Patents

Literature

2935results about "Reinforcing agents addition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

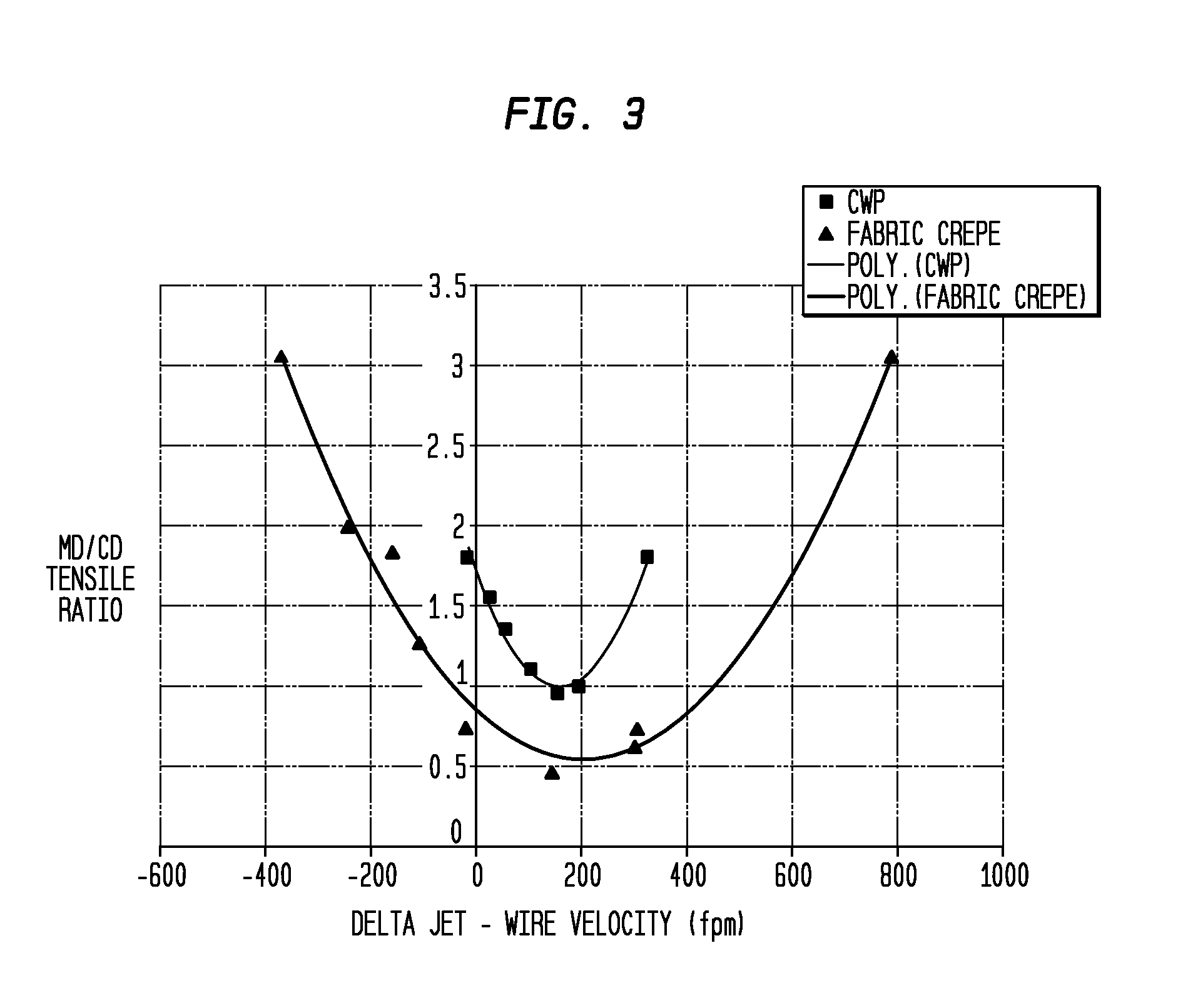

Fabric creped absorbent sheet with variable local basis weight

InactiveUS7494563B2Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

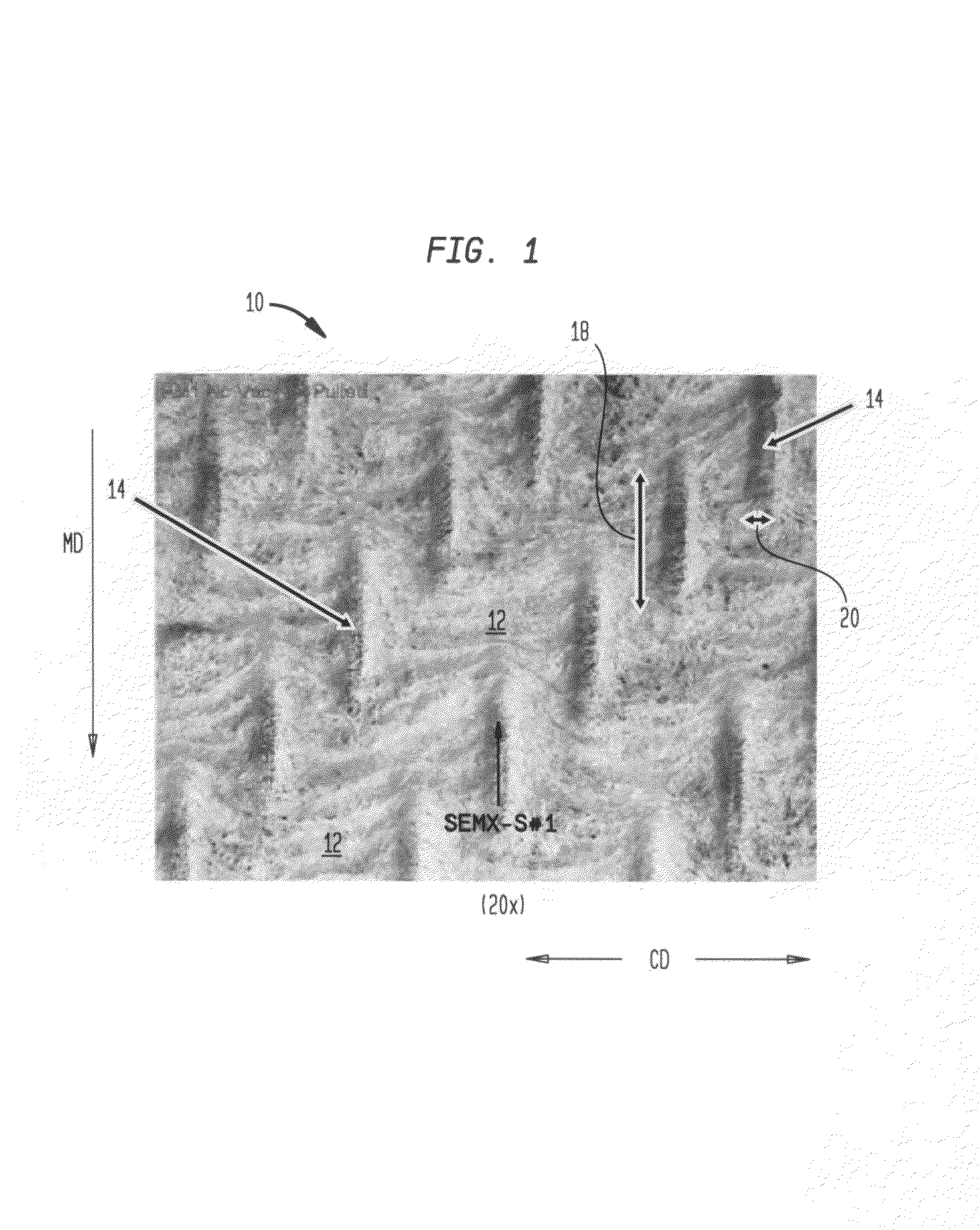

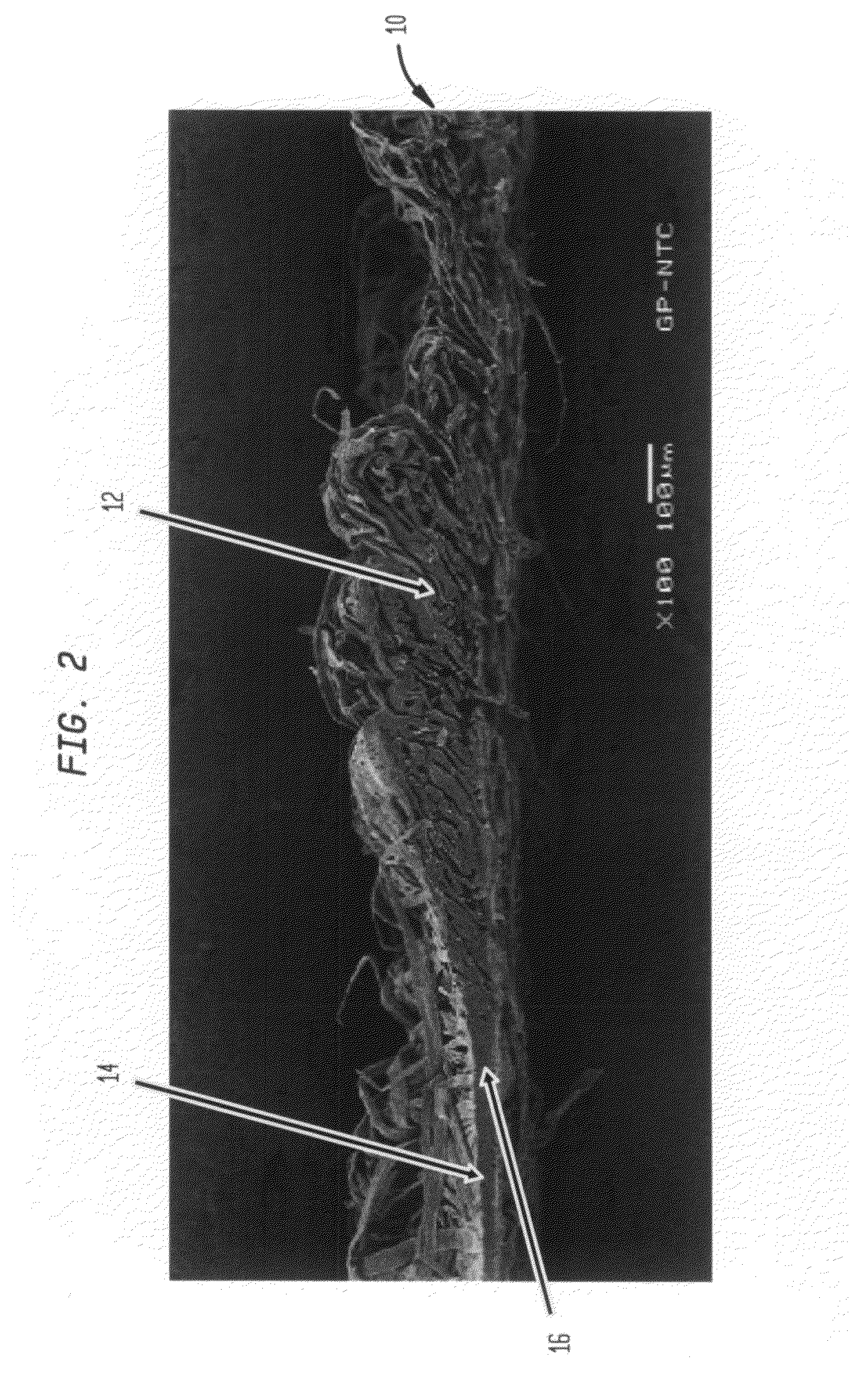

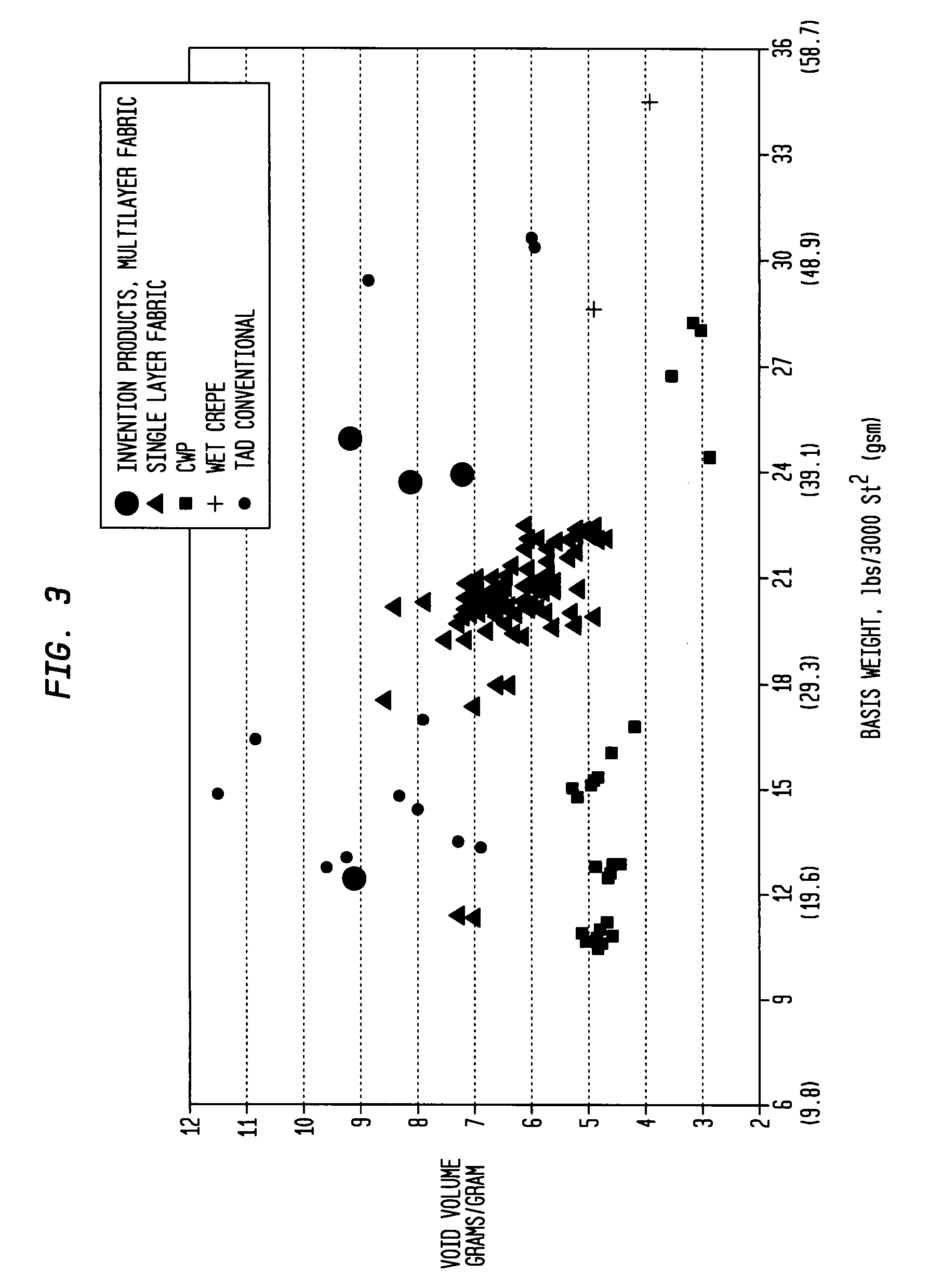

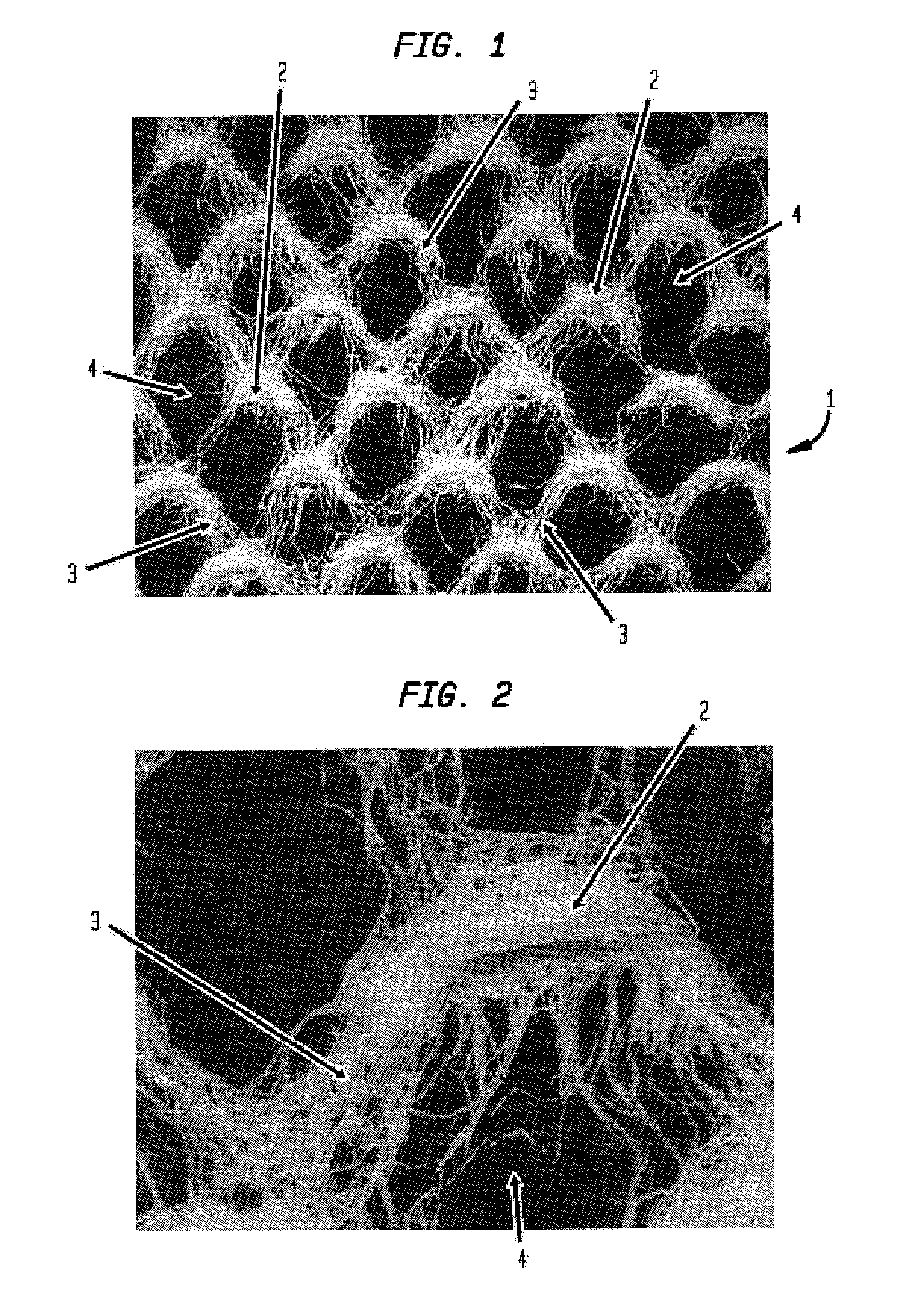

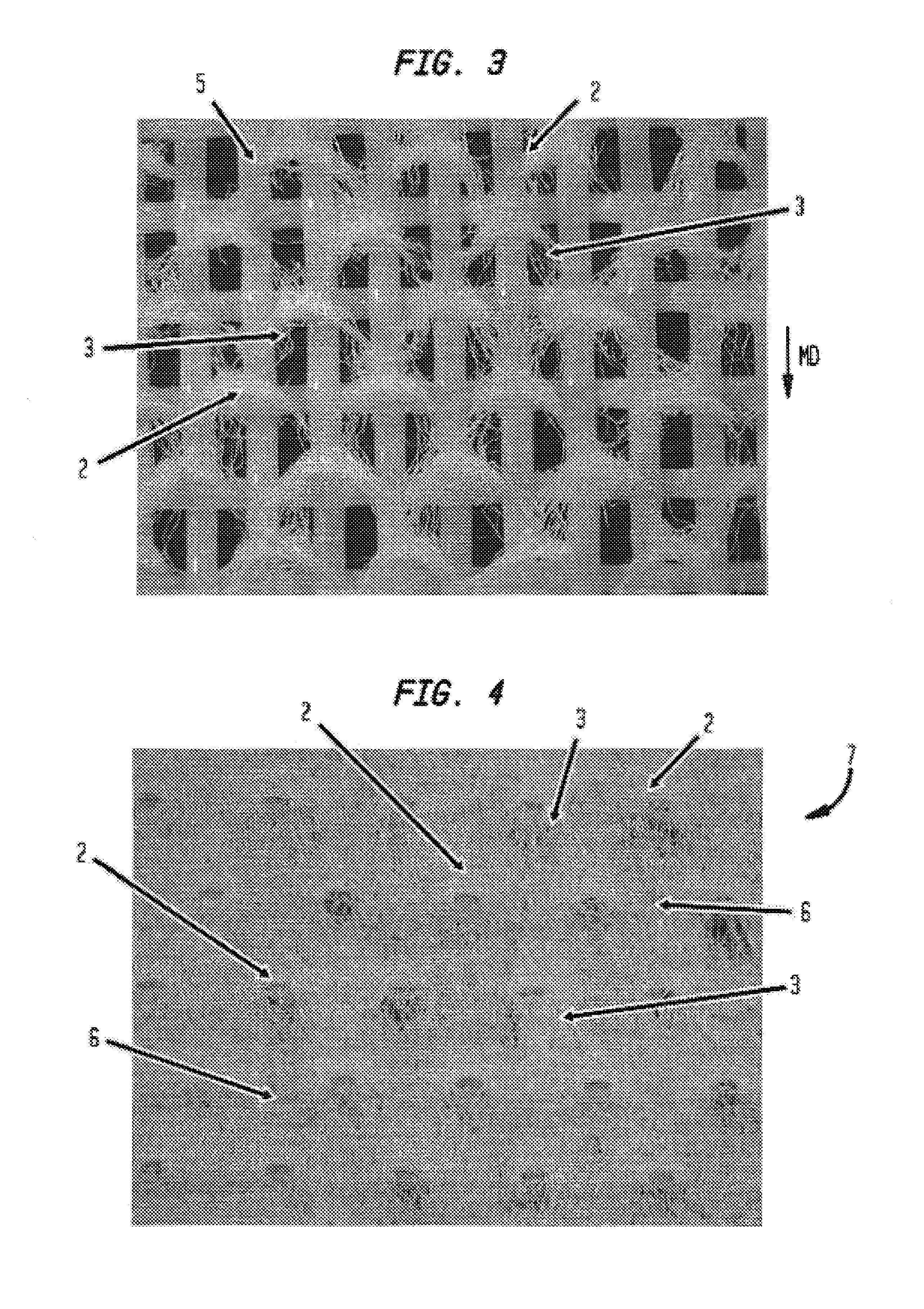

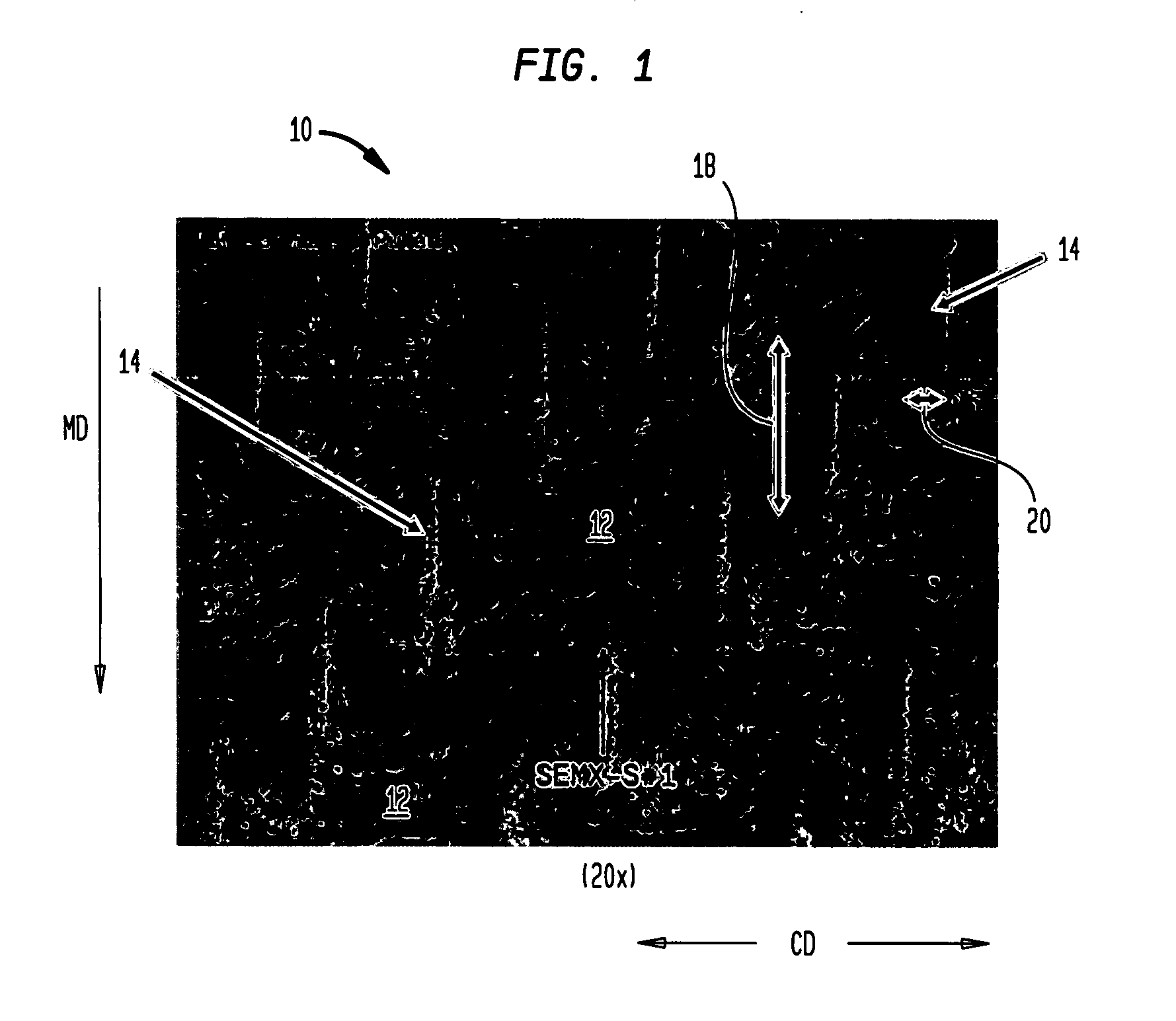

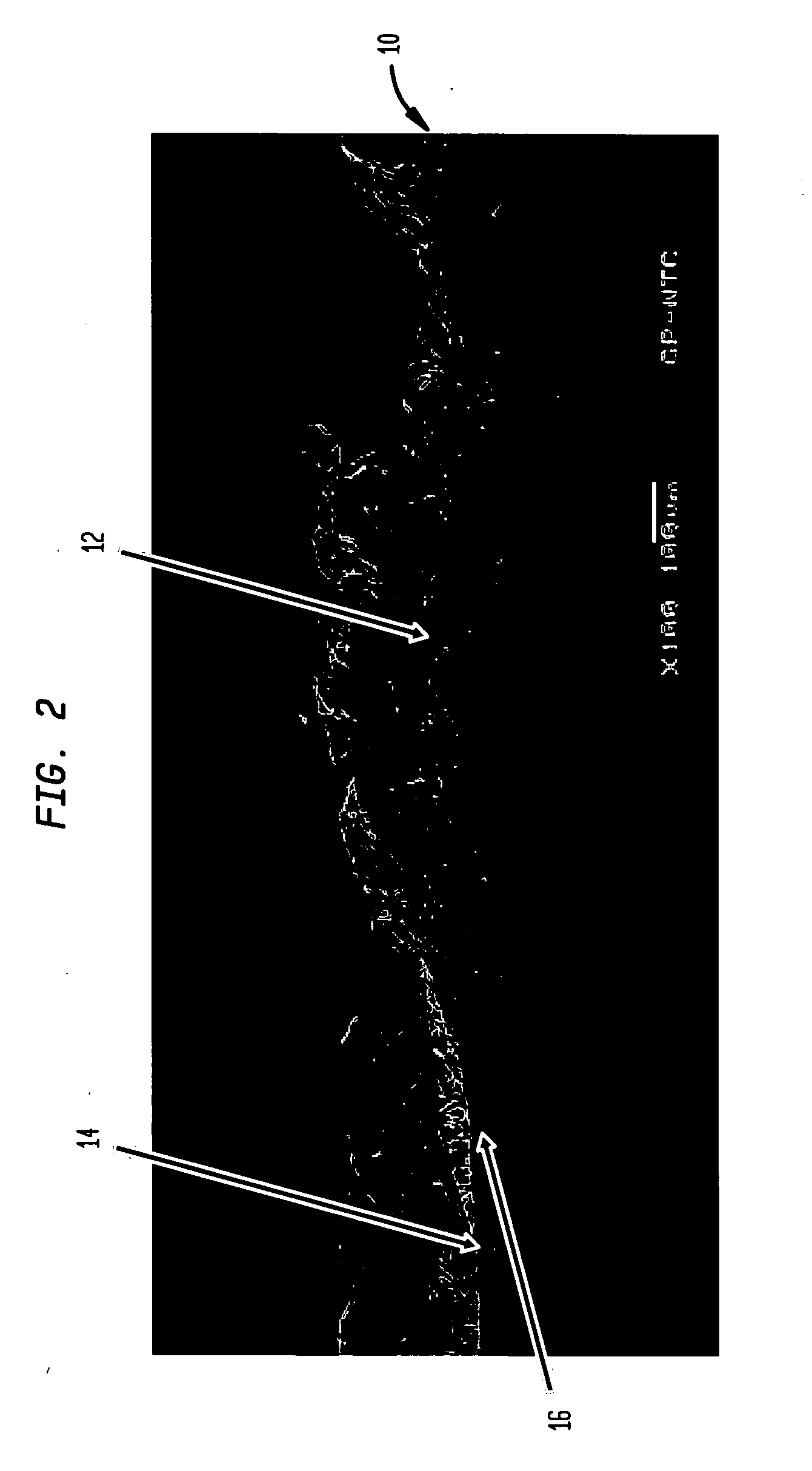

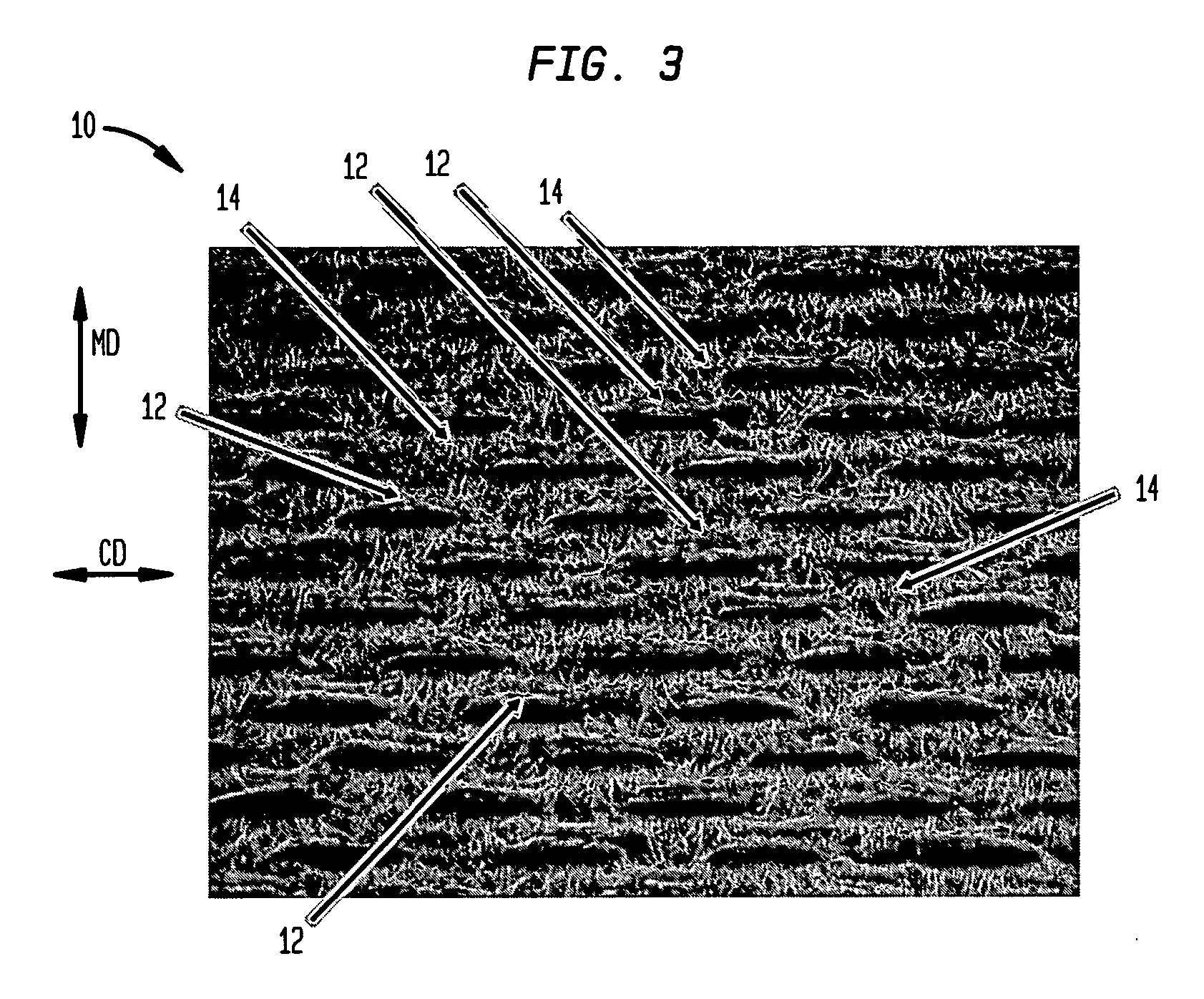

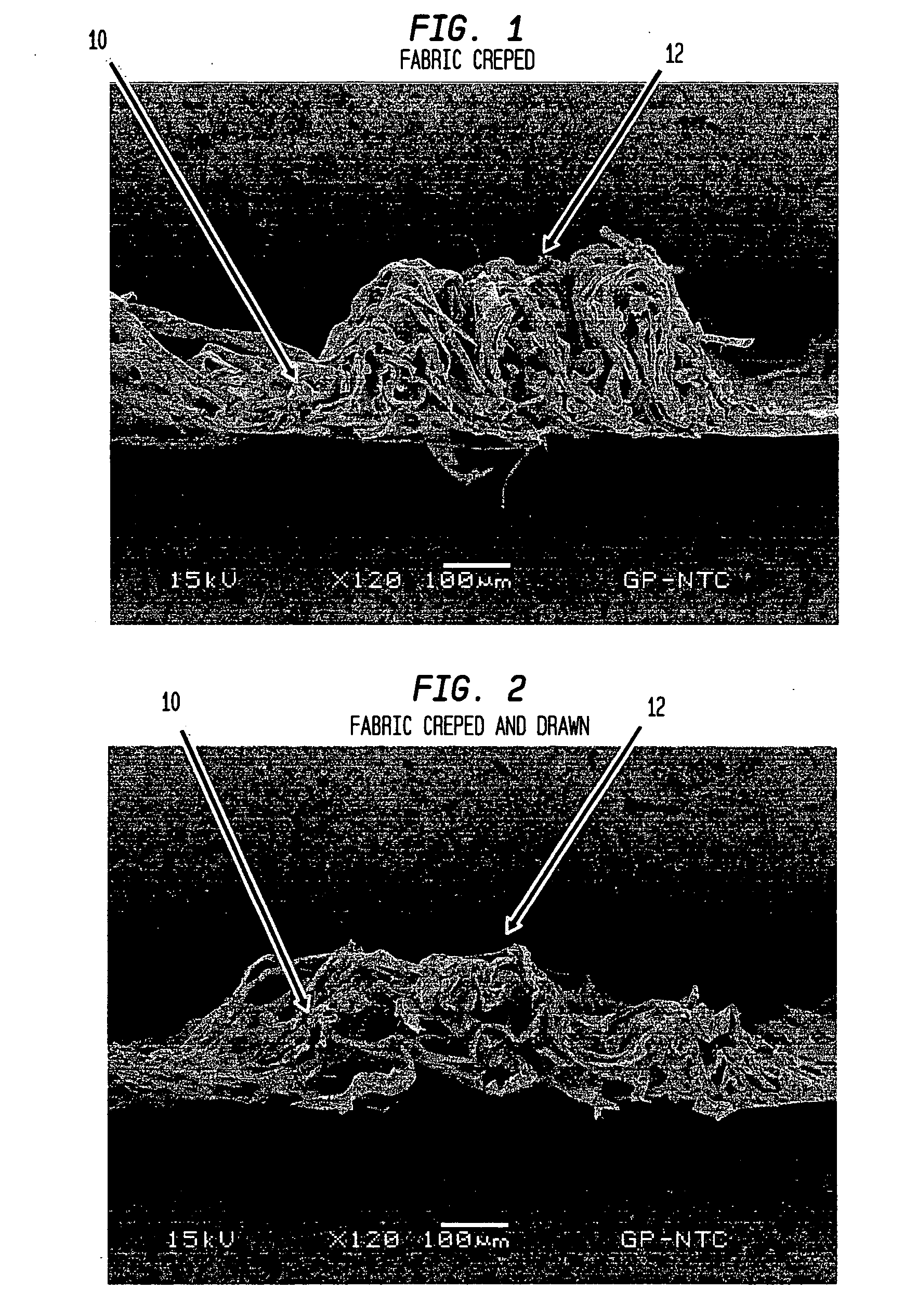

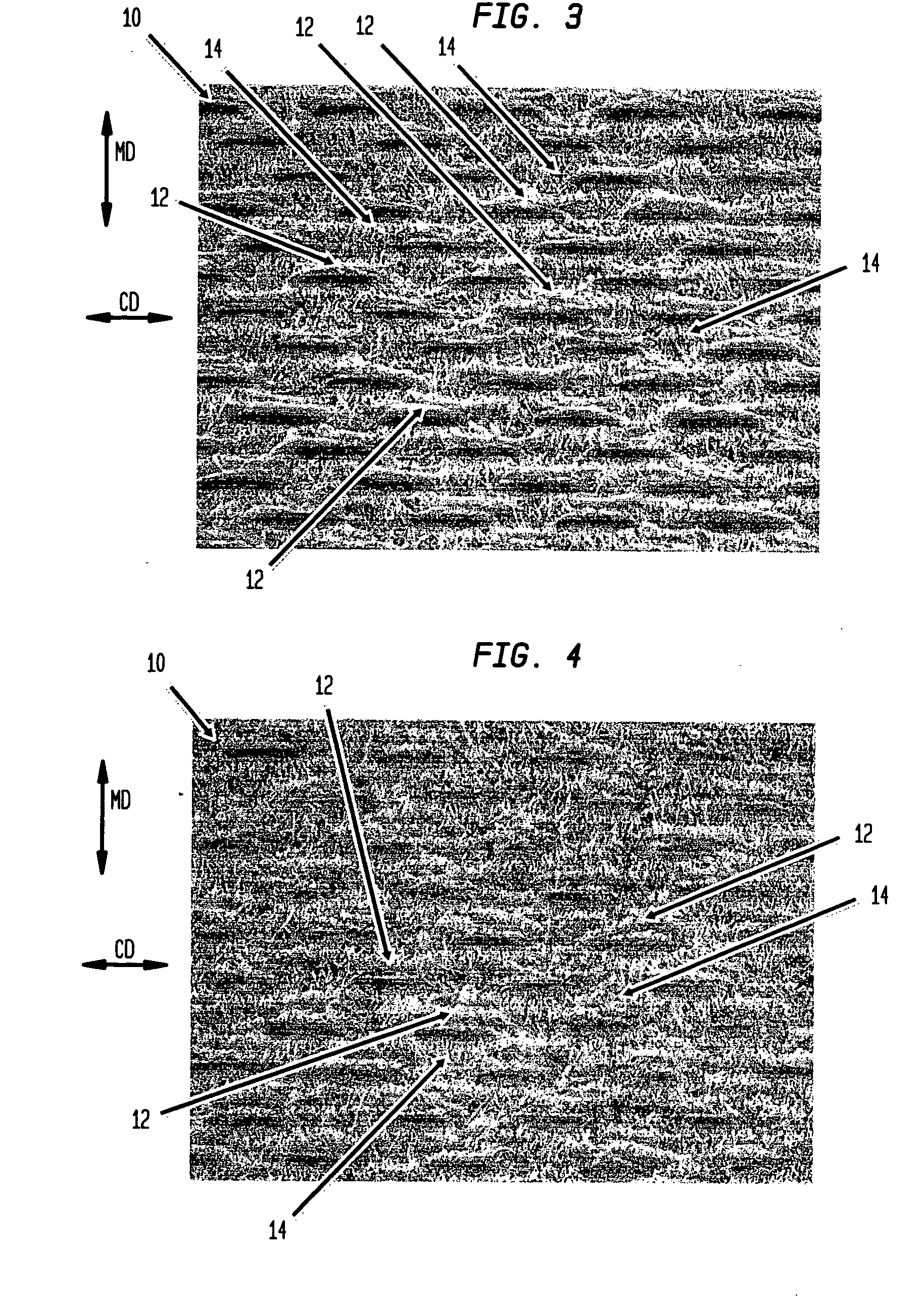

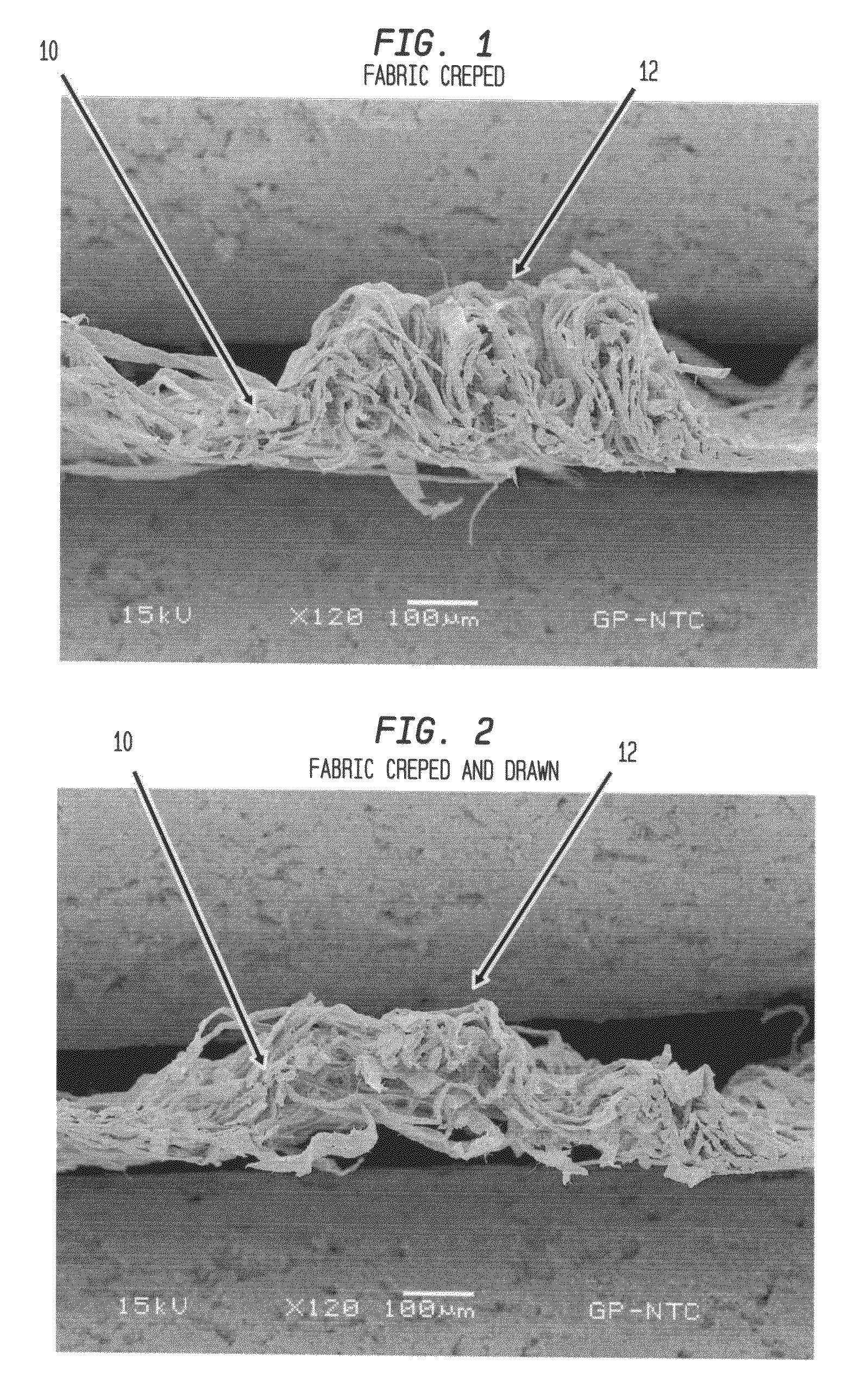

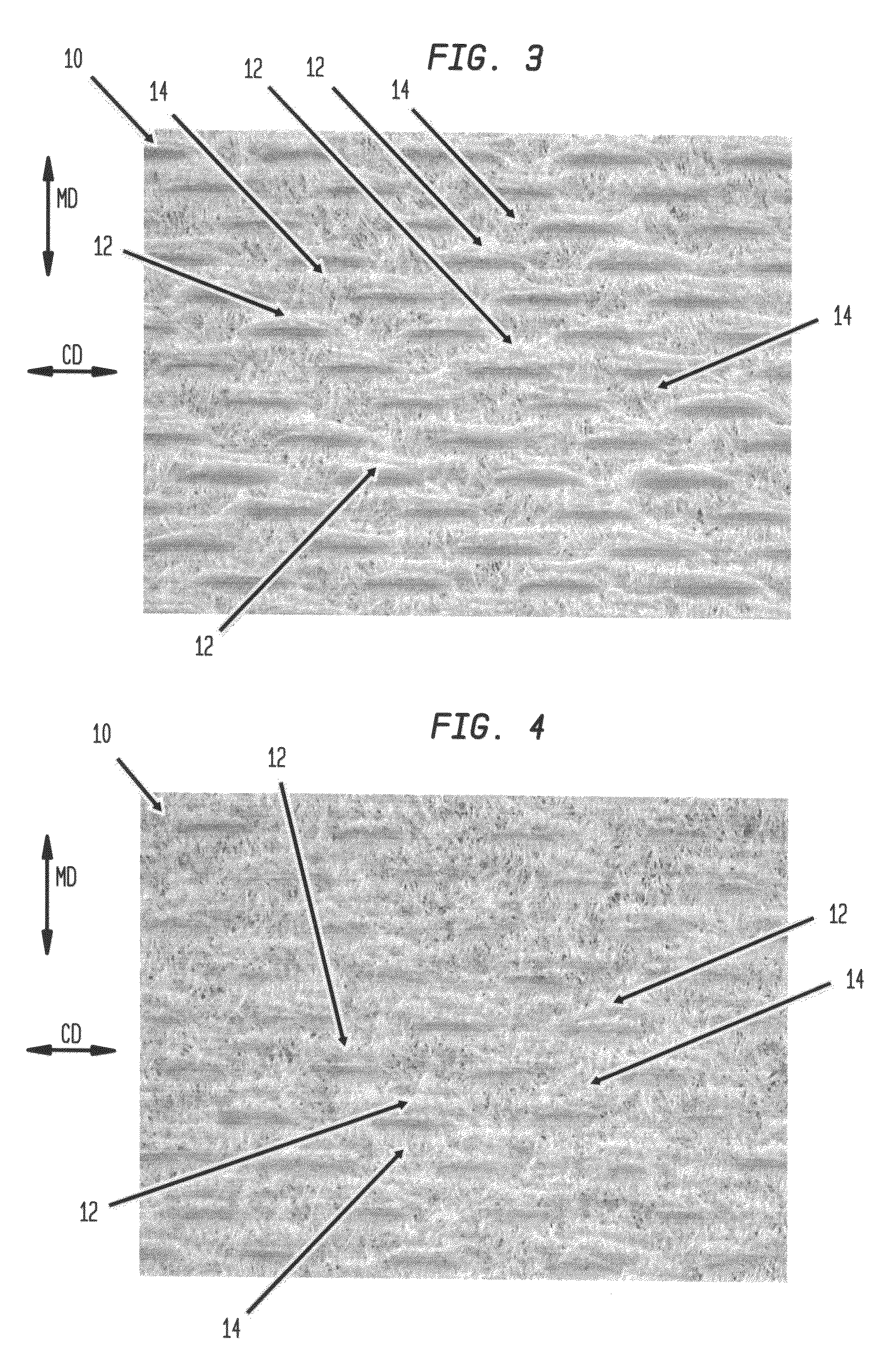

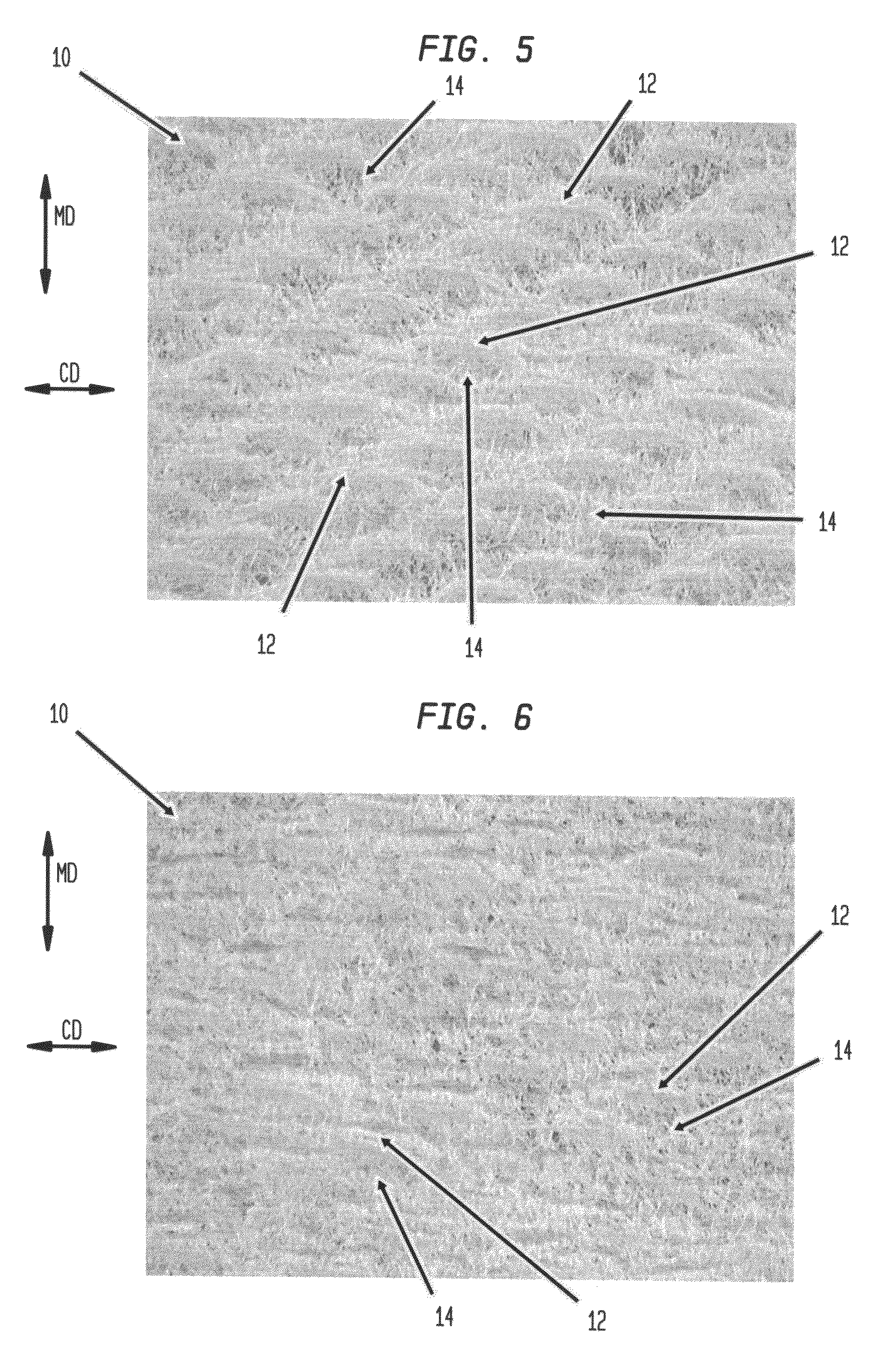

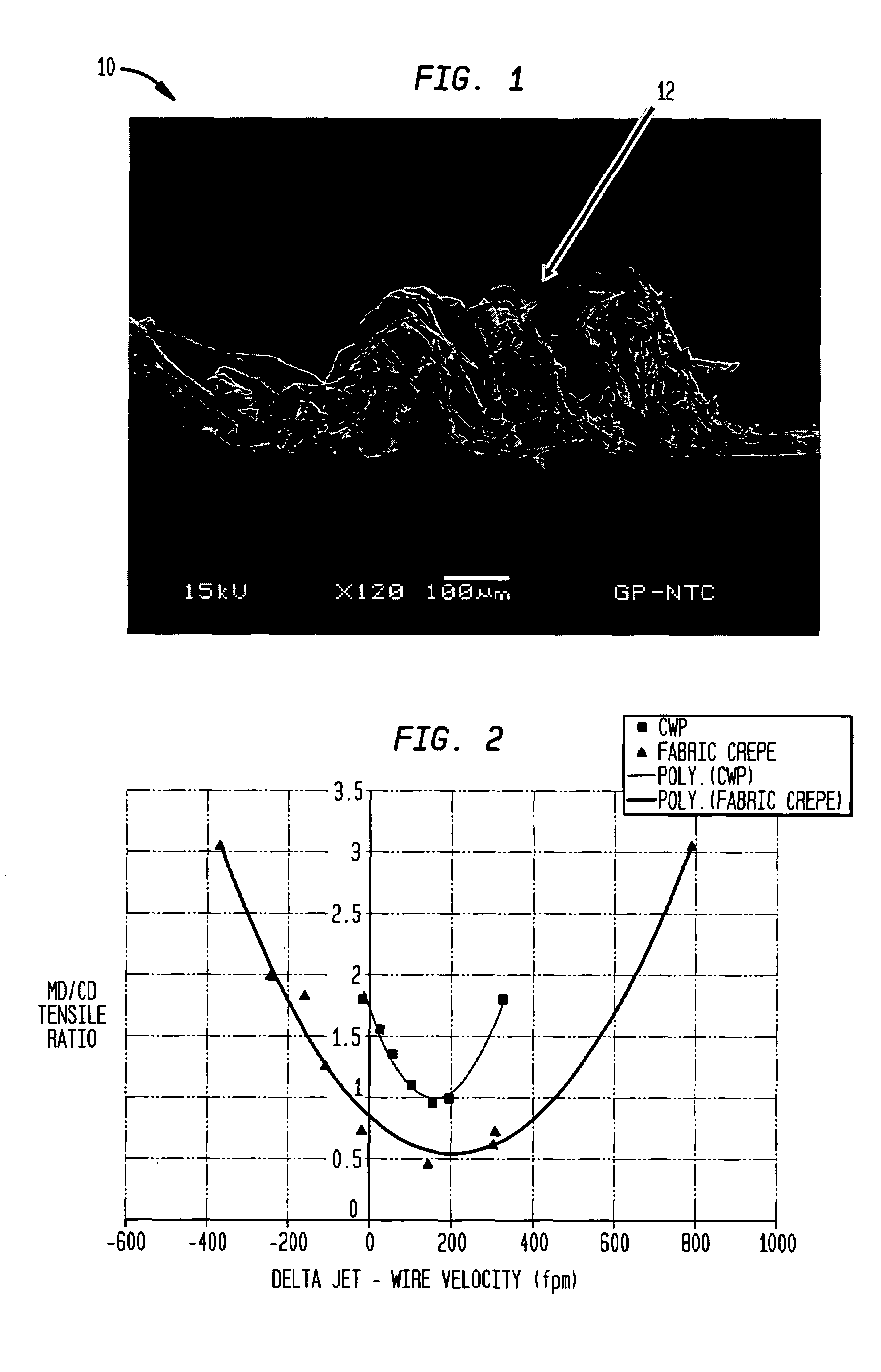

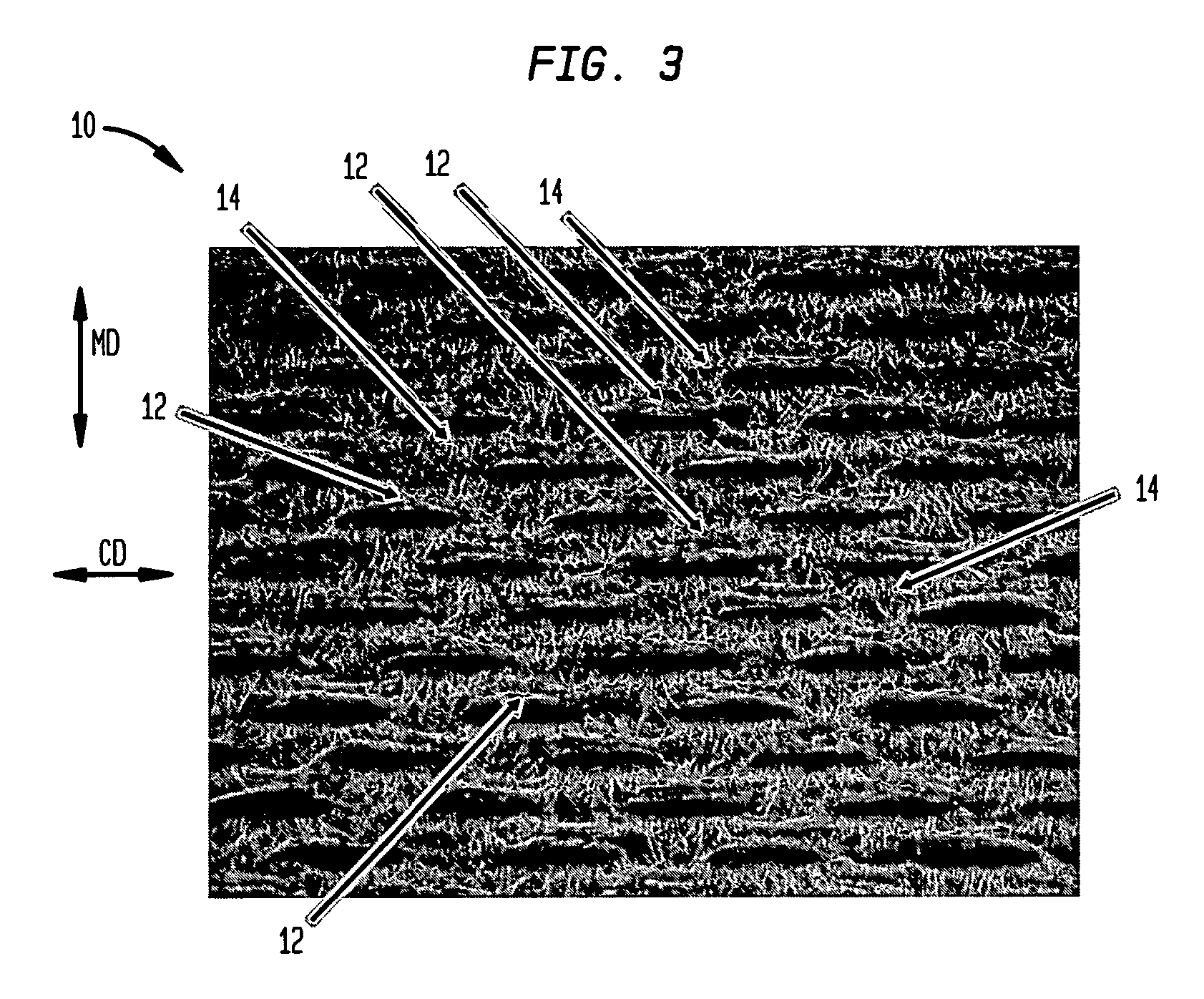

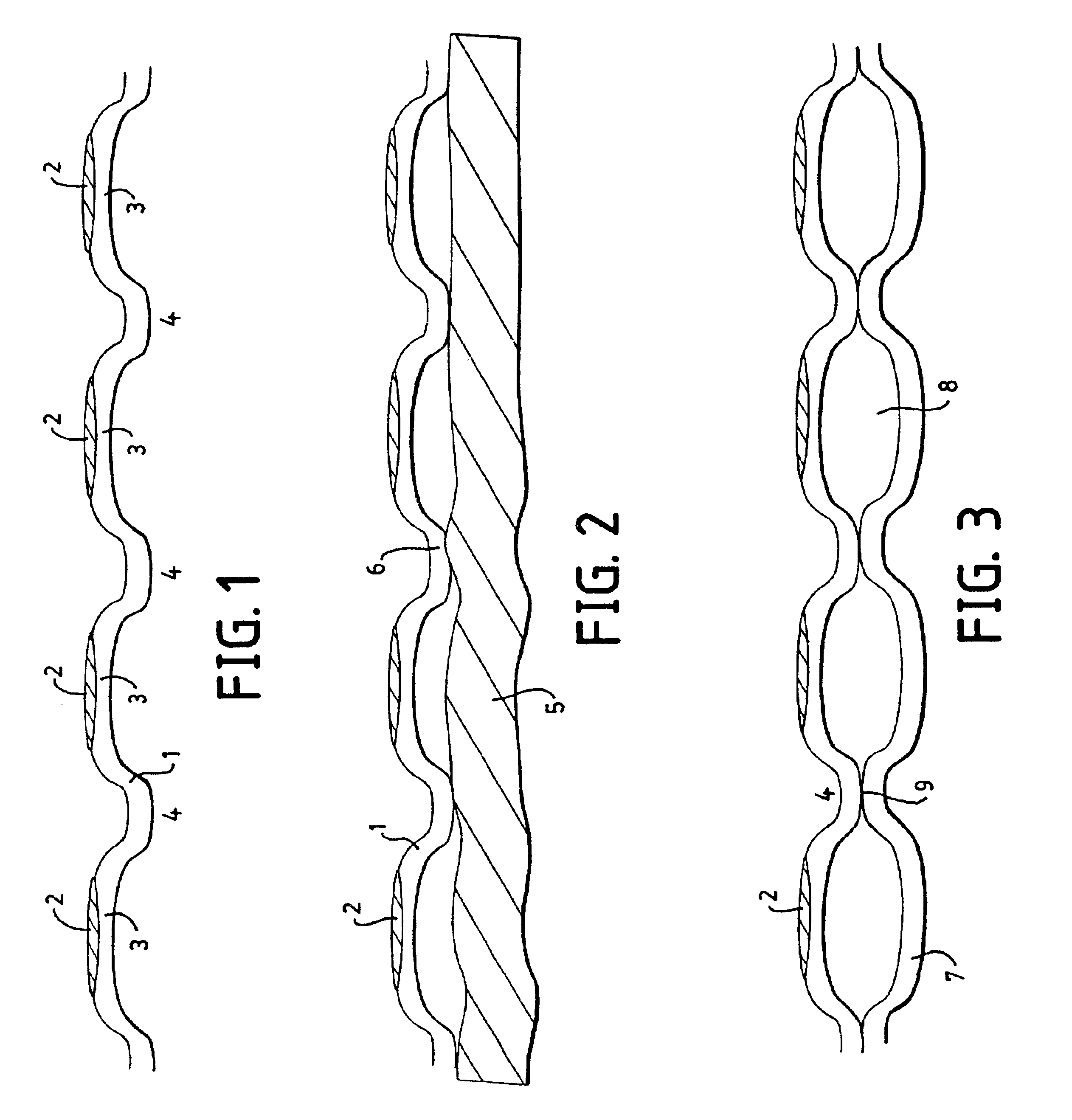

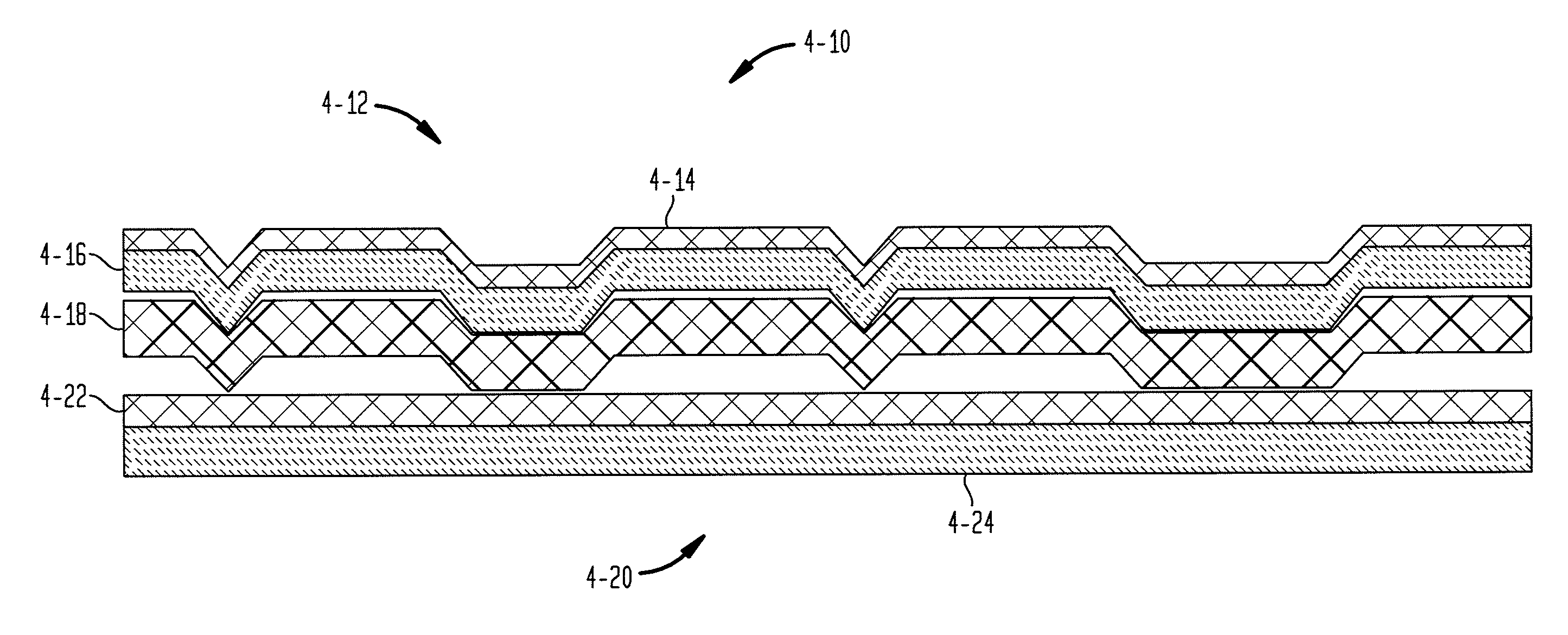

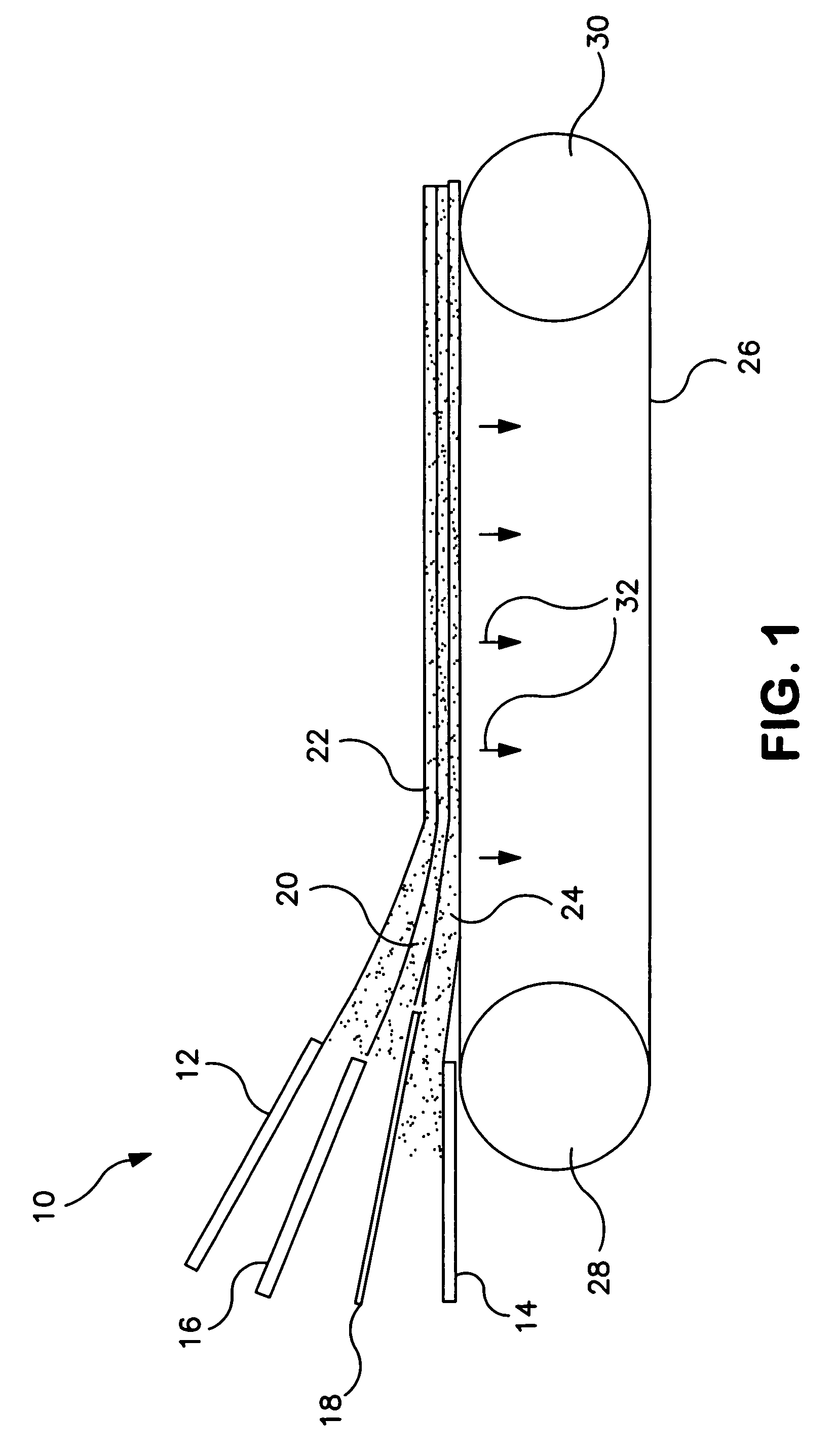

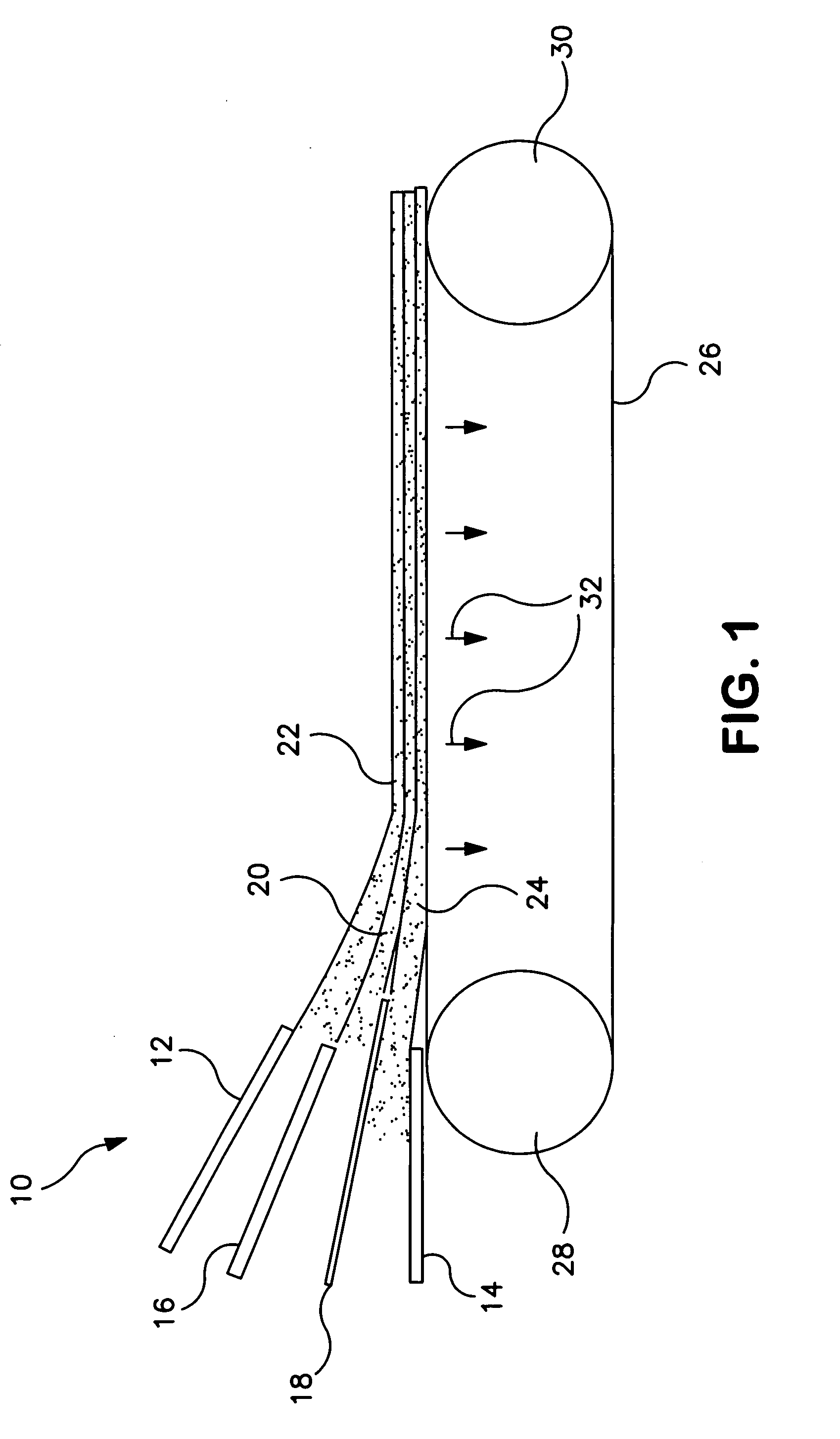

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

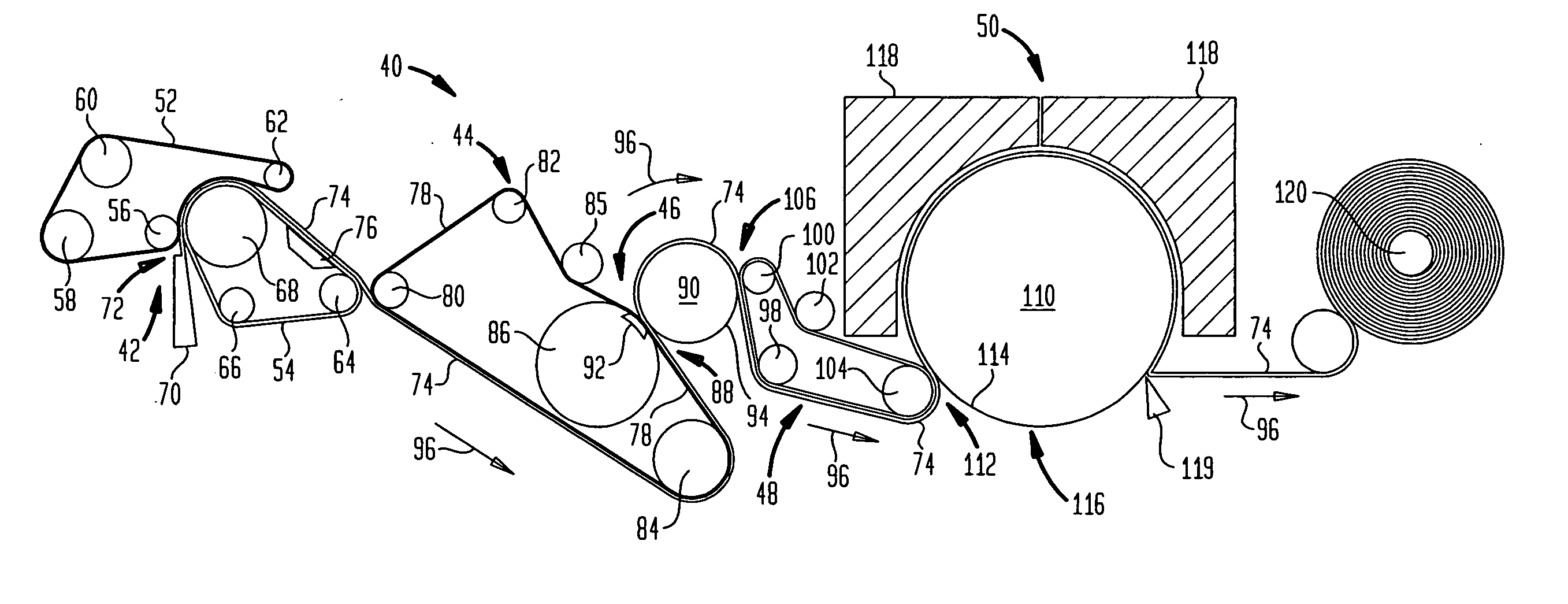

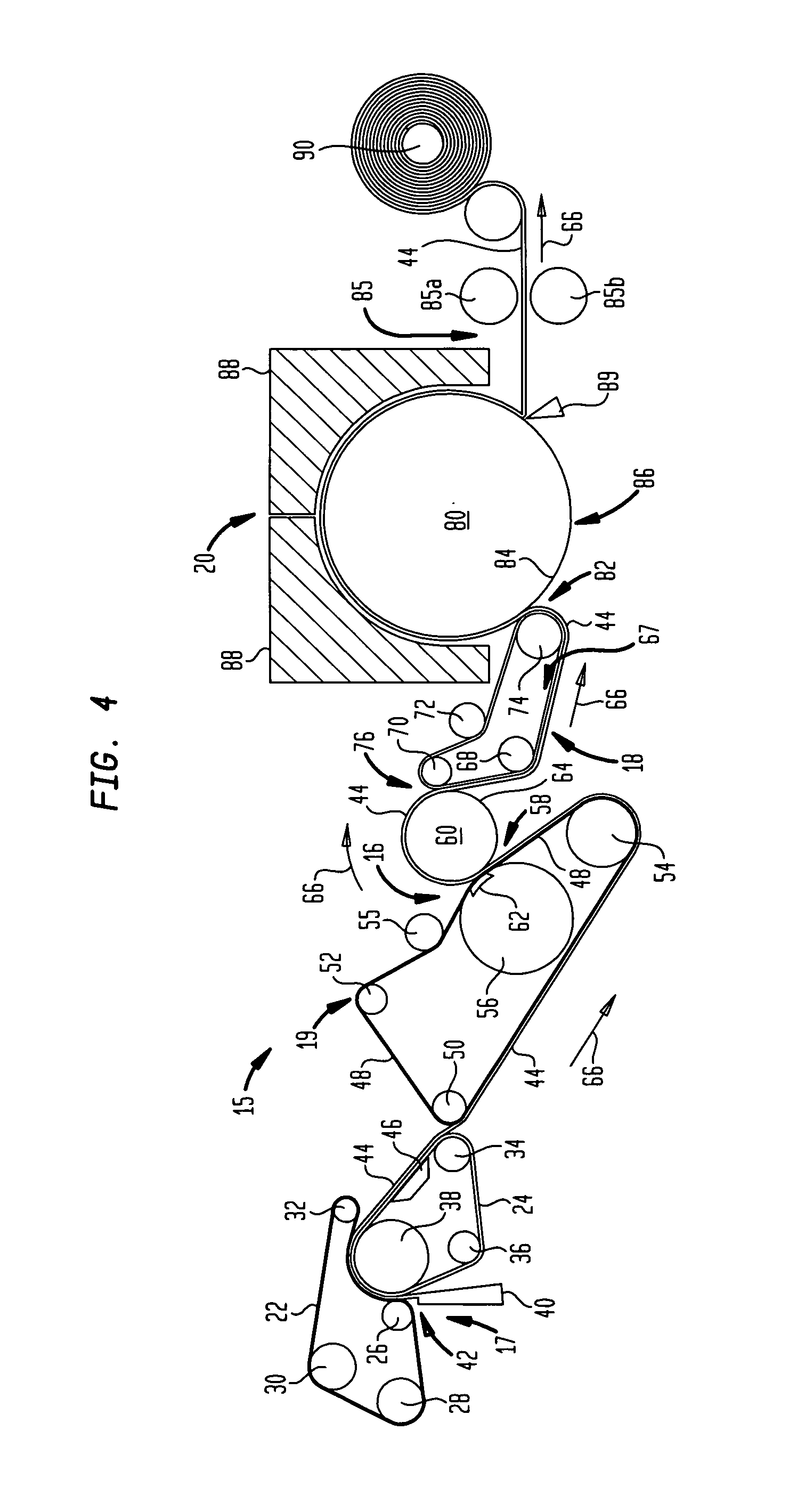

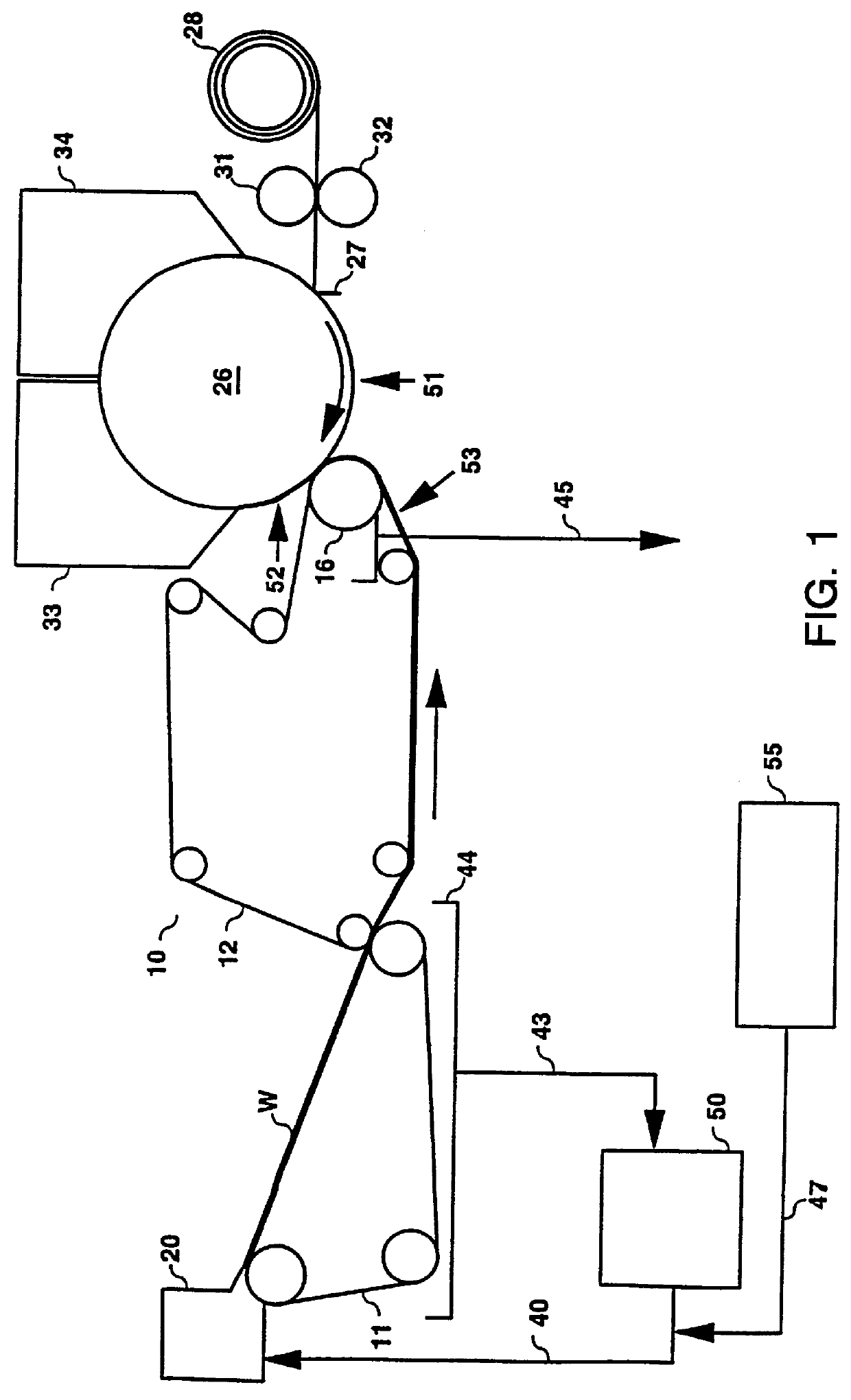

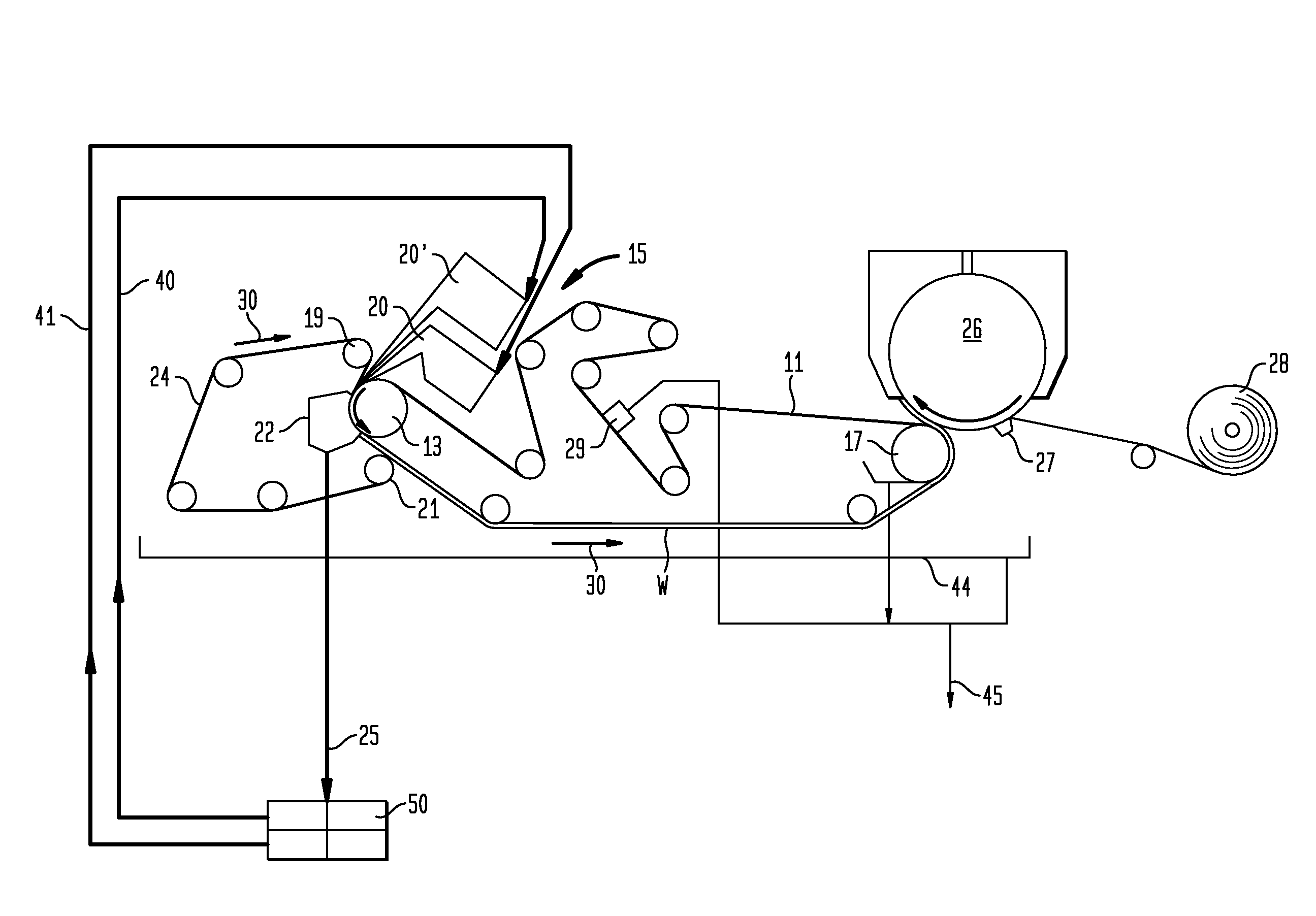

Fabric crepe process for making absorbent sheet

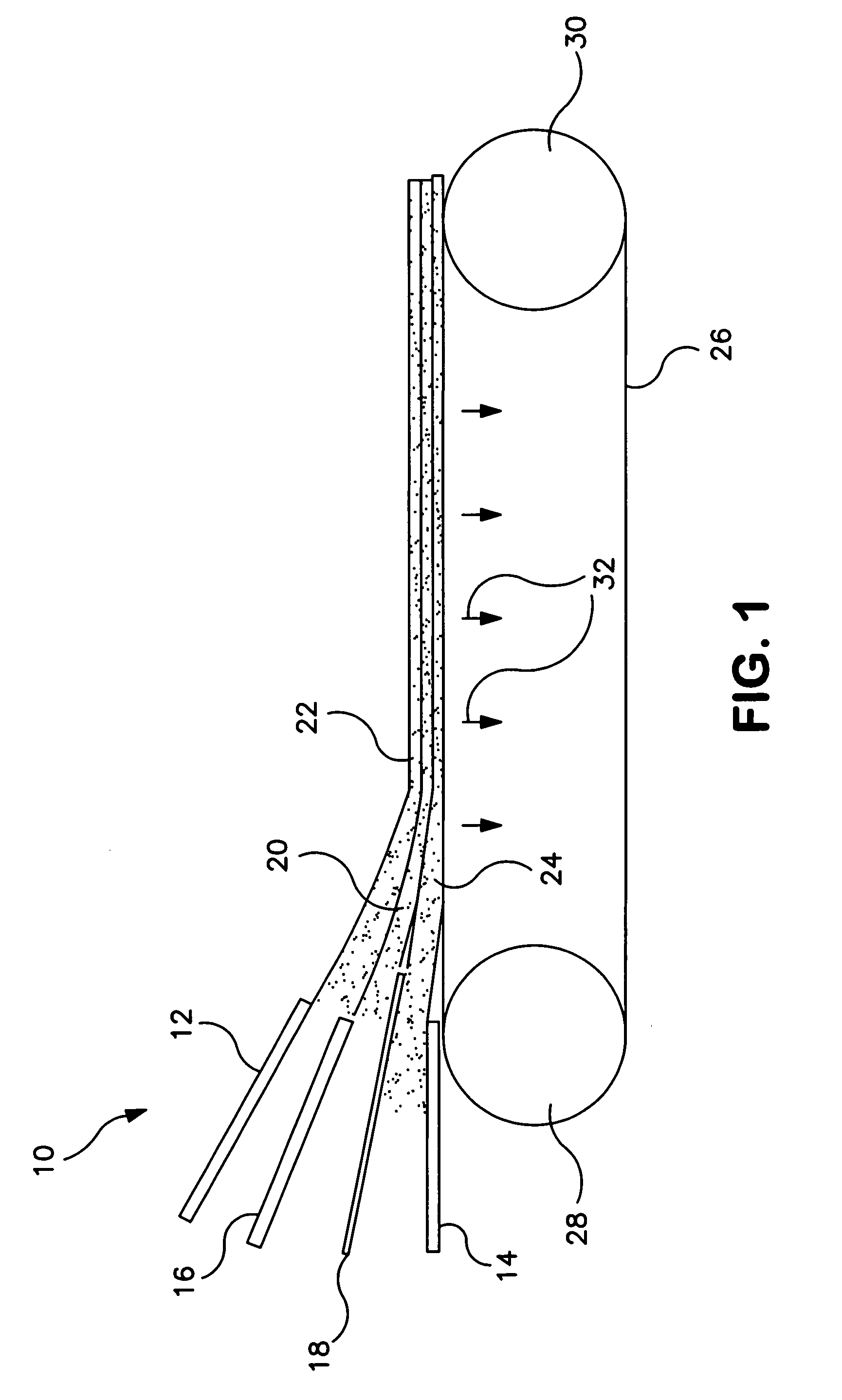

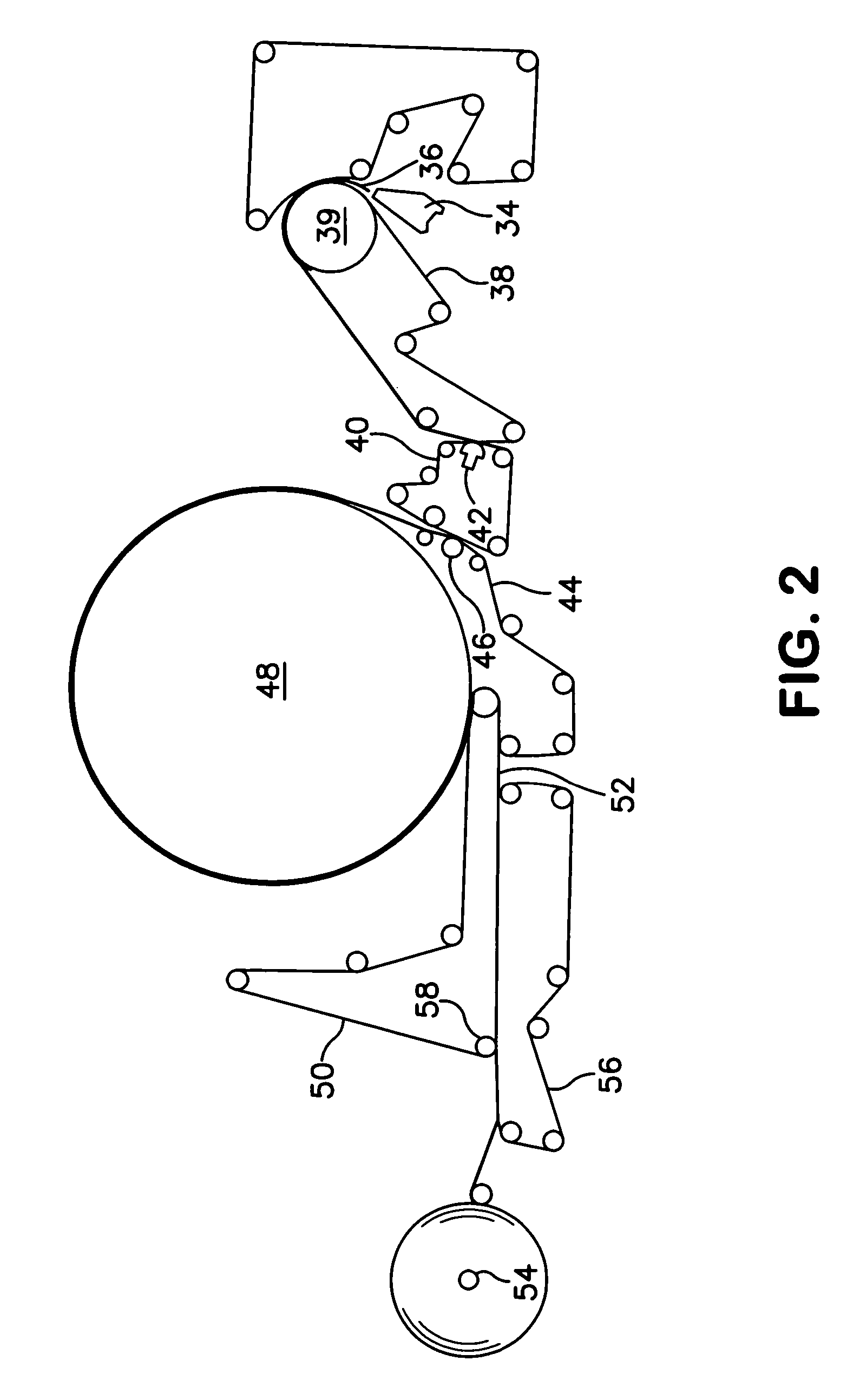

ActiveUS7399378B2High speed transmissionGuaranteed high speed operationNatural cellulose pulp/paperMechanical working/deformationFiberAdhesive

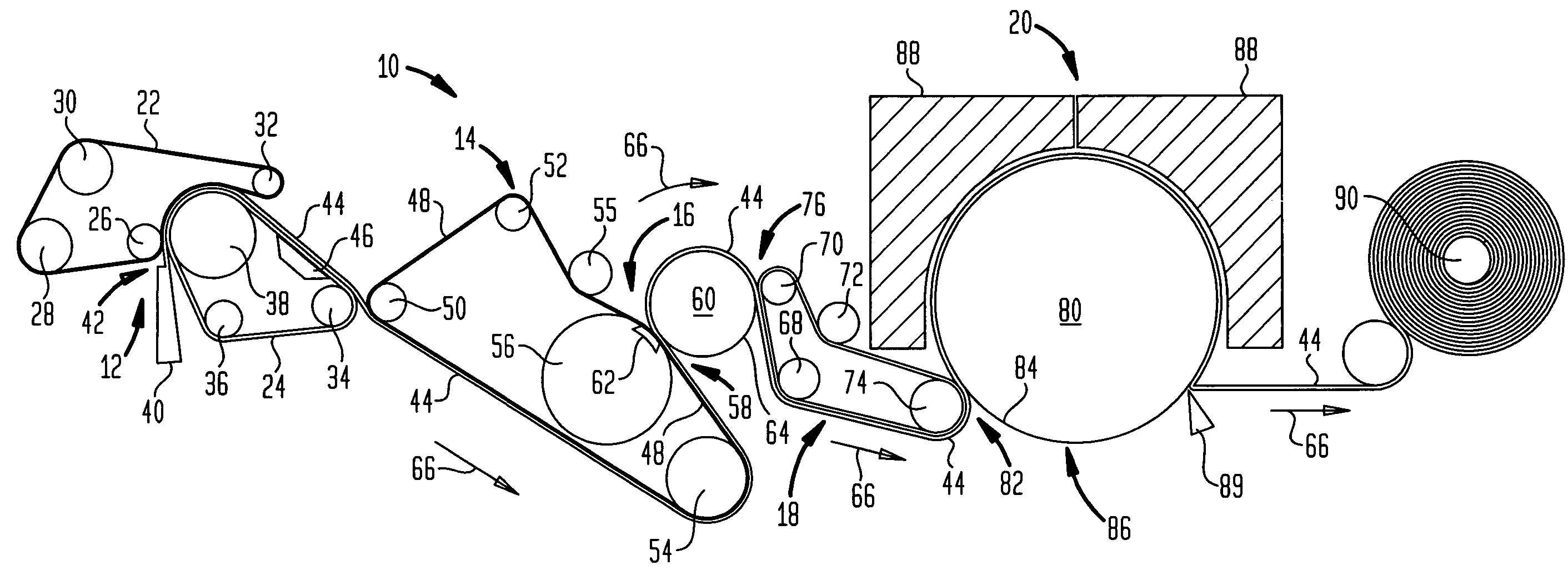

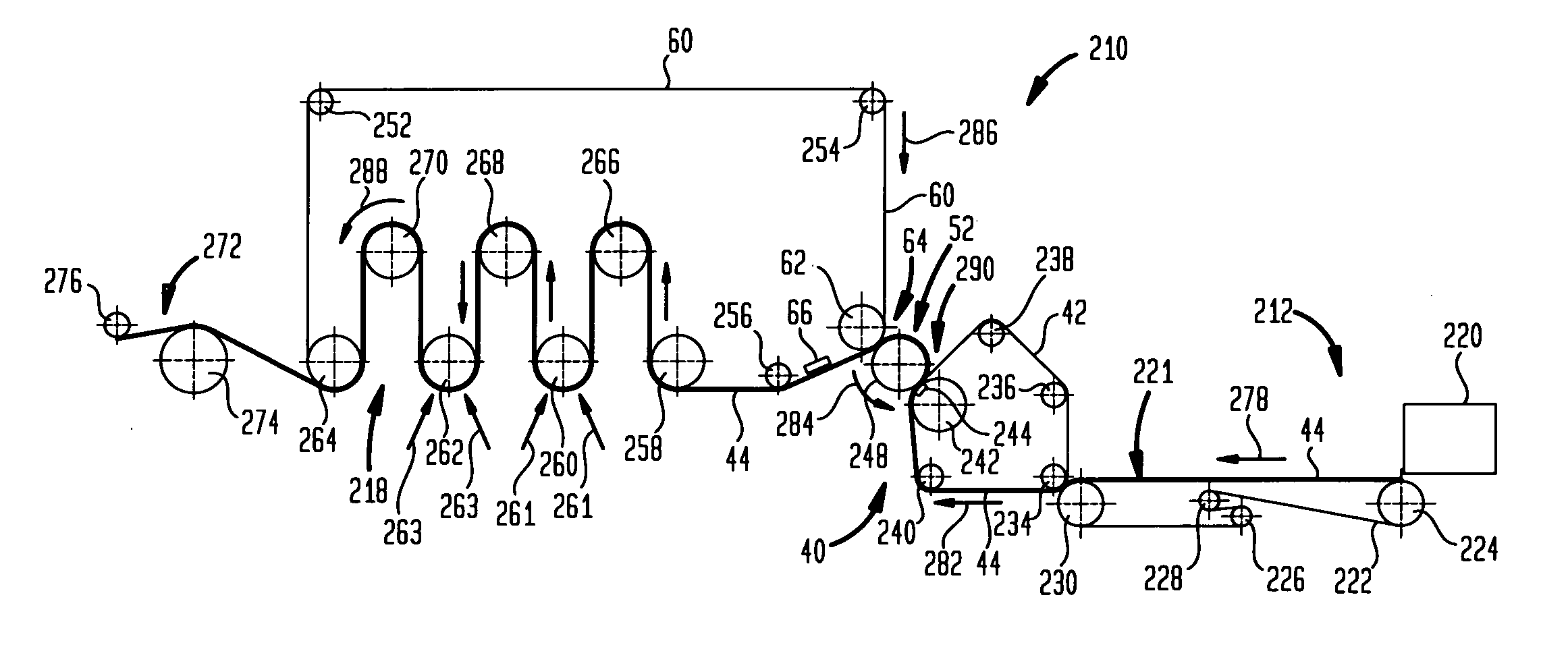

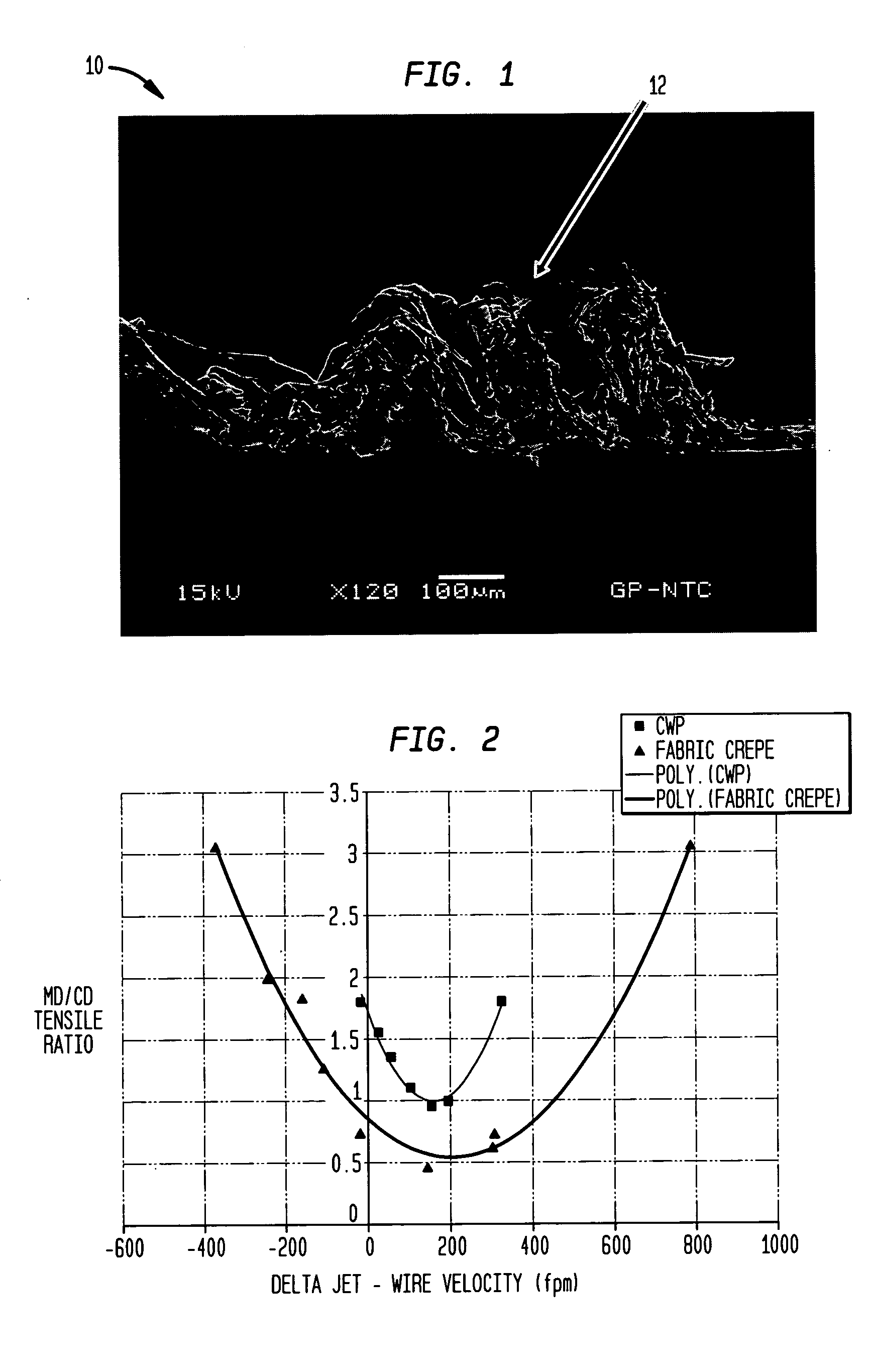

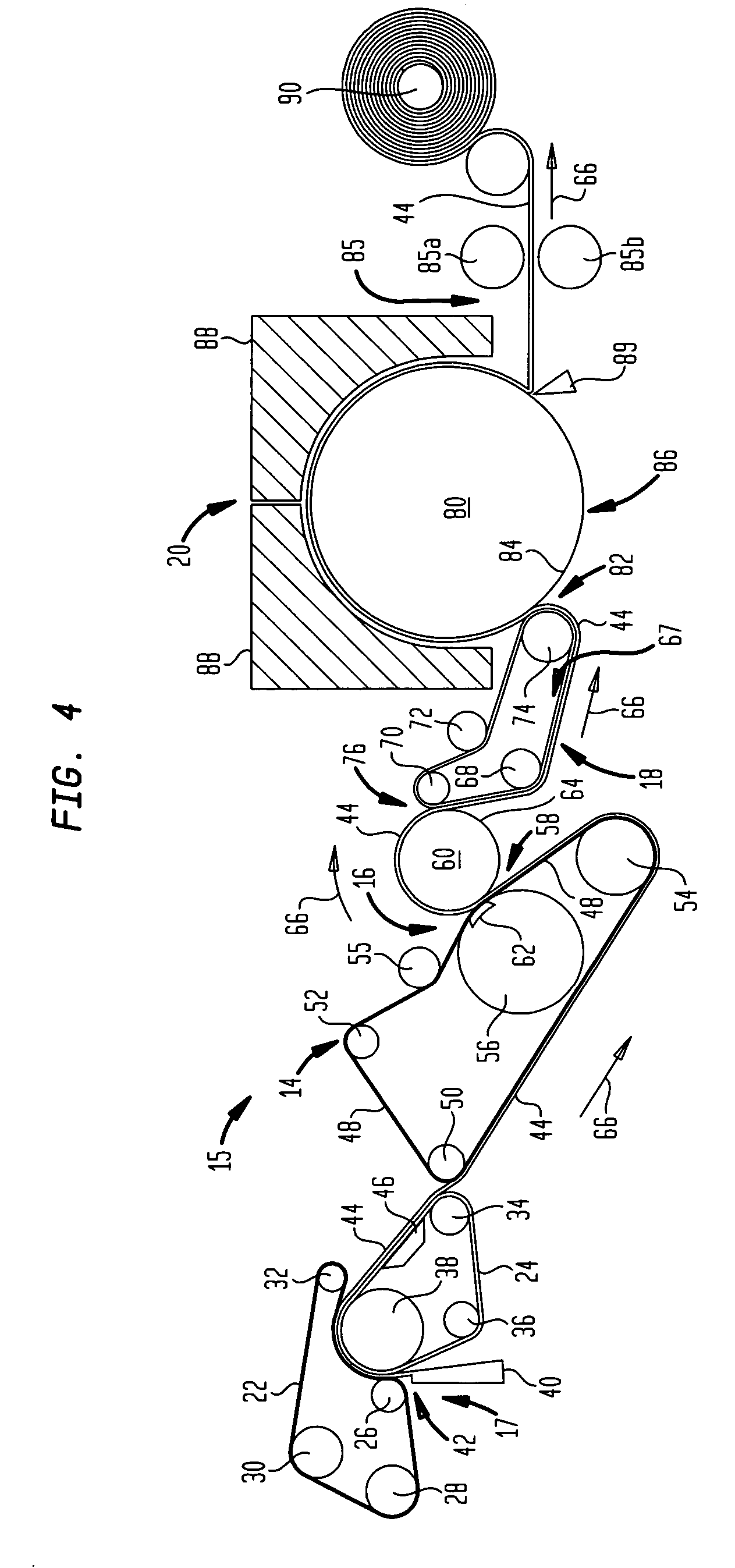

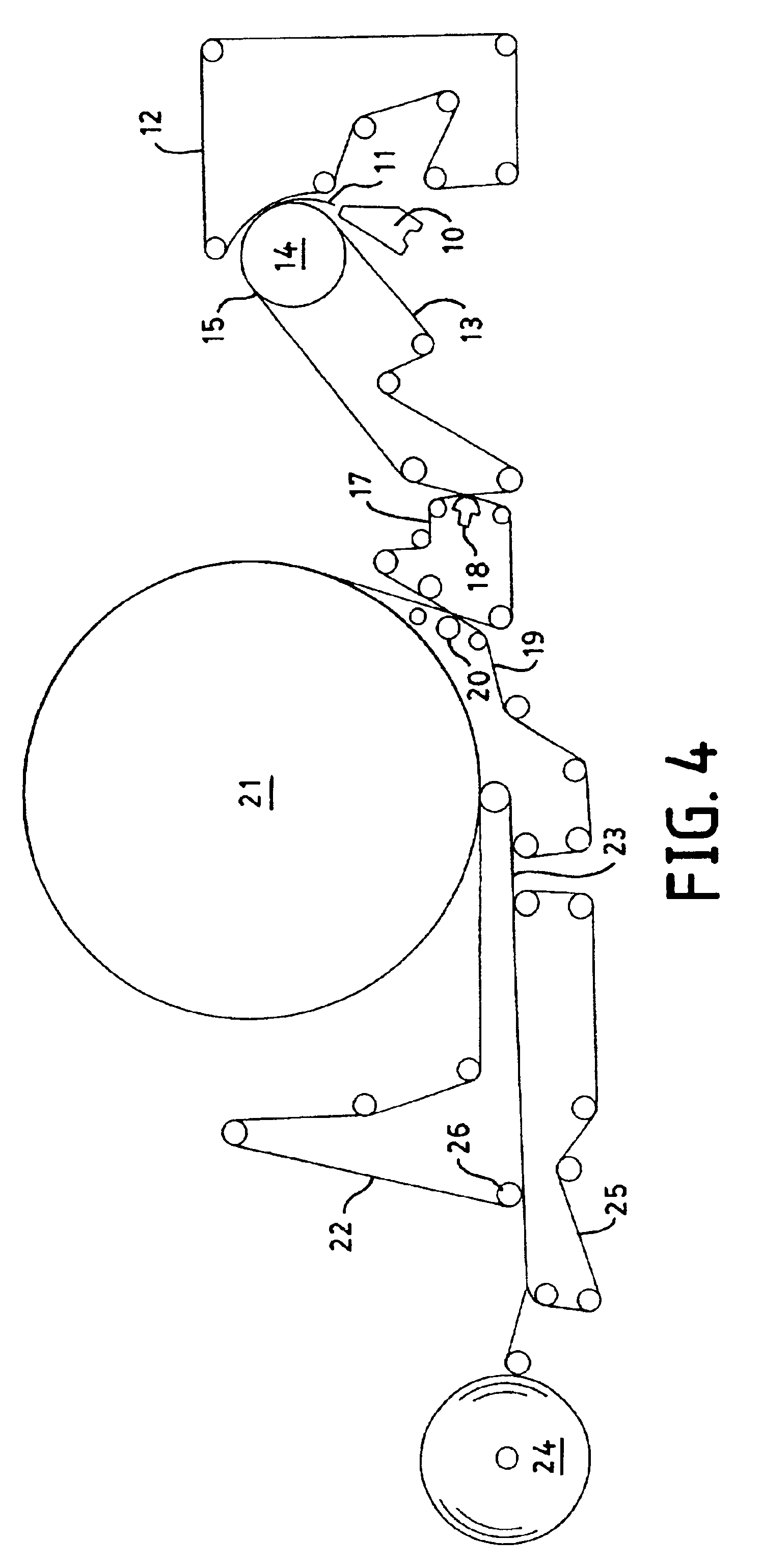

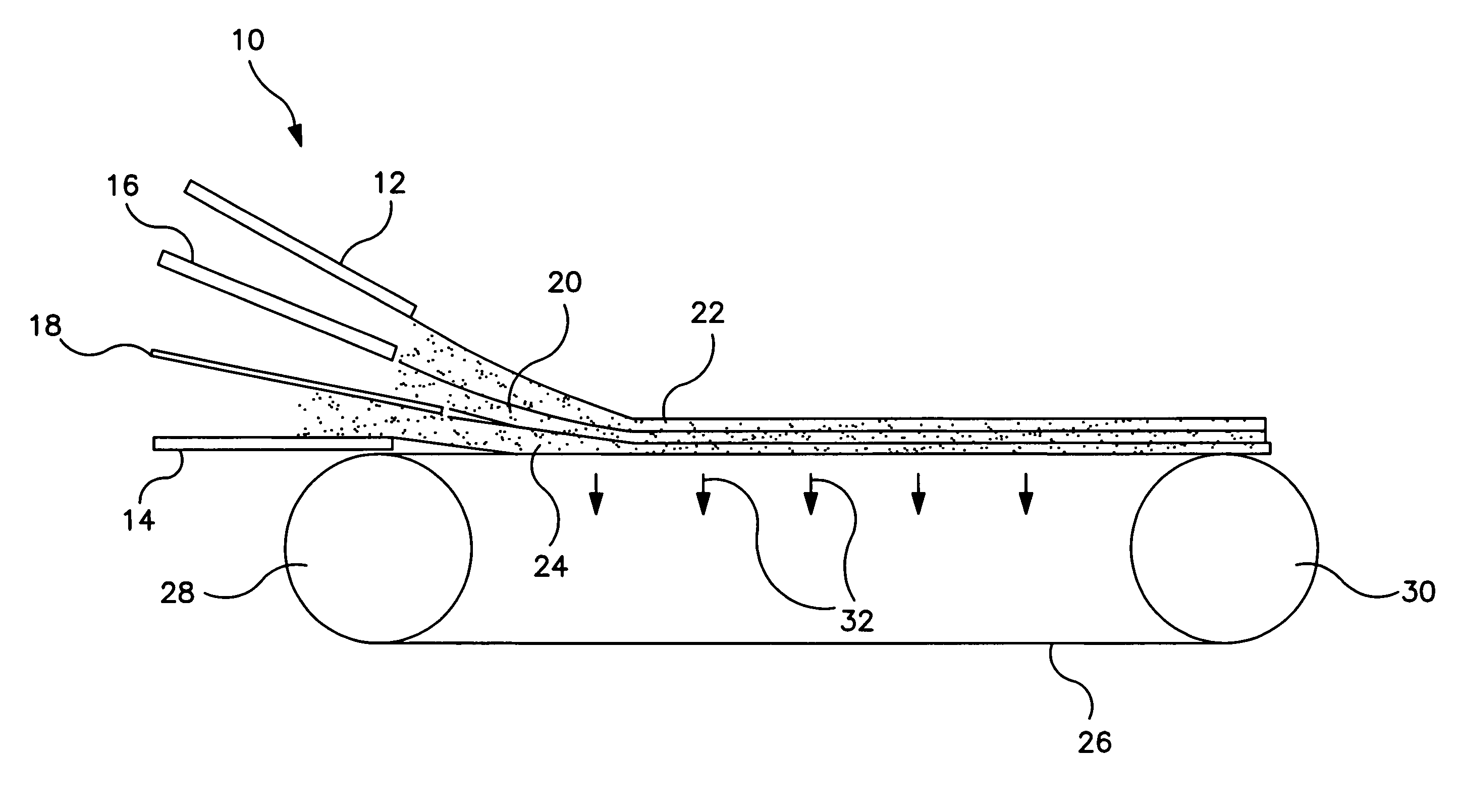

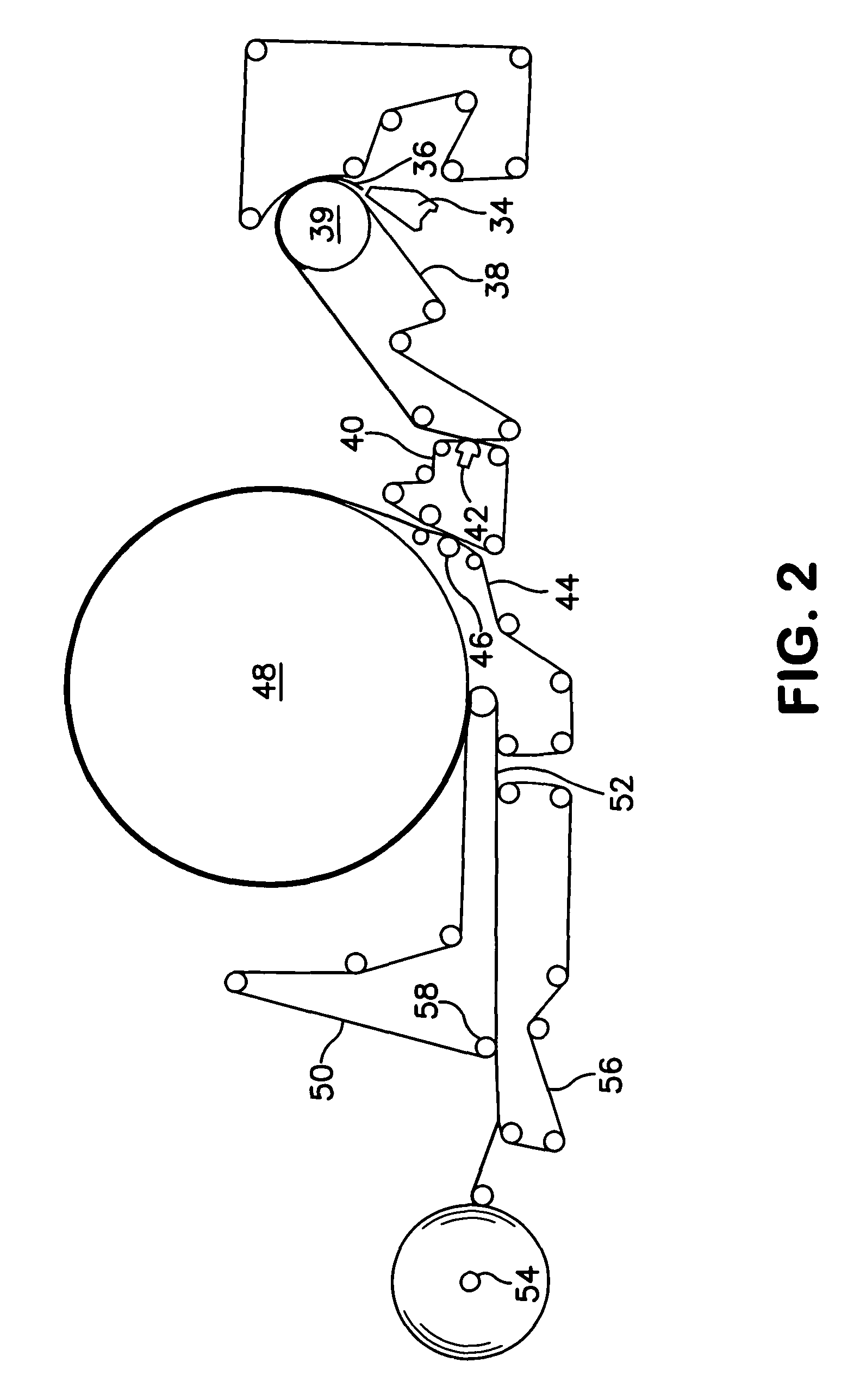

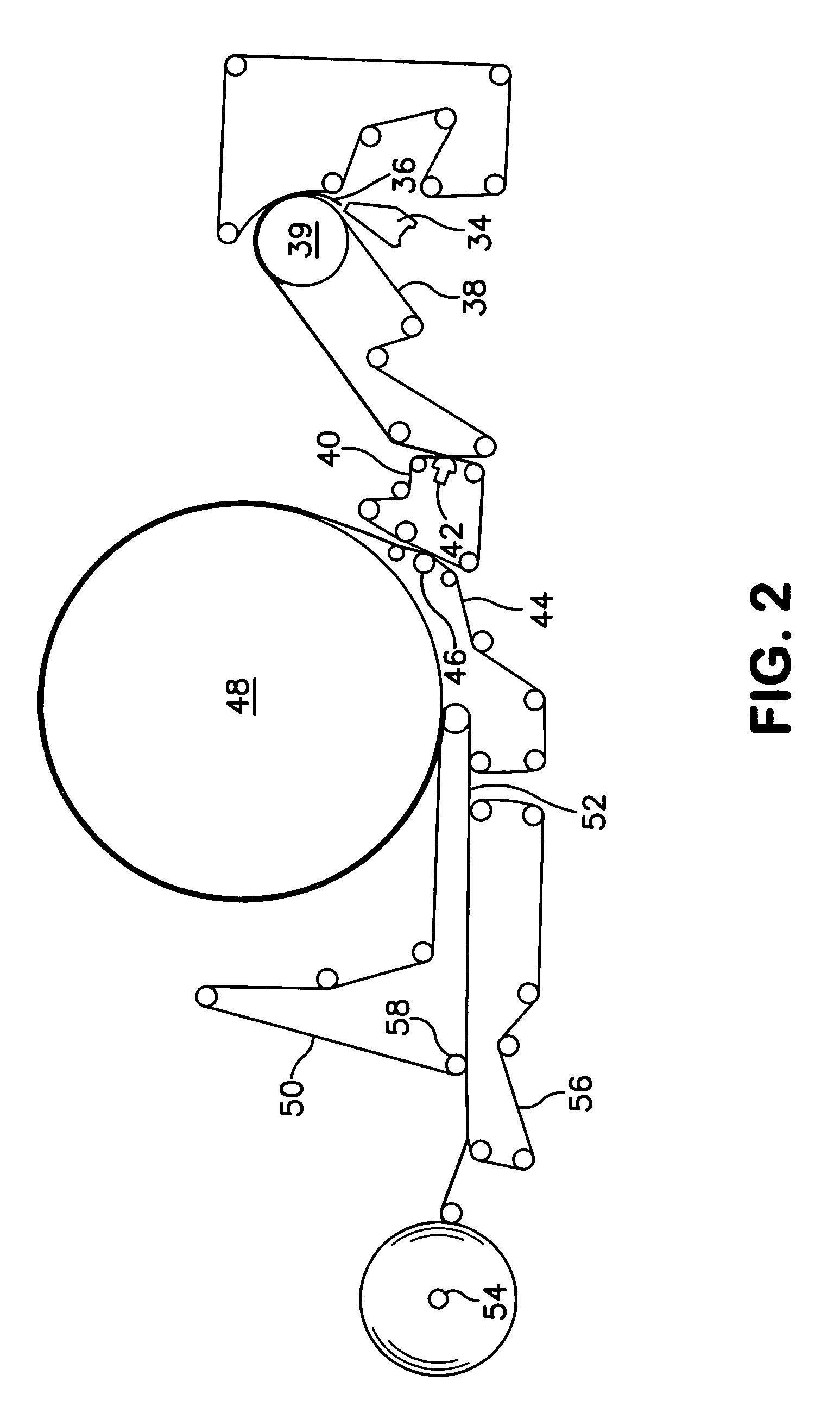

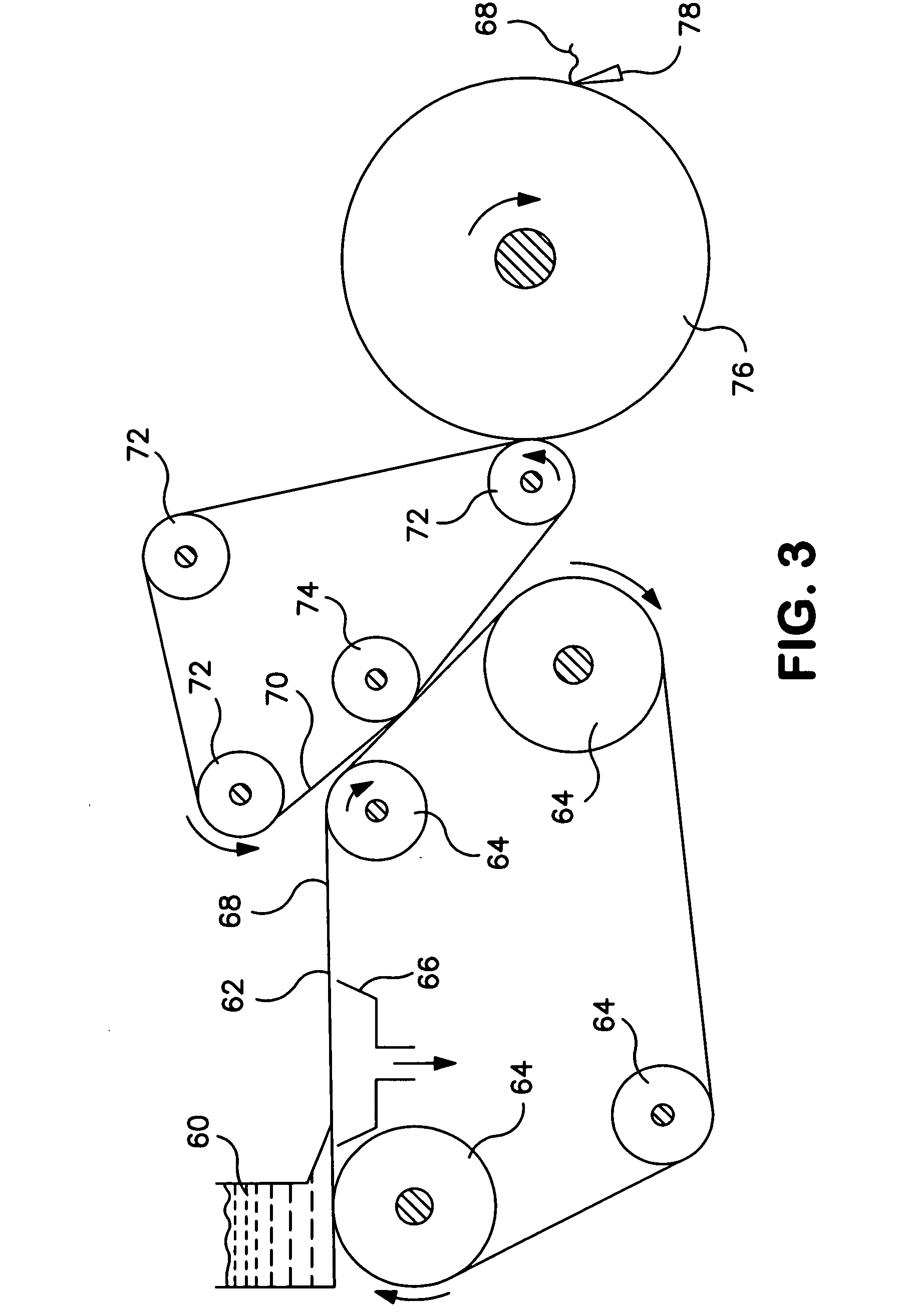

A process for making absorbent cellulosic paper products such as sheet for towel, tissue and the like, includes compactively dewatering a nascent web followed by wet belt creping the web at an intermediate consistency of anywhere from about 30 to about 60 percent under conditions operative to redistribute the fiber on the belt, which is preferably a fabric. In preferred embodiments, the web is thereafter adhesively applied to a Yankee dryer using a creping adhesive operative to enable high speed transfer of the web of intermediate consistency such as a poly(vinyl alcohol) / polyamide adhesive. An absorbent sheet so prepared from a papermaking furnish exhibits an absorbency of at least about 5 g / g, a CD stretch of at least about 4 percent, and an MD / CD tensile ratio of less than about 1.1, and also exhibits a maximum CD modulus at a CD strain of less than 1 percent and sustains a CD modulus of at least 50 percent of its maximum CD modulus to a CD strain of at least about 4 percent. Products of the invention may also exhibit an MD modulus at break 1.5 to 2 times their initial MD modulus.

Owner:GPCP IP HLDG LLC

Fabric creped absorbent sheet with variable local basis weight

InactiveUS20080029235A1Improve water absorptionSurprising softnessNatural cellulose pulp/paperMechanical working/deformationFiberPapermaking

An absorbent cellulosic sheet having variable local basis weight includes a papermaking-fiber reticulum provided with (i) a plurality of cross-machine direction (CD) extending, fiber-enriched pileated regions of relatively high local basis weight interconnected by (ii) a plurality of elongated densified regions of compressed papermaking fibers. The elongated densified regions have relatively low local basis weight and are generally oriented along the machine direction (MD) of the sheet and have an MD / CD aspect ratio of at least 1.5. The products are most preferably prepared by way of a compactive dewatering / wet crepe process.

Owner:GPCP IP HLDG LLC

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

ActiveUS20050241786A1The implementation process is simpleNatural cellulose pulp/paperMechanical working/deformationMedicineCellulose fiber

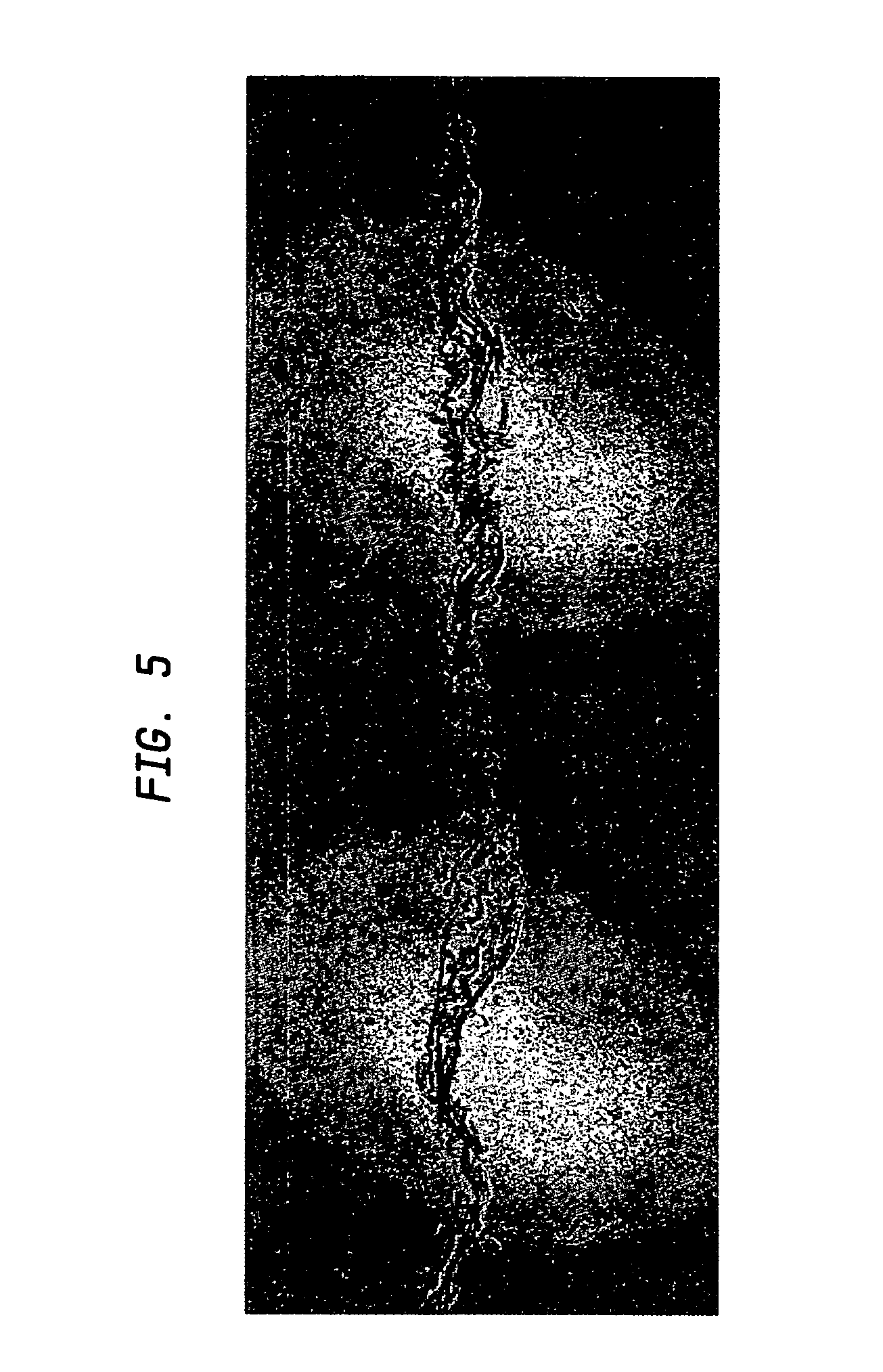

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

Hollow sphere organic pigment for paper or paper coatings

InactiveUS6139961ATrend downHigh molecular weightSynthetic resin layered productsCellulosic plastic layered productsVitrificationPaperboard

A hollow sphere organic pigment in which a core containing a void is encapsulated by a first shell polymer having a glass transition temperature greater than 50 DEG C., the first shell having polymerized thereon a second shell polymer having a glass transition temperature of -15 DEG C. to -50 DEG C. is provided. Also provided is a paper or paperboard coating composition containing the hollow sphere organic pigment, a method for improving the strength and opacity of a paper or paperboard coating by using the coating composition dried, a coated paper or paperboard bearing the dried coating composition, and a method for improving the strength and opacity of paper or paperboard by incorporating a particular hollow sphere organic pigment into the formed wet sheet.

Owner:ROHM & HAAS CO

Fabric crepe/draw process for producing absorbent sheet

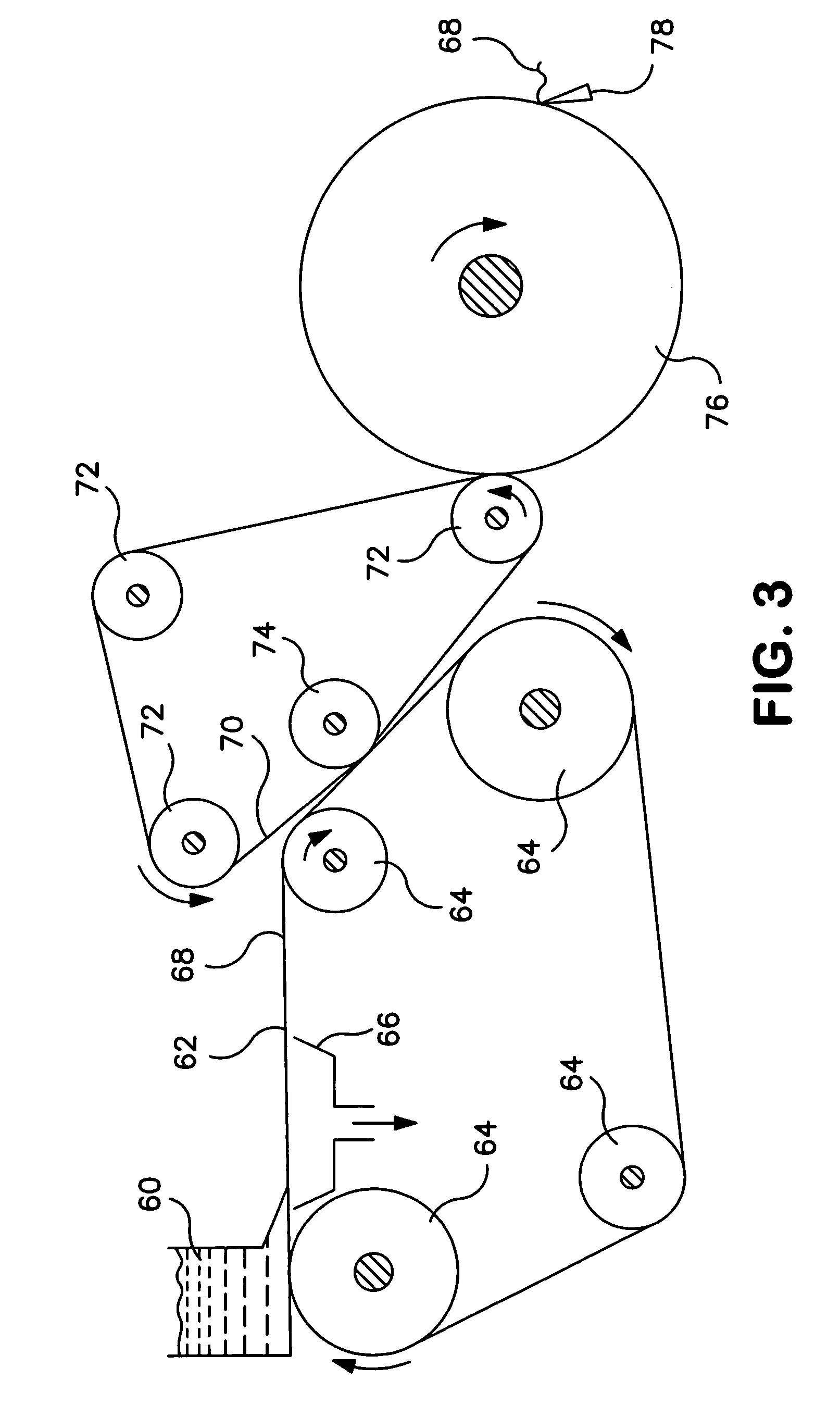

ActiveUS20050217814A1Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingFiberPapermaking

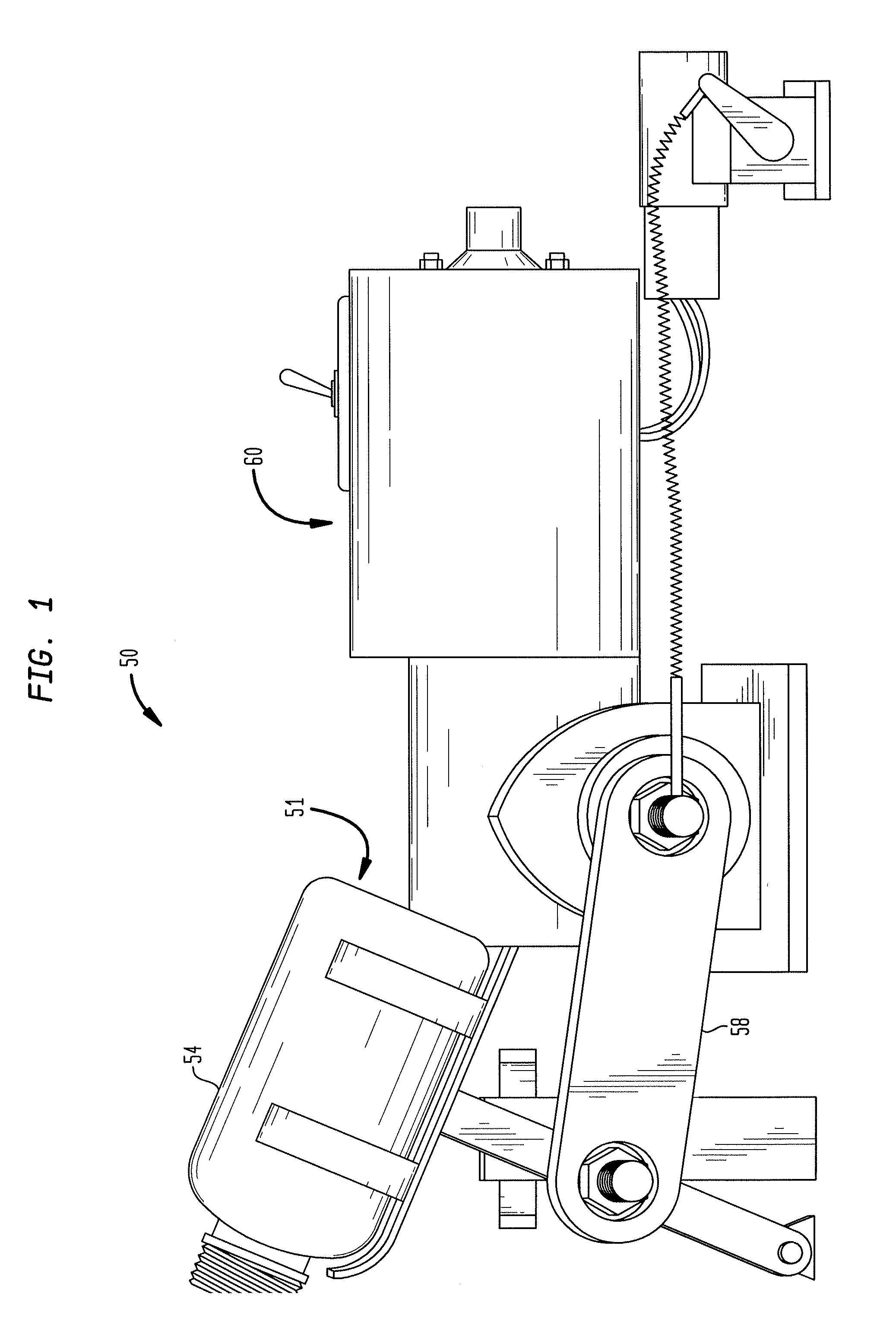

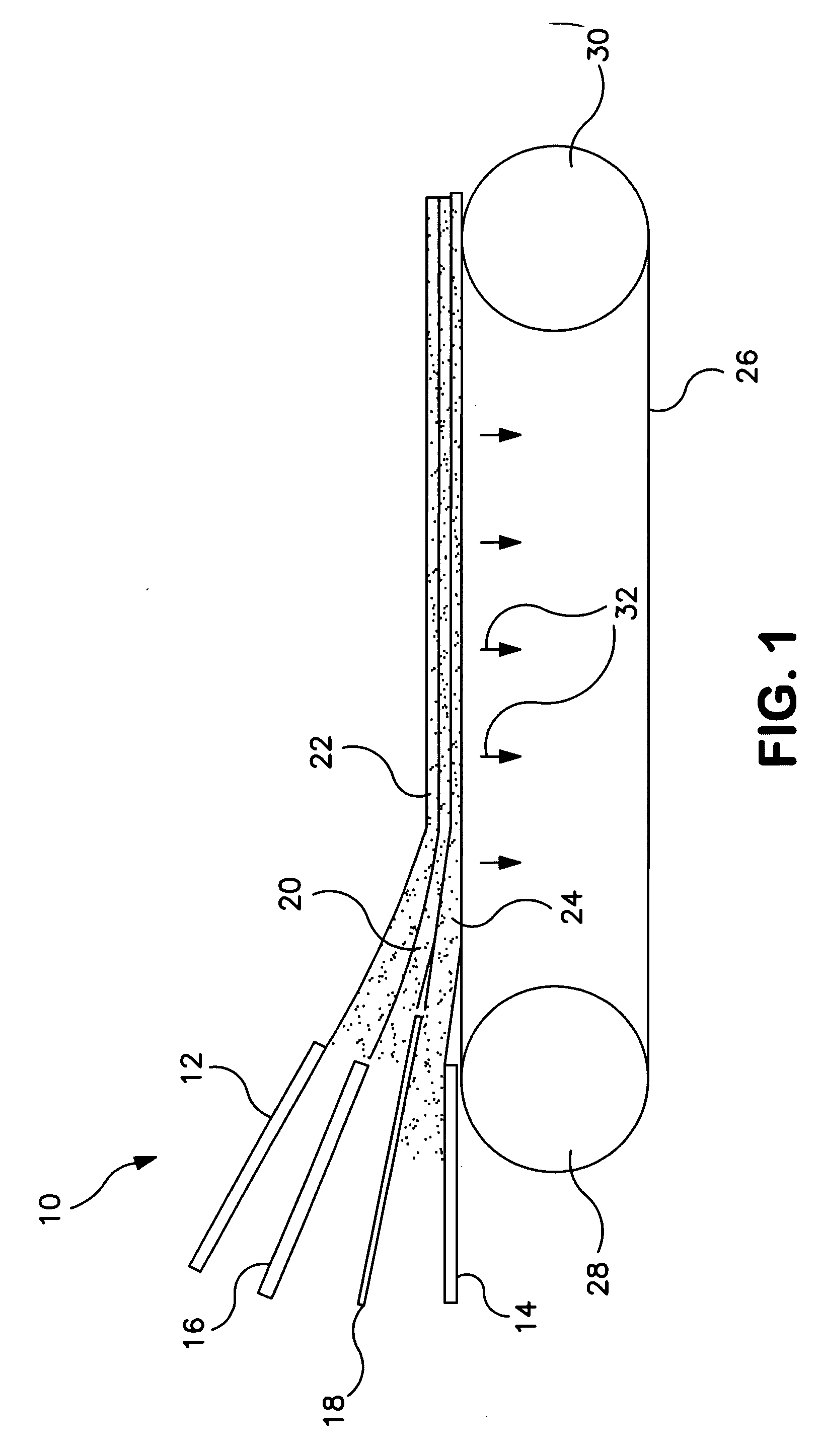

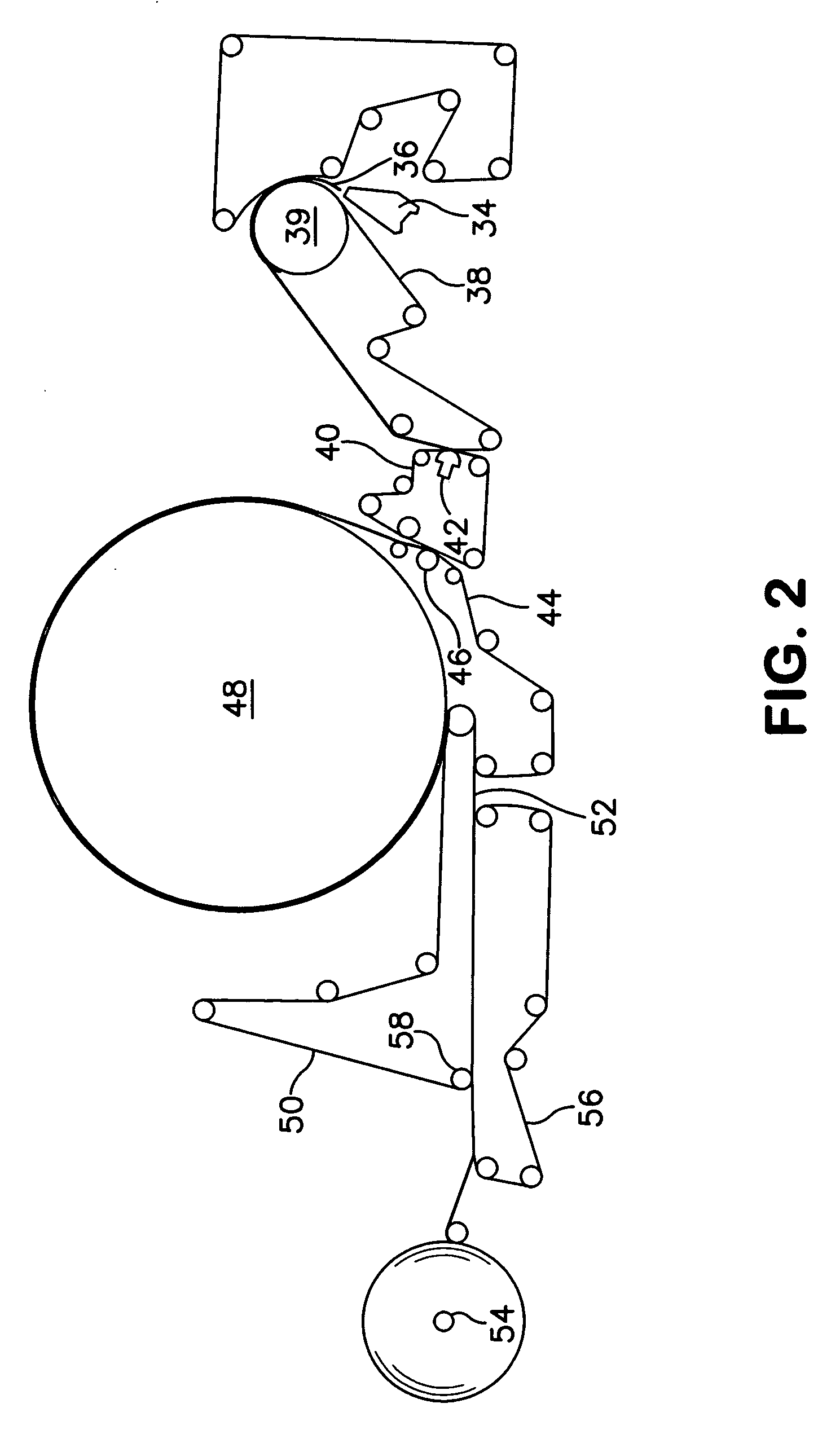

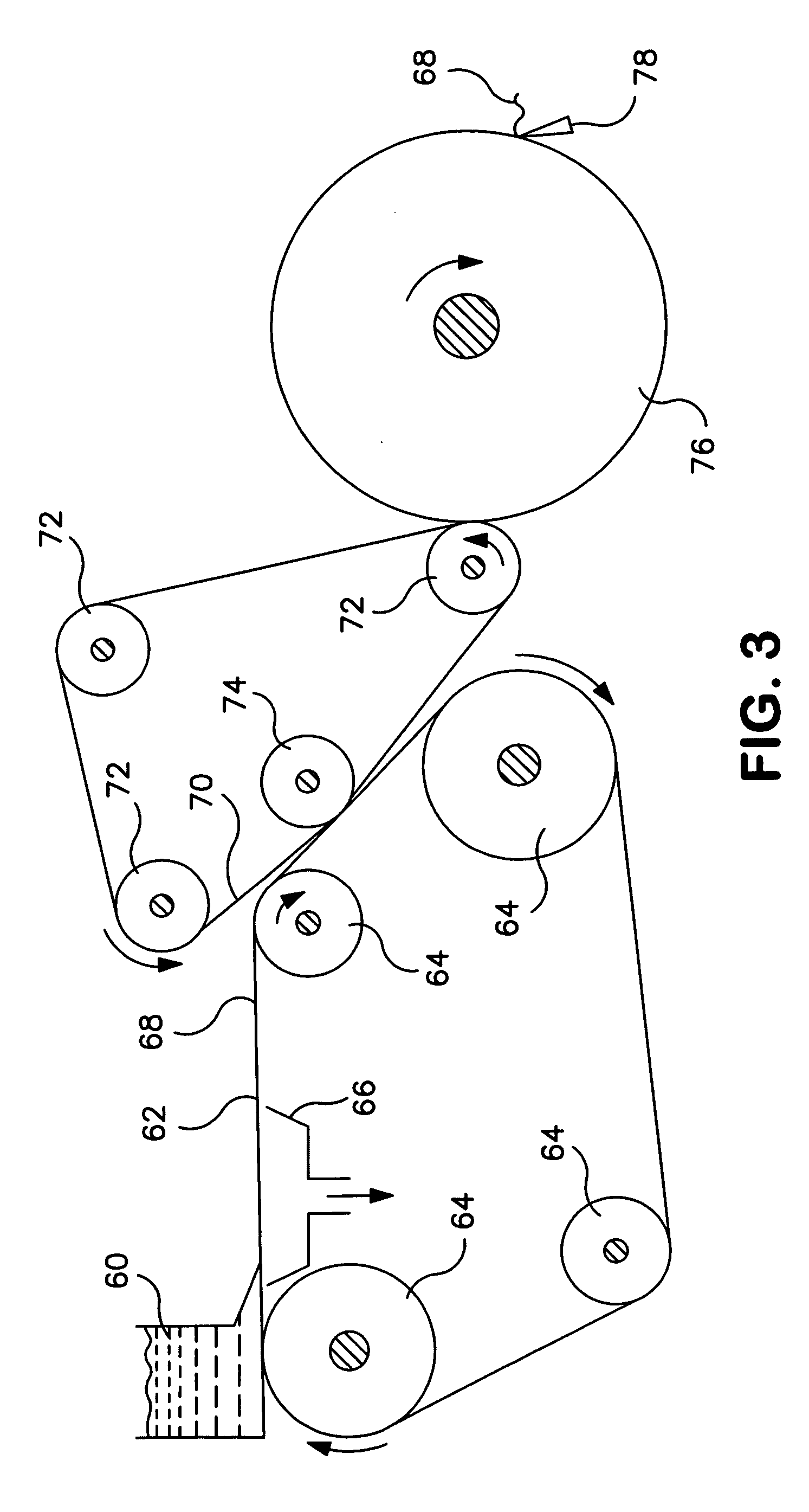

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Fabric crepe/draw process for producing absorbent sheet

ActiveUS7789995B2Increase in sizeDecrease sidednessMechanical working/deformationPaper coatingCelluloseFiber

A method of making a fabric-creped absorbent cellulosic sheet comprising: a) compactively dewatering a papermaking furnish to form a nascent web having an apparently random distribution of papermaking fiber; b) applying the dewatered web having the apparently random fiber distribution to a translating transfer surface moving at a first speed; c) fabric-creping the web from the transfer surface at a consistency of from about 30 to about 60 percent utilizing a patterned creping fabric, the creping step occurring under pressure in a fabric creping nip defined between the transfer surface and the creping fabric wherein the fabric is traveling at a second speed slower than the speed of said transfer surface, the fabric pattern, nip parameters, velocity delta and web consistency being selected such that the web is creped from the transfer surface and redistributed on the creping fabric to form a web with a drawable reticulum.

Owner:GPCP IP HLDG LLC

Soft tissue having temporary wet strength

Disclosed is a soft, low density paper product made using papermaking fibers and a cationic temporary wet strength resin. Such paper products have a density less than about 0.6 grams per cubic centimeter, a basis weight is between about 10 and about 65 grams per square meter, a dry strength less than about 500 grams per inch (197 grams per centimeter), a ratio of an initial wet strength to the dry strength greater than about 0.15:1, and a ratio of a thirty minute wet strength to the initial wet strength less than about 0.4. Methods for producing such paper products are also disclosed. The paper products may be produced either as homogeneous structures or as multi-layered structures and may be either creped or uncreped.

Owner:THE PROCTER & GAMBLE COMPANY

Wet-pressed tissue and towel products with elevated CD stretch and low tensile ratios made with a high solids fabric crepe process

An absorbent sheet of cellulosic fibers includes a mixture of hardwood fibers and softwood fibers arranged in a reticulum having: (i) a plurality of pileated fiber enriched regions of relatively high local basis weight interconnected by way of (ii) a plurality of lower local basis weight linking regions whose fiber orientation is biased along the machine direction between pileated regions interconnected thereby, wherein the sheet exhibits a % CD stretch which is at least about 2.75 times the dry tensile ratio of the sheet. Tensile ratios of from about 0.4 to about 4 are readily achieved.

Owner:GPCP IP HLDG LLC

Fabric-creped sheet for dispensers

ActiveUS7585388B2More MD stretchMore lengthMechanical working/deformationSpecial paperBiomedical engineeringSheet material

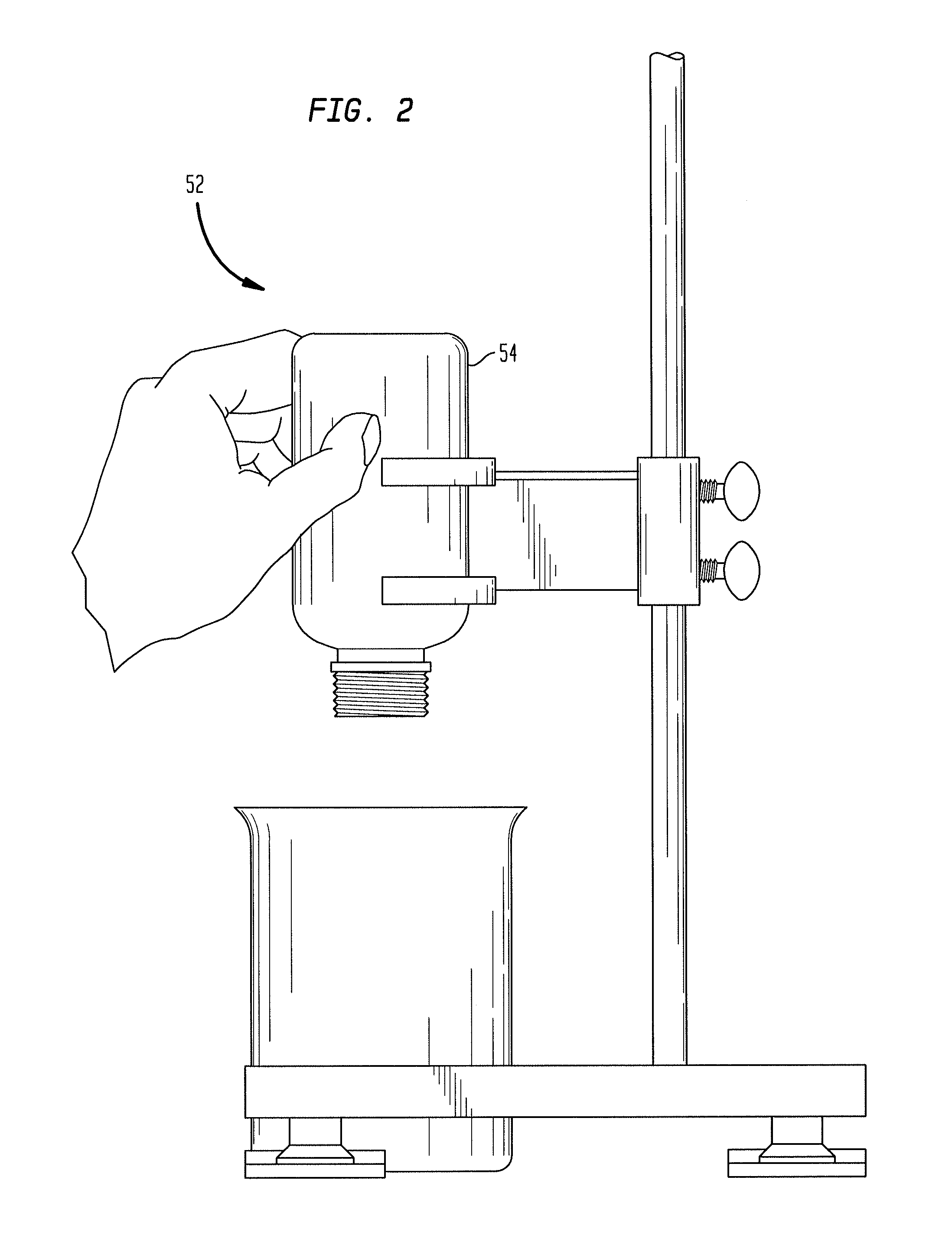

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Fabric-creped sheet for dispensers

ActiveUS20060289133A1More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationThird generationEngineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

Dual-zoned absorbent webs

InactiveUS6911573B2Fast shippingImprove adaptabilityNatural cellulose pulp/paperMechanical working/deformationCelluloseEngineering

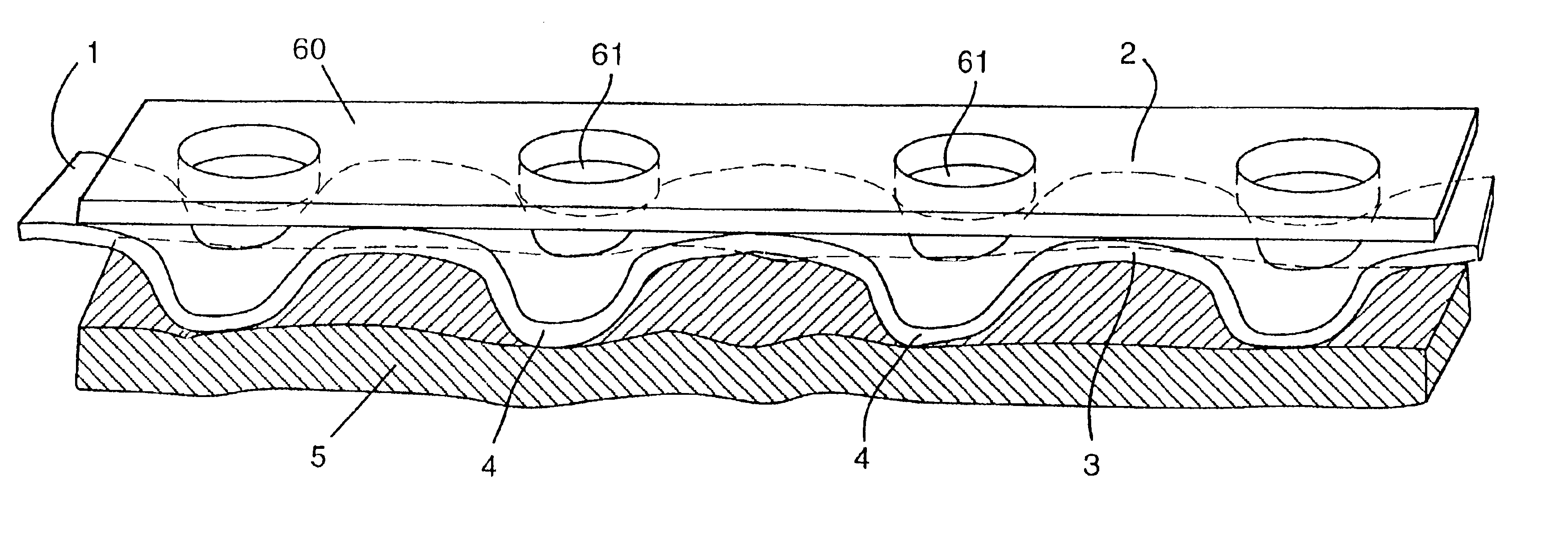

The present invention is a method for producing an absorbent article. A wet resillient, cellulosic basesheet having elevated and depressed regions with an Overall Surface Depth of at least 0.2 mm is prepared. The cellulosic basesheet has an upper surface and a lower surface. A contiguous, fibrous nonwoven web having a plurality of openings is integrally attached onto the upper surface of the cellulosic basesheet such that a portion of the openings are superposed over the depressed regions of the cellulosic basesheet. An absorbent core and an impervious web are attached to the lower surface of the cellulosic basesheet such that the absorbent core is sandwiched between the impervious web and the cellulosic basesheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of making fabric-creped sheet for dispensers

ActiveUS20060289134A1More MD stretchMore lengthNatural cellulose pulp/paperMechanical working/deformationThird generationBiomedical engineering

Fabric-creped absorbent sheet has an MD bending length of about 3.5 cm or more as well as an absorbency of about 3 g / g or more. The sheet is preferably produced without through drying or dry creping and is a low-dust product especially suitable for automatic towel dispensers.

Owner:GPCP IP HLDG LLC

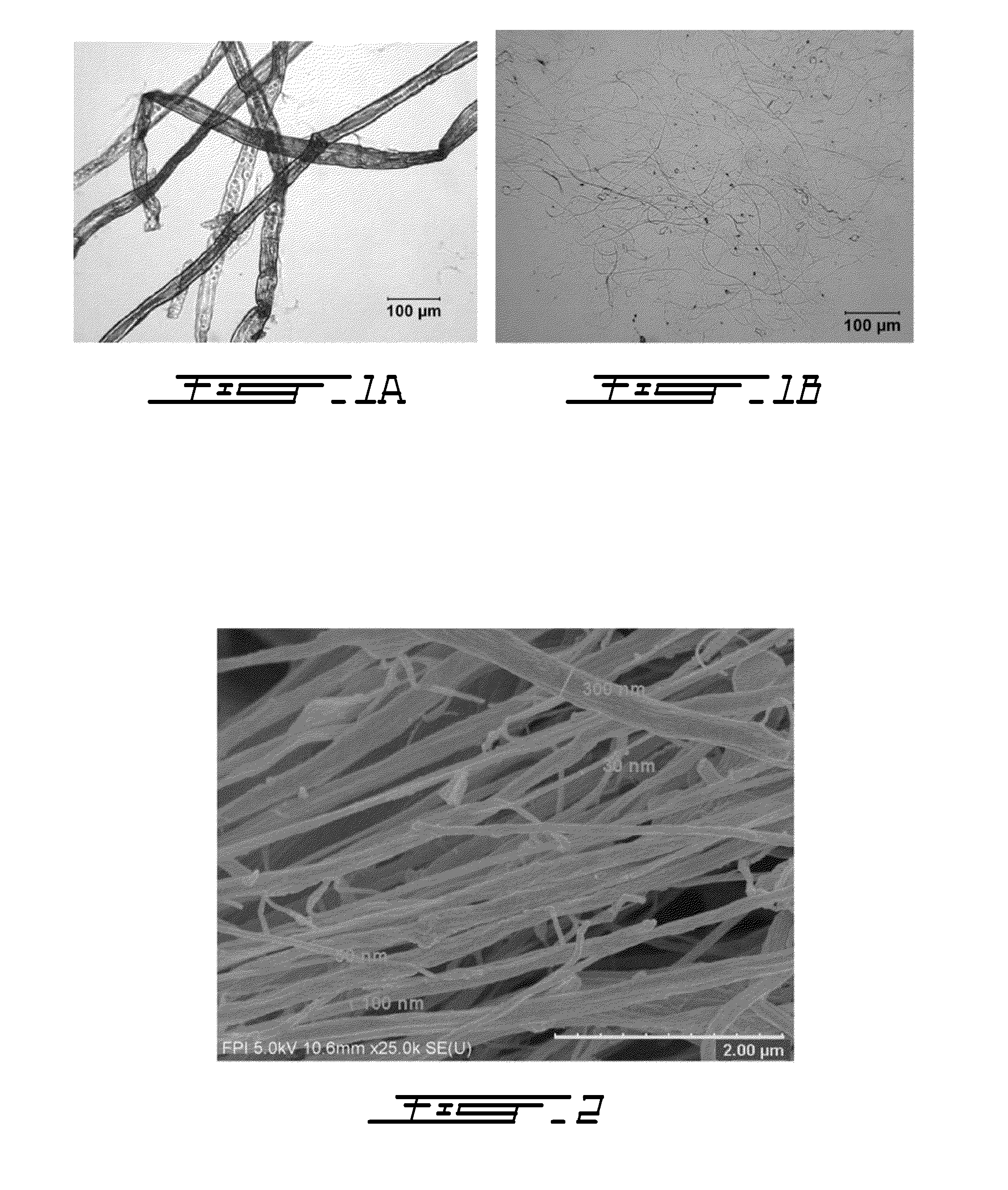

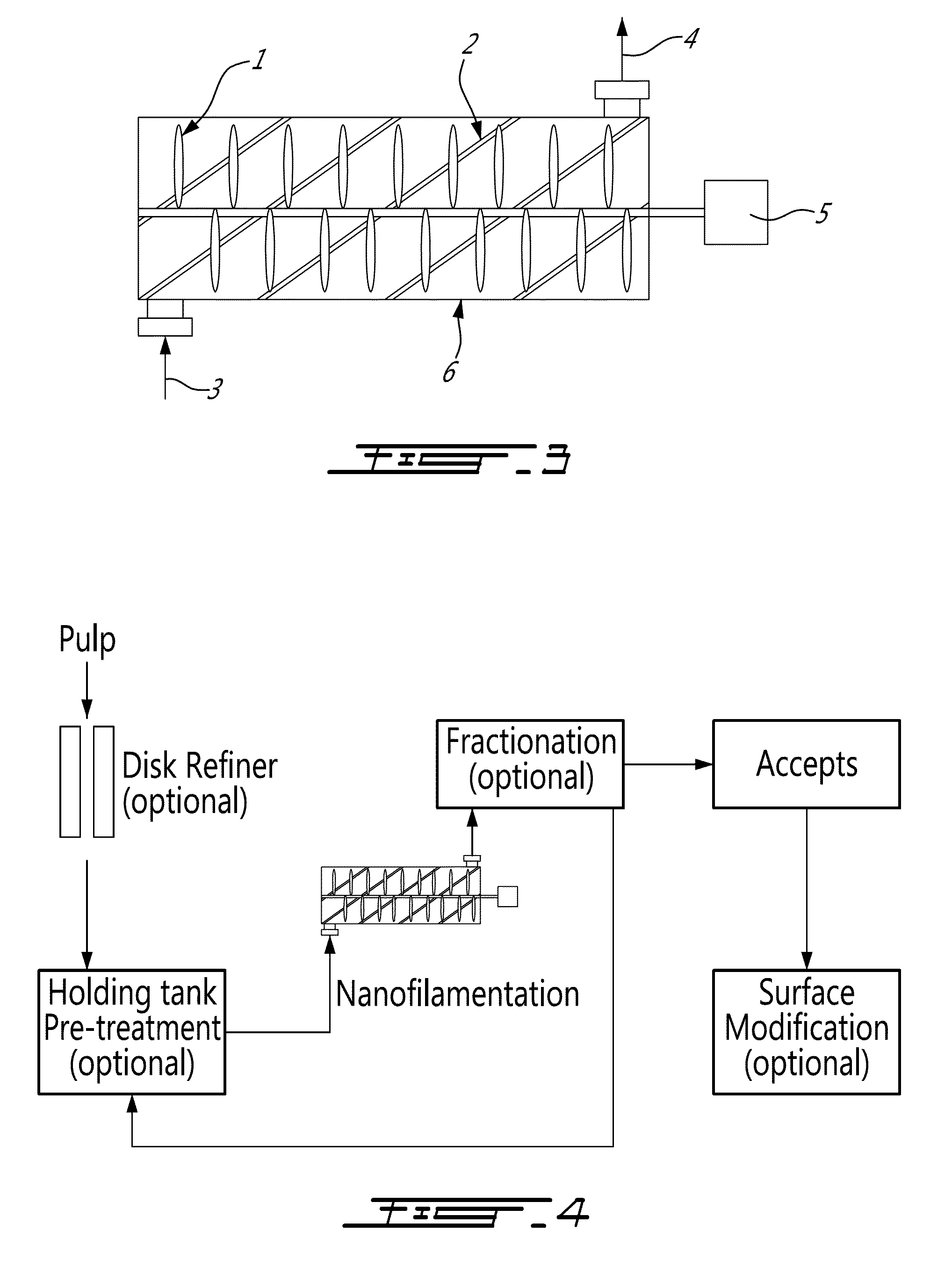

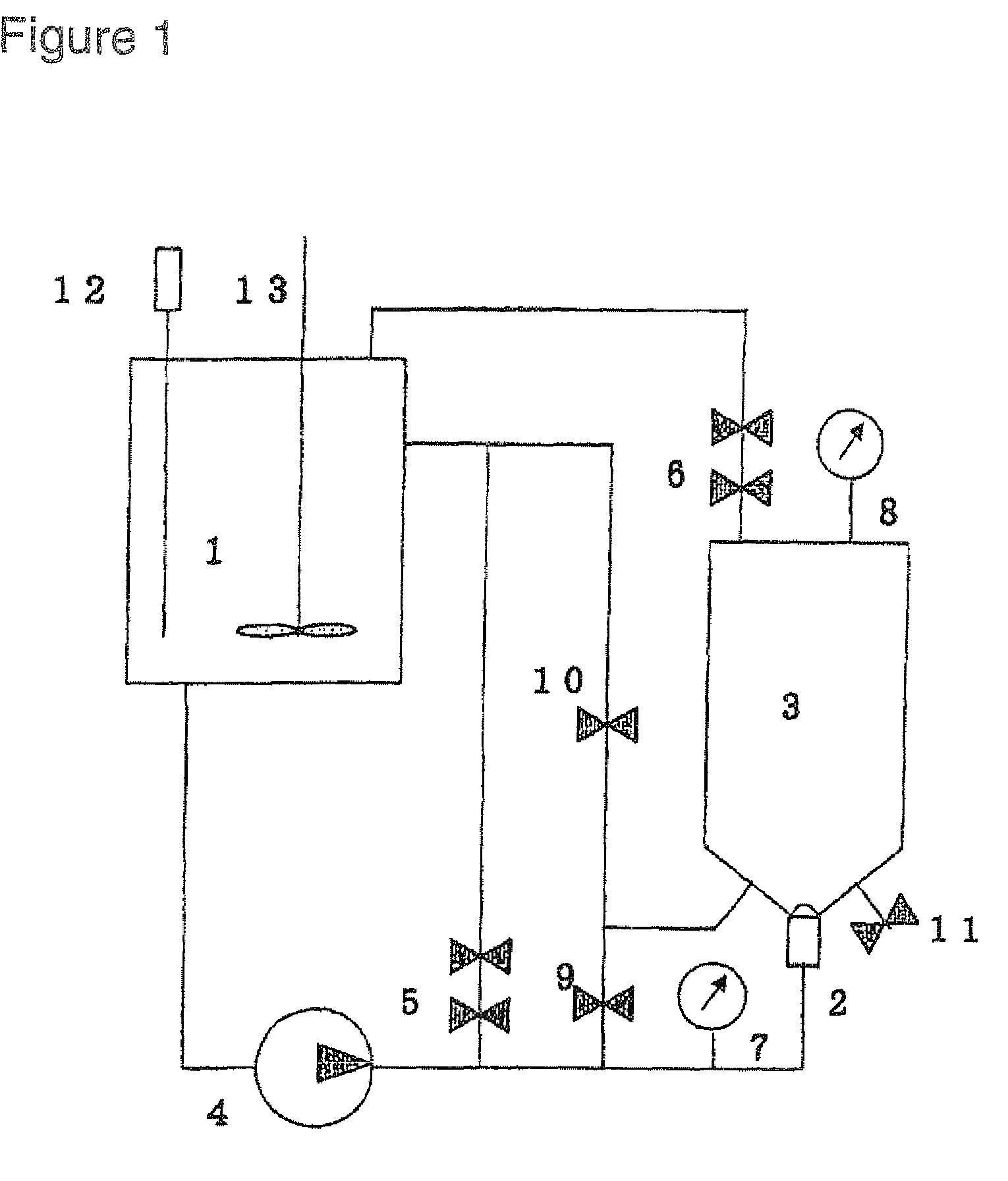

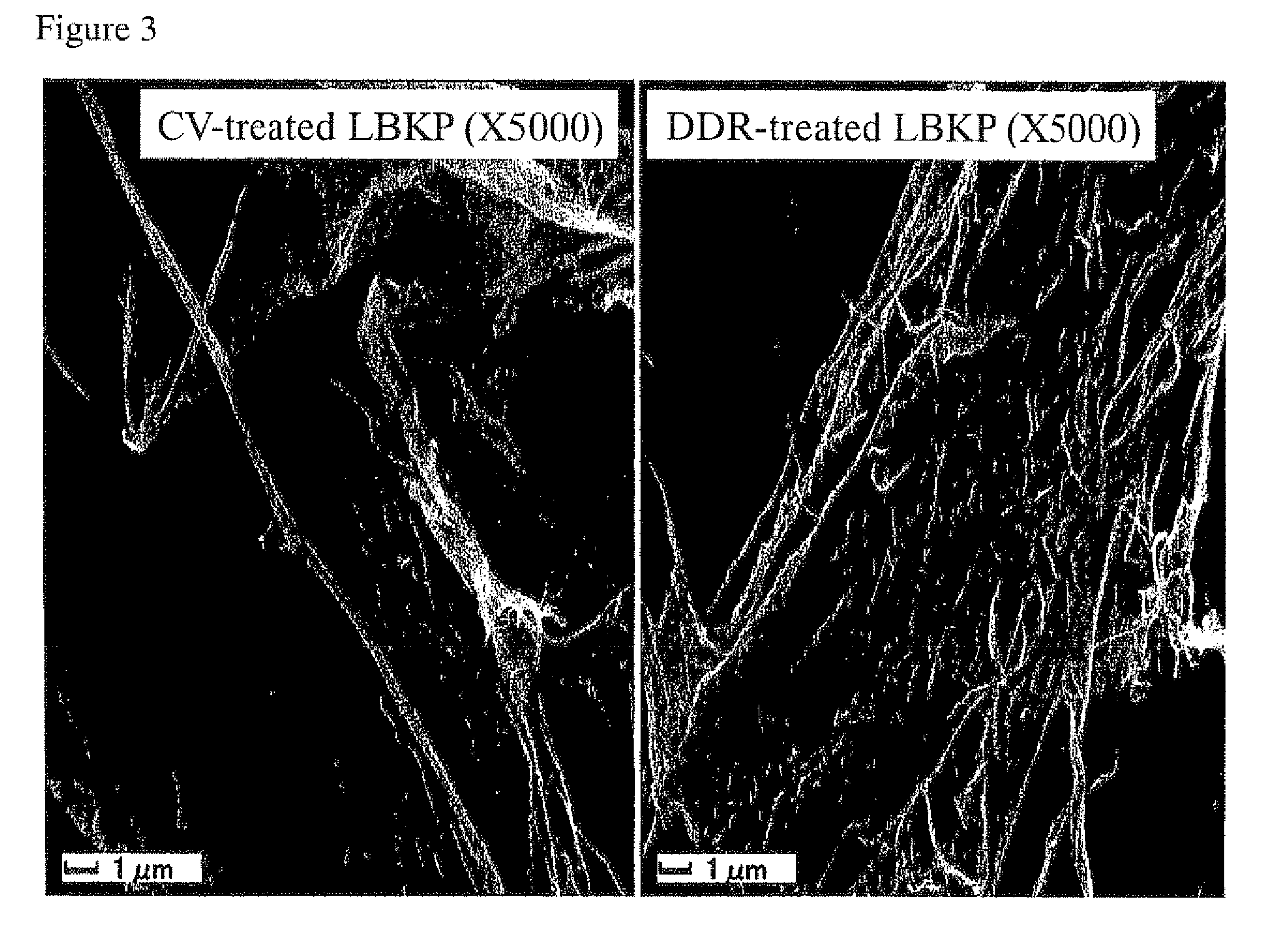

Cellulose nanofilaments and method to produce same

ActiveUS20110277947A1Improve strength propertiesMaterial nanotechnologyNatural cellulose pulp/paperPolymer sciencePaperboard

Cellulose nanofilaments from cellulose fibers, a method and a device to produce them are disclosed. The nanofilaments are fine filaments with widths in the sub-micron range and lengths up to a couple of millimeters. These nanofilaments are made from natural fibers from wood and other plants. The surface of the nanofilaments can be modified to carry anionic, cationic, polar, hydrophobic or other functional groups. Addition of these nanofilaments to papermaking furnishes substantially improves the wet-web strength and dry sheet strength much better than existing natural and synthetic polymers. The cellulose nanofilaments produced by the present invention are excellent additives for reinforcement of paper and paperboard products and composite materials, and can be used to produce superabsorbent materials.

Owner:FPINNOVATIONS INC

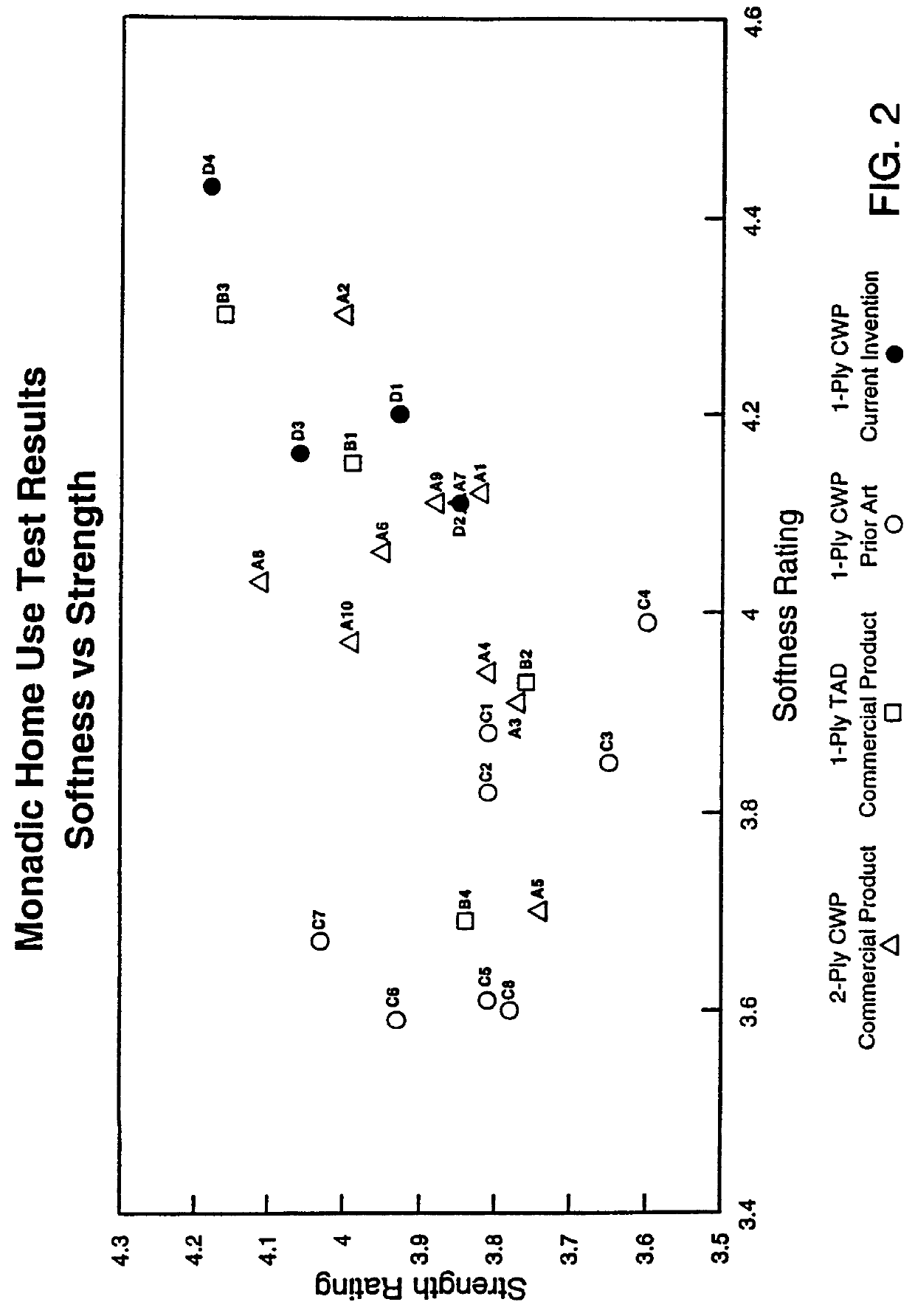

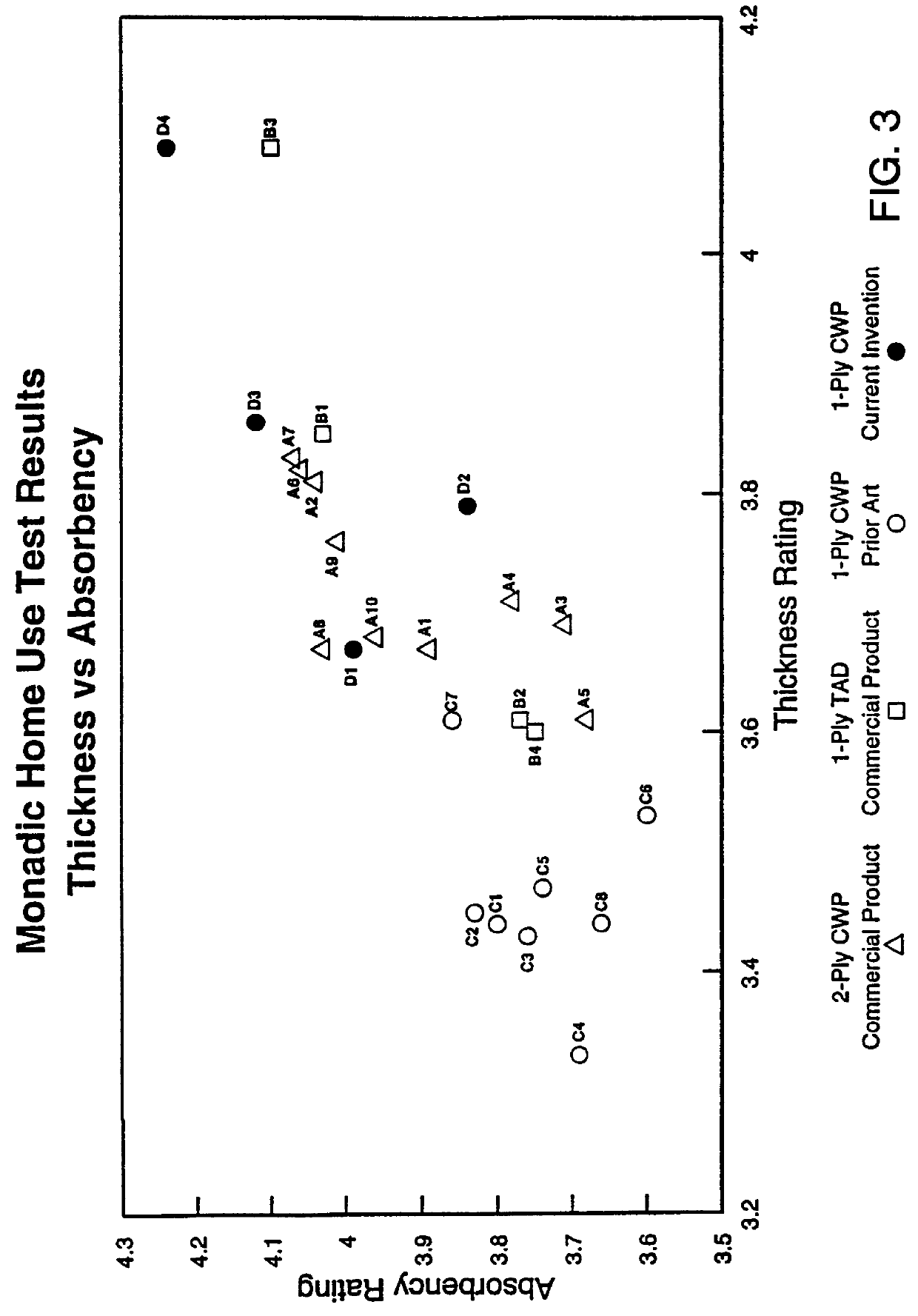

Soft, bulky single-ply tissue having low sidedness and method for its manufacture

The present invention relates to a soft, thick, single-ply tissue and to a process for the manufacture of such tissue product having a basis weight of at least about 15 lbs. / 3,000 square foot ream and having low sidedness, said tissue exhibiting: a specific total tensile strength of between 40 and 75 grams per 3 inches per pound per 3000 square feet ream, a cross direction specific wet tensile strength of between 2.75 and 7.5 grams per 3 inches per pound per 3000 square feet ream, the ratio of MD tensile to CD tensile of between 1.25 and 2.75, a specific geometric mean tensile stiffness of between 0.5 and 1.2 grams per inch per percent strain per pound per 3000 square feet ream, a friction deviation of less than 0.225, and a sidedness parameter of less than 0.275.

Owner:GEORGIA PACIFIC CONSUMER PRODS LP

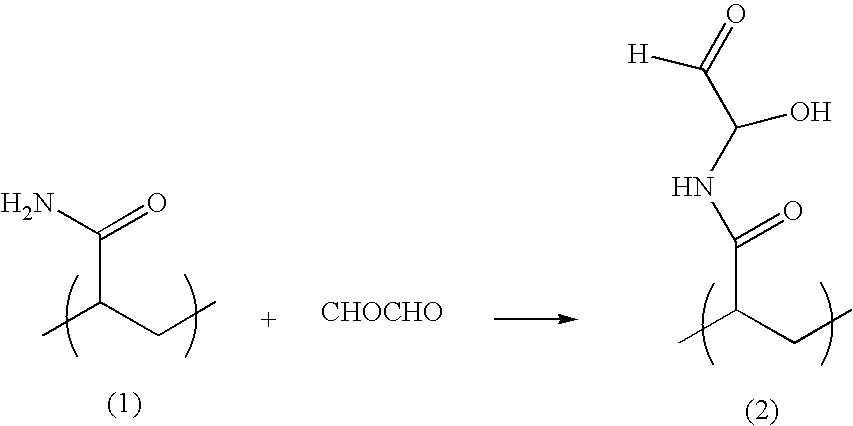

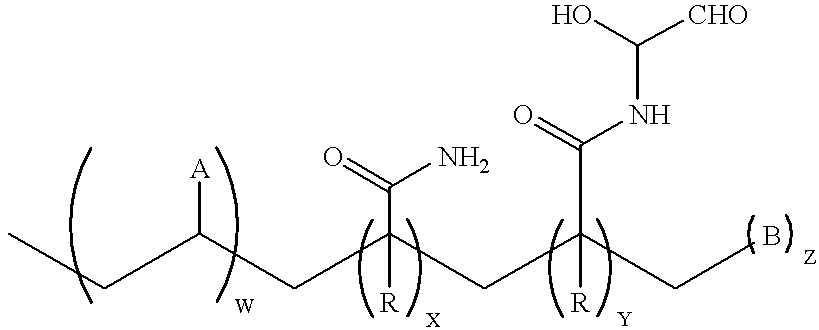

Blends of glyoxalated polyacrylamides and paper strengthening agents

Compositions comprising a blend of two or more paper strengthening agents have improved stability compared with previously known paper strengthening agents. One component is a polymeric paper strengthening agent, preferably a wet strengthening agent. The other component is a stabilized polyacrylamide prepared by (1) reacting a first portion of glyoxal with a polyacrylamide having pendant amide groups to form a first reaction mixture comprising polyacrylamide; (2) adding an acid to the first reaction mixture to form a second reaction mixture having a reduced pH and comprising the polyacrylamide; and (3) adding a second portion of glyoxal to the second reaction mixture to form the stabilized polyacrylamide. If desired, an aldehyde scavenger can be included in one or more of step (1), step (2), step (3), or the stabilized polyacrylamide. Such compositions can be used to enhance the strength of paper, particularly the wet strength of paper.

Owner:ECOLAB USA INC

Method for increasing the strength of a cellulosic product

InactiveUS7090745B2Increased amine contentSure easyNatural cellulose pulp/paperSpecial paperCellulosePolymer science

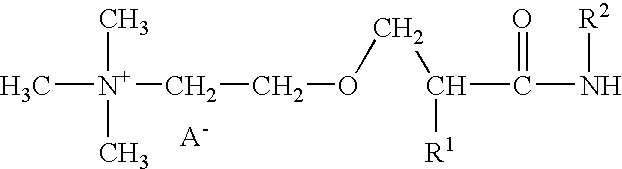

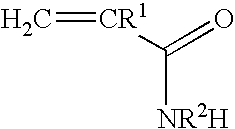

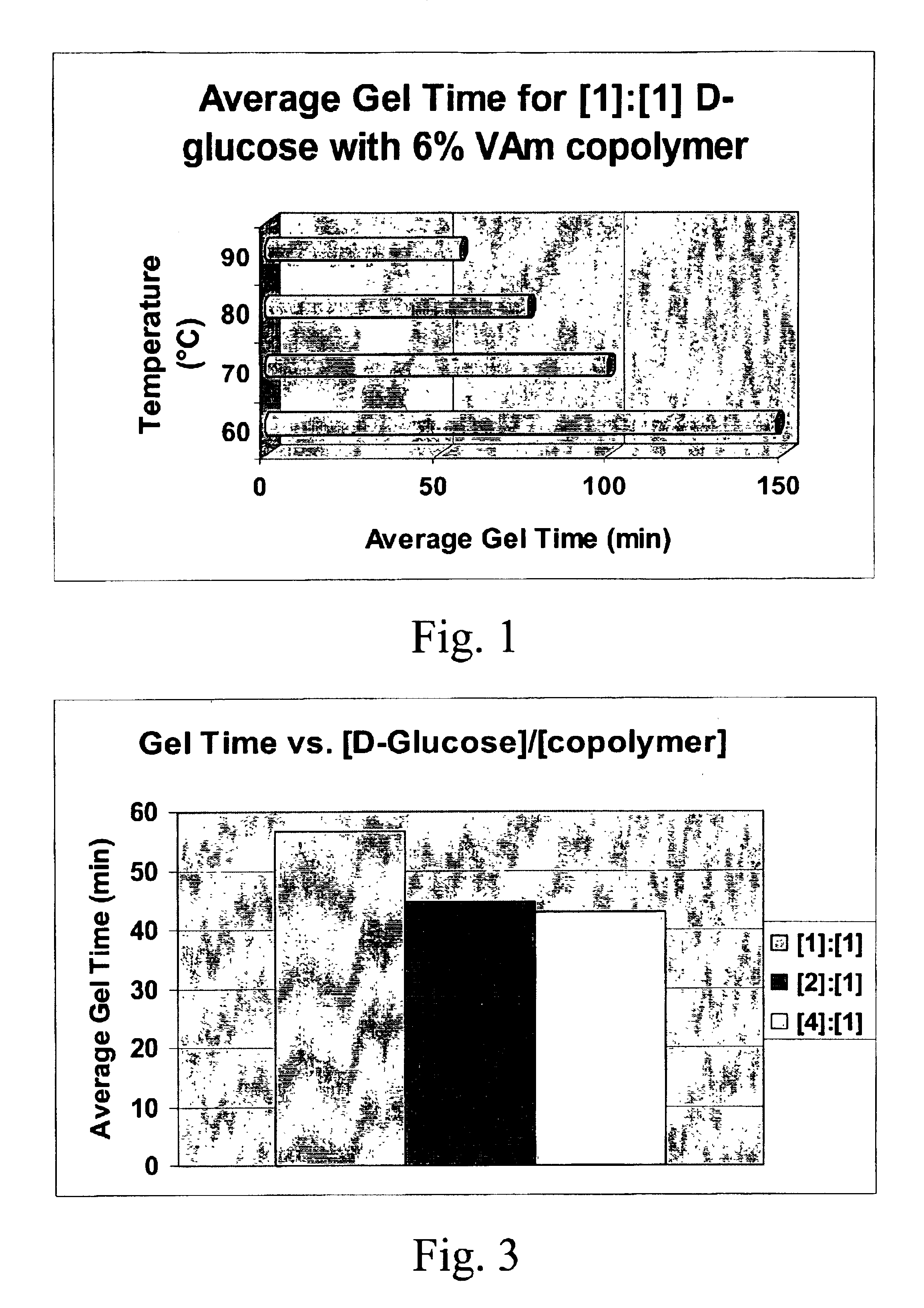

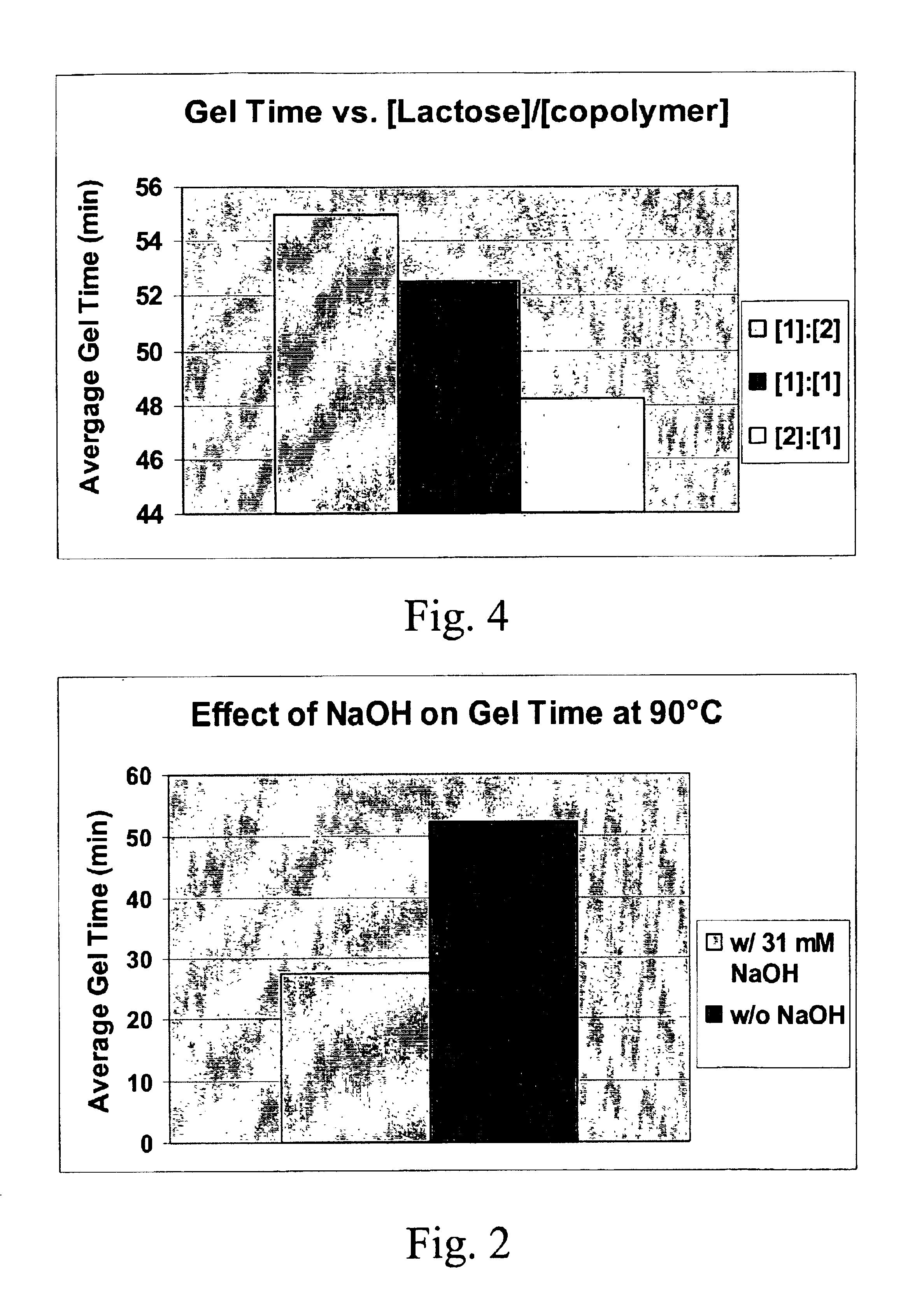

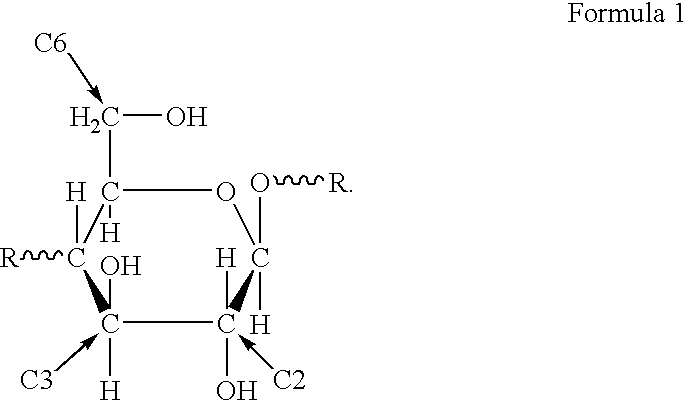

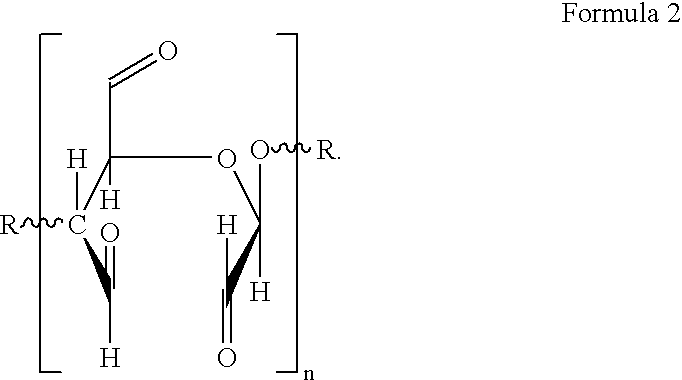

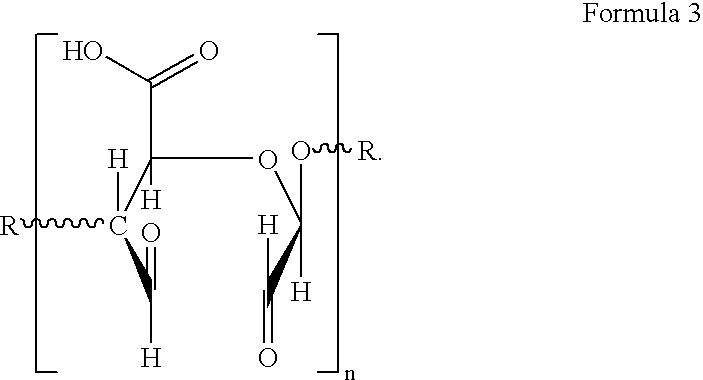

A composition includes at least one hydrophilic polymer containing primary (—NH2) and / or secondary (—NHR) amine groups and at least one saccharide containing a reducible function. A method of increasing the strength of paper includes the step of contacting the paper with a composition comprising (i) at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function. A hydrogel composition is formed from a mixture of at least one hydrophilic polymer containing at least two groups which are independently the same or different a primary amine group or a secondary amine group and at least one saccharide containing a reducible function.

Owner:UNIVERSITY OF PITTSBURGH +1

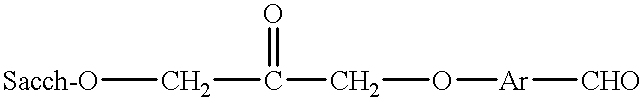

Oxidized polymeric carbohydrates and products made thereof

The present invention relates to a polysaccharide having functional groups, wherein said groups are aldehyde groups formed at positions C2 and / or C3 as well as at position C6 of the anhydroglucose units of the polysaccharide chain. Preferably the polysaccharide is a cellulosic fibrous material whose primary and secondary hydroxyl groups of the cellulose are oxidized into aldehyde groups at least in part by means of TEMPO oxidation and periodate oxidation.The invention also concerns a paper or nonwoven comprising the above polysaccharide. According to the invention a relative wet strength of more than 10% can be achieved.

Owner:SCA HYGIENE PROD AB

High Softness, High Durability Bath Tissues With Temporary Wet Strength

ActiveUS20130029105A1Improve tissue performanceGood flexibilityPersonal careReinforcing agents additionWet strengthCalipers

Owner:GPCP IP HLDG LLC

Creping process and products made therefrom

ActiveUS7883604B2Reduced strengthHigh strengthNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Treated tissue products having increased strength

InactiveUS20070137808A1Reduced strengthHigh strengthBiocideNatural cellulose pulp/paperFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

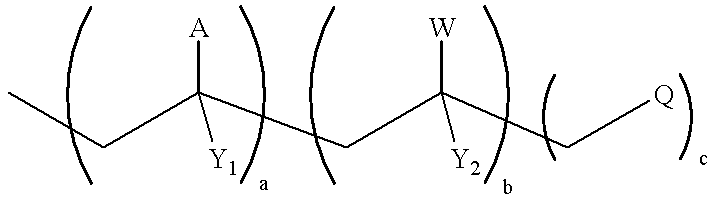

Method of using aldehyde-functionalized polymers to enhance paper machine dewatering

InactiveUS20050161181A1Accelerates the dehydration processNatural cellulose pulp/paperSpecial paperFiberPaper sheet

A method of enhancing the dewatering of a paper sheet on a paper machine comprising adding to the paper sheet about 0.05 lb / ton to about 15 lb / ton, based on dry fiber, of one or more aldehyde functionalized polymers comprising amino or amido groups wherein at least about 15 mole percent of the amino or amido groups are functionalized by reacting with one or more aldehydes and wherein the aldehyde functionalized polymers have a molecular weight of at least about 100,000.

Owner:ECOLAB USA INC

Process for production of paper or board

ActiveUS9605382B2Improve propertiesReinforcing agents additionPaper/cardboardCardboardPulp and paper industry

Owner:KEMIRA OY

Creping process and products made therefrom

ActiveUS20070137810A1High strengthImprove propertiesNatural cellulose pulp/paperMechanical working/deformationFiberPolymer science

Tissue products are disclosed containing an additive composition. The additive composition, for instance, comprises an aqueous dispersion containing an alpha-olefin polymer, an ethylene-carboxylic acid copolymer, or mixtures thereof. The alpha-olefin polymer may comprise an interpolymer of ethylene and octene, while the ethylene-carboxylic acid copolymer may comprise ethylene-acrylic acid copolymer. The additive composition may also contain a dispersing agent, such as a fatty acid. The additive composition may be incorporated into the tissue web by being combined with the fibers that are used to form the web. Alternatively, the additive composition may be topically applied to the web after the web has been formed. For instance, in one embodiment, the additive composition may be applied to the web as a creping adhesive during a creping operation. The additive composition may improve the strength of the tissue web without substantially affecting the perceived softness of the web in an adverse manner.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Premoistened tissue products

InactiveUS20070137811A1Reduced strengthImprove wet strengthBiocideNatural cellulose pulp/paperBiomedical engineering

Premoistened wiping products are disclosed. The premoistened wiping products contain one or more wetlaid tissue webs. The tissue webs may contain an additive composition which includes a thermoplastic resin. Once the additive composition is applied to the web, the web is embossed forming liquid resistant embossments. The embossments also form bond areas that can bond multiple plies of the tissue webs together. Once embossed, the one or more tissue webs are then contacted with a wiping solution in order to form the premoistened product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Printed, soft, bulky single-ply absorbent paper having a serpentine configuration and low sidedness and methods for its manufacture

InactiveUS6299729B1Good flexibilityLow sidednessNanotechNatural cellulose pulp/paperGramUltimate tensile strength

The present invention relates to a soft, thick, single-ply, printed, absorbent paper product having a Yankee side and an air side wherein the absorbent paper is printed on before or after embossing on the Yankee side, air side, or both sides, said absorbent paper exhibiting a serpentine configuration. This inventions also relates to a process for the manufacture of such absorbent paper product having a basis weight of at least about 12.5 lbs. per 3000 square foot ream and having low sidedness, said tissue exhibiting:a specific total tensile strength of between 40 and 200 grams per 3 inches per pound per 3000 square foot ream, a cross direction specific wet tensile strength of between 2.75 and 20.0 grams per 3 inches per pound per 3000 square foot ream, the ratio of MD tensile to CD tensile of between 1.25 and 2.75, a specific geometric mean tensile stiffness of between 0.5 and 3.2 grams per inch per percent strain per pound per 3000 square foot ream, a friction deviation of less than 0.250, and a sidedness parameter of less than 0.30. These single-ply, printed, absorbent paper products in the form of unembossed or embossed single-ply bathroom tissue, facial tissue, or napkin are useful articles of commerce. The single-ply absorbent paper products exhibit a printed sidedness value of DELTAE of less than 2.

Owner:GPCP IP HLDG LLC

Process for making abrasion resistant paper and paper and paper products made by the process

InactiveUS20050155731A1Improve optical brightnessLow friction surfacePaper after-treatmentPaper coatingPapermakingPaper sheet

In this papermaking process, a first strength agent is added to a stock suspension containing pulp and optionally other additives prior to its being formed into a web at the wet end of a papermaking machine. The web is then formed and processed into paper. A second strength agent is then applied to the surface of the paper. The strength agents may be selected to have opposite charge.

Owner:NAT GYPSUM PROPERTIES

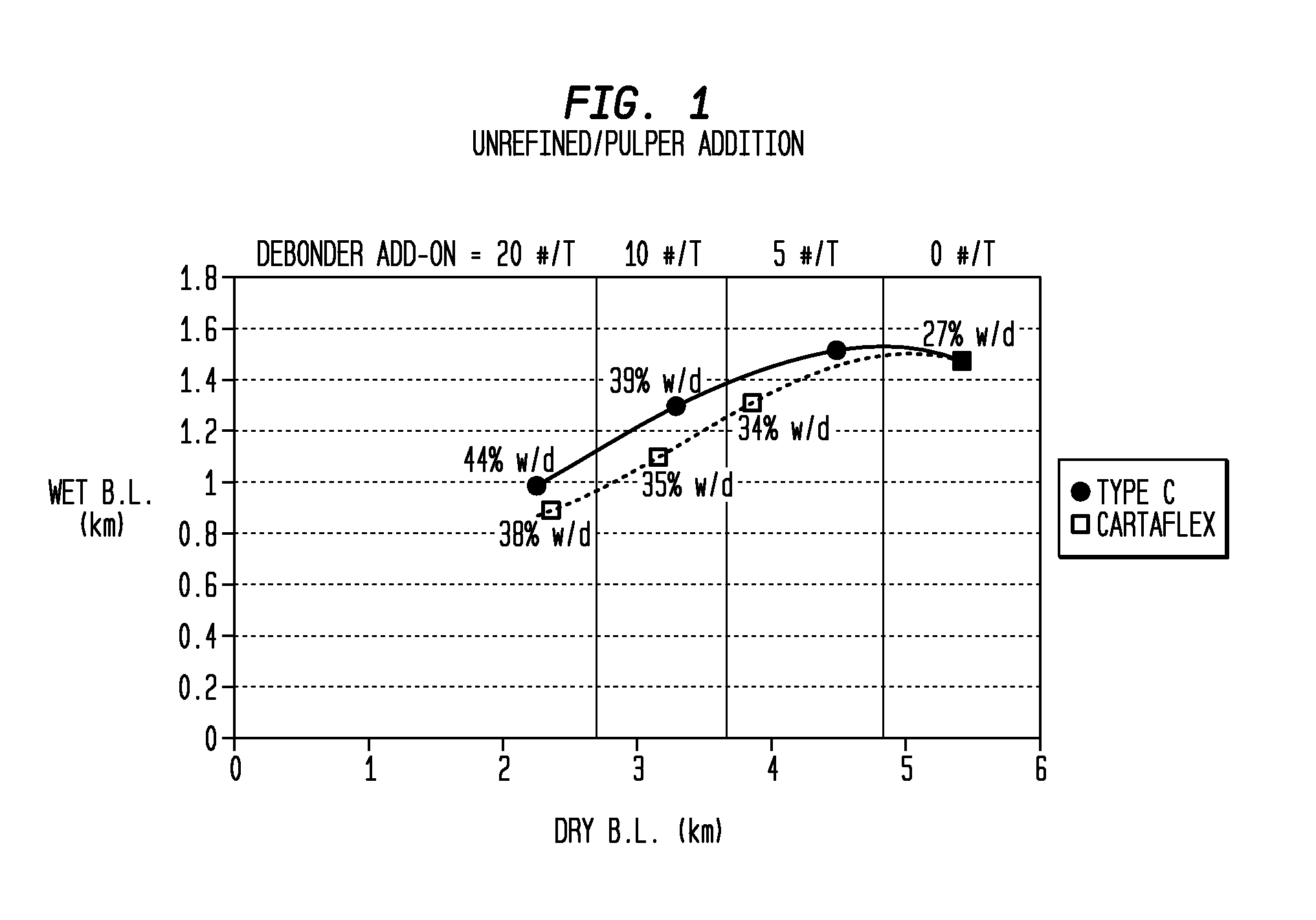

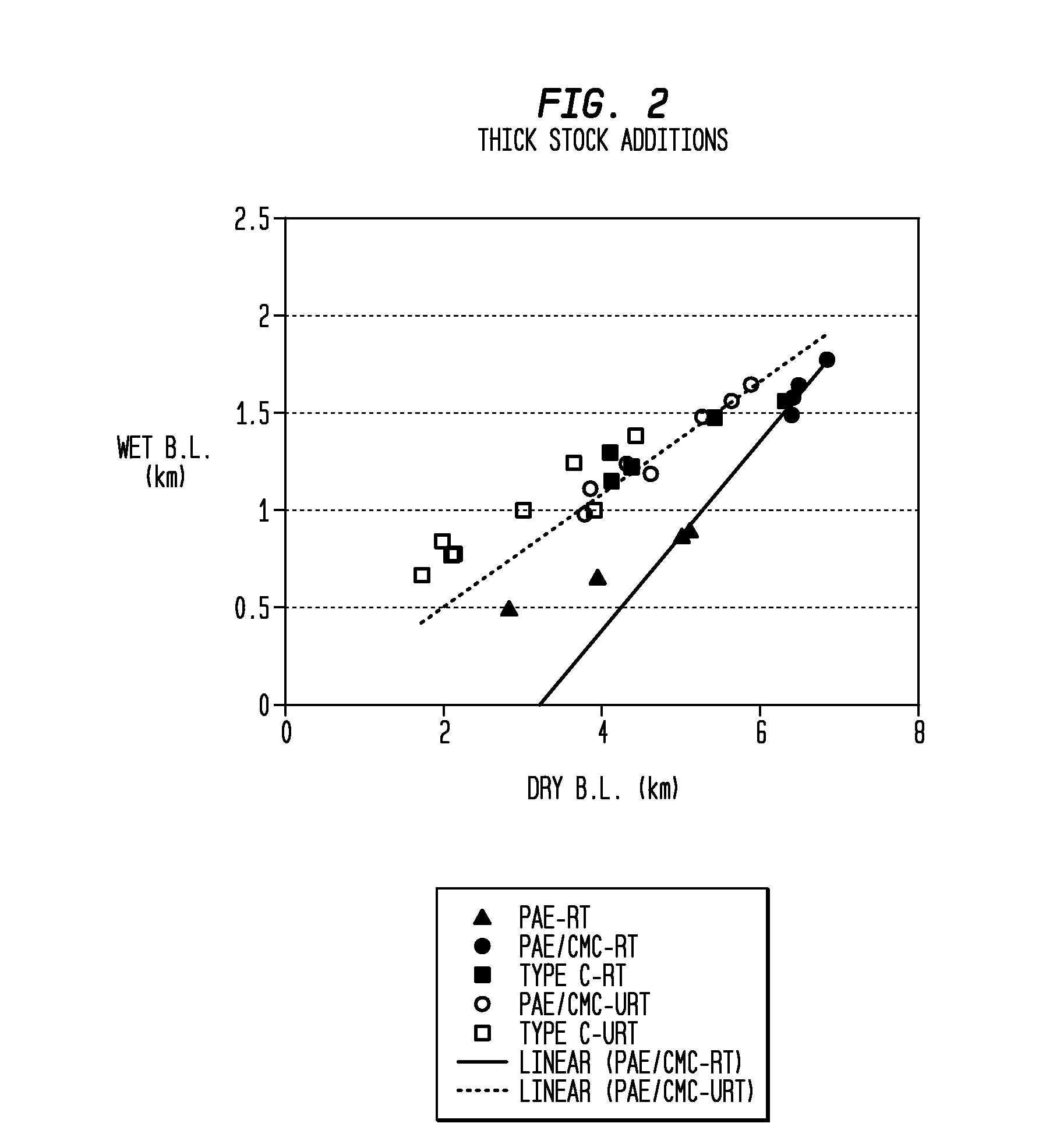

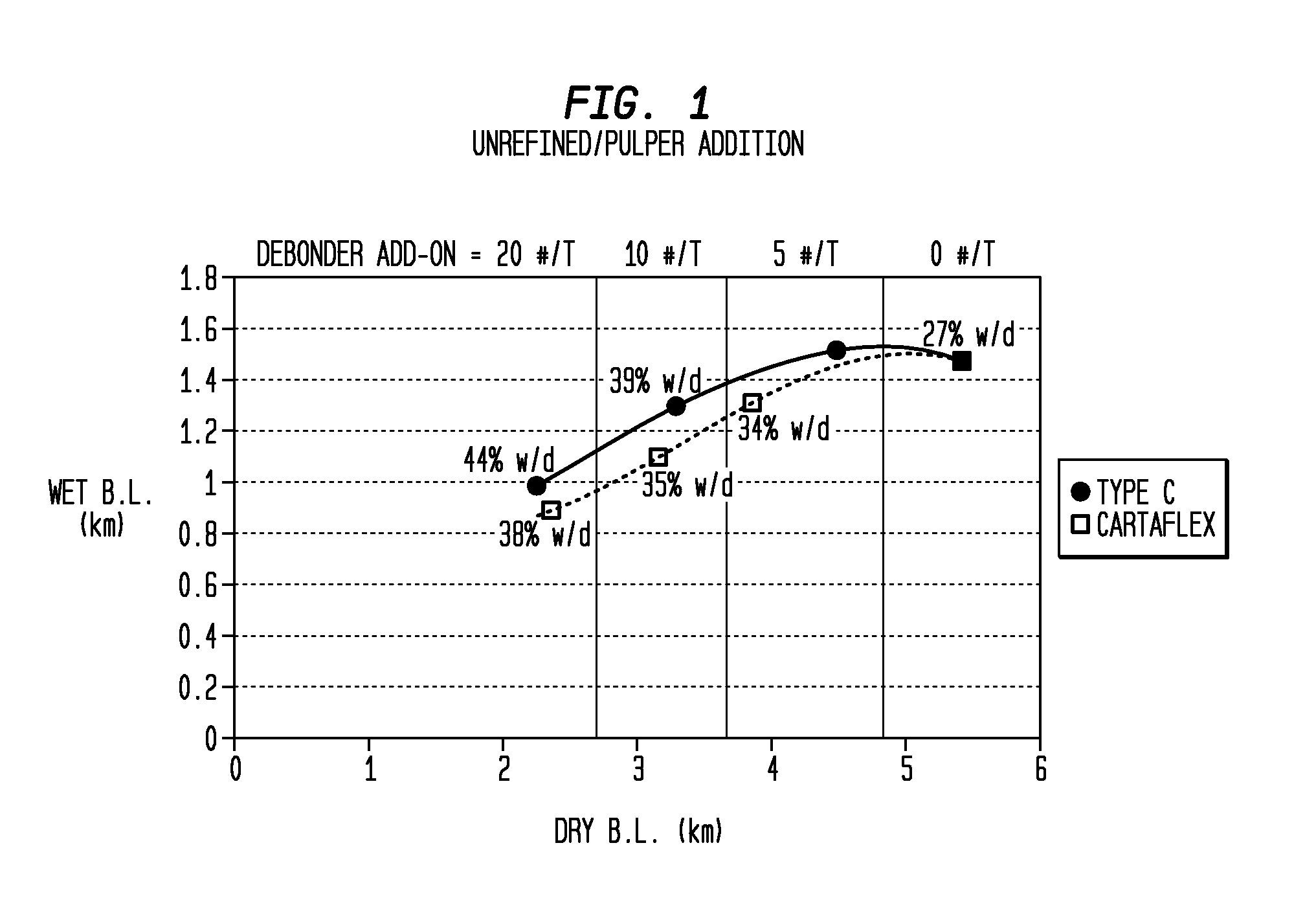

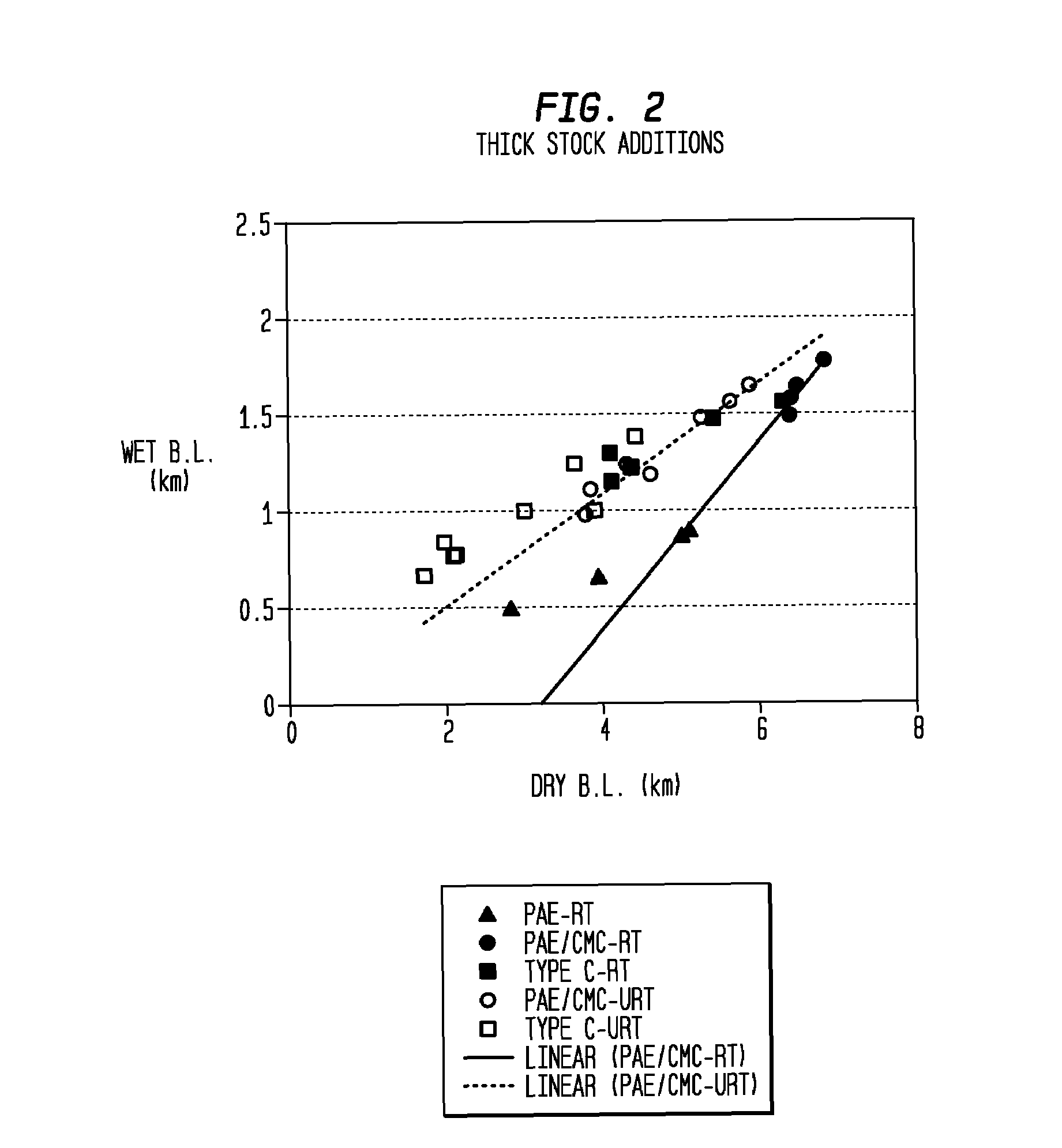

Method of Producing Absorbent Sheet with Increased Wet/Dry CD Tensile Ratio

ActiveUS20080083519A1Improve the level ofRaise the ratioCellulosic pulp after-treatmentNatural cellulose pulp/paperFiberEngineering

A method of making absorbent cellulosic sheet with increased wet / dry CD tensile ratio includes treating the fiber at high consistency with debonder in a pulper, for example. The process enables the use of large amounts of debonder in a wet-press process in order to achieve wet / dry CD tensile ratios of greater than 30%.

Owner:GPCP IP HLDG LLC

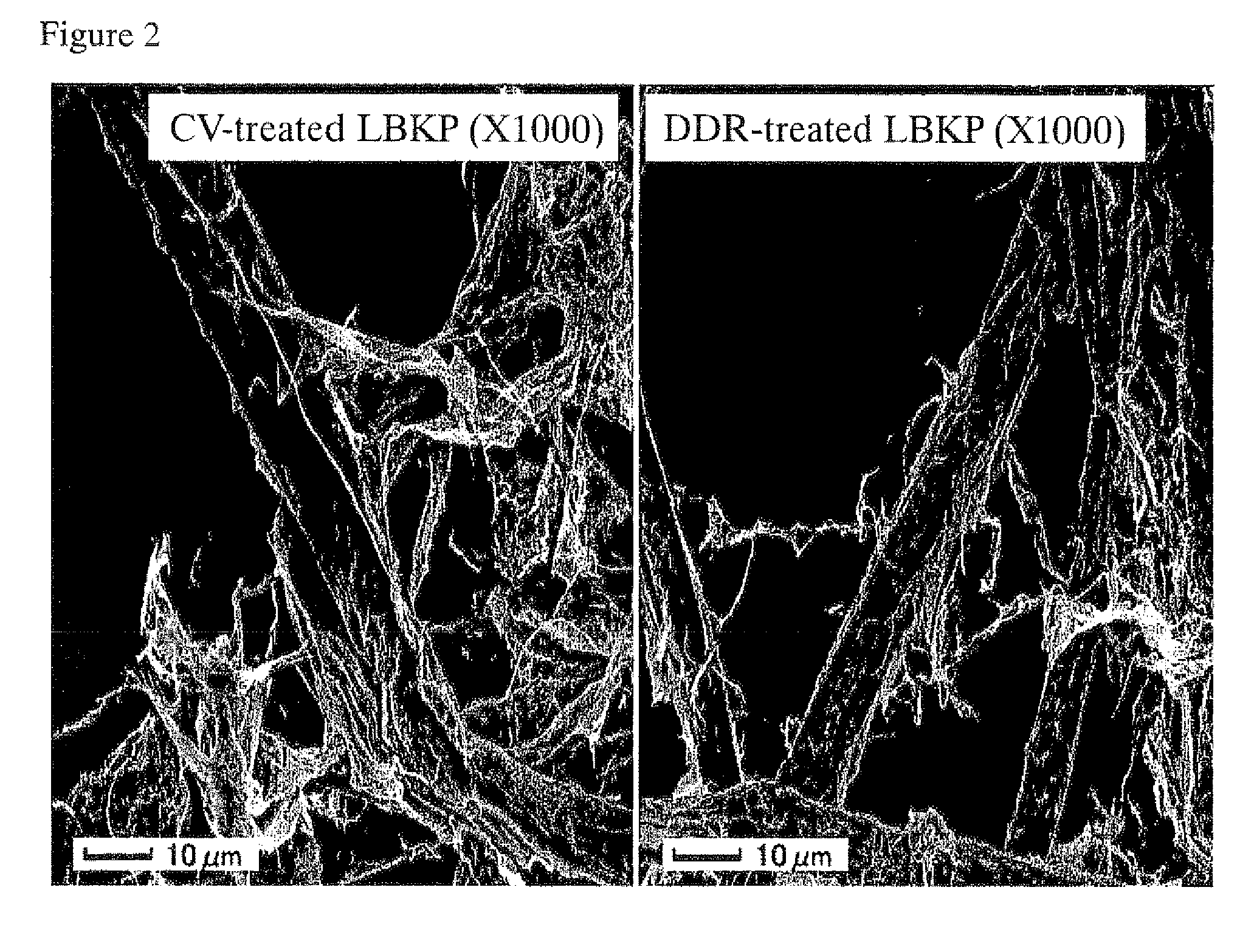

Cellulose-based fibrous materials

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

Method of producing absorbent sheet with increased wet/dry CD tensile ratio

ActiveUS7585392B2Improve the level ofRaise the ratioNatural cellulose pulp/paperMechanical working/deformationFiberEngineering

A method of making absorbent cellulosic sheet with increased wet / dry CD tensile ratio includes treating the fiber at high consistency with debonder in a pulper, for example. The process enables the use of large amounts of debonder in a wet-press process in order to achieve wet / dry CD tensile ratios of greater than 30%.

Owner:GPCP IP HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com