Thermal control system for rack mounting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

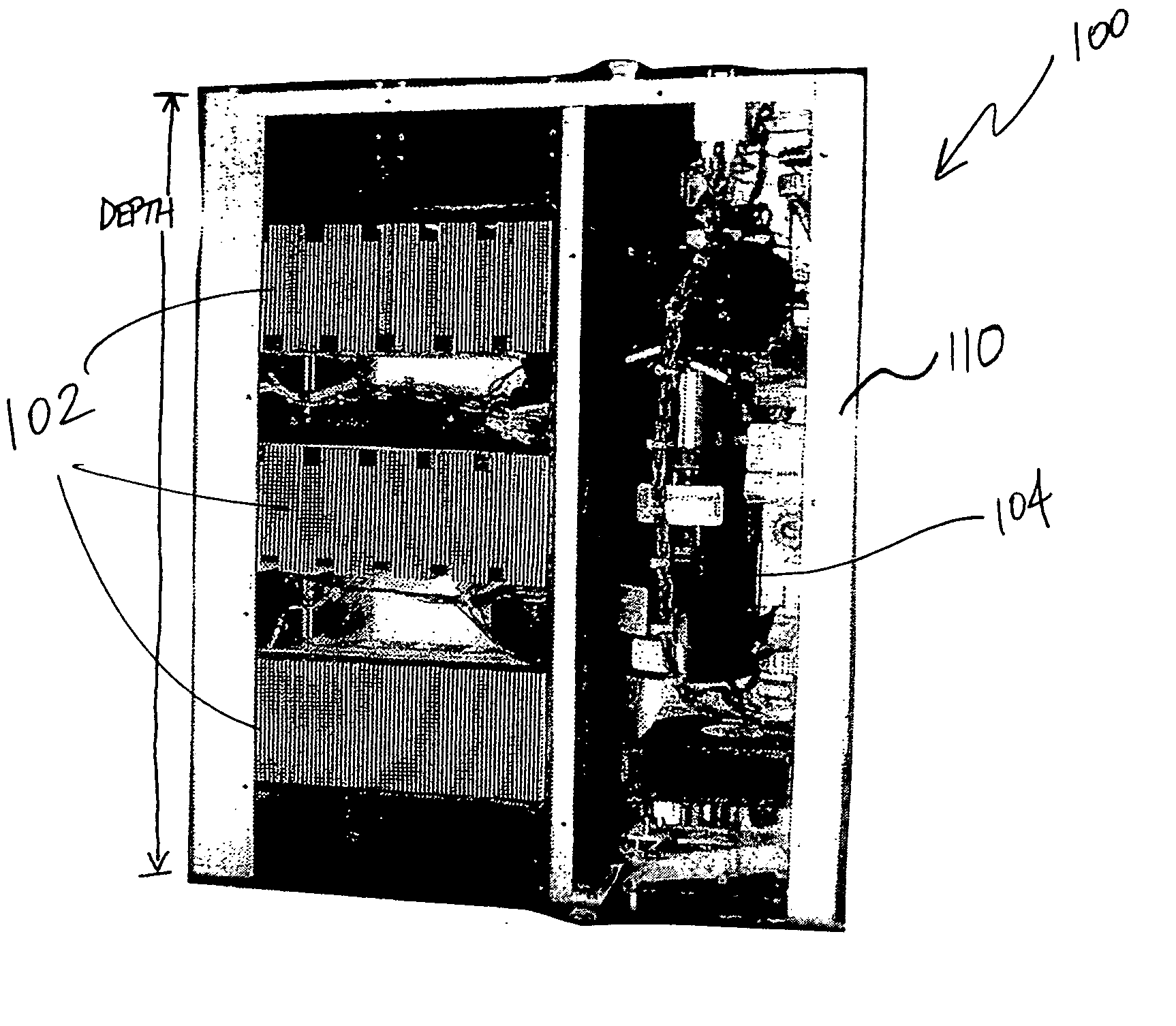

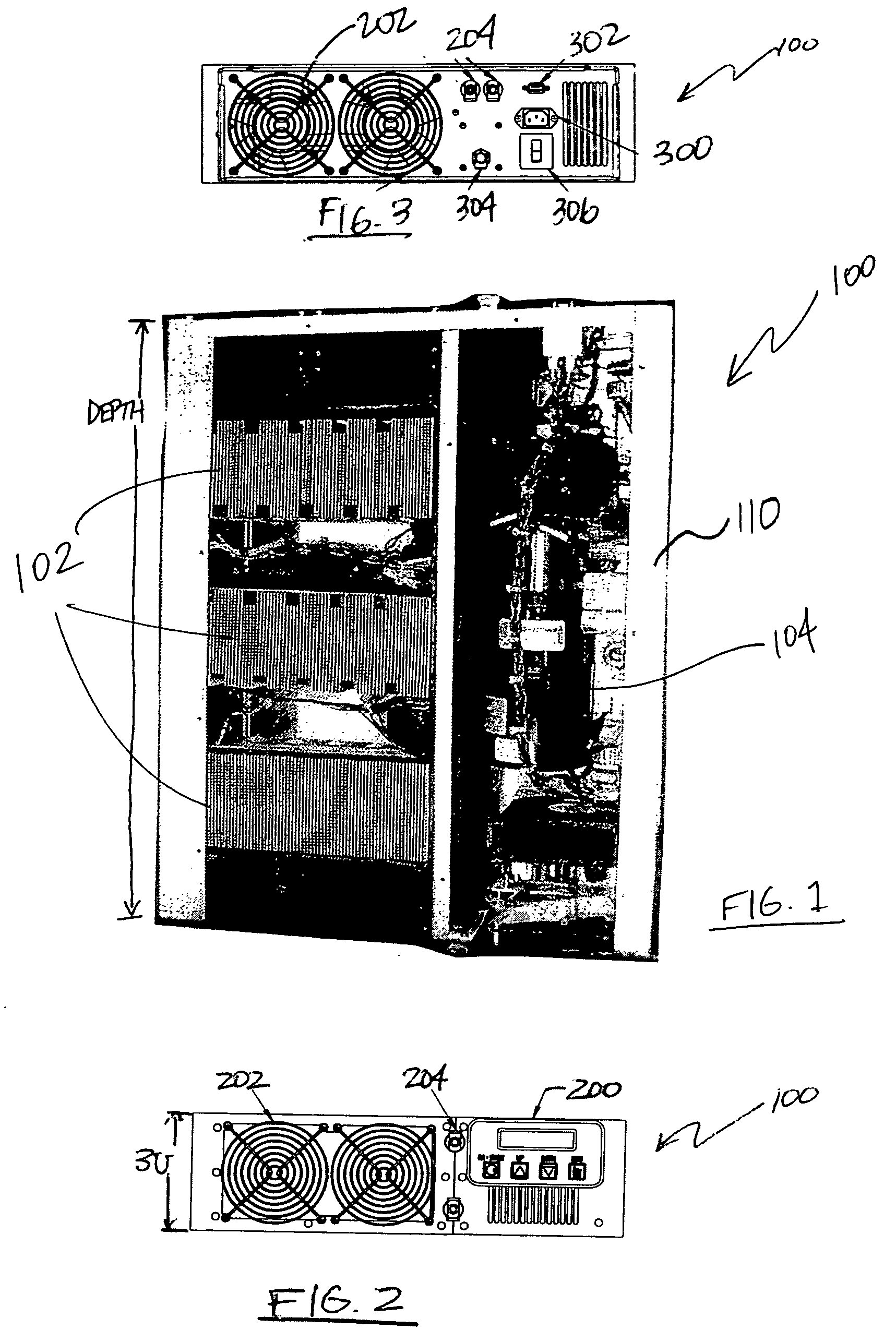

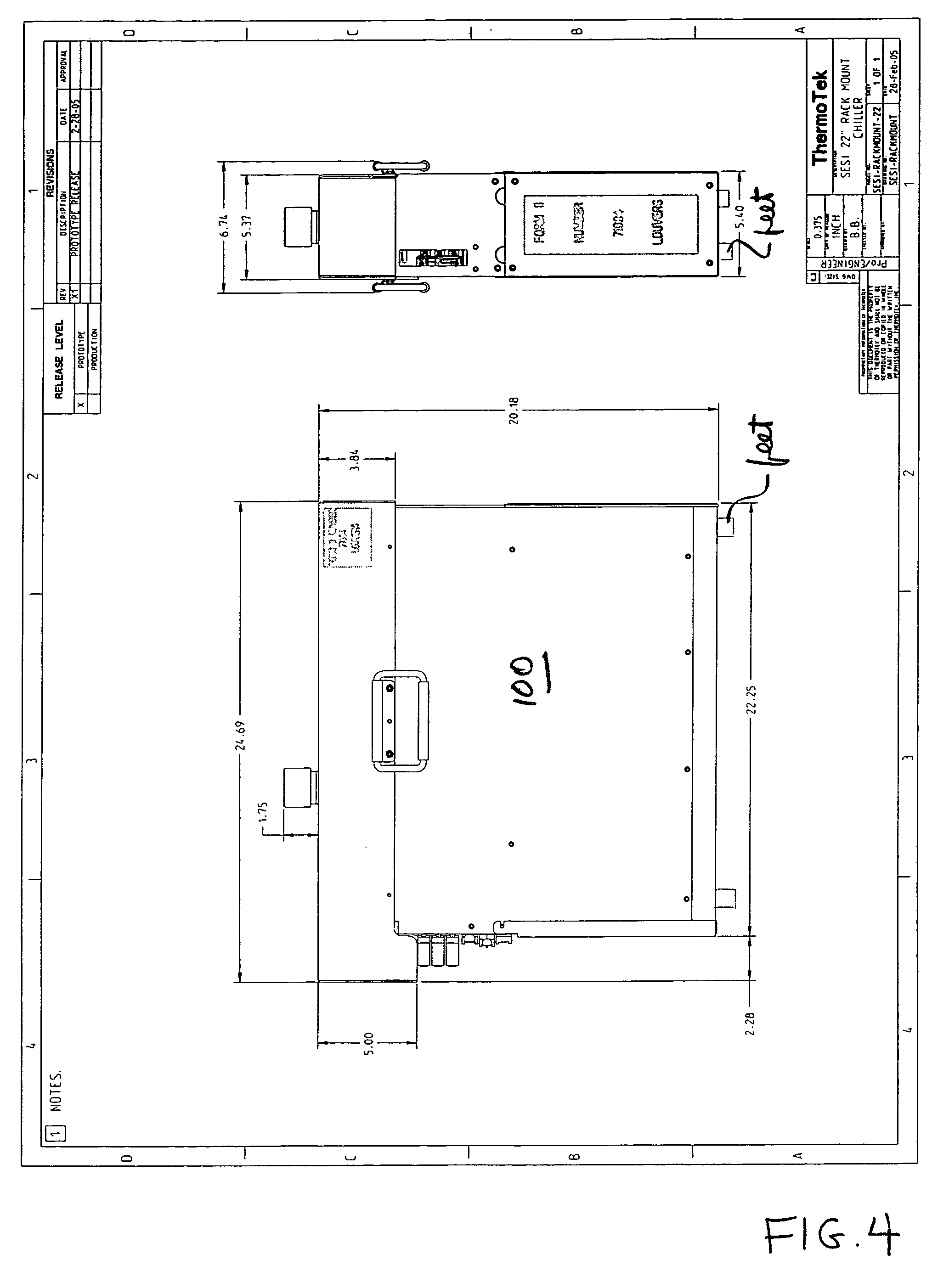

[0025] Referring now to FIG. 1, a top view of a temperature control system 100 in accordance with an embodiment of the present invention is illustrated. The temperature control system 100 utilizes a heat transfer fluid that is circulated in a closed loop to cool or heat components within a conventional rack. The heat transfer fluid may be, for example, a water / glycol mixture, although other heat transfer fluids may be utilized. In one embodiment, three HTA modules 102 are utilized to effect cooling and / or heating in the temperature control system 100, however embodiments of the present invention may include more or fewer HTA modules as desired. The temperature control system 100 may also include up to six internal fan assemblies (not shown) and an addition three internal fans with an external fan train. The fans may be oriented in a push / pull fan arrangement or other arrangement as desired. In alternate embodiments, fans on the heat transfer side are not included. Instead, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com