Super-high voltage grading ring and production process thereof

A technology of ultra-ultra-high voltage and equalizing rings, which is applied in the field of equalizing rings, can solve the problems of potential difference and failure of equalizing rings, and achieve the effect of small material shrinkage and convenient molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

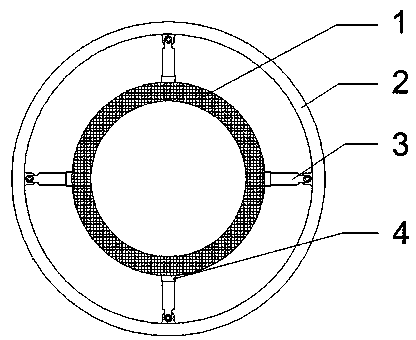

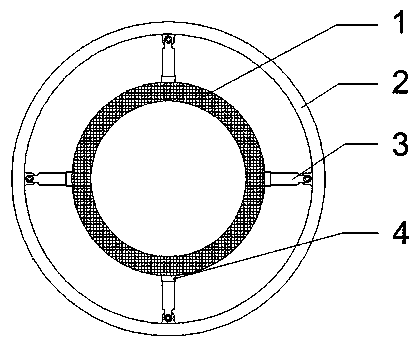

[0034] Such as figure 1 As shown, an ultra-high voltage grading ring includes a ring-shaped grading ring body 1, the grading ring body 1 is made of semiconductor materials, and the grading ring body 1 is coaxially equipped with an aluminum Ring 2, four connecting rods 3 are evenly distributed in the annular interval between the pressure equalizing ring body 1 and the aluminum ring 2, and the extension lines of the connecting rods 3 pass through the gap between the pressure equalizing ring body 1 and the aluminum ring 2 center of circle. The fixing method of the connecting rod is as follows: the outer peripheral surface of the pressure equalizing ring body 1 is provided with a mounting seat 4 for inserting the connecting rod 3 at a position corresponding to the connecting rod 3, and the connecting rod 3 The head end of the rod 3 is inserted into the mounting seat 4 , and the tail end of the connecting rod 3 is fixedly connected with the inner peripheral surface of the aluminum...

Embodiment 2

[0036] The difference between embodiment 2 and embodiment 1 is that the Al-Ag composite coating is prepared on the surface of the pressure equalizing ring body using a magnetron co-sputtering process, and the specific preparation process of the Al-Ag composite coating is as follows: The body of the equalizing ring is cleaned and dried (the specific cleaning and drying operations are as follows: sequentially sonicate in acetone for 20 minutes, in absolute ethanol for 20 minutes, in deionized water for 10 minutes, and then dry at 60°C for use), and then The direct current sputtering mode is adopted, the substrate loaded with parts rotates during sputtering, the substrate is not heated during the sputtering process, the Al target with a purity higher than 99.99% and the Ag target with a purity higher than 99.99% are used as the sputtering source, and argon is used The gas is the sputtering gas, the sputtering pressure is 0.5-1 Pa, the sputtering power of the Ag target and the Al t...

Embodiment 3

[0040] The pressure grading ring body of the ultra-ultra-high voltage grading ring in Example 1 is made of semiconductor materials with the following components:

[0041] Ingredients: earthy graphite 16.75 kg, industrial multilayer graphene 0.25 kg, phenolic resin for friction material 50 kg, SiO treated with silane coupling agent 2 33 kg.

[0042] The specific production process is as follows: the above-mentioned ingredients are mixed and ground by ball milling, and then sieved by a 200-mesh sieve to take the sieved material, and put into a mold for producing pressure equalizing rings for hot pressing molding, molding pressure: 30 MPa, molding temperature: 230°C, The dwell time was 50 minutes at a temperature of 230°C.

[0043] The properties of the prepared equalizing ring are as follows: electrical conductivity: 1.08s / m; bending strength: 128.31MPa; tensile strength: 195MPa; linear expansion coefficient: 0.22×10 -4 / ℃; material shrinkage: 0.45%; material density: 1.84g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com