Radiation cooling coating and preparation method thereof

A radiative cooling and coating technology, applied in the field of coatings, can solve the problems of increasing urban heat absorption and intensifying urban heat island effect, and achieve the effect of reducing heat island effect, excellent radiative cooling performance, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

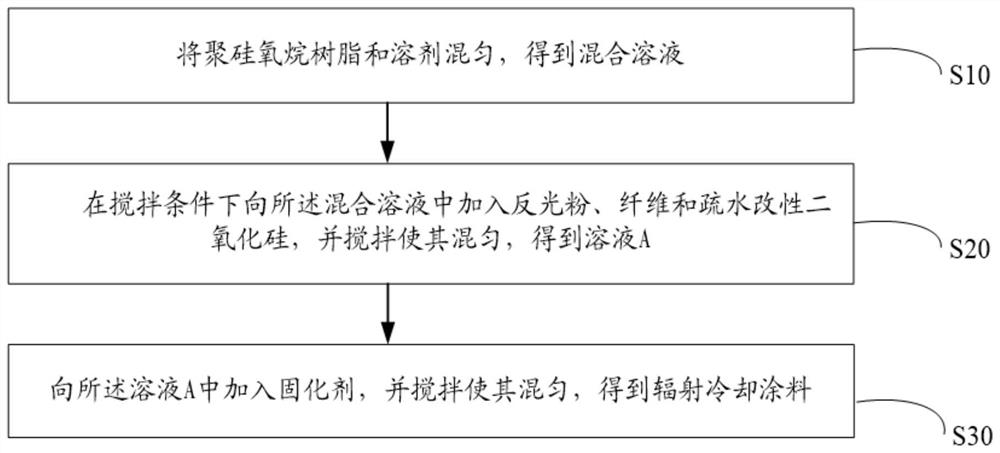

[0040] Based on the above-mentioned purpose, the present invention also proposes a kind of preparation method of radiation cooling paint as mentioned above, combining figure 1 Said, in one embodiment, the preparation method comprises the following steps:

[0041] Step S10, mixing the polysiloxane resin and the solvent to obtain a mixed solution.

[0042] During specific implementation, under the condition of 250-350 r / min, the polysiloxane resin and the solvent are sequentially poured into the airtight container and stirred for 8-12 minutes, so as to mix them uniformly to obtain a mixed solution. Preferably, stir at 300r / min for 10min to make it evenly mixed.

[0043] Step S20 , adding reflective powder, fiber and hydrophobically modified silica into the mixed solution under stirring condition, and stirring to make it evenly mixed to obtain solution A.

[0044] During specific implementation, reflective powder, fibers and hydrophobically modified silica were added to the mix...

Embodiment 1

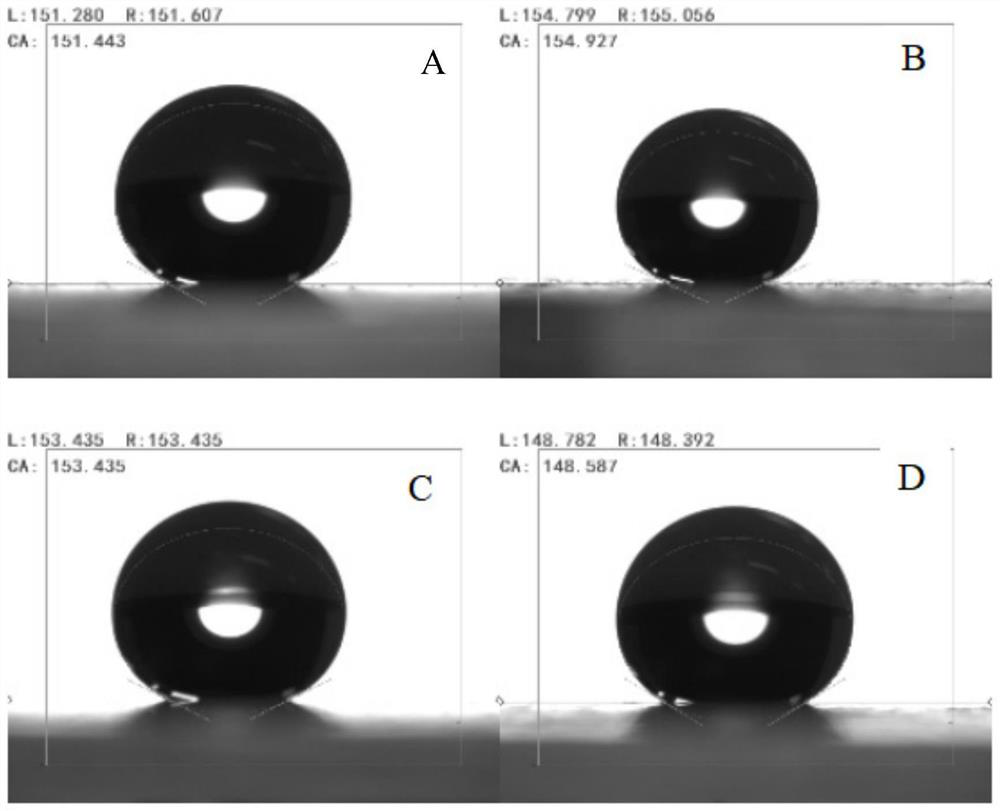

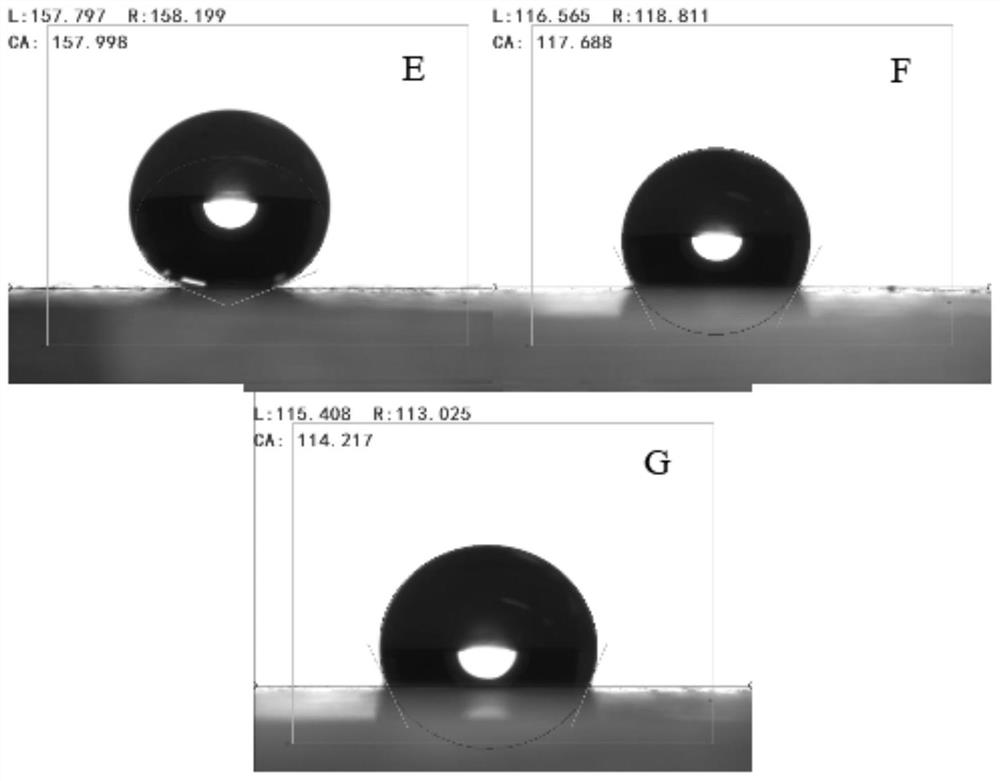

[0054] (1) The radiation cooling coating includes the following components in parts by weight: 5 parts of MQ silicone resin, 25 parts of 400-mesh reflective powder, 18 parts of hydrophobically modified silica with a particle size of about 1 μm, 1 part of aluminum silicate fiber, 48.75 parts of No. 200 solvent oil, 0.25 parts of curing agent; among them, hydrophobically modified silica is obtained by modifying PDMS with a particle size of 20nm, and then pulverized and sieved; the reflective powder is coated with aluminum on the second half of the surface glass beads with high refractive index.

[0055] (2) At 300r / min, pour polysiloxane resin and solvent into an airtight container and stir for 10 minutes to obtain a mixed solution; at 500r / min, add reflective powder, fiber and hydrophobic modification to the above mixed solution Silica, stirred for 30 min under airtight conditions, to obtain solution A. Add curing agent to the above solution A, and continue to stir for 5 minut...

Embodiment 2

[0057] (1) The radiation cooling coating includes the following components in parts by weight: 6 parts of MQ silicone resin, 20 parts of 400-mesh reflective powder, 20 parts of hydrophobically modified silica with a particle size of about 1 μm, 2 parts of aluminum silicate fiber, 48.7 parts of No. 200 solvent oil and 0.3 parts of curing agent; among them, the hydrophobically modified silica is the agglomerated powder of silicon dioxide with a particle size of 10nm modified by PDMS, and then crushed and sieved; the reflective powder is the second half High refractive index glass beads coated with aluminum.

[0058] (2) At 350r / min, pour polysiloxane resin and solvent into an airtight container and stir for 8 minutes to obtain a mixed solution; at 450r / min, add reflective powder, fiber and hydrophobic modification to the above mixed solution Silica, stirred for 35min under airtight conditions, to obtain solution A. Add the curing agent to the above solution A, and continue to s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com