Polyvinylidene fluoride hollow fiber film and preparation method thereof

A polyvinylidene fluoride and polyvinylidene fluoride resin technology, applied in the field of polyvinylidene fluoride hollow fiber membrane and its preparation, can solve problems such as easy deterioration, and achieve uniform mixing time reduction, pure water flux and average pore size The effect of increased size, quick extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

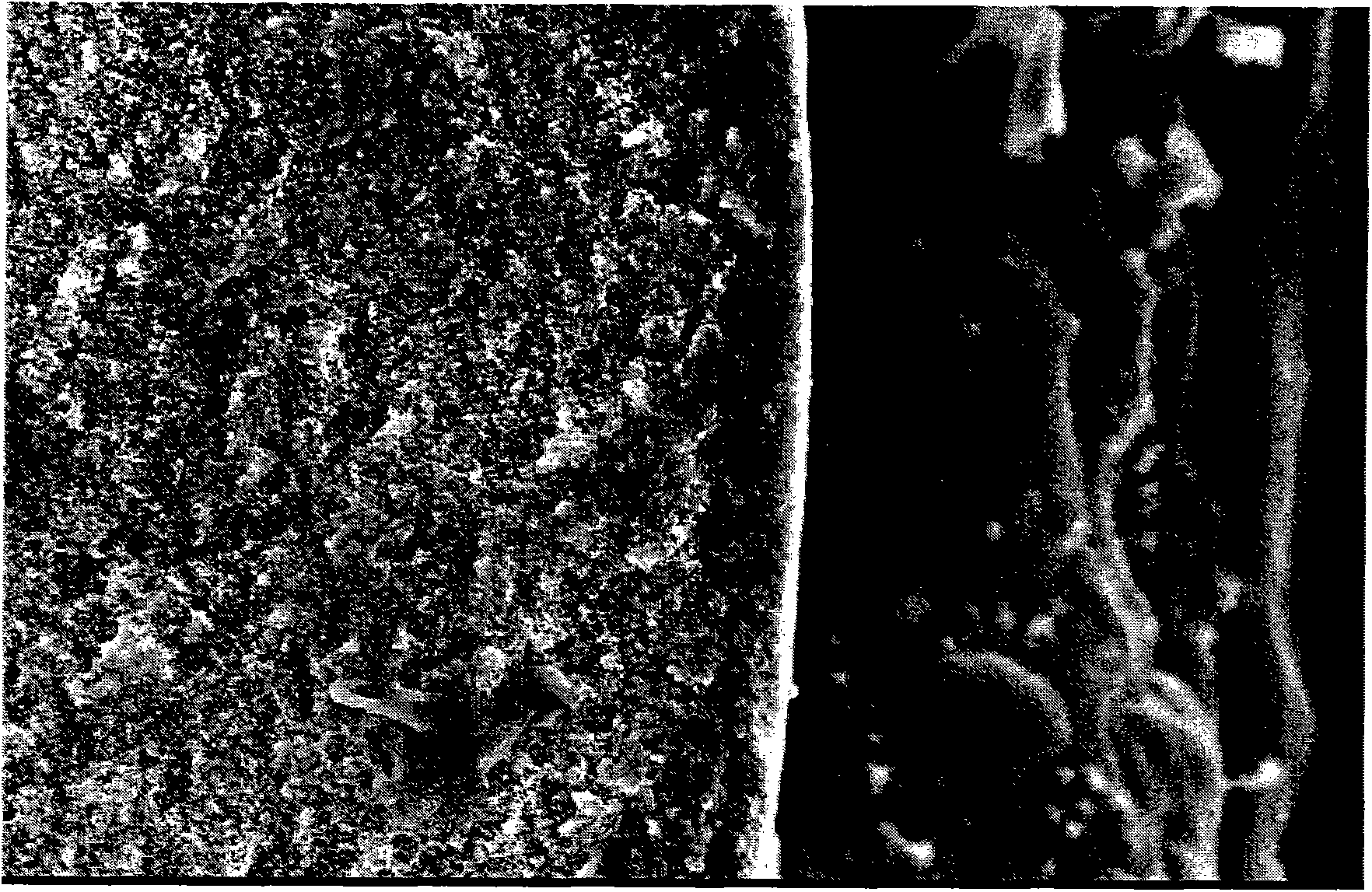

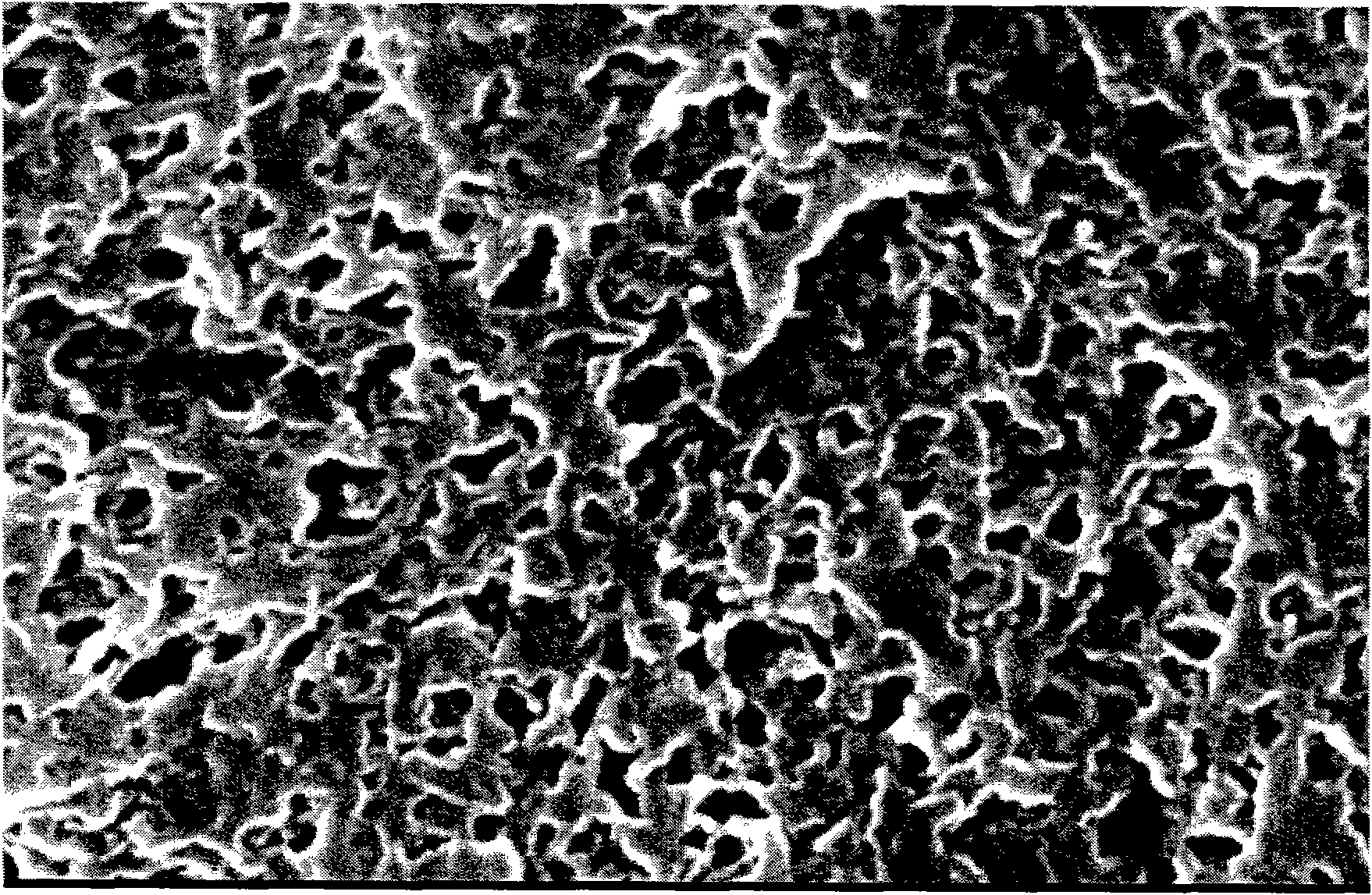

Image

Examples

Embodiment 1

[0046] 15% active nano zinc oxide, 45% polyvinylidene fluoride (molecular weight 250,000-400,000), 25% dioctyl phthalate, 10% dibutyl phthalate and 5% dimethylacetamide, in The high-speed mixer mixes at high speed to make the solids evenly disperse the organic phase, and then use a twin-screw extruder (screw diameter 20, length-to-diameter ratio: 40:1), control the temperature of the cylinder at 180°C and carry out mixing, pass through an annular gap with an outer diameter of 6mm and an inner diameter of 3mm, control the temperature of the nozzle at 190°C, and pass 5ml Air is injected into the hollow of the filament at a flow rate of 15ml / min, and the hollow filament is extruded from the center of the nozzle at a discharge rate of 15ml / min. The extruded hollow filaments are introduced into a pure water coagulation cooling bath 20mm away from the nozzle mouth, the temperature is controlled at 50°C, and pulled from the coagulation cooling bath at a speed of 10m / min to another 6...

Embodiment 2

[0050] Using the formula and preparation method of Example 1, the difference is that the cooling medium in the coagulation cooling bath is a mixed medium containing 5% dimethylacetamide and 95% water, and the residual amount of zinc in the prepared porous membrane silk is less than 0.5%.

[0051] The prepared polyvinylidene fluoride hollow fiber porous membrane has an outer diameter of 1.21 mm, an inner diameter of 0.58 mm, a porosity of 74.8%, an average pore diameter of 0.18 μm on the membrane surface, and a pure water flux of 2000 L / m 2 hr@0.1MPa, 25℃, tensile breaking strength 11MPa, tensile breaking elongation 190%, anti-crush strength> 0.8MPa.

Embodiment 3

[0053] 18% active nano calcium carbonate and 42% polyvinylidene fluoride (molecular weight 250,000-400,000), 25% dioctyl phthalate, 10% dibutyl phthalate and 5% dimethylacetamide, in The high-speed mixer mixes at high speed to make the solids evenly disperse the organic phase weight, and then use a twin-screw extruder (screw diameter 20, length-to-diameter ratio: 40:1), control the temperature of the cylinder at 180°C and carry out mixing, pass through an annular gap with an outer diameter of 6mm and an inner diameter of 3mm, control the temperature of the nozzle at 190°C, and pass 5ml Air is injected into the hollow of the filament at a flow rate of 15ml / min, and the hollow filament is extruded from the center of the nozzle at a discharge rate of 15ml / min. The extruded hollow filaments are introduced into a pure water coagulation cooling bath 20mm away from the nozzle mouth, the temperature is controlled at 50°C, and pulled from the coagulation cooling bath at a speed of 10m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com