Patents

Literature

909 results about "Thermal control system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Control System (large) Deployed. The large Thermal Control System is a deployable radiator used to dissipate waste heat into space (and atmosphere), pumping it out of hot parts anywhere on the craft, consuming an amount of electric charge (30 per minute)..

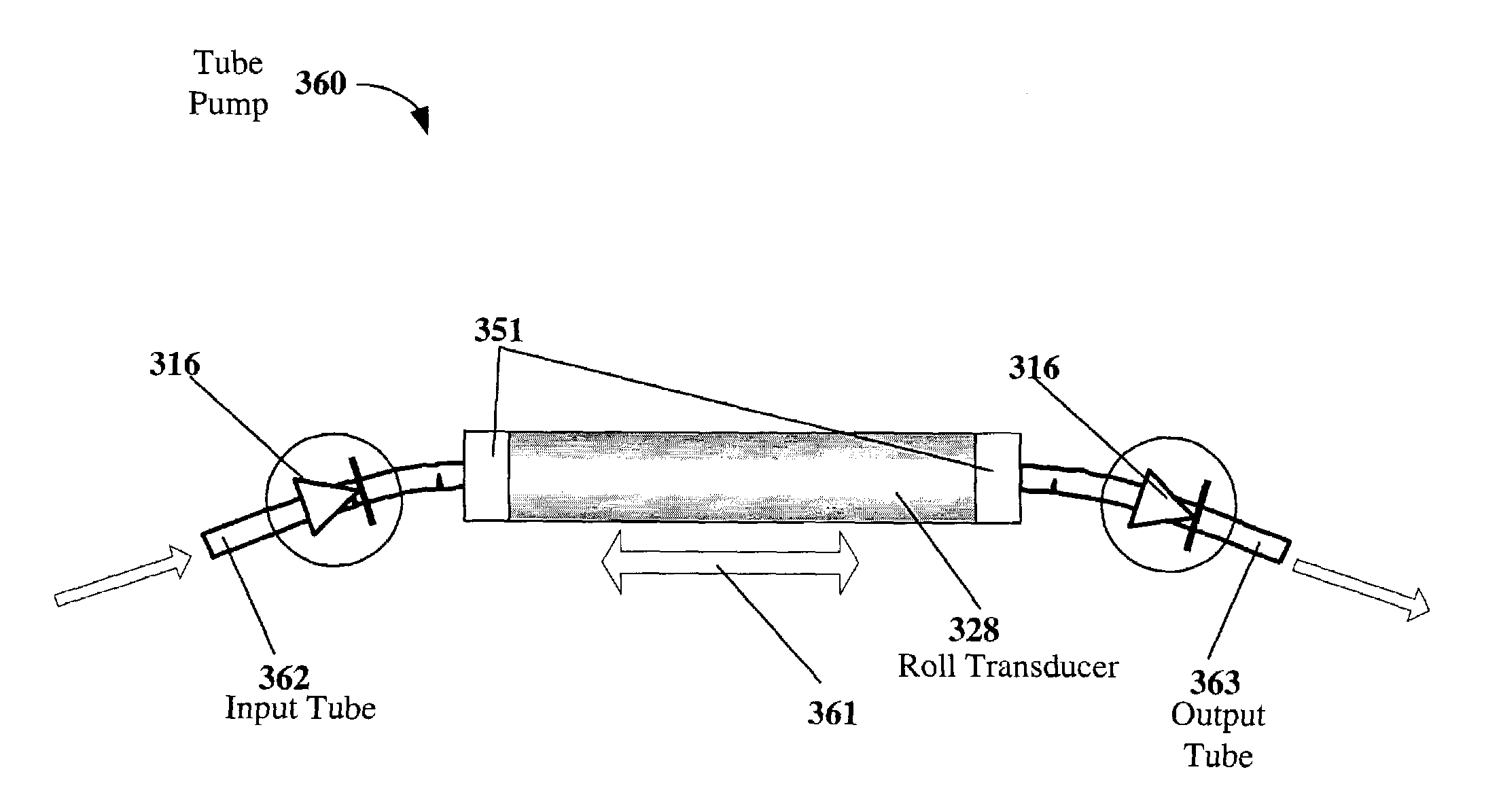

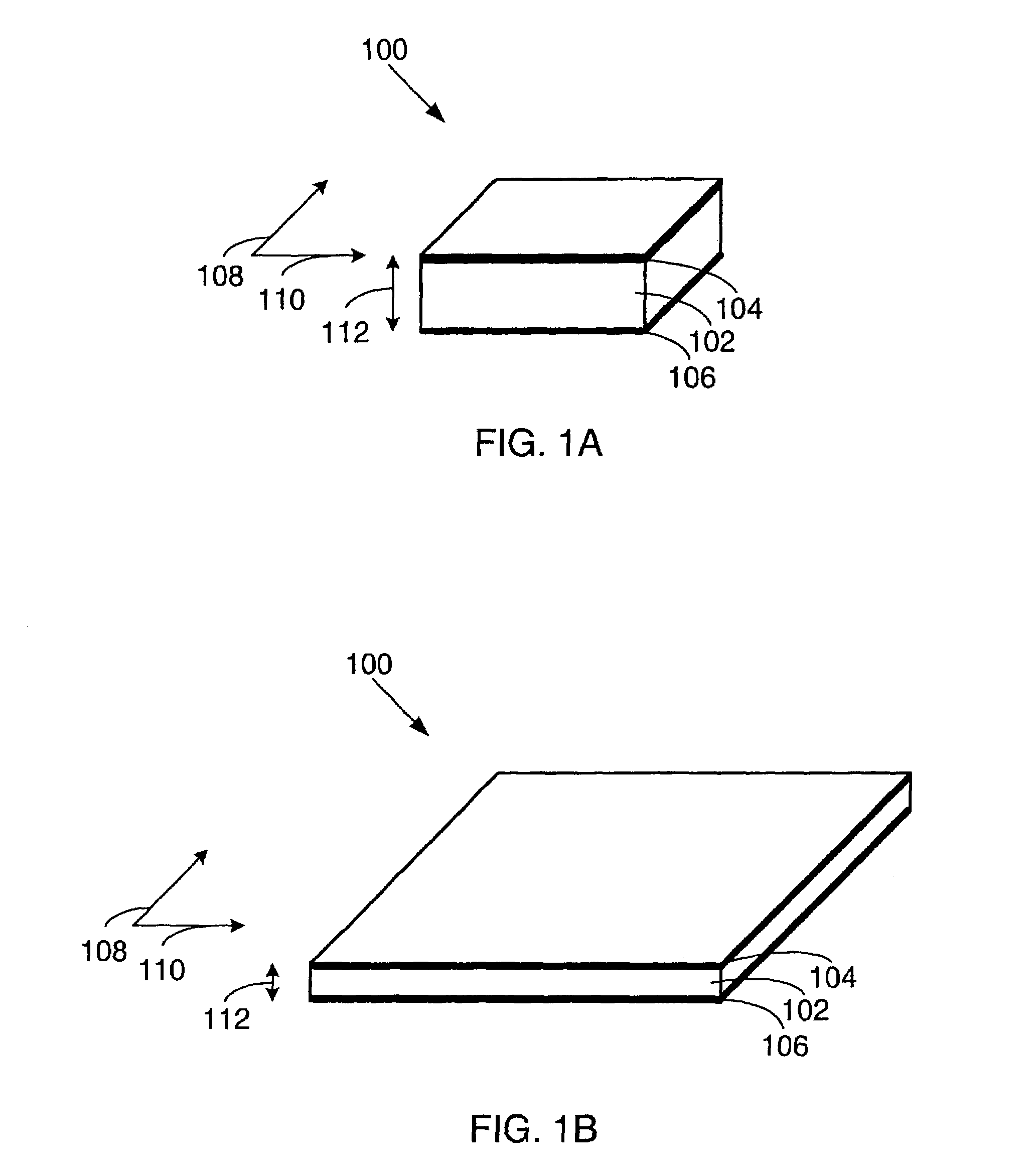

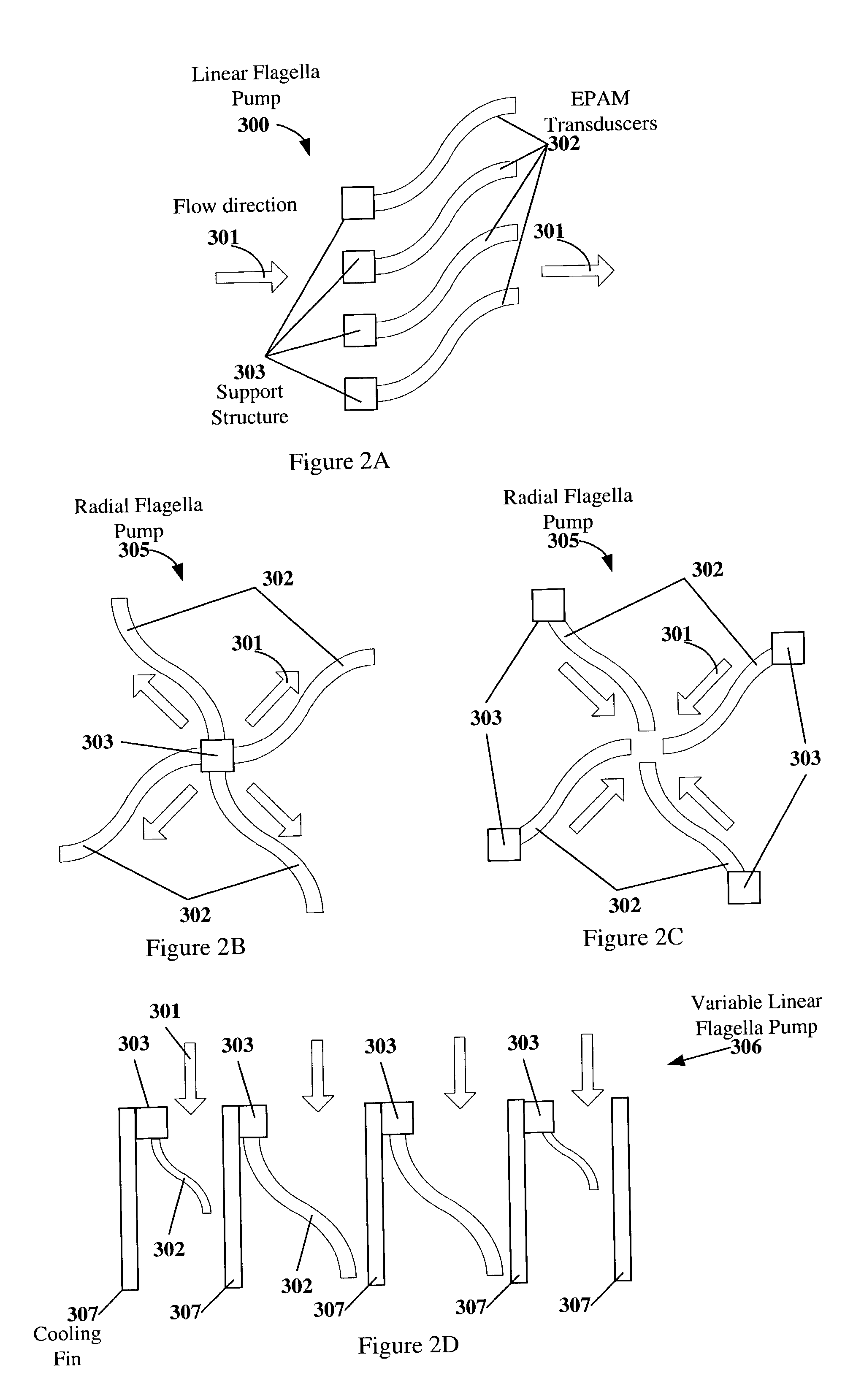

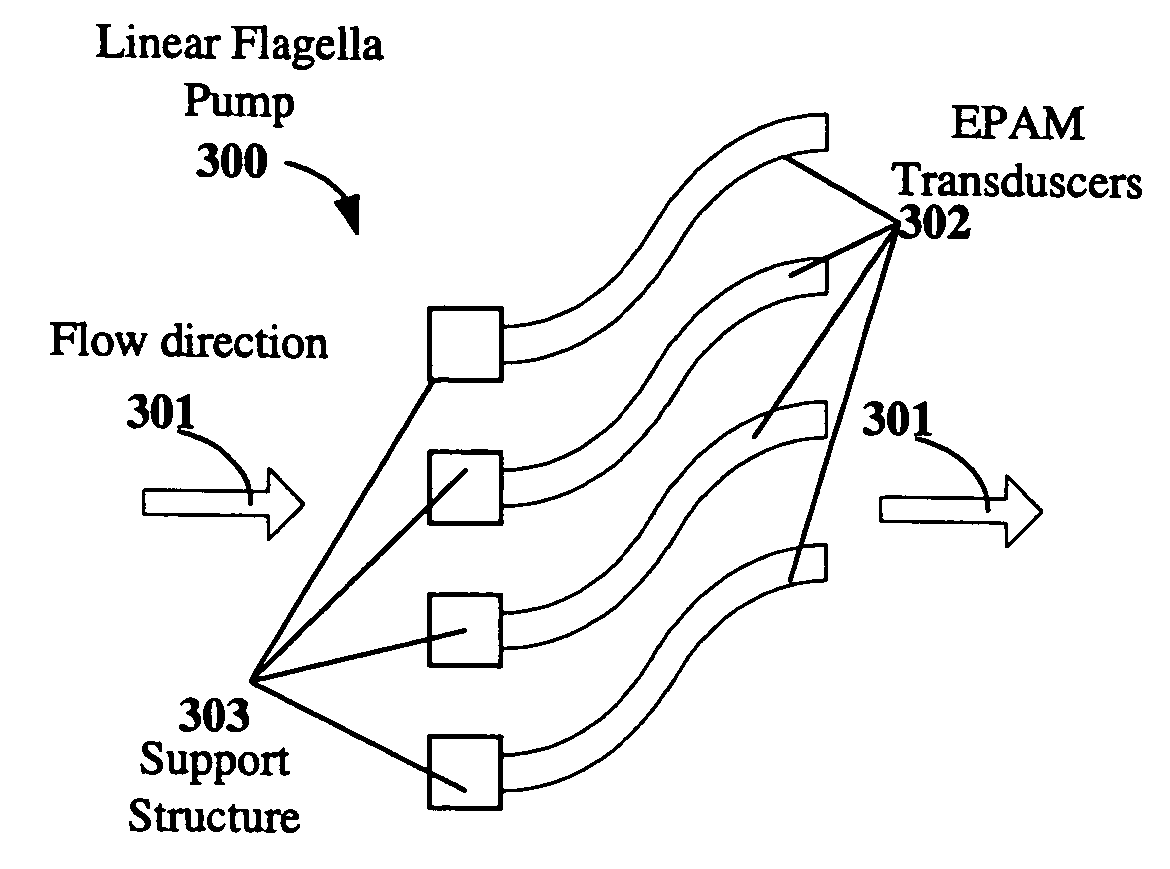

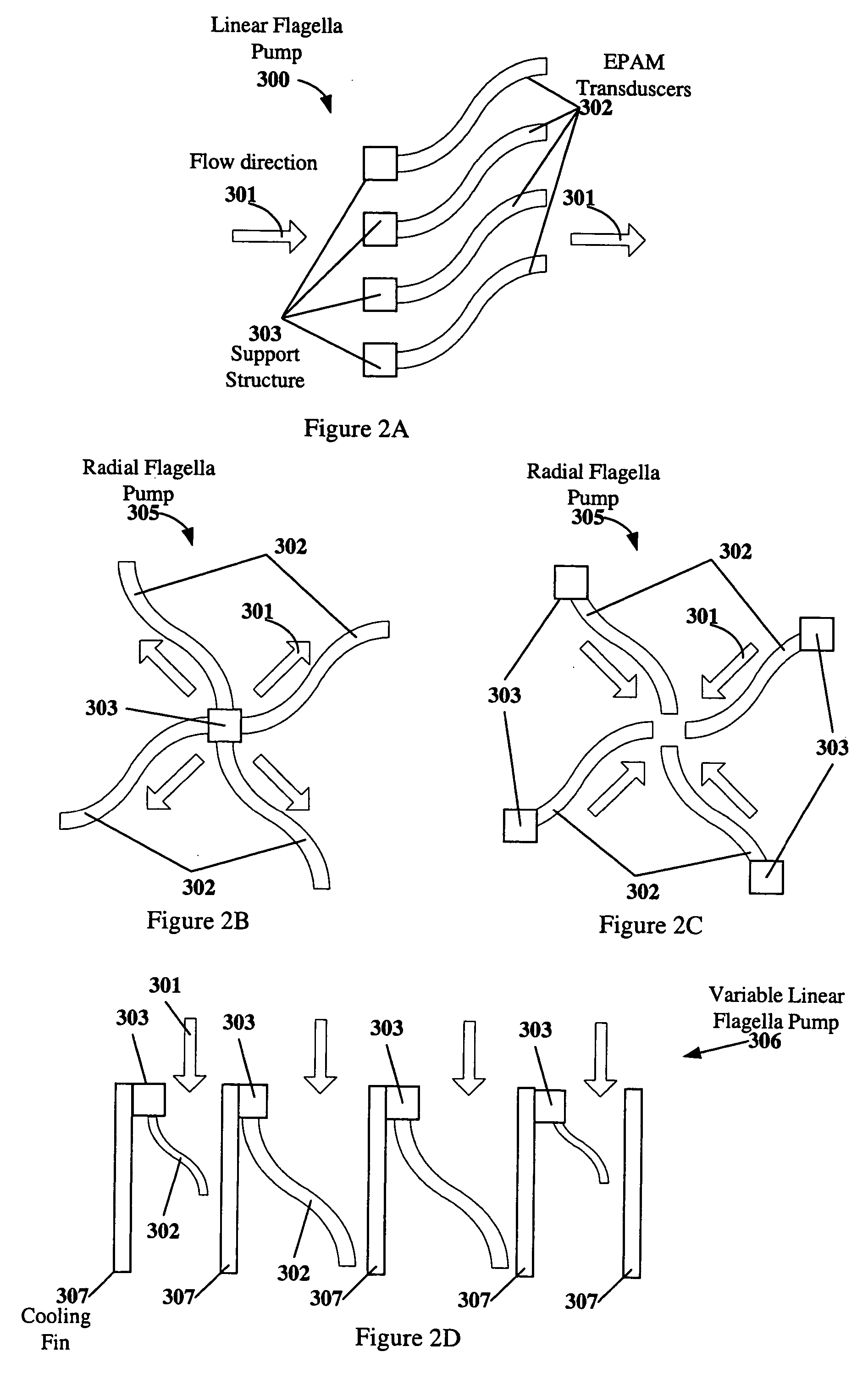

Electroactive polymer devices for moving fluid

InactiveUS7064472B2Improve mechanical responseImprove responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

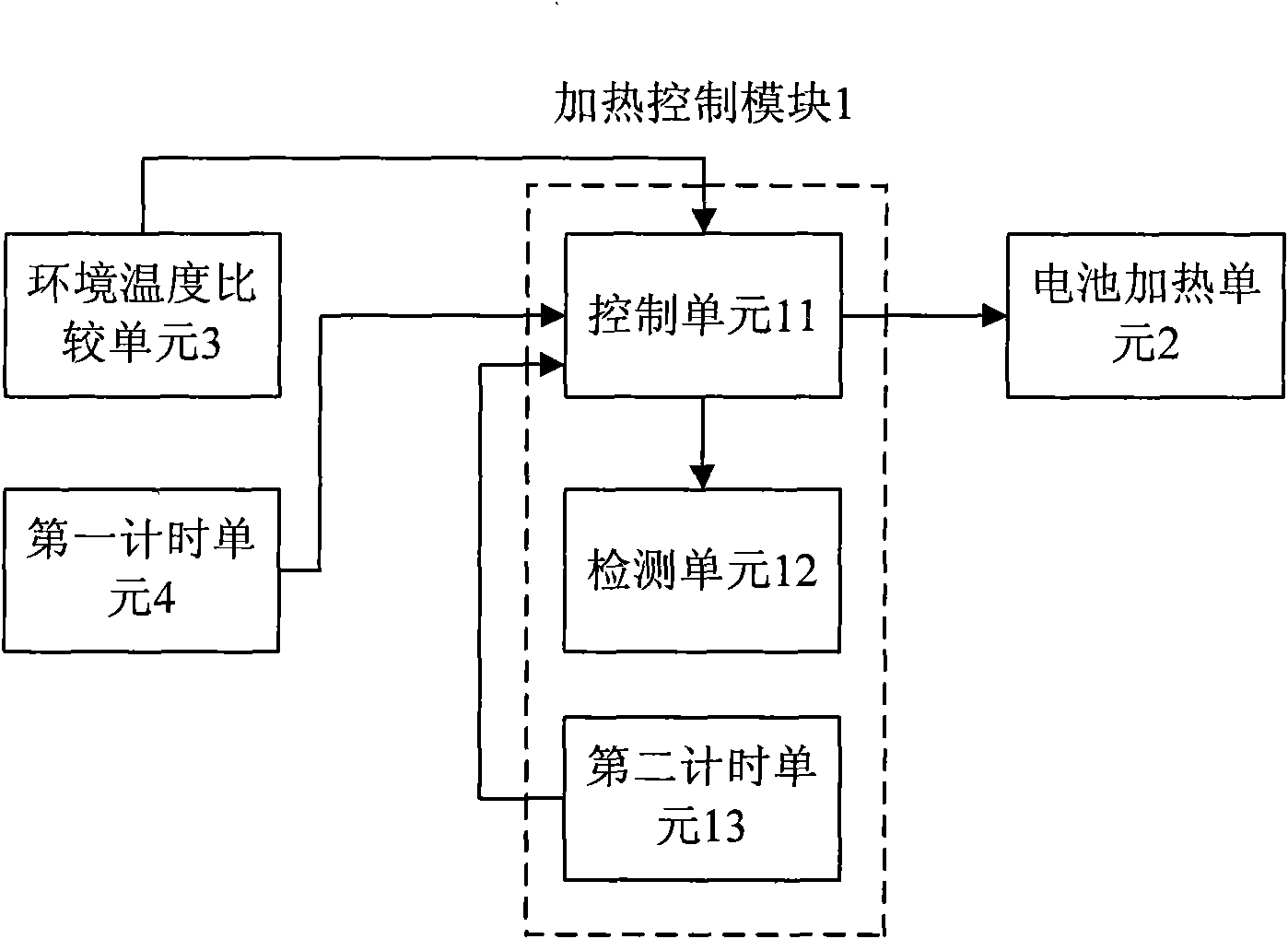

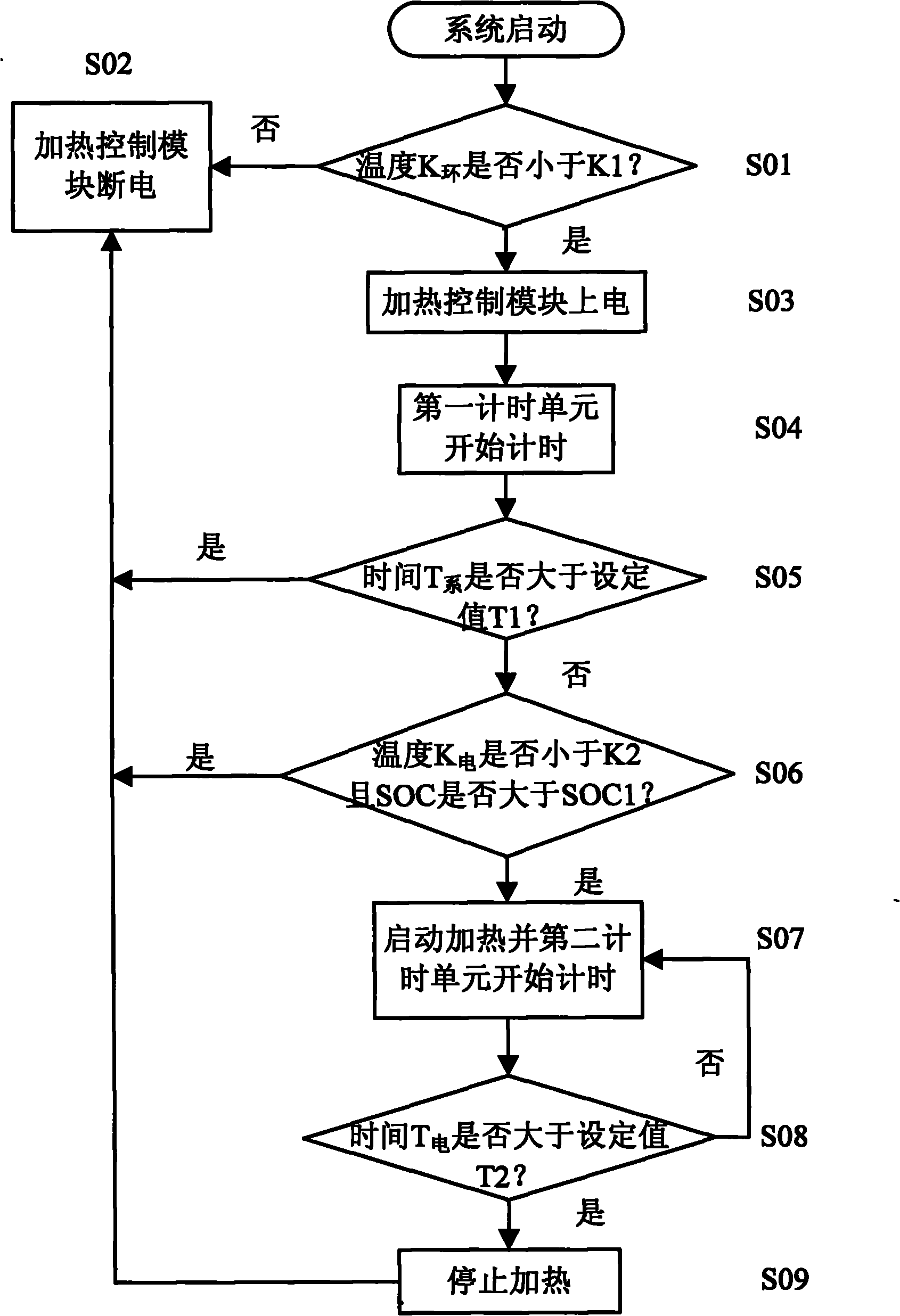

Battery heating control system for vehicles and control method thereof

ActiveCN102055042AGuaranteed charge and discharge performanceWill not harmSecondary cellsBattery state of chargeElectricity

The invention provides a battery heating control system for vehicles and a control method thereof. The battery heating control system comprises a heating control module and a battery heating unit; the heating control module is electrically connected with the battery heating unit; the battery heating unit is used for heating a battery; the heating control module is used for starting the heating ofthe battery by the battery heating unit when the condition of heating starting is met and stopping the heating of the battery by the battery heating unit when the condition of heating stop is met, wherein the starting of the battery heating unit meets the following conditions simultaneously that: the ambient temperature K ambient of the system reaches a temperature set value K1; the battery temperature K battery reaches a temperature set value K2; and the battery state of charge (SOC) reaches a set value SOC1 of the battery SOC. The battery heating control system for the vehicles and the control method can better protect the battery.

Owner:BYD CO LTD

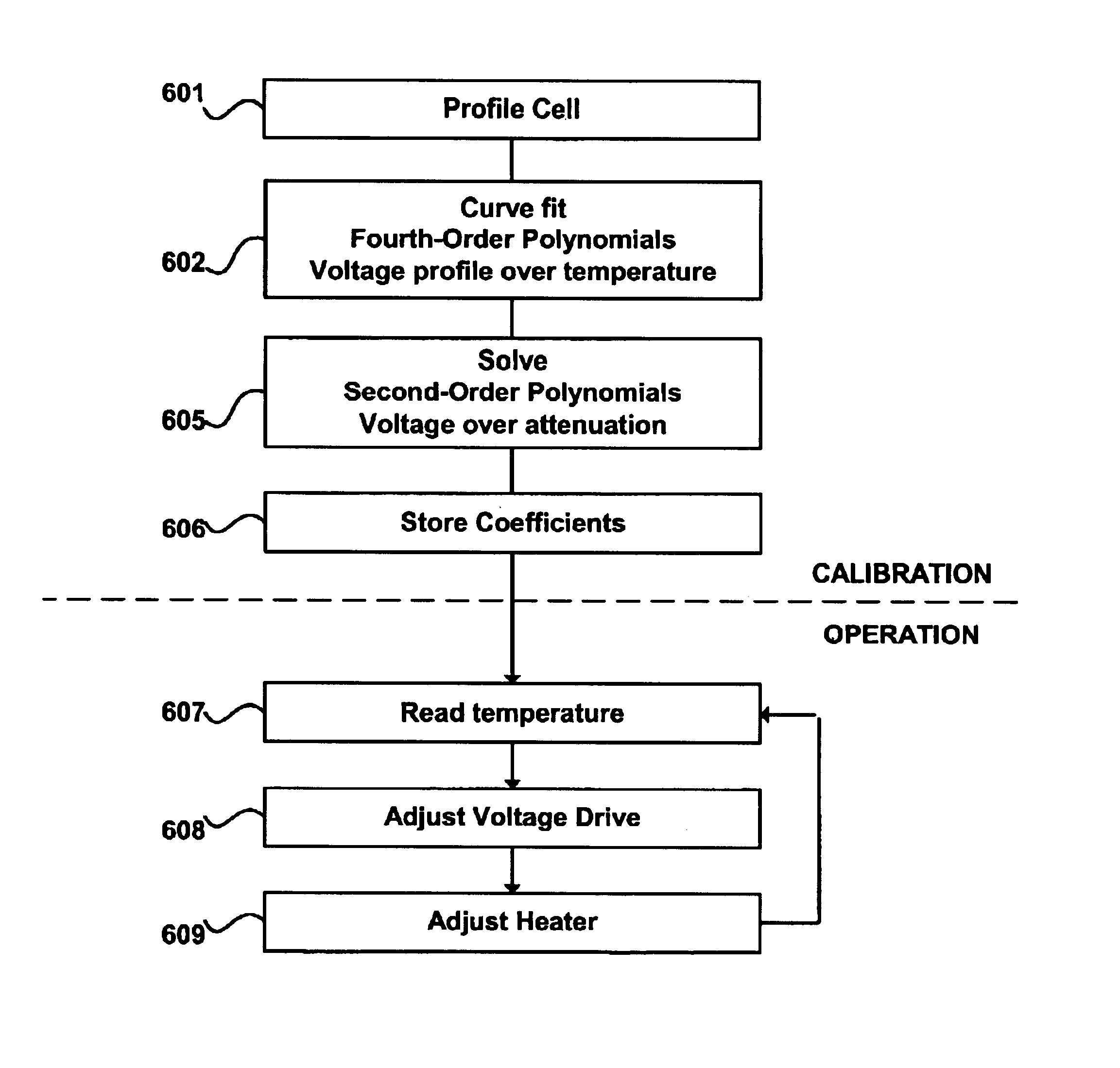

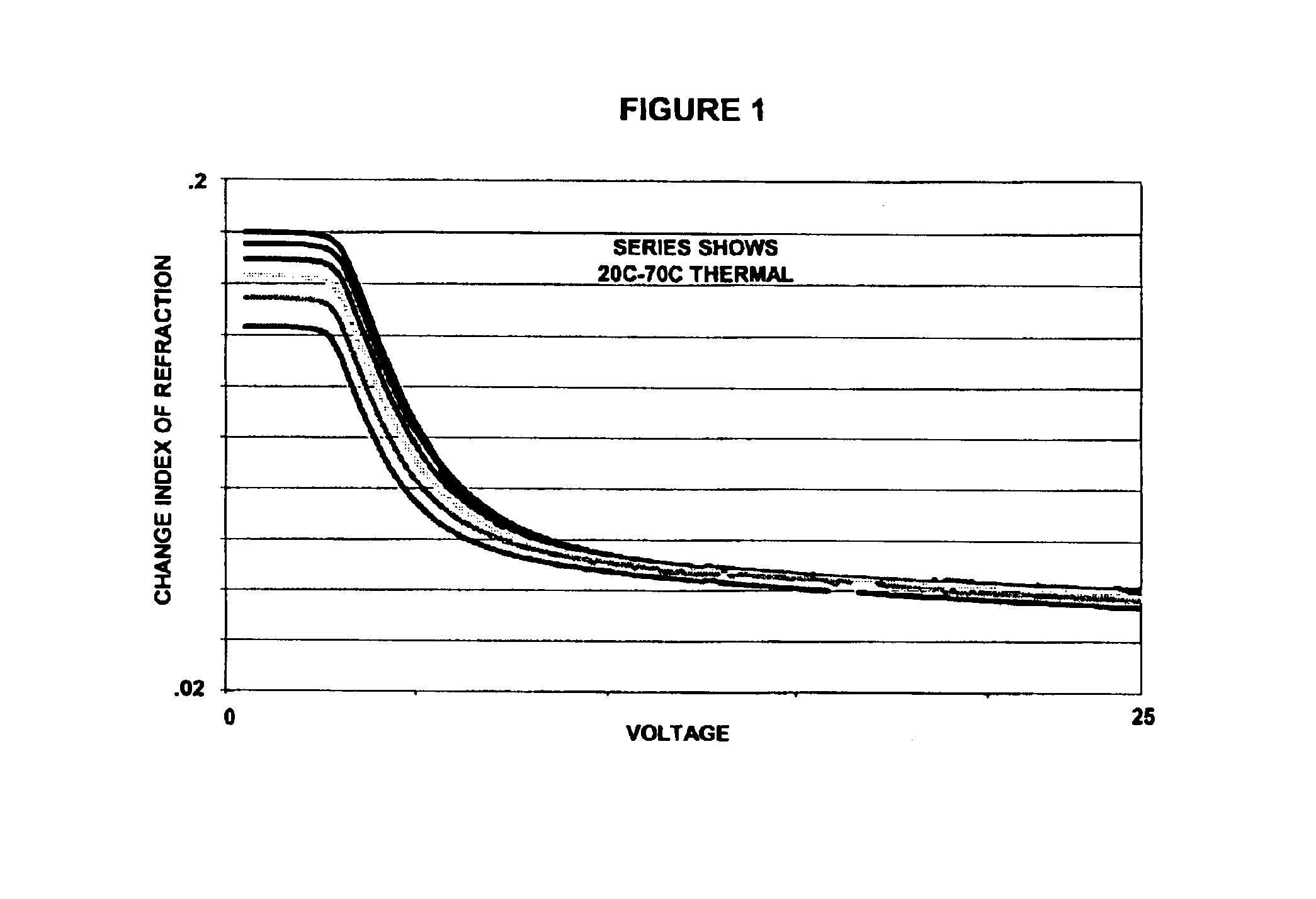

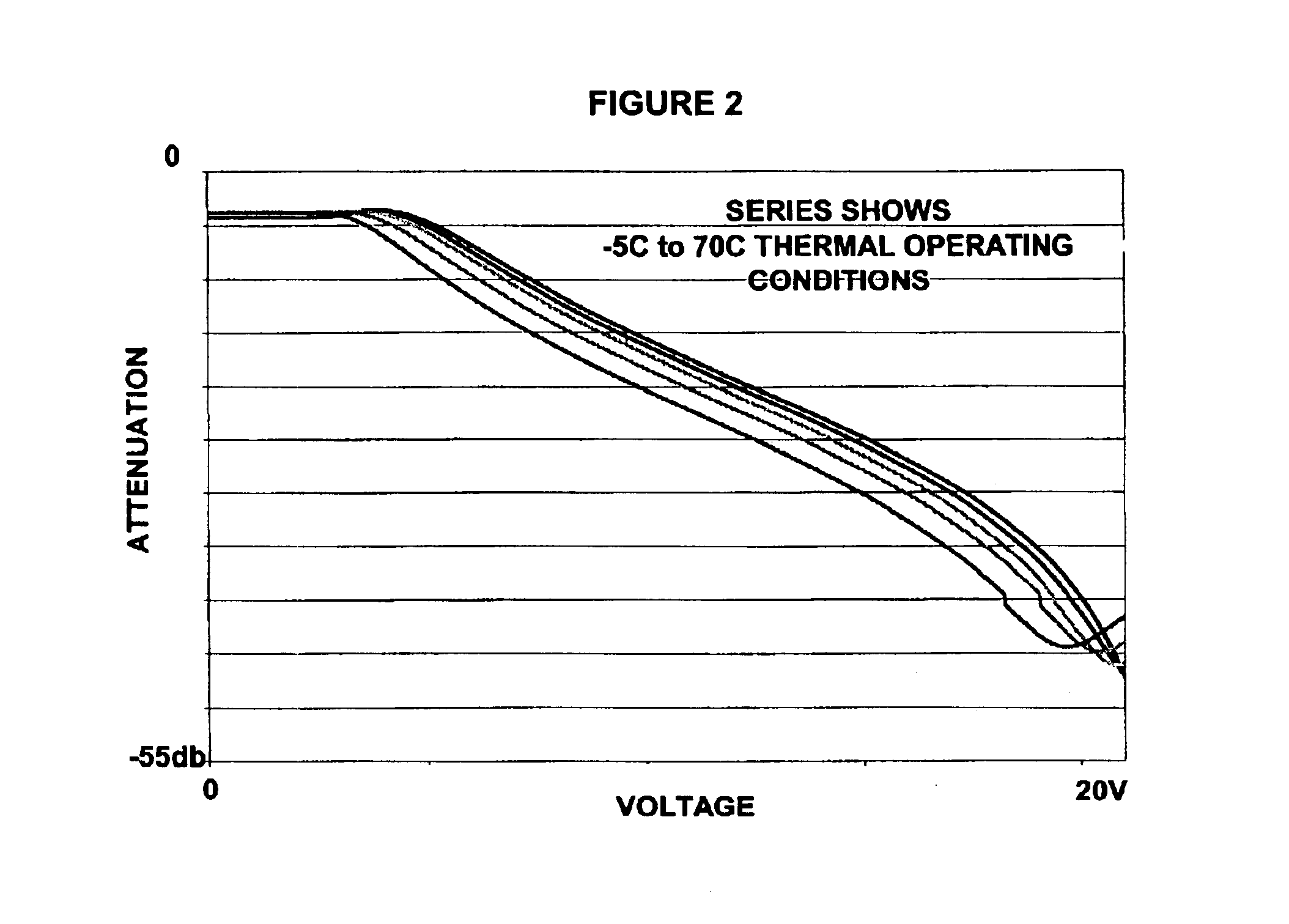

Thermal control system for liquid crystal cell

A thermal control system for a liquid crystal cell is presented that may utilize a time division scheme to multiplex temperature sensing and heating functions across active thermal elements such that the cell may generally be kept at a constant temperature. A calibration process characterizes the profile of the cell and generates a polynomial regression formula that provides the voltage drive output for a temperature and cell state input. The control system stores the state of the liquid crystal cell, the regression formula, and reads the temperature of the liquid crystal cell to compute end assert the temperature compensated voltage drive.

Owner:II VI DELAWARE INC

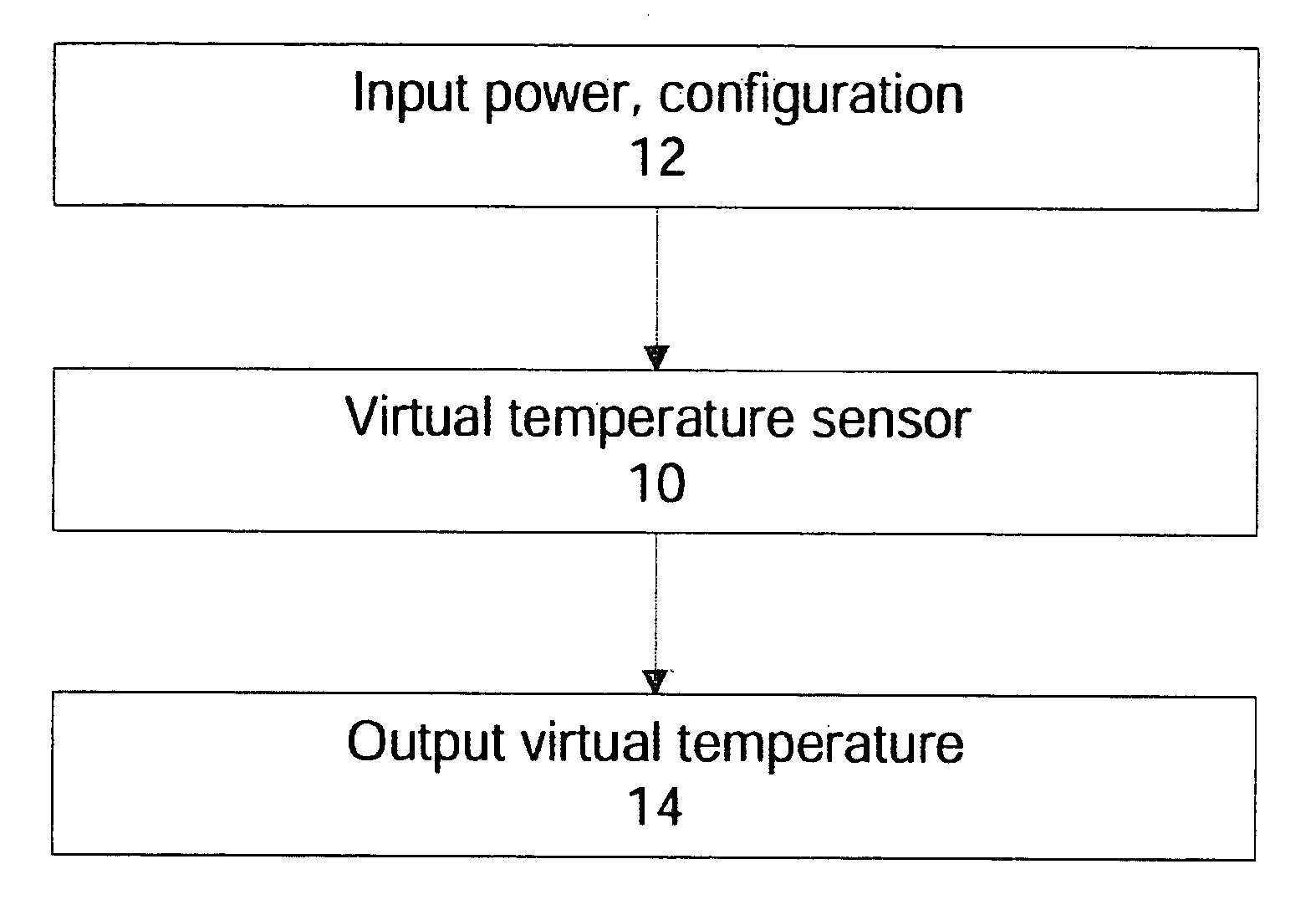

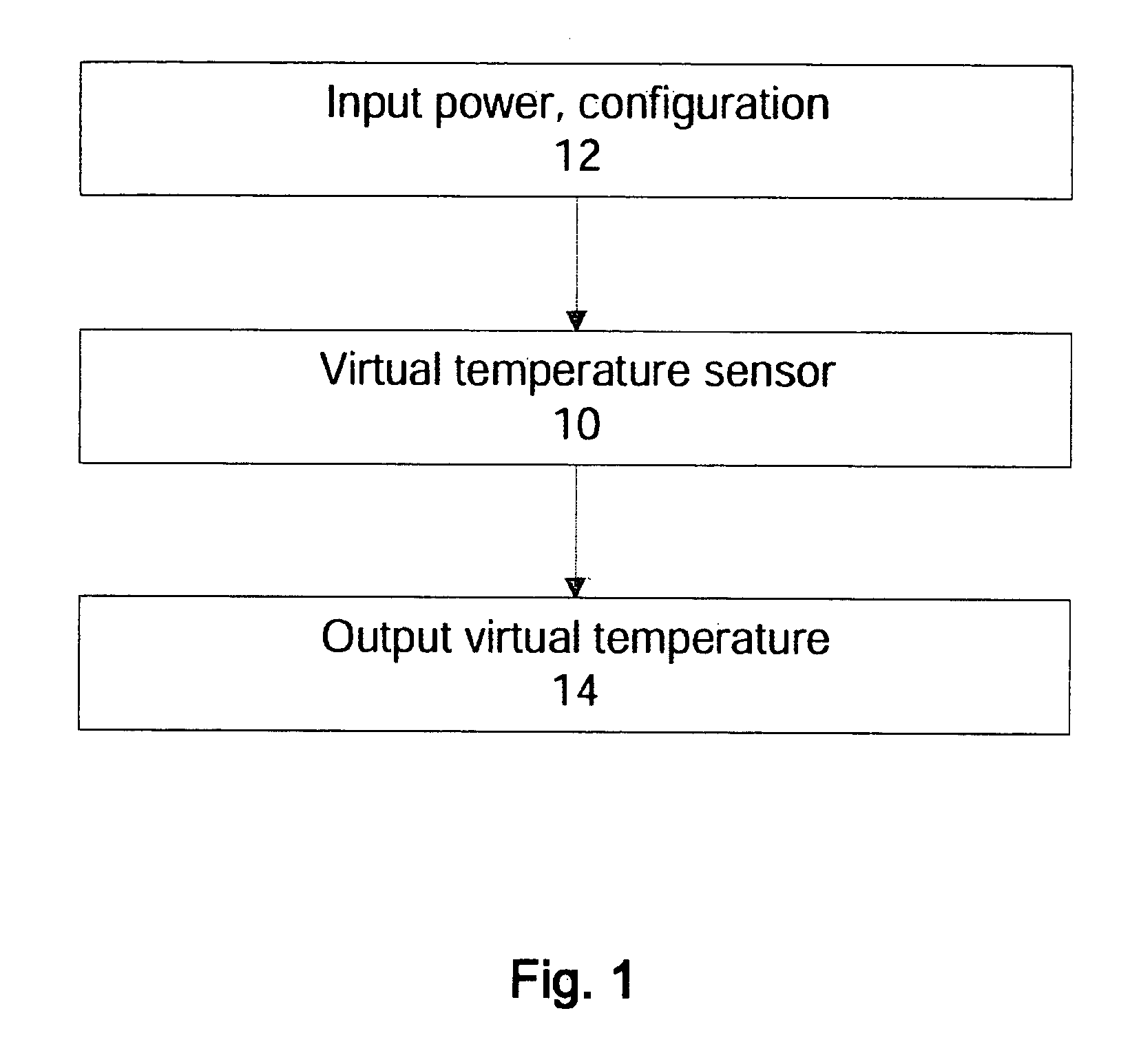

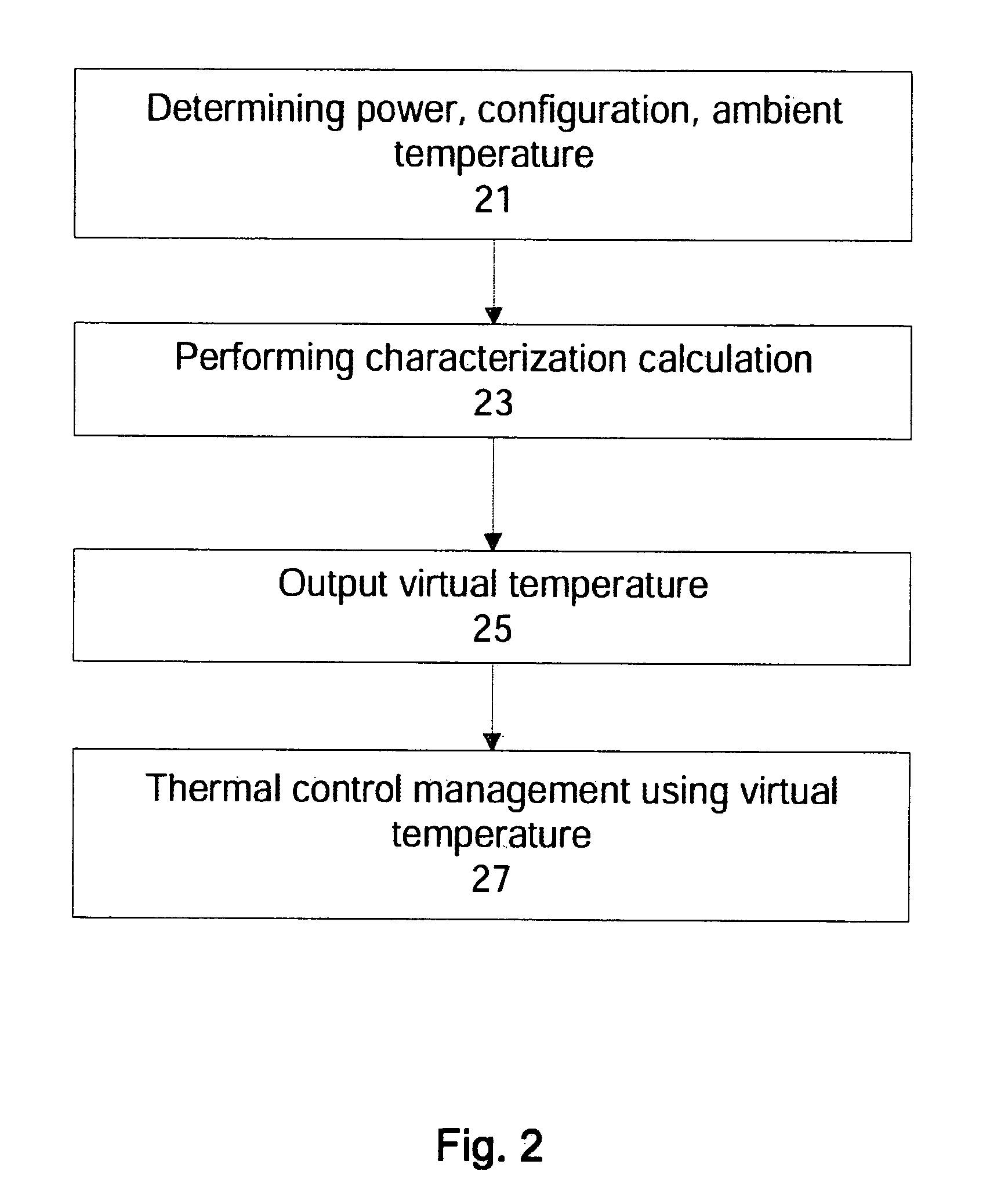

Method and apparatus for a thermal control system based on virtual temperature sensor

ActiveUS20080028778A1Energy efficient ICTDigital data processing detailsMathematical modelSystem configuration

Methods and apparatuses for providing virtual temperature sensor to control temperatures in a data processing system. In one aspect, a data processing system includes a virtual temperature sensor to provide system temperature for different system configurations, and a controller coupled to the sensor to control operations of the data processing system according to the virtual temperature. The virtual temperature sensor typically derives the temperature of a particular configuration of the data processing system using mathematical models or one or more operating parameters of the data processing system. In one example, the mathematical models include a characterization table which provides the measured temperature data from various system configurations. These measurements are performed with temperature sensors positioned in ideal locations for different configuration, and are preprocessed to provide the virtual temperature computation. The characterization table also includes thermal characteristics, such as thermal time constant and thermal resistance, of the critical components at multiple thermal control states.

Owner:APPLE INC

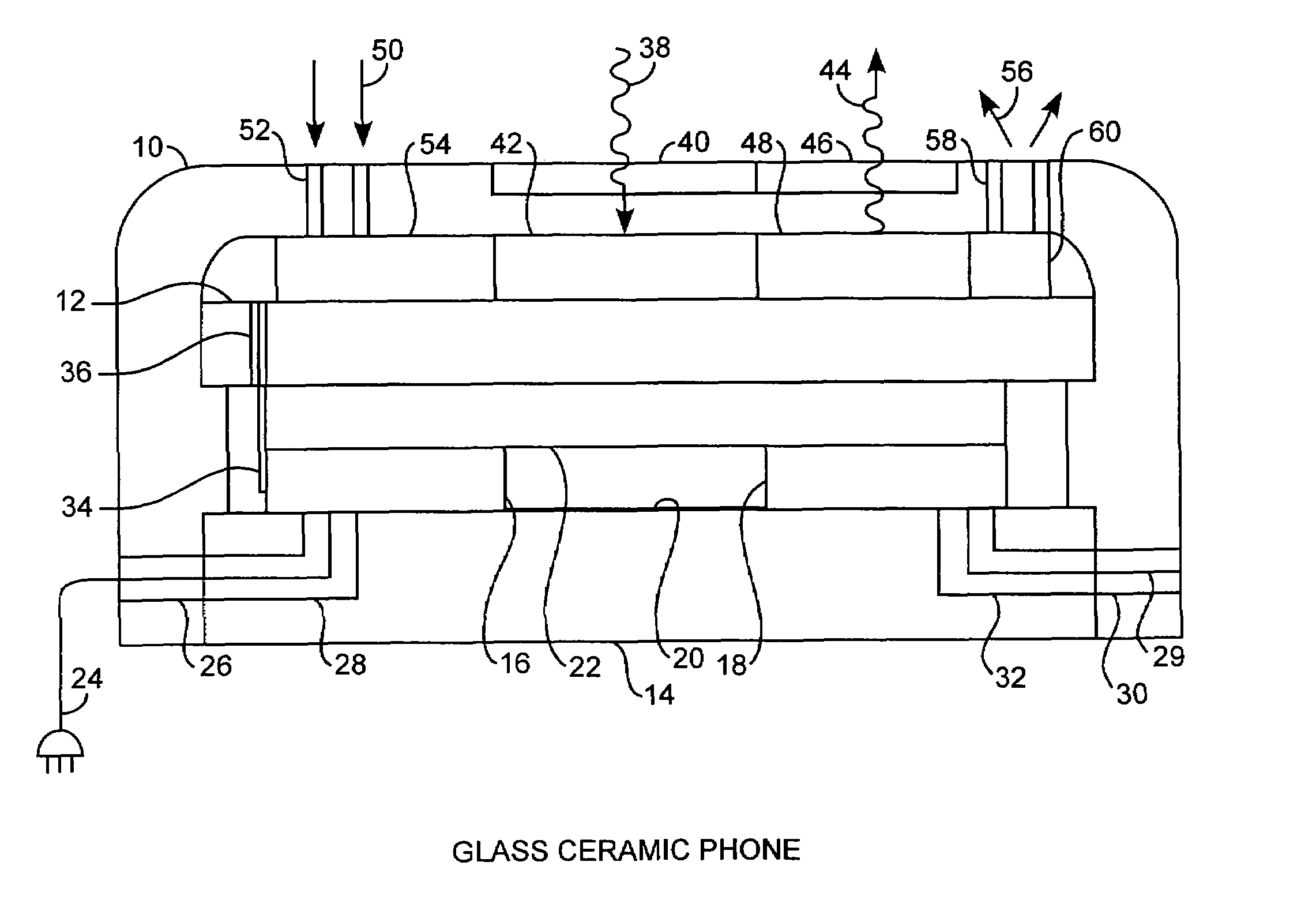

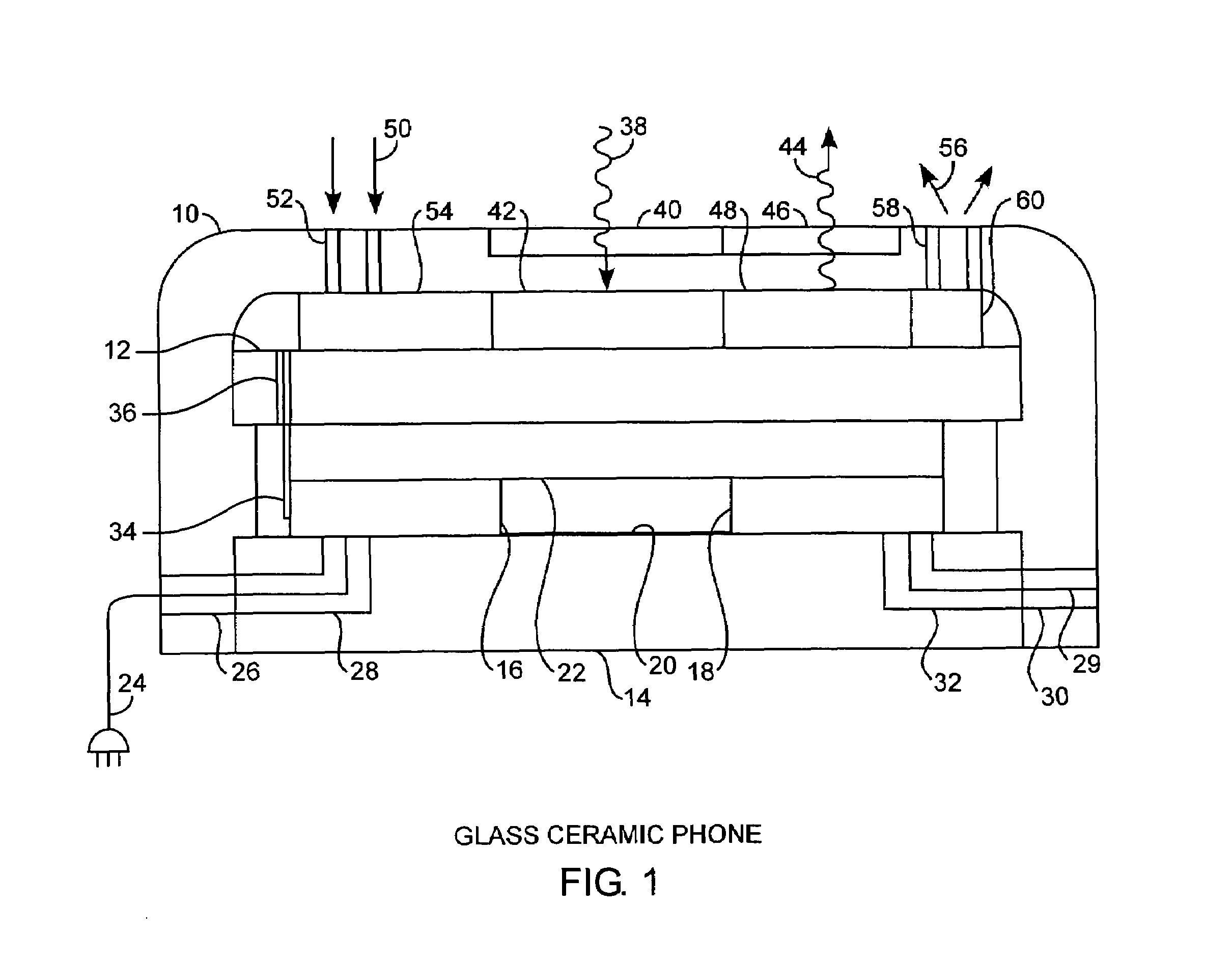

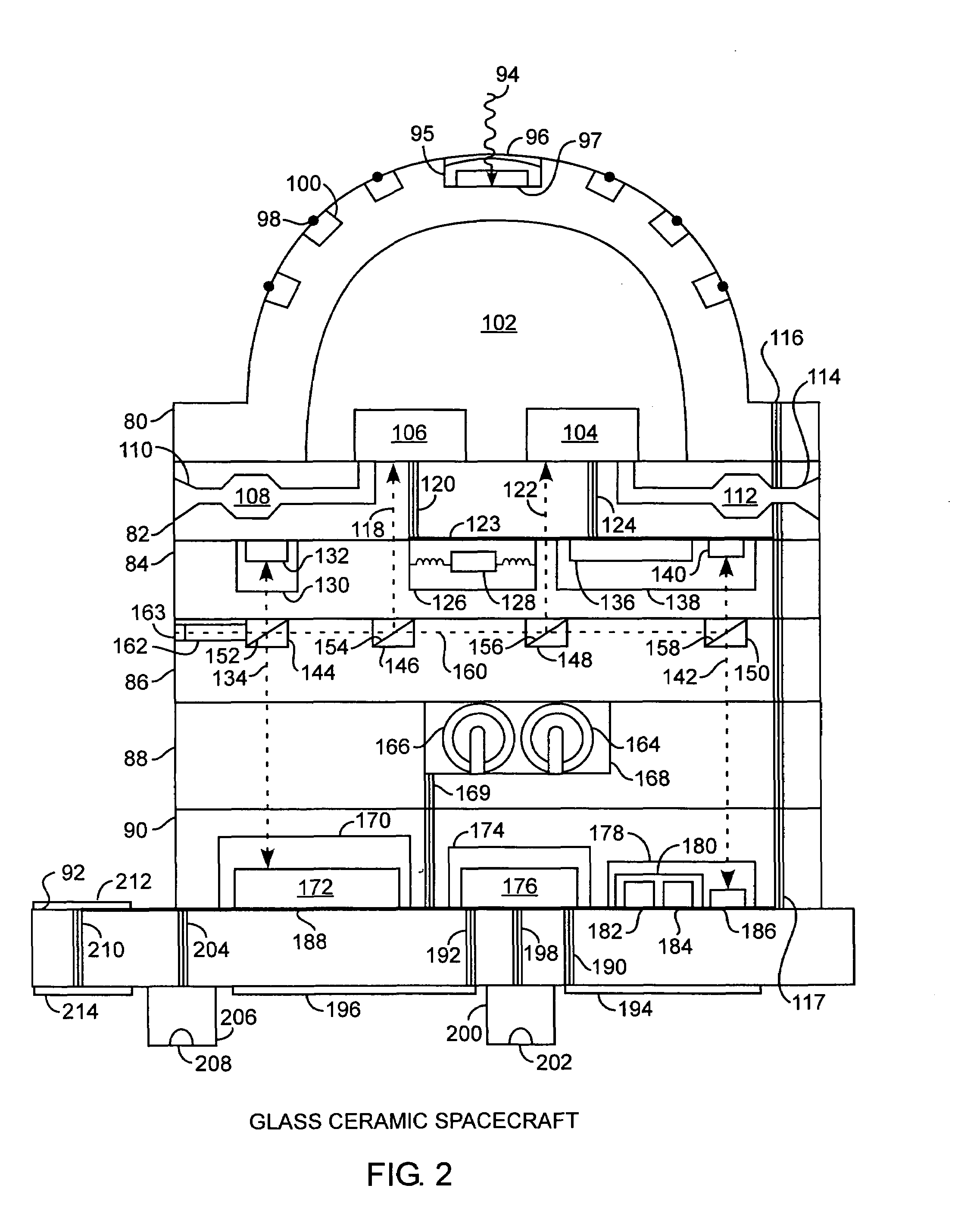

Integrated glass ceramic systems

ActiveUS6952530B2Improve structural strengthLow thermal conductivityCosmonautic propulsion system apparatusCosmonautic power supply systemsElectricityOptical communication

Integrated glass ceramic spacecraft include a plurality of glass ceramic components including molded, tempered, annealed, and patterned glass ceramic components coupled together for forming a support structure or frame or housing through which is communicated optical signals through an optical communications grid and electrical signals through an electrical communications grid, with the optical communications grid and electrical communication grid forming a composite electrooptical communications grid for spacecraft wide intercommunications. The support structure multifunctions as a frame, a housing, a support, a thermal control system, and as part of an electrooptical communications grid while encapsulating a plurality of optical, electronic, electrical, and MEMS devices between which is communicated the electrical and optical signals over the electrooptical communication grid.

Owner:THE AEROSPACE CORPORATION

Electroactive polymer devices for moving fluid

InactiveUS20060158065A1Improve responseTransducer detailsFlexible member pumpsHearing rangeThermal force

The invention describes devices for performing thermodynamic work on a fluid, such as pumps, compressors and fans. The thermodynamic work may be used to provide a driving force for moving the fluid. Work performed on the fluid may be transmitted to other devices, such as a piston in a hydraulic actuation device. The devices may include one or more electroactive polymer transducers with an electroactive polymer that deflects in response to an application of an electric field. The electroactive polymer may be in contact with a fluid where the deflection of the electroactive polymer may be used to perform thermodynamic work on the fluid. The devices may be designed to efficiently operate at a plurality of operating conditions, such as operating conditions that produce an acoustic signal above or below the human hearing range. The devices may be used in thermal control systems, such as refrigeration system, cooling systems and heating systems.

Owner:SRI INTERNATIONAL

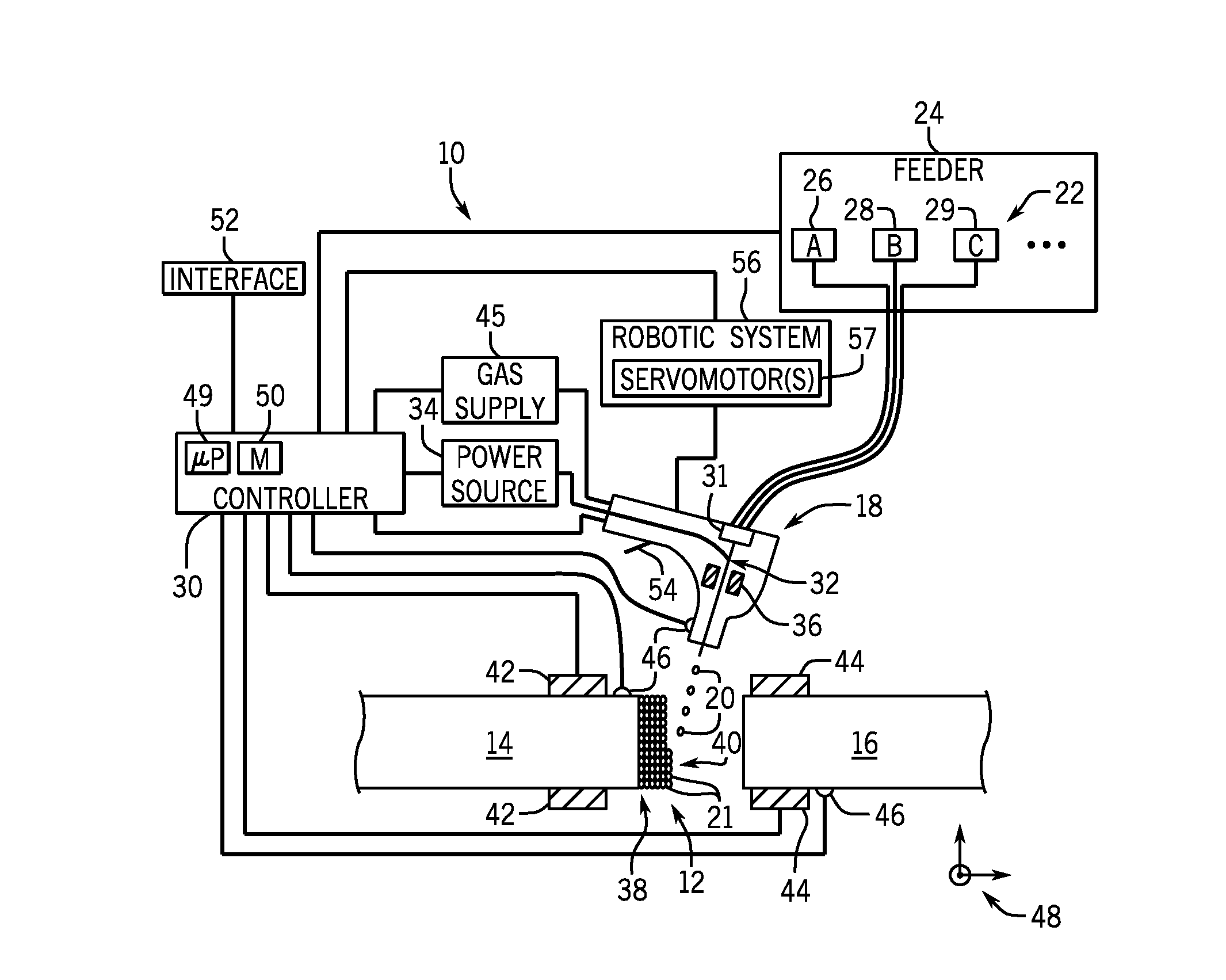

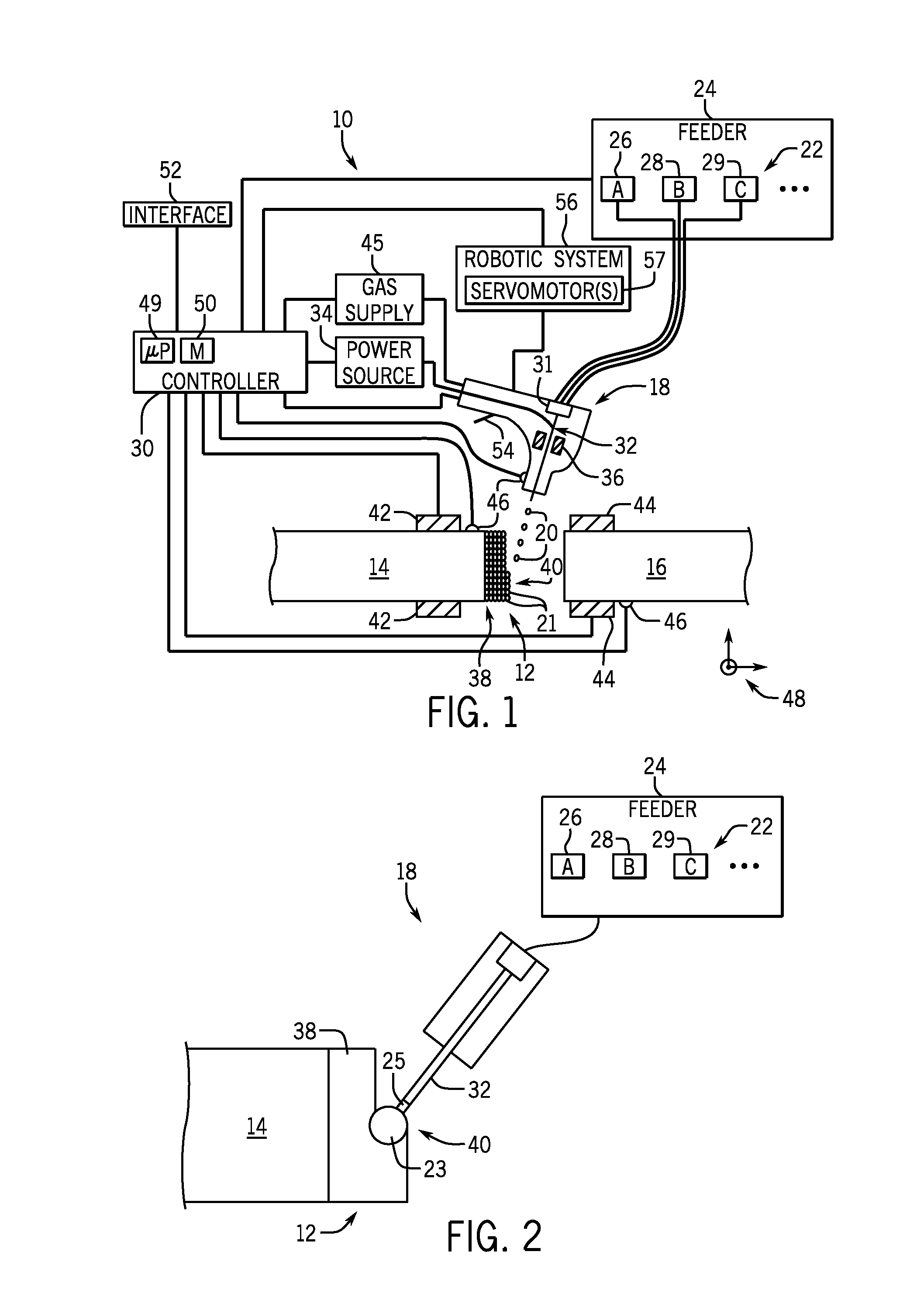

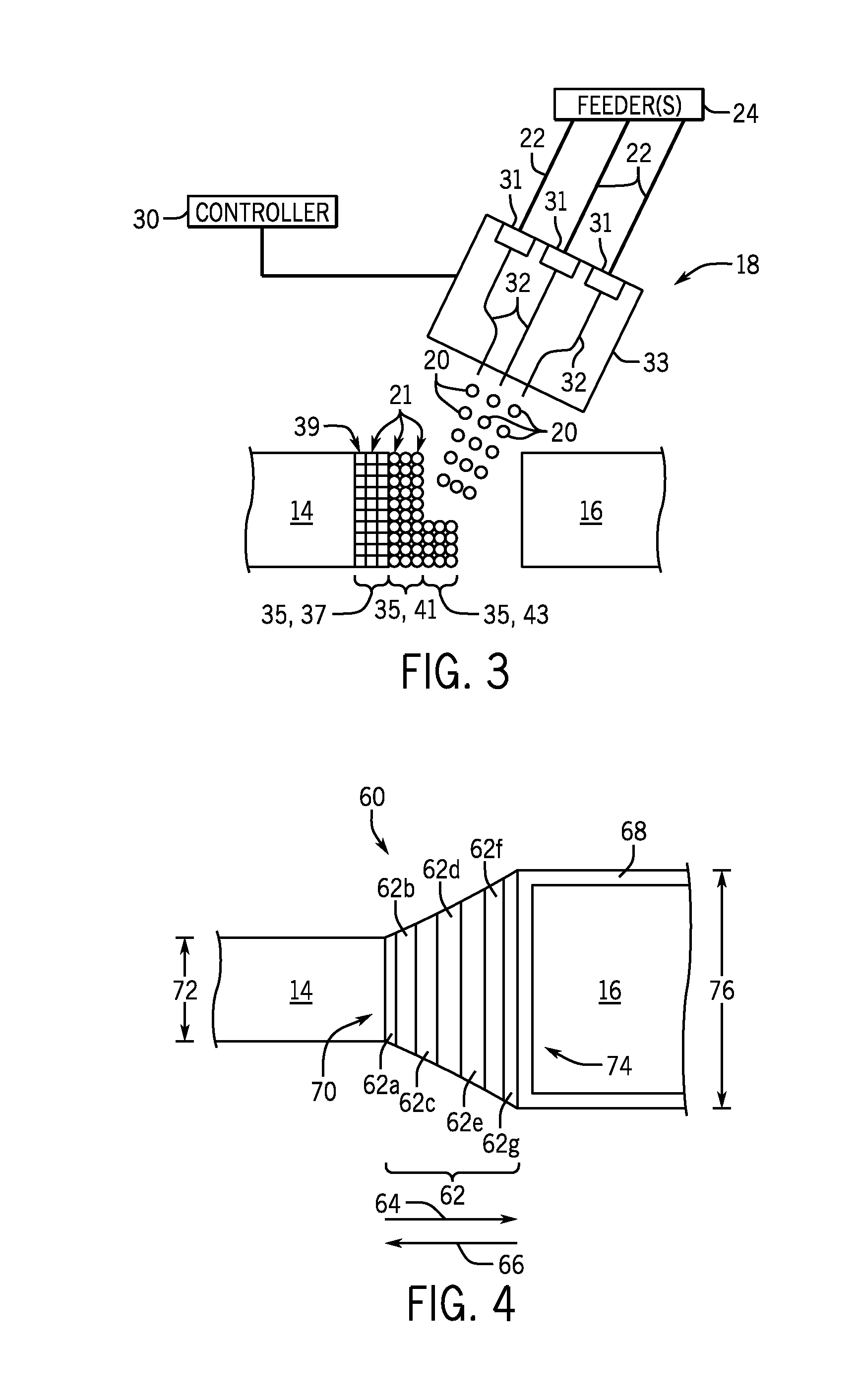

Additive manufacturing heating control systems and methods

ActiveUS20150021815A1Additive manufacturing apparatusMolten spray coatingTemperature controlControl system

An additive manufacturing system includes an additive manufacturing tool configured to supply a plurality of droplets to a part, a temperature control device configured to control a temperature of the part, and a controller configured to control the composition, formation, and application of each droplet to the plurality of droplets to the part independent from control of the temperature of the part via the temperature control device. The plurality of droplets is configured to build up the part. Each droplet of the plurality of droplets includes at least one metallic anchoring material.

Owner:ILLINOIS TOOL WORKS INC

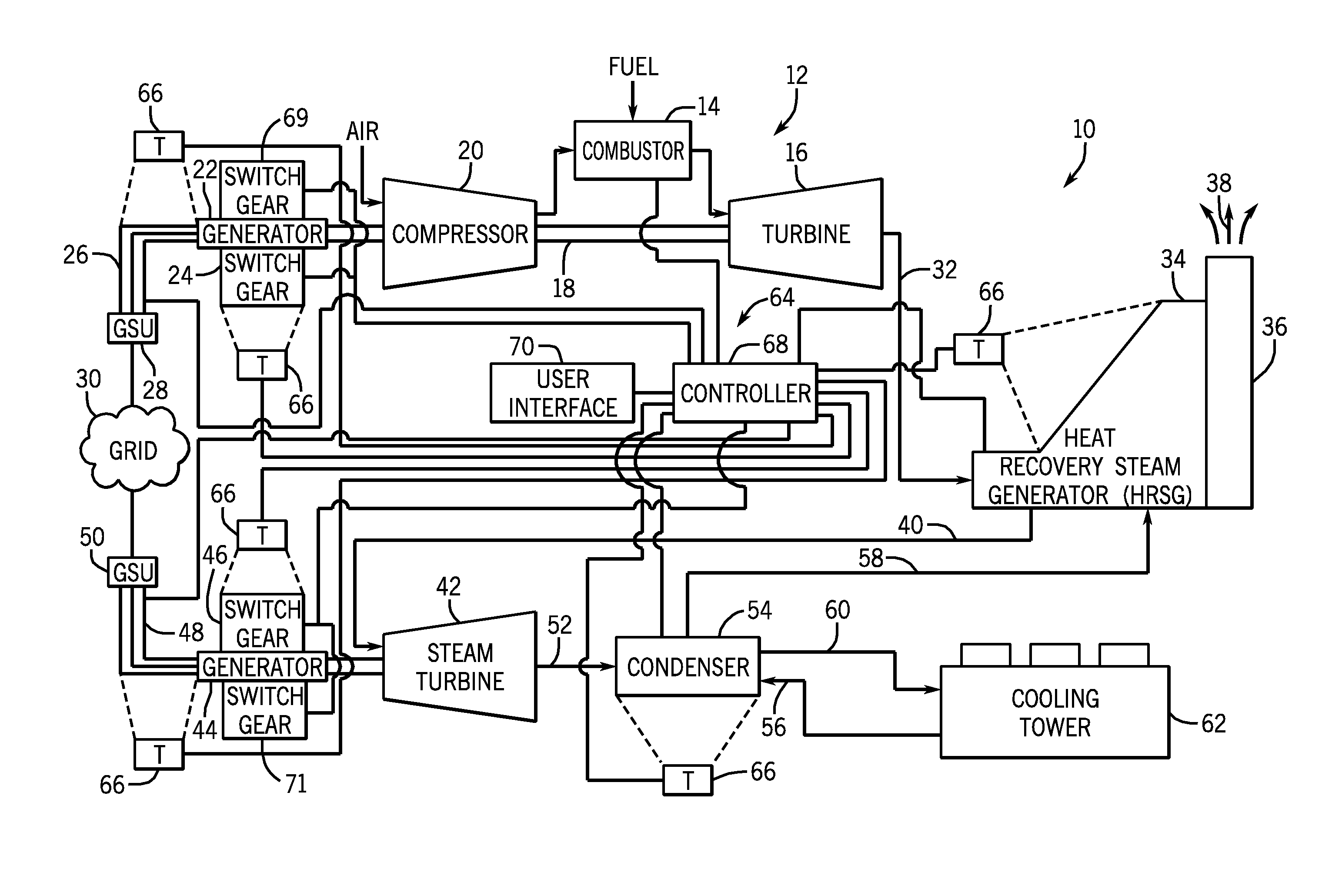

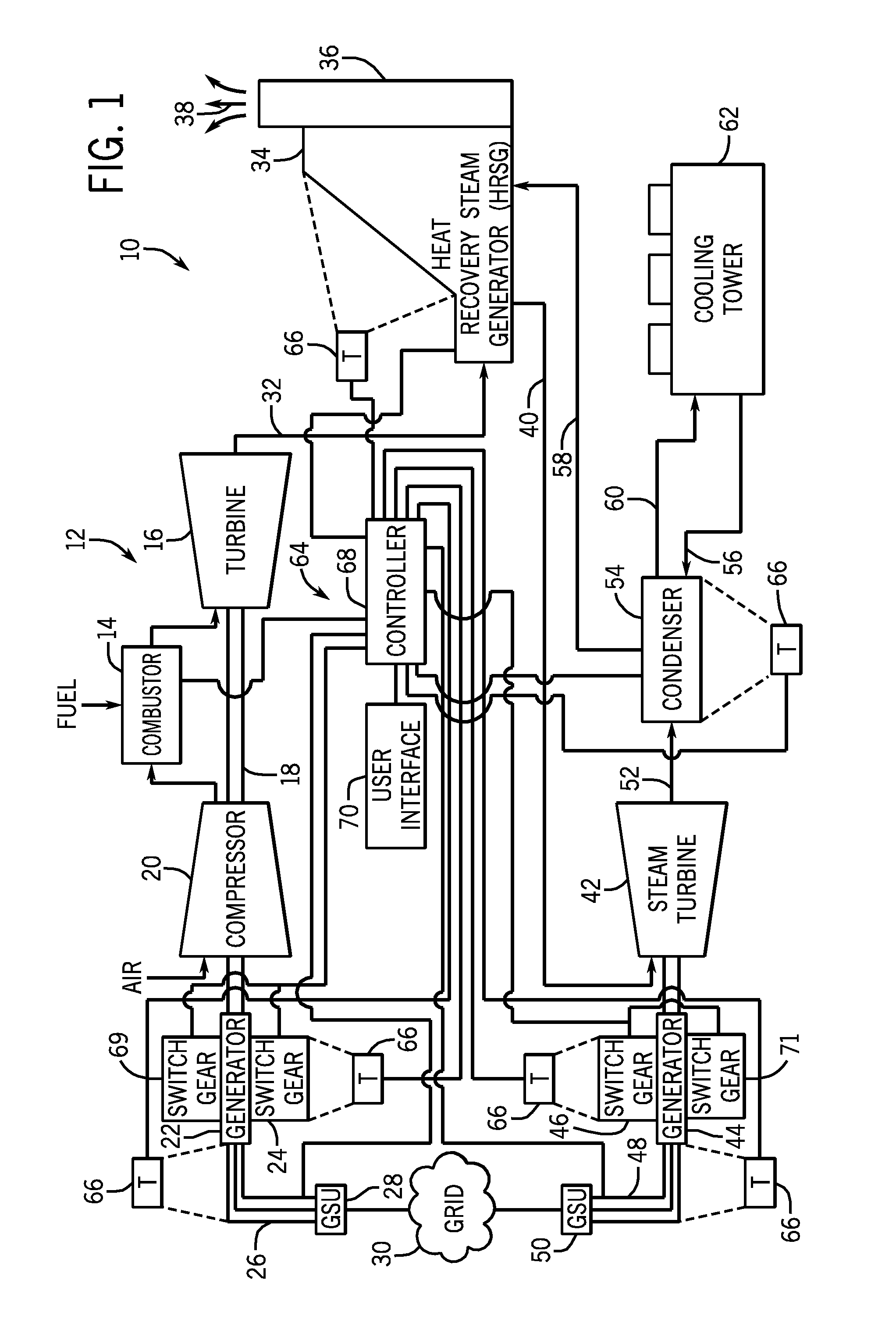

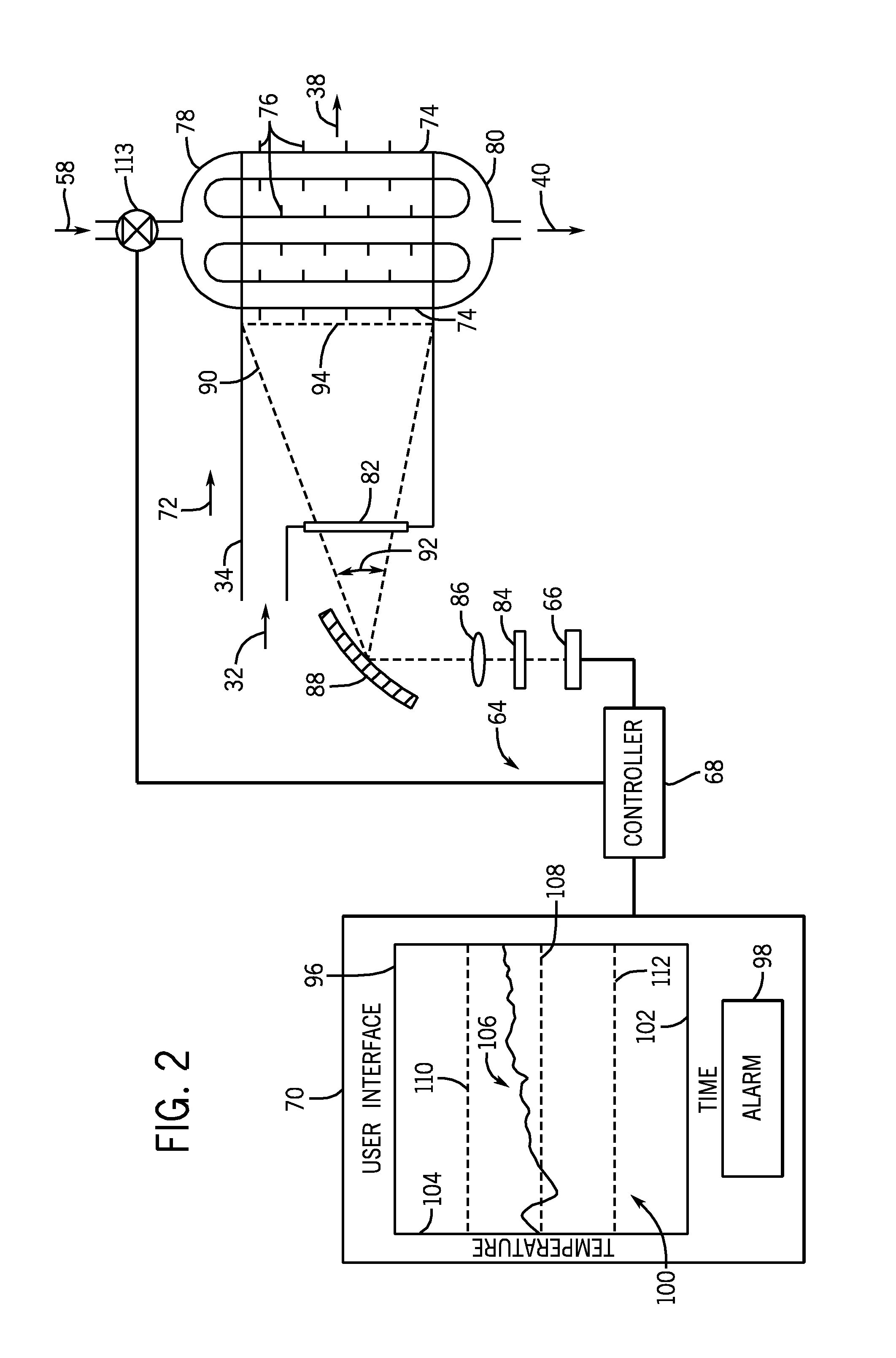

Thermal control system for fault detection and mitigation within a power generation system

InactiveUS20120031581A1Air-treating devicesSensing radiation from gases/flamesRadiation sensorThermal control system

A system includes a radiation sensor configured to direct a field of view toward at least one conduit along a fluid flow path into a heat exchanger. The radiation sensor is configured to output a signal indicative of a temperature of the at least one conduit. The system also includes a controller communicatively coupled to the radiation sensor. The controller is configured to determine the temperature based on the signal, to compare the temperature to a threshold range, and to adjust a fluid flow through the fluid flow path or the at least one conduit if the temperature deviates from the threshold range.

Owner:GENERAL ELECTRIC CO

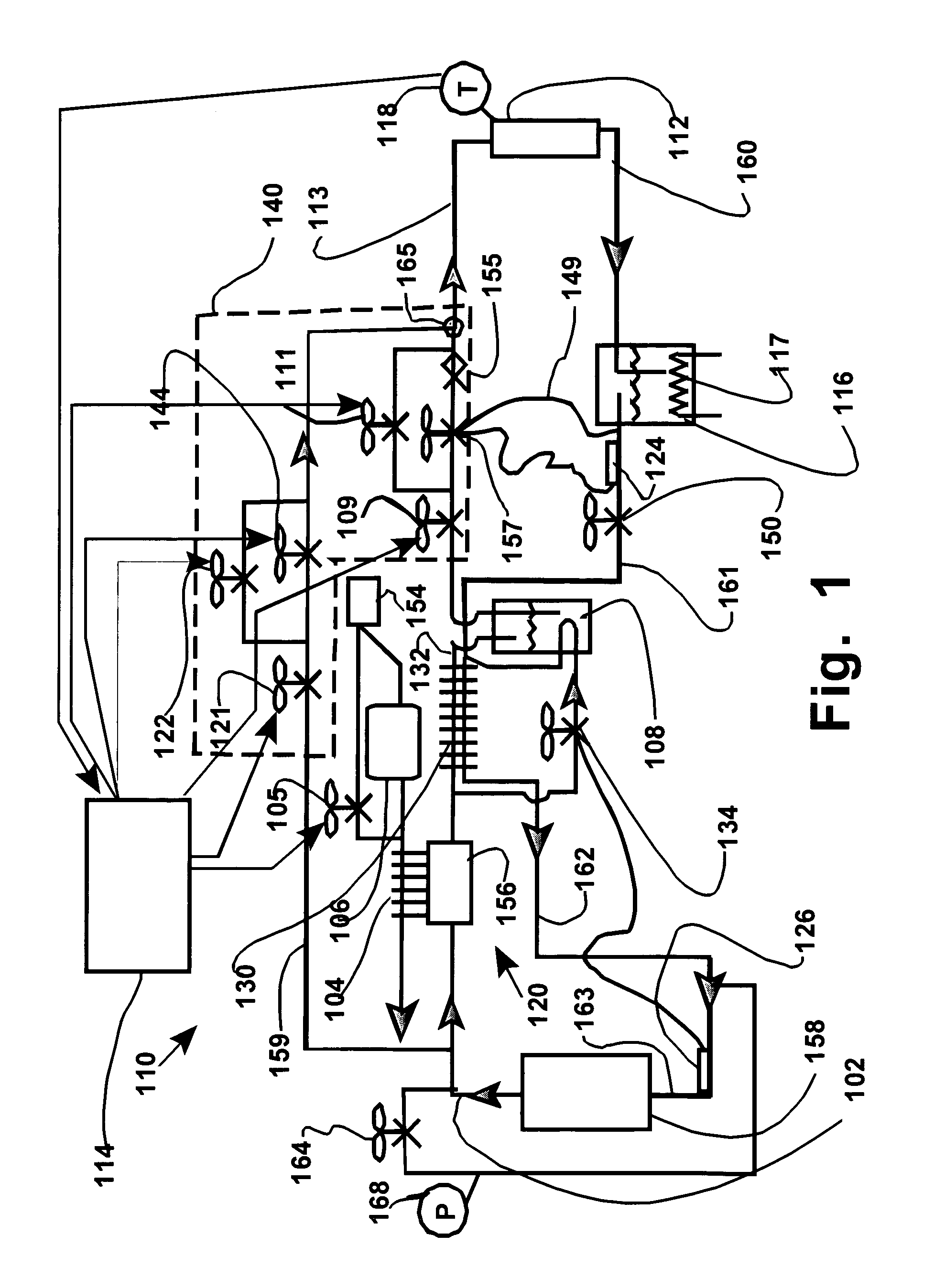

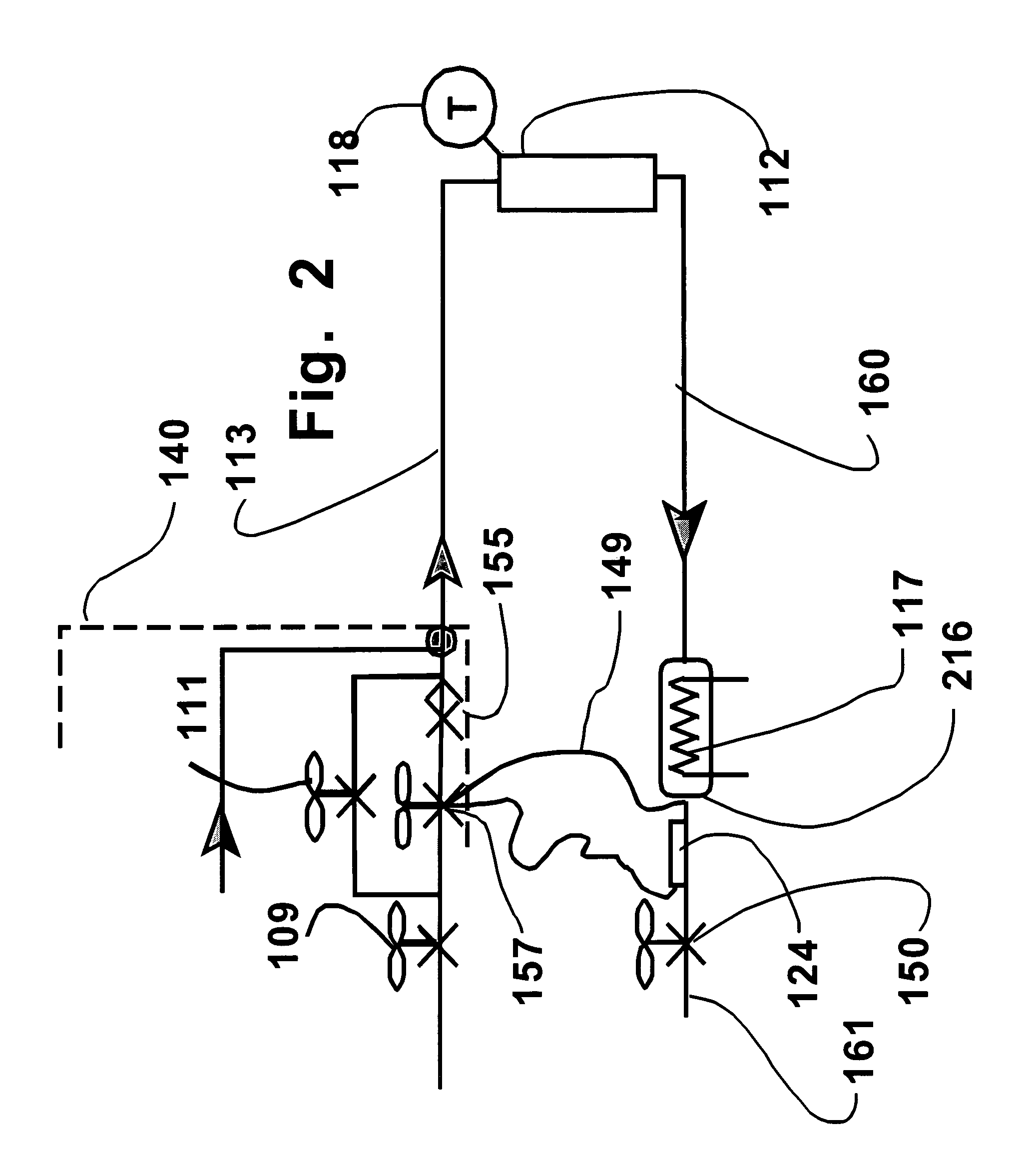

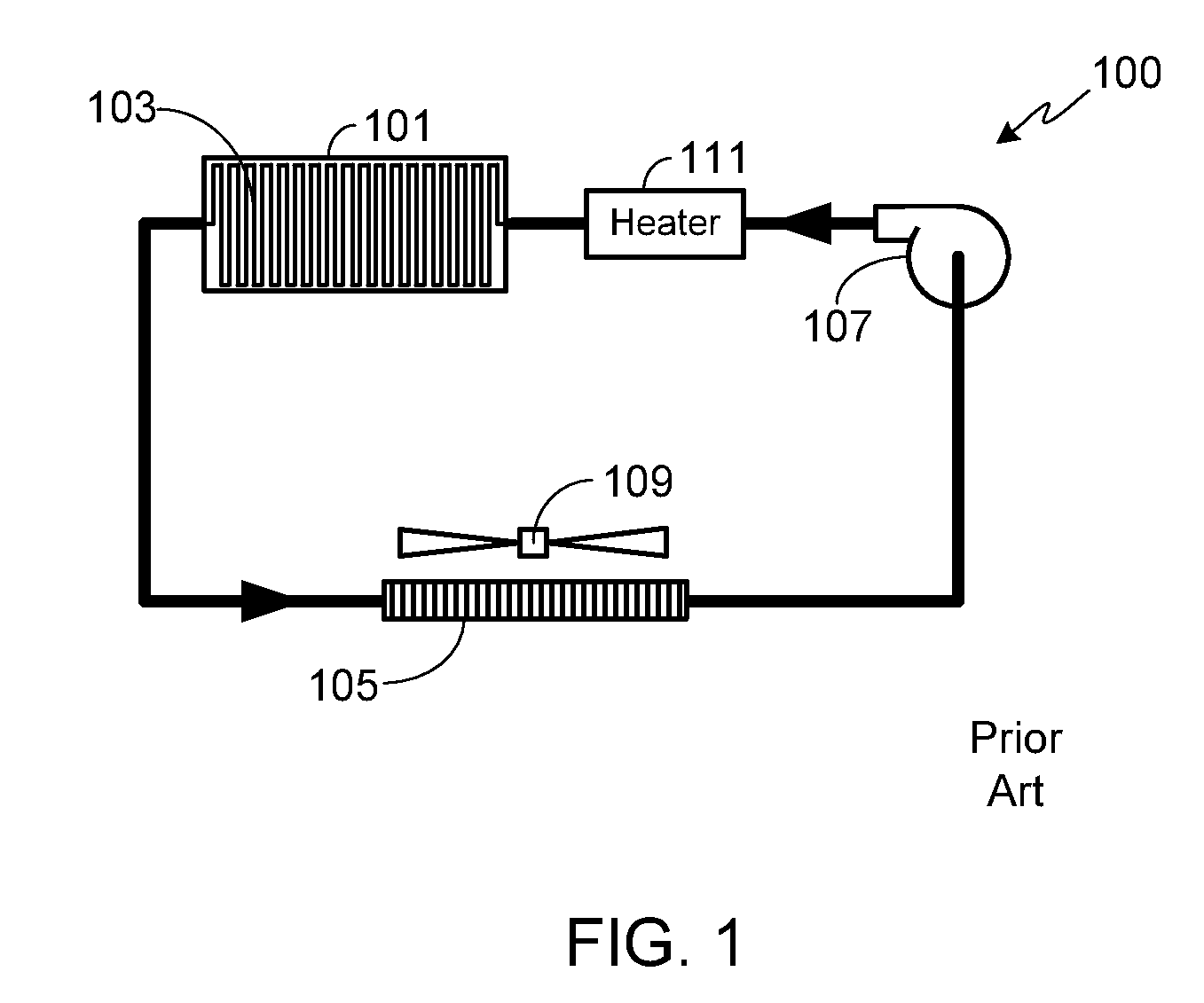

Thermal control system and method

ActiveUS7178353B2High speed responseHigh thermal efficiencyMechanical apparatusHeat pumpsProduct gasProcess engineering

A system and method for controlling the temperature of a process tool uses the vaporizable characteristic of a refrigerant that is provided in direct heat exchange relation with the process tool. Pressurized refrigerant is provided as both condensed liquid and in gaseous state. The condensed liquid is expanded to a vaporous mix, and the gaseous refrigerant is added to reach a target temperature determined by its pressure. Temperature corrections can thus be made very rapidly by gas pressure adjustments. The process tool and the operating parameters will usually require that the returning refrigerant be conditioned and processed for compatibility with the compressor and other units, so that cycling can be continuous regardless of thermal demands and changes.

Owner:BE AEROSPACE INCORPORATED

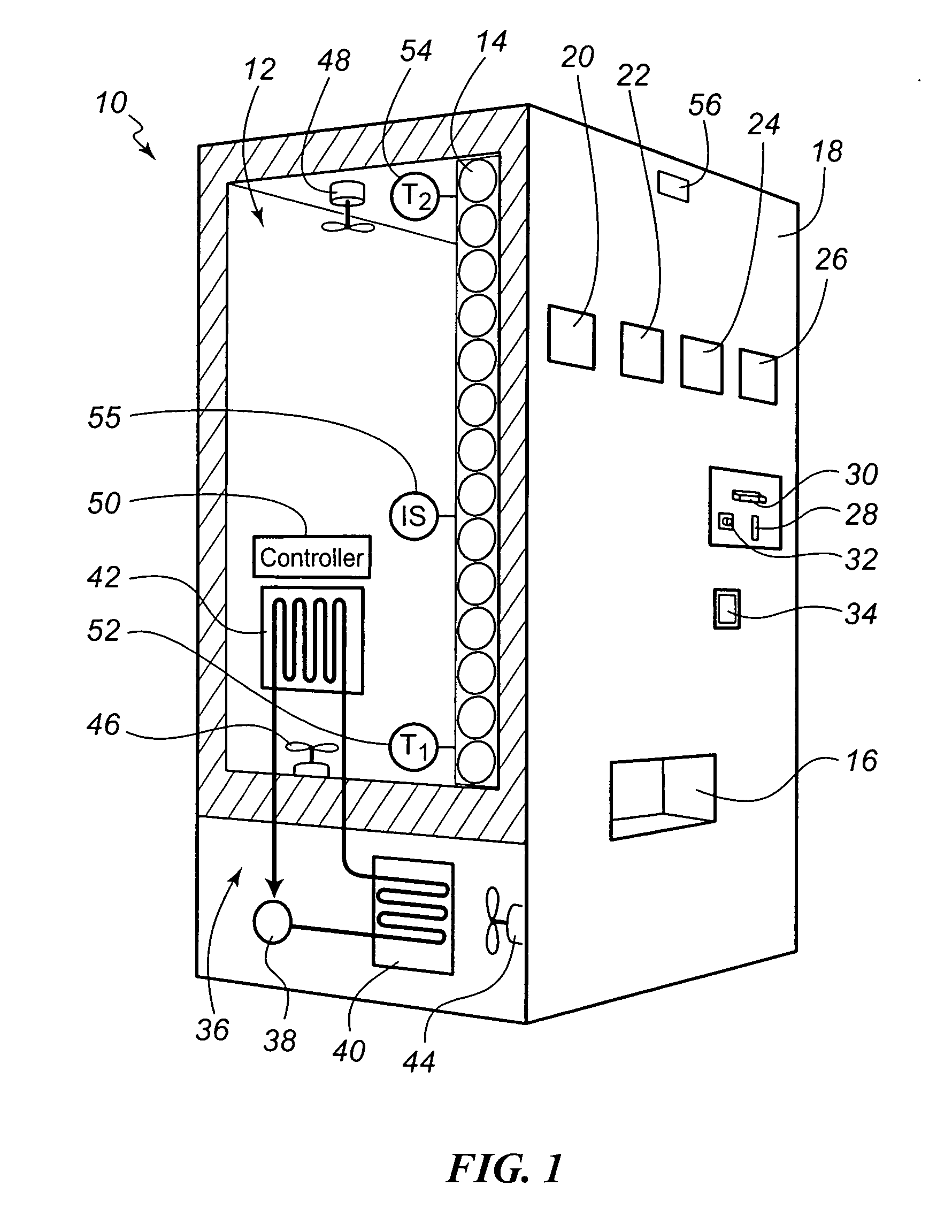

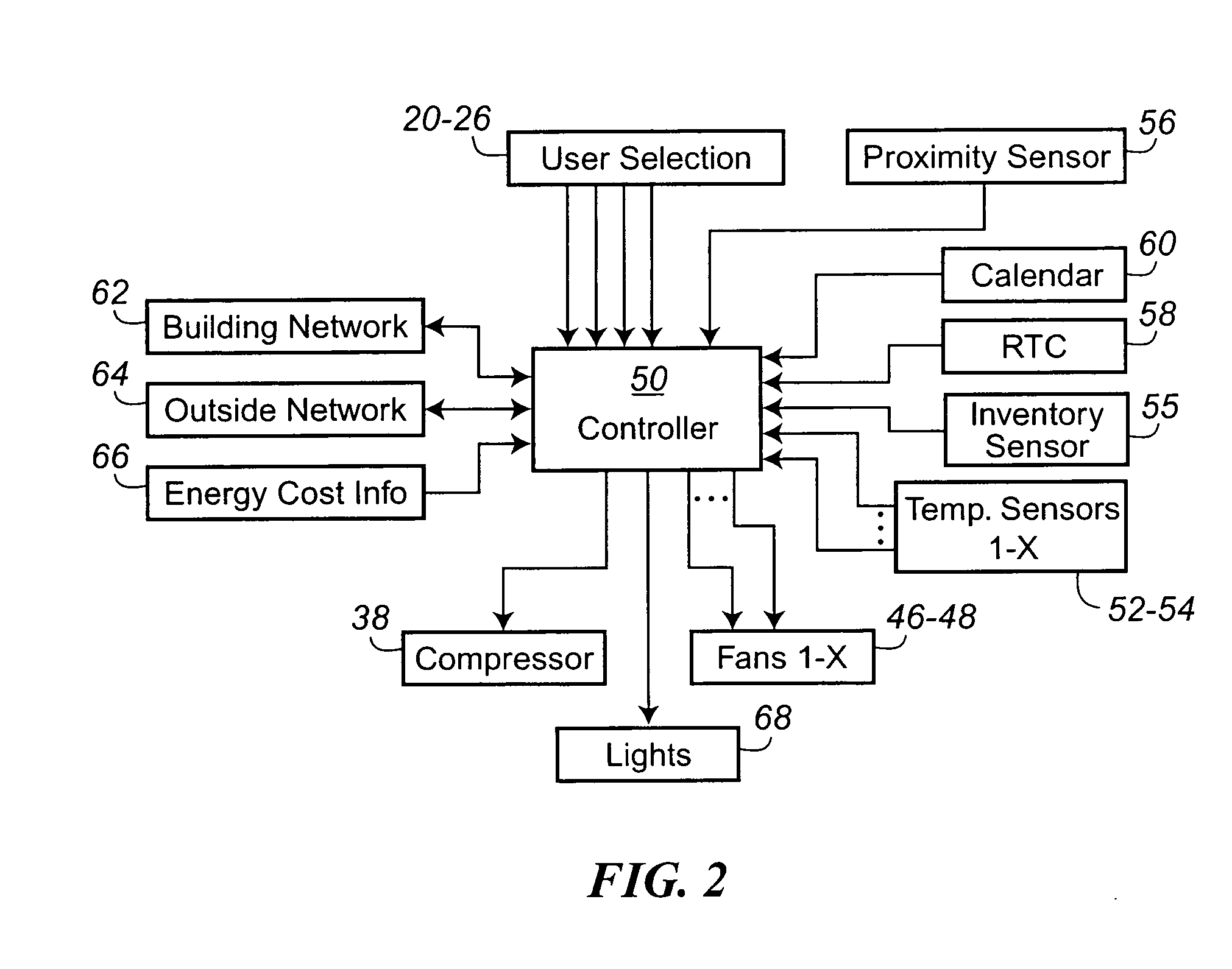

Compressor system for vending devices and the like

InactiveUS20070125104A1Reduce energy consumptionMinimize power consumptionShow cabinetsAuxillary controllers with auxillary heating devicesMedia controlsProcess engineering

An variable capacity compressor system operated by an adaptive energy usage management and thermal control system is provided to reduce the energy consumption and cost of operation of a vending machine. The variable capacity refrigeration system of the present invention includes the use of a variable or multi-speed compressor, a plurality of fixed capacity or speed compressors arranged in a compressor bank, a variable or multi-speed speed compressor with a plurality of refrigeration coils placed in vertical strata levels within the storage compartment, a plurality of fixed capacity or speed compressors arranged in a compressor bank with a plurality of refrigeration coils placed in vertical strata levels within the storage compartment operated by individual refrigerant media control valves, or a plurality of compressors with a plurality of refrigeration coils placed in vertical strata levels within the storage compartment coupled individually to a corresponding compressor, or combinations thereof.

Owner:RANCO OF DELAWARE

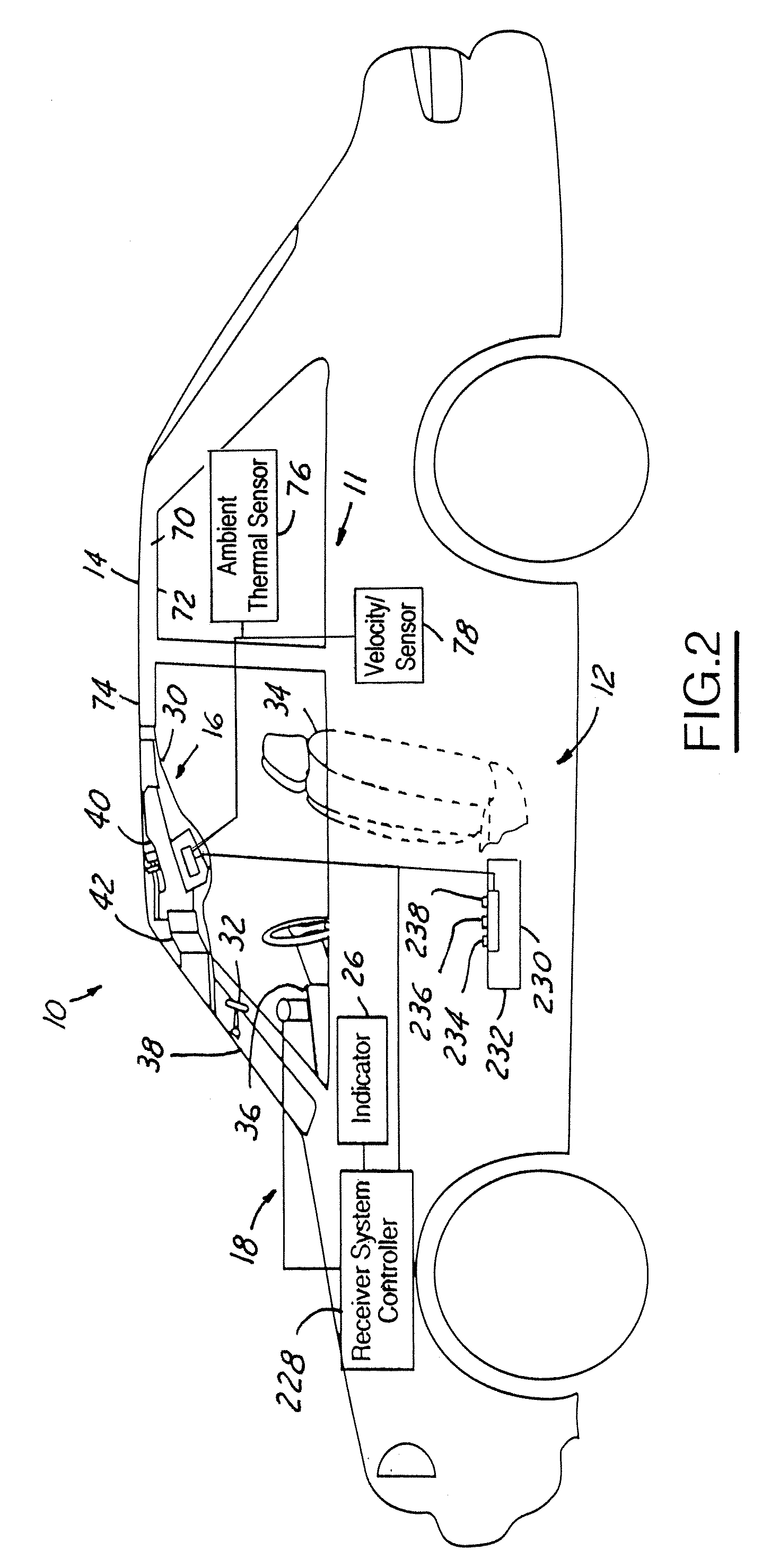

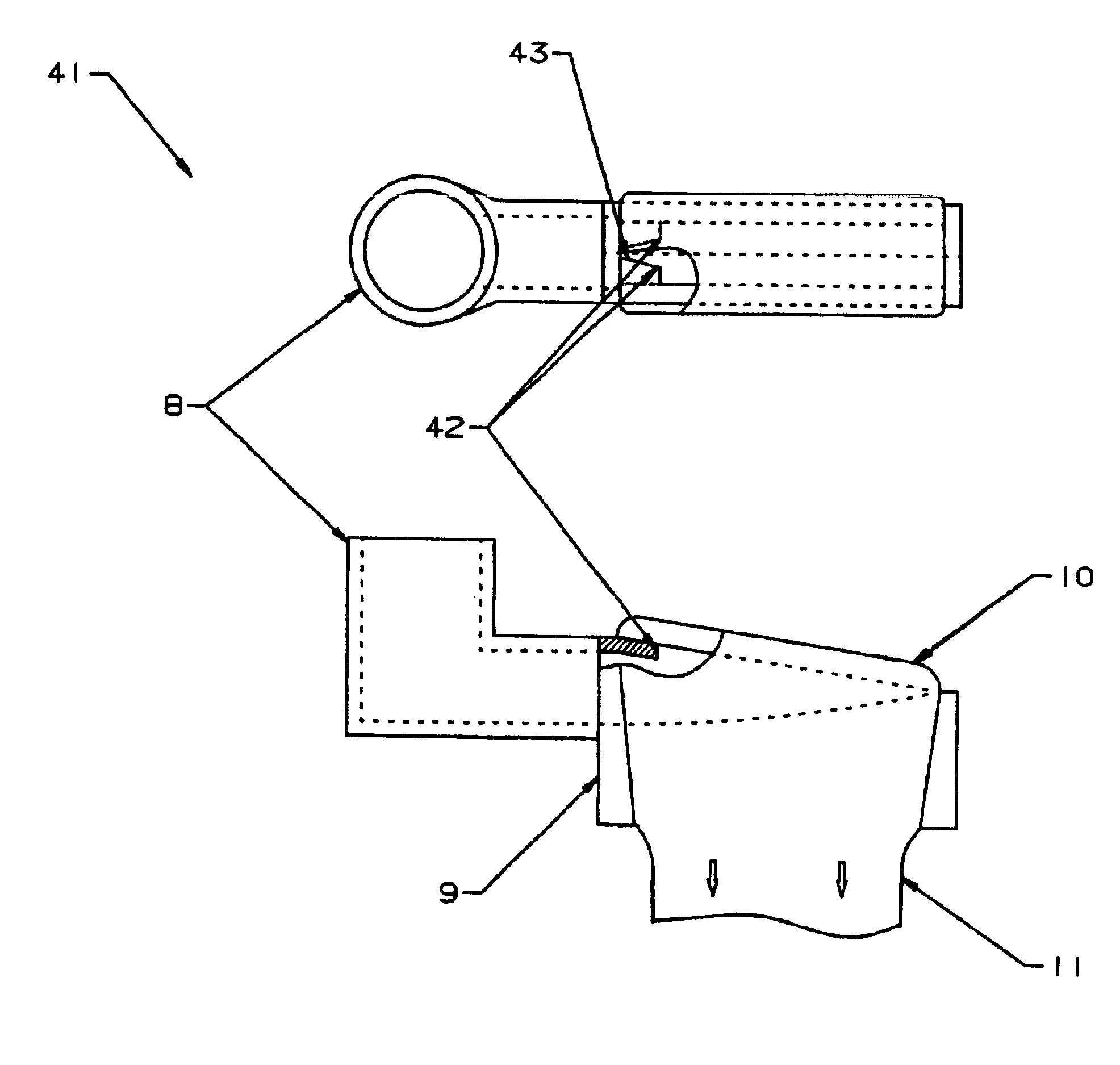

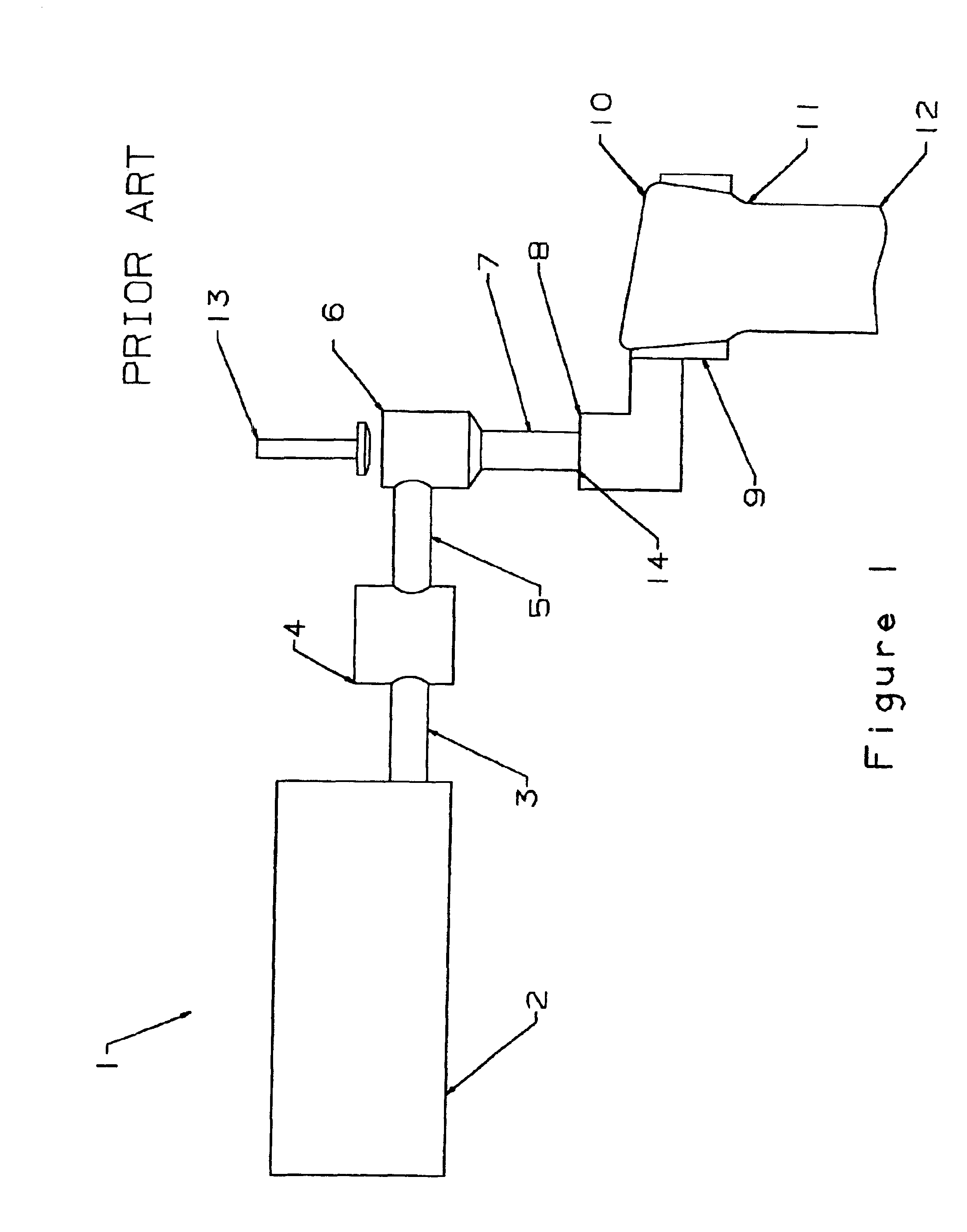

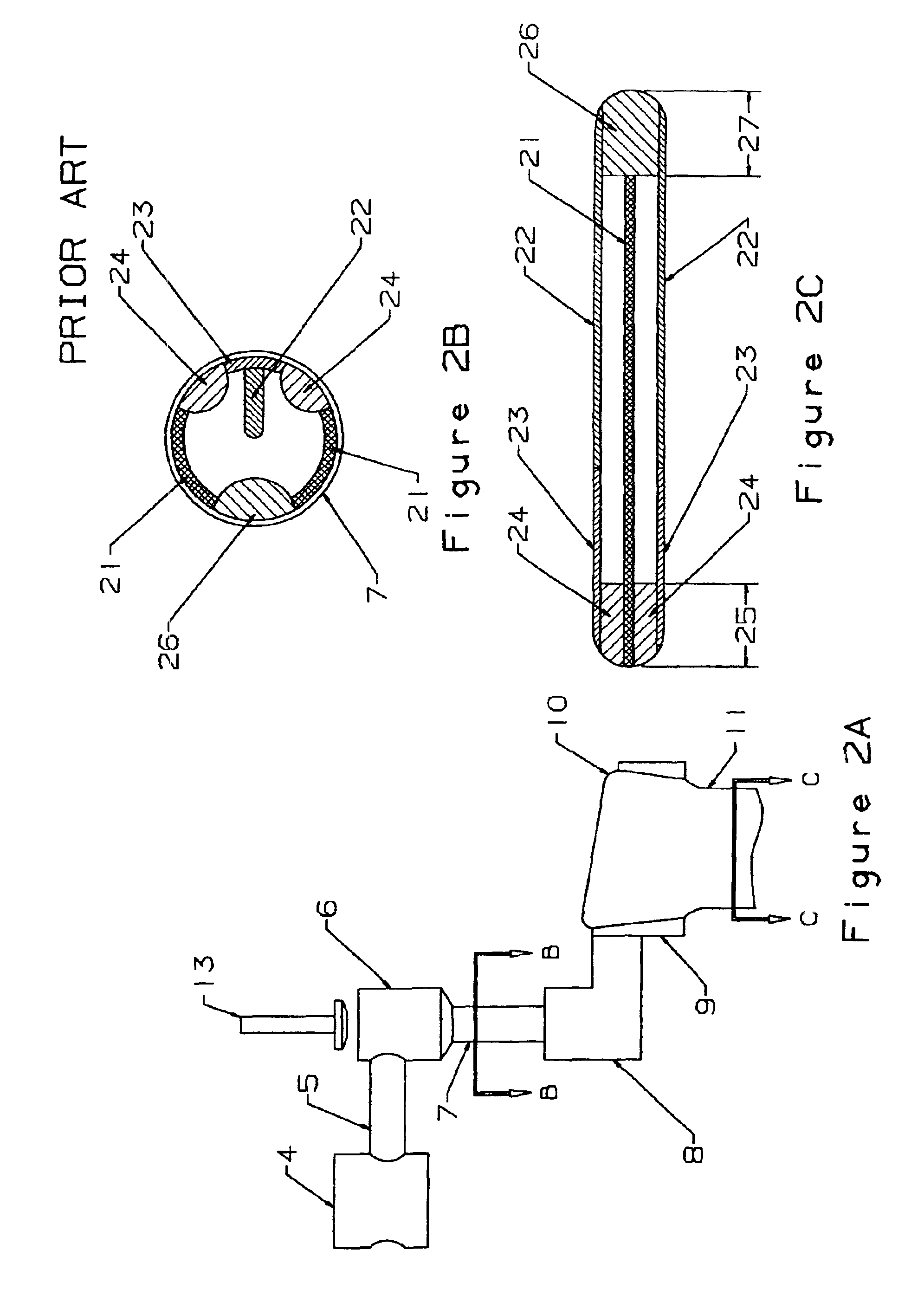

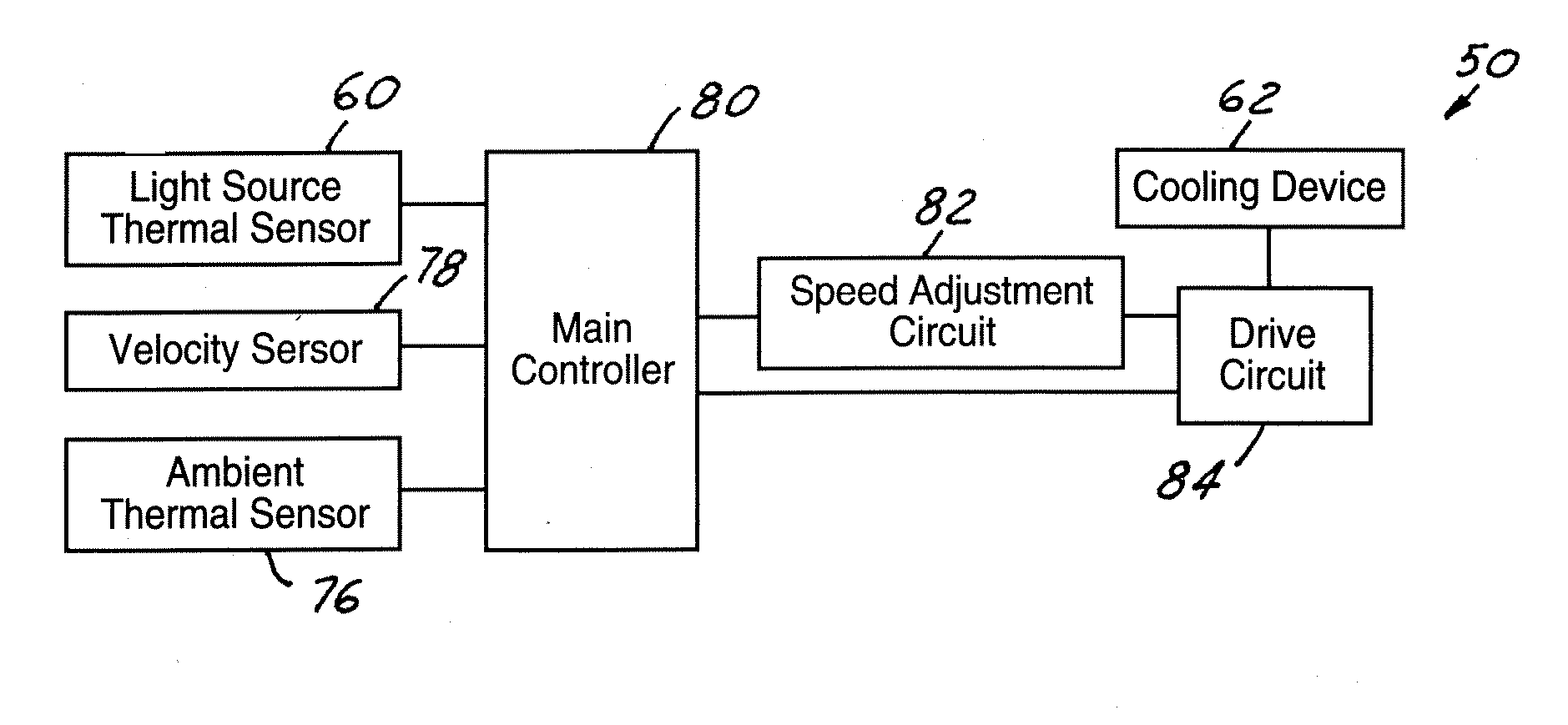

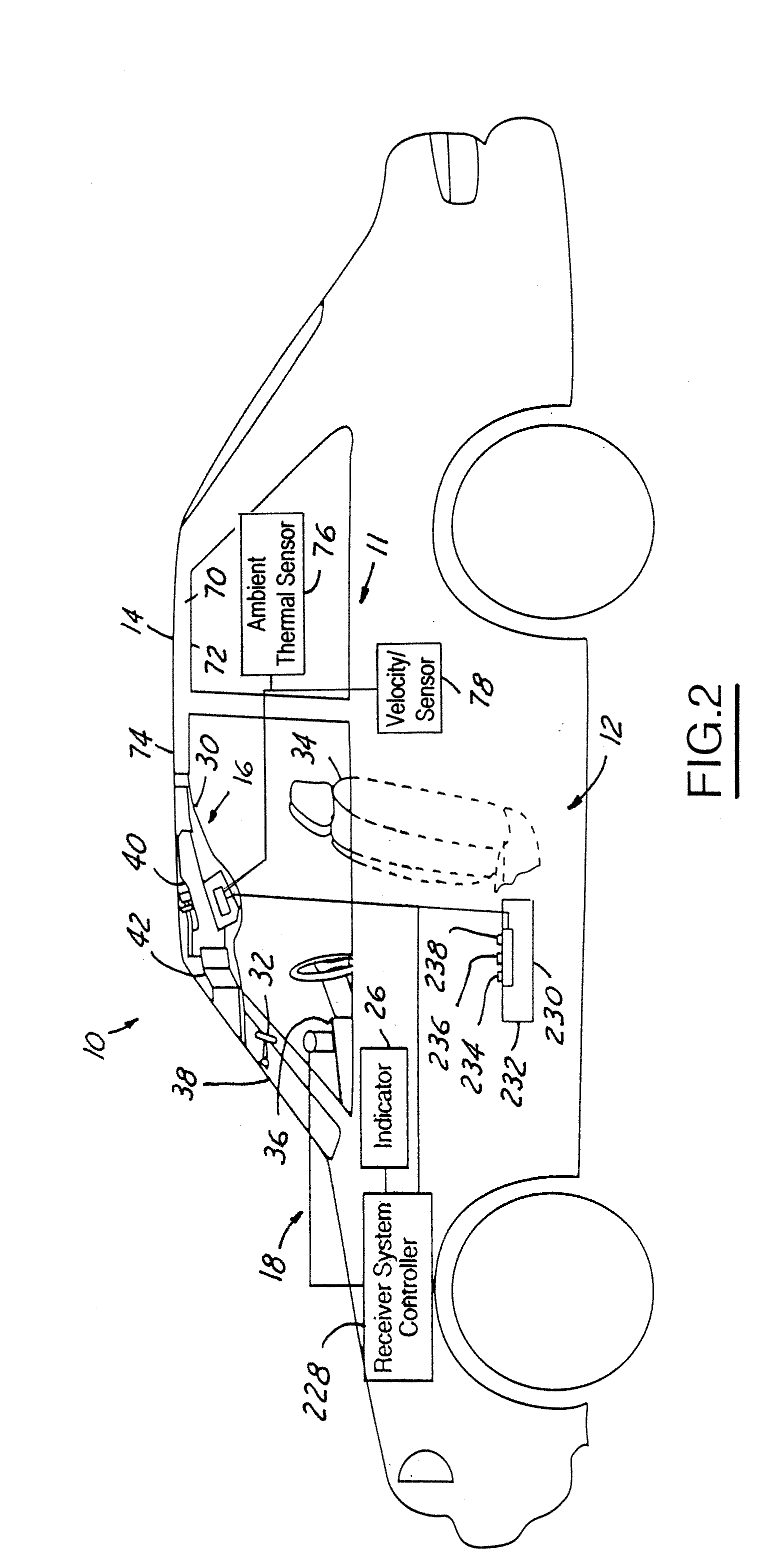

Active night vision cooling system

InactiveUS7015470B2Efficiently adjusts temperatureNoise minimizationLighting heating/cooling arrangementsSighting devicesNight visionEngineering

A thermal control system (11) for a light source (46) of a vision system (10) includes a cooling assembly (61) that has a cooling device (62) and is thermally coupled to the light source (46). A thermal sensor (60) is thermally coupled to the light source (46) and generates a light source temperature signal. A control circuit (50) is coupled to the cooling assembly (61) and to the thermal sensor (60) and operates the cooling device (62) when the light source temperature signal is above a minimum temperature limit.

Owner:LEAR CORP

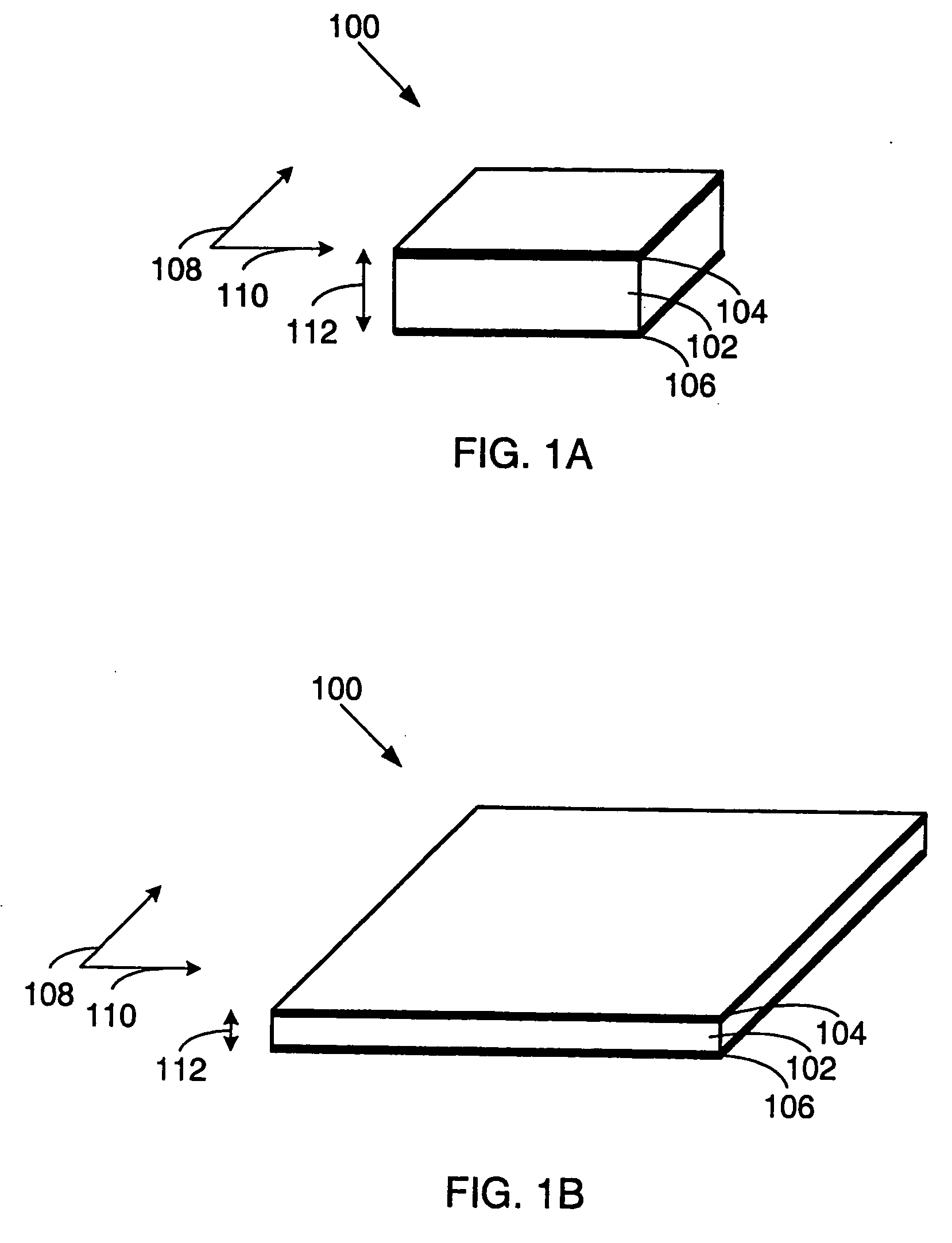

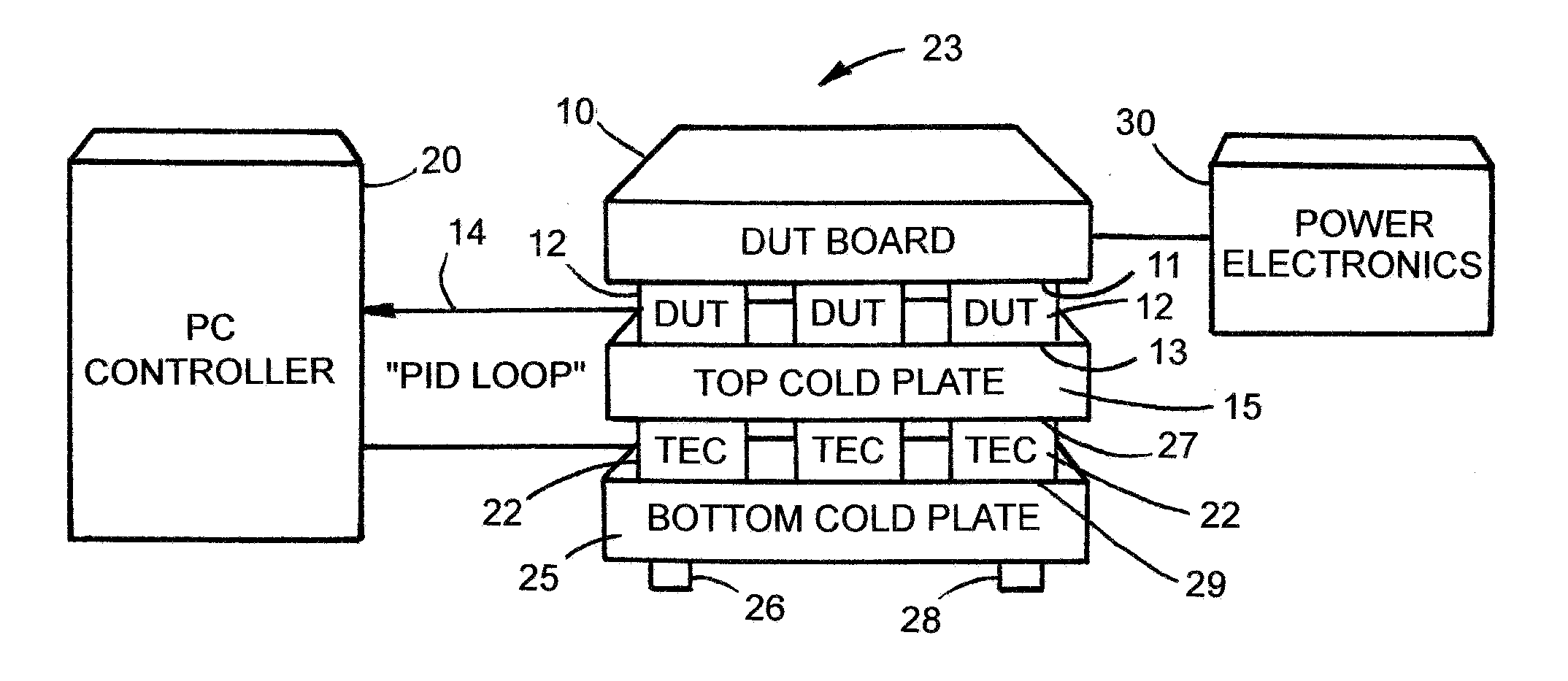

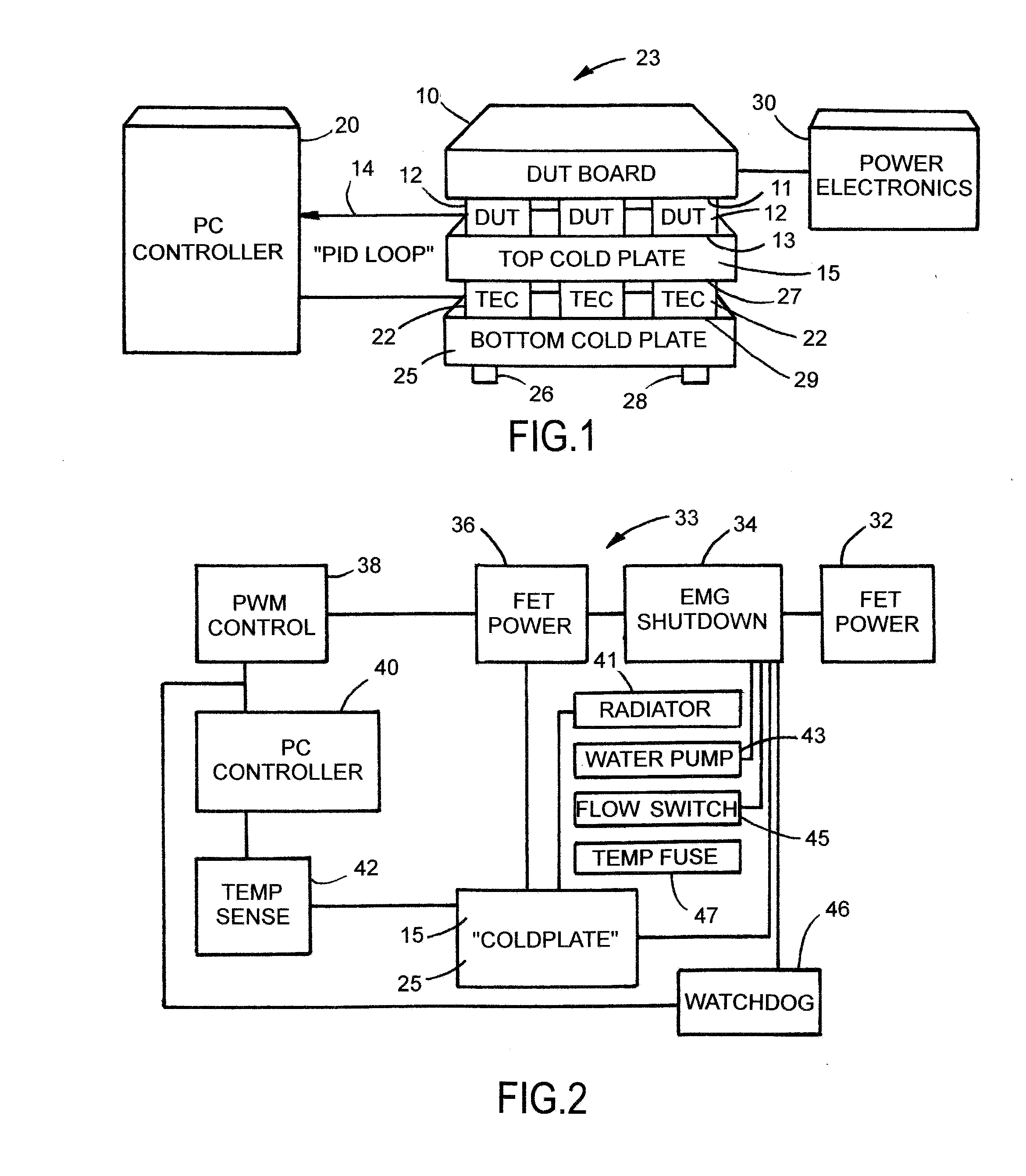

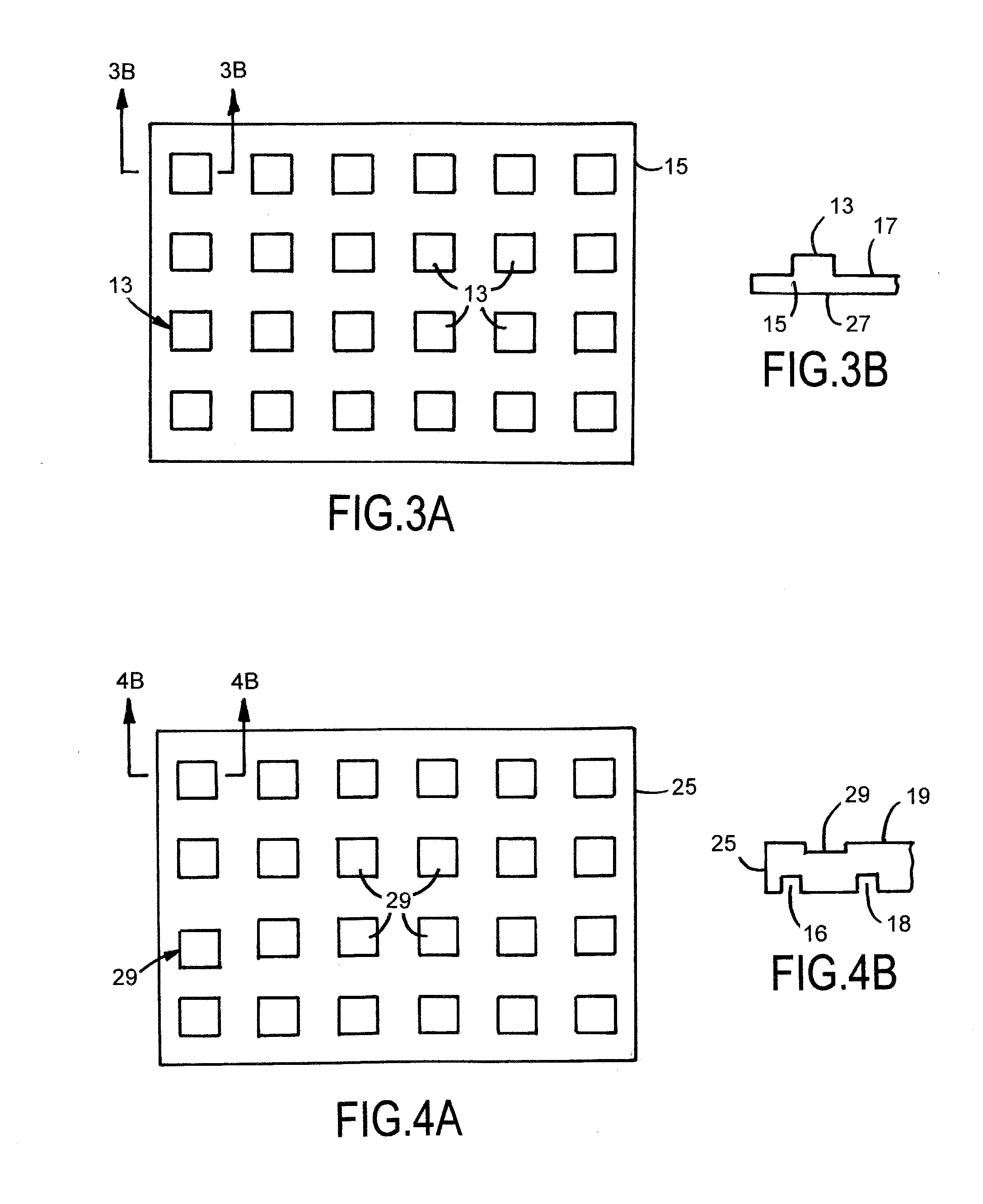

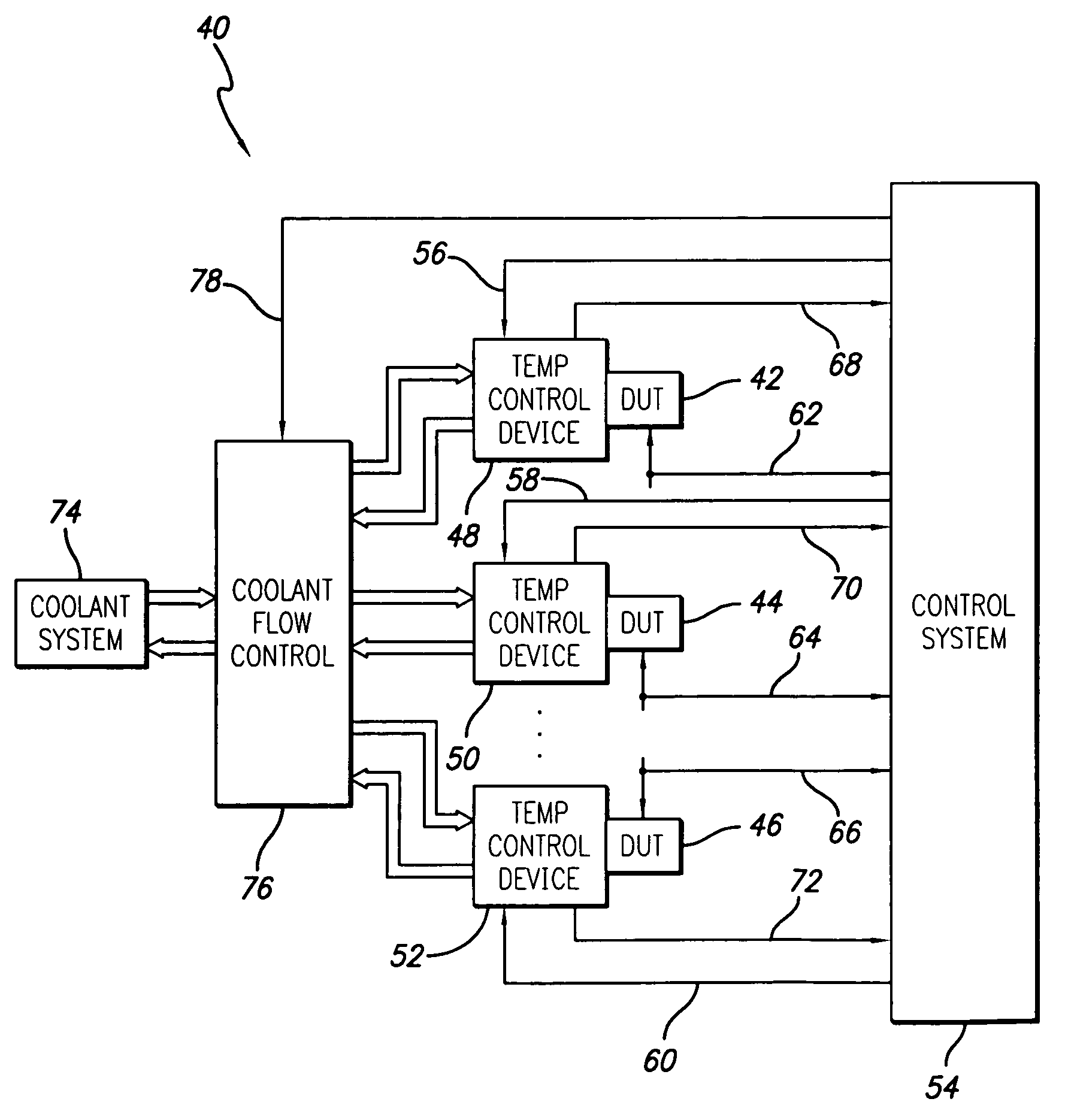

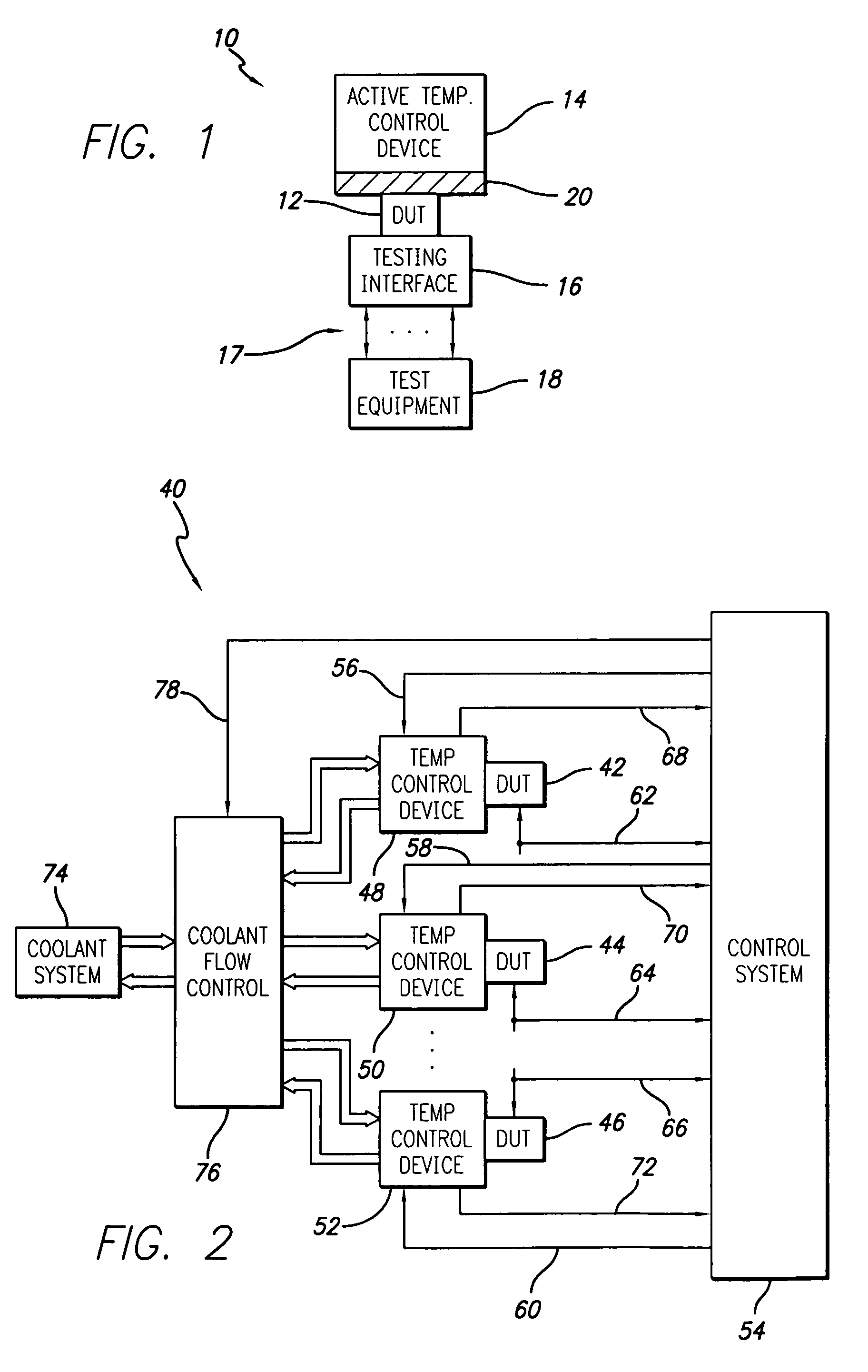

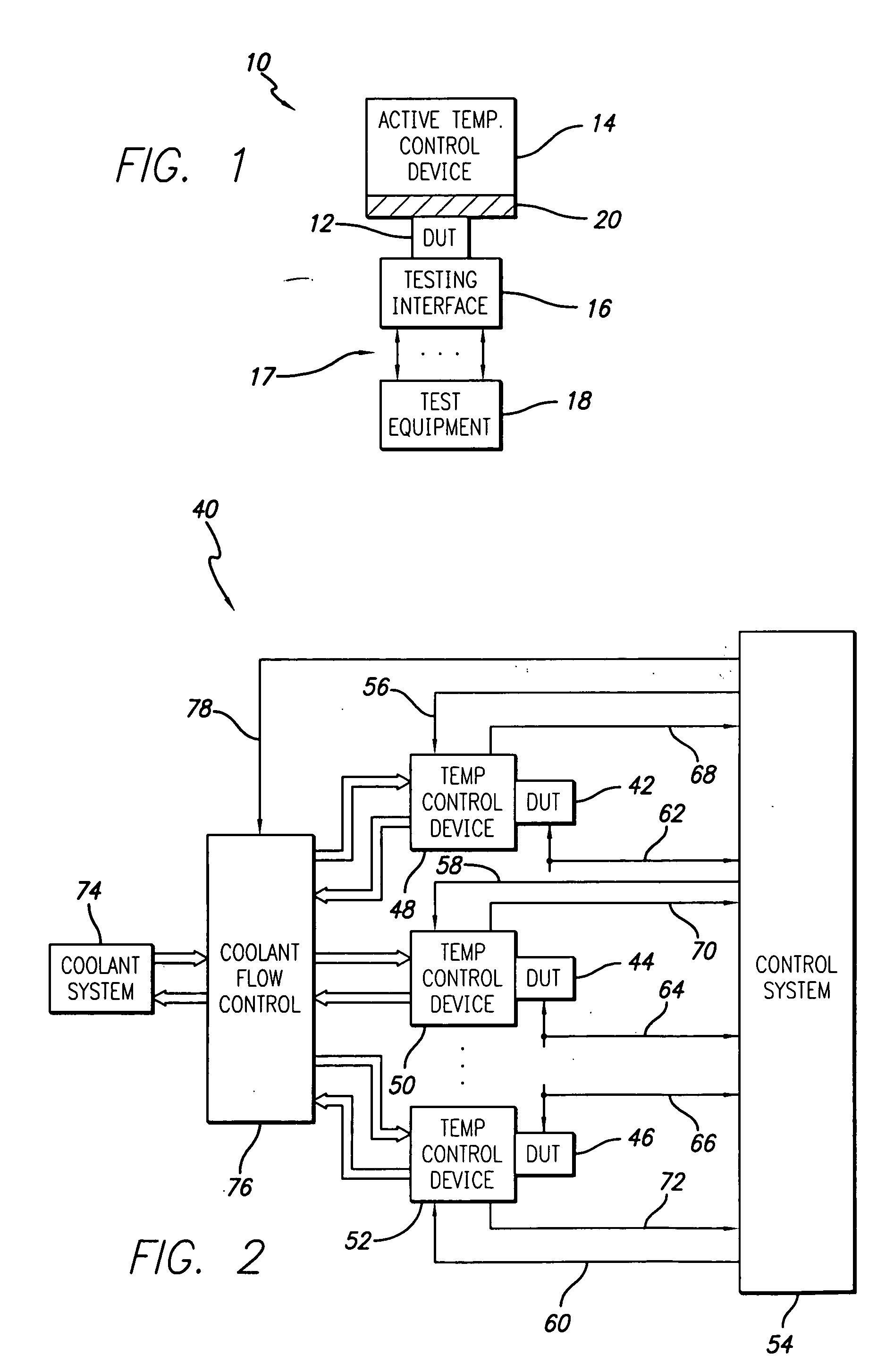

Systems and Methods for Thermal Control

ActiveUS20130285686A1Electronic circuit testingFault location by increasing destruction at faultDevice under testThermoelectric element

The present invention relates generally to a system and a method for thermal control. More particularly, the invention encompasses an apparatus for thermal control and management of at least one device under test (DUT). The inventive thermal control and management apparatus also allows for the management of a plurality of devices under test, and with each device under test having its own testing regimen. The thermal control and management of the device under test (DUT) is managed using at least one thermoelectric element or cooler (TEC), which can be used to either heat or cool the corresponding device under test (DUT).

Owner:SILICON TURNKEY SOLUTIONS

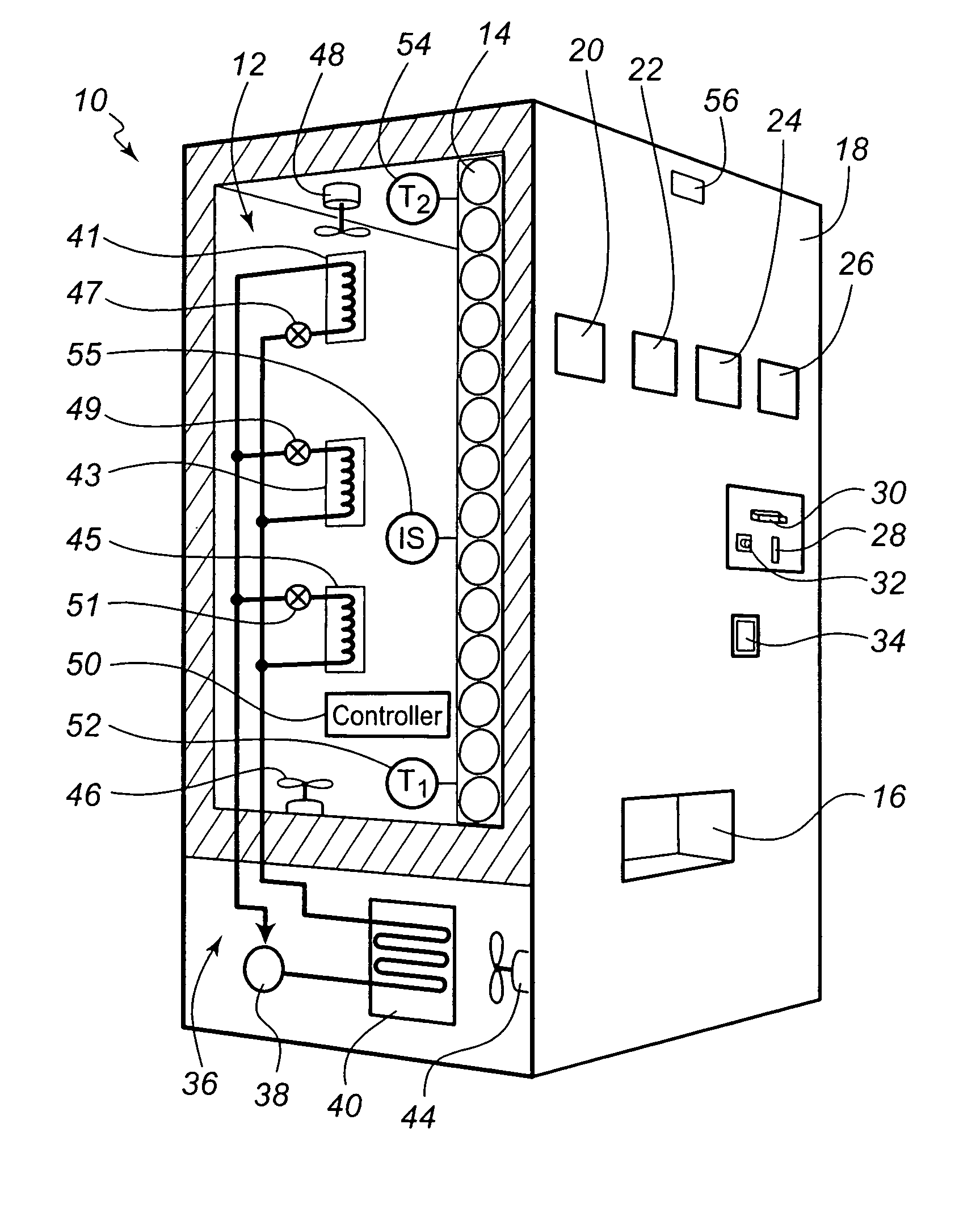

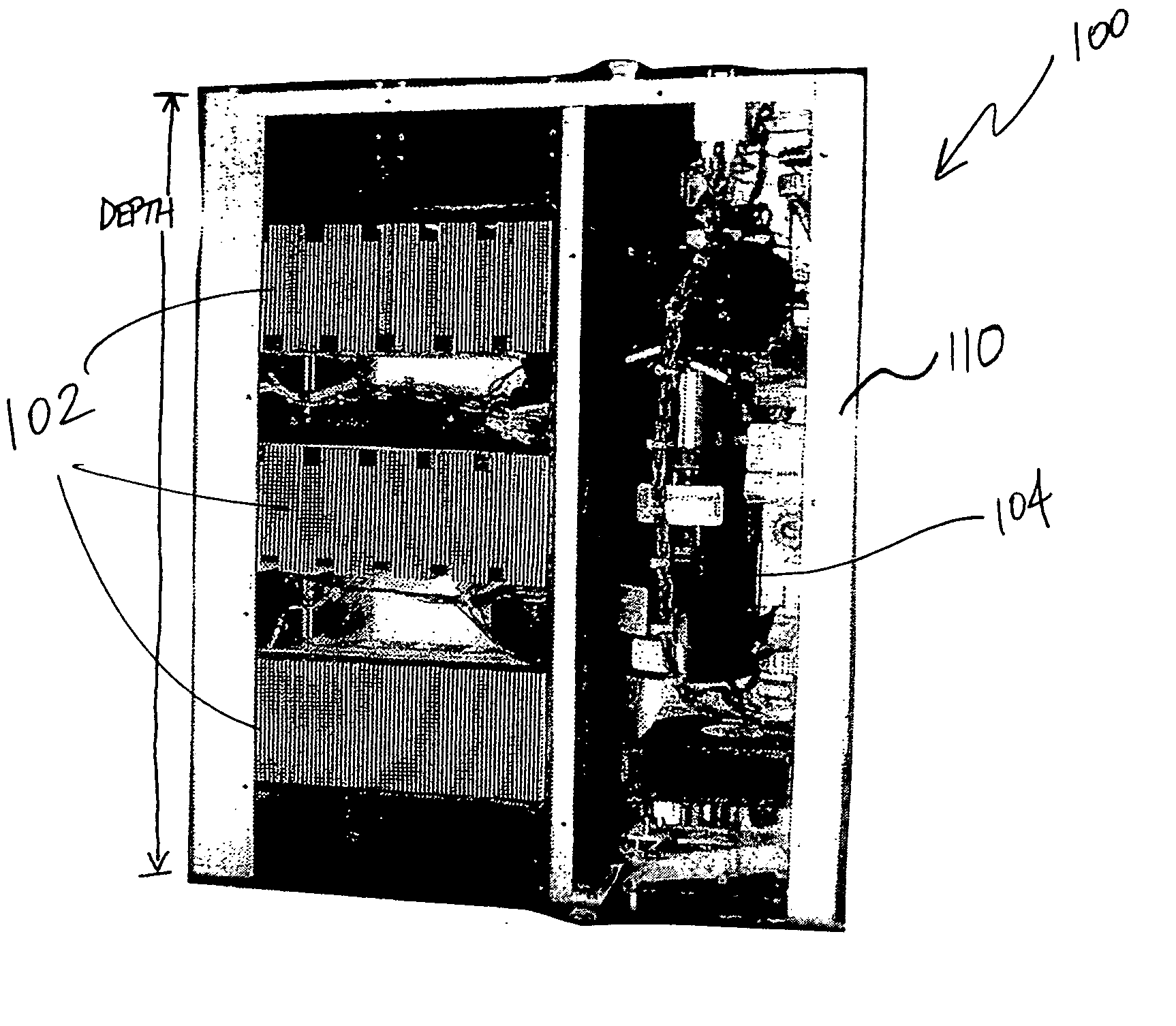

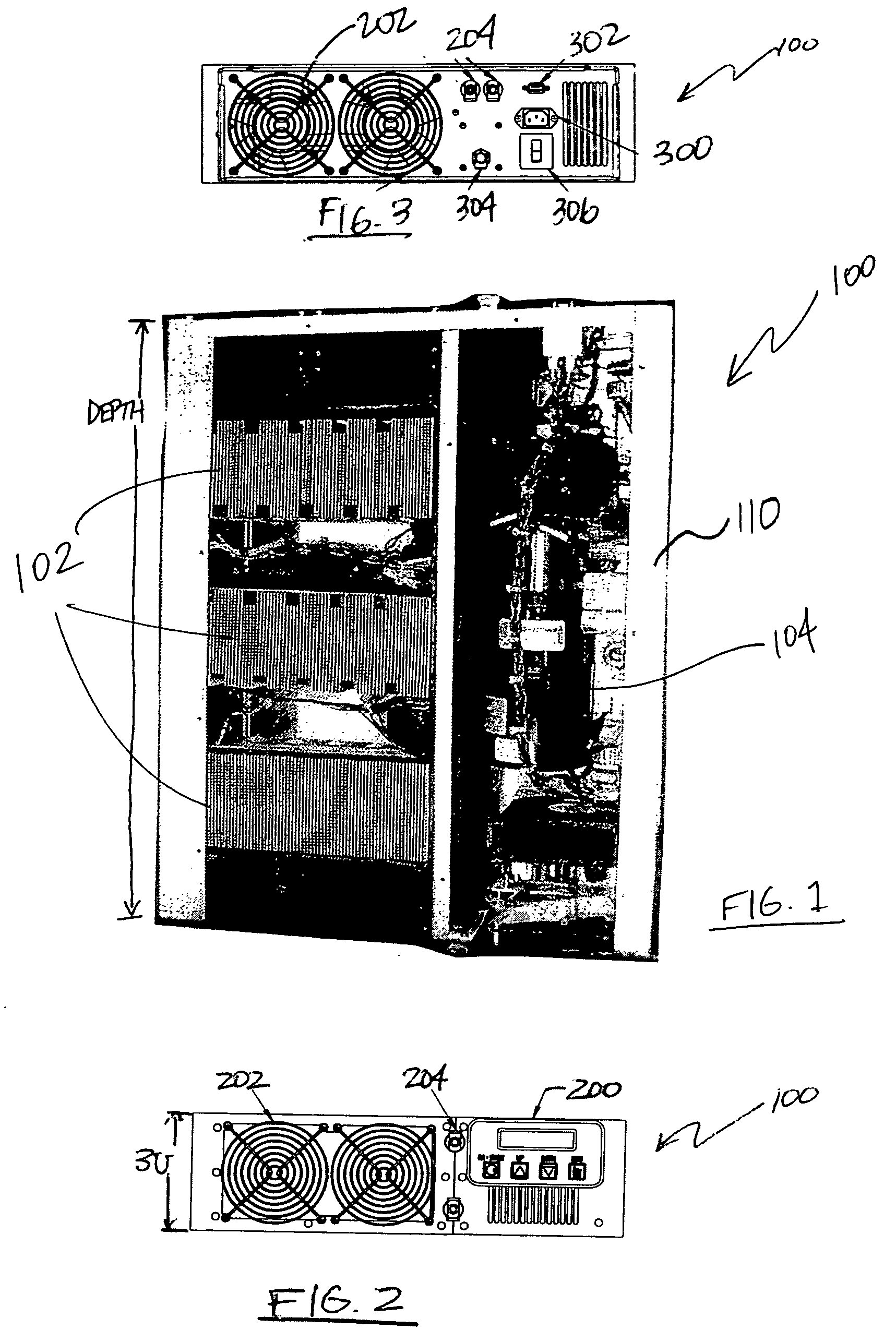

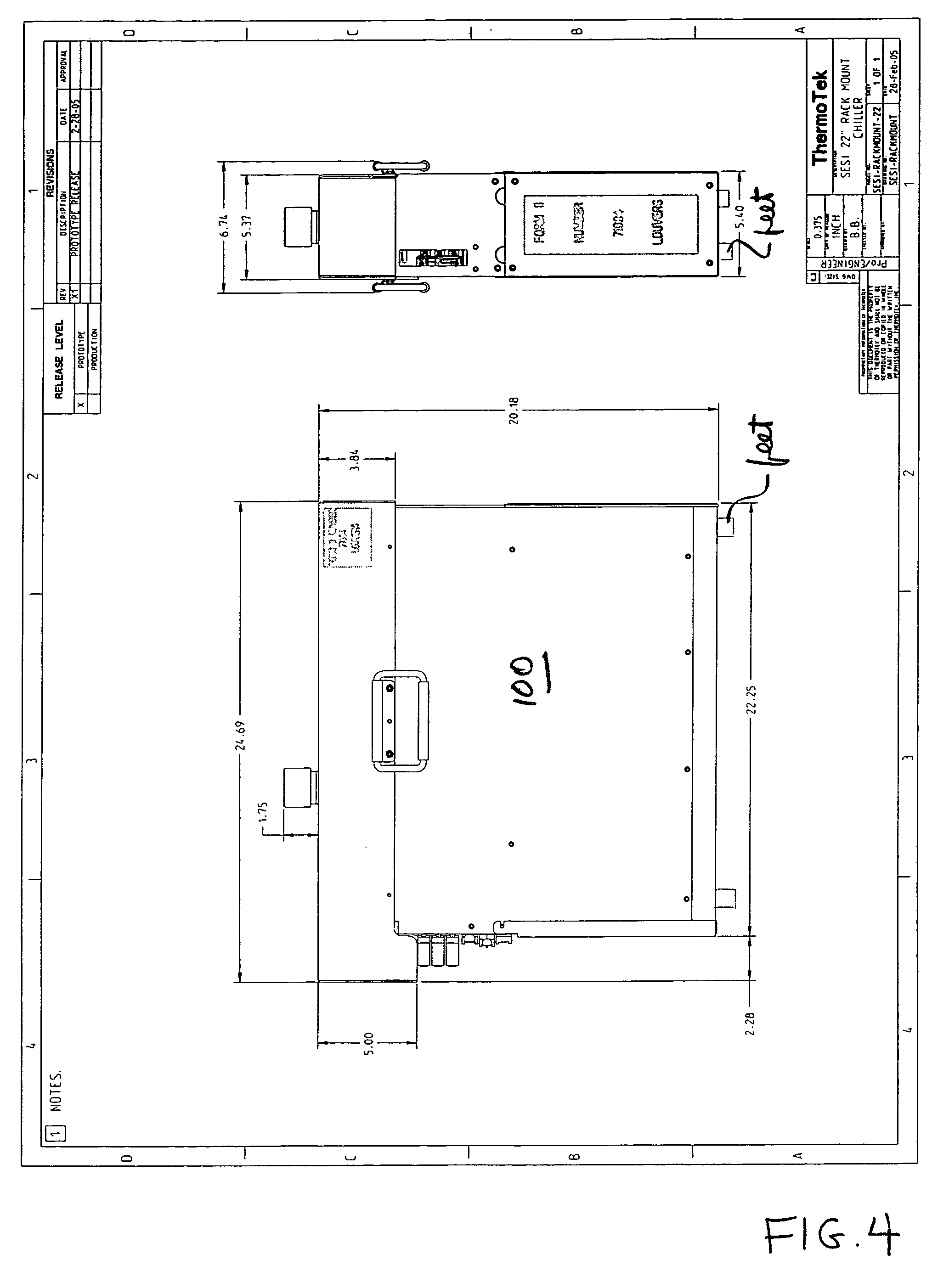

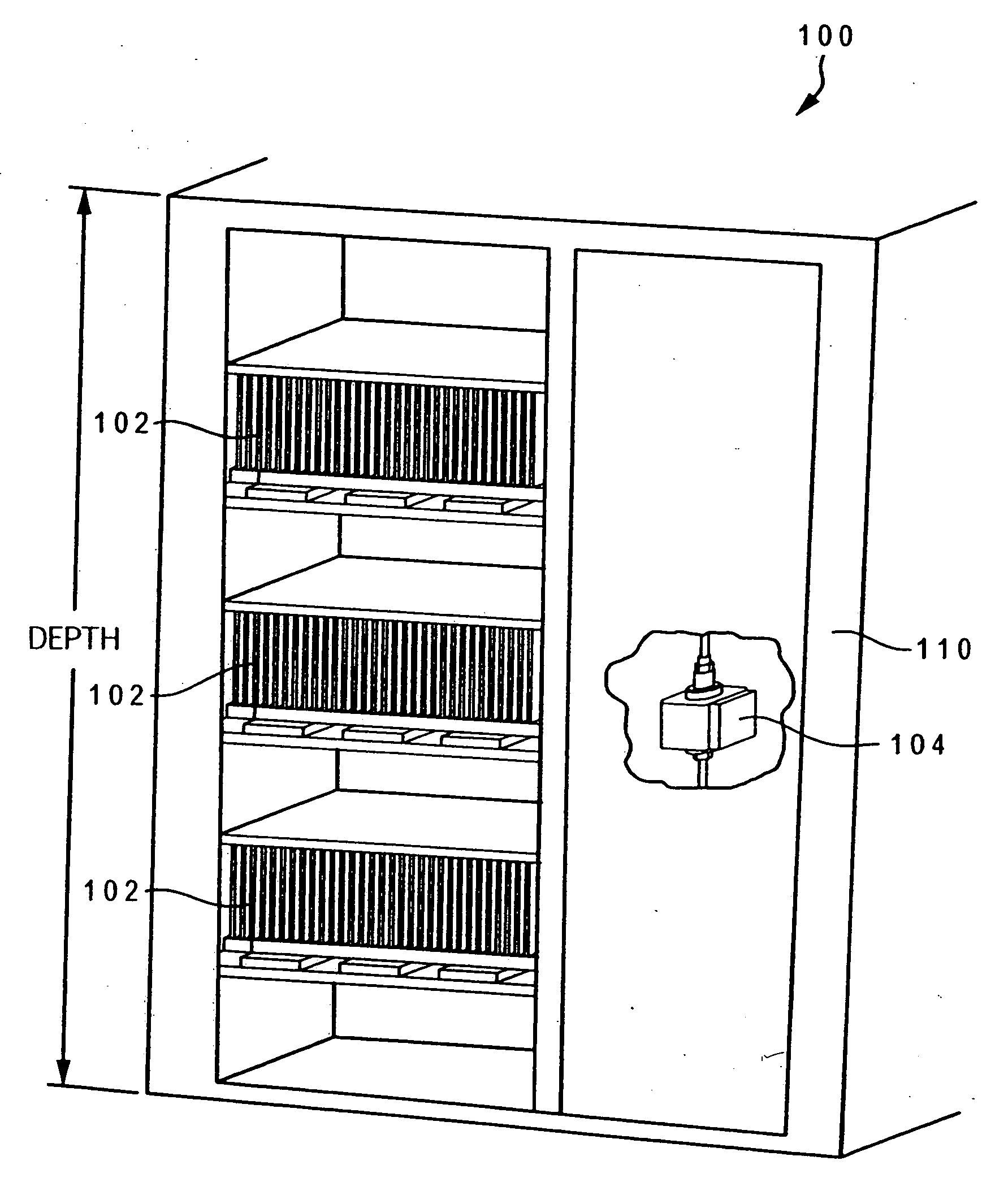

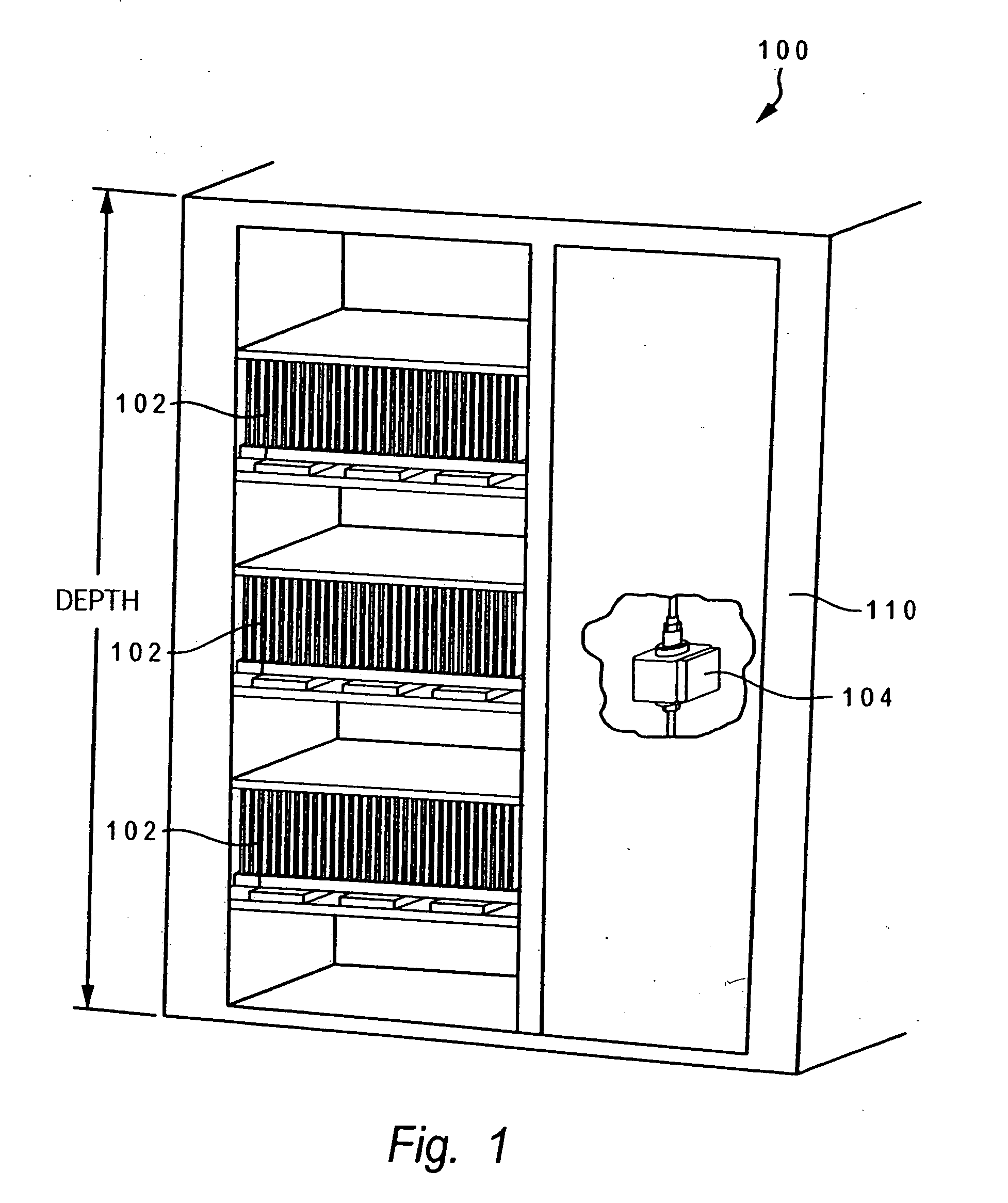

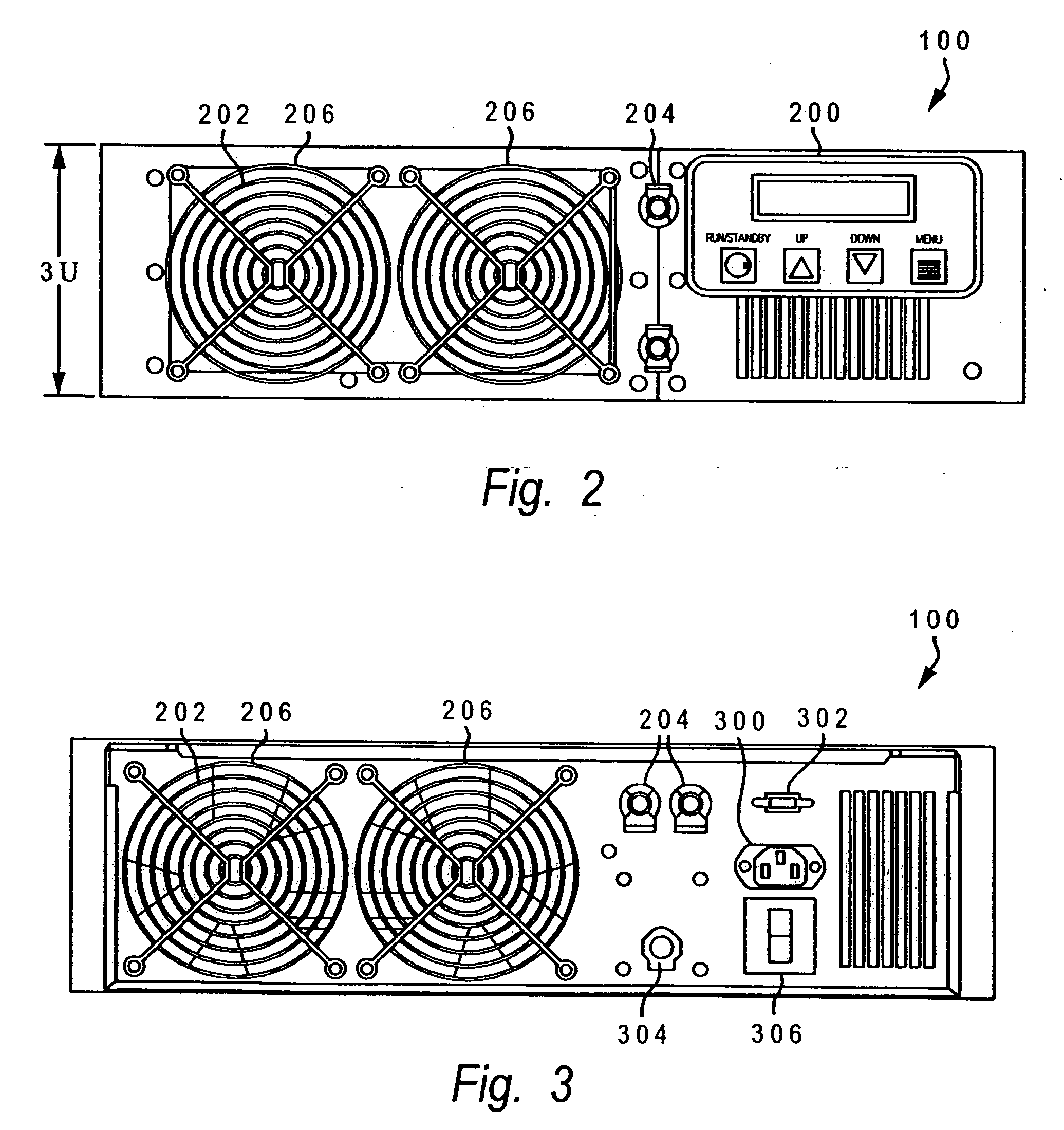

Thermal control system for rack mounting

InactiveUS20060034053A1Efficient transferCooling/ventilation/heating modificationsElectrical apparatus casings/cabinets/drawersEngineeringThermal control system

A thermal control system of a 3U height includes various modules for providing temperature control in a rack environment. The modules may be, for example, a power module, user interface module, various different pump assemblies, various different models of fan assemblies, HTAs, and / or a serial communication interfaces. This Abstract is provided to comply with rules requiring an Abstract that allows a searcher or other reader to quickly ascertain subject matter of the technical disclosure. This Abstract is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:THERMOTEK

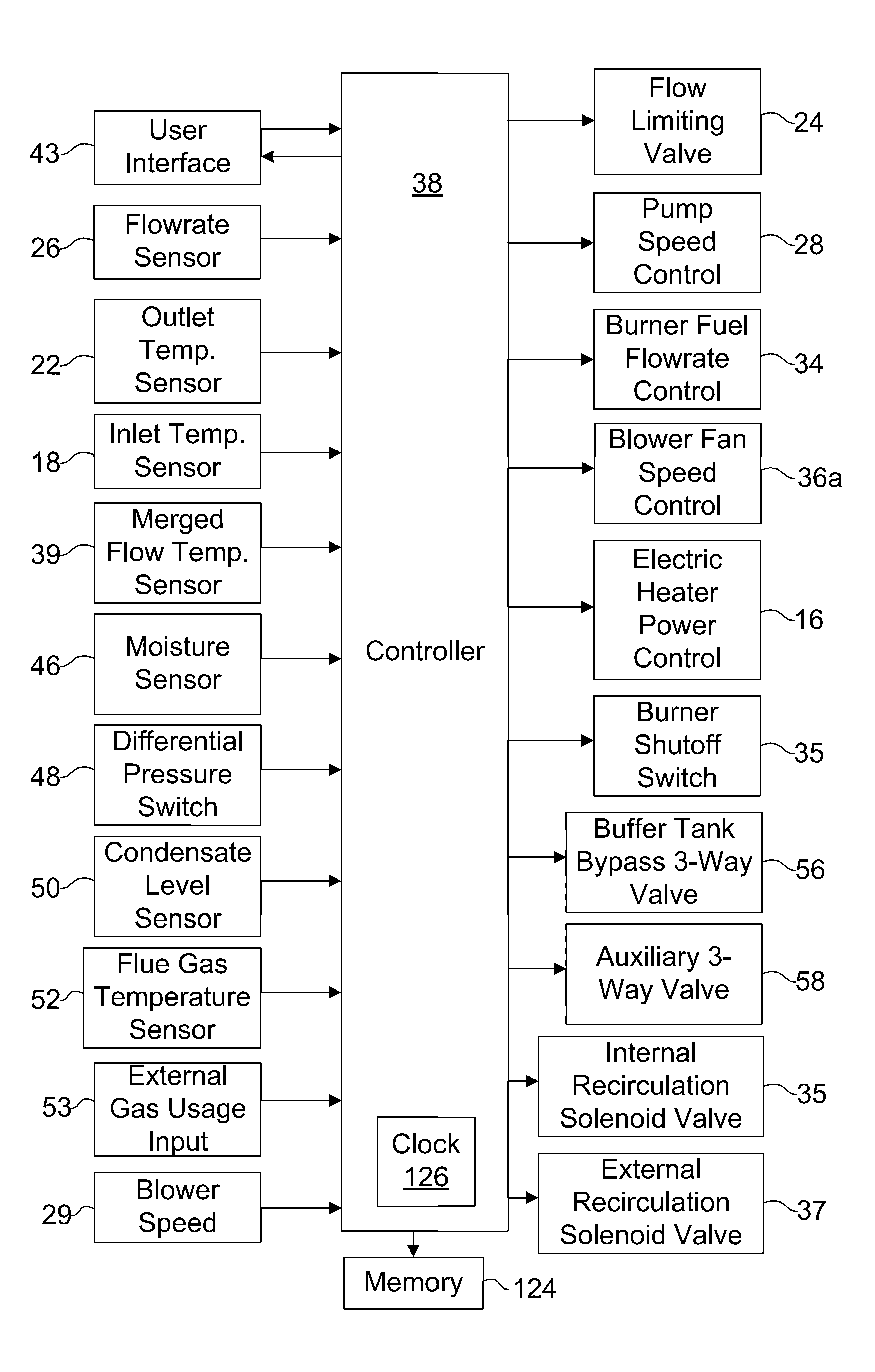

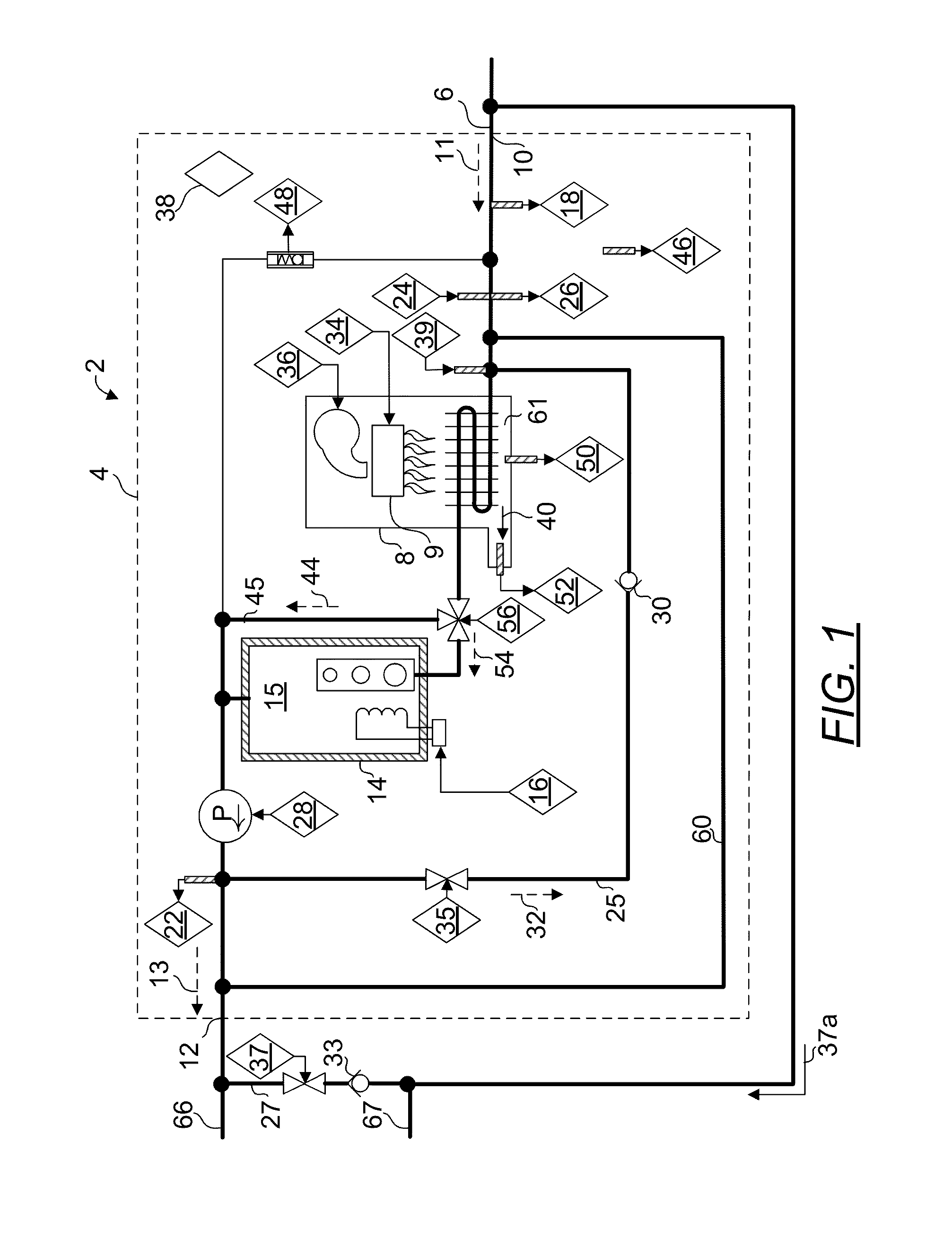

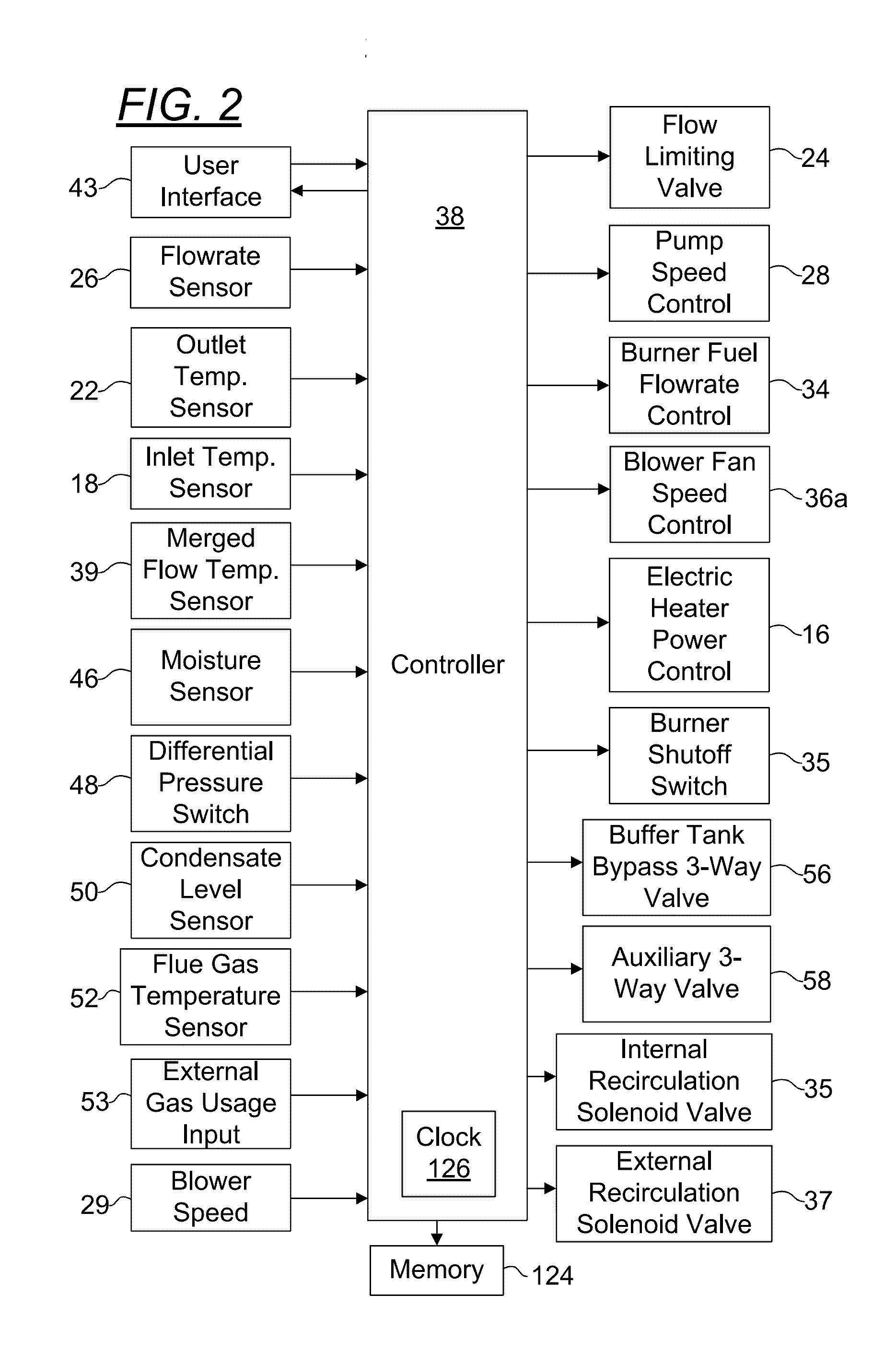

Adaptive heating control system for a water heater

ActiveUS20140229022A1Reduce delaysReduce wasteHeating fuelLighting and heating apparatusControl systemEngineering

Owner:INTELLIHOT

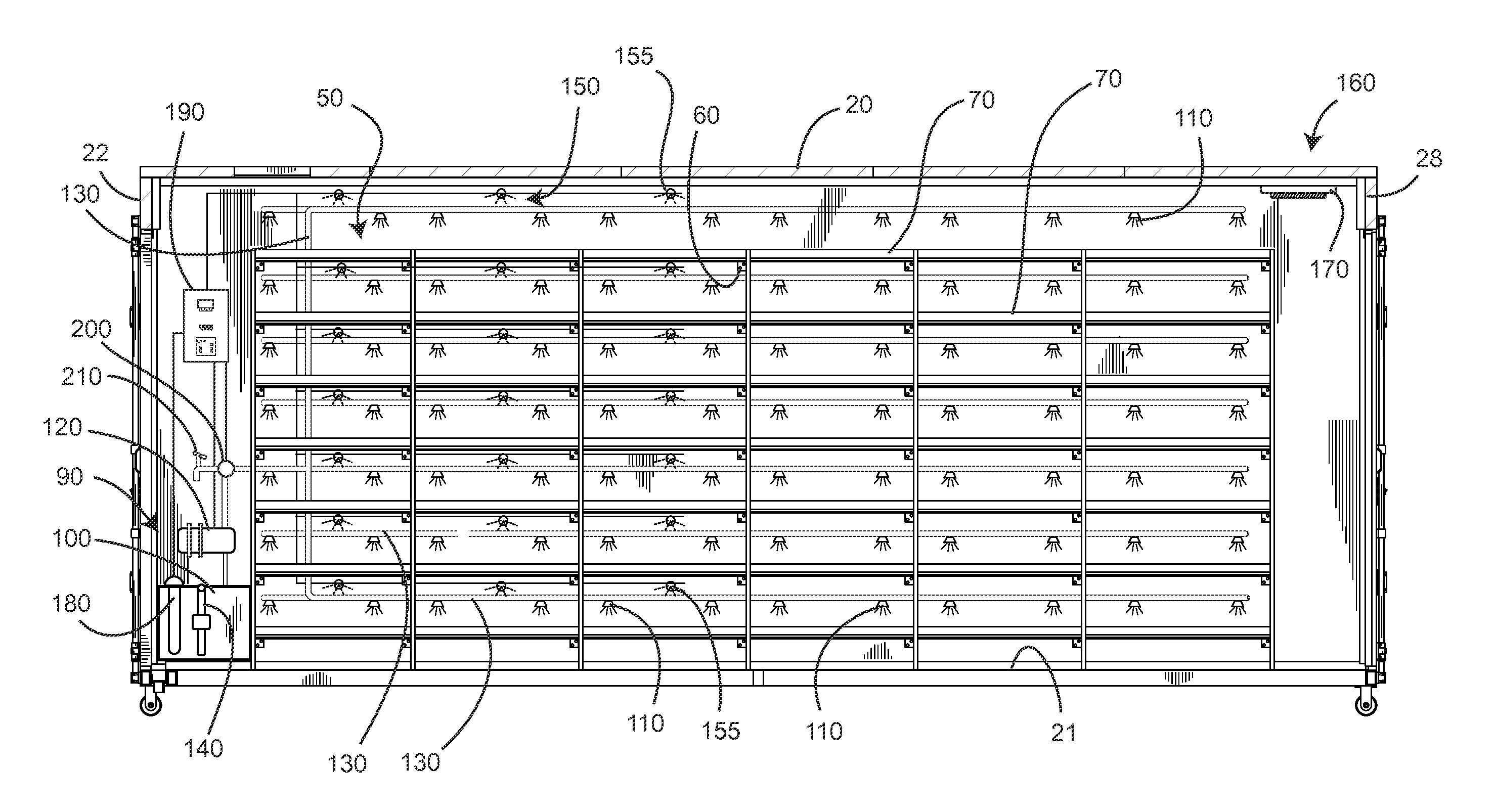

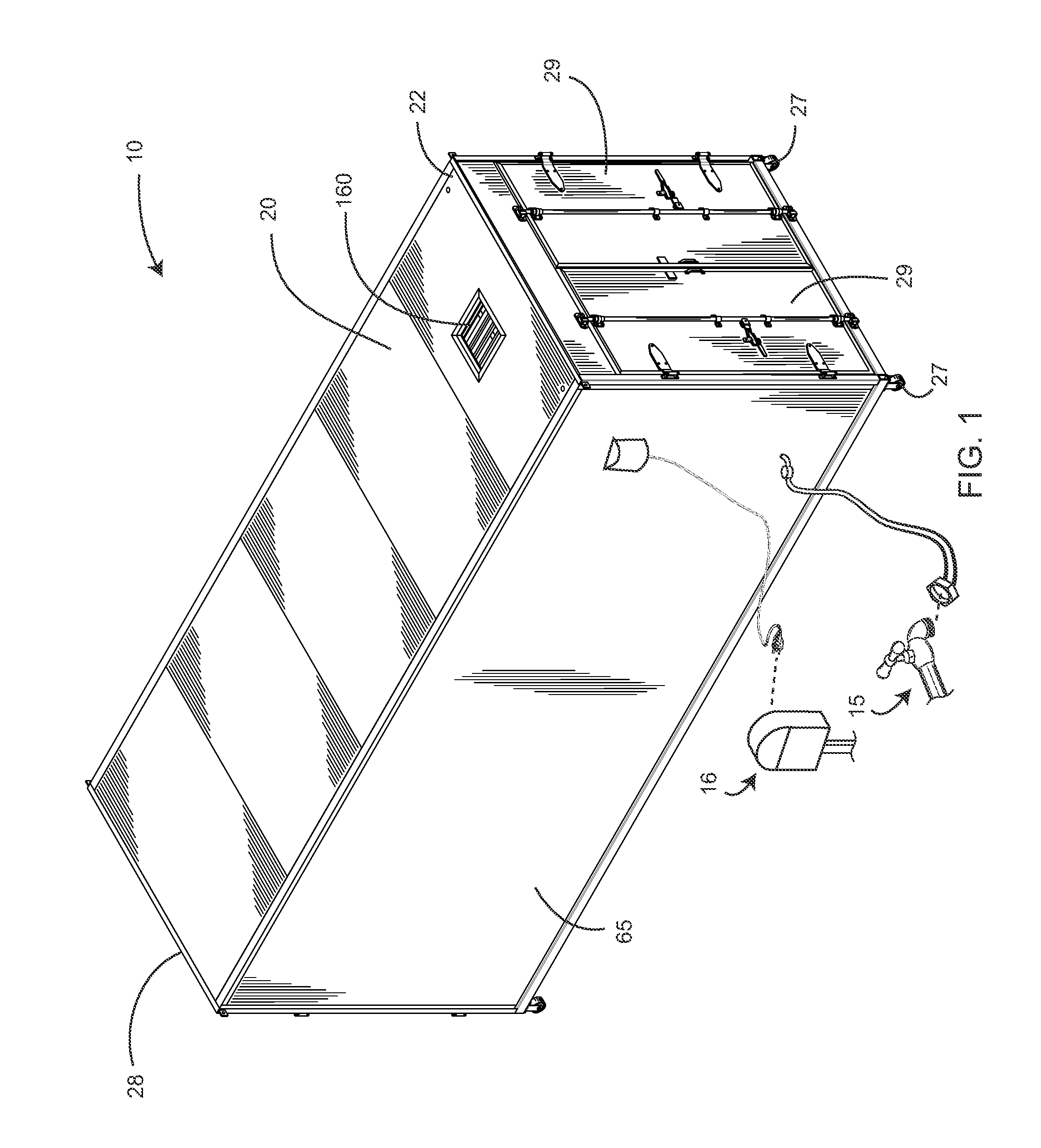

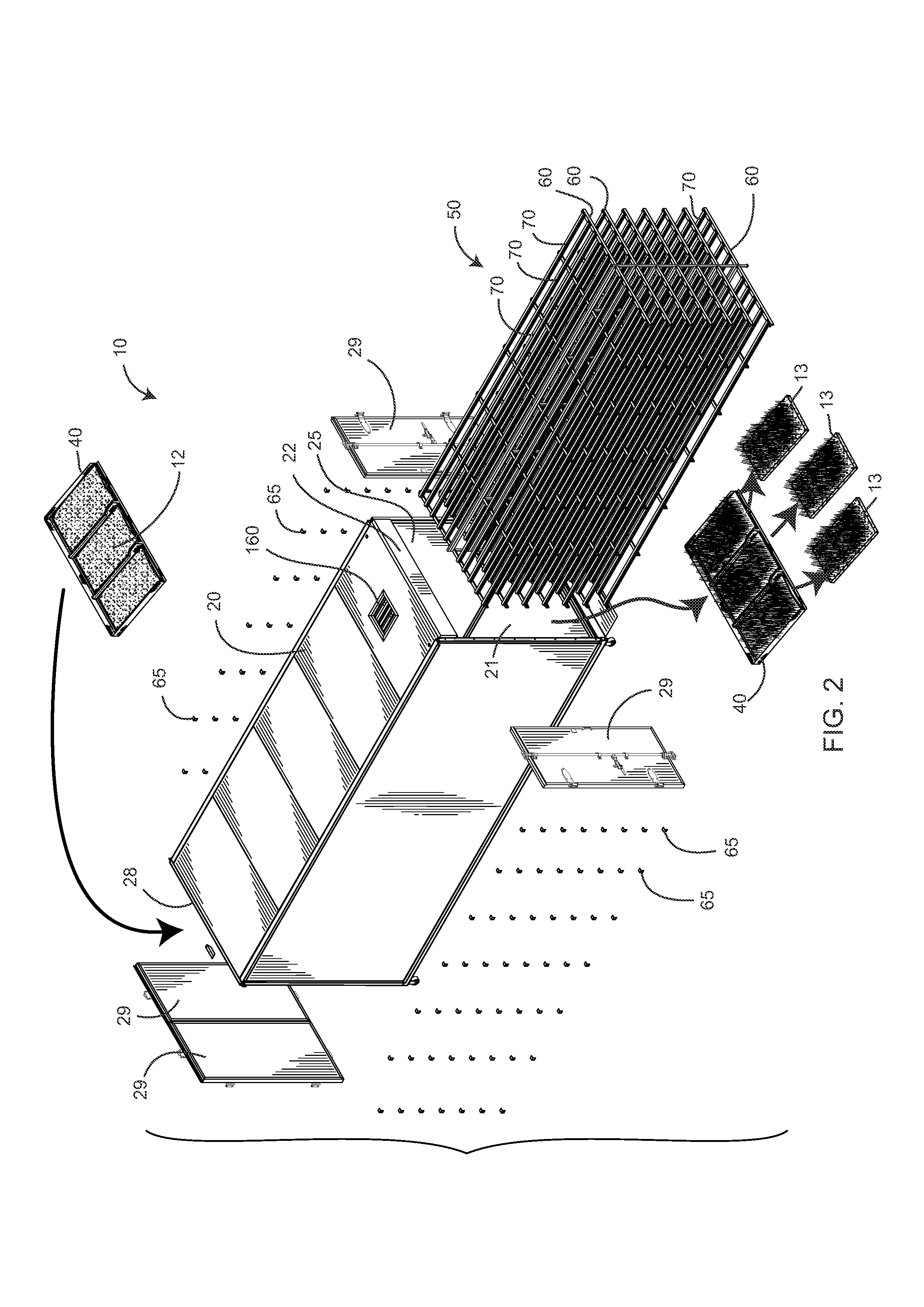

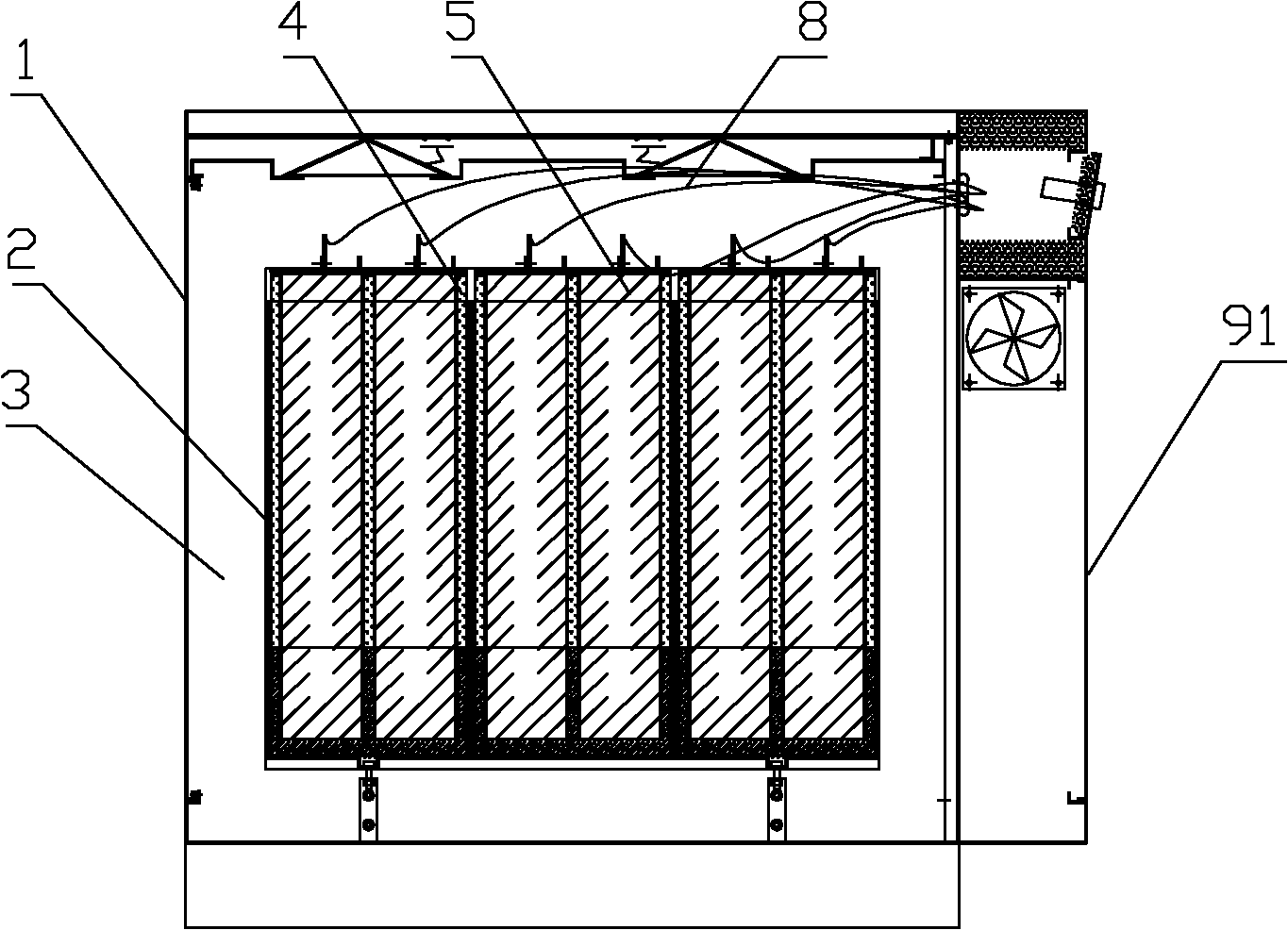

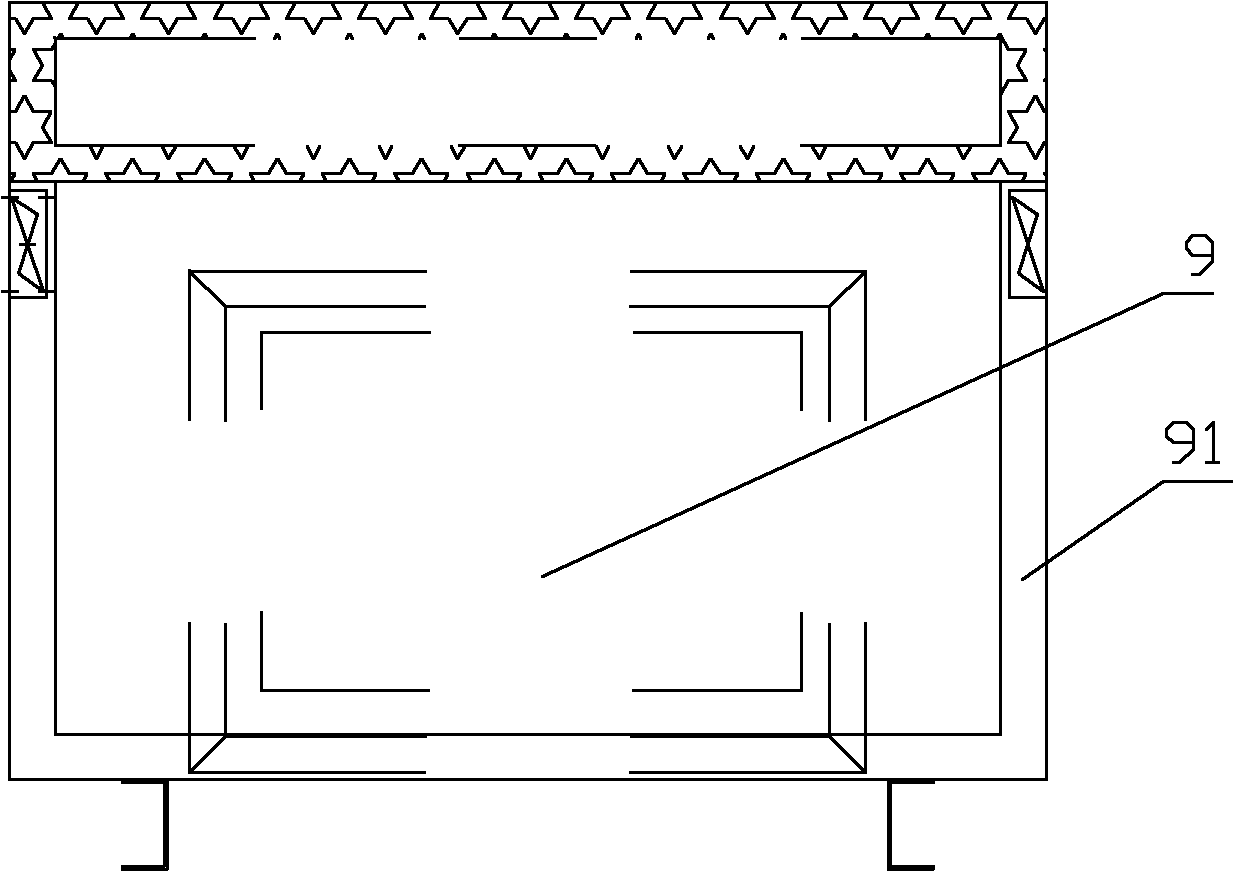

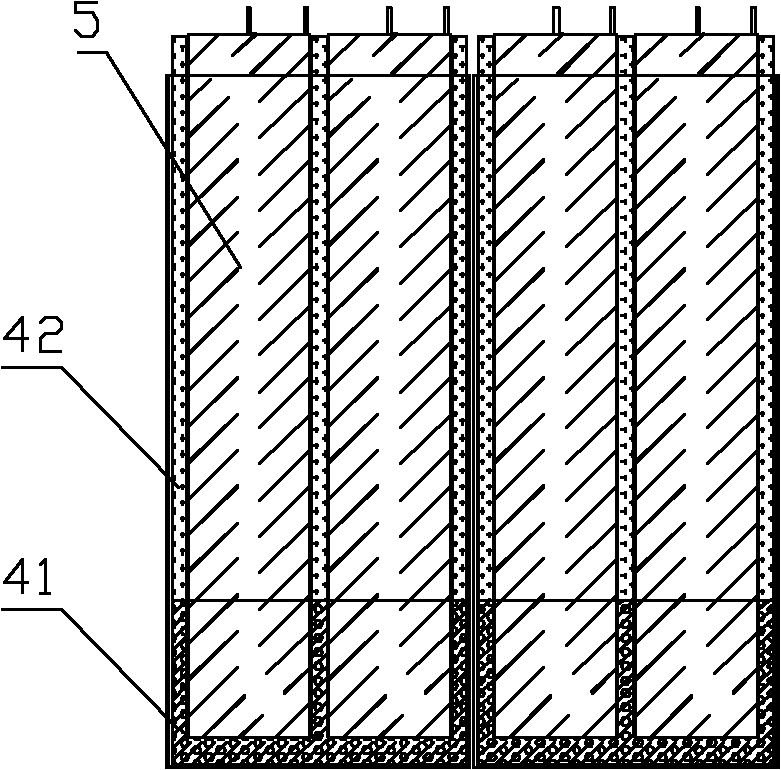

Fodder-growing enclosure

InactiveUS8234812B1Facilitate ready removalEasy to slideClimate change adaptationAgriculture gas emission reductionWater sourceEngineering

A transportable fodder production unit is disclosed that includes an insulated container having a front end and a rear end, a plurality of trays each having drain apertures through a bottom side thereof, a racking system for supporting each of the trays with a plurality of shelves extending from the front end of the container to the rear end of the container, an irrigation system attachable to a water source and having a water tank in fluid communication with a plurality of spray heads through a pump and a plurality of pipes, a lighting system that maintains a predetermined illumination within the container, a thermal control system that maintains the temperature inside the container within a predetermined temperature range, and a central control system for activating the other systems and maintaining electrical load balancing on a power source.

Owner:COLLESS TERRY +1

Overflow downdrawn glass forming method and apparatus

InactiveUS6889526B2Reduce unevennessEfficient degradationGlass furnace apparatusGlass drawing apparatusThermal creepEngineering

Owner:CORNING INC

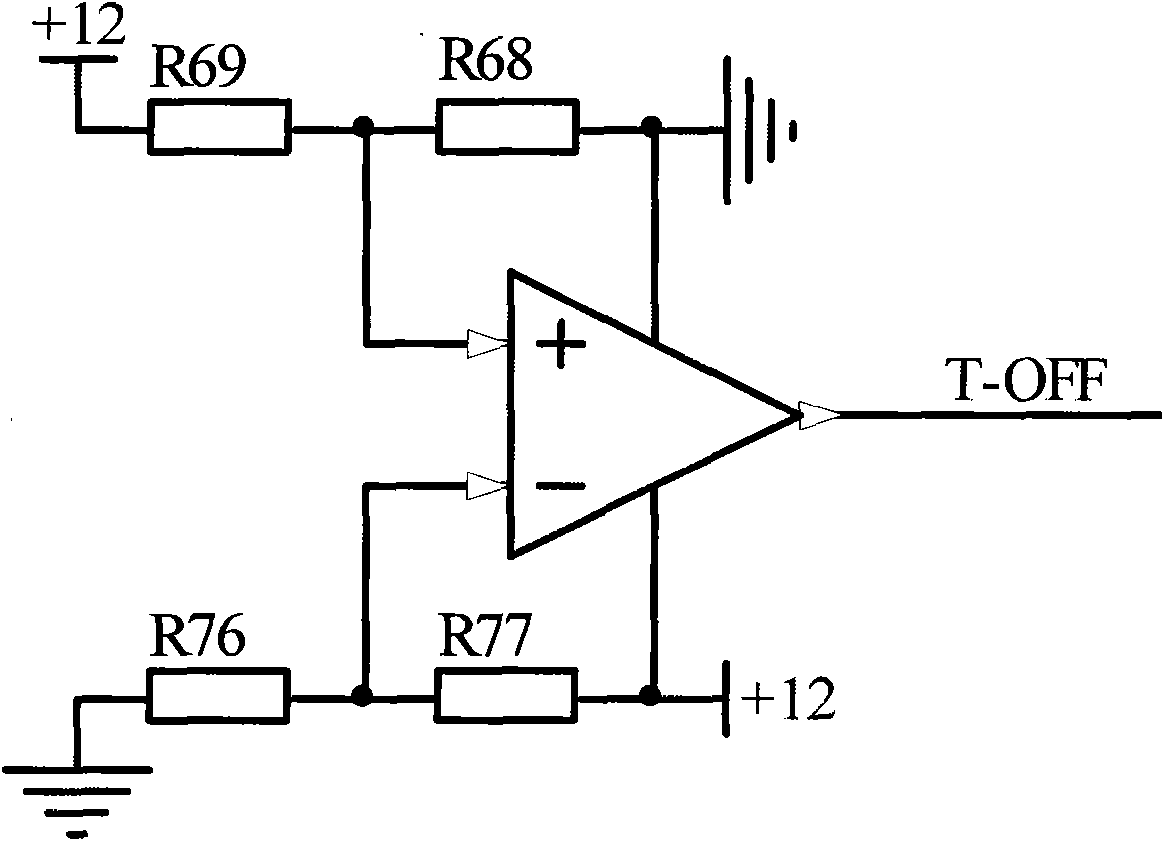

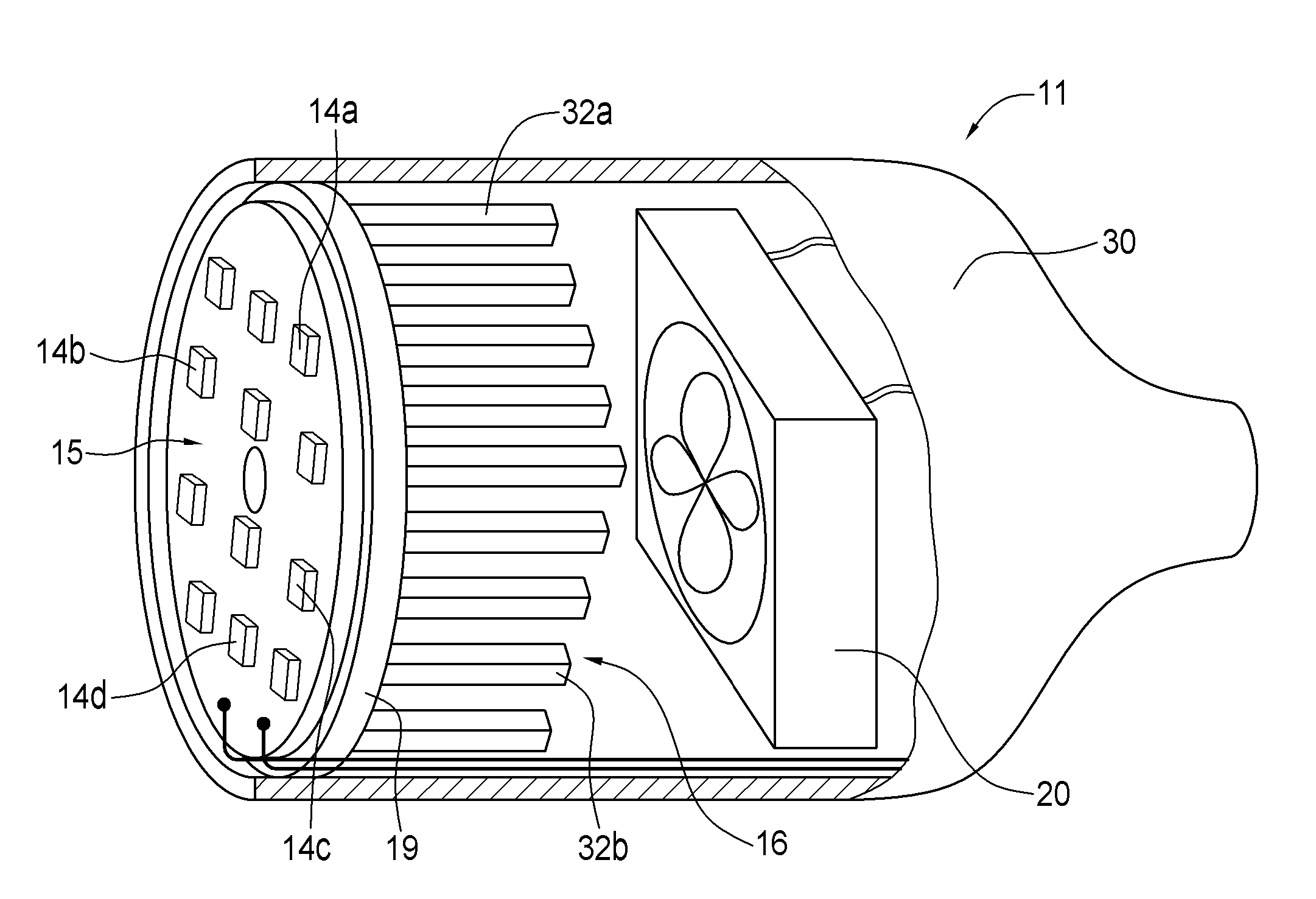

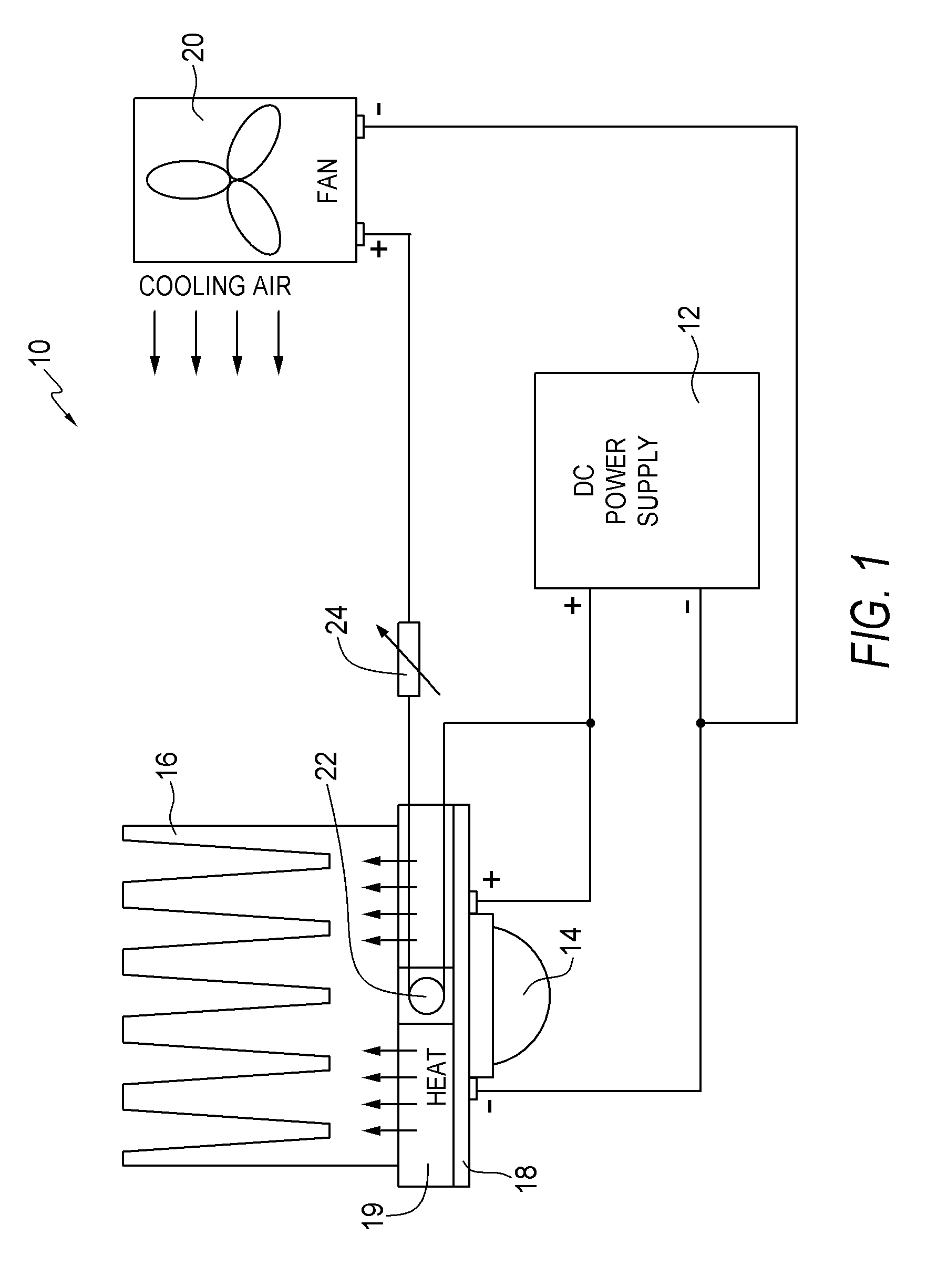

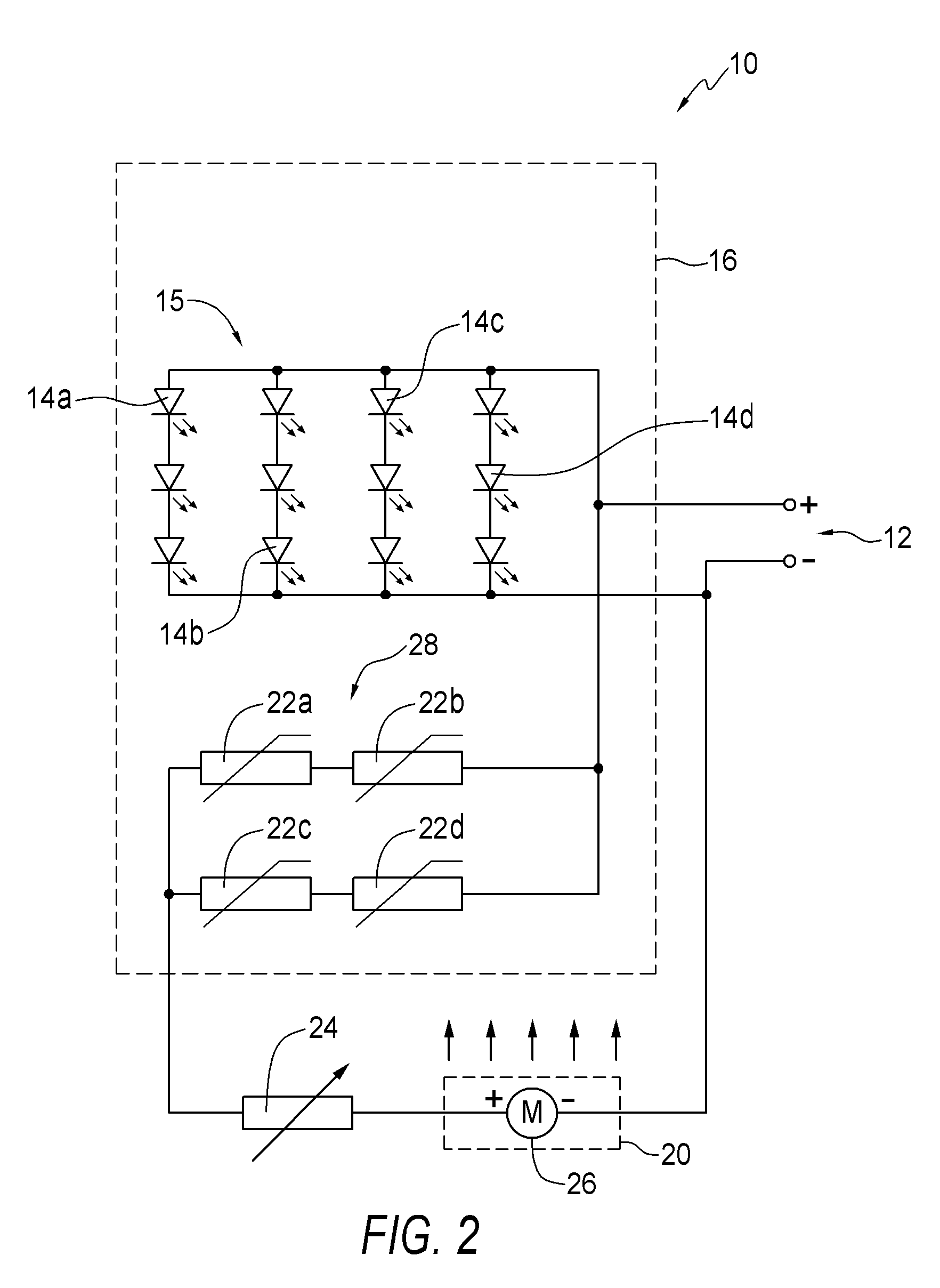

Thermal control system for a light-emitting diode fixture

InactiveUS20100027276A1Reduce in quantityPlanar light sourcesPoint-like light sourceElectricityElectrical resistance and conductance

A thermal control system for a light-emitting diode comprises a thermistor thermally coupled to a heat sink. Preferably the thermistor is disposed within a thermal conductive member. A power supply is electrically connected to the thermistor. A cooling device is electrically connected in series with the power supply and the thermistor. The thermistor is between the power supply and the thermistor. A rheostat may further be electrically connected, in series, between the thermistor and the power supply.

Owner:MP DESIGN

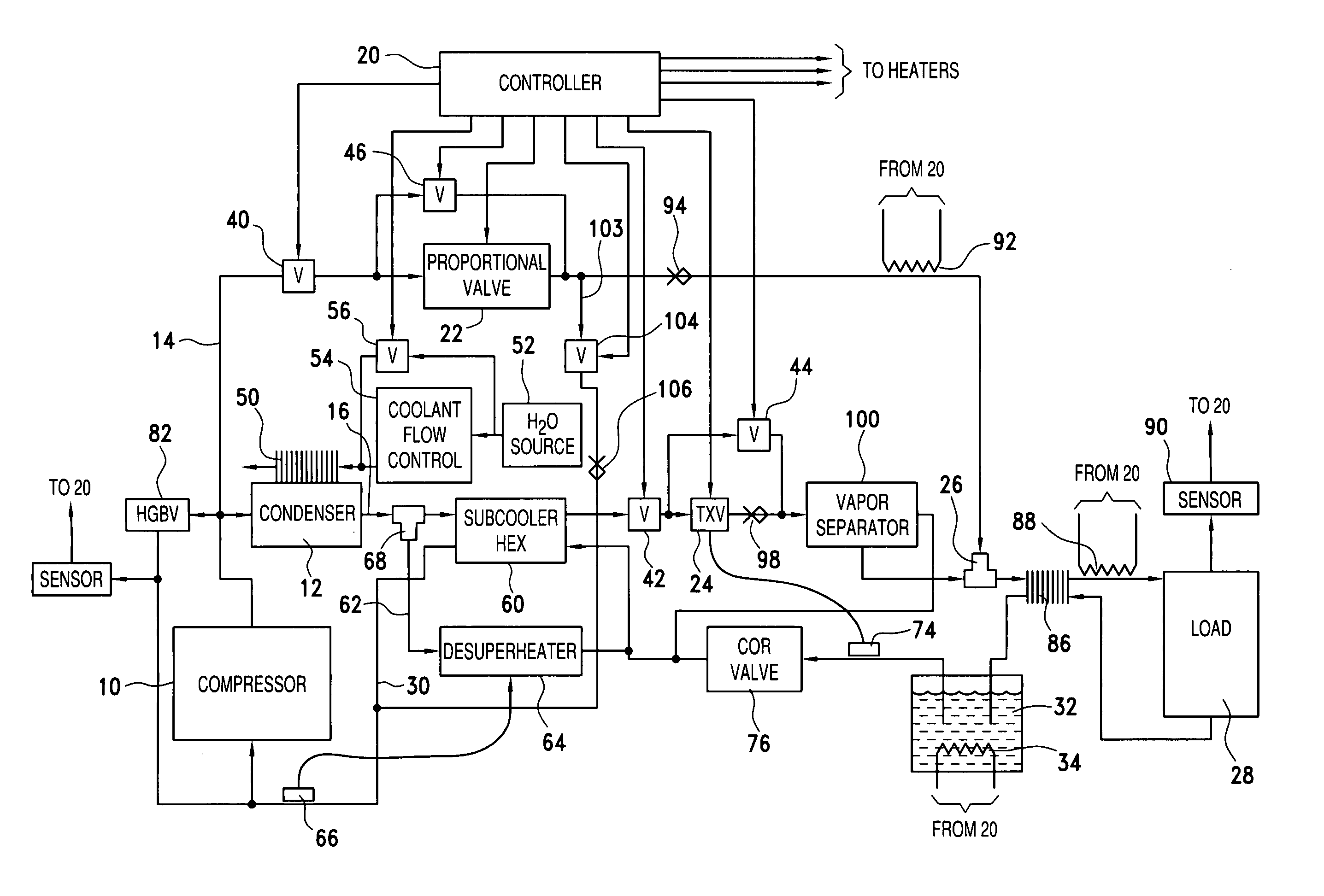

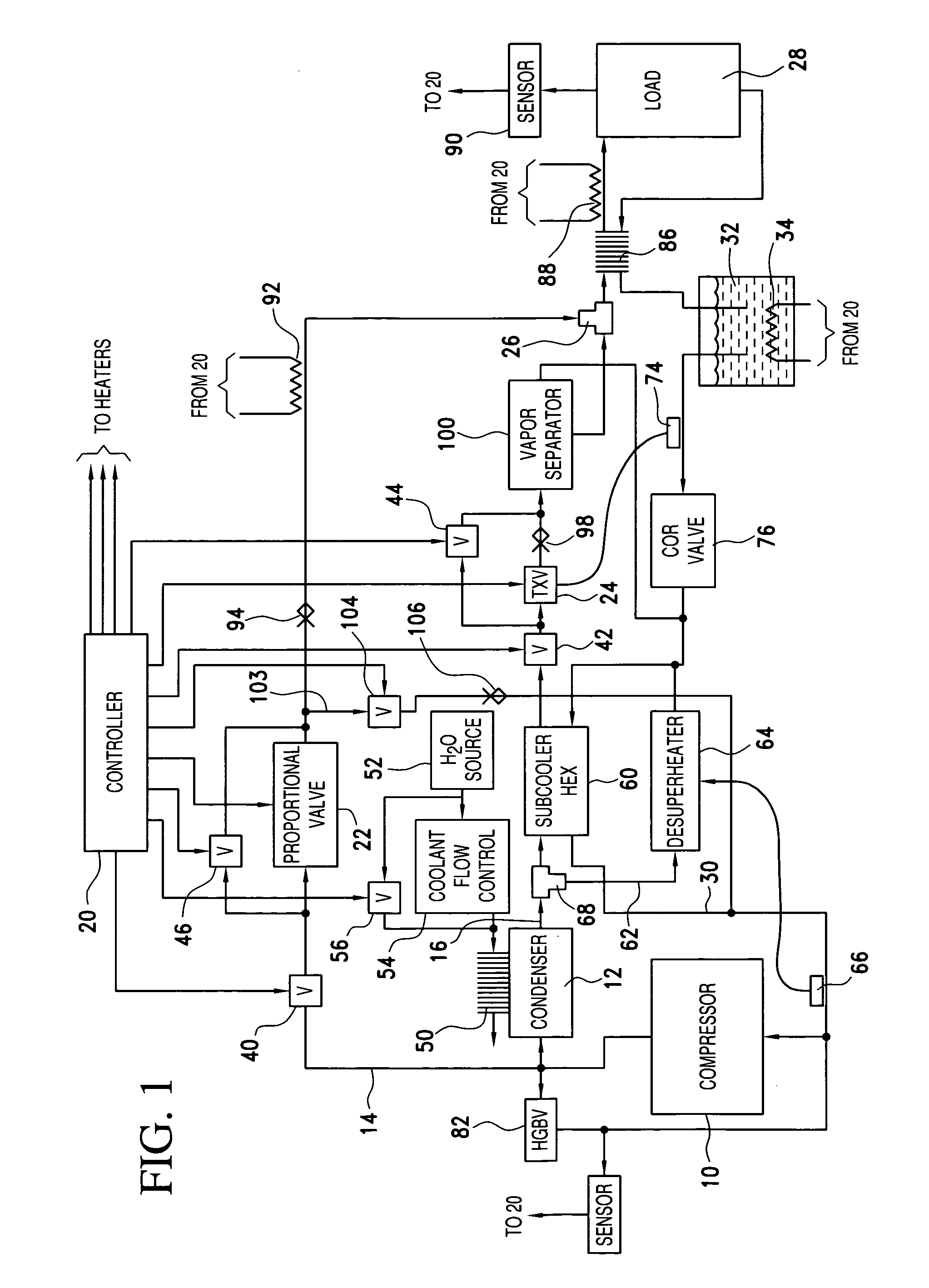

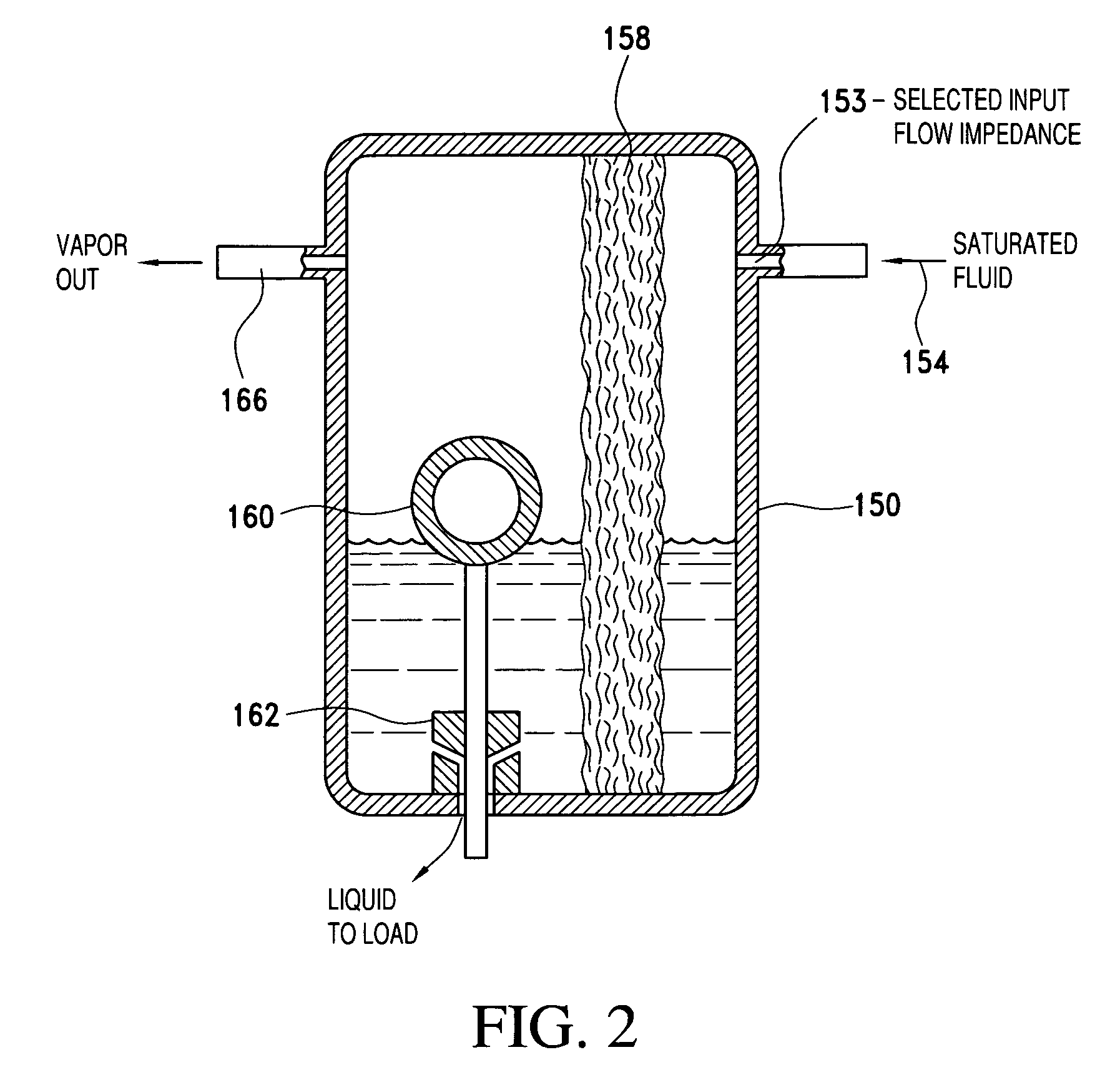

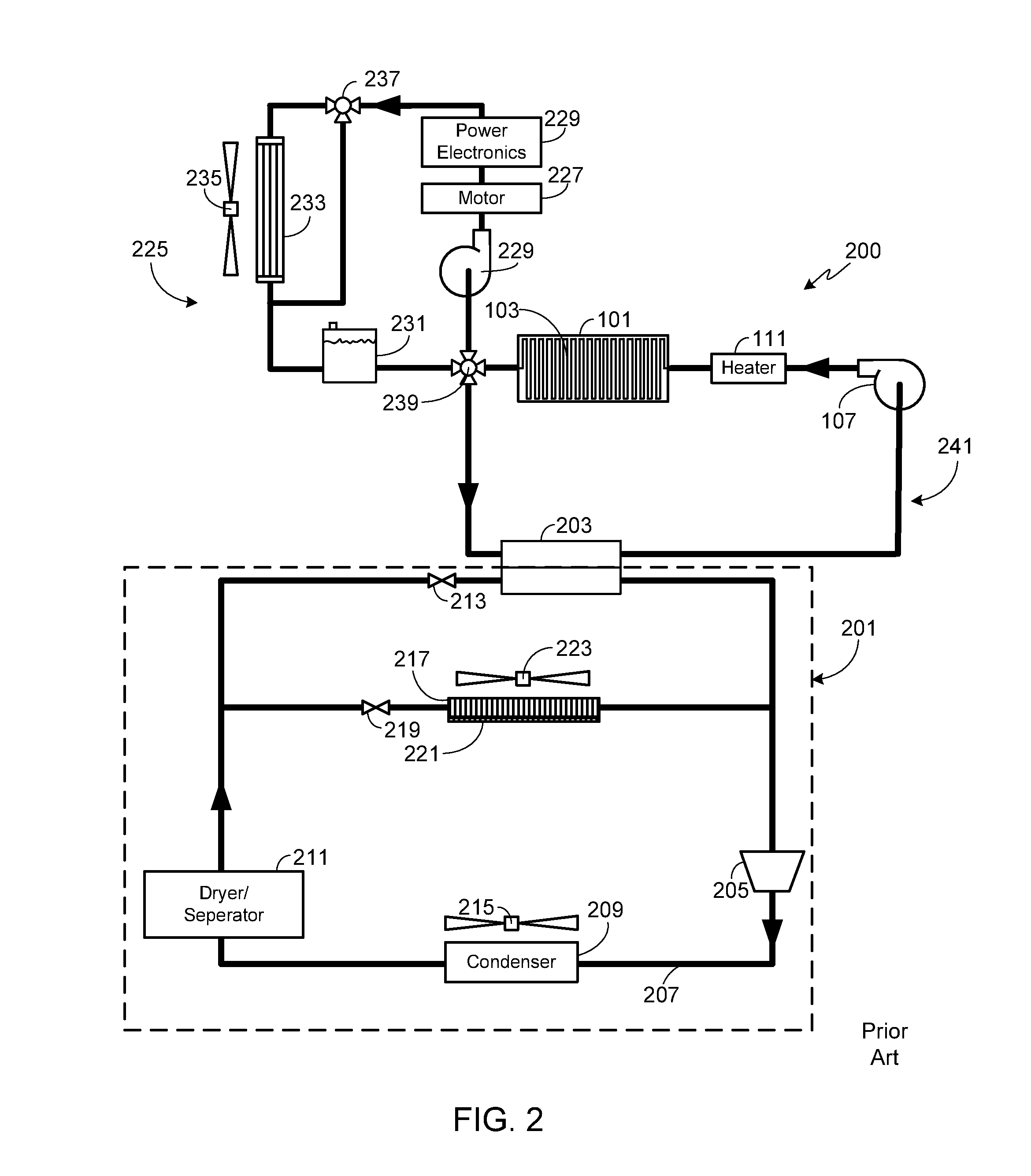

Thermal control system and method

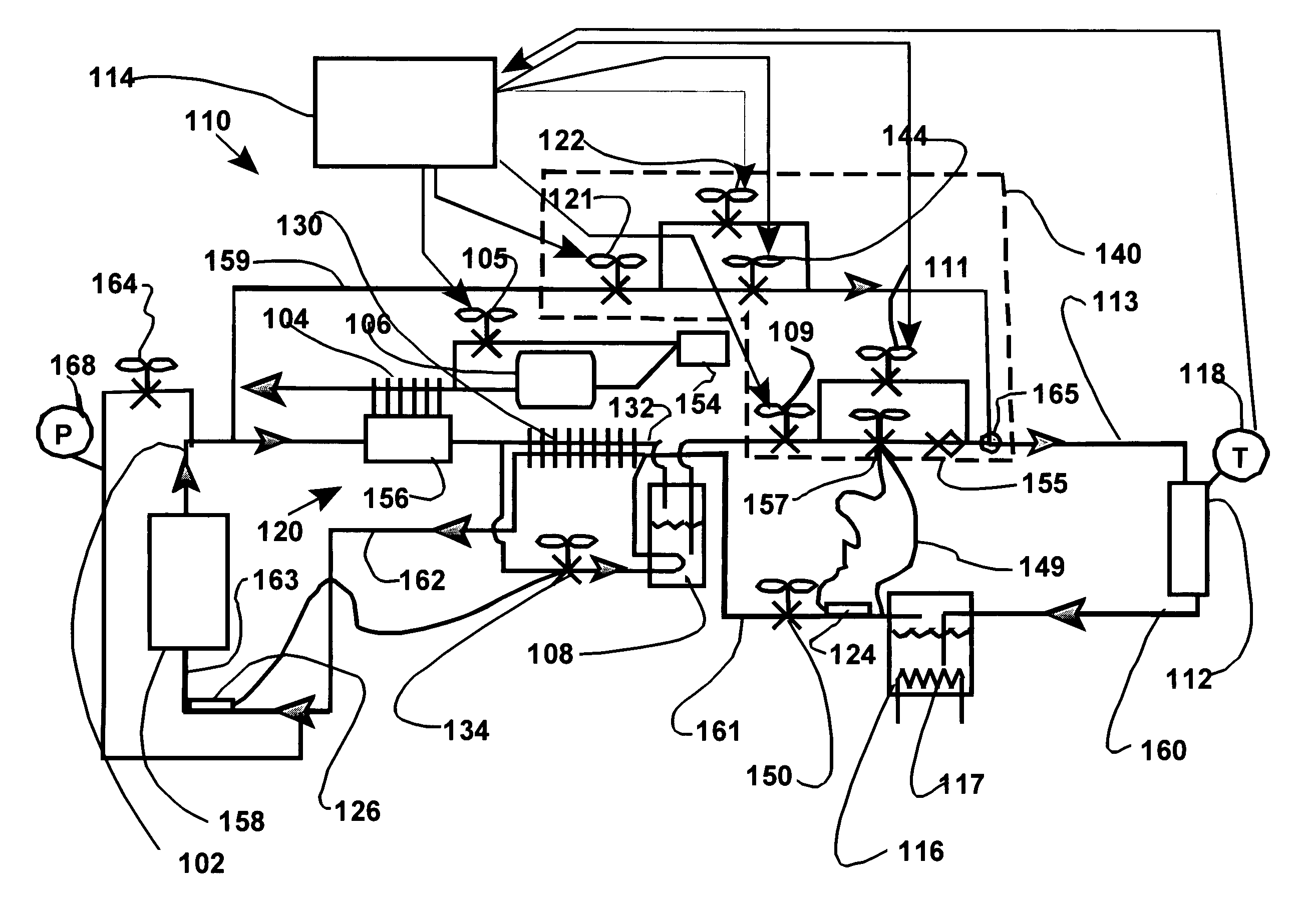

InactiveUS20070095097A1Lower overall pressure dropImprove efficiencyFluid circulation arrangementHigh rateThermal control system

Improvements in systems and methods which employ a two-phase fluid, such as a refrigerant, as a saturable fluid in direct heat transfer relation to a thermal load, are realized by extraction of vapor from the saturated fluid before heat exchange. Moreover, automatic changing of the paths under command of a controller enables charges to be effected between different modes at higher rates than in other systems by employing the variety of modes available in the direct transfer system.

Owner:ADVANCED THERMAL SCI

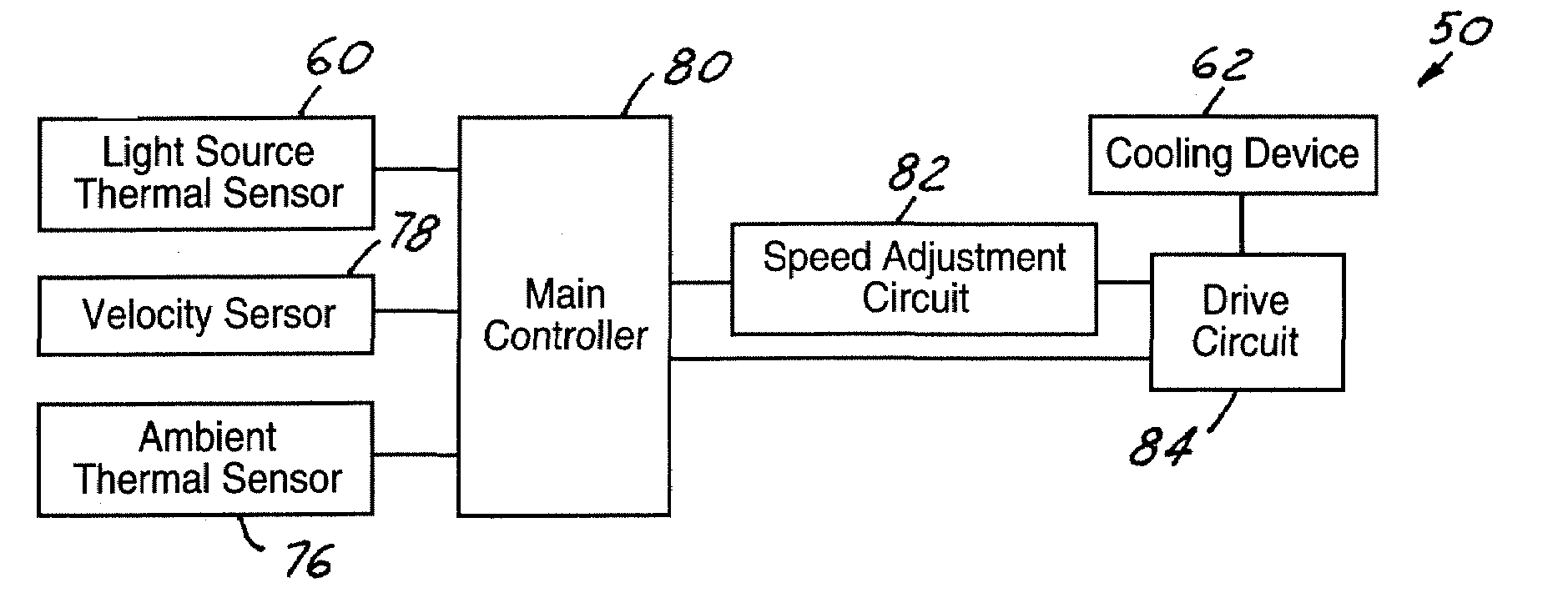

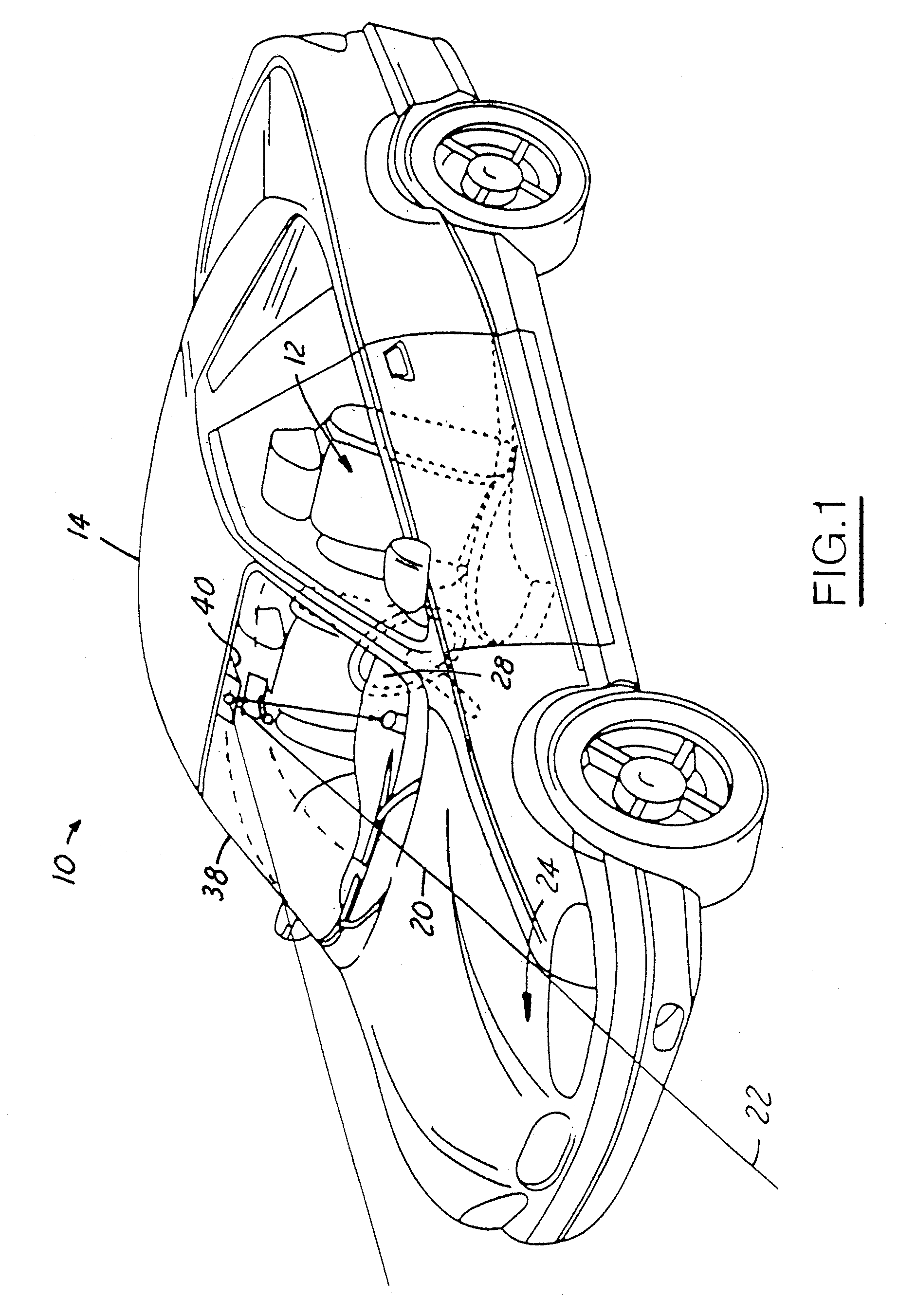

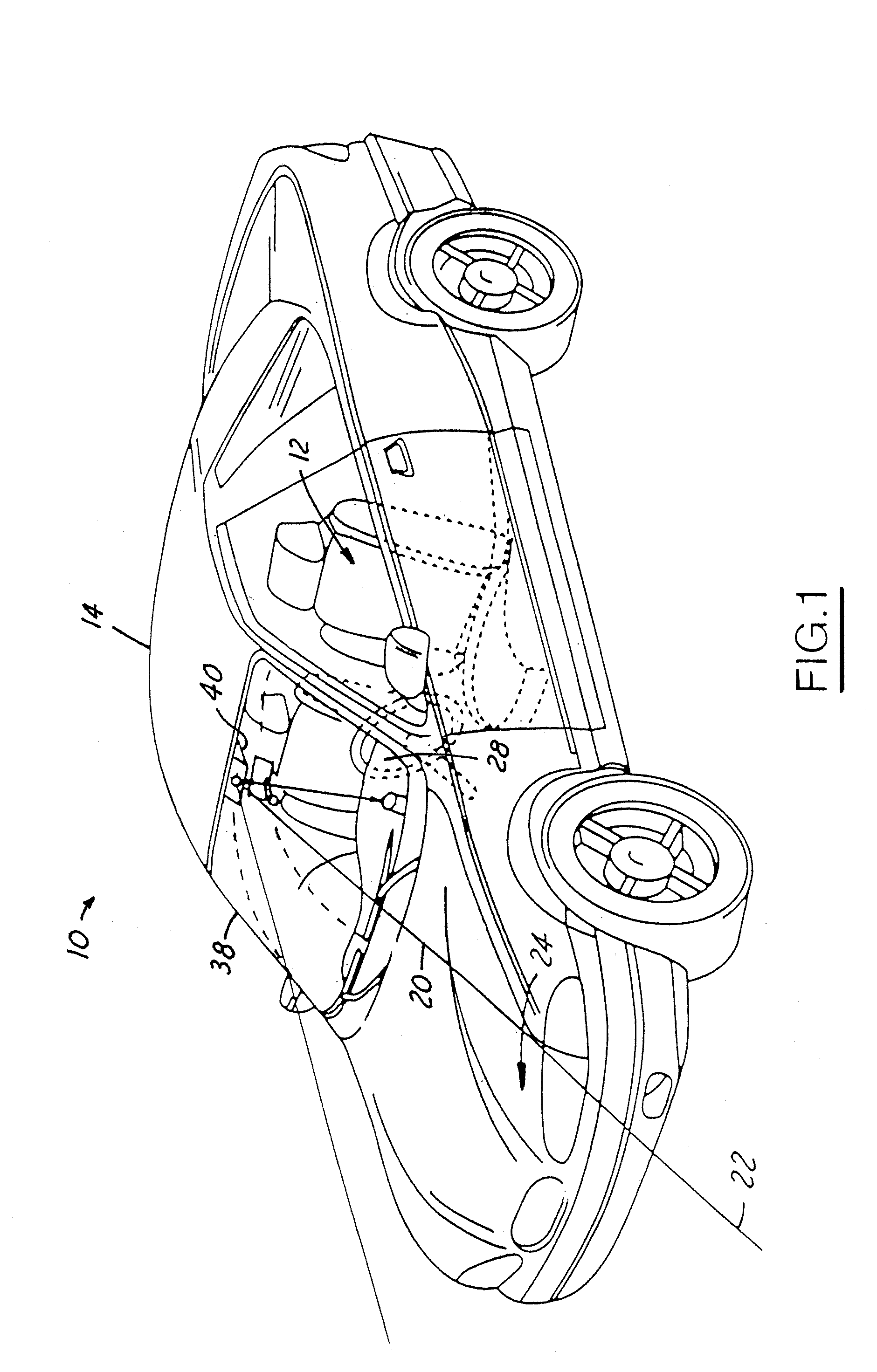

Active night vision cooling system

InactiveUS20050012039A1Minimizes operating noiseEfficiently adjusts temperatureLighting heating/cooling arrangementsSighting devicesNight visionEngineering

A thermal control system (11) for a light source (46) of a vision system (10) includes a cooling assembly (61) that has a cooling device (62) and is thermally coupled to the light source (46). A thermal sensor (60) is thermally coupled to the light source (46) and generates a light source temperature signal. A control circuit (50) is coupled to the cooling assembly (61) and to the thermal sensor (60) and operates the cooling device (62) when the light source temperature signal is above a minimum temperature limit.

Owner:LEAR CORP

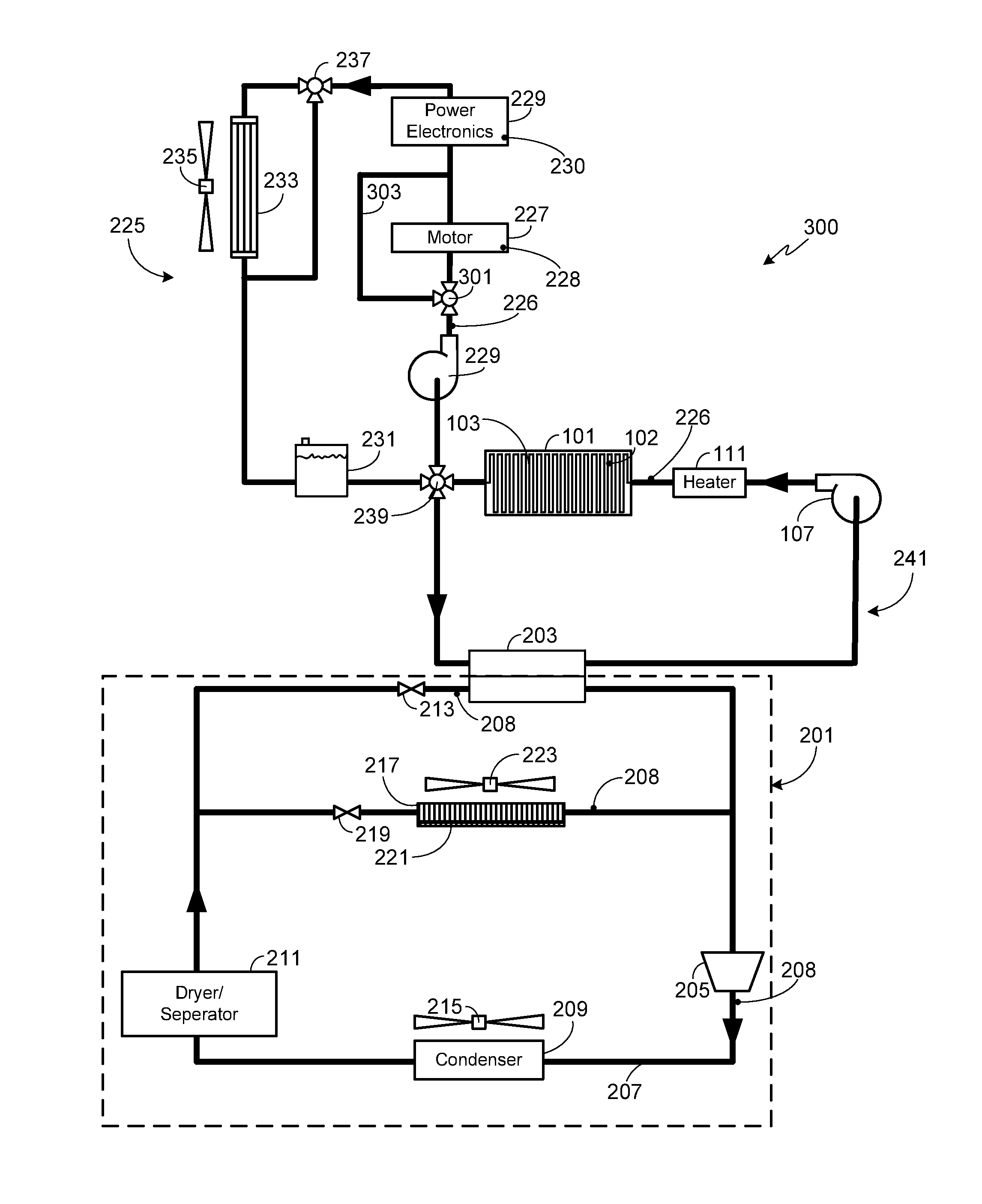

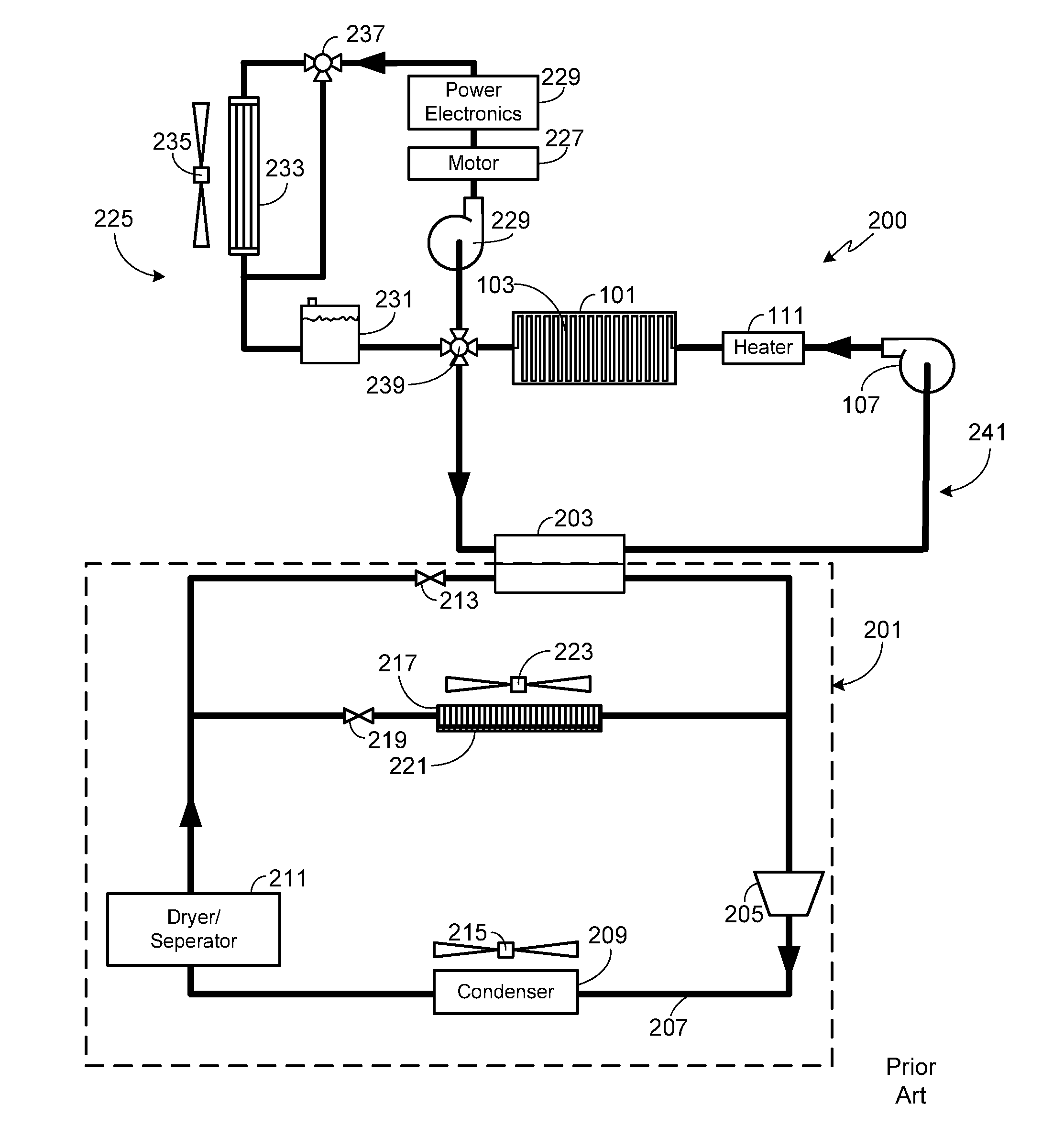

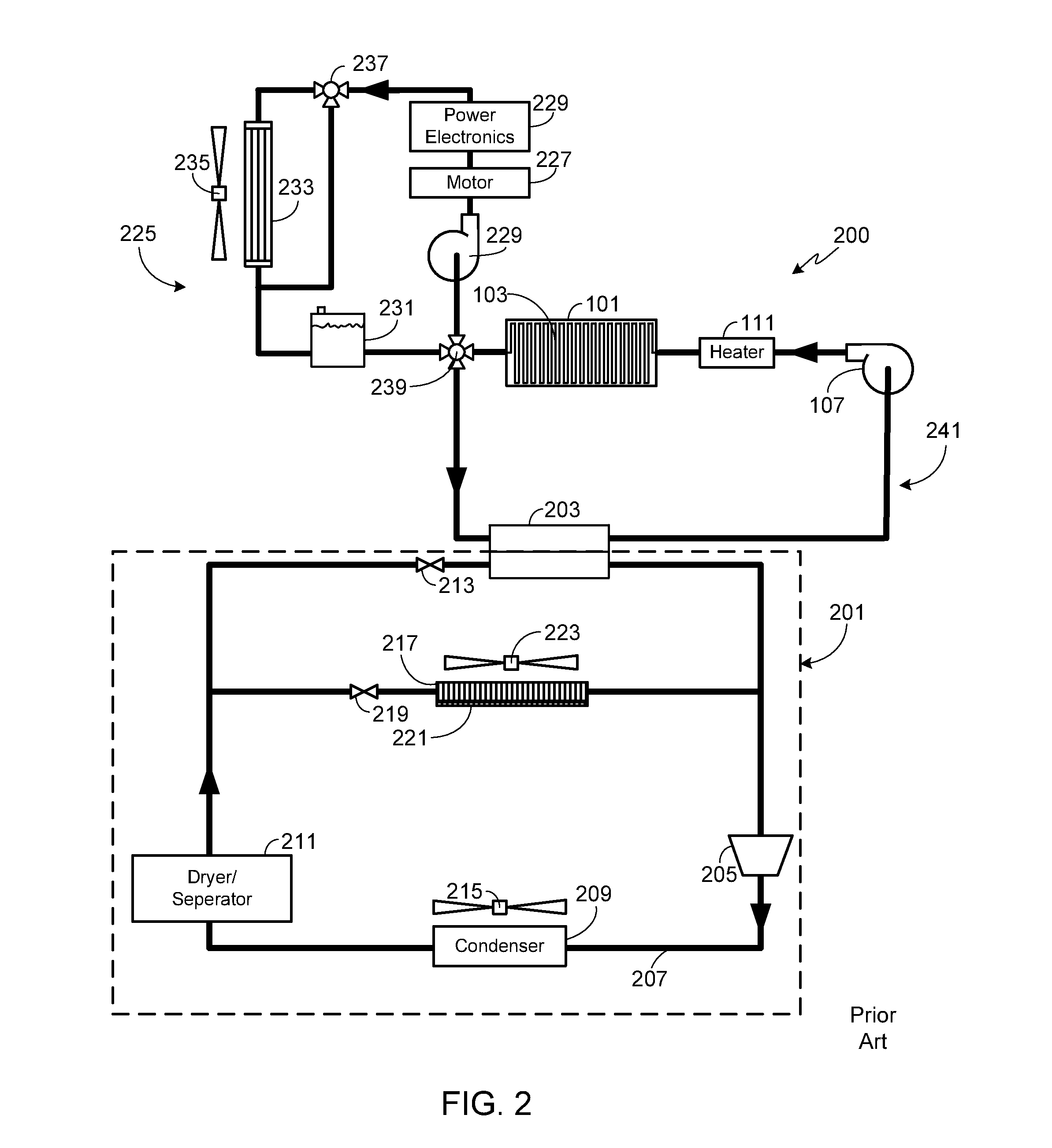

EV Muti-Mode Thermal Control System

ActiveUS20160318370A1Efficient thermal controlAir-treating devicesElectric devicesControl systemThermal management system

A thermal management system that utilizes a multi-mode valve assembly within the drive train control loop to provide efficient thermal control of the drive train components is provided. The multi-mode valve assembly allows the mode of thermal coupling between the thermal control loop and the various drive train components (e.g., vehicle propulsion motor, gearbox assembly, power electronics subsystem, etc.) to be varied in accordance with present conditions.

Owner:ATIEVA USA INC

Thermal control system for rack mounting

ActiveUS20090109622A1Indirect heat exchangersCooling/ventilation/heating modificationsTemperature controlThermal control system

A thermal control system of a 3U height includes various modules for providing temperature control in a rack environment. The modules may be, for example, a power module, user interface module, various different pump assemblies, various different models of fan assemblies, HTAs, and / or a serial communication interfaces.

Owner:THERMOTEK

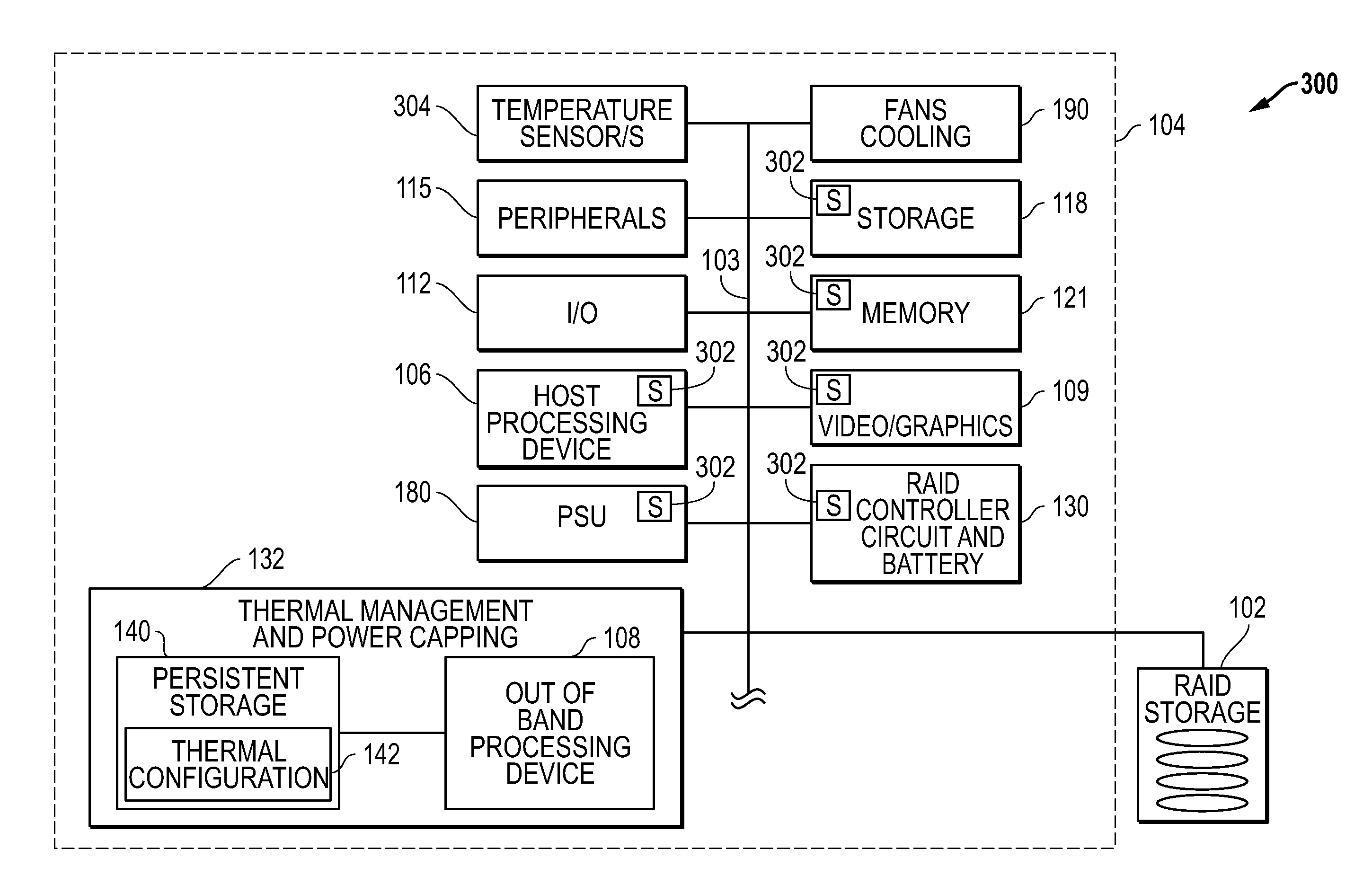

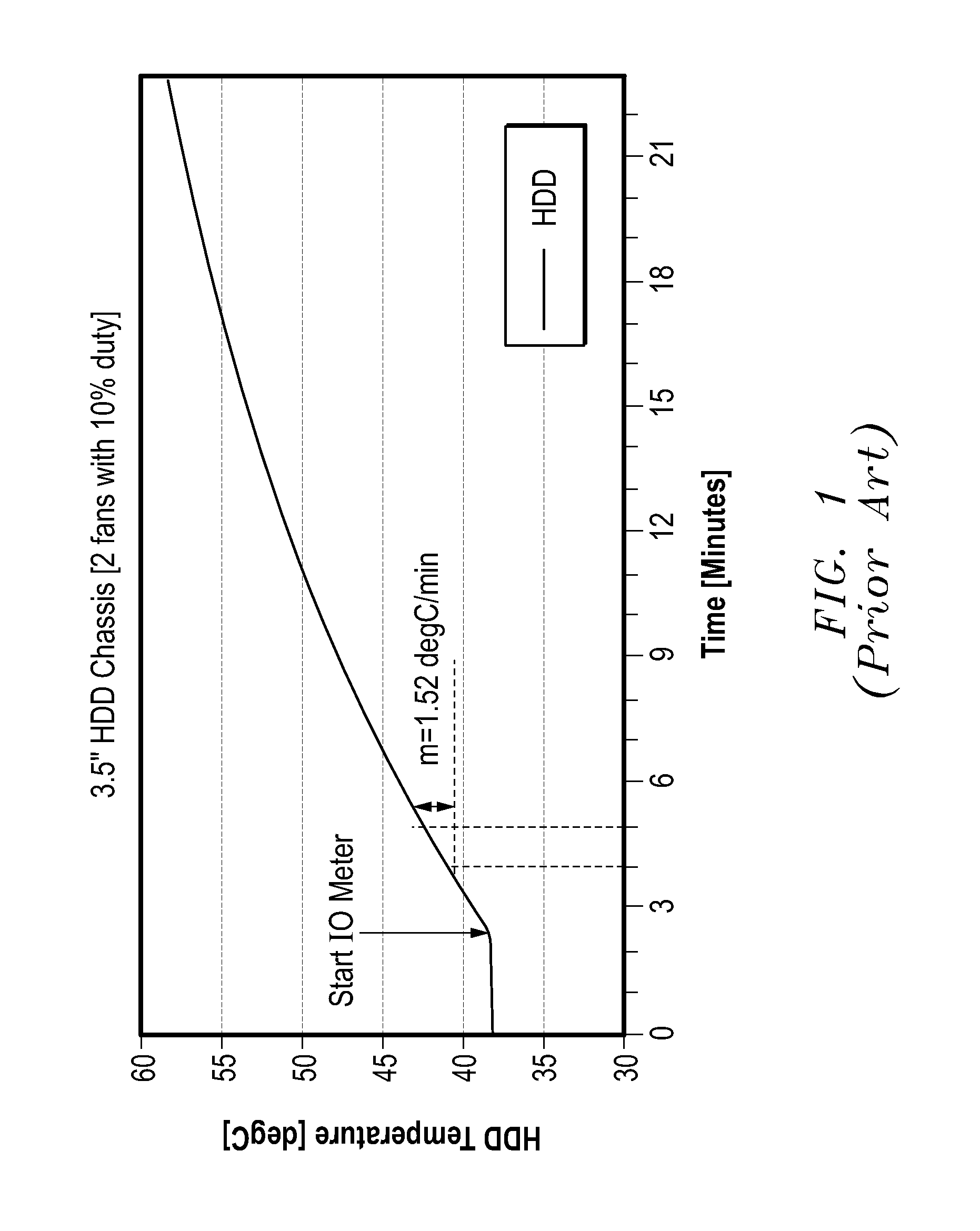

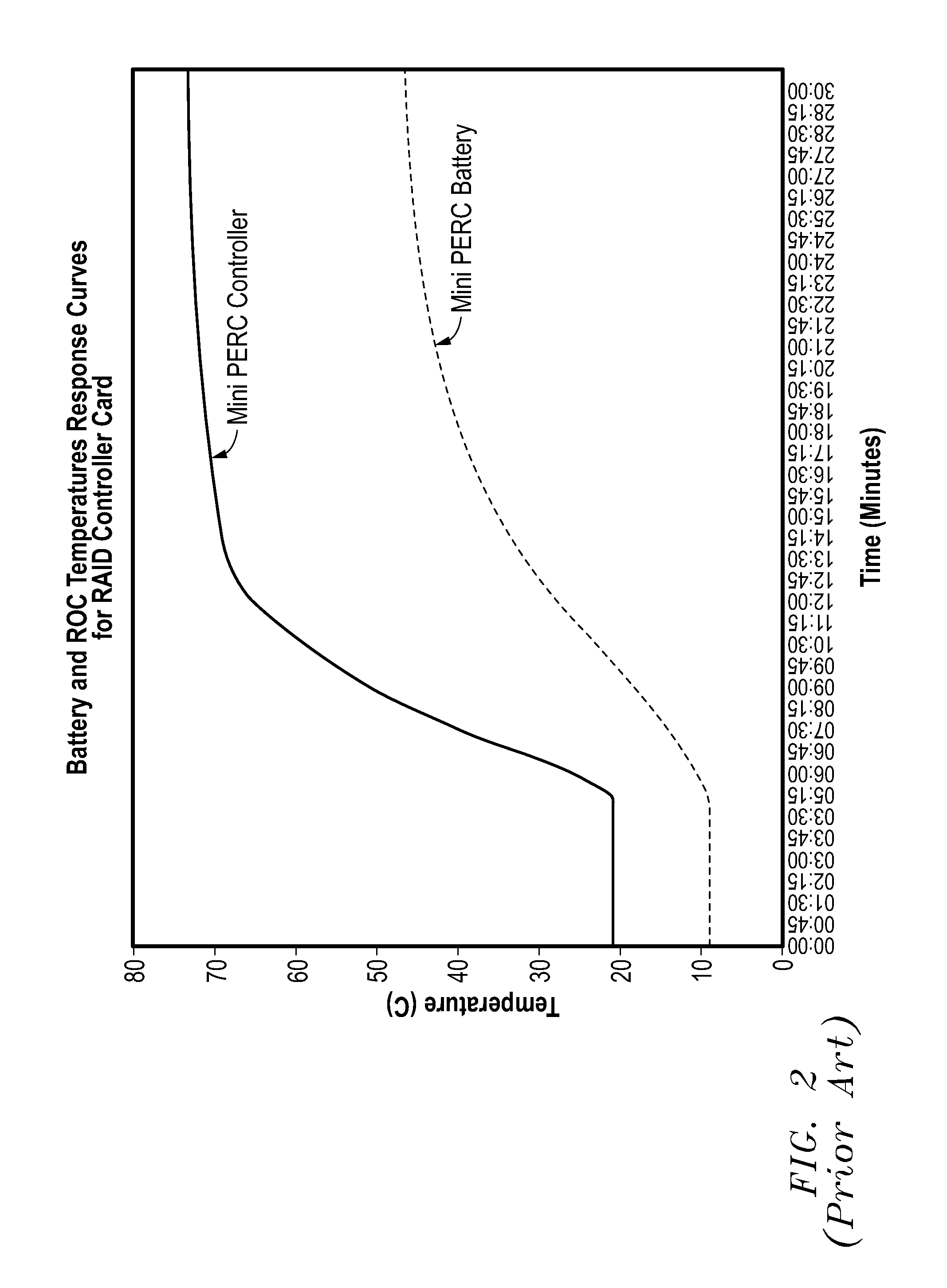

Thermal control systems and methods for information handling systems

ActiveUS20140032011A1Large temperature requirementImprove stabilityTemperature control using plurality of sensorsDigital data processing detailsComputer control systemClosed loop

Systems and methods are provided for information handling system thermal control that employ configuration-based temperature feedback, e.g., by using configuration-based fan speed control based on real time individual measured component temperatures. In one example, the disclosed systems and methods may be implemented to allow inputs from one or more hardware temperature sensors to set cooling fan speeds and / or power capping levels in a closed loop fashion, rather than relying solely (or at all) on system inlet ambient temperature.

Owner:DELL PROD LP

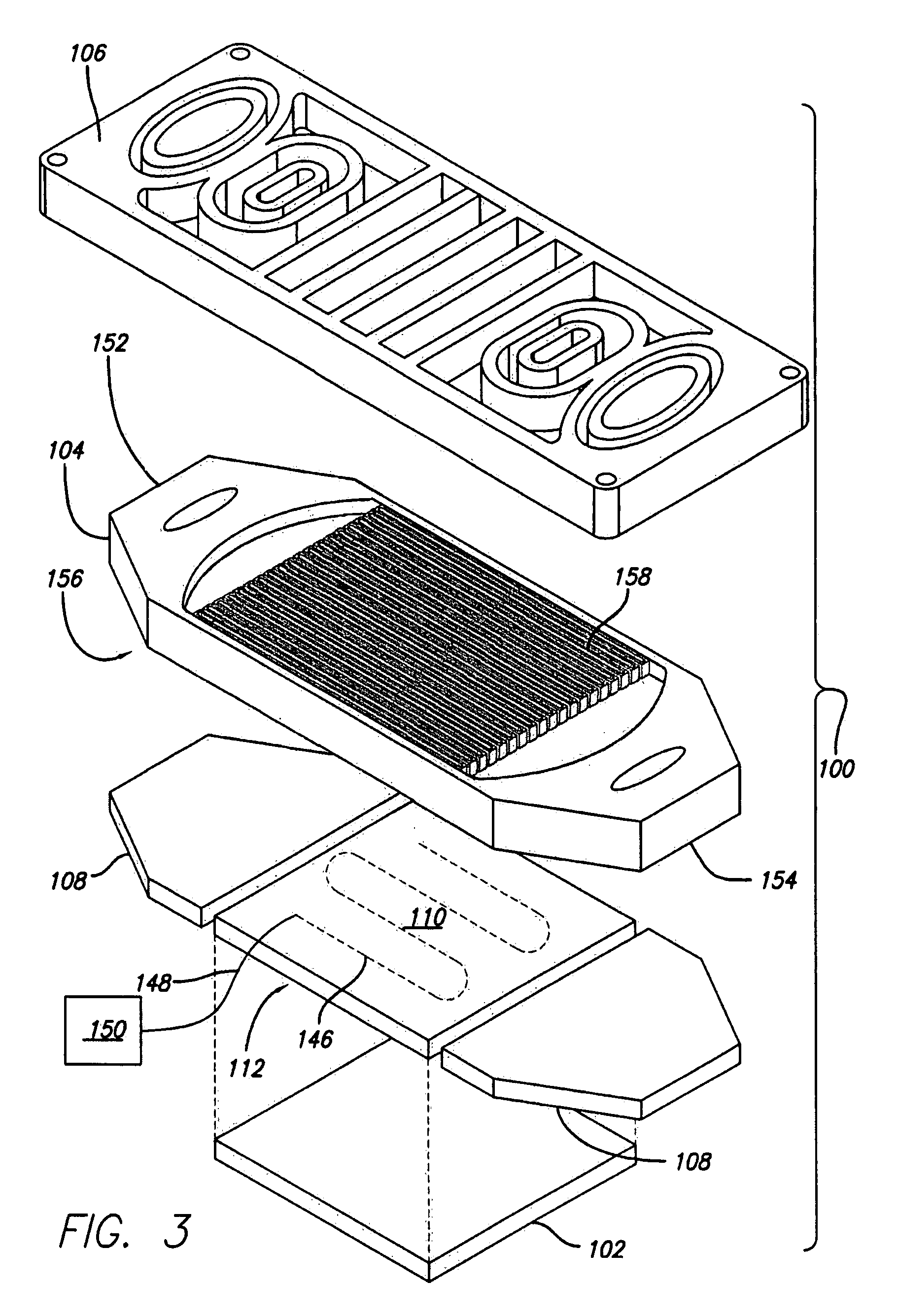

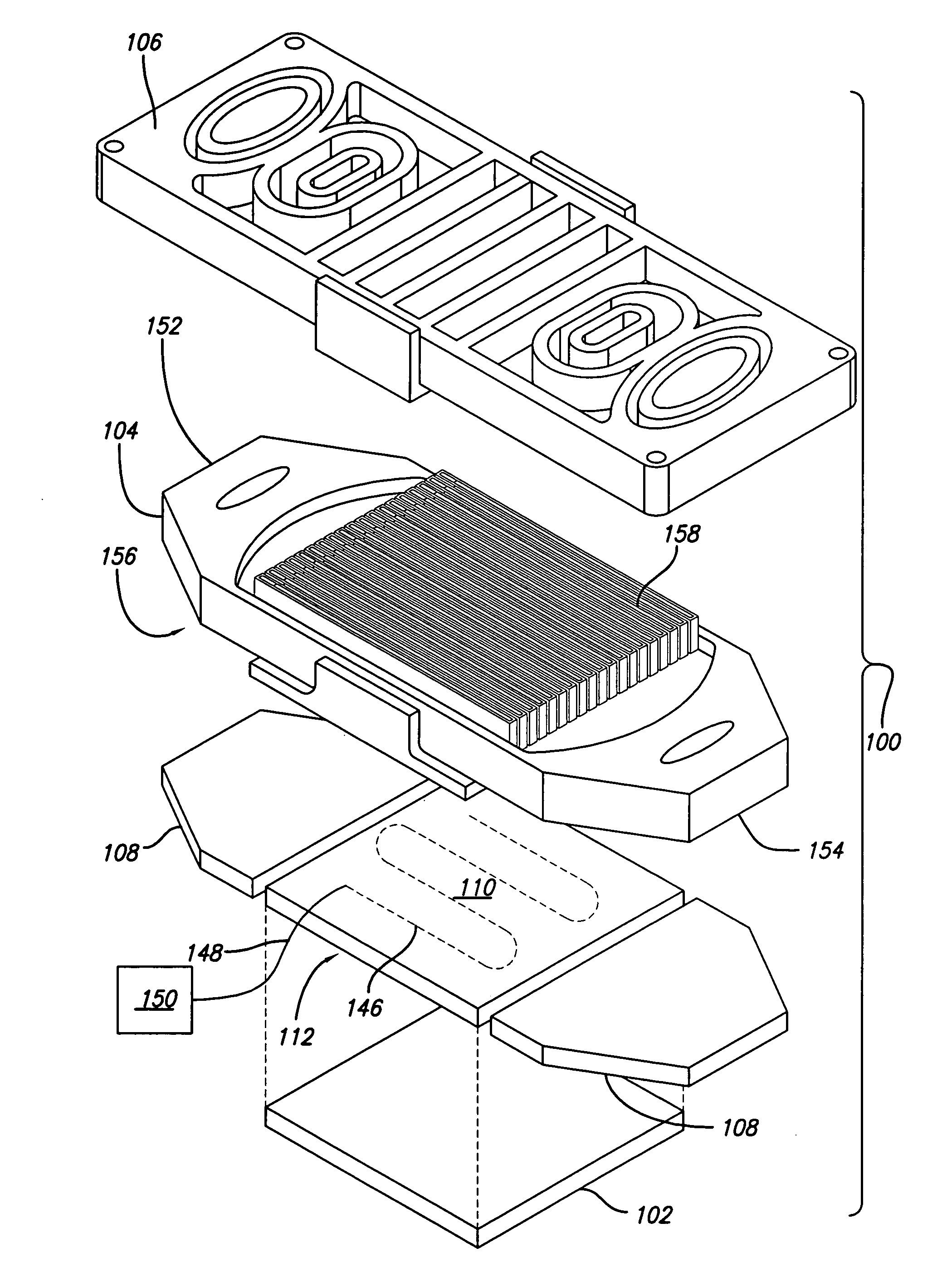

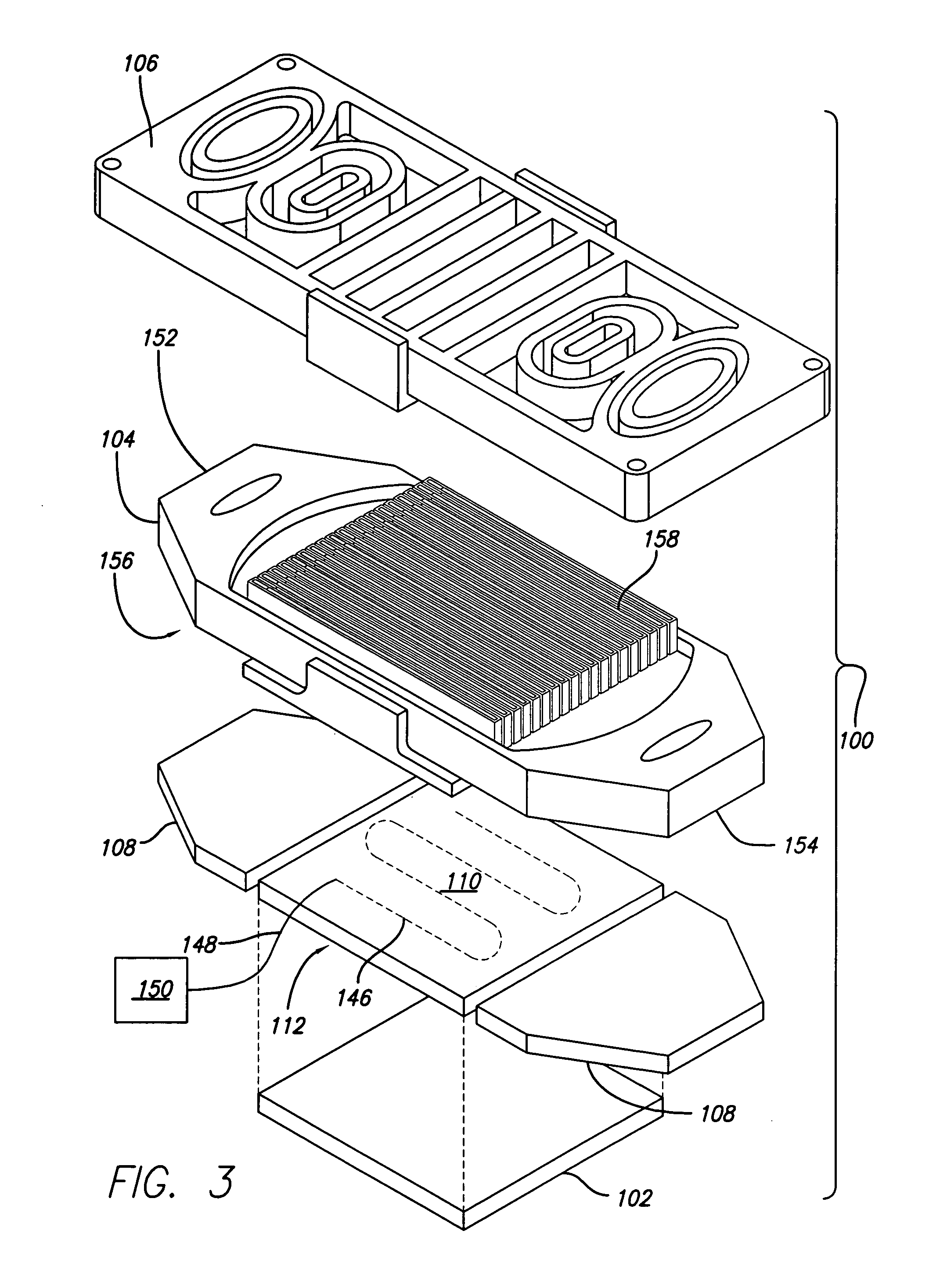

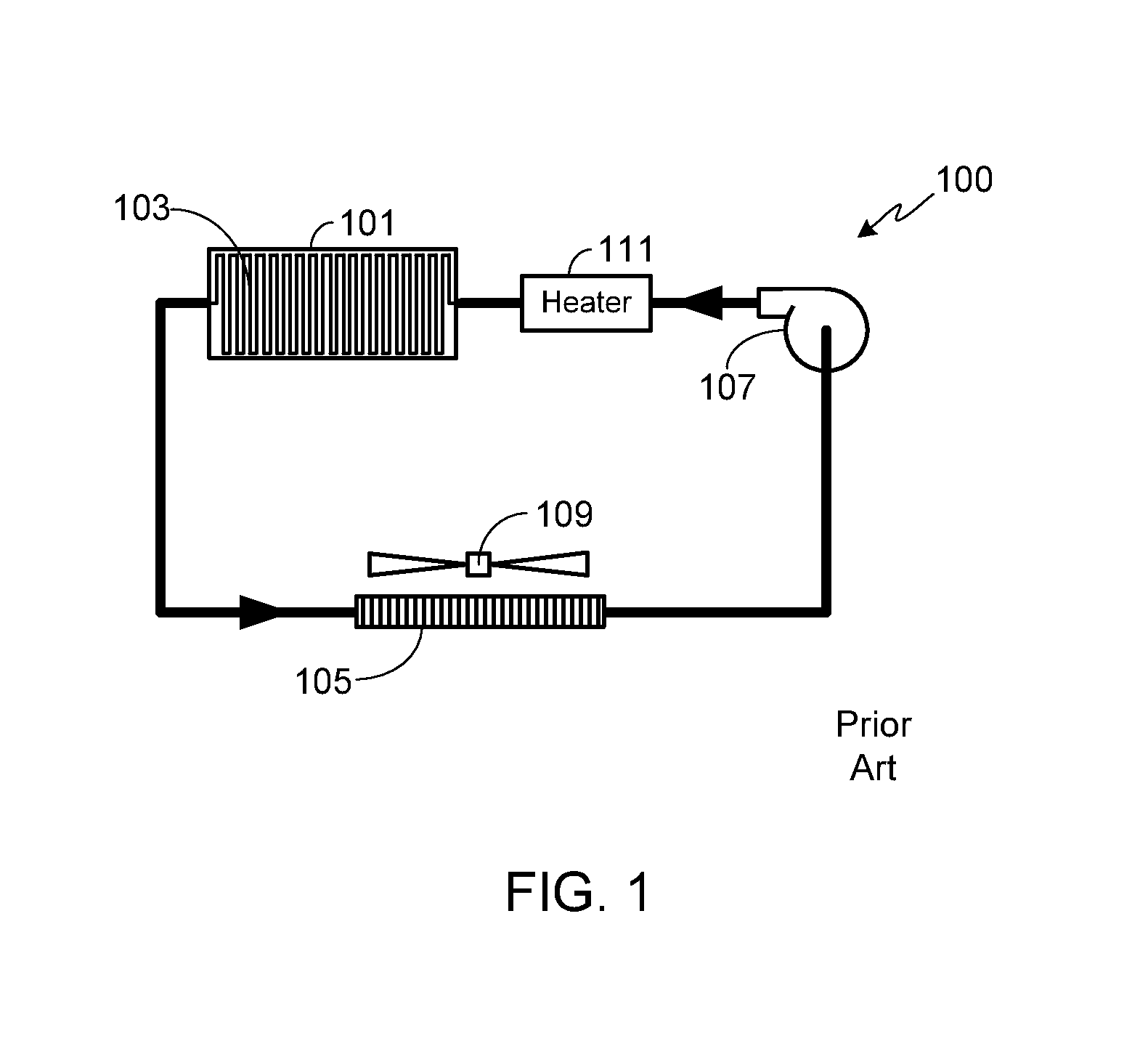

Active thermal control system with miniature liquid-cooled temperature control device for electronic device testing

InactiveUS7355428B2Fault location by increasing destruction at faultHeat exchange apparatusCounter flowEngineering

A temperature control system, which includes a miniature liquid-cooled heat sink, is used to provide a controlled temperature surface to an electronic device, such as a semiconductor device, during the testing or burn-in phase. In one embodiment, the system includes a miniature liquid-cooled heat sink device having a monolithic counter-flowing structure. In other embodiments, the system includes a heater, a flow control valve, a controller, and / or sensors.

Owner:DELTA DESIGN

Active thermal control system with miniature liquid-cooled temperature control device for electronic device testing

InactiveUS20050151553A1Quick changeFault location by increasing destruction at faultHeat exchange apparatusCounter flowDevice material

A temperature control system, which includes a miniature liquid-cooled heat sink, is used to provide a controlled temperature surface to an electronic device, such as a semiconductor device, during the testing or bum-in phase. In one embodiment, the system includes a miniature liquid-cooled heat sink device having a monolithic counter-flowing structure. In other embodiments, the system includes a heater, a flow control valve, a controller, and / or sensors.

Owner:DELTA DESIGN

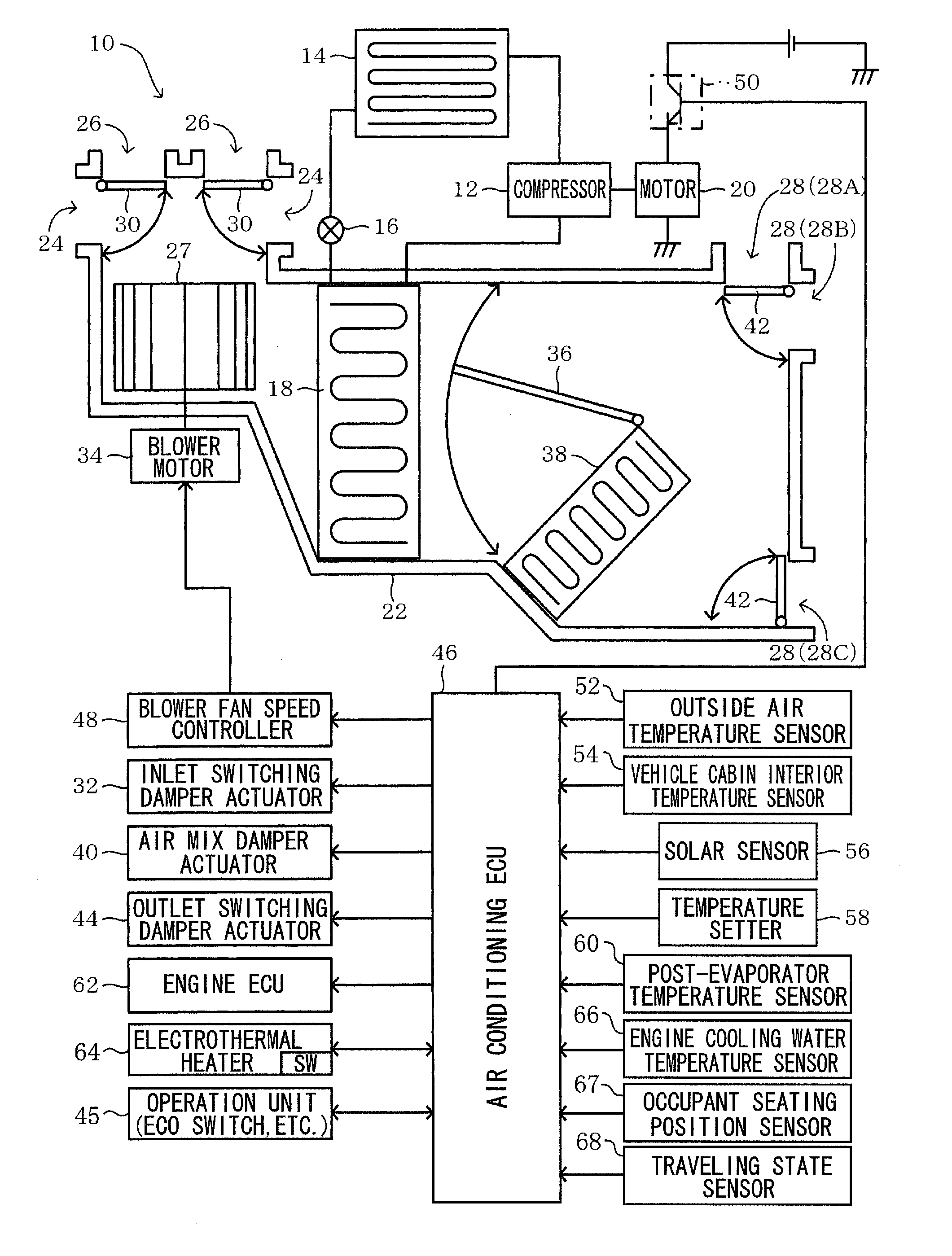

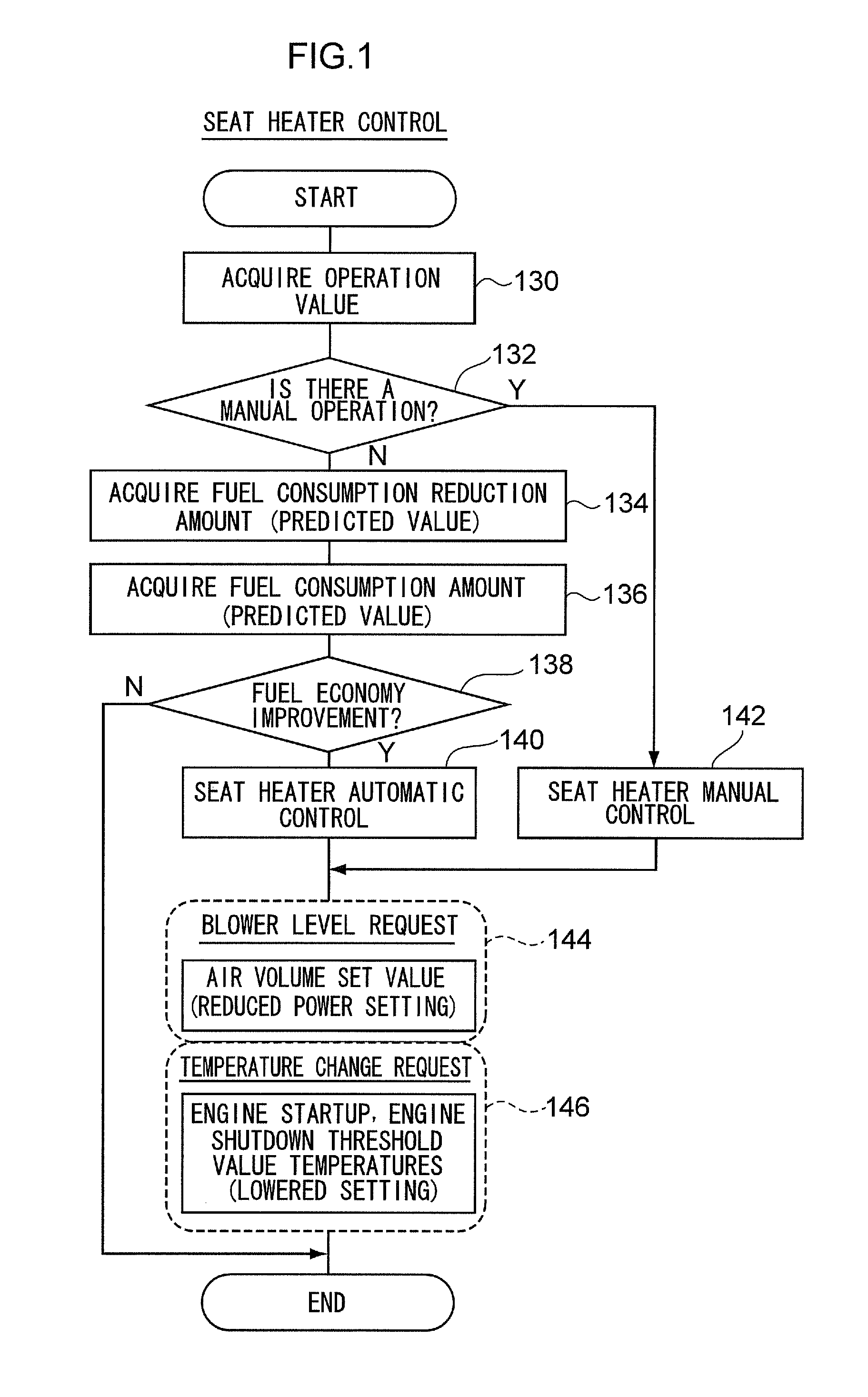

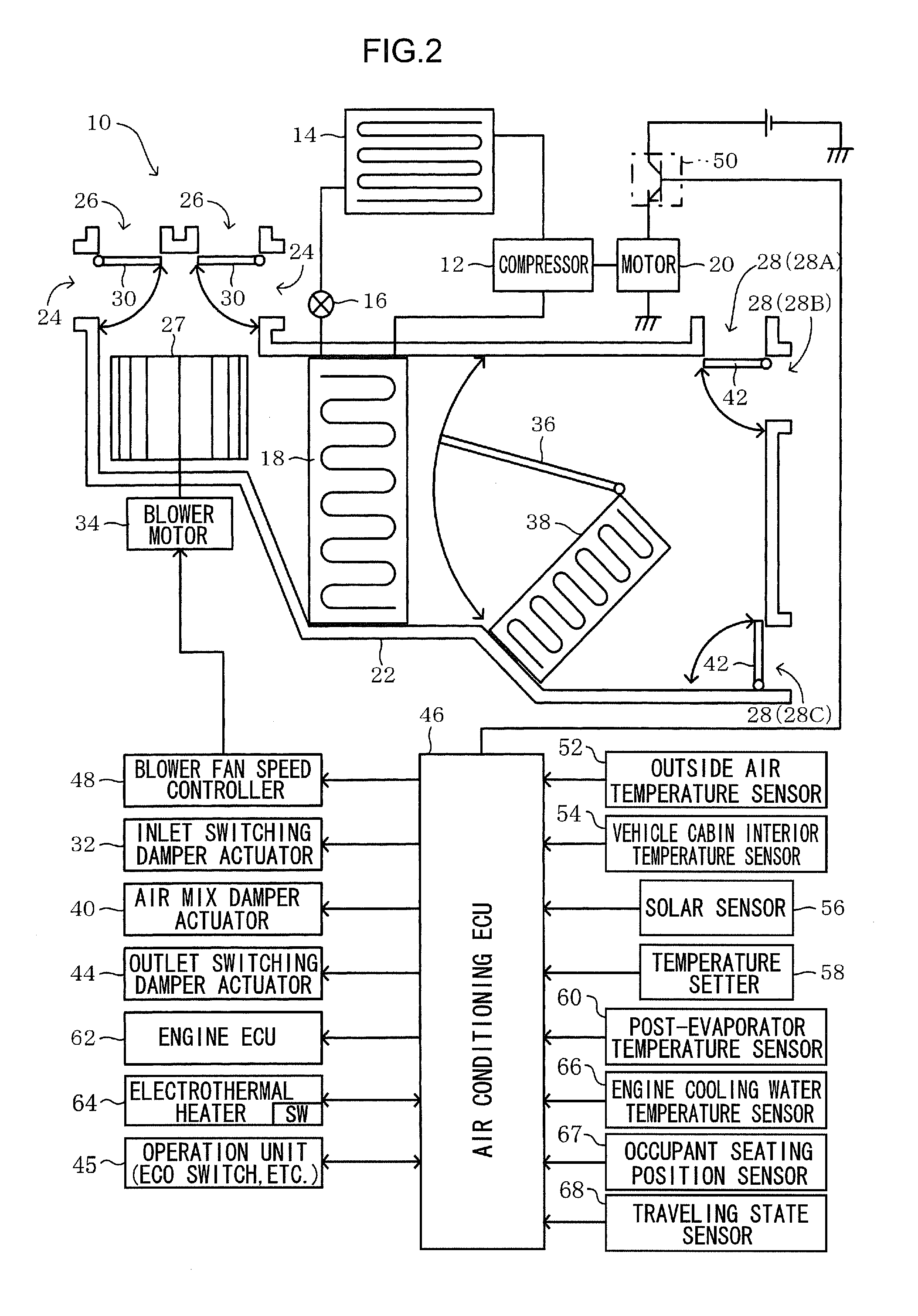

Vehicular heating control system, method, and computer-readable storage medium

ActiveUS20140110489A1Reduce fuel consumptionImprove fuel economyHybrid vehiclesVehicle seatsControl systemHeating effect

A vehicular heating control system, method, and program acquire an operation value that is a setting by an occupant and, when there is no manual operation, acquire a fuel consumption reduction amount and a fuel consumption amount and, when the fuel consumption reduction amount exceeds the fuel consumption amount and an improvement in fuel economy is expected, execute seat heater control, that is, heating by an electrothermal heater, decrease the wind force of a blower fan, and lower an engine startup threshold value. Heating by an air conditioning system and heating by the electrothermal heater are combined, so a heating effect is obtained while reducing the fuel consumption amount.

Owner:TOYOTA JIDOSHA KK

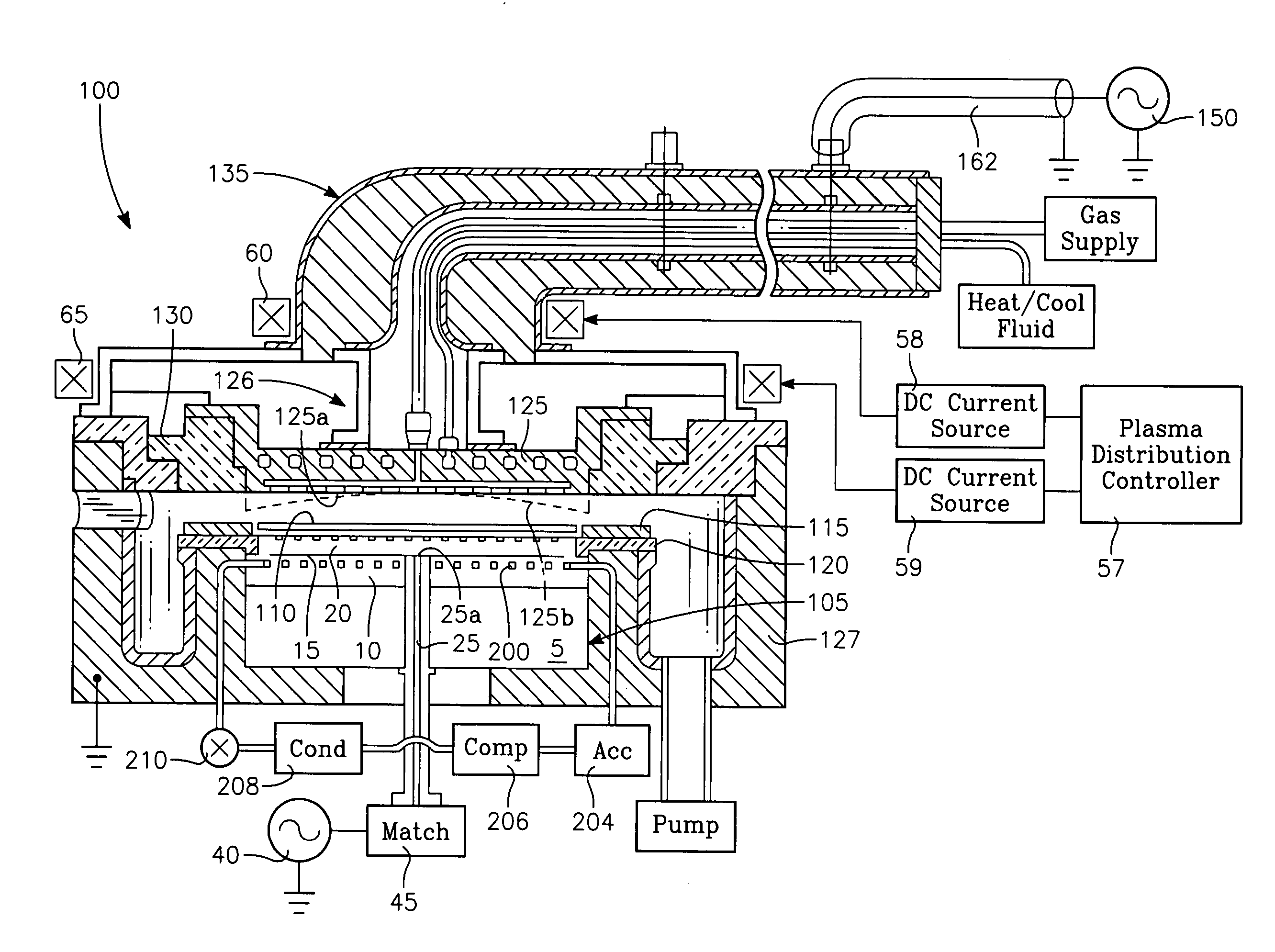

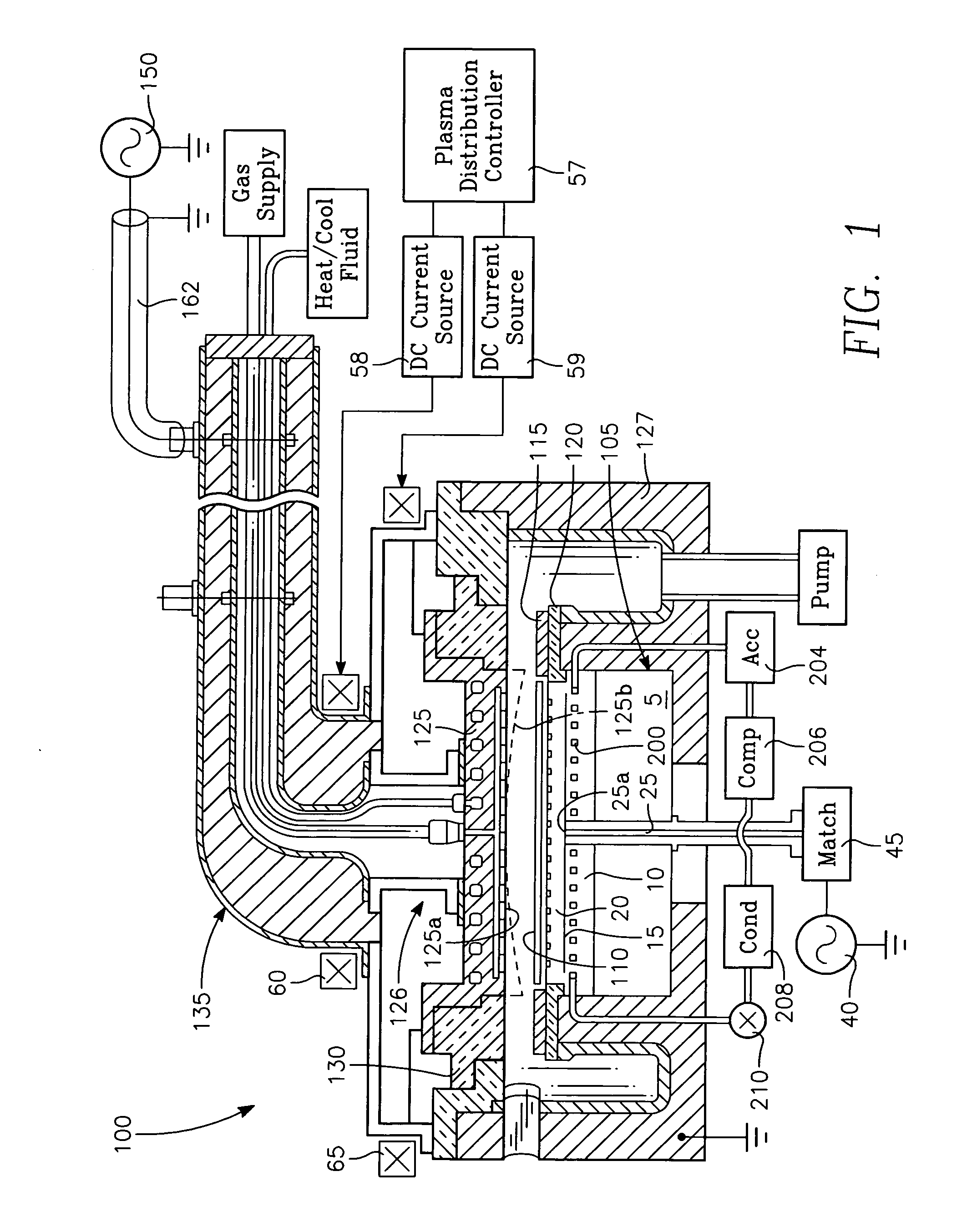

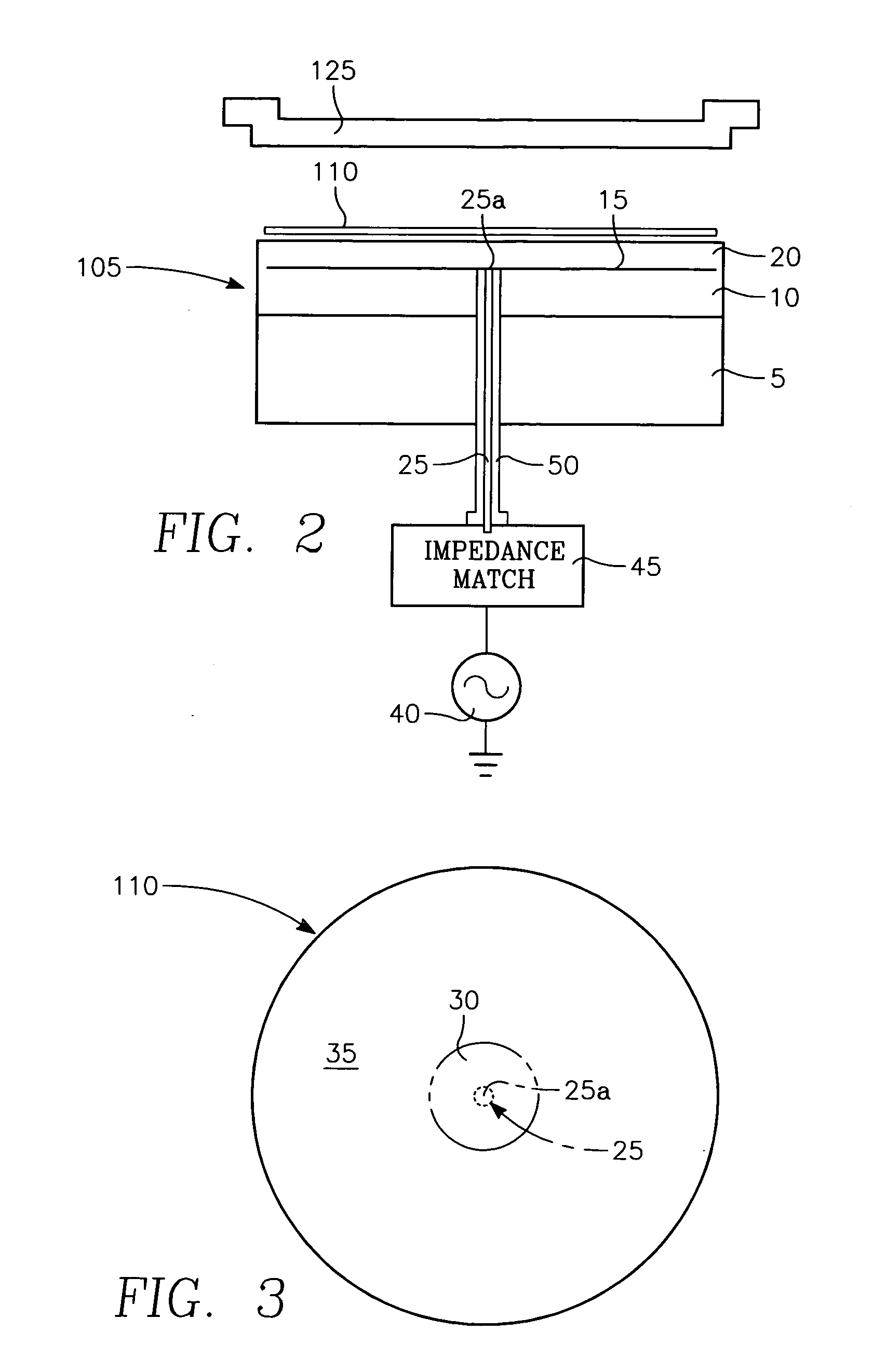

Plasma reactor with feed forward thermal control system using a thermal model for accommodating RF power changes or wafer temperature changes

ActiveUS20070091539A1Electric discharge tubesSemiconductor/solid-state device manufacturingNuclear engineeringThermal control system

A plasma reactor having a reactor chamber and an electrostatic chuck with a surface for holding a workpiece inside the chamber includes a backside gas pressure source coupled to the electrostatic chuck for applying a thermally conductive gas under a selected pressure into a workpiece-surface interface formed whenever a workpiece is held on the surface and an evaporator inside the electrostatic chuck and a refrigeration loop having an expansion valve for controlling flow of coolant through the evaporator. The reactor further includes a temperature sensor in the electrostatic chuck and a memory storing a schedule of changes in RF power or wafer temperature. The reactor further includes a thermal model capable of simulating heat transfer between the evaporator and the surface based upon measurements from the temperature sensor, and a control processor coupled to the thermal model and to the memory and governing the backside gas pressure source in response to a prediction from the model of a change in the selected pressure that would compensate for the next scheduled change in RF power or implement the next scheduled change in wafer temperature.

Owner:ADVANCED THERMAL SCI

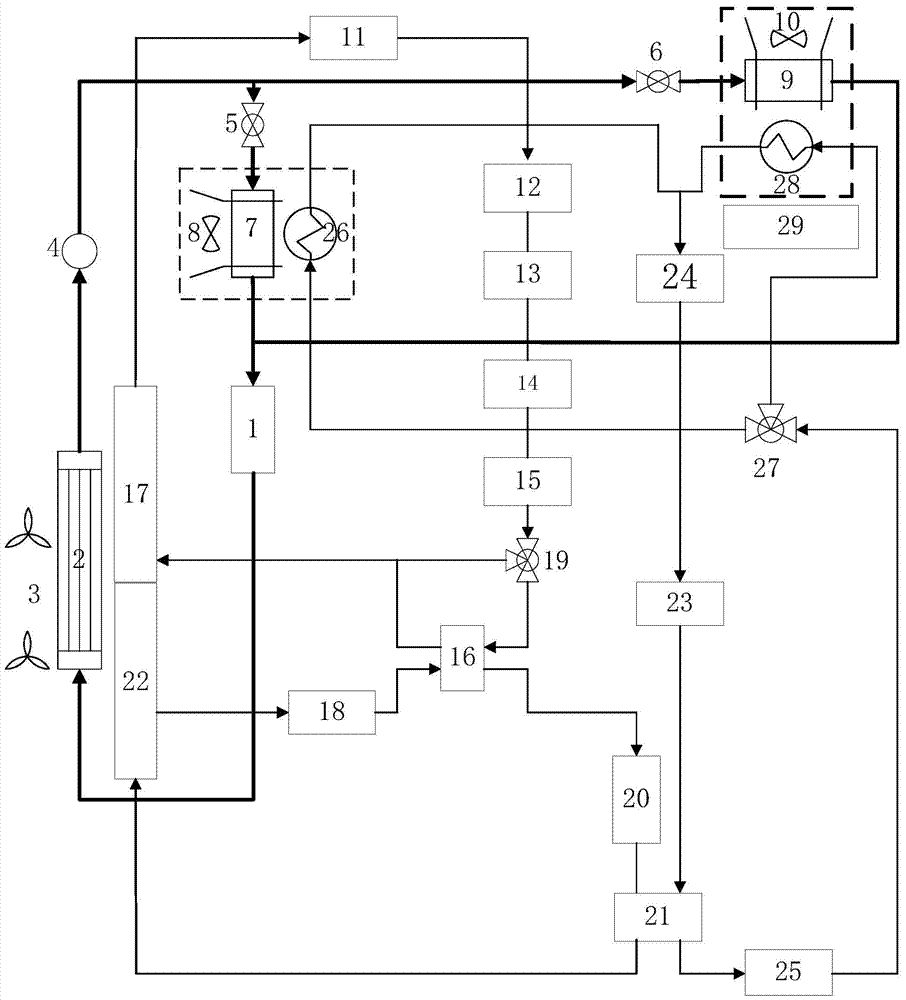

Heat control system for hybrid power or range-extending type electric automobile

InactiveCN103660916AImprove heating efficiencyImprove fuel efficiencyAir-treating devicesVehicle heating/cooling devicesDrive motorThermal control system

The invention discloses a heat control system for a hybrid power or range-extending type electric automobile. A power battery system supplies power to a refrigeration cycle system and a heating cycle system, and a whole automobile controller controls the refrigeration cycle system or the heating cycle system in the mode that the battery temperature and voltage information transmitted by the power battery system is collected through a CAN bus. An electric driving refrigeration cycle system preheats an engine for starting through heat generated by an electric appliance part, and an engine refrigeration cycle system enables the temperature of refrigeration liquid of the heating cycle system to be raised through heat generated after the engine is started. According to the heat control system, effective heat control over each component of the electric automobile is achieved, waste heat of electrical apparatus elements and waste heat of the engine are adopted for improving the heating efficiency of the electric automobile, heat waste is reduced, the energy utilization rate is improved, waste heat of a driving motor or an electric heater system can be used for preheating the engine, the engine burning efficiency is improved, and good control over heating or refrigerating of a power battery package can be achieved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

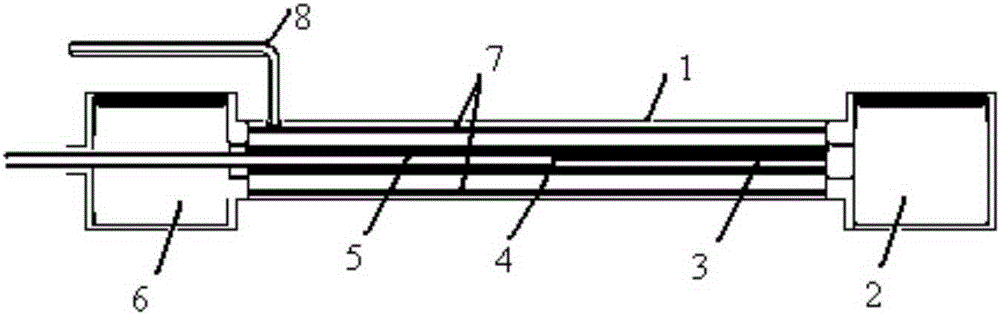

Insulation can special for sodium-sulphur battery

InactiveCN102054952AUniform temperatureEvenly heatedSecondary cellsCell component detailsControl systemElectrical battery

The invention discloses an insulation can special for a sodium-sulphur battery, comprising an outer shell and a liner. A heat-insulating layer is filled between the outer shell and the liner, the liner comprises a plurality of battery mounting brackets, each battery mounting bracket is provided with a battery mounting chamber for mounting batteries, the liner also comprises a plurality of baffleswhich uniformly partition the battery mounting brackets, a temperature detector and a heater are arranged in the same position in each partition, and a battery pack, the temperature detector and the heater are connected with a battery management system outside the insulation can through special cables to form a closed-ring heating control system. In the invention, small units are formed by a plurality of single batteries, the heater and the temperature detector and are partitioned by the baffles so as to uniformly heat each heated body (battery), and a full-closed ring and an answering-type control method of a heating point and a heated point are adopted to keep uniform temperature in an insulating state and realize high efficiency and low energy consumption.

Owner:徐荣辉

EV Muti-Mode Thermal Control System

InactiveUS20160318409A1Electric devicesPower to auxillary motorsControl systemThermal management system

A thermal management system that utilizes a multi-mode valve assembly within the drive train control loop to provide efficient thermal control of the drive train components is provided. The multi-mode valve assembly allows the mode of thermal coupling between the thermal control loop and the various drive train components (e.g., vehicle propulsion motor, gearbox assembly, power electronics subsystem, etc.) to be varied in accordance with present conditions.

Owner:ATIEVA USA INC

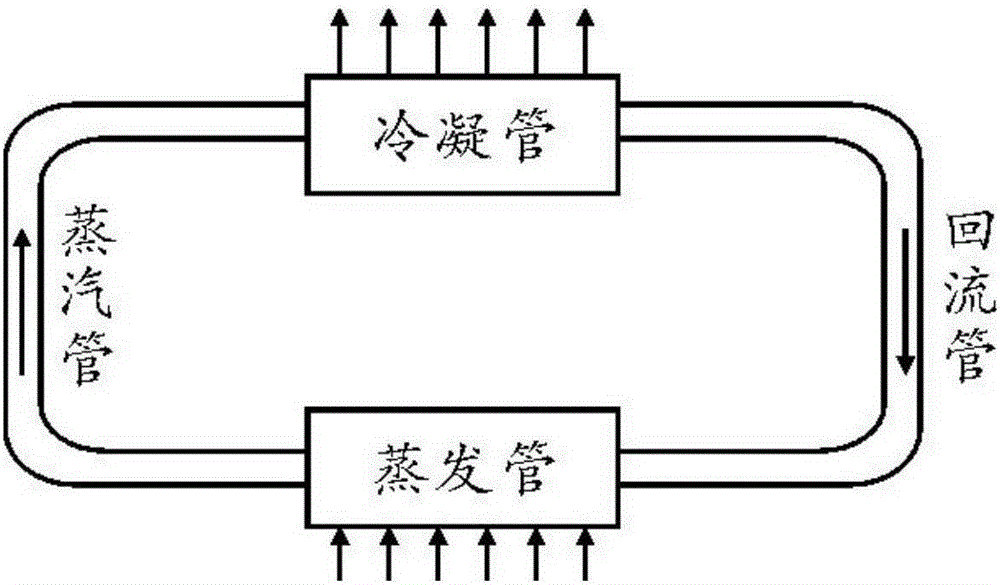

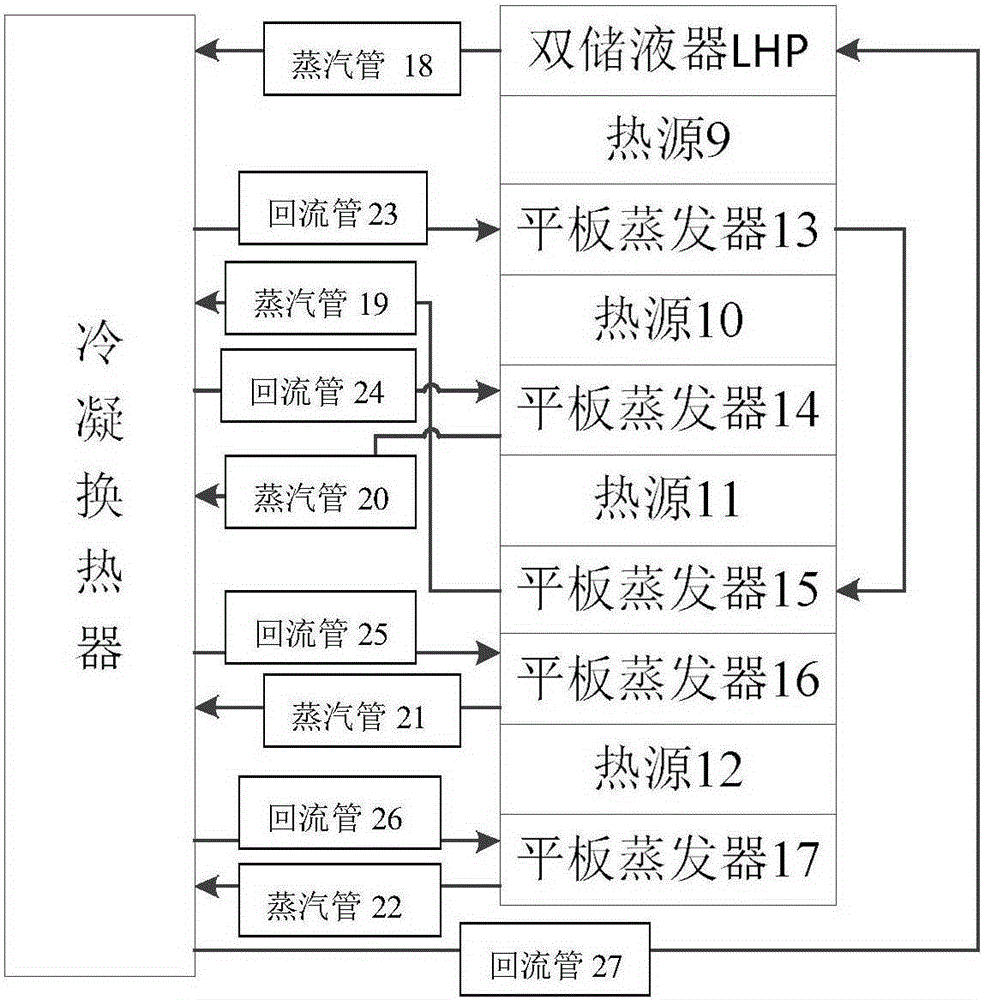

Thermal control loop heat pipe of integrated structure

InactiveCN105277028AImprove temperature uniformityImprove anti-acceleration abilityIndirect heat exchangersMicro-loop heat pipeEvaporation

The invention provides a thermal control loop heat pipe of an integrated structure. The thermal control loop heat pipe comprises a structure thermal control hollow metal pipe body filled with phase change media. The structure thermal control hollow metal pipe body is a loop heat pipe (LHP) formed by connecting a condensation pipe and an evaporator in series, the two sides of the evaporator are connected with liquid accumulators where a steam pipe and a reflux pipe pass, and the liquid accumulators on the two sides are both filled with liquid working media. After heat emitted by a heat source is absorbed by an evaporation pipe, the phase of the liquid working media is changed, the liquid working media enter the condensation pipe through the steam pipe to release heat to be condensed and flows back to the evaporation pipe through the reflux pipe, and then a complete loop heat pipe cycle is completed. According to the thermal control loop heat pipe, integration is adopted, a semiconductor refrigeration manner is used, heat emitted out of the interior of the complex structure can be effectively led out accordingly, and the application range of a heat pipe thermal control system is greatly expanded.

Owner:10TH RES INST OF CETC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com