Patents

Literature

1530 results about "Coated paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coated paper is paper which has been coated by a mixture of materials or a polymer to impart certain qualities to the paper, including weight, surface gloss, smoothness or reduced ink absorbency. Various materials, including Kaolinite, calcium carbonate, Bentonite, and talc can be used to coat paper for high quality printing used in packaging industry and in magazines. The chalk or china clay is bound to the paper with synthetic viscosifiers, such as styrene-butadiene latexes and natural organic binders such as starch. The coating formulation may also contain chemical additives as dispersants, resins, or polyethylene to give water resistance and wet strength to the paper, or to protect against ultraviolet radiation.

Hollow sphere organic pigment for paper or paper coatings

InactiveUS6139961ATrend downHigh molecular weightSynthetic resin layered productsCellulosic plastic layered productsVitrificationPaperboard

A hollow sphere organic pigment in which a core containing a void is encapsulated by a first shell polymer having a glass transition temperature greater than 50 DEG C., the first shell having polymerized thereon a second shell polymer having a glass transition temperature of -15 DEG C. to -50 DEG C. is provided. Also provided is a paper or paperboard coating composition containing the hollow sphere organic pigment, a method for improving the strength and opacity of a paper or paperboard coating by using the coating composition dried, a coated paper or paperboard bearing the dried coating composition, and a method for improving the strength and opacity of paper or paperboard by incorporating a particular hollow sphere organic pigment into the formed wet sheet.

Owner:ROHM & HAAS CO

Acicular calcite and aragonite calcium carbonate

InactiveUS6071336AIncrease costIncrease production costCalcium/strontium/barium carbonatesPigmenting treatmentToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

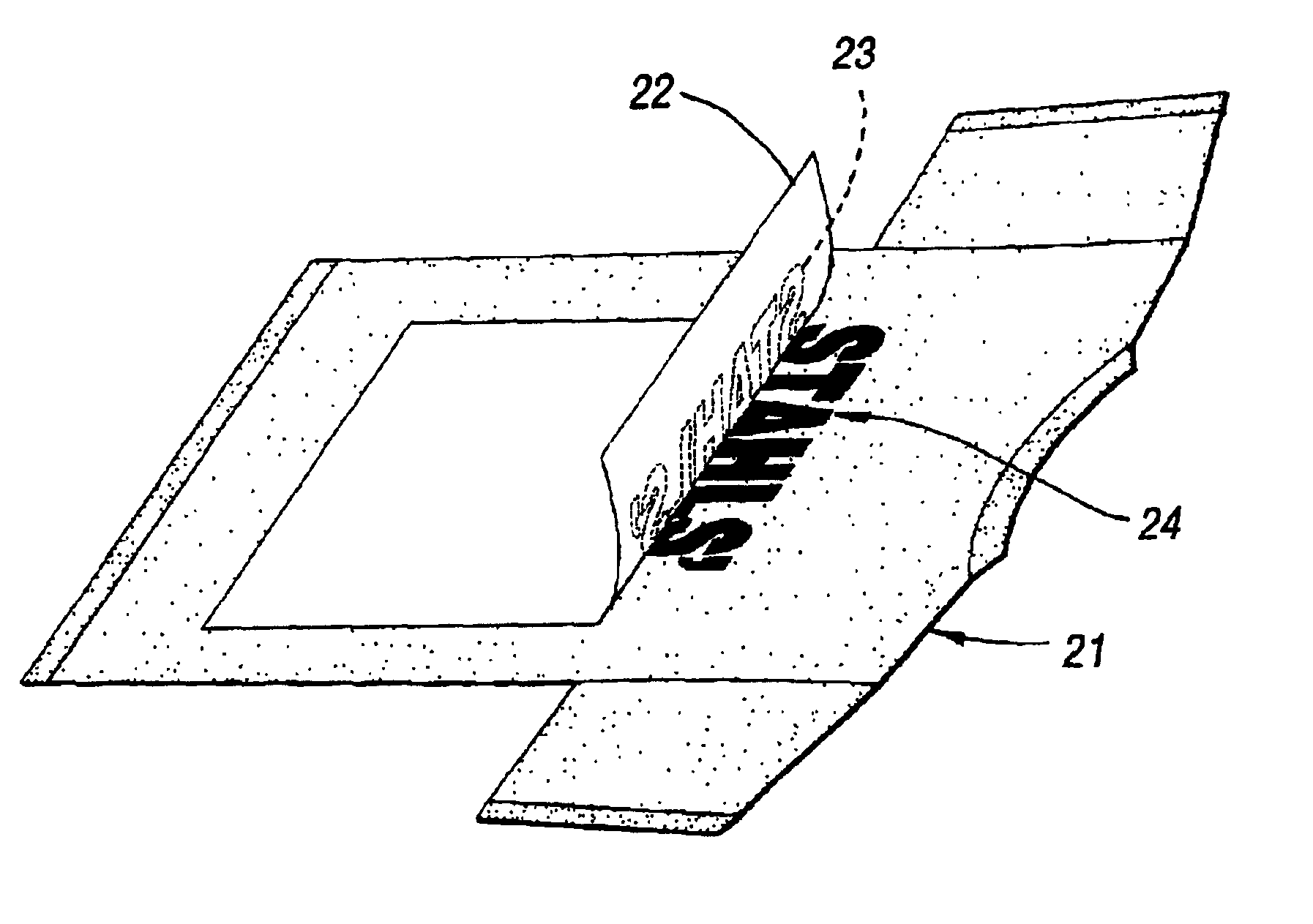

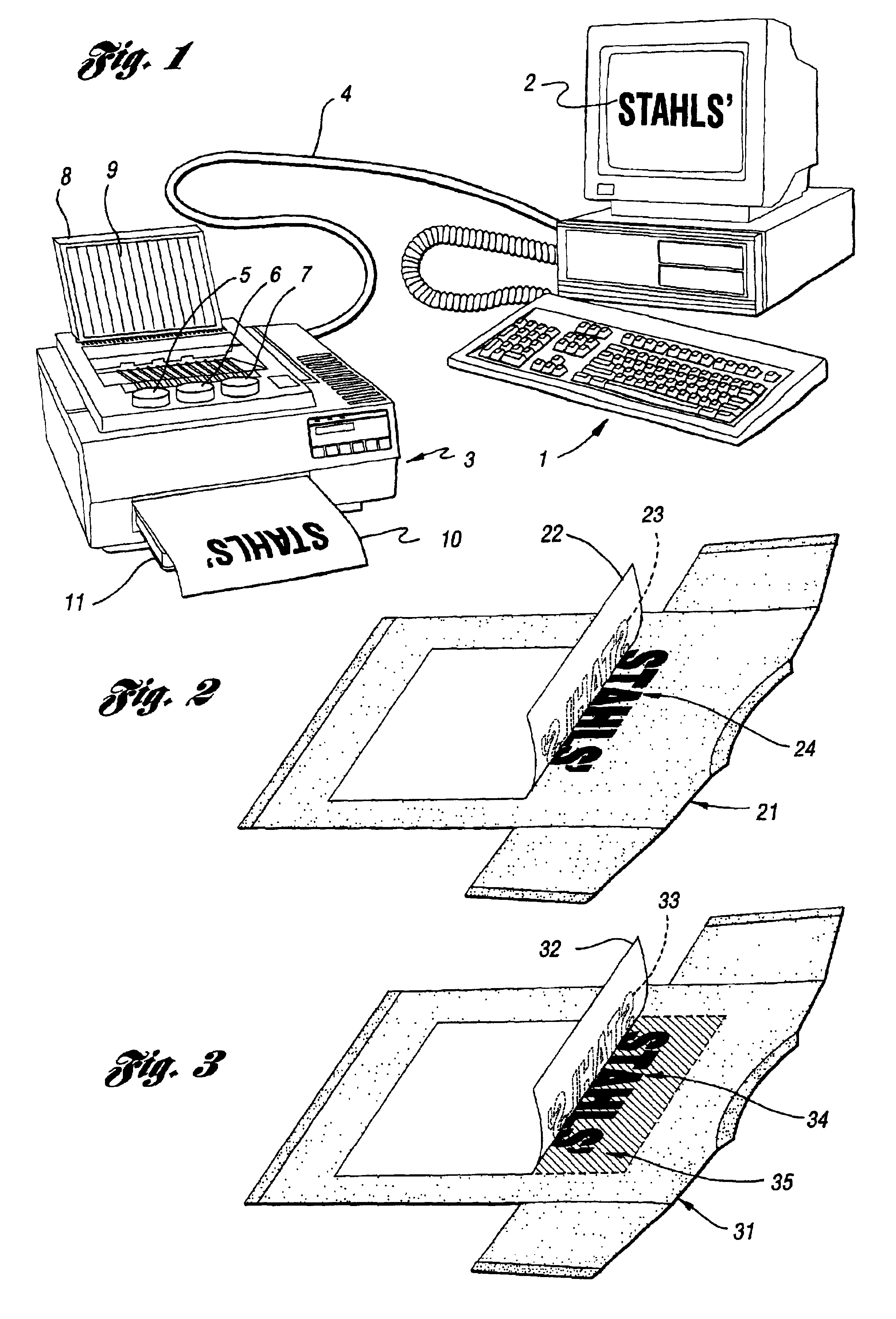

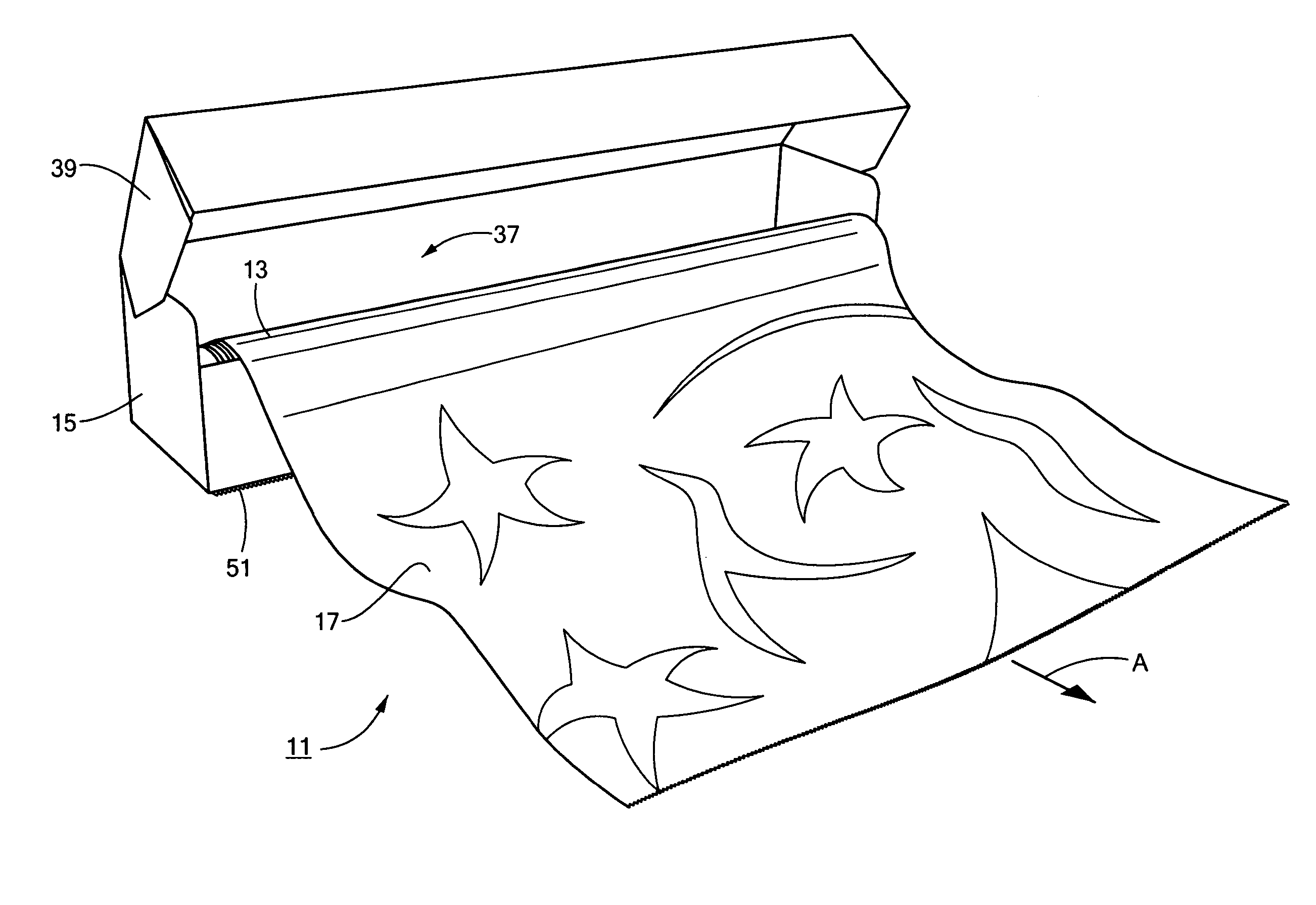

Decorative transfer process

InactiveUS6811840B1Produced economicallyHigh viscosityDecorative surface effectsPattern printingPolymer substratePolymer free

Transfers, suitable for applying complex designs to articles by the application of heat and pressure, are prepared simply and economically by printing the design onto plain paper or other fusible polymer-free substrate from a conventional ink-jet printer. The avoidance of polymer-coated paper allows the design to be transferred to fabric articles without altering the hand and feel of fabric in non-printed areas without the necessity of cutting the transfer from the substrate.

Owner:STAHLS INC

Acicular calcite and aragonite calcium carbonate

InactiveUS6022517AReduce conductivityIncrease production costCalcium/strontium/barium carbonatesAmmonium nitratesToothpasteCalcite

The present invention relates to a calcium carbonate composition having both calcite and aragonite crystalline morphology. More particularly, the present invention relates to an acicular calcite and an acicular aragonite product and a method for the production of the same and the use of such as fillers, additives and modifiers of consumer and commercial products such as toothpaste, paper, plastics and sealants. The acicular calcite / aragonite composition of the present invention provides a balance of properties such as sheet bulk, strength, stiffness, and sizing, when employed as a filler for paper. As a coating pigment, the acicular calcite / aragonite product of the present invention provides gloss characteristics suitable for dull and matte grades of low gloss coated paper. Upon further processing such as milling, grinding, or other means of comminution, the resulting product provides gloss characteristics suitable for high gloss coated paper. For paint formulations, the acicular calcite / aragonite composition of the present invention provides properties such as low sheen and high contrast ratio. As an additive in polymers, the acicular calcite / aragonite product of the present invention imparts reinforcing properties, rigidity, and impact strength, including sealant applications.

Owner:MINERALS TECH

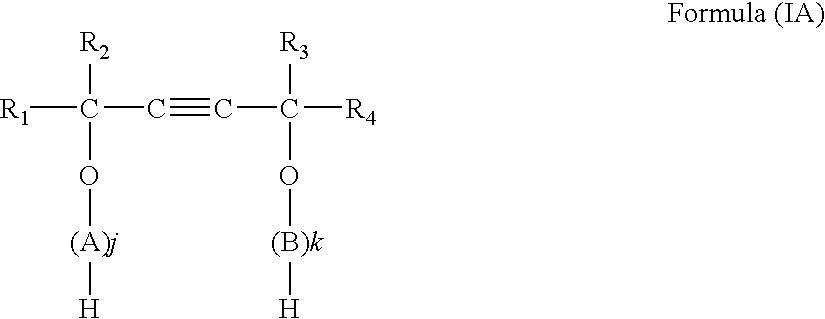

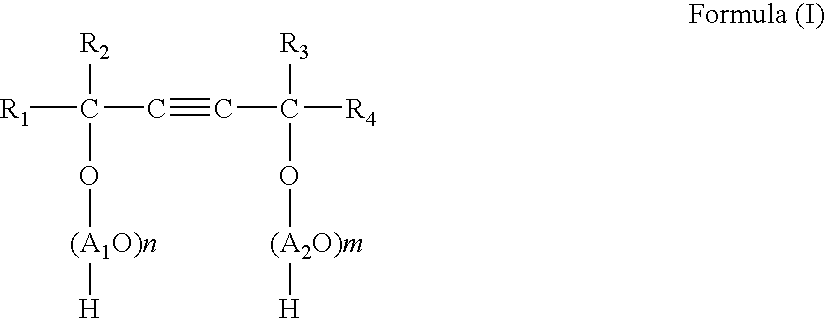

Inkjet ink

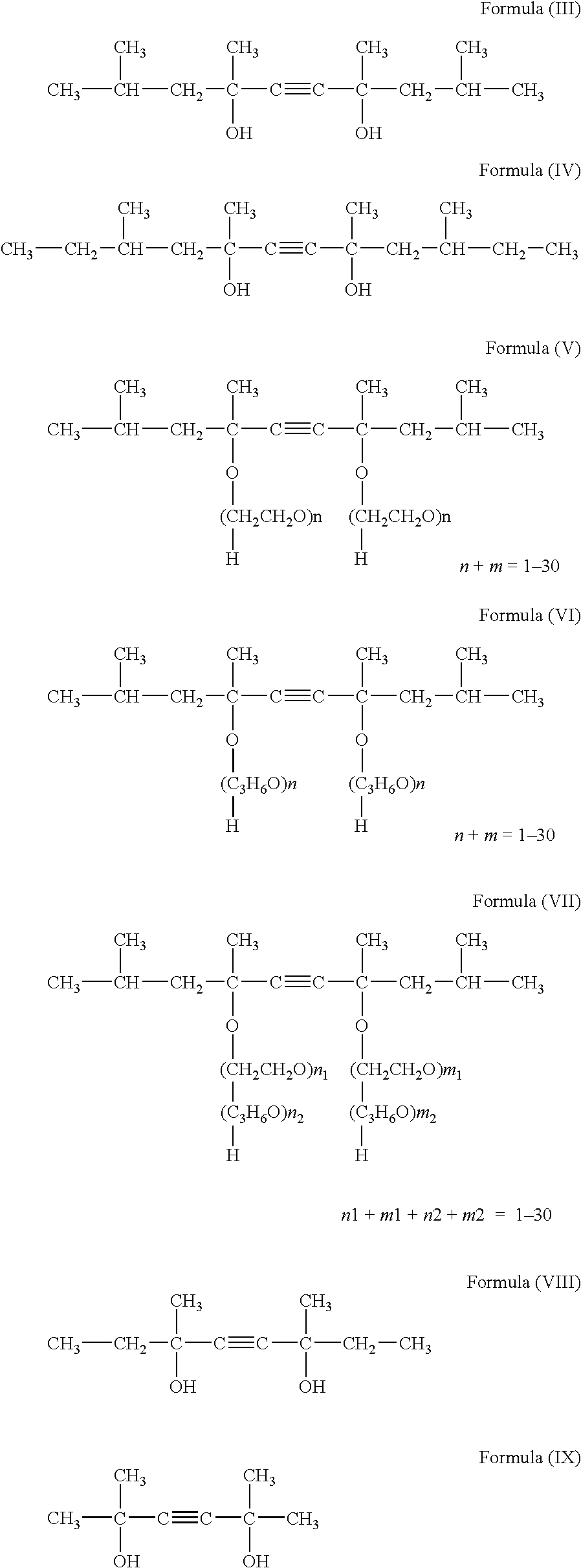

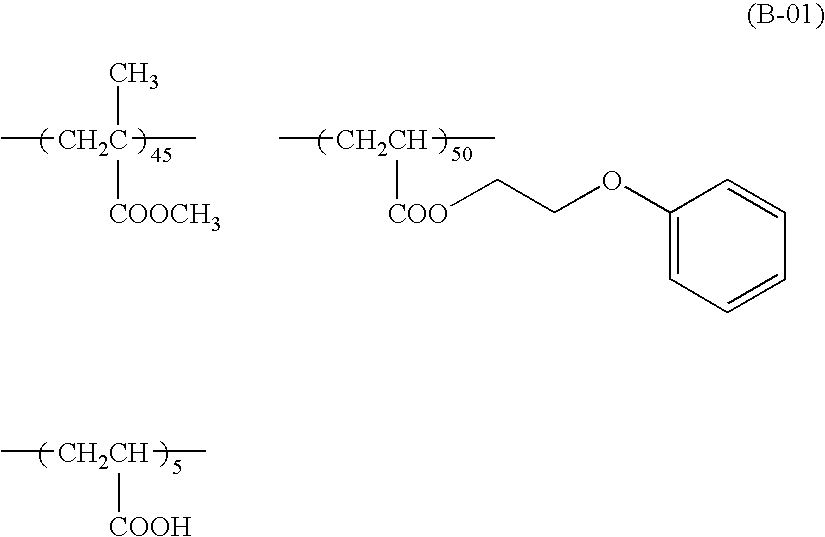

For the purpose of providing an ink for inkjet recording that allows substantially bleed-free printing to be performed on plain paper, and particularly recycled paper, and providing an inkjet ink capable of ensuring high print quality and maintaining high ejection stability on plain paper, recycled paper, and coated paper, the present invention provides an inkjet ink comprising, together with a coloring material and water, a nonionic substance that has acetylene bonds in the molecules thereof and that also has hydroxyl groups and / or alkylene oxide repeating structures (preferably a substance whose structure is shown by formula (IA) according to claim 2, a substance whose structure is shown by formula (I) according to claim 20, or the like), and a nonionic substance that has lipophilic units comprising alkyl groups or cycloalkyl groups and that also has alkylene oxide repeating structures (preferably a substance whose structure is shown by formula (IIA) according to claim 2, a substance whose structure is shown by formula (II) according to claim 20, or the like).

Owner:SEIKO EPSON CORP

Recyclable and repulpable ream wrap and related methods of manufacture

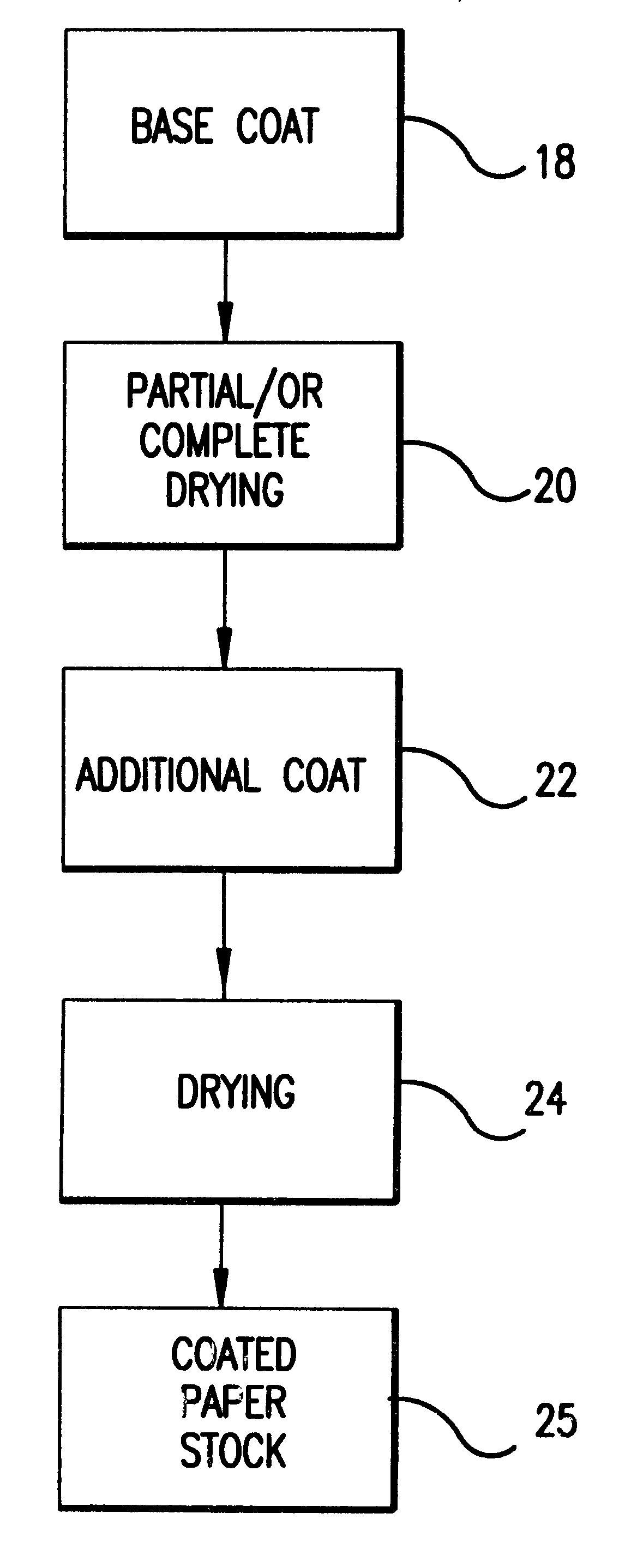

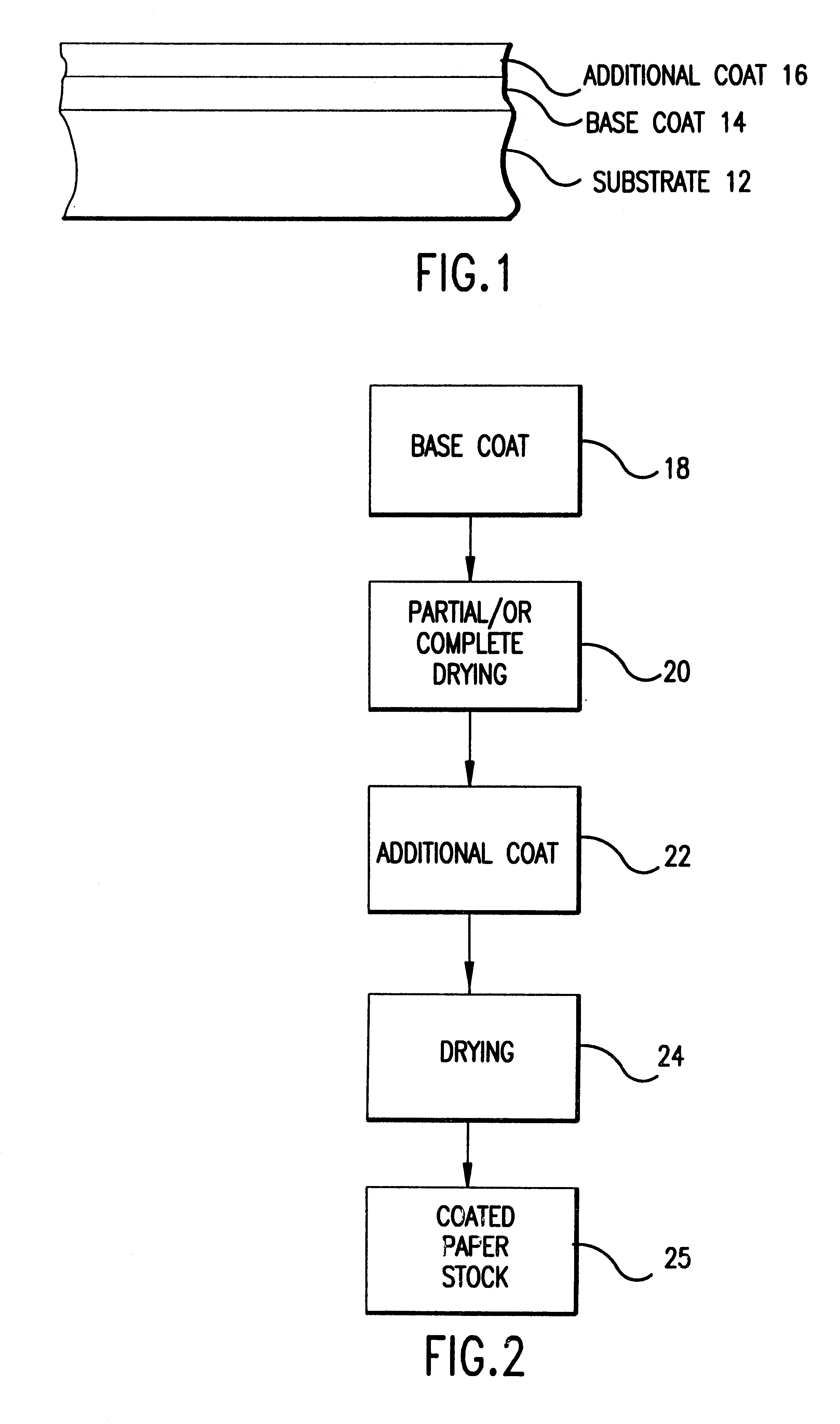

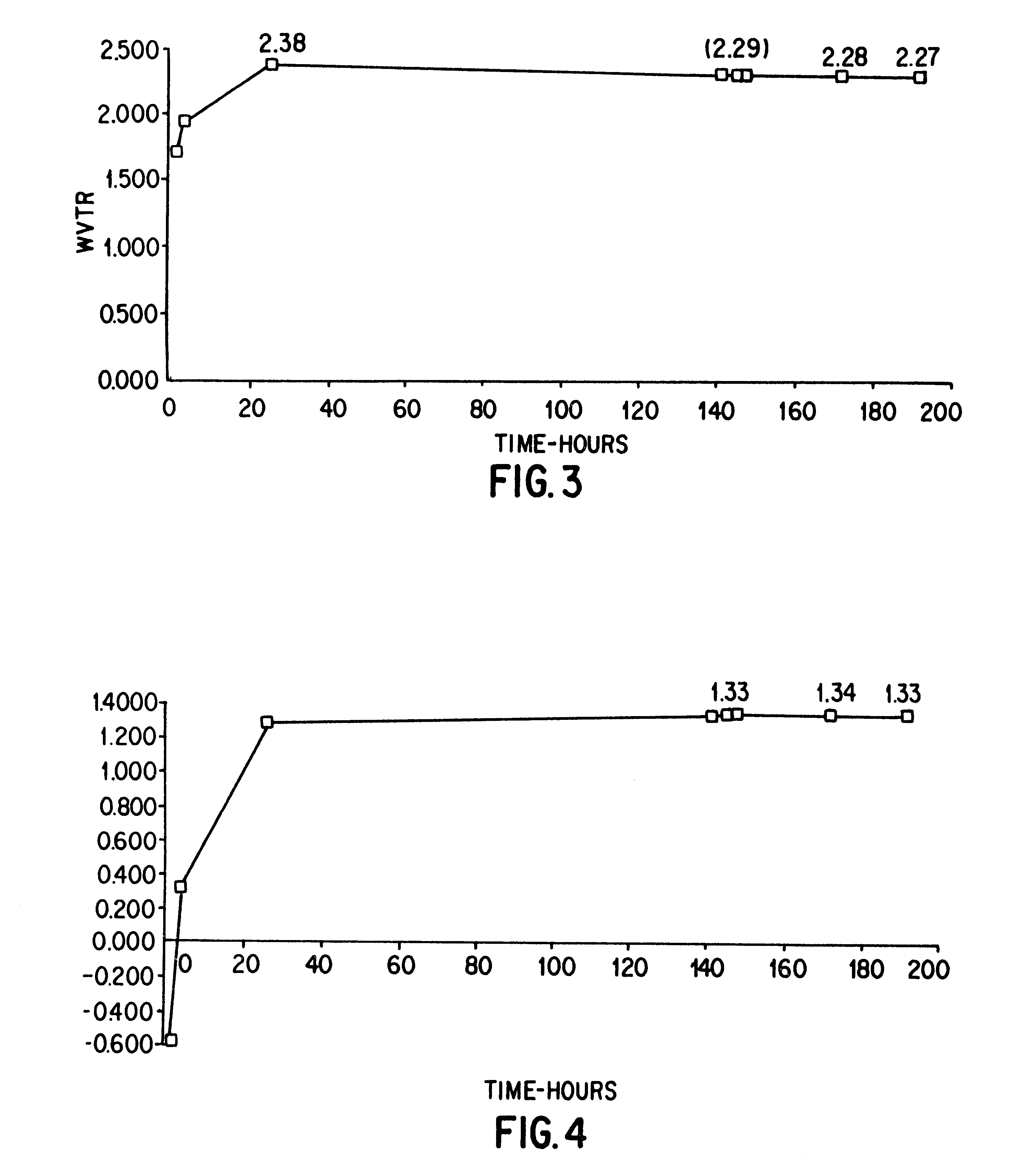

InactiveUS6548120B1Reduce penetrationReduce drying demandFlexible coversWrappersWater basedPolymer science

Recyclable and repulpable coated paper stock, preferably for use as ream wrap, comprising a substrate coated on at least one surface with a base coat and at least one additional coat over said base coat. Both coats are water based dispersions of a polymer selected from the group consisting of acrylic polymers, acrylic copolymers, polyvinyl acetate, polyvinyl alcohol, ethylene-vinyl acetate, polyvinyl chloride, styrene butadiene copolymers, polyvinylidiene chloride and its copolymers, or starch. The wax free coating forms a pin-hole free continuous film on the substrate which is resistant to water and water vapor. The invention also includes processes for making and recycling the invented coated paper stocks.

Owner:COATING EXCELLENCE INT

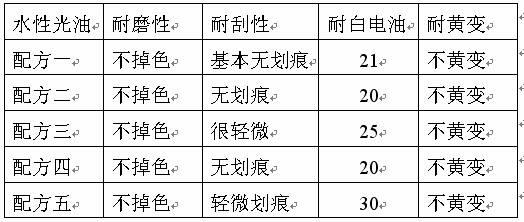

Water-based matte touch gloss oil and preparation method thereof

The invention discloses a water-based matte touch gloss oil and a preparation method thereof. The water-based matte touch gloss oil is prepared from the following raw materials in percentage by mass: 65-80% of water-based polyurethane dispersion, 10-20% of modified acrylic elastic emulsion, 1-3% of flatting agent, 3-5% of coupling agent, 3-5% of hand touch wax slurry, 1-3% of matting agent, 0.1-0.5% of defoamer, 0.5-2% of hand touch scratch-resistant agent, and 0-3% of water. The water-based matte touch gloss oil prepared from the materials is low in matte degree, and employs water as a diluent and contains no organic solvent or heavy metal; and the water-based matte touch gloss oil is natural and soft in color and luster without whiting, and good in color reveal property. Furthermore, the water-based matte touch gloss oil is suitable for surface coating treatment of high-quality paper, so that the coated paper feels like cotton, silk and velvet, and the paper finished product is good in matte degree and high in white gasoline resistance; the level of product packaging is greatly improved; and the water-based matte touch gloss oil is mainly applied to leatherette paper, imitation leather, calendered paper and some coated paper.

Owner:GUANGDONG YINGKE GRP CO LTD

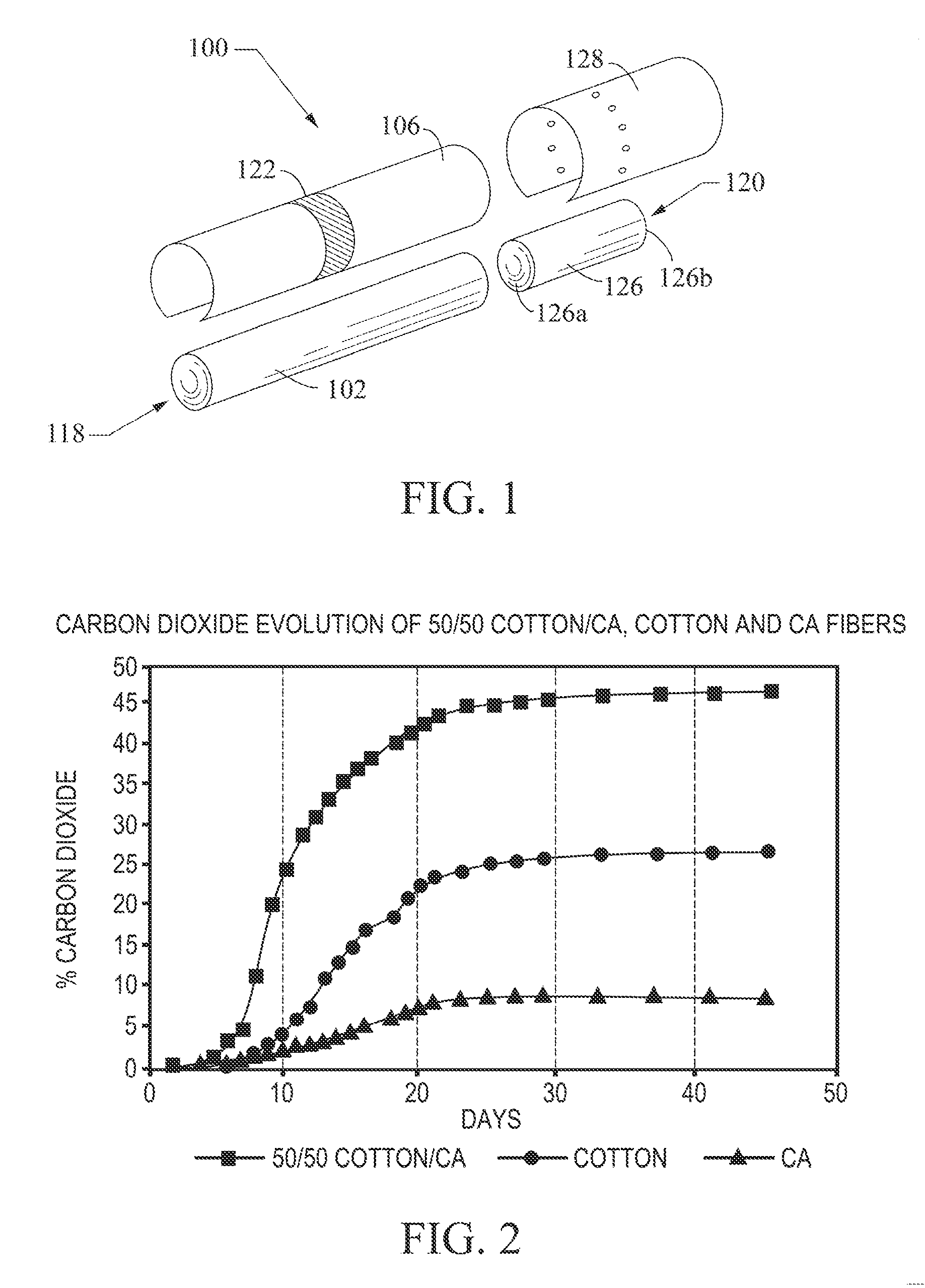

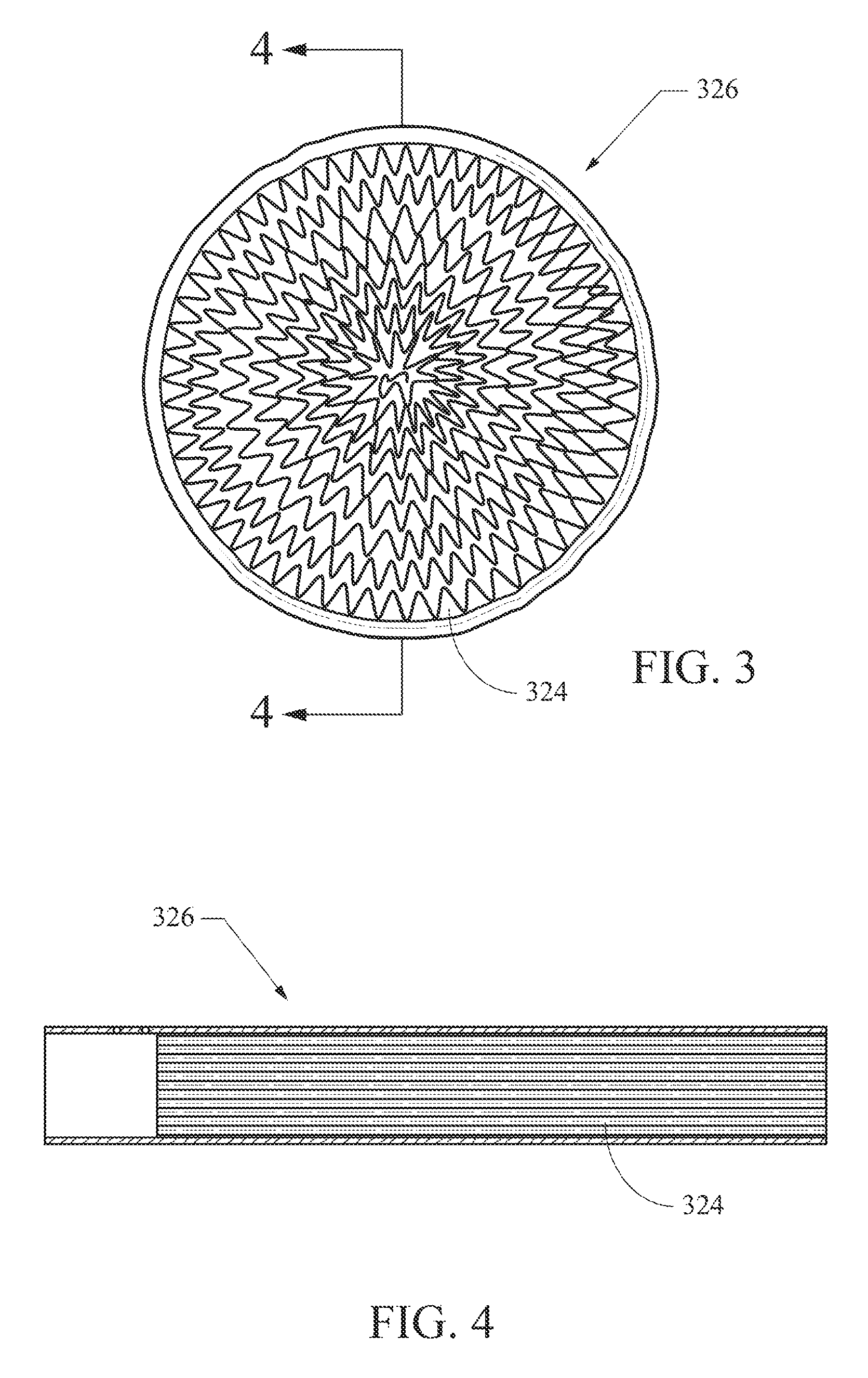

Coated paper filter

InactiveUS20120305015A1Improve degradation rateIncrease speedTobacco treatmentTobacco smoke filtersFiberCellulose acetate

A biodegradable paper substrate and / or biodegradable fiber (including fiber tow) may be coated with cellulose acetate and / or plasticized cellulose acetate for use in a filter material configured for application in a filter of a smoking article. Flocking and / or fibrillation methods may be used to deposit and / or generate a plurality of fibers that may protrude beyond a surface of the biodegradable substrate material. A filter made in accordance with this design may also include non-biodegradable material.

Owner:R J REYNOLDS TOBACCO COMPANY

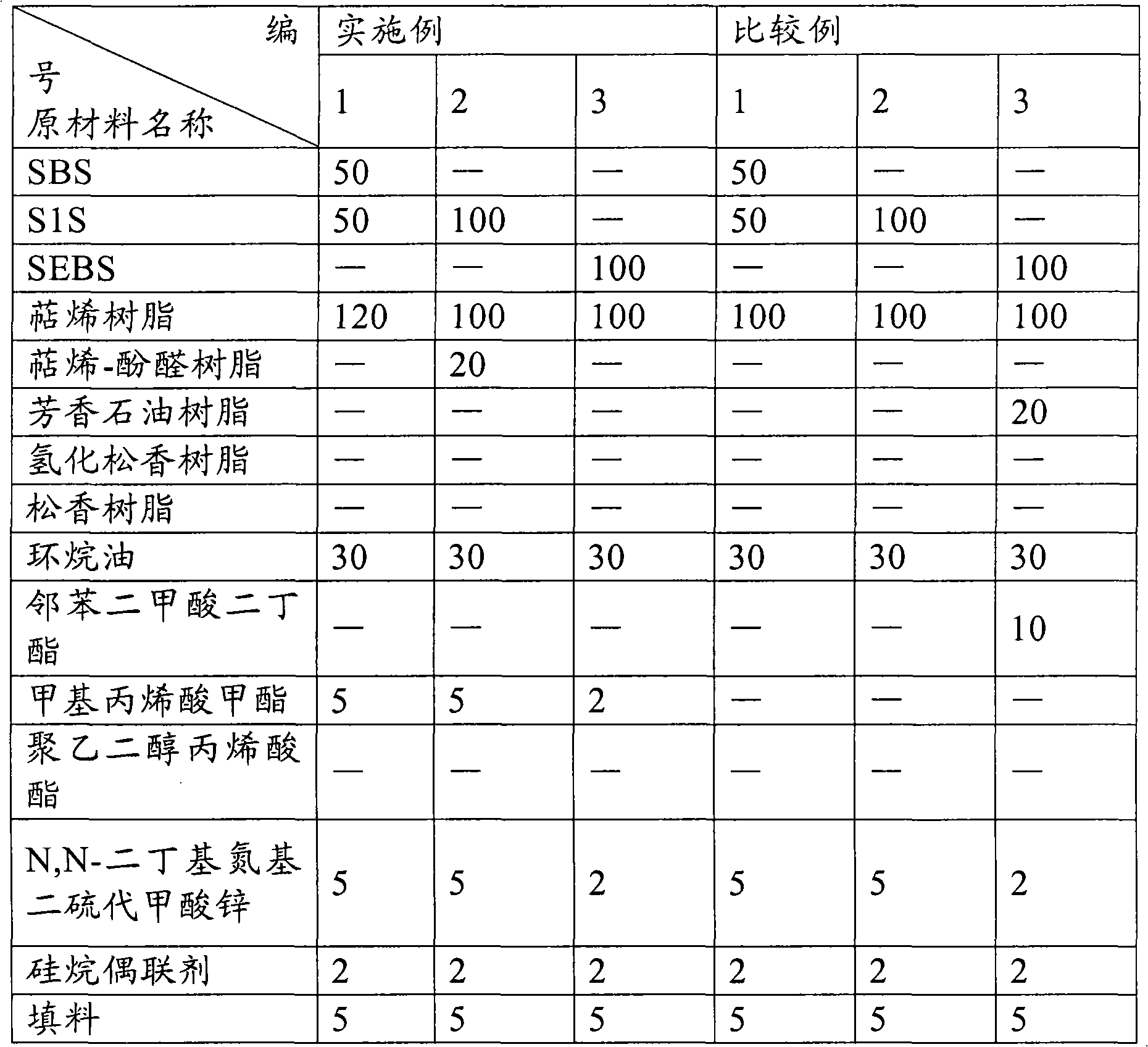

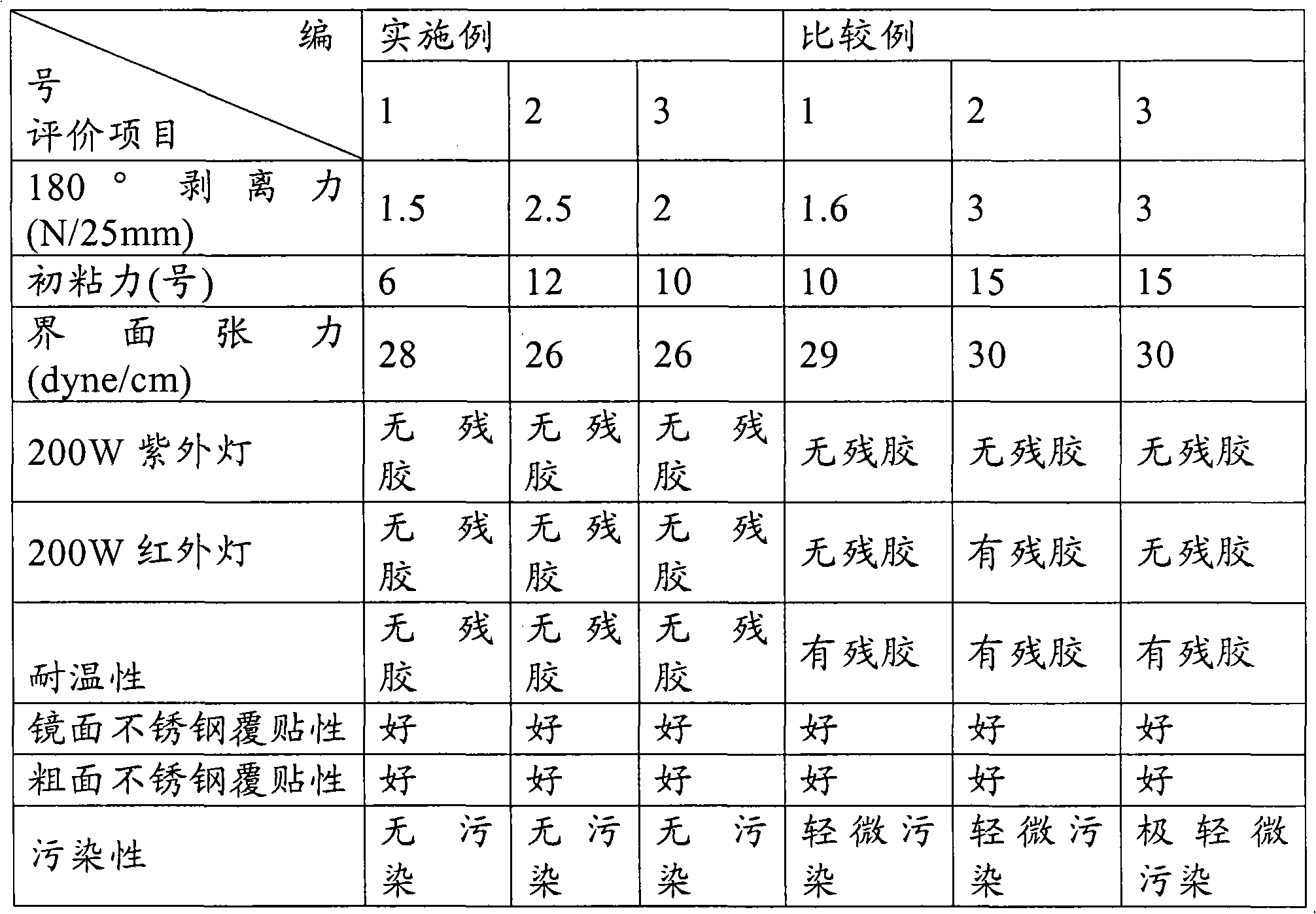

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

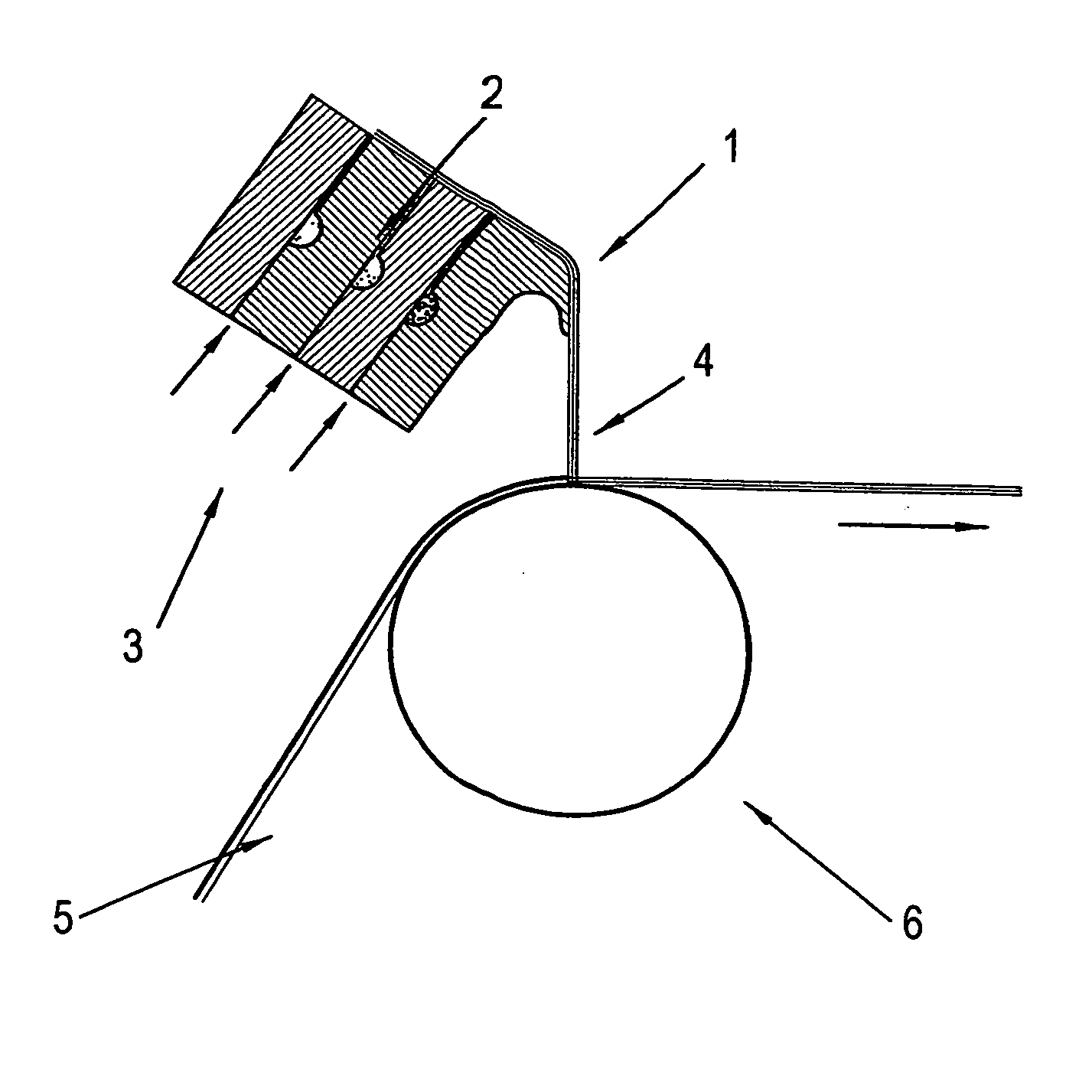

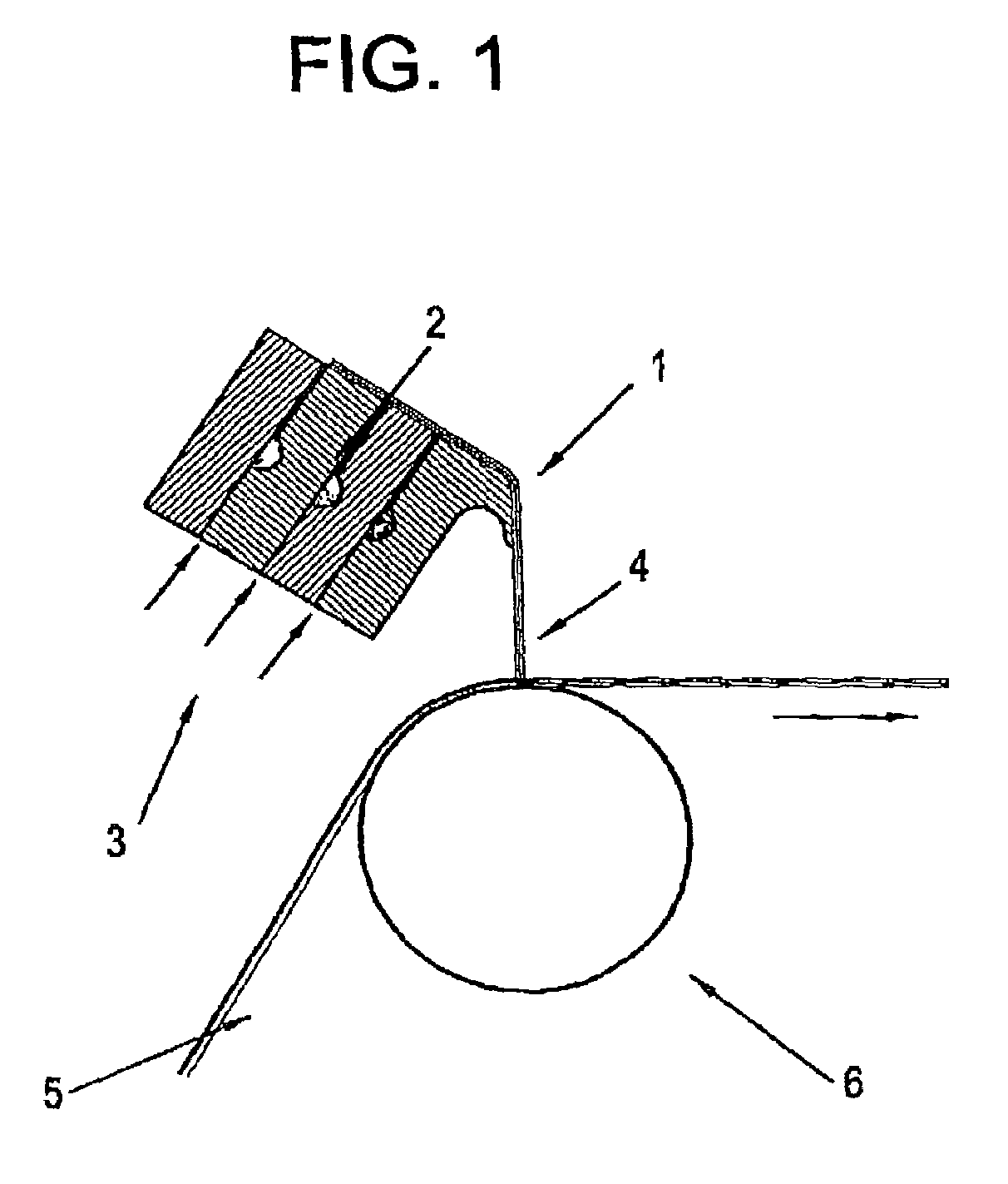

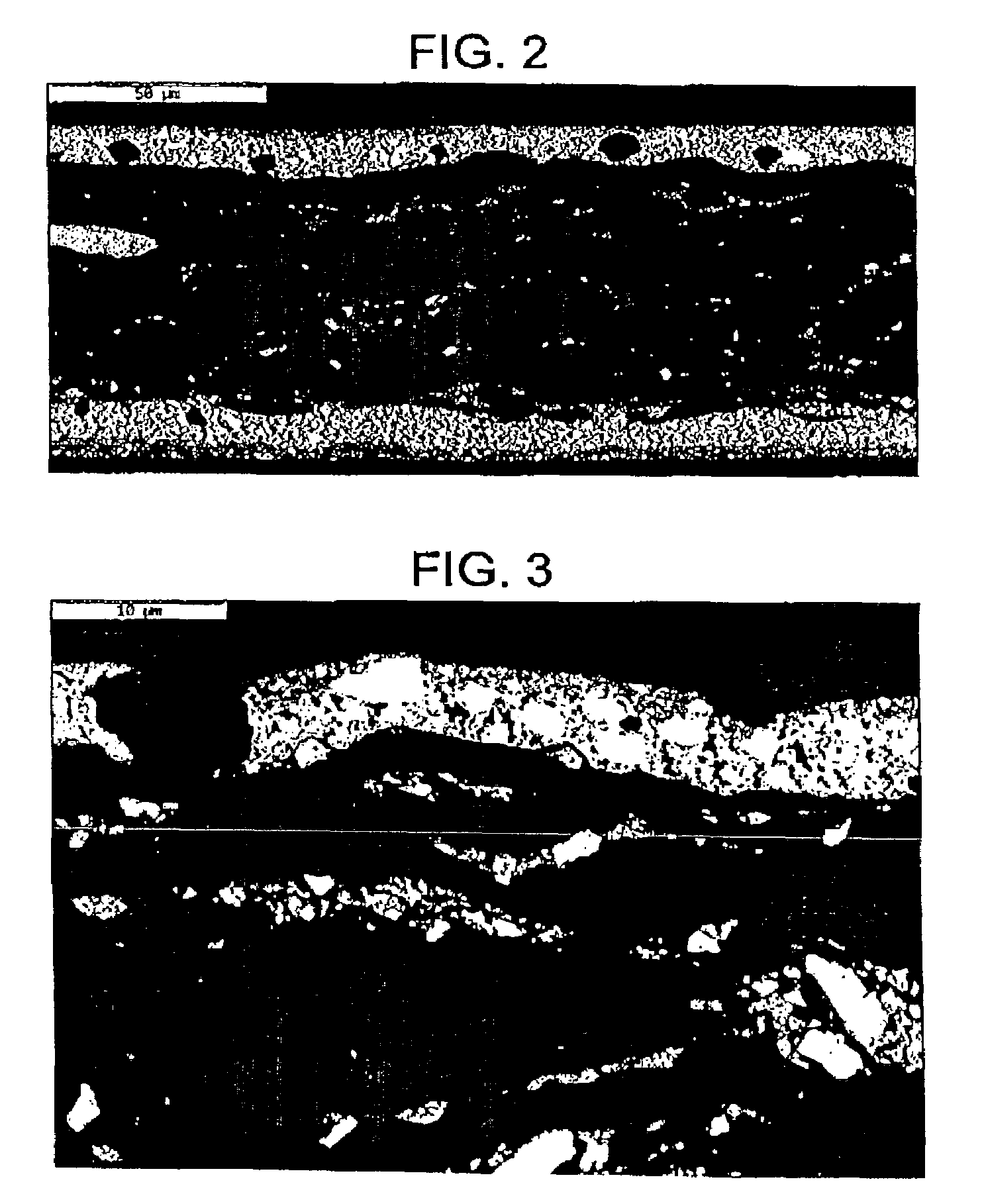

Process for making coated paper or paperboard

InactiveUS20050039871A1Increase shear viscosityEfficient use ofNon-fibrous pulp additionLiquid surface applicatorsPaperboardEngineering

The present invention refers to a method of producing a coated paper or paperboard, but excluding photographic papers, comprising the steps of: (a) forming a free flowing curtain comprising at least one layer, whereby the composition forming at least one layer of the free flowing curtain has a high shear viscosity of at least about 50 mPa.s, and (b) contacting the curtain with a continuous web substrate of basepaper and paperboard.

Owner:DOW GLOBAL TECH LLC

Gloss-coated paper with enhanced runnability and print quality

InactiveUS7018708B2Increase foam resistanceGuaranteed uptimeCoatings with pigmentsSynthetic resin layered productsMedicineOptical brightener

This invention provides a gloss-coated electrophotographic paper with superior runnability and print quality in colour and monochrome copiers and printers. The coated paper product comprises a paper substrate coated on at least one side with a pigmented coating. The pigment coating consists of a mixture of at least three different pigments and a binder. The coating may further include a lubricant. Optionally, the coating formulation may contain an optical brightening agent, a defoamer and a thickener. In addition, the gloss coated electrophotographic paper of this invention provides a superior toner adhesion in colour and monochrome electrophotographic imaging applications.

Owner:INT PAPER CO

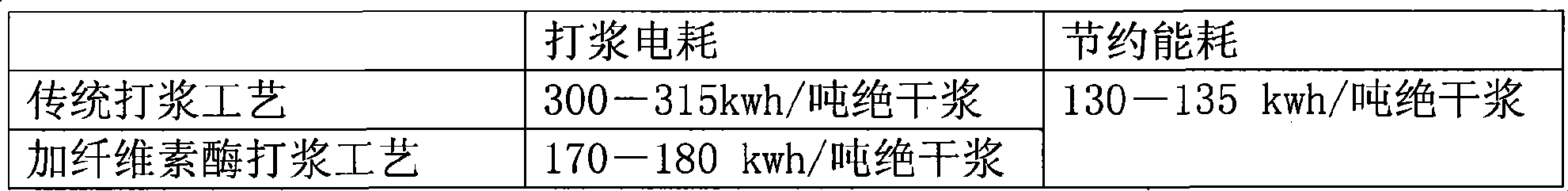

Method for preparing coated paper

ActiveCN101418532AImprove resource utilization efficiencyReduce manufacturing costInorganic fibres/flakesPaper coatingFiberCellulase

The invention relates to a method for preparing enamel paper. Through the addition of cellulase, the preparation method effectively reduces energy consumption of pulping and improves pulp quality; a mineral fiber ingredient is used to replace wood fiber so as to save wood resource and simultaneously reduce production cost; and the prepared enamel paper has anti-counterfeit function.

Owner:山东晨鸣纸业集团股份有限公司 +1

Compositions

Compositions such as filled and coated papers may include microfibrillated cellulose and inorganic particulate material.

Owner:FIBERLEAN TECH LTD

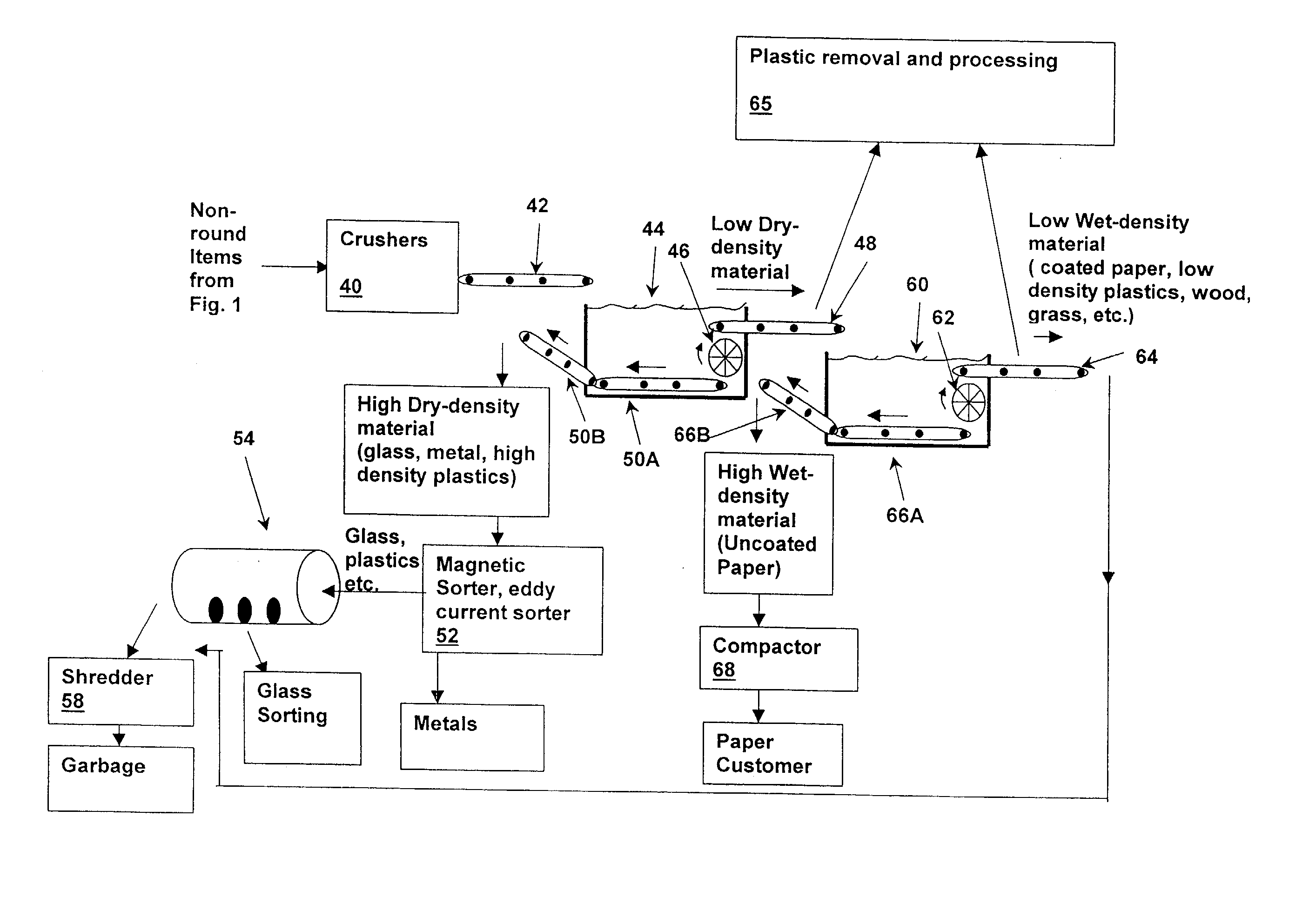

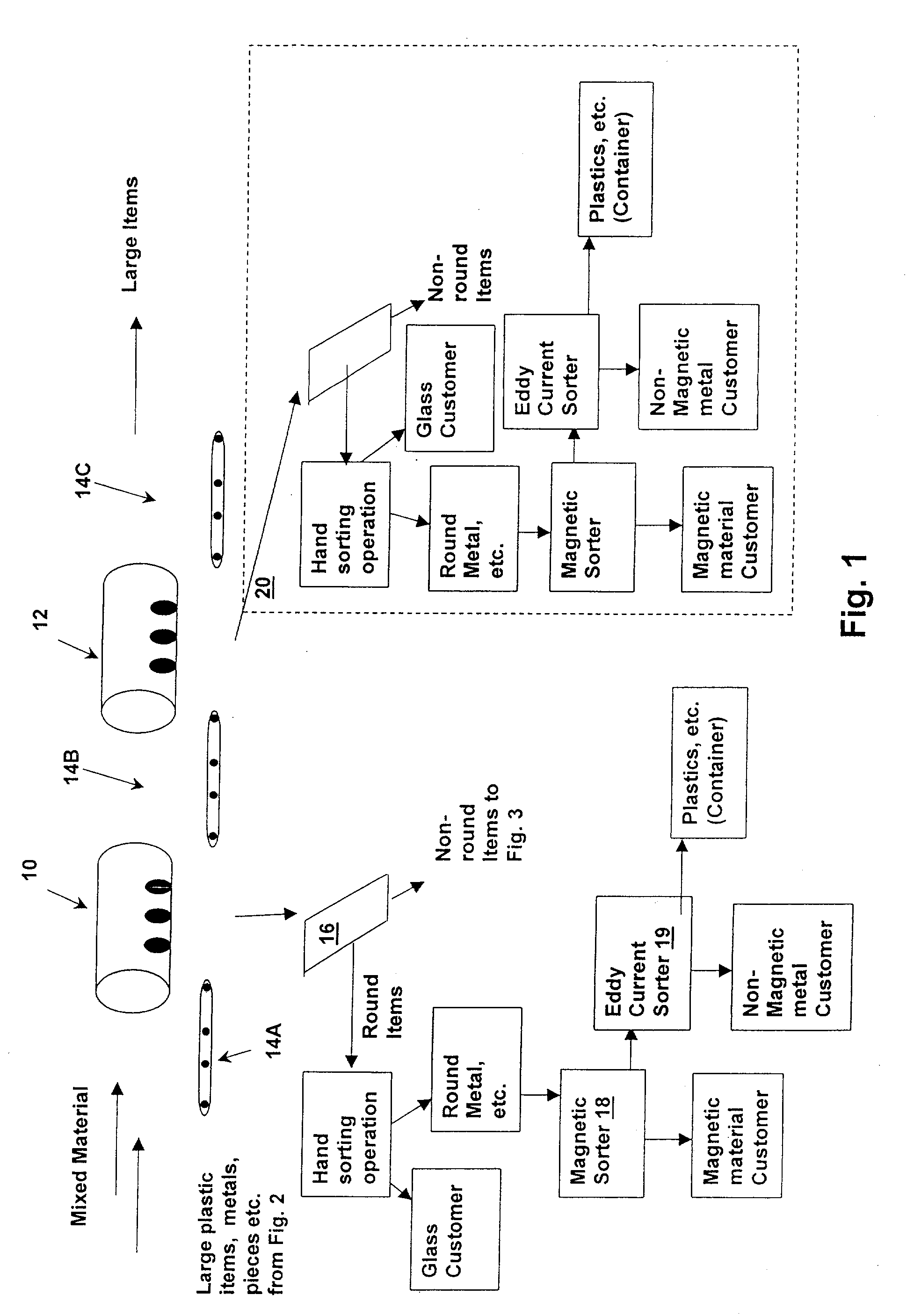

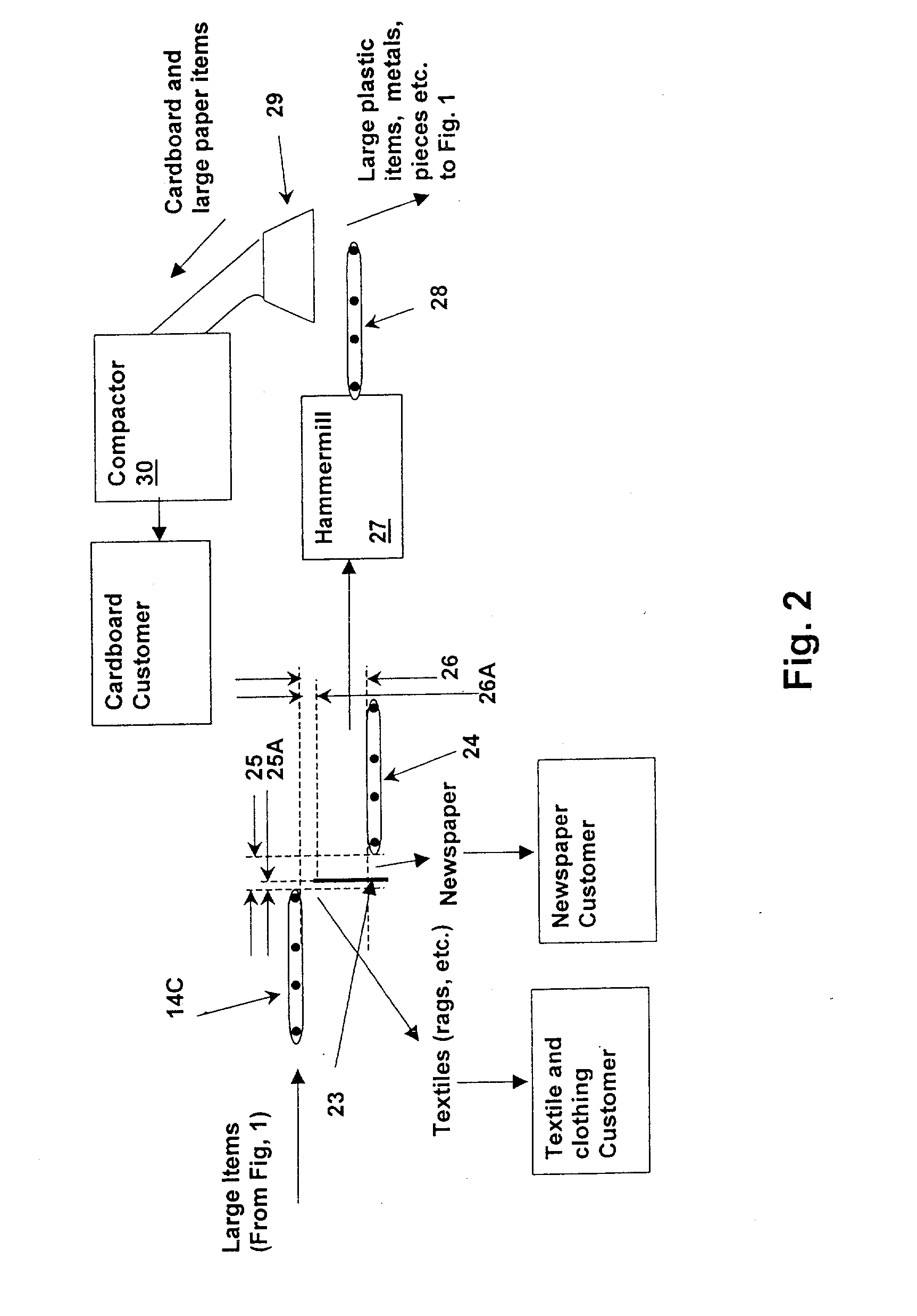

Method and system for separating and sorting recyclable materials from mixed waste streams

A method and system for separating and sorting recyclable materials from mixed waste streams provides improved separation and reduced cost in trash and recyclable material processing systems. A low surface-current bath is used within the sorting system to separate materials having a low wet-density, such as plastics and coated paper, from materials having a high wet-density, such as uncoated paper. A novel newspaper separation device using an appropriately-sized gap in a conveying system provides separation of newspaper from other large pieces of recyclable material or trash, while leaving heavier materials on the conveying system for further sorting. An improved plastics separator is included for separating plastics by melting-point range.

Owner:3R SYST L L C

Process for making multilayer coated paper or paperboard

InactiveUS7425246B2Reduce weightImprove efficiencyNon-fibrous pulp additionNatural cellulose pulp/paperFree fallingEmulsion

Owner:DOW GLOBAL TECH LLC

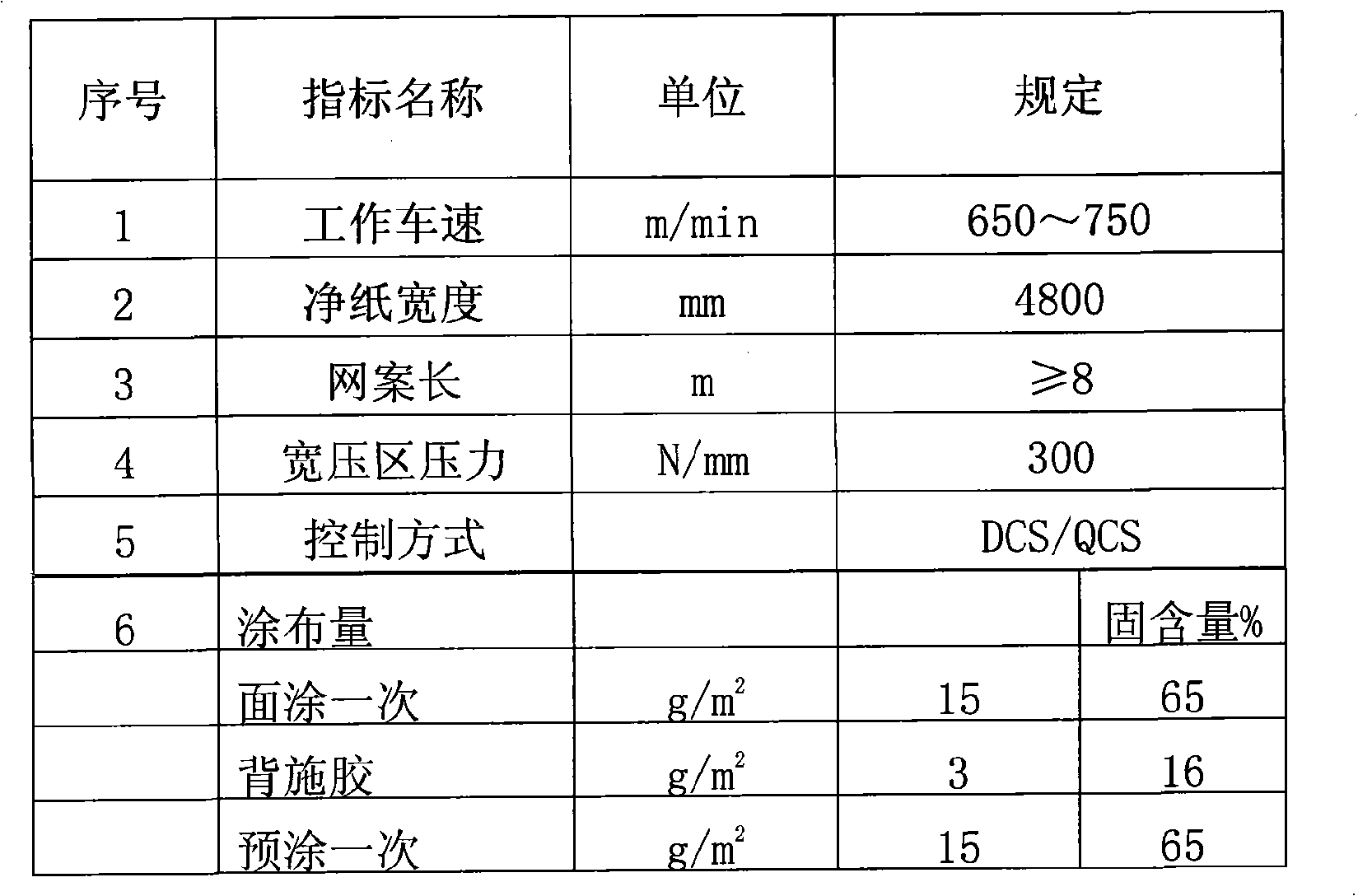

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

Biodegradable PE-coated paper material and preparation method thereof

ActiveCN102558797AGood compatibilityImprove bondingSpecial paperSynthetic resin layered productsElastomerAnti ageing

The invention discloses a biodegradable PE-coated paper material which comprises the following components in percentage by weight: 60-90% of polylactic acid, 5-40% degradable toughening resin, 1-10% of elastomer, 0.1-1.0% of processing aid and 0.1-1.0% of anti-aging agent. According to the invention, the compatibility of the polylactic acid and elastic degrading resin can be improved, the adhesion of the material and paper is improved, and the cost of the existing degrading PE-coated paper raw material is greatly reduced.

Owner:SHENZHEN ESUN IND

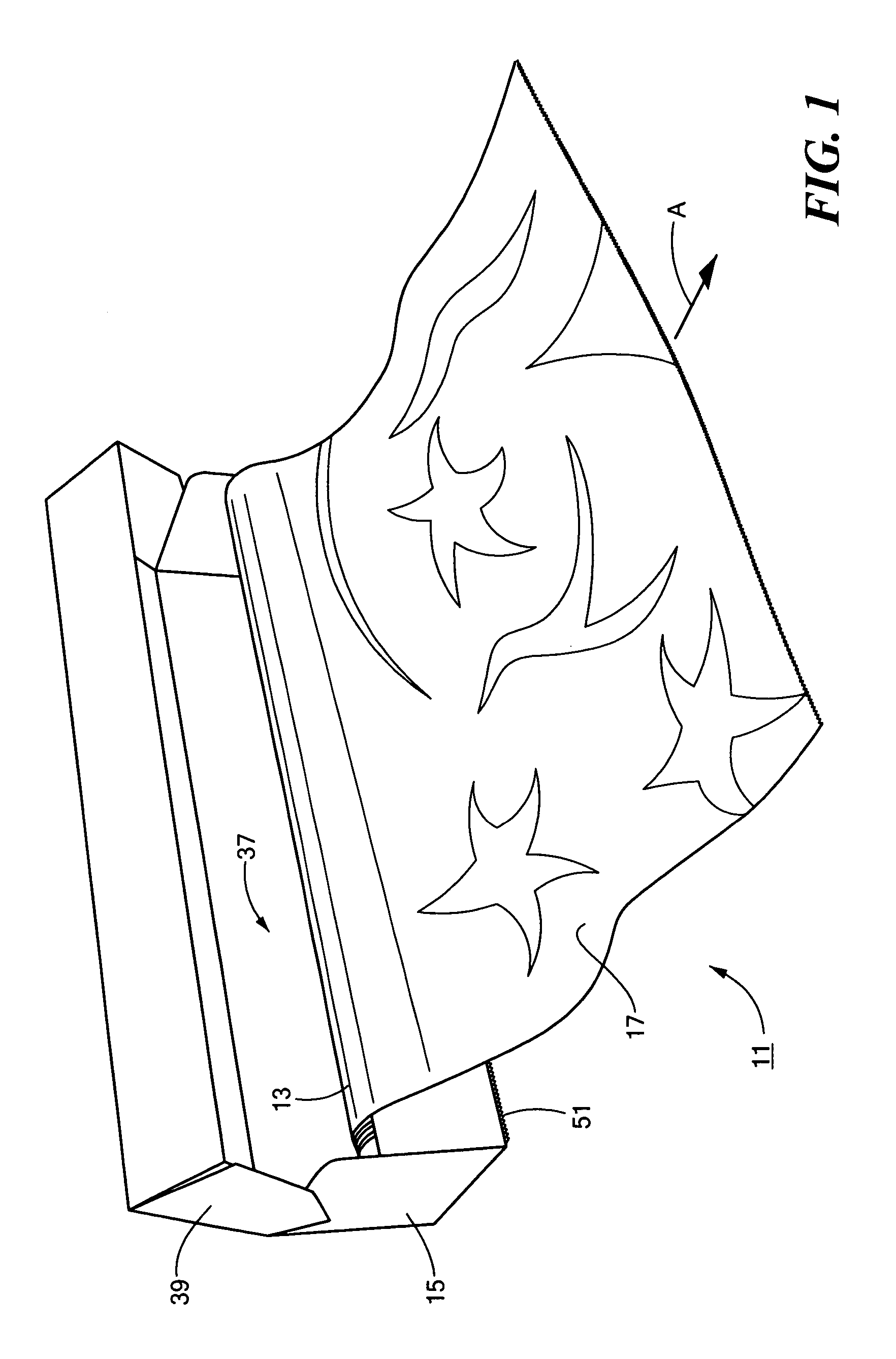

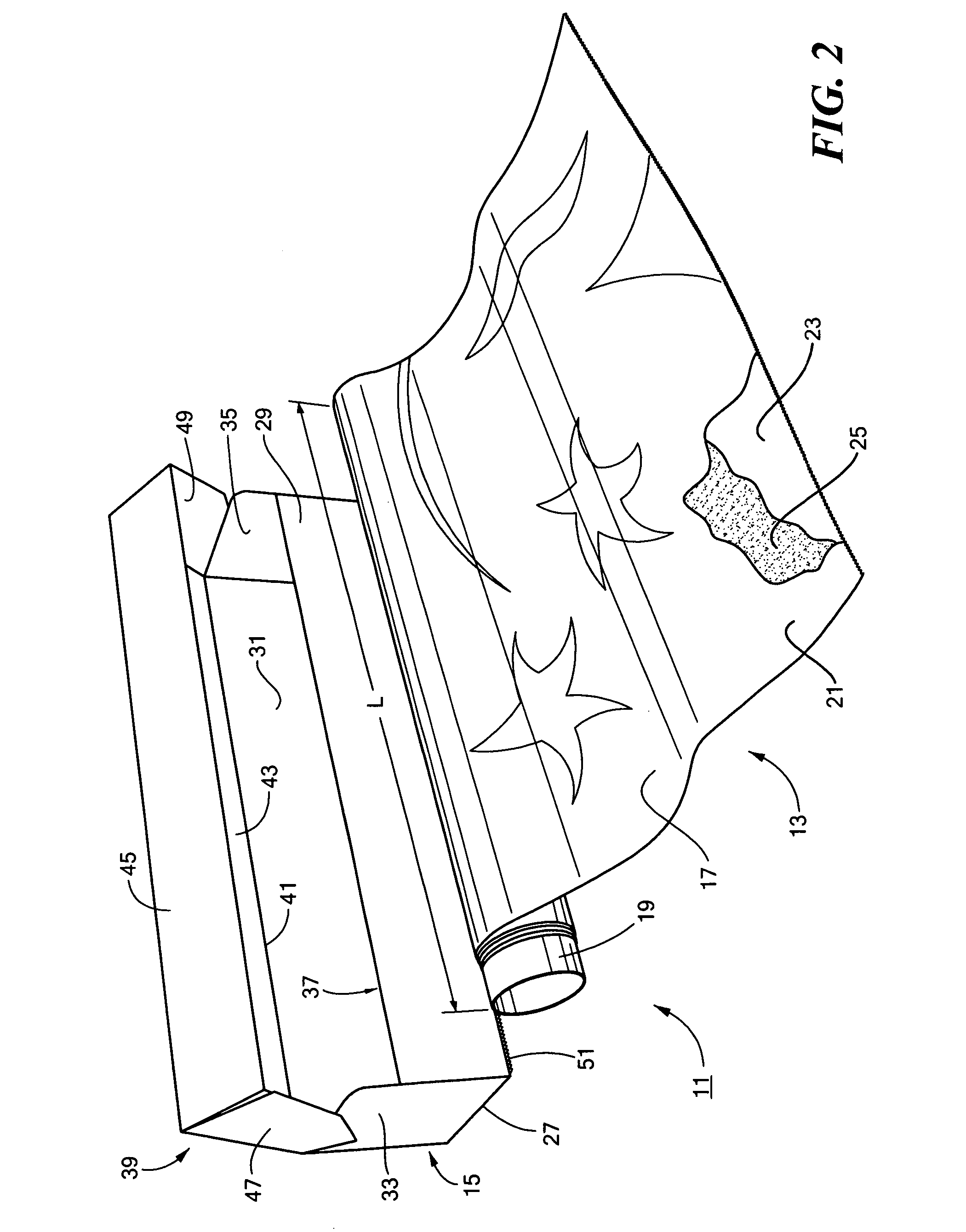

Gift wrap dispensing system

InactiveUS20070074986A1Small sizeEasy to carryContainers for annular articlesDispensing apparatusCardboardGift wrapping

A gift wrap dispensing system includes a roll of gift wrapping that is retained within an enclosable carton. The roll of gift wrapping is in the range of approximately 10-16 inches in length and includes a rigid cardboard tube on which a supply of wrapping paper is wound. The wrapping paper includes a decorative film, such as a holographic or metallized film, that is bonded onto a coated paper substrate using a layer of bonding material. The carton is preferably constructed from a unitary cardboard blank and includes a bottom panel, a front panel, a rear panel and a pair of side panels which together define a longitudinal cavity which is sized and shaped to receive the roll of gift wrapping. The carton additionally includes a lid that is pivotally coupled to the rear panel and that is designed to be pivoted between an open position and a closed position. In order to dispense a supply of wrapping paper, the lid of the carton is pivoted at least partially open. A user-defined section of the wrapping paper is extracted from the carton and is severed from the remainder of the roll of gift wrapping using an externally-accessible serrated cutting edge that is mounted on the carton. With the section of wrapping paper dispensed, the lid is pivoted closed to protect the remainder of the roll of gift wrapping pending further use.

Owner:KING MEDORA

Styrene-acrylate emulsion for surface coatings of coated paper

ActiveCN101704930AImprove surface strengthHigh glossPaper coatingCoatingsEmulsionEmulsion polymerization

The invention provides a styrene-acrylate emulsion for surface coatings of coated paper, which is prepared in emulsion polymerization mode by mixing the following raw materials in part by weight: 100 parts of mixed monomers; 0.7 to 4.5 parts of emulsifying agent; 0.4 to 4.5 parts of initiating agent; 2 to 4 parts of accelerating agent; 2 to 8 parts of crosslinking monomers; 4 to 20 parts of aqueous alkali; and 90 to 290 parts of water. The mixed monomers comprise the following monomers in part by weight: 20 to 44 parts of (methyl) acrylic ester; 50 to 74 parts of (methyl) styrene; and 6 to 10 parts of (methyl) acrylic acid. The styrene-acrylate emulsion for the surface coatings of the coated paper of the invention is a high-performance and environmentally-friendly product which can be used for paper coatings. When applied to the surface coatings of the coated paper, the product can obviously increase the surface strength of the coated paper and improve glossiness of paper coatings.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Water flexible painting plate ink and preparing method thereof

The invention relates to a waterborne soft printing ink comprising the components: film-forming resin emulsion of 8.7-47.2wt percent, waterborne acrylic color paste of 40-50wt percent, antifoam agent of 0.1-0.3wt percent, waterborne wax paste of 0.2-2.0wt percent, isopropyl alcohol of 2-8wt percent, ethylene glycol of 10-30wt percent, ethanolamine of 0.5-1wt percent and water of the rest percent. The invention further provides a method to prepare the waterborne soft printing ink. The waterborne soft printing ink of the invention is nontoxic and environmental friendly, has good safety, stable performance and good adaptability to coated art paper printing, and can be continuously used in printing without mackle, has clear printing effect and low production cost.

Owner:GUANGDONG YINGKE GRP CO LTD

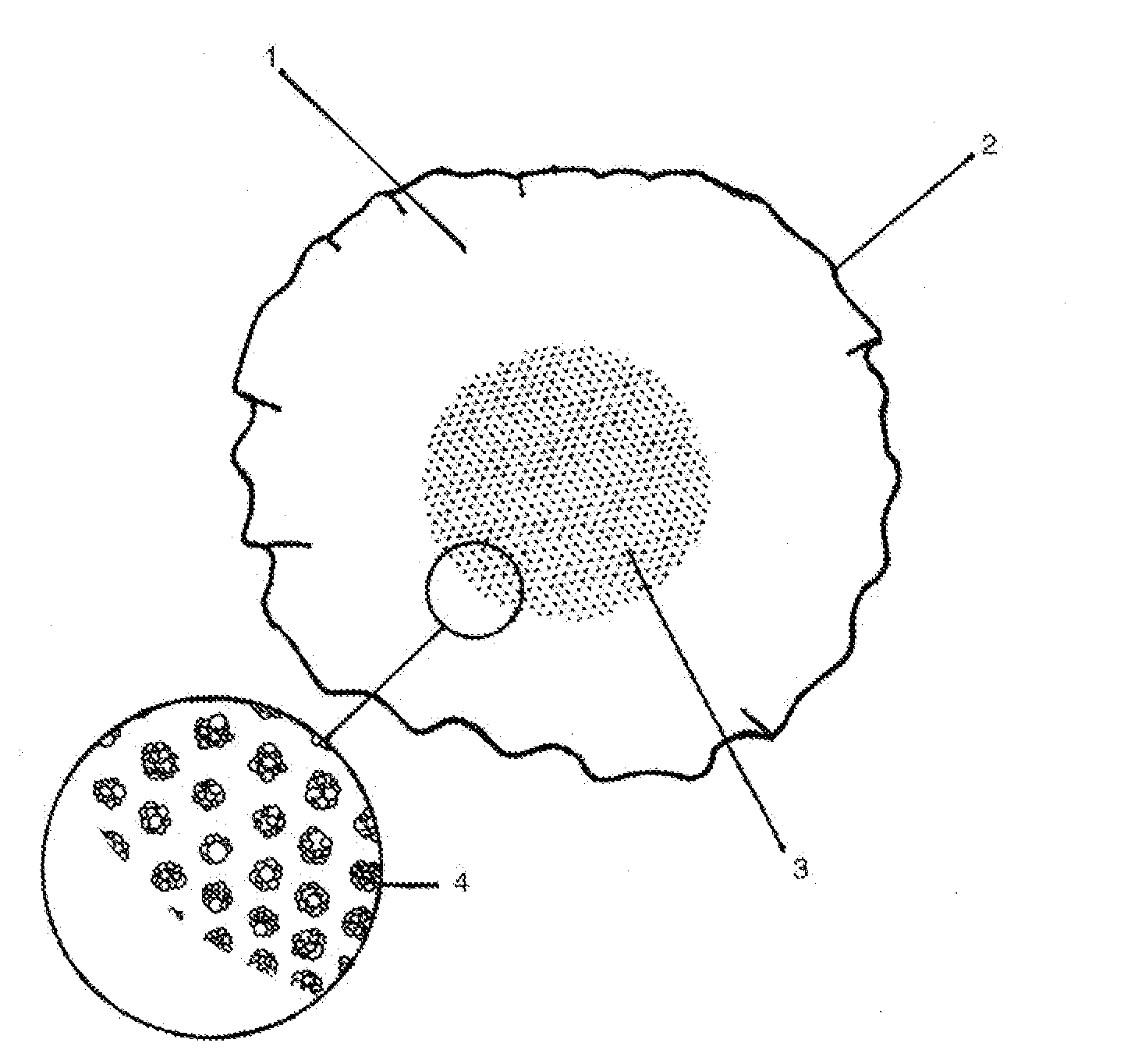

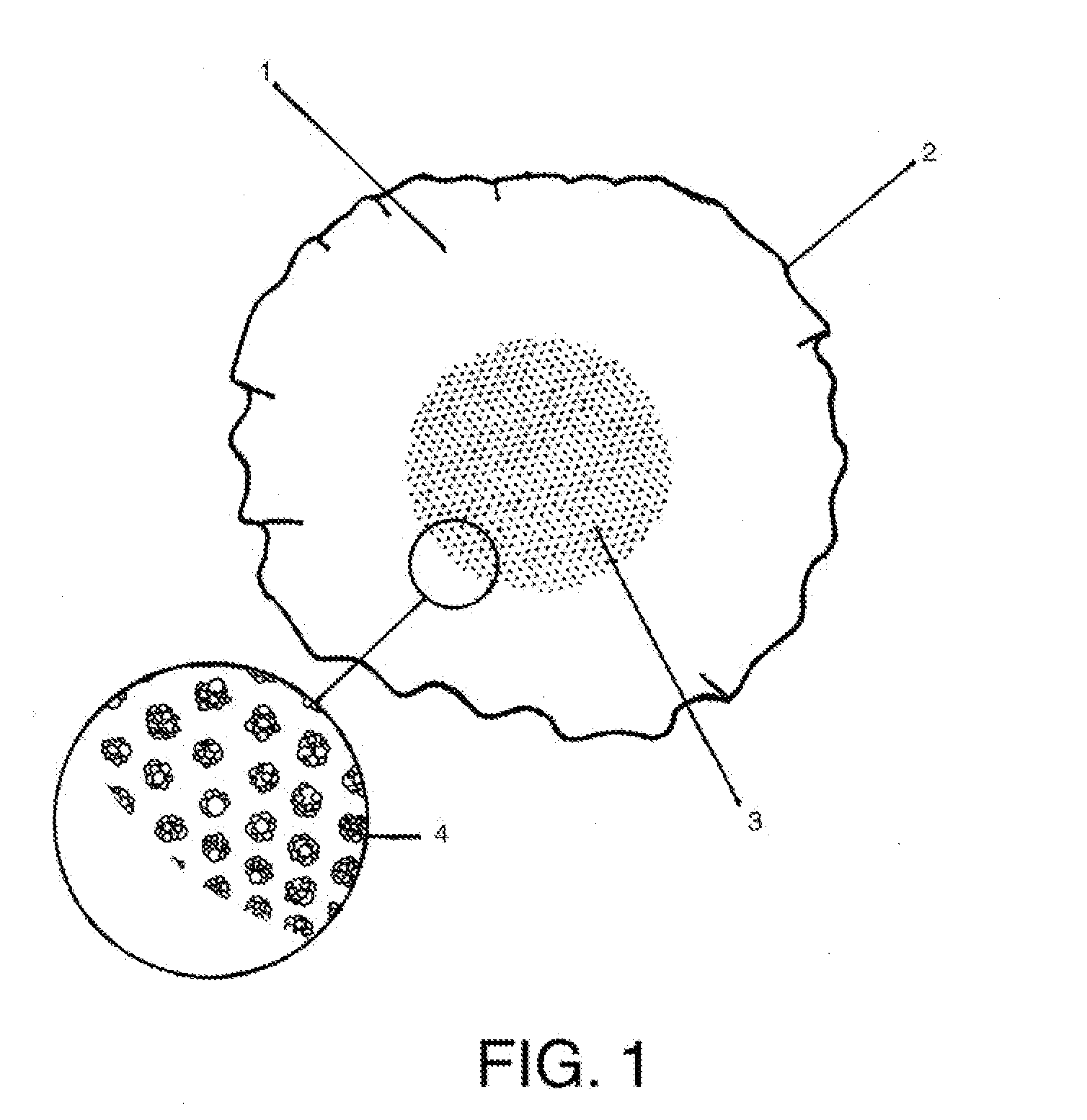

Method of enhancing beverages by means of a unique microencapsulated delivery system

The present invention provides a method of imparting flavor enhancers, (flavorings) flavor or aroma masking agents, medicinal additives, fragrances, vitamins, colorants, homeopathic and herbal remedies, appearance and characteristic modifiers and other ingredients to a brewed or steeped beverage such as coffee or tea by means of a microencapsulated delivery system incorporated onto a substrate or filter material such as those used in drip coffee makers or tea bags. The microcapsules are “printed” or laminated to the substrate filter paper in a pattern that allows water to pass through while the microcapsules filled with a flavoring liquid or solid is dissolved thus releasing the contents into the water stream resulting in a flavor-enhanced beverage. Alternative delivery may also be achieved by means of:a) A microcapsule coated paper disc that may simply be immersed in the hot beverage or;b) A microcapsule coated interior wall of a disposable container or cup (A paper coffee cup for example) until such time the hot fluid within the container dissolves the microcapsules thus releasing the latent additive ingredient or a primary formulation of ingredients constituting the entire beverage solution or mixture.Several variations of this technology may be adapted for use with hot, cold or ambient temperature beverage preparation methods. Further aspects of the invention will become apparent from consideration of the drawings and the ensuing description of preferred embodiments of the invention. A person skilled in the art will realize that other embodiments of the invention are possible and that the details of the invention can be modified in a number of respects, all without departing from the inventive concept. Thus, the following drawings, photos and description are to be regarded as illustrative in nature and not restrictive.

Owner:THE ADDITIVE ADVANTAGE

Composition for coating of printing paper

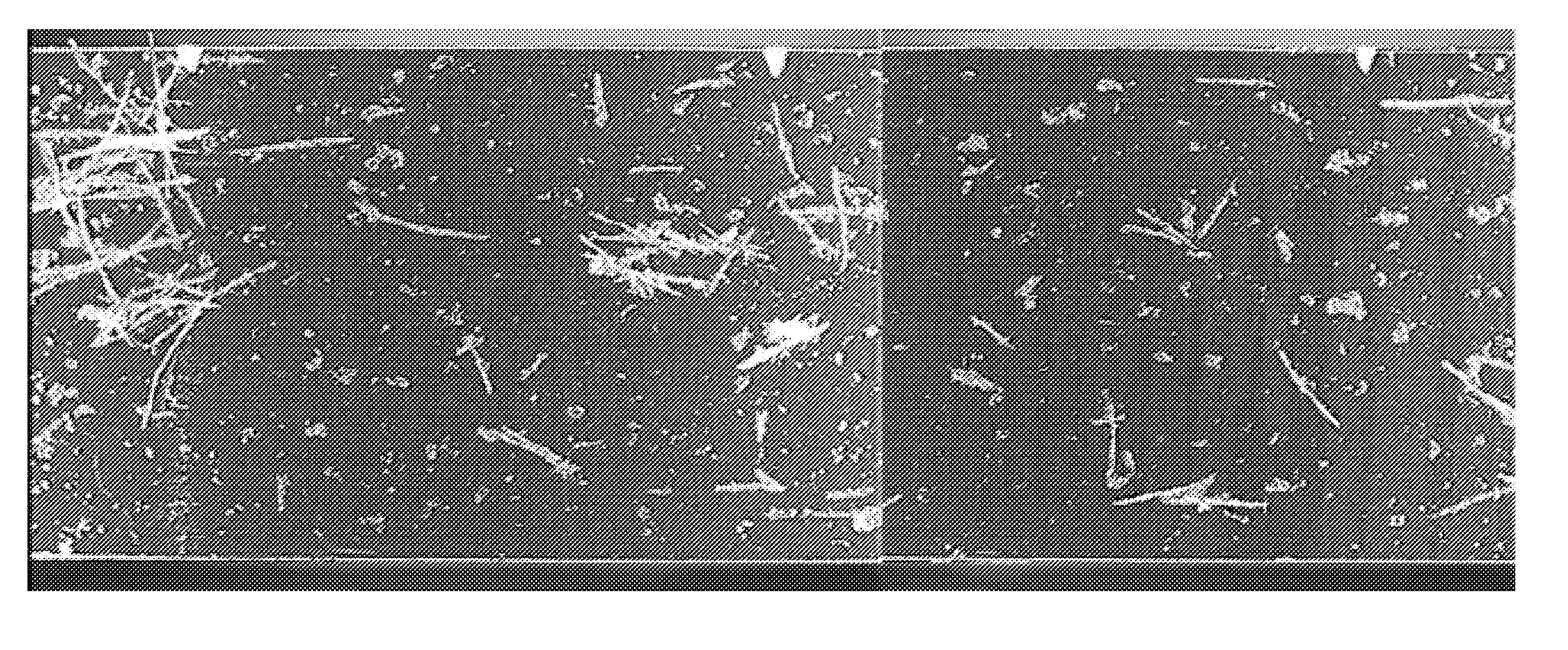

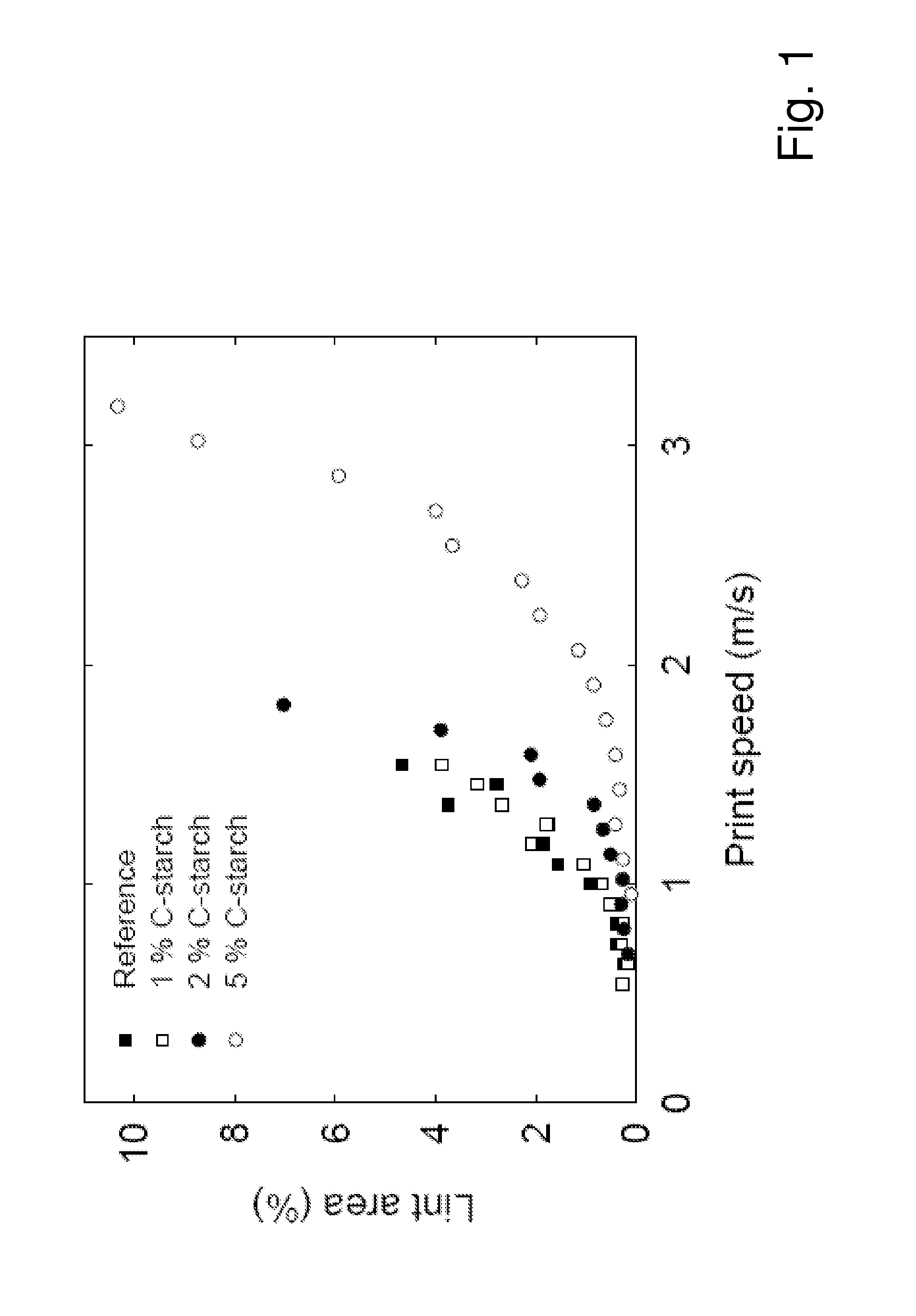

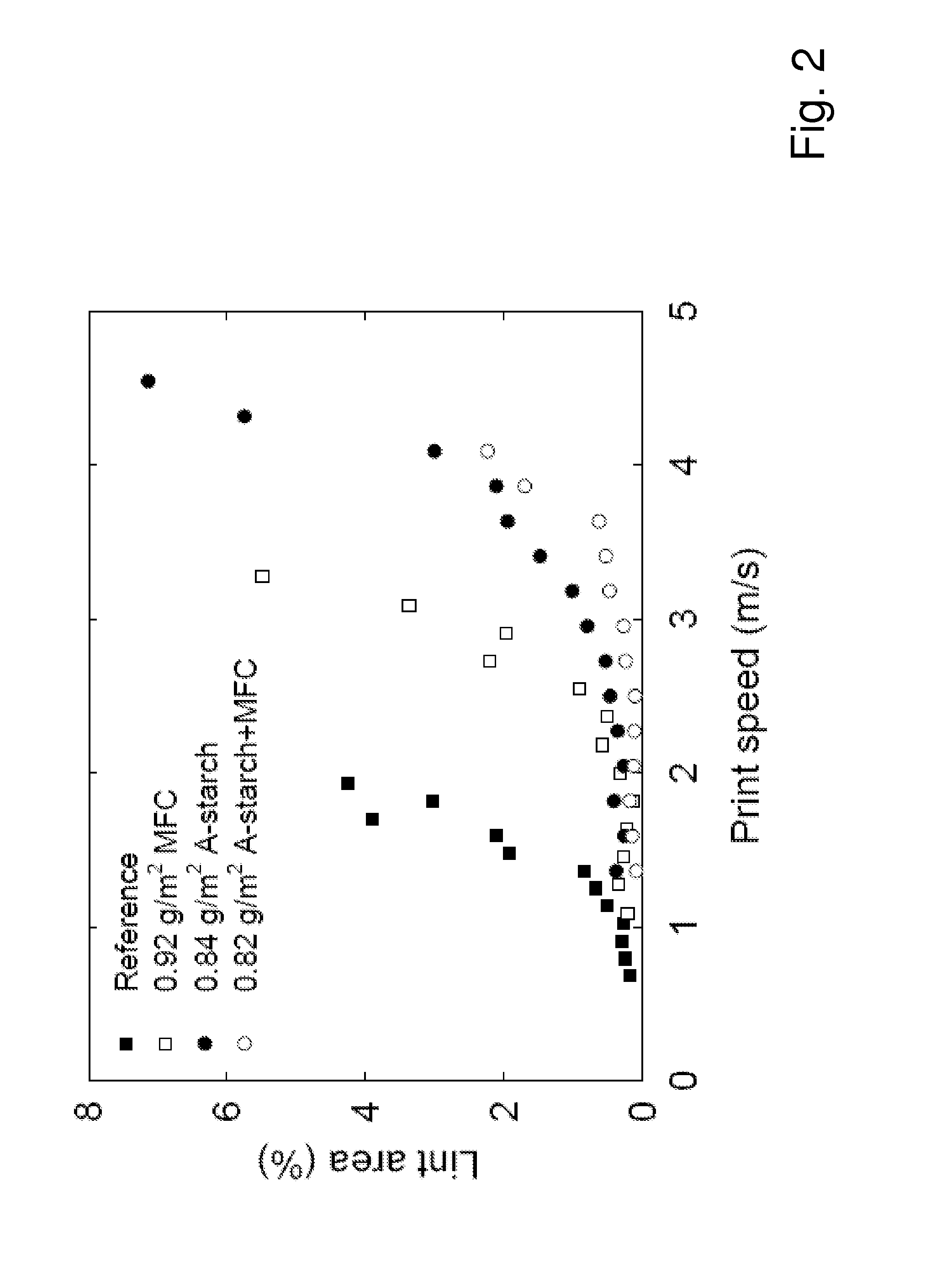

ActiveUS20110081554A1Reduced linting propensitySimple interfaceStarch dervative coatingsSpecial paperCelluloseColloid

The invention relates to compositions for coating of printing paper, said compositions comprising microfibrillated cellulose (MFC) and one or more polysaccharide hydrocolloids, and use of said compositions. Further, the invention relates to coated paper, comprising a first layer of polysaccharide hydrocolloid(s) and a second layer of MFC, and use of said paper. A method for reducing the linting and / or dusting of a paper is also disclosed.

Owner:INNVENTIA

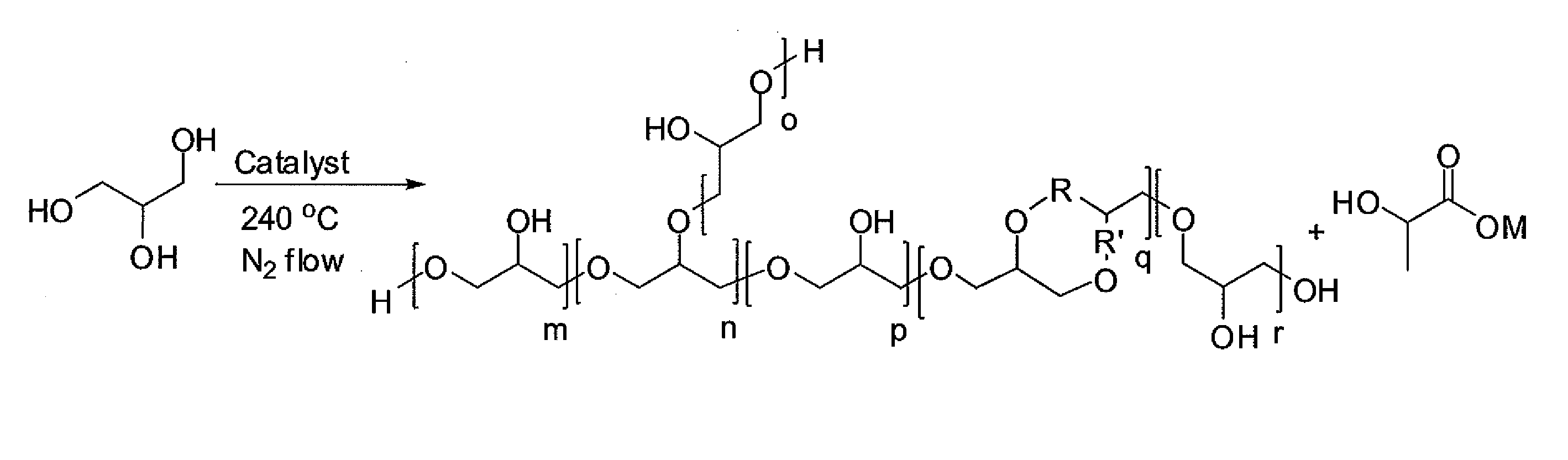

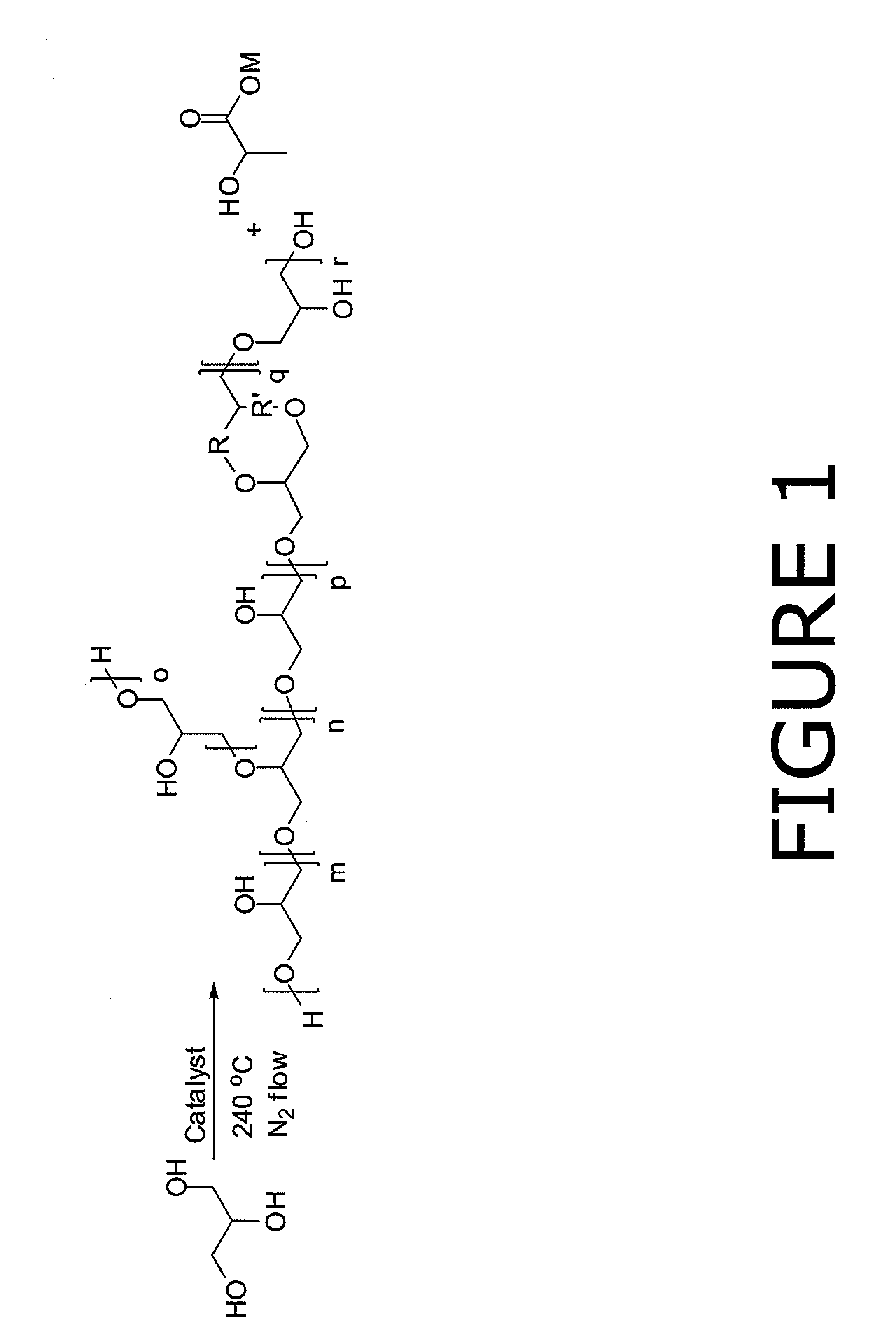

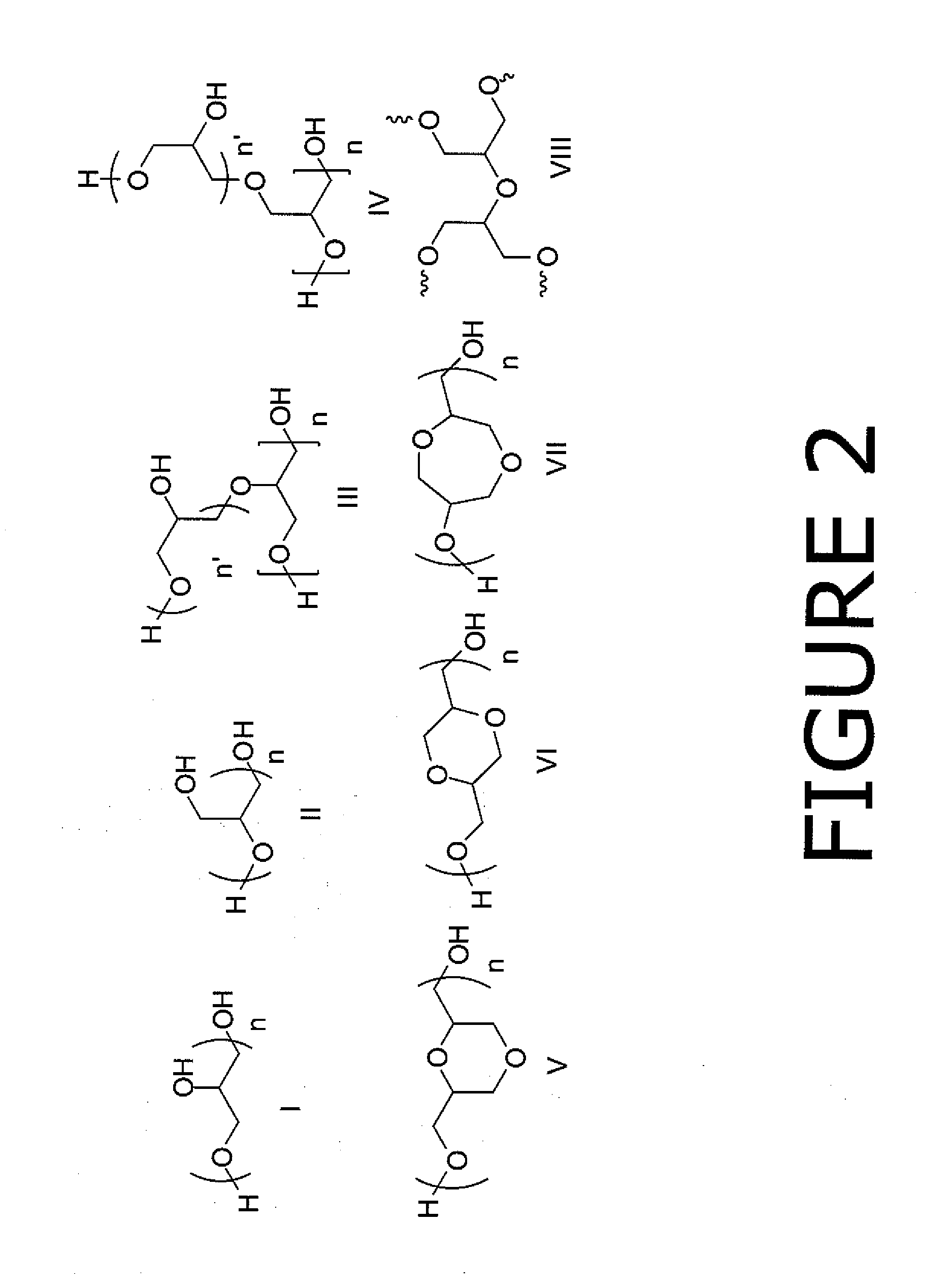

Production and composition of glycerol based polyols

ActiveUS20110092743A1Protection is in progressHigh proportionOrganic compound preparationCarboxylic acid salt preparationDistillationGlycerol

The invention provides a method of efficiently producing branched, cyclic glycerol-based polyols with a co-product as anti-biodegrading agent from inexpensive readily available glycerol monomer. The method involves polymerizing glycerol or glycerol with at least another monomer to multiple other monomers in the presence of particular amount of a strong base as the catalyst under a particular distillation environment. The polyol produced by the inventive method is beneficial of reducing scales in Bayer liquid for aluminum production process and improving brightness of coated paper substrates without greening effect.

Owner:ECOLAB USA INC

Ink-jet recording method

InactiveUS20100053236A1Image irregularities are conspicuousDecrease in surface glossinessMeasurement apparatus componentsDuplicating/marking methodsOrganic solventViscosity

An ink-jet recording method is provided, which includes (i) supplying on a coated paper a treatment liquid containing 15% by mass or more of a polyvalent metal compound for fixing the components contained in an ink composition and having a viscosity at 25° C. of from 2 mPa·s to 8 mPa·s, in an amount of from −50% to +50% with respect to the value of ΔV [ml / m2] determined by the following Formula (I); and (ii) recording an image by ejecting an ink composition containing a colorant, resin particles, an aqueous organic solvent and water by an ink-jet method on the coated paper to which the treatment liquid has been supplied. Vr represents a roughness index of the coated paper obtained from a measurement of liquid absorbability according to the Bristow method, and Vi represents the amount of transfer at an inflection point where the value of absorption coefficient of the coated paper changes in the measurement of liquid absorbability according to the Bristow method.ΔV=Vi−Vr Formula (I)

Owner:FUJIFILM CORP

Multi-layered paper coating latex having high swelling and contraction property, method for preparing the same, and paper coating composition containing the same

ActiveUS20080097019A1High swellingHigh contraction propertyPaper coatingCoatingsPolymer scienceGlass transition

Disclosed are paper coating latex, a method for preparing the same, and paper coating composition containing the same, characterized in that in the paper coating latex having a core-shell structure, the core is formed by the polymerization of monomer mixtures comprising 5 to 35 weight parts of ethylene unsaturated acid based on 100 weight parts of the core and the shell has glass transition temperature up to room temperature, lower than that of the core. The present invention has an effect of providing a high quality matte coated paper that has excellent printability such as ink drying rate, adhesion, etc., as well as low white paper gloss and improved print gloss by coating paper coating composition containing multi-layered paper coating latex having high swelling and contraction property on paper.

Owner:LG CHEM LTD

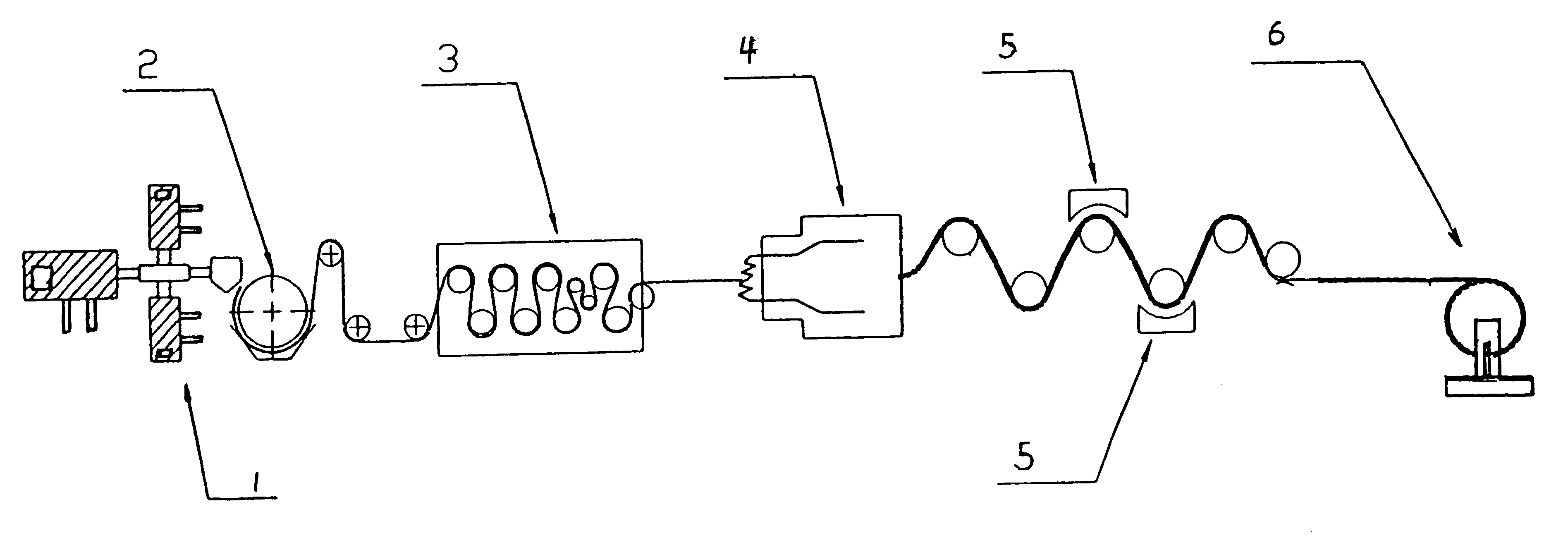

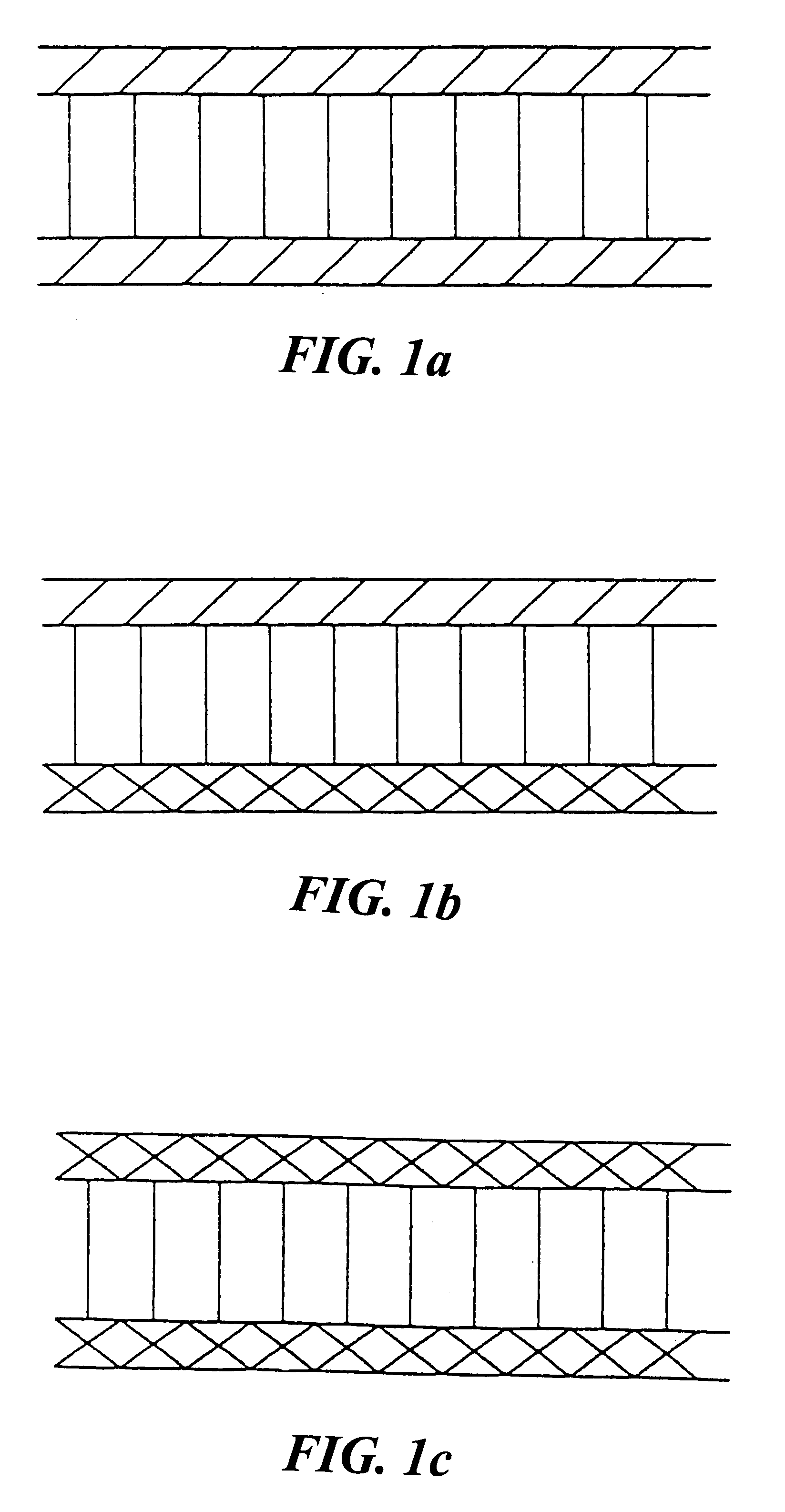

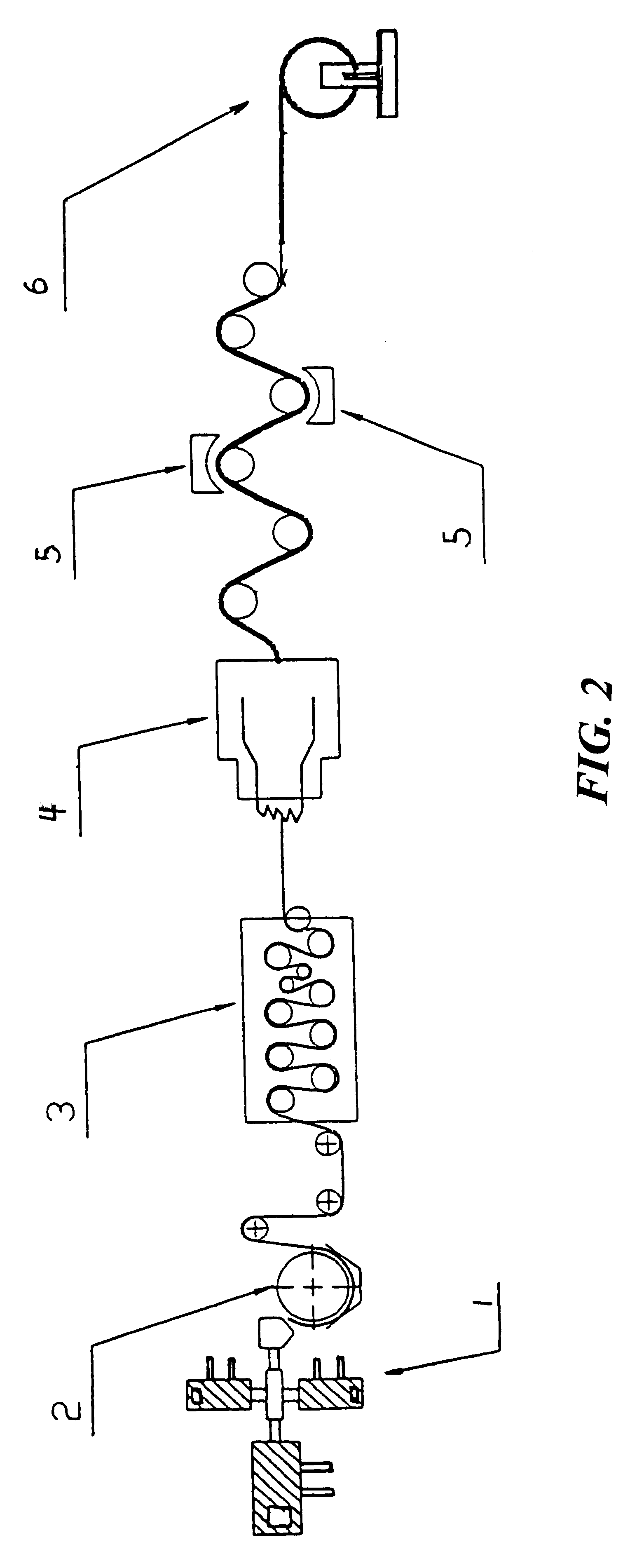

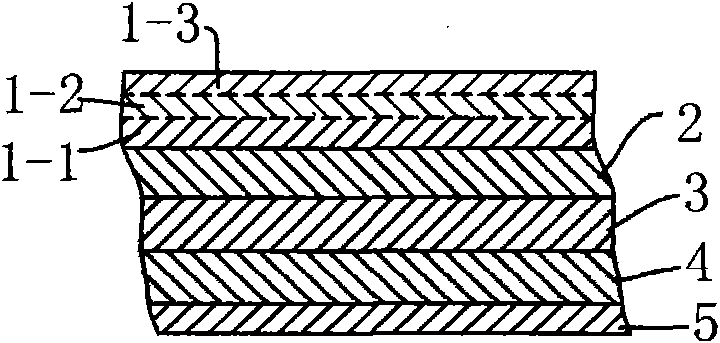

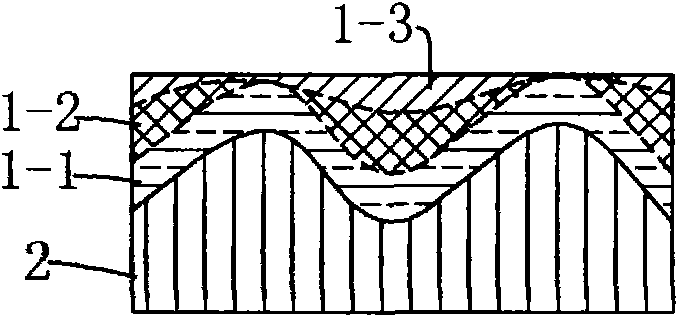

Process for producing a 3-layer co-extruded biaxially oriented polypropylene synthetic paper of thickness 25-250 mum

InactiveUS6364988B1High glossGood printabilityLamination ancillary operationsLayered product treatmentPolymer scienceBoPET

Disclosed is a process for producing a 3-layer co-extruded biaxially polypropylene (hereinafter as BOPP) synthetic paper of thickness 25-250 mum. More particularly, the invention relates to a process for producing a 3-layer biaxially-oriented PP synthetic paper by means of 3-layer co-extrusion wherein two different PP resin compositions are separately extruded by one primary and two secondary extruders first, and then are co-flowed by a same T-die to form a three layers coating sheet, and through cooling, biaxial orientation, corona treatment and winding to form a 3-layer co-extrusion synthetic paper of thickness 25-250 mum. The 3-layer structure of said 3-layer co-extrusion synthetic paper of thickness 25-250 mum can be made into three kinds, such as: paper sheet layer / foamed intermediate layer / paper sheet layer with double side paper sheet layer, paper sheet layer / foamed intermediate layer / resin layer with single side paper sheet layer and resin layer / foamed intermediate layer / resin layerwith double side high gloss resin layer.

Owner:NANYA PLASTICS CORP

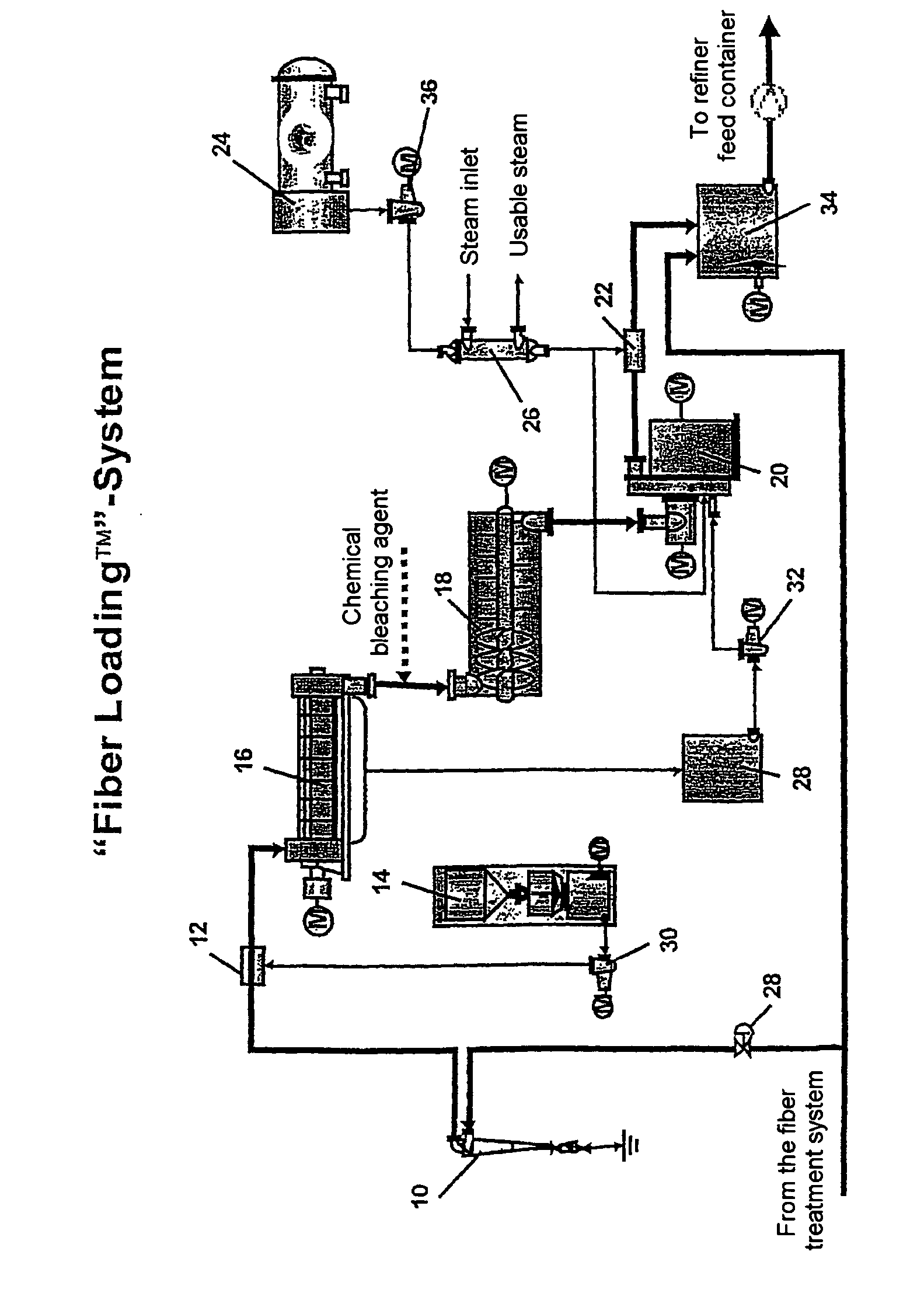

Method for preparing fibers contained in a pulp suspension

A method for one of preparing fibers contained in a pulp suspension and preparing coating color for coated papers including the steps of providing fibers in a suspension form having a predefined solids concentration; loading the fibers with a precipitation product; grinding the fibers with the precipitation product to thereby produce precipitation product particles having a dimension. The dimension being from approximately 0.05 μm to 5 μm. With an additional step of producing crystalline precipitation product particles using the precipitation product particles in an online process directly in a stock preparation line.

Owner:VOITH PATENT GMBH

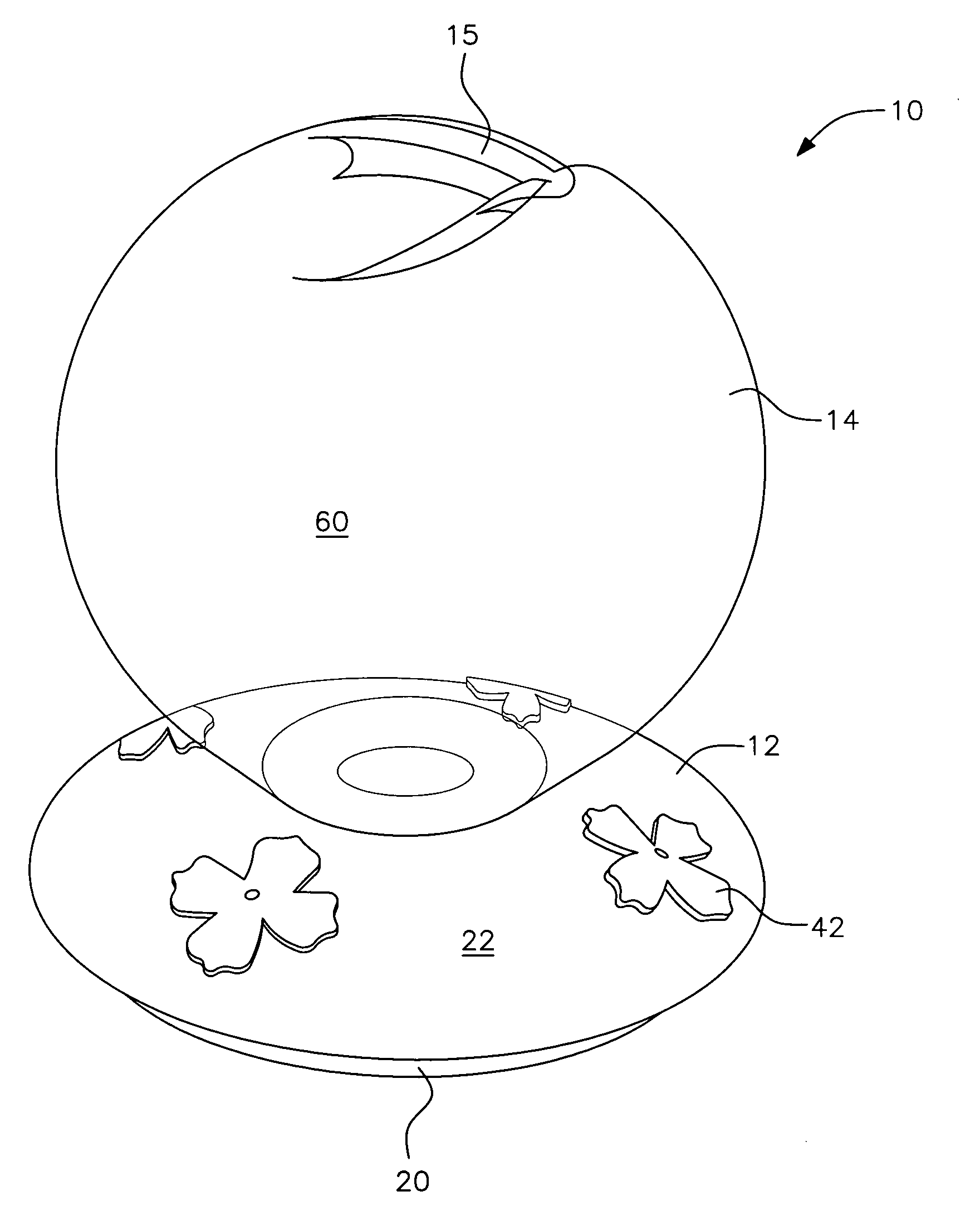

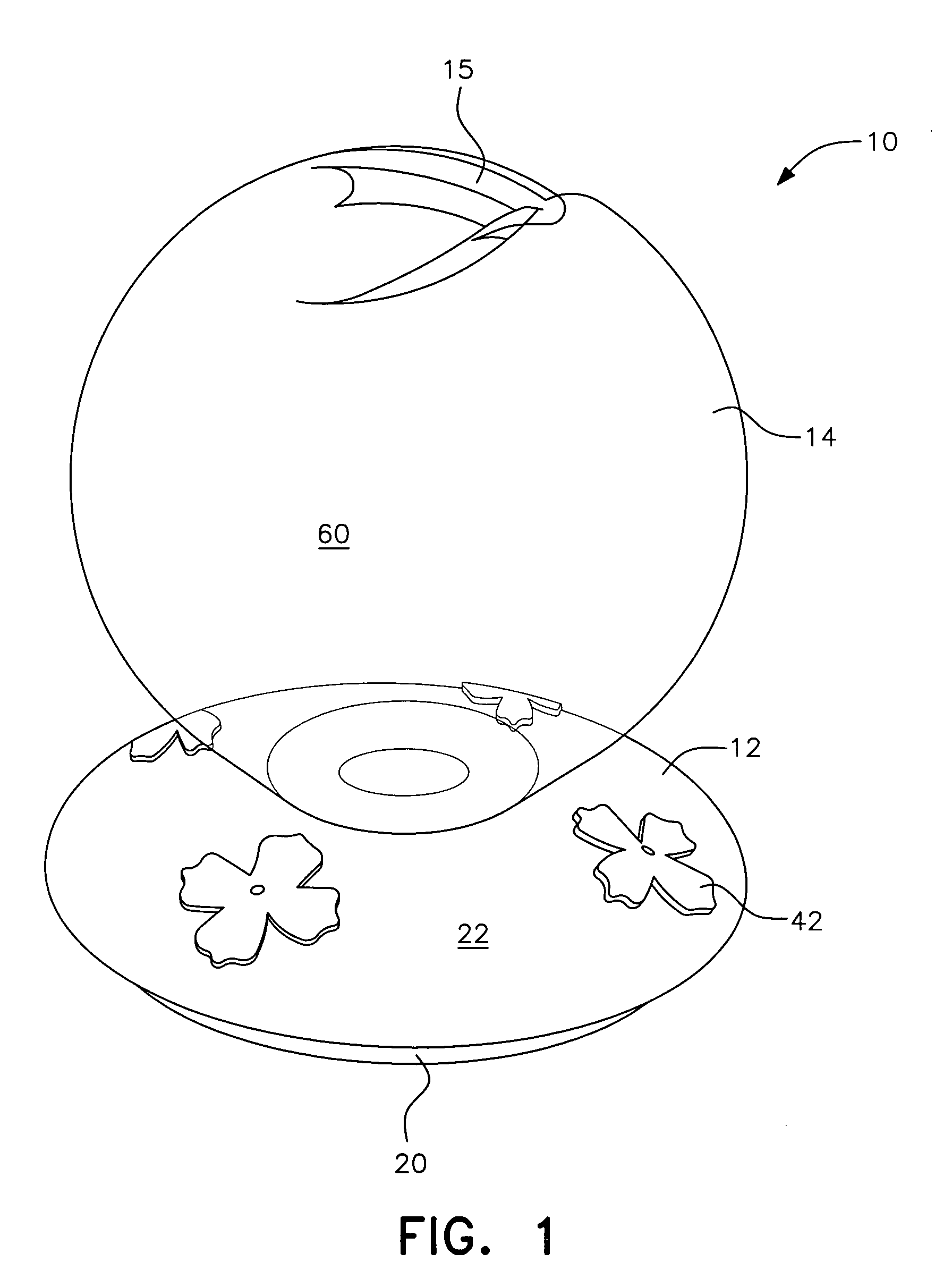

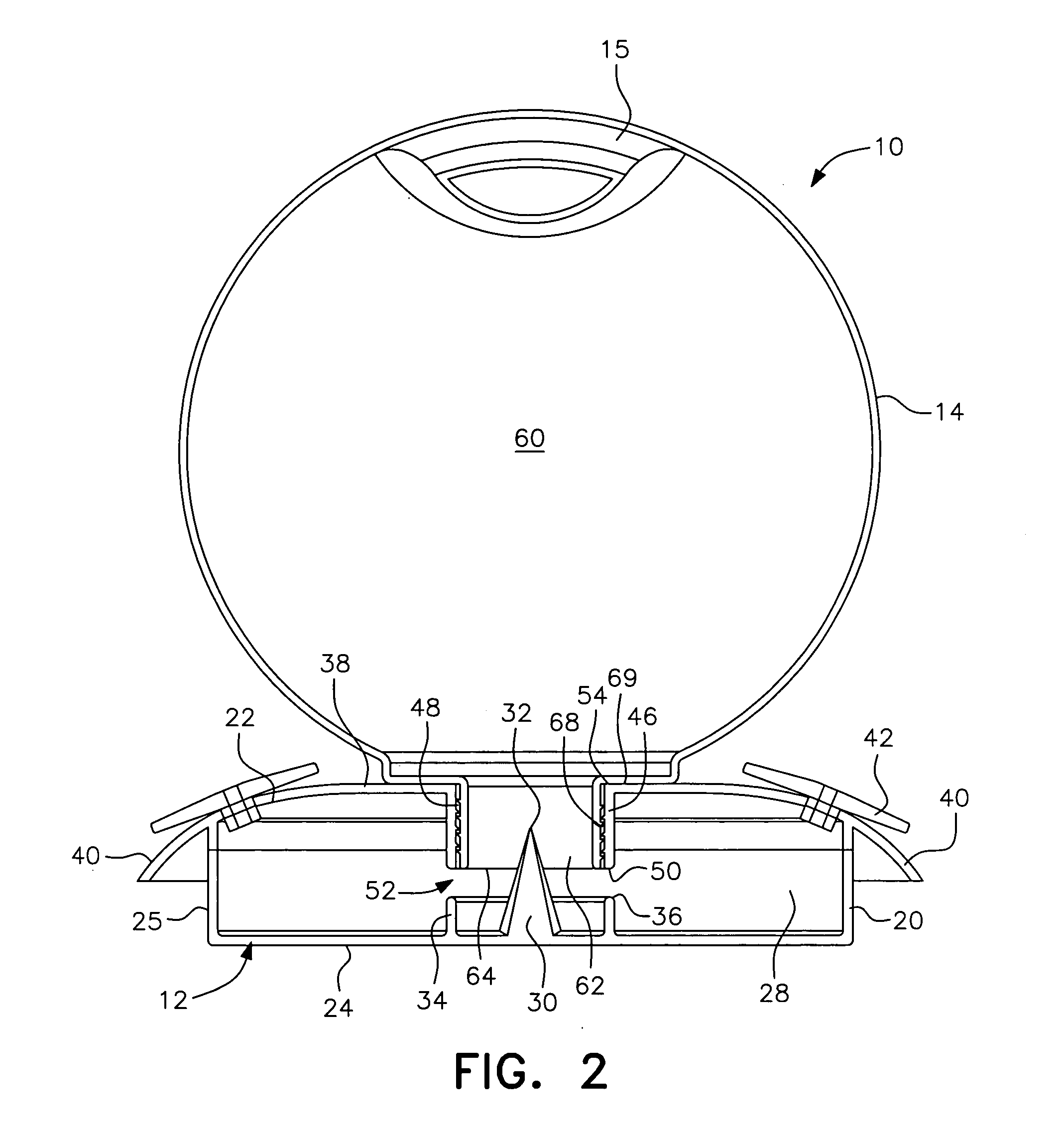

Hummingbird feeder with disposable reservoir and reusable base

ActiveUS20100251967A1Easy to store and protectEasy to removeAnimal watering devicesAvicultureEngineeringOpen structure

A liquid nectar hummingbird feeder has a reusable base with a feeding basin that receives a disposable cartridge containing a pre-filled volume of liquid nectar. The cartridge has a single bottleneck opening at a lower end which is initially sealed by a breakable seal in the form of a film layer of foil, coated paper stock, plastic or the like. The base includes a cartridge mounting and opening structure adapted to secure and open the cartridge bottleneck opening by rupturing the film layer seal to allow liquid nectar to flow from the cartridge into the feeding basin.

Owner:WOODSTREAM CORP

Method and composition for coating pre-sized paper with a mixture of a polyacid and a polybase

InactiveUS6197383B1Quality improvementHigh color fastnessCoatings with pigmentsWater-repelling agents additionHueWater resistant

The present invention features coating compositions and methods for improving the quality of images printed on a paper substrate. The novel coating compositions contain a coating agent comprising a mixture of a polyacid and a polybase. When applied to a sized paper substrate, the coating compositions provide a coated paper substrate that provides high quality printed images when printed with an ink containing a reactive dye having ionizable and / or nucleophilic groups capable of reacting with the coating agent. Images printed on a paper substrate coated with the coating composition of the invention are bleed-resistant, water-resistant (e.g., water-fast), and / or are characterized by an enhanced chroma and hue.

Owner:SRI INTERNATIONAL

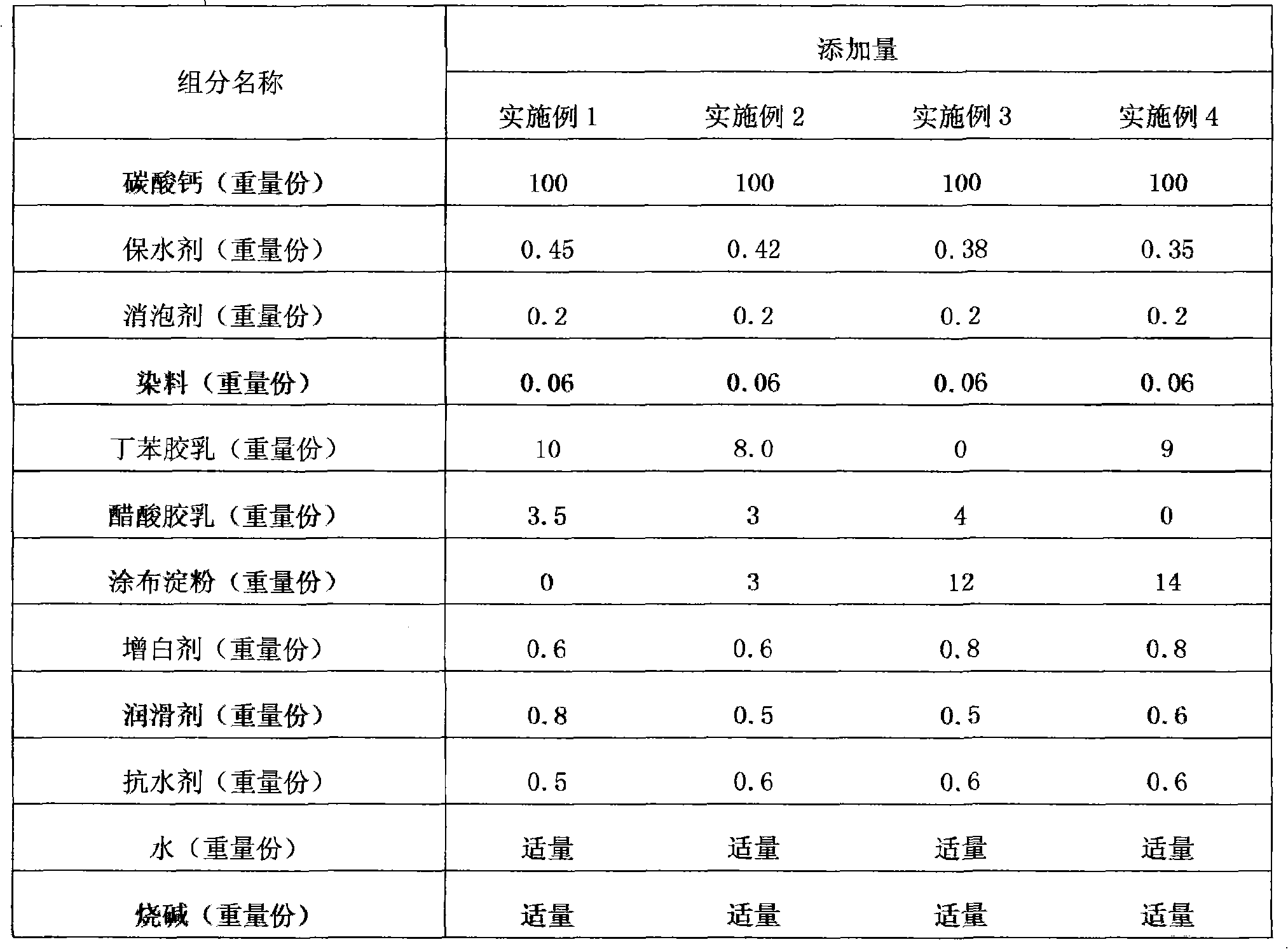

Coated white-top kraft liner board and manufacturing method thereof

ActiveCN101586317ARetention strengthIncrease productionNon-fibrous pulp additionCoatings with pigmentsSurface layerPaper sheet

The invention discloses a coated white-top kraft liner board, which comprises a coating layer, a surface layer, a lining, a bottom layer and a glue application layer, wherein the coating layer at least comprises two coating separated layers orderly arranged on the surface layer, and the coating separated layer positioned on the topmost has a level and smooth surface; the glue application layer is arranged on the surface of the bottom layer; and the ration of the coated white-top kraft liner board is between 120 and 220g / m, and the coating weight of the coating layer is between 12 and 40g / m. The invention also discloses a manufacturing method for the coated white-top kraft liner board. The invention adopts a compound coating method of film transfer coating and scraper coating, and the produced coated white-top kraft liner board well combines the advantages of a white-top kraft liner board and a high weight coated paper, has strong strength and good performance of indexes of lustrousness, smoothness and printability of the paper surface in the condition of low ration, and completely meets the requirement of advanced printing and packaging.

Owner:SHANDONG CENTURY SUNSHINE PAPER GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com