Continuous reflective high-standard hot melt coating

A high-temperature, coating technology, which is applied in the field of road marking paint and hot-melt road marking paint, can solve the problems of affecting night driving safety, loss of retroreflective performance, and decreased retroreflective performance of marking lines. Achieve the effect of improving visibility and visibility at night, guaranteeing long-term retroreflection value, and prolonging retroreflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

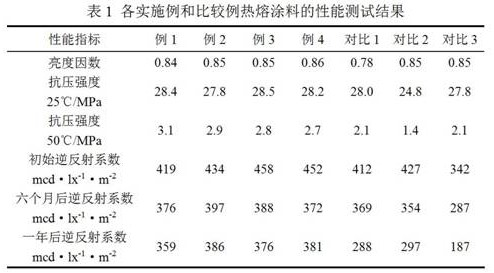

Examples

Embodiment 1

[0031] 10 kg of 16-30 mesh glass beads, 20 kg of 30-50 mesh glass beads, and 5 kg of 50-80 mesh glass beads are added into a mixer and stirred evenly to obtain mixed glass beads.

[0032] Weigh 10kg of C5 petroleum resin, 5kg of C9 hydrogenated petroleum resin, 3kg of maleic anhydride modified rosin resin, 30kg of mixed glass beads, 10kg of heavy calcium carbonate, 10kg of titanium dioxide, 2kg of oxidized polyethylene wax, 2kg of EVA, and phthalate Dioctyl diformate 2kg, mix and stir evenly, pack and obtain continuous reflective type high-standard hot-melt coating.

Embodiment 2

[0034] 6 kg of 16-30 mesh glass beads, 20 kg of 30-50 mesh glass beads, and 5 kg of 50-80 mesh glass beads are added into a mixer and stirred evenly to obtain mixed glass beads.

[0035] Weigh 15kg of C5 petroleum resin, 3kg of C9 hydrogenated petroleum resin, 1kg of maleic anhydride modified rosin resin, 30kg of mixed glass beads, 7kg of heavy calcium carbonate, 9kg of titanium dioxide, 1kg of oxidized polyethylene wax, 2kg of EVA, and phthalate Dimethyl diformate 2kg, mixed and stirred evenly, packed to obtain continuous reflective type high-standard hot-melt coating.

Embodiment 3

[0037] 10 kg of 16-30 mesh glass beads, 25 kg of 30-50 mesh glass beads, and 5 kg of 50-80 mesh glass beads are added into a mixer and stirred evenly to obtain mixed glass beads.

[0038] Weigh 12kg of C5 petroleum resin, 4kg of C9 hydrogenated petroleum resin, 1kg of maleic anhydride modified rosin resin, 35kg of mixed glass beads, 8kg of heavy calcium carbonate, 8kg of titanium dioxide, 1kg of polypropylene wax, 1kg of EVA, phthalate Dioctyl formate 1kg, mixed and stirred evenly, packaged to obtain continuous reflective high-standard hot-melt coatings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com