Novel energy-saving pouring gate pipe

A gate, a new type of technology, applied in the direction of casting molds, cores, pipes, etc., can solve the problems of affecting product quality, product impurities, high defective rate, and improve casting cost and casting quality, good wear resistance, The effect of small specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

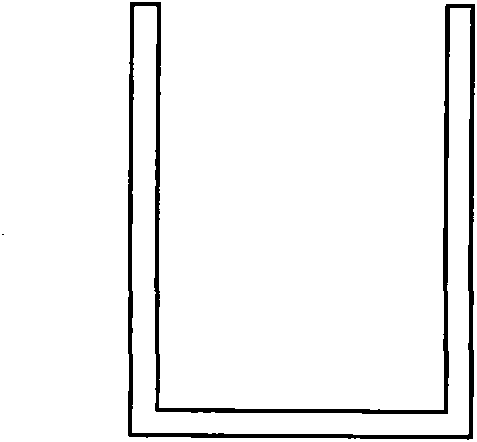

[0020] The new energy-saving sprue provided in this embodiment is cast by mixing clay, pottery clay and bauxite, wherein the content of clay is 50%, the content of pottery clay is 20%, and the content of bauxite is 30%. The sprue tube is round and straight (such as figure 1 shown).

Embodiment 2

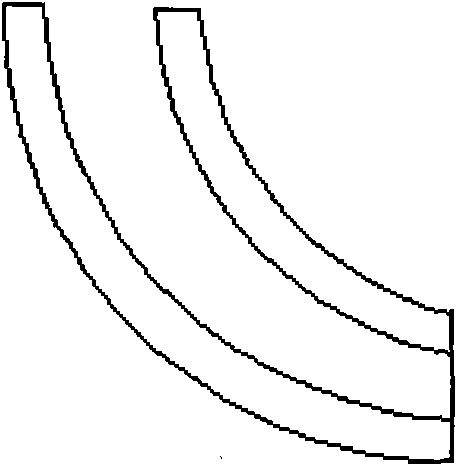

[0022] The new energy-saving sprue pipe provided in this embodiment is cast by mixing clay, pottery clay and bauxite, wherein the content of clay is 70%, the content of pottery clay is 10%, and the content of bauxite is 20%. The sprue pipe is a reducing elbow (such as figure 2 shown).

Embodiment 3

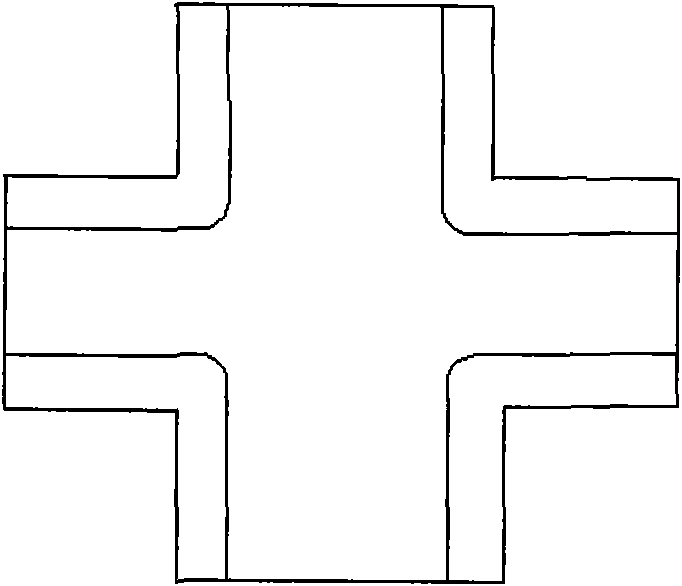

[0024] The new energy-saving sprue provided in this embodiment is cast by mixing clay, pottery clay and bauxite, wherein the content of clay is 60%, the content of pottery clay is 15%, and the content of bauxite is 25%. The sprue pipe is a variable-diameter four-way pipe (such as image 3 shown).

[0025] The sprue tube provided by the invention can be cast into any shape according to actual requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com