Patents

Literature

36results about How to "Good retroreflective performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

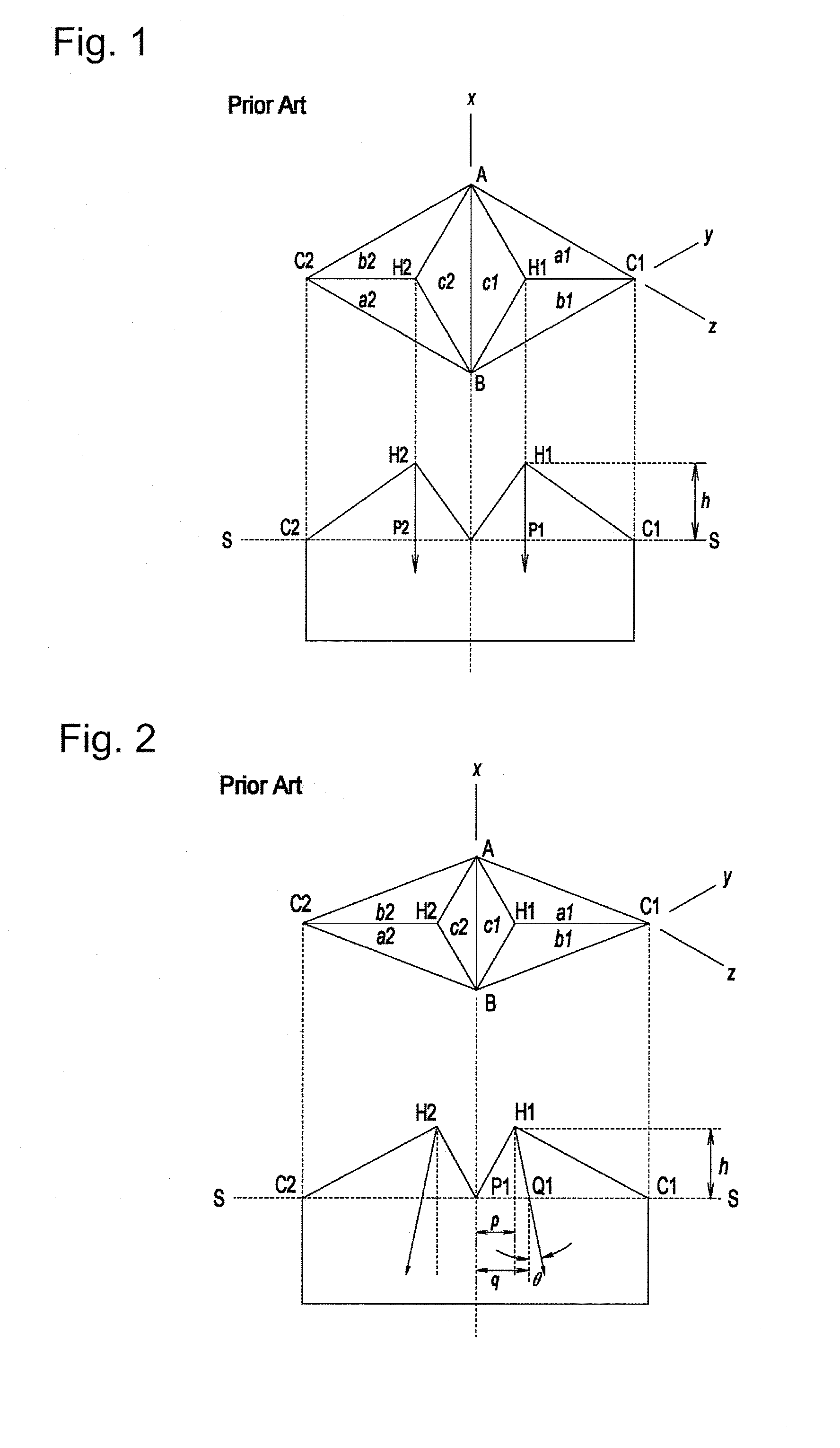

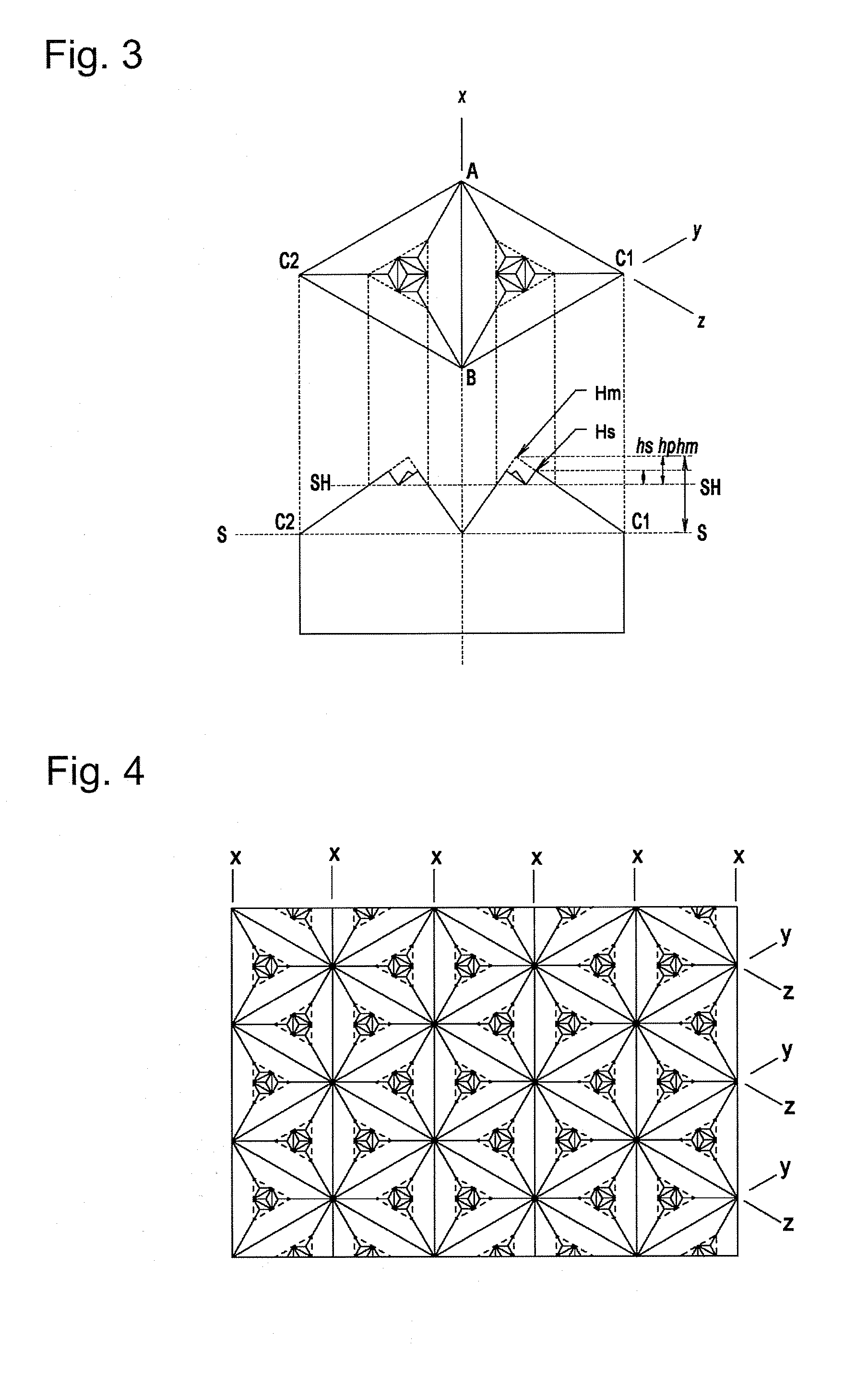

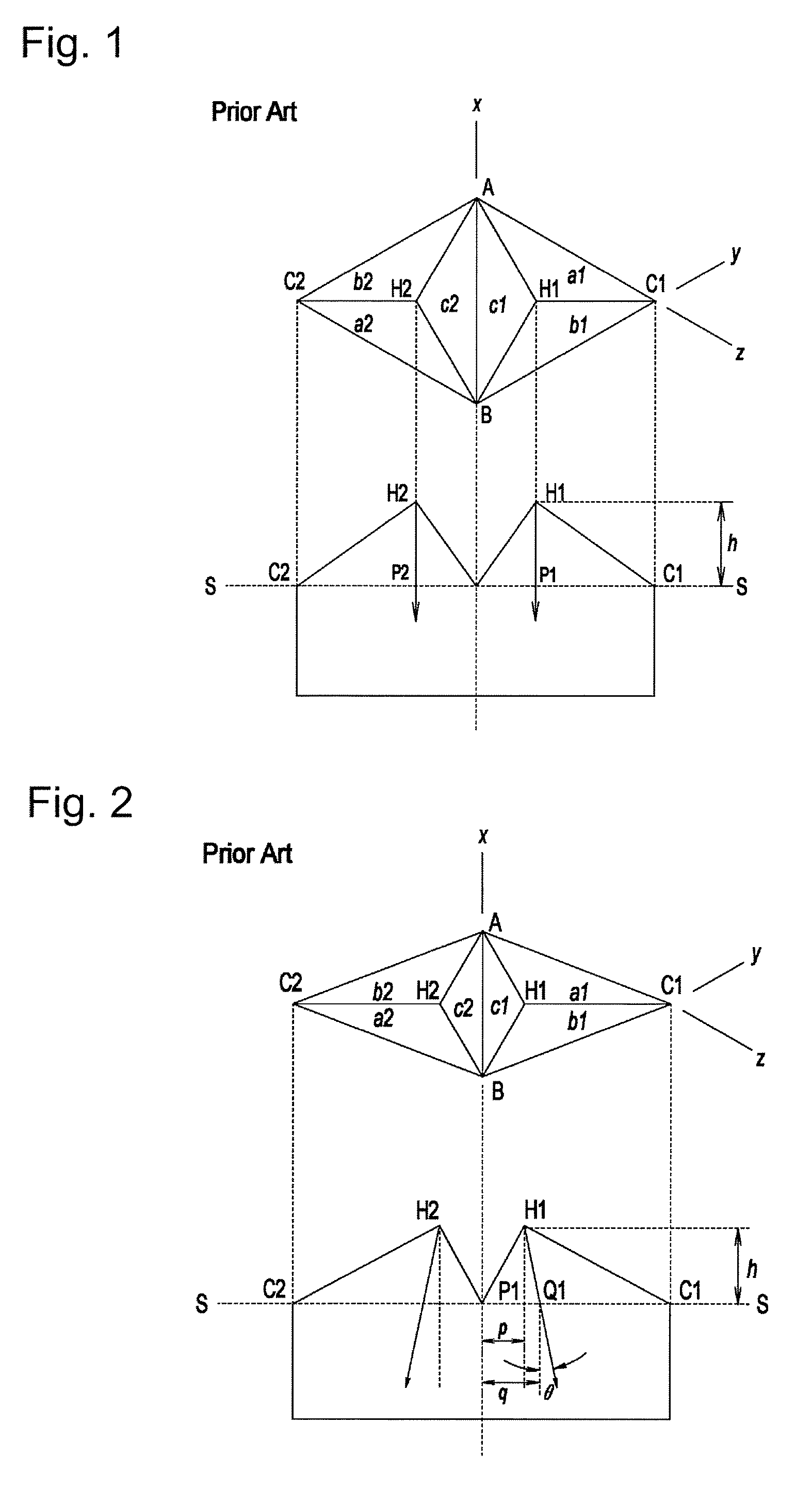

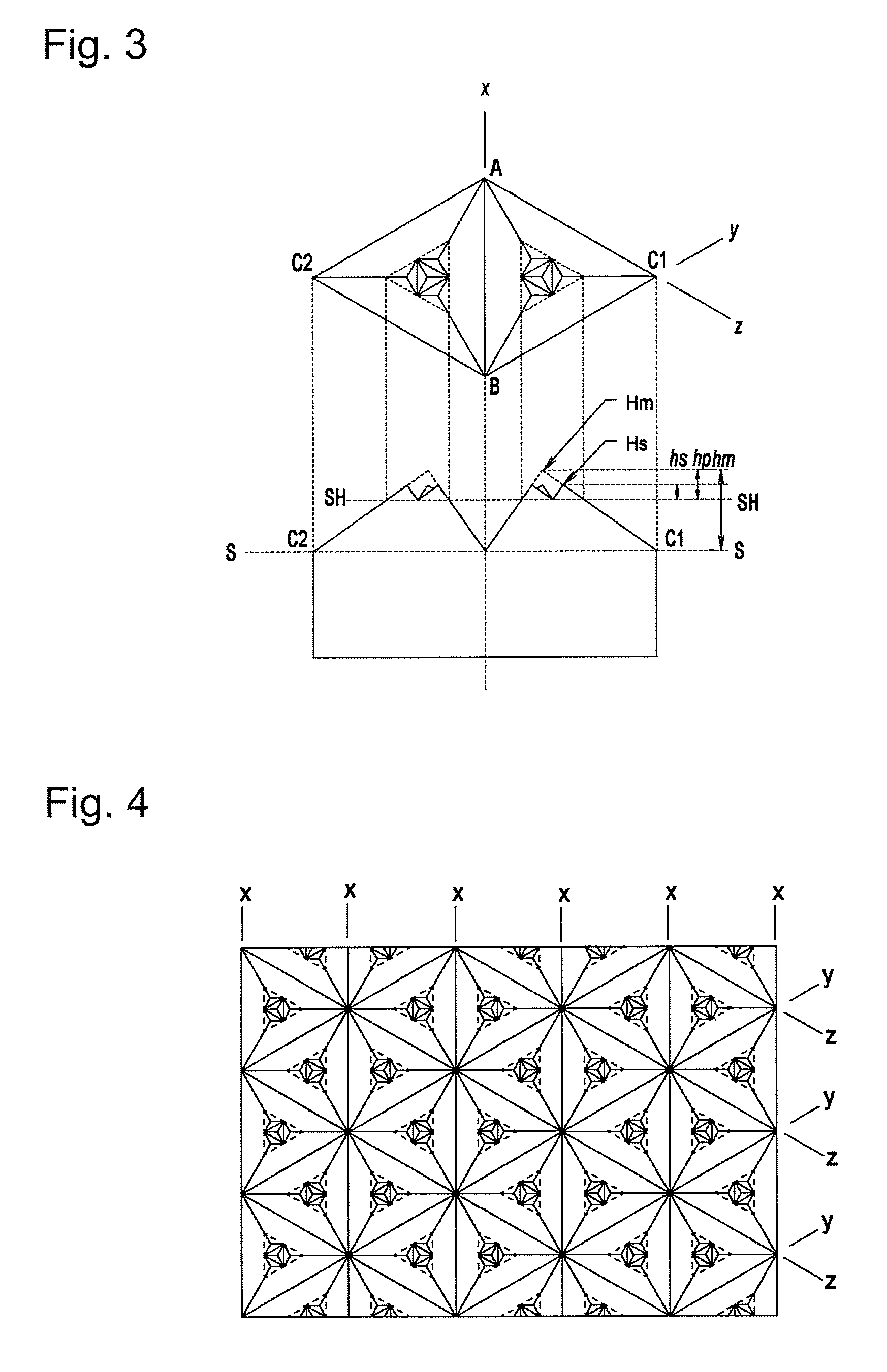

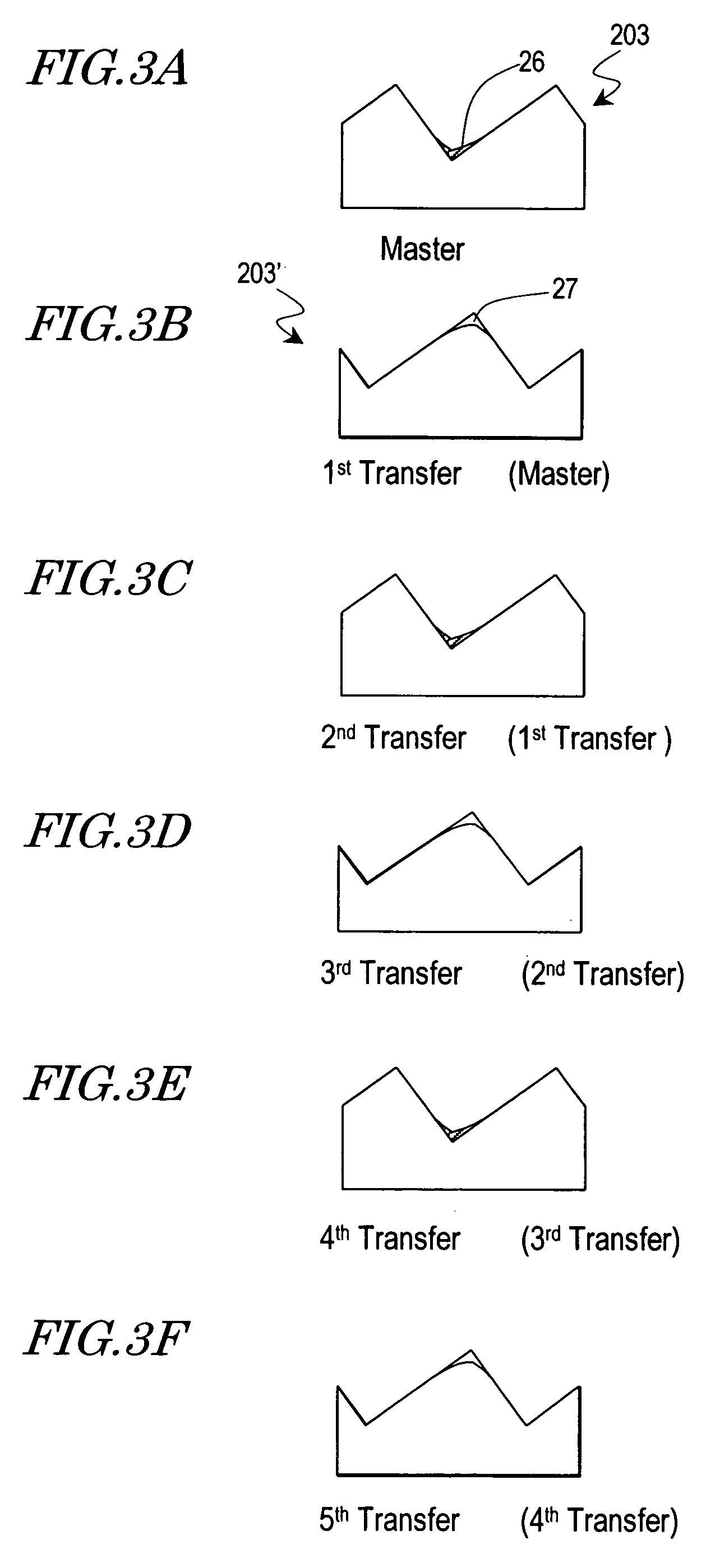

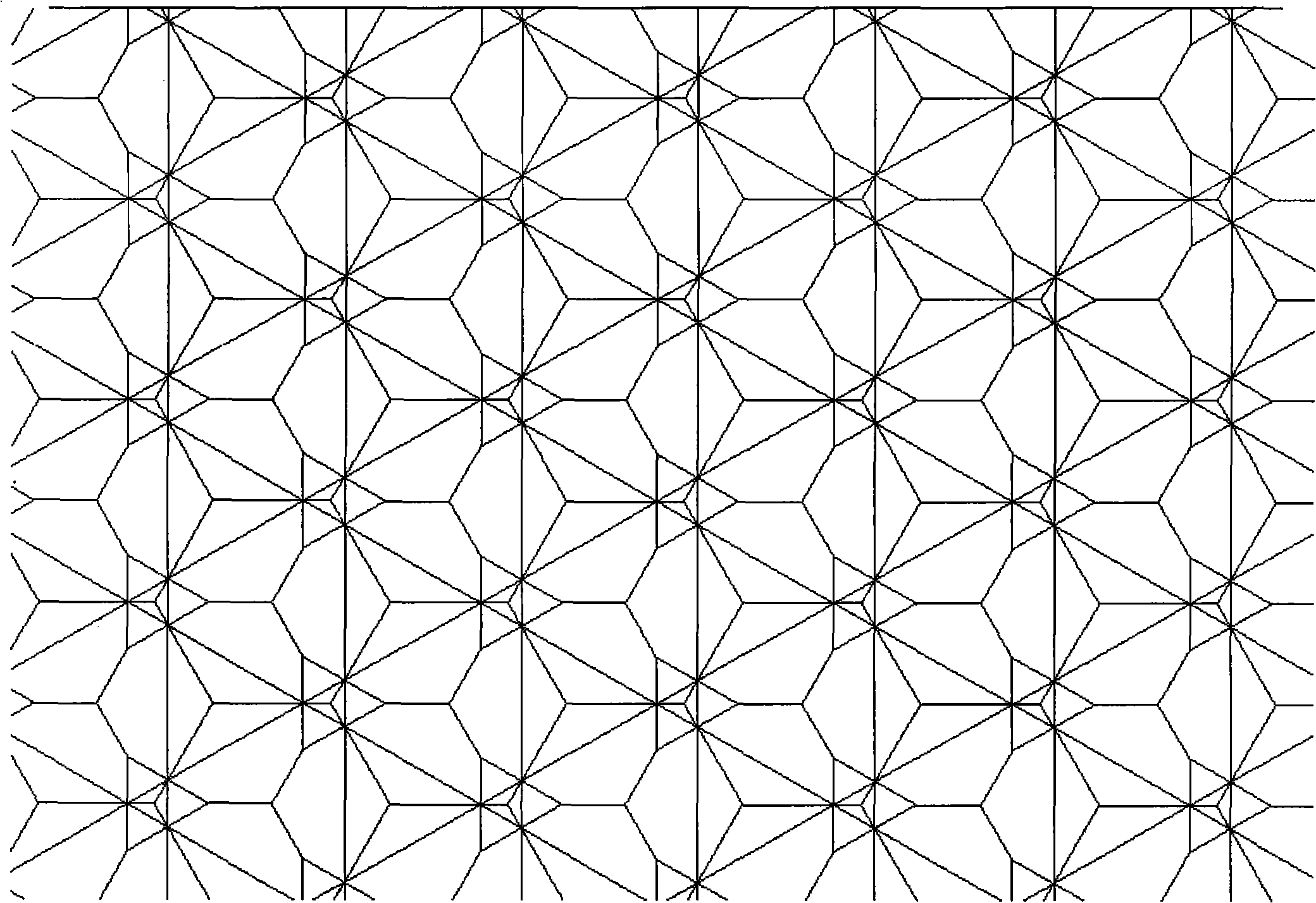

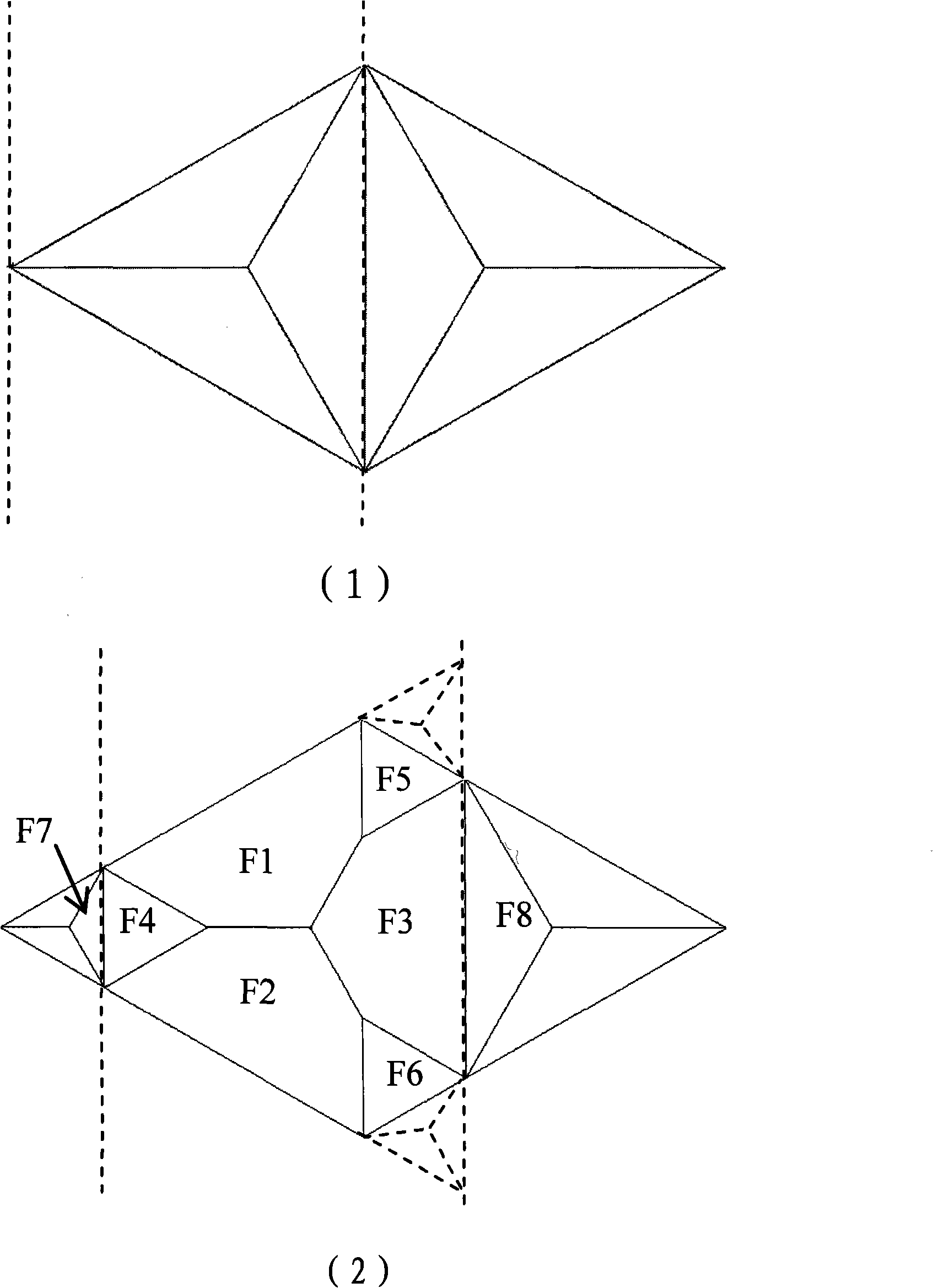

Composite Triangular-Pyramidal Cube-Corner Retroreflective Sheeting And Retroreflective Articles

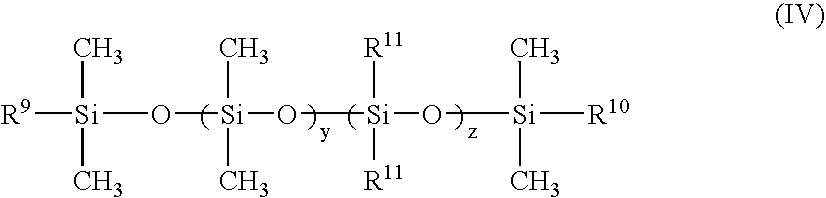

InactiveUS20090122405A1Enhance angularityGood for observationTraffic signalsRoad signsEngineeringTrigonal crystal system

Owner:NIPPON CARBIDE KOGYO KK

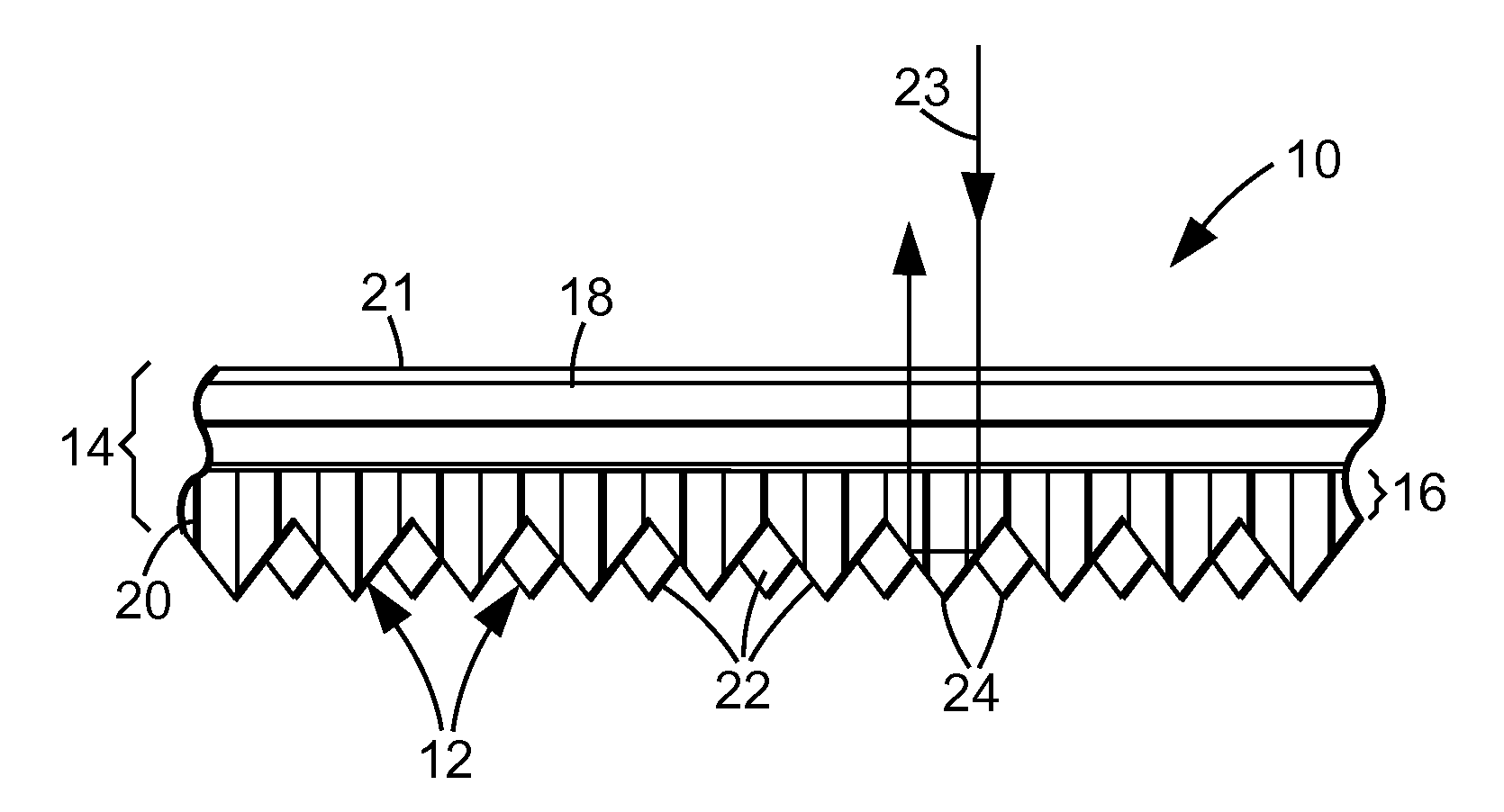

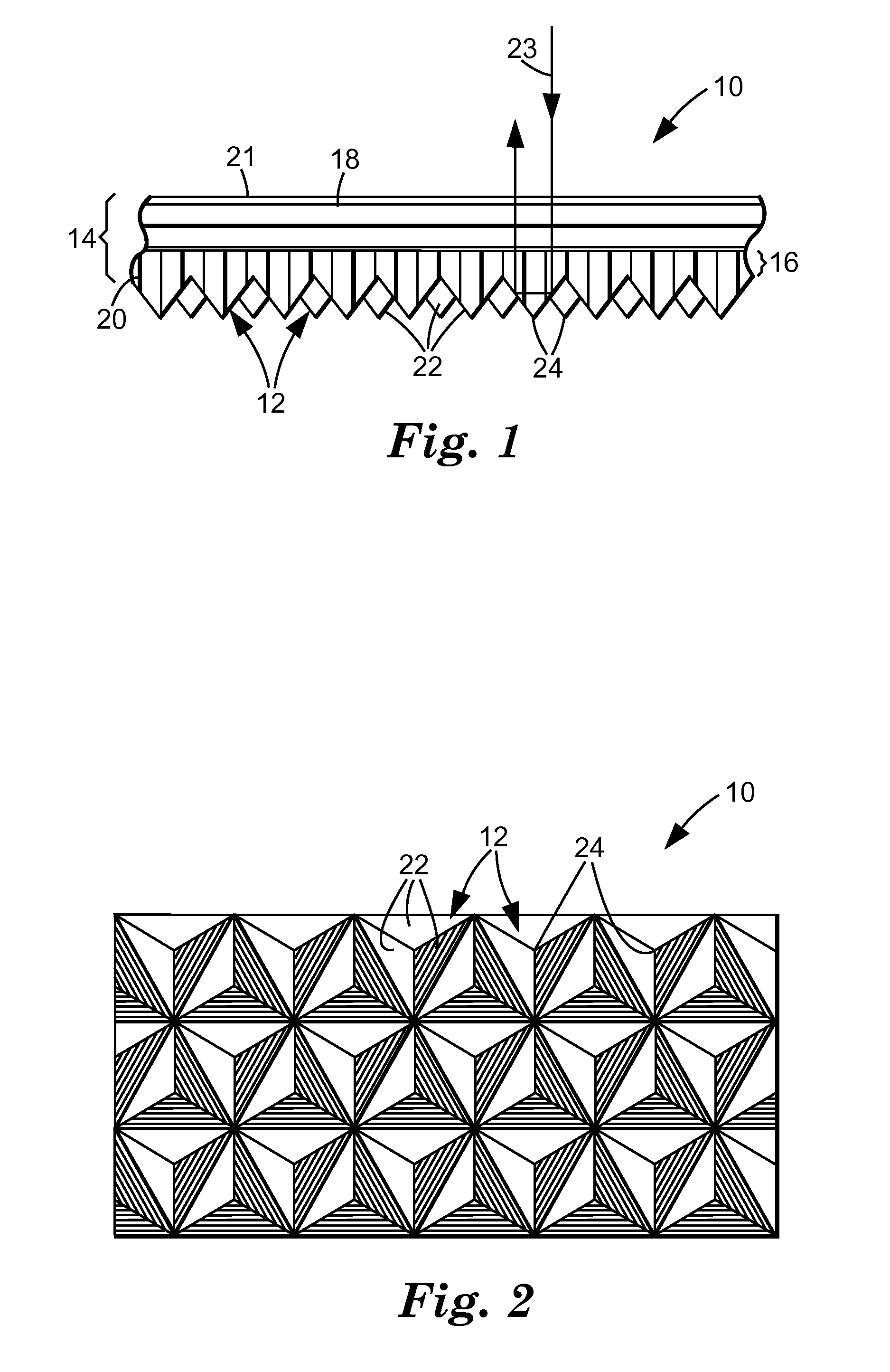

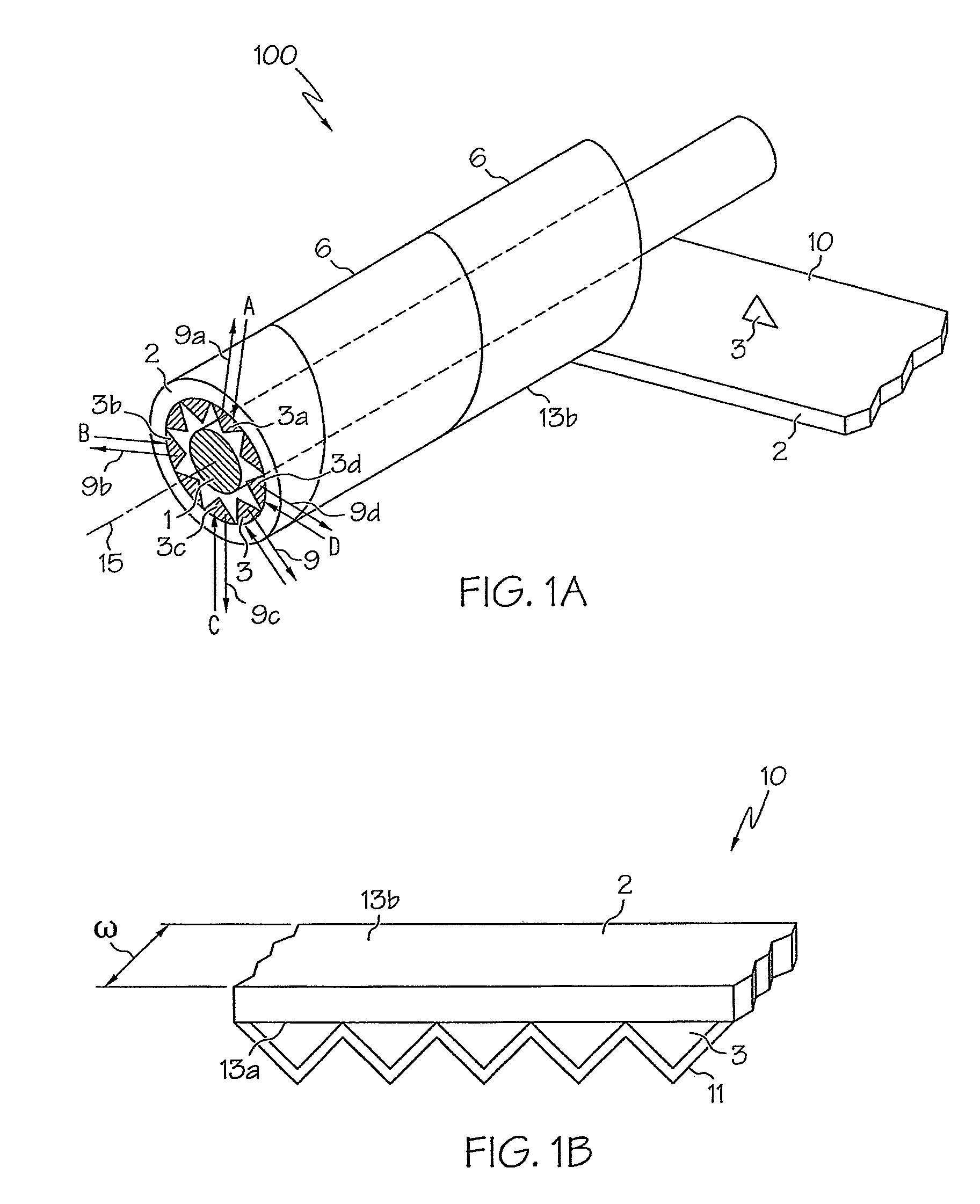

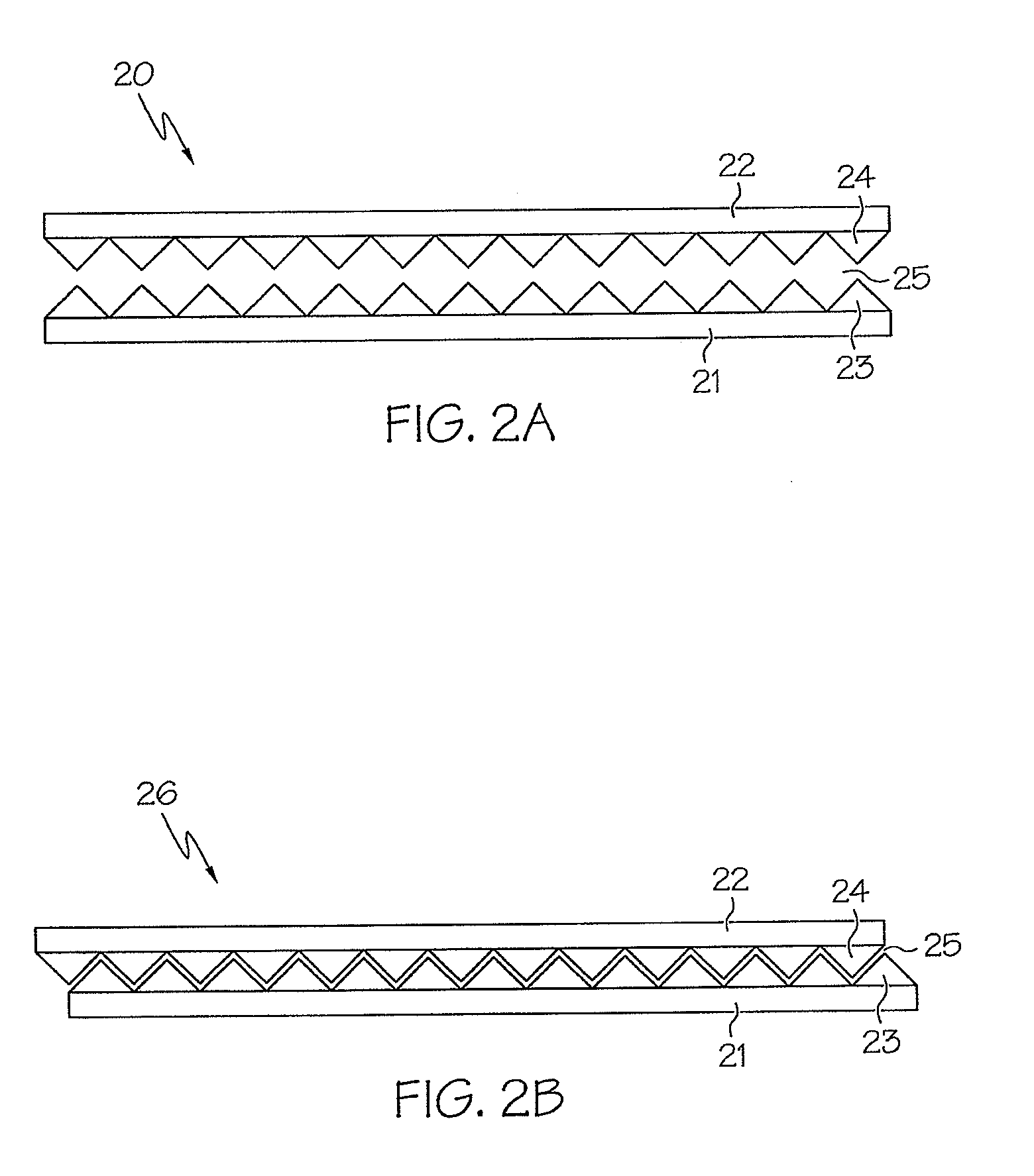

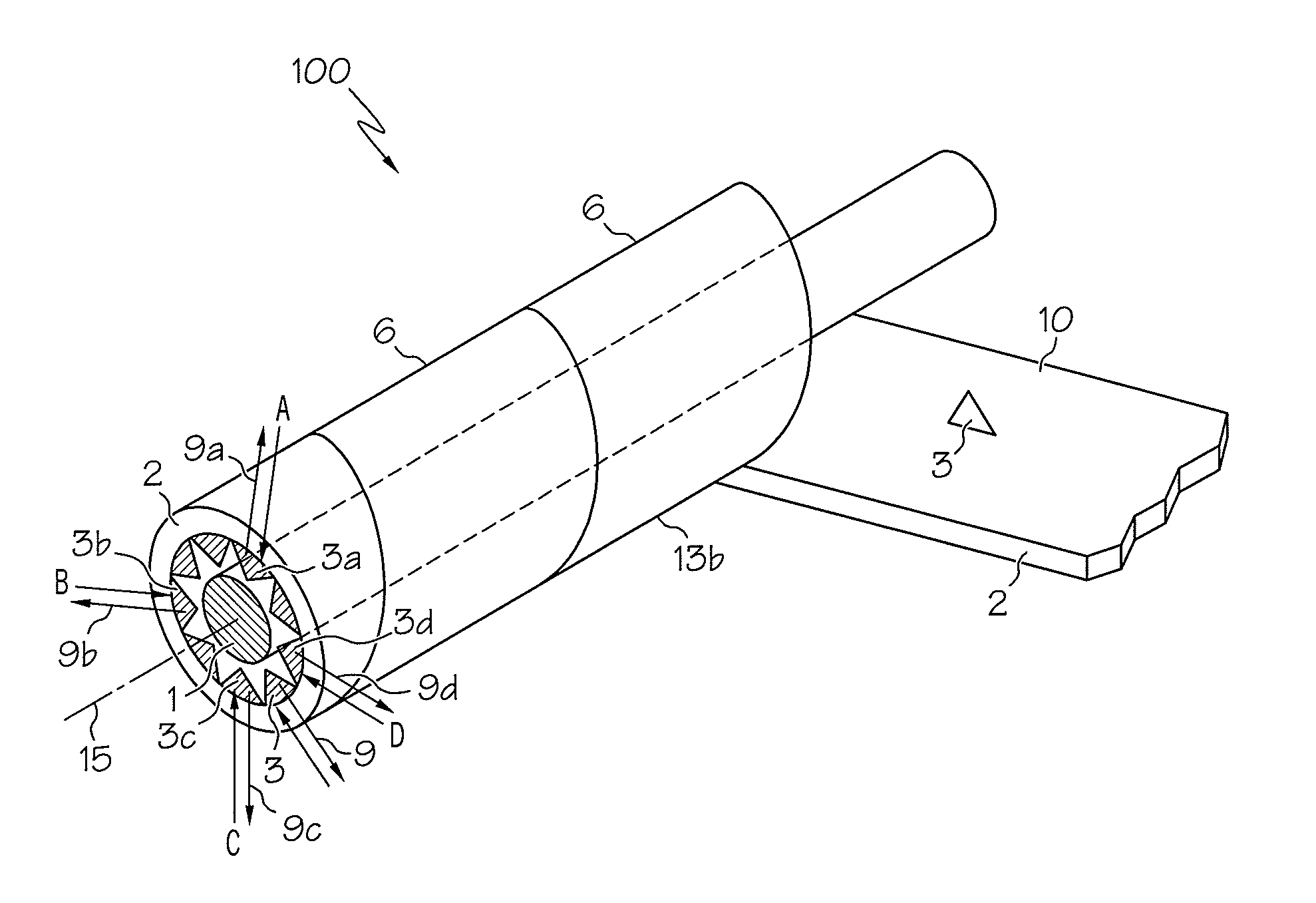

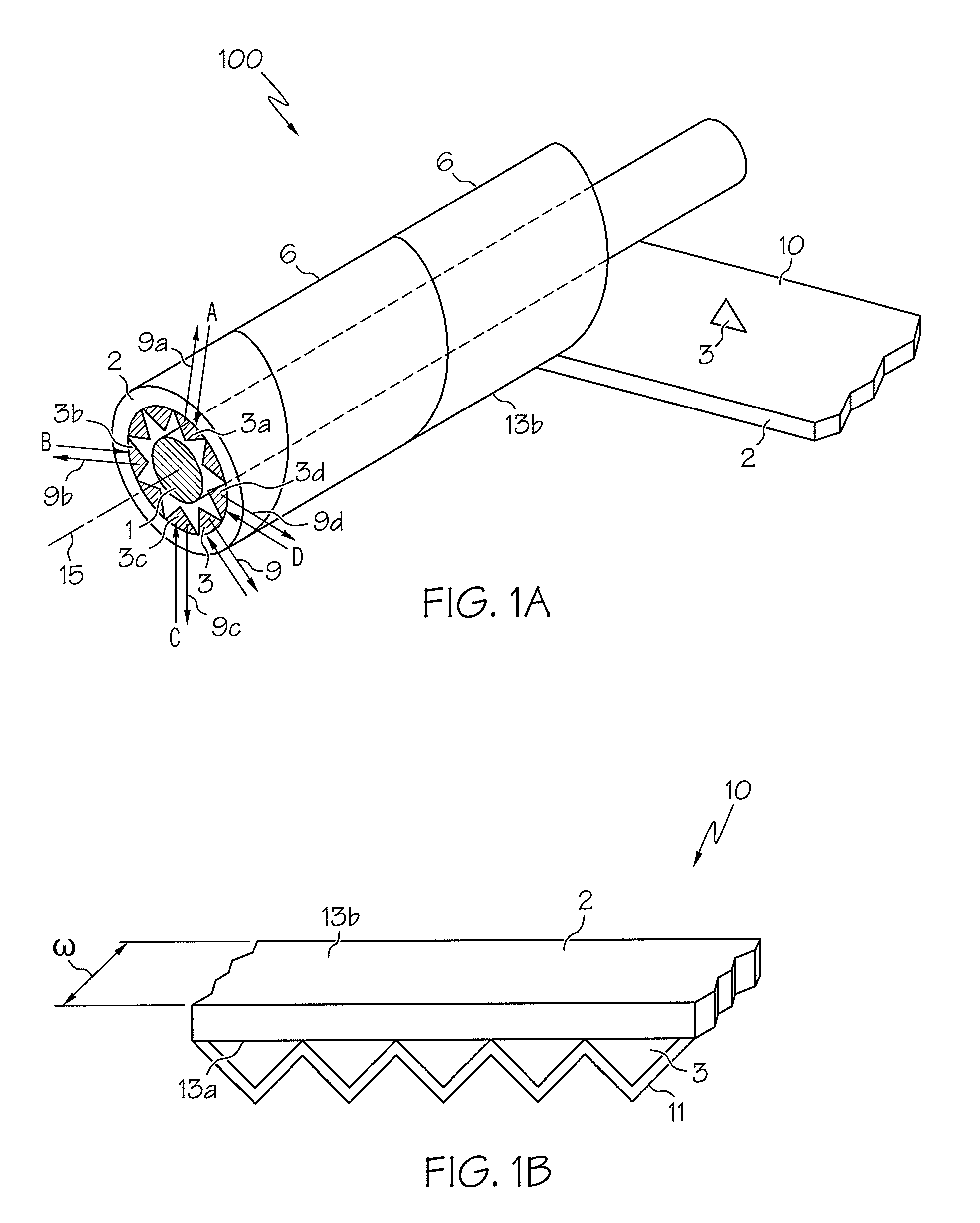

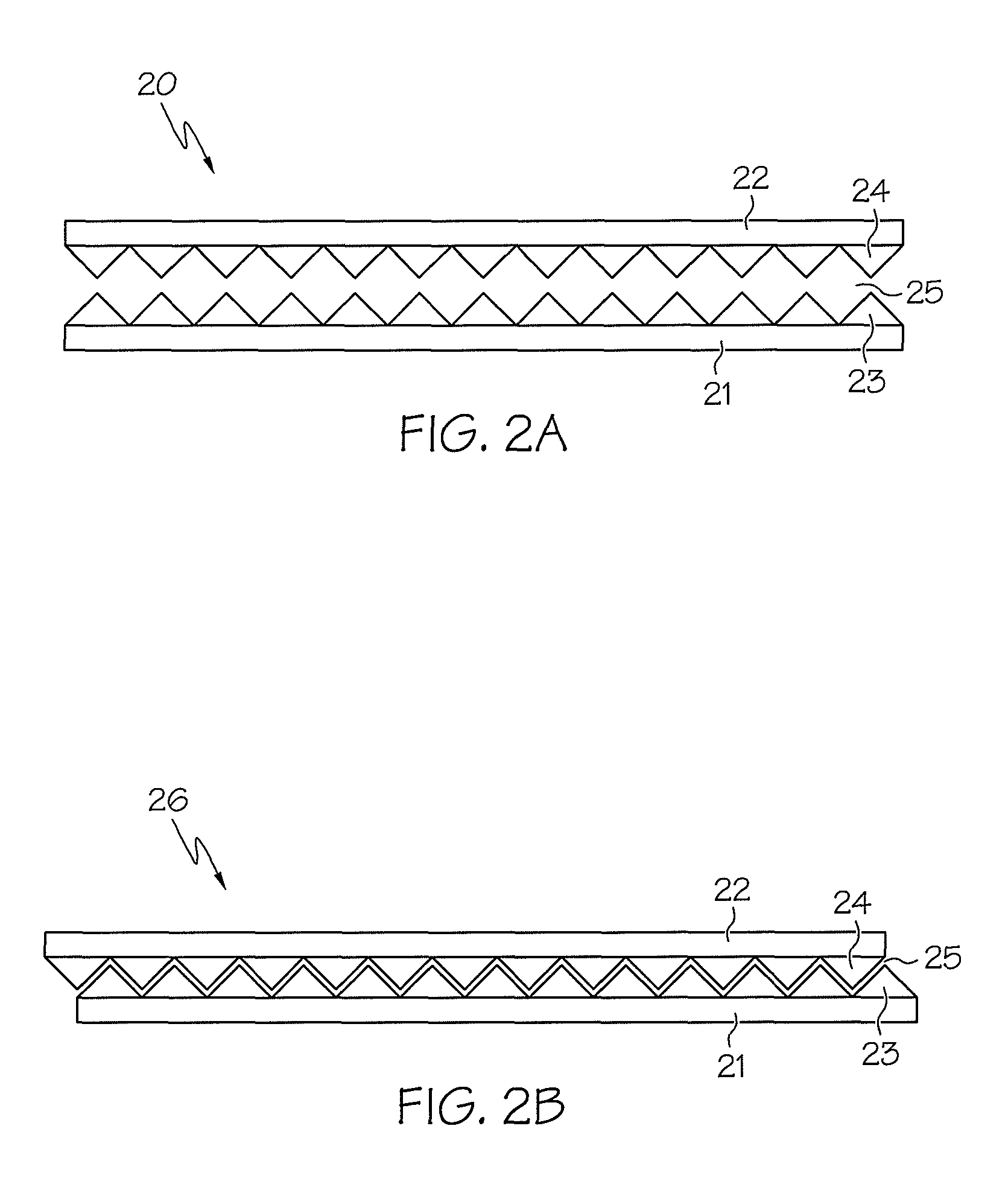

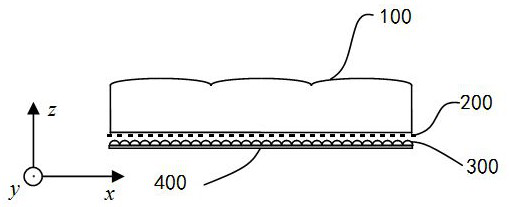

Flexible cube-corner retroreflective sheeting

InactiveUS20070014011A1Dimensional stabilityIncrease flexibilityLayered productsThin material handlingBiomedical engineeringElastic modulus

A retroreflective article 10 has a body portion 14 and a multitude of cube-corner elements 12 that project from a rear side 20 of the body portion 14. The body portion 14 includes a body layer 18 that contains a light-transmissible polymeric material having an elastic modulus less than 7×108 pascals. The cube-corner elements 12 contain a light transmissible polymeric material having an elastic modulus greater than 16×108 pascals. A retroreflective article of this construction can be highly flexed while maintaining good retroreflective performance.

Owner:3M INNOVATIVE PROPERTIES CO

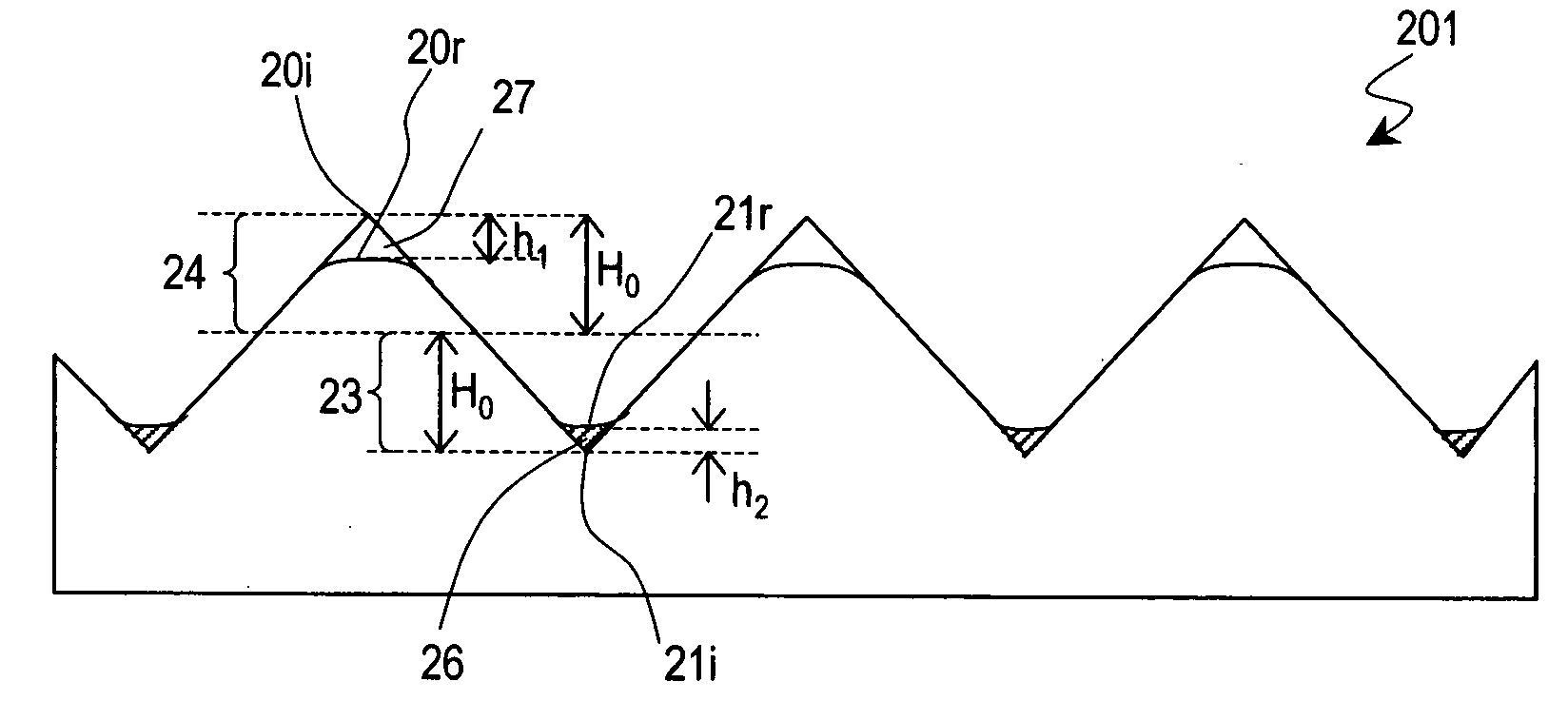

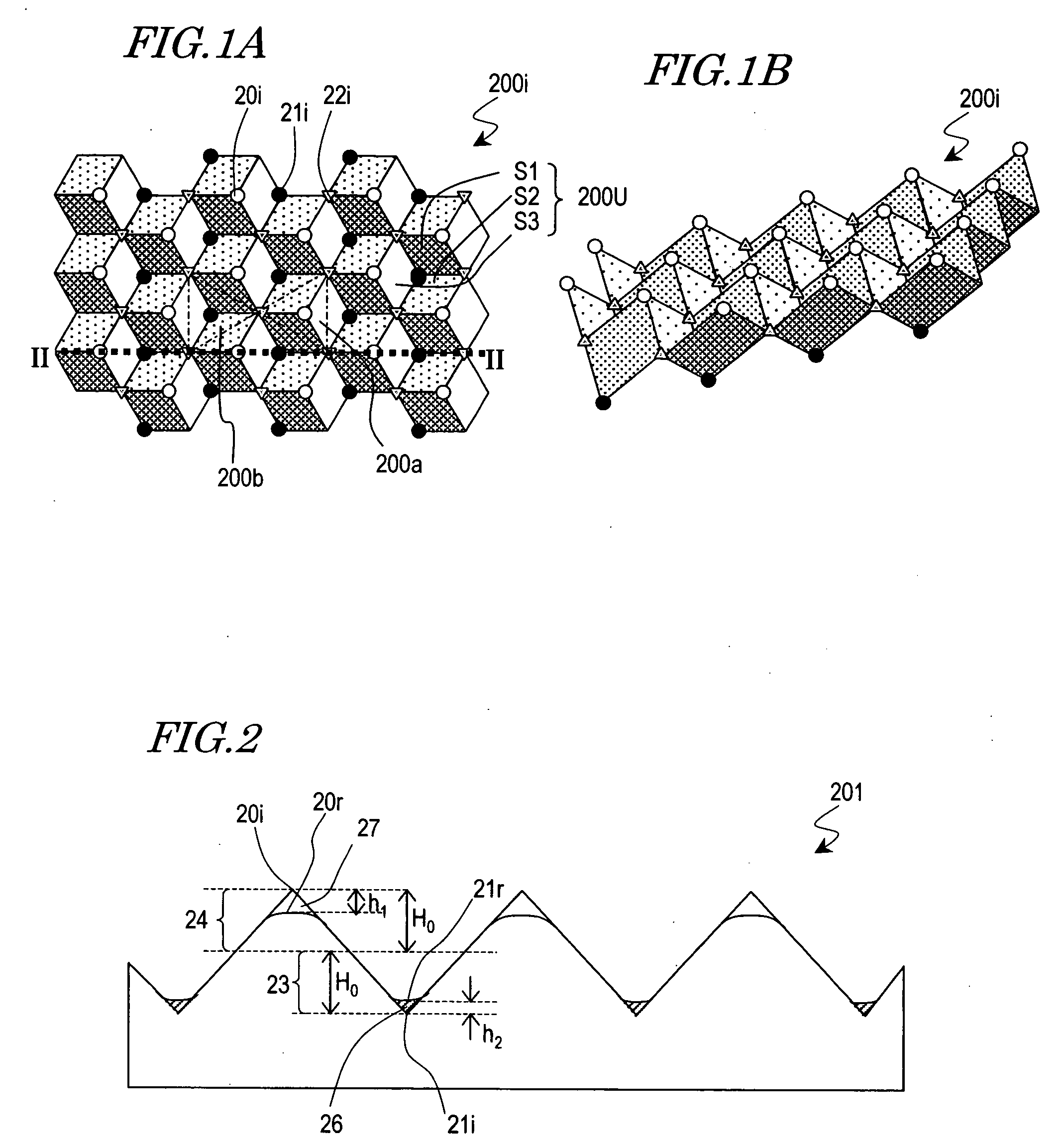

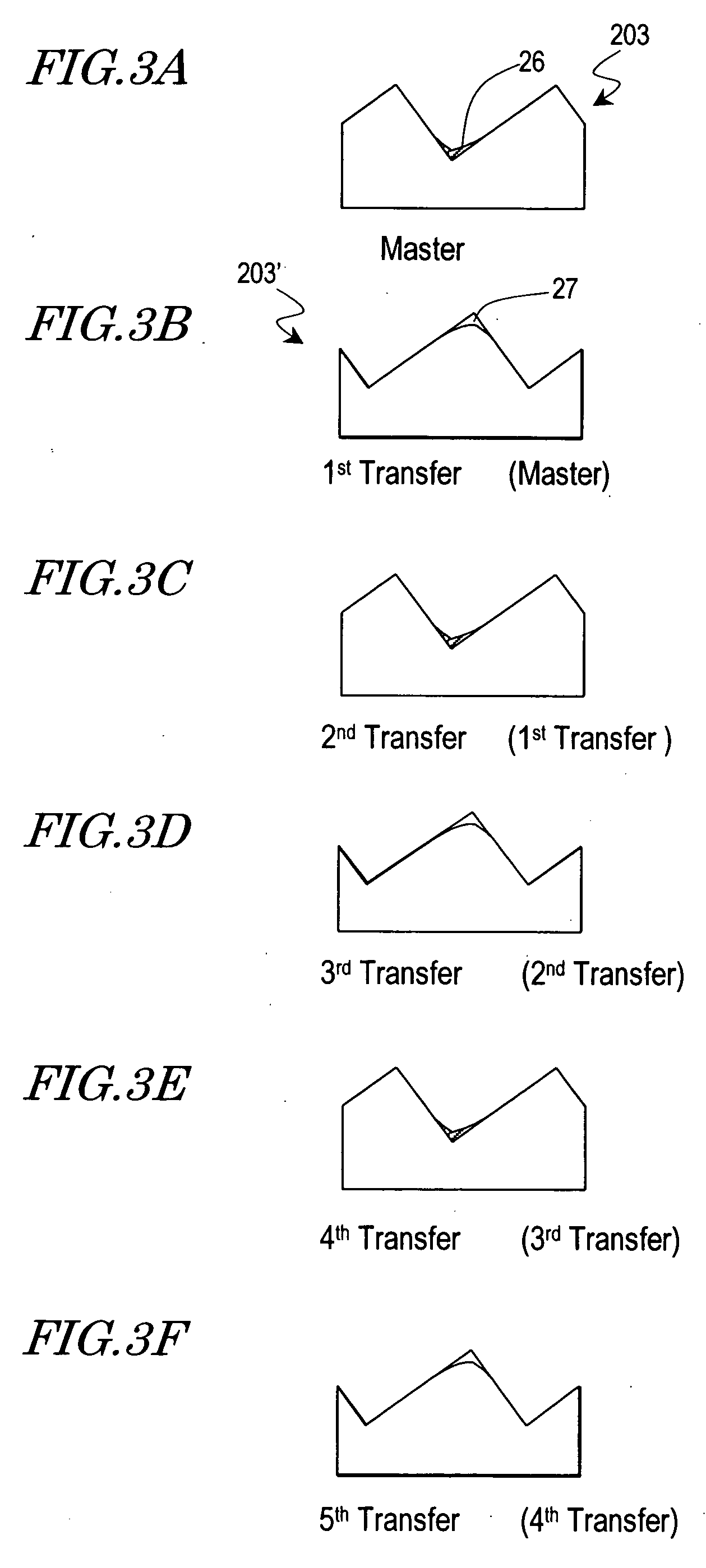

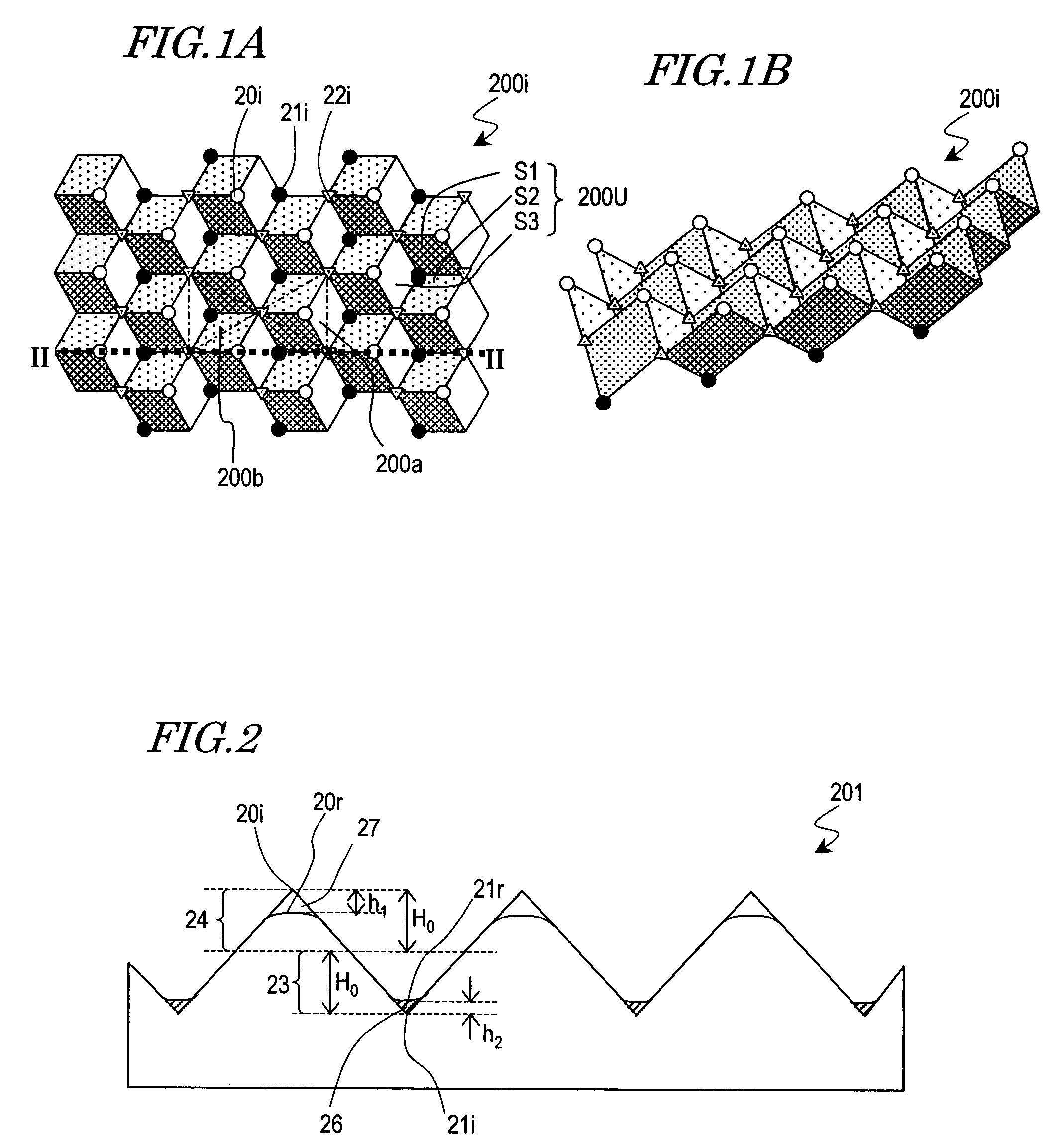

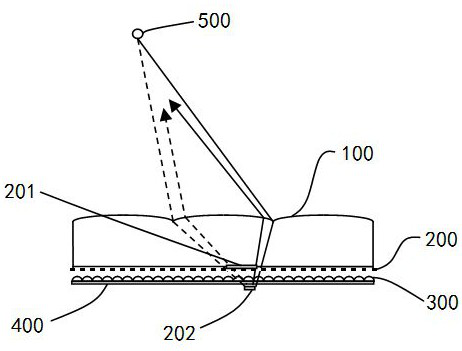

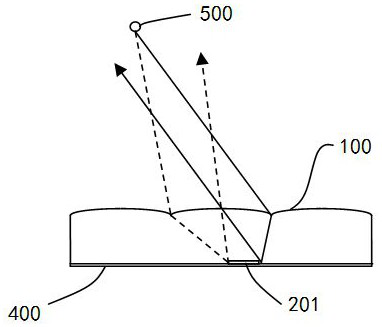

Corner cube reflector, method of making the reflector and reflective display device including the reflector

ActiveUS20050088743A1Good retroreflective performanceImprove the display effectNon-linear opticsOptical elementsPartition of unityDisplay device

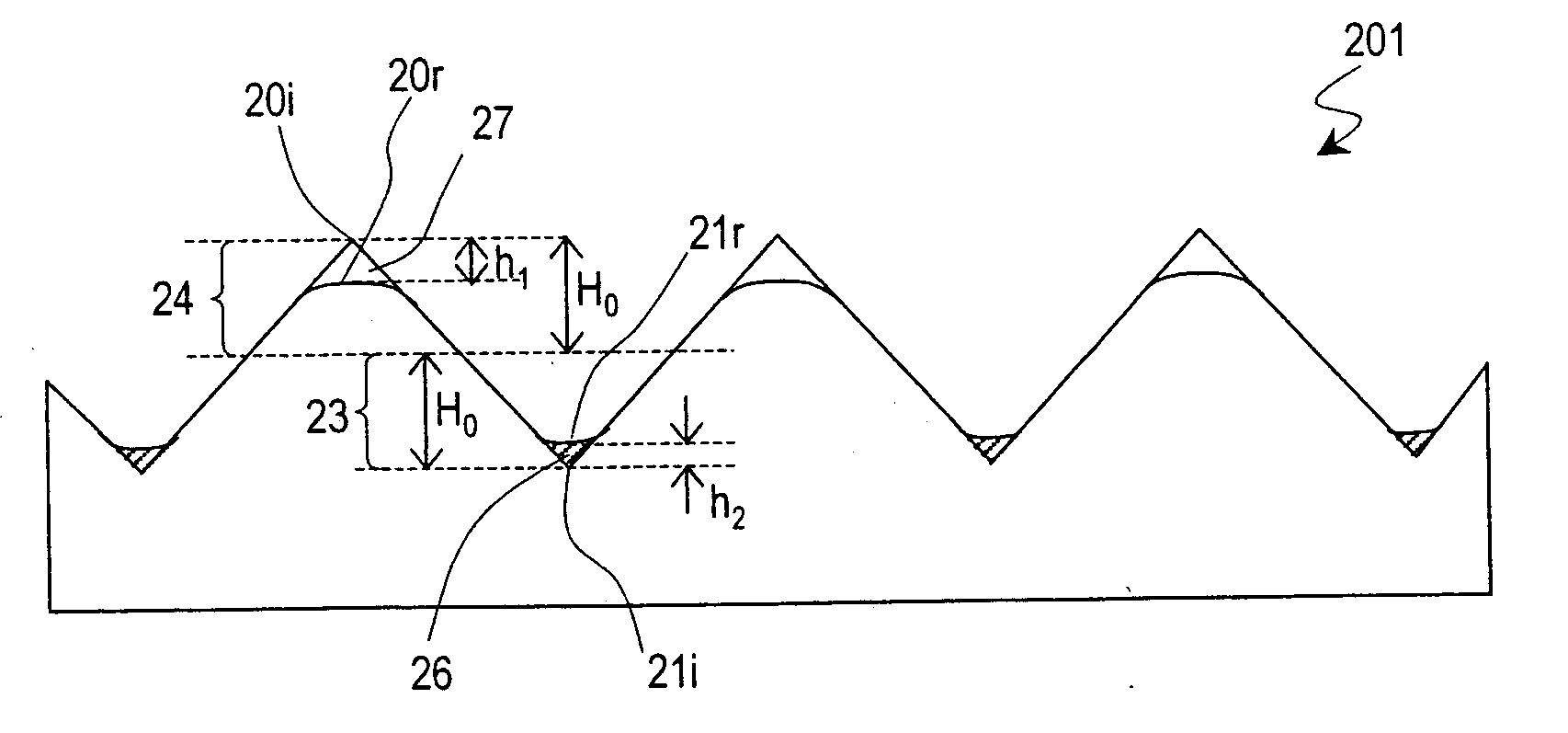

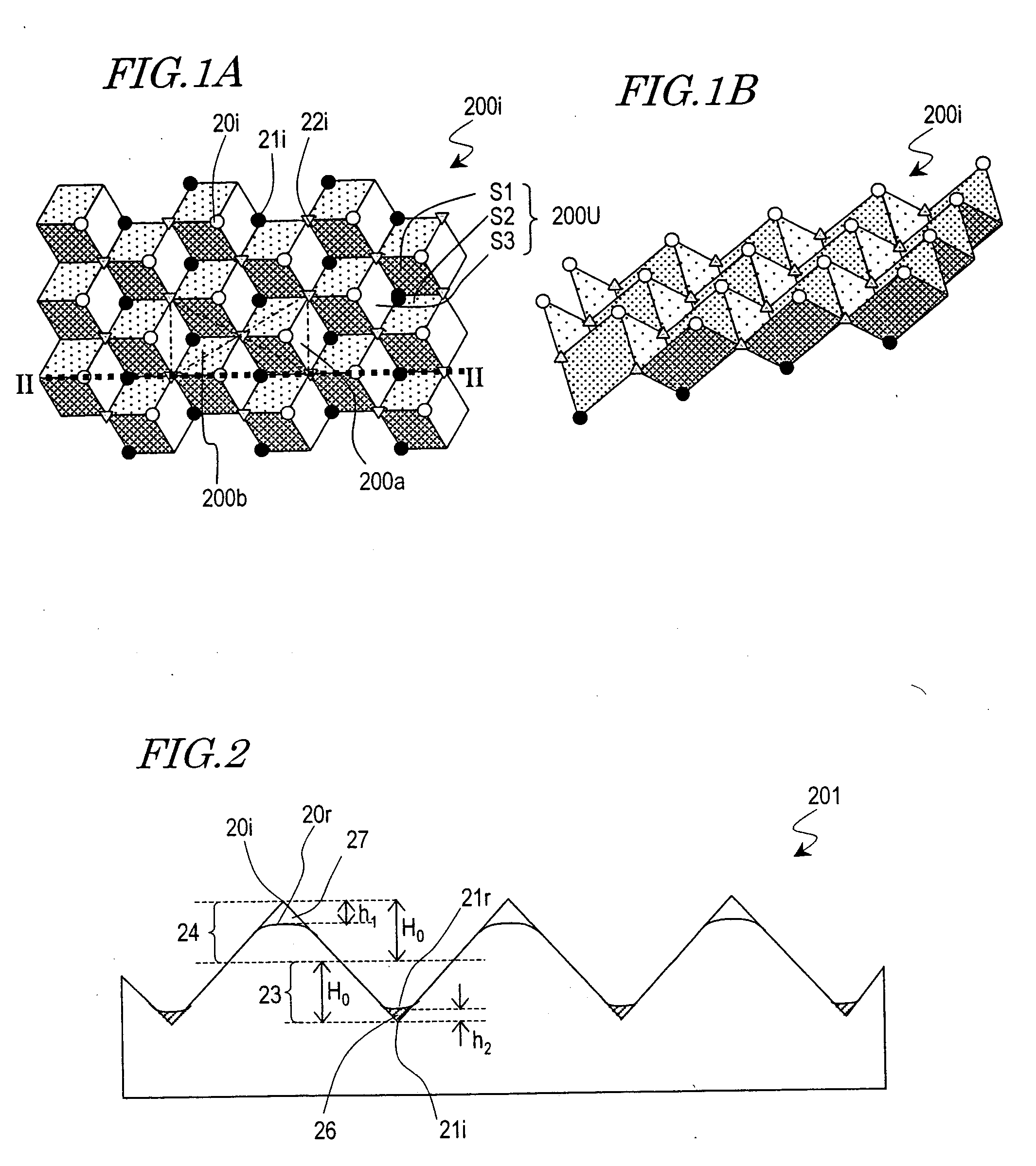

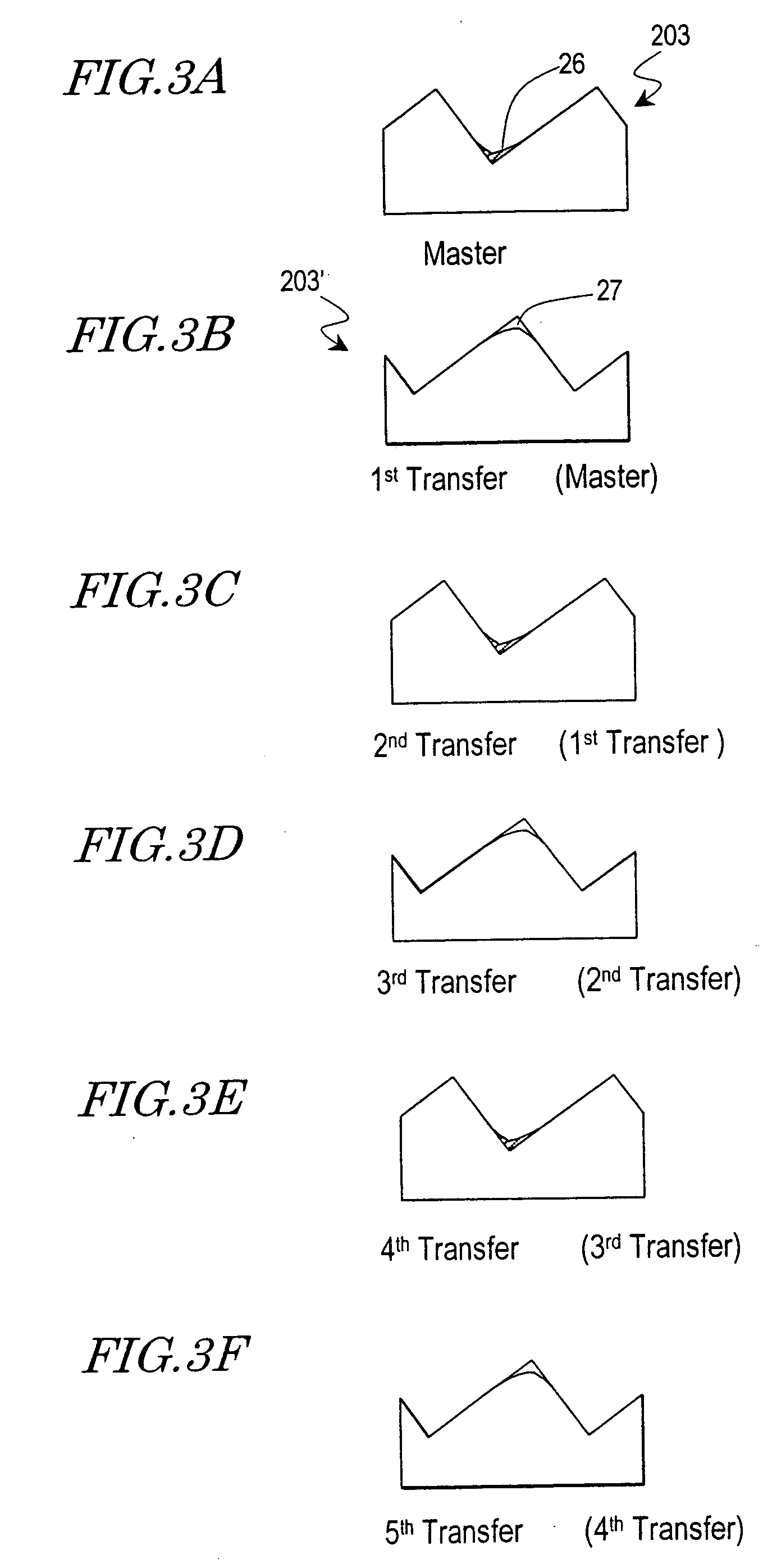

A corner cube reflector includes a two-dimensional arrangement of unit elements. The unit elements are arranged at a pitch of 200 μm or less. As viewed in a direction from which incoming light is coming, each unit element has a peak point and a bottom point. A peak portion, including the peak point, has an excessive portion and / or a missing portion as compared with an ideal peak portion of an ideal corner cube. The level of the peak point is lower than that of the ideal peak point of the ideal corner cube. An average level difference h2 between the level of the bottom point and that of an ideal bottom point of the ideal corner cube is smaller than an average level difference h1 between the level of the peak point and that of the ideal peak point.

Owner:SHARP KK

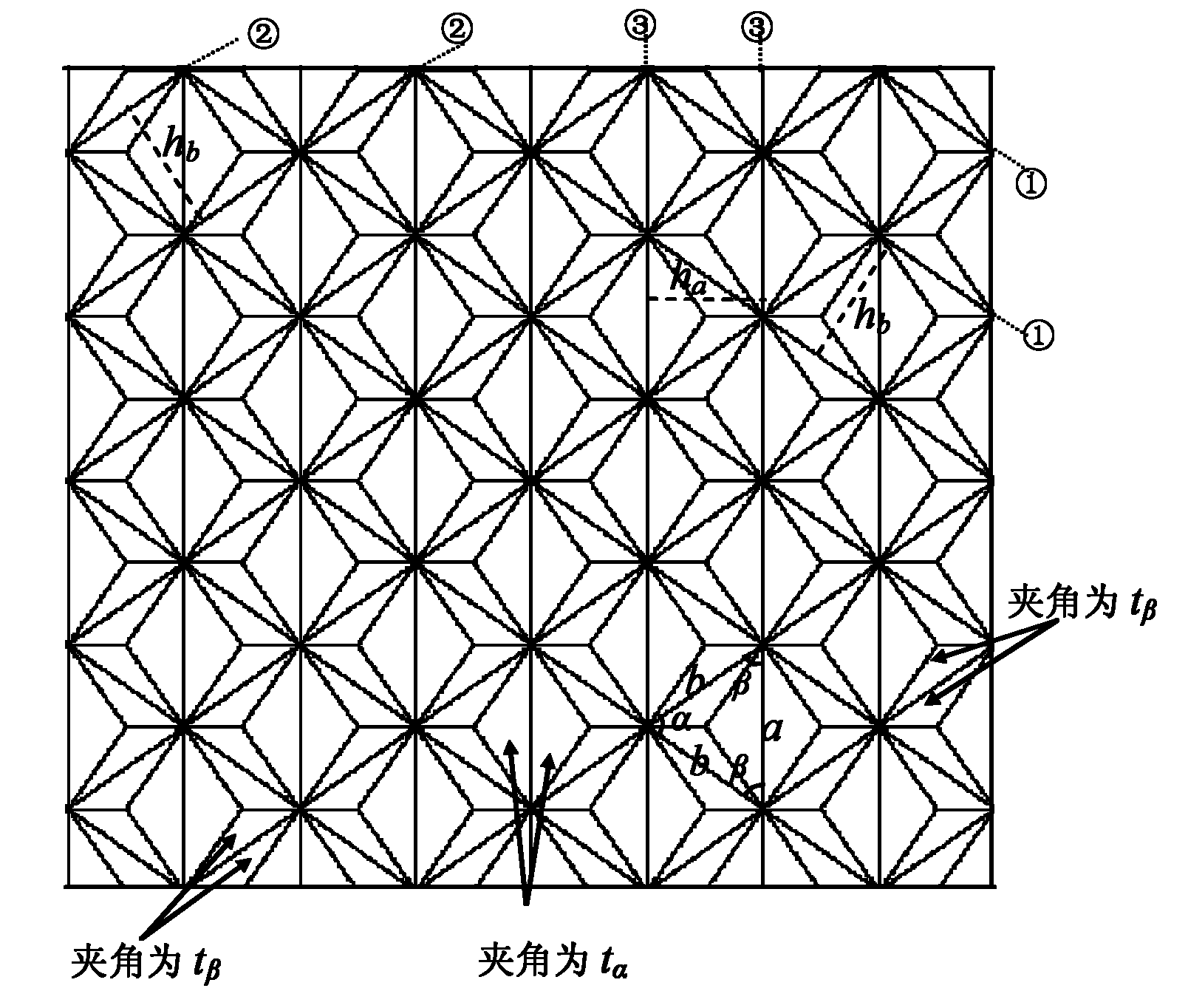

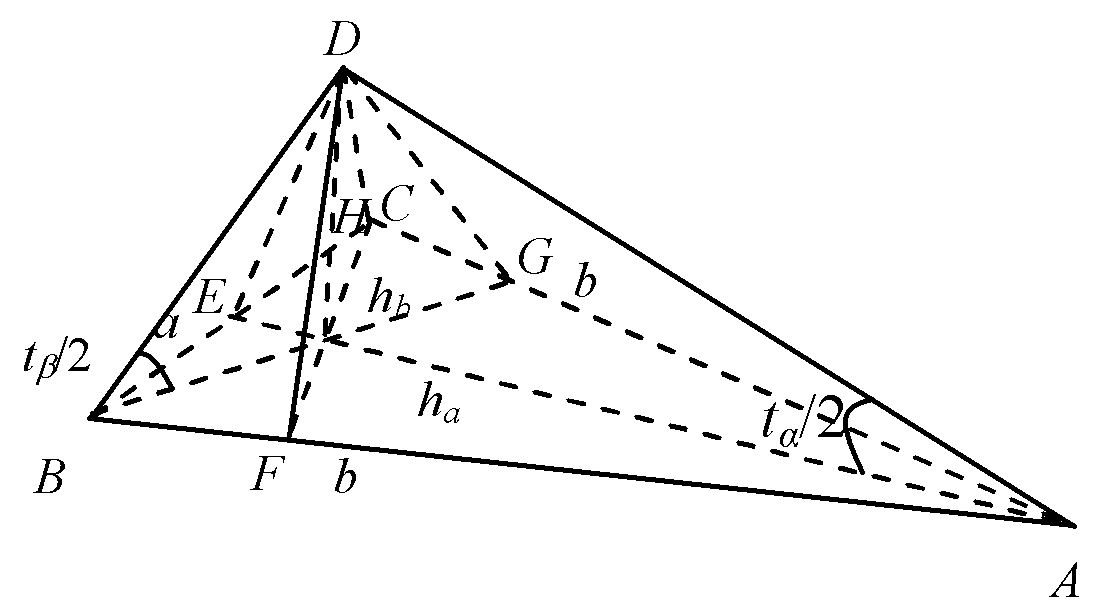

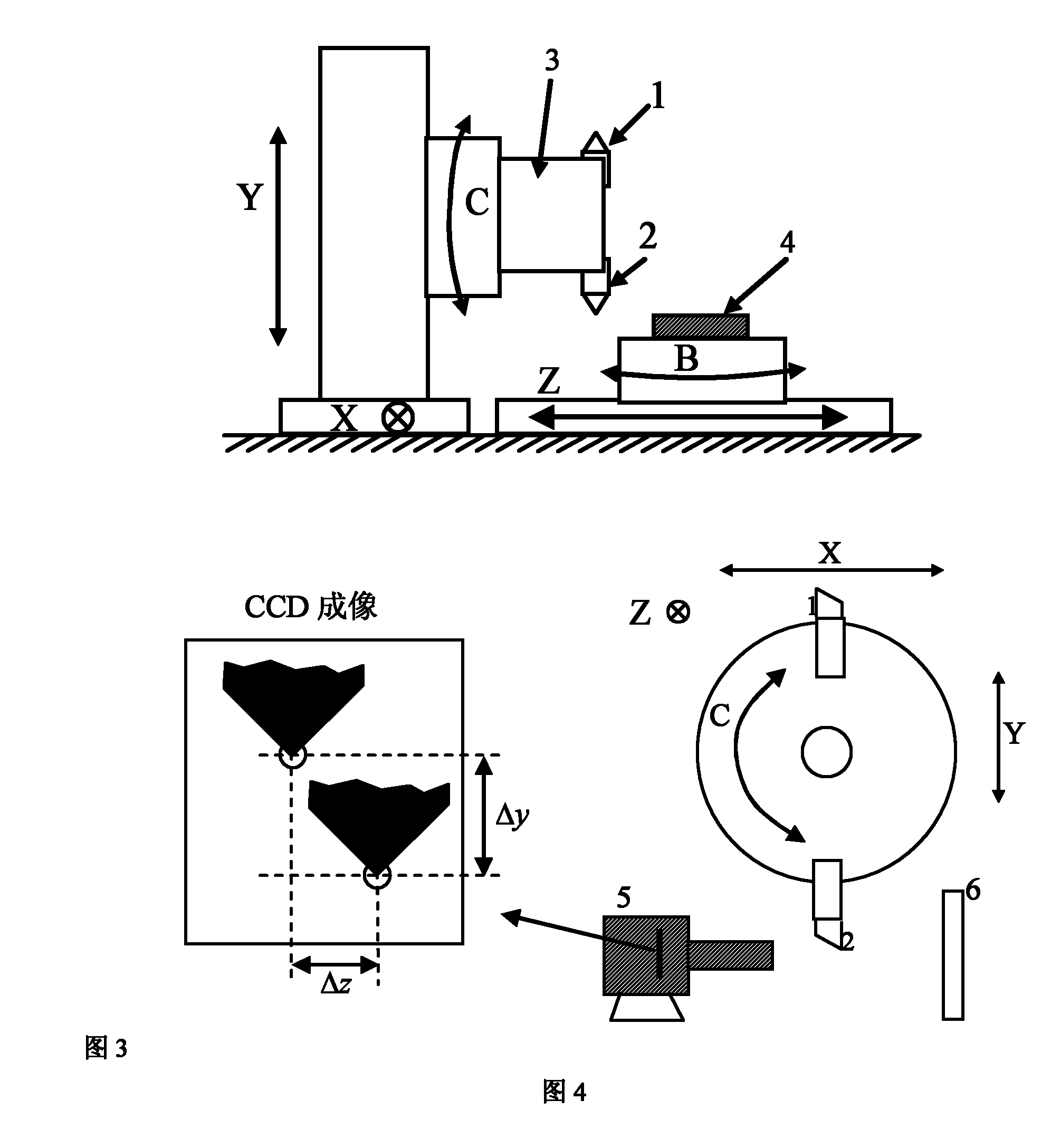

Isosceles micro prism and method for manufacturing mold

InactiveCN102156314AReduced retroreflective performanceLow retroreflective performanceMilling equipment detailsOptical elementsManufacturing technologyEngineering

The invention belongs to the technical field of retroreflective material manufacture, and relates to an isosceles micro prism. A micro prism unit constituting the isosceles micro prism is a tetrahedron; the bottom surface of the tetrahedron is an isosceles triangle; one of the three side surfaces is an isosceles triangle, the rest two side surfaces are the same hypotenuse triangles, and the three surfaces are perpendicular to one another and intersect at a structural vertex; and included angles between the side surfaces of the two hypotenuse triangles and the adjacent units are equal. The invention also provides a method for manufacturing a mold of the isosceles micro prism. By the micro prism structure provided by the invention, the retroreflective performance of the micro prism is reduced with the increase of an incidence angle.

Owner:TIANJIN UNIV

Retroreflective structures having a helical geometry

InactiveUS8033671B1Good retroreflective performanceGood lookingOptical elementsAngular orientationEngineering

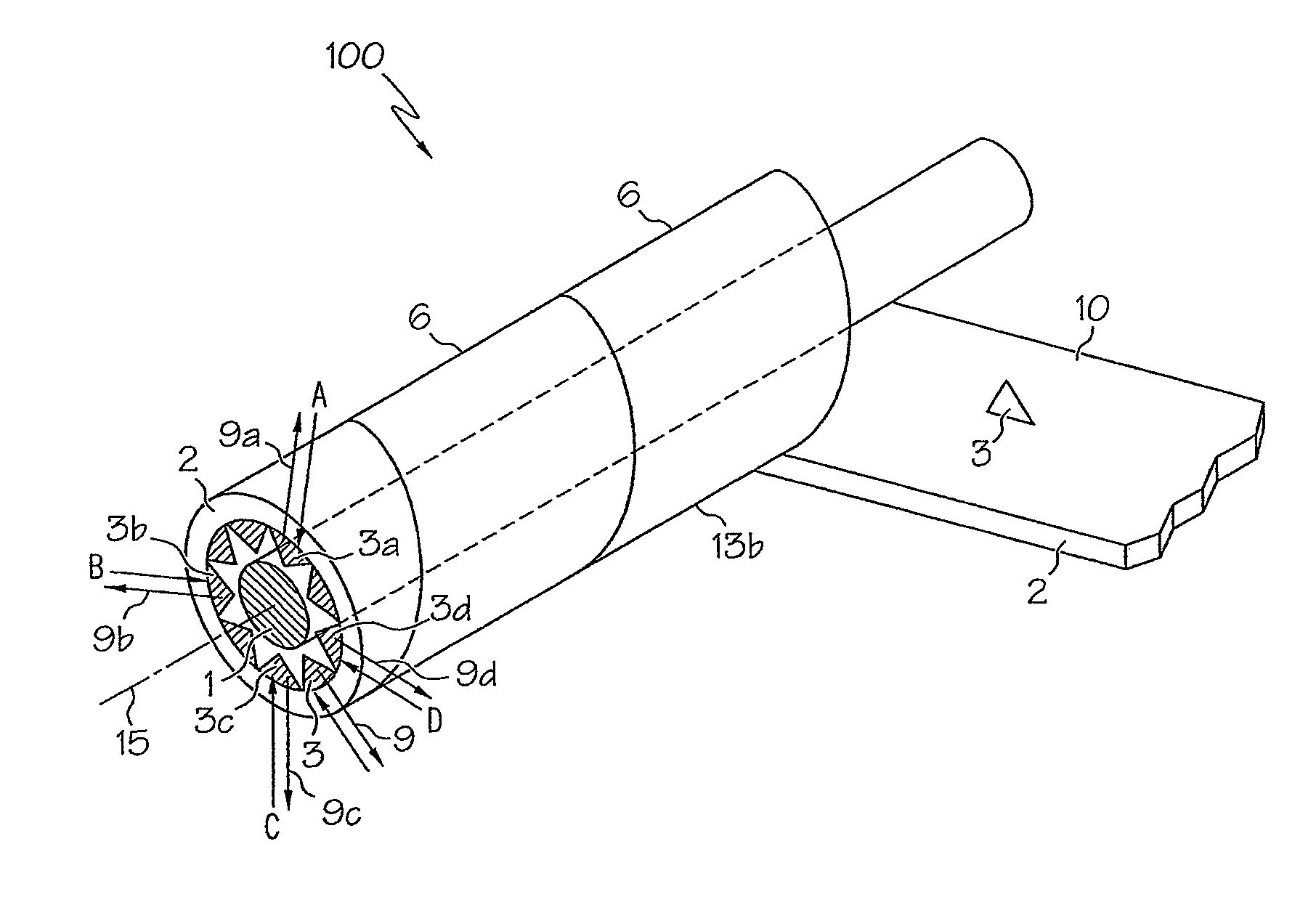

Retroreflective structures and methods of forming the same comprise a body of material extending along a helical path about a longitudinal axis and a plurality of retroreflective optical elements positioned along the helical path of the body of material, and constructed and arranged to retroreflect electromagnetic energy directed from a range of angular orientations about the longitudinal axis.

Owner:TECH SOLUTIONS & INVENTION

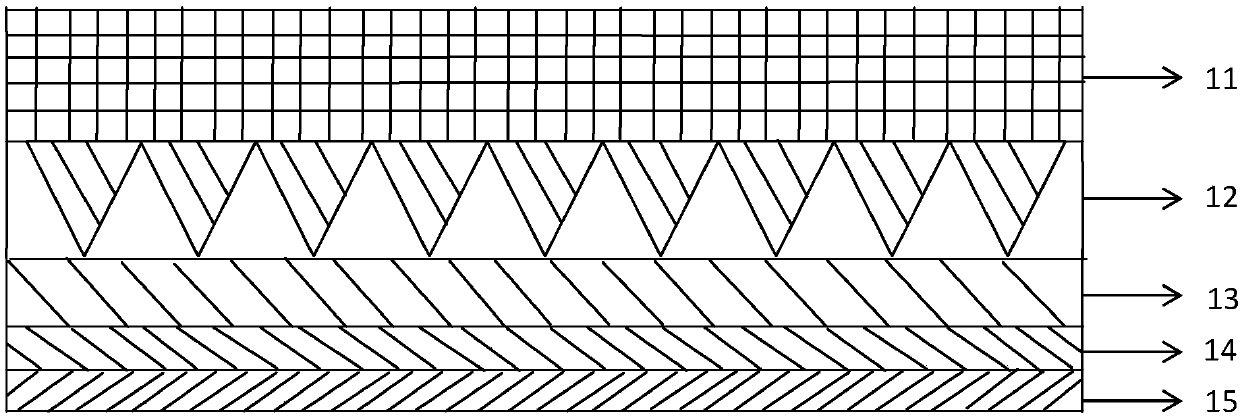

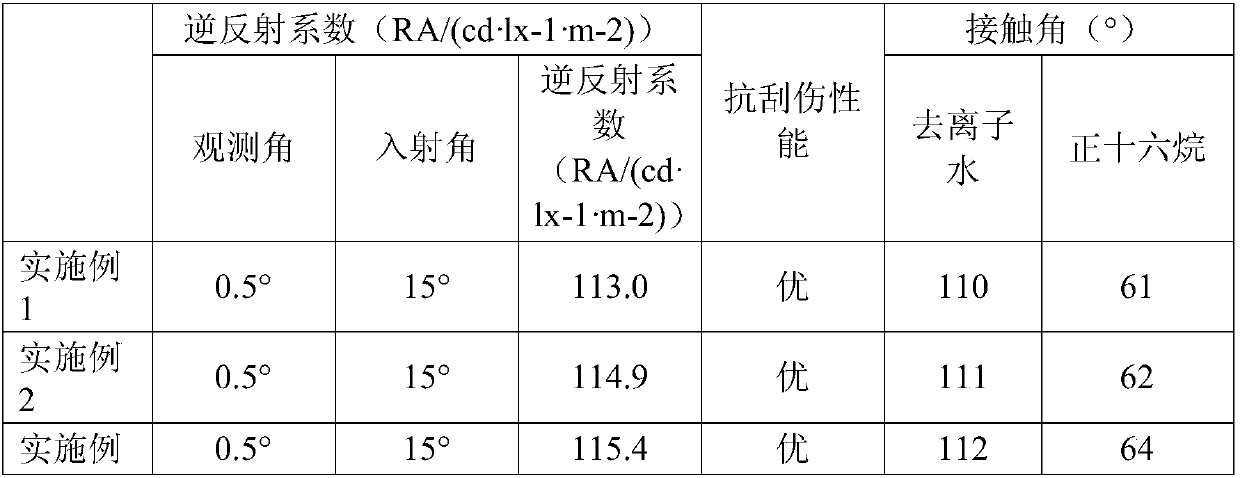

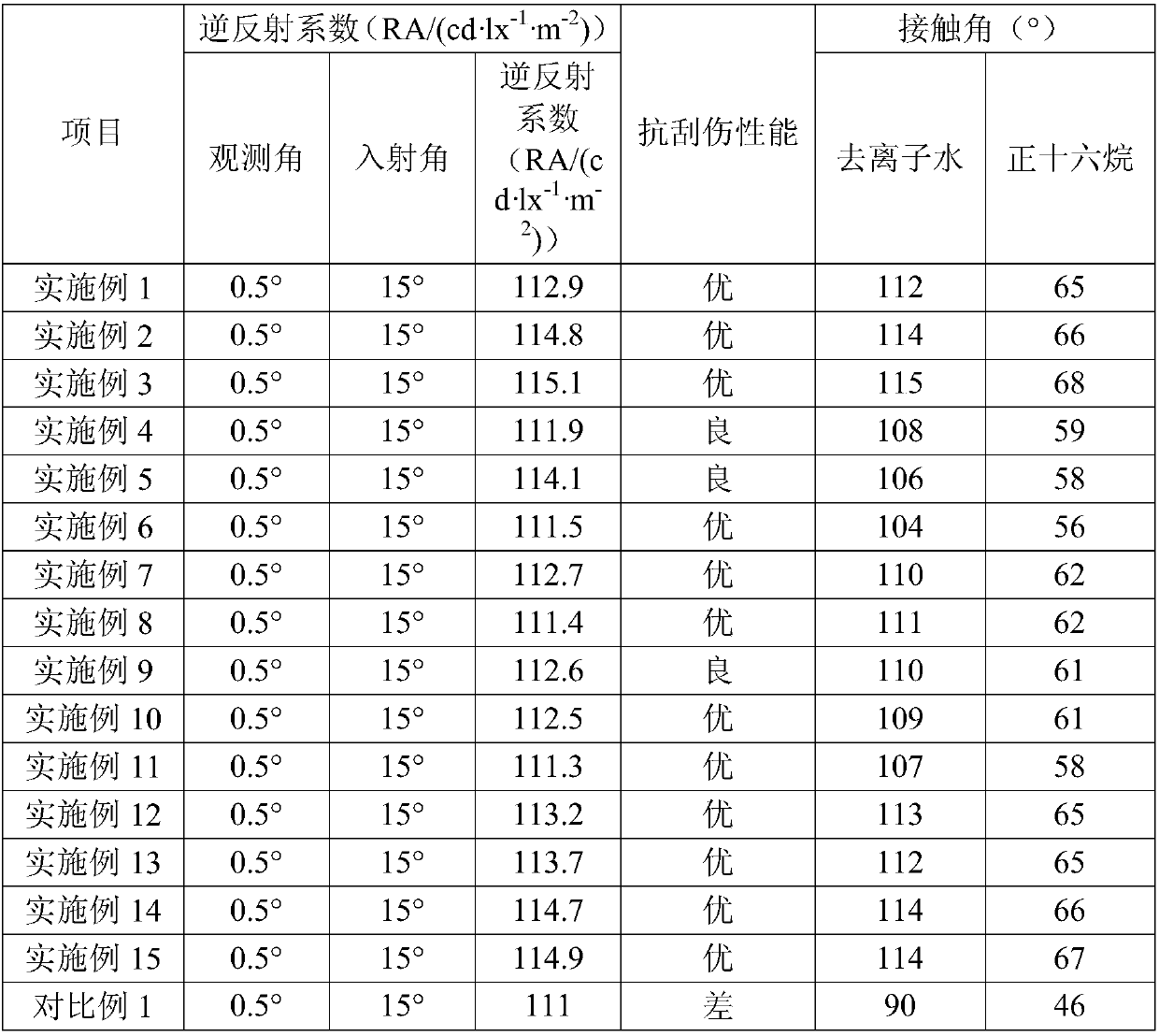

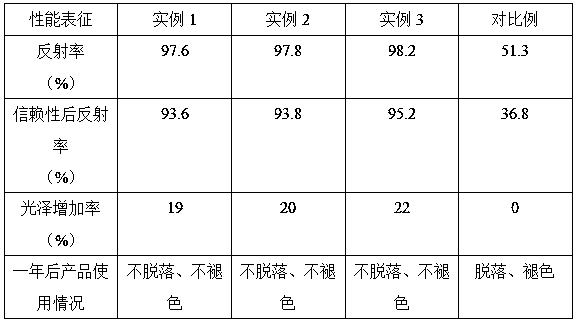

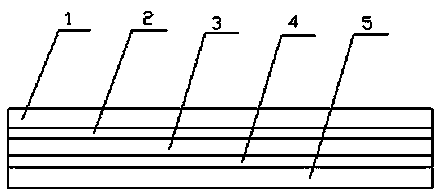

Reflecting film

InactiveCN108047979AAvoid scratchesHigh reflective brightnessAntifouling/underwater paintsPaints with biocidesOptoelectronicsPollution prevention

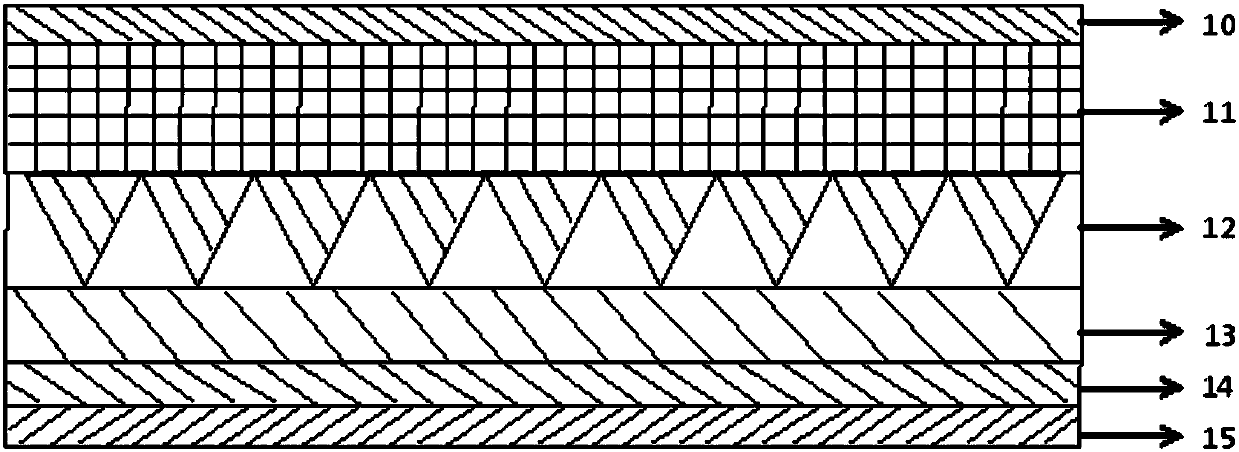

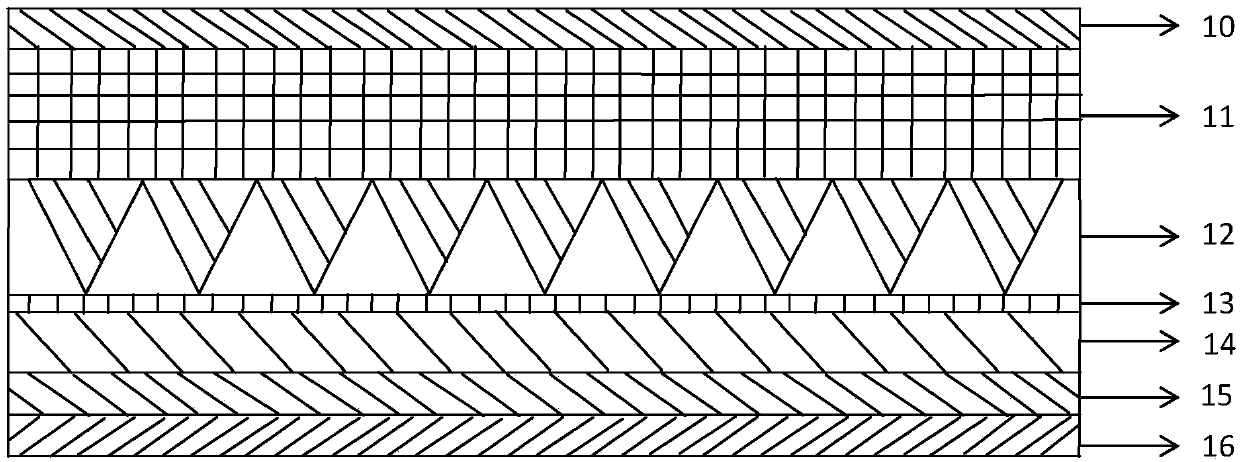

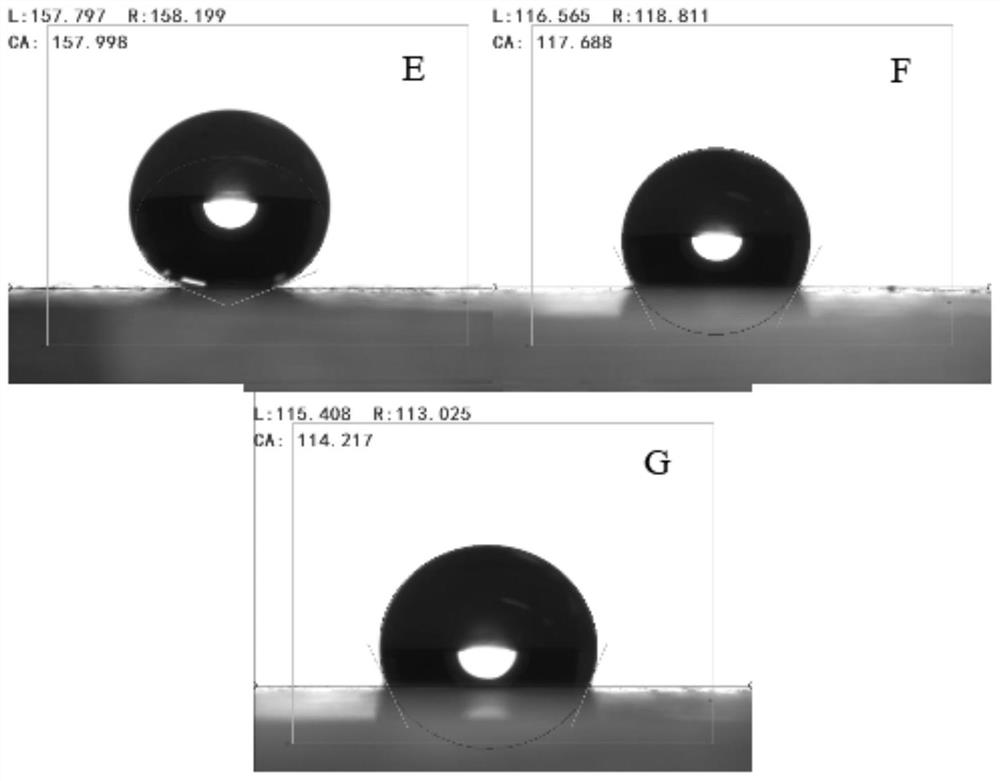

The invention relates to the technical field of optics and in particular relates to a reflecting film. In order to solve the problems that the reflecting brightness of the reflecting film is reduced and the reflecting film is scratched when the reflecting film is exposed to the external environment and is used, the invention provides the reflecting film. The reflecting film comprises a pollution-prevention and scratching-resisting coating, a substrate layer, a micro-prism structure layer, a sealing layer, a bonding layer and a stripping layer in sequence. When being exposed in the external environment and actually utilized, the reflecting film provided by the invention has the advantages of hydrophobic, oleophobic, pollution-prevention and scratching-resisting properties.

Owner:NINGBO EXCITON TECH

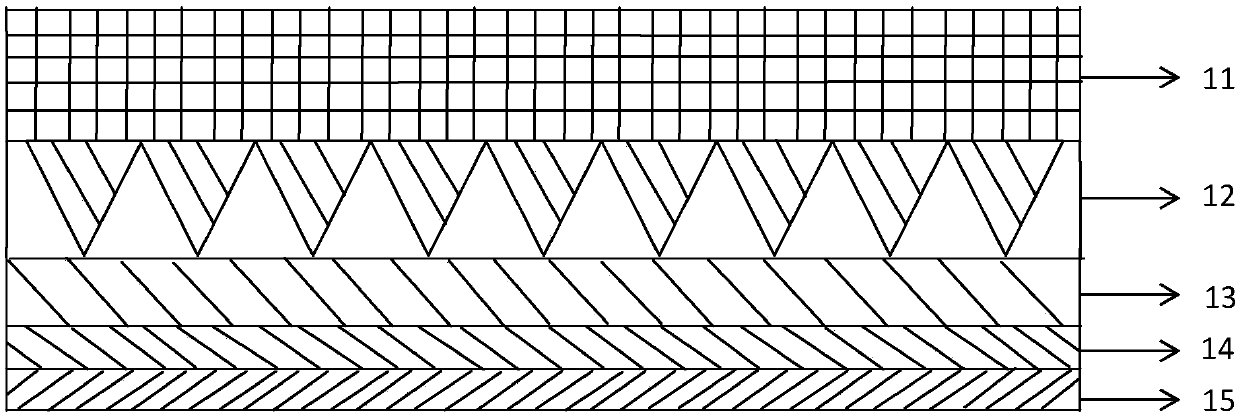

Sticking type retroreflective film and preparation method thereof

InactiveCN105301683ASimple preparation processEasy to useSynthetic resin layered productsCoatingsAdhesiveProtection layer

The invention relates to a sticking type retroreflective film, successively comprising four layers from top to bottom: a protection layer, a retroreflective layer, a sticking layer and a substrate layer, wherein the substrate layer is composed of a base material, an adhesive and an isolating film. A preparation method comprises: first, uniformly spraying the sticking layer on the surface of the substrate layer to form a stable structure; secondly, before complete solidification of the sticking layer, uniformly spraying the retroreflective film on the surface of the sticking layer; and finally, covering the transparent sticking layer on the surface of the retroreflective film to form the sticking type retroreflective film. The sticking type retroreflective film is prepared by employing four layer composite technology, and is simple and convenient to use; through a retroreflective microstructure, the sticking type retroreflective film possesses excellent retroreflective effects; an outer layer is covered by the protection layer, thereby prolonging the service life; meanwhile, preparation processes are simple, and raw materials are easy to obtain, thereby facilitating processing line production.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD

Micro prism reflective film

ActiveCN107817543AHigh reflective brightnessSolve the problem of not being able to achieve high reflectivityPrismsPrismOptoelectronics

The invention relates to the field of optical technologies, and in particular relates to a micro prism reflective film. In order to solve the problems of low reflection brightness and scratch of the existing reflective film in an external environment, the invention provides the micro prism reflective film. The micro prism reflective film comprises an anti-fouling anti-scratch coating, a substratelayer, a micro prism structure layer, a metal reflective layer and a sealing layer in order. The micro prism reflective film provided by the invention has the advantages of high reflection brightnessand scratch prevention in practical application in the external environment, and solves the problem that a micro prism reflective film provided with a traditional sealing layer cannot realize high reflectance.

Owner:NINGBO EXCITON TECH

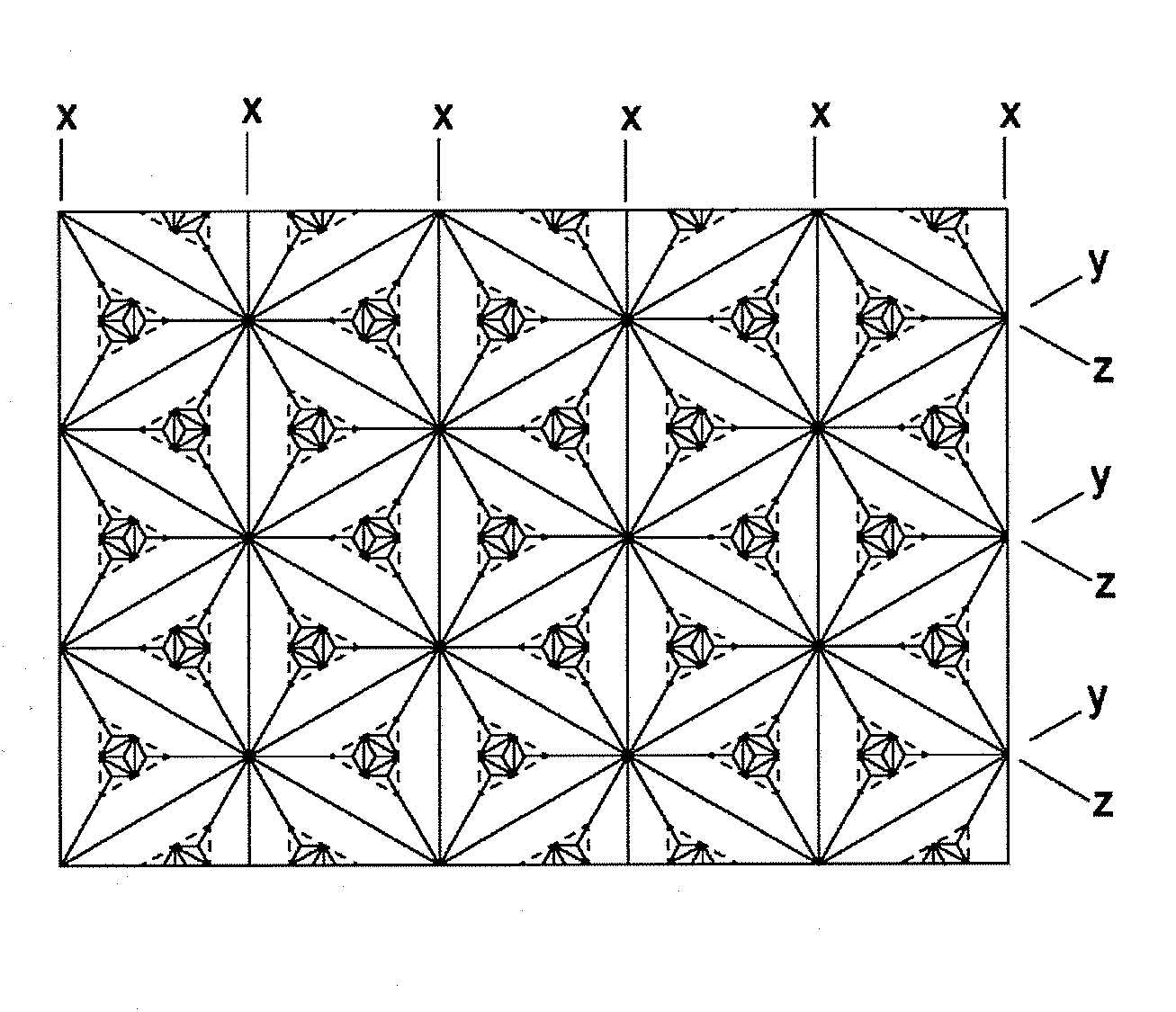

Composite triangular-pyramidal cube-corner retroreflective sheeting and retroreflective articles

InactiveUS7950813B2Good retroreflective performanceExcellent entrance angularityTraffic signalsRoad signsEngineeringTrigonal crystal system

Owner:NIPPON CARBIDE KOGYO KK

Color agent for road marking material and road making material using the same

InactiveUS20070251412A1Improve powerHigh strengthAlkali metal silicate coatingsInksInorganic particleHeat resistance

A color agent for a road marking material comprising composite particles having an average particle diameter of 0.01 to 10.0 μm, said composite particles comprising: inorganic particles; a gluing agent coating layer formed on surface of said inorganic particle; and an organic pigment coat formed onto said gluing agent coating layer in an amount of from 1 to 500 parts by weight based on 100 parts by weight of said inorganic particles. The color agent for a road marking material, contains no harmful elements and exhibits excellent tinting strength, hiding power, light resistance and heat resistance, and is suppressed in surface activity thereof. The road marking material using the color agent, shows a less change in hue with the passage of time and an excellent retroreflective property.

Owner:TODA IND

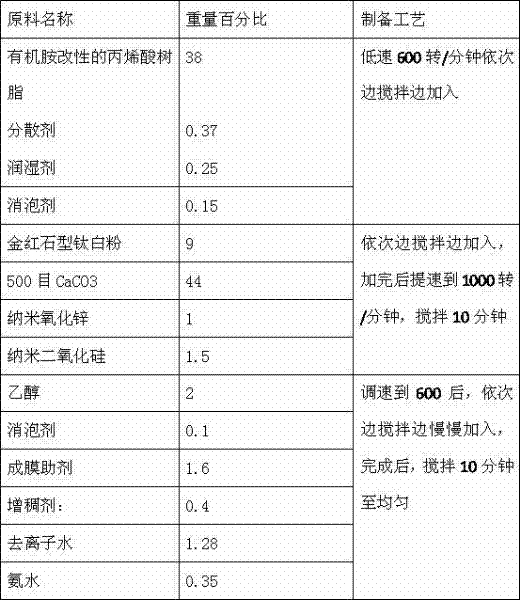

Water-soluble nanometer quick-drying road marking paint

The invention relates to quick-drying road marking paint, specifically a water-soluble nanometer quick-drying road marking paint, which is composed of modified acrylic resin, a dispersing agent, a wetting agent, a defoaming agent, rutile type titanium dioxide, 500-mesh calcium carbonate powder, 500-mesh quartz powder, 800-mesh mica powder, nano-silicon dioxide, nano-zinc oxide, ethanol (methanol), an antifoaming agent, a film-forming additive, an HEC thickener with a concentration of 1.5%, deionized water, and ammonia water. The paint of the invention has strong adhesion to a roadbed, and improves constraint anchoring to glass beads, thus not only improving the service life of the road marking paint, but also enhancing the visibility of a a road mark during night raining. The paint provided in the invention also has the advantages of simple and safe construction, and no environmental problem.

Owner:成都澳贝龙科技发展有限公司

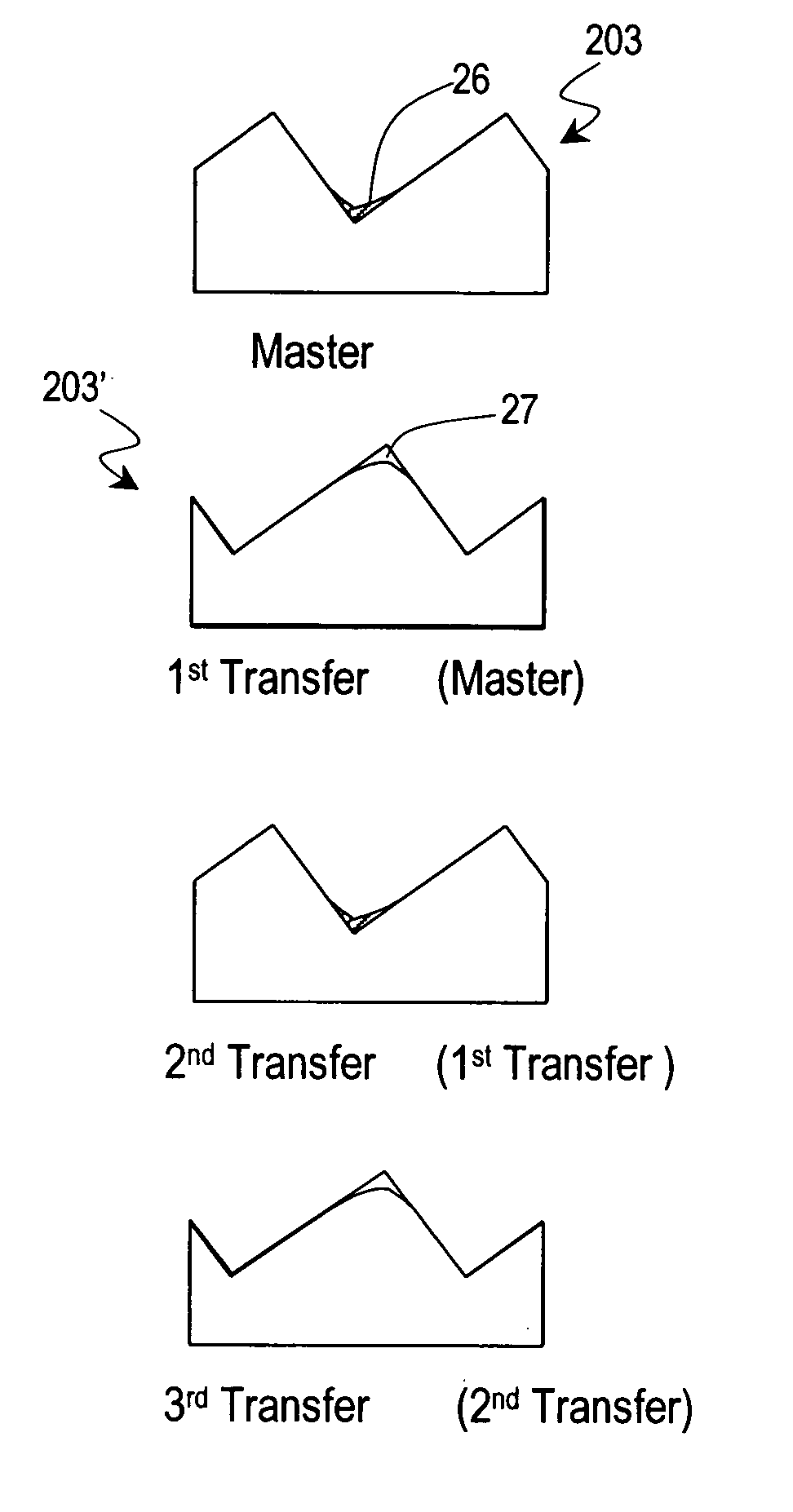

Corner cube reflector, method of making the reflector and reflective display device including the reflector

ActiveUS7188961B2Good retroreflective performanceImprove the display effectNon-linear opticsOptical elementsDisplay devicePrism

A corner cube reflector includes a two-dimensional arrangement of unit elements. The unit elements are arranged at a pitch of 200 μm or less. As viewed in a direction from which incoming light is coming, each unit element has a peak point and a bottom point. A peak portion, including the peak point, has an excessive portion and / or a missing portion as compared with an ideal peak portion of an ideal corner cube. The level of the peak point is lower than that of the ideal peak point of the ideal corner cube. An average level difference h2 between the level of the bottom point and that of an ideal bottom point of the ideal corner cube is smaller than an average level difference h1 between the level of the peak point and that of the ideal peak point.

Owner:SHARP KK

Methods of forming retroflective structures having a helical geometry

InactiveUS8157391B1Good retroreflective performanceGood lookingOptical elementsAngular orientationEngineering

Owner:TECH SOLUTIONS & INVENTION

High-elasticity reflection material and preparation method thereof

InactiveCN109337563AGood mechanical propertiesIncrease elasticityPolyurea/polyurethane coatingsReflecting/signal paintsAcrylic resinButyl acetate

The invention discloses a high-elasticity reflection material. The high-elasticity reflection material comprises the following raw materials in parts by weight: 10-15 parts of a polyurethane elastic solution, 15-25 parts of organic pigment, 10-15 parts of thermoplastic acrylic resin, 52-57 parts of butyl acetate, 1.5-2 parts of aluminum paste, 2-3 parts of a dustproof thickening thixotropic agent229, 0.5-1.0 part of an ultraviolet light absorber 531, 0.7-1.3 parts of an antioxidant 1010 and 0.2-0.6 part of an adhesion promoter. The preparation method of the high-elasticity reflection materialcomprises the following steps: S1, preparing the polyurethane elastic solution; S2, grinding color paste; S3, preparing a thermoplastic acrylic resin solution; and S4, preparing the reflection material. The prepared reflection material has good mechanical property, high elasticity, excellent reflection color and excellent outdoor weather-proof anti-ageing performance and retroreflection performance.

Owner:安徽新恒辉反光材料股份有限公司

Corner cube reflector, method of making the reflector and reflective display device including the reflector

InactiveUS20070081244A1Good retroreflective performanceImprove the display effectNon-linear opticsOptical elementsPartition of unityDisplay device

A corner cube reflector includes a two-dimensional arrangement of unit elements. The unit elements are arranged at a pitch of 200 μm or less. As viewed in a direction from which incoming light is coming, each unit element has a peak point and a bottom point. A peak portion, including the peak point, has an excessive portion and / or a missing portion as compared with an ideal peak portion of an ideal corner cube. The level of the peak point is lower than that of the ideal peak point of the ideal corner cube. An average level difference h2 between the level of the bottom point and that of an ideal bottom point of the ideal corner cube is smaller than an average level difference h1 between the level of the peak point and that of the ideal peak point.

Owner:SHARP KK

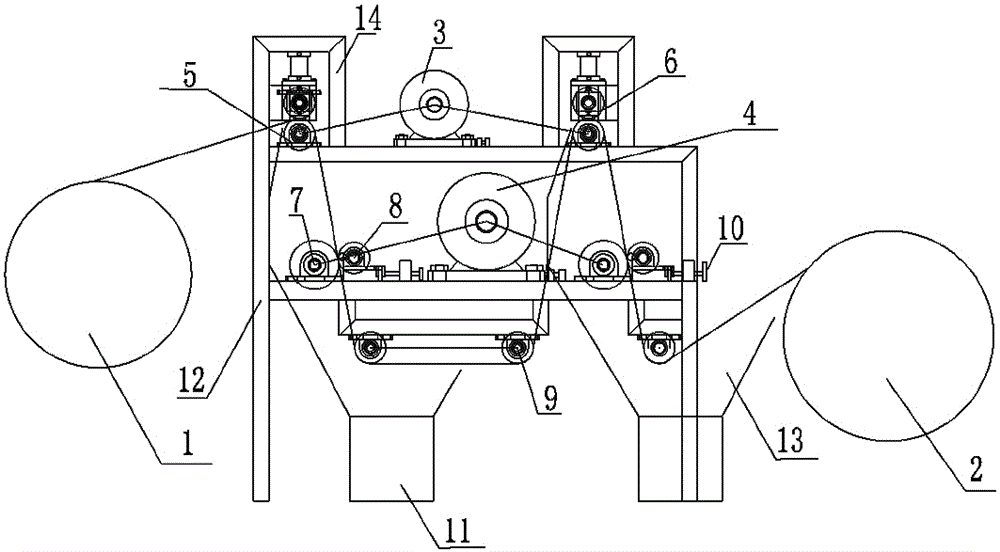

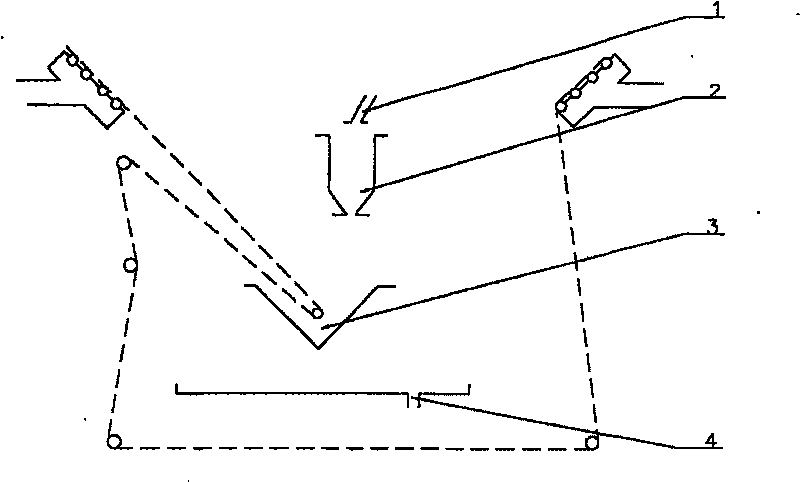

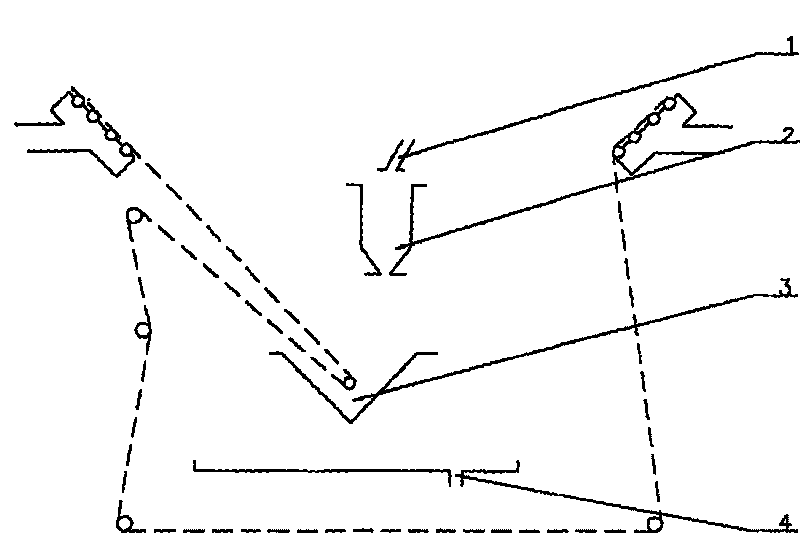

Semi-aluminized glass microbead production technology and bead brushing device of semi-aluminized glass microbeads

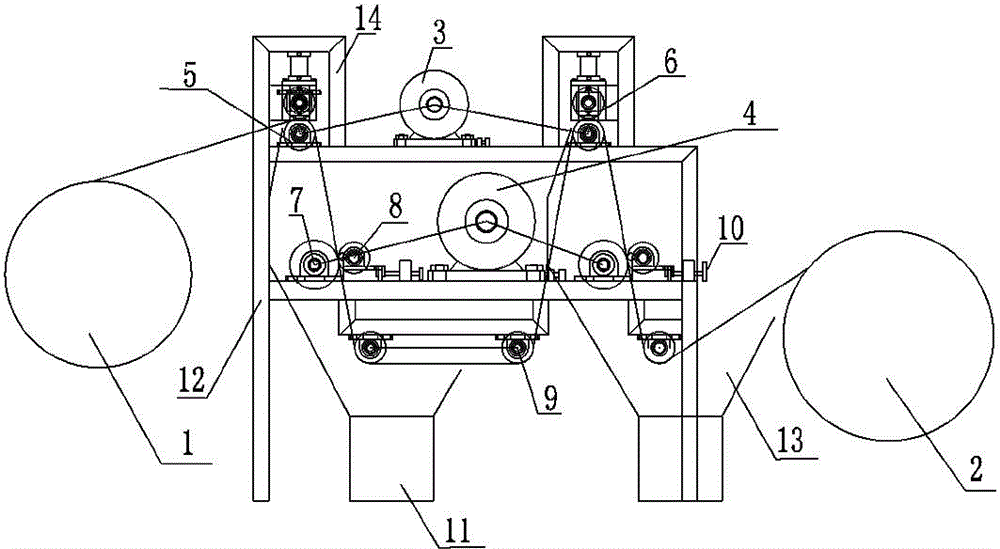

The invention discloses a semi-aluminized glass microbead production technology and a bead brushing device of semi-aluminized glass microbeads. A semi-aluminized layer is arranged plated on the surface of each glass microbead. The glass microbeads are formed through a bead embedding technology, the vacuum aluminizing technology and the bead brushing technology. During bead brushing, bead brushing is achieved through the bead brushing device of the semi-aluminized glass microbeads. The device is composed of a rack (12), an unwinding frame (1), a winding frame (2), a traction device, a brush roller (7), a tension roller (8), a flying preventing plate (13) and a collection trough (11). The semi-aluminized glass microbead production technology and the bead brushing device of the semi-aluminized glass microbeads have the advantages that the semi-aluminized glass microbeads are uniquely applied in the light reflecting printing ink field, play a role in light reflecting and alarming is played, the adhesive power between the semi-aluminized glass microbeads and screen printing glue is good, the semi-aluminized glass microbeads can be continuously collected on a large scale, collection efficiency is high, the flying amount is small, the semi-aluminized glass microbead flying amount is small, the aluminized layers on the surfaces of the glass microbeads are not damaged in the brushing process, and the semi-aluminized glass microbeads brushed away are clean without dust and have the higher retroreflection performance.

Owner:中节能(达州)新材料有限公司

Preparation method of high-brightness wide-angle reflecting material

InactiveCN109137536AHigh strengthImprove reflectivityTextiles and paperOptical elementsPolymethyl methacrylateLightness

The invention relates to a preparation method of a high-brightness wide-angle reflecting material, and belongs to the technical field of reflecting materials. According to the method, glass beads arecovered by a heterogeneous precipitation method, the high-brightness wide-angle reflecting material is prepared, a titanium dioxide thin film wraps the surfaces of the glass beads, the reflecting rateof the surfaces of the glass beads is improved, incidence light penetrates a crystal boundary through a short journey to reach the surfaces of the glass beads to generate retro-reflection is generated through refraction and reflection, a high visual effects are generated, the titanium dioxide wraps the glass beads, the reflecting rate of the surfaces of the glass beads is increased, light intensity is improved, and high visual induction is provided for people. The high-brightness wide-angle reflecting material is prepared by combining a bead spreading method and multiple processing methods, the exposed reflecting material is prepared by the bead spreading method, one layer of polymethyl methacrylate is sprayed, so that the glass beads are firmly combined on the base cloth, falling is omitted, so that the prepared high-brightness wide-angle reflecting material is good in rubbing resistance.

Owner:FOSHAN WANHE NEW ENERGY TECH CO LTD

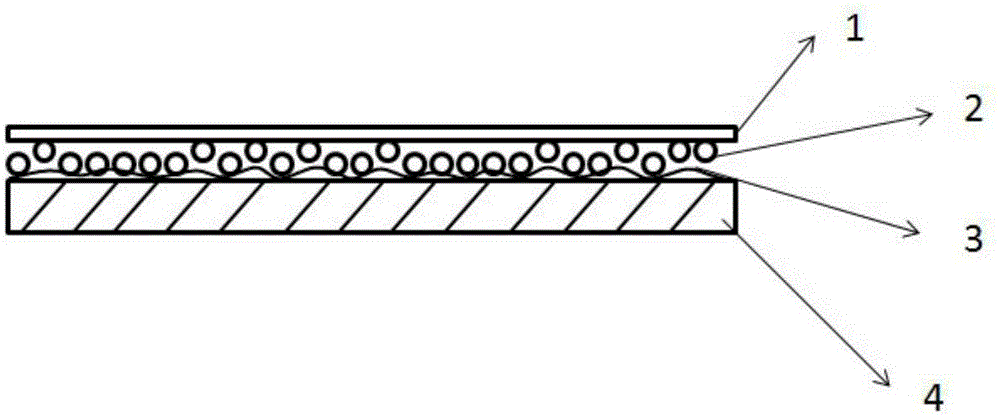

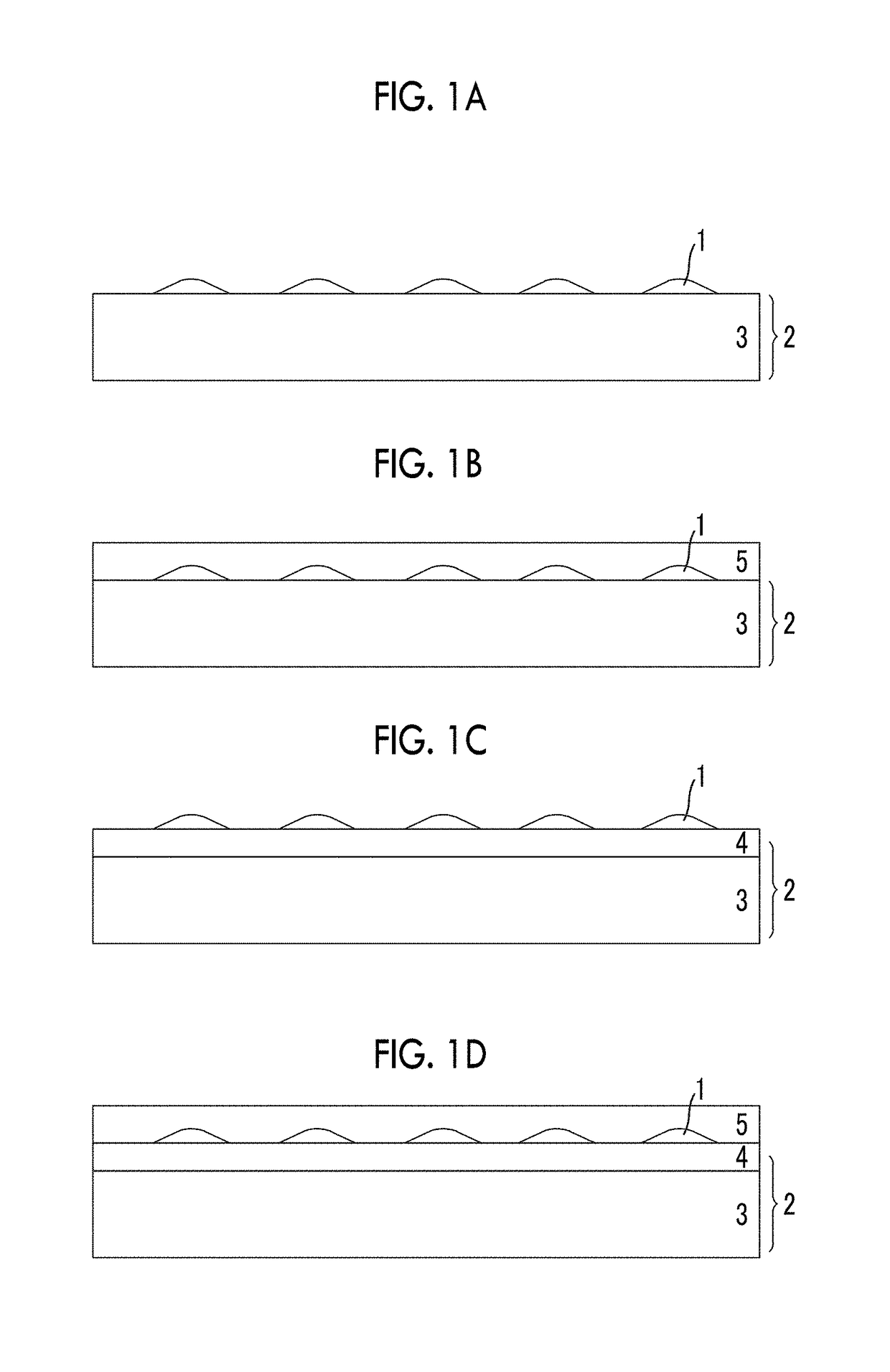

Novel light reflection film material

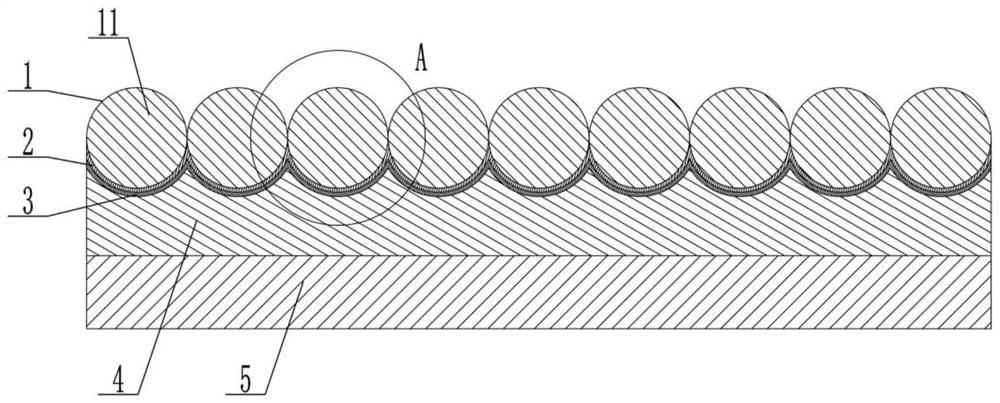

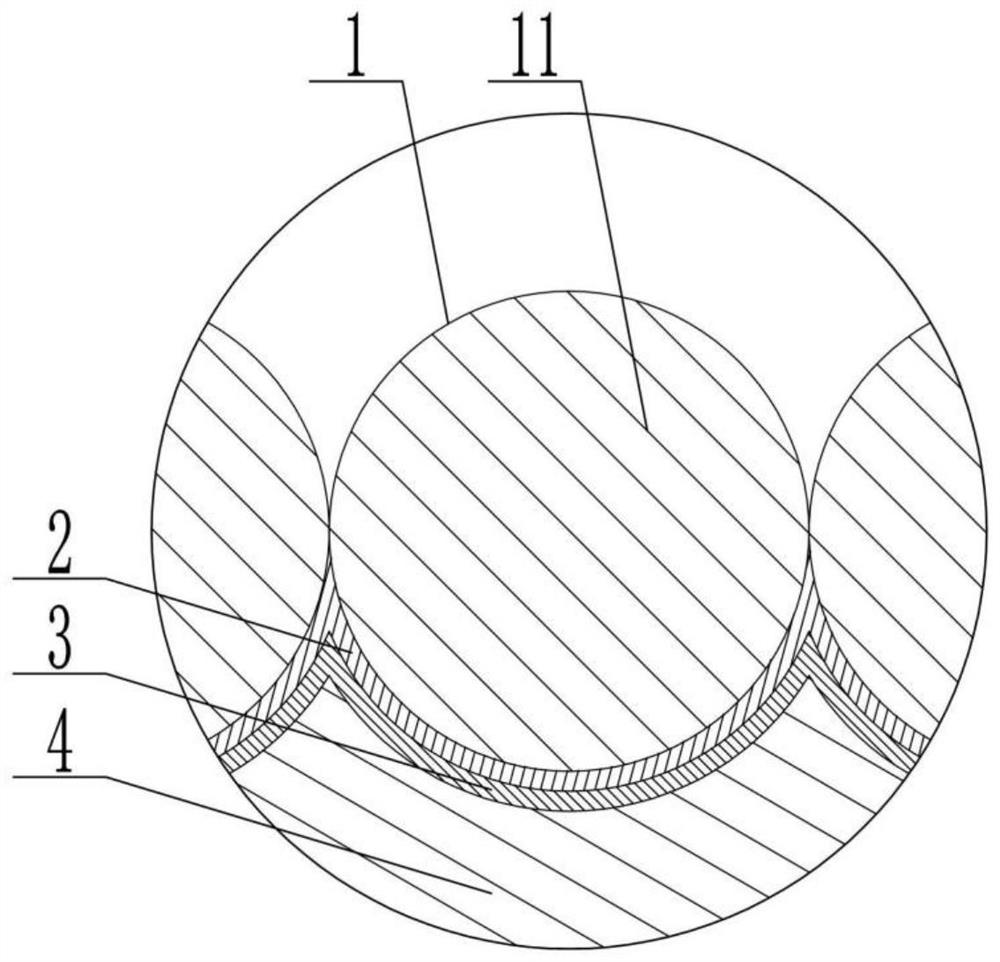

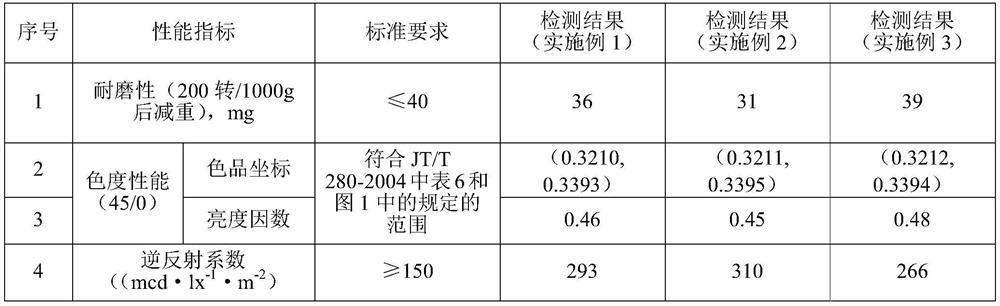

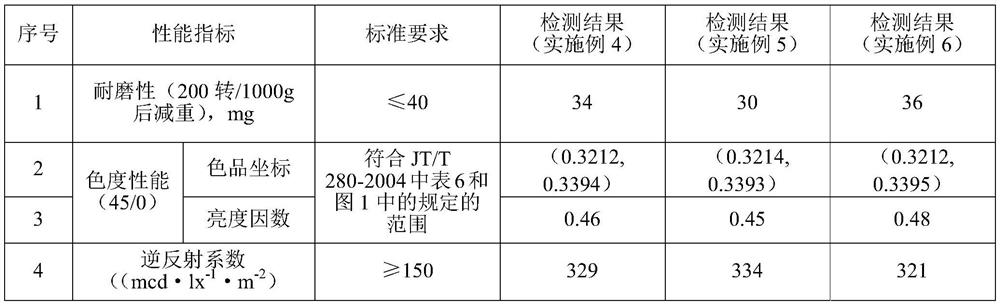

InactiveCN104111487AGood retroreflective performanceWith heat insulation and UV protectionSynthetic resin layered productsGlass/slag layered productsLight reflectionUltraviolet

The invention discloses a novel light reflection film material which comprises a light reflection film layer (1), a heat insulation film layer (2), a bottom film layer (3), a colloid layer (4) and a release protection layer (5). Due to the mode, the novel light reflection film material has the advantages of high retroreflection performance, stable heat insulation and ultraviolet isolation chemical property, stable structure, corrosion resistance, acid-alkaline resistance, biological erosion resistance, low cost, firmness, practicability, high intensity, abrasion resistance, light weight, convenience, simple structure, long service life and the like, and a wide market prospect in popularization of the novel light reflection film material is achieved.

Owner:JIANGSU HAODA

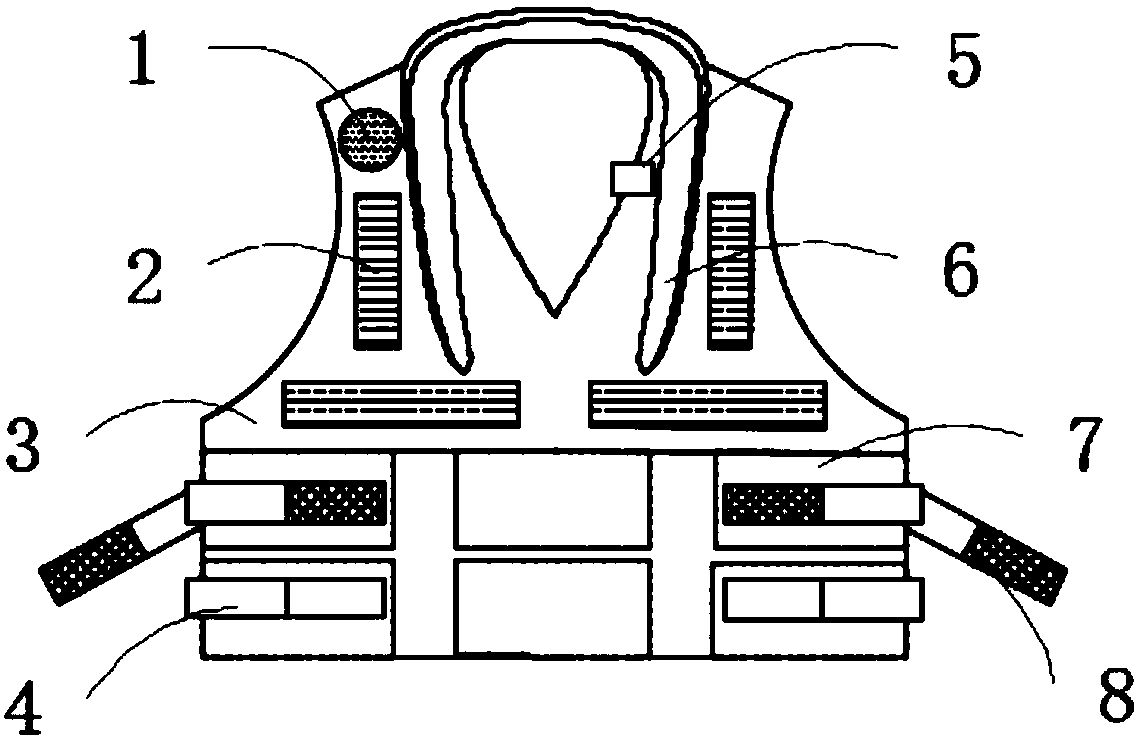

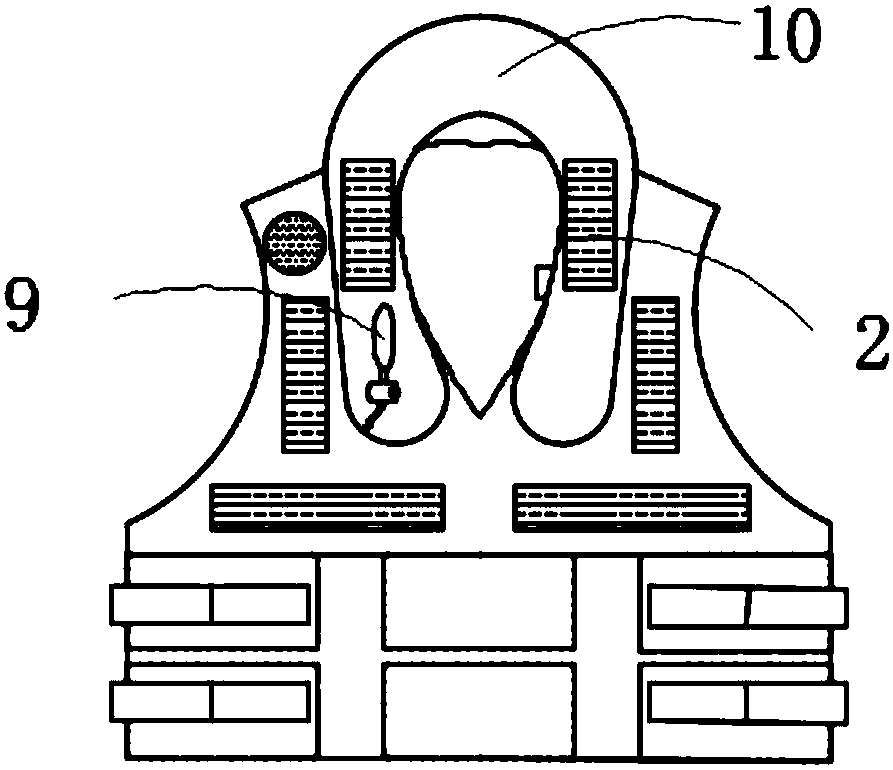

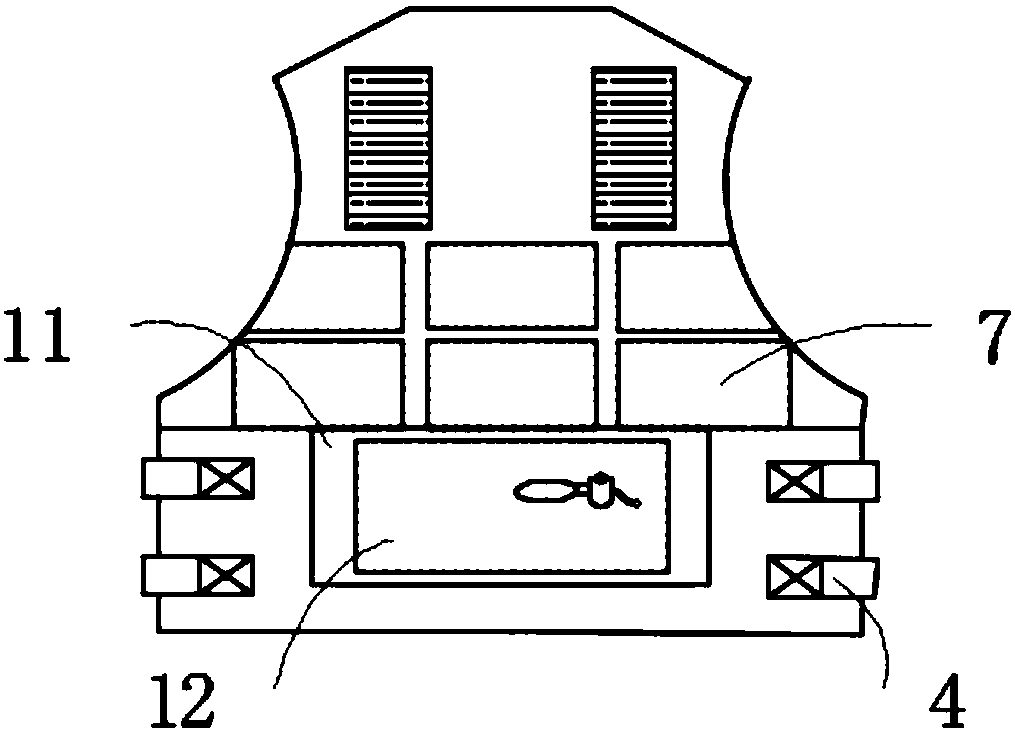

Onboard life jacket utilizing Beidou system

InactiveCN107600366AFirmly connectedIncrease chances of survivalVessel signalling devicesLife-savingSupply managementPower Management Unit

The invention discloses an onboard life jacket utilizing the Beidou system. The onboard life jacket comprises a Beidou RDSS sea lifesaving positioning beacon, a life jacket body, heating attaching pieces and an inflatable airbag. The Beidou RDSS sea lifesaving positioning beacon is fixed to the shoulder of the life jacket body, a Beidou RDSS radio frequency chip and a Beidou RDSS baseband chip areconnected through an A / D converter, a Beidou RDSS navigation unit is connected with an antenna in a controlling mode through a pre-amplifier (PA) and a low noise amplifier (LNA), and a terminal control unit is connected with the Beidou RDSS navigation unit in a controlling mode through an MCU module and a power supply management unit. The heating attaching pieces are evenly attached to the interior of the life jacket body, and the inflatable airbag is mounted at the neck of the life jacket body. An inflatable lifesaving device is mounted on the lower portion of the inner side of the life jacket body, and an alarm is mounted at a collar of the life jacket body. Self-rescue after falling into water can be realized by means of the life jacket body, the falling-into-water coordinates can be transmitted to a rescue center so that the rescue center can accurately carry out rescue, and position coordinate information can be accurately positioned in real time when emergency conditions occur.

Owner:NANJING RUIANTENG ENTERPRISE MANAGEMENT CONSULTING CO LTD

Preparation method of high-brightness colored microspheres

ActiveCN112608639ABest focus positionStrong adhesionEpoxy resin coatingsReflecting/signal paintsMembrane surfaceMicroparticle

The invention discloses a preparation method of high-brightness color microspheres. The preparation method comprises the following steps: S1, implanting glass microspheres into the surface of a PE film; S2, preparing a mixed coating A, and coating the surfaces of glass beads with the mixed coating A to form a color layer; S3, coating the surface of the color layer with a metal layer; S4, preparing a mixed coating B, and coating the surface of the metal layer with the mixed coating B to prepare a composite reflective film; S5, taking the composite reflective film, peeling off the glass beads from the PET substrate and the PE film, and then grinding and separating the glass beads through a grinding roller to obtain colored particles; S6, mixing metal iron microspheres with color particles, and then performing high-speed ball milling to obtain color microspheres; and S7, screening the color microspheres to finally obtain the high-brightness color microspheres. The colored microspheres prepared by the invention not only have a colored reflective effect, but also have the best retroreflection performance, and finally, the glass microspheres in the reflective paint coating achieve an excellent colored light effect at night, so that the defects in the prior art are overcome.

Owner:浙江龙游道明光学有限公司

Optical member and image display device including optical member

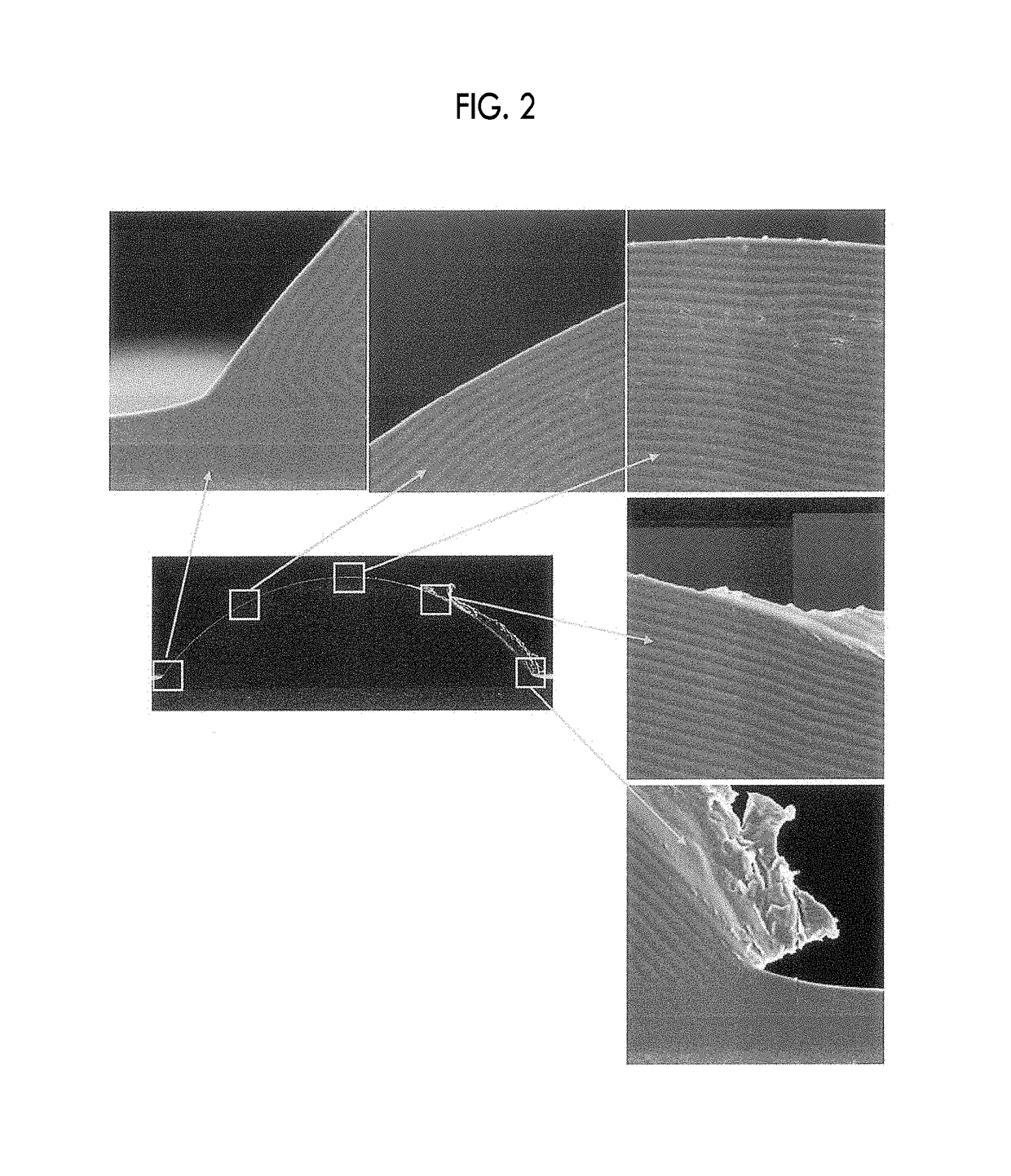

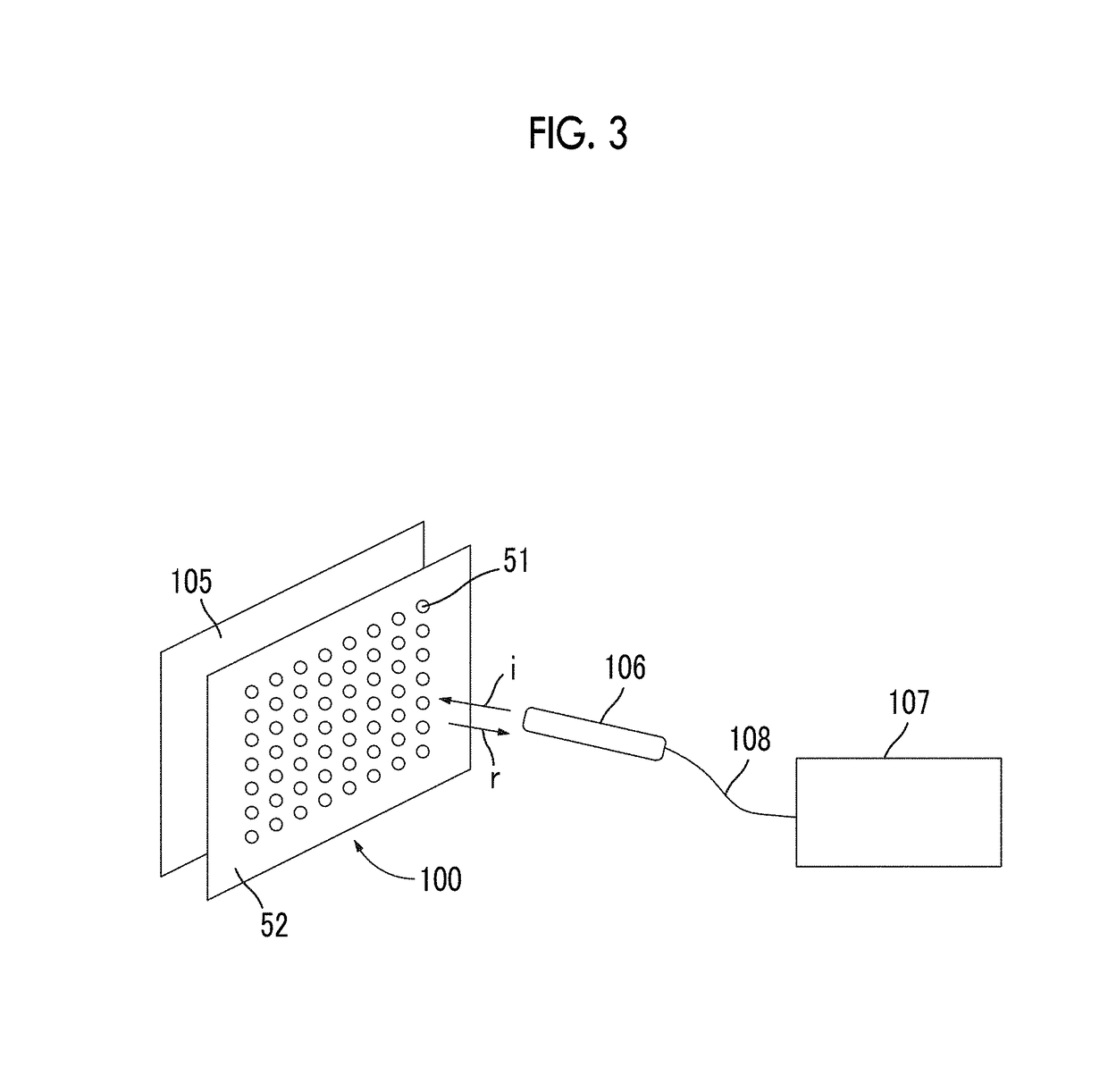

ActiveUS10222525B2Good retroreflective performanceInput/output for user-computer interactionNon-linear opticsDisplay deviceScanning electron microscope

The optical member of the present invention includes: a substrate; and a dot that is in contact with a surface of the substrate, in which the dot has wavelength selective reflecting properties, the dot is formed of a liquid crystal material having a cholesteric structure, the cholesteric structure has a stripe pattern including bright portions and dark portions in a cross-sectional view of the dot when observed with a scanning electron microscope, the dot includes a portion having a height which continuously increases to a maximum height in a direction moving from an end portion of the dot to the center of the dot, in the portion, an angle between a normal line perpendicular to a line, which is firmed using a first dark portion from a surface of the dot, and the surface is in a range of 70° to 90°, and the liquid crystal material includes a surfactant.

Owner:FUJIFILM CORP

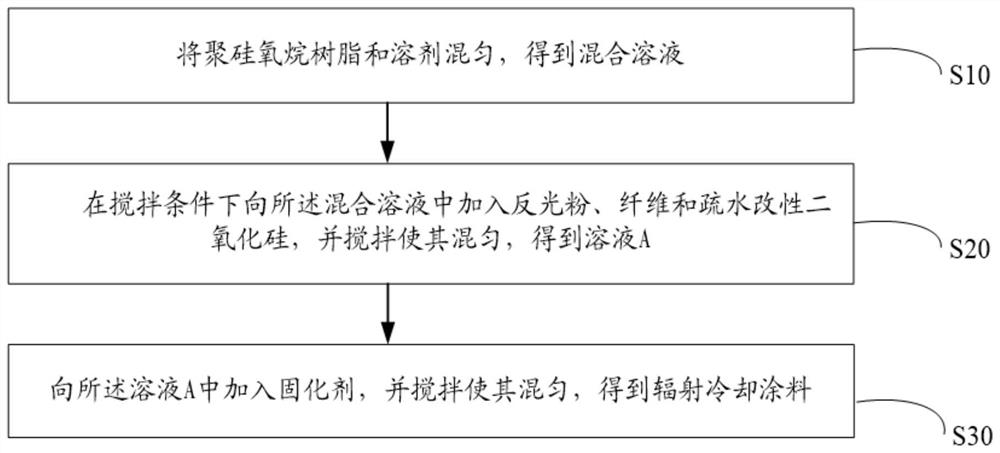

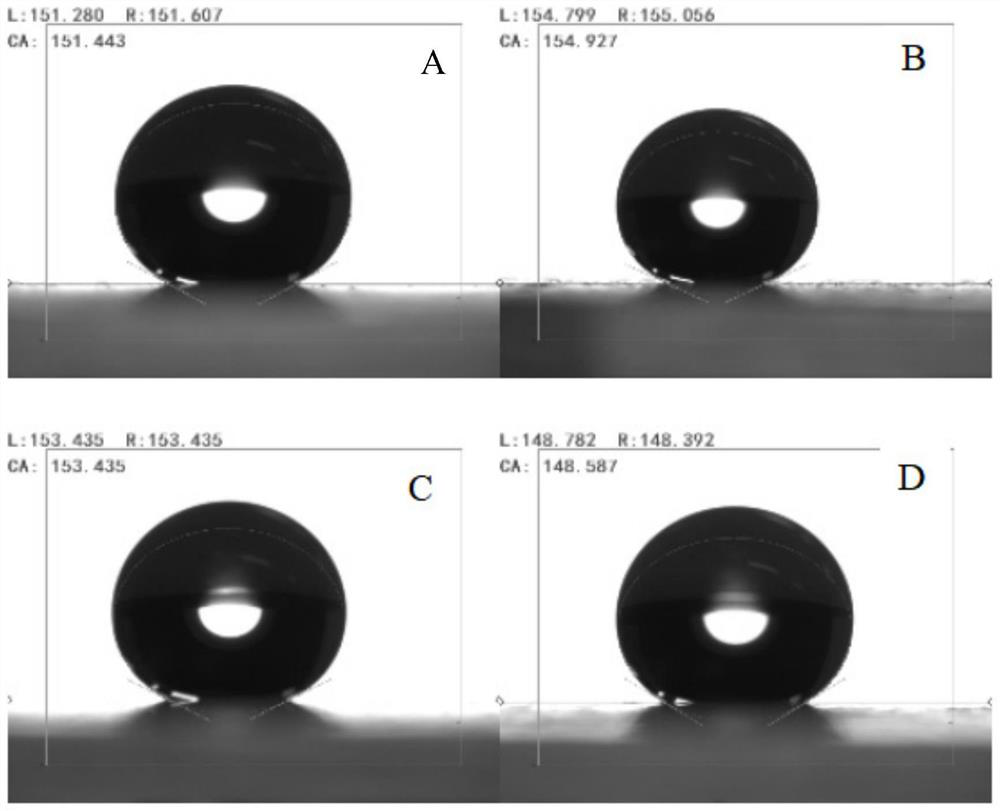

Radiation cooling coating and preparation method thereof

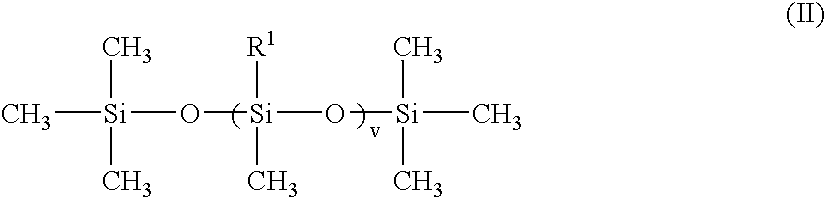

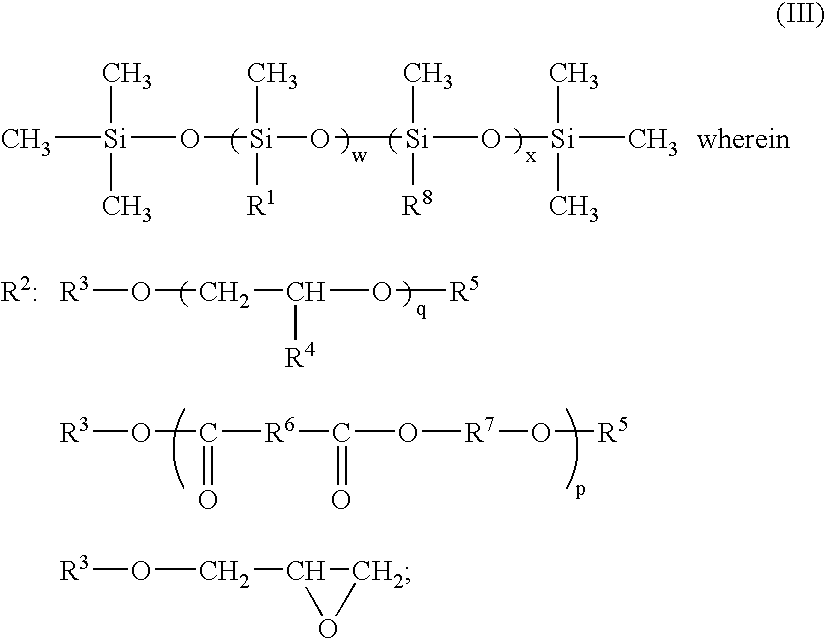

PendingCN114410219AExtended service lifeGood retroreflective performanceReflecting/signal paintsFiberFirming agent

The invention discloses a radiation cooling coating and a preparation method thereof, and relates to the technical field of coatings. Wherein the radiation cooling coating comprises the following components in parts by weight: 5-7 parts of polysiloxane resin, 20-25 parts of reflective powder, 18-22 parts of hydrophobic modified silicon dioxide, 1-3 parts of fibers, 40-50 parts of a solvent and 0.25-0.7 part of a curing agent. In the technical scheme provided by the invention, the polysiloxane resin has good corrosion resistance, ultraviolet resistance and hydrophobicity, so that the service life of the radiation cooling coating is longer; meanwhile, the polysiloxane resin and the silicon dioxide have a large number of silicon-oxygen bonds and have absorption peaks in the wave band of 8-14 microns, so that the radiation rate is excellent, and through the synergistic effect of the polysiloxane resin and the silicon dioxide, the radiation cooling performance is excellent; the reflective powder has excellent retroreflection performance, and by adding the reflective powder, the absorbed sunlight can be retroreflected into extremely cold space, so that multiple reflections of the sunlight among urban high-rise buildings are effectively reduced, and the heat island effect is further reduced.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

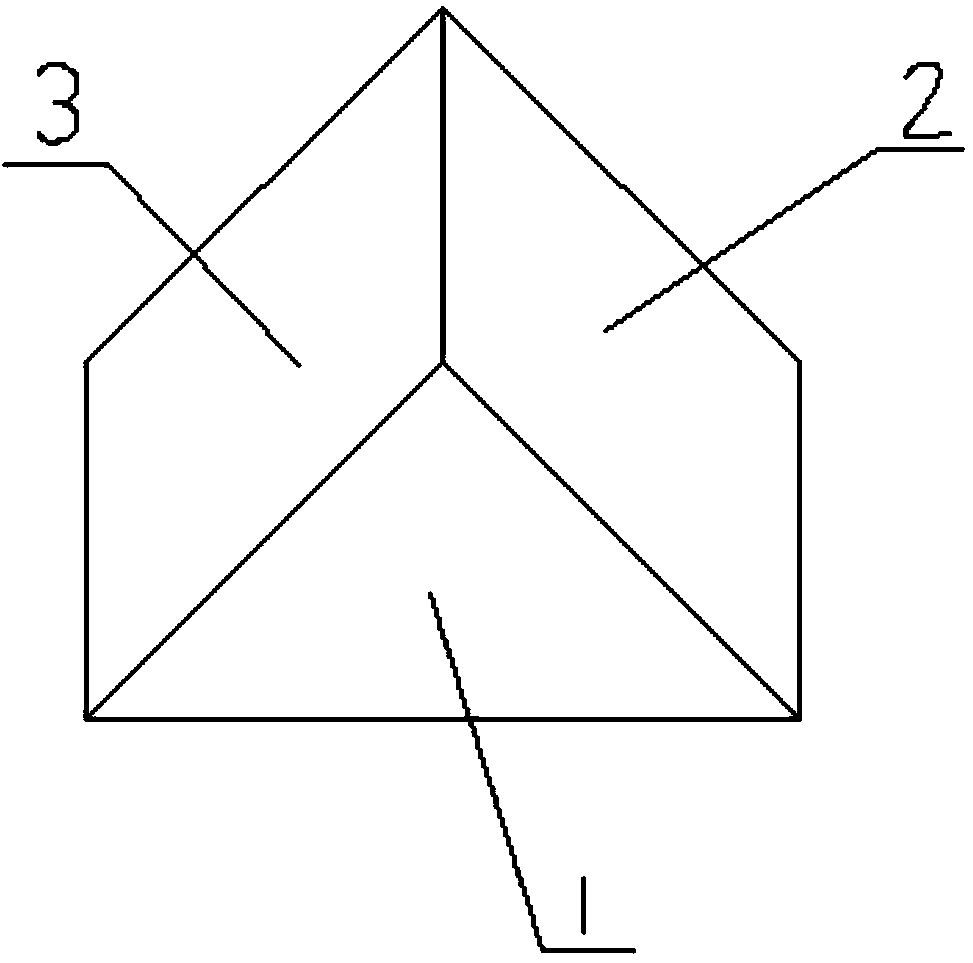

Three-dimensional deceleration marking

The invention discloses a three-dimensional deceleration marking which comprises color marking belt coatings coated on a road. A color marking belt is of a pentagon shape of a symmetric structure. The pentagon is divided into an isosceles triangle and two parallelograms symmetric in position through three middle lines. The isosceles triangle and the two parallelograms share one edge in pairs, and the bottom edge of the isosceles triangle is not shared. In the running direction of a vehicle, the bottom edge of the isosceles triangle is perpendicular to the running direction of the vehicle, and the two parallelograms are located in front of the bottom edge of the isosceles triangle. The isosceles triangle and the two parallelograms are respectively filled with one marking belt coating of a color, and the colors of the three marking belt coatings are different. The three-dimensional deceleration marking is low in cost, obvious in effect and capable of preventing the vehicle from badly damaging the road, and reduces road overhaul and maintenance cost.

Owner:SOUTHEAST UNIV

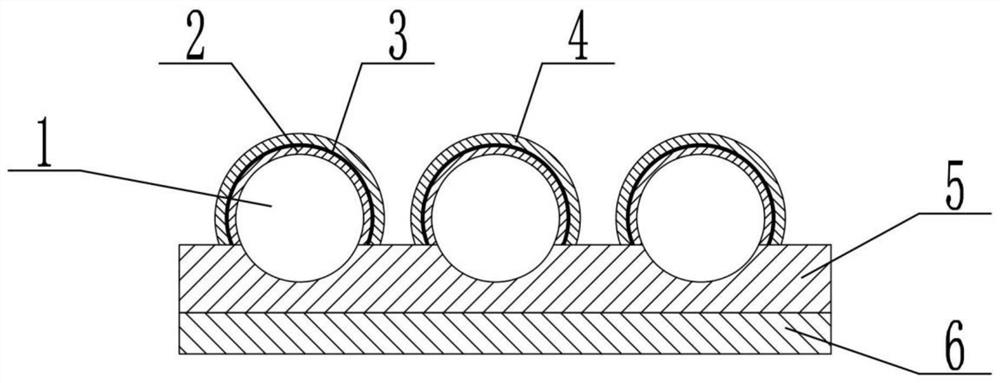

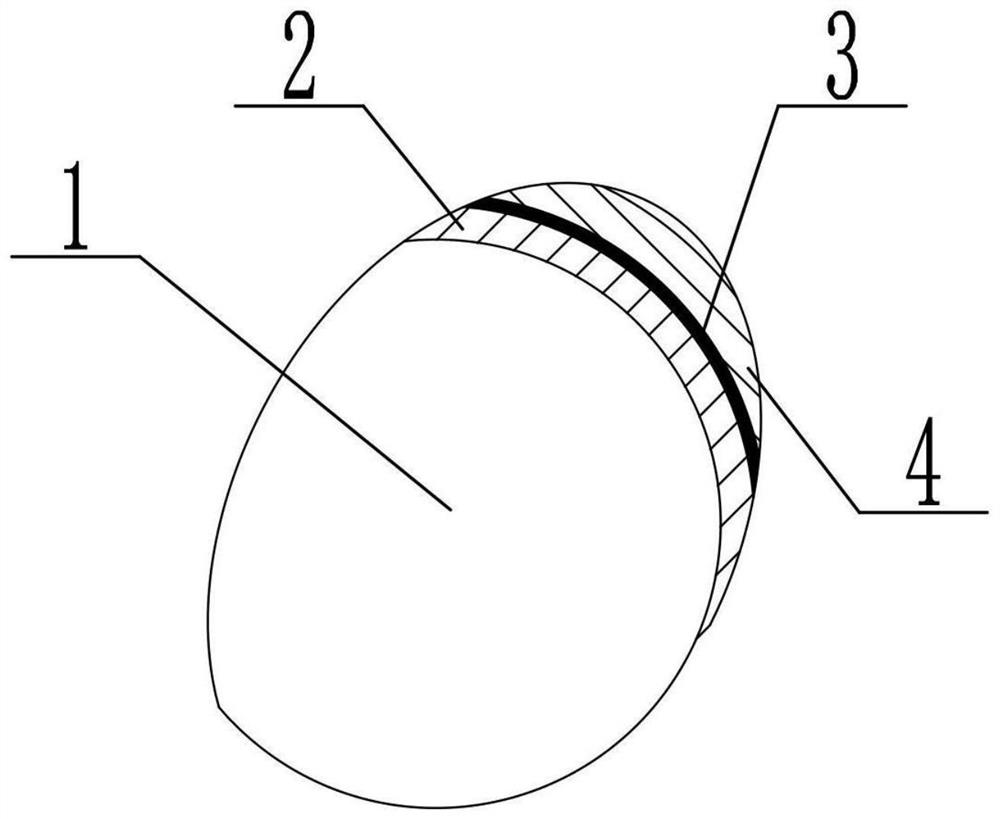

A production process of semi-aluminized glass microspheres and its bead brushing device

The invention discloses a semi-aluminized glass microbead production technology and a bead brushing device of semi-aluminized glass microbeads. A semi-aluminized layer is arranged plated on the surface of each glass microbead. The glass microbeads are formed through a bead embedding technology, the vacuum aluminizing technology and the bead brushing technology. During bead brushing, bead brushing is achieved through the bead brushing device of the semi-aluminized glass microbeads. The device is composed of a rack (12), an unwinding frame (1), a winding frame (2), a traction device, a brush roller (7), a tension roller (8), a flying preventing plate (13) and a collection trough (11). The semi-aluminized glass microbead production technology and the bead brushing device of the semi-aluminized glass microbeads have the advantages that the semi-aluminized glass microbeads are uniquely applied in the light reflecting printing ink field, play a role in light reflecting and alarming is played, the adhesive power between the semi-aluminized glass microbeads and screen printing glue is good, the semi-aluminized glass microbeads can be continuously collected on a large scale, collection efficiency is high, the flying amount is small, the semi-aluminized glass microbead flying amount is small, the aluminized layers on the surfaces of the glass microbeads are not damaged in the brushing process, and the semi-aluminized glass microbeads brushed away are clean without dust and have the higher retroreflection performance.

Owner:中节能(达州)新材料有限公司

A manufacturing process of washing-resistant high-brightness color reflective products

ActiveCN111515109BIncrease productivityGood coating effectLiquid surface applicatorsLamination ancillary operationsPolyesterPolymer science

Owner:浙江龙游道明光学有限公司

Environment-friendly two-component marking coating as well as preparation method, use method and application thereof

ActiveCN114045099AImprove adhesionImprove wear resistancePolyurea/polyurethane coatingsReflecting/signal paintsCarbamatePolymer solution

The invention discloses an environment-friendly double-component marking coating as well as a preparation method, a use method and application thereof. The coating consists of a component A, a component B and glass beads, wherein the component A comprises the following components in parts by mass: 50 to 55 parts of 655 resin, 45 to 50 parts of rutile type titanium dioxide, 50-60 parts of calcium carbonate, 0.1 to 0.2 part of a rheological agent 2; 0.2 to 0.4 part of a dispersing agent, and 0.1 to 0.2 part of a rheological agent 1; the component B comprises the following components in parts by mass: 50 to 55 parts of 659 resin, 45 to 50 parts of rutile type titanium dioxide, 50 to 60 parts of calcium carbonate, 0.1 to 0.2 part of a rheological agent 2, 0.2 to 0.4 part of a dispersant, 0.1 to 0.3 part of a rheological agent and a curing agent; wherein the mass ratio of A to B is 1:1, and the glass beads account for 18-25% of the sum of the mass of A and B; the part number of the rheological agent 1 in A is smaller than that in B; the addition amount of the curing agent is 1.5-2.0% of the mass sum of the resin in the component A and the component B; the rheological agent 1 is fumed silica with the specific surface area of (200 + / - 25) m2 / g, and the rheological agent 2 is a low-molecular-weight polymer solution containing urea / carbamate functional groups.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

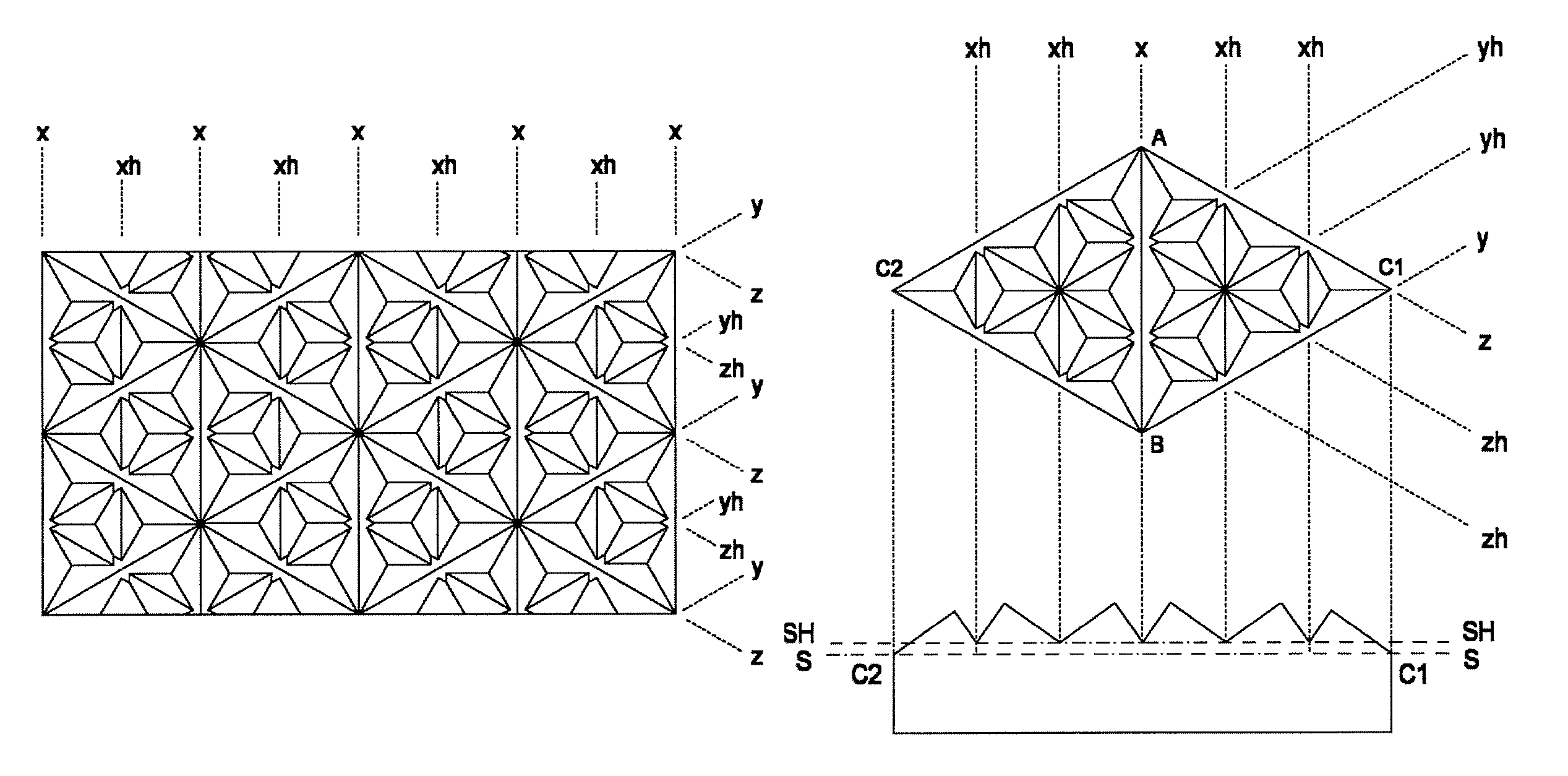

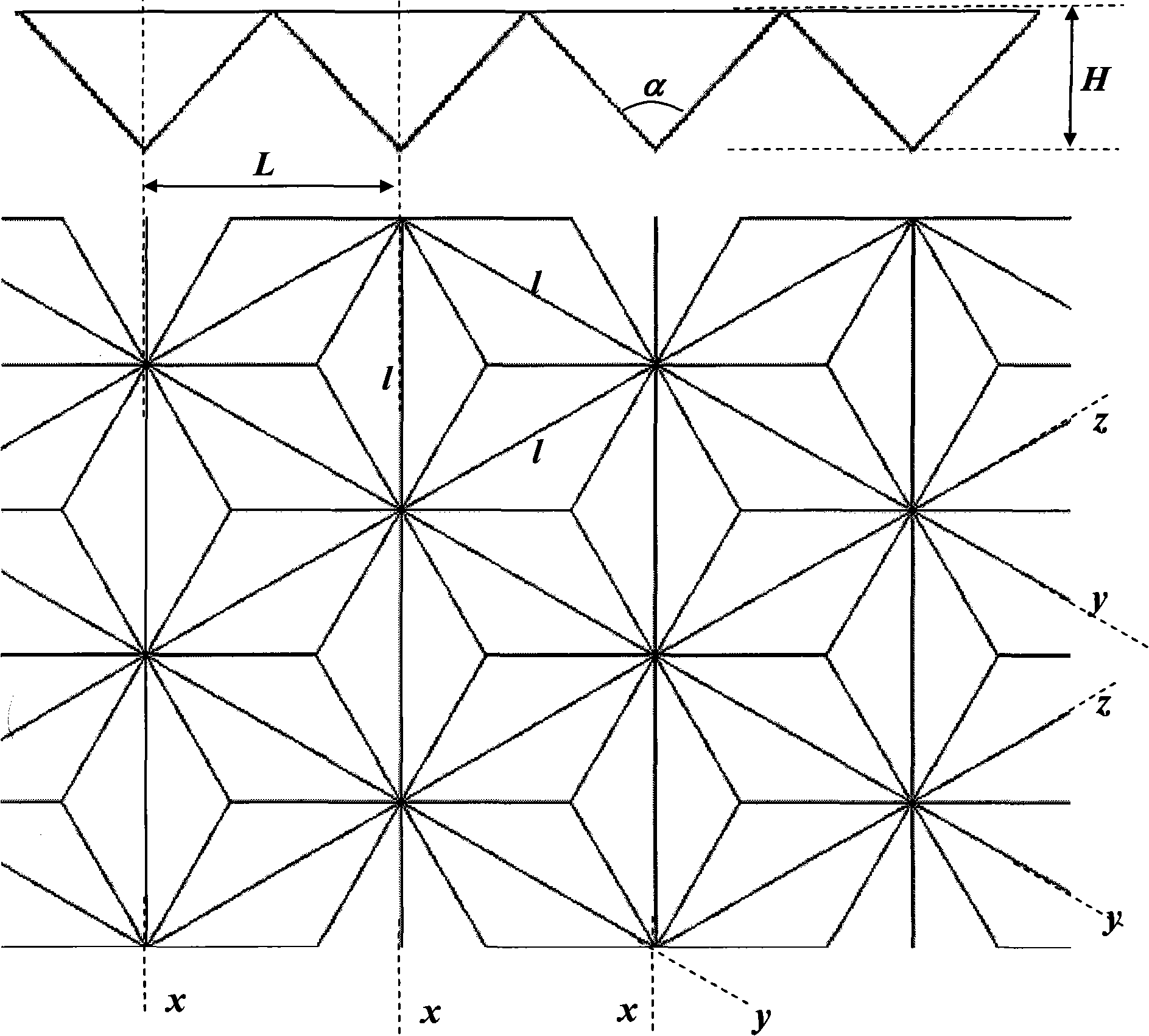

High-efficient retroreflective microprism and manufacturing method of mold thereof

ActiveCN101551480BIncrease the effective clear apertureImprove retroreflective performancePrismsUnit structurePrism

The present invention relates to a high-efficient retroreflective microprism. One unit structure is composed of a first regular triangular pyramid, a second regular triangular pyramid and a symmetrical hexagonal pyramid. Three edges of two regular triangular pyramids are perpendicular with one another and are positioned at two sides of symmetrical hexagonal pyramid. The symmetrical hexagonal pyramid is formed by cutting three corners of a three regular triangular pyramid. The shapes of three cut corners are same. Three new side surfaces of symmetrical hexagonal pyramid are obtained after cutting. The bottom surface of the three triangular pyramids is cut with three equilateral triangles. The bottom surface of the first regular triangular pyramid is one selected from three cut equilateral triangles. The angle between the adjacent side surfaces of the first regular triangular pyramid and the symmetrical hexagonal pyramid is 70.5288 degrees. The angle between the adjacent side surfaces ofthe second regular triangular pyramid and the symmetrical hexagonal pyramid is 70.5288 degrees. The invention simultaneously provides a method for manufacturing the microprism mold. The microprism provided by the invention has a simple structure. The mold manufacturing can be executed with a low cost.

Owner:TIANJIN UNIV

One-dimensional retroreflective sheet for stereoscopic display of projected light field

ActiveCN114355623BNarrow the range of scattering anglesReduce stripe sizeInstrumentsGratingLight beam

In the projected light field stereoscopic display, when the distance from the one-dimensional retroreflective sheet to the projector changes, the one-dimensional retroreflective effect will deteriorate. In order to solve this problem, the present invention proposes a one-dimensional retroreflective sheet for projection light field stereoscopic display. The one-dimensional retroreflective sheet for stereoscopic display of projected light field is composed of a first rod lens grating, a slit grating, a second rod lens grating and a diffuse reflection layer. The first cylindrical lens grating constitutes the first retroreflective structure. The second cylindrical lens grating and the diffuse reflection layer constitute the second retroreflective structure. The one-dimensional retroreflective sheet can optimize the one-dimensional retroreflective effect by using the restraining effect of the slit grating on the light beam and the compound retroreflective structure, so that the one-dimensional retroreflective sheet still has a good performance under the condition that the projector is relatively close. Retroreflection effect.

Owner:CHENGDU TECH UNIV

Bead planting technique used for high-strength reflecting film production

ActiveCN101369032BHigh densityGood retroreflective performanceSpecial surfacesCoatingsTemperature controlMicrosphere

Owner:CHANGZHOU HUA R SHENG REFLECTIVE MATERIAL

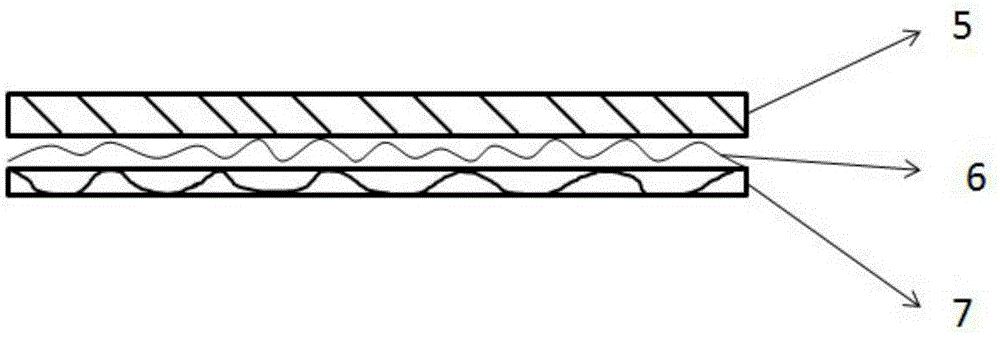

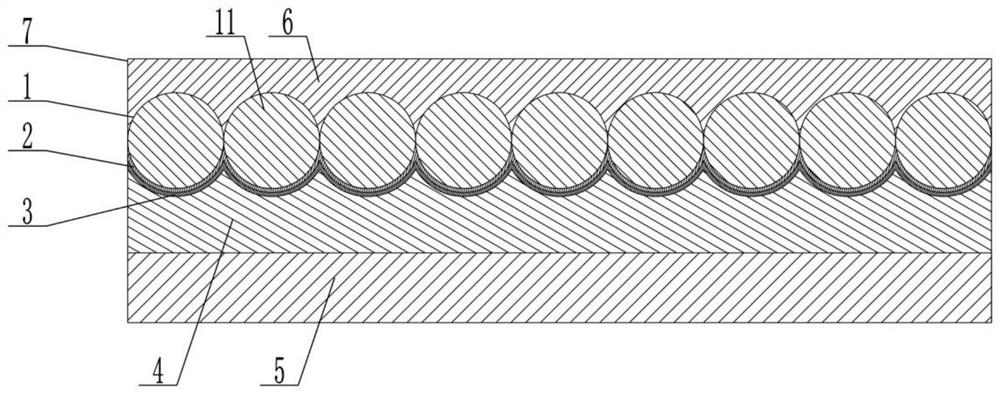

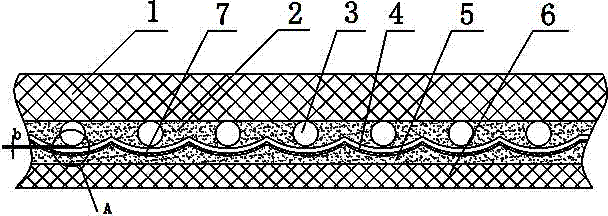

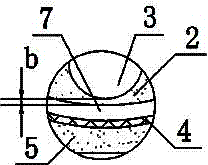

Lens embedment type reflective film and bead embedding process thereof

InactiveCN103197364BEasy to operateGood Appearance ControlLiquid surface applicatorsSynthetic resin layered productsMicrometerEmbedment

The invention relates to a lens embedment type reflective film which comprises a facial film (1), a bead embedding layer (2), an aluminum plating layer (4), a backing glue layer (5) and backing paper (6). The lens embedment type reflective film further comprises glass microbeads (3) and a focusing layer (7), wherein the glass microbeads (3) are embedded in the bead embedding layer (2), the focusing layer (7) is further arranged between the bead embedding layer (2) and the aluminum plating layer (4), the range of the distance b of lower surfaces of the glass microbeads (3) embedded into the surface of the bead embedding layer (2) is 0.5 micrometer-5 micrometers. A bead embedding process comprises the following steps of S1, screening of the glass microbeads (3); S2, uniform mixing; S3, bead embedding; S4, coating of the focusing layer (7); S5, aluminum plating; and S6, final molding. The lens embedment type reflective film and the bead embedding process have the advantages that operation is convenient, appearance control is easy to achieve, retroreflection performance is excellent, and cost is relatively low; and through the bead embedding process, floating beads can be prevented from being produced in embedding beads, and meanwhile the technical problem of difficult one-time wrapping of the glass microbeads is overcome.

Owner:SICHUAN ZHONGKE BETTER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com