A kind of production method of as-cast ferritic base nodular cast iron qt600-10

A production method and ferrite technology are applied in the field of ductile iron material control and casting production, which can solve the problems of low elongation, poor uniformity of matrix structure, and inability to overcome, and achieve the effect of improved elongation and unique method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

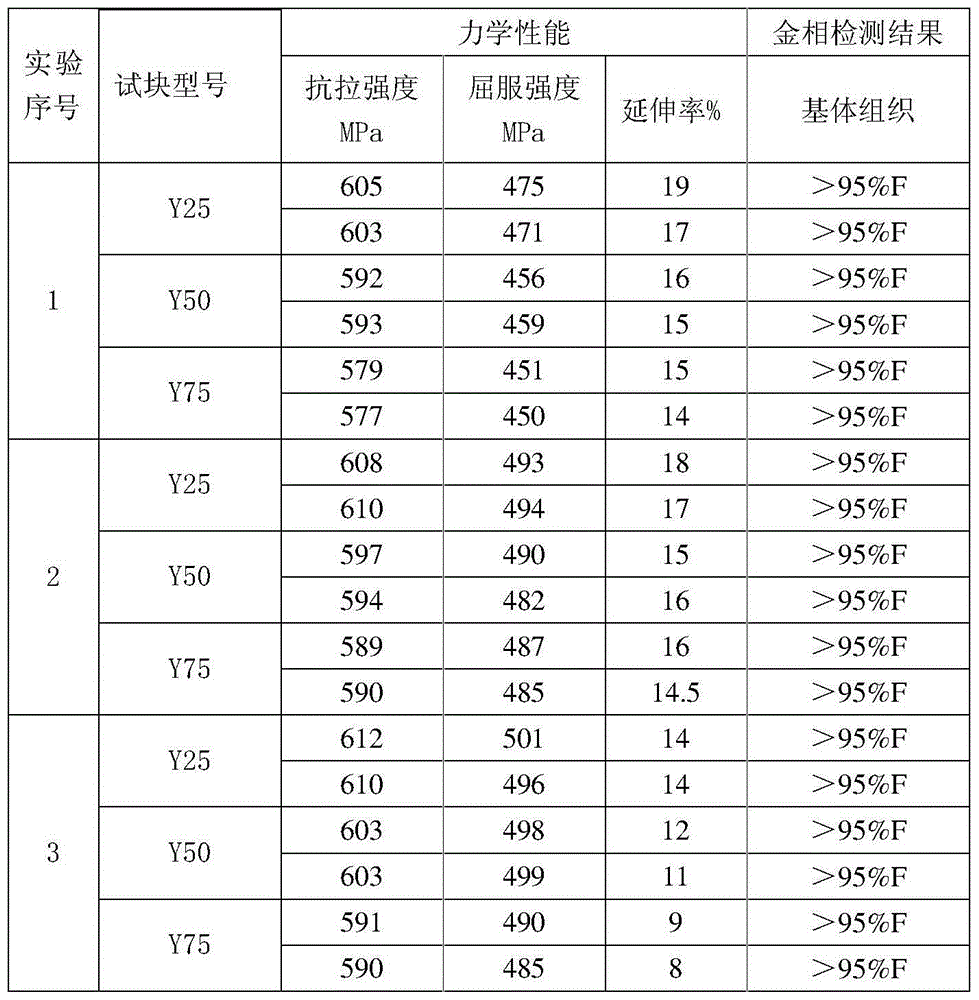

Examples

Embodiment 1

[0019] Embodiment one: a kind of production method of as-cast ferrite base nodular cast iron QT600-10, the method comprises the following steps:

[0020] a. Selection of raw materials: The weight percentage of raw materials is as follows: ball machine iron: 20%, scrap steel: 20%, ball pig iron: 60%;

[0021] b. Selection of auxiliary materials: auxiliary materials are nodulizers and inoculants;

[0022] c. Melting:

[0023] Add steel scrap first, then add the returned materials, and finally add pig iron, and control the temperature of the melting process at 1370°C

[0024] d. Sampling seasoning: when the smelting temperature reaches 1445°C, take a spectrum sample, adjust the furnace charge again according to the composition detected by the spectrum, and adjust the carbon equivalent. After seasoning, the carbon equivalent is 4.13; the weight percentage of each chemical element in the furnace is as follows: C: 3.3, Si: 2.5, Mn: 0.21, P: 0.03, S: 0.018.

[0025] e. Spheroidiza...

Embodiment 2

[0029] a. Selection of raw materials: The weight percentage of raw materials is as follows: ball machine iron: 20%, scrap steel: 20%, ball pig iron: 60%;

[0030] b. Selection of auxiliary materials: auxiliary materials are nodulizers and inoculants;

[0031] c. Melting:

[0032] Add steel scrap first, then add the returned materials, and finally add pig iron, and control the temperature of the melting process at 1370°C

[0033] d. Sampling seasoning: when the smelting temperature reaches 1445°C, take a spectrum sample, adjust the furnace charge again according to the composition detected by the spectrum, and adjust the carbon equivalent. After seasoning, the carbon equivalent is 4.14; the weight percentage of each chemical element in the furnace is as follows: C: 3.31, Si: 2.5, Mn: 0.21, P: 0.03, S: 0.016.

[0034] e. Spheroidization inoculation treatment: first add 1.2% silicon-magnesium alloy nodulizer by weight of molten iron to one side of the nodulizer, and after compa...

Embodiment 3

[0038] a. Selection of raw materials: The weight percentage of raw materials is as follows: ball machine iron: 20%, scrap steel: 20%, ball pig iron: 60%;

[0039] b. Selection of auxiliary materials: auxiliary materials are nodulizers and inoculants;

[0040] c. Melting:

[0041] Add steel scrap first, then add the returned materials, and finally add pig iron, and control the temperature of the melting process at 1370°C

[0042] d. Sampling seasoning: when the smelting temperature reaches 1445°C, take a spectral sample, adjust the furnace charge again according to the spectral detection composition, and adjust the carbon equivalent. After seasoning, the carbon equivalent is 4.0; the weight percentage of each chemical element in the furnace is as follows: C: 3.2, Si: 2.4, Mn: 0.18, P: 0.032, S: 0.018.

[0043]e. Spheroidization inoculation treatment: first add 1.5% silicon-magnesium alloy nodulizer by weight of molten iron to one side of the nodulizer bag, and after compactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com