Patents

Literature

106 results about "Forest product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A forest product is any material derived from forestry for direct consumption or commercial use, such as lumber, paper, or forage for livestock. Wood, by far the dominant product of forests, is used for many purposes, such as wood fuel (e.g. in form of firewood or charcoal) or the finished structural materials used for the construction of buildings, or as a raw material, in the form of wood pulp, that is used in the production of paper. All other non-wood products derived from forest resources, comprising a broad variety of other forest products, are collectively described as non-timber forest products (NTFP). Non-timber forest products are viewed to have fewer negative effects on forest ecosystem when providing income sources for local community.

Triglyceride/wax replacement for conventional slack and emulsified waxes used in forest products based composites

InactiveUS20050269728A1High mechanical strengthGood dimensional stabilitySynthetic resin layered productsAbsorbent padsForest productEmulsifying wax

The invention is directed to compositions and methods for enhancing the mechanical strength and dimensional stability of composite boards and structures.

Owner:ARCHER DANIELS MIDLAND CO

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

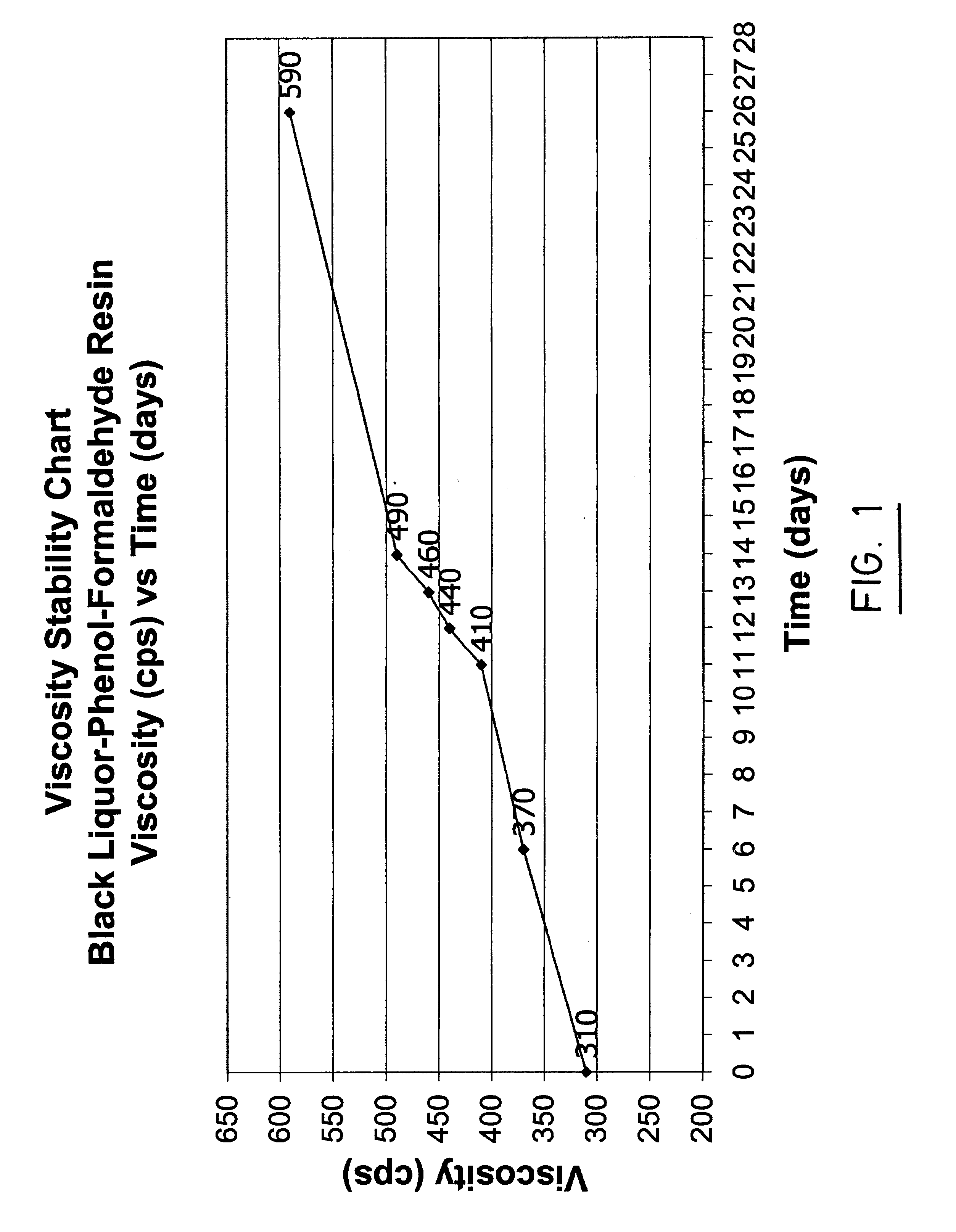

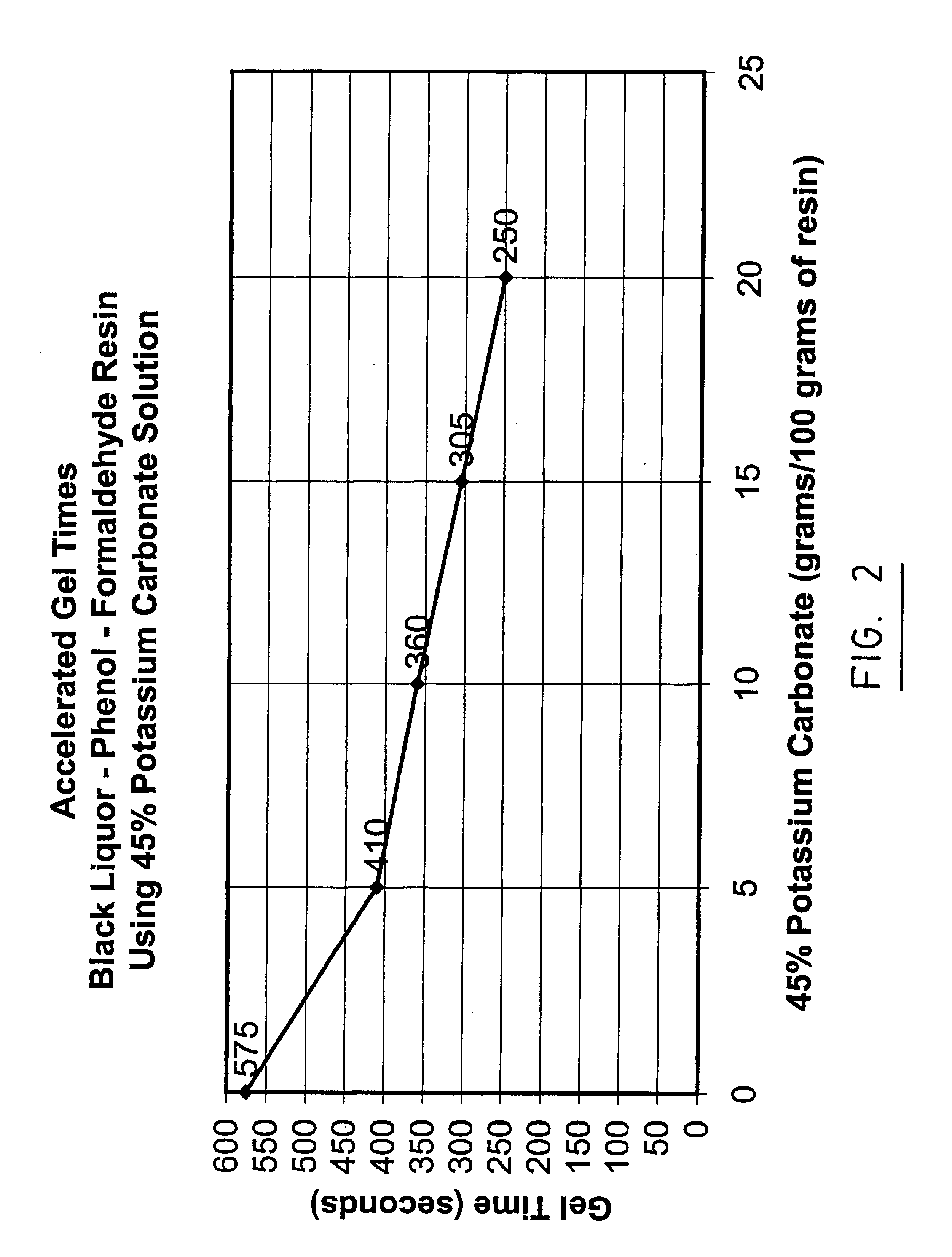

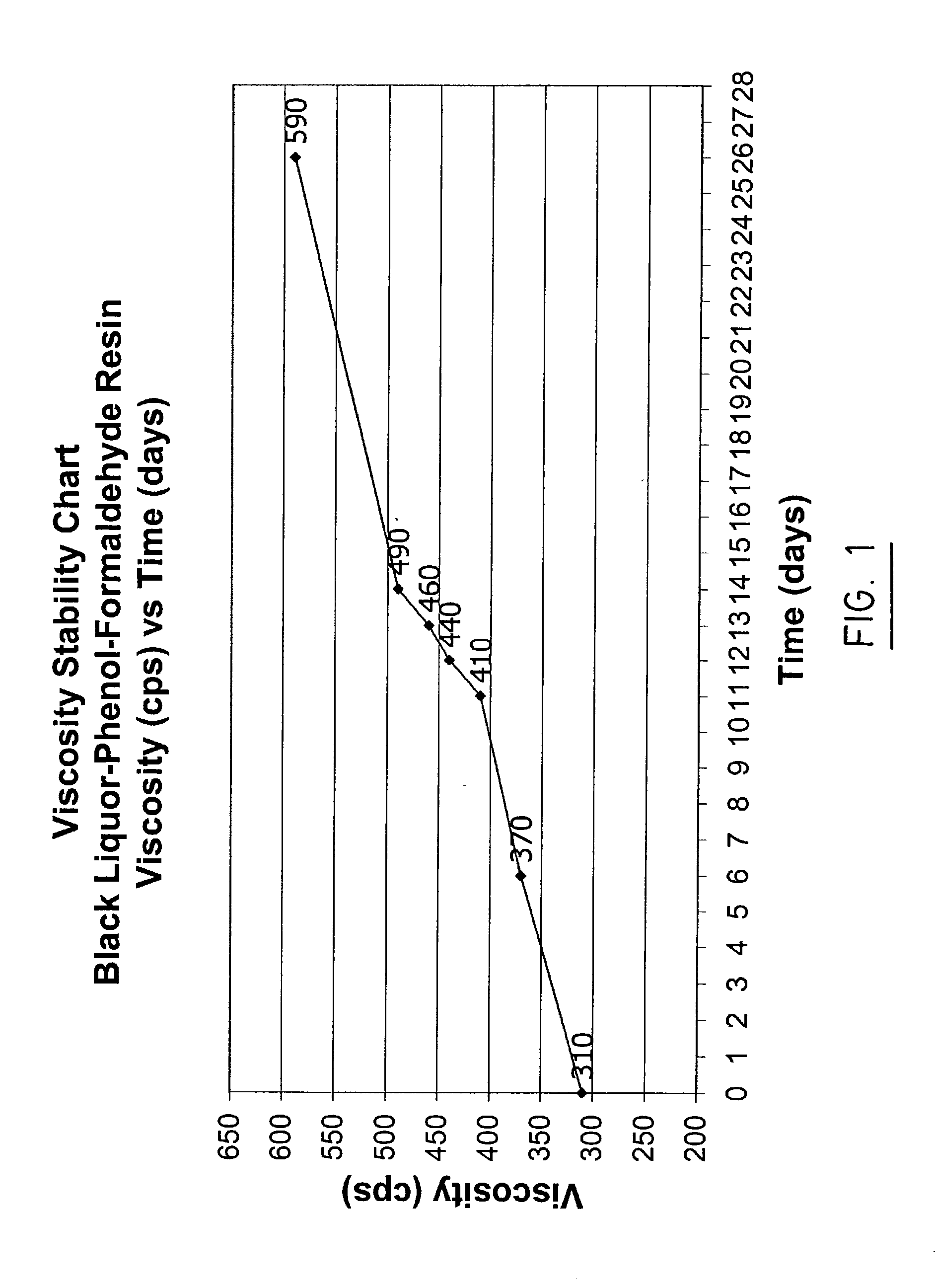

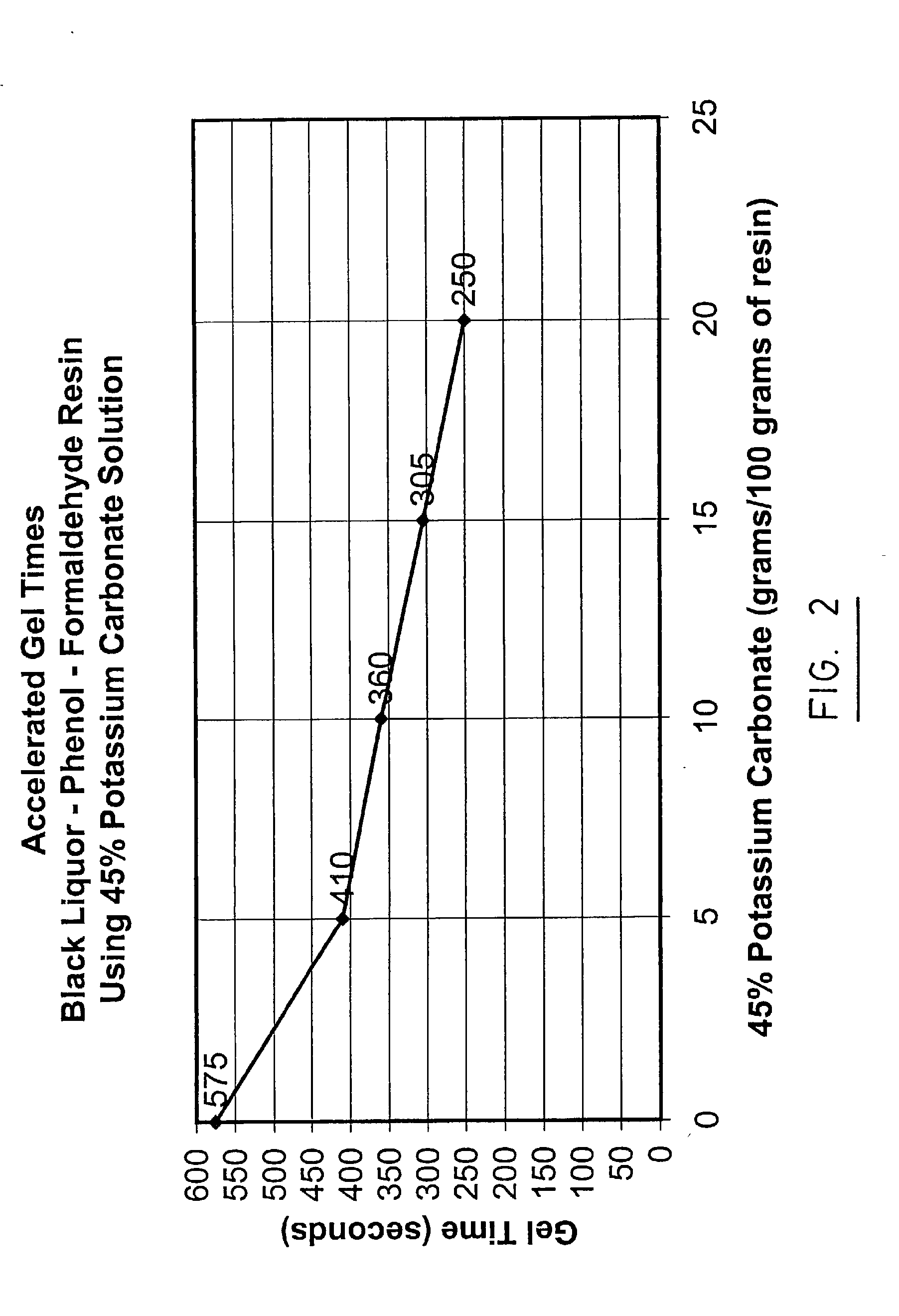

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Owner:CASCADES CANADA INC

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Disclosed is a process for preparing phenol-formaldehyde thermoset resin that can contain up to 80% by weight a black liquor, preferably a sodium carbonate black liquor. Black liquor are by-products extracted from pulping process, which normally contain lignosulfonates, kraft lignin or sodium carbonate lignin as well as salts, depending on the process that is used. The use of such a black liquor permits to obtain a stable copolymerized phenol-formaldehyde thermoset resin. In the process, the black liquor is first mixed with phenol in the pressure of a base. Then, formaldehyde is added together with a base in two successive steps. The obtained thermoset resin has bonding properties that meet or exceed the CSA and ASTM requirements for the engineered forest products, such as wafer boards or oriented strand boards at pressing cycles of 16 mm per second or less.

Owner:CASCADES CANADA INC

Wood-bamboo straw fiberboard and composite board and post wet-method production technique

The invention discloses a wood-bamboo-straw fiber board, and belongs to the technical field of forest product manufacturing. The fiber board is made from any one or two sorts of fiber materials from wood, bamboo, straw, or natural biological insect-resist agents including tobacco stick and the like, 3 to 5 percent of preservative, additives such as treating compound, reinforcing agent, waterproof agent and the like, 12 to 40 percent of fiber soakage moisture content, 6 percent of reinforcing agent starch, 0.5 to 1 percent of waterproof agent wax and rosin latex and 1 to 3 percent of hard board reinforcing agent; and the density of the mixture is controlled to be between 380KG / m<3> and 1,200 KG / m<3> so as to be made into the fiber board. Meanwhile, a preparation method provided reduces wood consumption, makes comprehensive and efficient use of straw and reduces environmental pollution caused by fiber board manufacturing through adopting straw burning and a wet method; moreover, the preparation method saves auxiliary materials and energy sources, thereby reducing cost; the wood-bamboo-straw fiber board does not have toxicity and public hazard, and is capable of being recycled and degradated to form beneficial biological cycle; and the intensity and decorative performance of both fiber board and composite board are improved, thereby enlarging application range.

Owner:郑林义

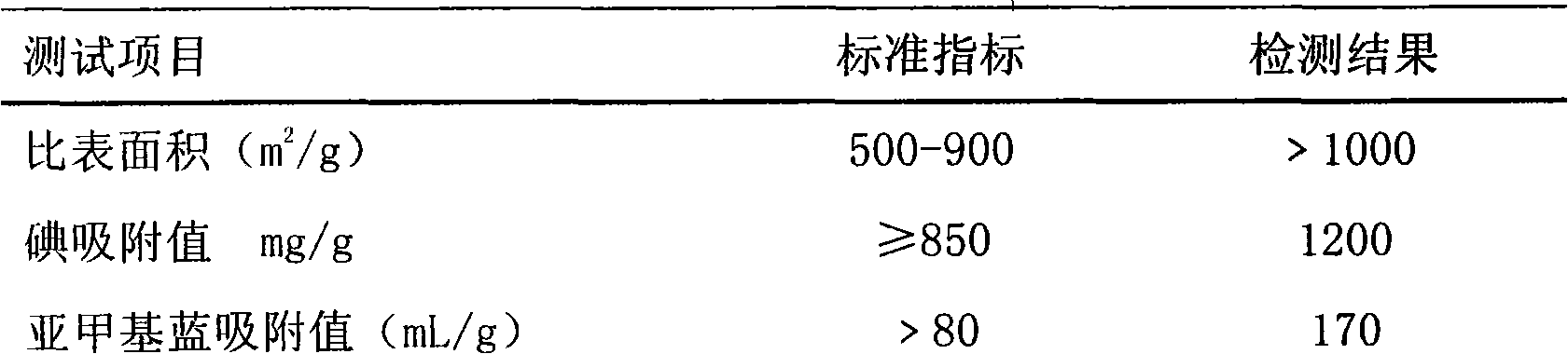

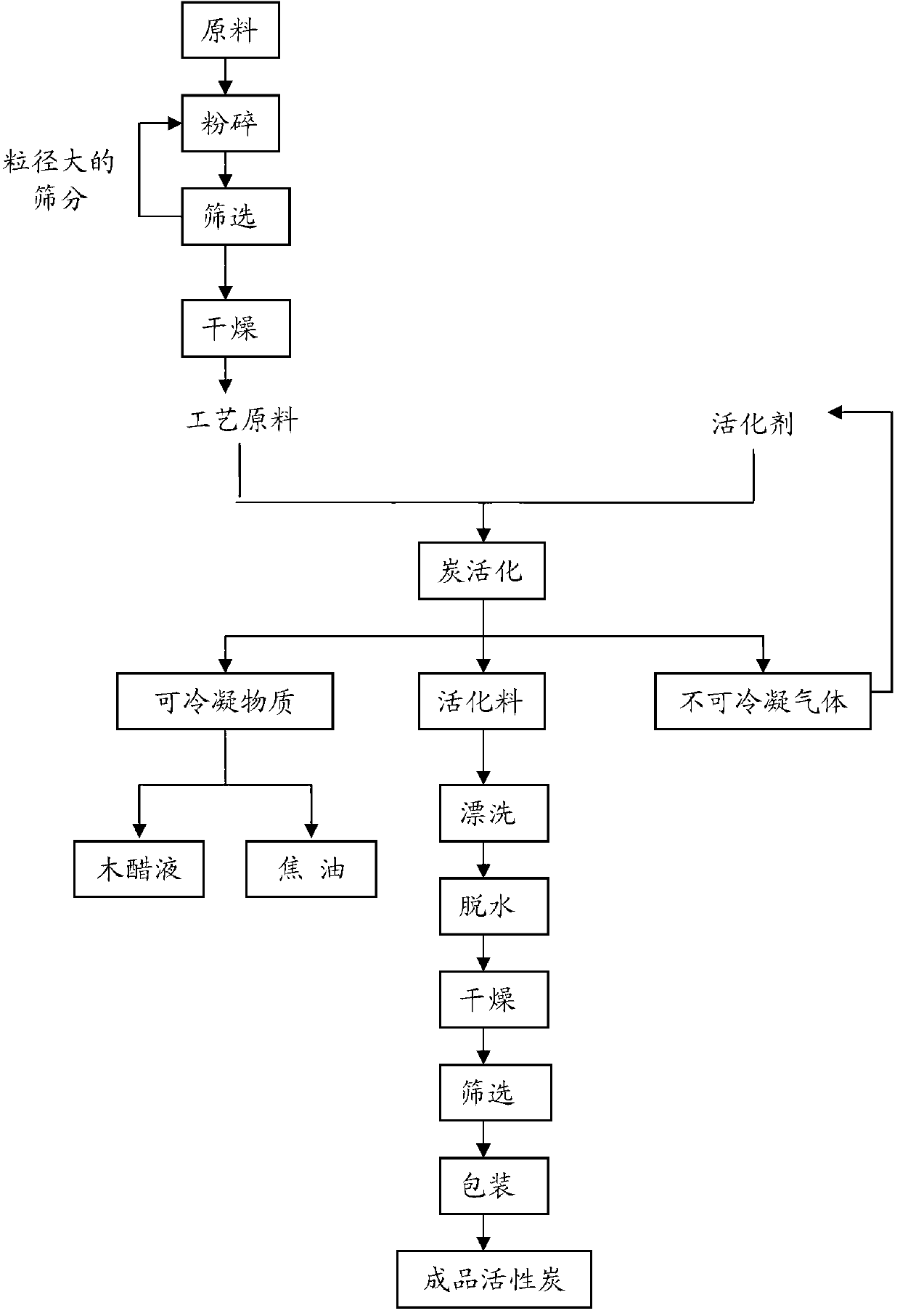

Method for preparing activated carbon from kernel of common macrocarpium fruit

The invention discloses a method for preparing activated carbon from the kernel of common macrocarpium fruit serving as a raw material, which comprises the following steps of: stirring by using an intermittent tank reactor which is treated by an anti-corrosion material to fully knead the pretreated raw material and an active agent, and carbonizing and activating at a certain temperature to obtain an activated material; and recovering the active agent, rinsing, dehydrating, drying and the like to obtain finished activated carbon. The kernel of the common macrocarpium fruit is forest product waste which is not utilized at present, so that the problem of multi-layer composite utilization of the forest product common macrocarpium fruit is solved, the production cost of the activated carbon is greatly reduced; meanwhile, a new resource capable of producing the activated carbon with high adsorption property is found for the activated carbon industry.

Owner:NORTHWEST A & F UNIV

Method for manufacturing fast-growing material through modification process

The invention relates to a method for manufacturing a fast-growing material through a modification process, which belongs to the technical field of forest product manufacturing. The method is characterized by adopting fast-growing timbers of an artificial forest as raw materials including low-volume-weight timbers of pine woods, cedarwoods, cotton woods, fortune paulownia wood, eucalyptus and the like. The method comprises the following steps: first sawing the fast-growing material into board square materials with the required specifications; and then performing the technical skills of soaking, cooking, pre-drying, hot pressing, cooling, shaping, dampening and the like. The modified board square materials produced by the manufacturing method are applied to manufacturing solid wood products of wooden floors, wooden furniture and the like, and the products are comparable with the products produced from natural broad-leaved trees no mater on technical targets or on functional targets.

Owner:阎建华

Method for disposing sludge generated in sewage treatment plant by using earthworms

InactiveCN102092912ANo secondary pollutionLow maintenanceBiological sludge treatmentBasementWoody plant

The invention provides a method for disposing sludge generated in a sewage treatment plant by using earthworms. The method comprises the following steps: finishing the sludge into a sludge basement layer material bed ridge for culturing earthworms; putting a layer of additives on the surface of the sludge basement layer material bed ridge; putting the earthworms in the additives; covering a layer of herbaceous and woody plant waste materials on the additives with the earthworms so as to form an earthworm-edible stacking layer consisting of the sludge, the additives and the herbaceous and woody plant waste materials; treating the herbaceous and woody plant waste materials by using the earthworms so that the herbaceous and woody plant waste materials are converted into wormcast; after separating the earthworms from the wormcast, recycling the earthworms; and putting the wormcast in a sun shed for drying. In the invention, the earthworm is utilized to treat the sludge so as not to generate secondary pollution, thus the method has obvious economic benefits; and the wormcast can be used as a base material for producing an organic fertilizer and used for forest product production or as a garden fertilizer after the sludge is converted into the wormcast.

Owner:刘波

Method for processing and manufacturing forest product nutrient health-care porridge

InactiveCN102742768AHave identityHave enjoymentFood preparationAdditive ingredientSenescence function

The invention relates to a method for processing and manufacturing a forest product nutrient health-care porridge. The forest product nutrient health-care porridge is processed and manufactured by black fungus superfine powder of which the original nutritional ingredients are kept by employing a physical processing method and mixed and soaked black rice, sticky rice, red bean, kidney bean, blueberry, hazelnuts, pine nut, lotus seed, medlar, candied date and white fungus. The forest product nutrient health-care porridge has the advantages of low technical requirements, basic investment and lowcost, is easily accepted, approved and eaten by common consumers and has the health-care effects of lowering lipid and losing weight and the like. The forest product nutrient health-care porridge belongs to a convenient and rapid food, integrates the health-care effects and nutritional ingredients of food ingredients of the traditional health-care porridge such as the black rice, sticky rice, redbean, kidney bean, lotus seed, candied date and white fungus, combines unique nutrient health-care effects of forest special products such as the black fungus, blueberry, hazelnuts and pine nut, and has the effects of lowering lipid and losing weight, strengthening the heart and the lung, tonifying spleen and appetizing, reinforcing intelligence and restoring consciousness, promoting the metabolism, prolonging life, resisting diseases, improving the immunity and delaying senescence.

Owner:吴洪军

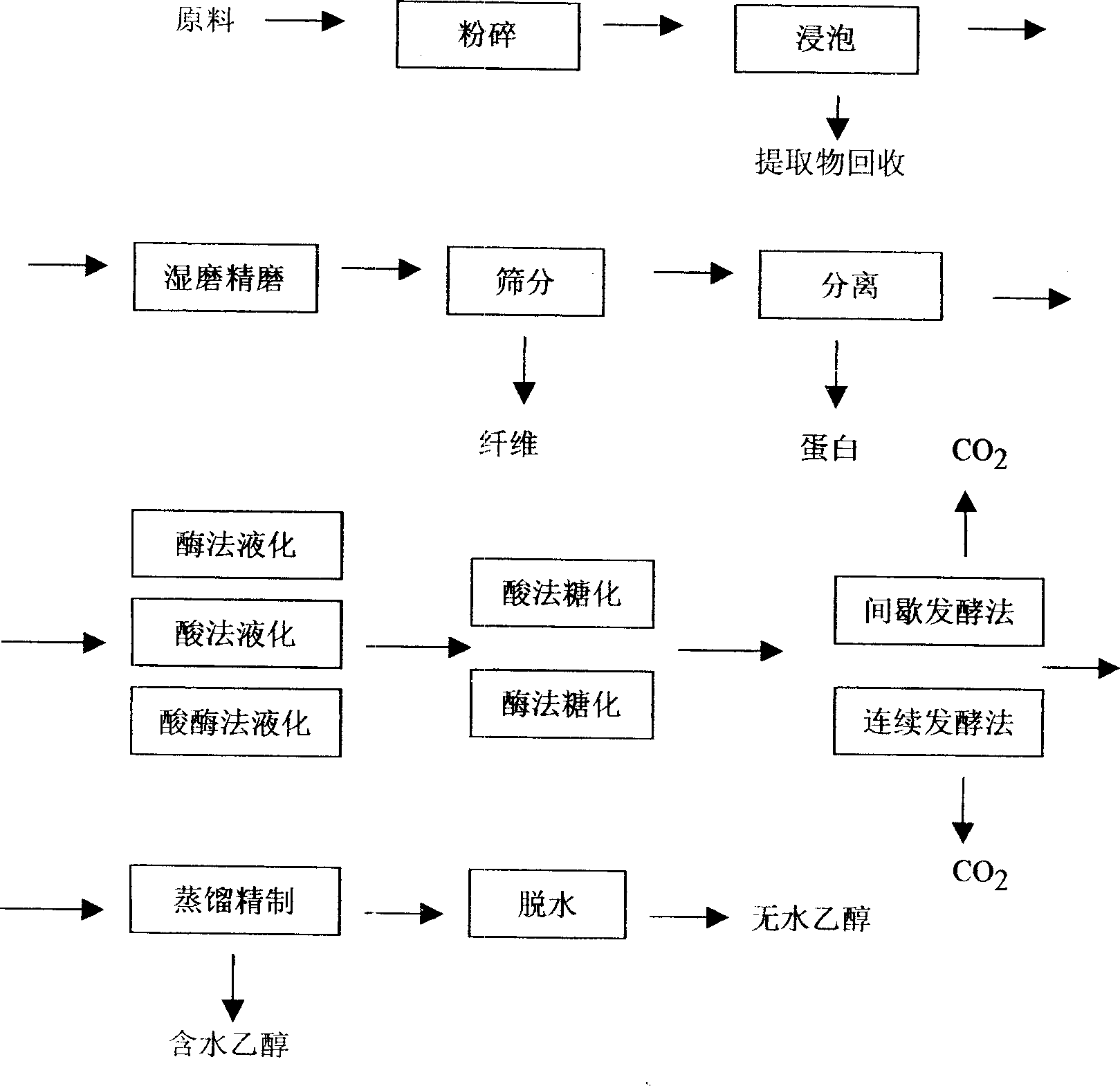

Method for producing ethanol by wild plant starch resource as acorn starch for substituting for grain

The invention relates to a method for preparing alcohol through saccharifying with wild plant starch resources such as acorn. It employs adverse current immersion method, continuous fermentation and raw material absorption dehydrolysis method. Said adverse current immersion method increases removing efficiency; continuous fermentation combines fermentation unit and distill units into one integrated processing device, and strengthens reaction kinetic effect; raw material absorption dehydrolysis method employs acorn powder or starch to prepare waterless alcohol through dehydrolysis, regeneration is avoided, which saves energy consumption. The biological renewable energy can reduce environmental pollution effectively, alleviating energy crisis, and saves grain. The gasoline fuel ethanol is prepared by using non- grain crop, which belongs to agricultural and forest products. The ethanol can be produced in large- scale, which reduces production cost and increase farmers income. So it is of great importance for developing clean energy by using wild plant.

Owner:周彦春 +1

Method for separating paclitaxel and related taxane substances

InactiveCN102260227AReduce manufacturing costHigh substance contentOrganic chemistryNatural productMass ratio

The invention discloses a method for separating paclitaxel and related taxane substances, and belongs to a technical method for chemically separating natural products and forest products. The method is characterized by comprising the following steps of: (1) uniformly mixing two kinds of macroporous resin in a certain mass ratio, and loading in a glass column to obtain a mixed resin packed column; and (2) dissolving a crude extract of taxus chinensis in a solvent in a ratio of 1:5 with stirring, adding an adsorbent, stirring until the solvent is completely volatilized, loading in the top end of the packed column, adding a gradient eluent for elution, collecting fractions in various gradients, and concentrating to obtain the paclitaxel and related taxane substances, which have obviously improved content. The raw materials used in the method are wide in range, and various crude extracts containing the paclitaxel and related taxane substances can be separated; the resin is commercially common resin, cheap and readily available; and the solvent is a common solvent which is low in toxicity and easy to recover. The production cost is low.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

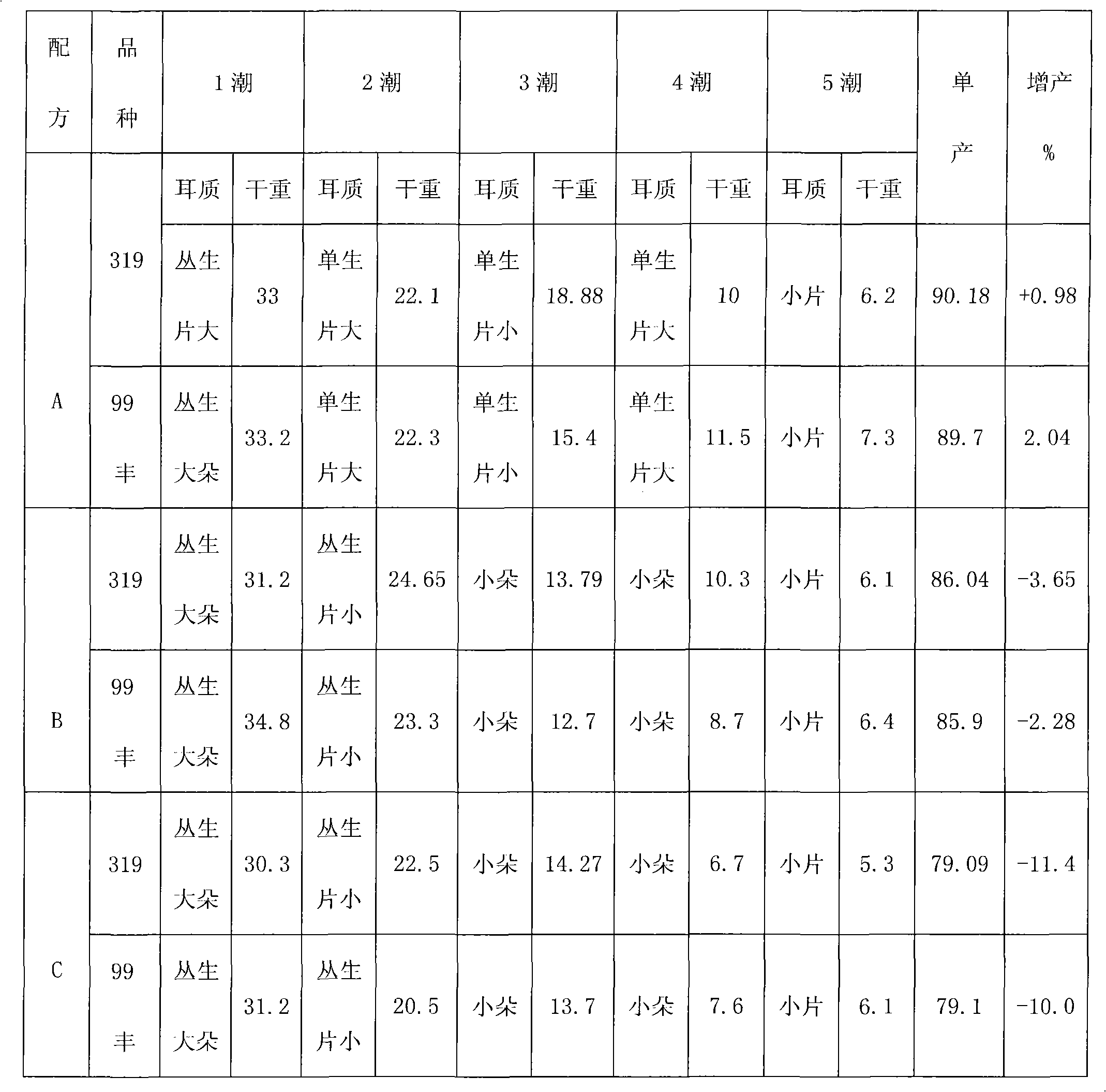

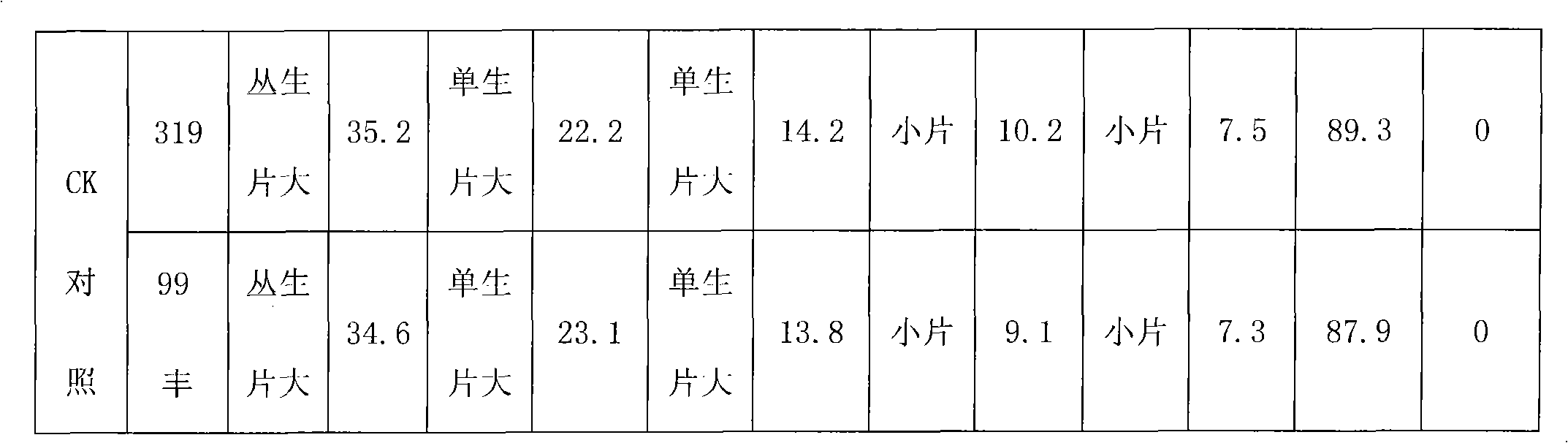

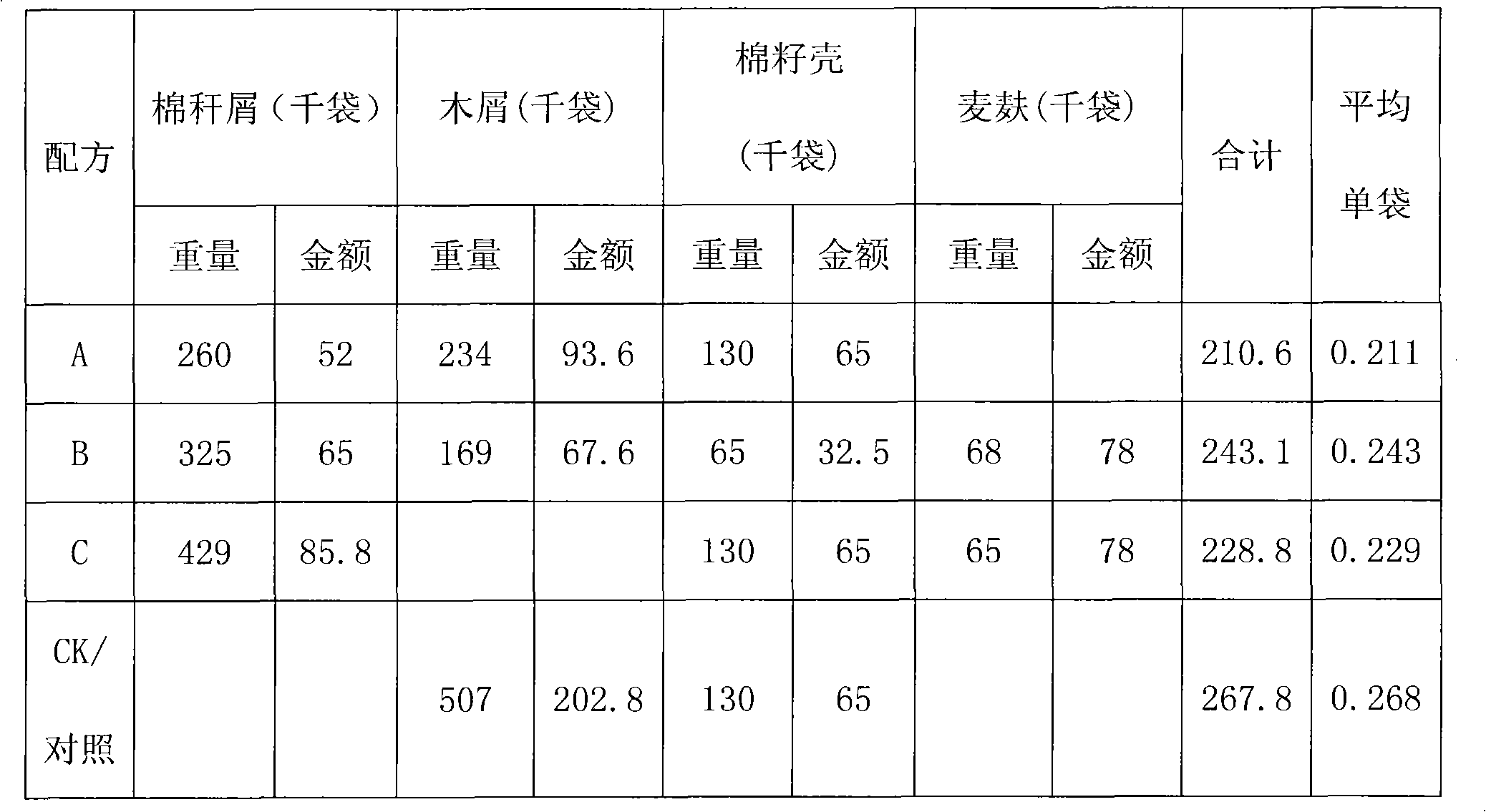

Formula of cotton stalk scrap bag-carried feed of auricularia polytricha and cultivating method of auricularia polytricha

InactiveCN101851135ATake advantage ofReduce consumptionFertilizer mixturesAuricularia polytrichaSawdust

The invention relates to a formula of cotton stalk scrap bag-carried feed of auricularia polytricha and a cultivating method of auricularia polytricha, in particular to a technique of cultivating the auricularia polytricha by using cotton stalk scraps as a main material to replace most of sawdust. The cultivating method comprises the main steps of feed preparation, formula preparation, bag makingand management from inoculation to fungus generation. The cultivating method of the auricularia polytricha has the advantages of making full use of agricultural wastes, reducing production cost, reducing consumption of forest products, realizing virtuous circle of substances and achieving larger ecological benefit.

Owner:DONGZHI COUNTY XINGNONG MUSHROOM PROCESSING

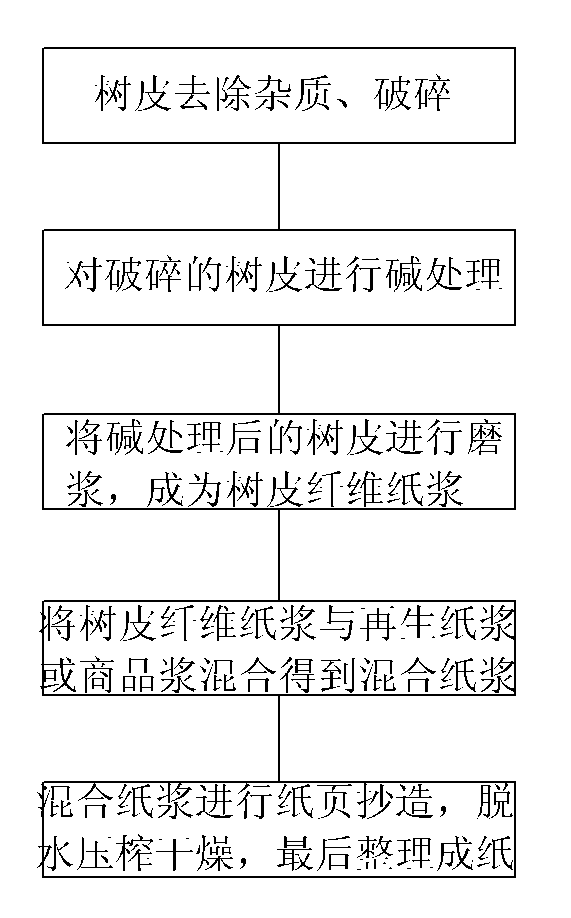

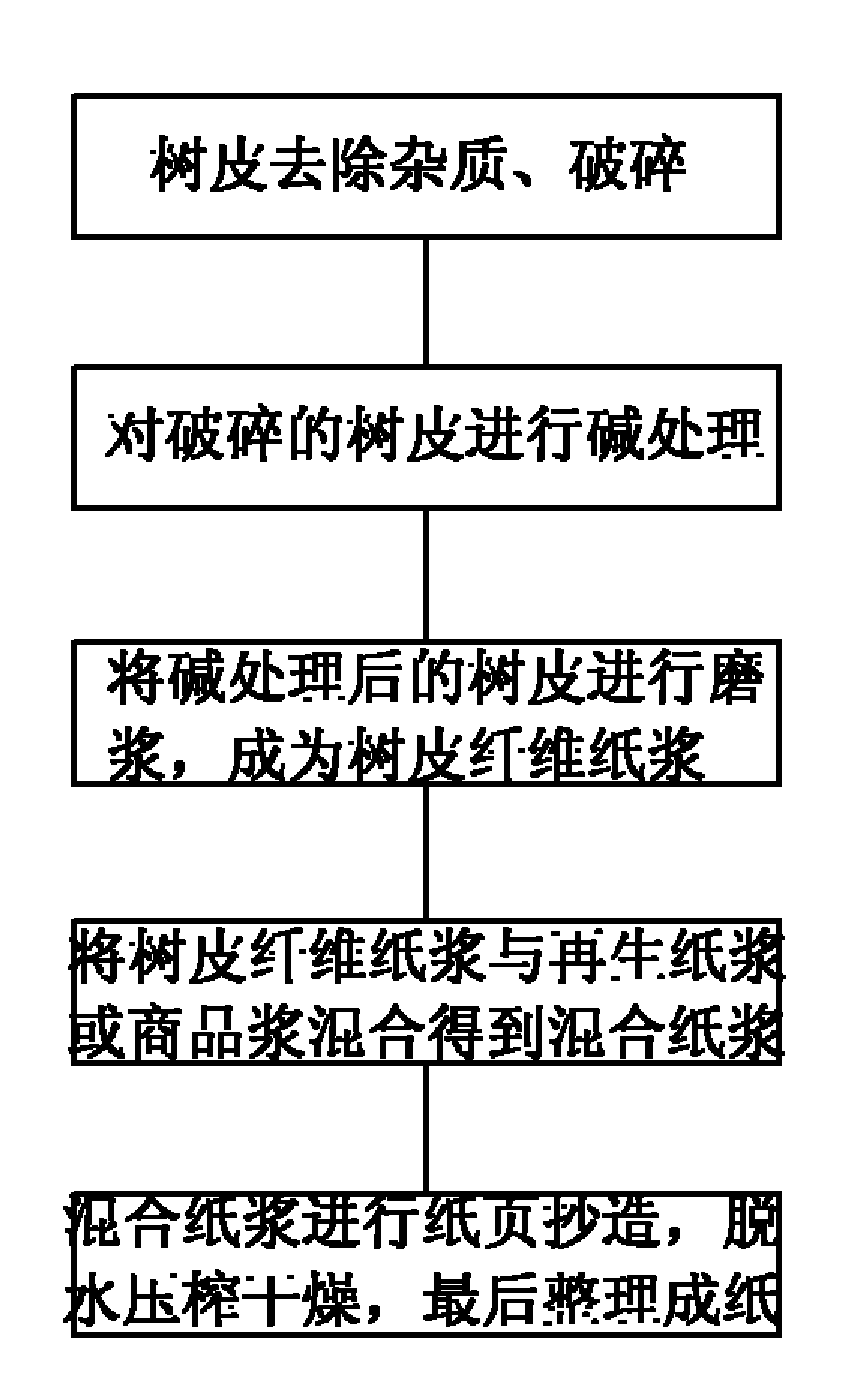

Method for pulping and making paper by using eucalyptus bark

InactiveCN102011334AThe process is practical and feasibleReduce pollutionPulping with inorganic basesPulp beating/refining methodsForest industrySocial benefits

The invention discloses a method for pulping and making paper by using eucalyptus bark. In the method, the eucalyptus bark is directly used for producing corrugated paper by crushing, alkaline treatment and pulp grinding; the crushed eucalyptus bark is directly used for producing high-grade corrugated paper after colored substances in the bark are extracted and the processes such as the alkaline treatment, the pulp grinding and the like are performed; and after the colored substances in the bark are extracted, colorless pulp is ground by the processes such as steaming, decolorizing, bleachingand the like for producing white paper. Forest product waste is changed into things of value to create a new process and develop and a new resource; the process is practical and feasible and can be performed in the normal papermaking factories and fiber manufacturers; the forest product waste which pollutes the environment is used for reducing environmental pollution; the incomes of forest workers and peasants are increased by selling the bark; and the method can be used for producing a high-grade pulp material, has low cost and can realize both social benefit and economic benefit of production enterprises.

Owner:梁锋

Production method of charred compound wood

InactiveCN103317567AReduce defective rateRefreshing log colorWood treatment detailsWood charring/burningSolid woodMasson pine

The invention discloses a production method of charred compound wood, belonging to the technical field of processing of forest products. The charred compound wood is produced by three working stages of common solid wood processing, homogeneous charred wood processing and charred compound solid wood processing. The production method has the beneficial effects that common solid wood and homogeneous charred wood have basically same characteristics by adopting common solid wood and homogeneous charred wood which are processed in the same batch as raw materials, and thus the rejection ratio of the charred compound solid wood product is greatly reduced. The charred compound wood is particularly suitable for an outer wall of a wooden house so that the clear color of log on the indoor wall space can be kept, the chemical preservation is replaced and the anti-corrosion property of the outdoor wall space is greatly improved. The charred compound wood can be produced by adopting masson pine wood as a raw material, and thus the application field of the masson pine wood is greatly enlarged, the economical value is increased, valuable timbers and tree species can be replaced, and the contribution is made for maintaining natural forest resources and protecting the nature environment.

Owner:重庆家和琴森木业有限公司

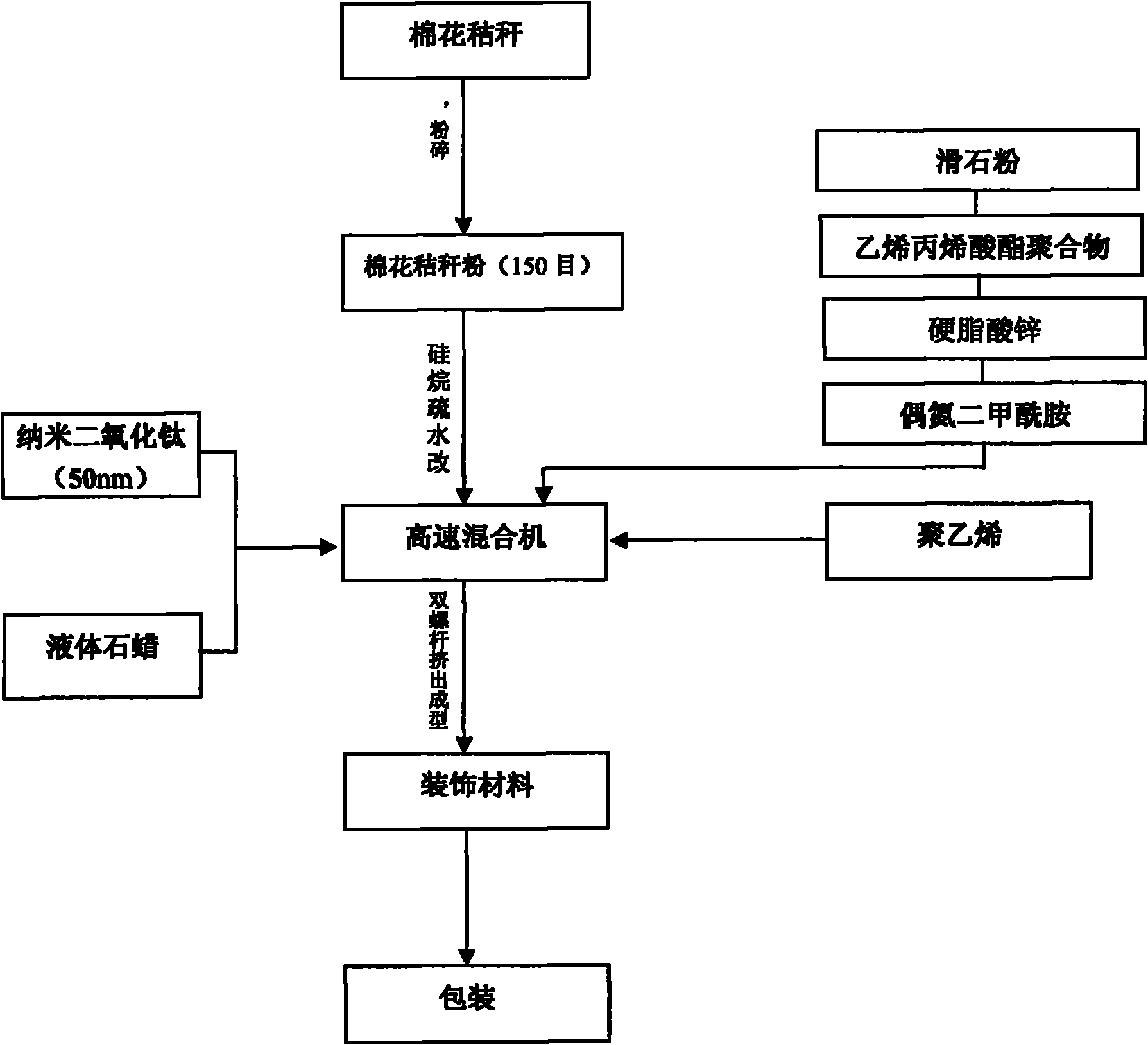

Antibacterial decorative material made by utilizing cotton stalk and preparation method thereof

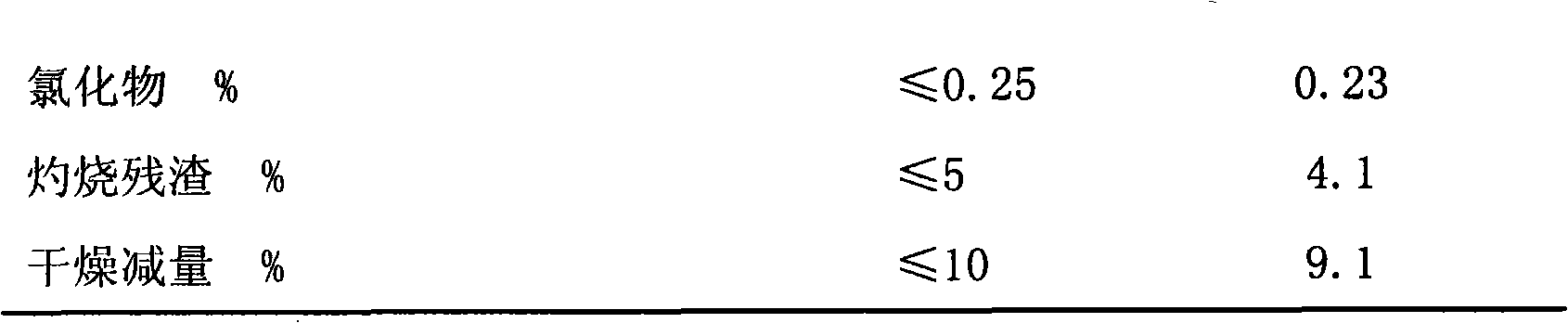

The invention belongs to the technical field of preparing domestic decorative material by utilizing cotton stalk. Concretely, the invention relates to the steps that nano titanium dioxide with photocatalyst effect is utilized to carry out modification treatment on cotton stalk, double screw one-step extrusion moulding process is adopted, and cotton stalk decorative material is produced. The invention also relates to a method for preparing the material. Double screw extrusion one-step moulding process is adopted. The domestic decorative material with environmental protection and antibacterial characteristics is prepared by components of cotton stalk powder, nano titanium dioxide, silane, fluid wax, polyethylene, azodicarbonamide, talcum powder, zinc stearate and ethylene acrylate polymer. The invention also discloses a preparation method of the material. The decorative material made by the invention is detected by Hubei Station for Quality Supervision and Inspection of Forest Product, the main technical indexes thereof are that bending strength is 27.3MPa and elastic modulus is 1747MPa. The product of the invention can completely substitute wood product, thus contributing to saving of wood usage amount and protection of forest resources.

Owner:HUAZHONG AGRI UNIV

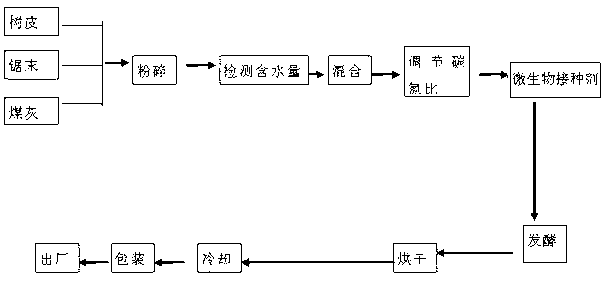

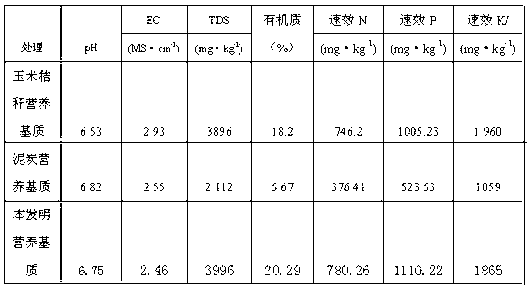

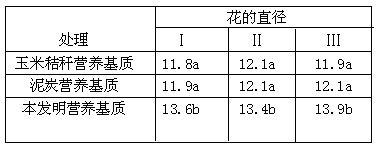

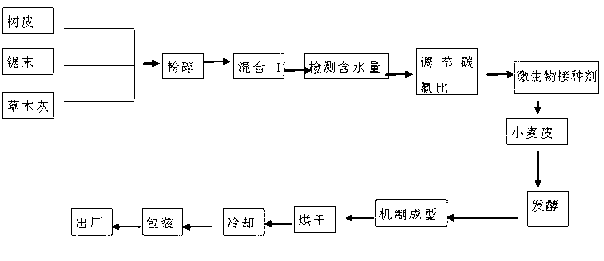

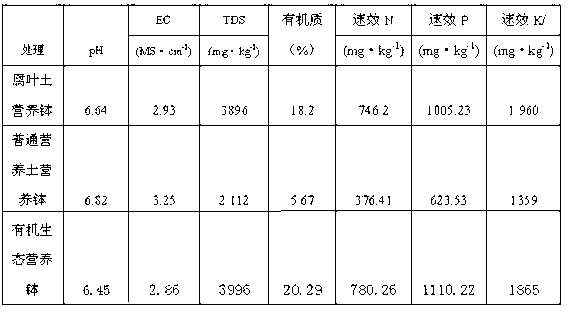

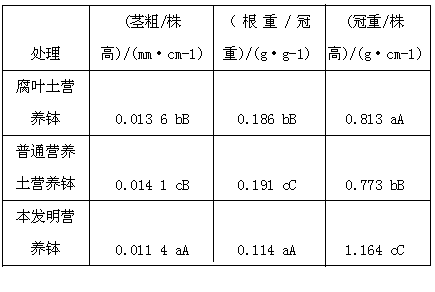

Purely natural organic nutritional matrix and preparation method thereof

InactiveCN103319232ALow costQuality improvementFertilizer mixturesControlled releaseLivestock manure

The invention relates to a cultivation matrix, and especially relates to a purely natural organic nutritional matrix and a preparation method thereof. The purely natural organic nutritional matrix is characterized in that the matrix is mainly prepared through using 40-60 parts by weight of bark, 20-40 parts by weight of sawdust, 10-30 parts by weight of coal ash, 0.1-1 part by weight of a biological fertilizer starter, and 1-5 parts by weight of livestock manure. The organic nutritional matrix prepared in the invention has the advantages of low cost, abundant resources and stable quality, solves the waste utilization, energy saving and emission reduction problems, and also solves the nuisance-free matrix production problem by utilizing forest product wastes to produce a soilless nutritional matrix. The addition of a constant quality of a plurality of controlled-release nutritional master batches avoids burnt seedlings caused by the early-stage excess release of a fertilizer, satisfies the nutrition needs of the whole growth period of tree peony, and has a nutritional expiration period reaching above 120d.

Owner:HEZE UNIV

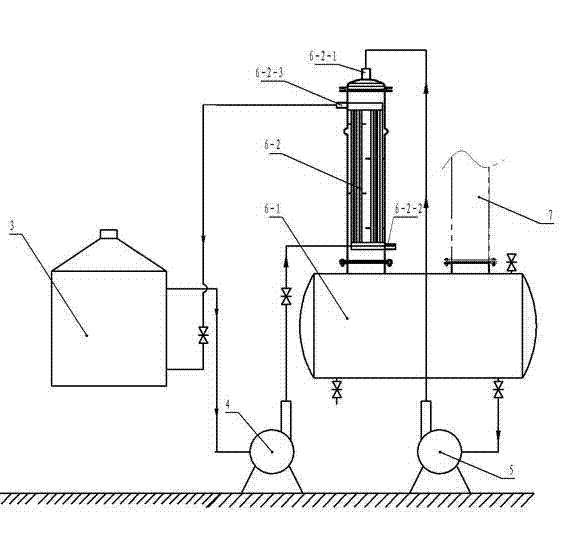

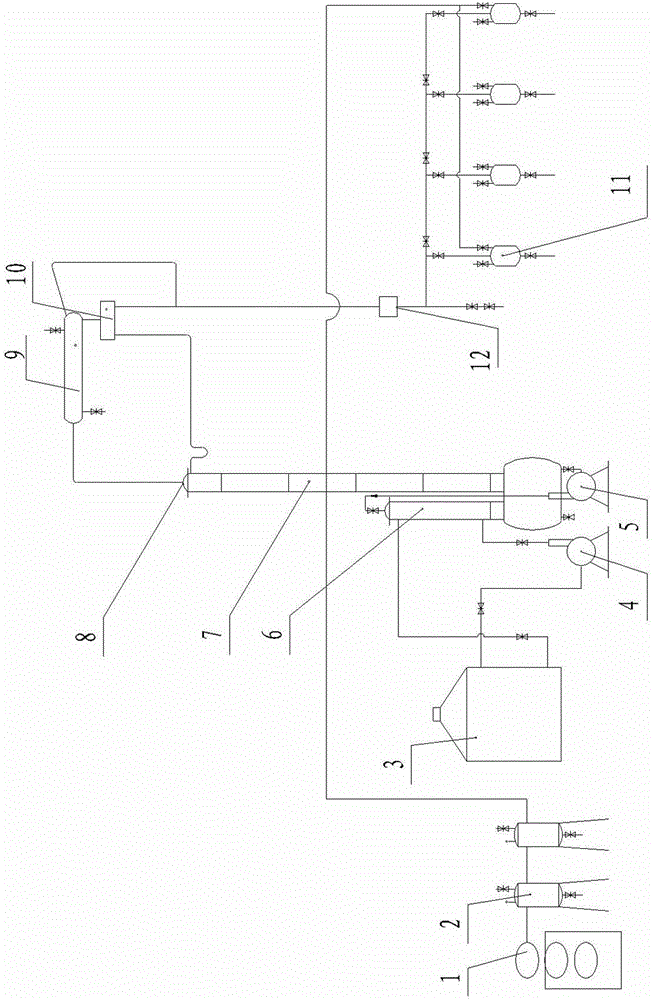

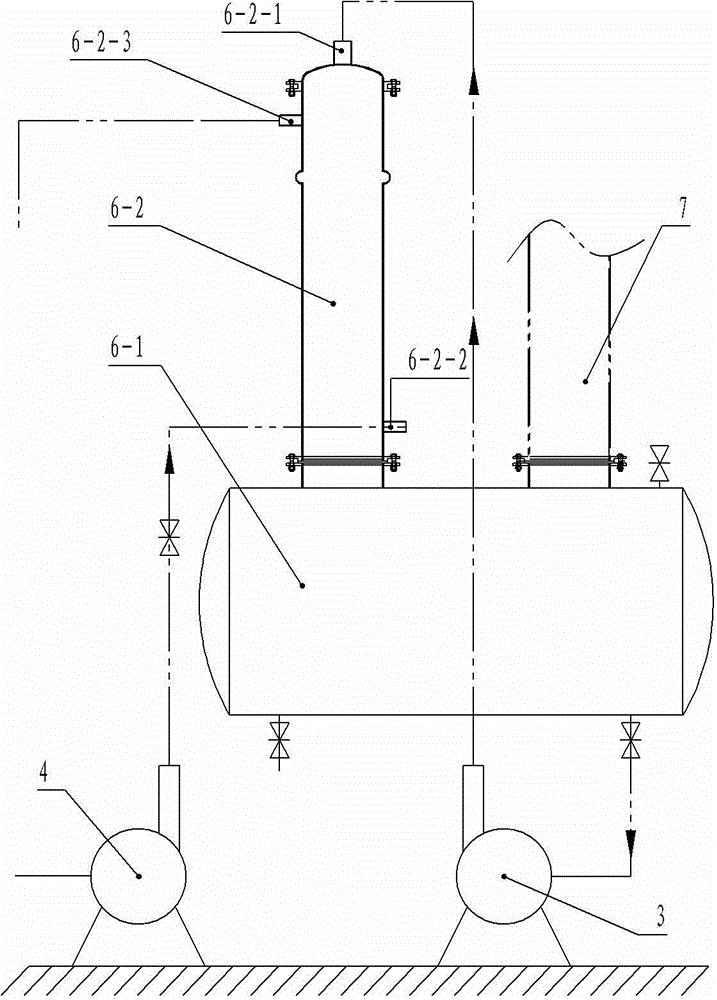

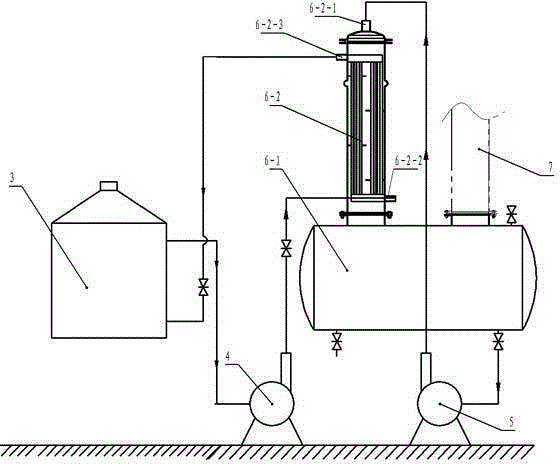

Natural cinnamaldehyde extraction device

ActiveCN102964229AEvenly heatedIncrease productivityCarbonyl compound separation/purificationManufacturing technologyDistillation

The invention discloses a natural cinnamaldehyde extraction device, and relates to the technical field of chemical equipment manufacturing of forest products. A raw material heater in a natural cinnamaldehyde evaporation device is arranged on the upper part of the outside of a raw material distillation still, the raw material heater and the raw material distillation still form a distillated raw material circulating system through a raw material circulating pump, and the raw material heater takes hot oil provided by a hot oil furnace as a heating medium; and multiple layers of corrugated mesh packing are filled in a distillation column of the natural cinnamaldehyde extraction device. The natural cinnamaldehyde extraction device disclosed by the invention can solve the problem that when the existing natural cinnamaldehyde extraction device distillates cinnamon oil and extracts natural cinnamaldehyde, an overheating situation is caused by the fact that the cinnamon oil is heated unevenly, so that the cinnamon oil is degenerative and the production efficiency is low.

Owner:广西京桂香料有限公司

Method for producing active carbon by pyrolysing pepper branches

ActiveCN103274399ARaw materials are easy to getLow costCarbon compoundsActivated carbonHigh absorption

The invention relates to a method for producing active carbon by pyrolysing pepper branches. The method comprises the following steps: a, detaselling the pepper branches, and airing or roasting and crushing; b, filling the crushed pepper branches by the step a in a rotary furnace, setting the temperature rising rate and temperature range of the rotary furnace, and heating to activate carbon in the presence of activating gases; and c, carrying out acid washing, water washing, drying, crushing and examination in a sieve, and then packaging the active carbon to prepare the product active carbon. Waste used by the invention not only solves the problem of multi-layer compound utilization of forest product pepper and greatly reduces the production cost of the active carbon, but also finds a novel resource capable of producing active carbon with high absorption for the active carbon industry.

Owner:韩城市金太阳花椒油脂药料有限责任公司

Method for preparing bamboo leaf polysaccharides from bamboo pulp

ActiveCN102911287ABroaden the way of productionIncrease added valueProteinase activityNatural product

The invention discloses a method for preparing bamboo leaf polysaccharides from bamboo pulp. The method comprises the following steps of: (1) adding amylase into the bamboo pulp to perform enzymolysis so as to remove starch, and adding lipase to perform enzymolysis so as to remove fat, then adding protease to perform enzymolysis so as to remove protein, and then performing high-temperature enzyme inactivation and centrifugal treatment to obtain a clarifying solution; (2) filtering the clarifying solution by adopting an ultrafiltration membrane device to obtain a concentrated solution of the bamboo leaf polysaccharides; and (3) drying the concentrated solution of the bamboo leaf polysaccharides to obtain powder of the bamboo leaf polysaccharides. According to the method disclosed by the invention, the preparation ways of the bamboo leaf polysaccharides are expanded, the cost is greatly reduced, the promotion of the development and the implementation of industrialization of technologies for the bamboo leaf polysaccharides can be benefited, the added value of bamboos, namely peculiar economic forest products in China can be further improved, the development of natural product resources is enriched, and the method further has a huge promotion effect on the economic development of the forestry and agriculture in China.

Owner:TECHNO (FUJIAN) FOOD INGREDIENTS CO LTD

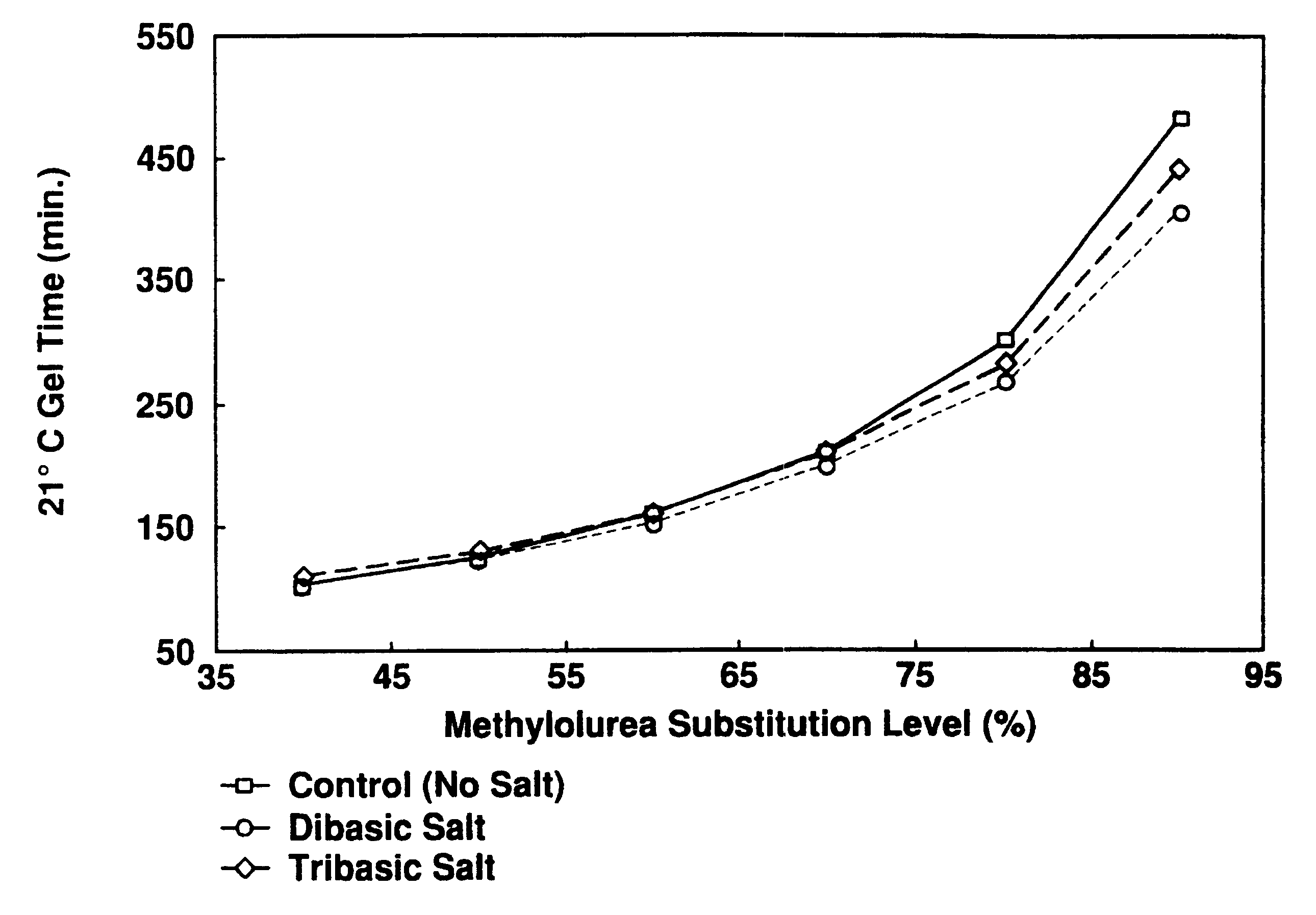

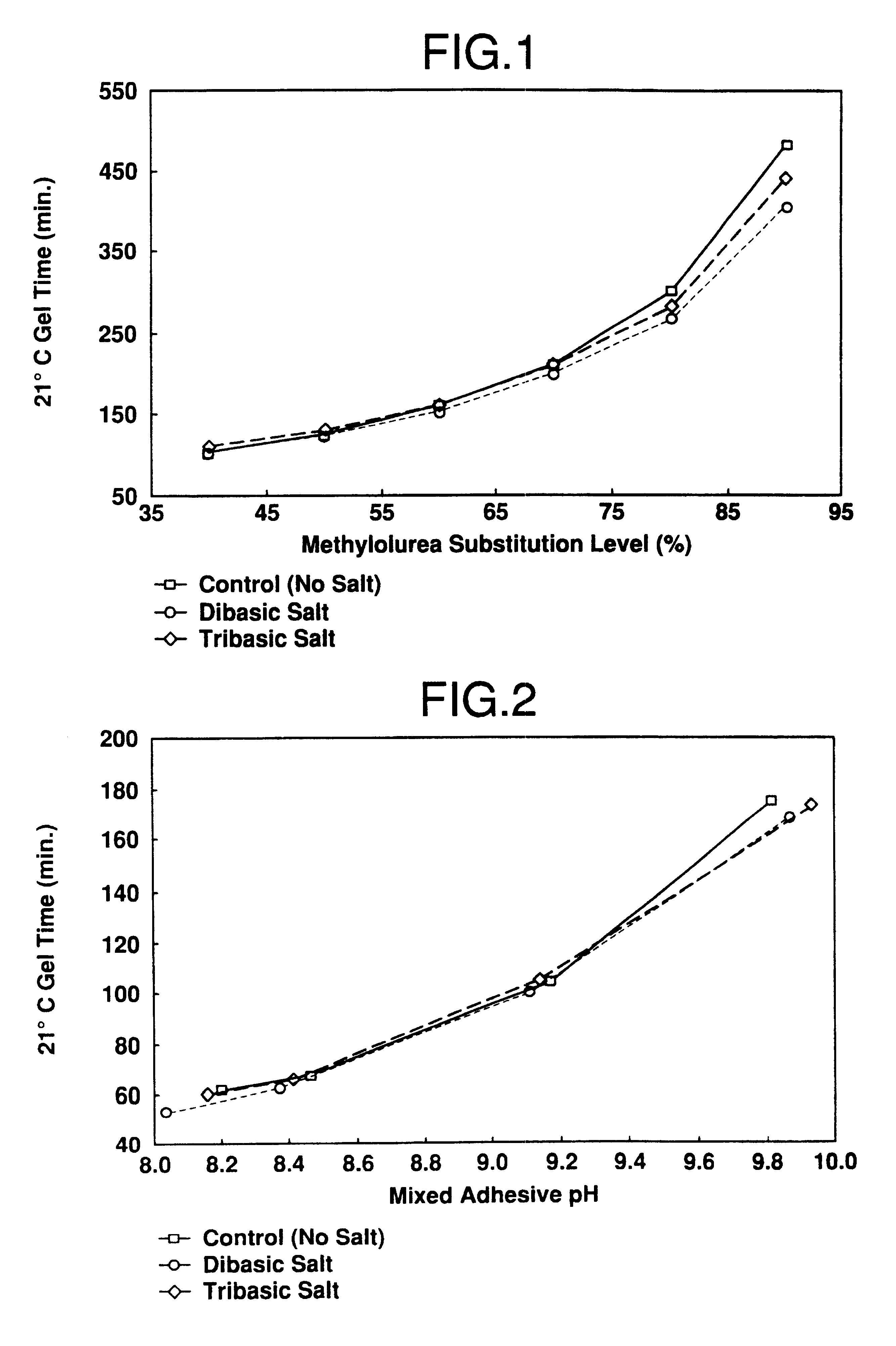

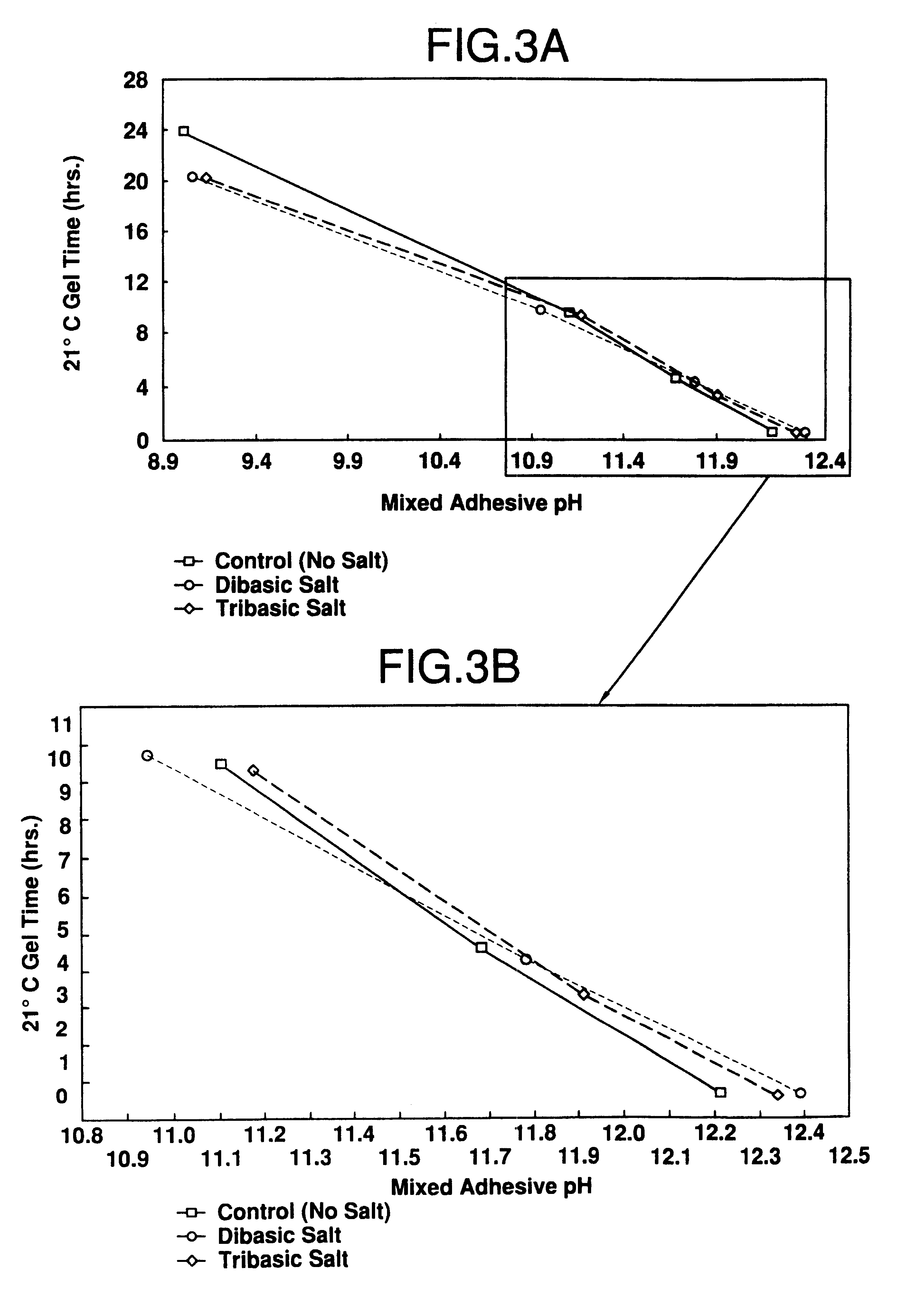

Composition and method for curing a resorcinol resin

InactiveUS6541576B1Good adhesionEmission reductionWood layered productsThin material handlingOxazolidinePHENOL/RESORCINOL

A catalyst curing system or hardener for resorcinolic resins, such as resorcinol-formaldehyde or phenol-resorcinol-formaldehyde resins including methylolurea. The methylolurea may be used in combination with oxazolidine in ratios ranging from 5:95 to 95:, by molar basis. The hardener crosslinks the resins which permits reduction or "fuming" of formaldehyde as well as control of gel times of the resulting adhesive. The hardener of the present invention if of particular utility in adhesives for use in the forest products industry.

Owner:HEXION INC

Organic ecological seedling cultivating pot and preparation method thereof

InactiveCN103288499ALow costAbundant resourcesBio-organic fraction processingOrganic fertiliser preparationMachining processSeedling

The invention relates to a seedling cultivating pot and a preparation method thereof, in particular relates to a purely natural seedling cultivating pot and a preparation method thereof, and provides a purely natural organic ecological seedling cultivating pot. The purely natural organic ecological seedling cultivating pot is characterized by being prepared from the following raw materials in parts by weight: 60 to 80 parts of bark, 10 to 30 parts of saw dust, 5 to 10 parts of plant ash, 1 to 5 parts of poultry excrement and 0.1 to 1 part of biological fertilizer leavening agent. The prepared organic nutrition pot is low in cost, wide in resource and stable in quality, so that not only are the problems of waste reutilization, energy conservation and emission reduction solved, but also forest product wastes are utilized to product the soilless nutrition pot, and therefore, the difficult problem of producing seedlings which are cultivated and strengthened in a pollution-free manner is solved. The nutrition pot is produced in an industrialization manner through equipment, so that the user operation is simplified; and the seedling cultivating efficiency and the seedling cultivating effect are improved greatly, so that the user benefit is increased. In addition, the pot is produced strictly according to the quality standard in a machining process in a factory, so that the reliable quality of the pot is ensured; and the seedling cultivating cost is lowered greatly. As a result, the pot provided by the invention is convenient for popularization.

Owner:HEZE UNIV

Natural cinnamaldehyde extraction process

ActiveCN102964228AIncrease productivityCarbonyl compound separation/purificationRefluxChemical industry

The invention discloses a natural cinnamaldehyde extraction process, and relates to the technical field of a forest product chemical industry. The process is implemented by taking natural cinnamon oil as a raw material through carrying out extraction in four stages, wherein in the first stage, the temperature of a distillation still is 110 DEG C, the temperature of the top of a distillation tower is 50 DEG C, and the reflux ratio is 0:1; in the second stage, the temperature of the distillation still is 140 DEG C, the temperature of the top of the distillation tower is 110 DEG C, and the reflux ratio is 10:1; and in the third stage, the internal temperature of the distillation still is 160 DEG C, the temperature of the top of the distillation tower is 140 DEG C, the reflux ratio is 0:1, until the collected distillate achieves the analytical calculation quantity of natural cinnamaldehyde. The process disclosed by the invention can solve the problem that in the processes of distilling cinnamon oil and extracting natural cinnamaldehyde, the cinnamon oil is subjected to partial fusion because the cinnamon oil is heated unevenly, so that the purity of natural cinnamaldehyde finished products and the output capacity of natural cinnamaldehyde are affected.

Owner:广西京桂香料有限公司

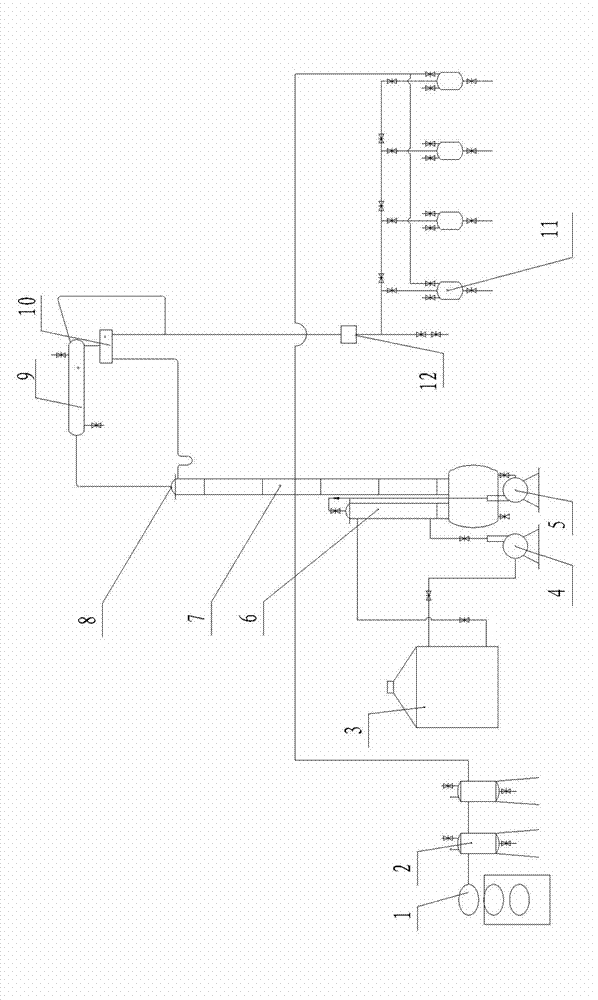

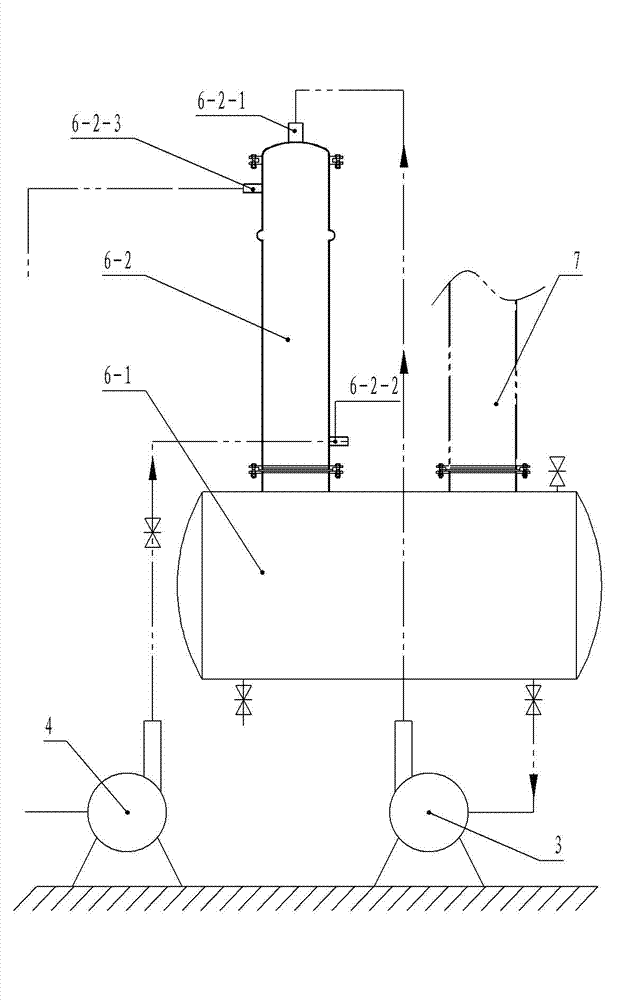

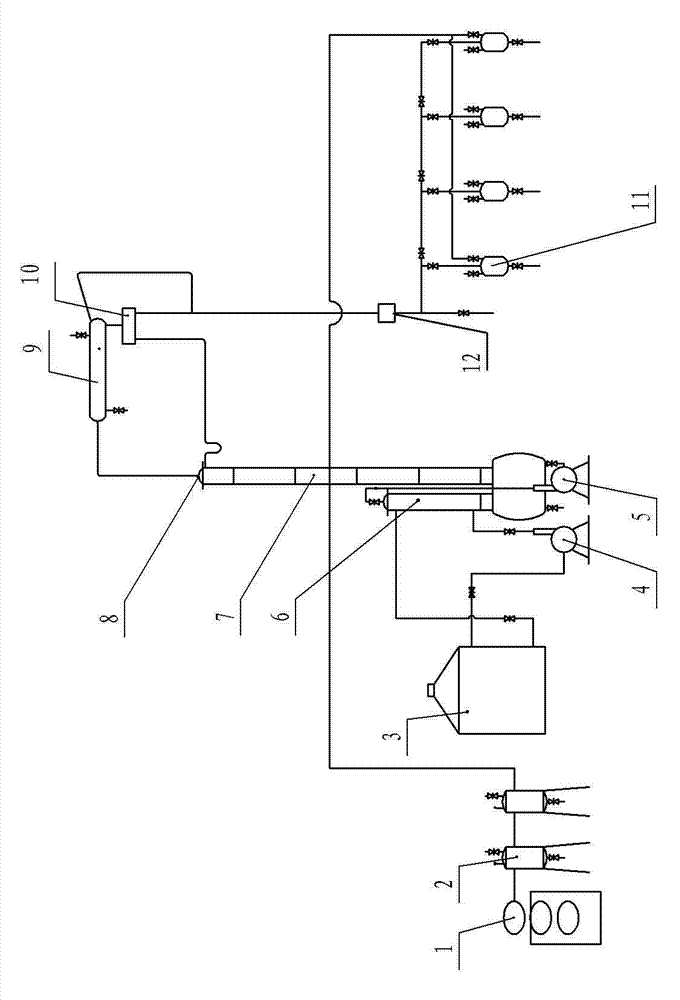

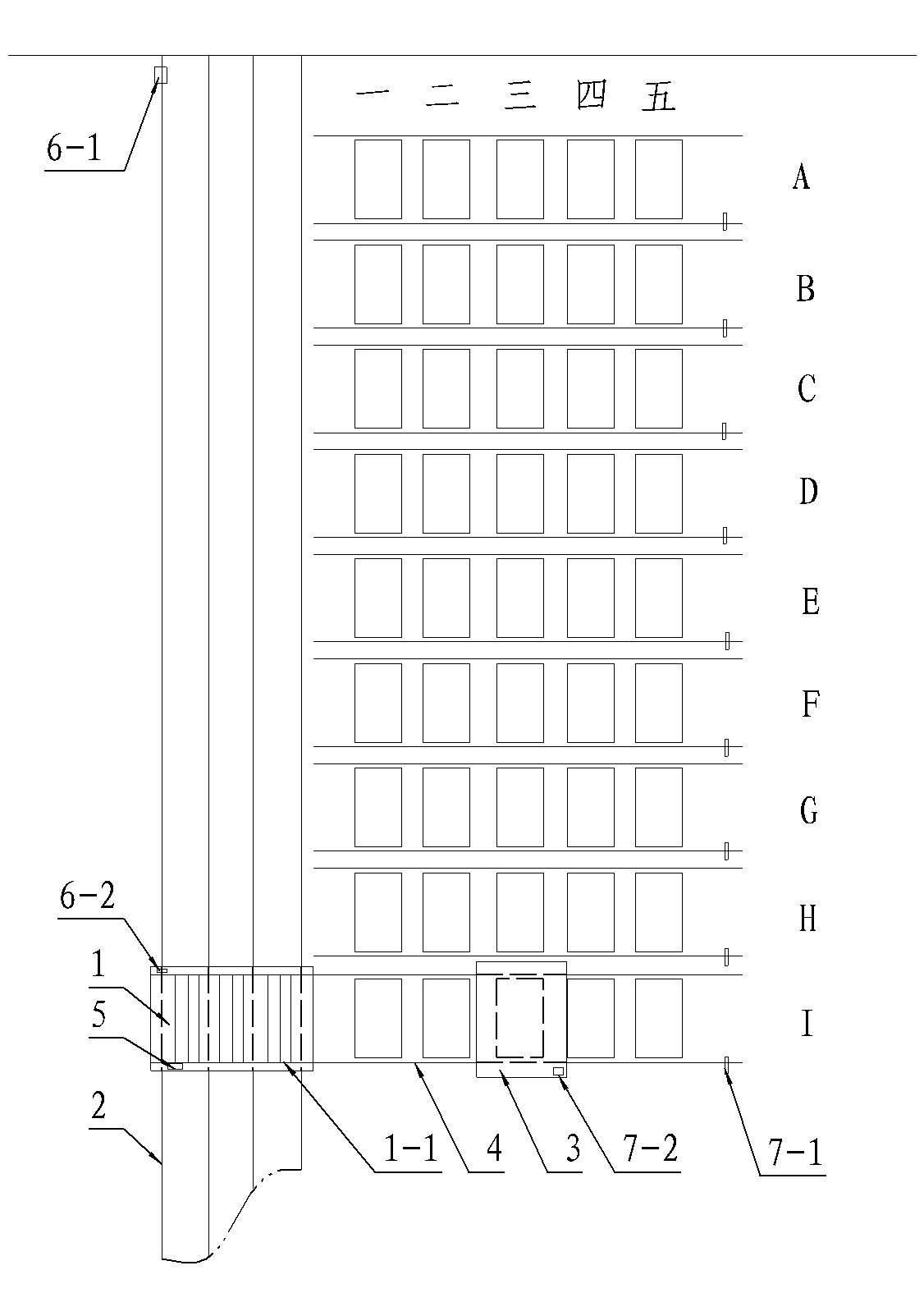

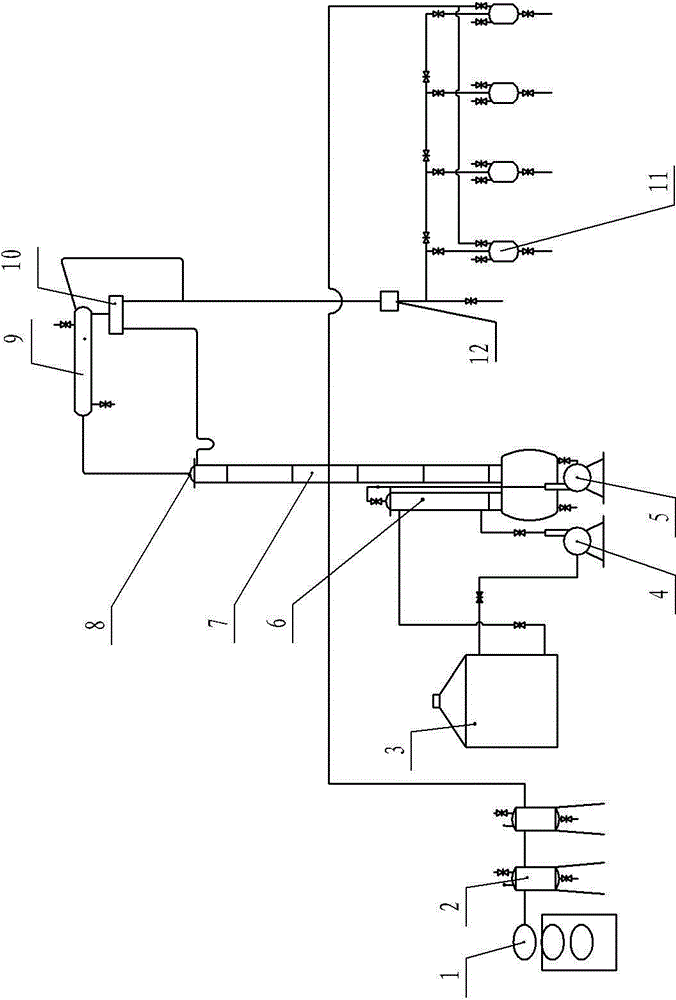

Production line automation transit warehouse

InactiveCN103010649AImprove space utilizationIncrease productivityStorage devicesProduction linePosition sensor

The invention discloses a production line automation transit warehouse, and relates to the technical field of chemical processing of forest products, in particular to a board production line automation transit warehouse. The production line automation transit warehouse comprises a transport vehicle running on a production line channel, wherein an on-vehicle stacking vehicle track and an on-vehicle stacking vehicle position sensor are arranged on the transport vehicle; a plurality of warehouse stacking vehicle tracks abutted with the on-vehicle stacking vehicle track are arranged on at least one side of the track of the transport vehicle, and a stacking vehicle is arranged on the on-vehicle stacking vehicle track or the warehouse stacking vehicle tracks; a transport vehicle position sensor for detecting the position of the transport vehicle on the track is arranged on the production line channel; and a stacking vehicle position sensor for detecting the position of the stacking vehicle on the warehouse stacking vehicle track is mounted on each warehouse stacking vehicle track. According to the production line automation transit warehouse, the problems of a production line transit warehouse that the space use ratio is not high and the production efficiency is low can be solved.

Owner:GUANGXI SUNWAY FOREST PROD IND

Method for purifying wild ginseng seeds

The invention relates to a seed cultivation method, in particular to a method for purifying wild ginseng seeds. The method comprises the following steps of: freezing ginseng seeds at the temperature of between -25 and -30 DEG C for 3 to 5 months, raising the temperature gradually in the natural state until the temperature is between 0 and 5 DEG C, and immersing in biological beneficial bacteria for 12 to 24 hours, so that seed hulls are cracked. By living bacteria and freezing, the hibernated ginseng seeds are reduced to a wild ginseng state after being planted to form a special shape, namely rhizomes are long, and fibrous roots are long and absorb nutrient in soil fully. According to the propagation growth habit of wild ginseng, multiple species such as natural wild Chinese medicinal herbs, forest products and the like are nurtured by utilizing the effective ecological environment and ecological space comprehensively. The breeding of the processed ginseng seeds, the processing of the seeds and the breeding of seedlings have specific characteristics, and the purity of the ginseng seeds is close to that of the wild ginseng, so the method has the huge social and economic benefits on the change of the quality and value of panax ginseng.

Owner:集安天域人参科技有限公司

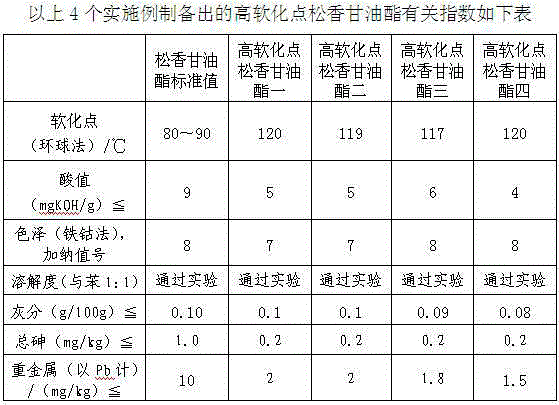

Method for preparing high-softening-point rosin glyceride

ActiveCN105038603AIncrease spawn rateLow acid valueNatural resin chemical modificationGlycerolAcid value

The invention discloses a method for preparing high-softening-point rosin glyceride, and relates to the technical field of forest product chemical rosin deep processing. According to the method, esterification synthesis of high-softening-point modified rosin with the softening point of 145-155 DEG C and glycerol is utilized to prepare high-softening-point rosin glyceride with the softening point of 115-120 DEG C. The problem that rosin glyceride which is 115 DEG C or above in softening point and free of foreign flavor cannot be prepared can be solved, the acid value of the prepared high-softening-point rosin glyceride is lowered to be 4-6, the Gardner value, measured by a Fe-Co method, of the color and luster is smaller than or equal to 8, and the quality is good; the reaction process is simple and easy to control, the reaction efficiency is high, and no by-product is generated.

Owner:广西贺州华川林产科技有限公司

Natural cinnamaldehyde extraction device

ActiveCN102964229BEvenly heatedIncrease productivityCarbonyl compound separation/purificationDistillationCinnamon Oil

The invention discloses a natural cinnamaldehyde extraction device, and relates to the technical field of chemical equipment manufacturing of forest products. A raw material heater in a natural cinnamaldehyde evaporation device is arranged on the upper part of the outside of a raw material distillation still, the raw material heater and the raw material distillation still form a distillated raw material circulating system through a raw material circulating pump, and the raw material heater takes hot oil provided by a hot oil furnace as a heating medium; and multiple layers of corrugated mesh packing are filled in a distillation column of the natural cinnamaldehyde extraction device. The natural cinnamaldehyde extraction device disclosed by the invention can solve the problem that when the existing natural cinnamaldehyde extraction device distillates cinnamon oil and extracts natural cinnamaldehyde, an overheating situation is caused by the fact that the cinnamon oil is heated unevenly, so that the cinnamon oil is degenerative and the production efficiency is low.

Owner:广西京桂香料有限公司

Natural cinnamaldehyde extraction process

ActiveCN102964228BIncrease productivityCarbonyl compound separation/purificationChemical industryDistillation

The invention discloses a natural cinnamaldehyde extraction process, and relates to the technical field of a forest product chemical industry. The process is implemented by taking natural cinnamon oil as a raw material through carrying out extraction in four stages, wherein in the first stage, the temperature of a distillation still is 110 DEG C, the temperature of the top of a distillation tower is 50 DEG C, and the reflux ratio is 0:1; in the second stage, the temperature of the distillation still is 140 DEG C, the temperature of the top of the distillation tower is 110 DEG C, and the reflux ratio is 10:1; and in the third stage, the internal temperature of the distillation still is 160 DEG C, the temperature of the top of the distillation tower is 140 DEG C, the reflux ratio is 0:1, until the collected distillate achieves the analytical calculation quantity of natural cinnamaldehyde. The process disclosed by the invention can solve the problem that in the processes of distilling cinnamon oil and extracting natural cinnamaldehyde, the cinnamon oil is subjected to partial fusion because the cinnamon oil is heated unevenly, so that the purity of natural cinnamaldehyde finished products and the output capacity of natural cinnamaldehyde are affected.

Owner:广西京桂香料有限公司

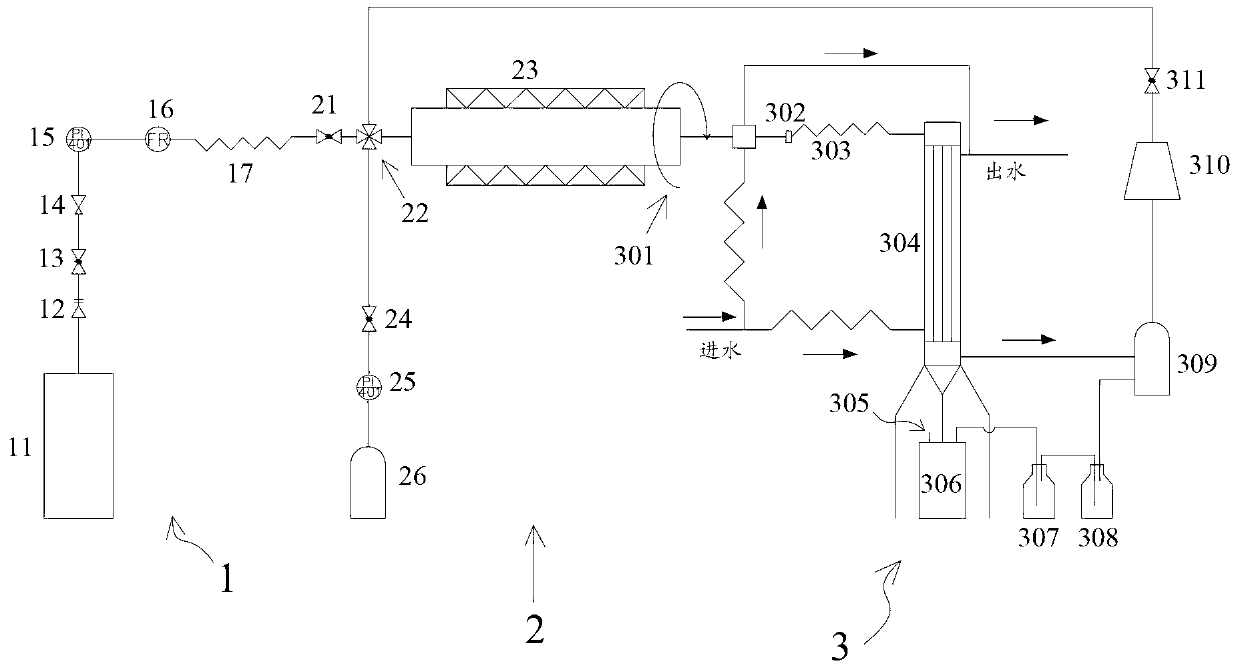

Efficient heterojunction ultraviolet light catalyst and preparation method and application thereof

ActiveCN105618090ASave raw materialsMild reaction conditionsPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionIndustrial effluent

The invention discloses an efficient heterojunction ultraviolet light catalyst and a preparation method of the efficient heterojunction ultraviolet light catalyst. The efficient heterojunction ultraviolet light catalyst is a heterojunction catalyst prepared from SrTiO3 and BiPO4. The preparation method comprises the following steps: putting SrTiO3 into a mixed solution of Bi(NO3)3.5H2O and Na3PO4; regulating the pH (Potential of Hydrogen) of the solution by HNO3; putting the solution in a hydrothermal reactor for heating after ultrasonic stirring; washing and drying a product, thus obtaining the efficient heterojunction ultraviolet light catalyst. The preparation method disclosed by the invention is simple and easy, the preparation process is simple, the cost is low, an MB (Methylene Blue) solution (of which the degradation rate is up to 97.94 percent) can be efficiently degraded under the illumination of ultraviolet light, and the preparation method has a good application prospect in forest product chemical wastewater, such as tannin extract, rosin and furfural, which is difficult to be biodegraded and other industrial wastewater.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for preparing rosin methyl ester and compound biodiesel raw material through pine oleoresin

InactiveCN102358844ALow priceReduce manufacturing costBiofuelsLiquid carbonaceous fuelsBiodiesel feedstockBiodiesel

The present invention relates to the technical fields of forest product deepening and processing, and renewable energy resources, and a method for preparing rosin methyl ester and a compound biodiesel raw material through pine oleoresin. The method comprises: mixing the pine oleoresin and turpentine oil according to a mass ratio of the pine oleoresin to the turpentine oil of 1:0.4-1.2; heating, melting and filtering; adding the resulting filtrate and methanol to an autoclave according to the mass ratio of the filtrate to the methanol of 1:0.05-0.5, introducing 0-4 MPa of CO2 to the autoclave, wherein the CO2 is adopted as a cosolven to carry out a reaction under a supercritical state or a subcritical state; carrying out standing and demixing for the product after completing the reaction, wherein the upper layer is an alcohol phase, and is subjected to atmospheric distillation to recover the methanol, the lower layer is an oil phase, is subjected to atmospheric distillation to recover the methanol, and then is subjected to a CO2 circulating gas introducing method or a super heating steam method to carry out vacuum distillation and separation to obtain the rosin methyl ester and the compound biodiesel raw material. The method provided by the present invention has advantages of simple production process, environmentally friendly property, no requirement of the catalysts, improvement of the economic feasibility of the biodiesel preparing through the pine oleoresin, and the like.

Owner:GUANGXI UNIV

Method for making wooden quality granule shape activated char used in recovering solvent

InactiveCN1385368ARecycling Technology ExcellenceHigh hardnessCarbon compoundsManufacturing technologyPhosphoric acid

The present invention belongs to a production technique of active carbon by using saw dust or discards of farm and forest products as raw material, and said production technique incldues the following steps: soaking raw material by using activating agent phosphoric acid soaking temp. is 100-200 deg.C, and the concentration of activating agent is 30 Be-60Be, after the raw material is softened and stickability-produced, kneading and extruding to obtain granular semi-finished product, then making the semi-finished product undergo the convertional processes of drying, carbonizing, chemical activating, recovering activating agent, removing impurity, drying, screening and packaging so as to obtain the invneted end product.

Owner:郑国炉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com