Low smell and scratch resistant thin-wall material and preparation method thereof

A scratch-resistant, low-odor technology, used in the preparation of scratch-resistant thin-walled materials, low-odor, low-odor, scratch-resistant thin-walled materials, can solve the problem of low fluidity, poor injection molding processability, unsuitable thin-walled materials. wall material preparation and other issues to achieve the effect of improving fluidity and reducing odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

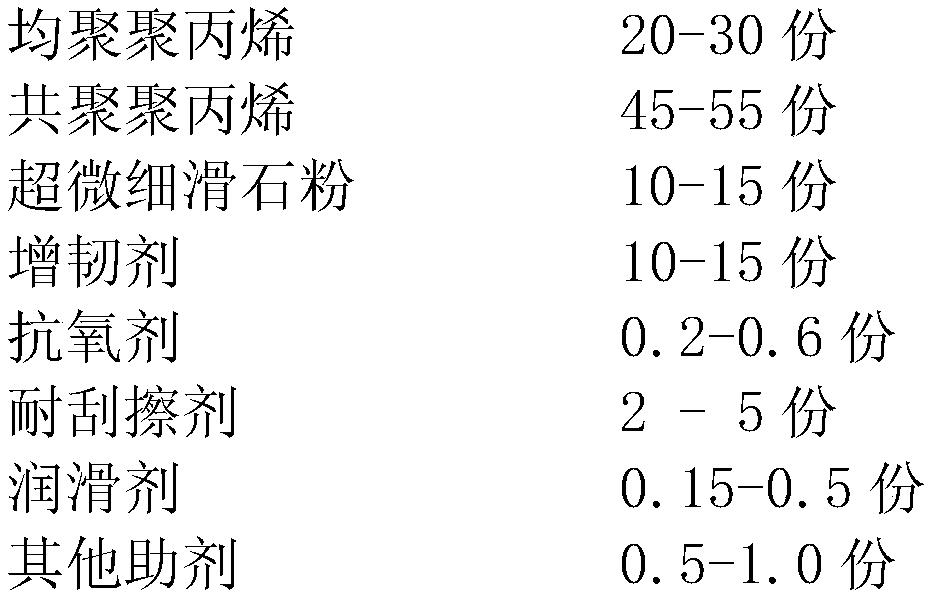

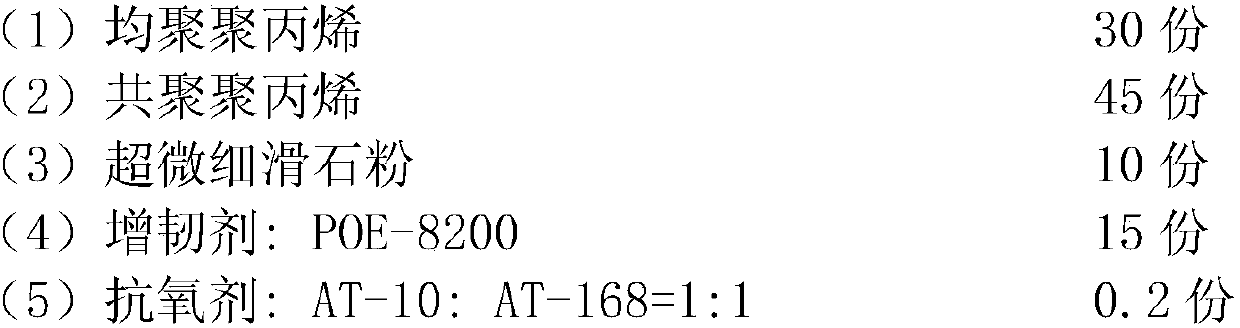

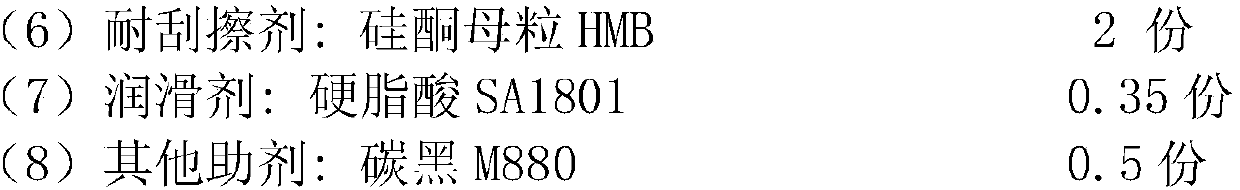

[0021] A low-odor, scratch-resistant thin-walled material, each raw material is weighed according to the following parts by weight:

[0022]

[0023]

[0024] Pour the raw materials of all components into a high-speed stirring pot and stir for 8 minutes to obtain a premix, feed the premix into a twin-screw extruder to melt and extrude, cool and draw, dry, and pelletize to obtain the low Odor, scratch resistant thin wall material. Concrete process parameter is as shown in table 1 in the present embodiment

Embodiment 2

[0026] A low-odor, scratch-resistant thin-walled material, each raw material is weighed according to the following parts by weight:

[0027]

[0028] Pour the raw materials of all components into a high-speed stirring pot and stir for 8 minutes to obtain a premix, which is fed into a twin-screw extruder for melt extrusion, and the granulation process and process parameters are the same as in Example 1.

Embodiment 3

[0030] A low-odor, scratch-resistant thin-walled material, each raw material is weighed according to the following parts by weight:

[0031]

[0032] Pour the raw materials of all components into a high-speed stirring pot and stir for 8 minutes to obtain a premix, which is fed into a twin-screw extruder for melt extrusion, and the granulation process and process parameters are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com