Photosensitive resin and preparation method thereof

A technology of photosensitive resin and epoxy resin, which is applied in the field of 3D printing new materials and photosensitive resin, can solve problems such as burn skin and human eye damage, and achieve the effects of reducing damage, avoiding potential safety hazards, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

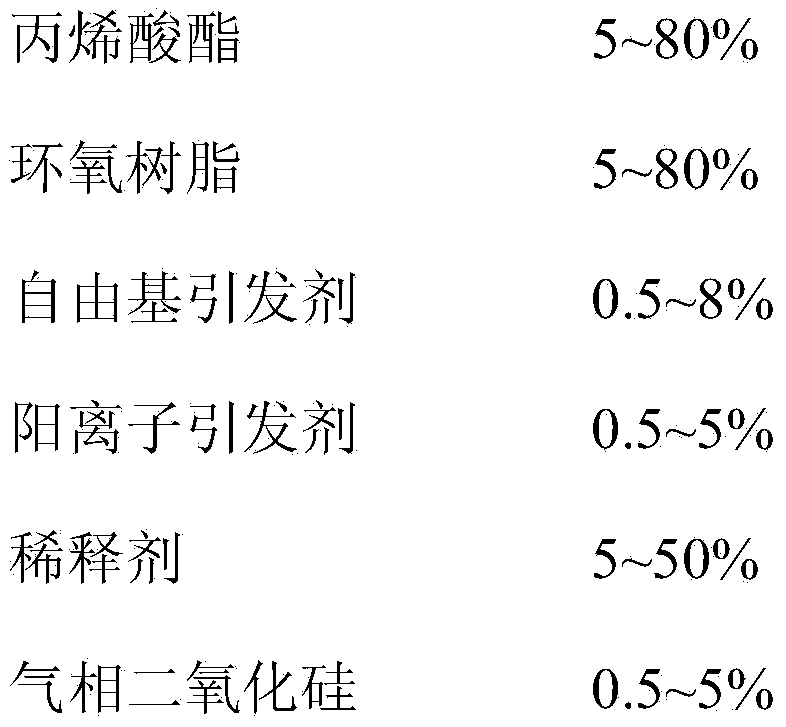

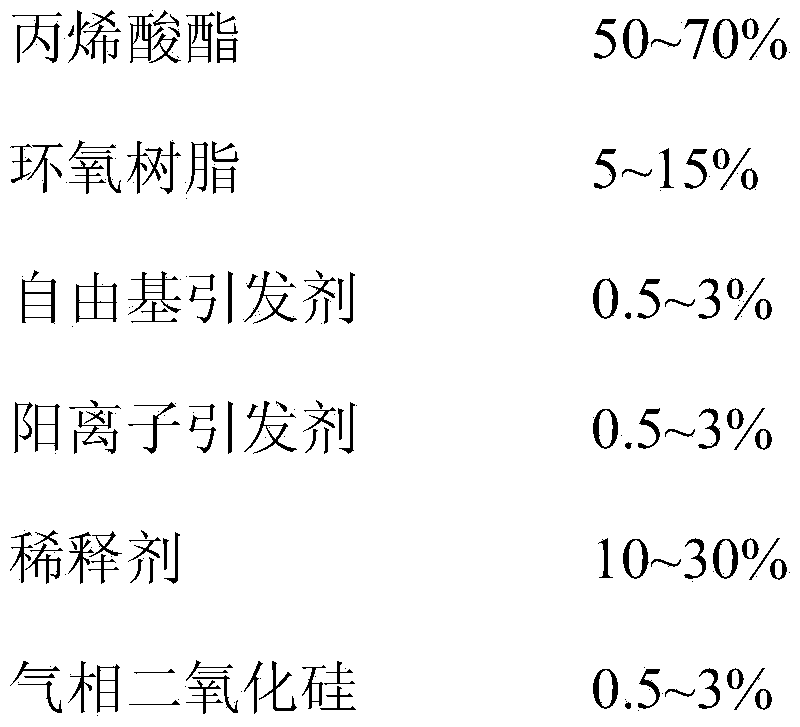

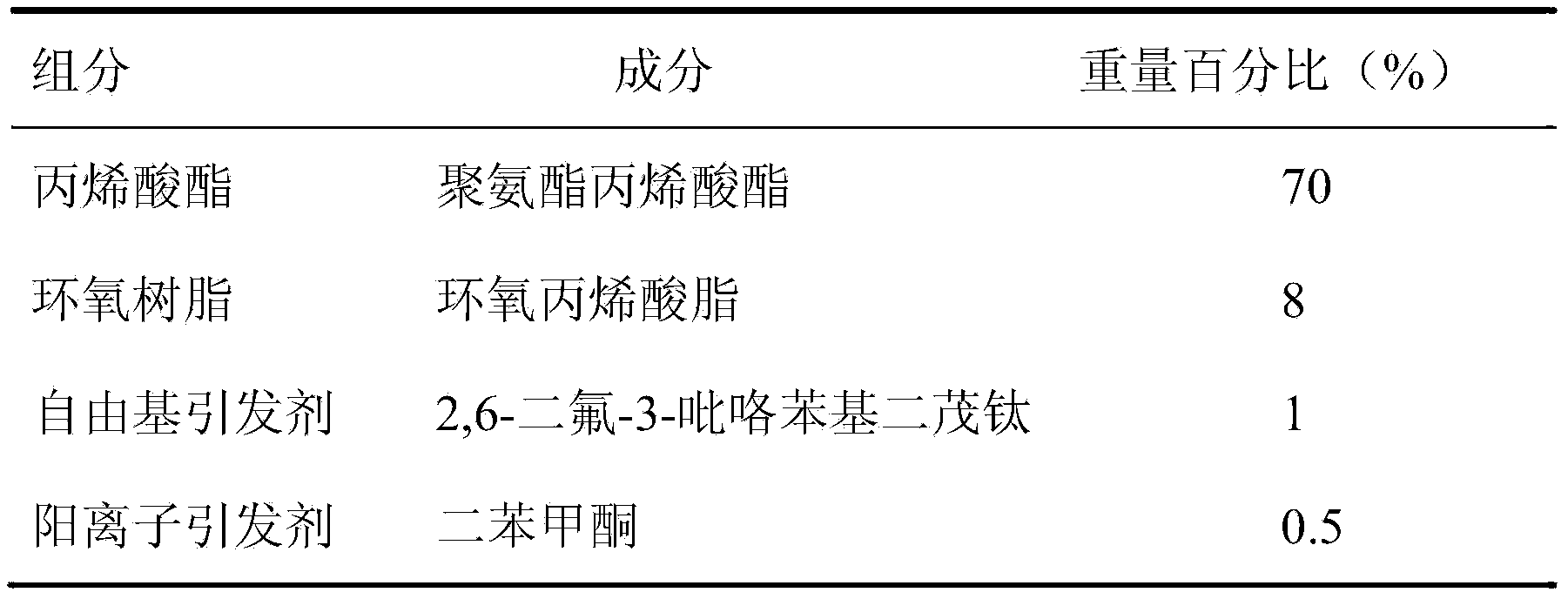

[0026] 1. Configure photosensitive resin raw materials according to the following ratio

[0027]

[0028]

[0029] 2. Preparation method

[0030] (1) In a special three-necked glass bottle equipped with a stirrer and a condenser, add 70 parts of polyurethane acrylate, 8 parts of epoxy acrylate, and 1 part of 2,6-difluoro-3-pyrrole phenyl titanocene , 0.5 parts of benzophenone, 18 parts of dipentaerythritol hexaacrylate to make it evenly mixed, and inject 2.5 parts of fumed silica while mixing;

[0031] (2) Heat the mixture obtained in step (1) to 60° C., and stir for 25 minutes at a stirring speed of 100 rpm to obtain a light yellow uniform liquid, which is sealed and stored, which is a photosensitive resin that can be cured based on blue light.

[0032] The photosensitive resin prepared by the above preparation method is cured with blue light with a wavelength of 440nm to obtain a 3D printed product.

Embodiment 2

[0034] 1. Configure photosensitive resin raw materials according to the following ratio

[0035]

[0036] 2. Preparation method

[0037] (1) Add 35 parts of polyurethane acrylate, 15 parts of aliphatic polyurethane acrylate, 38 parts of novolak epoxy resin, iodonium diaryl hexafluorophosphate, 0.5 parts, 5 parts of chlorinated benzophenone, and 5 parts of 1,6-hexanediol diacrylate are uniformly mixed, and 1.5 parts of fumed silica are injected while mixing;

[0038] (2) Heat the mixture obtained in step (1) to 70°C, and stir for 20 minutes at a stirring speed of 80 rpm to obtain a light yellow homogeneous liquid, which is sealed and stored, which is a photosensitive resin that can be cured based on blue light.

[0039] The photosensitive resin prepared by the above preparation method is cured with blue light with a wavelength of 450nm to obtain a 3D printed product.

Embodiment 3

[0041] 1. Configure photosensitive resin raw materials according to the following ratio

[0042]

[0043] 2. Preparation method

[0044] (1) In a special glass three-necked bottle equipped with a stirrer and a condenser tube, add 5 parts of aromatic polyurethane acrylate, 35 parts of epoxy acrylate, 45 parts of novolac epoxy resin, and iodonium triaryl hexafluoroarsenate 4 parts of salt, 4 parts of iodonium triaryl hexafluoroantimonate, 2 parts of benzoin dimethyl ether, and 4 parts of dipropylene glycol diacrylate are uniformly mixed, and 1 part of fumed silica is injected while mixing;

[0045] (2) Heat the mixture obtained in step (1) to 75°C, stir for 30 minutes at a stirring speed of 60 rpm, and seal it for storage to obtain a light yellow uniform liquid, which is a photosensitive resin that can be cured based on blue light.

[0046] The photosensitive resin prepared by the above preparation method is cured with blue light with a wavelength of 490nm to obtain a 3D pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com