Natural cinnamaldehyde extraction process

An extraction process and technology of cinnamaldehyde, applied in the field of extracting natural cinnamaldehyde, can solve the problems of fusion of cinnamon oil, uneven temperature of cinnamon oil, affecting the purity of natural cinnamaldehyde and the yield of natural cinnamaldehyde, and achieve high yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

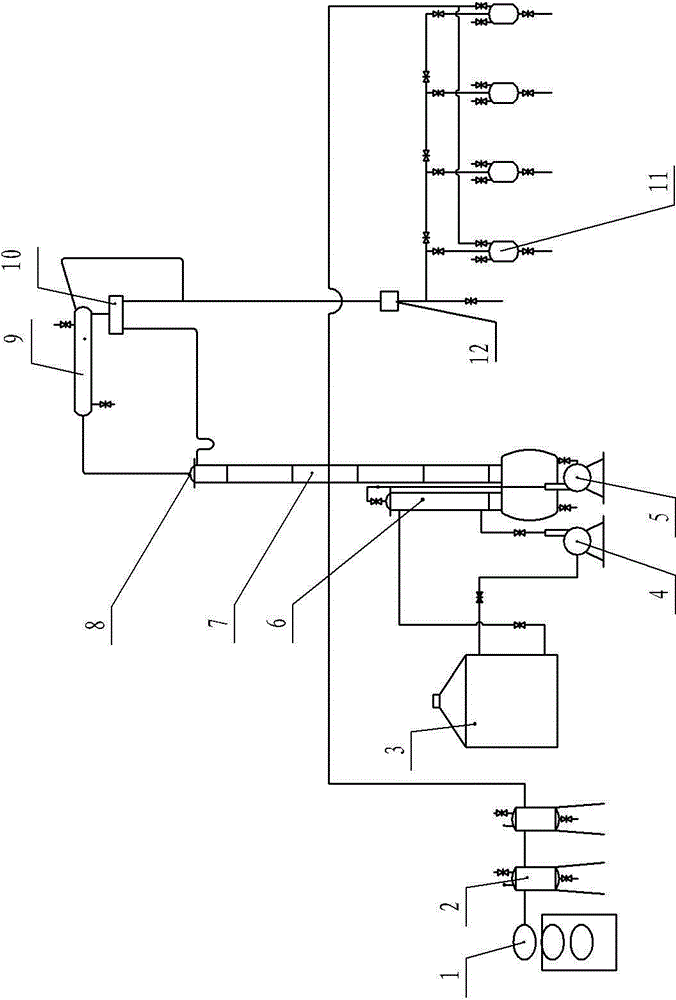

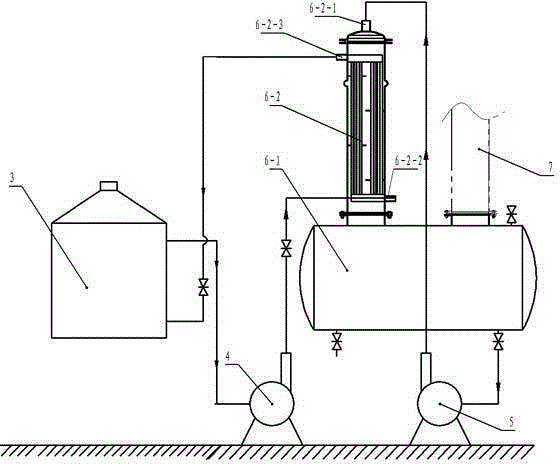

[0015] The extraction of natural cinnamaldehyde is carried out in special distillation equipment, such as figure 1 with figure 2 As shown, the distillation equipment has an evaporation equipment 6, and the evaporation equipment 6 is composed of a raw material still 6-1 and a distillation tower, and a raw material heater 6-2 is installed on the raw material still 6-1, and the raw material heater 6-2 uses Bolts are fixed on the raw material distillation kettle 6-1, and the inner cavity of the raw material heater 6-2 is equipped with a heat exchange core composed of many heat exchange tubes arranged in parallel and tube sheets closed at both ends of these heat exchange tubes. The outer space of the heat exchange tube of the heat exchange core is separated by 4 partitions into a raw material channel that loops around the partition. The raw material inlet 6-2-1 is located on the top of the raw material heater 6-2, and the raw material inlet 6-2- 2-1 is connected to the outlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com