Patents

Literature

5041 results about "Material selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material selection is a step in the process of designing any physical object. In the context of product design, the main goal of material selection is to minimize cost while meeting product performance goals. Systematic selection of the best material for a given application begins with properties and costs of candidate materials. For example, a thermal blanket must have poor thermal conductivity in order to minimize heat transfer for a given temperature difference.

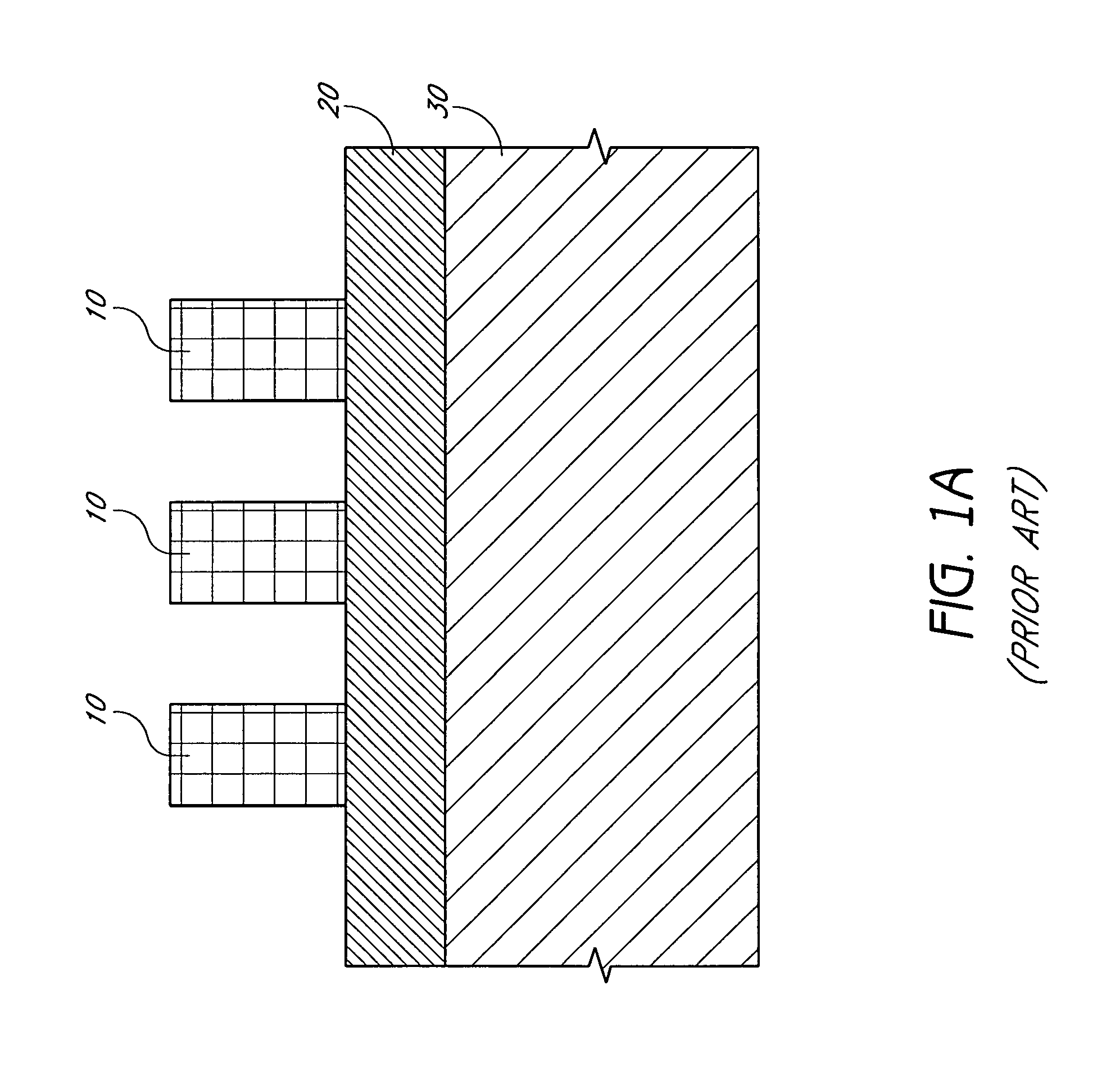

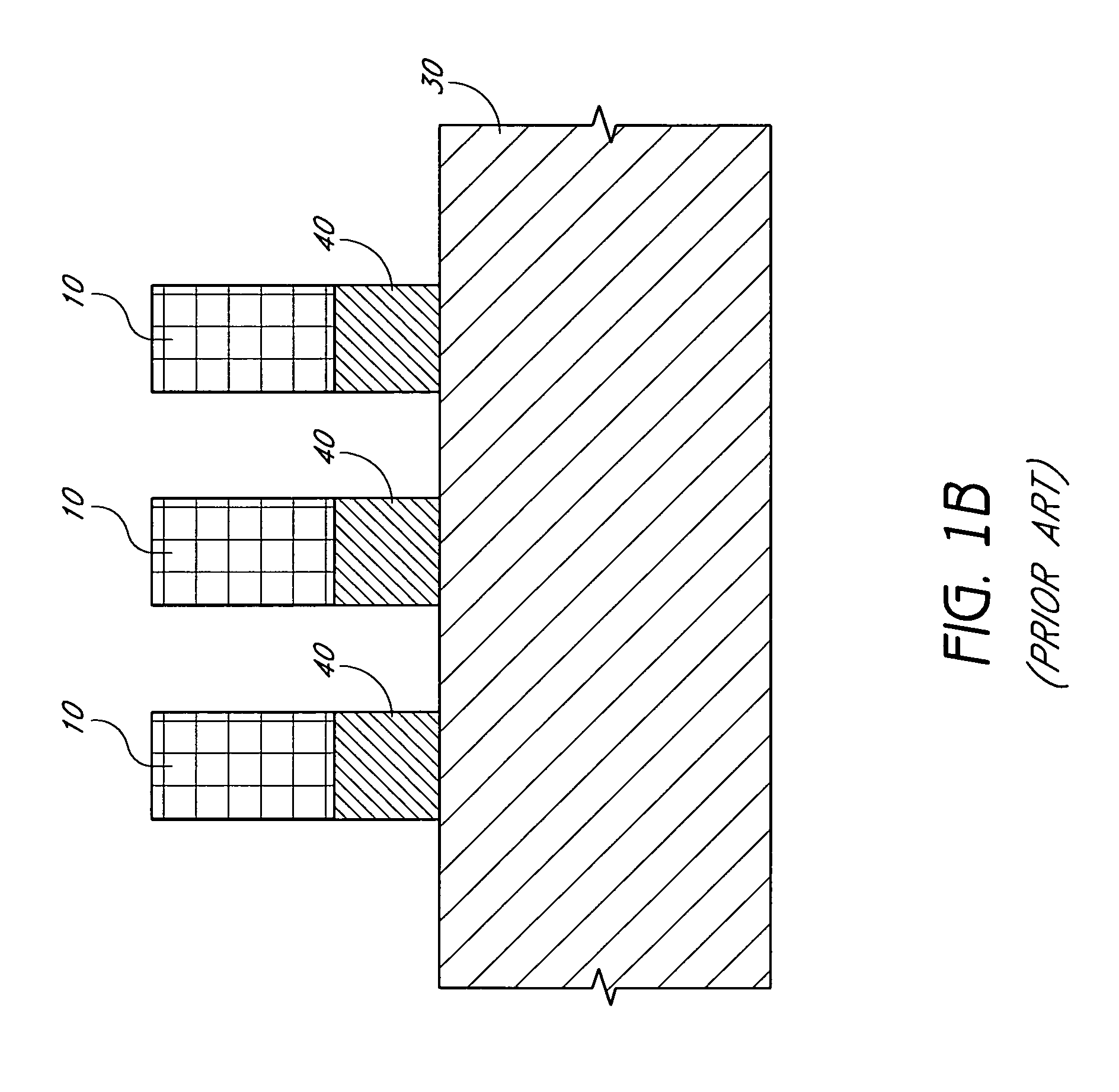

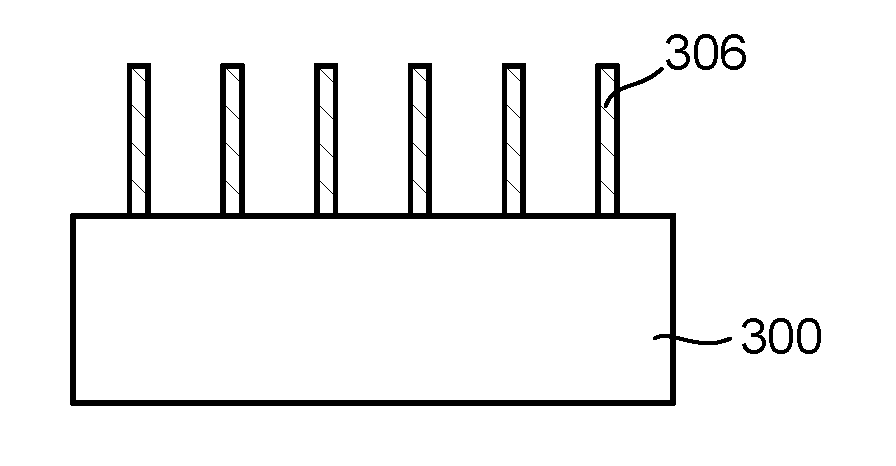

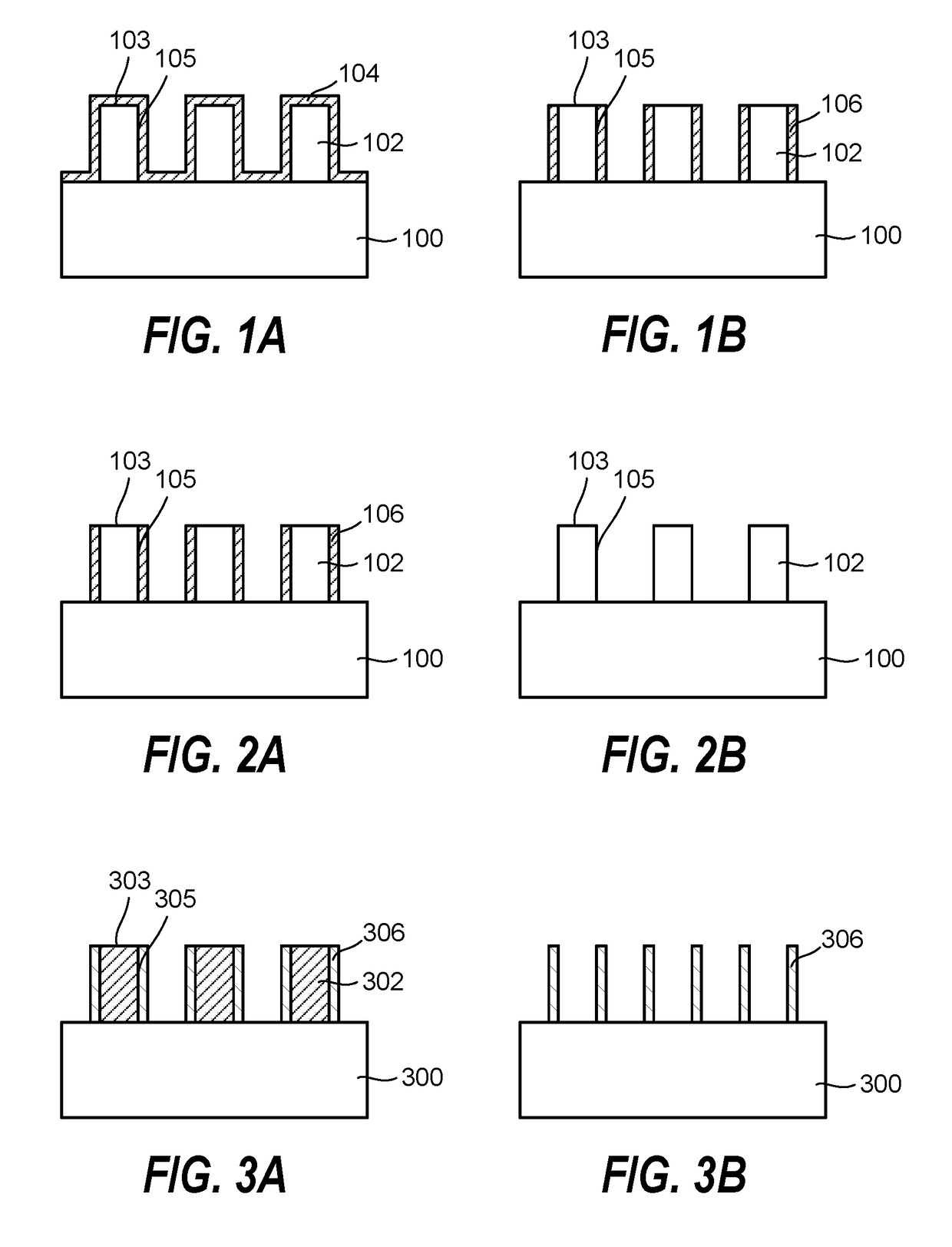

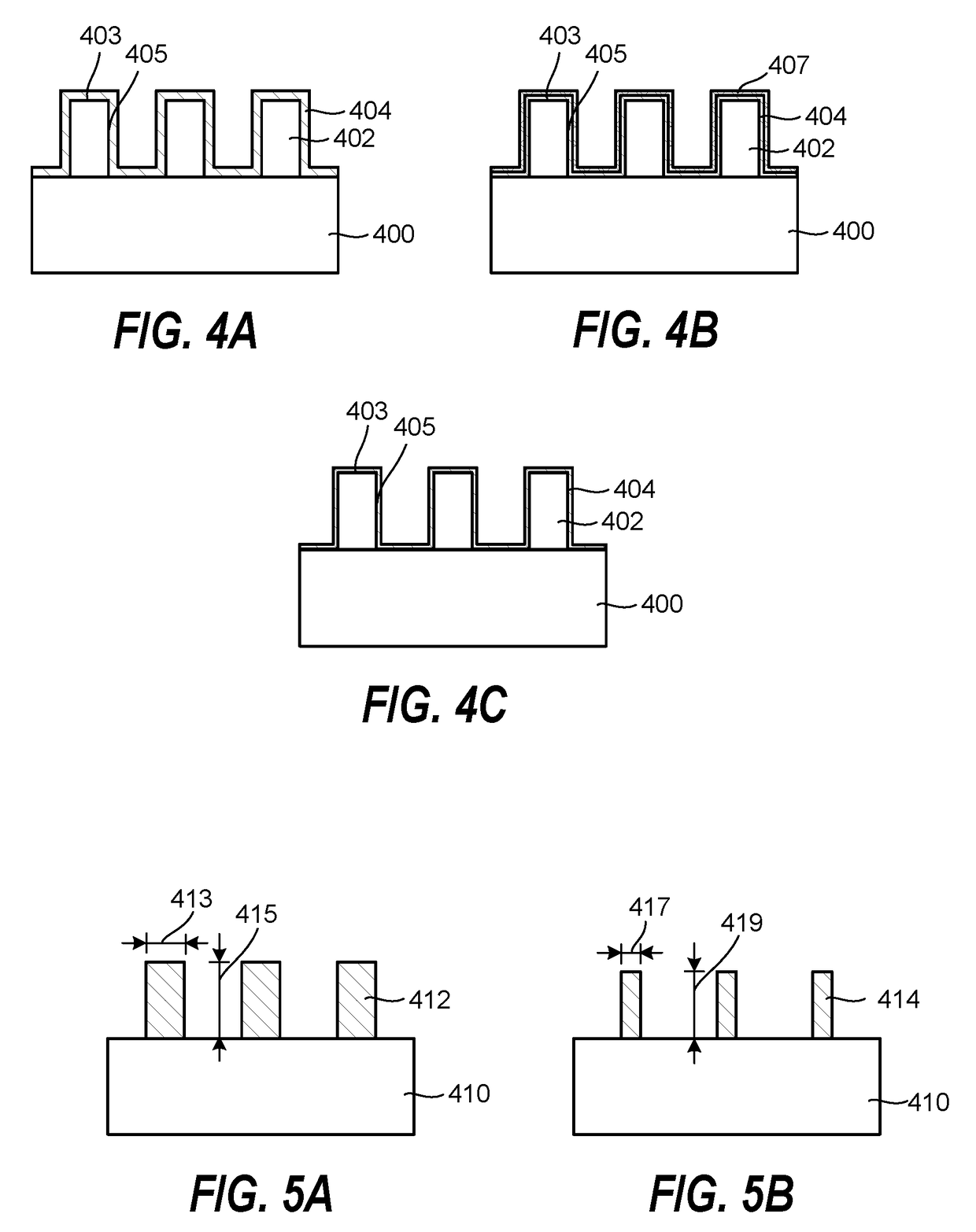

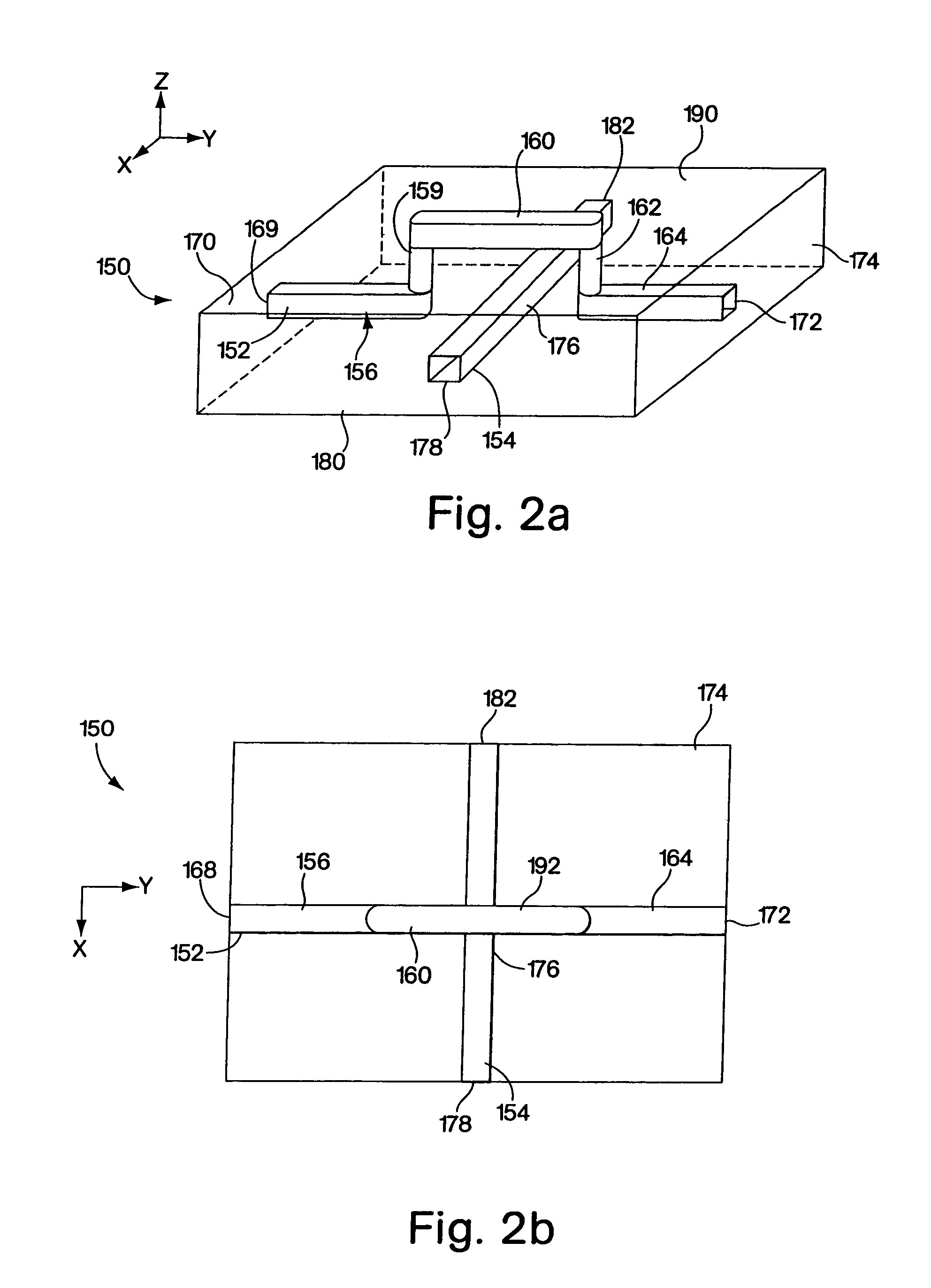

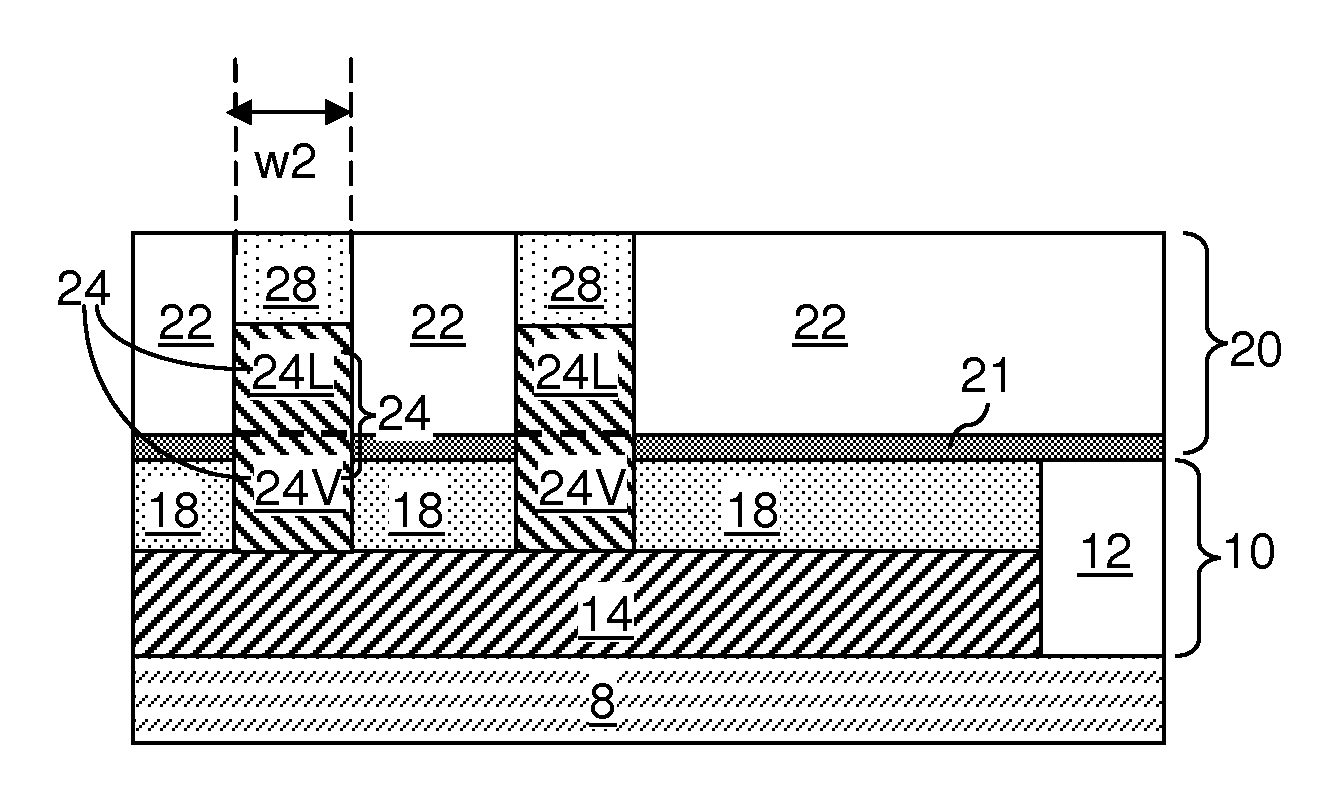

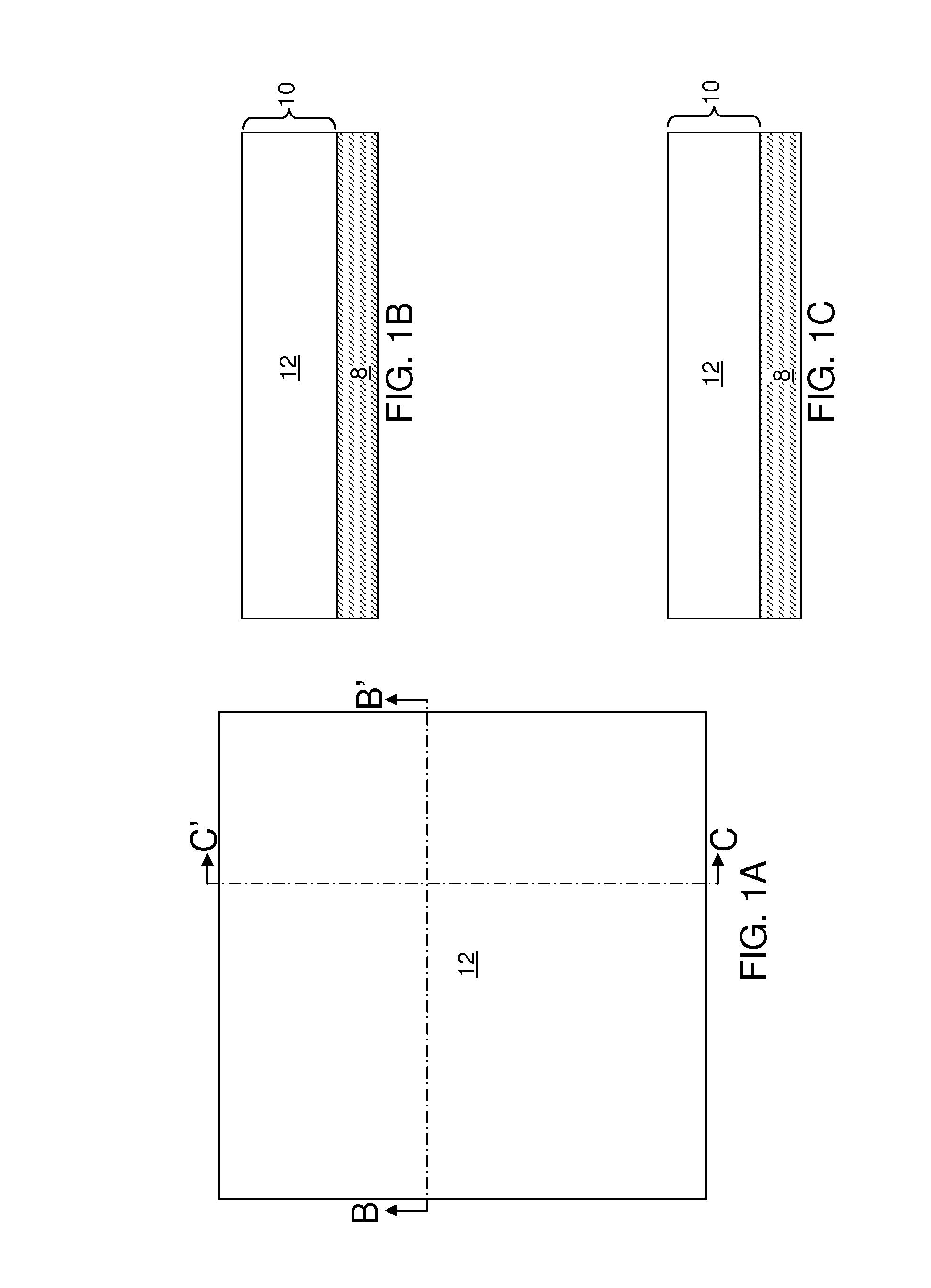

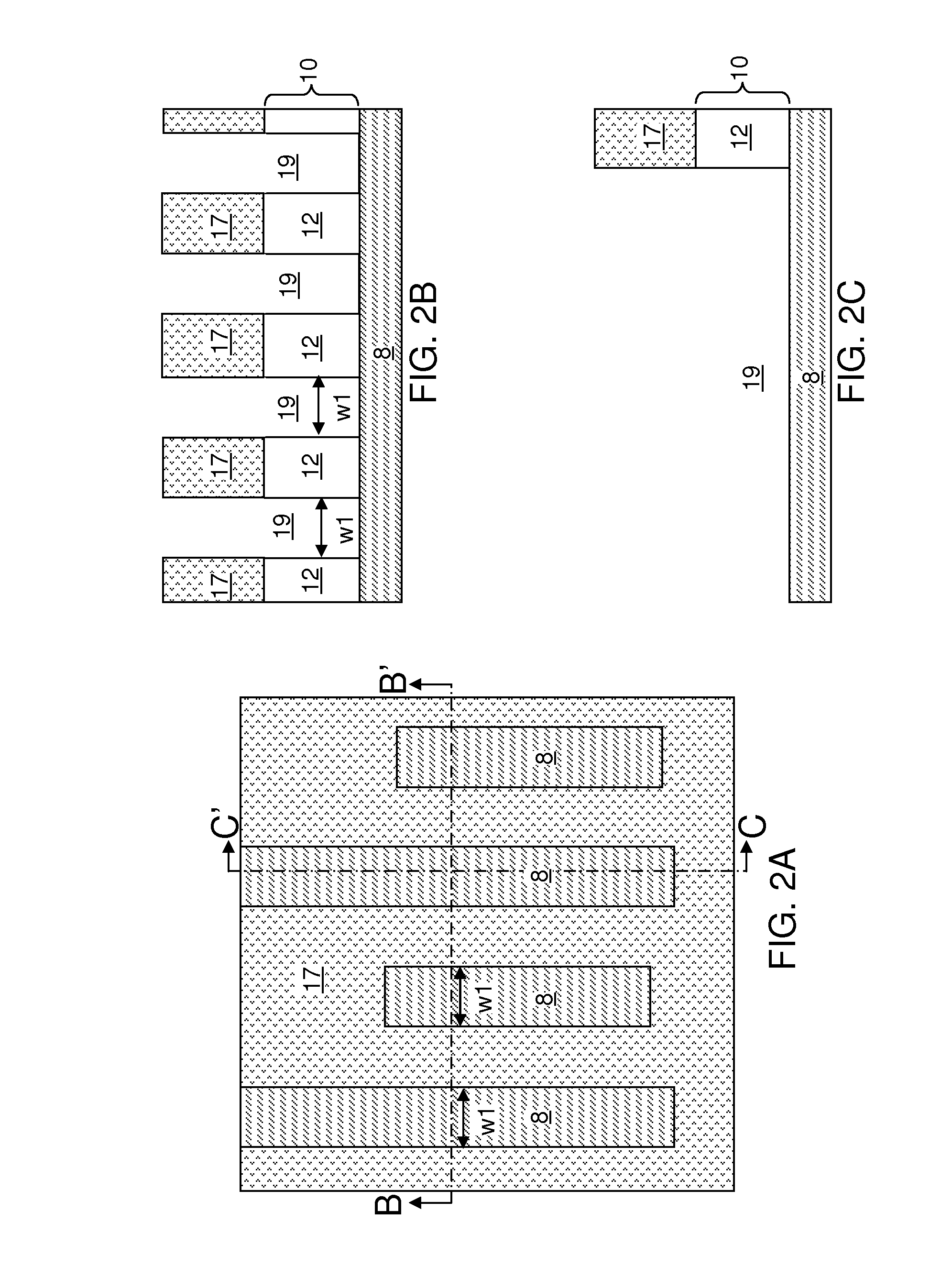

Pitch multiplication spacers and methods of forming the same

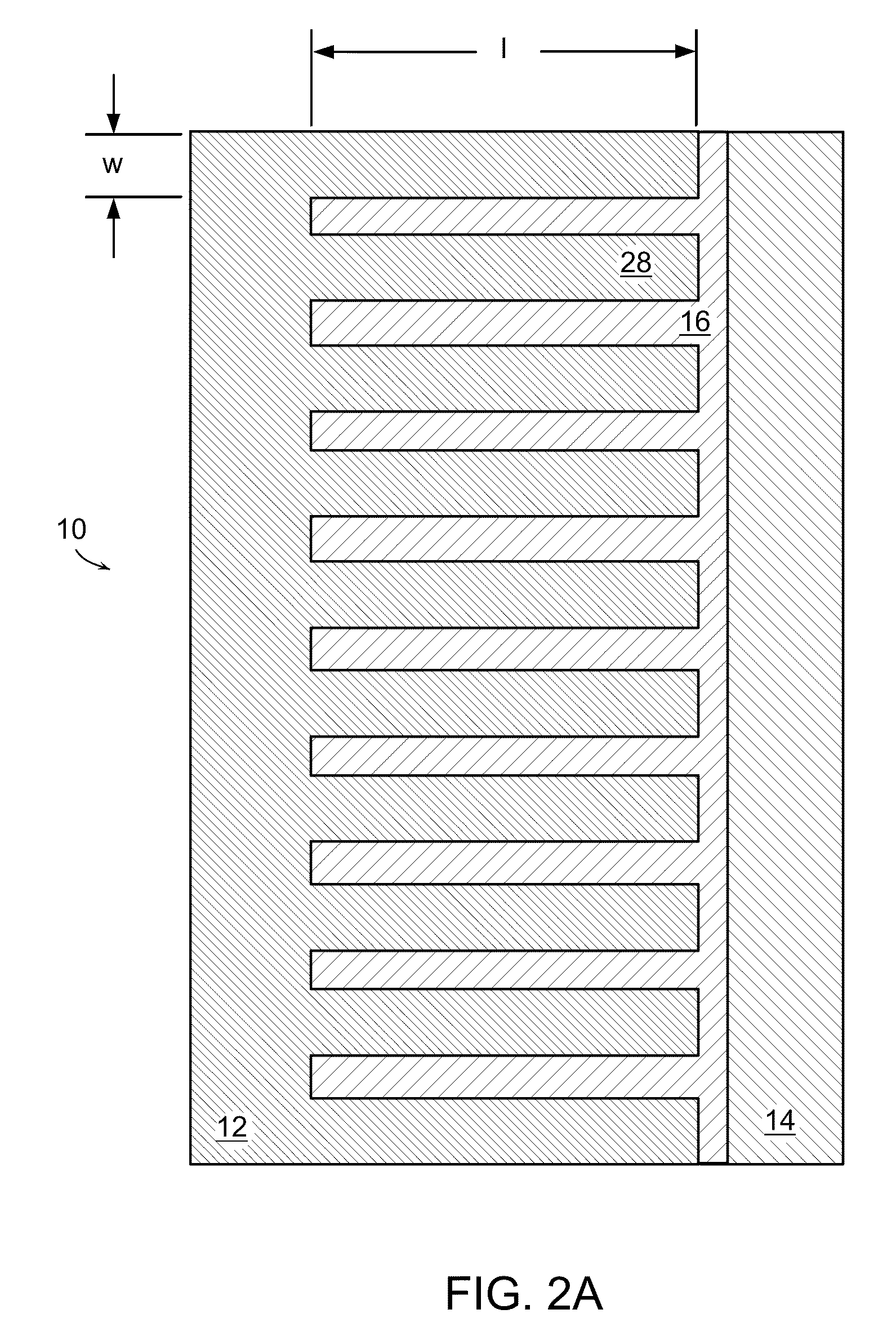

Spacers in a pitch multiplication process are formed without performing a spacer etch. Rather, the mandrels are formed over a substrate and then the sides of the mandrels are reacted, e.g., in an oxidization, nitridation, or silicidation step, to form a material that can be selectively removed relative to the unreacted portions of the mandrel. The unreacted portions are selectively removed to leave a pattern of free-standing spacers. The free-standing spacers can serve as a mask for subsequent processing steps, such as etching the substrate.

Owner:MICRON TECH INC

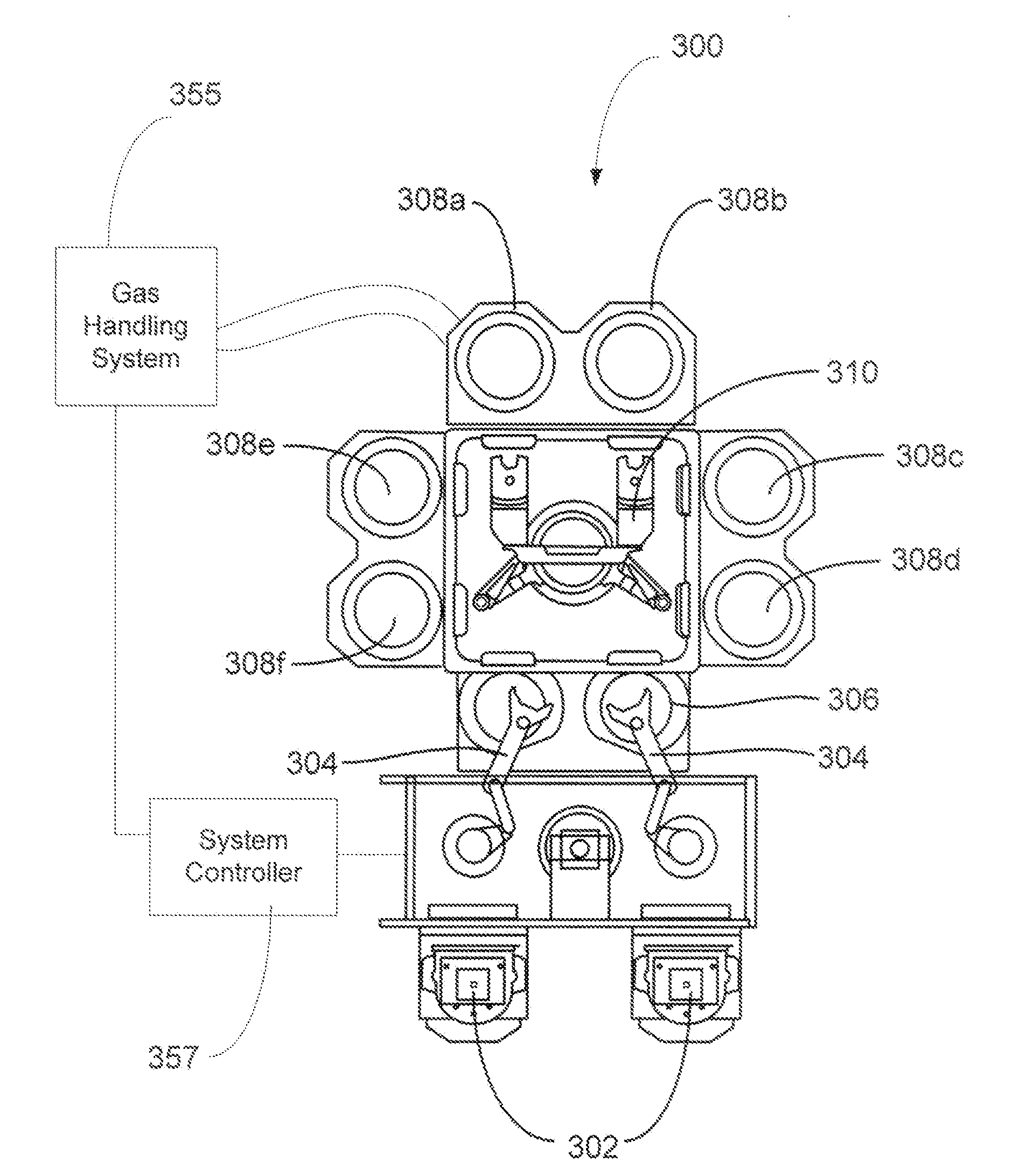

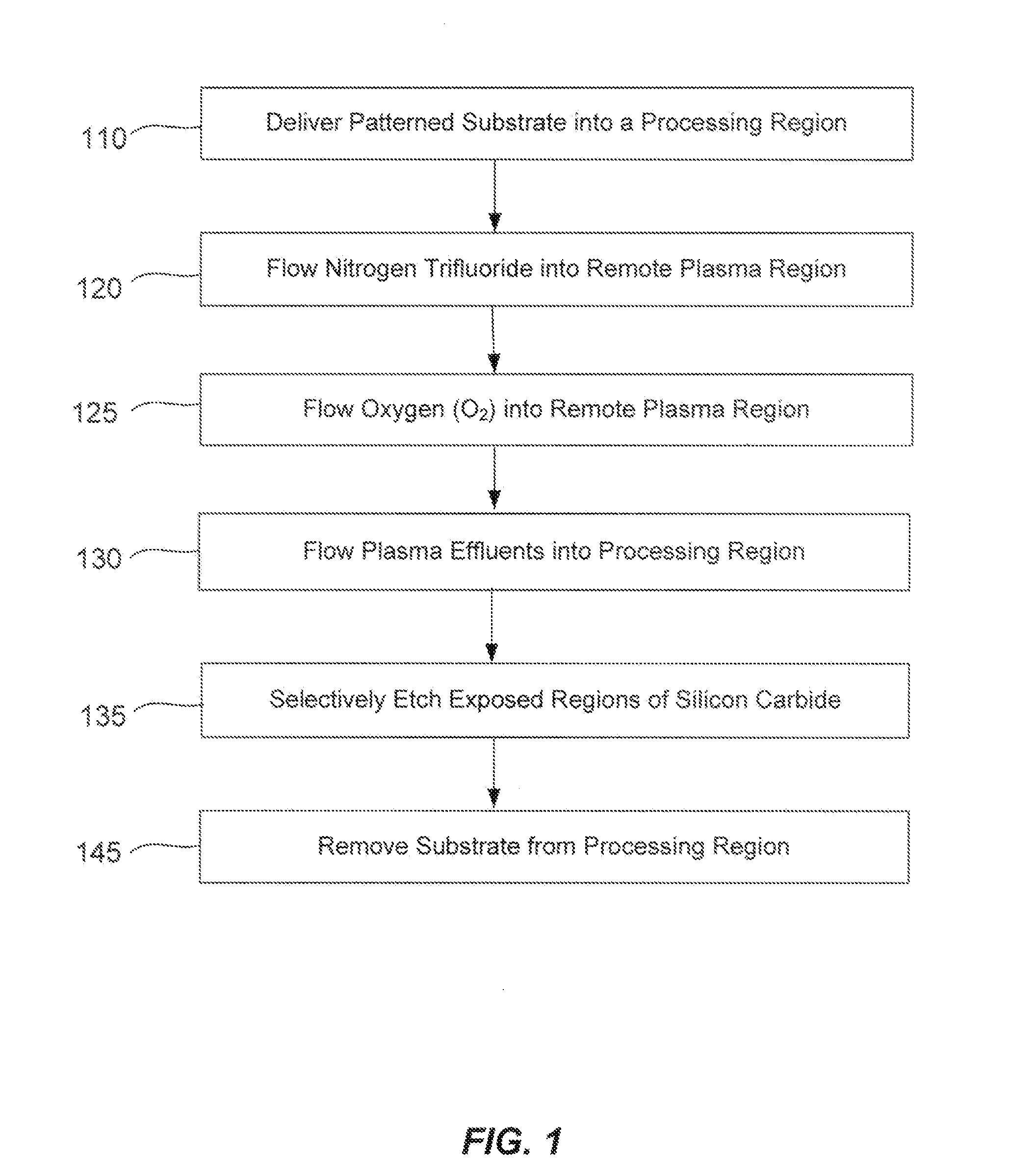

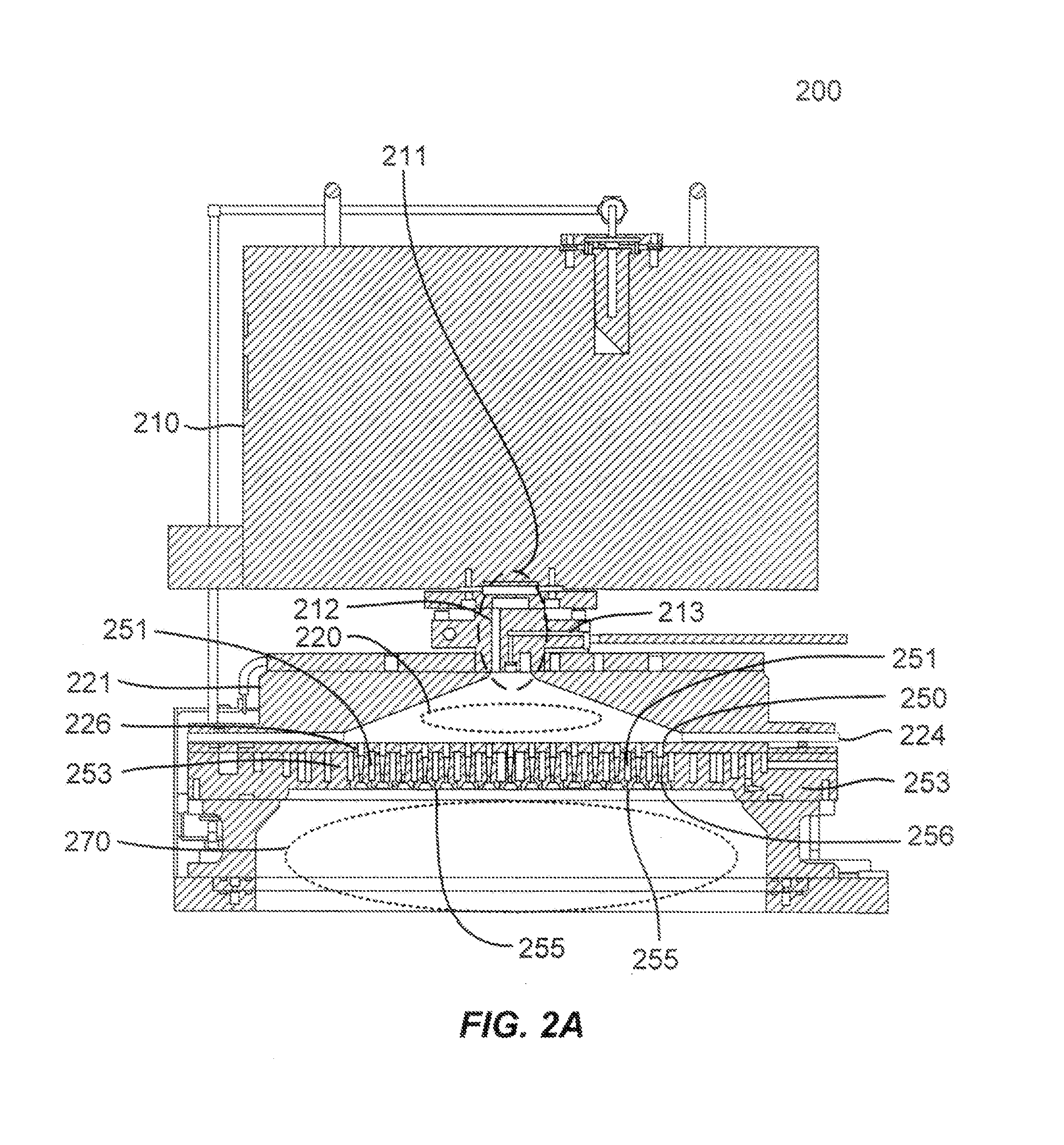

Dry-etch for silicon-and-carbon-containing films

InactiveUS20130034968A1Reduces and substantially eliminates numberMaterial removalSemiconductor/solid-state device manufacturingRemote plasmaSilicon oxide

A method of etching exposed silicon-and-carbon-containing material on patterned heterogeneous structures is described and includes a remote plasma etch formed from a fluorine-containing precursor and an oxygen-containing precursor. Plasma effluents from the remote plasma are flowed into a substrate processing region where the plasma effluents react with the exposed regions of silicon-and-carbon-containing material. The plasmas effluents react with the patterned heterogeneous structures to selectively remove silicon-and-carbon-containing material from the exposed silicon-and-carbon-containing material regions while very slowly removing other exposed materials. The silicon-and-carbon-containing material selectivity results partly from the presence of an ion suppression element positioned between the remote plasma and the substrate processing region. The ion suppression element reduces or substantially eliminates the number of ionically-charged species that reach the substrate. The methods may be used to selectively remove silicon-and-carbon-containing material at more than twenty times the rate of silicon oxide.

Owner:APPLIED MATERIALS INC

Method of selective silicon nitride etching

Embodiments of the invention provide a substrate processing method for selective SiN etching relative to other layers used in semiconductor manufacturing. According to one embodiment, the substrate processing method includes providing in a plasma processing chamber a substrate containing a first material containing silicon nitride and a second material that is different from the first material, forming a plasma-excited process gas containing NF3 and O2, and exposing the substrate to the plasma-excited process gas to selectively etch the first material relative to the second material. According to one embodiment, the second material may be selected from the group consisting of Si, SiO2, and a combination thereof.

Owner:TOKYO ELECTRON LTD

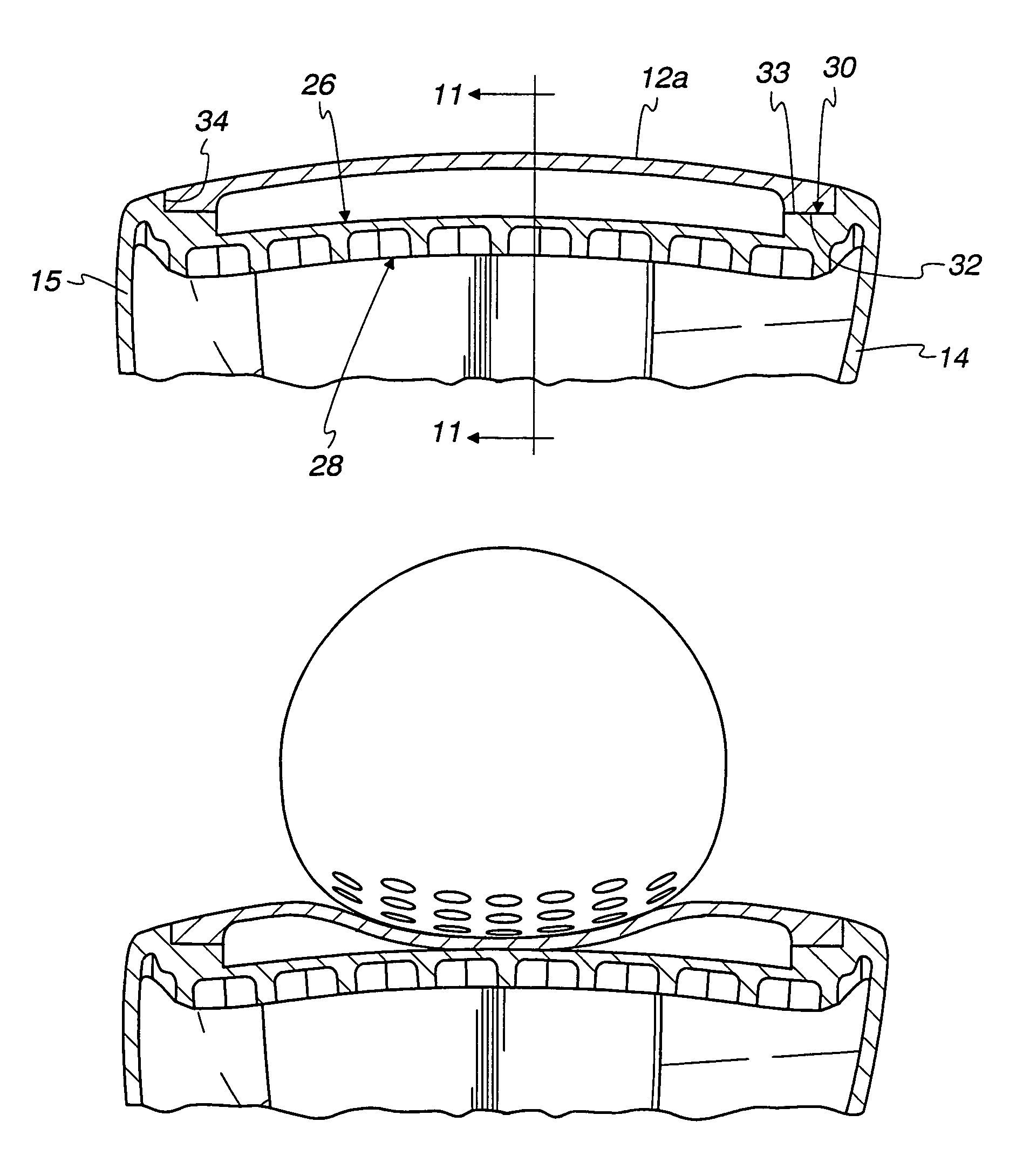

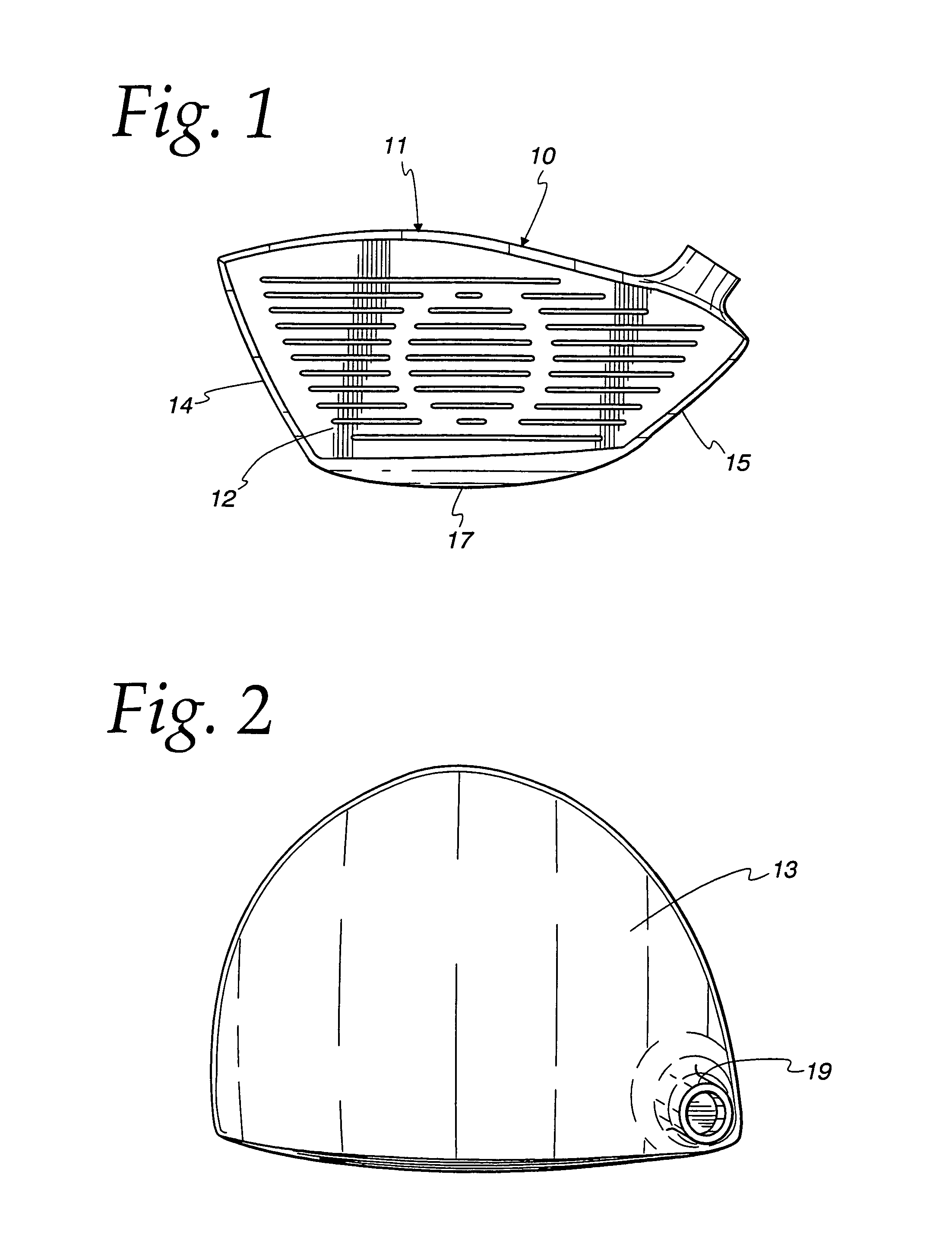

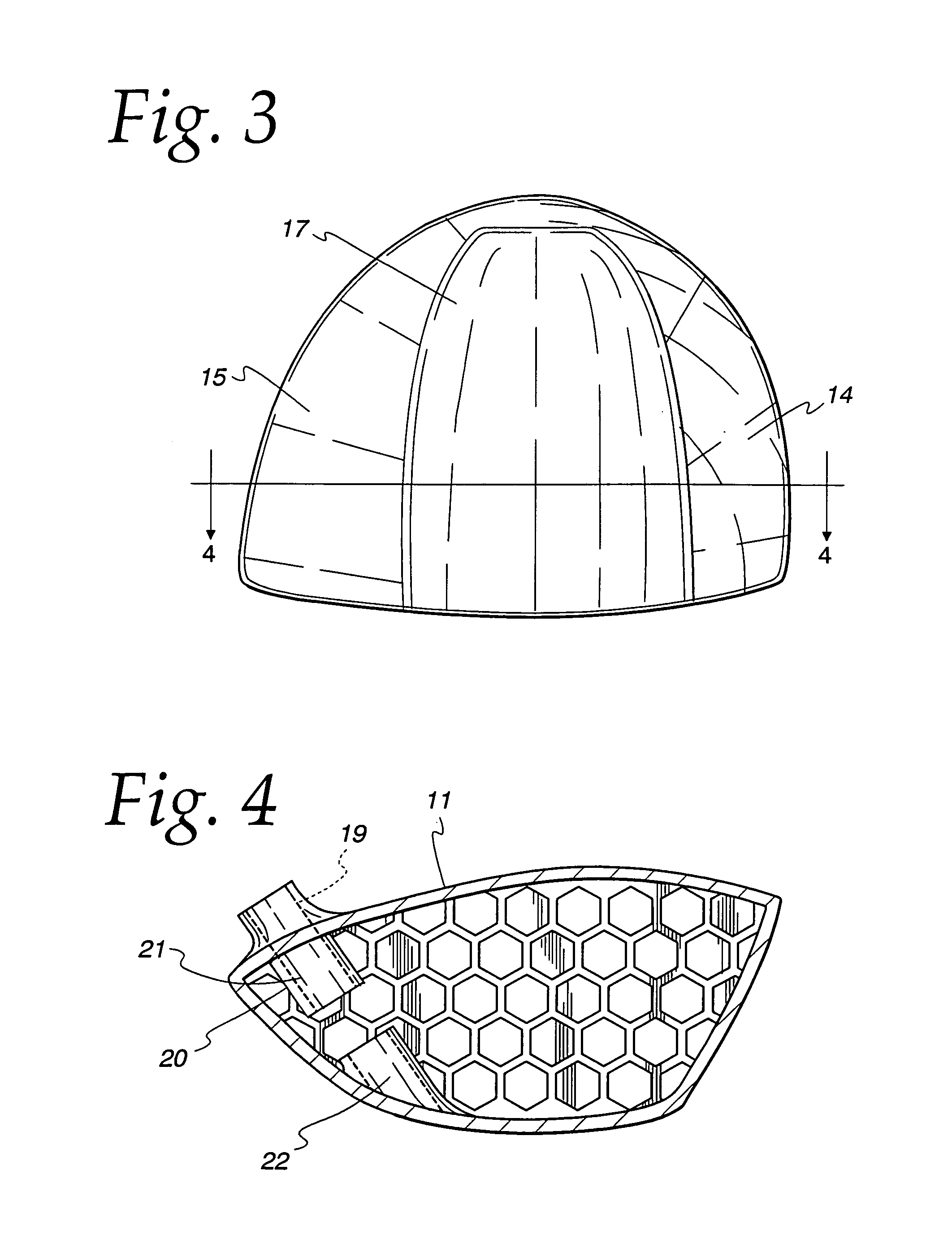

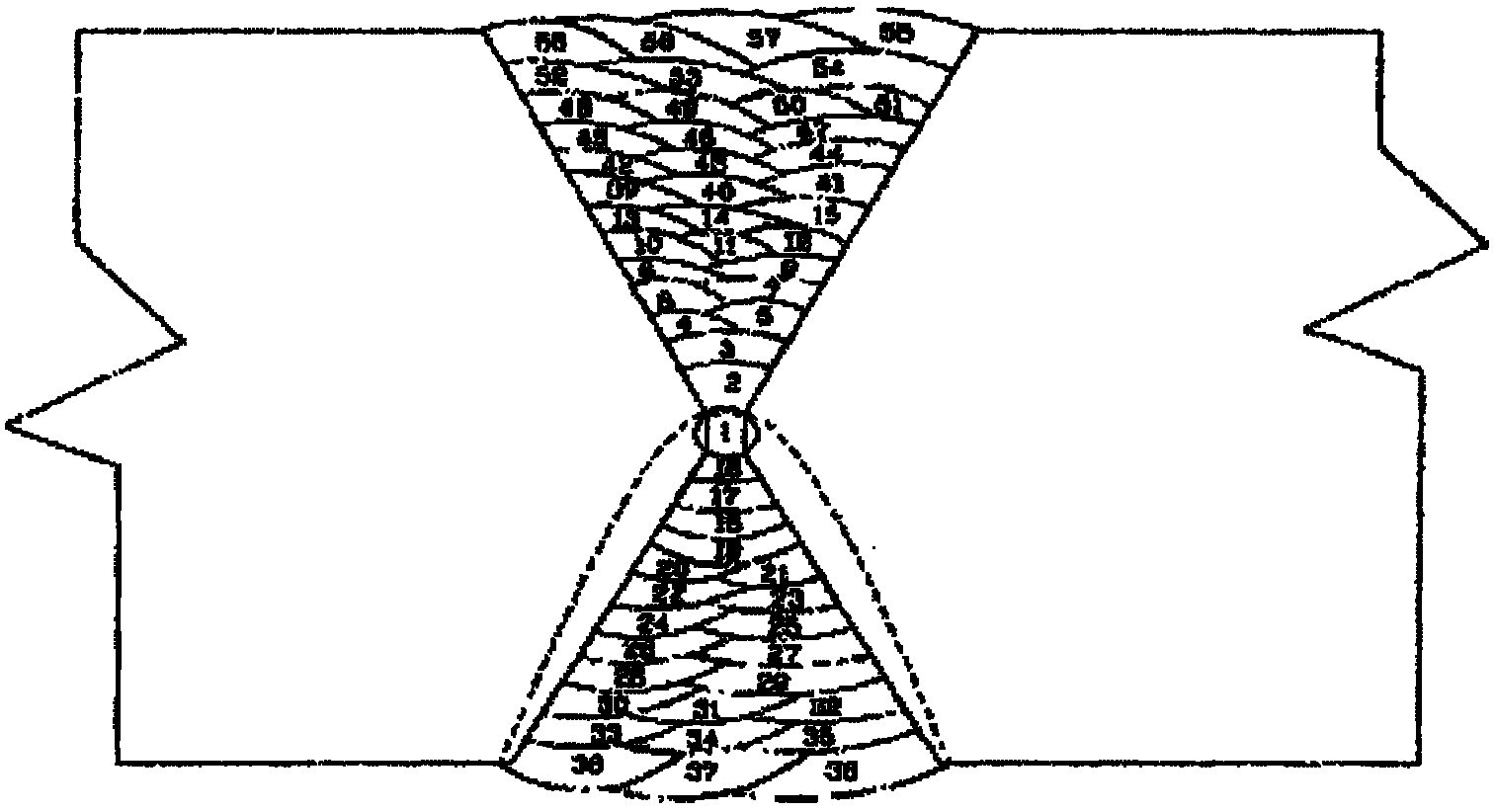

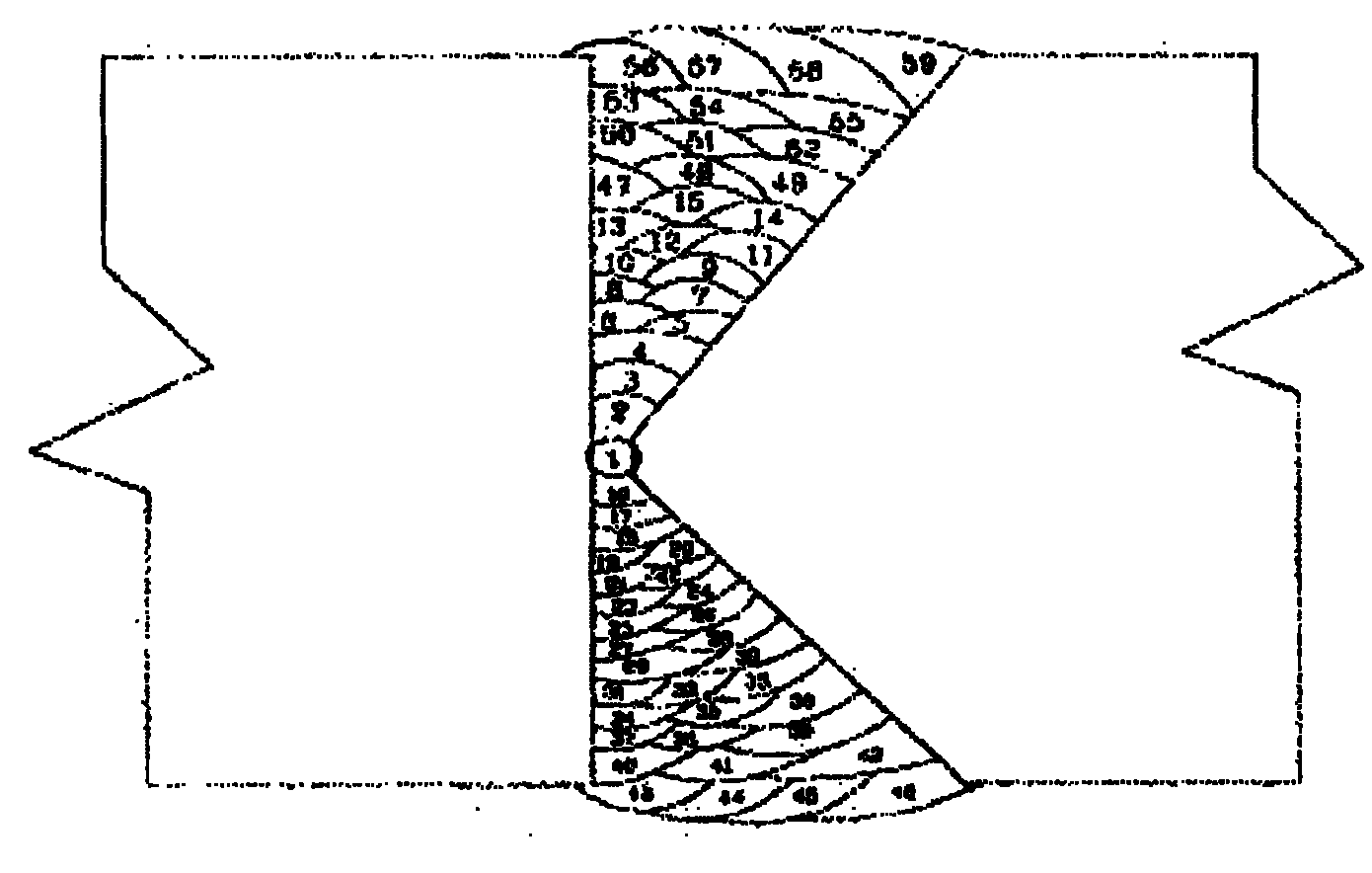

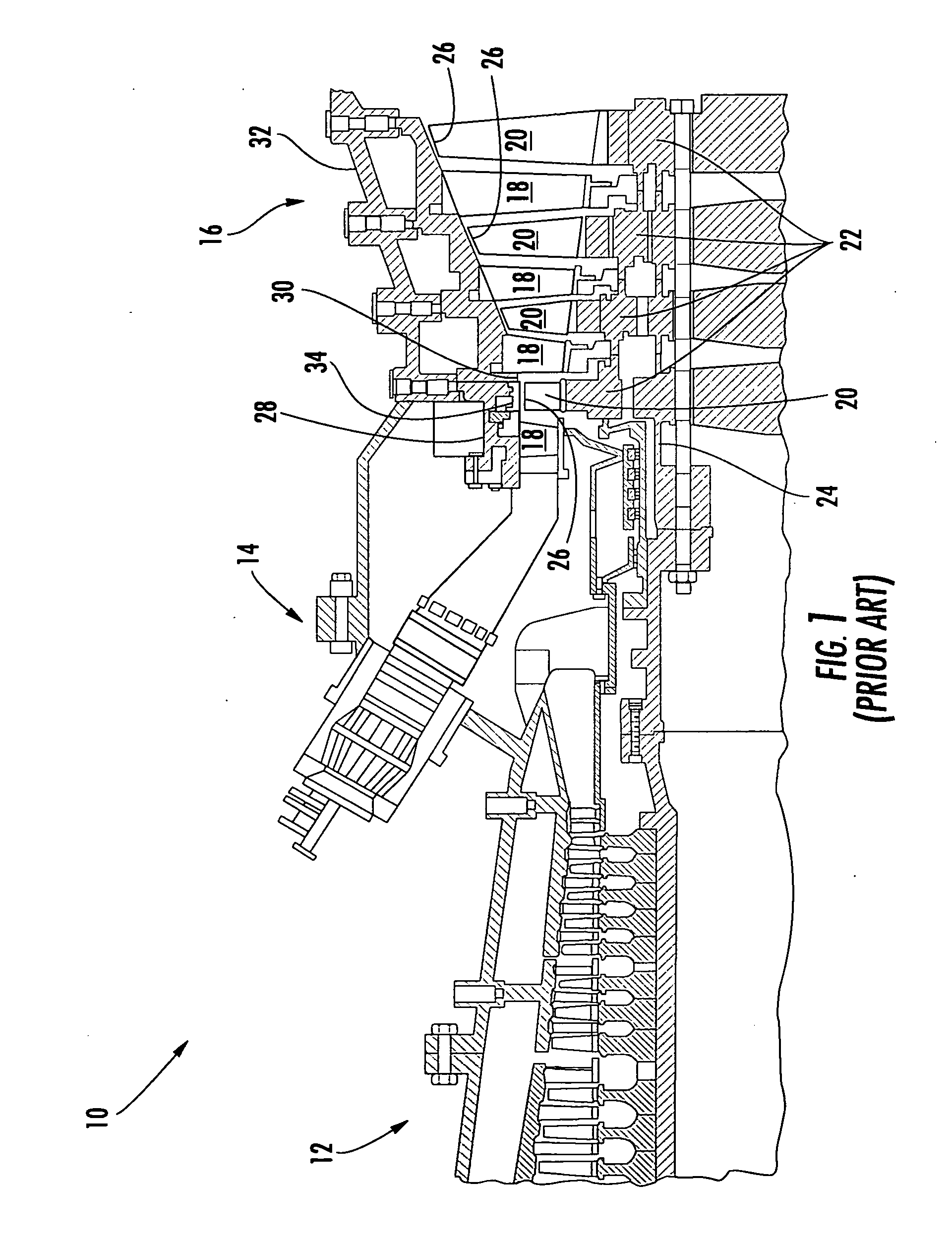

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

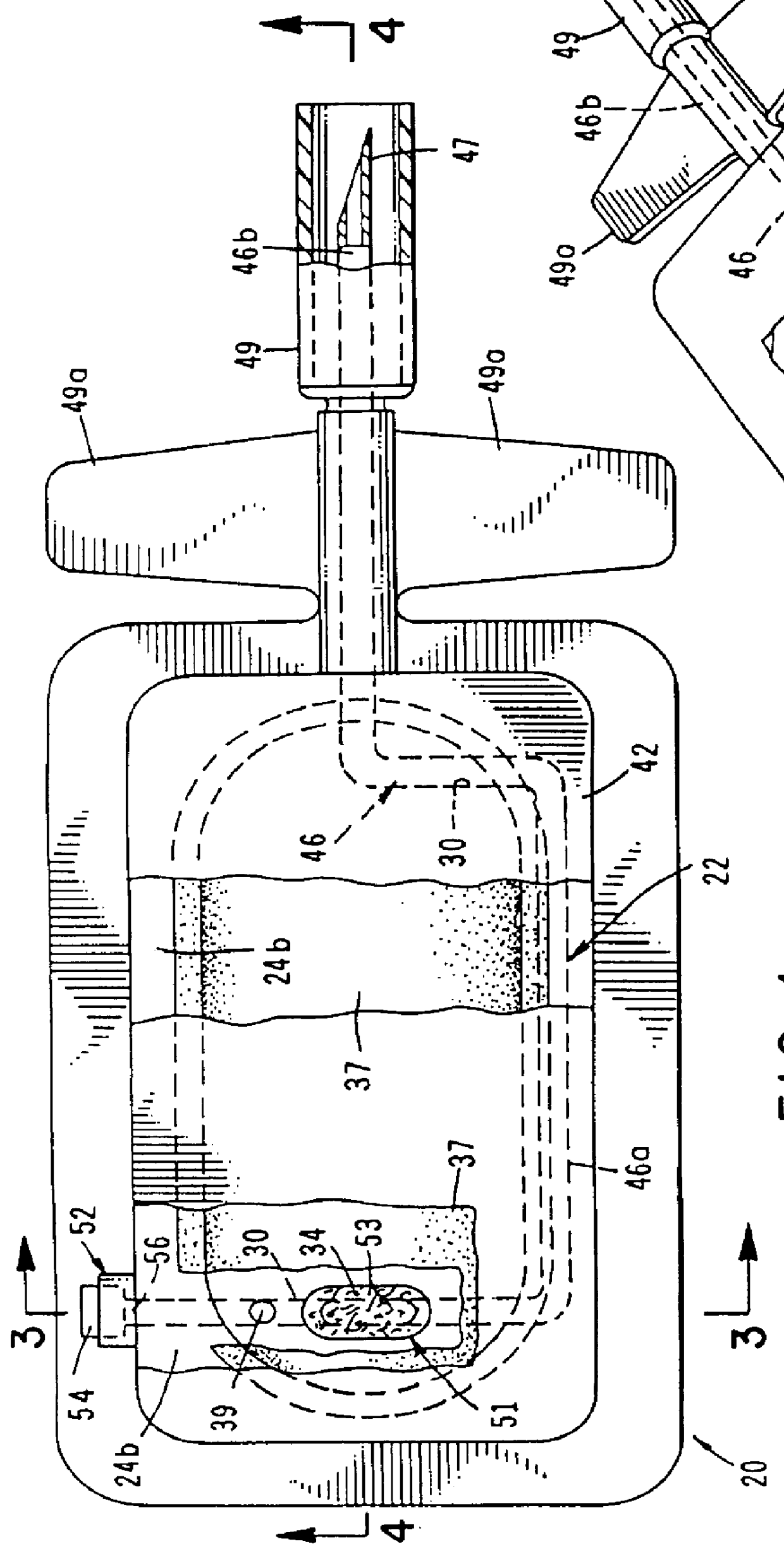

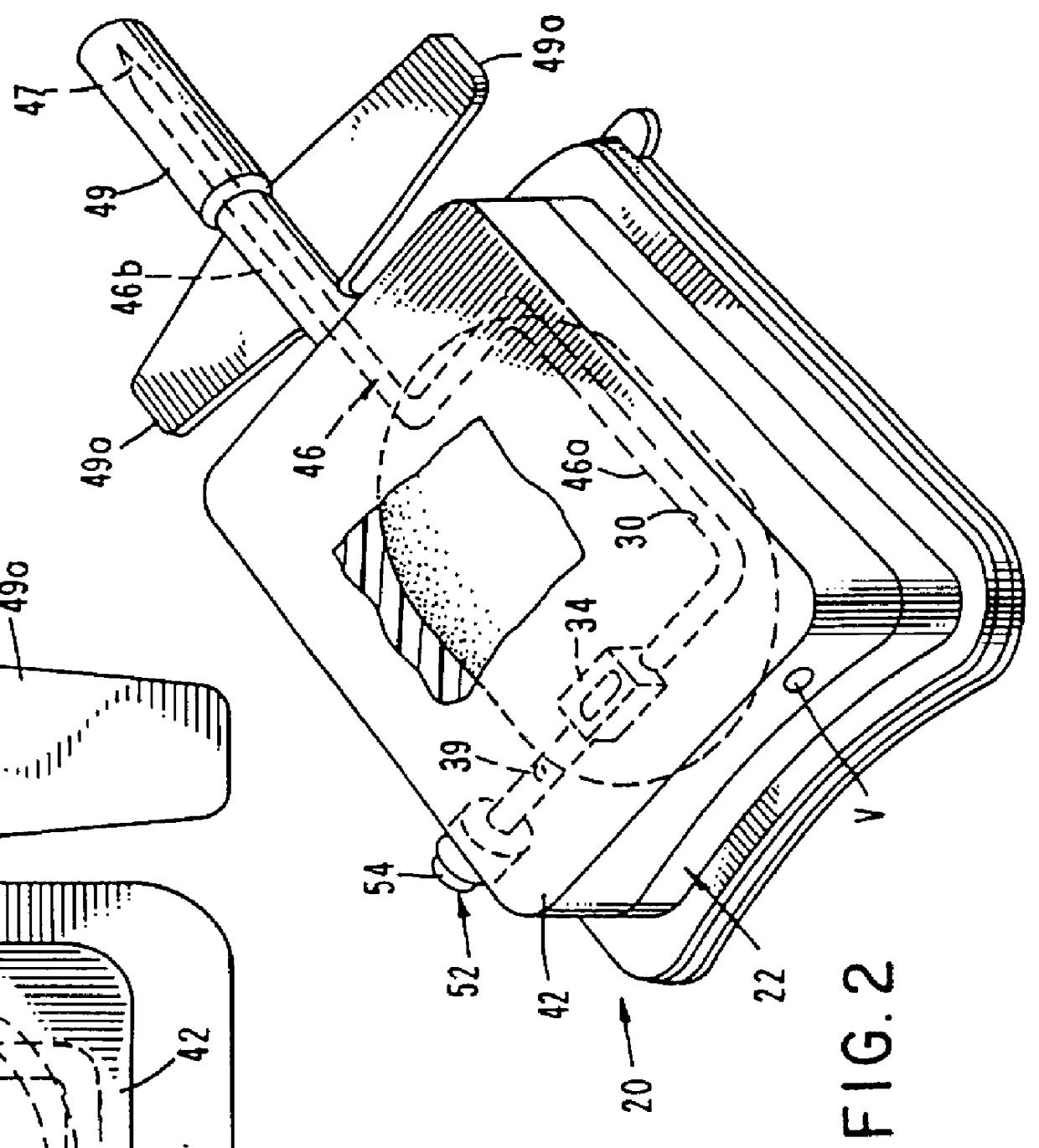

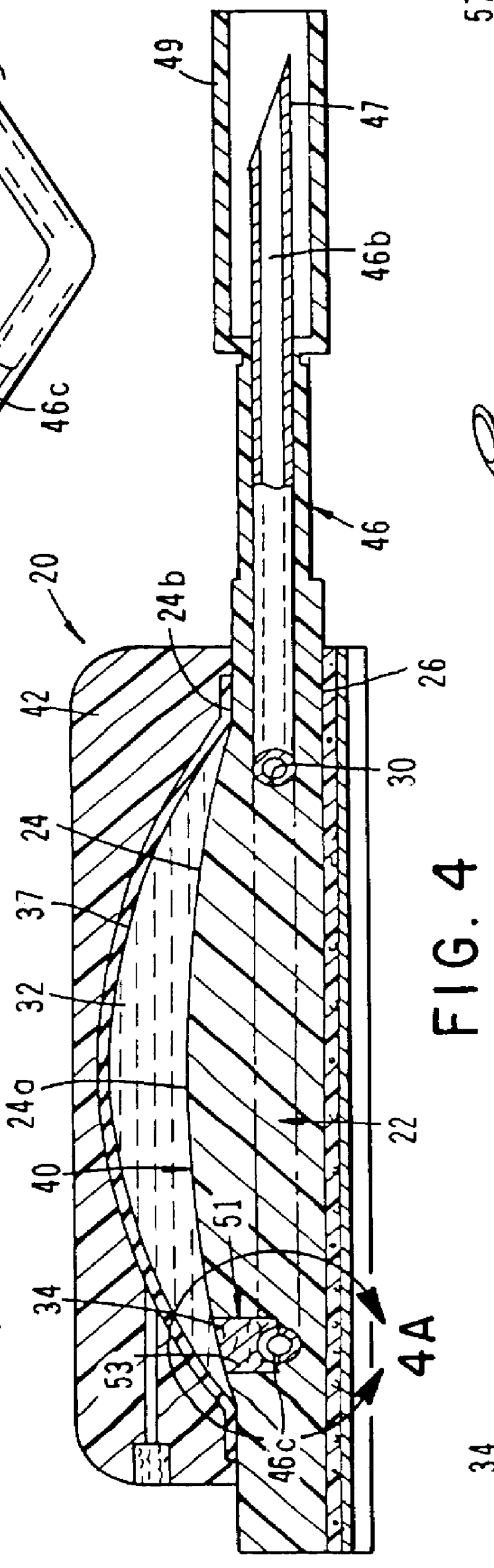

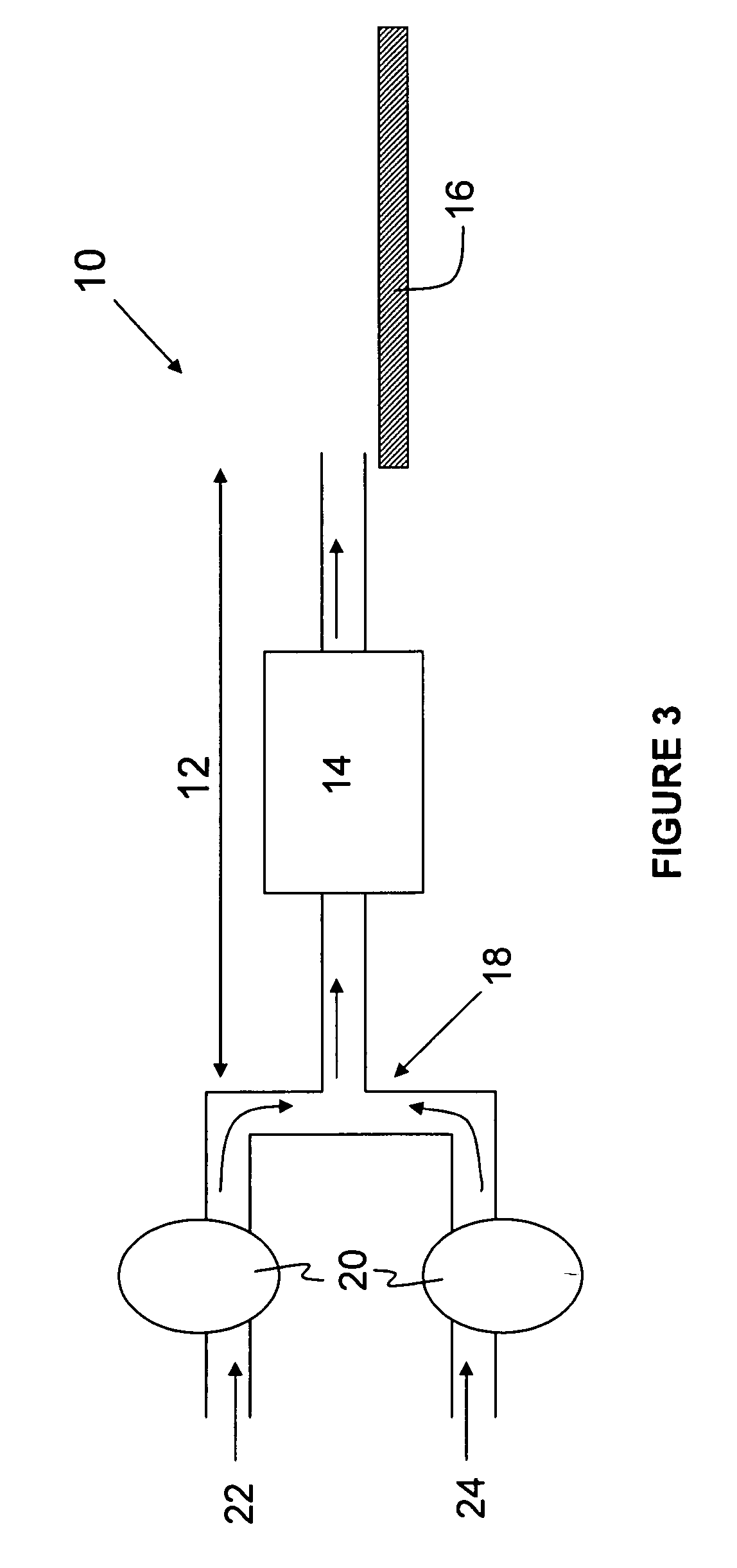

Fluid delivery device

An apparatus for accurately infusing fluids into a patient at specific rates over an extended period of time. The apparatus is of a low profile, laminate construction having a stored energy source in the form of a distendable membrane, which in cooperation with the base of the apparatus defines one or more fluid reservoirs each having a fluid inlet and a fluid outlet. The apparatus further includes a novel, conformable ullage made of formable materials. The conformable ullage uniquely conforms to the shape of elastomeric membrane as the membrane returns to its less distend configuration and in so doing can move between a central chamber and a toroidal chamber formed in the cover of the apparatus. This arrangement will satisfy even the most stringent medicament delivery tolerance requirements and will elegantly overcome the limitations of materials selection encountered in devices embodying solely rigid ullage construction. Additionally, the infusion cannula of the apparatus is connected to the base in a novel manner which permits expeditious subdermal delivery to the patient via a cannula which extends generally perpendicularly relative to the base.

Owner:PESCADERO BEACH HLDG

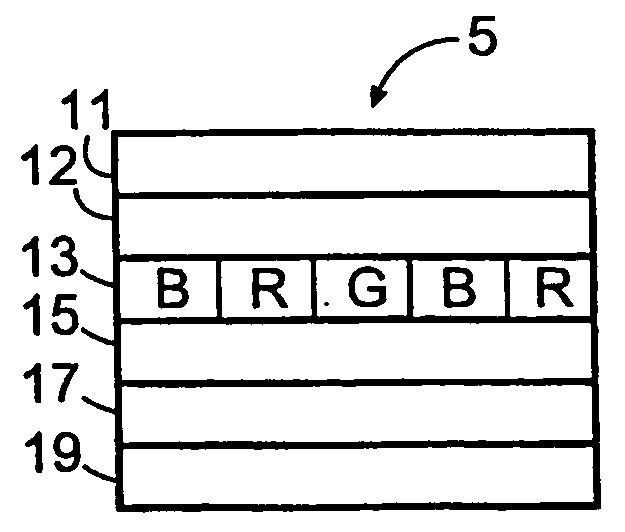

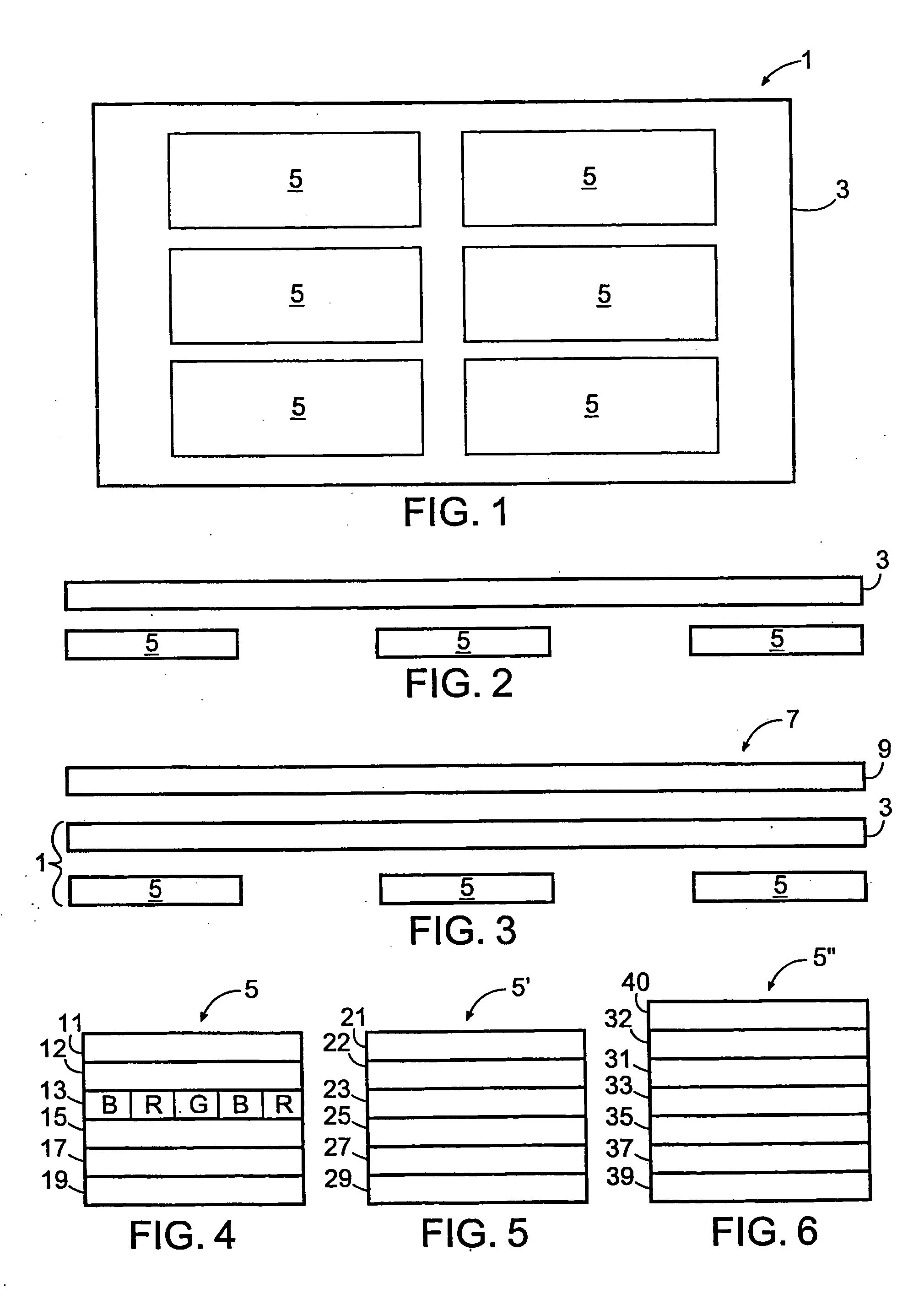

Organic light emitting diode (OLED) backlight

The present invention is directed to the use of a plurality of OLED displays and a diffuser to form a display backlight. Such a backlight can be used as an AMLCD backlight. The OLED displays can support NVIS compatibility by reducing current provided to red sub-pixels, and by limiting transmission of light beyond 630 nm, possibly by material selection or filtering using thin film optical coatings.

Owner:LITTON SYST INC

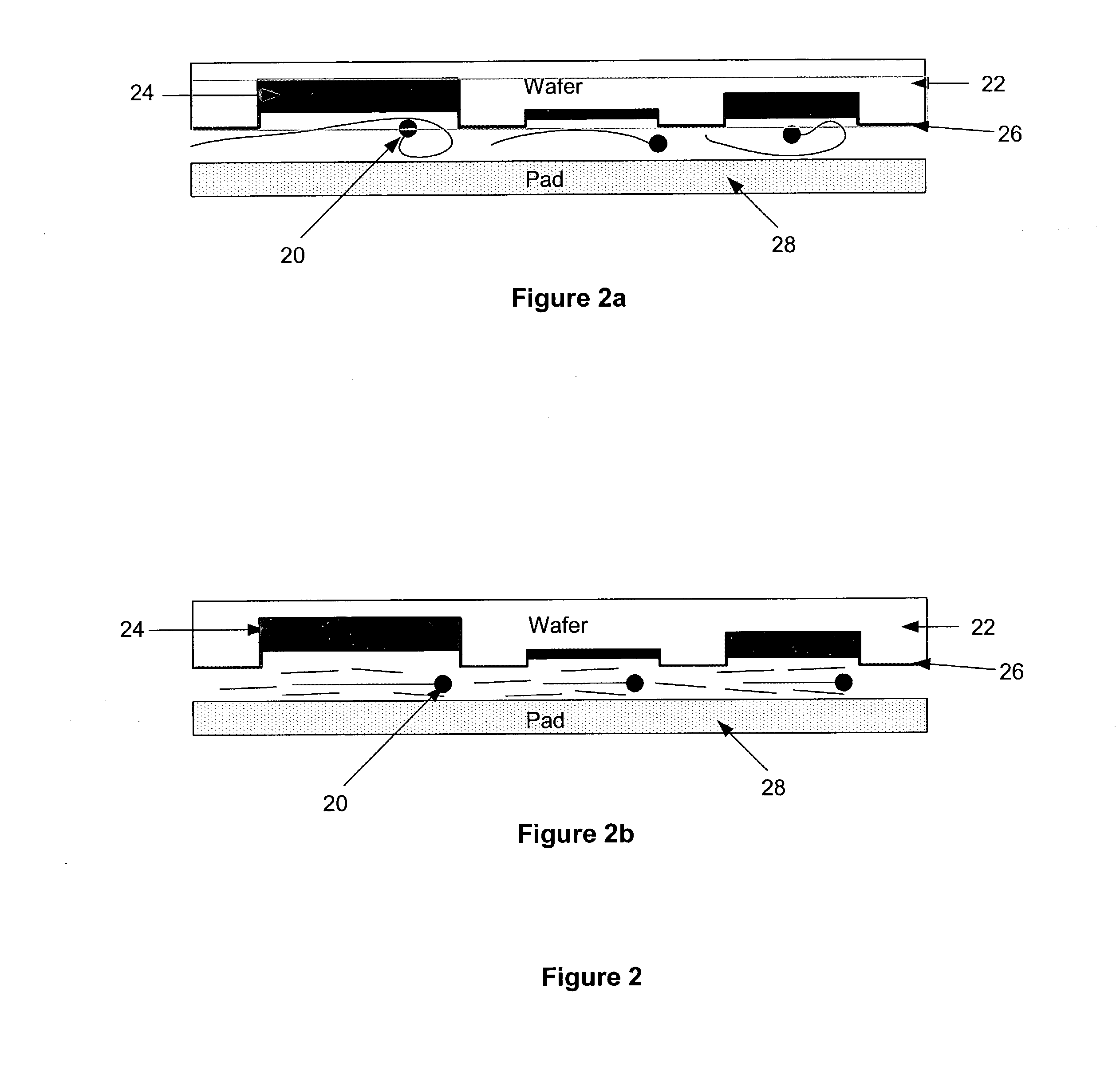

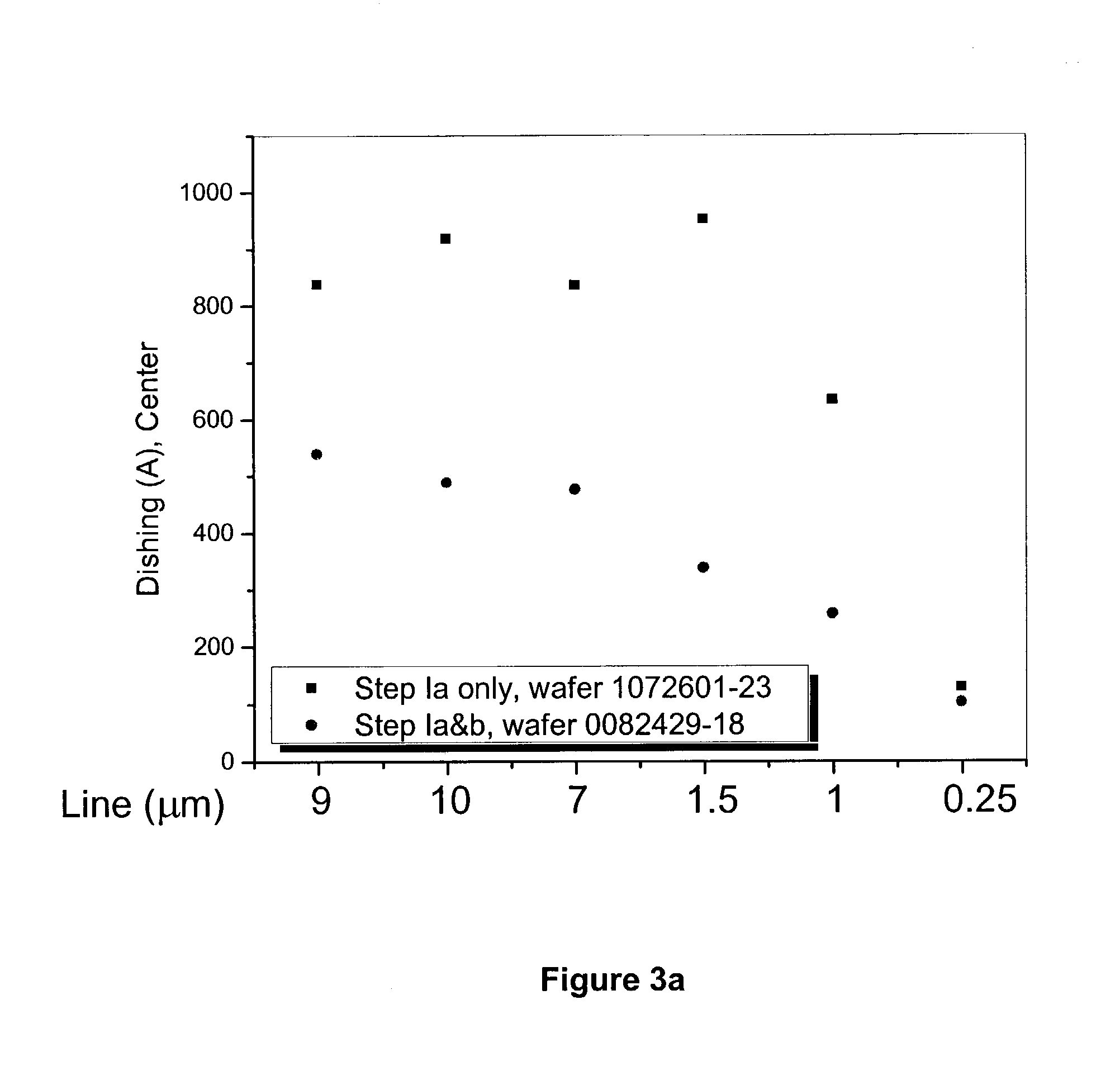

Chemical mechanical polishing compositions for copper and associated materials and method of using same

A CMP composition containing a rheology agent, e.g., in combination with oxidizing agent, chelating agent, inhibiting agent, abrasive and solvent. Such CMP composition advantageously increases the materials selectivity in the CMP process and is useful for polishing surfaces of copper elements on semiconductor substrates, without the occurrence of dishing or other adverse planarization deficiencies in the polished copper.

Owner:ADVANCED TECH MATERIALS INC

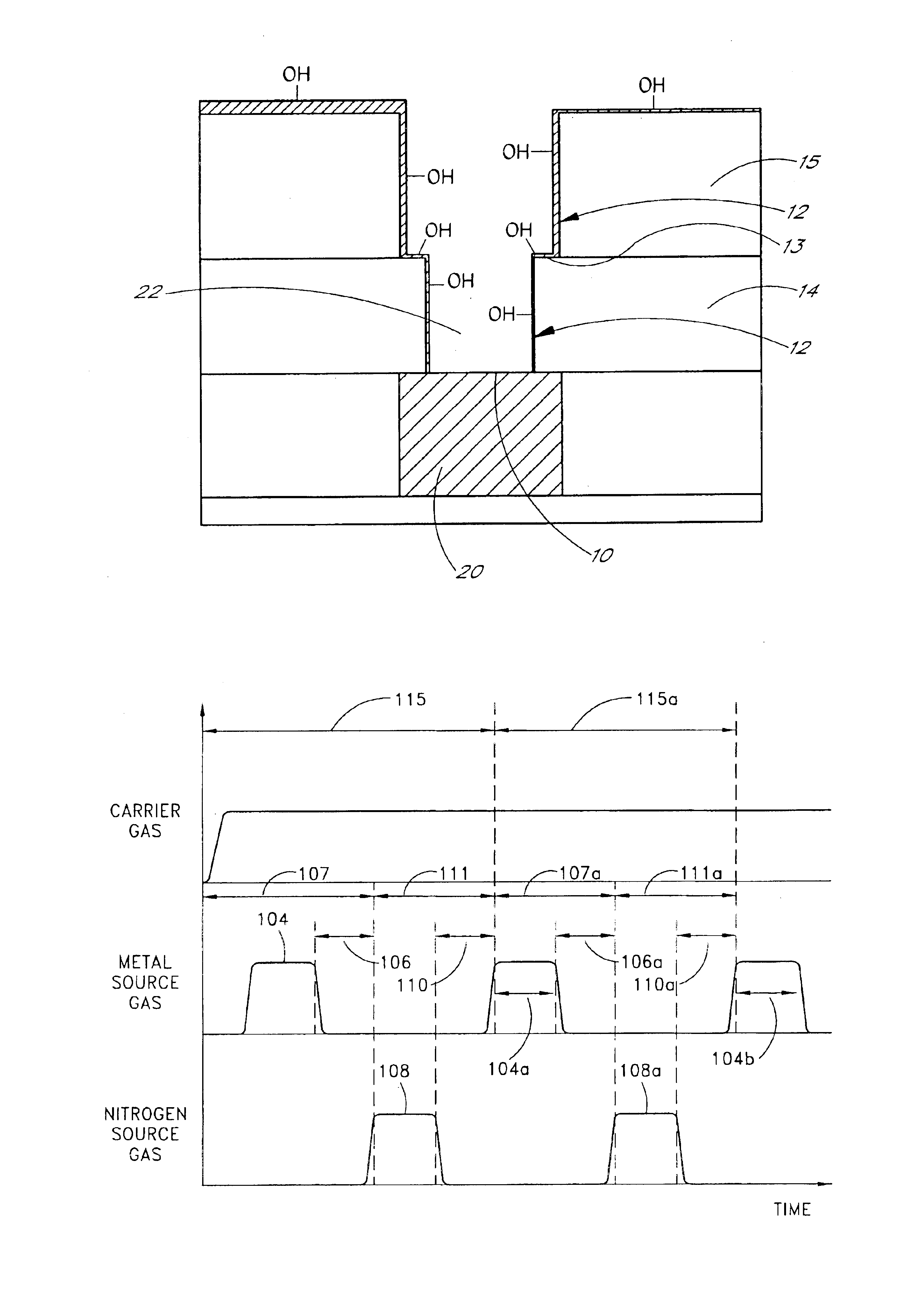

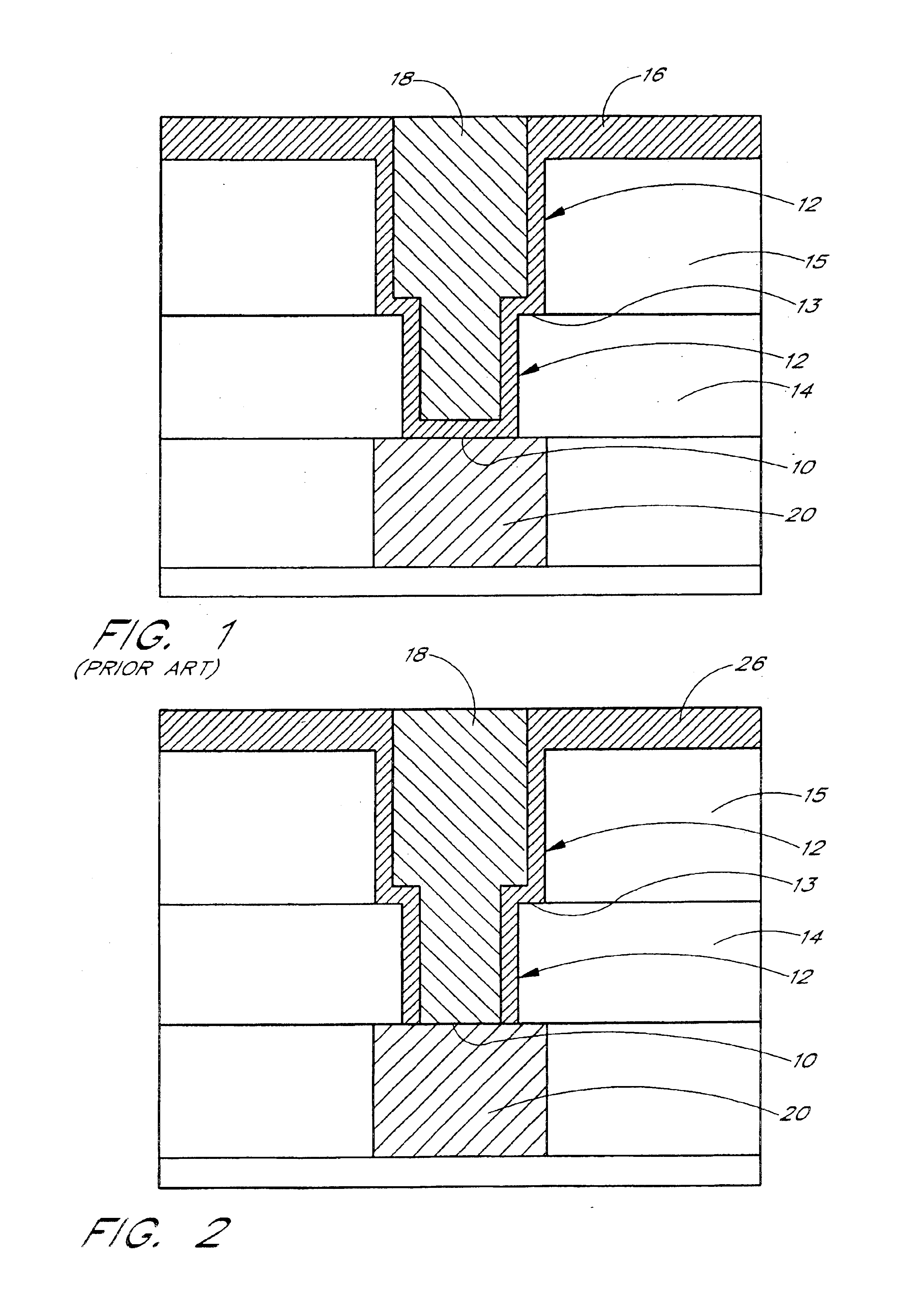

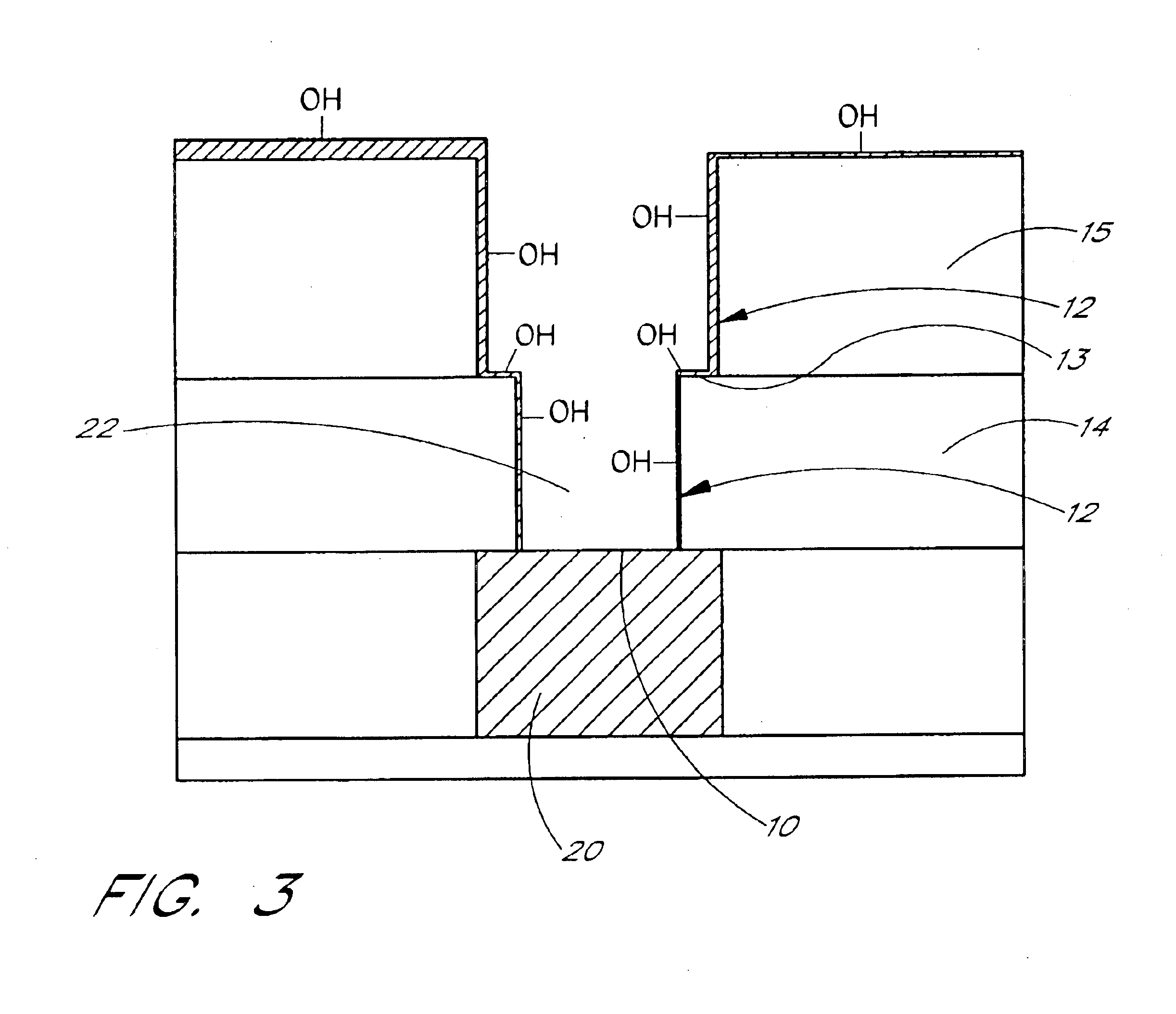

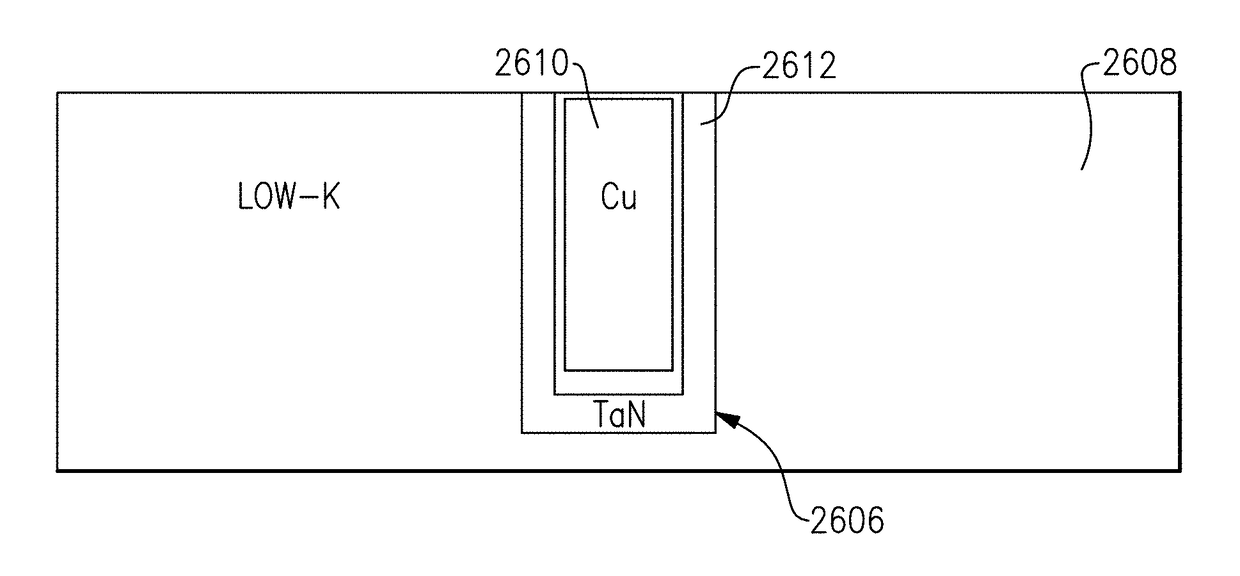

Method for bottomless deposition of barrier layers in integrated circuit metallization schemes

InactiveUS6852635B2Avoid depositionPolycrystalline material growthSemiconductor/solid-state device detailsContact formationEngineering

Methods are disclosed for selective deposition on desired materials. In particular, barrier materials are selectively formed on insulating surfaces, as compared to conductive surfaces. In the context of contact formation and trench fill, particularly damascene and dual damascene metallization, the method advantageously lines insulating surfaces with a barrier material. The selective formation allows the deposition to be “bottomless,” thus leaving the conductive material at a via bottom exposed for direct metal-to-metal contact when further conductive material is deposited into the opening after barrier formation on the insulating surfaces. Desirably, the selective deposition is accomplished by atomic layer deposition (ALD), resulting in highly conformal coverage of the insulating sidewalls in the opening.

Owner:INTERUNIVERSITAIR MICROELECTRONICA CENT VZW (IMEC) +2

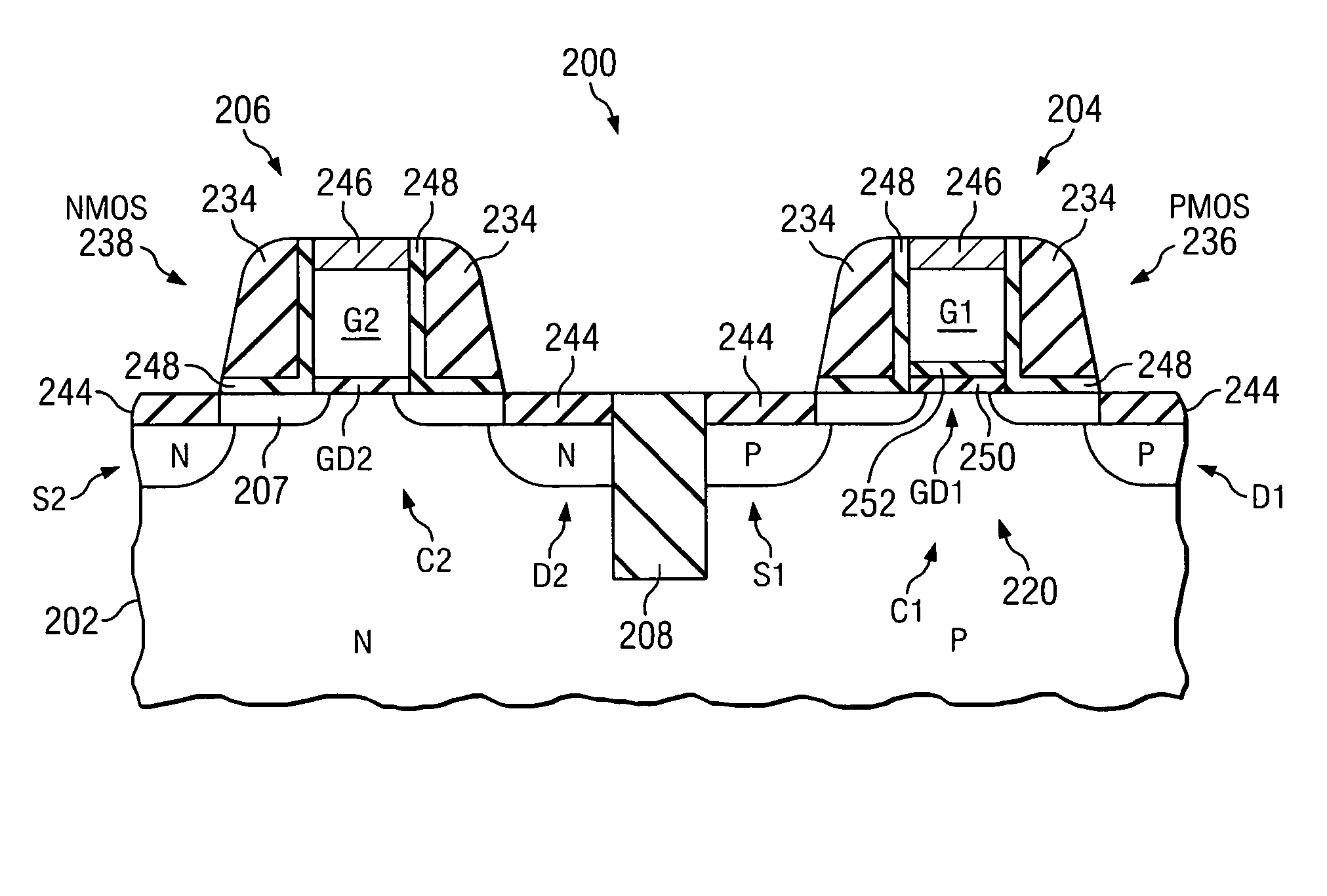

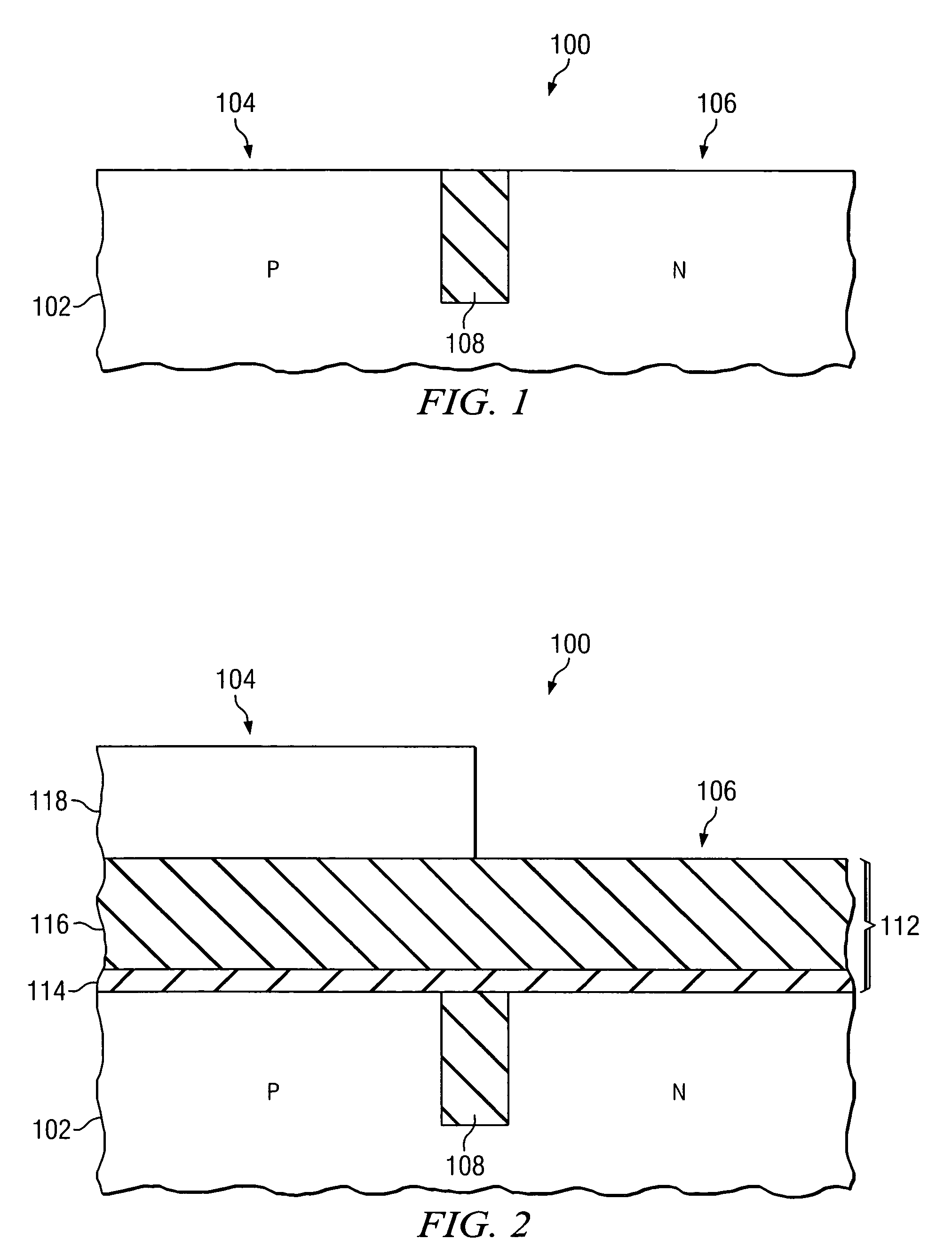

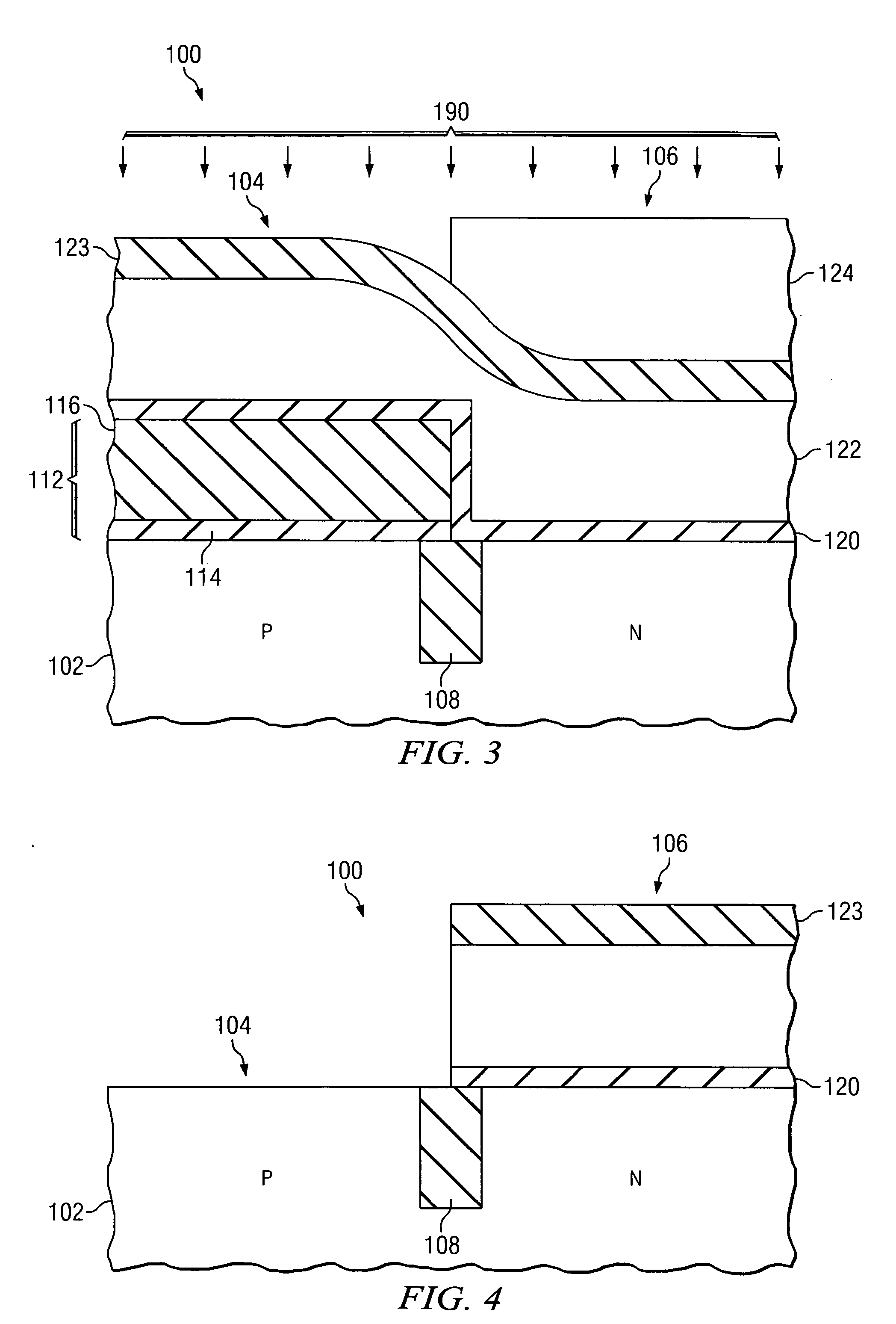

Transistor device and method of manufacture thereof

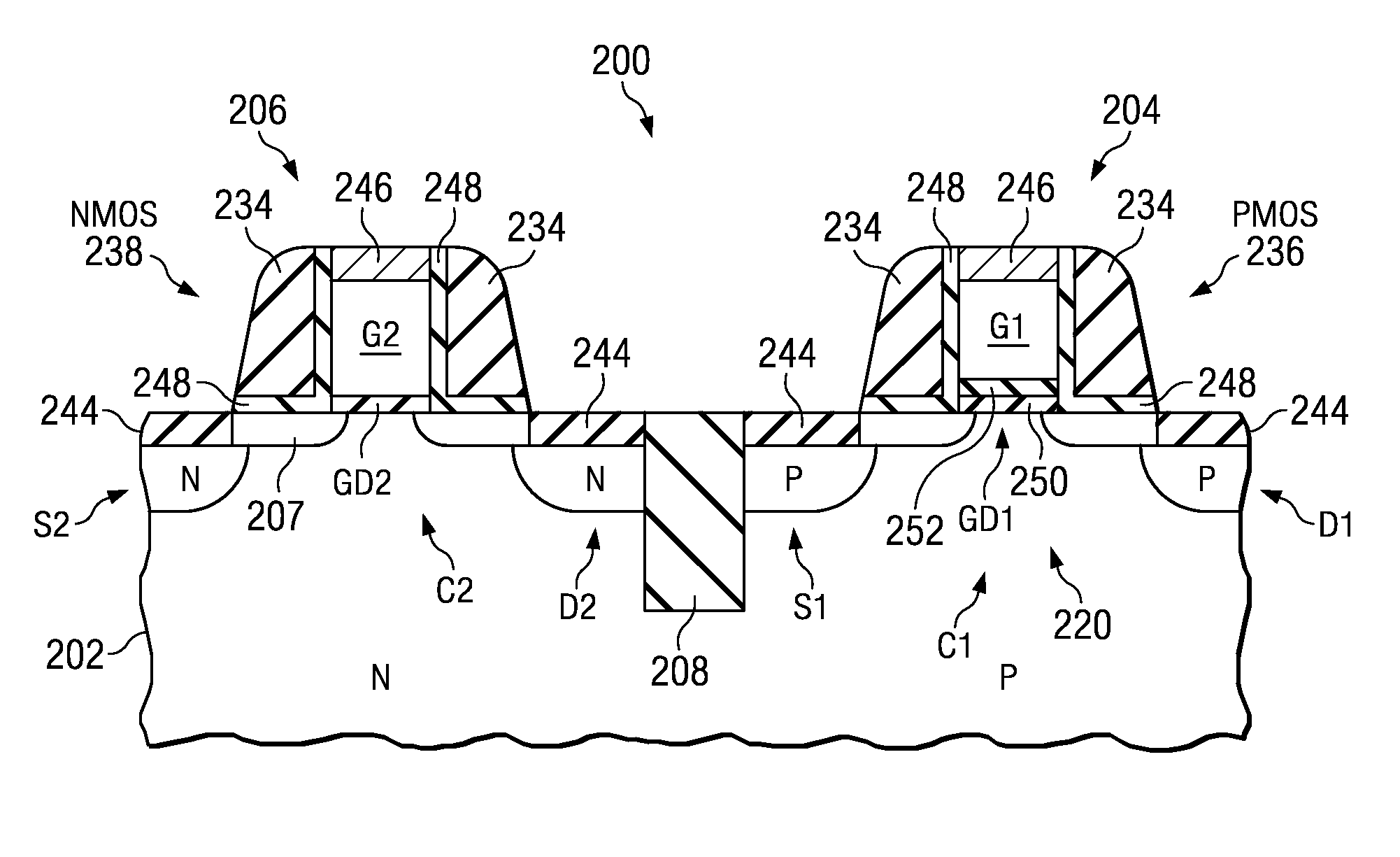

ActiveUS20060131652A1Easy to adjustThreshold voltage Vt is decreasedTransistorSolid-state devicesDopantCMOS

A method of forming transistors and structures thereof. A CMOS device includes high k gate dielectric materials. A PMOS device includes a gate that is implanted with an n type dopant. The NMOS device may be doped with either an n type or a p type dopant. The work function of the CMOS device is set by the material selection of the gate dielectric materials. A polysilicon depletion effect is reduced or avoided.

Owner:INFINEON TECH AG

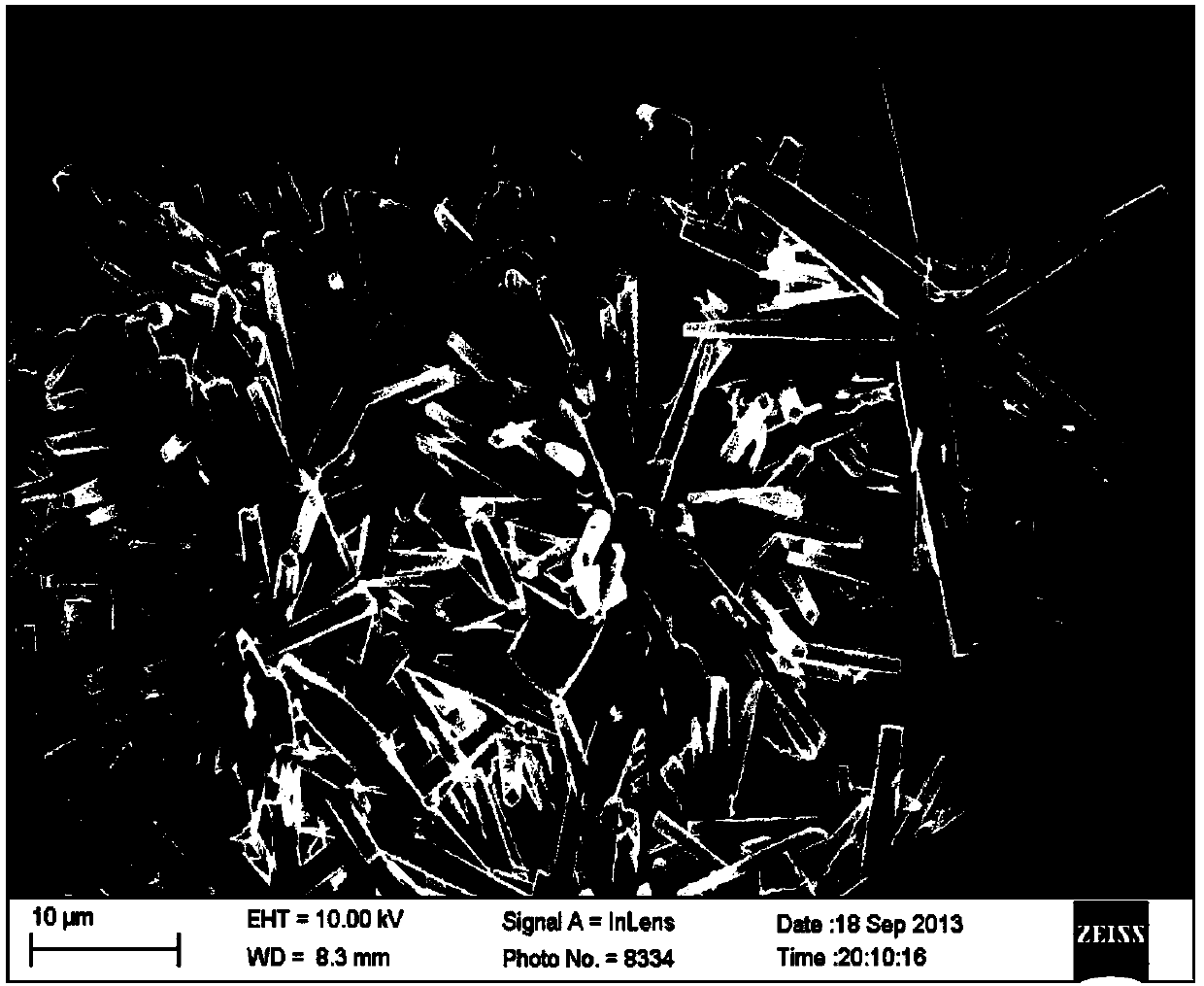

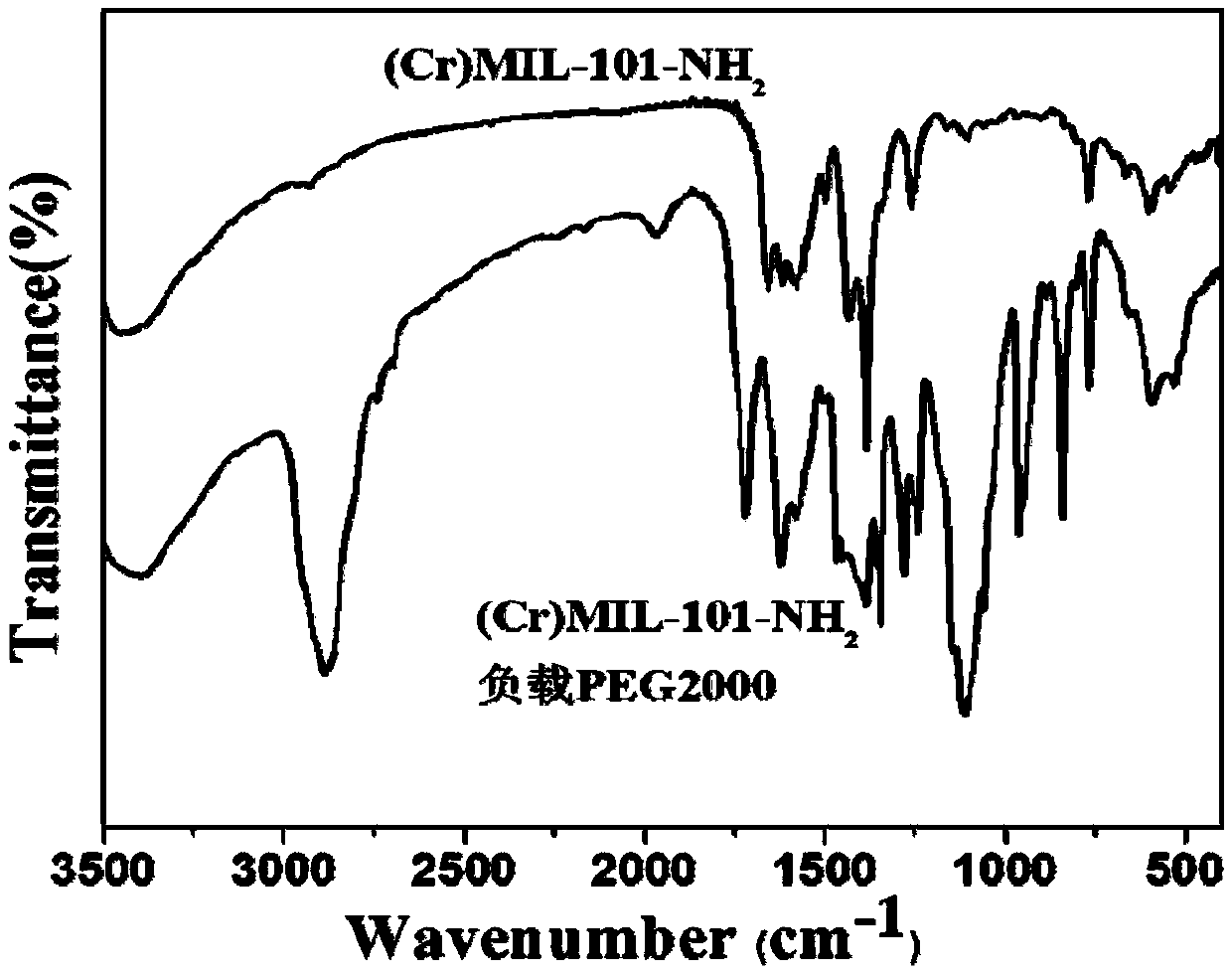

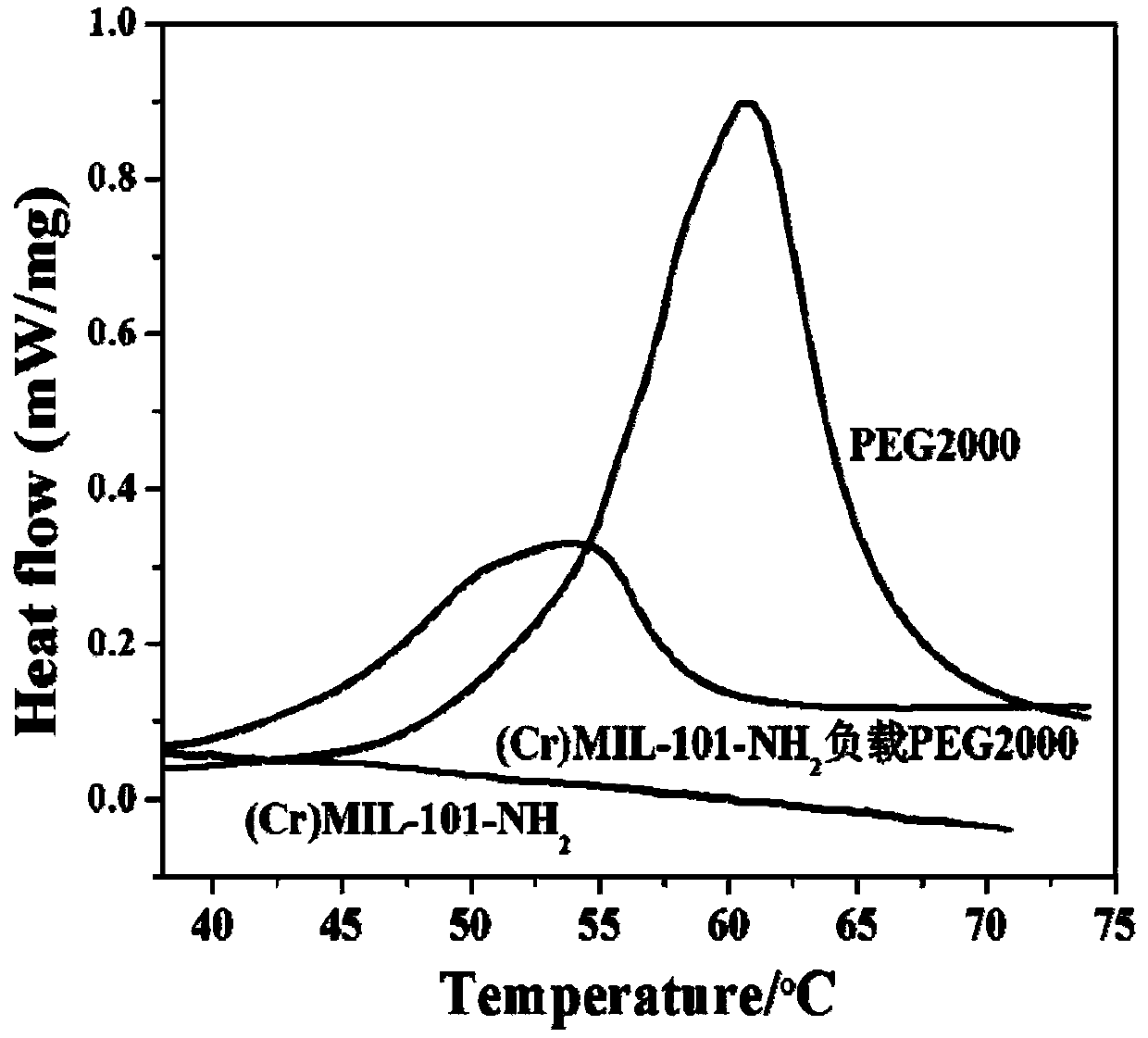

Preparation method of metal organic framework based composite phase-change material

InactiveCN103756646AWide range of choicesPrevent leakage and other issuesProductsReagentsMetal-organic frameworkElectrical polarity

The invention relates to a preparation method of a metal organic framework based composite phase-change material. The method comprises the steps that a metal organic framework material substrate is prepared selectively; hole diameter size design and hole channel polarity regulation and control are performed on the substrate according to the size and the kind of a core material, so that a phase-change core material to be loaded is matched better; the soluble phase-change core material is prepared into a solution; a metal organic framework material is dispersed in the prepared phase-change material solution; a phase-change material is adsorbed by utilizing an extra-large specific surface area and a nano hole channel structure of the metal organic framework material; drying is performed; and then the metal organic framework composite phase-change material with a shaping effect is obtained. According to the method, a novel metal organic framework based composite phase-change material is developed; the prepared metal organic framework based composite phase-change material can effectively avoid leakage and the like, and has the advantages of adjustable nano hole structure and wide core material selection range; the method is simple in technology and mild in reaction condition, and is suitable for scale production; and a raw material is cheap and easy to obtain.

Owner:UNIV OF SCI & TECH BEIJING

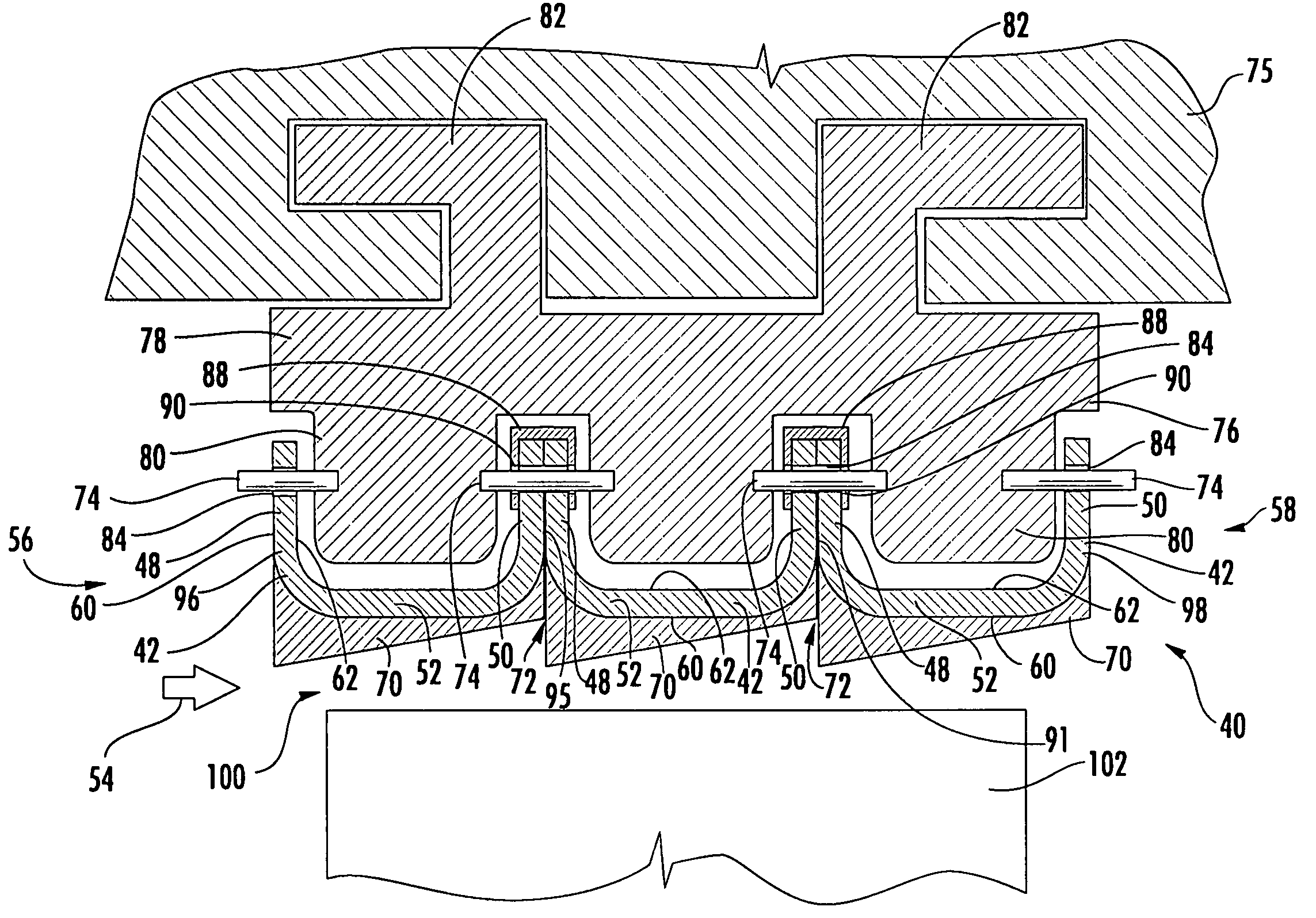

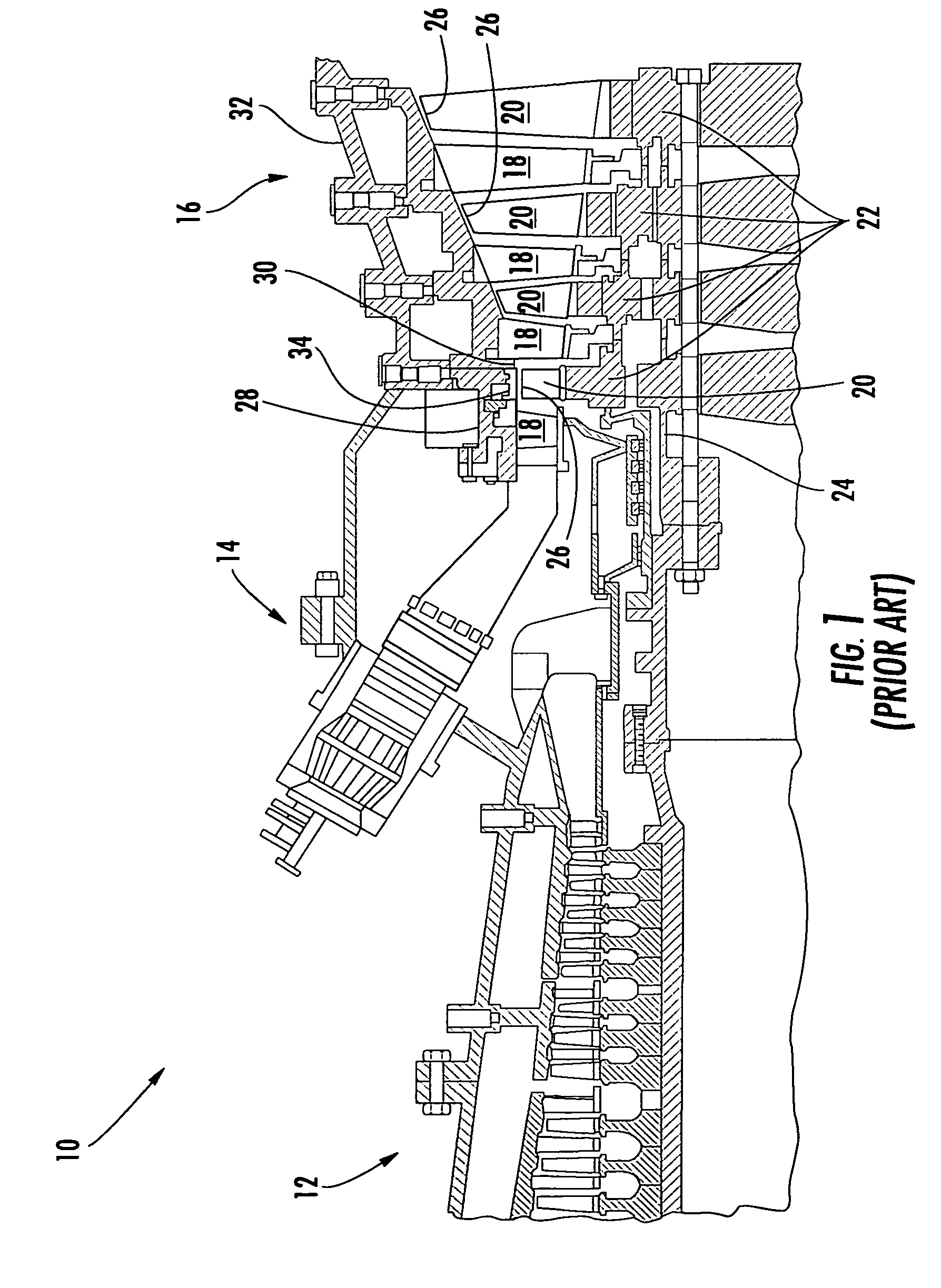

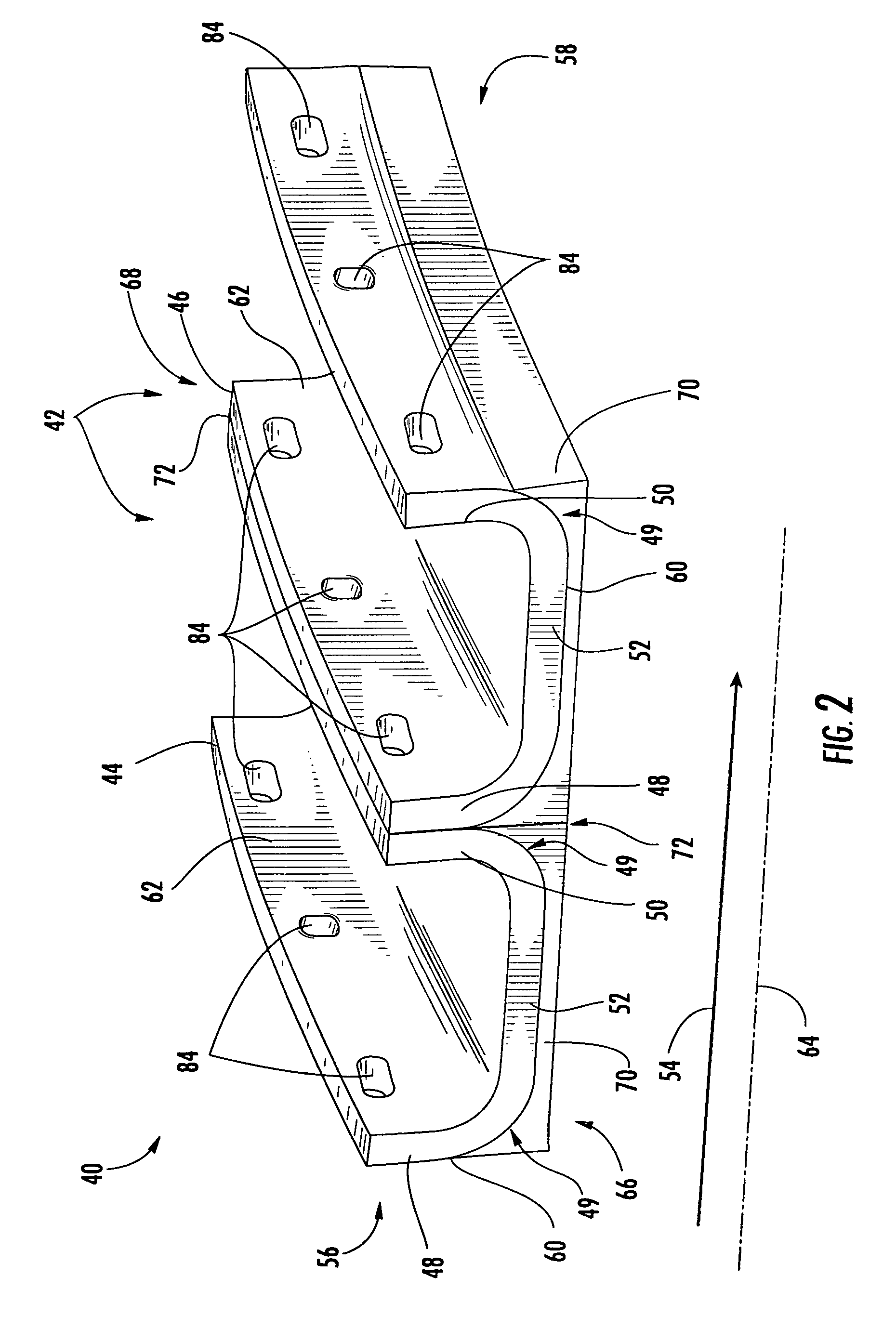

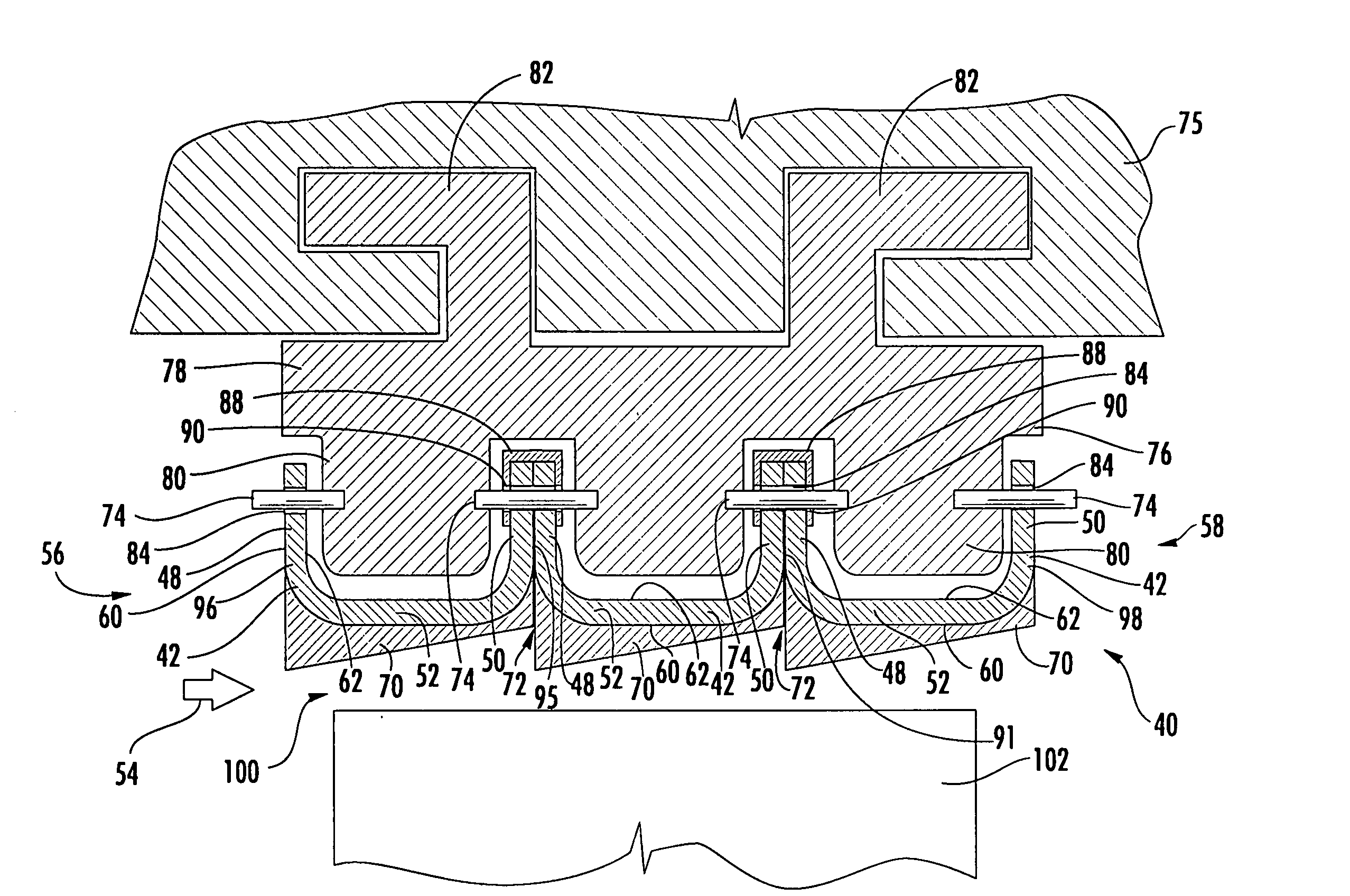

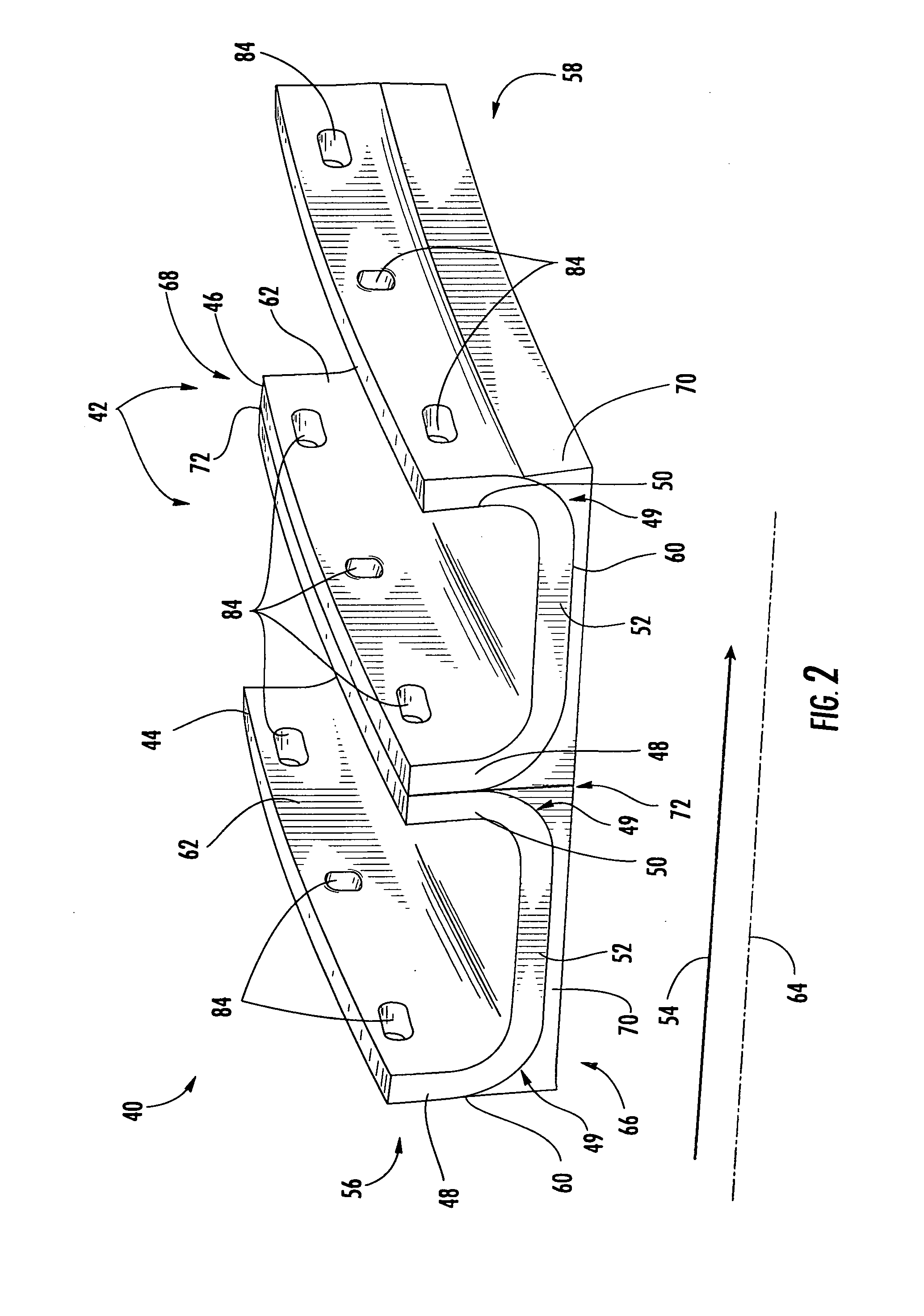

Turbine engine ring seal

InactiveUS7726936B2Reduce thicknessMinimize interfacePump componentsBlade accessoriesEngineeringTurbine

Aspects of the invention relate to a ring seal for a turbine engine. The ring seal can be made up of a plurality of circumferentially abutted ring seal segments. Each ring seal segment can comprise a plurality of individual channels. The channels can be generally U-shaped in cross-section with a forward span, and aft span and an extension connecting therebetween. The channels can be positioned such that the aft span of one channel can substantially abut the forward span of another channel. The plurality of separate channels can be detachably coupled to each other by, for example, a plurality of pins. The ring seal segment according to aspects of the invention can facilitate numerous advantageous characteristics including greater material selection, selective cooling, improved serviceability, and reduced blade tip leakage. Moreover, the configuration is well suited to handle the operational loads of the turbine.

Owner:SIEMENS ENERGY INC

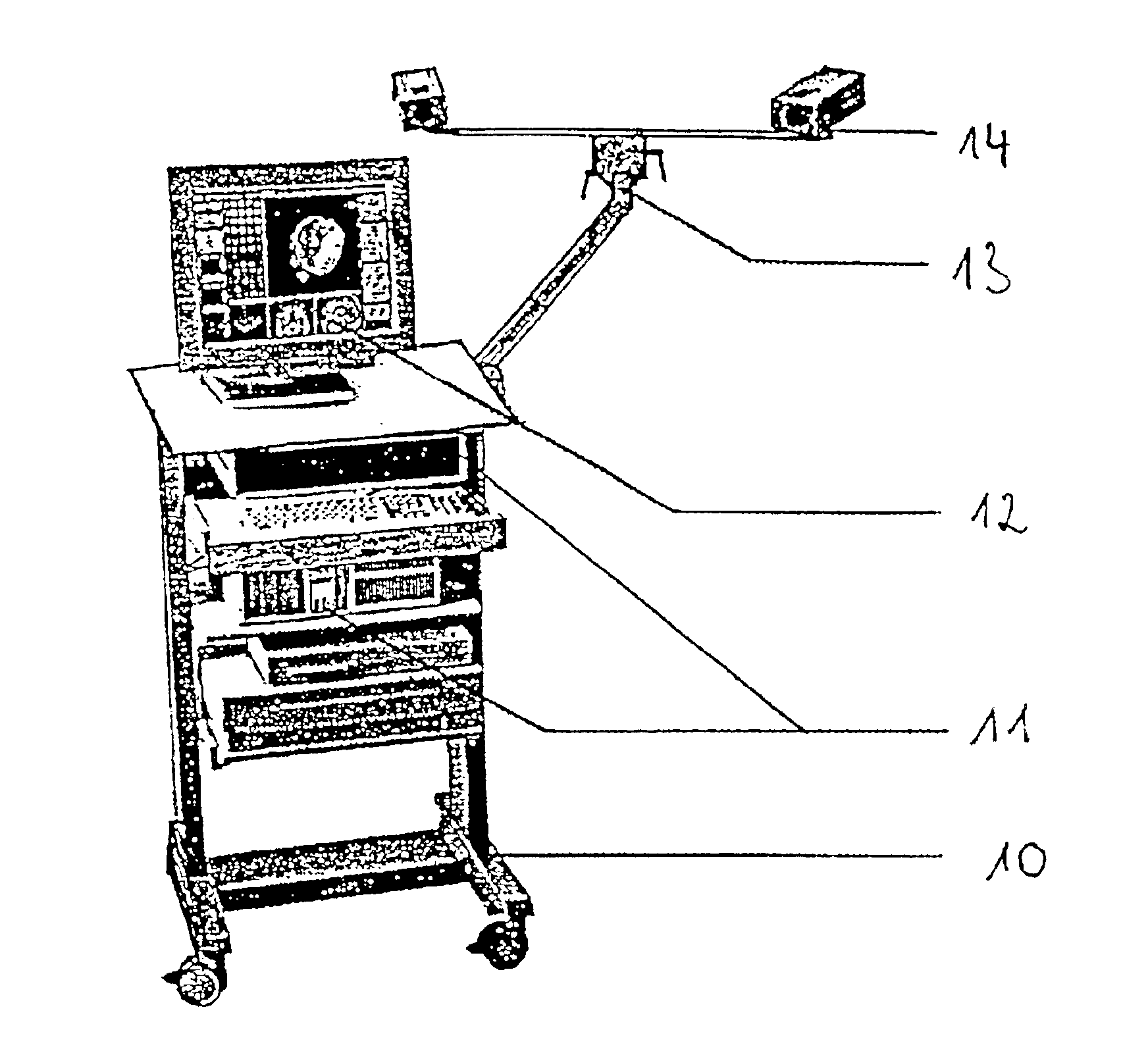

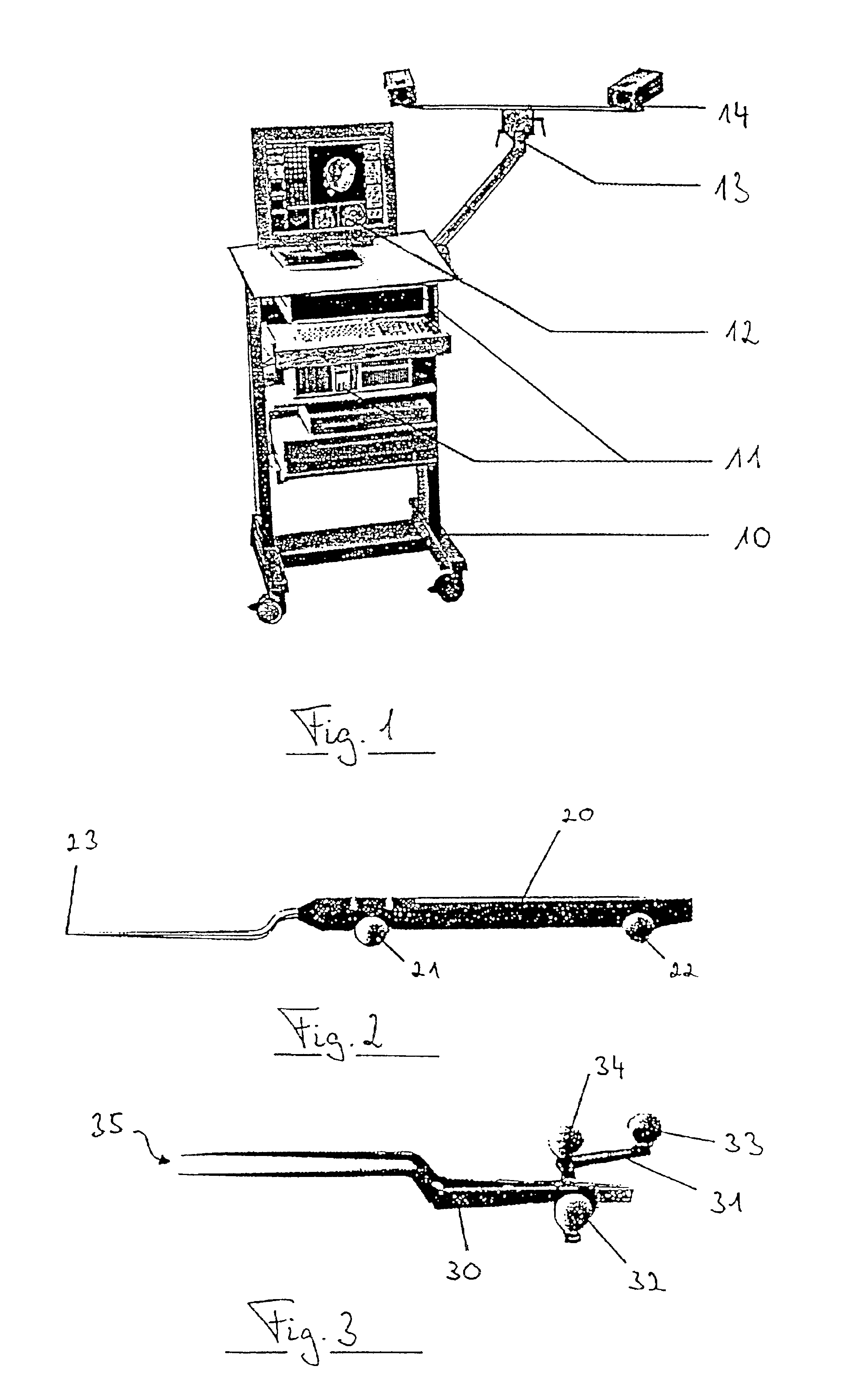

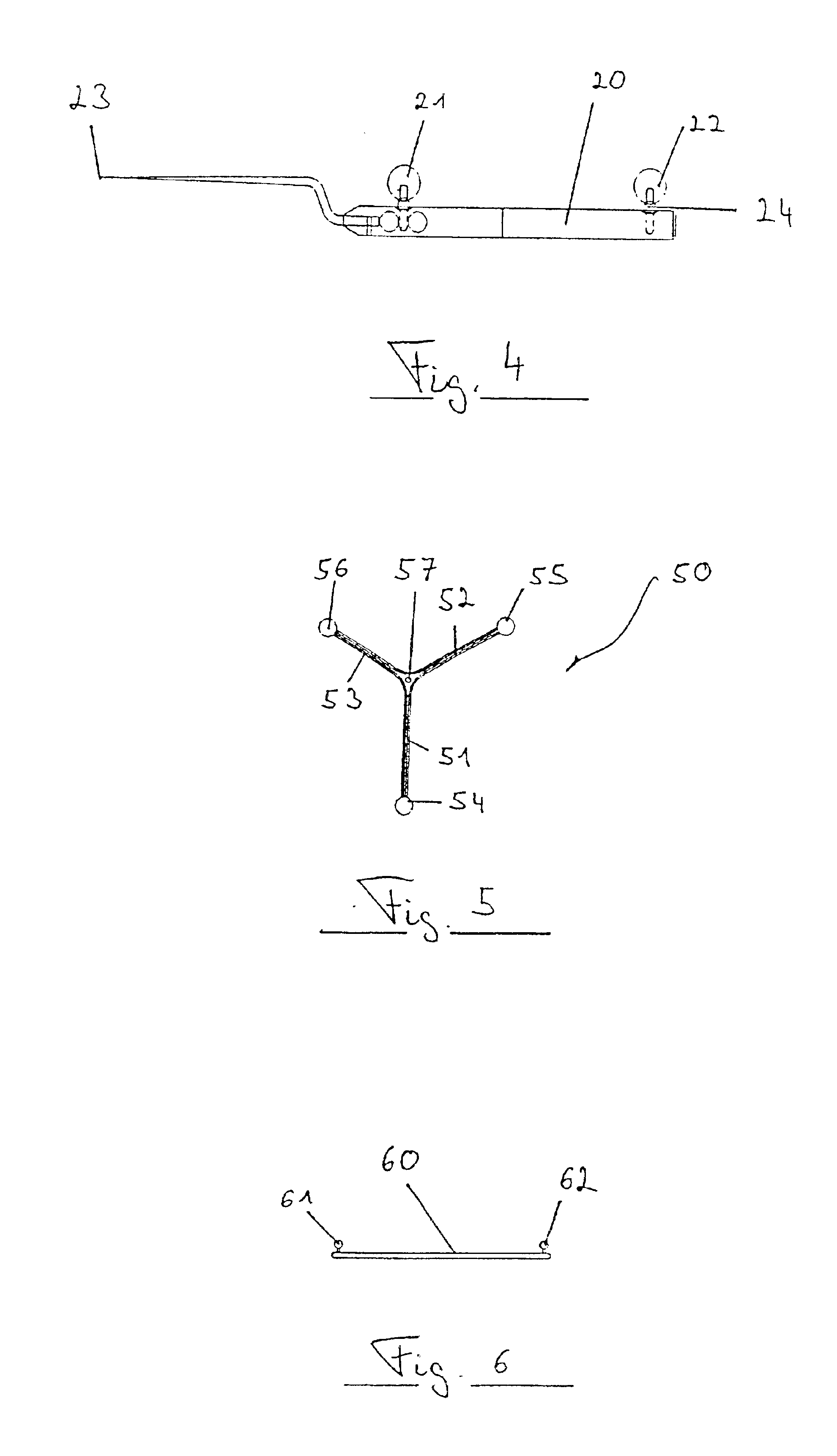

Neuro-navigation system

InactiveUS6859660B2Precise positioningEasy mappingUltrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsGraphicsSurgical microscope

The invention relates to a Neuro-navigation system comprising a reflector referencing system including passive reflectors and a marker system with markers or landmarks wherein the reflectors as well as the markers as regards their shape, size and material selection as well as their arrangement or attachment on the parts of the body to be operatively treated and on the surgical instruments are configured so that mapping their locations is substantially facilitated or is able to take place more accurately positioned by a computer / camera unit having a graphic display terminal as well as the operative treatment with the aid of this unit. Optionally a surgical microscope, an ultrasonic diagnostic system as well as a calibration procedure may be integrated in the Neuro-navigation system in accordance with the invention.

Owner:BRAINLAB

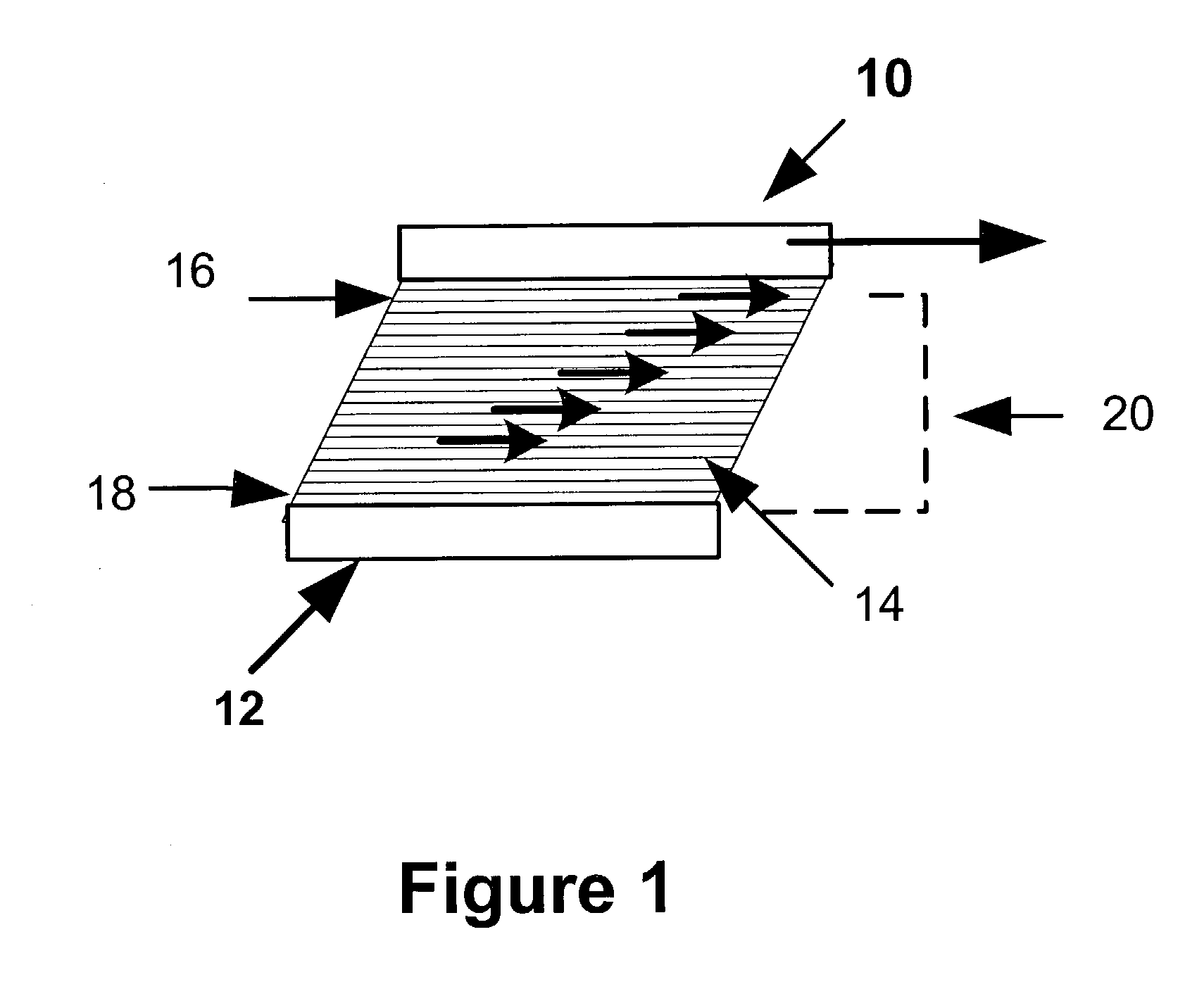

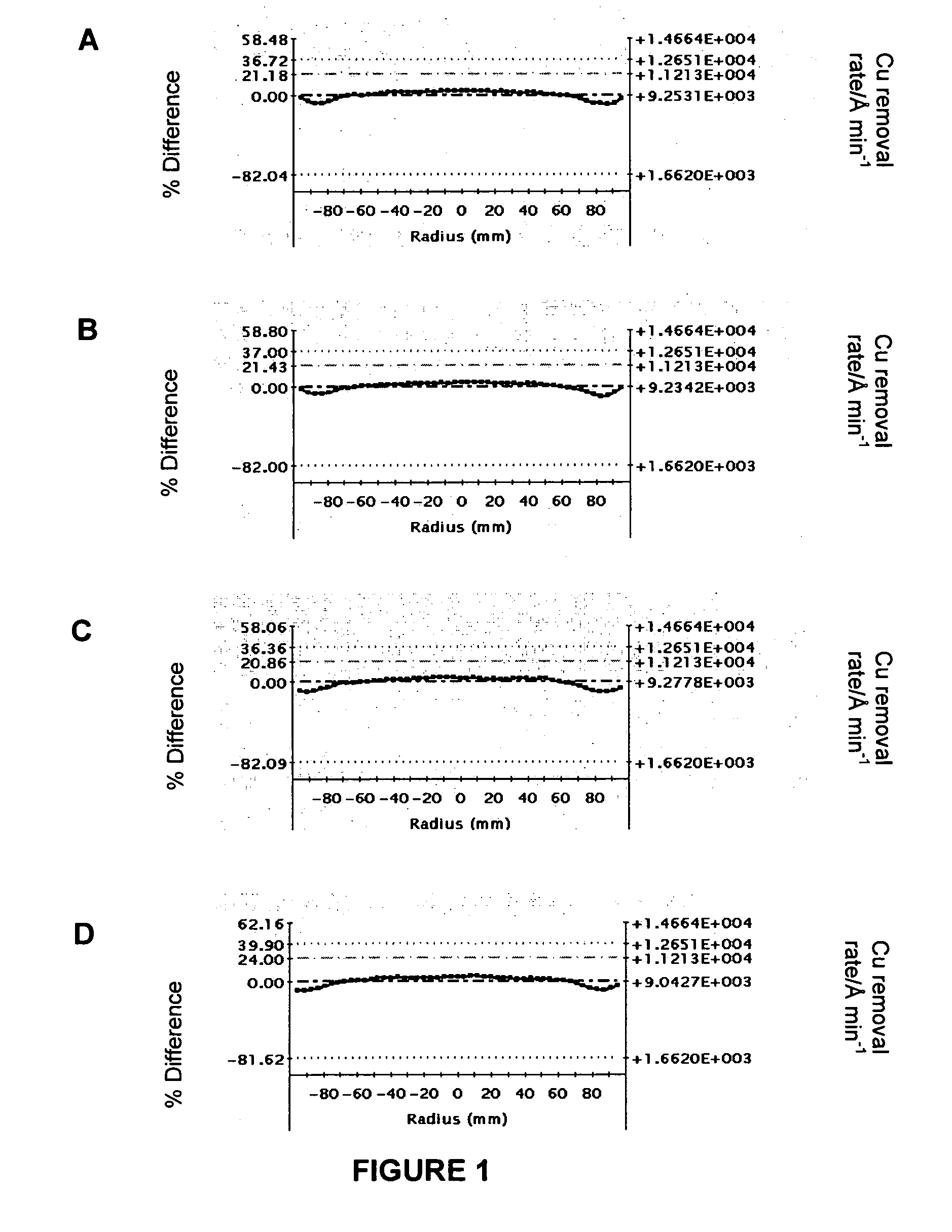

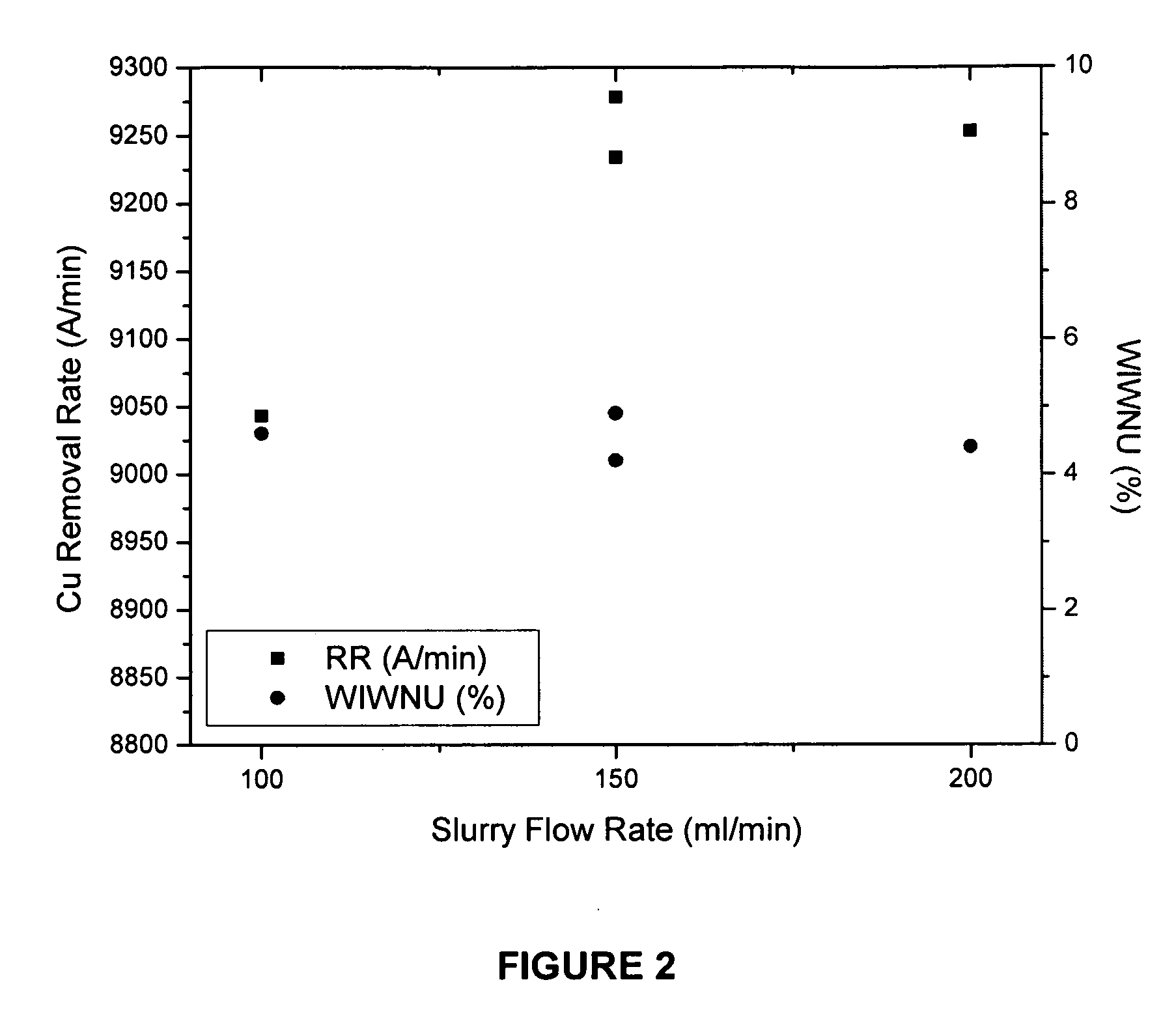

High throughput chemical mechanical polishing composition for metal film planarization

InactiveUS20080254628A1Semiconductor/solid-state device manufacturingLapping machinesMaterial removalHigh flux

A chemical mechanical polishing process including a single copper removal CMP slurry formulation for planarization of a microelectronic device structure preferably having copper deposited thereon. The process includes the bulk removal of a copper layer using a first CMP slurry formulation having oxidizing agent, passivating agent, abrasive and solvent, and the soft polishing and over-polishing of the microelectronic device structure using a formulation including the first CMP slurry formulation and at least one additional additive. The CMP process described herein provides a high copper removal rate, a comparatively low barrier material removal rate, appropriate material selectivity ranges to minimize copper dishing at the onset of barrier material exposure, and good planarization efficiency.

Owner:ADVANCED TECH MATERIALS INC

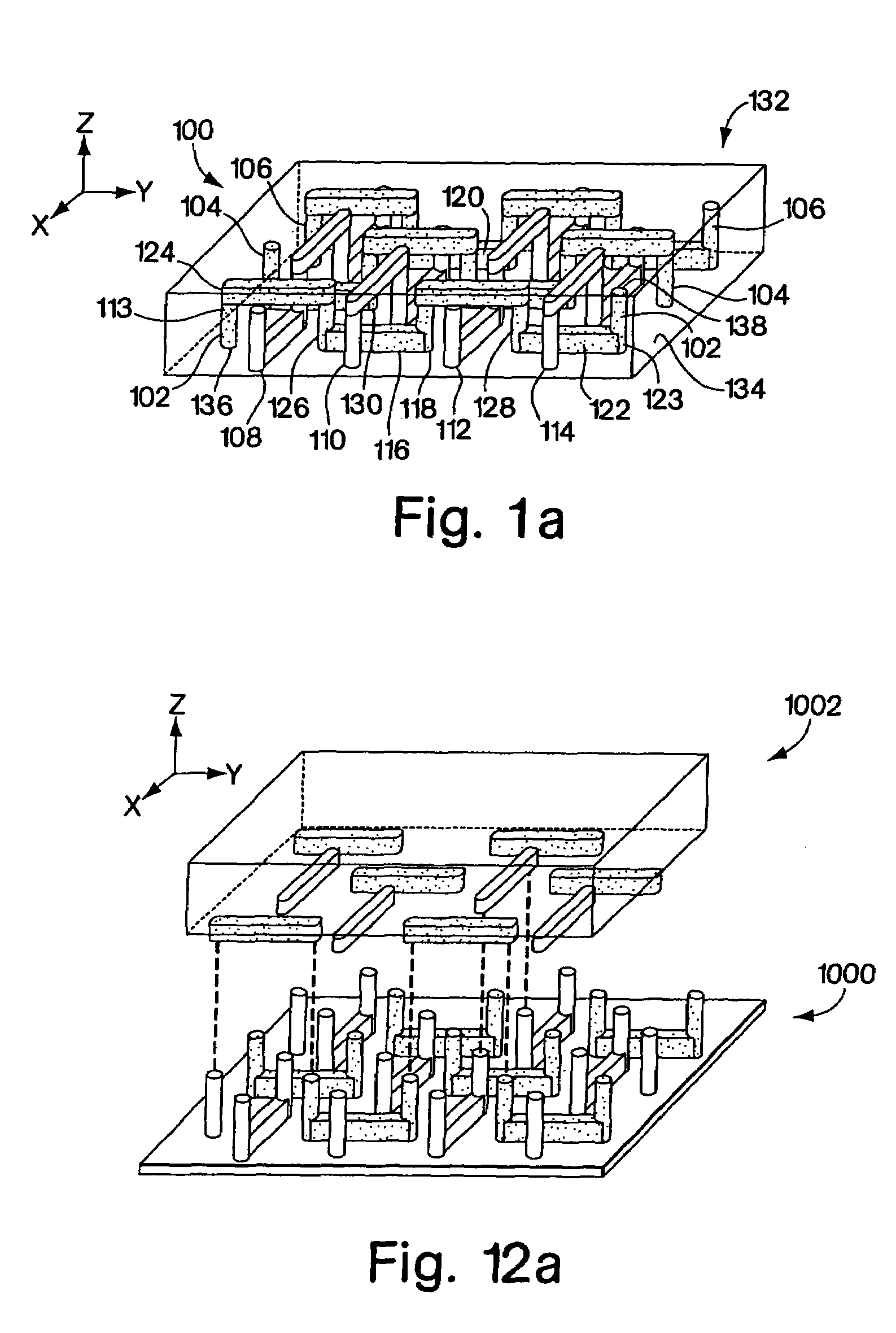

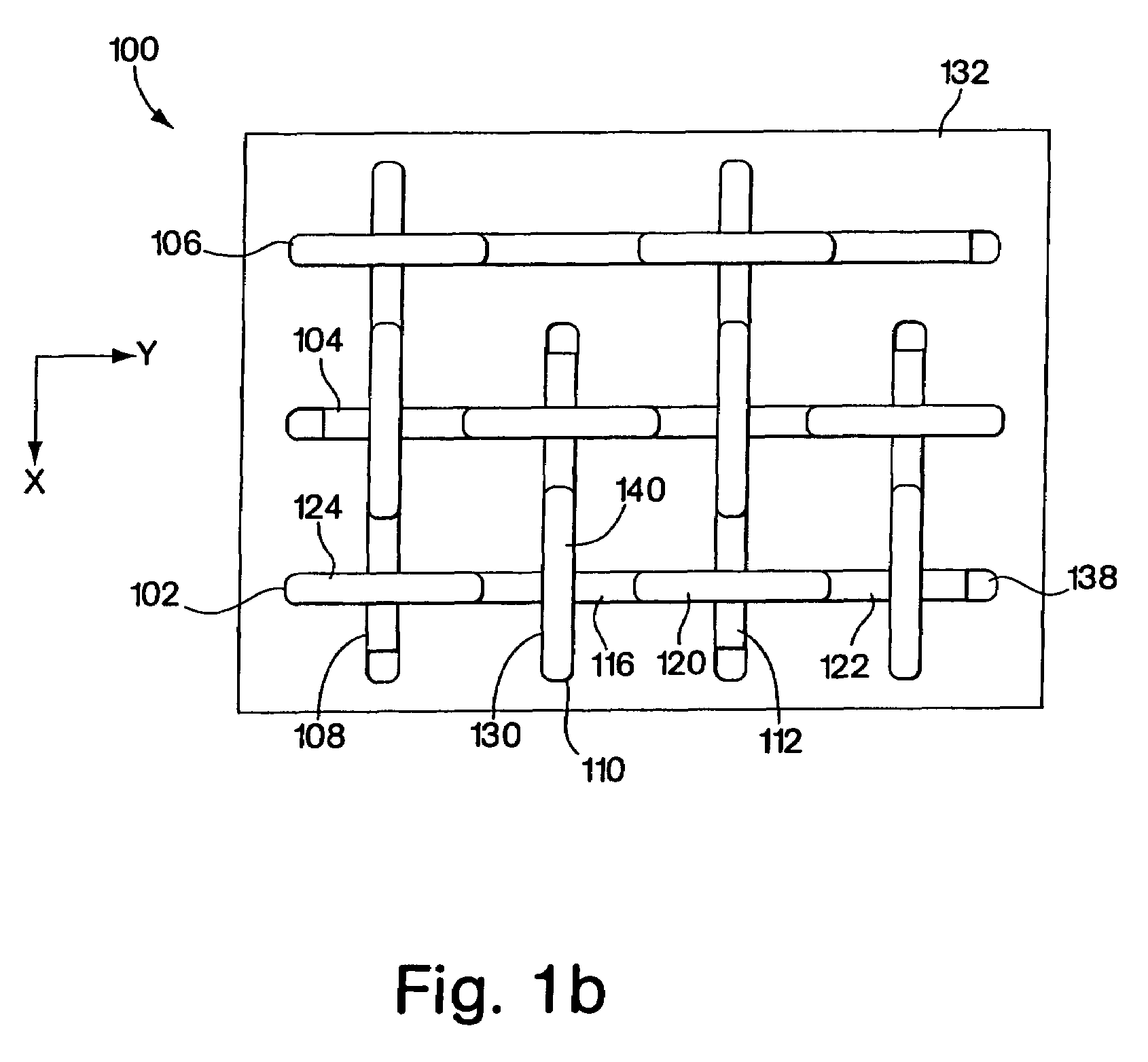

Patterning of surfaces utilizing microfluidic stamps including three-dimensionally arrayed channel networks

InactiveUS7267938B2Conveniently routedEasy stampingImmobilised enzymesFixed microstructural devicesSurface patternChannel network

The present invention describes improved microfluidic systems and procedures for fabricating improved microfluidic systems, which contain one or more levels of microfluidic channels. The methods for fabrication the systems disclosed can provide a convenient route to topologically complex and improved microfluidic systems. The microfluidic systems can include three-dimensionally arrayed networks of fluid flow paths therein including channels that cross over or under other channels of the network without physical intersection at the points of cross over. The microfluidic networks can be fabricated via replica molding processes utilizing mold masters including surfaces having topological features formed by photolithography. The present invention also involves microfluidic systems and methods for fabricating complex patterns of materials, such as biological materials and cells, on surfaces utilizing the microfluidic systems. Specifically, the invention provides microfluidic surface patterning systems and methods for fabricating complex, discontinuous patterns on surfaces that can incorporate or deposit multiple materials onto the surfaces. The present invention also provides improved microfluidic stamps or applicators for microcontact surface patterning, which are able to pattern onto a surface arbitrary two-dimensional patterns, and which are able to pattern multiple substances onto a surface without the need for multiple steps of registration or stamping during patterning and without the need to selectively “ink” different regions of the stamp with different materials.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

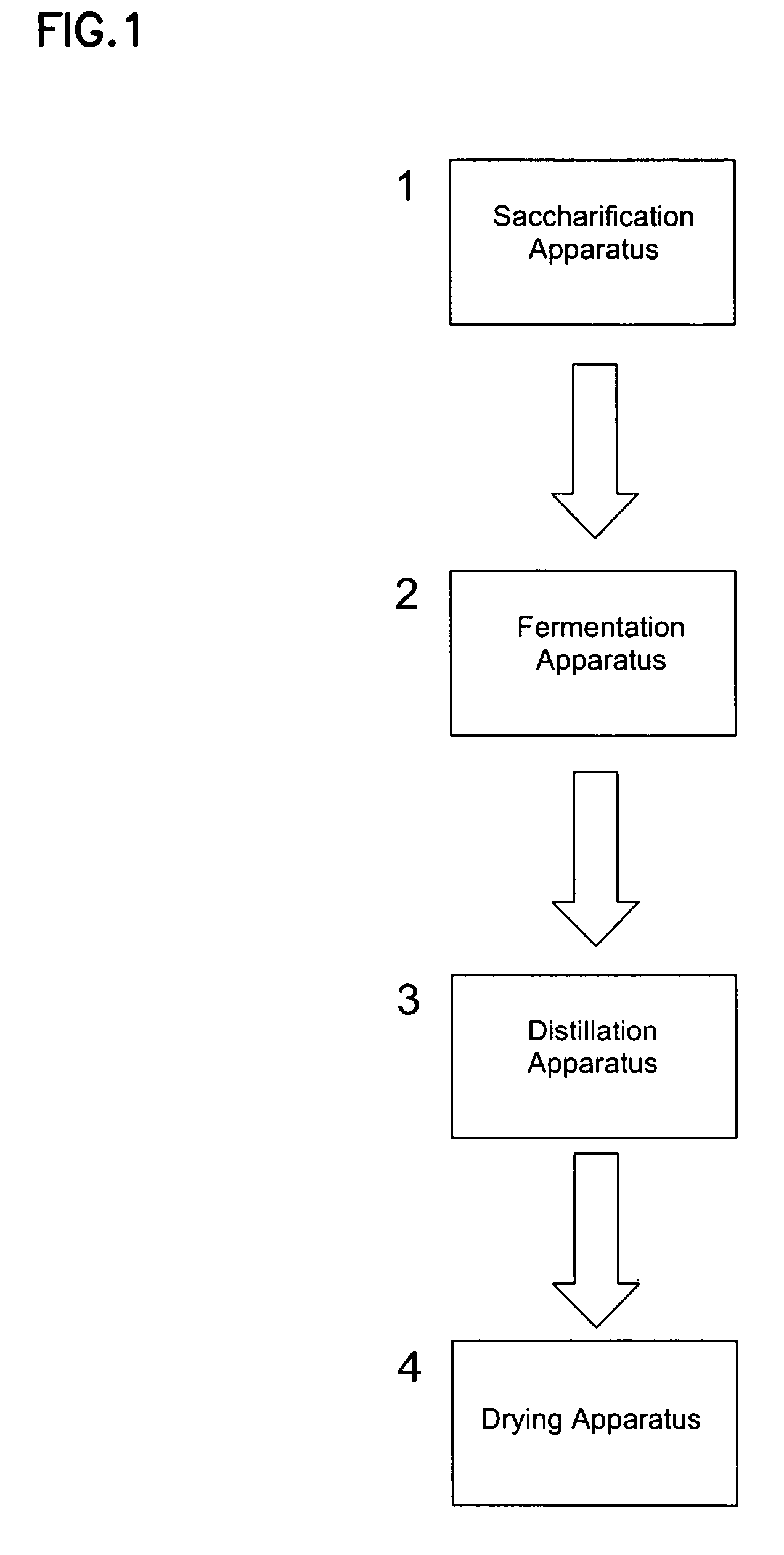

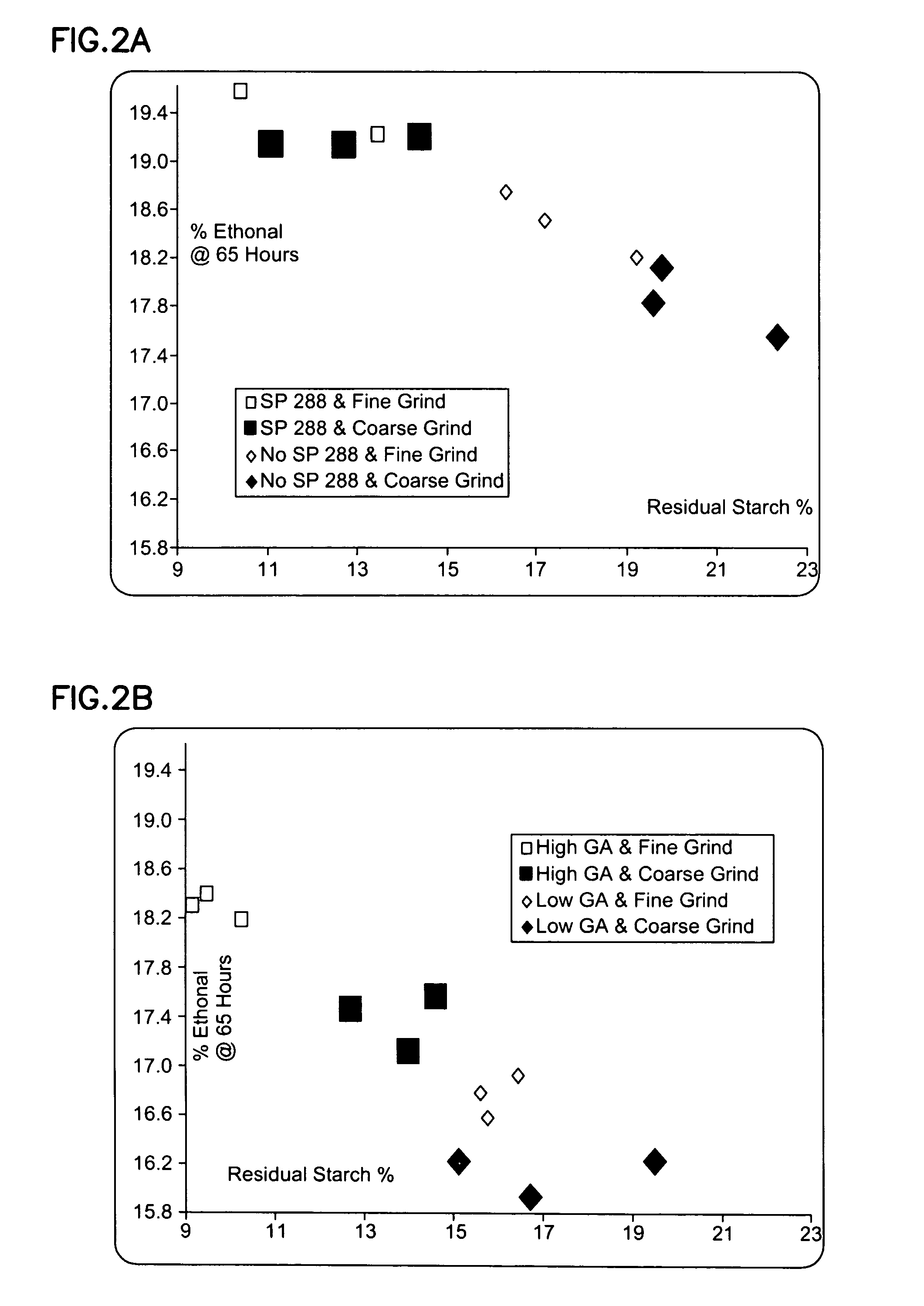

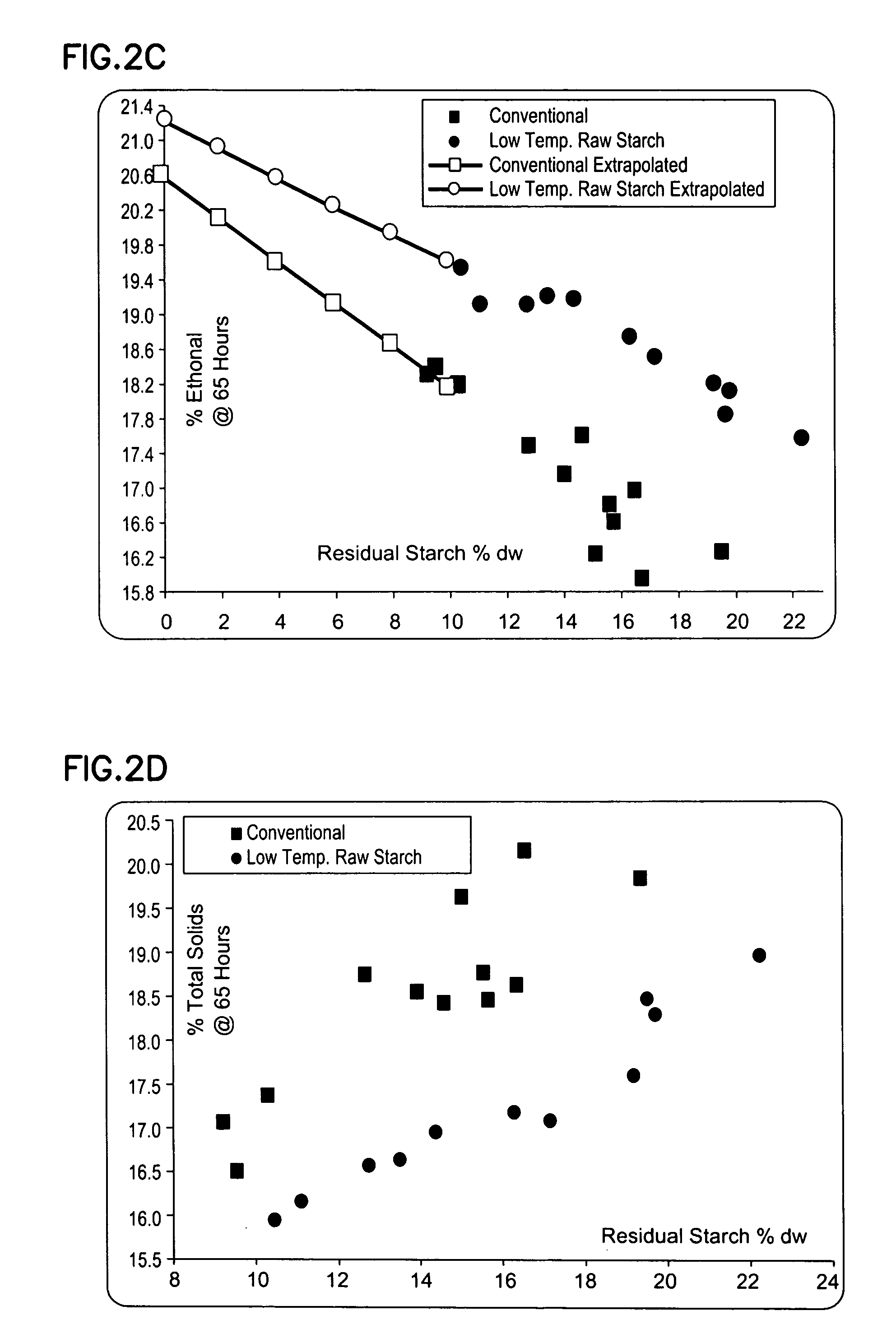

Methods and systems for producing ethanol using raw starch and selecting plant material

ActiveUS20070178567A1Improve the level ofDough treatmentWort preparationHigh alcohol beerStarch production

The present invention relates to methods for producing high levels of alcohol during fermentation of plant material, and to the high alcohol beer produced. The method can include selecting plant material. Selecting can include excluding plant material that has been exposed to high temperatures or that has had high moisture content.

Owner:POET RES INC

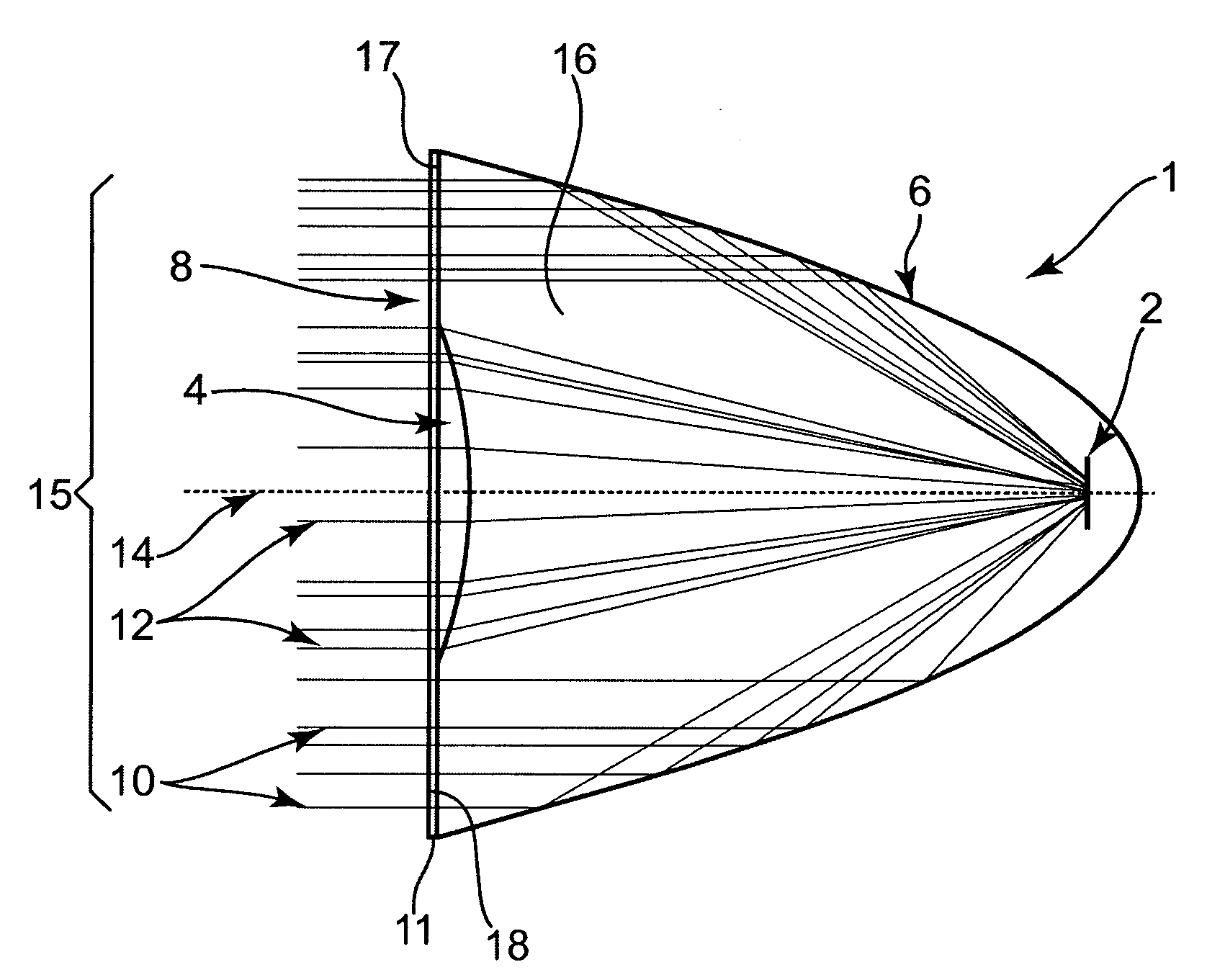

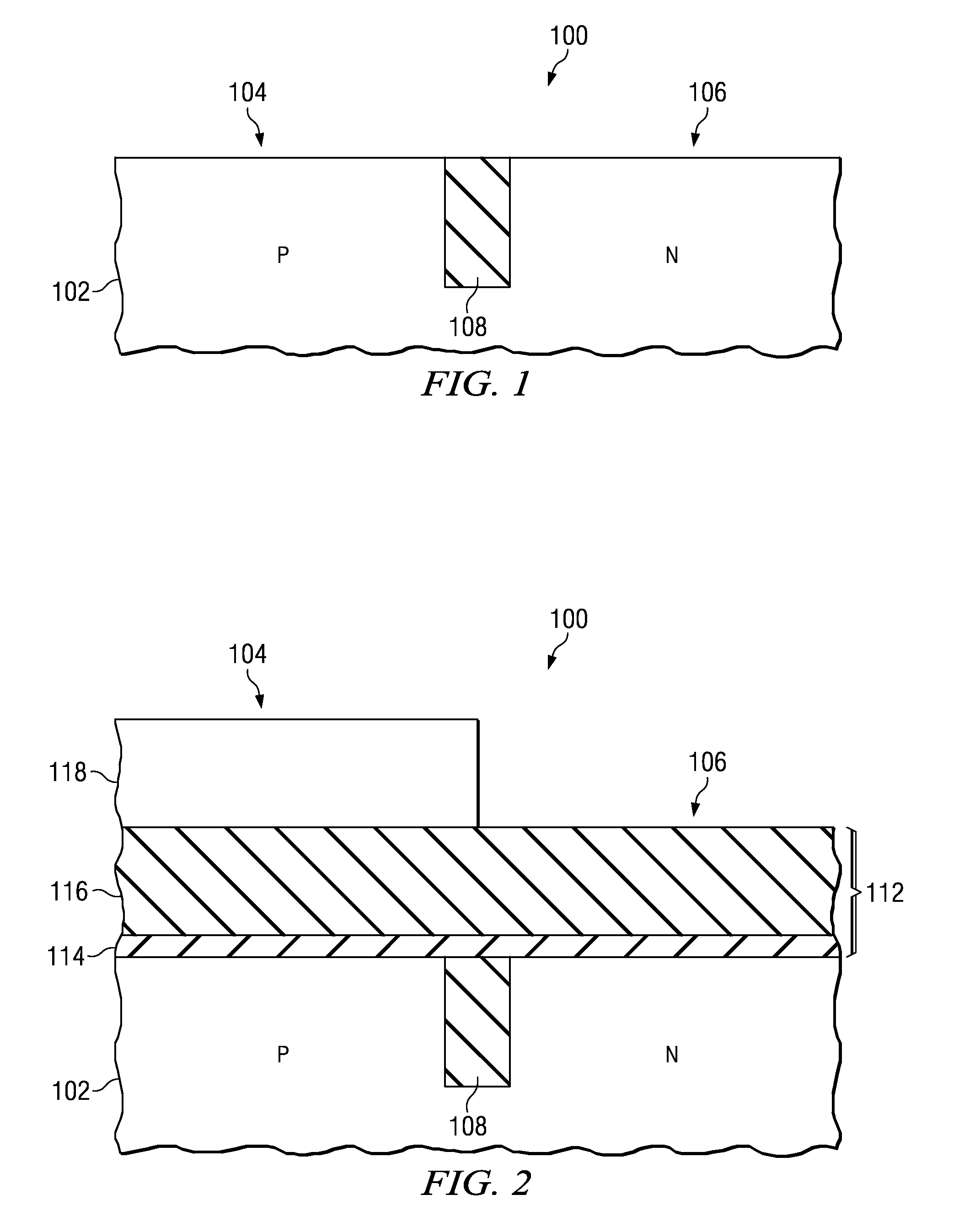

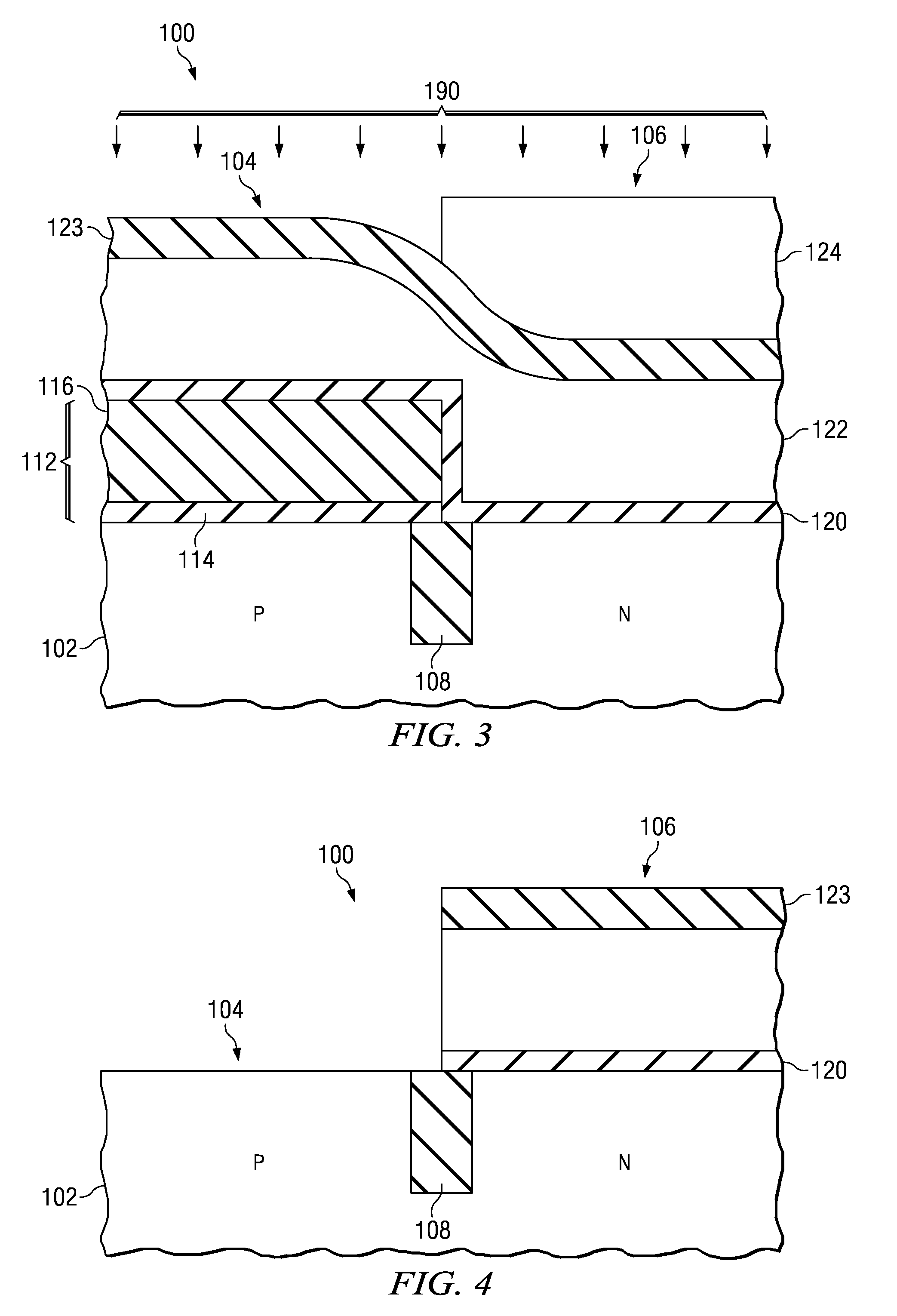

Substrate for and a process in connection with the product of structures

InactiveUS20040005444A1Easy to disassembleFacilitate NILSemi-permeable membranesFixed microstructural devicesResistMetallurgy

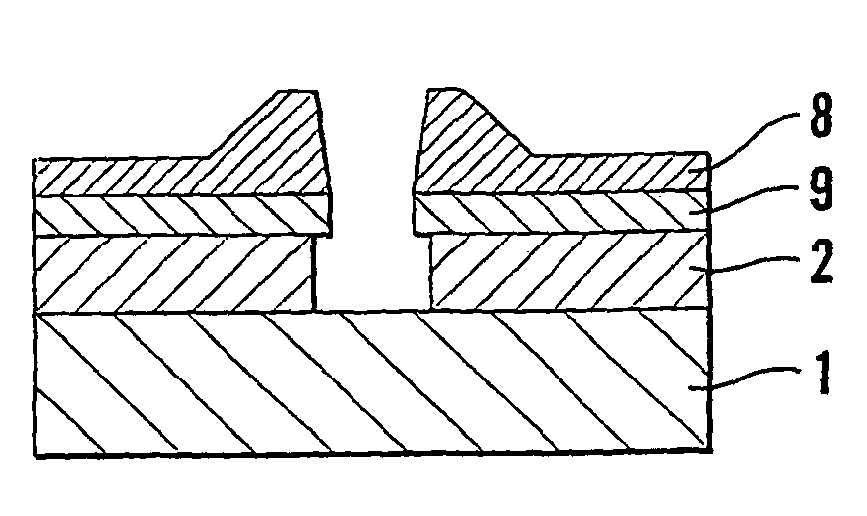

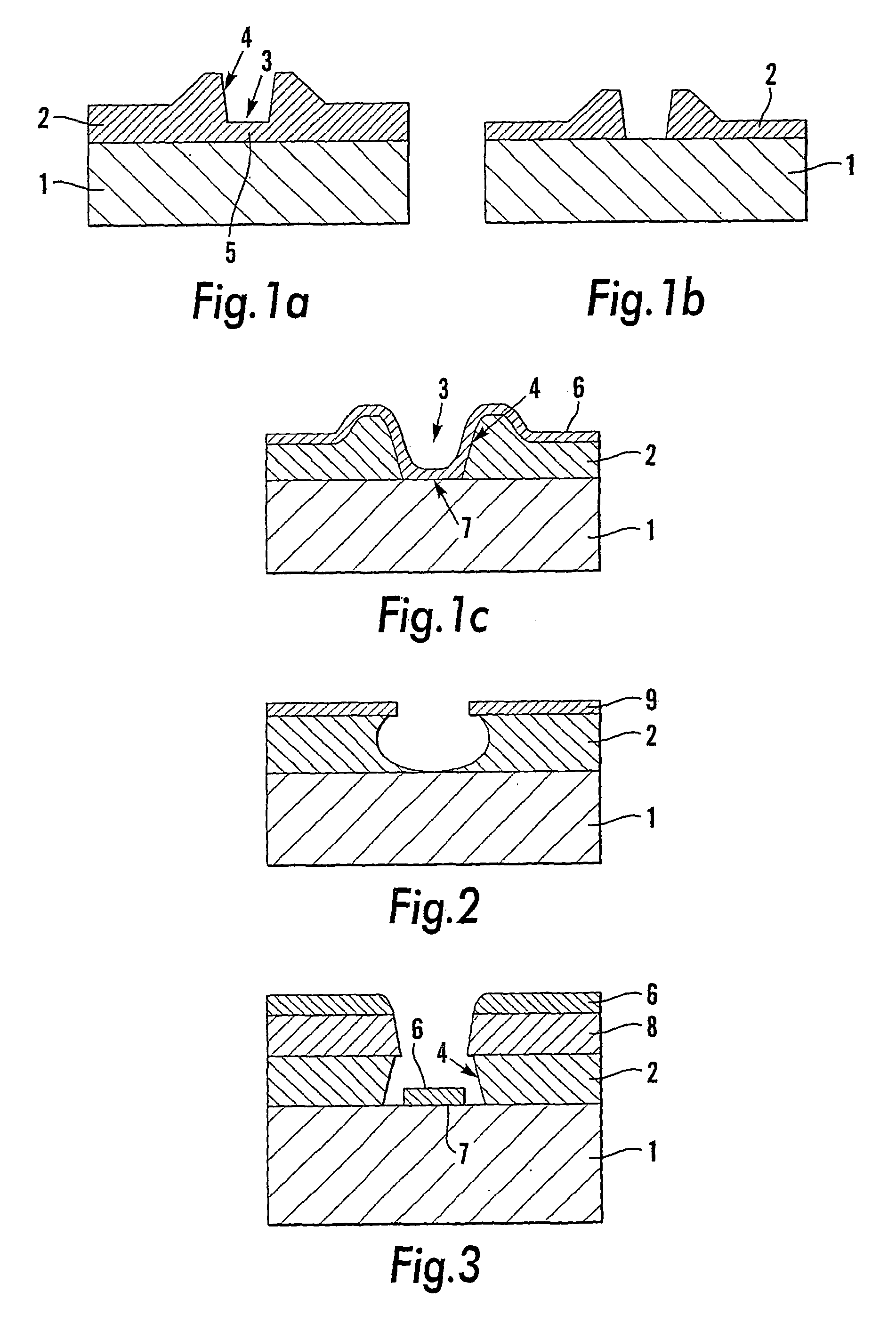

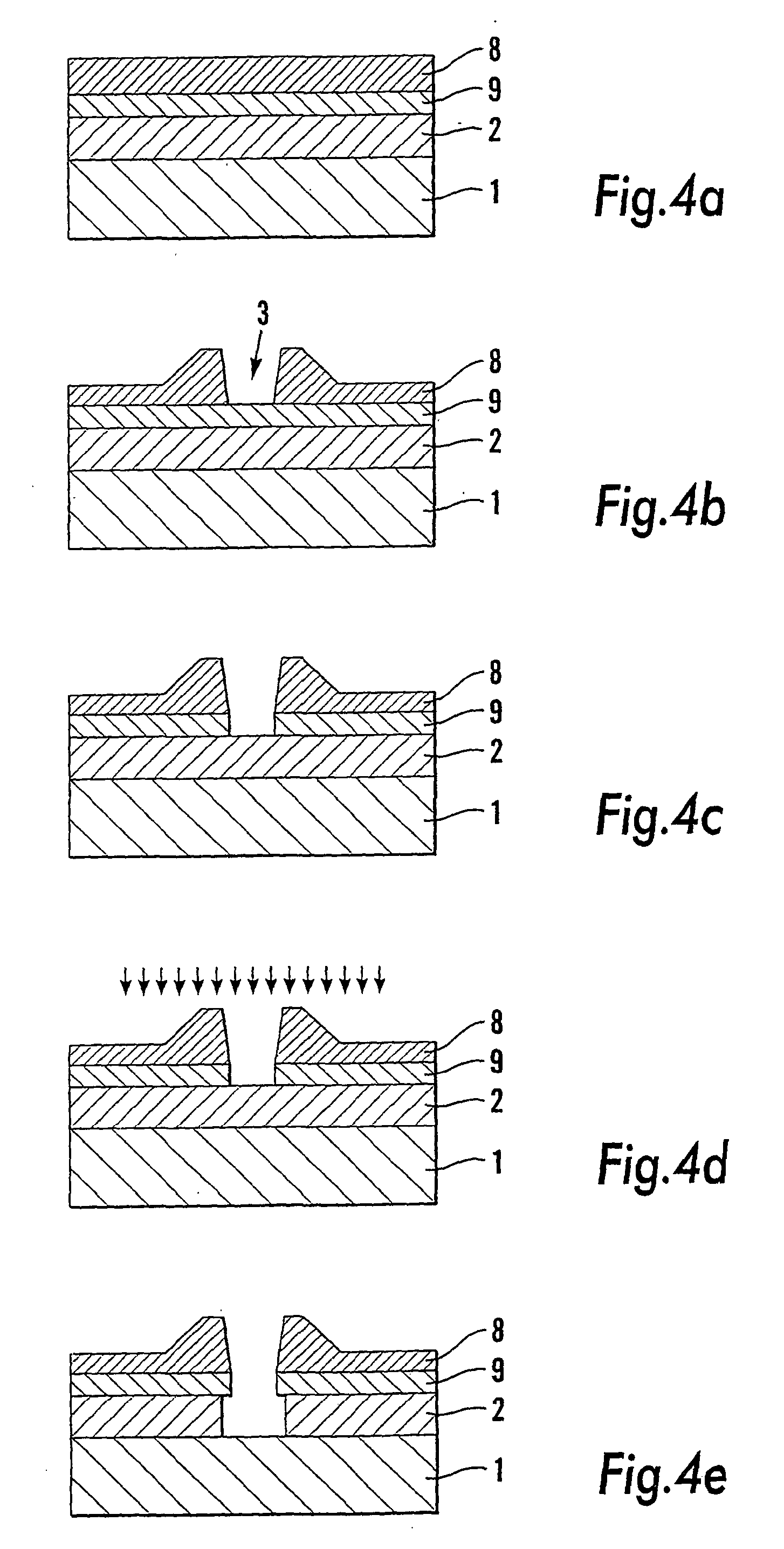

The invention relates to a substrate (1) comprising at least a first (2) and a second (8) coating layer on one surface of the substrate, for nanoimprint lithography, said first coating layer (2) consisting of a positive resist and said second (8) coating layer consisting of a negative resist. The invention also relates to a process in connection with nanoimprint lithography on the substrate (1), a pattern (3) of nanometre size being impressed in a first stage into the second coating layer (8) by means of a template (610), following which the first coating layer (2), in a second stage, is exposed to a chiefly isotropic developing method on surfaces thereof that have been exposed in connection with said first stage, a method for developing and material for said first and second coating layers being selected so that the first coating layer (2) is developed more quickly than the second coating layer (8), so that an undercut profile is obtained in the coating layers.

Owner:OBDUCAT AB SE

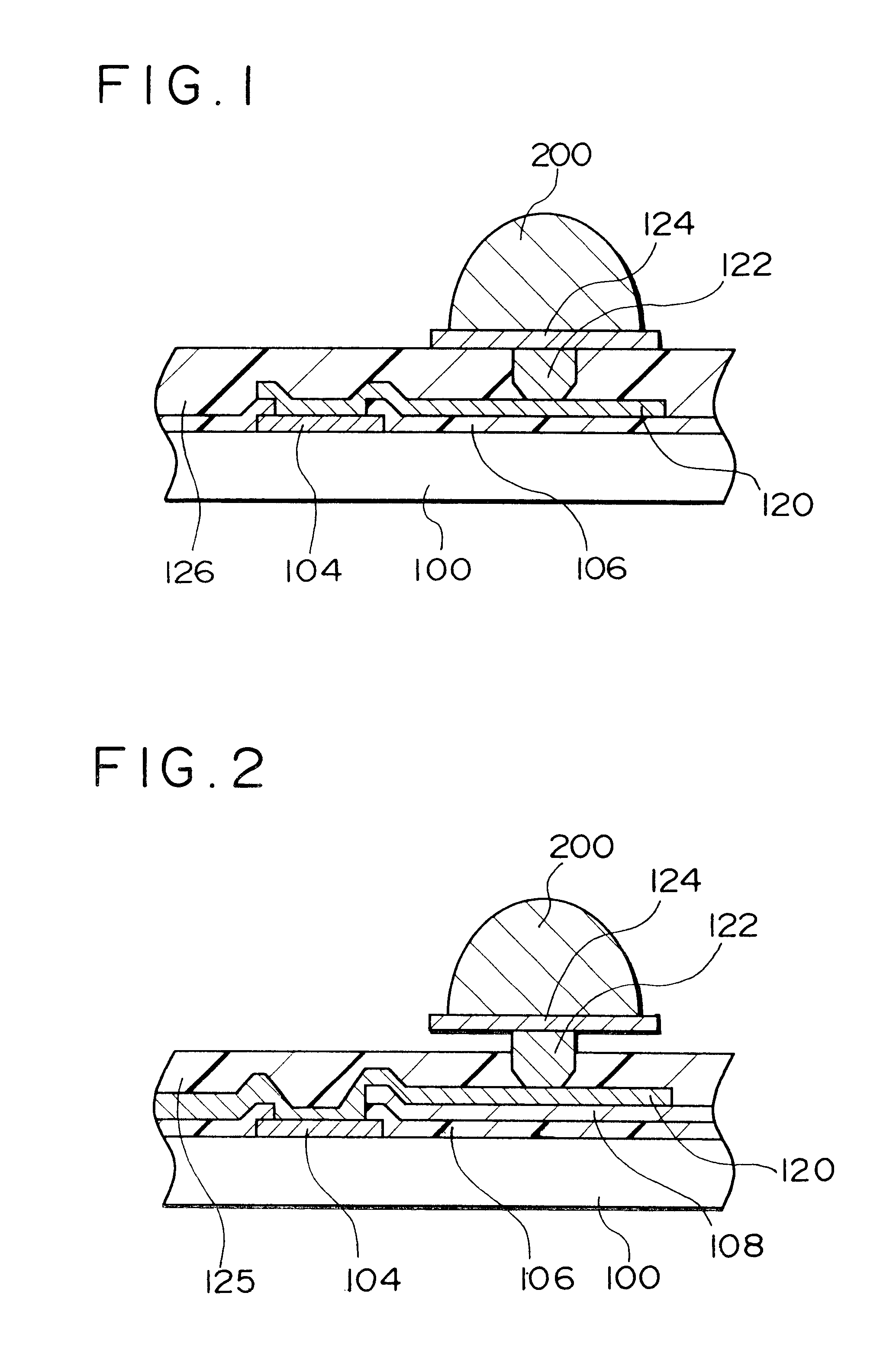

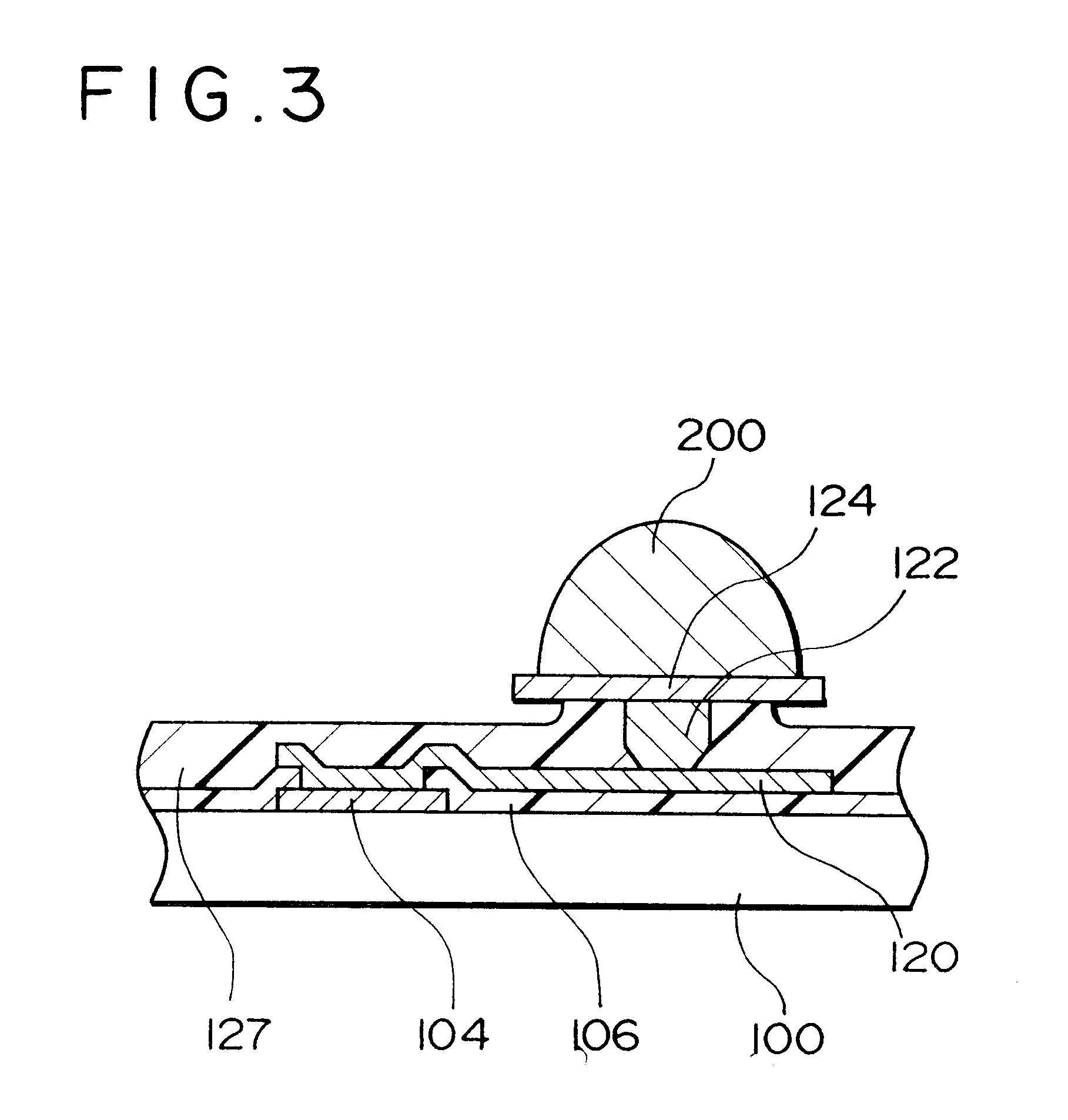

Semiconductor device and method of manufacturing the same, circuit board and electronic instrument

InactiveUS6181010B1Easy to transformEffective absorptionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipElectronic instrument

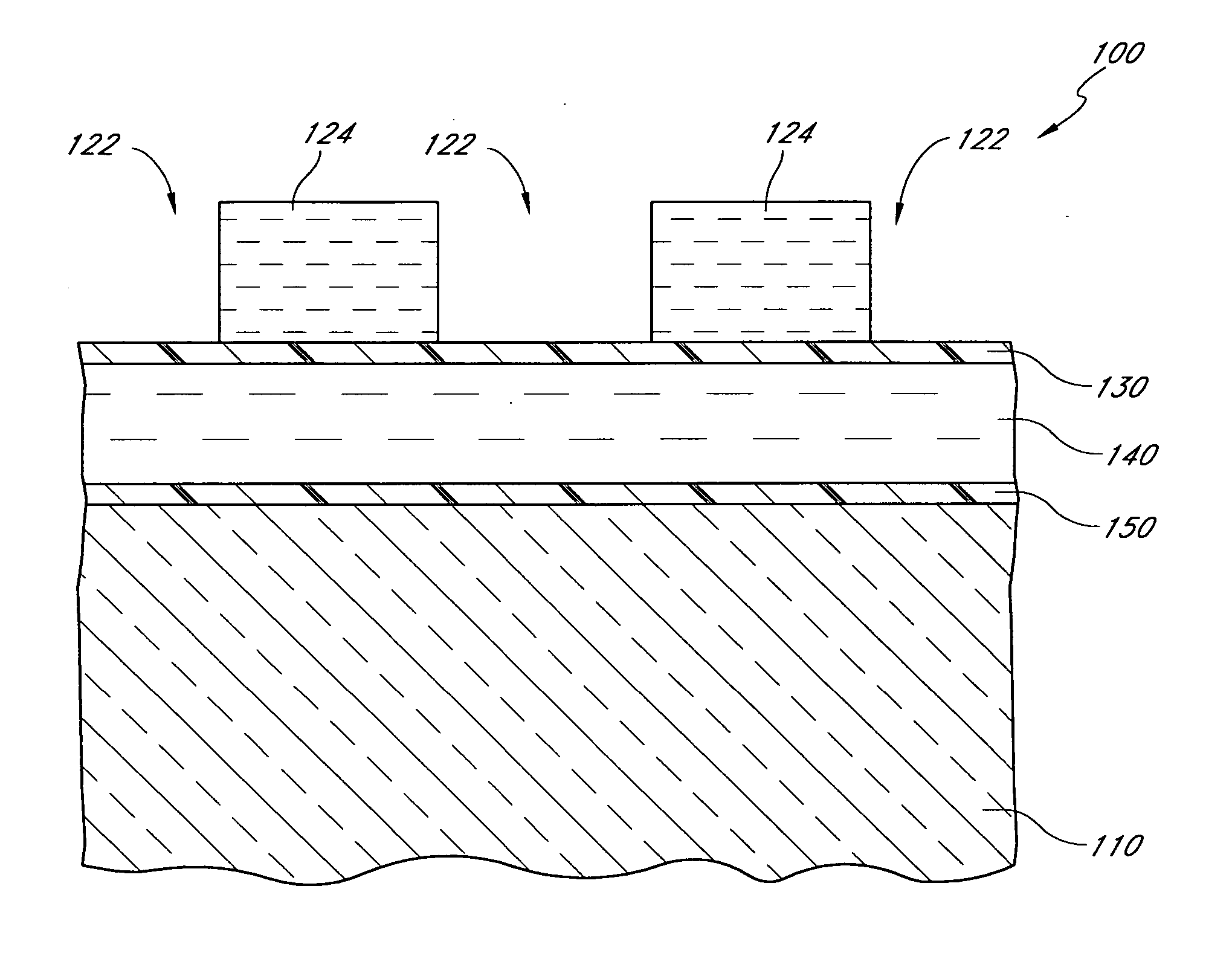

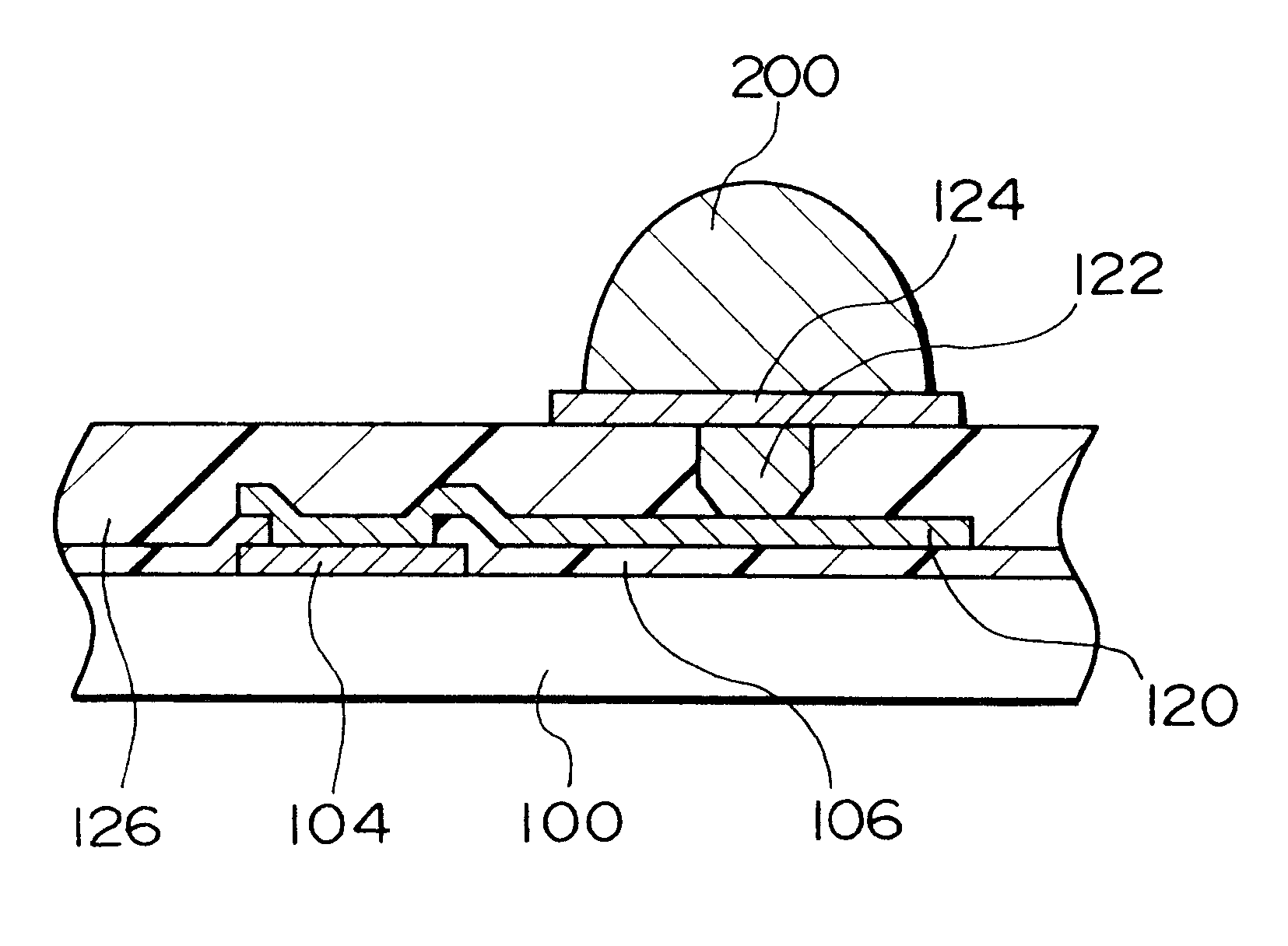

A semiconductor device and method of manufacturing the same, a circuit board and an electronic instrument are such that without substrate material selection or additional steps after connection, connection reliability can be assured, while direct connection to a substrate is possible, further allowing an electronic instrument to be made more compact and lightweight. The semiconductor device comprises a semiconductor chip (100) having electrodes (104), an interconnect layer (120) connected to the electrodes (104), a conducting layer (122) provided on the interconnect layer (120) avoiding the area of the electrodes (104), an underlying metal layer (124) having a size larger than the peripheral outline of the conducting layer (122) provided on the conducting layer (122) and easier to be deformed than the conducting layer (122), bumps (200) provided on the underlying metal layer (124), and a resin layer (126) provided on the periphery of the conducting layer (122).

Owner:SEIKO EPSON CORP

Marine engineering large thick steel plate submerged arc welding process method in low-temperature environment

InactiveCN101879645AIncrease productivityReduce labor intensityArc welding apparatusWelding/cutting media/materialsEngineeringWeld seam

The invention belongs to the field of welding, in particular to a process method applicable to marine engineering large thick steel plate submerged arc welding in low-temperature environment, which comprises a welding method, welding material selection, a welding order, a welding process and the selection and control of various welding process parameters. The method renders with carbon dioxide gas protection welding, and fills and faces through an automatic submerged arc welding; stops welding when the welding reaches more than two thirds of the thickness of a large groove during the welding process, clears chips on the back side and completes the welding of the other side; finally completes the welding of the first side; strictly controls all relevant process parameters of the welding during the welding process, and solves the problems of poorer anti-crack toughness of welding seams and heat affected zones caused by too high cooling speed of the welding seams and too high temperature; can ensure good anti-crack toughness of a welding seam connector without heat treatment after welding; and can meet the requirements of welding of an E36 plate with the thickness of 35 to 77mm under the working environment at the temperature of above -30DEG C, simplifies the production process, shortens the production cycle and reduces the cost.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Elastomeric CMOS based micro electromechanical varactor

InactiveUS20060003482A1Increase capacitance densityIncreased side wall areaCapacitor with electrode distance variationMultiple capacitorsElastomerElectrical polarity

A micro electro-mechanical system (MEMS) variable capacitor is described, wherein movable comb electrodes of opposing polarity are fabricated simultaneously on the same substrate and are independently actuated. The electrodes are formed in an interdigitated fashion to maximize capacitance. The MEMS variable capacitor includes CMOS manufacturing steps in combination with elastomeric material selectively used in areas under greatest stress to ensure that the varactor will not fail as a result of stresses that may result in the separation of dielectric material from the conductive elements. The combination of a CMOS process with the conducting elastomeric material between vias increases the overall sidewall area, which provides increased capacitance density.

Owner:IBM CORP

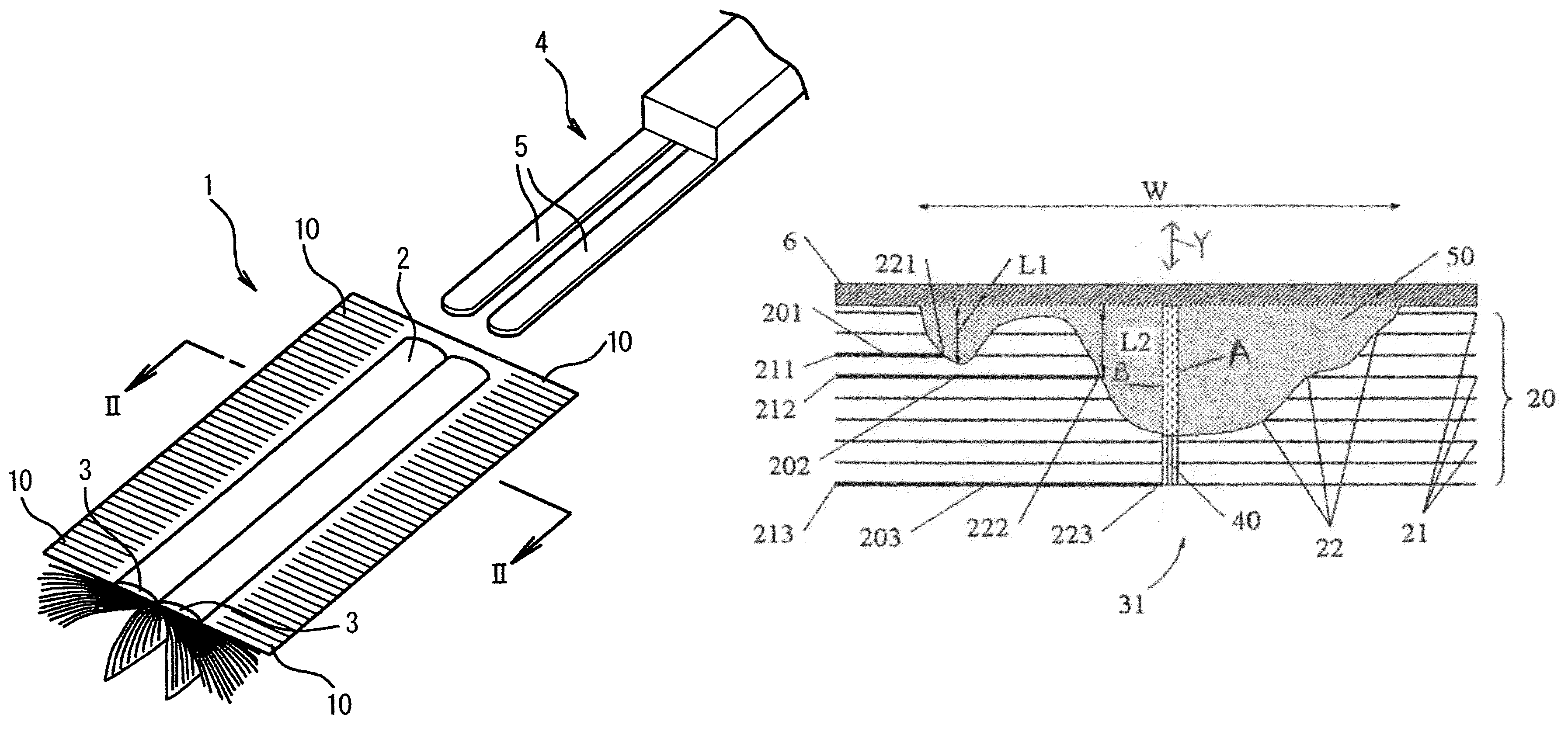

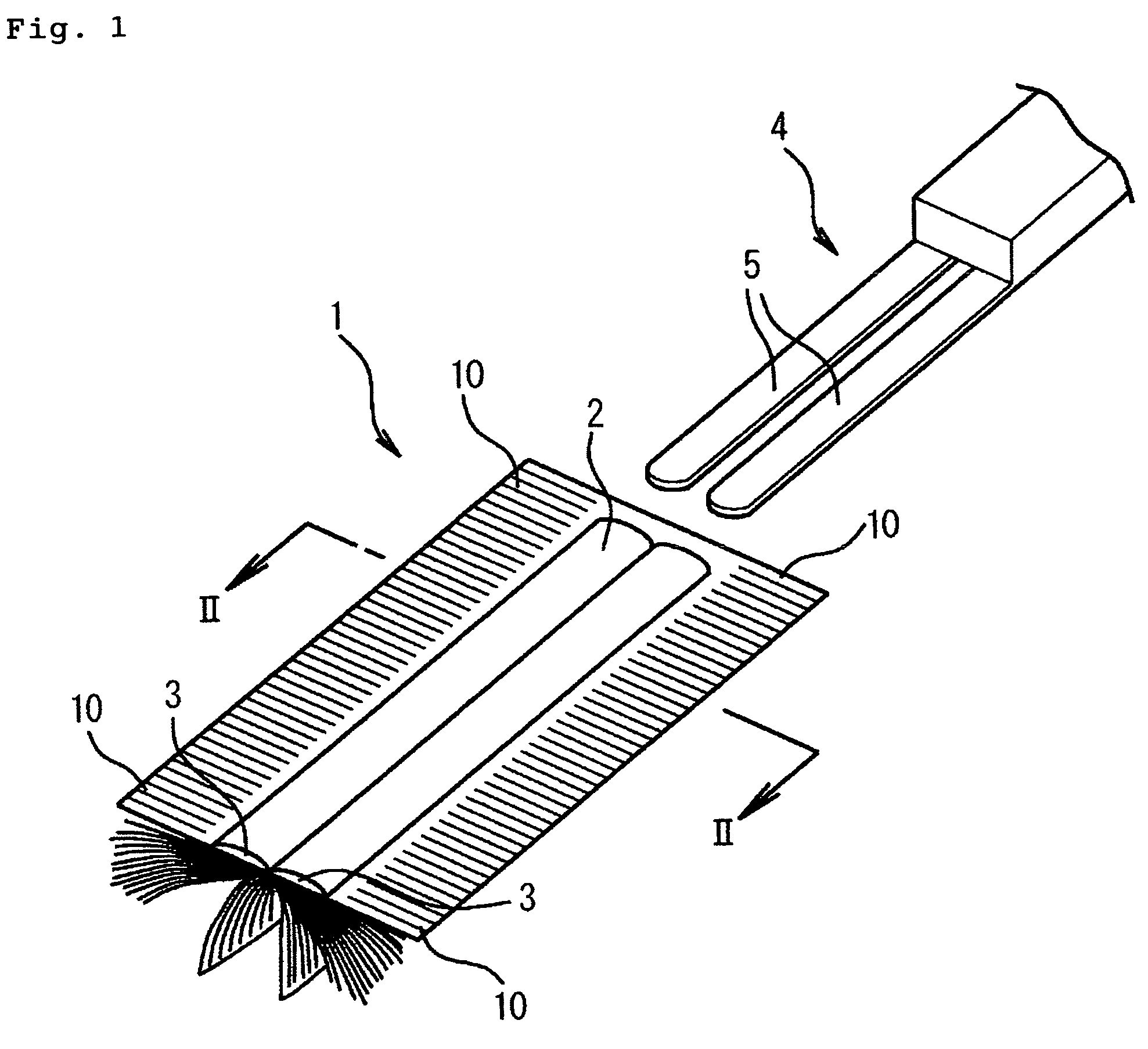

Cleaning device and process for producing the same

InactiveUS8146197B2Long operating timeLow costBoard cleaning devicesCarpet cleanersFiber bundleAdhesive

Owner:YAMADA KIKUO

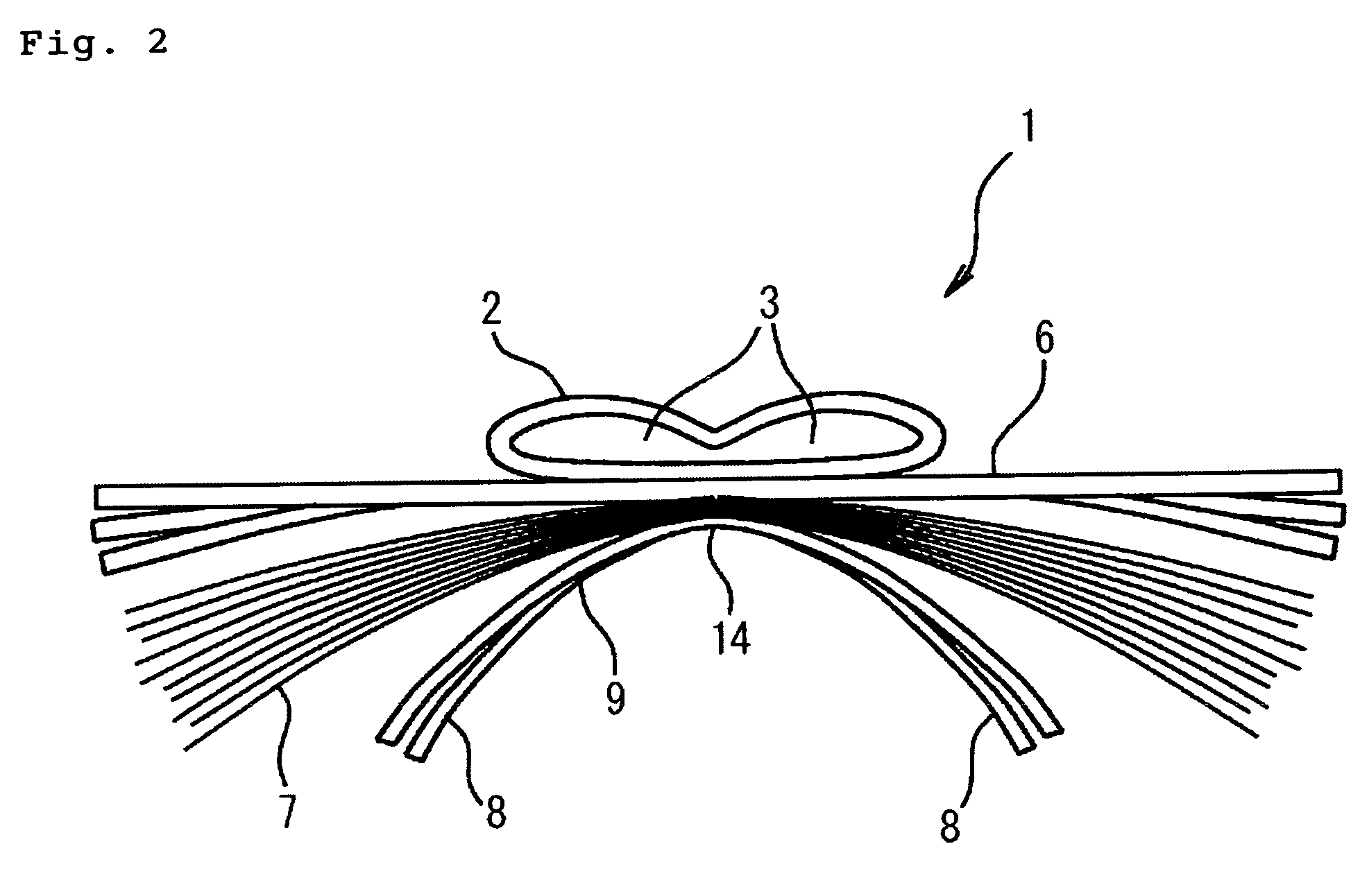

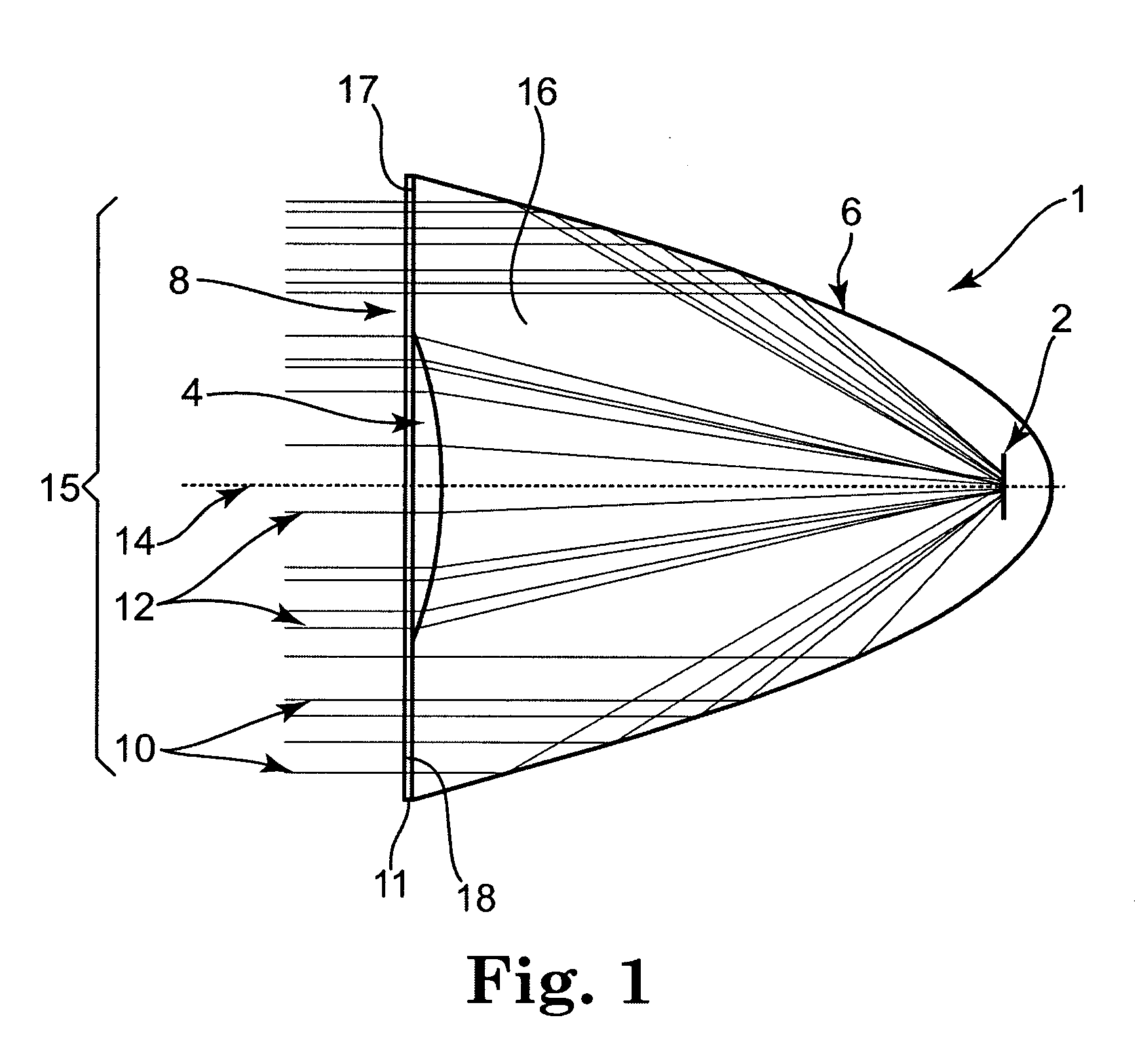

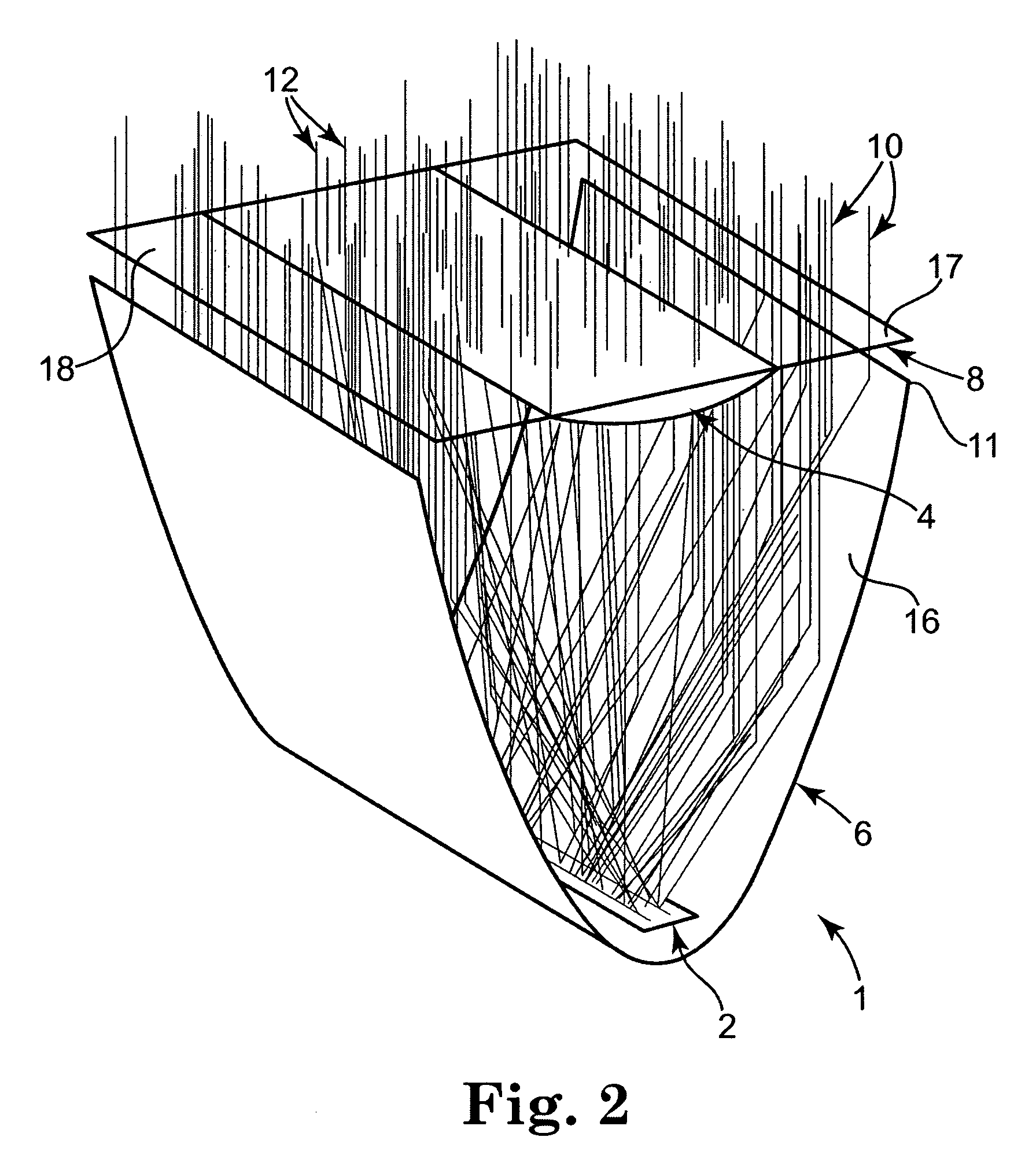

Photovoltaic receiver for solar concentrator applications

InactiveUS20090000662A1Impact performanceMaintaining dielectricFinal product manufactureLaminationDielectricThermal energy

The present invention provides solar concentrators incorporating photovoltaic receiver assemblies with improved thermal dissipation, dielectric, encapsulation, and cell / wiring protection characteristics. The concentrators are particularly useful for photovoltaic power systems such as rooftop mounted systems. The present invention teaches that the geometry of the substrate used to support receiver assemblies can have a dramatic impact upon thermal / dielectric performance. In particular, the present invention teaches how contours incorporated into such substrates can improve thermal performance (i.e., dissipation of thermal energy from photovoltaic cells through the substrate) while still maintaining dielectric and encapsulation objectives. In the past, dielectric and encapsulation objectives have been obtained at the expense of such thermal dissipation. Also, material choice and form also impacts thermal, dielectric, and encapsulation performance. In preferred embodiments, components of receiver assemblies are provided in sheet form and laminated together in the course of making the receiver assemblies.

Owner:SOLIANT ENERGY INC

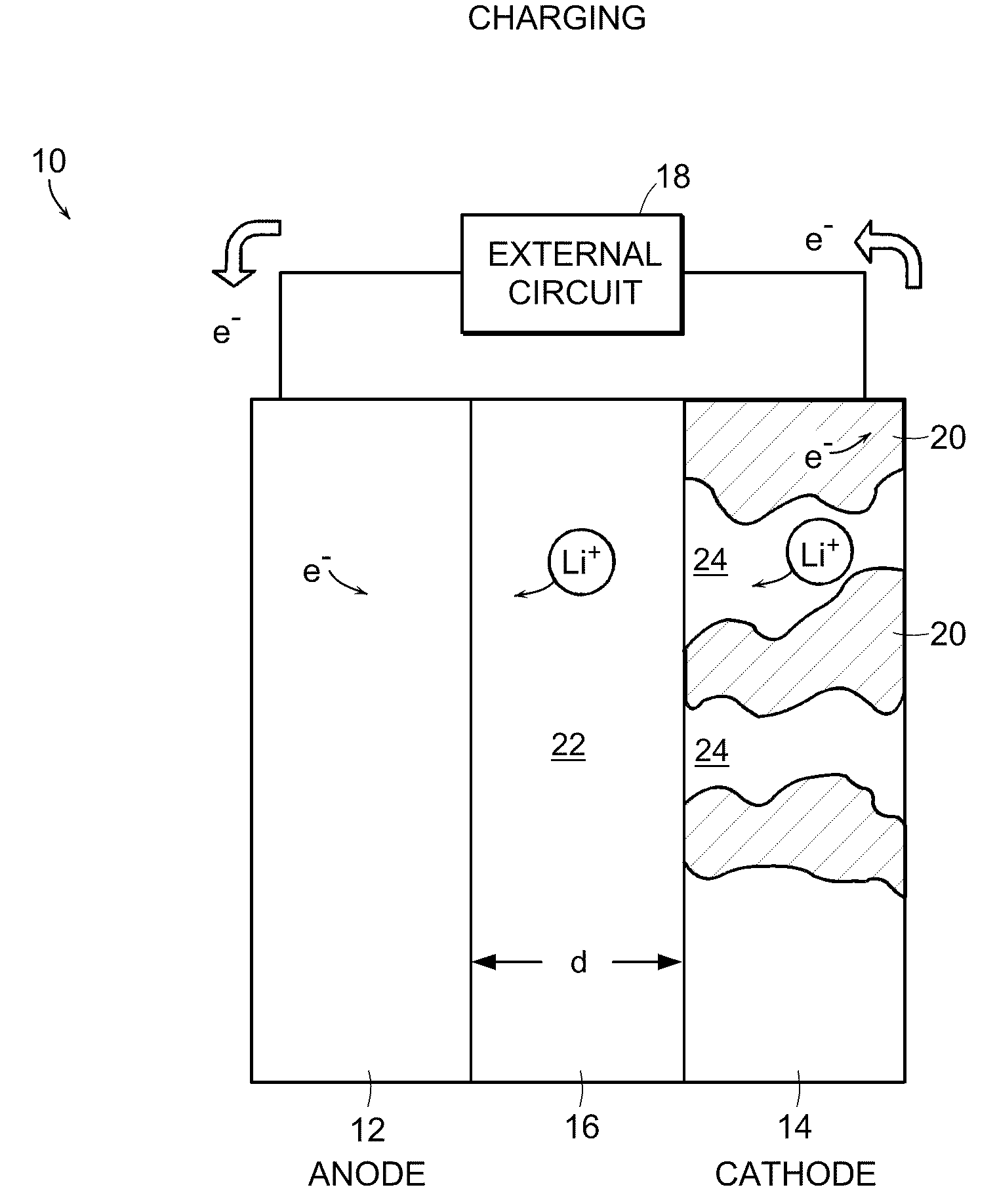

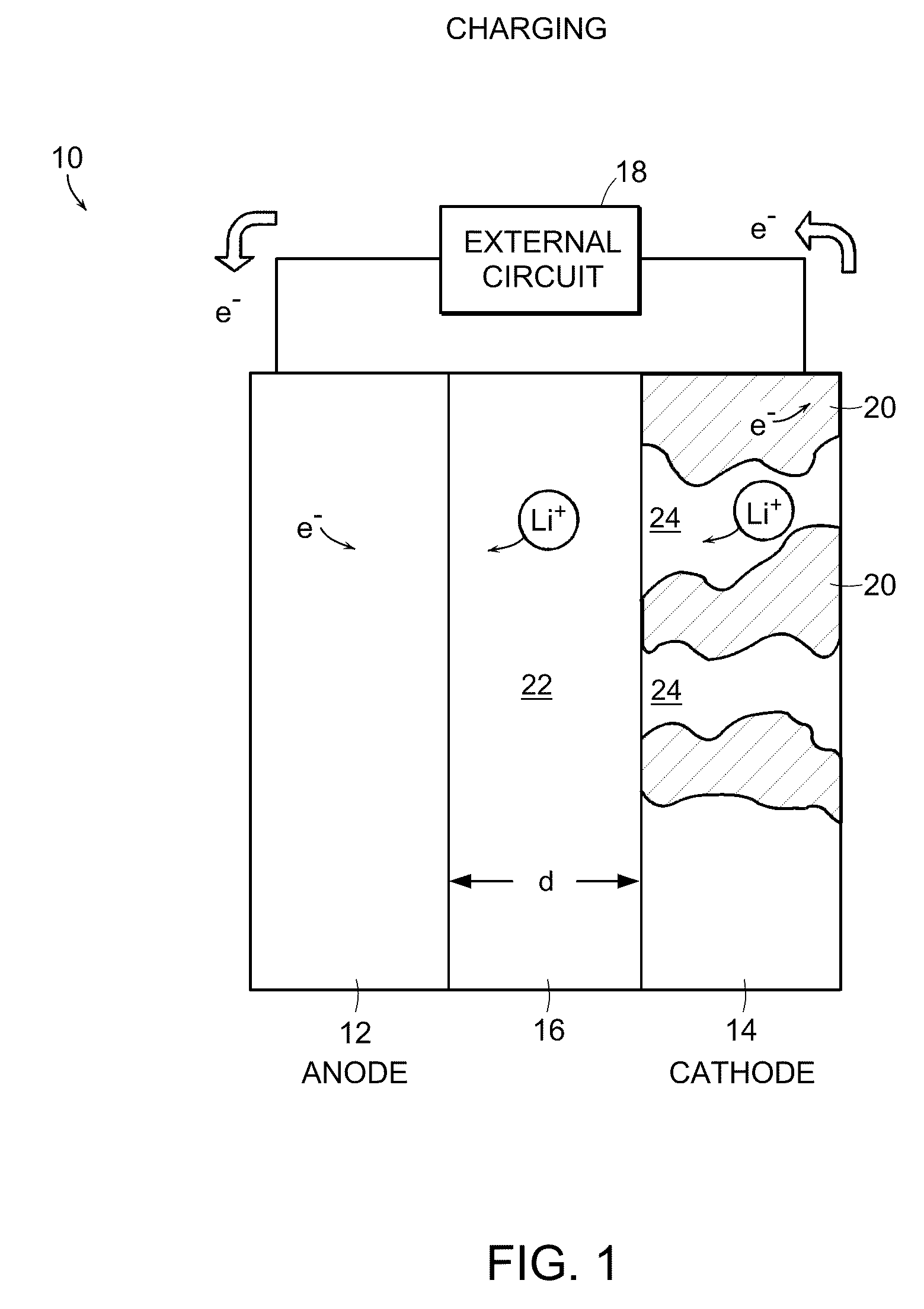

Battery structures, self-organizing structures and related methods

InactiveUS20100003603A1Maximizes electrode interface areaDistance minimizationFinal product manufactureElectrode carriers/collectorsElectricityEngineering

An energy storage device includes a first electrode comprising a first material and a second electrode comprising a second material, at least a portion of the first and second materials forming an interpenetrating network when dispersed in an electrolyte, the electrolyte, the first material and the second material are selected so that the first and second materials exert a repelling force on each other when combined. An electrochemical device, includes a first electrode in electrical communication with a first current collector; a second electrode in electrical communication with a second current collector; and an ionically conductive medium in ionic contact with said first and second electrodes, wherein at least a portion of the first and second electrodes form an interpenetrating network and wherein at least one of the first and second electrodes comprises an electrode structure providing two or more pathways to its current collector.

Owner:A123 SYSTEMS LLC

Transistor Device and Method of Manufacture Thereof

InactiveUS20080233694A1Depletion effect is reduced and avoidedEasy to adjustTransistorSolid-state devicesDopantCMOS

A CMOS device includes high k gate dielectric materials. A PMOS device includes a gate that is implanted with an n-type dopant. The NMOS device may be doped with either an n-type or a p-type dopant. The work function of the CMOS device is set by the material selection of the gate dielectric materials. A polysilicon depletion effect is reduced or avoided.

Owner:INFINEON TECH AG

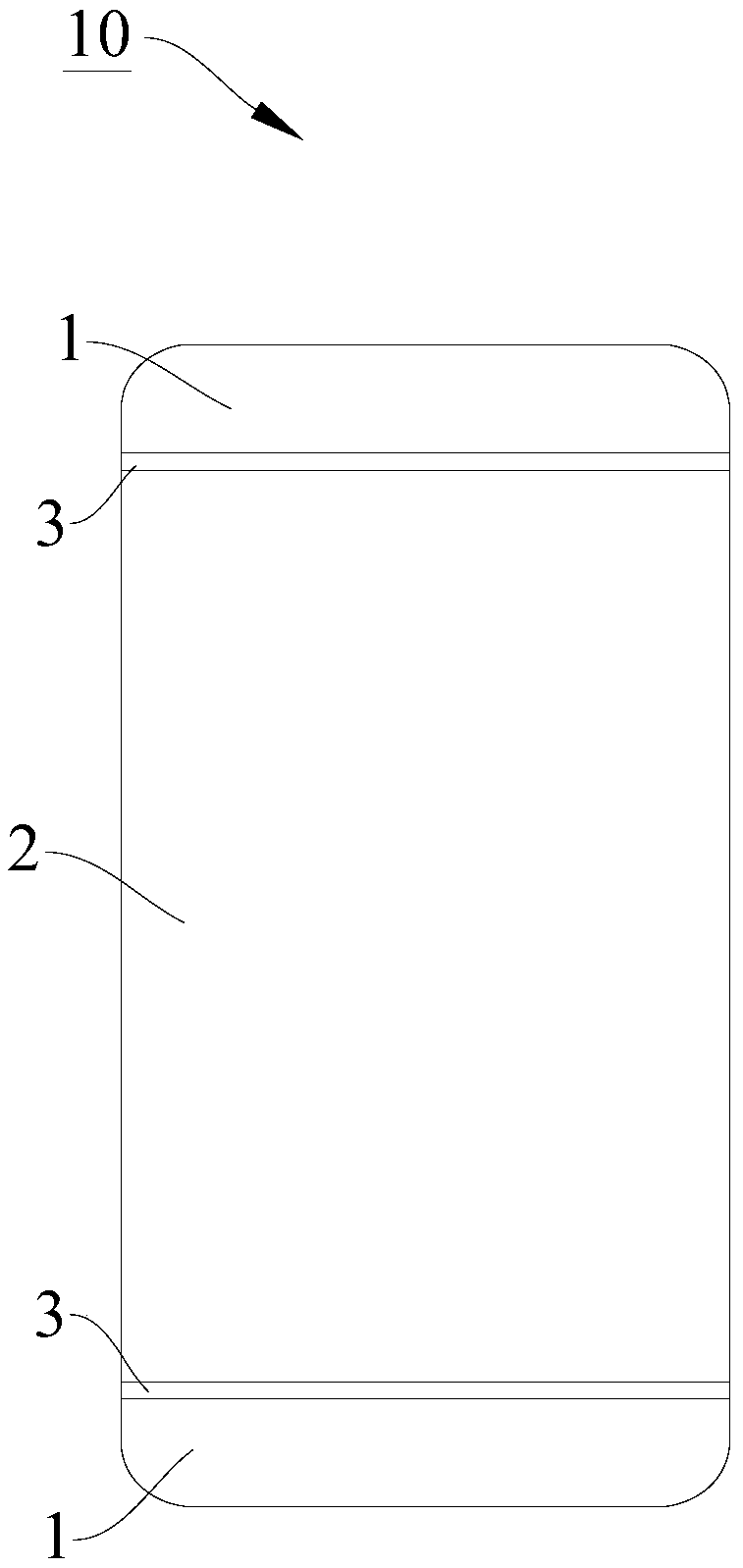

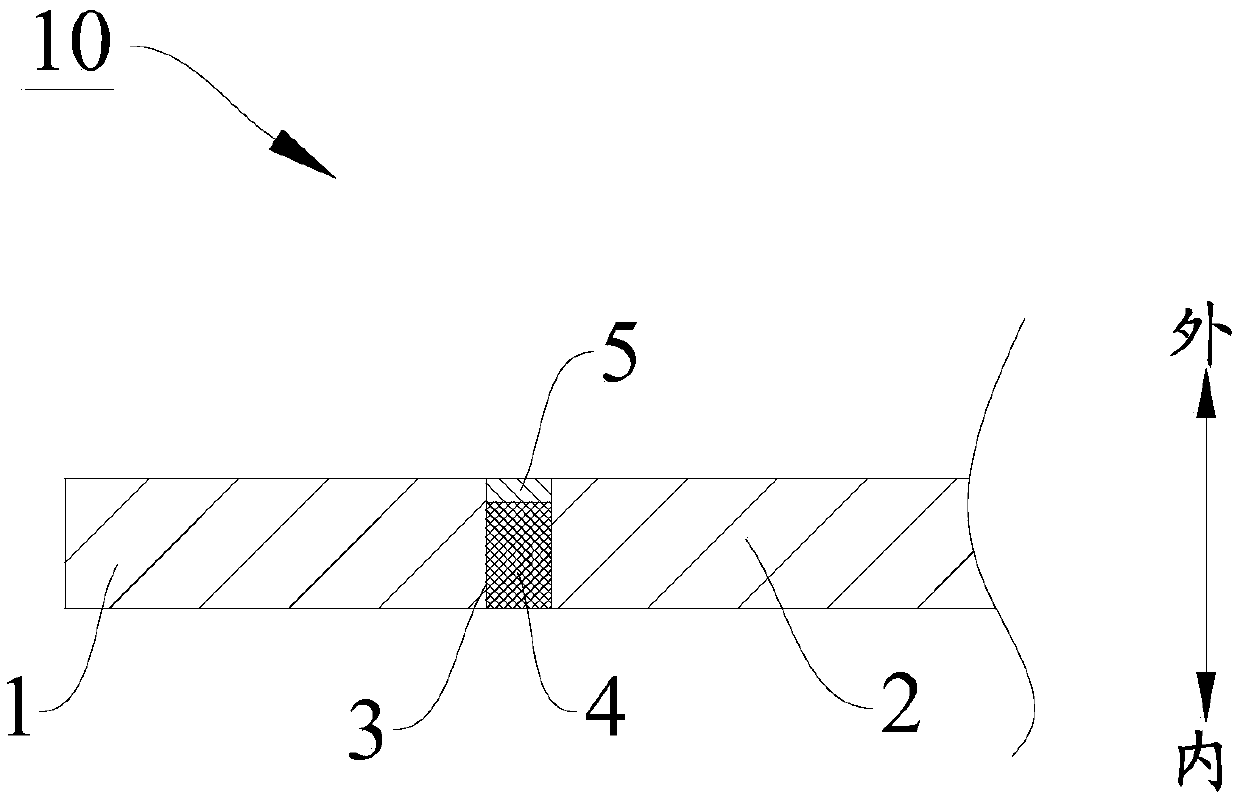

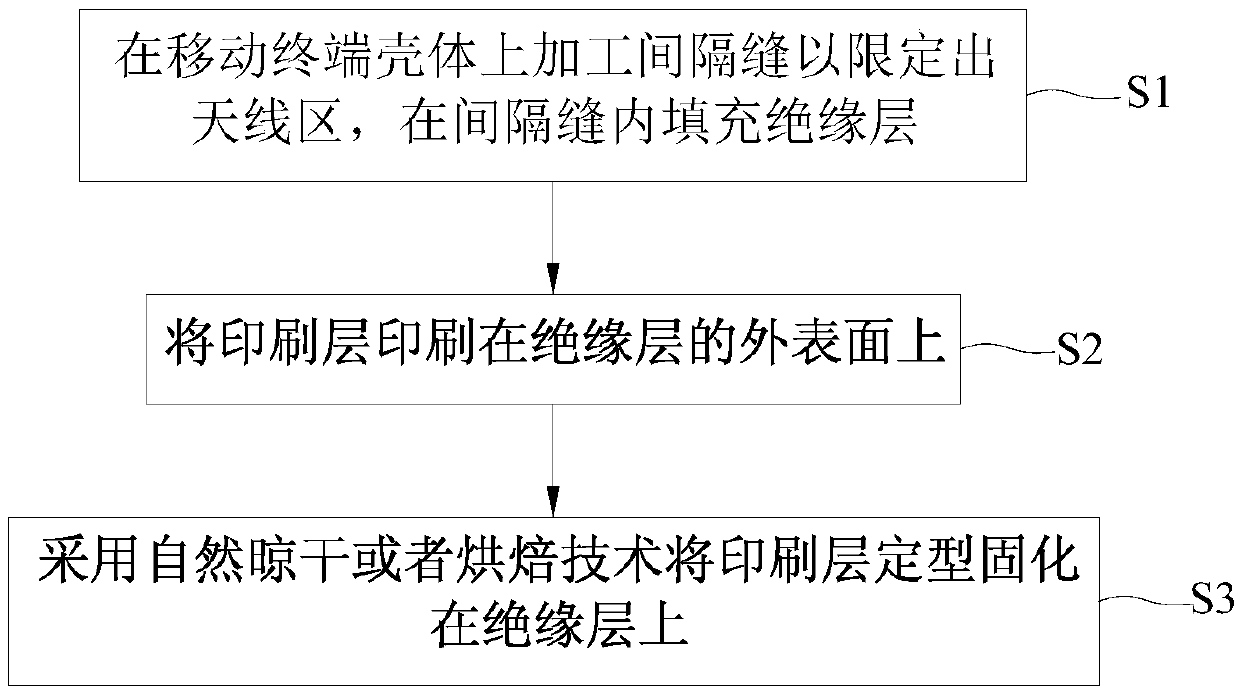

Mobile terminal housing and processing method thereof

InactiveCN105517389AColorful designLittle impact on shapeCasings/cabinets/drawers detailsMetal casingsEngineeringMetal

The invention discloses a mobile terminal housing and a processing method of the mobile terminal housing. The mobile terminal housing is a metal housing, and is provided with interval seams for dividing the mobile terminal housing into antenna areas and a remaining area; each interval seam is internally filled with an insulating layer; a printing layer is arranged on the outer surface of each insulating layer. The mobile terminal housing disclosed by the invention has the advantages that the printing layer is arranged on the outer surface of each insulating layer, and the printing layer can be formed into various types, so that the design of the mobile terminal housing is rich and colorful, and the diversification requirements of users are met; because of the decoration effect of the printing layer, the influence of the texture and color of the insulating layer to the appearance of the mobile terminal housing is reduced, therefore the material selection range of the insulating layer is wider, and a better-performace and cheaper material is beneficially selected.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

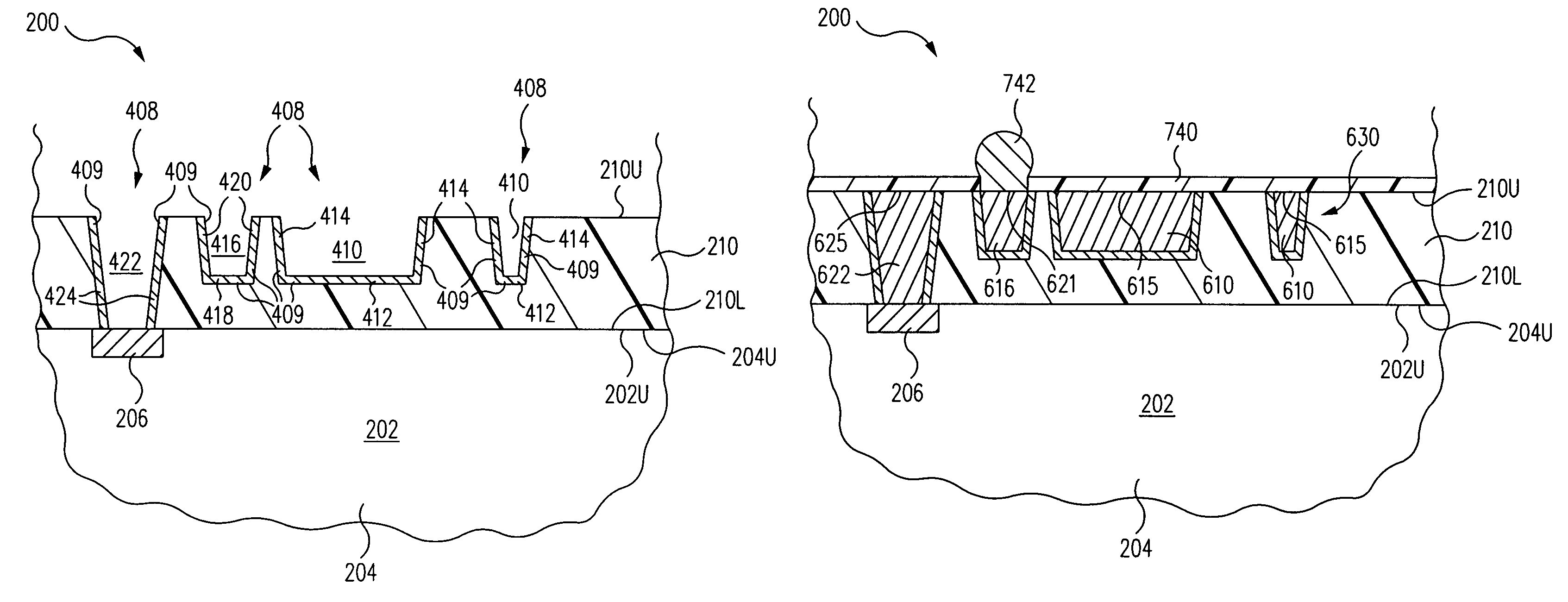

Dual damascene dual alignment interconnect scheme

InactiveUS20130328208A1Semiconductor/solid-state device detailsSolid-state devicesDielectric layerPhotoresist

A stack of a first metal line and a first dielectric cap material portion is formed within a line trench of first dielectric material layer. A second dielectric material layer is formed thereafter. A line trench extending between the top surface and the bottom surface of the second dielectric material layer is patterned. A photoresist layer is applied over the second dielectric material layer and patterned with a via pattern. An underlying portion of the first dielectric cap material is removed by an etch selective to the dielectric materials of the first and second dielectric material layer to form a via cavity that is laterally confined along the widthwise direction of the line trench and along the widthwise direction of the first metal line. A dual damascene line and via structure is formed, which includes a via structure that is laterally confined along two independent horizontal directions.

Owner:ALSEPHINA INNOVATIONS INC

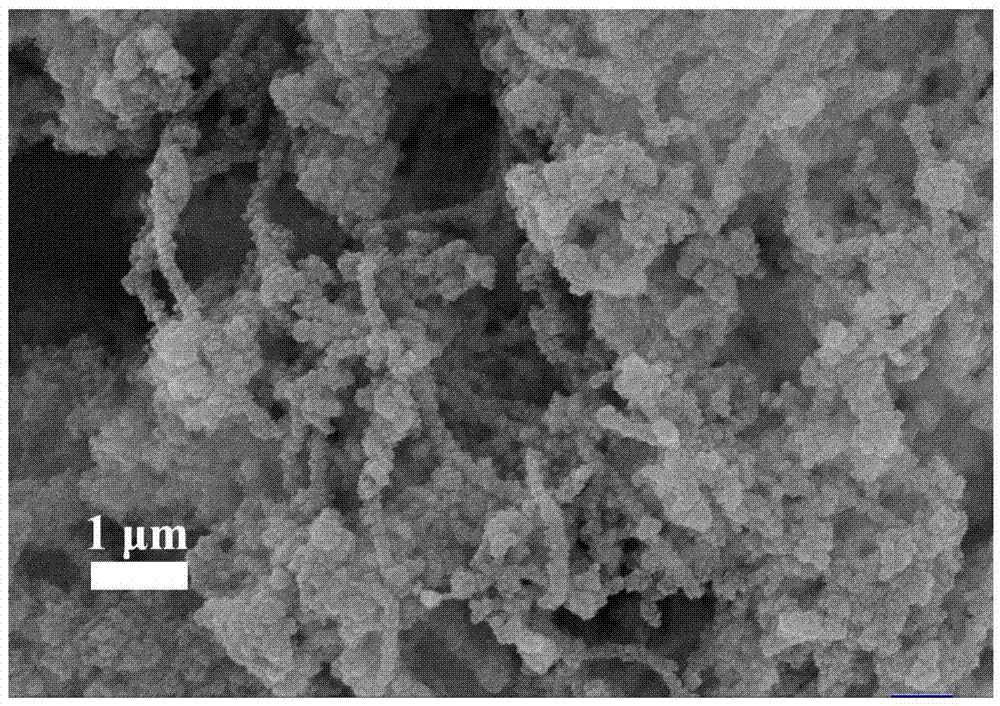

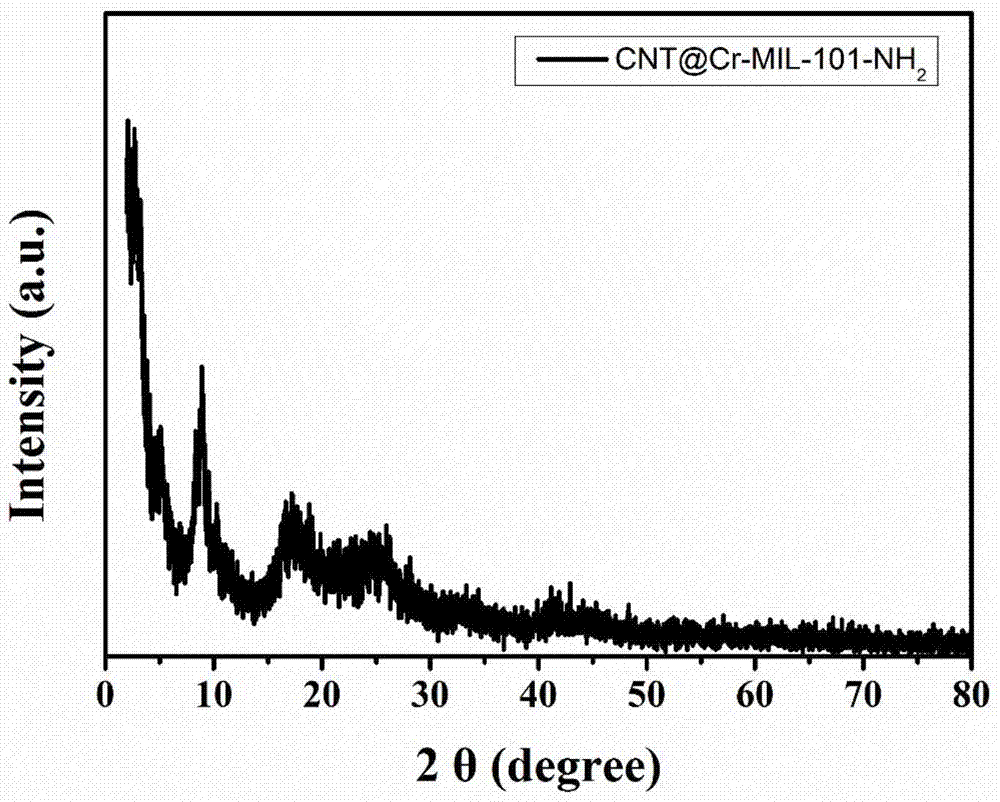

Preparation method for carbon-containing material metal organic framework-based composite phase change material

InactiveCN104745149AImprove heat transfer performanceImprove cycle stabilityHeat-exchange elementsModified carbonMetal-organic framework

The invention discloses a preparation method for a carbon-containing material metal organic framework-based composite phase change material and belongs to the field of nano composite materials and composite phase change materials. The preparation method comprises the following steps: carrying out in-situ growth of MOFs particles on a polyvinylpyrrolidone (PVP)-modified carbon material surface by adopting a hydrothermal method to prepare a carbon-containing material metal organic framework-based porous carrier material; then, dispersing a carbon material @MOFs porous carrier material into a prepared solution containing a phase change core material by adopting a solution dipping method; adsorbing a phase change core material by utilizing an oversized specific surface area of the metal organic framework material and a nao duct structure; and drying at a temperature higher than the phase change material to obtain the carbon-containing material metal organic framework-based composite phase change material. The material can be used for improving the heat transfer performances of the composite phase-change material, effectively preventing core material leakage, and has the advantages of wide core material selection range. The composite phase change material prepared by the method provided by the invention is excellent in heat transfer performance, good in circulating stability, simple in process and suitable for large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

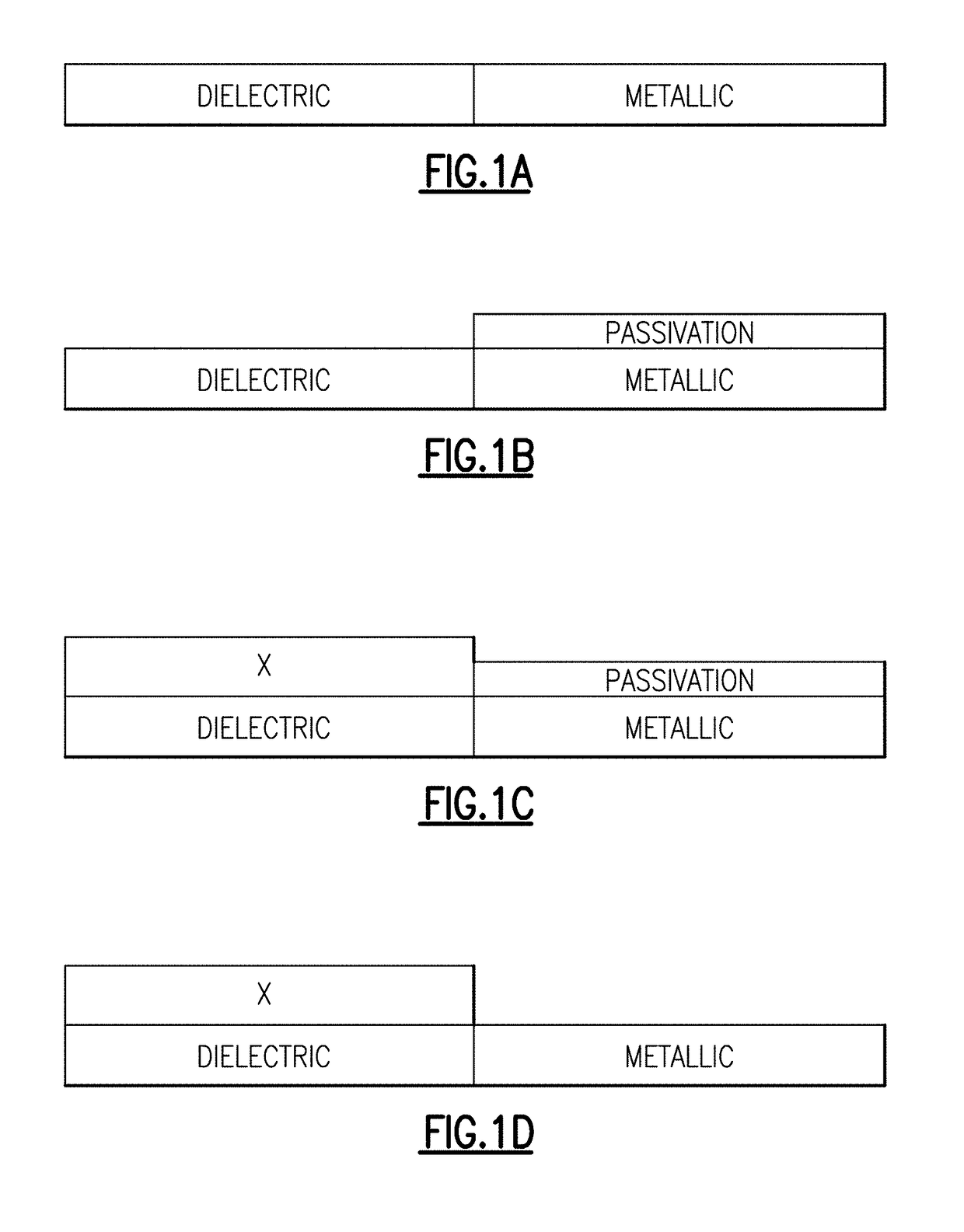

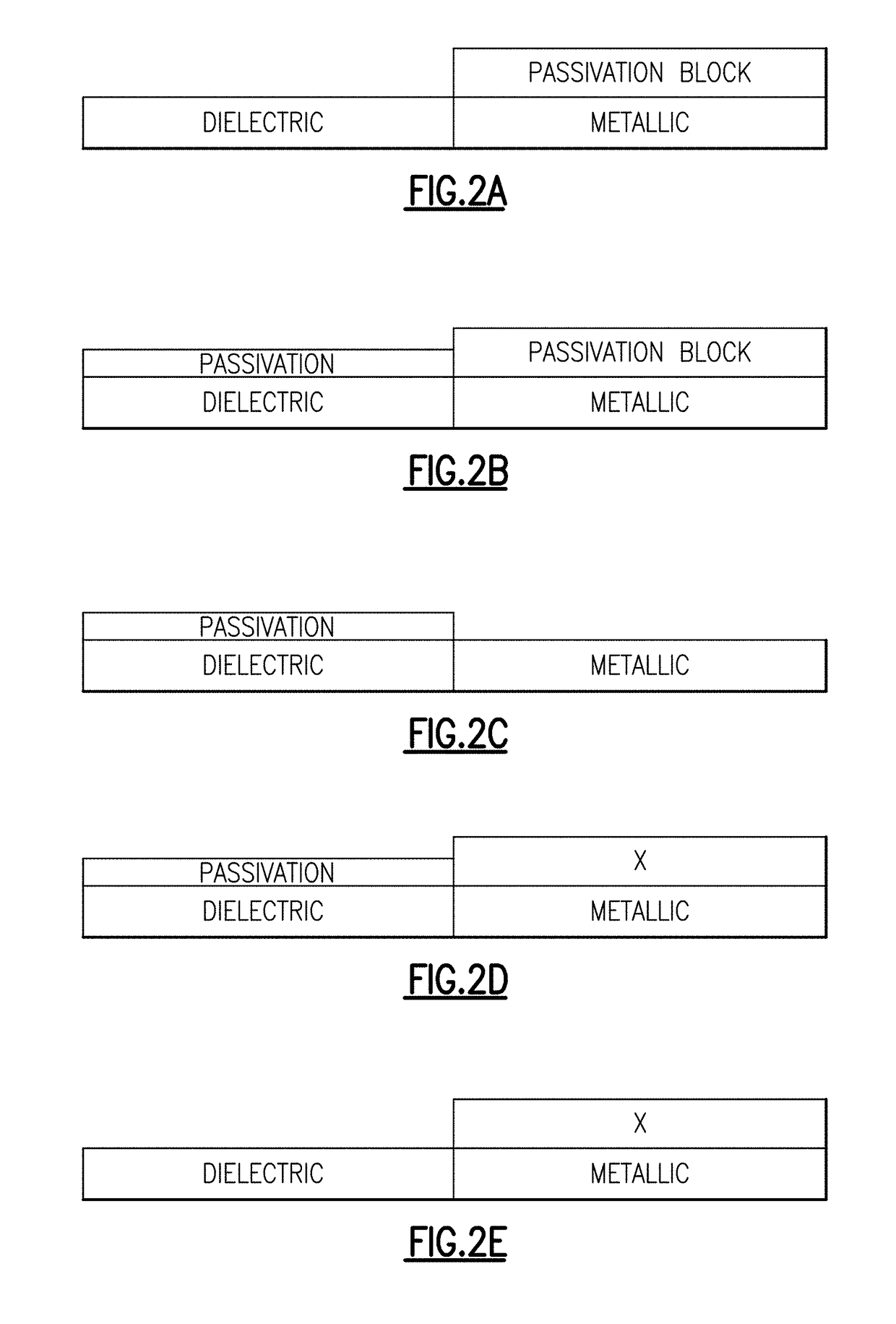

Selective passivation and selective deposition

ActiveUS20180233350A1Semiconductor/solid-state device detailsSolid-state devicesDielectric surfaceSelective deposition

Methods for selective deposition, and structures thereof, are provided. Material is selectively deposited on a first surface of a substrate relative to a second surface of a different material composition. A passivation layer is selectively formed from vapor phase reactants on the first surface while leaving the second surface without the passivation layer. A layer of interest is selectively deposited from vapor phase reactants on the second surface relative to the passivation layer. The first surface can be metallic while the second surface is dielectric, or the second surface is dielectric while the second surface is metallic. Accordingly, material, such as a dielectric, can be selectively deposited on either metallic or dielectric surfaces relative to the other type of surface using techniques described herein. Techniques and resultant structures are also disclosed for control of positioning and shape of layer edges relative to boundaries between underlying disparate materials.

Owner:ASM IP HLDG BV

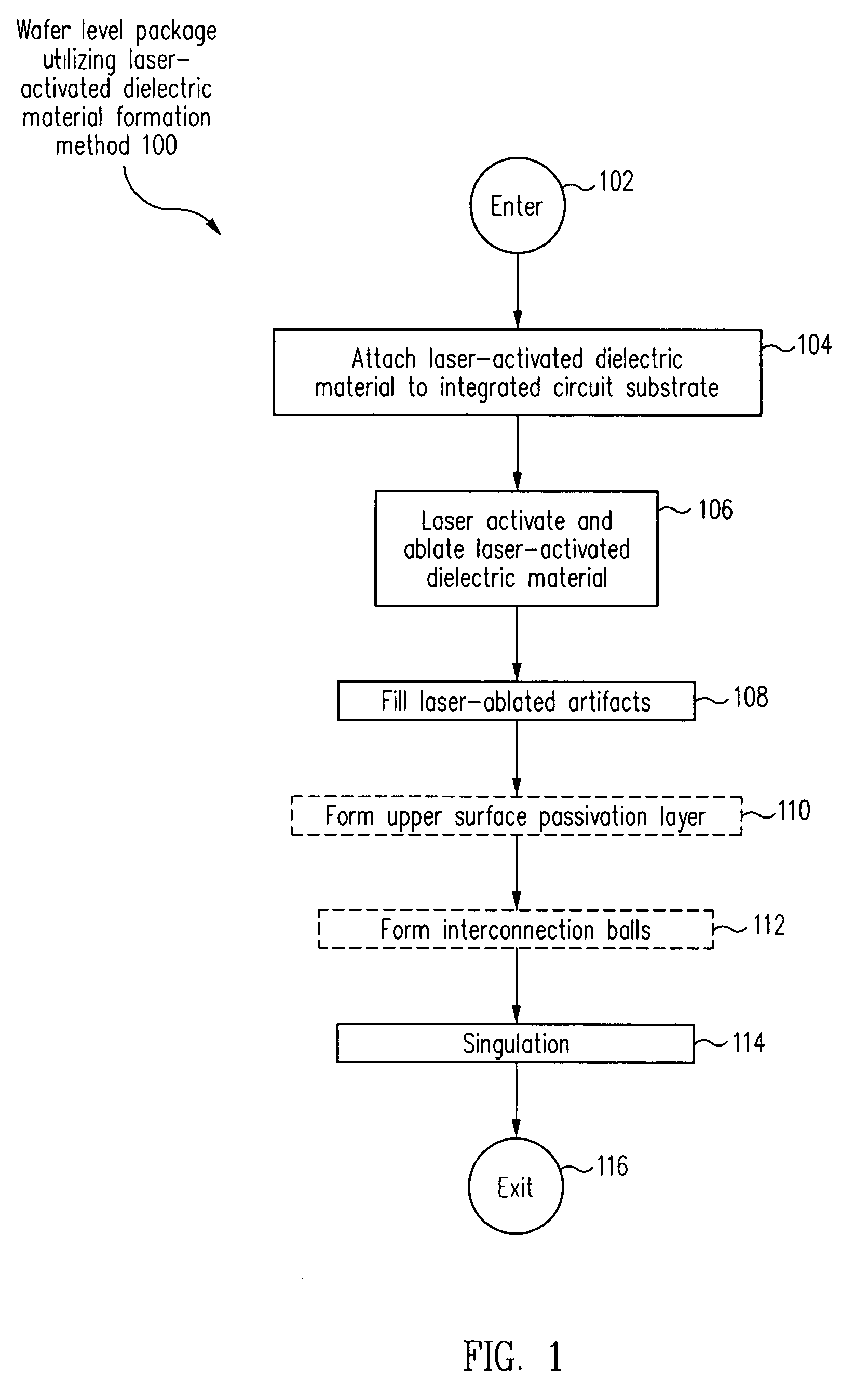

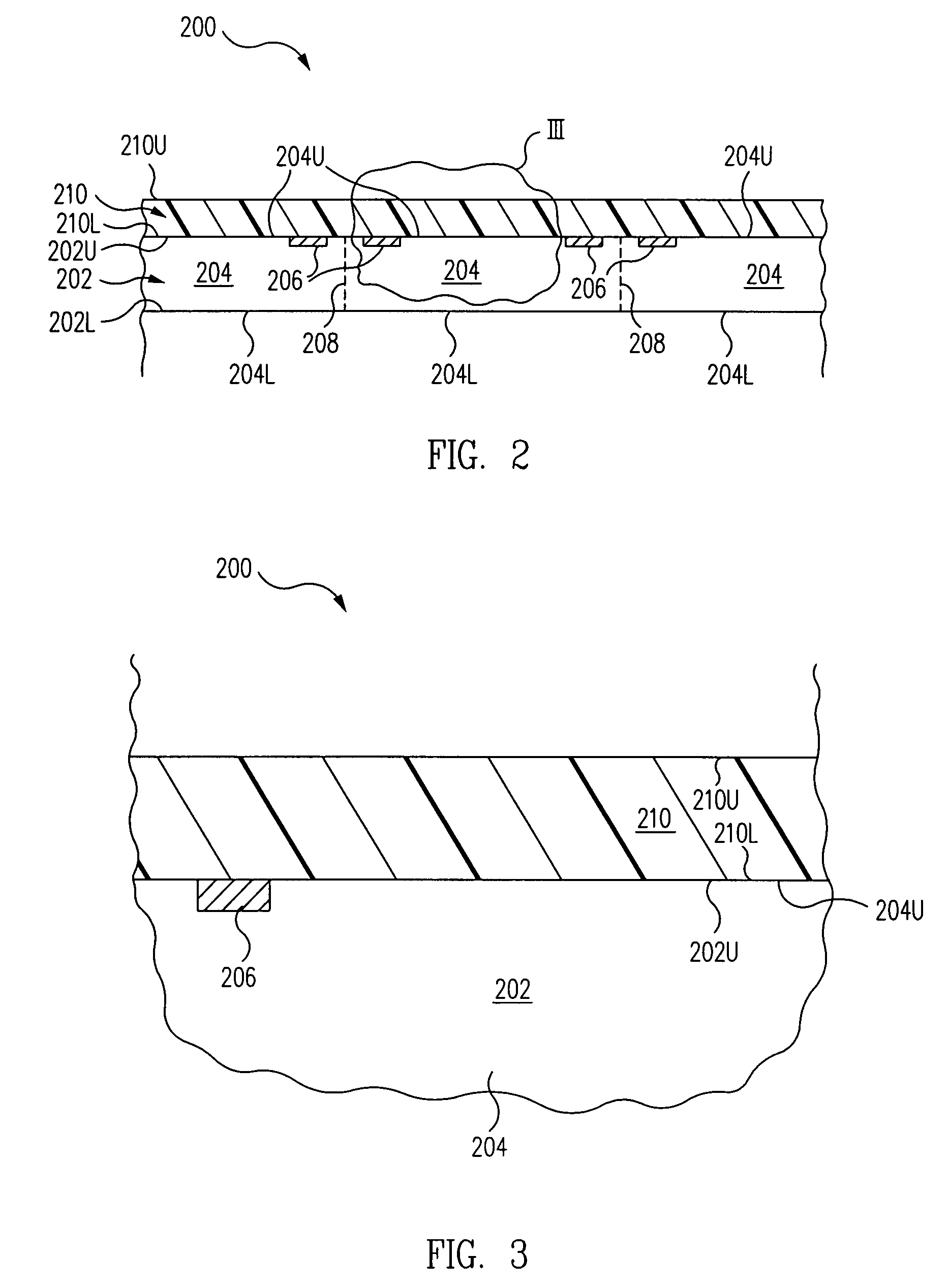

Wafer level package utilizing laser-activated dielectric material

ActiveUS7632753B1Low costMinimum operationSemiconductor/solid-state device detailsSolid-state devicesDielectricElectronic component

A method of forming a wafer level package includes attaching a laser-activated dielectric material to an integrated circuit substrate to form an assembly, the integrated circuit substrate including a plurality of electronic components having terminals on first surfaces thereof. The laser-activated dielectric material is laser activated and ablated with a laser to form laser-ablated artifacts in the laser-activated dielectric material and simultaneously to form an electrically conductive laser-activated layer lining the laser-ablated artifacts. The laser-ablated artifacts are filled using an electroless plating process in which an electrically conductive filler material is selectively plated on the laser-activated layer to form an embedded circuit pattern within the laser-activated dielectric material.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

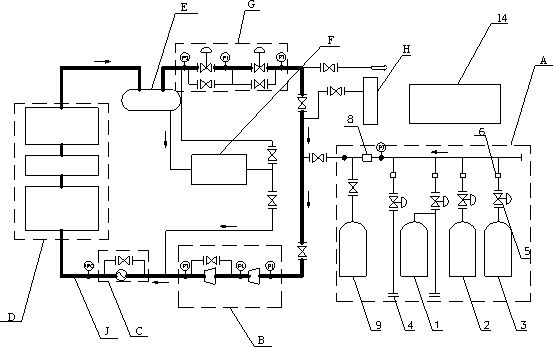

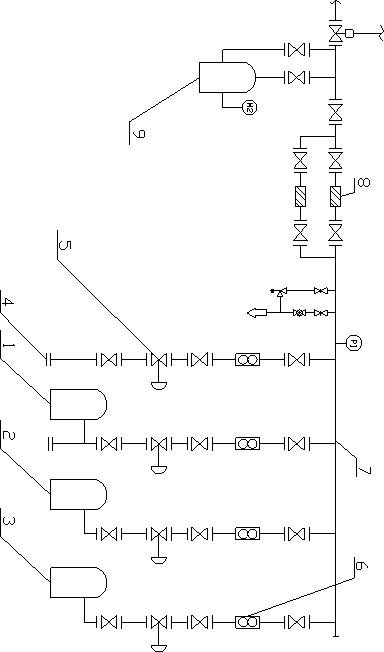

Acid medium transmission pipeline welded joint and parent metal corrosion simulation testing device and method

InactiveCN102305761AIn line with the actual situationWide range of working conditionsWeather/light/corrosion resistanceWashoutStimulation tests

The invention provides a large-scale multifunctional corrosion stimulation test rack taking a test circular road as a main part, which is used for simulating the corrosion condition of high acid natural gas containing H2S, CO2 and Cl on a pipeline parent metal and a welded joint under the pipeline transmission condition. The device and the method provided by the invention can be applied to pipeline parent bodies with different pipe diameters, materials, steel grades and wall thicknesses, or a welded joint corrosion test; and test functions such as test on corrosion of the pipe section parent metal and the welded joint, sulfide stress cracking (SSC), hydrogen induced cracking (HIC), washout, corrosion inhibitor effect, welding process evaluation, corrosion monitoring method comparison, pipeline-corrosion-preventing process optimization and the like are integrated into a whole; and the test functions, such as preference of the corrosion process in the pipeline are integrated into a whole, thus reasonable material selection and safe welding quality are guaranteed, and the corrosion condition of the corresponding corrosion condition on the welded joint and the parent metal is known.

Owner:SOUTHWEST PETROLEUM UNIV

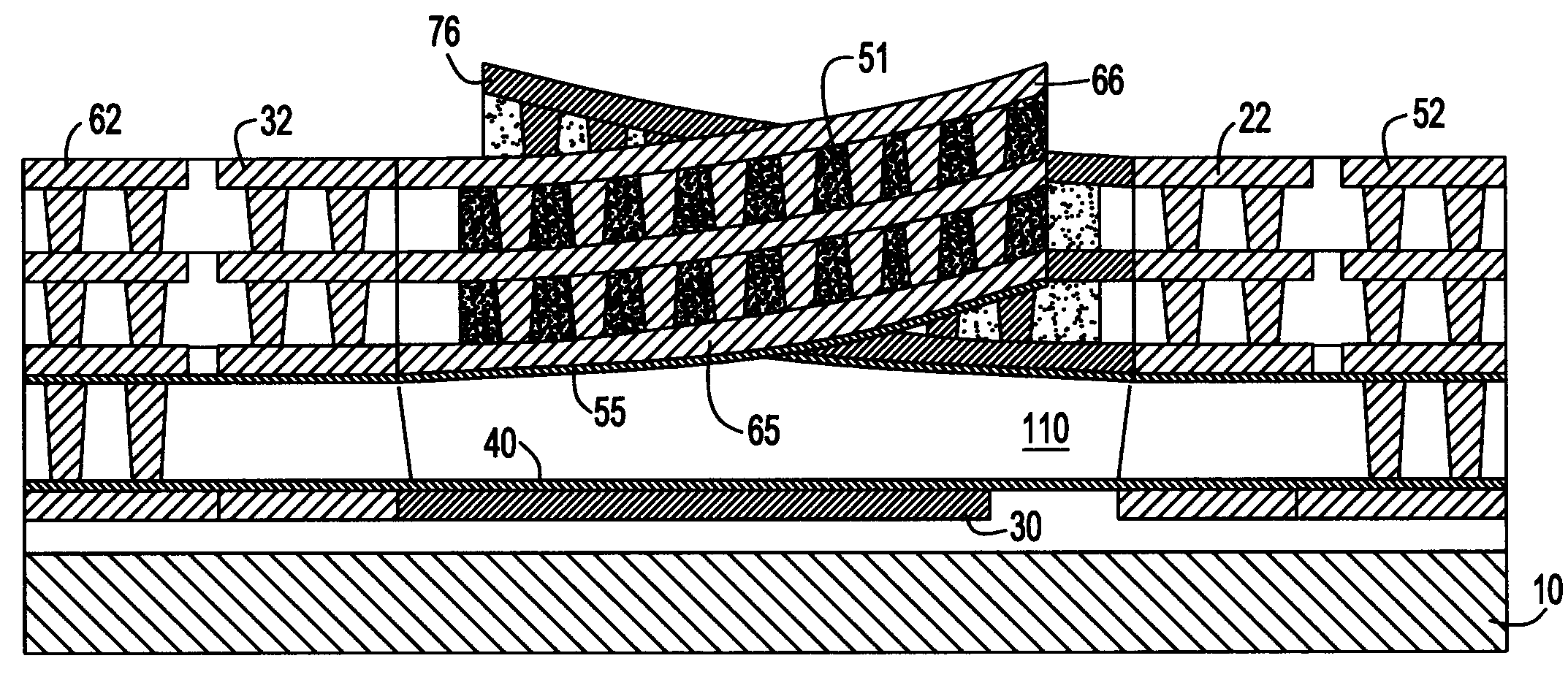

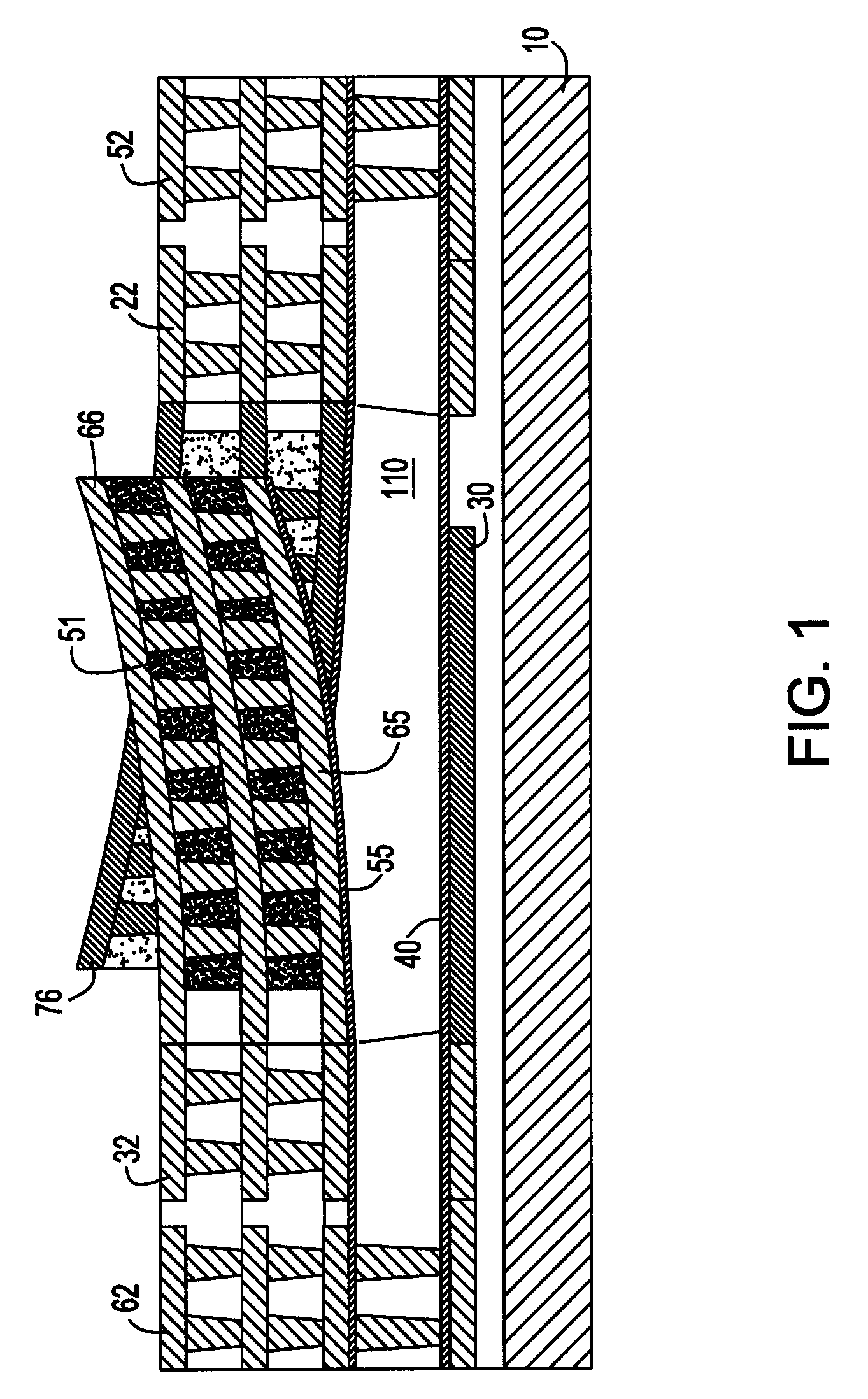

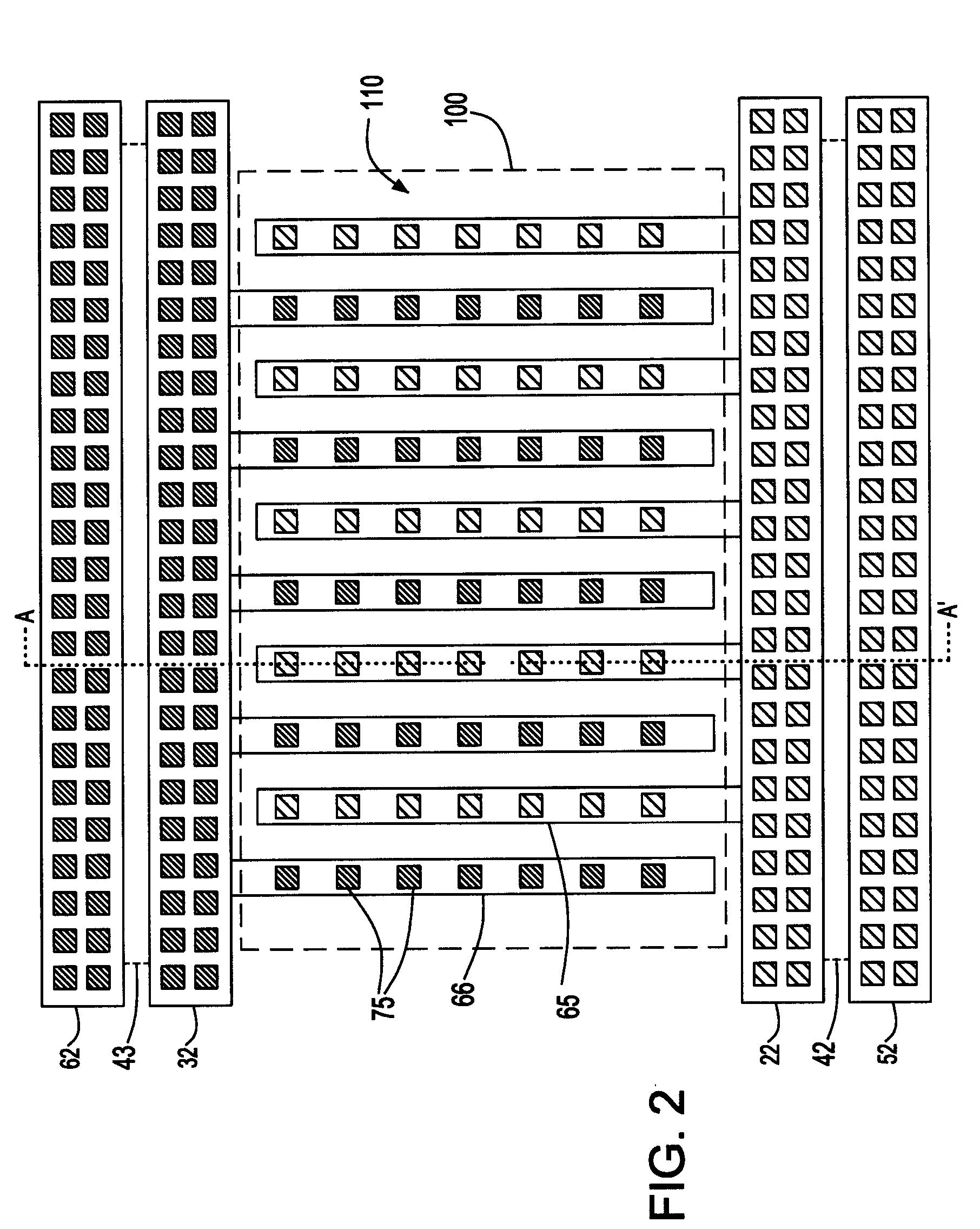

Turbine engine ring seal

InactiveUS20100104426A1Coolant leakage can be minimizedReduce thicknessPump componentsBlade accessoriesEngineeringTurbine

Aspects of the invention relate to a ring seal for a turbine engine. The ring seal can be made up of a plurality of circumferentially abutted ring seal segments. Each ring seal segment can comprise a plurality of individual channels. The channels can be generally U-shaped in cross-section with a forward span, and aft span and an extension connecting therebetween. The channels can be positioned such that the aft span of one channel can substantially abut the forward span of another channel. The plurality of separate channels can be detachably coupled to each other by, for example, a plurality of pins. The ring seal segment according to aspects of the invention can facilitate numerous advantageous characteristics including greater material selection, selective cooling, improved serviceability, and reduced blade tip leakage. Moreover, the configuration is well suited to handle the operational loads of the turbine.

Owner:SIEMENS ENERGY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com