Garbage disposal waste heat power generation system with internal steam pipe

A technology for thermal power generation system and garbage disposal, applied in the steam generation method using heat carrier, steam engine device, machine/engine, etc., can solve the problems of high operation and maintenance costs, low incineration temperature, secondary pollution, etc., and avoid garbage Odor leakage, simple structure and flow, and the effect of avoiding tar clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

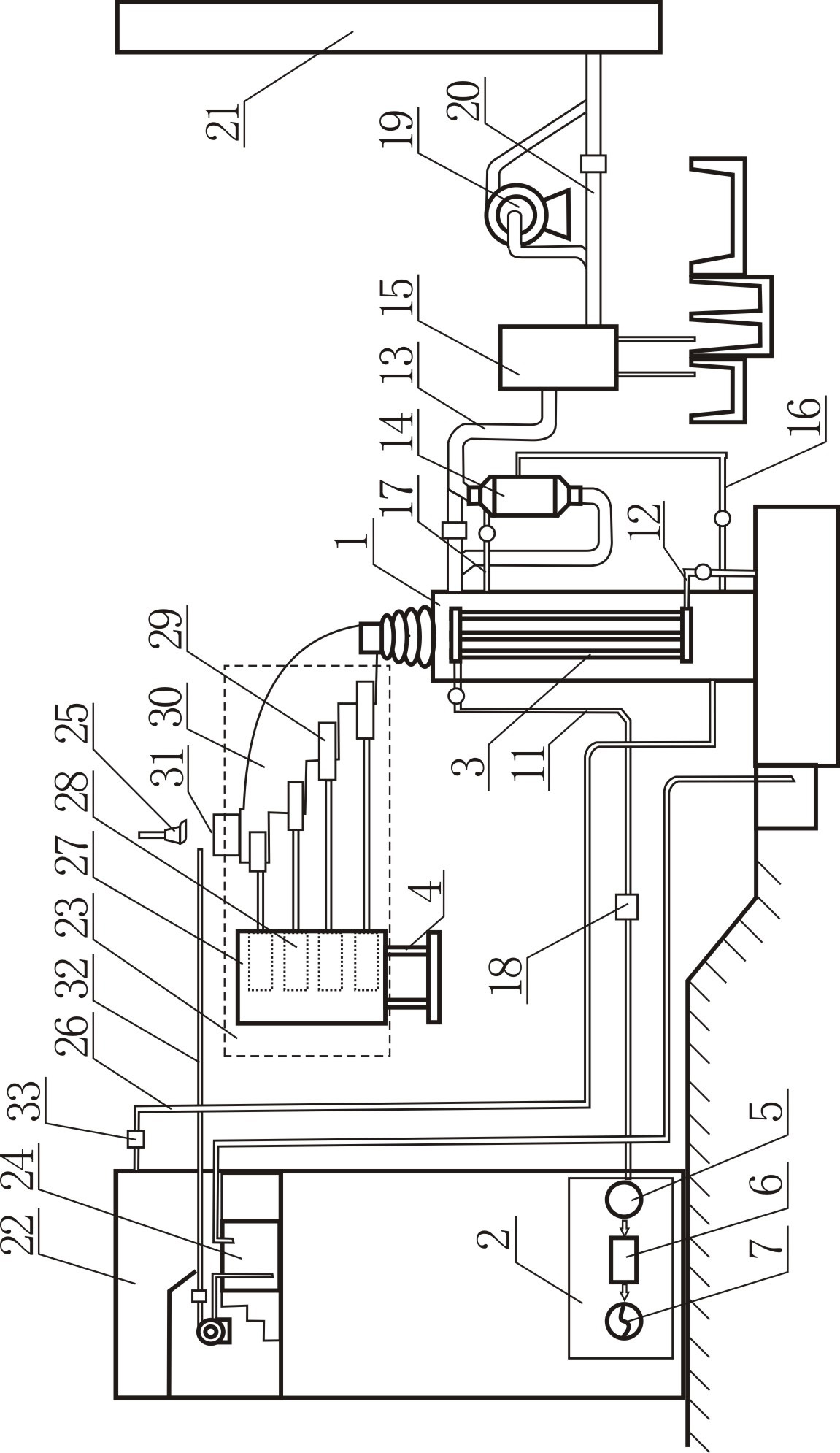

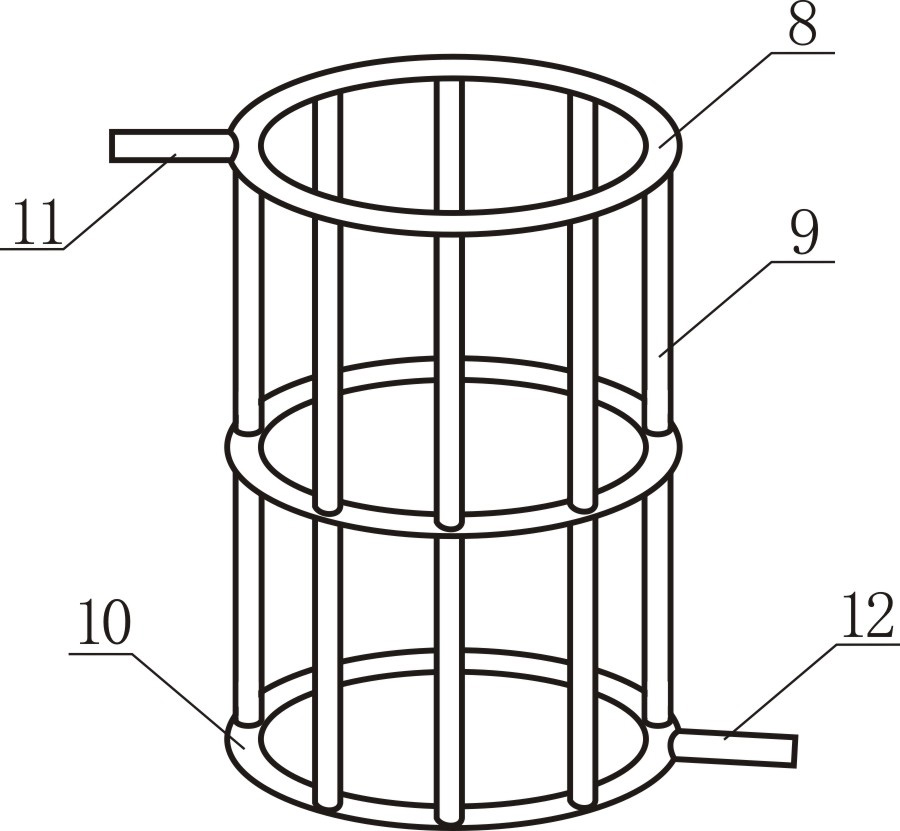

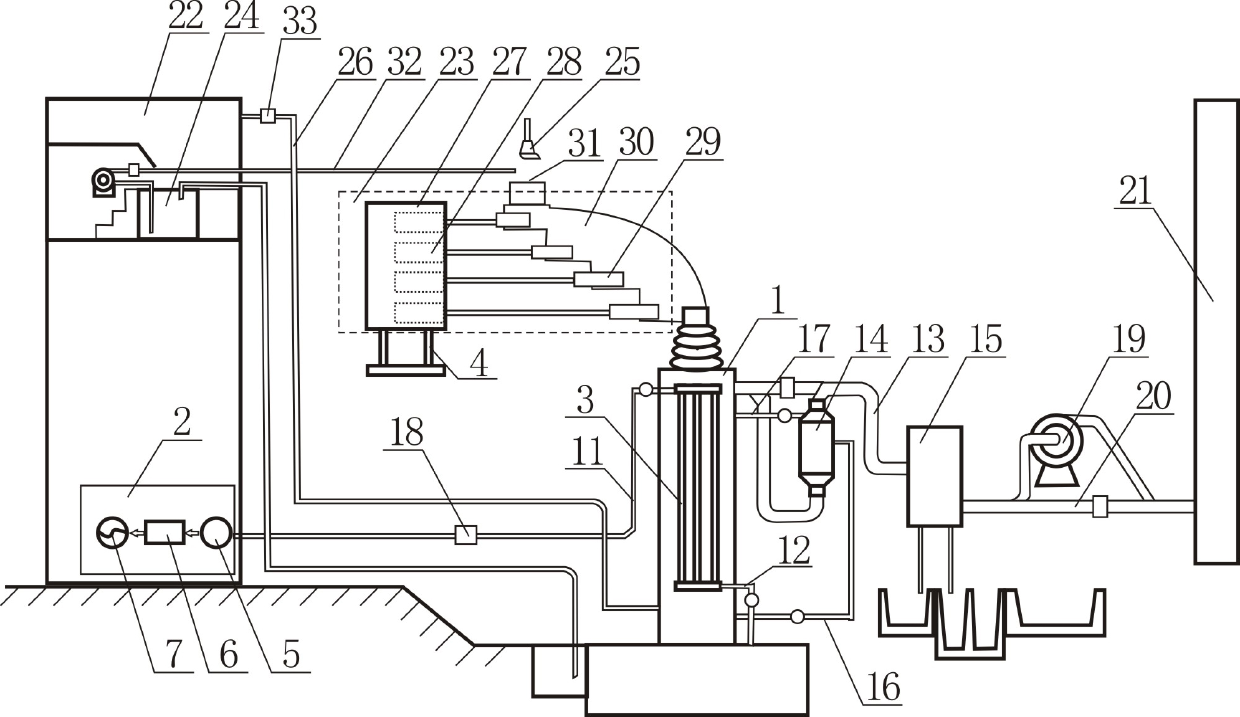

[0026] Such as figure 1 , 2 As shown, the built-in steam tube type waste heat power generation system includes a waste gasifier 1 and a steam turbine power generation device 2, wherein the steam turbine power generation device 2 includes a steam generator 3, a steam discharge pipe 11, a steam drum 5, steam turbine 6 and generator 7, steam bag 5, steam turbine 6 and generator 7 are connected successively, and described steam generator 3 is arranged in garbage gasifier 1; The cylindrical cage structure formed by the straight pipe 9 and the lower annular pipe 10, the two ends of each straight pipe 9 communicate with the upper annular pipe 8 and the lower annular pipe 10 respectively; the upper annular pipe 8 and one end of the steam discharge pipe 11 The other end of the steam discharge pipe 11 is connected with the steam drum 5, and the lower annular pipe 10 is connected with a water inlet pipe 12, and the water inlet pipe 12 and the steam discharge pipe 11 are respectively pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com