Patents

Literature

1776 results about "Steam drum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

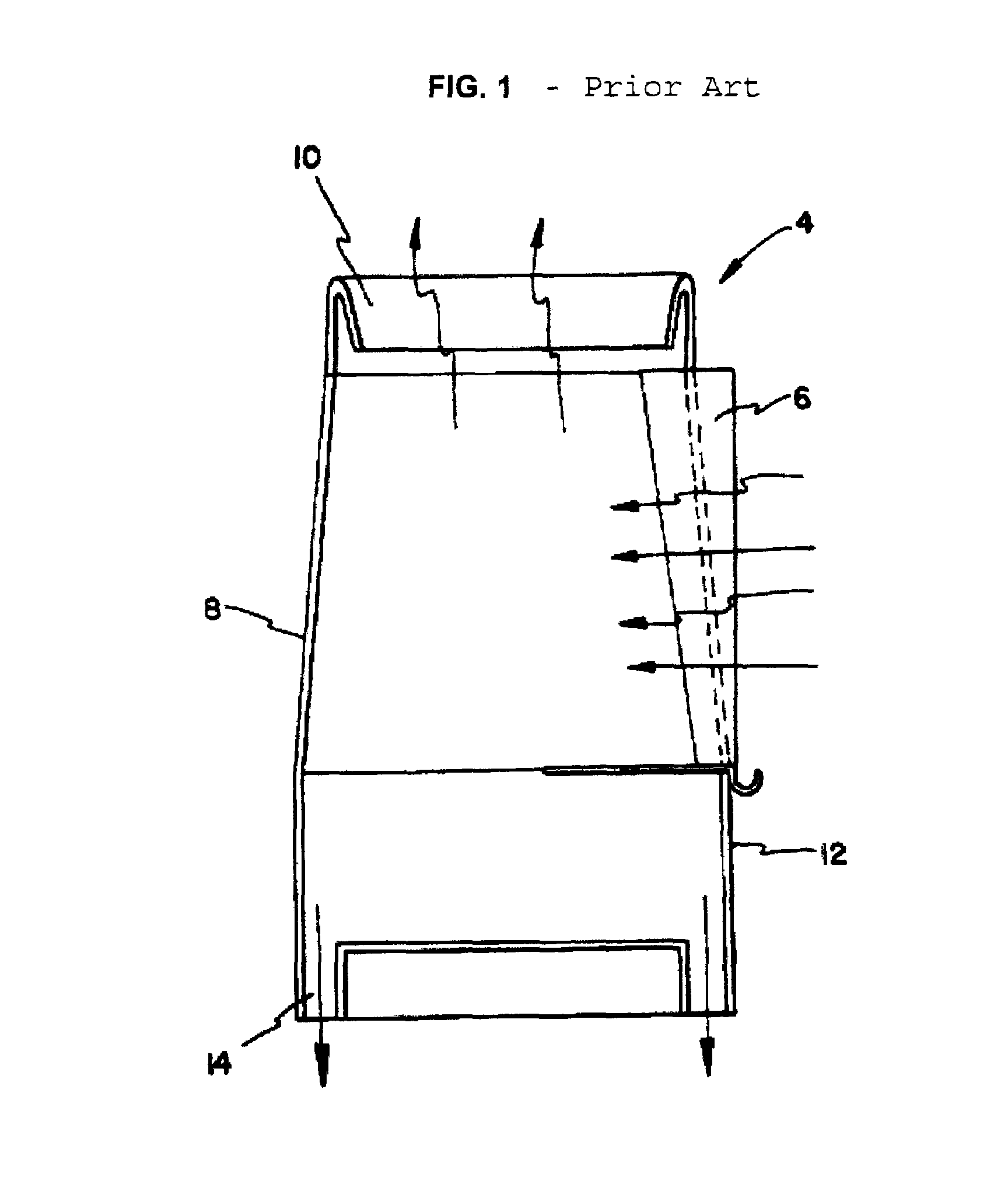

A steam drum is a standard feature of a water-tube boiler. It is a reservoir of water/steam at the top end of the water tubes. The drum stores the steam generated in the water tubes and acts as a phase-separator for the steam/water mixture. The difference in densities between hot and cold water helps in the accumulation of the "hotter"-water/and saturated-steam into the steam-drum.

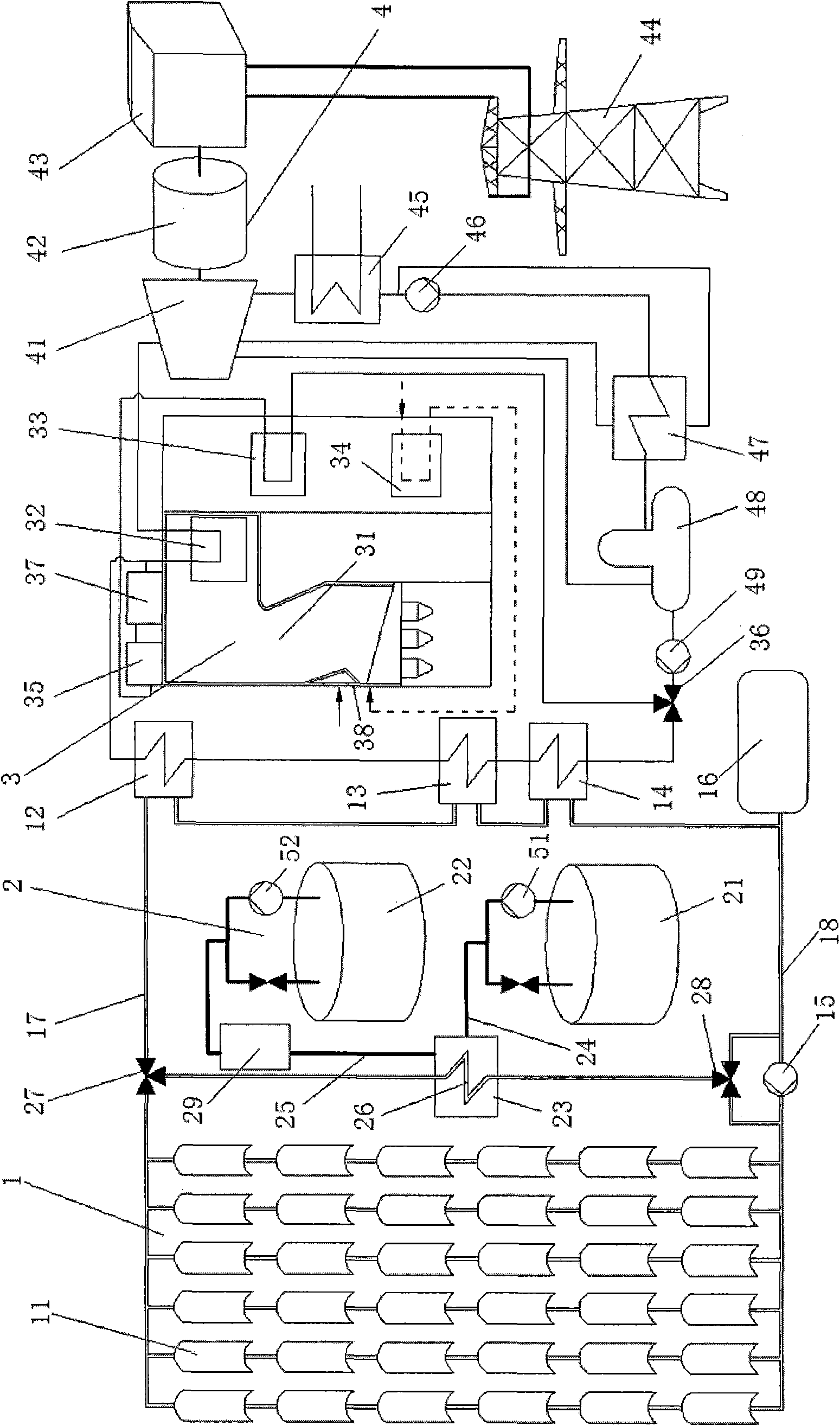

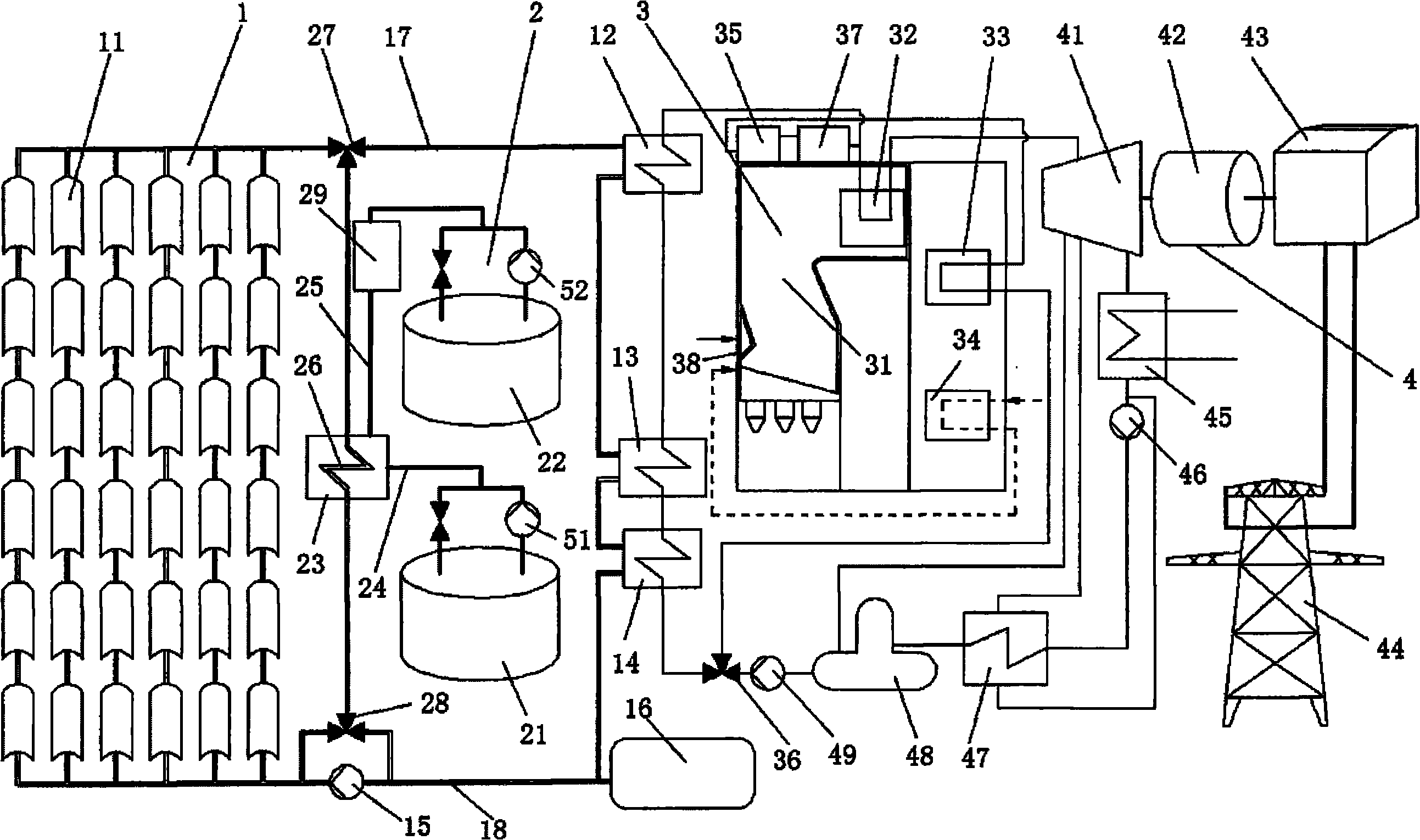

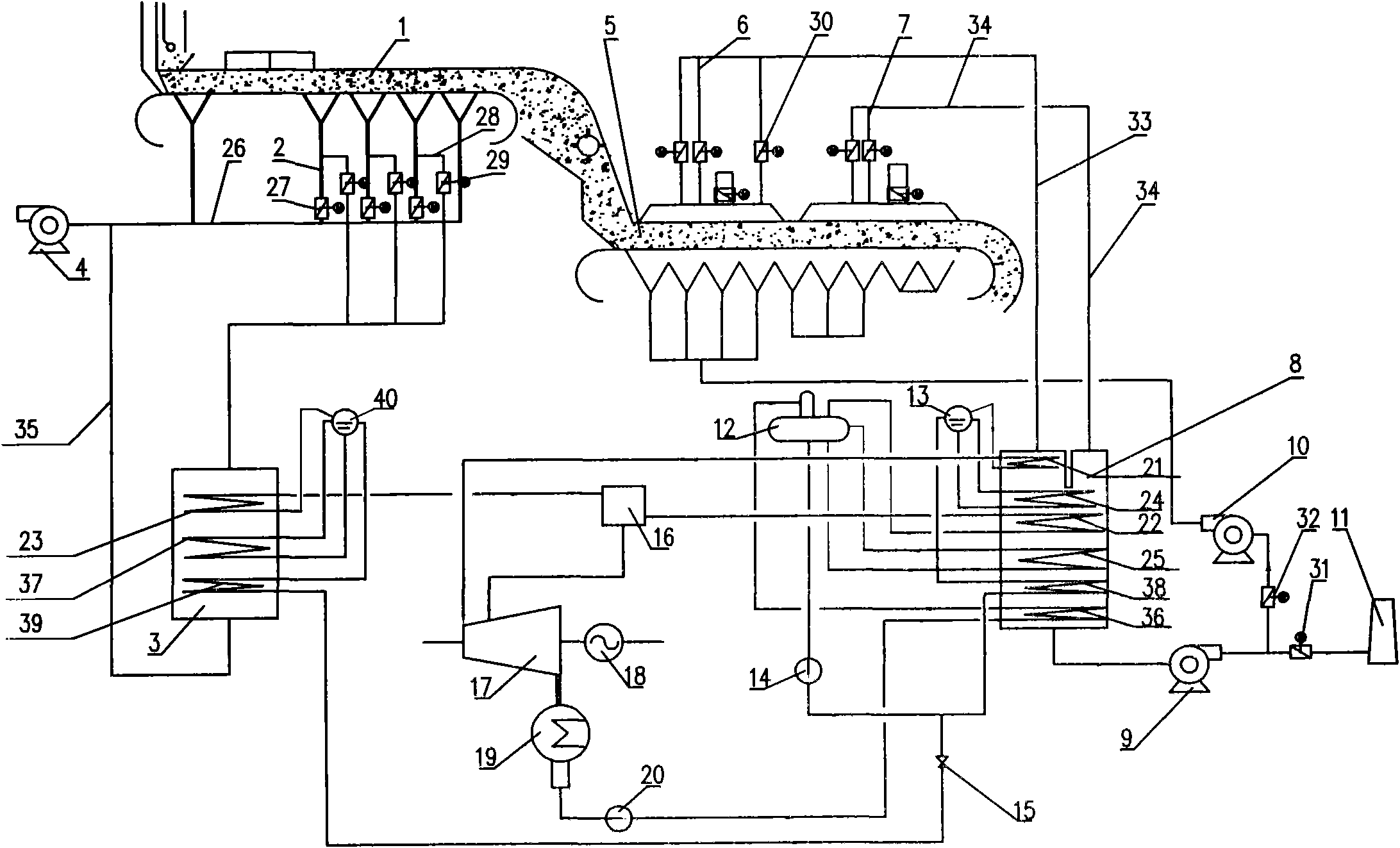

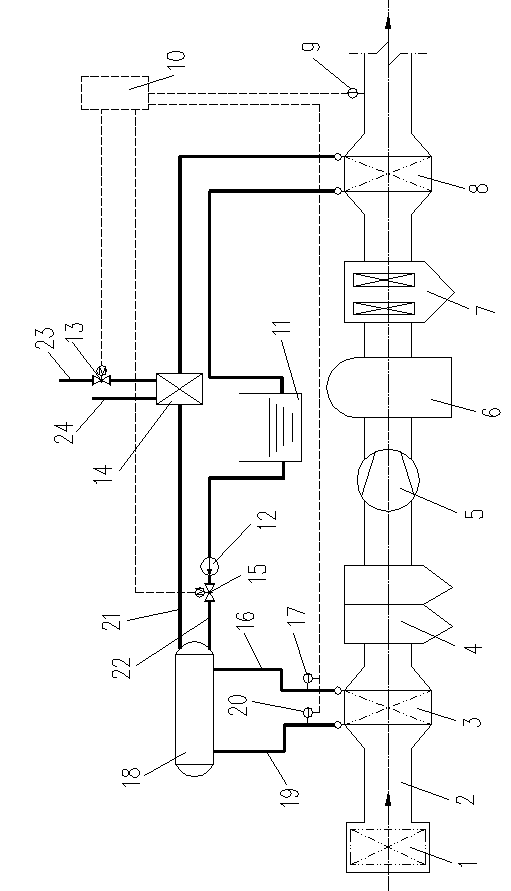

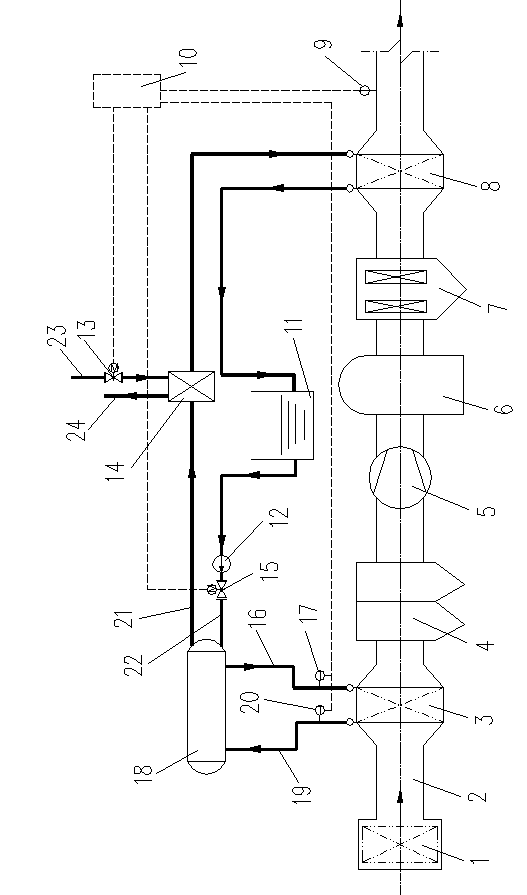

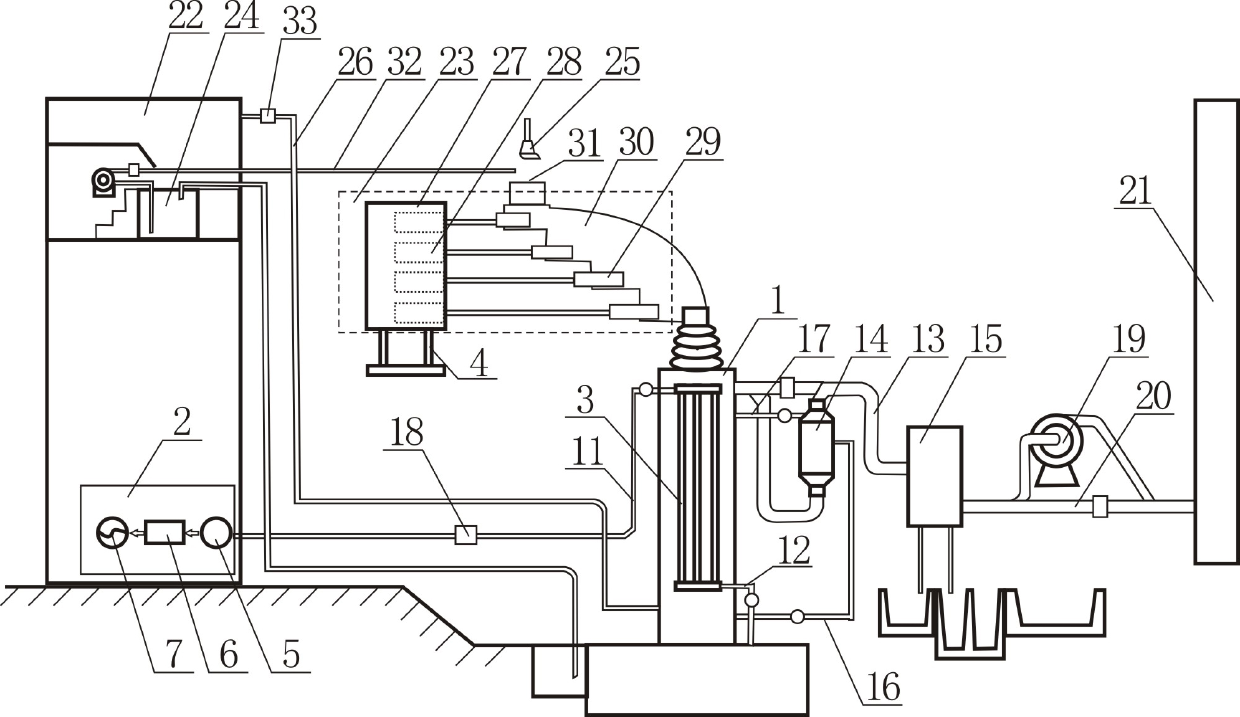

Method and system for combing solar energy thermal power generation with biomass power generation

ActiveCN101876299AReduce dosageReduce procurement costsSteam generation heating methodsFrom solar energyThermal energyCounter flow

The invention relates to a method and a system for combining solar energy thermal power generation with biomass power generation. When the method is used for generating electricity in the daytime (a fine day), one path of heat transfer oil heated in a heat collection field passes through a heat exchanger to ensure that counter-flow water is heated up into superheated steam at the temperature of between 360 and 380 DEG C; and the other path of the heat transfer oil heated in the heat collection field passes through the heat exchanger to heat up a fused salt so as to perform energy storage. The water heated in a water cooled wall of a biomass boiler is changed into steam which enters a steam header and a steam-water separator, then is heated to the temperature of between 535 and 545 DDEG C after being sent into a super-heater of the boiler together with the steam at the temperature of between 360 and 380 DEG C, and then is supplied to a steam turbine to drive a generator to finish the power generation process. During receiving electric valley adjustment, the biomass boiler maintains the minimum stable combustion state. The self power generation of the method and the system can be used for supplying electricity to an electric heater in a fused salt heat storage system to heat the fused salt and perform secondary energy storage for a fused salt heat tank. During the night, or when a solar energy condition is not good, the heat energy stored in the fused salt is released by the heat exchanger to generate electricity.

Owner:北京京仪集团有限公司

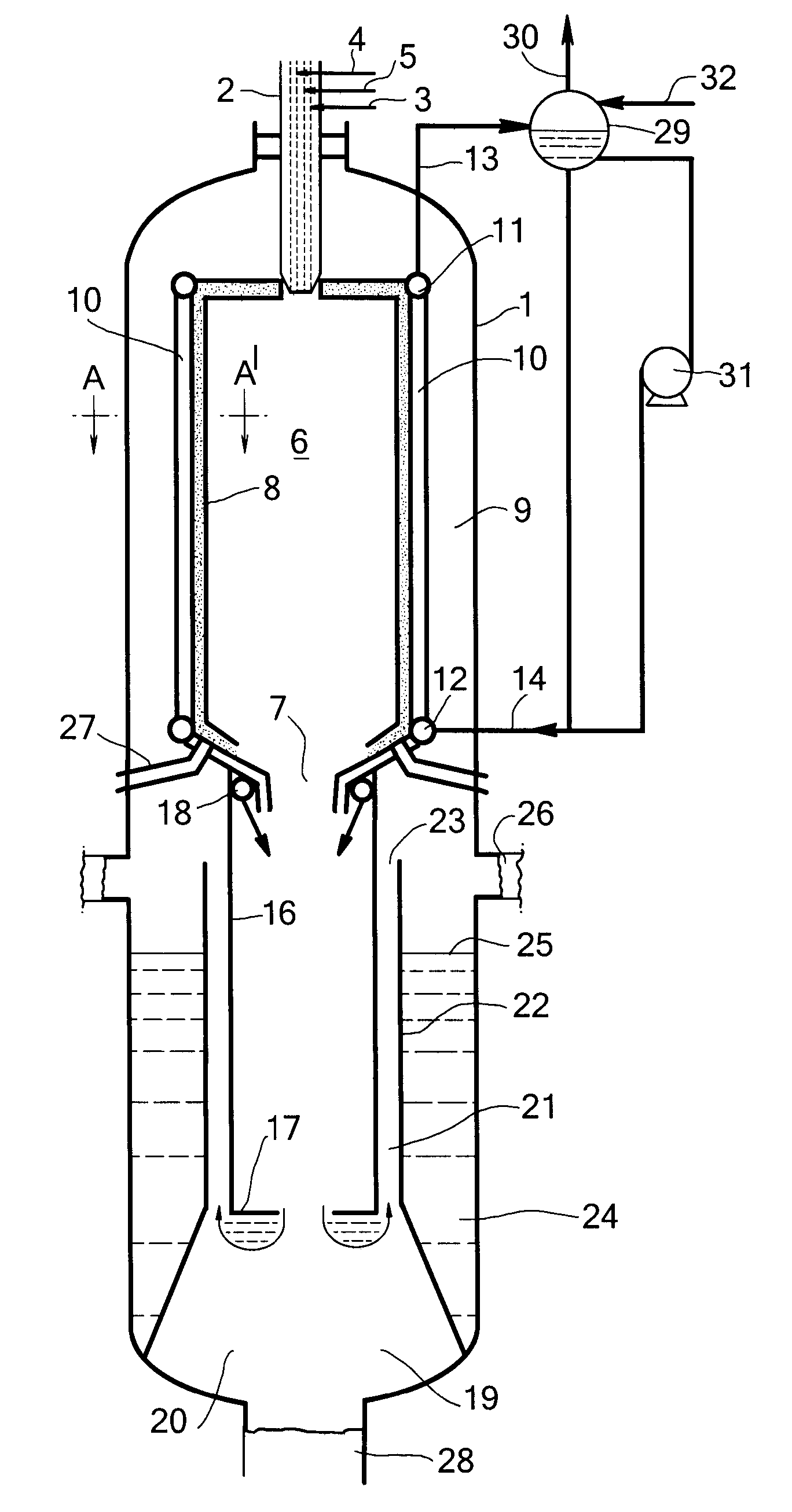

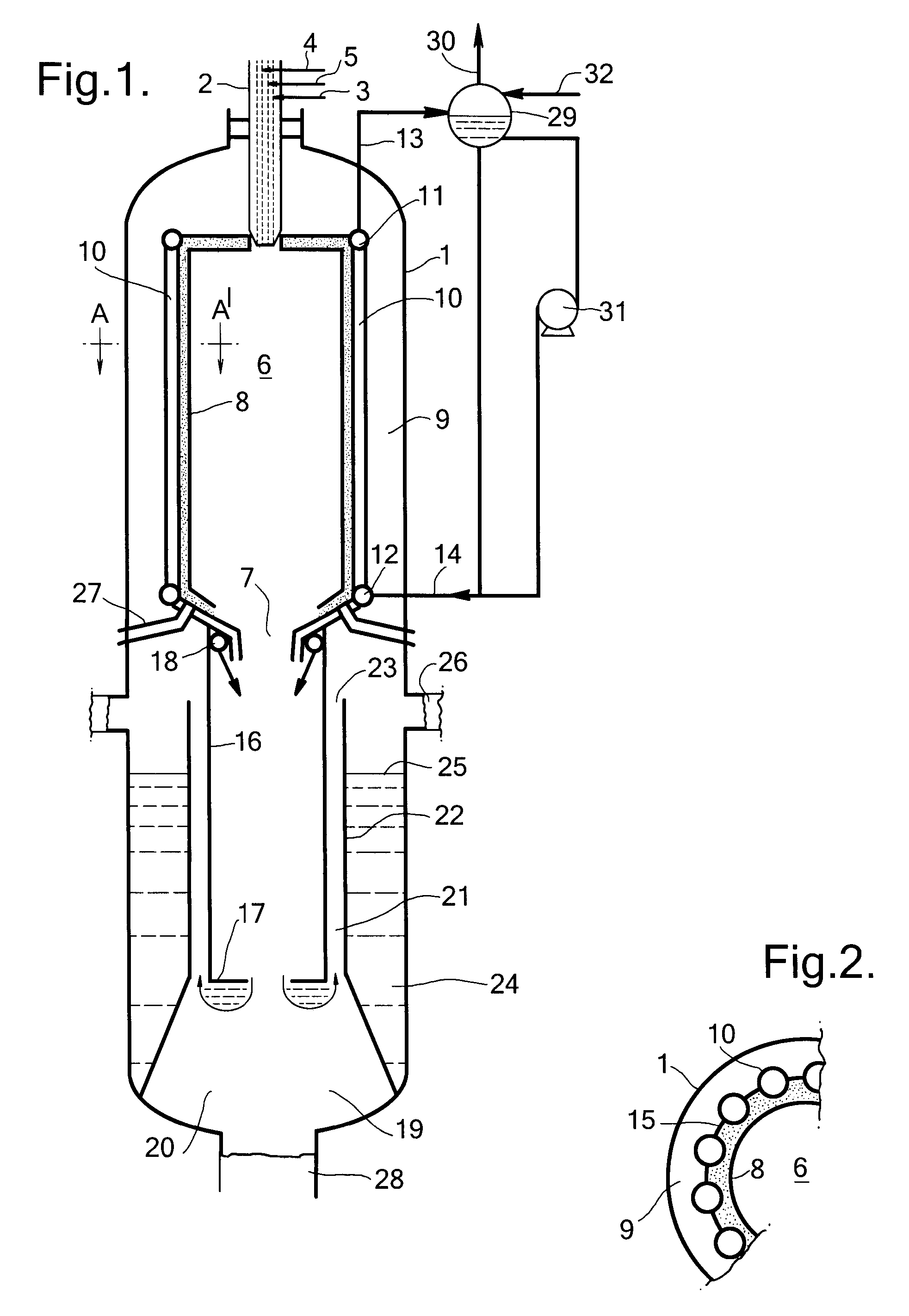

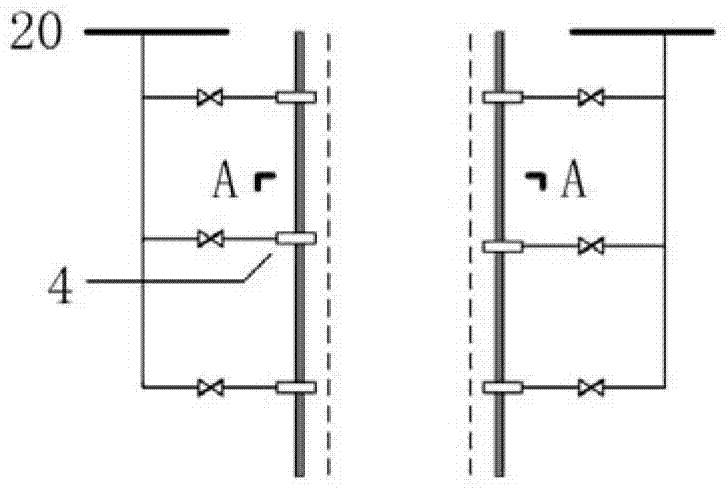

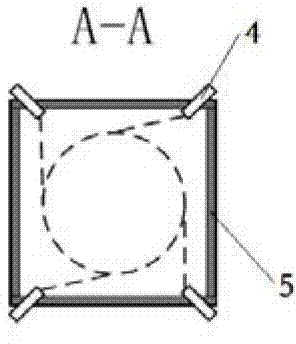

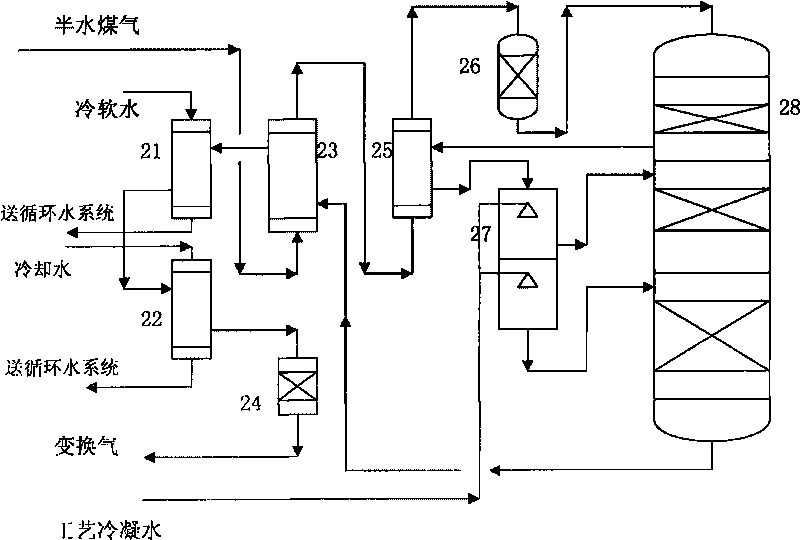

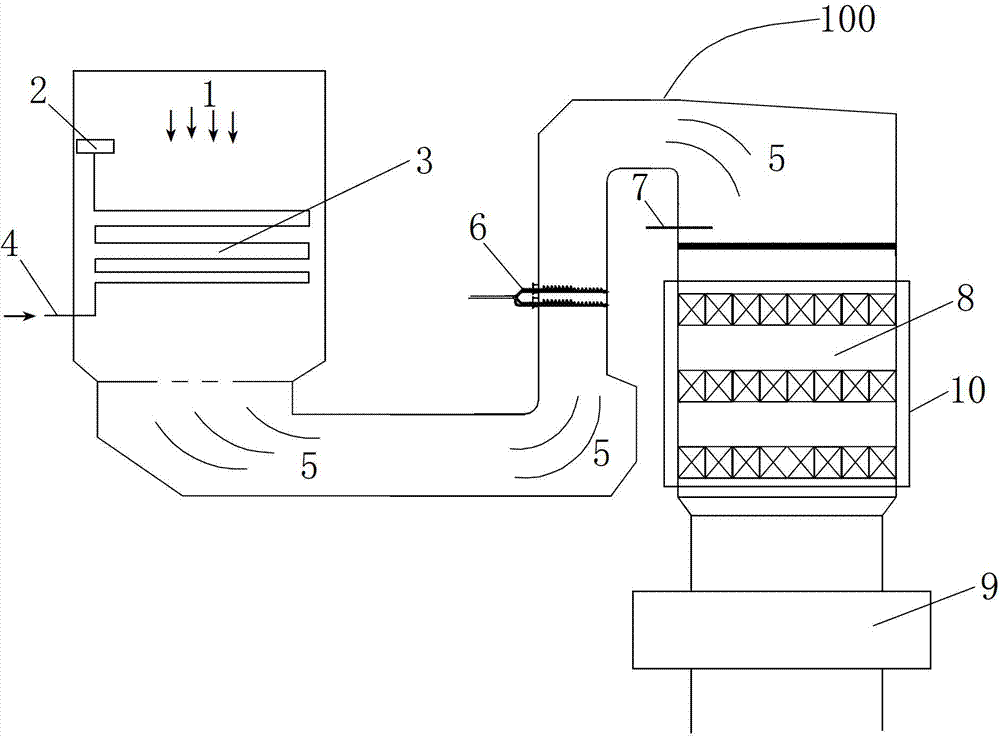

Gasification reactor

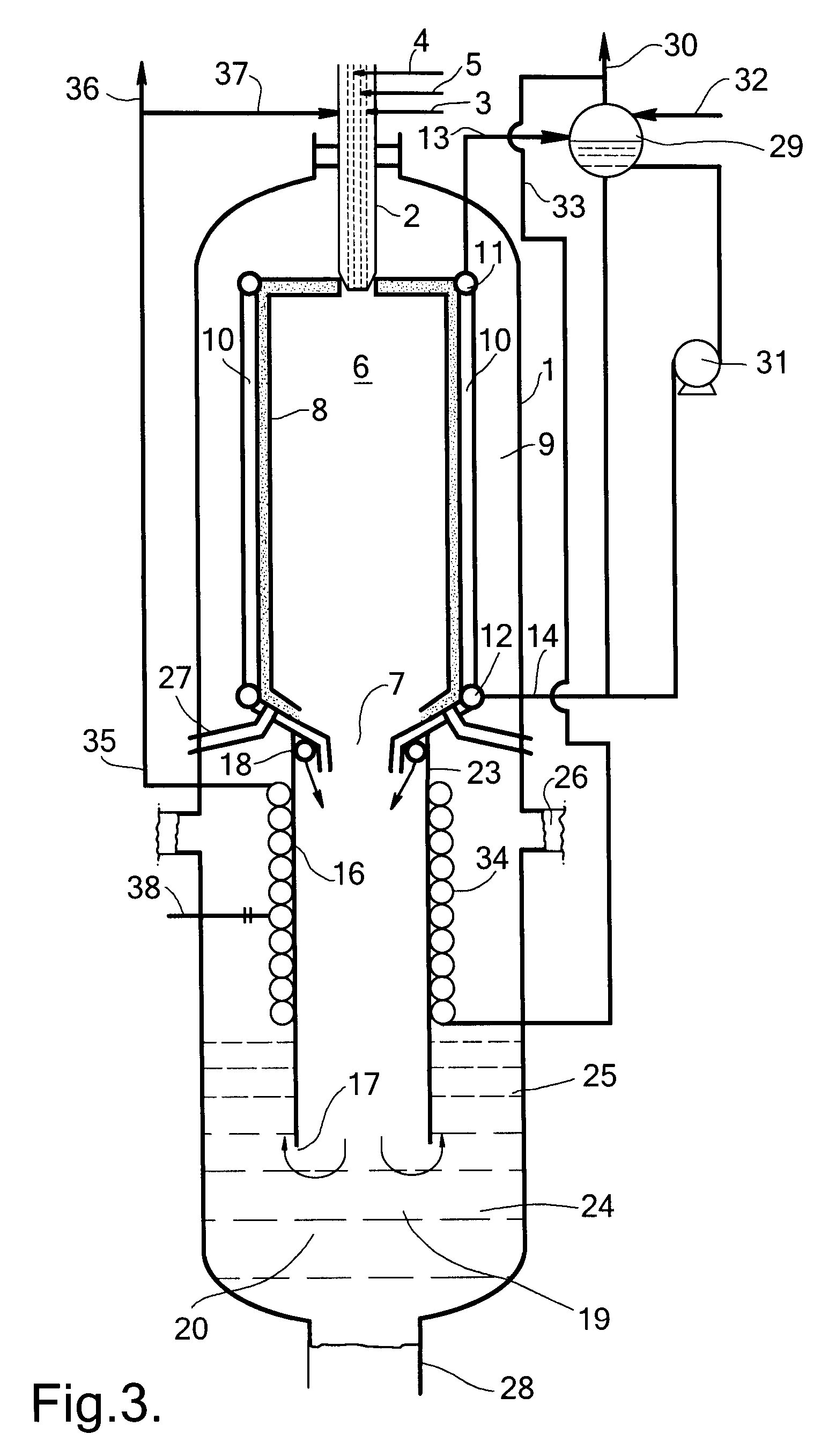

ActiveUS20080172941A1Gasifier mechanical detailsGas modification by gas mixingHigh elevationCombustor

A gasification reactor comprising a vessel (1), provided at its upper end with a downwardly directed burner (2), and provided with supply conduits for an oxidizer gas (3), a carbonaceous feed (4) and a moderator gas (5), a combustion chamber (6) in the upper half of the vessel provided with a product gas outlet (7) at its bottom end and an opening for the outlet of the burner (2) at its top end, wherein between the wall of the combustion chamber (6) and the wall of the vessel (1) an annular space (9) is provided, and wherein the wall of the combustion chamber (6) comprises an arrangement of interconnected parallel arranged tubes (10) resulting in a substantially gas-tight wall running from a common lower arranged distributor (12) to a higher arranged common header (11), said distributor (12) provided with a cooling water supply conduit (14) and said header (11) provided with a steam discharge conduit (13) and wherein the steam discharge conduit (13) and the water supply conduit (14) are fluidly connected to a steam drum (29) and wherein the steam drum (29) is provided with a supply conduit (32) for fresh water and wherein the steam drum (29) is positioned at a higher elevation than the common header (11).

Owner:AIR PROD & CHEM INC

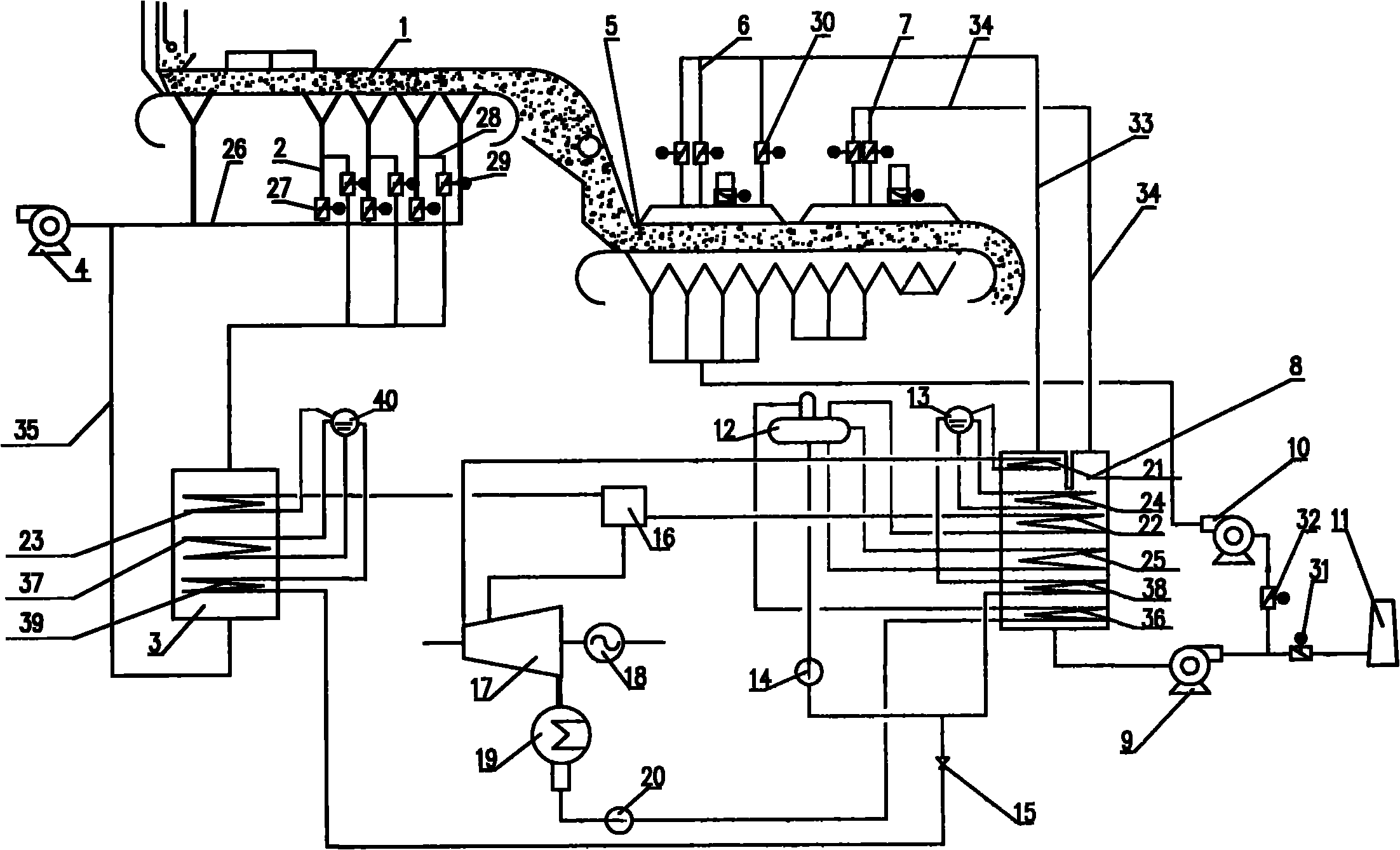

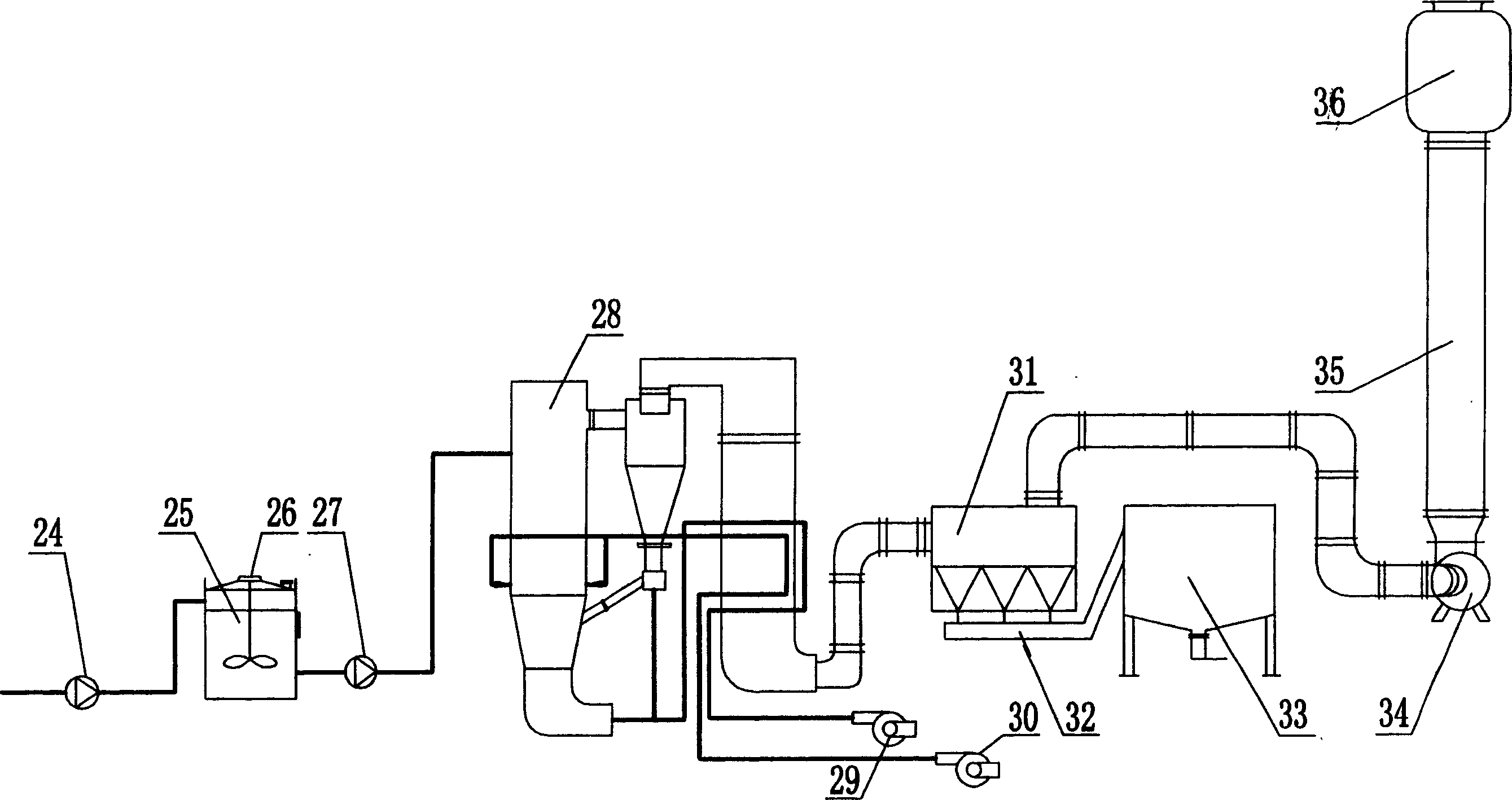

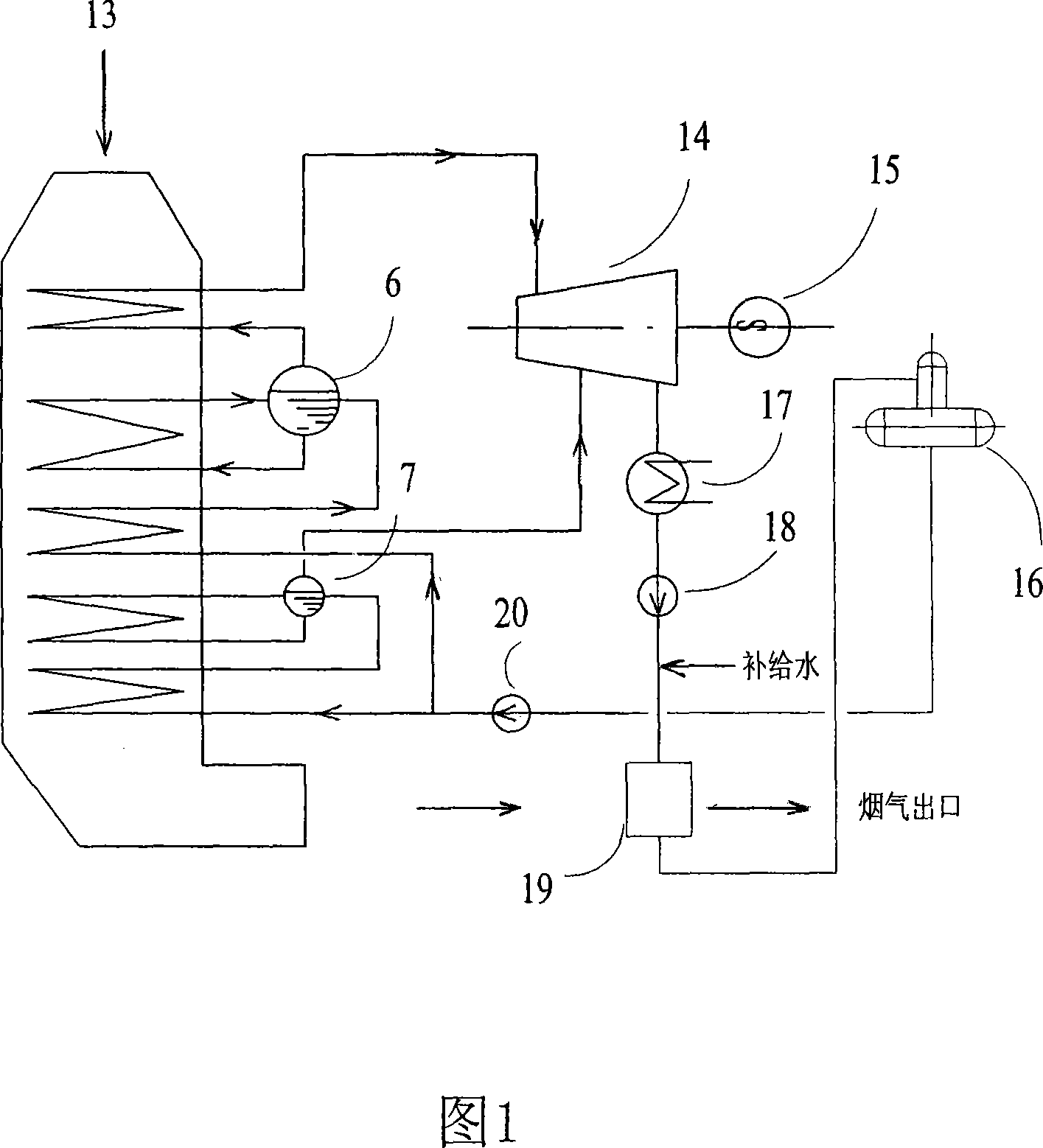

System and method for using sintering waste heat to generate electricity

InactiveCN101806230AImprove utilization efficiencyIncrease waste heat power generationIncreasing energy efficiencySteam engine plantsElectricityExhaust fumes

The invention discloses a system and a method for using sintering waste heat to generate electricity and belongs to the technical field of sintering waste heat electricity generation of the steel works. The system comprises a sintering machine, a hot gas outlet pipe, a gas waste heat boiler, a main exhaust fan, a ring cooling machine, a first and second stage heat waste gas collecting pipe, a waste gas heat boiler, a draught fan, a circulating fan, a chimney, a low pressure steam drum, a middle pressure steam drum, a feed pump, a pressure reducing valve, a collecting header, a steam turbine, a generator, a condenser and a condensate pump. The invention realizes utilizing the waste heat of the non-desulfurization flue header of the sintering machine without arranging an inducing fan by reasonably designing the hot gas connecting mode of the air box at the tail part of the sintering machine and the gas resistance of the waste gas heat boiler. First and second stage sealing covers of the ring cooling machine are uniformly provided with a plurality of waste gas branch pipes so as to realize uniform distribution of the waste gas pressure in the sealing covers and reduce air leakage. Part of waste gas is adopted to circulate to improve the temperature of the waste gas. Compared with the existing system for using sintering waste heat to generate electricity, the system of the invention sufficiently uses the waste heat of the sintering system, improves the waste heat generated energy and reduces the operation cost.

Owner:湖南永清环境科技产业集团有限公司

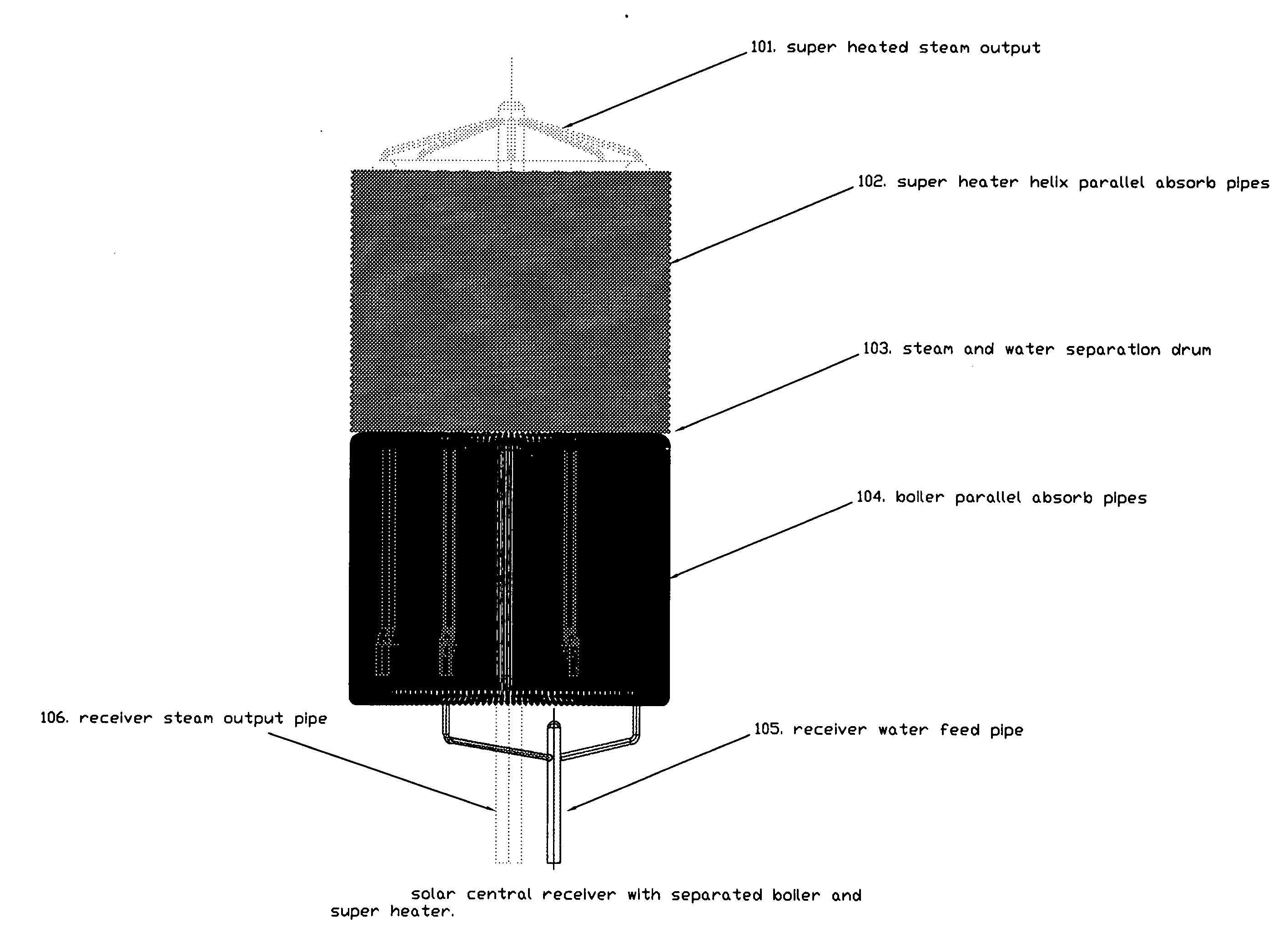

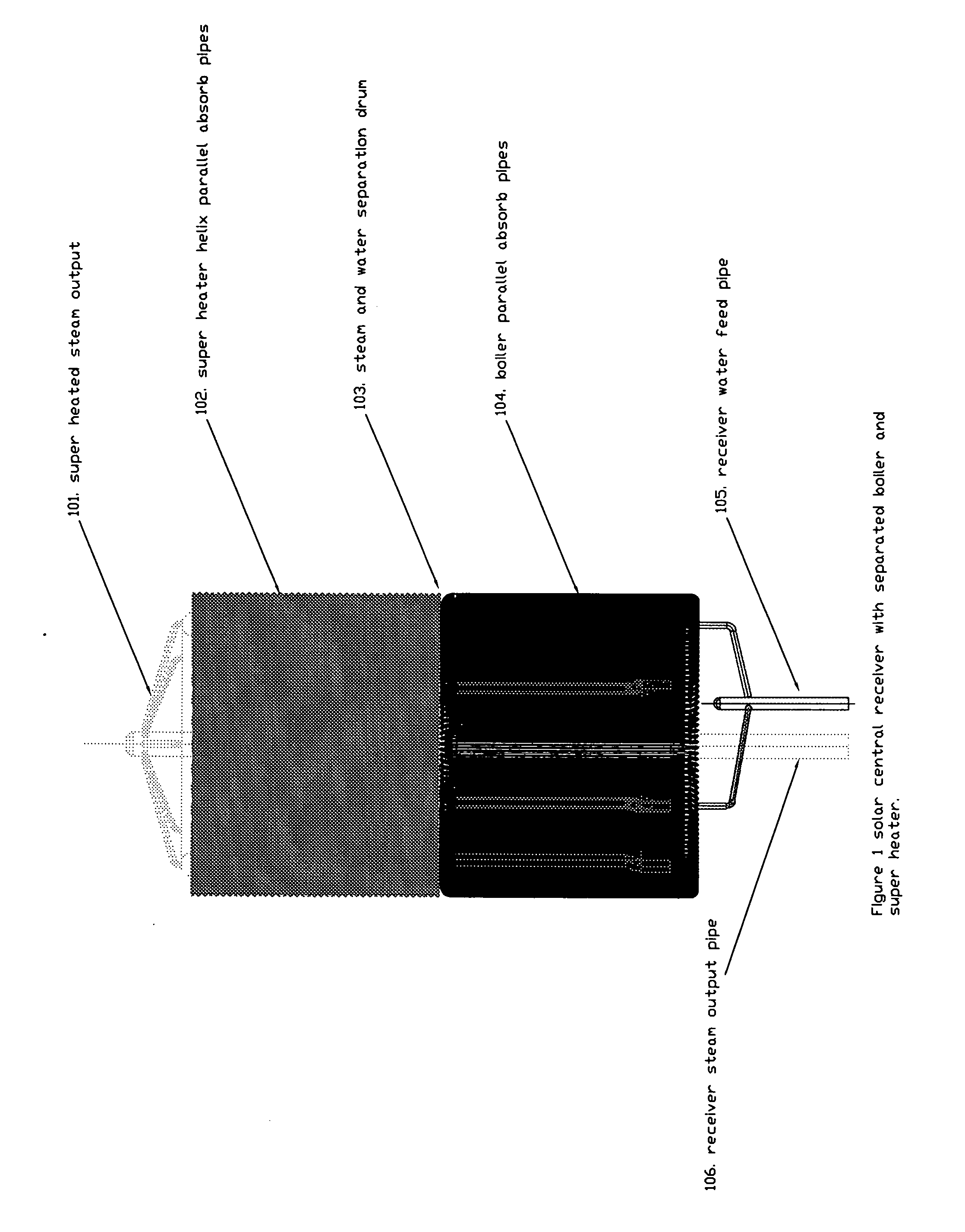

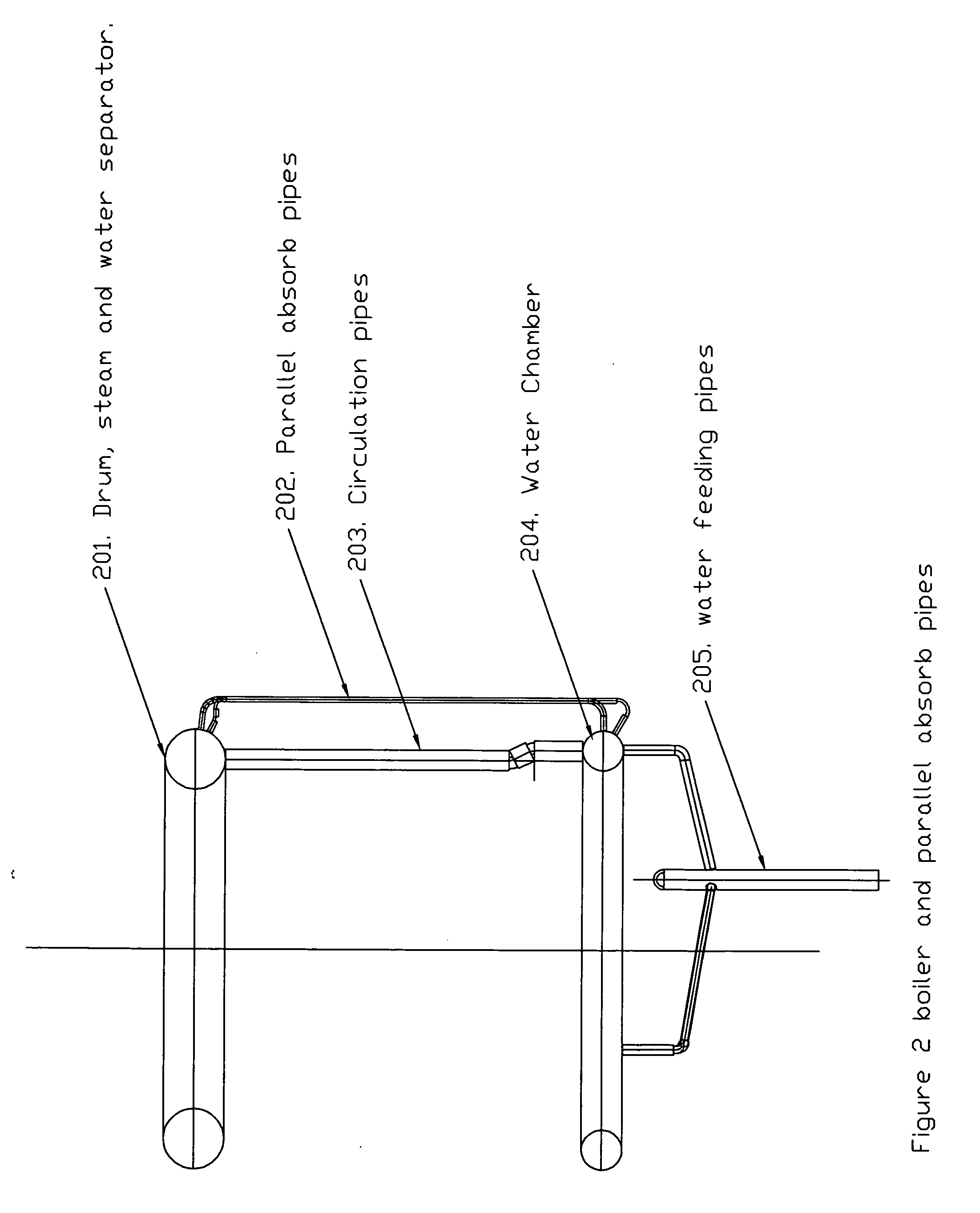

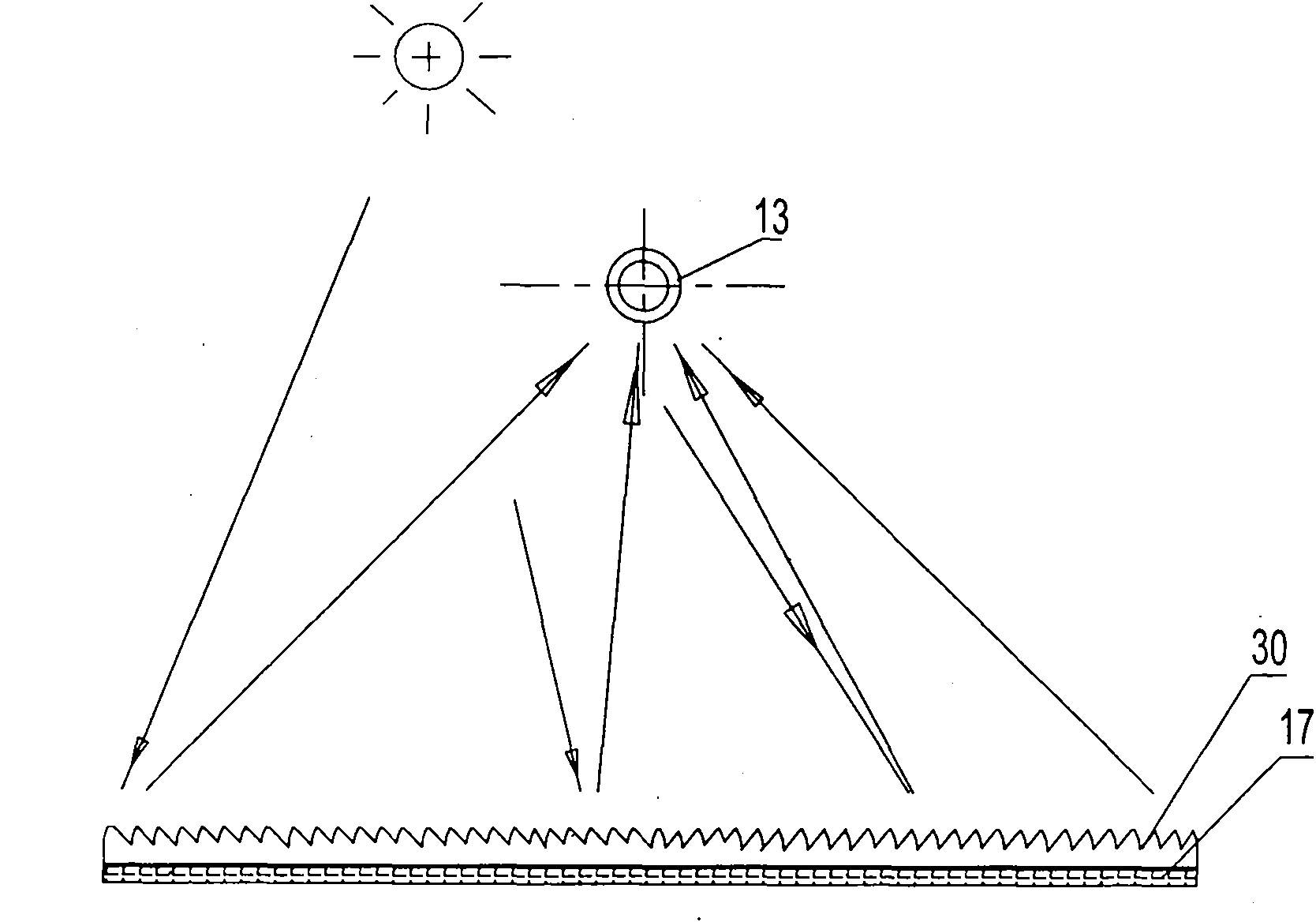

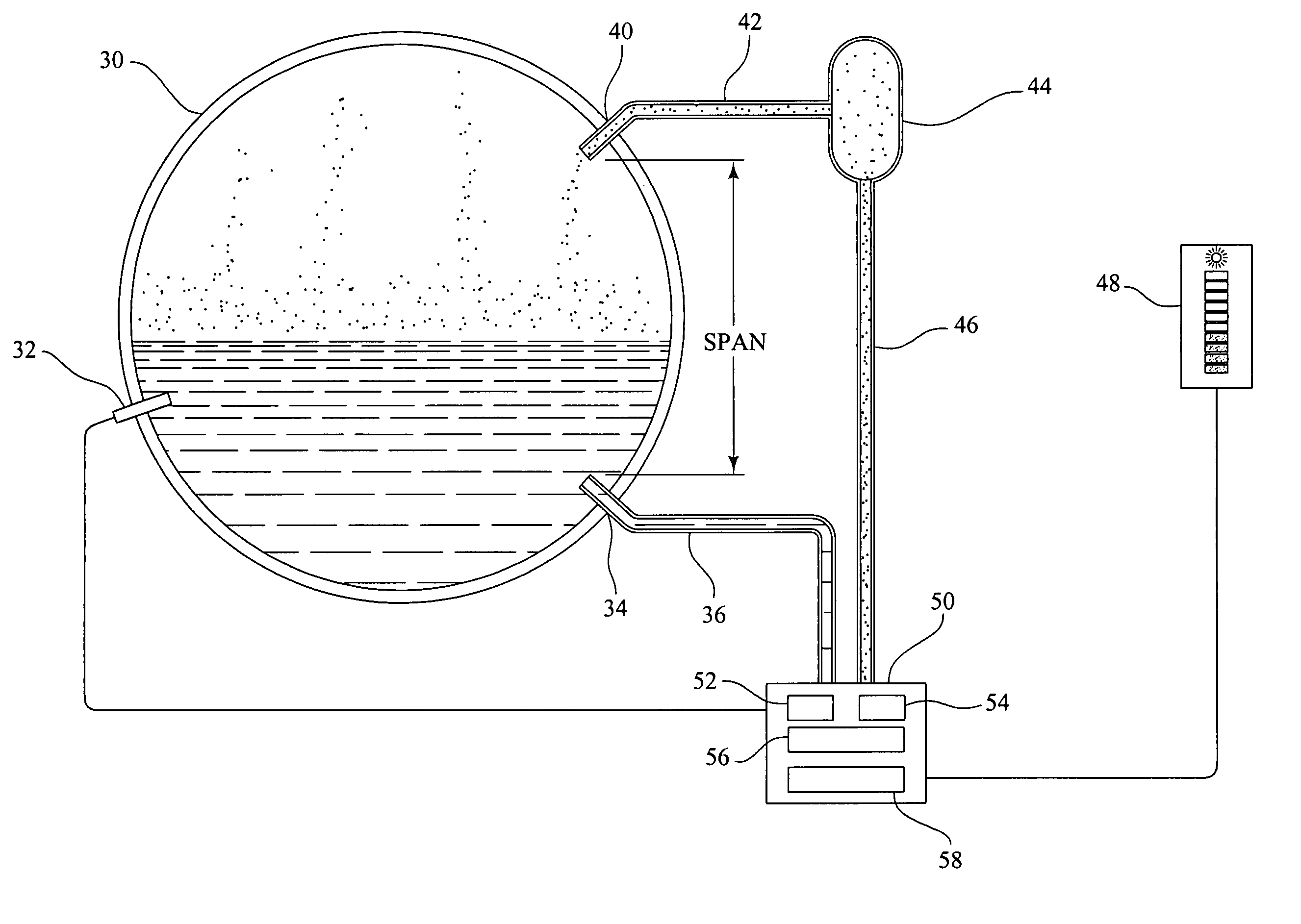

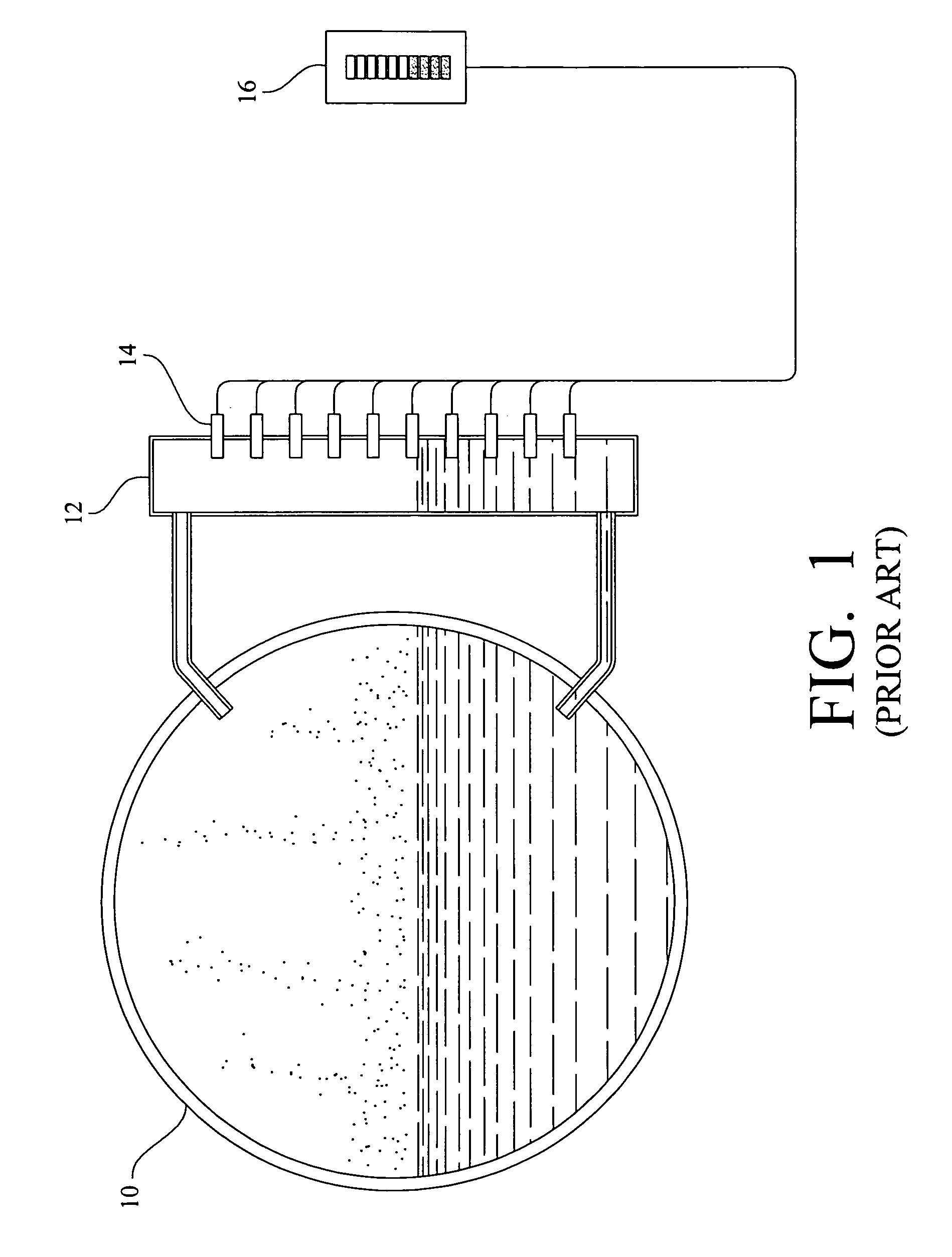

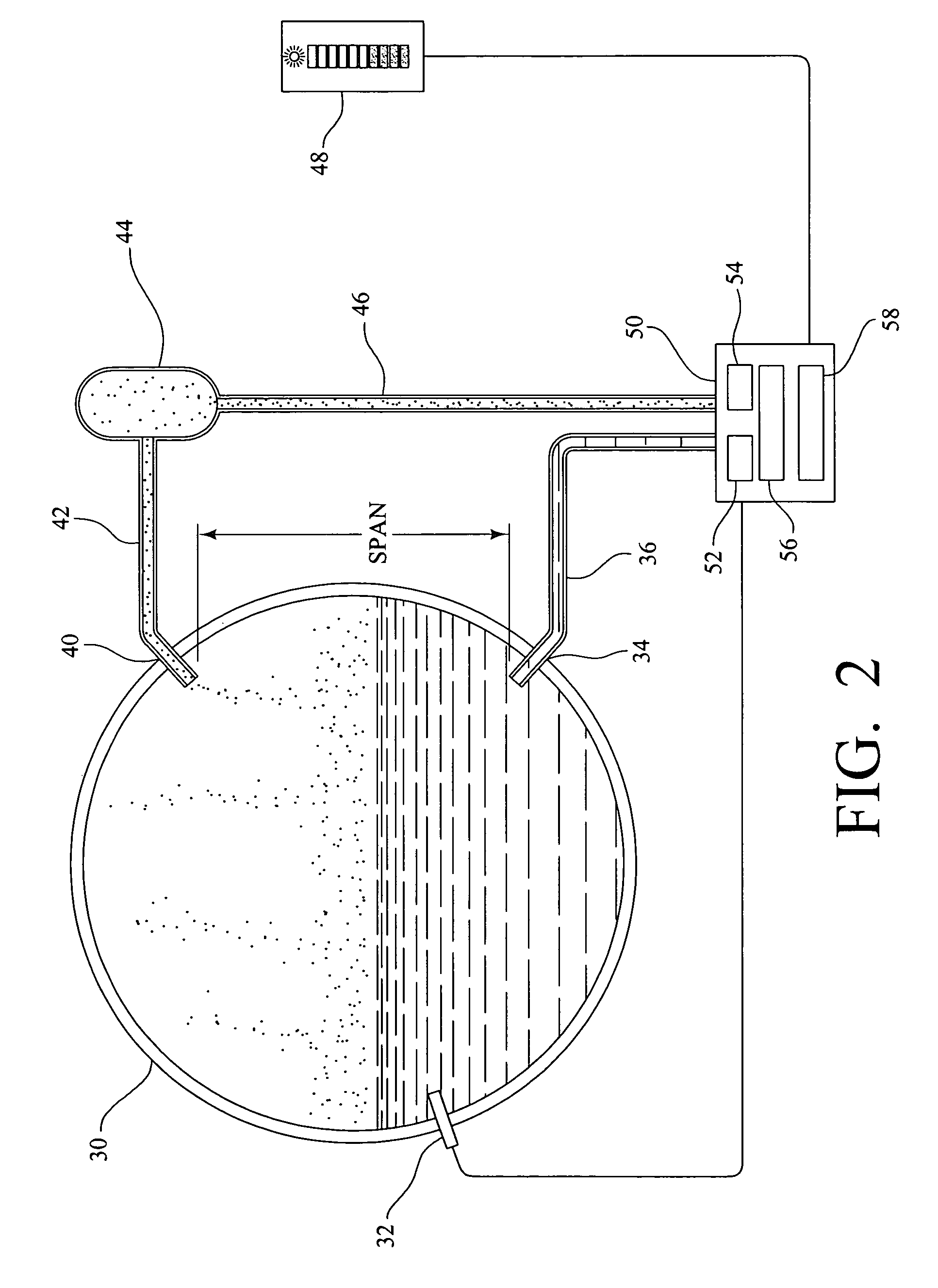

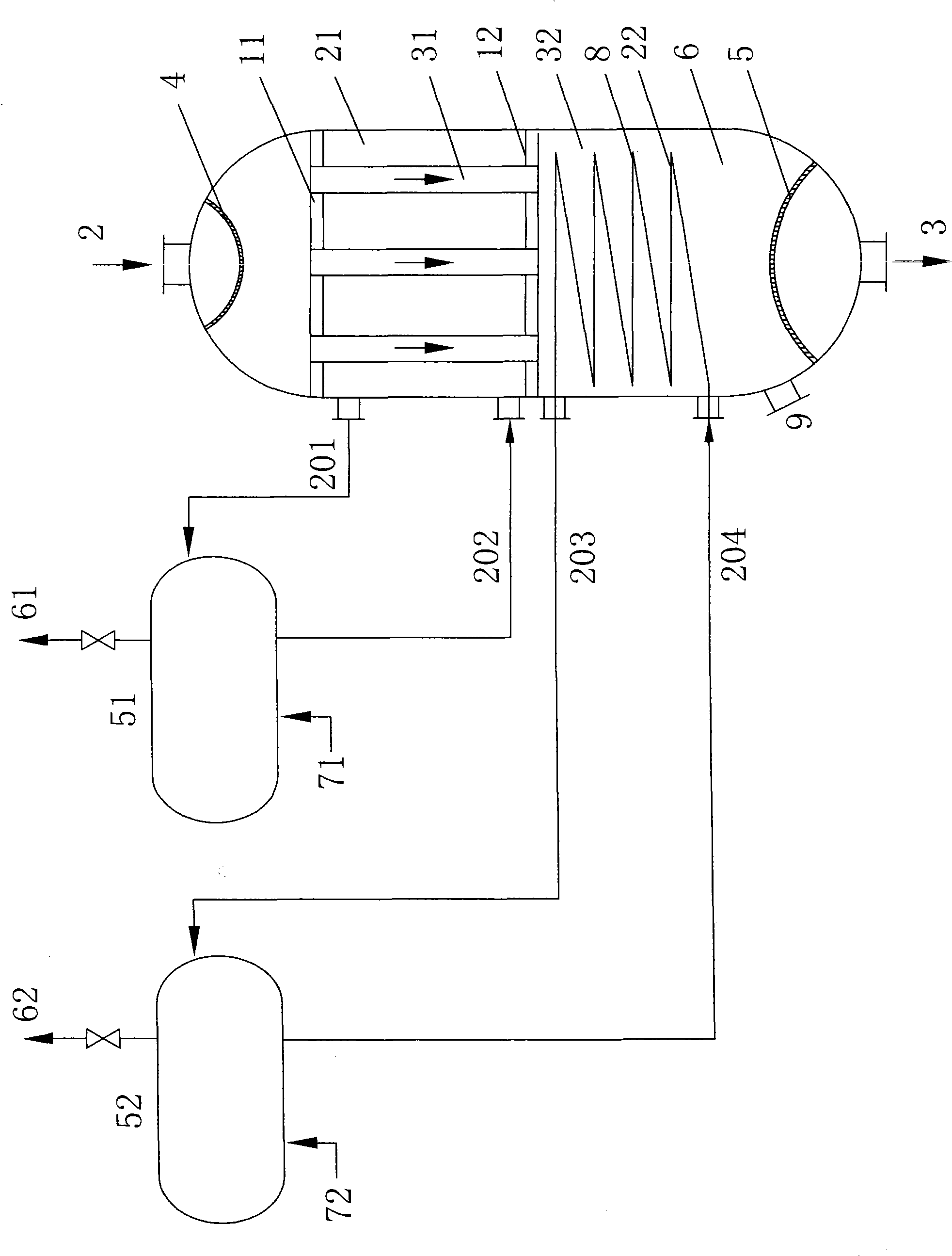

Method and apparatus of solar central receiver with boiler and super-heater

InactiveUS20080078378A1High solar flux densityInhibit thermal stressSolar heating energySolar heat devicesEngineeringSuperheater

A solar tower central receiver with separated boiler and Super-Heater allows better control on the output steam's temperature. The boiler takes higher solar flux density and works at lower temperature while the Super-Heater takes lower solar flux and works at high temperature to optimize the cost to performance ratio. The solar fluxes of the boiler and super-heater are adjustable through the pointing of the heliostats. The boiler consists of parallel pipes as solar absorber and the Super-Heater consists of helix parallel pipes as solar absorber. The steam drum chamber interconnects boiler and Super-Heater. The absorb pipes and circulation pipes are connected to water chamber, steam drum chamber, and Super-Heater chambers. The water level sensor and temperature sensors provide information regarding the operating status of the receiver.

Owner:ZHU YANONG

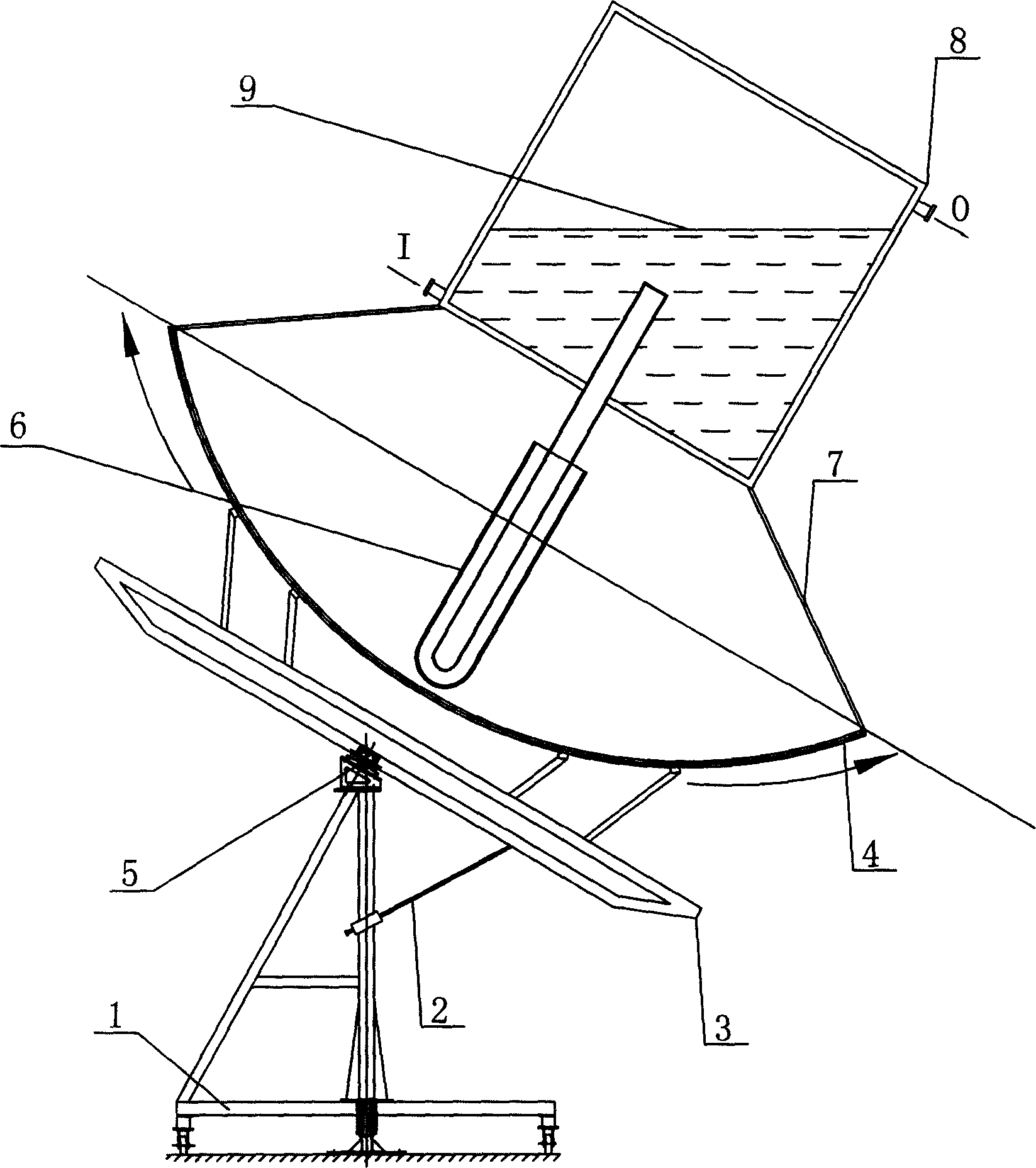

Heat pipe type spherical disc type solar energy light and heat collector

InactiveCN1908549ALow costPromote absorptionSolar heating energySolar heat devicesHeating effectEngineering

The present invention relates to a heat pipe type spherical disc type solar energy light and heat collector, belonging to the solar energy heat collection establishment technical field, which includesa spherical reflecting mirror disposed on the solar energy optical tracker system and a steam drum supported above the reflecting mirror. The steam drum is made up of an inlet and an outlet and stored up with working medium. A heat pipe type vacuum heat collecting pipe is arranged on the focusing part of the spherical reflecting mirror. The heating zone of the heat pipe type vacuum heat collecting pipe is positioned on the condensing wimble of the spherical reflecting mirror. The cooling zone of the heat pipe type vacuum heat collecting pipe is inserted into the working medium of the stream drug. The invention has simple technology, low cost, scientific design and easy to generalization and application. It has been found that the invention has fast tempera the rise, excellent heating effect, high efficiency, suitable for large scale industrialization production, secure and reliable performance.

Owner:HOHAI UNIV

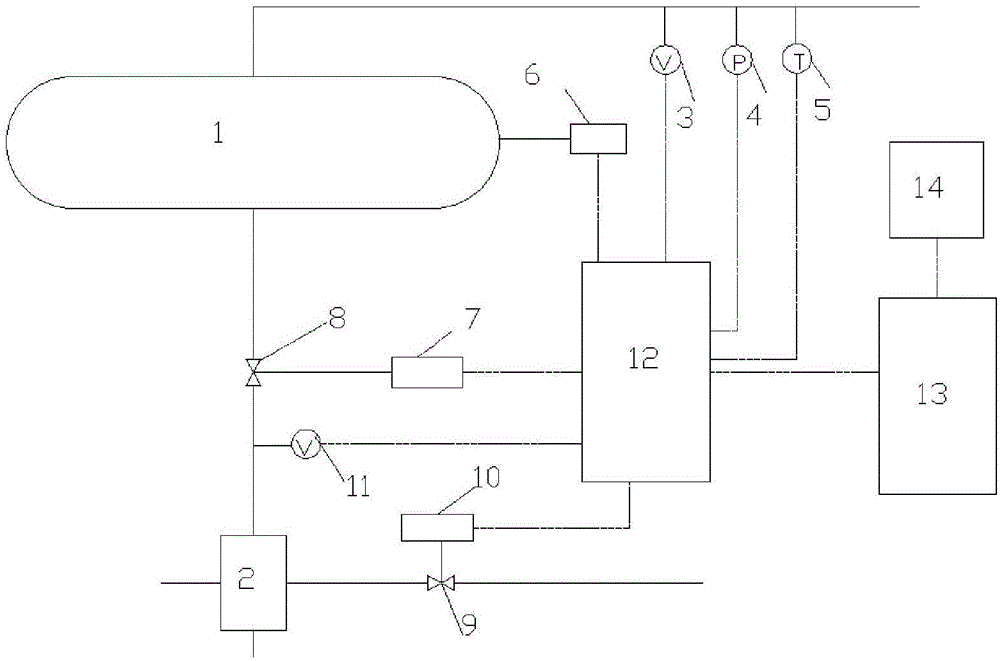

Intelligent measurement and control boiler system dynamically calculating water loss according to drum water level

InactiveCN105135406AKeep abreast of the operation status in timeAvoid wastingBoiler indication operationsBoiler cleaning apparatusData connectionEngineering

The invention provides a boiler system. A monitoring diagnosis controller calculates water loss of a boiler by calculating the ratio of the sum of the steam mass, the change mass of drum water and the sewage discharge mass to the mass of water input into the boiler. The monitoring diagnosis controller is in data connection with a cloud server, so that monitored data are transmitted to a cloud server; the cloud server is connected with a client side, and the client side can obtain the monitored data by means of the cloud server. By means of the client side, the operation condition of water loss of the boiler can be mastered in time, and by means of the client side, the situation that due to water loss of the boiler, a large amount of heat is wasted can be avoided in time.

Owner:SHANDONG UNIV OF TECH

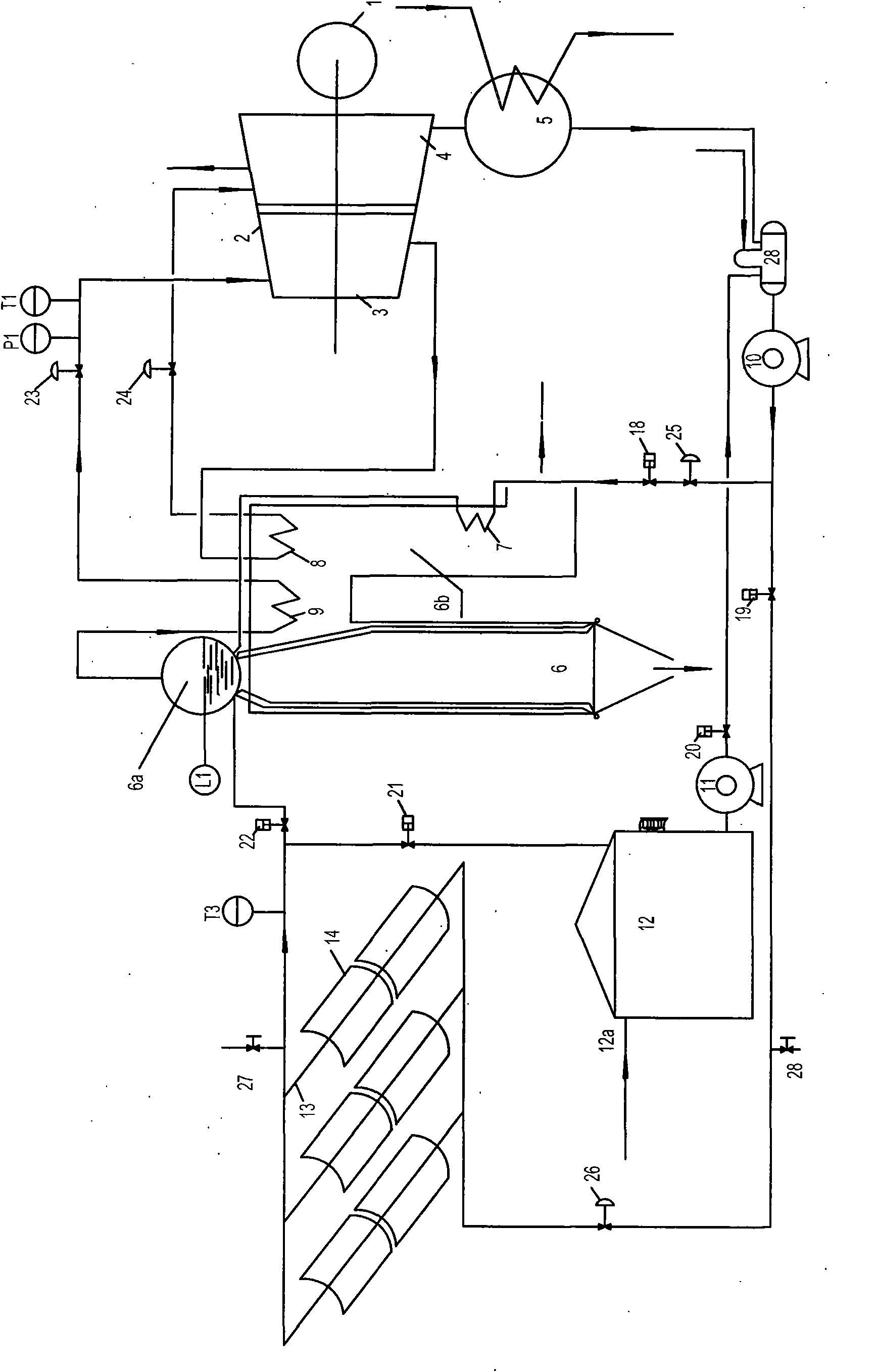

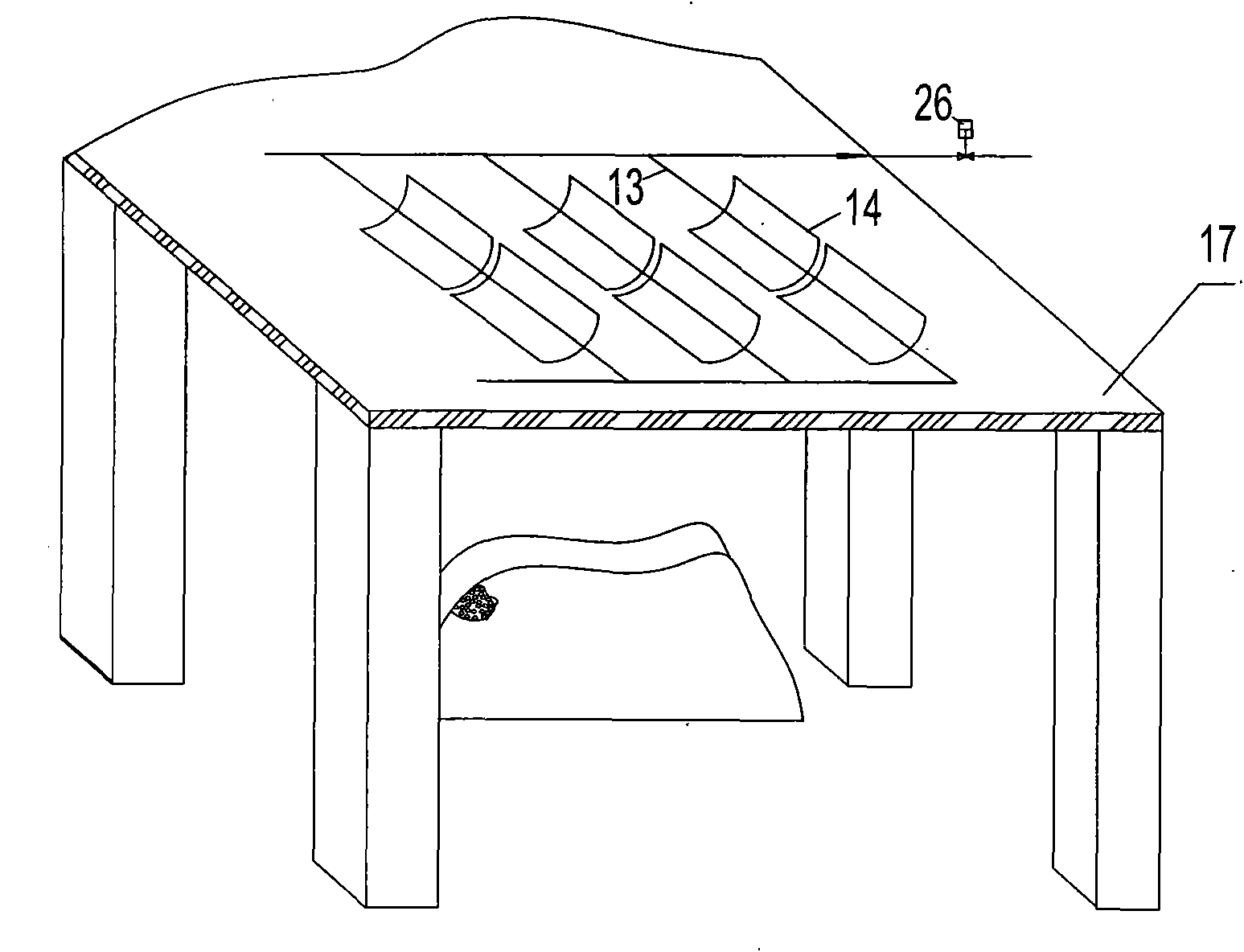

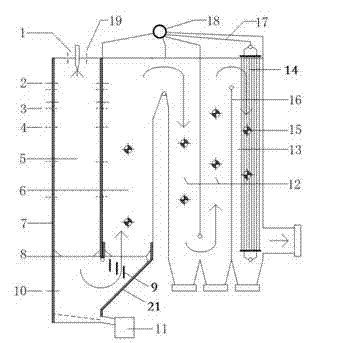

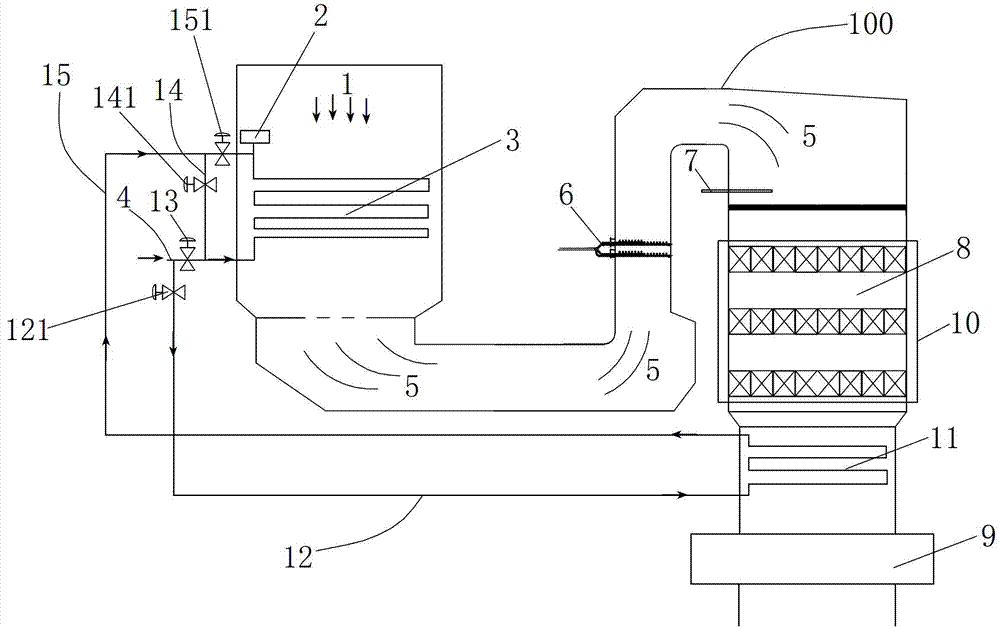

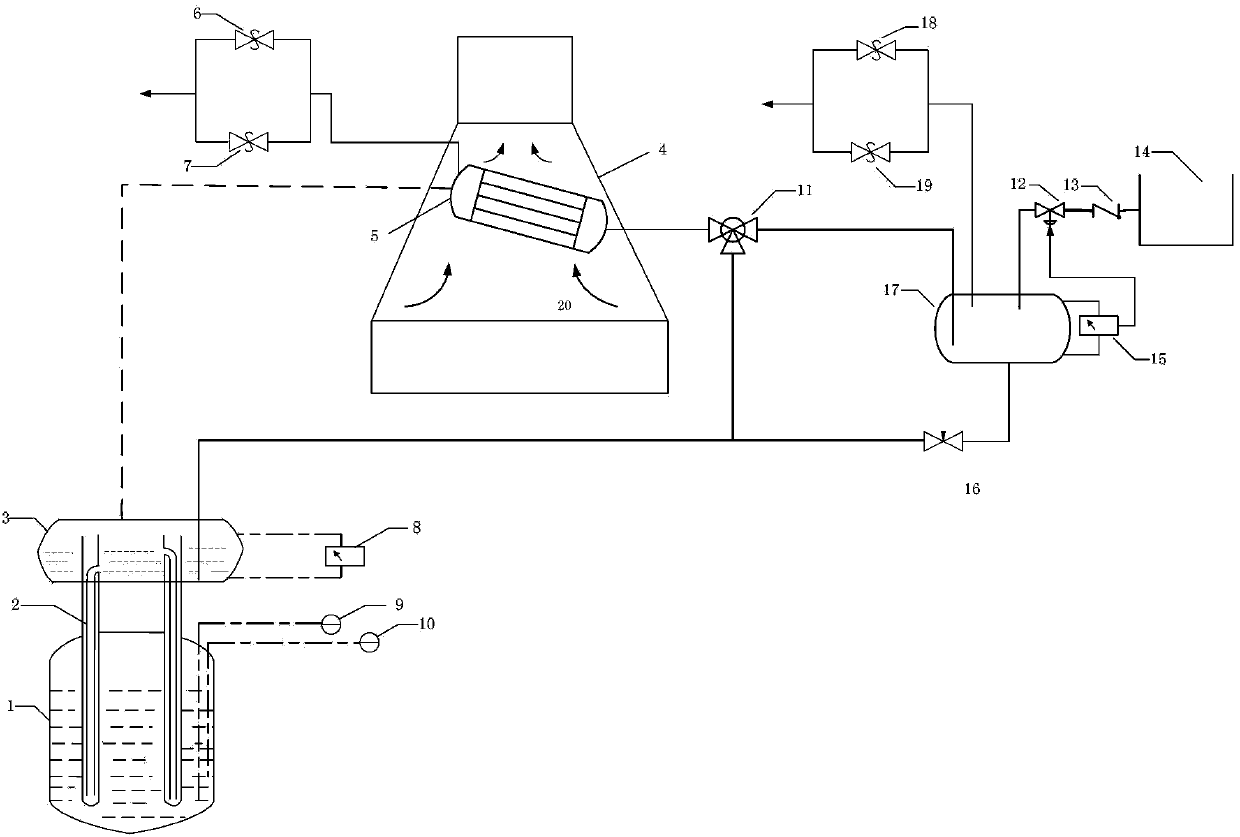

Solar power generation method and system taking biomass boiler as auxiliary heat source

ActiveCN101968041ASolve the problem of antifreeze in winterHigh thermal efficiencySolar heating energyFrom solar energyWater storage tankEngineering

The invention discloses a solar power generation method and a solar power generation system taking a biomass boiler as an auxiliary heat source. The system comprises a solar condensation heat collecting device, a biomass boiler device and a steam turbine generator system, wherein the solar condensation heat collecting device takes water as a medium and is combined by adopting medium-pressure solar vacuum heat collecting pipes in a series-parallel matrix; the outlet of the solar condensation heat collecting device is communicated with the bottom of a steam pocket of the biomass boiler; and the steam outlet of the steam pocket of the biomass boiler is connected with a cylinder of a steam turbine generator. A de-aerator and a water supply pump are connected in series in the water inlet pipeline of the solar condensation heat collecting device. A steam re-heater is connected in series in the connected pipeline of the steam outlet of the steam pocket of the biomass boiler and the cylinder of the steam turbine generator; the steam re-heater is connected to the cylinder of the steam turbine generator; and the steam re-heater is placed in a flue of the biomass boiler. A water supply tank is a desalting water storage tank, and the desalting water storage tank is connected with the de-aerator through the water supply pump and connected with the outlet of the solar condensation heat collecting device through a first control valve.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Burning process and burning boiler for processing high-density saliferous organic wastewater

ActiveCN103047659AGuaranteed combustion temperatureReduce flue gas velocityCombustion technology mitigationIncinerator apparatusChemical industryGas burner

The invention discloses a burning process and a burning boiler for processing high-density saliferous organic wastewater. The burning boiler comprises a down heat insulation boiler cavity, a multilevel radiation cooling chamber, a convection heat exchange chamber, an ash blowing device, a steam outlet pipe and a steam pocket. The down heat insulation boiler cavity comprises a waste liquid atomizing spraying gun, a two-layer auxiliary gas burner, a secondary air nozzle, an air flow shielding device, a water cooling wall, a fireproof material, a compensation fuel gas burner, a liquid slag removing device and a root portion air nozzle. A radiation heat exchange chamber I comprises a water cooling wall, a fireproof material and a flow guide device. The convection heat exchange chamber comprises a water cooling wall and a convection screen. The burning process effectively controls and optimizes the problems of stable complete burning of heat value high-moisture waste liquid, heating surface slag bonding and ash accumulation, tail heating surface low temperature corrosion, NOX discharge and the like, has good processing effect on the high-density saliferous organic wastewater, achieves effective recycle of resources and is suitable for organic wastewater burning processing of chemical industries.

Owner:BEIJING NATION POWER GRORP +1

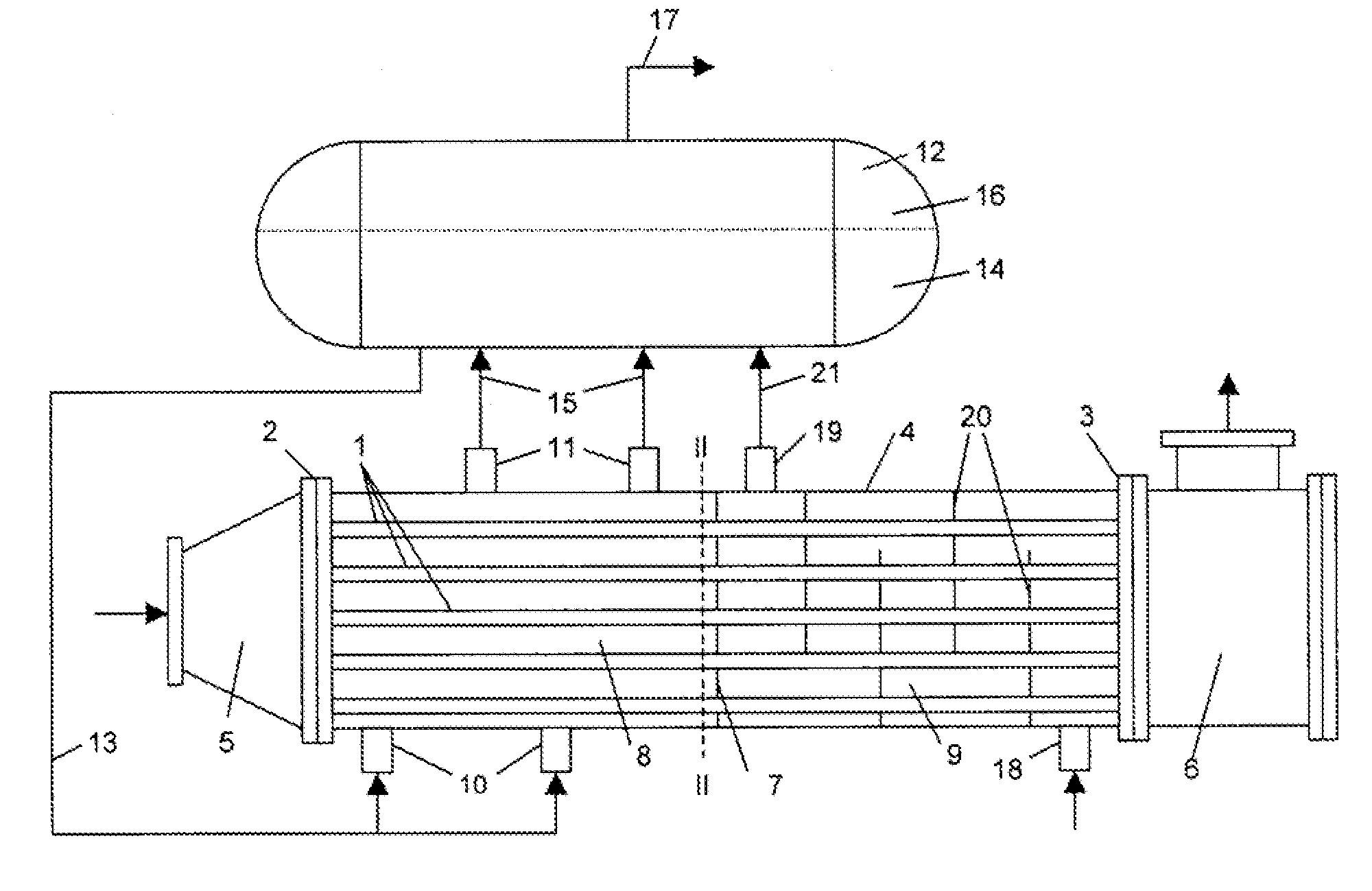

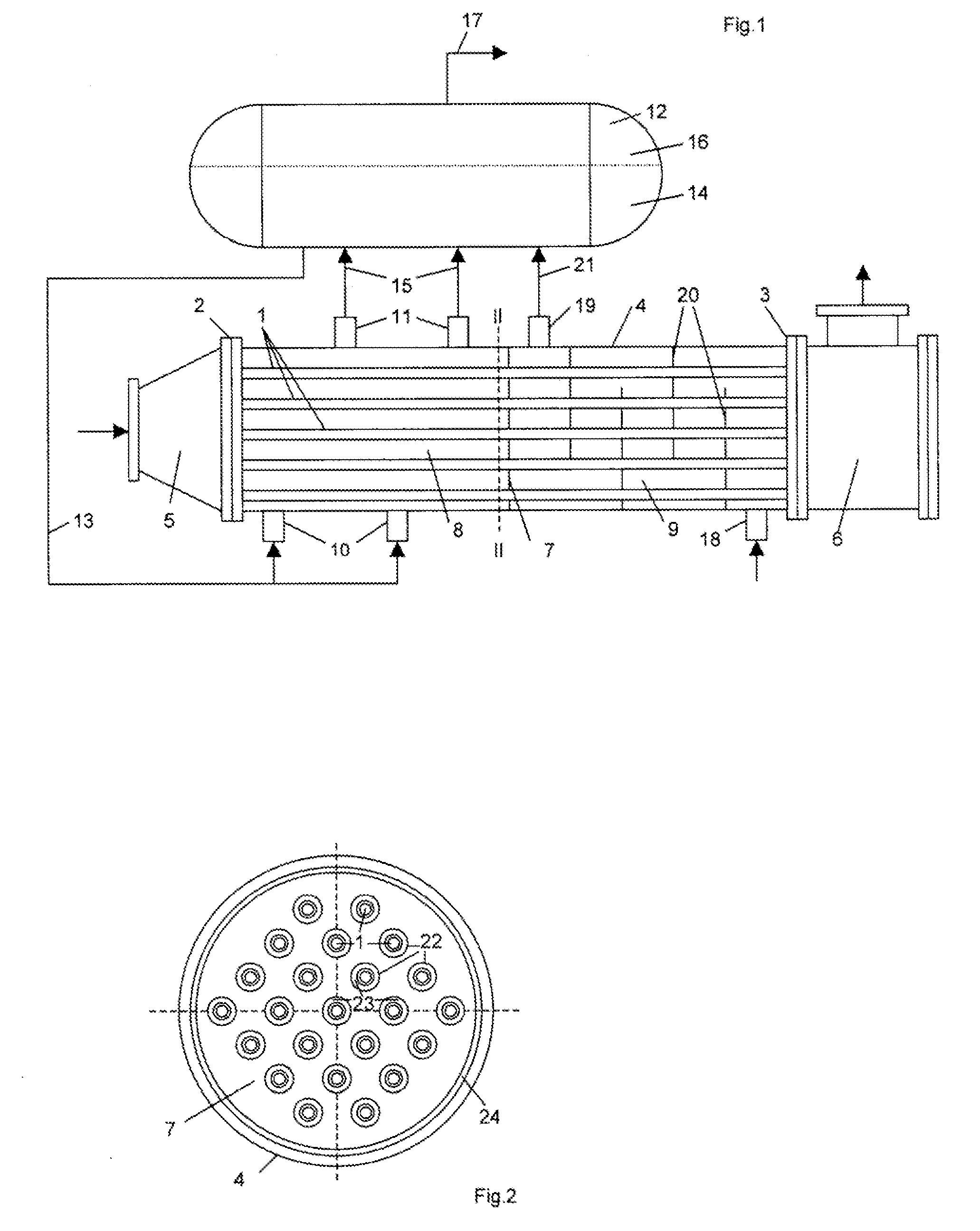

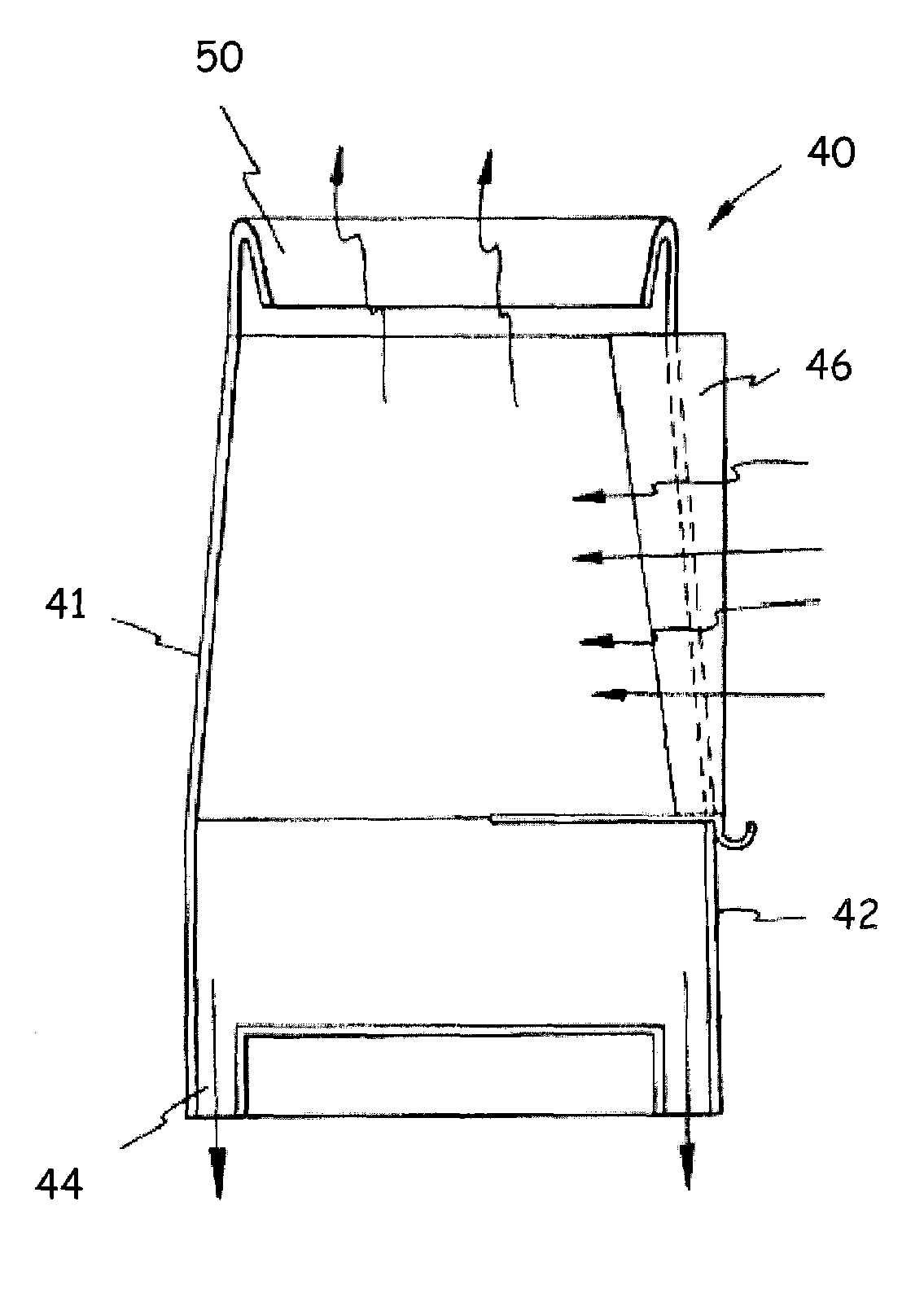

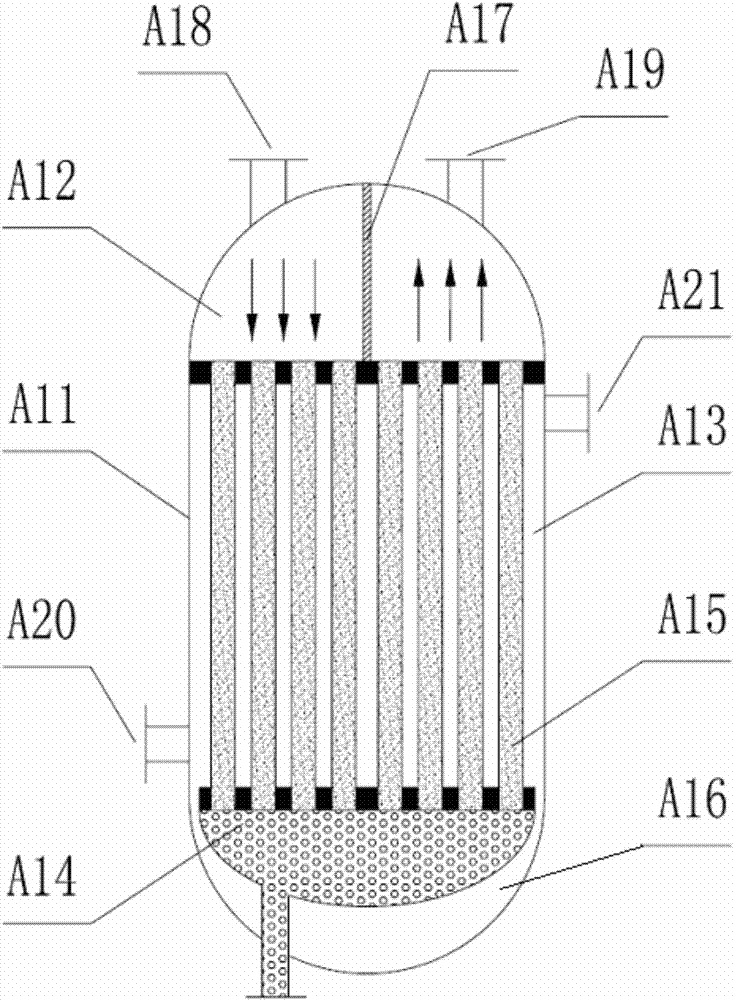

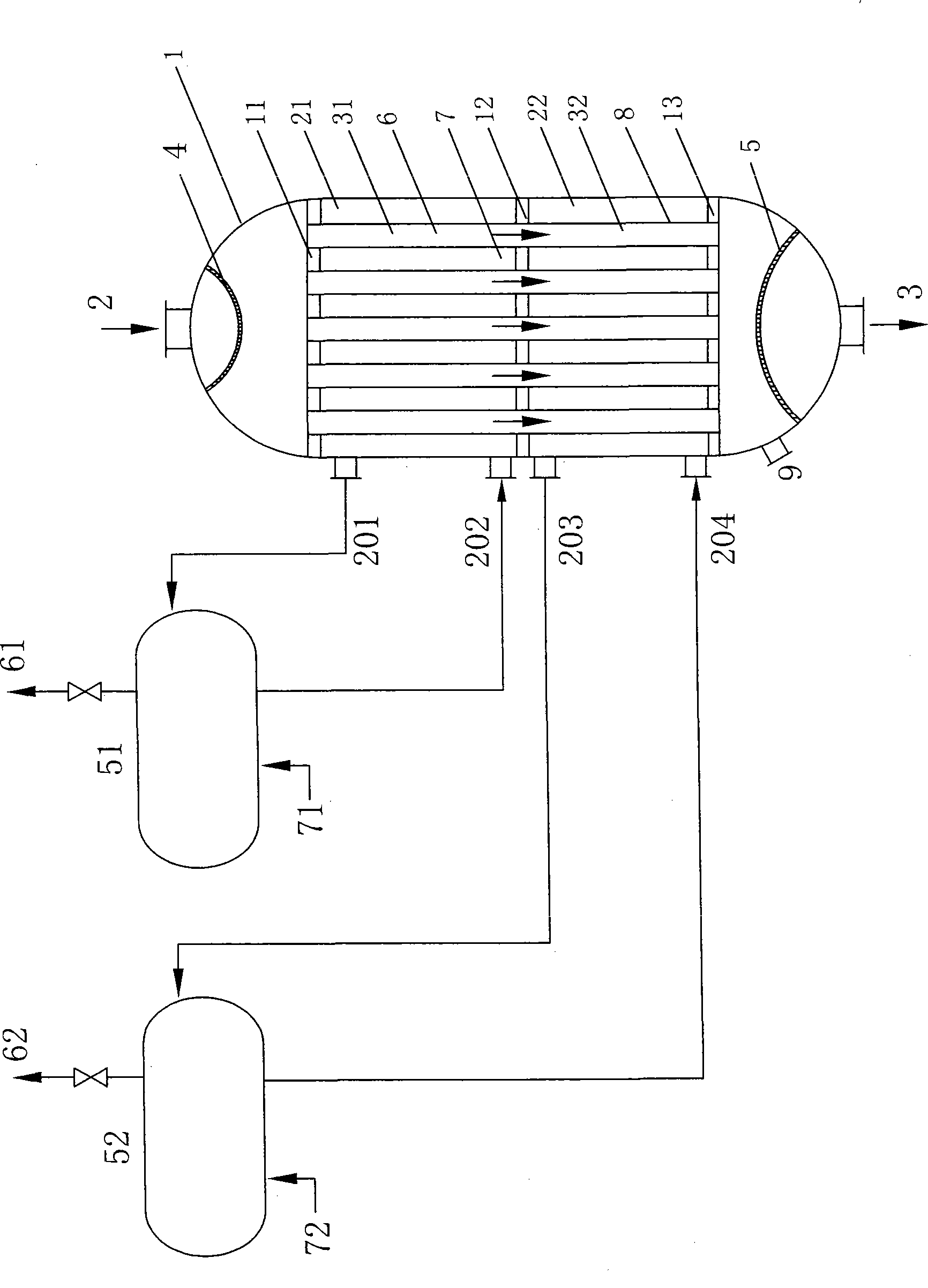

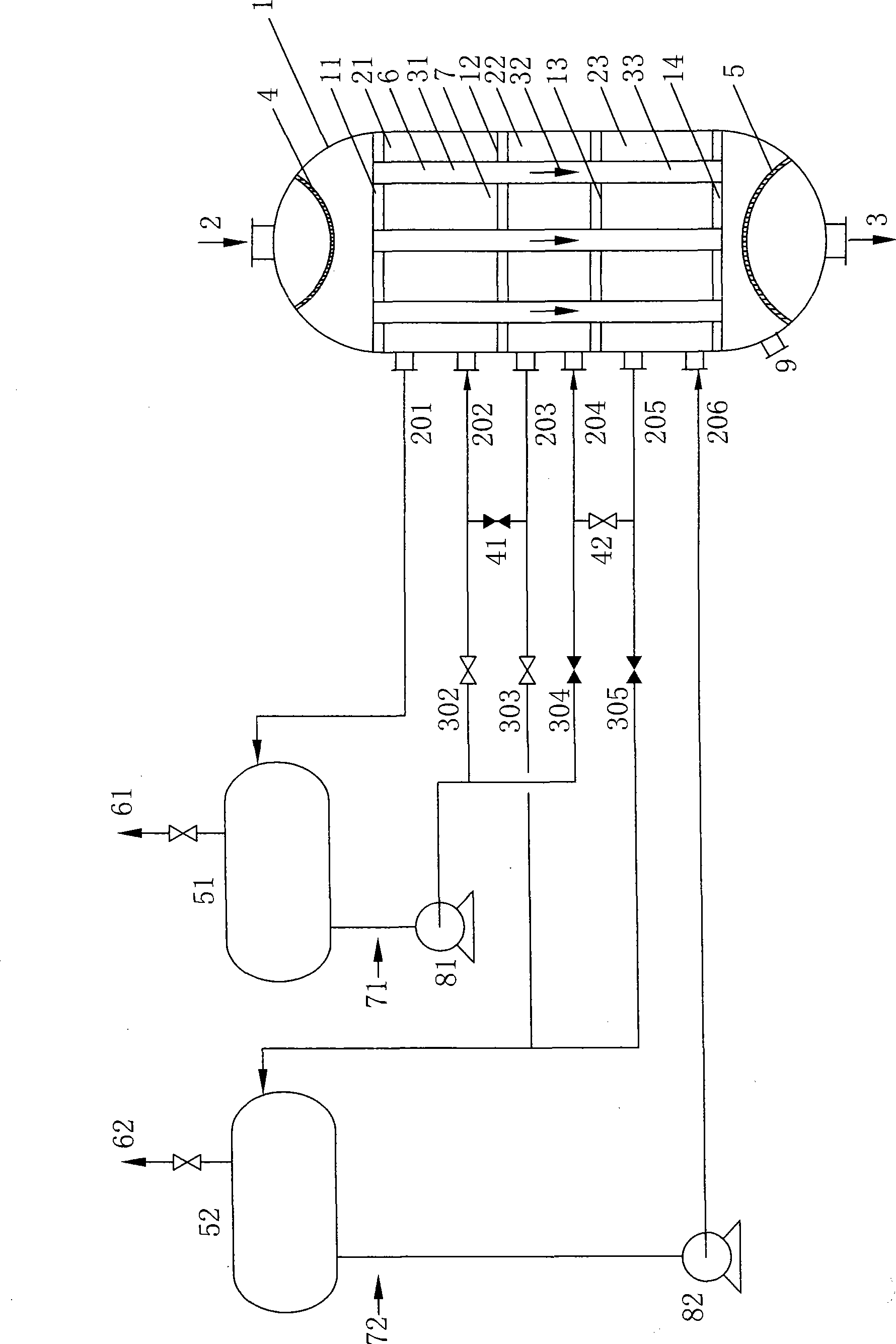

Heat exchanger for cooling reaction gas

ActiveUS20080121383A1Improve cooling effectSimple structureSteam generation heating methodsHeat exchanger casingsPlate heat exchangerNuclear engineering

A heat exchanger for cooling reaction gas, wherein the respective ends of heat exchanger tubes, through which the reaction gas flows, are inserted in a respective tube plate and are surrounded by a jacket, at the two ends of which are provided a respective end chamber that is partially delimited by one of the tube plates and serves for the supply and withdrawal of the reaction gas; water, as cooling agent, flows through the inner chamber of the heat exchanger that is surrounded by the jacket and that is divided by a partition, extending perpendicular to the heat exchanger tubes, which extend through it, into two partial chambers disposed one after the other in the direction of flow of the reaction gas, each partial chamber being provided with its own supply connectors and outlet connectors for the cooling agent; boiling water flows through the partial chamber that is disposed on the inlet side for reaction gas and that is connected via a supply line and withdrawal lines with a water / steam drum; feed water flows through the partial chamber that is disposed on the outlet side for the reaction gas and that is connected via a withdrawal line with the water / steam drum. The partition between the two partial chambers permits the passage of the cooling agent that flows in the inner chamber of the heat exchanger.

Owner:BORSIG AG

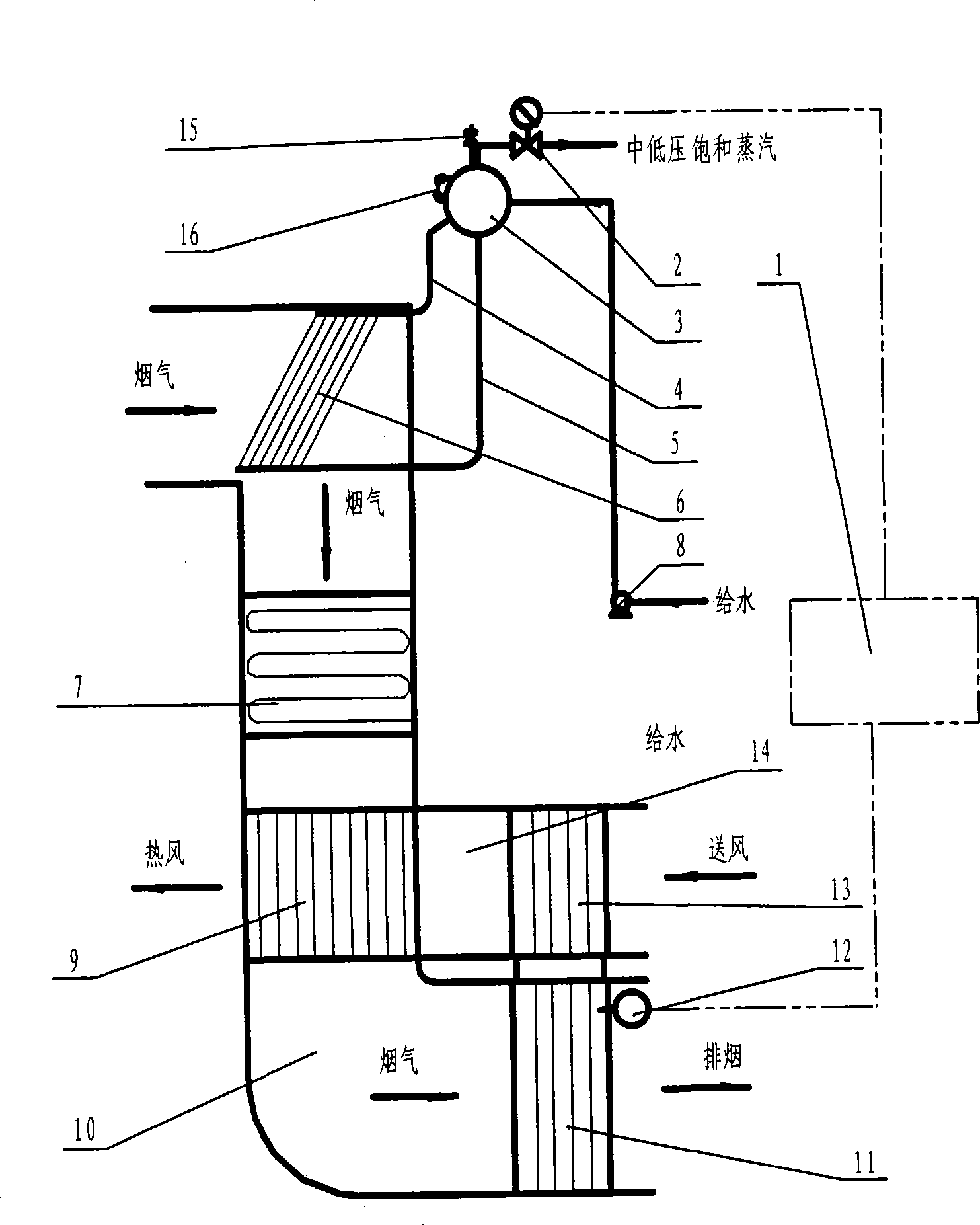

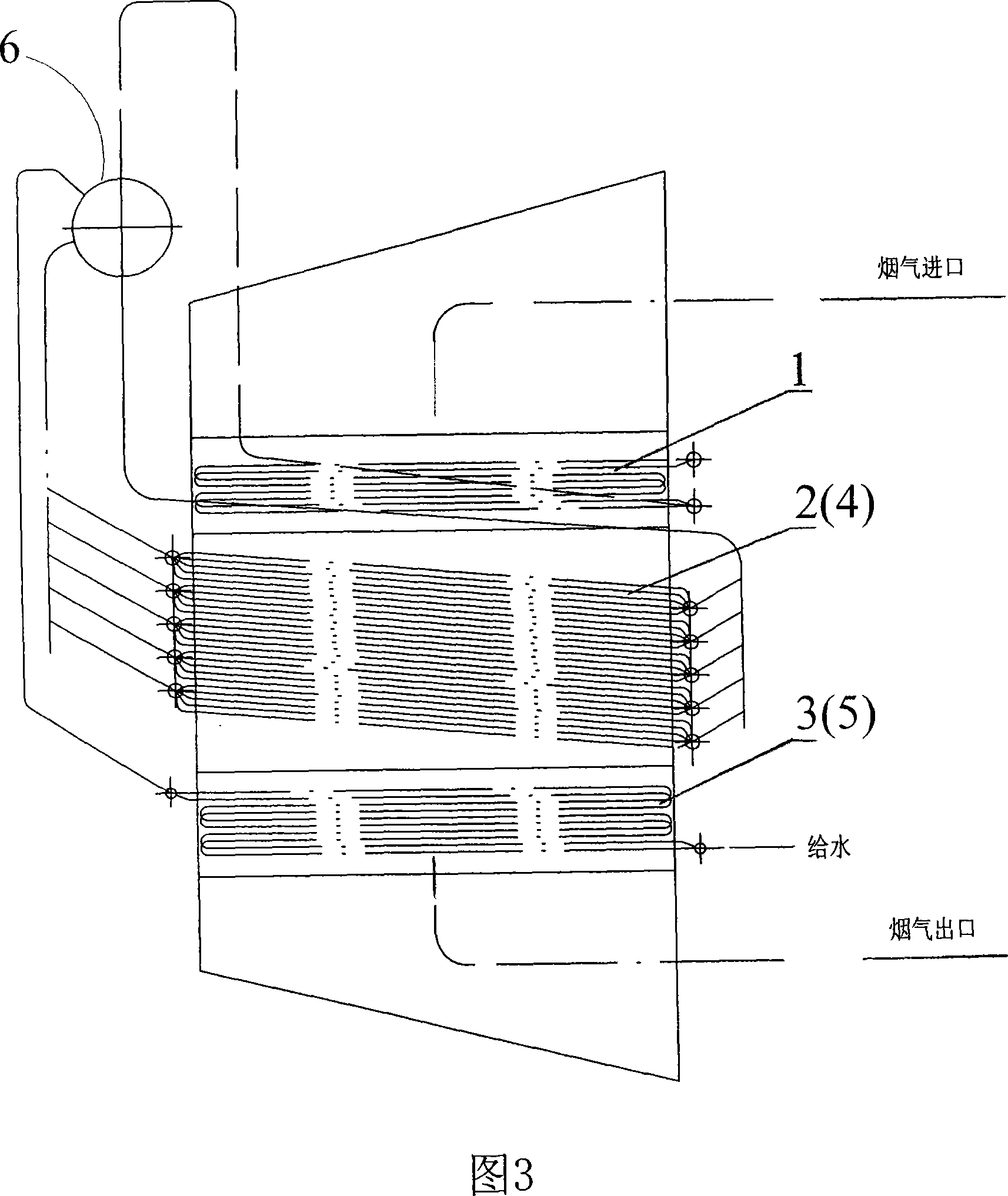

Composite phase change heat exchanger with medium and low pressure

InactiveCN101398265AAvoid condensationIndirect heat exchangersHeat exchange apparatusAir preheaterAutomatic control

The invention discloses a composite phase change heat exchanger with a medium-pressure and low-pressure evaporator, which comprises the medium-pressure and low-pressure evaporator and a steam header which are communicated by an ascending pipe and a descending pipe, a water feeding pipe and a steam outputting pipe are arranged on the steam header, an upper section of the composite phase change heat exchanger is positioned in a wind channel of an original air preheater, and a lower section of the composite phase change heat exchanger is positioned in a back flue channel of the air preheater; an automatic control device of the composite phase change heat exchanger adjusts and controls the heat exchange volume of the evaporator and the wall temperature of the lower section of the composite phase change heat exchanger. The composite phase change heat exchanger not only directly produces low-pressure or medium-pressure steam by using the recycled heat through a steam generating device and provides heat usage as a heat supply, but also controls the thermal equilibrium among the heat exchange volumes of the flue gas, the medium-pressure and low-pressure evaporator, a coal economizer and the wall of the air preheater by adjusting the steam flow of the steam outputting pipe of the steam header through the automatic control device, and consequently leads the flue gas temperature at the outlet to be higher than a flue gas acid dew point on the lower section wall surface of the composite phase change heat exchanger, avoids moisture condensation and achieves the purpose of utilizing waste heat of the flue gas to the utmost degree.

Owner:杨本洛 +1

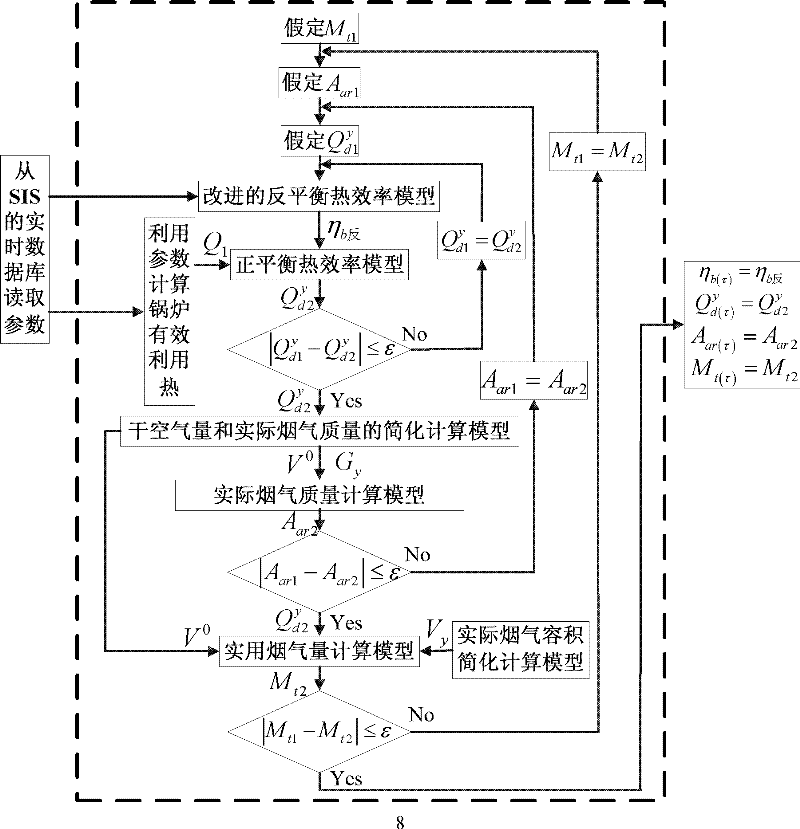

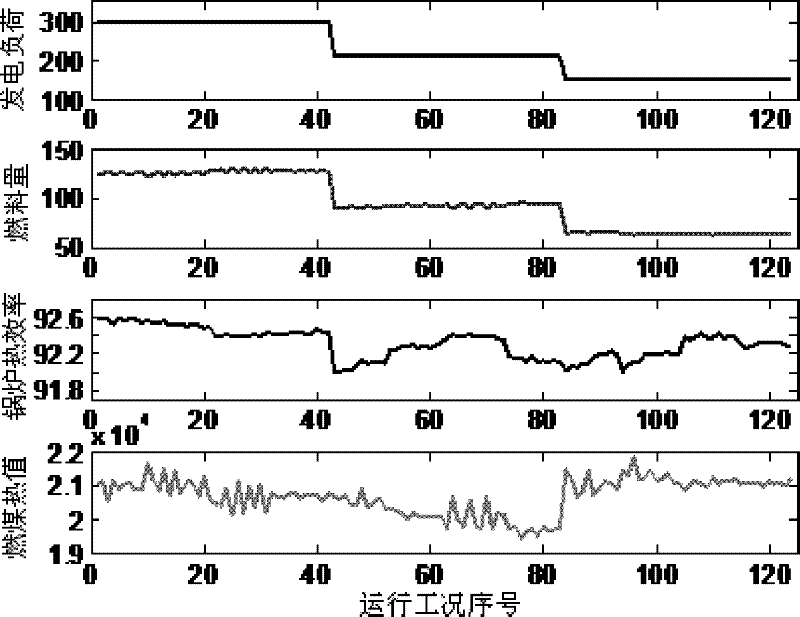

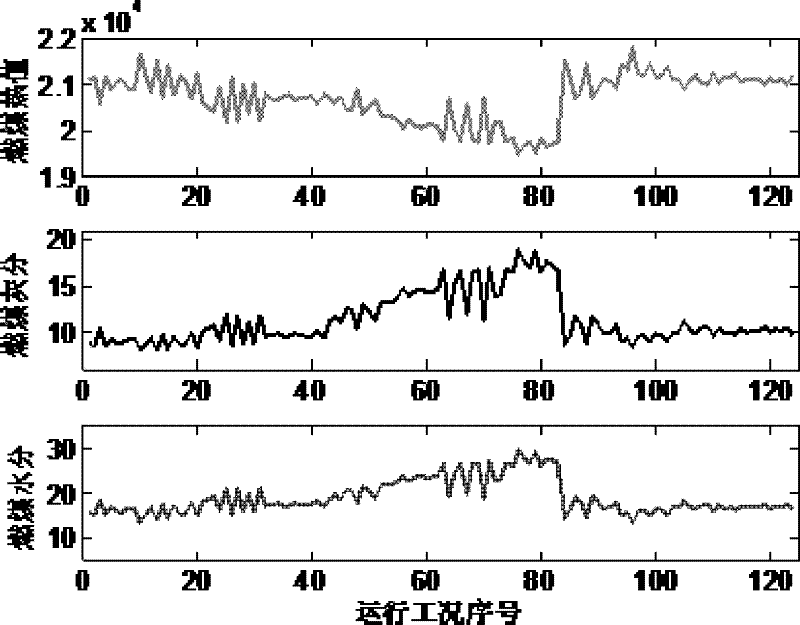

Synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content

InactiveCN102494714AVerify correctnessImprove calculation accuracyStructural/machines measurementSteam pressureEvaporation

The invention relates to a synchronous reckoning method of utility boiler efficiency and coal heat value as well as ash content and moisture content, wherein air supply temperature, smoke exhaust temperature, smoke exhaust oxygen content, carbon content in fly ash, boiler-fed fuel content, boiler evaporation amount, assembly electric generating load, main steam pressure temperature, reheated steam inlet / outlet pressure temperature, water supply pressure temperature and flow rate, steam drum pressure, reheater temperature lowering water jet amount and steam extraction pressure temperature of each heater of high pressure cylinder are read through a plant-level supervisory information system (SIS) of a thermal power plant; and the parameters as the water temperature and drainage temperature of the inlet / outlets of different-level heaters of the high pressure cylinder are synchronously reckoned by hypothesizing the initial values of the coal heat value, the coal ash content and the coal moisture content, utilizing a boiler anti-balance heat efficiency model, a dry air amount required for theoretical combustion and actual smoke quality simplified calculating model, an actual smoke quality calculating model, an actual smoke volume calculating model, an actual smoke amount calculating model, a boiler positive-balance heat efficiency model and a boiler effective utilized heat model, and establishing prediction and rectification methods.

Owner:SOUTHEAST UNIV

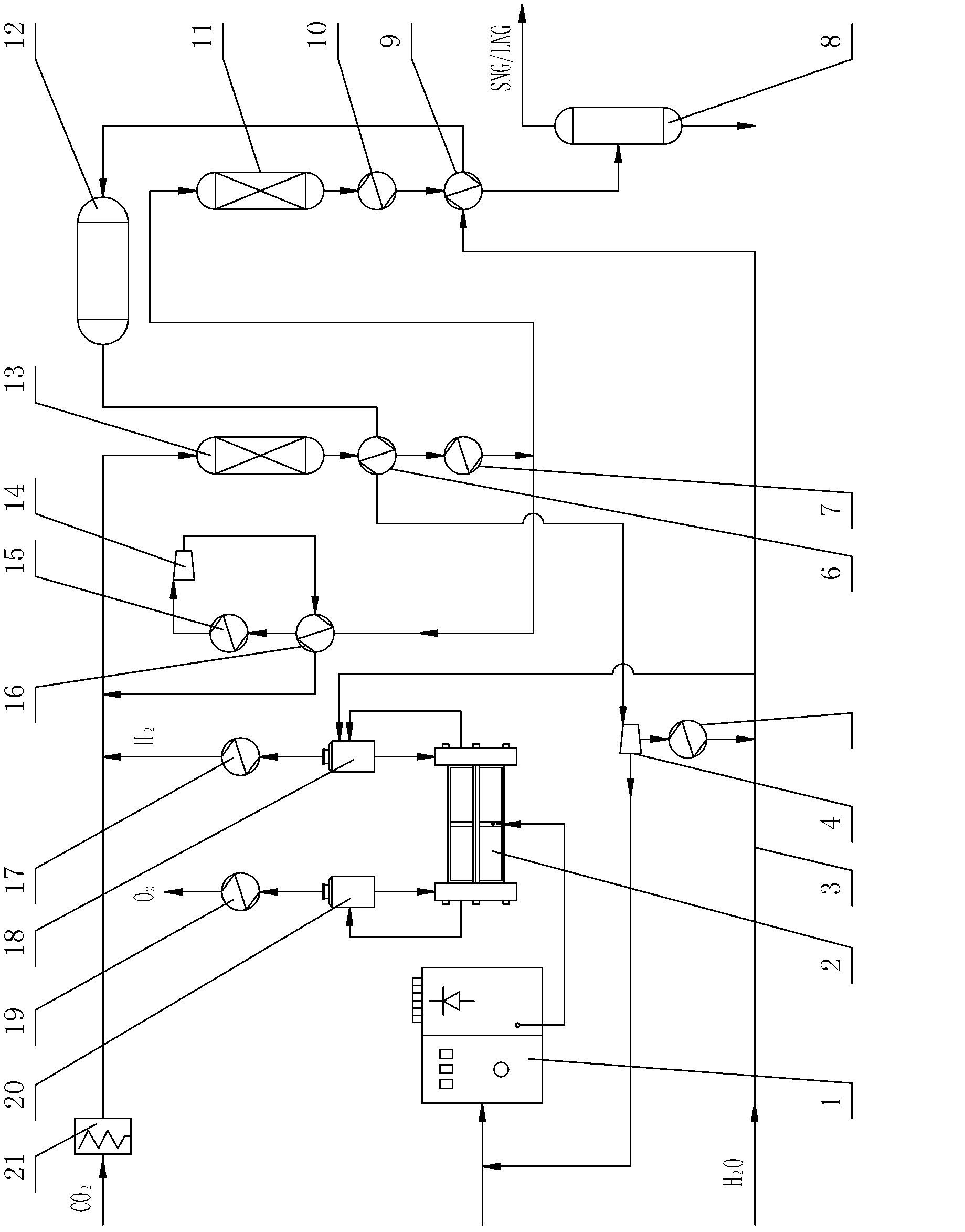

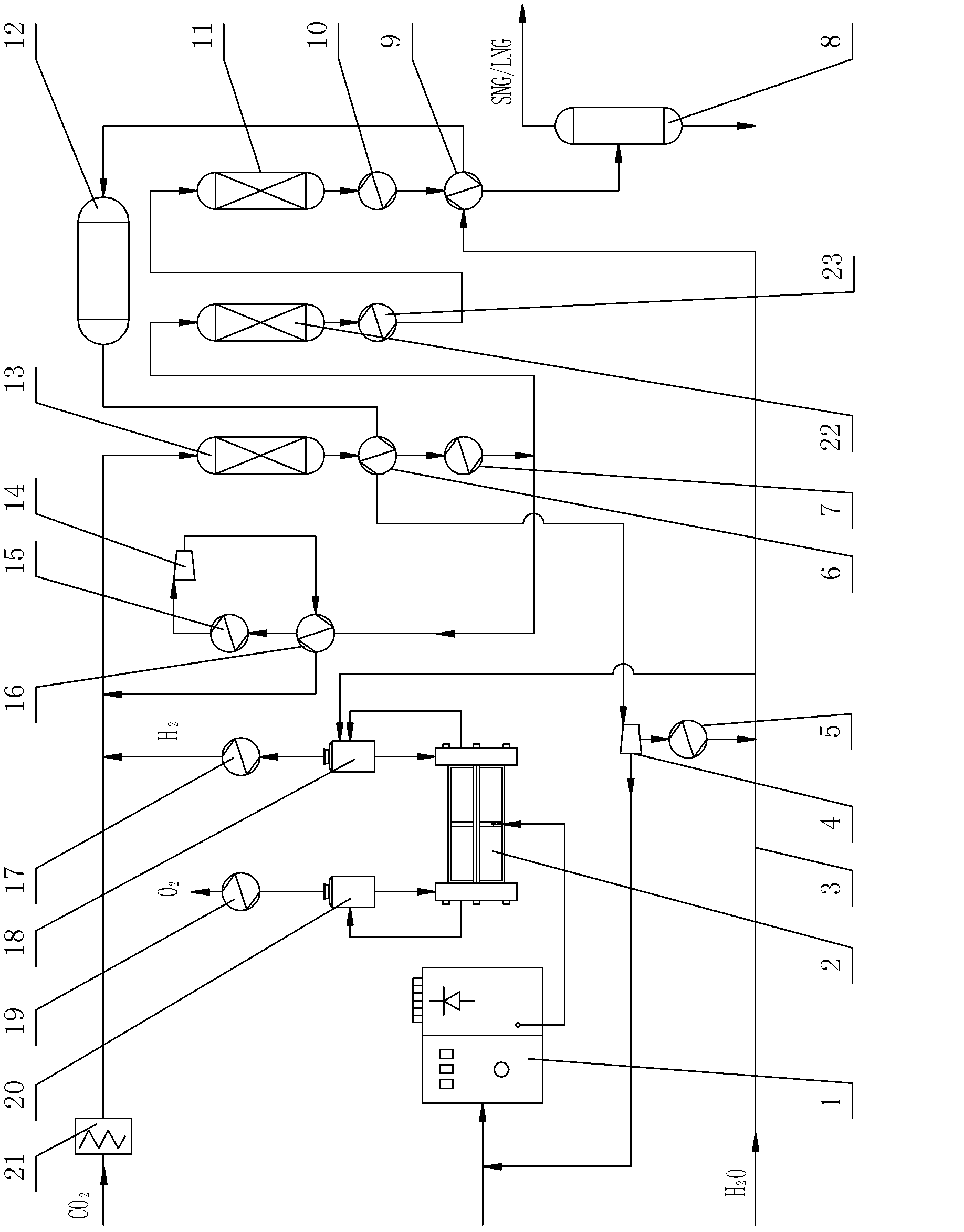

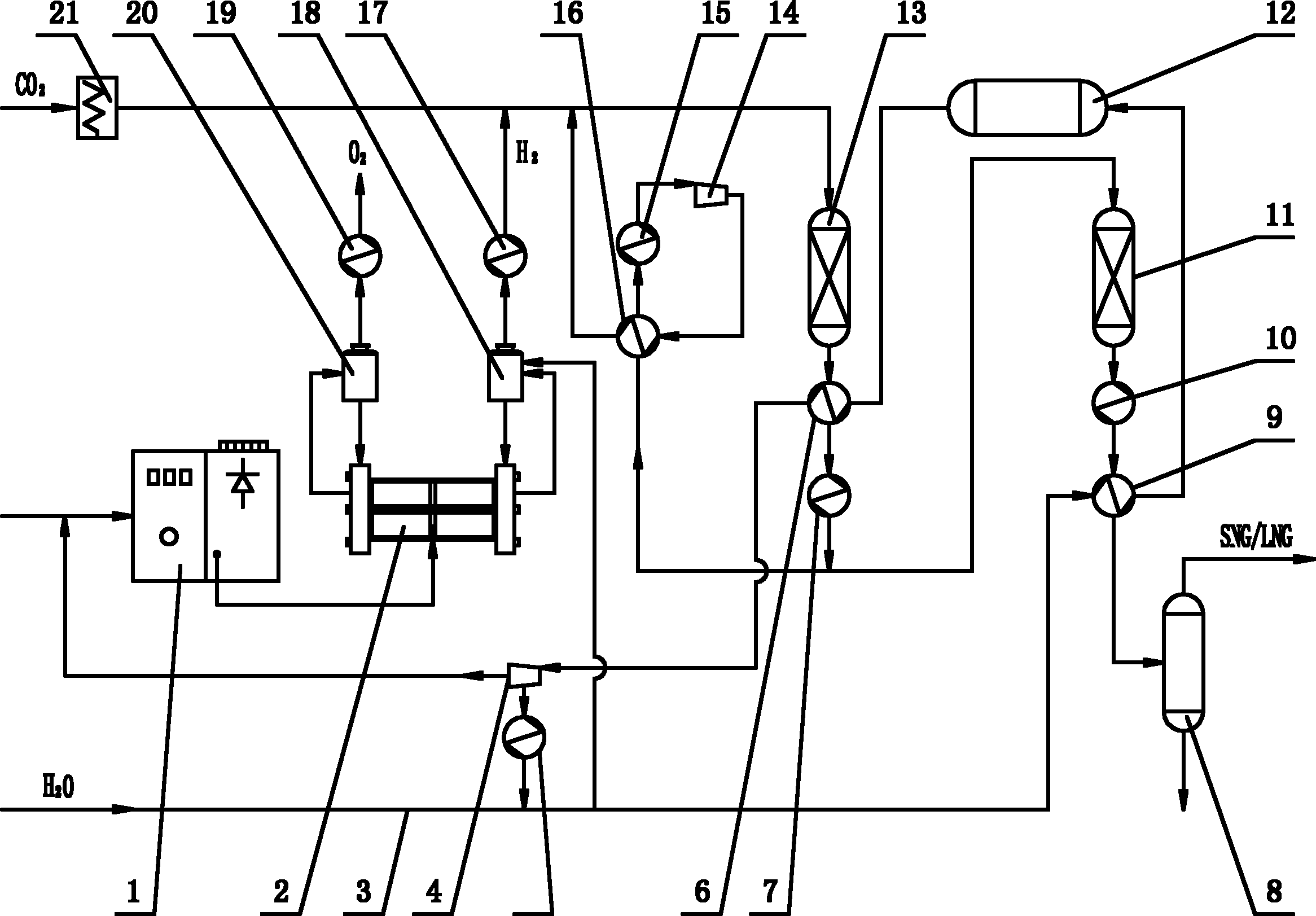

Process and equipment for converting carbon dioxide in flue gas into natural gas by using dump power energy

ActiveCN102660340AEasy to importSolve the problem of difficult power storageCellsHydrocarbon from carbon oxidesElectrolysisWater vapor

The invention discloses a process and equipment for converting carbon dioxide in flue gas into natural gas by using dump power energy. According to the process, water is electrolyzed by using the dump power energy to generate hydrogen gas; the hydrogen gas and carbon dioxide captured from industrial flue gas are enabled to generate methanation reaction; meanwhile, water is heated by using the heat generated by the methanation reaction to generate superheated water vapor for driving a steam turbogenerator to generate power which is used for supplementing power energy for electrolyzing water, and thus natural gas which can be conveniently stored or conveyed is obtained by synthesizing. The equipment is mainly formed by combining a transforming and rectifying device, an electrolytic bath, a steam turbogenerator, a carbon dioxide heater, at least two-stage of fixed bed reactors, various indirect heat exchangers, a steam drum, a natural gas condenser and a process water pipeline. According to the process and equipment disclosed by the invention, the defects that internet obstacles exist or power is excessive in a short time and difficult to store in a mode of generating power by using renewable energy sources are effectively overcome, the problem that the environment is polluted by room temperature gases in a mode of generating power by using fossil energy is effectively solved and the renewable energy sources and carbon dioxide waste gas can be reasonably utilized.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

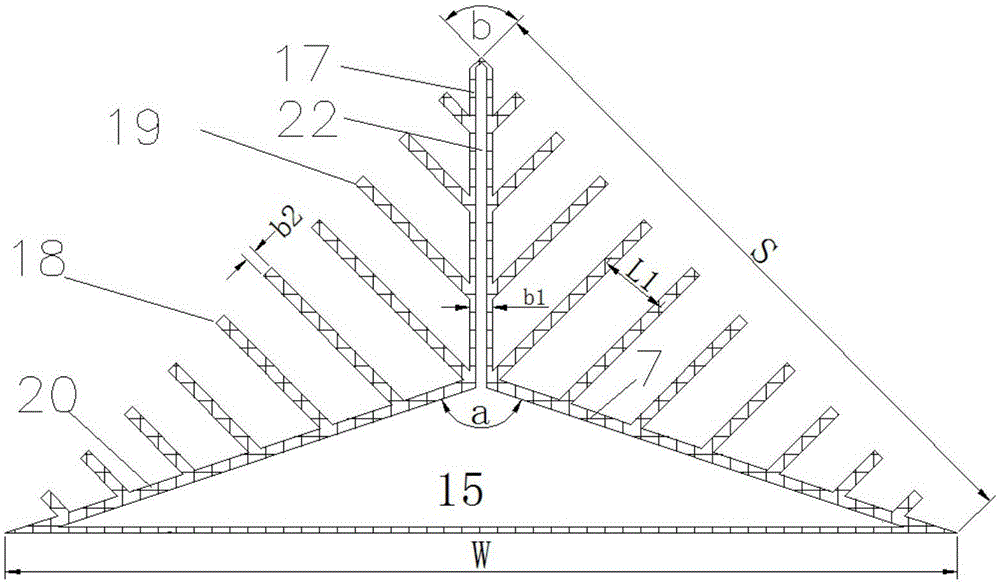

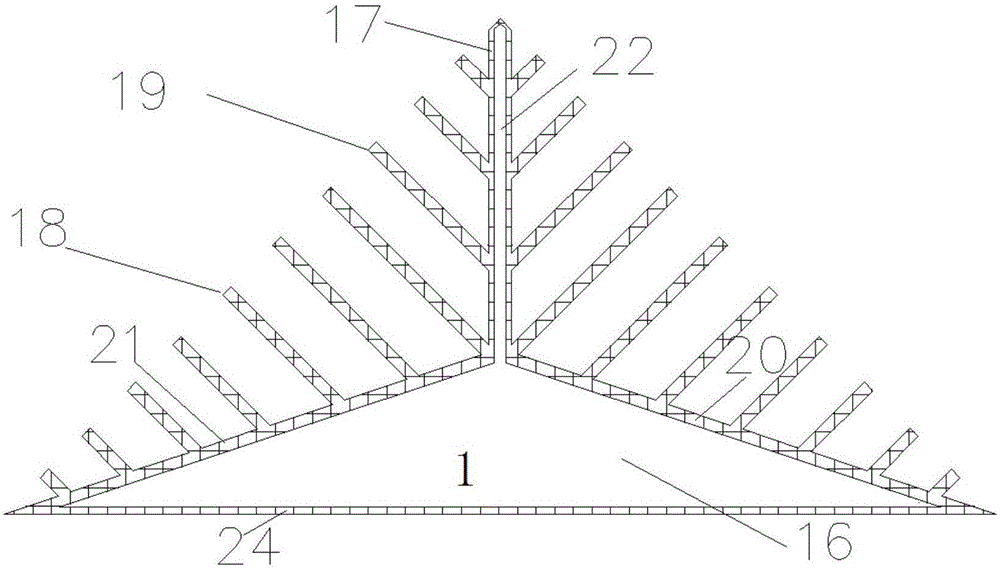

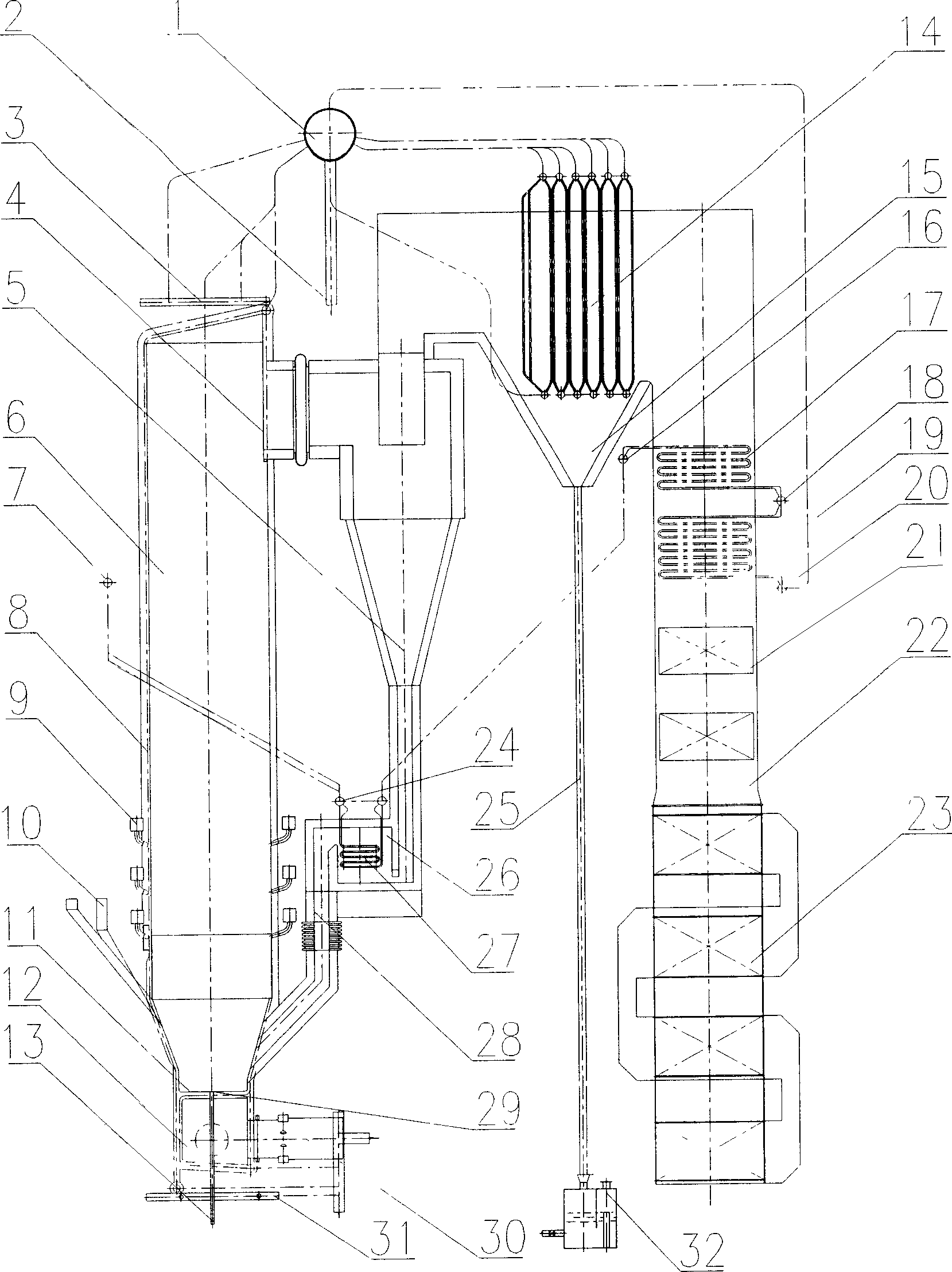

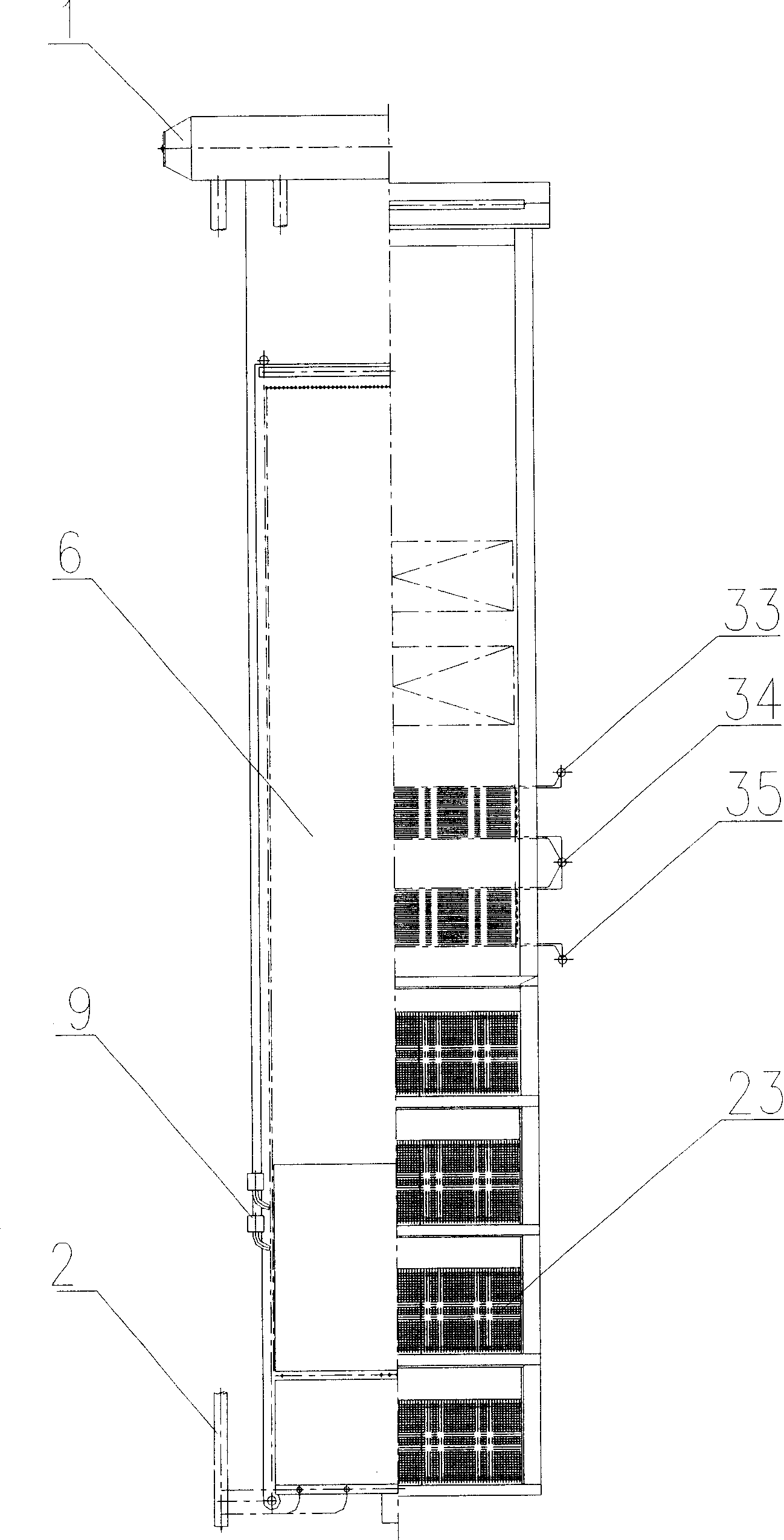

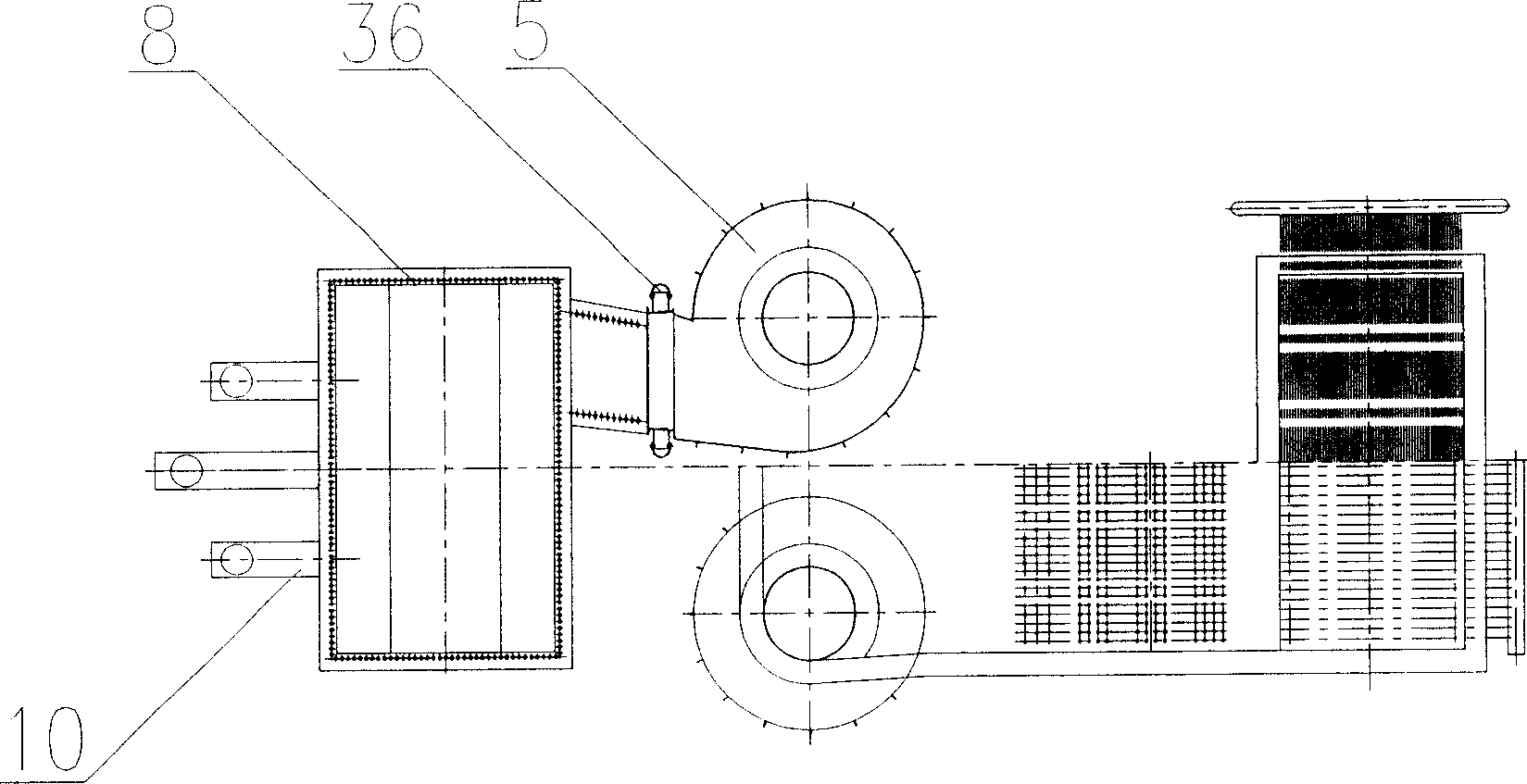

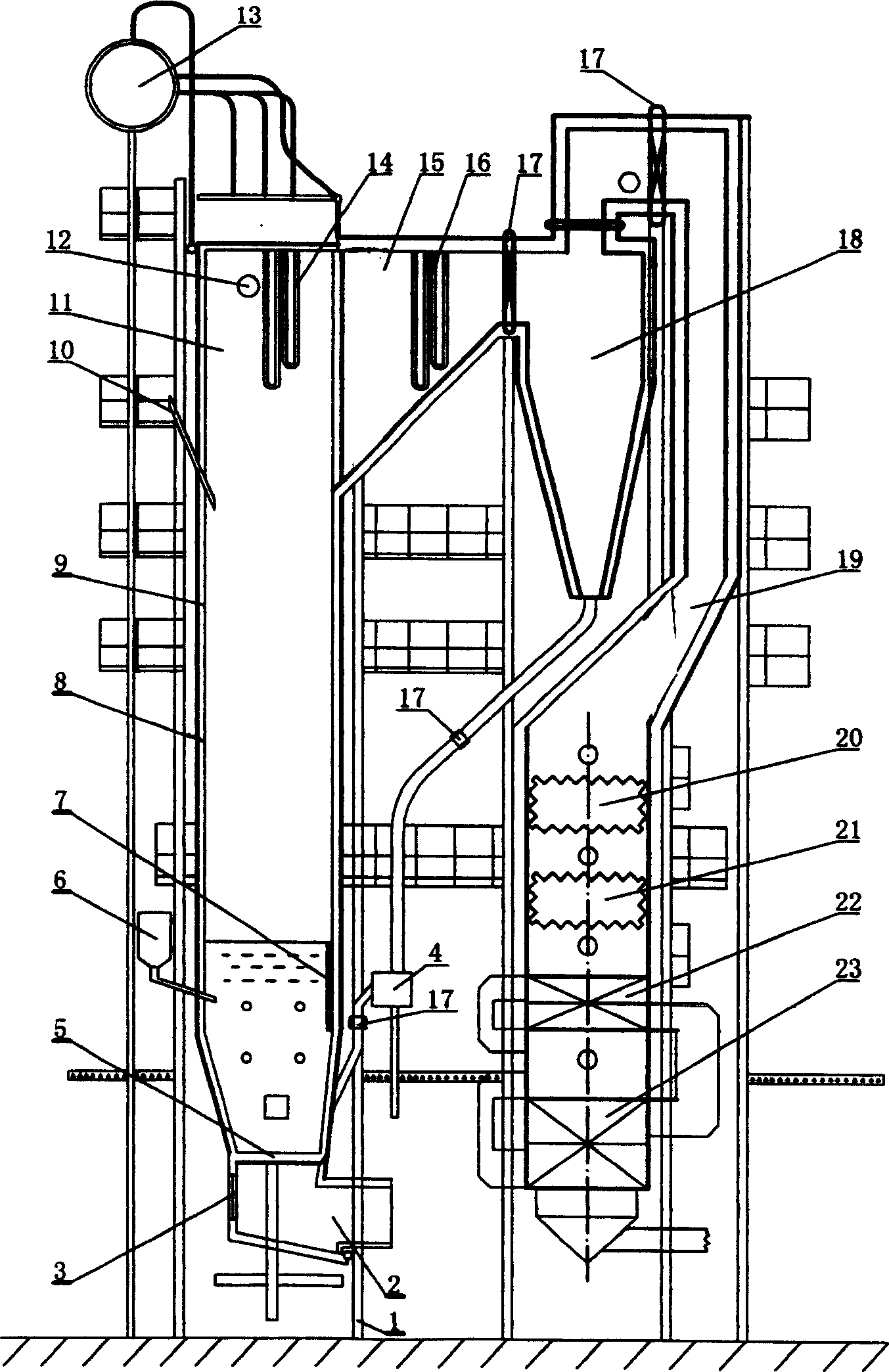

Straw circulation fluidized-bed combustion boiler

InactiveCN1912461AGood load regulation performanceAvoid corrosionFluidized bed combustionCombined combustion mitigationAir preheaterCombustion chamber

A recirculation fluidized bed combustion boiler of straw is prepared as setting material feed mouth and residue extraction mouth on firepot, setting cooling device being connected to ignition combustion chamber and refeeder with secondary wind opening at bottom of firepot, using water cooling wall with top and bottom collection boxes as side wall of firepot, connecting outlet of firepot to separation device being connected to refeeder and two stages of thermo reduction devices separately, connecting one stage of thermo reduction device to a overheat unit with economizer and preheater as well as setting steam pocket and water supply pipe at top of firepot.

Owner:SHANDONG GUODIAN TECH CONSULTING +1

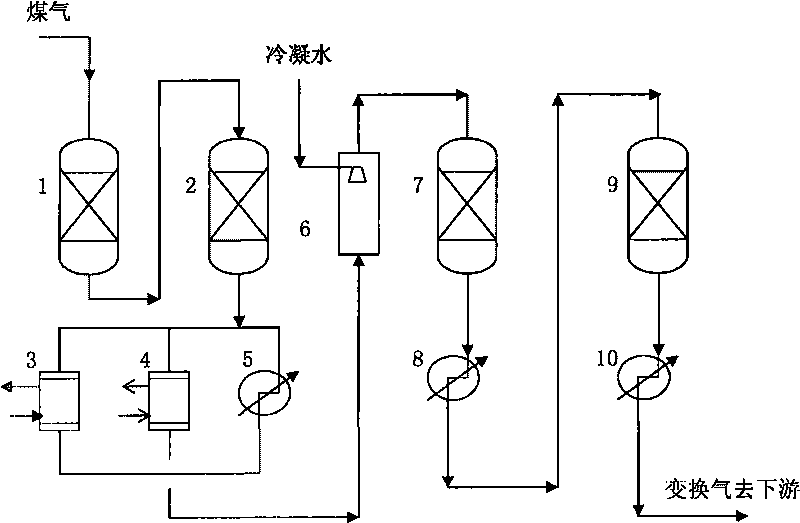

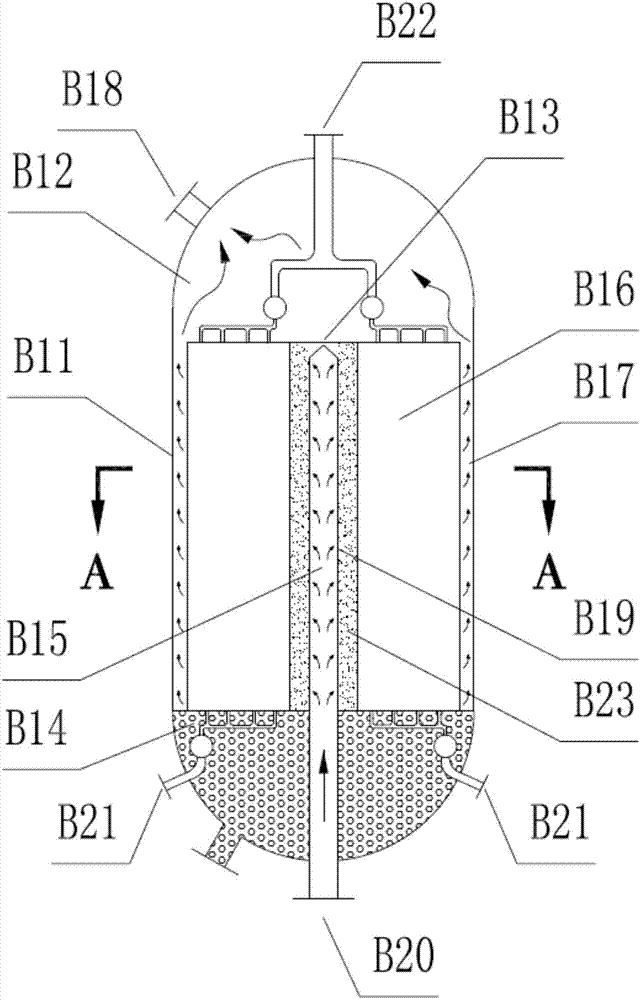

Isothermal low-temperature CO shift reactor

ActiveCN101721956AStable temperatureLess added steamHydrogenChemical/physical processesWater vaporSteam drum

The invention relates to an isothermal low-temperature CO shift reactor which is reaction equipment used for carrying out a reaction that CO and water vapor are converted into CO2 and H2 under certain low temperature. The isothermal low-temperature CO shift reactor comprises a radial basket in a cylindrical shell, a vapor chamber and a water chamber, wherein a catalyst is filled in the radial basket with a central tube to form a catalyst bed, and the catalyst bed is internally provided with a plurality of suspension heat exchange tubes containing water; the upper ends of short tubes are communicated with the water chamber, while the lower ends are inserted into the heat exchange tubes, and the upper ends of the heat exchange tubes are communicated with the vapor chamber; the catalyst bed is also provided with an inversed U-shaped tube, and both ports of the inversed U-shaped tube are respectively connected with two concentric annular tubes; one annular tube is connected with a vapor outlet of a vapor packet through a connecting tube and a vapor inlet, while the other annular tube is communicated with an annular space between the cylindrical shell and the radial basket through a corresponding connecting tube, and an unreacted gas inlet is also communicated with the annular space; a water outlet of the vapor packet is connected with the water chamber; and a vapor outlet of the vapor chamber is connected to a vapor inlet of the vapor packet. The isothermal low-temperature CO shift reactor can continuously release heat and continuously remove reaction heat by using another medium so as to maintain the reaction to be carried out at isothermal low temperature.

Owner:HUNAN ANCHUN ADVANCED TECH

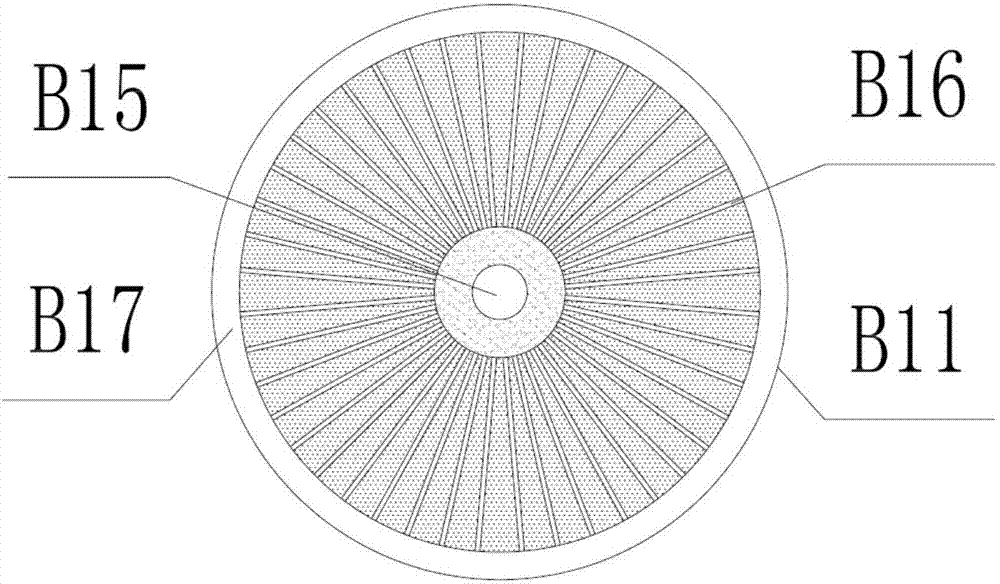

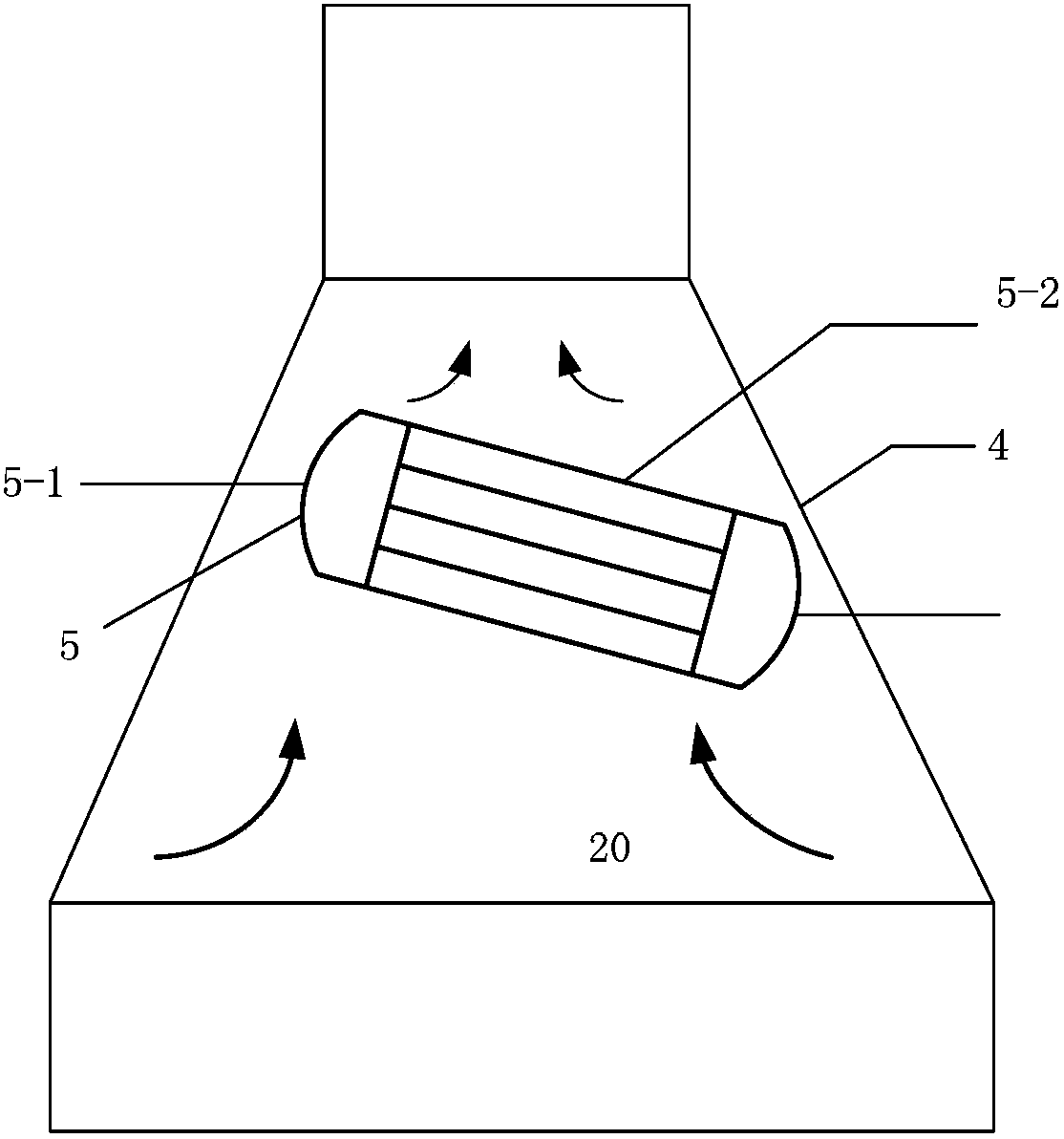

Steam/water conical cyclone separator

ActiveUS7637699B2Improve the cyclone separatorSmall diameterLiquid degasificationReversed direction vortexCycloneEngineering

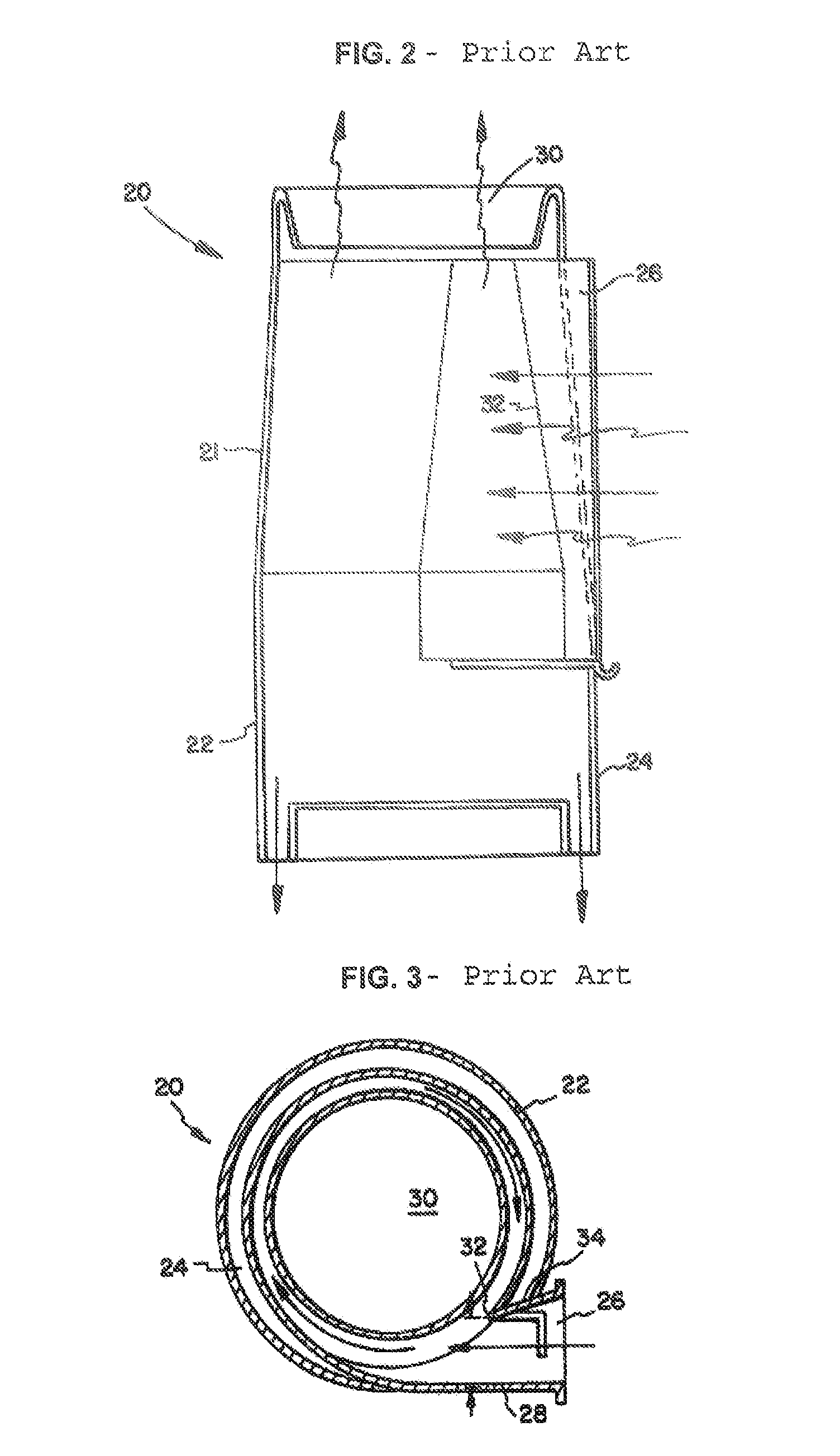

A conical cyclone separator for separating steam from water in a steam / water mixture supplied to a steam drum of a boiler. A widened tangential inlet extends the axial length of the conical portion of the separator, increasing the width of the inlet while causing no derogation in steaming capacity and substantially lowering pressure drop. The inlet design of this separator is compatible with smaller diameter steam drums unable to currently utilize conventional separators.

Owner:THE BABCOCK & WILCOX CO

Smoke reheating device of combining phase-change heat exchanger with net gas heater

ActiveCN102997267ASolve the problem of air leakageSolve the cloggingLighting and heating apparatusAir preheaterGas heater

The invention relates to a smoke reheating device of combining a phase-change heat exchanger with a net gas heater. No smoke reheating device capable of preventing a chimney from being corroded, and emitting white smoke and misty rain, and the like exists at present. The smoke reheating device comprises a smoke flue, and a smoke thermometer, wherein the smoke reheating device is characterized by also comprising an air pre-heater, the phase-change heat exchanger, the neat gas heater, a terminal controller, a downcomer, a condensed refrigerant thermometer, a phase-change heat-exchange steam pocket, a riser pipe, a heat transfer medium thermometer, a water inlet pipe, a water return pipe, a steam inlet pipe and a steam outlet pipe; the air pre-heater, the phase-change heat exchanger and the net gas heater are arranged inside the smoke flue; one end of the water inlet pipe is fixed on the phase-change heat-exchange steam pocket; the other end is fixed on the net smoke heater; and the smoke thermometer, a steam regulating valve, a flow regulating valve, the condensed refrigerant thermometer and the heat transfer medium thermometer are electrically connected with the terminal controller. The smoke reheating device can avoid the situations that the chimney is corroded, emits white smoke and misty rain.

Owner:HANGZHOU HUADIAN ENERGY ENG

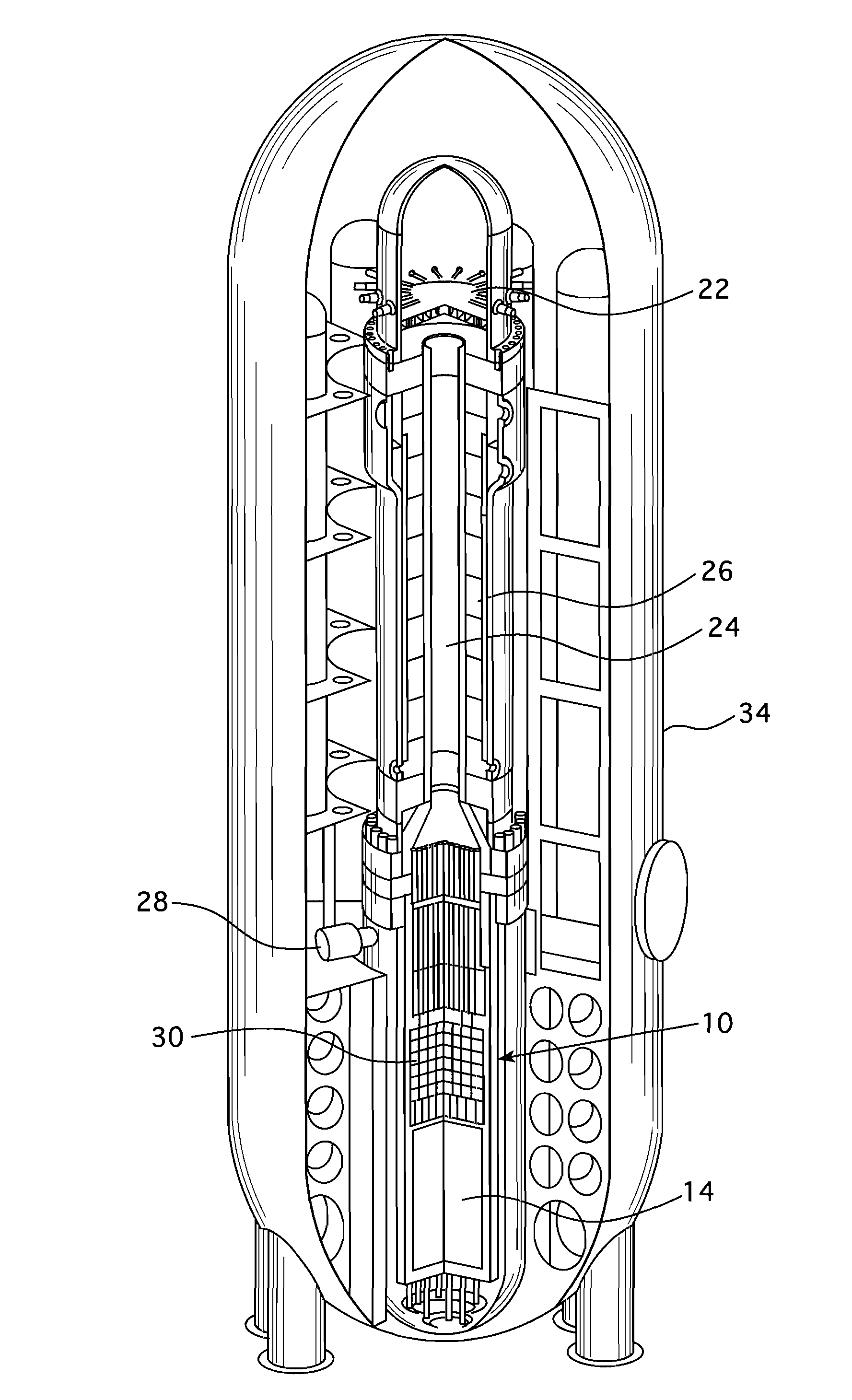

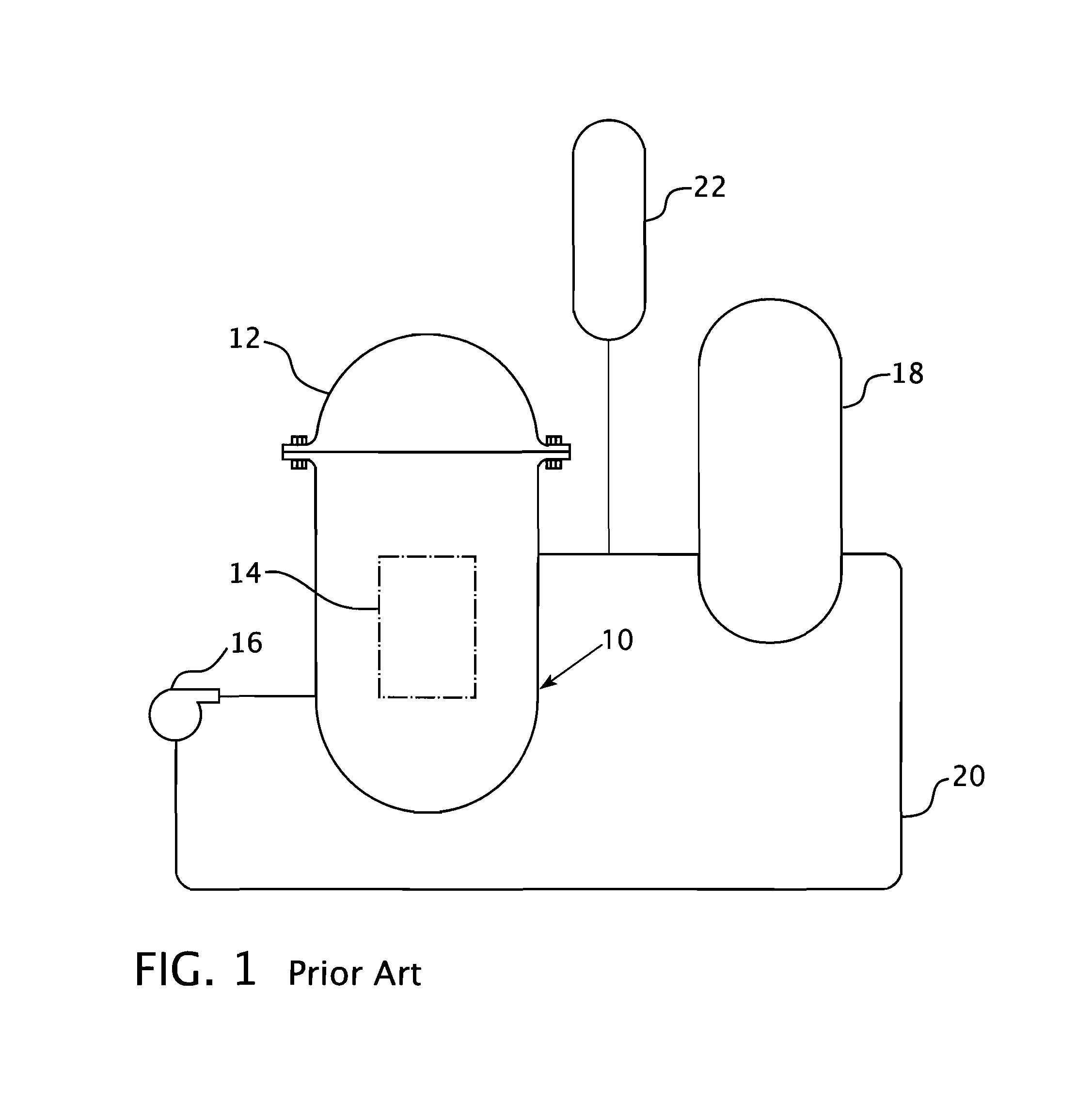

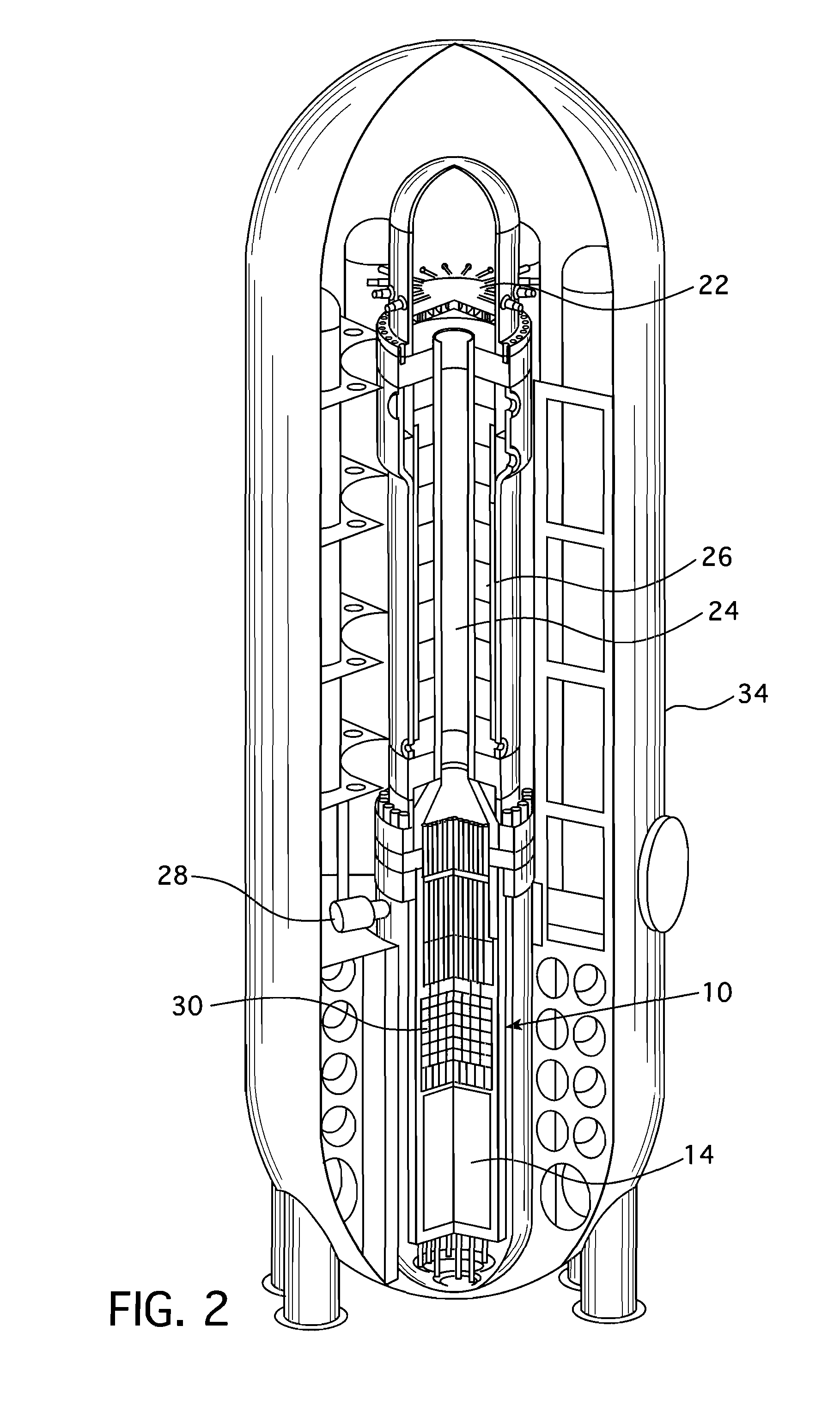

Pressurized water reactor compact steam generator

ActiveUS20130336442A1Facilitate natural recirculation of recirculatingBoiler drums/headersIntegral reactorsPressurized water reactorSteam drum

A steam generator system for a pressurized water reactor which employs an external to containment steam drum and recirculation loop piping. The steam generator system changes the arrangement of a typical pressurized water reactor recirculation steam generator by relocating the functions of steam separation and feedwater preheating outside of the reactor coolant system. The steam generator system and thermal hydraulic conditions are selected in order to minimize the size of the steam generator heat exchanger component volume inside of the containment. The external steam drum component can be isolated in accident conditions when desired and is used as a source of secondary fluid inventory for improved decay heat removal capability and tolerance for loss of feedwater events. Thus, the steam generator component volume inside of the containment is reduced and the amount of maintenance required for the reactor coolant system components are similarly reduced.

Owner:WESTINGHOUSE ELECTRIC CORP

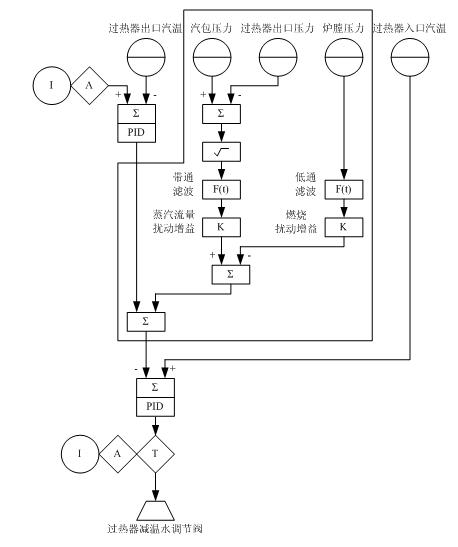

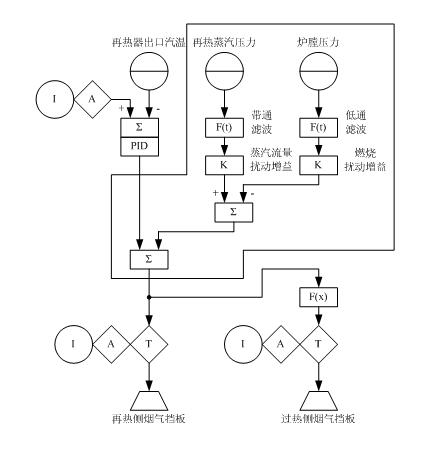

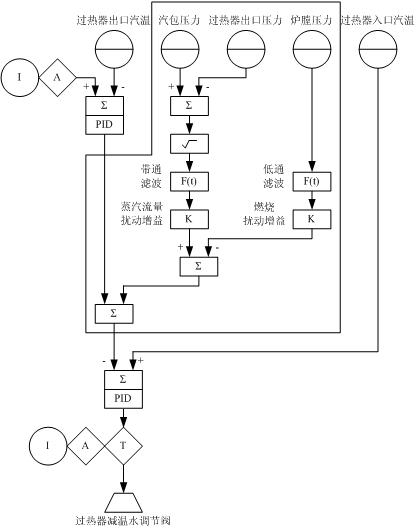

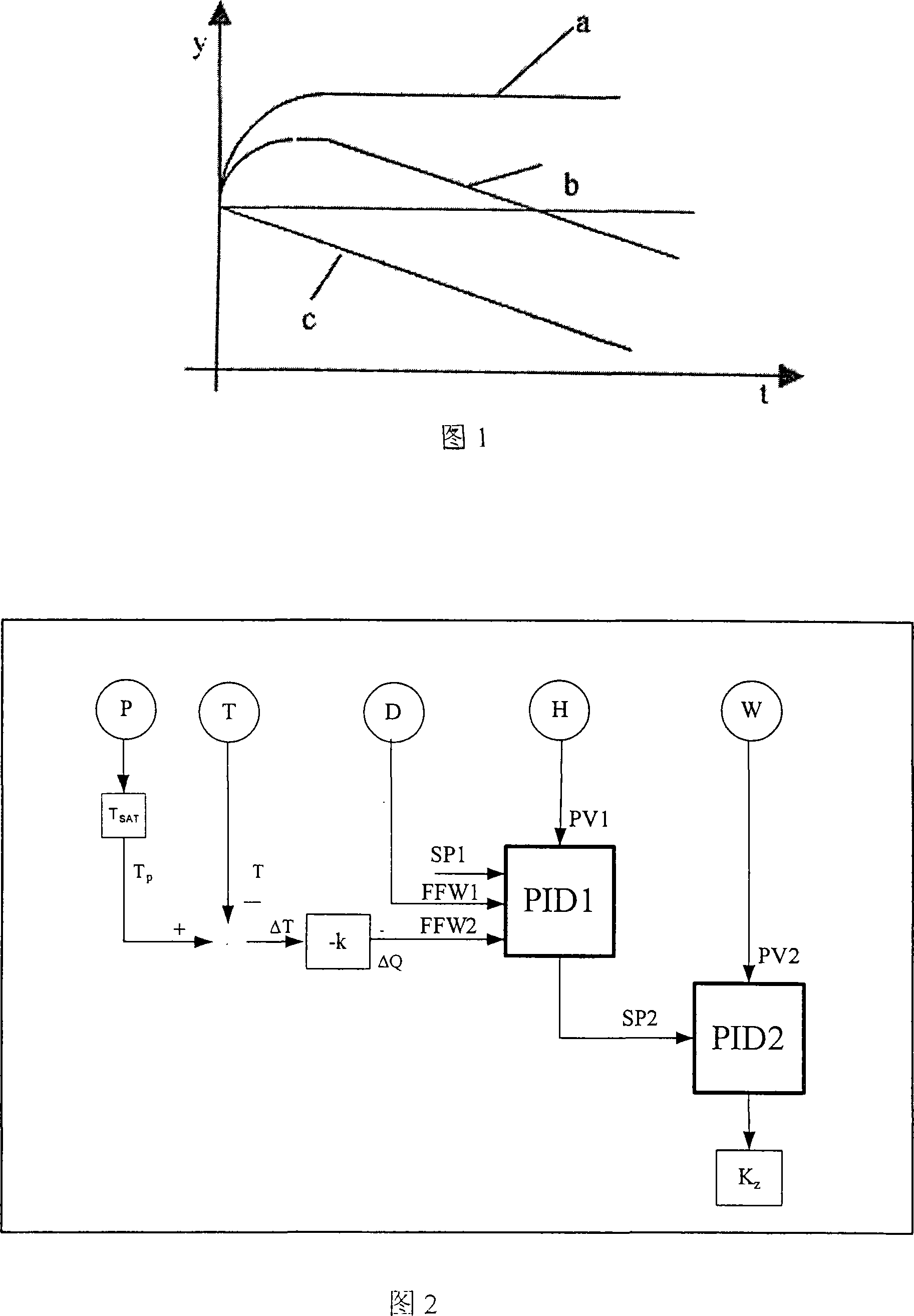

Feedforward signal control method in boiler steam temperature automatic control system

InactiveCN102012017AImprove qualityReduce steam temperature fluctuationsSuperheating controlSteam pressureAutomatic control

The invention discloses a feedforward signal control method in a boiler steam temperature automatic control system, which is used for improving quality of boiler steam temperature control. The technical scheme comprises the following steps of: measuring boiler furnace pressure, boiler steam pocket pressure (or steam-water separator pressure), boiler overheater outlet steam pressure, and boiler reheater outlet steam pressure; and calculating by utilizing the signals to form a combustion disturbing signal, an overheat steam flow disturbing signal, a reheat steam flow disturbing signal, an overheat steam temperature control system feedforward signal and a reheat steam temperature control system feedforward signal in turn. The method can effectively improve the quality of boiler steam temperature control, reduces steam temperature fluctuation caused by combustion disturbance and steam flow disturbance, does not need any additional hardware equipment, only needs increasing a little of software control logic, has low cost and cannot reduce the system reliability.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

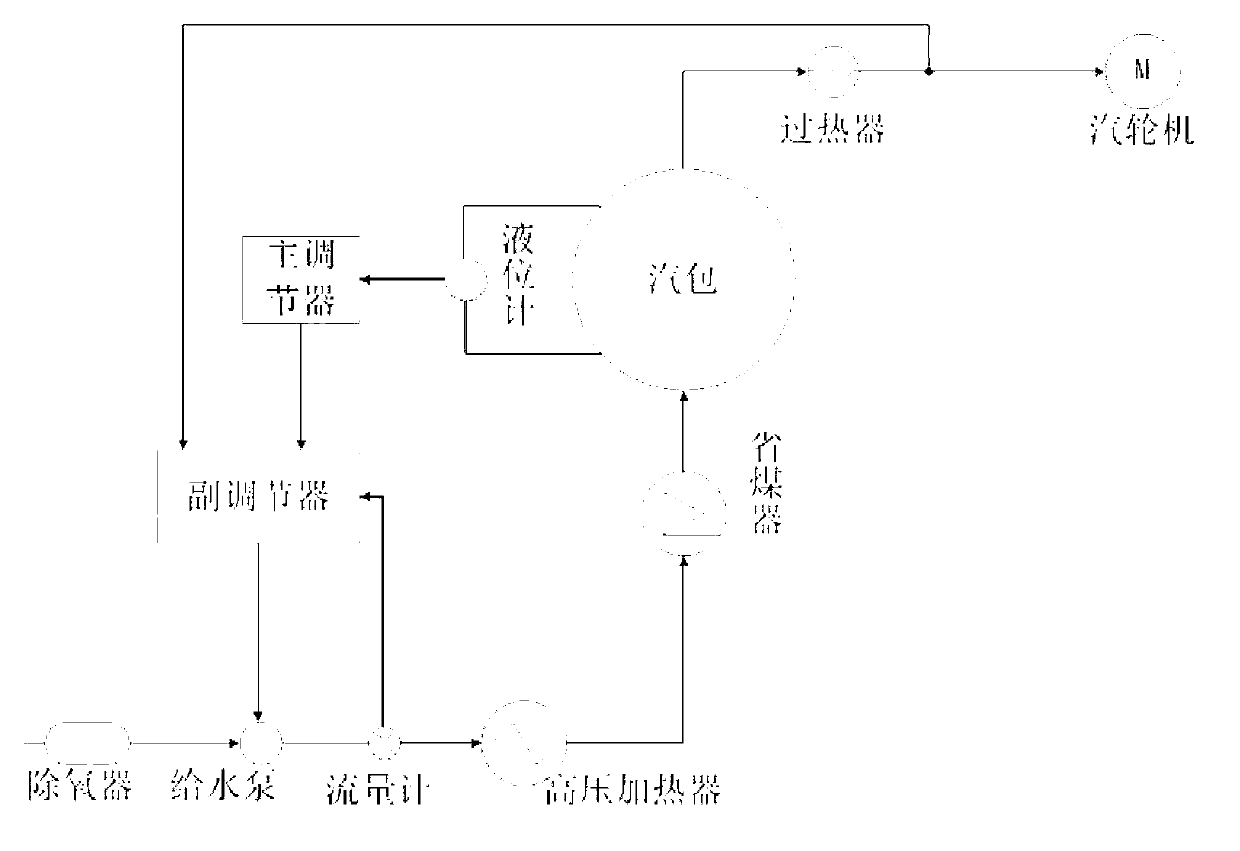

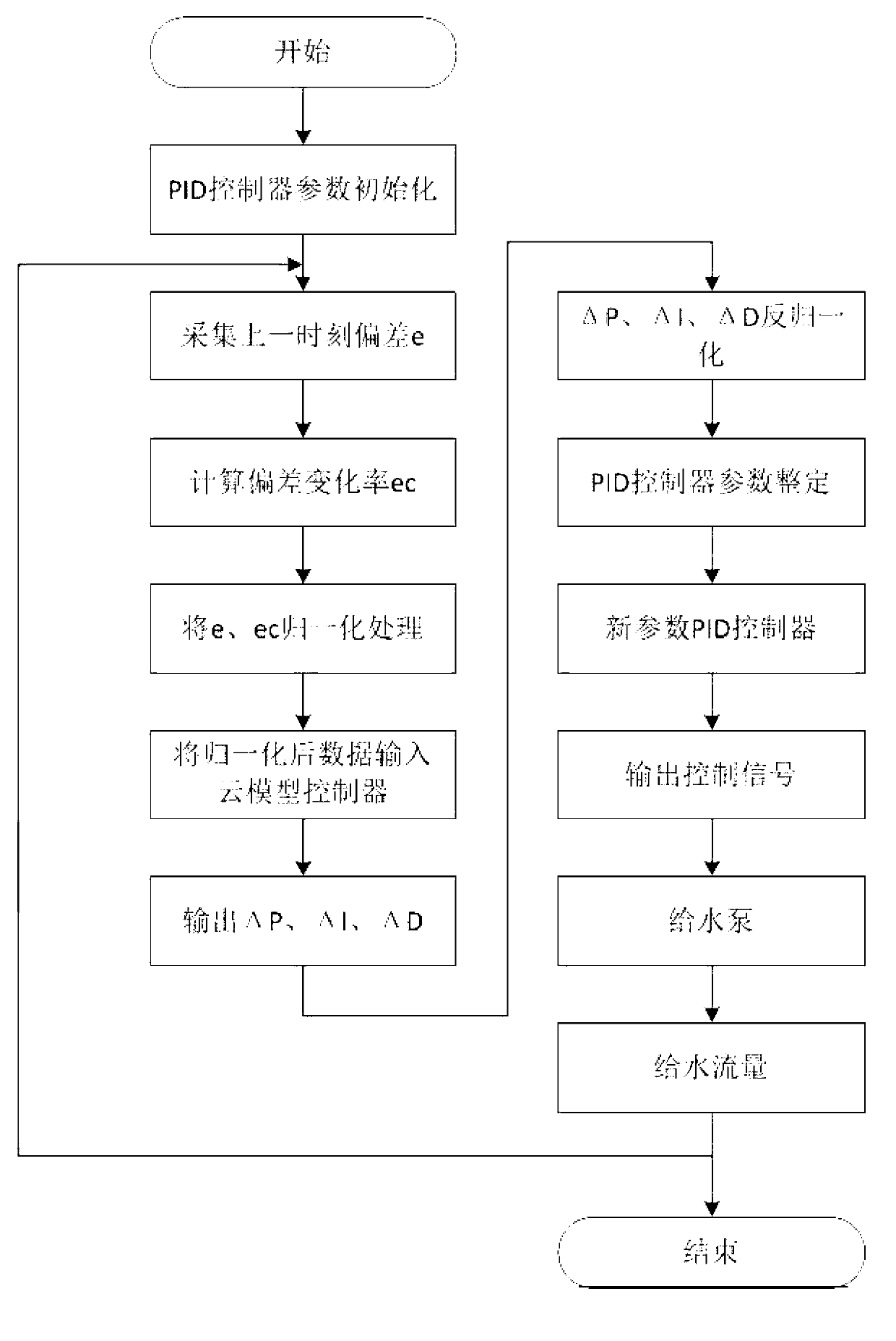

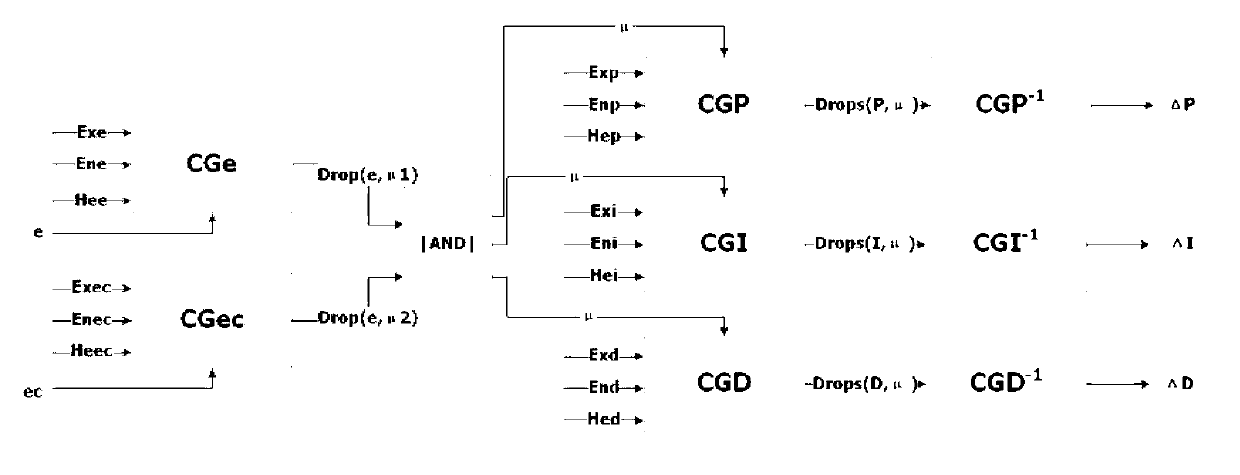

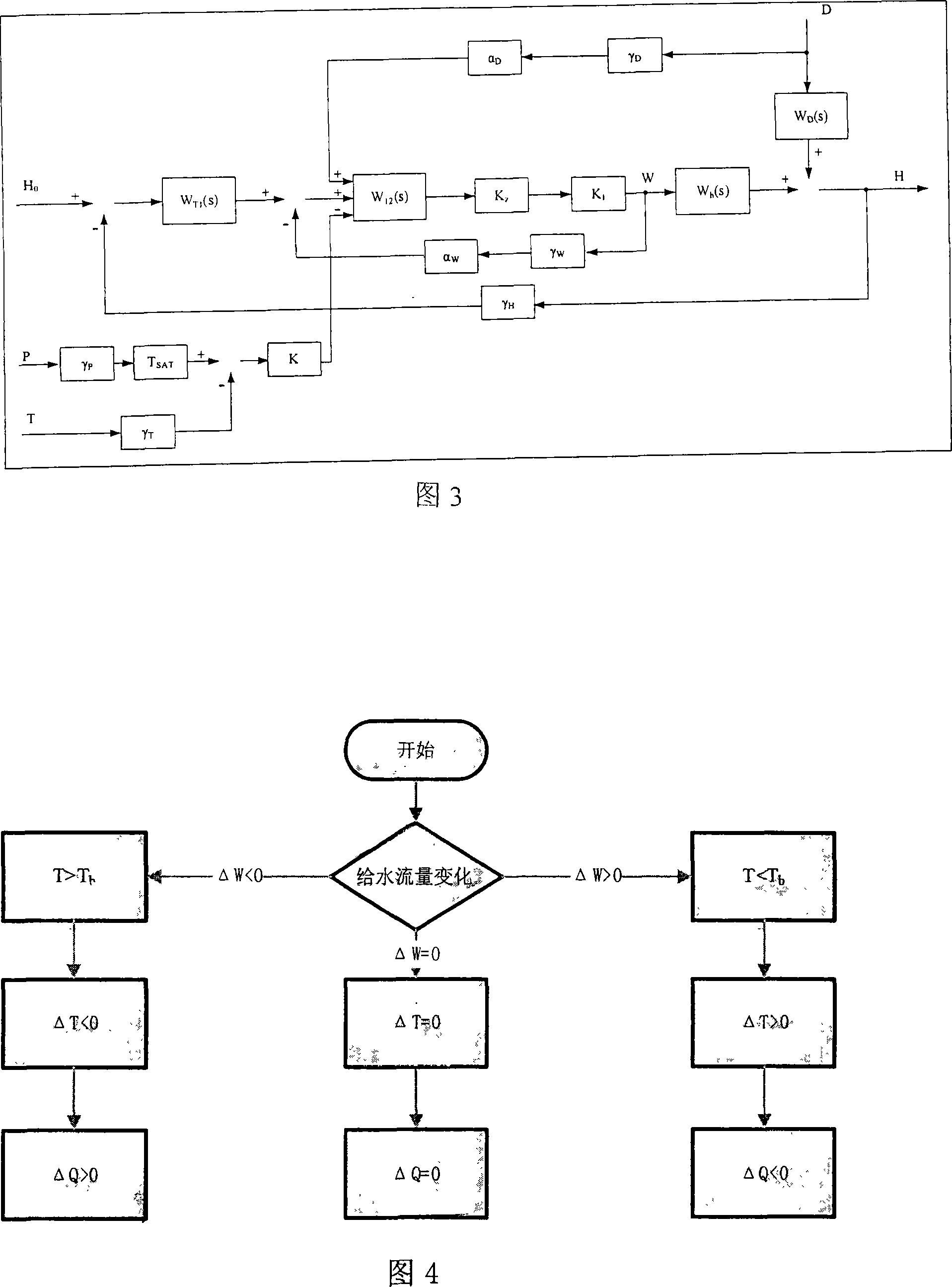

Boiler drum water level self-adaptation PID (proportion integration differentiation) control method

InactiveCN102997222AImprove control qualityWater feed controlProportion integration differentiationControl system

The invention discloses a boiler drum water level self-adaptation PID (proportion integration differentiation) control method in the technical field of electric control. According to the technical scheme, the method comprises the steps of: establishing a two-dimensional dual-input three-output cloud model controller; collecting and controlling system deviation variable quantity e, and calculating the deviation variable rate ec; establishing PID controller setting values delta P, delta I and delta D; substituting the system deviation variable quantity e and the deviation variable rate ec into the two-dimensional dual-input three-output cloud model controller; outputting the setting values delta P, delta I and delta D through seasoning; carrying out linear calculation with a conventional PID controller again, wherein the PID controller which generates novel parameters after setting determines the system output quantity. The boiler drum water level self-adaptation PID control method provided by the invention improves the stability of a boiler drum water level control system, accelerates the system response speed, and intensifies the anti-interference capability on disturbing signals.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

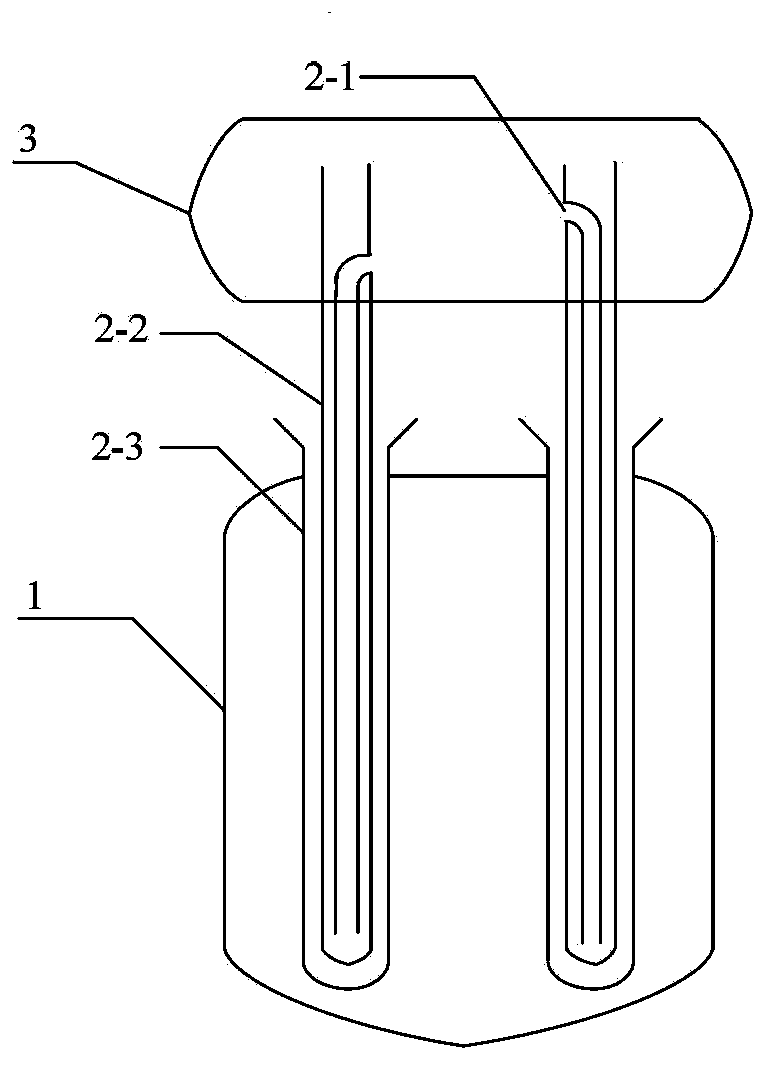

Method for recovering waste heat from coke oven raw gas

ActiveCN103131432AQuality assurancePrevent poppingCoke oven safety devicesEnergy inputWater vaporCoke oven

The invention relates to a method for recovering waste heat from a coke oven raw gas. The method utilizes water as a heat exchange medium, water exchanges heat with the raw gas having a temperature of about 650-750DEG C in a riser heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 480-550DEG C, the heat exchange medium forms a vapor-water mixture after heating, and enters a vapor bag, and the vapor-water mixture is separated to form high temperature water and saturated vapor by a vapor-water separator in the vapor bag; the raw gas discharged from the riser heat exchanger undergoes heat exchange in a bridge tube heat exchanger, the temperature of the raw gas subjected to the heat exchange decreases to 280-350DEG C, and the high temperature water obtained after the separation of the vapor-water separator undergoes heat exchange by the bridge tube heat exchanger, enters the vapor bag and generates saturated vapor, wherein the outer wall of the heat exchanger is cleaned through high-pressure ammonia water intermittent spray or water vapor intermittent blow in the bridge tube; and finally the temperature of the raw gas is reduced to 80-85DEG C by adopting ammonia water, and then the raw gas enters a gas collection tube. The method furthest recovers the waste heat of the raw gas and guarantees the continuous normal work of the heat exchangers under a complex condition.

Owner:BEIJING RISUN TECH CO LTD

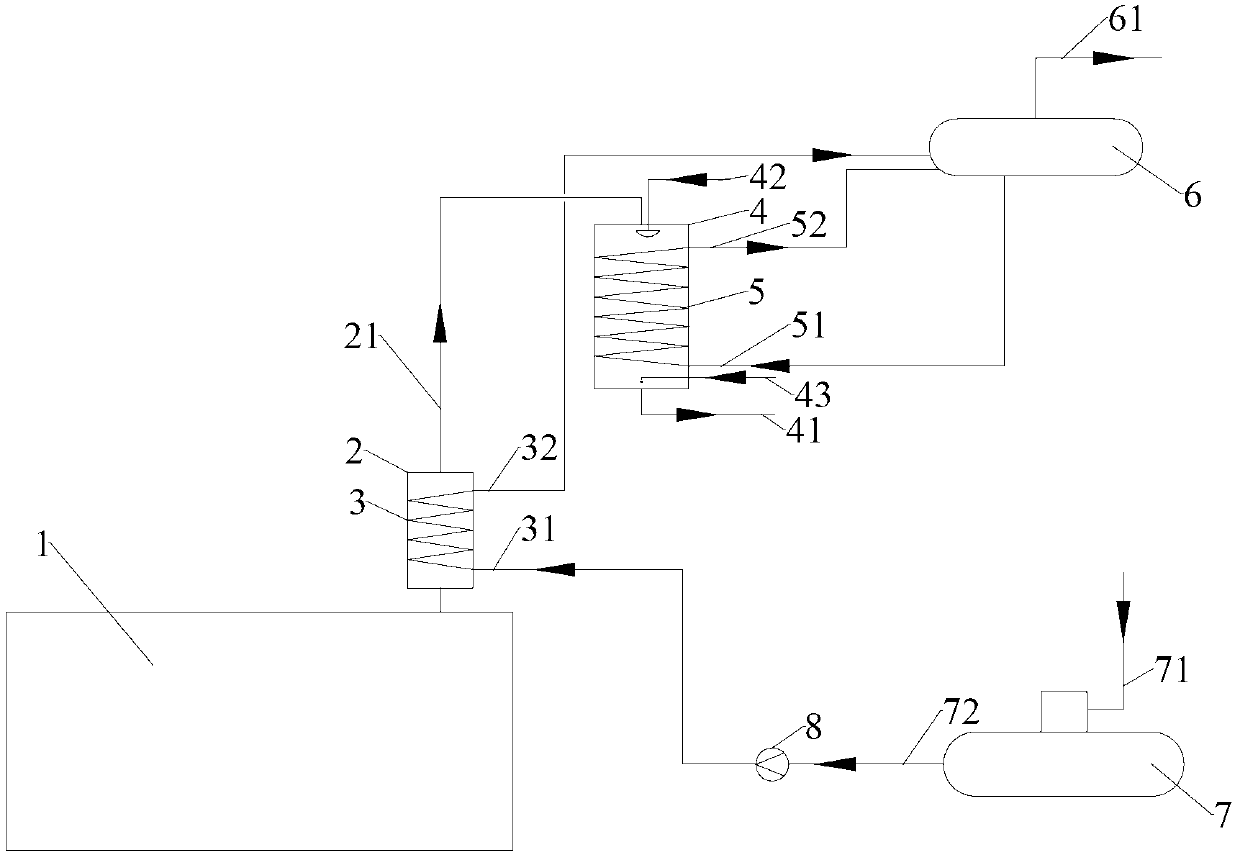

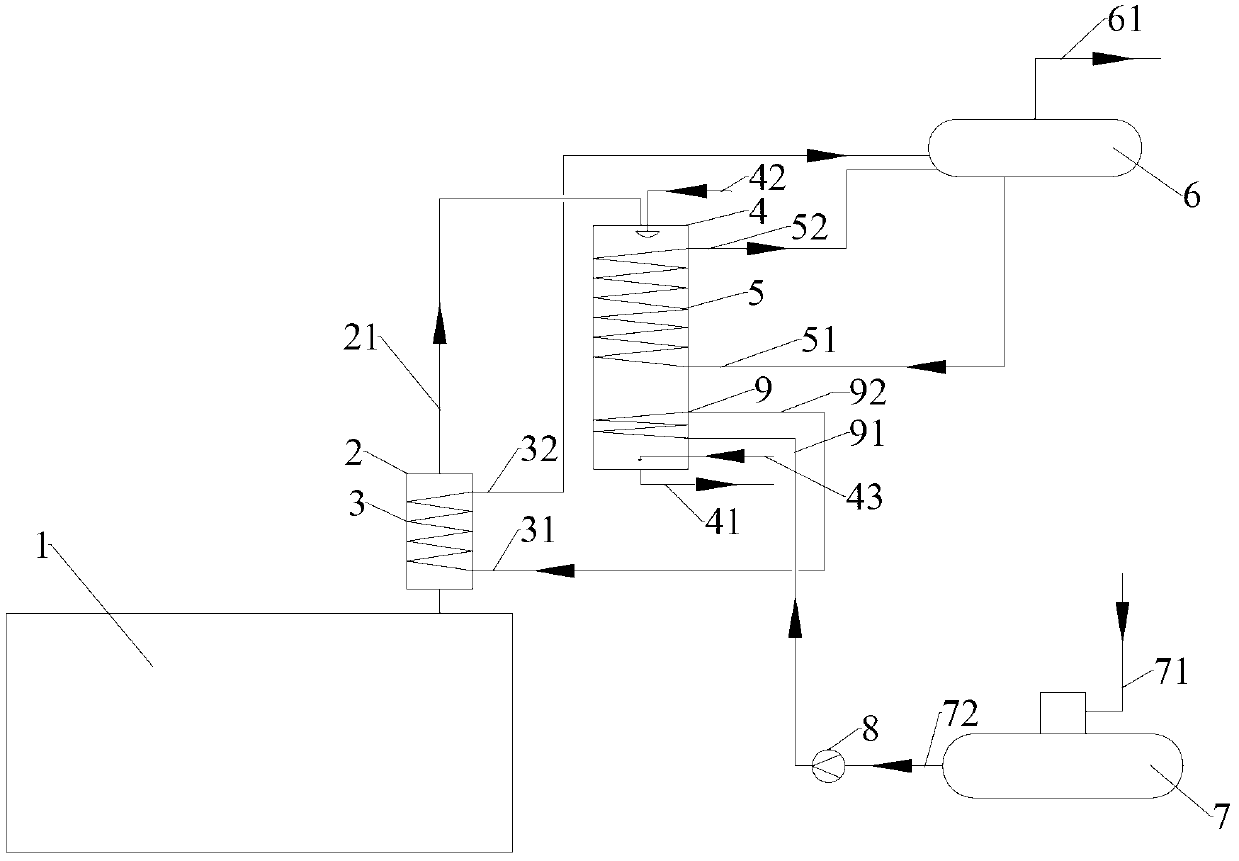

Method for correcting water level of steam drum based on temperature and pressure

ActiveCN101135438AImprove dynamic qualityGuaranteed uptimeSteam separation arrangementsWater feed controlEngineeringLinearity

This invention relates to a correctional method of water level in the steam drum based on the temperature and pressure that belongs to the heat process control field including the following steps: the temperature difference DeltaT is linear to the water supply flow increment in small range, DeltaQ=-kDeltaT, theDeltaQ is used as the feedforward value in the main circuit of the cascade control of the water level in the steam drum, to eliminate the adverse effect of 'false water level' on the water supply control. When the load increases,DeltaQ>0, and the steam drum working condition is nearly stable, the correctional value is 0; when the load decreases, the controlled water supply is suppressed, DeltaQ<0; when the water flow increases, the temperature T of the steam drum decreases and the water supply flow increment DeltaQ<0; when the water supply flow is nearly constant, the correctional value is 0; when the water supply flow decreases, the controlled supply flow increases, DeltaQ>0. This method introduces the effect of steam drum pressure and water temperature on the steam bubble in the steam drum water to correct the water level control, which suppresses the overshoot phenomenon and ensures the steady operation of the boiler.

Owner:CHINA ELECTRIC POWER RES INST +1

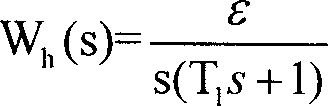

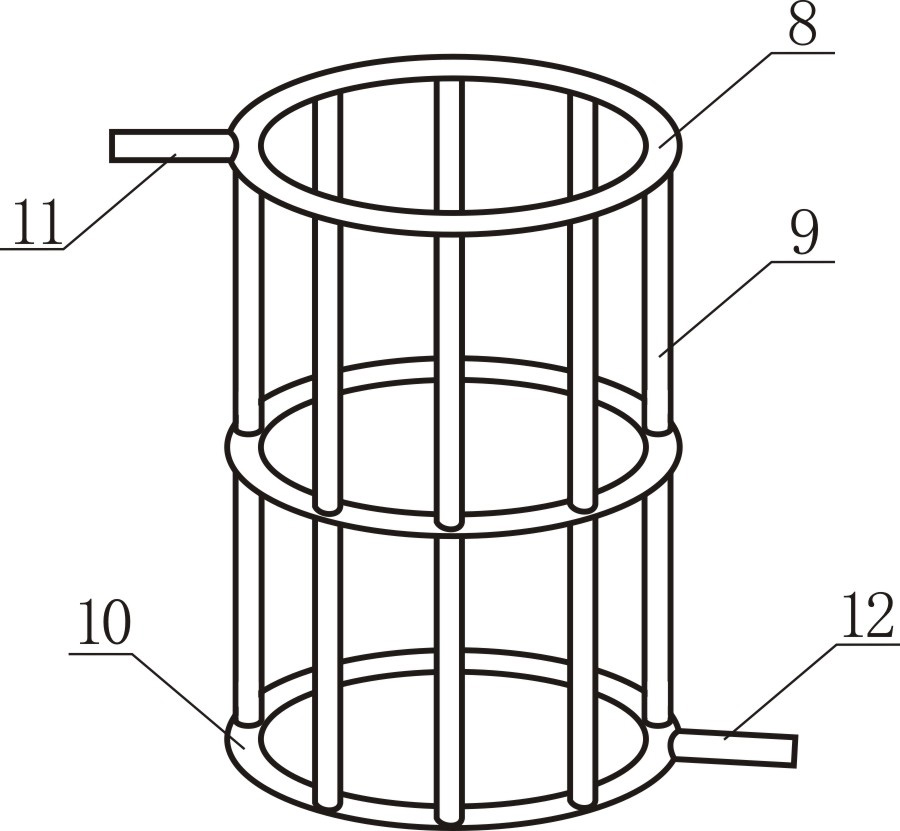

Garbage disposal waste heat power generation system with internal steam pipe

InactiveCN102606236AMaximize recoverySimple structure and processEnergy inputSteam engine plantsFlue gasSteam power

The invention discloses a garbage disposal waste heat power generation system with an internal steam pipe, which comprises a garbage gasifier and a turbine steam power generation device. The turbine steam power generation device comprises a steam generator, a steam discharge pipe, a steam drum, a steam turbine and a power generator, wherein the steam drum, the steam turbine and the power generator are sequentially connected, and the steam generator is arranged in the garbage gasifier and is of a cylindrical cage type structure comprising an upper annular pipe, a plurality of straight pipes and a lower annular pipe. As the steam generator is arranged in the garbage gasifier to realize primary heat exchange and a heat exchanger is additionally arranged in a flue gas channel to realize secondary utilization, heat generated in garbage disposal is used to the maximum extent, the technique with low heat utilization rate of a waste heat boiler for traditional garbage disposal steam power generation in the past is thoroughly changed, and garbage disposal heat recovery is maximized. Owing to a four-step hydraulic pusher, garbage is increasingly looser in the process of entering the garbage gasifier, and is not blocked.

Owner:SHENZHEN JUNENG BIOMASS GASIFICATION TECH

Apparatus and method for determining a liquid level in a steam drum

An apparatus for determining a density-compensated liquid level in a vessel containing a mixture of liquid and vapors comprises a temperature sensor which produces a signal that is proportional to the temperature of the mixture; and a processing apparatus that includes one or more pressure sensors that allow for a measurement of an operating pressure and a differential pressure between the mixture in the vessel and a constant reference leg. The processing apparatus further includes an integral microprocessor for calculating the respective specific gravities of the liquid and vapor portions of the mixture based on the operating pressure, and then computing the density-compensated liquid level in the vessel based on such calculations of specific gravity and the differential pressure.

Owner:VOGT POWER INT

System and method for improving operation capacity of SCR (Silicon Controlled Rectifier) denitration device in electric power plant

ActiveCN103084064AWill not affect the original operating parametersExtension of timeDispersed particle separationAir preheaterSilicon-controlled rectifier

The invention discloses a system and a method for improving the operation capacity of an SCR (Silicon Controlled Rectifier) denitration device in an electric power plant. The system comprises an economizer, a guide plate, an ammonia injection device, a temperature sensor, a denitration device, a cryogenic heat exchanger and an air preheater, wherein an inlet pipeline of the cryogenic heat exchanger, which is connected to a water inlet of the cryogenic heat exchanger, is branched from a water supply inlet pipeline of the economizer, an outlet pipeline of the cryogenic heat exchanger is arranged between a water outlet of the cryogenic heat exchanger and a steam pocket, one series-connection pipeline is arranged between the water supply inlet of the economizer and the outlet pipeline of the cryogenic heat exchanger, a series-connection valve is arranged on the series-connection pipeline, an outlet valve of the cryogenic heat exchanger is arranged on the outlet pipeline of the cryogenic heat exchanger, an inlet flow control valve of the economizer is arranged on the water supply inlet pipeline of the economizer, so that parallel connection or series connection of the cryogenic heat exchanger and the economizer is realized. The invention also discloses the method for improving the operation capacity of SCR denitration device in the electric power plant.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

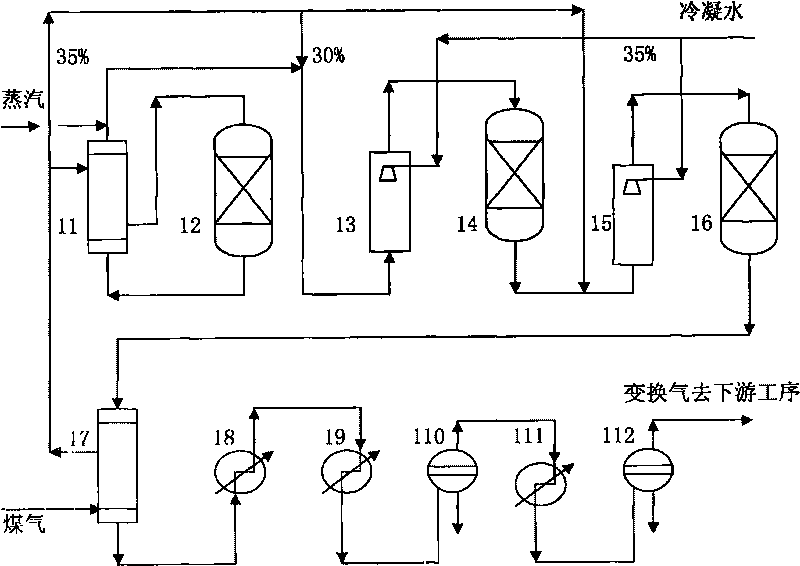

Isothermal conversion process of high-concentration carbon monoxide and system thereof

InactiveCN104709875AReduced risk of methanation side reactionsReduce resistanceHydrogenHigh concentrationMethanation

The invention discloses an isothermal conversion process of high-concentration carbon monoxide and a system thereof, and solves the problems of long procedure period, high system resistance and short in catalyst life in the existing conversion process. According to the adopted technical scheme, raw material gas flows through a raw material gas separator, so that water carried by the raw material gas is separated; then the raw material gas is filtered by a filter, and then is introduced into a shell side of a gas cooling conversion reactor to be preheated; the preheated raw material gas is introduced into a water cooling conversion reactor I to carry out conversion reaction; steam pocket byproduct steam is used for removing reaction heat of the conversion reaction; conversion gas out of the water cooling conversion reactor I is returned to the shell side of the gas cooling conversion reactor to preheat the raw material gas in the shell side,, so s to remove the reaction heat and continue to carry out conversion reaction; the conversion gas out of the gas cooling conversion reactor is further subjected to heat recycling, and after the condensed liquid is separated, the conversion gas is subsequently introduced into the downstream process. The isothermal conversion process of high-concentration carbon monoxide is simple in process, high in system reliability, low in methanation side reaction, short in process, low in system resistance, long in service life of catalyst, and low in equipment investment and operation cost.

Owner:WUHUAN ENG

Oil field steam filling boiler of circulation fluidized bed using water coal slurry as fuel

InactiveCN1563793ACurb emissionsRealize direct desulfurizationFluidized bed combustionApparatus for fluidised bed combustionWear resistantEngineering

The oil well gas injecting boiler has screw pump in pressure of 0.2-0.4 MPa to supply fuel from the upper part of the boiler, single steam drum in naturally circulating mode to obtain high pressure steam of 17.5-21 MPa; quartzite and limestone powder as fuidizing medium for low multiplying factor circulation; and power amount of limestone powder for clean burning at temperature of 850-950 deg.c. The boiler of the present invention has water cooling furnace wall, coated heat resistant and corrosion resistant refractory material and sprayed heat resistant and wear resistant Ni-Cr alloy, pipe type backwards bent boiler top, coal economizer of ribbed spiral pipes, cyclonic separator with wear resistant material, water cooling wall with inner thread pipe, high temp alloy steel material in high temperature and high pressure sections, welded support frame structure, flexible 3D expanding section in important joint part, and hydrostats.

Owner:SHENYANG DAVID ENVIRONMENT PROTECTION & ENERGY SAVING EQUIP LTD

Fixed bed composite reaction equipment

ActiveCN101480592AQuick responseRelease more heat of reactionChemical/physical processesMethanationFixed bed

The invention relates to fixed bed combined reaction equipment which mainly comprises a cylindrical shell with an end enclosure, a reaction gas inlet and a reaction gas outlet on the shell, a porous gas distributor, a porous gas collection plate, a catalyst layer and a heat exchange pipe for cooling media to transfer heat; steam headers provided with stream pressure adjusting valves form a cooling medium circular loop of which catalysts in at least one heat exchange reaction area are filled in the pipe. The fixed bed combined reaction equipment ensures that heat transfer is designed according to the requirement on the amount of the reaction heat transfer in the reaction, is used for the synthesis of methanol and dimethyl ether, methanation, F-T reaction, the preparation of phthalic anhydride by ortho-xylene oxidation and other strong-effect reaction processes, reduces the temperature difference, improves the reaction efficiency and the yield, saves energy, reduces consumption and achieves the large-sized aim.

Owner:杭州林达化工技术工程有限公司

Passive residual heat exhausting system for molten salt reactor

InactiveCN103400608AImprove intrinsic safetyIncrease cooling powerNuclear energy generationCooling arrangementSystems designEngineering

The invention aims to provide a passive residual heat exhausting system for a molten salt reactor. The passive residual heat exhausting system comprises a salt discharging pot, heat exchanging elements, a steam pocket and a ventilator, wherein the upper part of each heat exchanging element is located in the steam pocket, the lower part of each heat exchanging element is located in the salt discharging pot, and other parts of each heat exchanging element are located between the steam pocket and the salt discharging pot; each heat exchanging element comprises a heat transferring pipe; each heat transferring pipe is internally provided with a middle sleeve; each middle sleeve comprises an inner wall and an outer wall; a channel for steam to flow through is formed between each inner wall and the corresponding outer wall; a water inlet pipeline is formed in the inner wall of each middle sleeve, a water inlet is formed in the top of each water inlet pipeline, and the bottom end of each water inlet pipeline is disconnected and is communicated with the corresponding channel; the ventilator is internally provided with an air cooler; an air cooler inlet is formed in the end part of the air cooler and a fin pipe is arranged in the middle of the air cooler; the steam pocket is communicated with the air cooler inlet. According to the passive residual heat exhausting system for the molten salt reactor provided by the invention, the passive working capability of the system is improved, the problems of high fault rate and the like caused by the design of an active system are solved, and therefore, the safety of the residual heat exhausting system for the molten salt reactor is improved.

Owner:HARBIN ENG UNIV

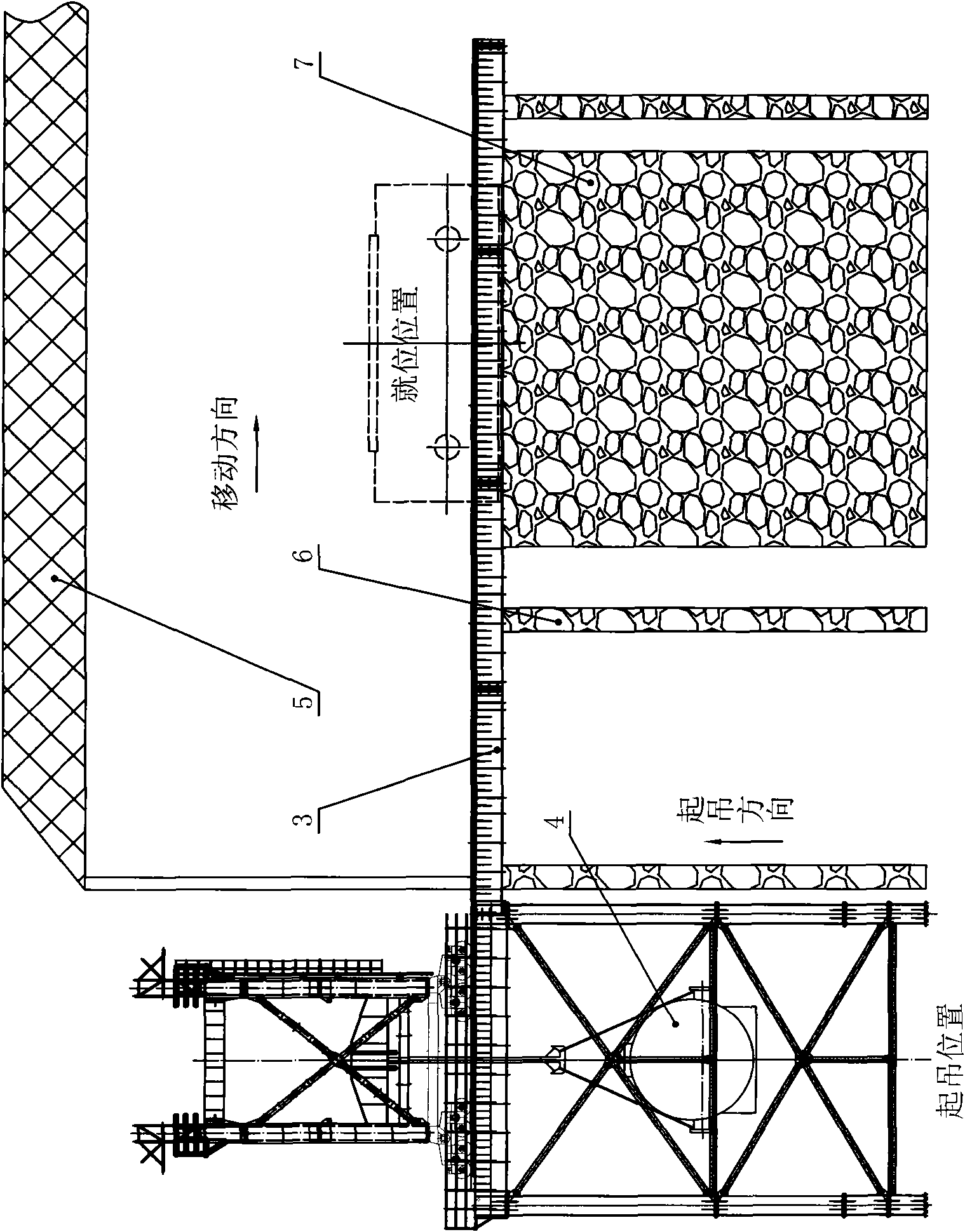

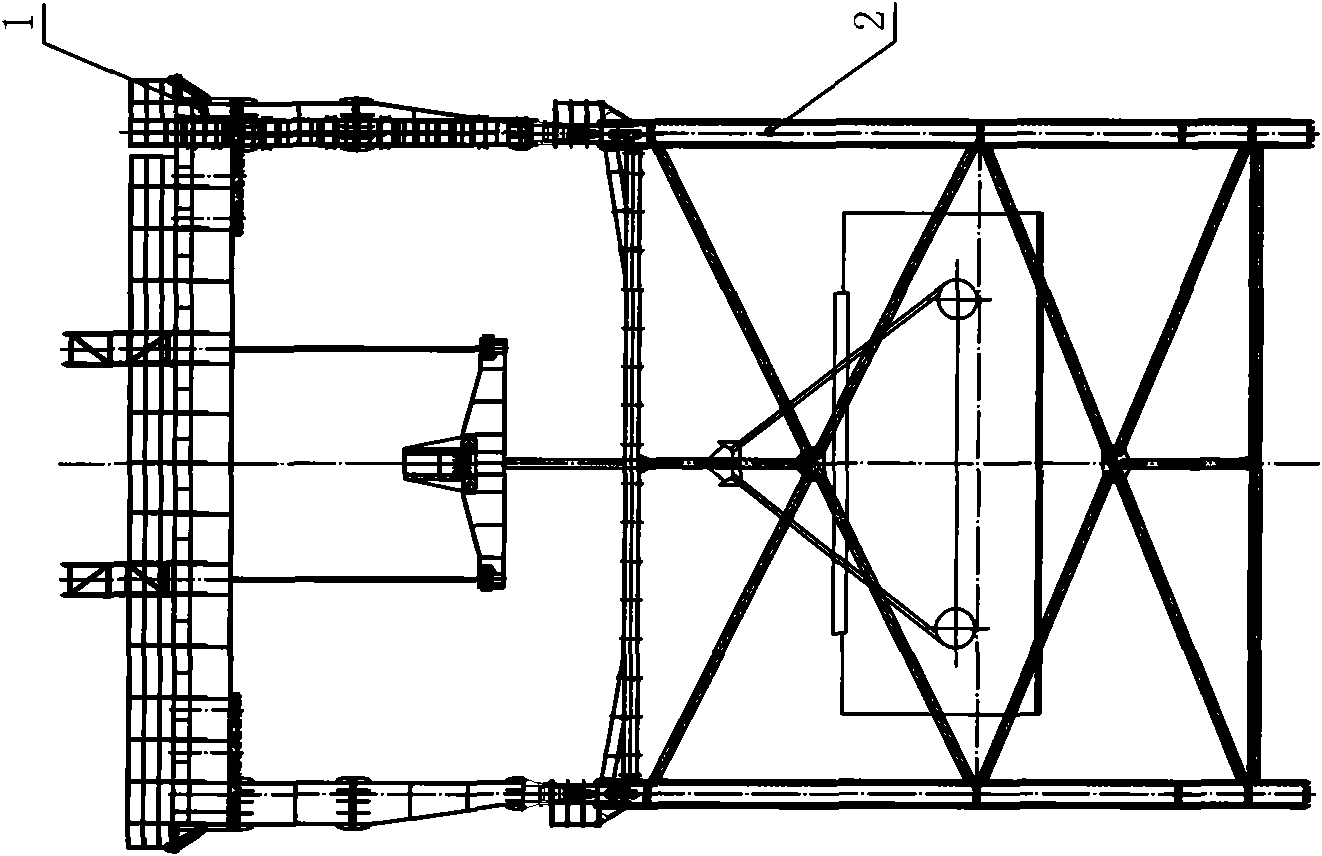

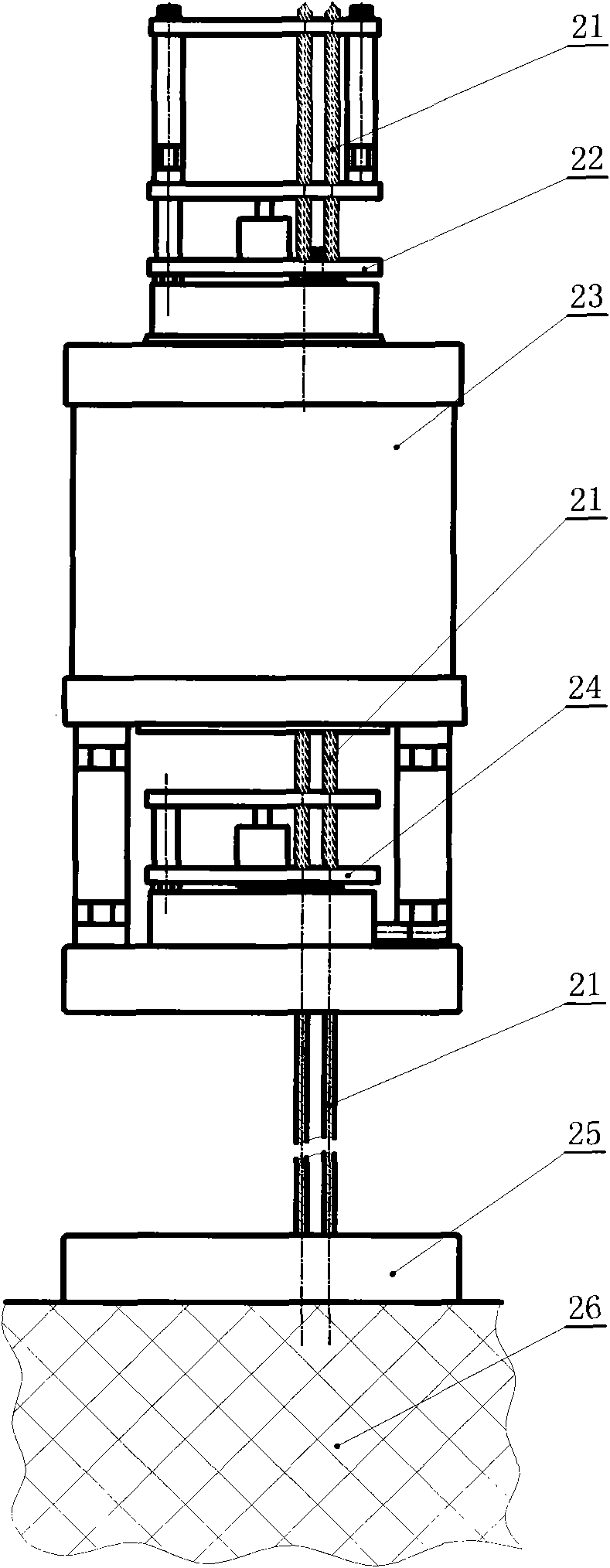

Multifunctional combined type lifting framework for installing large scale electrical power unit

ActiveCN101580211AMeet the needs of installation and constructionVarious combinationsLoad-engaging girdersTravelling cranesTransformerEngineering

The invention relates to a multifunctional combined type lifting framework which is a heavy-duty hoisting steel structure designed by combining the installation and construction requirements of large scale equipment in power industry. The lifting framework mainly comprises a moving rack 1, a fixing rack 2, a track girder 3, auxiliary components, etc; wherein, the moving rack 1 is arranged at the installing position of a steel wire type hydraulic lifting device to realize horizontal shifting of a lifted part 4; the fixing rack 2 is installed at the outer side of the end part of a steam turbine building 5 to support the moving rack 1; the track girder 3 is installed on an upright post 6 of the steam turbine building for providing a travelling track for the moving rack 1; the auxiliary components are used for installing steam drums, main transformers, etc. The multifunctional combined type lifting framework has the characteristics of multiple functions, various combining forms and the like, can meet the installing needs of stators, the steam drums, the main transformers and the like of all levels of thermal generator sets with of 1000MW and below when being matched with the steel wire type hydraulic lifting device, and has the advantages of safety and reliability, convenient assembly and transportation, high construction efficiency and the like, thus providing a brand-new solution for the installation of the large scale electrical power units.

Owner:CHINA ELECTRIC POWER RES INST +1

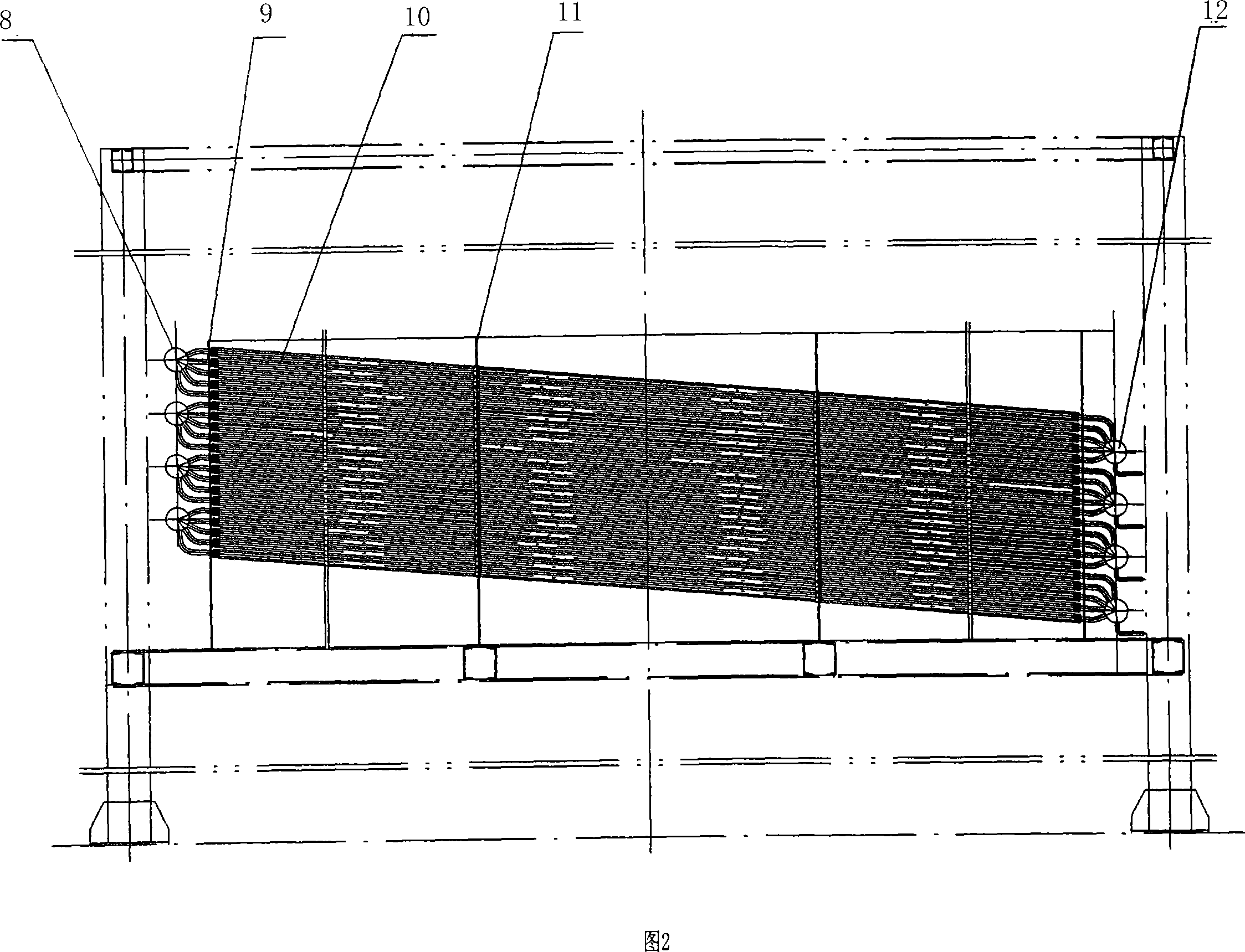

Sinter cooler low temperature waste gas residual heat boiler and power generating system thereof

InactiveCN101021305AEasy to discharge ashSmall footprintSteam boilersSteam boilers componentsWhole bodyEvaporation

The present invention provides an exhaust-heat boiler capable of effectively utilizing low-temperature heat transmission to make power generation and its power generation system. Said exhaust-heat boiler whole body adopts vertical type arrangement and tube-box type structure, in the boiler tube-box interior are successively set super heater, evaporation zone, low-pressure evaporation zone, coal economizer and low-pressure coal economizer from top to bottom, in which the evaporation zone and low-pressure evaporation zone have several groups of evaporators, these evaporators are obliquely placed in smoke flue, their inclination angle is 5 deg-15 deg. Said invention also provides the concrete structure of every evaporator, and provides the working principle of said exhaust-heat boiler and its power generation system and their concrete operation method.

Owner:JIANGSU DONGJIU HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com