Patents

Literature

40 results about "Matrix production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Matrix production is based on categorized, standardized production cells. These can be arranged in virtually any number in a grid layout. All cells are equipped with product-neutral equipment and product-specific basic functions.

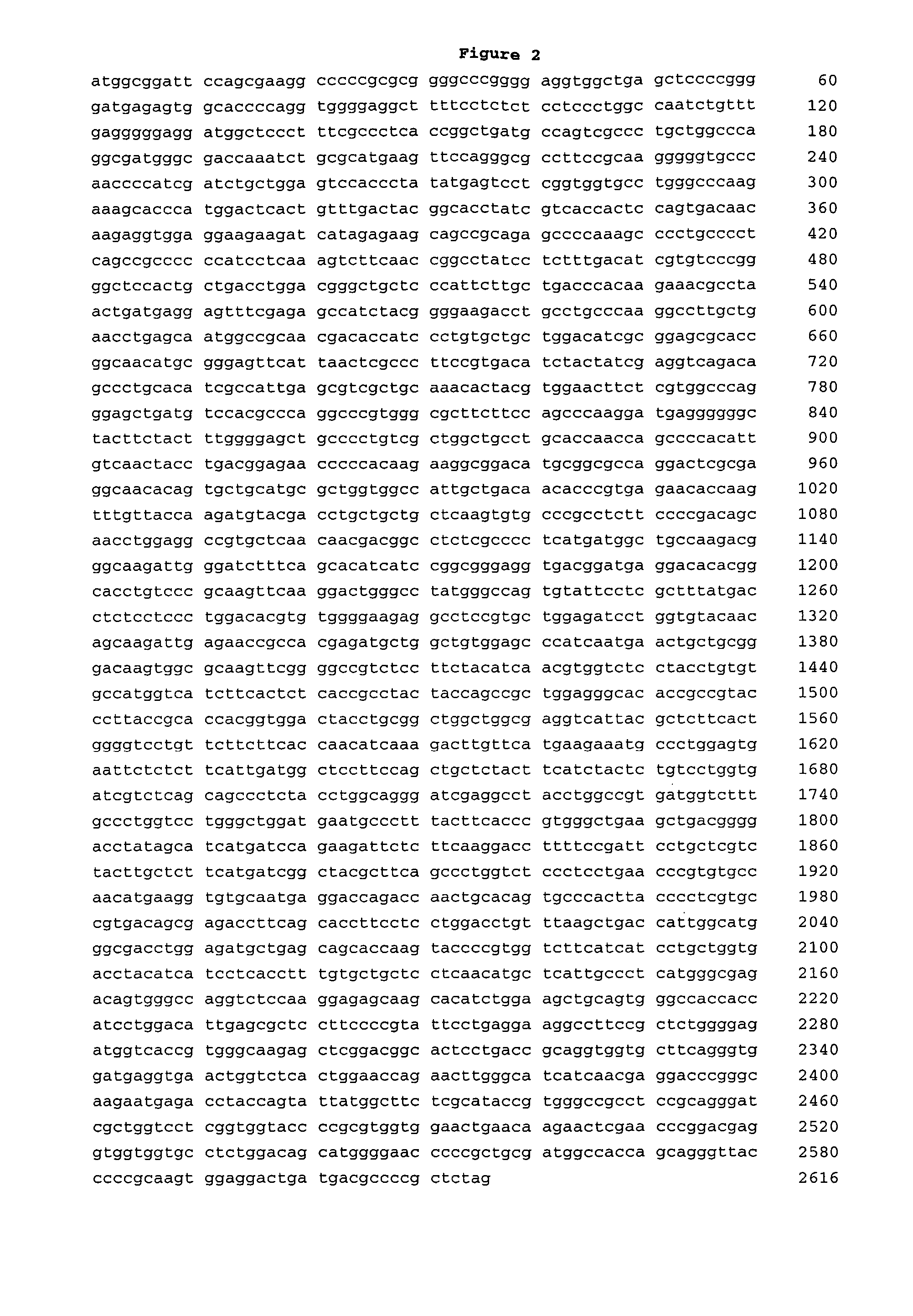

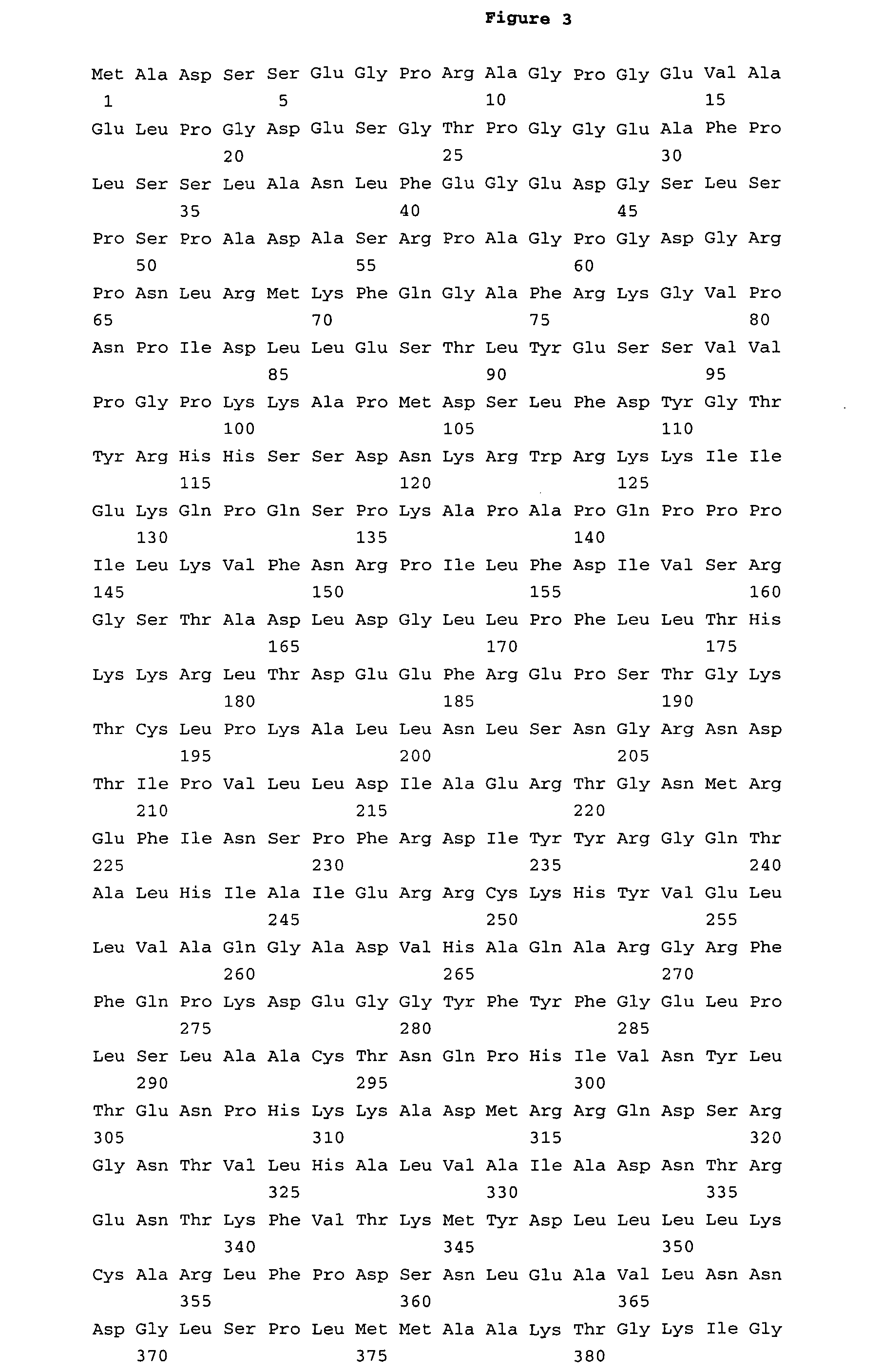

EB Matrix Production from Fetal Tissues and its Use for Tissue Repair

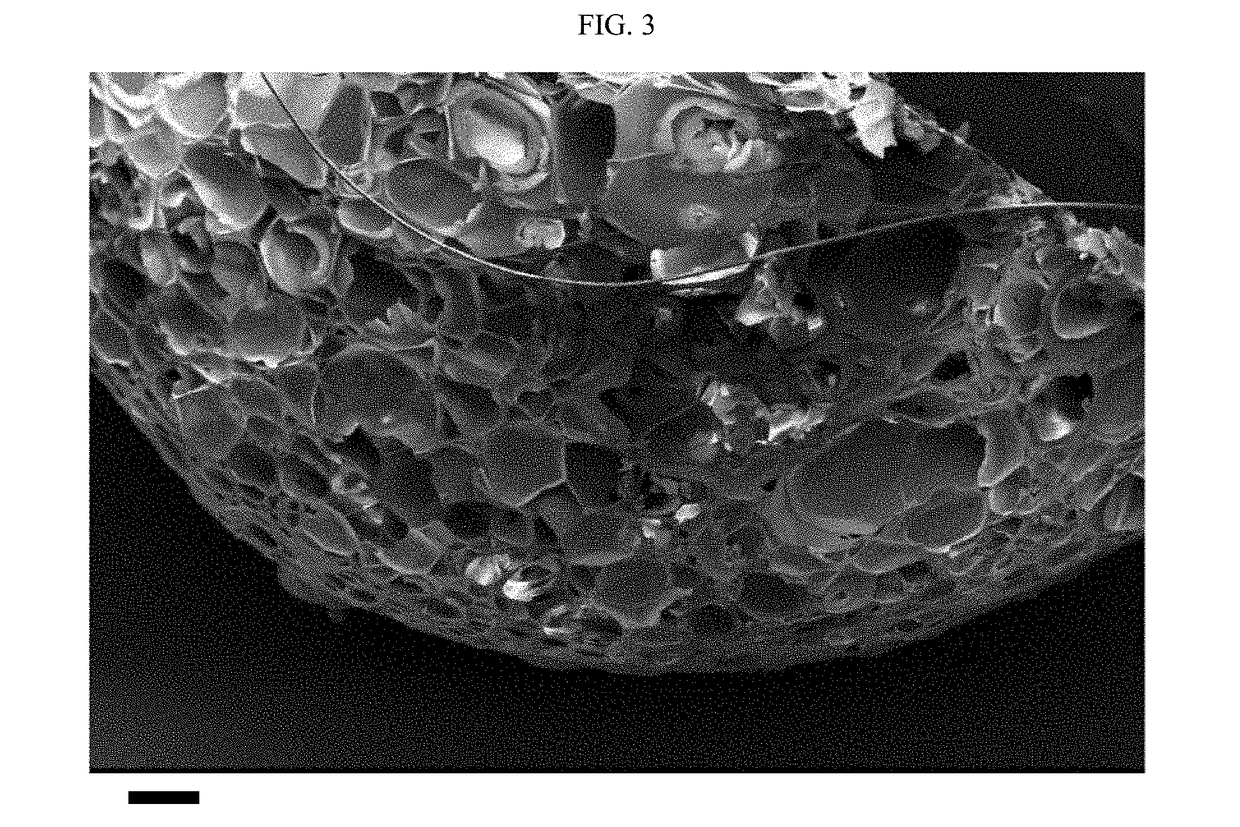

InactiveUS20020146393A1Reducing biological propertyPreserve strengthBiocideHepatocytesCross-linkTissue repair

<heading lvl="0">Abstract of Disclosure< / heading> A method of forming and preserving a bioremodelable, biopolymer scaffold material by subjecting animal tissue, particularly fetal or neo-natal tissue, to chemical and mechanical processing. The process includes, but is not limited t, harvesting the tissue, optionally extracting growth and differentiation factors from the tissue, inactivating infective agents of the tissue, mechanically expressig undesirable components frm the tissue, delipidizing the tissue, washing the tissue, optionally drying the tissue, and optionally cross-linking the tissue not necessarily in the order described. The resulting product, EBM, is characterized by its microbial, fungal, viral and prion inactivated state. EBM is storng, bioremodelable, drapable and does not undergo calicification. EBM supplants previous inventions because of its unique method of preparation and broad applicability in tissue reengineering

Owner:TEI BIOSCI

Light ground mass industrial machine-shaping process technology

InactiveCN101253845AReduce labor intensityProtect environmentBio-organic fraction processingBiofuelsEcological environmentEngineering

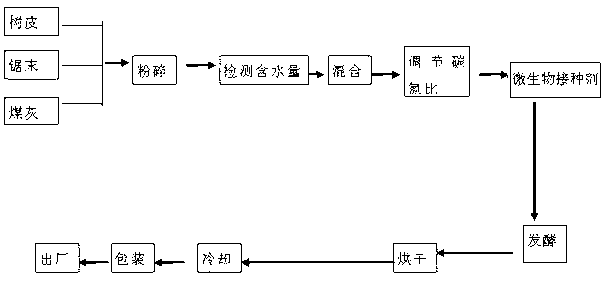

A technology for industrialized processing and molding of a light matrix includes the steps of crushing agricultural and forest waste first, composting the waste with beneficial microbes, namely EM bacteria for fermentation, conducting rational sifting and matrix matching, using a light-matrix processing and molding machine to process the scattered matrix into an enteroid matrix container with a diameter of 35mm to 50mm, and then cutting the matrix container into small sections, namely matrix sections in the length of 80mm to 100mm, thereby suiting both the cultivation of eucalyptus grafts and the upper bag of the seedling container for tissue-culture rooting. The technology, which can be used for industrialized matrix production, greatly reduces labor intensity and protects ecological environment. The matrix, belonging to composite matrix, can be used for seeding, cuttage and transplant of plants and for the cultivation of other seedlings for greening purpose, with a high survival rate and robust root systems.

Owner:CHINA EUCALYPT RES CENT

EB matrix production from fetal tissues and its use for tissue repair

A method of forming and preserving a bioremodelable, biopolymer scaffold material by subjecting animal tissue to chemical and mechanical processing. In addition to skin tissue, another source of EBM is a blood vessel. EBM may be used for hernia repair, colon, rectal, vaginal and or urethral prolapse treatment; pelvic floor reconstruction; muscle flap reinforcement; lung tissue support; rotator cuff repair or replacement; periosteum replacement; dura repair; pericardial membrane repair; soft tissue augmentation; intervertebral disk repair; and periodontal repair. EBM may also be used as a urethral sling, laminectomy barrier or spinal fusion device.

Owner:TEI BIOSCI

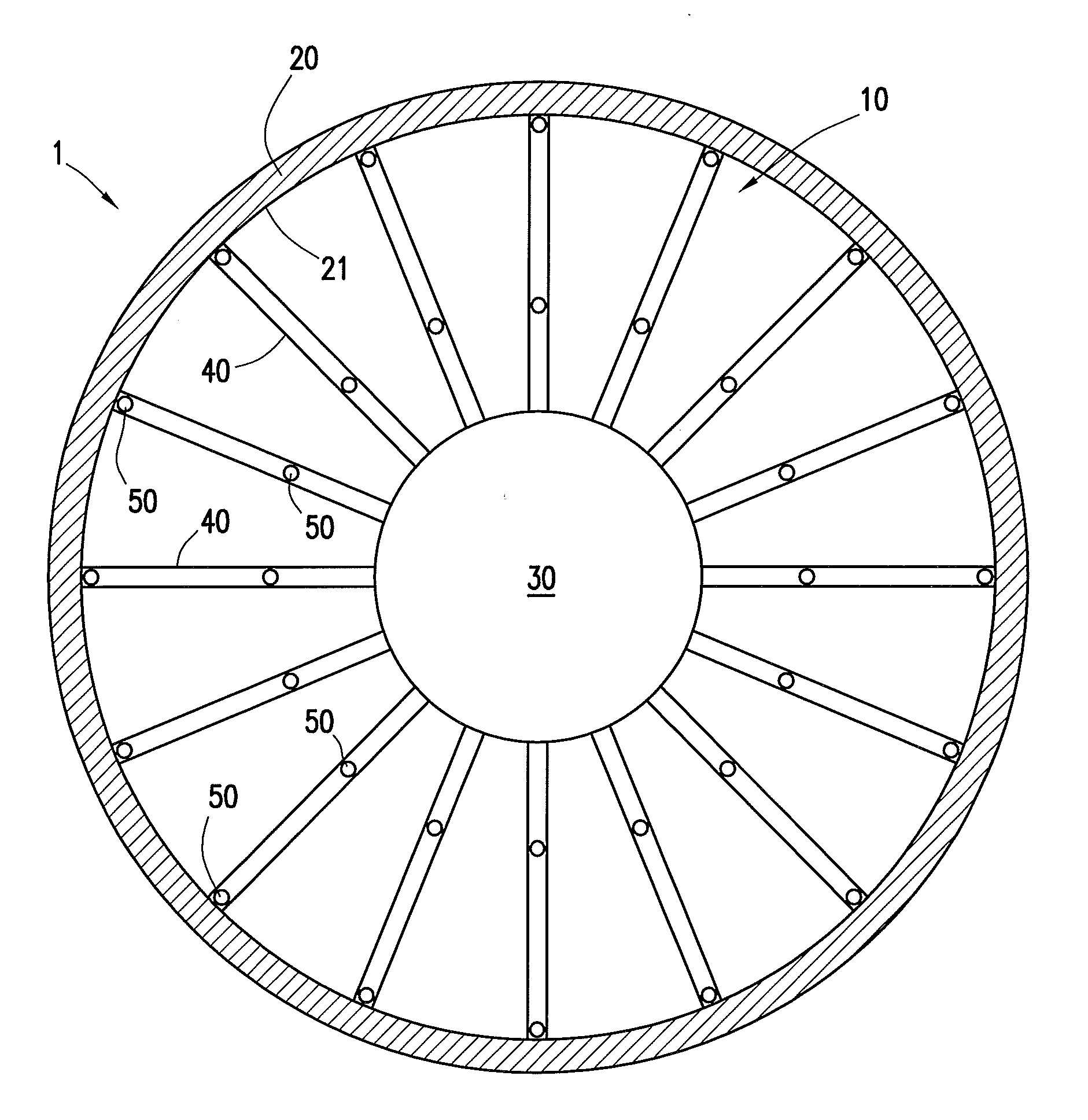

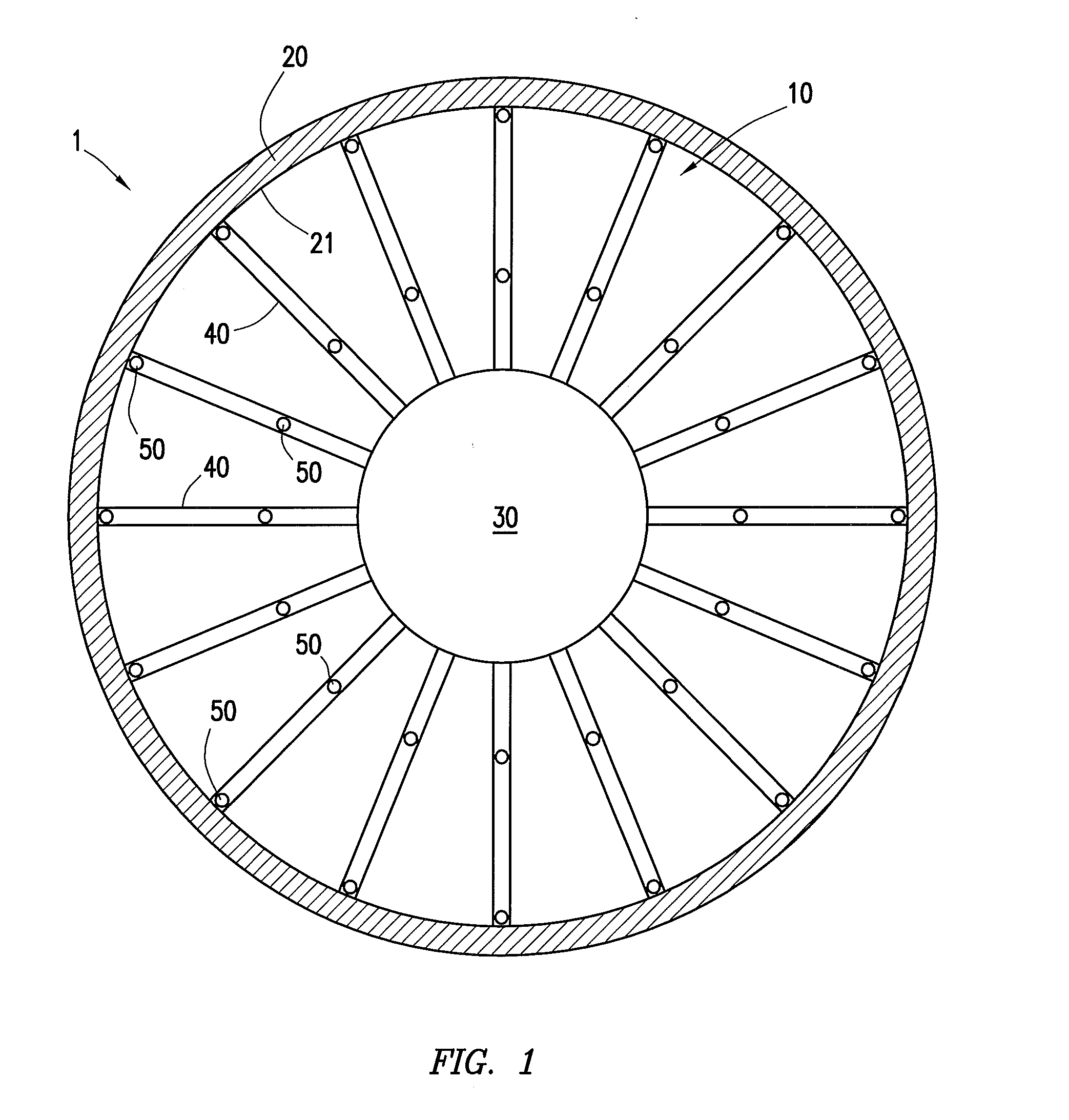

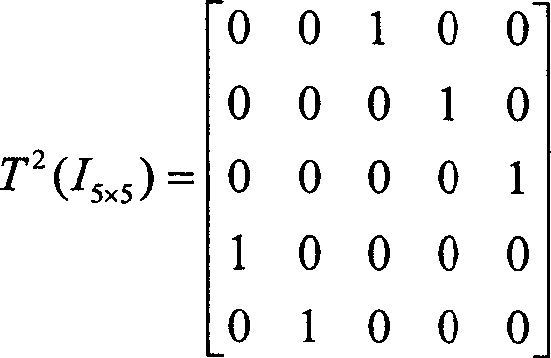

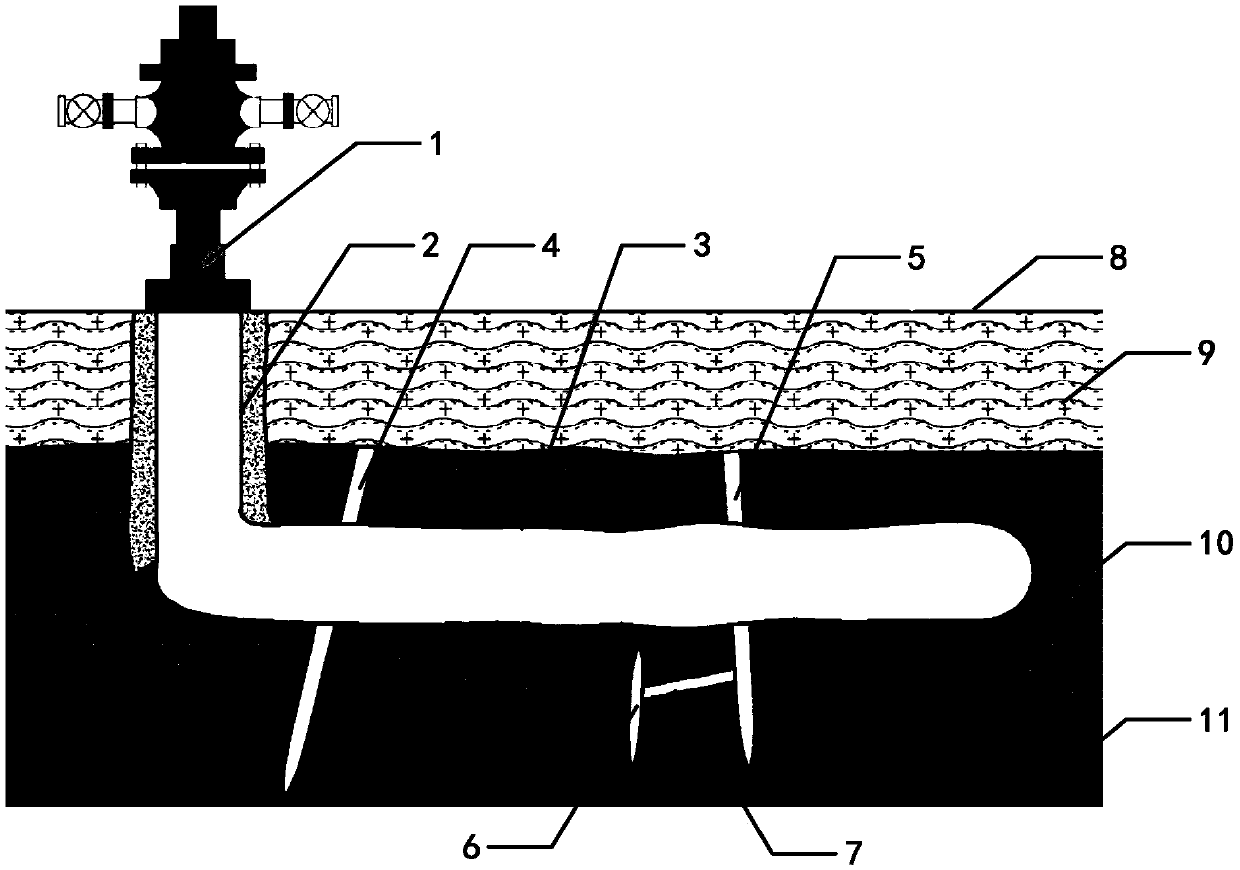

Matrix temperature production logging tool

A matrix production logging tool for measuring the temperature of produced fluids in a wellbore. Accurate production allocation to the pathways between the oil / gas well and the reservoir provides required data for the economic optimization of the techniques and procedures used to complete future wells. The low maintenance tool provides precise upstream, downstream and inflow temperature measurements of produced fluids within the wellbore.

Owner:CONOCOPHILLIPS CO

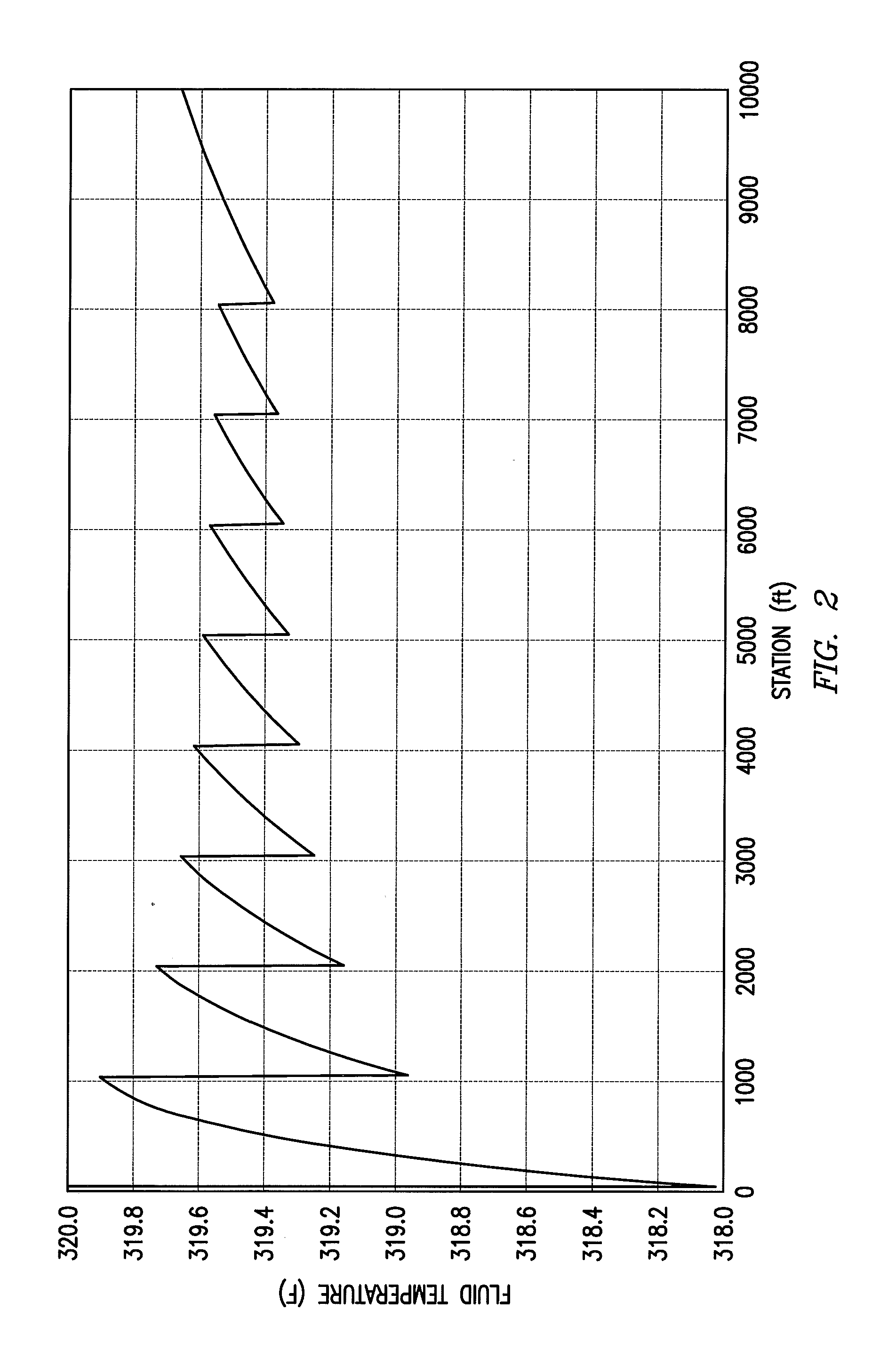

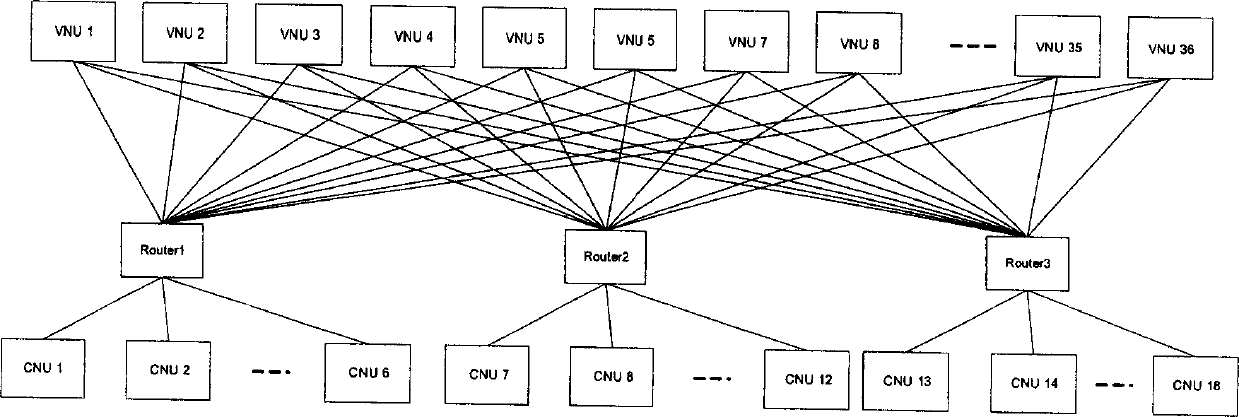

High structural LDPC coding and decoding method and coder and decoder

InactiveCN1625057AError correction/detection using multiple parity bitsError correction/detection using arithmatic codesDecoding methodsRound complexity

This invention discloses a highly structured LDPC coding and decoding methods. The code is through the checking matrix production unit of the encoder based on the pre-set code rate, column weight and row weight of HS-LDPC code to produce an odd-even checking matrix, and input the result into a compounding code unit of a coder, the compounding code unit calculates the input data information and the odd-even checking matrix, output the data information united by the odd-even checking information bit and input data information. The decoding method is according the need of the matrix odd-even checking code, pre-set the changeable node units, checks the number of the node units and the connecting units and the connecting structure, the changeable node units and the checking node units together complete the iterative decoding process of HS-LDPC code. This method can greatly reduce the complication of the hardware implementation of the entire decoder, compromises easily of the complicated degree and the speed of the hardware realization process.

Owner:TIMI TECH

EB Matrix production from fetal tissue and its use for tissue repair

InactiveUS20050013802A1Improve suppression propertiesTissue strength is preservedBiocideHepatocytesCross-linkTissue repair

A method of forming and preserving a bioremodelable, biopolymer scaffold material by subjecting animal tissue, particularly fetal or neo-natal tissue, to chemical and mechanical processing. The process includes, but is not limited to, harvesting the tissue, optionally extracting growth and differentiation factors from the tissue, inactivating infective agents of the tissue, mechanically expressing undesirable components from the tissue, delipidizing the tissue, washing the tissue, optionally drying the tissue, optionally cross-linking the tissue not necessarily in the order described. The resulting product, EBM, is characterized by its microbial, fungal, viral and prion inactivated state. EBM is strong, bioremodelable, drapable and does not undergo calcification. EBM supplants previous inventions because of its unique method of preparation and broad applicability in tissue reengineering.

Owner:TEI BIOSCI

EB matrix production from fetal tissues and its use for tissue repair

InactiveUS20050008708A1Improve abilitiesImprove propertiesPeptide/protein ingredientsSkeletal disorderTissue repairUrethral Sling

A method of forming and preserving a bioremodelable, biopolymer scaffold material by subjecting animal tissue to chemical and mechanical processing. In addition to skin tissue, another source of EBM is a blood vessel. EBM may be used for hernia repair, colon, rectal, vaginal and or urethral prolapse treatment; pelvic floor reconstruction; muscle flap reinforcement; lung tissue support; rotator cuff repair or replacement; periosteum replacement; dura repair; pericardial membrane repair; soft tissue augmentation; intervertebral disk repair; and periodontal repair. EBM may also be used as a urethral sling, laminectomy barrier or spinal fusion device.

Owner:TEI BIOSCI

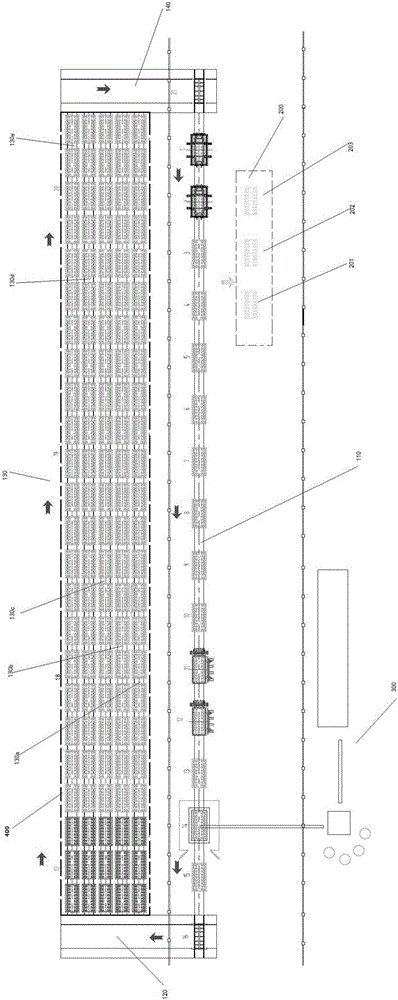

Assembly-line automatic manufacturing technology for pre-stressed concrete track board unit by pre-tensioning method

ActiveCN106466882AImprove turnover rateReduce areaDischarging arrangementBallastwayManufacturing technologyAutomatic control

The invention provides an assembly-line automatic manufacturing technology for a pre-stressed concrete track board unit by a pre-tensioning method. Traction equipment drives a model to flow on a track according to a time beat, wherein the time beat is working time of each station; the model bears tensioning stress, and all the stations are lined up on an assembly line and work together at the same time; and the quality and the working progress of each station are controlled by a sensor, and each station is commanded by a central control system, so that the operation of the whole system is controlled. Compared with a matrix production method, the assembly-line automatic manufacturing technology has the advantages that temporary components such as a tensile pedestal are eliminated, the model turnover rate is increased by 50 percent, the area of a factory is reduced by 30 percent or above, and the number of workers is reduced by 50 percent or above. The production process fulfills the aims of full-automatic control, informationalized transmission of key data, remote monitoring, and relocation and quick installation of all sets of equipment according to engineering requirements.

Owner:SHANDONG LINQU SLEEPER

Rice seedling matrix and preparation method thereof

InactiveCN105294184AReduce utilizationAvoid damageBio-organic fraction processingOrganic fertiliser preparationHigh fertilityInsect pest

The invention relates to the technical field of seedling matrixes of crops and particularly relates to a rice seedling matrix and a preparation method thereof. The rice seedling matrix with good permeability and high fertility is particularly prepared from the main raw materials of crop straws, cow mature, rice husk, seed cakes, microbial zymophyte and the like through steps of material preparation, soaking, straw piling, straw composting, matrix preparation and the like. The rice seedling matrix comprises the following main raw materials in percentage by weight: 35%-45% of the crop straws, 27%-34% of the rice husk, 16%-24% of the cow mature and 7%-15% of seed cakes, wherein 1kg of the microbial zymophyte is used in each 5-6 cubic meters of the crop straws. According to the preparation method, the soil-free matrix production is realized, the utilization of non-renewable resources is reduced, the damage caused to farmland soil resources is reduced, the environment is protected, the factory seedling is realized, the cost is lowered, the plant diseases and the insect pests are reduced, the content of soil organic matters is increased, and the yield and the milled rice rate can be increased.

Owner:ANHUI PROVINCE LVFU AGRI TECH CO LTD

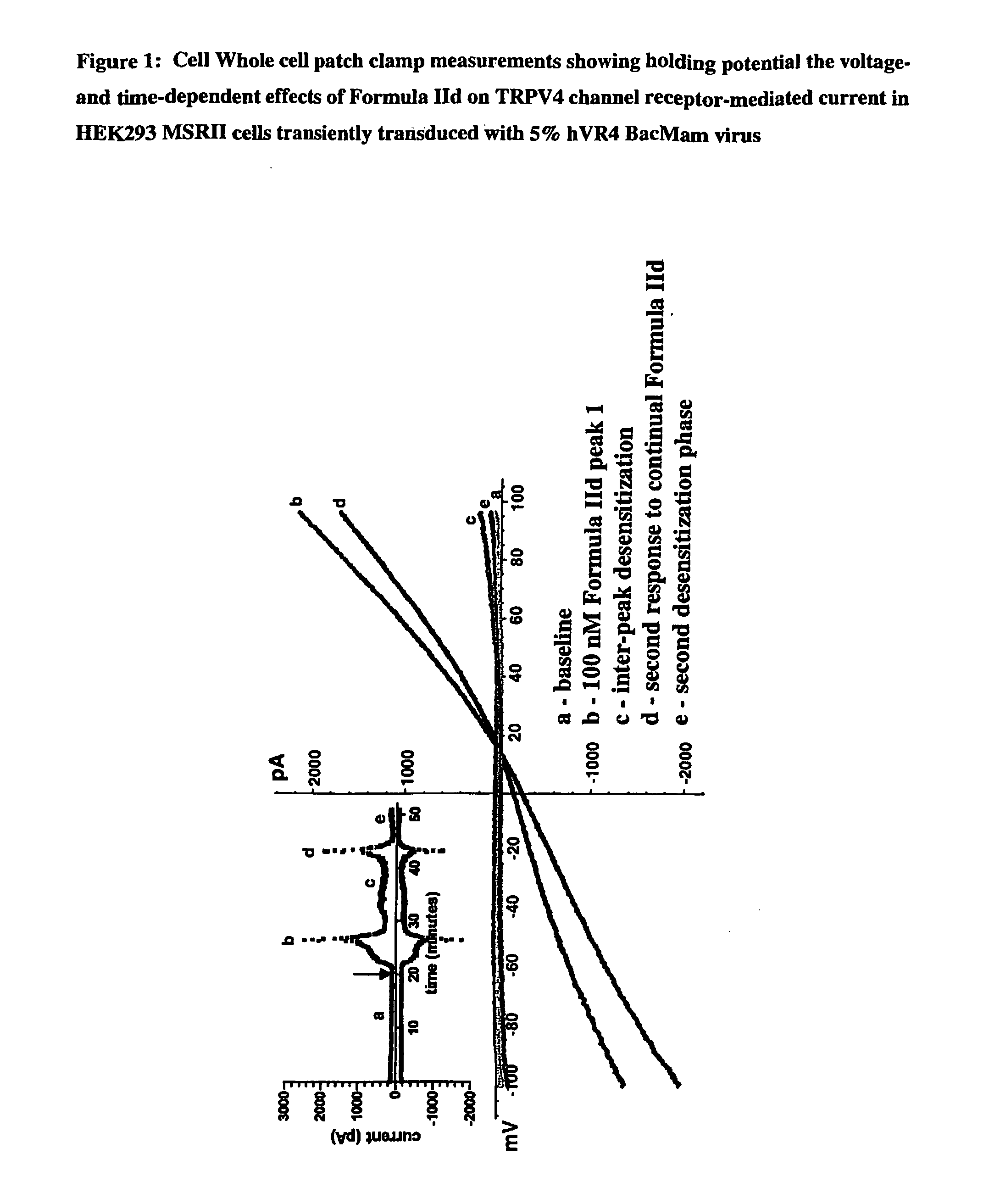

Method for Activating Trpv4 Channel Receptors by Agonists

InactiveUS20070259856A1Reduce the amount requiredIncrease currentBiocideSenses disorderAgonistMatrix production

This invention relates to methods for activating a TRPV4 channel receptor, thereby reducing the production and / or release of matrix degrading enzymes by a cell expressing a TRPV4 channel receptor, thereby reducing the breakdown of an extra-cellular matrix. Also contemplated within the scope of the invention are methods of attenuating the inhibition of matrix production.

Owner:SMITHKLINE BECKMAN CORP

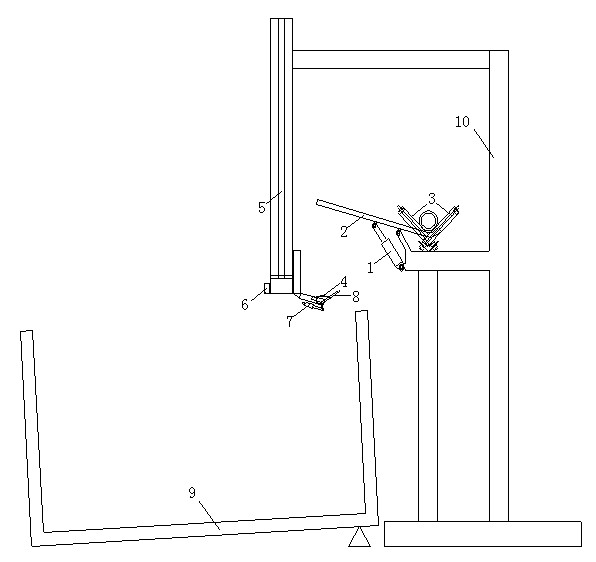

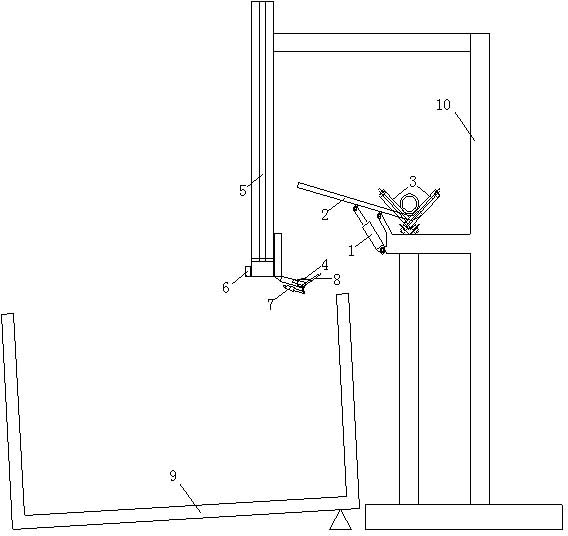

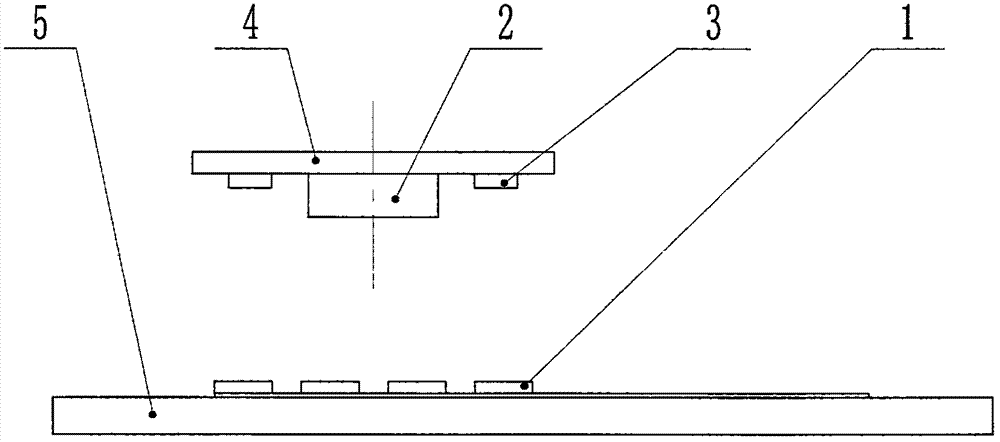

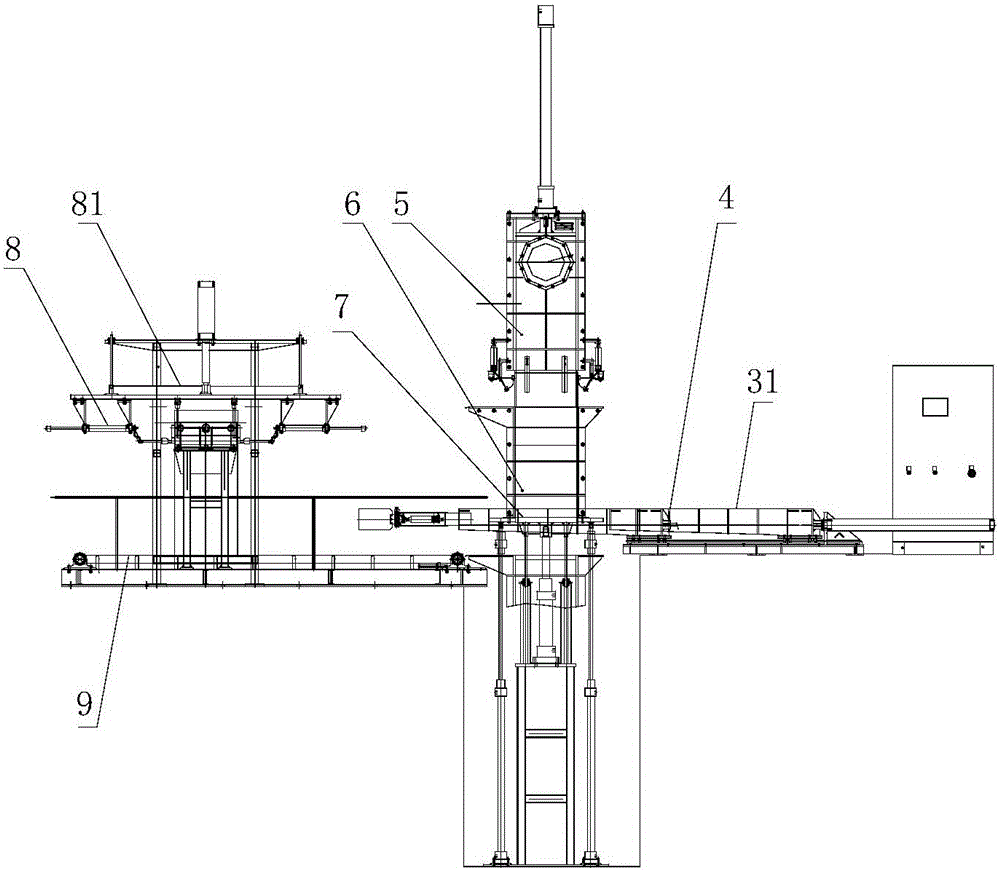

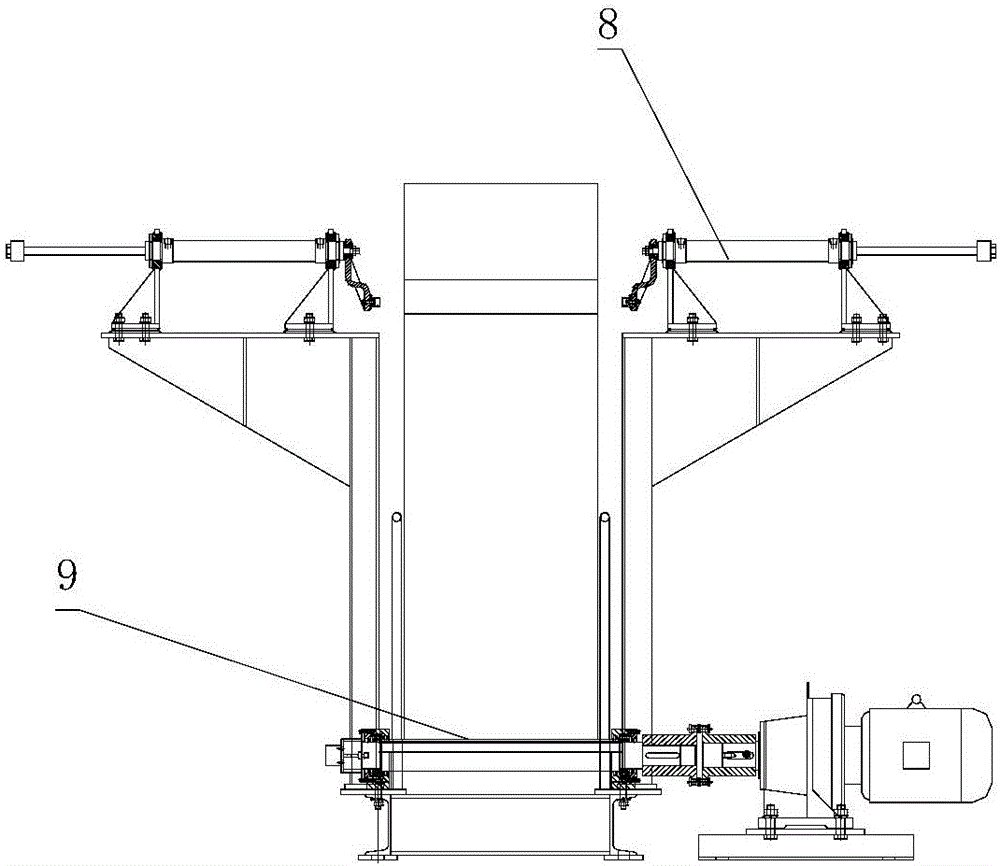

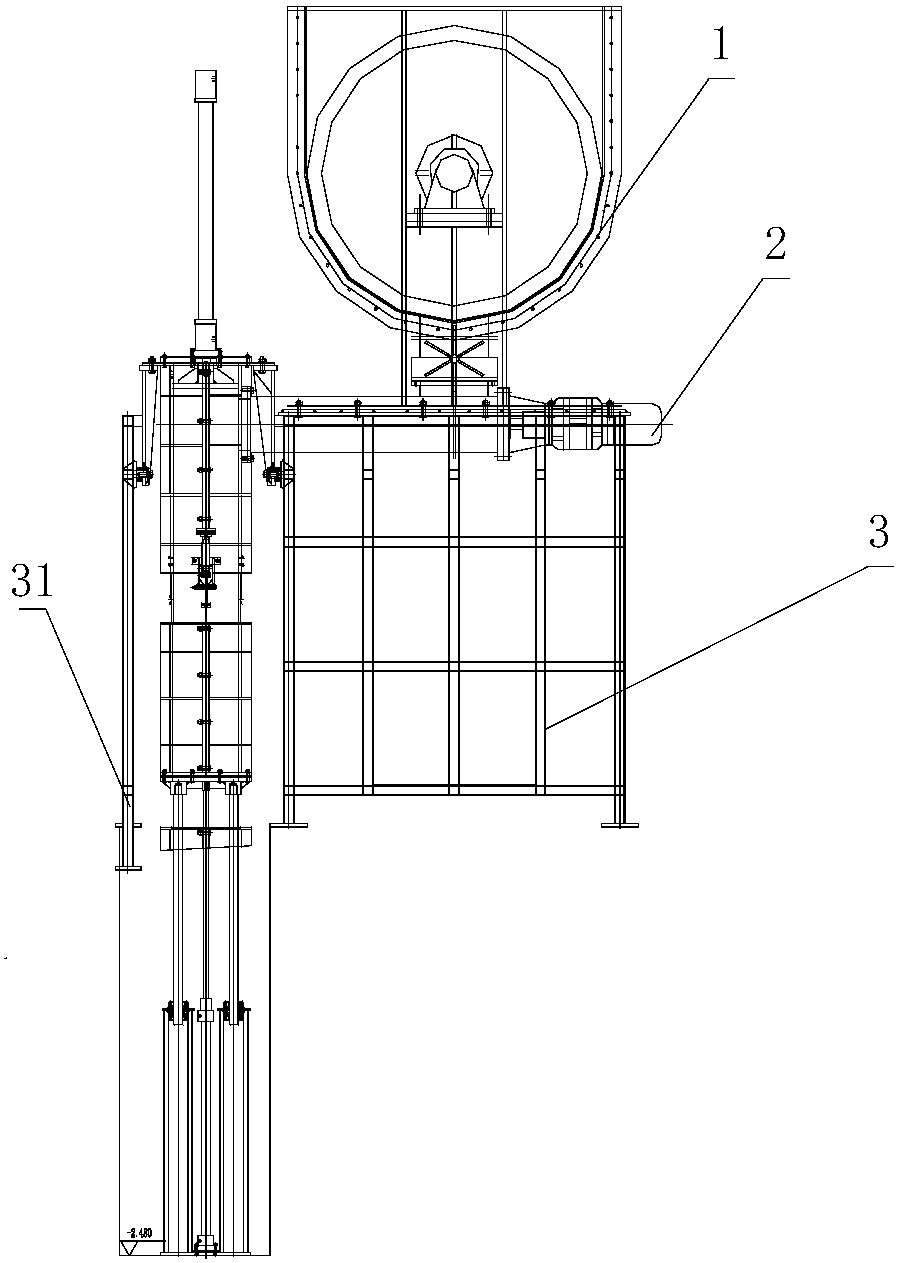

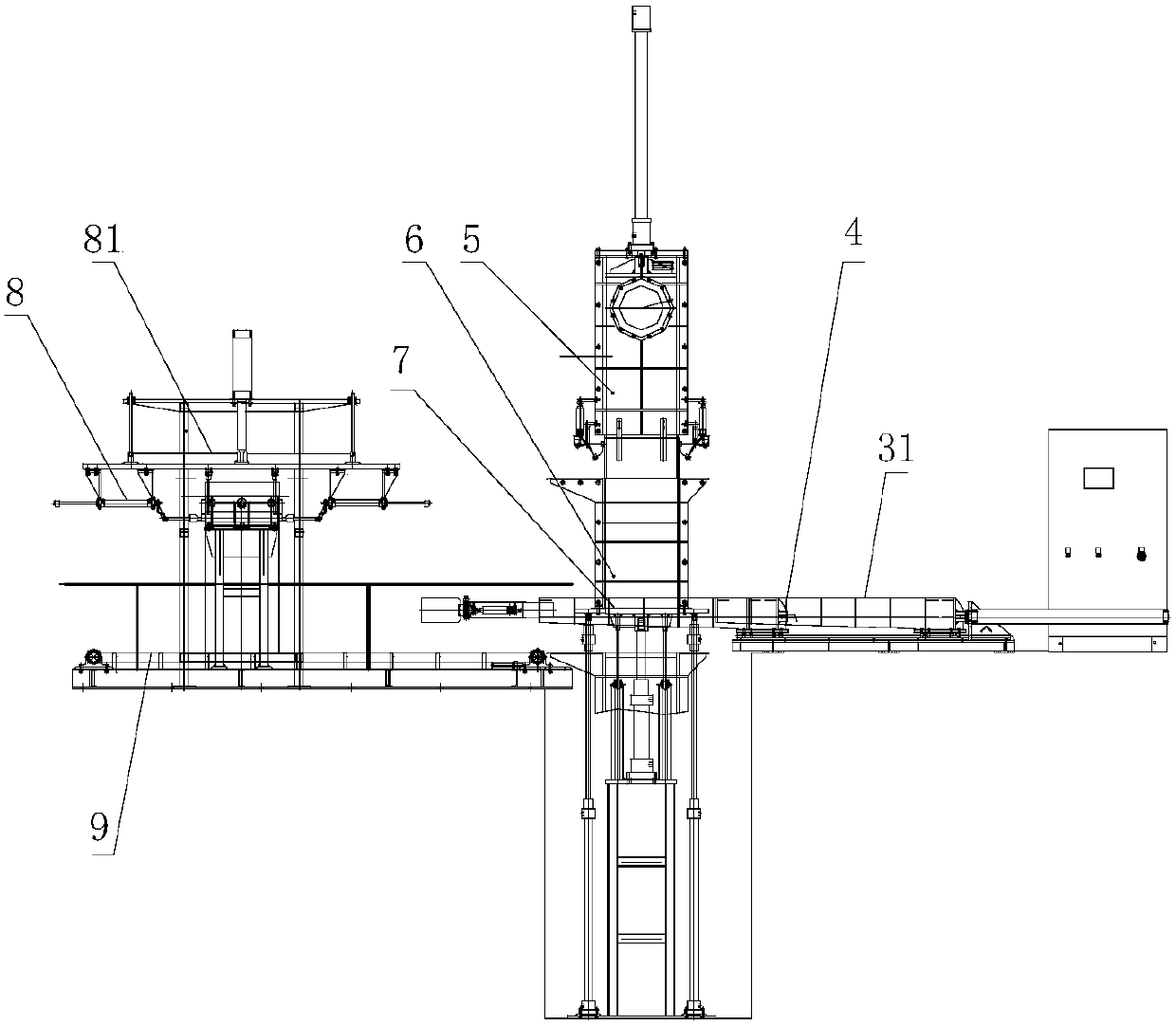

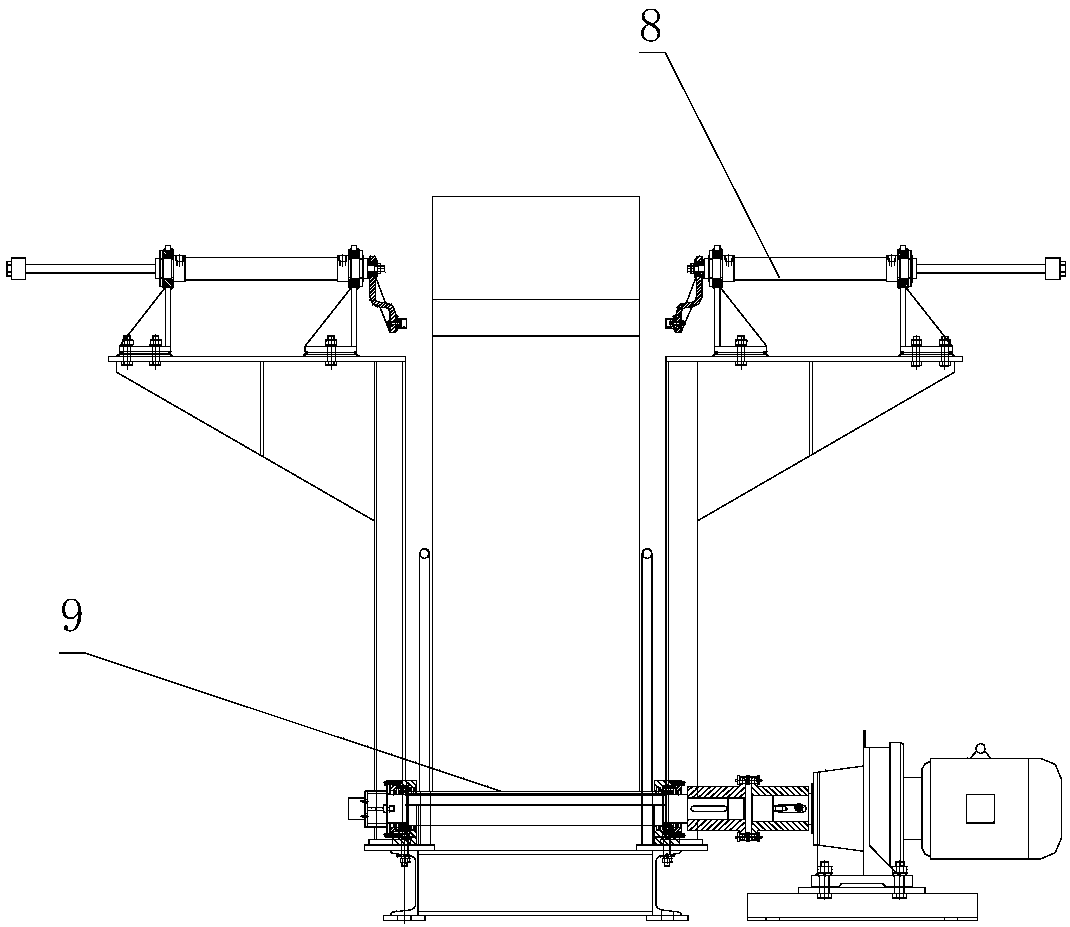

An automatic discharging and receiving device for a skewed roller straightening machine

ActiveCN102284565AAvoid product qualityReduce accidentsMetal-working feeding devicesPositioning devicesManipulatorMatrix production

The invention discloses an automatic discharging and receiving device of a cross roll straightening machine, formed by combining a frame (10), a discharging device, a receiving device, and a material rack (9), wherein the discharging device and the receiving device are installed on the frame (10); the discharging device is located at the lateral upside of the receiving device; and the material rack (9) is located on the lower part of the receiving device. The discharging device is composed of a manipulator cylinder (1), a manipulator (2) and a plurality of groups of brackets (3); the receiving device is composed of a contact switch (4), upper and lower cylinders (5), inductive switches (6), a lever (8) and a lever cylinder (7); the inductive switches (6) are located at the lower sides of the upper and lower cylinders (5); and the contact switch (4), the lever cylinder (7) and the lever (8) are installed at the other sides of the lower parts of the upper and lower cylinders (5). The automatic discharging and receiving device of a cross roll straightening machine disclosed by the invention has the advantages of increasing product quality, reducing accident occurrence, increasing production efficiency, saving production cost and the like, and the device can be widely applied in the related industries such as photosensitive drum matrix production.

Owner:CYMA PRECISION ALUMINUM

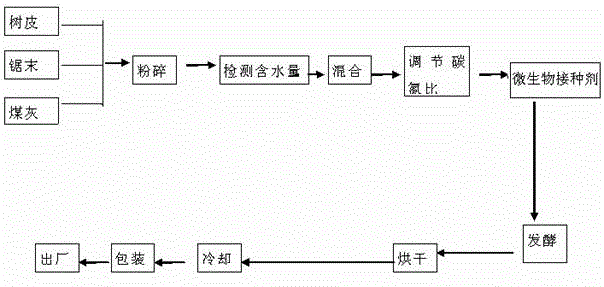

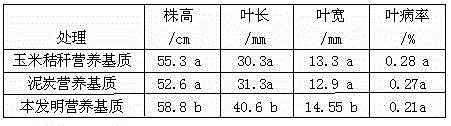

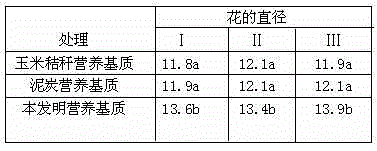

Purely natural organic nutritional matrix and preparation method thereof

InactiveCN103319232ALow costQuality improvementFertilizer mixturesControlled releaseLivestock manure

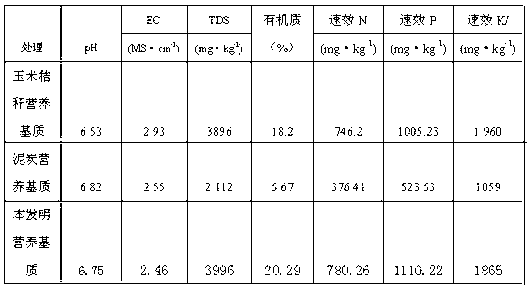

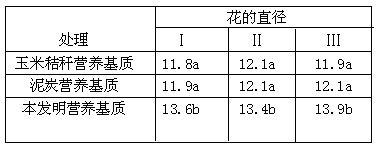

The invention relates to a cultivation matrix, and especially relates to a purely natural organic nutritional matrix and a preparation method thereof. The purely natural organic nutritional matrix is characterized in that the matrix is mainly prepared through using 40-60 parts by weight of bark, 20-40 parts by weight of sawdust, 10-30 parts by weight of coal ash, 0.1-1 part by weight of a biological fertilizer starter, and 1-5 parts by weight of livestock manure. The organic nutritional matrix prepared in the invention has the advantages of low cost, abundant resources and stable quality, solves the waste utilization, energy saving and emission reduction problems, and also solves the nuisance-free matrix production problem by utilizing forest product wastes to produce a soilless nutritional matrix. The addition of a constant quality of a plurality of controlled-release nutritional master batches avoids burnt seedlings caused by the early-stage excess release of a fertilizer, satisfies the nutrition needs of the whole growth period of tree peony, and has a nutritional expiration period reaching above 120d.

Owner:HEZE UNIV

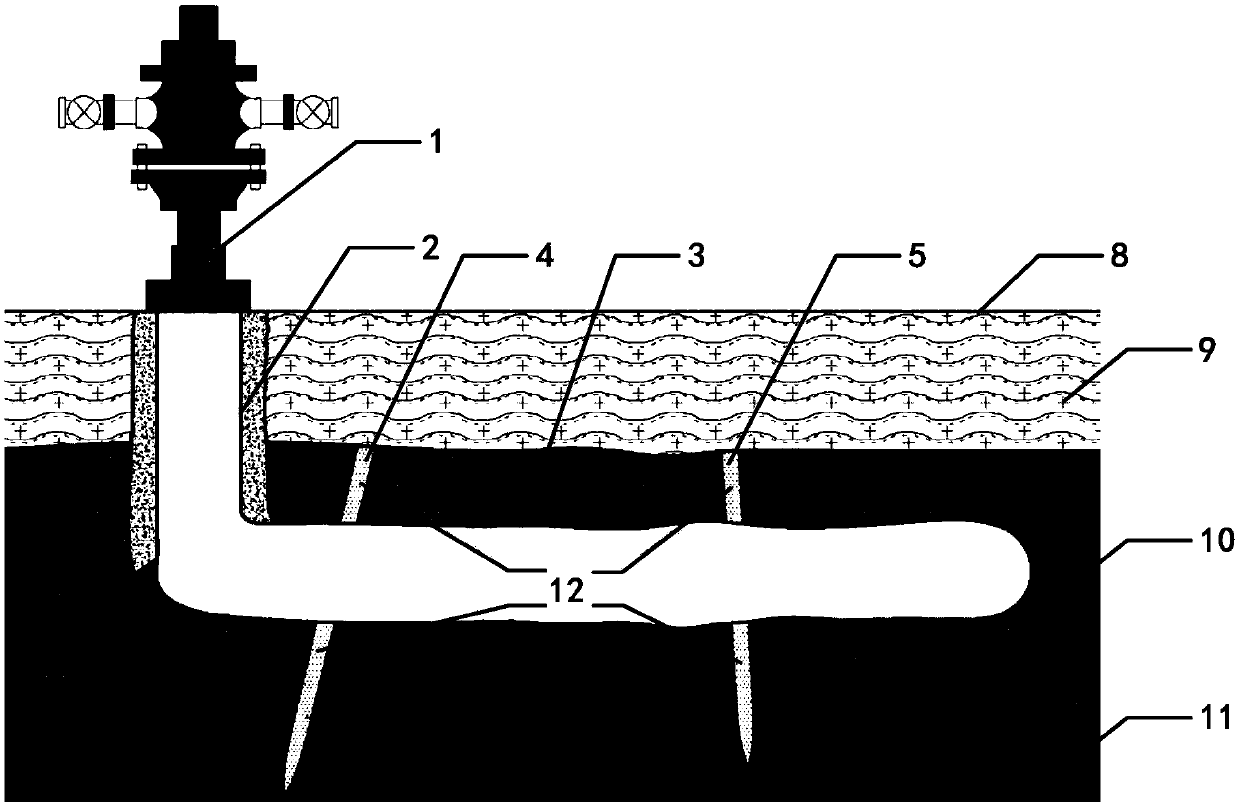

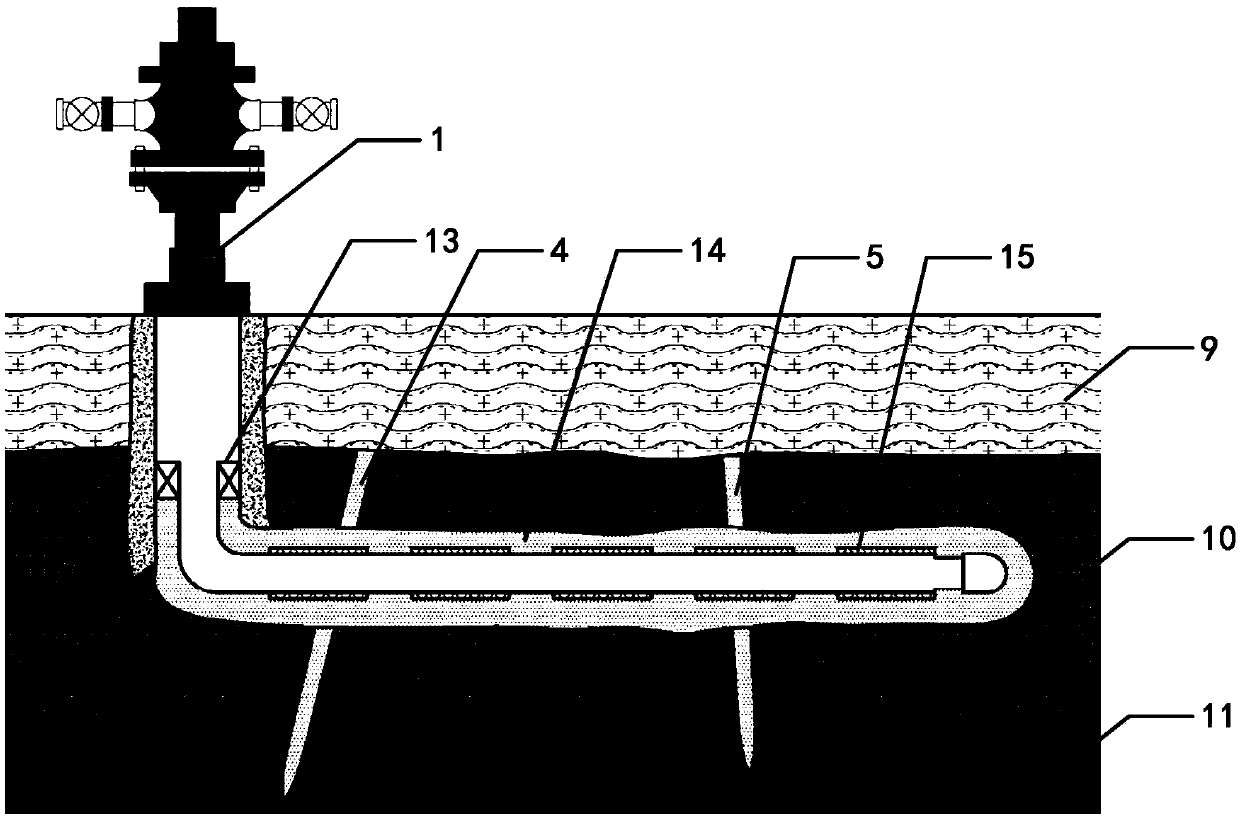

Oil well filling packer particle precipitation and oil increasing method for crack-type oil and gas reservoirs

PendingCN109653707ASolve the problem of channeling water productionImprove the blocking effectSurveyFluid removalInjection pressureMatrix production

The invention relates to an oil well filling packer particle precipitation and oil increasing method for crack-type oil and gas reservoirs. The method comprises the following steps: (1) injecting filling liquid carrying packer particles into a wellbore and cracks by virtue of a wellhead until reaching or exceeding the formation fracture / fracture extension pressure, or until reaching zero injectionvolume per unit injection pressure, or until reaching a preset packer particle filling volume; (2) putting into production. According to the oil well filling packer particle precipitation and oil increasing method for the crack-type oil and gas reservoirs, the problem of channeling water in various types of cracks can be effectively solved by directly filling and stoping filling the cracks, filling an annular space and filling from a water injection well to a production well, and in particular, the two-pressure-stage pressurized filling way and stoping filling way are adopted, so that the packer particles smoothly enter the gapless cracks, the sealing effect of the cracks is effectively improved, the guiding capability of various cracks can be reduced, and the water output of the wells isreduced; meanwhile, the pressure gradient during the matrix production is further improved, the utilization degree of matrix oil and gas is improved, and the recovery ratio is improved.

Owner:ANTON BAILIN OILFIELD TECH (BEIJING) CO LTD

Rapid propagation method applicable to golden camellia in mountainous areas

InactiveCN107660438AHigh rooting rateAchieve efficient breedingCultivating equipmentsVegetative propogationWaxIndole acetic acid

The invention discloses a rapid breeding method suitable for Camellia camellia in mountainous areas, comprising: S1, treatment of Camellia camellia mother tree: selecting side branches on the mother camellia camellia tree and peeling them circularly; S2, preparing large cuttage stems: cutting and girdling treatment After the side branch, the top is sealed with wax, and the girdling mouth on the side branch is soaked in indole acetic acid solution to obtain a large cuttage; S3, making the rooting matrix: S4, rooting treatment in the cutting box: the rooting matrix in S3 and the cuttings obtained in S2 Put the large poles into the cutting box for root-promoting treatment to obtain cutting seedlings; S5, transplanting and post-processing: after the root system of the cutting seedlings grows to 3cm, take the cutting seedlings out of the cutting box and move them to the hillside for planting. The present invention adopts large poles for cuttings, uses a cutting box to accelerate root growth, and develops the root system, so as to improve the rooting rate and transplanting survival rate of camellia camellia, and realize the efficient breeding of camellia camellia.

Owner:黄世强

Method for cucumber cultivation with vinegar residue matrix

InactiveCN103907458ASuitable growth environmentImprove survival rateBio-organic fraction processingClimate change adaptationGreenhouse cultivationFermentation

A method for cucumber cultivation with vinegar residue matrix includes the steps of vinegar residue matrix production, seed airing and plantation density determination. Vinegar residue matrix production includes steps of preparing raw materials, adding fungus and mixing, composting for fermentation and obtaining finished products, wherein making flat plats 1m in width and 5m in length in a greenhouse, scattering 30-40kg vinegar residue matrix in each plat with the border dike height of 20cm, leveling, harrowing and irrigating completely. Seed airing includes: airing seeds for 1-2days before seeding, selecting a proper seeding time according to crop rotation, wherein the proper seeding time for cultivation of overwintering batch is from the last ten-day in September to the first twenty-day in October, seedling and raising for early spring solar greenhouse and greenhouse cultivation is normally completed from the middle ten-day in November to the middle ten-day in January in the next year. The plantation density determination includes: according to a cucumber close planting technique, determining the line spacing of a main row to be 1-1.2m and the row spacing to be 20-30cm and keeping about 2200 seedlings each mu.

Owner:郑兴义

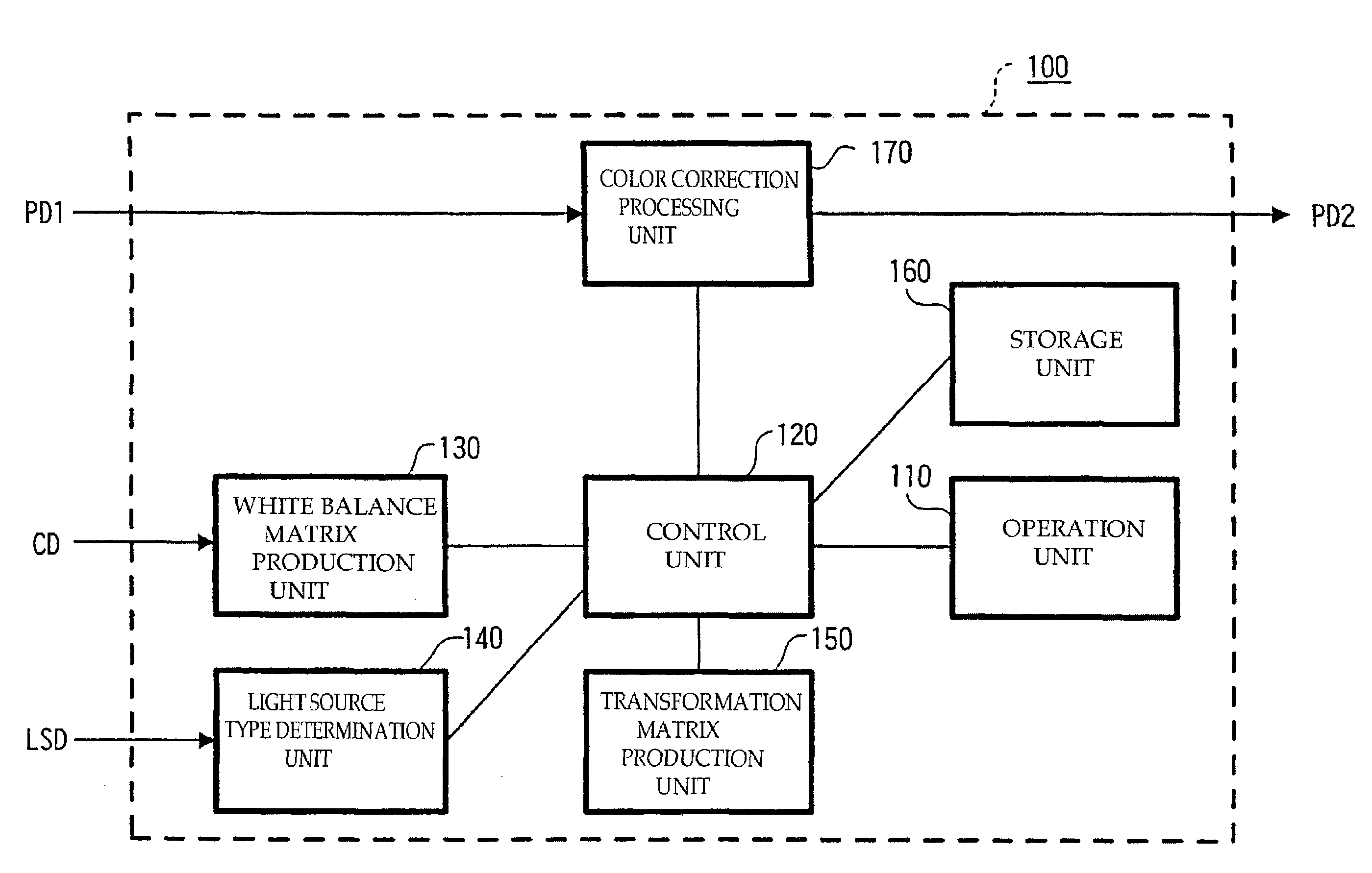

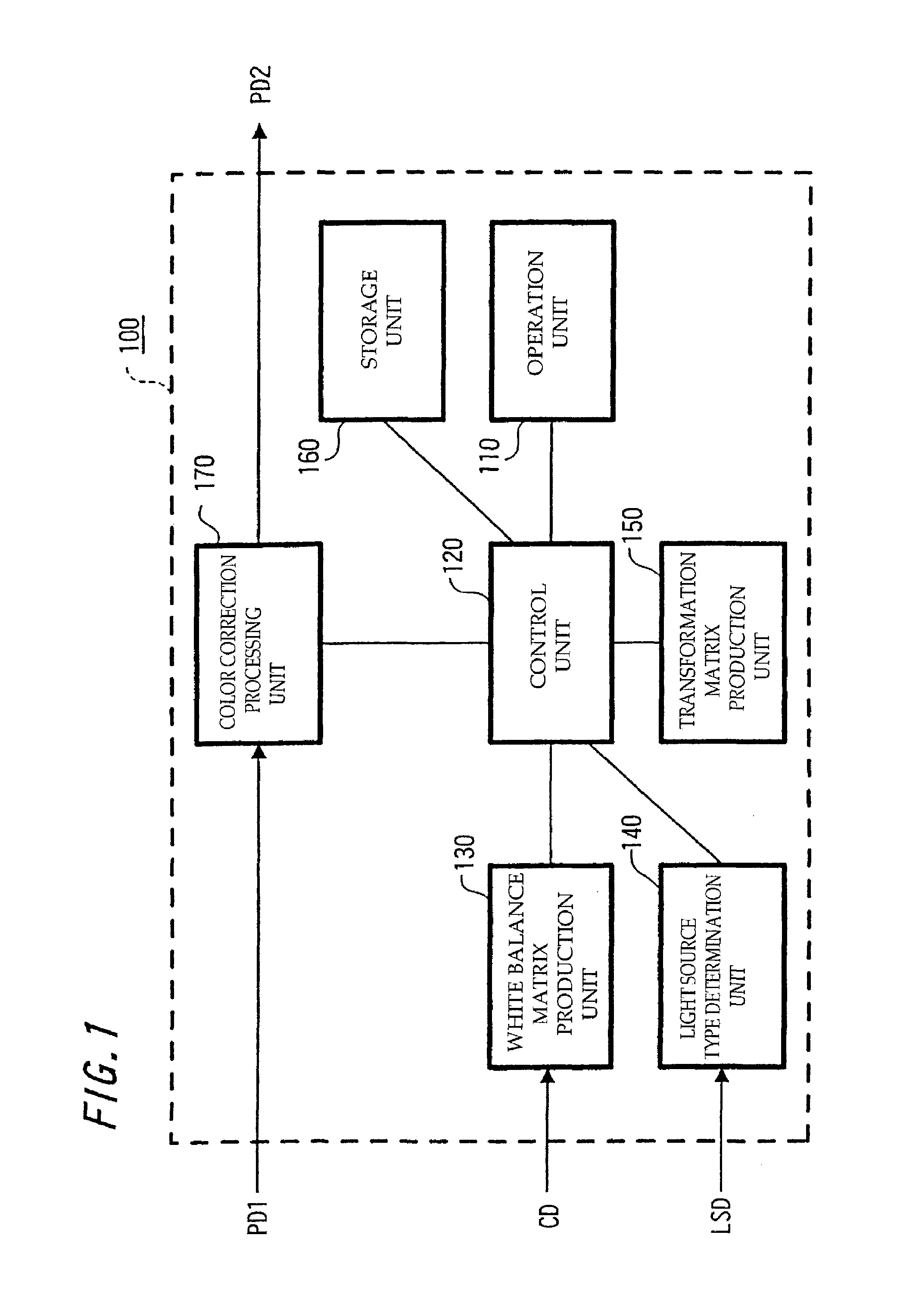

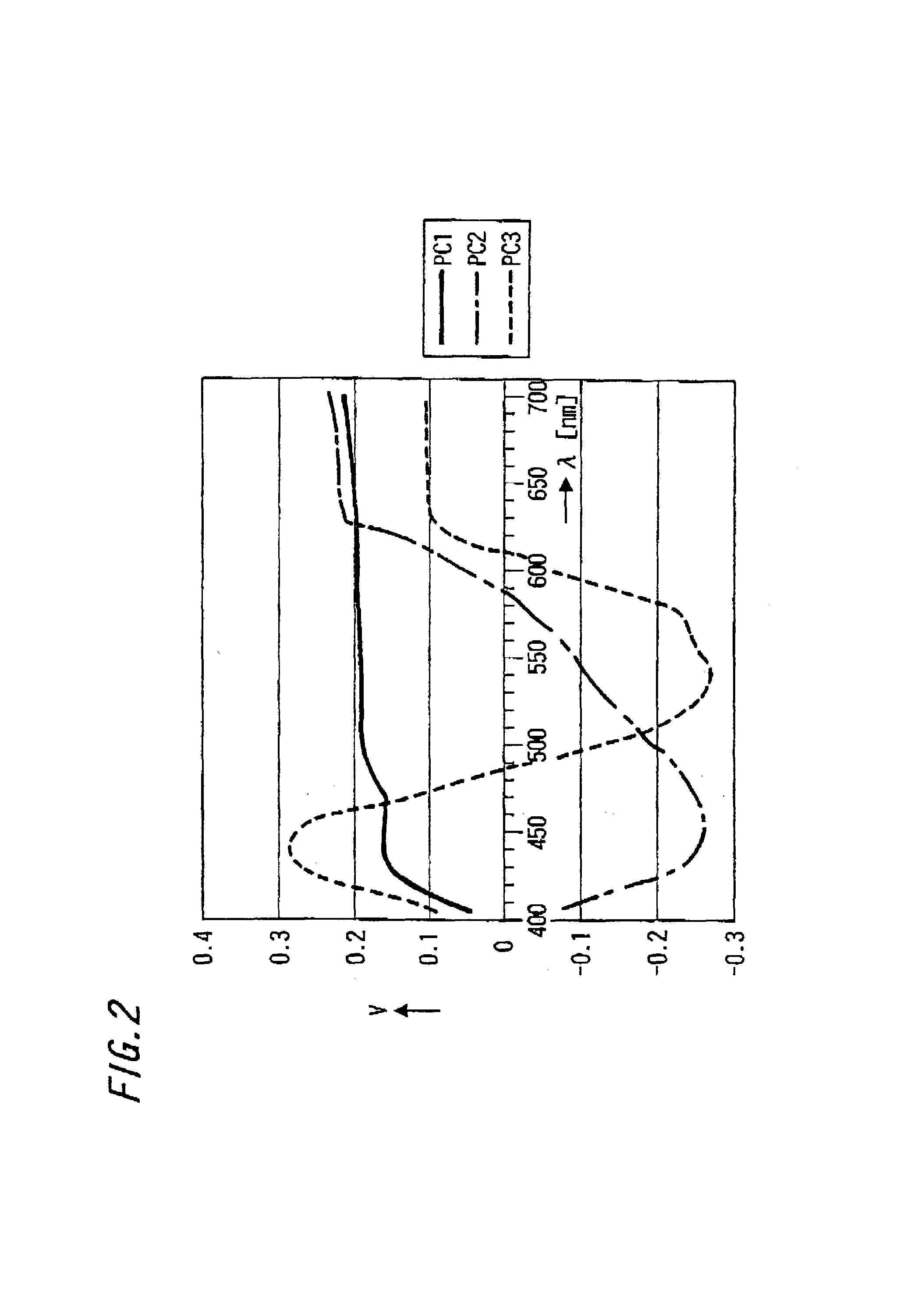

Color reproduction corrector for image input device and color reproduction correction method

InactiveUS7227571B2Television system detailsColor signal processing circuitsColor correctionPicks up objects

The present invention has an object to provide a color reproduction correcting device for image input apparatus capable of excellently reproducing colors without difficulties, even when an image is reproduced under an observation light source that is different from an image pick-up light source in terms of color rendering. The present invention has white balance matrix production means 130 that receives chromaticity point data from the image input apparatus to produce a correction matrix for white balance, light source type determination means 140 that receives information on the image pick-up light source from the image input apparatus to determine the types of the image pick-up light source and an image color reproduction light source, transformation matrix production means 150 that produces a transformation matrix reflecting the optical characteristics of the picked-up object by using predetermined color matching function data, spectral characteristic data regarding the image pick-up light source and color reproduction light source, of the types determined by the light source type determination means 140, optical characteristics data on a predetermined picked-up object, and correction matrix data for white balance, and color correction processing means 170 that performs color reproduction correction with respect to the image data using the transformation matrix.

Owner:SONY CORP

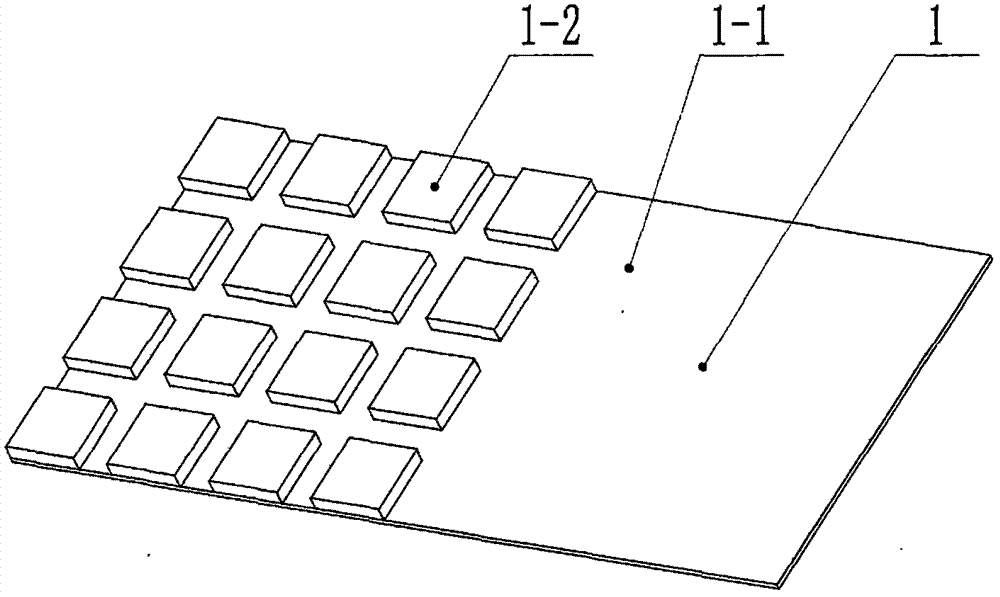

Test strip in matrix distribution, production process of test strip and detection method

The invention provides a test strip in matrix distribution, a production process of the test strip and a detection method. The test strip has a rectangular substrate, medicinal blocks are arranged onthe substrate in a matrix form, and the production process of the test strip has two optionable methods, i.e. a twice pasting and thrice cutting method and a point glue injection pasting method respectively. The detection method adopts fixed image acquisition, the test strip substrate broadens and shortens, the medicinal blocks are concentrated together so as to be convenient for immersion and use, as the medicinal blocks are concentrated together, a test strip analyzer can adopts a fixed image acquisition method, thus greatly simplifying the detection mechanism of the test strip analyzer, andreducing the design, production, manufacturing cost of the test strip analyzer.

Owner:姜志凌 +1

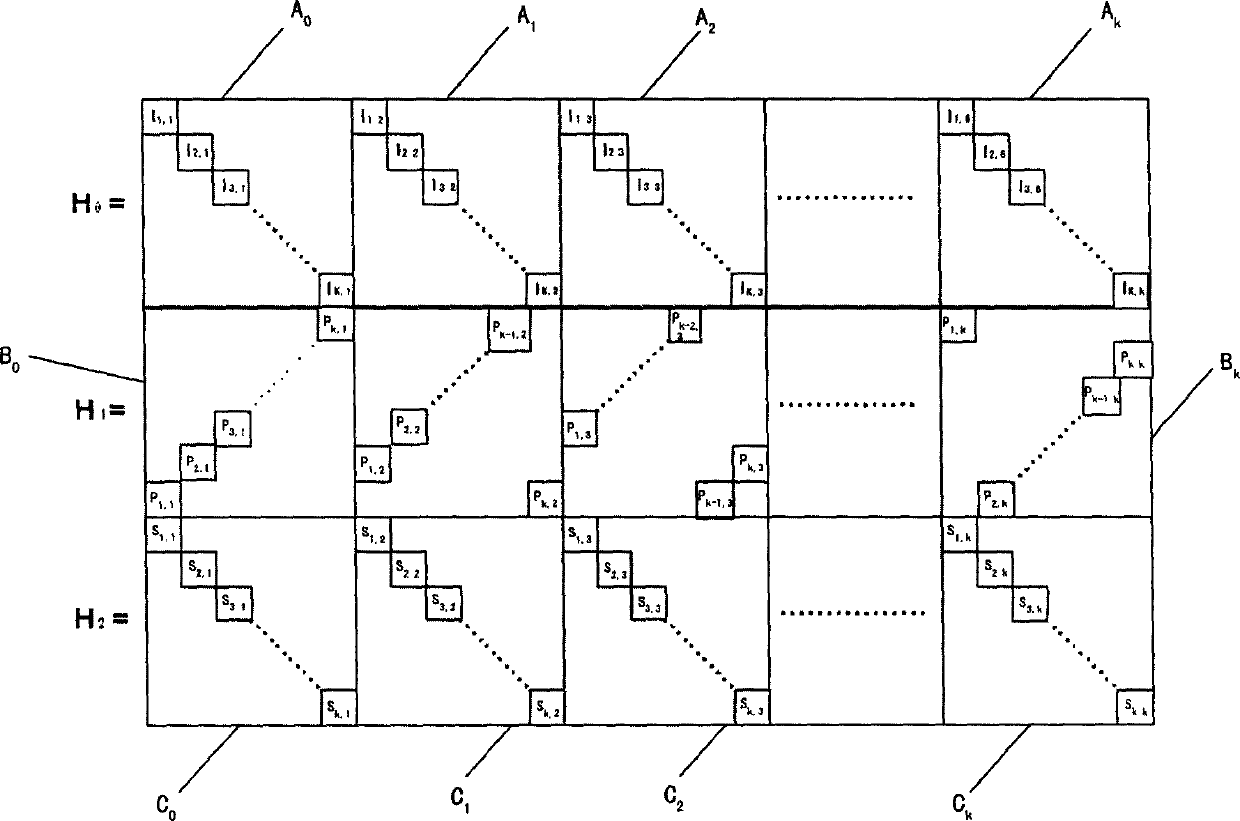

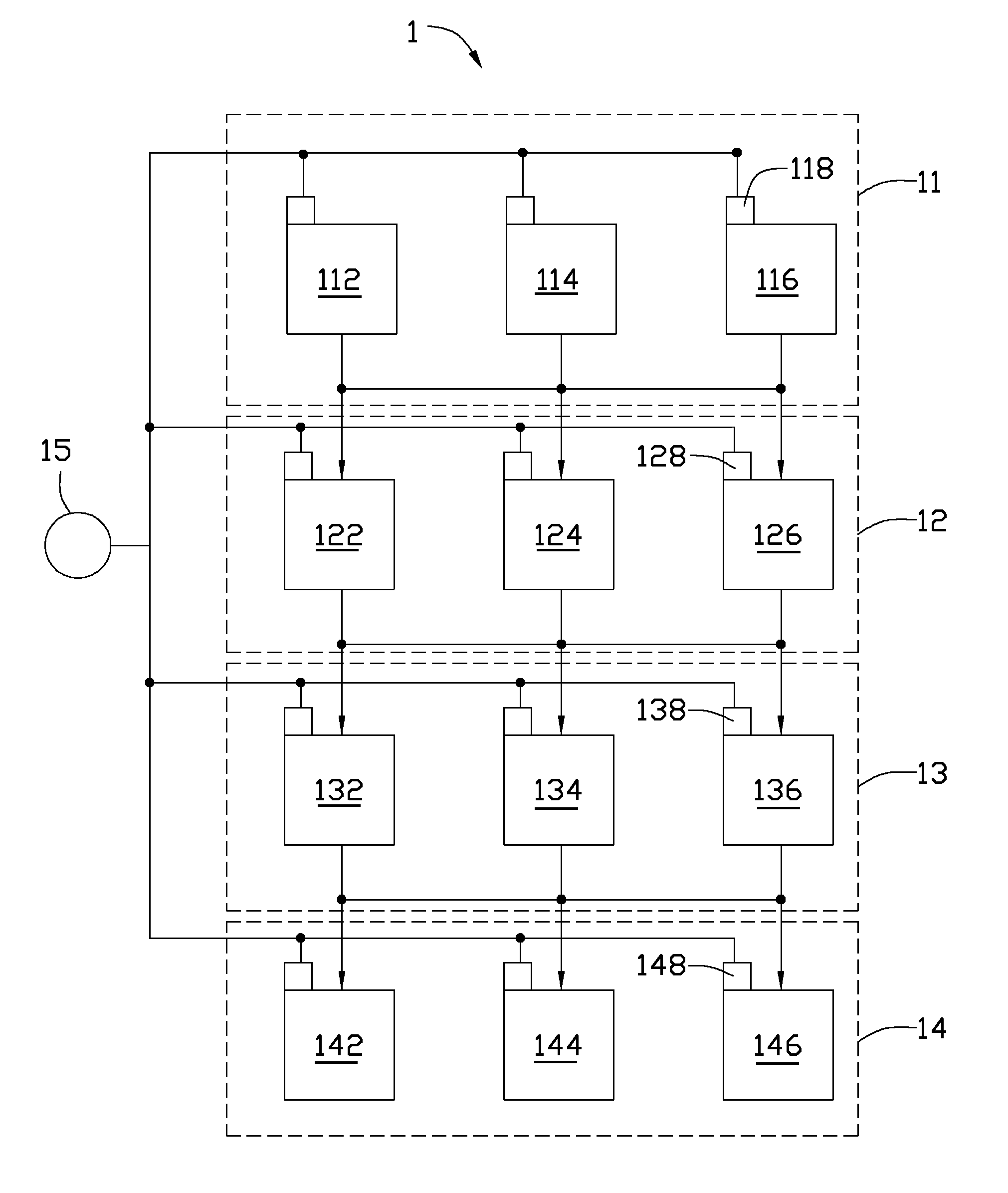

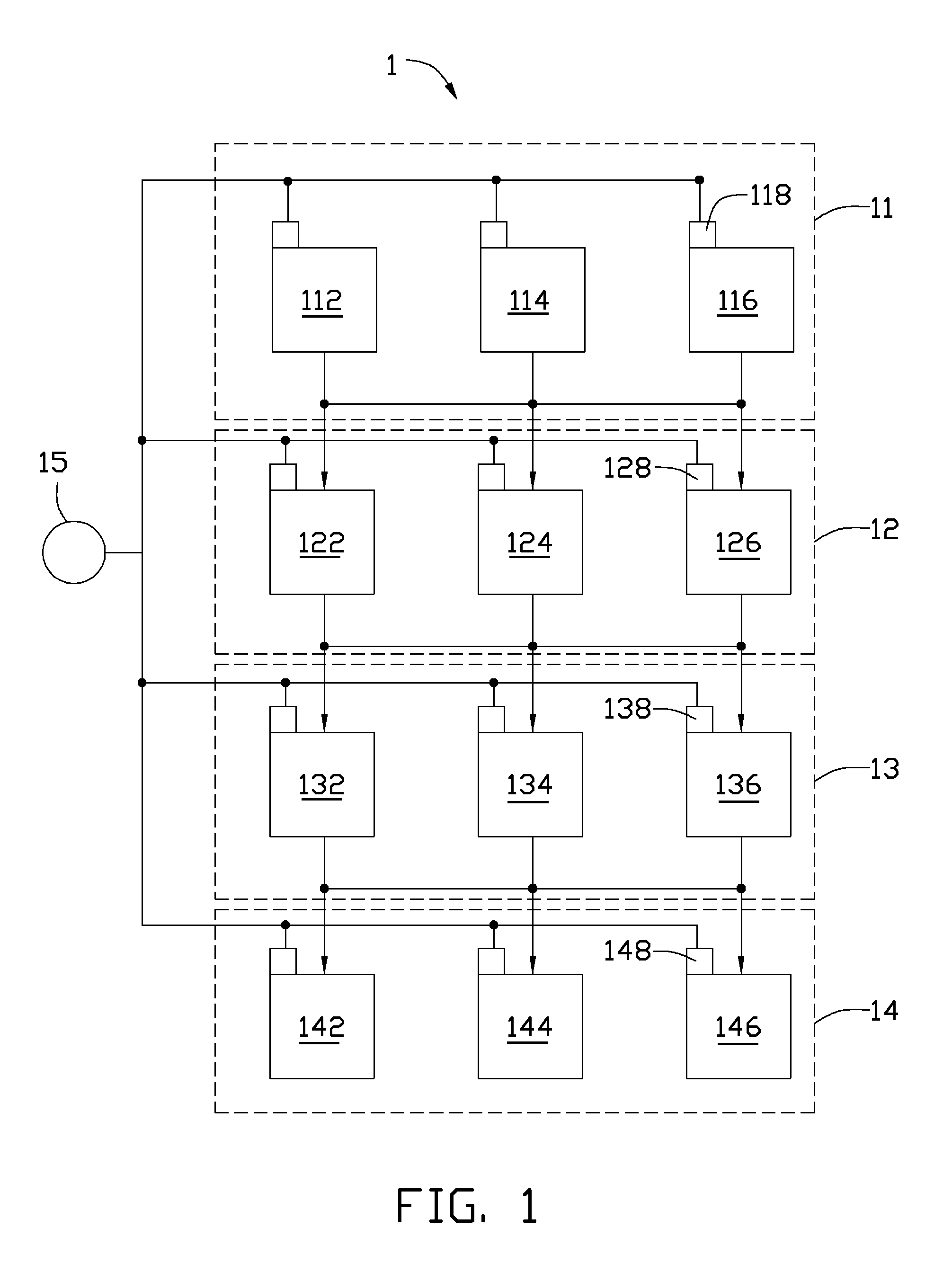

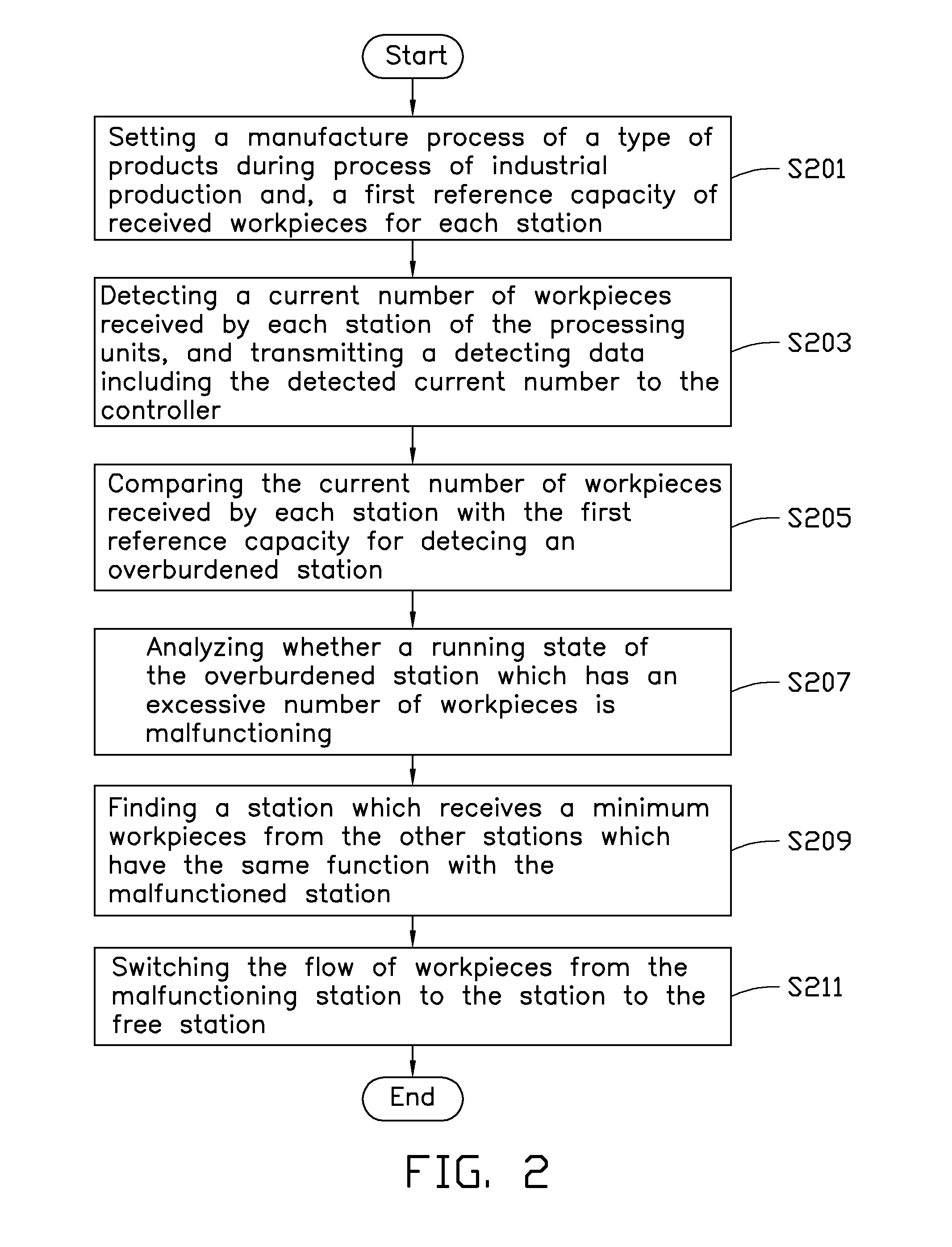

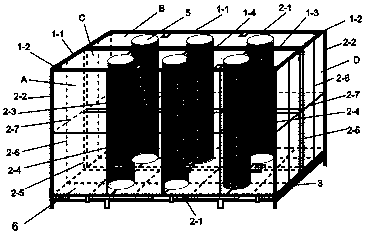

Matrix production system and control method thereof

InactiveUS20130338811A1Production speed of this production line may be slowed downReduce productionTotal factory controlSpecial data processing applicationsProduction lineProcess engineering

A matrix production system for a production line includes a plurality of processing units, a controller, and a plurality of detectors. Each processing unit covers a plurality of stations having the same or similar functions. Each station has a detector. The controller sets an initial flowchart during process of industrial production and a known first reference capacity for each station. A current number of workpieces at each station is detected. The controller compares the current number with the first reference capacity to determine an overburdened station or otherwise and then analyzes a running state of overburdened station determined as being overburdened to establish a malfunctioning station, and if malfunctioning, switches the flow of workpieces from the malfunctioning station to a station with the greatest amount of available or free capacity.

Owner:FU TAI HUA IND SHENZHEN +1

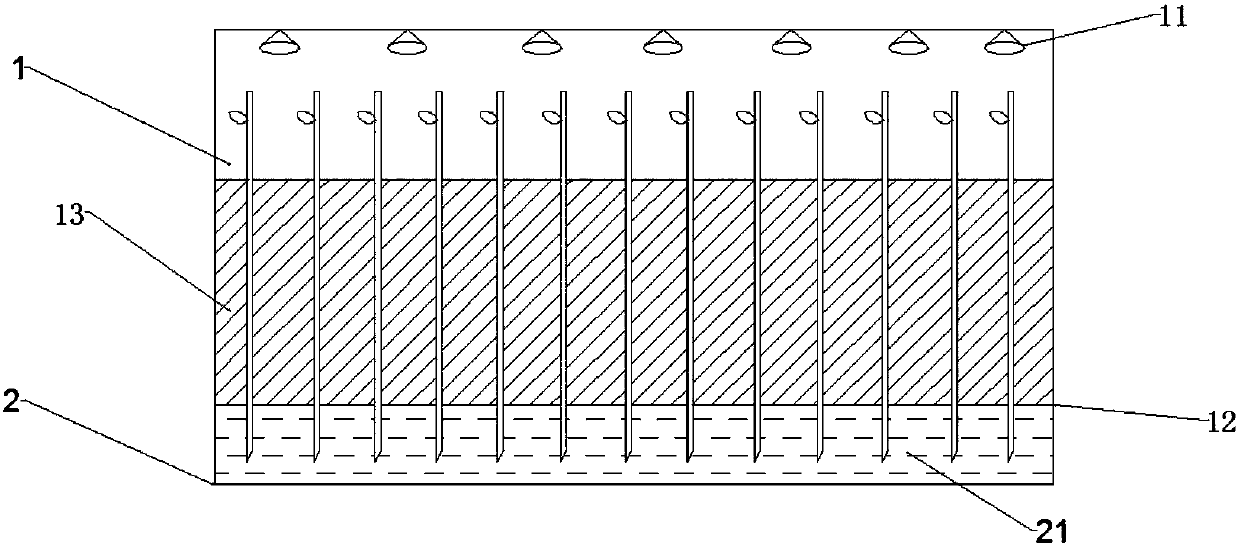

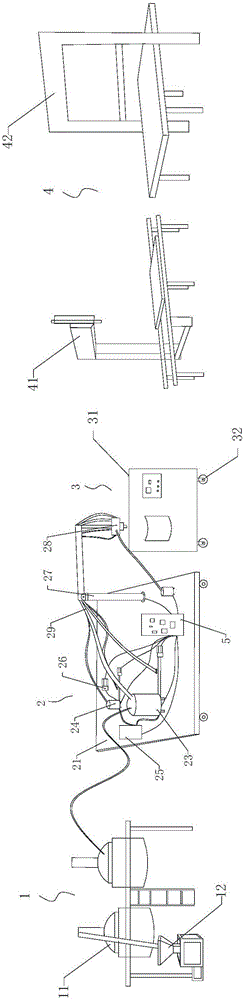

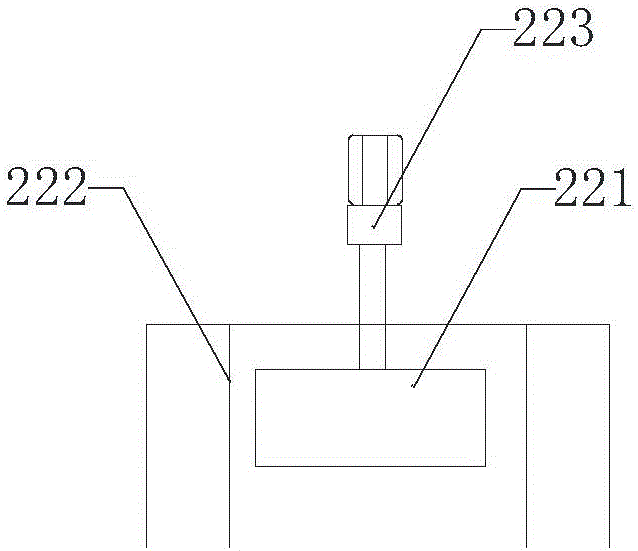

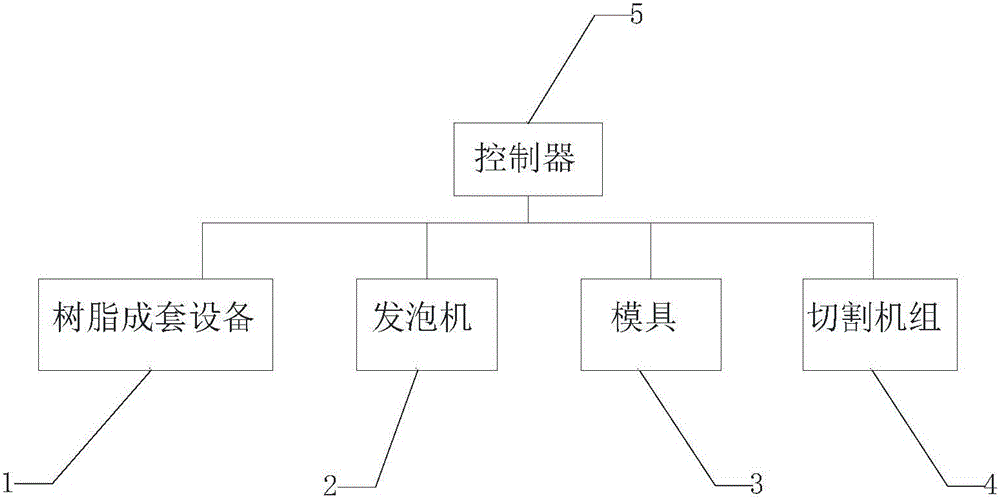

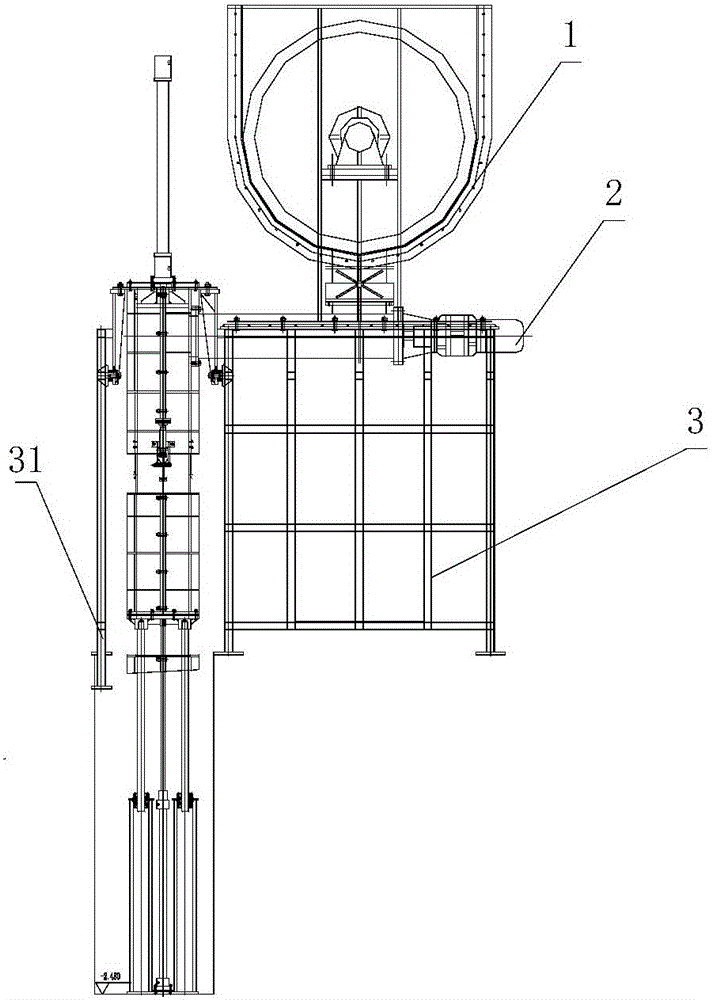

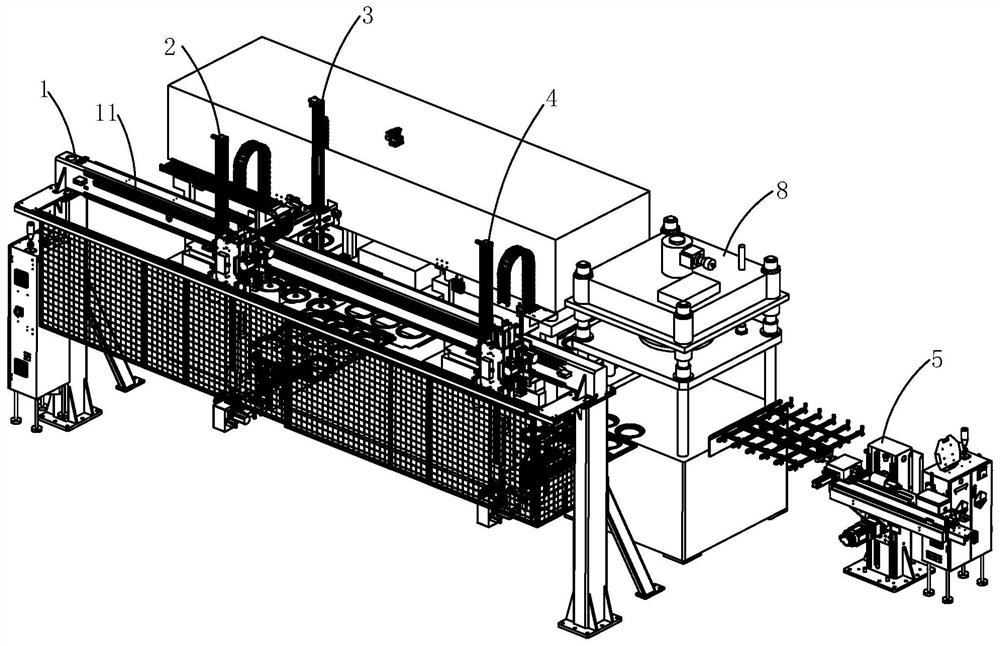

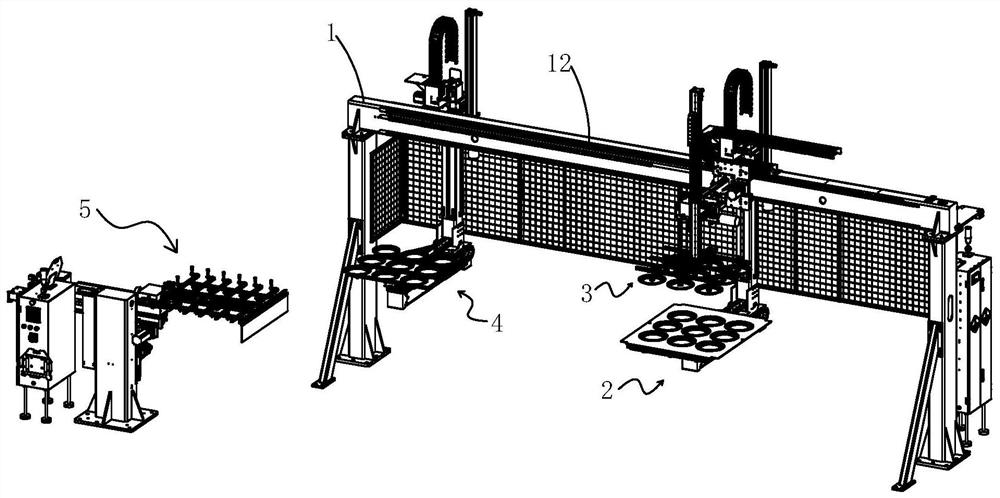

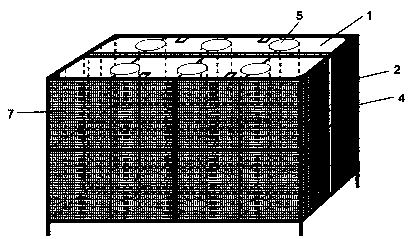

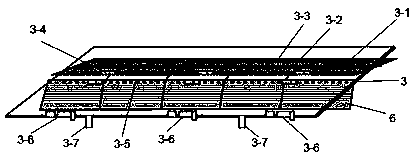

Soilless culture matrix flow production line, production technology and pallet

ActiveCN106376442APrecisely control the feeding amountPrecisely control feeding timeGrowth substratesCulture mediaProduction lineFoaming agent

The invention belongs to the soilless culture technical field, and provides a soilless culture matrix flow production line comprising a controller, and resin complete equipment, a foaming machine, a die and a cutting unit respectively connected with the controller and arranged in sequence; the resin complete equipment is connected with the foaming machine; the resin complete equipment comprises a reaction vessel connected with a raw material storage tank of the foaming machine; the foaming machine comprises a chassis, and a curing agent storage tank, a water cooling machine and a rotation column arranged on the chassis; the cutting unit comprises a vertical cutter, a horizontal cutter and a tapper; the invention also provides a soilless culture matrix production technology, and a pallet prepared by using the soilless culture matrix flow production line and the production technology; the soilless culture matrix flow production line, the production technology and the pallet are practical, scientific and reasonable in design, and can solve the technical problems in the prior art that a production flow is tedious, large in labor intensity, and quality is hard to control; the problems also comprises the foaming agent storage danger, a matrix is large in workload and poor in effect in usage, and the matrix form design is not reasonable.

Owner:河北汇亚新材料集团股份有限公司

Efficient automatic biological matrix compressing and packaging machine convenient to use

The invention discloses an efficient automatic biological matrix compressing and packaging machine convenient to use. The efficient automatic biological matrix compressing and packaging machine comprises a main rack and an auxiliary rack. A compressing work frame is arranged in the middle portion of the main rack. An upper compressing box and a lower compressing box are sequentially arranged at the upper end of an inner cavity of the compressing work frame from top to bottom. A screw blender is arranged in the middle portion of the top end of the auxiliary rack. A screw feeder is arranged at the lower end of the screw blender. According to the efficient automatic biological matrix compressing and packaging machine convenient to use, compressing and packaging are automatically finished in the boxes, the functions of material blending and automatic feeding are integrated, and the automation degree is high. Several procedures are integrated on one machine to be finished, the machine has a good man-machine operation function, modification is convenient, and the efficient automatic biological matrix compressing and packaging machine convenient to use can be suitable for different expansion soft materials and meets the requirements of small and medium size biological matrix production enterprises. Functions of material blending, automatic material filling, automatic compressing, automatic bag feeding, sealing and the like can be achieved through the machine, the production efficiency is improved, the labor intensity is lowered, and the storage and logistics cost is reduced.

Owner:FUJIAN PROVINCE SAN MING JIERUI MACHINERY AUTOMATION

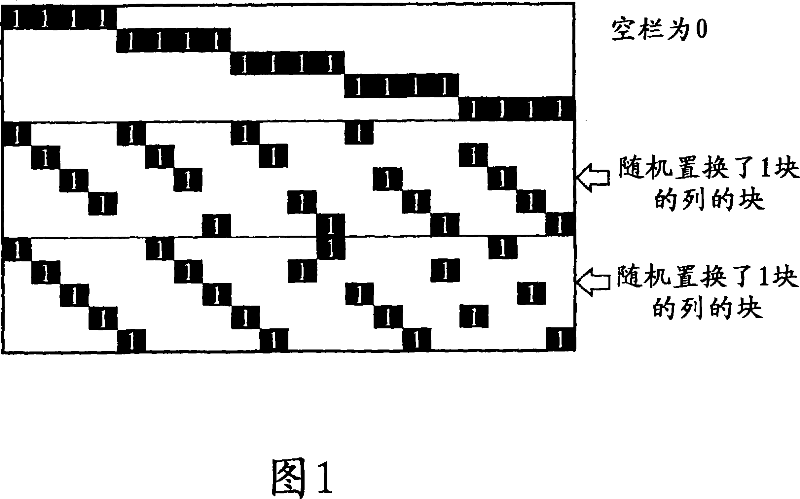

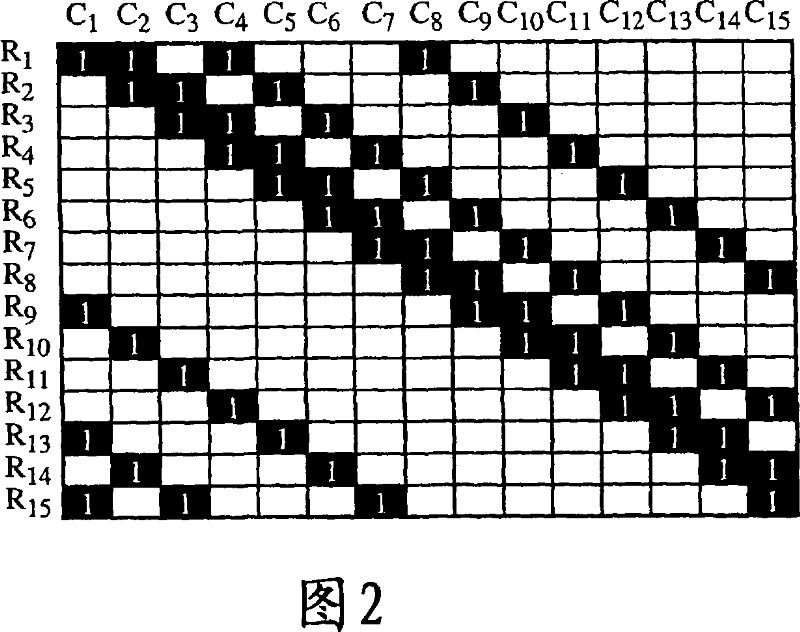

Checking matrix forming device and communication device

InactiveCN101036300AStable characteristicsStrong error correction abilityChecking code calculationsCode conversionLow-density parity-check codeLow density

A predetermined information length, a predetermined coding rate and a predetermined maximum order of the column are used to calculate parameters for a pseudo random number permutation matrix. The calculated parameters for the pseudo random number permutation matrix are used, with a pseudo random number sequence and a Latin square matrix, to produce the pseudo random number permutation matrix. A predetermined information length, a predetermined coding rate and a predetermined maximum order of the column are used to calculate parameters for possible order distribution combinations for optimizing the order distribution of production of a check matrix that can be constructed by use of the pseudo random number permutation matrix. The order distribution of the check matrix production is optimized with the calculated possible order distribution combinations used as forced conditions. The optimized order distribution of the check matrix production is used to arrange the produced pseudo random number permutation matrix to produce a check matrix to be used for low-density parity check codes.

Owner:MITSUBISHI ELECTRIC CORP

Modernized mushroom production method

InactiveCN103907480AEmission reductionSignificant energy saving and environmental protection benefitsHorticulturePlant diseaseCompost

The invention discloses a modernized mushroom production method. The modernized mushroom production method is characterized in that products produced by bases include fresh mushrooms, canned mushrooms, mushroom matrixes containing strains and organic fertilizers from fruited residues; fields of the bases are divided into first zones, second zones, third zones and fourth zones, the first zones mainly comprise storage meadows, manure storage pits and grass soaking pits, the second zones mainly comprise primary and secondary fermentation tunnels, briquetting workshops and equipment libraries; the third zones mainly comprise air-conditioned mushroom houses, refrigerating chambers, soil-covered chambers, power distribution rooms and boiler rooms, and the fourth zones mainly comprise mushroom product processing factories, strain factories, office buildings and living quarters; the production technical scheme of the bases includes mushroom strain production, mushroom matrix production and mushroom plantation production. The modernized mushroom production method has the advantages that obvious energy conservation and environmental protection effects can be realized owing to tunnel fermentation, and the efficiency is high; a tunnel fermentation technology is implemented for composts for agaricus bisporus, accordingly, the produced composts are high in selectivity and are disease-resistant, and the yield can be increased; organic matters from the fruited residues become the excellent organic fertilizers, so that production in a positive ecological cycle can be implemented.

Owner:郑伏成

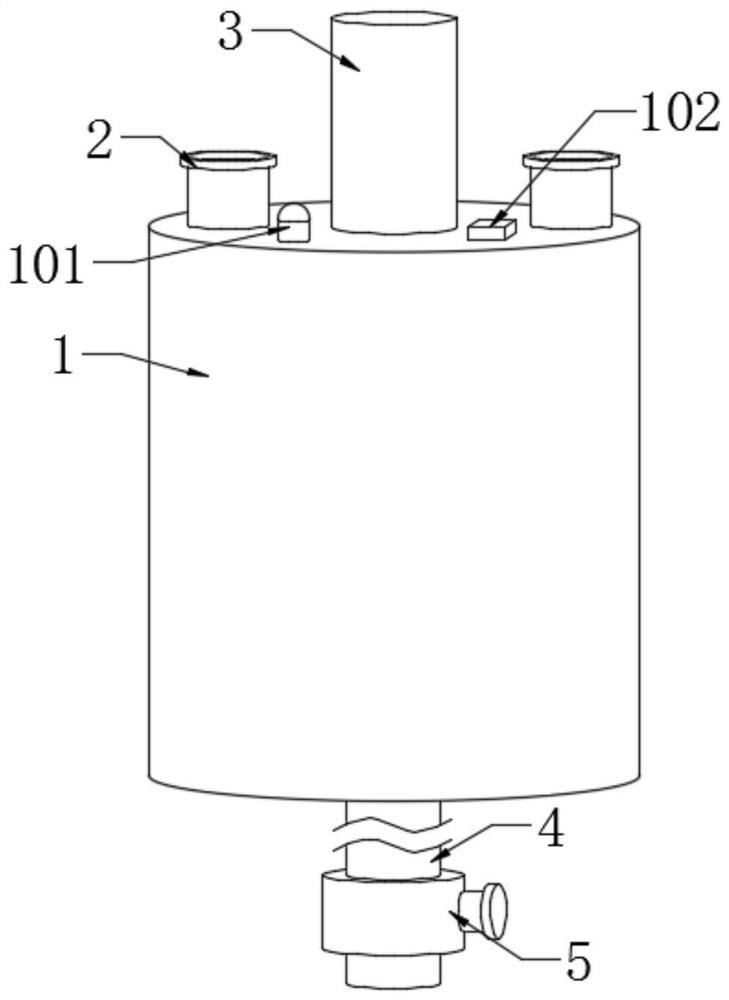

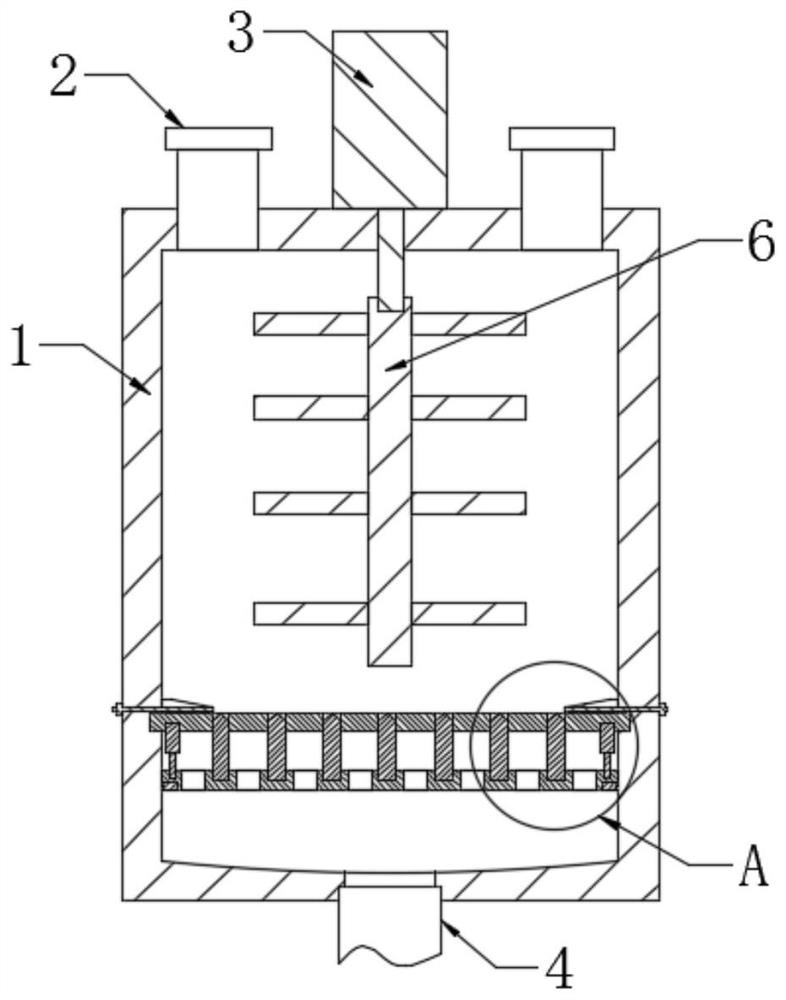

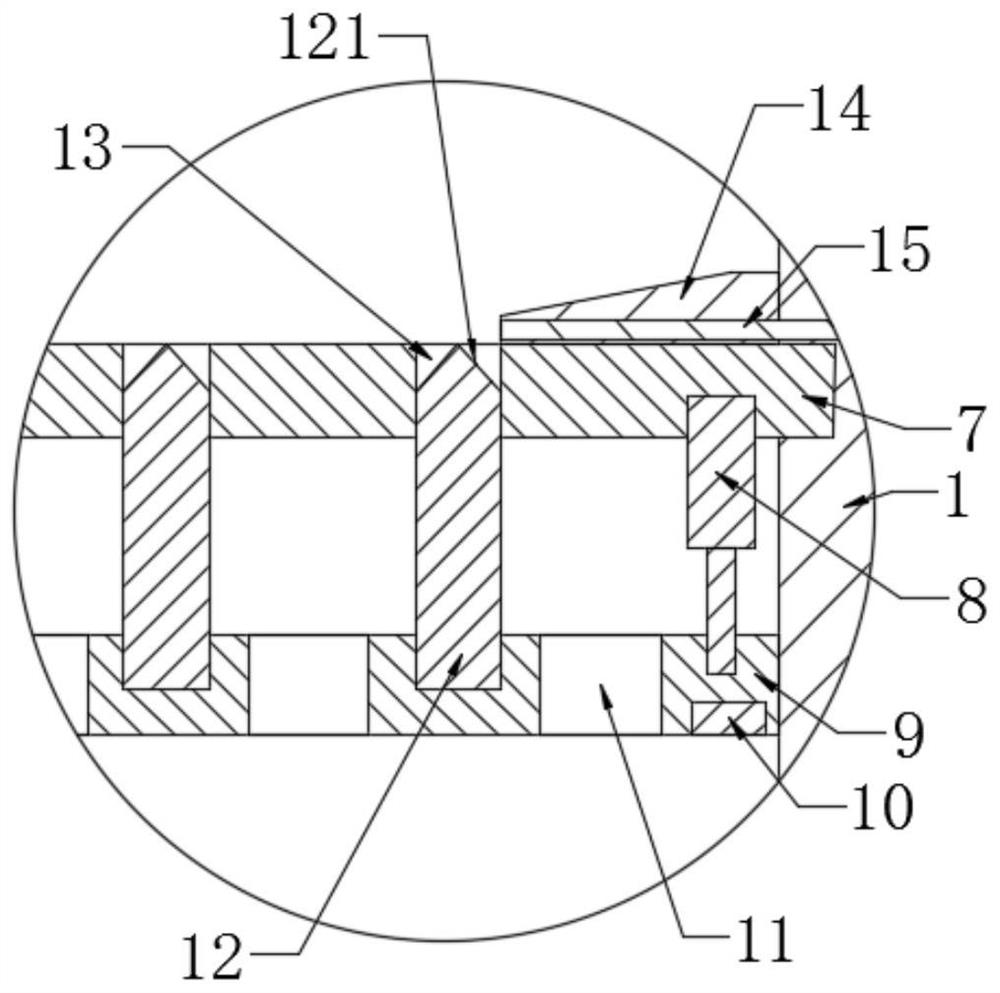

Device for preventing different mixed materials from falling and layering in matrix production and using method thereof

PendingCN113842832APrevent blanking and delaminationEvenly dispersedShaking/oscillating/vibrating mixersRotary stirring mixersElectric machineStructural engineering

The invention provides a device for preventing different mixed materials from falling and layering in matrix production and a using method thereof. The device comprises a shell, wherein the top of the shell is provided with a motor, a stirring rod is installed on an output shaft of the motor, a supporting partition plate used for preventing materials from falling is installed in the shell, electric push rods are symmetrically installed at the bottom of the shell, a dispersing plate is installed on a telescopic shaft of the electric push rod, a plurality of plugs are installed on the dispersing plate, a plurality of dispersing holes are formed in the dispersing plate, a plurality of through holes used for being connected with the plugs are formed in the supporting partition plate, materials are stirred through a stirring rod, and the effect of preventing the materials from being stacked in a layered mode is achieved. The device is reasonable in structure, convenient to assemble and install, good in layered accumulation prevention effect, uniform in discharging dispersion effect and high in potted plant survival rate, and warning is convenient and fast.

Owner:江苏培蕾基质科技发展有限公司

A convenient and efficient bio-matrix automatic compression packaging machine

The invention discloses an efficient automatic biological matrix compressing and packaging machine convenient to use. The efficient automatic biological matrix compressing and packaging machine comprises a main rack and an auxiliary rack. A compressing work frame is arranged in the middle portion of the main rack. An upper compressing box and a lower compressing box are sequentially arranged at the upper end of an inner cavity of the compressing work frame from top to bottom. A screw blender is arranged in the middle portion of the top end of the auxiliary rack. A screw feeder is arranged at the lower end of the screw blender. According to the efficient automatic biological matrix compressing and packaging machine convenient to use, compressing and packaging are automatically finished in the boxes, the functions of material blending and automatic feeding are integrated, and the automation degree is high. Several procedures are integrated on one machine to be finished, the machine has a good man-machine operation function, modification is convenient, and the efficient automatic biological matrix compressing and packaging machine convenient to use can be suitable for different expansion soft materials and meets the requirements of small and medium size biological matrix production enterprises. Functions of material blending, automatic material filling, automatic compressing, automatic bag feeding, sealing and the like can be achieved through the machine, the production efficiency is improved, the labor intensity is lowered, and the storage and logistics cost is reduced.

Owner:FUJIAN PROVINCE SAN MING JIERUI MACHINERY AUTOMATION

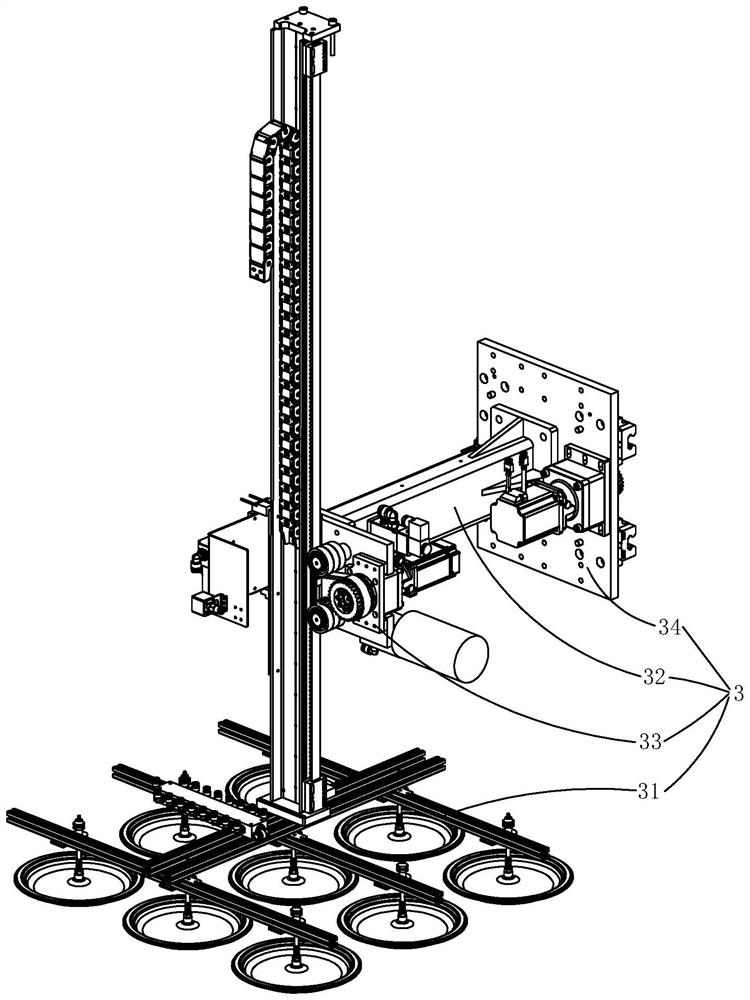

Intelligent paper matrix taking and placing manipulator

PendingCN112894762ASimple structureSmall footprintProgramme-controlled manipulatorTextiles and paperControl engineeringManipulator

The invention relates to the technical field of paper matrix production equipment, in particular to an intelligent paper matrix taking and placing manipulator. The intelligent paper matrix taking and placing manipulator comprises a pick-and-place fixing arm, a pick-and-place bracket, a pick-and-place guide rail, a pick-and-place sliding block and a pick-and-place driving mechanism; the pick-and-place bracket comprises a pick-and-place frame and a pick-and-place frame mounting part which is arranged at one end of the pick-and-place frame and is fixedly connected with the pick-and-place frame; the pick-and-place guide rail is arranged on the pick-and-place fixing arm and extends in the length direction of the pick-and-place fixing arm; the pick-and-place sliding block is fixedly connected with the pick-and-place frame and is arranged on the pick-and-place guide rail in a sliding manner; and the pick-and-place driving mechanism is arranged on the pick-and-place fixing arm, fixedly connected with the pick-and-place sliding block and used for driving the pick-and-place sliding block to move along the pick-and-place guide rail so as to drive the pick-and-place bracket to move relative to the pick-and-place fixing arm. The intelligent paper matrix taking and placing manipulator is simple in structure and small in occupied space; and the taking and placing driving mechanism is arranged on the taking and placing fixing arm, so that the structure is further simplified, the manufacturing cost can be reduced, and installation is more convenient and faster.

Owner:GUANGDONG CLAW ROBOT CO LTD

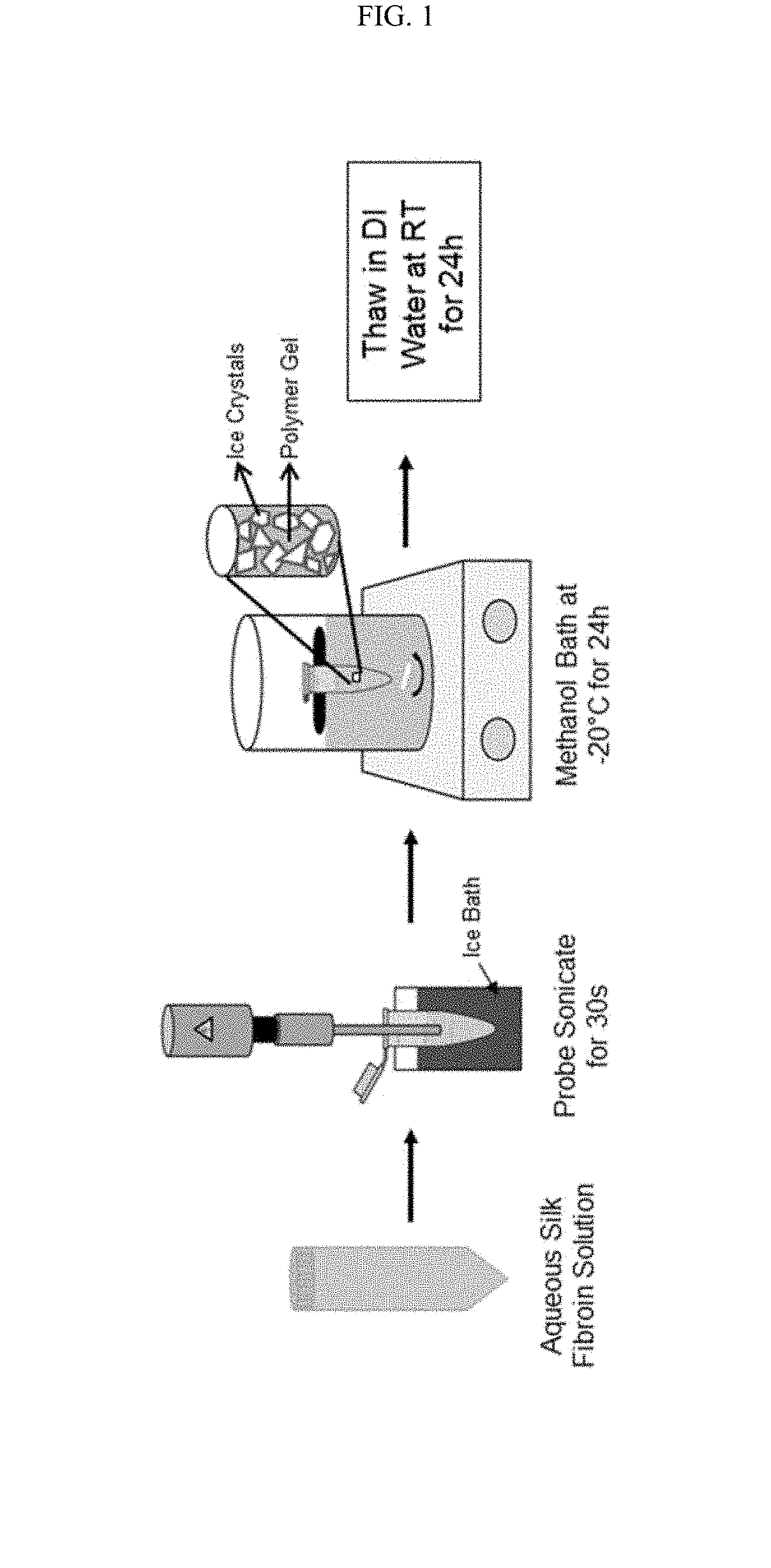

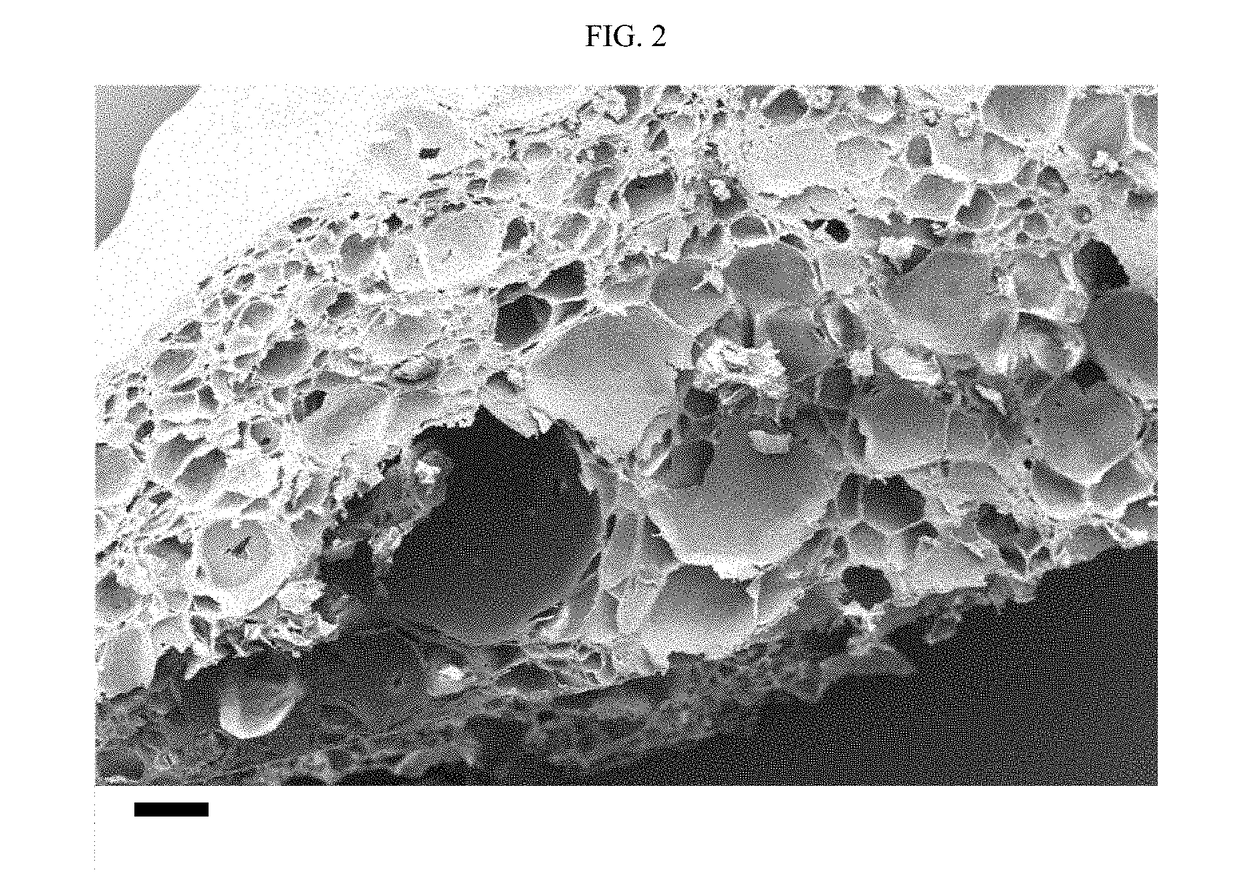

Silk fibroin cryogels

InactiveUS20180243475A1Improve mechanical stabilityBroad and significant impactTissue regenerationProsthesisCell-Extracellular MatrixBone tissue engineering

Disclosed are silk fibroin cryogels and methods for preparing silk fibroin cryogels. The silk fibroin cryogels can be used to promote cellular chemotaxis, enhance cell proliferation, enhance extracellular matrix production, promote calcified matrix production, and increase angiogenesis. The silk fibroin cryogels can further be used in the treatment of dermal wounds (burns, chronic wounds, etc.), bone tissue engineering and oral and maxillofacial repair.

Owner:SAINT LOUIS UNIVERSITY

Purely natural organic nutritional matrix and preparation method thereof

InactiveCN103319232BLow costQuality improvementFertilizer mixturesControlled releaseLivestock manure

The invention relates to a cultivation matrix, and especially relates to a purely natural organic nutritional matrix and a preparation method thereof. The purely natural organic nutritional matrix is characterized in that the matrix is mainly prepared through using 40-60 parts by weight of bark, 20-40 parts by weight of sawdust, 10-30 parts by weight of coal ash, 0.1-1 part by weight of a biological fertilizer starter, and 1-5 parts by weight of livestock manure. The organic nutritional matrix prepared in the invention has the advantages of low cost, abundant resources and stable quality, solves the waste utilization, energy saving and emission reduction problems, and also solves the nuisance-free matrix production problem by utilizing forest product wastes to produce a soilless nutritional matrix. The addition of a constant quality of a plurality of controlled-release nutritional master batches avoids burnt seedlings caused by the early-stage excess release of a fertilizer, satisfies the nutrition needs of the whole growth period of tree peony, and has a nutritional expiration period reaching above 120d.

Owner:HEZE UNIV

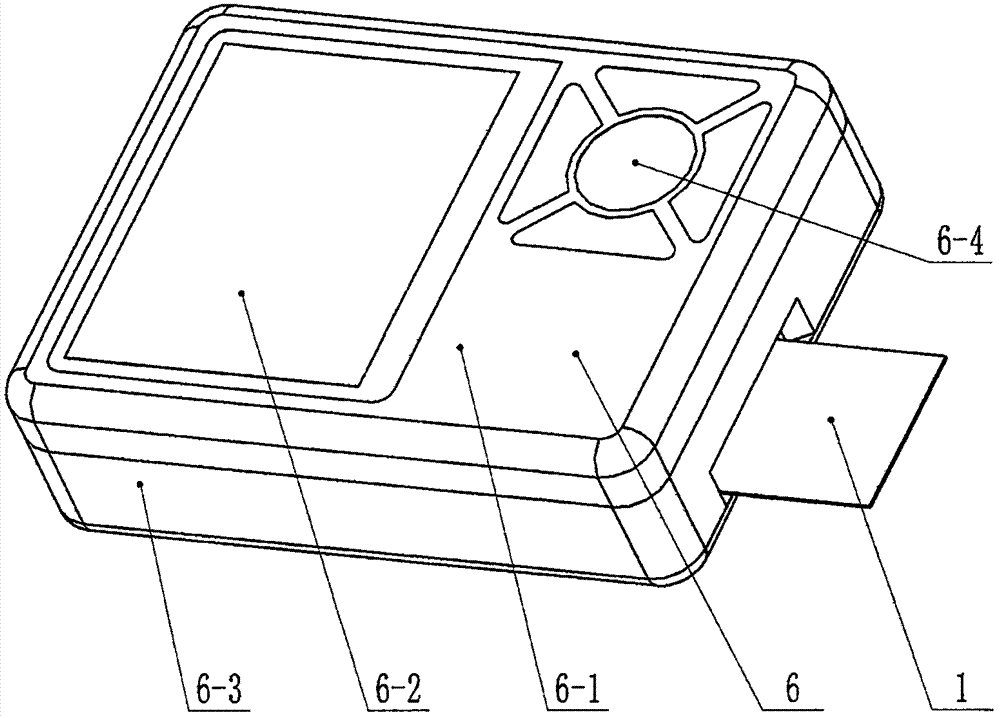

Matrix fermentation device with interlayers, chimneys and movable bottom doors, and application

InactiveCN107805093ASimple processIntensive low-carbon fermentationBio-organic fraction processingOrganic fertiliser apparatusSemi automaticEngineering

The invention discloses a matrix fermentation device with interlayers, chimneys and movable bottom doors, and application thereof. The device is of a steel barrier type frame structure, which is formed by a frame opening (1), a frame body (2) and a frame bottom (3). The device is characterized by further comprising the interlayers (4), the chimneys (5) and the movable bottom doors (6); the interlayers (4) are double-sided zinc coating steel wire mesh plate at intervals being 50 to 80mm arranged in the middle of the device, divide the device into 2 to 4 silos, and form hollow aeration layers; the chimneys (5) are arranged in the separated silos and are 4 to 6 hollow ventilated cylindrical holes penetrating through the frame opening (1) and the frame bottom (3); the movable bottom doors (6)are arranged on the bottom part of the device and comprise two movable doors so as to be convenient to discharge. The device adopts the mesh plate hollow interlayers and the chimneys to naturally ventilate; when the device is applied to carry out matrix fermentation, one-time stirring-free static fermentation and semi-automatic discharging through the movable bottom plates can be realized, so thatthe device is convenient to use and good in effect. The device is made of steel materials so as to be reasonable in structure and long in service life, and can be multilayer stacked, so that a fermentation space is saved, and the device is particularly suitable to be applied to industrial solid waste raw material fermentation treatment carried out by matrix production enterprises.

Owner:江苏兴农基质科技有限公司

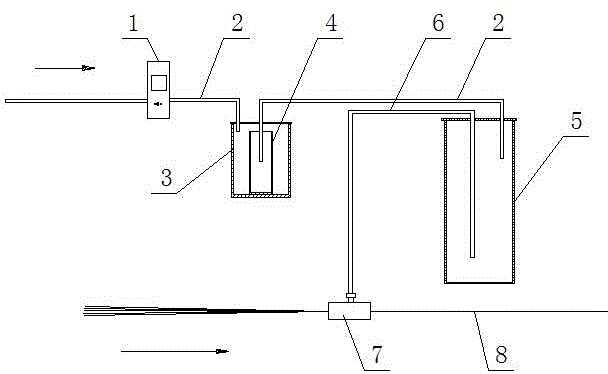

Device for improving ribbon matrix production stability

ActiveCN105108953ASafe and stable production statusDemand air pressure has no effectCoatingsRibbon cableEngineering

The invention relates to a device for improving ribbon matrix production stability, and belongs to the technical field of optical fiber ribbon cable processing. The device comprises a compressed air precision pressure regulating valve, an air pipe, a double-shell type large air tank, a double-shell type inner air tank, a resin tank and the like, wherein an air inlet of the compressed air precision pressure regulating valve is connected to an air source, and an air outlet of the compressed air precision pressure regulating valve is connected to the double-shell type large air tank; the double-shell type inner air tank is arranged in the double-shell type large air tank and is connected to the resin tank by the air pipe; and the resin tank is connected to a ribbon matrix mold by a resin conveying pipe. The device has the beneficial effects that when the production of a reel of ribbon matrix optical fibers is completed and the device stops operating in a production process, residual air pressure in the resin tank back presses resin sent to the air pipe, so that the resin is not in contact with the air pipe connected to the compressed air precision pressure regulating valve, thereby ensuring the safe and stable production state of the precision pressure regulating valve. The device solves the problem that when a conventional device stops operating and a reel is changed every time, residual air pressure in the resin tank can back press and send the resin to the compressed air pipe, which causes scattering of optical fiber ribbons.

Owner:HUBEI KAILE SCI & TECH

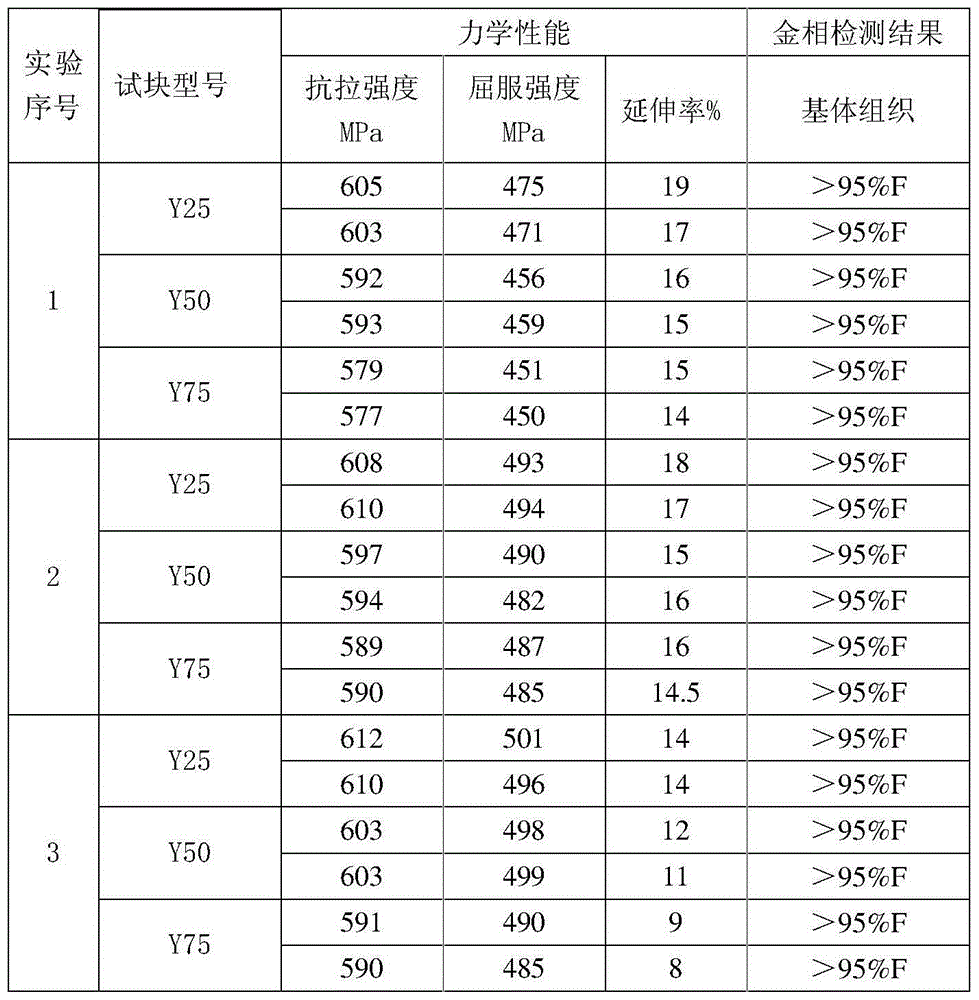

A kind of production method of as-cast ferritic base nodular cast iron qt600-10

The invention relates to control and casting production methods of a ductile cast iron material and particularly relates to a production method of a casting-state ferrite-base ductile cast iron QT600-10. The production method is characterized by comprising the following steps of raw material selection, auxiliary material selection, smelting, sampling, mixing, nodularizing, inoculation treatment and pouring. The production method has the advantages that the method is unique, the ductility of the ductile cast iron is obviously improved, the ductile cast iron has the mechanical properties of high strength and plasticity and good machinability, the machining cost can be lowered, and the machining efficiency is increased.

Owner:KOCEL EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com