Patents

Literature

214results about How to "Good thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

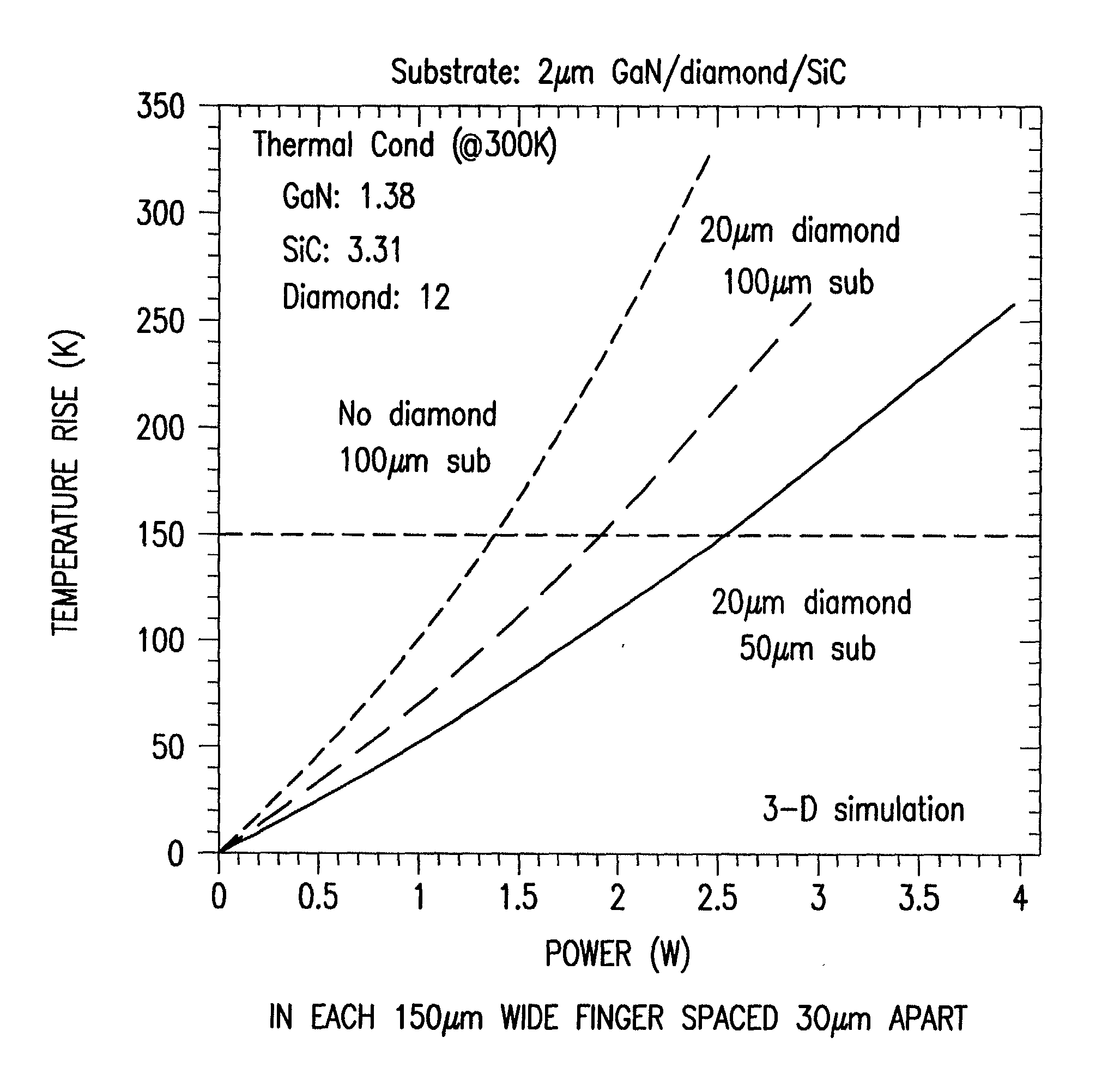

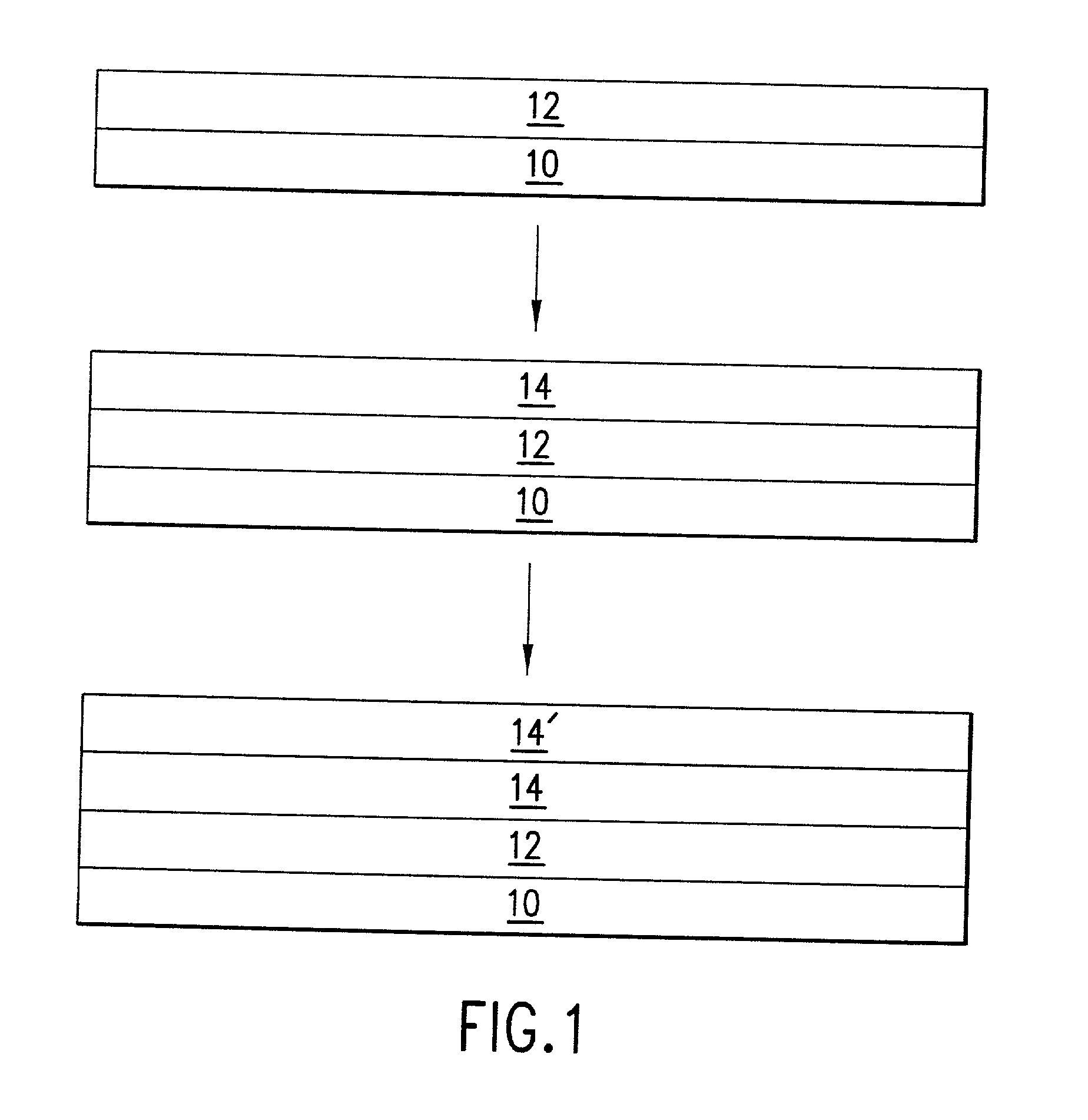

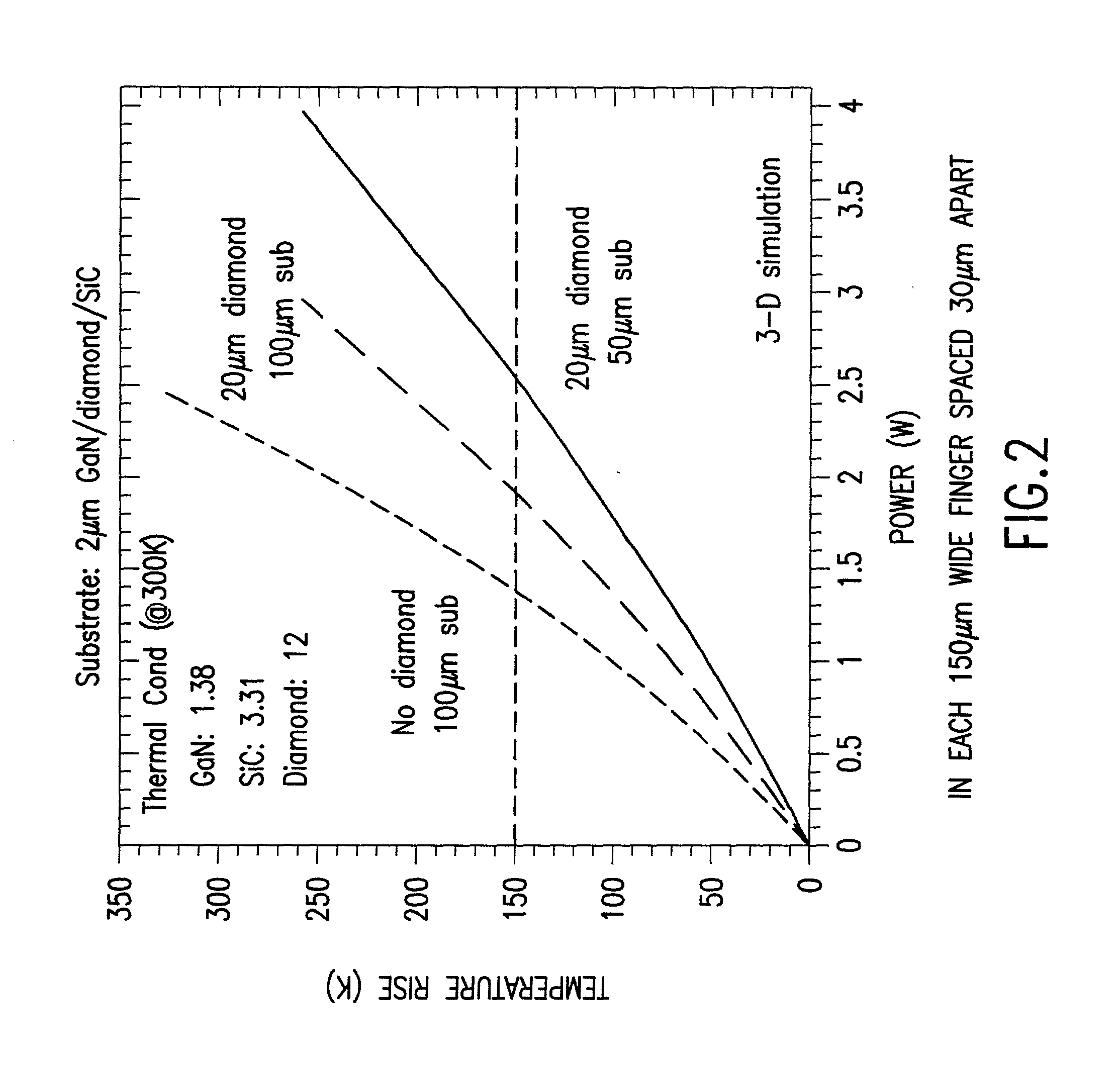

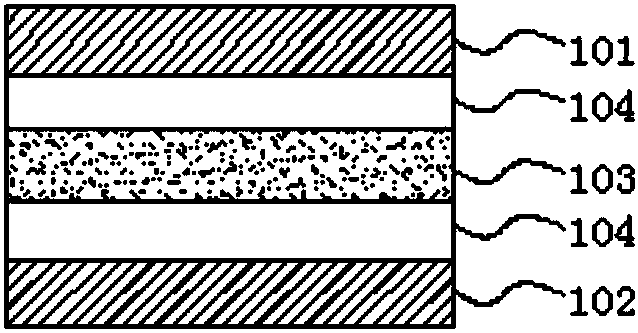

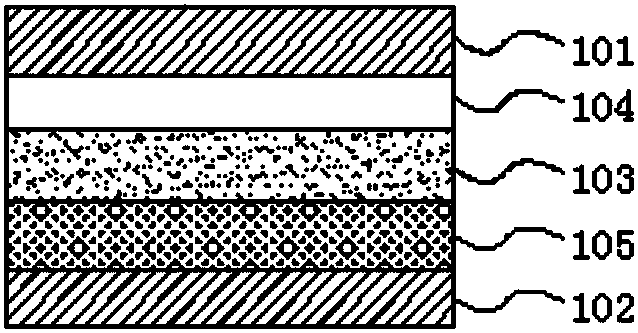

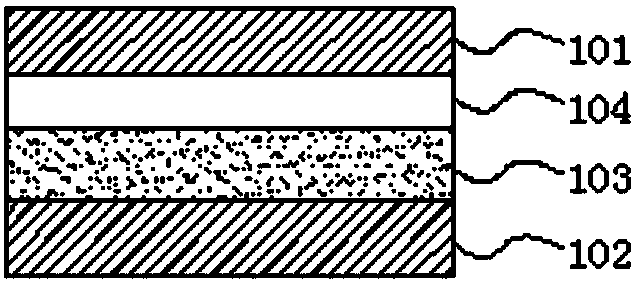

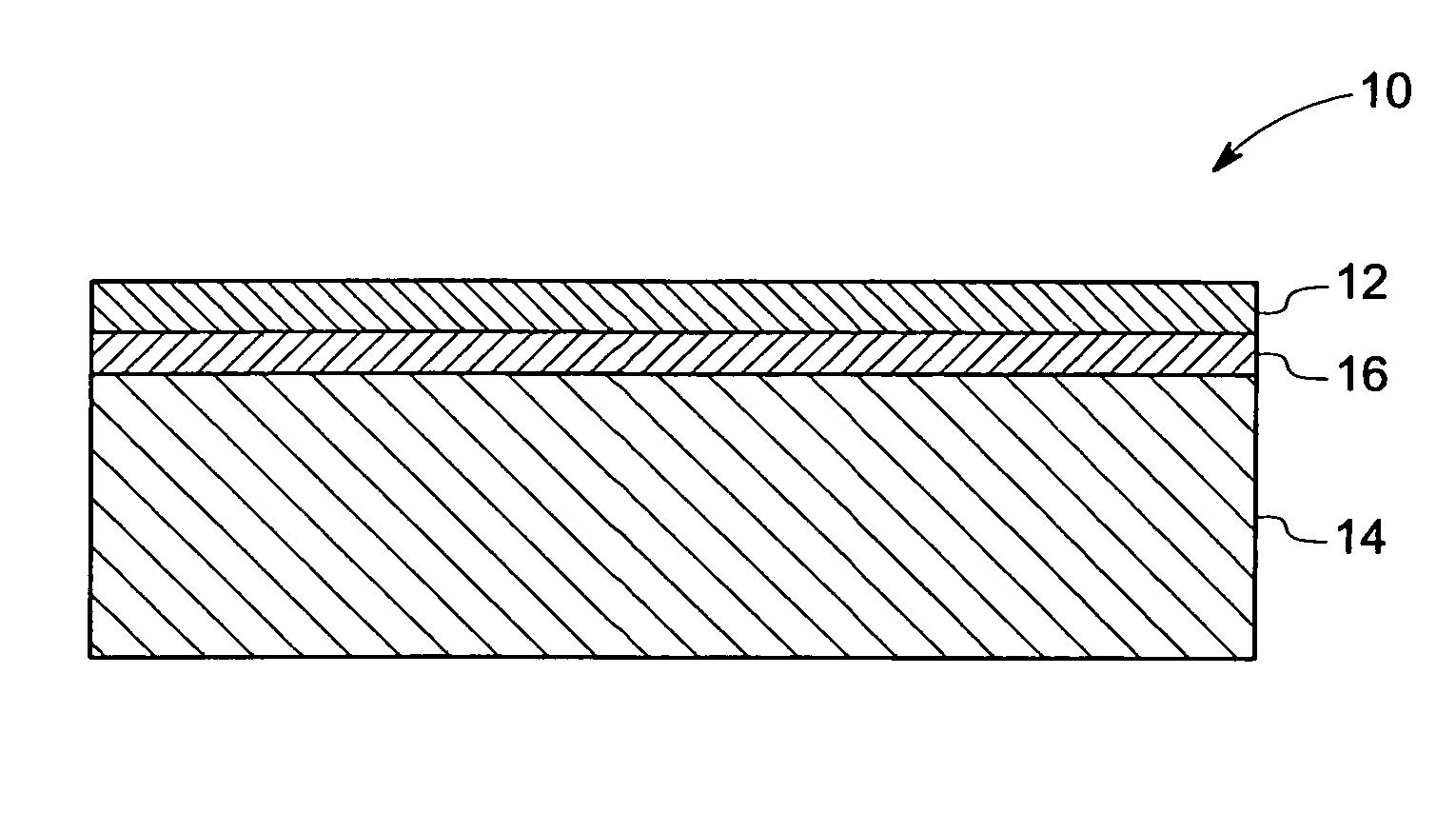

Electronic device with composite substrate

InactiveUS20020096106A1Fast heat conductionGood thermal expansionPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal dilatationComposite substrate

A method for making a multilayered electronic device with at least one epitaxial layer grown on a single-crystal film bonded to a composite wherein at least one layer is polycrystalline, the method includes the step of bonding a single-crystal film at least one of the epitaxial layers on the single-crystal film wherein thermal coefficients of expansion for the substrate and the epitaxial layer are closely matched.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Low melting point glass and glass ceramic composition

InactiveUS6355586B1Essential and effective for stabilizing the glassIncreased durabilityTube sealing materialsGlass-ceramicLow melting point

A low melting point glass consisting essentially of, as represented by mol % based on the following oxides:wherein SnO+ZnO+P2O5+B2O3 is at least 76 mol %, Li2O+Na2O+K2O is from 0 to 9 mol %, MgO+CaO+SrO+BaO is from 0 to 35 mol %, and the molar ratio of SnO to ZnO is less than 1.

Owner:ASAHI GLASS CO LTD

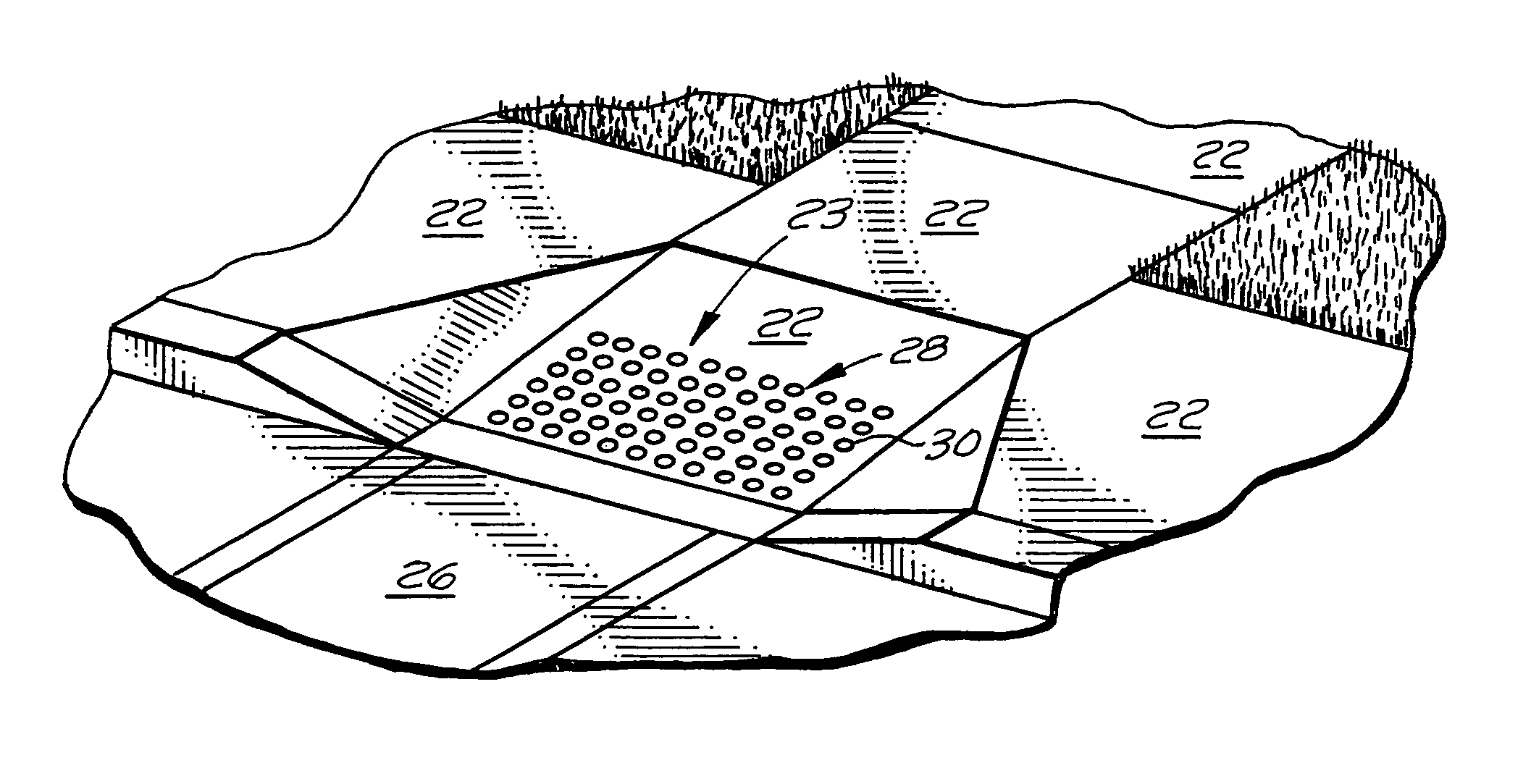

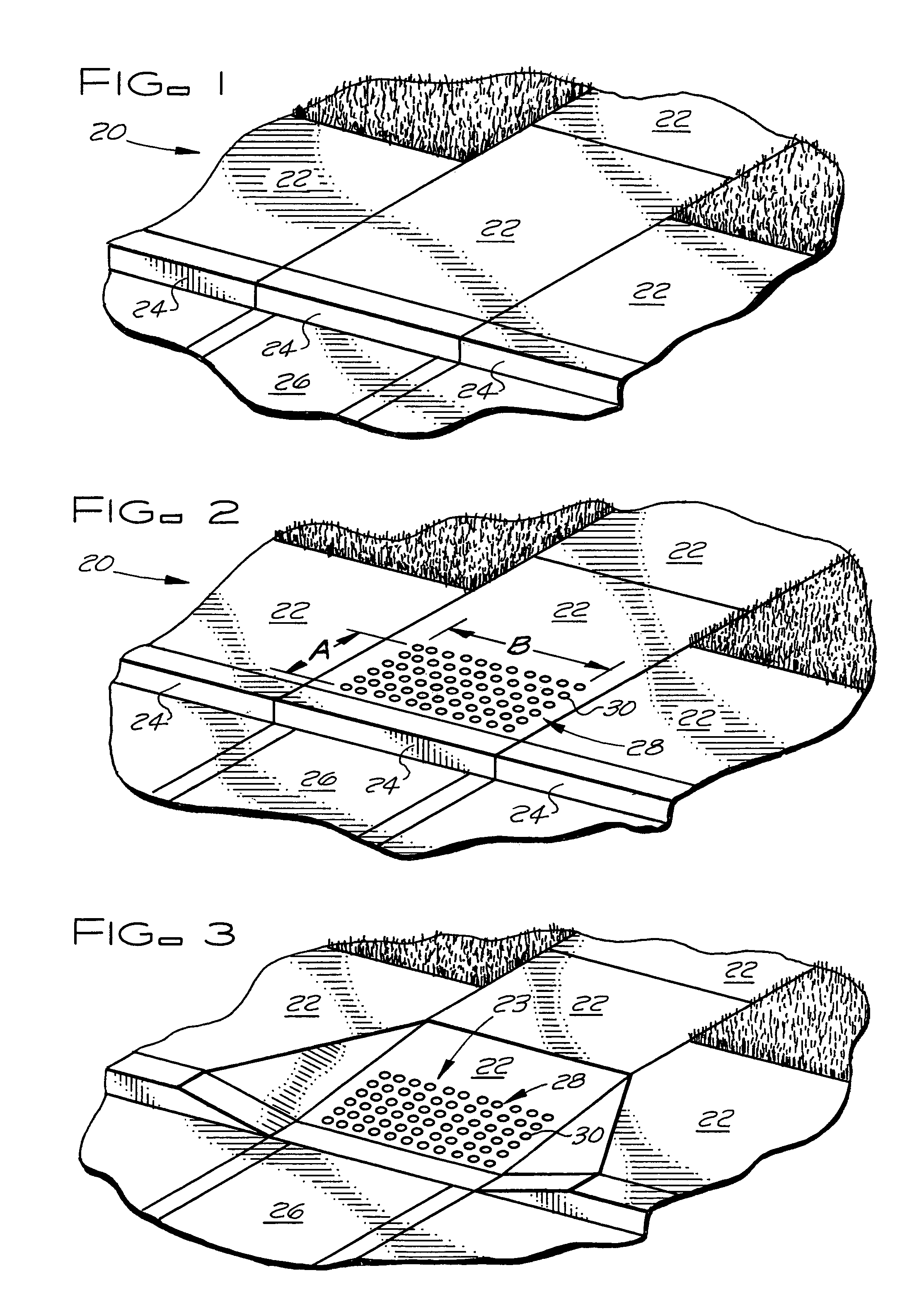

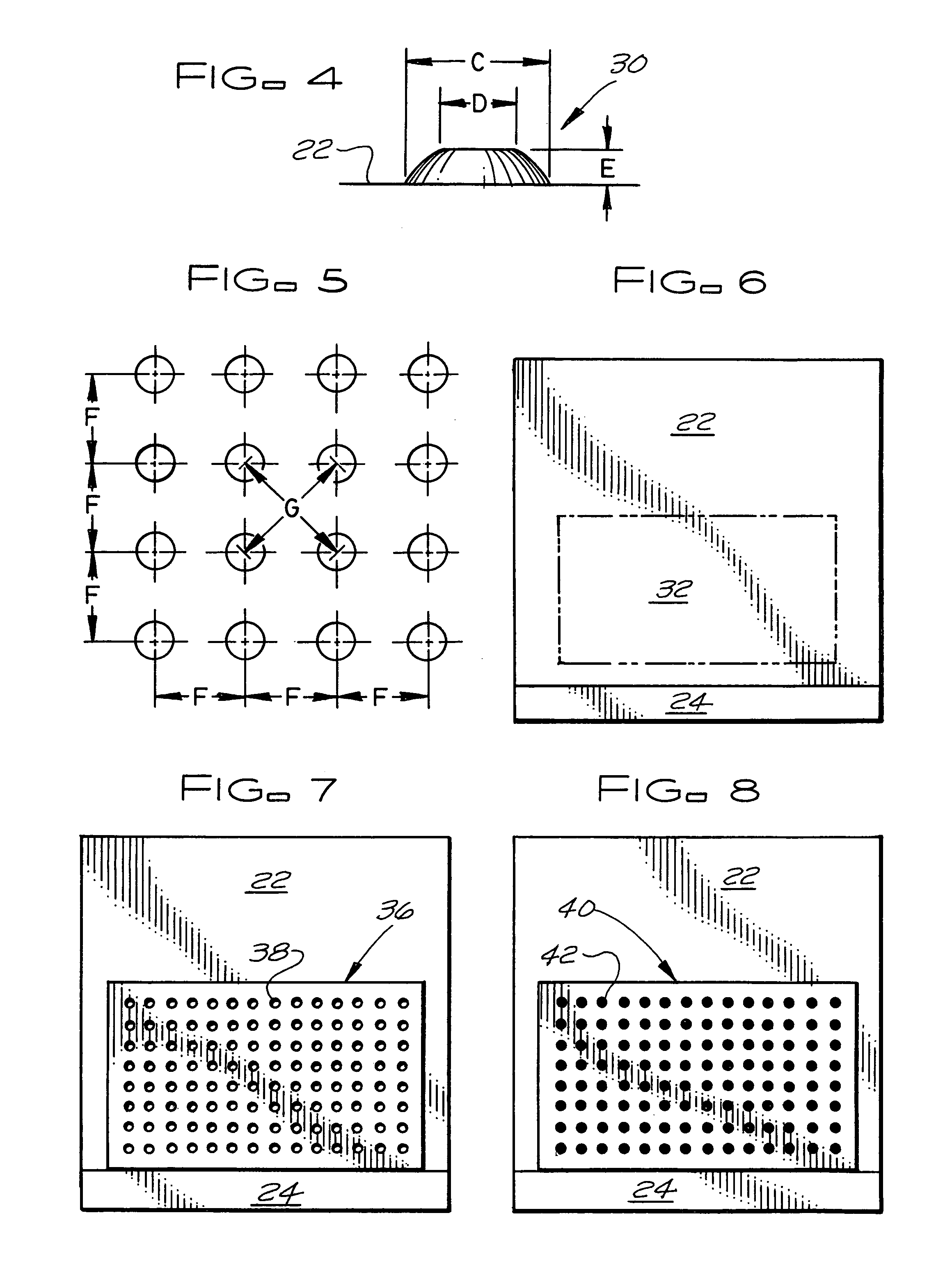

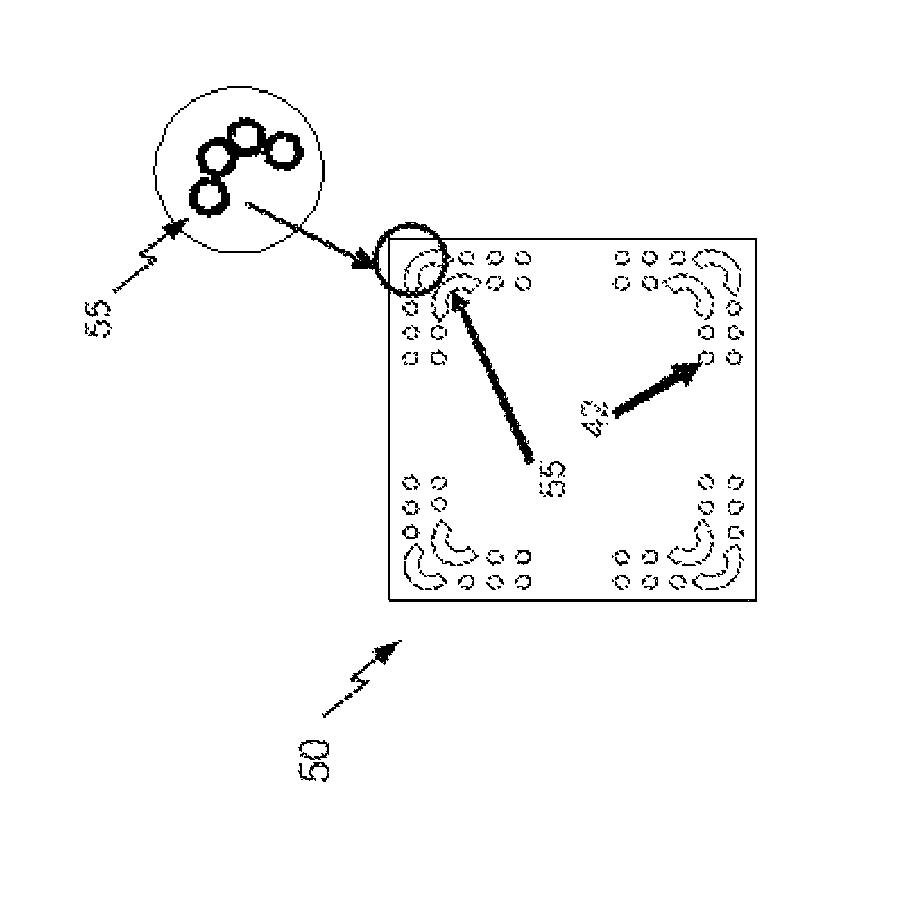

Tactile warning surfaces for walkways and method

InactiveUS6971818B1Equal delayEasy to seePaving gutters/kerbsWalking aidsStructural engineeringSurface structure

A tactile warning surface structure having underfoot detectability is formed in place by a method wherein the shank portions of a plurality pins are inserted into and bonded to a plurality of holes formed in an upper surface of a concrete slab of a walkway. The holes are located within a defined area of the upper surface of the concrete slab and are spaced from each other in a predetermined pattern so that, when the shank portions of the pins are inserted into and bonded to the holes in the concrete slab with the upper end head portions of the pins projecting upward beyond the upper surface of the concrete slab at least a minimum distance, the pins in the defined area of the upper surface of the concrete slab form a tactile warning surface having underfoot detectability.

Owner:SCHABACKER NOLAN D

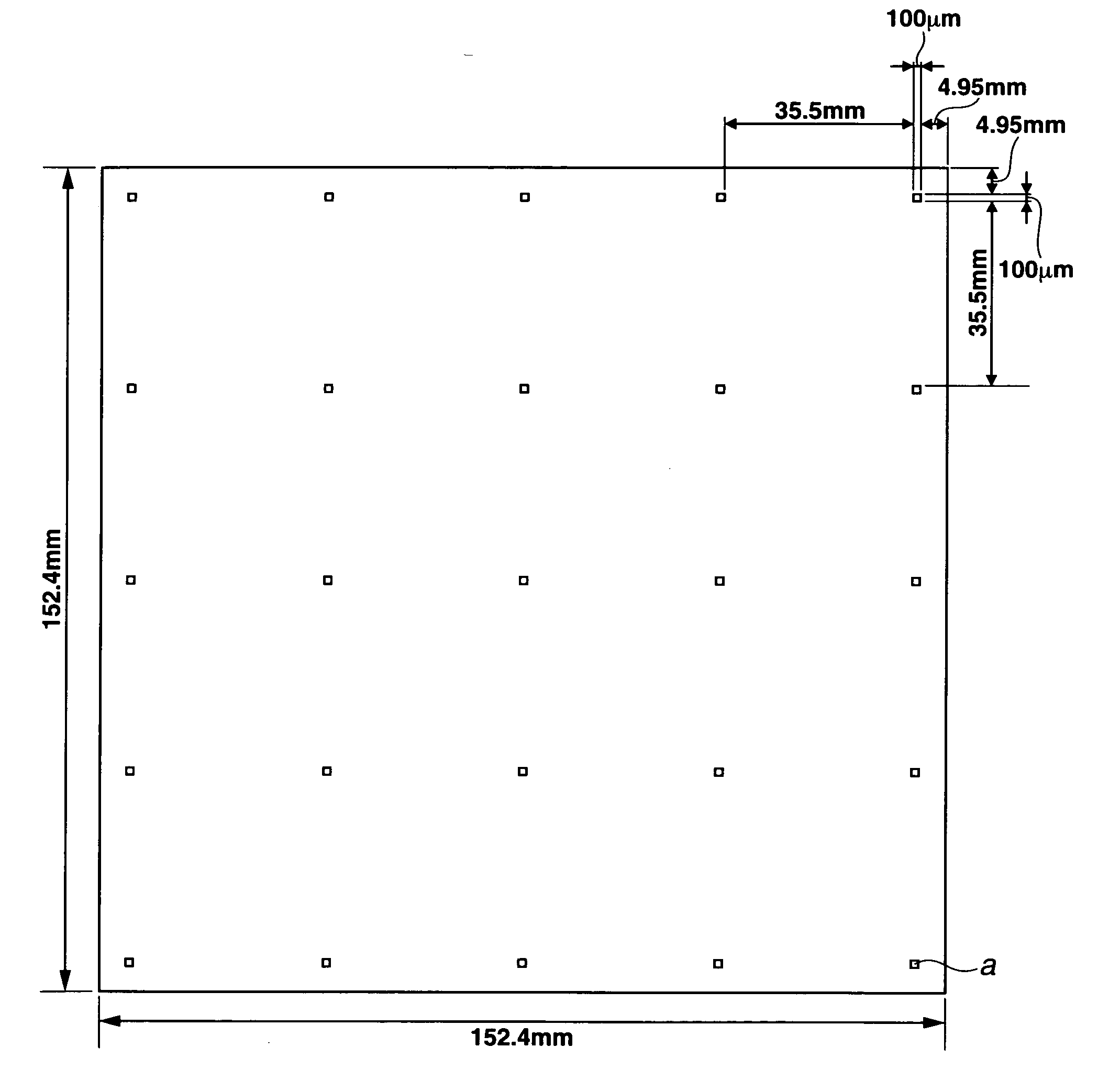

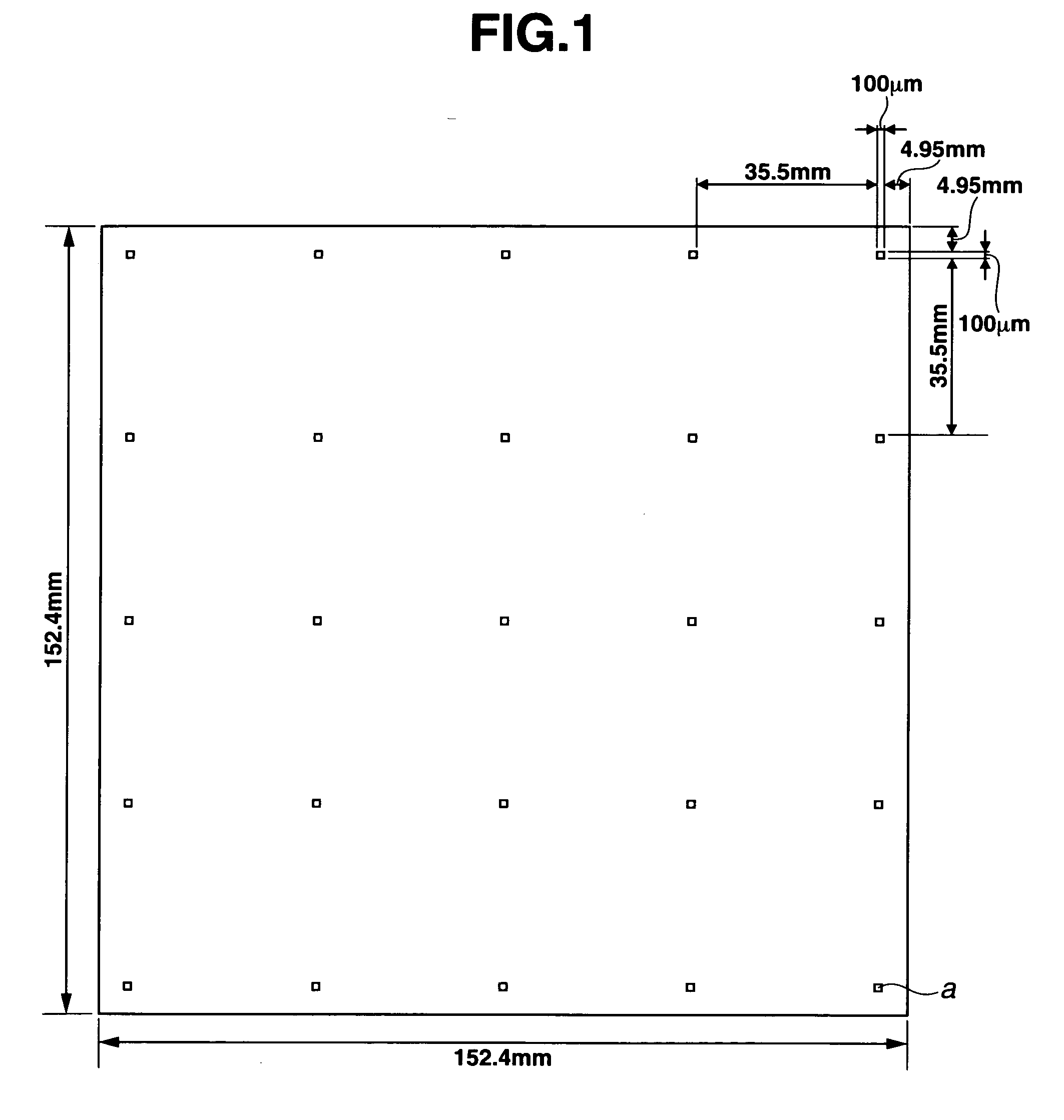

Titania-doped quartz glass and making method, EUV lithographic member and photomask substrate

ActiveUS20070134566A1Improve homogeneityImprove flatnessRadiation/particle handlingNanoinformaticsTransmittanceConcentration gradient

A titania-doped quartz glass containing 3-12 wt % of titania at a titania concentration gradient less than or equal to 0.01 wt % / μm and having an apparent transmittance to 440 nm wavelength light of at least 30% at a thickness of 6.35 mm is of such homogeneity that it provides a high surface accuracy as required for EUV lithographic members, typically EUV lithographic photomask substrates.

Owner:SHIN ETSU CHEM IND CO LTD

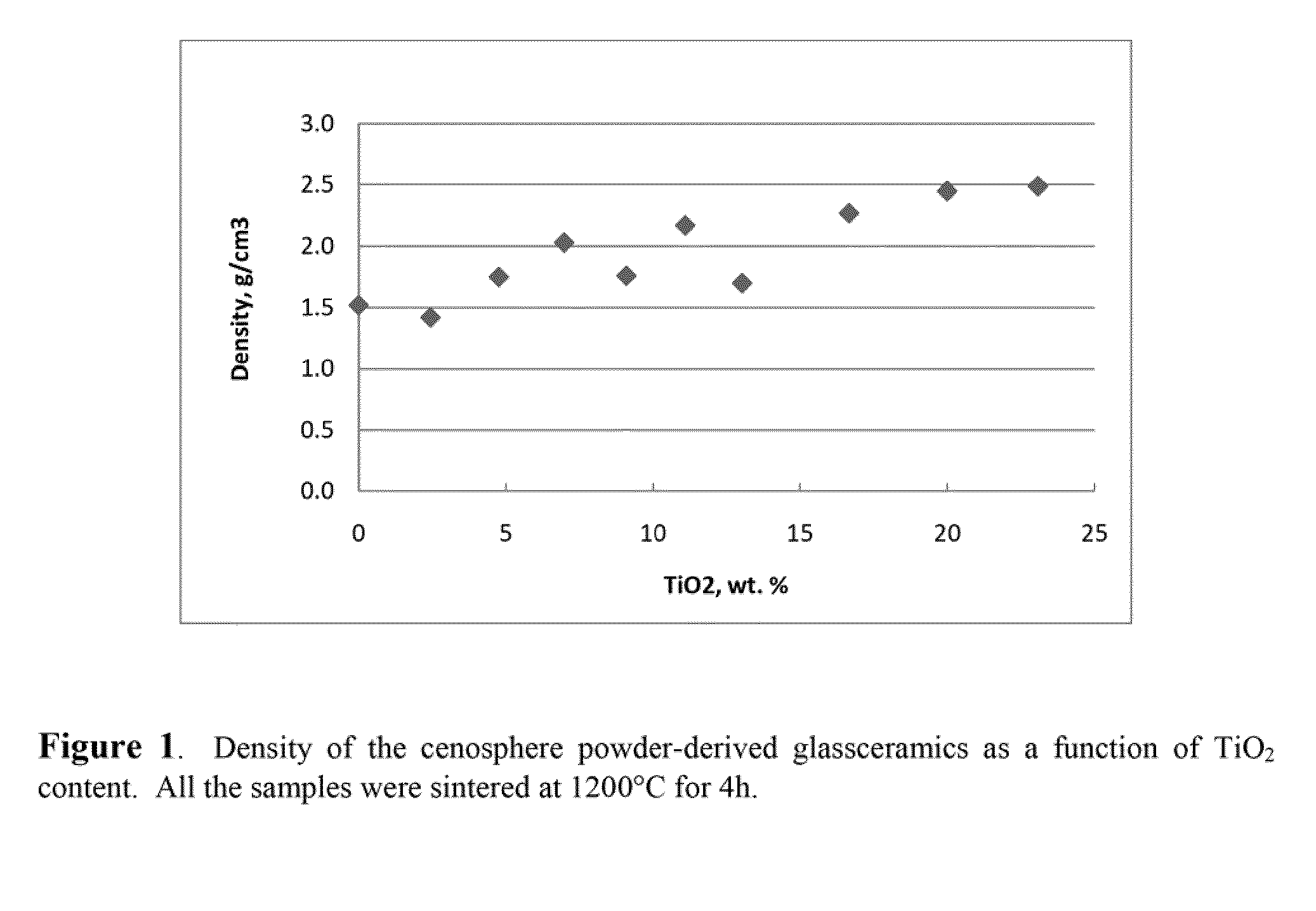

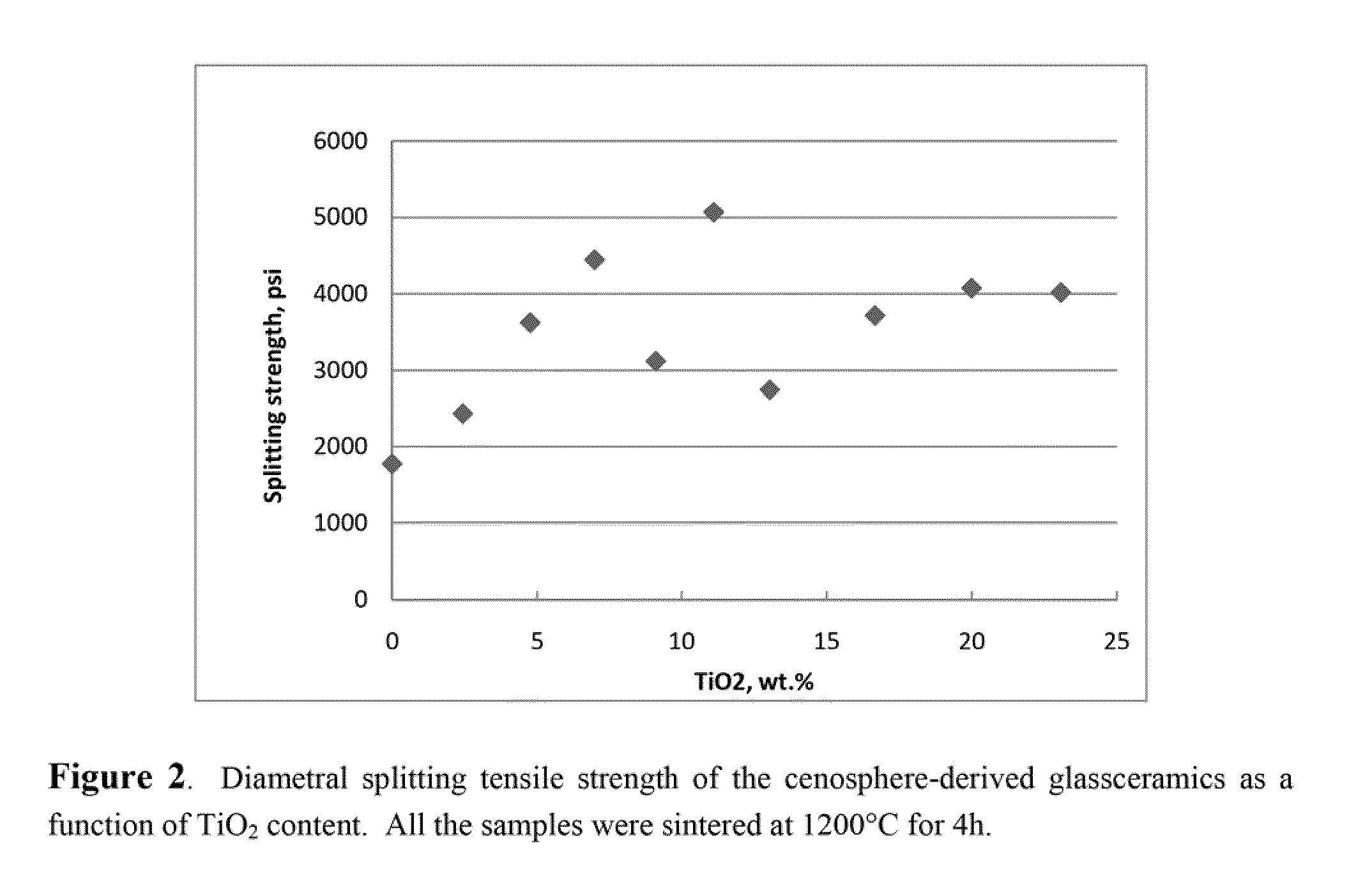

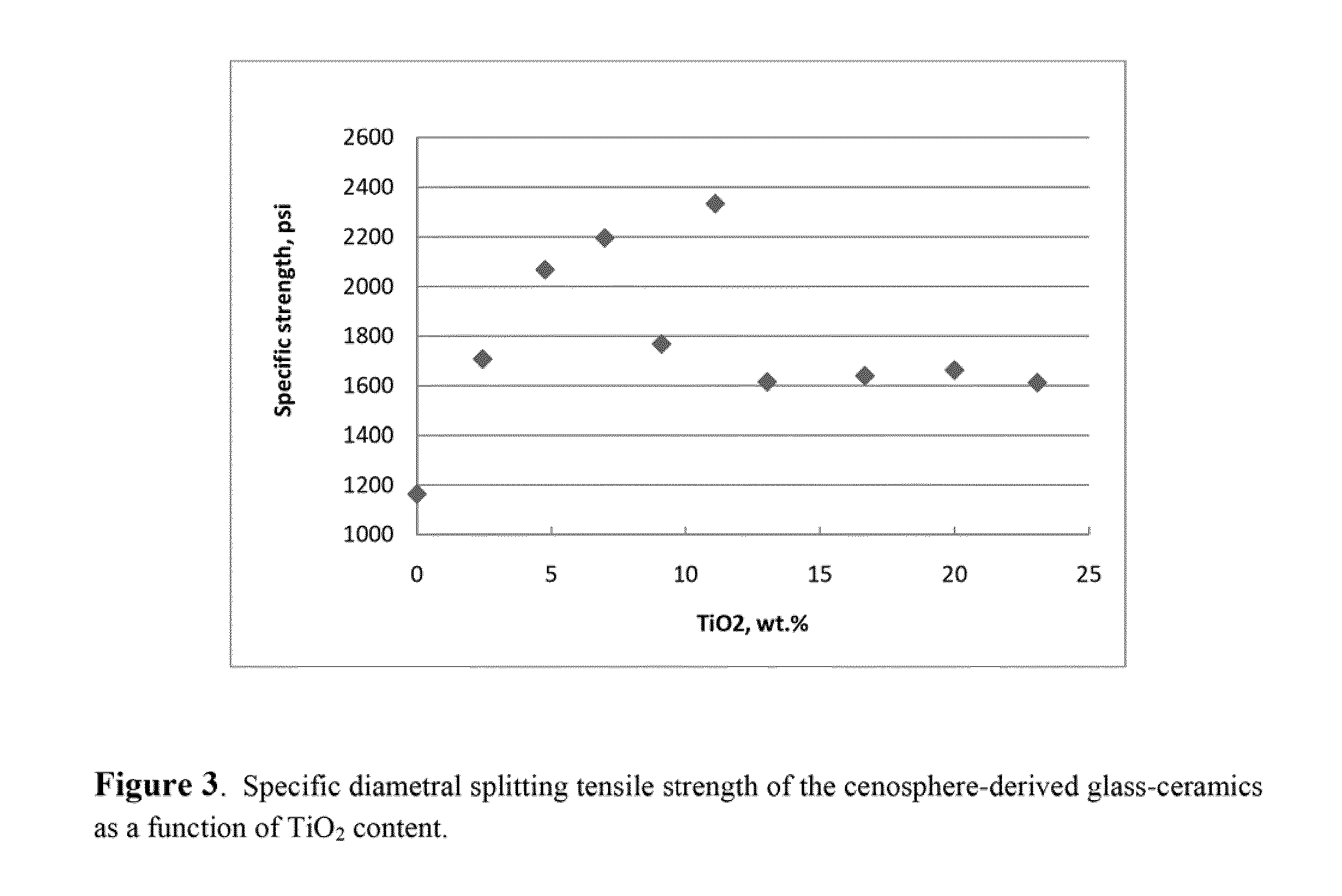

Proppant having a glass-ceramic material

ActiveUS8178476B2Increase stiffnessReduce the amount of solutionFluid removalFlushingGlass-ceramicEnvironmental geology

The present invention relates to glass-ceramic proppants which can be used to prop open subterranean formation fractions, as well as other uses. Proppant formulations are further disclosed which use one or more proppants of the present invention. Methods to prop open subterranean formation fractions are further disclosed. In addition, other uses for the proppants of the present invention are further disclosed, as well as methods of making the glass-ceramic proppants.

Owner:HALLIBURTON ENERGY SERVICES INC

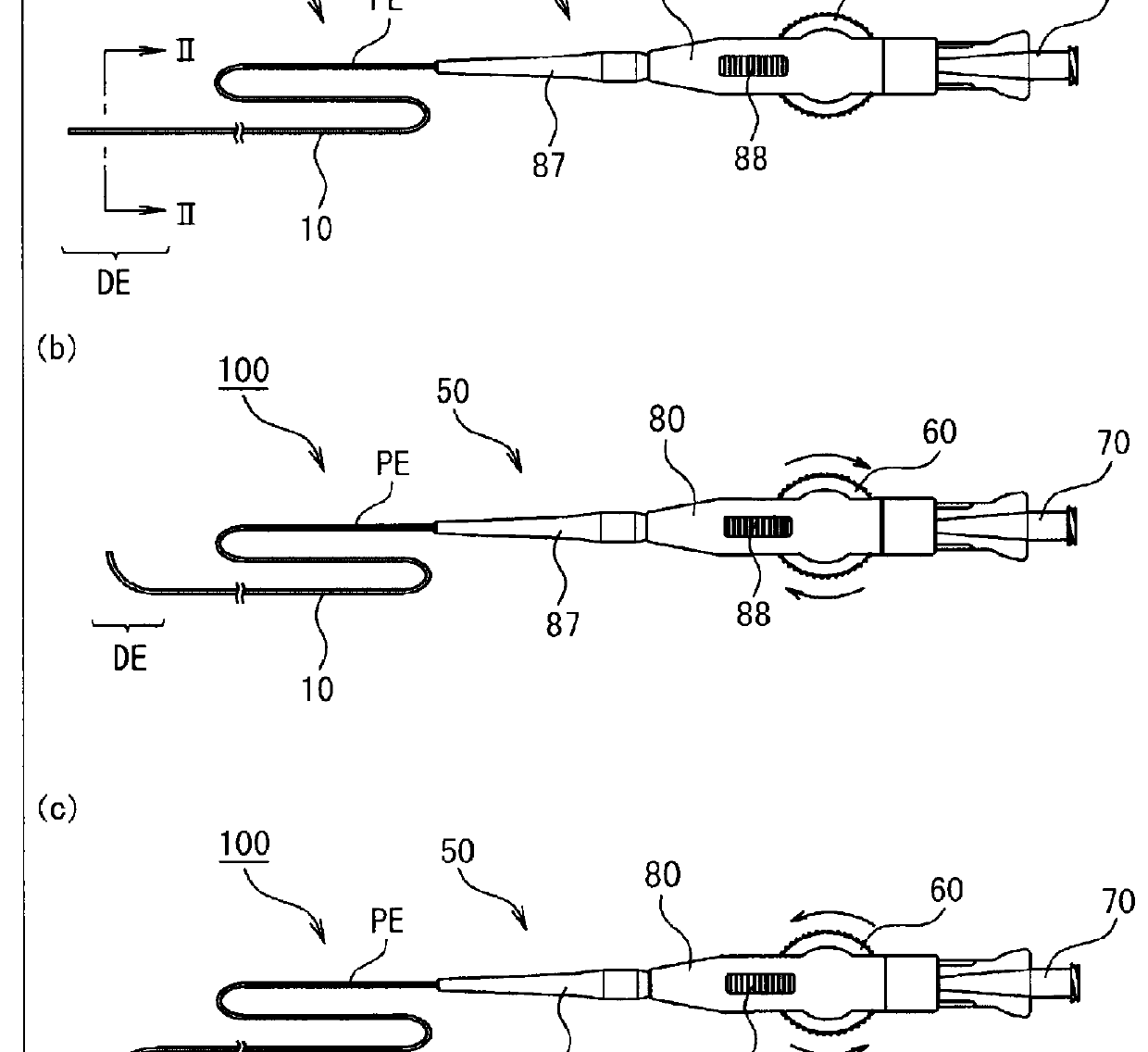

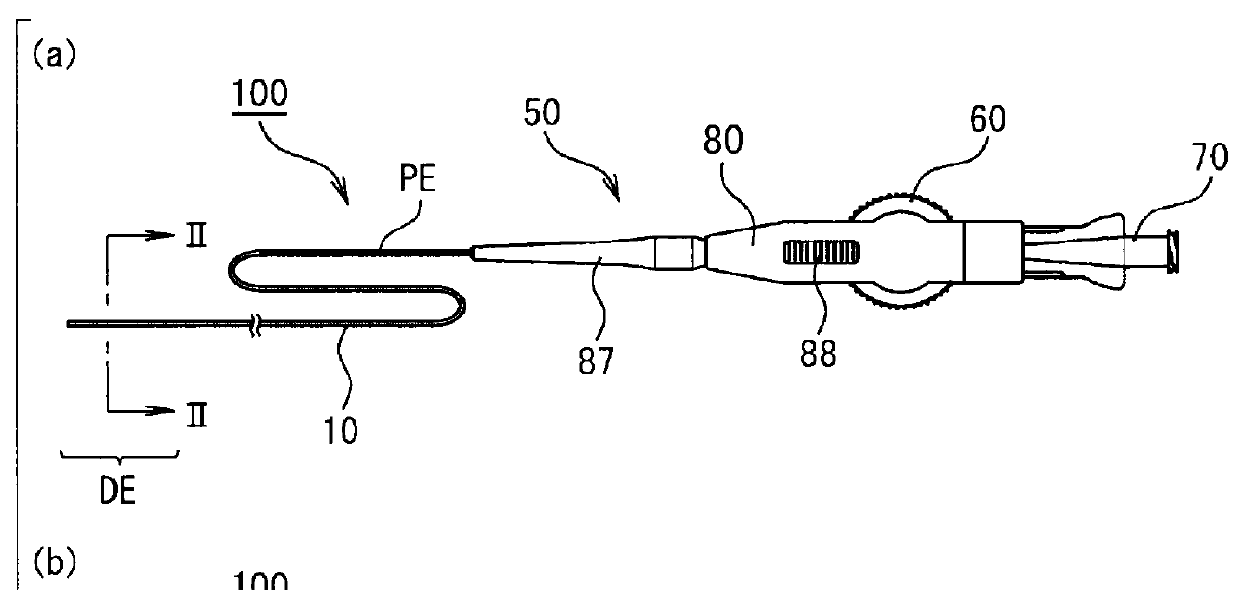

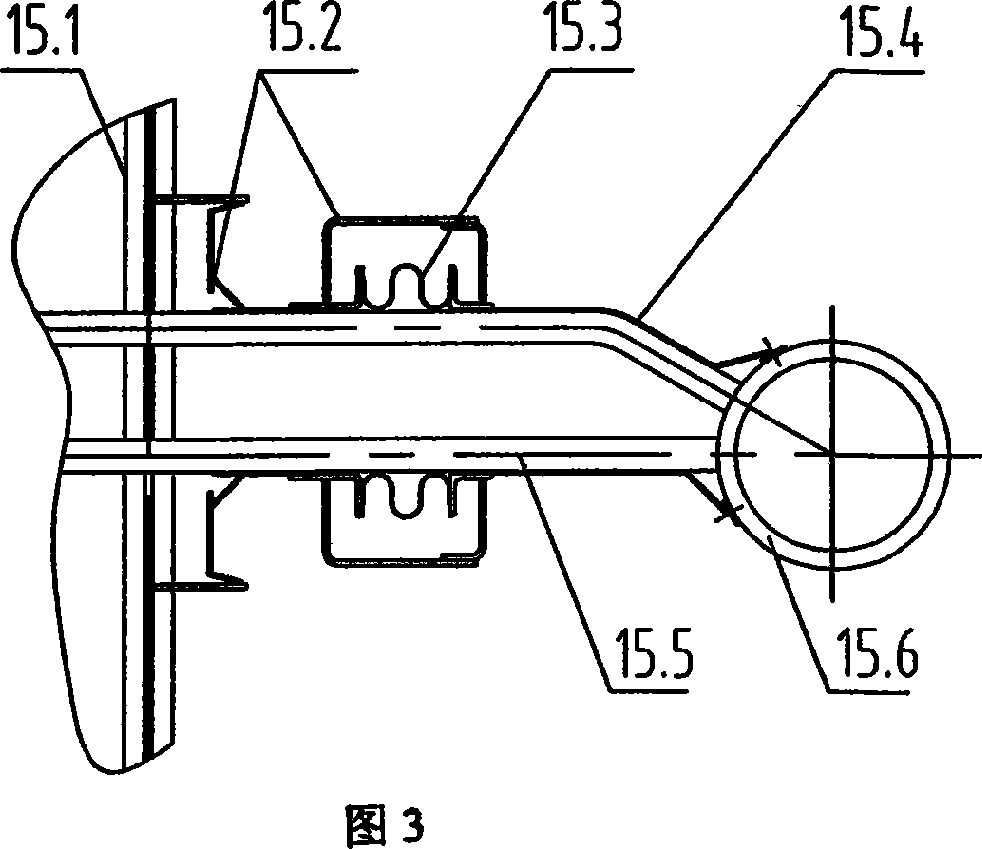

Catheter, catheter manipulation part, and catheter manufacturing method

ActiveUS20160051796A1Easily brokenEasy to bendPackage sterilisationMedical devicesPath lengthPull force

A catheter of the invention includes an elongated flexible tubular main body; a plurality of manipulation wires inserted through the tubular main body and having tips connected to a distal part of the tubular main body; a manipulation-part main body provided at a base end of the tubular main body; and a bending manipulation part. The bending manipulation part has an engagement part engaging with base ends of the manipulation wires, and individually applies pulling force to the plurality of manipulation wires through pulling operations so as to bend the distal part of the tubular main body. The bending manipulation part is provided so as to be movable with respect to the manipulation-part main body. The path lengths of the plurality of manipulation wires from the tips thereof to the engagement part are simultaneously increased or decreased when the bending manipulation part and the manipulation-part main body move relative to each other.

Owner:SUMITOMO BAKELITE CO LTD

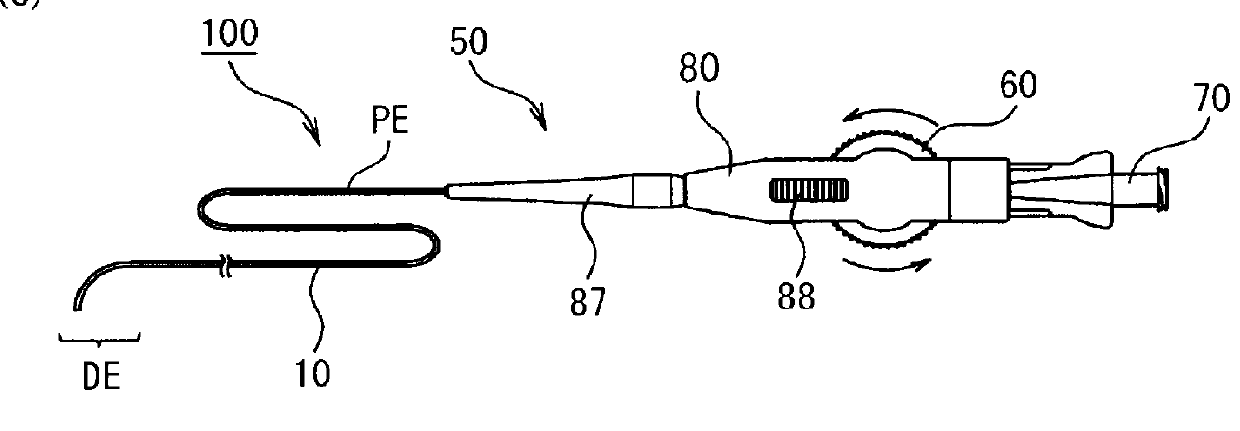

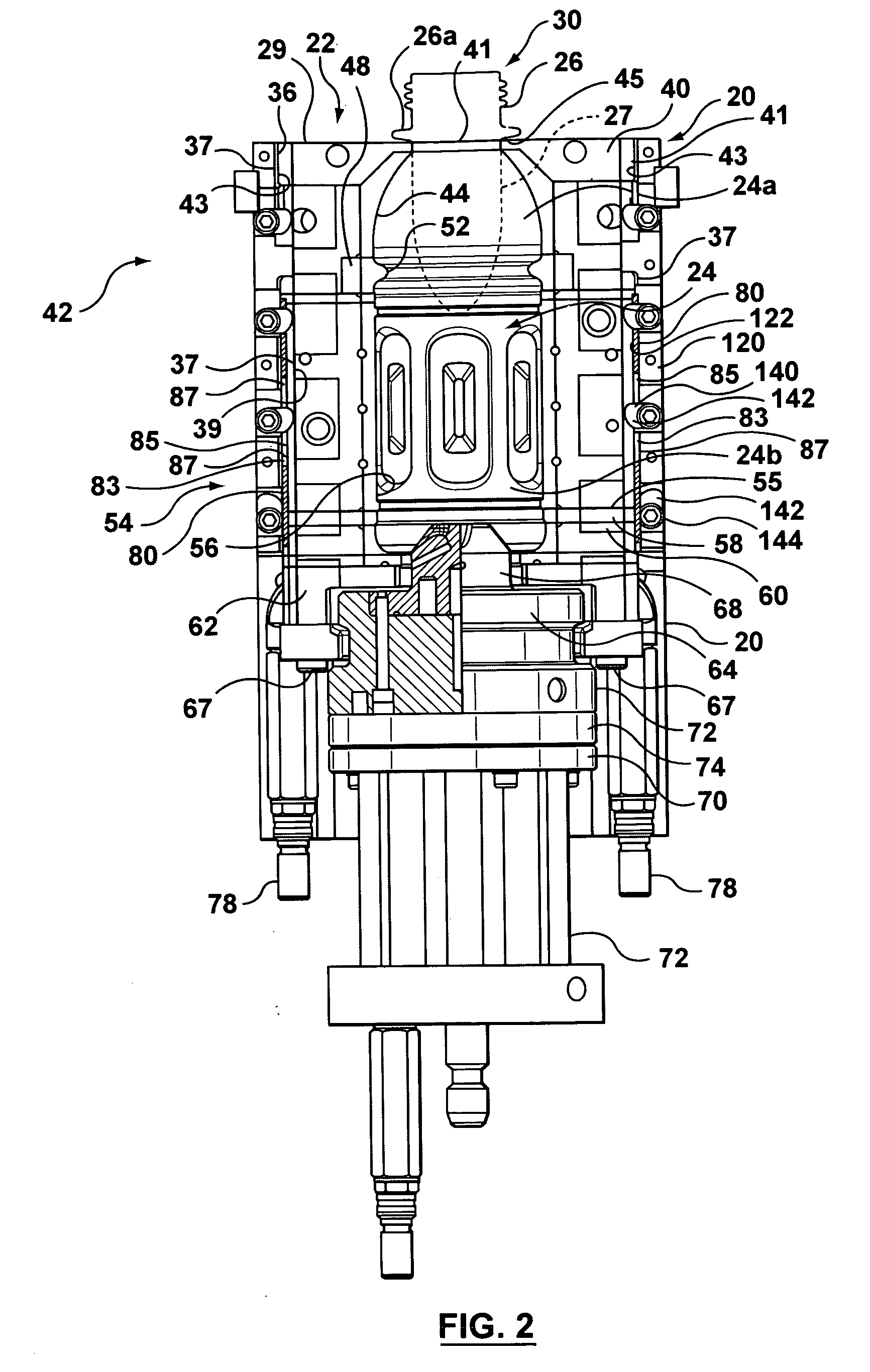

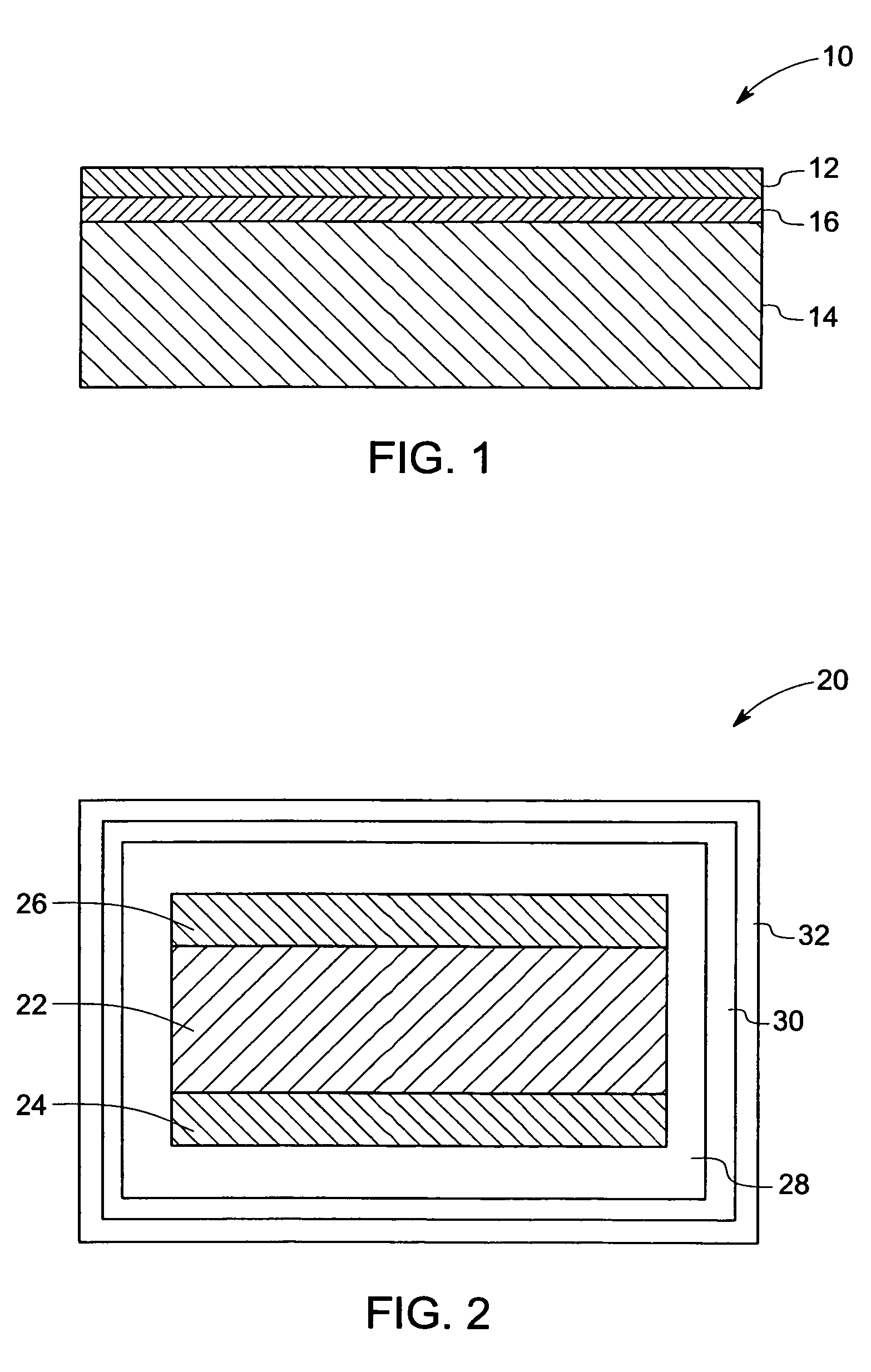

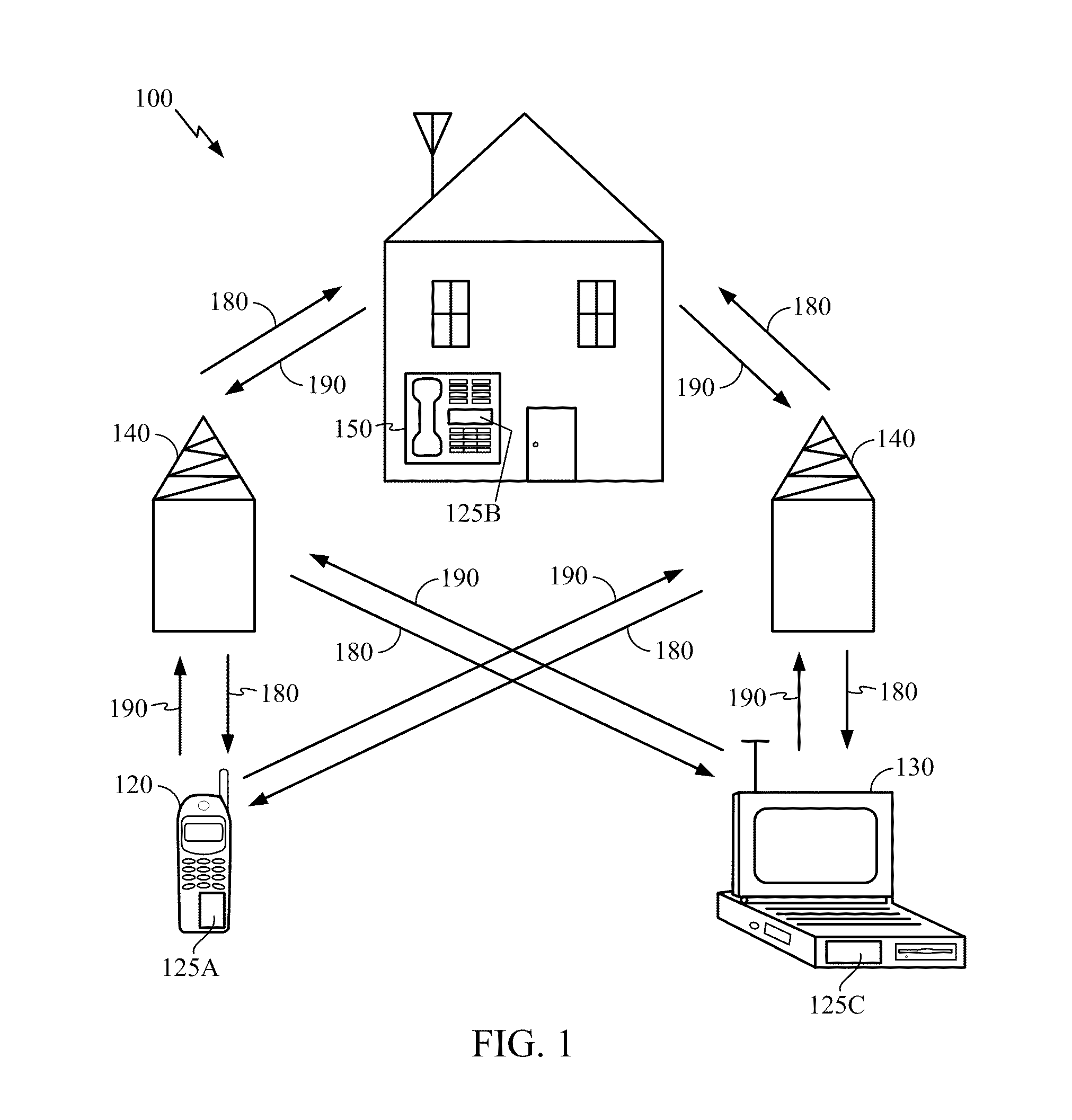

Apparatus and Method for Controlling Semiconductor Die Warpage

ActiveUS20110147895A1Reduce warpageGood thermal expansionSemiconductor/solid-state device detailsDetecting faulty computer hardwareSemiconductor chipStress relief

A semiconductor die has through silicon vias arranged to reduce warpage. The through silicon vias adjust the coefficient of thermal expansion of the semiconductor die, permit substrate deformation, and also relieve residual stress. The through silicon vias may be located in the edges and / or corners of the semiconductor die. The through silicon vias are stress relief vias that can be supplemented with round corner vias to reducing warpage of the semiconductor die.

Owner:QUALCOMM INC

Proppant Having A Glass-Ceramic Material

ActiveUS20110146985A1Improve the overall coefficientIncrease stiffnessFluid removalFlushingGlass-ceramicEnvironmental geology

The present invention relates to glass-ceramic proppants which can be used to prop open subterranean formation fractions, as well as other uses. Proppant formulations are further disclosed which use one or more proppants of the present invention. Methods to prop open subterranean formation fractions are further disclosed. In addition, other uses for the proppants of the present invention are further disclosed, as well as methods of making the glass-ceramic proppants.

Owner:HALLIBURTON ENERGY SERVICES INC

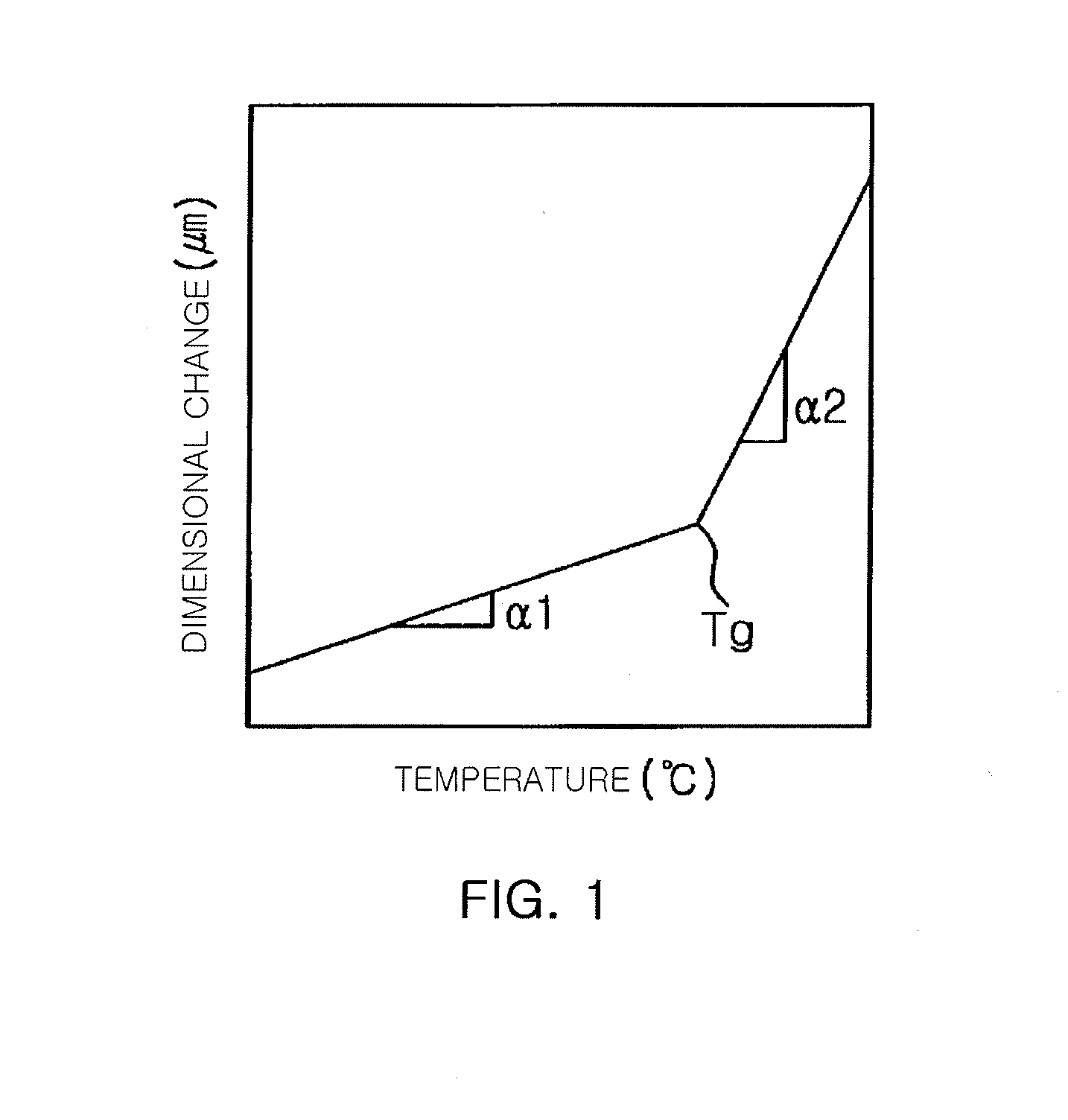

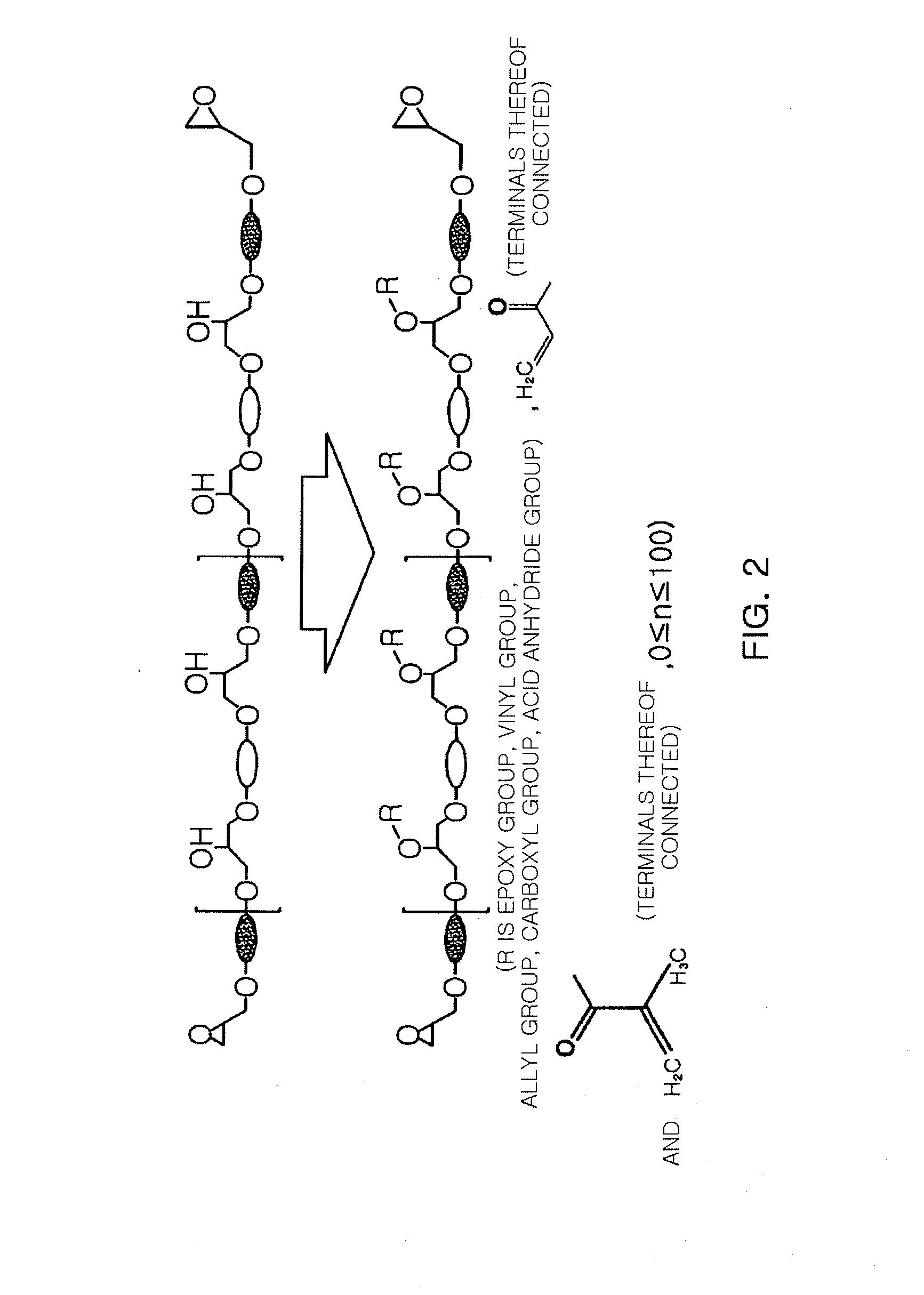

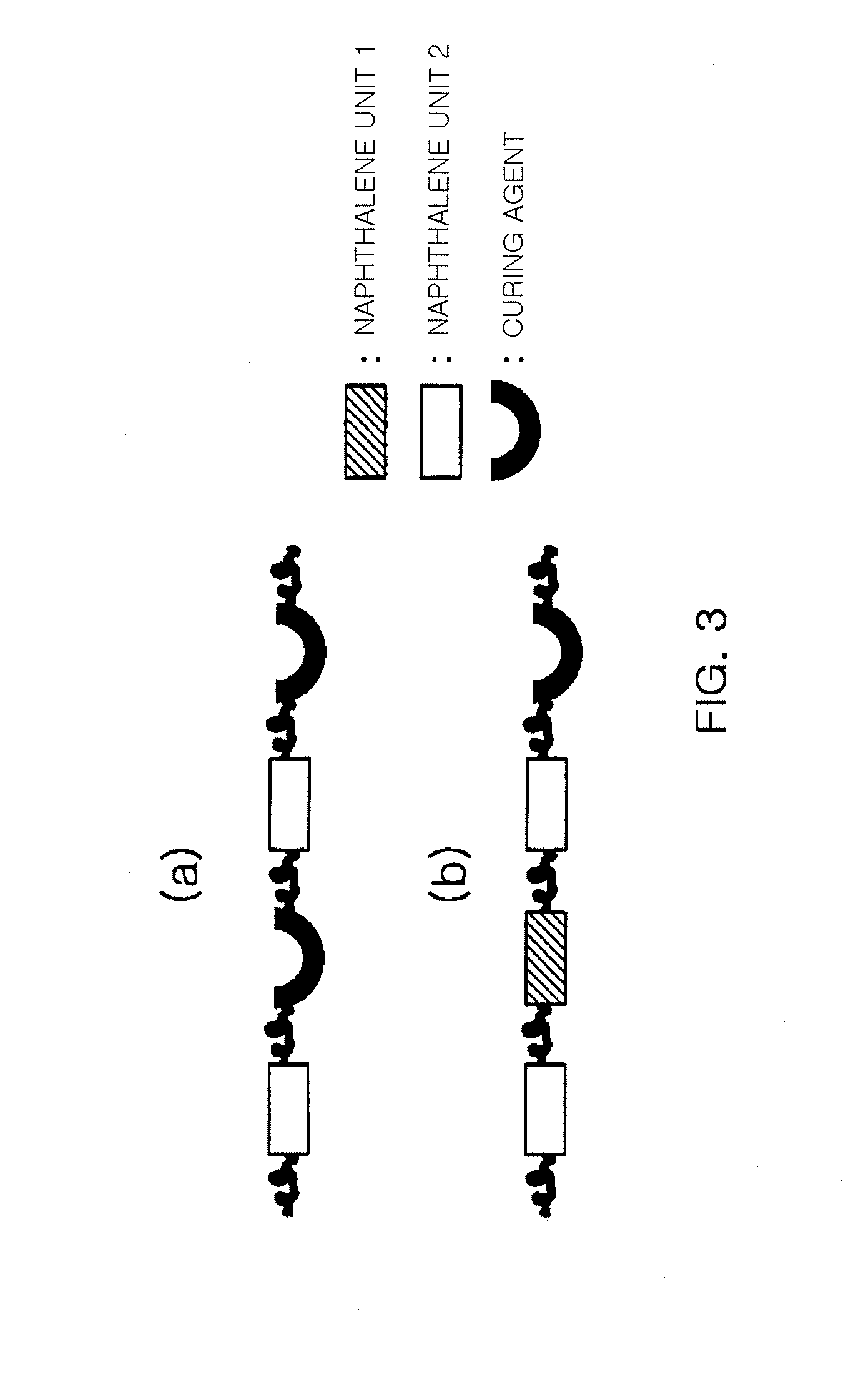

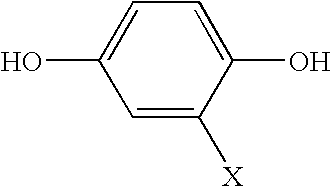

Novel epoxy resin and epoxy resin composition comprising the same

The present invention relates to a novel epoxy resin having improved heat-resistance, thermal expansion properties and processability, and to a thermosetting resin composition comprising the same. To this end, the present invention provides an epoxy resin of Chemical Formula 1 as disclosed in the Description, an epoxy resin composition comprising the same, and a packaging, substrate and transistor formed thereof. When a composition that contains an epoxy resin with a specific side functional group according to the present invention and / or an epoxy resin with a specific core structure is cured, a filler forms a strong chemical bond with the epoxy resin, thereby maximizing filling effects of the filler for the epoxy resin. Moreover, with the specific core structure, heat resistance and heat expansion properties of a cured product are substantially improved (CTE is reduced), and enhanced glass transition properties, strength and processability are demonstrated.

Owner:KOREA INST OF IND TECH

Fusion formable alkali-free intermediate thermal expansion coefficient glass

ActiveUS20130037105A1Increase efficiencyImprove battery efficiencyFinal product manufactureSynthetic resin layered productsOptoelectronicsHigh strain

A compositional range of high strain point and / or intermediate expansion coefficient alkali metal free aluminosilicate and boroaluminosilicate glasses are described herein. The glasses can be used as substrates or superstrates for photovoltaic devices, for example, thin film photovoltaic devices such as CdTe or CIGS photovoltaic devices or crystalline silicon wafer devices. These glasses can be characterized as having strain points ≧600° C., thermal expansion coefficient of from 35 to 50×10−7 / ° C.

Owner:CORSAM TECH

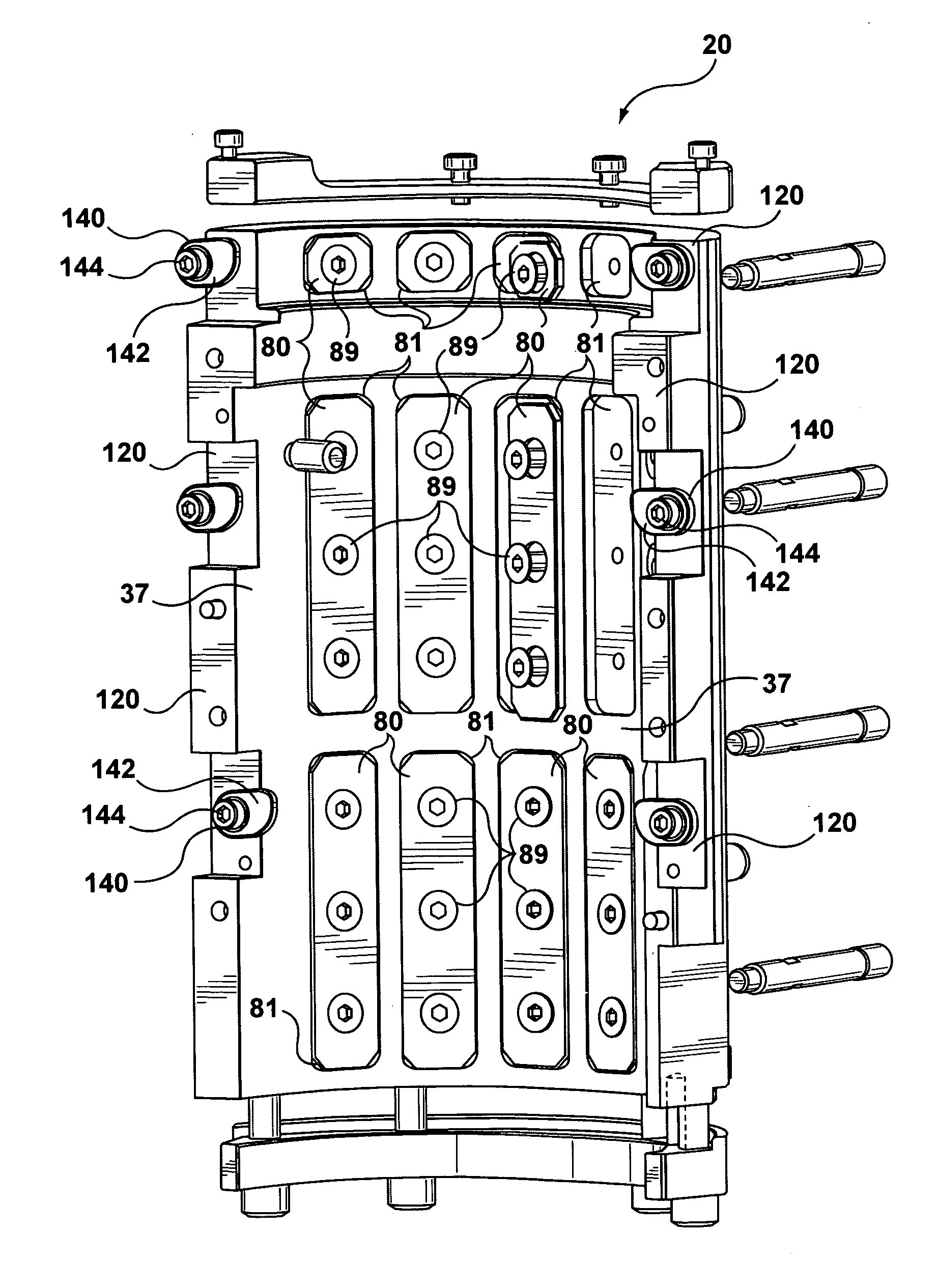

Mold assembly

ActiveUS20100203186A1DurableGood thermal expansionMouldsConfectioneryEngineeringMechanical engineering

A mold assembly has two mold half shells each having an outer and inner wall for defining the shape of a container to be formed. Two mold half carriers each have an inner wall overlaying and spaced from a corresponding mold shell outer wall for supporting the shells in the assembly. At least one insulating pad is sandwiched between the inner wall and the corresponding outer wall and is secured to one of the inner wall and the outer wall. The pad supports the outer wall in non-contacting and buffering relation relative the carrier inner wall. Each pad may be secured in a recessed seat in the respective wall. Pads may be secured in recessed seats having a depth less than the thickness of the pad. Pads absorb mold operational forces to reduce wear, reduce conduction from shell to carrier and facilitate the use of different-sized shells with one carrier.

Owner:WENTWORTH MOLD

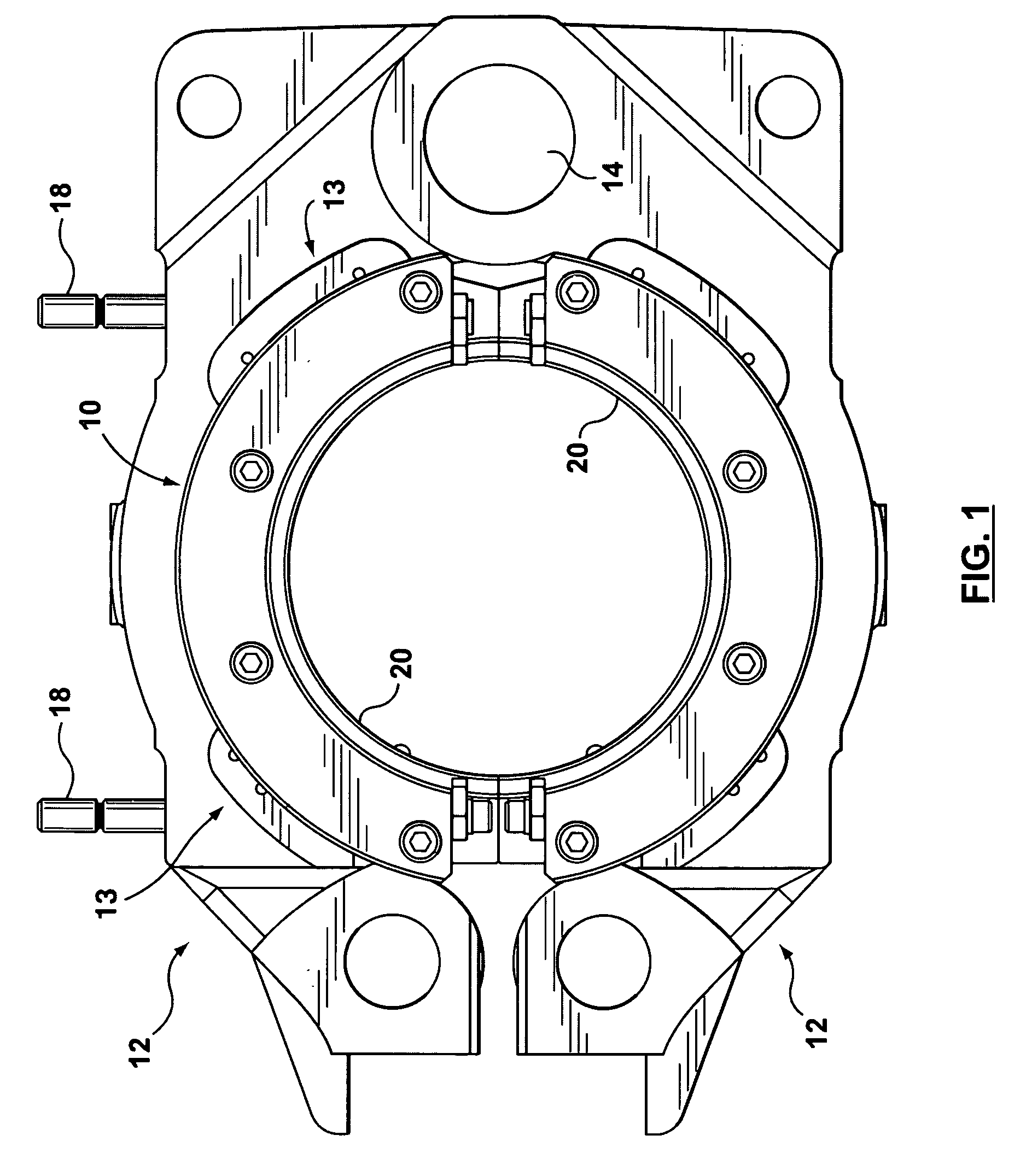

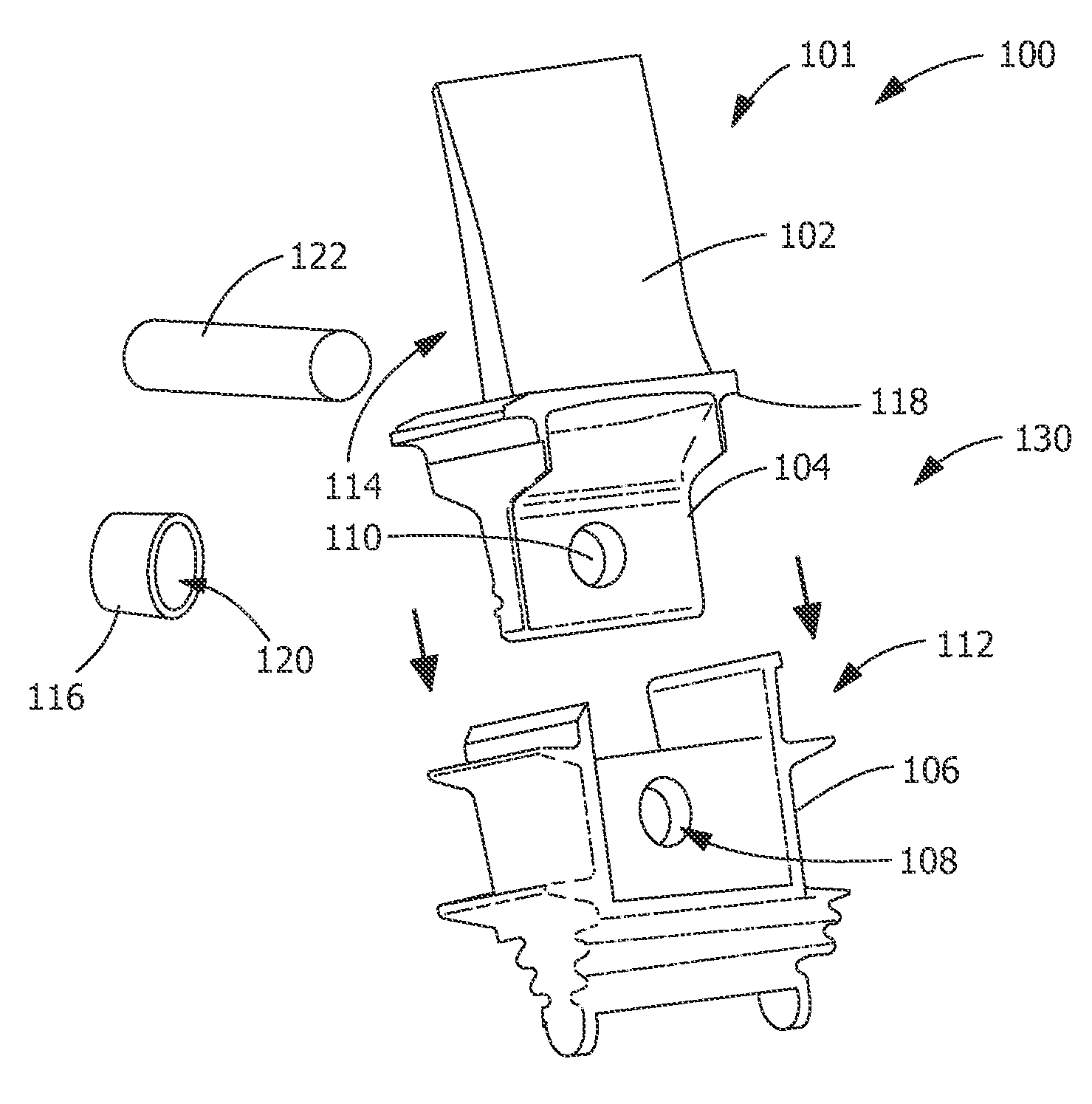

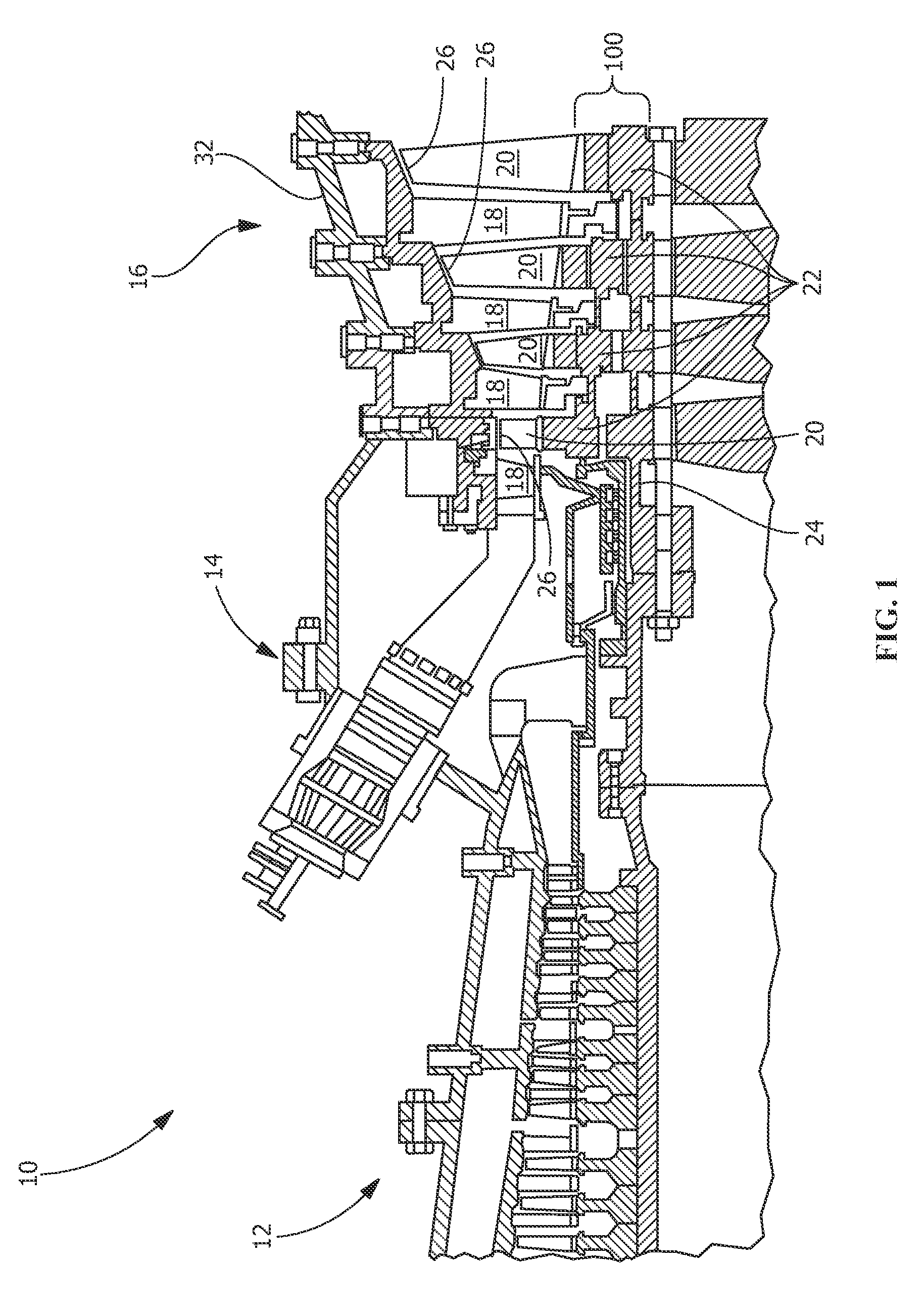

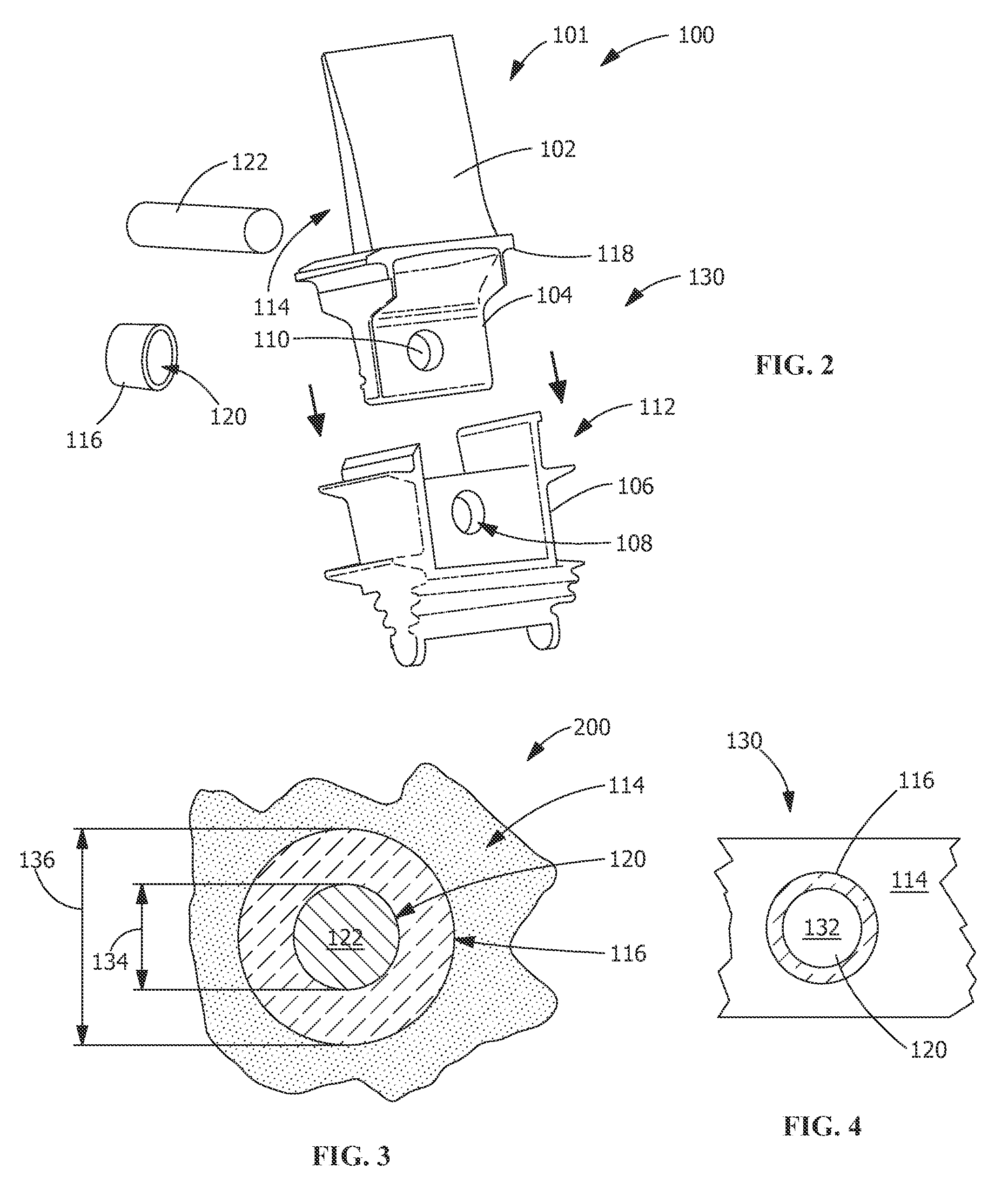

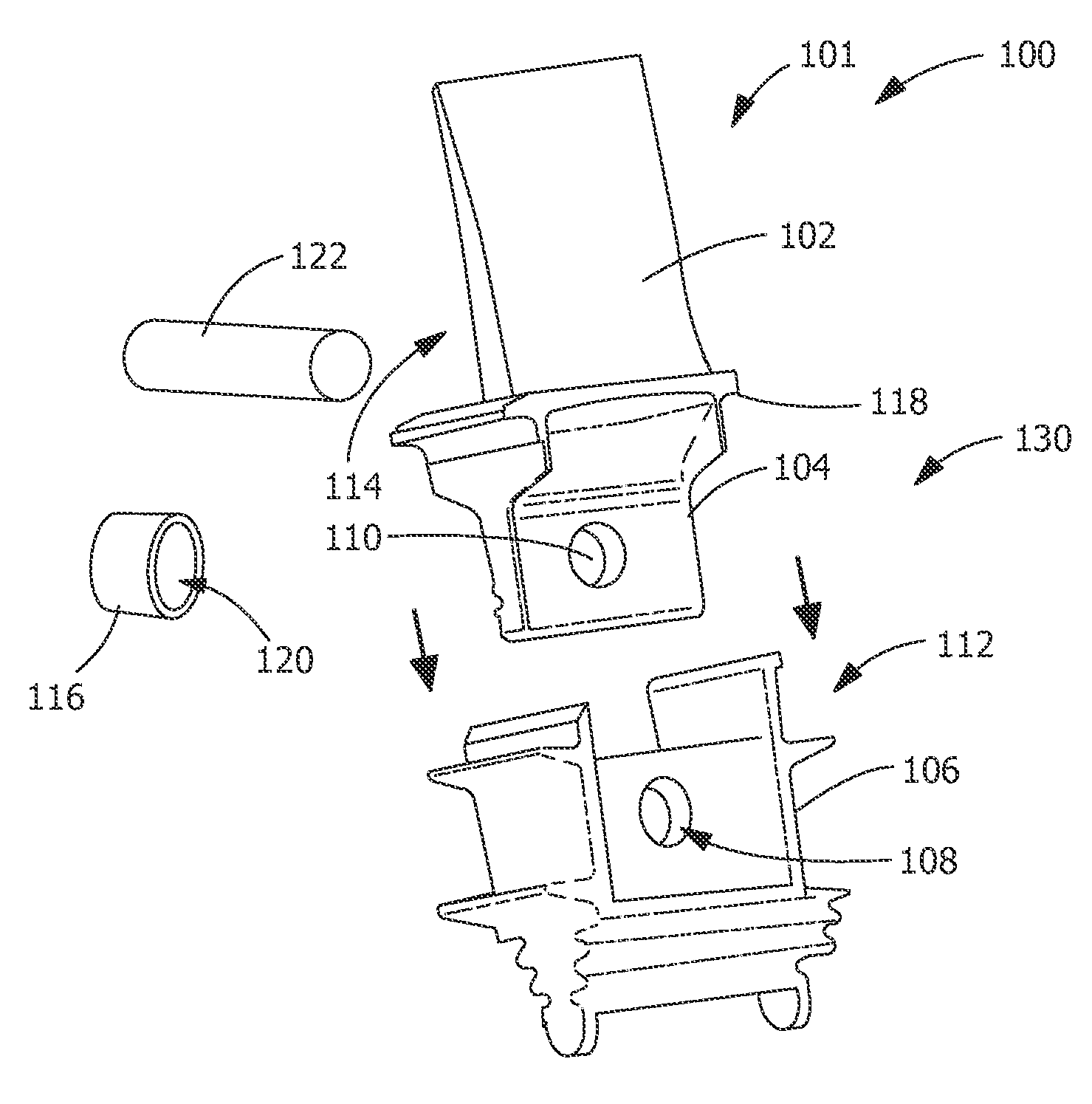

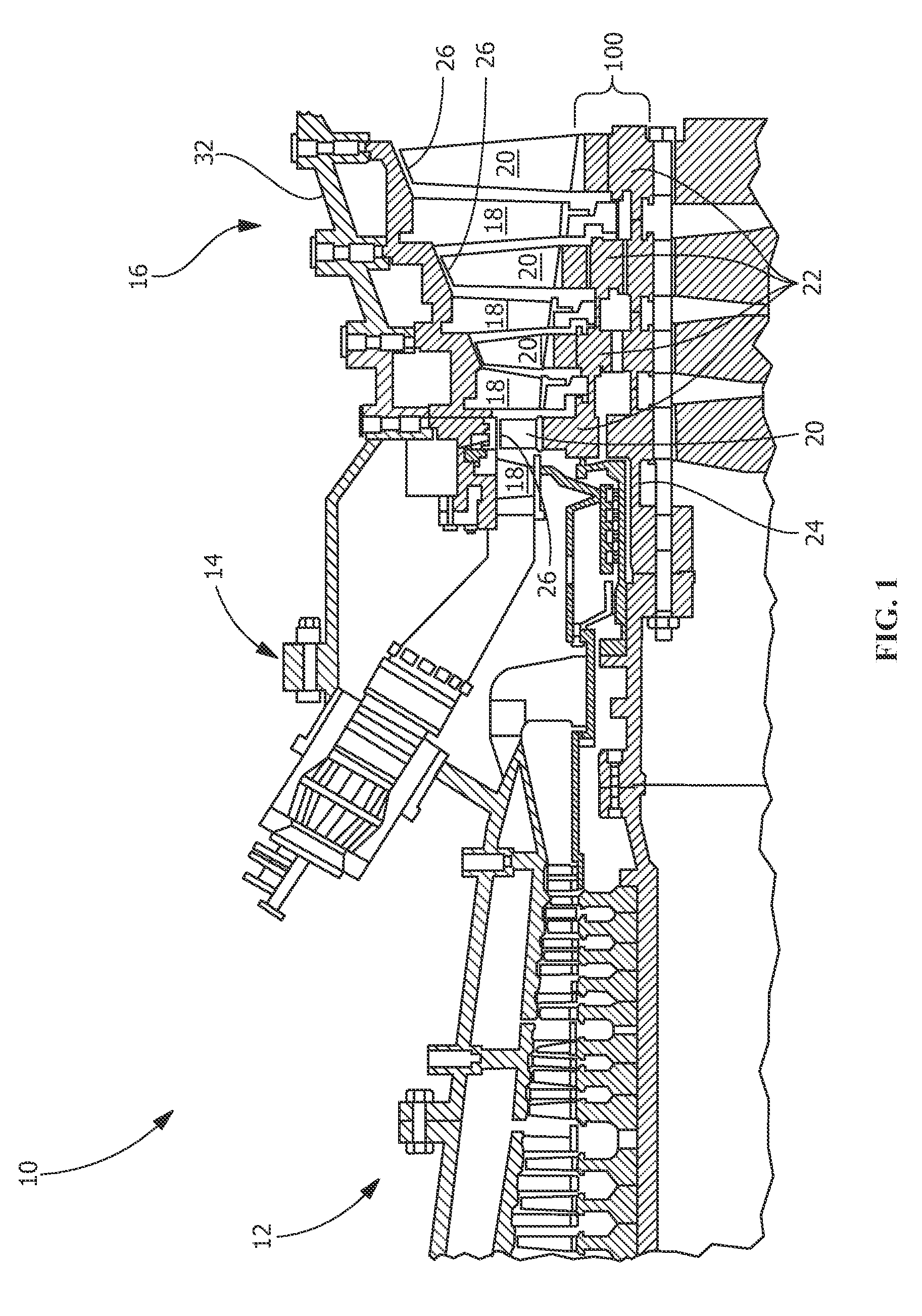

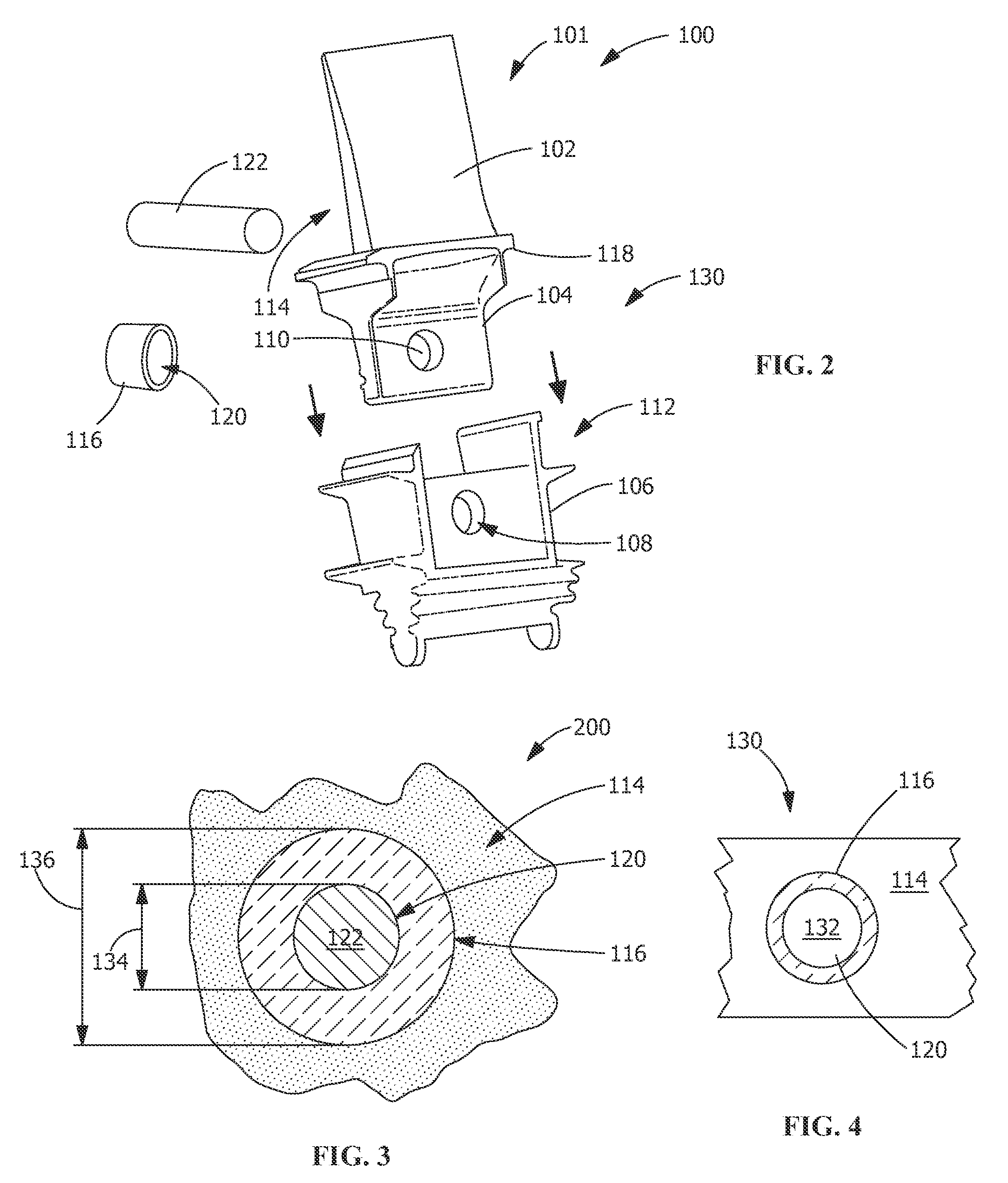

Connecting system for metal components and cmc components, a turbine blade retaining system and a rotating component retaining system

ActiveUS20130243601A1Relieve pressureReduce vibrationPropellersPump componentsTurbine bladeEngineering

A connecting system for metal component and CMC components, a turbine blade retaining system and rotating component retaining system are provided. The connecting system includes a retaining pin, a metal foam bushing, a first aperture disposed in the metal component, and a second aperture disposed in the ceramic matrix composite component. The first aperture and the second aperture are configured to form a through-hole when the metal component and the ceramic matrix composite component are engaged. The retaining pin and the metal foam bushing are operably arranged within the through-hole to connect the metal component and the ceramic matrix composite component.

Owner:GENERAL ELECTRIC CO

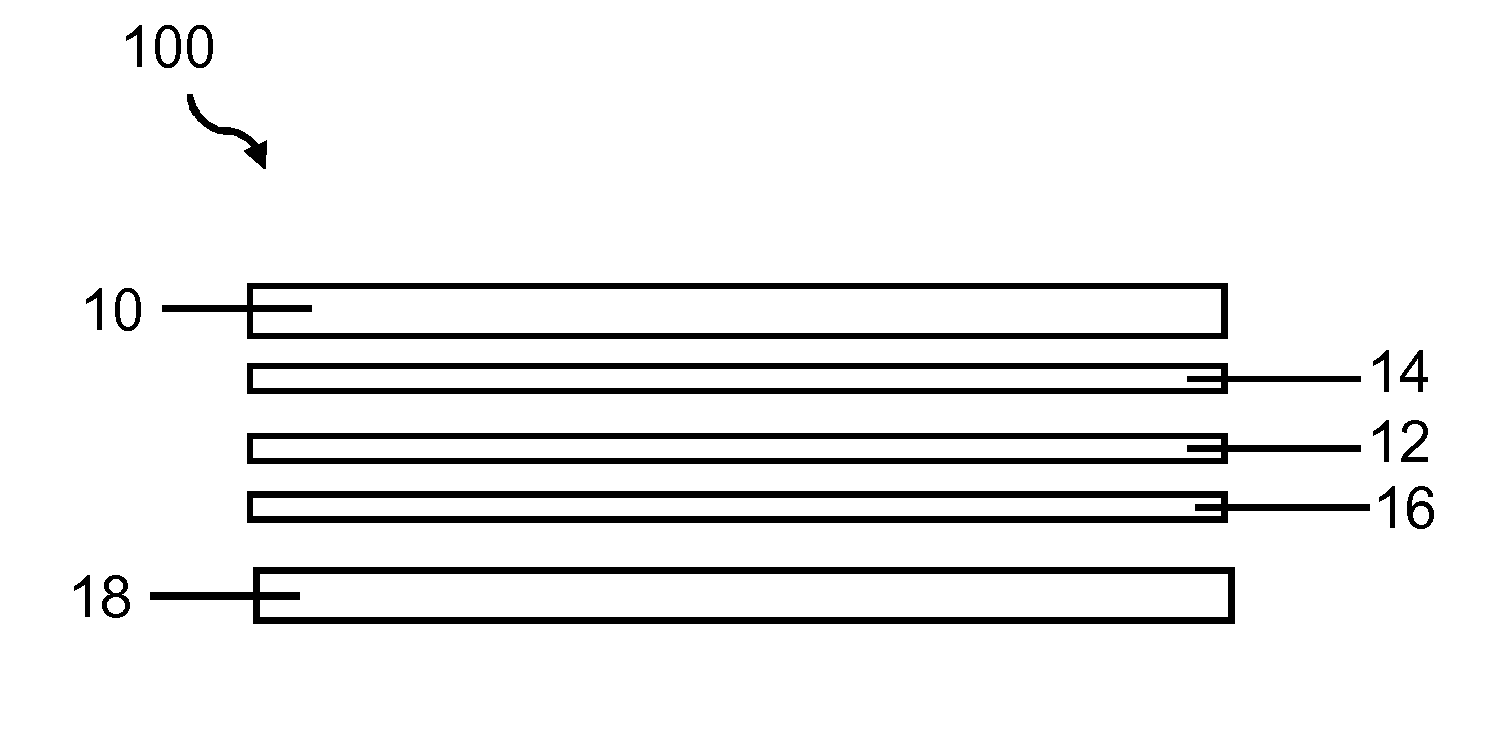

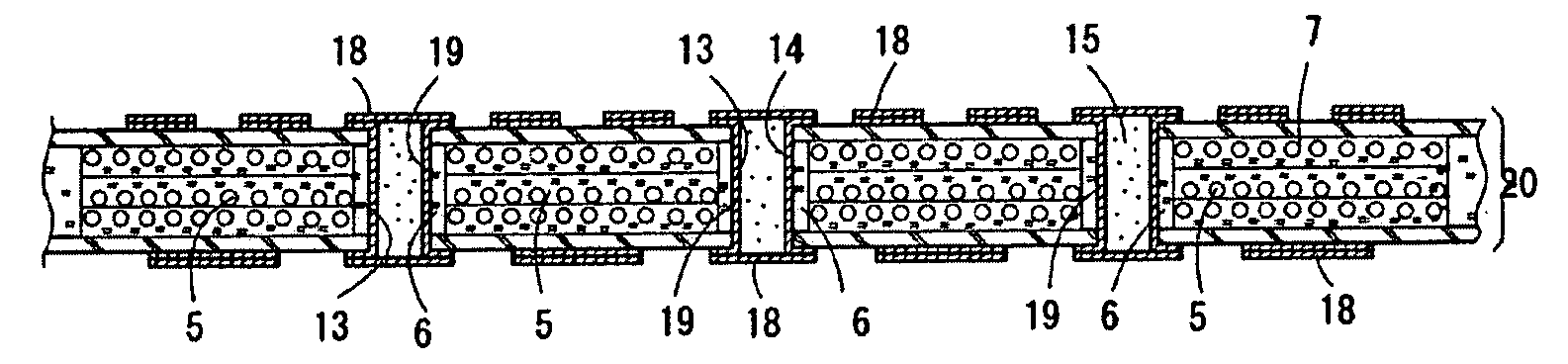

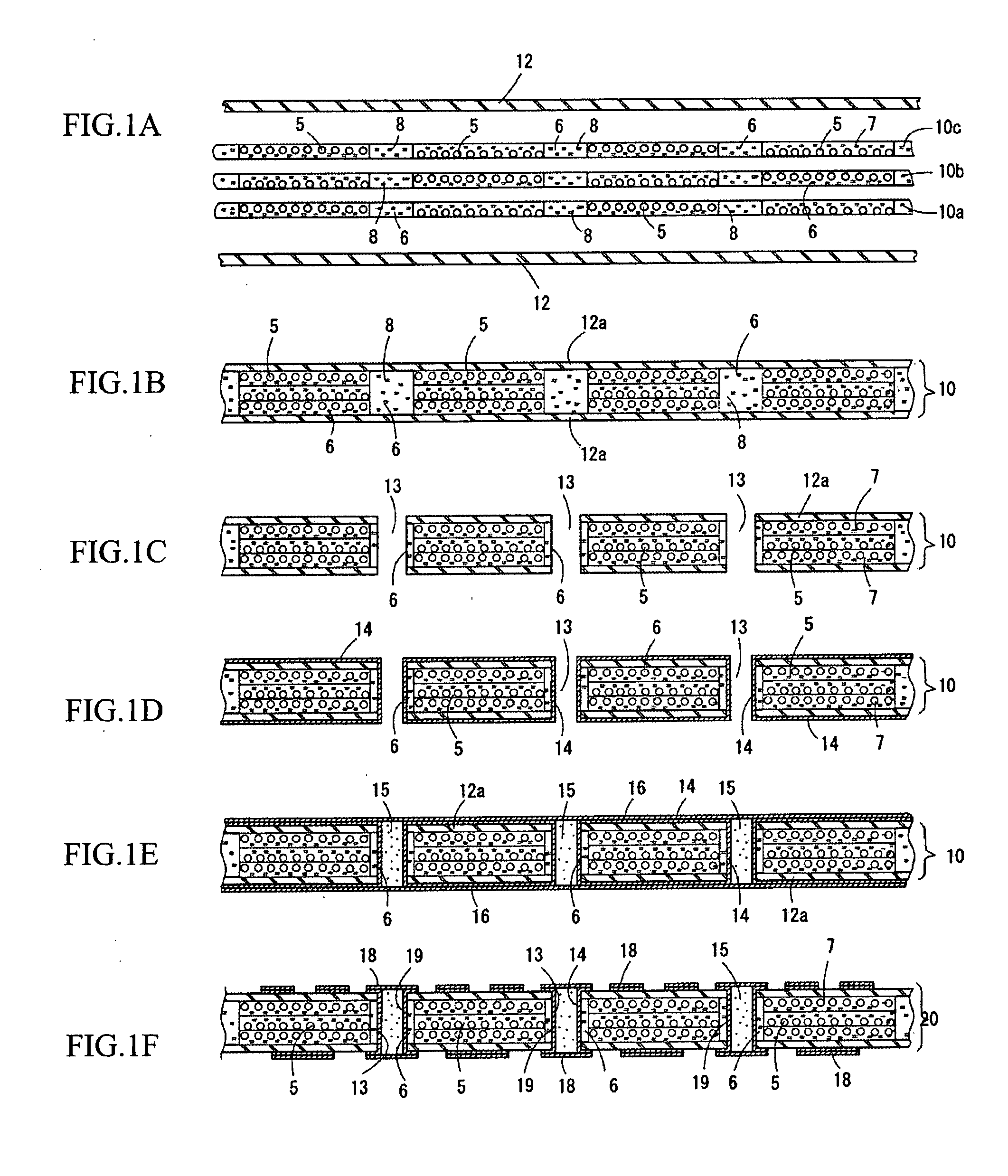

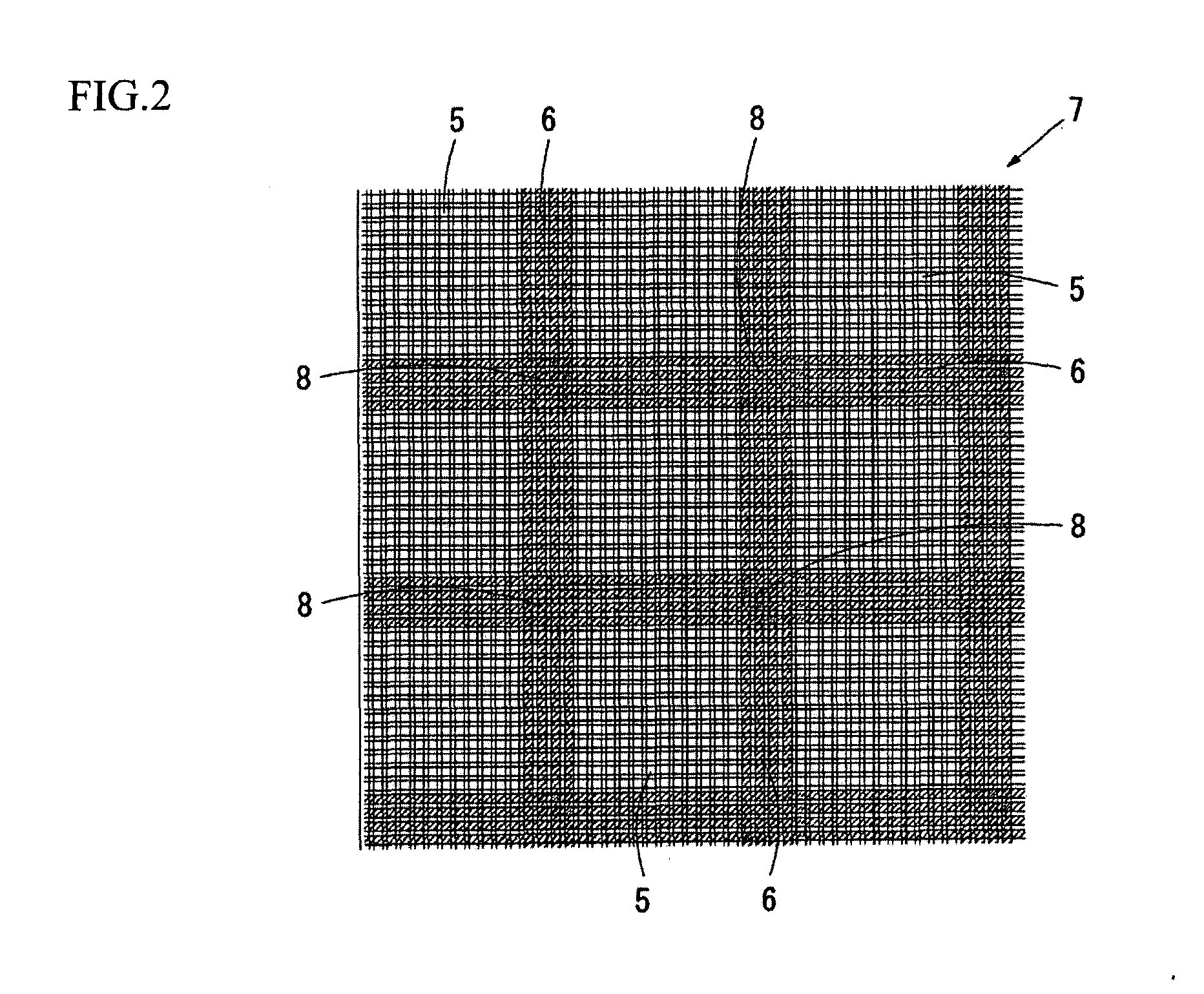

Circuit board and method of manufacturing the same

ActiveUS20090095521A1Avoid electrical shortingEasy constructionPrinted circuit assemblingPrinted circuit aspectsFiberThermal compression

A circuit board has plated through holes which are laid out with a fine pitch and meets requirements relating to characteristics such as the thermal expansion coefficient of the circuit board. A method of manufacturing a circuit board includes: a step of forming a core portion by thermal compression bonding prepregs which include first fibers that conduct electricity and second fibers that do not conduct electricity, which have the second fibers disposed at positions where plated through holes will pass through, and which are impregnated with resin; a step of forming through holes at positions in the core portion where the second fibers are disposed; and a step of forming a conductive layer on inner surfaces of the through holes to form plated through holes at positions that do not interfere with the first fibers and thereby produce a core substrate.

Owner:SHINKO ELECTRIC IND CO LTD

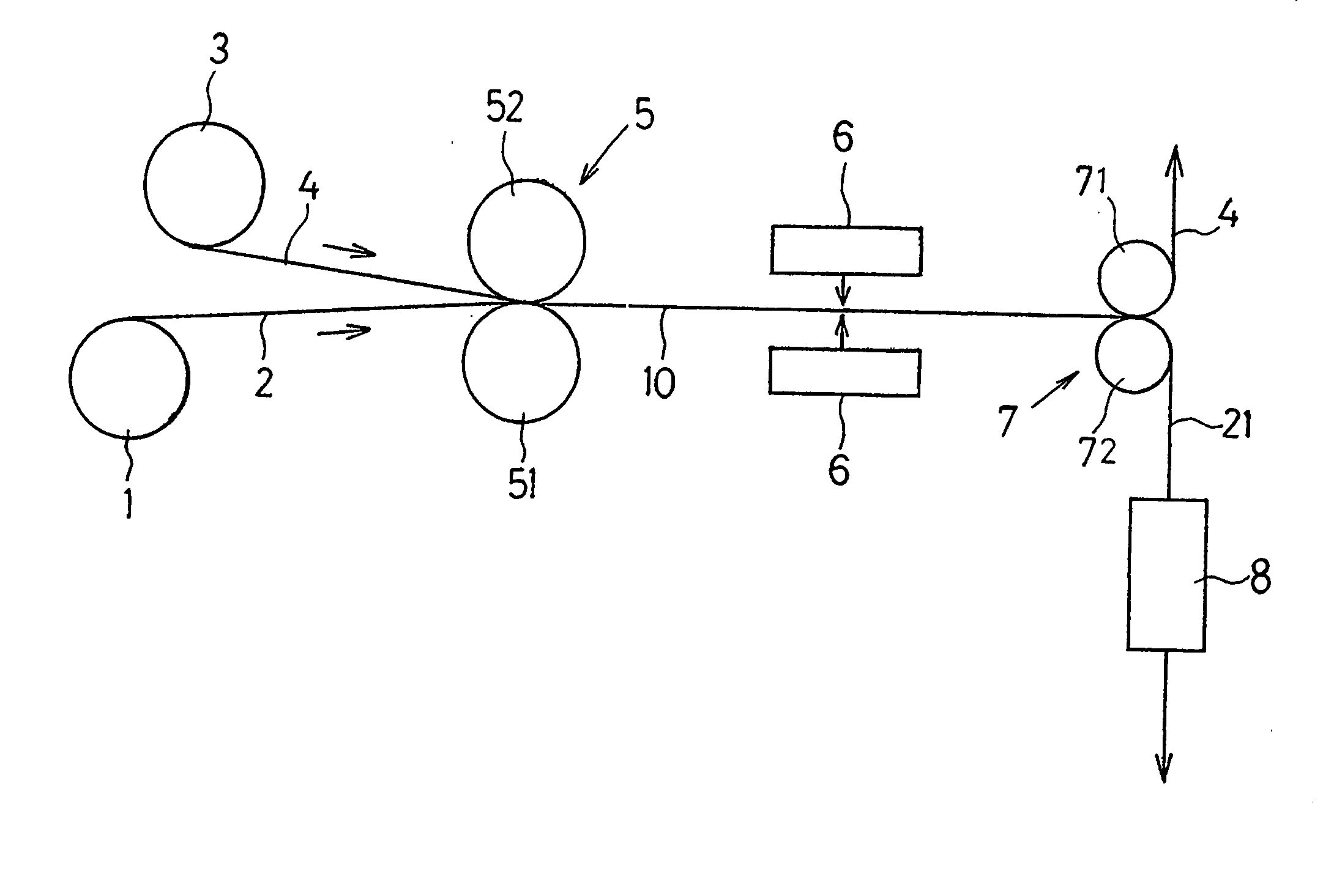

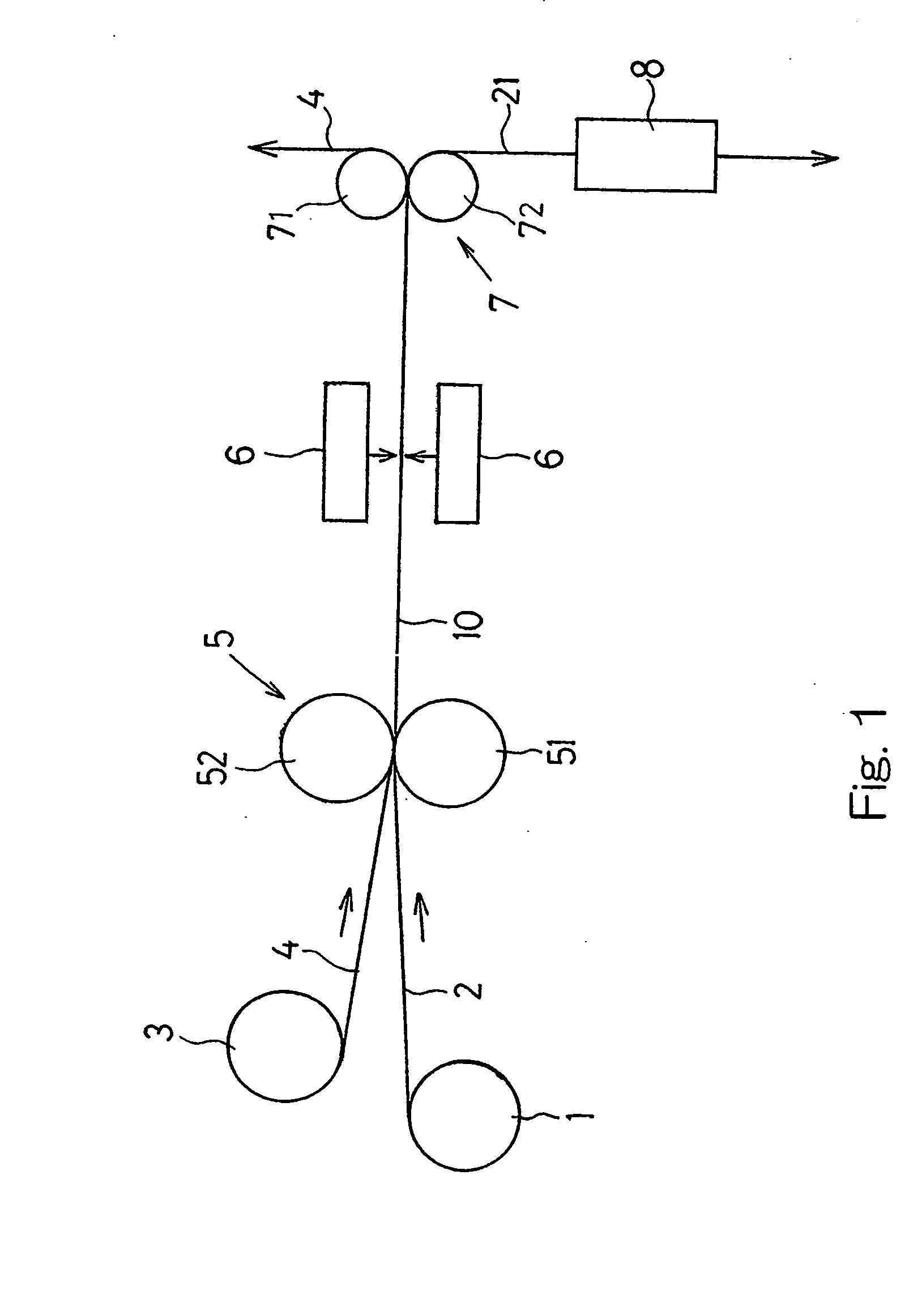

Method of making liquid crystal polymer films

ActiveUS20050067739A1Reduction of thermal expansion coefficientHigh coefficient of thermal expansionAdhesive processesLamination ancillary operationsPolymer scienceHeating time

A method of making a thermotropic liquid crystal polymer film includes continuously heat treating of the thermotropic liquid crystal polymer film 2 while the latter is jointed to a sheet-like support member 4, and subsequently separating the heat-treated thermotropic liquid crystal polymer film 2 from the support member 4. The continuous heat treatment of the thermotropic liquid crystal polymer film 2 then jointed to the support member 4 is carried out for a predetermined heating time within the range of 5 to 60 seconds at a predetermined heating temperature T° C. equal to or higher than the melting point Tm° C. of the thermotropic liquid crystal polymer film less 15° C. (i.e., Tm−15° C.), but lower than the melting point Tm° C. (thus, Tm−15° C.≦T° C.<Tm° C.), to thereby increase the thermal expansion coefficient of the thermotropic liquid crystal polymer film.

Owner:KURARAY CO LTD

LCP (Liquid Crystal Polymer) or fluoride polymer high-frequency high-transmission double-sided copper clad laminate and FPC (Flexible Printed Circuit)

PendingCN108045022AReasonable structureReduce process stepsLaminationLamination apparatusCopper foilHigh frequency

The invention discloses an LCP (Liquid Crystal Polymer) or fluoride polymer high-frequency high-transmission double-sided copper clad laminate which comprises a first copper foil layer, a second copper foil layer, a first very low dielectric glue layer and at least one insulating polymer layer, wherein the first very low dielectric glue layer is positioned between the first and second copper foillayers; the Rz value of the inner surfaces of the first and second copper foil layers is 0.1-1.0 micron; the insulating polymer is at least one of a first LCP polymer layer or a first fluoride polymerlayer; the first very low dielectric glue layer is a glue layer with a Dk value of 2.0-3.5 and a Df value of 0.002-0.010; the first polyimide layer is an insulating polymer layer with a Dk value of 2.20-3.50 and a Df value of 0.002-0.010. The double-sided copper clad laminate and the FPC disclosed by the invention have excellent electrical properties and also have cost advantages, short manufacture procedure processes, low thermal expansion coefficients, stable dk / df performances in high-temperature and humidity environments, ultra-low water absorption rate, excellent UV laser drilling abilities, low rebound, suitableness for high-density assembly and excellent mechanical properties.

Owner:KUSN APLUS TEC CORP

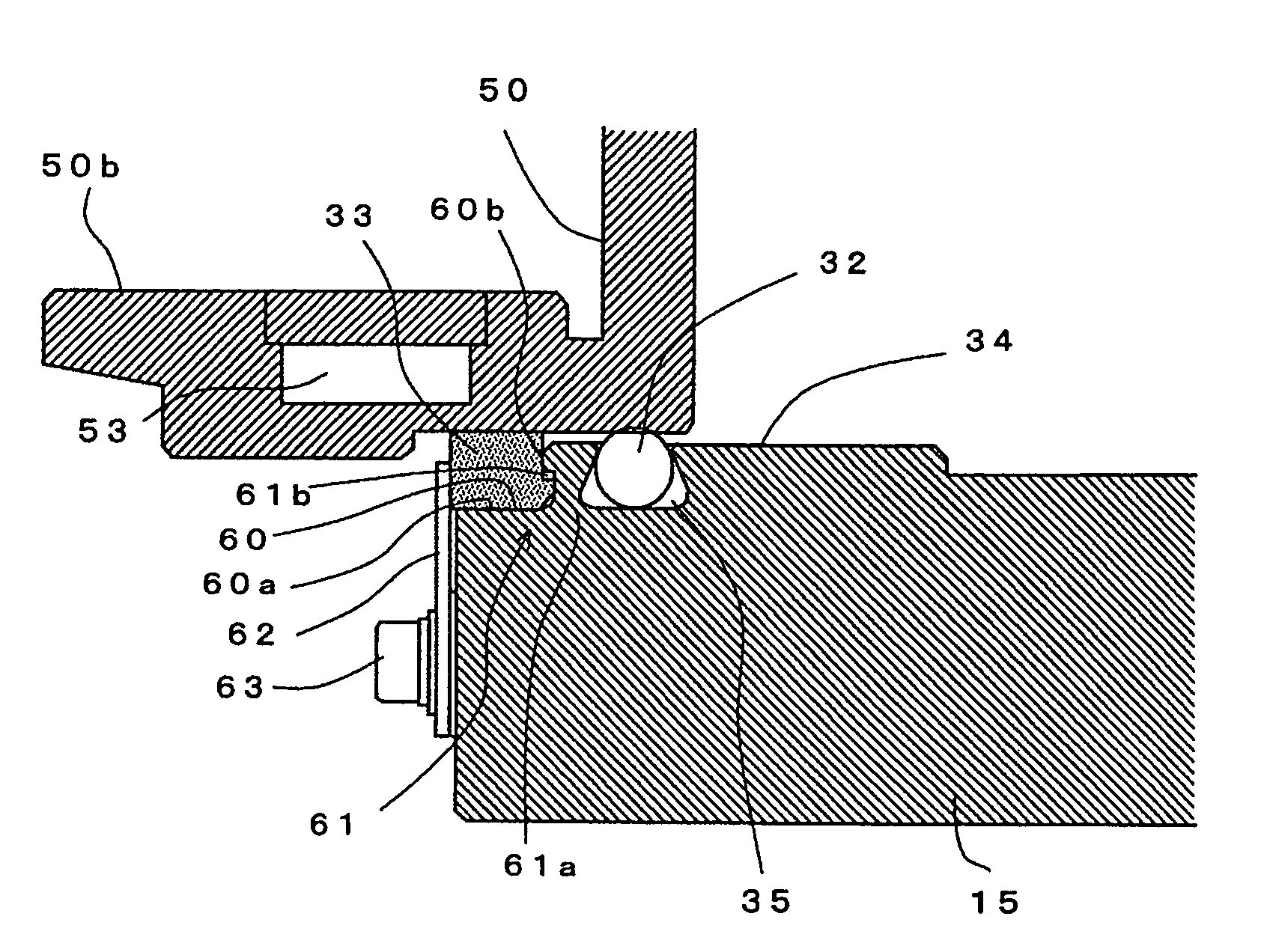

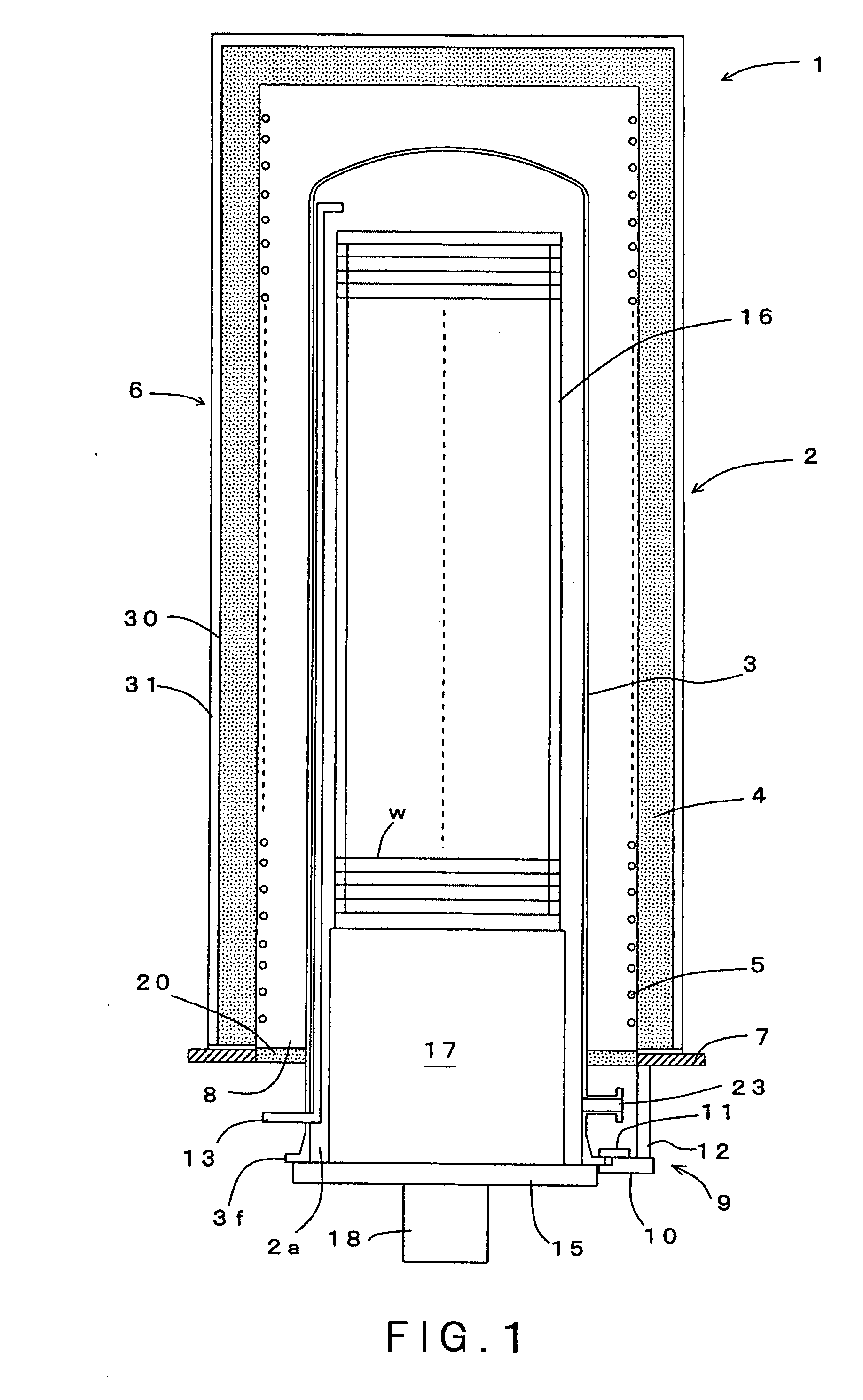

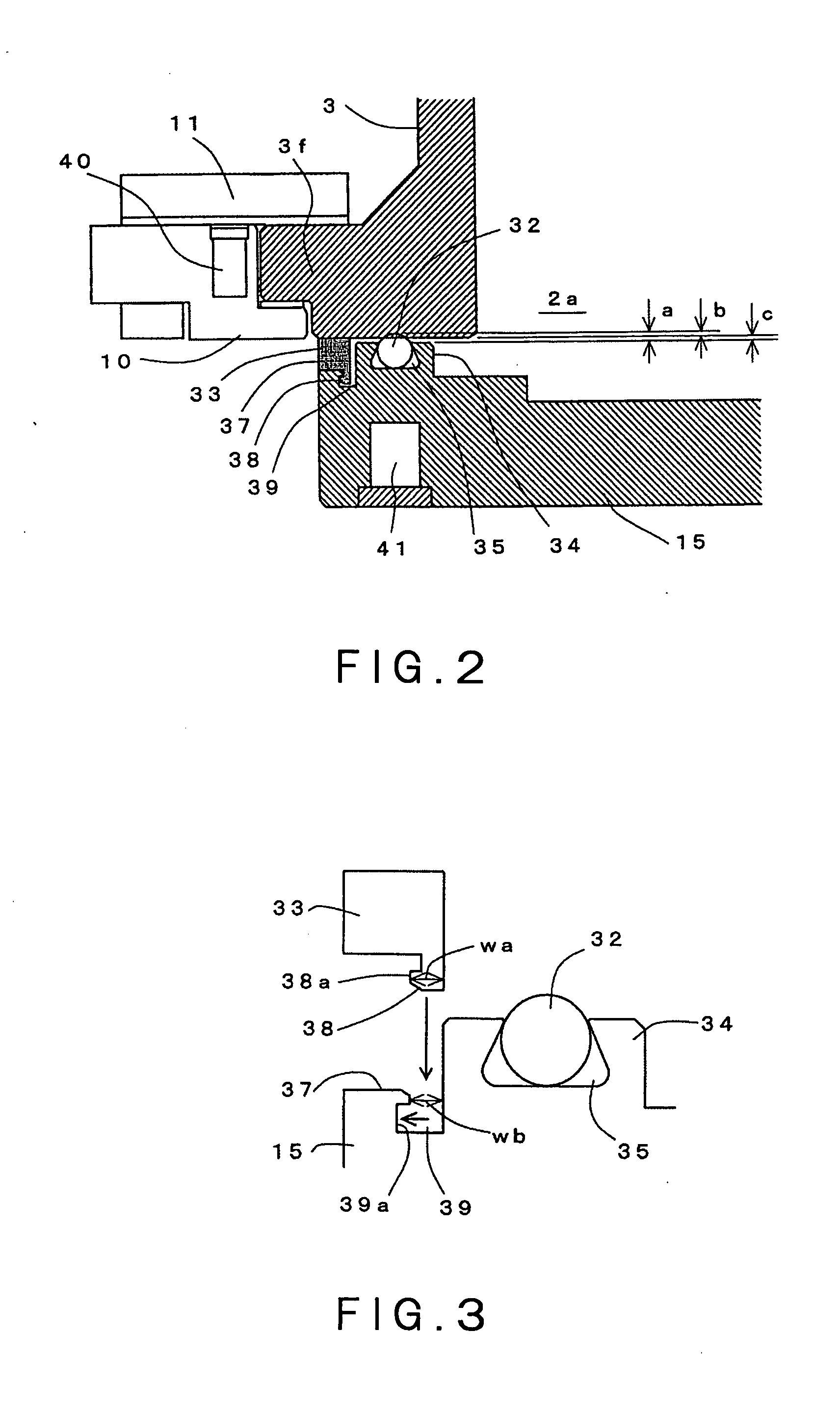

Heat treatment apparatus

ActiveUS20080090195A1Avoid damageExtend working lifeFurnace componentsSemiconductor/solid-state device manufacturingInternal pressureThermal treatment

Disclosed is a heat treatment apparatus which includes a processing vessel having a furnace throat at its bottom and adapted to accommodate process objects therein to perform a heat treatment to the process objects under reduced pressure, the processing vessel having a vessel main body made of quartz, a metallic lid adapted to support thereon a holder for holding a plurality of process objects so as to load and unload the holder into and from the processing vessel and to close and open the furnace throat, and an annular sealing member disposed on the lid to seal a gap between the lid and the furnace throat. A contact-preventing member is disposed between the lid and the furnace throat to prevent contact of the lid with the furnace throat due to squashing of the sealing member that would otherwise occur when an internal pressure of the processing vessel is reduced.

Owner:TOKYO ELECTRON LTD

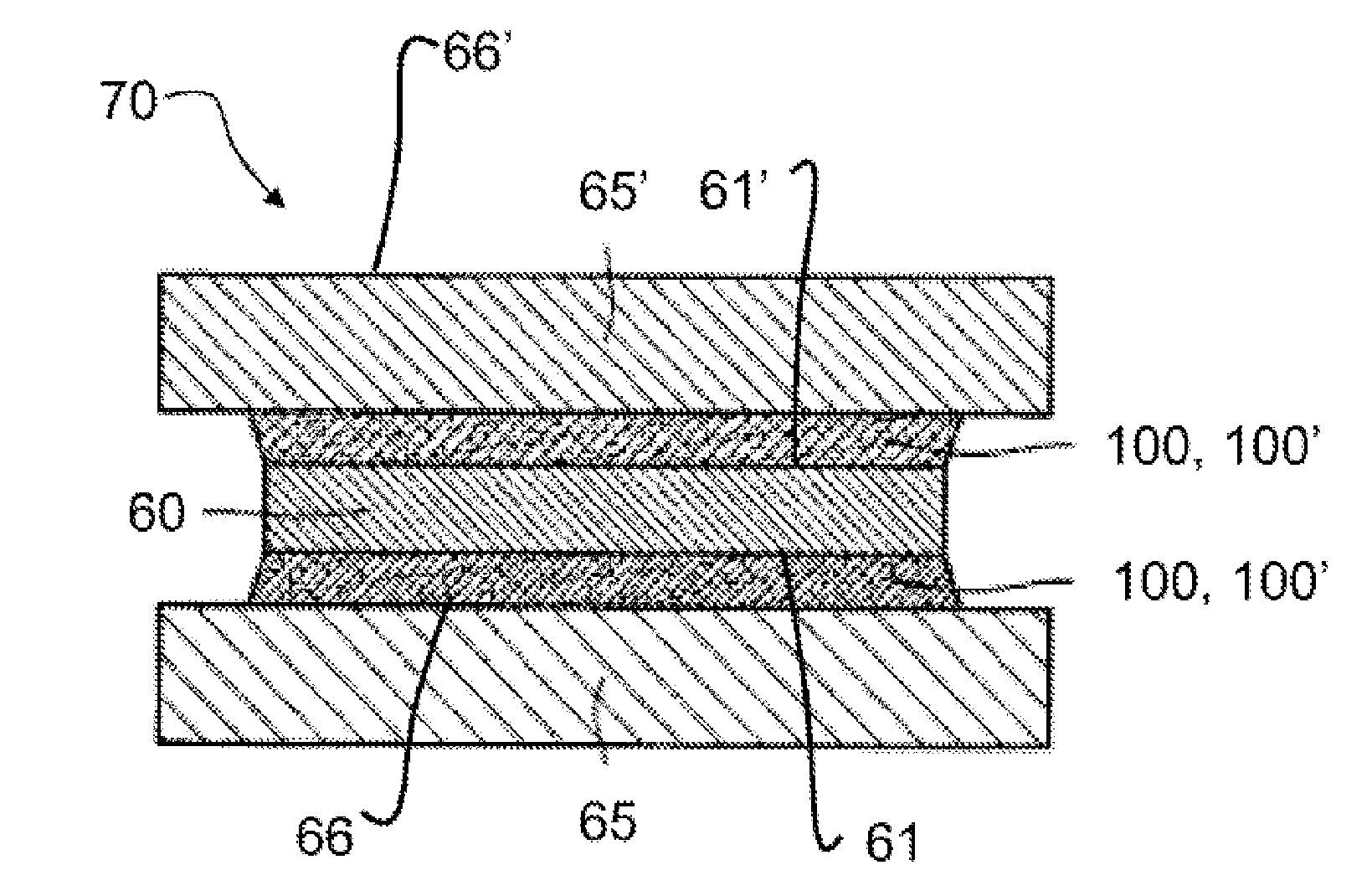

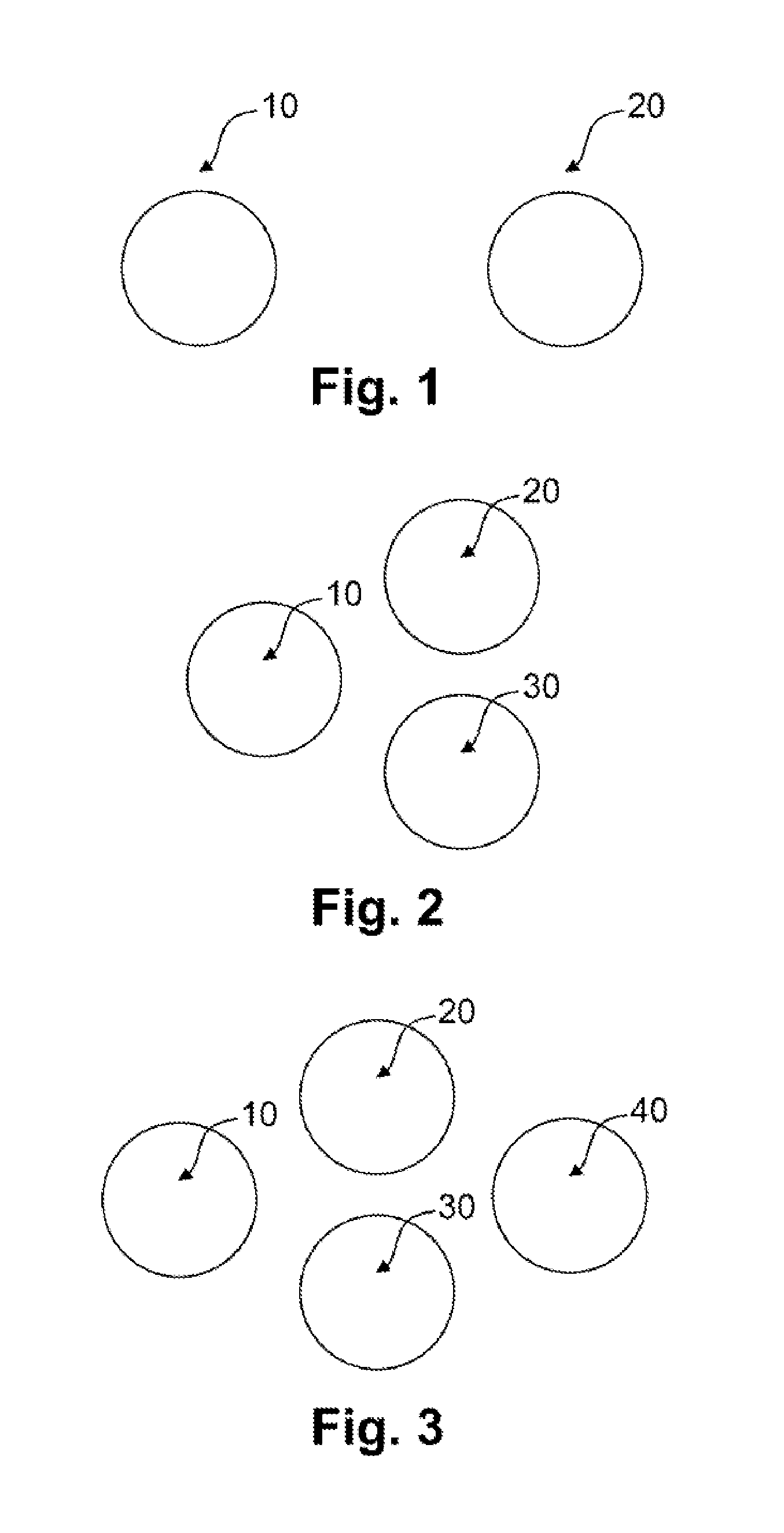

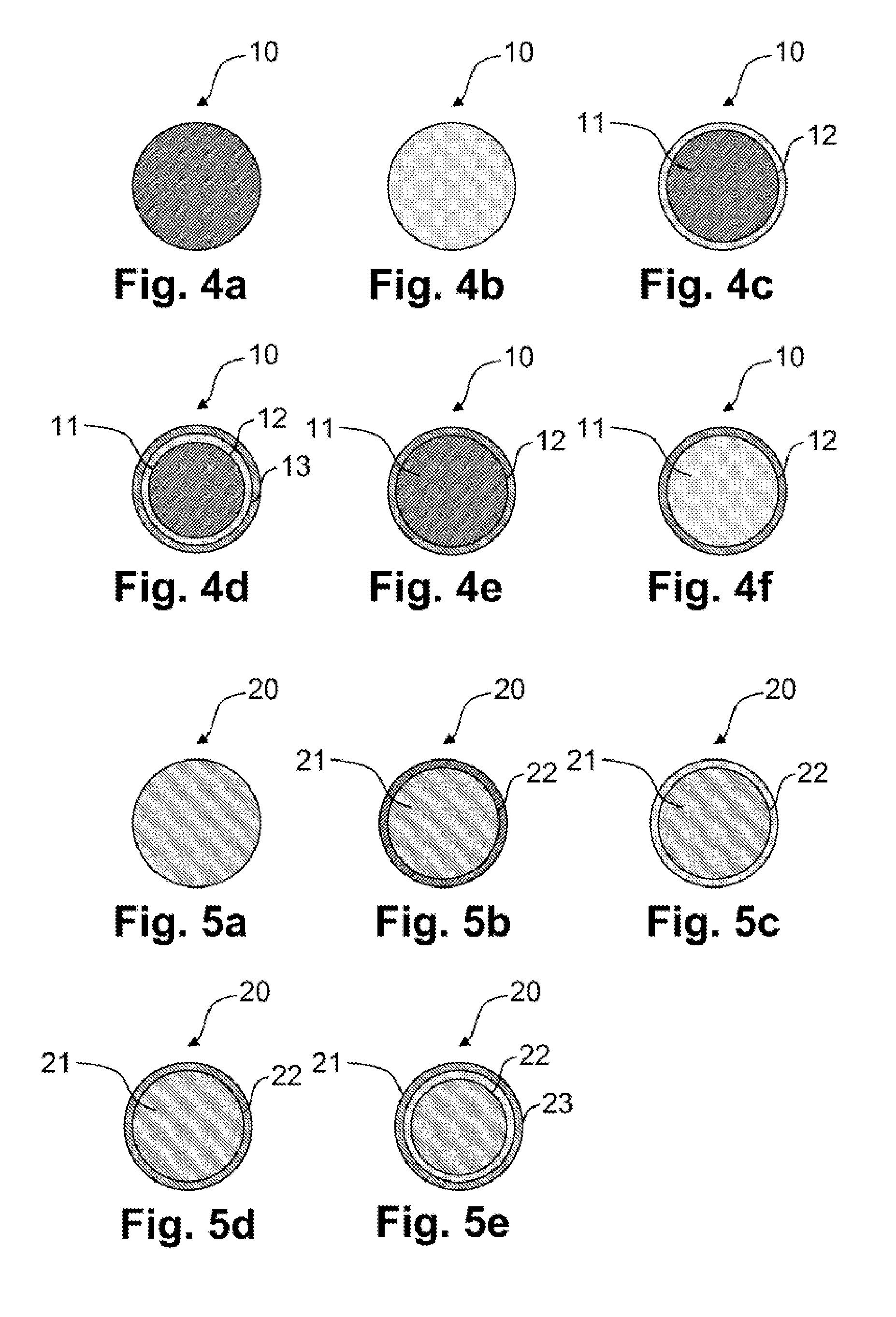

Starting material and process for producing a sintered join

InactiveUS20130216848A1Reduction factorAdvantageous effect elasticityPrinted circuits stress/warp reductionSolid-state devicesSiliconSILICONE DIOXIDE

The present invention relates to a starting material for producing a sintered join. In order to avoid the formation of cracks in the case of fluctuating thermal loading, the starting material comprises second particles 20, in addition to metallic first particles 10, which at least proportionately contain elemental silicon and / or silicon dioxide. In addition, the present invention relates to the use of elemental silicon and / or silicon dioxide for reducing the coefficient of thermal linear expansion α of a starting material 100 of a sintered join 100′ or of a sintered join 100′, in particular in a sintered paste, a sintered powder or a sintered material preform. Furthermore, the present invention relates to sintered joins 100′, to electronic circuits 70 and also to processes for forming a thermally and / or electrically conductive sintered join.

Owner:ROBERT BOSCH GMBH

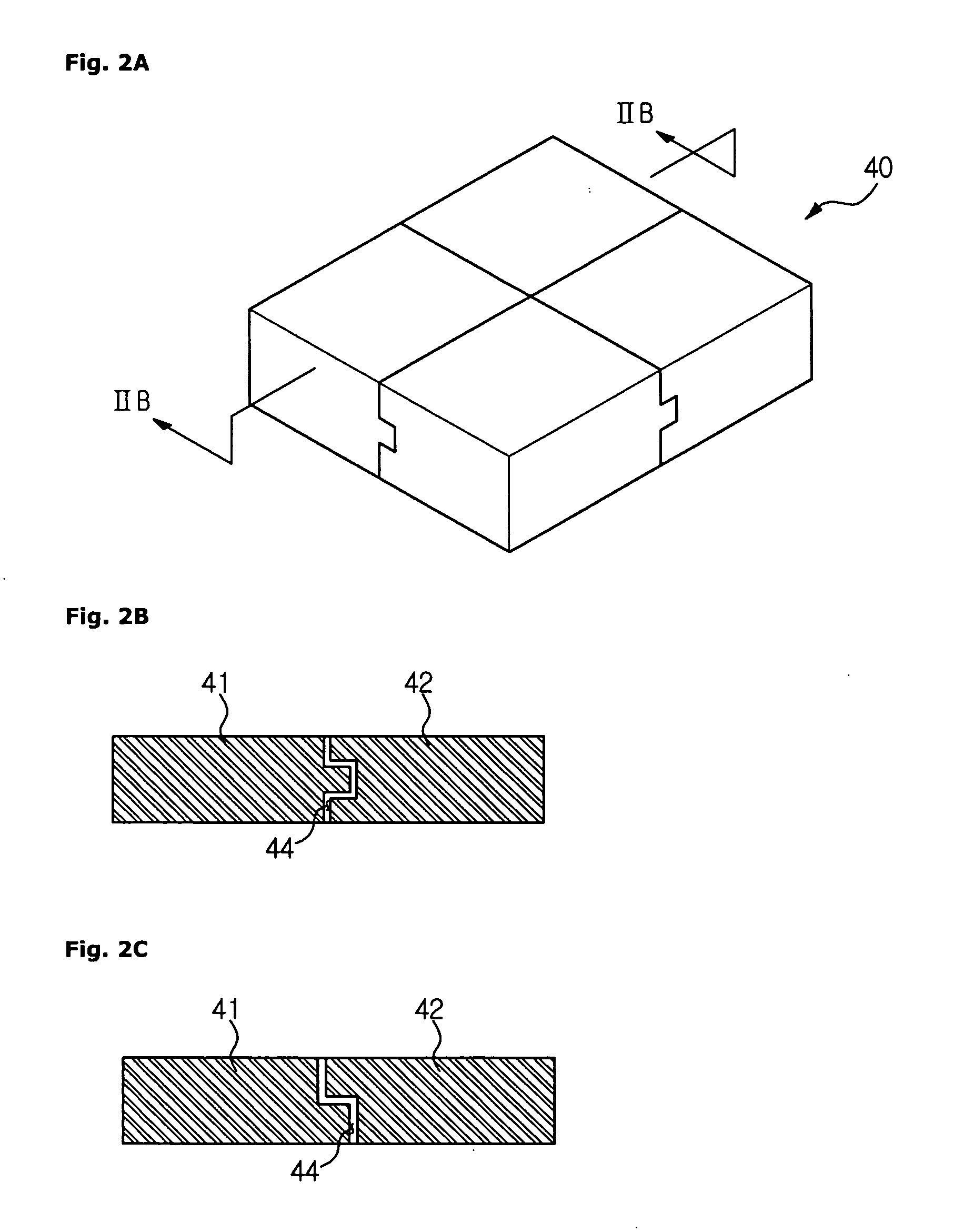

Coating structure and method

InactiveUS8247080B2Prolong lifeGood thermal expansionLiquid surface applicatorsVacuum evaporation coatingRare earthThermal expansion

A coating structure including an outer coating comprising aluminum; and an interlayer disposed between a substrate and the outer coating is provided. The interlayer may include a rare earth metal, a transition metal, or a noble metal. The interlayer may have one or more property of being less responsive to halogen etching relative to the outer coating; having a coefficient of thermal expansion that is greater than the coefficient of thermal expansion of the substrate and less than the coefficient of thermal expansion of the outer coating or vice versa; having a color different from the color of the outer coating; having a electrical conductivity different from the electrical conductivity of the outer coating. A method of making is article is provided. The method may include securing an interlayer to a substrate surface, and securing an outer coating to a surface of the interlayer opposite the substrate.

Owner:GENERAL ELECTRIC CO

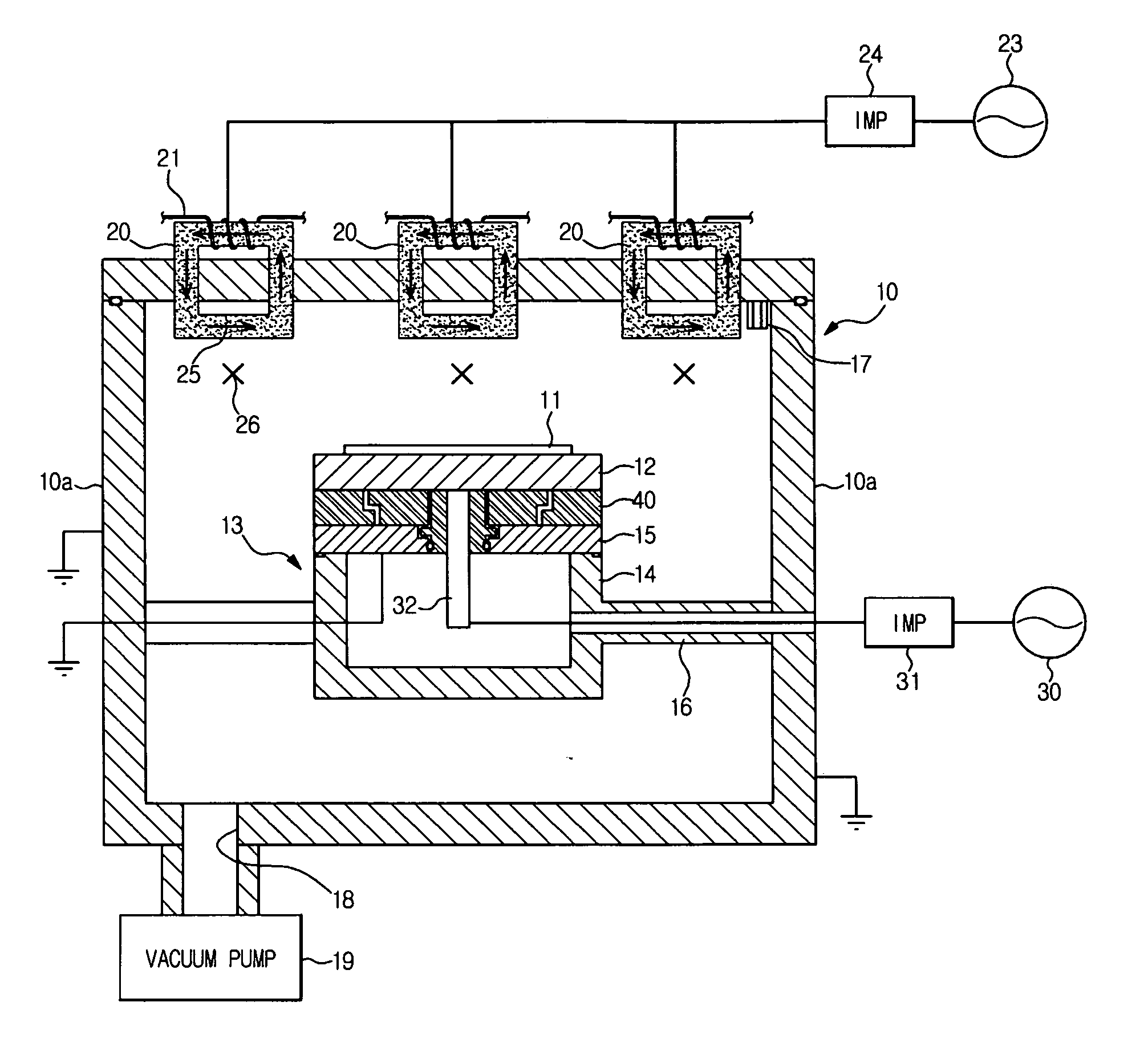

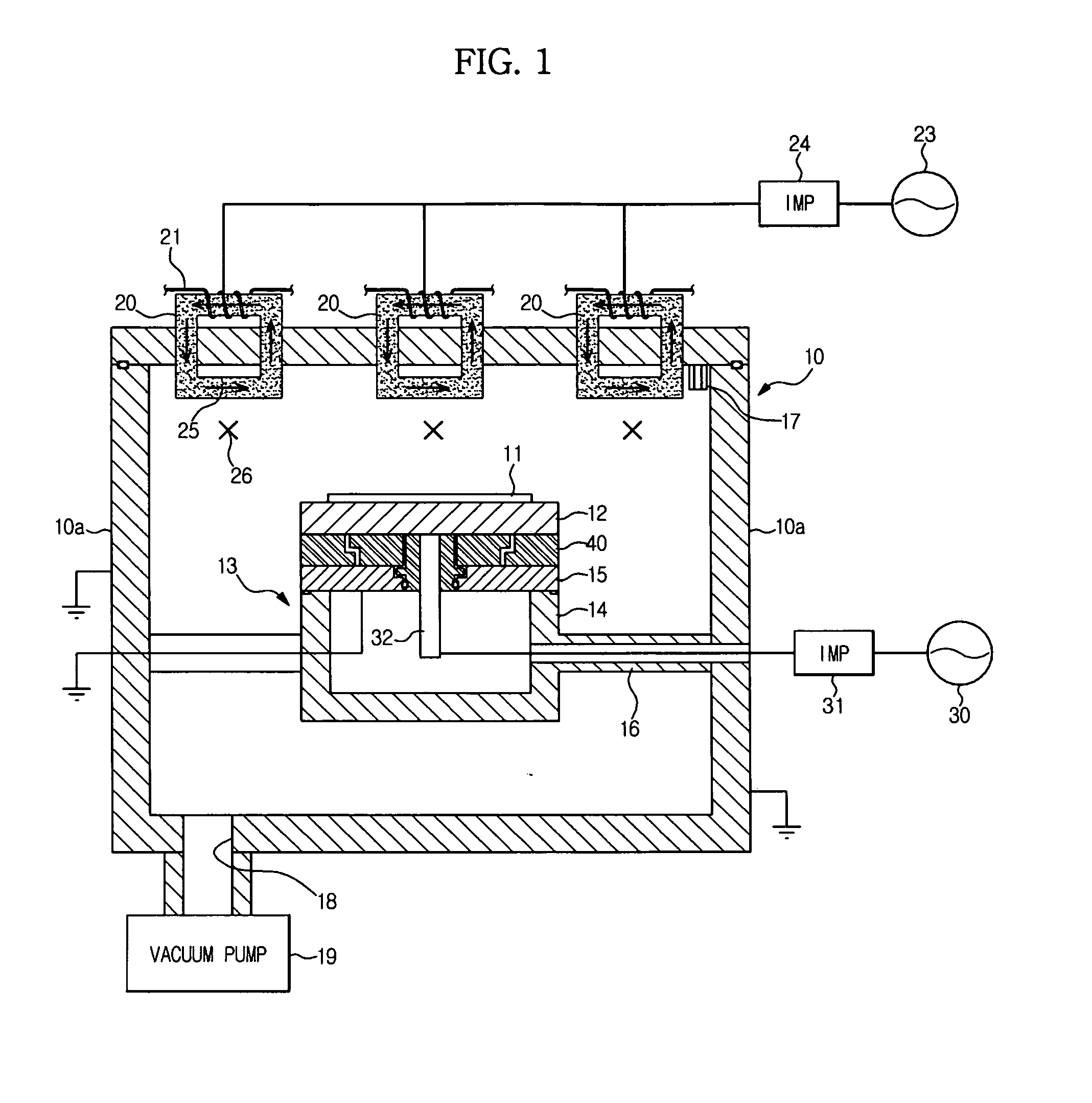

Plasma generating device

InactiveUS20100083902A1Prevent or reduce damagePrevent and reduce generationElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

A plasma generating device is disclosed, which generates plasma by supplying a bias RF power in the initial state in an inductive coupled plasma (ICP) system. Especially, an insulator which insulates a ground member from a susceptor supplied with the bias RF power is separated into at least two pieces such that the thermal expansion of the insulator can be generated similarly to adjoining parts.

Owner:SAMSUNG ELECTRONICS CO LTD

Inorganic-organic composite grouting material

The invention discloses an inorganic-organic composite grouting material, which is prepared from the following raw materials in parts by weight: 60-70 parts of portland cement, 20-30 parts of aluminate cement, 5-10 parts of polymer emulsion, 30-40 parts of mineral admixture, 0.1-0.3 parts of defoaming stabilizer, 6-9 parts of excitant, 0.1-0.3 parts of water-retaining agent, 0.2-0.4 parts of surface active agent, 2-6 parts of bentonite, 0.3-0.5 parts of fine sand, 0.4-0.6 parts of sodium carbonate, 0.03-0.05 parts of ceramic fiber, 0.01-0.03 parts of emulsion powder, 0.03-0.05 parts of dolomite, 0.01-0.03 parts of pyrophyllite and 4-8 parts of methyl sodium silicate. According to the inorganic-organic composite grouting material provided by the invention, the flexibility of a polymer and the rigidity of the mineral admixture are utilized to carry out joint modification, so that the grouting material with favorable performance is acquired, and the application range of the grouting material is further widened.

Owner:王璐

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

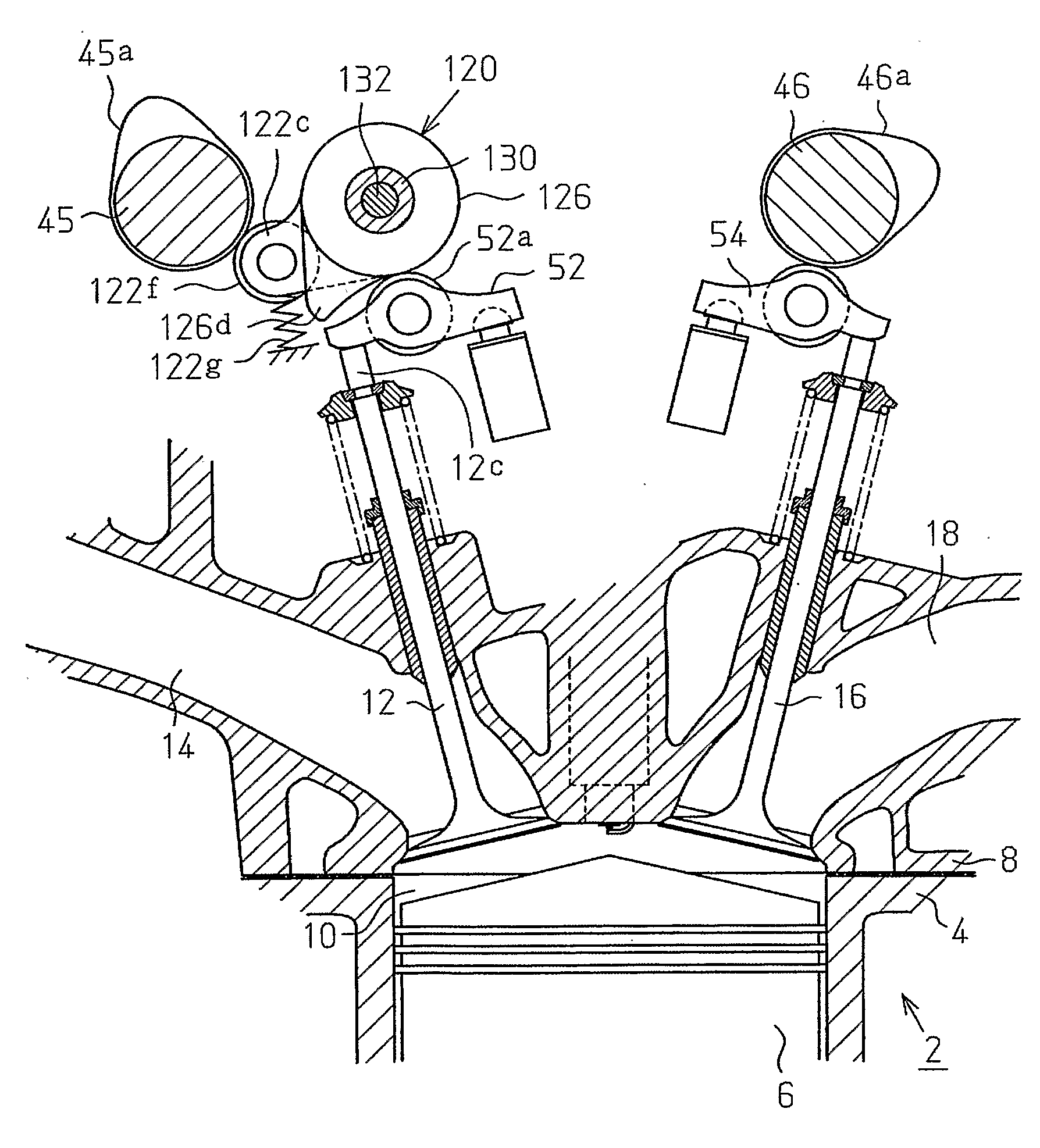

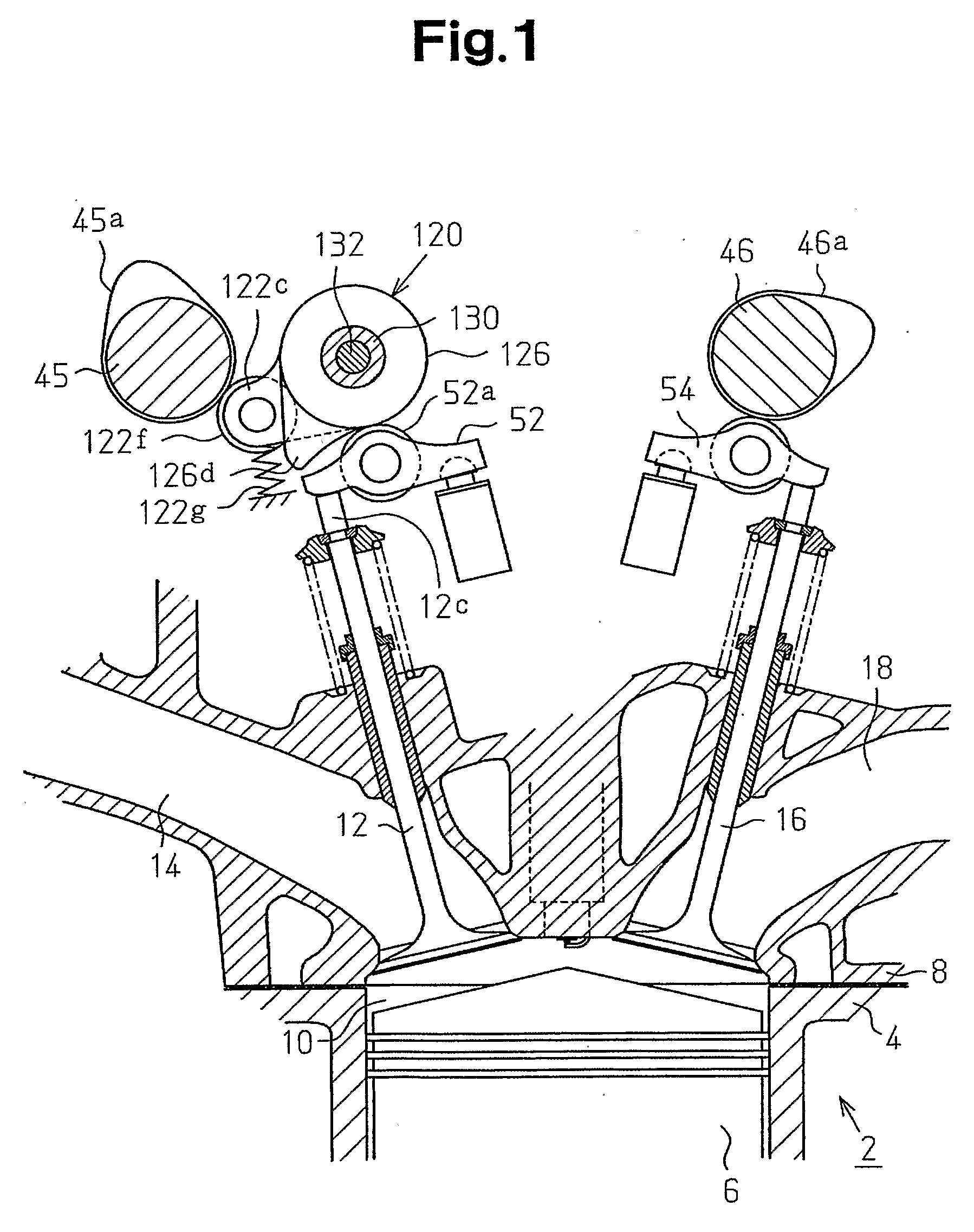

Variable valve actuation mechanism for an internal combustion engine

InactiveUS20070163523A1Prevent differenceReduce weightValve arrangementsMachines/enginesEngineeringVALVE PORT

Engaging portions 132c, each of which is engaged with a slider gear, are made of an iron based material, and coupler shafts 132d are made of an aluminum alloy material that is the same material as that of a cylinder head. Therefore, compared to a case where the control shaft 132 is entirely made of an iron based material, the thermal expansion coefficient of the control shaft 132 is closer to that of the cylinder head. Therefore, even if the ambient temperature changes, the position of each engaging portion 132c relative to the cylinder head is prevented from being displaced. Also, since the engaging portions 132c are made of an iron based material, the engaging portions 132c have a sufficient strength, which prevents the control shaft 132 from being deformed.

Owner:TOYOTA JIDOSHA KK

Lead-free glass compositions for decorating ceramic materials

A new lead-free glass flux suitable for the decoration of ceramic materials comprises SiO2, Al2O3, B2O3 and Li2O as essential components. The lead-free glass flux is a glass mixture in which a glass composition having a relatively low coefficient of thermal expansion and a glass composition having a relatively high coefficient of thermal expansion and a relatively high chemical resistance are mixed at an appropriate ratio.

Owner:NORITAKE CO LTD

Metal ceramic composite material preparation method

InactiveCN104858394AImproves the ability to resist shock loadsImprove thermal conductivityMaterials preparationCeramic composite

Owner:杨文澍

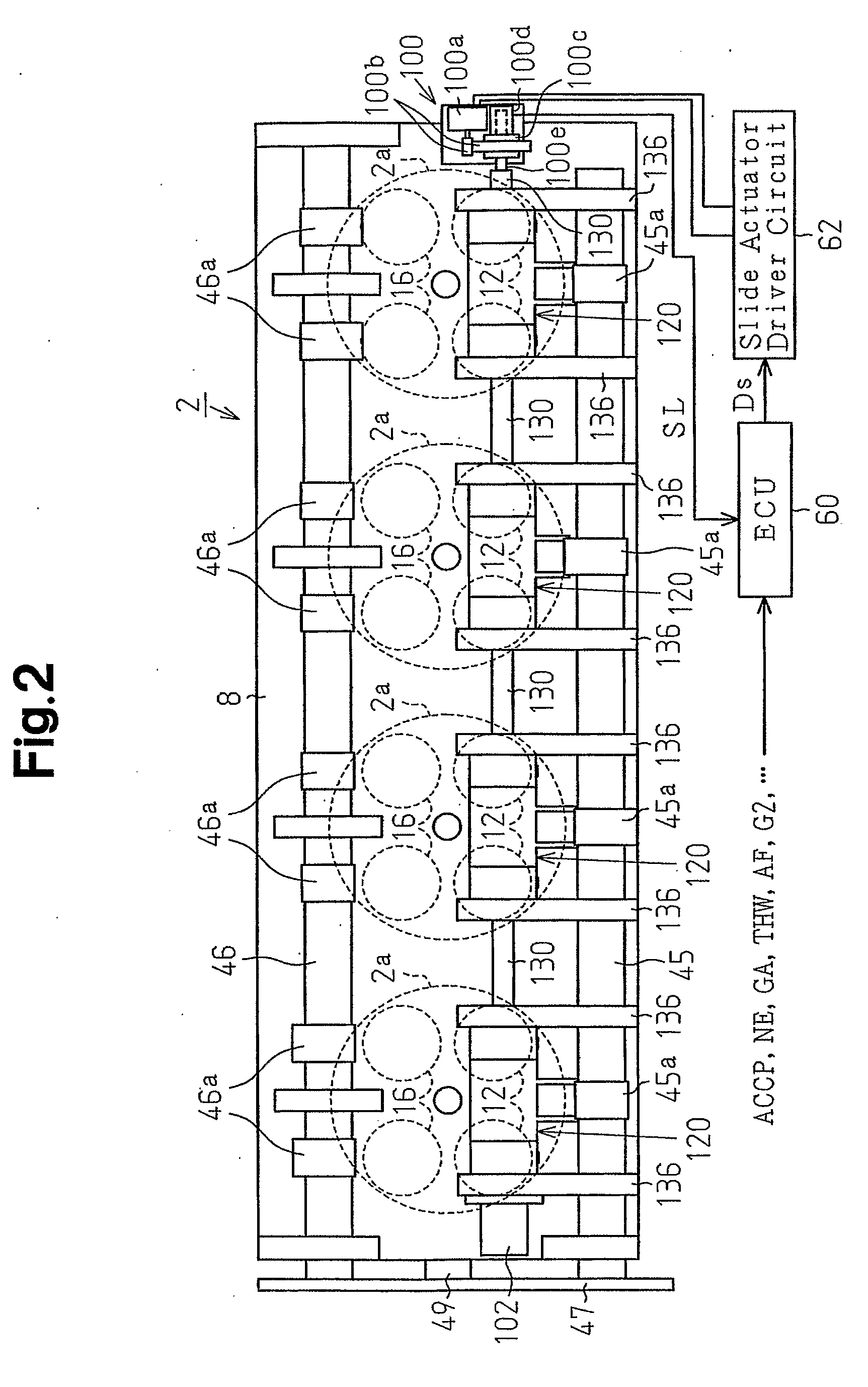

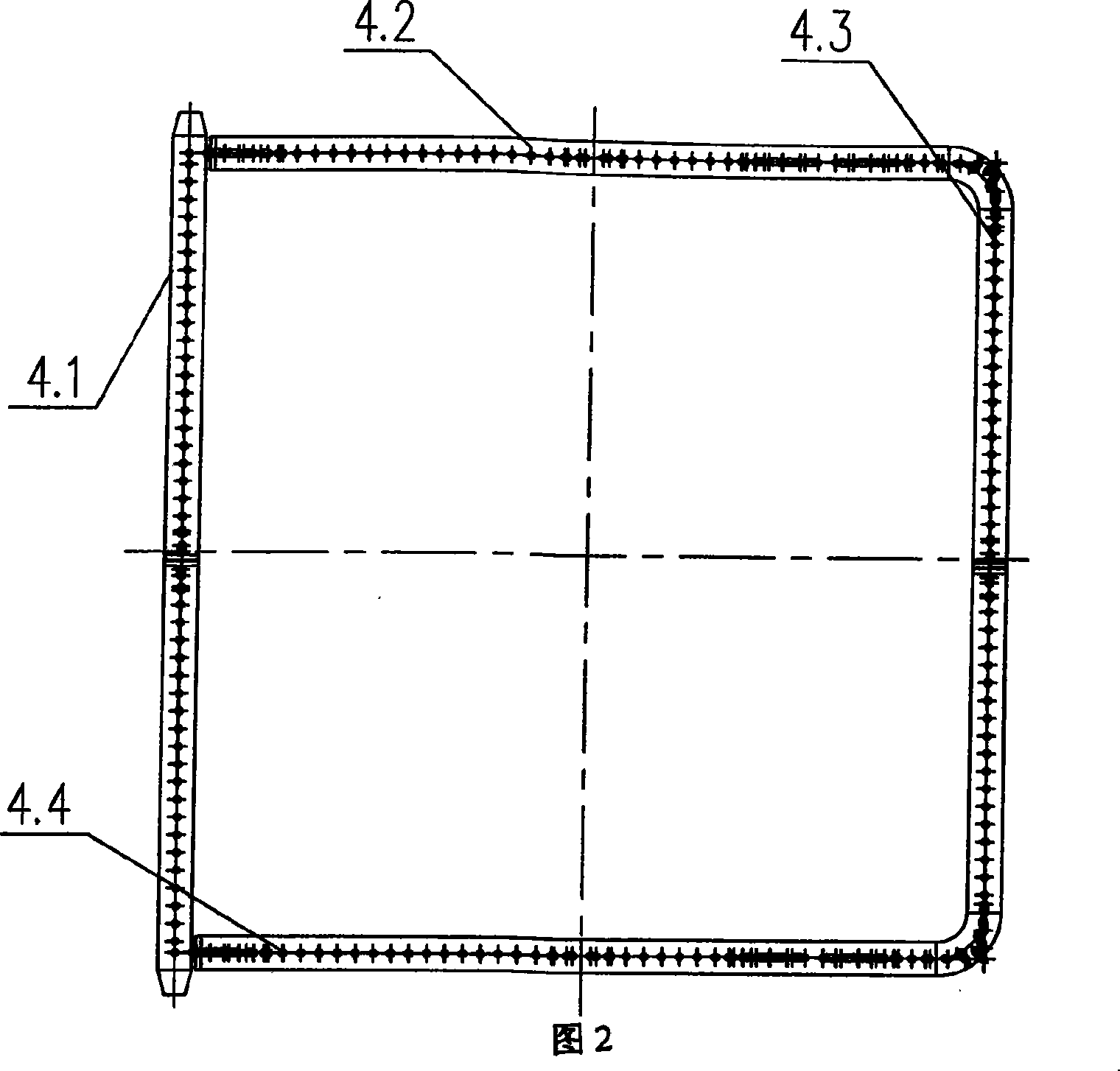

Film type wall sealing dry coke quenching waste heat boiler

ActiveCN101067489AGood thermal expansionGood sealingSteam generation using hot heat carriersSuperheaterCoal

The invention relates to a residue thermal boiler sealed with the film wall including the upright column, the beam, the steeve, the film wall hearth, the ceiling pipe, the condenser pipe, the superheater, the evaporator, the coal economizer and boiler outlet. The film wall hearth is suspended on the beam by the steeve. The condenser pipe, the superheater, the evaporator are set in the film wall hearth from up to down. The hearth is enclosed by the front film wall, the left film wall, the back film wall and the right film wall. The superheater and the evaporator are suspended by the ceiling pipe which is suspended on the beam by the steeve. The part which the superheater and the evaporator pass the film wall is sealed by the ripple expanding structure. The coal economizer top and the lower end of film wall hearth are connected and sealed by the expanding node; the lower end of coal economizer is connected to the boiler outlet by the expanding node. The invention has the good sealing, antiwear and heat expansion character, also it works stable.

Owner:JIANGSU SHUANGLIANG BOILER

Apparatus and method for controlling semiconductor die warpage

ActiveUS8710629B2Reduce warpageGood thermal expansionSemiconductor/solid-state device detailsSolid-state devicesStress reliefThermal expansion

A semiconductor die has through silicon vias arranged to reduce warpage. The through silicon vias adjust the coefficient of thermal expansion of the semiconductor die, permit substrate deformation, and also relieve residual stress. The through silicon vias may be located in the edges and / or corners of the semiconductor die. The through silicon vias are stress relief vias that can be supplemented with round corner vias to reducing warpage of the semiconductor die.

Owner:QUALCOMM INC

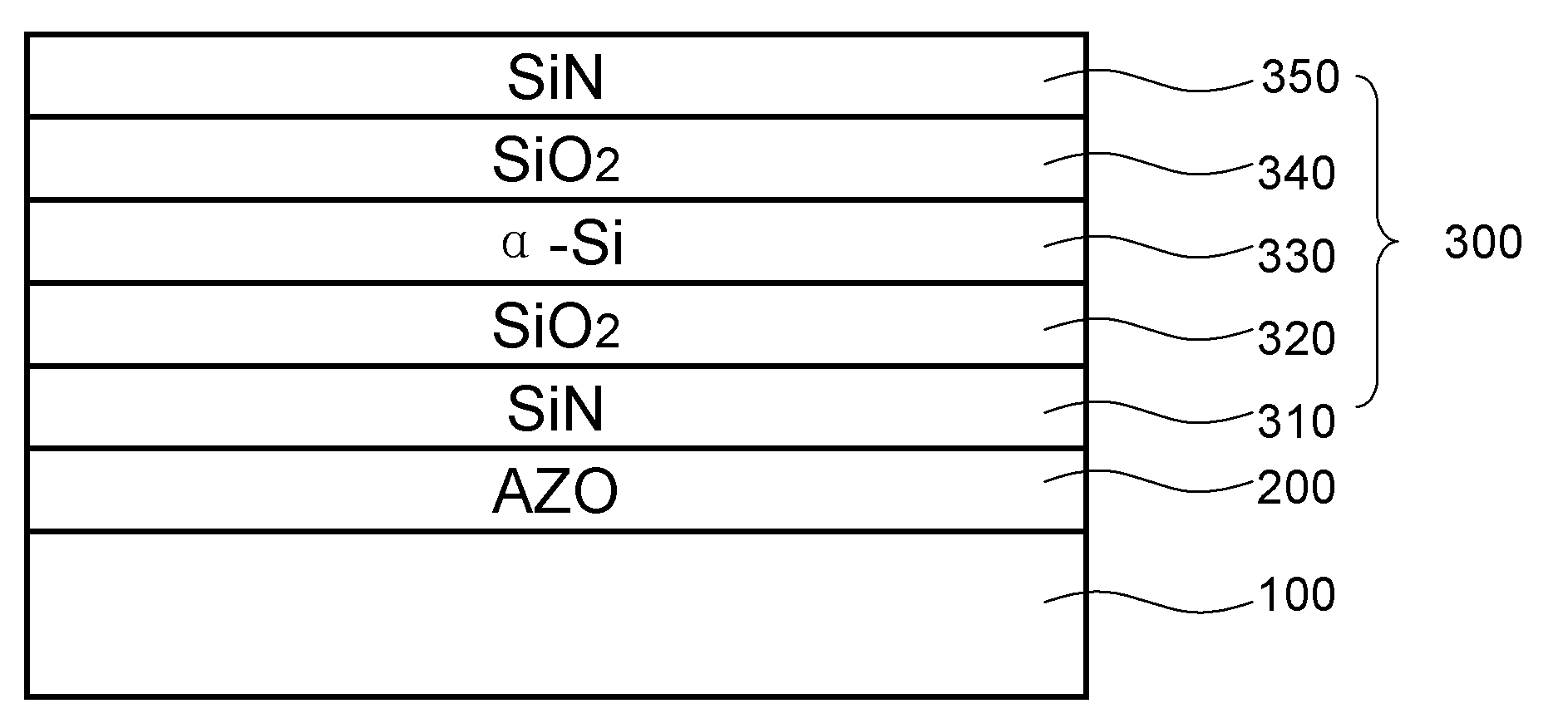

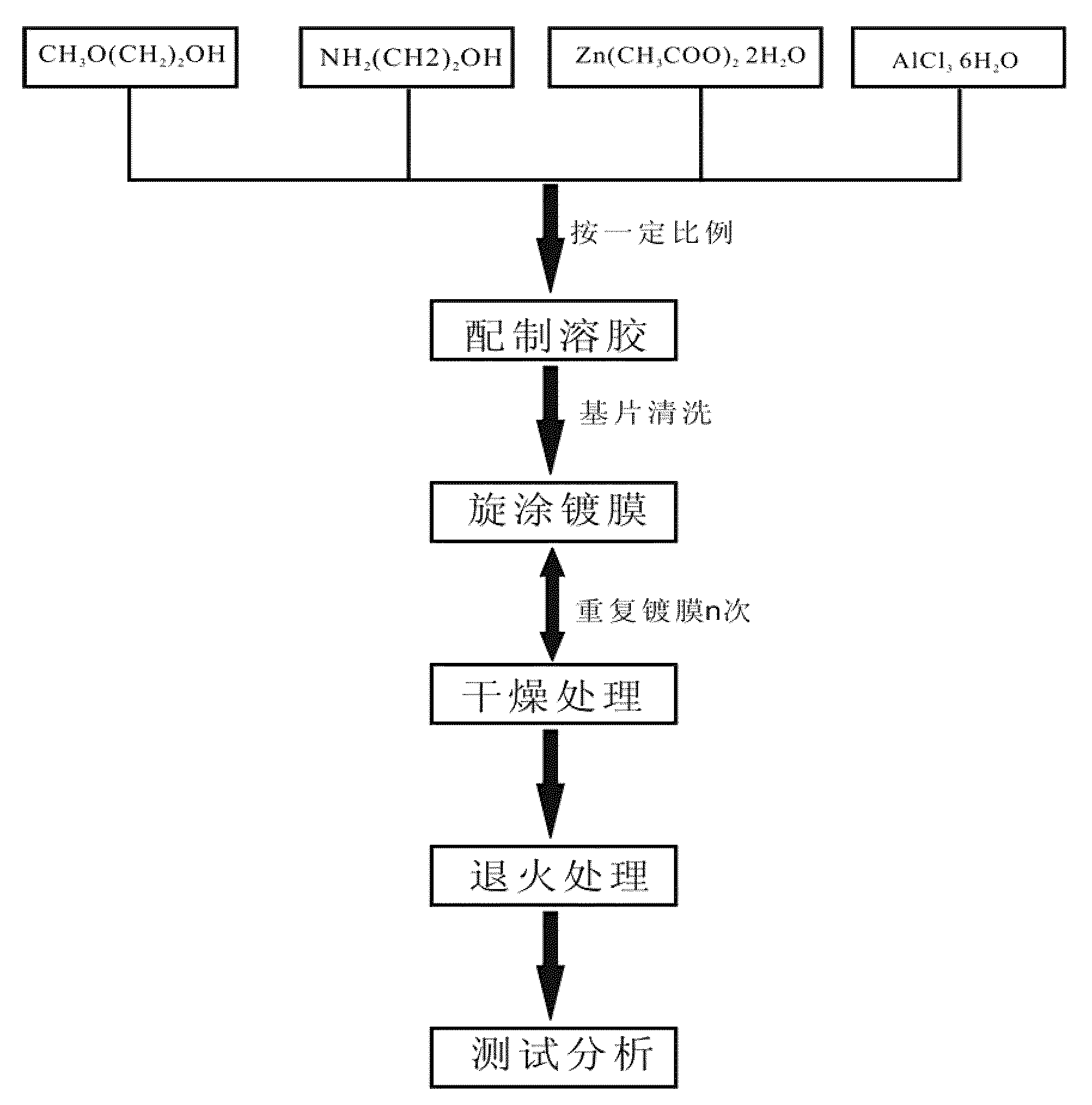

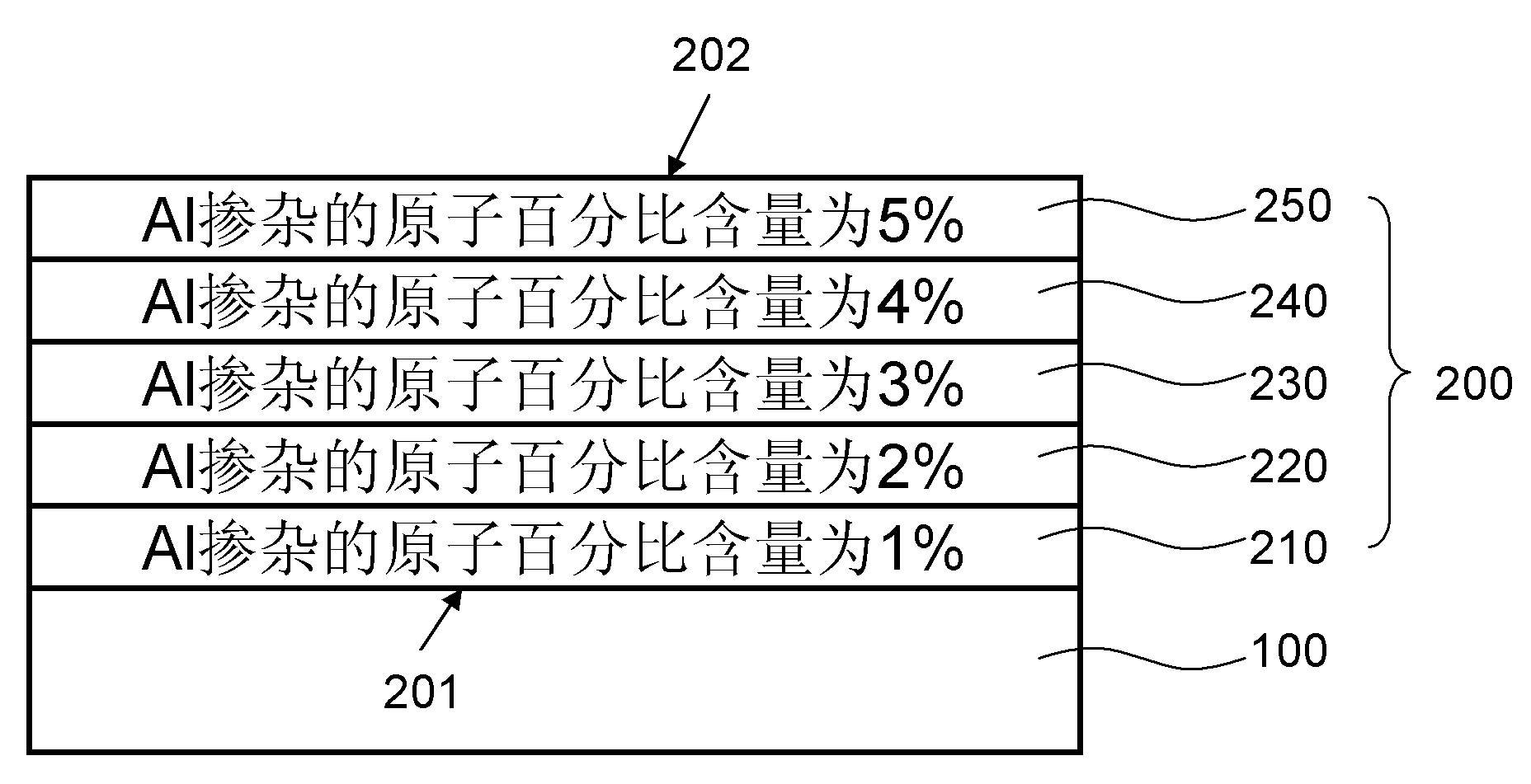

AZO thin film, preparing method and MEMS device comprising AZO thin film

ActiveCN103508406AImprove conductivityLow costDecorative surface effectsSolid-state devicesComposite filmAluminum doped zinc oxide

An aluminum-doped zinc oxide (AZO) thin film (200), a preparation method thereof, and a micro electro mechanical system (MEMS) device comprising same. The AZO thin film (200) is formed on a substrate (100), the aluminum dosage concentration of the AZO thin film (200) being increased gradually in the thin film thickness direction; in the preparation method, the AZO thin film (200) is prepared by using a sol-gel method; the MEMS device uses the AZO thin film (200) and form a composite thin film layer (300) on the AZO thin film (200) through chemical vapor deposition filming. The AZO thin film (200) has desirable conductivity, has good lattice matching with the composite thin film layer (300), has matched thermal expansion and low cost, and is nontoxic, pollution free, and simple in preparation.

Owner:CSMC TECH FAB2 CO LTD

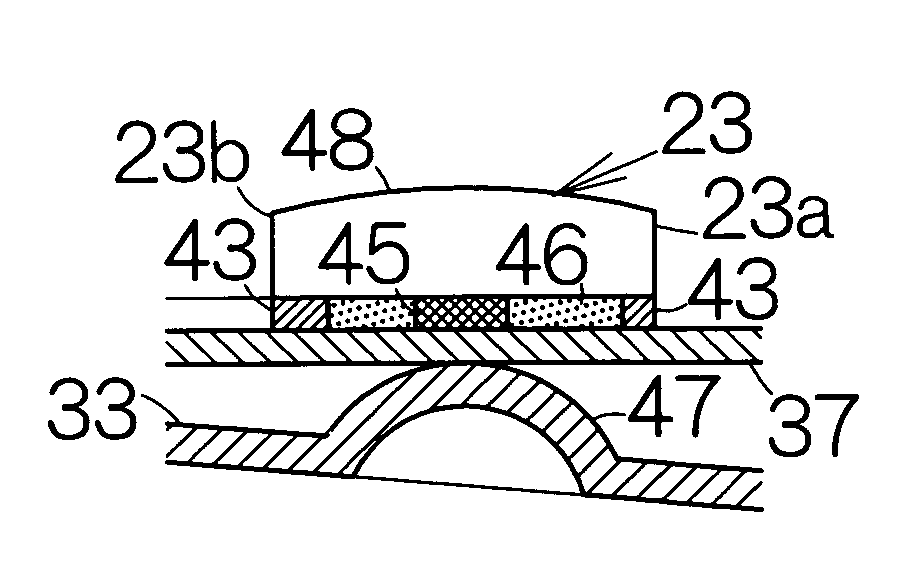

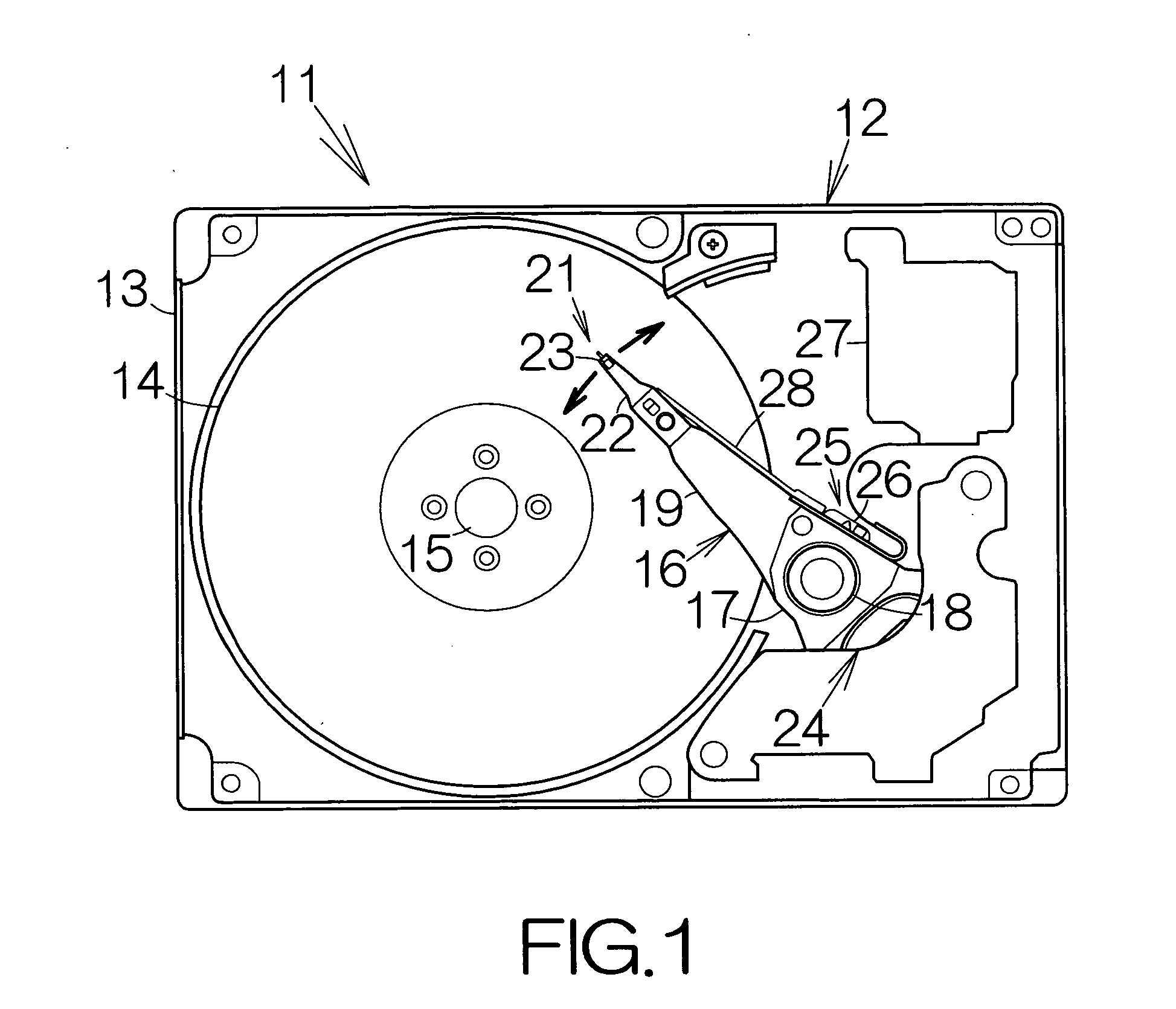

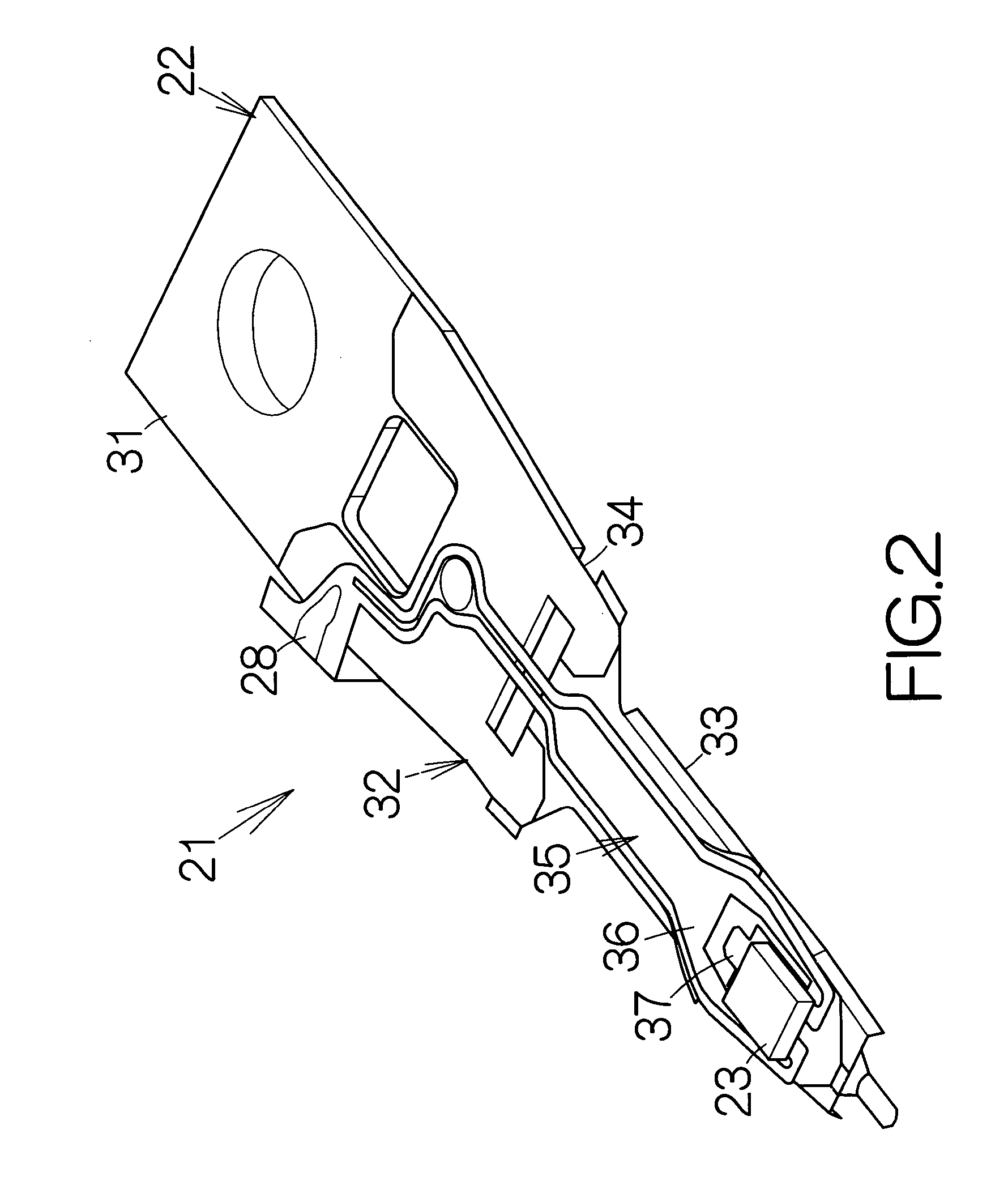

Head suspension assembly contributing to constant flying height of head slider

InactiveUS20060209462A1Avoid deformationEffectively contributing to establishmentRecord information storageFluid-dynamic spacing of headsEngineeringThermal expansion

An adhesive layer is interposed between a head slider and a support member for fixing the head slider to the support member. A deformation body is interposed between the head slider and the support member. The deformation body has a coefficient of thermal expansion larger than that of the adhesive layer. The deformation body expands in response to rise in temperature. An internal force is induced in the head slider so as to distance the head slider away from the support member. Since the adhesive layer serves to fix the head slider to the support member, the internal force is transformed into stress in the head slider. The thermal expansion induces stress in the head slider in response to the rise in temperature. The stresses are balanced with each other, so that the head slider is prevented from deformation.

Owner:FUJITSU LTD

Connecting system for metal components and CMC components, a turbine blade retaining system and a rotating component retaining system

ActiveUS9175571B2Relieve pressureReduce vibrationEngine fuctionsBlade accessoriesTurbine bladeEngineering

A connecting system for metal component and CMC components, a turbine blade retaining system and rotating component retaining system are provided. The connecting system includes a retaining pin, a metal foam bushing, a first aperture disposed in the metal component, and a second aperture disposed in the ceramic matrix composite component. The first aperture and the second aperture are configured to form a through-hole when the metal component and the ceramic matrix composite component are engaged. The retaining pin and the metal foam bushing are operably arranged within the through-hole to connect the metal component and the ceramic matrix composite component.

Owner:GENERAL ELECTRIC CO

Method for printing combustion chamber lining by using GRCop-42 spherical powder

ActiveCN111515391AImprove conductivityGood thermal expansionAdditive manufacturing apparatusTransportation and packagingCombustion chamberSand blasting

The invention discloses a method for printing a combustion chamber lining by using GRCop-42 spherical powder. The GRCop-42 alloy spherical powder comprises the following chemical components in percentage by weight: 2-4wt% of Cu, 2-4wt% of Cr and Nb. The method comprises the following steps of: 1) heating the spherical powder in vacuum, cooling the spherical powder along with a furnace, then performing ultrasonic vibration, screening the spherical powder and preparing to discharge the spherical powder into the furnace; 2) establishing a process model of a part, and slicing the model in layers to form a laser scanning path of each layer; 3) setting process parameters of powder laying and printing equipment, placing a rear bottom plate substrate, and fully laying the GRCop-42 spherical powderin a powder cylinder; 4) starting the equipment and starting printing and forming; 5) after laser scans one layer, descending a forming cylinder by one layer, then ascending the powder cylinder by one layer, laying a layer of copper powder on the processed layer surface by using the powder in the powder cylinder through a scraper, then descending the powder cylinder, and repeating the steps on each layer until the printing of the structure is finished; 6) performing annealing treatment; and 7) cutting and separating the structure from the substrate, and performing sand blasting on the surfaceof the structure. The method solves the problem of domestic application of advanced materials, and meets the preparation requirement of an aerospace copper alloy structure.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com