Gift wrap dispensing system

a gift wrapping and dispensing system technology, applied in the field of gift wrapping, can solve the problems of inability to be stored in the most readily available household storage area, high risk of significant damage, and inconvenient to manufacture, etc., and achieve the effects of convenient storage and handling, compact size, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

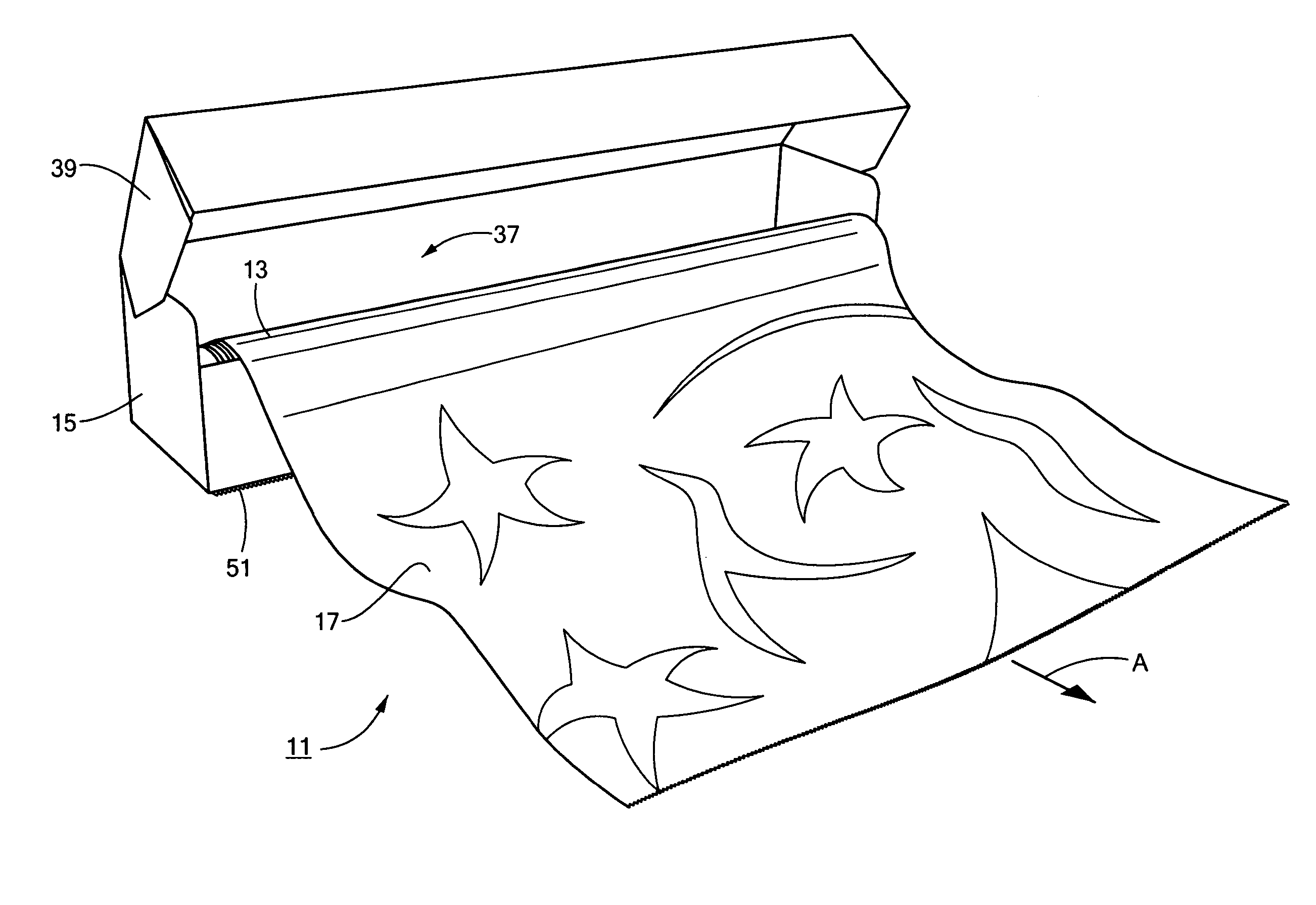

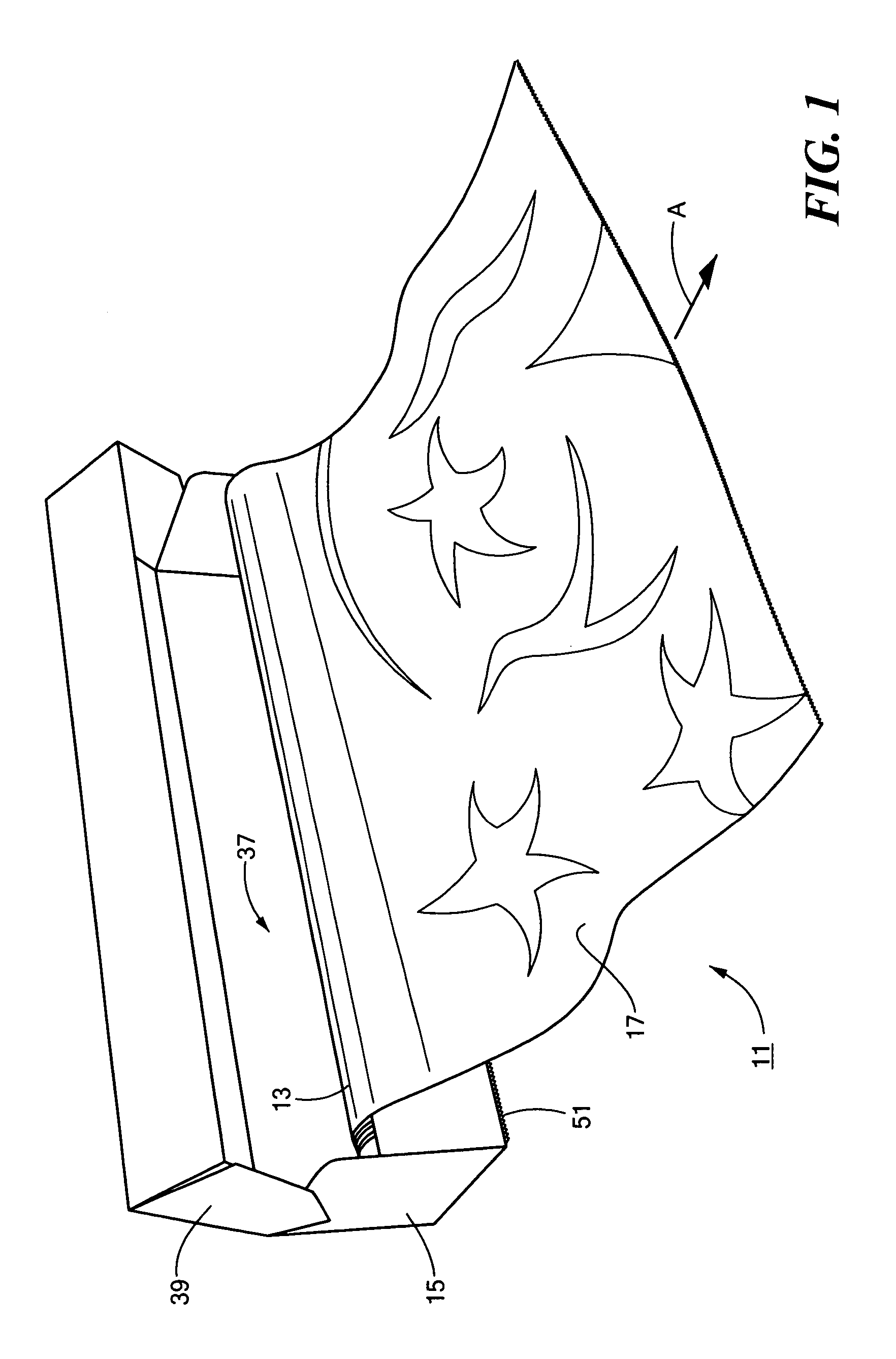

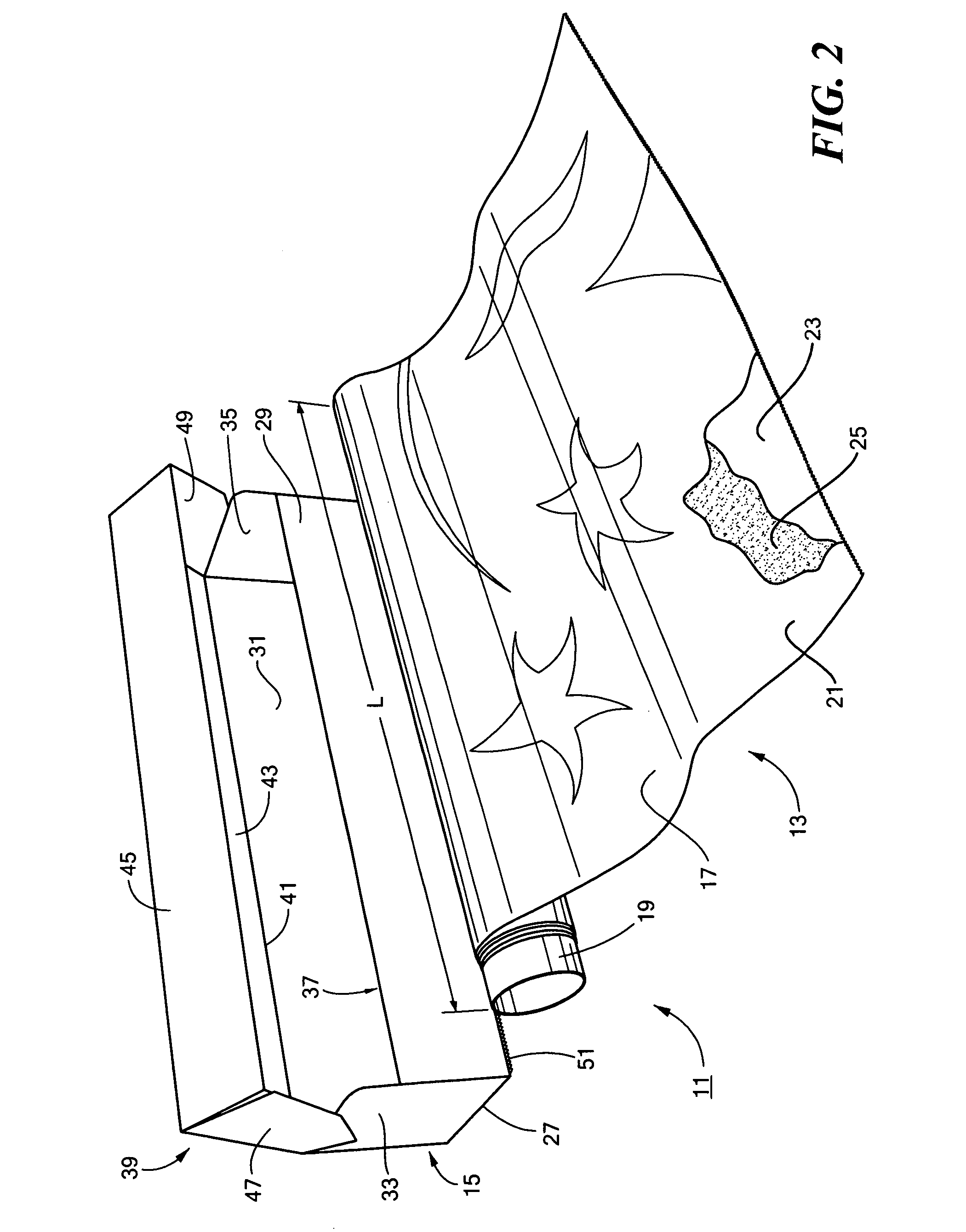

[0025] Referring now to FIGS. 1 and 2, there are shown perspective and exploded perspective views, respectively, of a novel system for dispensing gift wrap, the system being constructed according to the teachings of the present invention and identified generally by reference numeral 11.

[0026] Gift wrap dispensing system 11 comprises a roll of gift wrapping 13 that is retained within an enclosable carton 15.

[0027] As seen most clearly in FIG. 2, roll of gift wrapping 13 comprises a generally rectangular sheet of wrapping paper 17 that is wound onto a disposable tube 19. Tube 19 is preferably provided in the form of a hollow, cylindrical length of heavy paper or cardboard tubing which is suitably rigid so as to retain wrapping paper 17 in its rolled configuration.

[0028] It should be noted that the overall length L of roll of gift wrapping 13 is preferably in the range of approximately 10 inches to approximately 16 inches, which is considerably shorter in length than most convention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com