Lining-reinforced hollow fiber membrane tube as well as preparation device and preparation method thereof

A preparation device and enhanced technology, which is applied in the field of preparation of polymer hollow fiber microporous membranes, can solve problems such as membrane layer peeling, and achieve the effects of improving adhesion, strengthening strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

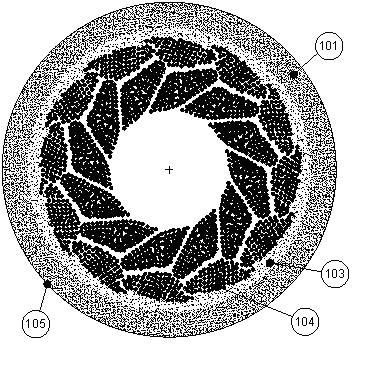

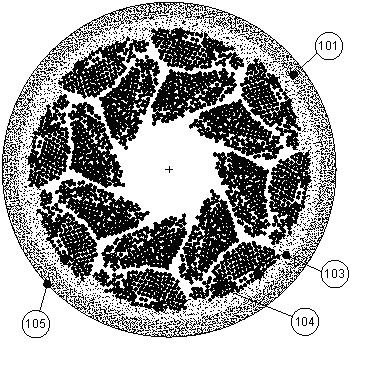

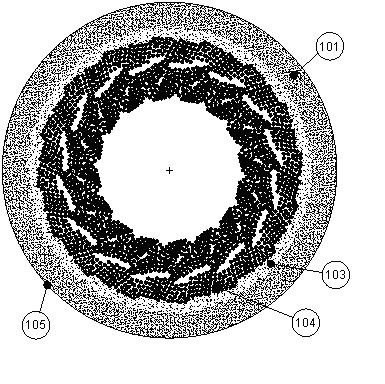

[0079] This example illustrates the structure and construction of the lining-reinforced hollow fiber membrane preparation device of the present invention.

[0080] The lining reinforced hollow fiber membrane preparation device of the present invention mainly consists of a casting liquid tank 1, a defoaming tank 2, a blending stock solution storage tank 3, a spinning box 4, a transition layer pre-coating tank 7, and a coating machine The head 8, the film-forming tunnel 9, the coagulation bath 10, the rinsing tank 11, the godet roll 12 and the winding wheel 13; wherein, the inside of the spinning box 4 is respectively provided with a blend liquid pump 5 and a casting liquid pump 6 ; The coating head 8 is set in the film-forming tunnel 9;

[0081] On the one hand, the liquid outlet of the blending stock solution storage tank 3 is connected to the inlet of the blend liquid pump 5 through a valve, and the outlet of the blend liquid pump 5 is connected to the upper side of the feed ...

Embodiment 2

[0088] This example illustrates the method for preparing a liner-reinforced hollow fiber membrane tube using the liner-reinforced hollow fiber membrane tube preparation device described in Example 1.

[0089] Step 1, prepare the lined braided tube:

[0090] The lining braided tube is braided by chemical fiber multifilament, which has excellent chemical stability and mechanical strength. The material is one or a mixture of polyamide fibers, polyester fibers, and polyurethane fibers. Factors such as braiding density, chemical fiber filament denier, and braiding spindle number affect the size and performance of the liner. The weaving density of the present invention is 20-60 meshes, and the liner pipe with high weaving density becomes smaller in shape, but the output is low; while the problem at low density is that the elongation is high and easy to deform, which in turn affects the overall performance of the membrane pipe. Preferably, the weaving density is 25-40 mesh. The nu...

Embodiment 3

[0122] In this embodiment, hollow fiber membrane tubes are prepared according to the method of Example 2, wherein the selected conditions and the properties of the prepared membrane tubes are as follows:

[0123] The braided tube is prepared from chemical fiber filament polyester fiber, the density of the braided tube is 45 mesh, the number of braided spindles is 24, the outer diameter of the obtained braided tube is 1.65 mm, and the inner diameter is 0.85 mm. Solef 1010 and HSV 900 two kinds of polyvinylidene fluoride resins with different weight-average molecular weights were used to blend and prepare the casting solution. The solvent was dimethylacetamide (DMAC) with a content of 56%. Polyvinylpyrrolidone (PVP) K17, PEG400 and glycerin were selected as the polymer water-soluble pore-forming agent, hydrophilic thickener and non-solvent respectively, and the contents of each component are listed in Table 1. The above raw materials are put into the reaction kettle in the order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com