Patents

Literature

2935 results about "Hollow fiber membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

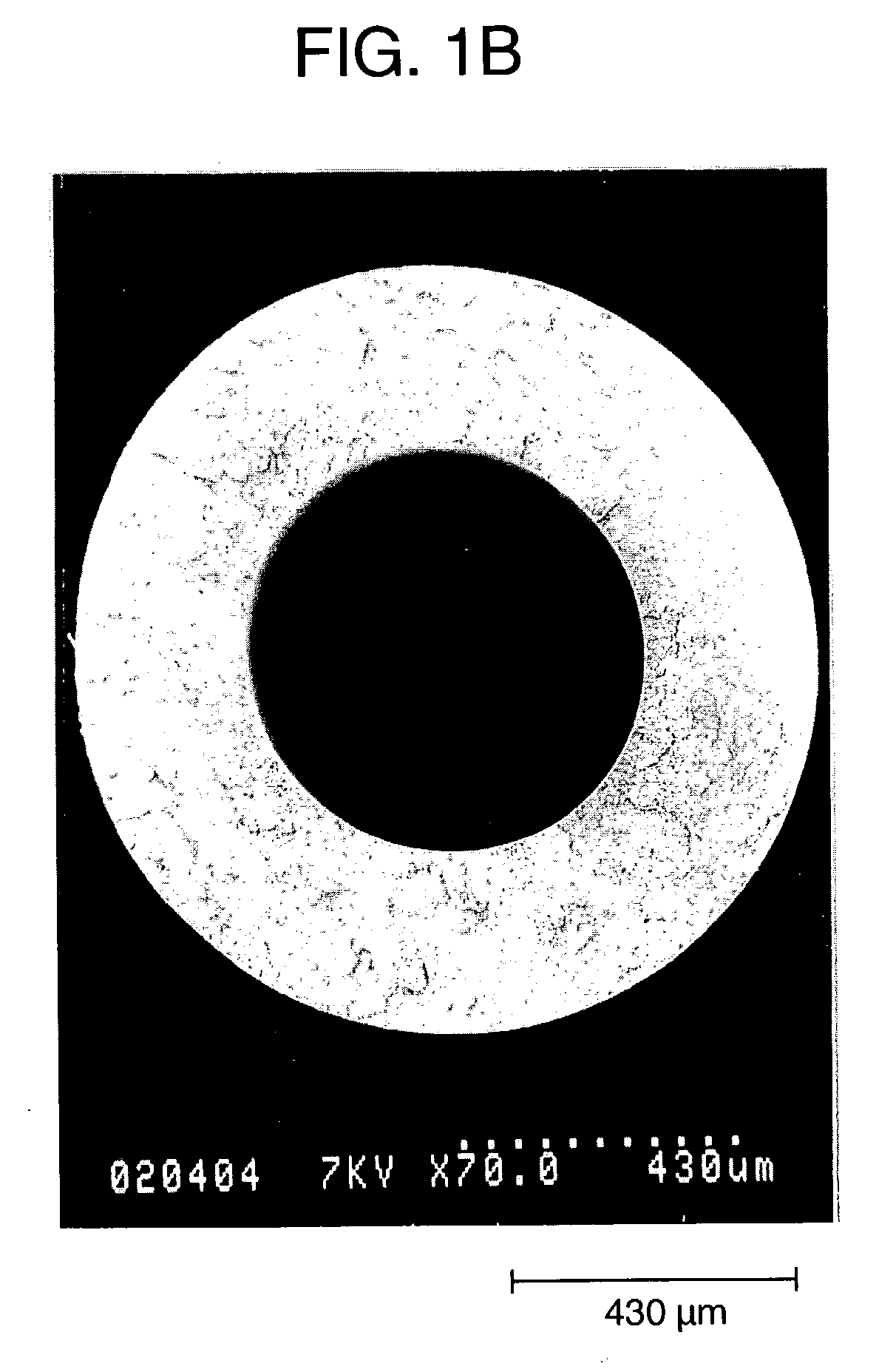

Hollow fiber membranes (HFMs) are a class of artificial membranes containing a semi-permeable barrier in the form of a hollow fiber. Originally developed in the 1960s for reverse osmosis applications, hollow fiber membranes have since become prevalent in water treatment, desalination, cell culture, medicine, and tissue engineering. Most commercial hollow fiber membranes are packed into cartridges which can be used for a variety of liquid and gaseous separations.

Advanced submerged membrane modules, systems and processes

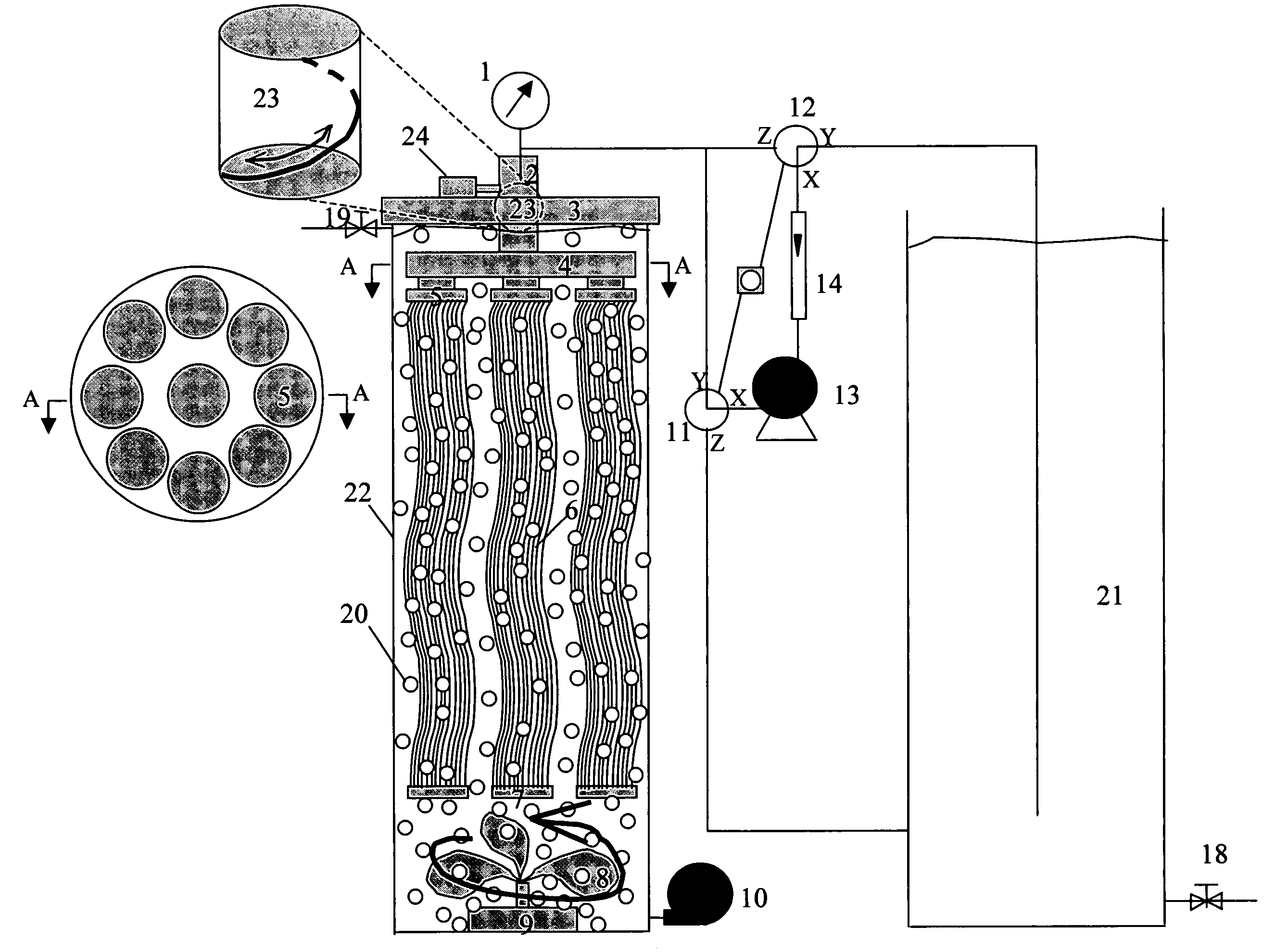

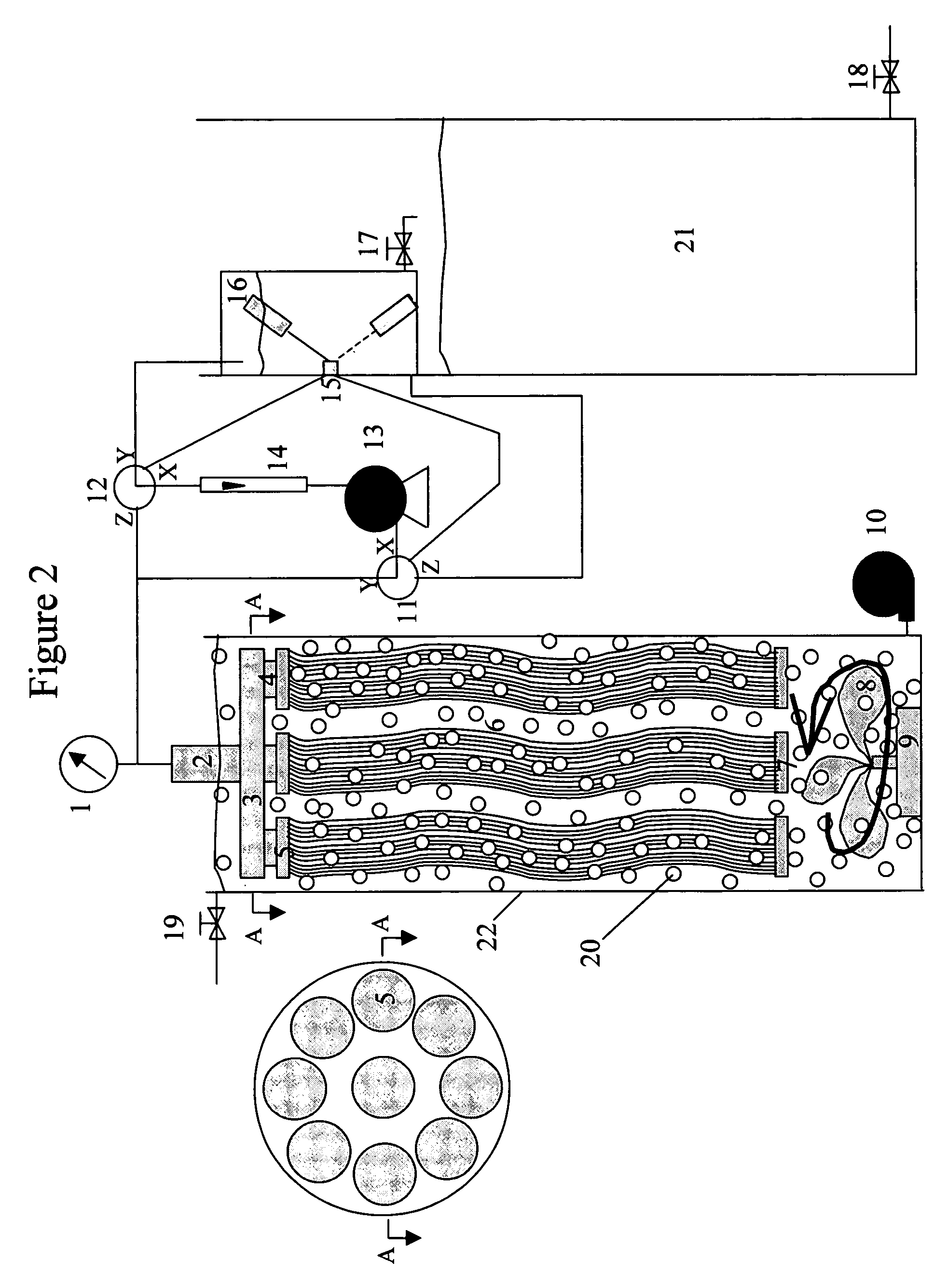

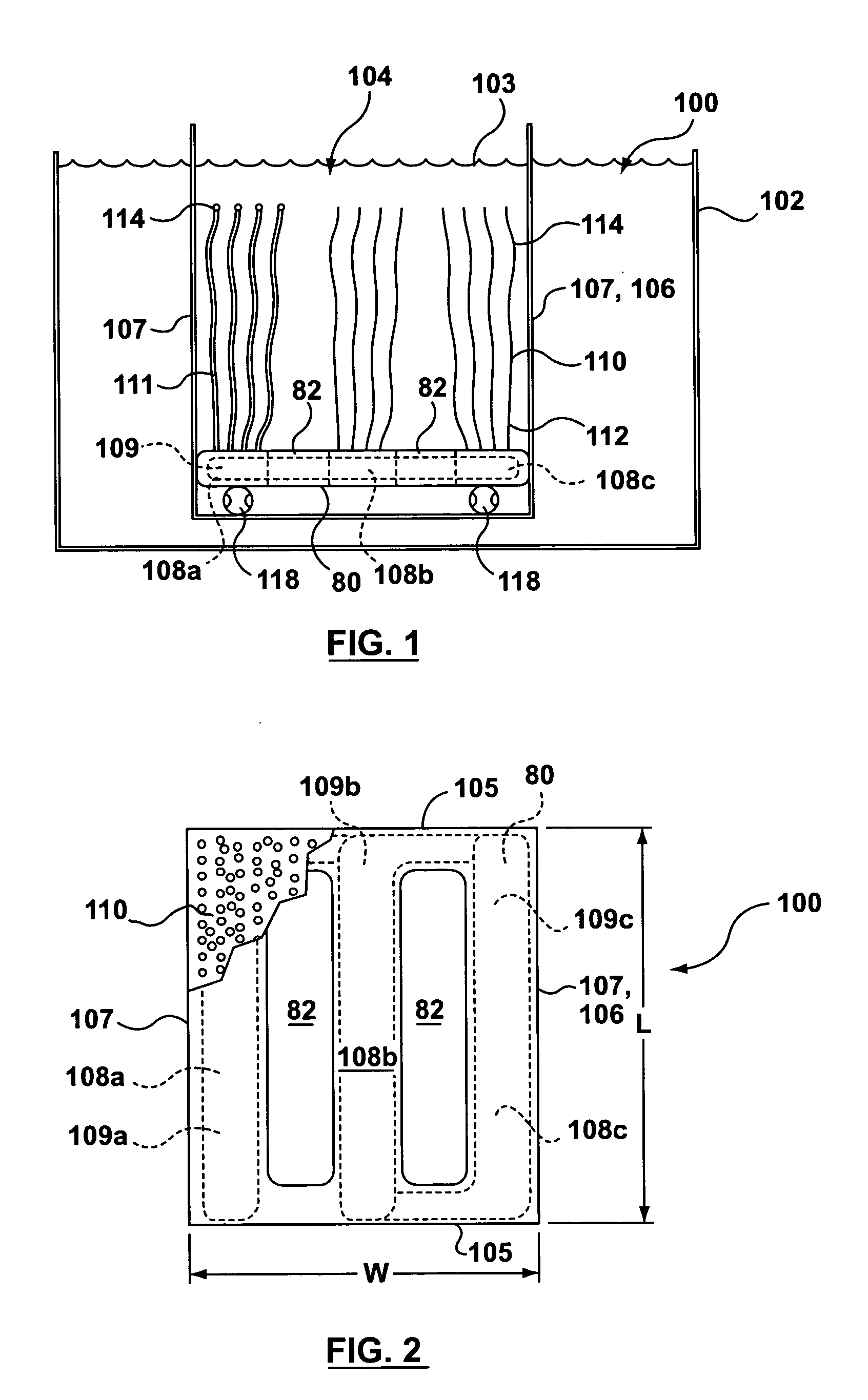

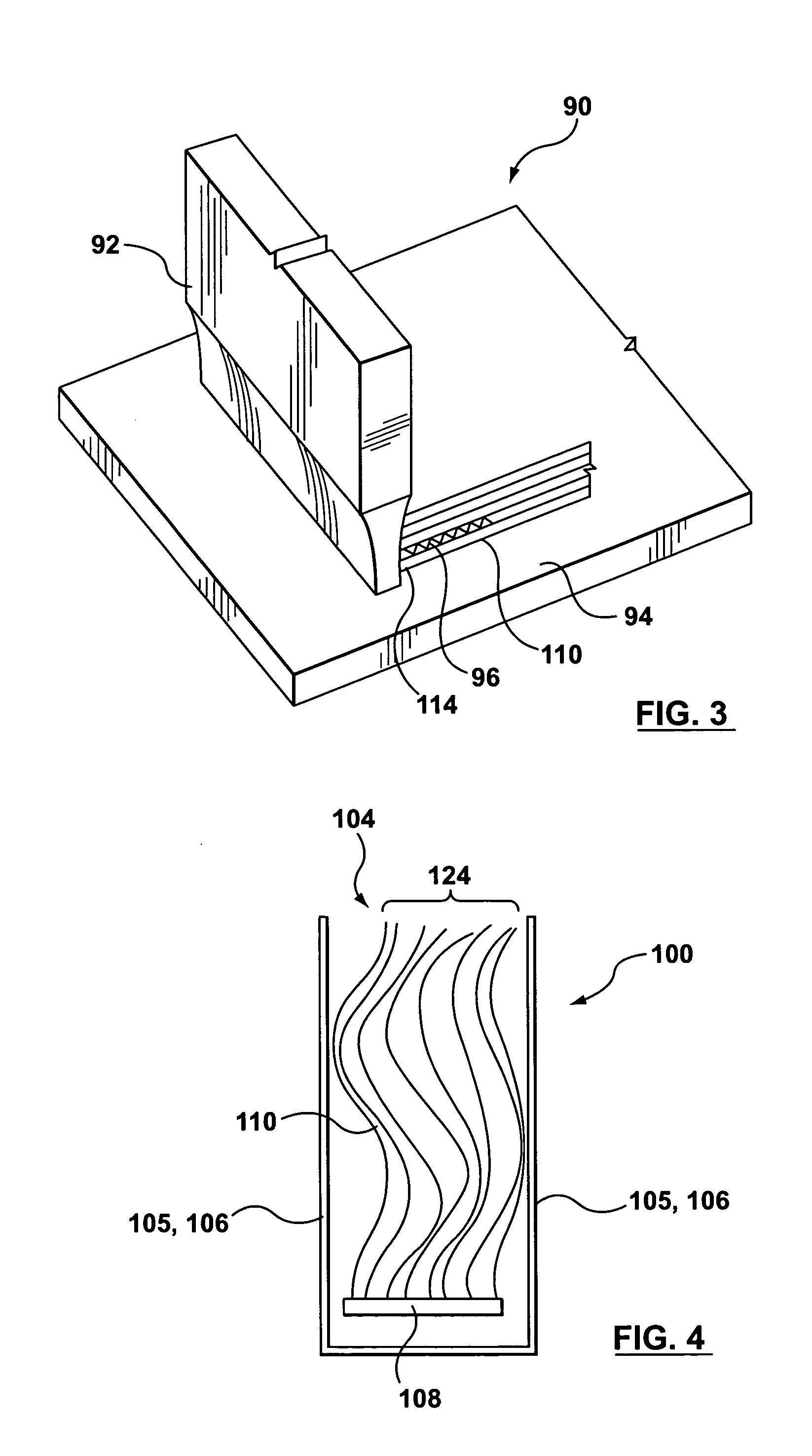

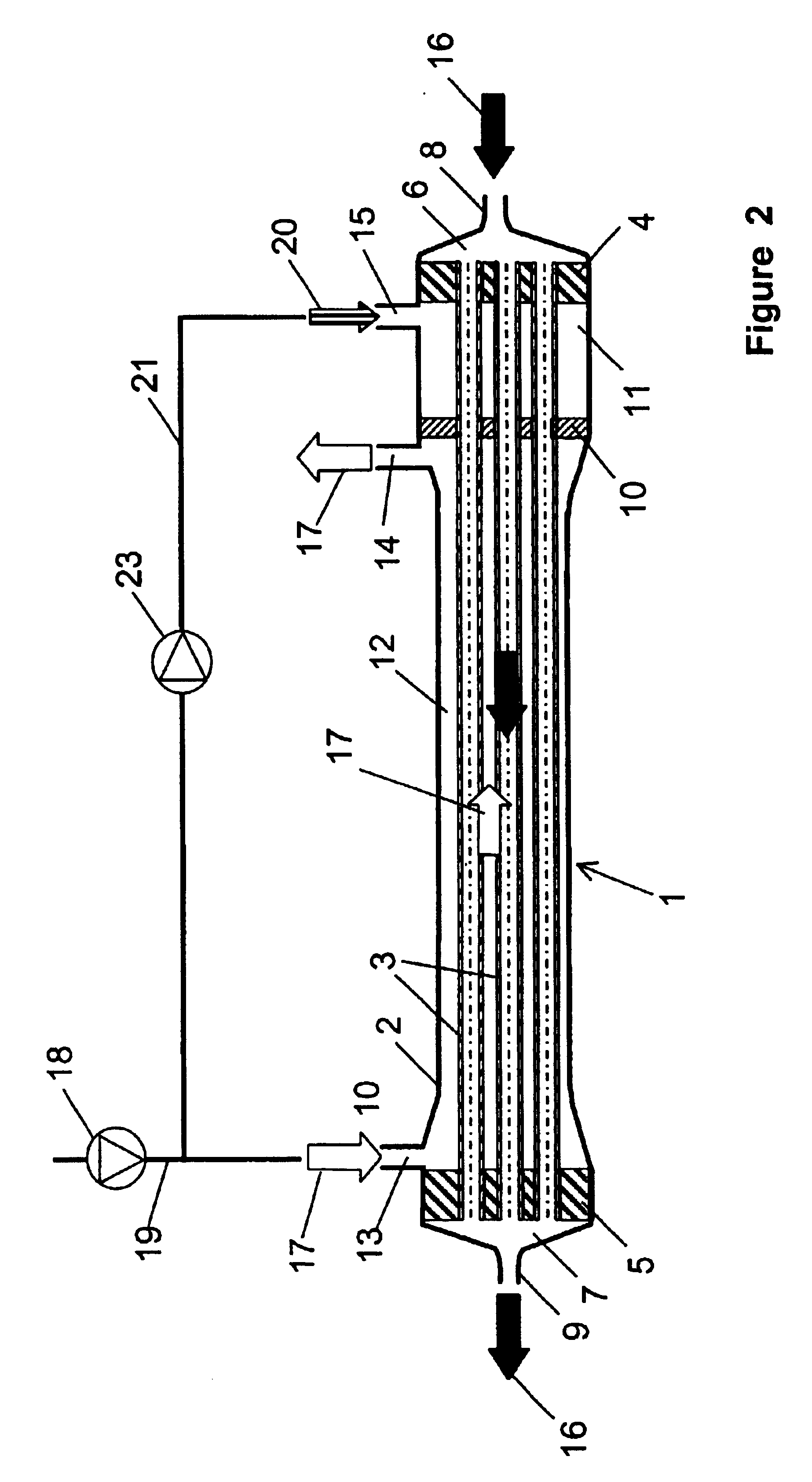

Advanced submerged membrane systems are provided. Said submerged membrane systems have multiple membrane modules comprising of strips of flat sheet membrane, bundles of self-support hollow fiber membranes braided together for reinforcement, tubular membranes, and braid supported hollow fiber membranes. Said submerged membrane systems have alternating relay, or two-way floating switch or computer to control filtration and back flush / pulse cleaning. Said submerged membrane systems have an oscillating motor, and aerator which can generate liquid vortex (whirlpool) flow around membrane to keep membrane from fouling. The present invention provides advanced submerge membrane systems at very low cost for drinking water production, wastewater treatment and membrane bioreactors for biotech, pharmaceutical and other industries.

Owner:JI JIANG

Method and apparatus for determining the state of fouling/cleaning of membrane modules

InactiveUS6161435AVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTime domainSpiral wound

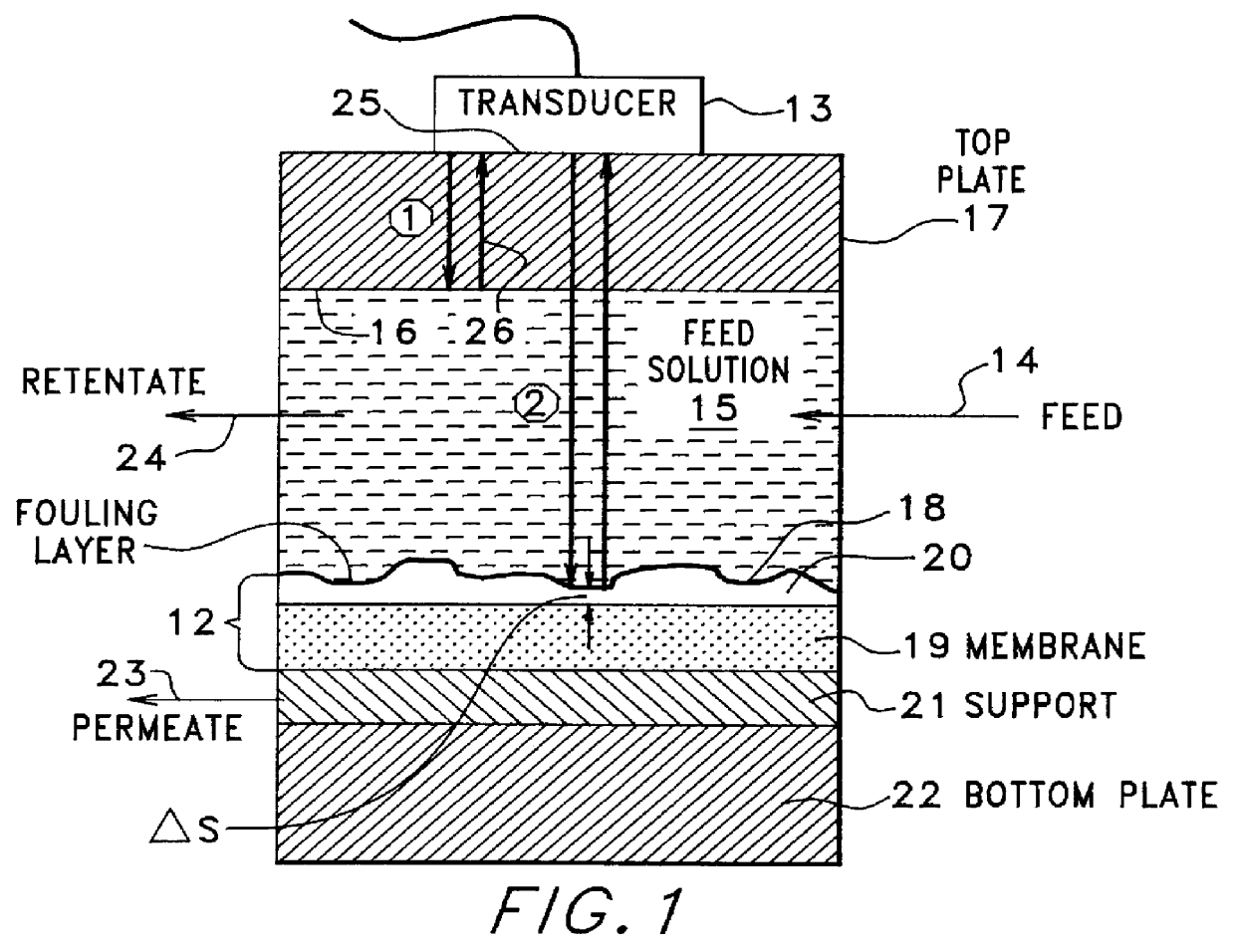

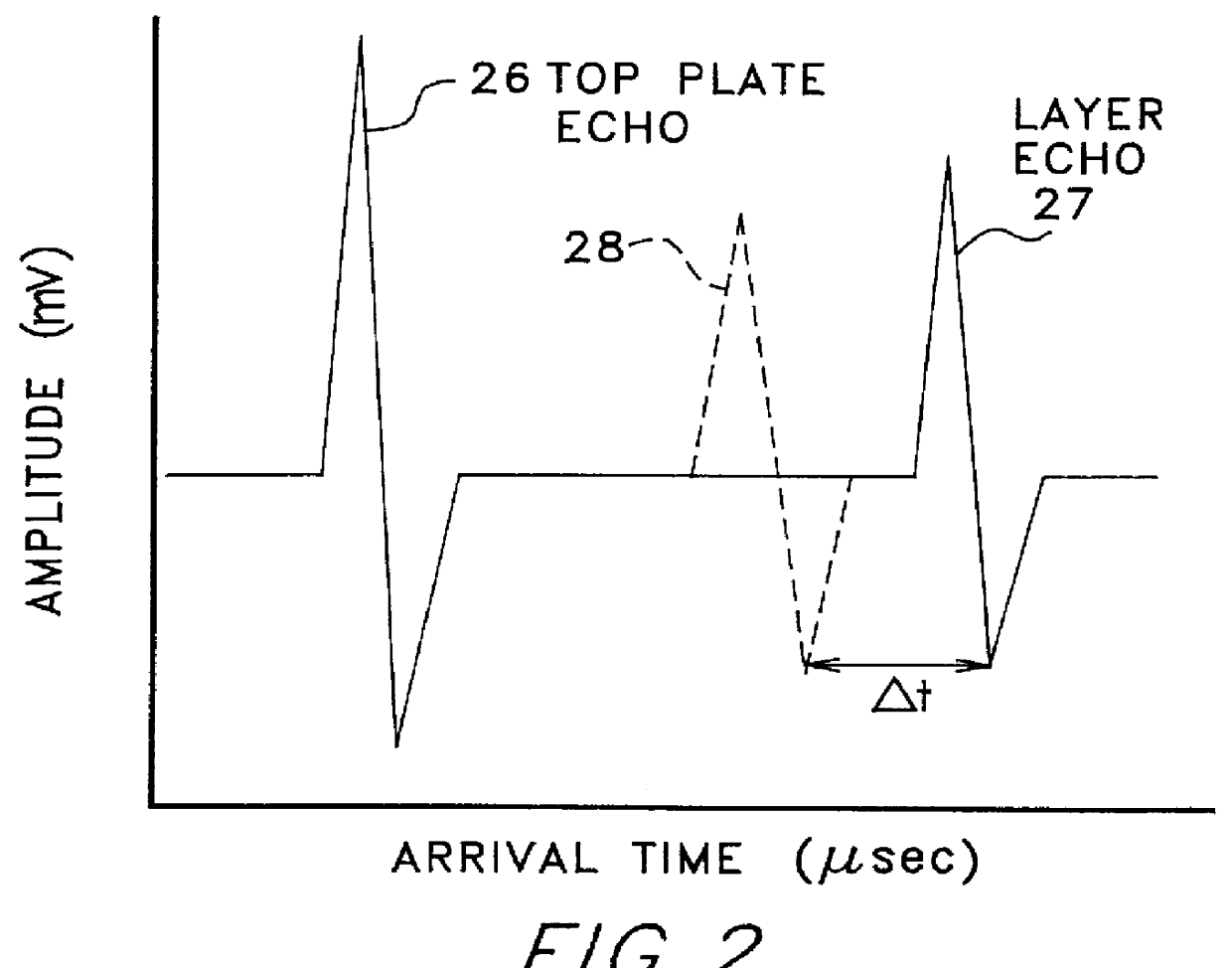

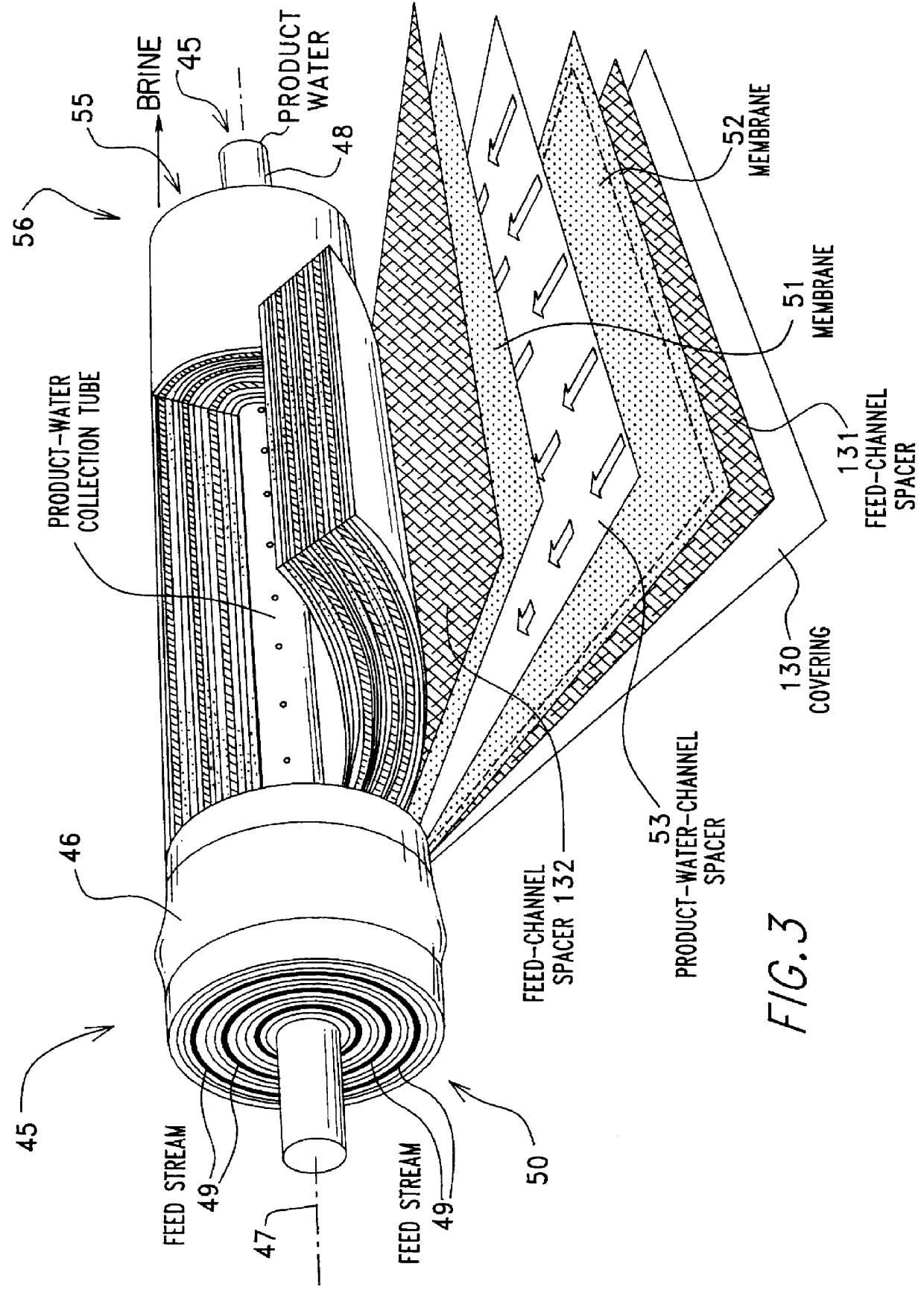

The fouling state of a polymeric membrane within the high pressure housing of a spiral wound or a hollow fiber membrane module is determined. An ultra sonic transducer positioned with its emitting face in physical engagement with the outer surface of the housing is pulse energized by a pulser / receiver device. A membrane echo signal is detected by a receiver of the pulser / receiver device. A reference echo signal indicative of a fouled or an unfouled state of the membrane is compared to the echo signal to determine the membrane fouling state. The echo to reference comparing step can be based upon comparing amplitude domain signals, comparing time-domain signals, comparing combinations of amplitude domain and time-domain signals, and comparing transformations of amplitude domain and time-domain signals. A clean or a fouled reference echo can be provided from a clean or a fouled membrane and then stored for use during a liquid separation process, or a clean reference echo signal can be obtained on-line from a second transducer whose echo signal is derived from an area of the membrane known to remain relatively unfouled during the liquid separation process, or a clean or fouled reference echo signal can be provided for later use during a cleaning process or during a liquid separation process. Multiple transducers and a switching network can sample the fouling state at different positions within the membrane module.

Owner:UNIV TECH

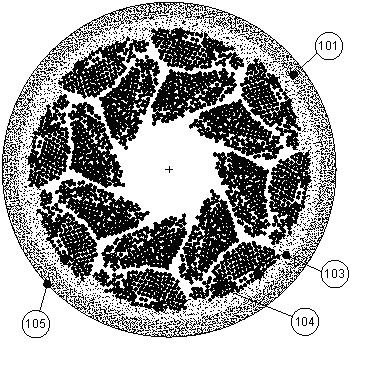

Hollow fiber membrane module

InactiveUS7160455B2Practical pressure resistanceReduce breakageMembranesSemi-permeable membranesFiltrationMechanical engineering

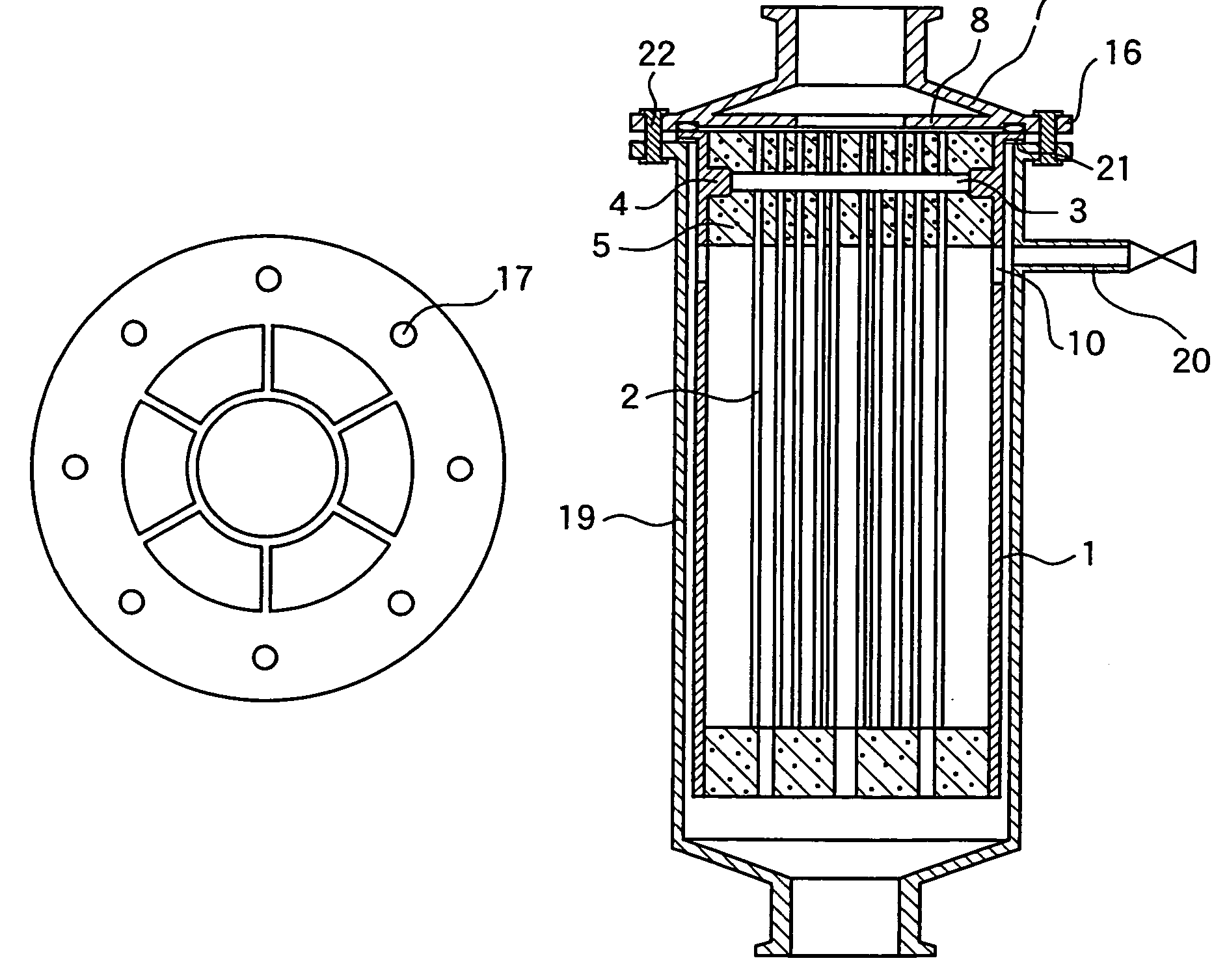

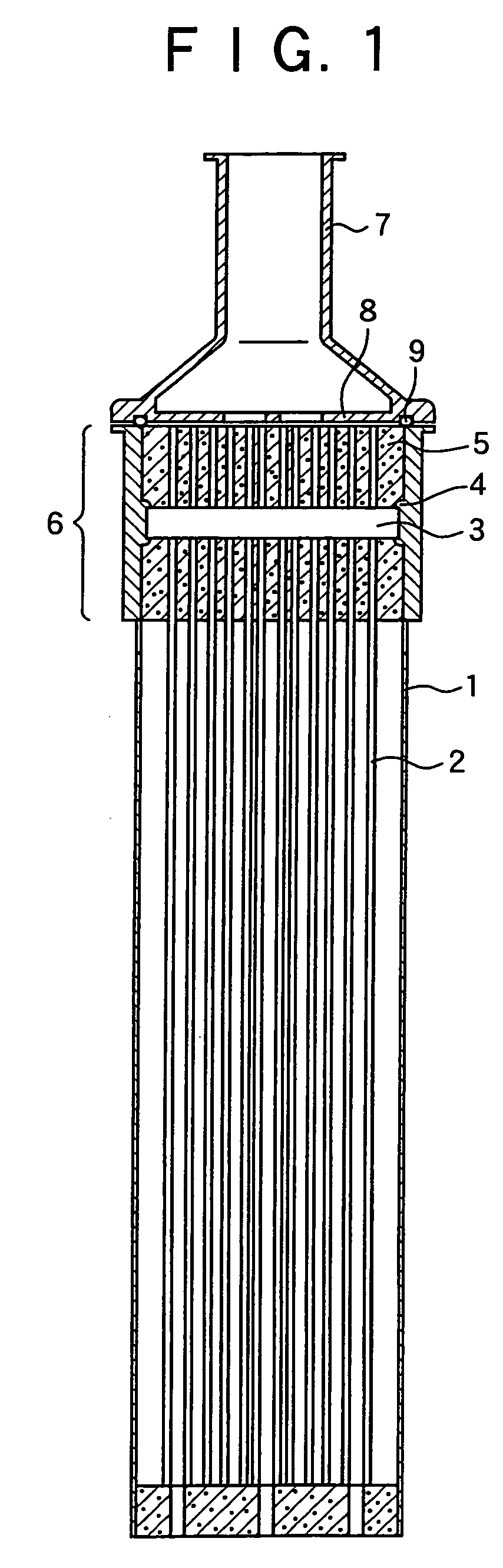

A hollow fiber membrane module comprising a module housing, a hollow fiber membrane bundle comprising a plurality of hollow fiber membranes, at least one end portion of the bundle being fixed on the housing through a flexible potting material, and a rib or ring embedded in the potting portion, the rib or ring being fixed on an inner wall of the housing, and the rib or ring being embedded in the potting portion without directly contacting the hollow fiber membrane, and the filtration method using the same. The hollow fiber membrane module can maintain a practical pressure resistance.

Owner:ASAHI KASEI KK

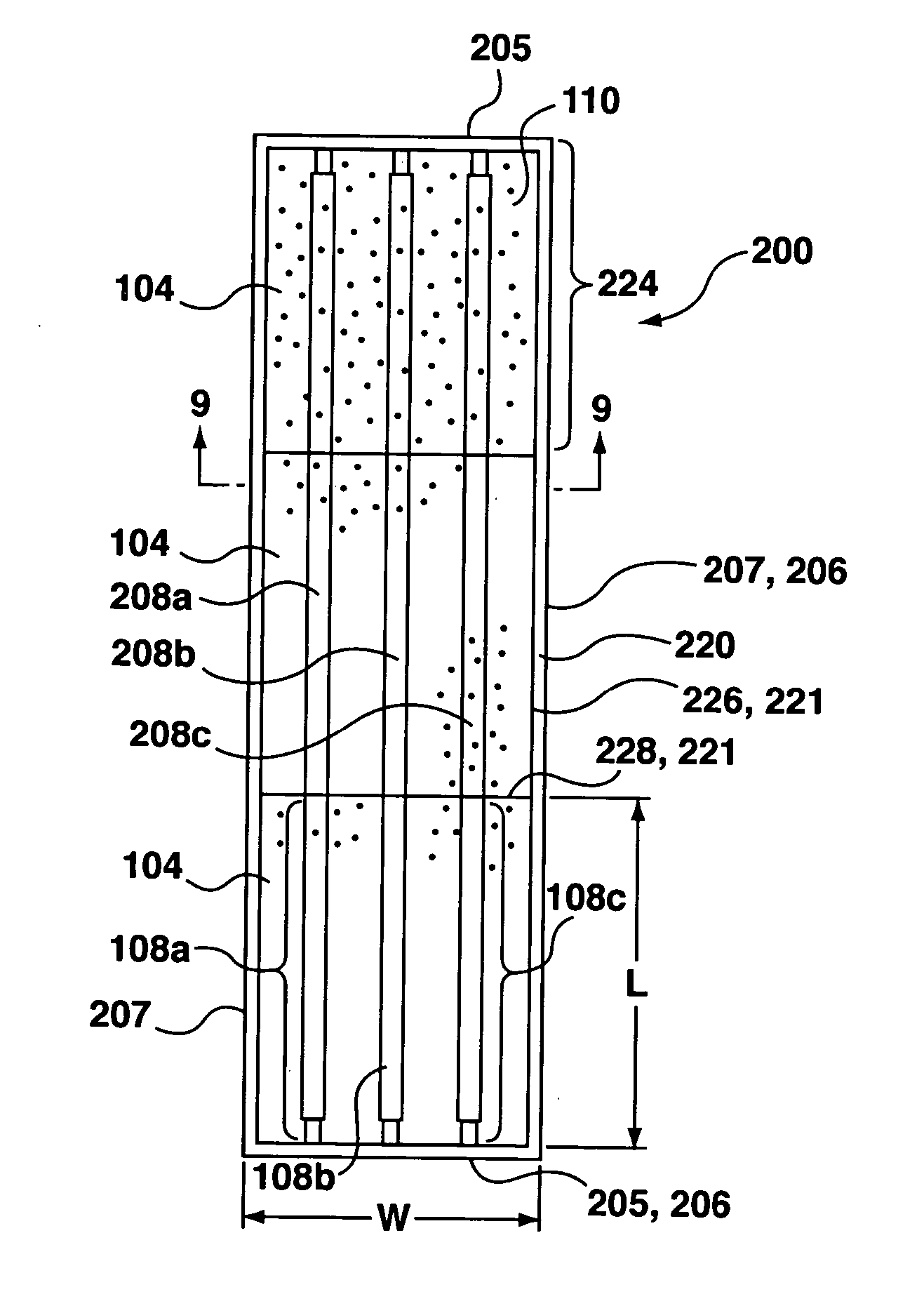

Membrane bioreactor having single header membrane module

A filtration apparatus for filtering liquid has a filtration cell having generally vertical front and rear panels spaced apart to define a cell length, and generally vertical side panels extending between the front and rear panels and spaced apart to define a cell width. A plurality of header segments are provided in the cell, each header segment having a permeate channel. A plurality of hollow fiber membranes are associated with each header segment and extend generally upright between the cell panels, each membrane having a lumen in flow communication with the permeate channel of the associated header segment and a lower end secured to the associated header segment and a loose upper end.

Owner:ZENON ENVIRONMENTAL INC

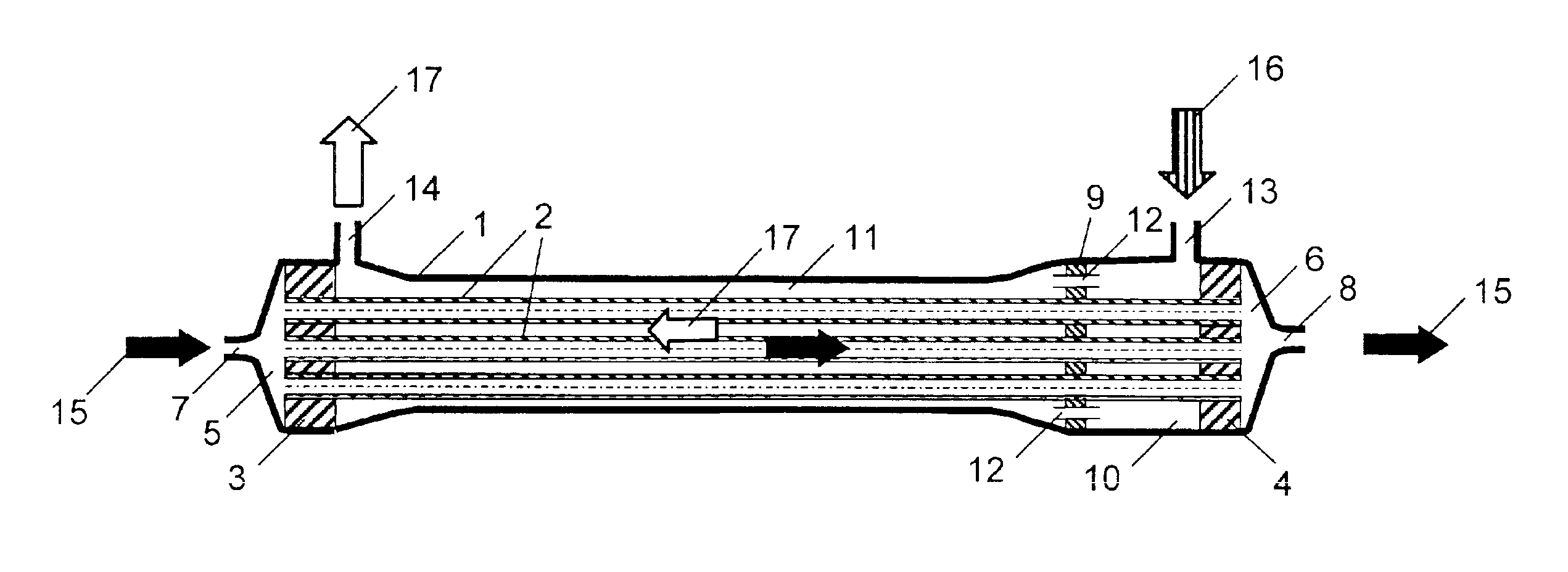

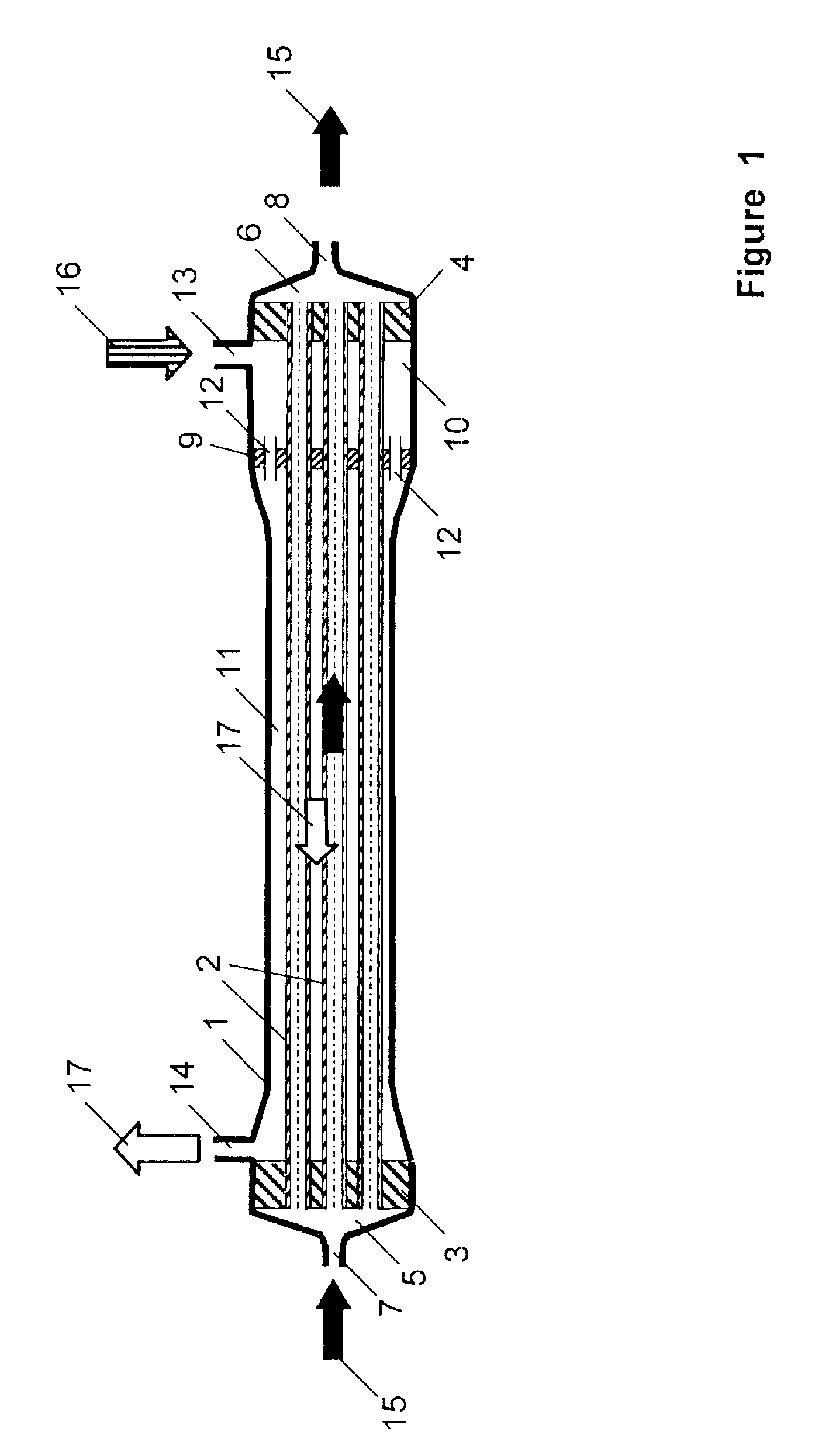

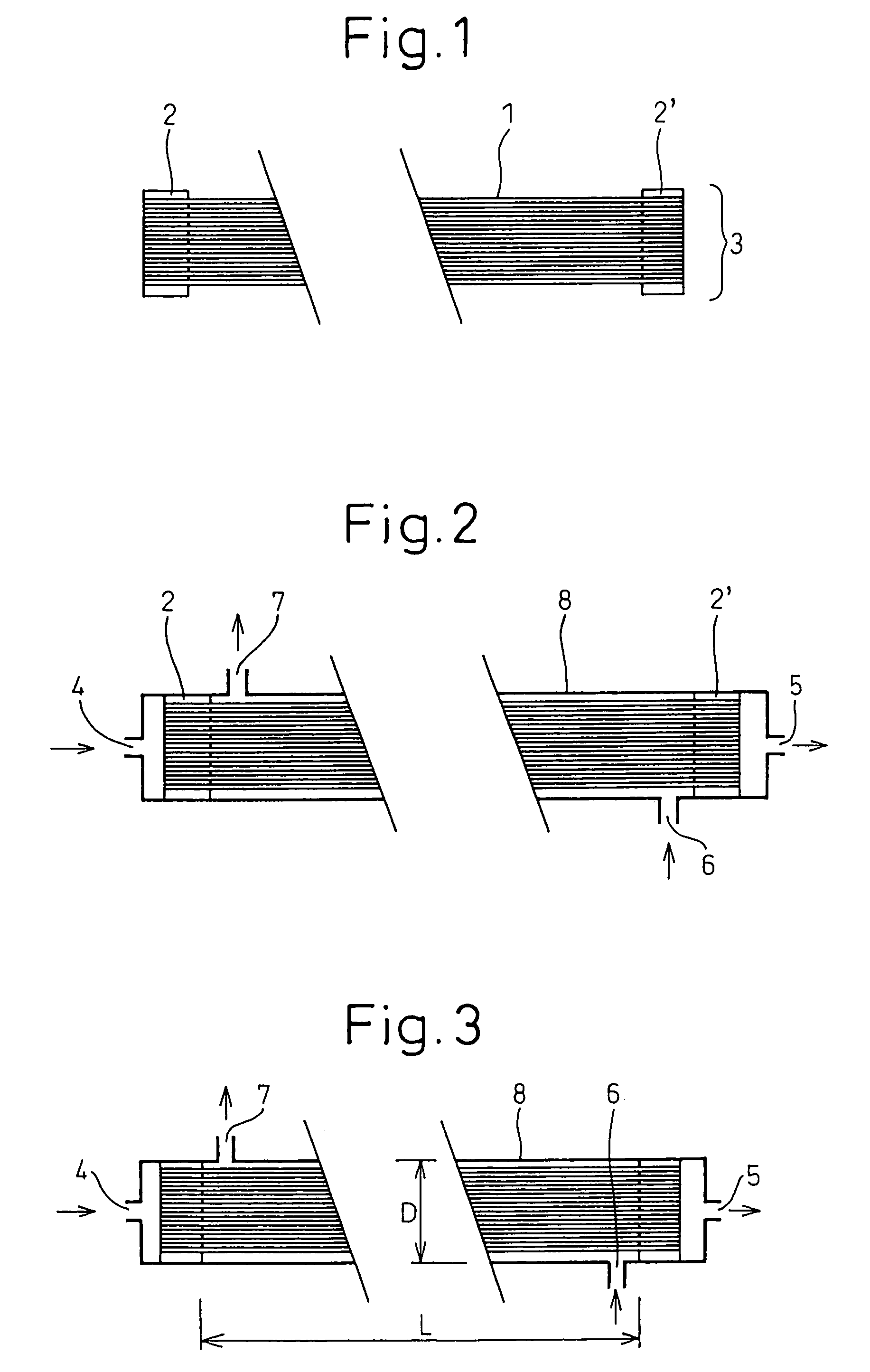

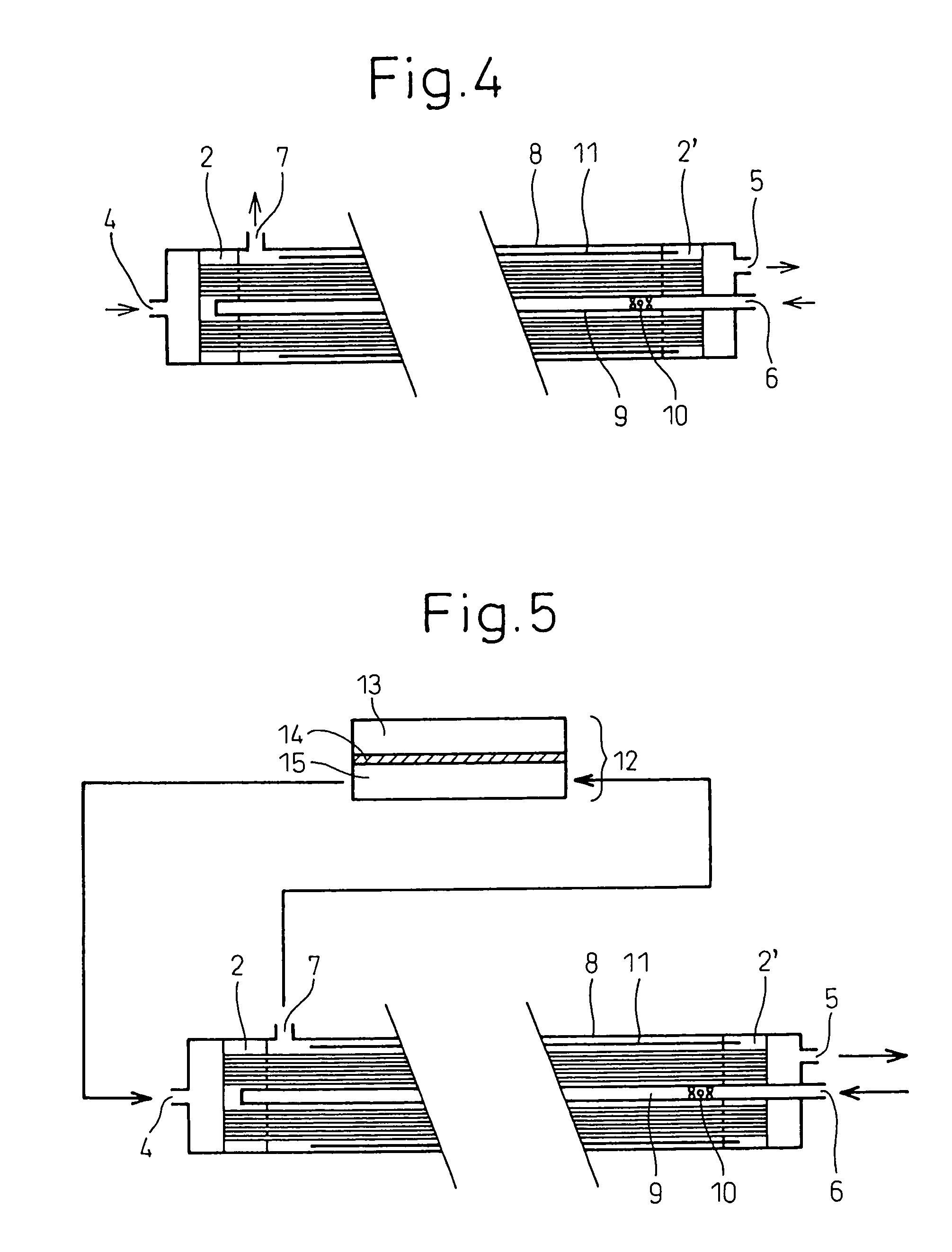

Membrane module for the hemodiafiltration with integrated pre- or postdilution of the blood

InactiveUS6918886B1Simple and compact structureImproved ability to predetermineSolvent extractionHaemofiltrationHemodialysisEngineering

A membrane module for hemodiafiltration having a cylinder-shaped housing and a bundle of hollow-fiber membranes capable of supporting fluid flow and arranged in the direction of the longitudinal extent of the housing. The ends of the hollow-fiber membranes are embedded in a fluid-tight manner in first and second sealing compounds joined to the housing inner wall in a fluid-tight manner. The exterior space formed around the hollow-fiber membranes and delimited by the first and second sealing compounds and the housing inner wall is divided along the longitudinal extent of the housing into a dialyzate space and a substituate space by a dividing wall that is made from a substantially dimensionally stable material. The dividing wall encloses each hollow-fiber membrane and is arranged substantially transversely to the hollow-fiber membranes. The dialyzate space and substituate space each have at least one opening for introducing or draining a fluid. In the exterior space, at least one throttle is arranged by which the dialyzate space and substituate space are in fluid communication with each other.

Owner:MEMBRANA

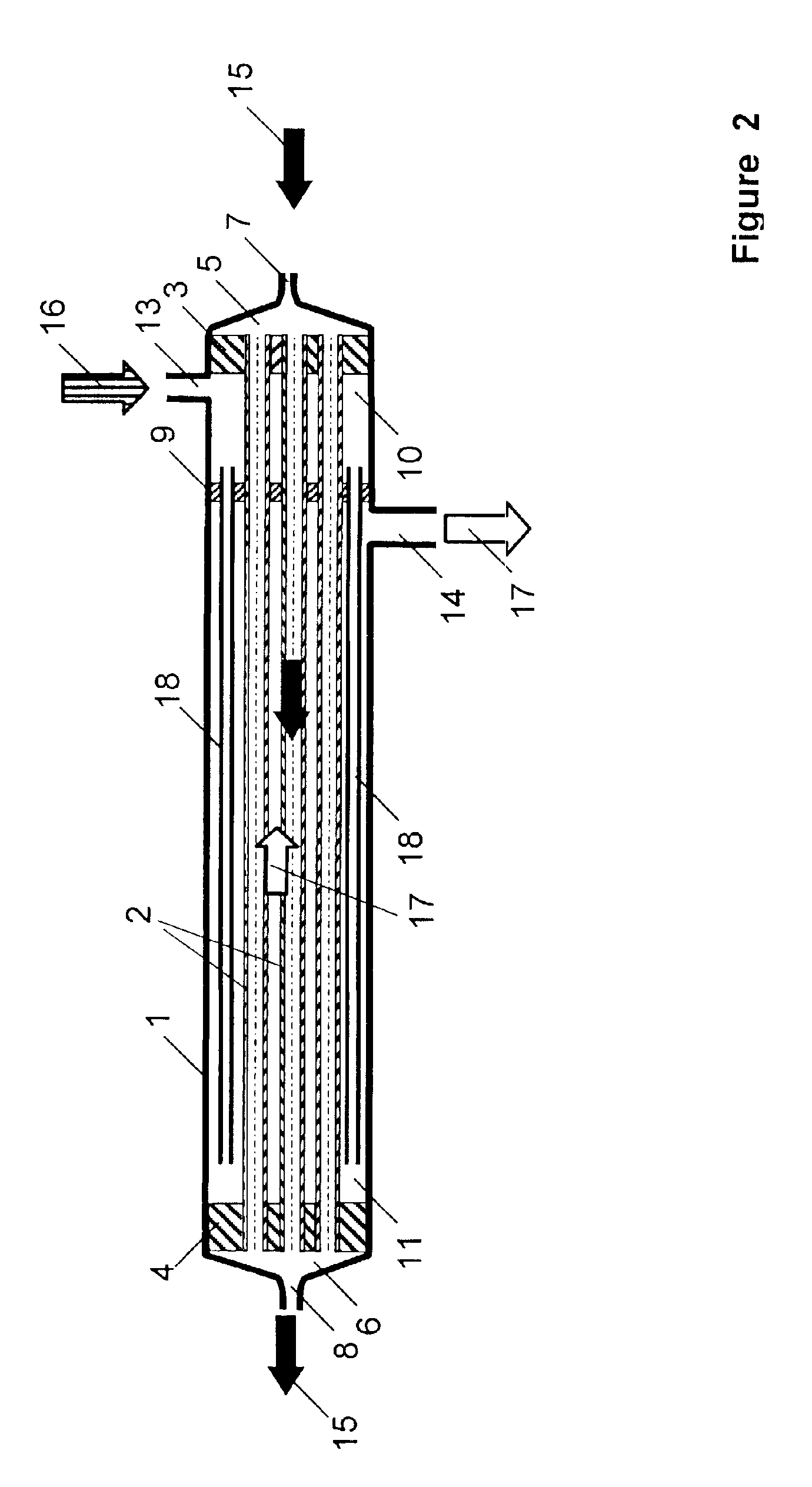

Hemodiafiltration system and method

A hemodiafiltration system for treating blood which has module having a housing in which hollow-fiber membranes are arranged in the direction of the longitudinal extent and are embedded at their ends in first and second sealing compounds joined to the inner wall of the housing in a fluid-tight manner. The membrane module also has a dialyzate space and a substituate space separated from the dialyzate space in a fluid-tight manner by a continuous dividing wall. The membrane module further includes means for delivering and withdrawing a dialyzate to and from the dialyzate space, and means for delivering a substituate to the substituate space. The hollow-fiber membranes are used for blood treatment, filtration of the substituate, and delivery of the substituate to the blood. An exterior space is formed around the hollow-fiber membranes that is delimited by the inner wall of the housing and sealing compounds and is divided along the longitudinal extent of the housing by a dividing wall into the substituate space and the dialyzate space, the dividing wall encloses each individual hollow-fiber membrane.

Owner:MEMBRANA

Hollow fiber membrane filters in various containers

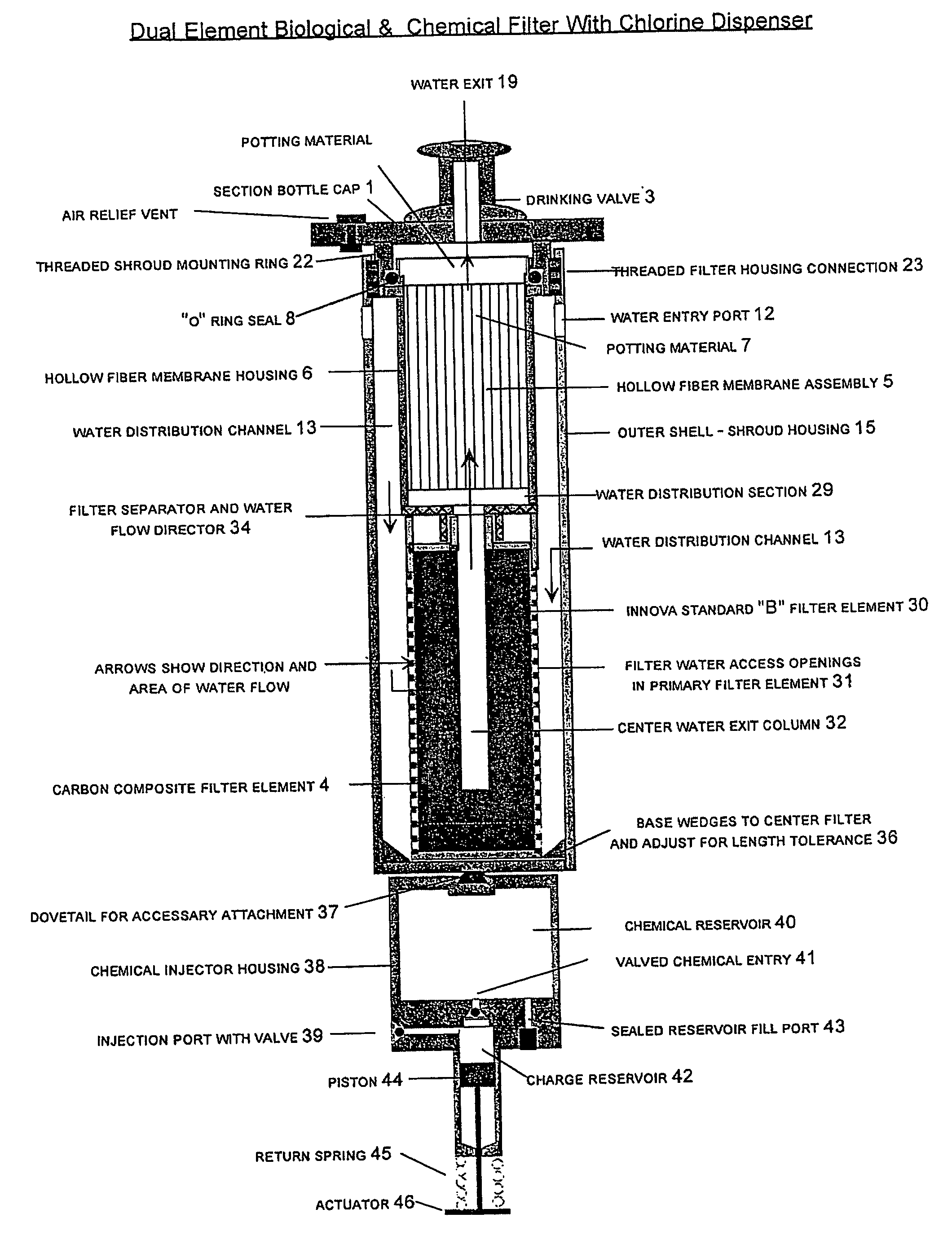

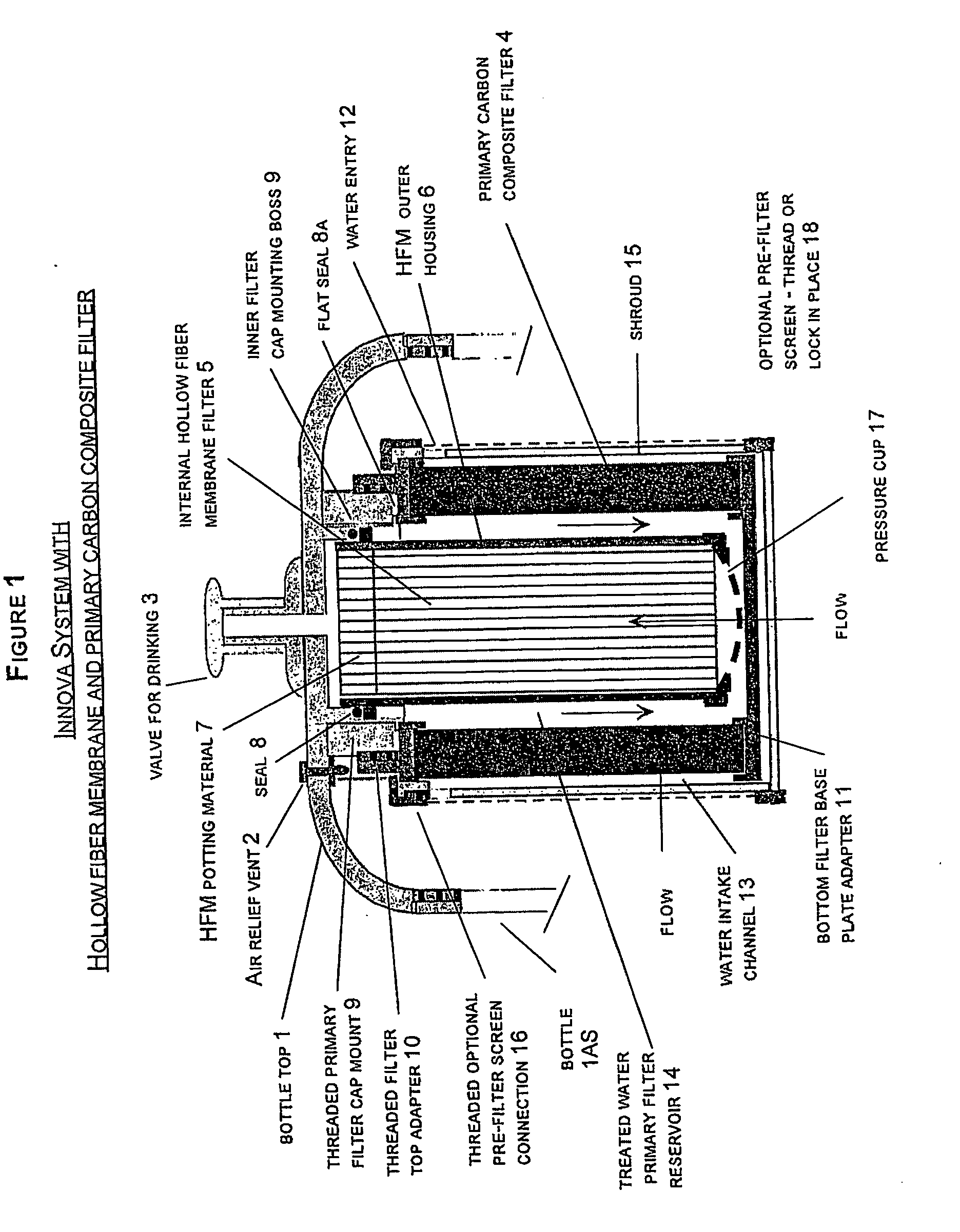

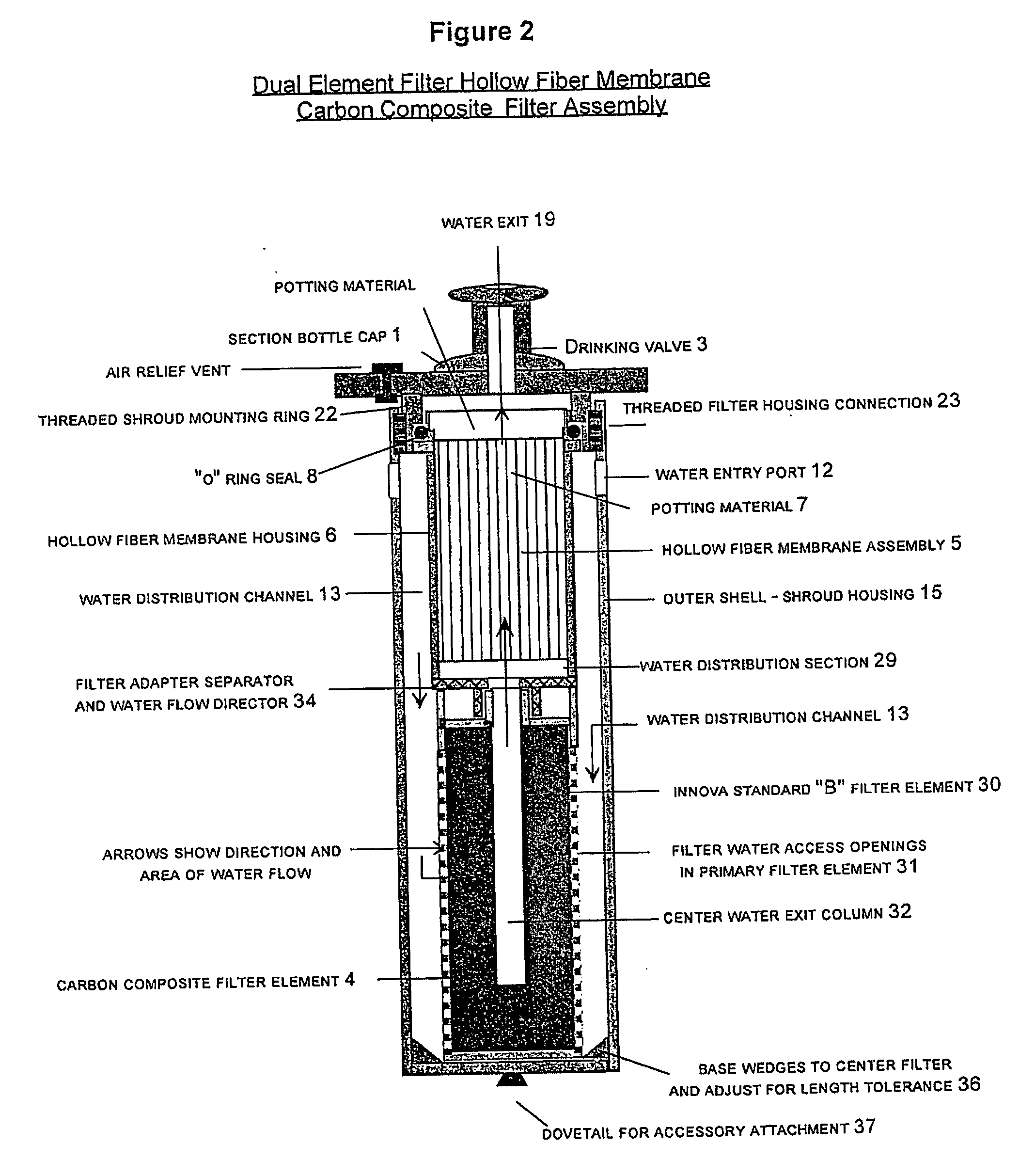

InactiveUS20050035041A1Eliminate the problemAvoid accumulationTravelling sacksUltrafiltrationCarbon compositesWater filter

A water filter cooperable with a water container includes both a carbon composite filter (30) and a bundle of micro porous hollow fiber membranes (5) in fluid communication with the carbon composite filter (30). An influent side of the hollow fiber membrane (5) is continuously immersed in water whereby air is prevented from being reintroduced to the hollow fiber membrane (5).

Owner:INNOVAPURE WATER

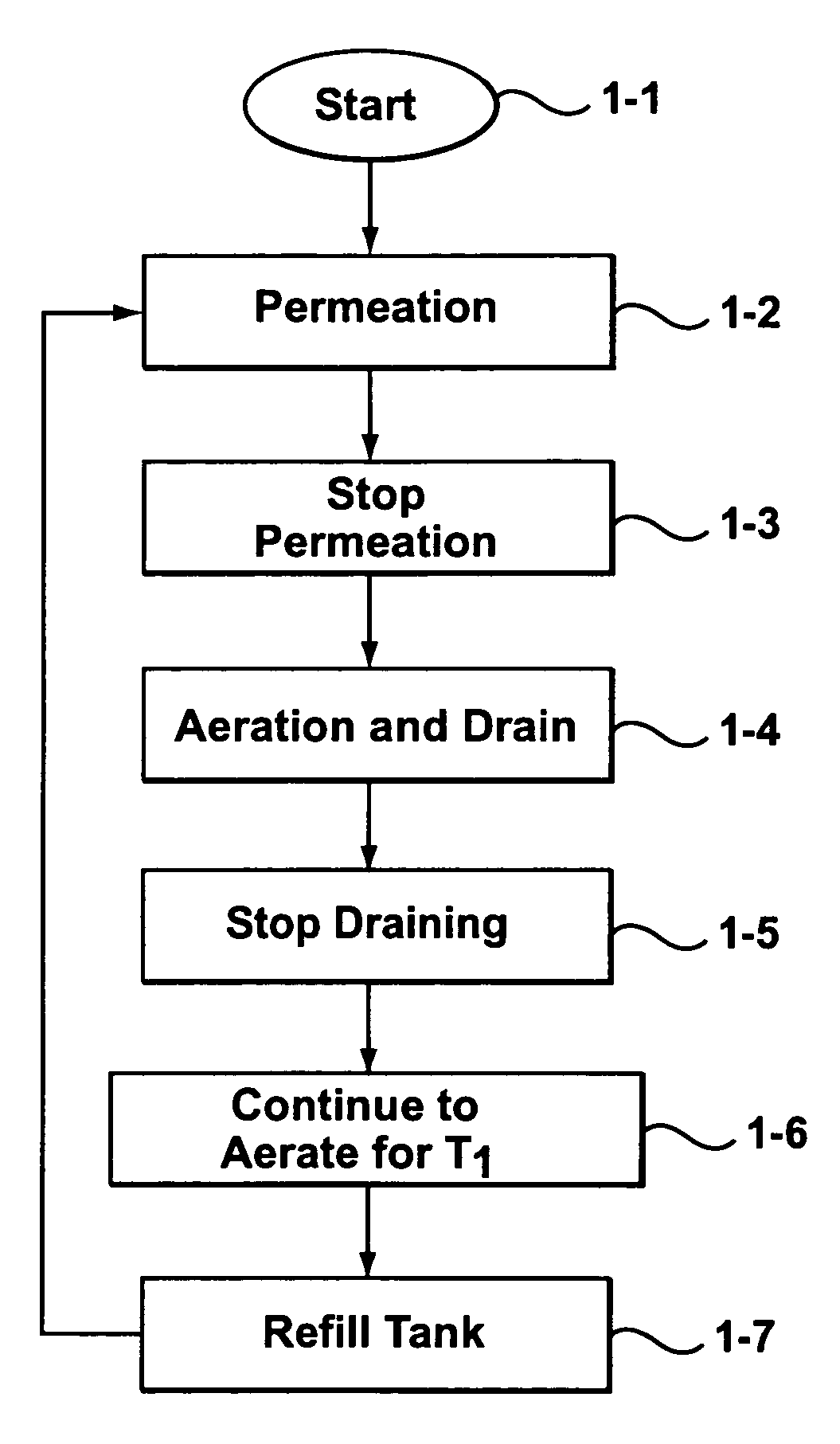

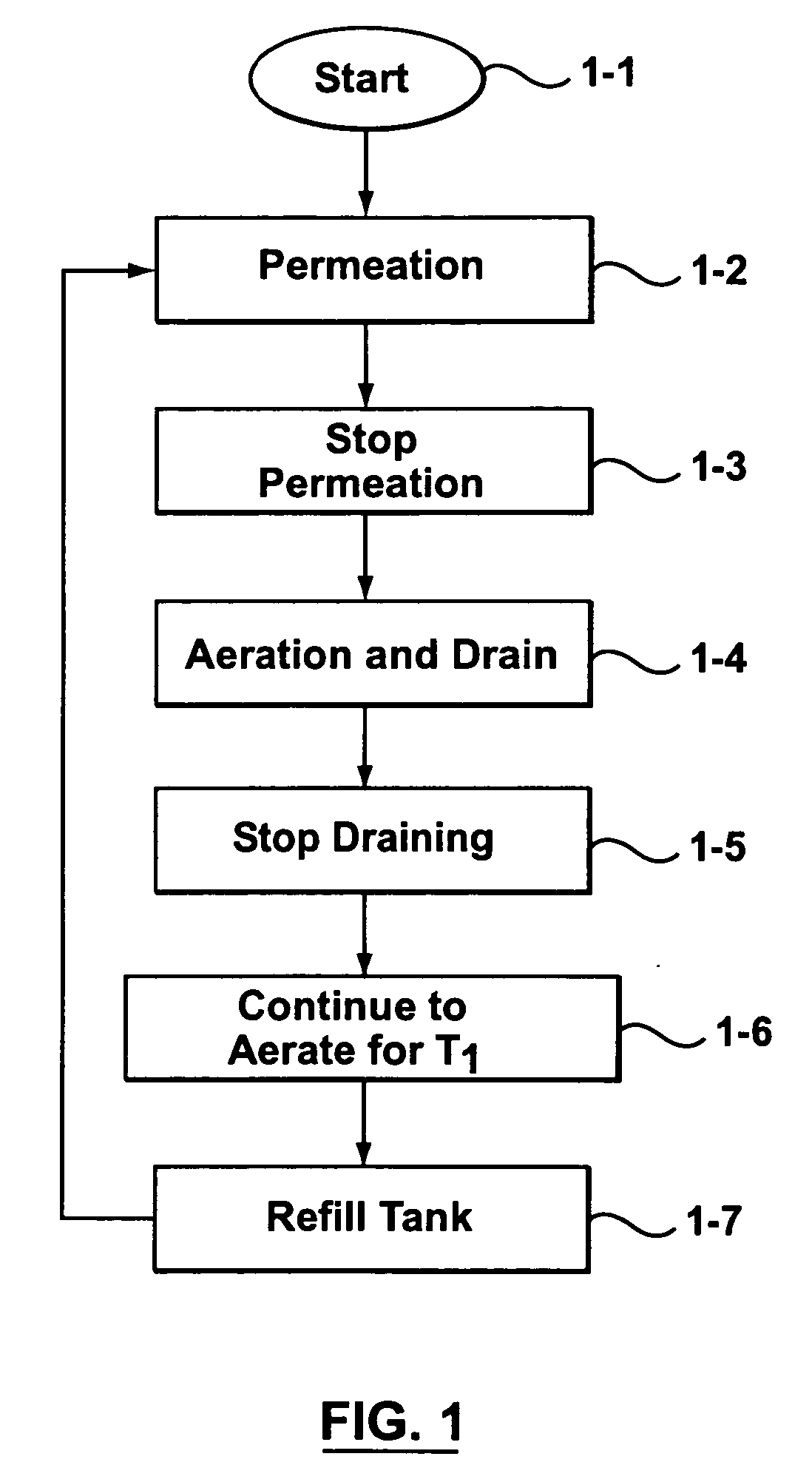

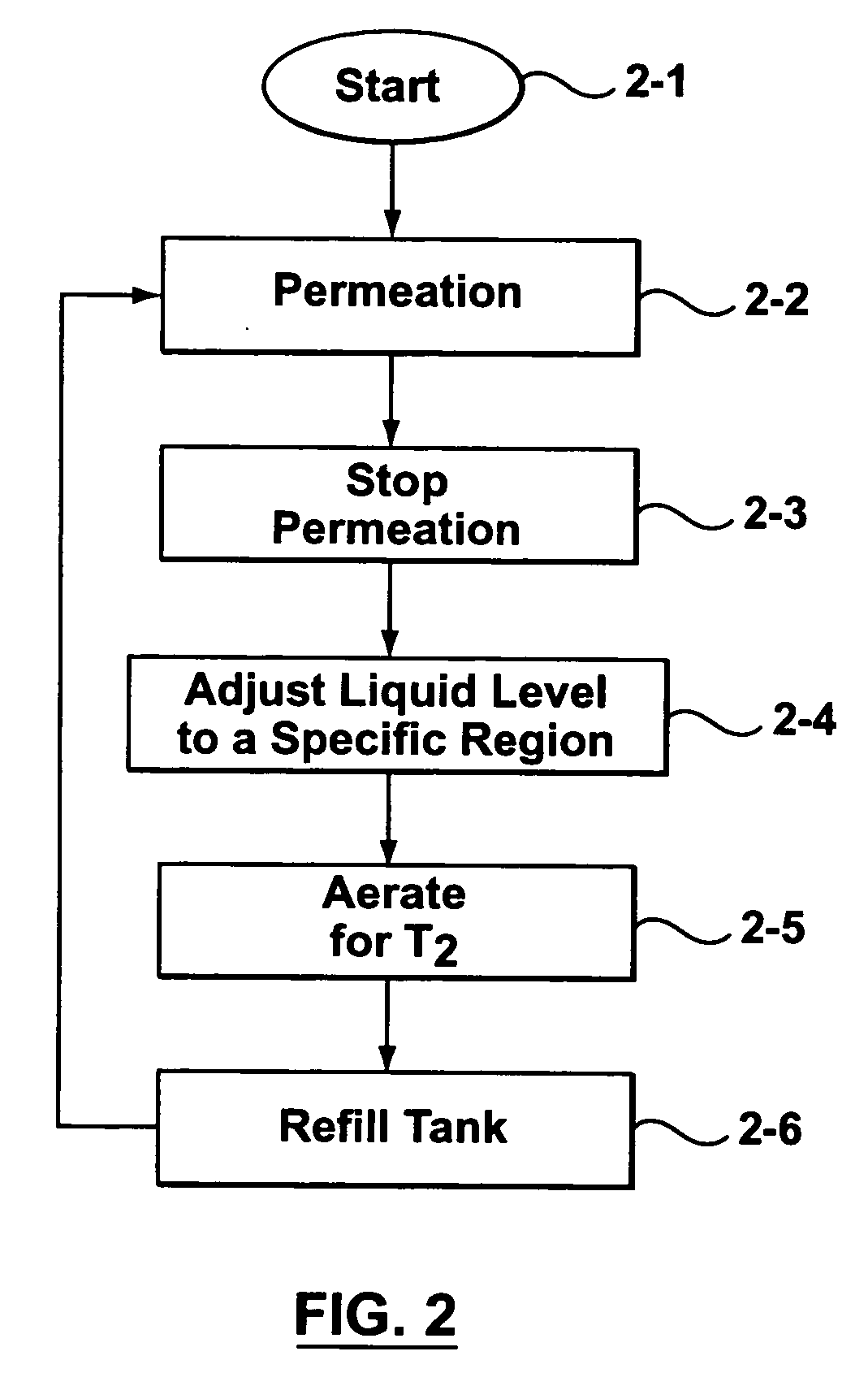

Membrane filter cleansing process

InactiveUS20060065596A1Reduce accumulationLower the liquid levelMembranesSemi-permeable membranesFiberHollow fibre membrane

Immersed hollow-fiber membrane filtration systems sometimes encounter process problems as a result of solids accumulation in and around the hollow fibers. The solids can accumulate to the point where they begin to dewater and form a mud like substance known as sludge. In some embodiments of the invention there is provided a process for substantially preventing the accumulation of sludge build-up on membrane fibers and / or cleansing membrane fibers that have been fouled by a substantial sludge build-up. Many of these embodiments involve aerating a membrane tank in which the membrane fibers are immersed after the water level has been reduced to near the level of solids accumulation. In some embodiments of the invention, the energy released by bursting bubbles at the liquid-air interface is employed to prevent fouling of membrane fibers and / or cleanse fouled membrane fibers.

Owner:ZENON TECH PARTNERSHIP

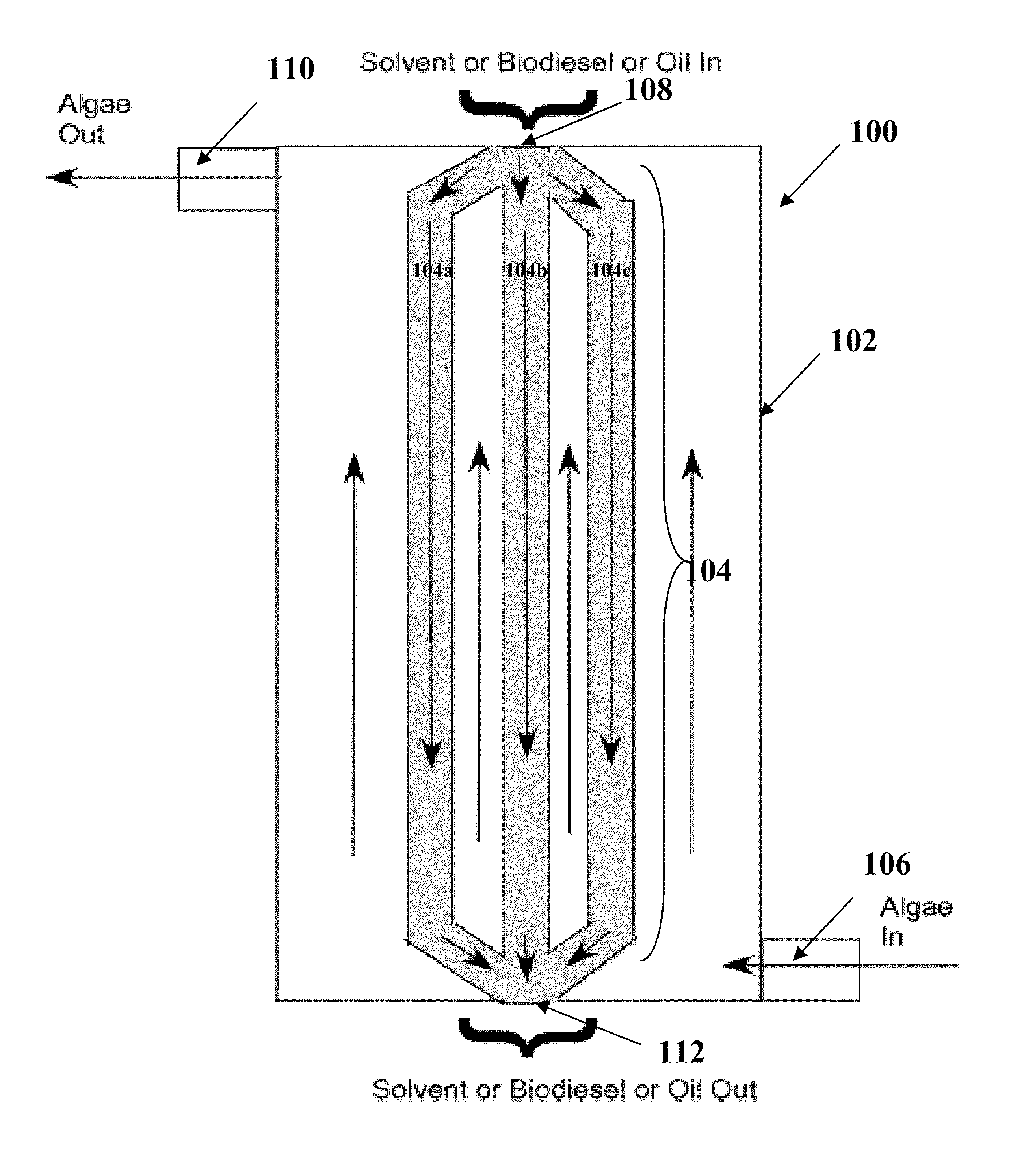

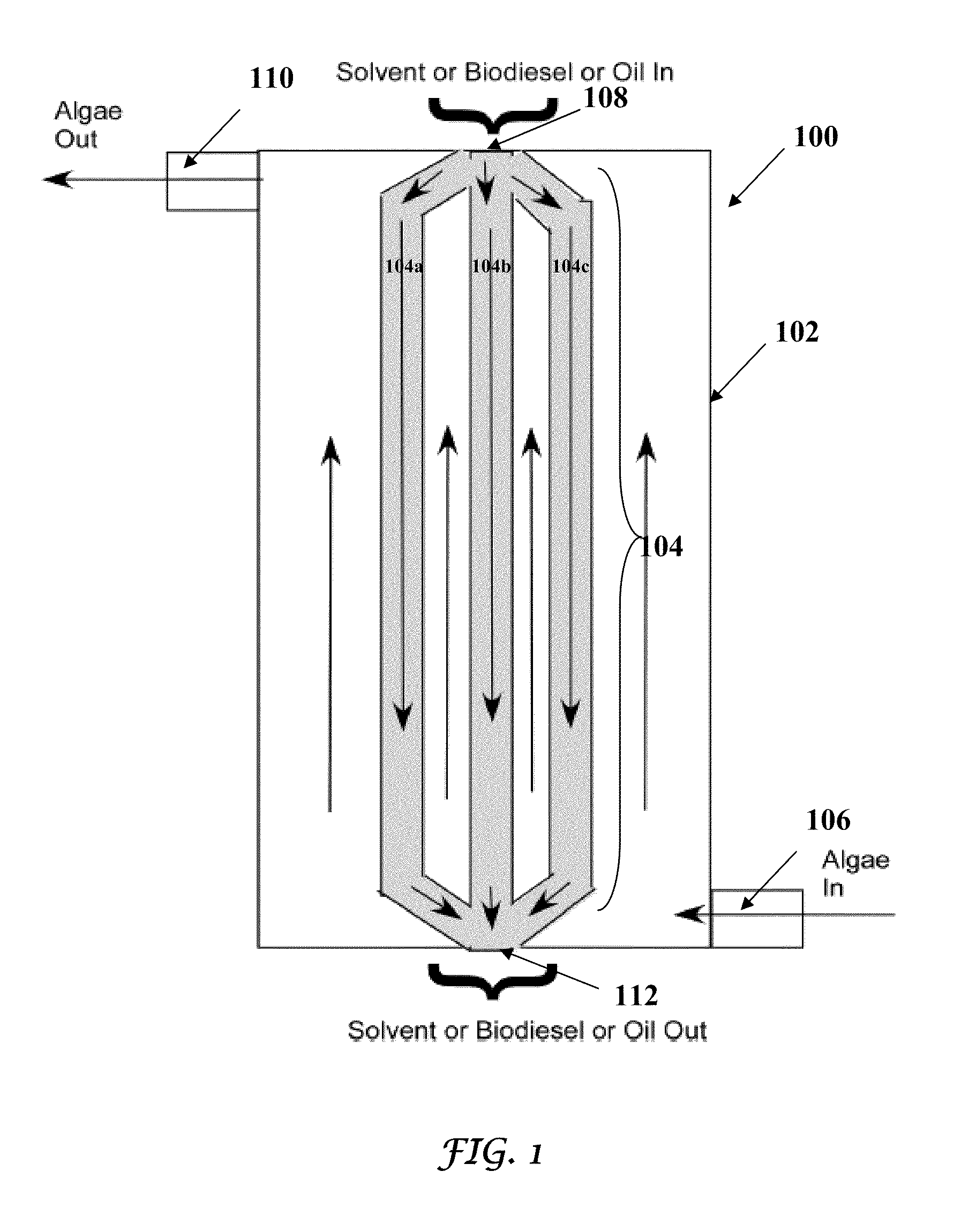

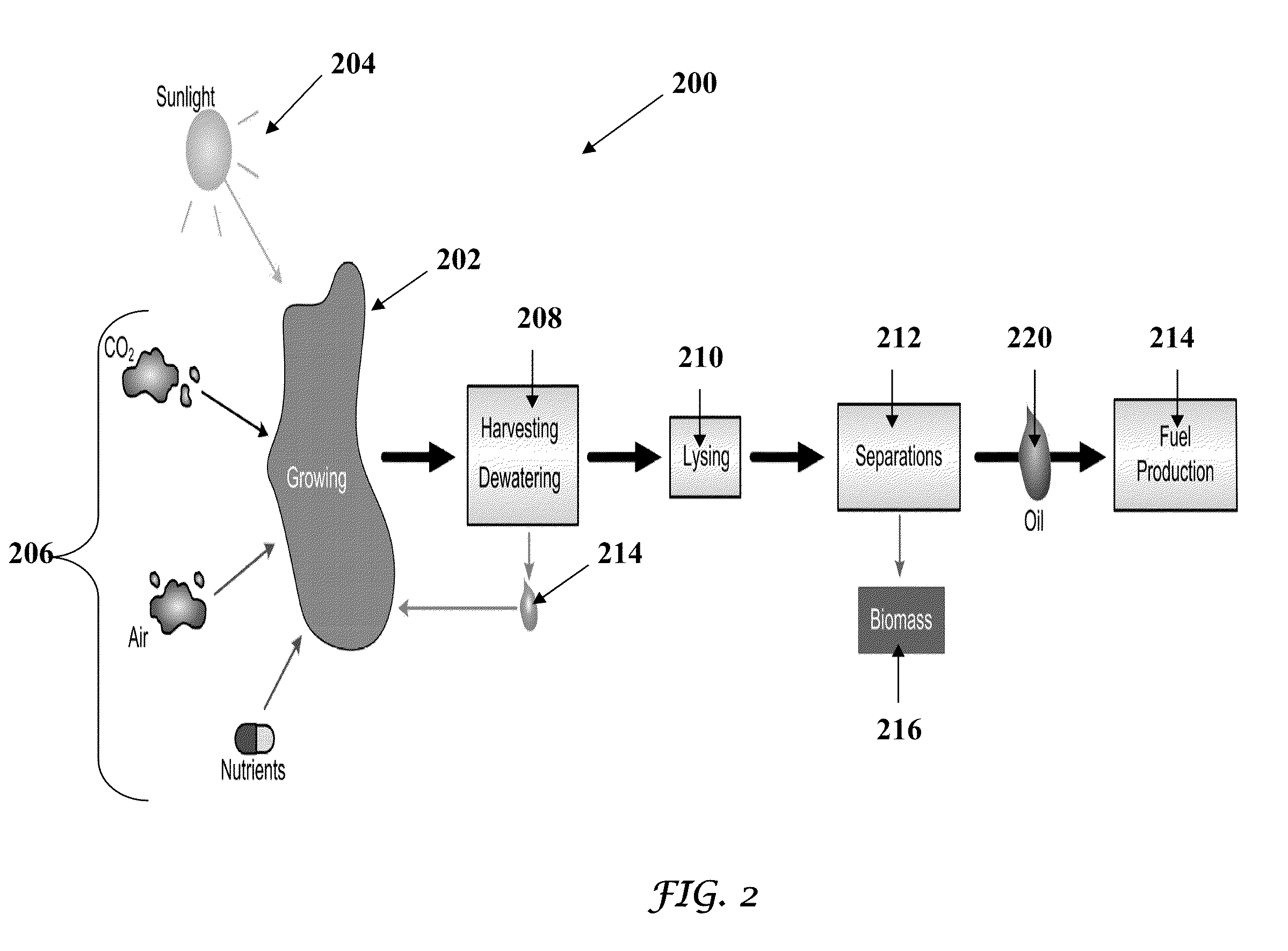

Non-Dispersive Process for Insoluble Oil Recovery From Aqueous Slurries

ActiveUS20110174734A1Efficient separationEliminate the problemFatty acid chemical modificationFatty acids production/refiningBiodieselBeta-Carotene

The development and application of a novel non-polar oil recovery process utilizing a non-dispersive solvent extraction method to coalesce and recover oil from a bio-cellular aqueous slurry is described herein. The process could apply to recovery of algal oil from a lysed algae slurry, recovery of Omega fatty acids from a bio-cellular aqueous feed, recovery of Beta-carotene from a bio-cellular aqueous feed and for the removal from produced water in oil production and similar type applications. The technique of the present invention utilizes a microporous hollow fiber (MHF) membrane contactor. The novel non-polar oil recovery process described herein can be coupled to a collecting fluid (a non-polar solvent such as heptane, a biodiesel mixture or the previously extracted oil) that is circulated through the hollow fiber membrane. In cases where the biodiesel mixture or the previously extracted oil is used the solvent recovery step (e.g. distillation) can be eliminated.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

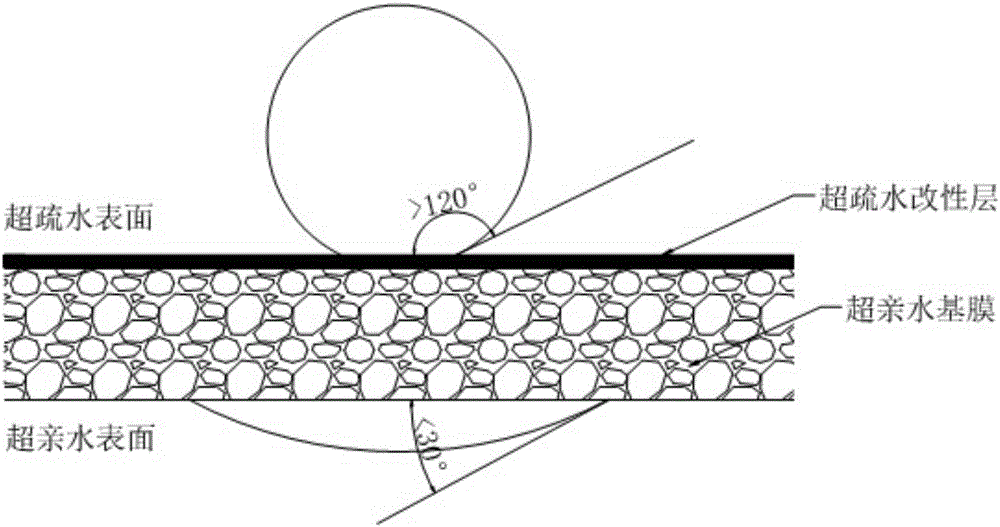

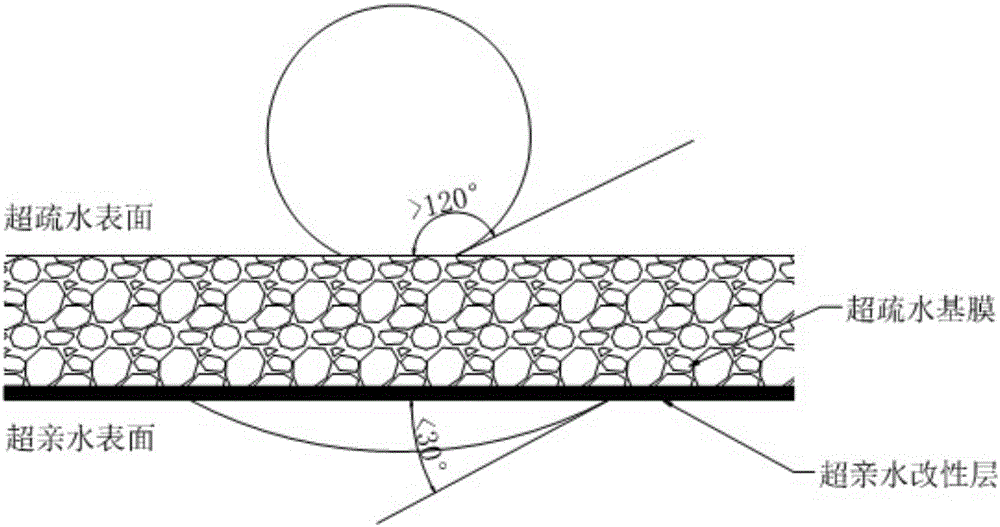

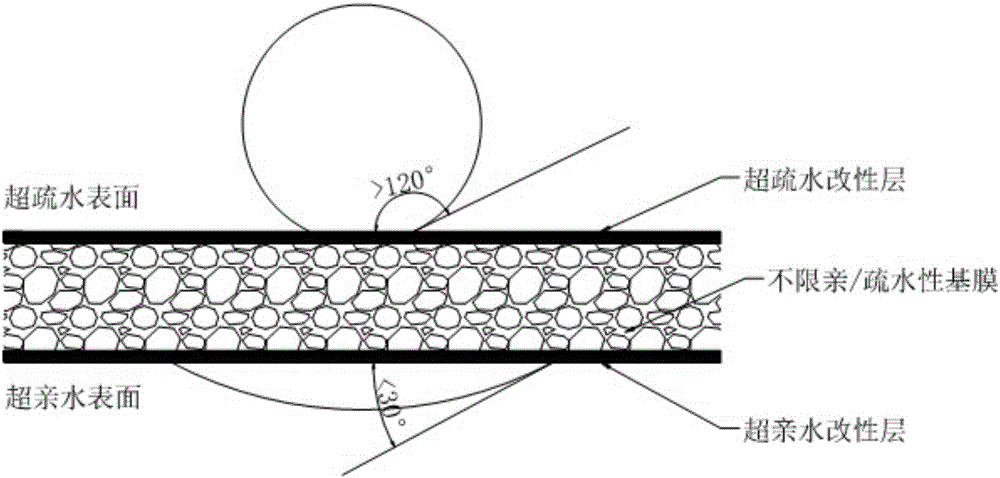

Asymmetric ultra-hydrophilic/hydrophobic dual-property polymer membrane and preparation method thereof

ActiveCN106268355AImprove anti-pollution performanceReduce adhesionMembranesSemi-permeable membranesPore diameterHollow fiber membrane

The invention relates to a membrane separation technique and aims at providing an asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane and a preparation method thereof. According to the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane, a base membrane is a flat sheet membrane or a hollow fiber membrane, one side of the base membrane is a hydrophilic side, the water contact angle of the hydrophilic side is not greater than 30 degrees, the other side of the base membrane is a hydrophobic side, and the water contact angle of the hydrophobic side is not smaller than 120 degrees. The prepared asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane is of the type of the flat sheet membrane or the hollow fiber membrane and belongs to an ultra-micro filter membrane category, and the pore diameter range of the membrane is 0.01-2.0 microns. Therefore, the hydrophilic and hydrophobic properties on double sides are different, one side is hydrophilic, the other side is hydrophobic, and the asymmetric ultra-hydrophilic / hydrophobic dual-property polymer membrane shows asymmetric hydrophilic / hydrophobic properties and is a novel water treatment membrane.

Owner:ZHEJIANG UNIV

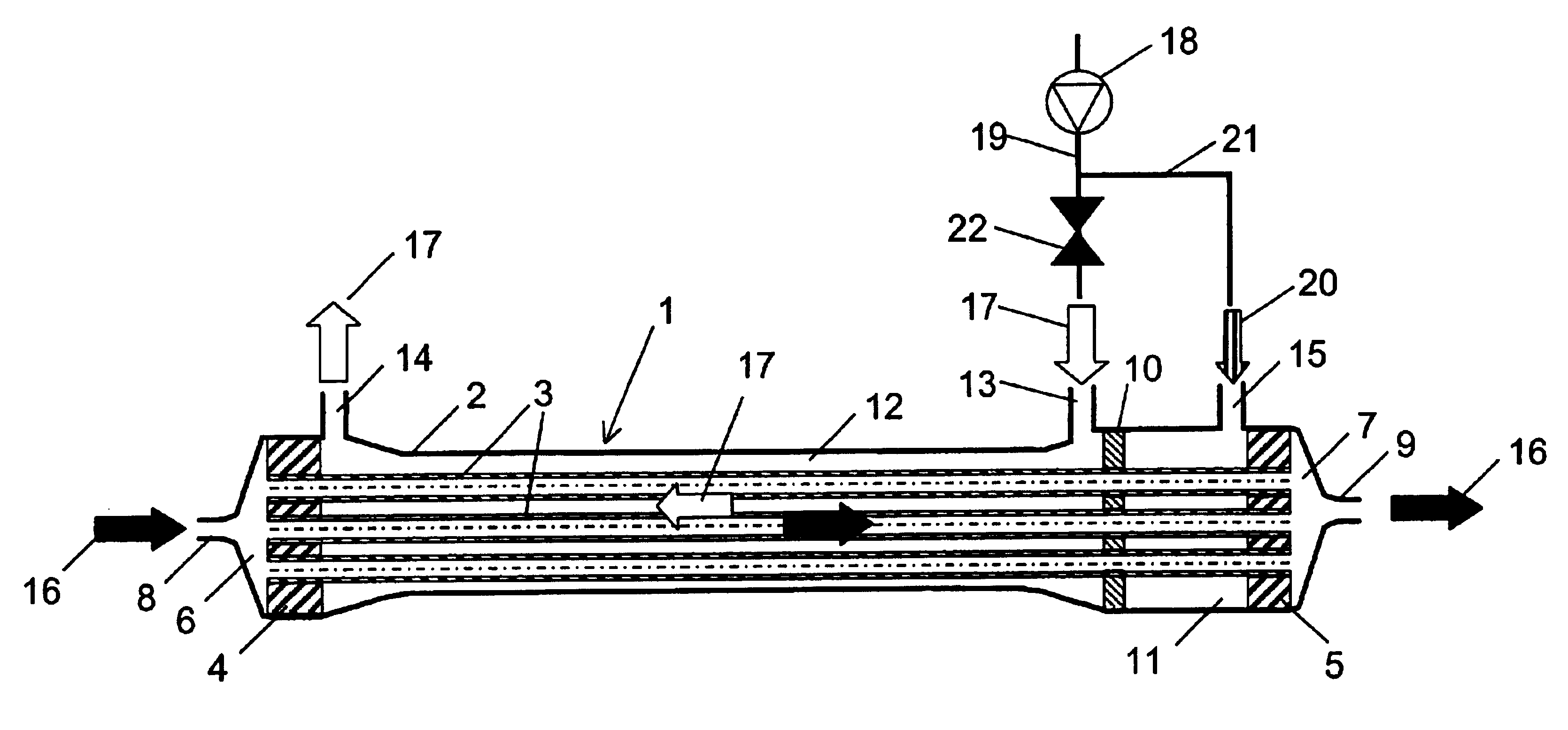

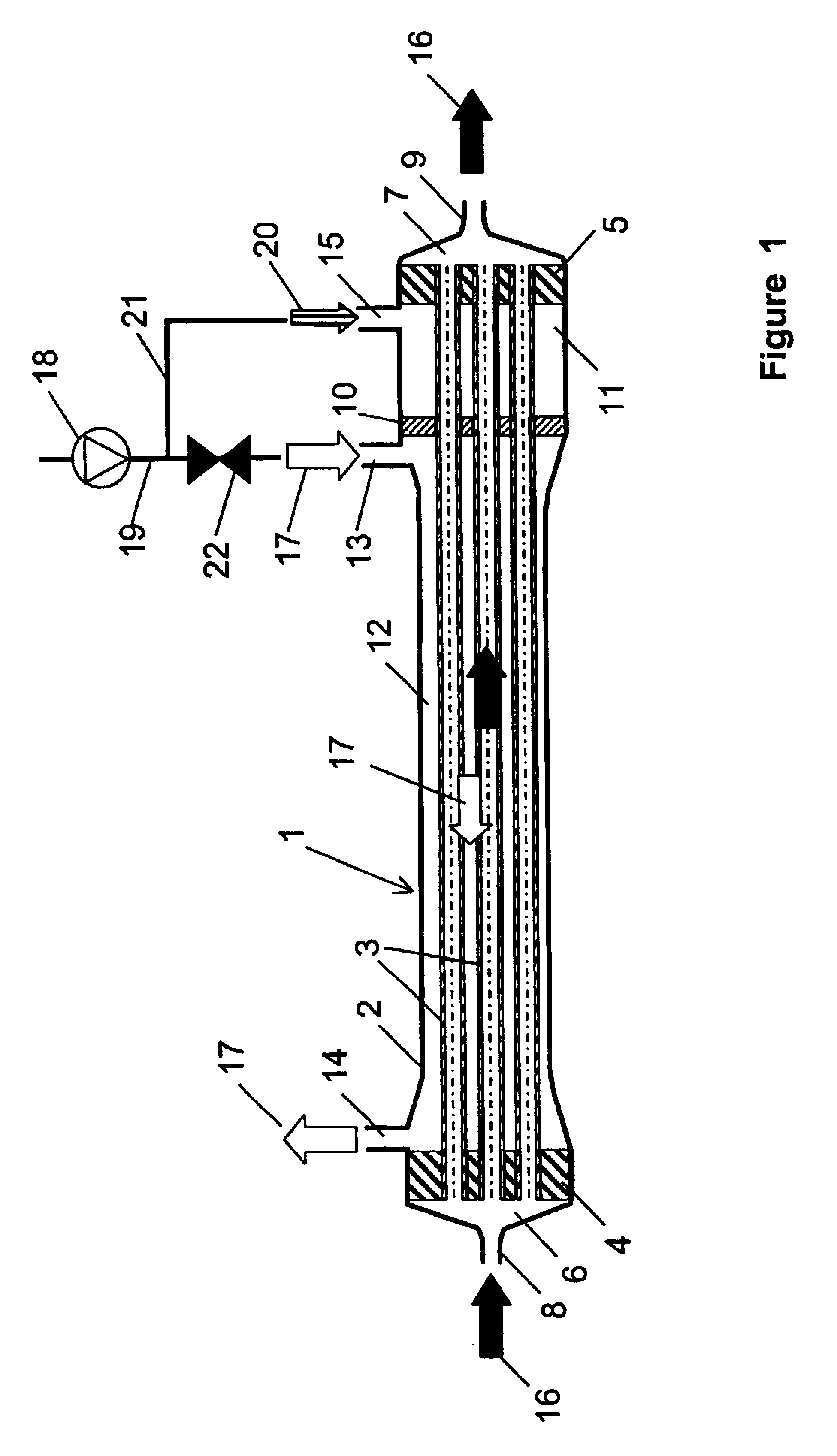

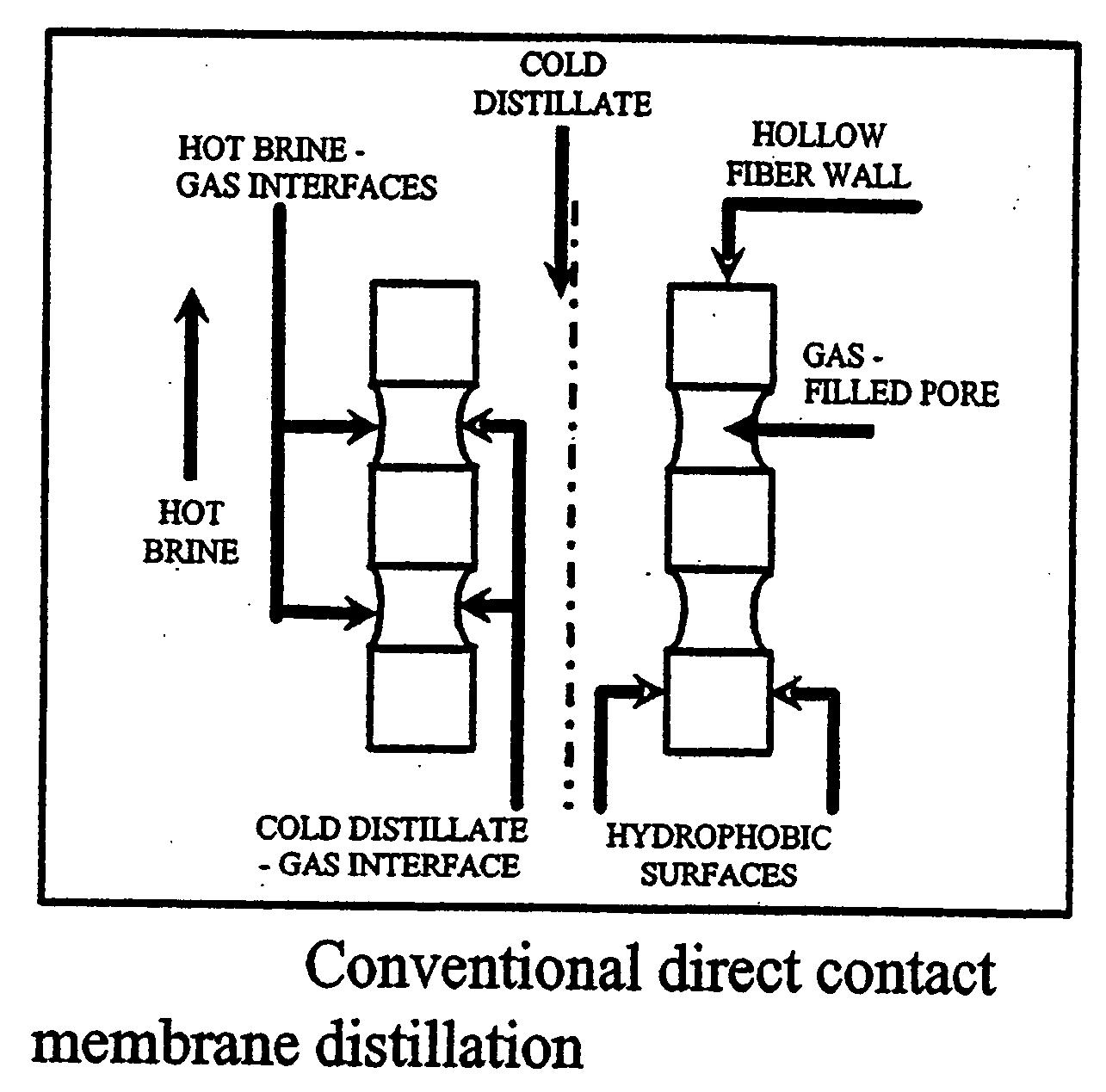

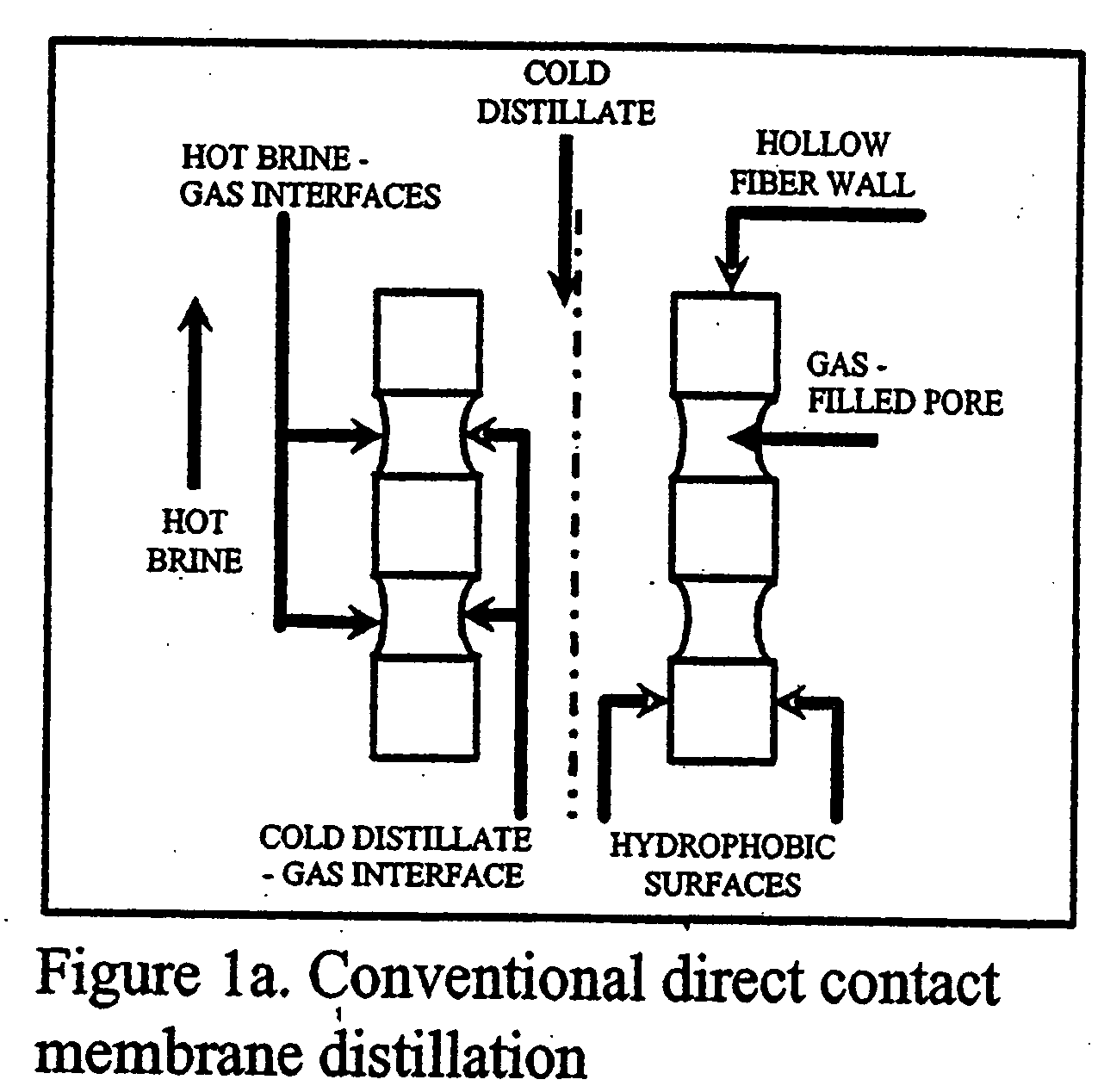

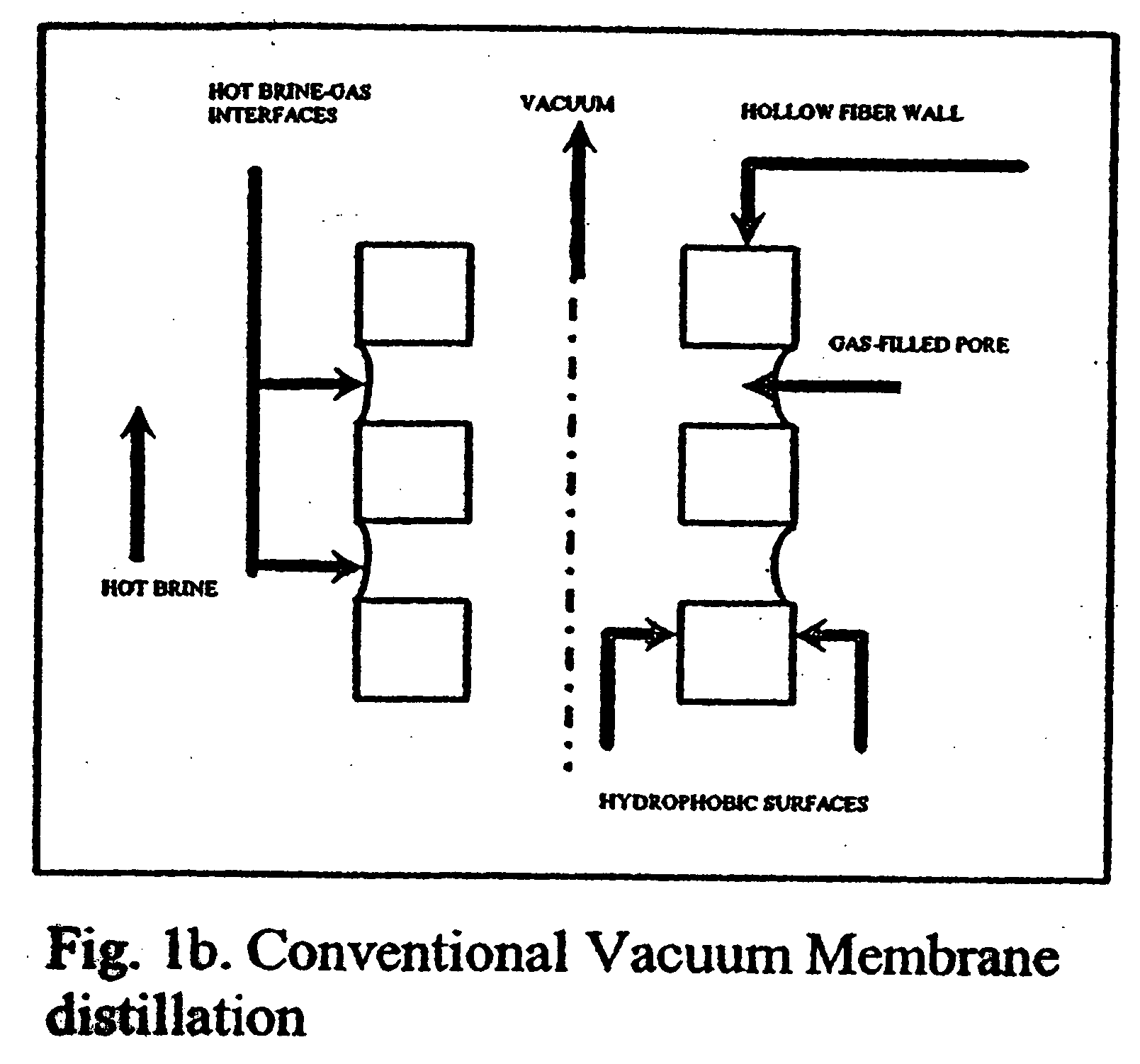

Devices and methods using direct contact membrane distillation and vacuum membrane distillation

ActiveUS20060076294A1Eliminate pore wettingReduce lossesGeneral water supply conservationSolid sorbent liquid separationFiberHollow fibre membrane

DCMD and VMD systems and methods for use in desalination applications are provided. The DCMD and VMD systems employ coated porous hydrophobic hollow fiber membranes. The coatings advantageously function to essentially eliminate pore wetting of the membrane, while permitting substantially unimpeded water vapor permeance through the fiber walls. The DCMD and VMD membranes are characterized by larger fiber bore diameters and wall thicknesses. The membranes substantially reduce the loss of brine sensible heat, e.g., heat loss via conductive heat flux through the membrane wall and the vapor space and, in exemplary embodiments, the brine-side heat transfer coefficient is dramatically enhanced by horizontal / vertical cross flow of brine over the outside surface of the coated fibers. Superior water vapor fluxes are achieved with the systems and methods.

Owner:NEW JERSEY INSTITUTE OF TECHNOLOGY

Preparation method for homogeneously-enhanced polyvinylidene fluoride hollow fiber membrane

ActiveCN102600733AImprove hydrophilicityImprove interfacial bond strengthMembranesSemi-permeable membranesPolymer scienceSpinning

Owner:TIANJIN POLYTECHNIC UNIV

Braid-reinforced hollow fiber membrane

InactiveUS7267872B2Improve permeabilityImprove reliabilityEnvelopes/bags making machineryMonocomponent synthetic polymer artificial filamentPolymer sciencePolymer resin

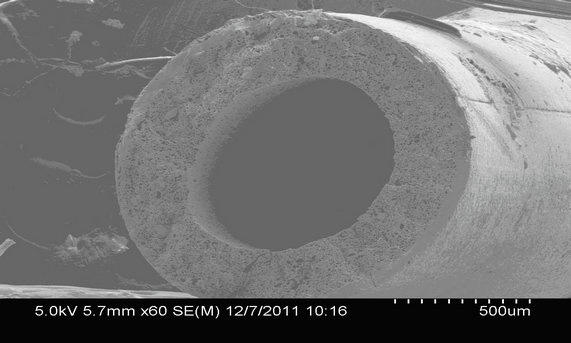

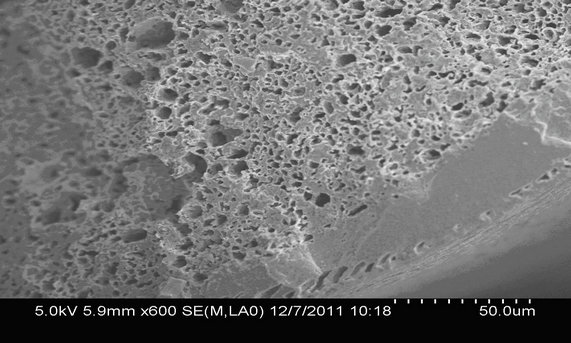

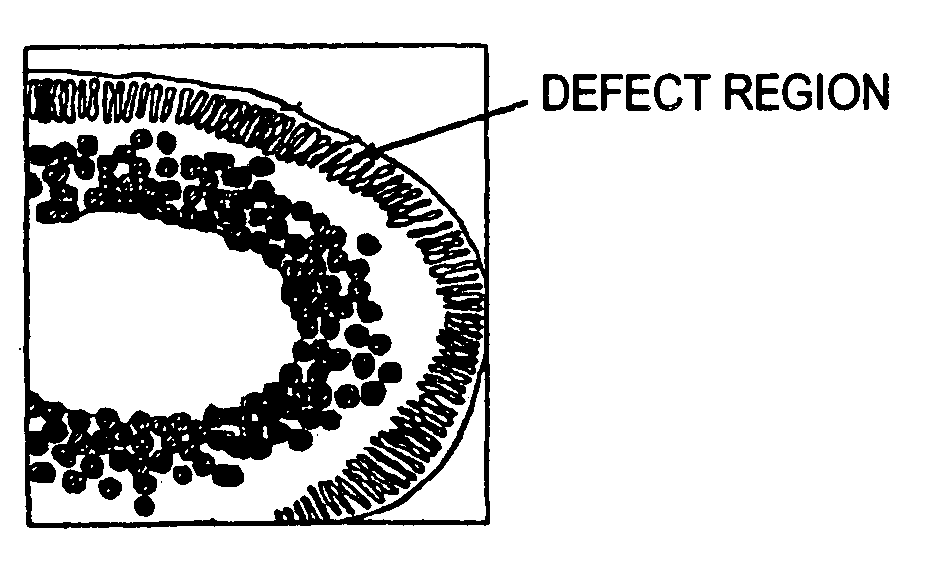

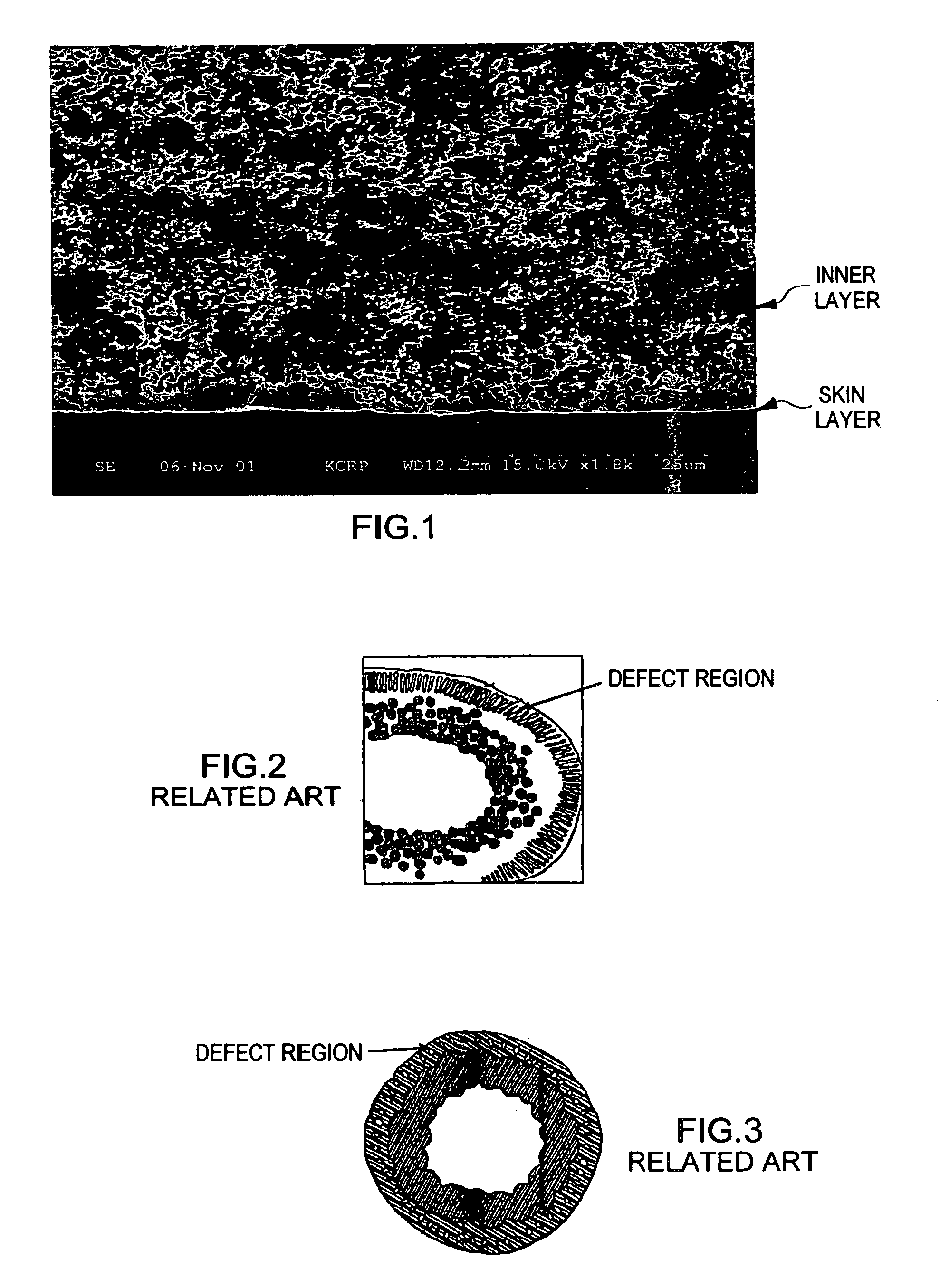

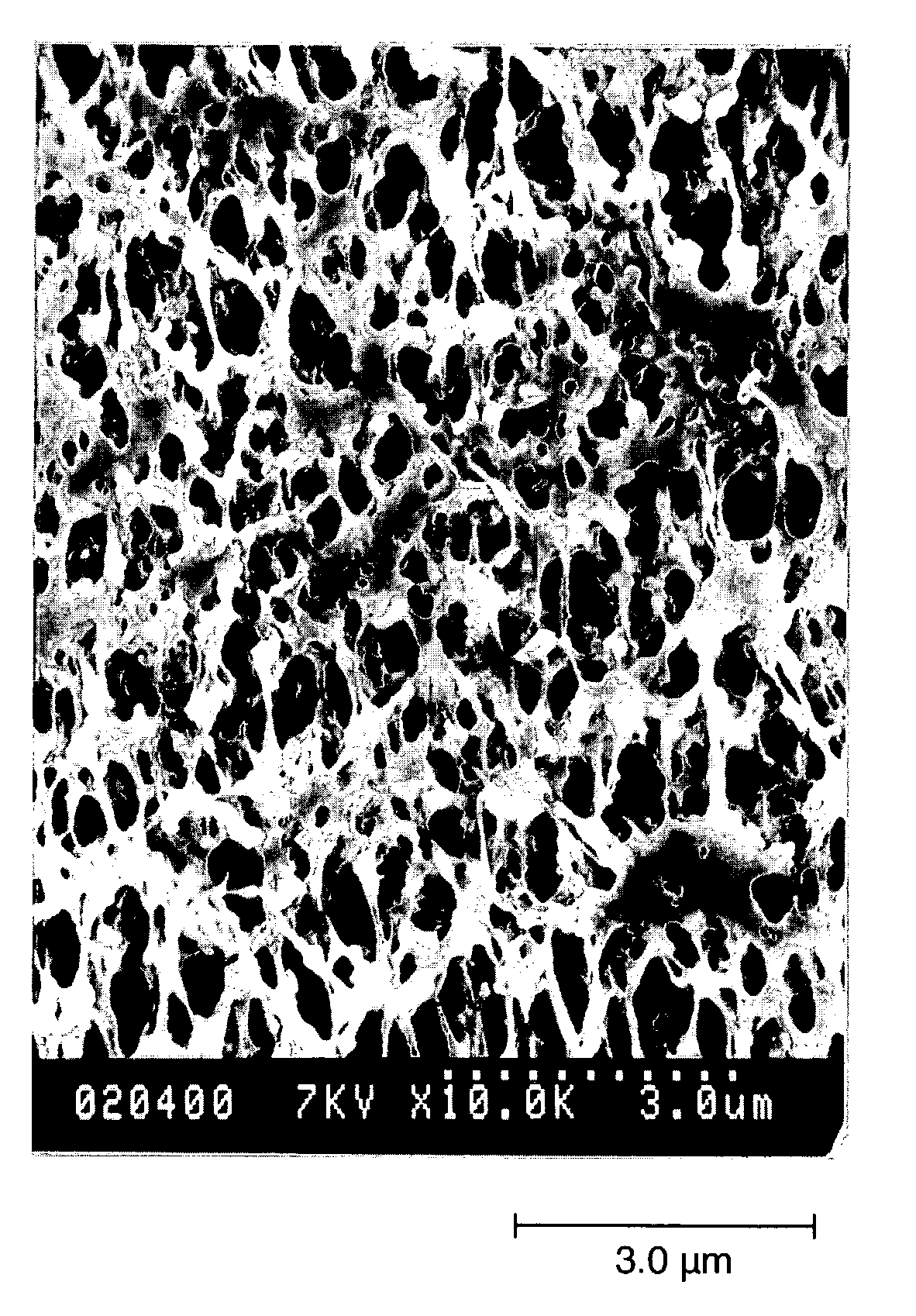

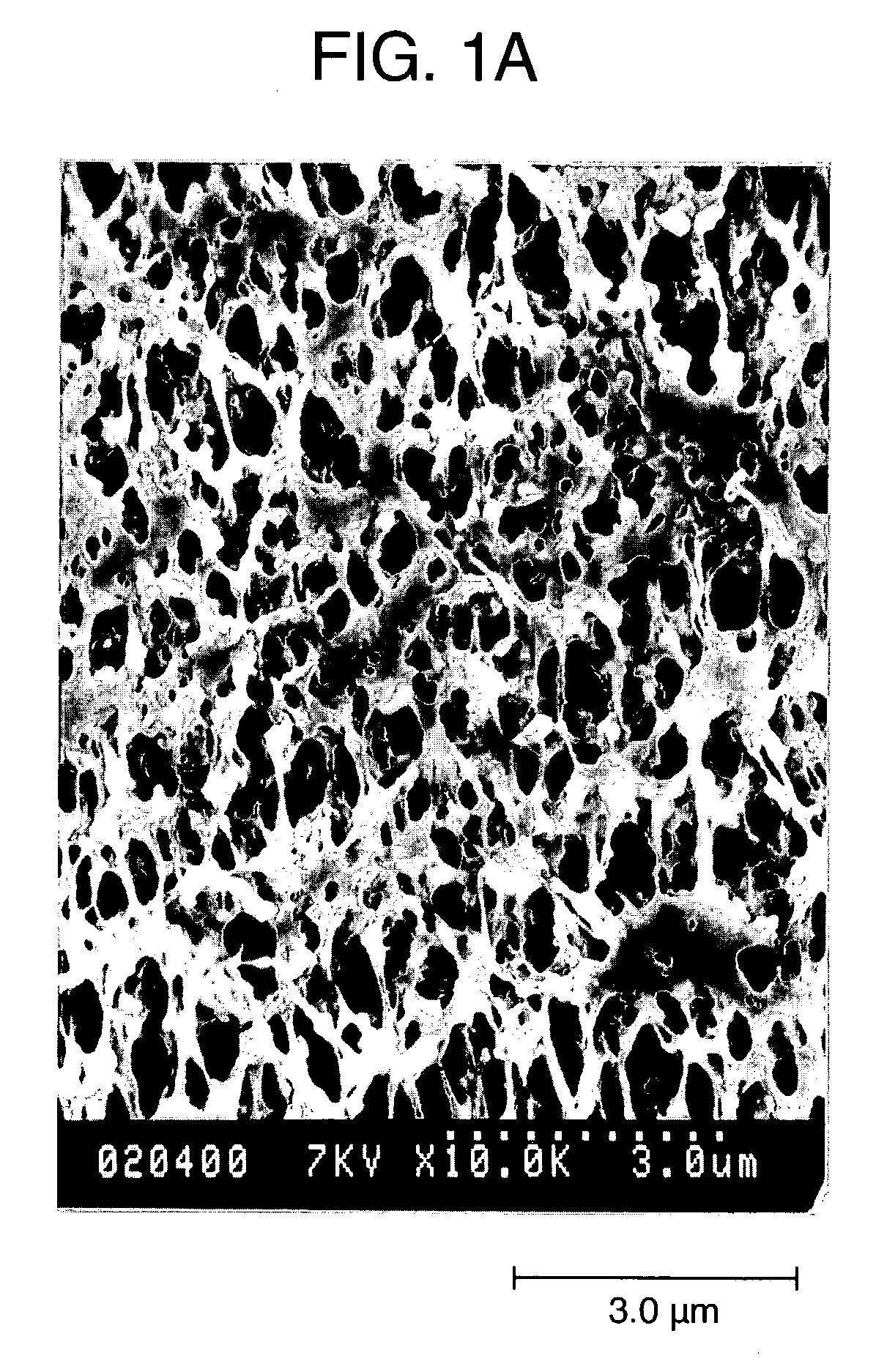

A braid-reinforced hollow fiber membrane which includes a reinforcing material of a tubular braid and a polymer resinous thin film coated on the surface of the reinforcing material. The polymer resinous thin film has a skin layer with micro pores having a diameter in the range from 0.01 to 1 μm and an inner layer of a sponge structure with micro pores having a diameter less than 10 μm.The hollow fiber membrane exhibits excellent mechanical strength, reliable filtration and simultaneously, good water permeability.

Owner:KOLON IND INC

Method for producing hollow yarn film

InactiveUS20030107150A1Effect of shaking is smallHigh in resistance against marringWrappers shrinkageFilament/thread formingYarnFiltration

In a method for producing hollow fiber membranes which comprises melt kneading a mixture comprising polyvinylidene fluoride and an organic liquid or a mixture comprising polyvinylidene fluoride, an organic liquid and an inorganic fine powder, extruding the kneaded mixture to form hollow fibers, and extracting the organic liquid or the organic liquid and the inorganic fine powder from the hollow fibers, which includes the steps of drawing the hollow fibers before or after termination of the extraction and then shrinking the fibers. According to this method, it is possible to stably produce hollow fiber membranes having dense pores and having a high water permeation performance, excellent endurance and stain resistance, and which are suitable for filtration uses such as removal of turbidity of water.

Owner:ASAHI KASEI KK

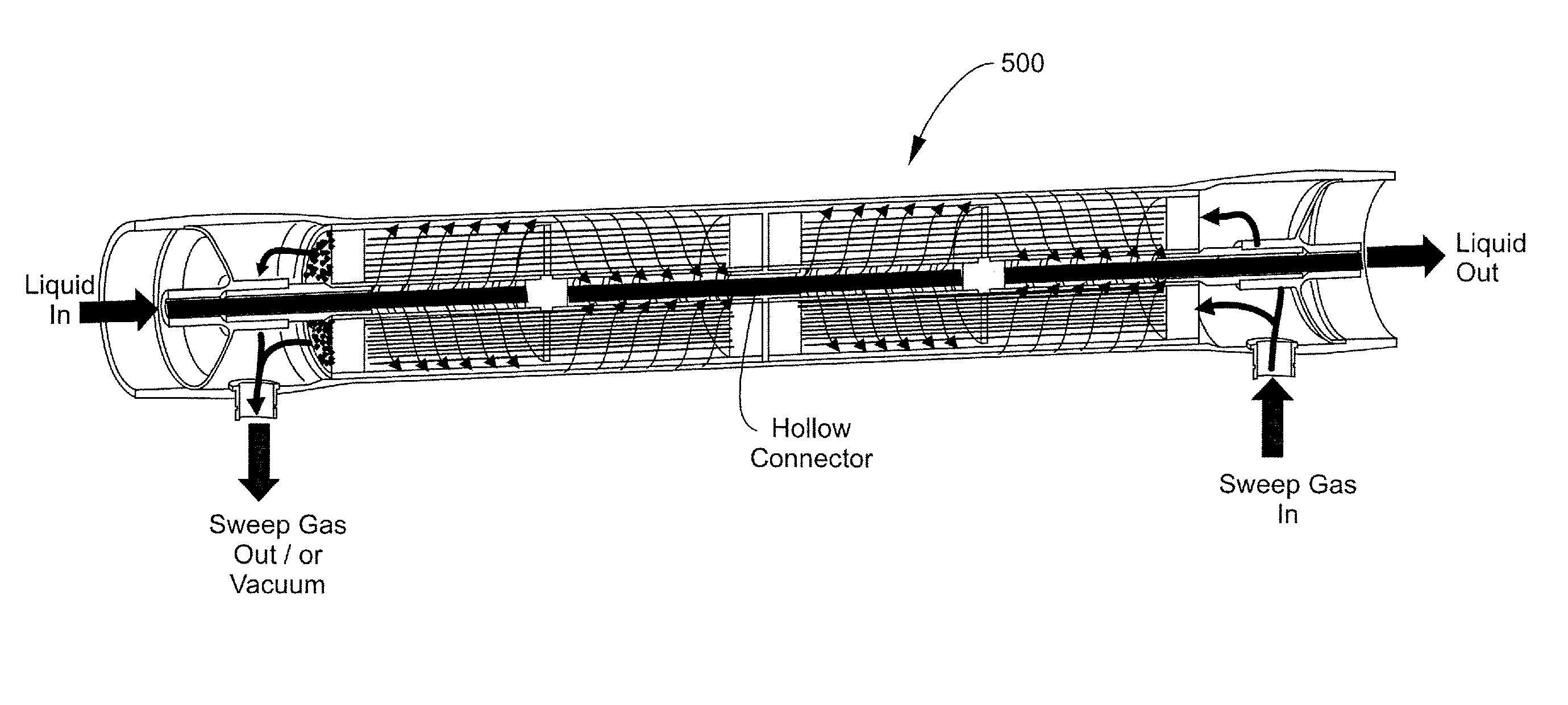

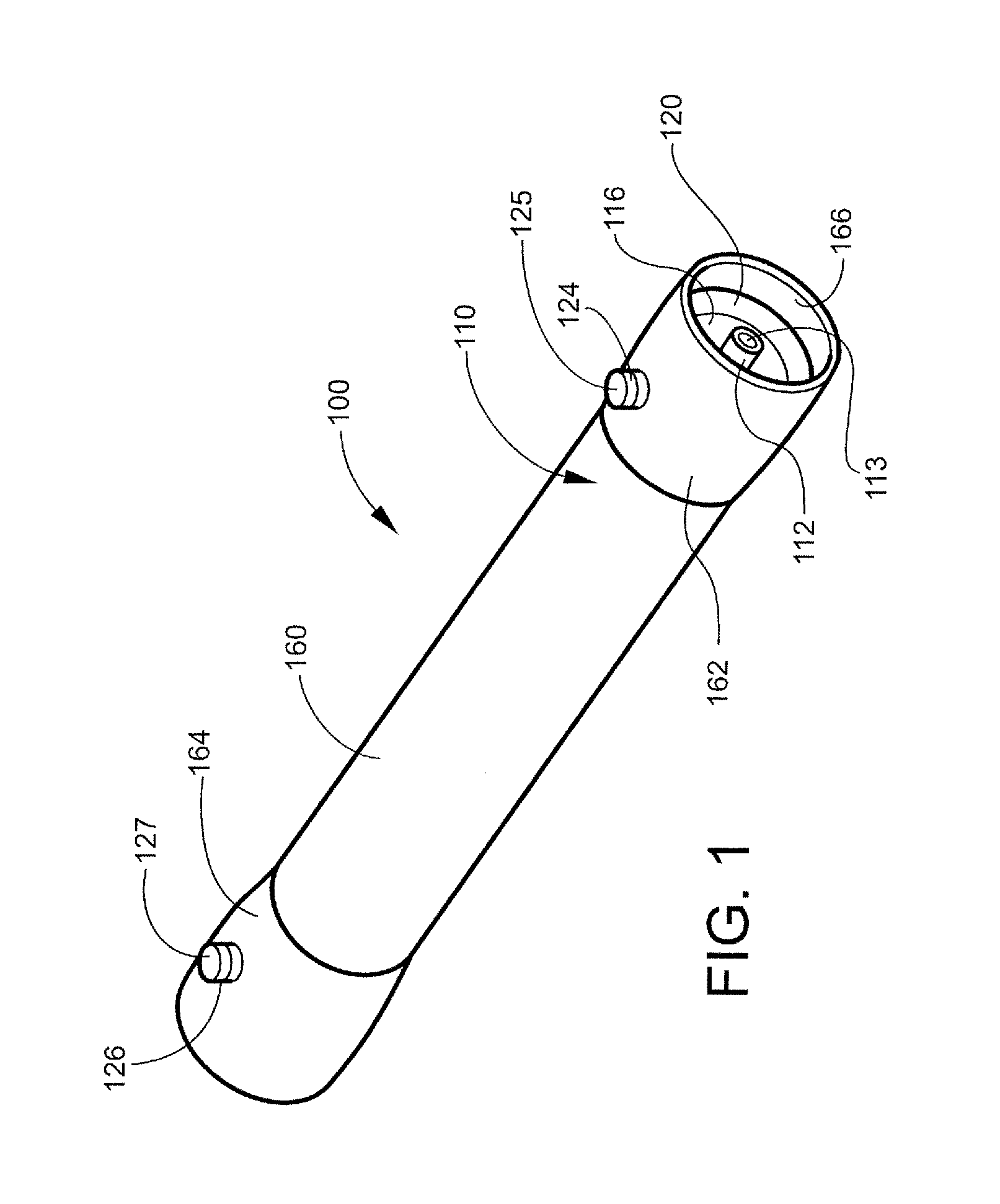

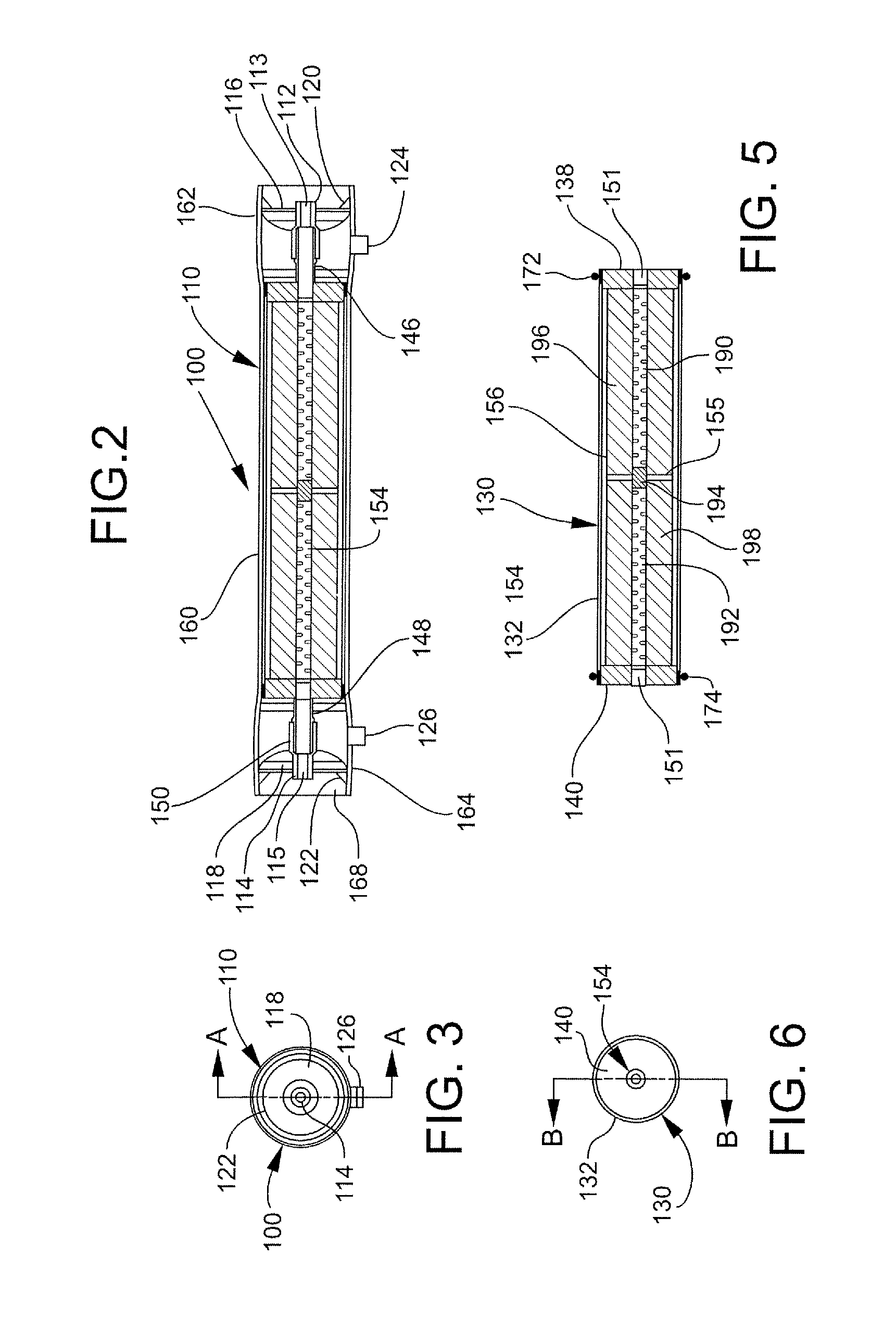

High pressure liquid degassing membrane contactors and methods of manufacturing and use

ActiveUS20110036240A1Cost-effectiveImprove water qualityMembranesIsotope separationPolypropyleneCorrosion resistant

In accordance with at least selected embodiments of the present invention, an improved liquid degassing membrane contactor or module includes a high pressure housing and at least one degassing cartridge therein. It may be preferred that the high pressure housing is a standard, ASME certified, reverse osmosis (RO) or water purification pressure housing or vessel (made of, for example, polypropylene, polycarbonate, stainless steel, corrosion resistant filament wound fiberglass reinforced epoxy tubing, with pressure ratings of, for example, 150, 250, 300, 400, or 600 psi, and with, for example 4 or 6 ports, and an end cap at each end) and that the degassing cartridge is a self-contained, hollow-fiber membrane cartridge adapted to fit in the RO high pressure housing.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation

The invention provides a method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation, which comprises the following steps of: preparing four lactobacillus direct-throwing fermentation agents such as lactobacillus rhamnosus, pediococcus acidilactici, streptococcus thermophilus and lactobacillus brevis; then soaking brown rice for 10 hours at 30 DEG C, and germinating for 12 hours at 2 DEG C to prepare germinated brown rice; adding 3 times water into the germinated brown rice, grinding milk by adopting colloid, gelatinizing and saccharifying the milk, adding 150 grams of direct-throwing fermentation agents into each ton of liquid rice milk, and performing standing fermentation for 6 hours at the temperature of between 38 and 40 DEG C; and centrifuging the liquid rice milk at 5,000 revolutions per minute, removing residue, adding xylitol according to the clear liquid volume for blending, filtering the liquid by using a hollow fiber membrane, performing ultrahigh-temperature instantaneous sterilization for 2 seconds at 143 DEG C, and filling the liquid with pillow-type package or tetra package to obtain a finished product.

Owner:黑龙江大荒春酒业有限公司

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

InactiveCN102266728AHigh porosityImprove throughputSemi-permeable membranesBreaking strengthNon solvent

The invention relates to a polyvinylidene fluoride hollow fiber membrane and a preparation method thereof. The hollow fiber membrane uses polyvinylidene fluoride as the membrane material, and adds polymer pore-forming agents, surfactants, inorganic additives and solvents to make the casting liquid, and uses dry-wet method, that is, non-solvent-induced phase separation method to spin Process to prepare polyvinylidene fluoride hollow fiber membranes. The prepared polyvinylidene fluoride hollow fiber membrane has good flexibility and high strength at the same time, the tensile breaking strength is 3.5-6MPa; it has good hydrophilicity, and the pure water at a pressure of 0.1MPa and a temperature of 25°C The flux is 300~3200L / m2·H.

Owner:HUIZHOU QIXIN MEMBRANE PURIFICATION & ENVIRONMENTPROTECTION

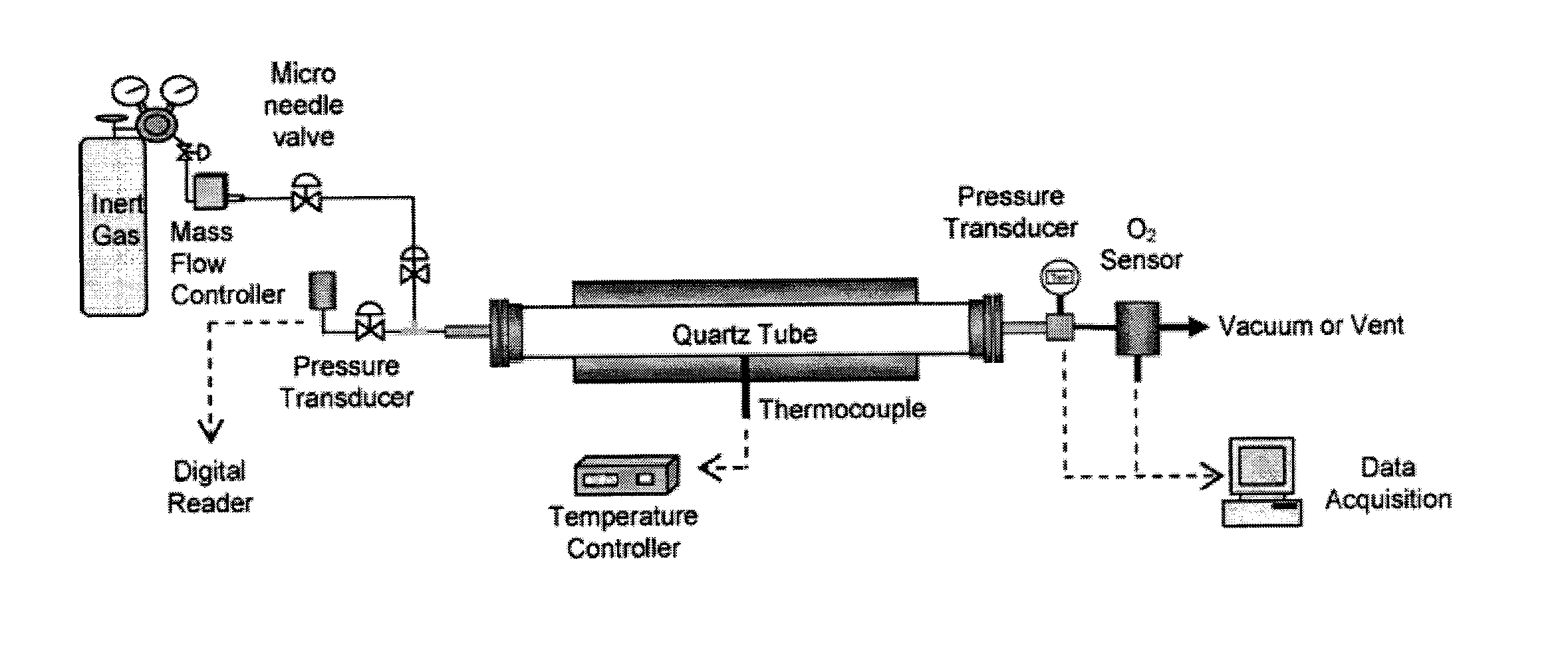

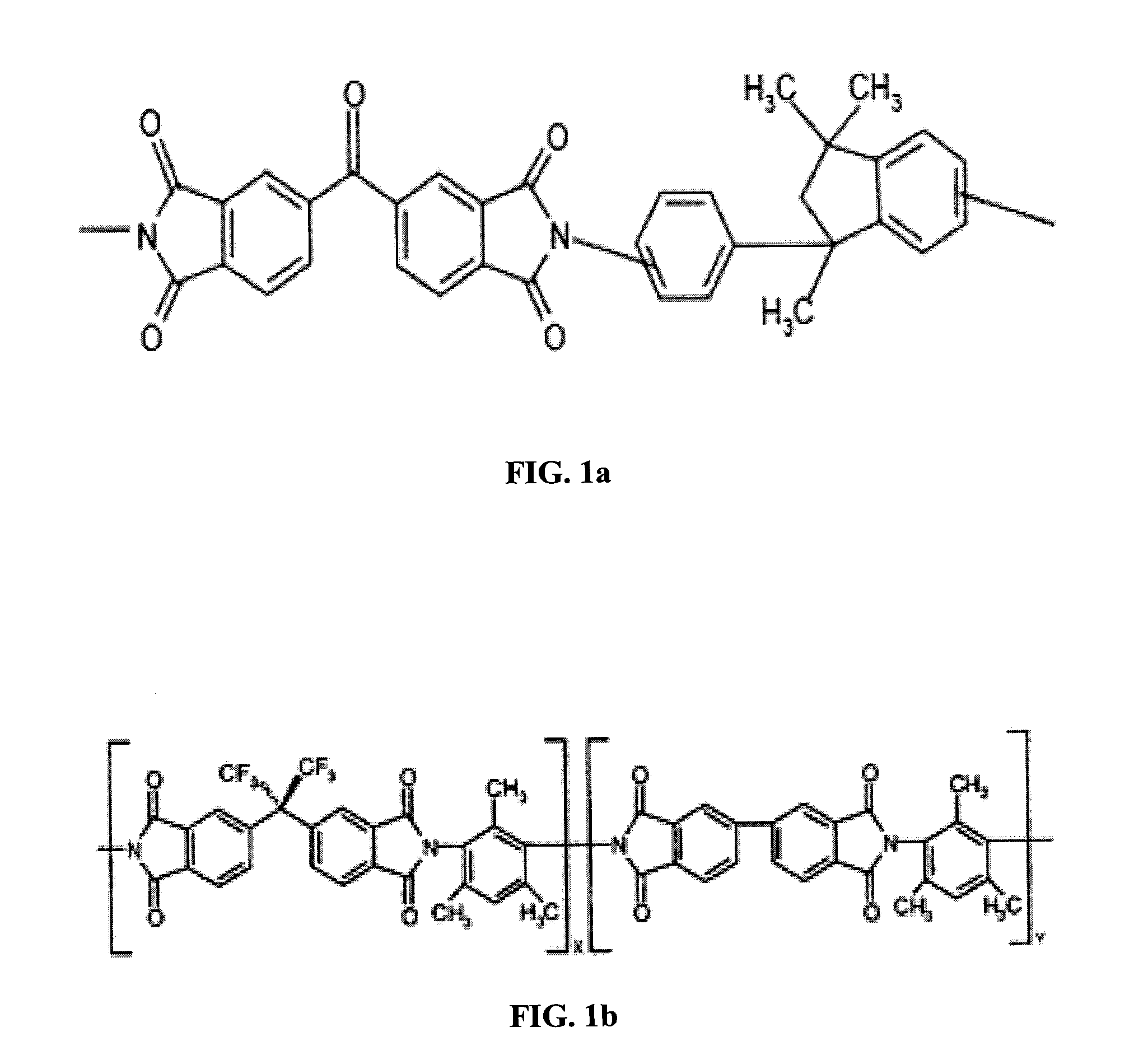

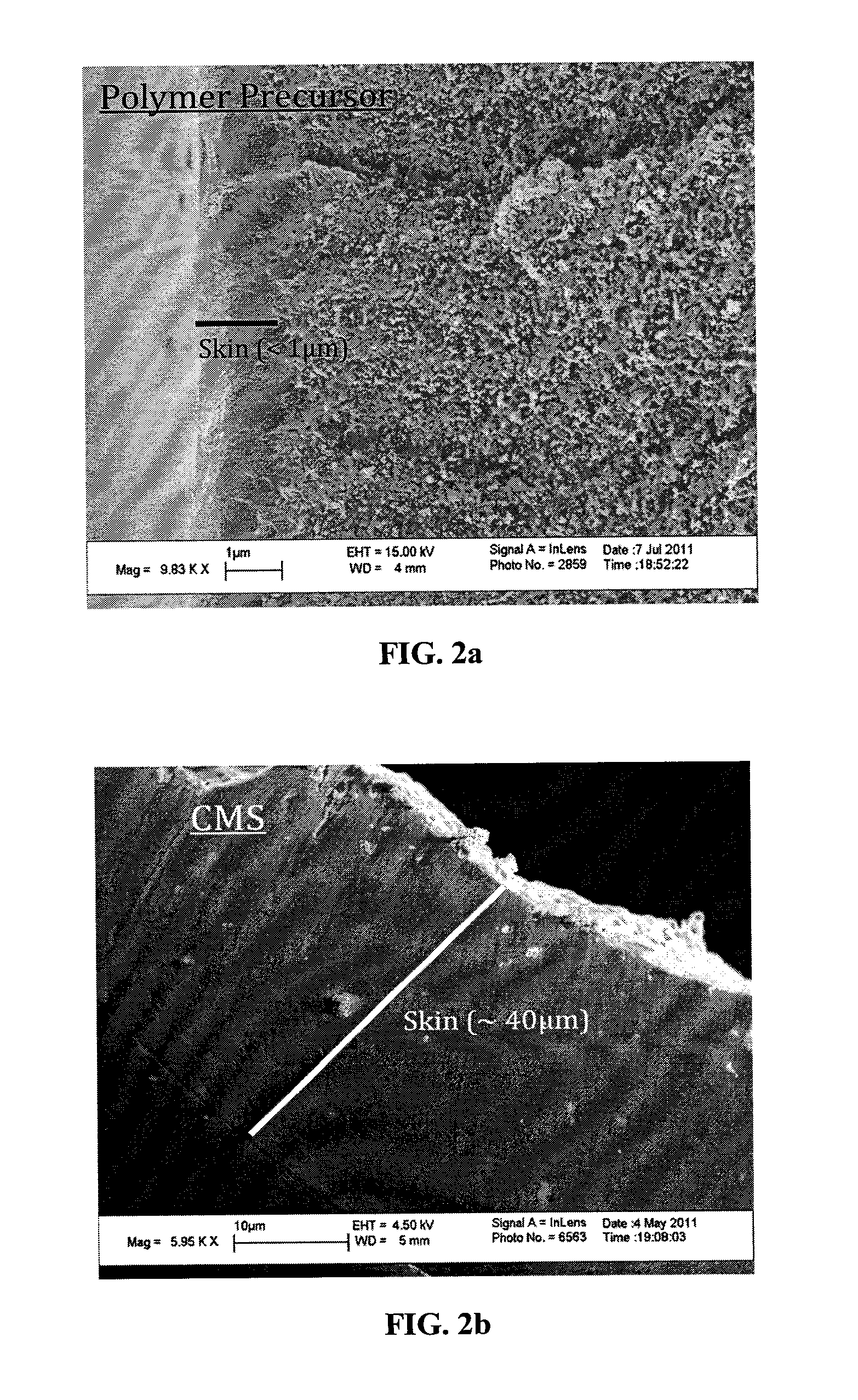

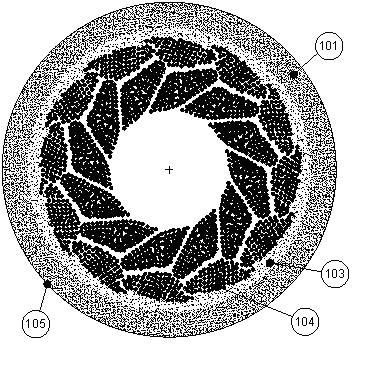

Stabilization of Porous Morphologies for High Performance Carbon Molecular Sieve Hollow Fiber Membranes

ActiveUS20130152793A1Improve separation efficiencyReducing and eliminating conventional dropSemi-permeable membranesMembranesImideMolecular sieve

Carbon molecular sieves (CMS) membranes having improved thermal and / or mechanical properties are disclosed herein. In one embodiment, a carbon molecular sieve membrane for separating a first and one or more second gases from a feed mixture of the first gas and one or more second gases comprises a hollow filamentary carbon core and a thermally stabilized polymer precursor disposed on at least an outer portion of the core. In some embodiments, the thermally stabilized polymer precursor is created by the process of placing in a reaction vessel the carbon molecular sieve membrane comprising an unmodified aromatic imide polymer, filling the reaction vessel with a modifying agent, and changing the temperature of the reaction vessel at a temperature ramp up rate and ramp down rate for a period of time so that the modifying agent alters the unmodified aromatic imide polymer to form a thermally stabilized polymer precursor.

Owner:AIR LIQUIDE ADVANCED TECH U S +1

Lining-reinforced hollow fiber membrane tube as well as preparation device and preparation method thereof

ActiveCN102160967AIncrease asymmetryLow elongationSemi-permeable membranesHollow fibrePolymer science

The invention relates to a lining-reinforced hollow fiber membrane tube as well as a preparation device and preparation method thereof, belonging to the field of preparation of polymer hollow fiber microporous membranes. In the membrane tube, a film forming chimney is designed reasonably, a coating layer on a braided tube led from a coating machine is subjected to controllable steam diffusion-induced phase inversion firstly, and then enters a coagulating bath, so that an open-pore surface skin layer with high porosity is formed on a film separation layer, and the radial direction of the membrane layer is in an integral asymmetric and interpenetrating cell-shaped structure; a composite material is selected to prepare a transition layer, so that the transition layer has excellent adhesive force and hardness, excellent compatibility with a surface separation layer and tiny cubical contraction in a phase conversion process at the same time; optimized braided tube size and braiding densityare selected to ensure that the braided tube has lower flexibility; and a method capable of maintaining reasonable roundness and the like in the production process ensures that the lining polyvinylidene fluoride (PVDF) hollow ultrafiltration membrane tube has the advantages of integral asymmetric structure with high integrity, high-porosity surface separation layer, higher back pressure enduring capability and the like.

Owner:南京久盈膜科技有限公司

Porous ceramic membrane support with flat structure and preparation method thereof

ActiveCN102688700AReduce frictionAvoid accumulationSemi-permeable membranesPolyvinyl alcoholAdhesive

The invention relates to a porous ceramic membrane support with a flat structure and a preparation method thereof, and belongs to the technical field of ceramic membrane supports. The ceramic membrane support is flat and consists of two flat membrane supports; a certain space is reserved between the two flat membrane supports; at least one supporting column is distributed in the space; and at least one water outlet passage is formed in each flat membrane support, so that flowing resistance of filtrate in the support with the flat structure is reduced. The ceramic aggregate of the support is one or more of alumina, zirconia, silicon dioxide, silicon carbide, titanium oxide, mullite and cordierite; the pore-forming agent is starch, graphite, phenolic resin spheres and the like; and the adhesive is methylcellulose, polyvinyl alcohol and the like. The porosity of the prepared porous ceramic membrane support with the flat structure can reach 30 to 50 percent, the aperture is 20 to 200 nanometers, and the compressive strength can reach 20 to 40MPa; and the support can be used for substituting an organic hollow fiber membrane bioreactor, and has great potential application in the fields of sewage treatment, fine chemical industry and the like.

Owner:TSINGHUA UNIV +1

High temperature gas separation membrane suitable for OBIGGS applications

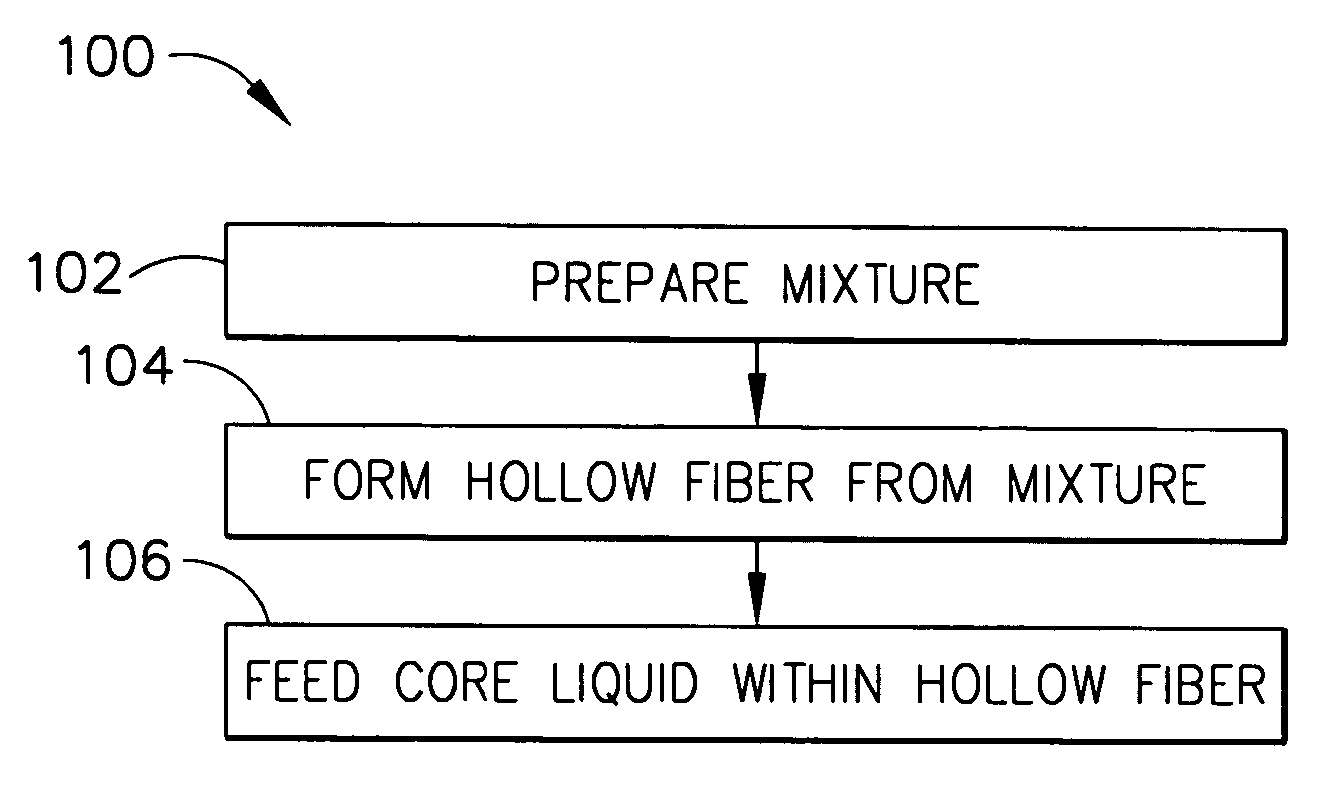

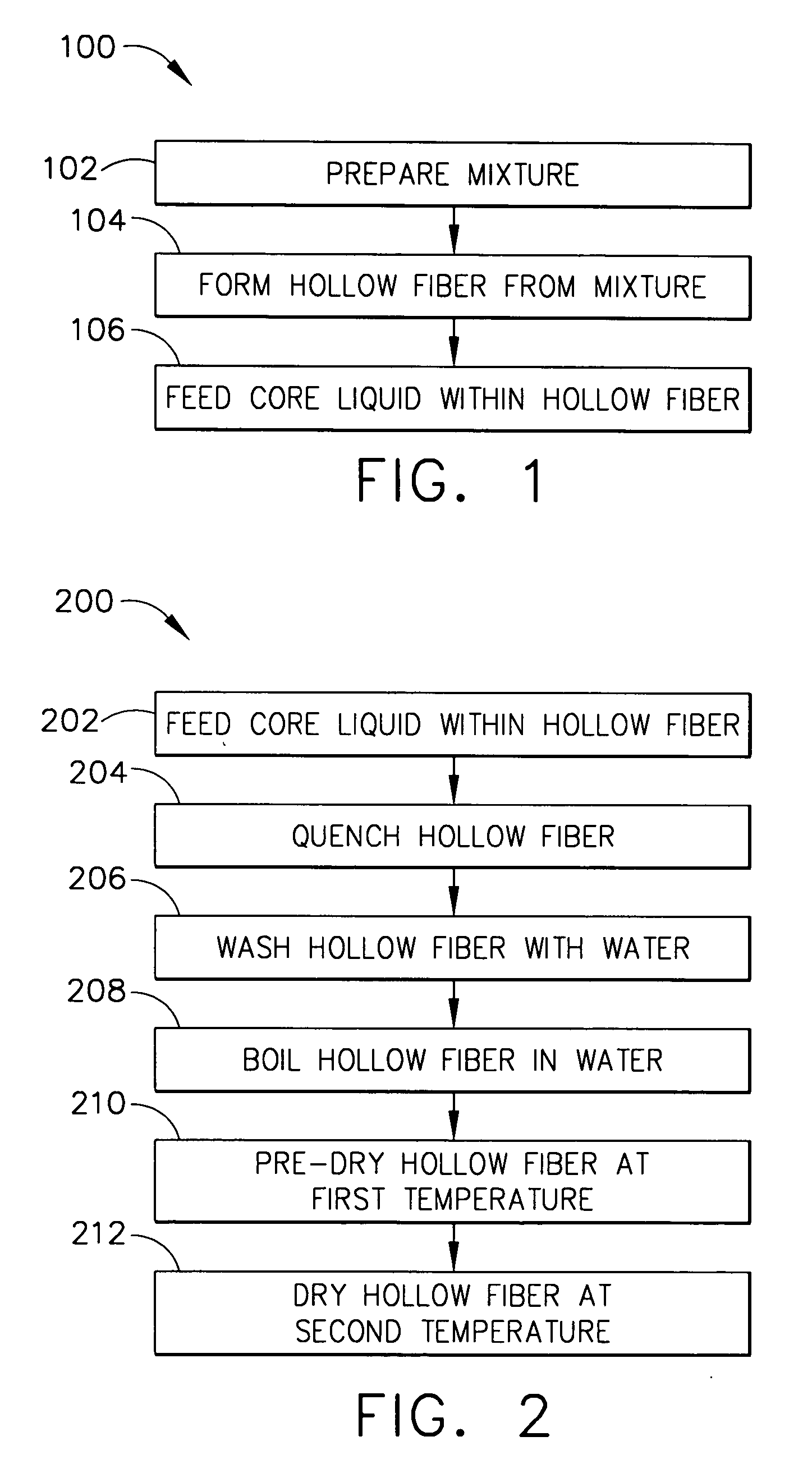

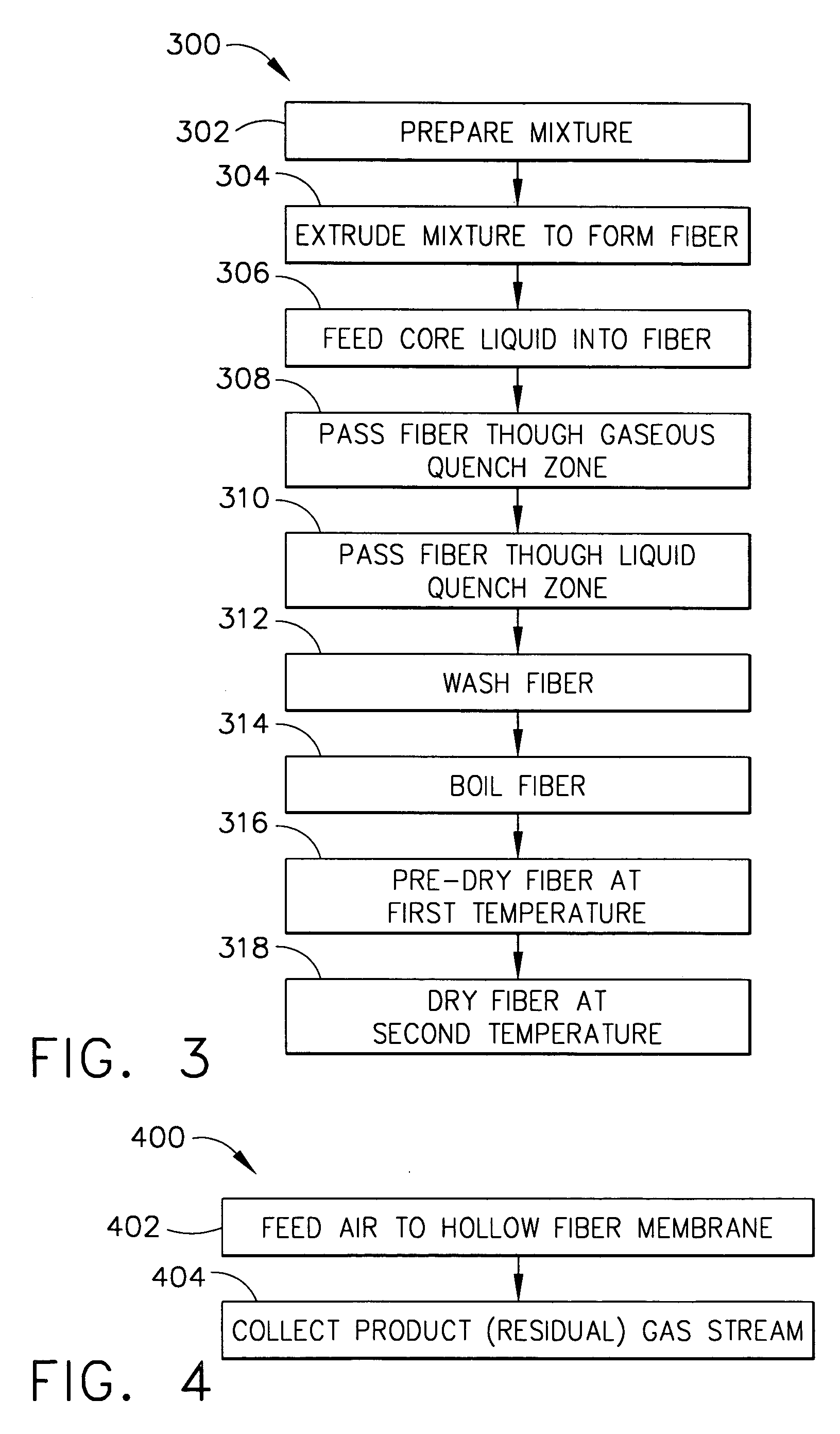

Gas separation membranes and methods for preparing such membranes. The gas separation membranes of the instant invention can separate oxygen and nitrogen in air to provide nitrogen enriched air (NEA), and are stable during exposure to temperatures of at least about 160° C. The gas separation membranes of the instant invention may be formed from polyetherimide by extruding a hollow fiber using a core liquid, quenching the extruded fiber in dry air to promote loss of solvent and non-solvent, and drying the fiber. Methods for separating bleed air fed directly from an aircraft precooler to a high temperature gas separation hollow fiber membrane, to provide NEA, are also disclosed.

Owner:HONEYWELL INT INC

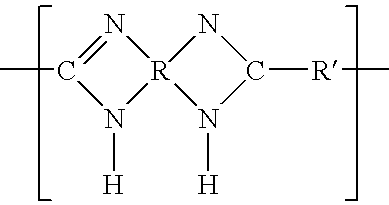

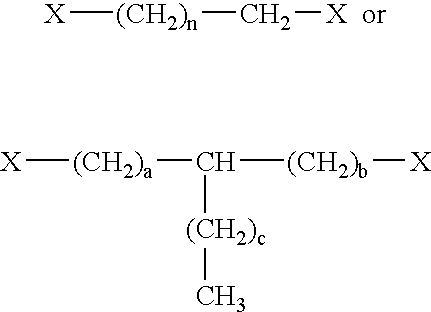

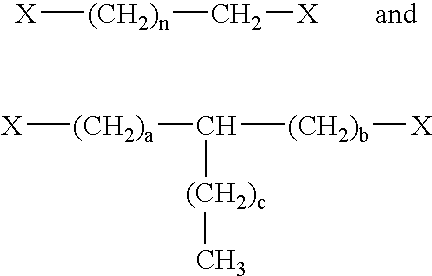

Solvent-resistant microporous polybenzimidazole membranes and modules

Solvent-resistant polybenzimidazole membranes, methods of making them and crosslinking them and composite membranes and hollow fiber membrane modules from them are disclosed.

Owner:BEND RES

Polyvinylidene fluoride hollow fiber membrane and preparation method thereof

InactiveCN101954248AImprove anti-pollution performanceGuaranteed high temperature performanceSemi-permeable membranesFibre treatmentChemical industryDouble diffusion

The invention relates to a polyvinylidene fluoride hollow fiber membrane and a preparation method thereof, belonging to the field of chemical industry. The pore size of the membrane is 0.02-0.5 micrometers, the thickness is 0.2-0.5 millimeters, and the external diameter of membrane wires is 1-2 millimeters. A membrane making liquid comprises the following components in percentage by weight: 15-30% of polyvinylidene fluoride resin, 1-10% of hydrophilic polymer, 0.5-5% of functional polymer or polymer monomer, 0.1-5% of surfactant, 0.1-15% of inorganic or organic polymer pore-forming agent, 0.1-5% of nano additive and 40-71% of solvent. The preparation method of the polyvinylidene fluoride hollow fiber membrane comprises the following step of: effectively controlling the interfacial tension between the membrane making liquid and a solidifying liquid and the double diffusion permeation speed of the solidifying agent and the solution on the interface by properly adjusting the ratio of all components and using the surface moistening and dispersing actions of the surfactant, the dispersing and thickening actions of the pore-forming agent and the hydrophilic action of the hydrophilic substance. Thus, the hydrophilic polyvinylidene fluoride hollow fiber membrane with high permeability is prepared.

Owner:QINGDAO SEACON WATER SERVICE TECH

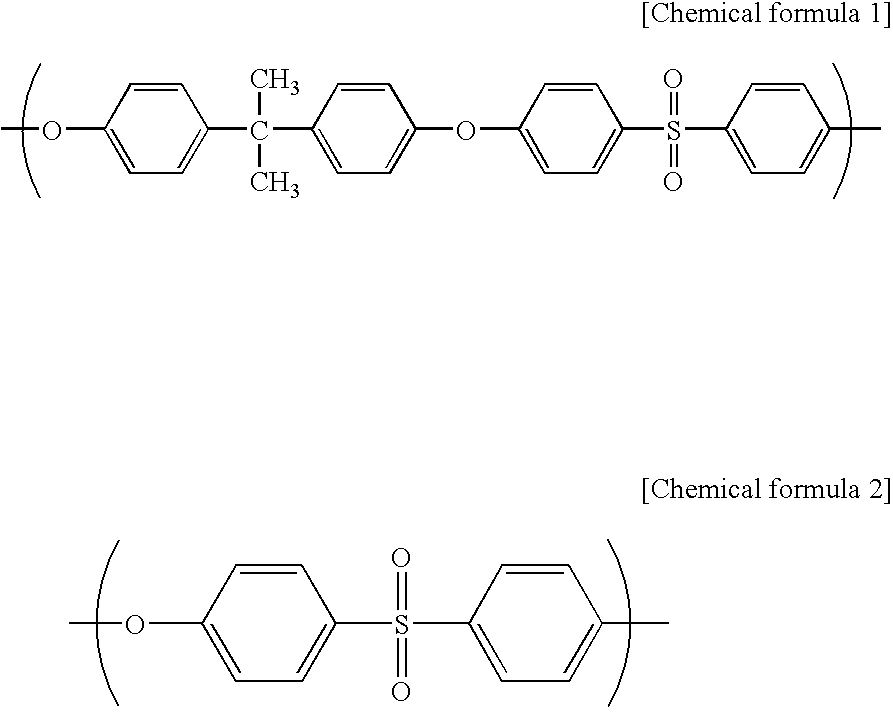

Polysulfone Type Selectively Permeable Hollow Fiber Membrane Module and Process for Manufacturing the Same

ActiveUS20080044643A1Light weightImprove performance stabilityMembranesSemi-permeable membranesPolymer scienceHydrophilic polymers

The invention relates to a hollow fiber membrane module comprising polysulfone type selectively permeable hollow fiber membranes which contain a polysulfone-based resin and a hydrophilic polymer as main components, wherein (A) the content of the hydrophilic polymer in the uppermost layer of the inner surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the proximate layer of the inner surface of the membrane, and (B) the content of the hydrophilic polymer in the uppermost layer of the outer surface of the hollow fiber membrane is at least 1.1 times larger than the content of the hydrophilic polymer in the uppermost layer of the inner surface of the membrane. The hollow fiber membrane module is exposed to a radioactive ray, on condition that the oxygen concentration of an ambient atmosphere around the hollow fiber membrane is from 0.001 to 0.1%, and that the moisture content of the hollow fiber membrane to the weight thereof is from 0.2 to 7 mass %.

Owner:NIPRO CORP

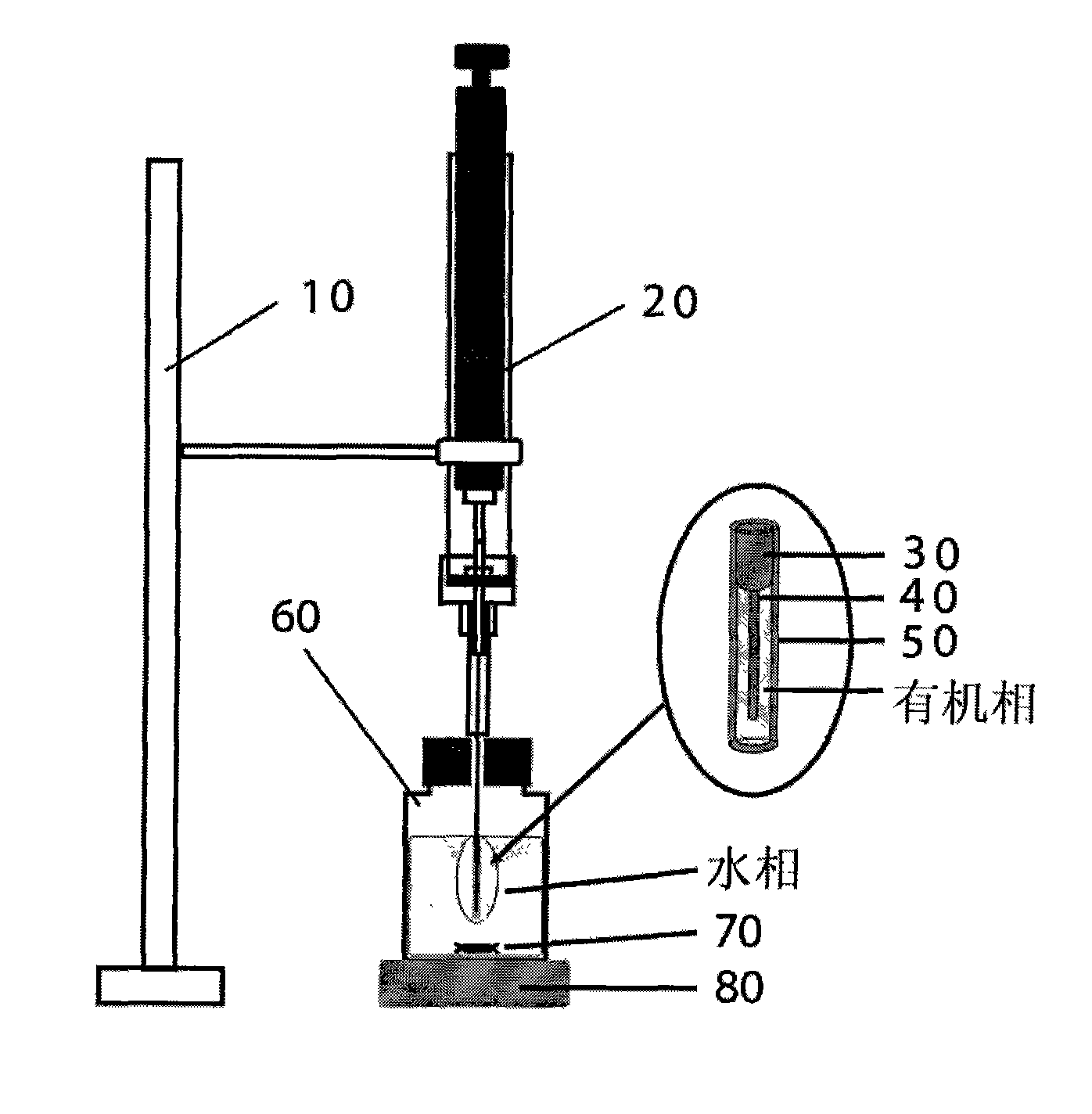

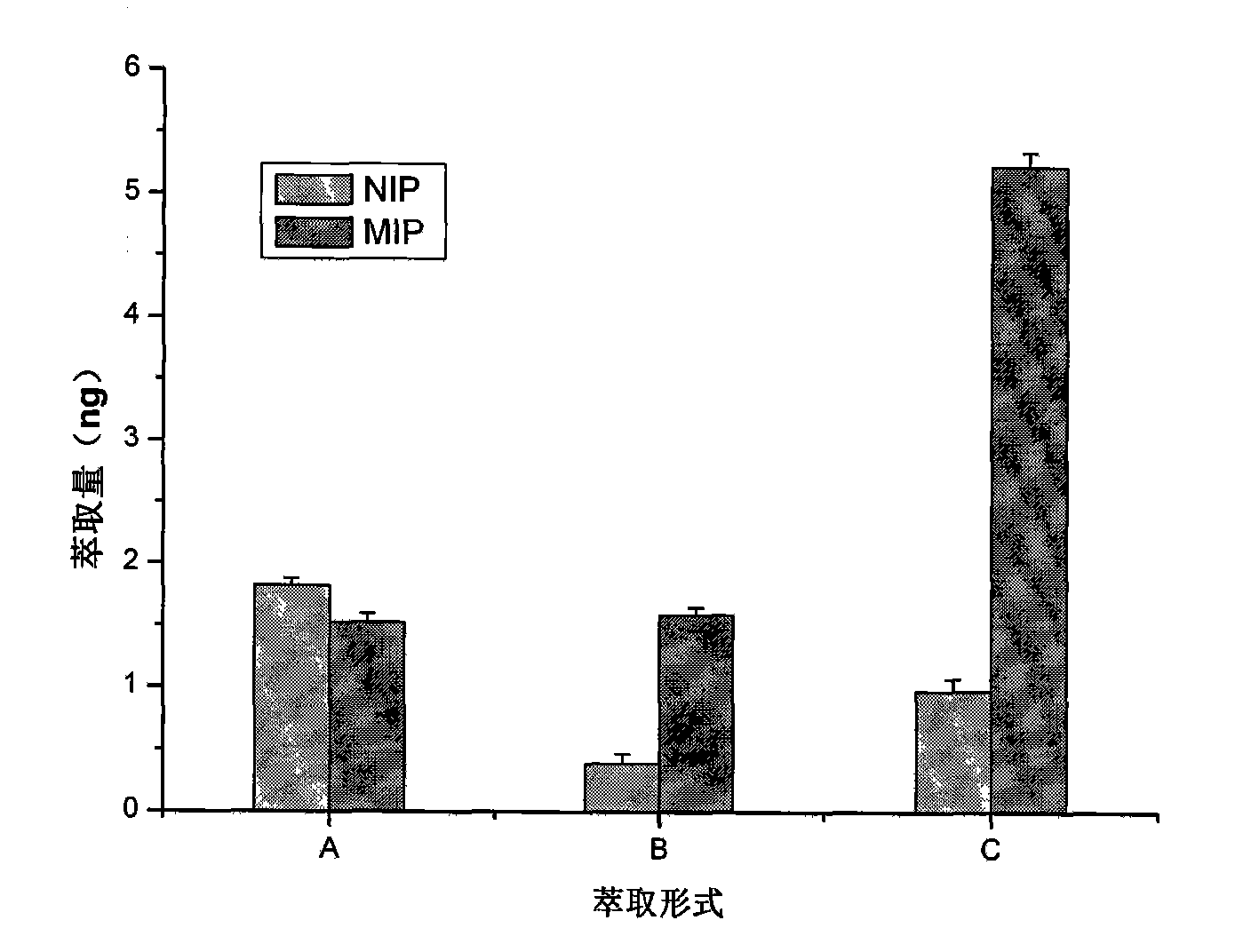

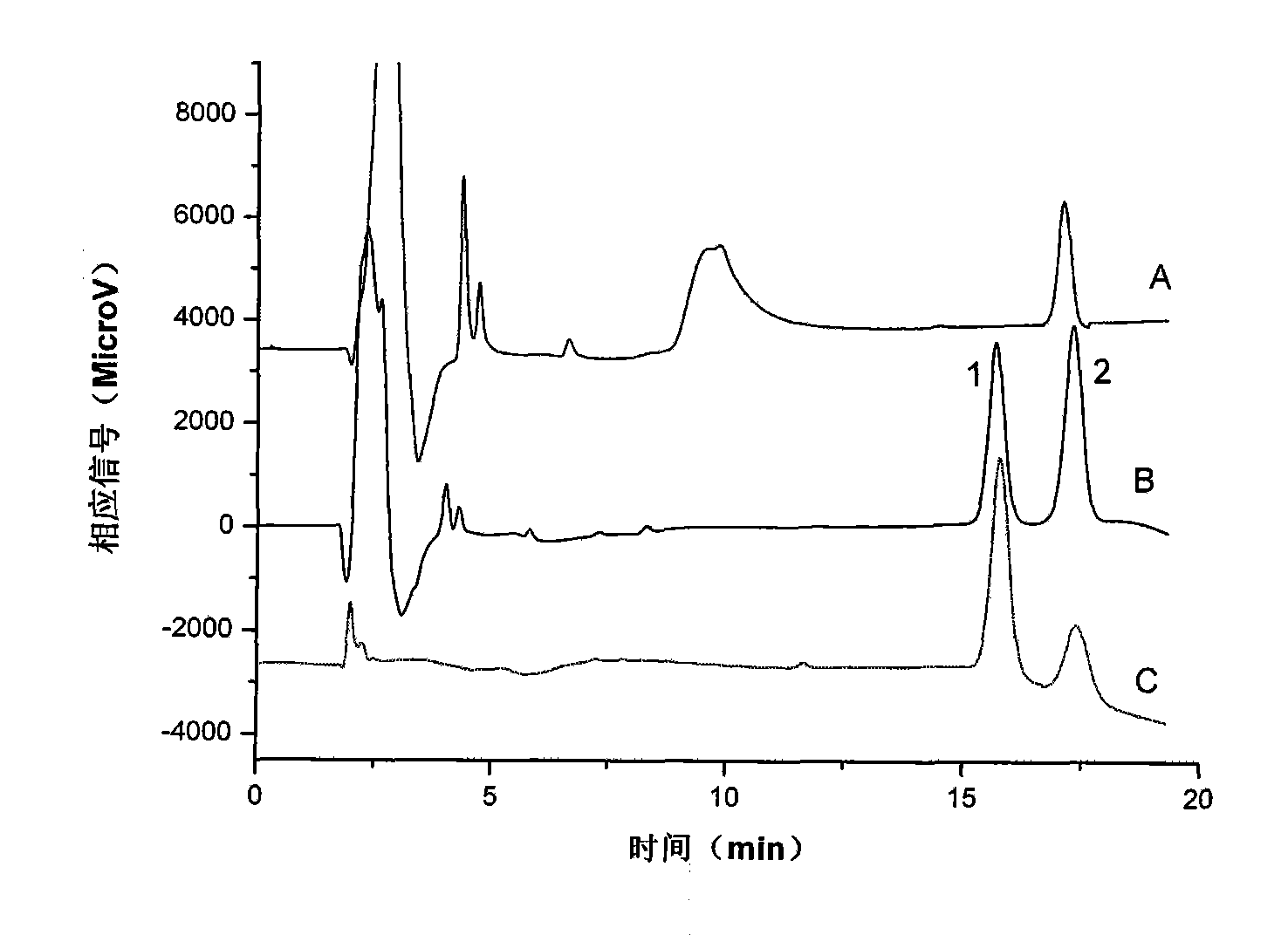

Device and method for combined use of molecular imprinting solid phase microextraction and hollow fiber liquid phase microextraction, and application thereof

InactiveCN101637668AHigh enrichment factorAnalysis fitIon-exchange process apparatusIon-exchanger regenerationHollow fibre membraneFiber

The invention discloses a device and a method for the combined use of molecular imprinting solid phase microextraction and hollow fiber liquid phase microextraction, and the application thereof. The device consists of a solid phase microextraction device, a molecular imprinting solid phase microextraction probe, a hollow fiber membrane, an extraction bottle and a stirrer. The molecular imprintingsolid phase microextraction probe is inserted in to a hollow fiber membrane cavity containing organic solvent, fixed and then directly positioned into a sample solution to be measured for purpose of liquid-solid phase synchronous microextraction. During the microextraction, analytes permeate the hollow fiber membrane, are then enriched in the organic solvent and then undergo secondary extraction and enrichment under the action of the molecular imprinting solid phase microextraction probe. The device is simple, operates conveniently, facilitates the combined use with an analyzer, is suitable for the separation and enrichment of organics with trace amounts in complex water phase samples obtained from the fields such as environment, food, medicine, biology and the like.

Owner:SUN YAT SEN UNIV

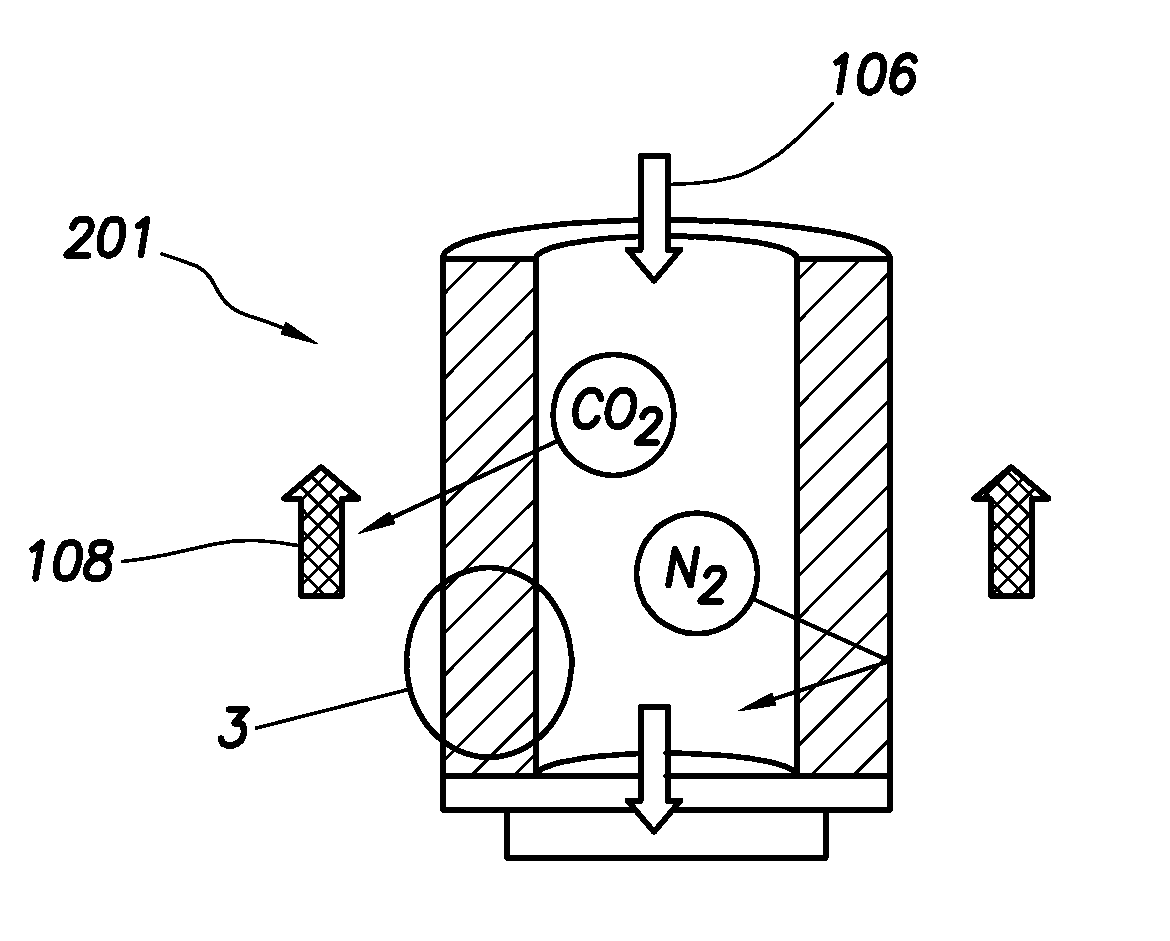

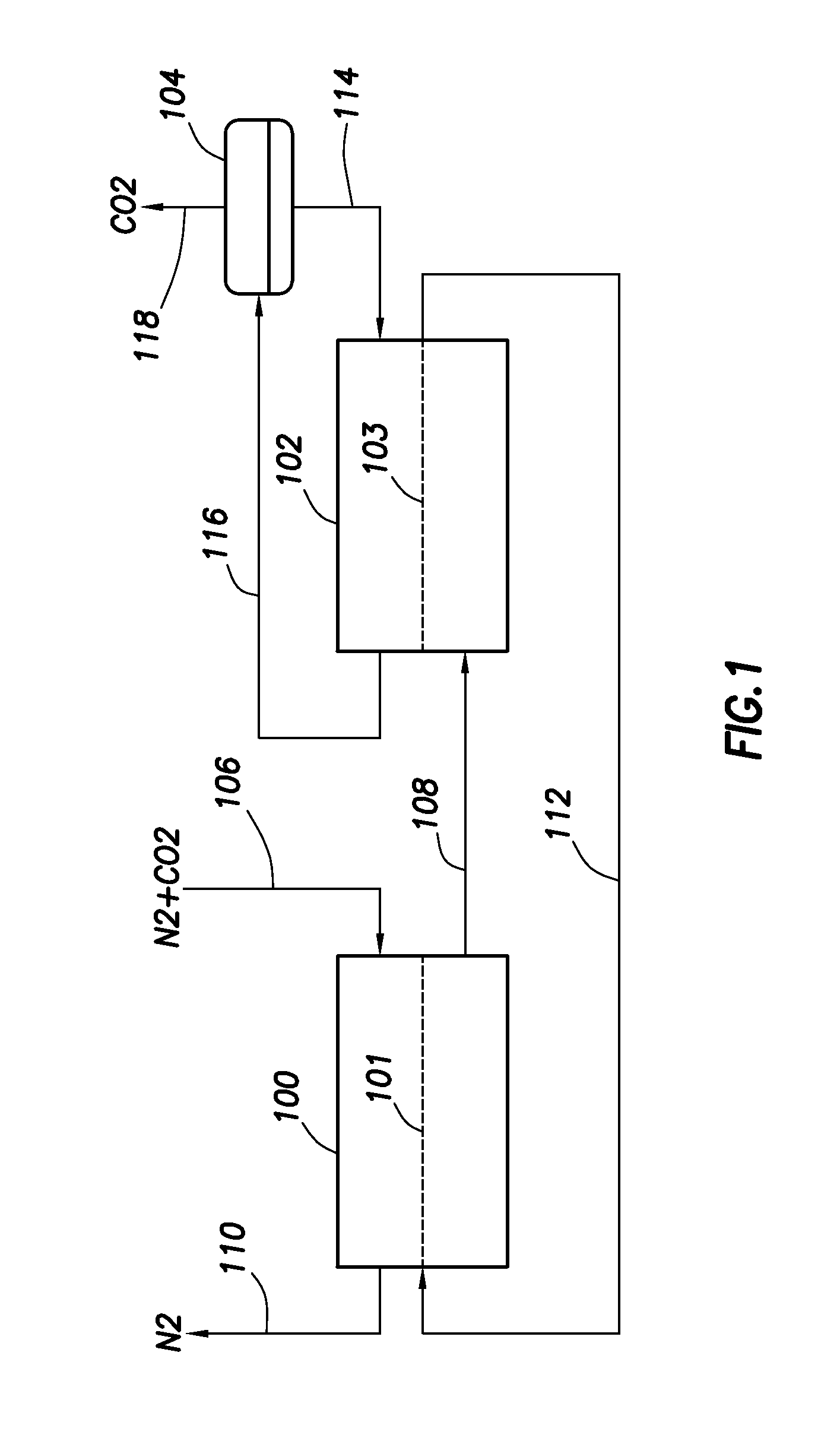

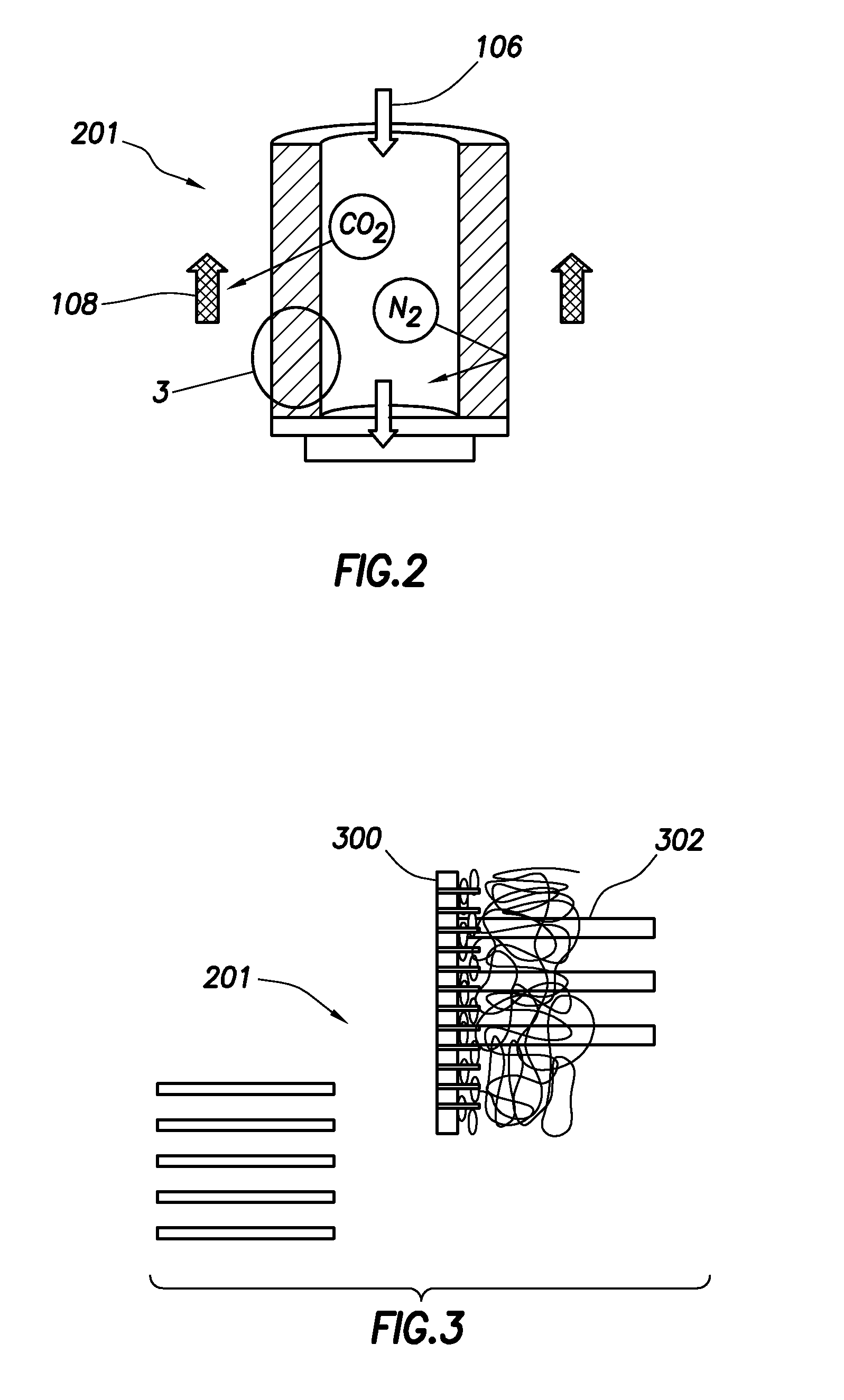

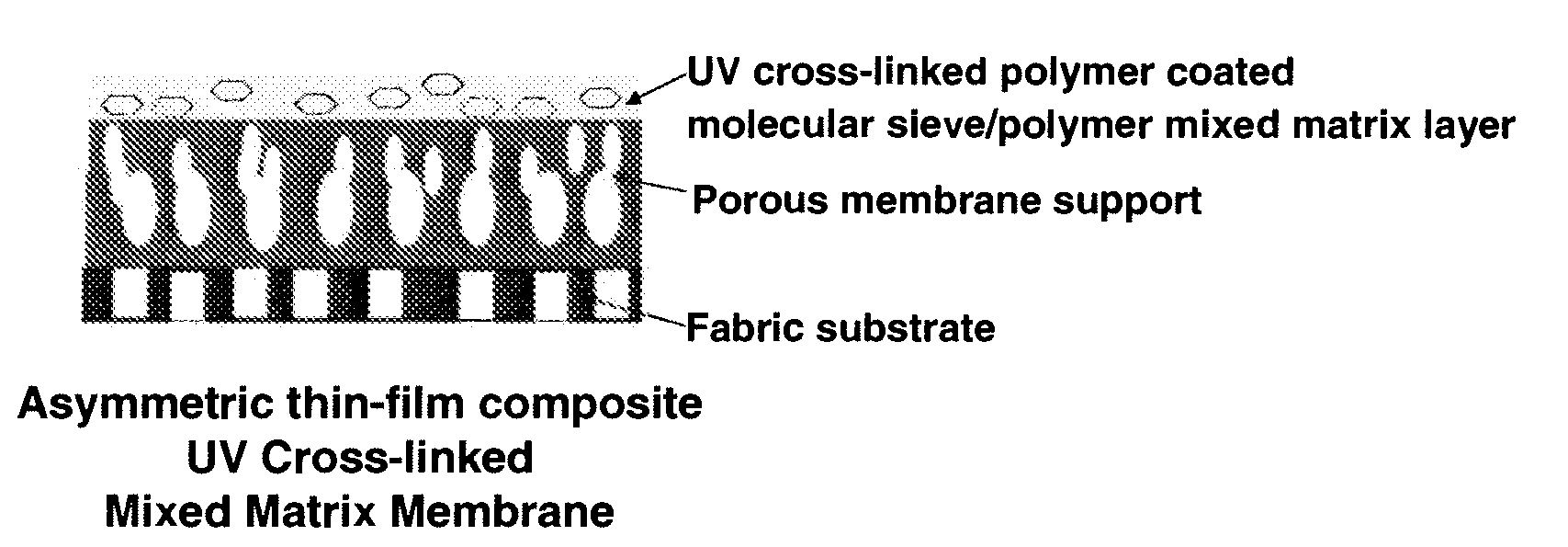

Hollow-fiber membrane contactors

Methods and apparatus relate to recovery of carbon dioxide and / or hydrogen sulfide from a gas mixture. Separating of the carbon dioxide, for example, from the gas mixture utilizes a liquid sorbent for the carbon dioxide. The liquid sorbent contacts the gas mixture along asymmetric hollow-fiber membranes that enable transfer of the carbon dioxide from the gas mixture to the liquid sorbent.

Owner:PHILLIPS 66 CO

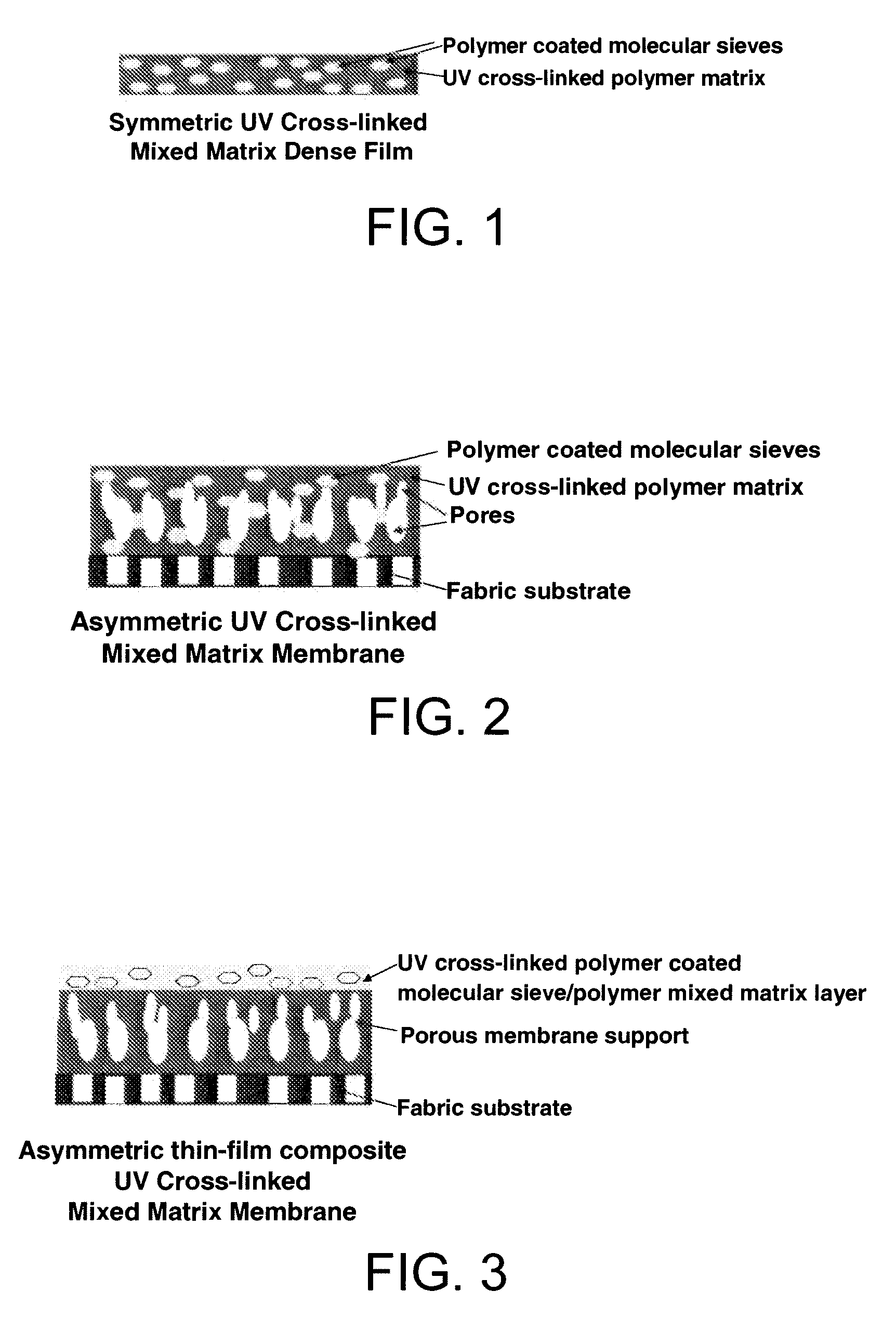

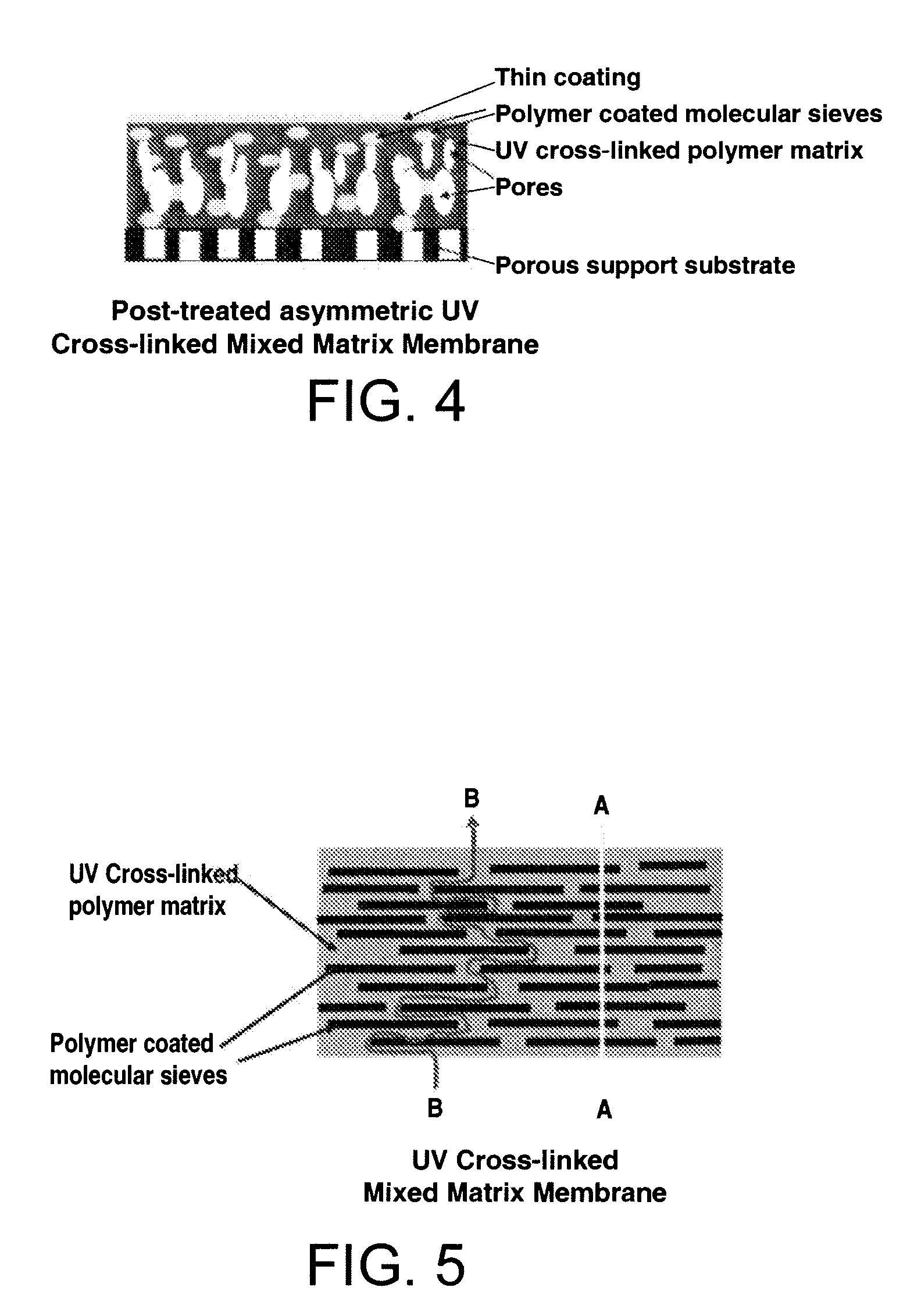

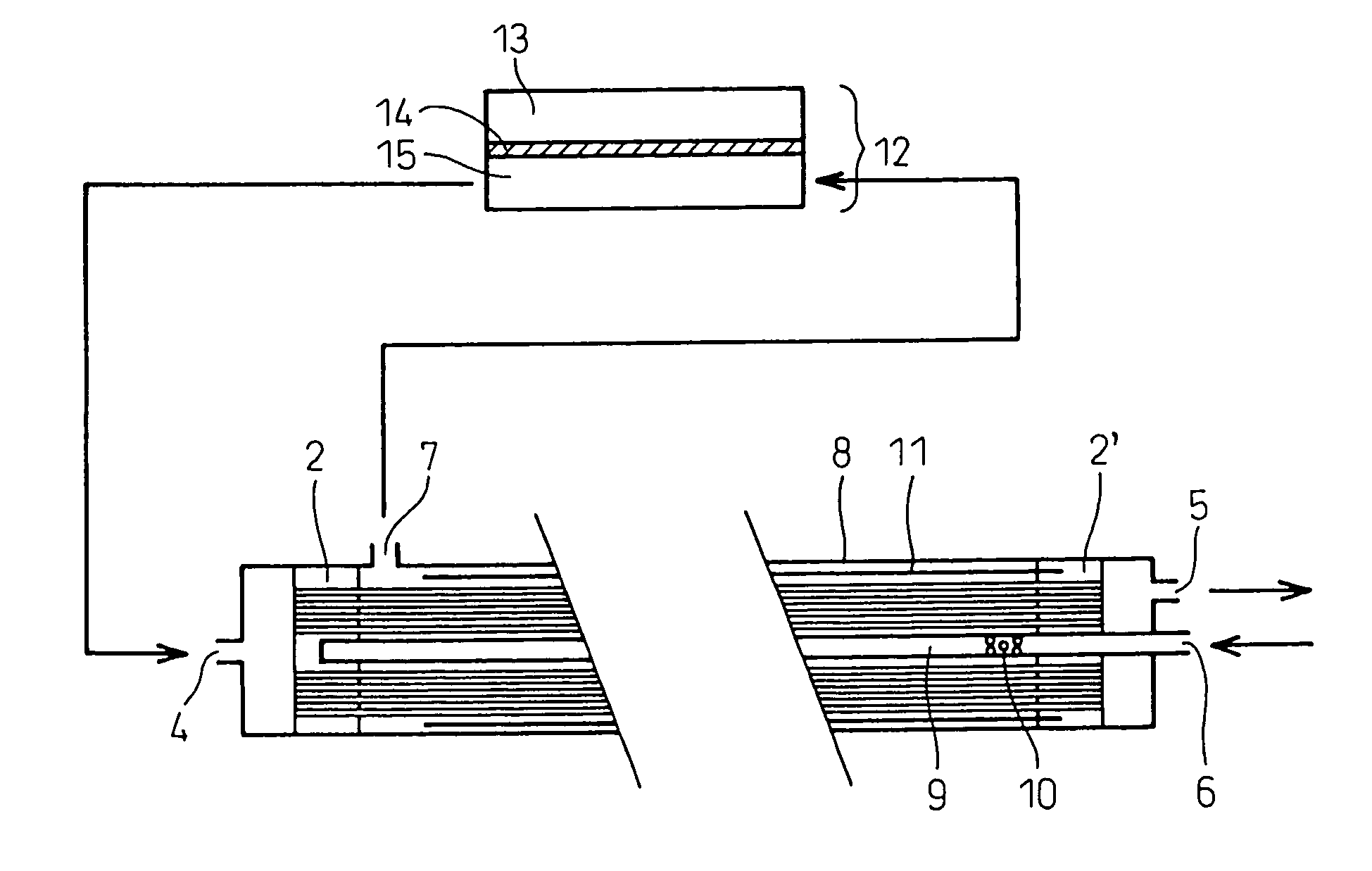

UV cross-linked polymer functionalized molecular sieve/polymer mixed matrix membranes for sulfur reduction

InactiveUS20080295692A1Easy to separateAverage permeabilityMembranesSemi-permeable membranesCross-linkPolymer chemistry

The present invention discloses high performance UV cross-linked polymer functionalized molecular sieve / polymer mixed matrix membranes (MMMs), the method of making these membranes, and the use of such membranes for separations. These UV cross-linked MMMs were prepared by incorporating polyethersulfone functionalized molecular sieves such as AlPO-14 and UZM-25 into a continuous UV cross-linkable polymer matrix followed by UV cross-linking. The UV cross-linked MMMs in the form of symmetric dense film, asymmetric flat sheet membrane, or asymmetric hollow fiber membranes described in the current invention have good flexibility and high mechanical strength, and exhibit significantly enhanced selectivity and permeability over the polymer membranes made from the corresponding continuous polyimide polymer matrices for carbon dioxide / methane (CO2 / CH4) and hydrogen / methane (H2 / CH4) separations. The MMMs of the present invention are suitable for a variety of liquid, gas, and vapor separations such as deep desulfurization of gasoline and diesel fuels.

Owner:UOP LLC

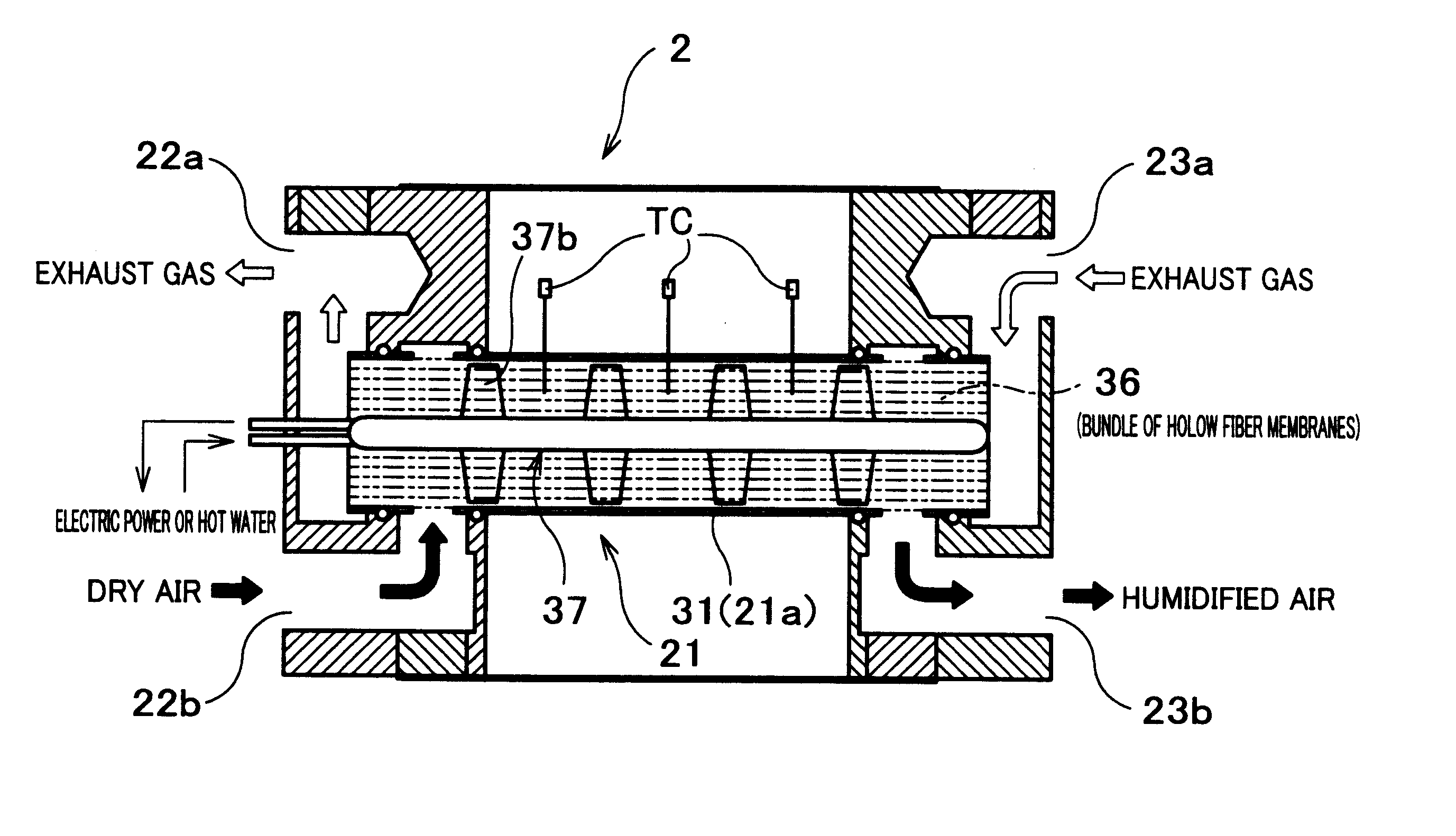

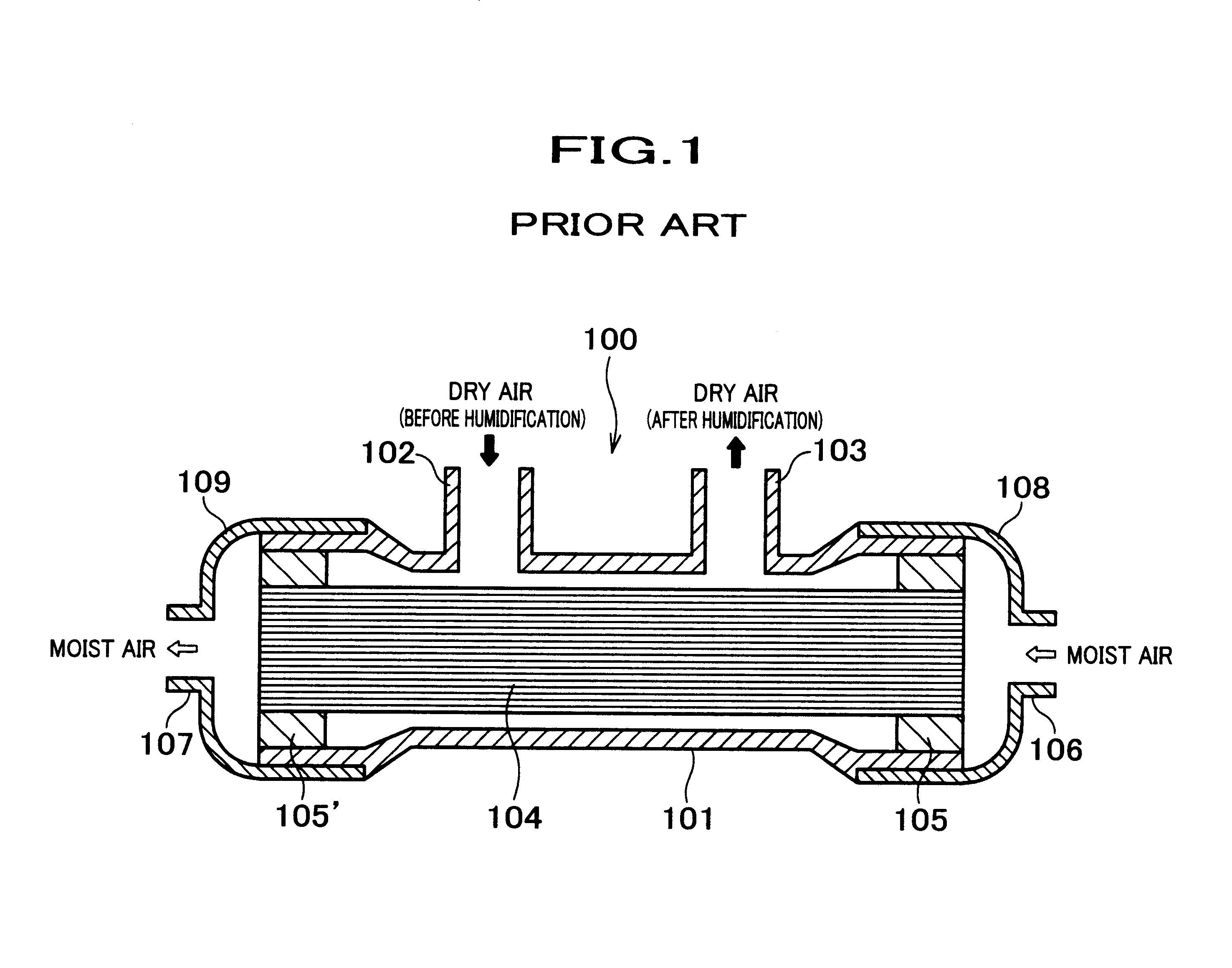

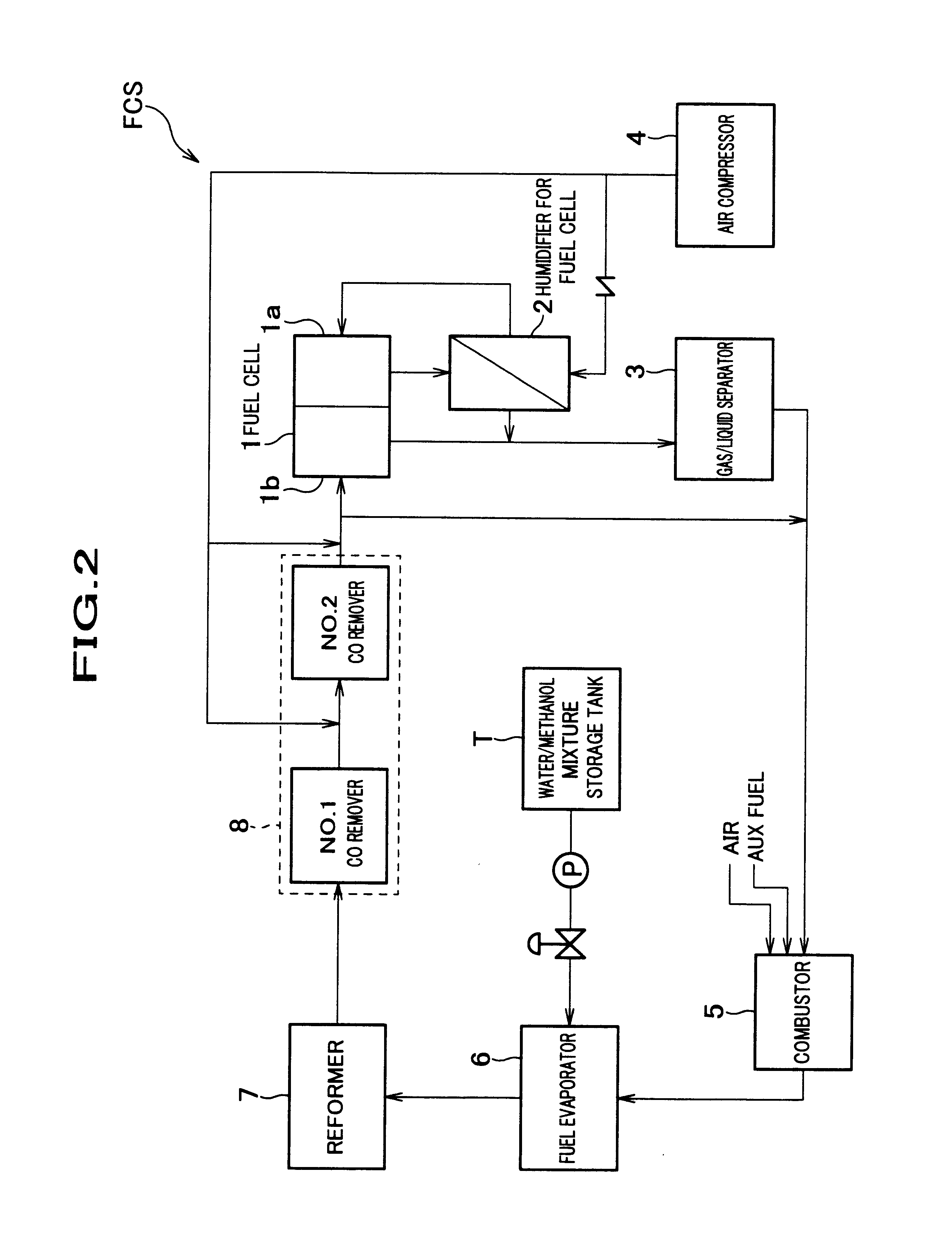

Fuel cell-use humidifier

An object of the present invention is to provide a humidifying apparatus capable of improving the humidification efficiency while lowering the pressure loss of gas even when a low-pressure gas is used, and is suitably usable for fuel cells. The present invention relates to a humidifying apparatus for fuel cells, fabricated by loading a hollow fiber membrane element into a container such that the space communicating with the hollow side of the hollow fiber membranes is isolated from the space communicating with the outer side of the hollow fiber membranes, wherein (a) the inner diameter of the hollow fiber membrane is larger than 400 μm, (b) the water vapor permeation rate (P′H2O) of the hollow fiber membranes is 0.5×10−3 cm3 (STP) / cm2·sec·cm Hg or more, (c) the ratio (P′H2O / P′O2) of the water vapor permeation rate to the oxygen gas permeation rate of the hollow fiber membranes is 10 or more, and (d) the elongation at tensile break of the hollow fiber membranes after hot water treatment in hot water at 100° C. for 50 hours is 80% or more of that before the hot water treatment; particularly, the present invention relates to a humidifying apparatus for fuel cells where, if the effective length of the hollow fiber membrane element is L and the inner diameter of the container into which the hollow fiber membrane element is loaded is D, L / D is 1.8 or more.

Owner:UBE IND LTD

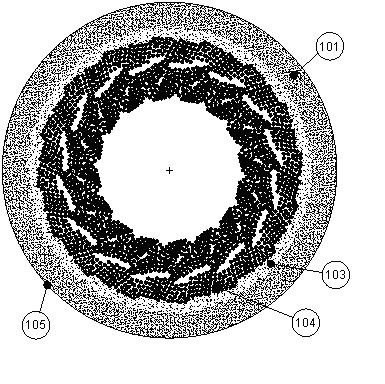

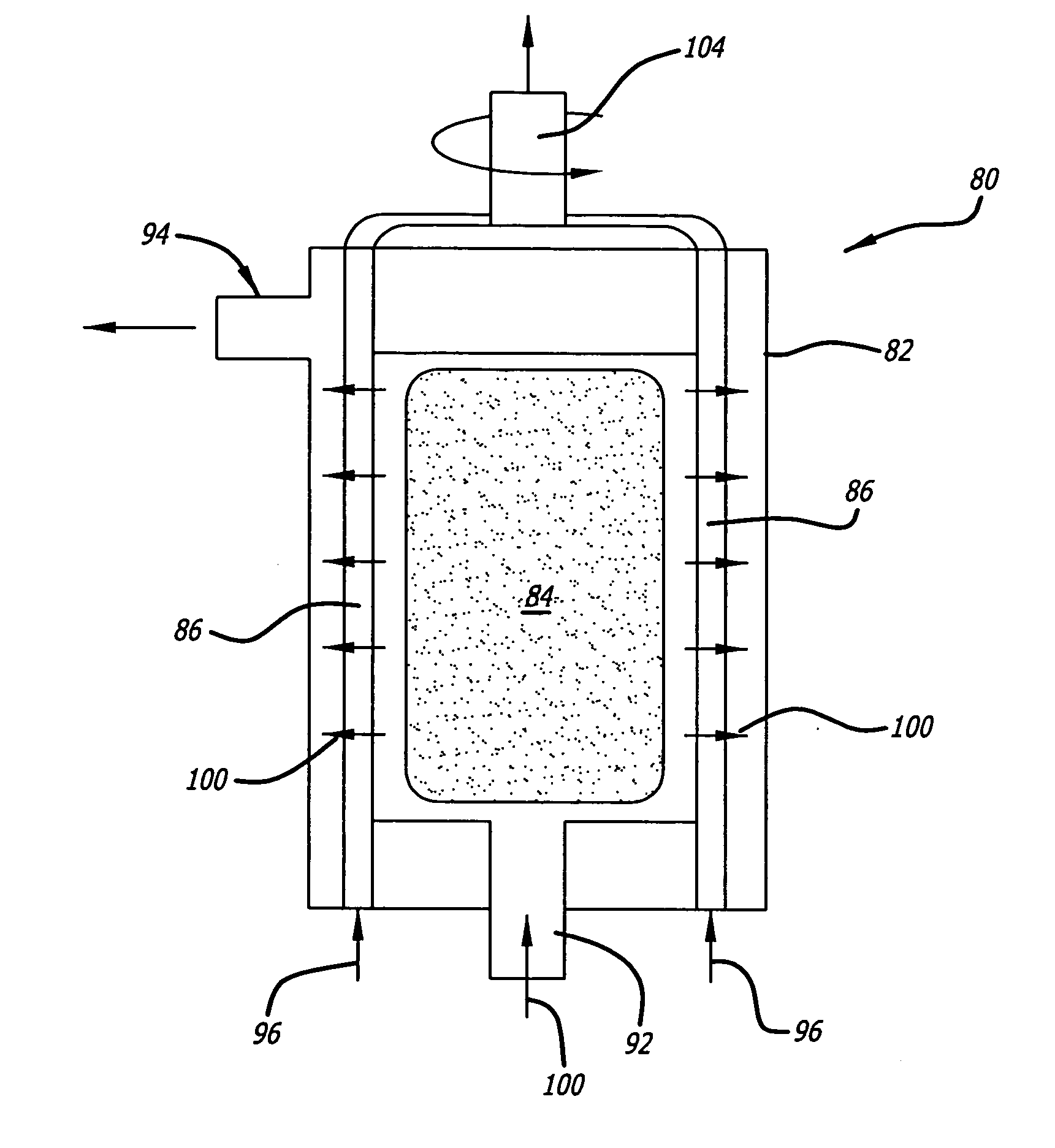

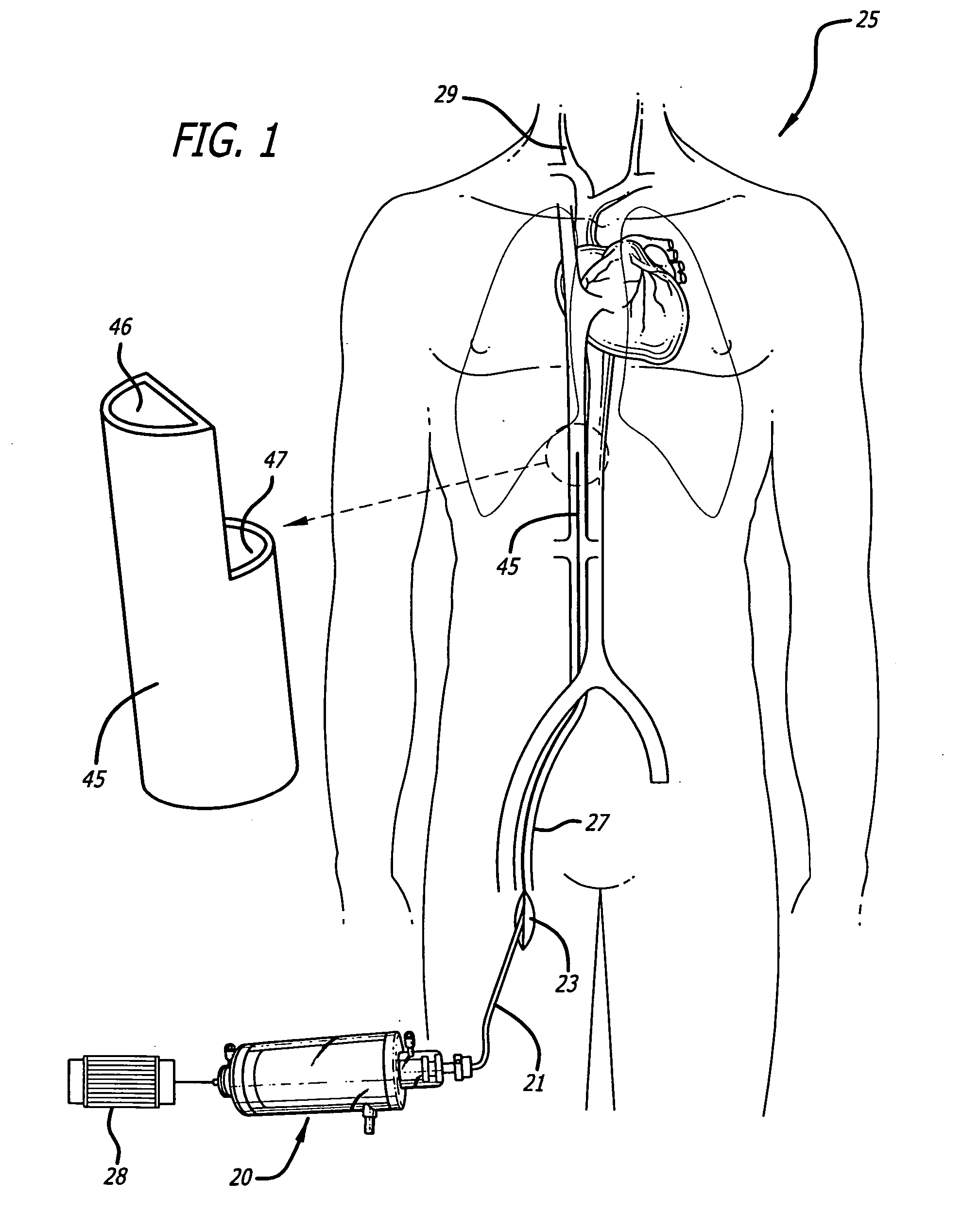

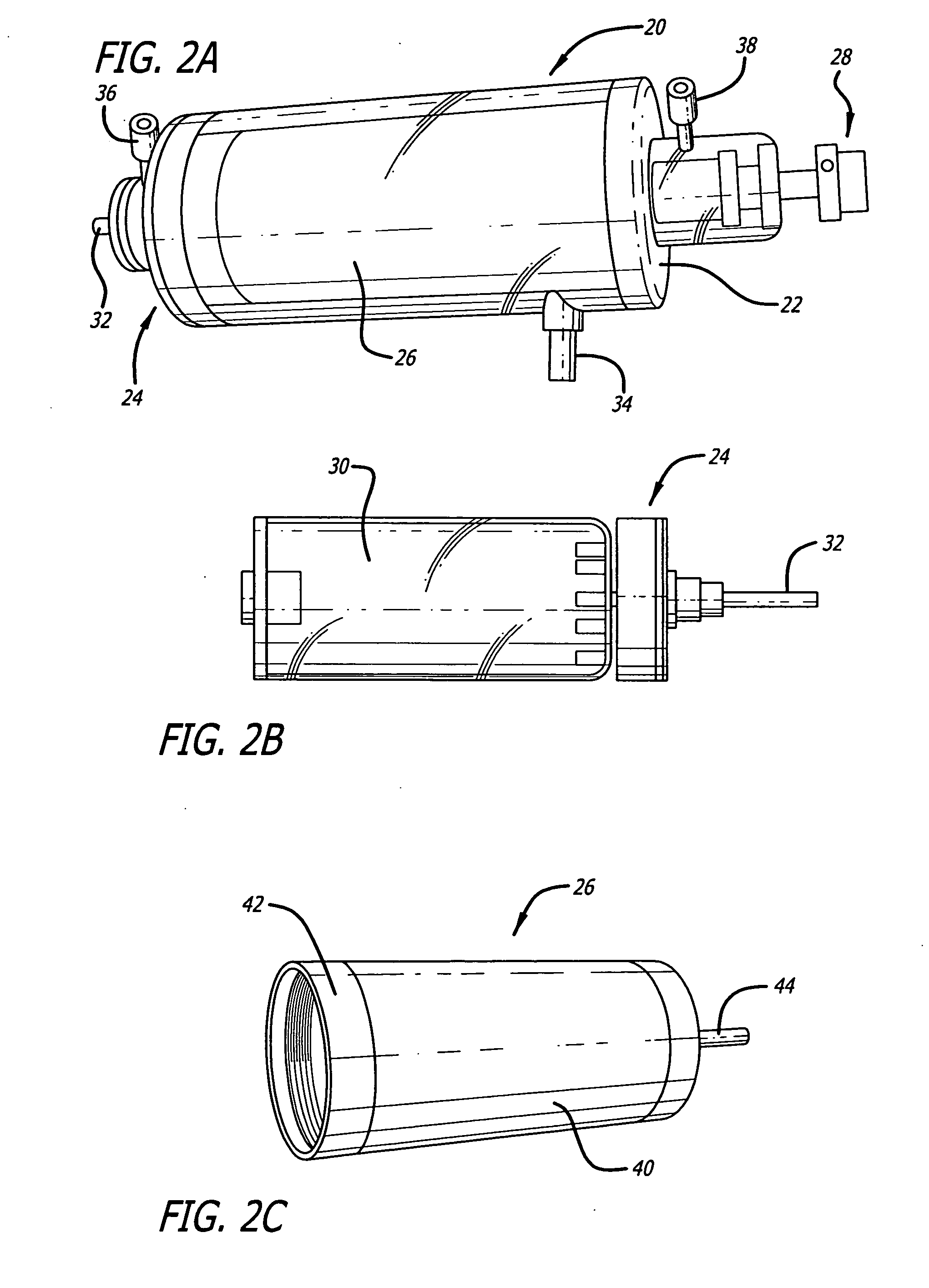

Paracorporeal respiratory assist lung

ActiveUS20070020142A1Increase gas exchangeConstant flowMembranesSemi-permeable membranesPorosityFiber bundle

A paracorporeal respiratory assist lung is configured with an annular cylindrical hollow fiber membrane (fiber bundle) that is rotated at rapidly varying speeds. Fluid (for example, blood) is introduced to the center of the device and is passed radially through the fiber bundle. The bundle is rotated at rapidly changing velocities with a rotational actuator (for example, a motor or magnetic coupling). The rotation of the fiber bundle provides centrifugal kinetic energy to the fluid giving the device pumping capabilities and may create Taylor vortexes to increase mass transfer. Rotation of the fiber bundle increases the relative velocity between the fluid and the hollow fibers and increases the mass transfer. The porosity of the fiber bundle may be varied to enhance gas exchange with the blood. Alternatively, a rotating core may be used with a stationary fiber bundle.

Owner:ALUNG TECH INC +1

Humidifier

InactiveUS6554261B2Heating can be necessaryLighting and heating apparatusMixing methodsFuel cellsEngineering

A humidifier includes a housing that accommodates bundles of a large number of water permeable hollow fiber membranes arranged along the longitudinal direction of the housing. Two different gasses having different moisture contents pass through outside and inside of the bundle of the hollow fiber membranes separately to exchange their moistures through the hollow fiber membranes resulting in the dry gas of lesser moisture content being humidified. A heating or temperature adjuster is provided to maintain the temperature of the exhaust gas introduced to the humidifier or the bundles of hollow fiber membranes substantially at a temperature of a fuel cell in operation.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com