Adjustable shoe-making machine base

A shoe-making machine and an adjustable technology, which is applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of inability to effectively adjust the height, waste of transport capacity, troublesome installation and use, etc., so as to improve convenience and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

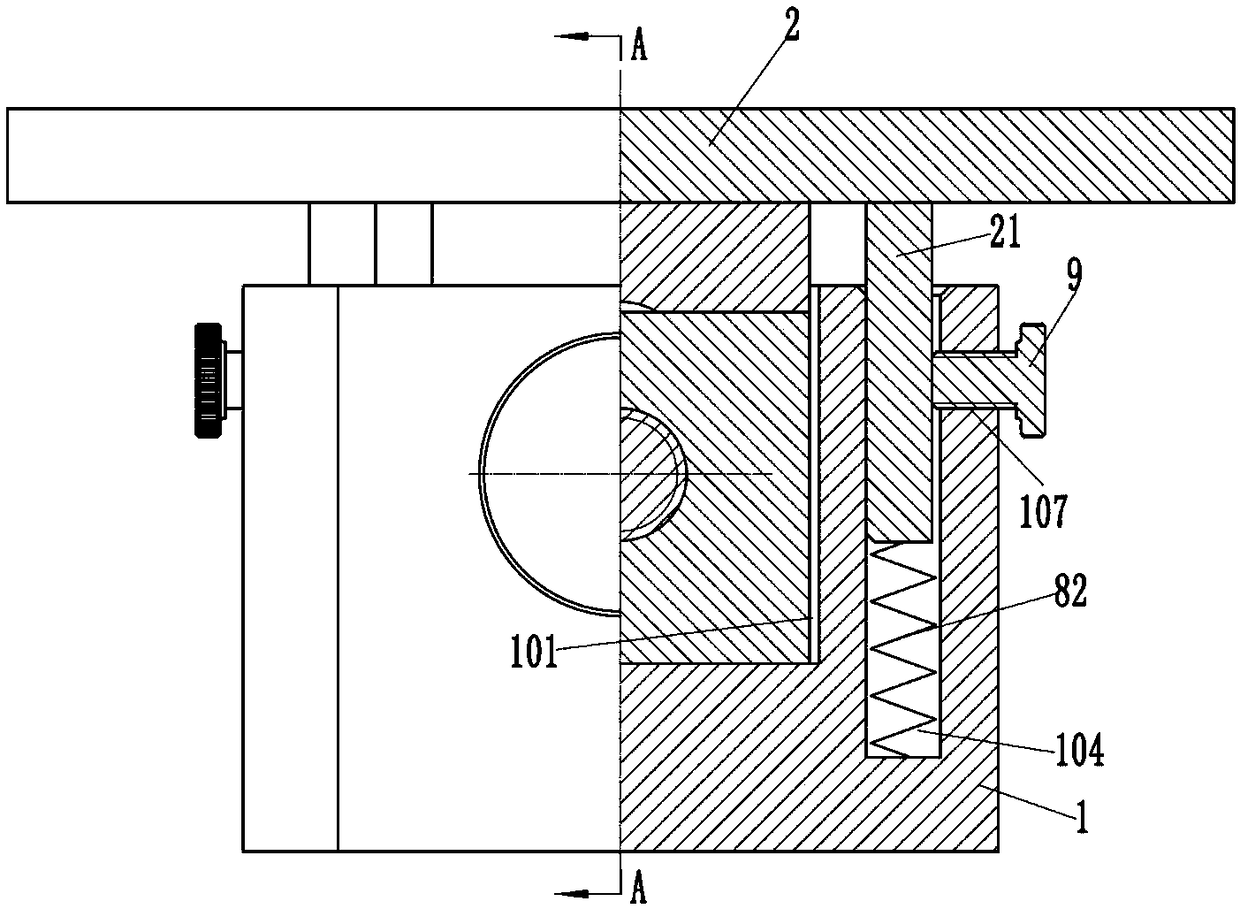

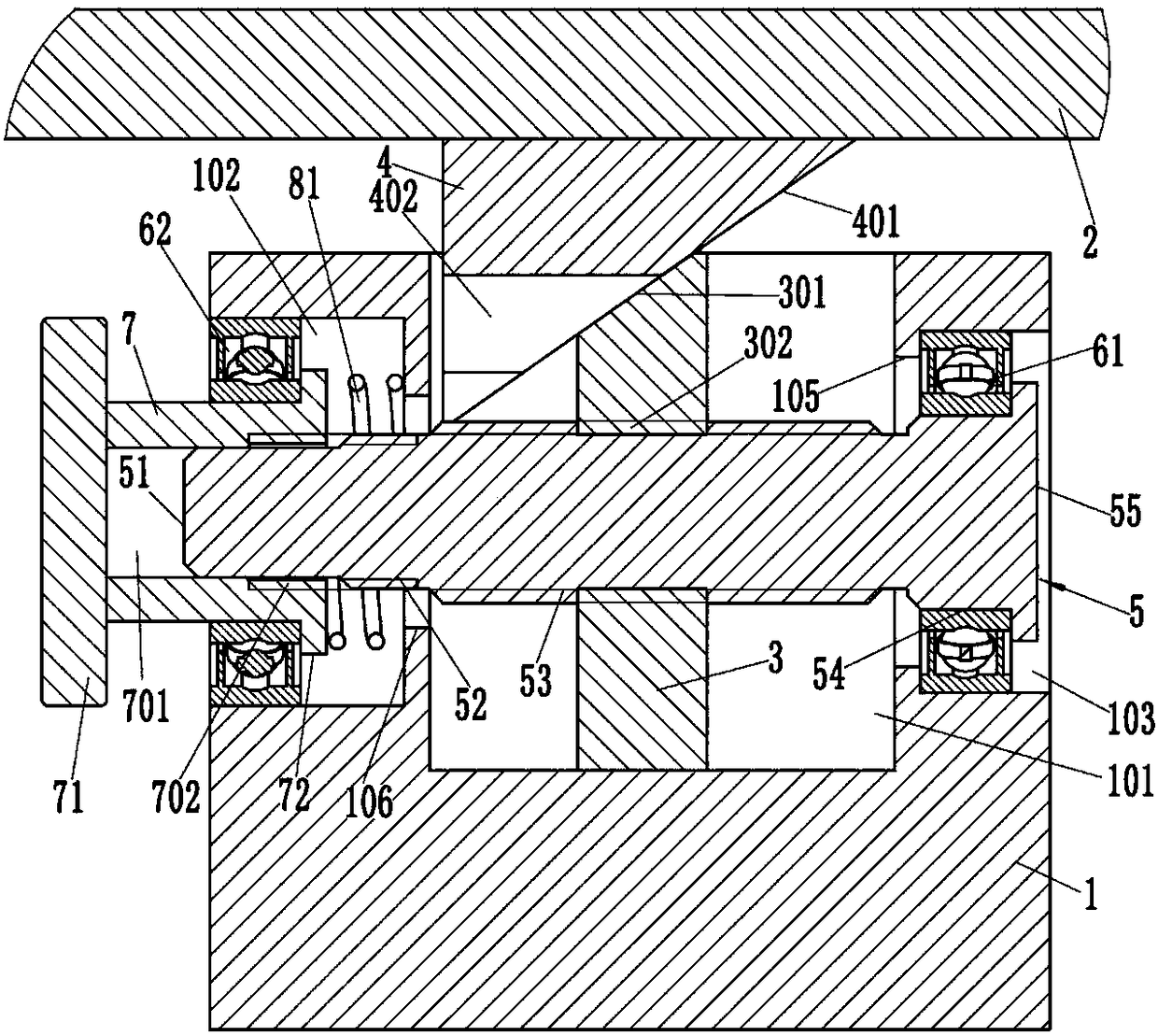

[0014] Examples, see e.g. Figure 1 to Figure 2 As shown, an adjustable shoe-making machine base includes a rectangular base 1 and a shoe-making machine bottom plate 2 arranged above the rectangular base 1. The rectangular base 1 is formed with a rectangular hole 101 with an upper side opening and two guide holes. 104, two parallel guide rods 21 are fixed on the bottom surface of the bottom plate 2 of the shoemaking machine, and the guide rods 21 are inserted into the guide holes 104; A through hole 102, a second through hole 103 communicating with the rectangular hole 101 is formed on the rear side wall of the rectangular base 1, the active block 3 is sleeved in the rectangular hole 101, and the upper slope 301 of the active block 3 is pressed against On the lower slope 401 of the driven block 4, the driven block 4 is fixedly connected with the shoemaking machine base plate 2, and the driving block 3 is connected with a drive shaft 5, and the drive shaft 5 includes an integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com