Film type wall sealing dry coke quenching waste heat boiler

A waste heat boiler and membrane wall technology, which is applied in the fields of waste heat boilers and CDQ waste heat boilers, can solve the problems of low operation stability of waste heat boilers, poor thermal expansion performance, and low boiler efficiency, and achieve compact structure, good thermal expansion, The effect of less air leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

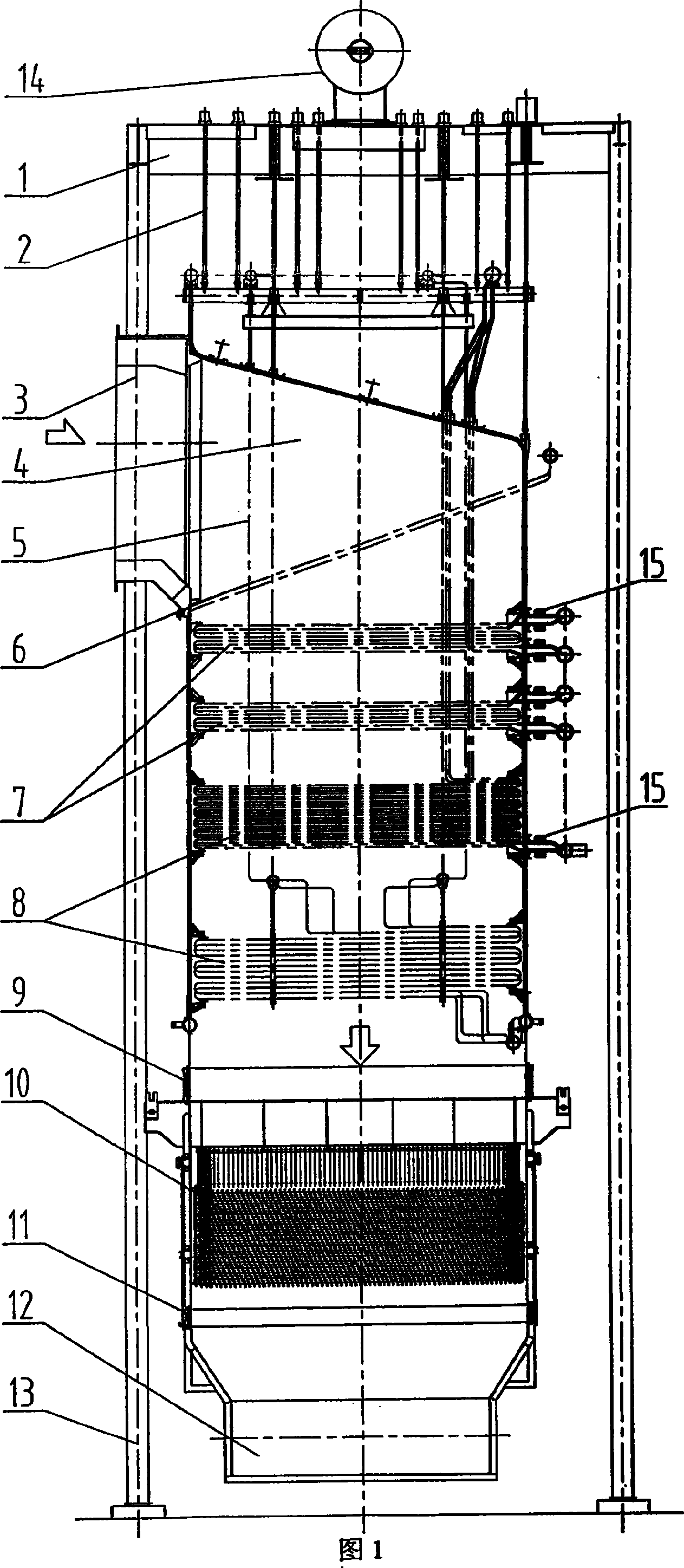

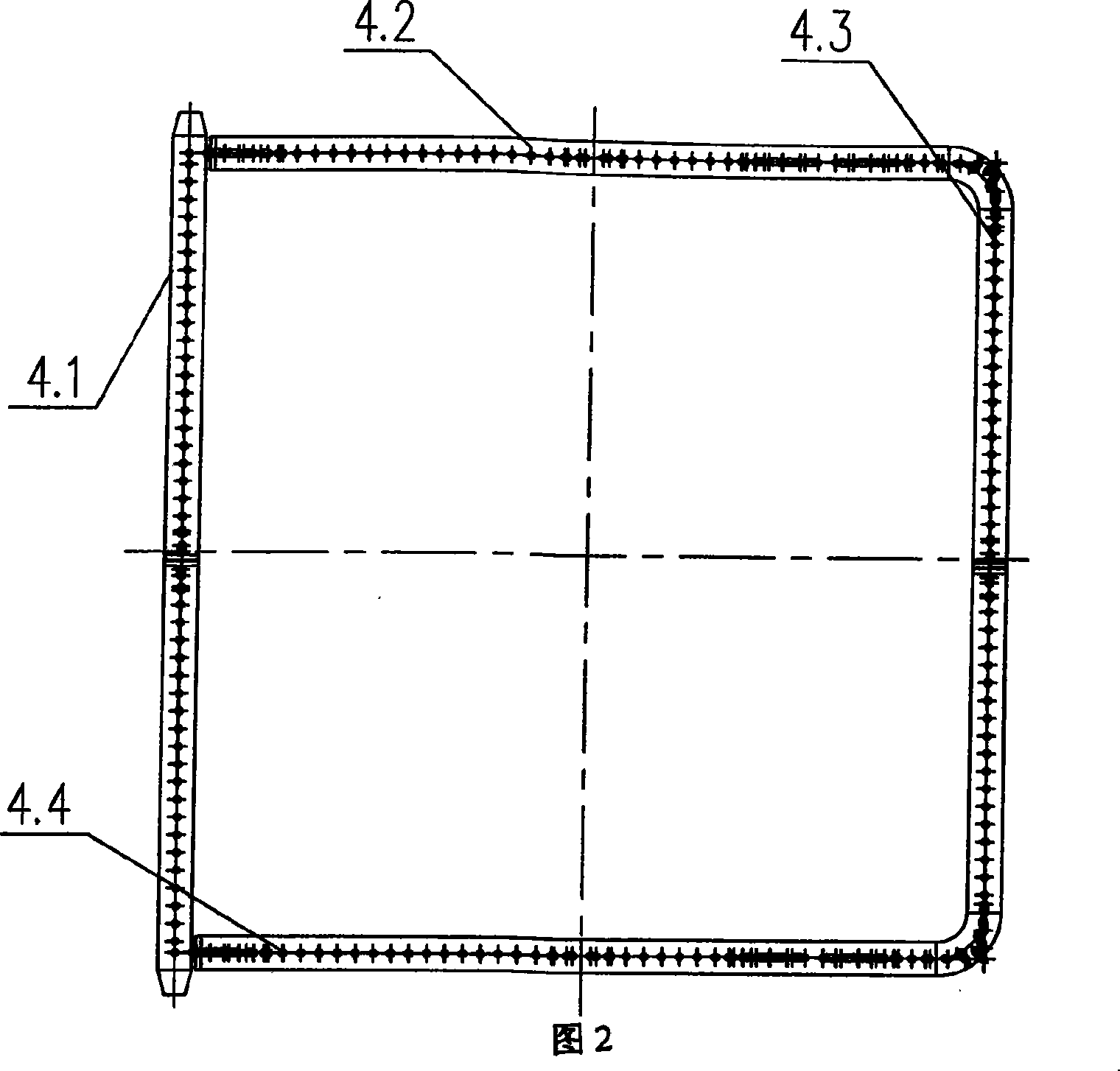

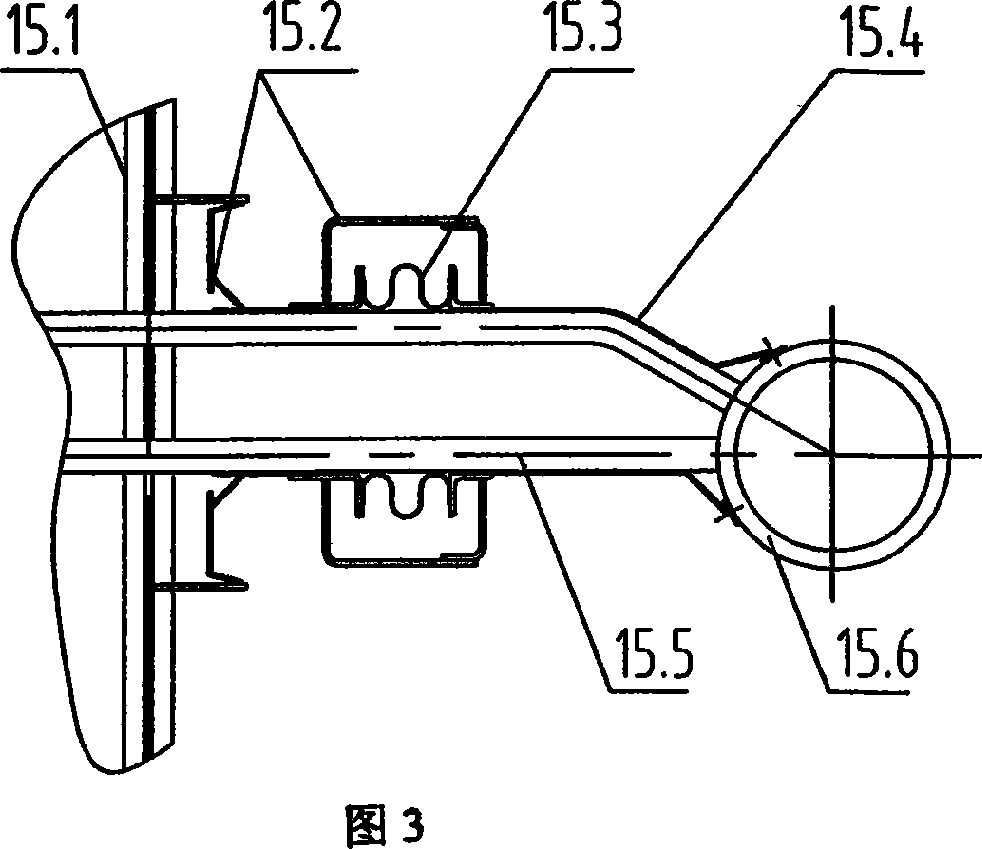

[0032] Referring to Fig. 1, the present invention is a coke dry quenching waste heat boiler with membrane wall seal. , ceiling pipe 5, condenser pipe 6, superheater 7, evaporator 8, expansion joint 9, economizer 10, expansion joint 11, steam drum 14, boiler inlet 3 and boiler outlet 12. There are four upright columns 13 arranged in two parallel rows. There are two crossbeams 1, which are erected between the two rows of upright columns 13 in the front row and the back row respectively. superior. A condenser pipe 6 , a superheater 7 and an evaporator 8 are sequentially arranged in the membrane hearth 4 from top to bottom. The membrane hearth 4 is surrounded by a front membrane wall 4.1, a left membrane wall 4.2, a rear membrane wall 4.3, and a right membrane wall 4.4, as shown in FIG. 2 . Wherein, the condensing pipe 6 is made of the front wall film type wall pipe without welding flat steel, stretched, and passes through the rear wall film type wall 4.3, the superheater 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com