Automatic generation device of motherboard and operation method thereof

A technology of automatic generation and main board, applied in software deployment, secondary processing of printed circuit, electrical components, etc., can solve problems such as inability to complete work in an orderly manner, scattered work station procedures, complex operation of processing equipment, etc., to reduce labor costs , the effect of high degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

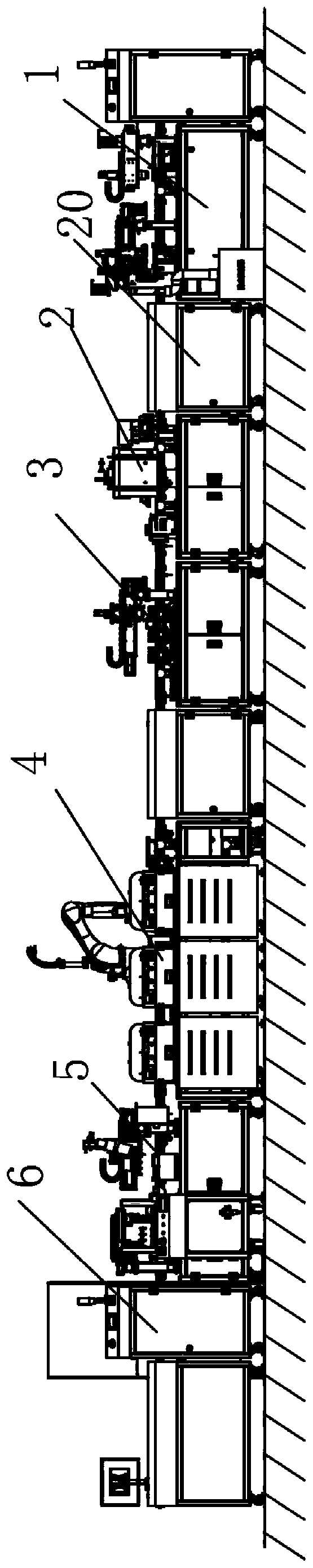

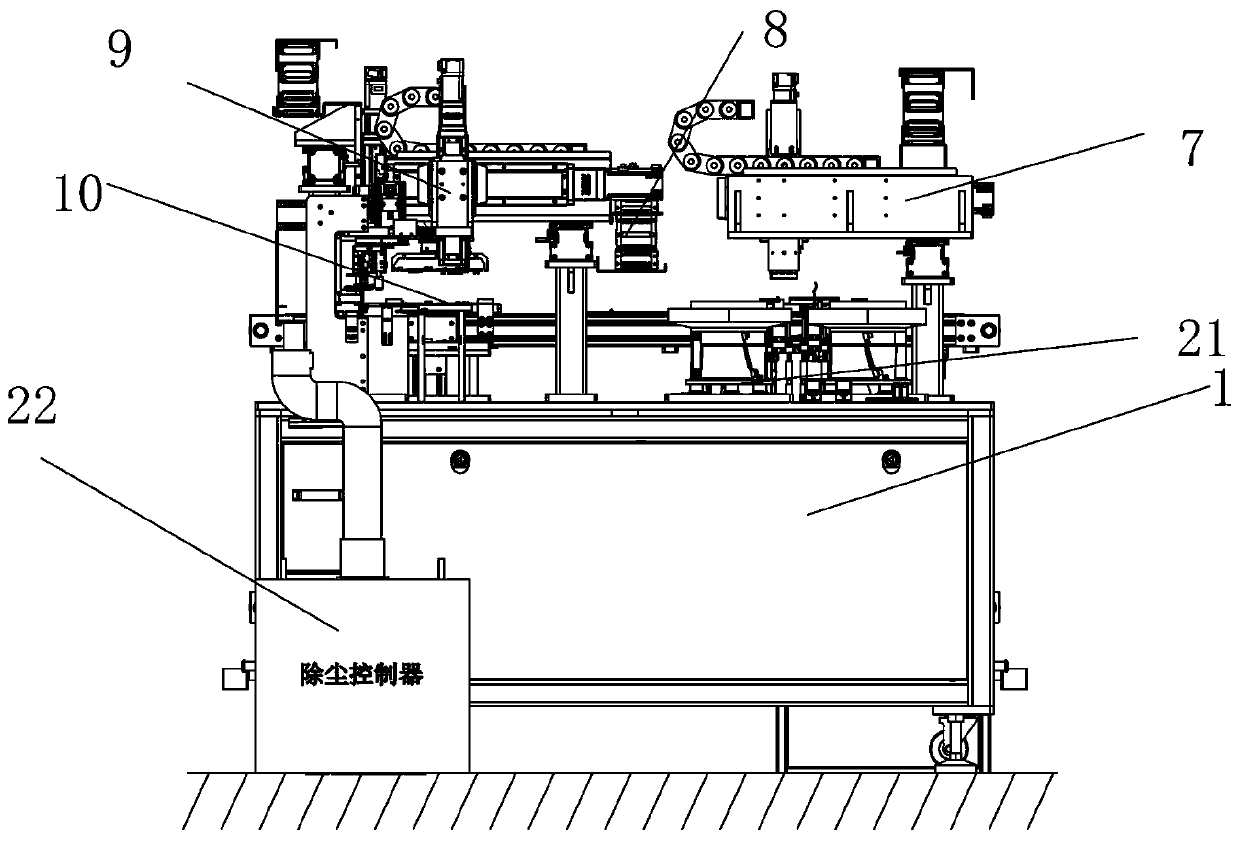

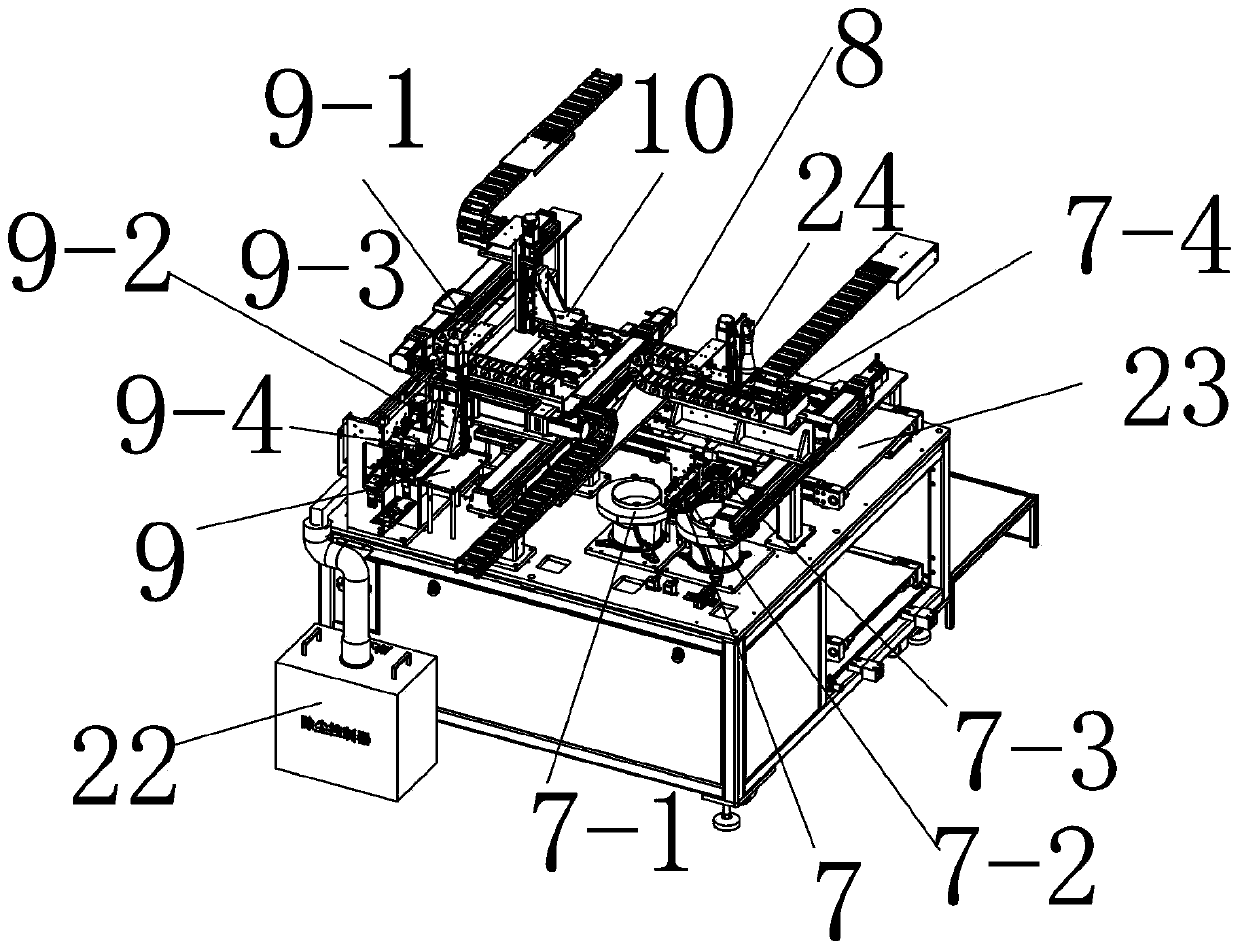

[0041] Such as Figure 1-Figure 7 As shown, the automatic generation equipment of a kind of mainboard provided by this embodiment includes a frame 20, on which an automatic conveyor belt with a carrier disk 21 is arranged, and the following are connected in sequence from right to left on the automatic conveyor belt part:

[0042] The integrated gantry-type three-axis module is used to complete the handling and grabbing work, which can realize the automatic assembly of the PCB main board and the connector 1;

[0043] Burn the PCB main board on the product after the operation of the sub-board insertion machine 1 process, and automatically solder the burned PCB main board and the connector for connection soldering and burning equipment 2;

[0044] Automatic labeling machine 3 for automatically labeling products after soldering and burning equipment;

[0045]CCA testing equipment 4 for CCA testing of products after the automatic labeling machine 3;

[0046] Hot-melt gluing equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com