Patents

Literature

133 results about "Radiative cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

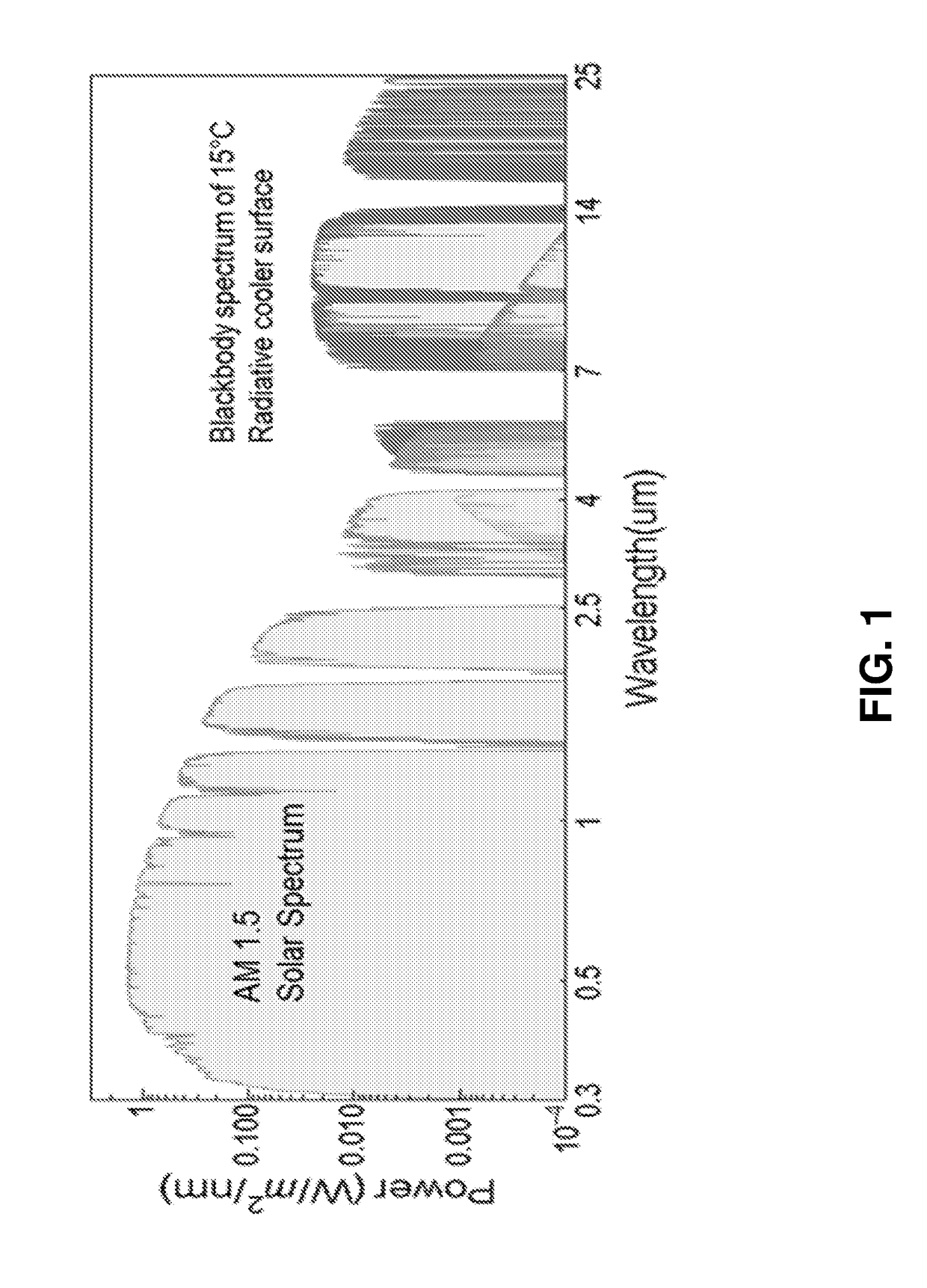

Radiative cooling is the process by which a body loses heat by thermal radiation.

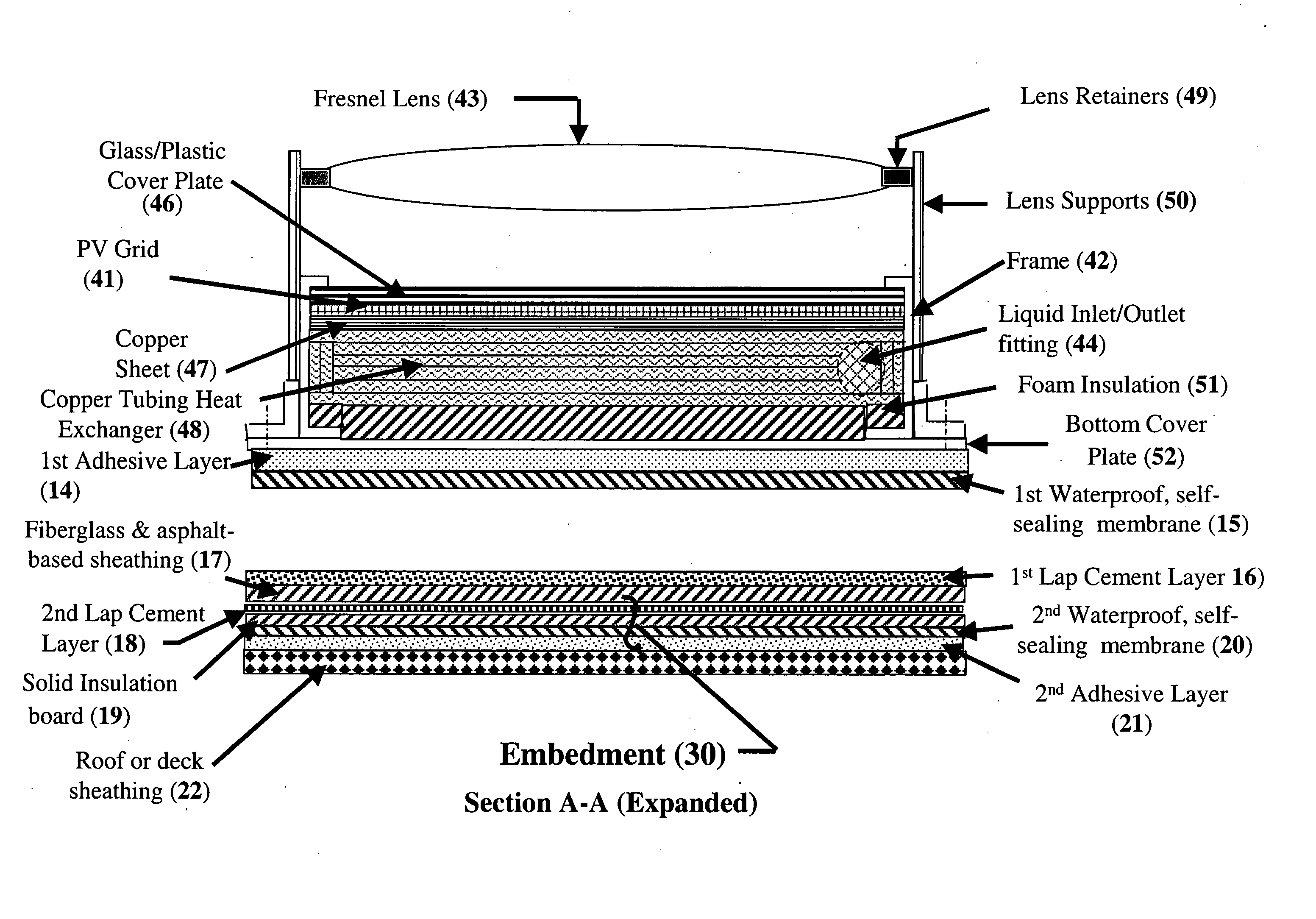

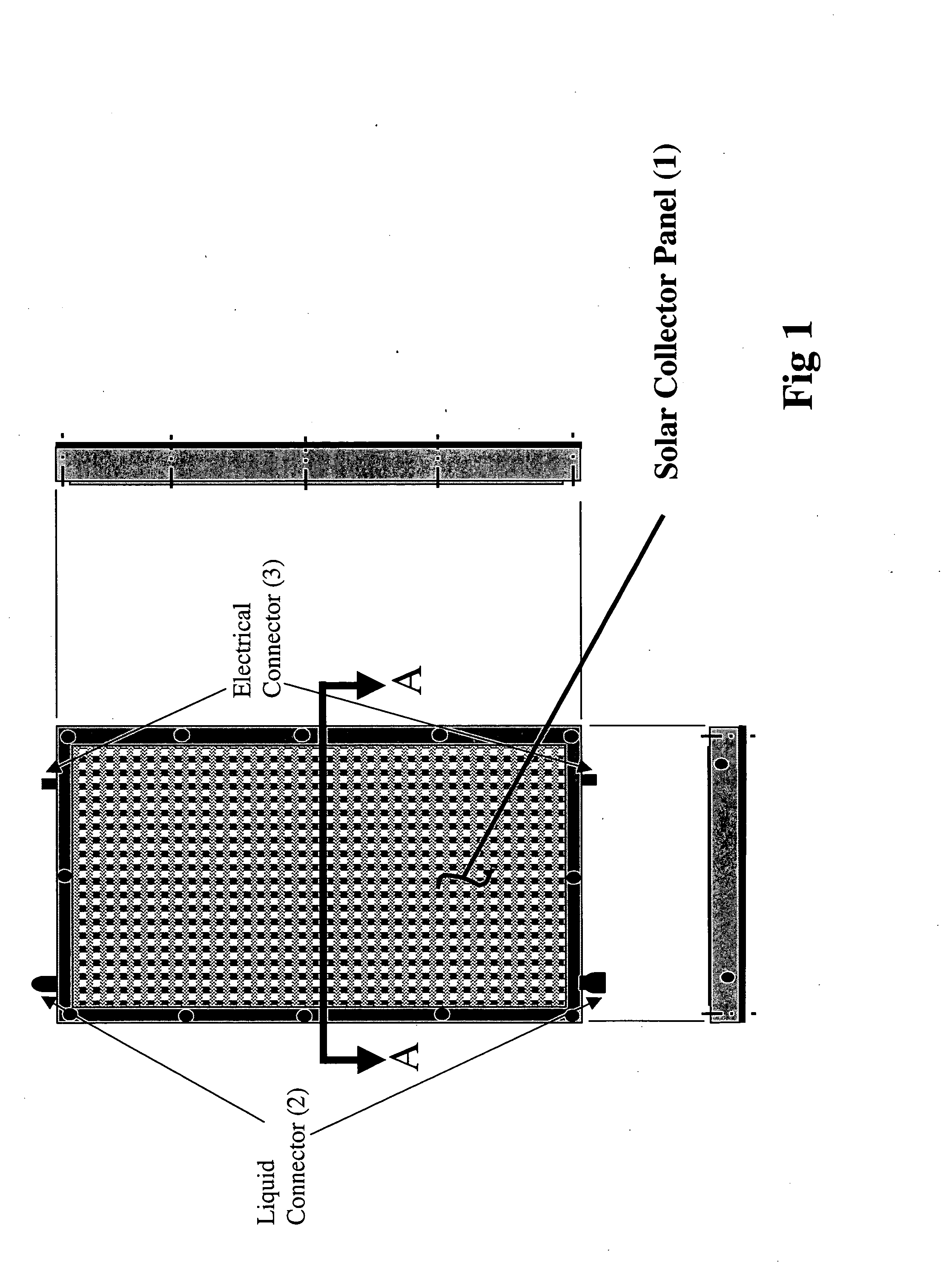

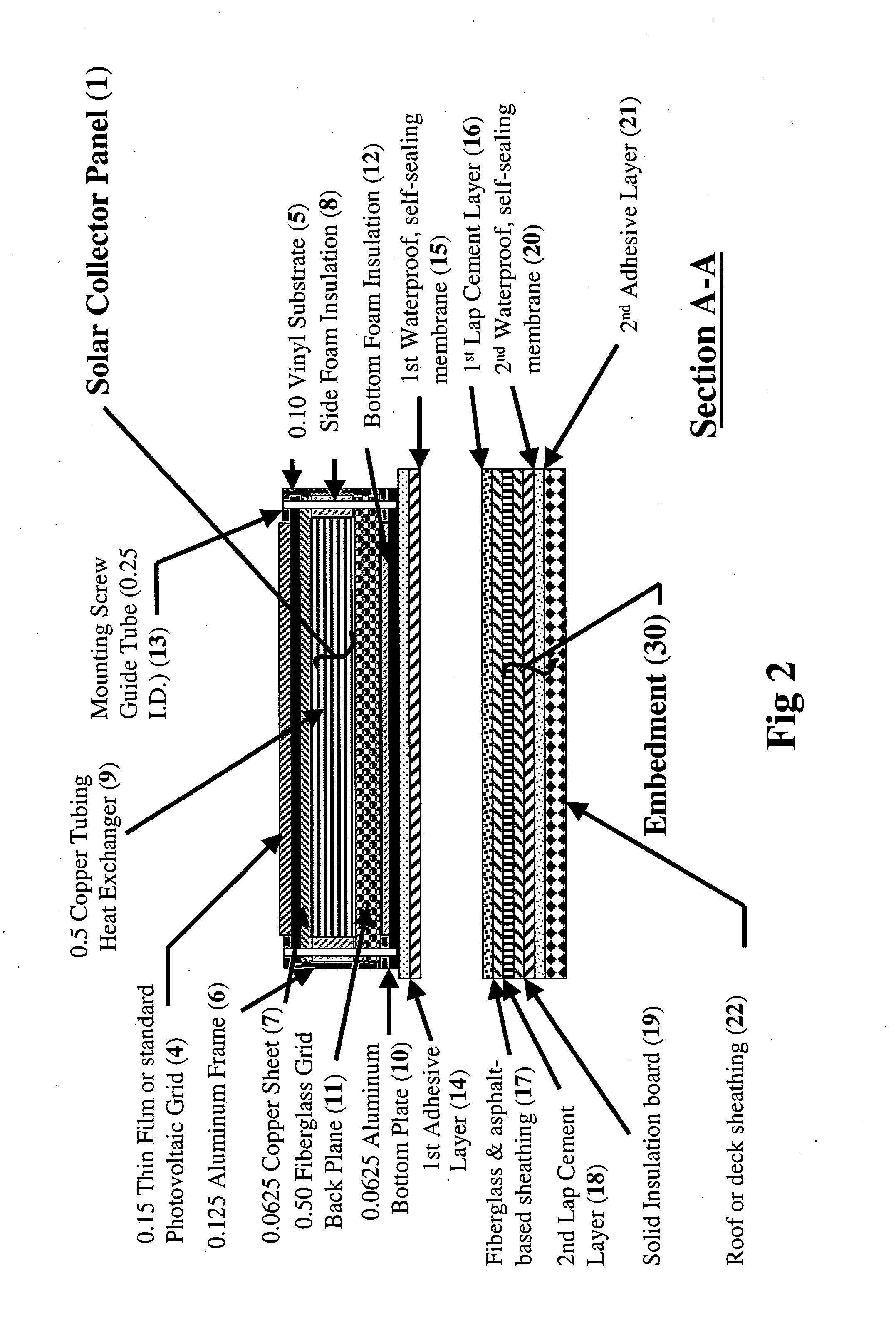

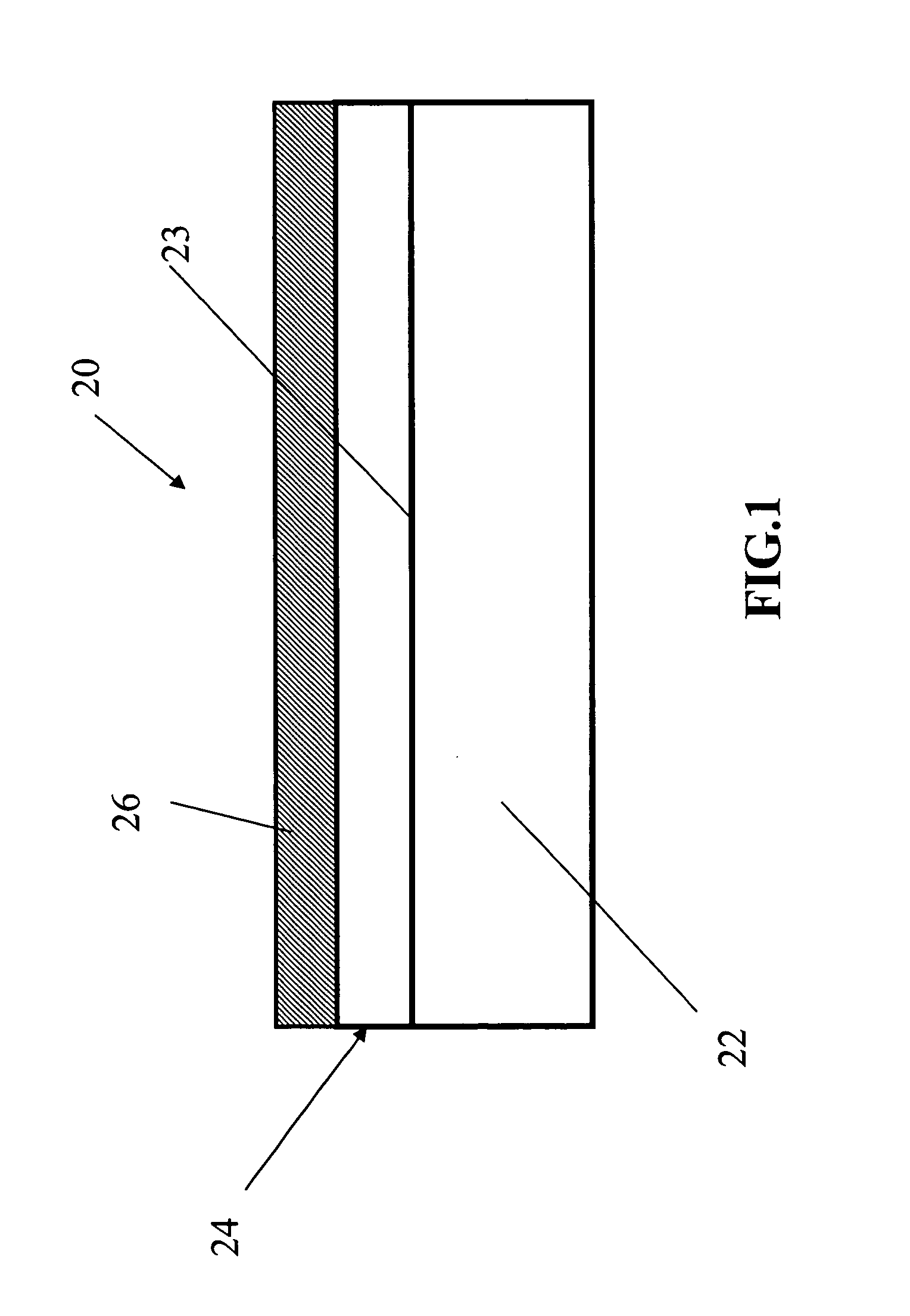

Integrated solar energy roofing construction panel

InactiveUS20050133082A1Reduce installation costsLabor savingSolar heating energySolar heat devicesThermal energyEngineering

A solar assembly comprising two components: a multi-functional solar collecting apparatus and a mounting embedment integrated with building construction material. The mounting embedment component is affixed to a building frame structure using standard construction techniques and receives the multi-functional solar collecting apparatus that is secured with fasteners. The multi-functional solar collecting apparatus converts solar energy to electrical energy using a photovoltaic grid mounted on a copper plate that provides even temperature dispersion across the plate and acts as a thermal radiator when the apparatus is used as a radiant cooler; and a plurality of interconnected heat transfer tubes located within the apparatus enclosure disposed on the plane below the copper plate but conductively coupled to the copper plate for converting the solar energy to thermal energy in a fluid disposed within the heat transfer tubes.

Owner:KONOLD ANNEMARIE HVISTENDAHL +1

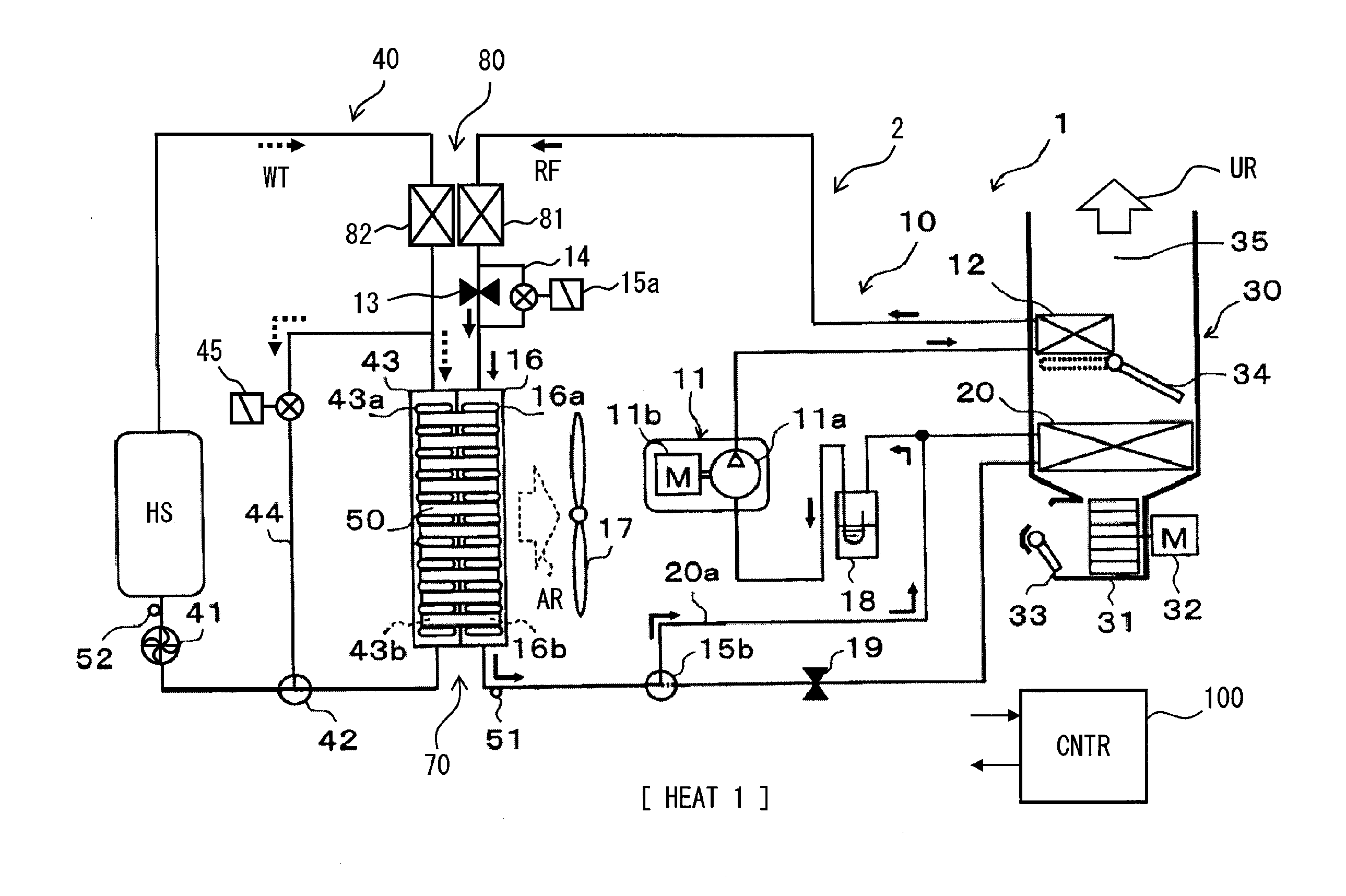

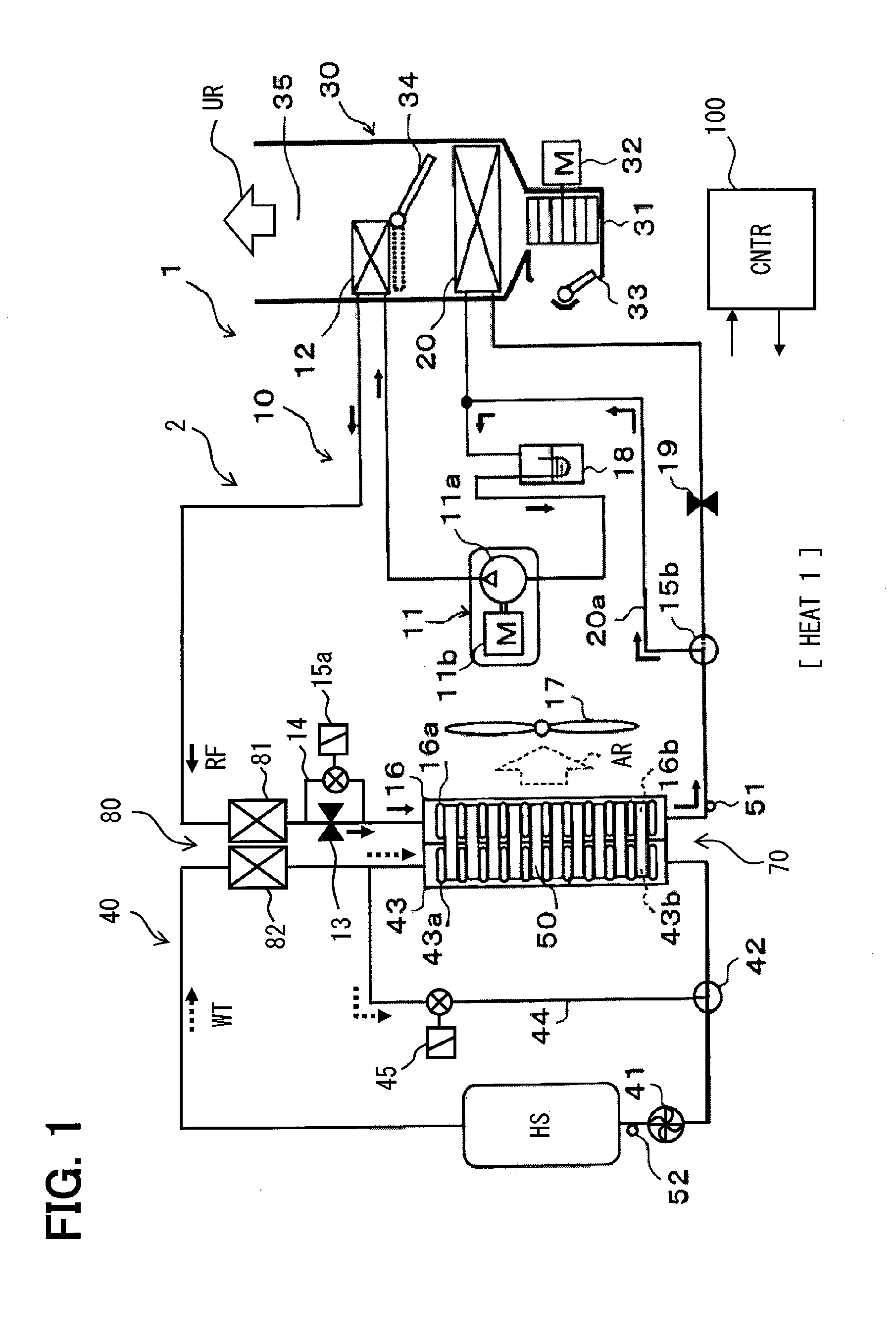

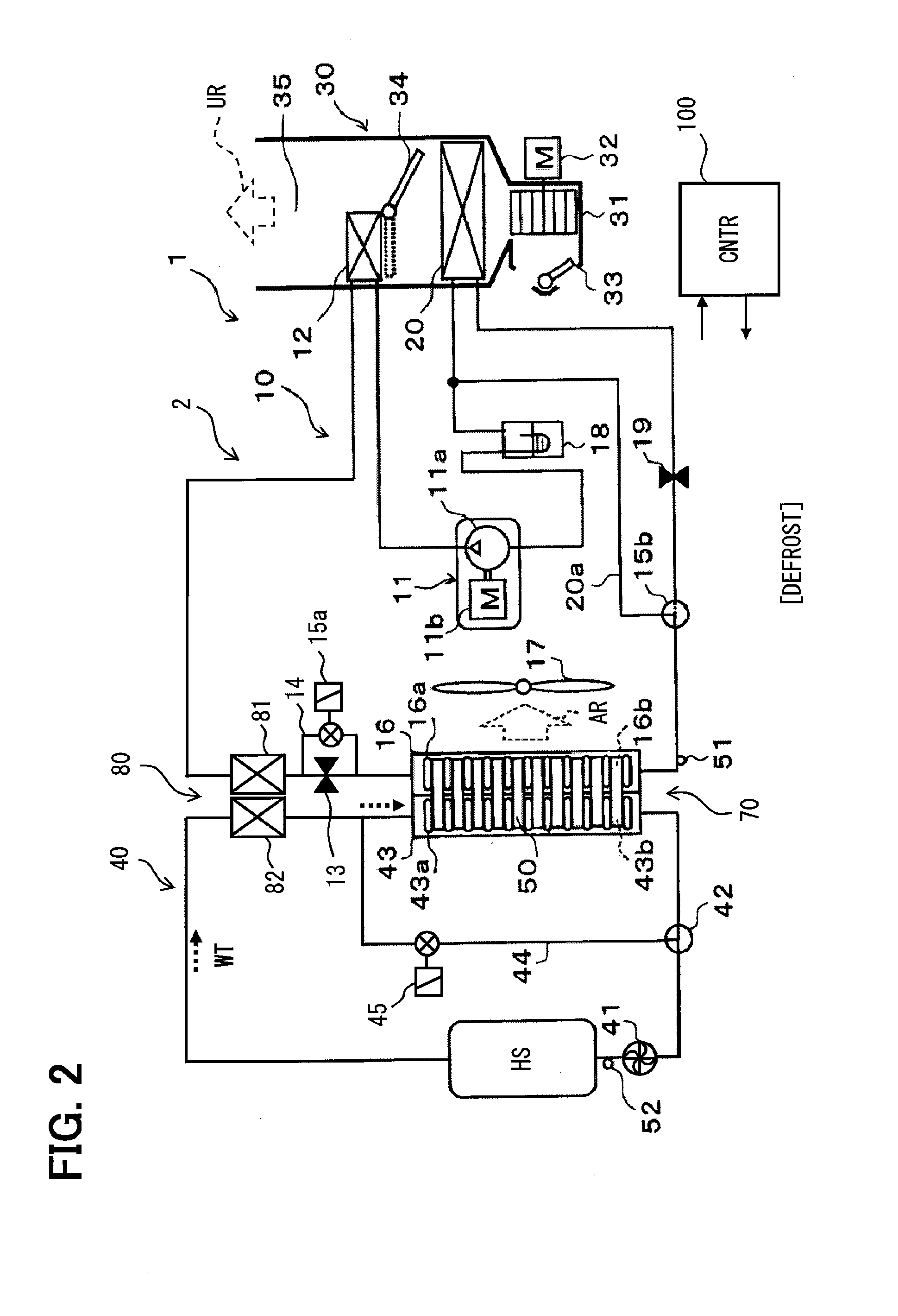

Heat pump cycle

ActiveUS20140318170A1Improve performanceSuppression of of improvedHeat pumpsEvaporators/condensersEngineeringHigh pressure

A heat pump cycle includes a refrigerant circuit and a coolant circuit. A first heat exchanger and a second heat exchanger are disposed between the refrigerant circuit and the coolant circuit. The first heat exchanger includes an exterior heat exchanger that functions as an evaporator in a heating operation, and a radiator for radiating heat of a coolant. The second heat exchanger transmits a heat of high-pressure refrigerant to the coolant in the heating operation. A temperature of refrigerant within the second heat exchanger is higher than a temperature of refrigerant within the first heat exchanger. The heat obtained from the second heat exchanger is supplied to the first heat exchanger through the coolant. Further, the heat obtained from the second heat exchanger is stored in the coolant. In defrosting operation, the coolant that has stored the heat therein is supplied to the first heat exchanger.

Owner:DENSO CORP

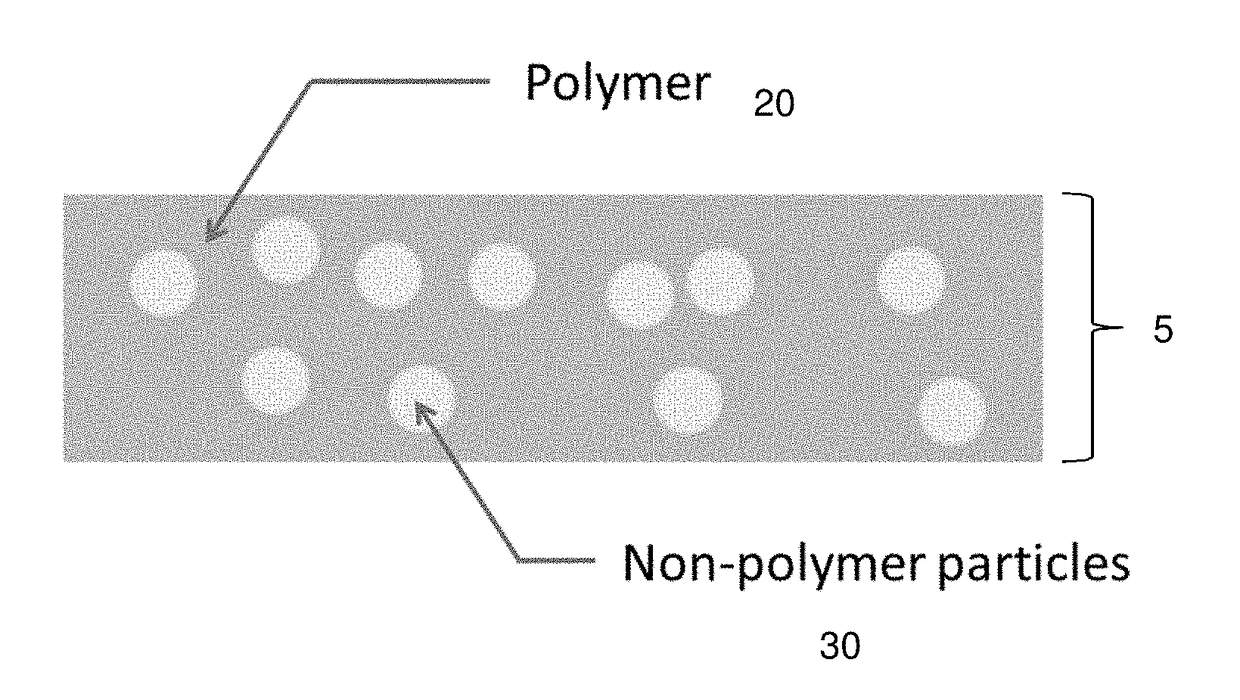

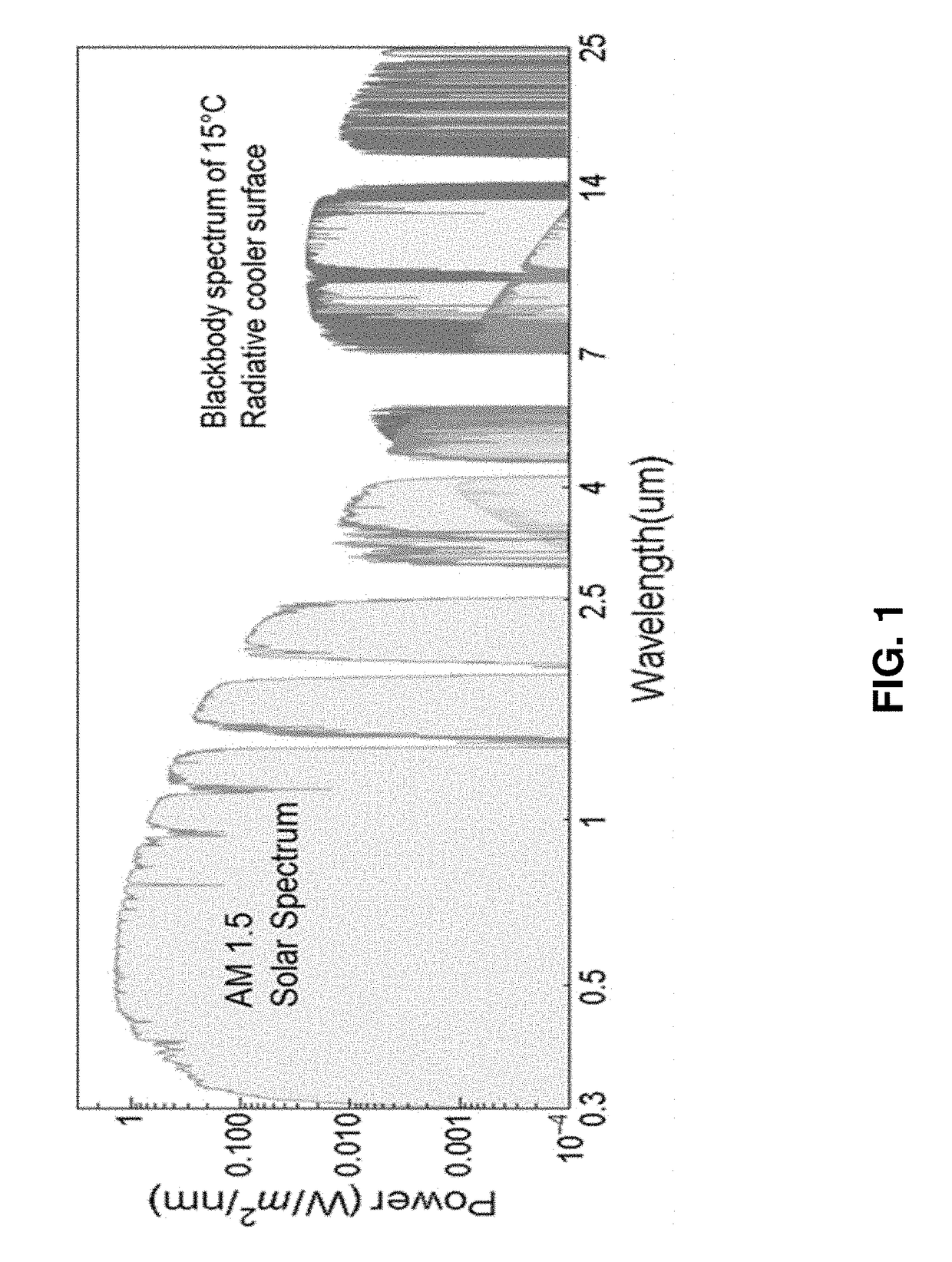

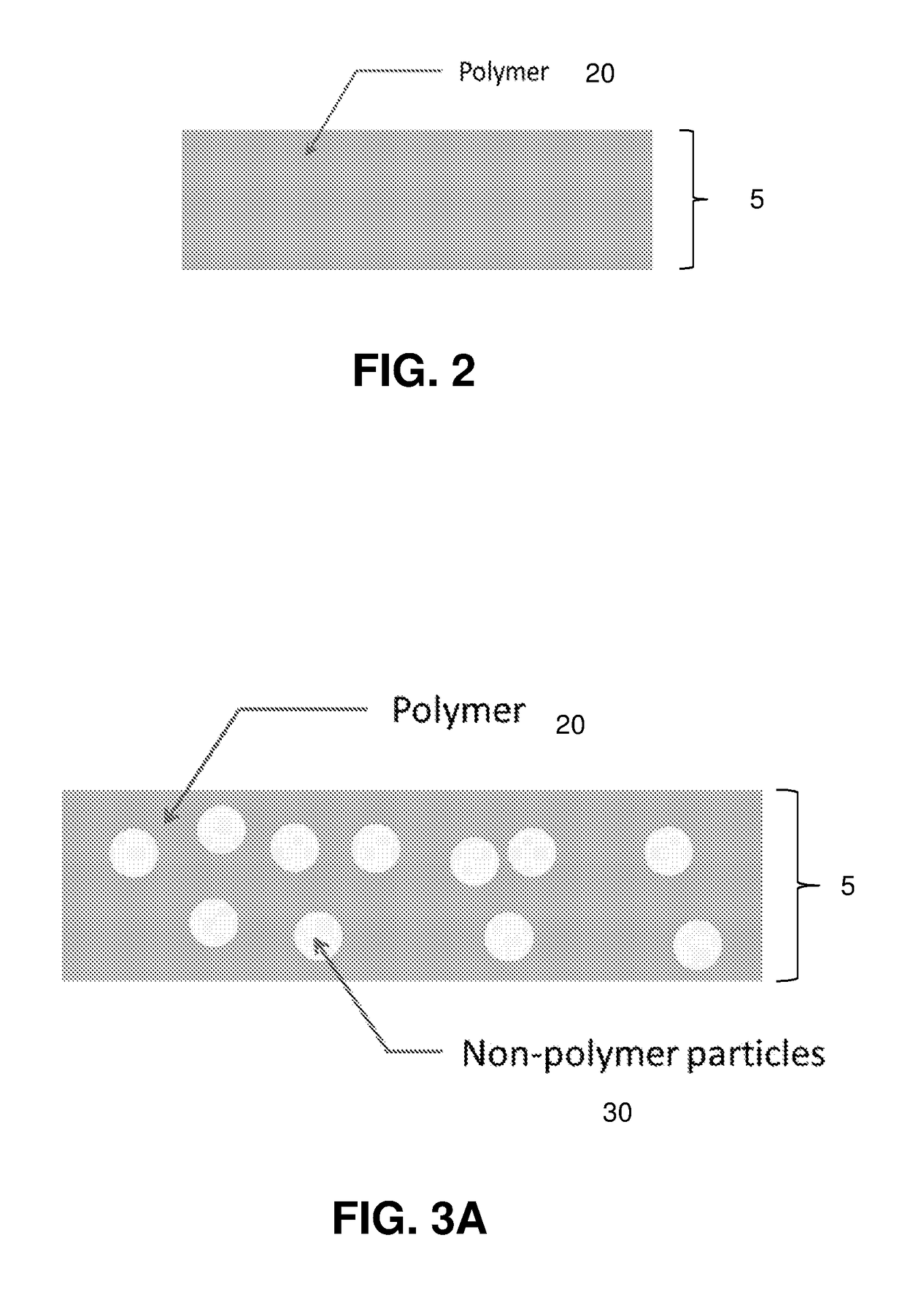

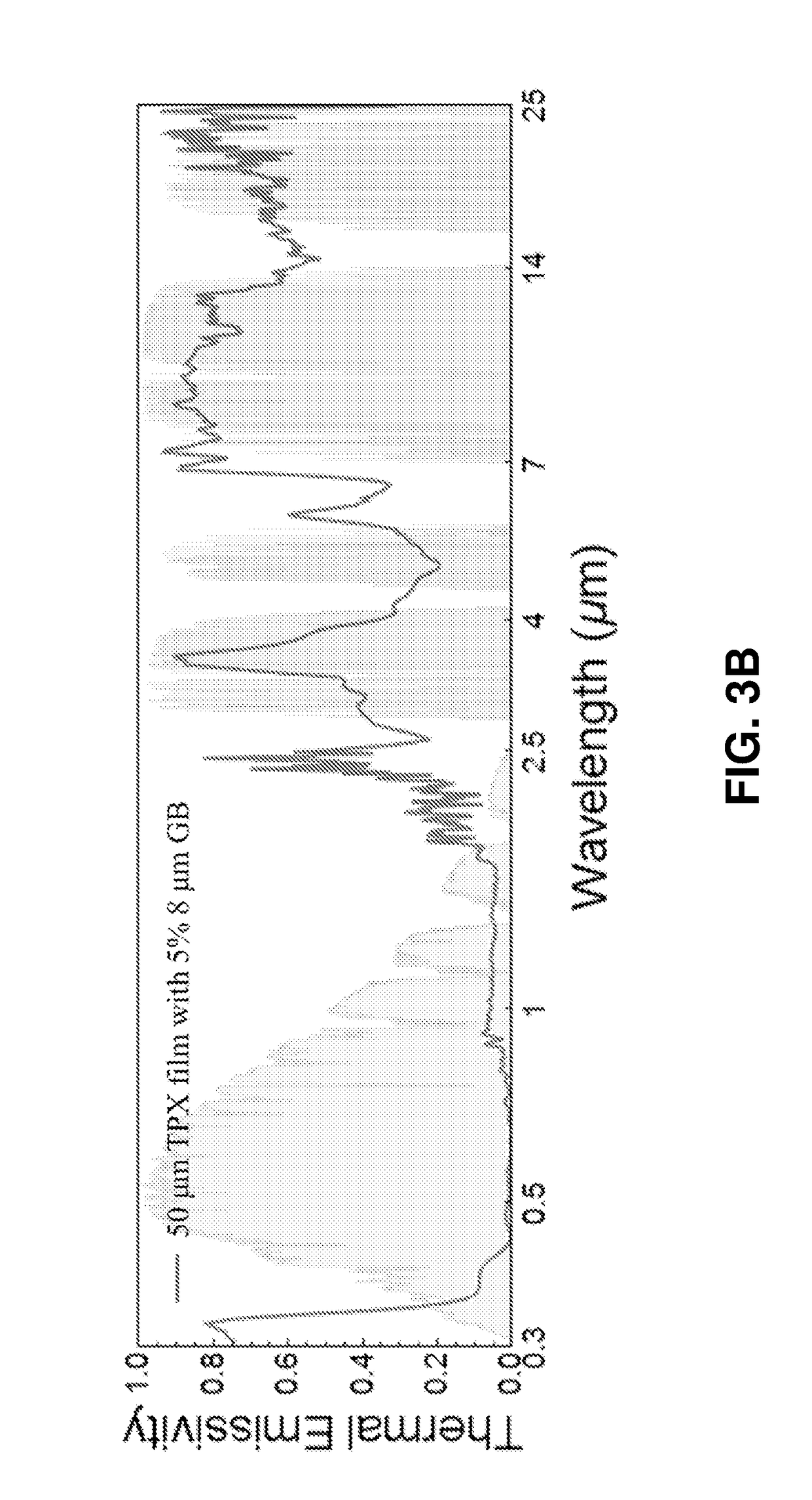

Radiative cooling structures and systems

ActiveUS20170248381A1Cheap and effectiveEasy to integrateSynthetic resin layered productsCoatingsThermal radiationRadiative cooling

Polymer-based selective radiative cooling structures are provided which include a selectively emissive layer of a polymer or a polymer matrix composite material. Exemplary selective radiative cooling structures are in the form of a sheet, film or coating. Also provided are methods for removing heat from a body by selective thermal radiation using polymer-based selective radiative cooling structures.

Owner:UNIV OF COLORADO THE REGENTS OF +1

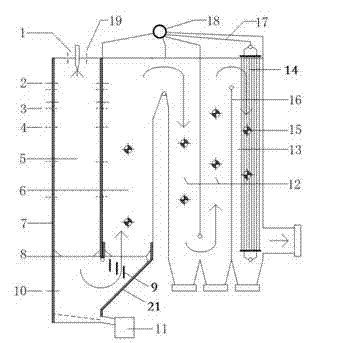

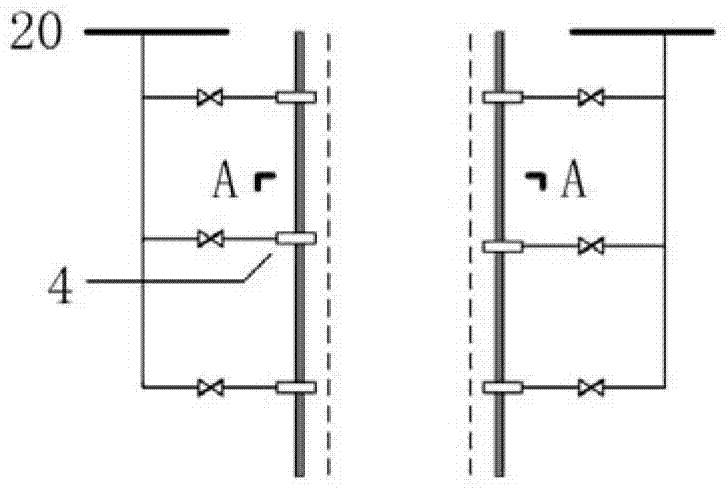

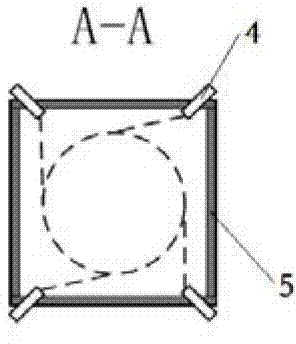

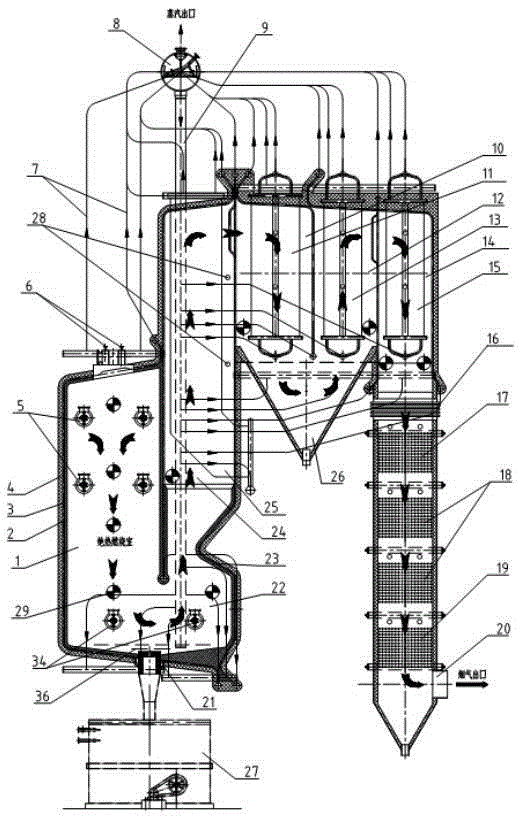

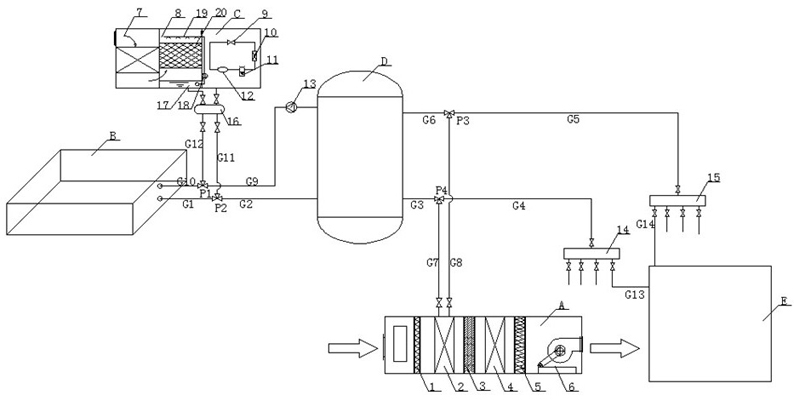

Burning process and burning boiler for processing high-density saliferous organic wastewater

ActiveCN103047659AGuaranteed combustion temperatureReduce flue gas velocityCombustion technology mitigationIncinerator apparatusChemical industryGas burner

The invention discloses a burning process and a burning boiler for processing high-density saliferous organic wastewater. The burning boiler comprises a down heat insulation boiler cavity, a multilevel radiation cooling chamber, a convection heat exchange chamber, an ash blowing device, a steam outlet pipe and a steam pocket. The down heat insulation boiler cavity comprises a waste liquid atomizing spraying gun, a two-layer auxiliary gas burner, a secondary air nozzle, an air flow shielding device, a water cooling wall, a fireproof material, a compensation fuel gas burner, a liquid slag removing device and a root portion air nozzle. A radiation heat exchange chamber I comprises a water cooling wall, a fireproof material and a flow guide device. The convection heat exchange chamber comprises a water cooling wall and a convection screen. The burning process effectively controls and optimizes the problems of stable complete burning of heat value high-moisture waste liquid, heating surface slag bonding and ash accumulation, tail heating surface low temperature corrosion, NOX discharge and the like, has good processing effect on the high-density saliferous organic wastewater, achieves effective recycle of resources and is suitable for organic wastewater burning processing of chemical industries.

Owner:BEIJING NATION POWER GRORP +1

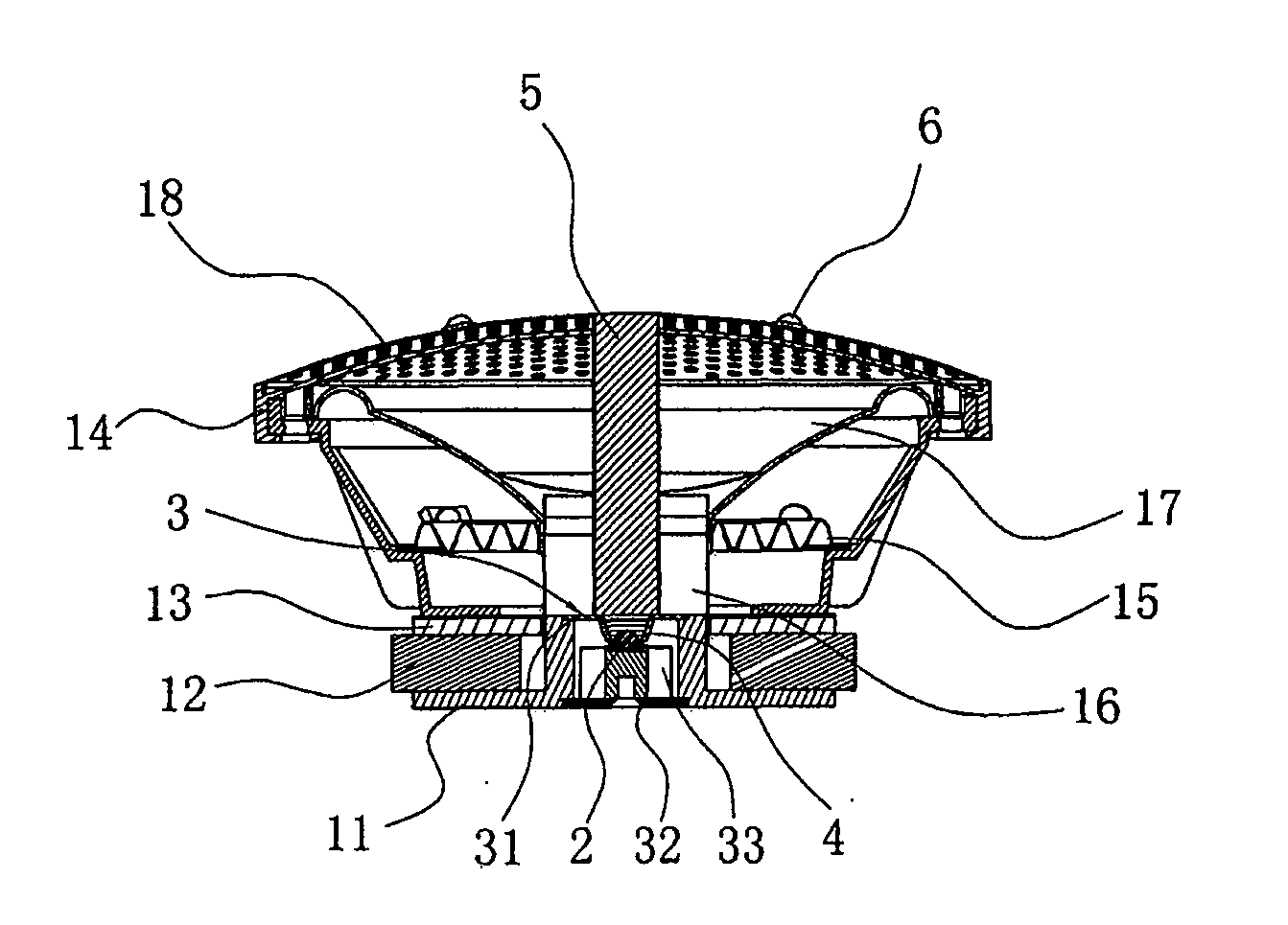

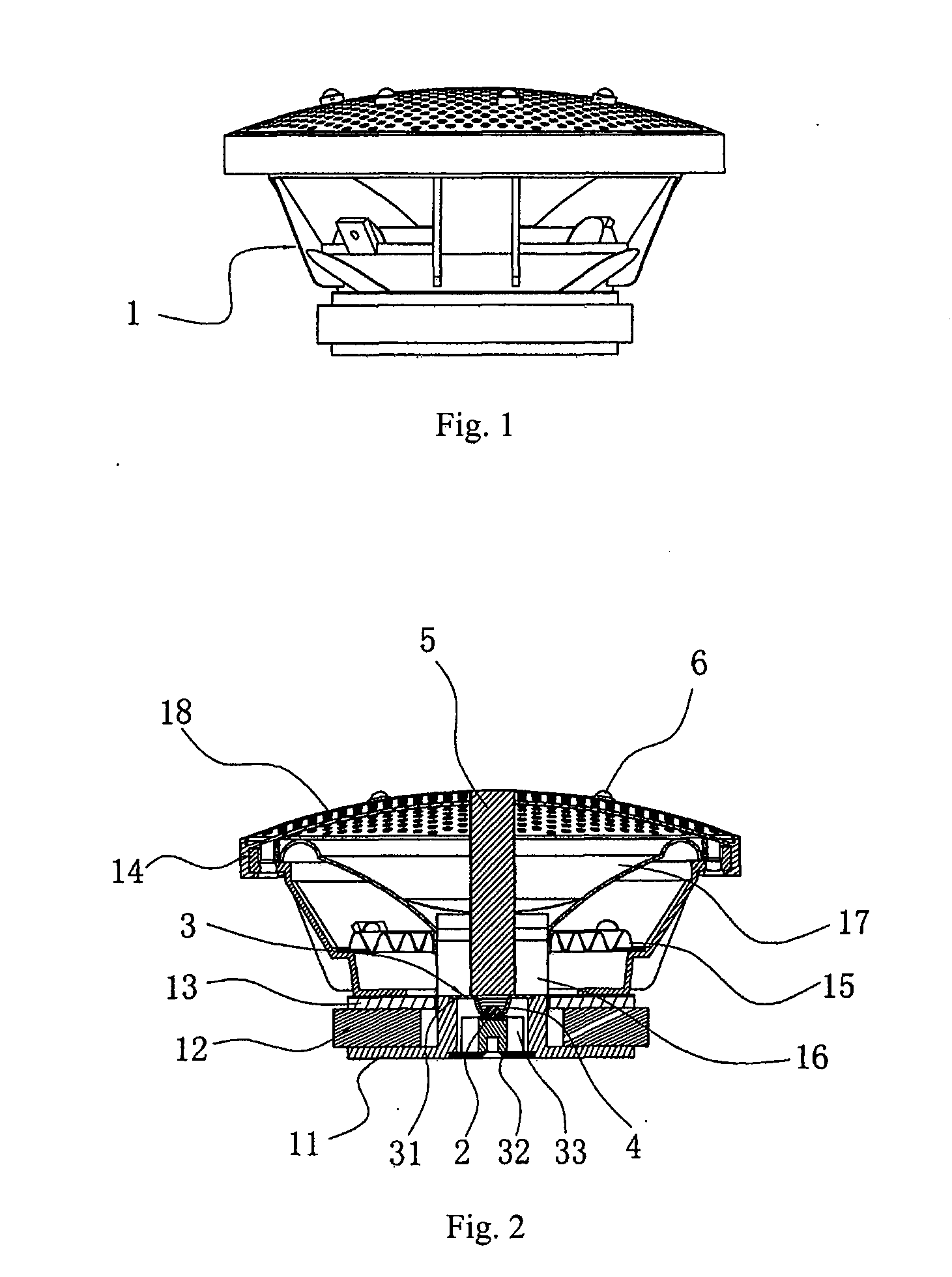

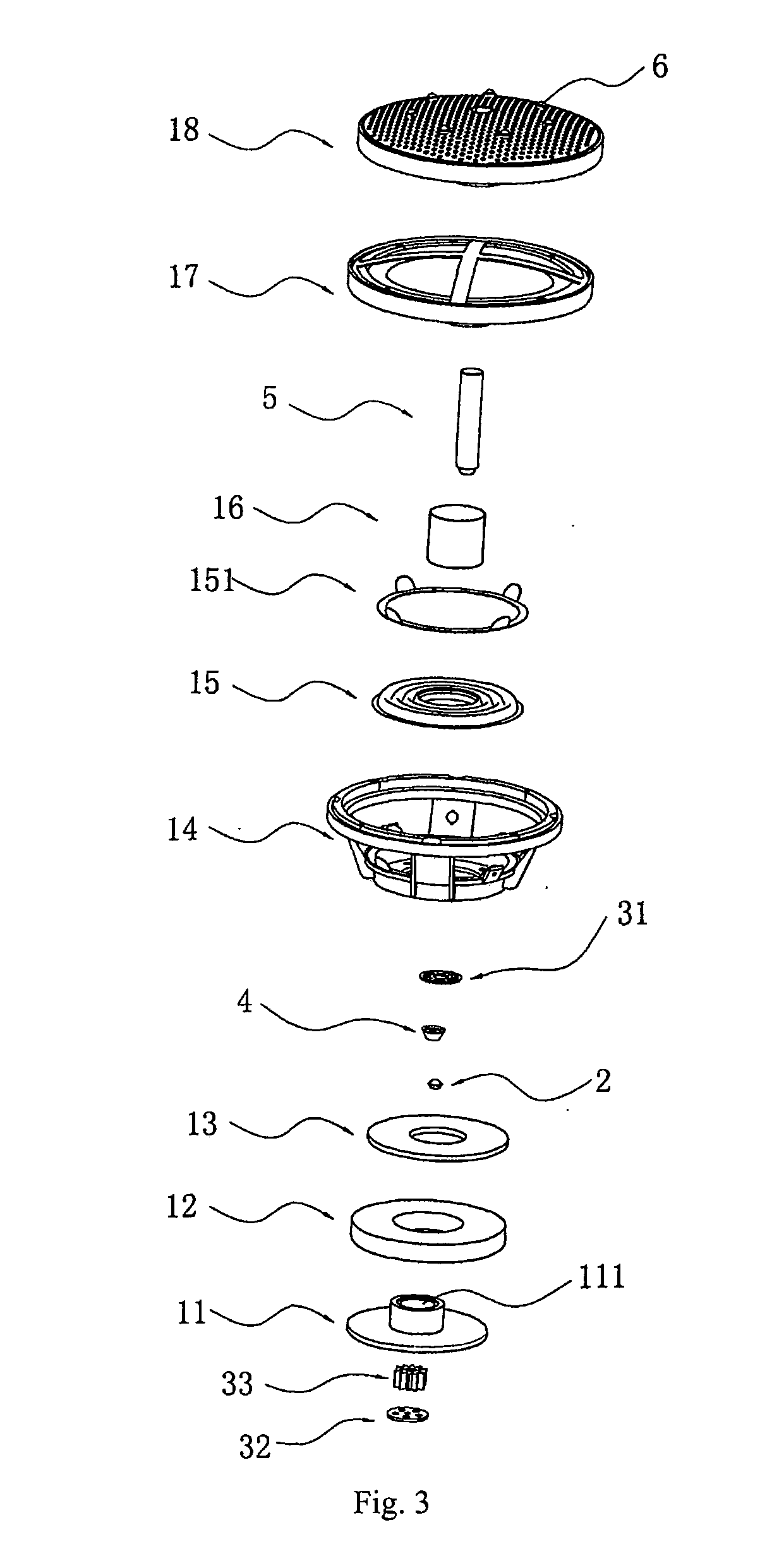

Loudspeaker and alarm with luminous element

InactiveUS20100316247A1Convenient lightingFind quicklyTransducer detailsSignalling system detailsEngineeringLoudspeaker

A loudspeaker has an alarm and a luminous element, these being an improvement upon exiting loudspeakers having luminous elements. The luminous element is an illuminating lamp. A radiative cooling fin is mounted near the illuminating lamp. The use of radiator cooling firework permits a larger power light to be selected as the luminous element. This makes the loudspeaker capable of functioning as a substitute light source within an area. Also, the assembly employs an alarm with the loudspeaker. The brighter light emitted by the illuminating lamp on each loudspeaker provides better illumination. The lamp may also flash according to pre-programmed directions for the purpose of indicating a path and thereby helping people to escape from danger. Further, where the external power source fails, the loudspeaker assembly has a built-in emergency power source, ensuring that the loudspeaker and the illuminating lamp can still work normally.

Owner:DING FENG

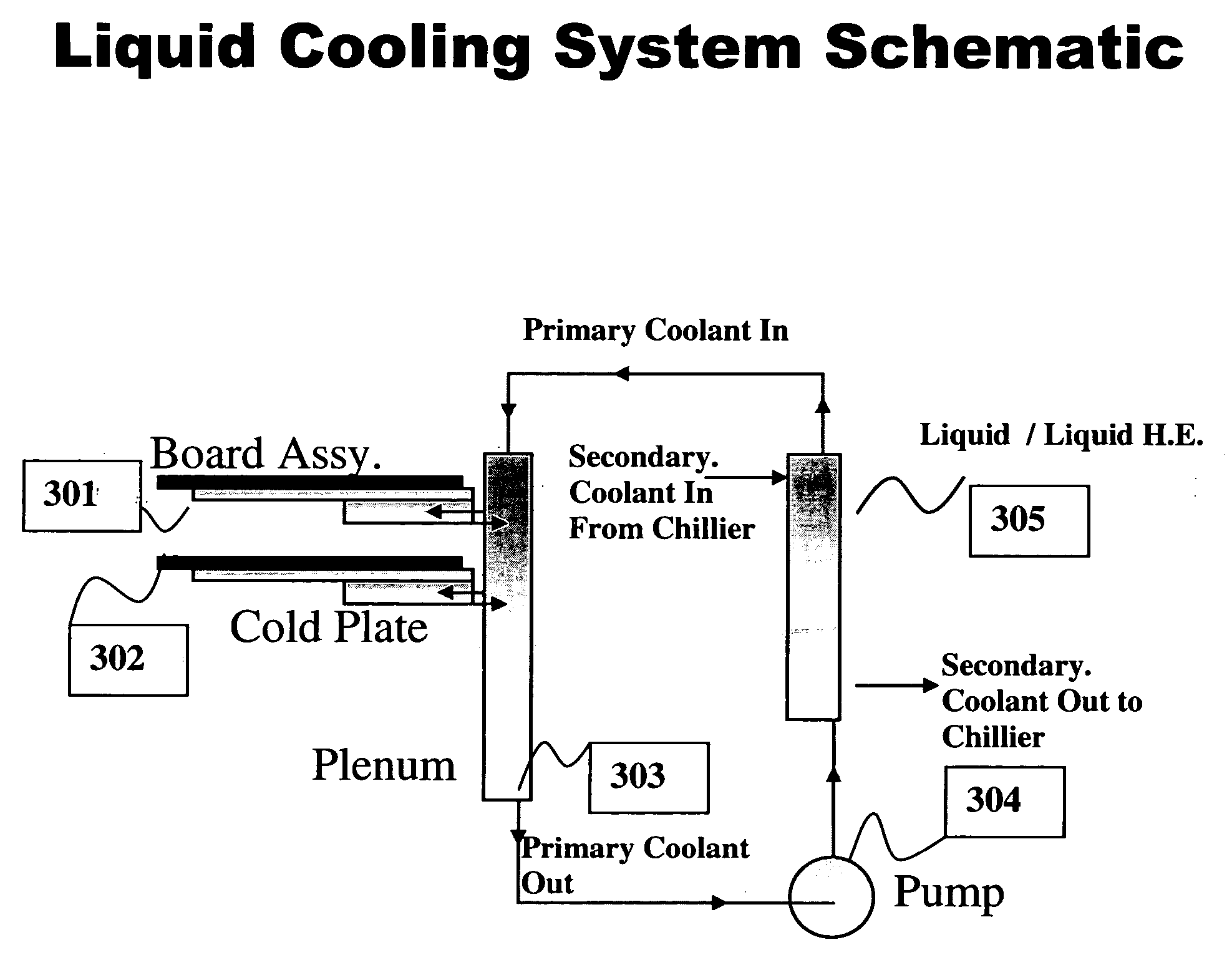

High performance cooling systems

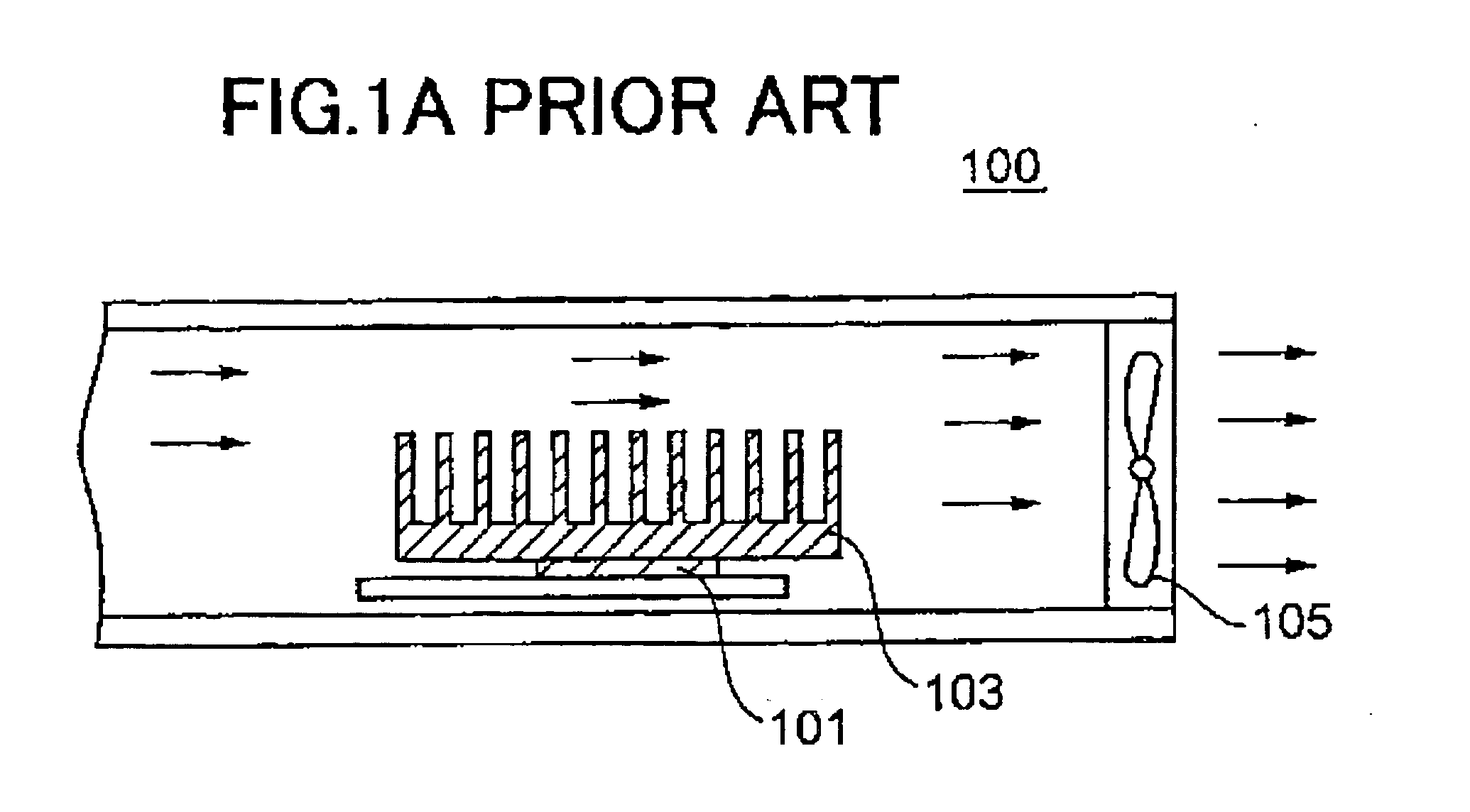

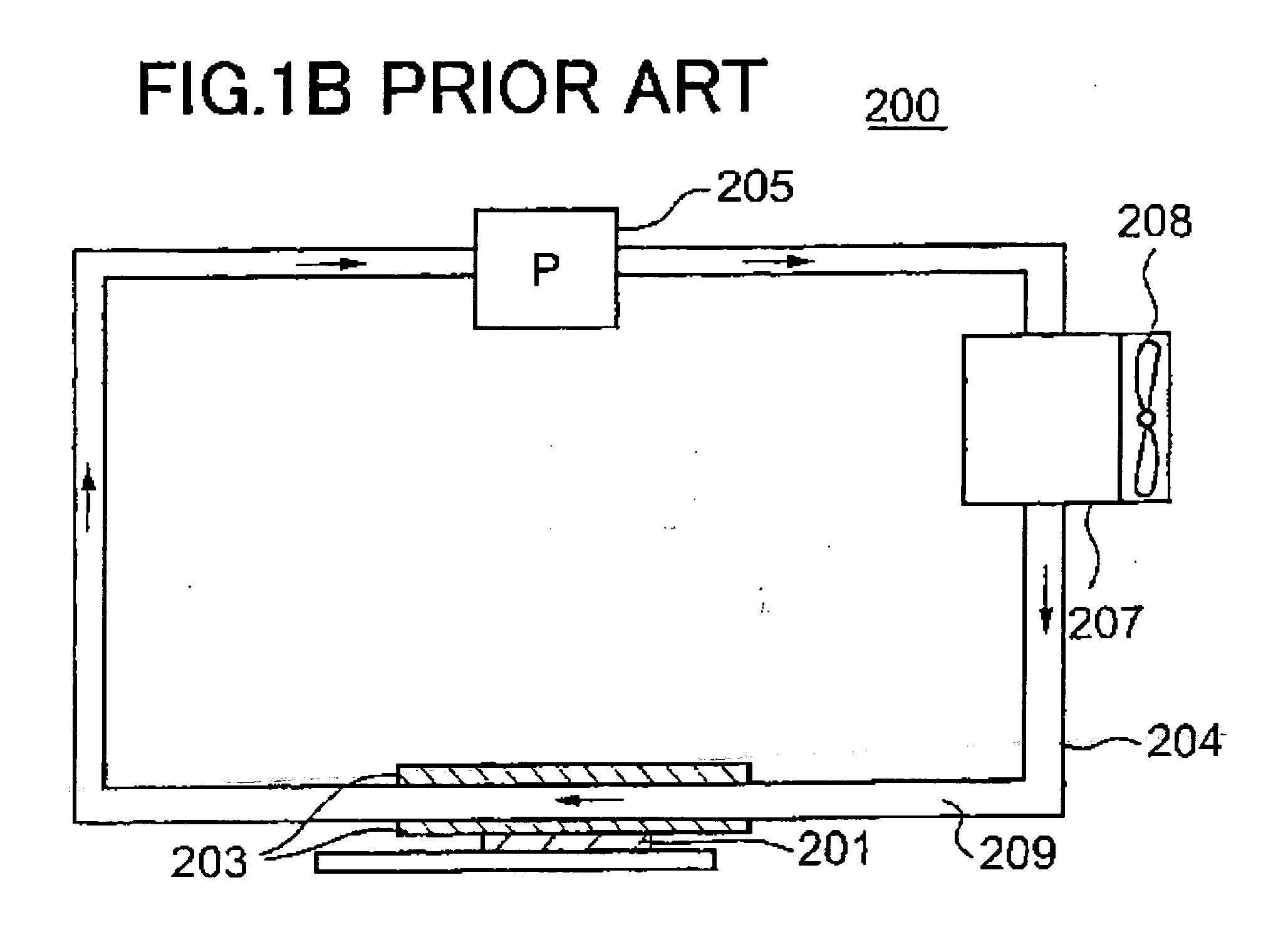

InactiveUS20050174735A1Large capacityIncrease power consumptionIndirect heat exchangersCooling/ventilation/heating modificationsNuclear engineeringLiquid cooling system

High Performance cooling systems for cooling a heat source is disclosed. The cooling systems can be air cooling system, liquid cooling system, or space radiation cooling system. Air cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and liquid to air heat exchanger. Liquid cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and liquid to liquid heat exchanger. Space radiation cooling system includes at least high performance cold plate or cold plates, plenum, liquid pump, and space radiator. Several coolant fluids are available and can be used as a primary system coolant depending on the application.

Owner:DELTA ENGINEERS

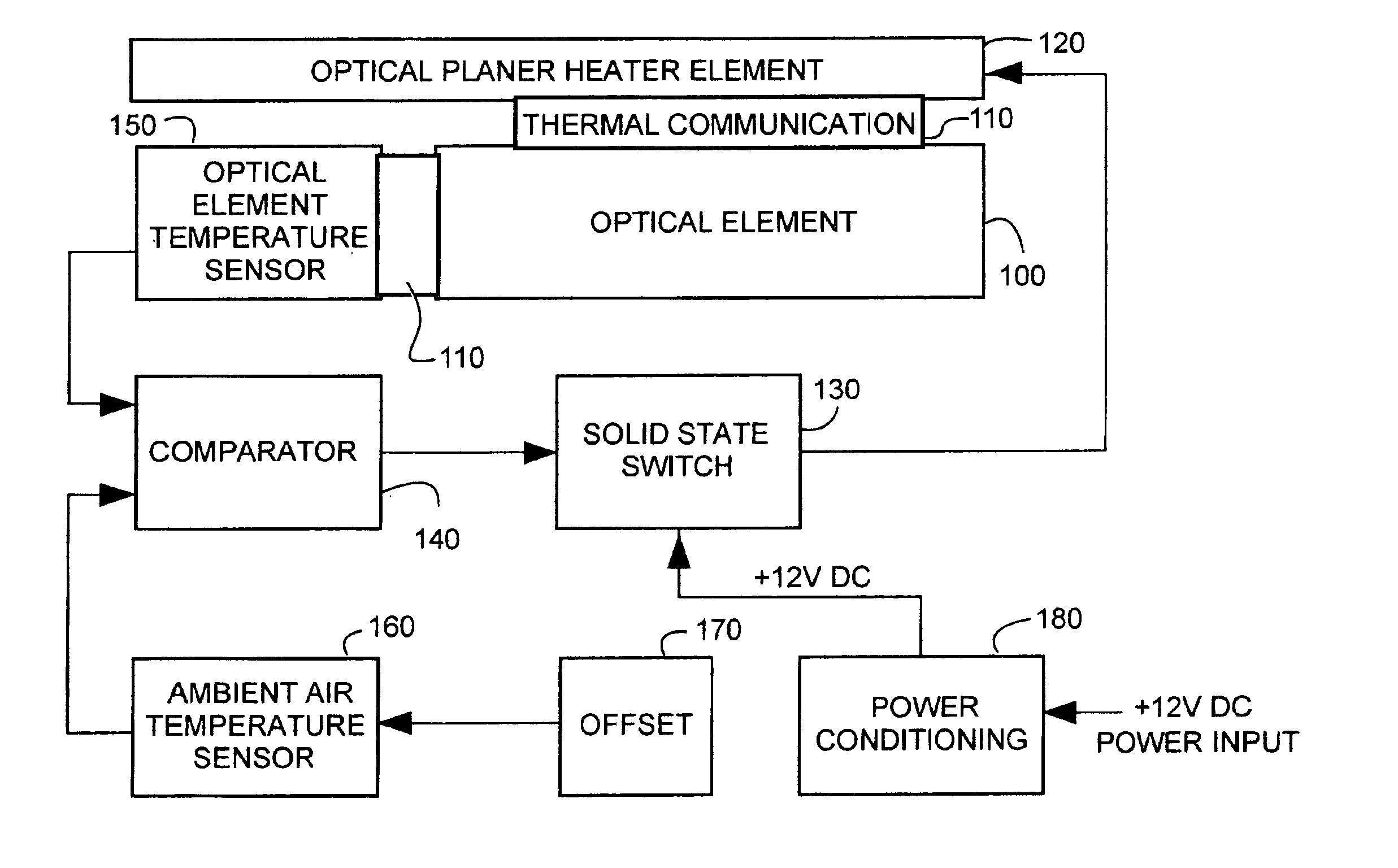

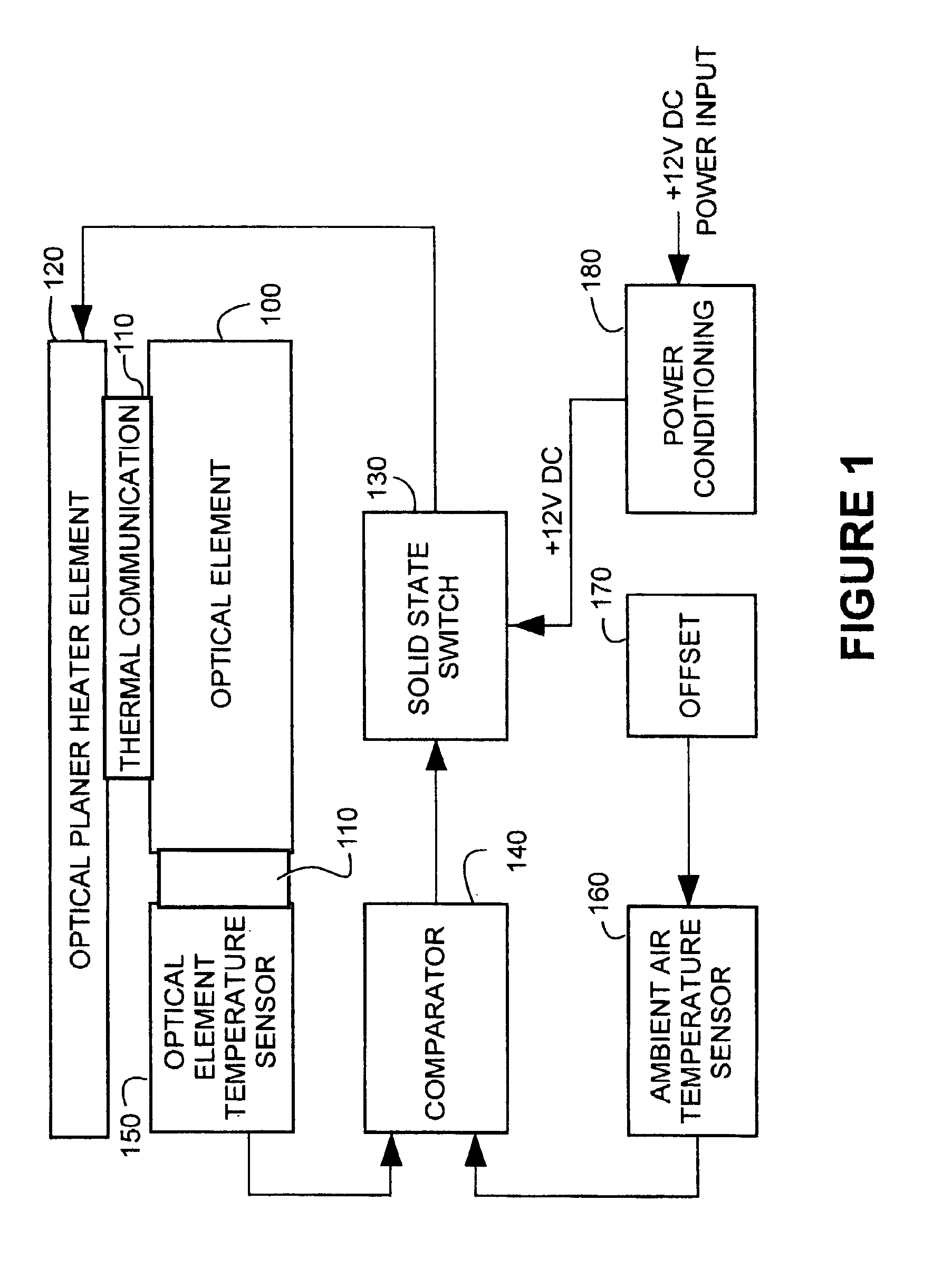

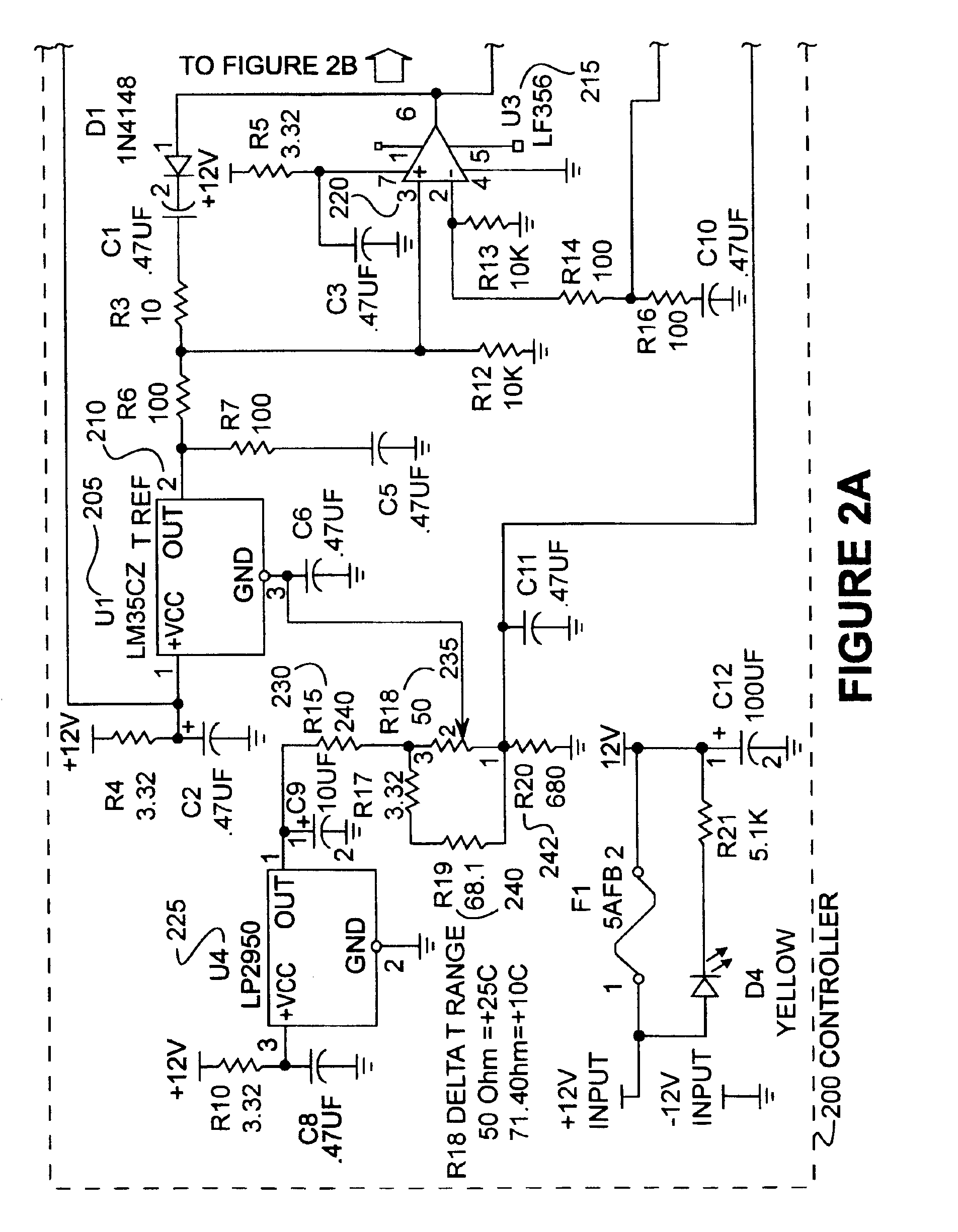

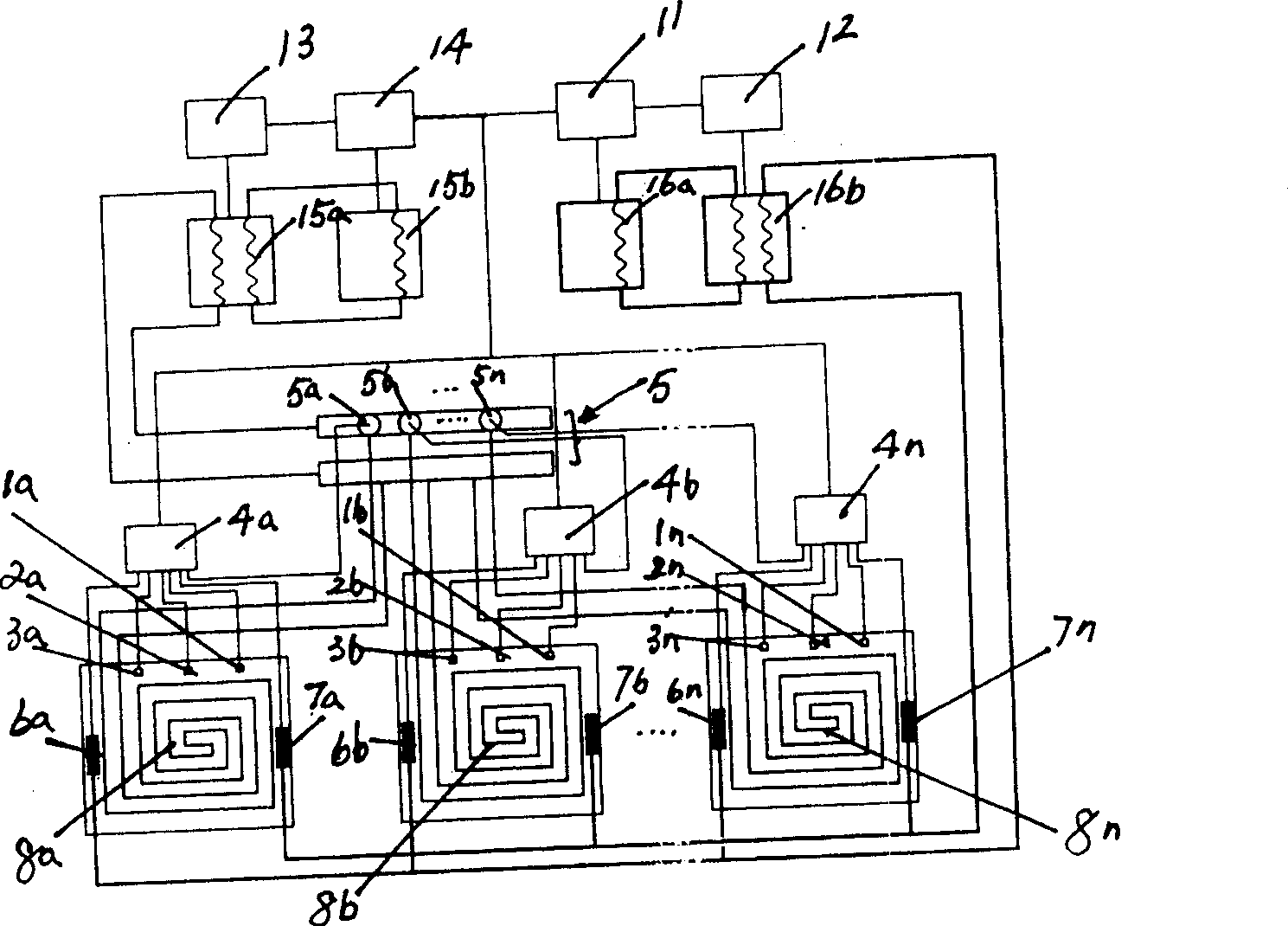

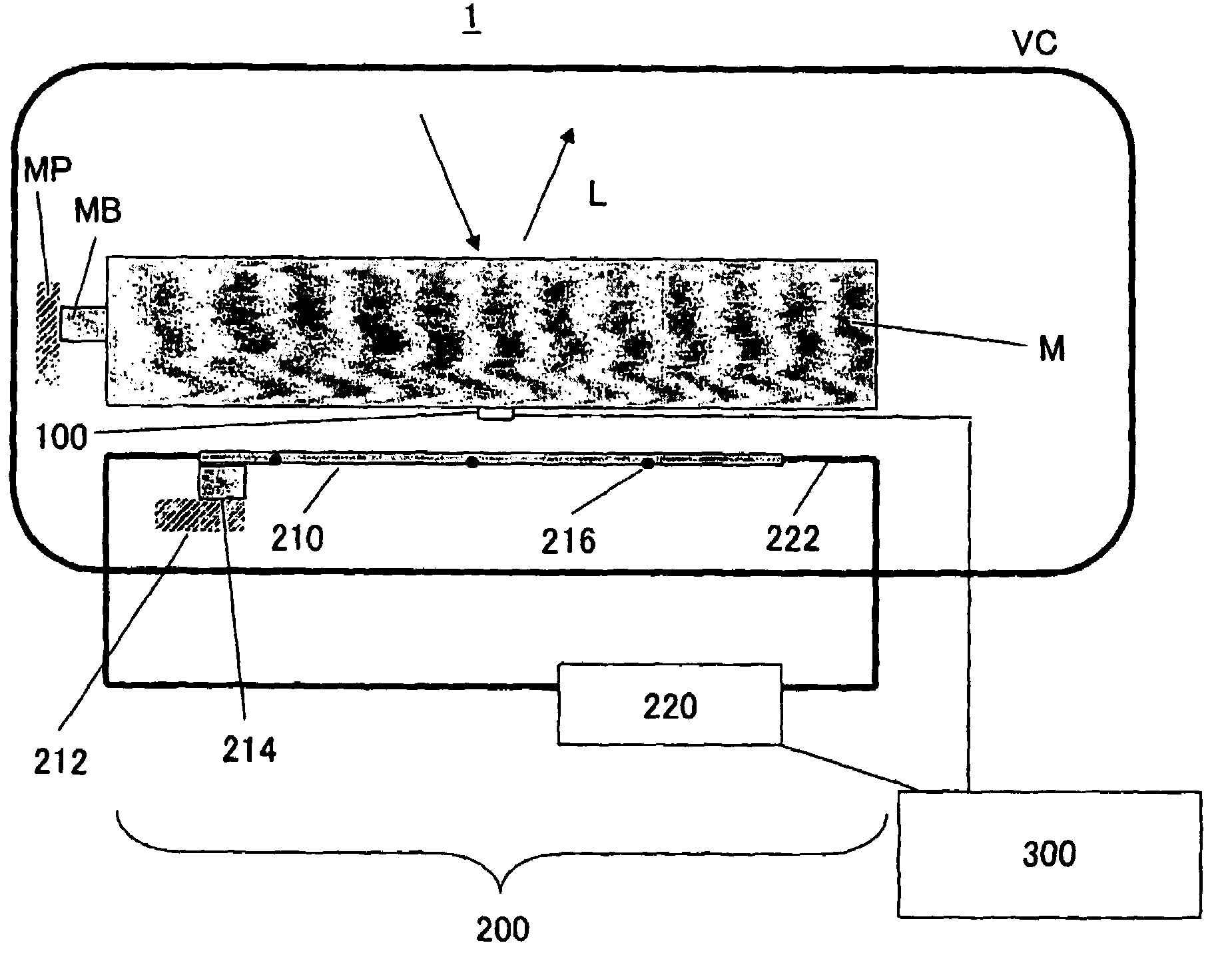

Thermal condensate reducer for optical devices

The present invention provides a method and system to overcome and eliminate the effects of condensation contamination of optical surfaces that are induced by radiative cooling. The invention counteracts the effects of radiative cooling on optical surfaces and maintains an optical system within a very tight limit to the ambient temperature by utilizing a resistive heater element that is in contact with the optical components subject to condensation. In thermal contact with this optical component is a solid-state precision temperature sensor. In addition, there is a matching solid-state precision temperature in thermal contact with the ambient air but thermally isolated from the optical element. Signals from these two sensors are applied to a comparator that functions to generate a data signal when the optical surface temperature is less than the ambient or reference temperature. This data signal is used to activate a solid-state power switch that applies a voltage to a resistive heating element. An offset may also be applied to the reference temperature sensor allowing compensation for the thermal resistance of the system comprised of the optical component, optical component attachment heater and temperature sensor.

Owner:REMOTE SIGHTS

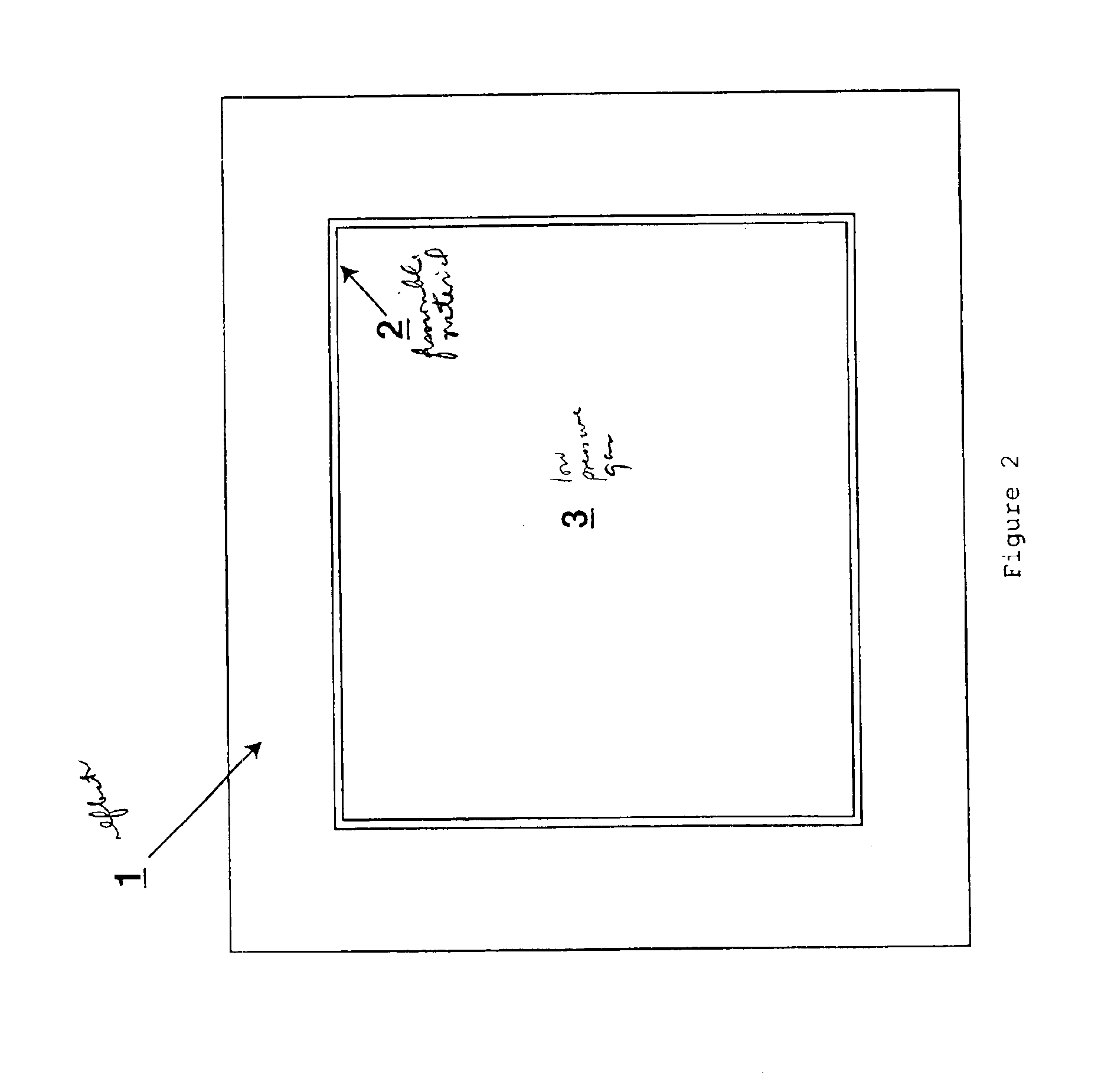

Passive fluorescent cooling

The combination of an infrared phosphor fluorescing at wavelengths between 8 μm and 13 μm with a wavelength-selective cold mirror glazing transparent to the fluoresced radiation can create a device capable of providing passive radiative cooling in tropical heat and humidity in locations with an unobstructed view of sky. The concentration of thermal radiative energy into the narrow band radiated by the phosphor, and the reflection of infrared radiation outside that band, provides more net cooling through saturation humidity at 37° C. than does a black-body or conventional selective radiator.

Owner:JAFFER AUBREY

Radiative cooling structures and systems

ActiveUS20190086164A1Low costEasy to integrateHeat storage plantsClimate change adaptationThermal radiationRadiative cooling

Polymer-based selective radiative cooling structures are provided which include a selectively emissive layer of a polymer or a polymer matrix composite material. Exemplary selective radiative cooling structures are in the form of a sheet, film or coating. Also provided are methods for removing heat from a body by selective thermal radiation using polymer-based selective radiative cooling structures.

Owner:UNIV OF COLORADO THE REGENTS OF +1

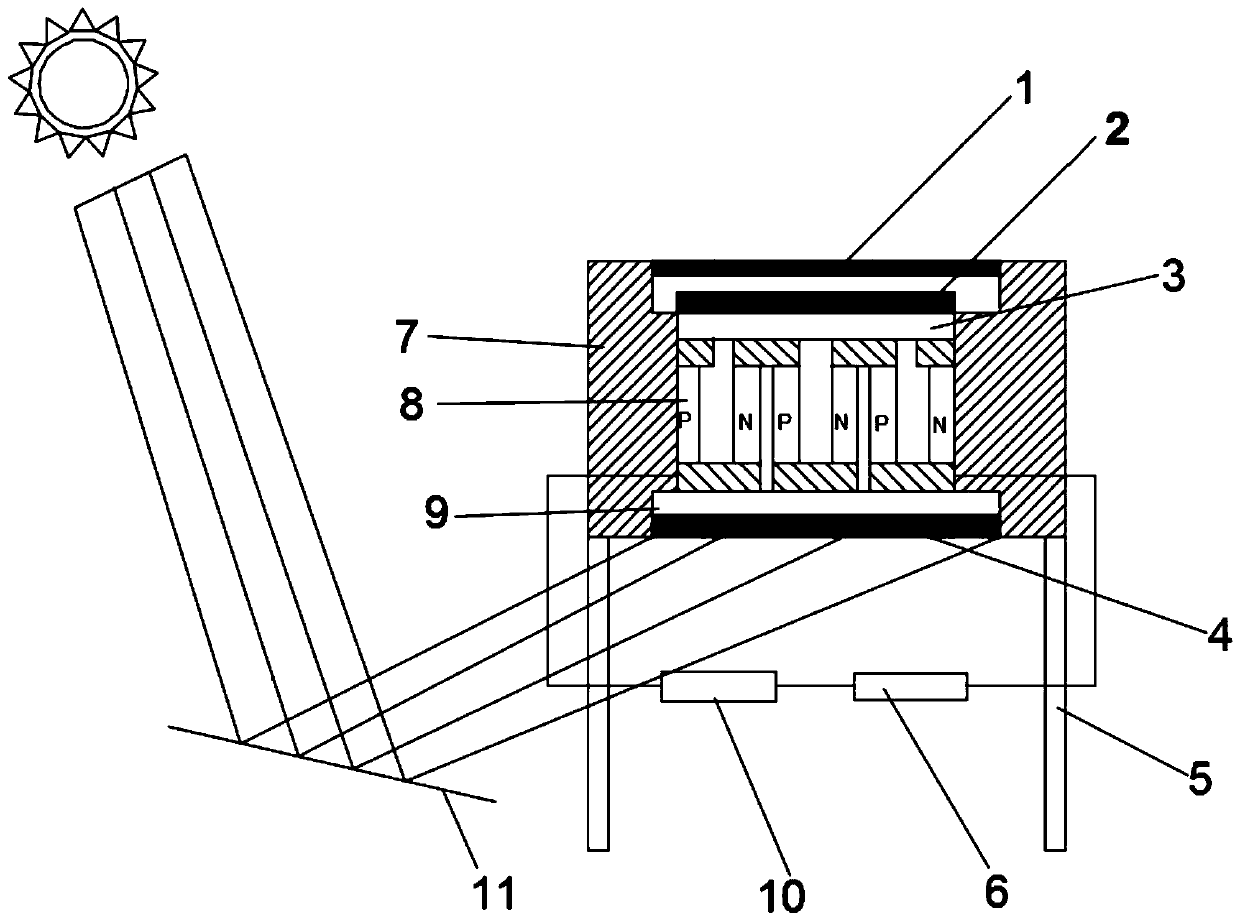

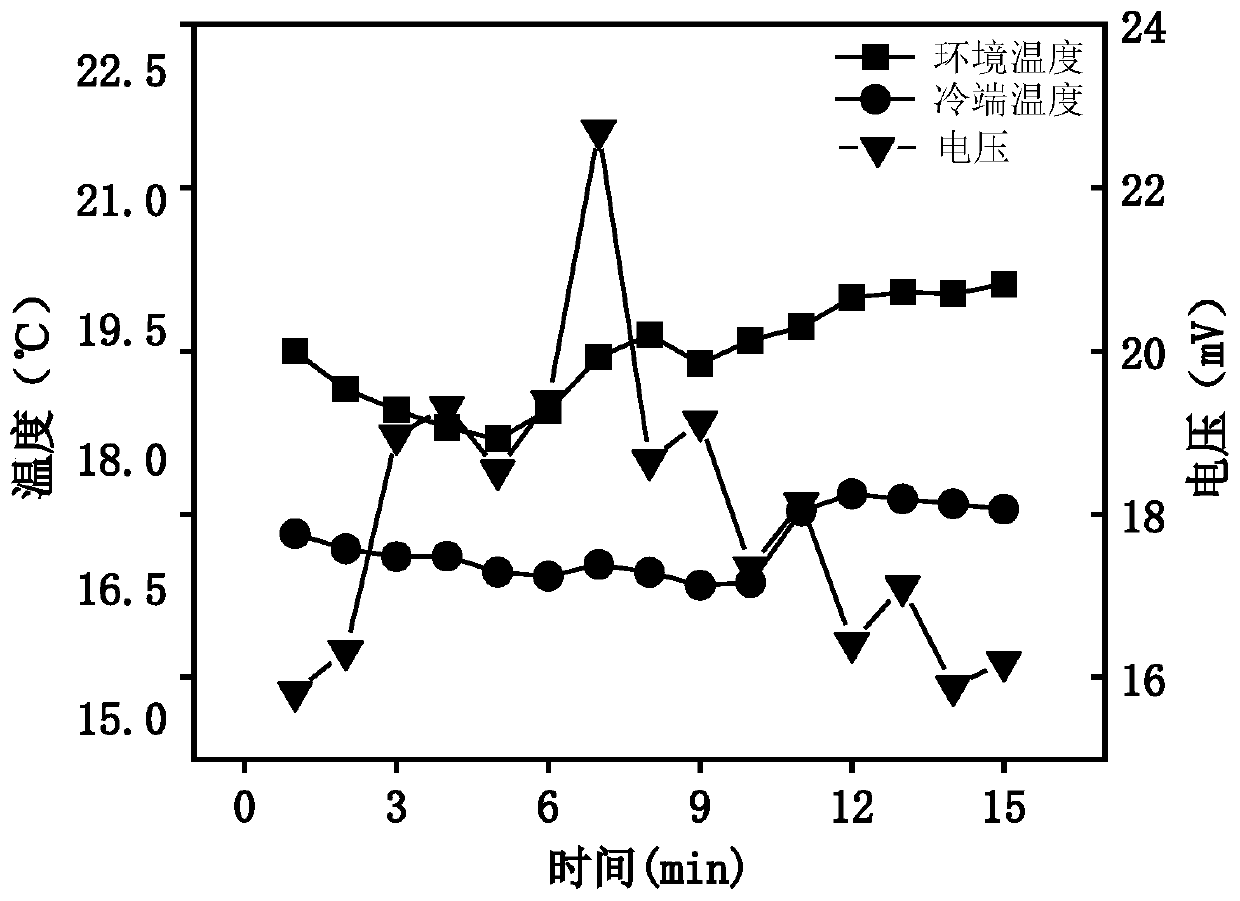

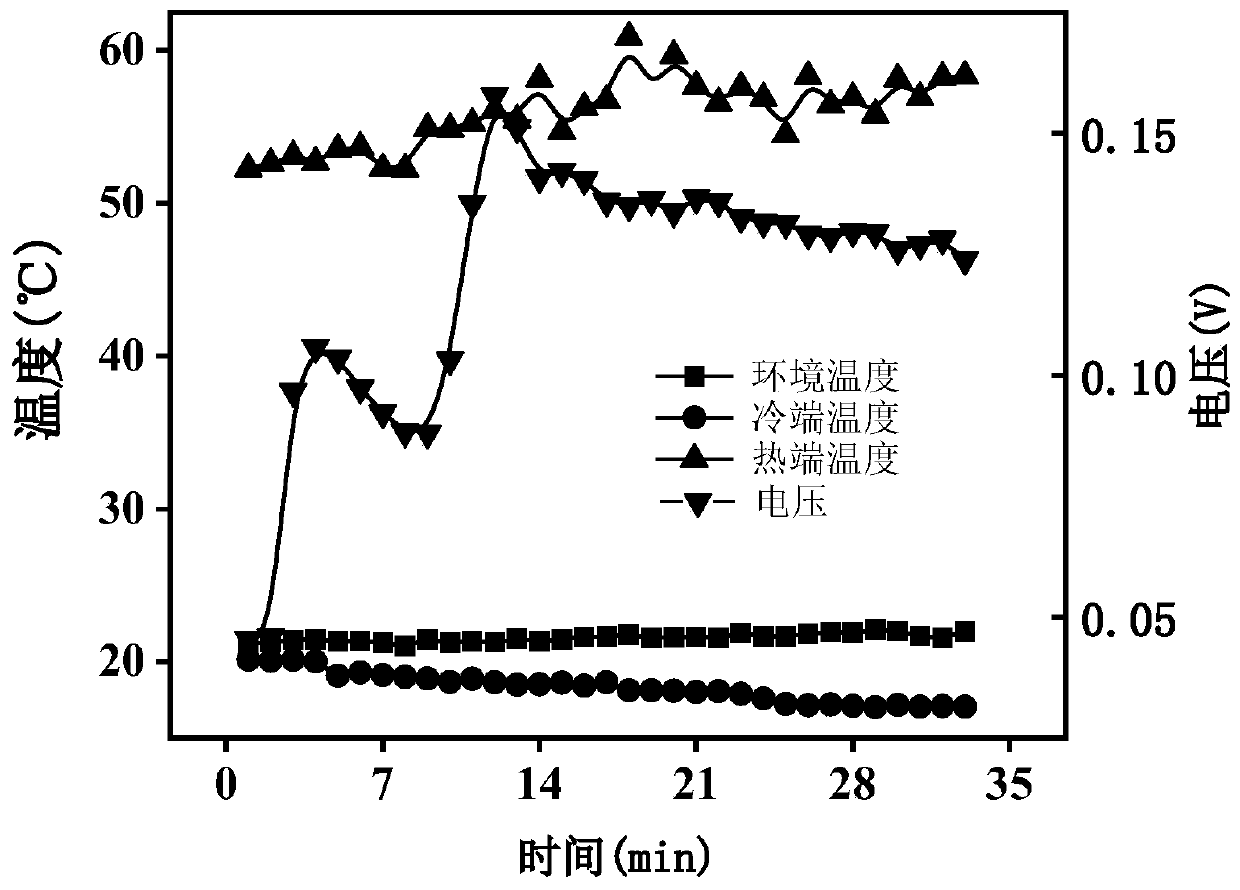

Thermoelectric power generation device based on radiation refrigeration and efficient absorption of solar energy

ActiveCN110138277AReduce the temperatureLow costThermoelectric device with peltier/seeback effectGenerators/motorsData acquisitionEngineering

A thermoelectric power generation device based on radiation refrigeration and efficient absorption of solar energy includes a carbon nanoparticle film, a semiconductor thermoelectric power generationsheet assembly, a radiation cooling film, supporting pillars arranged under the semiconductor thermoelectric power generation sheet assembly, and a reflective concentrator reflecting sunlight to the lower surface of the carbon nanoparticle film. The semiconductor thermoelectric power generation sheet assembly includes an upper insulating heat conduction plate I, a semiconductor thermoelectric device and a lower insulating heat conduction plate II arranged in turn from top to bottom. A load and a data collector are connected in turn between the two ends of the semiconductor thermoelectric device. The radiation cooling film is attached to the upper surface of the upper insulating heat conduction plate I, and the carbon nanoparticle film is attached to the lower surface of the lower insulating heat conduction plate II. The radiation refrigeration end of the device can achieve lower temperature by radiation heat exchange with outer space, and the temperature can be 10 more degrees lower than the ambient temperature, so that a large temperature difference and a high voltage are formed at the two ends of the semiconductor thermoelectric device, and the problem of less heat exchange between the traditional heat sink and the environment per unit time is solved.

Owner:CHINA UNIV OF MINING & TECH

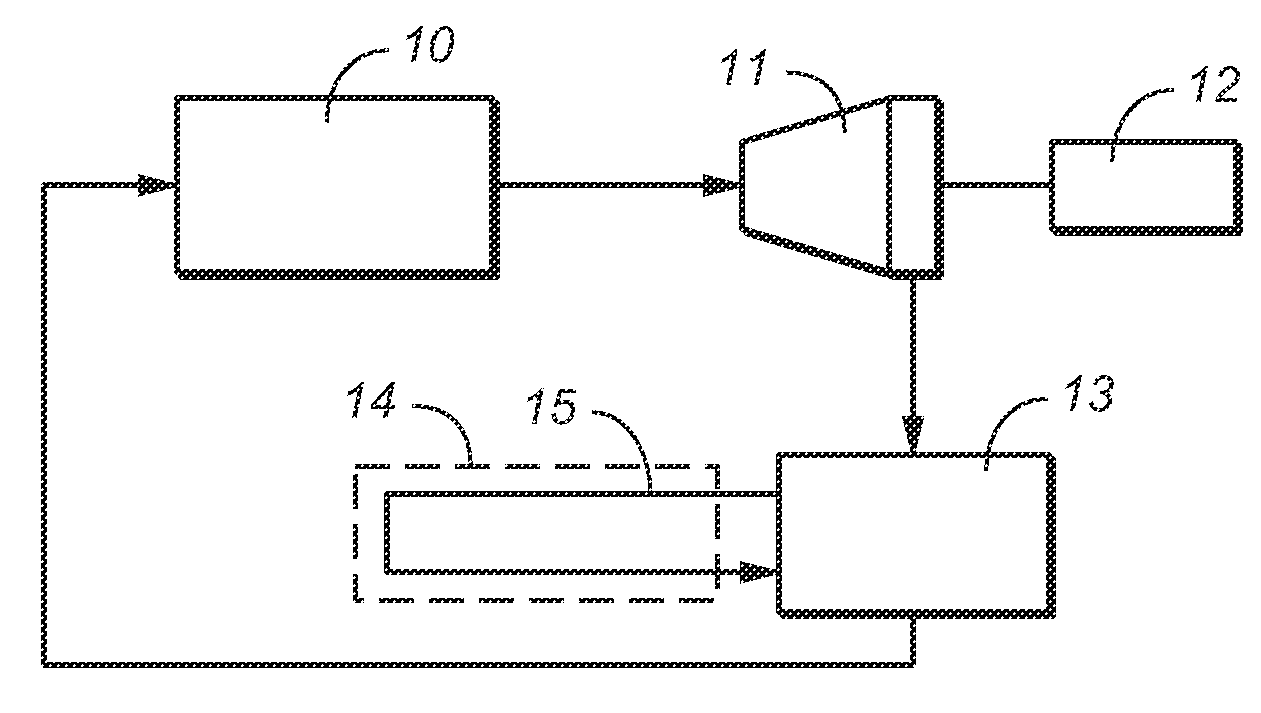

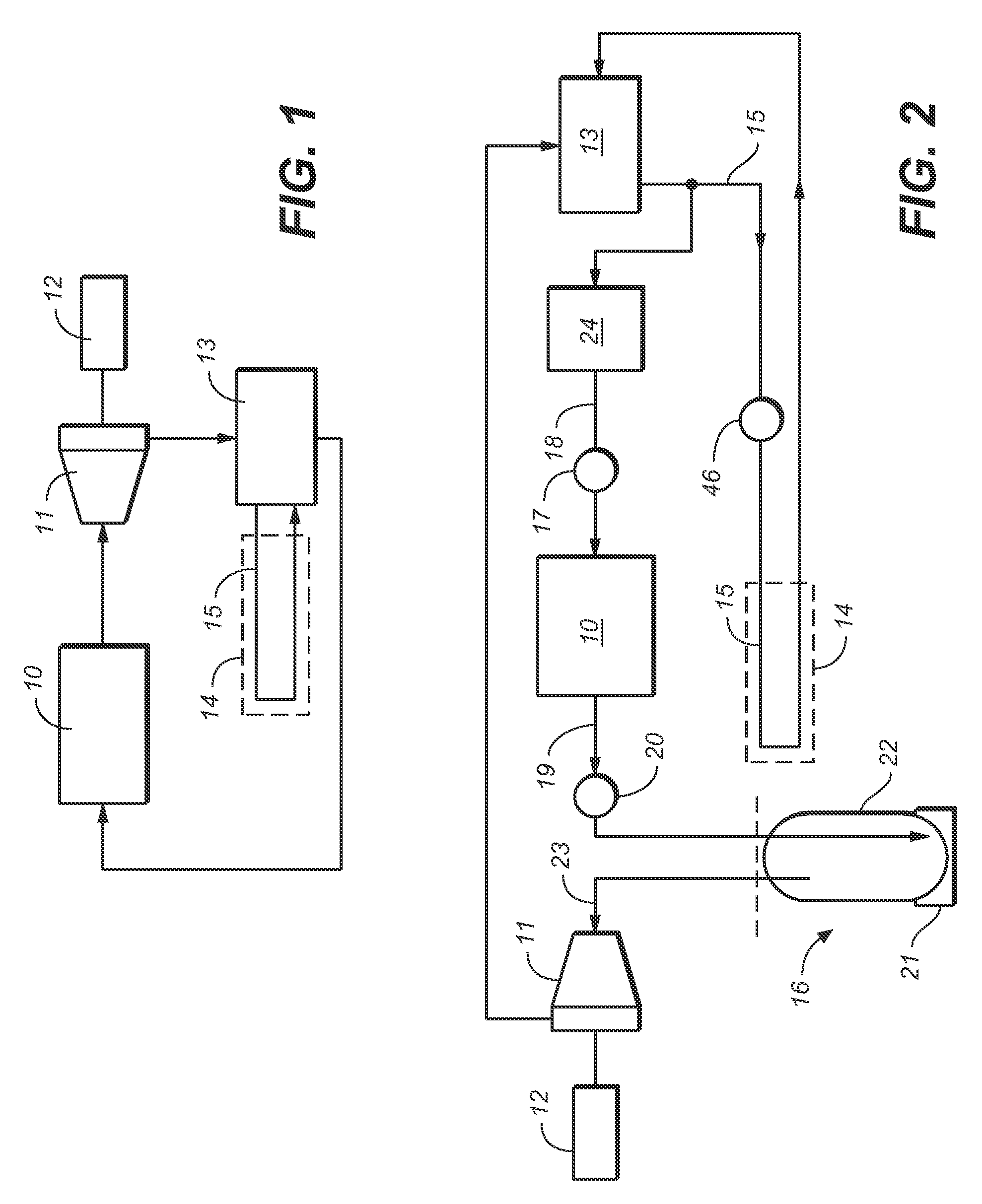

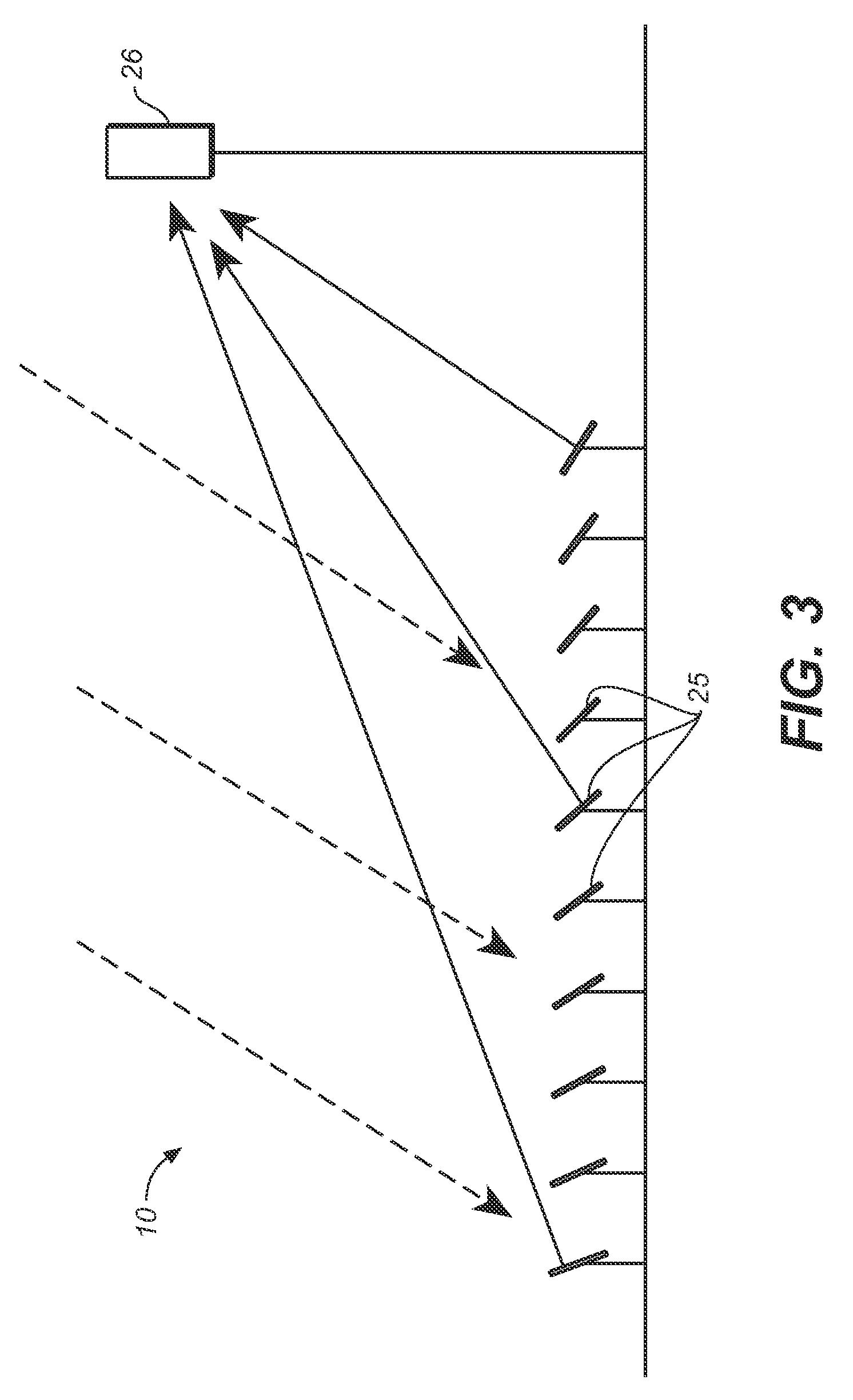

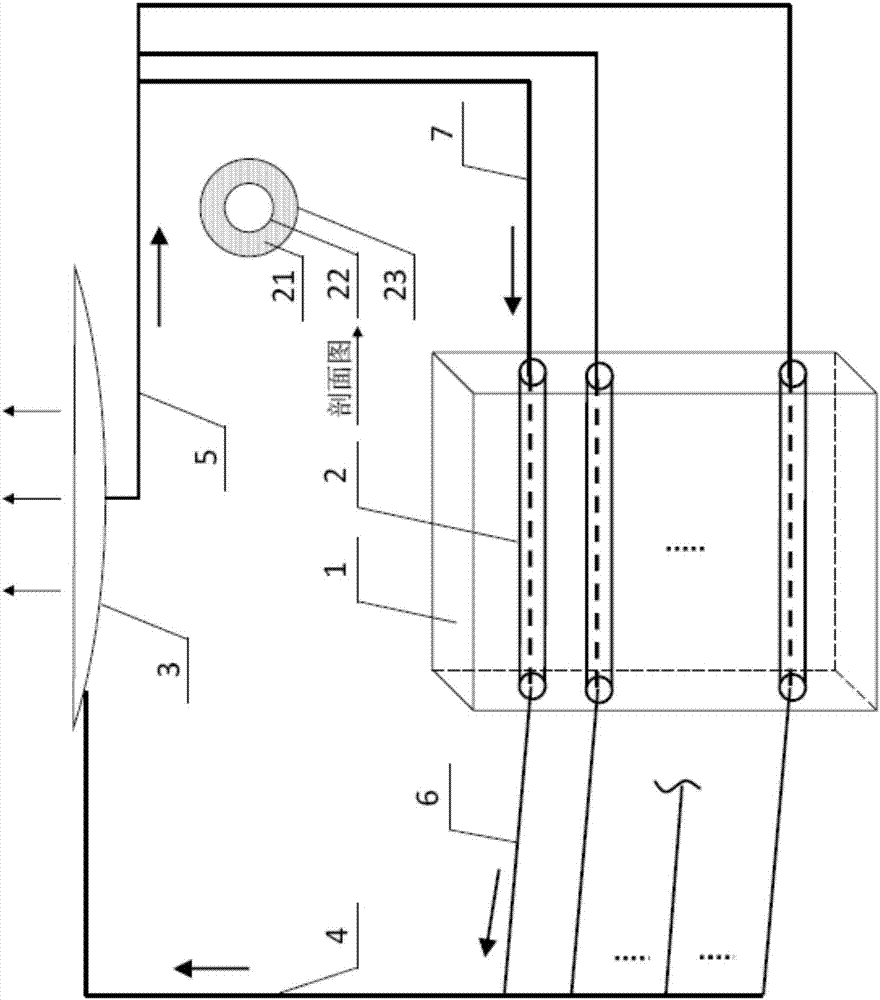

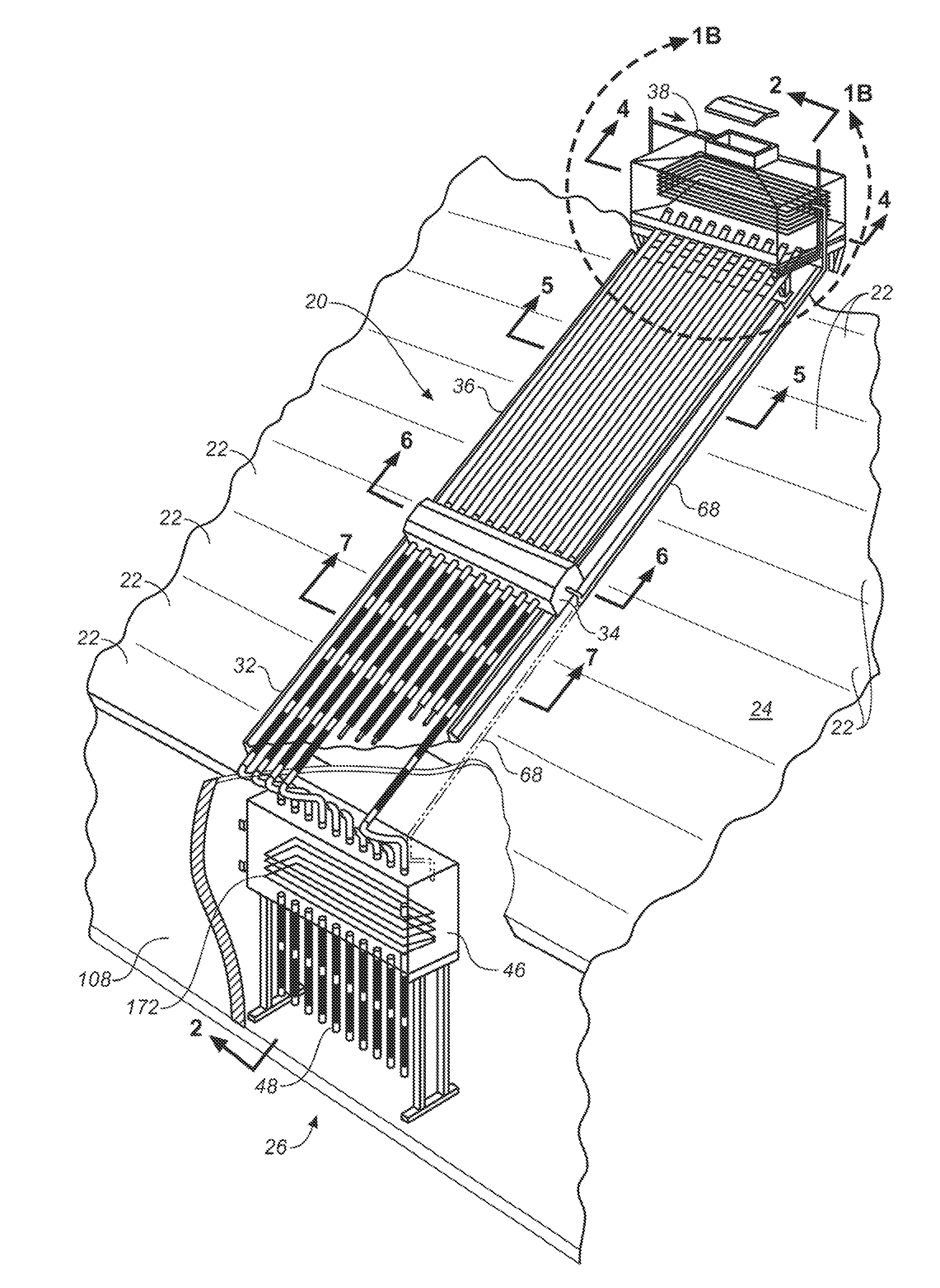

Convective/radiative cooling of condenser coolant

A system for effecting cooling of a coolant fluid is provided, the system comprising: a solar energy collector system; and fluid channels for the coolant fluid that are at least partially above ground level and are at least partially shaded by the solar energy collector system. The system may comprise a system for cooling a condenser coolant fluid in a thermal power plant incorporating a solar energy collector system, the system comprising: one or more solar energy reflectors; and fluid channels for the coolant fluid that are at least partially above ground level and are at least partially shaded by one or more of the solar energy reflectors. Solar energy reflector carrier arrangements for use in said system, and methods and thermal power plants utilizing said system are further provided.

Owner:AREVA SOLAR

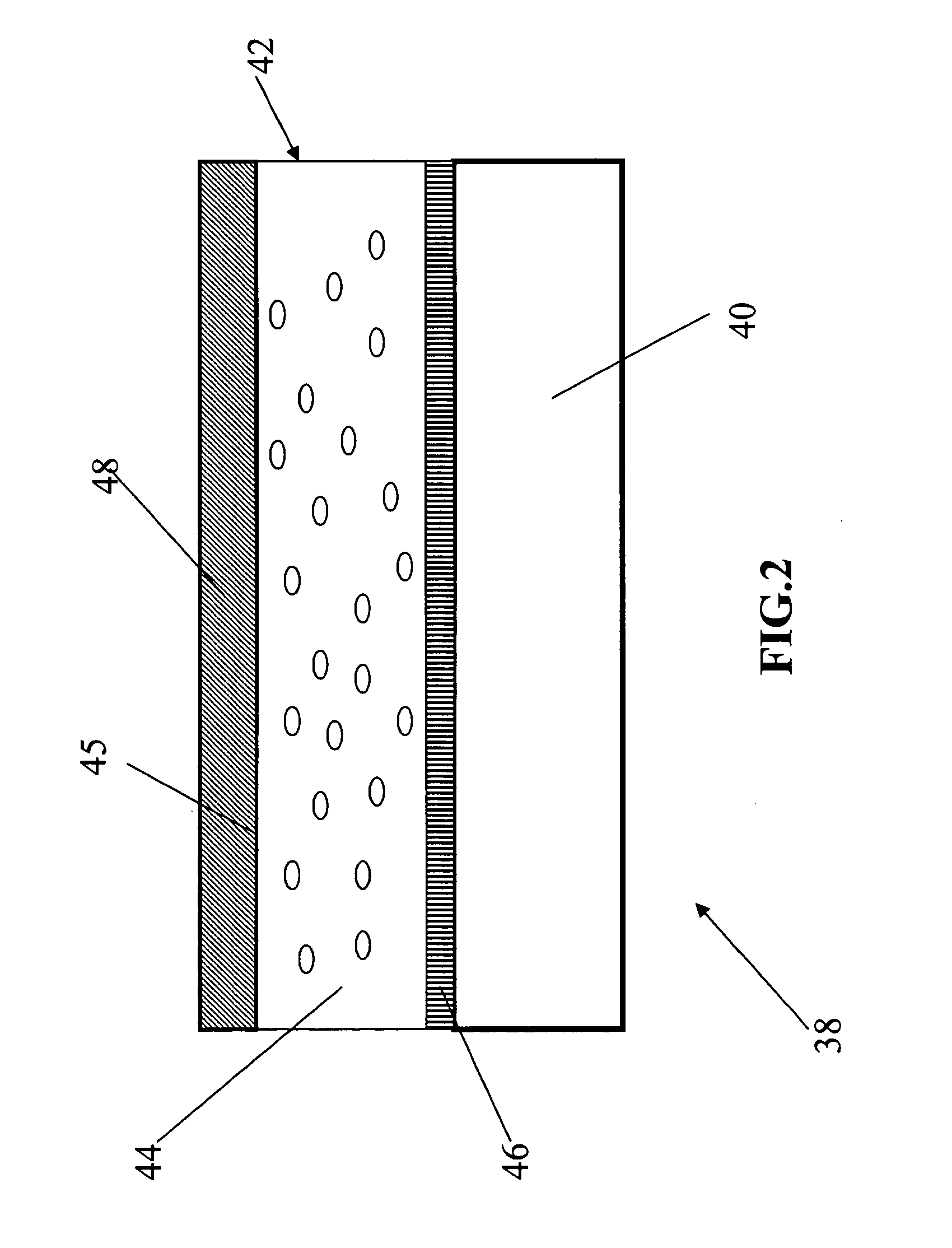

Self-cooled photo-voltaic device and method for intensification of cooling thereof

InactiveUS20060162762A1Improve cooling effectEasy to fabricatePV power plantsPhotovoltaic energy generationPre-chargeRadiative cooling

The invention provides a self-cooled PV device that consists of a PV unit and a radiative cooling unit with specific cooling-enhancing means that covers the solar-energy absorbing side of the PV unit. The aforementioned specific radiation enhancing means may have an electric charge positively induced in the radiative cooling unit for re-arranging the spectrum of the IR radiation towards the spectral range of the ATW. The radiation enhancing means may be comprised of a pre-charged texture formed on the light-receiving surface of the PV unit and coated with an anti-reflection film, a sealed chamber filled with a dipole gas or a mixture of gases, or a combination of the pre-charged texture and the aforementioned gas-filled chamber.

Owner:GILMAN BORIS

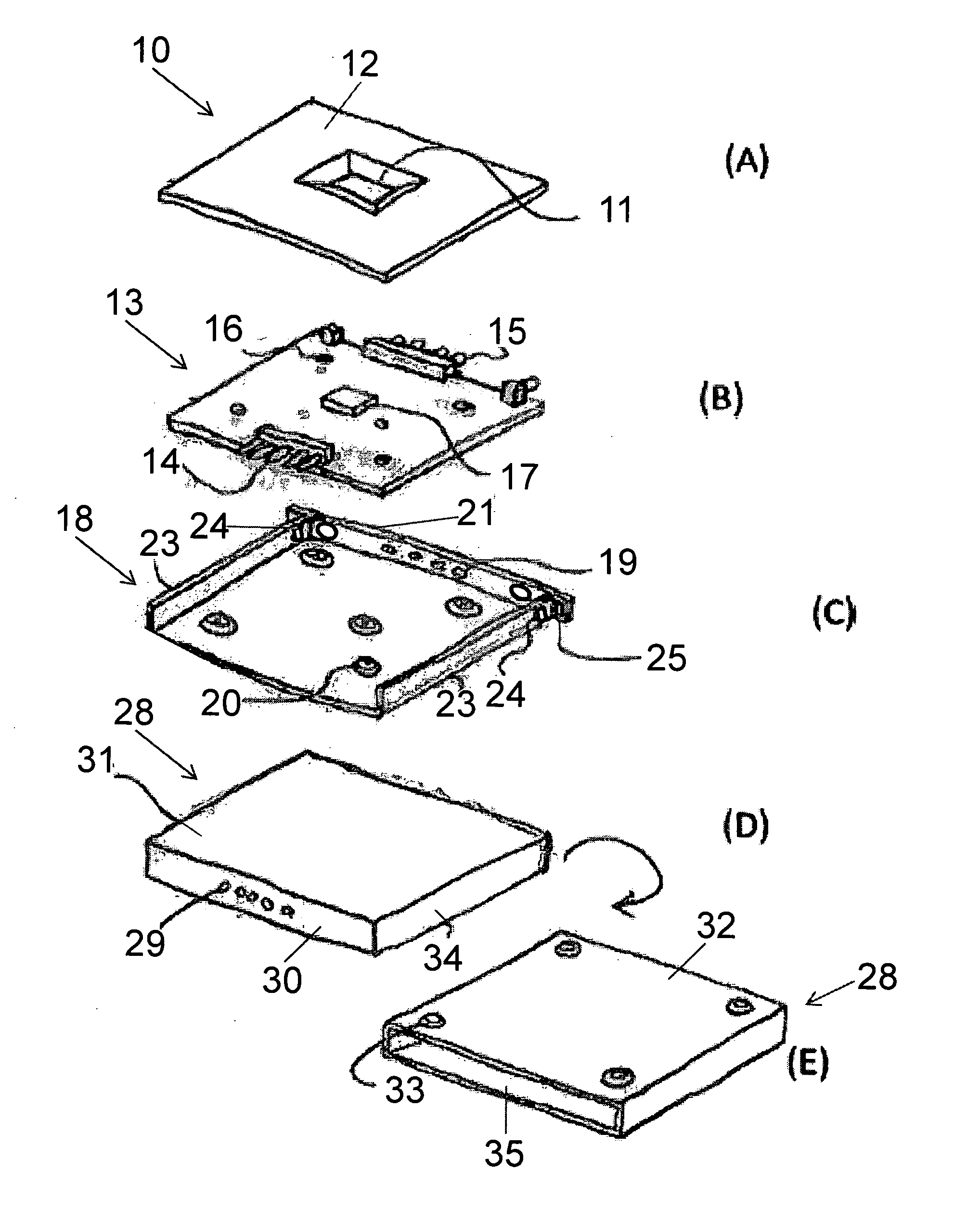

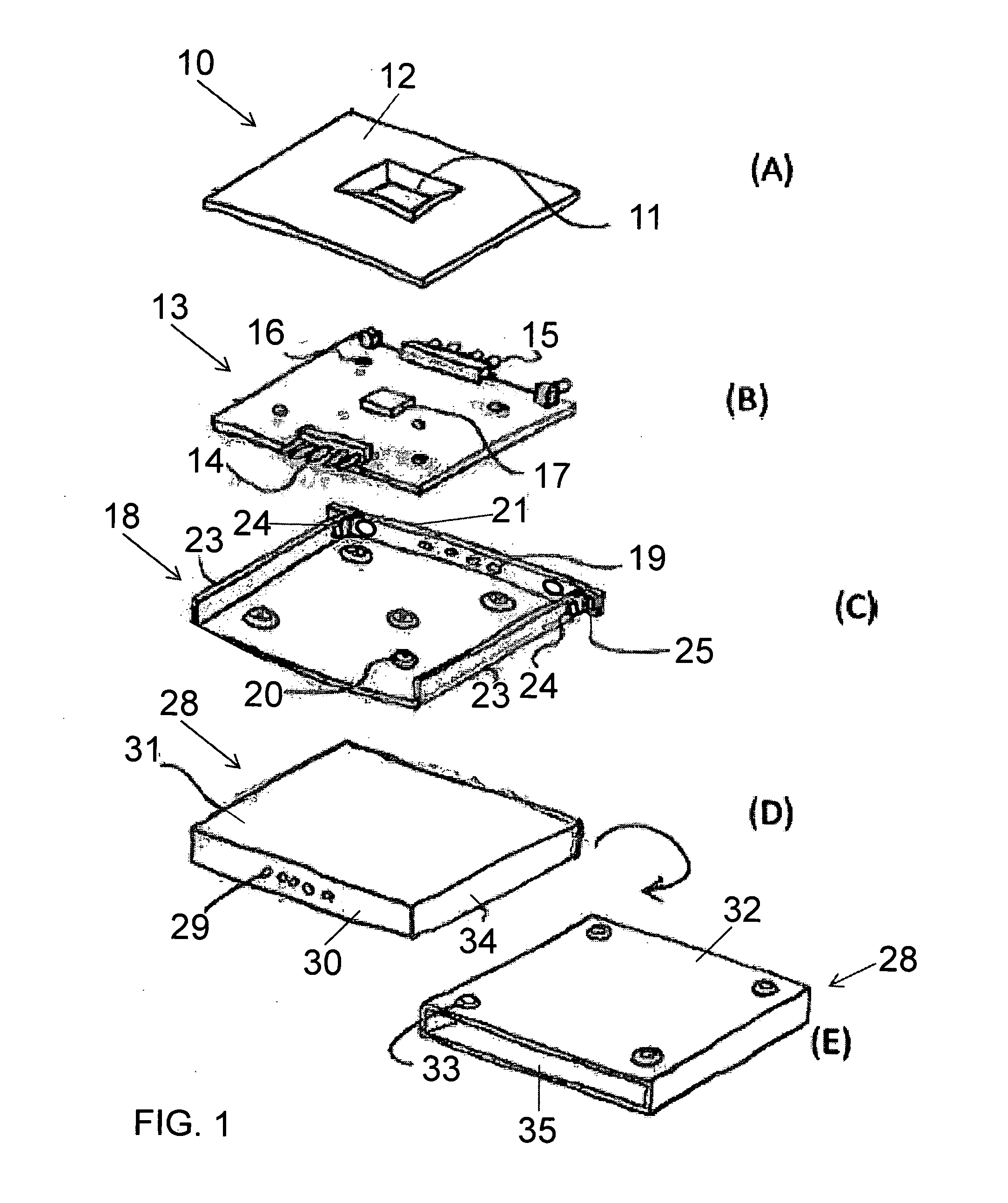

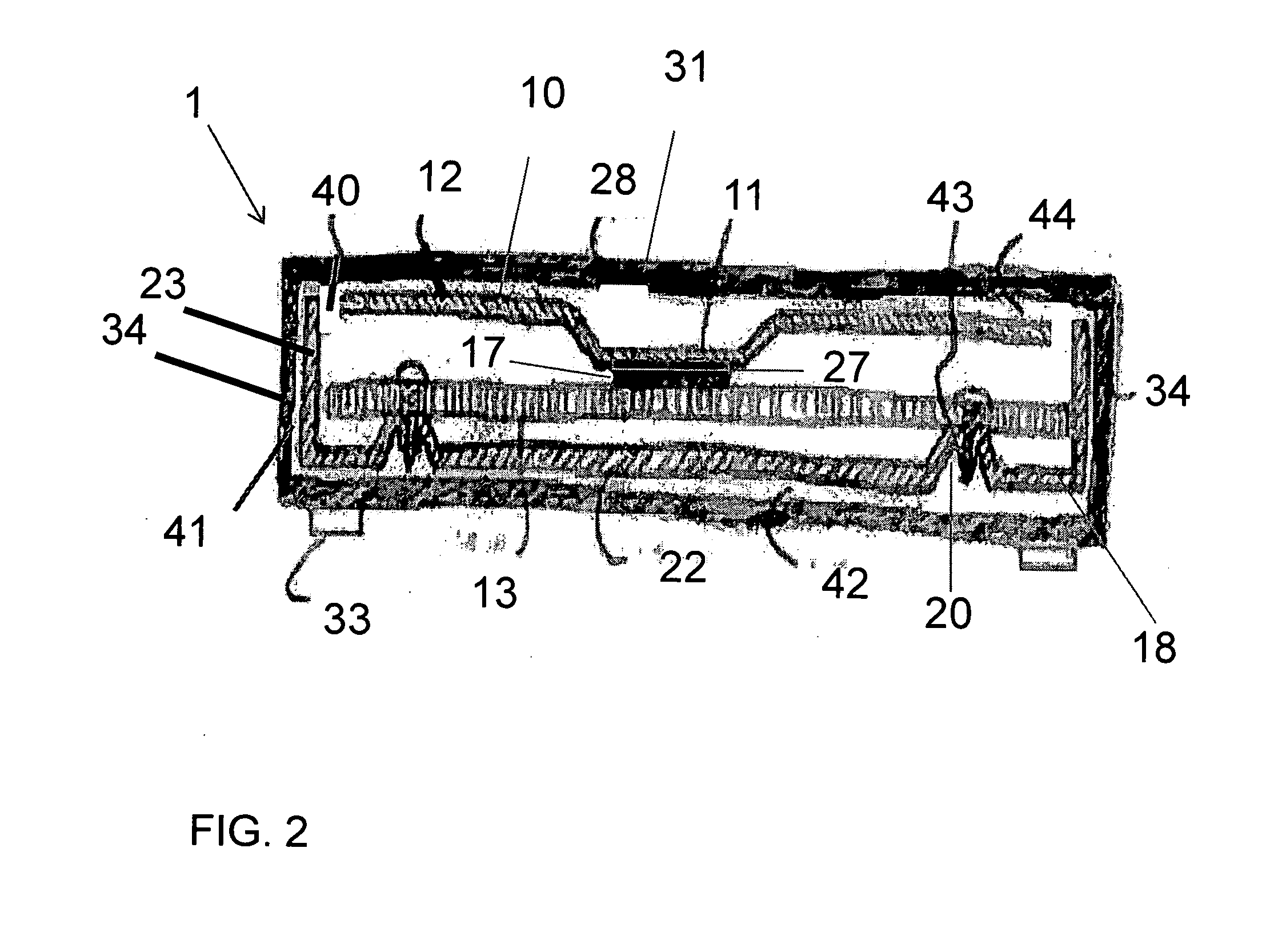

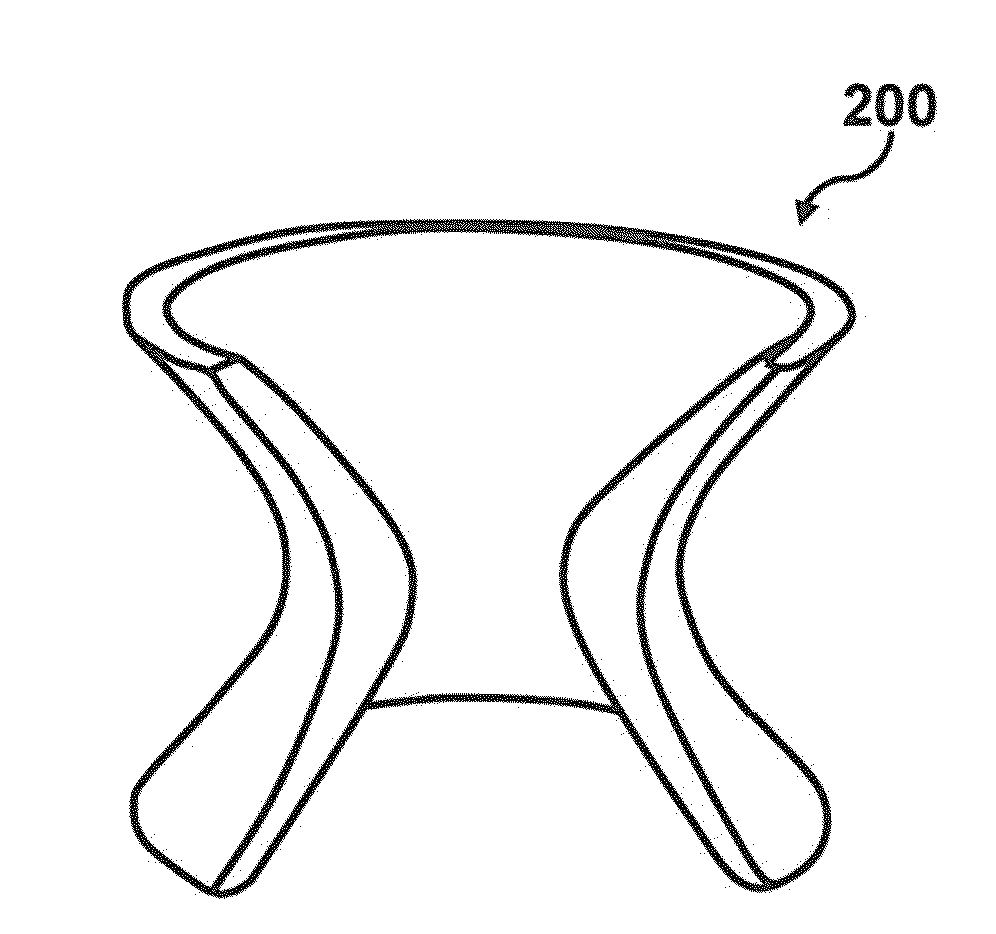

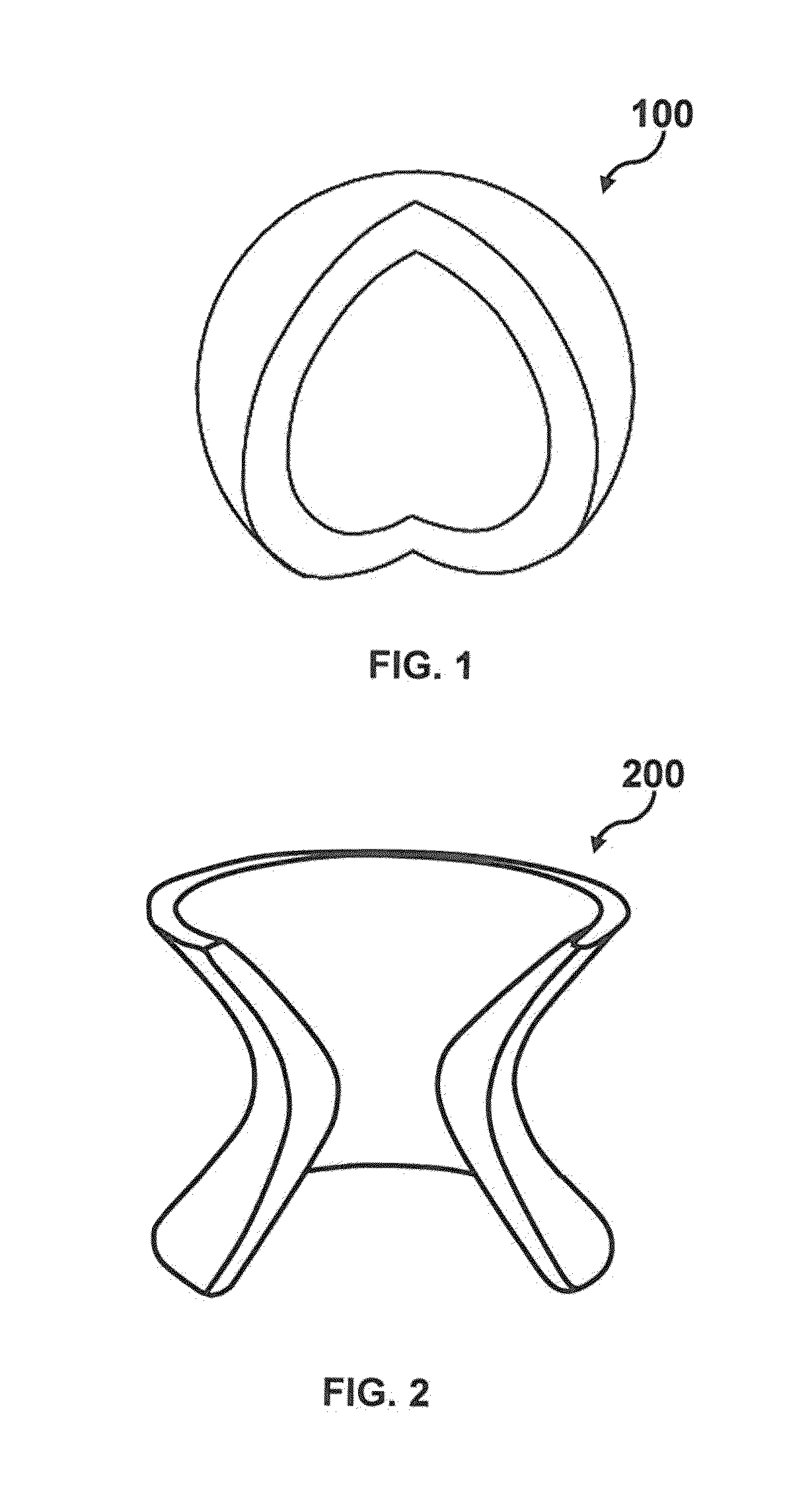

Miniature multilayer radiative cooling case wtih hidden quick release snaps

A passive cooling arrangement for an electronic housing assembly is disclosed which comprises a frame disposed in the housing assembly; a circuit board supported in the frame; a heat generating component disposed on the circuit board; and a heat sink configured with a substantially flat peripheral portion and a depression portion, the substantially flat peripheral portion facing and being nearly coextensive with an outer wall of said housing assembly, and the depression portion being in thermal engagement with the heat generating component on the circuit board, whereby heat generated by the heat generating component can be passively thermally conducted through the depression portion and into the substantially flat peripheral portion of the heat sink, and thereafter dissipated in a generally uniform manner through the outer wall of the housing assembly. The frame comprises a base with embosses which support the circuit board in a position enabling the thermal engagement of the heat generating component and the depression portion of the heat sink. The outer wall of the housing assembly is preferably unvented and the housing assembly is preferably oriented in use with the outer wall facing upwardly.

Owner:INTERDIGITAL CE PATENT HLDG

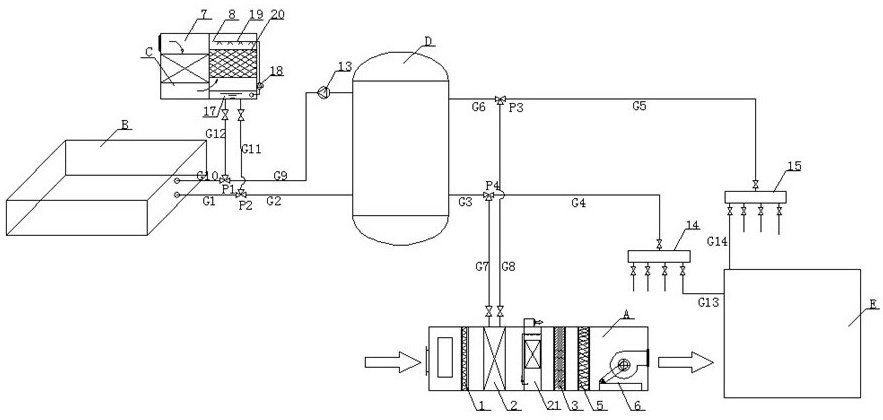

Flooring radiative cooling air conditioning system

InactiveCN1740671ASolve condensationSpace heating and ventilation safety systemsLighting and heating apparatusCold airAir volume

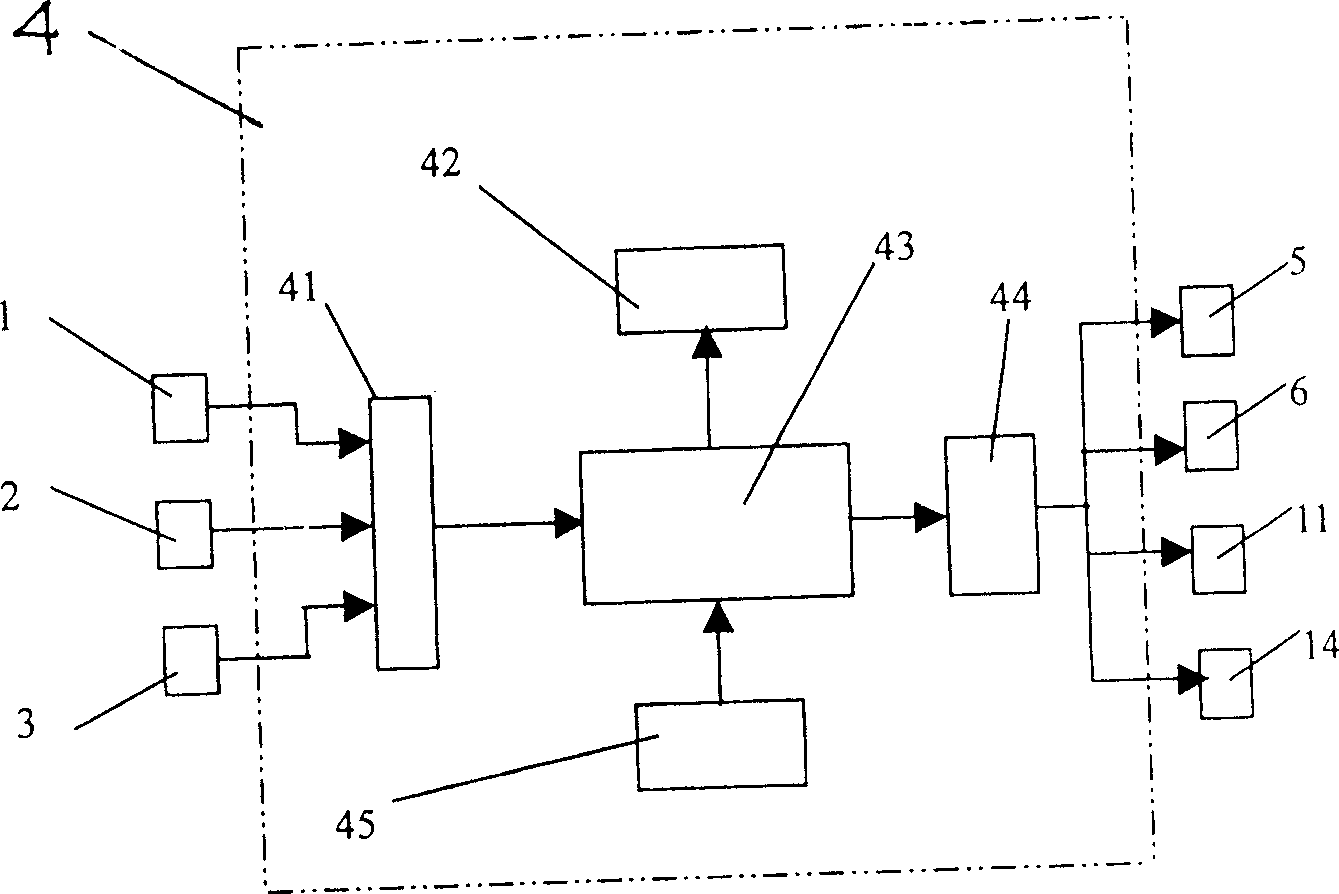

A kind of floor radiating refrigeration air conditioner includes one cold source machine , which is connected with collecting breeching and pipe coil that is setting under various areas floor through tubing; one cold air machine which leads to various areas through blast pipe and outgoing air pipe; temperature and humidity controlling apparatus arranged on various areas, which are composed of information collecting module, manual imputing module, calculation controlling module, displaying module and dictates outputting module and positioned in a controlling box. Through monitoring indoor temperature, floor temperature, air humidity around floor by sensor, control corresponding area cooling providing amount and wind providing amount depend on the monitored data and request of preventing dewing,

Owner:上海塔格工贸有限公司

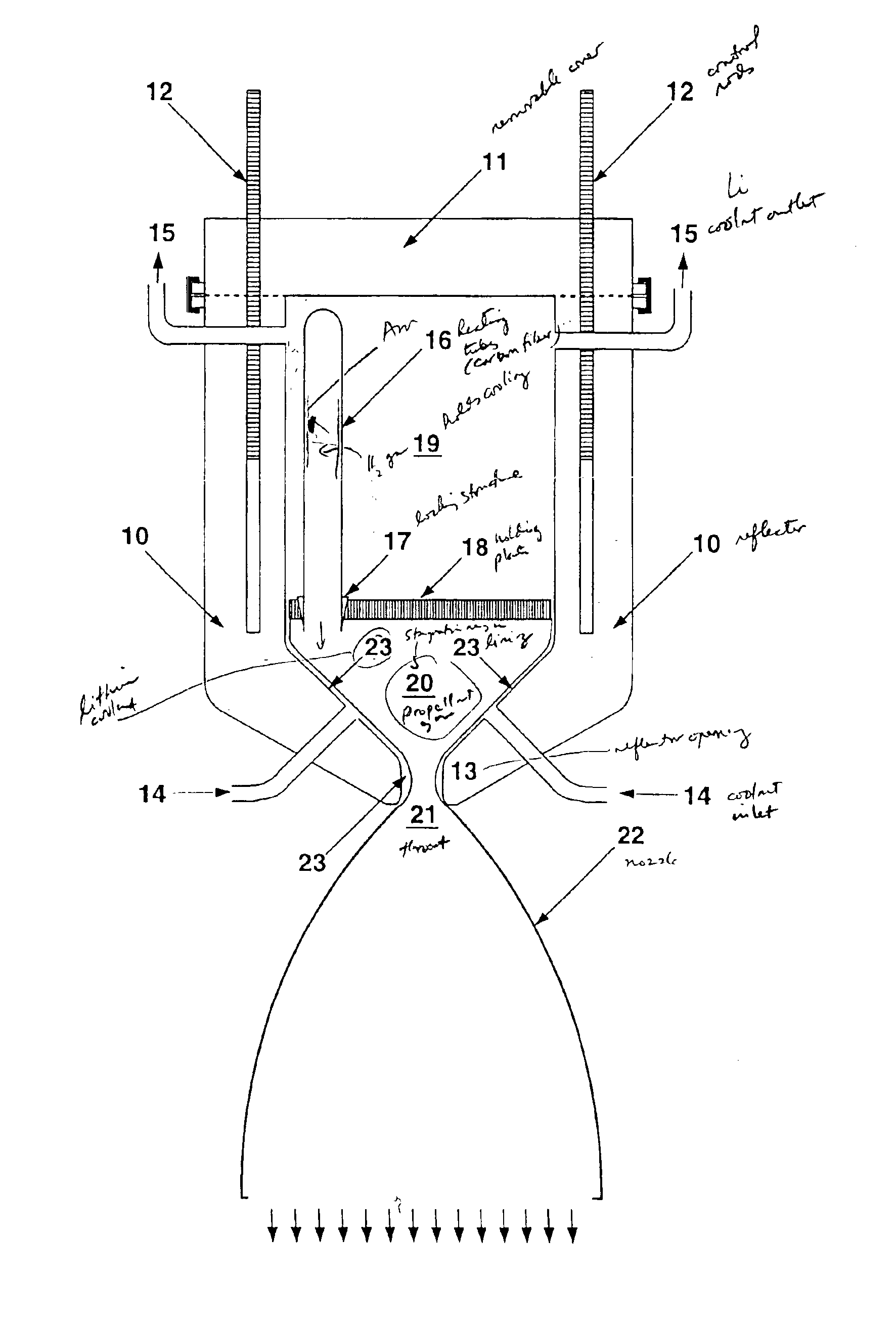

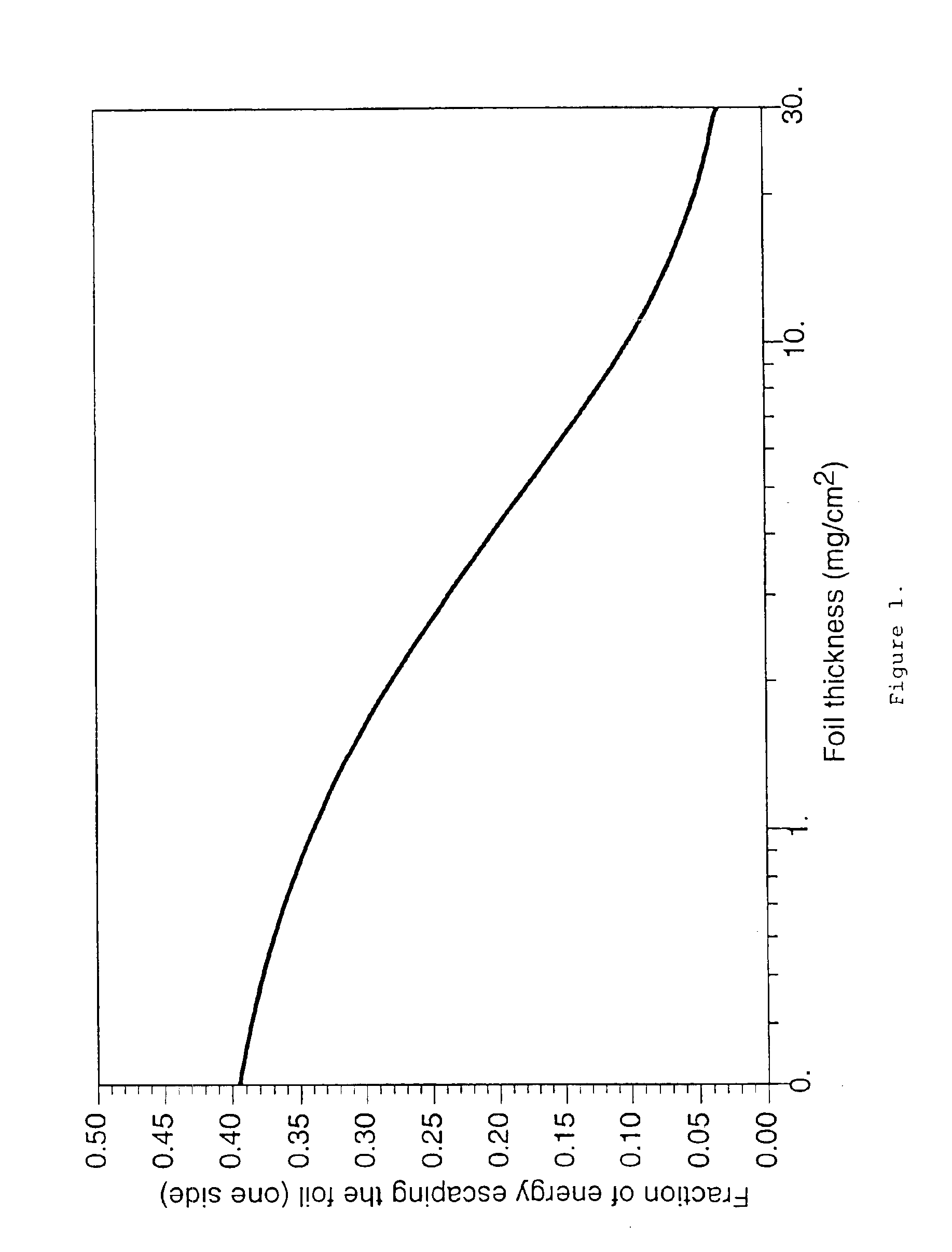

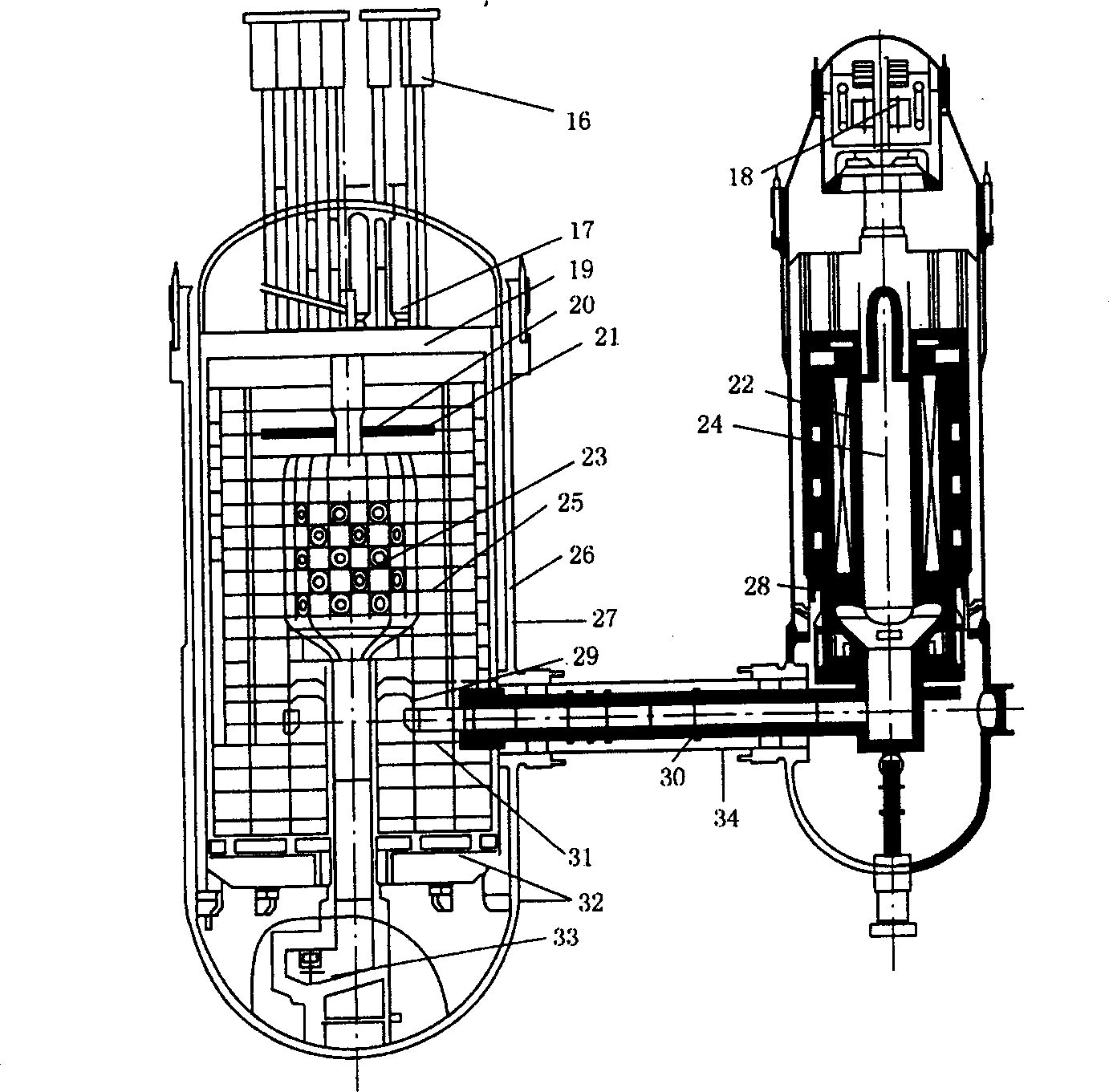

Device for heating gas from a thin layer of nuclear fuel, and space engine incorporating such device

InactiveUS6876714B2Efficient heatingCosmonautic vehiclesCosmonautic propulsion system apparatusDirect heatingSurface power density

A gas, e.g. hydrogen, at relatively low pressure is directly heated by the fission fragments (FF) emitted by a thin layer of fissile material, e.g. 242mAm, deposited on the inner wall of a chamber which is kept cooled at a typical temperature of about 1,000 / 1,500 K. The gas is preferably emitted as capillary flow from the walls of cylindrical tubes. Its temperature progressively increases until it reaches an equilibrium value of the order of 9,500 K, at which point FF heating and radiative cooling balance. With a relatively modest surface power density at the foil of 200 W / cm2, the specific, volume-averaged power given to the H gas may be as large as 0.66 MWatt / g. Heating powers up to megawatts for each gram of gas are therefore feasible with acceptable foil surface heating. The gas heating method can be used in rocket engines for deep space propulsion.

Owner:ENTE PER LE NUOVE TECH LENERGIA E LAMBIENTE ENEA

Wall automatic heat storage and heat removal device and method for achieving wall automatic heat insulation through same

InactiveCN107130694AAchieving heat release from condensationImprove thermal insulation performanceWallsHeat storage plantsLiquid stateLower grade

The invention discloses a wall automatic heat storage and heat removal device. The device comprises embedded tubes filled with phase change materials used for absorbing heat of a wall, liquid branch tubes, steam branch tubes and a radiation cooling device, wherein working media flow in embedded inner tubes, and accumulated heat can be taken away by the flowing working media; the liquid branch tubes are communicated with one end of each embedded inner tube and used for the liquid working media to flow and enter the embedded inner tubes; the steam branch tubes are communicated with the other ends of the embedded inner tubes, the phase change materials stores and transmits the heat to the liquid working media in the embedded inner tubes, and the liquid working media obtained after heat absorption are heated and then evaporated to be in a gaseous state; the radiation cooling device is communicated with a liquid main tube and a steam main tube separately, and the gaseous working media discharged from the steam main tube enter the radiation cooling device and then are cooled to be in a liquid state and flow into the liquid branch tubes communicated with the radiation cooling device. While the phase change materials are applied, low-grade energy generated by sky background radiation is fully utilized; a wall active heat insulation technology and device are adopted, so that the aims of maintaining the indoor heat comfort and reducing the energy consumption of an air conditioner are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

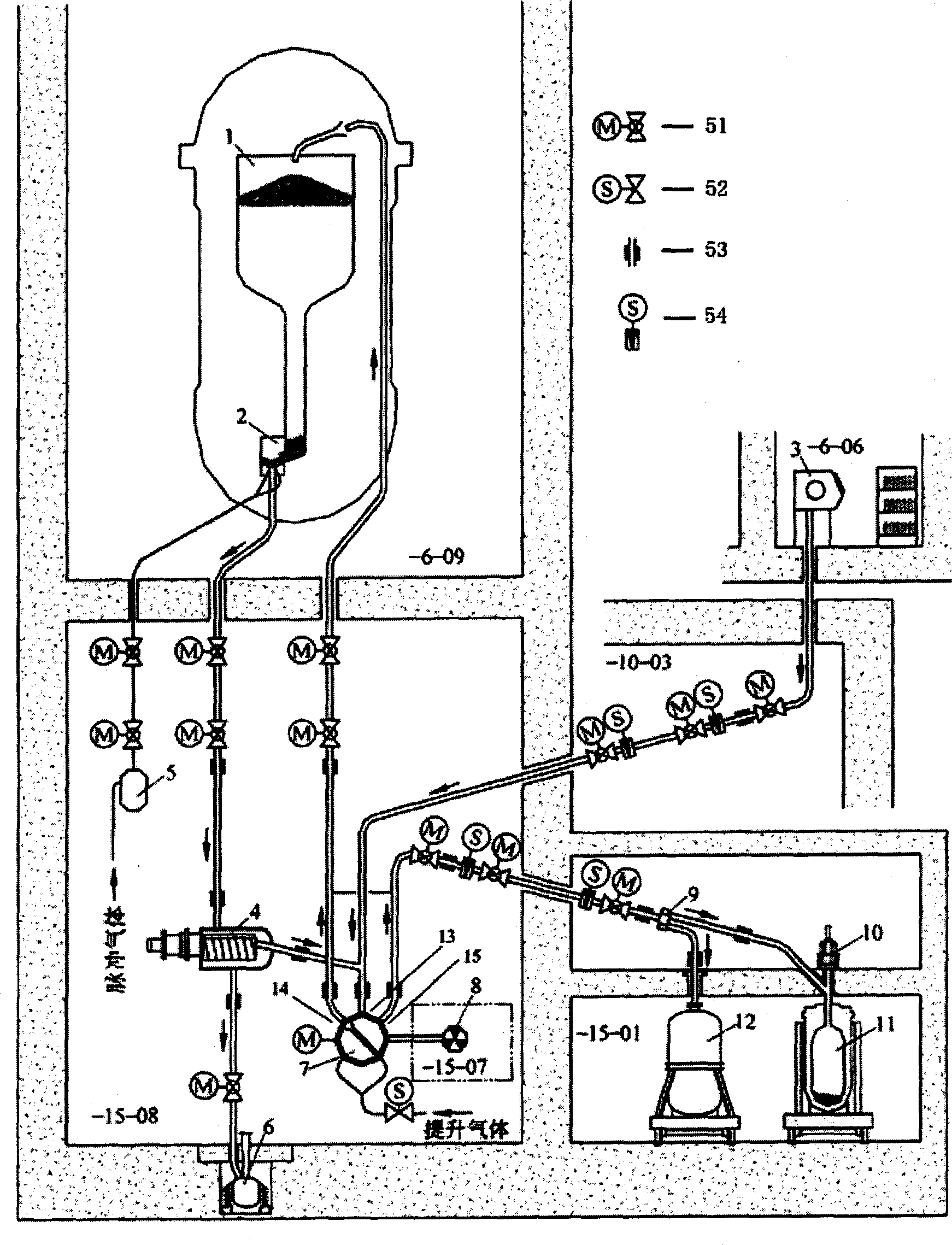

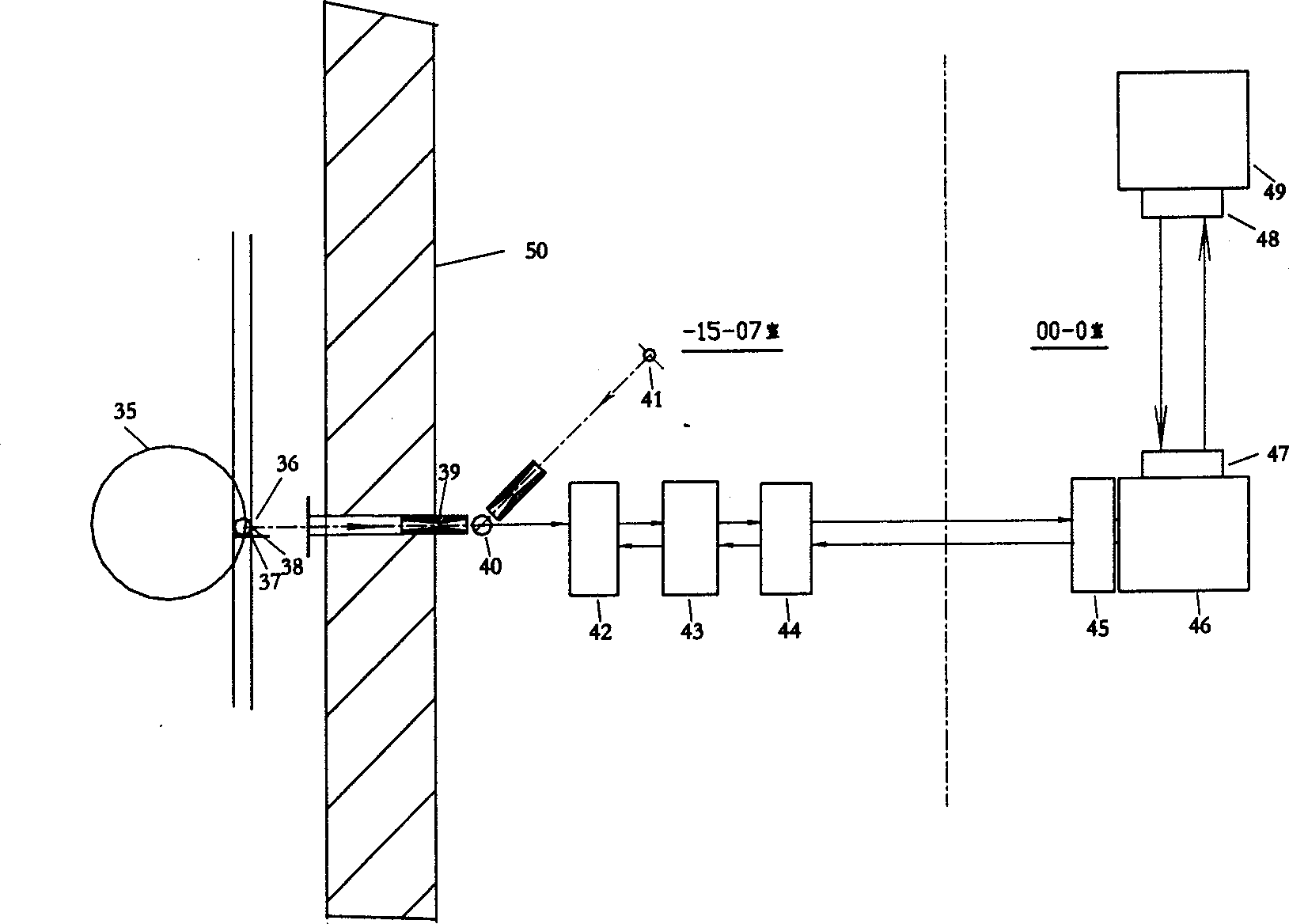

Online measuring method for burn-up level of fuel element of sphere type modular high-temperature gas-cooling reactor

ActiveCN1866408AEasy to separateMode of operation is not affectedNuclear energy generationNuclear monitoringCounting rateNuclear reactor

The related testing technique for nuclear reactor comprises: the upper machine starts up burn-up level measuring program; the fuel element is radiated and cooled; the PLC controls to send the element to lift position with same axis as the collimator and then notify the upper machine for measurement; the high-pure gamma-spectrometer measures the count of 0.661642MeV gamma radioactive ray emitted by 137Cs during decay, and calculates counting rate for the ray to determine whether takes out the core or returns to original core for work, and it sends the measured result to the main control system through a PLC. This invention is not to contact.

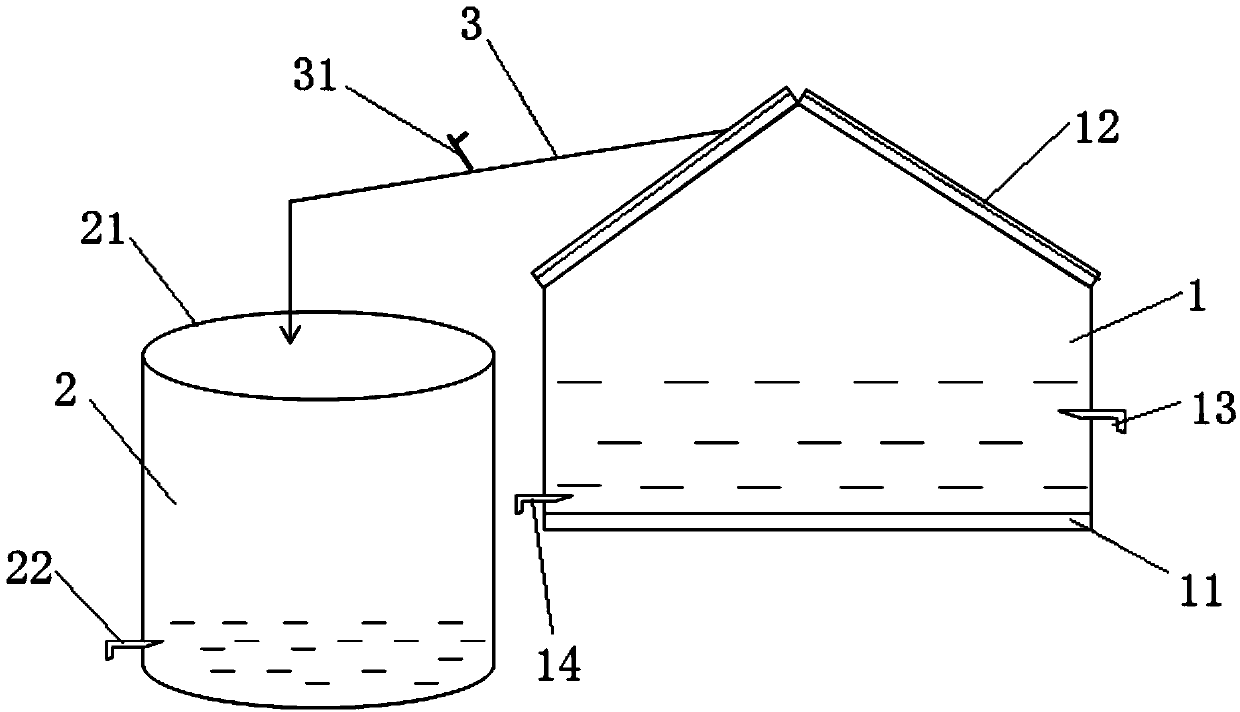

Radiative cooling-type seawater desalination device

PendingCN109607648ASimple structureLow costGeneral water supply conservationSeawater treatmentEngineeringEvaporation chamber

The invention discloses a radiative cooling-type seawater desalination device. The radiative cooling-type seawater desalination device comprises an evaporation chamber, a condensation chamber and a communication device, wherein a black heat-absorbing layer is arranged at the bottom of the evaporation chamber, a seawater inlet and a brine outlet are formed in the side surface of the evaporation chamber, and a radiative cooling membrane is arranged on the outer surface of the condensation chamber; and the communication device communicates with the evaporation chamber and the condensation chamber. The invention aims to provide the radiative cooling-type seawater desalination device, and a simple structure, low cost and energy saving and environmental protection are achieved.

Owner:NINGBO RADI COOL ADVANCED ENERGY TECH CO LTD

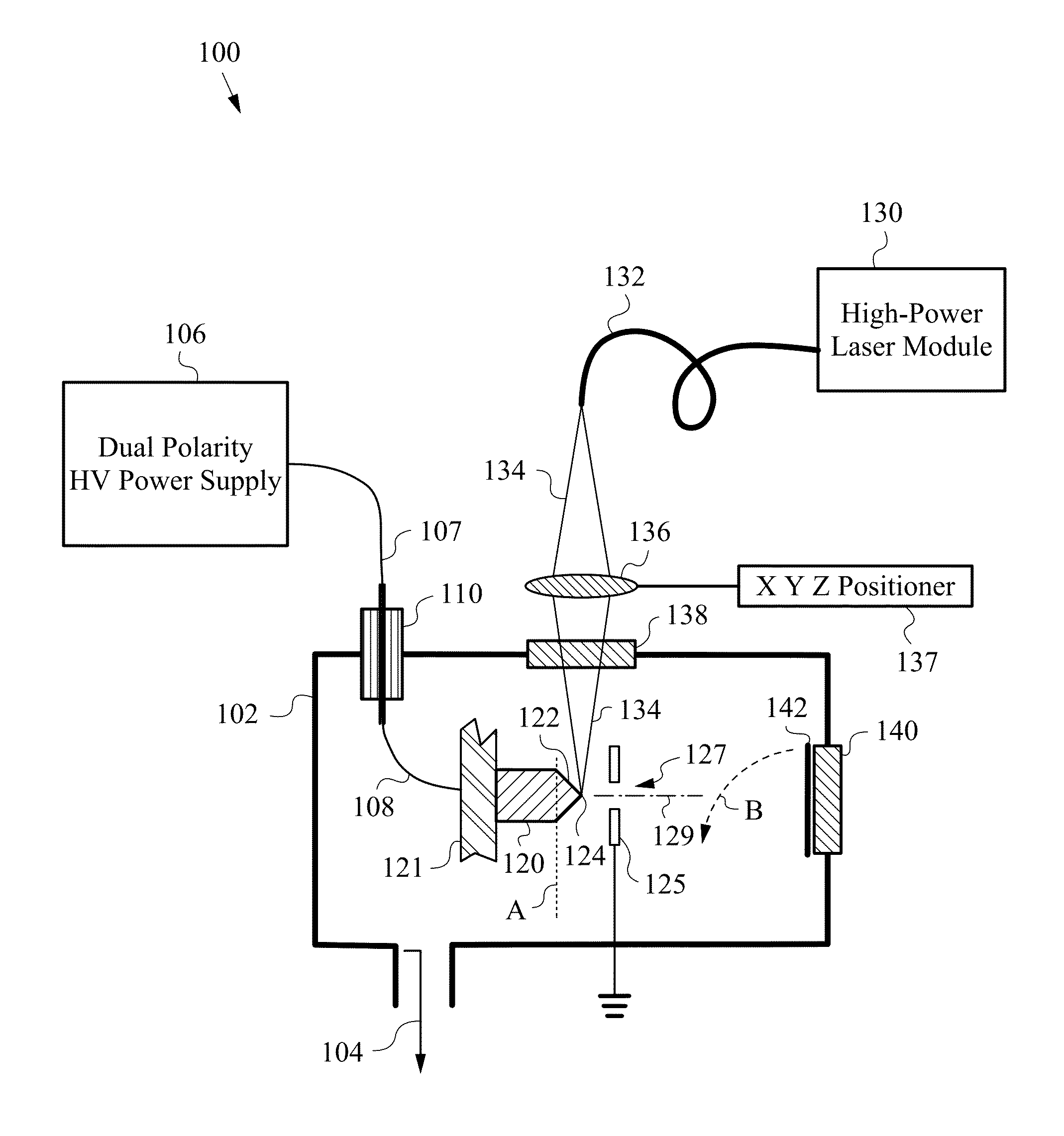

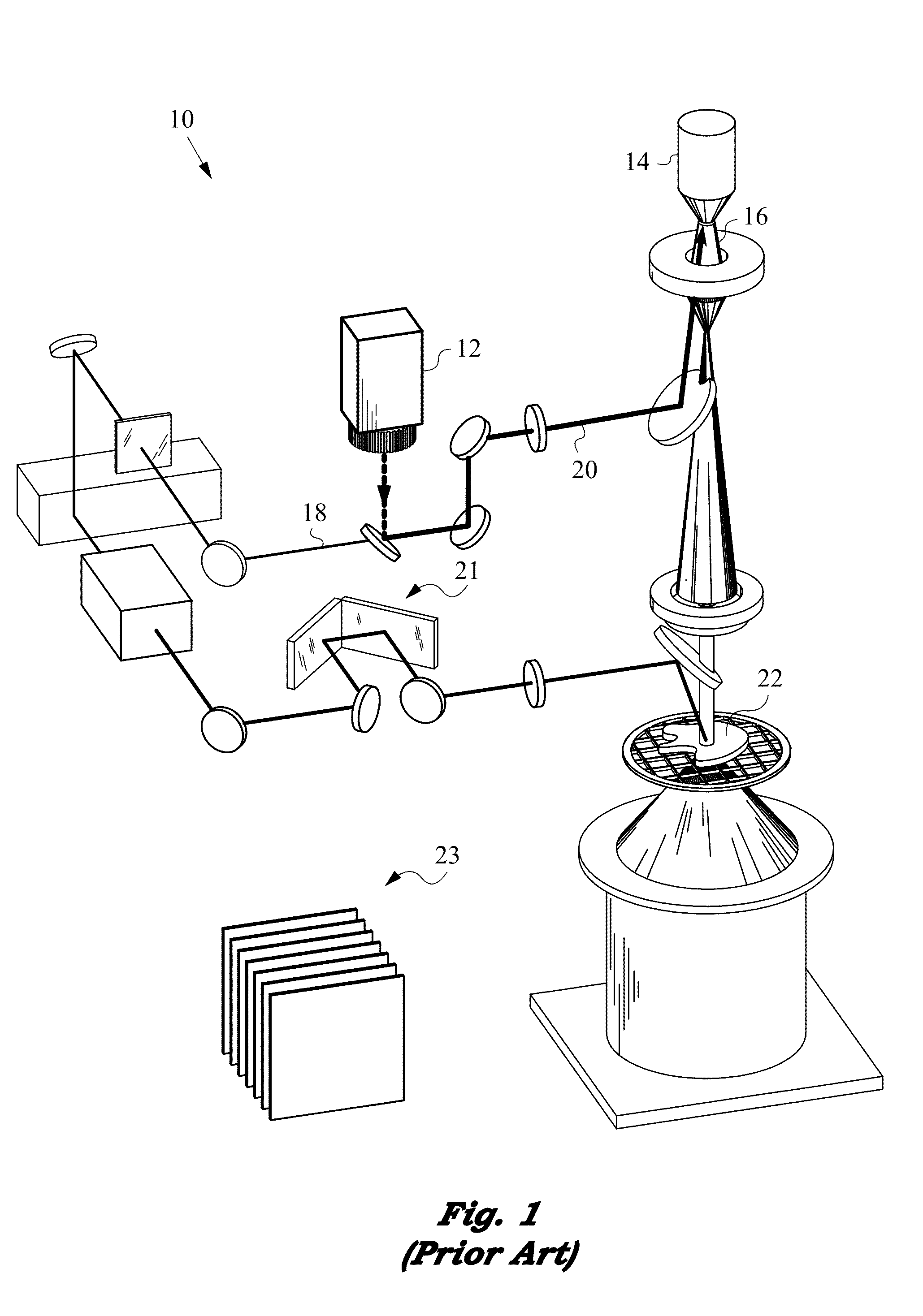

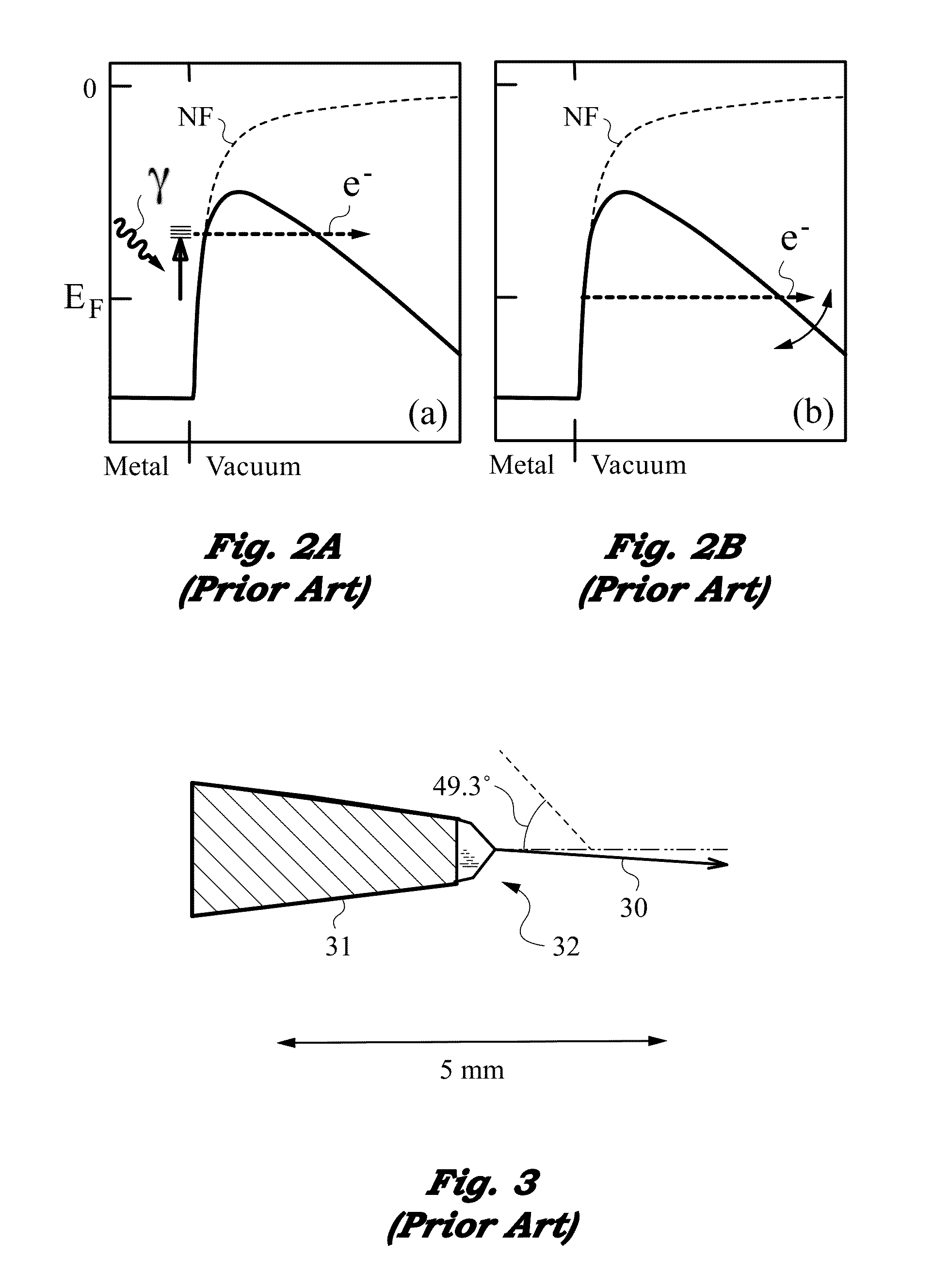

Bright and Durable Field Emission Source Derived from Refractory Taylor Cones

ActiveUS20150123010A1Reliably and cost-effectively producedReduce operating costsRadiation/particle handlingElectrode and associated part arrangementsChemical elementQuenching

A method of producing field emitters having improved brightness and durability relying on the creation of a liquid Taylor cone from electrically conductive materials having high melting points. The method calls for melting the end of a wire substrate with a focused laser beam, while imposing a high positive potential on the material. The resulting molten Taylor cone is subsequently rapidly quenched by cessation of the laser power. Rapid quenching is facilitated in large part by radiative cooling, resulting in structures having characteristics closely matching that of the original liquid Taylor cone. Frozen Taylor cones thus obtained yield desirable tip end forms for field emission sources in electron beam applications. Regeneration of the frozen Taylor cones in-situ is readily accomplished by repeating the initial formation procedures. The high temperature liquid Taylor cones can also be employed as bright ion sources with chemical elements previously considered impractical to implement.

Owner:HIRSCH GREGORY

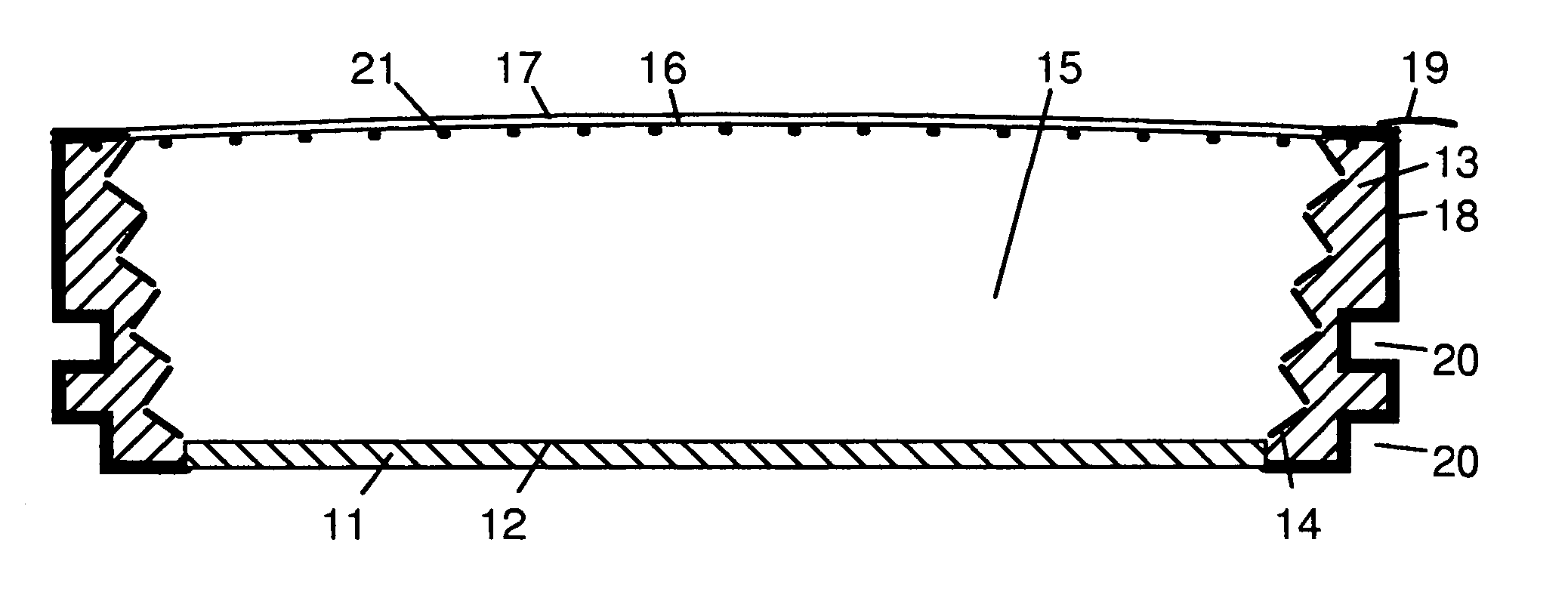

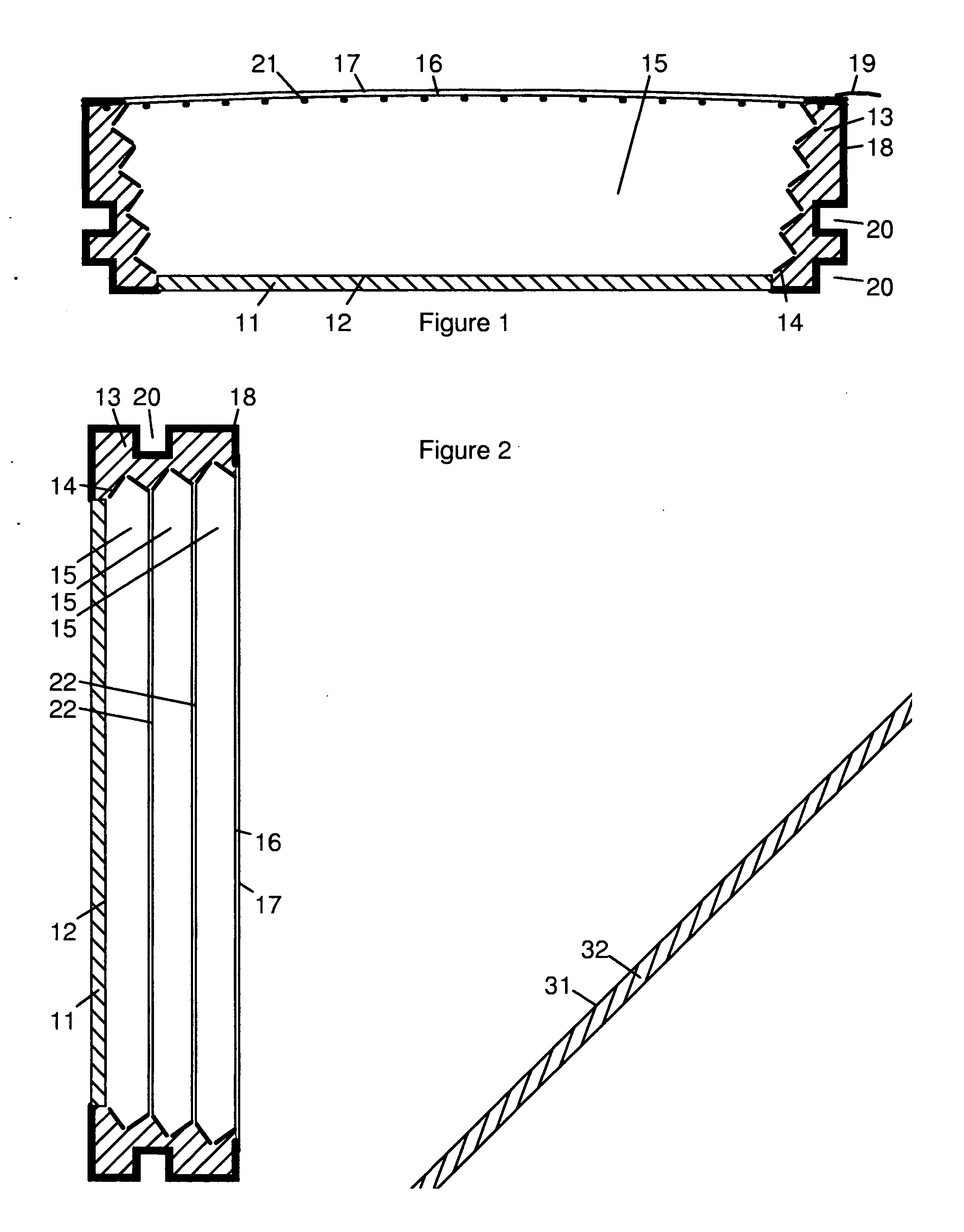

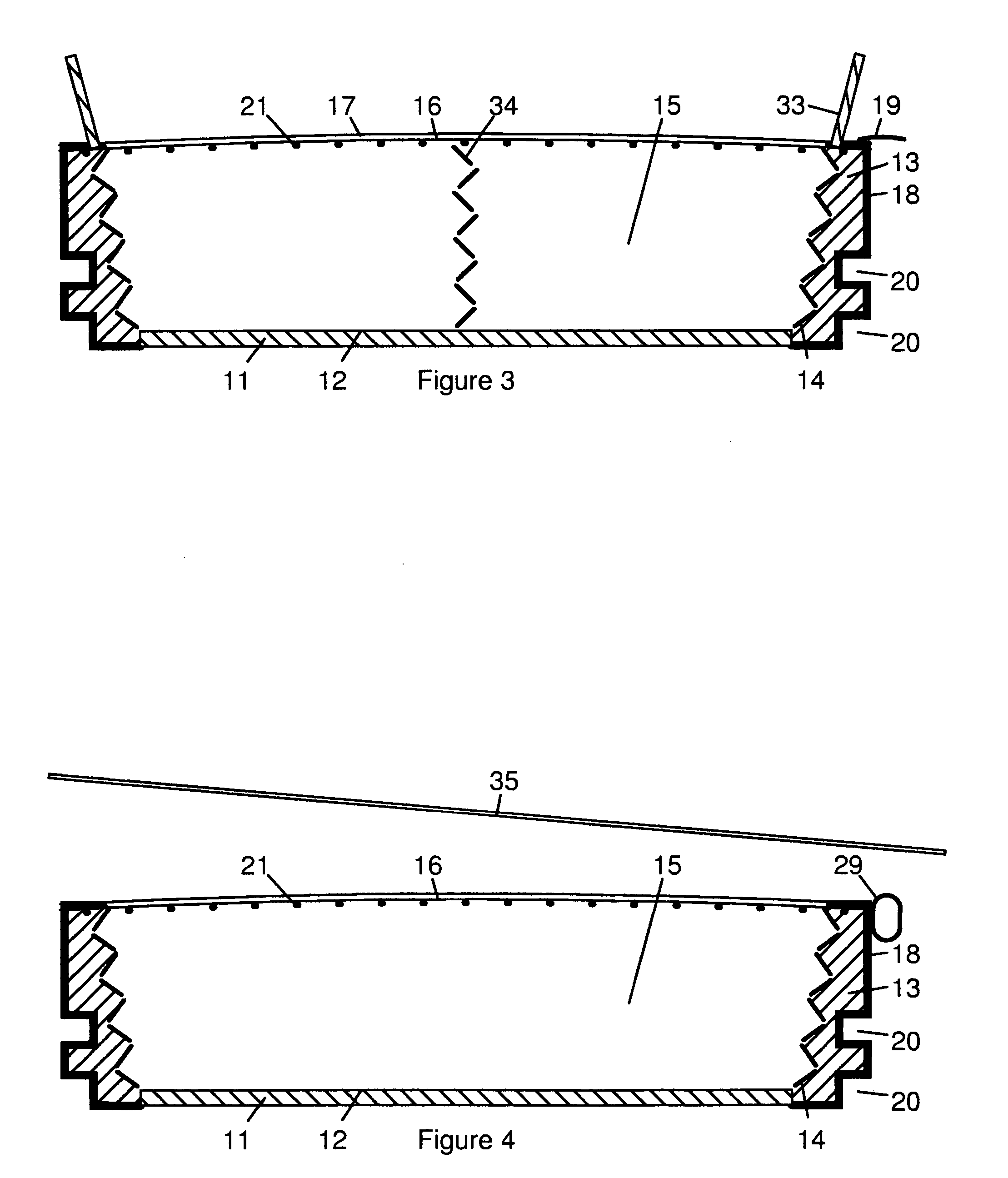

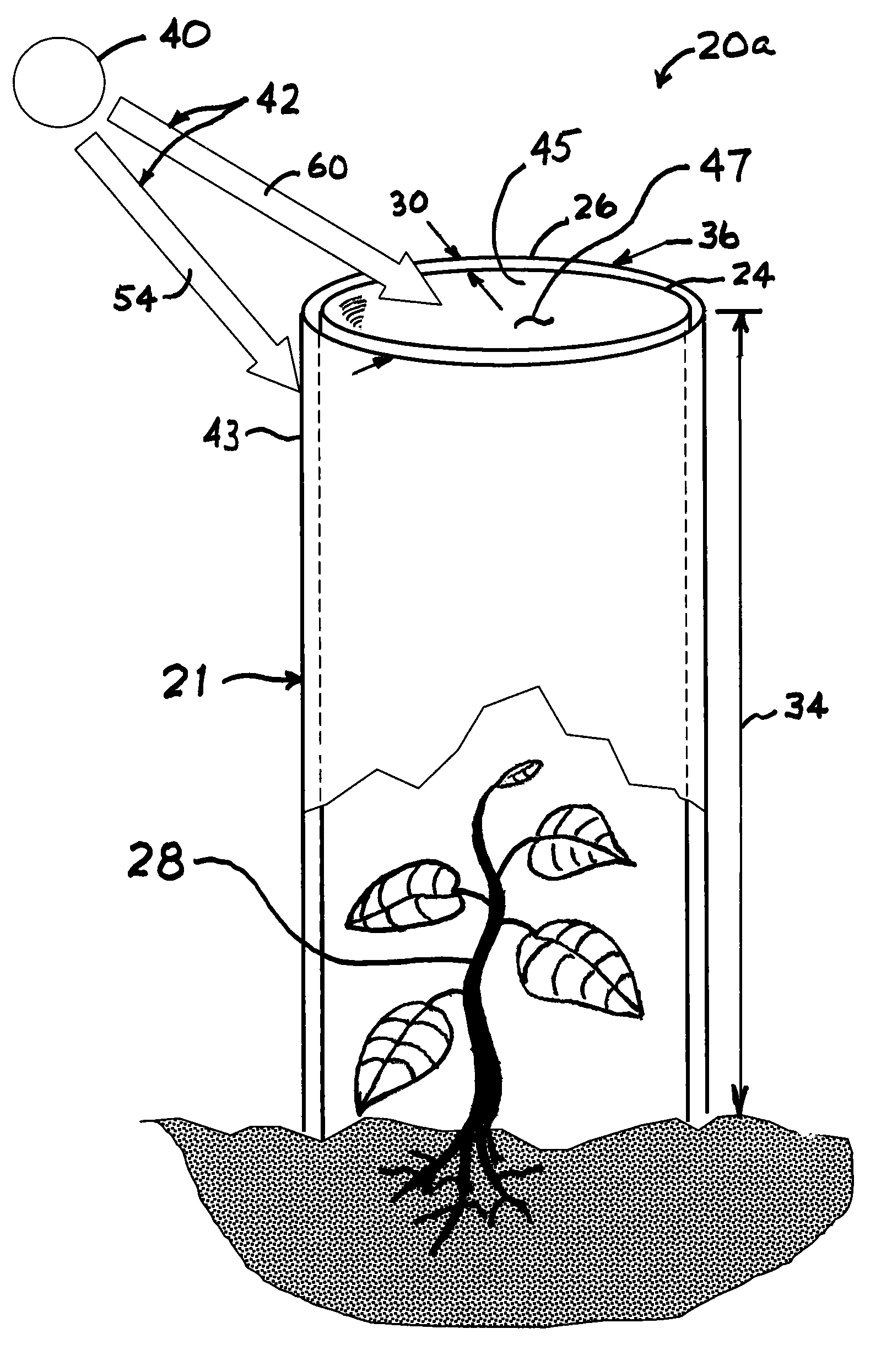

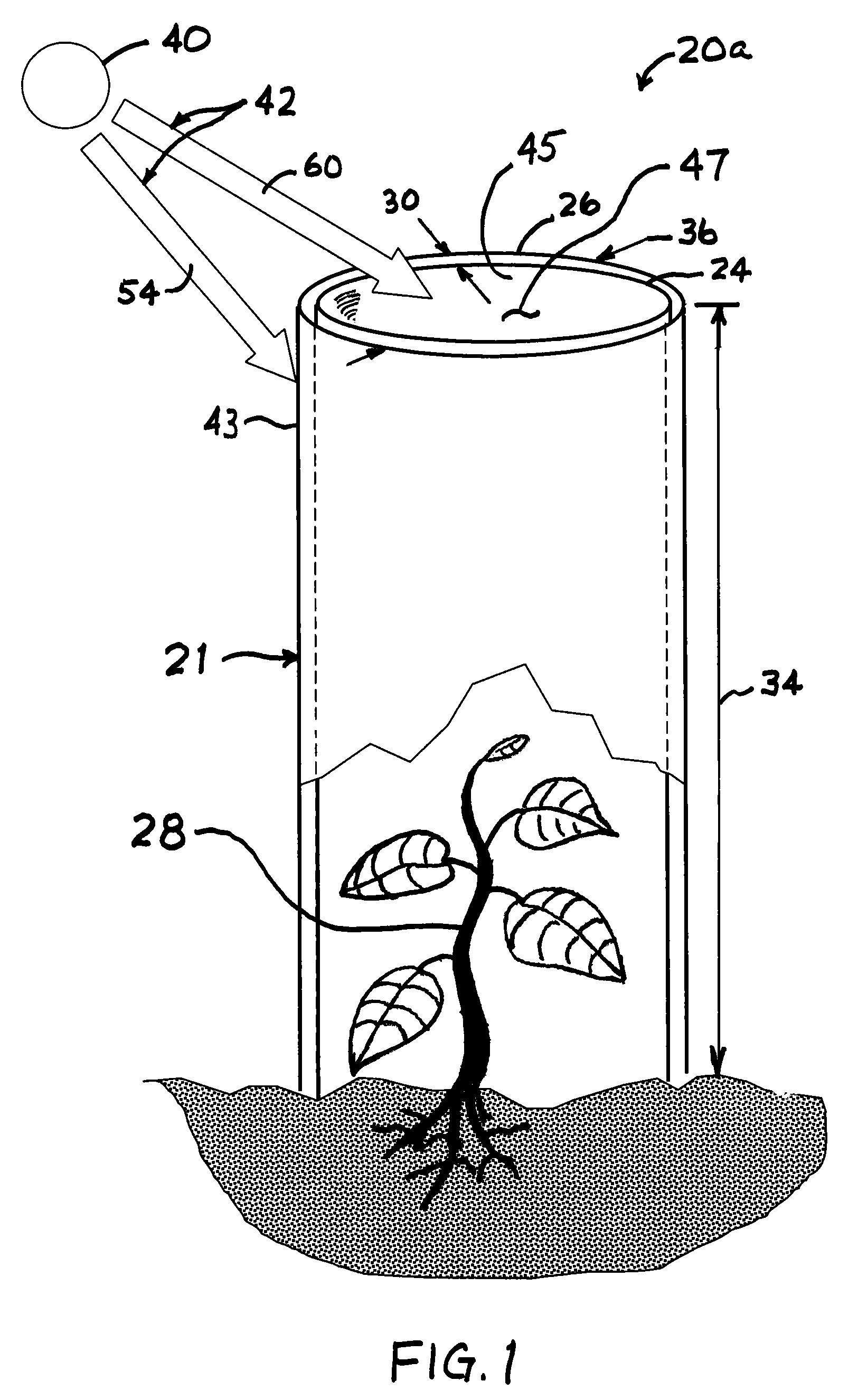

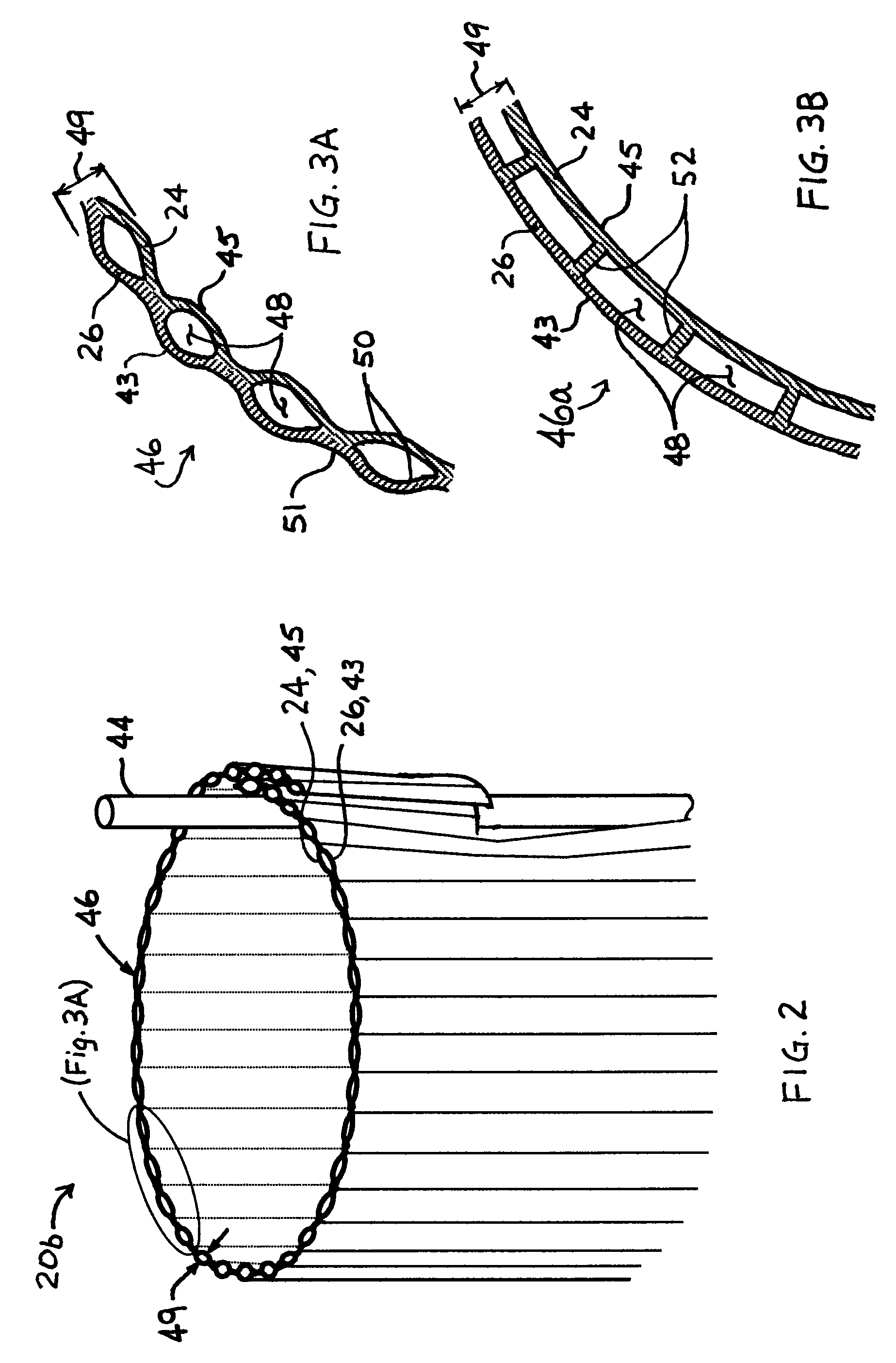

Spectrally selective grow tube

InactiveUS8171668B2Inhibition of colonizationReducing invitationFlower holdersPlant protective coveringsLighting spectrumBiology

A spectrally selective grow tube or tree shelter that improves the establishment of woody plant forms by reduction and / or elimination of certain biotic and abiotic stress factors. The grow tube may provide an enhanced micro climate that is humid and rich in CO2 and promotes photosynthesis by selectively propagating photosynthetically active radiation. In addition to providing a physical barrier to wind and herbivores, certain embodiments of the grow tube can also provide protection from chemical sprays while permitting ventilation of the grow tube. Various embodiments of the spectrally selective grow tube may comprise separate interior and exterior members for enhancement of the interior and exterior surface functions and that may be co-extruded. The interior member may be dyed or pigmented to selectively transmit wavelengths of the visible spectrum known to promote photosynthesis, such as red light and / or blue light. The exterior member may include a semi-reflective coating such as TiO2 or ZnS that reflects at least a portion of the visible light spectrum while enabling transmission of infrared wavelengths therethrough for radiative cooling.

Owner:PLANTRA

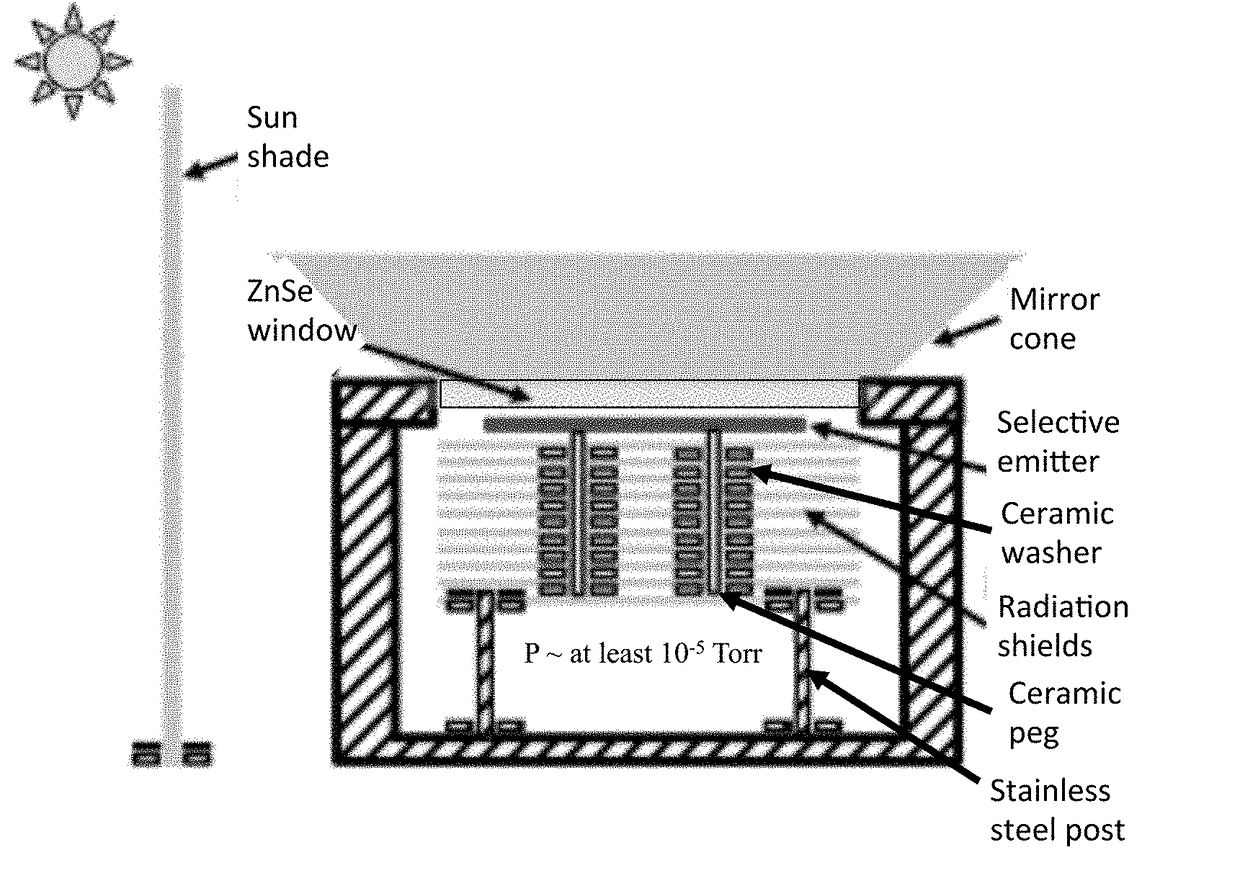

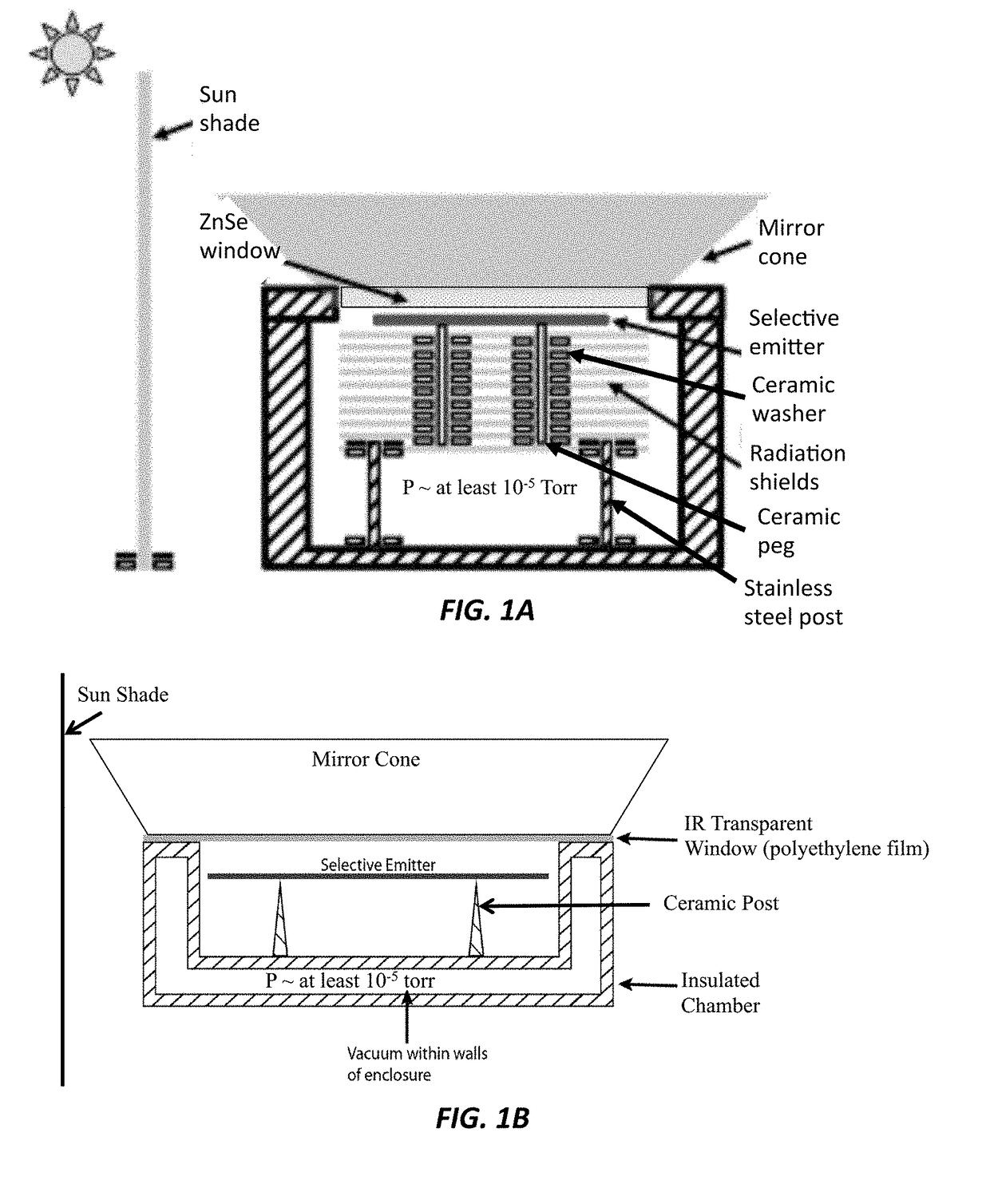

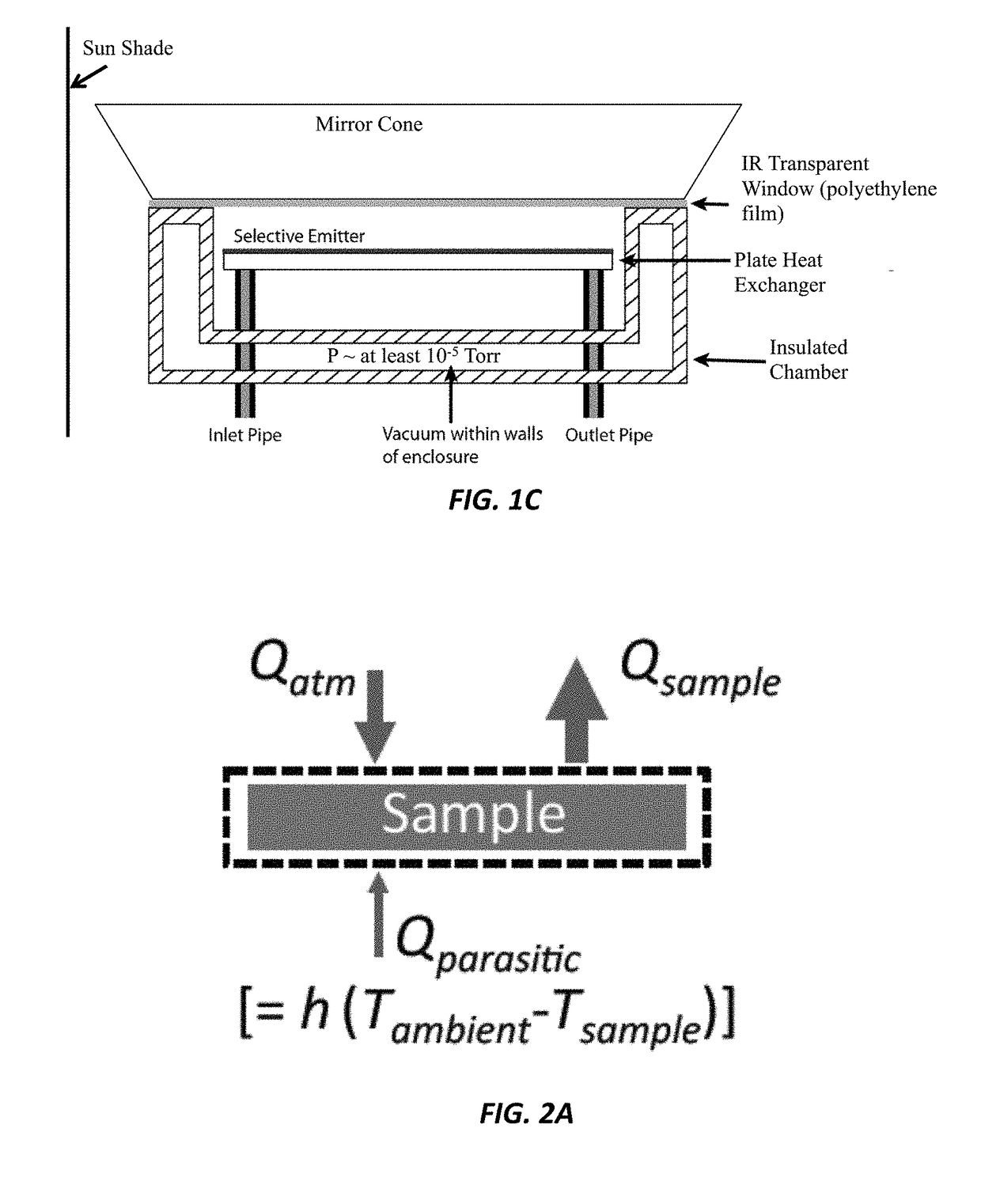

Ultrahigh-Performance Radiative Cooler

A radiative cooler is provided having a thermally insulated vacuum chamber housing that is configured to support a vacuum level of at least 10-5 Torr, an infared-transparent window that is sealably disposed on top of the thermally insulated vacuum chamber and is transparet in the range of 8-13 μm, a selective emitter disposed inside the chamber, a mirror cone on the infared-transparent window, a selective emitter inside the chamber and is configured to passively dissipate heat from the earth into outer space through the infared-transparent window and is thermally decoupled from ambient air and solar irradiation but coupled to outer space, a heat exchanger with inlet and outlet pipes disposed below the selective emitter to cool water flowing through the pipe, a sun shade disposed vertically outside the chamber to minimize direct solar irradiation, and a mirror cone to minimize downward atmospheric radiation.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

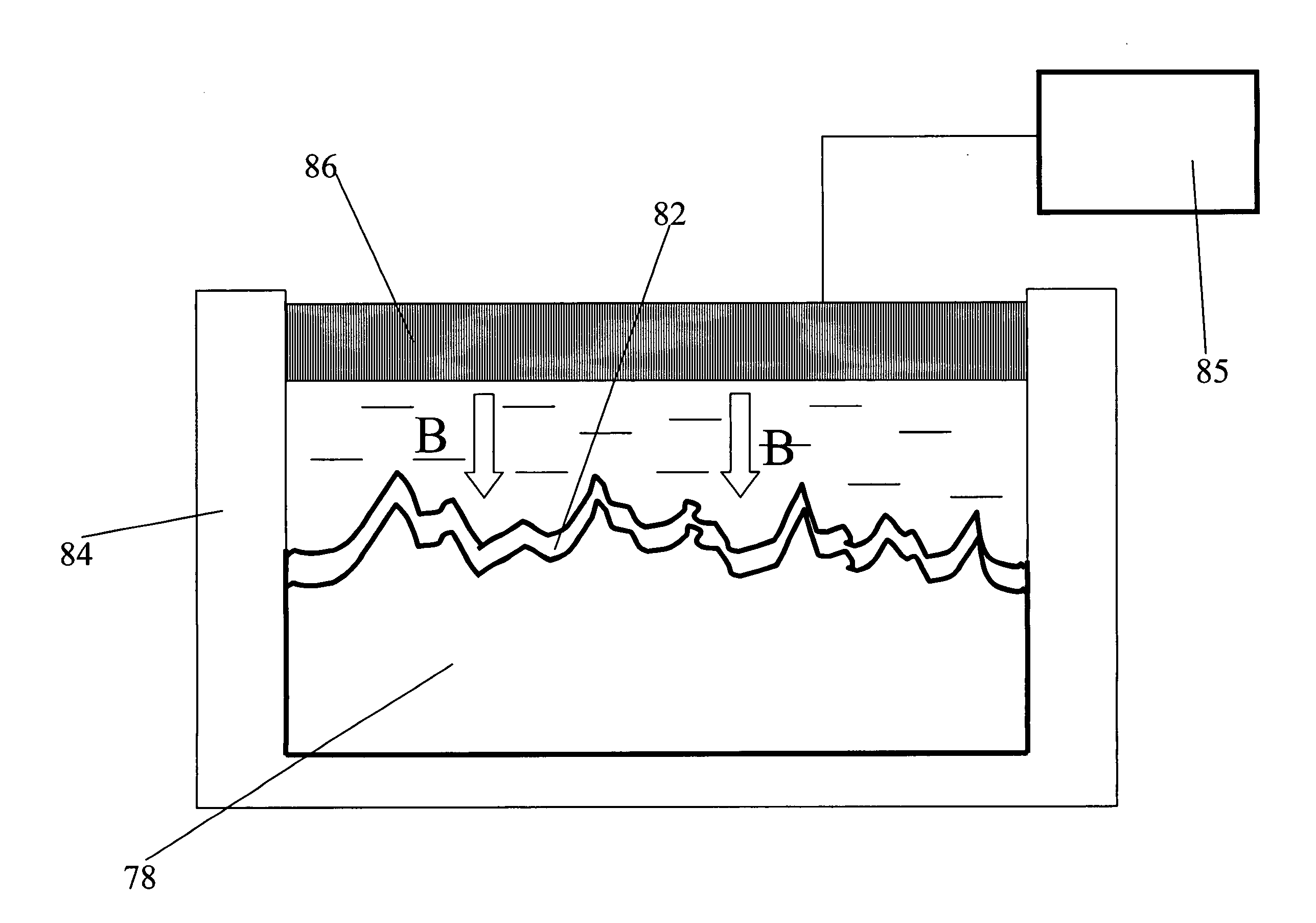

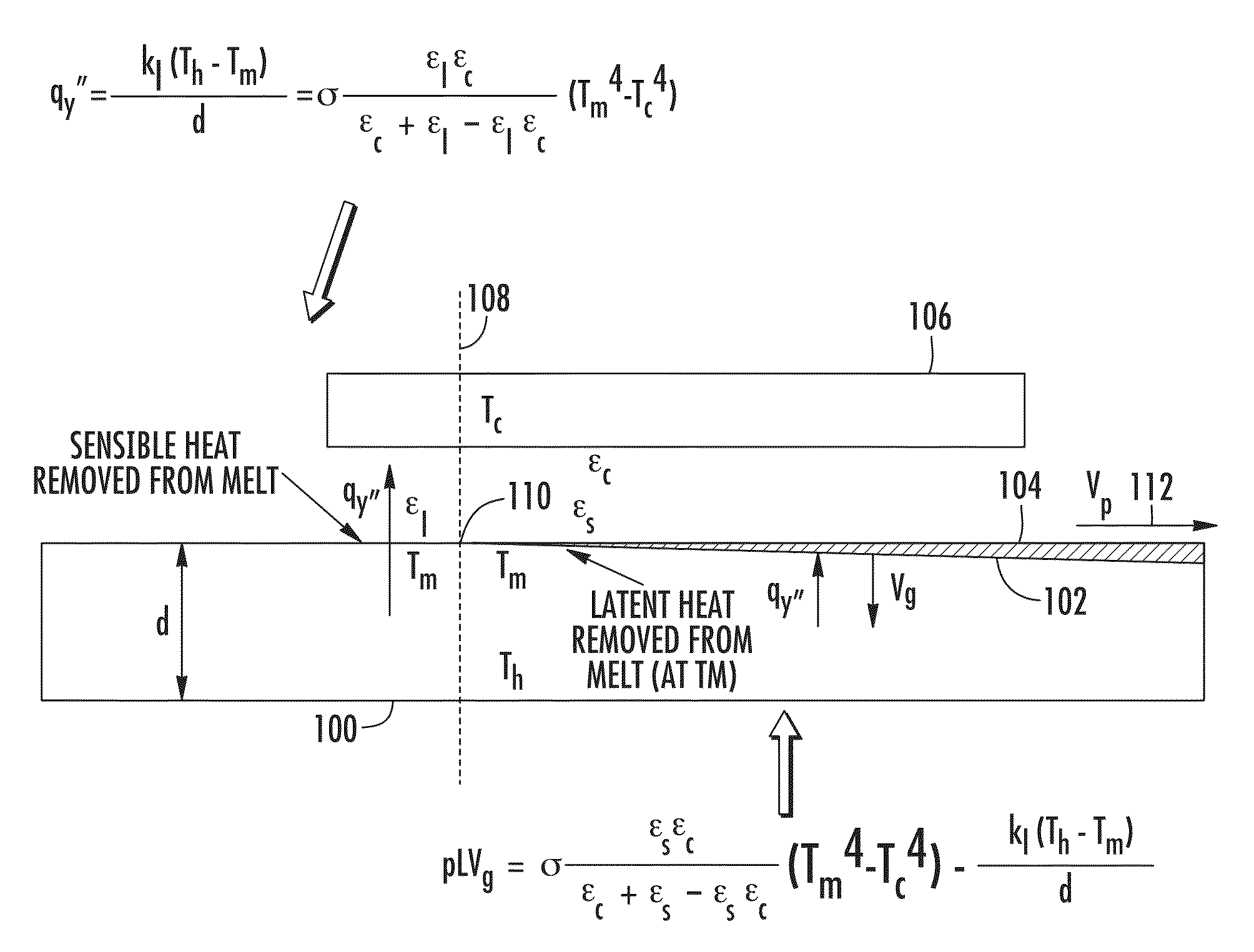

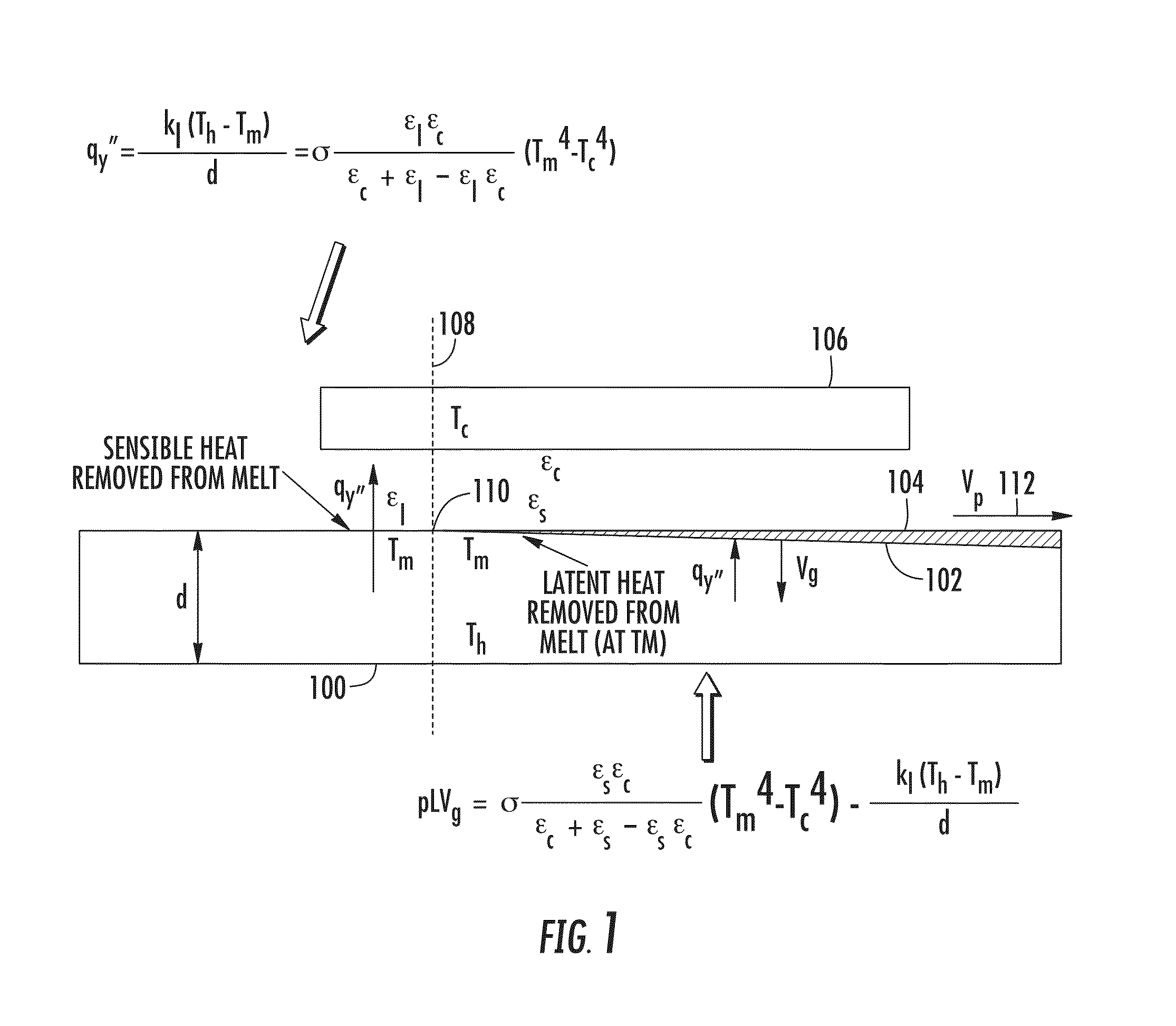

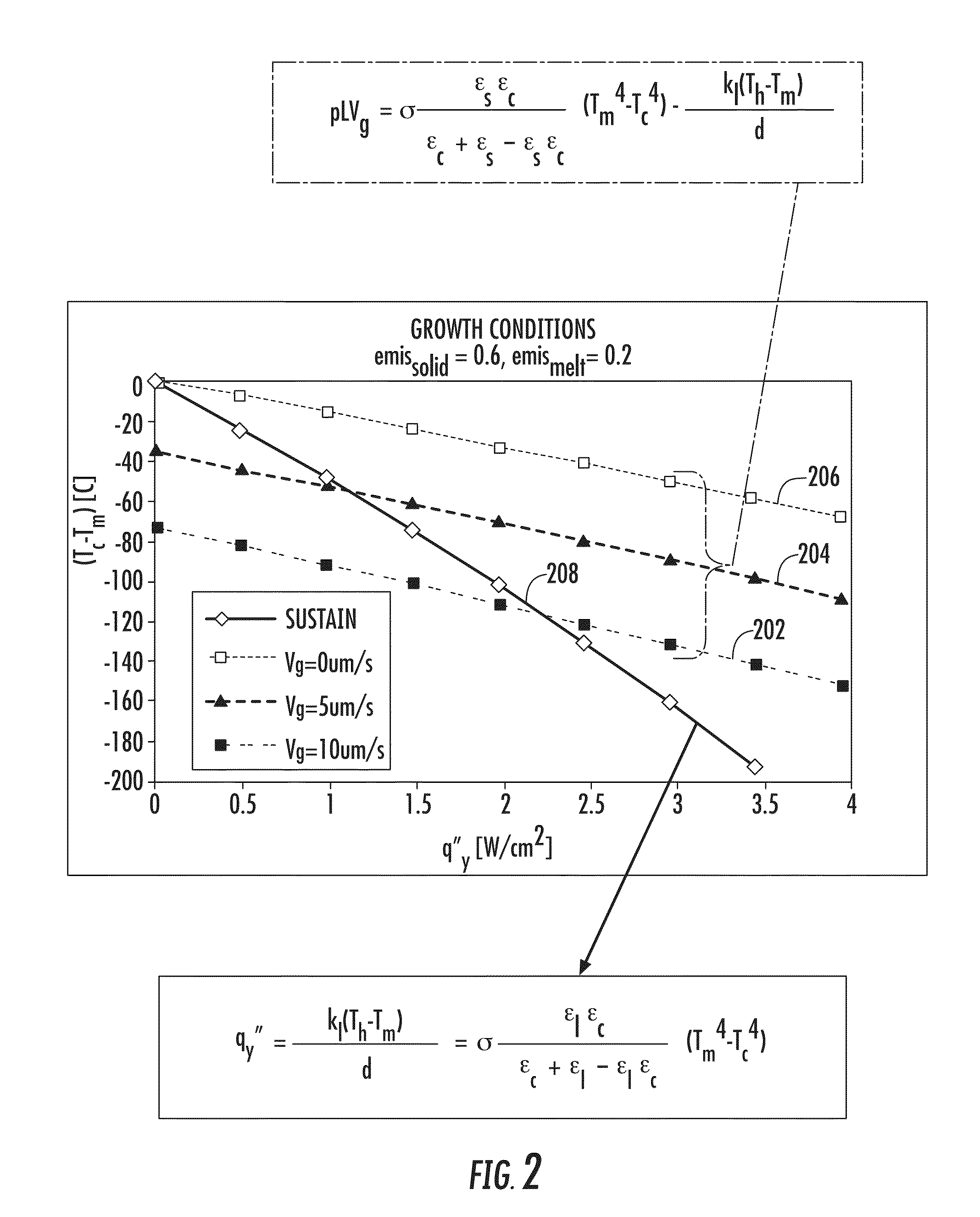

Method for achieving sustained anisotropic crystal growth on the surface of a melt

InactiveUS20130213296A1Well formedPolycrystalline material growthBy zone-melting liquidsLeading edgeHeat flow

A method of horizontal ribbon growth from a melt includes forming a leading edge of the ribbon using radiative cooling on a surface of the melt, drawing the ribbon in a first direction along the surface of the melt, and removing heat radiated from the melt in a region adjacent the leading edge of the ribbon at a heat removal rate that is greater than a heat flow through the melt into the ribbon.

Owner:VARIAN SEMICON EQUIP ASSOC INC

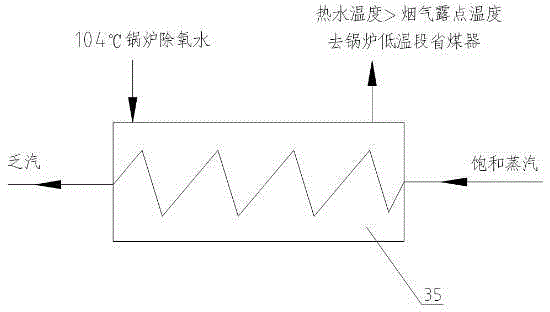

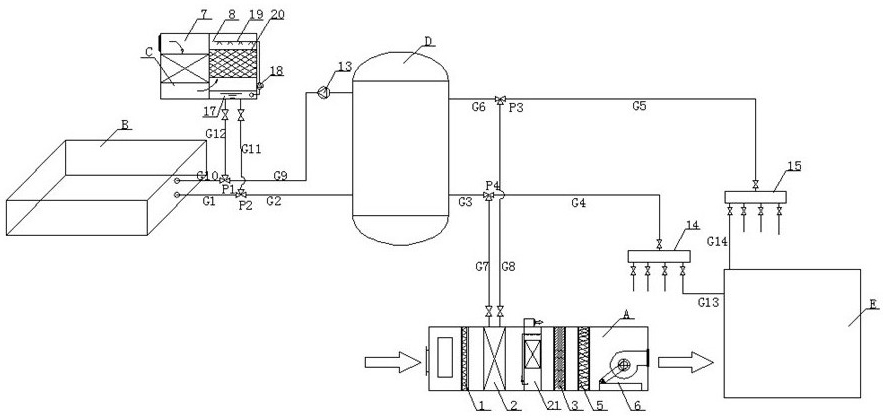

Incineration boiler for high-concentration salty organic waste liquid

ActiveCN105240861AReduce incineration costsSimple preparation processChemical industryIncinerator apparatusCombustion chamberThermal insulation

The invention discloses an incineration boiler for high-concentration salty organic waste liquid. The environment-friendly and energy-saving requirements for harmlessness, reduction and resourcezation of high-concentration salty organic waste liquid are met through high-temperature incineration and waste heat recovery. The incineration boiler structurally and mainly comprises auxiliary combustors, waste liquid spray guns, a thermal insulation hearth combustion chamber, a steering chamber, a radiation cooling chamber, a radiation water-cooling pipe panel, convection current evaporation pipe panels, a steam pocket, a high-temperature economizer, a low-temperature economizer, an ash falling bucket, a flue connection expansion joint and a furnace wall. The thermal insulation hearth combustion chamber is formed by a hearth wall-covering film type water-cooling wall in a defined manner, salty waste liquid is combusted, and recycling is conducted in a salt dissolving tank. High-temperature smoke generated in combustion sequentially enters the thermal insulation combustion steering chamber, a quenching chamber, the multiple stages of convection current evaporation cooling chambers and the economizers to be subjected to heat energy recovery. The incineration boiler has the beneficial effects of being simple in manufacturing process, convenient to maintain, safe and stable in running, and suitable for being used and popularized in high-concentration salty organic waste liquid processing in the industries of chemical engineering, oil refining, papermaking and the like.

Owner:大连科林能源工程技术开发有限公司

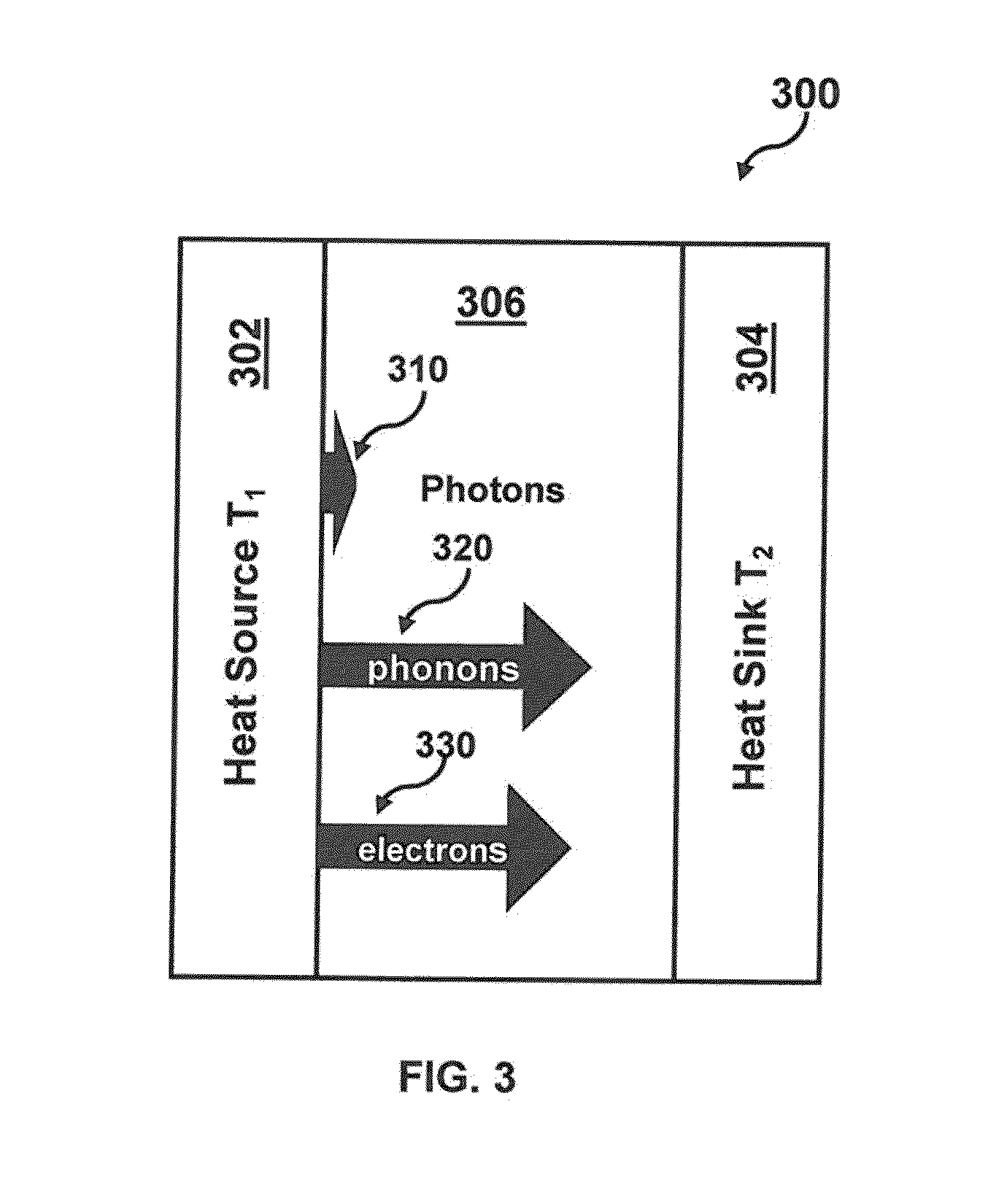

Radiative cooling of optoelectronic devices using hyperbolic metamaterials

InactiveUS20130340990A1Semiconductor/solid-state device detailsSolid-state devicesStefan–Boltzmann lawLaws of thermodynamics

A method of radiative cooling of optoelectronic devices using a hyperbolic metamaterial TIM layer below the heat generating optoelectronics is disclosed. Optoelectronic devices are optimized for high radiative heat conductance due to broad hyperbolic frequency band in the Long-Wavelength Infrared (LWIR) range with an efficient electromagnetic black hole thermal interface between the metamaterial TIM layer and a metallic heat sink. A modified Stefan-Boltzmann law in the hyperbolic metamaterial layer enables domination of the radiative heat transfer in the TIM layer. The broadband divergence of the photonic density of states in hyperbolic metamaterials leads to an increase in radiative heat transfer, beyond the limit set by the Stefan-Boltzmann law. The resulting radiative thermal hyper-conductivity approach or even exceed heat conductivity via electrons and phonons in regular solids.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC +1

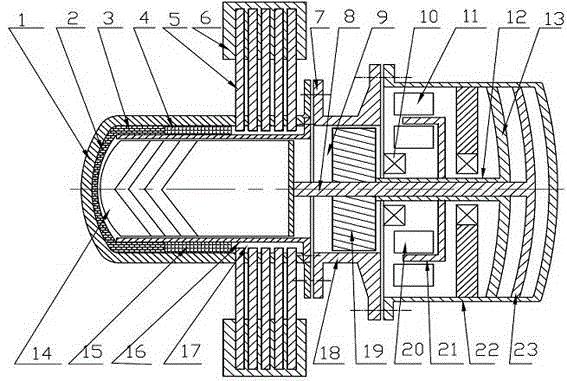

Spatial radiation-cooled free-piston Stirling engine

InactiveCN103953456AImprove heating efficiencyHigh System Thermal PerformanceHot gas positive displacement engine plantsCooling chamberWater cooling

A spatial radiation-cooled free-piston Stirling engine belongs to the field of Stirling engine utilization. A heater (3) and a heat regenerator (15) are respectively mounted in a heating chamber (2) and a heat regeneration chamber (4) of a displacer piston cylinder. The heater (3) is integrally foamed porous material as a turbulator for intensifying the heat exchange between the air and an outer cylinder (1), and the heat regenerator (15) is made of integrally foamed porous material; circular heat tubes (5) are mounted in a cooling chamber (17), wherein the part of the cooling chamber, in which the circular heat tubes (5) are mounted, is an evaporation section, the middle part is a thermal leakage current section, and the part which stretches out of the outer cylinder (1) is a heat dissipation section or a condensation section; a radiation shield (6) is mounted on the circular heat tubes (5) and the heat dissipation section to carry out radiative cooling; the radiation shield (6) is of a rib plate structure. Because the spatial radiation-cooled free-piston Stirling engine uses the integrally foamed porous material to intensify heat exchange in the heating chamber, the heating capability is enhanced; because the heat tubes are utilized to carry out radiative cooling, the difficulty of spatial water cooling is decreased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

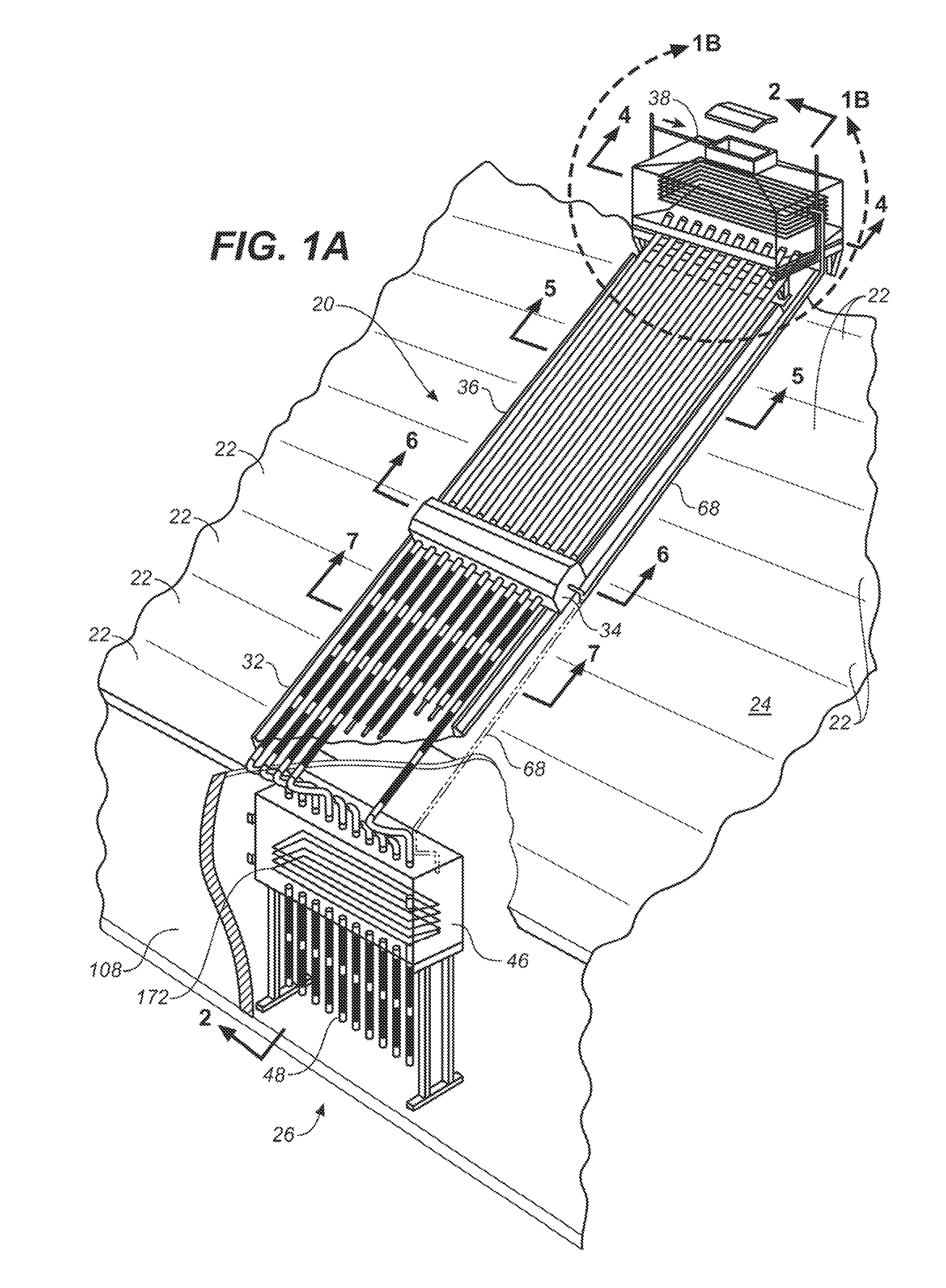

Coaxial tube solar heater with nighttime cooling

InactiveUS20120227730A1Improve the immunityImprove efficiencySolar heating energyCentral heating with accumulated heatCoaxial cableWater storage tank

Disclosed is a solar water-heating-and-cooling system (20) that included a collector array panel (32, 36) having thermosyphon coaxial heating / cooling tubes (52). The disclosed system (20) avoids damaging the collector array panel (32, 36) by filling the tubes (52): 1. only when environmental conditions ensure that damage won't occur,—and / or 2. using a filling method that ensures that damage won't occur. Thermosyphon coaxial heating / cooling tubes (52) disclosed herein may be open both at their upper and lower ends. Tubes (52) that are open at their, lower end enables capturing radiative cooling of liquid present within the tubes (52). A cold water storage tank (46) and cold radiator array (48) included in the water-heating-and-cooling system (20) permits preserving and using the radiative ‘cooling. Also disclosed are coaxial tubes (104, 106) that enable simpler and easier installation of the system (20), and also provide a less architecturally intrusive system (20).

Owner:TEOH SIANG TEIK

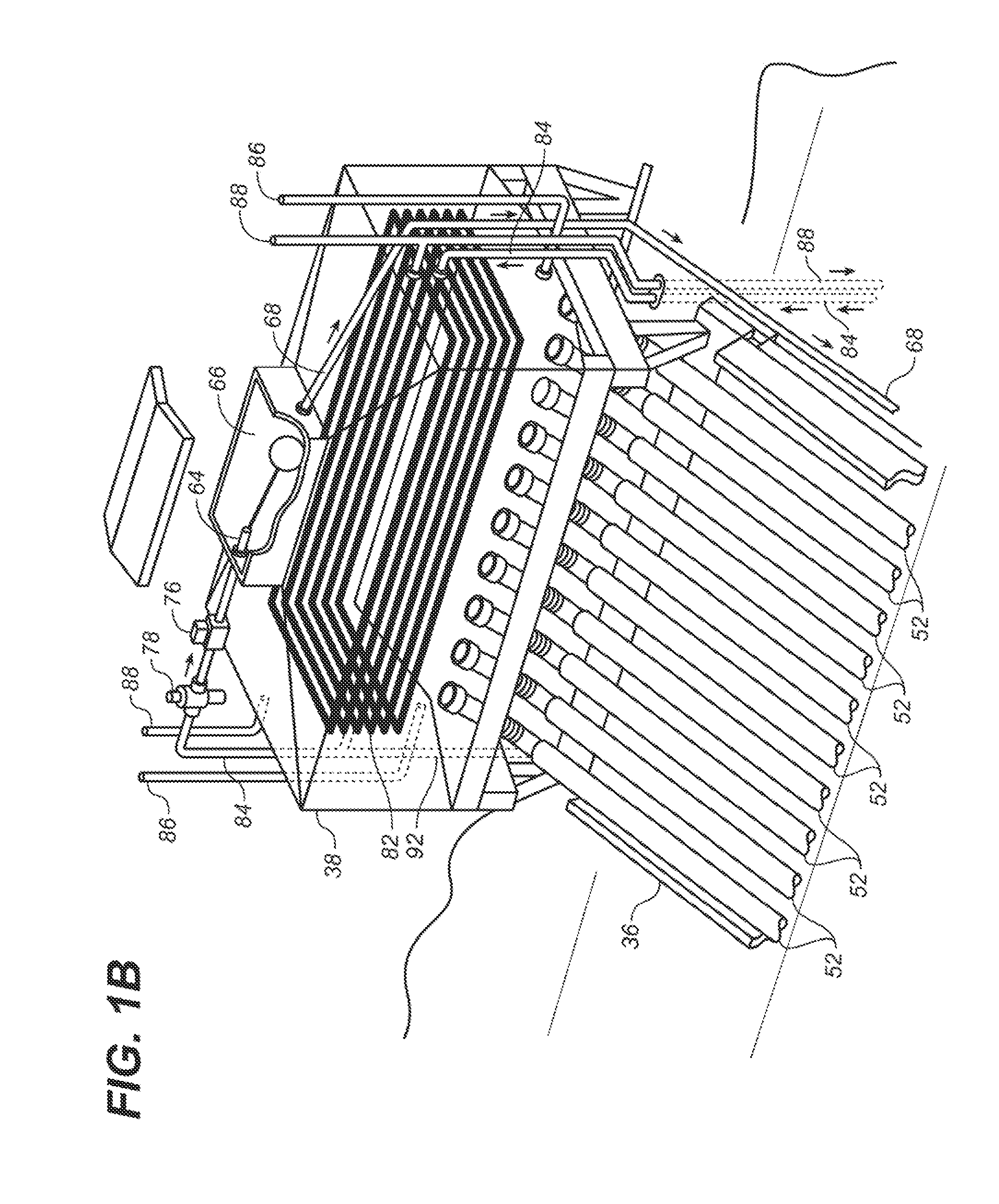

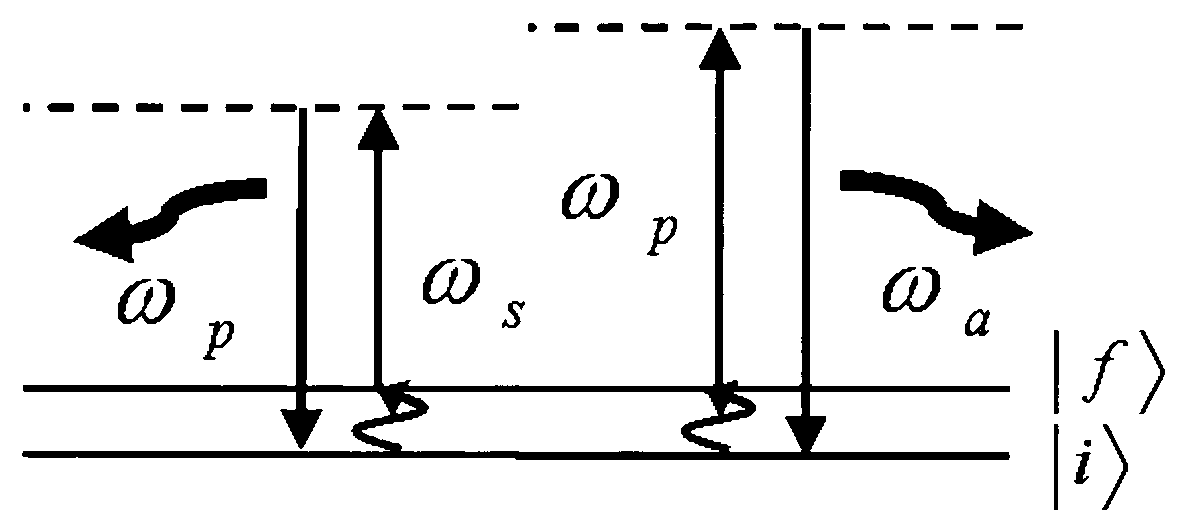

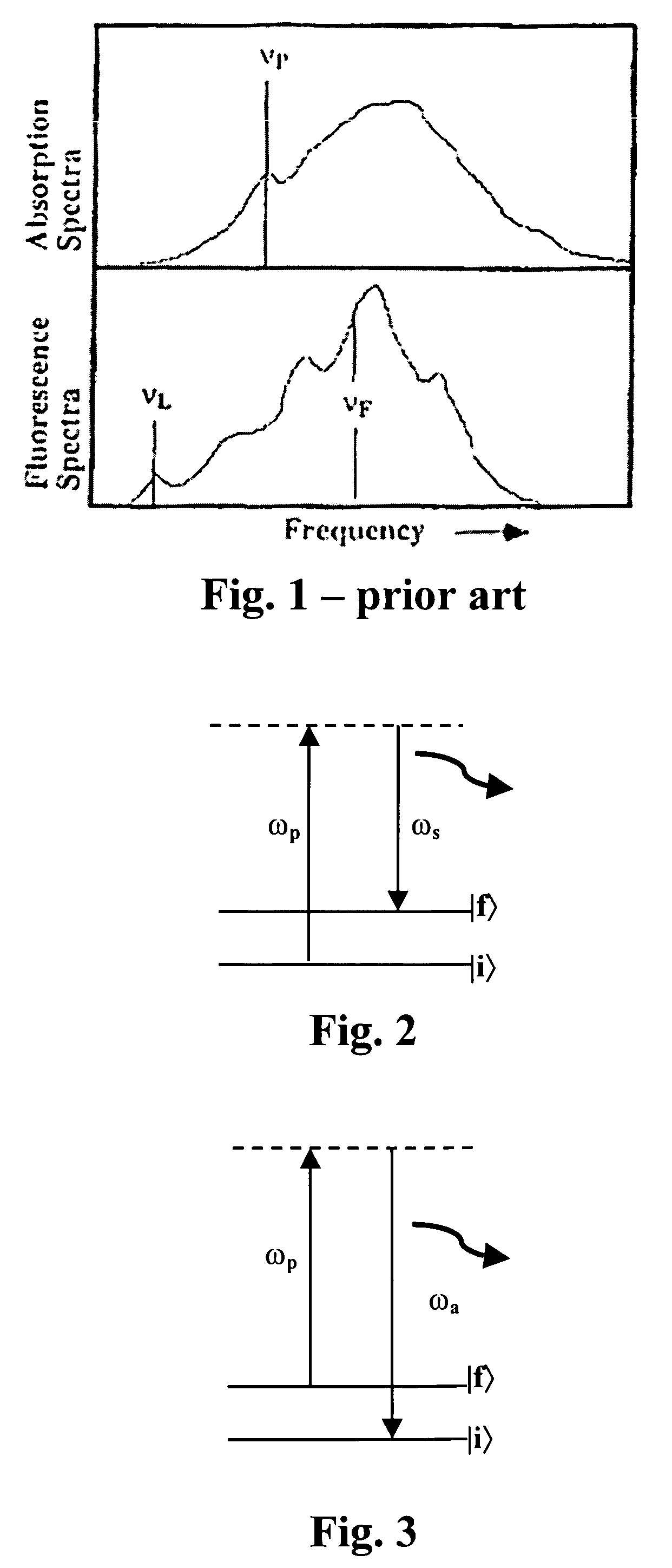

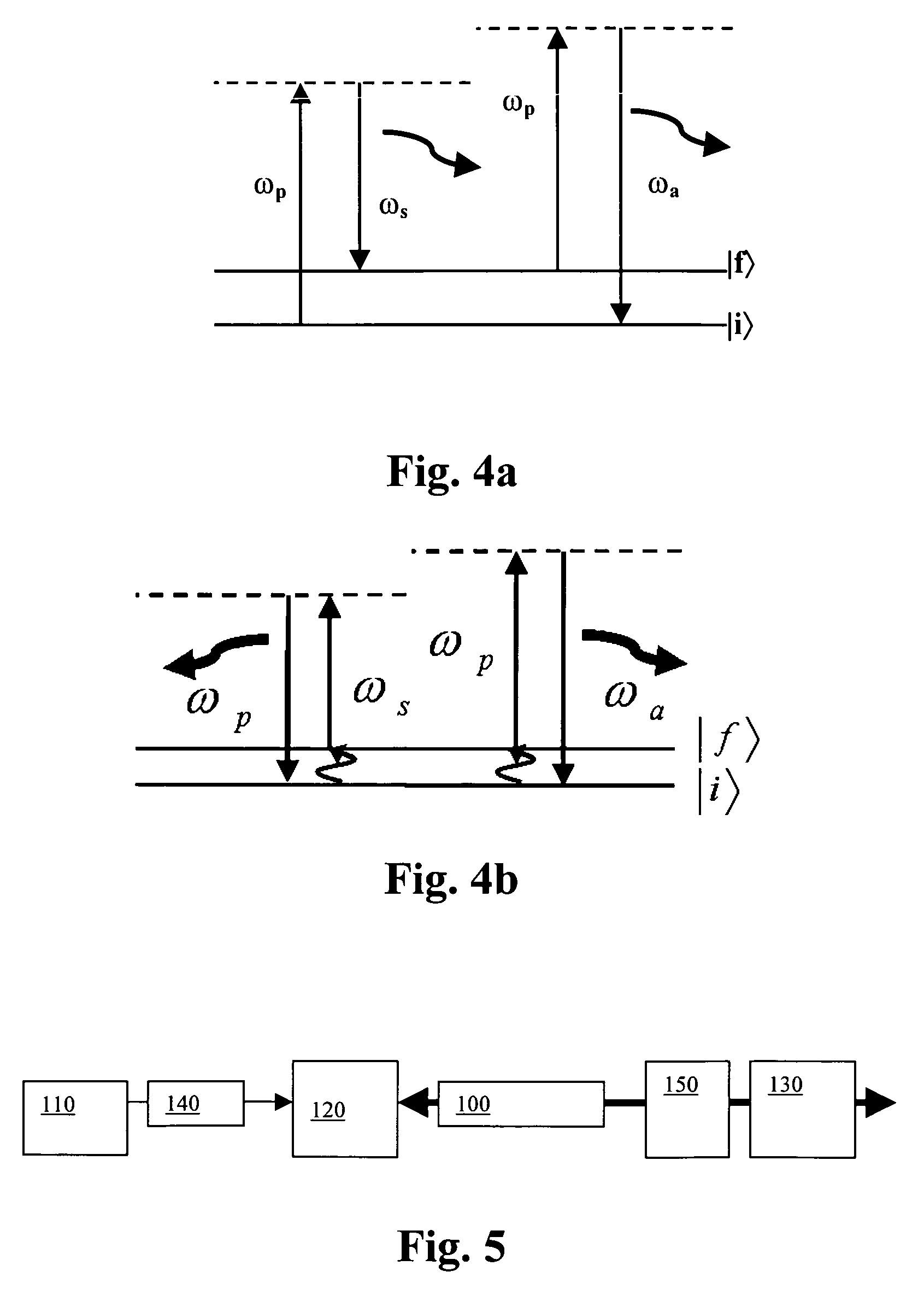

Cooling an active medium using raman scattering

InactiveUS20090052482A1Easy to combineMore homogenous temperature distributionLaser using scattering effectsLaser cooling arrangementsControl systemThermal control system

A method is described for setting up a system comprising an active medium. The method comprises thermally controlling the system comprising an active medium by radiative cooling. The radiative cooling thereby is based on stimulated and / or coherent Raman scattering processes. In particular embodiments, the thermally controlling may be obtained by tailoring the efficiencies of the Raman scattering processes by optimising at least one of a number of system parameters. The invention furthermore relates to systems thus obtained, to methods for thermally controlling systems comprising an active medium that generate radiation and to computer program products for performing the methods for setting up systems comprising an active medium and thermally controlled by radiative cooling using stimulated and / or coherent Raman scattering processes.

Owner:VRIJE UNIV BRUSSEL

Evaporative cooling air-conditioning system combining nocturnal radiation cooling technology and cold-accumulating technology

InactiveCN101936584AImprove efficiencyTake advantage ofLighting and heating apparatusSpace heating and ventilation detailsNuclear engineeringWater flow

The invention discloses an evaporative cooling air-conditioning system combining a nocturnal radiation cooling technology and a cold-accumulating technology. The vapor cooling air-conditioning system comprises a vapor cooling fresh air unit, a radiator, a high-temperature cooling water unit, a cold-accumulating water tank and a sensible heat terminal which are connected by a pipeline to form a loop, wherein a water collector and a water distributor are arranged to distribute water streams, and a triple valve is arranged in the pipeline to control the direction of the water streams. The vapor cooling air-conditioning system combines an evaporative cooling technology, a nocturnal radiation cooling technology and a cold-accumulating technology, sufficiently uses natural energy sources, reduces environmental pollution and saves energy sources.

Owner:XI'AN POLYTECHNIC UNIVERSITY

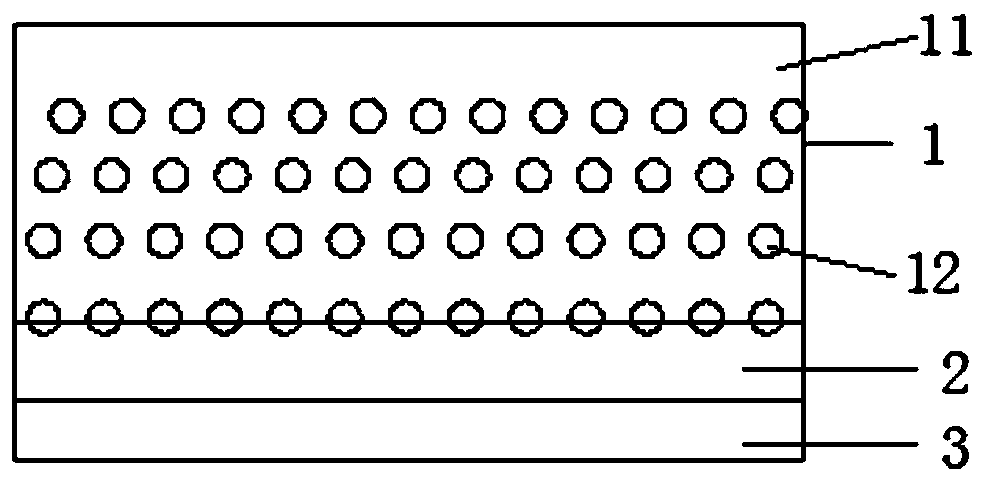

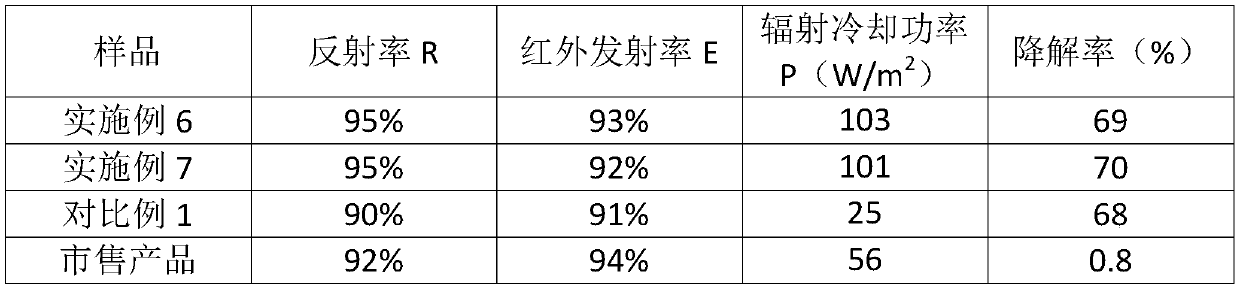

Radiative cooling film and production method and application thereof

PendingCN110744900AHigh transparencyHigh light transmittanceSynthetic resin layered productsFlat articlesEmissivityThin membrane

The invention relates to a radiative cooling film and a production method and application thereof. The radiative cooling film comprises a radiative cooling layer, a flat and smooth layer and a reflection layer which are sequentially arranged, wherein the radiative cooling layer comprises polylactic resin, cooling particles, a coupling agent and a light stabilizer, the surface, close to one side ofthe flat and smooth layer, of the radiative cooling layer is uneven, the flat and smooth layer and the radiative cooling layer fit closely, and the surface, close to one side of the reflection layer,of the flat and smooth layer is flat and smooth. According to the radiative cooling film and the production method and application thereof, the radiative cooling layer and the flat and smooth layer are produced by means of a casting and co-extrusion technology, and the reflection layer is produced by means of vacuum evaporation aluminizing; and the mean reflectance of the radiative cooling film in all the wave bands of 300-2500 nanometers is equal to or larger than 95%, the infrared emitting ability E in the wave band of 8-13 micrometers is equal to or larger than 92%, radiative cooling powerP in direct sunlight is equal to or larger than 100 W / m<2>, a product has degradation performance, and a degradation rate, measured by soil burial experiment, of the product can reach 69%.

Owner:厦门银蚁新能源科技有限公司

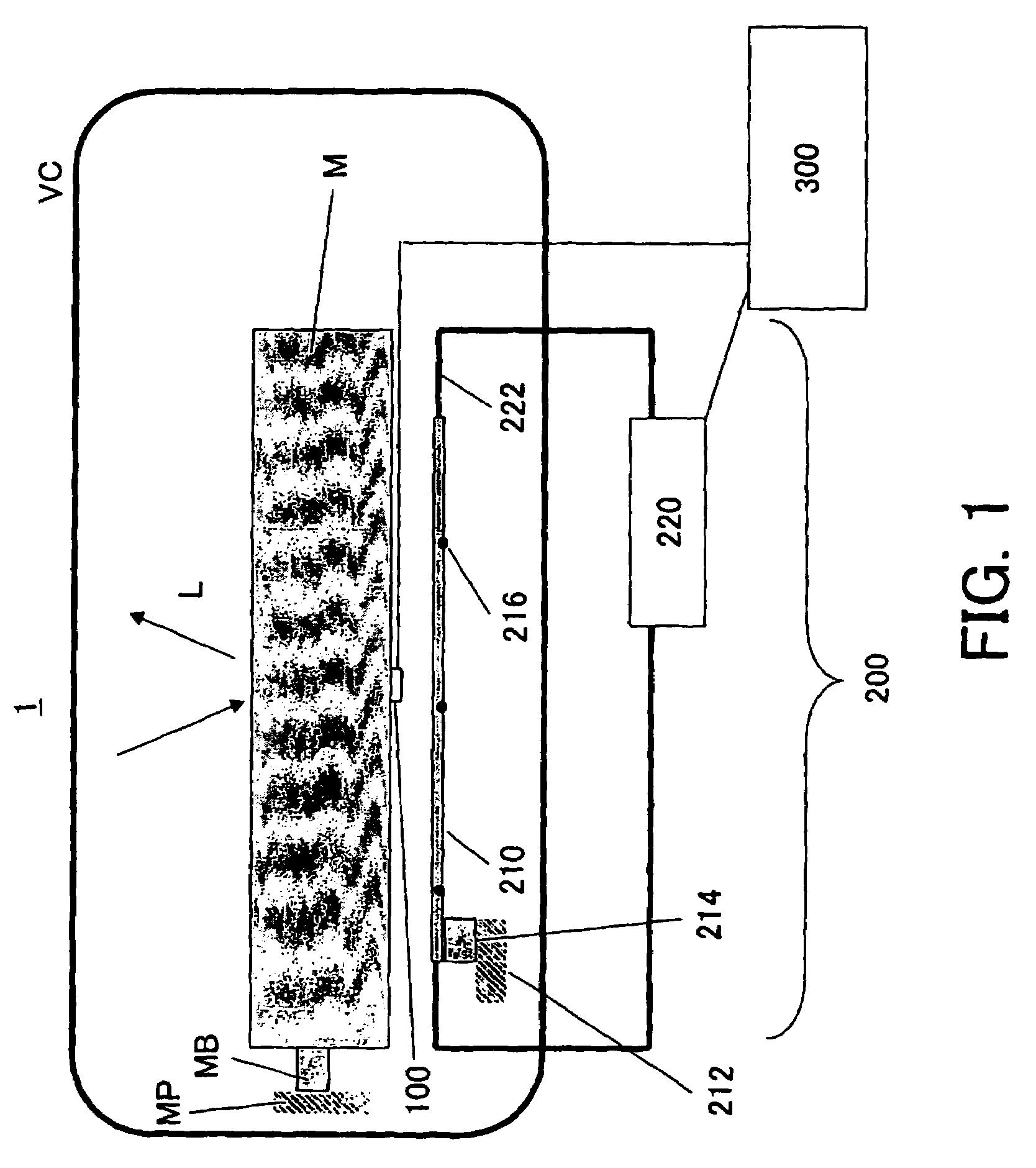

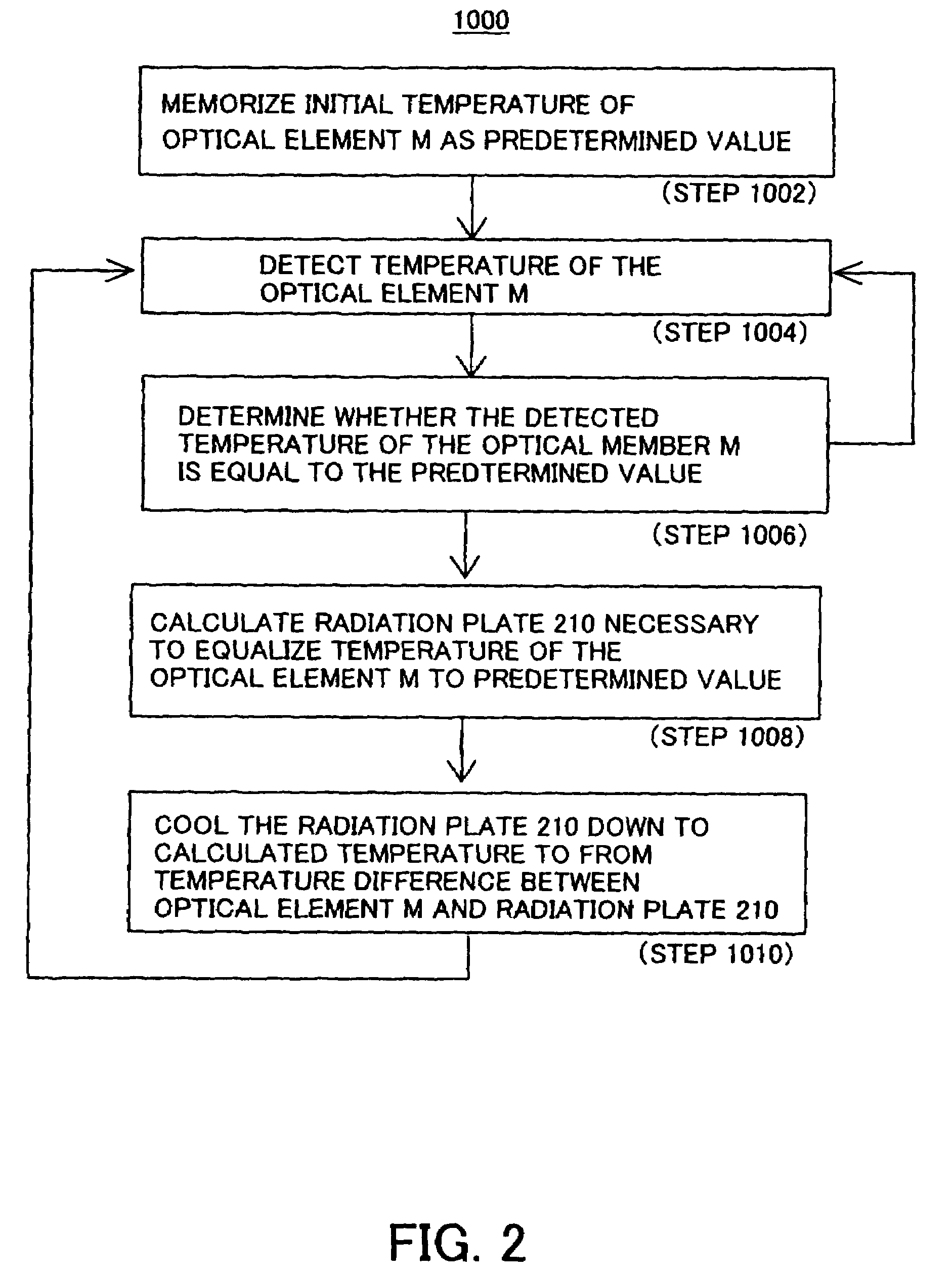

Cooling apparatus and method, and exposure apparatus having the cooling apparatus

InactiveUS7191599B2Reduce distortionMachines using electric/magnetic effectsPhotomechanical exposure apparatusEngineeringRadiant heat transfer

A cooling apparatus for cooling an optical element provided in a vacuum atmosphere includes a radiational cooling part, arranged apart from the optical element, for cooling the optical element by radiation heat transfer, and a controller for controlling temperature of the radiation cooling part.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com