Patents

Literature

571results about How to "Small volume shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

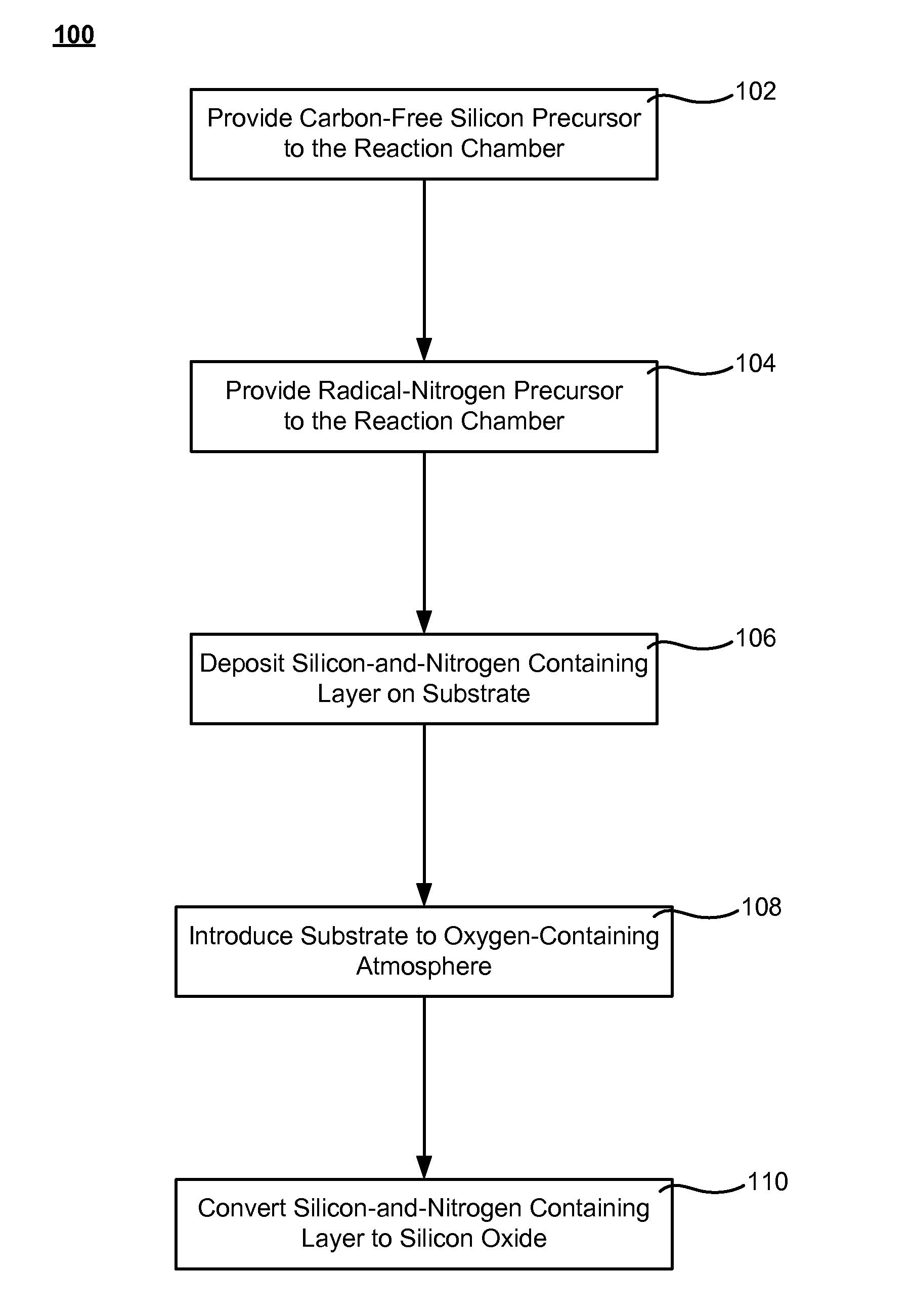

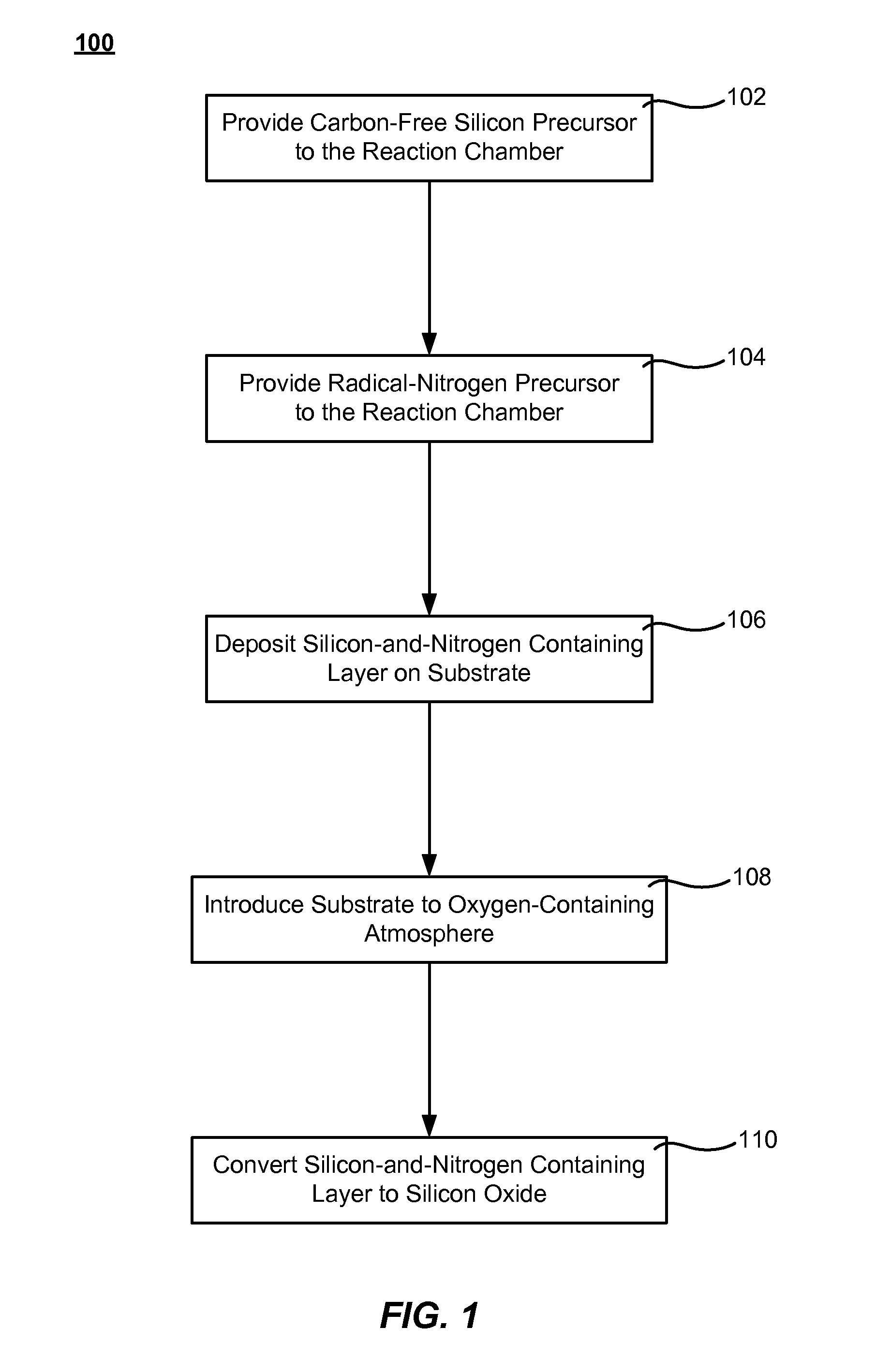

Formation of silicon oxide using non-carbon flowable CVD processes

ActiveUS20110034039A1Less poreReduce Shrinkage ProblemsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogenSilicon oxide

A method of forming a silicon oxide layer is described. The method may include the steps of mixing a carbon-free silicon-and-nitrogen containing precursor with a radical precursor, and depositing a silicon-and-nitrogen containing layer on a substrate. The silicon-and-nitrogen containing layer is then converted to the silicon oxide layer.

Owner:APPLIED MATERIALS INC

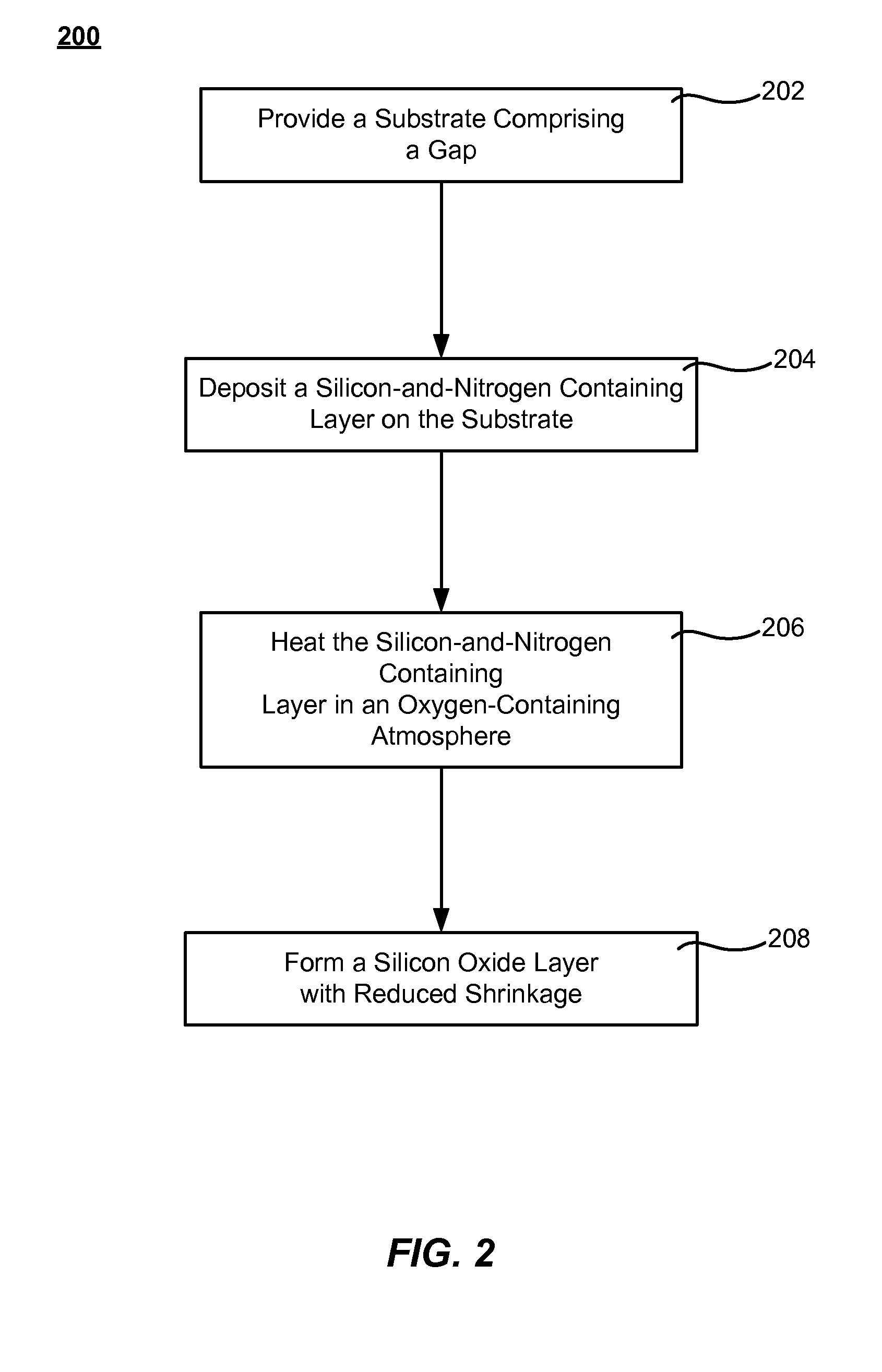

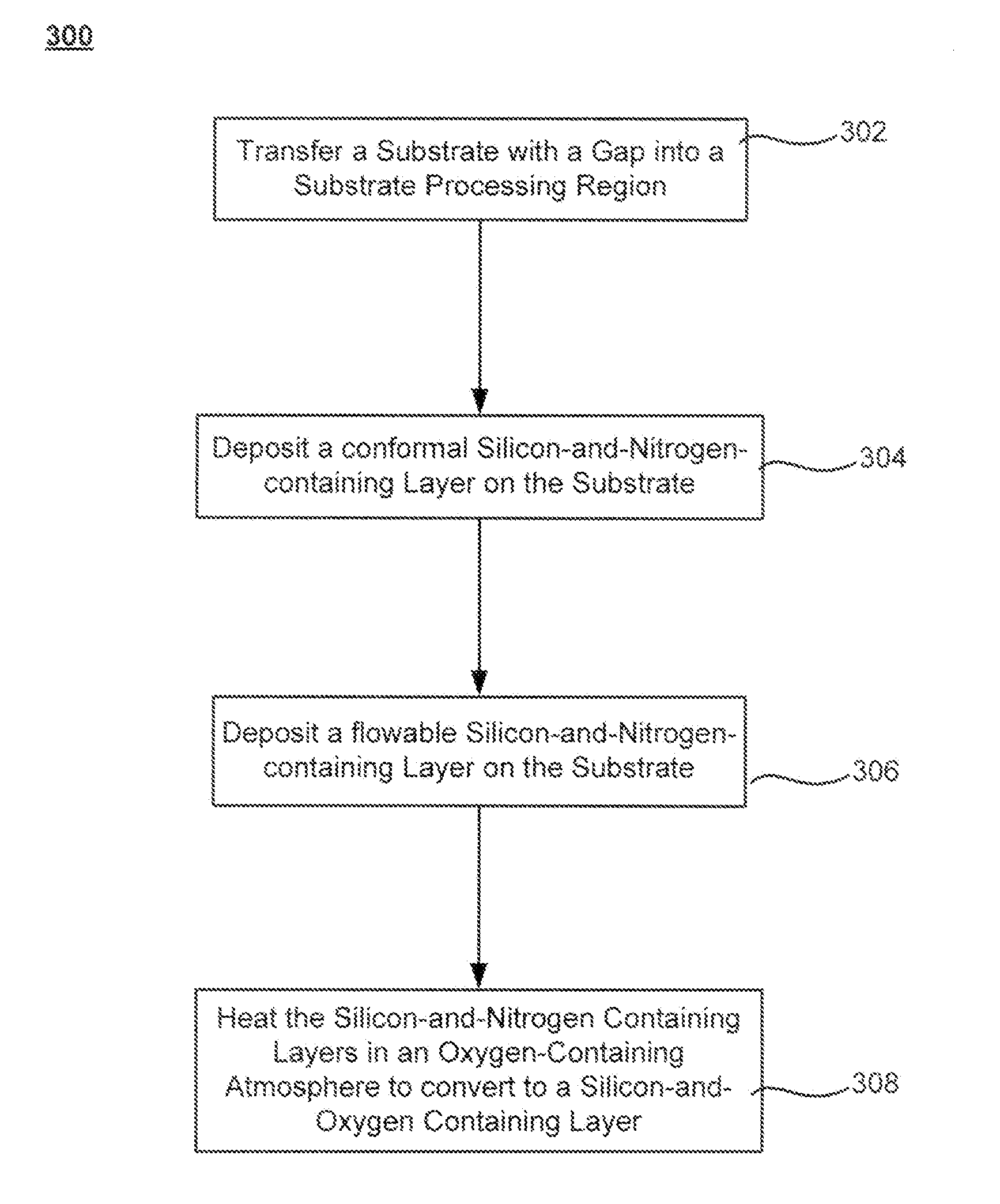

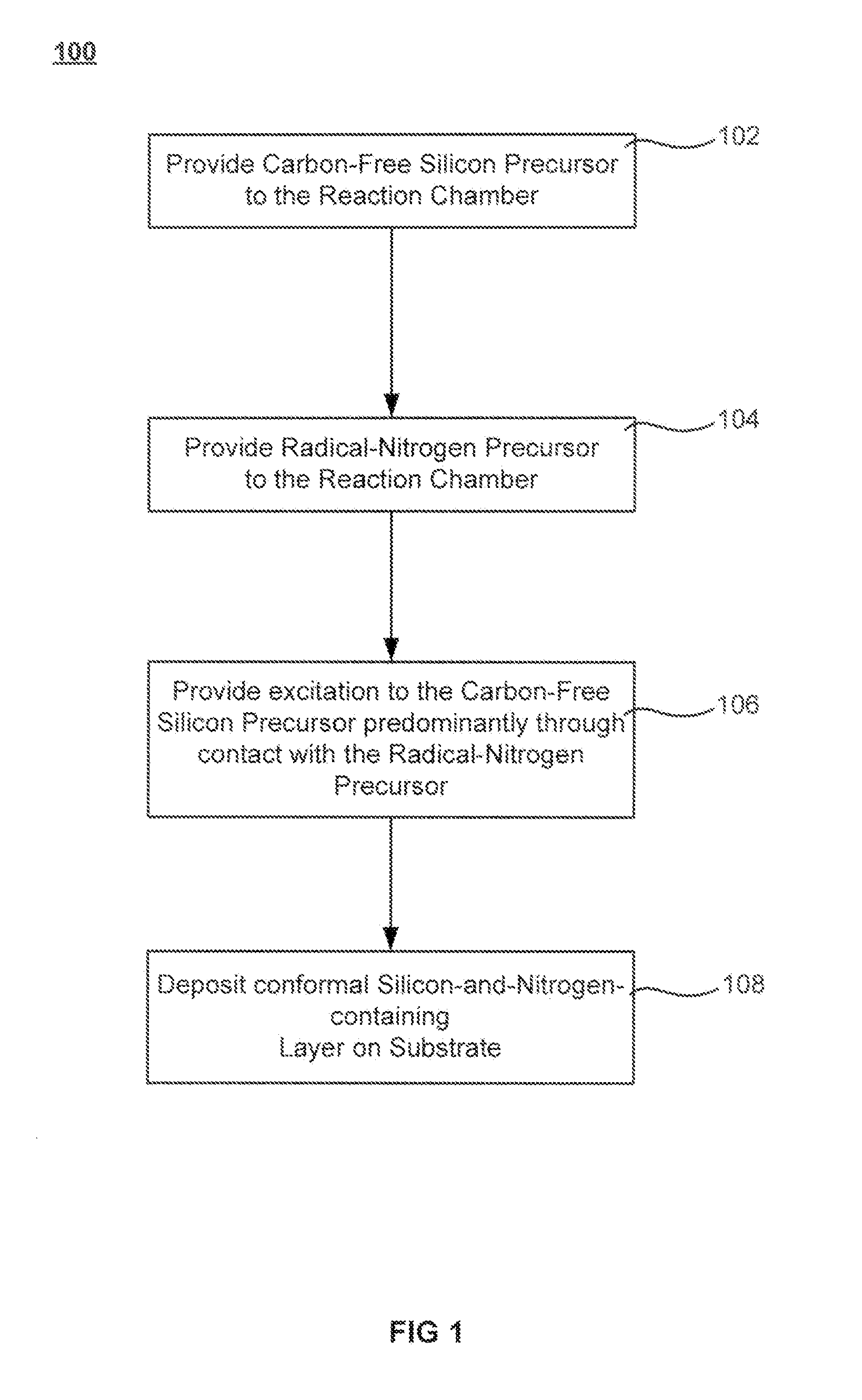

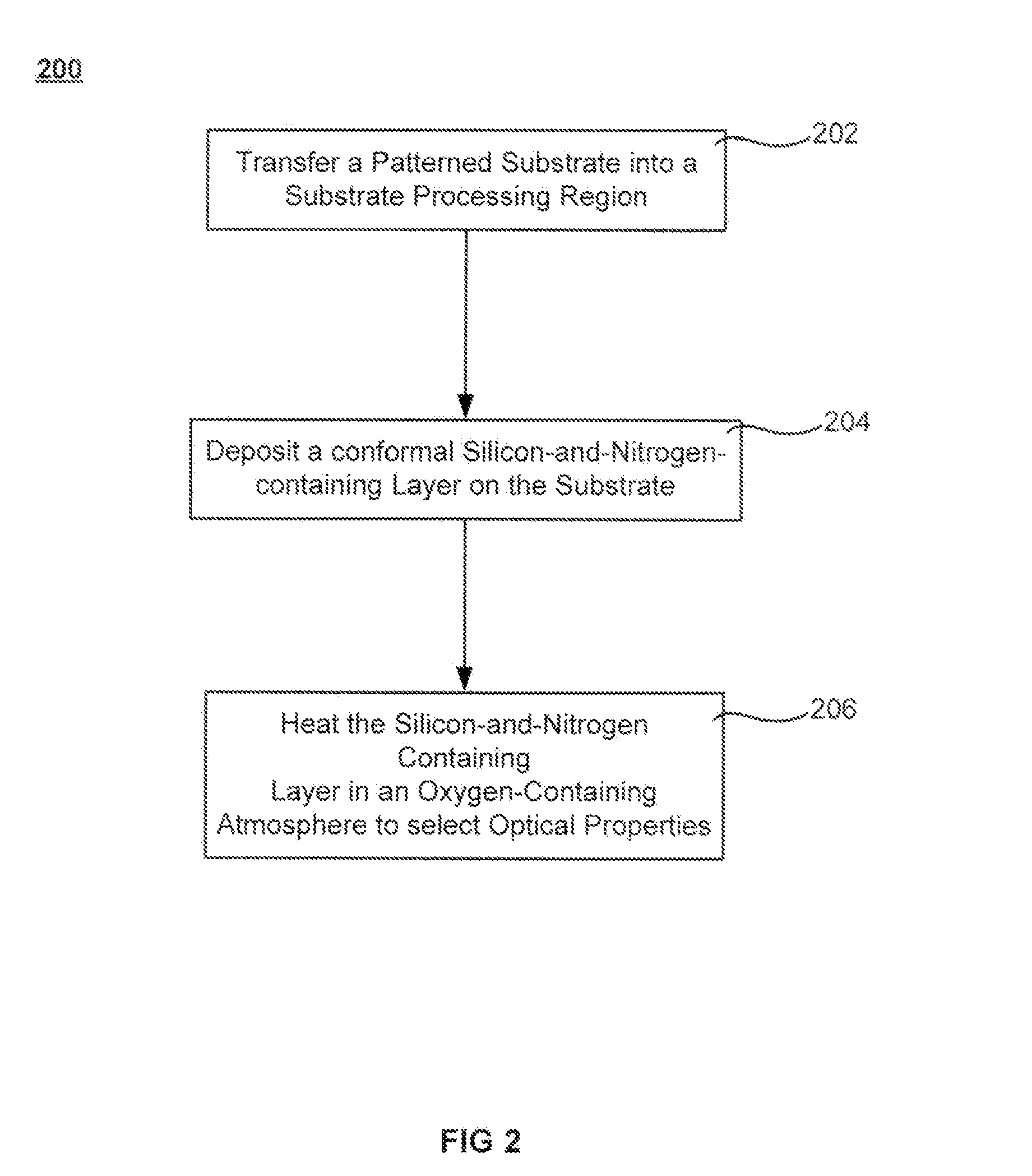

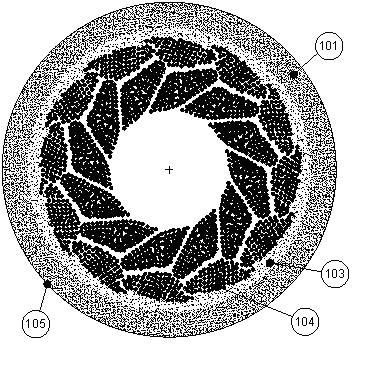

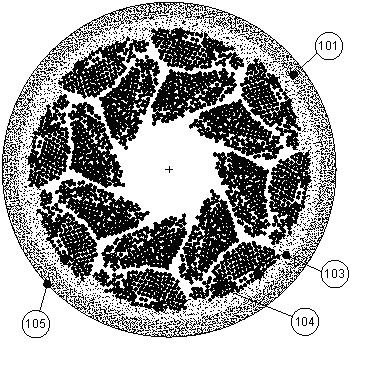

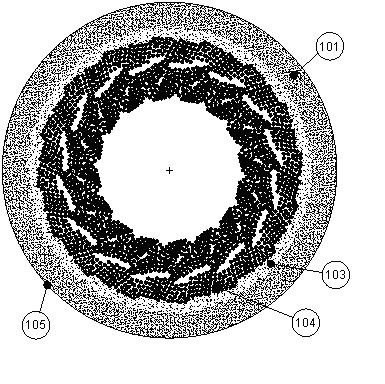

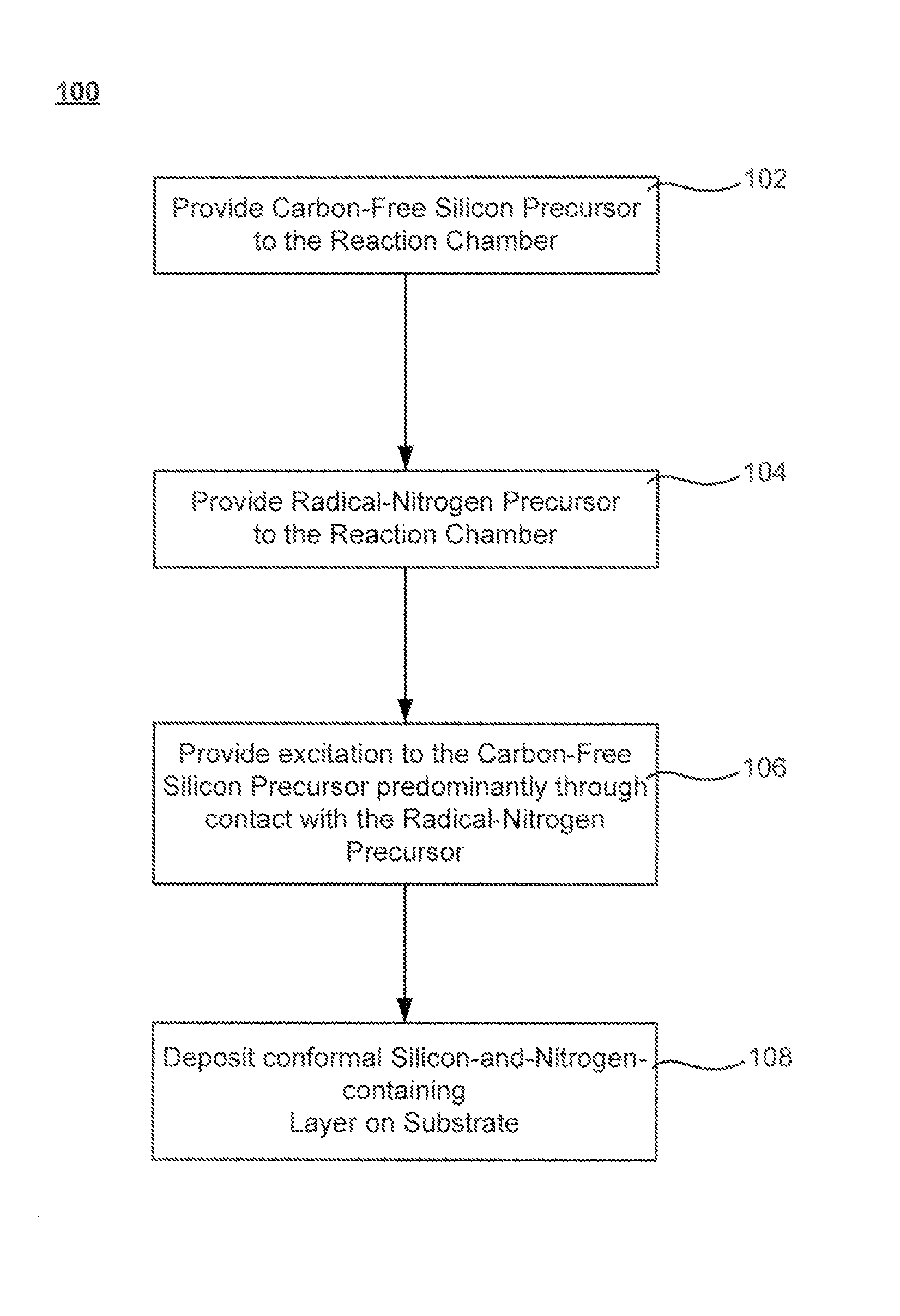

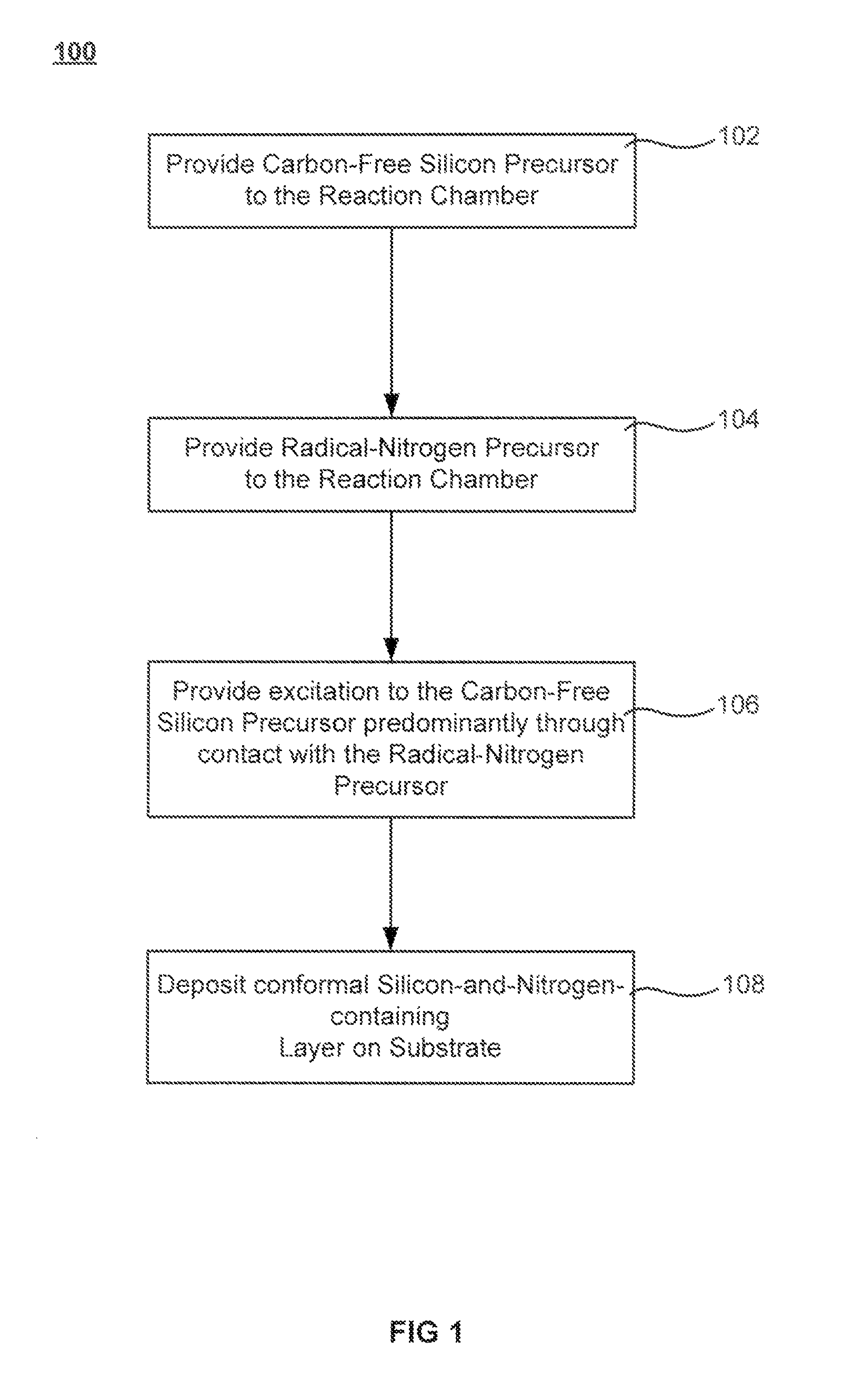

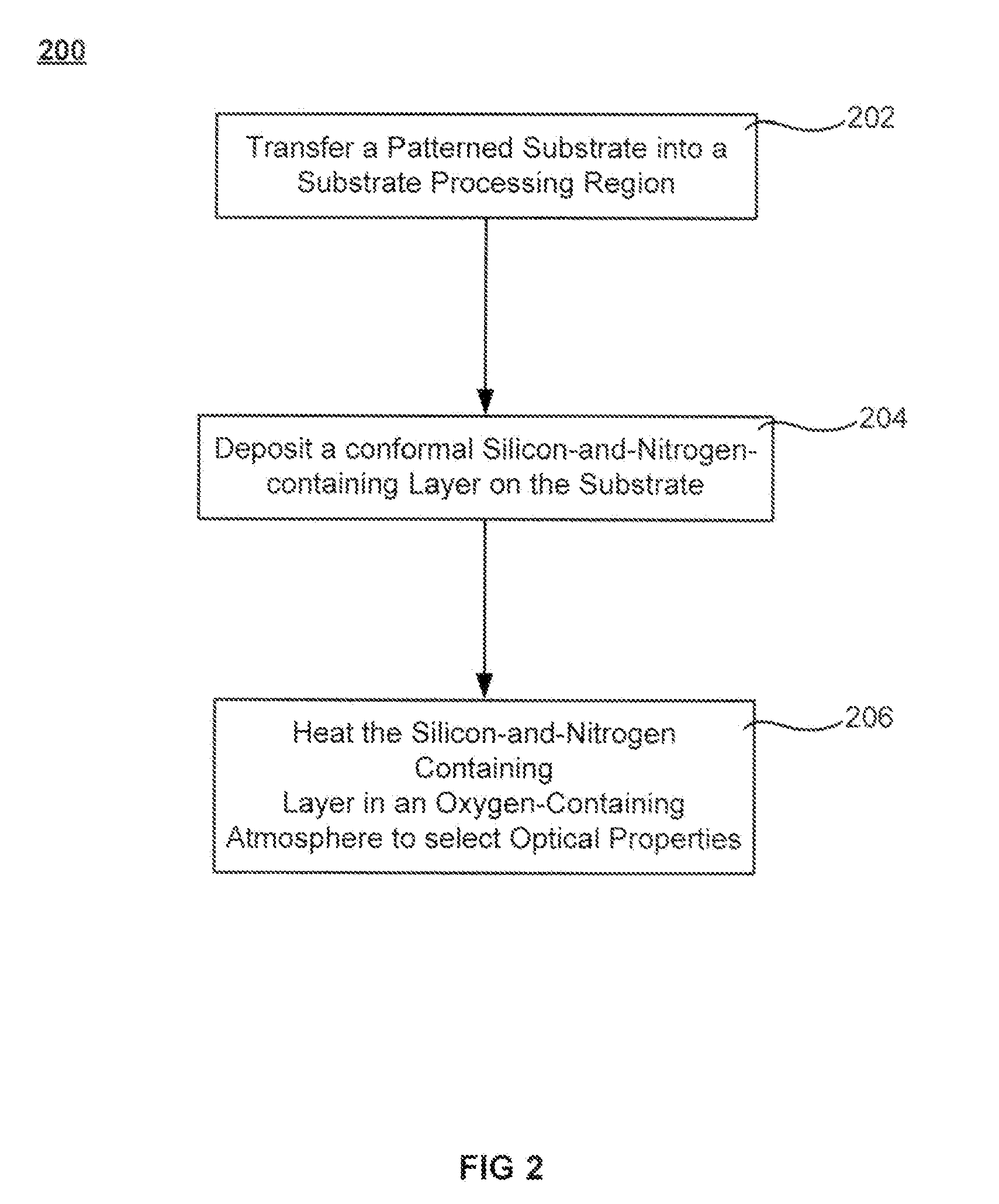

Conformal layers by radical-component CVD

ActiveUS20110217851A1Less volume shrinkageImprove wettabilitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptical propertyHydrogen

Methods, materials, and systems are described for forming conformal dielectric layers containing silicon and nitrogen (e.g., a silicon-nitrogen-hydrogen (Si—N—H) film) from a carbon-free silicon-and-nitrogen precursor and radical-nitrogen precursor. The carbon-free silicon-and-nitrogen precursor is predominantly excited by contact with the radical-nitrogen precursor. Because the silicon-and-nitrogen film is formed without carbon, the conversion of the film into hardened silicon oxide is done with less pore formation and less volume shrinkage. The deposited silicon-and-nitrogen-containing film may be wholly or partially converted to silicon oxide which allows the optical properties of the conformal dielectric layer to be selectable. The deposition of a thin silicon-and-nitrogen-containing film may be performed at low temperature to form a liner layer in a substrate trench. The low temperature liner layer has been found to improve the wetting properties and allows flowable films to more completely fill the trench.

Owner:APPLIED MATERIALS INC

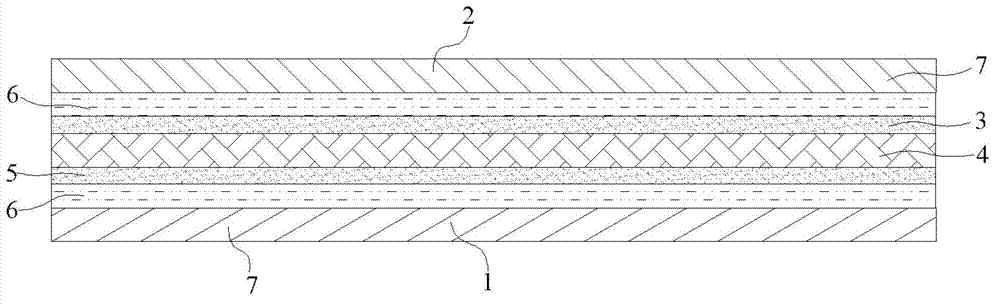

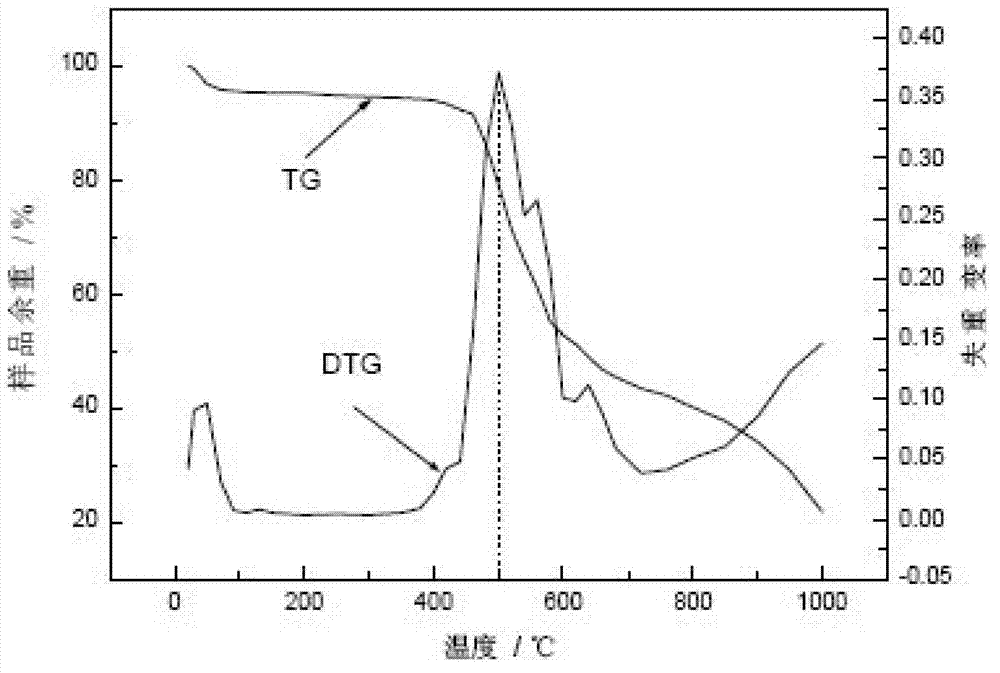

Heat-dissipating double-sided adhesive tape with ultrahigh heat conductivity coefficient

ActiveCN103045119AAvoid local overheatingAchieve uniformityCarbon compoundsFilm/foil adhesivesPolymer sciencePolyamide

The invention discloses a heat-dissipating double-sided adhesive tape with an ultrahigh heat conductivity coefficient. Ethylene glycol or triethylamine is added into a polyamic acid solution, the resulting mixture is put in an oven in a vacuum environment and maintained at 100 DEG C for 0.9-1.1 hours, the temperature is raised to 300 DEG C and maintained for 0.9-1.1 hours, followed by natural cooling, to produce a polyimide film; the polyimide film is heated up to 250 DEG C from room temperature and then heated up to 500 DEG C, and further heated up to 1200 DEG C at a rate of 9-11 DEG C / min, to produce a prefired carbonized film; the prefired carbonized film obtained in the step 4 is rolled by a calendar; the rolled product is heated up to 2400 DEG C at a rate of 19-21 DEG C / min and maintained for 0.9-1.1 hours and then heated up to 2900 DEG C at a rate of 19-21 DEG C / min and maintained for 1.8-2.2 hours, followed by cooling, to produce a fired graphite film; and subsequently the graphite film is rolled to obtain a graphite coating. The heat transfer performance of the double-sided adhesive tape in both the vertical and the horizontal directions are improved, so as to prevent local overheat of the adhesive tape and ensure uniformity of heat transfer performance of the adhesive tape.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

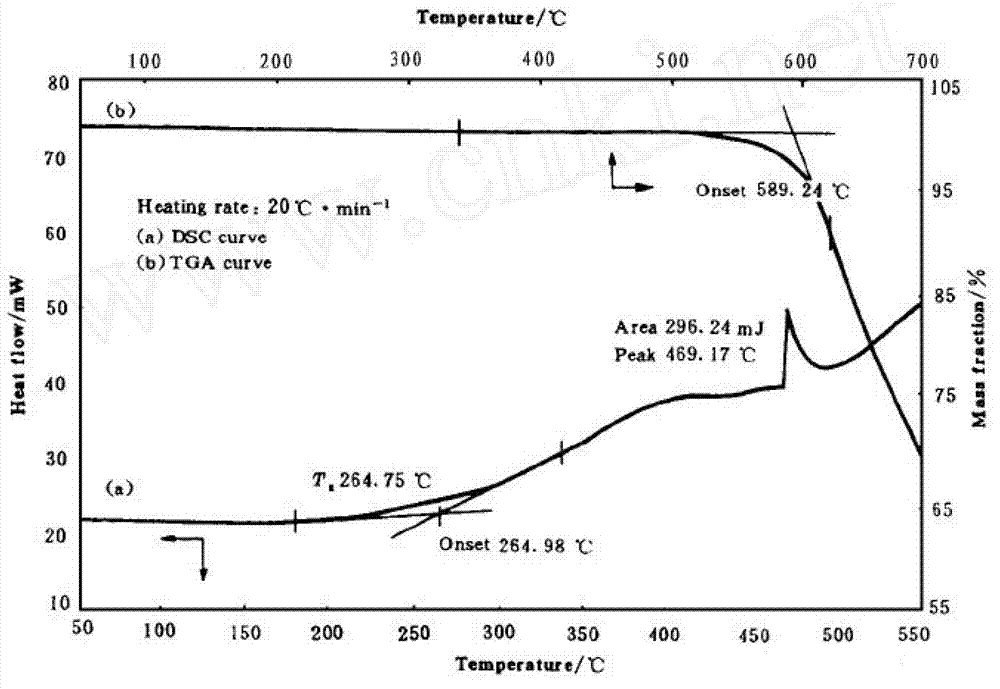

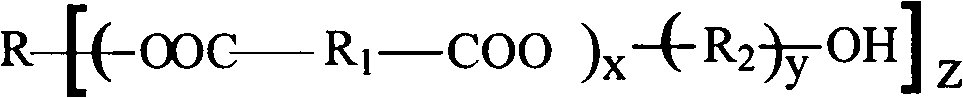

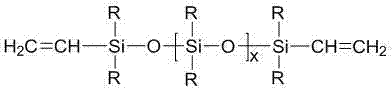

Preparation method and application of resin having double curing groups

InactiveCN101824152AHigh viscosityTo achieve the effect of initial bondingPolyureas/polyurethane adhesivesInksEpoxyUV curing

The invention discloses a preparation method and application of resin having double curing groups. The resin having double curing groups comprises epoxy monoacrylate and polyurethane acrylate chain segments and has the following structure. The molecule of the resin having double curing groups has an acrylate double bond (a curing free radical) and an epoxy group (a curing or thermally curing anion), so the brittleness of a cured film is reduced and the flexibility of the cured film is improved and the resin can be used in ultraviolet curing paint, adhesive and ink. The resin can improve large shrinkage factor of a single acrylate free radical curing system and large brittleness and poor flexibility of the UV curing film and the like and can also solve the problem that a several-resin mixed compounding system has unstable performance, uneven local curing, poor compatibility among resin and the like.

Owner:SHENZHEN POLYTECHNIC

Lining-reinforced hollow fiber membrane tube as well as preparation device and preparation method thereof

ActiveCN102160967AIncrease asymmetryLow elongationSemi-permeable membranesHollow fibrePolymer science

The invention relates to a lining-reinforced hollow fiber membrane tube as well as a preparation device and preparation method thereof, belonging to the field of preparation of polymer hollow fiber microporous membranes. In the membrane tube, a film forming chimney is designed reasonably, a coating layer on a braided tube led from a coating machine is subjected to controllable steam diffusion-induced phase inversion firstly, and then enters a coagulating bath, so that an open-pore surface skin layer with high porosity is formed on a film separation layer, and the radial direction of the membrane layer is in an integral asymmetric and interpenetrating cell-shaped structure; a composite material is selected to prepare a transition layer, so that the transition layer has excellent adhesive force and hardness, excellent compatibility with a surface separation layer and tiny cubical contraction in a phase conversion process at the same time; optimized braided tube size and braiding densityare selected to ensure that the braided tube has lower flexibility; and a method capable of maintaining reasonable roundness and the like in the production process ensures that the lining polyvinylidene fluoride (PVDF) hollow ultrafiltration membrane tube has the advantages of integral asymmetric structure with high integrity, high-porosity surface separation layer, higher back pressure enduring capability and the like.

Owner:南京久盈膜科技有限公司

Conformal layers by radical-component CVD

ActiveUS8563445B2Less pore formationSmall volume shrinkageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogenOptical property

Methods, materials, and systems are described for forming conformal dielectric layers containing silicon and nitrogen (e.g., a silicon-nitrogen-hydrogen (Si—N—H) film) from a carbon-free silicon-and-nitrogen precursor and radical-nitrogen precursor. The carbon-free silicon-and-nitrogen precursor is predominantly excited by contact with the radical-nitrogen precursor. Because the silicon-and-nitrogen film is formed without carbon, the conversion of the film into hardened silicon oxide is done with less pore formation and less volume shrinkage. The deposited silicon-and-nitrogen-containing film may be wholly or partially converted to silicon oxide which allows the optical properties of the conformal dielectric layer to be selectable. The deposition of a thin silicon-and-nitrogen-containing film may be performed at low temperature to form a liner layer in a substrate trench. The low temperature liner layer has been found to improve the wetting properties and allows flowable films to more completely fill the trench.

Owner:APPLIED MATERIALS INC

Free radical- cation type ultraviolet photo-curing cementing agent and its preparation method

InactiveCN101007929AFast curingImprove performanceOrganic non-macromolecular adhesiveEpoxyUltraviolet lights

The invention discloses a free radical- cationic ultraviolet light curing adhesive agent and the preparing method. Said adhesive agent comprises diluting agent, light initiating agent and low-molecular polymer which contains free radical and cation. Said low molecular polymer is prepared with epoxy resin, acroleic acid, catalyst and inhibitor. The curing speed of ultraviolet light curing adhesive agent is high, the double- bond group of acrylate is cured in a short time after radiation by ultraviolet light to make the adhesive agent possess initial adhesive force, the epoxy group continues cross- linking and curing after ultraviolet light withdraw according to cation initiation principle, and the adhesive force is reinforced further to meet requiement for adhesive force by electronics and optical products. The invention is characterized by no solvent, simple operation, convenient connection process and suitability for batch production.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

Curing agent for filling iron tailings and preparation method thereof

The invention discloses a curing agent for filling iron tailings and a preparation method thereof and belongs to the technical field of mine safety. The curing agent comprise the following components in parts by mass: 0-70 parts of fly ash, 10-80 parts of superfine mineral slag powder, 0-70 parts of superfine steel slag powder, 0-20 parts of an alkaline activator, 0-20 parts of an sulfate activator, 0.1-1 part of a foam stabilizer and 2-5 parts of a microcapsule in which aluminum powder is used as a core material. The preparation method of the curing agent comprises the steps of firstly weighting fly ash, superfine mineral slag powder, superfine steel slag powder, alkaline activator, sulfate activator and foam stabilizer according to the blending ratio of the components of the curing agent, adding all the components in a stirrer, quickly stirring for 5-15 minutes, adding microcapsule in which aluminum powder is used as a core material and slowly stirring for 2-5 minutes to obtain the curing agent for filling iron tailings. The curing agent for filling iron tailings provided by the invention has strong curing capability and is simple and controllable in use and operation.

Owner:罗强

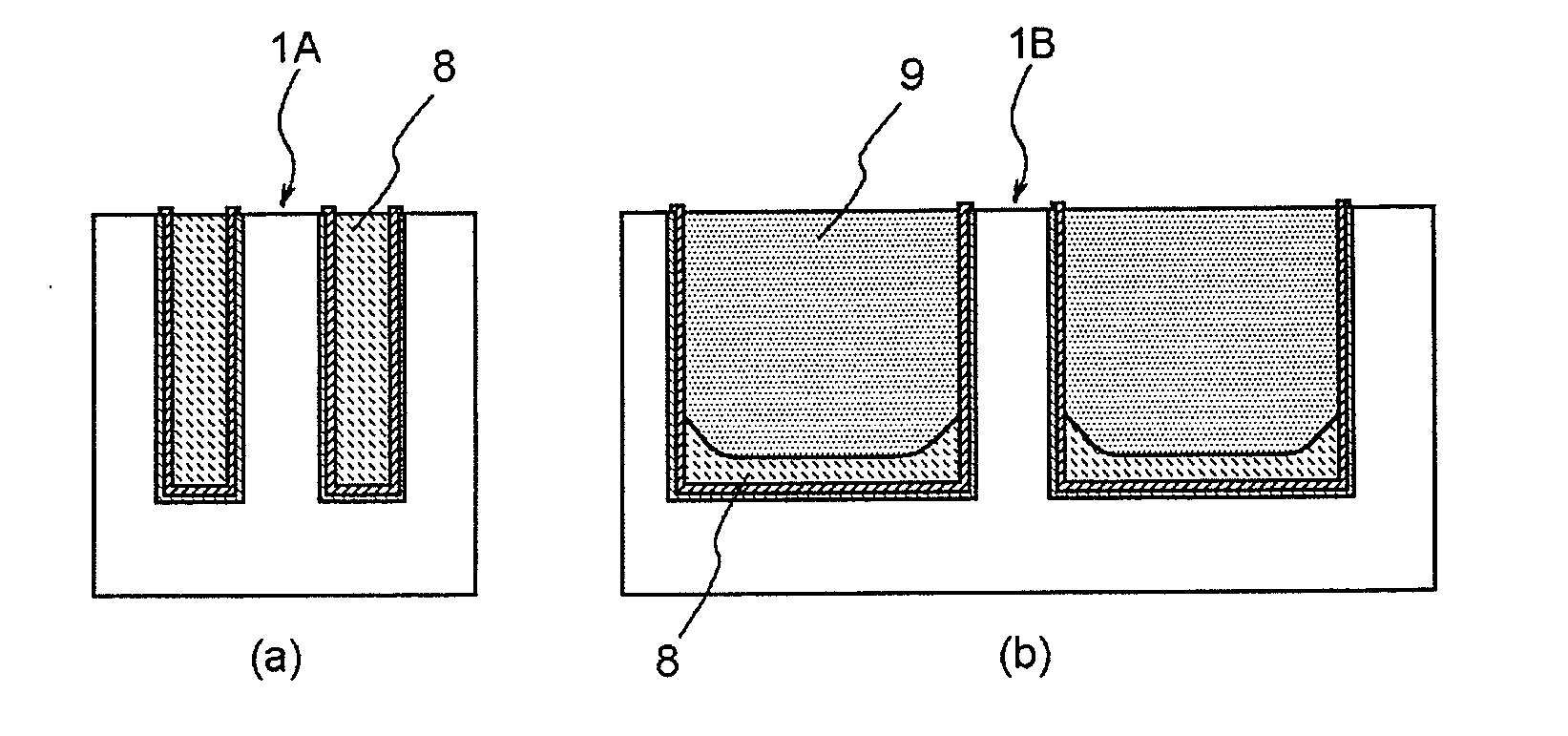

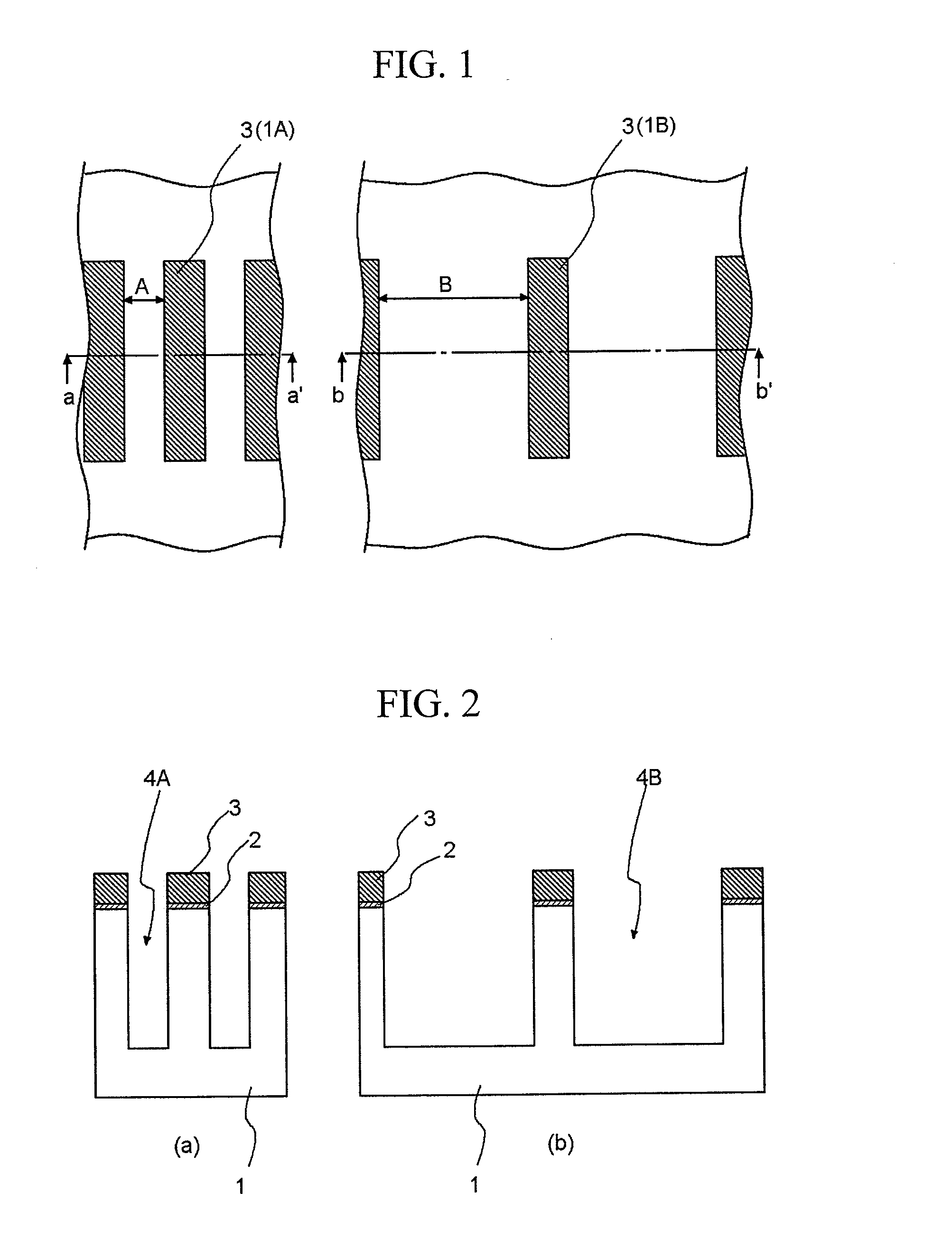

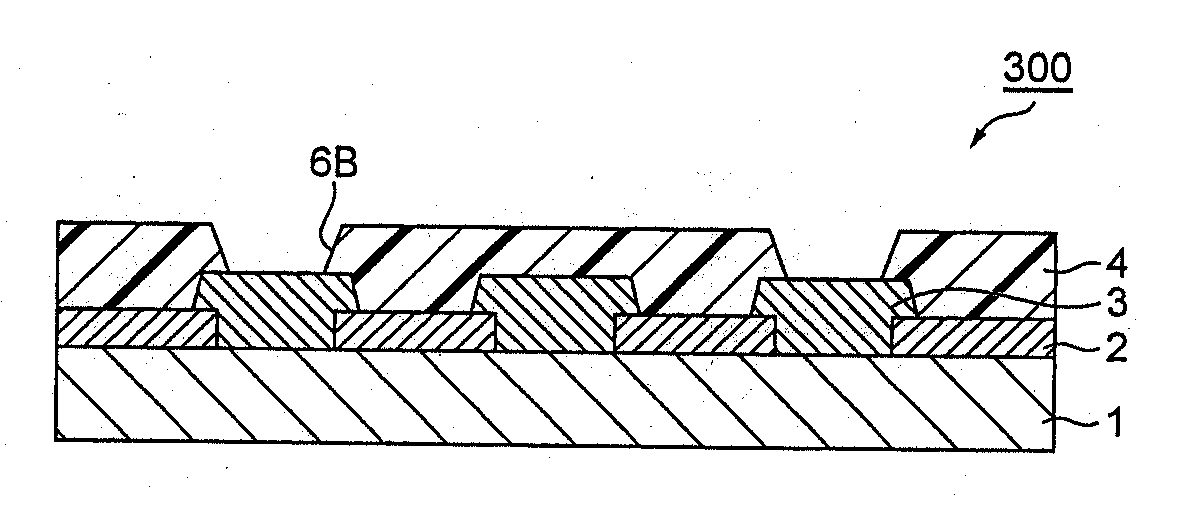

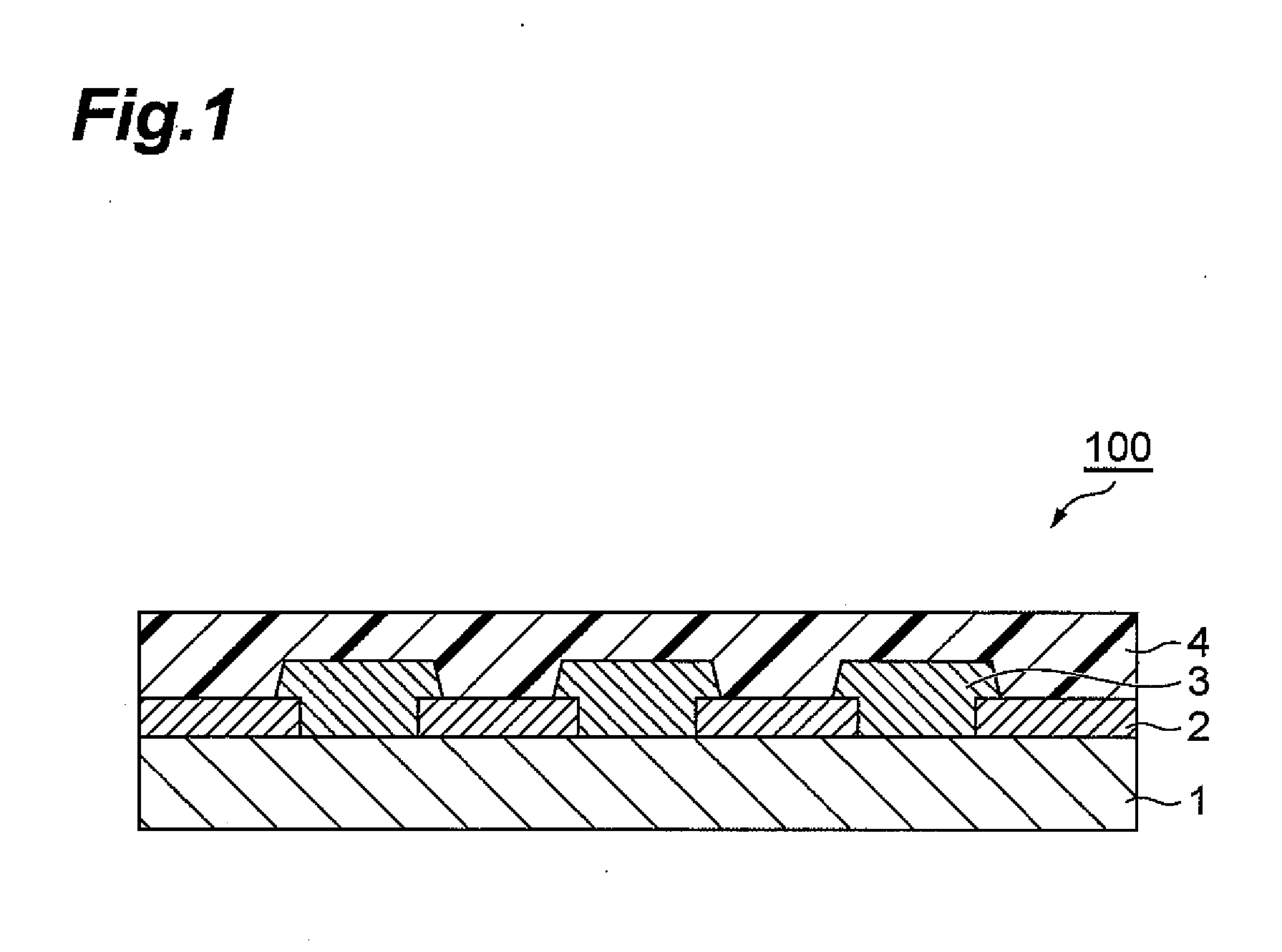

Method for manufacturing semiconductor device

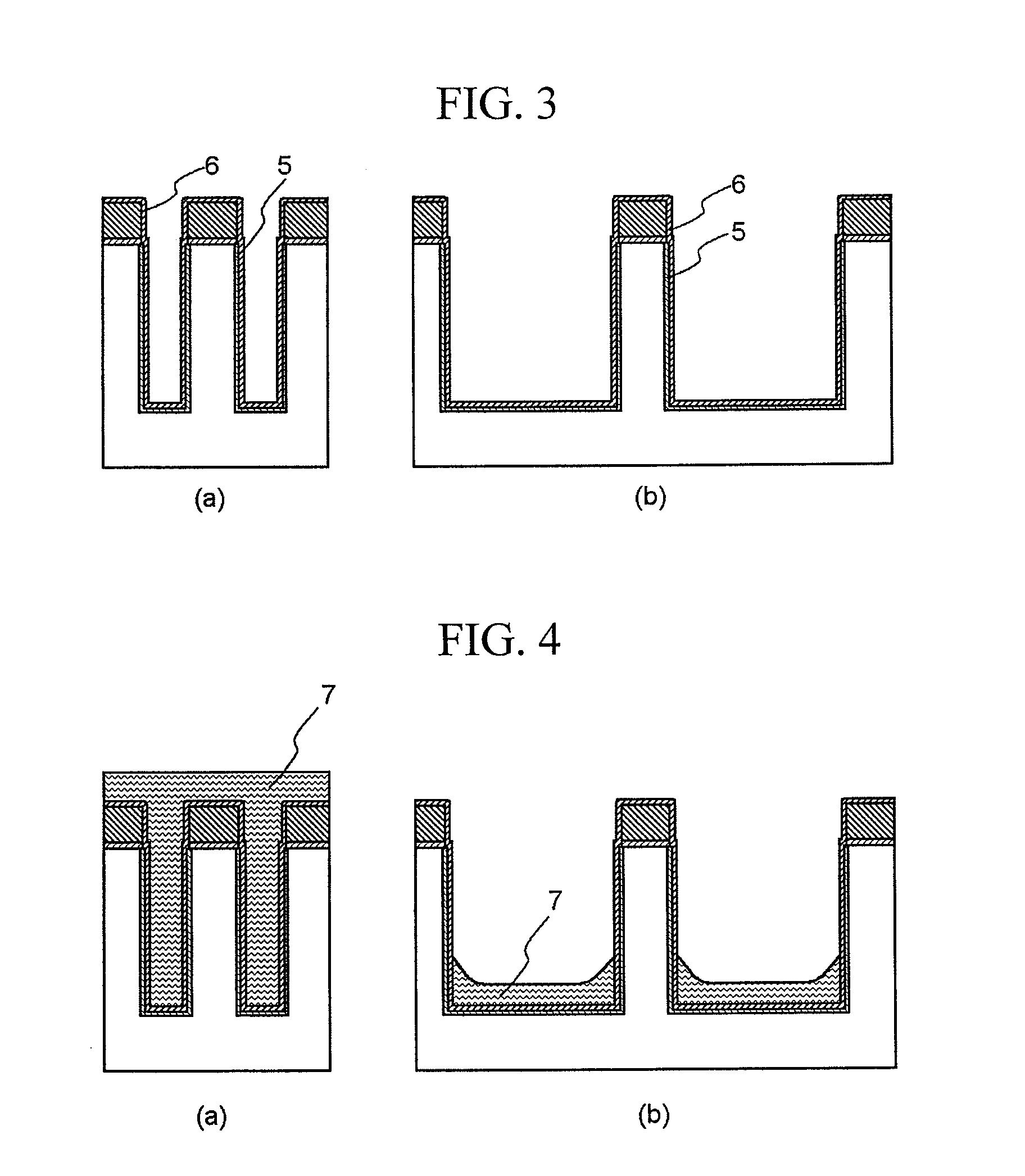

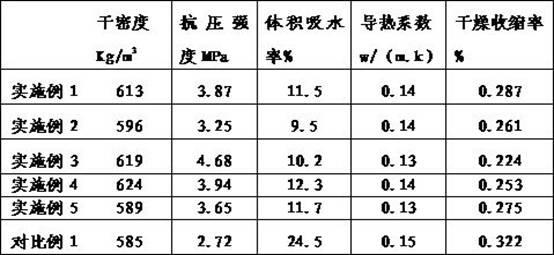

InactiveUS20120276713A1Small volume shrinkageSemiconductor/solid-state device manufacturingSilicon oxideNitride

Disclosed is a method for manufacturing a semiconductor device, which provides an isolation region in which a dense silicon oxide film is formed in a trench that requires high aspect ratio. The method includes forming an isolation trench using, as an etching mask, a nitride mask film formed on a substrate, forming a liner nitride film in the isolation trench, depositing a flowable silazane compound by a CVD method such that the height of the flowable silazane compound is higher than the upper surface of the nitride mask film from the upper portion of the trench, performing heat treatment under an oxidizing atmosphere to convert the flowable silazane compound film into a silicon oxide film and simultaneously densifying therefor, and planarizing the silicon oxide film to the height of the upper surface of the nitride mask film.

Owner:LONGITUDE LICENSING LTD

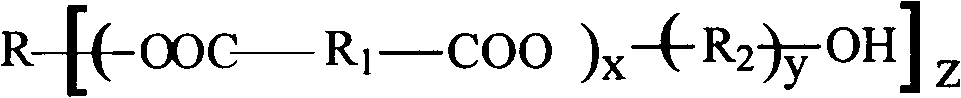

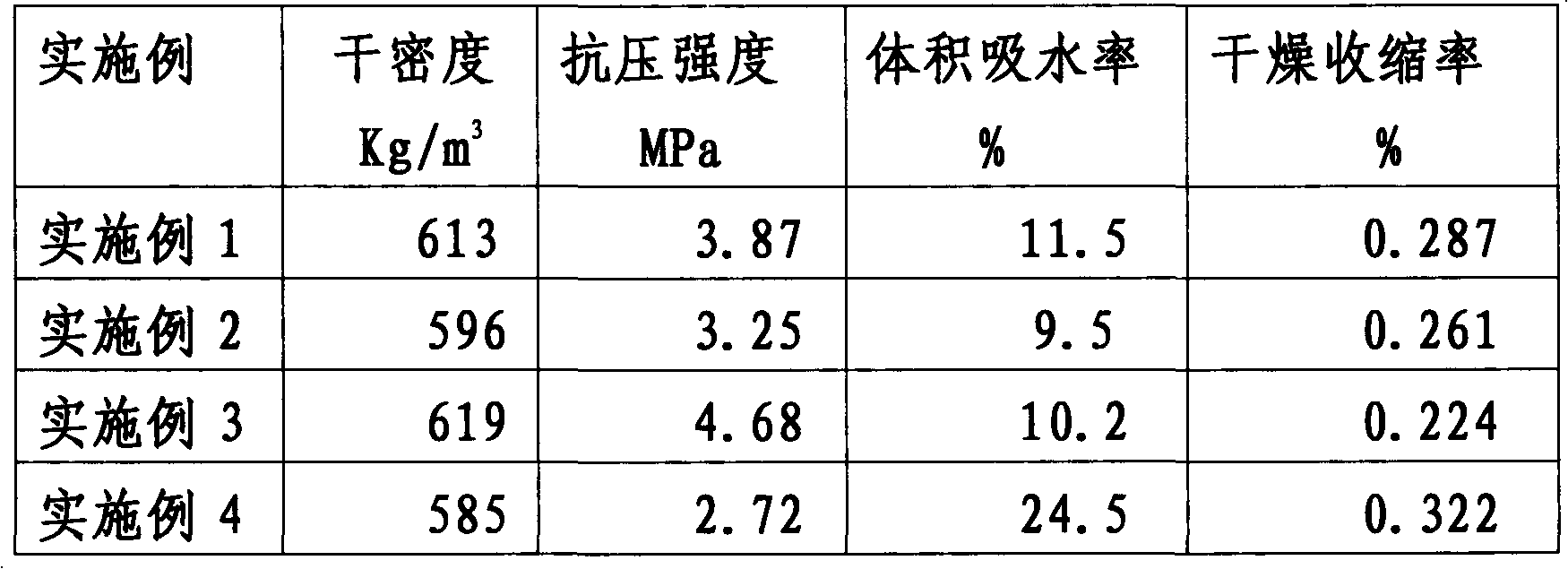

Flame retardant heat-insulation foam concrete and preparation method thereof

The invention discloses flame retardant heat-insulation foam concrete which consists of the materials by mass as follows: 30-60 parts of cement; 30-70 parts of coal ash; 10-40 parts of mineral powder; 0.05-1. 0 part of water reducing agent; 0.02-0.2 part of cellulose ether; 0.05-1.0 part of water repellent; 1-10 parts of anhydrous anhydrite; 0.06-0.2 part of polypropylene fiber; 0.1-0.4 part of foaming agent; and 0.30-0.60 part of water. The advantages are as follows: the foam concrete has high strength, low shrinkage and good water repellent property; the heat insulation performance is good and can meet different heat-insulation requirements of buildings; the preparation technology is simple; and industrial wastes such as coal ash, mineral powder and the like are utilized fully, and the flame retardant heat-insulation foam concrete has excellent environment-protection effects of utilizing waste, saving energy and the like, as well as better economic benefit.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Polyurethane complex film adhesive and preparation method thereof

The invention relates to a polyurethane complex film adhesive and a preparation method thereof. The polyurethane complex film adhesive comprises a solidifying agent A component and a main agent B component, wherein the solidifying agent A component is an isocyanate-terminated prepolymer obtained by reacting polyisocyanate with polyalcohol a; the main agent B component is a polyhydroxylated compound prepared by reacting special polyalcohol, epoxy resin and polyalcohol b with polyisocyanate; the mole ratio of the functional groups of the A and B components is NCO:OH=(1.0-2.0):1. The process for preparing the polyurethane complex film adhesive is simple; the prepared product has the advantages of high initial viscosity, good wetting property on a base material, good hydrolysis resistant stability, wetness and heat resistance, long opening time, good compatibility, high adhesive force on metals, chemical resistance, good compound flexible package appearance and high stripping strength, can be used for series complex films with generality, high solid content, solvent-less lamination, and the like and overcomes the defects of low solid content, poor wetness, poor hydrolysis resistance, no wetness and heat resistance, short opening period, poor composite adhesive force on the metals, and the like of a common polyurethane complex film adhesive.

Owner:WANHUA CHEM BEIJING +2

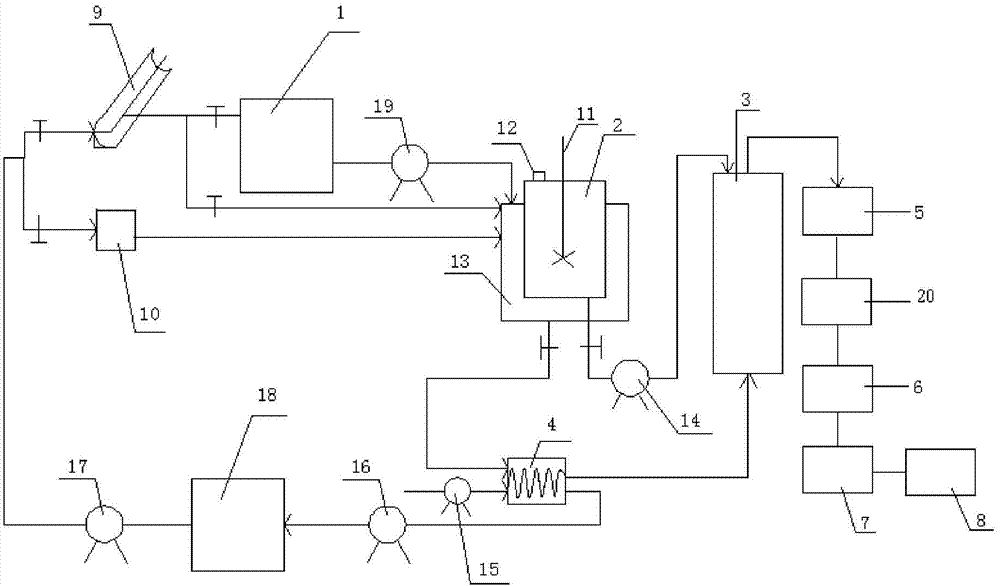

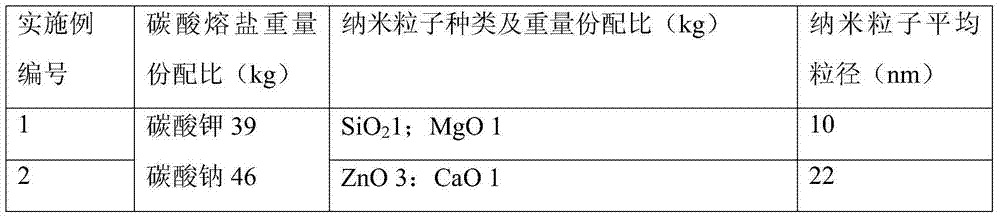

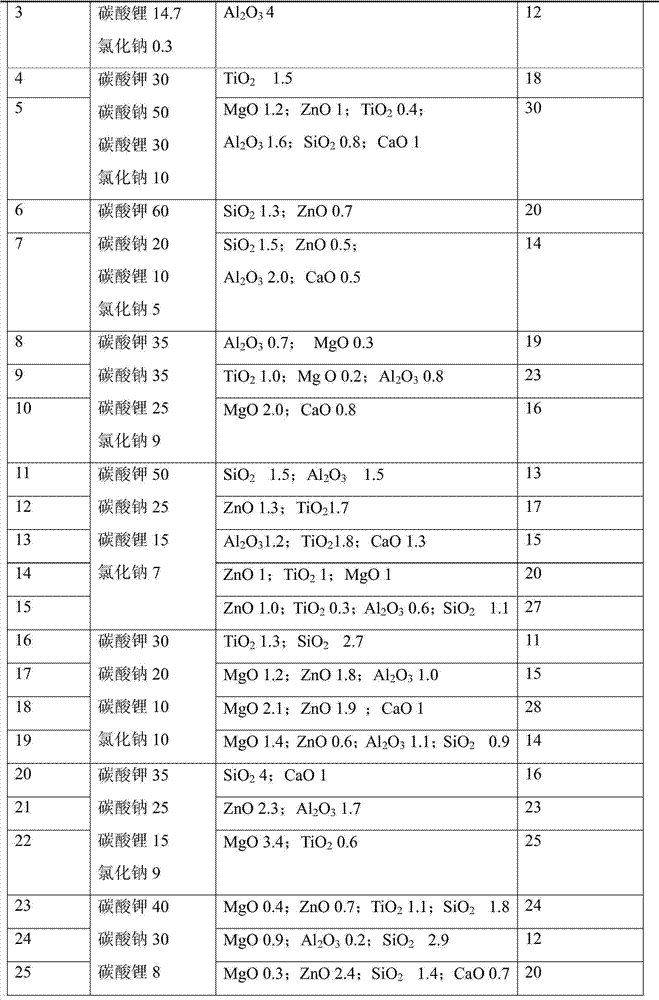

Molten nano-carbonate heat transfer and accumulation medium, and preparation method and application thereof

ActiveCN103923619AHigh safe use upper limit temperatureReduce volume shrinkage ratioHeat-exchange elementsHeat stabilityNanoparticles dispersion

The invention provides a molten nano-carbonate heat transfer and accumulation medium, and a preparation method and an application thereof, and belongs to the technical field of heat storage and transmission. The molten nano-carbonate heat transfer and accumulation medium contains a molten carbonate system formed by potassium carbonate, sodium carbonate, lithium carbonate and sodium chloride, nanoparticles are added into the molten carbonate system, and the nanoparticles are metal oxide and / or nonmetal oxide; and the nanoparticles are dispersed into the molten carbonate system, and the molten nano-carbonate heat transfer and accumulation medium is formed through compounding. The melting point of molten nano-carbonate is low, so the molten nano-carbonate heat transfer and accumulation medium has an upper limit use temperature of 800DEG C, has a good heat stability and a high heat conductivity, and is very suitable for the heat accumulation and transfer systems of industrial energy accumulation and solar photo-thermal power generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

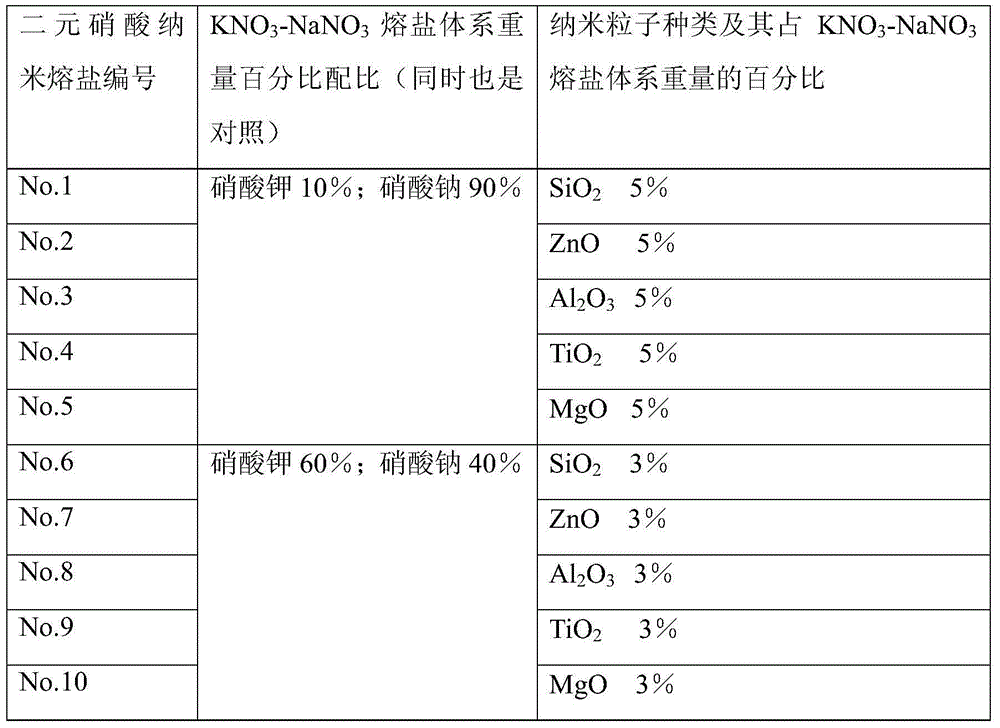

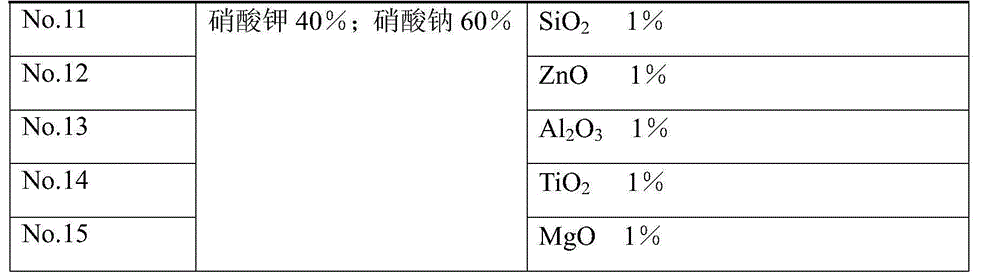

Nanometer molten binary nitrate heat-transfer heat-storage medium and preparation method thereof

ActiveCN103911121AImprove thermal conductivityImprove thermal stabilityFrom solar energySolar heat devicesMolten saltHeat stability

The invention relates to a nanometer molten binary nitrate heat-transfer heat-storage medium and a preparation method thereof and belongs to the field of solar photo-thermal electricity generation. The nanometer molten binary nitrate heat-transfer heat-storage medium is characterized in that nano-particles are dispersed in a KNO3-NaNO3 and KNO3-NaNO2 solid-liquid phase-change molten binary nitrate system at a high temperature so that the nanometer molten binary nitrate heat-transfer heat-storage medium is compounded, and the nano-particles comprise SiO2, ZnO, Al2O3, TiO2, CaO and / or MgO nanoparticles. The nanometer molten binary nitrate heat-transfer heat-storage medium solves the problem that the existing nanometer molten binary nitrate system has a low heat conductivity coefficient, poor heat stability and a narrow use temperature scope and can be widely used in the technical field of solar photo-thermal electricity generation.

Owner:QINGHAI ENESOON NEW MATERIAL TECH & SCI CO LTD

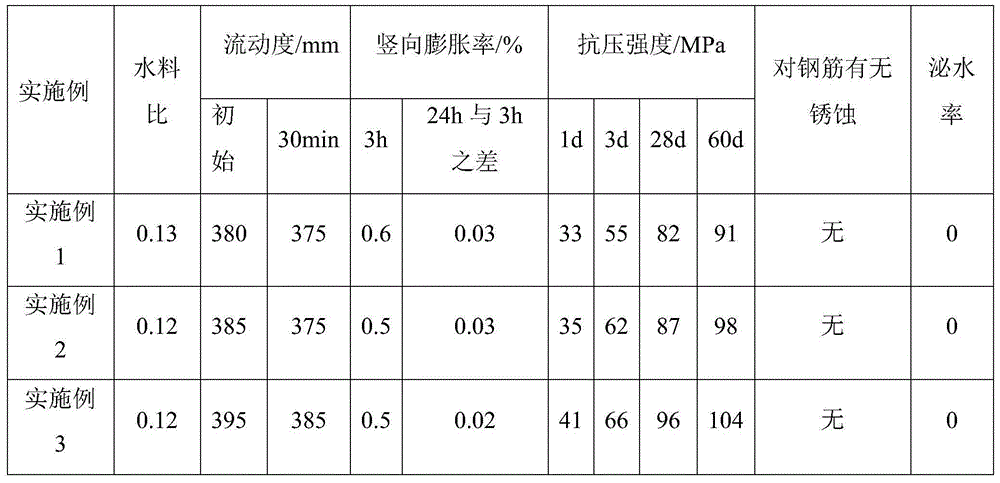

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

High-expansion fireproof sealant and preparation thereof

ActiveCN101302420AImprove sealingSmall volume shrinkageNon-macromolecular adhesive additivesOther chemical processesFire resistanceSealant

The invention discloses high intumescent fire stopping mastic and a method for preparing the same. The mastic is prepared by taking acrylate emulsion (or elastic styrene-acrylate emulsion), polybutene (or polyisobutylene), glycol, emulsifying agent and tritolyl phosphate as base materials with addition of certain auxiliary materials. The preparation method is as follows: the base materials are added into a reaction kettle according to certain mass portion, stirred, slowly heated and insulated for a period of time, and transferred into a colloid stirrer; auxiliary materials such as ammonium polyphosphates, flame-retarding aluminum hydroxide, flame-retarding zinc borates, calcium carbonates, expandable graphite, iron oxide red and glass fibers are gradually added into the mixture under the condition of stirring; and the process of stirring is continued until a colloid is uniform. The fire stopping mastic prepared by adoption of the method can be quickly carbonized and expanded to 5 to 8 times of the prior volume in case of fire, and can not fall off; the strength and the heat insulation after solidification are good, and the fire resistance is very good; and the adhesion is strong and the elasticity is good. The high intumescent fire stopping mastic and the method are particularly suitable for fire compartmentation of various penetrating penetration assemblies such as cables, cable bridges, pipes and so on.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

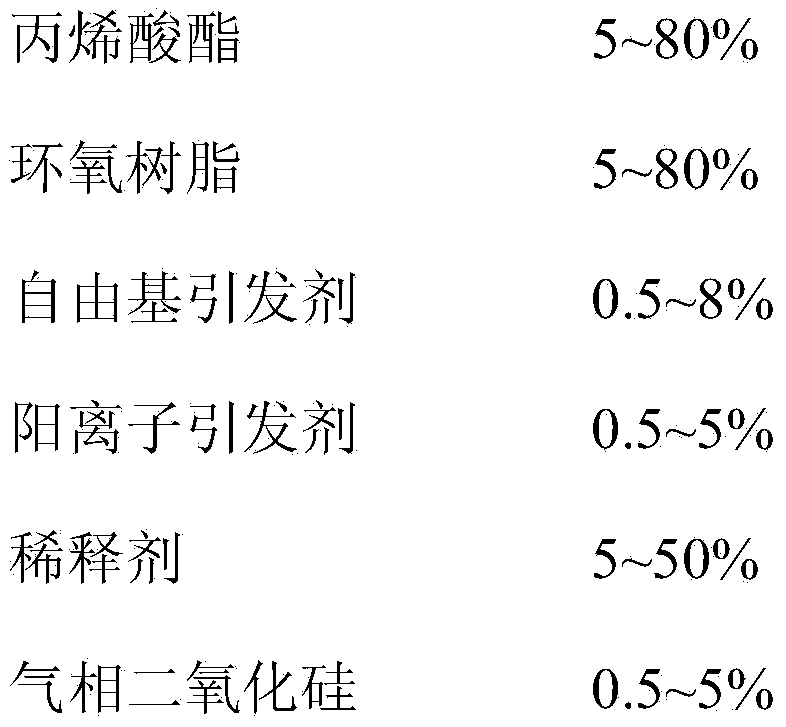

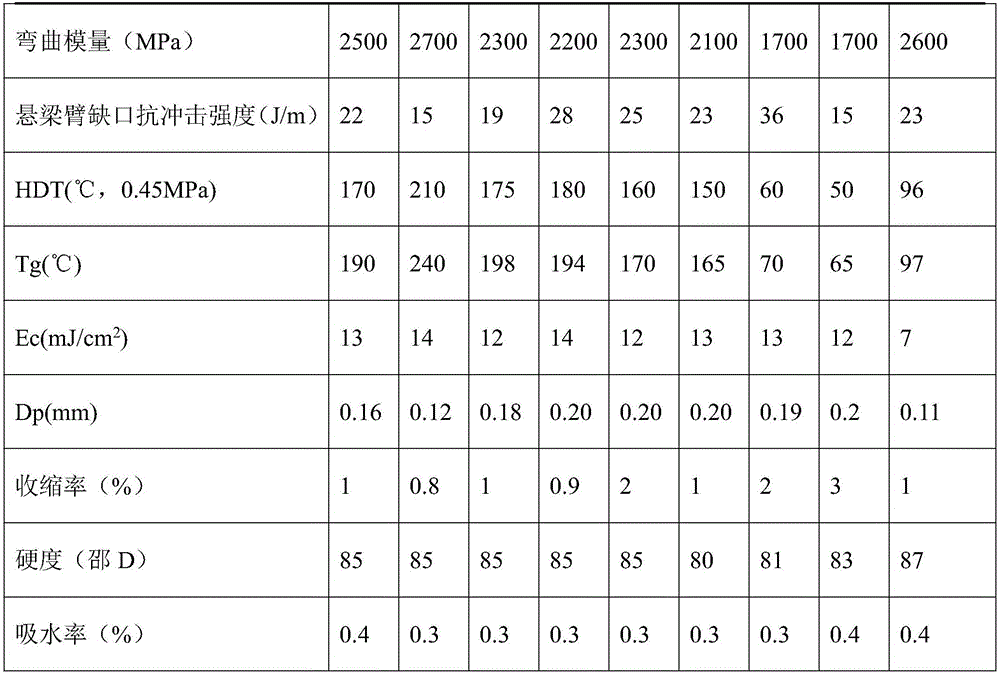

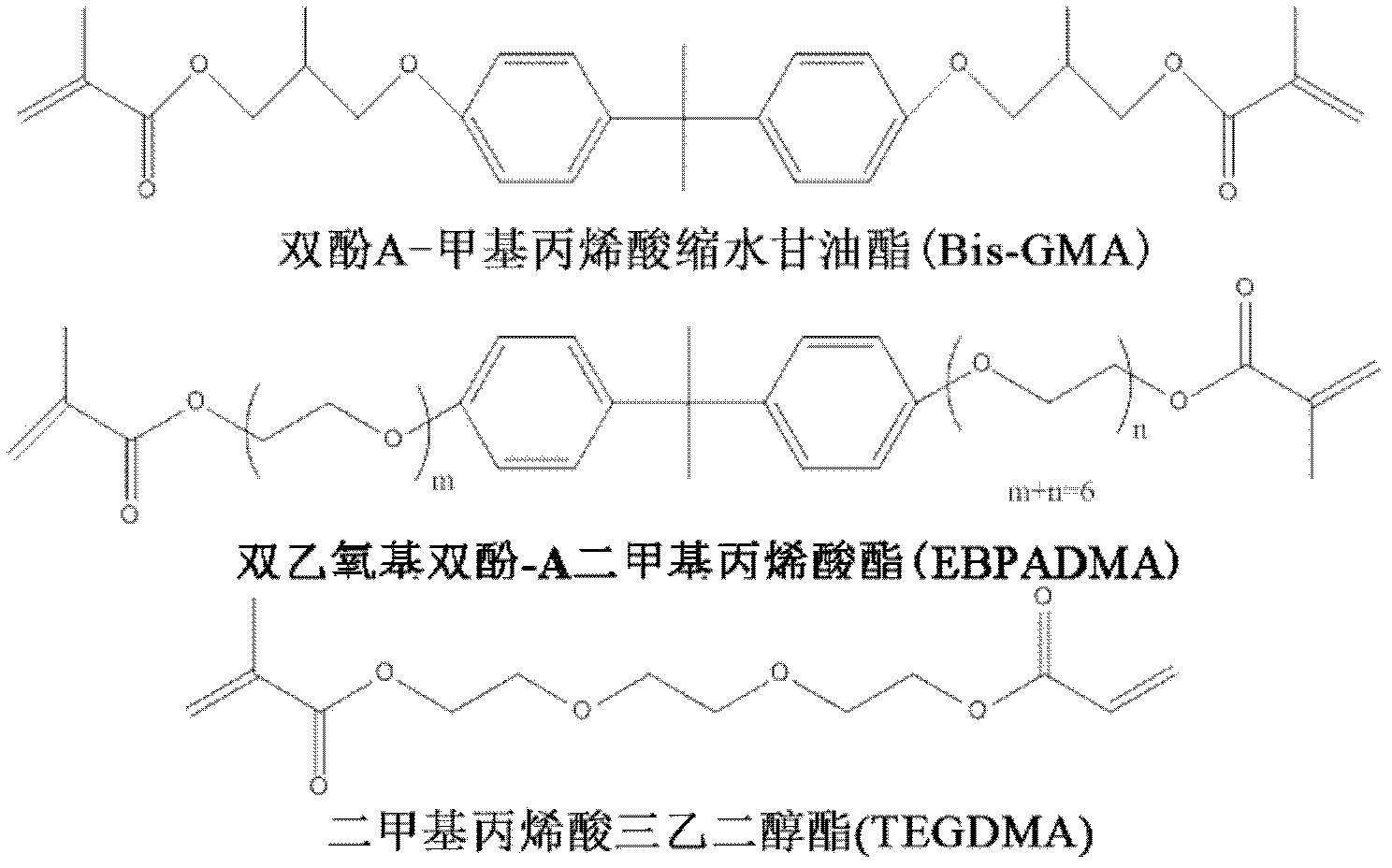

Photosensitive resin and preparation method thereof

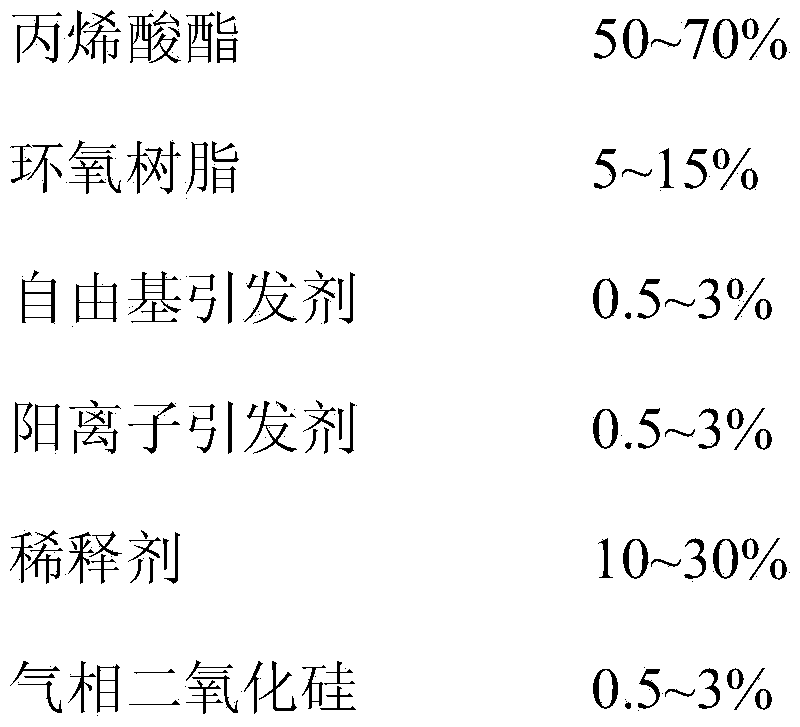

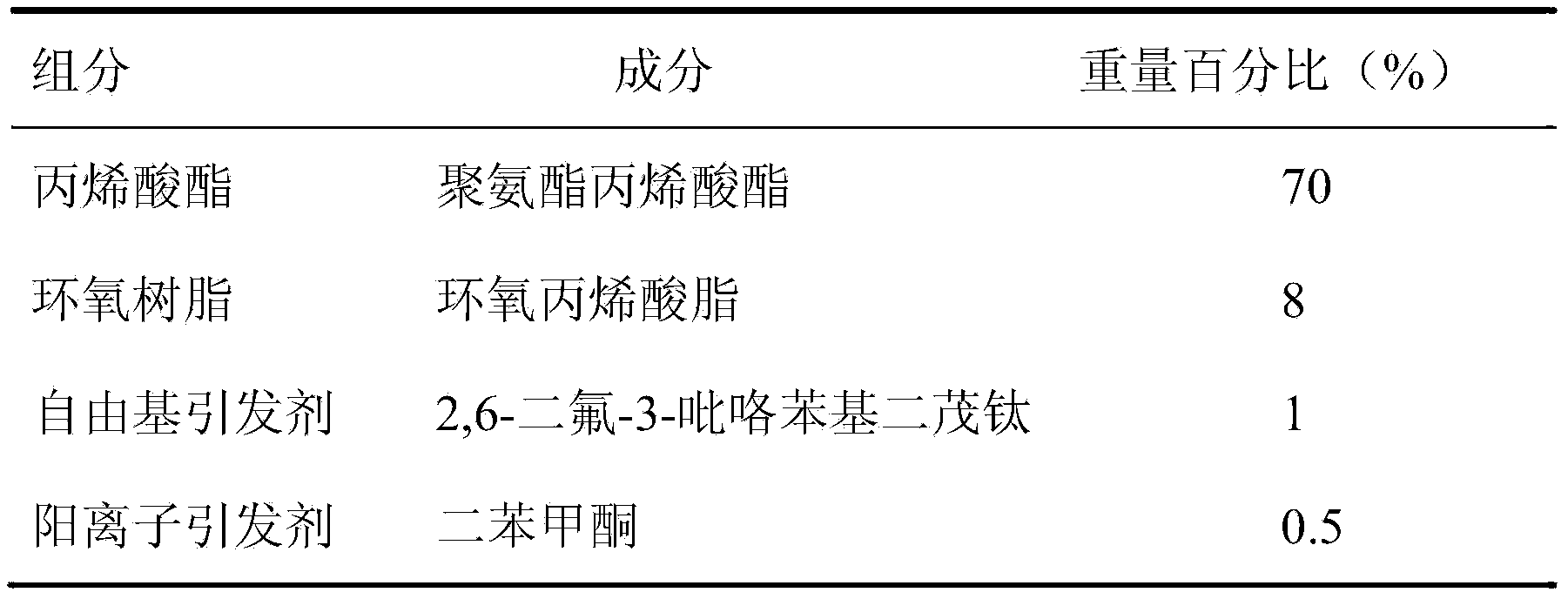

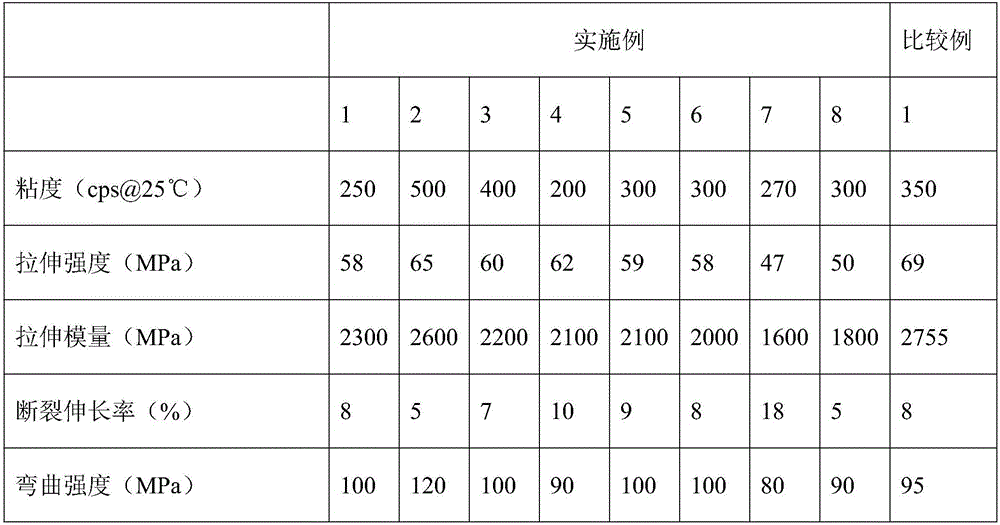

The invention belongs to the field of novel 3D printing materials and in particular belongs to the field of photosensitive resin. The photosensitive resin is prepared from the following components in percentage by weight: 5-80% of acrylic ester, 5-80% of epoxy resin, 0.5-8% of a radical initiator, 0.5-5% of a cationic initiator, 5-50% of a diluent and 0.5-5% of gas phase silicon dioxide. Flexural modulus and tensile modulus of the photosensitive resin reach over 2000Mpa; the photosensitive resin is high in capability of resisting bending deformation stress in an elastic limit, high in strength, low in possibility of deforming and high in mechanical strength; the service life is greatly prolonged; the volume shrinkage rate is about 1.0%; the ultralow volume shrinkage rate is achieved; the industrial use requirement can be met.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

High-strength composite salt core material for low-melting-point alloy casting, salt core and preparation method

ActiveCN106670376AImprove flexural strengthReduce energy consumptionFoundry mouldsFoundry coresAlloySodium nitrate

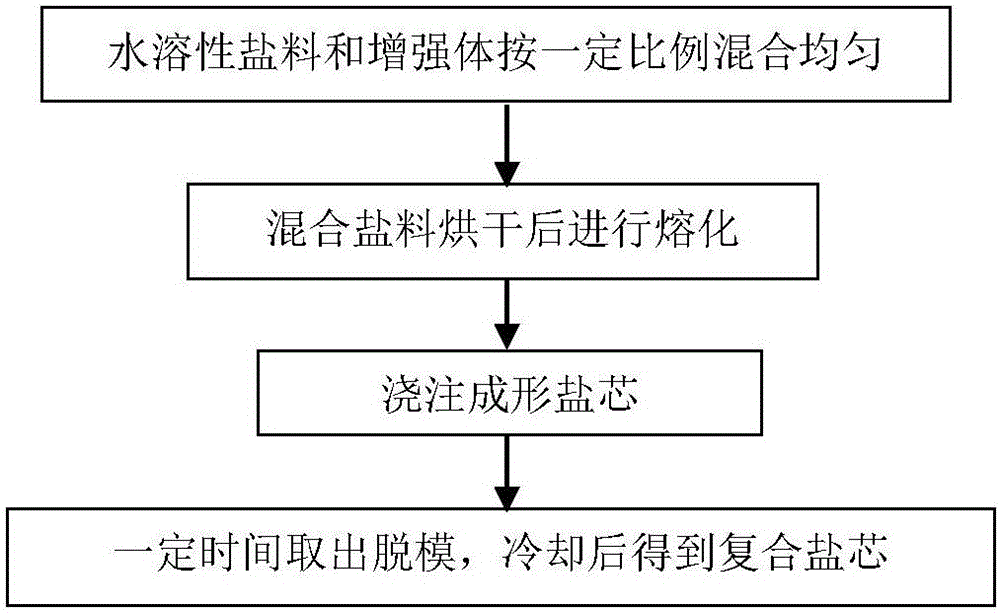

The invention belongs to the technical field of casting, and particularly relates to a high-strength composite salt core material for low-melting-point alloy casting. The high-strength composite salt core material comprises, by mass, 70%-100% of water-soluble inorganic salt and 0%-30% of a reinforcement, wherein the water-soluble inorganic salt comprises one of low-melting-point salts including potassium nitrate and sodium nitrate, and at least one of high-melting-point salts including potassium chloride, sodium chloride, potassium bromide and sodium bromide, and positive ions of the low-melting-point slats are the same as positive ions of the high-melting-point salts. The invention further discloses a preparation method of a high-strength composite salt core, and an obtained salt core product. The prepared composite salt core has extremely high bending strength, excellent hygroscopicity and small volume shrinkage, and the comprehensive performance is excellent. In addition, the preparation technique of the high-strength composite salt core is simple, raw materials are cheap, and industrial production is easy.

Owner:HUAZHONG UNIV OF SCI & TECH

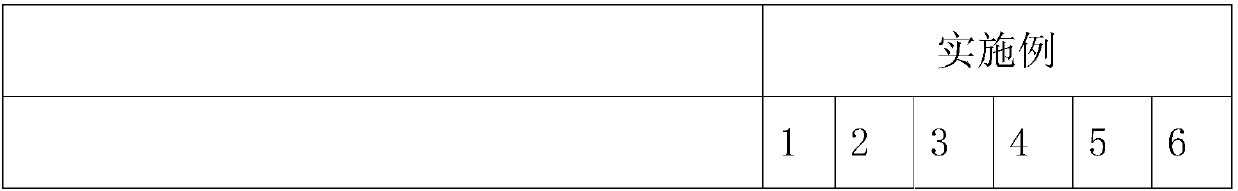

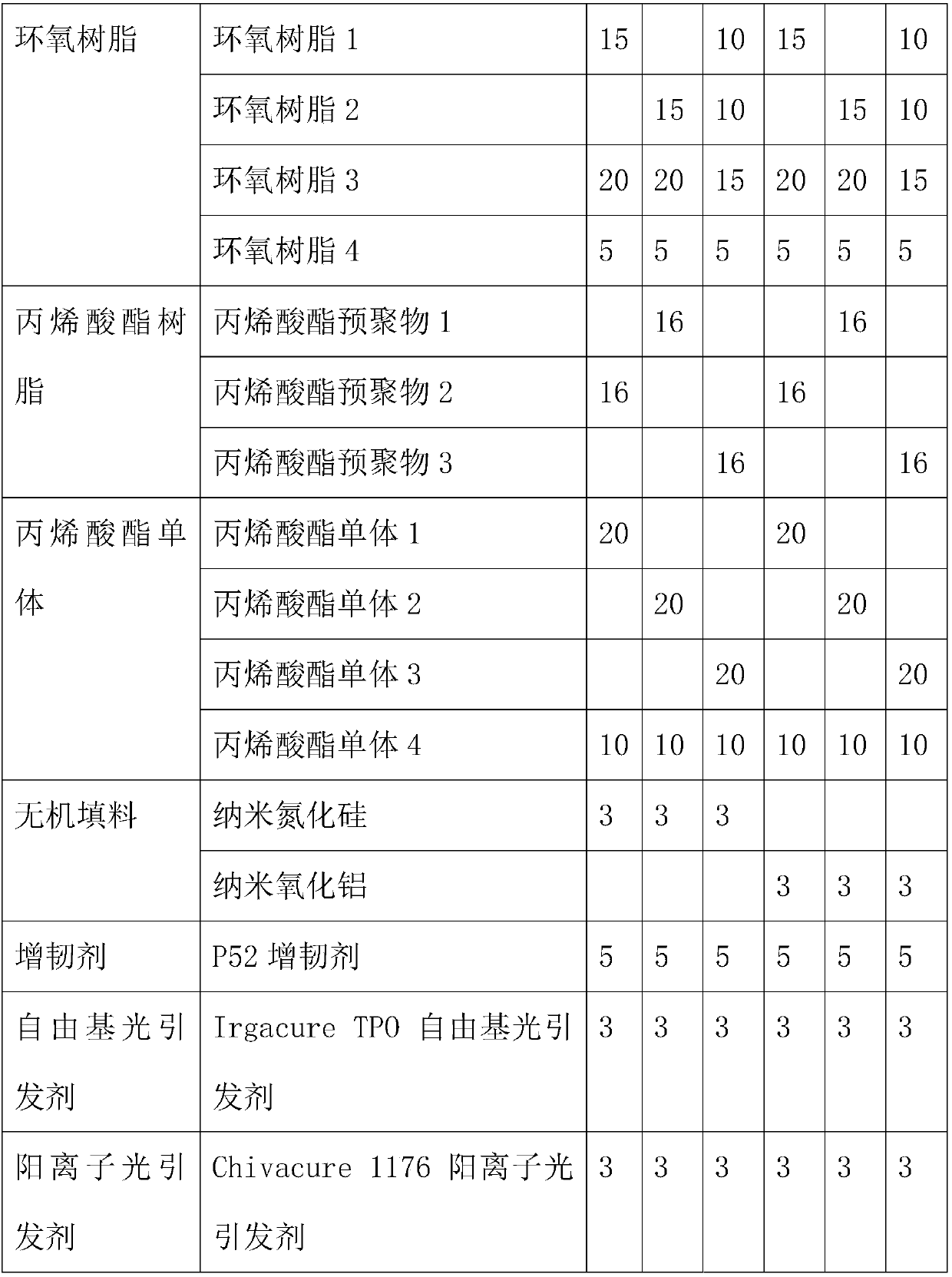

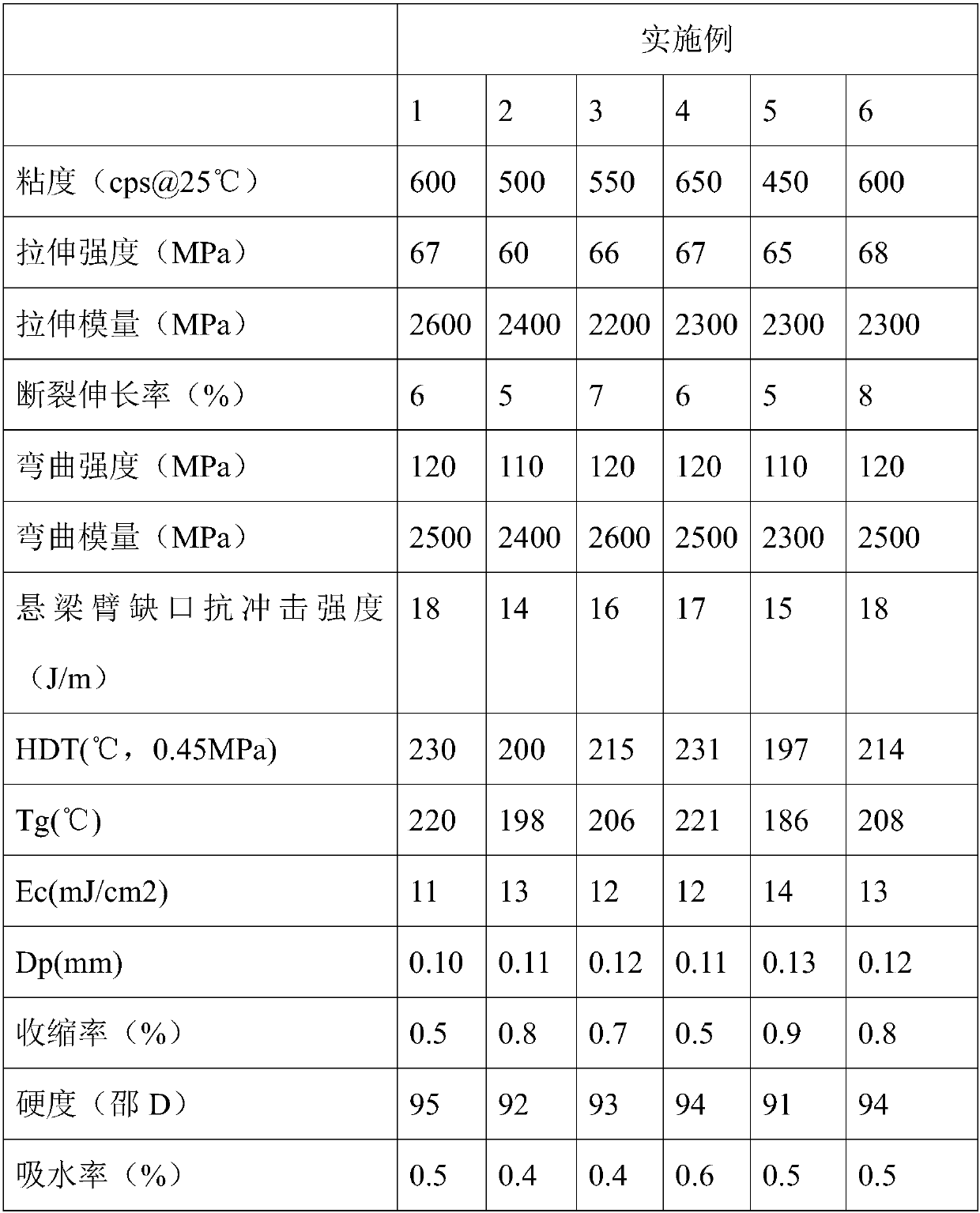

High-temperature-resistant photosensitive resin composition used for photocuring rapid formation

The invention discloses a high-temperature-resistant photosensitive resin composition used for photocuring rapid formation. The high-temperature-resistant photosensitive resin composition comprises the following components in parts by weight: 20-70 parts of epoxy resin, 8-40 parts of acrylic resin, 10-40 parts of acrylate monomers, 0.5-5 parts of inorganic nano-particle filler, 1-20 parts of a flexibilizer, 0.5-10 parts of a free radical photoinitiator and 0.5-10 parts of a cationic photoinitiator, based on 100 parts in total. The high-temperature-resistant photosensitive resin composition is high in reaction speed, is small in volume shrinkage after being cured, is low in water absorption and is high in dimension stability of products; the products have high temperature resistance, can keep normal high-temperature-resistant requirements, have considerable toughness, and are not damaged as a result of embrittlement in a using process.

Owner:ZHONGSHAN GREATSIMPLE TECH CO LTD

Composite phase-change material for mobile heat supply and preparation method thereof

ActiveCN103113854ANo precipitationFast heat storage and releaseChemical industryHeat-exchange elementsMolten stateMass ratio

The invention discloses a composite phase-change material for mobile heat supply and a preparation method thereof. The composite phase-change material is formed by compounding 97.5-99.5 wt% of mixed inorganic salts and 0.5-2.5 wt% of non-metal nano material. The preparation method comprises the following steps: mixing a plurality of inorganic salts according to mass ratio, stirring, adding into a vacuum heating furnace, and heating into a molten state, wherein the temperature of the vacuum heating furnace is controlled at 40-50 DEG C higher than the phase-change temperature of the mixed inorganic salts; and adding the non-metal nano material into the molten salts, and magnetically stirring for more than half an hour to prepare the uniform and stable molten-state composite phase-change material. Compared with the prior art, the composite phase-change material disclosed by the invention has the advantages of high heat-conducting property, high heat accumulation density, small volume shrinkage and the like, can satisfy different application requirements, and is especially suitable for moderate-temperature waste heat recovery.

Owner:QINGDAO AOHUAN NEW ENERGY GRP CO LTD

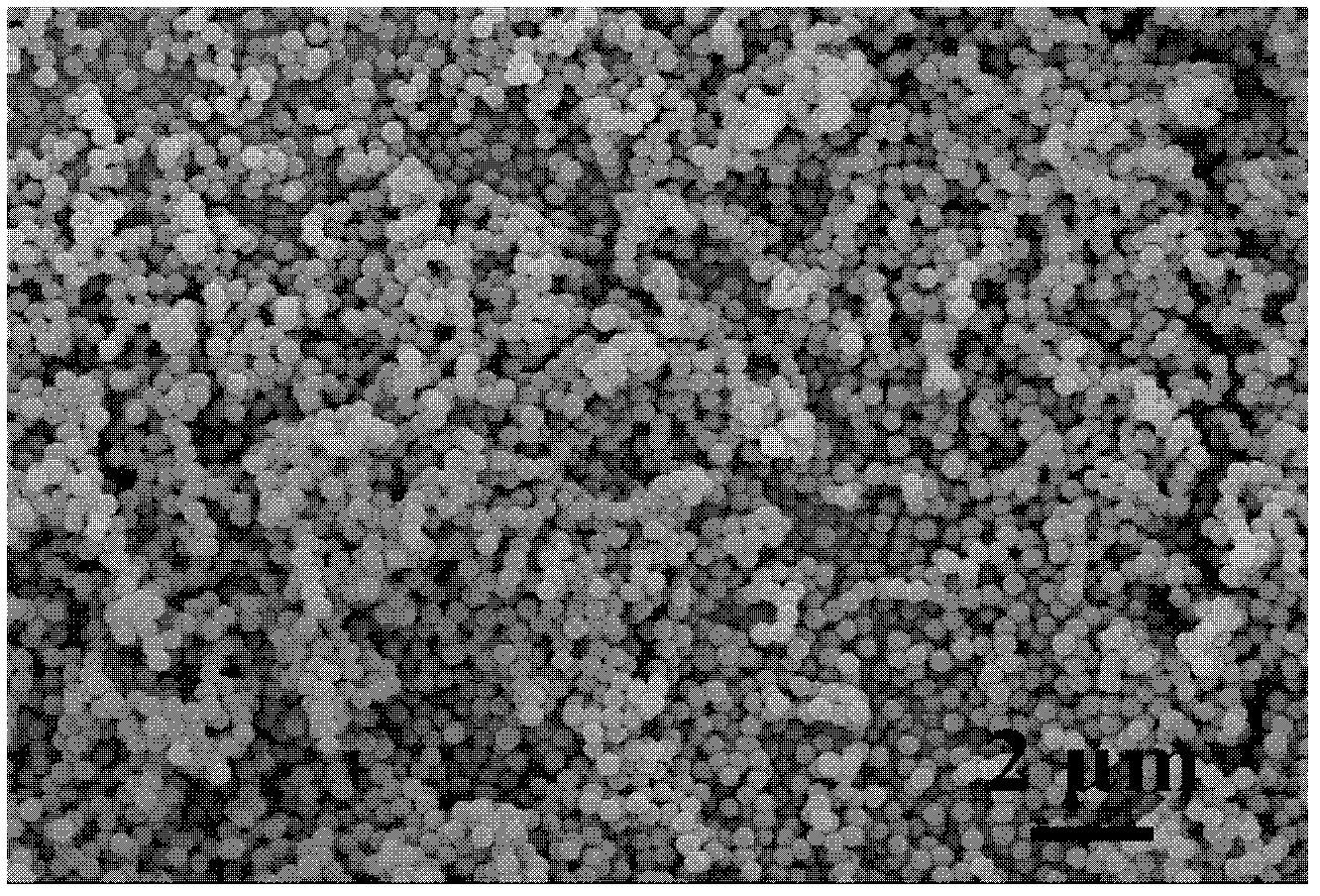

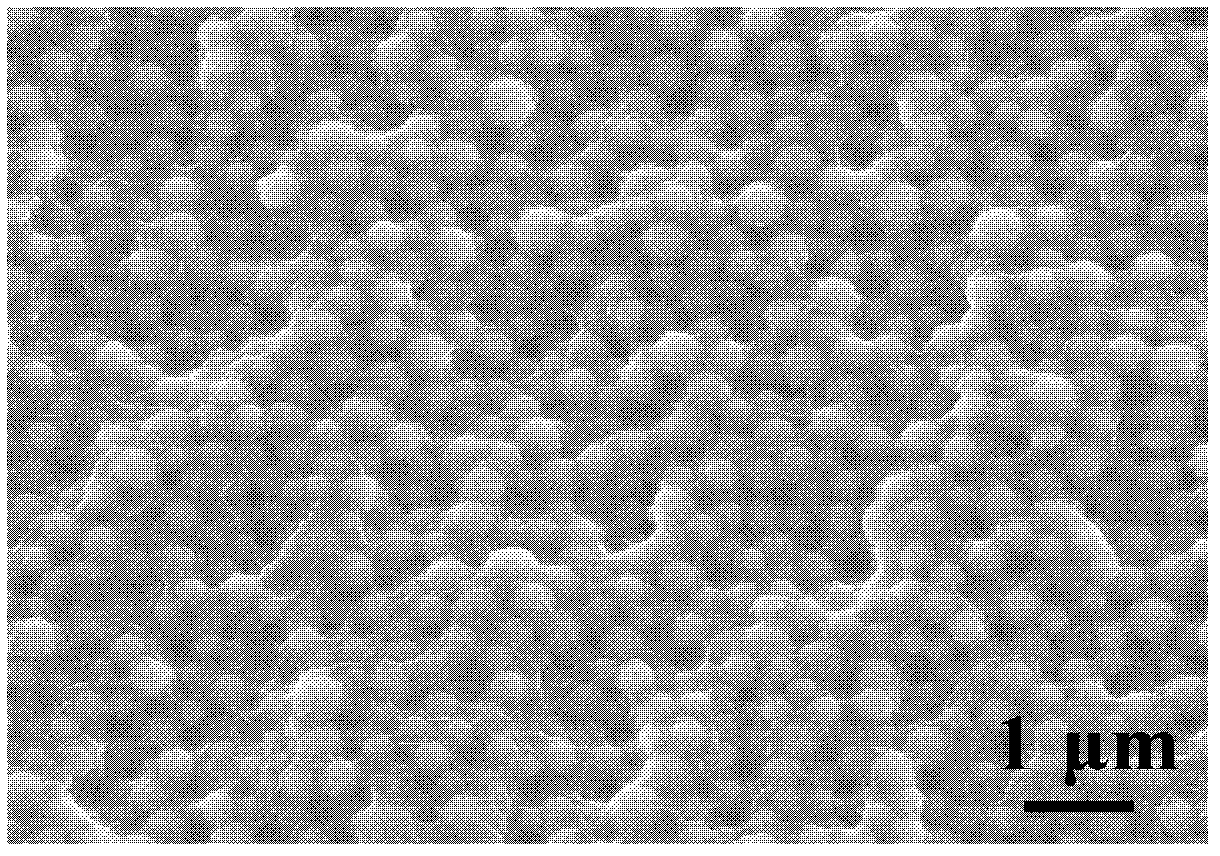

Composite dental restoration resin with silica microspheres as filler and preparation method thereof

InactiveCN102552046AGood dispersionGood physical and mechanical propertiesImpression capsDentistry preparationsMicrosphereResin matrix

The invention relates to a composite dental restoration resin with silica microspheres as filler and a preparation method thereof. In percentage by weight, the resin consists of 25 to 34.7 percent of resin matrix, 0.3 percent of photoinitiator and 65 to 74.7 percent of silane coupling agent surface-modified inorganic filler. The preparation method includes the following steps: (1) preparing processed SiO2; (2) further obtaining modified monodisperse submicron silica microspheres; (3) uniformly mixing the resin matrix and the photoinitiator, so that the composite dental restoration resin is obtained. The physical and mechanical properties of the composite dental restoration resin obtained by the invention are excellent, the service life is long, the prices of materials are low, curing shrinkage is low, and the composite dental restoration resin can be used as photocured composite resin for dental restoration. The preparation method is simple, the materials are easy to obtain, and are relatively cheap, and the invention is suitable for industrialized production.

Owner:DONGHUA UNIV

Polyurethane cement mortar and preparation method thereof

InactiveCN103420657ASmall volume shrinkageStrong resistance to deformationPolymer scienceCrack resistance

The invention discloses polyurethane cement mortar and a preparation method thereof. The polyurethane cement mortar comprises the following materials: 50 to 70 parts of cement, 100 to 140 parts of 30 to 150 meshes' silver sand, 10 to 35 parts of water, 1.5 to 6 parts of early strength agent, 0.9 to 2.4 parts of water-reducing agent, and 20 to 25 parts of one-component polyurethane, wherein the one-component polyurethane comprises isocyanate, polyether 220, polyether 330, catalyst and solvent. The invention further discloses the corresponding preparation method which comprises the following steps: leading a small quantity of polyurethane resin in cement mortar, uniformly dispersing the cement mortar in the cement substrate, and carrying out hydration of cement and solidification of polyurethane simultaneously to form an integral structure through mutual filling. The polyurethane cement mortar prepared according to the preparation method overcomes the defects of large air shrinkage deformation, poor impermeability, crack resistance and corrosion resistance, high density and the like of common mortar which is low in tension or compression ratio, and has the excellent performances of high freezing resistance, leakage resistance, corrosion resistance, ductility ratio, and deformation resistance, low volume shrinkage ratio, and the like.

Owner:安徽省思维新型建材有限公司

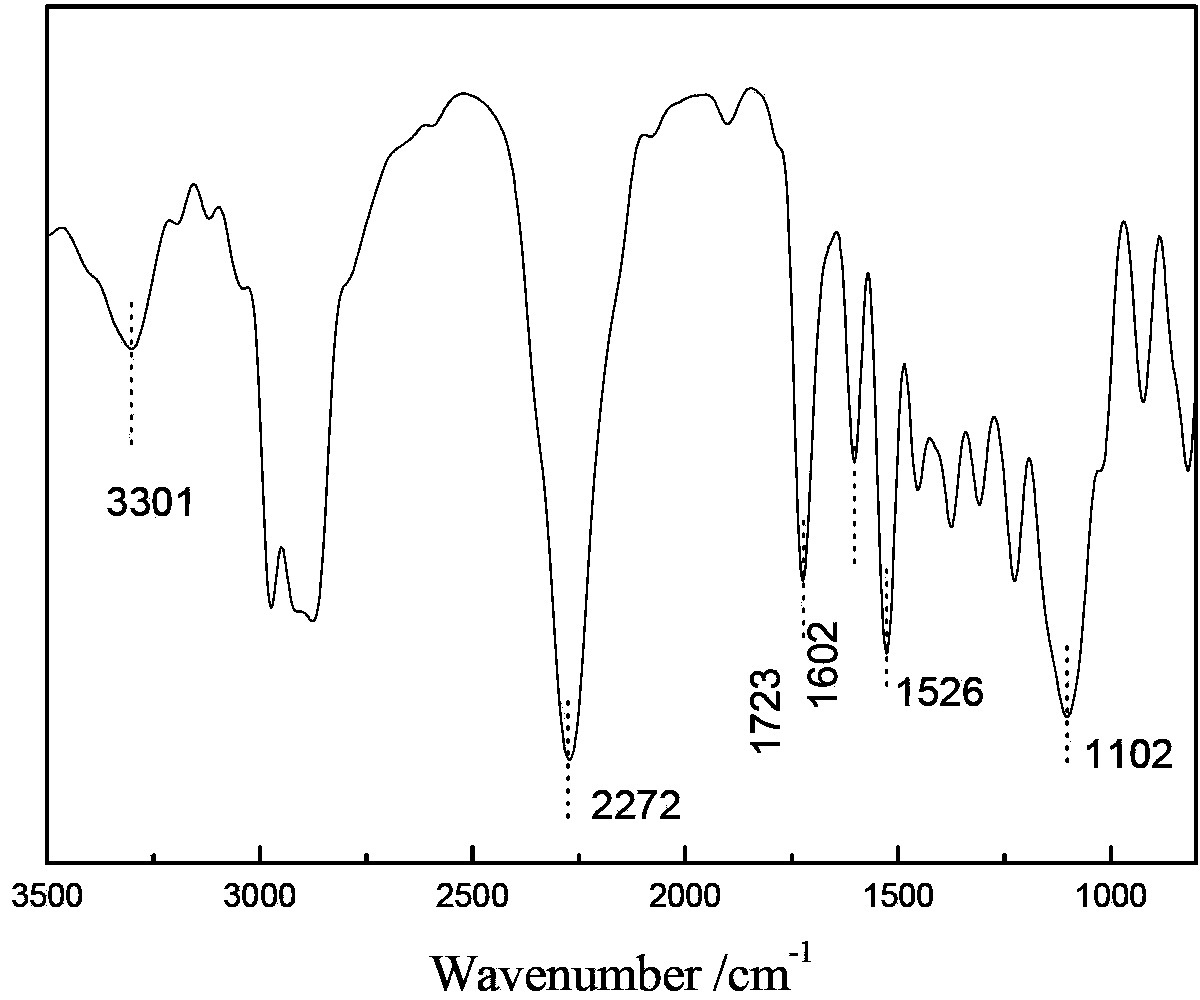

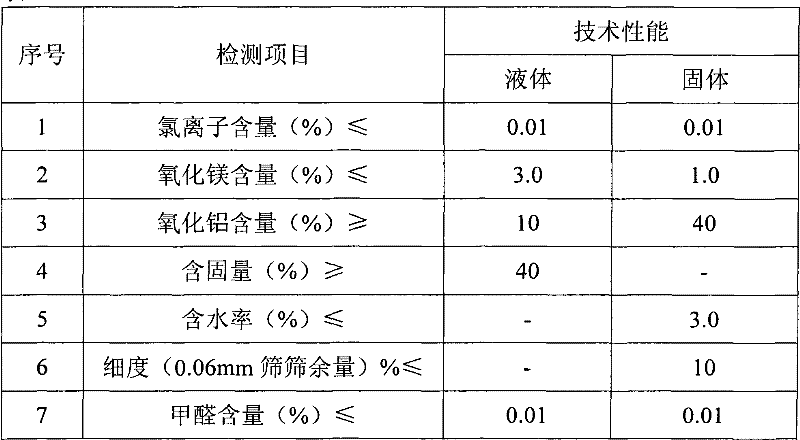

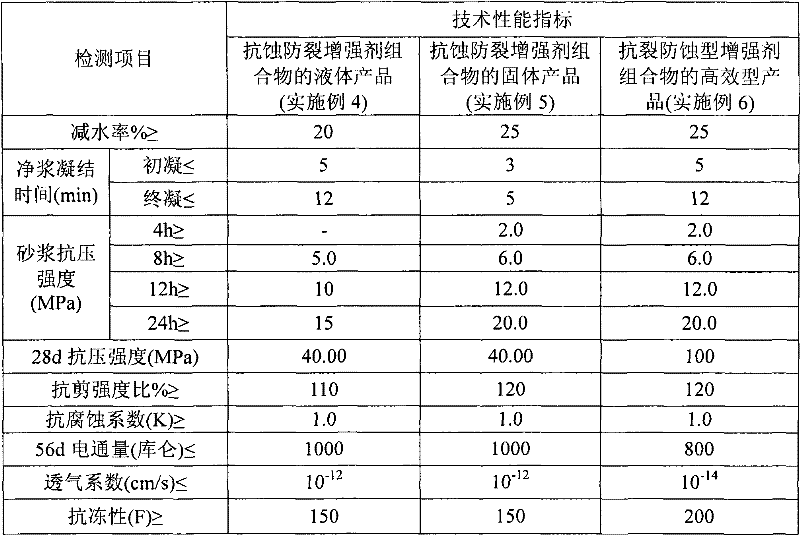

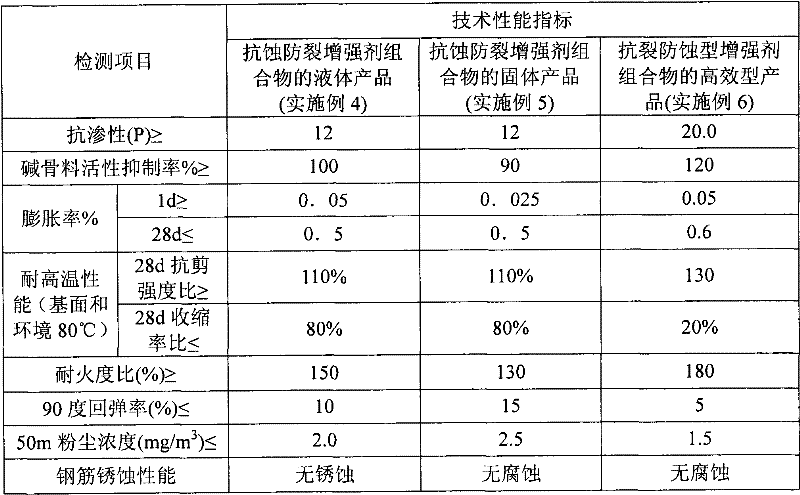

Anti-corrosion anti-cracking reinforcing agent composition and preparation method thereof

The invention relates to an anti-corrosion anti-cracking reinforcing agent composition for concrete, mortar, and net slurry used in injection (first-aid repair) engineering, and a preparation method thereof. The composition comprises the following components on a percentage basis: 2-50% of micro-expansive powder, 5-30% of reinforcing powder, 5-20% of anti-corrosion compacting agents, 10-20% of plasticizers, 1-6% of catalysts, and 10-60% of carriers. The composition of the invention prepares solid and liquid products by processes of melting refinement, polymerization, ball milling, jet milling, complex formulation, and the like, and thus meets construction process requirements of different first-aid repair endurance engineering.

Owner:四川巨星新型材料有限公司

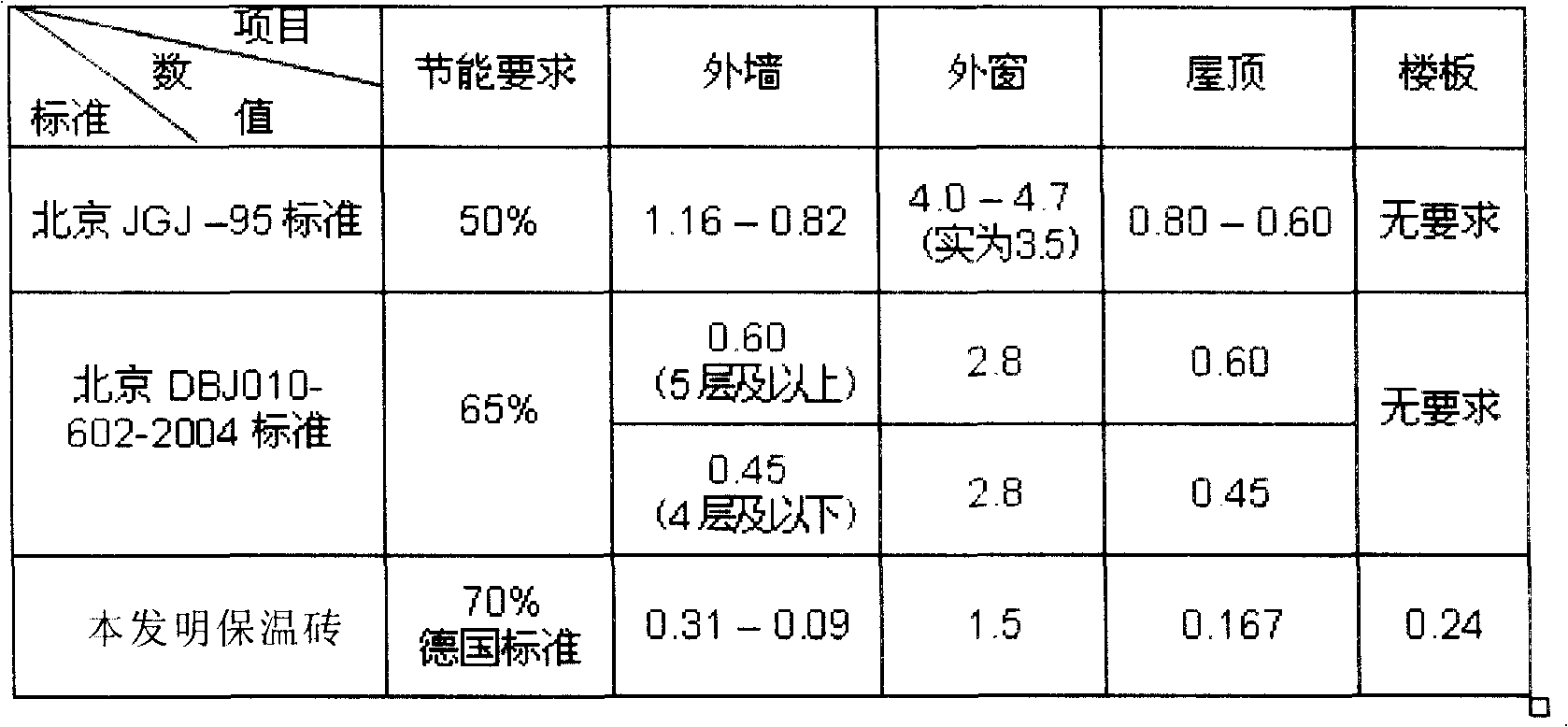

Polystyrene insulating brick and its production method and use method

InactiveCN101319540AEasy to get materialsProtect land resourcesBuilding componentsBrickArchitectural engineering

The invention discloses a polystyrene insulating brick, a manufacturing method and an application method. The insulating brick is completely made from a polystyrene material, and is of a stereostructure; moreover, the insulating brick is provided with at least one stand column through hole from an upper surface to a lower surface and at least one transverse threading hole from a left side face to a right side face; the upper surface and the lower surface of the insulating brick are respectively provided with a convex building block spigot and a concave building block spigot which are corresponding to each other; and the left surface and the right surface of the insulating brick are respectively provided with a convex building block spigot and a concave building block spigot which are corresponding to each other. The manufacturing method manufactures the polystyrene insulating brick by means of a one-step forming mould; moreover, the polystyrene insulating brick can be used in the wall body of a less-than-five-story building, and has simple manufacturing technique, thereby reaching ideal effects in energy conservation and emission reduction; in addition, the polystyrene insulating brick has low cost, convenient construction and excellent heat insulation effect.

Owner:陶国延

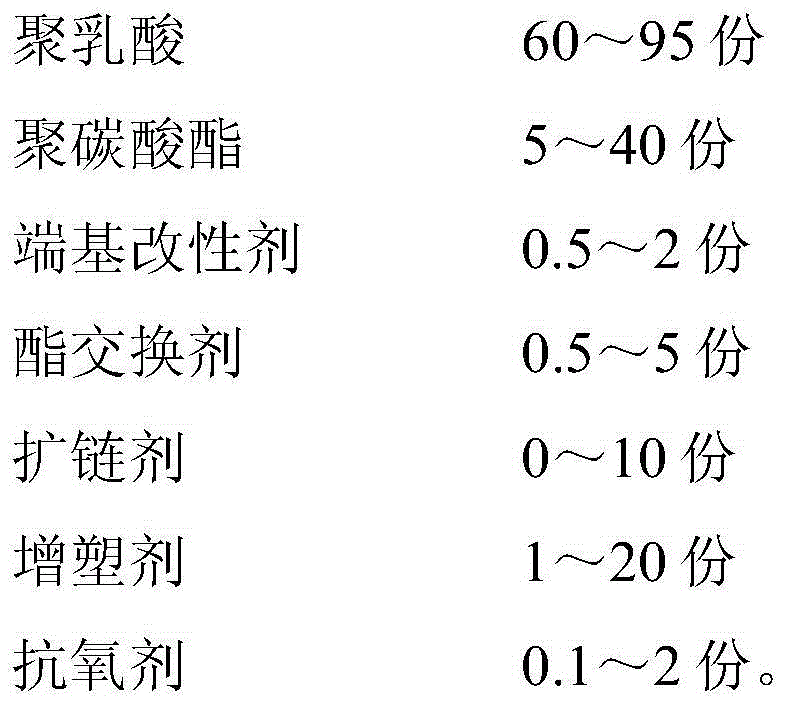

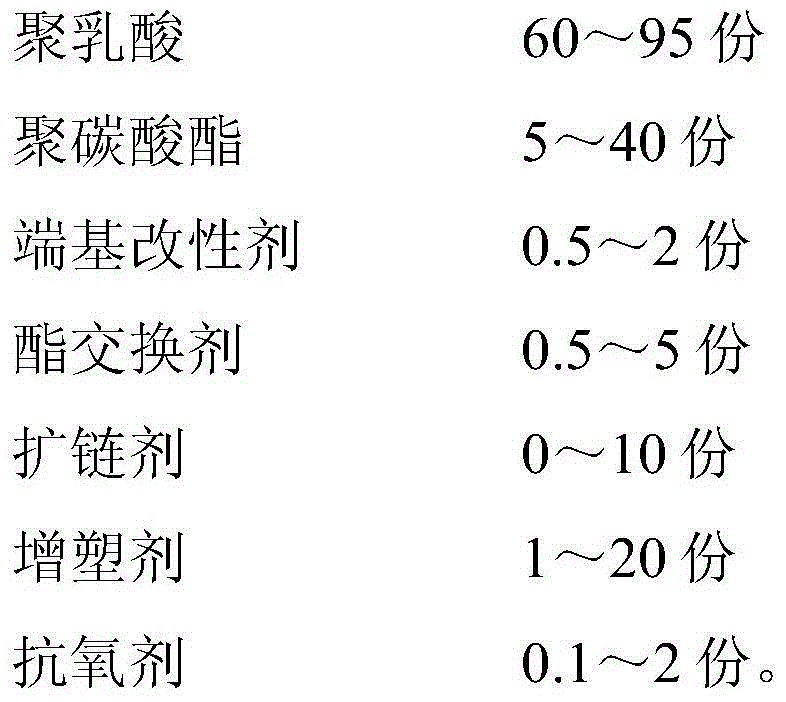

Polylactic acid/polycarbonate alloy material for 3D printing and preparation method thereof

ActiveCN104693709AImproved thermal stabilitySmall volume shrinkageAdditive manufacturing apparatusModified methodPolycarbonate

The invention belongs to the technical field of a macromolecular material and discloses a polylactic acid / polycarbonate alloy material for 3D printing and a preparation method thereof. The alloy material is prepared from the following components in parts by weight: 60-95 parts of polylactic acid, 5-40 parts of polycarbonate, 0.5-2 parts of end-group modifier, 0.5-5 parts of ester exchanger, 0-10 parts of chain extender, 1-20 parts of plasticizer and 0.1-2 parts of antioxidant. By adopting a two-step blending and modifying method, the mutual dissolution of polylactic acid and polycarbonate is promoted, the thermal stability and machinability of the alloy material are improved and the volume shrinkage of the material is reduced. The alloy material has the advantages of being low in cost and high in performance, can be applied to a 3D printing process and enriches the varieties of 3D macromolecular materials.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

Fluorine salt-based nano high temperature phase change heat storage composite material and preparation method thereof

InactiveCN101613593AImprove thermal conductivityLight in massSolar heat devicesHeat-exchange elementsMolten stateHeat conducting

The invention provides a fluorine salt-based nano high temperature phase change heat storage composite material, which is characterized by compounding nano material and fluorine salt material to form uniform and stable compound. The synthetic method comprises the following steps: stirring evenly fluorine salt and placing into a vacuum electric furnace; heating to a temperature which is above the phase change temperature by 50-100 DEG C; degassing and dehydrating to lead the fluorine salt in a melting state; adding nano metal particles which account for 1%-5% of the total mass to molten salt crystals; magnetically stirring the molten material for 10-60min with the heat preservation ultrasound of 10-120min; and preparing the uniform and stable fluorine salt-based nano high temperature phase change heat storage composite material. The prepared fluorine salt-based nano high temperature phase change heat storage composite material has the advantages of rapid heat storage and heat release, high heat storage density and good heat-conducting property, can be used in various fields like space station solar energy thermo-motive power generating system, solar power generation, high temperature residue heat recycling and the like, and is in particular applicable to a heat absorber of the space solar energy thermo-motive power generating system.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

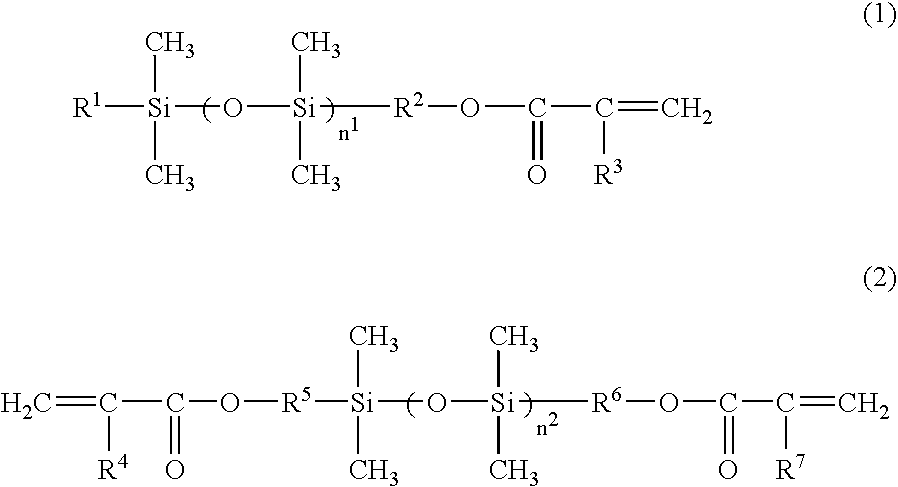

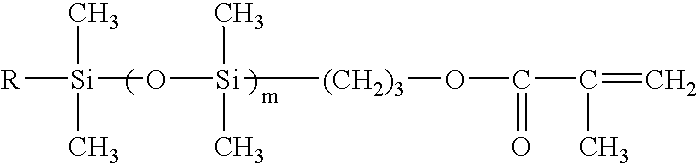

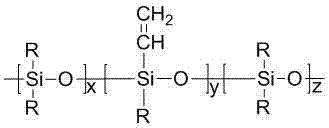

Surface Treatment Agent

InactiveUS20080076883A1Easy to disassembleSatisfactory applicabilityPolyurea/polyurethane coatingsPolishing compositionsPolymer scienceSilylene

The present invention discloses a surface treatment agent comprising: (A) an acrylic resin having a hydrolysable silyl group, a hydroxyl group and a polysiloxane chain; (B) an organopolysiloxane having a hydrolysable silyl group; and (C) an organopolysiloxane not having a hydrolysable silyl group.

Owner:KANSAI PAINT CO LTD

Flame retardant and heat-insulation foamed concrete and preparation method thereof

InactiveCN102320858AHigh strengthImprove flame retardant insulation performanceCeramicwareFoam concreteCellulose

The invention belongs to a flame retardant and heat-insulation building material, relates to flame retardant and heat-insulation foamed concrete and a preparation method thereof. In the prior art, the foamed concrete has disadvantages of low strength, large shrinkage, easy cracking due to water absorption. The flame retardant and heat-insulation foamed concrete provided by the present invention comprises the following materials, wherein the materials comprise, by mass, 30-60 parts of cement, 30-70 parts of fly ash, 10-40 parts of mineral powder, 0.05-1.0 parts of a siloxane water reducing agent, 0.02-0.2 parts of a cellulose ether, 0.05-1.0 parts of a silane water-repelling agent, 1-10 parts of anhydrite, 0.06-0.2 parts of polypropylene fibers, 0.1-0.4 parts of a foaming agent and 0.30-0.60 parts of water. The flame retardant and heat-insulation foamed concrete and the preparation method provided by the present invention have the following advantages that: the foamed concrete has characteristics of high strength, low shrinkage and good water repellency; the foamed concrete has excellent heat insulation property, such that different heat insulation requirements of the building can be met; the preparation process is simple; the industrial waste materials such as fly ash, mineral powder and the like are adopted so as to protect the environment.

Owner:杨淑贤

Positive-type photosensitive resin composition, method for production of resist pattern, semiconductor device, and electronic device

ActiveUS20110250396A1High sensitivity and resolutionHigh yieldPhotosensitive materialsLayered productsResistSolvent

A positive-type photosensitive resin composition includes (A) a phenol resin modified by a compound having an unsaturated hydrocarbon group having 4 to 100 carbon atoms; (B) a compound that produces an acid by light; (C) a thermal crosslinking agent; and (D) a solvent. The positive-type photosensitive resin composition according to the present invention can be developed by an alkaline aqueous solution, and an effect thereof is that a resist pattern having sufficiently high sensitivity and resolution, excellent adhesion, and good thermal shock resistance can be formed.

Owner:RESONAC CORP

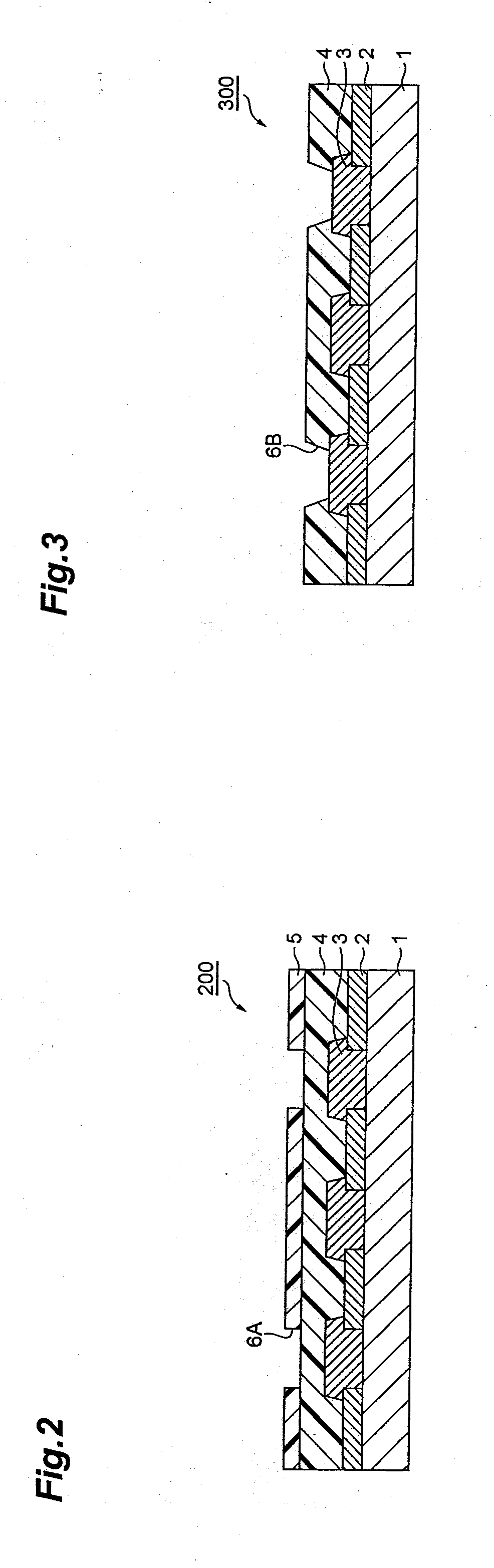

High-hardness photosensitive resin composition used for light curing rapid prototyping

The invention discloses a high-hardness photosensitive resin composition used for light curing rapid prototyping. The photosensitive resin composition is prepared from, by weight, 25-60% of epoxy resin, 15-45% of acrylate oligomer, 15-35% of acrylate monomer, 1-10% of inorganic filler, 5-20% of flexibilizer, 1-8% of free-radical photoinitiator and 1-8% of cationic photoinitiator, wherein the weight percentages of all the components sum up to 100%. The photosensitive resin composition is high in hardness and high in strength, meanwhile, the high-temperature resistant requirements can be met, and the gap in the market requiring for high hardness can be filled up.

Owner:ZHONGSHAN GREATSIMPLE TECH CO LTD

Room-temperature addition silicon rubber putty-type dental impression material applied to primary impression

ActiveCN103655212ASmall volume shrinkageGood dimensional stabilityImpression capsDental impression compositionsDental crownsPutty

The invention discloses a room-temperature addition silicon rubber putty-type dental impression material applied to primary impression. The room-temperature addition silicon rubber putty-type dental impression material is composed of a substrate component and a catalytic component in a blending manner, wherein the substrate component is composed of vinyl silicone oil, hydrogen silicone oil, a bulking agent, an enhancer and other assistants according to a certain ratio; the vinyl silicone oil contains more than two vinyl functional groups; the hydrogen silicone oil contains more than three Si-H functional groups; the catalytic component is composed of vinyl silicone oil, a catalyst, a bulking agent, an enhancer and other assistants according to a certain ratio; and the catalyst is a complex of chloroplatinic acid and vinyl silicone oil. The room-temperature addition silicon rubber putty-type dental impression material is rational in formula, and easy to operate, the elastic recovery of the cured material can be up to 99.8%, the curing time is 3-5 minutes, the shore hardness is about 65, and the dental impression material is finely copied into 0.02mm and clearly visible, and can be applied to fabrication of accurate dental crowns, and delivery of dental bridges, false teeth, articulation registration and oral cavity tissue.

Owner:JIANGXI LYUTAI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com