Preparation method of high-brightness wide-angle reflecting material

A reflective material, high-brightness technology, used in optics, optical components, textiles and papermaking, etc., can solve the problems of small viewing angle range and short viewing distance, and achieve excellent retro-reflection performance, enhanced reflective effect, and bright light. The effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

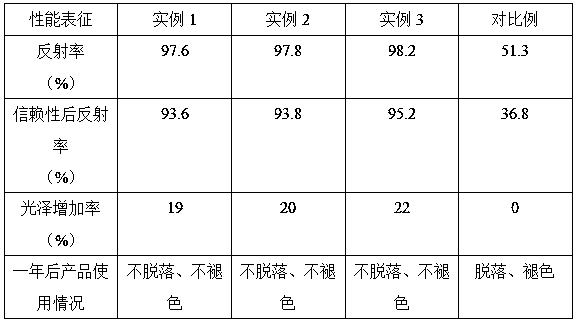

Examples

example 1

[0025] In parts by weight, weigh 20 parts of glass microspheres, 1 part of sodium dodecylbenzenesulfonate, 10 parts of titanium sulfate solution, and 40 parts of deionized water, mix the glass microspheres and deionized water evenly, and drop Add sodium dodecylbenzenesulfonate, stir magnetically at 50°C for 1 hour to obtain a mixed solution, add titanium sulfate solution dropwise, continue stirring for 3 hours, adjust the pH of the system to 9 with ammonia water, obtain a suspension, and filter to obtain a filter residue , washed with deionized water until neutral, and placed in an oven at 80°C to dry to constant weight to obtain a dry filter residue, which was placed in a muffle furnace and calcined at a temperature of 500°C for 2 hours, followed by Cool to obtain modified glass beads; mix acrylic resin and polyurethane resin at a mass ratio of 2:1, stir for 1 hour at a stirring speed of 80r / min to obtain a binder, and mix aluminum silver powder with a mass ratio of 1:3 Mix w...

example 2

[0027] In parts by weight, weigh 28 parts of glass microspheres, 3 parts of sodium dodecylbenzenesulfonate, 13 parts of titanium sulfate solution, and 50 parts of deionized water, mix the glass microspheres and deionized water evenly, drop Add sodium dodecylbenzenesulfonate, stir magnetically at 55°C for 1.5 hours to obtain a mixed solution, add titanium sulfate solution dropwise, continue stirring for 4 hours, adjust the pH of the system to 9 with ammonia water, obtain a suspension, and filter to obtain The filter residue was washed with deionized water until it was neutral, and dried in an oven at a temperature of 90°C to a constant weight to obtain a dry filter residue, which was placed in a muffle furnace and calcined at a temperature of 600°C for 3 hours. Cool in the furnace to obtain modified glass beads; mix acrylic resin and polyurethane resin at a mass ratio of 2:1, and stir for 1.5 hours at a stirring speed of 90r / min to obtain a binder, and mix the acrylic resin and ...

example 3

[0029]In parts by weight, weigh 35 parts of glass microspheres, 5 parts of sodium dodecylbenzenesulfonate, 16 parts of titanium sulfate solution, and 60 parts of deionized water, mix the glass microspheres and deionized water evenly, and drop Add sodium dodecylbenzenesulfonate, stir magnetically at 60°C for 2 hours to obtain a mixed solution, add titanium sulfate solution dropwise, continue stirring for 5 hours, adjust the pH of the system to 10 with ammonia water, obtain a suspension, and filter to obtain a filter residue , washed with deionized water until neutral, and placed in an oven at a temperature of 100°C to dry to constant weight to obtain a dry filter residue, which was placed in a muffle furnace and calcined at a temperature of 700°C for 5 hours, followed by the furnace Cool to obtain modified glass beads; mix acrylic resin and polyurethane resin at a mass ratio of 2:1, stir for 2 hours at a stirring speed of 100r / min to obtain a binder, and mix aluminum silver powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com