Patents

Literature

55results about How to "Meet the requirements of industrial use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

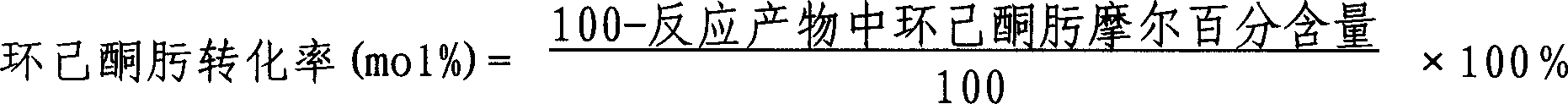

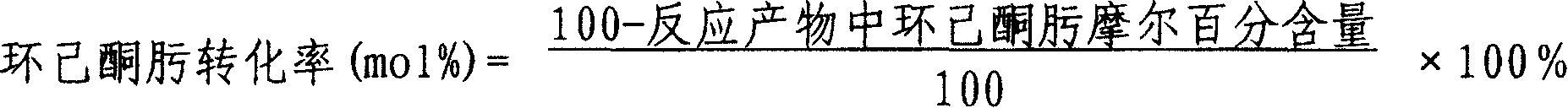

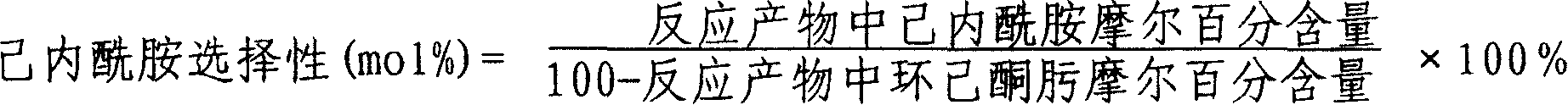

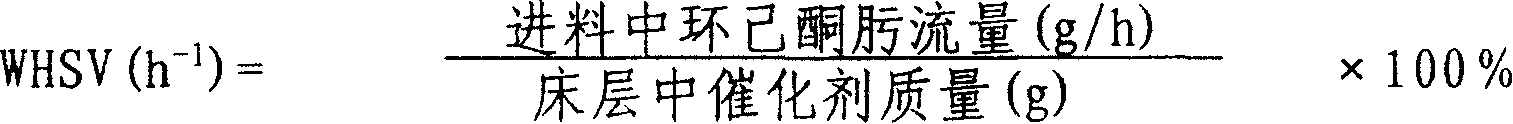

Method for preparing catalyst of containing MFI structured molecular sieve

ActiveCN1600428APromote regenerationImprove conversion rateLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

A MFI-molecular sieve catalyst for preparing caprolactam from cyclohexanone oxime by gas-phase Beckmann rearrangement is prepared through proportionally mixing MFI-molecular sieve with alkaline silica gel, shaping, drying and calcining. It has high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

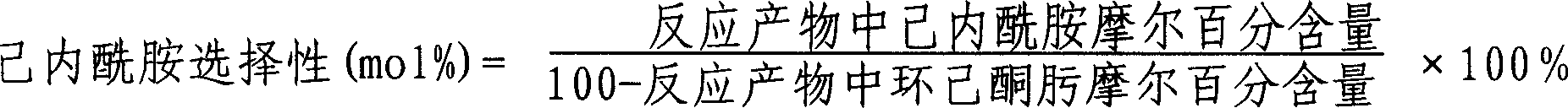

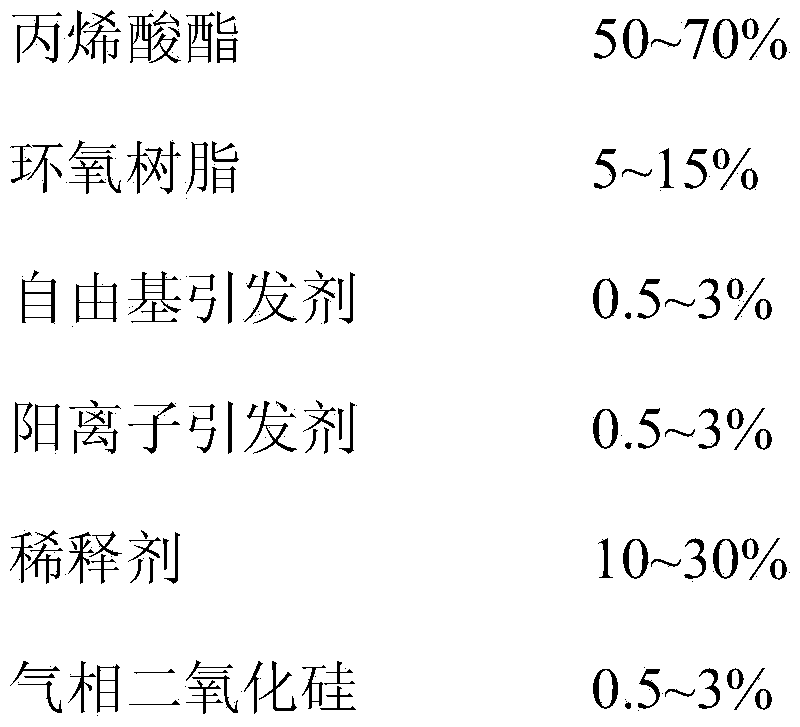

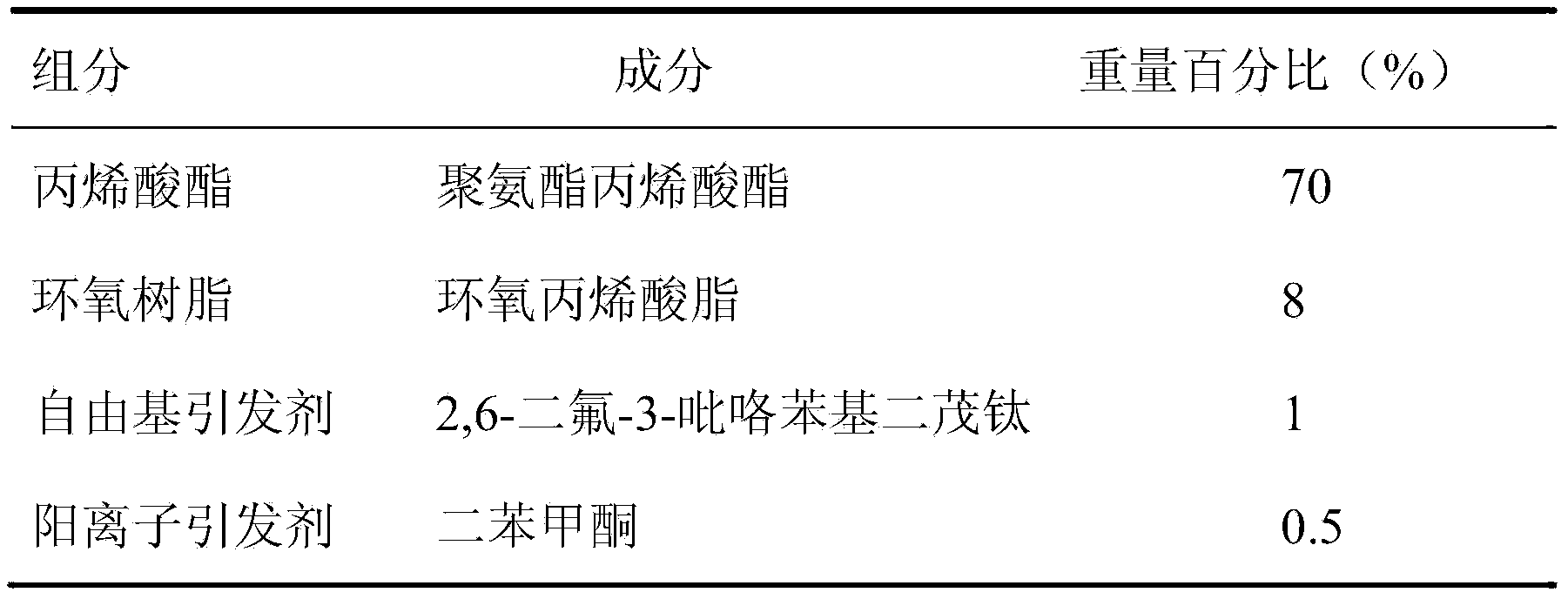

Photosensitive resin and preparation method thereof

The invention belongs to the field of novel 3D printing materials and in particular belongs to the field of photosensitive resin. The photosensitive resin is prepared from the following components in percentage by weight: 5-80% of acrylic ester, 5-80% of epoxy resin, 0.5-8% of a radical initiator, 0.5-5% of a cationic initiator, 5-50% of a diluent and 0.5-5% of gas phase silicon dioxide. Flexural modulus and tensile modulus of the photosensitive resin reach over 2000Mpa; the photosensitive resin is high in capability of resisting bending deformation stress in an elastic limit, high in strength, low in possibility of deforming and high in mechanical strength; the service life is greatly prolonged; the volume shrinkage rate is about 1.0%; the ultralow volume shrinkage rate is achieved; the industrial use requirement can be met.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

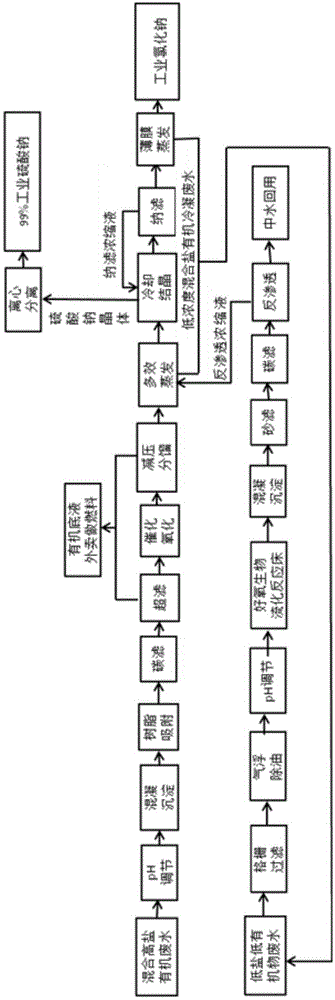

Treatment method and treatment system for high-concentration mixed salt organic wastewater

ActiveCN105254141AQuality improvementImprove reuse rateMultistage water/sewage treatmentAlkali metal chloridesHigh concentrationFractionation

The invention provides a treatment method for high-concentration mixed salt organic wastewater. The treatment method for the high-concentration mixed salt organic wastewater comprises the following steps: carrying out coagulating sedimentation on the high-concentration mixed salt organic wastewater, so as to obtain sediments and mixed liquor; carrying out vacuum fractionation on the mixed liquor, so as to obtain fraction and fractional distillate; carrying out evaporative crystallization on the fractional distillate, so as to obtain sodium salt and low-concentration mixed salt organic condensate wastewater; carrying out aerobic biological treatment on the low-concentration mixed salt organic condensate wastewater, so as to obtain low-concentration organic wastewater; carrying out reverse osmosis treatment on the low-concentration organic wastewater, so as to obtain treated wastewater and a reverse osmosis concentrate solution; and carrying out evaporative crystallization on the reverse osmosis concentrate solution, so as to obtain sodium salt, wherein the high-concentration mixed salt organic wastewater contains sodium salt, heavy metal ions and organic matters. The treatment method for the high-concentration mixed salt organic wastewater has the advantages that the sodium salt in the wastewater can be efficiently recycled, treated wastewater can meet industrial usage requirements, reuse rate is high, and zero wastewater discharge is realized. The invention also provides a treatment system for the high-concentration mixed salt organic wastewater.

Owner:安徽中飞科技有限公司

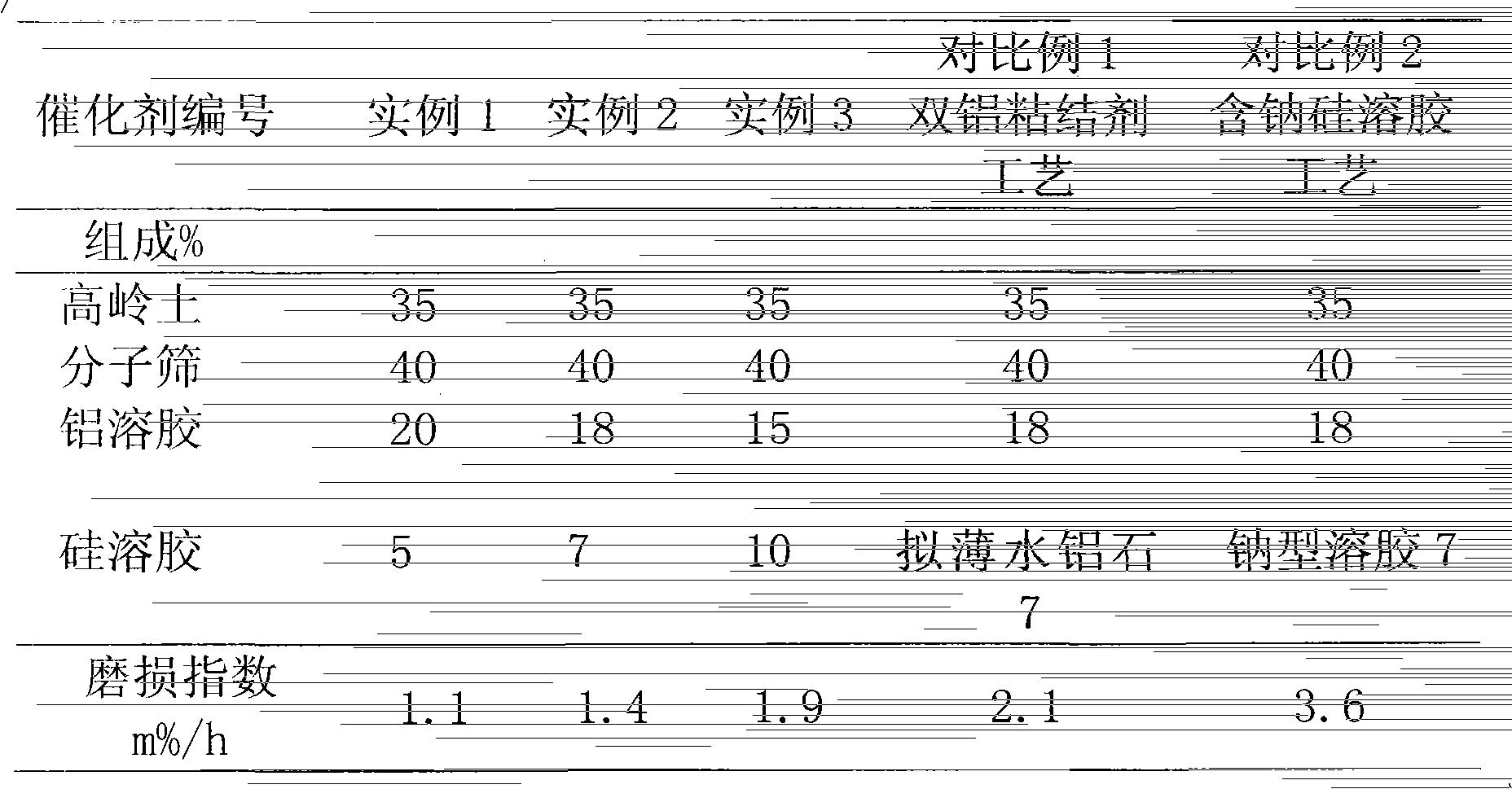

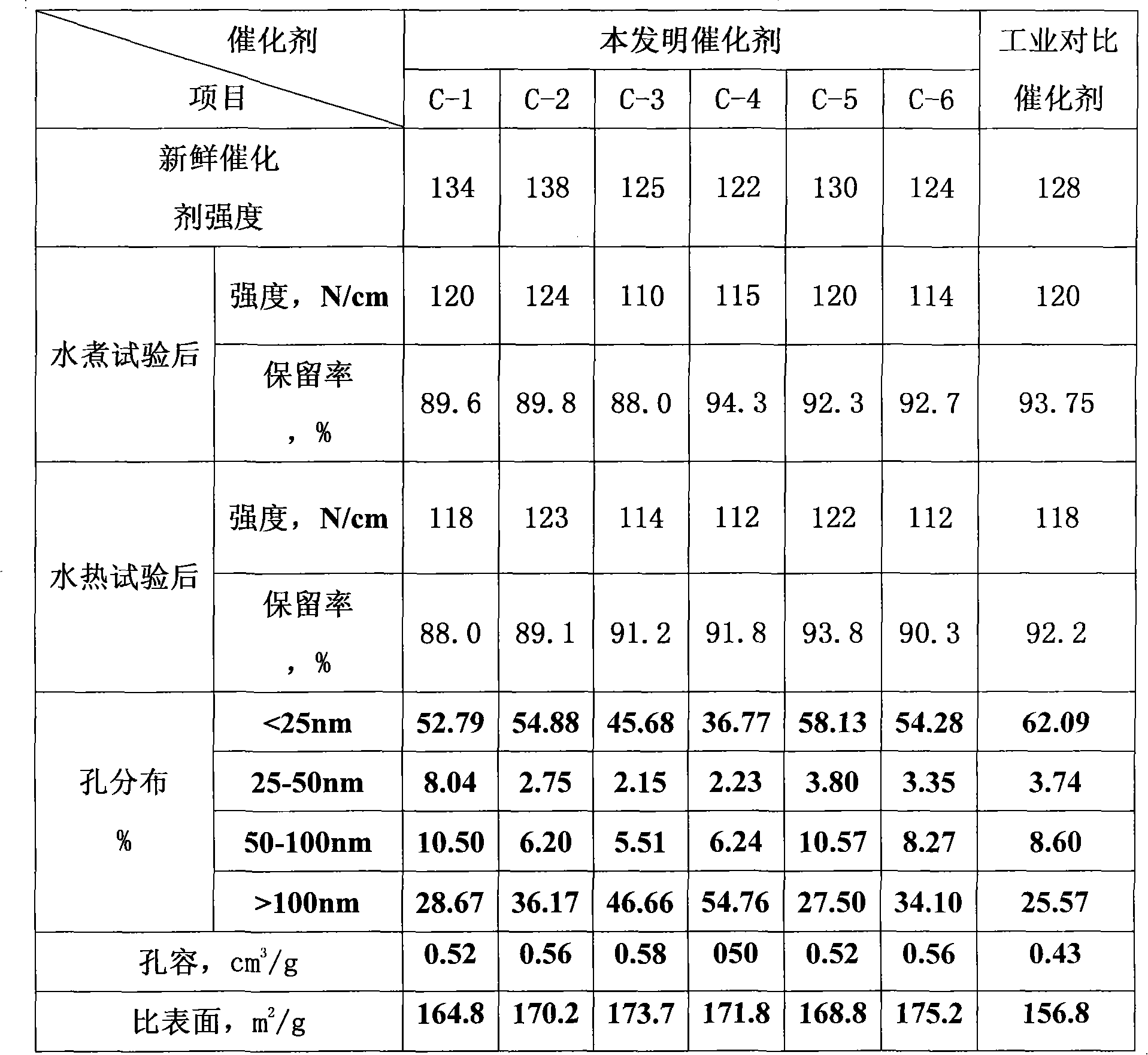

FCC (Fluid Cracking Catalyst) catalyst containing silicon binder and preparation method thereof

InactiveCN103447070AHigh molecular sieve contentModulation responsivenessCatalytic crackingMolecular sieve catalystsBoehmiteChemistry

The invention provides a preparation method of an FCC (Fluid Cracking Catalyst) catalyst containing a silicon binder. The method comprises the following steps: mixing and pulping clay, molecular sieve slurry, pseudo-boehmite, hydroxyl aluminum chloride (alumina sol) and a silica sol binder to prepare catalyst slurry; then, spraying and drying the catalyst slurry; then, washing and drying the catalyst slurry to obtain a catalyst product. The method is characterized in that three binders pseudo-boehmite, alumina sol and silica sol serve as a compound binder, and the use level of silica sol can be regulated in a larger amplitude, thereby, providing an effectively method for preparing an alumino silica gel FCC catalyst. The catalyst prepared by the method provided by the invention has the characteristics of good strength, strong heavy oil cracking capacity, high light liquid yield and the like.

Owner:湖北赛因斯科技开发有限公司

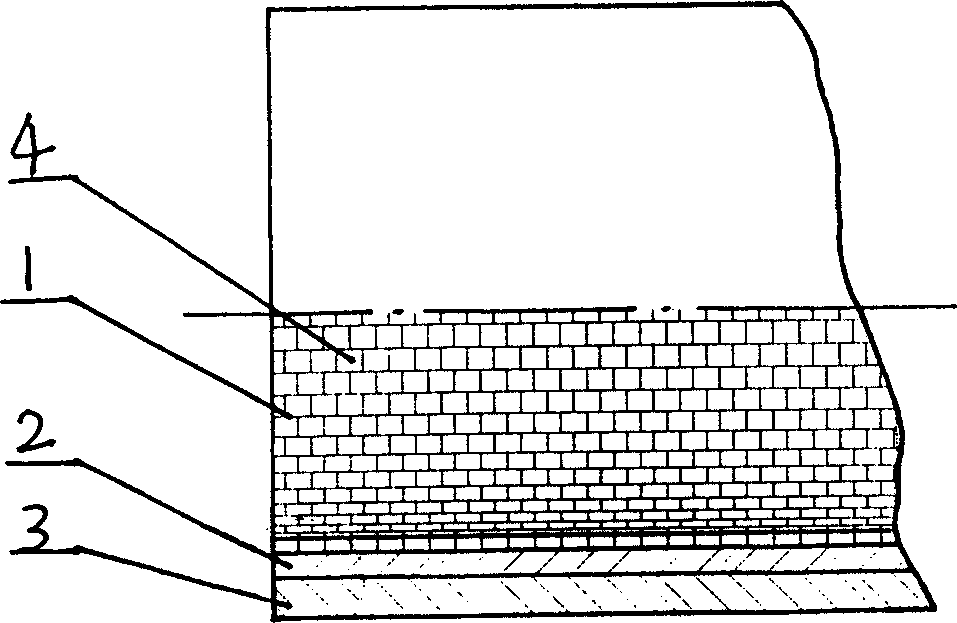

Ceramic and glass reinforced plastic composite tube and preparing method thereof

This invention relates to a kind of ceramics, glass steel compound pipe which is composed of ceramic inner layer, middle connection layer and glass steel layer. The process method comprises the following steps: spraying resin middle connection layer on the inner ceramic pipe layer; then compounding glass steel outer layer. The compound pipe middle connection layer and the ceramic layer and the glass steel outer layer are tightly combined, which makes best use of the ceramic characteristics and the glass steel materials. The invention are most used in transmission of liquid medium with solid particles and the powders.

Owner:ZHONGCAI HIGH NEW MATERIAL +1

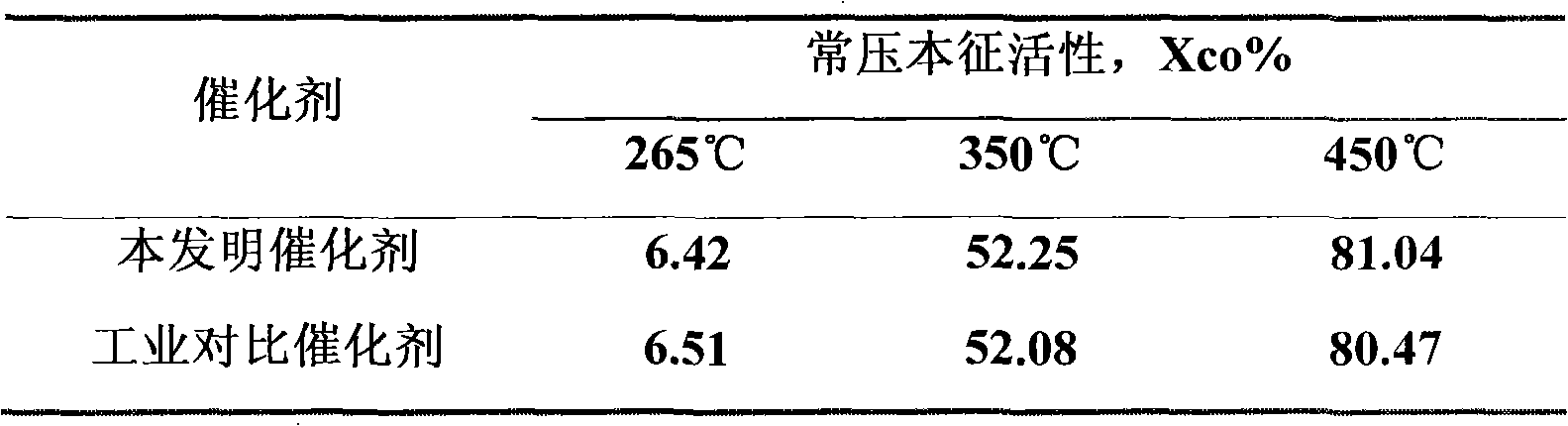

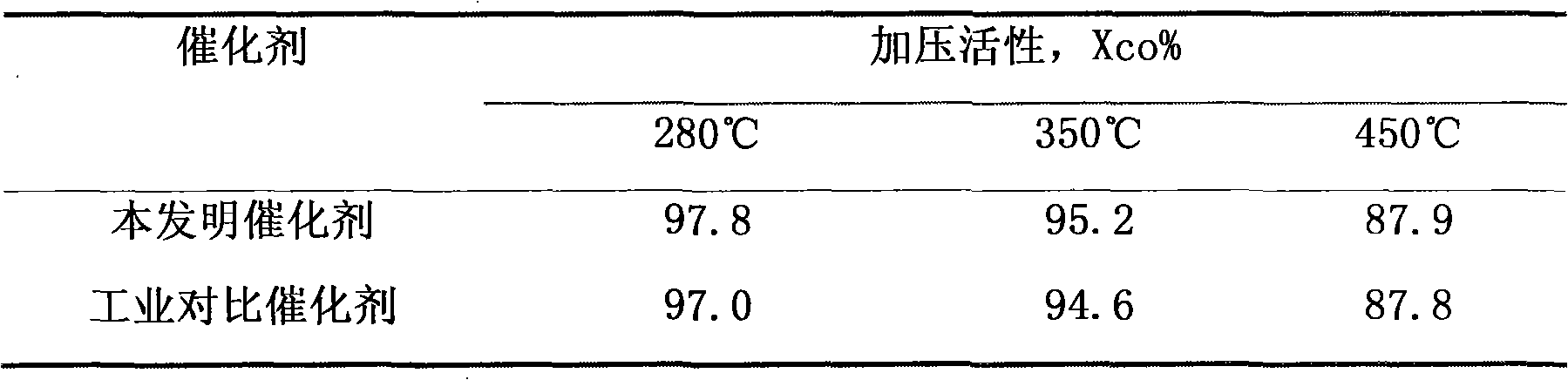

Method for preparing clean CO sulfur tolerant shift catalyst

ActiveCN102049262AHigh strengthImprove stabilityHydrogenCatalyst activation/preparationSulfurNitric oxide

The invention provides a method for preparing a clean CO sulfur tolerant shift catalyst. The mode of adding active ingredients and an alkali metal aid is optimized, the active ingredients are high in dispersibility on the surface of a carrier and difficult to lose, and the catalyst is prepared by an immersion method and also can be directly prepared by a kneading method. The preparation method issimple and practicable; and the prepared clean CO sulfur tolerant shift catalyst has higher strength, strength stability and structural stability; the wastage rate of the active ingredients is low, the activity stability is high, the catalyst has high capacity of resisting poisonous substances such as carbonyl iron, and the physicochemical properties meet industrial requirement. In the process ofpreparing the catalyst, pollutant gases such as nitric oxides are not generated, and the cleanliness and environmental friendliness are achieved.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of synthetic magnesium calcium sand and preparation method thereof

InactiveCN102285806AHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

Manufacturing method of edible printing ink for ink jet printing and using method thereof

The invention provides a preparation method and application method of edible ink for inkjet printing. This ink can form printed records with good identification and certain water resistance on the surface of various foods (including tablets), food contact materials, food packaging materials, etc. The raw materials of this inkjet ink are approved food additives, including shellac, cellulose resin, ethanol, water and so on. The manufacture method of this ink-jet ink is: a, food coloring is dispersed or dissolved in the aqueous solution that contains cellulose resin to make color base dispersion, contains the water more than 50wt% in this dispersion; B, shellac Dissolve in dehydrated alcohol and make shellac solution, contain the dehydrated alcohol more than 50wt% in this shellac solution; c, color paste dispersion is dispersed in shellac solution again, add a certain amount of conductive salt sodium lactate, pH Regulator ammonium carbonate, humectant, emulsifier, defoamer, etc.; d, filter filling.

Owner:HUBEI KEYIHUA SANDT CO LTD

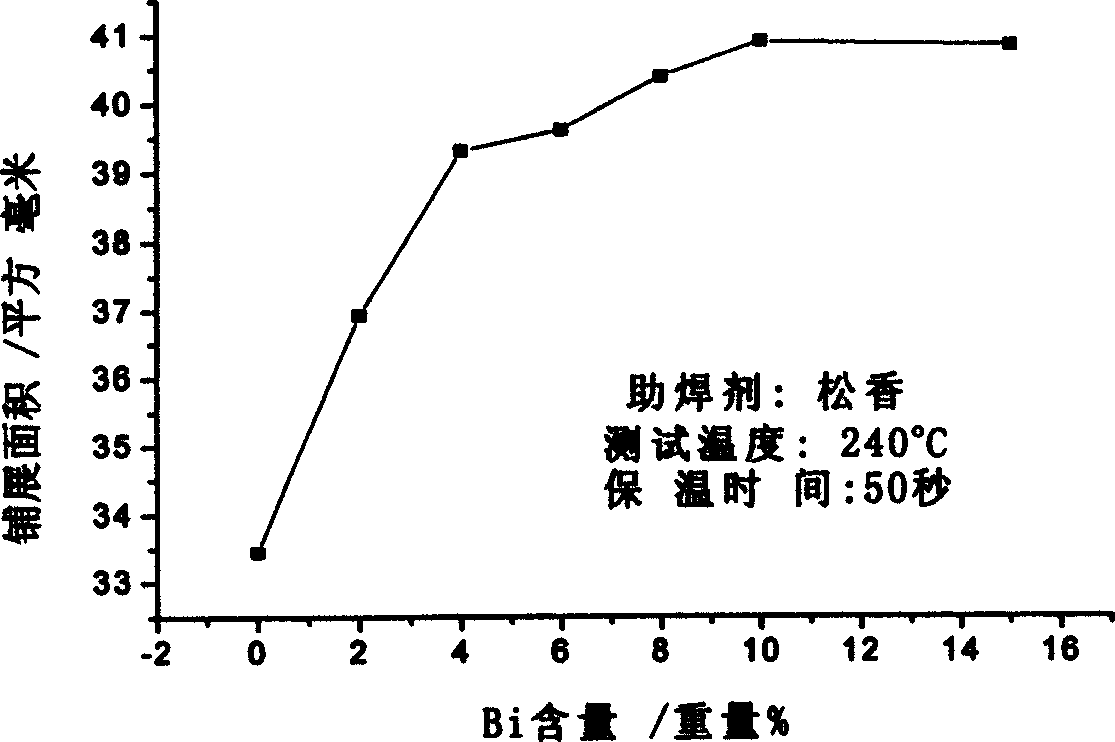

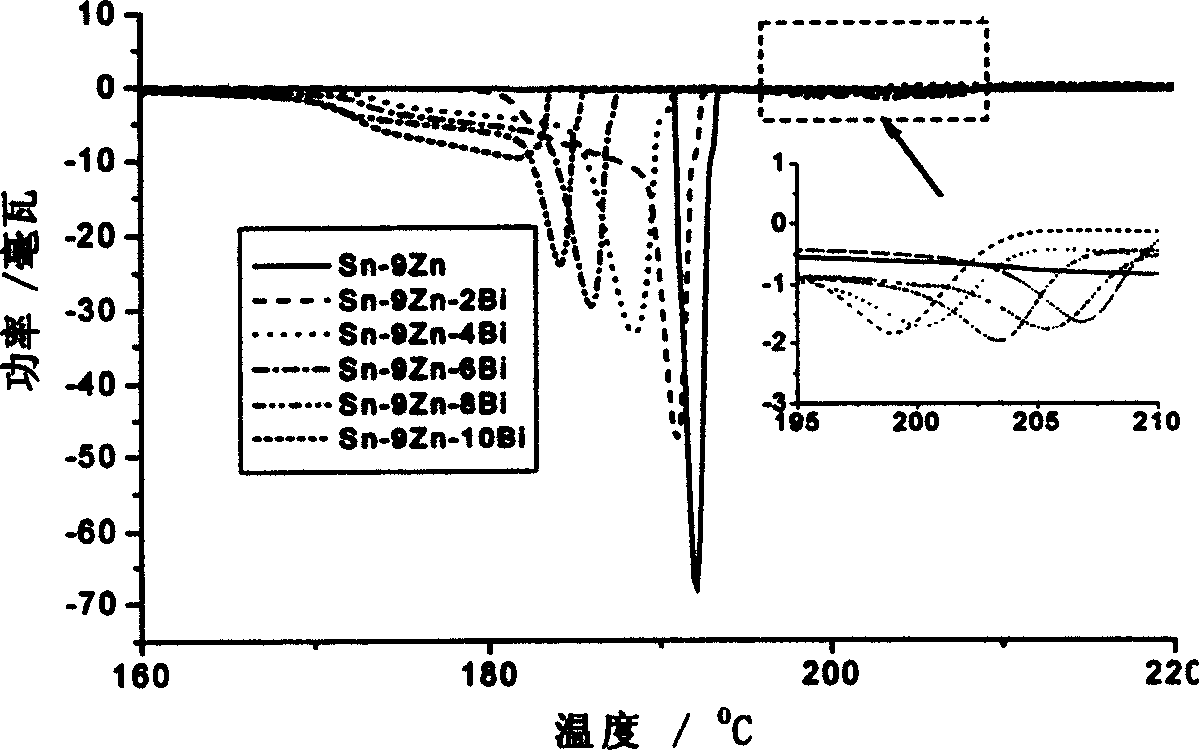

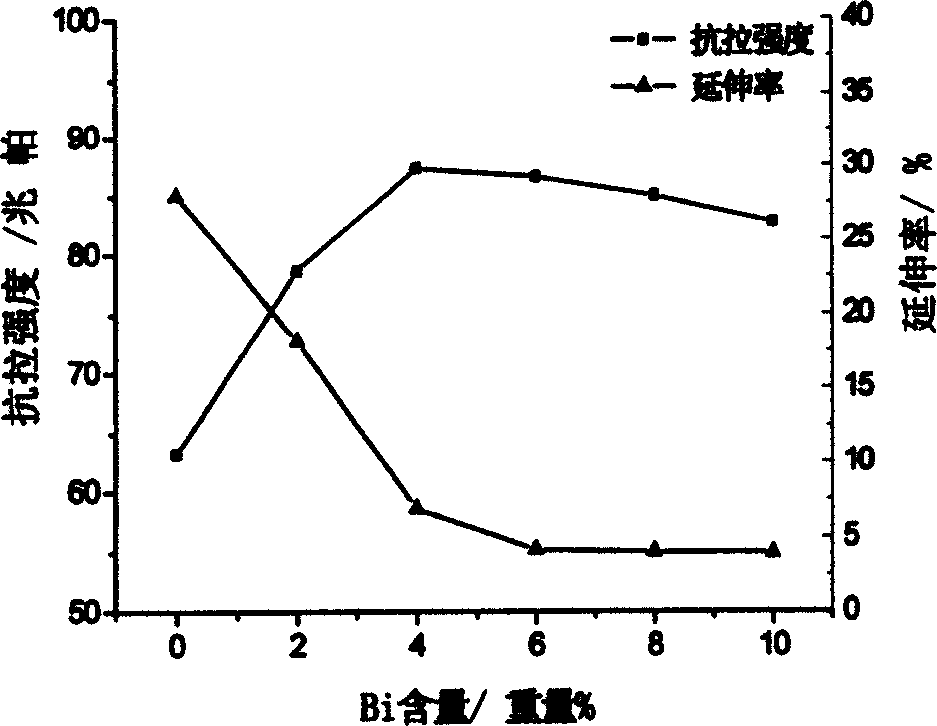

Low melting point tin-zinc solder without lead and soldering paste

InactiveCN1644301AImprove antioxidant capacityHigh heat resistance requirementsWelding/cutting media/materialsSoldering mediaAlloyZinc

A low-smelting-point non-lead SnZn-alloy solder is prepared from Zn (5-9 wt.%), Bi (0.5-4), Nd (0.01-0.5) and Sn (rest). Its solder paste features that the Sn or Sn-alloy particles are coated on the surface of each solder particle for high stability and high antioxidizing power.

Owner:SOUTHEAST UNIV

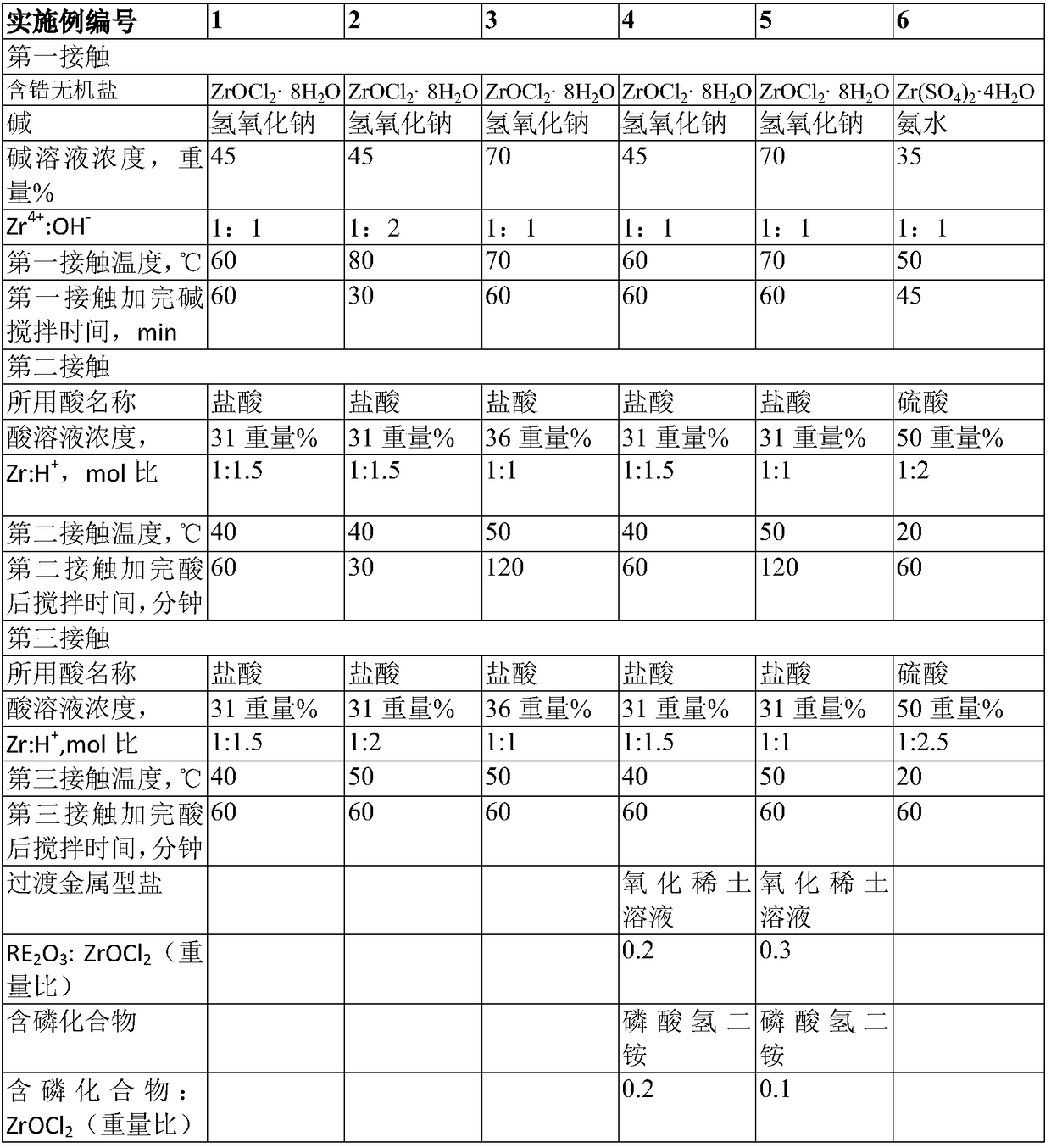

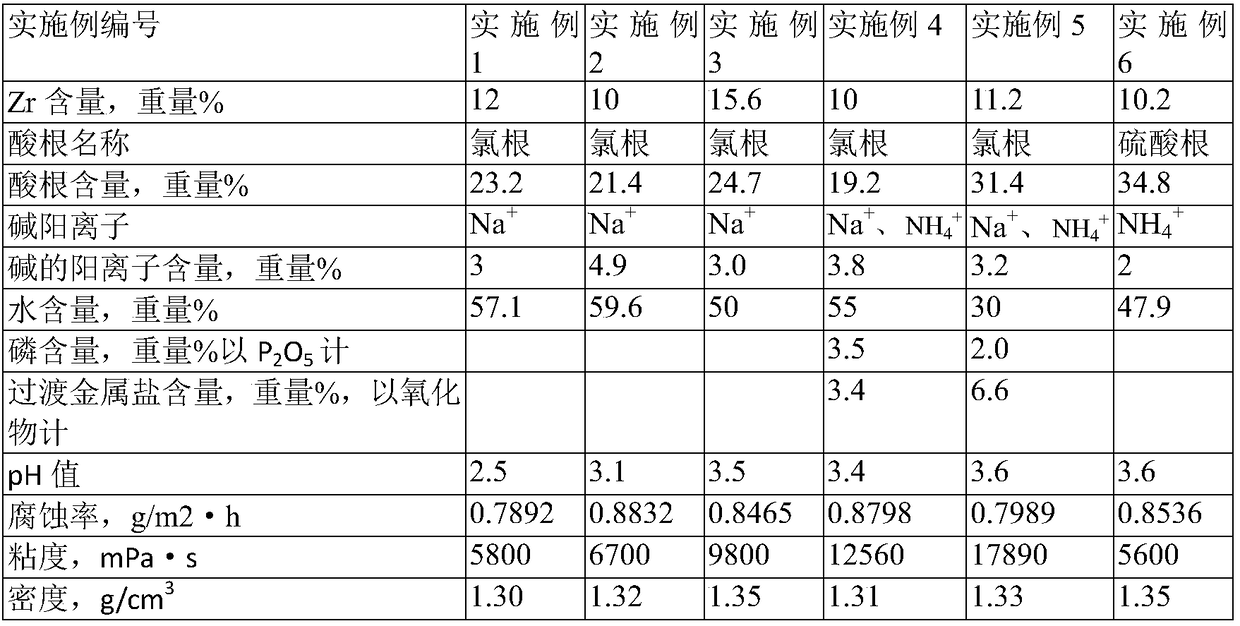

Zirconium sol, preparation method and applications thereof

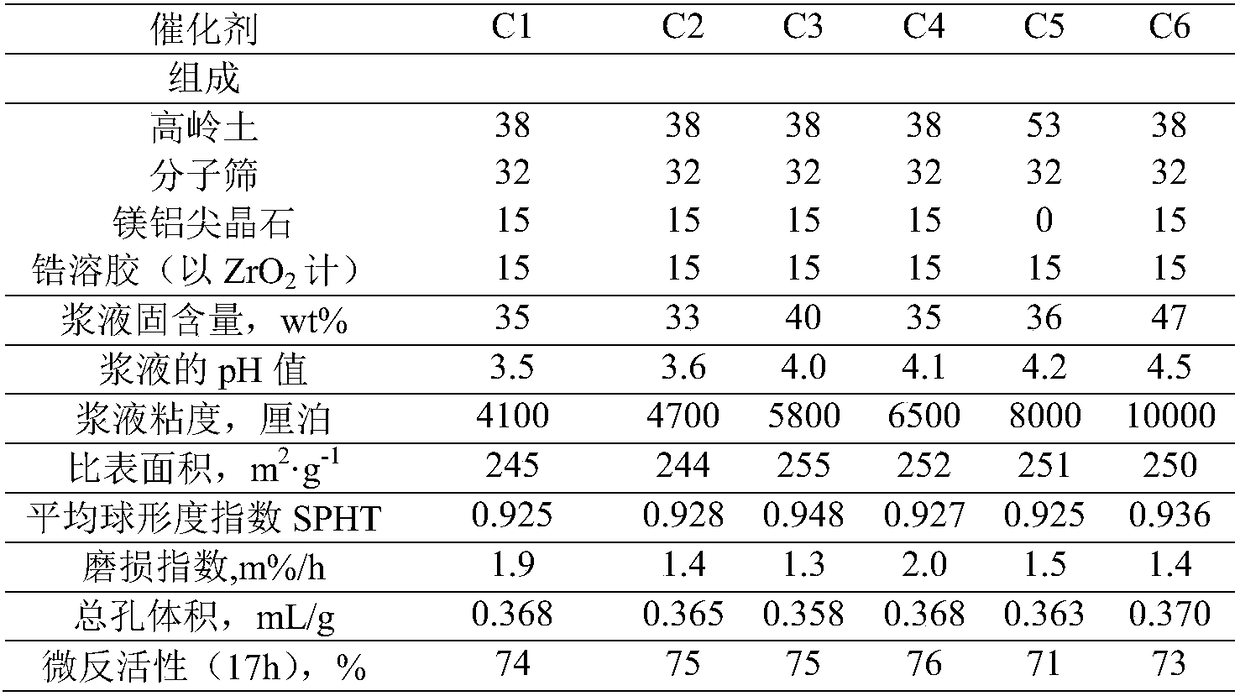

ActiveCN109110808AImprove adhesionLess corrosiveCatalytic crackingMolecular sieve catalystsCracking reactionViscosity

The invention relates to a zirconium sol, a preparation method and applications thereof, wherein the zirconium sol has a corrosion rate of not more than 1 g / m<2>.h, the pH value of 2.5-4, and the viscosity of more than 1000 mPa.s. The preparation method comprises: carrying out first contact on a zirconium-containing salt and an alkali solution, wherein a molar ratio of Zr to OH<-> is 1:1-2; carrying out second contact on the first contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3, and preferably the temperature of the first contact is 20-30 DEG C higher than the temperature of the second contact; and carrying out third contact on the second contact mixture and an acid, wherein a molar ratio of Zr to H<+> is 1:1-3. According to the present invention, the zirconium sol is used for preparing catalytic cracking catalysts, can improve the sphericity of the catalyst, and can improve the hydrocarbon oil cracking reaction effect of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Austenitic stainless steel

InactiveCN1654696AMeet the requirementsStrong acid and alkali corrosion resistanceCavitationHigh wear resistance

The present invention is one kind of austenitic stainless steel composition and features its composition of C not more than 0.12 wt%, Si not more than 1.00 wt%, Mn 5.00-7.00 wt%, P not more than 0.045 wt%, S not more than 0.030 wt%, Ni 2.00-4.00, Cr 16.00-18.00 and Cu 1.50-3.50 wt% except Fe and other impurity. The austenitic stainless steel composition has relatively low cost, high acid and alkali corrosion resistance, especially high sea water cavitation resistance, high strength, high toughness, high wear resistance, and expansion as high as 40-50 %, and is suitable for use in container, especially ocean shipping container.

Owner:青岛马士基集装箱工业有限公司

Novel energy-saving pouring gate pipe

InactiveCN101644358AHigh strengthEasy to makeFoundry mouldsFoundry coresWear resistanceUltimate tensile strength

The invention discloses a novel energy-saving pouring gate pipe cast by mixing clay, argil and bauxite. The pouring gate pipe has the advantages of light weight, favorable wear resistance, corrosion resistance, high integrated intensity and favorable integrated performance and can meet the requirements of industrial use. The pouring gate pipe greatly saves resources and energy, effectively avoidscasting defects such as adhering sand, sand inclusions, sand cuts, sand holes and the like, and enhances the cost and the quality of the casting.

Owner:于海峰

Synthetic silicon oxynitride raw material and preparation method thereof

InactiveCN105253865AHigh purityShort synthesis reaction timeNitrogen and non-metal compoundsPhysical chemistryNitrogen atmosphere

The invention relates to a synthetic silicon oxynitride raw material and a preparation method thereof. A technical scheme adopted in the invention is characterized in that the method comprises the following steps: mixing 50-60wt% of elemental silicon with 40-50wt% of silica, and carrying out ball milling in a ball mill until the granularity is 4.5-6.5[mu]m to obtain a ball milled powder; and putting the ball milled powder in an atmosphere furnace, heating in highly pure nitrogen atmosphere at a heating rate of 10-12DEG C / min to 1000-1100DEG C, heating at a heating rate of 6-8DEG C / min to 1400-1500DEG C, and carrying out heat insulation for 4-9h to obtain the synthetic silicon oxynitride raw material. The method has the advantages simplicity, short production period, low cost, and no need of special synthesis devices or processing technologies; and the prepared synthetic silicon oxynitride raw material has the characteristic of high Si2N2O purity and completeness of grown crystal grains.

Owner:WUHAN UNIV OF SCI & TECH

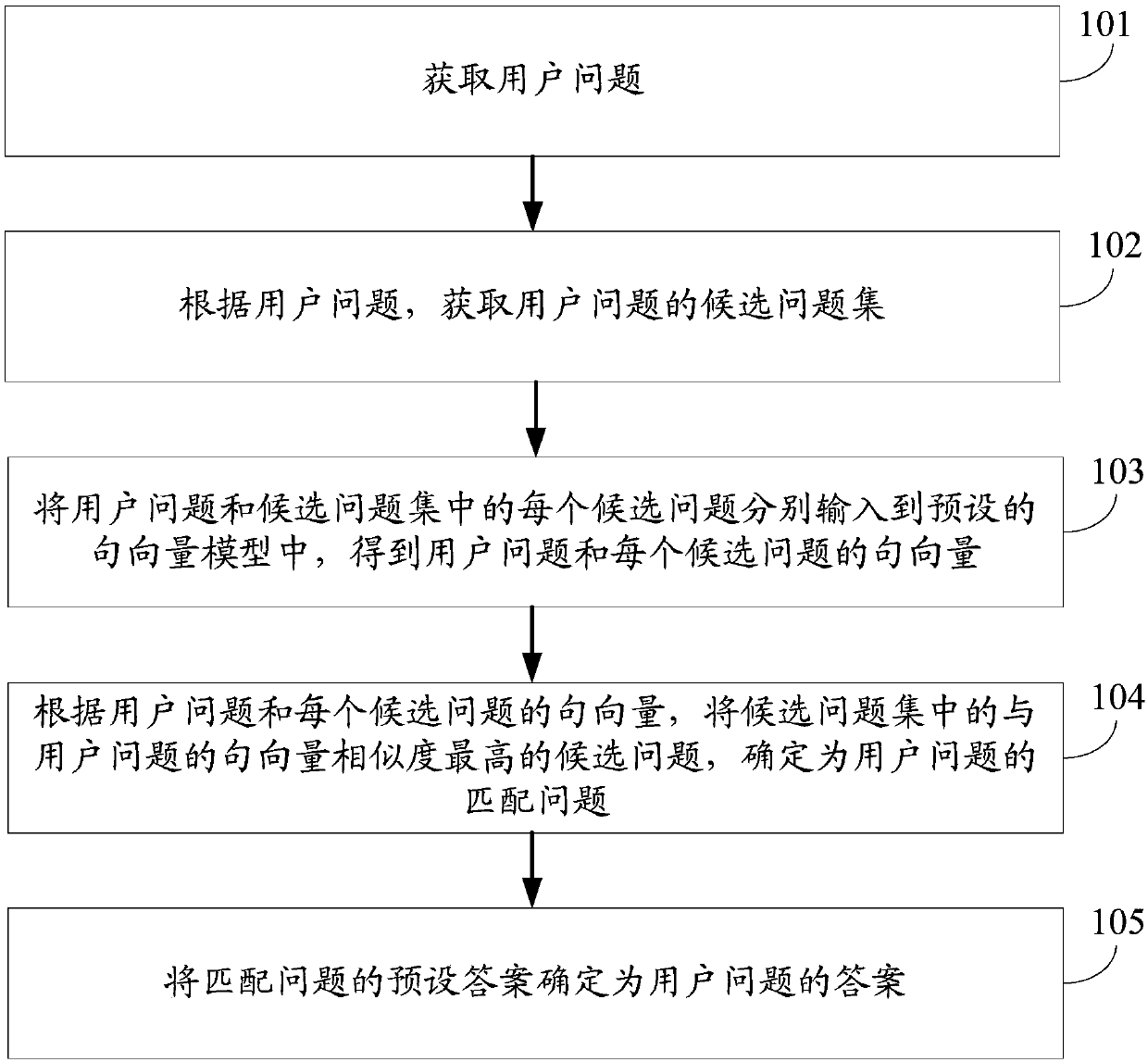

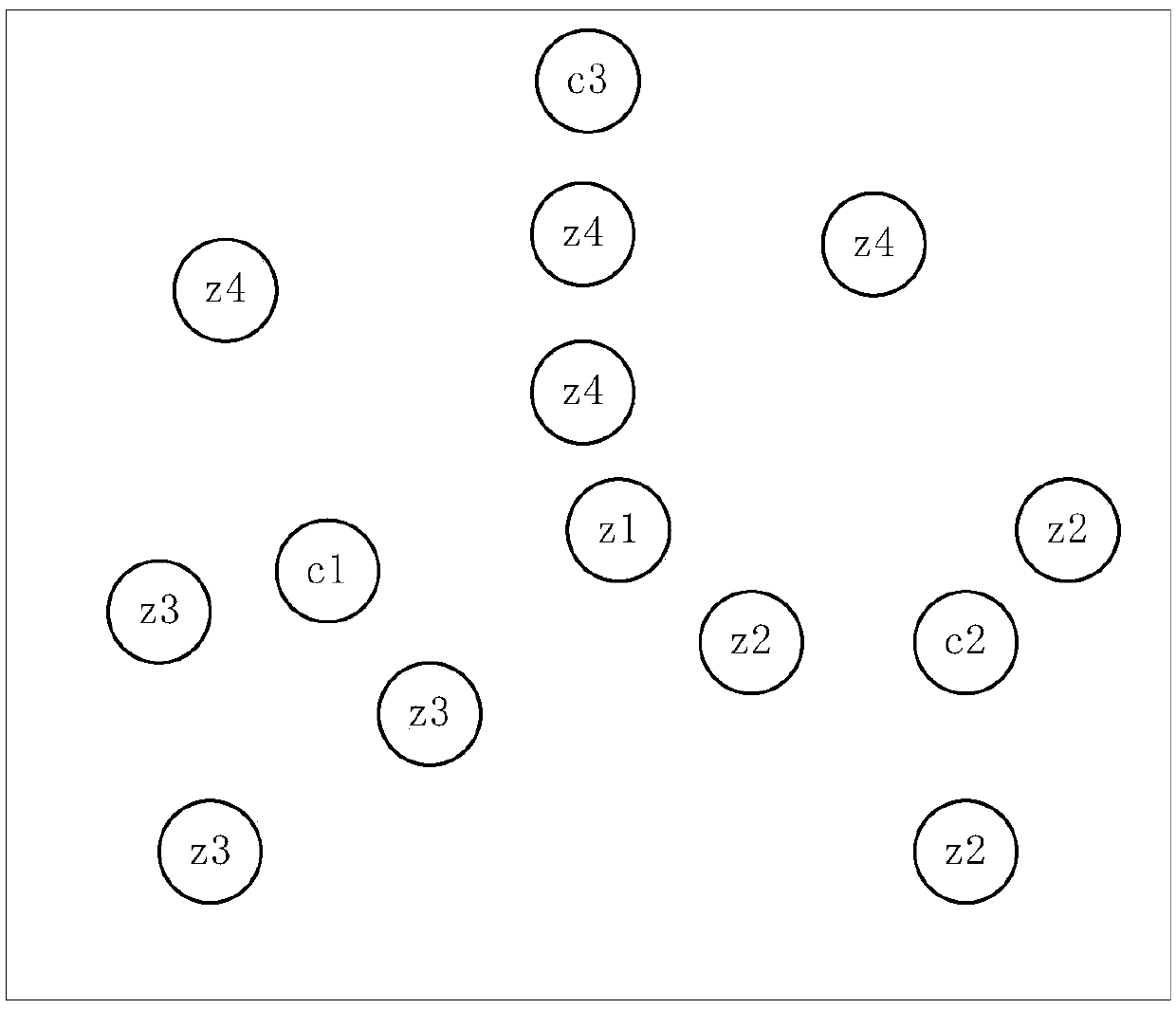

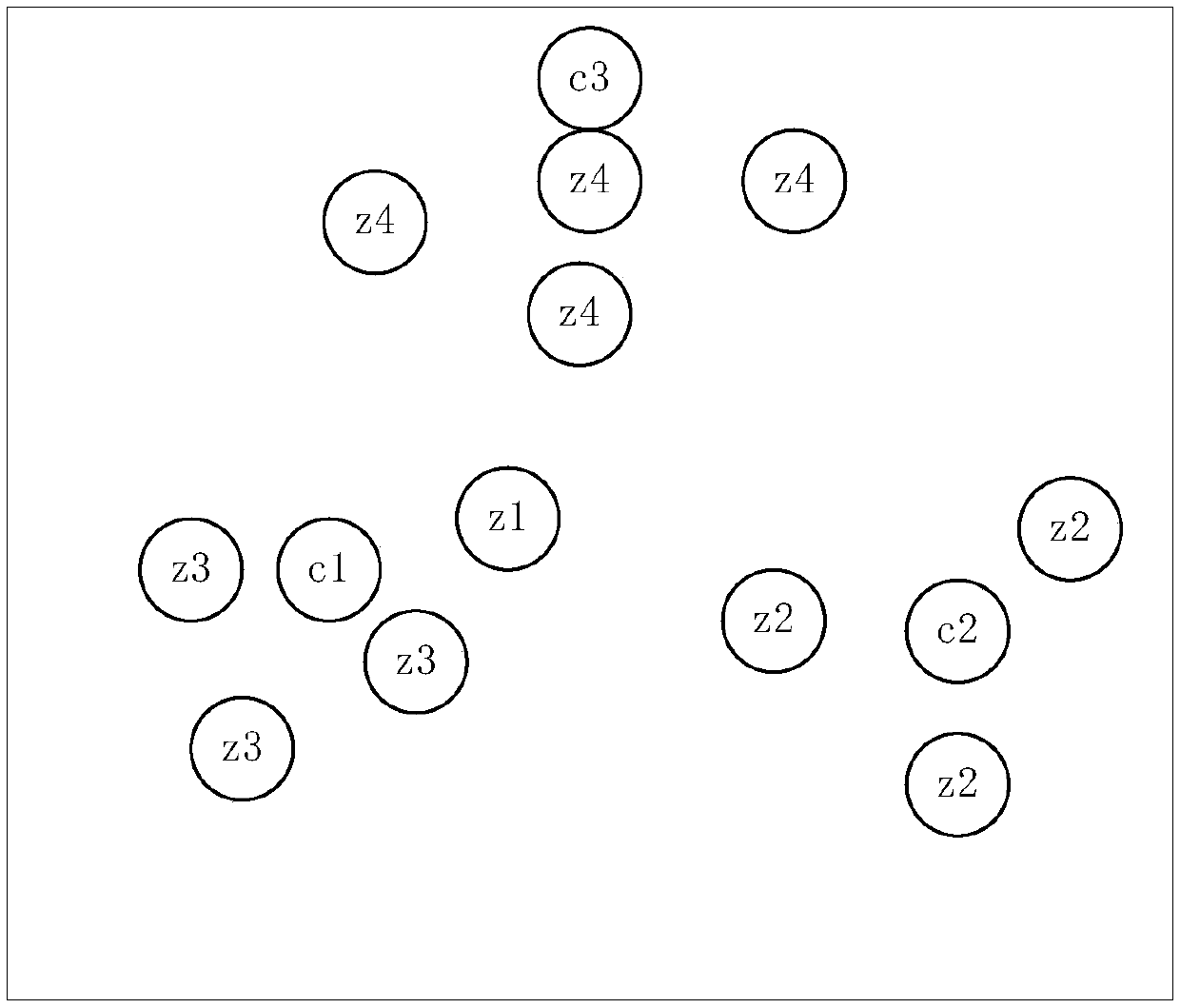

Question and answer method and device and terminal equipment

PendingCN111046147AImprove accuracyReduce construction costsDigital data information retrievalSpecial data processing applicationsTerminal equipmentQuestions and answers

The invention provides a question and answer method and device and terminal equipment. The question and answer method comprises the steps of obtaining a user question; obtaining a candidate question set of the user questions according to the user questions; respectively inputting the user question and each candidate question in the candidate question set into a preset sentence vector model to obtain sentence vectors of the user question and each candidate question; according to the user problem and the sentence vector of each candidate problem, determining the candidate problem with the highest similarity with the sentence vector of the user problem in the candidate problem set as a matching problem of the user problem; determining a preset answer matched with the question as an answer ofthe user question, wherein the preset sentence vector model is obtained by training the collected user intention recognition corpus. According to the scheme, the answers to the user questions can be obtained on the premise of not using the question-answer matching model, and the question answers with high accuracy can be obtained by combining the preset sentence vector model.

Owner:MASHANG CONSUMER FINANCE CO LTD

Novel ice-covering-proof coating and preparation method thereof

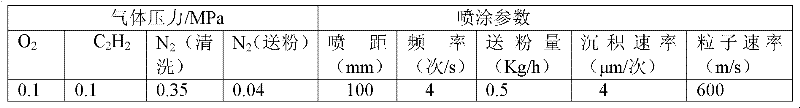

InactiveCN102443326AIncrease surface areaInhibition of icingOther chemical processesCoatingsGas explosionTransmission line

The invention relates to a novel ice-covering-proof coating and a preparation method thereof, belonging to the technical field of power transmission line protection. The ice-covering-proof coating is prepared from a composite material which has a particle size of 10-50 mu m and contains glass powder and polytetrafluoroethylene, wherein the mass percent of the glass powder is 50-90%, and the mass percent of the polytetrafluoroethylene is 10-50%; the thickness of the sprayed coating is 15-25 mu m, the coating with thickness of 5-10 mu m is in a small bulge structure, and a micro nanometer structure is formed on the surface of the small bulge structure; and the spraying method can be gas explosion spraying or supersonic flame spray coating. The surface of the coating has fine hydrophobicity, and can effectively inhibit the ice covering phenomenon of the power transmission line, thereby ensuring the stable operation of the power transmission line; the coating material has the characteristics of persistent low temperature resistance, high heat radiation performance, high ageing resistance and the like; and the preparation method based on gas explosion spraying or supersonic flame spray coating ensures the high bonding strength between the coating and a matrix and the low surface temperature and large surface roughness of the workpiece, thereby effectively avoiding the covering of ice and water.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

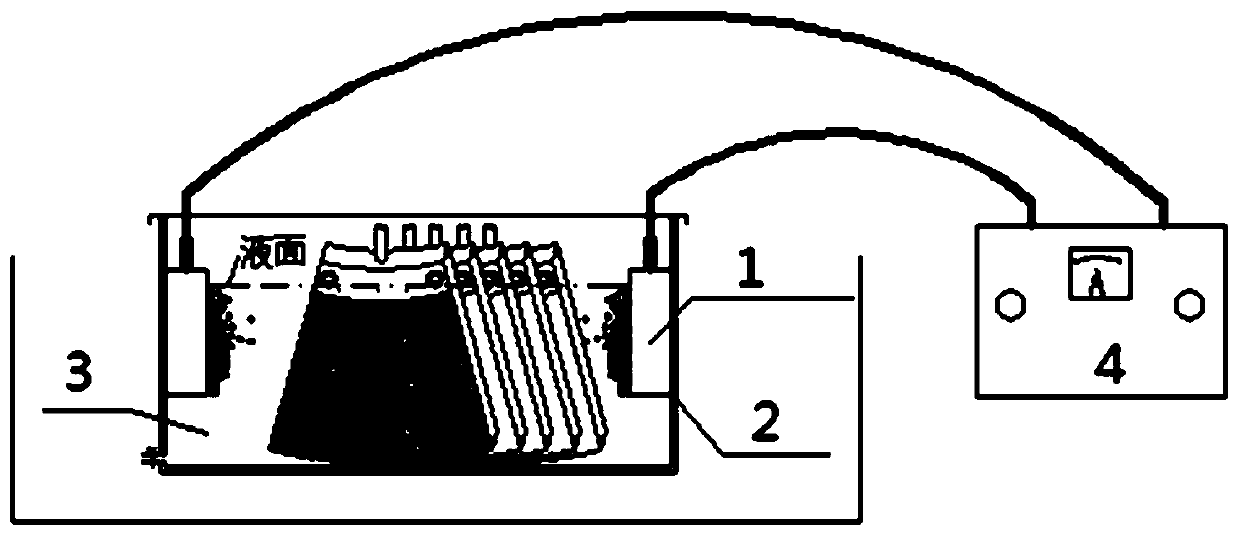

Method for preparing nano zinc oxide wires

ActiveCN102220596AMeet the requirements of industrial useMaterial nanotechnologyElectrolysis componentsElectrolysisElectrochemistry

The invention discloses a method for preparing nano zinc oxide wires by using solid nuclear track technology. In the method, through nuclear pore film with a pore diameter of 100 to 600 nanometer is used as a template, a 110-to-200-nanometer-thick gold layer is plated on one side of the nuclear pore film, and a 10-to-40-micrometer-thick copper layer is deposited on the gold layer electrochemically; then a platinum wire is used as an anode and a gold, copper substrate is used as a cathode, zinc oxide is electrochemically deposited to form zinc oxide nanowires, wherein electrolyte is mixed solution of 0.05 to 0.2mol / L KCl, 2 to 7mmol / L ZnCl2 and 3 to 8 mmol / L H2O2, the pH value is 6.5 to 7.5, the electrolysis voltage is 0.8 to 1.5V, and the electrochemical deposition time is 1 to 5 hours. The diameter of the produced zinc oxide nanowires is 100 to 600 nanometers, and the length is 5 to 8 micrometers.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

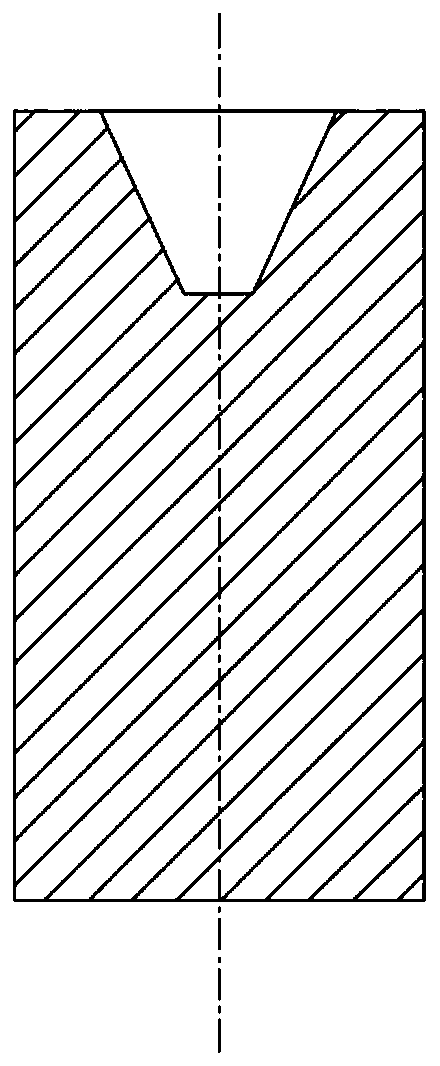

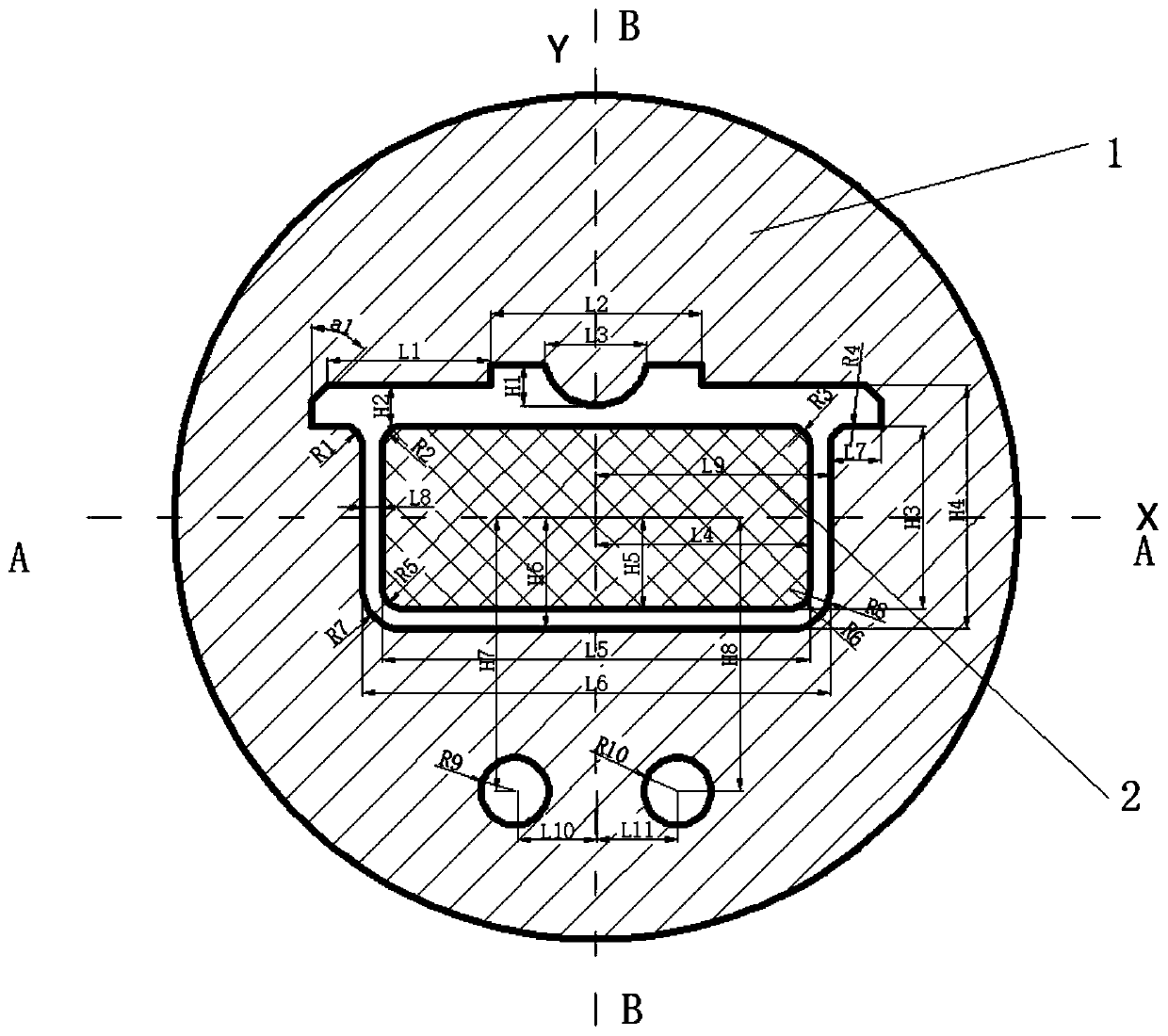

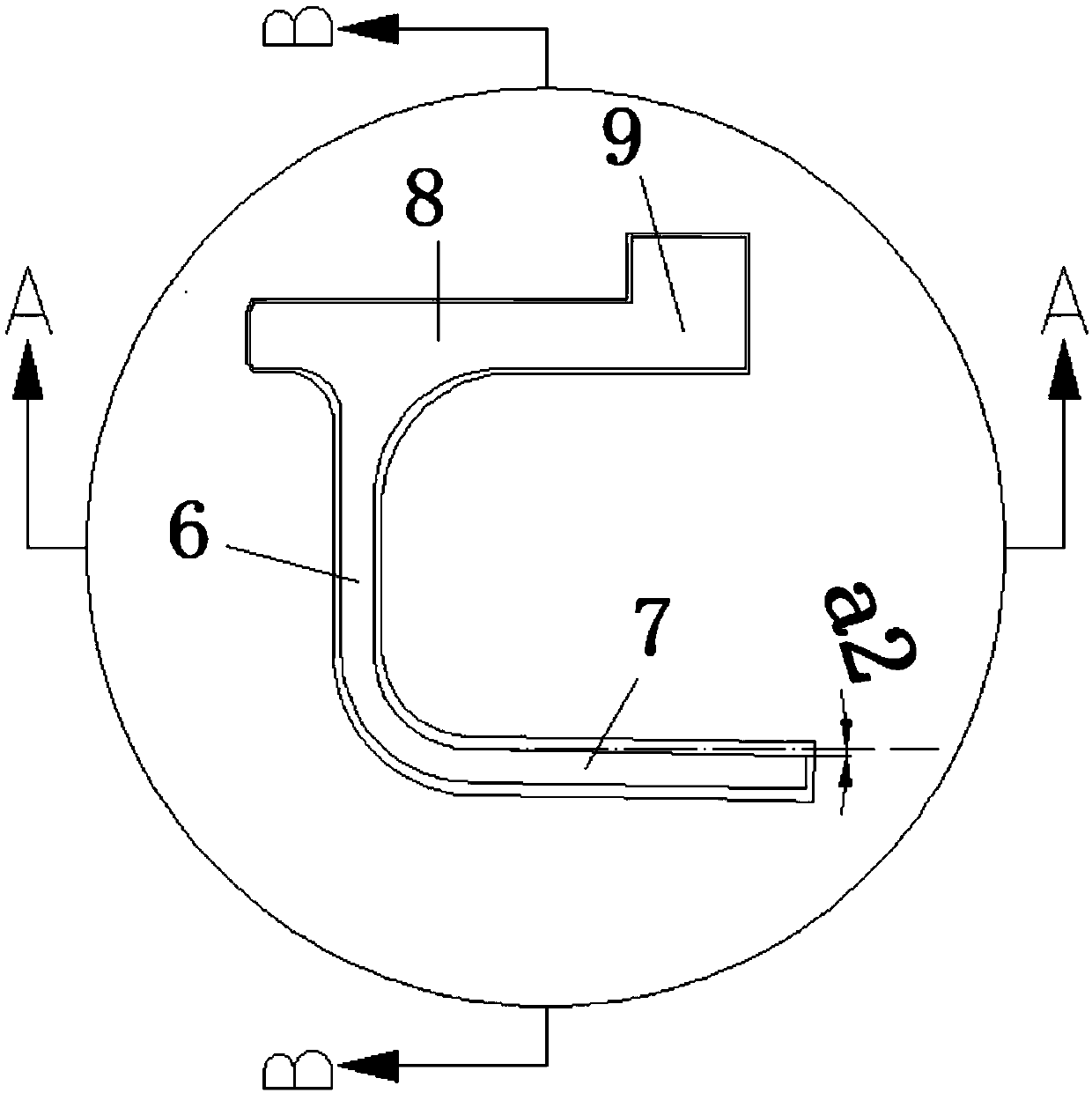

Hot extrusion die and hot extrusion overall forming method of special-shaped square pipe

ActiveCN111451309AImproves wall thickness uniformityImprove surface qualityShaping toolsExtrusion diesThermodynamicsManufacturing technology

The invention relates to a hot extrusion die and a hot extrusion overall forming method of a special-shaped square pipe, and belongs to the fields of an extrusion forming technology and a special-shaped material manufacturing technology. The problem that in the prior art, the special-shaped square pipe cannot be prepared with a hot extrusion overall forming method is solved. The hot extrusion overall forming method of the special-shaped square pipe includes the steps that 1, a blank is heated and broached; 2, the broached blank is heated at a second time; 3, the blank is subjected to hot extrusion through the hot extrusion die of the special-shaped square pipe; and 4, the special-shaped square pipe obtained after hot extrusion forming is air-cooled to room temperature, and the surface quality and the mechanical performance of the special-shaped square pipe are checked. The prepared special-shaped square pipe is good in surface quality and high in dimensional precision, all performanceindexes meet the design requirements through physical and chemical analysis and mechanical performance testing, and the overall quality meets the industrial use requirements.

Owner:CENT IRON & STEEL RES INST +1

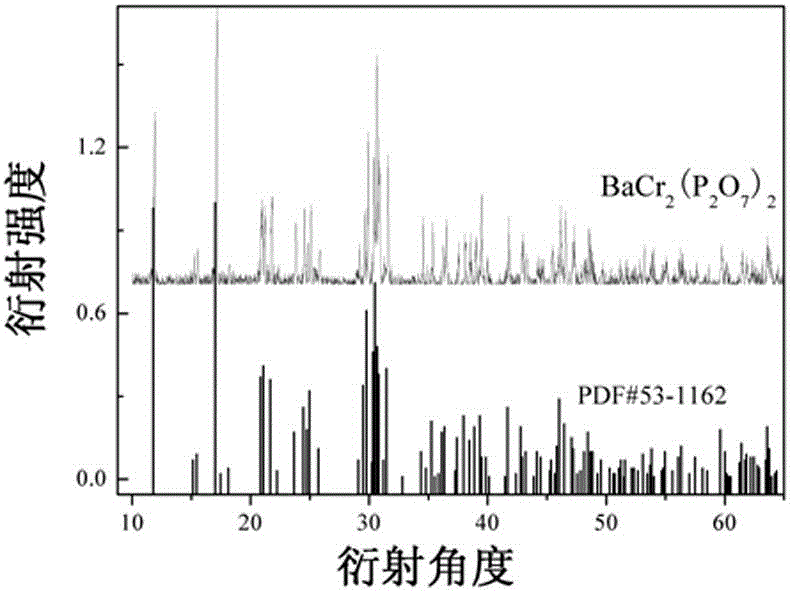

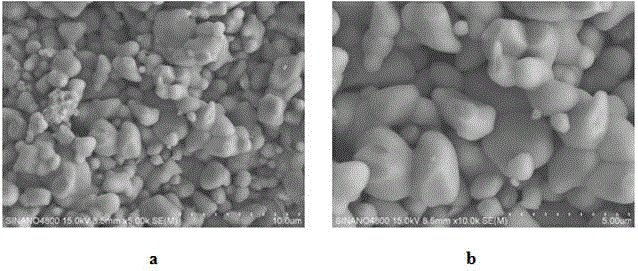

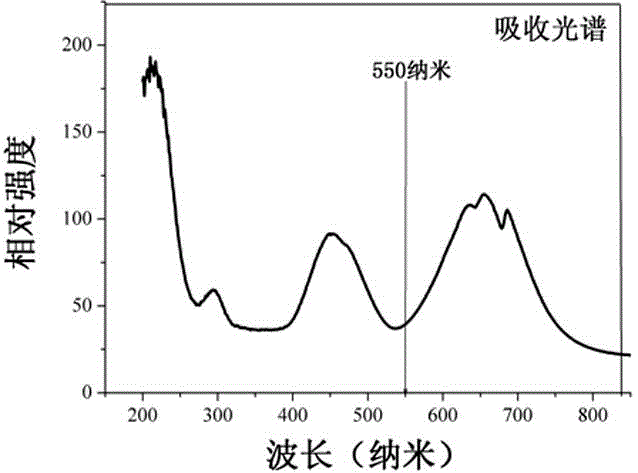

Phosphate inorganic material, method for producing same and application

InactiveCN102942168AEasy to fillGood weather resistancePhosphorus compoundsChemical solutionAlkaline earth metal

Owner:SUZHOU UNIV

Recycling method for activated carbon-based desulfurizer

ActiveCN107774268AEliminate vulcanization stepImprove practicalityMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementSolvent

The invention belongs to the technical field of chemical waste recycling, in particular to a recycling method for an activated carbon-based desulfurizer. The method comprises the following steps: carrying out oxidation drying on the activated carbon-based desulfurizer in a desulfurization tank; performing solid-liquid separation after mixing the desulfurizer with catalytically cracked diesel oil to obtain a desulfurizer material; mixing the obtained desulfurizer material with No. 6 solvent oil continuously and then carrying out solid-liquid separation to obtain treated activated carbon; takingalumina, titanium dioxide and activated carbon as raw materials to prepare a composite oxide carrier; taking cobalt, molybdenum and nickel as active components, and rare earth elements as additives,and loading on the carrier by an impregnation method to obtain a semi-finished catalyst; carrying out anaerobic roasting on the semi-finished catalyst to obtain a finished catalyst. According to the invention, a hydrogenation catalyst is prepared by completely recycling waste activated carbon-based desulfurizer as a part of the raw materials, therefore, and suitable for hydrofining of cracking gasoline after one-stage hydrogenation, and performances of the hydrogenation catalyst meet requirements of industrial use.

Owner:CHINA PETROLEUM & CHEM CORP

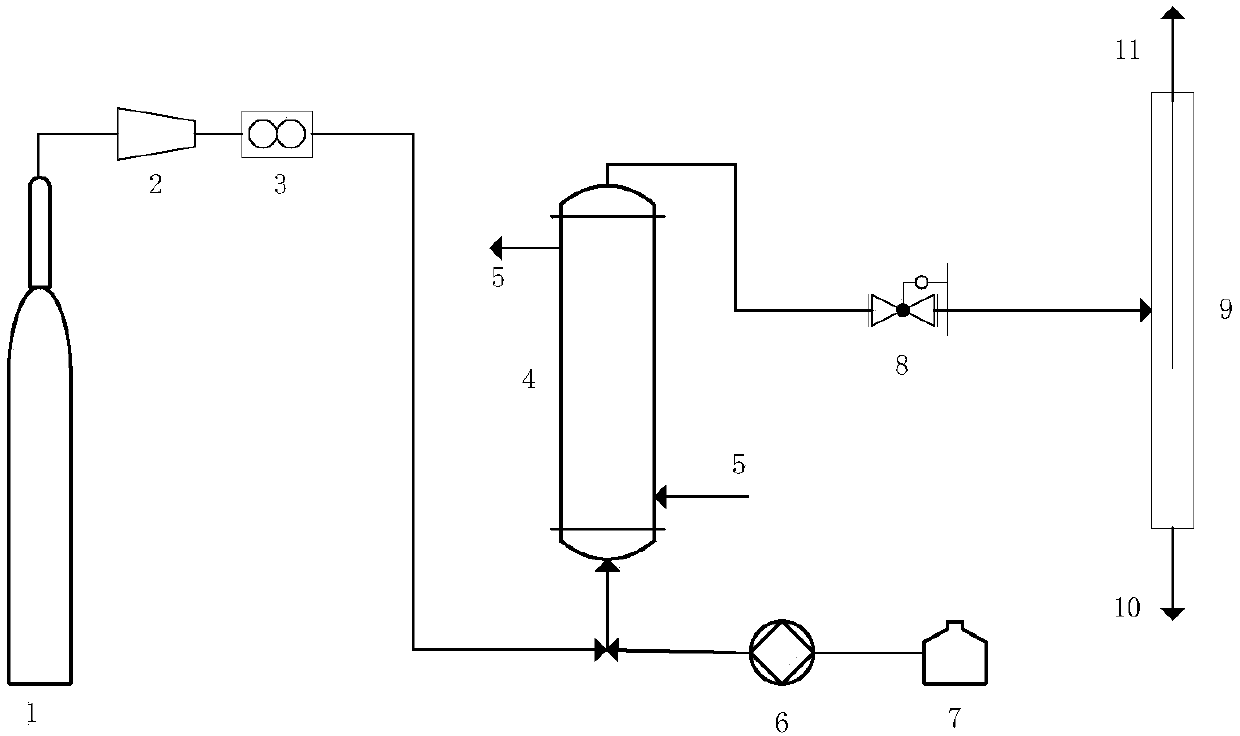

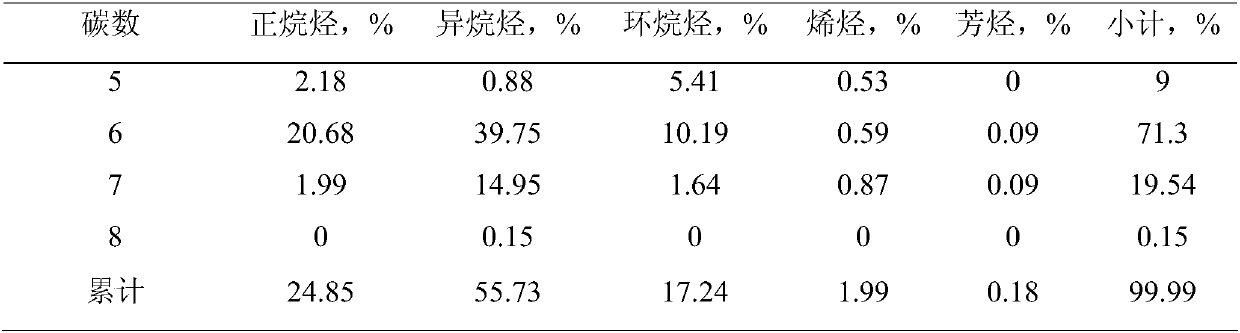

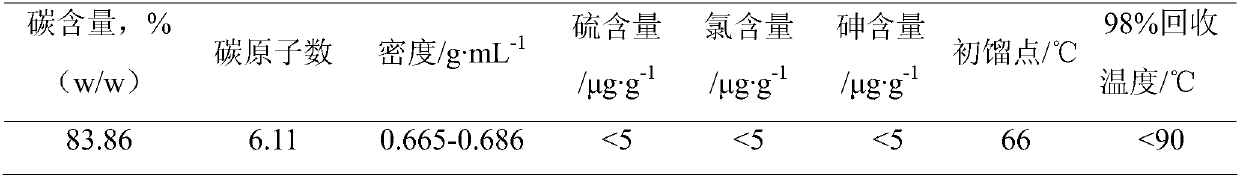

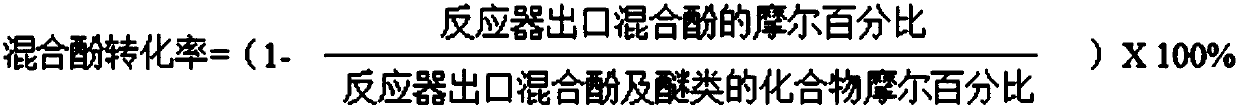

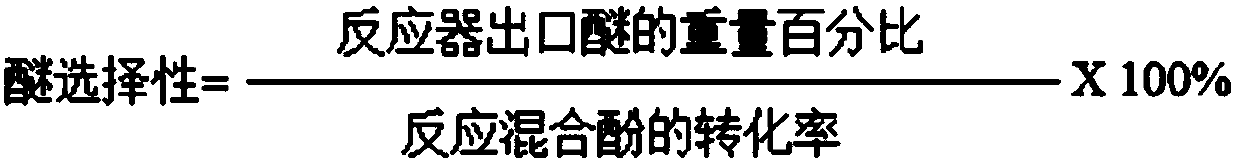

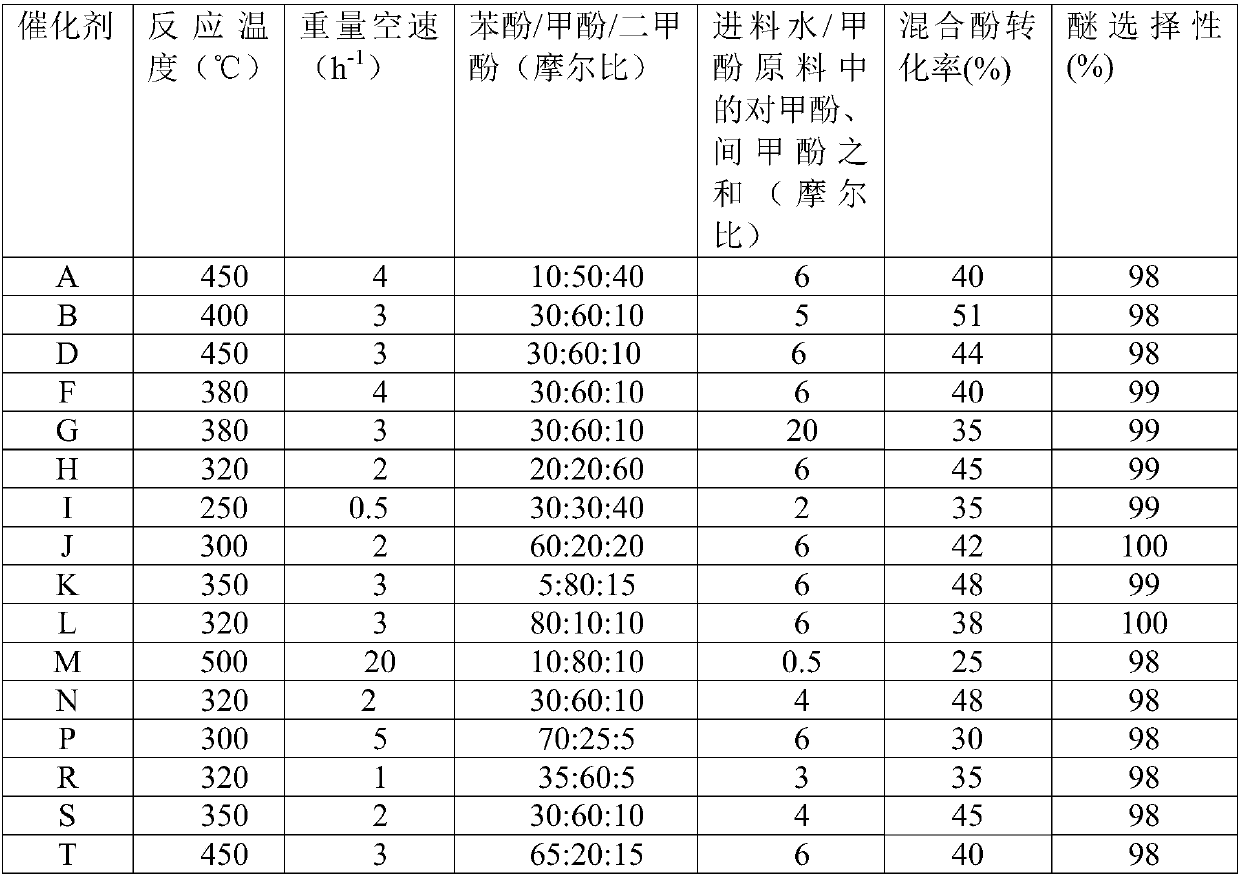

Gaseous phase etherifying production method of complex ether with mixed phenol methanol

ActiveCN109942383AImprove performanceImprove stabilityMolecular sieve catalystsCatalyst activation/preparationEtherReaction zone

The invention discloses a gaseous phase etherifying production method of complex ether with mixed phenol methanol. The method at least comprises the following steps: feeding a mixture containing mixedphenol and methanol through a reaction zone containing an etherifying catalyst, and reacting to obtain ether. The method for producing complex ether with mixed phenol and methanol uses mixed phenol and methanol as raw materials, has the etherified product selectivity of over 98 percent, has good catalyst stability, does not have equipment corrosion in the production process, is an environment-friendly catalyst, and has an excellent industrial application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing catalyst of containing MFI structured molecular sieve

InactiveCN1322927CPromote regenerationImprove conversion rateLactams preparationMolecular sieve catalystsBeckmann rearrangementMolecular sieve

A MFI-molecular sieve catalyst for preparing caprolactam from cyclohexanone oxime by gas-phase Beckmann rearrangement is prepared through proportionally mixing MFI-molecular sieve with alkaline silica gel, shaping, drying and calcining. It has high conversion rate and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-temperature fume dust-collection oxidation-resistant metal fiber sintered felt filtering material

InactiveCN107174871AHigh breaking strengthImprove antioxidant capacityFiltration separationMetal fiberFiltration

The invention discloses a method for preparing a high-temperature fume dust-collection oxidation-resistant metal fiber sintered felt filtering material. According to the method, a microwave sintering process is adopted, the sintering time is shortened, the heating velocity of a metal fiber sintered felt in the sintering process is effectively increased, and the sintering temperature can be also reduced, so that excessive growth of fiber crystal granules is prevented, the breaking strength of a single fiber is improved, and furthermore the breaking strength of an overall fiber sintered material is improved; and an electroplating method is further adopted to electroplate an amorphous-state plated Ni-P alloy layer on the surface of the metal fiber sintered felt, so that the surface quality of metal fiber felt is improved, defects of the micro-fine fiber surface of the metal fiber feltare eliminated, the oxidation resistance of the fiber felt is improved, and in addition, due to deposition of a Ni-P alloy, the aperture of the fiber felt is smaller and smaller, the air permeability of the fiber felt is degraded gradually, the bubbling pressure is gradually increased, the filtration precision is improved, and industrial use requirements can be completely met.

Owner:ANHUI GUONENG YISHENG ENVIRONMENTAL PROTECTION SCI & TECH

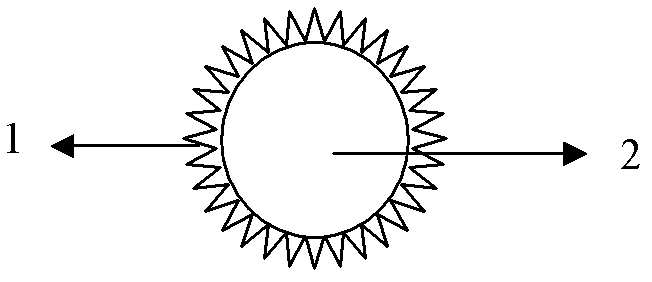

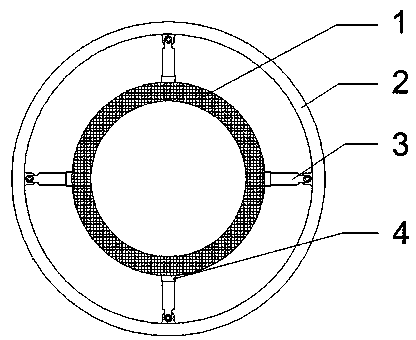

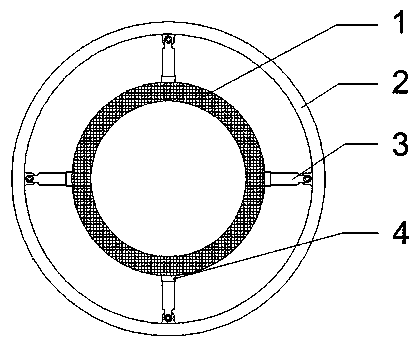

Super-high voltage grading ring and production process thereof

InactiveCN110010314ANot easy to breakdown failureImprove conductivityVacuum evaporation coatingSputtering coatingSemiconductor materialsPotential difference

The invention provides a super-high voltage grading ring and a production process thereof, aiming at the problems that the existing grading ring material is easy to cause potential difference and failure of the grading ring under the super-high voltage. The super-high voltage grading ring comprises an annular grading ring body which is made of semiconductor materials, the outer portion of the grading ring body is coaxially provided with an aluminum ring, a plurality of connection rods are uniformly distributed in an annular interval between the grading ring body and the aluminum ring, and theextension lines of the connection rods pass through the centers of circles of the grading ring body and the aluminum ring. By using the semiconductor material, the produced grading ring has an electric field under the super-high voltage to fundamentally avoid the potential difference problem, and the grading ring is not easy to cause breakdown of a device when the voltage generates voltage jump soas to obviously improve the whole reliability of the device.

Owner:平顶山正植科技有限公司

High-stability phenol-yellowing-resistant silicone oil softener and preparation method thereof

PendingCN114703669AFeel goodReduce usageLight resistant fibresGrip property fibresPolymer scienceSilicone oil

The invention belongs to the technical field of textile softeners, and particularly relates to a high-stability phenol-yellowing-resistant silicone oil softener and a preparation method thereof. The high-stability phenol-yellowing-resistant silicone oil softening agent is prepared from the following components in parts by mass: 5 to 40 parts of silicone oil, 2 to 20 parts of an emulsifier, 0.2 to 1 part of a co-emulsifier, 2 to 15 parts of a solvent, 0.5 to 5 parts of a phenol-yellowing-resistant agent and 15 to 120 parts of deionized water. The softening agent provided by the invention overcomes the difficulties of serious phenolic yellowing of high-amine-value silicone oil and poor compatibility of an anti-phenolic yellowing agent and the softening agent by preferably selecting reasonable raw materials, has excellent phenolic yellowing resistance and soft hand feeling, also has good acid resistance, alkali resistance, roll sticking resistance, shear resistance, centrifugation, compounding stability and other stability, and is suitable for industrial production. And industrial use requirements and export requirements are met.

Owner:ZHEJIANG TRANSFAR FUNCTIONAL NEW MATERIAL CO LTD +2

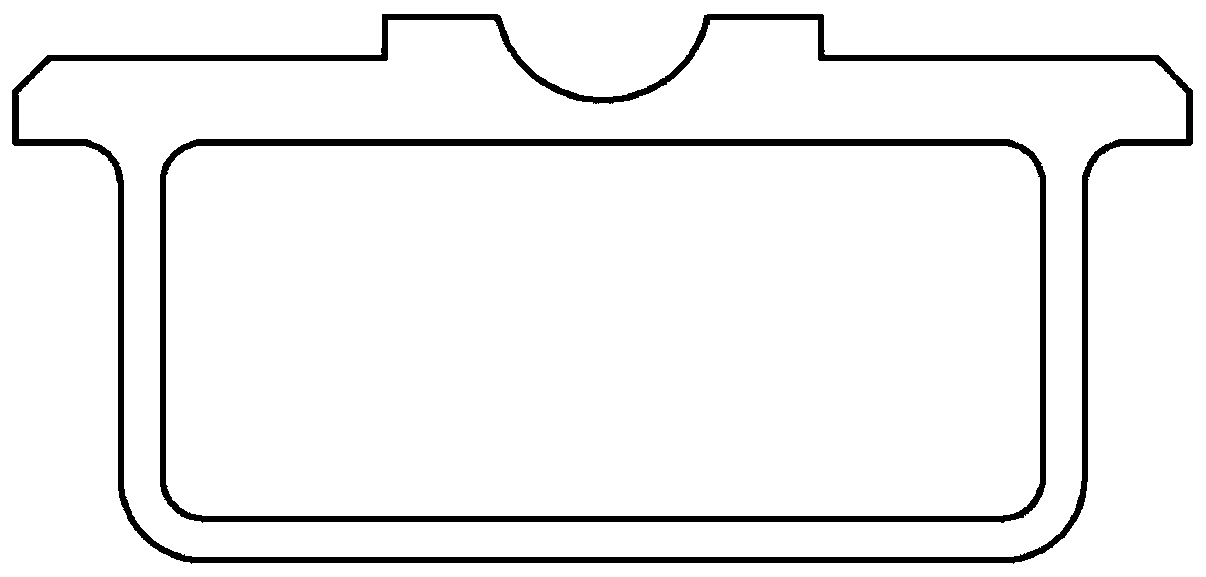

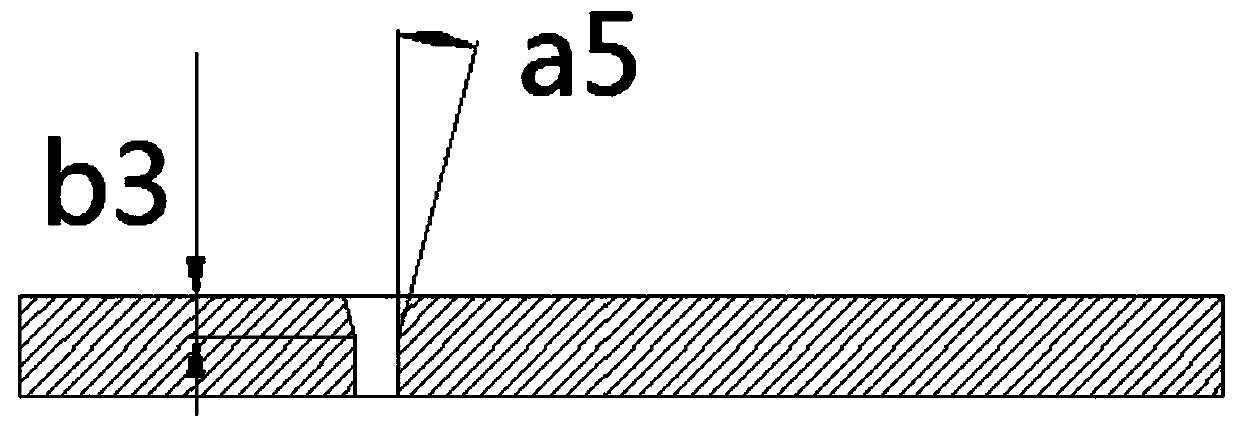

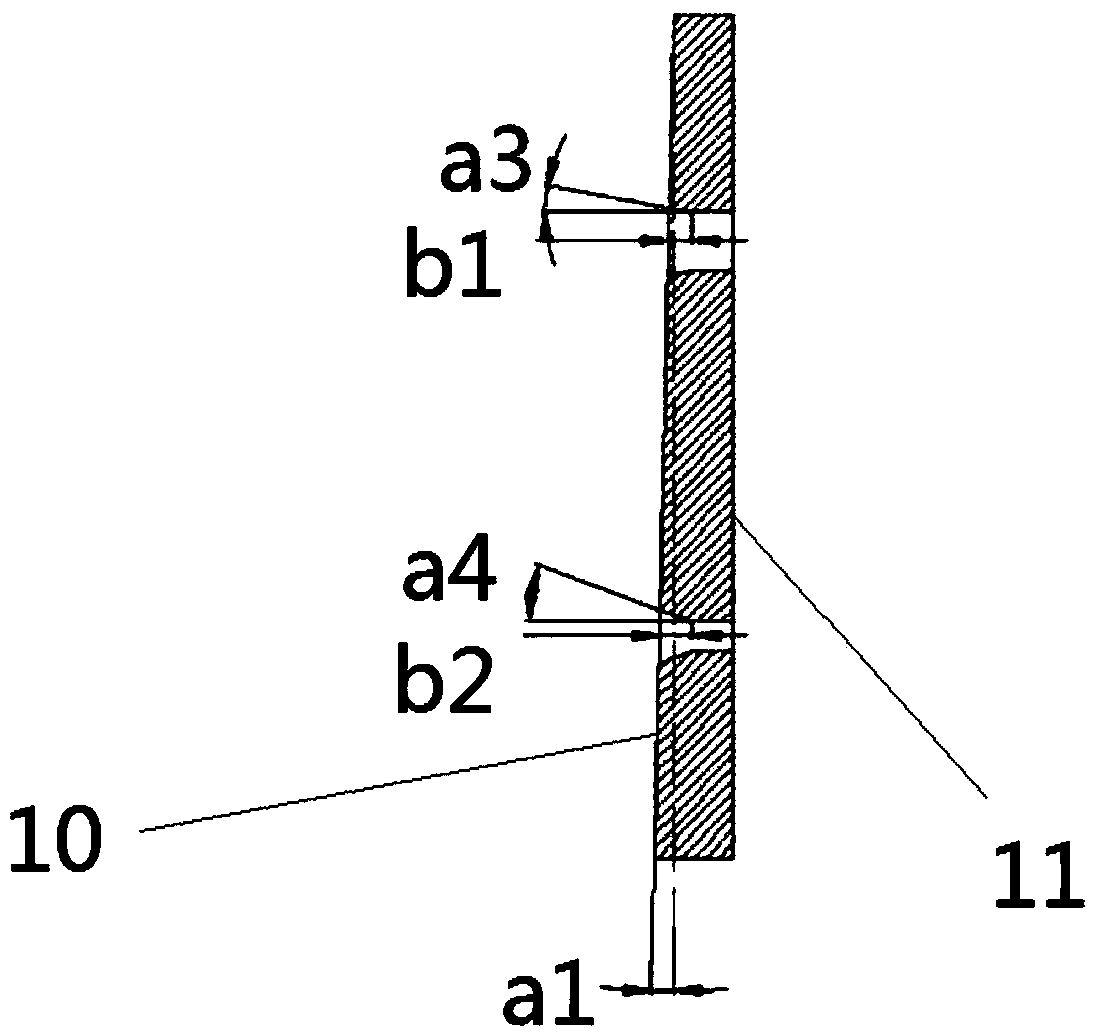

Extrusion forming method of J-shaped steel

ActiveCN109604360AGuaranteed dimensional accuracyReduce distortionExtrusion diesExtrusion control devicesExtrusionPolymer science

The invention relates to an extrusion forming method of J-shaped steel, and belongs to the technical field of an extrusion forming technology and profile manufacturing. The method solves the problemsthat the surface quality of J-shaped steel prepared by using a forming method in the prior art is poor, and the size precision cannot meet the requirement. The extrusion forming method of the J-shapedsteel comprises the following steps that extrusion equipment extrudes a blank; the blank enters a J-shaped glass cushion; and the blank enters an extrusion die with a J-shaped through hole. Accordingto the extrusion forming method of the J-shaped steel, the effect that the J-shaped steel is produced by using the die through a hot extrusion forming method is achieved.

Owner:CENT IRON & STEEL RES INST +1

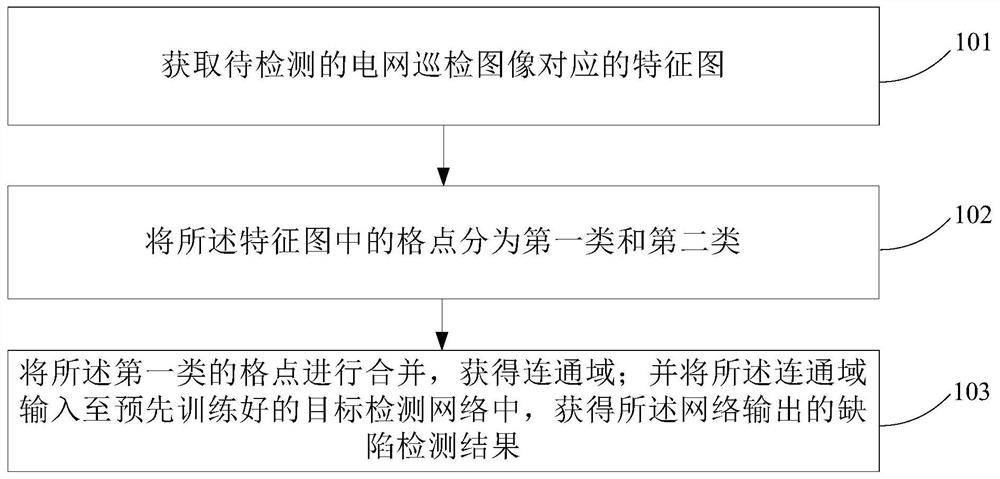

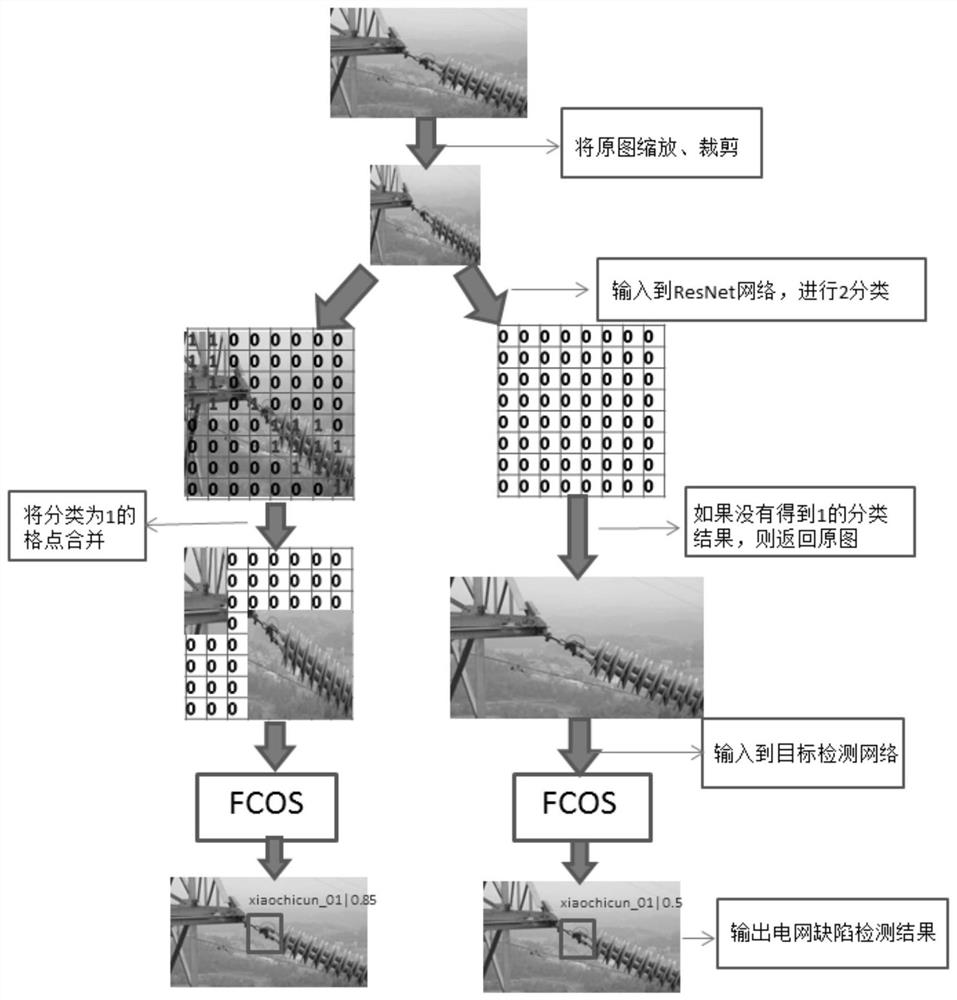

Power grid defect detection method and system

ActiveCN113012107AImprove accuracyEasy to detectImage analysisCharacter and pattern recognitionPattern recognitionPower grid

The embodiment of the invention provides a power grid defect detection method and system, and the method comprises the steps: obtaining a feature map corresponding to a to-be-detected power grid inspection image, the feature map comprises a plurality of grid points, and each grid point corresponds to one region of the image; grid points in the feature map are divided into a first class and a second class, the first class represents a defect area, and the second class represents a background area; merging the grid points of the first type to obtain a connected domain; and inputting the connected domain into a pre-trained target detection network to obtain a defect detection result output by the network. According to the embodiment of the invention, the proportion of the defect target in the whole picture is very low for the power grid inspection picture which is data with a complex background, and the accuracy of the model can be obviously improved by extracting the target and then performing classification regression on the target through a coarse-to-fine rapid power grid defect detection method.

Owner:JIANGSU FRONTIER ELECTRIC TECH

Regeneration treatment technology of cutting edge material silicon carbide

The invention discloses a regeneration treatment technology of a cutting edge material silicon carbide. The technology comprises the steps such as solid-liquid separation, acid washing, alkali washing, hydraulic classification, pH regulation and drying. By adopting a method of purification through chemical reaction and particle size re-classification through hydraulic settling, the silicon carbide in waste mortar is regenerated, and the indexes such as purity and particle size of the regenerated silicon carbide reach the standard for sure. Through the treatment technology, the cutting edge material silicon carbide is regenerated, the performance indexes of the obtained product are relatively good, and the product can be applied to the silicon wafer cutting industry as a regenerated cutting edge material and completely meets the requirements of industrial application.

Owner:任海涛

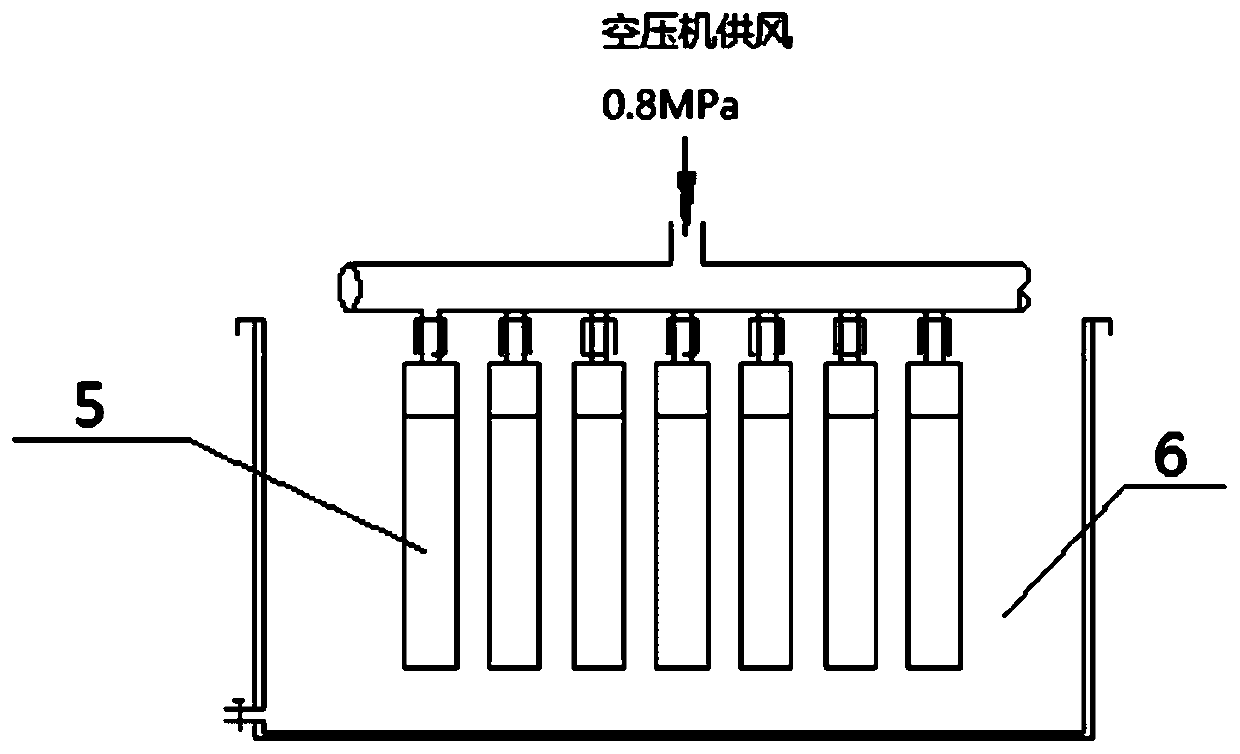

Mining ceramic filter plate cleaning device and using method thereof

InactiveCN110947244ARecycling is possibleMeet the requirements of industrial useCleaning using gasesCleaning using liquidsTransducerProcess engineering

The invention discloses a mining ceramic filter plate cleaning device and a using method thereof. The mining ceramic filter plate cleaning device comprises an ultrasonic oscillation device, a soakingdevice and a back flushing device, wherein the ultrasonic oscillation device comprises an ultrasonic transducer (1) and an ultrasonic signal generator (4); the soaking device comprises a cleaning tank(2), and the cleaning tank (2) contains concentrated hydrochloric acid with the mass fraction of 36%; and the back flushing device comprises a back flushing device tank body, and a pressure tank, anair compressor and a connecting hose which are connected in sequence. By utilizing the mining ceramic filter plate cleaning device, the surfaces and capillary micropores of blocked waste ceramic filter plates can be cleaned up, the industrial use requirement is met, the waste ceramic filter plates are recycled, and the production cost is saved.

Owner:中矿金业股份有限公司

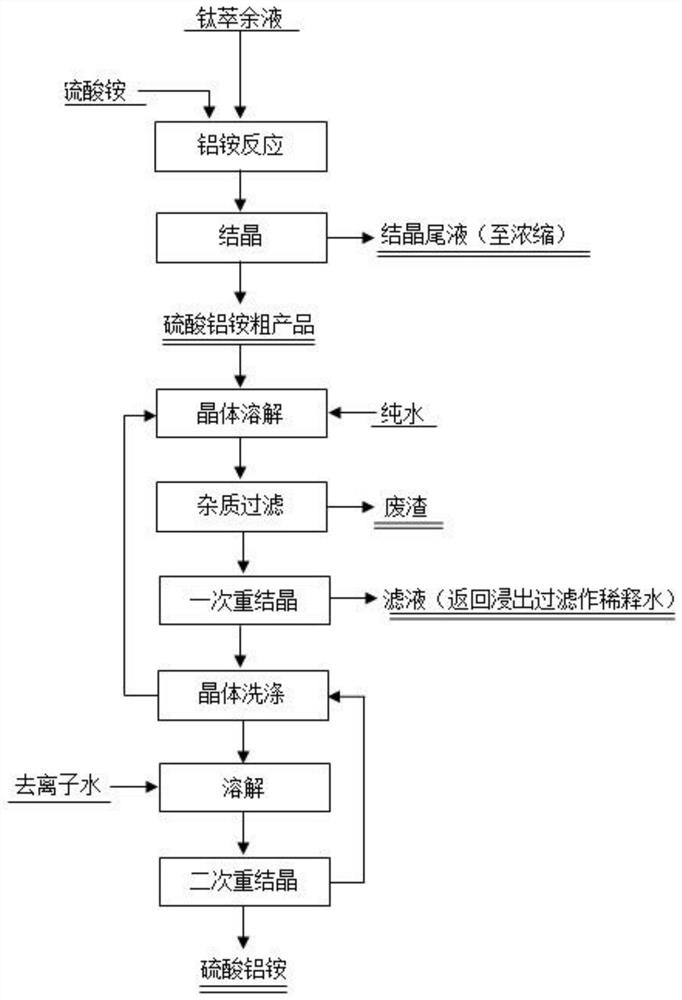

Process for preparing aluminum ammonium sulfate by crystallizing two-stage leaching raffinate

ActiveCN111732119AMeet the requirements of industrial useProcess efficiency improvementAluminium sulfatesPhysical chemistryAluminum ammonium sulfate

The invention discloses a process for preparing aluminum ammonium sulfate by crystallizing two-stage leaching raffinate, wherein the process comprises the following steps: (1) adding ammonium sulfateinto the raffinate to carry out ammonium-aluminum reaction, and crystallizing to obtain an aluminum ammonium sulfate crude product; (2) adding a dissolving solution into the aluminum ammonium sulfatecrude product for dissolving, filtering, and carrying out vacuum crystallization to obtain a purer aluminum ammonium sulfate crude product; and (3) adding deionized water into the purer aluminum ammonium sulfate crude product for dissolving, and freezing and crystallizing to obtain the pure aluminum ammonium sulfate product. The ammonium-aluminum reaction is carried out to obtain the aluminum ammonium sulfate crude product; then vacuum crystallization and filtration are carried out to obtain the aluminum ammonium sulfate crude product with the purity of 80% or above; and finally, freezing, crystallizing and filtering are carried out to obtain the aluminum ammonium sulfate product with the concentration of about 99%. Therefore, aluminum in the two-stage leaching raffinate is effectively recycled, and the recycled aluminum ammonium sulfate crude product is further purified to meet the requirements of industrial use.

Owner:雅安市鑫辉矿业有限公司 +2

Synthetic calcium magnesite and preparation method thereof

InactiveCN102285806BHigh purityNo damage to high temperature performanceCalcium hydroxideMechanical press

The invention relates to synthetic calcium magnesite and a preparation method thereof. The preparation method comprises the steps of firstly carrying out ball milling on 25-30wt% of calcium hydroxide and 70-75wt% of magnesium hydroxide to reach the grain size within 30 mu m, heating the ball-milled mixture in a muffle furnace to 700-900 DEG C, and insulating heat for 0.25-0.5 hour; adding water the amount of which is 20-25wt% of the mixture to the calcined mixture, and digesting for 1-2 hours; and then adding an additive the amount of which is 1-3wt% of the digested mixture to the digested mixture, stirring, carrying out mechanical press shaping by a semi-dry method, naturally drying for 12-15 hours, baking at the temperature of 100-120 DEG C for 12-15 hours, finally firing in a high-temperature furnace at the temperature of 1600-1750 DEG C, insulating heat for 3-5 hours and crushing to obtain the synthetic calcium magnesite. The preparation method provided by the invention has the advantages of simple process and no need for special synthesis equipment and treatment technology. The synthesized calcium magnesite has the characteristics of high purity, wide application range, good sintering performance, good hydration resistance, and no influence on high-temperature use performance.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com