Patents

Literature

55 results about "Wall thinning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wall thinning. noun. The amount of reduction from original wall thickness of pipe or tube to the amount of wall thickness remaining in the extrados of a bend after forming.

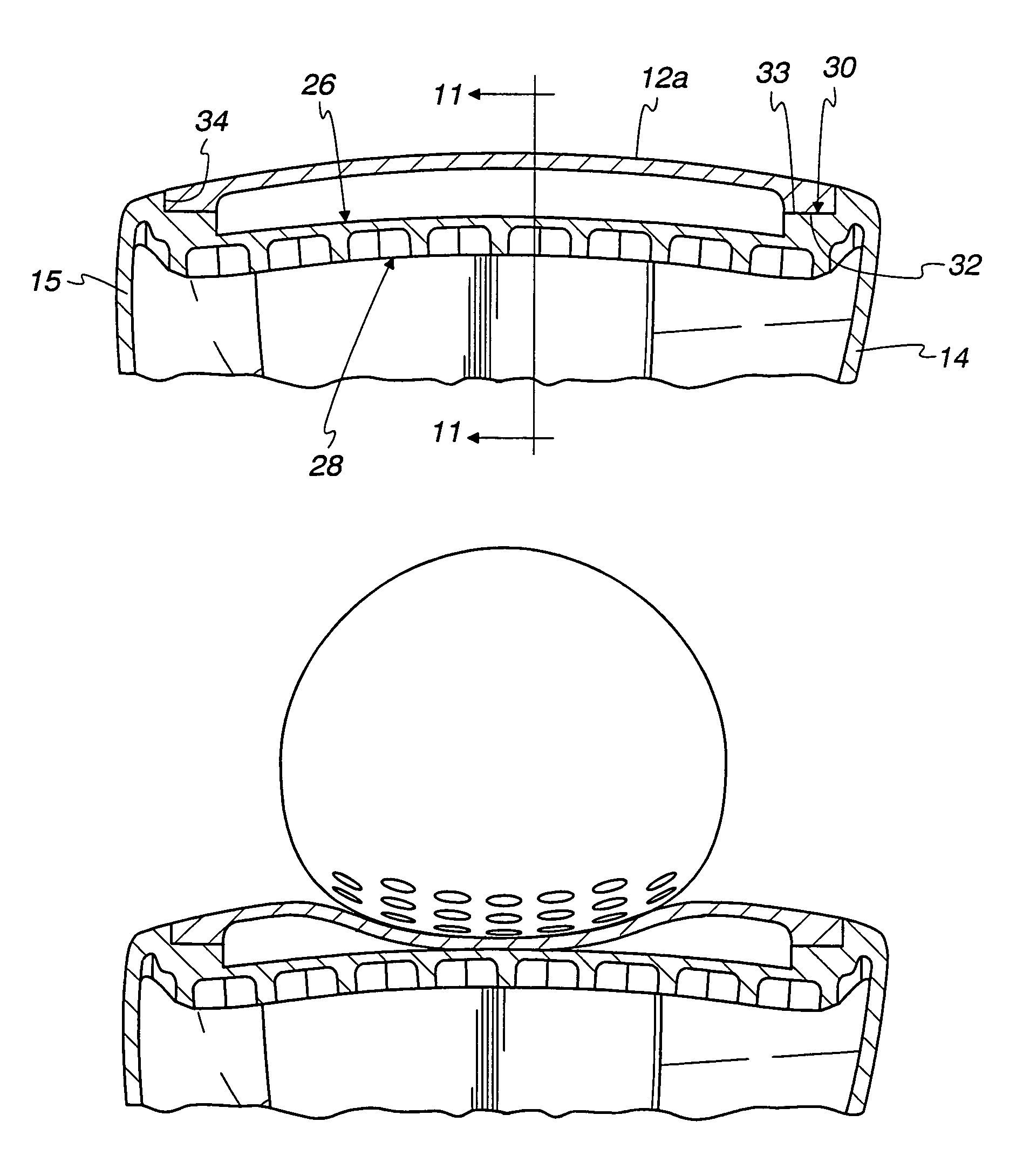

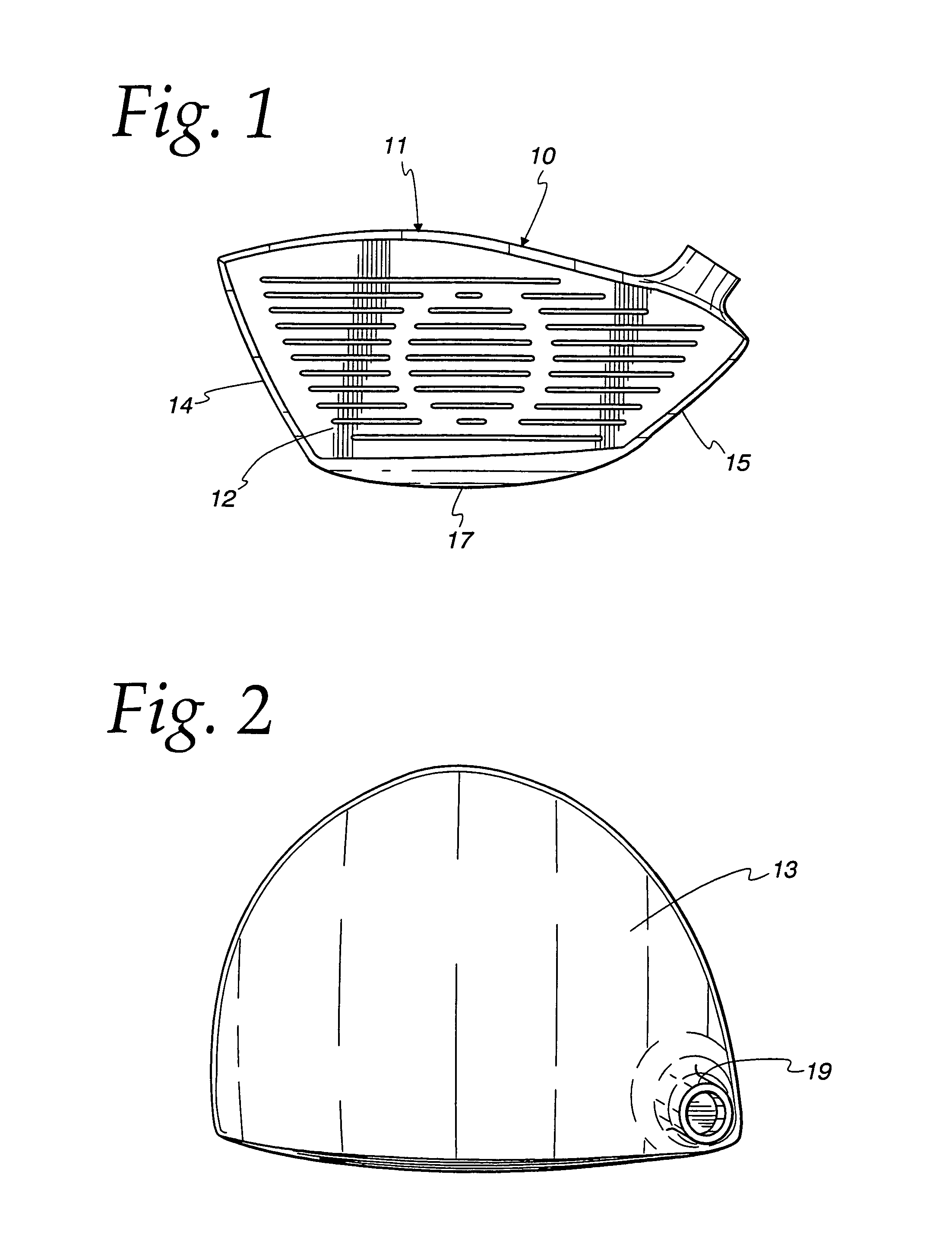

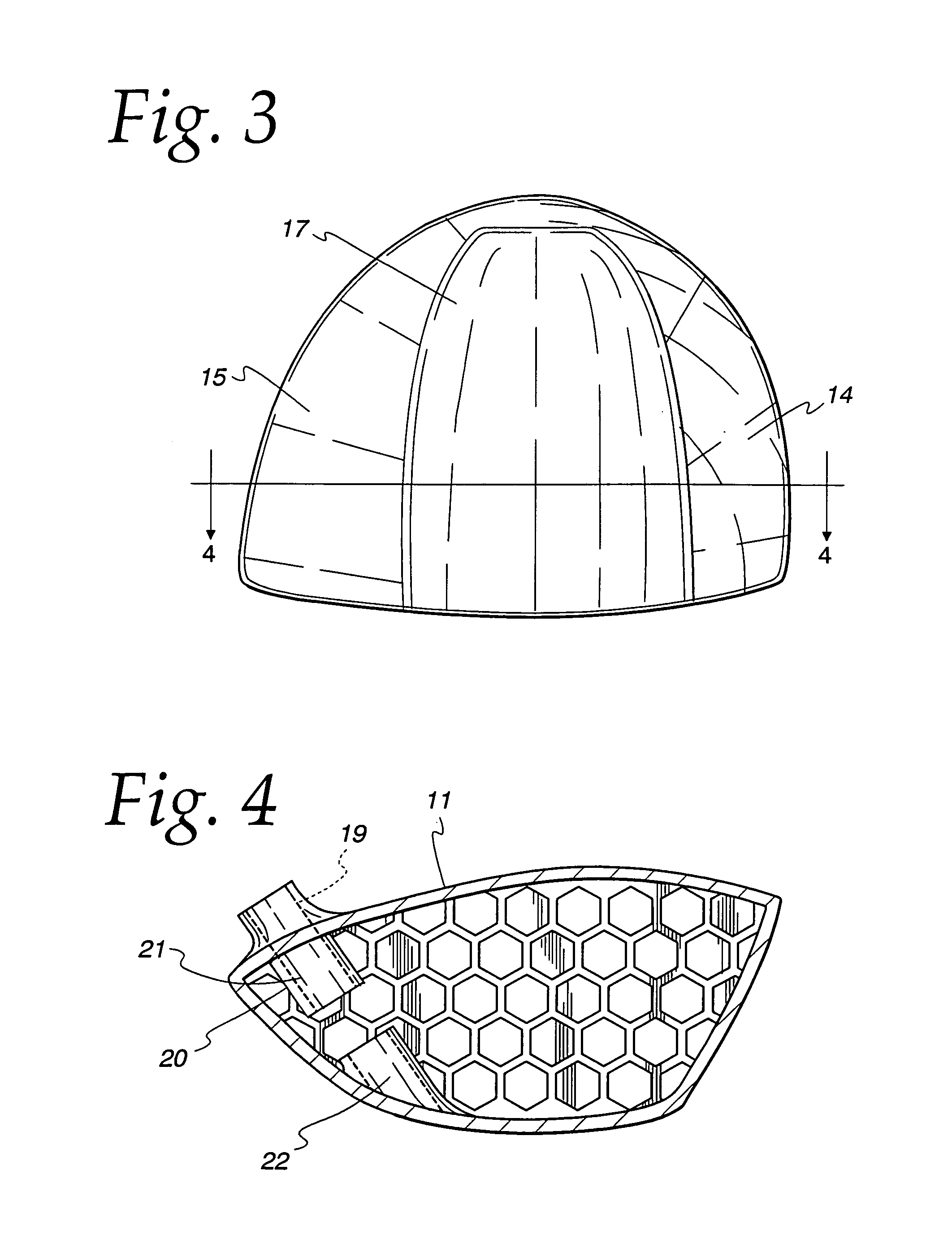

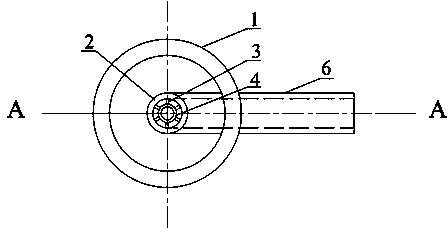

Golf club face flexure control system

InactiveUS6979270B1High modulusImprove energy transferGolf clubsRacket sportsControl systemGolf Ball

An improved line of golf clubs tailored to the golfer. The face wall firstly is designed so that the face wall modulus of elasticity increases from a low modulus for the low swing speed range to progressively higher modula for the higher swing speed ranges. Face modulus can be altered by a variety of techniques including face wall thinning, material selection and heat treatment or a combination thereof. In each of the swing speed range clubs, the face has a first modulus of elasticity determined by the face itself and after the face deflects to a predetermined value, the face modulus is significantly increased by a secondary wall parallel to and closely spaced behind the face wall.

Owner:KARSTEN MFG CORP

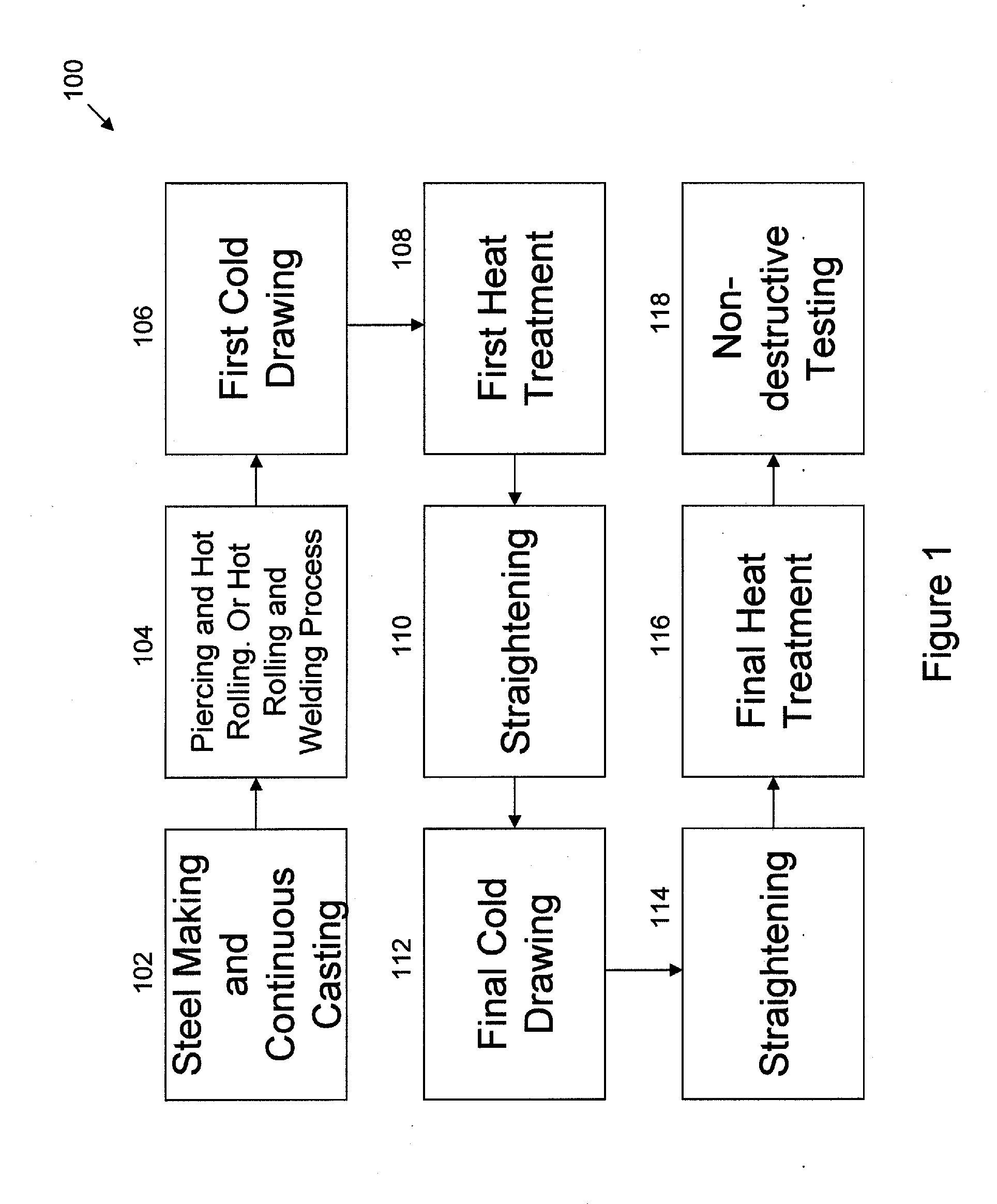

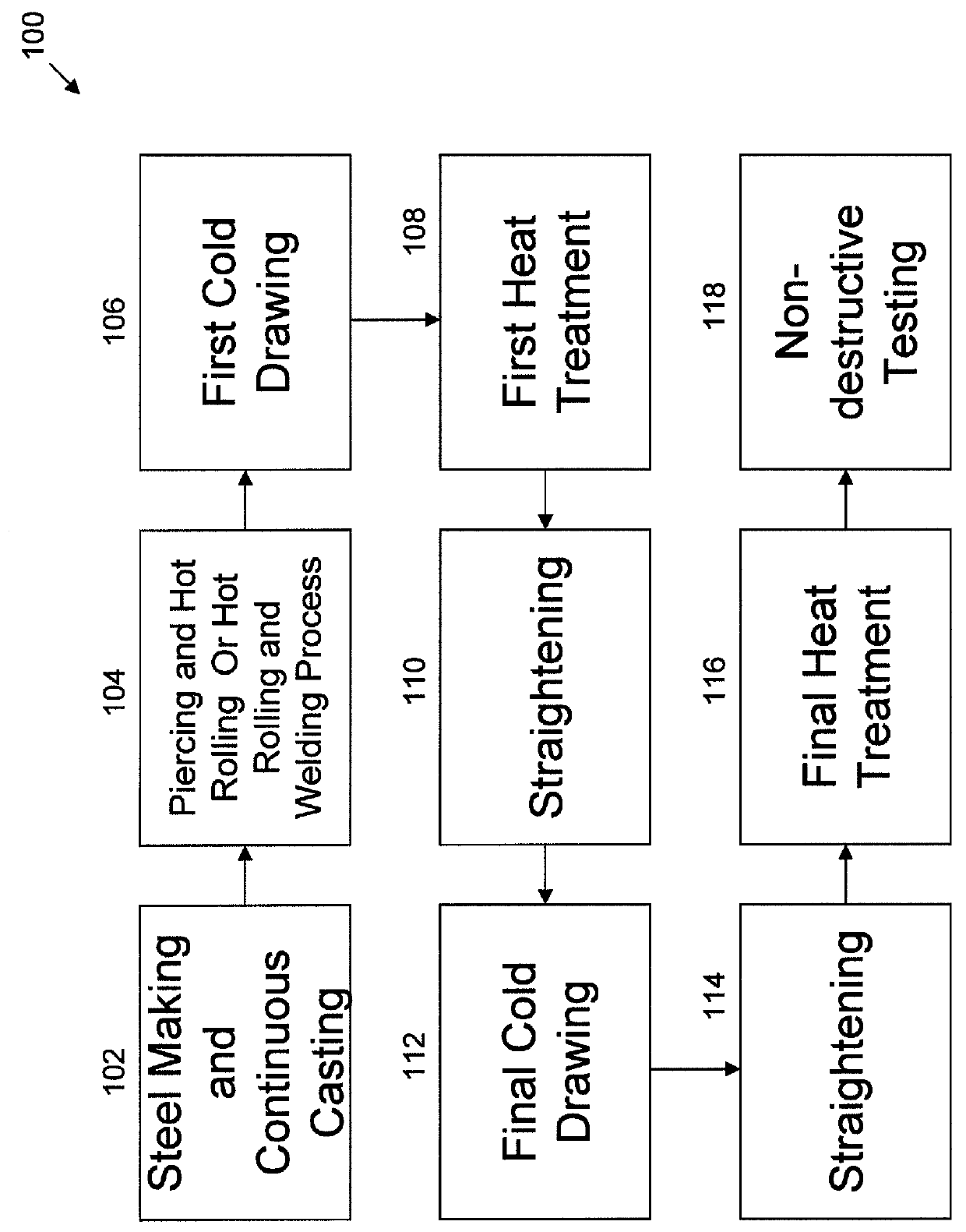

Methods of manufacturing steel tubes for drilling rods with improved mechanical properties, and rods made by the same

ActiveUS20130264123A1Reduce areaReduce the cross-sectional areaDrilling rodsFurnace typesHardnessWear resistance

Embodiments of the present disclosure are directed to methods of manufacturing steel tubes that can be used for mining exploration, and rods made by the same. Embodiments of the methods include a quenching of steel tubes from an austenitic temperature prior to a cold drawing, thereby increasing mechanical properties within the steel tube, such as yield strength, impact toughness, hardness, and abrasion resistance. Embodiments of the methods reduce the manufacturing step of quenching and tempering ends of a steel tube to compensate for wall thinning during threading operations. Embodiments of the methods also tighten dimensional tolerances and reduce residual stresses within steel tubes.

Owner:TENARIS CONNECTIONS

Manufacturing method of high alloy seamless steel tube

InactiveCN101811149AImprove surface qualityImprove lubrication conditionsManufacturing cost reductionPunching

The invention discloses a manufacturing method of high alloy seamless steel tube, comprising the following technical steps: (1) producing a high alloy hollow shell with centrifugal casting technology; (2) heating the hollow shell and plugging the opening of the hollow shell when heating; (3) reaming and wall thinning for the hollow shell after being heated by using a perforating machine so as to form a blank; (4) tube rolling for the bland by using a pipe and tube mill so as to form a pierced billet; (5) sizing and reducing for the pierced billet by using a sizing and reducing machine so as to obtain the high alloy seamless steel tube. The blank with the manufacturing method uses centrifugal casting for the hollow shell and lubricant is added by using the characteristic of hollow shell, thereby avoiding the problems of high alloy material in the technologies of forging, rolling and punching such as low metal yield and high rejection rate due to difficult deformation, thereby greatly reducing the manufacturing cost.

Owner:XINXING DUCTILE IRON PIPES CO LTD

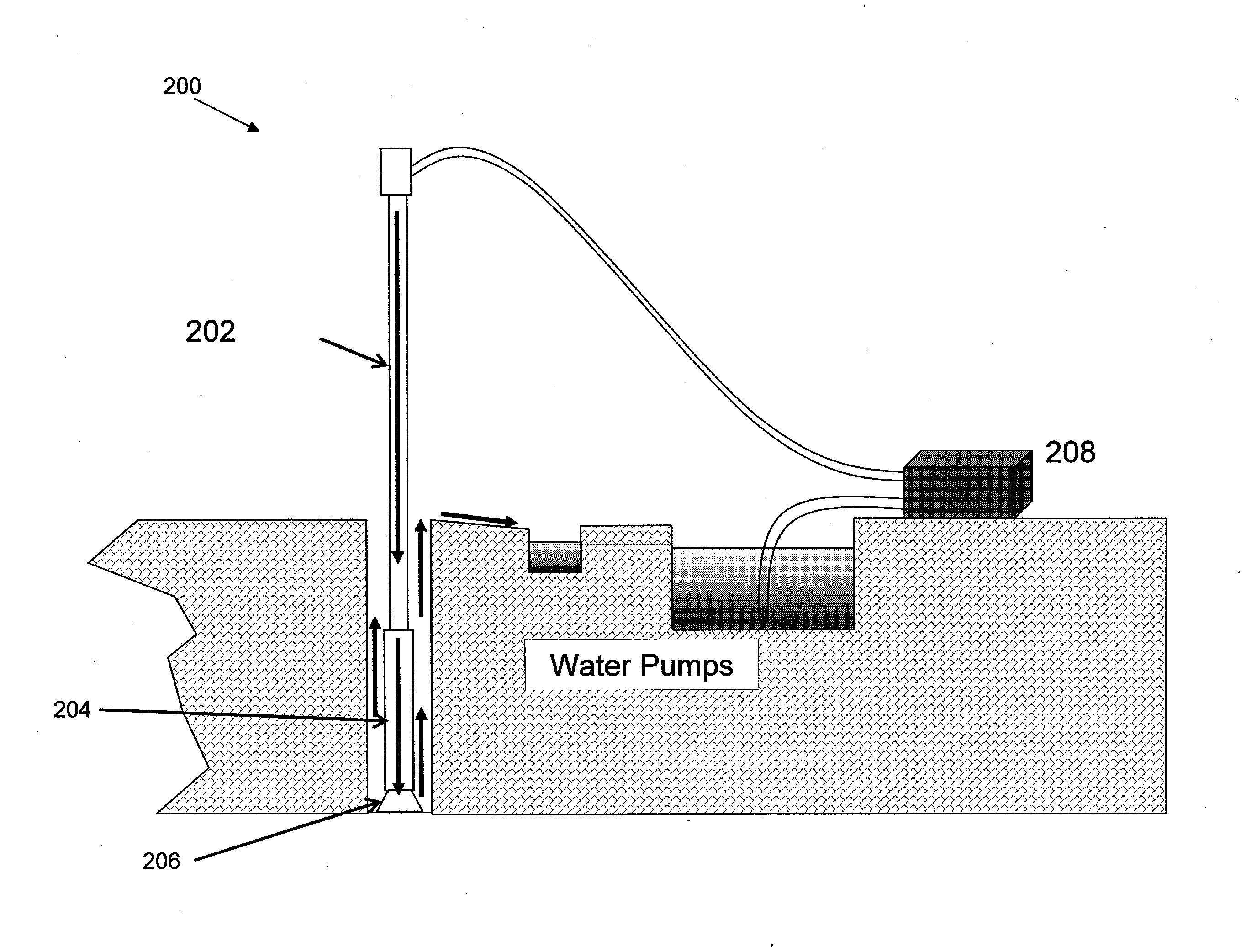

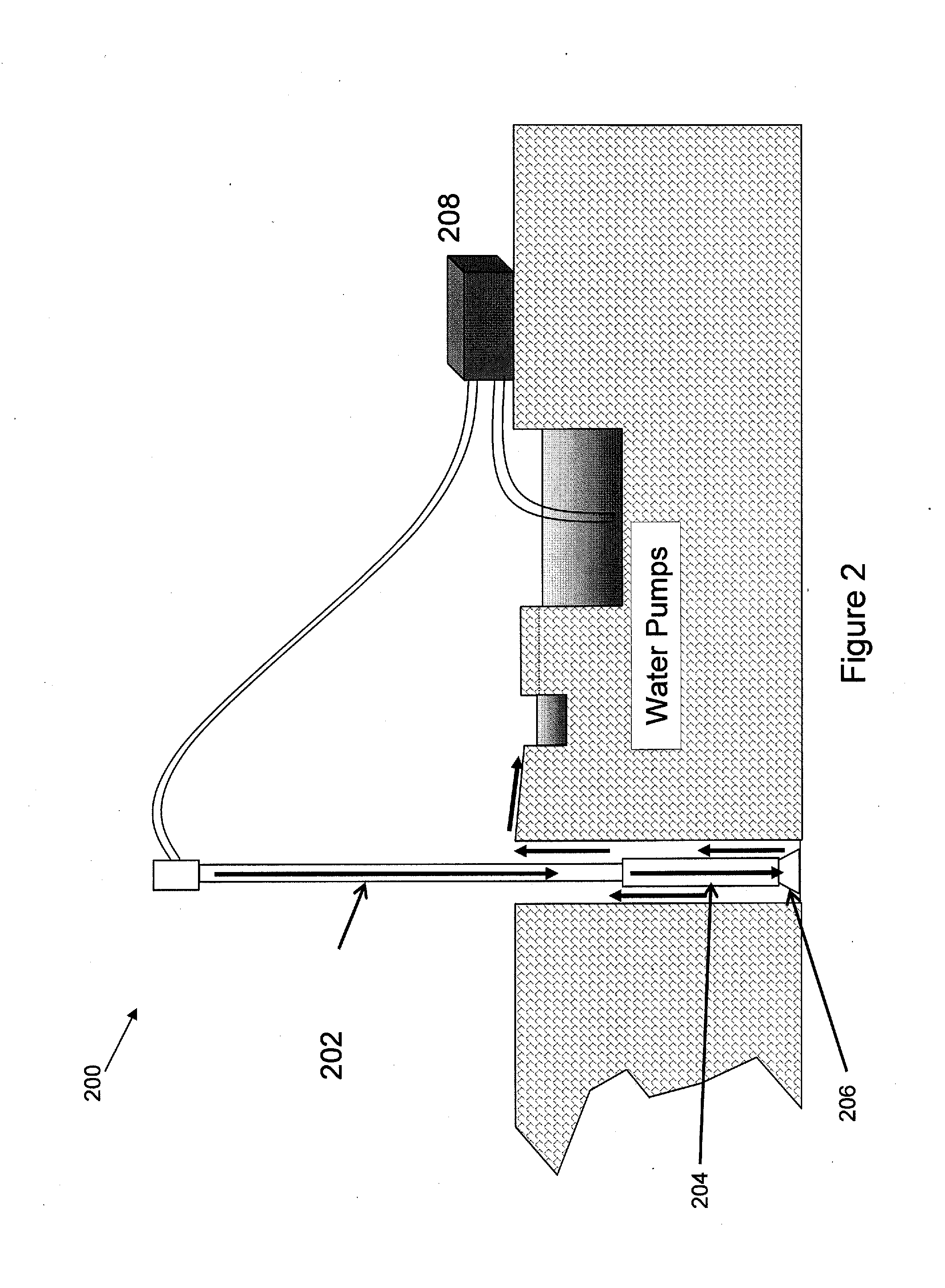

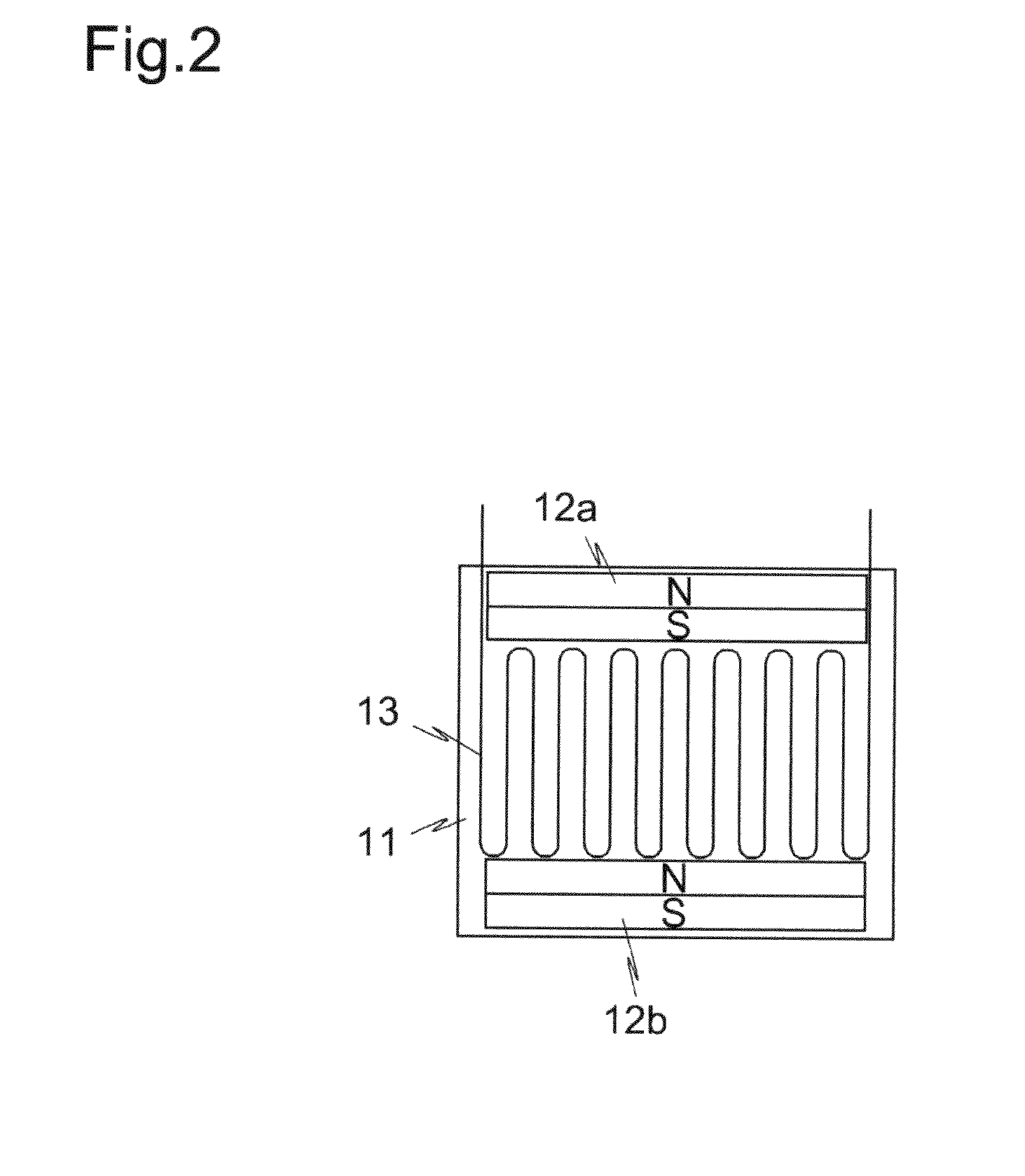

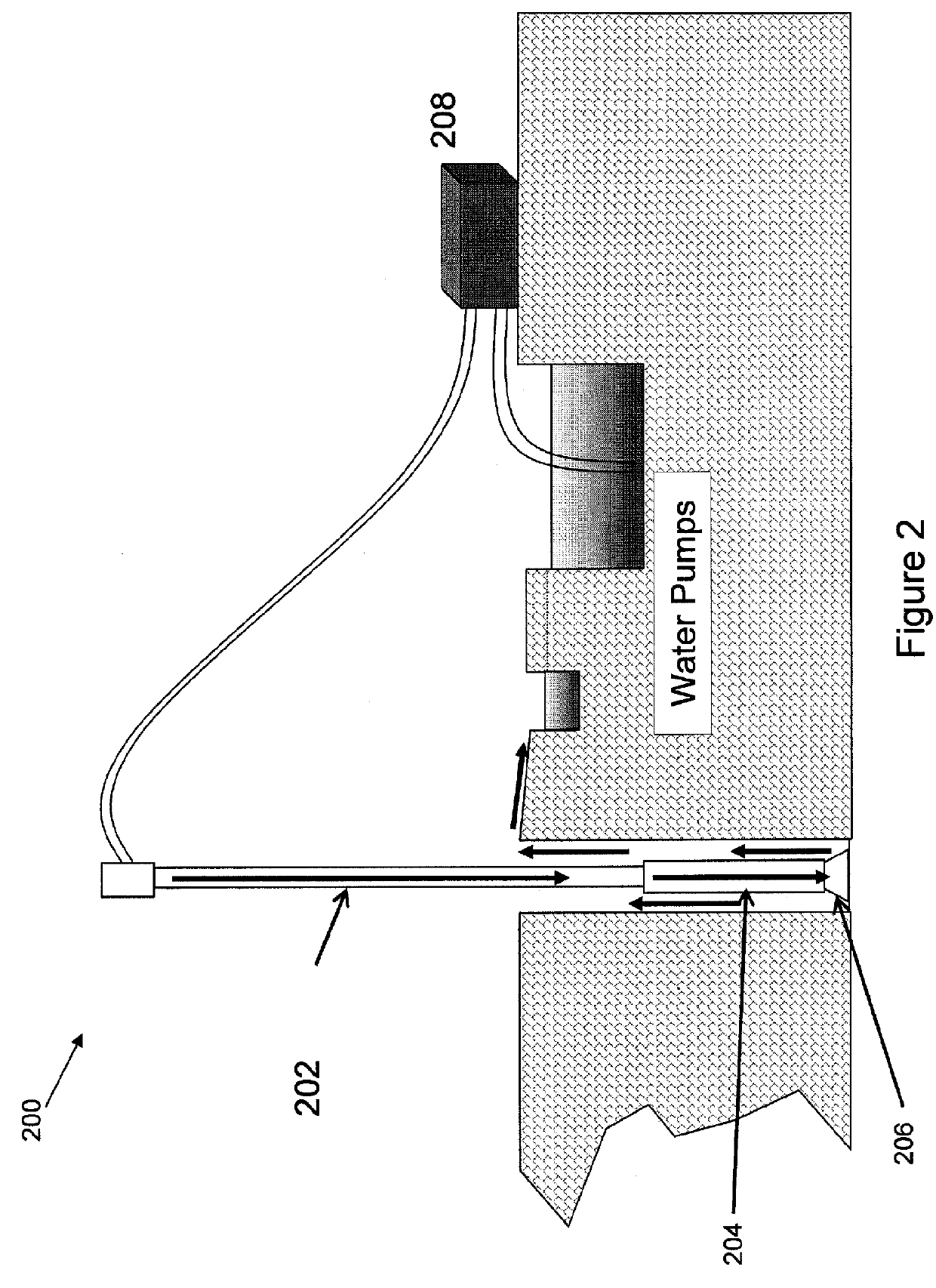

Method and apparatus for monitoring wall thinning of a pipe using magnetostrictive transducers and variation of dispersion characteristics of broadband multimode shear horizontal (SH) waves

InactiveUS20100244591A1Analysing solids using sonic/ultrasonic/infrasonic wavesPiezoelectric/electrostriction/magnetostriction machinesMeasuring outputEngineering

Magnetostrictive transducers for monitoring wall thinning in a pipe, and an apparatus and method for monitoring wall thinning in a pipe using magnetostrictive transducers are provided. The magnetostrictive transducers generate broadband multimode shear horizontal (SH) waves, and allow the generated SH waves to travel along the pipe, thus correctly monitoring a status of the wall thinning of the pipe. The apparatus includes a transmitting transducer which is installed outside of a pipe and generates shear horizontal (SH) waves traveling along the pipe, a receiving transducer which is spaced apart from the transmitting transducer and measures the shear horizontal (SH) waves traveling along the pipe, and a controller for monitoring wall thinning of the pipe by exciting and measuring output signals of the transmitting and receiving transducers.

Owner:KOREA RES INST OF STANDARDS & SCI

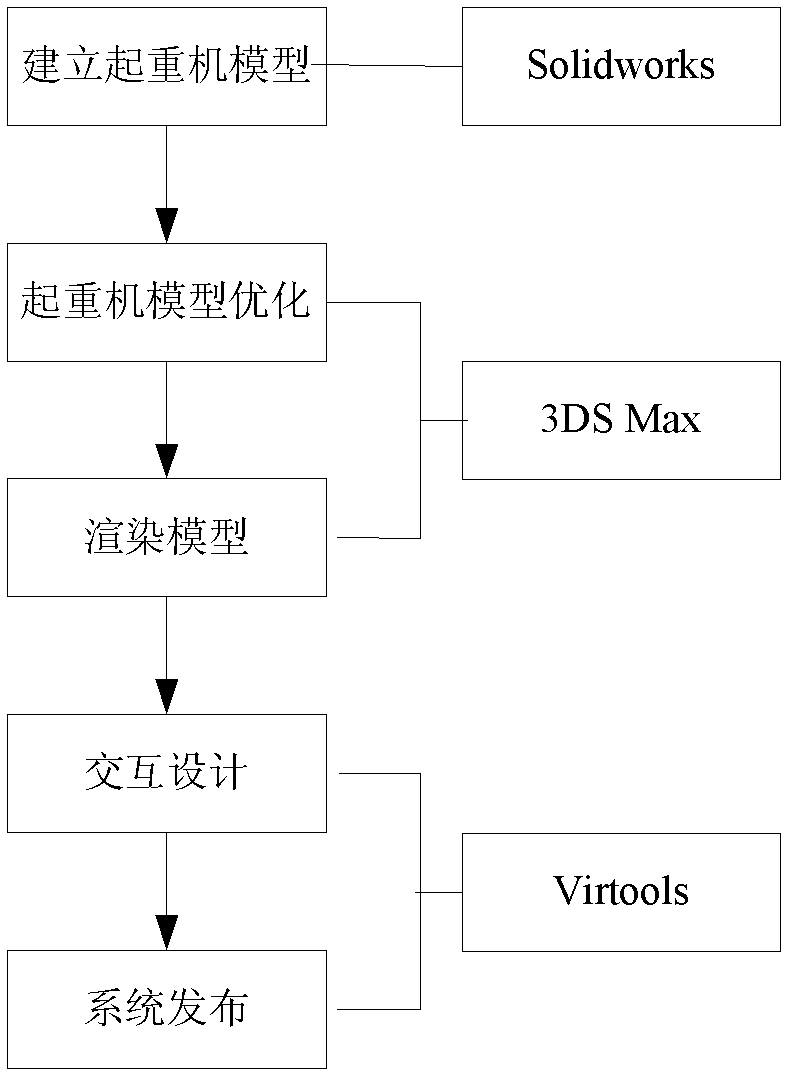

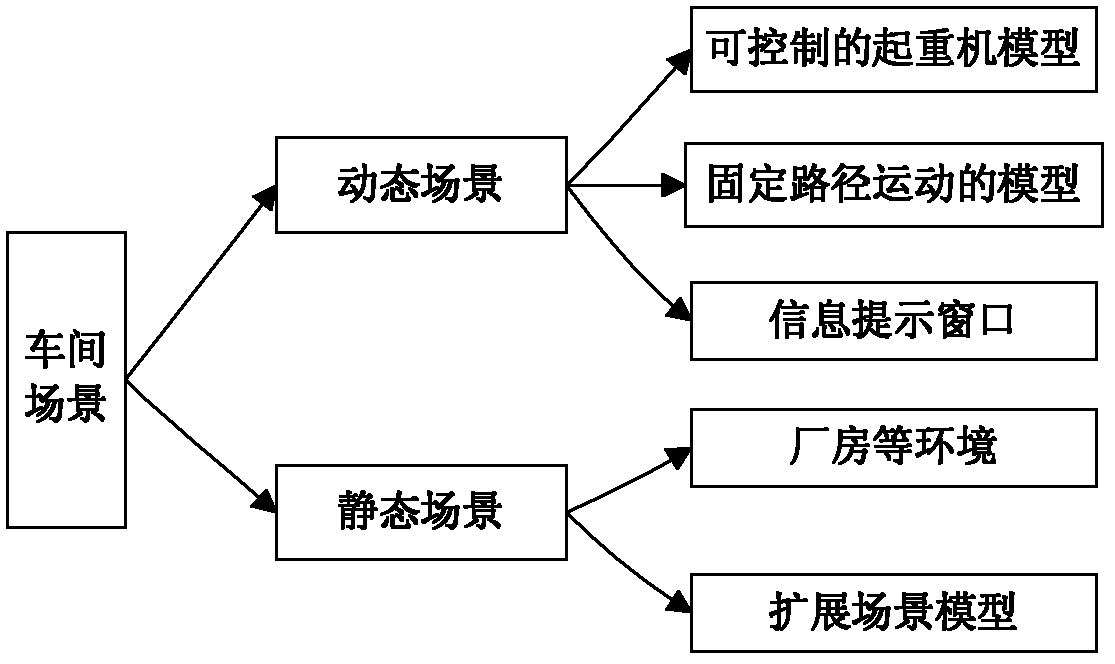

Creating method for virtual double-bridge crane based on Virtools

InactiveCN102360396AReduce operational riskReduce training costsSpecial data processing applications3D modellingPunchingEngineering

The invention provides a creating method for a virtual double-bridge crane based on Virtools, which comprises the steps of: (1) creating models of parts and components of a crane in SolidWorks by operations of stretching, rotating, wall thinning, arranging a characteristic array and punching, assembling the parts according to assembly relation, and outputting the models in a .stl format; (2) leading out the assembled crane, and introducing the models in a 3DS Max environment to edit and amend an integral crane model; (3) introducing the output .nmo scenes and models to the Virtools for optimization, test and recombination, and designing by a behavior interaction module provided by the Virtools; and (4) issuing the created virtual crane system in a .vmo format through the Virtools, and the client can access to the system via an IE browser after mounting a Virtools Web Player. The invention has the advantages of high efficiency, low cost and good instantaneity.

Owner:ZHEJIANG UNIV OF TECH +1

Methods of manufacturing steel tubes for drilling rods with improved mechanical properties, and rods made by the same

Embodiments of the present disclosure are directed to methods of manufacturing steel tubes that can be used for mining exploration, and rods made by the same. Embodiments of the methods include a quenching of steel tubes from an austenitic temperature prior to a cold drawing, thereby increasing mechanical properties within the steel tube, such as yield strength, impact toughness, hardness, and abrasion resistance. Embodiments of the methods reduce the manufacturing step of quenching and tempering ends of a steel tube to compensate for wall thinning during threading operations. Embodiments of the methods also tighten dimensional tolerances and reduce residual stresses within steel tubes.

Owner:TENARIS CONNECTIONS

Boiler four-pipe real-time service life assessment method considering wall thickness reduction and overheating influence

ActiveCN109992825AOverall failure factorThe failure factor is accurateDesign optimisation/simulationSpecial data processing applicationsMetallic materialsEngineering

The invention relates to a boiler four-pipe real-time service life evaluation method considering wall thickness reduction and overheating influence, and belongs to the technical field of metal materials. The method comprises the following steps: (a) calculating the pipe wall thinning condition by a system according to the operating environment and material characteristics of four pipes of a boiler; (b) calculating the thinning rate of four pipes of the boiler, and (c) calculating the remaining life of the thinned boiler pipe according to a strength checking theory; (d) calculating the stress of the position of the weld joint for the boiler pipe with the weld joint; (e) correcting the remaining life; (f) evaluating the service life of the boiler tube from the perspective of the temperatureand the lasting strength of the boiler tube; (g) correcting and calculating the service life of the boiler tube under the condition of exceeding the designed and calculated wall temperature and overheating; and (h) evaluating and calculating the comprehensive service life Rf of the boiler tube under the combined action of wall thickness reduction and overheating. According to the method, the failure factors of the four pipes of the boiler can be comprehensively covered, and the state and the service life can be accurately evaluated.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

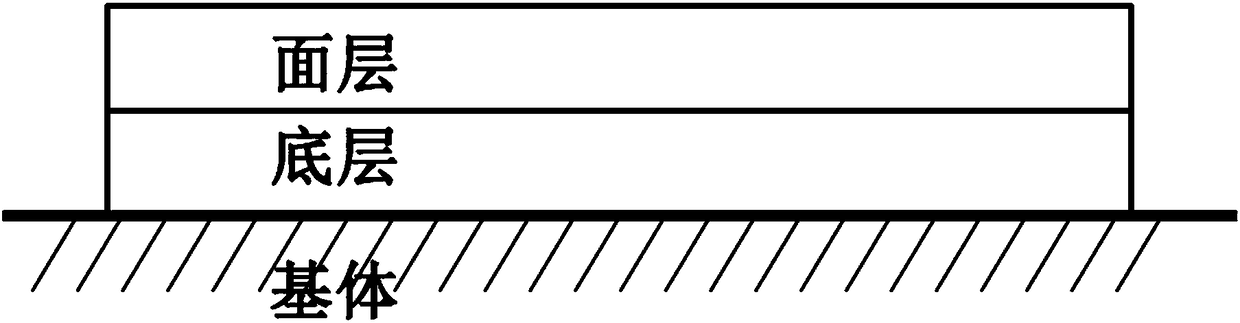

Chloridization corrosion resistant double-layer structure alloy coating for heating surface of garbage incinerator and preparation method

The invention discloses a chloridization corrosion resistant double-layer structure alloy coating for a heating surface of a garbage incinerator. The double-layer structure comprises a chloridizationcorrosion resistant bottom layer and a solid particle erosion resistant surface layer, wherein the chloridization corrosion resistant bottom layer comprises components in percentage by mass as follows: 20%-23% of Cr, 8%-10% of Mo, 3.15%-4.15% of Nb, 5% of Fe, 1% of Co, 0.5% of Mn, 0.5% of Si, 0.4% of Al, 0.4% of Ti and the balance of Ni and inevitable impurities; the solid particle erosion resistant surface layer comprises components in percentage by mass as follows: 80% of NiCr and 20% of Cr3C2; the chloridization corrosion resistant bottom layer in the double-layer structure coating is prepared with an activated combustion HVAF (high velocity air fuel) spraying process; the solid particle erosion resistant surface layer in the double-layer structure coating is prepared with an HVOF (highvelocity oxygen fuel) spraying process. The problems of pipe wall thinning and pipe explosion caused by the fact that the heating surface of the garbage incinerator is easily corroded by high-temperature chloride and eroded by solid particles are solved, and the service life and the maintenance cycle of pipes on the heating surface of the garbage incinerator are prolonged greatly.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for manufacturing fracture surface changing seamless aluminium-alloy tubular product

InactiveCN103286152AUniform structureImprove product qualityExtrusion diesExtrusion mandrelsMechanical engineeringWall thinning

The invention discloses a method for manufacturing a fracture surface changing seamless aluminium-alloy tubular product, which belongs to the technical field of aluminium alloy materials. The method comprises the following steps of: producing internal thickened parts, namely fixing the front part of an extrusion pin in an extrusion die hole before starting extruding in production, thereby extruding a front-end internal thickened part under the state, and retracting the extrusion pin to ensure that a shrinking part can face to the die hole, thereby manufacturing a rear-end internal thickened part; producing a normal-size part, namely moving the extrusion pin ahead to narrow a gap between the die hole and the extrusion pin and thin a tube wall, thereby manufacturing the normal-size part on the front end of a raw material of the extruding tubular product; producing an outer thickened part, namely moving the extrusion pin ahead to enlarge the gap between the die hole and the extrusion pin so as to increase the wall thickness of the outer thickened part because the inner diameter of the part of the tubular product raw material is reduced. The method provided by the invention has the beneficial effects that the fracture surface changing seamless tubular product can be produced, one-step extrusion forming is realized, the material organization of the product in a length direction is uniform and consistent, the product quality is greatly improved, the manufacturing technique is simplified, and the production cost is reduced.

Owner:吉林麦达斯铝业有限公司

Flow adjusting type water filling structure for reaction effluent pipeline

InactiveCN104235549AReduce disorderGuaranteed stabilityPipe elementsBranching pipesMaterial ErosionWater flow

The invention discloses a flow adjusting type water filling structure for a reaction effluent pipeline. An inlet section of a water filling circular pipe is vertically crossed and fixedly connected with a main circular pipe, the inlet section and an outlet section of the water filling circular pipe are connected by a 90-degree elbow in the main circular pipe, the interior of a hole in the outlet section of the water filling circular pipe is provided with a flow adjusting circular pipe, the outlet section of the water filling circular pipe and the flow adjusting circular pipe are connected into a whole by flow adjusting plates which are uniformly arranged along the circumferential direction of the flow adjusting circular pipe, and the flow adjusting circular pipe, the outlet section of the water filling circular pipe and the main circular pipe are coaxially arranged. The structure has the advantages that the outlet section of the water filling pipe is provided with a flow adjusting part, so the turbulence degree of the water filling flow is reduced, and the stability of the water flow entering the reaction effluent pipeline is guaranteed; the water filling outlet is vertically and upwards arranged, so the impact of the water filling flow on the pipeline at single side under the action of gravity is effectively avoided; the problems of erosion corrosion, wall thinning and hole penetration of pipelines near water filling points caused by the water filling flow turbulence are solved, the occurrence of non-scheduled shutdown accidents is reduced, and the service life of a multi-phase flow pipeline system is prolonged.

Owner:ZHEJIANG SCI-TECH UNIV

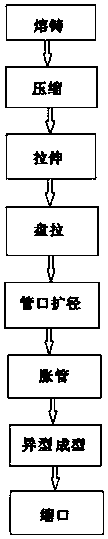

Manufacturing method of special-shaped pipe

InactiveCN107900132ASolve the problem of shortcomings that are not easy to circulateSmooth circulationSurface oxidationWork in process

The invention discloses a method for manufacturing a special-shaped pipe. The method includes the following steps: Step 1: melting and casting; using a high-temperature device to melt the finished copper plate material from a solid state to a liquid state, extruding and forming a copper pipe blank through a mold, and oxidizing it The surface is oxidized and washed; step 2: compression, stretching, coil drawing and cutting; the hollow copper tube raw material is compressed into a hollow copper tube semi-finished product, and the diameter of the tube wall is from thick to thin. The semi-finished product is stretched, the stretching force is 300-400KN, the stretching speed is 120-180m / min, the diameter of the pipe wall becomes thinner, and the copper round pipe is transported to the coil drawing equipment for secondary stretching. Copper tubes are stretched into different diameters, and copper tubes of different diameters are cut according to classification. The invention adopts the production method of special-shaped tubes, which solves the problem that the refrigeration medium is not easy to circulate, has high production efficiency, saves resources, produces high-quality products, and can ensure smooth circulation of the refrigeration medium.

Owner:靖江市新东机械零部件制造有限公司

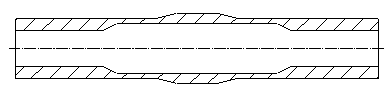

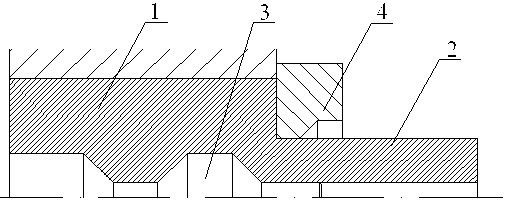

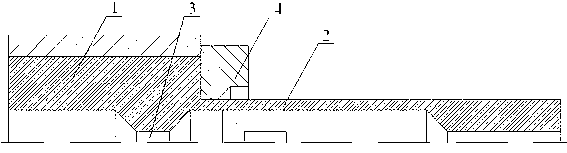

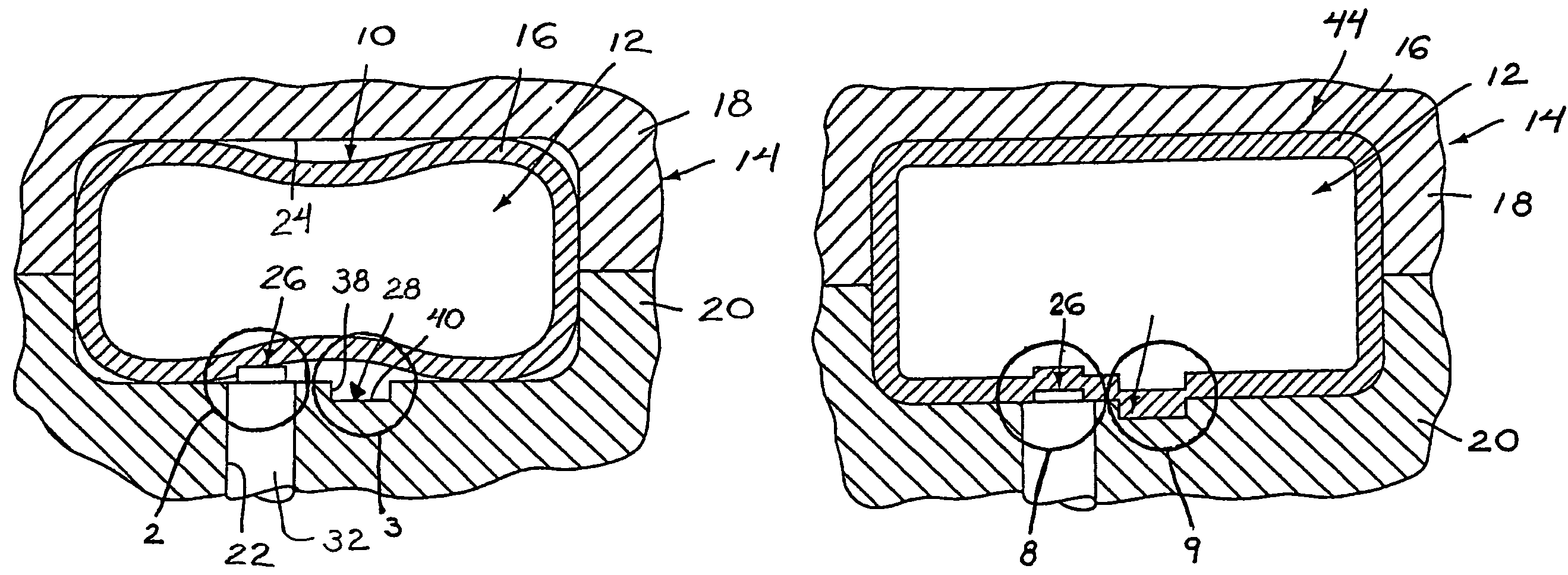

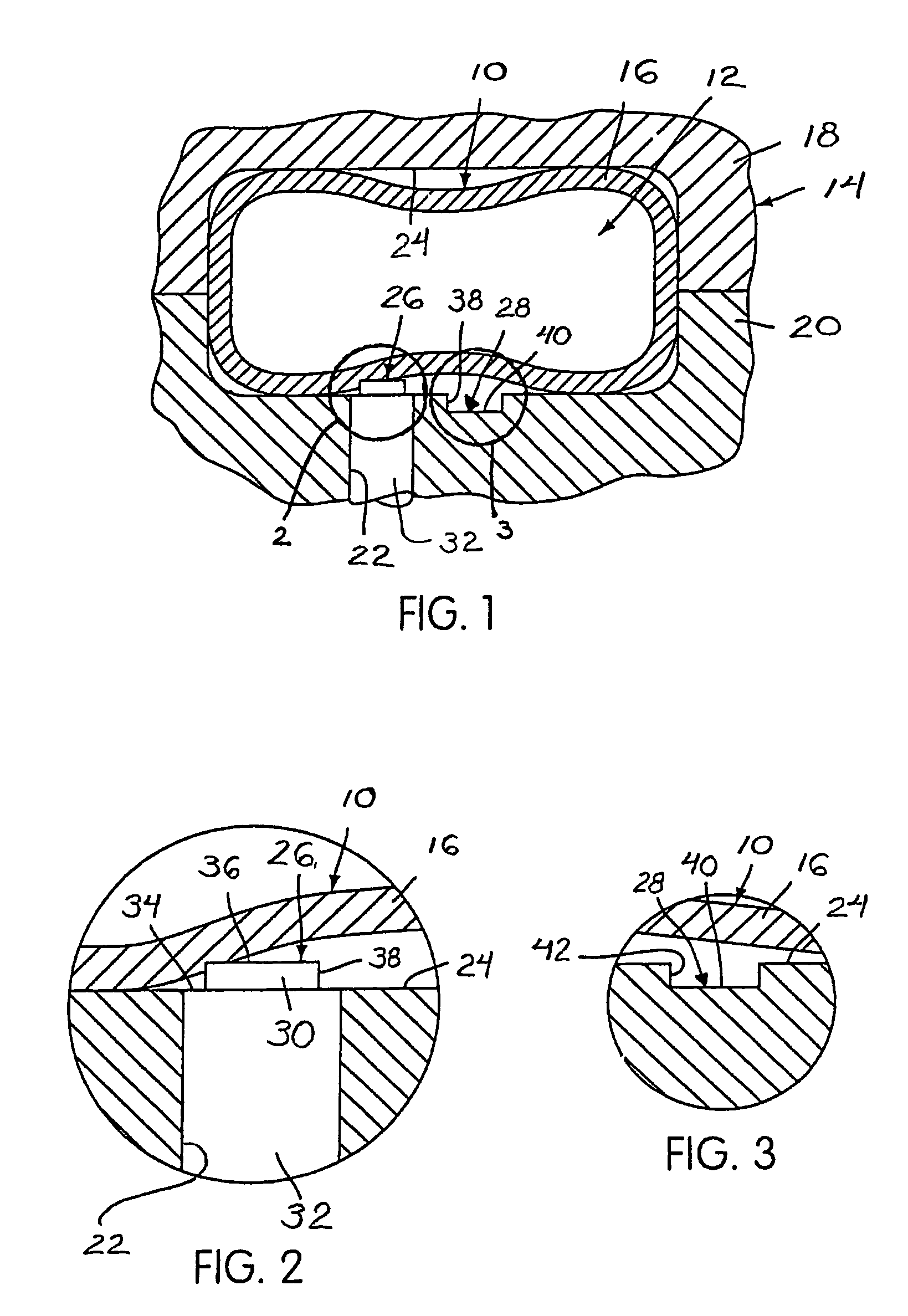

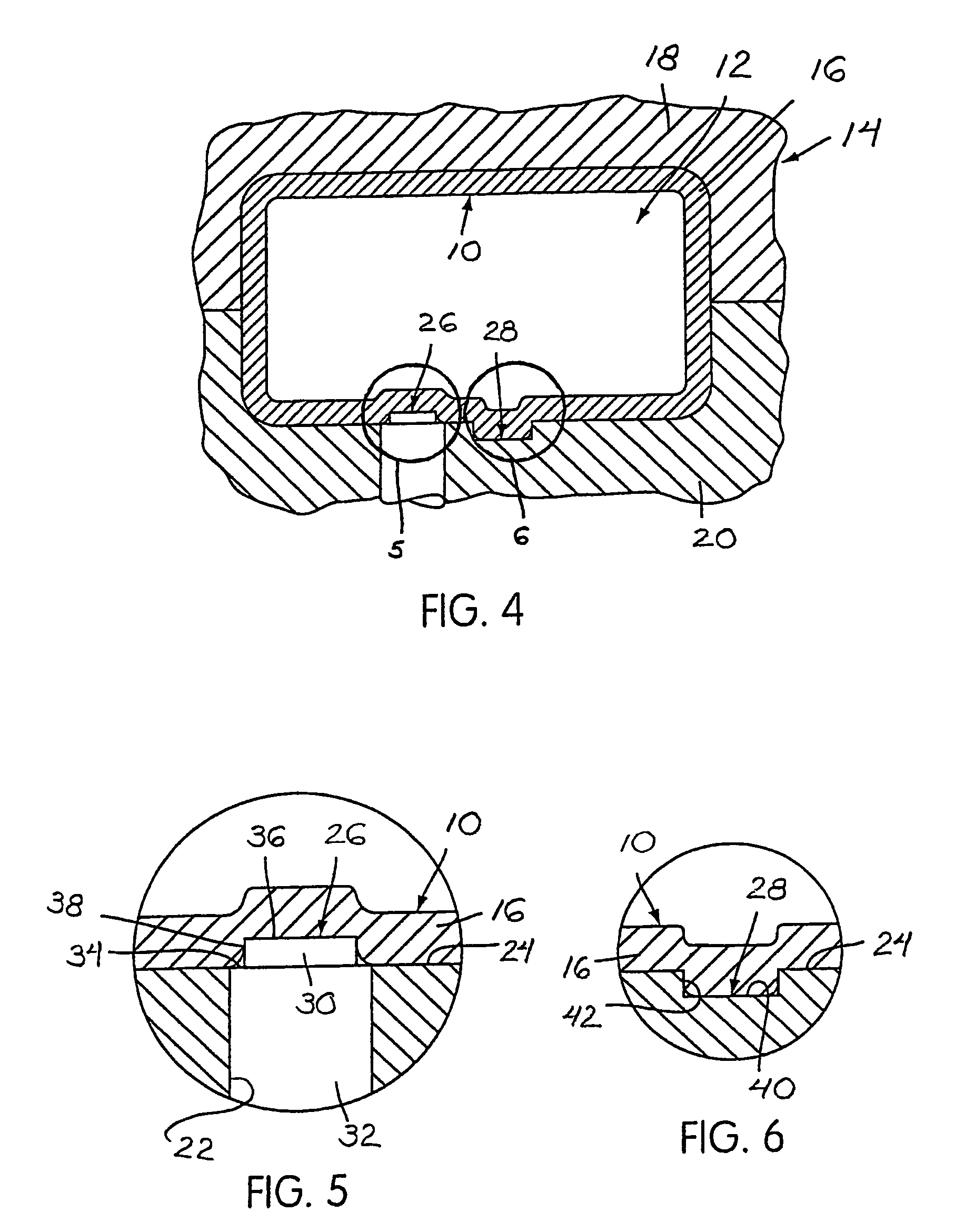

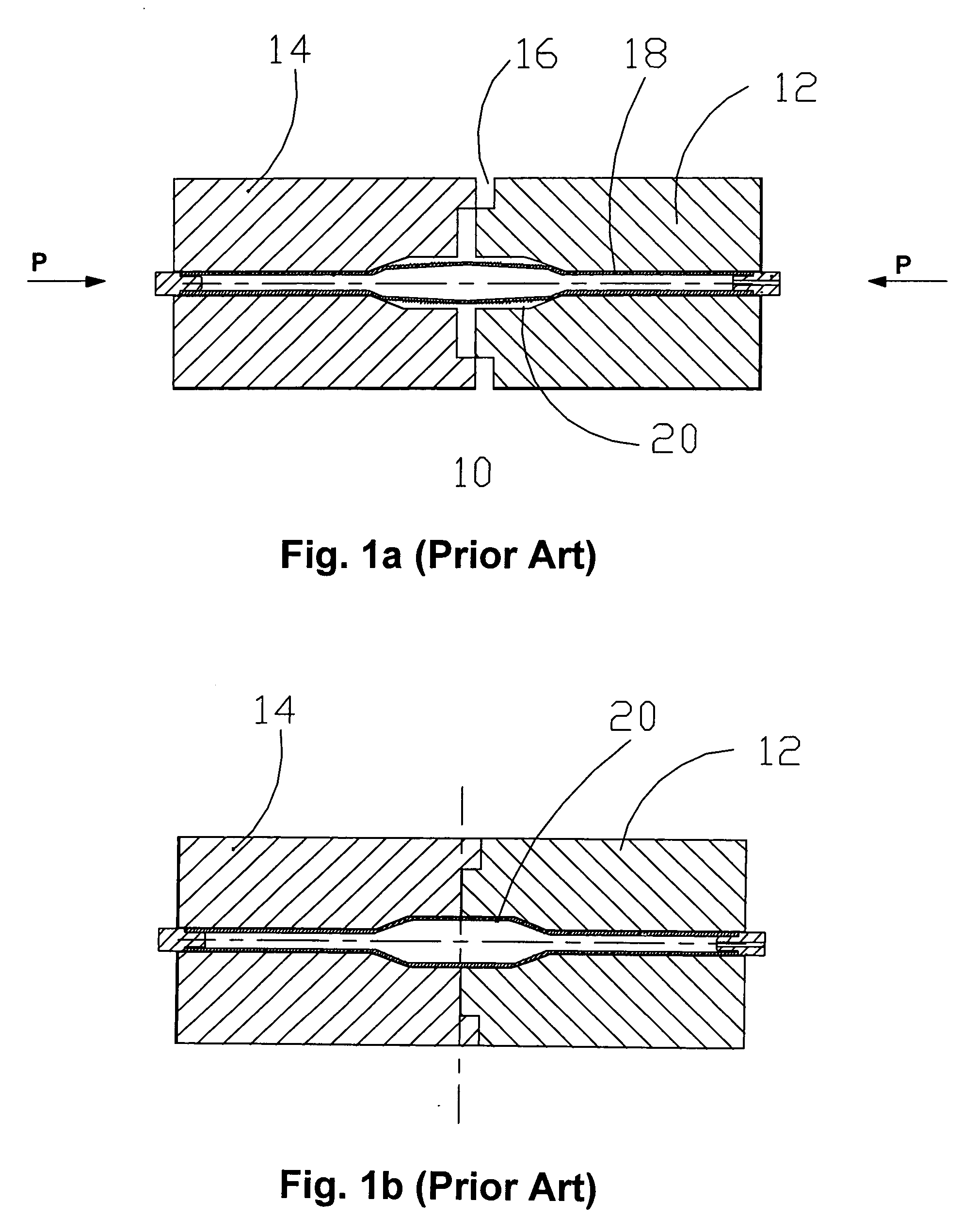

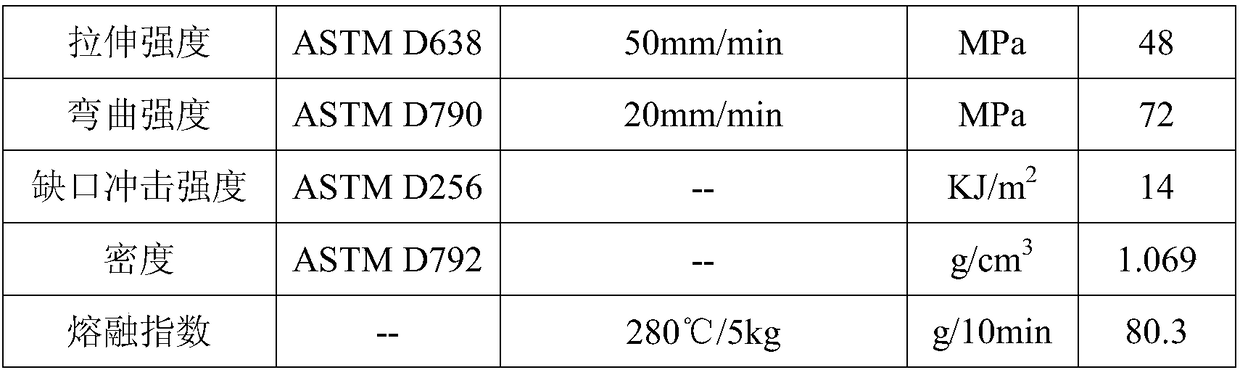

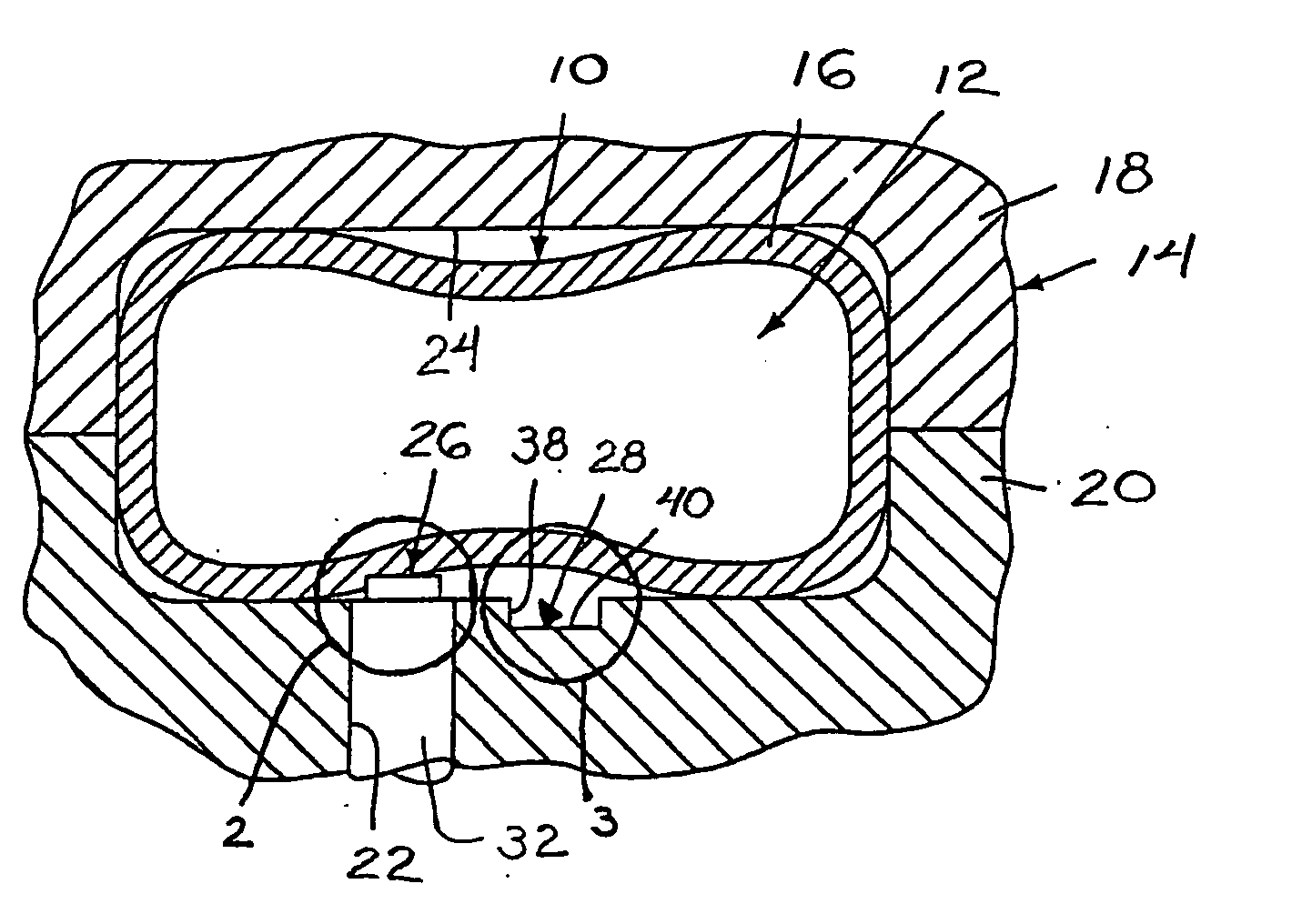

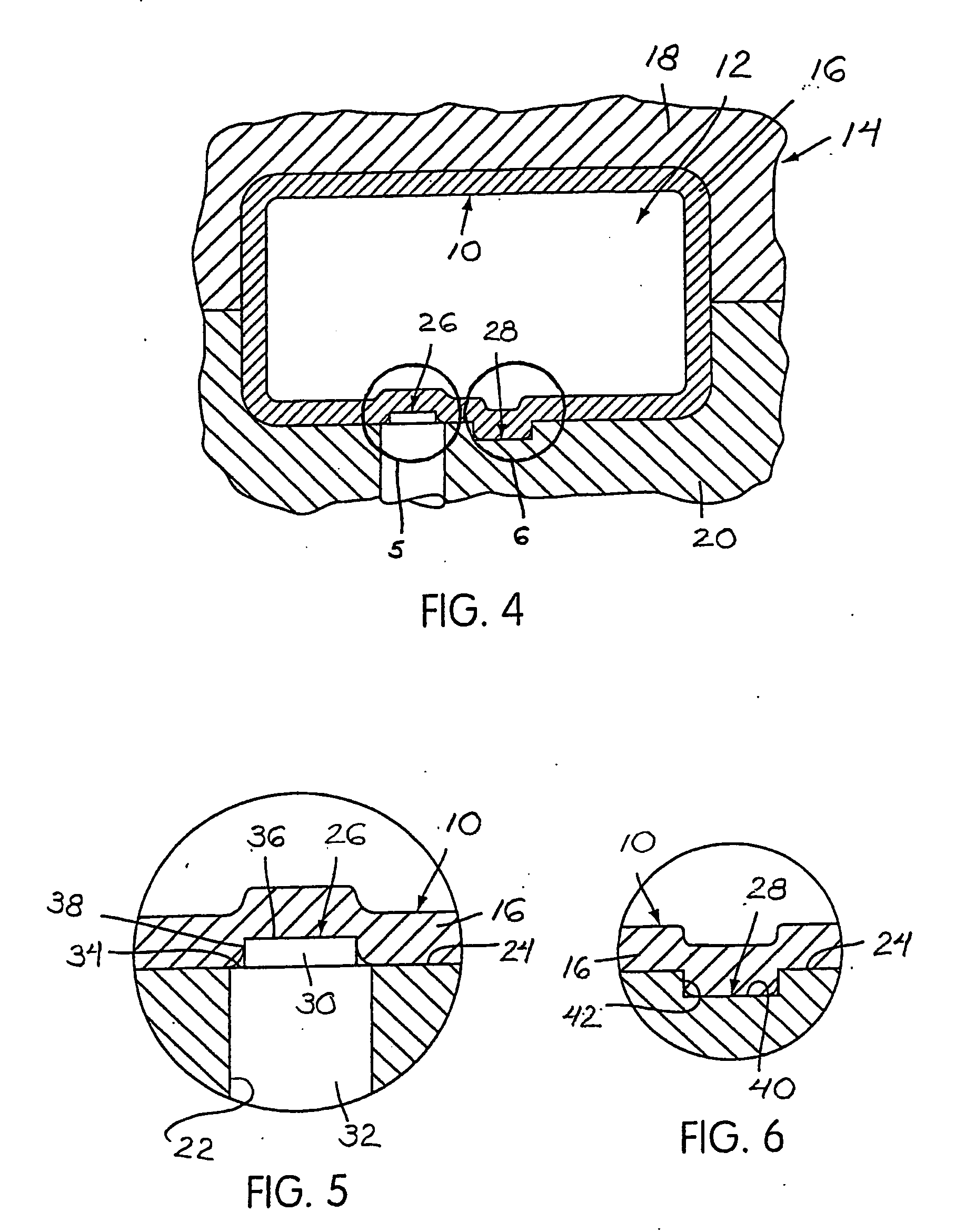

Method of forming hydroformed member with opening

A method for manufacturing a hydroforming member includes the step of providing a blank (10). The blank (10) is defined by blank wall (16). The blank (10) is placed in a die assembly (14) having a die cavity (12) defined by a die surface (24). The blank (10) is expanded so that the blank wall (16) is forced against the die surface (24) to form the hydroformed member. A portion of the blank wall conforms against a wall-thinning element (26, 28) positioned along the die surface (24) to form a removable wall section (46, 50) in a portion of the blank wall (24). The removable wall section (46, 50) is then removed from the blank wall (16) to form an opening in the hydroformed member.

Owner:MAGNA INTERNATIONAL INC

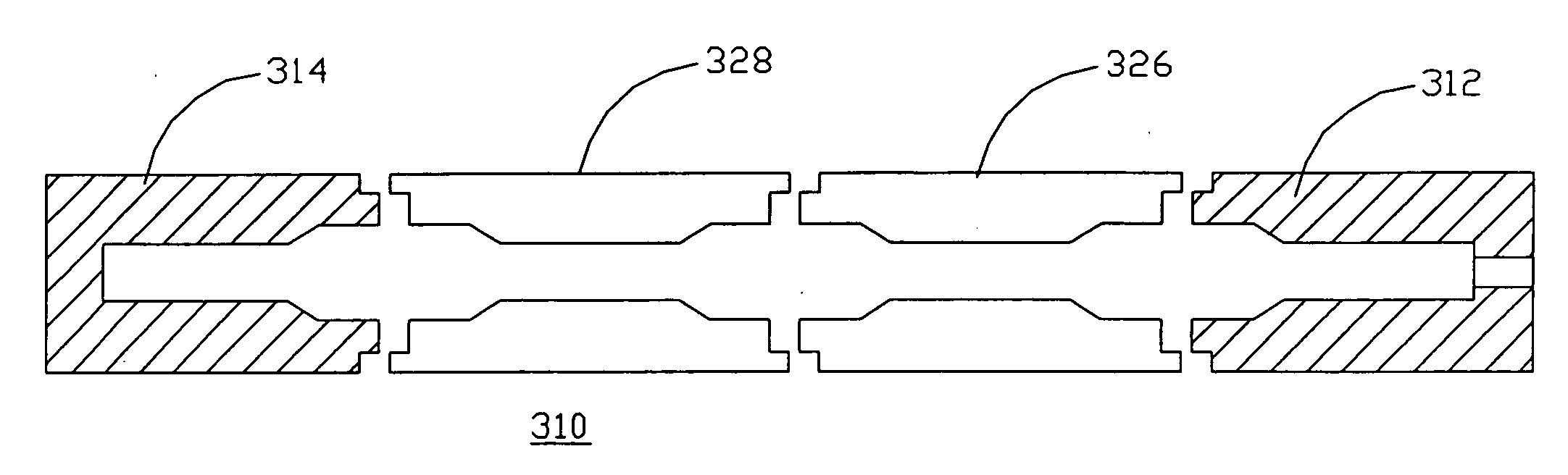

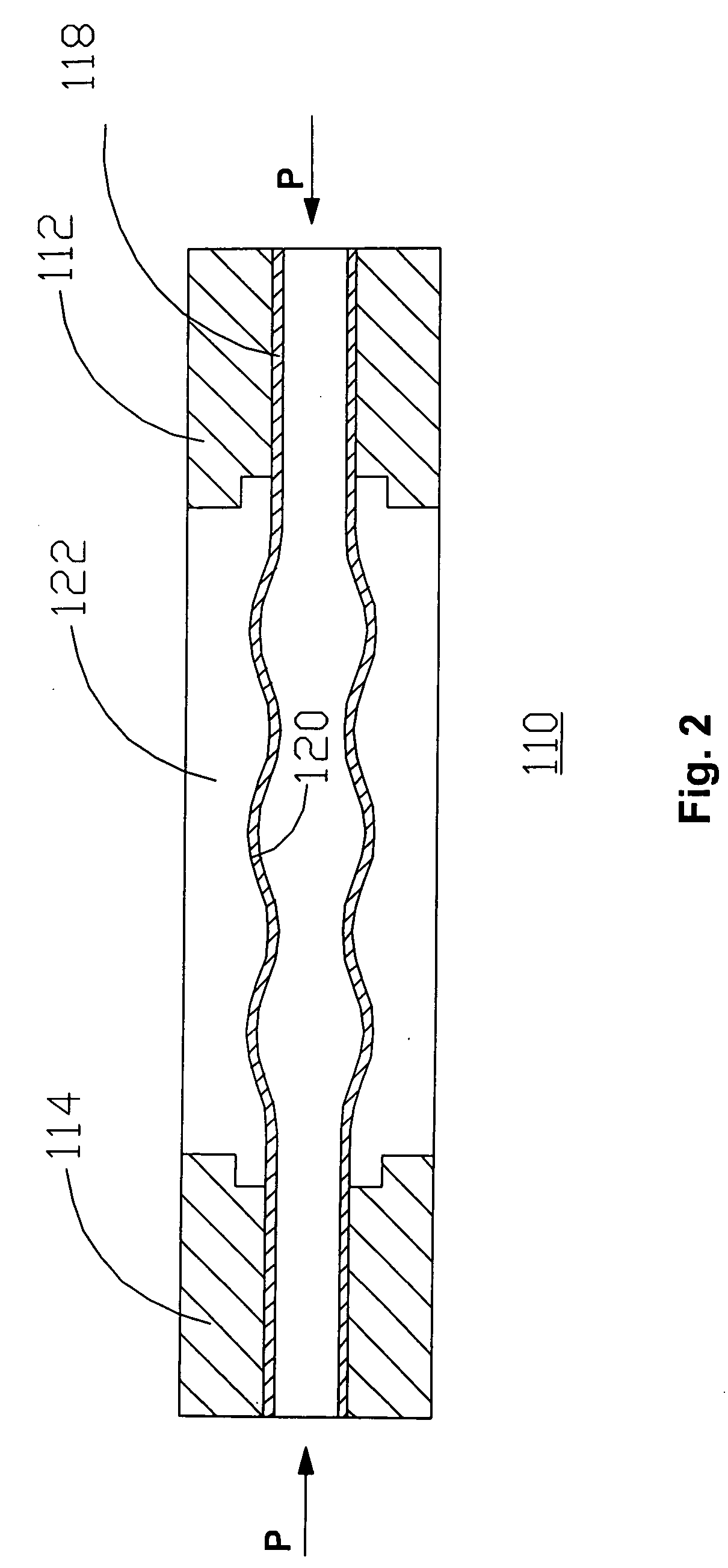

Techniques for reducing wall thinning during a hydroforming operation

It has been found that a compressive force assists in obtaining desired cold flow characteristics of a tubular steel work piece during a hydroforming operation. It has also been found that the most desirable results are achieved when the compressive force applied to the ends of the tubular steel work piece is just slightly less than the force that drive the tubular steel work piece into its yield point. A work piece previously formed by the above mentioned hydroforming operation may now be bent and subjected to a secondary hydroforming operation to produce a bent hydroformed tubular steel finished work piece having complex geometry.

Owner:GHARIB MOHAMED

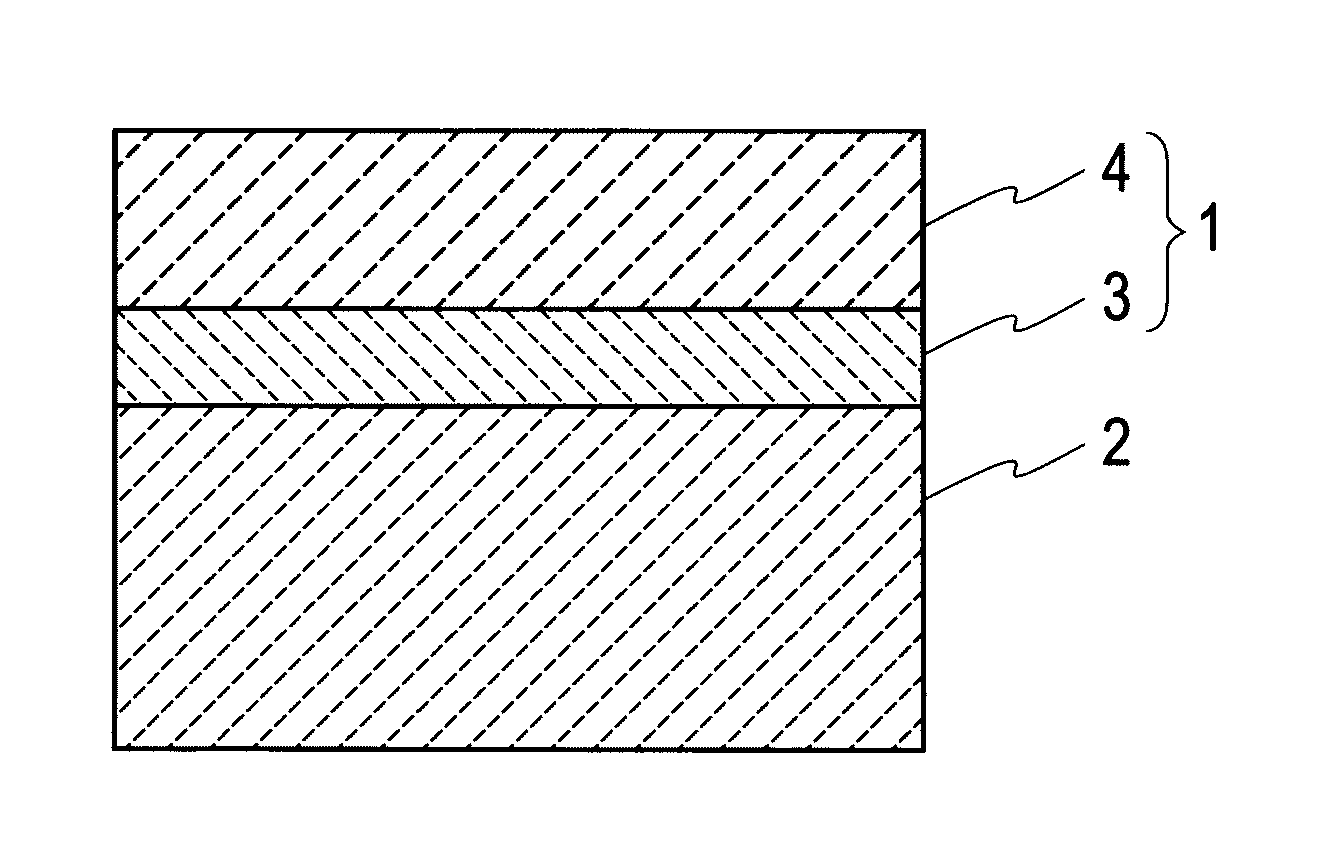

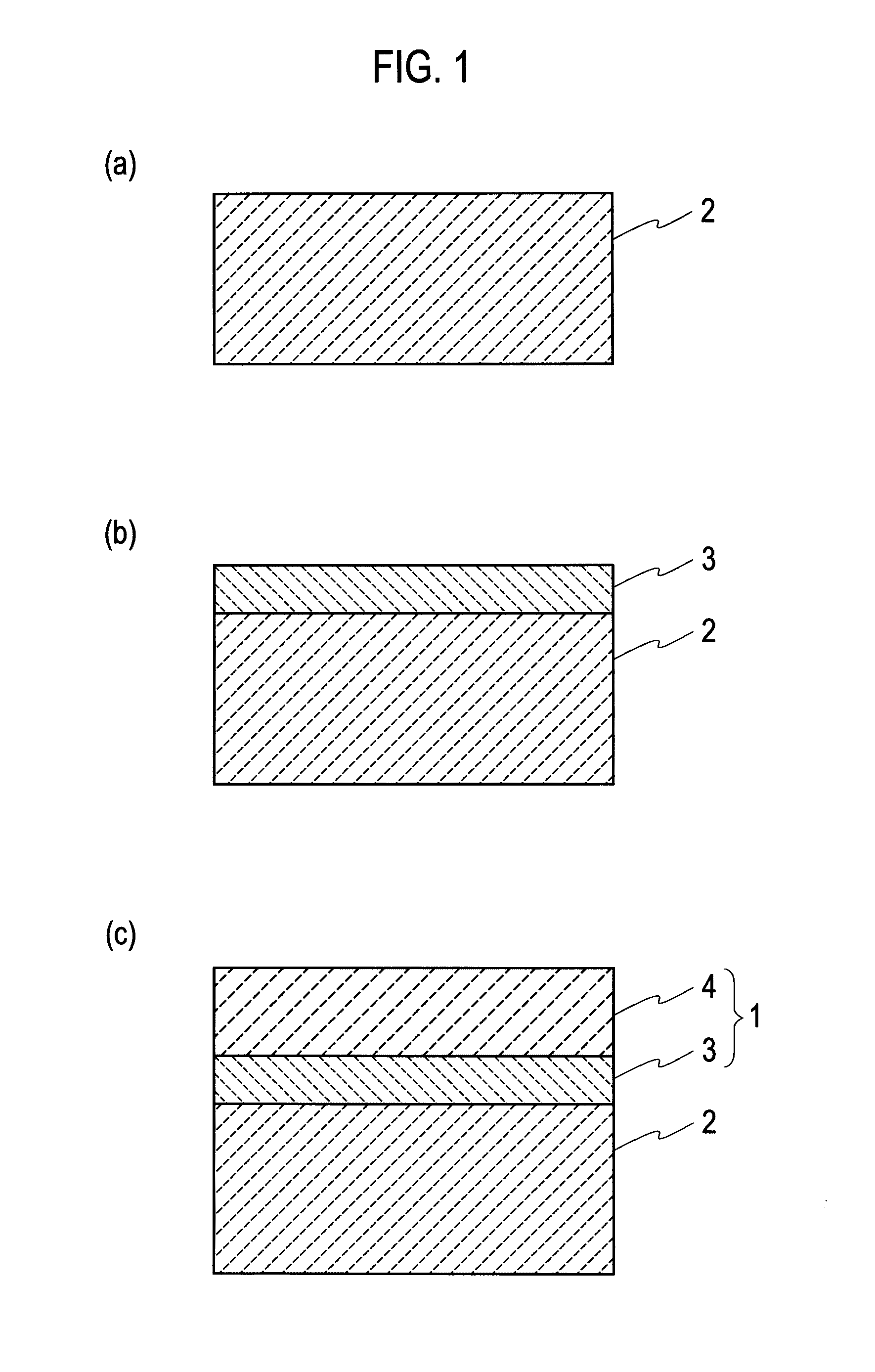

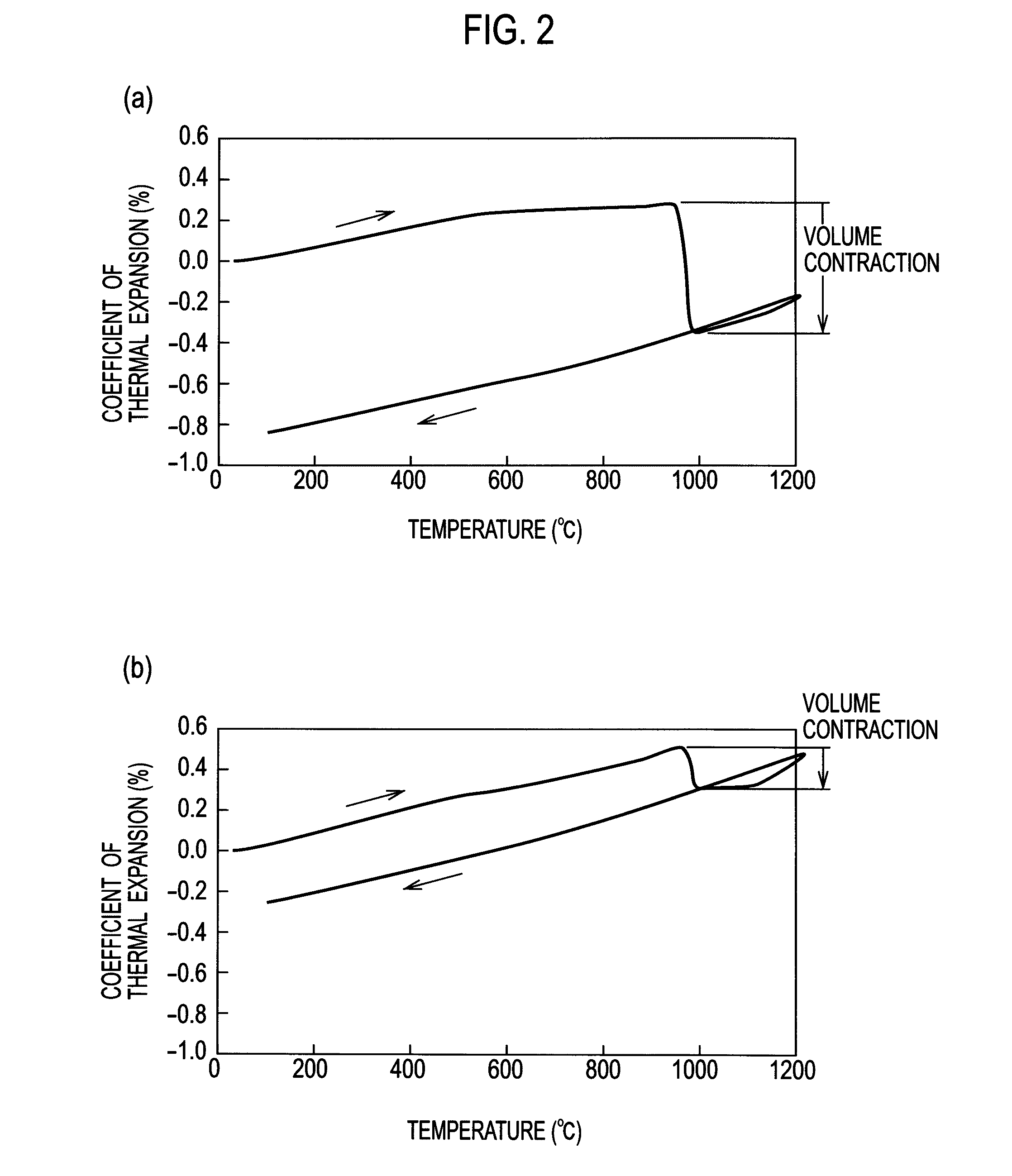

Coating structure and surface processing method

A high temperature component (2) has an intermediate layer (3) formed by a spraying on a surface in part thereof and comprised of an oxide ceramics set containing a glass, and an environment resistant coat (4) formed on a surface of the intermediate layer (3) and comprised of a coating material having a heat resistance and a water vapor wall-thinning resistance. The oxide ceramics set is a set of kinds of oxide ceramics adapted to be unchanged in crystalline phase, or isometric in cubic volume even when phase-changed, within a temperature range from a room temperature to 1,400 degrees C., the set of kinds of oxide ceramics having a coefficient of thermal expansion between a coefficient of thermal expansion of an SiC series ceramics matrix composite constituting the high temperature component (2) and a coefficient of thermal expansion of the coating material constituting the environment resistant coat (4).

Owner:IHI CORP

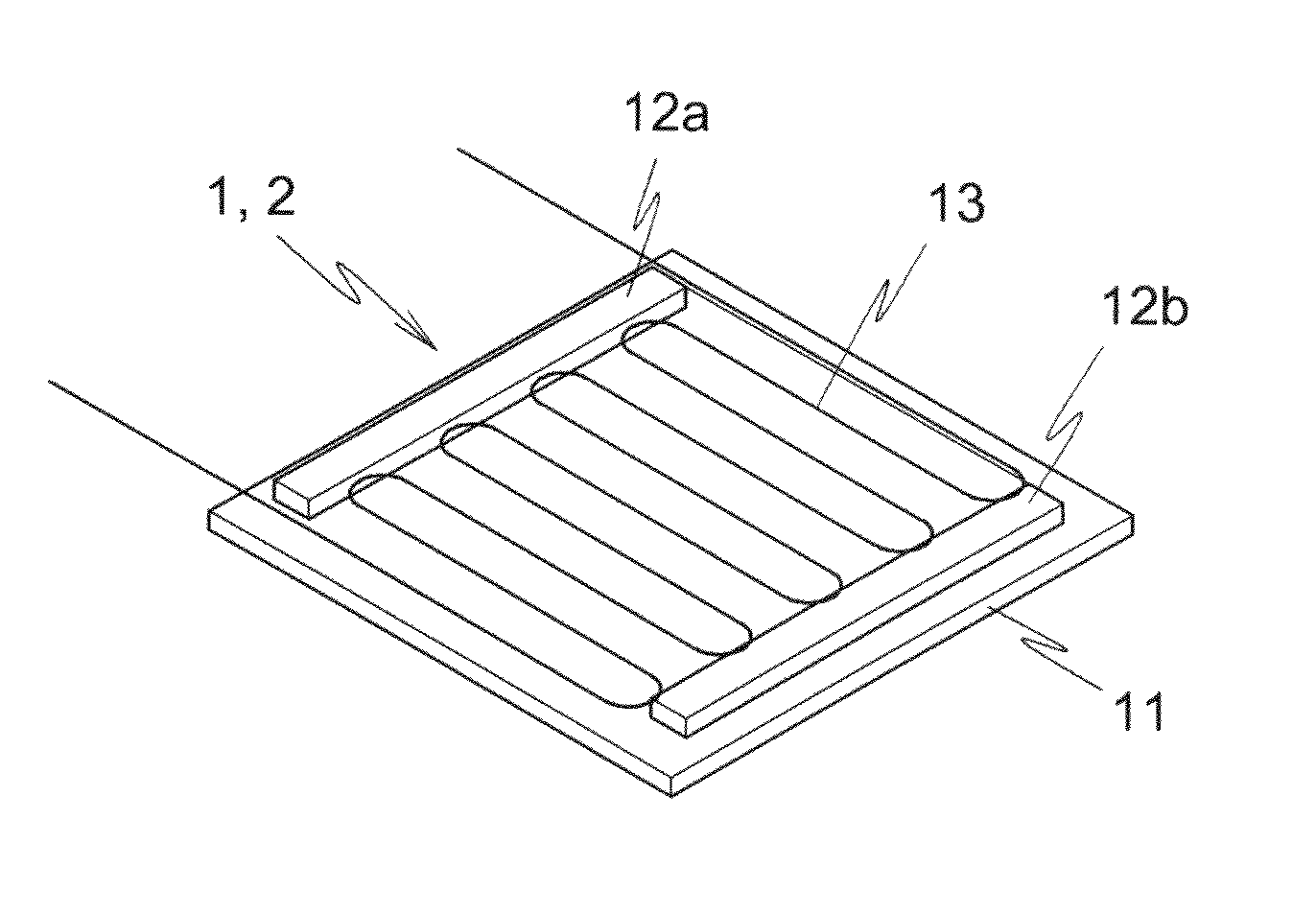

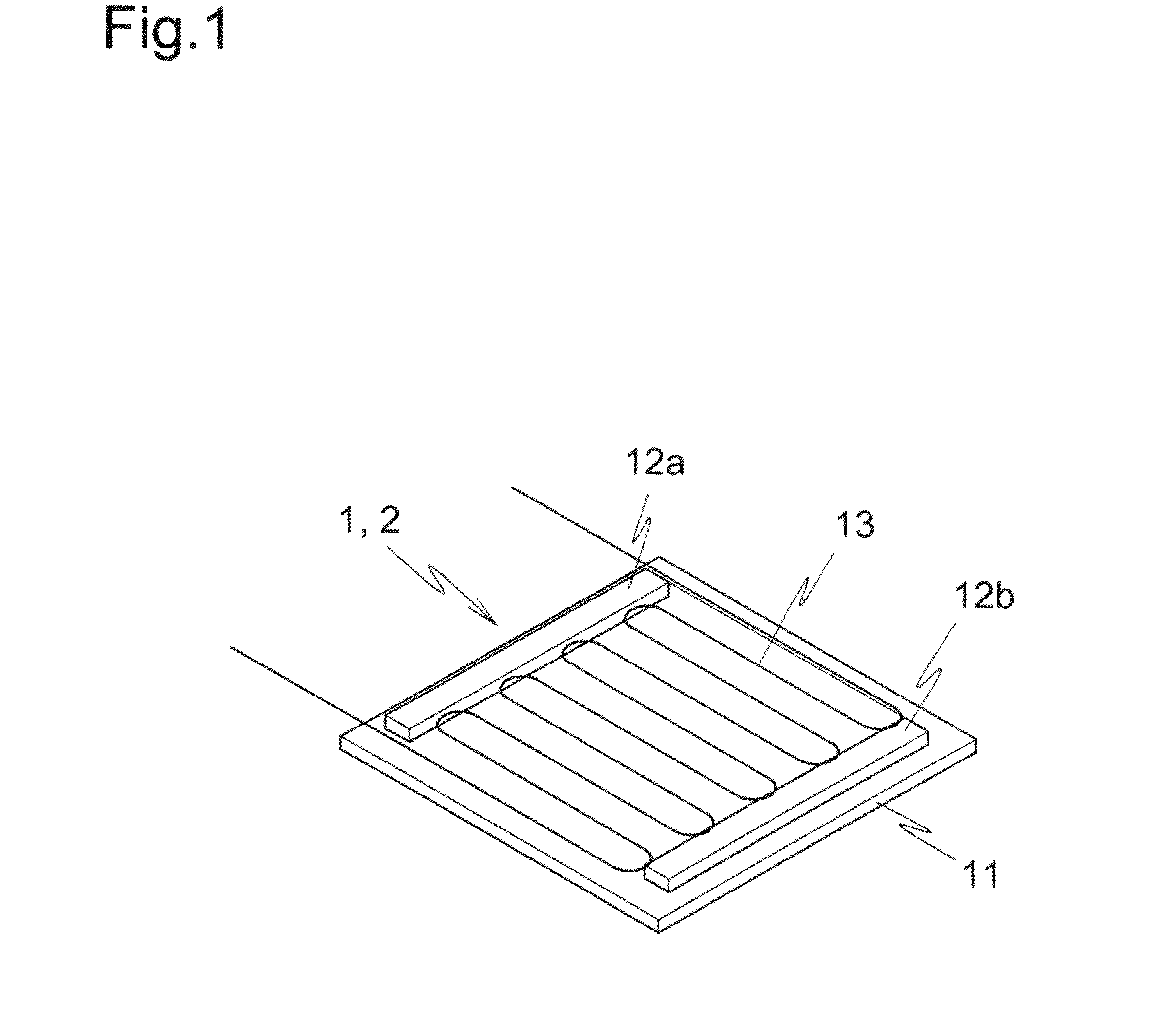

Aluminum alloy radiating fin for heat exchanger

The invention relates to an aluminum alloy radiating fin for a heat exchanger. The aluminum alloy radiating fin comprises the composition by the weight percentage: 0.3-0.5% of silicon, 1.8-2.0% of manganese, 0.05-0.08% of nickel, 0.3-0.5% of copper, 0.01-0.03% of magnesium, 0.1-0.3% of iron, 1.5-2.0% of zinc, 0.001-0.0015% of yttrium, 0.01-0.03% of titanium, 0.0001-0.00015% of boron, and the balance being aluminum and inevitable impurities. Wall thinning and weight lightening of the aluminum alloy radiating fin for the heat exchanger become possible, and in addition, the reliability of a heat radiating fin material and the heat exchanger is improved.

Owner:吴高峰

Method for producing ferrite stainless steel pipe

The invention discloses a method for producing a ferrite stainless steel pipe. The method is characterized in steps of: raw material smelting, shaped billet casting, hot centering, perforating and blank pipe obtaining, wall thinning, sizing, testing, rust preventing, and packaging. The steel pipe comprises components of, by weight: no more than 0.015% of C, no more than 0.015% of N, 0.3-0.5% of Si, 0.3-0.7% of Mn, 17-25% of Cr, no more than 0.03% of P, no more than 0.01% of S, no more than 0.002% of O, and balance of Fe and inevitable impurities. Compared to prior arts, the method provided by the invention has substantial technical advancements and important economic significance. The method is suitable for industrial popularization and application.

Owner:刘群联

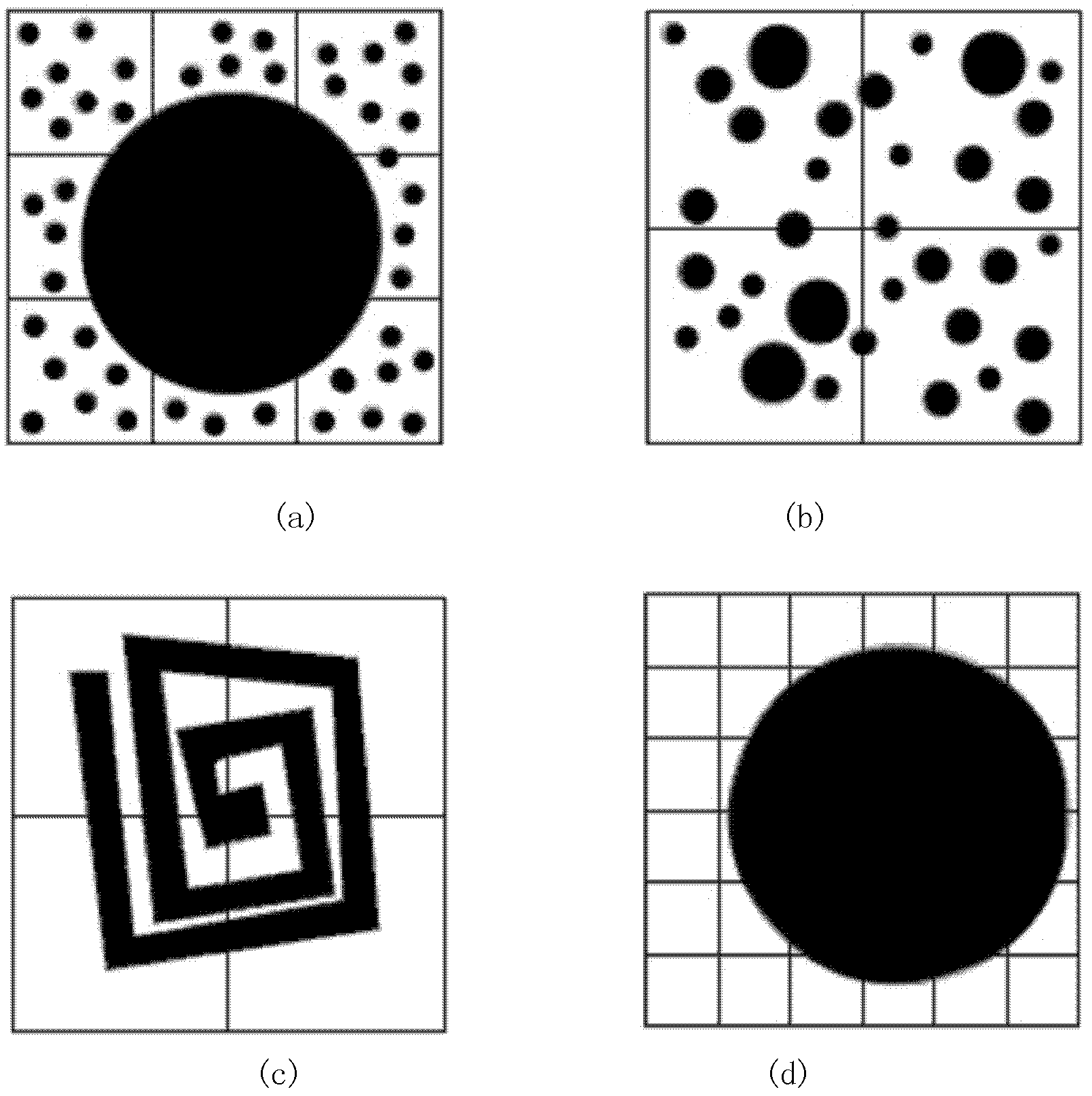

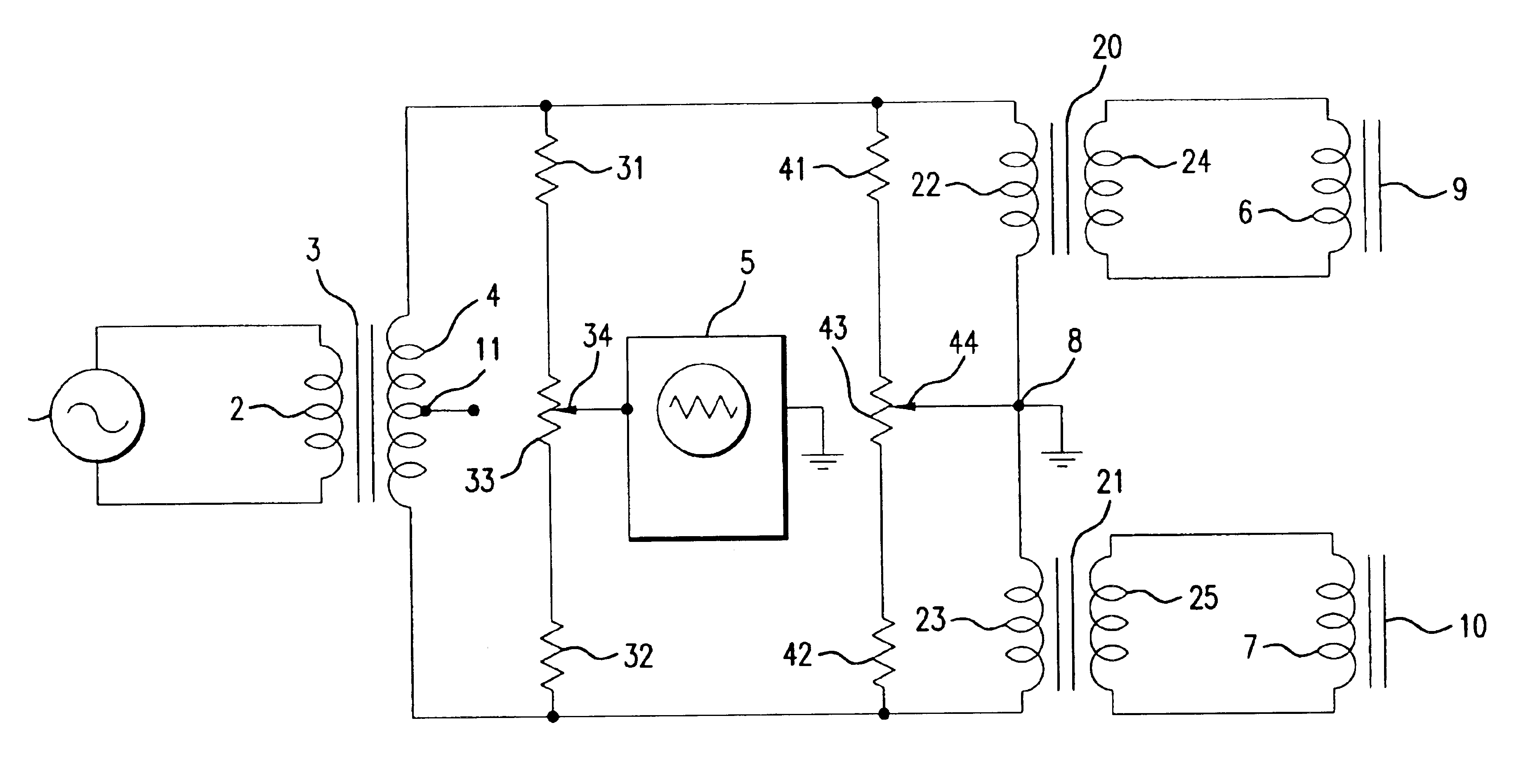

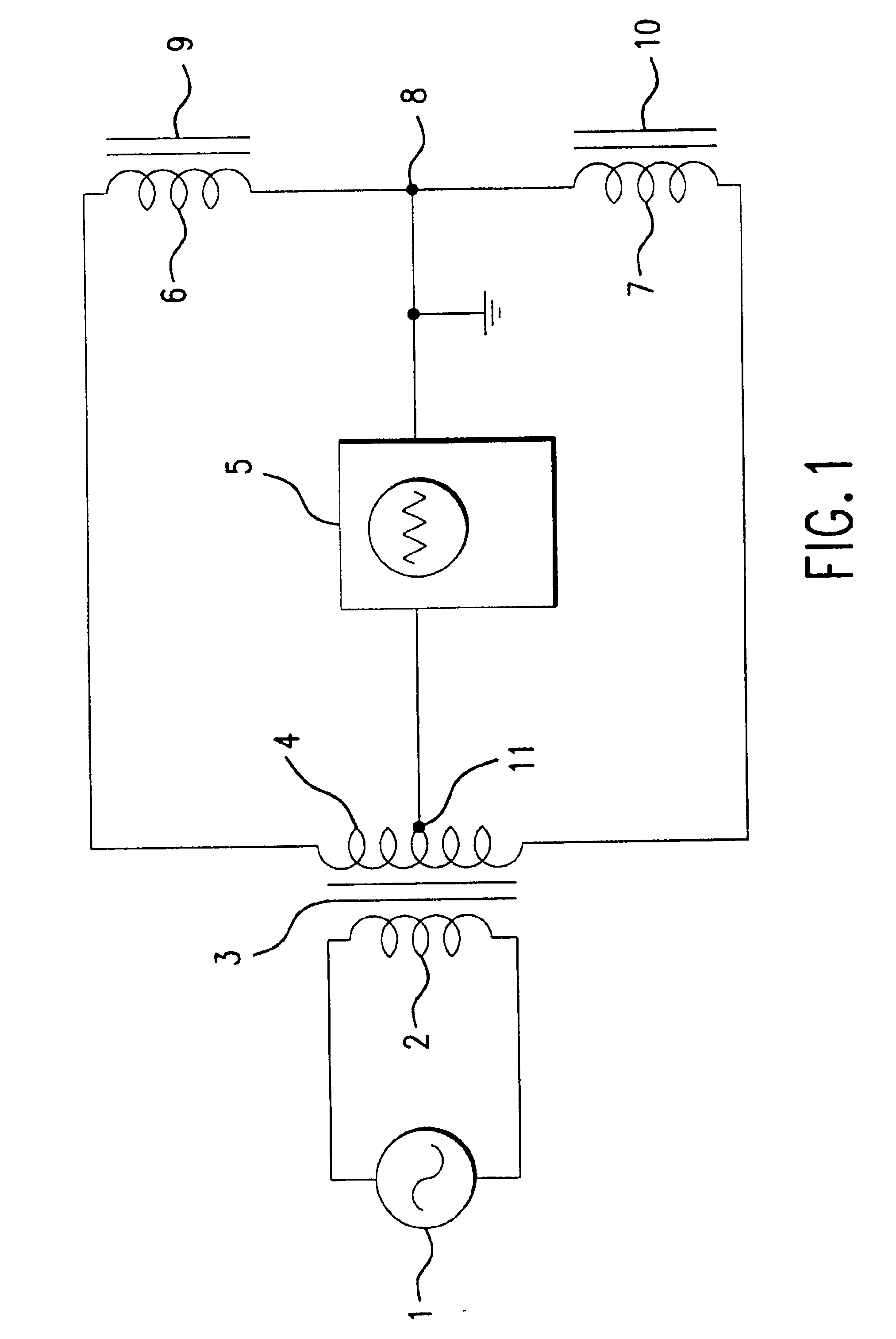

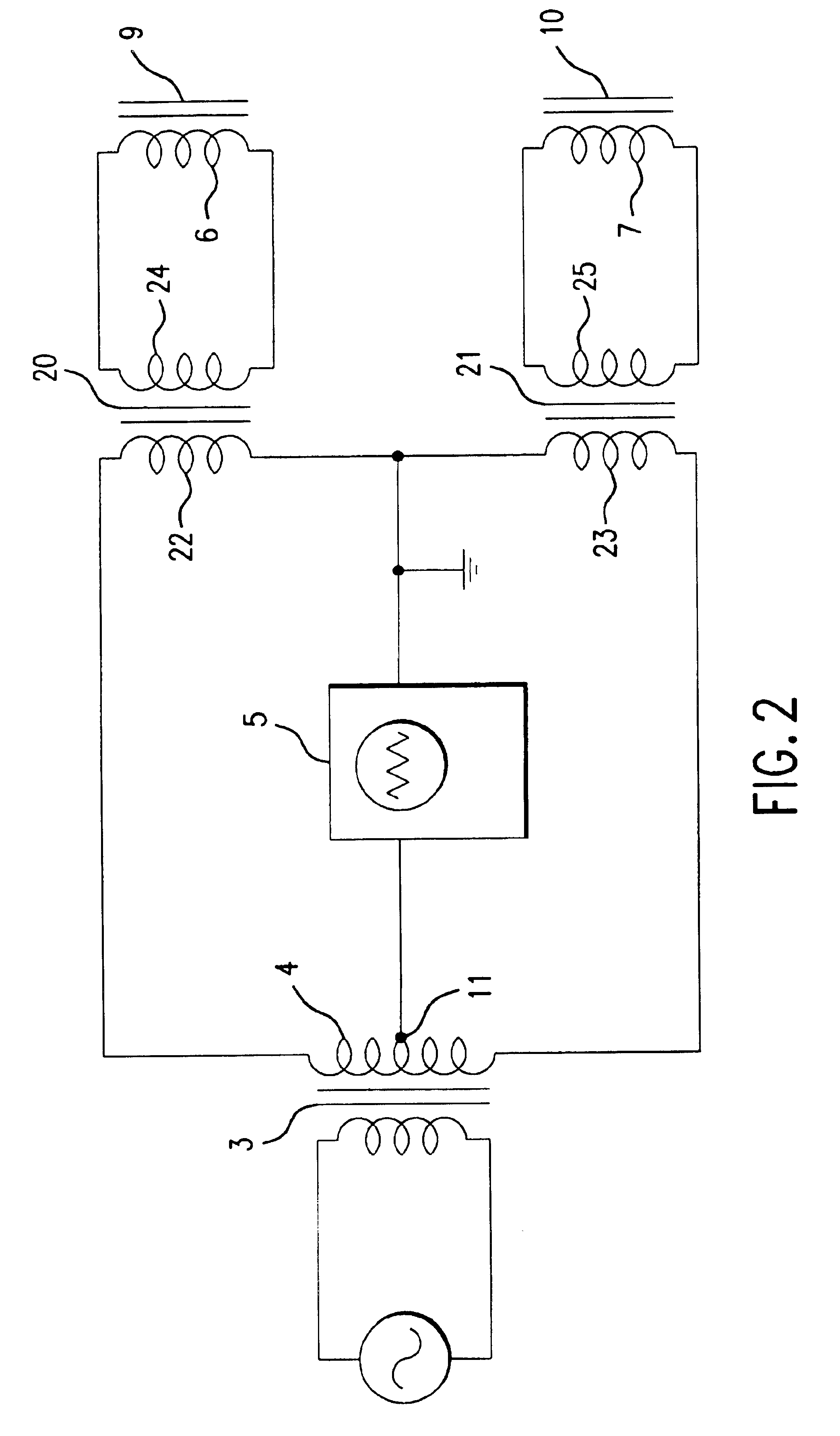

Mutual inductance bridge for detection of degradation in metallic components

InactiveUS6844722B2Reduce morbidityMagnetic property measurementsUsing electrical meansTransformerImpedance matching

An inductive bridge circuit using mutual inductances to transform impedances is used for detection of wall-thinning defects in metals. The bridge circuit has a first test coil placed adjacent to a good metal section and a second test coil placed adjacent to a metal to be tested. The bridge circuit compares the inductance in the first coil and inductance in the second test coil to compare wall thinning defects. The apparatus may also include first and second measuring transformers which are connected between the bridge circuit and the test coils where the transformers provide for impedance matching and reduced current requirements in the bridge. The circuit may also include one or more potentiometer circuits connected across the bridge which are used for compensating for imbalance of impedance between the first and second test coils when the coils both have known good metal sections adjacent to them.

Owner:AVISTAR

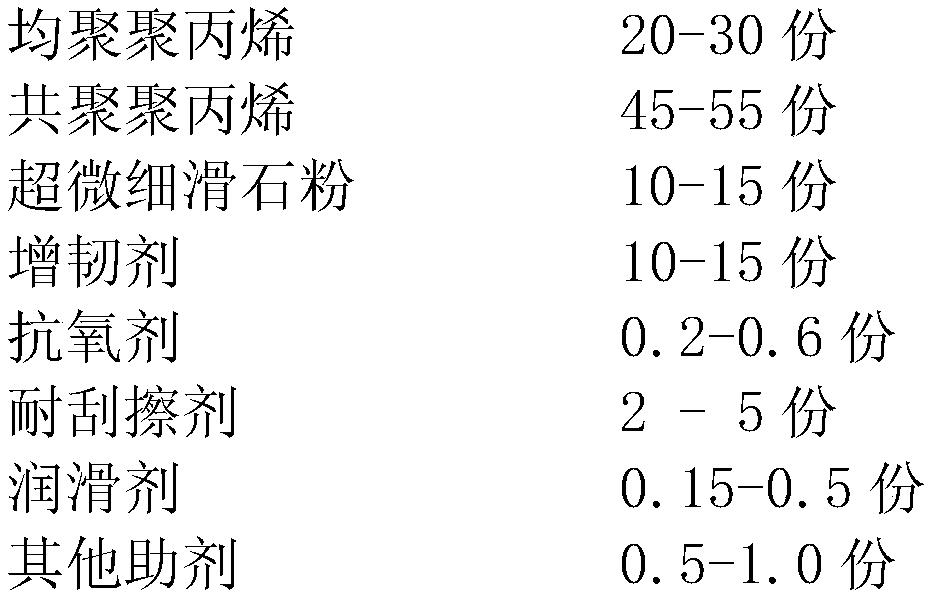

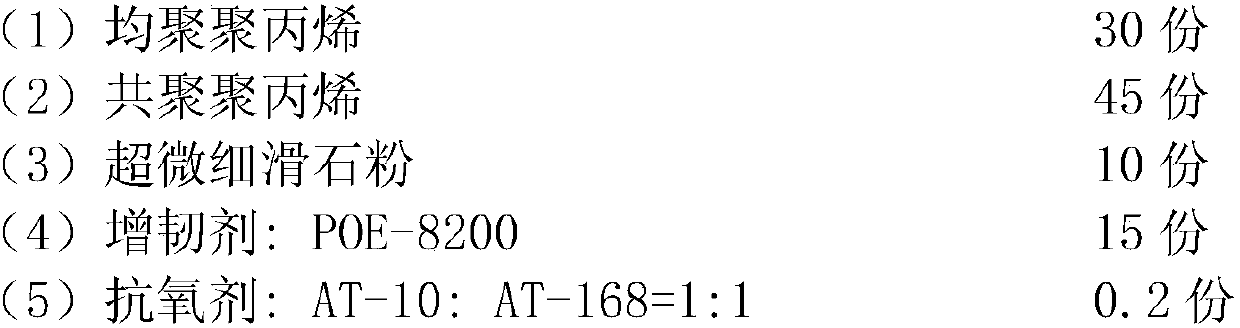

Low smell and scratch resistant thin-wall material and preparation method thereof

The invention discloses a low smell and scratch resistant thin-wall material and a preparation method thereof. The low smell and scratch resistant thin-wall material is prepared from the following rawmaterials of, in parts by weight, 20-30 parts of homo-polypropylene, 45-55 parts of co-polypropylene, 10-15 parts of ultramicro fine talcum powder, 10-15 parts of flexibilizers, 0.2-0.6 part of an antioxidant, 2-5 parts of scratch resistant agents, 0.15-0.5 part of a lubricating agent, and 0.5-1.0 part of other assistants. The surface scratch resistance of the material can be improved, wall thinning of automobile parts can be achieved, and the material cost is lower.

Owner:贵州凯科特材料有限公司

Compound de-foaming agent suitable for bottle ware glass production

ActiveCN107235627AImprove production pass ratePromote ruptureGlass furnace apparatusGlass productionDischarge efficiencyKerosene

The invention discloses a compound de-foaming agent suitable for bottle ware glass production. The compound de-foaming agent mainly comprises a main component and a solvent component, wherein the main component comprises a foam breaker composed of titanium compounds, a foam wall thinning agent composed of sodium nitrate and potassium nitrate and a solvent combustion efficiency optimizer ferrocene; the solvent component contains diesel oil, aviation kerosene, heavy oil or mixture thereof at any ratio; the flashing point of the solvent is at 38 DEG C or above; and the main component is dissolved in the solvent or is suspended in the solvent in a sold particle state. The compound de-foaming agent disclosed by the invention can form new small bubbles on a floating molten glass bubble wall so as to achieve the function of thinning the foam wall, and meanwhile, can boost the foam breaking in the manner of reducing the local viscosity and surface tension of the bubble wall so as to accelerate the breaking of bubble layers on the molten glass surfaces in different temperature areas of a kiln without increasing the highest temperature of a bottle ware kiln, so that the foam discharging efficiency of the molten glass can be increased, and the influence of the bubble defects of the bottle ware glass can be reduced.

Owner:WUHAN UNIV OF TECH

Machining method for thin-walled titanium alloy tube

InactiveCN111744960AReduce consumptionShort process flowFurnace typesMetal rolling arrangementsMaterial consumptionTitanium

The invention discloses a machining method for a thin-walled titanium alloy tube. The method includes the steps that a titanium rod is selected according to the diameter of a finished tube, heated to910+ / -2 DEG C and perforated to obtain a tube blank with the same diameter; then, the temperature is controlled to be 870+ / -2 DEG C, and perforation is performed a second time to increase the diameterand reduce the wall thickness; at least three passes of cold rolling are performed to obtain the finished product, wherein the ratio of the inner diameter reduction to the wall thickness reduction ofthe tube blank in each pass is controlled to be 1-22.5 in a successively increased manner, and the pass machining rate of rolling is 40%-67%; and after each pass of rolling, deoiling and pickling areperformed, the titanium tube is washed after pickling, drying is performed after thorough washing, vacuum heat treatment is performed after drying, and the titanium tube is straightened after vacuumheat treatment. Through the technology, the machining process is short, the material consumption is small, and the yield is high. The ultrathin-walled titanium tube prepared by the method has the outer diameter of 55 mm-100 mm and the wall thickness of 0.2 mm-0.8 mm, and the ratio of the wall thickness to the outer diameter is not greater than 0.008.

Owner:张家港海岸钛业有限公司

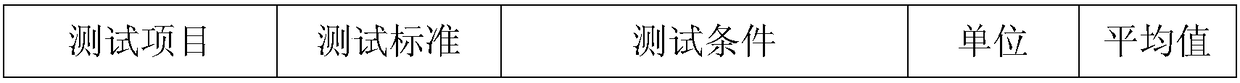

PPO/PA alloy material suitable for wall thinning and preparation method thereof

InactiveCN108299823AImprove liquidityMeet the requirements of injection molding processing larger size thin-walled partsAntioxidantAlloy

The invention discloses a PPO / PA alloy material suitable for wall thinning and a preparation method thereof. The PPO / PA alloy material is composed of following six components in parts by weight: 10 to60 parts of PPO resin, 20 to 70 parts of PA resin, 3 to 10 parts of compatilizer, 5 to 15 parts of flexibilizer, 1 to 5 parts of flow modifier, and 0.1 to 1 part of antioxidant. The alloy material has the advantages that the flow modifier greatly improves the flowing performance of the alloy material, and the modified material can be used to prepare large size thin wall parts by injection moulding.

Owner:SHANGHAI PRET COMPOSITES +4

Method of forming hydroformed member with opening

A method for manufacturing a hydroforming member includes the step of providing a blank (10). The blank (10) is defined by blank wall (16). The blank (10) is placed in a die assembly (14) having a die cavity (12) defined by a die surface (24). The blank (10) is expanded so that the blank wall (16) is forced against the die surface (24) to form the hydroformed member. A portion of the blank wall conforms against a wall-thinning element (26, 28) positioned along the die surface (24) to form a removable wall section (46, 50) in a portion of the blank wall (24). The removable wall section (46, 50) is then removed from the blank wall (16) to form an opening in the hydroformed member.

Owner:MAGNA INTERNATIONAL INC

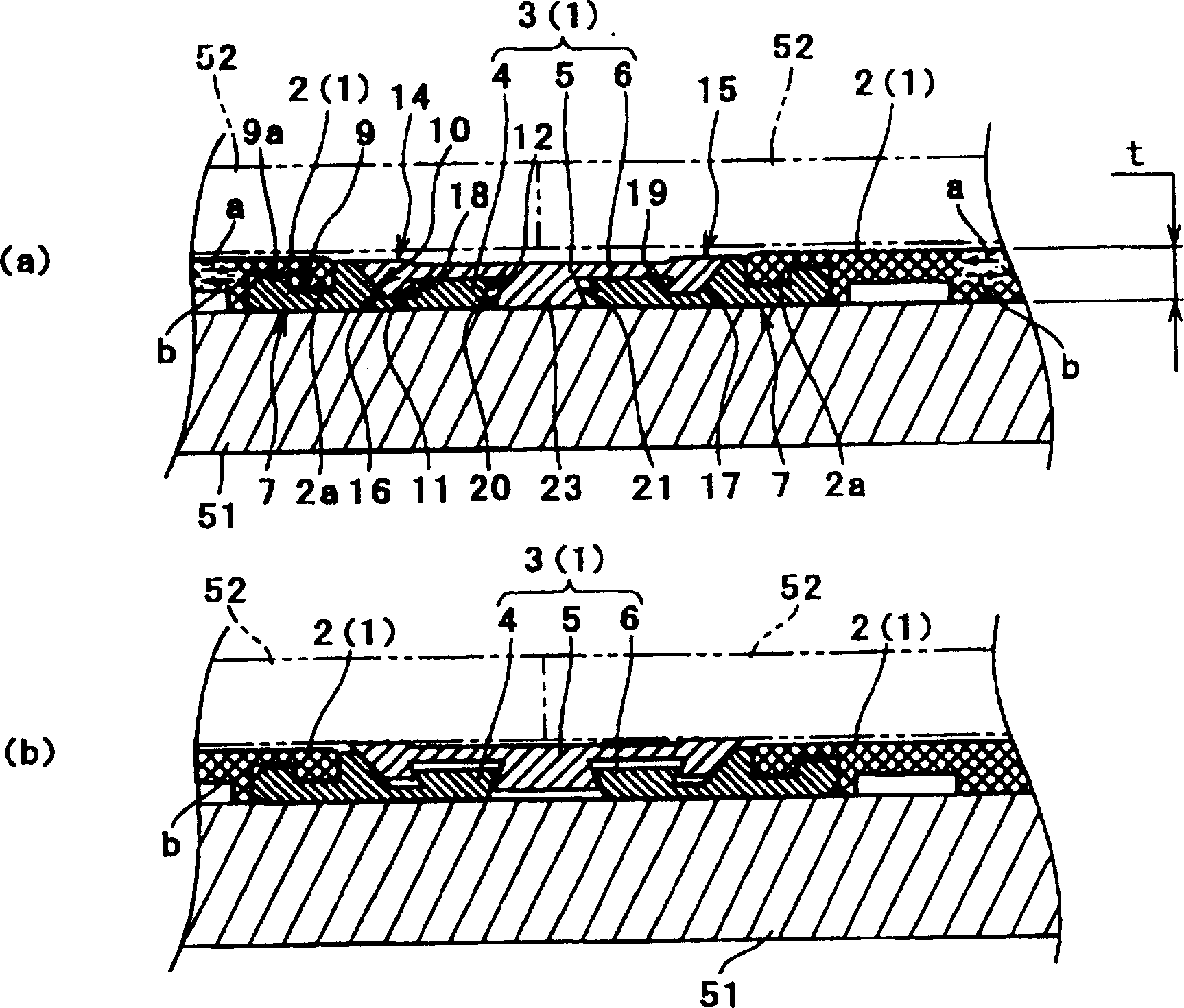

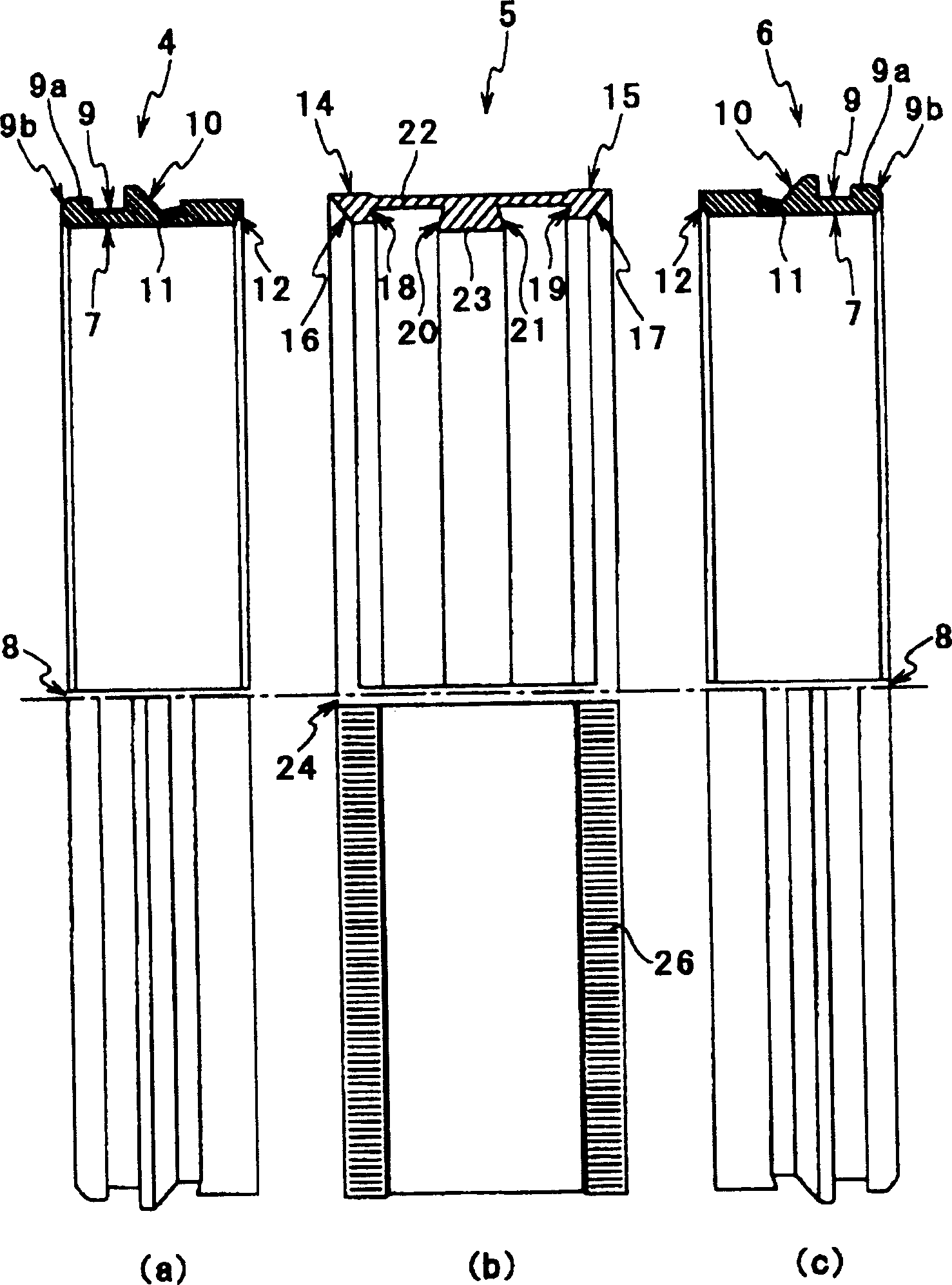

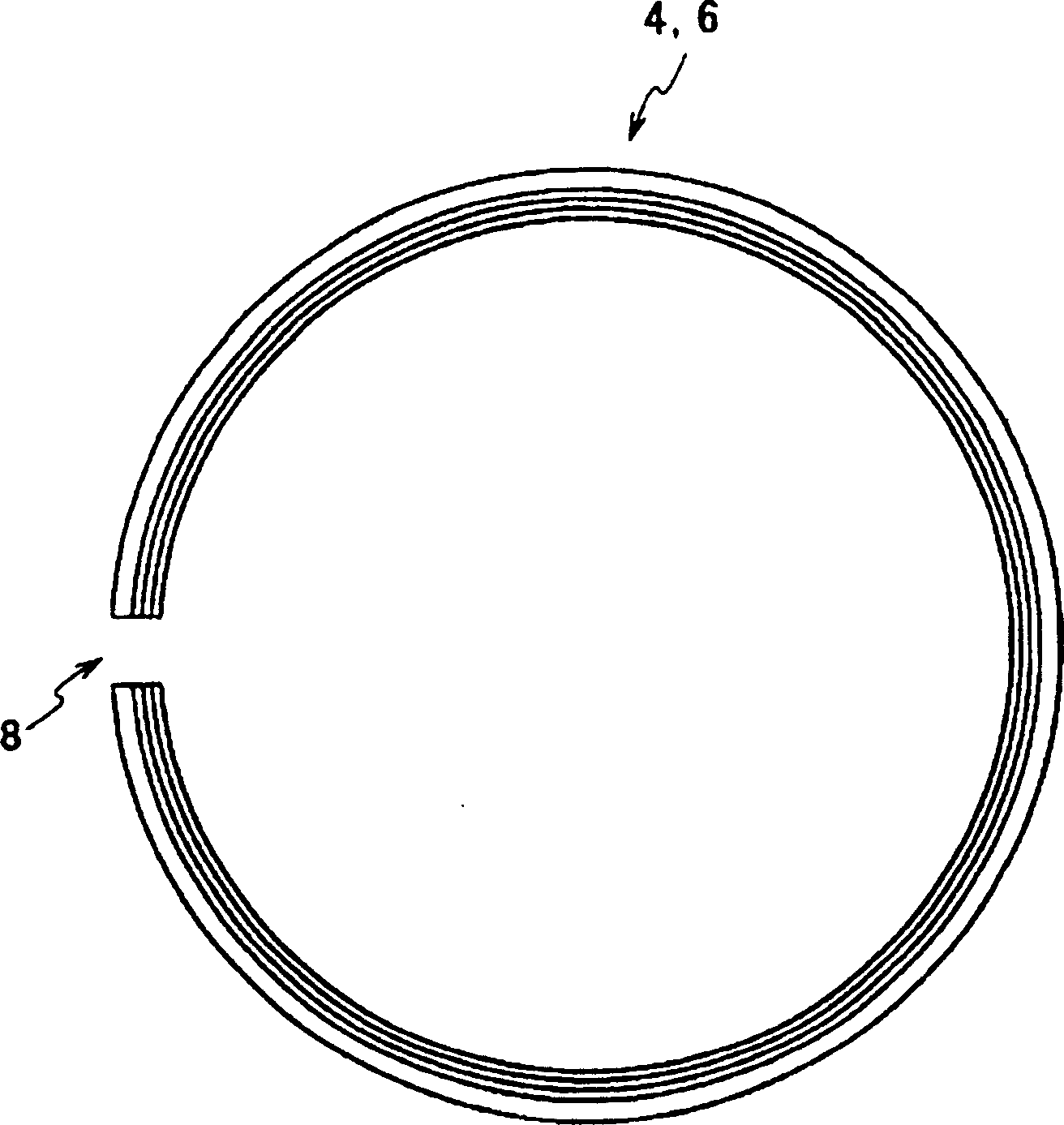

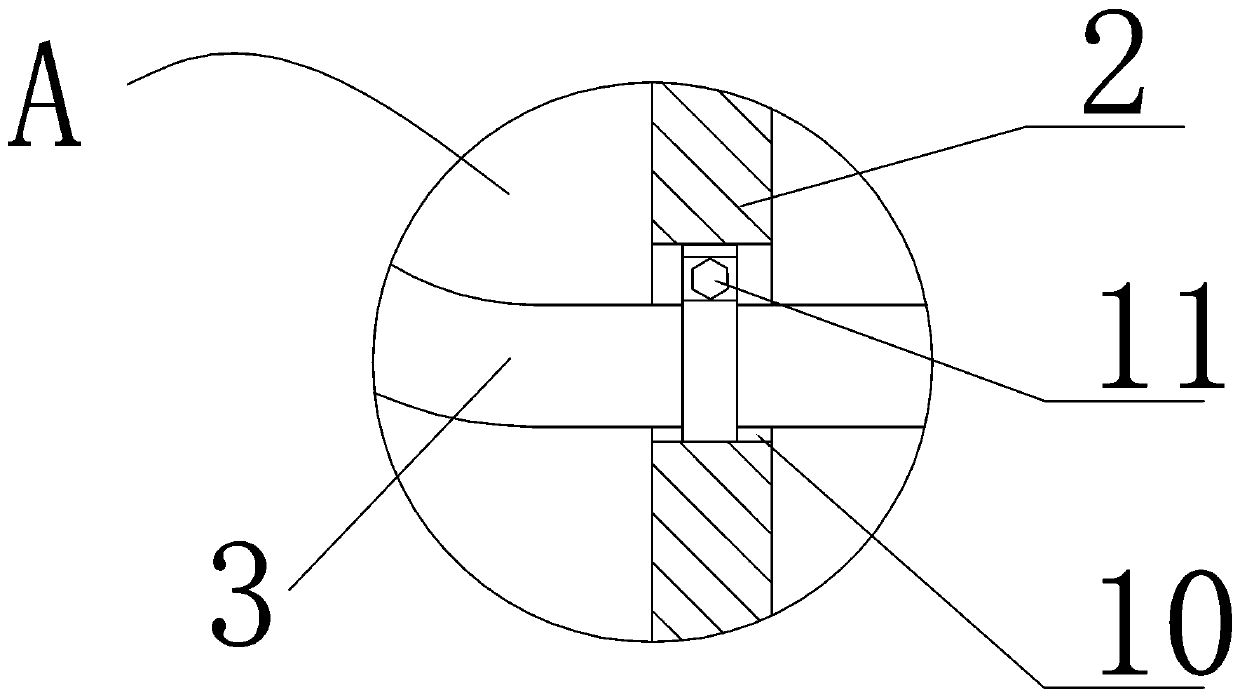

Tubular pipe fastener

InactiveCN1440921AInhibition diameter becomes smallerLow natural vibrationFilament handlingBobbinEngineering

The invention discloses a bobbin chuck device capable of facilitating extracting a bobbin with a chuck piece certainly separated from the bobbin in releasing and extracting the bobbin from a bobbin holder, and capable of attaining wall thinning and high-speed handling of the bobbin holder. A chuck piece 3 includes a first member 5 for the bobbin 52 and second members (4, 6) for a rotating cylinder 51. The first member 5 and the second members (4, 6) relatively approach or are separated from each other in the axial direction of the rotating cylinder 51, so that the first member 5 and the second members (4, 6) are respectively energized toward or released from the bobbin 52 and the rotating cylinder 51. When the first member 5 and the second members (4, 6) are relatively moved so that both of the members may be respectively energization-released, both of the members are kept in mutual engagement, and an engagement part for separating the first member 5 from the bobbin 52 is provided on the first member 5 and the second members (4, 6) respectively.

Owner:MURATA MASCH LTD

Composite debubbling agent applicable to liquid crystal glass production

InactiveCN107056044AImprove production pass ratePromote ruptureGlass furnace apparatusGlass productionKeroseneSolid particle

The invention discloses a composite debubbling agent applicable to liquid crystal glass production. The composite debubbling agent mainly comprises a main component and a solvent component, wherein the main component comprises a titanium compound-containing bubble breaker, a bubble wall thinning agent consisting of tin oxide and magnesium sulfate, and a solvent combustion efficiency optimizer pentadiiron; the solvent component contains diesel, aviation kerosene, heavy oil or a mixture thereof according to any ratio; the flash point of the solvent is higher than or equal to 38 DEG C; the main component is dissolved in the solvent or suspended in the solvent in the state of solid particles. Through the formation of new small bubbles on the walls of floating bubbles in glass liquid, the effect of thinning the bubble walls is achieved; moreover, through reduction of the local viscosity and the surface tension of the bubble walls, bubble breakage is promoted so as to achieve the purpose that breakage of the bubble layers on the surface of the glass liquid in different temperature zones of a kiln can be accelerated, without needing to raise the maximum temperature of the liquid crystal kiln, so that the bubble removing efficiency of the glass liquid is improved and the influence caused by liquid crystal glass bubble defects is reduced.

Owner:WUHAN UNIV OF TECH

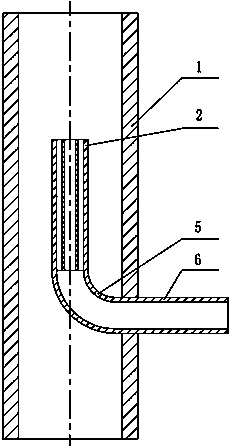

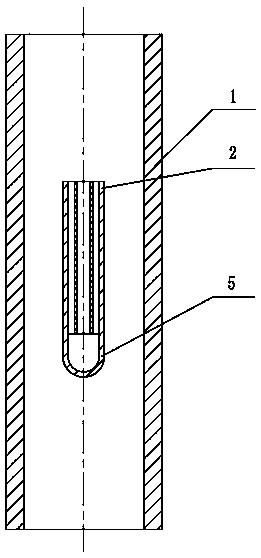

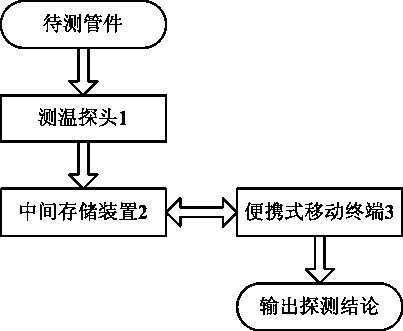

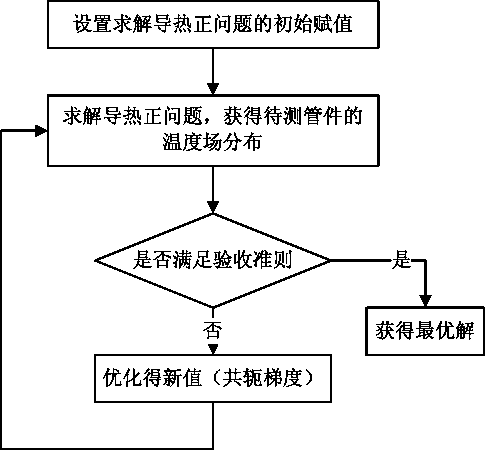

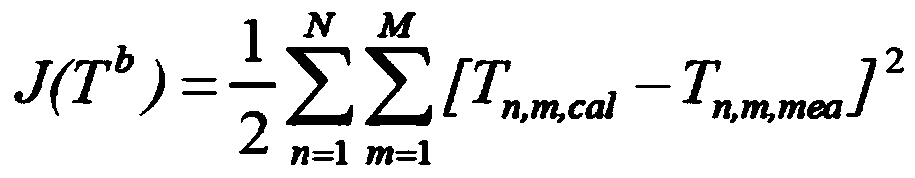

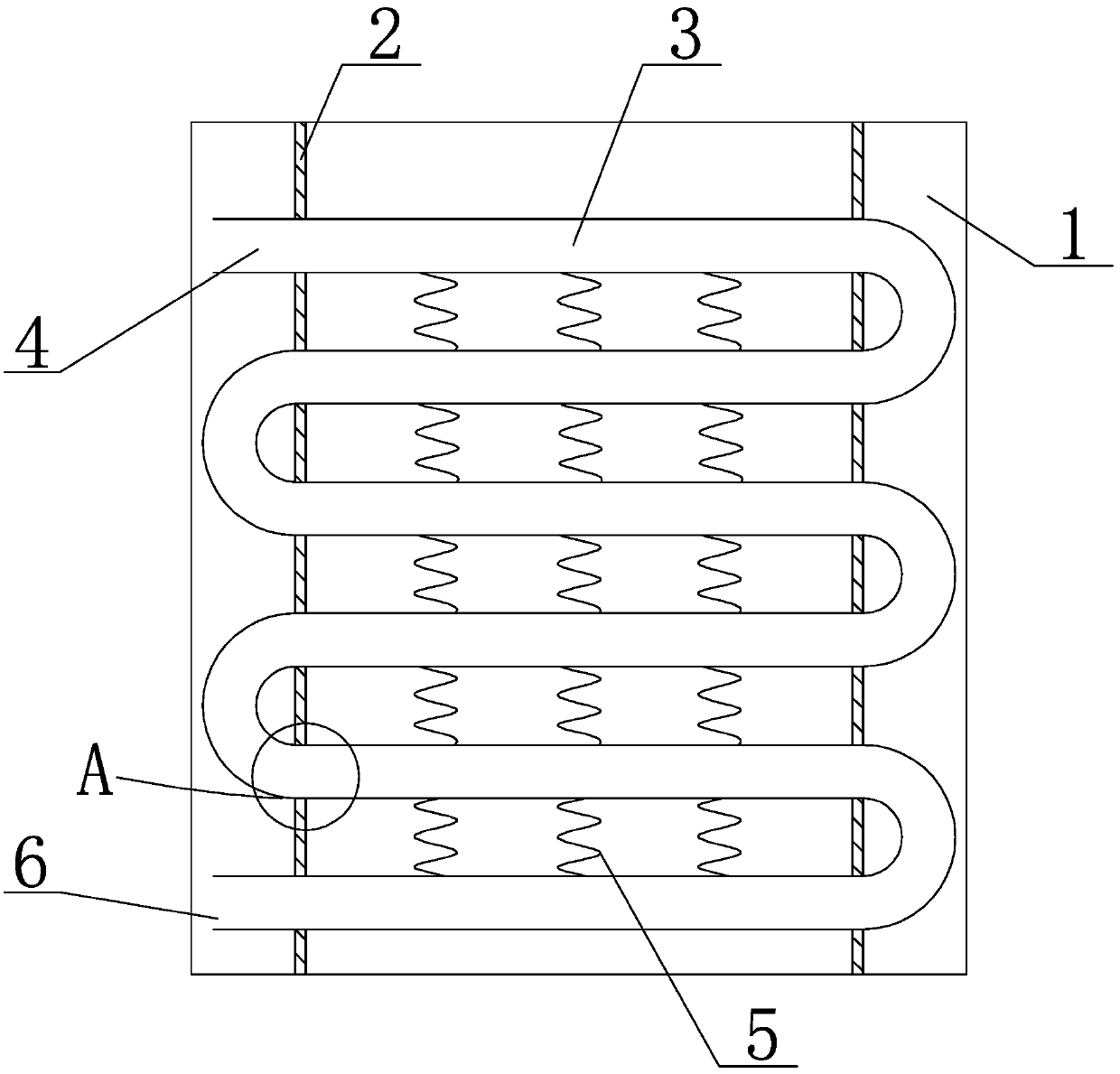

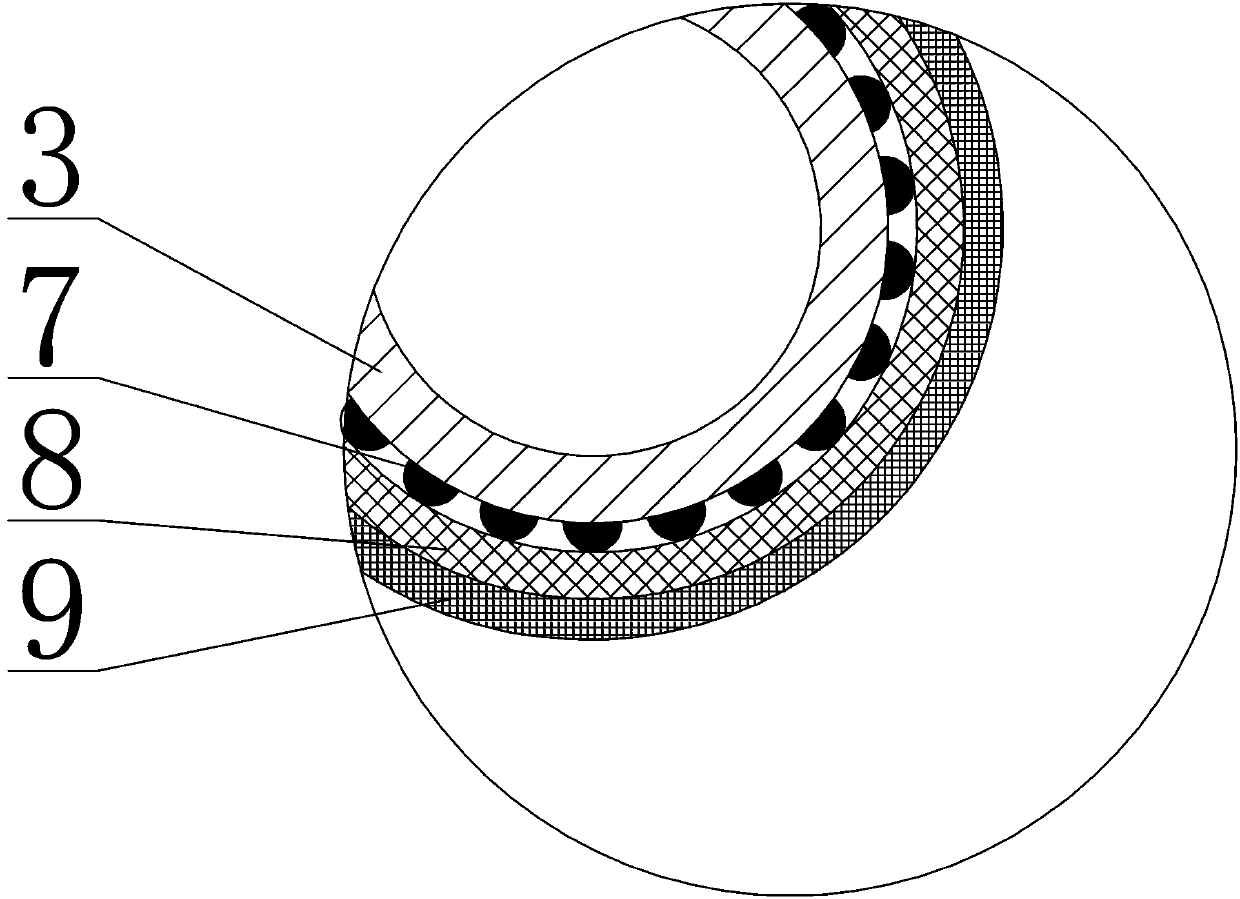

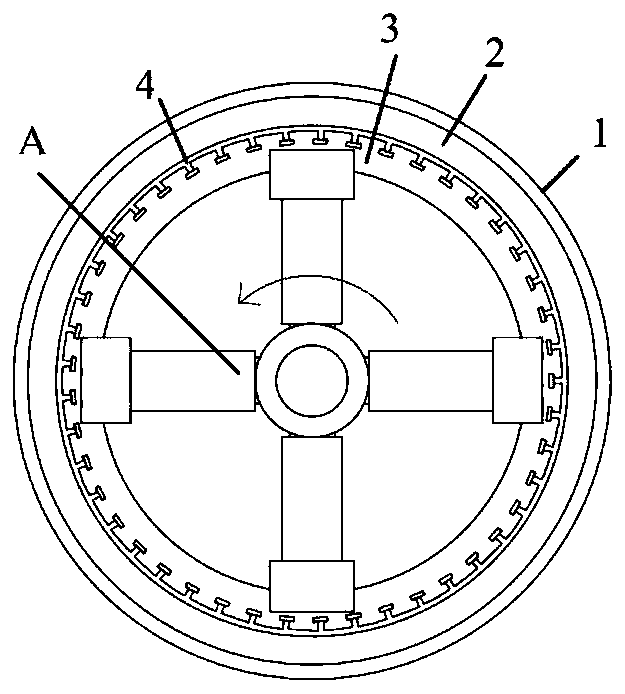

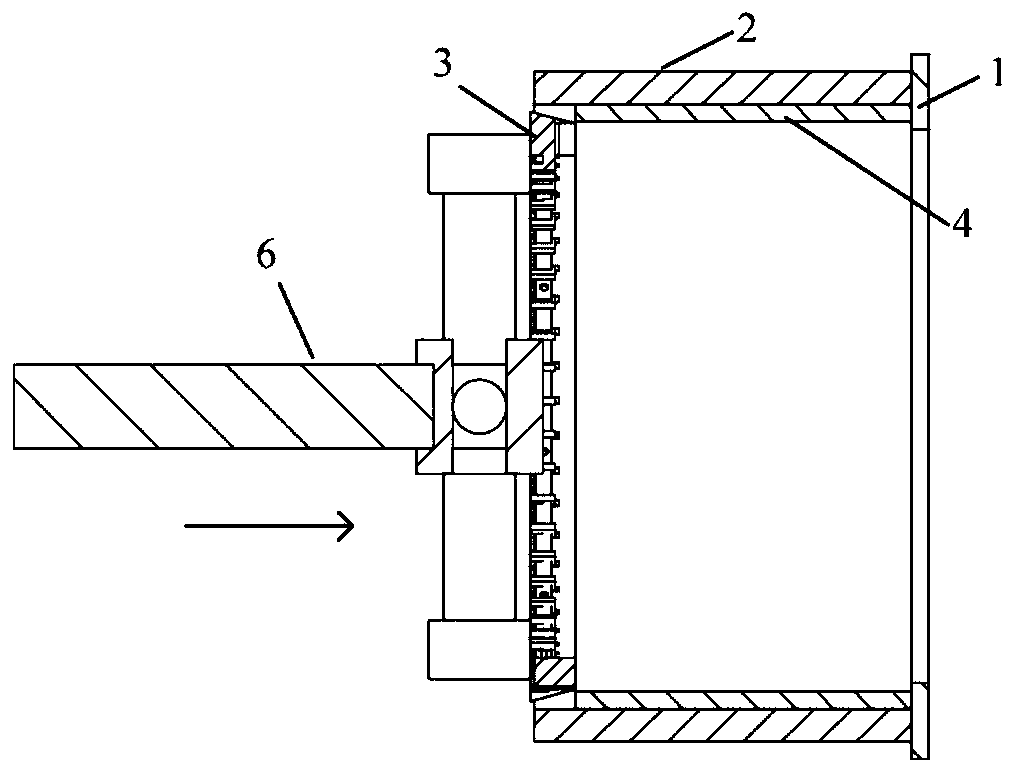

Conventional island pipe wall thinning detecting device and method for nuclear power plant

ActiveCN109655027ASave human resourcesAvoid common industrial risksThermometer detailsThermometers using electric/magnetic elementsNuclear powerEngineering

The invention provides a conventional island pipe wall thinning detecting device and method for a nuclear power plant. The device includes a temperature measuring probe which is arranged at an outer pipe wall surface of a to-be-detected pipe and is used for measuring the temperature of the outer pipe wall surface of the to-be-detected pipe, a middle storage device used for receiving and storing atemperature measuring signal transmitted by the temperature measuring probe, and a portable mobile terminal which is plugged on the middle storage device and is used for receiving the temperature of the outer pipe wall surface of the to-be-detected pipe from the middle storage device and acquiring thickness of the pipe wall of the to-be-detected pipe based on the heat conduction condition. The device is advantaged in that dismounting temperature insulation equipment and setting scaffolds can be omitted, a lot of human resources are saved, high efficiency is achieved, one-time investment is achieved, cost for calibration of the temperature measuring probe and periodic maintenance of the mobile terminal is only required, and economic property is further achieved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +2

Boiler economizer with supersonically sprayed abrasion and corrosion resistant coating

InactiveCN107781802AImprove wear resistanceImprove corrosion resistanceCoatingsHeat exchange apparatusResistWear resistant

The invention discloses a boiler economizer with a supersonic spraying wear-resistant and anti-corrosion coating, which comprises a fire-resistant wall, the outer wall of the fire-resistant wall is vertically provided with support plates, and the support plates are the same two groups, two groups The support plate is left-right symmetrical on the outer wall of the refractory wall, and the outer wall of the support plate is horizontally provided with water-cooled pipes. In the present invention, an anti-corrosion coating is sprayed on the outer wall of the water-cooling tube, and a high-temperature-resistant coating is sprayed on the outer wall of the anti-corrosion coating. The outer wall of the high-temperature resistant coating is sprayed with a wear-resistant coating, which increases the wear resistance and corrosion resistance of the economizer water-cooled pipe, and slows down the long-term wear of the material carried by the flue gas. The wall of the water-cooled pipe is rapidly thinned. The problem is that through the cooperation of the water-cooled tube and the elastic part, the economizer's water-cooled tube has a powerful relief effect when it is heated and expanded, and it prevents the water-cooled tube from cracking, sealing failure, and explosion due to the absence of a corresponding force-relieving device. gray problem.

Owner:HUBEI SANNING CHEM

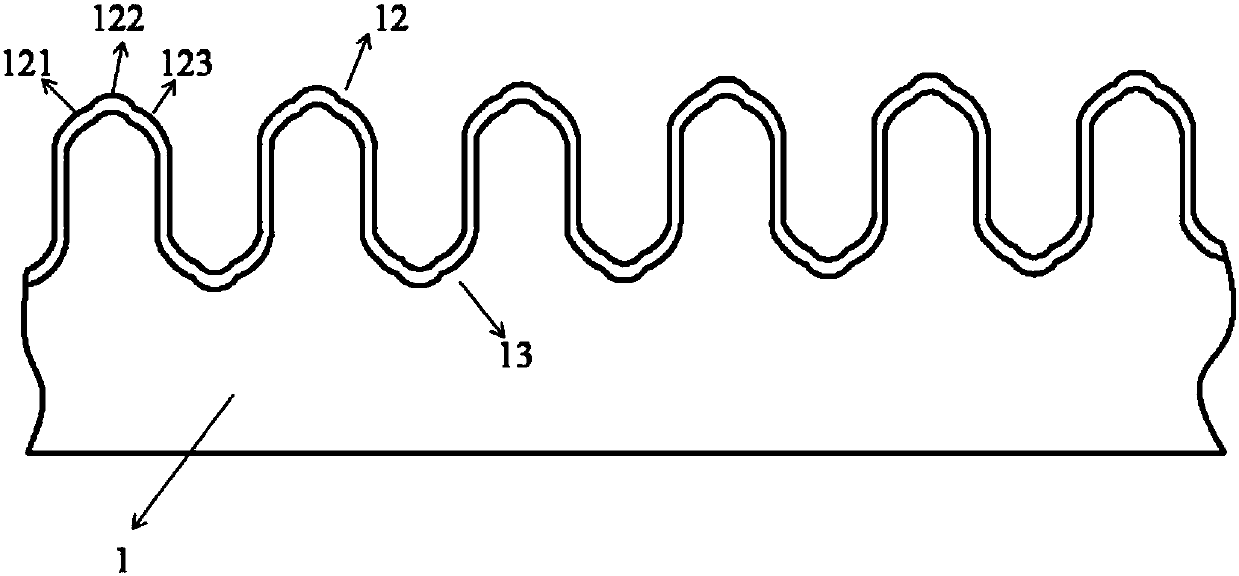

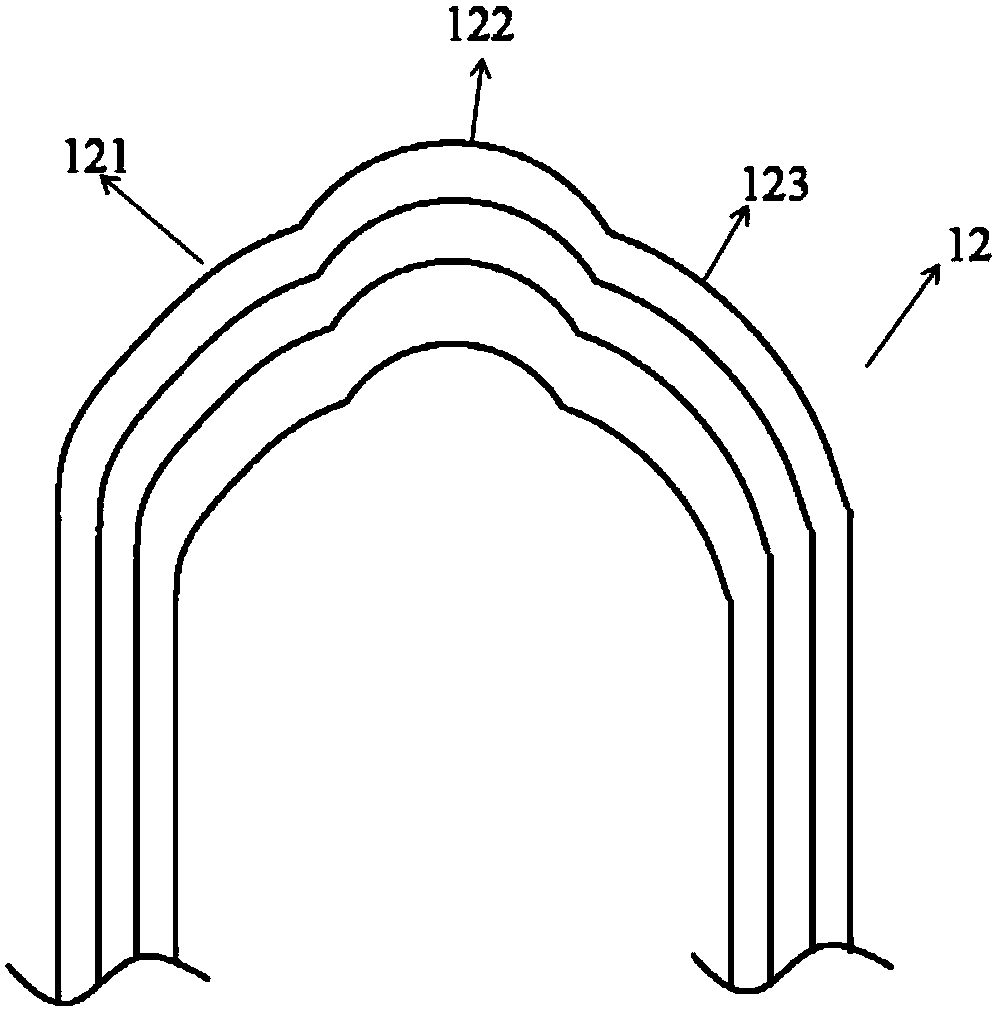

Corrugated pipe

The invention discloses a corrugated pipe which comprises a body. A plurality of peak parts and a plurality of valley parts continuously alternate on the body in the longitudinal direction; the shapesof the multiple peak parts are the same, and the cross sections of the peak parts are each in a U shape; U-shaped arc sections are composed of the first arc section, the second arc section and the third arc section; the curvature radiuses of the first arc section and the third arc section are R1, the curvature radius of the second arc section is R2, and R2 is smaller than R1; the circle centers of the first arc section and the third arc section coincide, and the circle centers of the second arc section and the third arc section do not coincide; and the shapes of the valley parts are the sameas those of the peak parts. In the extrusion forming process of the corrugated pipe, the problems of inner wall corrugation and outer wall thinning cannot occur to bent parts, and therefore the service life is prolonged; and the corrugated pipe is resistant to high temperature and high pressure and can be used under the working conditions that the temperature is 400 DEG C, and the pressure is 250KG.

Owner:NANTONG SHIFA SHIP MACHINERY

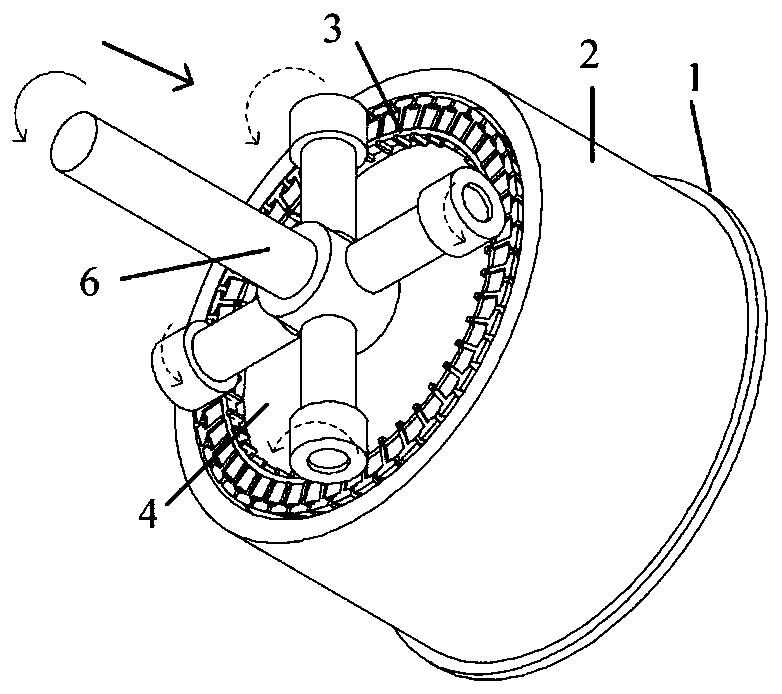

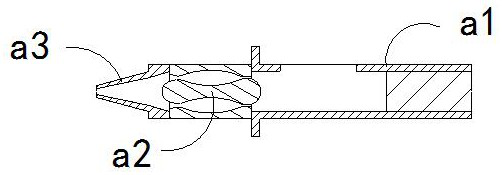

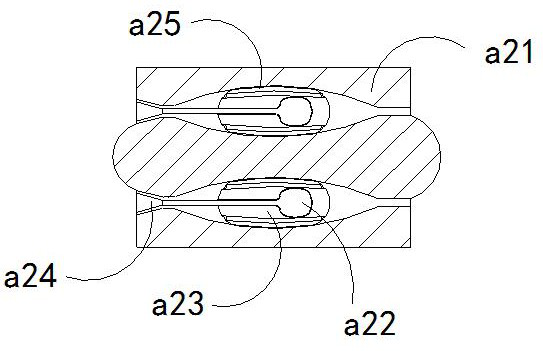

Processing device and processing method for inner rib tube

ActiveCN111283994AReduce external forceEasy to implementHollow articlesMechanical engineeringWall thinning

The invention discloses a processing device and a processing method for an inner rib tube, and belongs to the field of material plastic processing. According to the processing method applying the processing device for the inner rib tube, an elastic sliding form is rolled on a tubular blank, so that an inner rib can be formed at one time in a tube body, and in the processing process, the tubular blank is locally deformed when sliding form teeth of the elastic sliding form are in contact with the tubular blank, at the same time, wall thinning and inner rib filling are completed. The processing method is easier to implement since required external force is smaller. The processing method has the characteristics that the processing efficiency is high, the use range is wide, the weldless qualityis high, material is saved, and the production cost is low.

Owner:CHANGAN UNIV

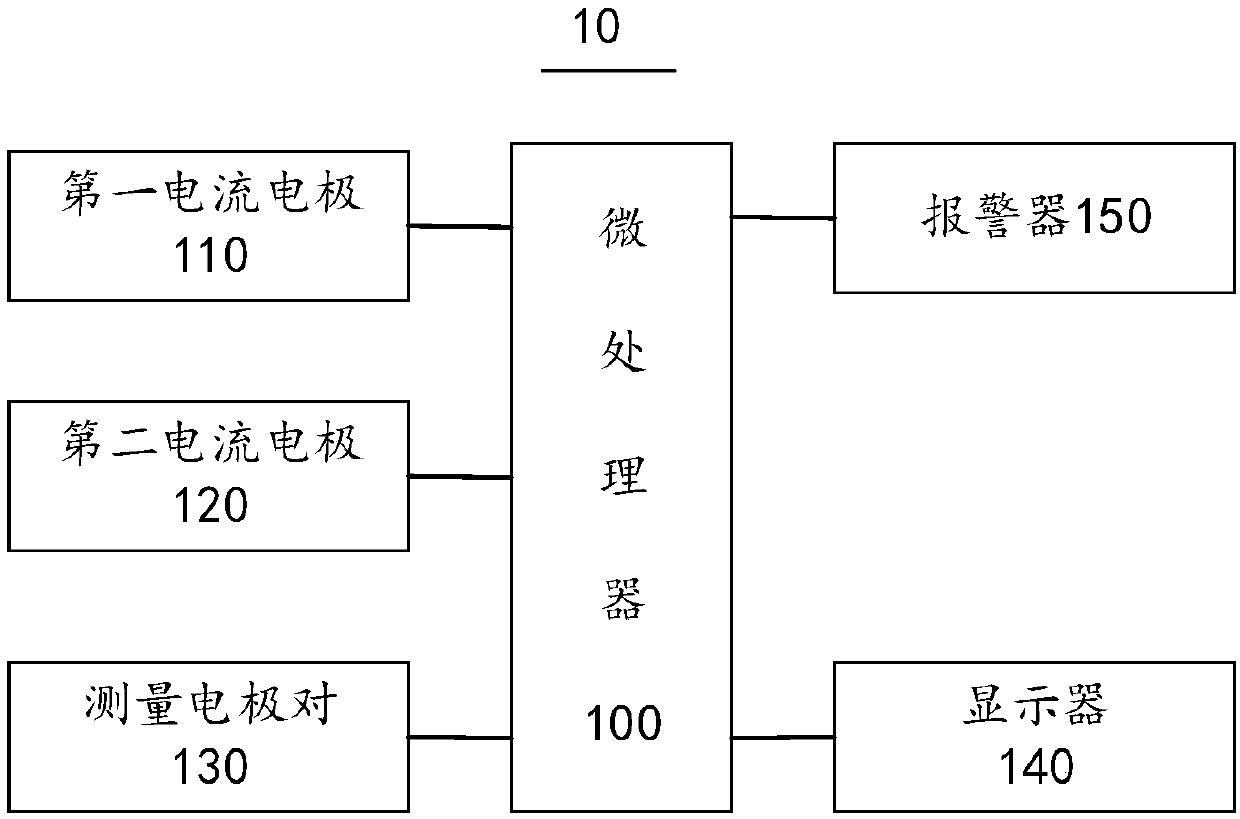

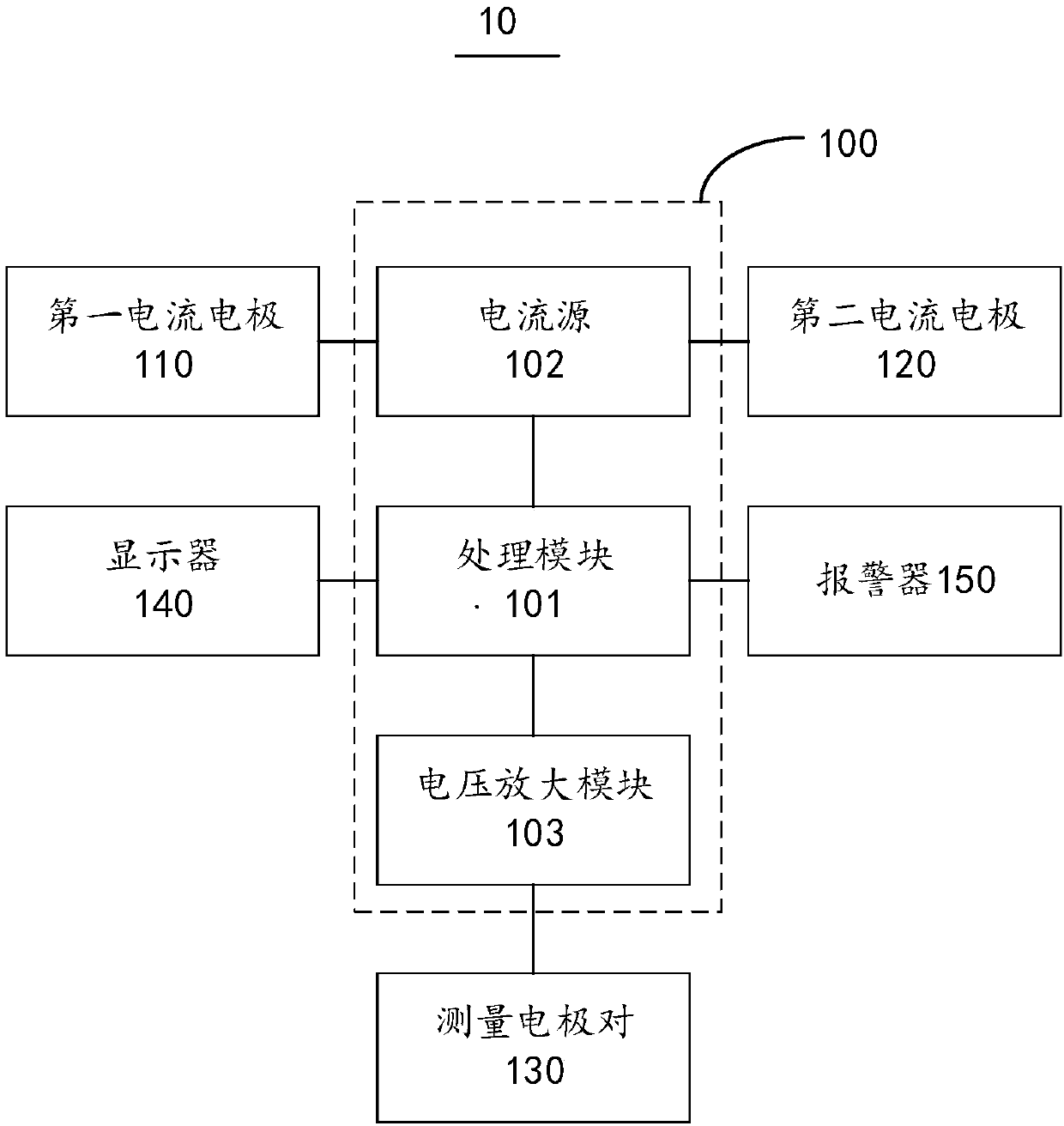

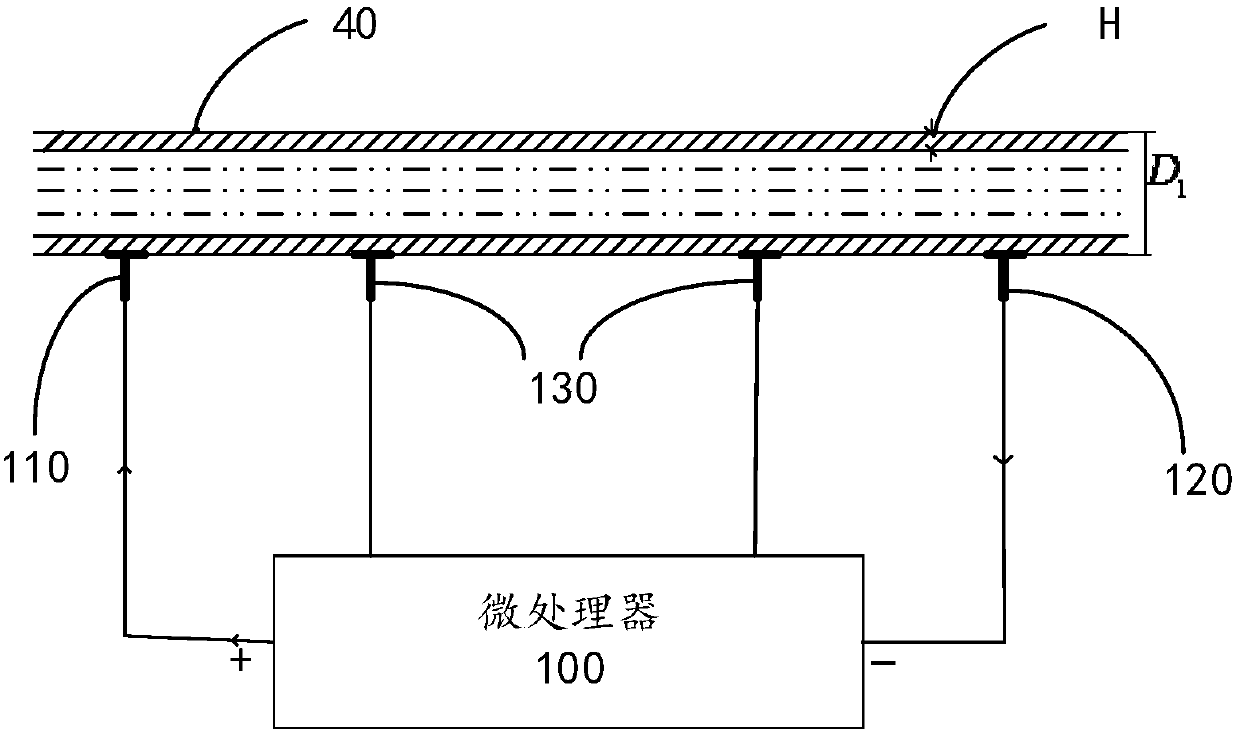

A wall thickness monitoring apparatus and system

PendingCN107655395ARealize measurementAccurate measurementElectrical/magnetic thickness measurementsElectricityOperational costs

The embodiments of the invention provide a wall thickness monitoring apparatus and system. The wall thickness monitoring apparatus comprises a micro-processor, a first current electrode, a second current electrode and measuring electrode pairs located between the first current electrode and the second current electrode. The first current electrode, the second current electrode and the measuring electrode pairs are located on the outer side of a pipe wall; the micro-processor is electrically connected with the first current electrode, the second current electrode and the measuring electrode pairs; the micro-processor is used for supplying currents to the first current electrode and the second current electrode and detecting voltages values in the measuring electrode pairs to calculate the thickness at the corresponding position of each measuring electrode pair. The apparatus and the system can accurately obtain wall thickness values of devices such as pipelines in a running process, greatly reduce monitoring and operation costs in a thickness measuring process, and effectively prevent problems such as leak and bursting caused by excessive thinning of pipe walls.

Owner:成都六惠科技有限公司

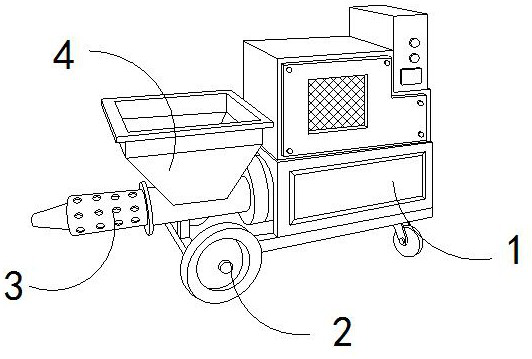

Automatic adjustable interior decoration spraying device

The invention discloses an automatic adjustable interior decoration spraying device. The automatic adjustable interior decoration spraying device structurally comprises a machine body, moving wheels,a discharging pipe and a feeding hopper, wherein the moving wheels are movably clamped to the side of the machine body; the feeding hopper is fixedly embedded in the upper end of the discharging pipe;the discharging pipe is mounted at the front end of the machine body; cement mortar entering the discharging pipe through the feeding hopper generates outward thrust on a separation mechanism, the separation mechanism can guide in non-solidified fluid cement mortar inwards firstly, and thus a rolling plate can roll the cement mortar squeezed between the rolling plate and the inner wall of a frame; through the throwing force generated by upward swinging and resetting of a swinging plate, an outward extending strip can stretch out upwards along a bearing plate to be inserted into the cement mortar; and when the outward extending strip completely contracts, a hollow groove can be reserved in the cement mortar, thus the surface wall of the solidified cement mortar can be thinned, and the solidified thin-wall cement mortar can be broken through by the cement mortar sprayed out next time.

Owner:广州畅新生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com