Golf club head having internal fins for resisting structural deformation and mechanical shockwave migration

a golf club head and internal fin technology, applied in the field of golf clubs, can solve the problems of deformation of the metal wood driver club head, deformation of the wood club head, and inability to resist structural deformation, and achieve the effect of increasing and decreasing heigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

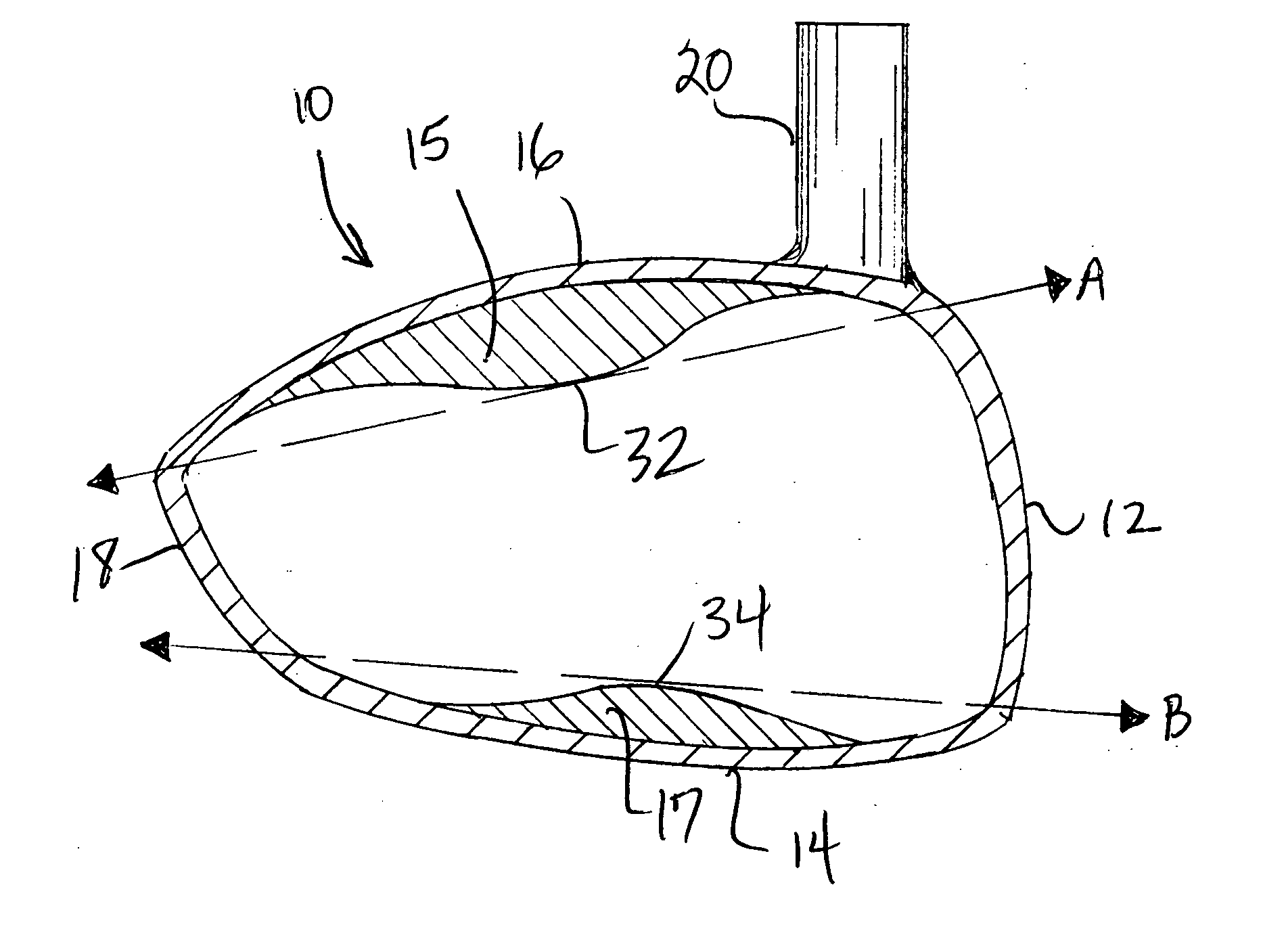

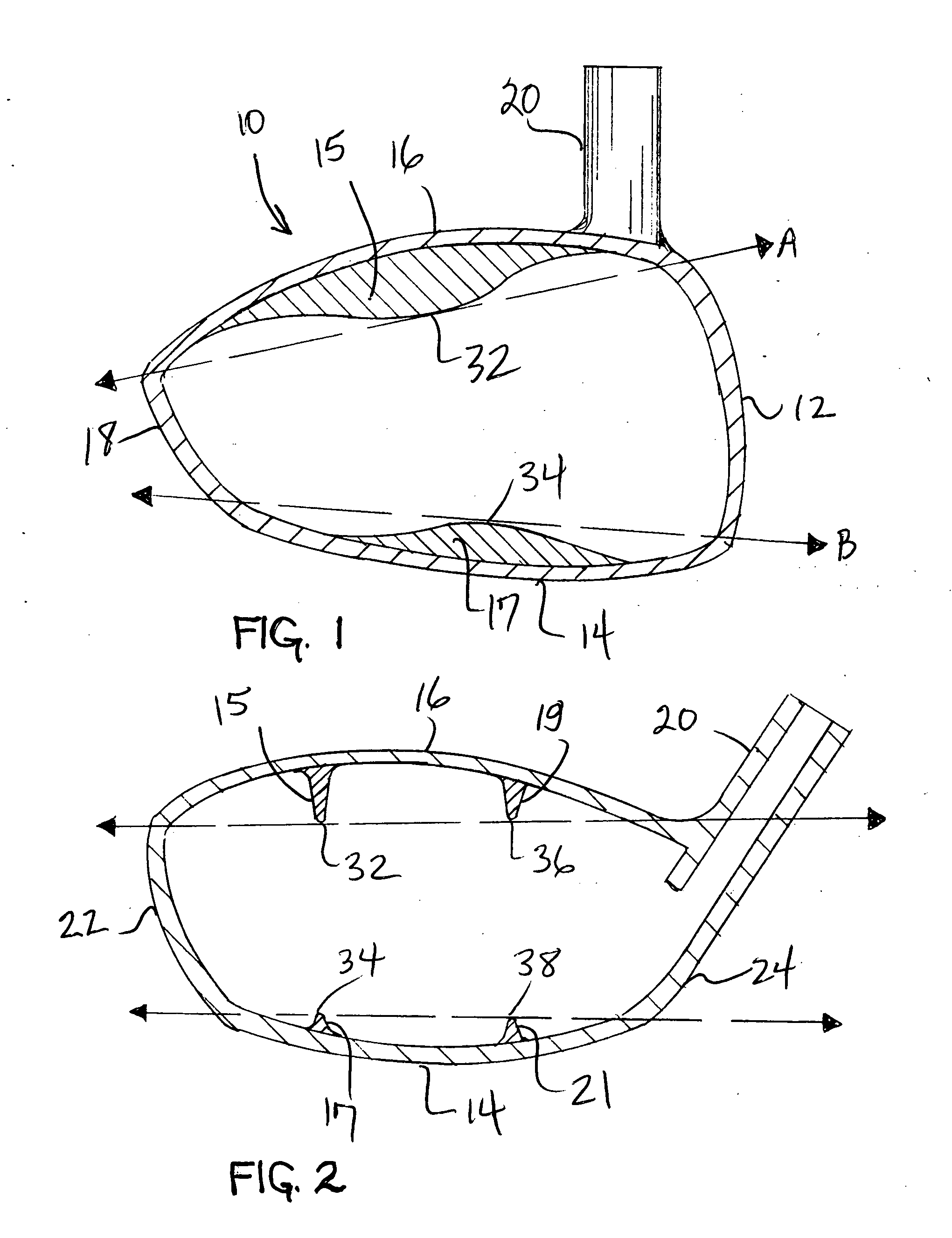

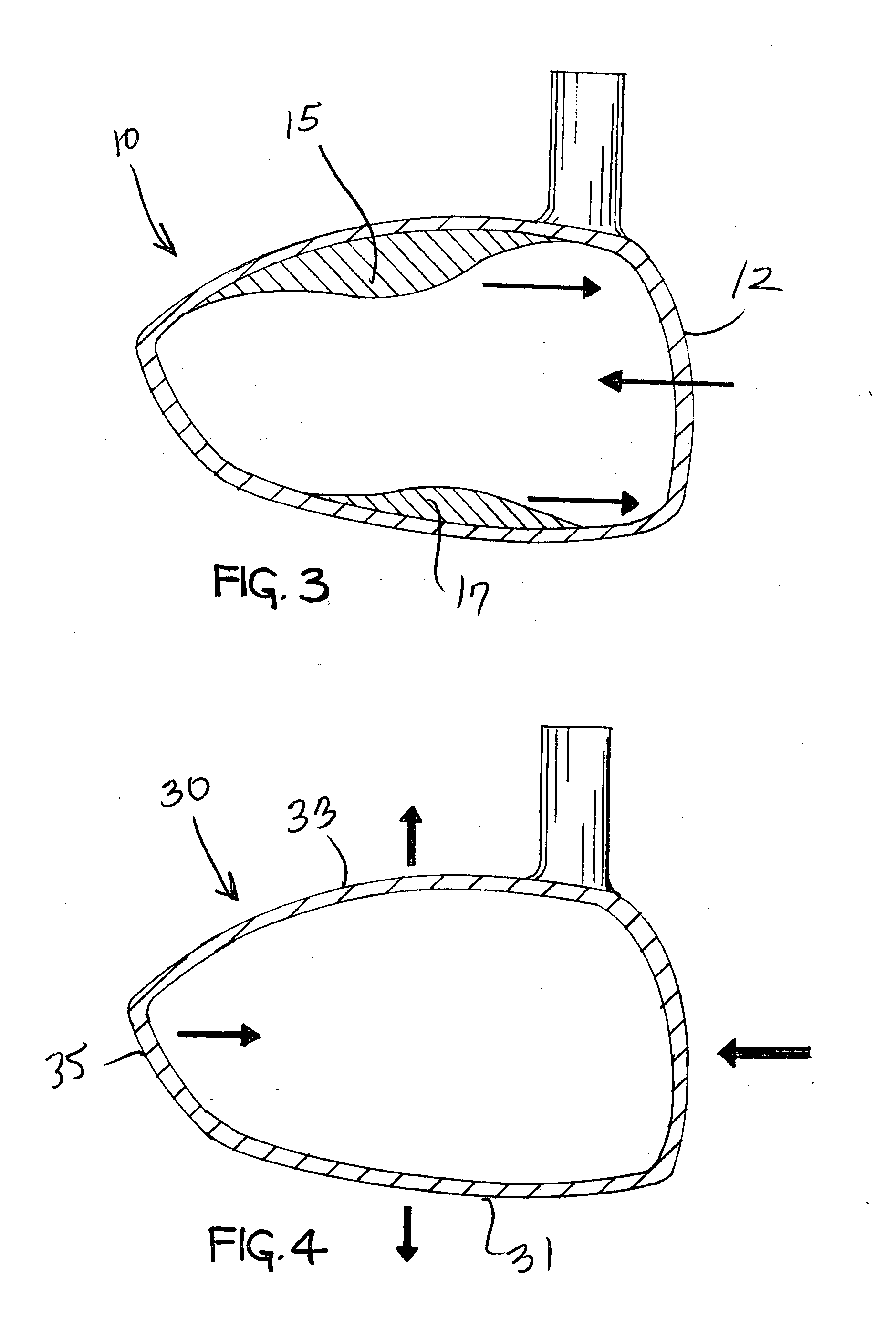

[0042] Referring to the accompanying drawings and initially to FIGS. 1-4, it will be seen that an improved metal wood golf club head 10 according to a preferred embodiment of the present invention, comprises a hitting surface or face 12, a sole 14, a crown 16, a skirt 18, a hosel 20, a toe 22 and a heel 24. These are conventional features of a typical club head. Those features that are novel and unique to the present invention comprise fins 15,17,19 and 21. While the illustrated embodiment employs four such fins, (i.e., two along the interior of crown 16 and two along the interior of sole 14) it will be understood that the actual number may be other than four. Moreover, each such fin is preferably of varying height with a maximum height or apex that coincides with an imaginary surface drawn between demarcation or transition points on the intersections between different club head surfaces. By way of example, fin 15 has an apex 32 which coincides with a plane “A” defined by the inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com