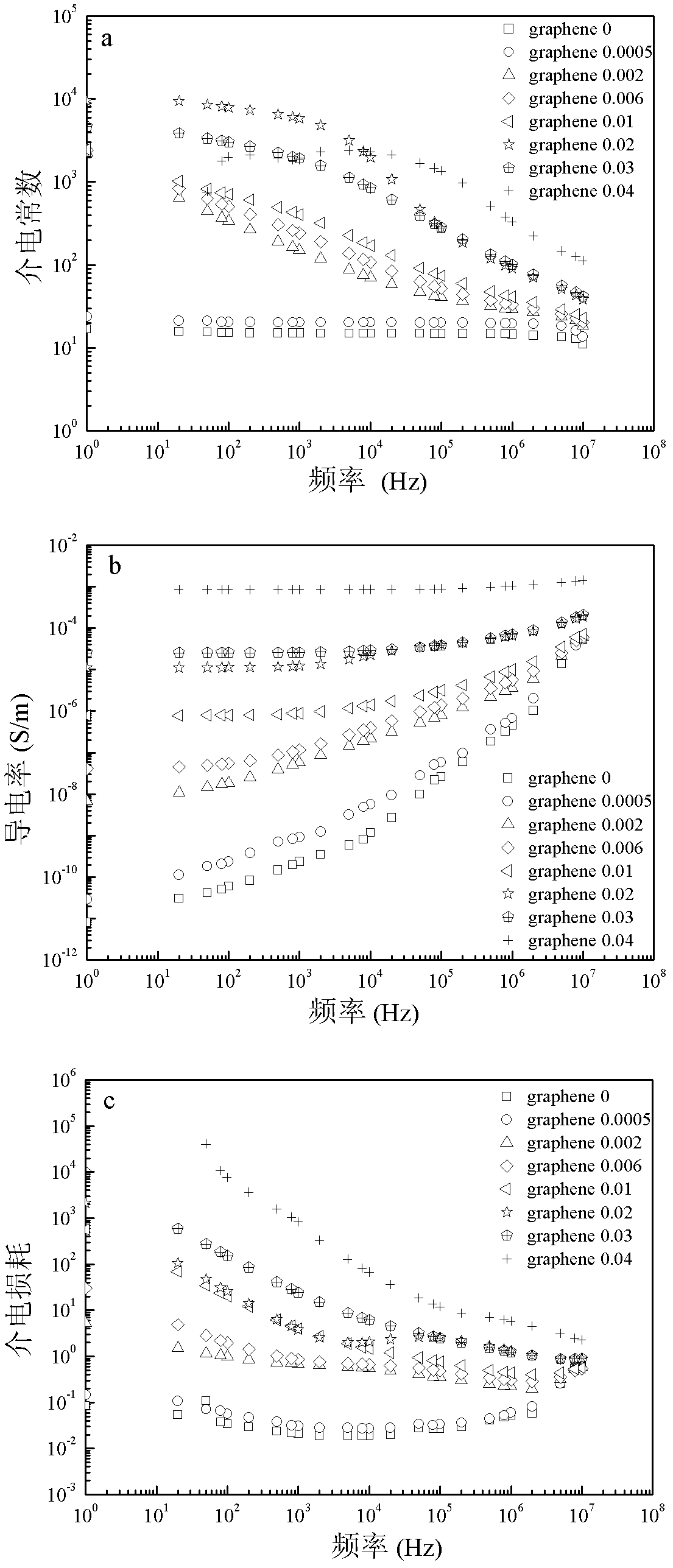

Polyvinylidene fluoride/graphene composite and preparation method thereof

ActiveCN102604275AHigh dielectric constantImprove toughnessFixed capacitorsDielectricPolyvinylidene difluoride

The invention discloses polyvinylidene fluoride / graphene composite and a preparation method thereof. The preparation method includes: reducing oxidation graphene by reductant, mixing the reduced graphene and polyvinylidene fluoride with N, N-dimethylacetamide solvent to be solution, drying and hot-pressing the solution to obtain the polyvinylidene fluoride / graphene composite. The prepared polyvinylidene fluoride / graphene composite has the following advantages that 1) dielectric constant of the polyvinylidene fluoride / graphene composite is high and can reach 7940 on the condition of 100Hz frequency and the weight percentage of the graphene is 0.02; and 2) flexibility is fine. Meanwhile, the preparation method has the advantages of simple operation and high stripping and dispersing degree of graphene and the like.

Owner:嘉善县国创新能源研究院

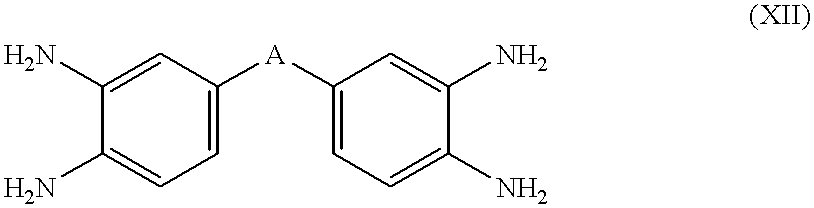

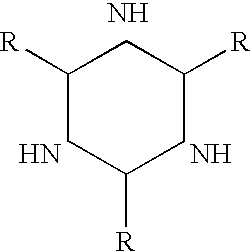

Curable perfluoroelastomer composition

Perfluoroelastomer compositions comprising perfluoroelastomers having copolymerized units of tetrafluoroethylene, a perfluoro(vinyl ether), and a nitrile-containing cure site monomer are cured with certain nitrogen-containing nucleophilic compounds. The nucleophilic compounds also act as dual curatives in perfluoroelastomer compositions which incorporate other curing agents.

Owner:DUPONT POLYMERS INC

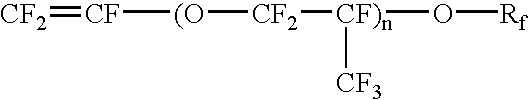

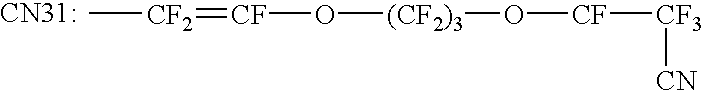

Perfluoroelastomers having a low glass transition temperature and method of making them

InactiveUS6730760B2The polymerization reaction is fastDesirable mechanical propertyVinyl etherVitrification

A method of making a curable fluoroelastomer is disclosed. The method comprises the steps ofpreemulsifying at least one perfluorovinylether in water, andcopolymerizing the preemulsified perfluorovinylether with a gaseous fluorinated monomer in the presence of a cure site monomer. The method provides a fluoroelastomer having a glass transition temperature of less than -10° C. Also disclosed is a fluoroelastomer that consists essentially of a perfluorovinylether of formula (I) as defined below, a cure site component, perfluoromethylvinylether, and tetrafluoroethylene and / or chlorotrifluoroethylene.

Owner:3M INNOVATIVE PROPERTIES CO

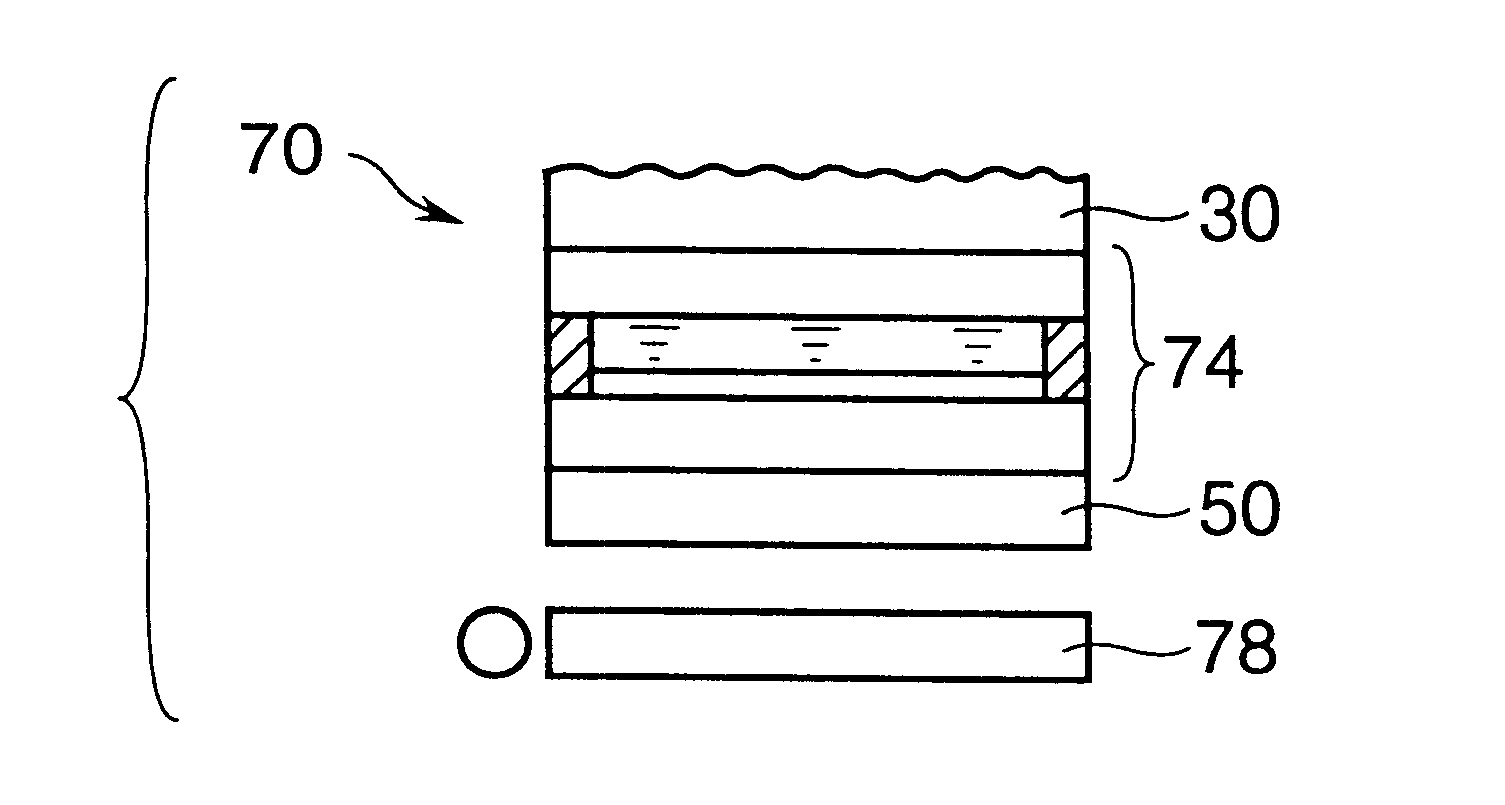

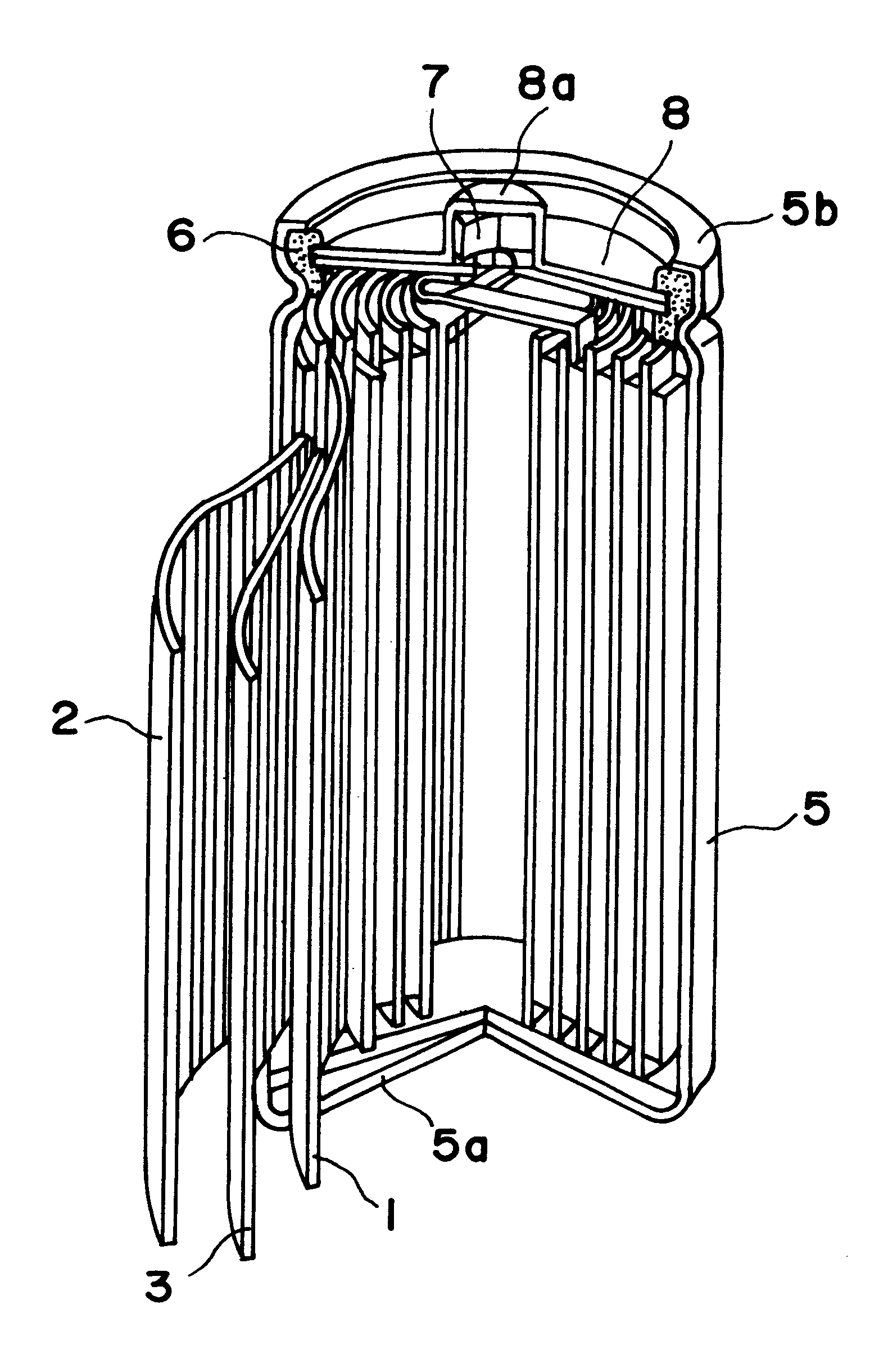

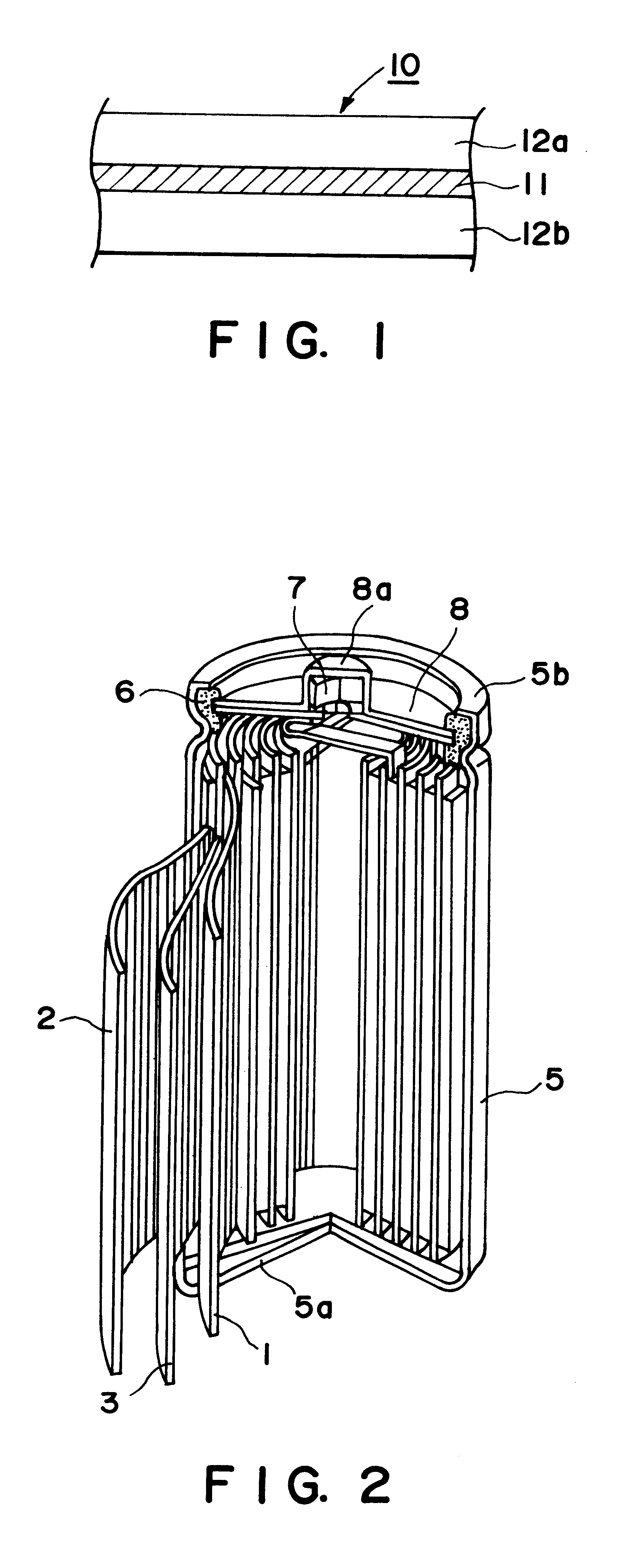

Method of making polymer electrolyte electrochemical cells

InactiveUS6852138B1Reduce contentEasy temperatureElectrode carriers/collectorsOrganic electrolyte cellsPolymer electrolytesHexafluoropropylene

The invention relates to a method for the preparation of a polymer electrolyte electrochemical cell using an electrolyte precursor, said precursor comprising one or more solvents, one or more salts and a polymer which dissolves in the solvent at a first temperature (Tdissol) and which is capable of forming a gel on subsequent cooling following heating to a second temperature (Tgel). Tdissol being lower than Tgel, which method comprises: (a) heating the electrolyte precursor to Tdissol; (b) optionally cooling the electrolyte precursor, (c) incorporating the electrolyte precursor into the electrochemical cell; (d) heating the electrochemical cell to Tgel; (e) cooling the polymer electrochemical cell to ambient temperature to bring about gelling of the polymer electrolyte. Preferably the polymer is a homopolymer or copolymer from the group of monomers of vinyl fluoride, vinylidenefluoride, trifluoroethylene, tetrafluoroethylene and hexafluoropropylene.

Owner:DANIONICS ASIA

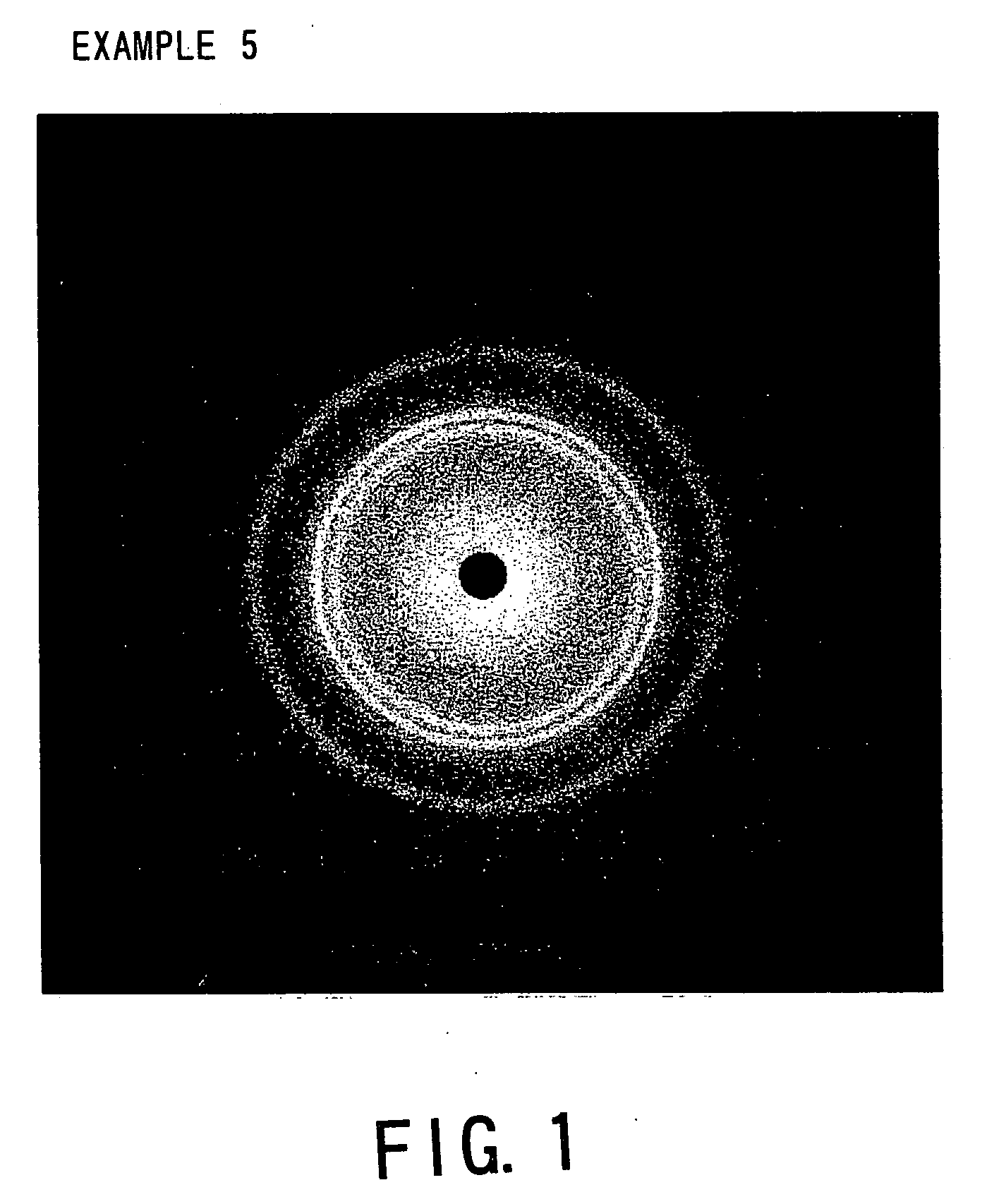

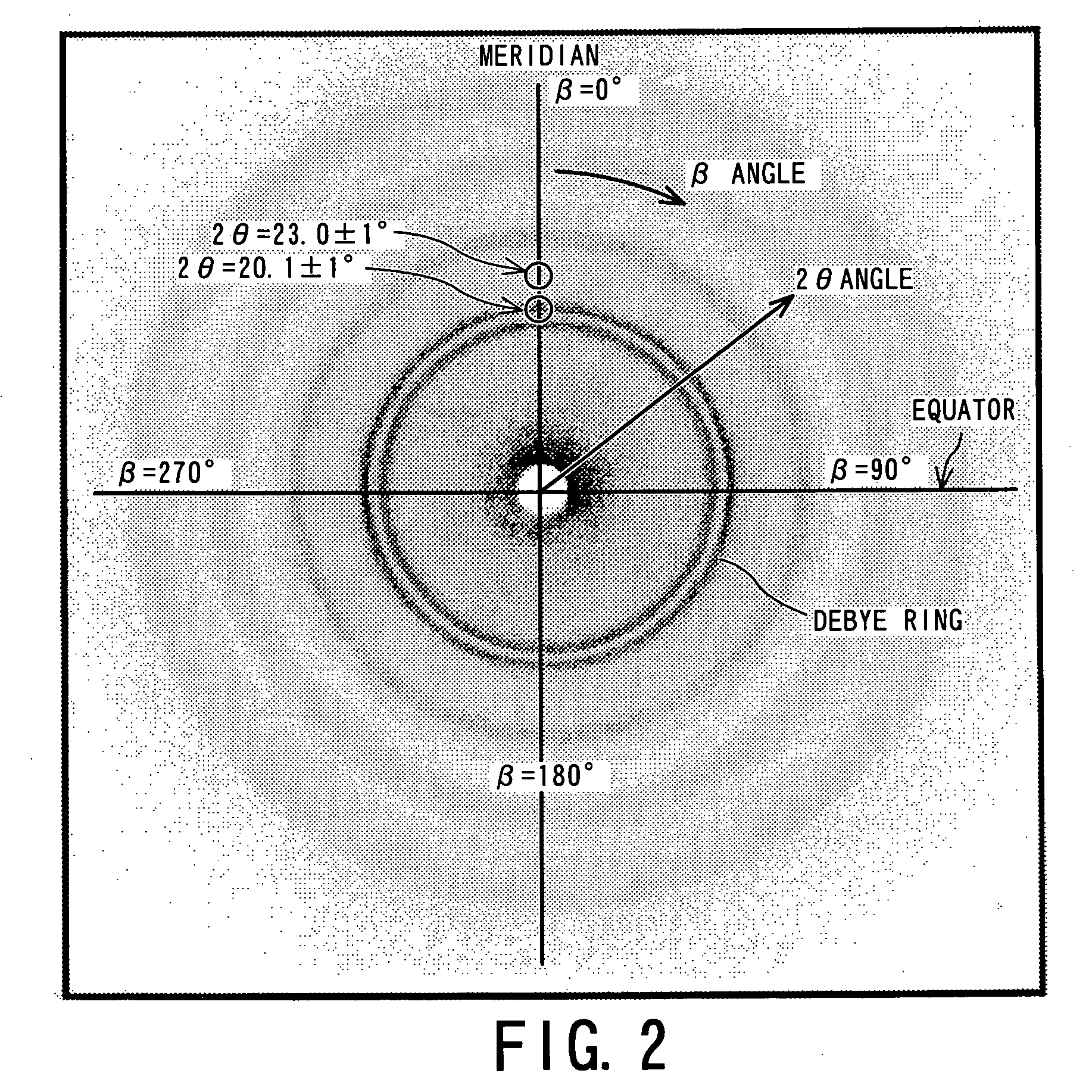

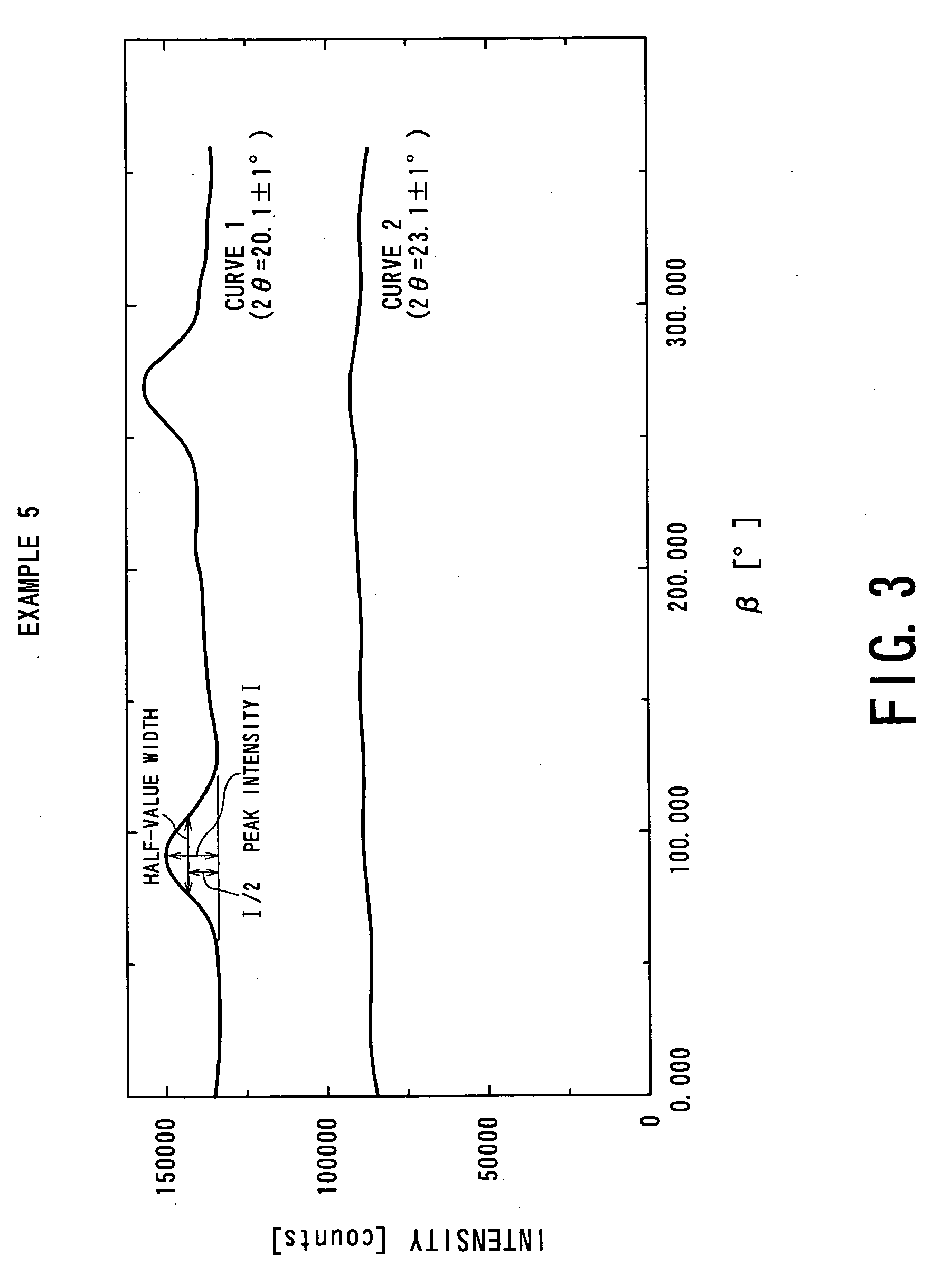

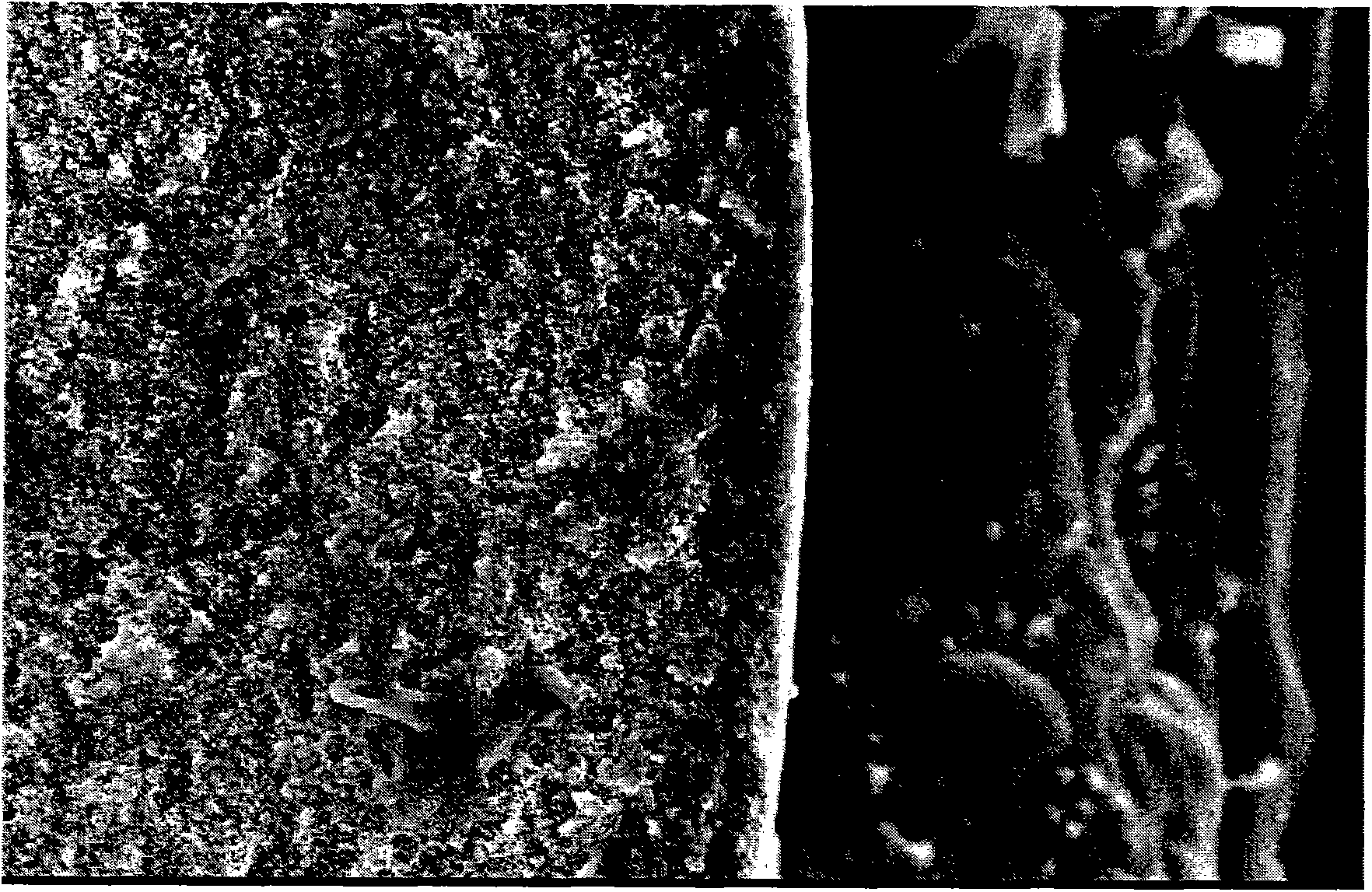

Porous membrane of vinylidene fluoride resin and process for producing the same

ActiveUS20060178480A1Improve heat distortion resistanceFacilitate stretchingSemi-permeable membranesMembranesSolventPorous membrane

There is provided a porous membrane of vinylidene fluoride resin which has pores of appropriate size and distribution and also excellent mechanical strength represented by tensile strength and elongation at break and is useful as a microfiltration membrane or a separator for batteries. The porous membrane of vinylidene fluoride resin is characterized by the presence in mixture of a crystalline oriented portion and a crystalline non-oriented portion as confirmed by X-ray diffraction, and is produced by subjecting a melt-extruded composition obtained by mixing a vinylidene fluoride resin having a molecular weight distribution which is appropriately broad and high as a whole with a plasticizer and a good solvent for vinylidene fluoride resin, to cooling for solidification from one surface, extraction of the plasticizer and stretching.

Owner:KUREHA KAGAKU KOGYO KK

Polyvinylidene fluoride hollow fiber film and preparation method thereof

ActiveCN101590374AProper temperature regulationExtraction is easy and fastMembranesSemi-permeable membranesFiberPolyvinylidene difluoride

The invention discloses a polyvinylidene fluoride hollow fiber film and a preparation method thereof. The polyvinylidene fluoride hollow fiber film comprises the following components by weight percent: 20-60% of polyvinylidene fluoride resin, 10-50% of organic pore-forming agent, 1-30% of inorganic pore-forming agent and 5-30% of solvent. The preparation method comprises the following steps: mixing, squeezing, cooling, stretching, extracting the organic pore-forming agent and the inorganic pore-forming agent, and thermally shaping. The obtained polyvinylidene fluoride hollow fiber film has the advantages of high strength, good performance, better hydrophilicity, simple preparation process and energy saving.

Owner:江苏美能膜材料科技有限公司

Polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane and preparation and application

ActiveCN105498553AImprove hydrophilicityEasy to separateMembranesUltrafiltrationCoated membraneFiltration membrane

The invention belongs to the technical field of composites, and discloses a polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane and preparation and application. The preparation method comprises the steps that MIL-100 (Fe) prepared through a hydrothermal method is ultrasonically dispersed in solvent, polyvinylidene fluoride and a pore-forming agent are sequentially added, stirring is conducted for 12-24 h to enable the added substances to be dissolved and blended to be uniform, and a membrane casting solution is formed; the membrane casting solution is defoamed and put on a support for membrane coating, staying of a coated membrane in the air is conducted for 30-60 s, the membrane is immersed into a coagulating bath for solvent exchange, and the polyvinylidene fluoride and metal-organic framework composite ultra-filtration membrane is obtained. The metal-organic framework material MIL-100 (Fe) is added to the composite ultra-filtration membrane, the hydrophily of the ultra-filtration membrane is improved, the separating capacity of the membrane is improved, the anti-pollution capacity of the ultra-filtration membrane is improved, the service life of the membrane is prolonged, and a good application prospect is achieved.

Owner:SOUTH CHINA UNIV OF TECH

Fluoropolymer coating compositions containing adhesive polymers and substrate coating process

ActiveUS20070166469A1Strong adhesionIncreased durabilityPretreated surfacesSpecial surfacesEpoxyPolymer science

A liquid fluoropolymer coating composition and a process for using the composition to make fluoropolymer coated polymeric substrates. The liquid fluoropolymer composition comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer, solvent, and compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. In the process, the composition is applied to a polymeric substrate comprising functional groups on its surface that interact with said compatible adhesive polymer to promote bonding of said fluoropolymer coating to said substrate. The solvent is removed from the coating composition applied to the substrate to form a fluoropolymer coating on the substrate.

Owner:DUPONT ELECTRONICS INC

Porous layer, laminated body, nonaqueous electrolyte secondary battery member including the porous layer, and nonaqueous electrolyte secondary battery including the porous layer

ActiveUS20170098809A1Improve shutdown characteristicsImprove featuresSecondary cellsCell component detailsPorous layerPolyvinylidene difluoride

The present invention provides, as a porous layer that can be used for a member for a non aqueous secondary battery having excellent shutdown characteristics, a porous layer including a polyvinylidene fluoride-based resin, wherein, assuming that a sum of individual amounts of crystal form α and crystal form β contained in the polyvinylidene; fluoride-based resin is 100 mol %, the amount of crystal form α contained in the polyvinylidene fluoride-based resin is not less than 10 mol % and not more than 65 mol %.

Owner:SUMITOMO CHEM CO LTD

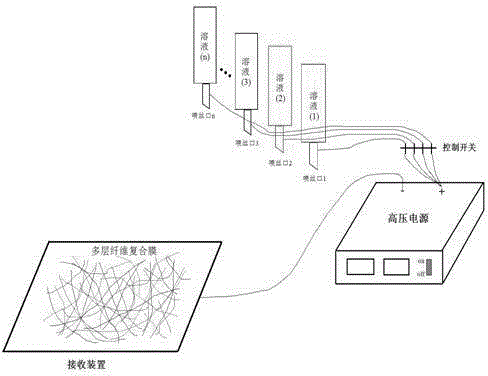

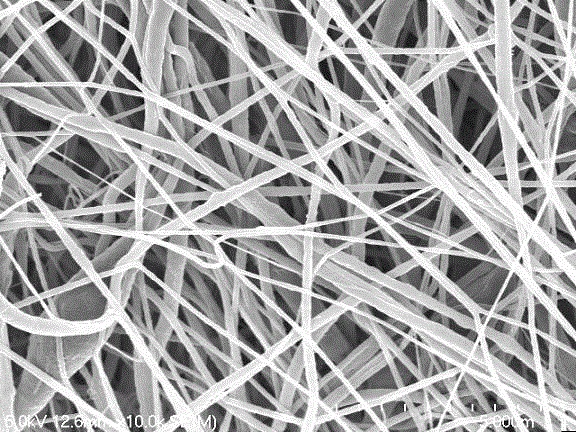

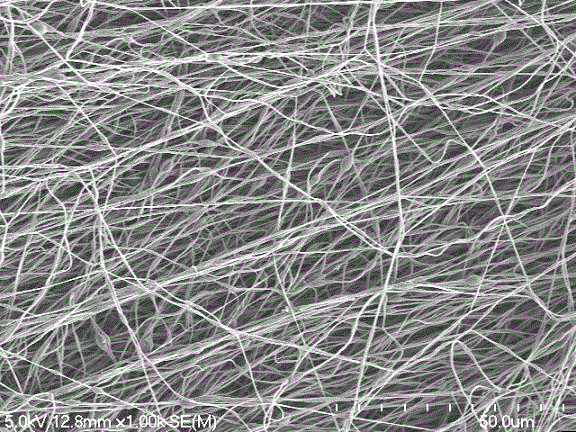

Polyvinylidene-fluoride-based composite fibrous membrane, preparation method and application thereof

InactiveCN103147224AHigh porosityIncrease membrane fluxCell component detailsNon-woven fabricsFiberLithium-ion battery

The invention provides a polyvinylidene-fluoride-based composite fibrous membrane, which comprises a polyvinylidene fluoride fibrous layer with the thickness ranging from 5 mu m to 120 mu m, wherein the diameters of the fibers range from 80 nm to 1500 nm; the polyvinylidene fluoride fibrous layer comprises the components in percentage by mass as follows: 15%-95% of polyvinylidene fluoride and 5%-85% of a modifier; and the modifier comprises a polymer and / or inorganic oxide. The preparation method is simple and feasible; the used raw materials and equipment are cheap; the prepared composite fibrous membrane has the advantages of high porosity and membrane flux, good mechanical strength and thermal stability, uniform thickness, controllability and the like; and when applied to a lithium ion battery, the composite fibrous membrane can improve the ionic conductivity and the charge-discharge performance of the high current of the battery, and shows good electrochemical performance and circulative performance.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

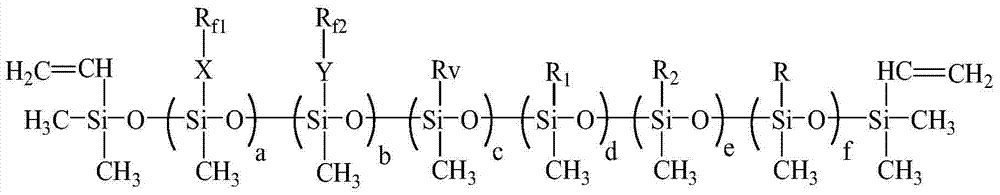

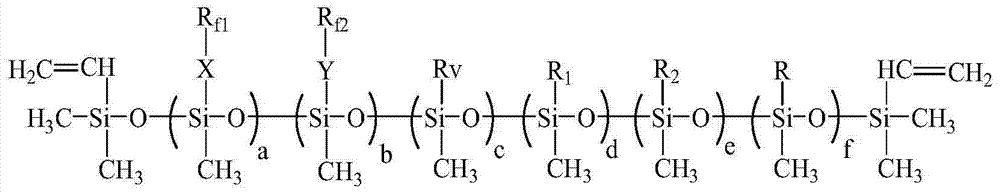

Fluorine-containing polysiloxane release agent and preparation method thereof

The invention discloses a fluorine-containing polysiloxane release agent and a preparation method thereof. The fluorine-containing polysiloxane release agent is prepared from vinyl fluoride silicone oil with an imide heterocyclic ring as a matrix matched with hydrogen-containing silicone oil, an inhibitor and a catalyst in a mixing manner. The fluorine-containing polysiloxane release agent does not utilize any solvent, so that the damage to the environment and a human body caused by an organic solvent is effectively avoided; the cured release film has a good anti-sticking effect by introducing a fluorine-containing long-chain substituent. Meanwhile, improvement of the adhesive fastness between the release agent and a polyester or polyimide film base material is facilitated by the imide heterocyclic substituent added to the vinyl fluoride silicone oil.

Owner:SHENZHEN GUANHENG NEW MATERIALS TECH

Polyvinylidene fluoride microporous film preparation method

The invention relates to a polyvinylidene fluoride microporous film preparation method by thermally induced phase separation, particular to a polyvinylidene fluoride microporous film preparation method by mixing the high temperature solvent and nonsolvent of the polyvinylidene fluoride in certain proportion to form a compound thinner. The method includes the following steps: polyvinylidene fluoride with the mass percentage of 20-60% and a corresponding compound thinner with the mass percentage of 80-40% are added into a stirring kettle, high-temperature digestion and standing deaeration are carried out in sequence to obtain homogeneous casting solution; the casting solution is directly coated on a supporting net by direct knifing to be planar or is spun by a spinneret to be hollow fibrillar, then the casting solution is dipped into cooling fluid for split phase solidification; and the thinner contained in solidification products is extracted, thus obtaining the polyvinylidene fluoride microporous film. The polyvinylidene fluoride microporous film prepared by the invention is high in film strength and large in water flux with the sections which have a uniform and run-through spongelike structure.

Owner:TSINGHUA UNIV

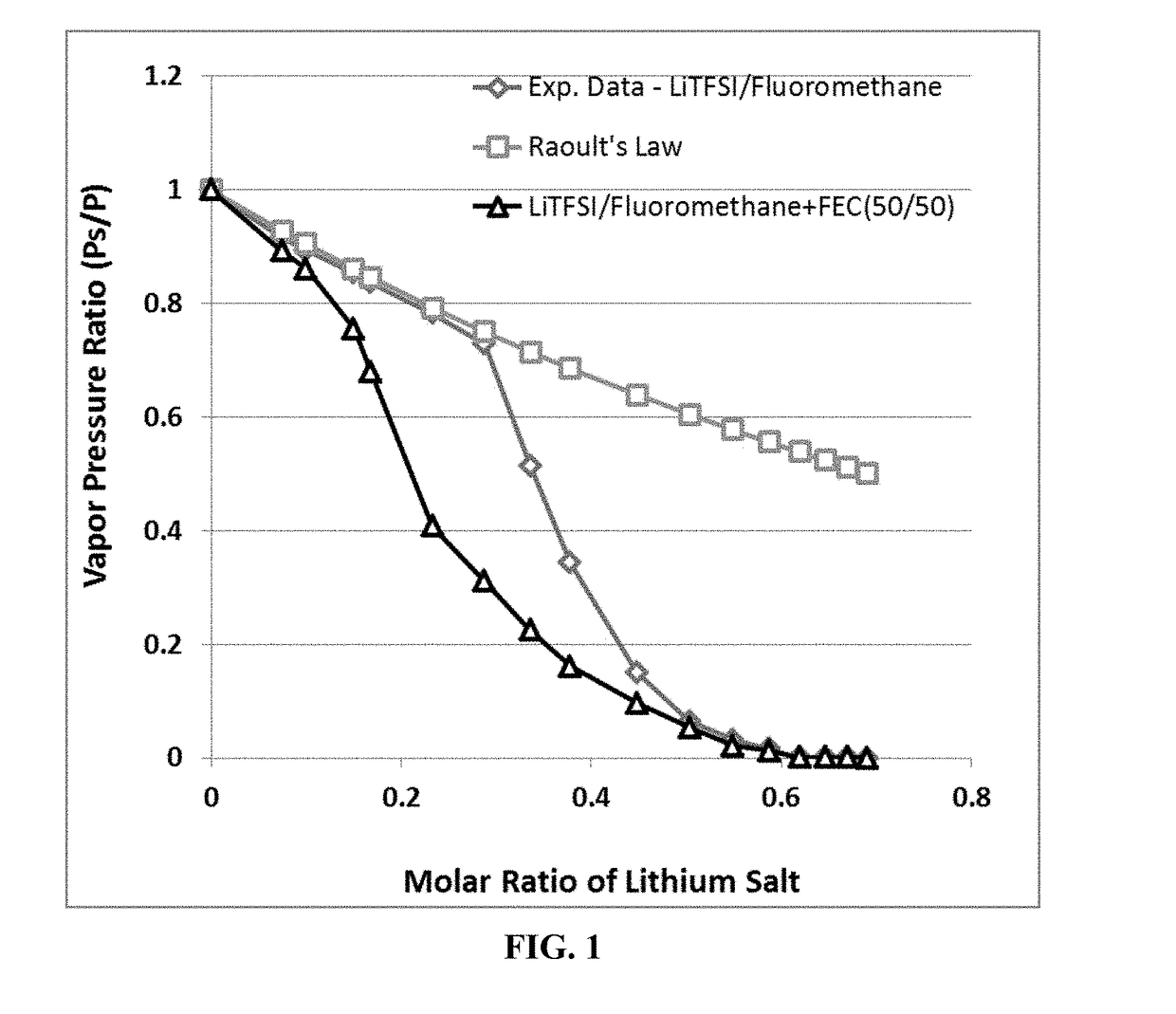

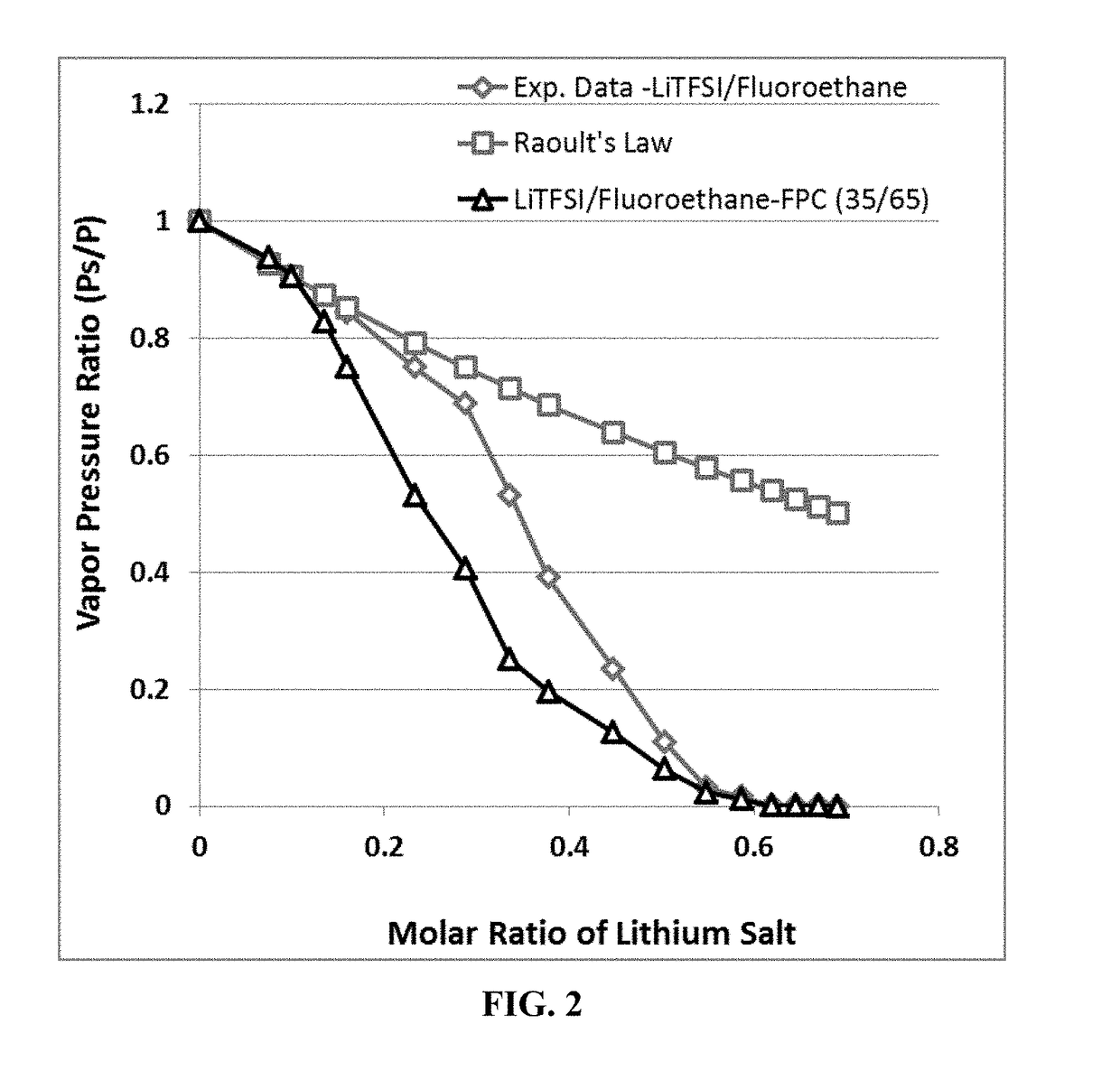

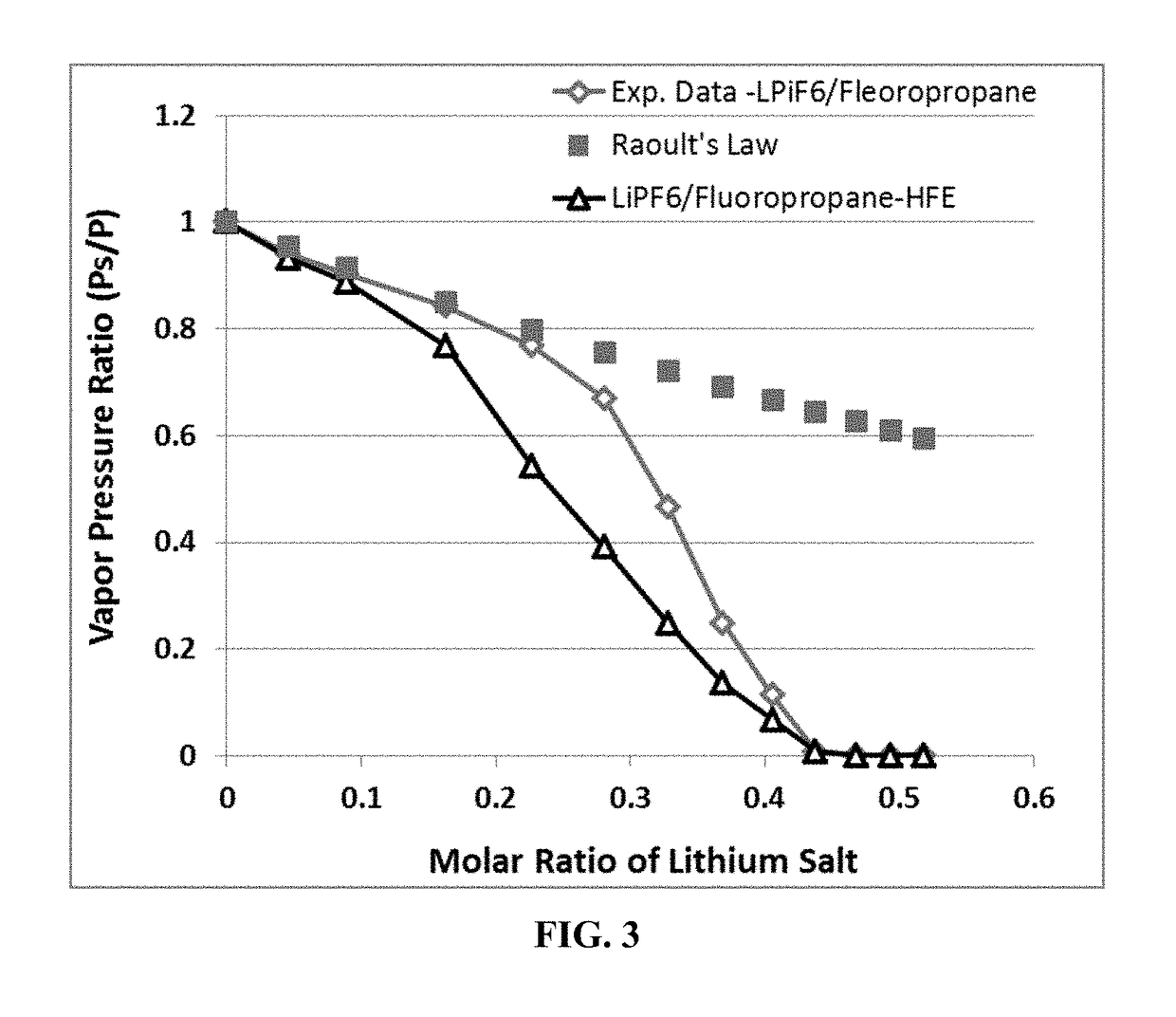

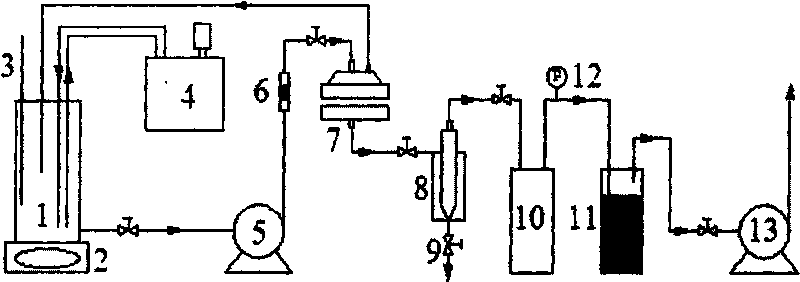

Non-flammable Electrolyte Containing Liquefied Gas and Lithium Secondary Batteries Containing Same

ActiveUS20180375156A1Flammability of any liquefied gas solvent can be effectively suppressedImprove solubilityOrganic chemistryCell electrodesElectrolytic agentDifluoroethyne

A rechargeable lithium cell comprising a cathode, an anode, an optional ion-permeable membrane disposed between the anode and the cathode, a non-flammable salt-retained liquefied gas electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in or mixed with a liquefied gas solvent having a lithium salt concentration greater than 1.0 M so that the electrolyte exhibits a vapor pressure less than 1 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquefied gas solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the liquefied gas solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquefied gas solvent is selected from methane, fluoromethane, difluoromethane, chloromethane, dichloromethane, ethane, fluoroethane, difluoroethane, tetrafluoroethane, chloroethane, dichloroethane, tetrachloroethane, propane, fluoropropane, chloropropane, ethylene, fluoroethylene, chloroethylene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Fluoropolymer Coated Film, Process for Forming the Same, and Fluoropolymer Liquid Composition

ActiveUS20080261037A1Strong adhesionIncreased durabilityFilm/foil adhesivesSynthetic resin layered productsCross-linkPolymer science

A process for forming a multilayer film includes coating a polymeric substrate film with a liquid fluoropolymer coating. The liquid fluoropolymer coating includes a fluoropolymer, solvent, a compatible cross-linkable adhesive polymer, and a cross-linking agent. The process further includes cross-linking the compatible cross-linkable adhesive polymer to form a cross-linked polymer network in the fluoropolymer coating, removing the solvent from the fluoropolymer coating, and adhering the fluoropolymer coating to the polymeric substrate film. A liquid fluoropolymer coating composition includes a fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride, solvent, a compatible cross-linkable adhesive polymer, and a cross-linking agent. A fluoropolymer coated film includes a polymeric substrate film and a fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating includes a fluoropolymer and a compatible cross-linked adhesive polymer.

Owner:DUPONT ELECTRONICS INC

PDMS/PVDF pervaporation composite membrane, preparation method and application thereof

InactiveCN101703898AHigh permeation fluxEasy to prepareSemi-permeable membranesCarboxylic compound separation/purificationAcetic acidMicrofiltration membrane

The invention discloses a PDMS / PVDF (polydimethylsiloxane / polyvinylidence fluoride) pervaporation composite membrane which comprises a polyvinylidence fluoride supporting layer and a polydimethylsiloxane separating layer with different bore diameters. The composite membrane has high separating capability and separating efficiency when applied to separating acetic acid in an acetic acid water solution. The PDMS / PVDF pervaporation composite membrane comprises a separating layer and a supporting layer, wherein the separating layer is uniformly attached on the supporting layer, the total thickness of the composite membrane is 120-150 micrometers, the thickness of the skin separating layer is 30-40 micrometers, the supporting layer is made of polyvinylidence fluoride microfiltration membranes with bore diameters being respectively 0.1-2.0 micrometers, and the separating layer is made of the polydimethylsiloxane.

Owner:NANJING UNIV OF TECH

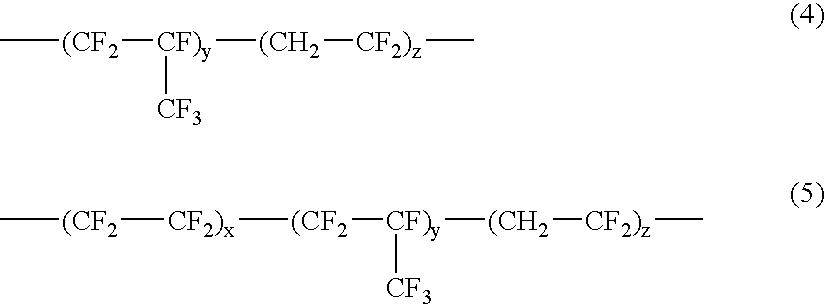

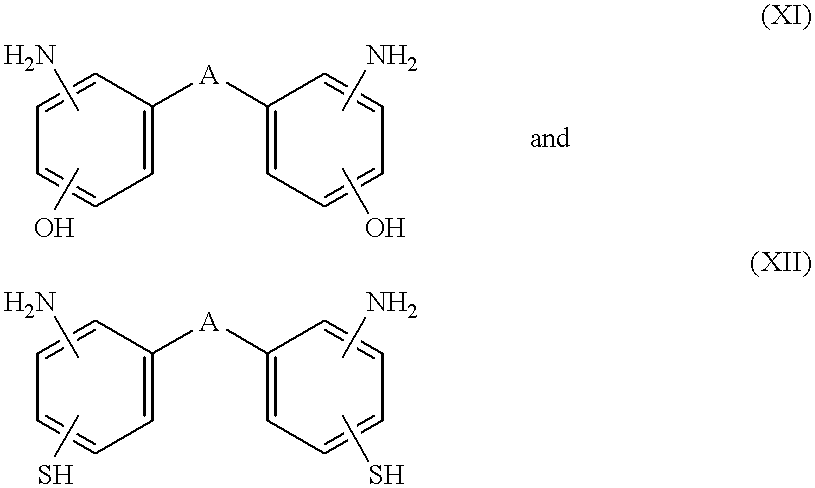

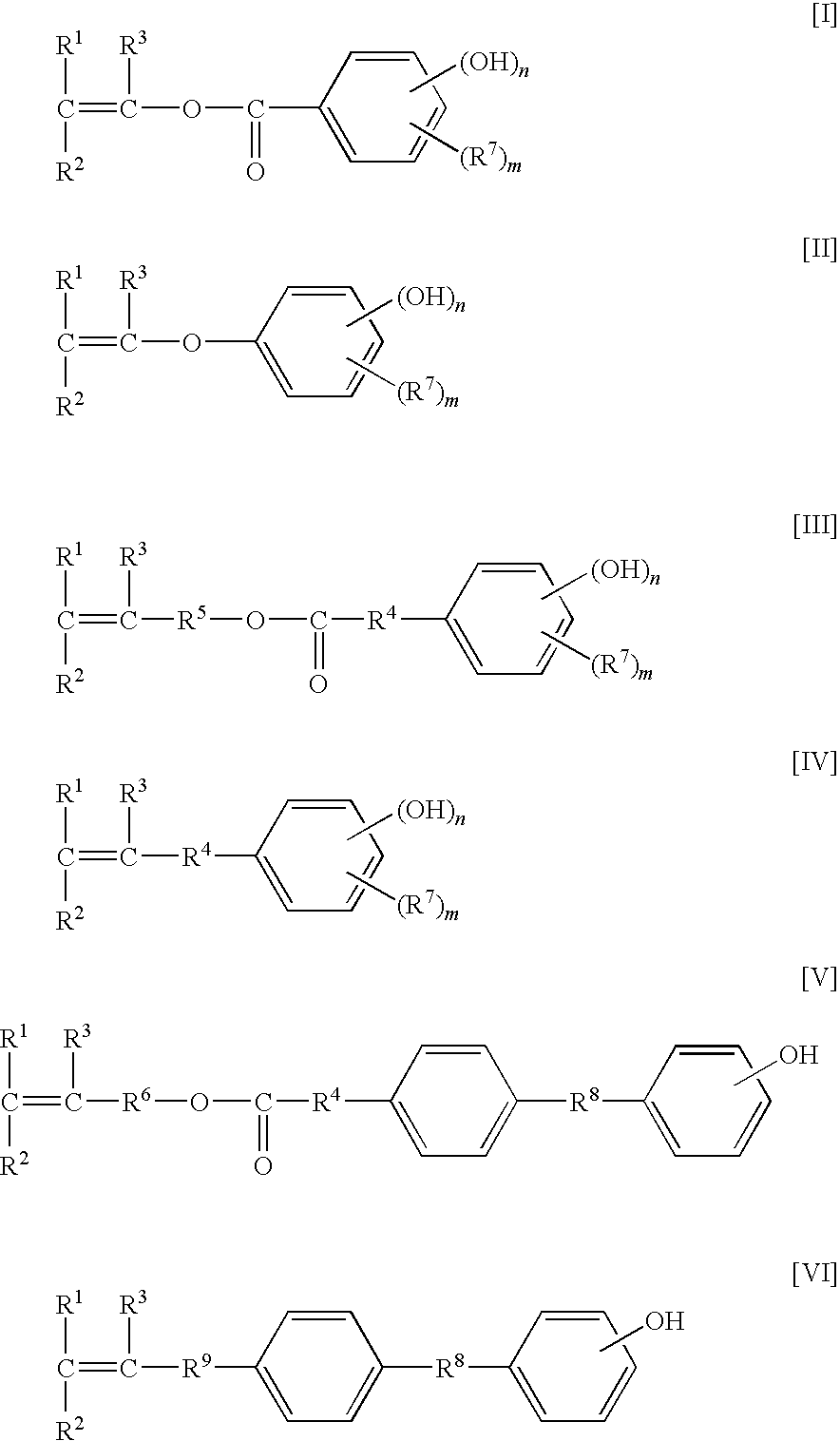

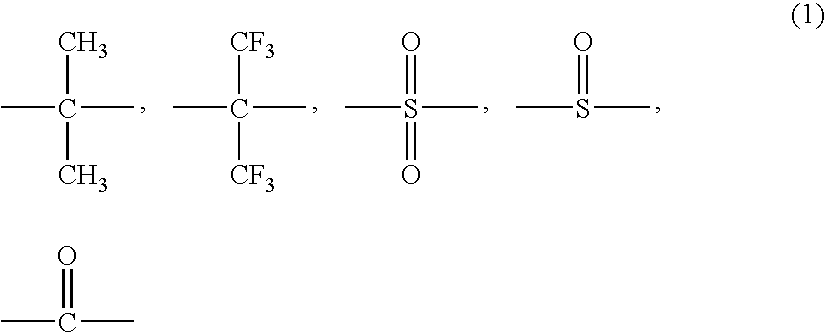

Novel fluorinated polymer

InactiveUS20090186986A1Excellent cross-linking reactivityMaintain good propertiesPolymer scienceHexafluoropropylene

The present invention provides a fluorinated polymer excellent in the crosslinking reactivity, crosslinked rubber physical properties and chemical resistance, and its crosslinked rubber.A fluorinated polymer comprising repeating units (a) based on at least one monomer selected from the group consisting of ethylenic unsaturated compounds each having a hydroxyphenyl group, repeating units (b) based on at least one fluoromonomer selected from the group consisting of tetrafluoroethylene, hexafluoropropylene, vinylidene fluoride, 3,3,3-trifluoropropene, 1,3,3,3-tetrafluoropropene, 1,1,2-trifluoroethylene, vinyl fluoride, 1,2-difluoroethylene and CF2═CF—O—Rf (wherein Rf is a C1-8 saturated perfluoroalkyl group or a perfluoro(alkoxyalkyl) group) and, if necessary, repeating units (c) based on at least one hydrocarbon monomer selected from the group consisting of ethylene, propylene and CH2═CH—O—R1.

Owner:ASAHI GLASS CO LTD

Free radical polymerization method for fluorinated copolymers

This invention concerns a process for production of copolymers, especially functionalized, or, at least partially fluorinated copolymers by means of a polymerization process comprising: co-polymerizing, in aqueous emulsion, one or more monomers selected from the group consisting of tetrafluoroethylene, trifluoroethylene, vinylidene fluoride, vinyl fluoride, ethylene, chorotrifluoroethylene, hexafluoropropylene, perfluoromethyl vinyl ether, and perfluoroethyl vinyl ether with a fluorinated co-monomer having limited water solubility, said comonomer being dispersed in the form of droplets of certain sizes.

Owner:EI DU PONT DE NEMOURS & CO

Composite polymer electrolyte for lithium ion battery and preparation method thereof

InactiveCN102044702AGood compatibilityGood dispersionSecondary cellsHexafluoropropyleneLithium compound

The invention relates to a composite polymer electrolyte for a lithium ion battery and a preparation method thereof. The electrolyte takes a polymer as a matrix, and an organic-inorganic composite polymer electrolyte formed by modified nano fillers is uniformly dispersed in the matrix; the modified nano fillers comprise nano oxides, ferroelectric powder or lithium-containing compounds, and the mass of the modified nano fillers accounts for 0.5%-30% of that of the polymers; and the polymers comprise polyoxyethylene, polyacrylonitrile, polymethylmethacrylate, polyvinylidene fluoride and polyvinylidene fluoride-hexafluoropropylene copolymer and a blending and copolymerization system thereof. In the invention, methoxylpolyethylene glycol acrylate is adopted to modify the nano fillers, and the surface modification improves the dispersing performance of a polymer system, therefore, the aggregation of nano particles in the polymer system is restrained, the function of the nano particles for promoting the dissociation of lithium salt in the polymer electrolyte is better exerted, a fast ion conduction channel of the fillers / polymer interface is formed and forms dispersive stress of a three-dimensional network with the polymeric matrix. Therefore, the mechanical property of the whole polymer system is improved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

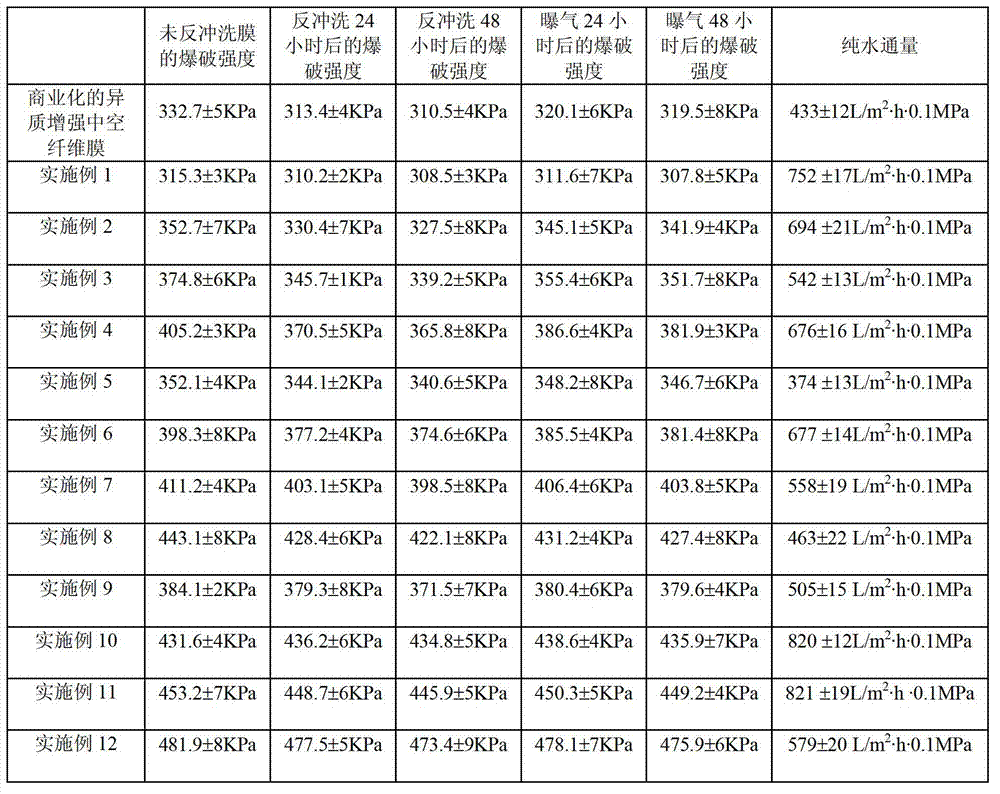

Preparation method of heterogeneous enhanced polyvinylidene fluoride hollow fiber membrane with high bursting strength

ActiveCN102784566AEfficient removalGood compatibilitySemi-permeable membranesPolyvinylidene difluoridePolyvinylidene fluoride

The invention discloses a preparation method of heterogeneous enhanced polyvinylidene fluoride hollow fiber membrane with high bursting strength, wherein a hollow weaved pipe is used as a supporting material, a pre-coating modulated hollow weaved pipe is prepared by the steps of pre-treatment by using alkali and surfactant solution, pre-coating by using polyvinylidene fluoride solution, high-speed centrifugal separation and drying, and then the heterogeneous enhanced polyvinylidene fluoride hollow fiber membrane with high bursting strength is prepared by evenly coating polyvinylidene fluoride membrane forming solution on the surface of the hollow weaved pipe. The preparation method has simple process and low cost, and enables the heterogeneous enhanced polyvinylidene fluoride hollow fiber membrane to have the advantages of high bursting strength, high pass and high tensile strength and to be greatly improved in the shearing resistance and shock resistance.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com