Flow adjusting type water filling structure for reaction effluent pipeline

An effluent and reaction technology, applied in the direction of pipes, pipe components, branch pipelines, etc., can solve the problems of increased water flow instability, injection casing erosion, pipeline erosion, etc., to reduce unplanned shutdown accidents, The effect of prolonging the service life and avoiding shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

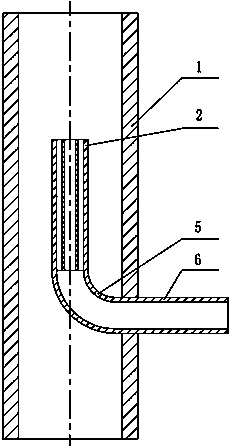

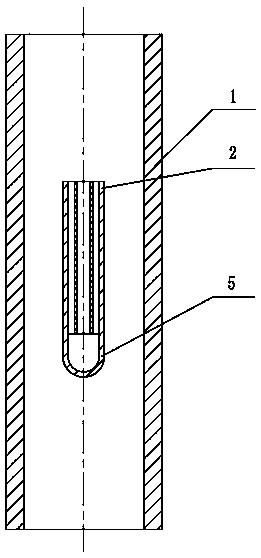

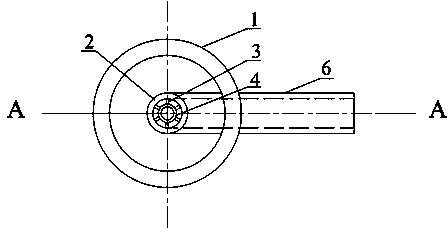

[0018] Such as figure 1 , figure 2 , Figure 5 Shown, the present invention comprises main round pipe 1, water injection round pipe outlet section 2, rectifying plate 3, rectification round pipe 4, 90 ° elbow 5 and water injection round pipe inlet section 6; Water injection round pipe inlet section 6 and main round pipe 1 perpendicular to each other and fixed by welding; the outlet end of the inlet section 6 of the water injection pipe circle and the inlet end of the outlet section 2 of the water injection pipe circle are connected by welding through the 90° elbow 5 in the main round pipe 1, and the welding process requires smoothness Flat; the rectification round pipe 4 is coaxially installed in the hole 2 of the outlet section of the water injection round pipe, and the outlet section 2 of the water injection round pipe 2 is connected with the rectification round pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com