Patents

Literature

114 results about "Hot melt coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot melt coating is the application of a layer to a substrate by pre-melting the desired material and then allowing or forcing the material to cool, solidifying the layer. The process is widely used in industry, particularly for pressure-sensitive adhesives on thin substrates- self-adhesive labels.

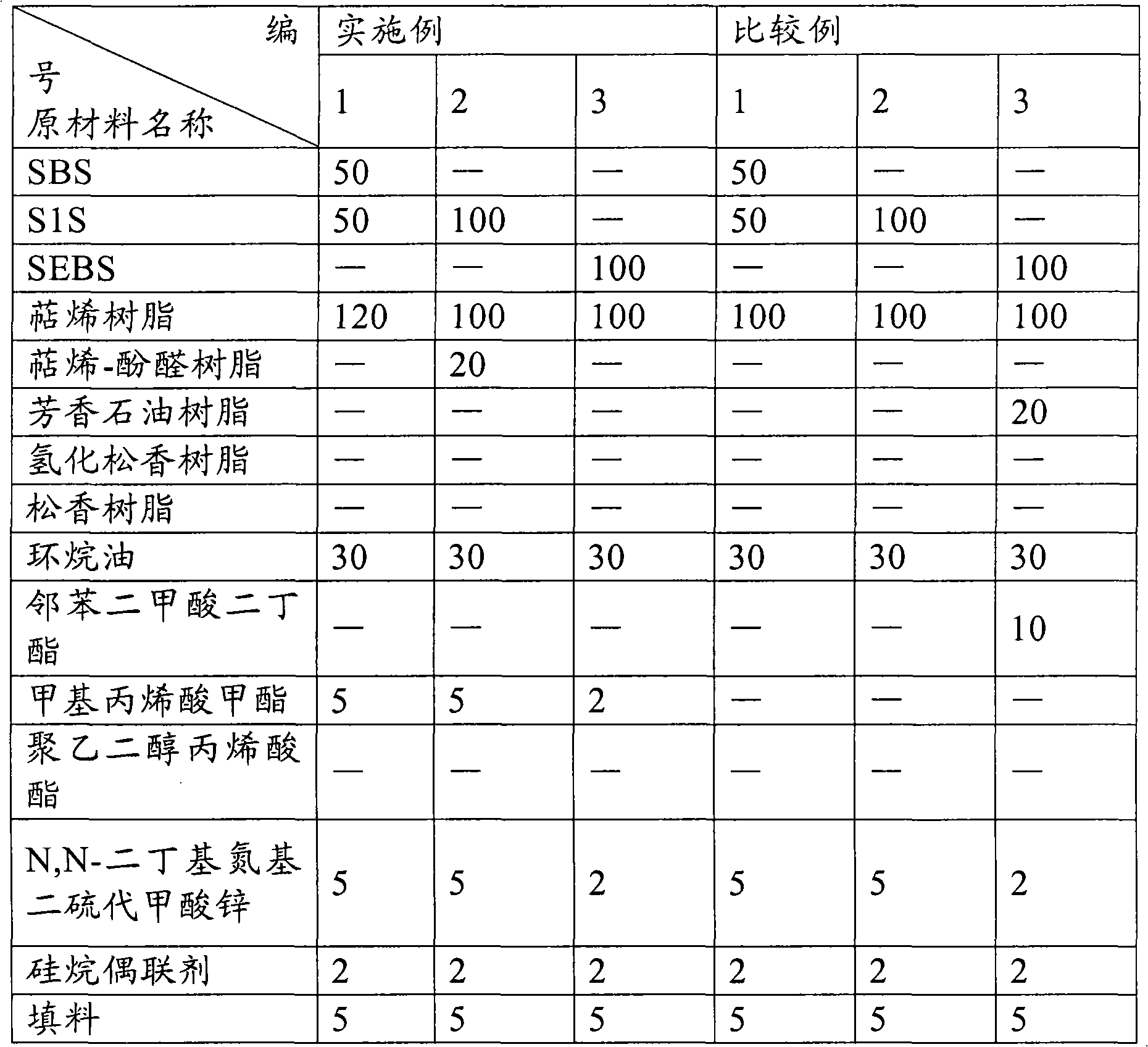

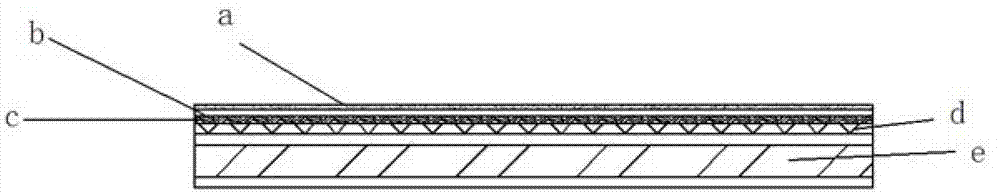

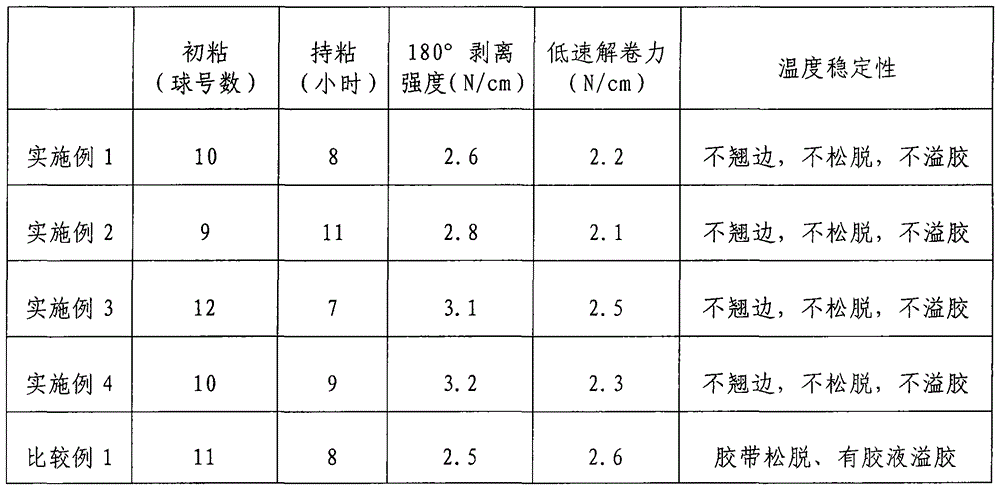

Preparation methods of hot melt pressure-sensitive adhesive and protective film as well as hot melt pressure-sensitive adhesive

ActiveCN102051149AImprove heat resistanceGood weather resistanceLiquid surface applicatorsNon-macromolecular adhesive additivesTectorial membranePolyolefin

The invention discloses preparation methods of a hot melt pressure-sensitive adhesive and a protective film as well as the hot melt pressure-sensitive adhesive. The preparation method of the hot melt pressure-sensitive adhesive comprises the following steps: adding thermoplastic elastomers, a tackifier, a plasticizer, an antiager, an antioxidant, a crosslinker, a filler and the like into a double-mixed column mixer, stirring, heating until the materials are melted down, and uniformly mixing to obtain the pressure-sensitive adhesive. The preparation method of the protective film comprises the following steps: directly pumping the melted and uniformly mixed pressure-sensitive adhesive into a coating roll of the a hot melt coating machine by a heat transfer pump, coating the pressure-sensitive adhesive onto one face of a polyolefin plastic film or thin plastic-coated paper, cooling, and rolling to obtain the protective film (paper). The hot melt pressure-sensitive adhesive disclosed by the invention can obtain good initial stickiness, cohesion and age stripping property by changing the different ratio of the thermoplastic elastomer as well as the variety and usage amount of the tackifier. The prepared polyethylene (PE) film substrate protective film has low interfacial tension, good initial stickiness, high cohesion and high temperature resistance, light resistance and weather resistance, and the comprehensive performance and product cost of the hot melt pressure-sensitive adhesive disclosed by the invention are better than those of the traditional solvent pressure-sensitive adhesive taking natural rubber as the main material.

Owner:KUNSHAN BYE MACROMOLECULE MATERIAL CO LTD

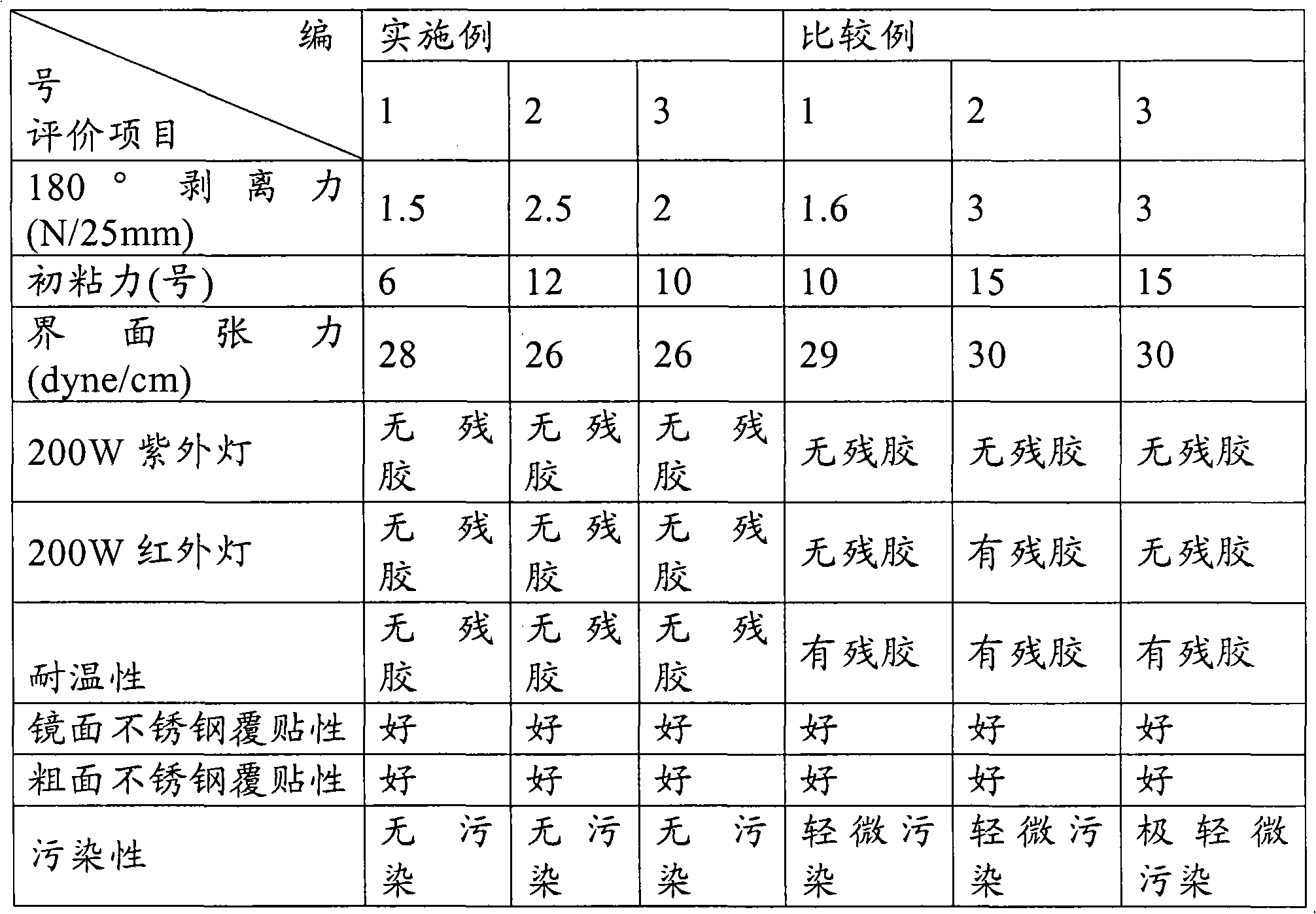

Manufacturing method for non-aqueous electrolyte secondary battery and used electrode thereof

InactiveCN1525591AFully automatedAvoid various problems caused by pasteElectrode rolling/calenderingFinal product manufactureHot melt coatingMaterials science

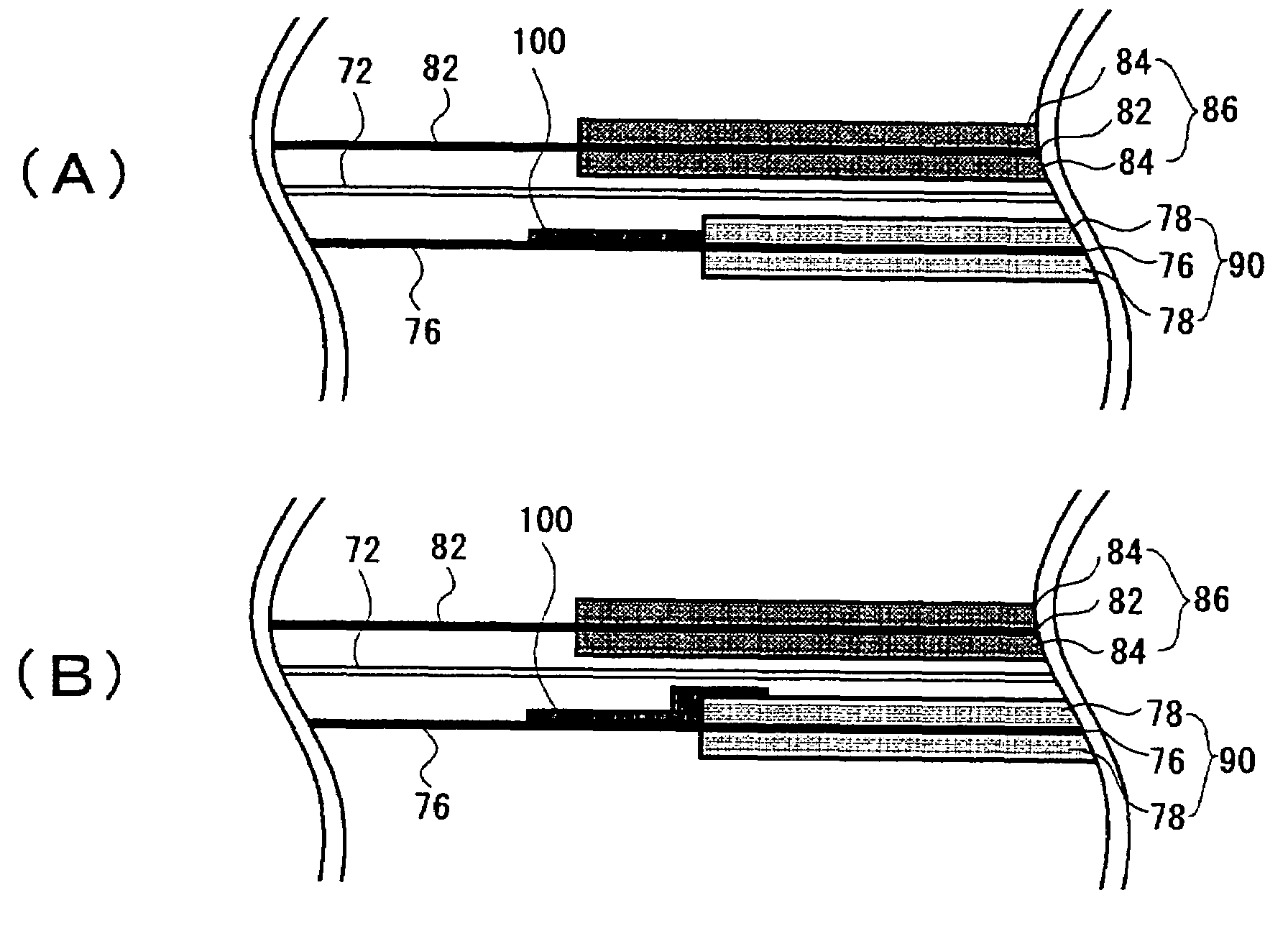

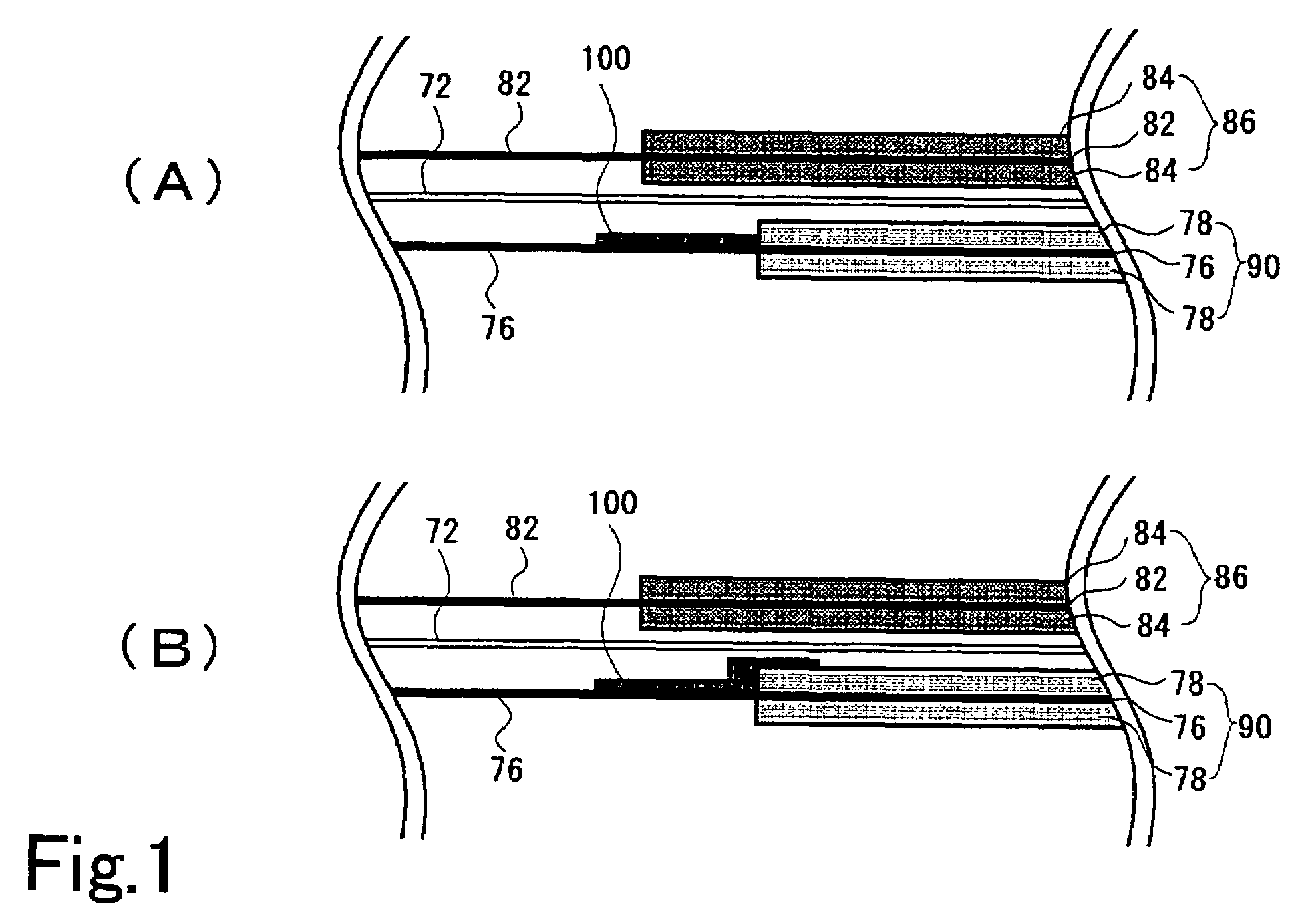

In this nonaqueous electrolyte secondary battery having a positive electrode 90 formed by applying a positive electrode mix 78 containing a positive electrode active material storing and releasing lithium ions onto a metallic core foil 76, the negative electrode 86 formed by applying a negative electrode mix 84 containing a negative electrode active material storing and releasing lithium ions onto a metallic core foil 82, and a spiral electrode body laminated and rolled through a separator 72, an insulating layer 100 is formed in the portion facing the portion coated with the negative electrode mix 84 in the negative electrode 86 through the separator 72, which is the portion uncoated with the positive electrode mix where the positive electrode mix 78 of the positive electrode 90 is not applied onto the metallic core foil 76, by a dry coating method, a thermal fusing method, or a hot melt coating method.

Owner:SANYO ELECTRIC CO LTD

Nonwoven fabric base gluing tapes and method for producing the same

ActiveCN101423739AImprove wear resistanceImprove noiseLiquid surface applicatorsFilm/foil adhesivesHot melt coatingThermoplastic elastomer

The invention relates to a non-woven fabric based adhesive tape and a producing method thereof. The adhesive tape is produced by directly spread-coating a thermoplastic elastomer hot-melt pressure-sensitive adhesive on terylene and nylon non-woven fabric substrates by a common hot melt coating machine. The thermoplastic elastomer hot-melt pressure-sensitive adhesive is prepared by heating and blending a block copolymer thermoplastic elastomer and auxiliary agents such as tackifying resin, softening agent, age inhibitor, filler, crosslinking agent,and colorant according to certain proportion. The non-woven fabric based adhesive tape has the advantages that the non-woven fabric based adhesive tape has good mechanical property and adhesion performance, better temperature stability, wear resistance, and noise absorption performance, and good manual tear-out performance, also has simple and convenient production process, no environmental pollution, and lower cost, and is suitable for the covering and binding of cable bundles, in particular for the covering and binding of cable bundles in automotive bodies.

Owner:HEBEI YONGLE TAPE CO LTD

Non-aqueous electrolyte secondary battery and manufacturing methods of an electrode used therein

InactiveUS7258948B2Reduce production efficiencyLowering possible occurrenceElectrode rolling/calenderingFinal product manufactureHot melt coatingEngineering

To provide a non-aqueous electrolyte secondary battery adapted to prevent an internal short circuit between an positive electrode and a negative electrode caused by the penetration of electrically conductive micro particles through a separator, which occurs when winding up electrodes, and manufacturing methods of an electrode used therein, whereby the non-aqueous electrolyte secondary battery having a coiled electrode assembly is formed through the multilayer winding of an positive electrode 90 having a metallic collector 76 coated with an positive electrode mixture 78 composed of an positive electrode active material that occludes and liberates lithium ions, a negative electrode 86 having a metallic collector 82 coated with a negative electrode mixture 84, composed of a negative electrode active material that occludes and liberates lithium ions, and a separator 72 interposed between the positive electrode and the negative electrode, wherein the positive electrode 90 has an insulating layer 100 formed by means of the dried coating method, the heat seal tape method, or the hot melt coating method on a portion of the metallic collector 76 which is uncoated with the positive electrode mixture 78 and opposed to the negative electrode 86 coated with the negative electrode mixture 84, through the separator 72.

Owner:SANYO ELECTRIC CO LTD

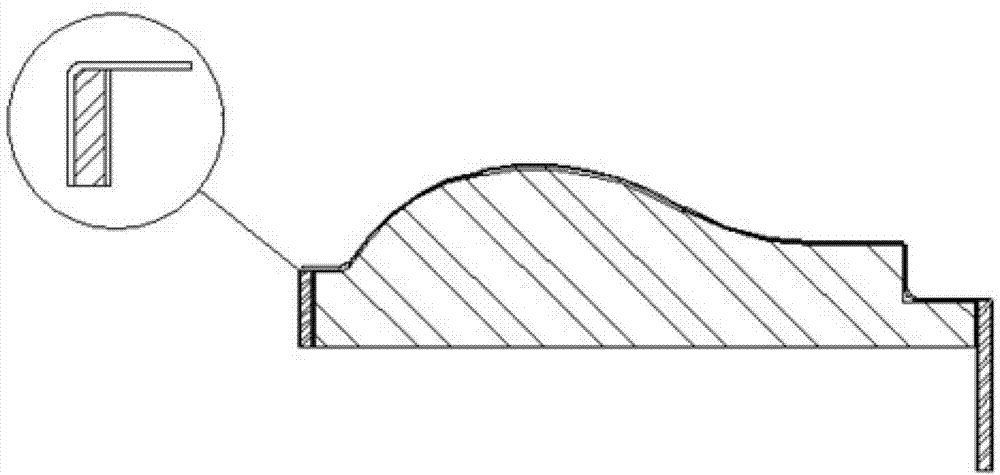

UV (ultraviolet) paint veneering plywood and method for coating special-shaped base material

ActiveCN103395102ASolve bottlenecksIncrease diversityWood veneer joiningWood layered productsHot melt coatingWoven fabric

The invention discloses UV (ultraviolet) paint veneering plywood and a method for coating a special-shaped base material. The UV paint veneering plywood for coating the special-shaped base material comprises heatable and bendable plywood, a non-woven fabric, a wood veneer, a UV paint surface and a PET (polyethylene terephthalate) protective film. A coating groove which corresponds to the special-shaped base material is formed in the lower surface of the heatable and bendable plywood, hot melt coating adhesive is arranged in the coating groove, the heatable and bendable plywood is adhered on the special-shaped base material by the hot melt coating adhesive, the non-woven fabric is laminated between the upper surface of the heatable and bendable plywood and the lower surface of the wood veneer, the UV paint surface is arranged on the upper surface of the wood veneer, and the PET protective film is arranged on the UV paint surface. The UV paint veneering plywood and the method have the advantages that various shapes can be formed according to different special-shaped base materials by the aid of a coating technology of the environment-friendly UV paint veneering plywood, so that the product diversity and the high efficiency are improved for finished wood sections in the decoration and household industries.

Owner:HUIZHOU CHENGPIN WOOD SECTION BAR TECH

UV-cured acrylic esters hot-melt pressure sensitive adhesive and preparation method thereof

InactiveCN101358118ALow costReduce energy consumptionEster polymer adhesivesIsooctyl acrylateHot melt coating

The present invention provides an ultraviolet-curing acrylic hot-melt pressure-sensitive adhesive, which is characterized in that the solid content is 100 percent and that the viscosity is between 2000CPS and 3500 CPS when the environmental temperature is 80 DEG C. The material formula of the ultraviolet-curing acrylic hot-melt pressure-sensitive adhesive contains 2-ethylhexyl acrylate, butyl acrylate, winyl acetic ester, acrylic acid, molecular weight regulator, azodiisobutyronitrile, viscosity regulator and photic curing agent. The present invention also provides a method for preparing the ultraviolet-curing acrylic hot-melt pressure-sensitive adhesive. The ultraviolet-curing acrylic hot-melt pressure-sensitive adhesive provided by the present invention, which helps to reduce cost and energy consumption and is applicable to an ordinary hot melt coating machine, has the advantages of high curing rate, good stability and low shrinkage rate.

Owner:SHANGHAI ZEAFEE DIGITAL INKJET COMPOSITE MATERIALCO

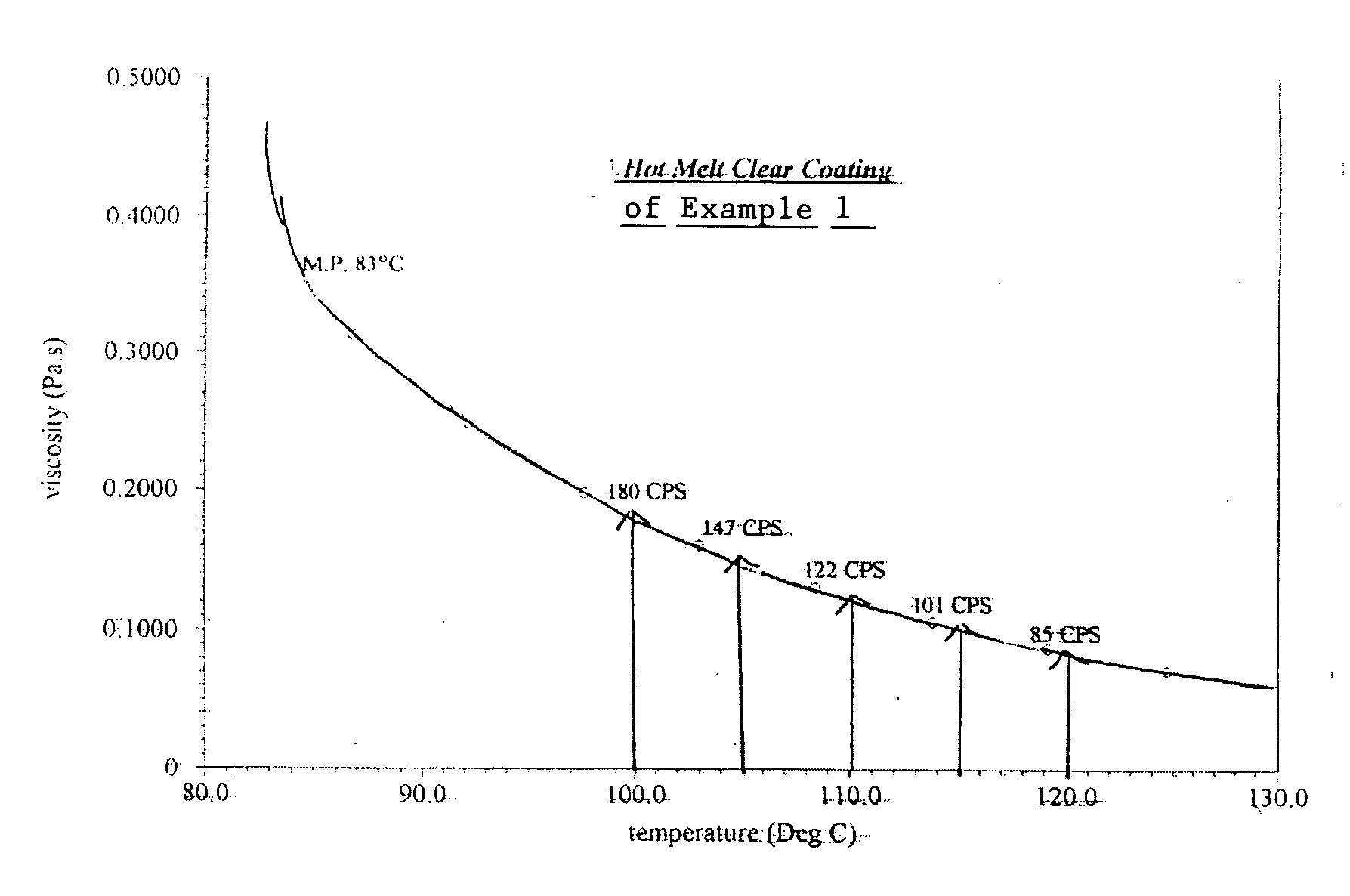

Hot melt coating compositions and methods of preparing same

Solvent-free hot melt coating compositions composed of a solid linear alcohol, a thermoplastic binder, and a wax which are solid at room temperature, with a melting point of about 75° C. or greater, that when heated to a temperature between about 90° C. and about 135° C., forms a molten coating composition having a viscosity between 100 cps and 1200 cps and method for preparing same.

Owner:SUN CHEM CORP

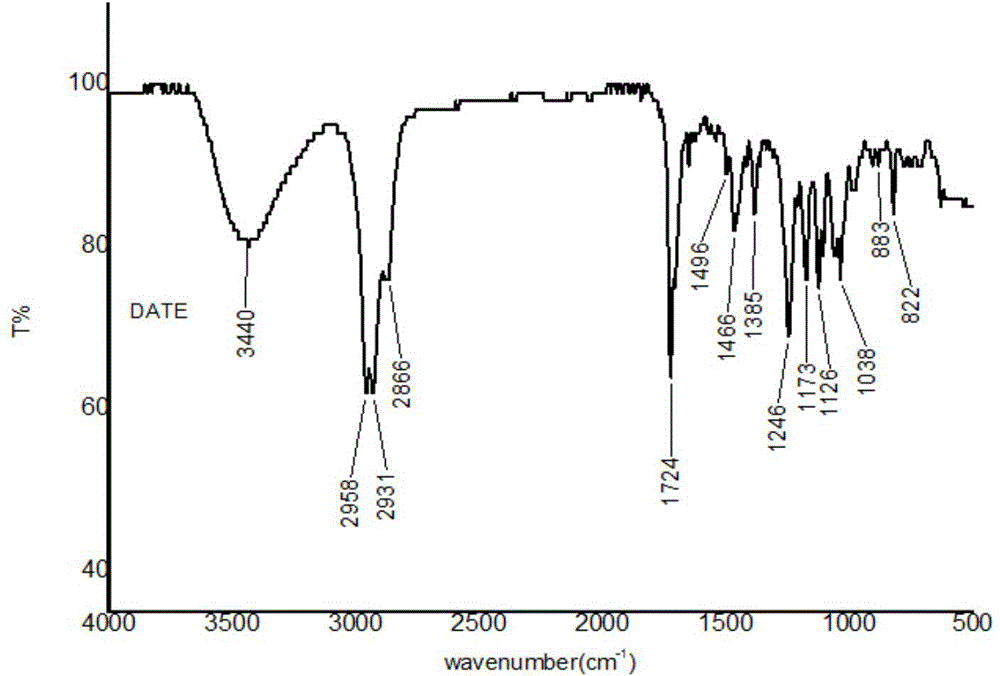

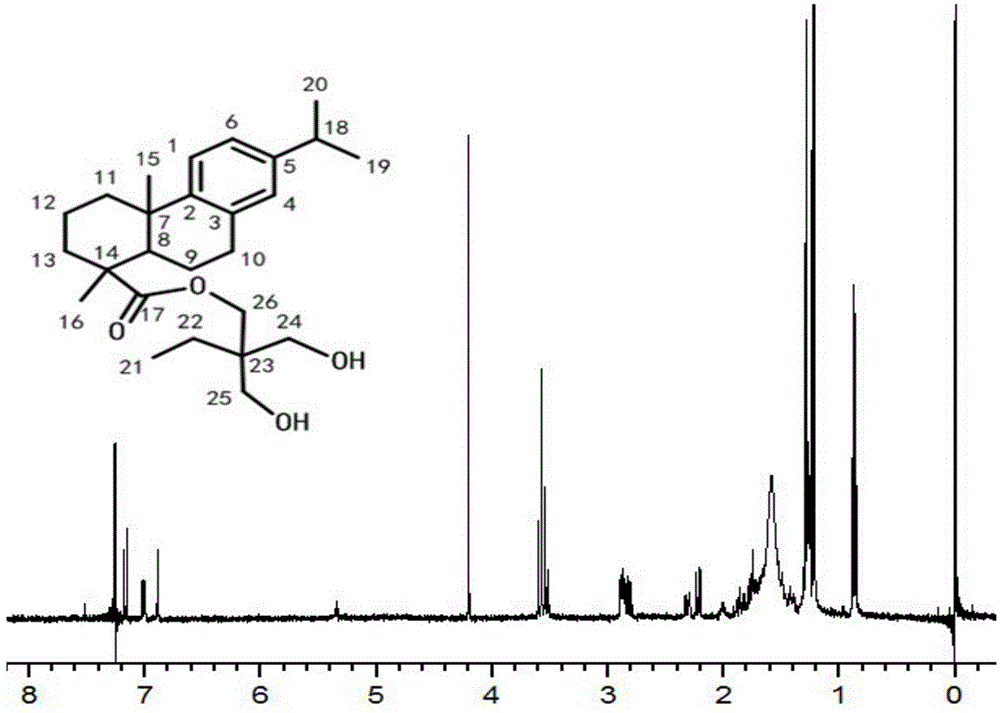

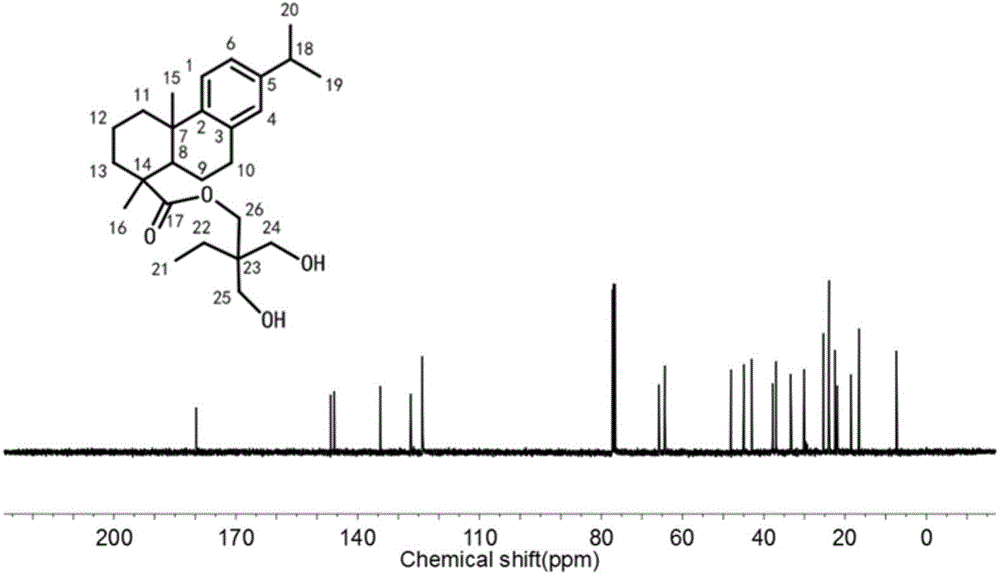

Rosin triol ester as well as preparation method and application thereof

InactiveCN104693024ABiodegradableLow costOrganic compound preparationTransportation and packagingTrimethylolpropaneTriol

The invention discloses a rosin triol ester and a preparation method therefore. The chemical name of the rosin triol ester is trimethylolpropane dehydroabietyate. The preparation method of the rosin triol ester comprises the following steps: by taking dehydroabietic acid and trimethylolpropane as the raw materials, EDC / DMAP as the catalysts, and any one of methylene chloride, tetrahydrofuran and N,N-dimethyl formamide as the solvent, performing an esterification reaction at normal temperature to synthesize the trimethylolpropane dehydroabietyate. The esterification method is completed in one step; the steric hindrance can be effectively overcome; the yield is high; the reaction is performed at room temperature so that the energy consumption can be reduced; the byproducts are soluble in water and easy to purify; the smell is light and few three wastes are generated; and the solvent selection range is wide. The ester prepared by use of the method is wide in use, and can be used as plasticizers and modifiers of various resins, excellent adhesives for pressure-sensitive and thermosensitive adhesive tapes, hot melt coatings, surface activators and pharmaceutical vectors.

Owner:GUANGXI UNIV FOR NATITIES

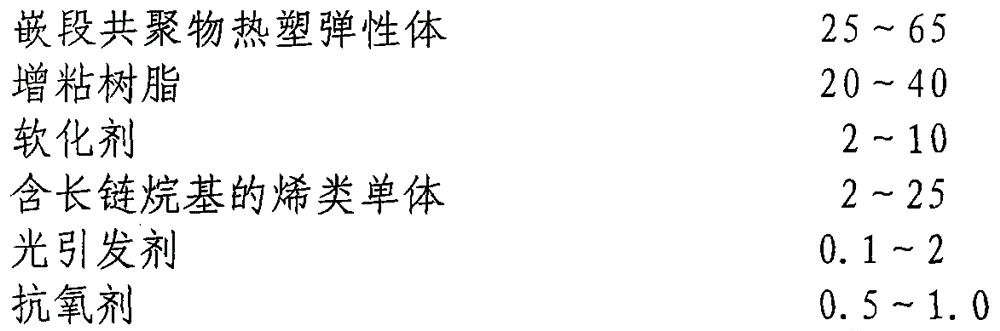

Automotive wire harness cloth-based adhesive tape manufactured with UV-curable hot-melt pressure-sensitive adhesive, and manufacturing technology thereof

ActiveCN104927697AAdhesive tape has good temperature resistanceImprove temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesEnvironmental resistanceManufacturing technology

The invention relates to a novel environment-friendly, temperature-resistant and wear-resistant cloth-based adhesive tape manufactured with ultraviolet (UV) curable hot-melt pressure-sensitive adhesive, and a manufacturing technology thereof. According to the pressure-sensitive adhesive tape, a novel UV-curable hot-melt pressure-sensitive adhesive is directly spread on a terylene fabric or nonwoven fabric substrate with a hot-melt coating machine equipped with a UV lamp; and the pressure-sensitive adhesive is subjected to crosslinking curing under UV irradiation, such that the adhesive tape is obtained. The UV-curable hot-melt pressure-sensitive adhesive is obtained by heating and blending certain proportions of a block copolymer thermoplastic elastomer, tackifying resin, a softener, an olefinic monomer containing long-chain alkyl, and auxiliary agents such as a photo-initiator and an antioxidant. The cloth-based adhesive tape has excellent mechanical performance, adhesive performance, high-temperature resistance and wear resistance. The adhesive tape also has the advantages of low hot-melt coating temperature, simple manufacturing process, and no environment pollution. The adhesive tape is suitable for coating and bundling cable bundles at different parts in an automotive body. The adhesive tape can especially satisfy application requirements at high-temperature resistant parts at the engine inside the automotive. A long-term temperature resistance grade of the adhesive tape reaches 125 DEG C.

Owner:HEBEI YONGLE TAPE CO LTD

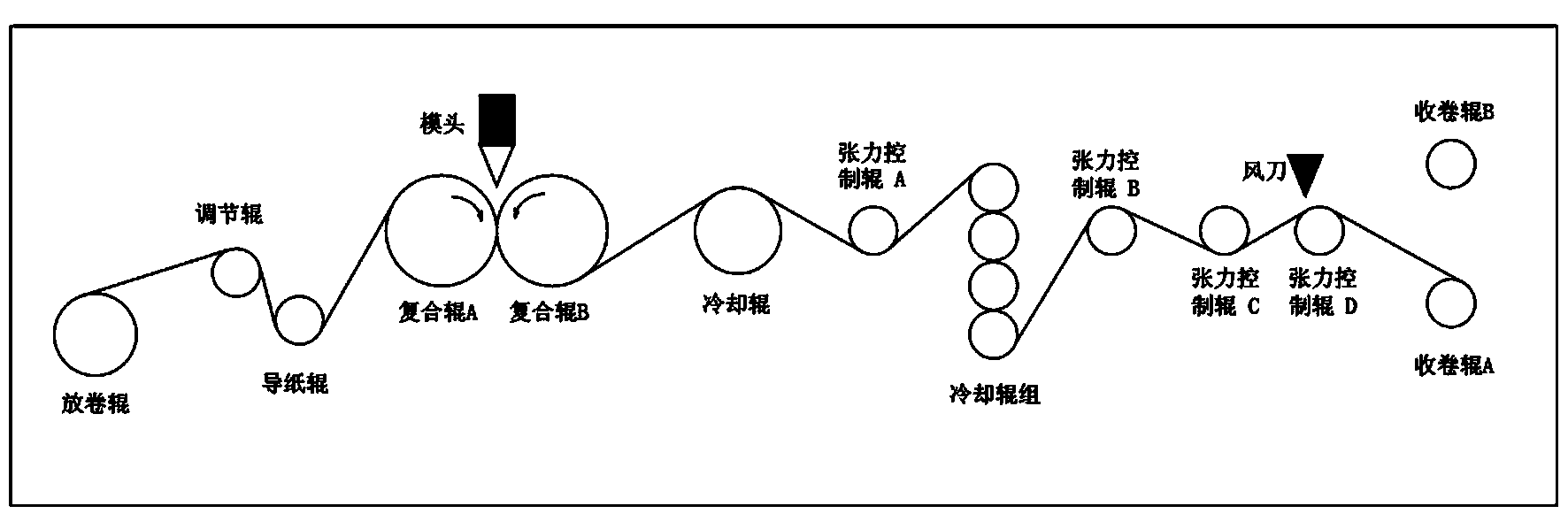

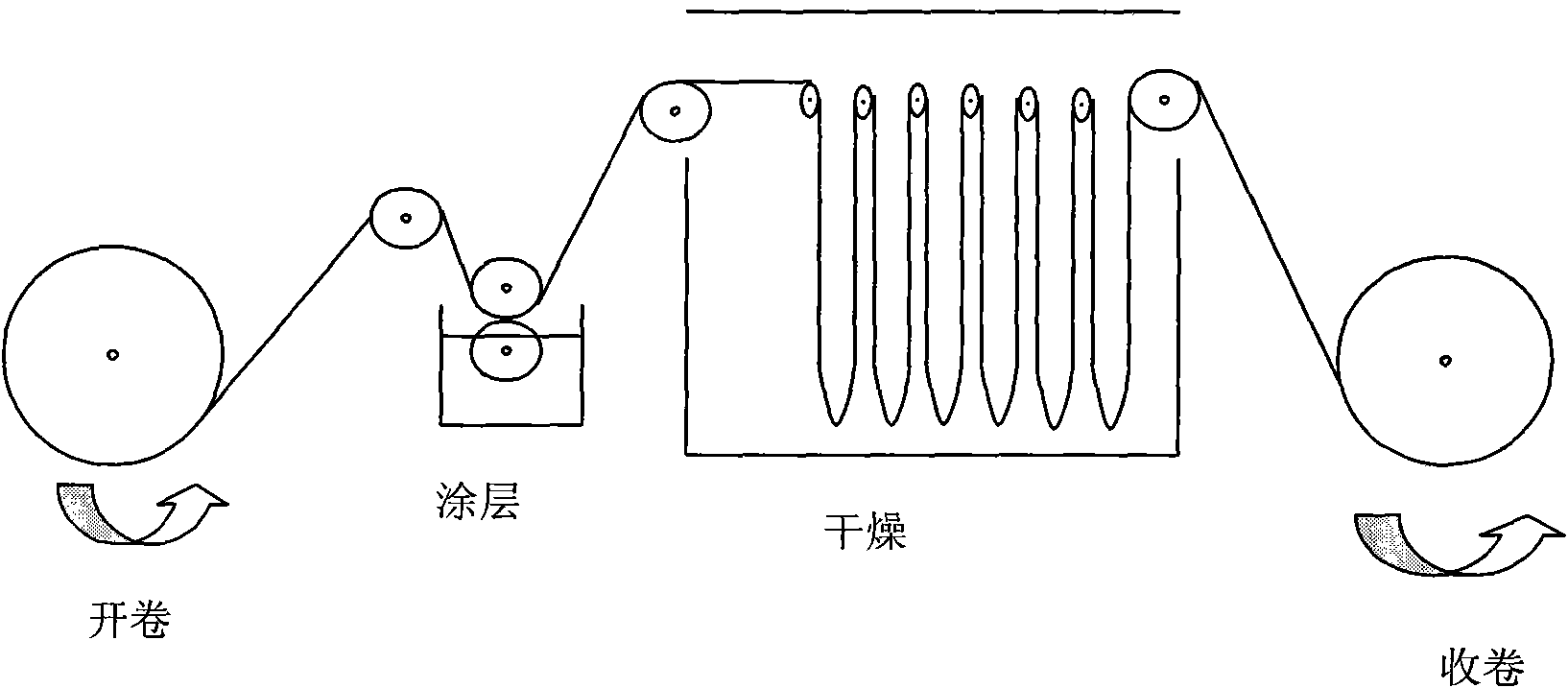

Paperless hot melting coating device and technology

ActiveCN103506250ASolve the problem of energy consumptionSolution areaLiquid surface applicatorsCoatingsHot melt coatingHigh energy

The invention provides a paperless hot melting coating device which comprises a rack and a plurality of rolls, wherein the rolls are connected with one another by a conveying device; the rolls include an unwinding roll, an adjusting roller, a paper guide roll, a laminating roll A, a laminating roll B, a cooling roll, a tension control roll A, a cooling roll group, a tension control roll B, a tension control roll C, a tension control roll D and a winding roll A or a winding roll B which are sequentially connected with the rack; the laminating rolls are connected with a die head; and an air knife is arranged on the tension control rolls. The invention further provides a paperless hot melting coating technology. Compared with the traditional hot melting coating technology, the paperless hot melting coating technology solves the problems of high release paper cost, more release transfer procedures, high energy consumption and large equipment floor area, and has the advantages of high technology speed, high finished product rate, small equipment floor area and low cost.

Owner:GUANGDONG YETOM NEW MATERIALS CO LTD

Fabric-based adhesive tape produced from UV-cured hot-melt pressure-sensitive adhesive and applicable to automobile wiring harness and production technology thereof

InactiveCN108285749AAdhesive tape has good temperature resistanceImprove temperature resistanceNon-macromolecular adhesive additivesInksPolyesterManufacturing technology

The invention relates to a novel environment-friendly, temperature-resistant and wear-resistant fabric-based adhesive tape produced from an ultraviolet (UV)-cured hot-melt pressure-sensitive adhesiveand a production technology thereof. The pressure-sensitive adhesive tape is produced by directly coating a polyester fabric or non-woven fabric base material with the novel UV-cured hot-melt pressure-sensitive adhesive by using a hot-melt coating machine equipped with an UV lamp, and curing the pressure-sensitive adhesive by UV irradiation in a crosslinking manner; the UV-cured hot-melt pressure-sensitive adhesive is prepared by heating and blending a block copolymer thermoplastic elastomer, tackifying resin, a softening agent, a long-chain alkyl-containing vinyl monomer, a photoinitiator, anantioxidant and other auxiliary agents according to a certain ratio. The fabric-based adhesive tape not only has excellent mechanical properties, adhesive performance, high temperature resistance andfriction resistance, but also is relatively low in hot-melt coating temperature, simple and convenient in production technology and free of environment pollution, is applicable to packaging and bundling of cable bundles in different parts of an automobile body, particularly can meet the using requirements on high temperature-resistant parts of an engine inside an automobile, and has the long-termtemperature resistance level of 125 DEG C.

Owner:TIANJIN PUZHENG POWER TECH CO LTD

Polyurethane moisture-curing hot melt coating glue, as well as preparation method and application thereof

InactiveCN102660217AEnvironmentally friendlyNo drying processPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention belongs to the technical field of a chemical adhesive, and relates to a polyurethane moisture-curing hot melt coating glue used for covering a special-shaped surface of furniture and a decoration component, and a preparation method of the polyurethane moisture-curing hot melt coating glue. The polyurethane moisture-curing hot melt coating glue comprises the raw materials based in parts by weight: polyester polyol mixture, diisocyanate, plasticizer, chain extender and tackifying resin, wherein the relative molecular mass of the polyester polyol mixture is 2000-8000, and consists of trade names including PHL-1600, PH-2000, CMA-1044 and CMA-44; and the diisocyanate is selected from one or more of benzhydryl diisocyanate, toluene diisocynate and hexamethylene diisocyanate. The polyurethane moisture-curing hot melt coating glue does not contain any organic solvent, has the solid content of 100%, is rapid in moisture curing and simple in operation, is higher in final bonding strength by crosslinking curing, is compact in binding, and can show the artistic aesthetic feeling of the original work delicately.

Owner:舒跃辉

Novel environmentally-friendly lining paper for cigarettes

InactiveCN103981773AHigh barrierChange appearanceSpecial paperPaper/cardboardHot melt coatingMicrocrystalline wax

The invention discloses a novel environmentally-friendly lining paper for cigarettes. The novel environmentally-friendly lining paper comprises a lining paper (1) and a barrier layer (2) coating the surface of the lining paper (1), a microcrystalline wax coating coats between the lining paper (1) and the barrier layer (2), and the barrier layer (2) is an aqueous polyvinyl alcohol layer. The novel environmentally-friendly lining paper utilizes microcrystalline wax, does not contain any solvent, has no pollution, is nuisanceless, has a fast curing rate and high operationality, only needs a hot melt coating process, produces viscidity by cooling and does not produce VOC residues.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

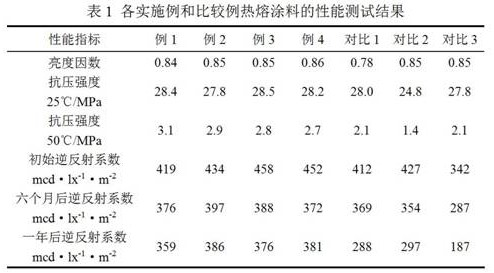

High-brightness reflective hot melt coating material and preparation method thereof

ActiveCN109370323AImprove wear resistanceImprove thermal stabilityLuminescent paintsReflecting/signal paintsCrack resistanceRare earth

The invention provides a high-brightness reflective hot melt coating material and a preparation method thereof. The high-brightness reflective hot melt coating material is prepared from the followingmain components in parts by weight: 10 to 15 parts of an EVA (Ethylene Vinyl Acetate) hot melt adhesive, 3 to 5 parts of SEBS (Styrene Ethylene Butadiene Styrene Copolymer), 5 to 10 parts of a reflective material, 10 to 20 parts of titanium dioxide, 10 to 30 parts of filler, 1 to 3 parts of nano strontium aluminate fluorescent powder and 0.5 to 1 part of a rare-earth luminescent material. The high-brightness reflective hot melt coating material provided by the invention is capable of remarkably increasing the wear resistance, the thermal stability and the cracking resistance on the premise that other properties of the high-brightness reflective hot melt coating material are not reduced; the nano strontium aluminate fluorescent powder and the rare-earth polymer luminescent material are cooperatively used in the high-brightness reflective hot melt coating material, the rare-earth polymer luminescent material is capable of absorbing and accumulating light rays exposed by headlights and converting the light rays into visible light under the environment of poor light rays at night or in rainy days, and the rare-earth polymer luminescent material is in combined action with the fluorescent powder and glass beads, so that the luminescent intensity is ensured, and the visibility is enhanced.

Owner:浙江欧路德交通科技有限公司

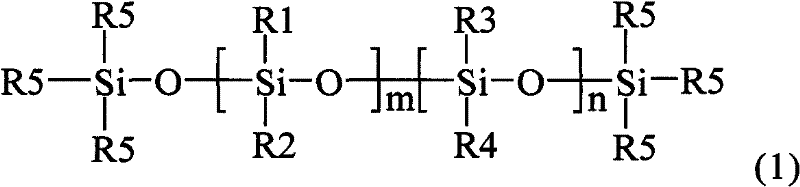

Electron beam cured, nonfunctionalized silicone pressure sensitive adhesives

InactiveCN102203190ASynthetic resin layered productsPretreated surfacesHot melt coatingSilicone fluid

Methods of preparing silicone pressure sensitive adhesives are described. The methods include electron beam curing nonfunctionalized silicone materials, e.g., silicone fluids and gums. Hot melt processing the nonfunctionalized silicone materials prior to electron beam crosslinking, and crosslinked adhesives prepared by such methods are also described. Adhesives prepared by hot melt coating and electron beam curing nonfunctionalized silicone materials and adhesive articles incorporating such adhesives are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

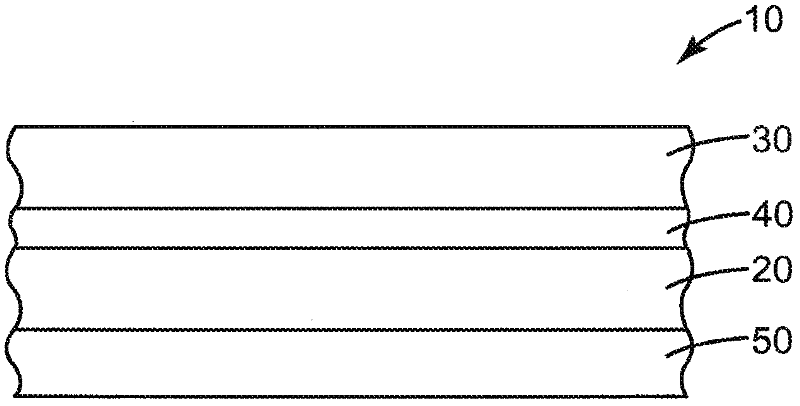

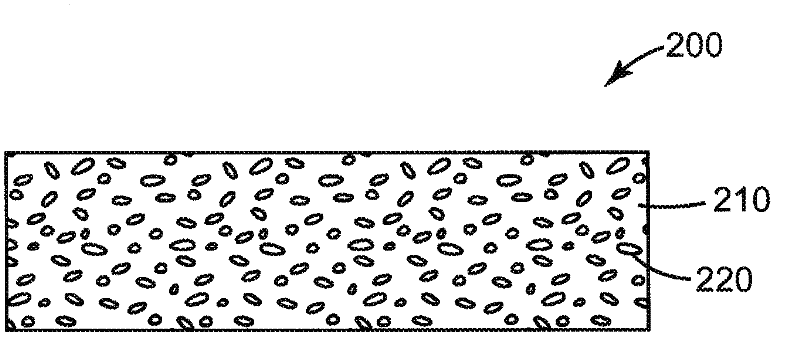

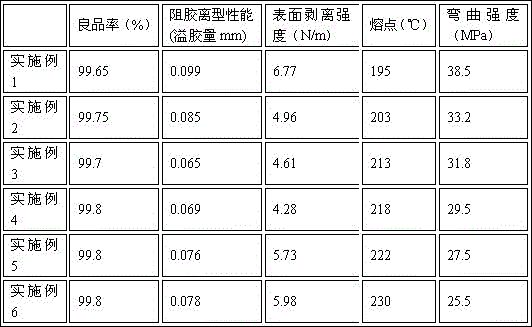

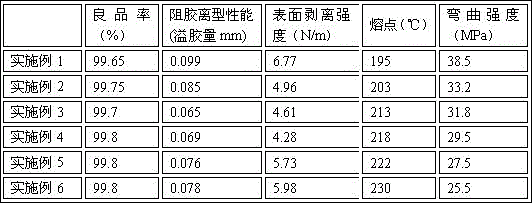

Flexible circuit board gum inhibition release paper release layer hot-melt resin composition, gum inhibition release paper and production method of gum inhibition release paper

ActiveCN105926362AHigh melting pointImprove surface peel strengthNon-fibrous pulp additionPaper coatingFlexible circuitsFlexural strength

The invention discloses a flexible circuit board gum inhibition release paper release layer hot-melt resin composition, a gum inhibition release paper and a production method of the gum inhibition release paper. The hot-melt resin composition comprises, by mass, 5-30 parts of polypropylene, 60-85 parts of poly(4-methyl-1-pentene), 0-5 parts of polyethylene and 5-20 parts of polybutylene terephthalate; and the flexible circuit board gum inhibition release paper is formed through coating the surface of paper with the hot-melt resin composition in a hot melt manner and through carrying out high frequency corona to form surface micro-pores. Combination of hot-melt coating and high frequency corona micro-pore technologies changes the overflow amount of an adhesive in the hot pressing process of a flexible circuit board in order to improve the gum inhibition function, and modified resin is added to improve the melting point, the surface peeling strength and the bending strength of a release layer, so the yield is improved; the production method has the advantages of simplicity, easy process control and low cost; and the gum inhibition release paper has the advantages of excellent gum inhibition release performance, very low peeling strength, high temperature resistance and high bending strength.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

Continuous reflective high-standard hot melt coating

InactiveCN112662267AHigh strengthImprove wear resistanceRosin coatingsReflecting/signal paintsHot melt coatingPetroleum resin

The invention discloses a continuous reflective high-standard hot melt coating, which is prepared by mixing 13-20 parts of a resin film-forming substance, 30-35 parts of mixed glass beads, 10-20 parts of a filler and 3-6 parts of a functional aid, and the resin film-forming substance is prepared by mixing C5 petroleum resin, C9 hydrogenated petroleum resin and maleic anhydride modified rosin resin; and the mixed glass beads are formed by mixing glass beads with three particle size grades of 16-30 meshes, 30-50 meshes and 50-80 meshes. The continuous retroreflection value and the conventional performance of the coating are superior to those of a traditional hot melt coating, the later retroreflection performance can last for more than one year, and the road marking maintenance cost is reduced.

Owner:SHANXI ZHONGTU TRAFFIC TECH CO LTD +1

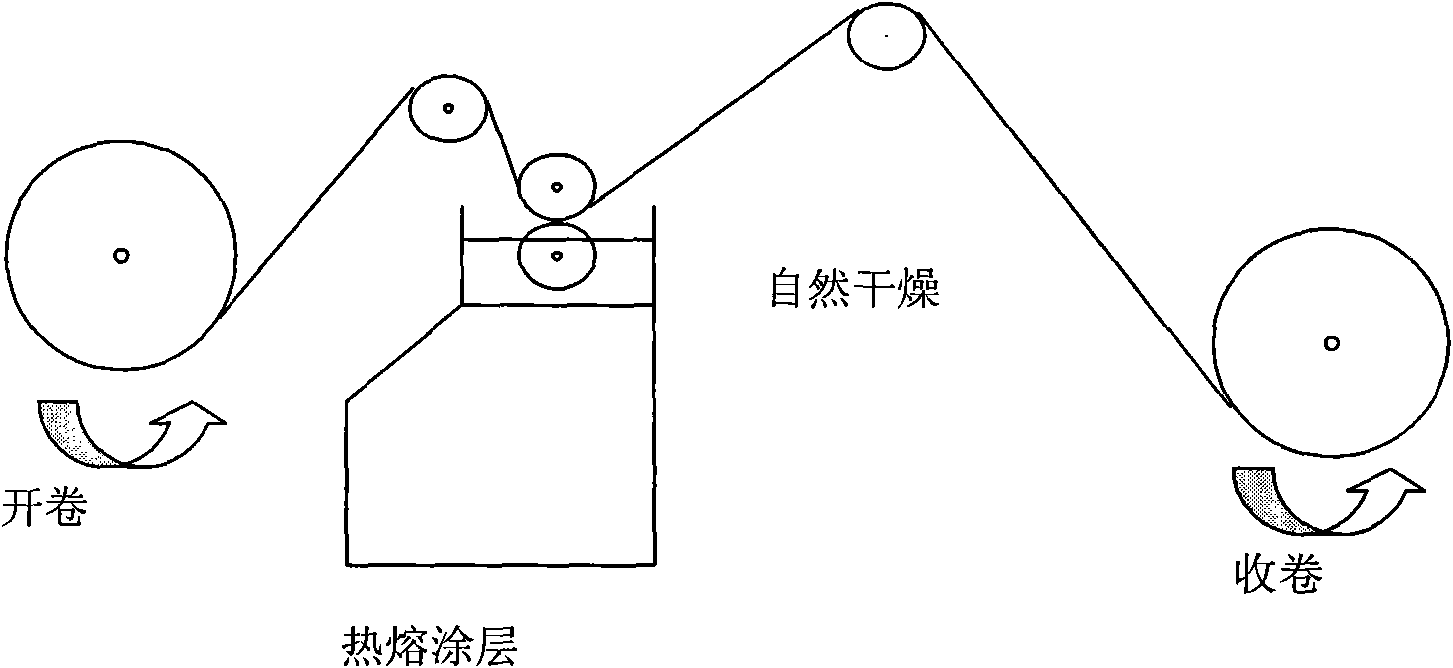

Method for forming hot melt super coating on coated abrasive tool

InactiveCN102009038ADense surface structureLow costLiquid surface applicatorsAbrasion apparatusHot melt coatingStearate

The invention discloses a method for forming a hot melt super coating on a coated abrasive tool, which is to heat and melt a material and coat the molten material by a roller coating equipment onto the surface of the coated abrasive tool, and is characterized in that: the material is stearate, or a mixture of stearate and paraffin wax or a mixture of stearate, paraffin wax and antioxidant or mixture of stearate, paraffin wax, antioxidant and EVA resin or PP resin and is heated and melted at the temperature of 110 to 160 DEG C; the molten stearate or mixtures of the stearate is coated on the surface of abrasive paper or abrasive cloth by hot melt coating equipment; and naturally cooling, drying and obtaining hot melt coating products. The hot melt coating has the advantages of no toxicity, no solvent, low cost, short production route and the like compared with water soluble or solvent coating, and the obtained abrasive tool has a more compact surface structure and has the advantages of blockage prevention, burn prevention and the like in use.

Owner:ZIBO RIKEN MT COATED ABRASIVES

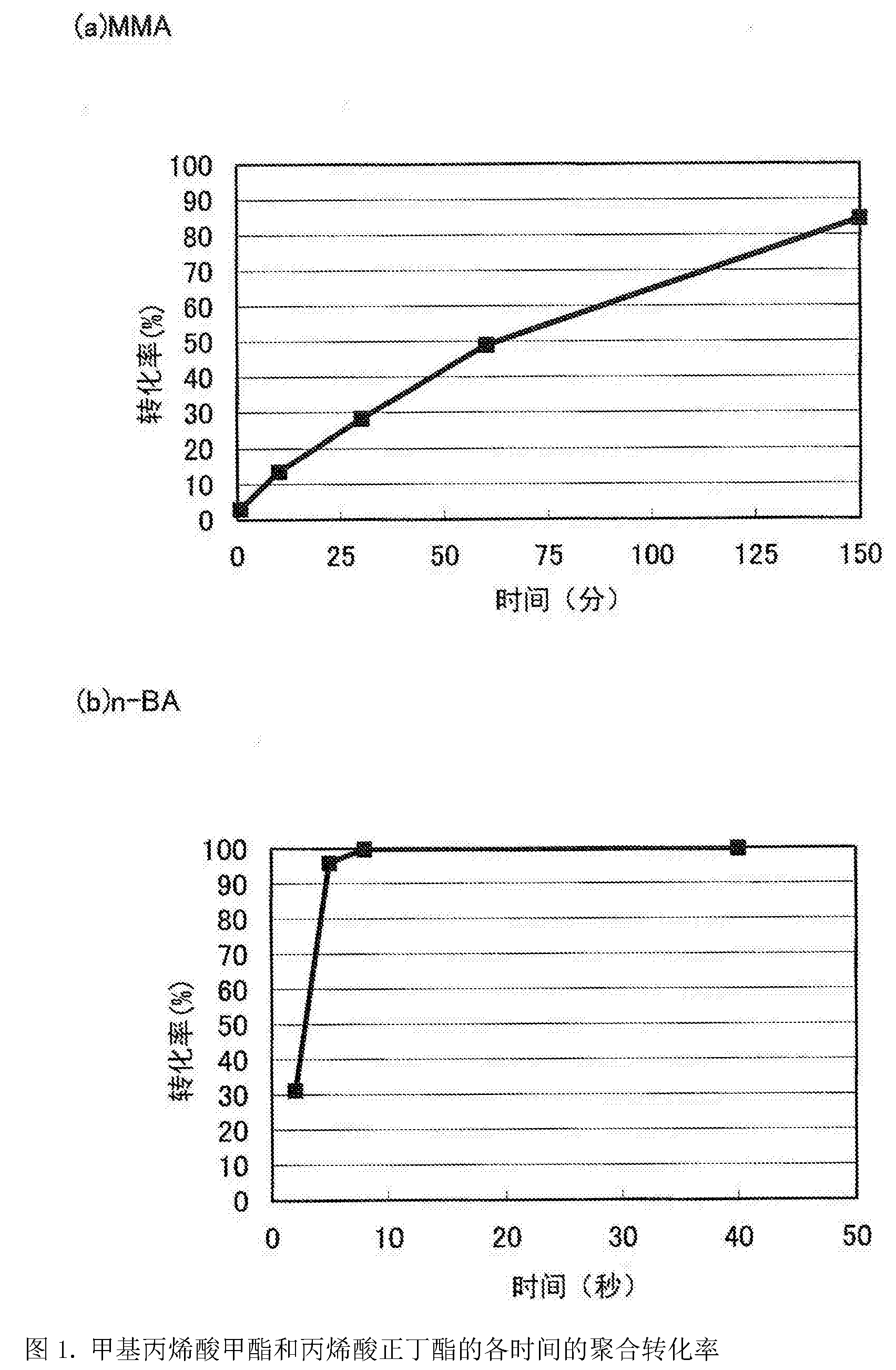

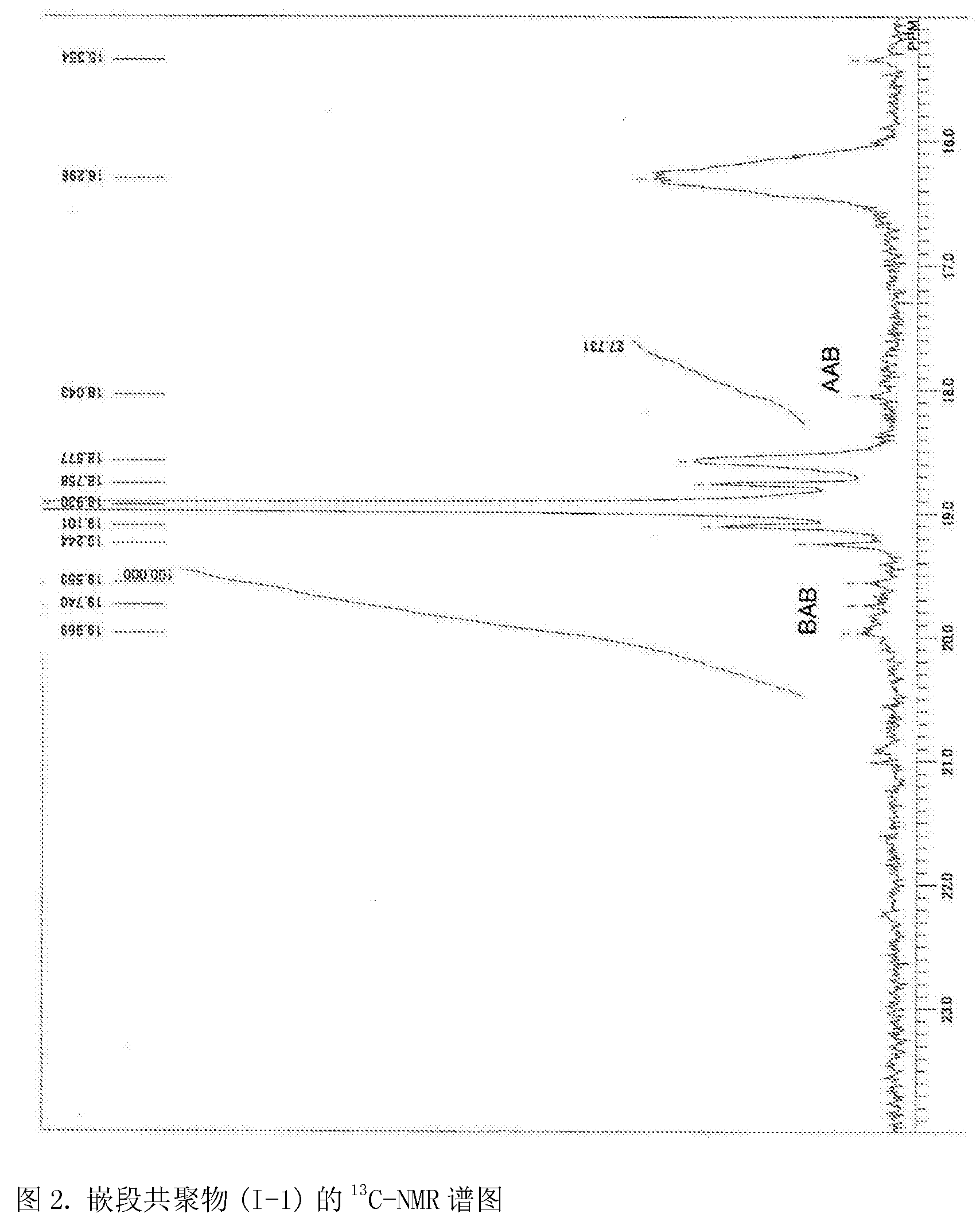

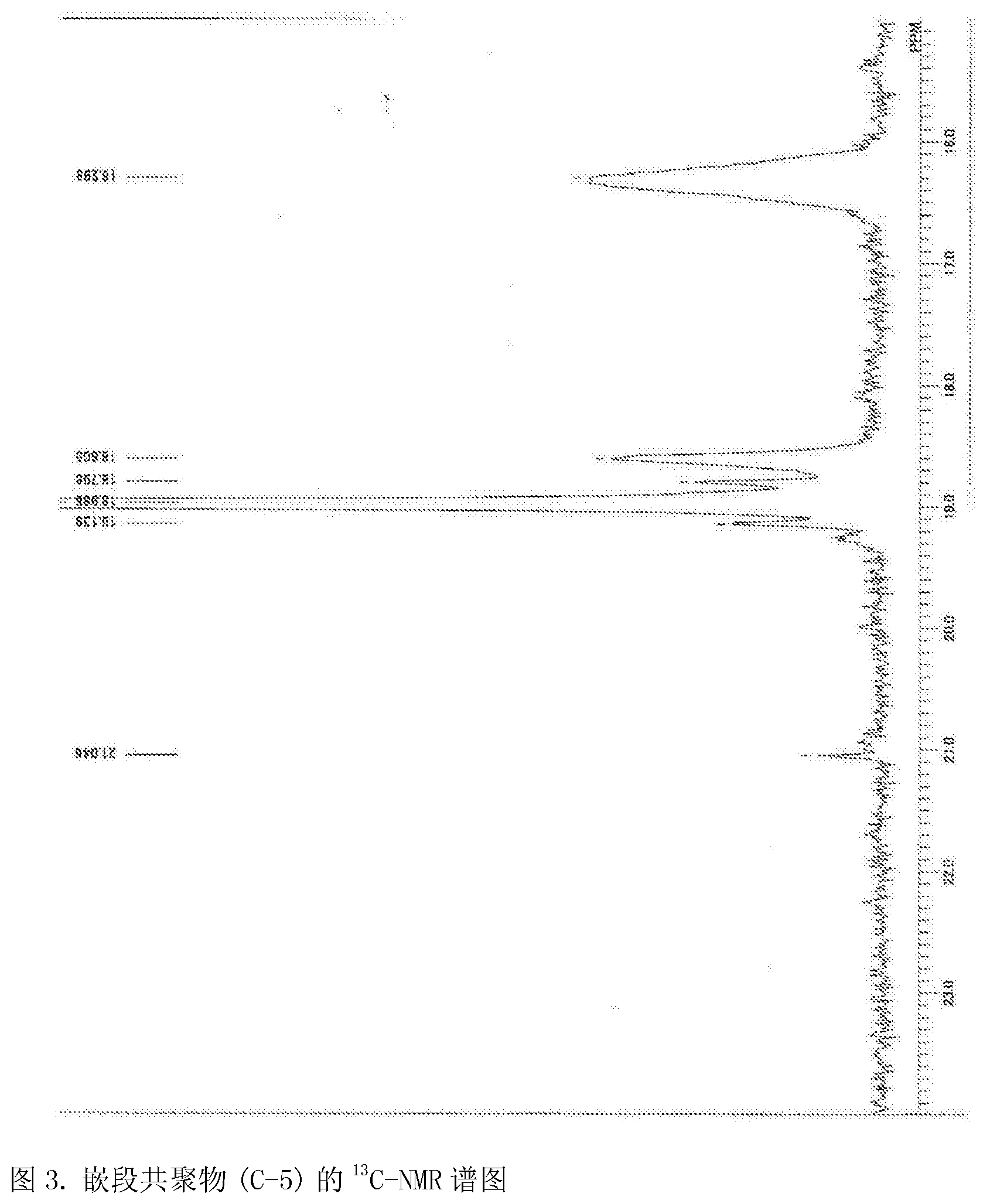

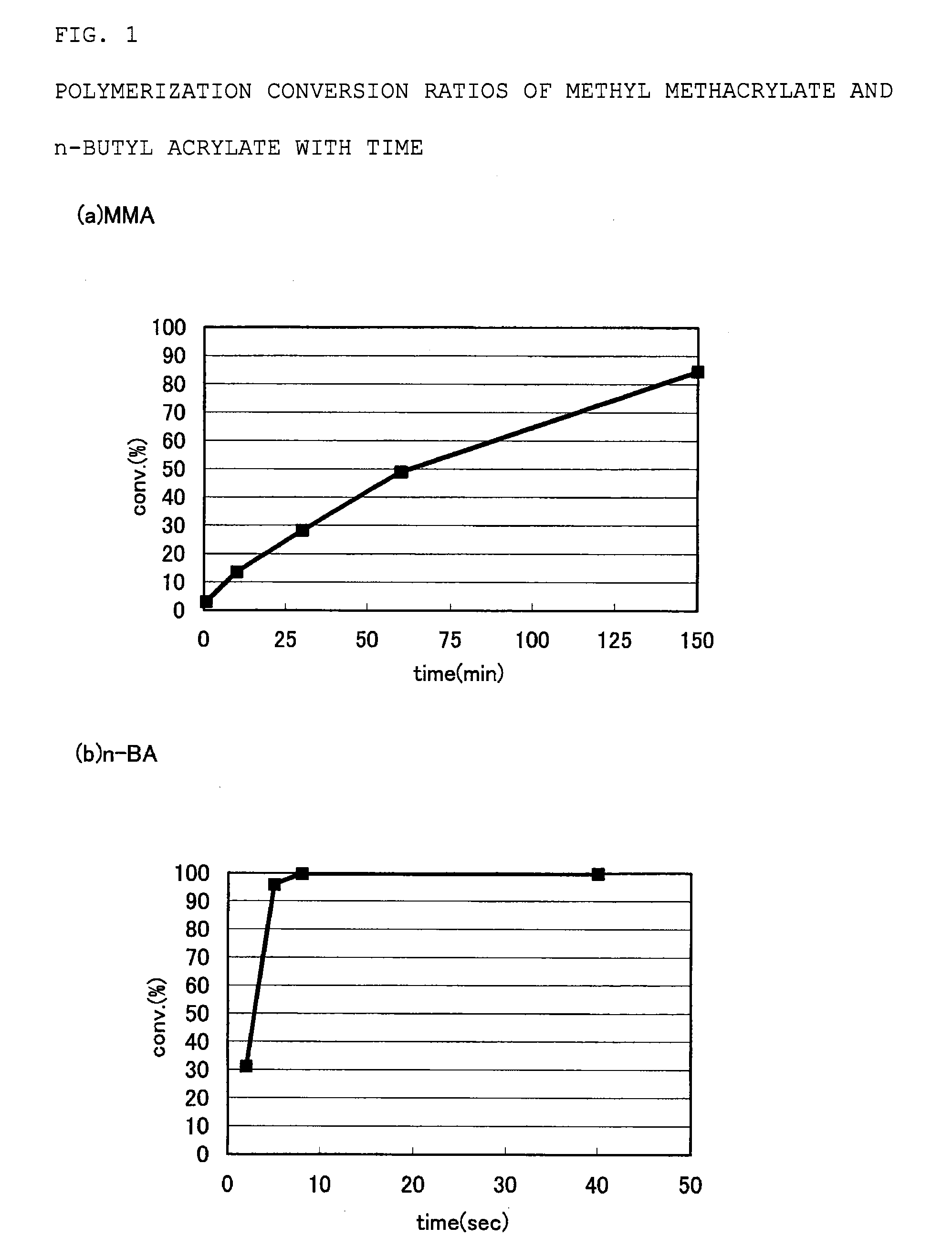

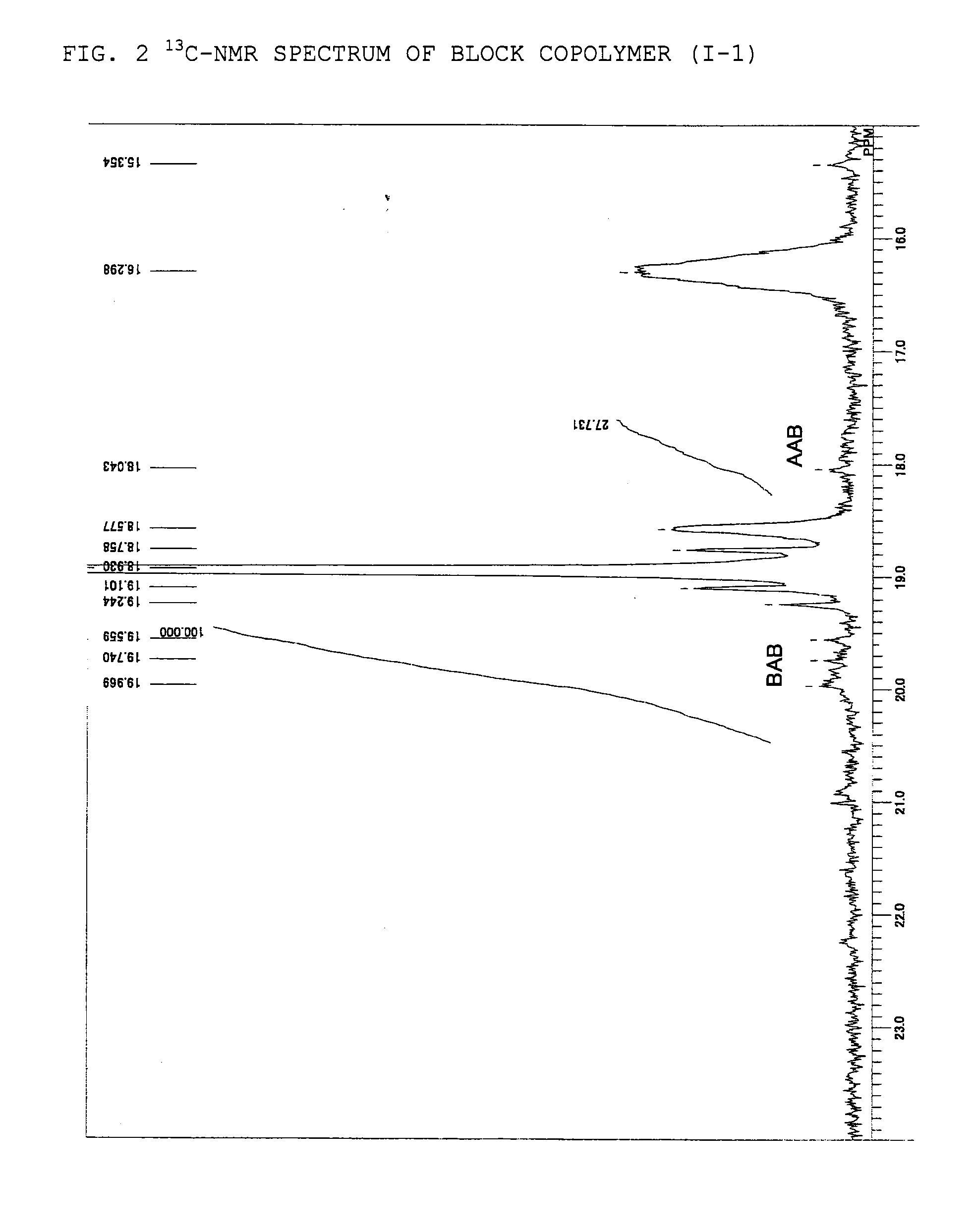

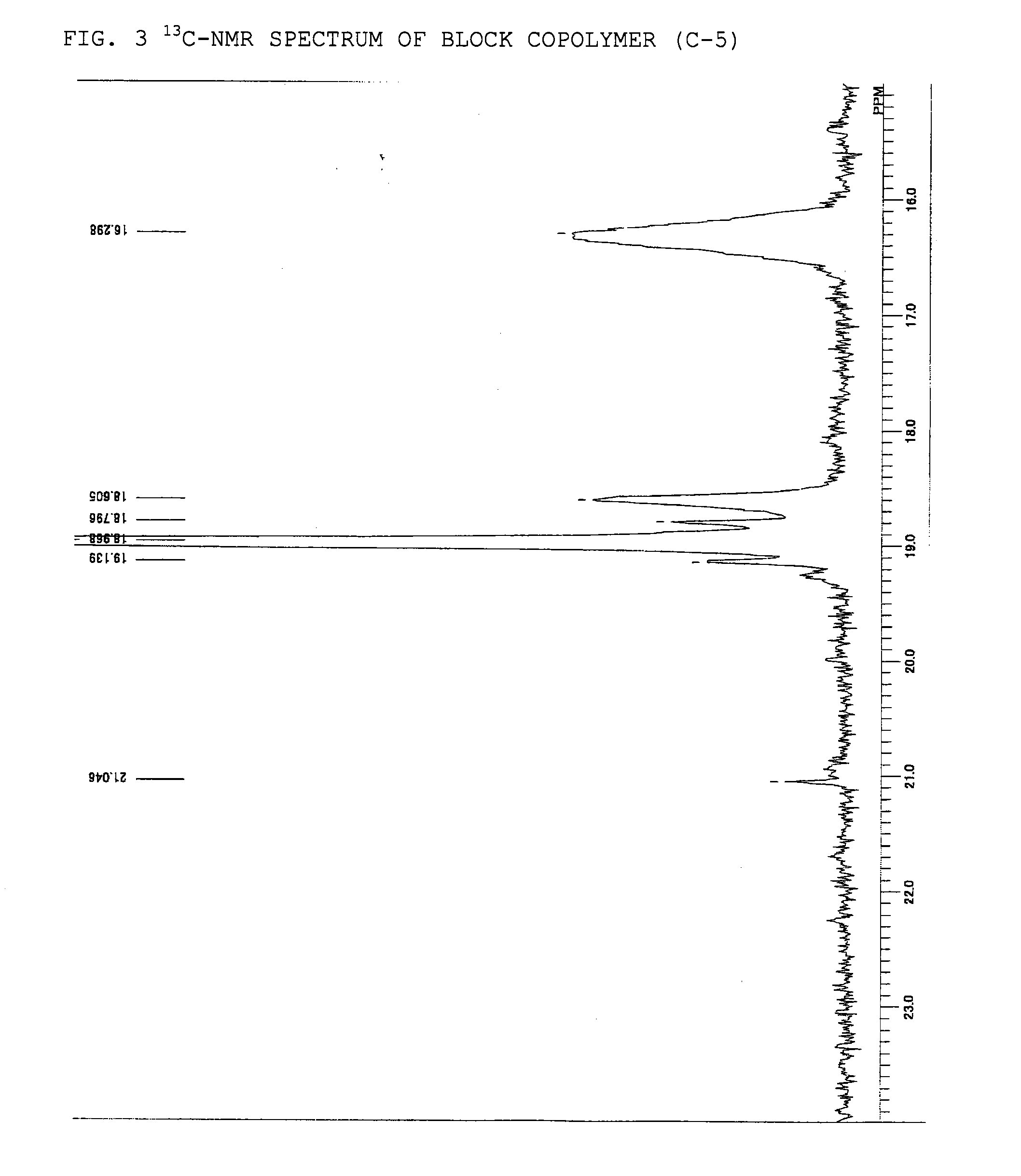

Adhesive containing block copolymer

Provided are: an acrylic-based hot-melt adhesive that is superior in terms of both hot-melt coating characteristics and holding strength, is favorable for application in hot-melt coating methods that coat at a high speed at low temperatures, has superior transparency and weather resistance, and furthermore has superior adhesion at low temperatures; and a block copolymer favorable for use with respect to same. The present invention produces an adhesive containing a block copolymer having at least one structure represented by the general formula -[A1]-[B / A2]- (wherein: [A1] indicates a polymer block comprising a structural unit derived from a methacrylic ester (A1); [B / A2] indicates a copolymer block comprising a structural unit derived from an acrylic ester (B) and a structural unit derived from a methacrylic ester (A2); and the copolymer block [B / A2] has a gradient copolymer block section at which the copolymer ratio of the methacrylic ester (A2) continues to increase from the section of bonding to the copolymer block [A1]), having a total content of structural units derived from the methacrylic ester (A1) and the methacrylic ester (A2) of 5-60 mass%, having a weight average molecular weight (Mw) of 30,000-300,000, and having a molecular weight distribution (Mw / Mn) of 1.0-1.5.

Owner:KURARAY CO LTD

Paper and plastic composite light packaging film, manufacturing method thereof, and tag bag

InactiveCN106364118AImprove visual effectsReduce usageSynthetic resin layered productsBagsGramHot melt coating

The invention discloses a paper and plastic composite light packaging film. The paper and plastic composite light packaging film sequentially comprises an outer layer, a middle layer and an inner layer from outside to inside; and the outer layer is a BOPP film with the thickness of 15-20 [mu]m, the middle layer is brown paper with the gram weight of 24-35 g / m<2>, and the inner layer is a PP film with the thickness of 15-25 [mu]m. A manufacturing method of the paper and plastic composite light packaging film comprises the following steps: 1, producing the brown paper and the BOPP film; 2, carrying out hot melt coating on one side of the brown paper with the PP film through an extrusion tape casting technology in order to obtain a middle layer and inner layer composite structure; and 3, bonding the BOPP film with the other side of the brown paper through a composite process in order to obtain the paper and plastic composite light packaging film. The invention also discloses a tag bag. The surface of a bag body made of the paper and plastic composite light packaging film is provided with an unpacking notch, the corresponding position of the bag body is provided with a seal label used for covering the unpacking notch, and the inner side of the seal label is provided with a removable glue layer which can be bonded to the surface of the bag body.

Owner:浙江粤海包装新材料有限公司

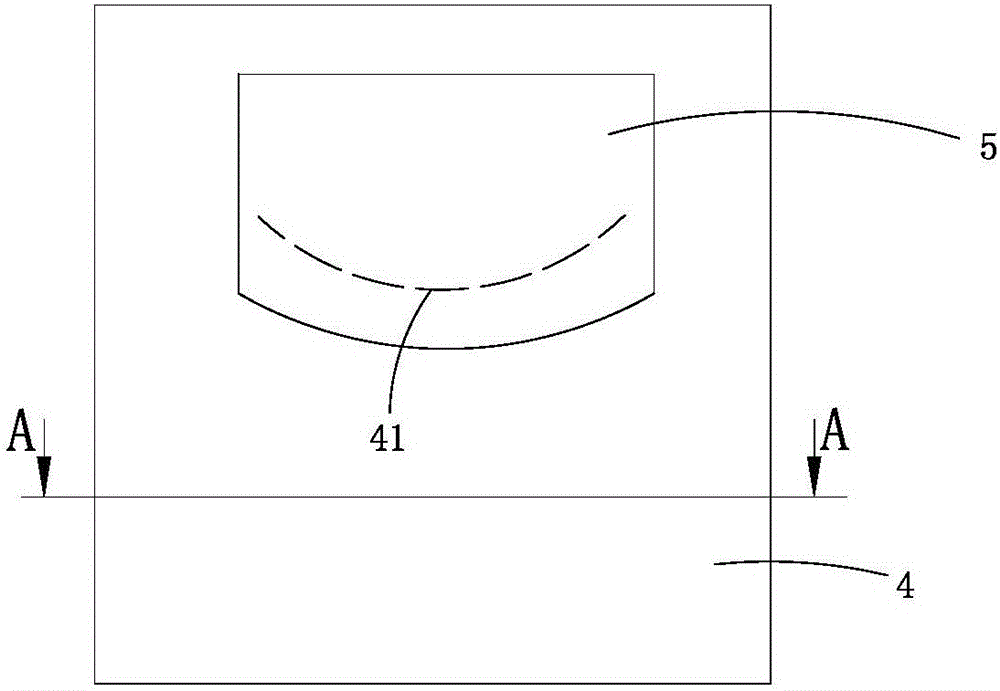

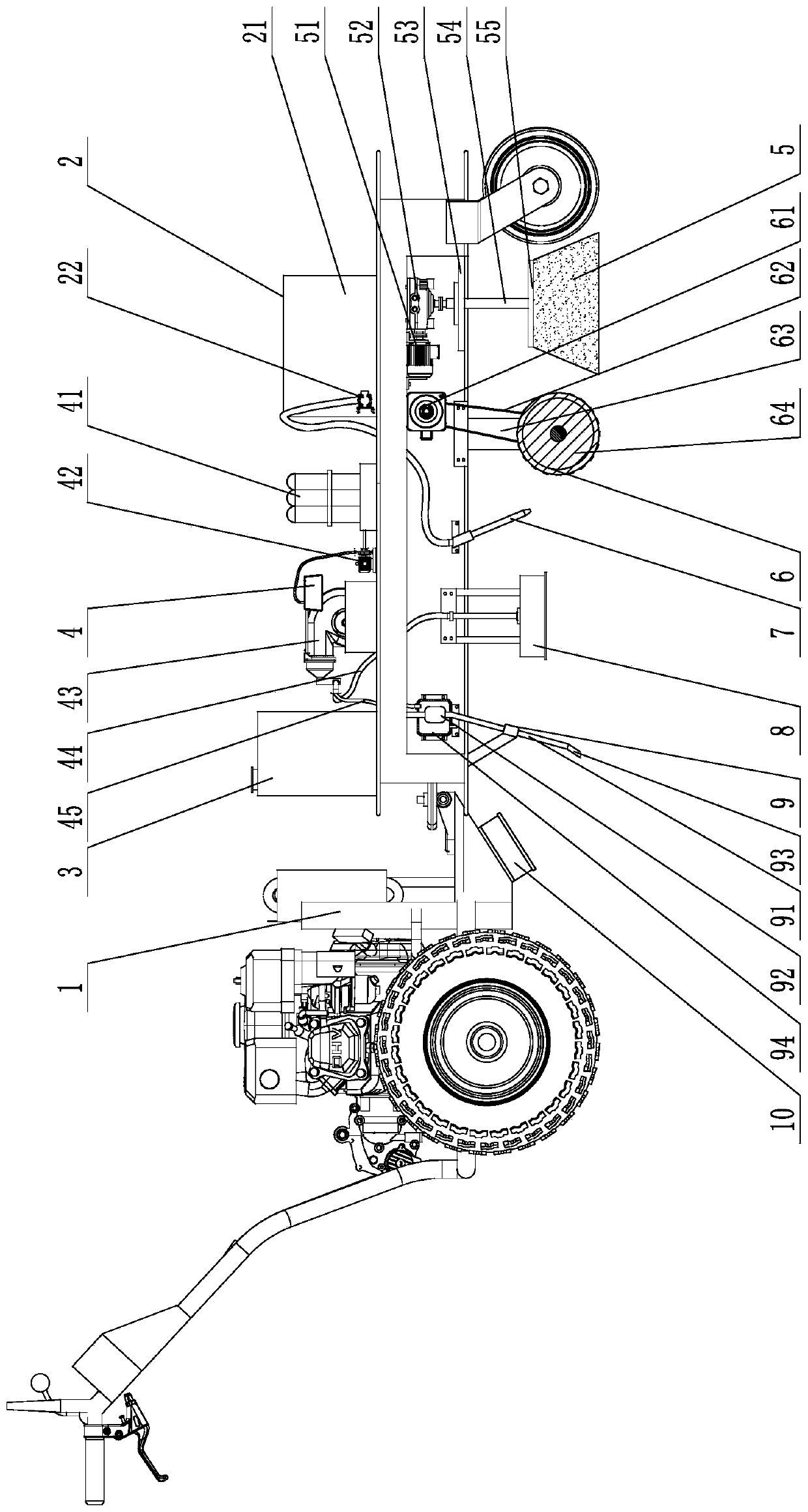

Road and bridge marking device

InactiveCN111455798AIncrease the cleaning processImprove adhesionRoad cleaningRoads maintainenceHot melt coatingStructural engineering

The invention provides a road and bridge marking device, and mainly relates to the field of road equipment. The road and bridge marking device comprises a vehicle body, a wheel train is arranged at the bottom of the vehicle body. A high-pressure water system, a hot-melt coating kettle and a fuel heating system are arranged at the top of the vehicle body; a sweeper, a friction device, a high-pressure water spray head, a dryer, a hot melt coating spray head and an air cooler are sequentially arranged at the bottom of the vehicle body from the front end to the rear end, the high-pressure water spray head is matched with the high-pressure water system, and the dryer and the hot melt coating spray head are both matched with the fuel heating system. The road and bridge marking device has the beneficial effects that the road cleaning procedure can be added before hot-melting marking, a clean and tidy road surface environment is provided for road hot-melting marking, and therefore the attachment effect of hot-melting marks on the road surface is better, and the service life is longer.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

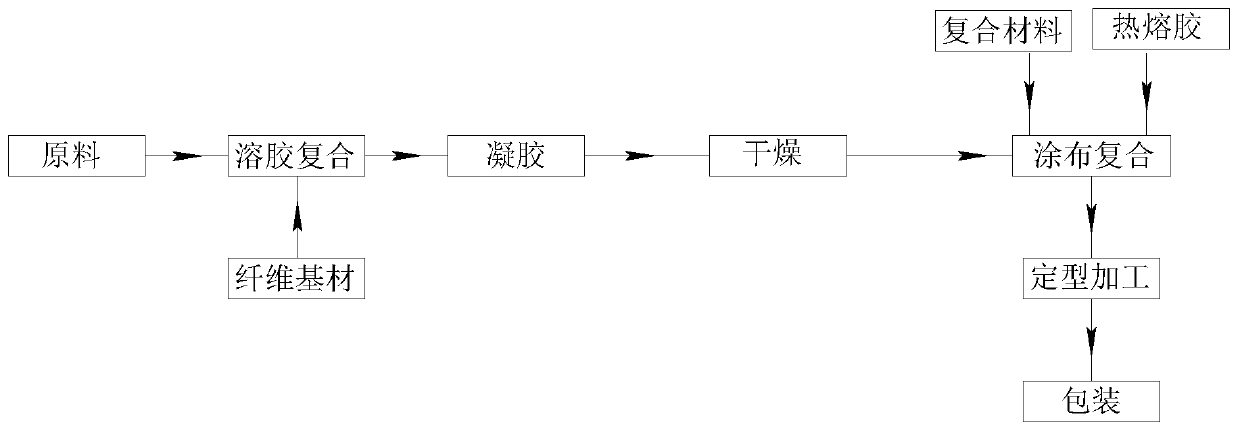

Continuous production process and application of aerogel felt composite material

The invention discloses a production process and application of an aerogel felt composite material. The preparation method of the aerogel felt composite material comprises the steps: (1) taking raw materials, namely a sol raw material and a fiber base material, continuously mixing, and carrying out sol compounding; (2) carrying out continuous mixing forming curing of the sol complex under the action of quantitative alkali liquor serving as a catalyst, to obtain gel; (3) drying the gel to form an aerogel felt; (4) continuously feeding the dried aerogel felt, a hot melt adhesive, a composite material and an auxiliary material into a hot melt coating machine, and compounding; and (5) carrying out continuous shaping processing and packaging on the aerogel composite material subjected to hot coating to finish the preparation. The adhesive force of aerogel powder on the composite material is enhanced, and the product quality of the aerogel felt is improved; through compounding of multiple materials, the comprehensive mechanical property is further improved on the basis of original excellent heat insulation and sound insulation, and the composite material can be widely applied to the fields of building decoration materials, heat supply pipe network materials, new energy automobiles and household appliances.

Owner:鑫创新材料科技(徐州)有限公司

Hot melt coating for road sign and preparation method thereof

InactiveCN104059466ASolve the problems of poor wear resistance and short service lifeExtended service lifePolyester coatingsRoad surfaceGlass microsphere

The invention relates to a hot melt coating for road sign and a preparation method thereof, and belongs to the technical field of polymer materials. The coating provided by the invention comprises the following raw materials by weight: 50-70 parts of petroleum resin, 5-10 parts of tackifier resin, 10-20 parts of polyester resin, 5-15 parts of silicone resin, 6-17 parts of soya-bean oil alkyd resin, 8-15 parts of phenolic resin, 3-12 parts of aluminum metaphosphate, 5-10 parts of titanium dioxide, 30-50 parts of calcium carbonate and 10-20 parts of hollow glass microspheres. The hot melt coating for road sign provided by the invention can effectively enhance the wear resistance and weather resistance of the coating, improves the adhesion stress of the coating with the pavement and prolongs the service life of the coating.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Adhesive containing block copolymer

ActiveUS20160122603A1Improve heat resistanceGood weather resistanceAdhesivesMethacrylateHot melt coating

Provided are an acrylic hot-melt adhesive that has both good hot-melt processability and good holding power, that is suitable for applications to a hot-melt coating method in which coating is performed at a low temperature at a high speed, that has good transparency and good weather resistance, and that further has good adhesiveness at low temperatures, and a block copolymer suitable for use in the adhesive. Prepared is an adhesive containing a block copolymer having at least one structure represented by a general formula: -[A1]-[B / A2]- (where, in the formula, [A1] represents a polymer block composed of a structural unit derived from a methacrylic acid ester (A1), [B / A2] represents a copolymer block composed of a structural unit derived from an acrylic acid ester (B) and a structural unit derived from a methacrylic acid ester (A2), and the copolymer block [B / A2] has a gradient copolymer block section in which a copolymerization ratio of the methacrylic acid ester (A2) continuously increases from a section connected to the polymer block [A1]), and having a total content of the structural units derived from the methacrylic acid ester (A1) and the methacrylic acid ester (A2) of 5% to 60% by mass, a weight-average molecular weight (Mw) of 30,000 to 300,000, and a molecular weight distribution (Mw / Mn) of 1.0 to 1.5.

Owner:KURARAY CO LTD

High-grade rainproof clothing linings

The proposal of the present invention provides a soft but well-pressed high-grade rainproof clothing lining which integrates the performances of water resistance, moisture permeability, static electricity resistance and washing durability. The lining is characterized in that 20D-25D / 12F polyamide filament which is spun by adding antistatic master batch; a light material of high-density polyester pongee is compounded with a PU hot melt coating to manufacture the lining which is provided with the water resistance, the moisture permeability and static electricity resistance; the lining and the PU hot melt coating are agglutinated perfectly, which does not allow the clothing to infiltrate water, and the washing durability matches well with the clothing material; the lining is very practical and is widely used for the military use and the civil use and used in the normal, casual, or leather clothing field.

Owner:JIANGSU SHENGHONG CHEM FIBRE CO LTD

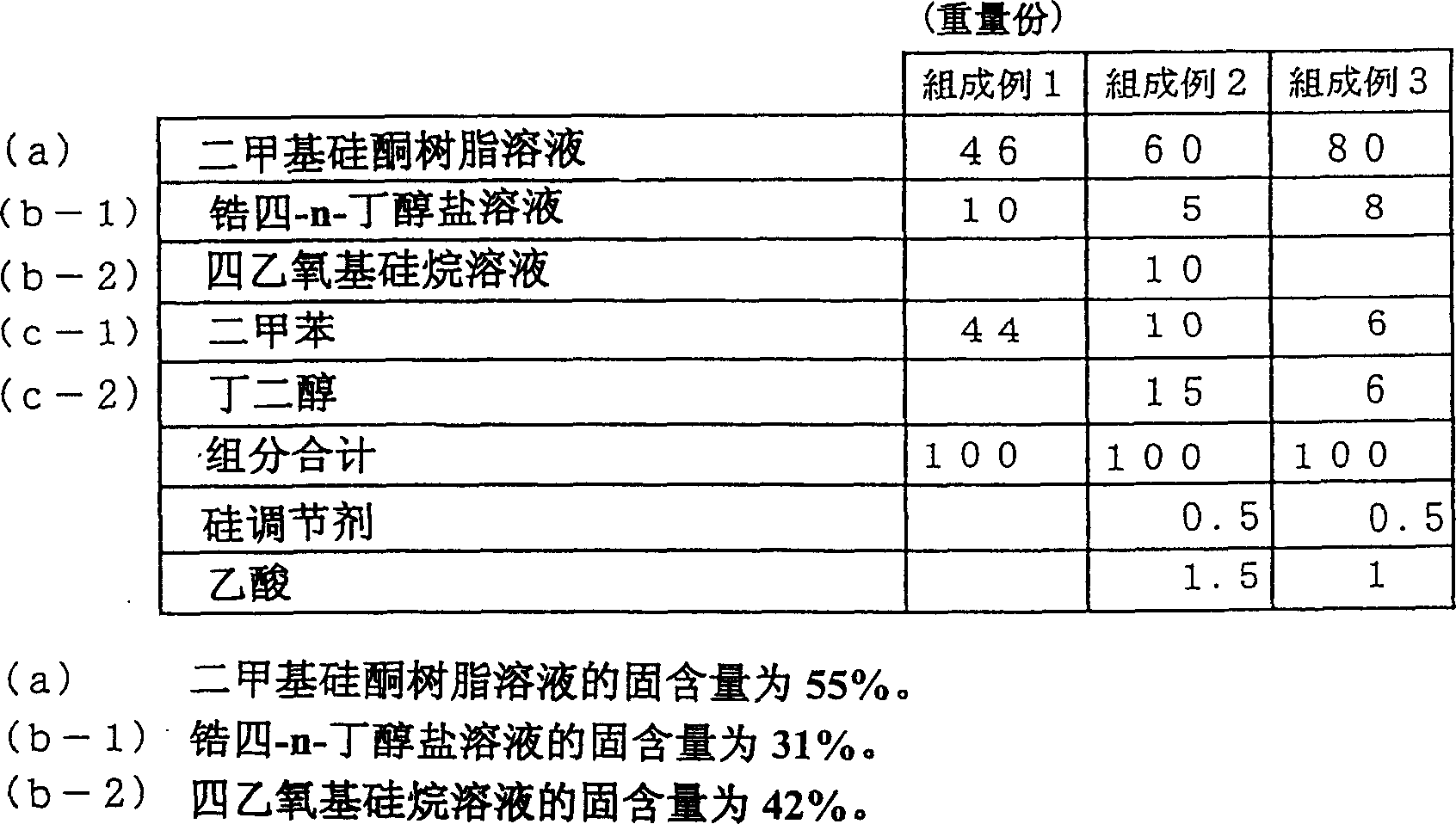

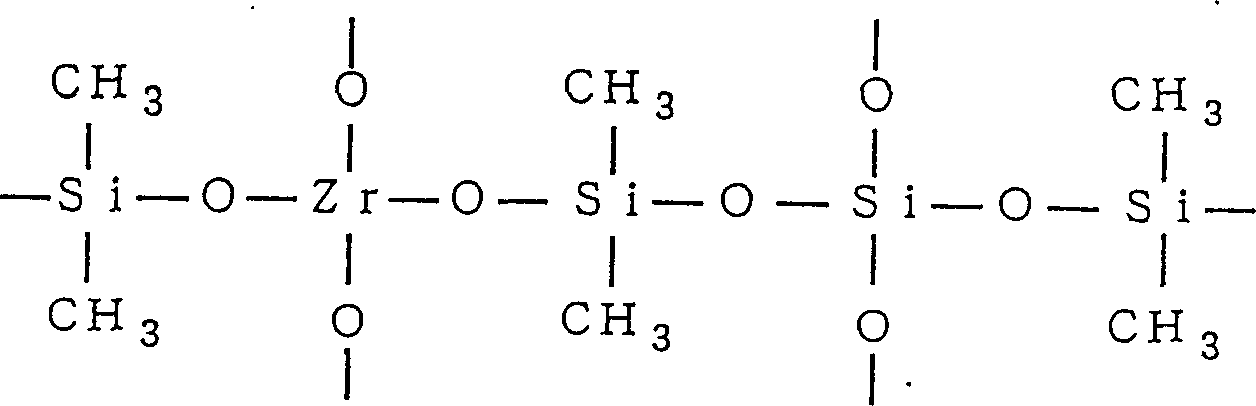

Ceramic insulating electrical wire, composition,coil for coating and sound coil for loudspeaker

InactiveCN1468027AMaintain heat resistanceGood flexibilityElectrical transducersElectrical conductorPolyamide

The invention provides an electric wire with ceramic insulation sheath produced by, applying the coating composition containing zirconium compound and silicon compound on the conductor for heat solidifying, forming a ceramic insulation sheathed film, and applying organic solvent hot melt paint that can make polyamide resinoid or medlin resinoid dissolve for heat solidifying, forming a hot melt sheathed film, thus producing the self hot-melting ceramic insulation sheathed electric wire which can retain coil characteristic under high temperature. The invention can also be used to the spiral of the high output loudspeaker voice coils.

Owner:TOHOKU PIONEER CORP +2

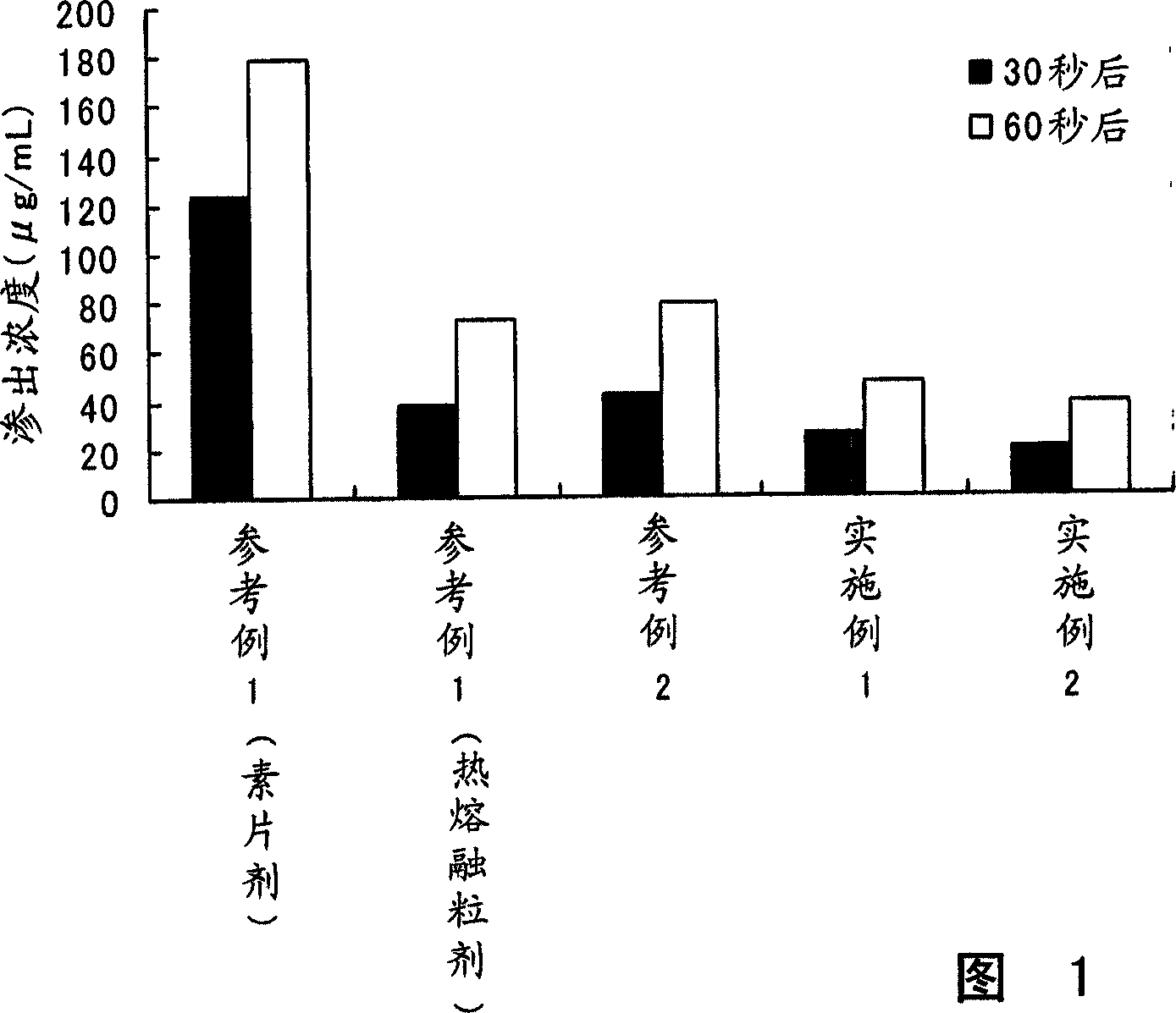

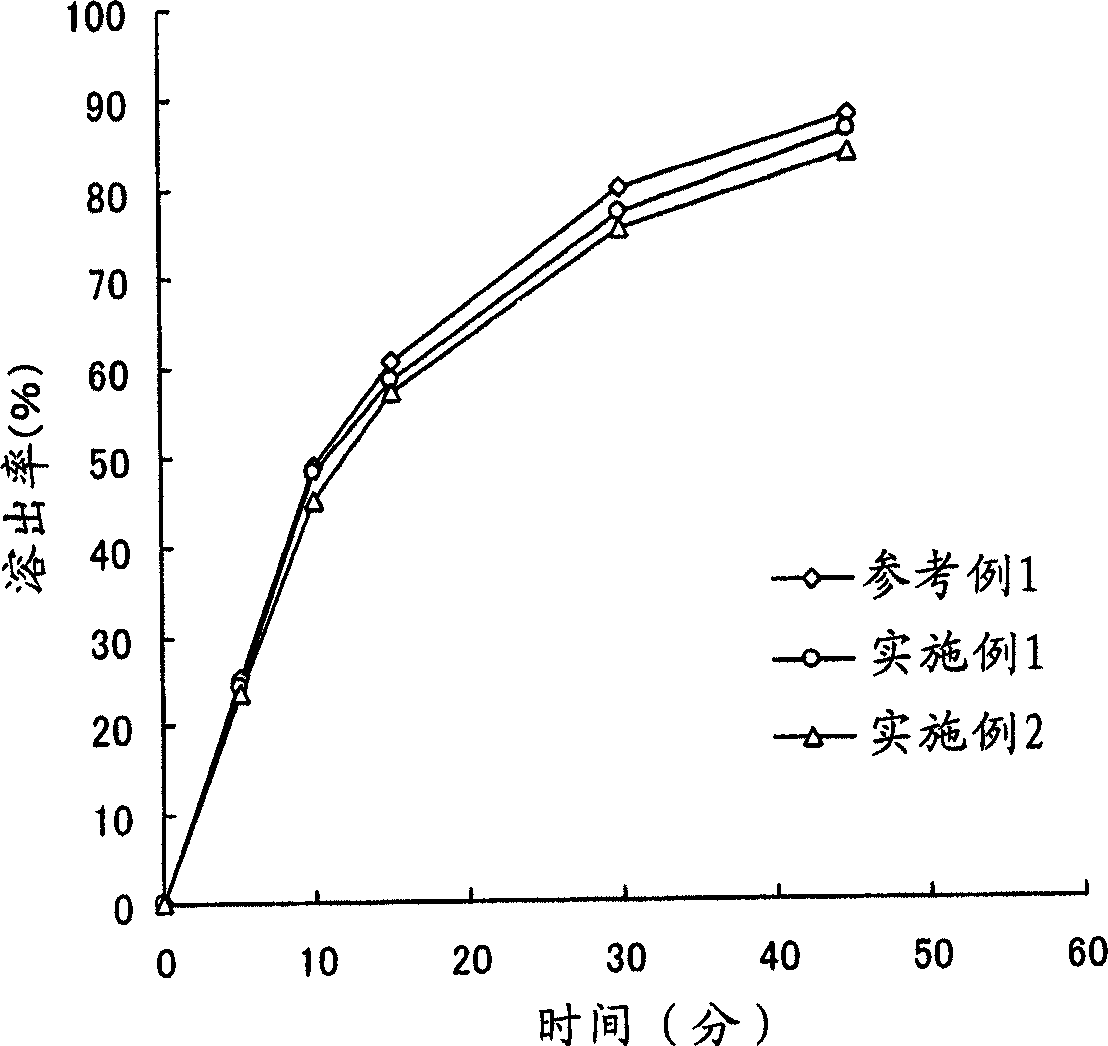

Process for producing coated preparation having relieved unpleasantness

ActiveCN1874759APromote dissolutionSuppress unpleasant tasteAntibacterial agentsOrganic active ingredientsHot melt coatingDrug compound

A coated preparation having a relieved unpleasantness can be produced by heating uncoated grains which contains a drug compound and a waxy substance, adding a powdery waxy substance at such a temperature as moistening the surface of the former waxy substance, and then hot-melt coating the surface of the uncoated grains. The dosing properties of the coated preparation can be further improved by blending sweetening subtilaes, which have been obtained by the wet granulation method with the use of a binder liquor having a sweetener and a binder dissolved or dispersed therein, therewith.

Owner:SHIONOGI & CO LTD

Preparation method of compact high thermal conductivity ceramic substrate

InactiveCN108484150AOmit the heat treatment processSimple preparation processCeramicwareGreen tapeAluminium hydroxide

The invention discloses a preparation method of a compact high thermal conductivity ceramic substrate, and belongs to the technical field of ceramic substrates preparation. After carbon dioxide is introduced in a sodium aluminate solution, superfine aluminium hydroxide crystal grains are formed, mullite powder is doped to achieve bonding and toughening effects to avoid cracking deformation causedwhen an alumina ceramic substrate is subjected to sinter molding, and the alumina ceramic substrate is more compact. Polyester resin with high thermal deformation energy is used as a copper clad carrier, and through high stress bonding of the resin and the ceramic substrate, reliable bonding is generated; copper obtained through reduction of cuprous oxide in a hot melt coating and atoms of the ceramic substrate diffuse mutually to form a bonding layer through diffuse bonding, so that a composite plate is formed through tight bonding of the copper surface and the ceramic substrate, and an ablated metal thermal conductive layer is formed; and copper in a micro perforation of a green tape forms a thermal conductive net in the ceramic substrate, so that the thermal conductivity of the ceramicsubstrate is enhanced, and the application prospect is wide.

Owner:胡果青

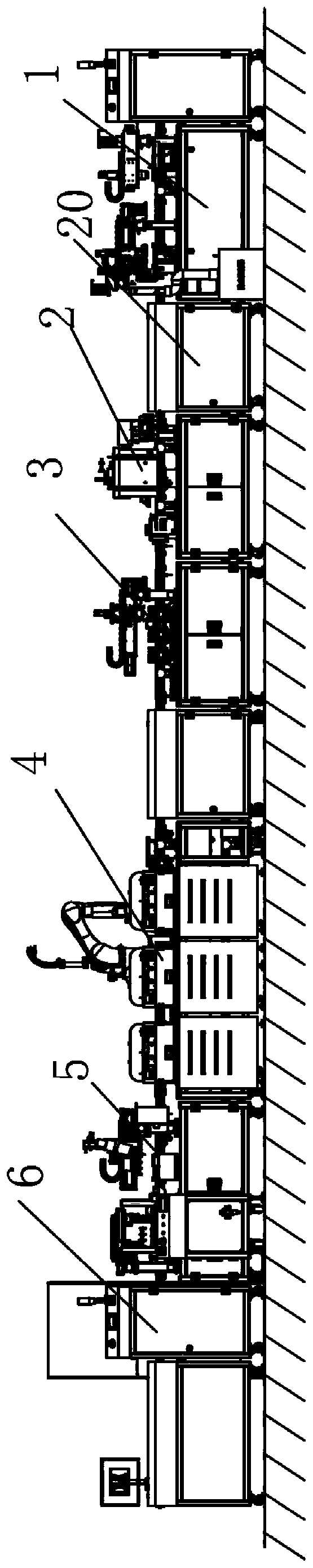

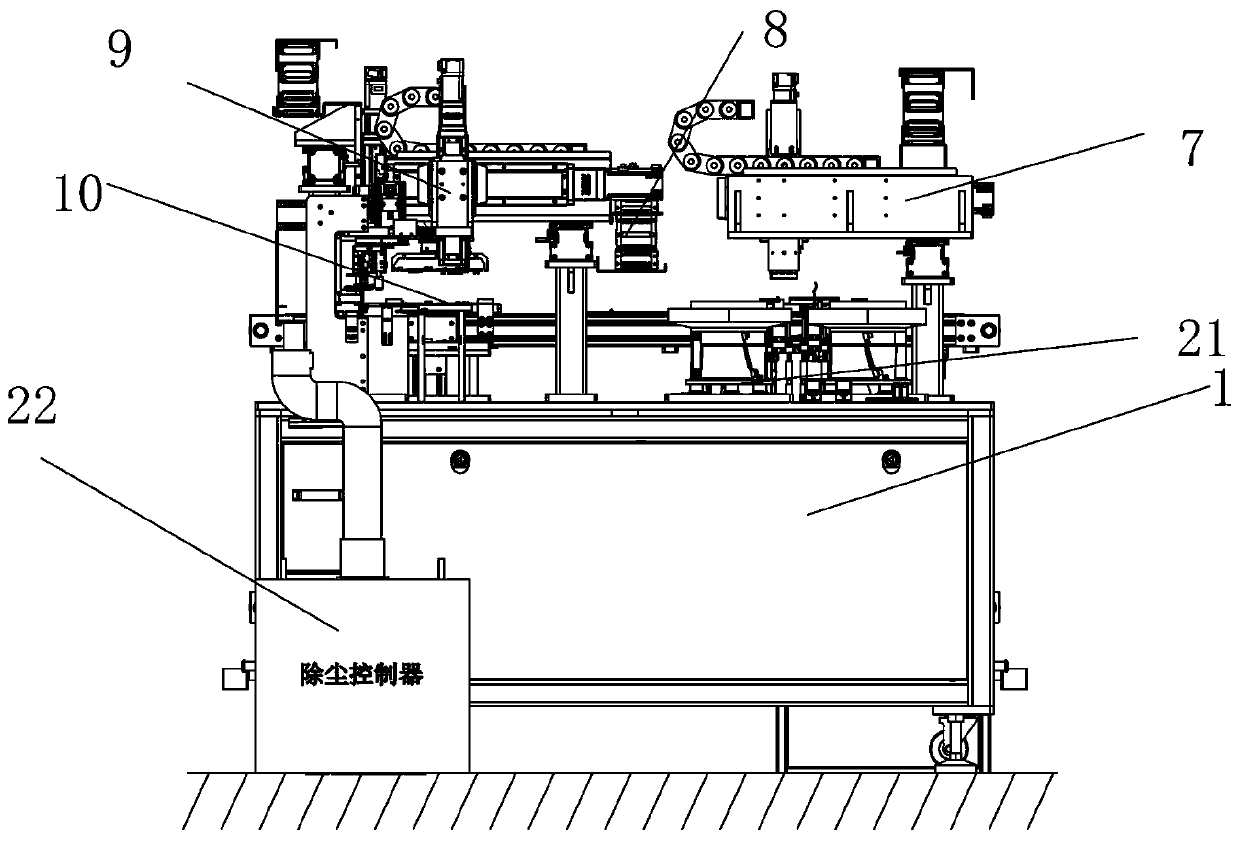

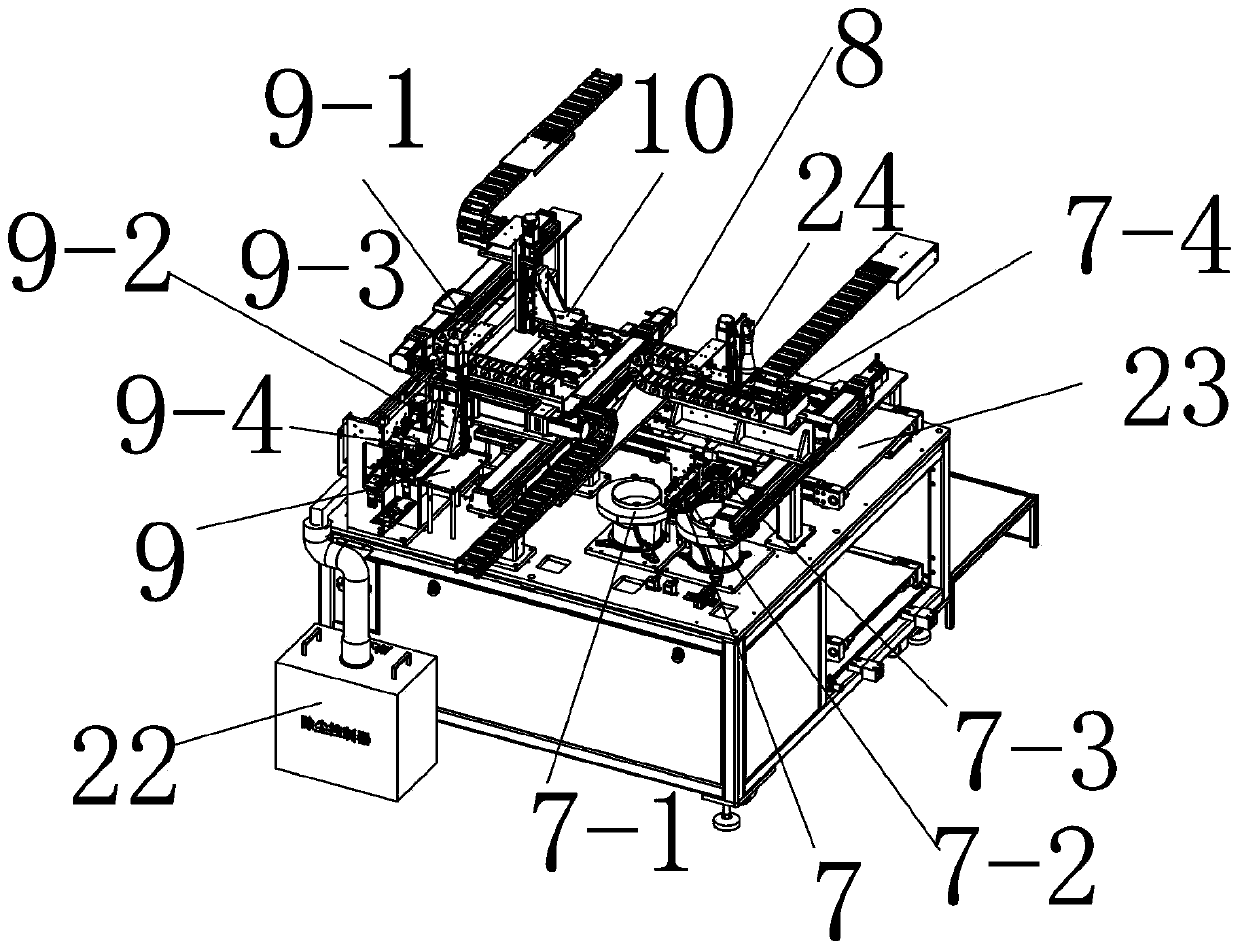

Automatic generation device of motherboard and operation method thereof

ActiveCN110113930AHigh degree of integrationReduce labor costsPrinted circuit assemblingNon-metallic protective coating applicationHot melt coatingEngineering

The invention discloses an automatic generation device of a motherboard and an operation method thereof. The device includes a frame, wherein an automatic conveyor belt with a carrier plate is arranged on the frame, and components connected in order from right to left on the automatic conveyor belt are a board distribution inserting machine which utilizes an integrated gantry-type three-axis module to complete handling and grasping and is capable of automatically assembling PCB main boards and connectors; connecting, soldering and burning equipment which is used for performing program burningof the PCB boards on products after operation of the board distribution inserting machine and is used for performing automatic soldering of the burned PCB main boards and the connectors; an automaticlabeling machine used for automatically labeling the products; CCA test equipment used for performing CCA testing of the products; hot melt coating equipment used for performing hot melt coating of the products which pass the CCA test equipment test; and automatic cutting equipment used for automatically cutting the main boards of the hot melt coating equipment. The device is advantaged in that work efficiency is improved, and manpower cost is reduced.

Owner:深圳橙子自动化有限公司

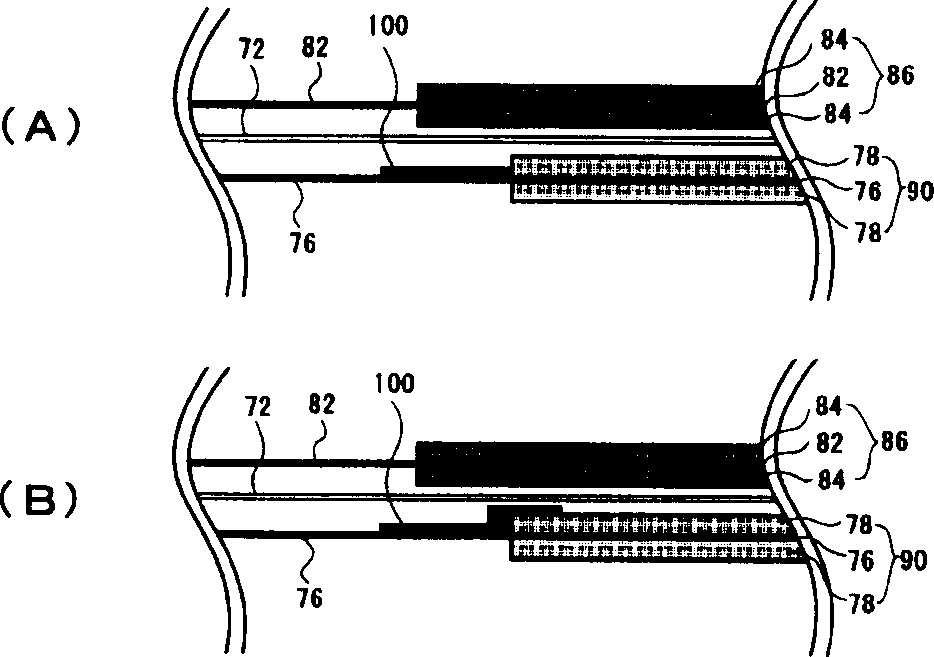

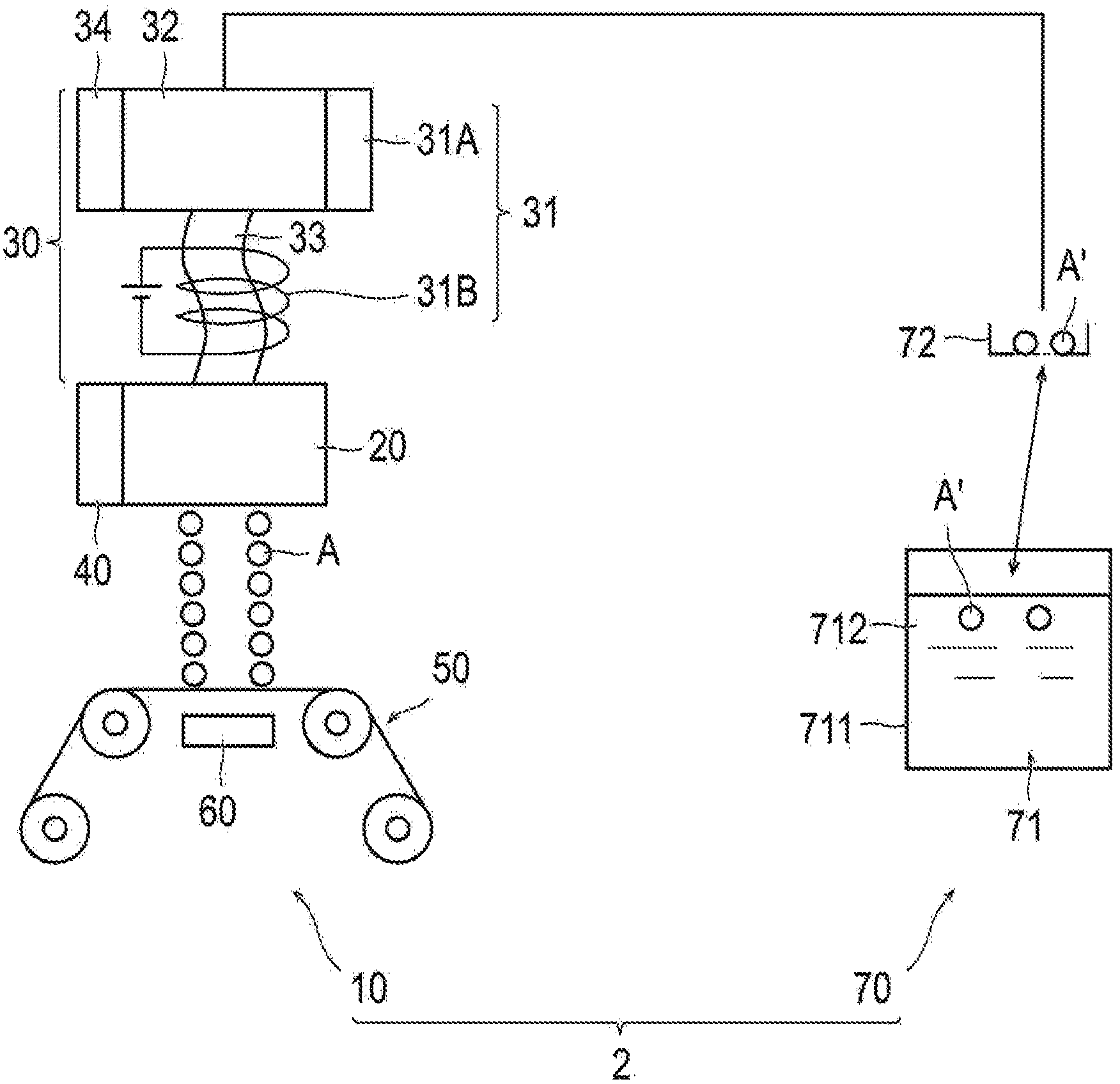

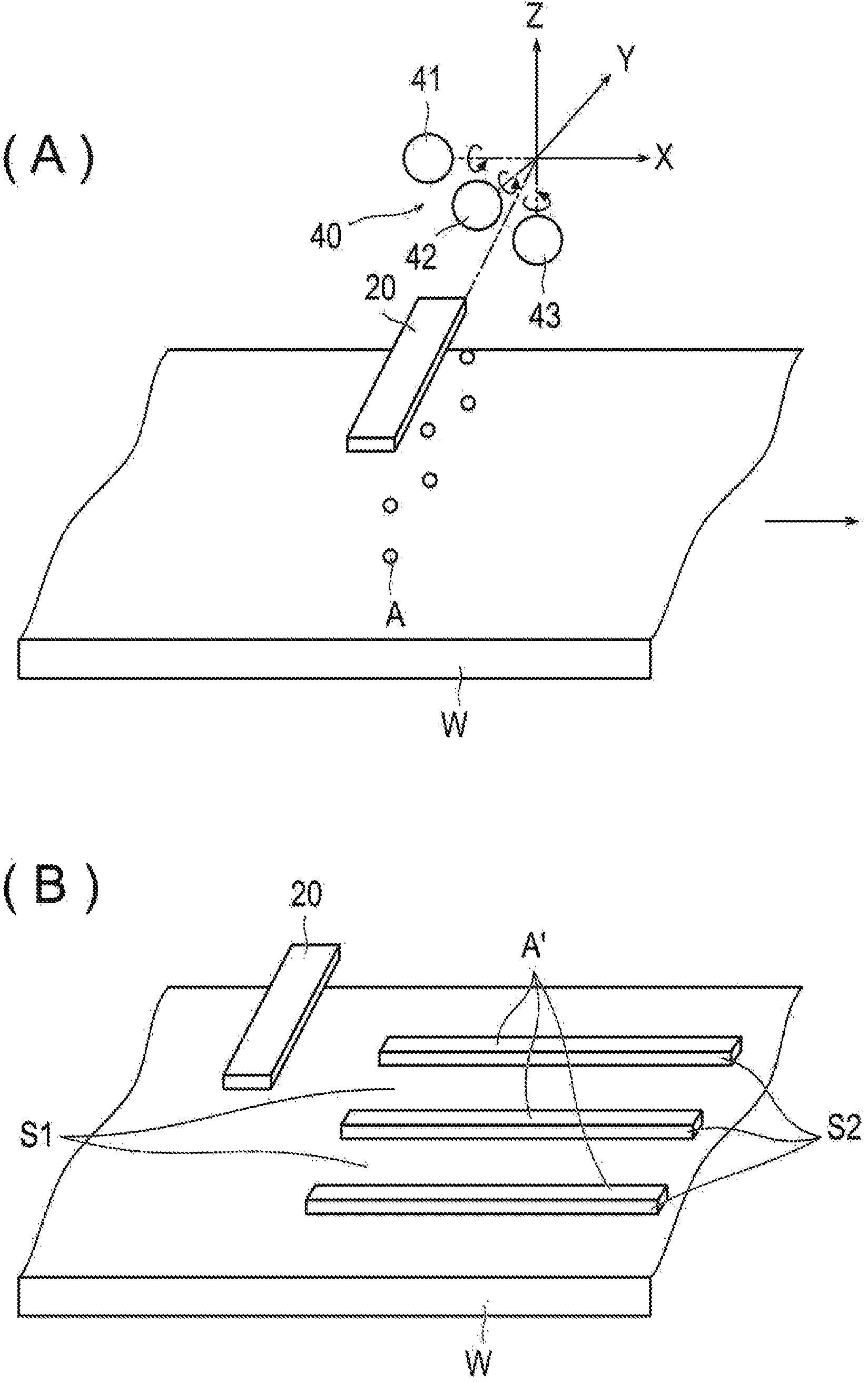

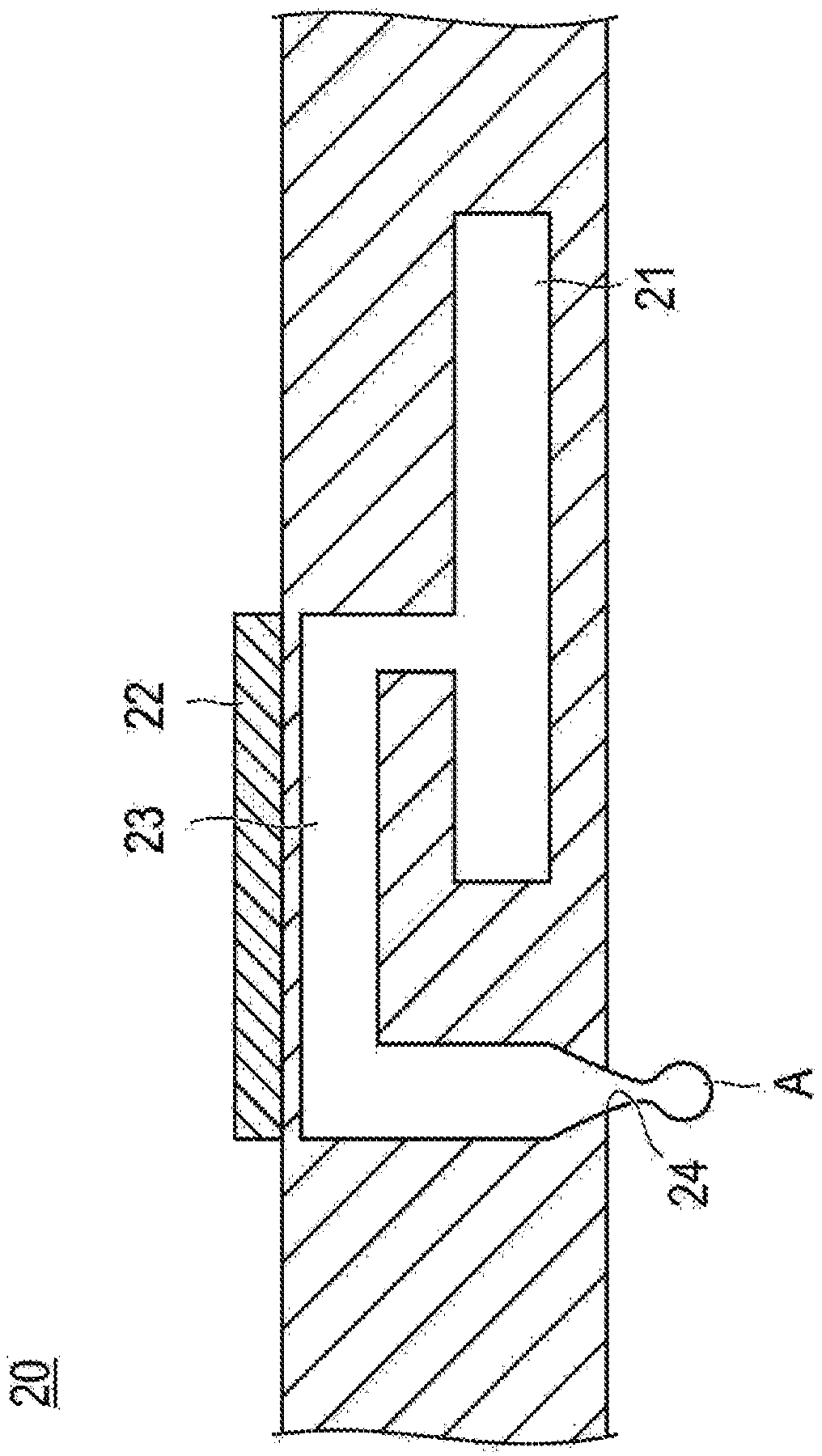

Application device, removal device, application and removal system as well as application method, removal method, and application and removal method

InactiveCN104411413AEasy to operateLiquid surface applicatorsLayered productsHot melt coatingParaffin oils

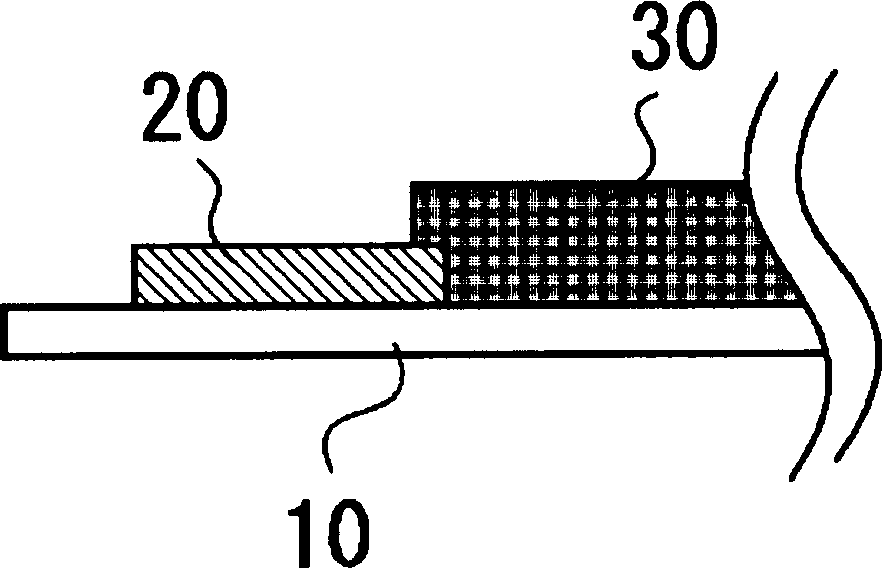

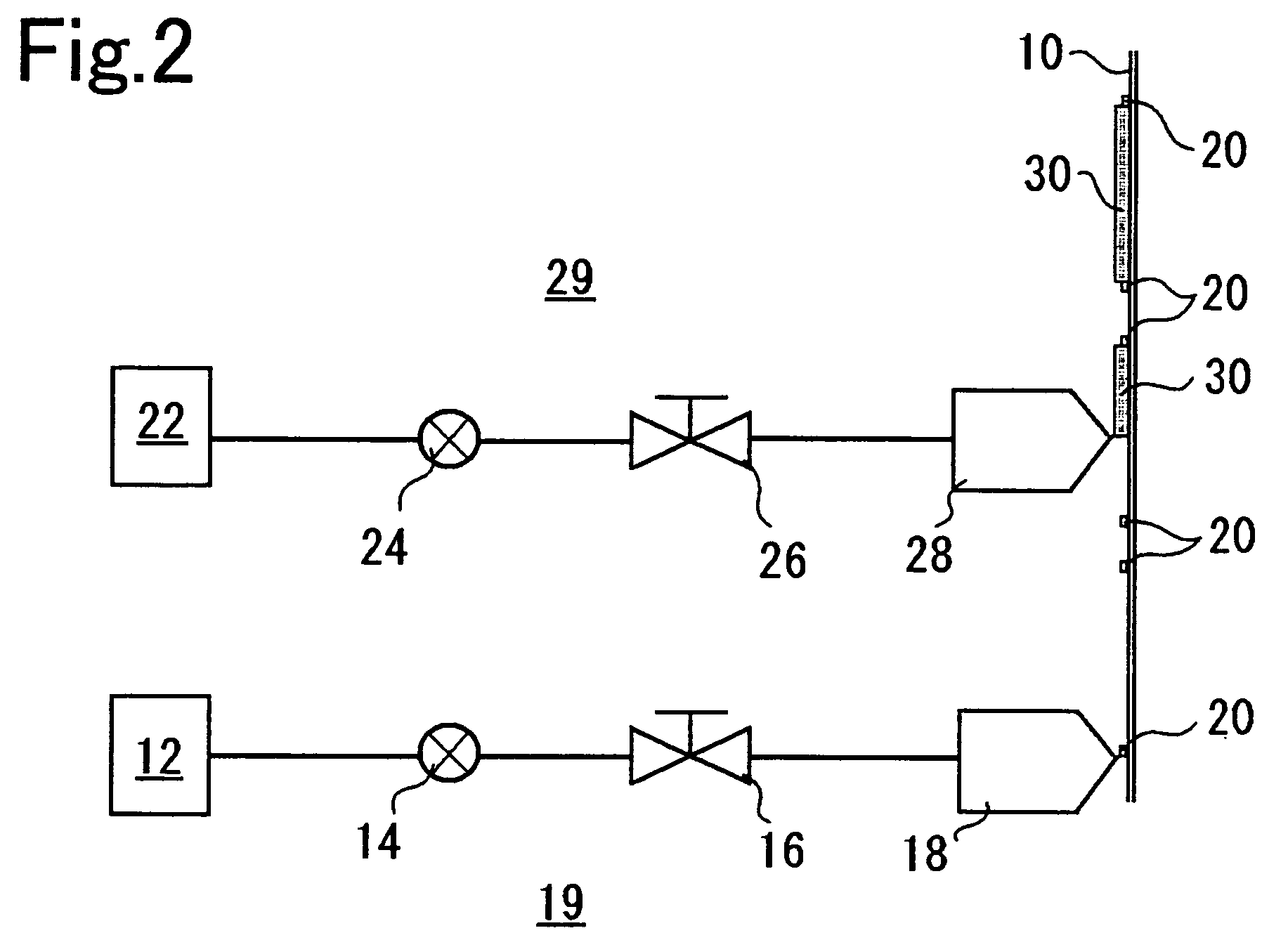

The present invention is an application device (10) for applying a hot melt coating material (A) only on the non-treated surfaces (S2) of a coating object, which comprises treated surfaces (S1) where surface treatment is to be performed and non-treated surfaces (S2) where surface treatment is not to be performed, the device comprising: an inkjet unit (20) for discharging melted coating material (A) toward the coating object; a supply unit (30) for supplying the melted coating material (A) to the inkjet unit (20); and a heating means (31) for melting the coating material (A), the heating means being provided on the supply unit (30). Another invention removes coating material (A), which is a paraffin-containing masking agent and has been coated only on the non-treated surfaces (S2) of the coating object, still in solid form from the coating object using a refrigerant of a temperature less than the melting point of paraffin or in liquid form from the coating object using a fluid of a temperature at or above the melting point of paraffin. Said various configurations allow the formation of masking on small, complex non-treated surfaces as well as easy removal of the masking agent.

Owner:JE INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com