Marine damping sleeve frame

A shock-absorbing sleeve, marine technology, applied in the direction of spring/shock absorber, spring/shock absorber design features, spring, etc., can solve the problems of time-consuming and labor-intensive, safety can not be guaranteed, etc., to achieve a small amount of construction, The effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The invention provides a marine shock-absorbing sheath. The present invention will be described in detail below with reference to the accompanying drawings, but the following content does not limit the present invention.

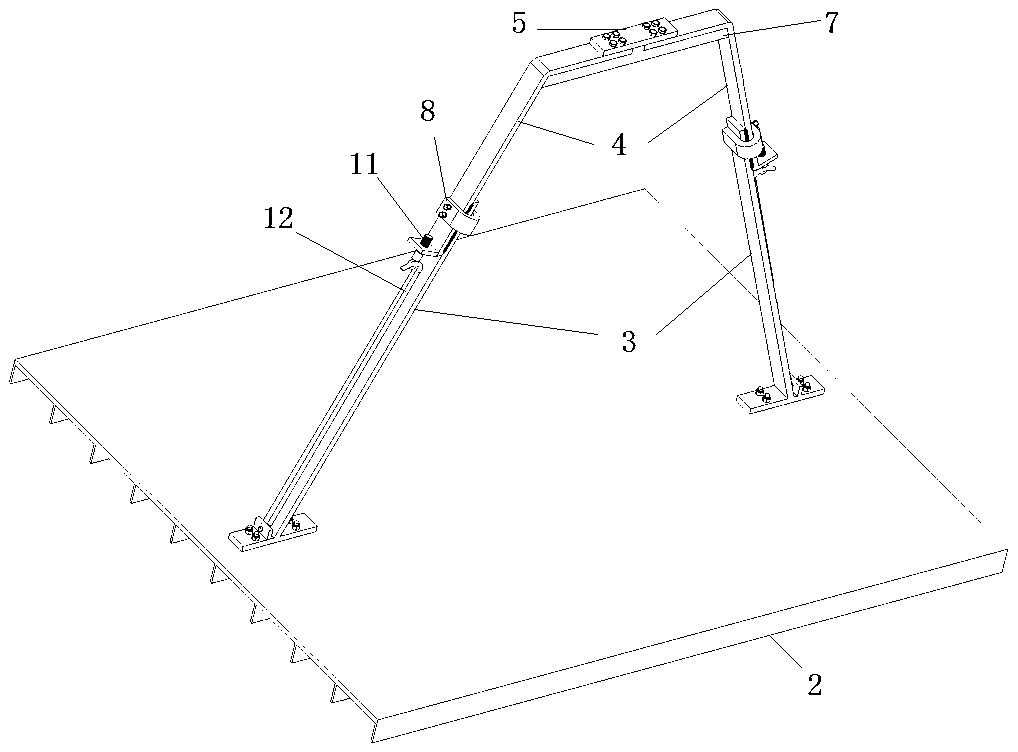

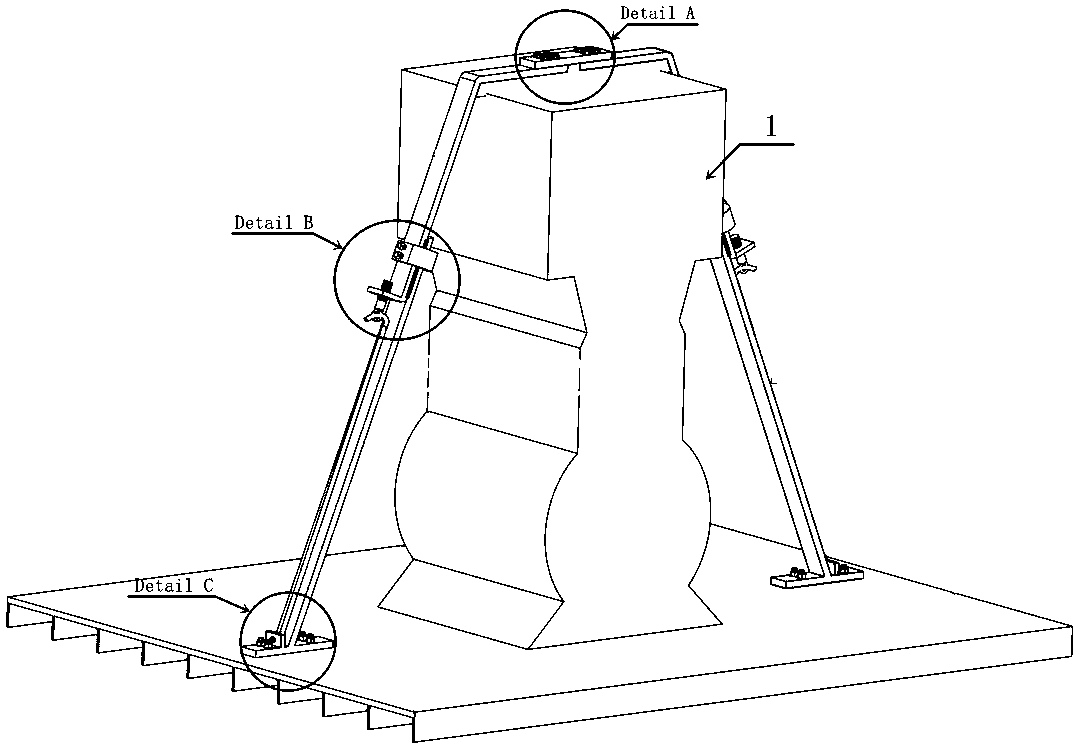

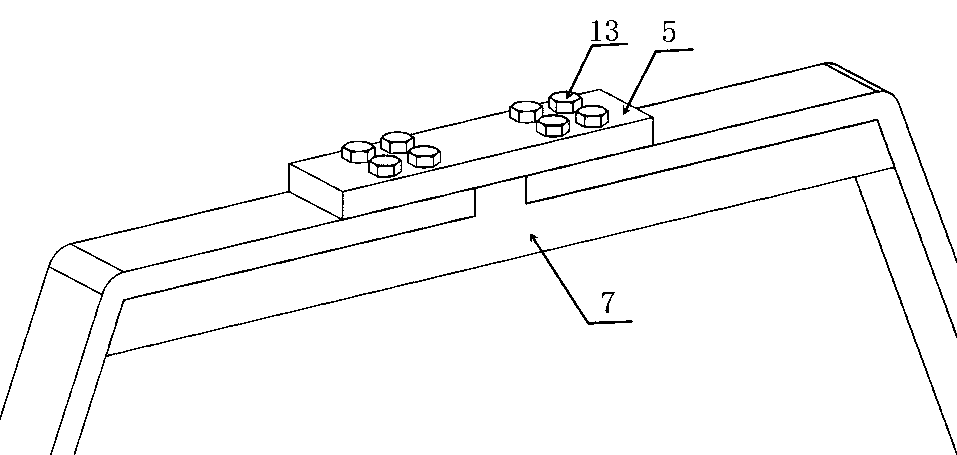

[0049] The purpose of the present invention is to provide a marine shock-absorbing sheath. as attached figure 1 - attached image 3 Shown, the feature of the present invention is, comprises: lower steel frame 3, upper steel frame 4, positioning plate 5, U-shaped clamp 8, eyelet bolt 11, steel wire rope 12, rubber pad 7.

[0050] Wherein, the equipment 1 stands on the deck 2; the positioning plate 5 is arranged on the top of the equipment 1; the upper steel frame 4 includes two, and each upper steel frame 4 is composed of a first end panel and a second end panel The first end panel of the upper steel frame 4 is symmetrically arranged on the top of the equipment 1, and the positioning plate 5 is fixed to the first end panels of the two upper steel fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com