Patents

Literature

136results about How to "Play a transitional role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

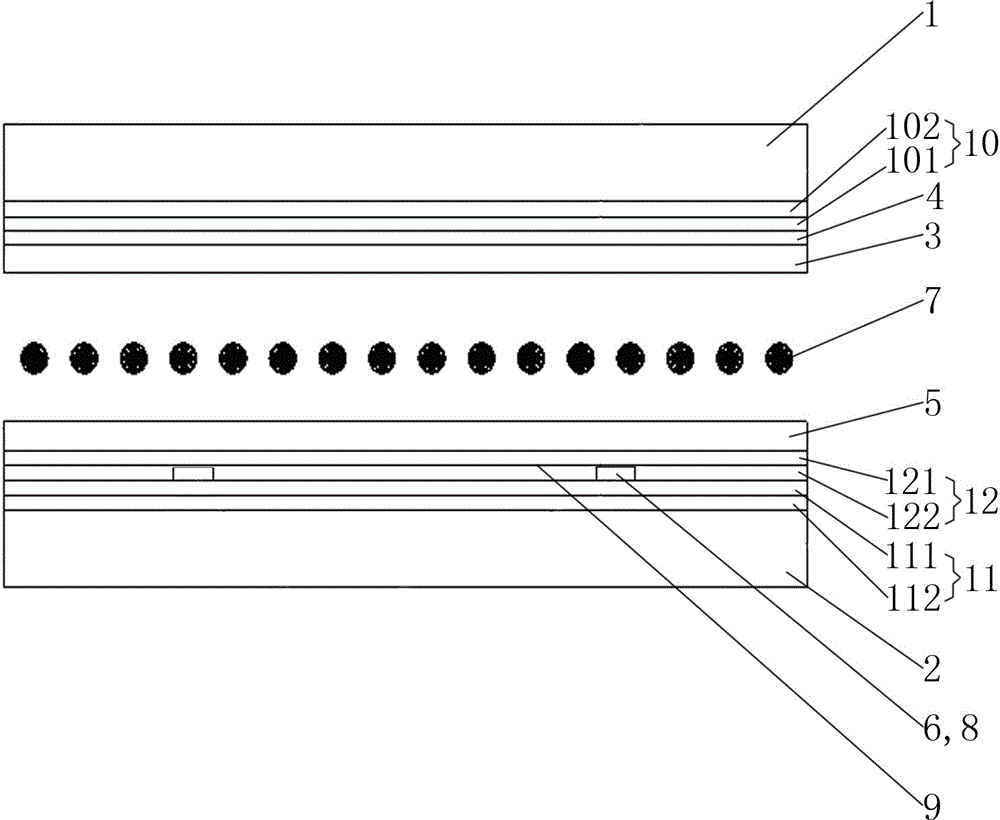

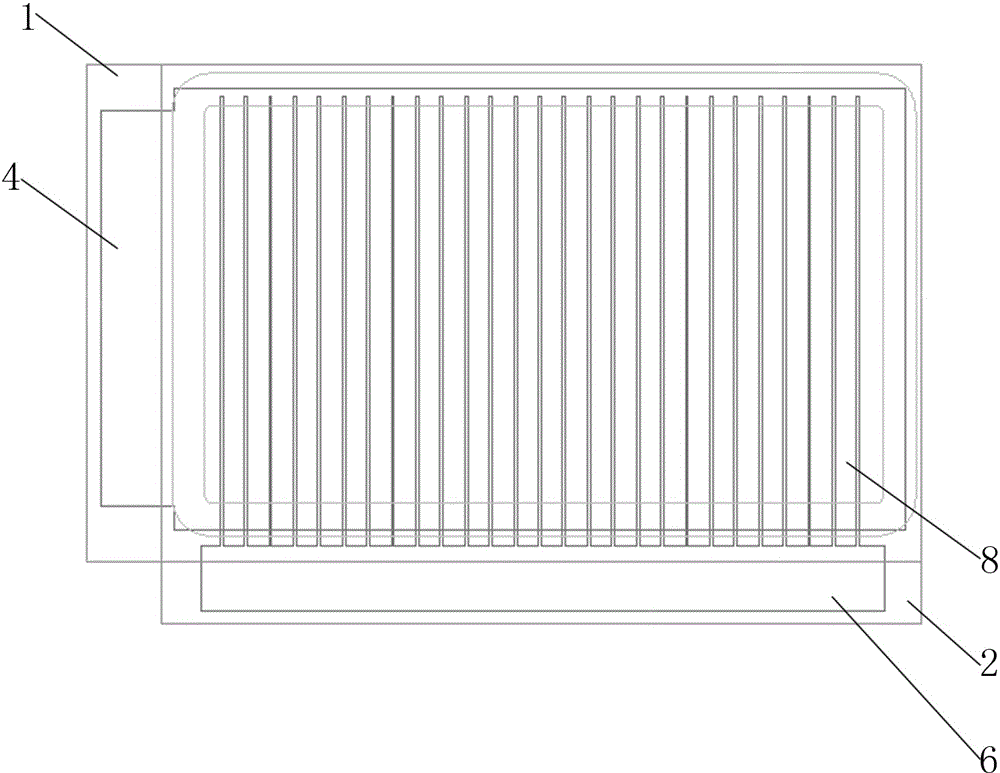

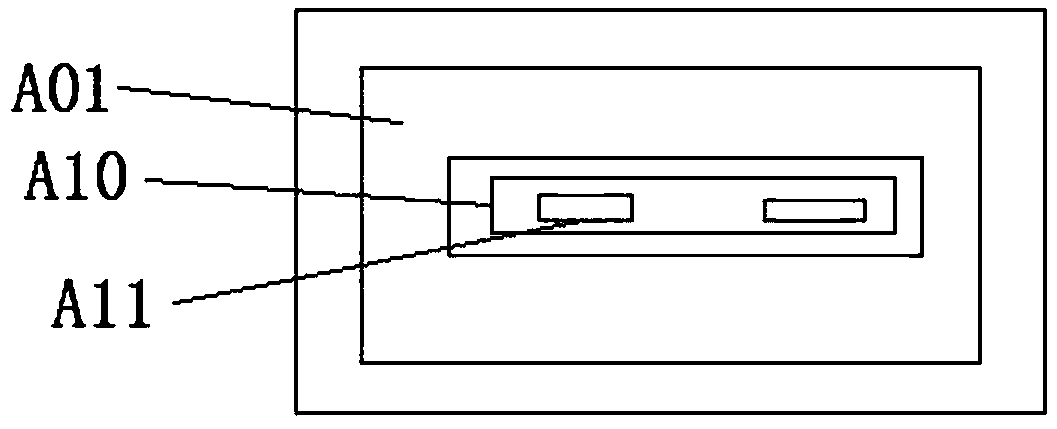

Display panel and display device

ActiveCN110874990APromote lowerMitigating the impact of optical performanceTelevision system detailsColor television detailsPixel densityDisplay device

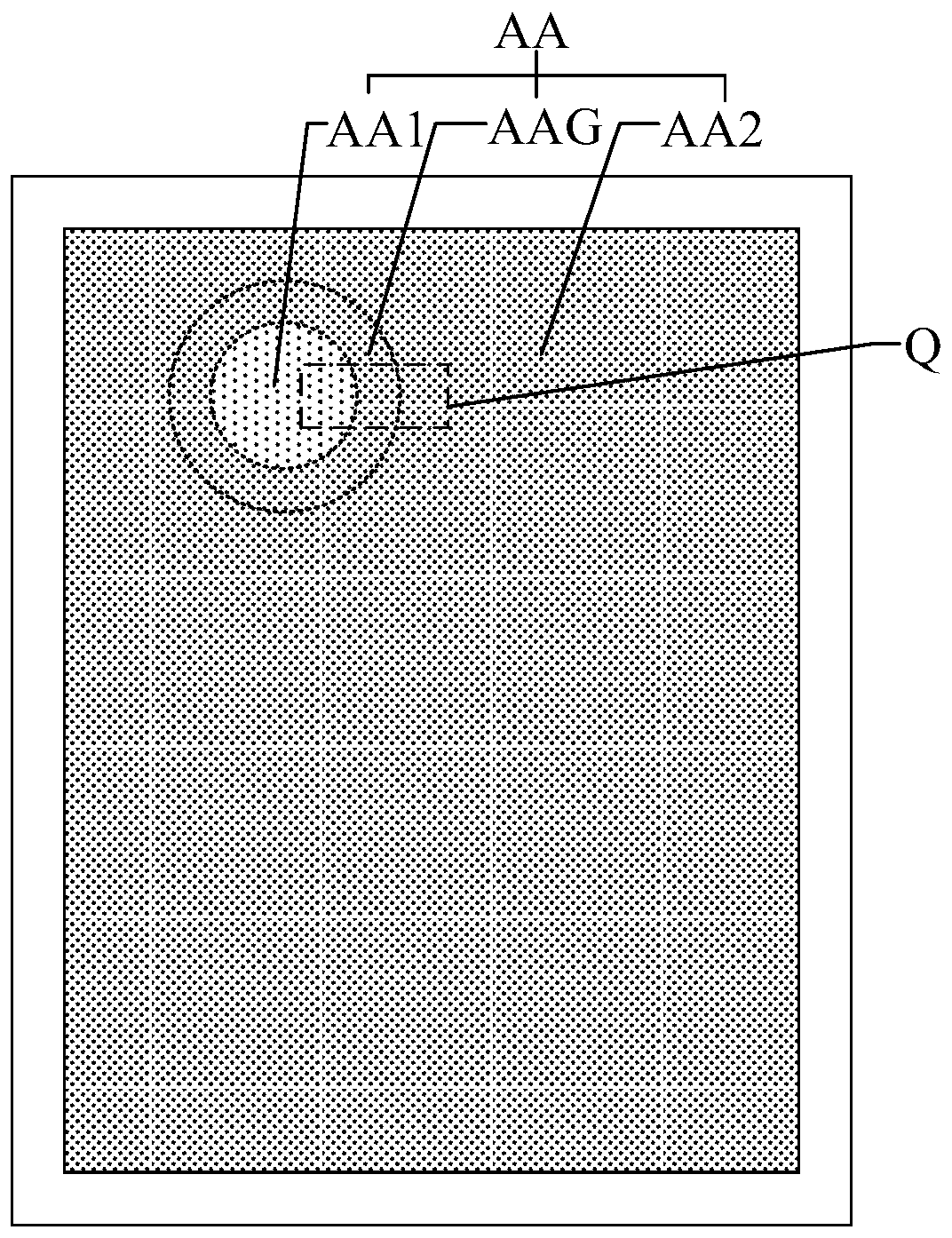

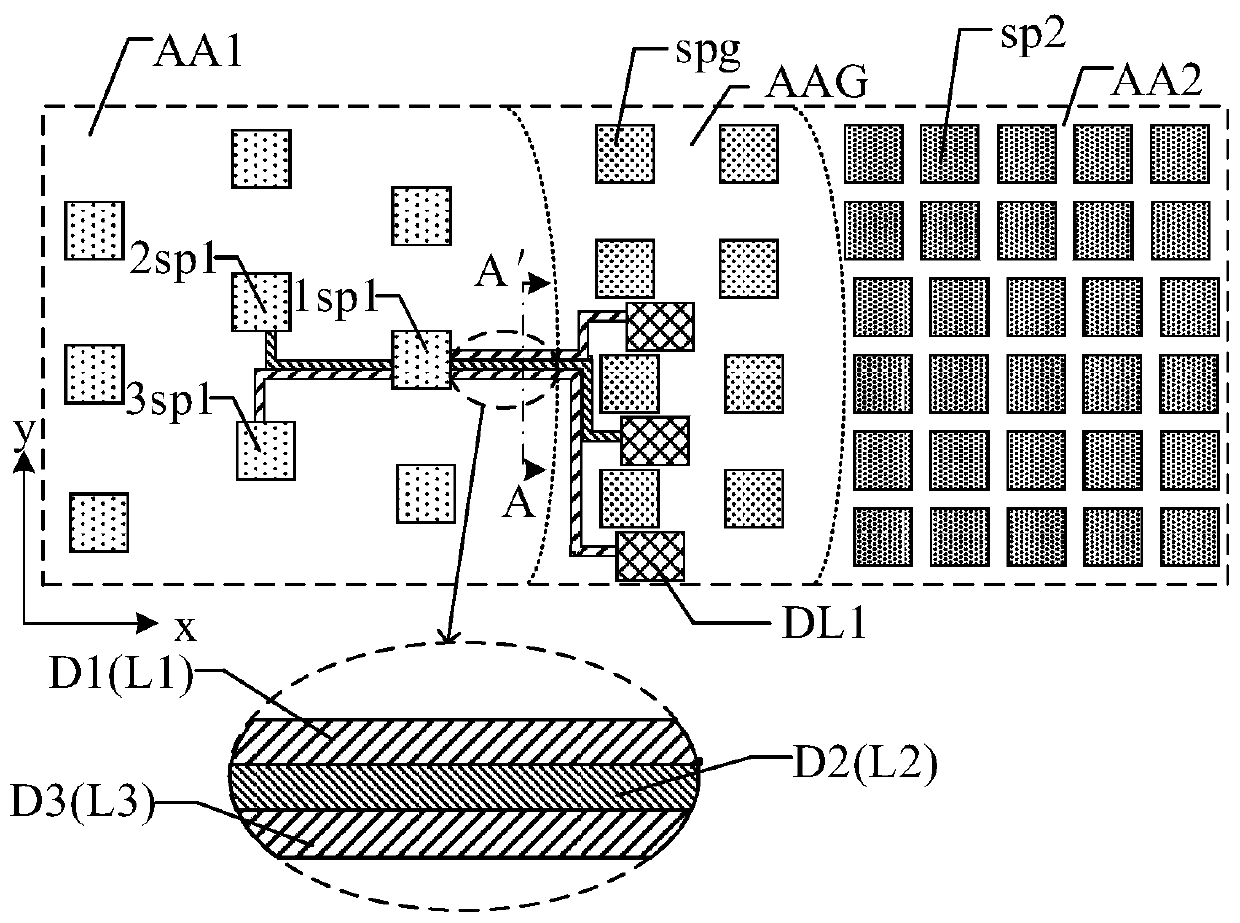

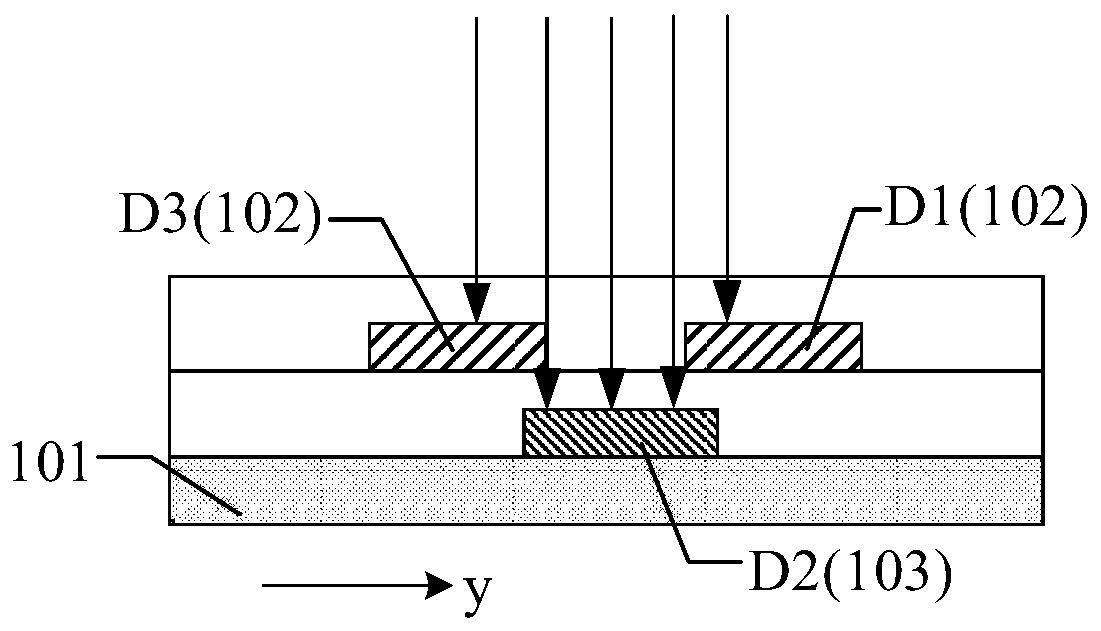

The embodiment of the invention provides a display panel and a display device. The display panel comprises a display area, wherein the display area comprises a first display area, a transition area and a second display area, wherein the sub-pixel density of the first display area, the transition area and the second display area is gradually increased. The first display area comprises a plurality of first sub-pixels, and a first pixel circuit for driving the first sub-pixels is located in the transition area, so that the light transmission area of the first display area is increased. The firstsub-pixels are electrically connected with the first pixel circuit through a connecting line. Each of a first line segment, a second line segment and a third line segment belongs to a different connecting line, and the first line segment, the second line segment and the third line segment all extend in a first direction and are sequentially arranged in a second direction. There is no gap between the first line segment and the second line segment arranged in sequence, and there is no gap between the second line segment and the third line segment arranged in sequence, so that the light transmittance of the first display area can be improved, the diffraction phenomenon when the light ray penetrates through the first display area is improved, and the optical performance of an under-screen optical device is improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

Method for frying purple yam under vacuum condition

The invention discloses a method for frying purple yam under a vacuum condition, which comprises the following steps that: (1) fresh purple yam is cleaned, peeled and cut into strips or pieces, immediately put into color protection solution to protect the color for 5min, fished out and blanched in the color protection solution with the same components for 2 to 3min at 95 to 100DEG C; (2) the blanched purple yam is fished out, and fried for 20min at the vacuum conditions of 93 to 97DEG C of hot oil temperature and 0.085MPa to 0.095MPa of vacuum degree; (3) the fried purple yam is centrifuged and de-oiled for 3 to 5min in the vacuum state; and (4) is centrifuged and de-oiled purple yam is taken out, cooled to room temperature by cold air, packaged under the vacuum condition or after being filled with nitrogen, and the purple yam strip or piece products are prepared. The method is convenient to operate, and the products have violet red color, above 80 percent of retention rate of anthocyanin, attractive color and above 6 months of product warranty period, and are applicable to industrial production.

Owner:ZHEJIANG UNIV

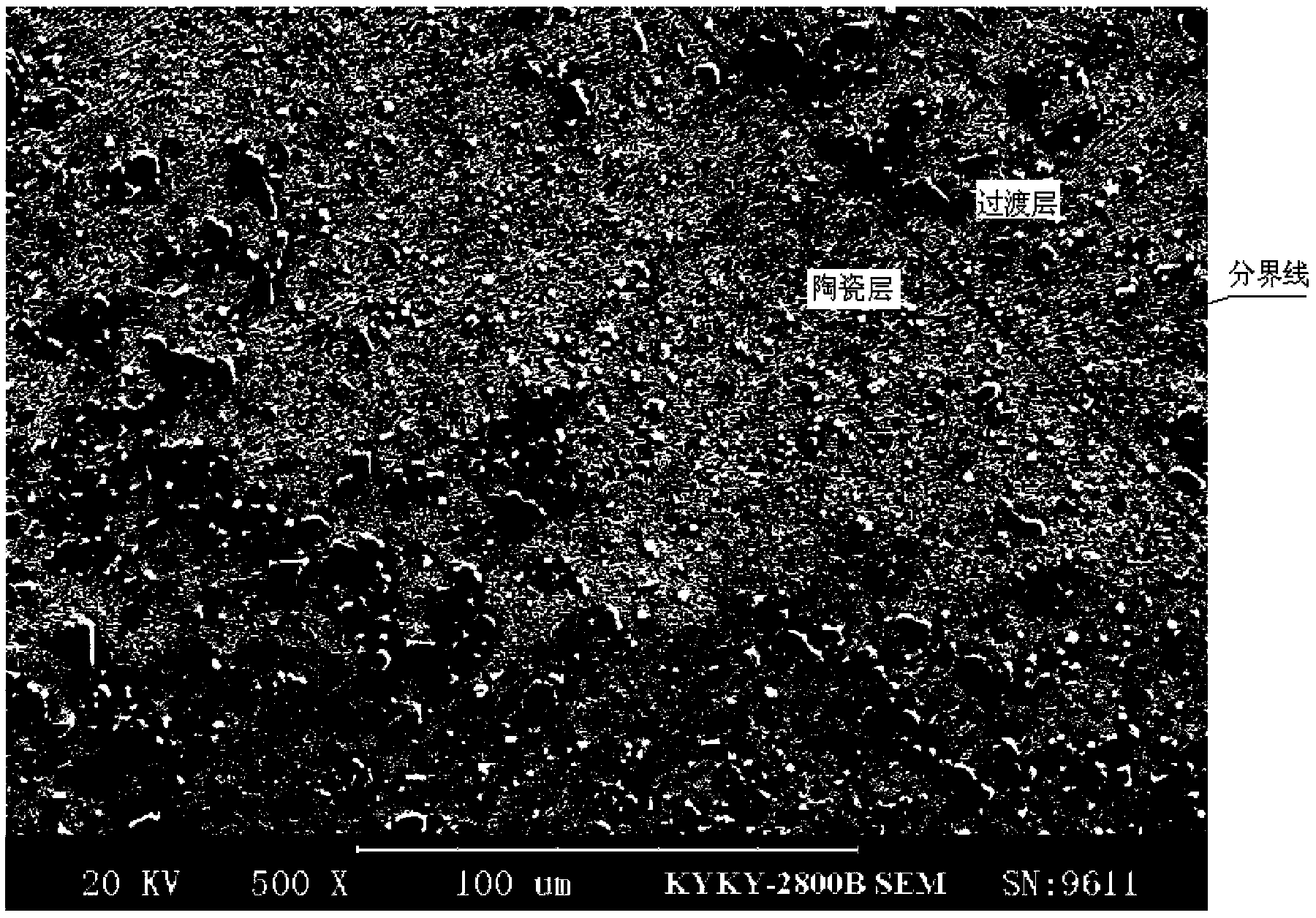

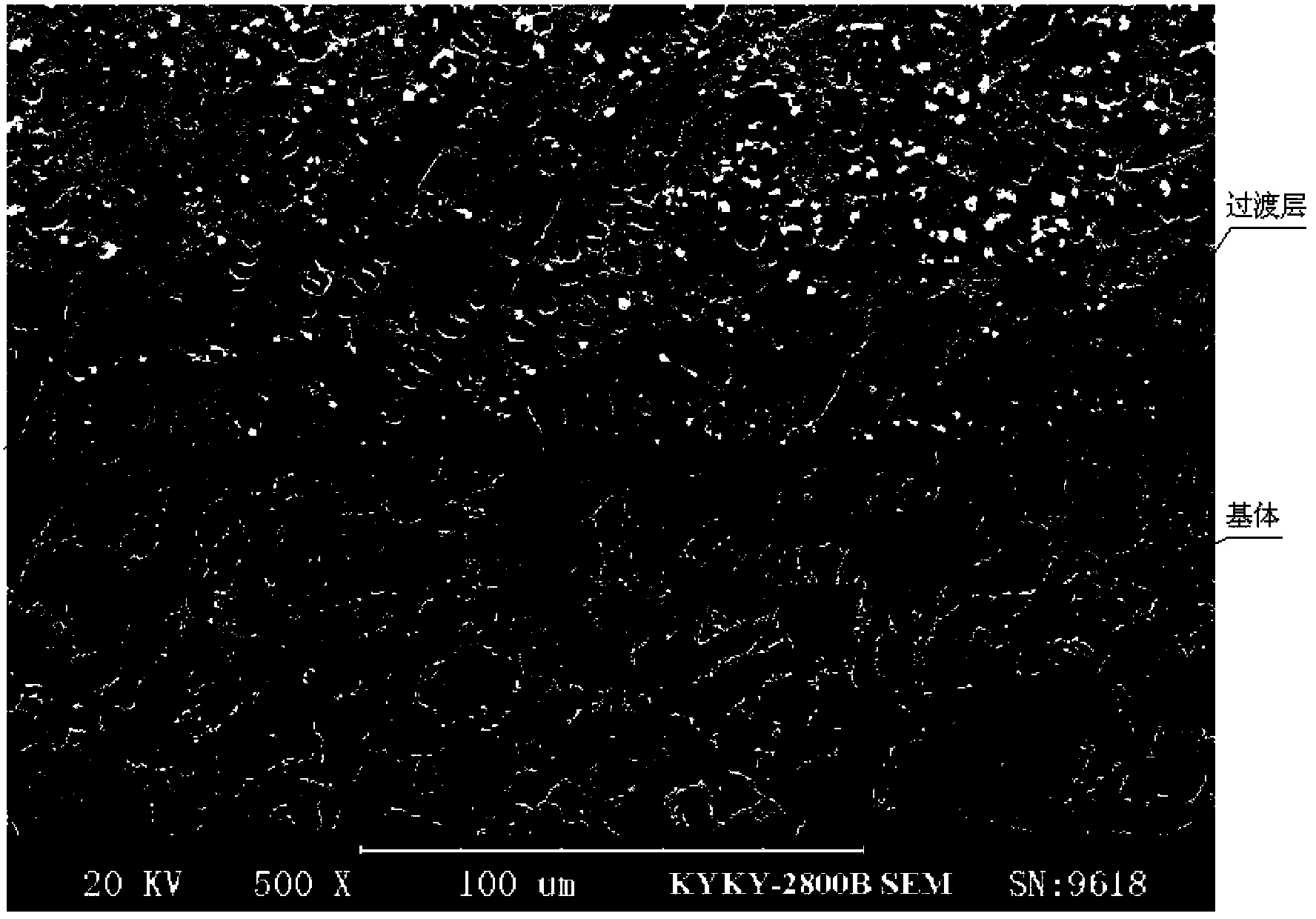

Gradient wear-resistant coating for carrier roller of conveyor belt and preparation method of gradient wear-resistant coating

ActiveCN103361591AHigh hardnessHigh bonding strengthMolten spray coatingPlasma welding apparatusWear resistantCeramic coating

The invention discloses a gradient wear-resistant coating for a carrier roller of a conveyor belt and a preparation method of the gradient wear-resistant coating. The gradient wear-resistant coating is characterized in that a layer of NiCrBSi self-fluxing alloy powder is spray-welded on the surface of a preprocessed carbon steel carrier roller as a transition layer, and the NiCrBSi self-fluxing alloy powder and the mixed powder of Fe, Ti, WC and B4C are simultaneously spray-welded on the transition layer so as to form a ceramic coating on the transition layer, wherein a nickel-base self-fluxing alloy is taken as an adhesive base phase of the ceramic coating, and TiB2, TiC, Fe2B, Fe3C and WC high-hardness ceramic particles are taken as wear-resistant strengthening phases of the ceramic coating. According to the gradient wear-resistant coating, the nickel-base self-fluxing alloy is taken as the transition layer between the ceramic coating and the carbon steel carrier roller, the wettability is good, and the transition layer presents good metallurgical bonding with a matrix; and meanwhile, the thermal stresses of the coating and matrix materials are relieved, and the residual stress in the coating is reduced, so that the coating simultaneously has excellent wear resistance and corrosion resistance.

Owner:SHANDONG UNIV OF SCI & TECH

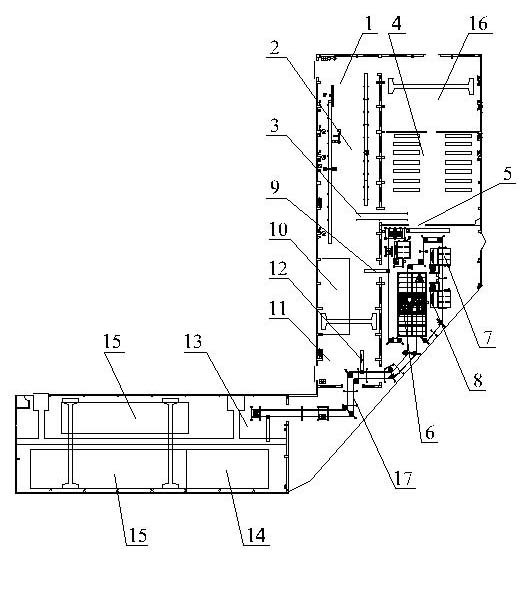

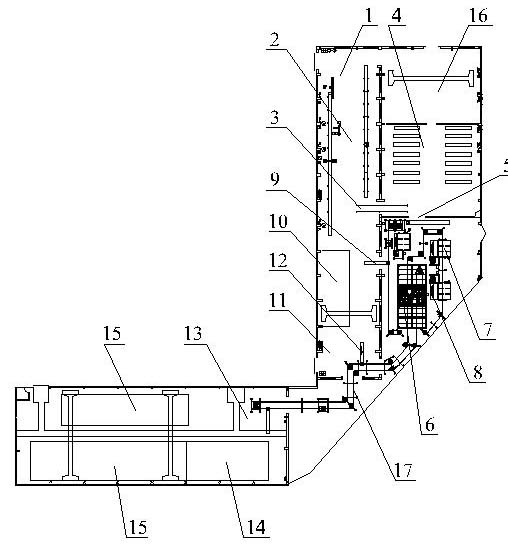

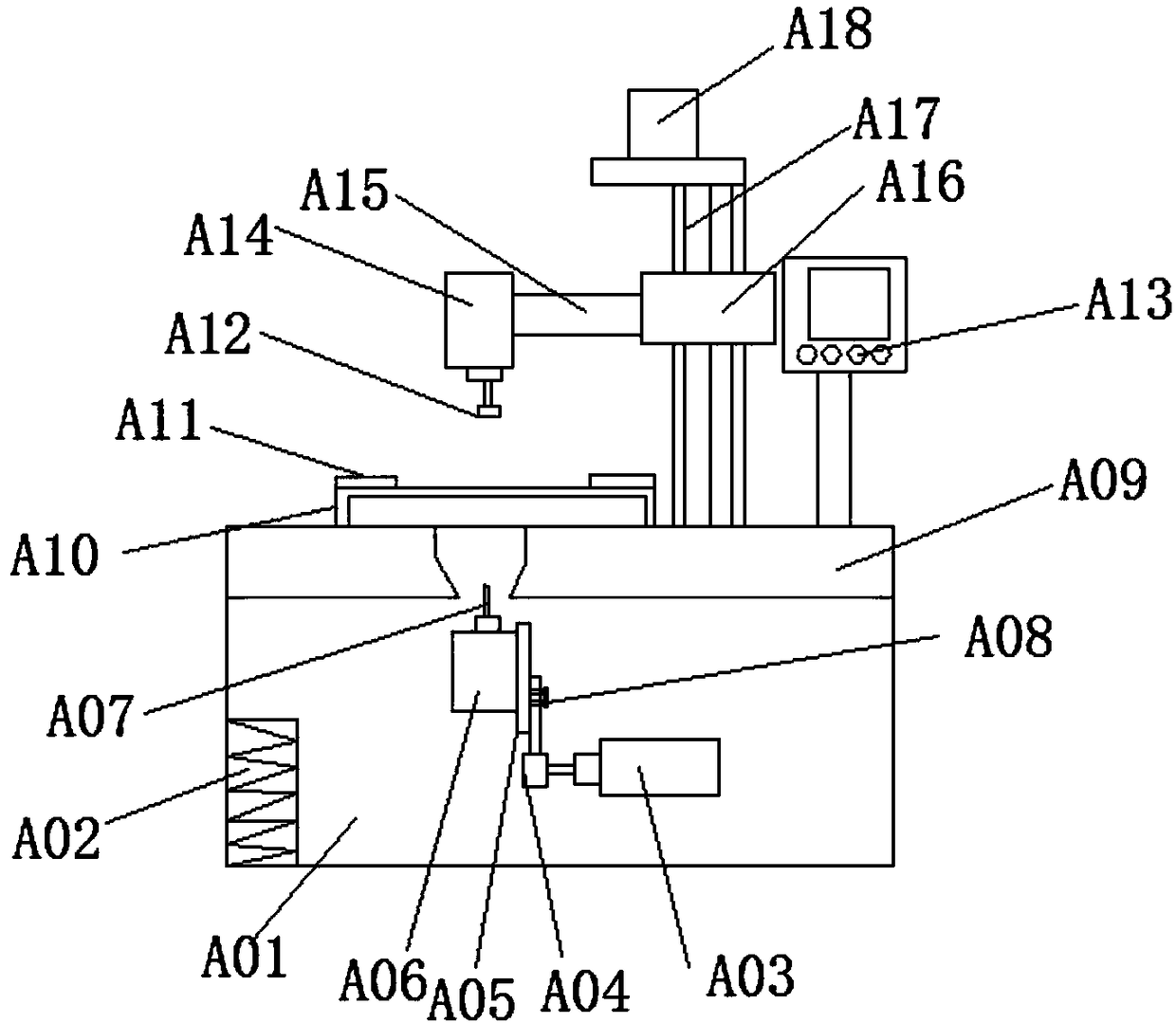

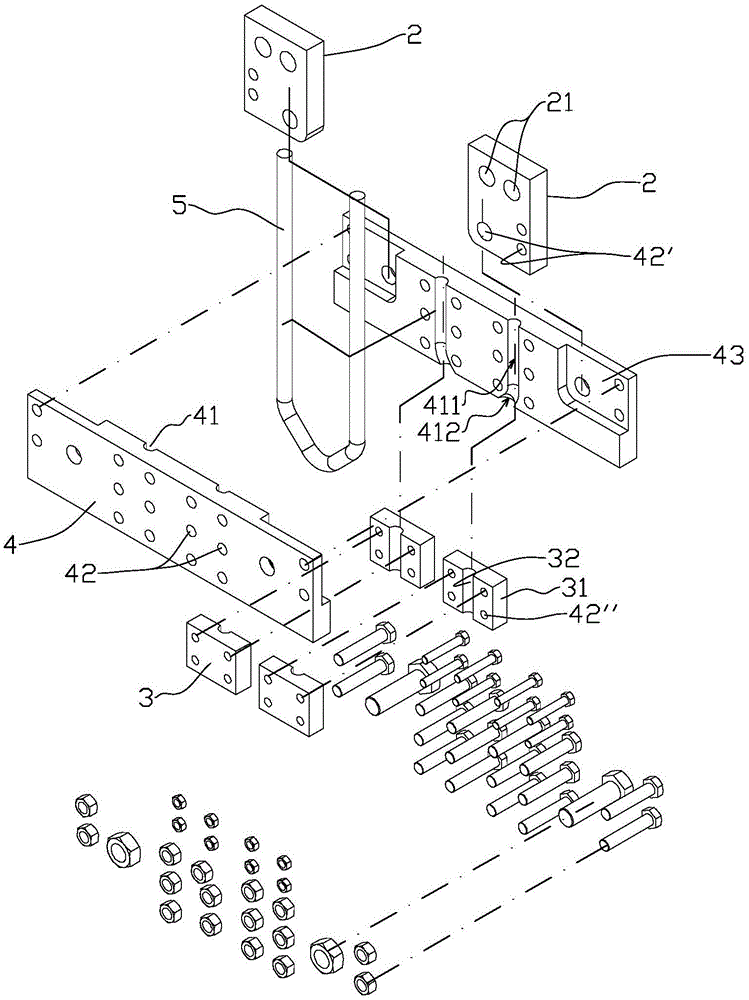

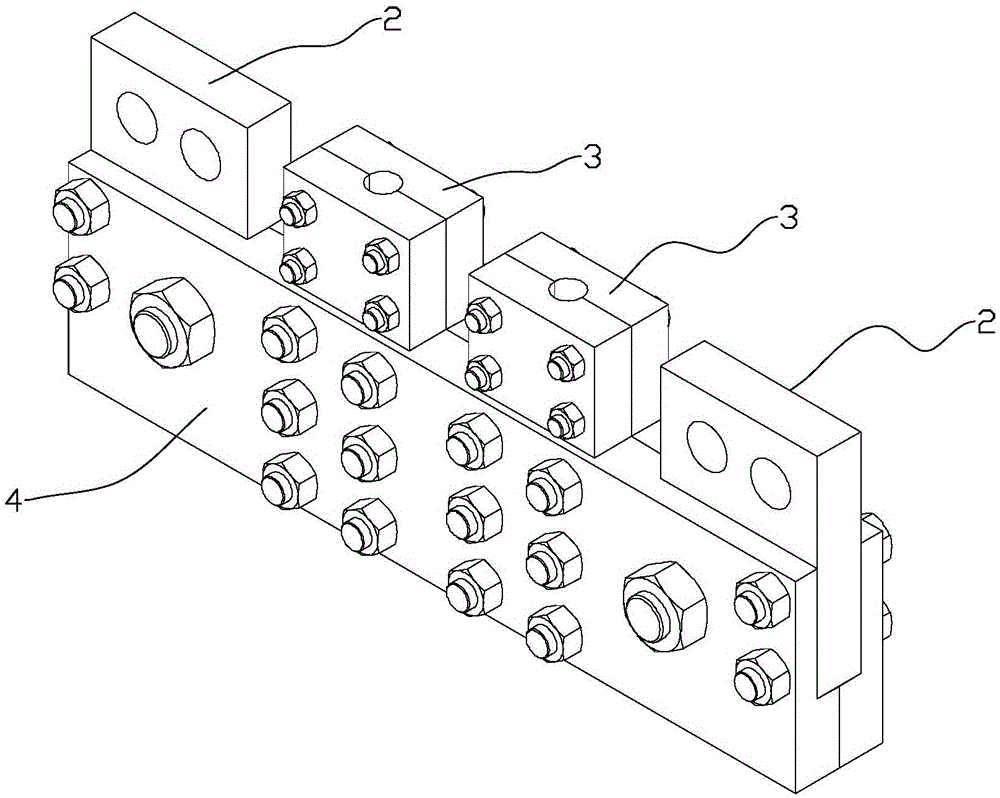

Flexible assembly technology of low-voltage motor and assembly line thereof

ActiveCN101951082AEasy to assemblePlay a transitional roleManufacturing dynamo-electric machinesLow voltageEngineering

The invention discloses a flexible assembly technology of a low voltage motor and an assembly line thereof. The assembly process comprises the following steps in sequence: a stator enters an assembly area from the top line of a piece feeding area to start motor assembly, and then enters a pretreatment area from the underline of a primary underline area; the appearance of the motor is subjected to fine treatment in the pretreatment area; the motor enters a primary painting area to paint and dry an end cover from the top line of a primary top line area, and then a fan and an end shield are assembled on line; the motor enters an experimental area from the underline of a secondary underline area; a motor experiment is carried out in a test area, and then the motor enters a perfect area after test permission to be perfectly assembled in the perfect area; the motor enters a secondary painting area to be painted and dried from the top line of a secondary top line area, and then is packaged at the underline of a package area; and after packaging, the motor enters a finished motor storage area to be stored. The time and beat of each assembly link can be flexibly regulated and controlled so as to realize flexible assembly, thus not only reserving the advantage of the assembly line facilitating line production but also meeting the production requirements of various species, small batch and multiple specifications.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

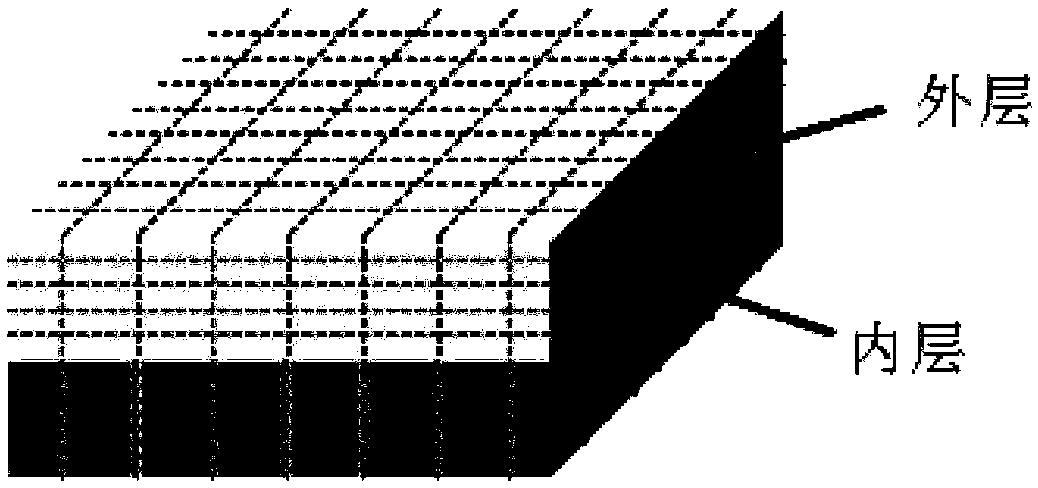

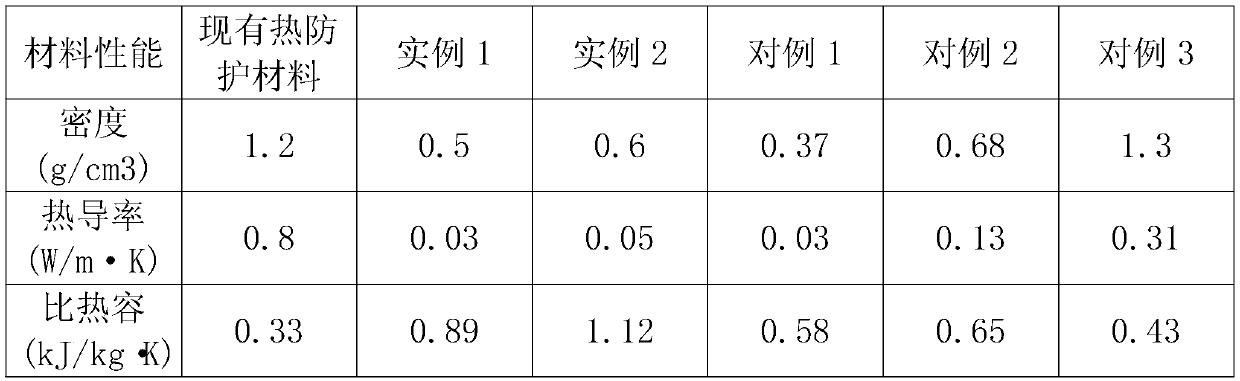

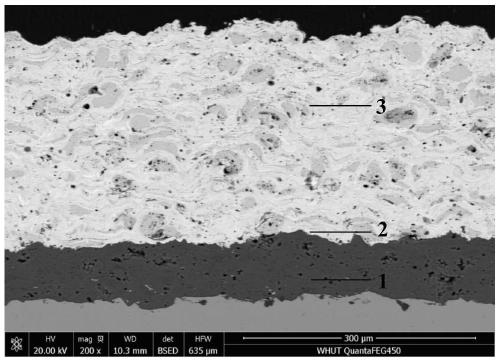

Integrated density gradient thermal protection material and preparation method thereof

ActiveCN111331941AGuaranteed insulation effectLow costSynthetic resin layered productsThermal protectionFiber reinforcement

The invention provides an integrated density gradient thermal protection material and a preparation method thereof. The thermal protection material comprises a matrix and a reinforcement body, whereinthe matrix is of a network-shaped porous resin structure; the reinforcement body comprises a fiber reinforcement body inner layer with a second volume density and a fiber reinforcement body outer layer with a first volume density arranged on the inner layer; a network-shaped porous structure is further dispersed and cured in the fiber reinforcement body outer layer and the fiber reinforcement body inner layer, and the first volume density is 0.5-2.0 g / cm<3>; and the second volume density is 0.05-0.4 g / cm<3>. The method comprises the following steps: preparing the reinforcement body; preparinga solution of a matrix raw material; injecting the solution into the reinforcement body to enable the reinforcement body to fully infiltrate the solution; and curing at a resin curing temperature. The technical problems that an outer heat-proof layer of an existing heat-proof material is prone to oxidation and cannot be used for a long time, an inner heat-insulating layer is long in forming process period and high in cost, and the overall heat-proof effect is poor due to a preparation method can be solved.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

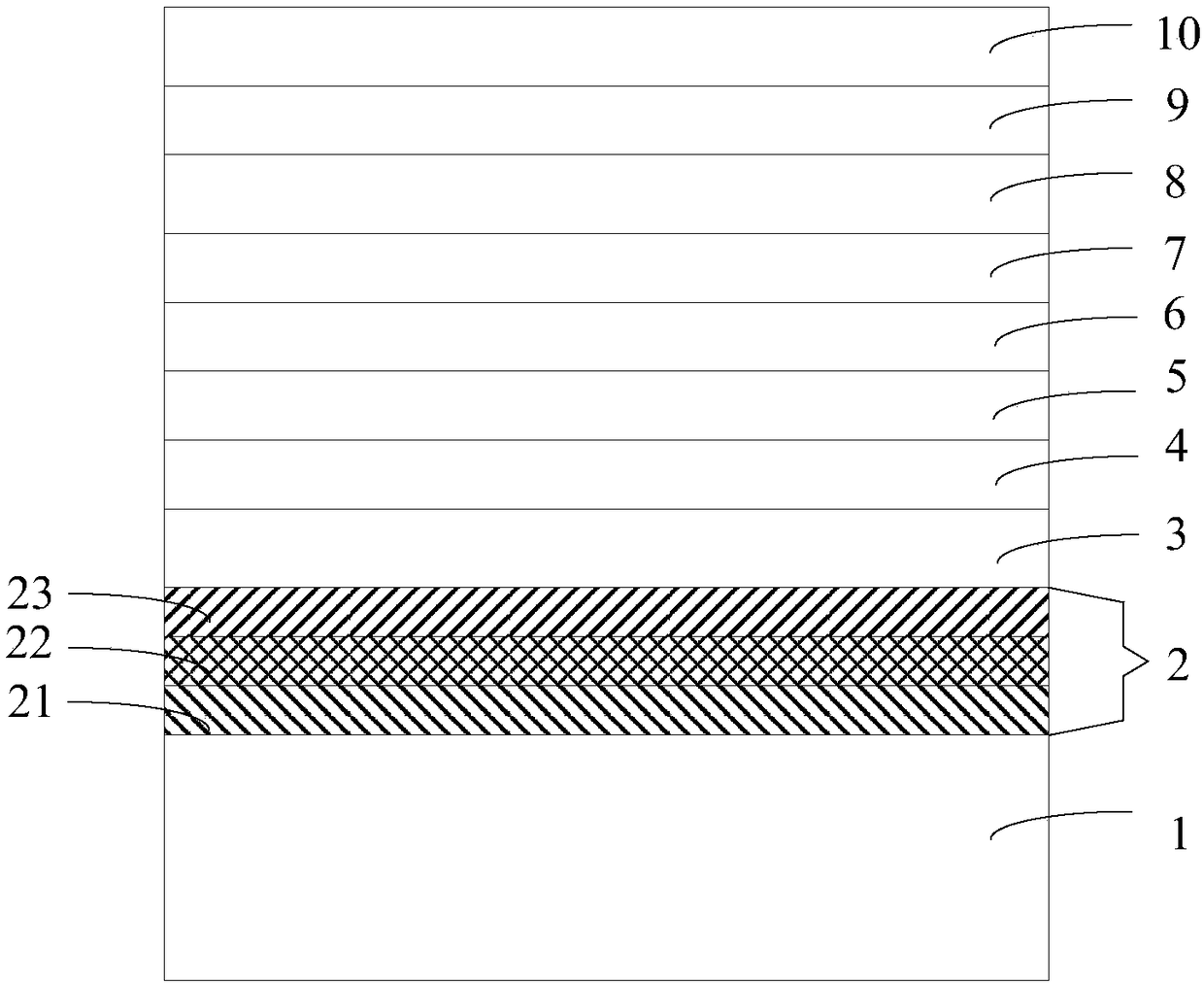

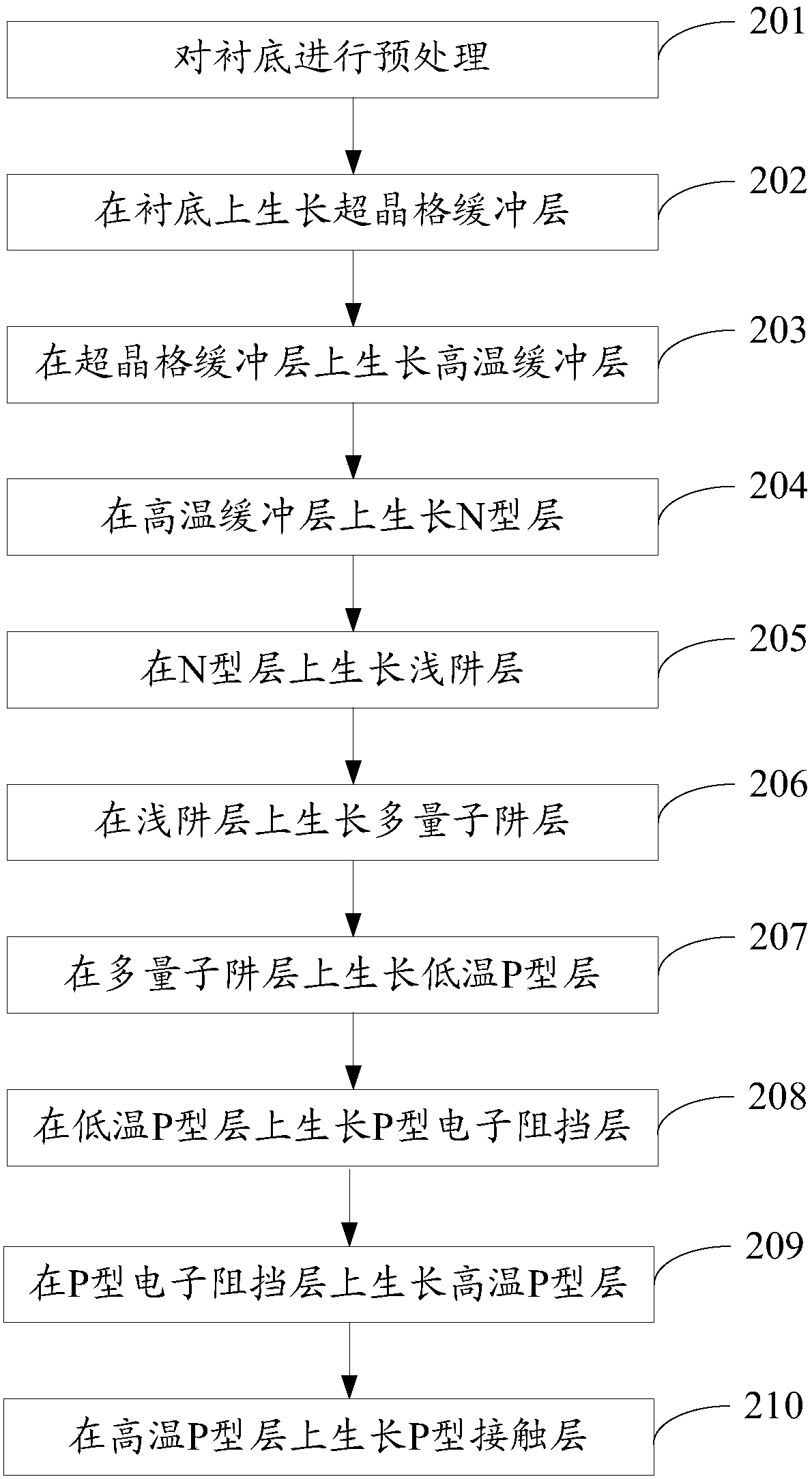

Gallium-nitride-based light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN108110098AIncrease the lattice constantReduced stress polarization effectsSemiconductor devicesQuantum wellLattice mismatch

The invention discloses a gallium-nitride-based light emitting diode epitaxial wafer and a manufacturing method thereof, belonging to the technical field of semiconductors. The gallium-nitride-based light emitting diode epitaxial wafer comprises a superlattice buffer layer, wherein the superlattice buffer layer is of a superlattice structure comprising N periods, and the superlattice structure ofeach period comprises a first sublayer, a second sublayer and a third sublayer which are laminated on a substrate. Through doping Al into the first sub-layer, the lattice mismatch between the substrate and a GaN layer can be alleviated, the defect density can be reduced, and the crystal quality of the entire epitaxial layer can be improved, thereby improving the anti-static capability of an LED. Through doping Mg into the second sublayer, a transition between the first sublayer and the second sublayer can be achieved. Through doping In into the third sublayer, the lattice constant of the thirdsublayer can be increased, thereby accelerating a stress release speed of an N-type layer, reducing the stress polarization effect of a multi-quantum well layer, and increasing the luminous efficiency of the LED.

Owner:HC SEMITEK ZHEJIANG CO LTD

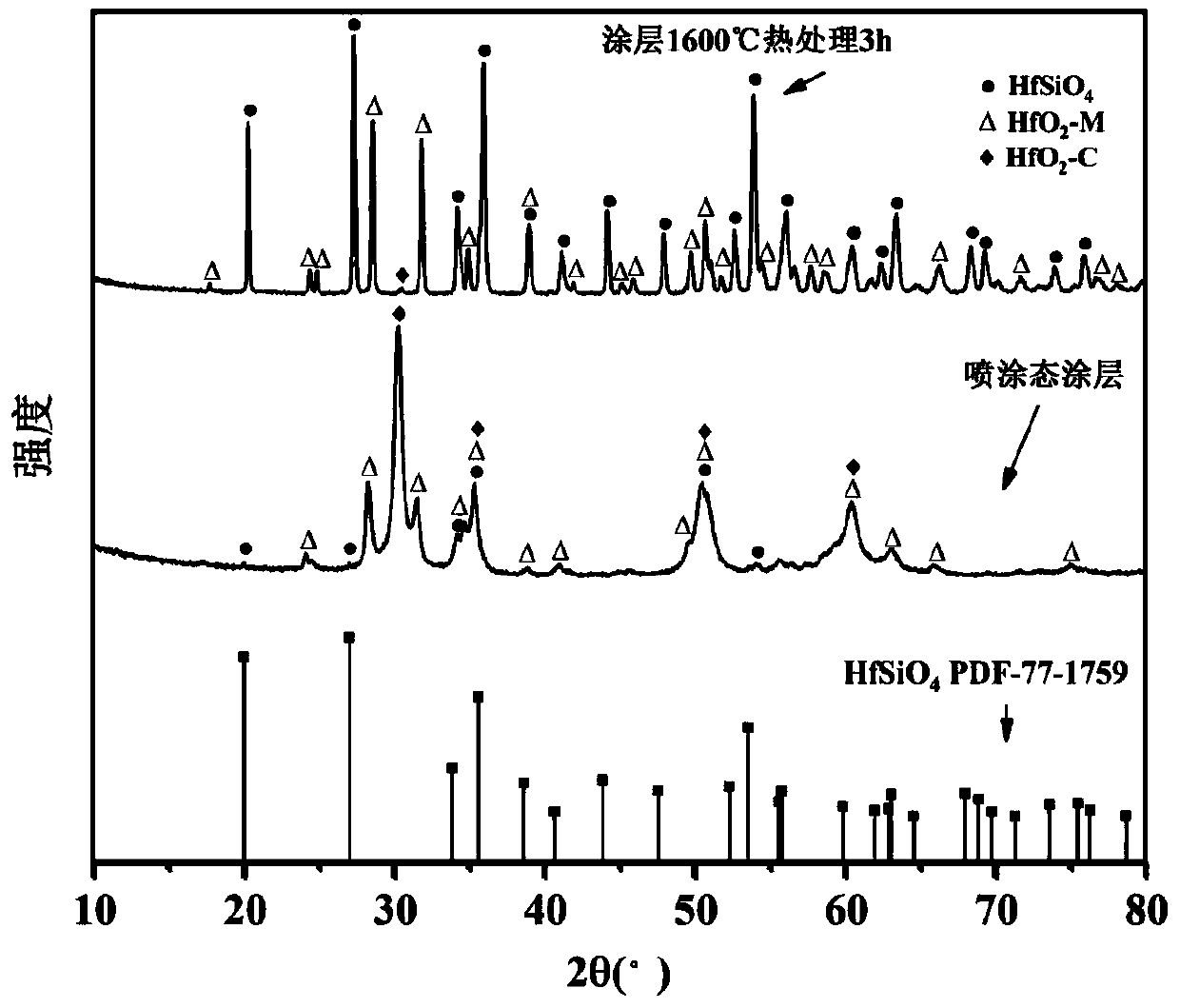

Hafnium silicate environment barrier coating for ceramic-based composite material matrix and preparation method thereof

The invention provides a hafnium silicate environment barrier coating for a ceramic-based composite material matrix and a preparation method thereof. The preparation method comprises the following steps: (1) mixing HfO2 and SiO2, carrying out wet mixing and ball milling on a ball mill, drying, grinding, sieving, sintering, and carrying out a high-temperature solid-phase reaction; (2) after the high-temperature solid-phase reaction is finished, adding deionized water for slurry preparation, then performing ball milling, and performing spray granulation to obtain an HfSiO4 powder material; (3) firstly spraying a Si layer on the surface of a ceramic-based composite matrix as a priming coat, and then spraying the HfSiO4 powder material on the surface of the priming coat as a surface layer to form a multi-layer coating; and (4) carrying out a heat treatment on the multi-layer coating to obtain the environmental barrier coating. Due to the added heat treatment, the crystallinity of the HfSiO4 surface layer is improved, the binding force of each layer of the coating is better, the stability is higher, and the water and oxygen resistance of the environment barrier coating is greatly improved. The provided preparation method is simple and easy to control, and is easy for industrial production and application.

Owner:WUHAN UNIV OF TECH

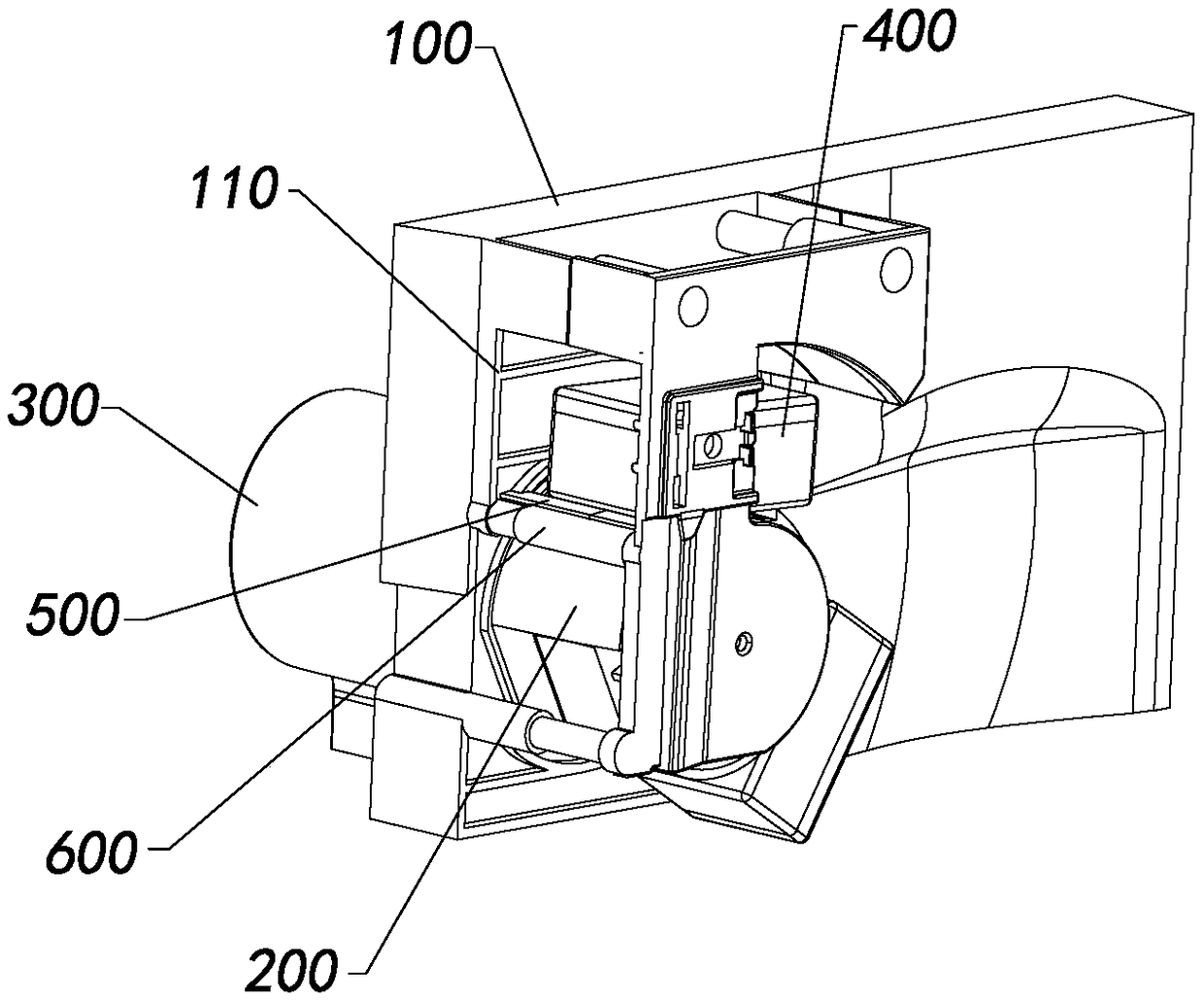

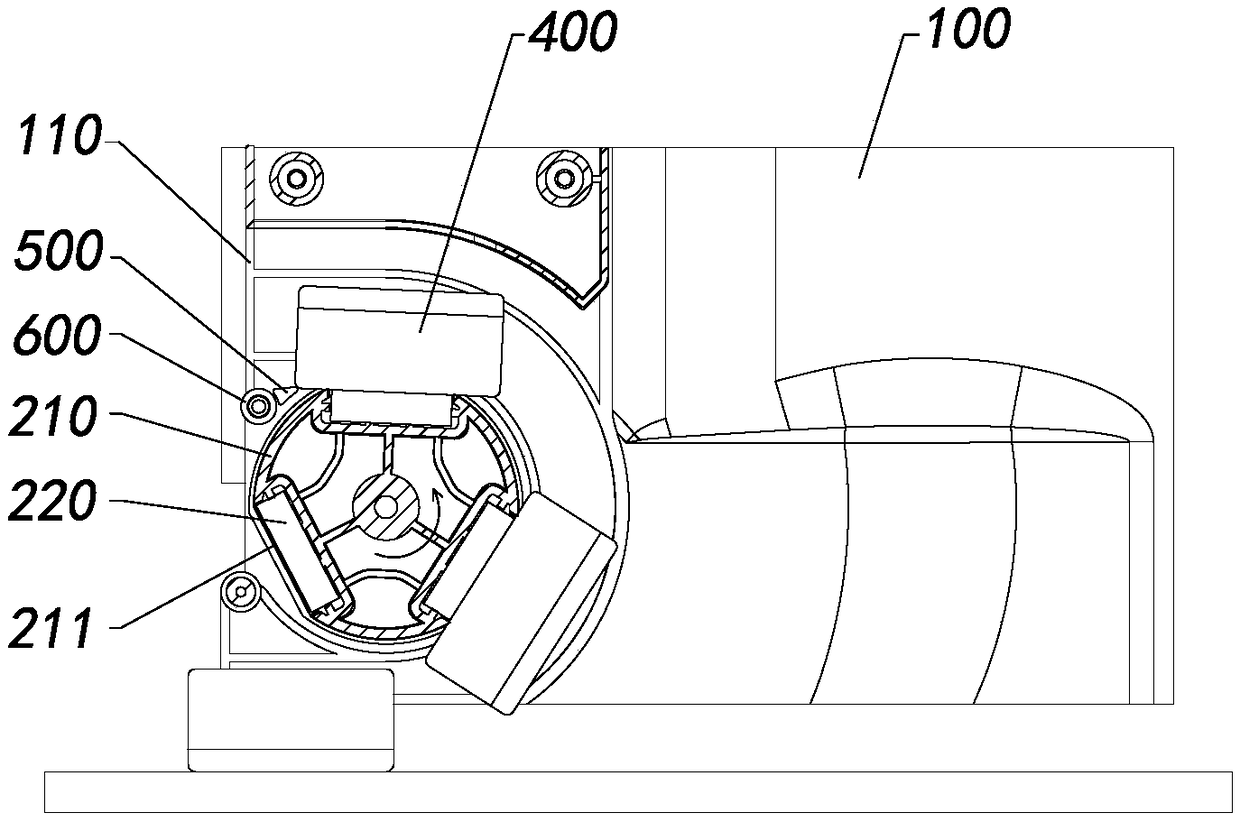

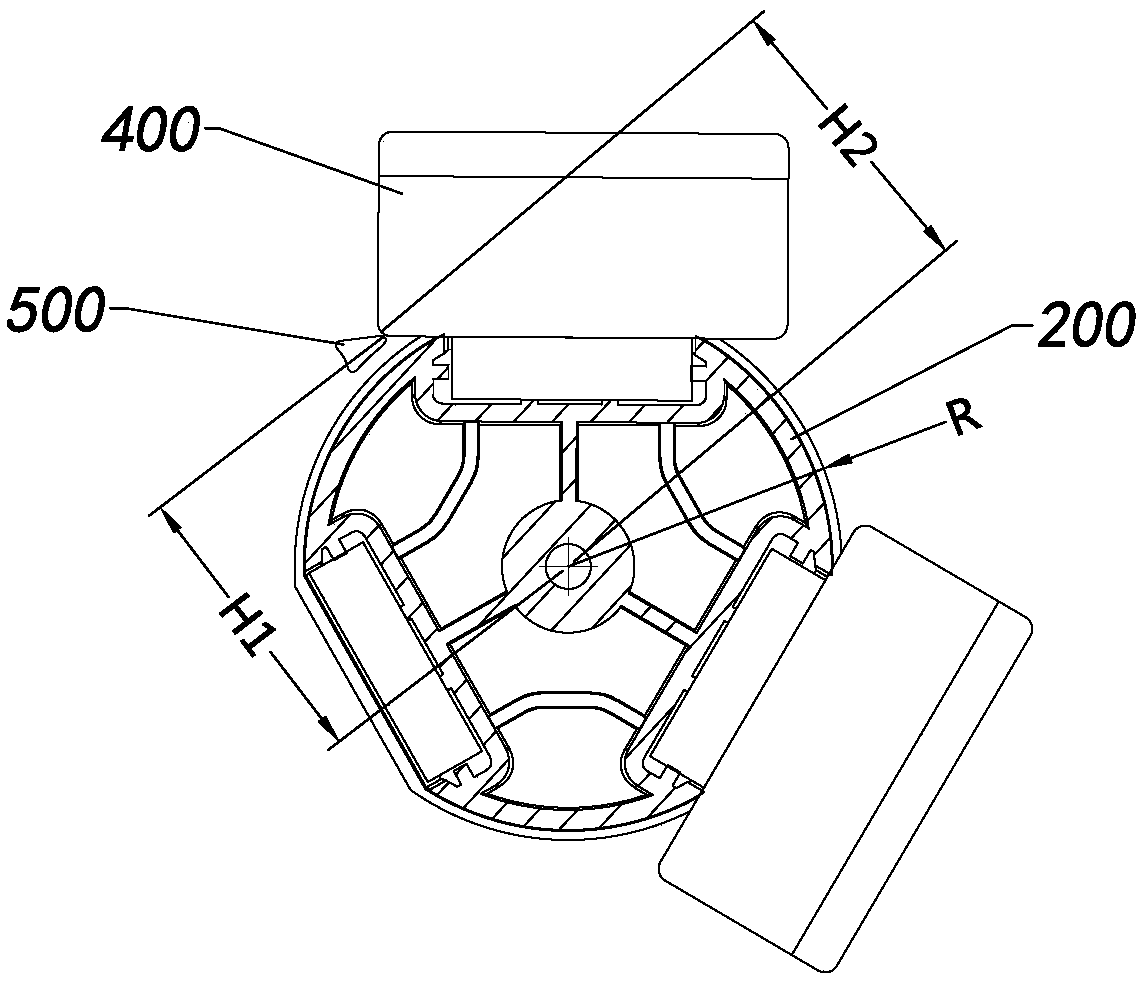

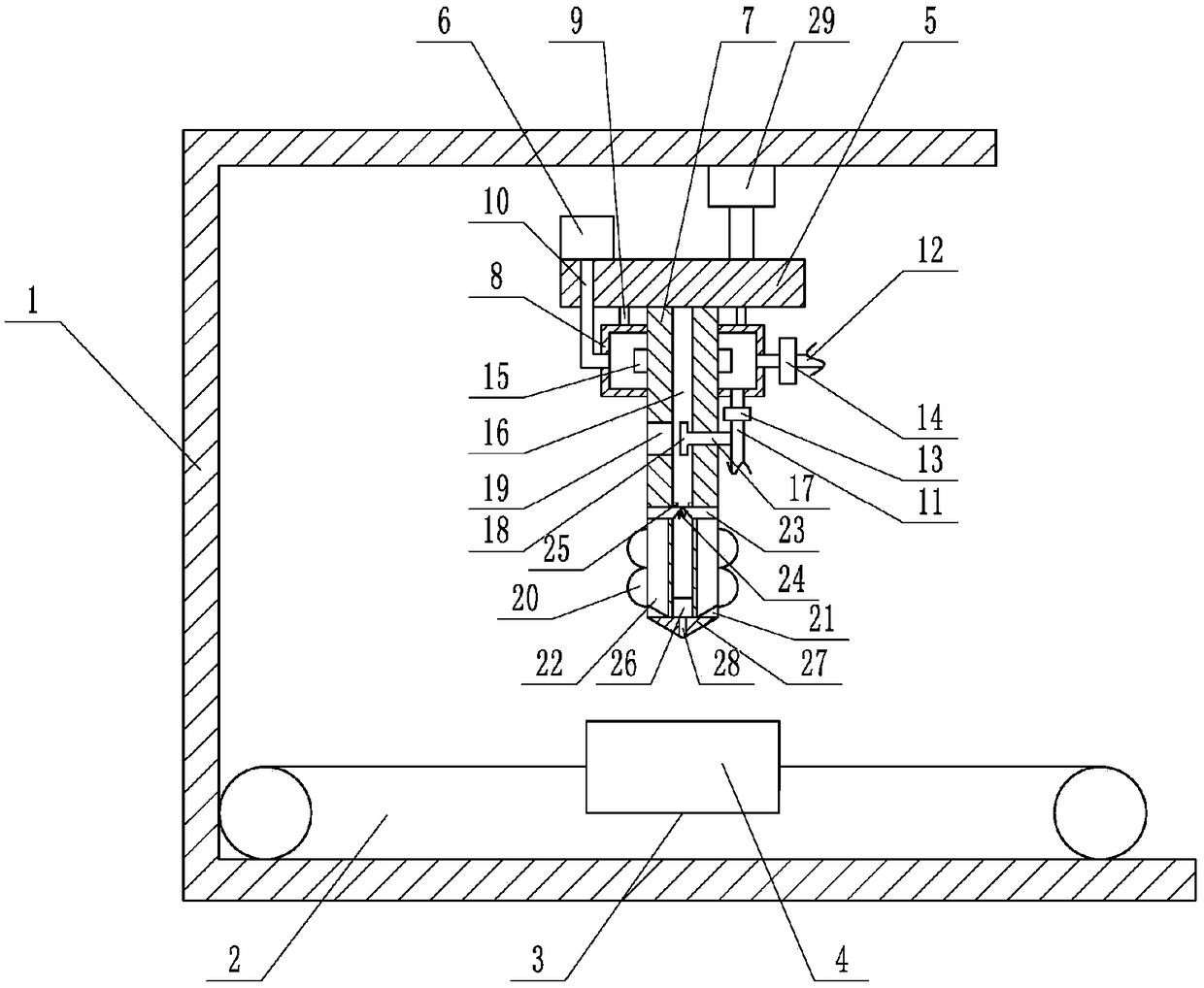

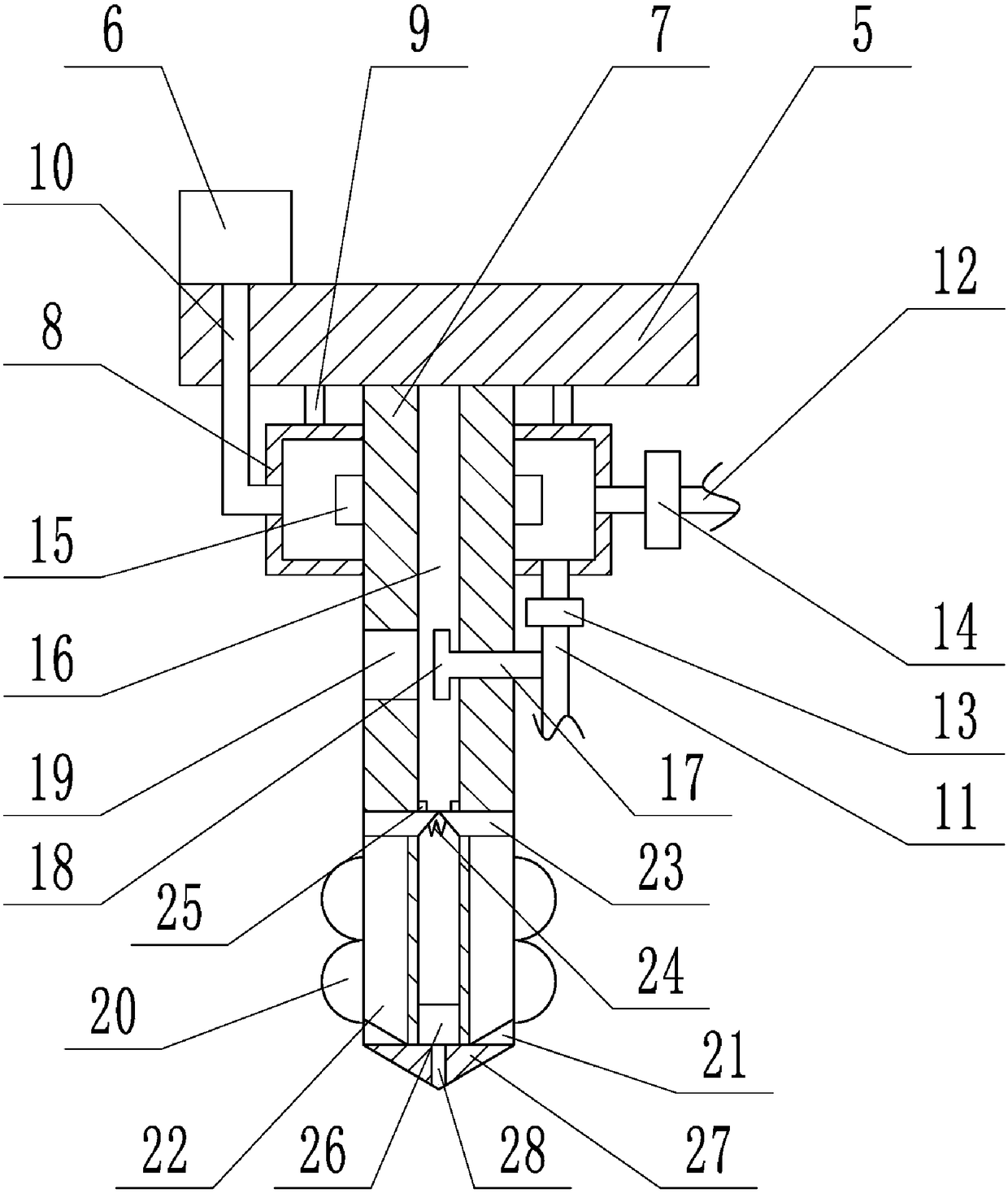

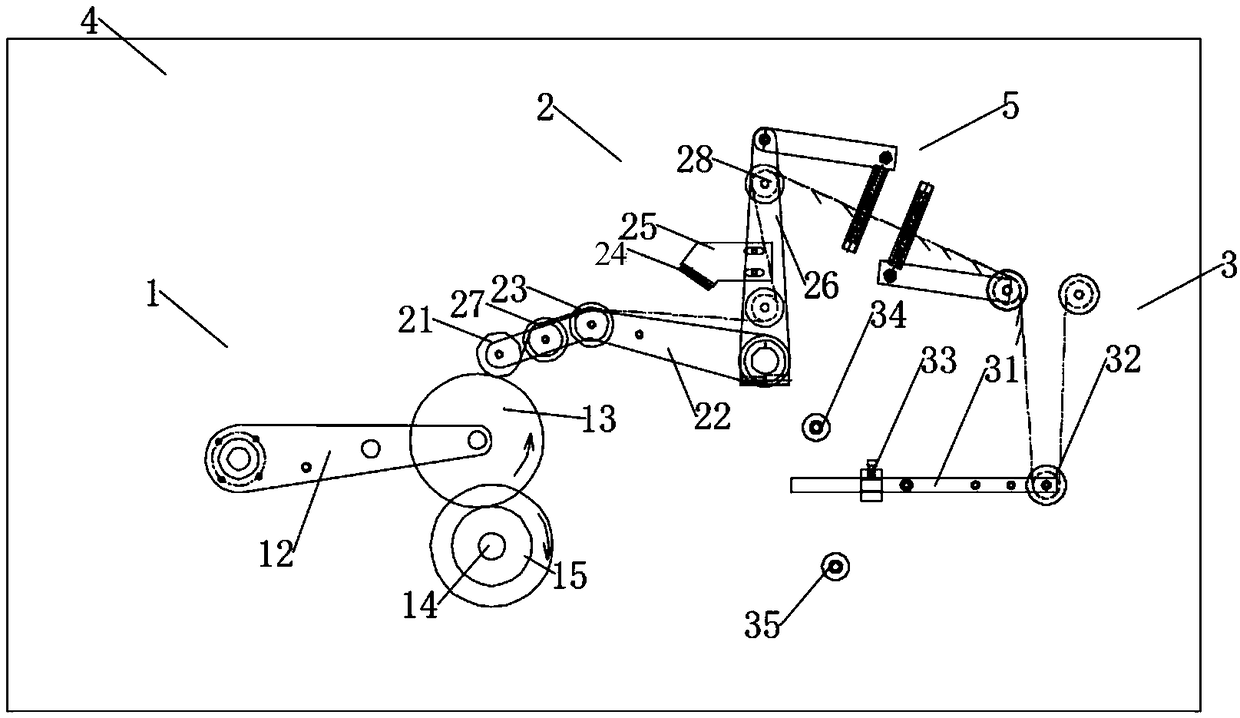

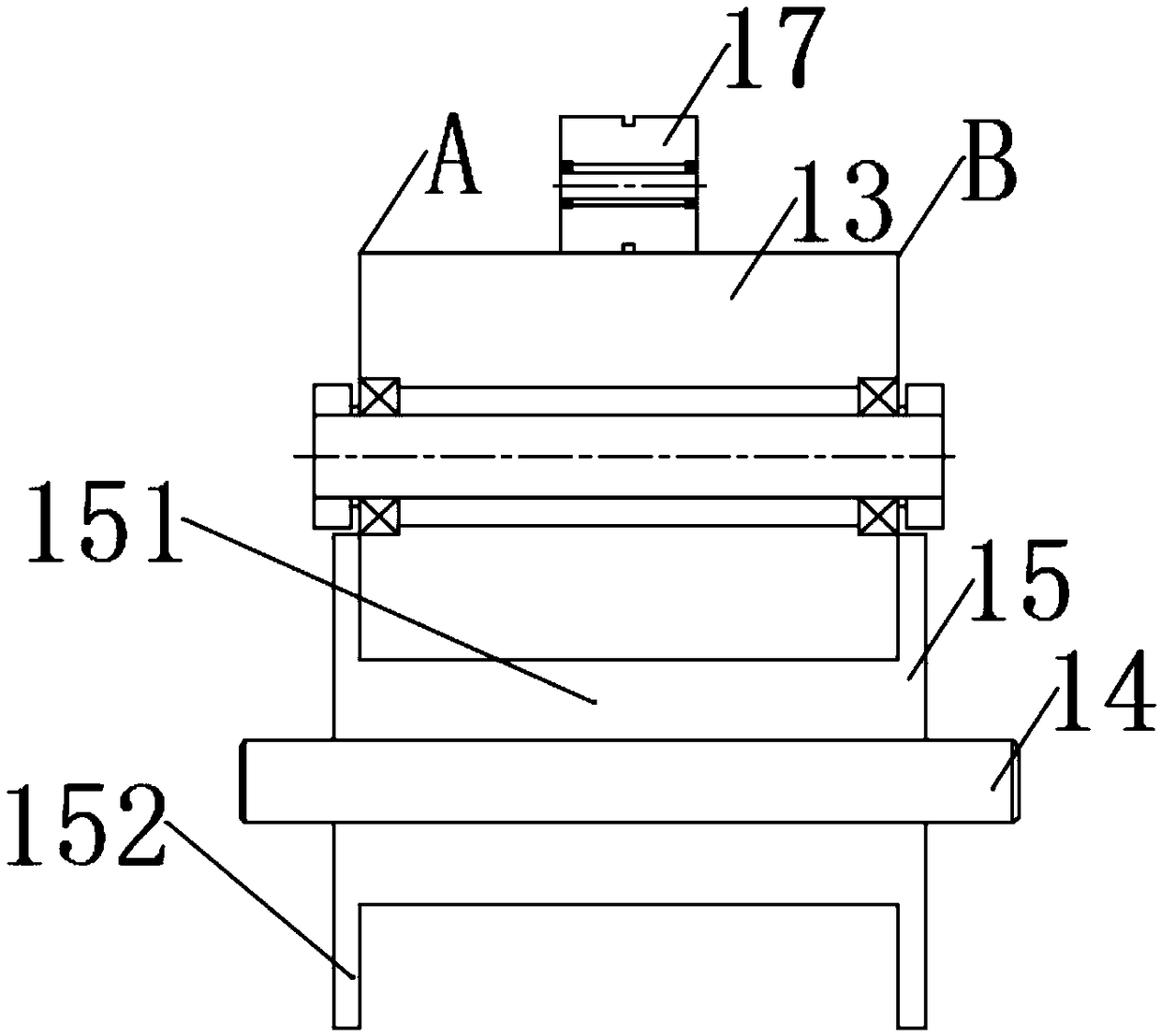

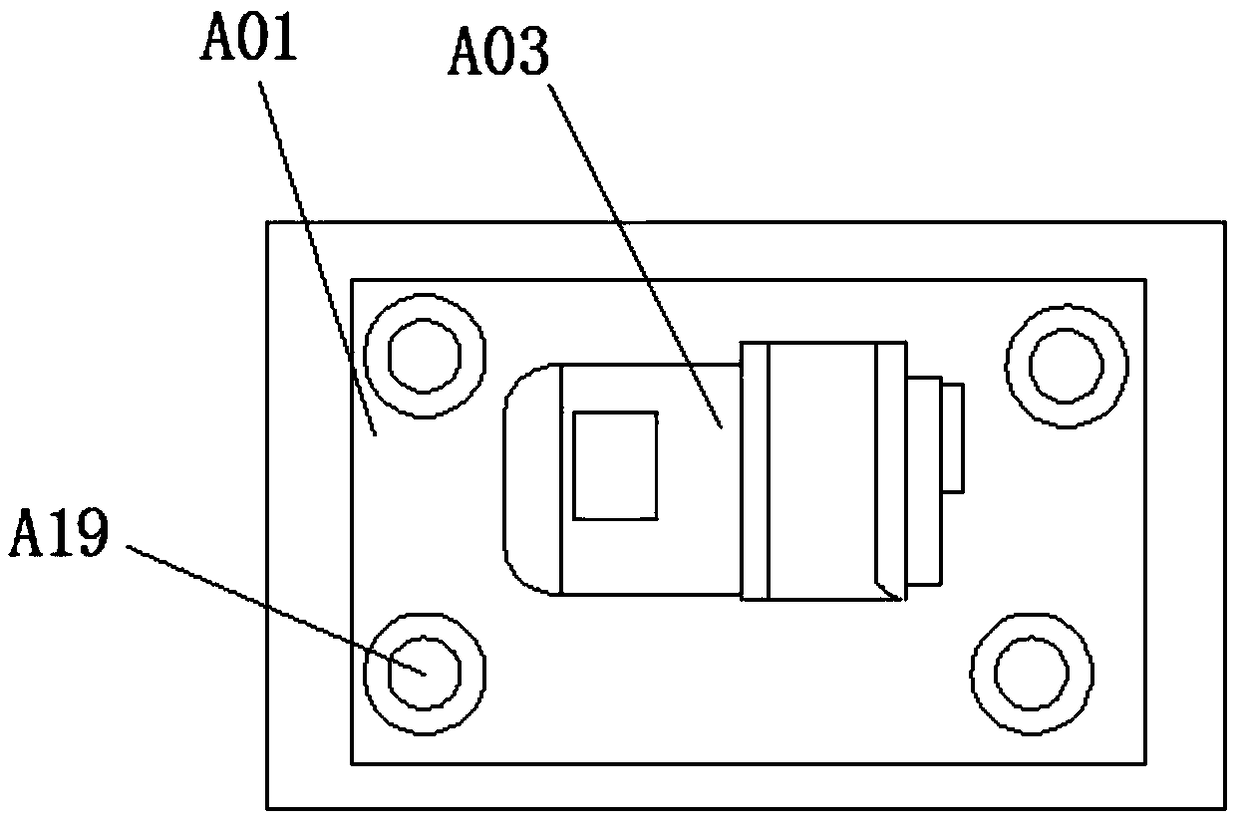

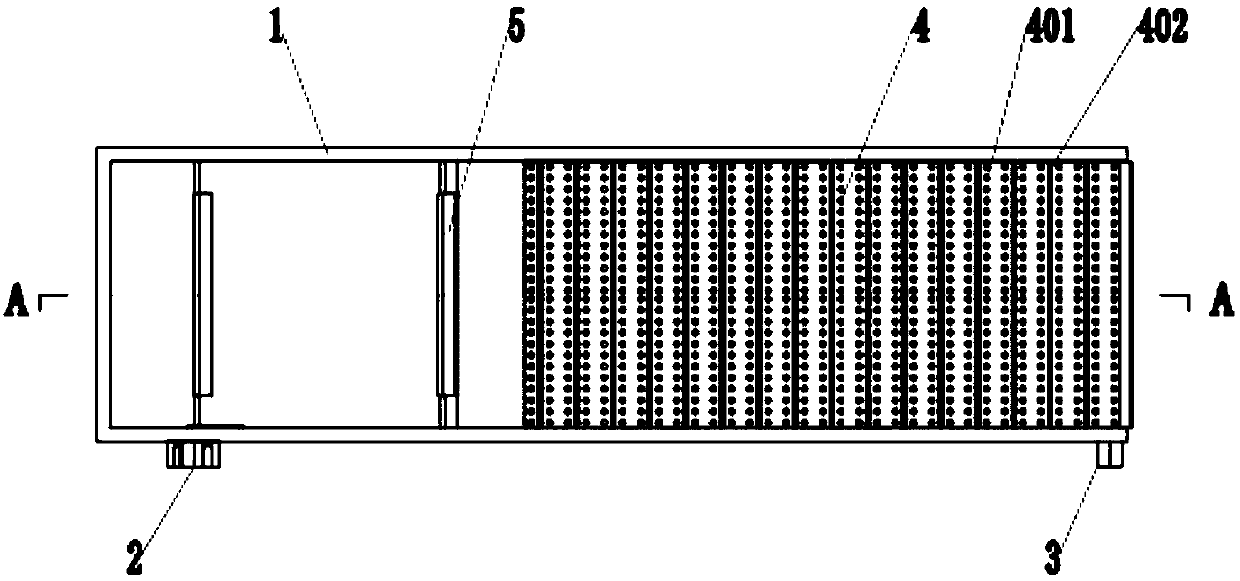

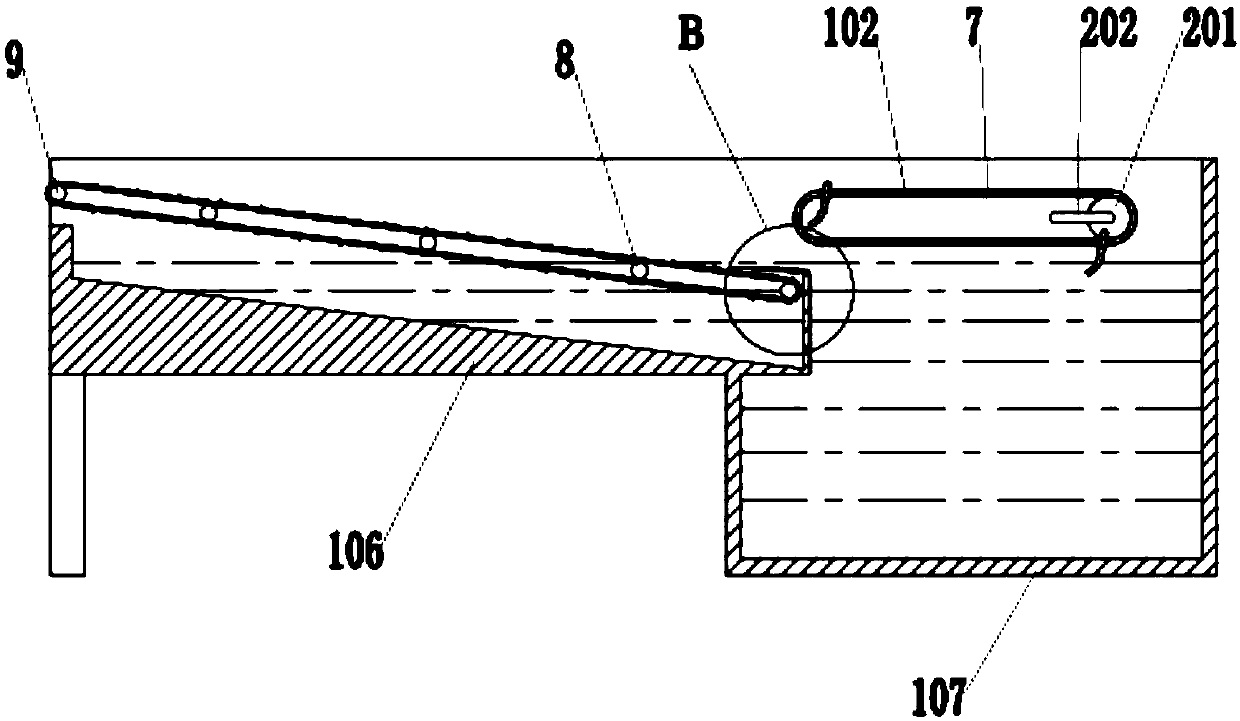

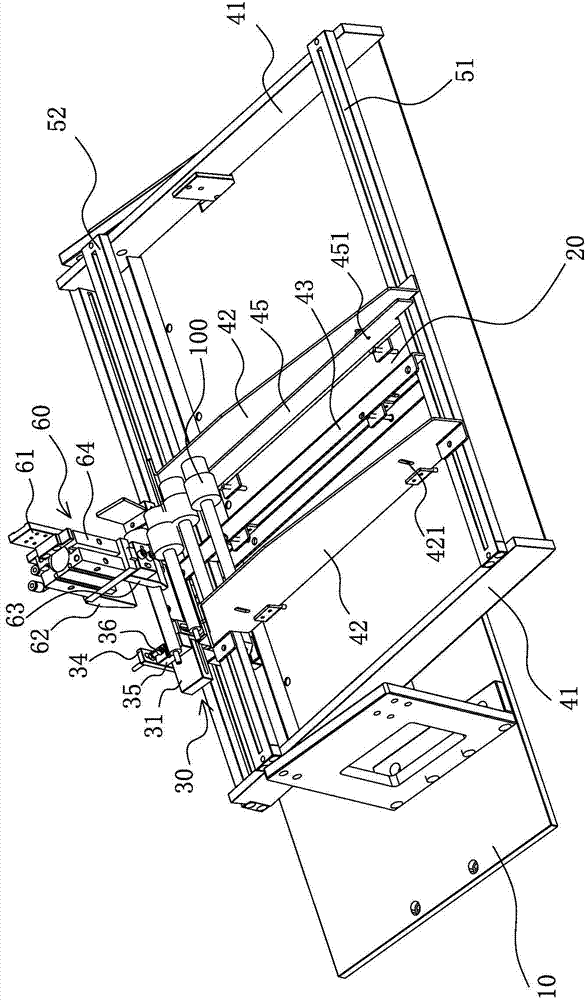

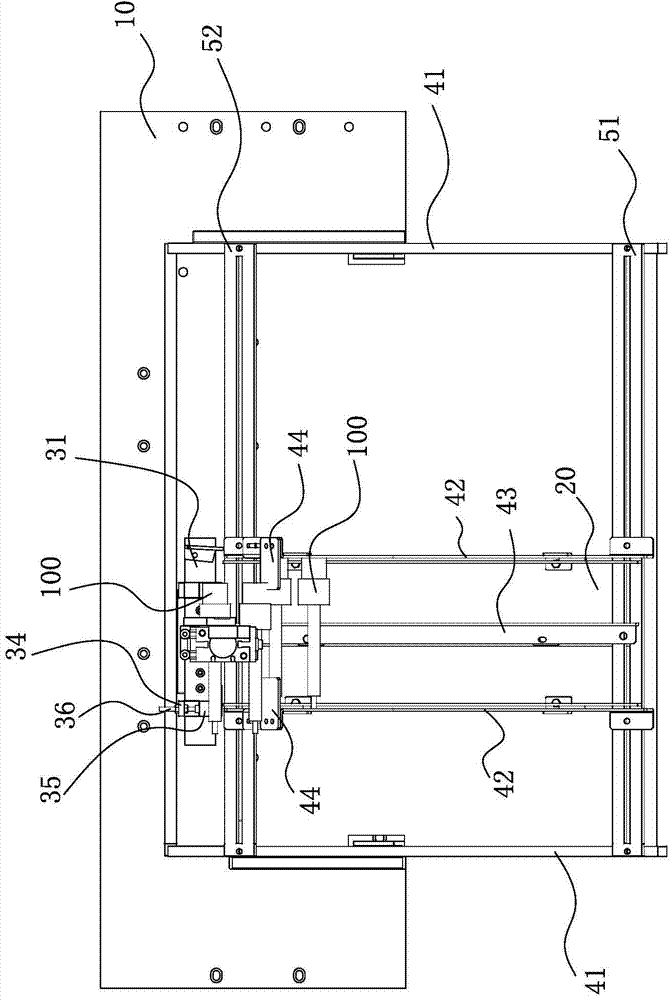

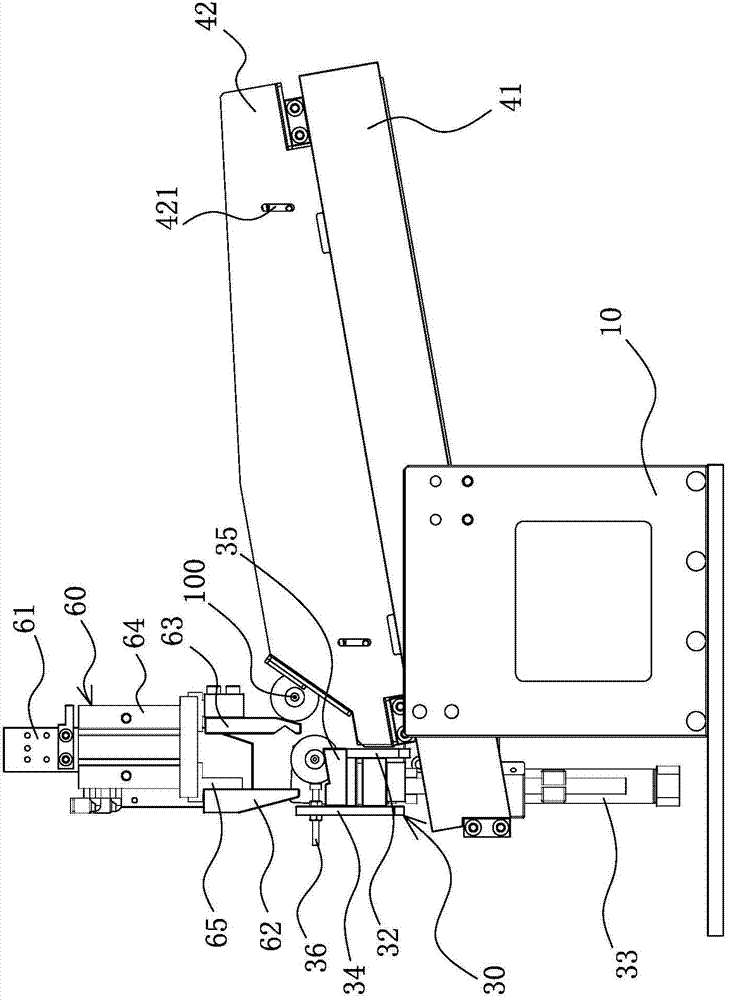

Tile conveying device for automatic mahjong machine and automatic mahjong machine

PendingCN108786098ASimple structureShorten the lengthIndoor gamesMechanical engineeringElectric machine

The invention discloses a tile conveying device for an automatic mahjong machine and the automatic mahjong machine, and belongs to the field of chess and card entertainment equipment. The defects thatexisting tile conveying devices are complicated in tile conveying mode and structure, high in cost and the like are overcome. The tile conveying device for the automatic mahjong machine comprises a tile conveying bracket, a tile sucking wheel and a tile blocking piece; the tile sucking wheel is installed on the tile conveying bracket and driven by a tile conveying motor to rotate, mahjong tiles are sucked to the tile sucking wheel and rotate along with the tile sucking wheel, the tile blocking piece is located on a rotation track of the mahjong tiles and used for blocking the mahjong tiles moving to the tile blocking piece so that the mahjong tiles moving to the tile blocking piece can be separated from the tile sucking wheel and conveyed out of the tile conveying bracket. By means of thetile conveying device, the existing tile conveying mode relying on a conveying belt is changed, the conveying belt and a tile discharging wheel are omitted, a tensioning mechanism of the conveying belt is also omitted, the length of the tile conveying bracket is shortened, the structure of the tile conveying device is greatly simplified, and the space occupied by the tile conveying device is reduced.

Owner:MATSUOTA MECHANICAL & ELECTRICAL CHINA CO LTD

Polyethylene film with easy straight-line tearing and preparation method for polyethylene film

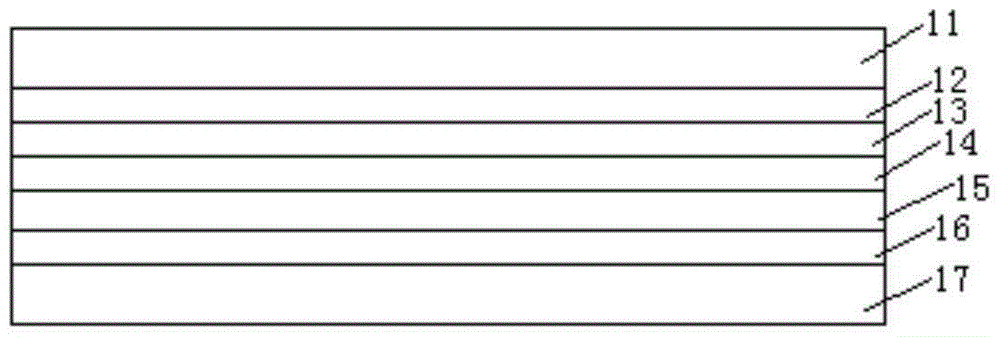

ActiveCN105172291AIncreased degree of directional crystallizationStraight line easy to tear performance is goodFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a polyethylene film with easy straight-line tearing and a preparation method for the polyethylene film. The film comprises a composite layer, a first intermediate layer, a second intermediate layer, a third intermediate layer, a fourth intermediate layer and a heat-seal layer which are mutually contacted in sequence; the composite layer comprises linear low density polyethylene and low density polyethylene of which the melt index is 2.5 to 4.0g / 10min; the first intermediate layer comprises high density polyethylene and the low density polyethylene of which the melt index is 2.5 to 4.0g / 10min; the second intermediate layer comprises the high density polyethylene; the third intermediate layer comprises the high density polyethylene and the low density polyethylene of which the melt index is 2.5 to 4.0g / 10min; the fourth intermediate layer comprises the linear low density polyethylene and the low density polyethylene of which the melt index is 2.5 to 4.0g / 10min; the heat-seal layer comprises metallocene polyethylene and low density polyethylene of which the melt index is 1.5 to 2.5g / 10min. The polyethylene film has better straight-line tearing performance.

Owner:HUANGSHAN NOVEL

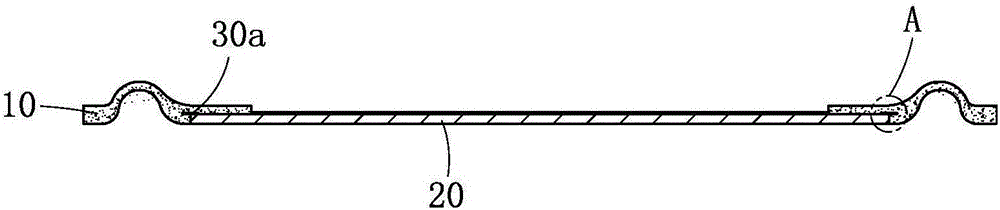

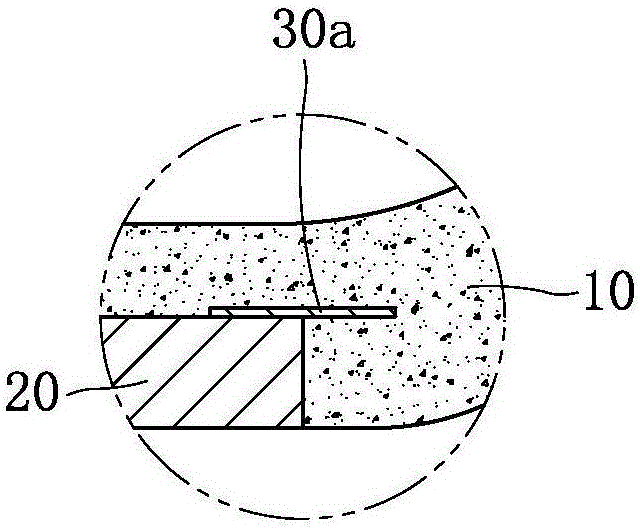

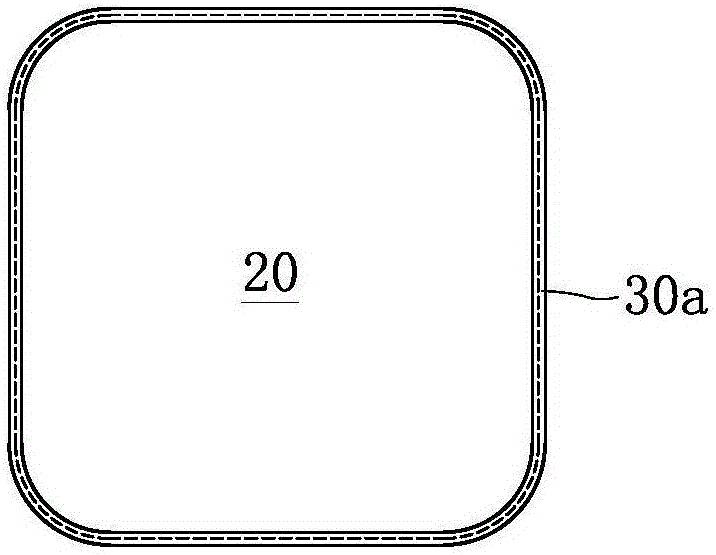

Vibration diaphragm and miniature sounder with the vibration diaphragm

InactiveCN106231506AEnhanced stretch and stretchImprove stability and reliabilityLoudspeakersPlane diaphragmsEngineering

Owner:GOERTEK INC

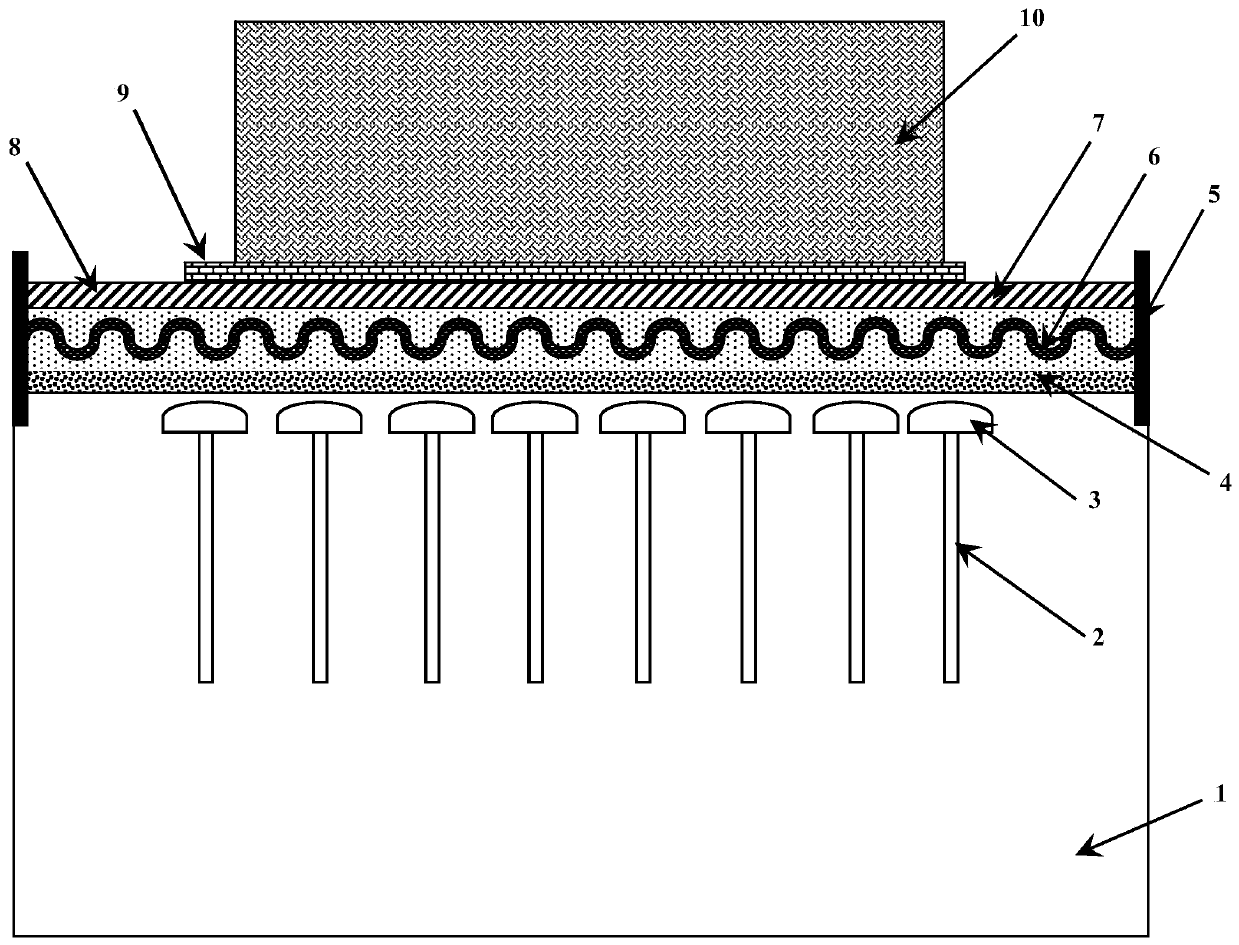

Anti-frost heaving and anti-seismic composite foundation structure

PendingCN111364495AImprove bearing capacityIncrease frictionProtective foundationSoil preservationFrost heavingCold area

The invention discloses an anti-frost heaving and anti-seismic composite foundation structure. The anti-frost heaving and anti-seismic composite foundation structure includes a plurality of rigid captype piles, a coarse sand cushion layer, a rubber pebble stiffened cushion layer, a rubber quake isolation cushion layer and a raft plate, the multiple rigidity cap type piles are evenly arranged in foundation soil, the coarse sand cushion layer is positioned on the foundation soil, the rubber pebble stiffened cushion layer is located on the coarse layer, the rubber quake isolation cushion layer is located on the rubber pebble stiffened cushion layer, the raft plate is located on the rubber quake isolation cushion layer, a blocking plate is placed on the periphery of the coarse sand cushion layer, the rubber pebble stiffened cushion layer, and the rubber quake isolation cushion layer, a building is built on the raft plate. The foundation structure can effectively prevent the foundation frost heave and the earthquake damage deformation and fracture under earthquake in a cold area, improve the mechanics performance of the foundation structure; effectively lower or avoid the enormous economic loss caused by the earthquake and the freezing damage.

Owner:BAICHENG NORMAL COLLEGE

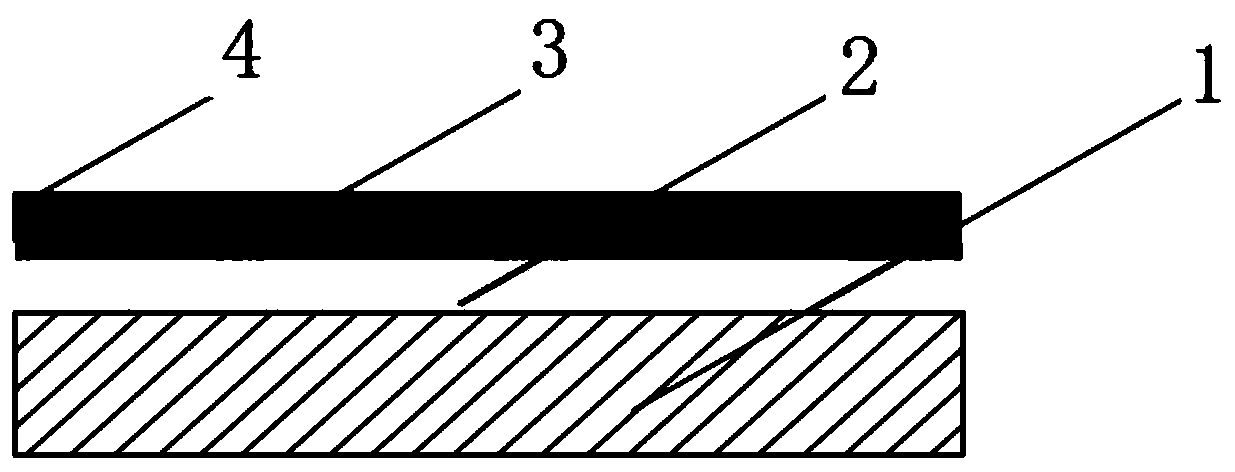

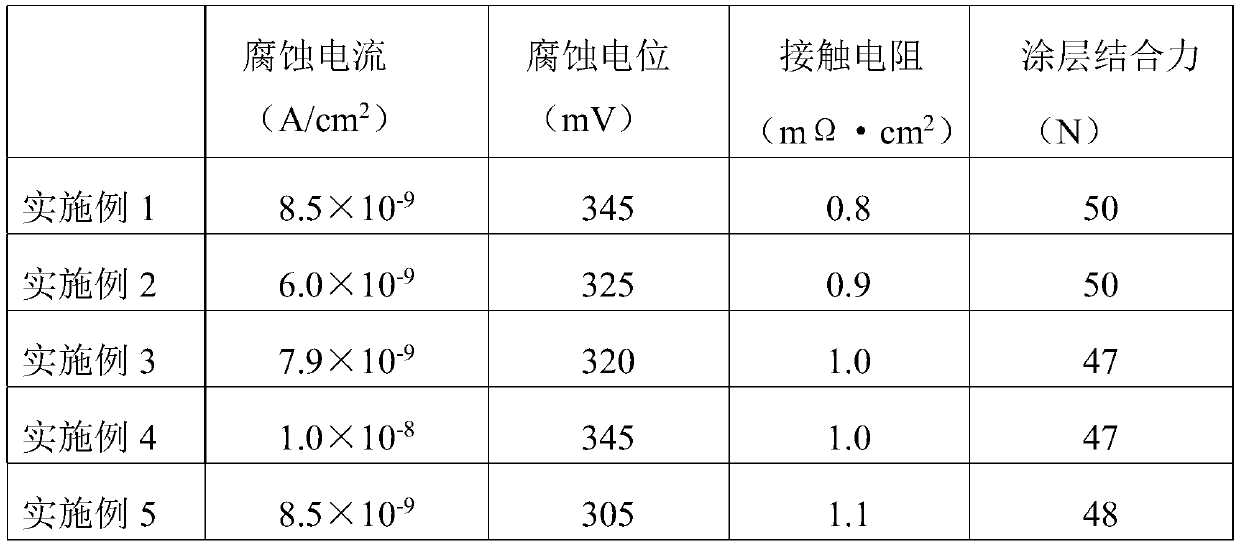

Metal bipolar plate and preparation method thereof and fuel cell

ActiveCN110808384AFast coating speedImprove densification performanceVacuum evaporation coatingSputtering coatingCarbon filmFuel cells

The invention relates to a metal bipolar plate and a preparation method thereof and a fuel cell, and relates to the technical field of fuel cells. The main adopted technical scheme is that the metal bipolar plate comprises a metal substrate, a Cu nano layer, a graphene layer and an amorphous carbon film. The Cu nano layer is deposited on the metal substrate, the graphene layer is prepared on the Cu nano layer and the amorphous carbon film is deposited on the graphene layer. The fuel cell includes the metal bipolar plate. The metal bipolar plate is mainly used for improving the corrosion resistance and the electrical conductivity of the metal bipolar plate and improving the bonding force between the coating and the metal substrate, thus prolonging the service life of the metal bipolar plateand the fuel cell.

Owner:浙江锋源氢能科技有限公司 +1

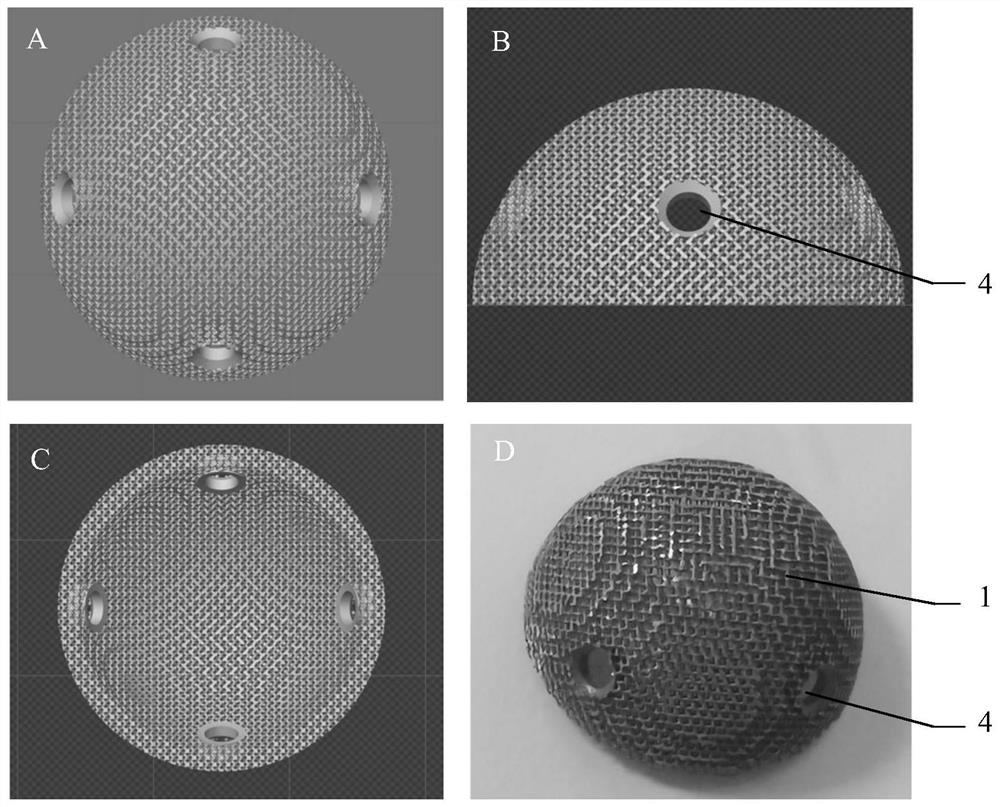

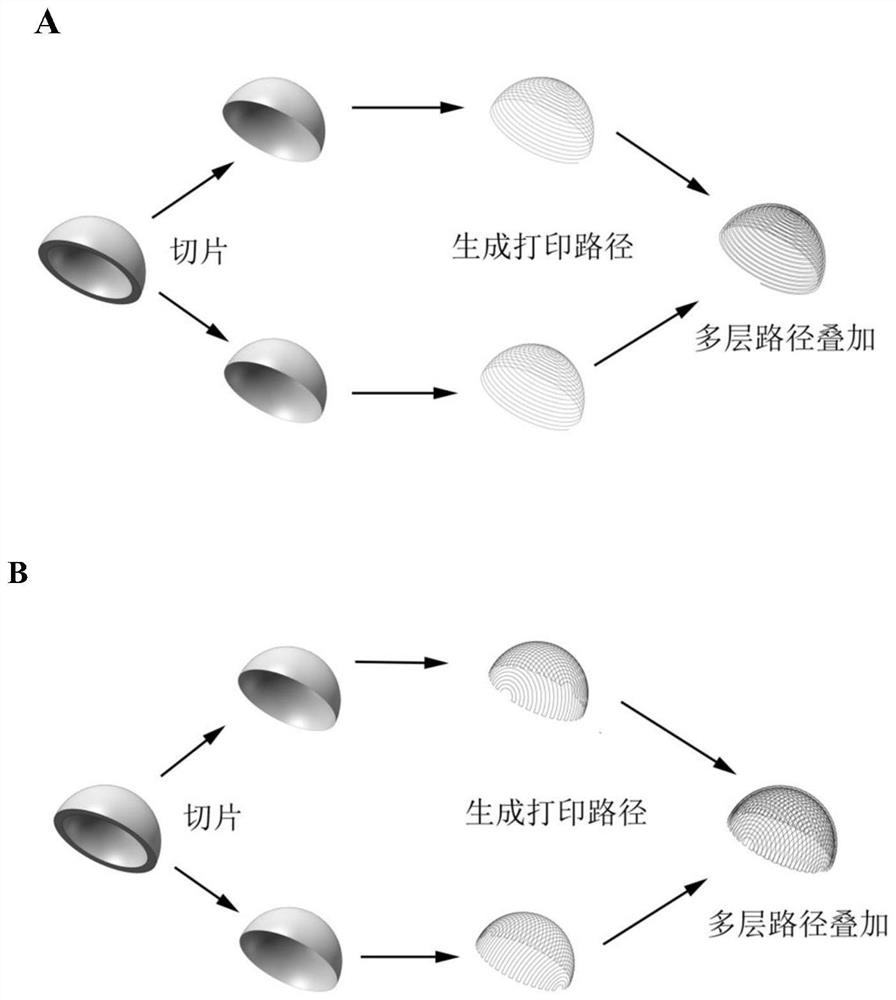

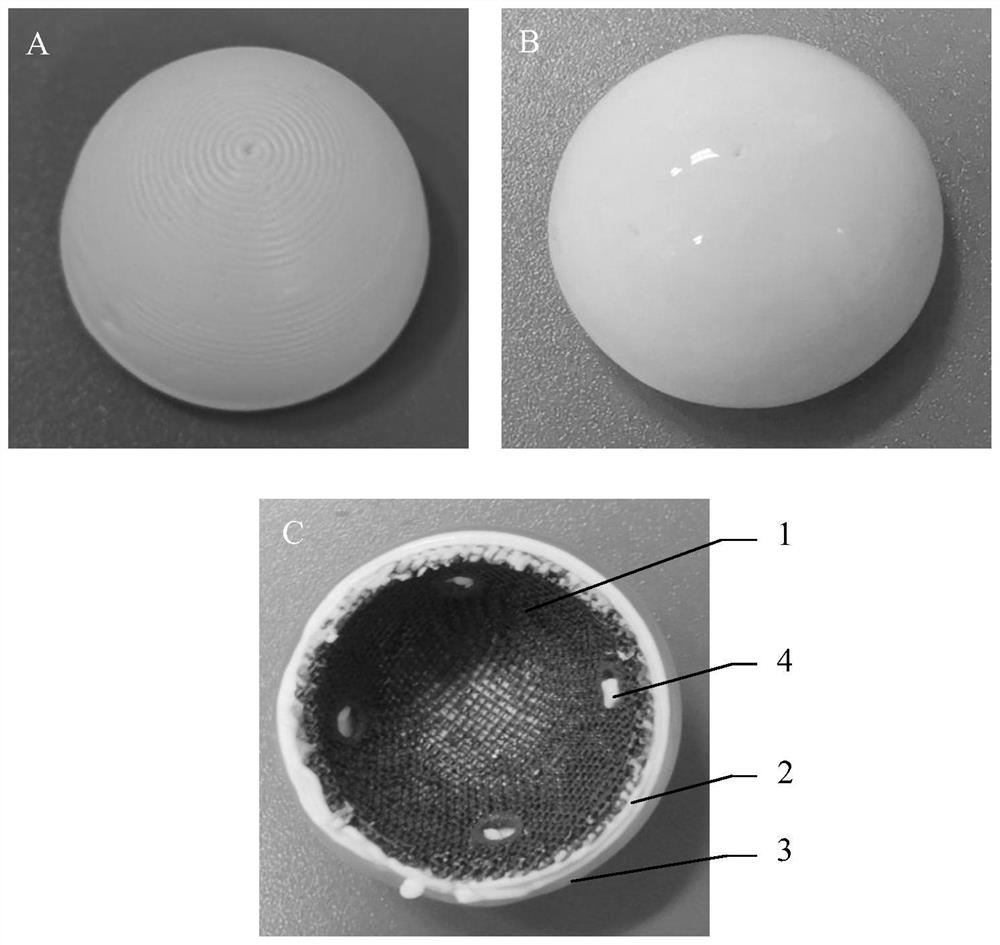

Multilayer bionic joint based on curved surface 3D printing and preparation method thereof

PendingCN112076009ATo achieve the effect of integrationAids in healingJoint implantsTomographyPorous tantalumBones joints

The invention discloses a bionic bone joint based on curved surface 3D printing and a preparation method thereof. The multilayer bionic joint is formed by an inner layer, a middle layer and an outer layer which are in close contact in sequence, wherein the inner layer is a porous tantalum metal support, the middle layer is a solid biological ceramic support, the outer layer is a solid gelatin / sodium alginate composite hydrogel support, the inner layer, the middle layer and the outer layer are all of an arc-shaped shell structure, the radian of the arc-shaped shell is 120-240 degrees, and a cell loading cavity formed by continuous or discontinuous edges formed by protruding outwards from the surface of the outer layer and grooves formed between the edges is formed in the surface of the outer layer. The multilayer bionic joint is large in arc surface radian and suitable for repairing large-area osteochondral joint defects, and the repairing area can be larger than 1 / 2 of the area of thewhole joint. Cells are inoculated into the cell loading cavity, so that the adhesion rate of the cells is increased, and the problem that the surface of the outer layer of the bionic joint is smooth,so that the inoculated cells are not prone to adhesion is solved.

Owner:AFFILIATED ZHONGSHAN HOSPITAL OF DALIAN UNIV +1

Anti-reflective electrically-driven 3D liquid crystal lens

InactiveCN105022202AReduce reflectionIncrease contrastCoatingsNon-linear opticsRefractive indexContrast ratio

The invention relates to an anti-reflective electrically-driven 3D liquid crystal lens. The anti-reflective electrically-driven 3D liquid crystal lens comprises a first substrate, a second substrate, a first alignment layer, a first electrode, a second alignment layer and a second electrode, wherein the first alignment layer and the first electrode are arranged on the inner side of the first substrate, and the second alignment layer and the second electrode are arranged on the inner side of the second substrate. A liquid crystal layer is arranged between the first substrate and the second substrate. The first electrode is a whole-face continuous electrode, and the second electrode is composed of a plurality of side-by-side linear electrodes. A first anti-reflective layer is arranged between the first electrode and the first substrate and is a transparent insulating film layer. The overall refractive rate of the first anti-reflective layer is larger than the refractive rate of the first substrate and smaller than the refractive rate of the first electrode. By arranging the first anti-reflective layer between the first electrode and the first substrate, reflection of the film layer between the first electrode and the first substrate is reduced, and therefore the reflective rate of the 3D liquid crystal lens is greatly decreased, and an image displayed under the bright environment is made to have high contrast.

Owner:SHANTOU GOWORLD DISPLAY (PLANT II) CO LTD

Chinese traditional medicine agent for treating children nephropathy syndrome

InactiveCN101062245AEnhance phagocytosisRaise the ratioUrinary disorderPlant ingredientsPrevalent Nephrotic SyndromePseudostellaria

The invention relates to a traditional Chinese medicinal composition for treating children's nephropathy which comprises the following raw materials: dried rehmannia root 12g,anemarrhena rhizome 9g, yellow-corktree bark 6g,root bark of tree peony 9g, astragalus root 15g,pseudostellaria root 9g, poria cocos wolf 12g, Chinese yam 12g and oldenlandia 15g.

Owner:张德勇

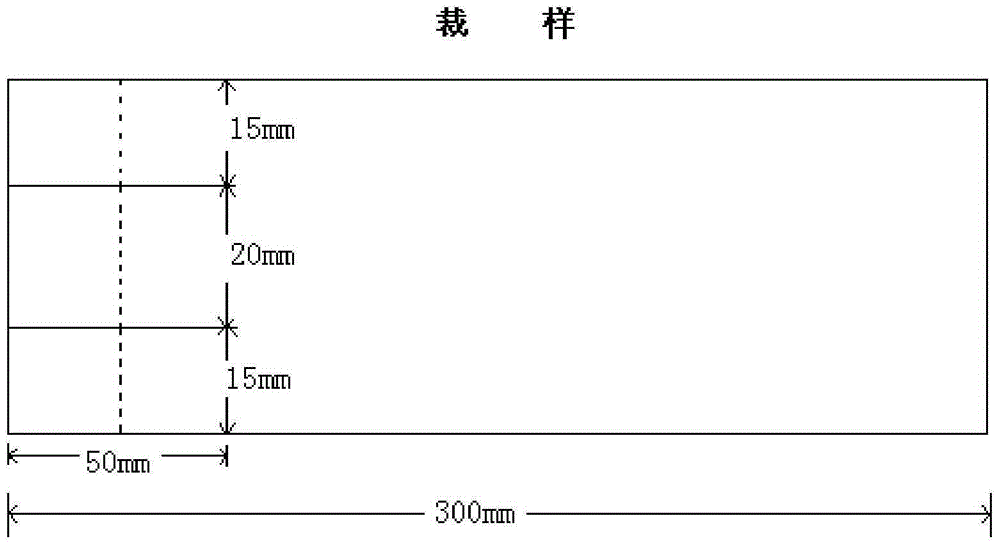

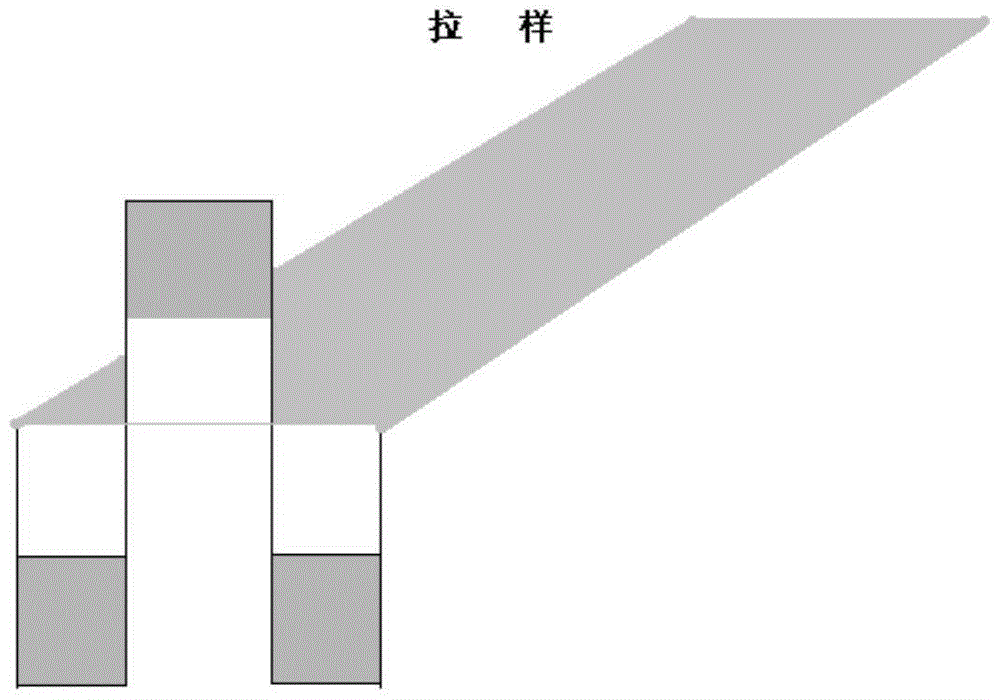

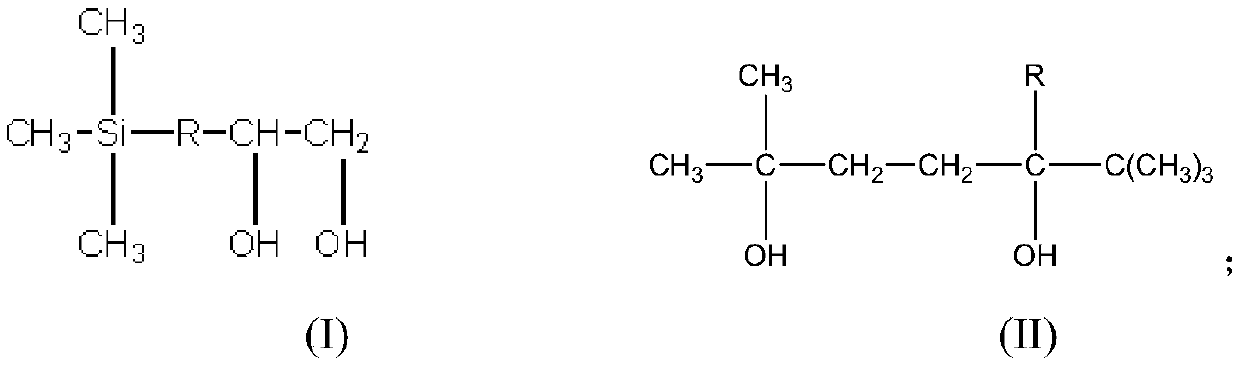

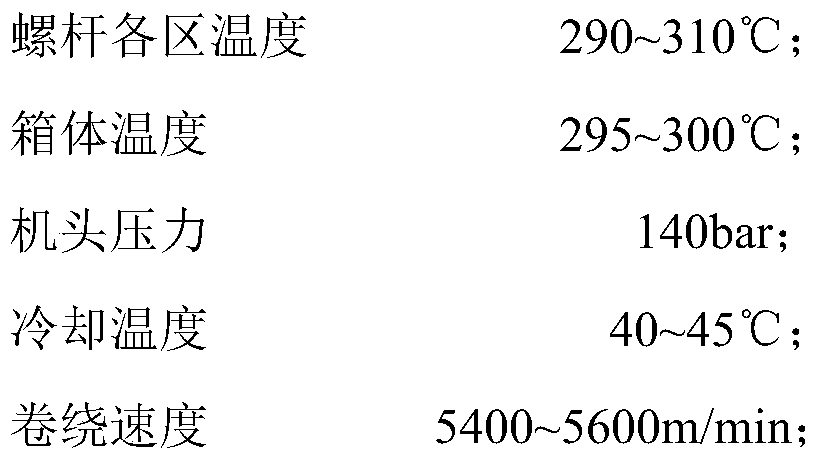

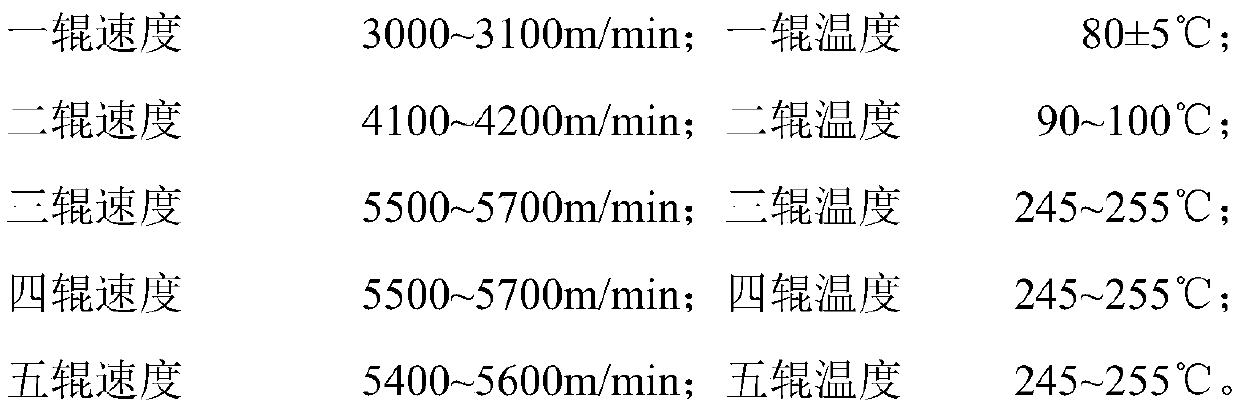

Polyester heat-resistant canvas and preparation method thereof

ActiveCN109750376AIncrease the free volume of spaceChange interaction forceFibre typesSynthetic resin layered productsYarnTert butyl

The invention relates to polyester heat-resistant canvas and a preparation method thereof. The preparation method comprises the steps that after modified polyester industrial yarn weaving cloth is padded with RFL impregnation liquid, a rubber layer is calendered on the surface of the modified polyester industrial yarn weaving cloth, then vulcanizing is conducted, and thus the polyester heat-resistant canvas is prepared; the modified polyester industrial yarn is prepared from a modified polyester melt through solid-phase polycondensation viscosity increasing, melting, metering, extruding, cooling, oiling, stretching, thermal shaping and winding; and a preparation method of modified polyester before solid-phase polycondensation viscosity increasing comprises the steps that terephthalic acid,ethylene glycol, dihydric alcohol with a trimethylsilyl pendant group, and dihydric alcohol with a tert-butyl pendant group are mixed evenly and then subjected to esterification reaction and polycondensation reaction successively; and the peeling grade of a prepared product is five, the use temperature range is minus 50 DEG C to plus 150 DEG C, the tear strength is greater than or equal to 7.0 N / mm, and the bonding strength is greater than or equal to 7.0 N / mm. The preparation method is simple in technology and low in cost; and the prepared product is high in bonding strength and good in application prospect.

Owner:JIANGSU HENGLI CHEM FIBER

Motorcycle parts conveying device

InactiveCN108544233APlay a limiting rolePrevent rotationOther manufacturing equipments/toolsMetal working apparatusPunchingEngineering

The invention belongs to the technical field of material conveying devices, and particularly relates to a motorcycle parts conveying device which comprises a rack. A drilling mechanism is slidably connected onto the rack; a conveying mechanism is further fixedly arranged on the rack; the drilling mechanism comprises a slide plate and a rotary rod; the rotary rod is rotatably connected with the slide plate; an air inlet chamber is rotatably connected onto the rotary rod; a first exhaust pipe is arranged on the air inlet chamber; a blade is arranged on the rotary rod in an air inlet pipe; a slide hole is formed in the rotary rod; a wind wheel is rotatably connected into the first exhaust pipe and is coaxially provided with a negative pressure blade; the negative pressure blade is located inthe slide hole; two sliding chutes are formed in the rotary rod; cutting blades are slidably connected into the two sliding chutes; check blocks are fixedly arranged on the cutting blades; a pressingblock is arranged in the slide hole; a drill bit is arranged on the rotary rod; an air hole is formed in the drill bit; and a dull polish ball is further arranged on the rotary rod. The motorcycle parts conveying device provided by the invention can be adopted for punching, grinding and polishing a workpiece, so that an operation process is simplified; and the motorcycle parts conveying device isusually used for punching motorcycle parts.

Owner:重庆荣爵摩托车有限公司

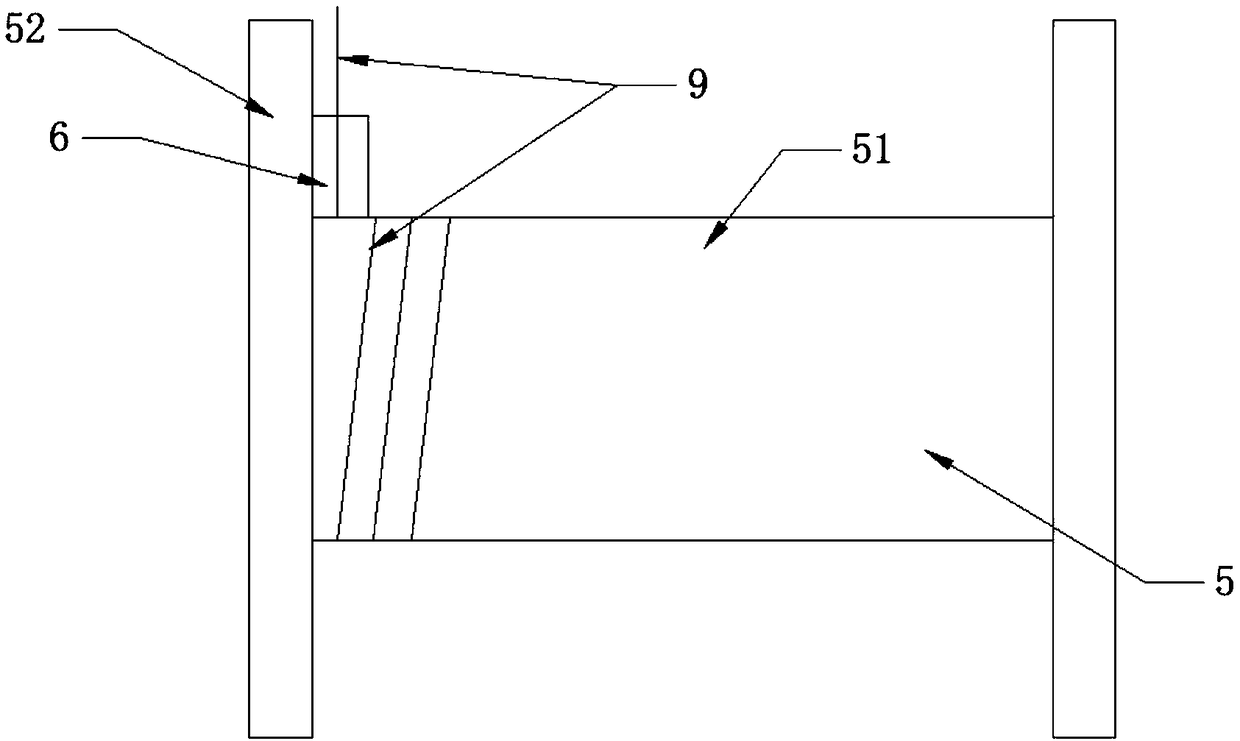

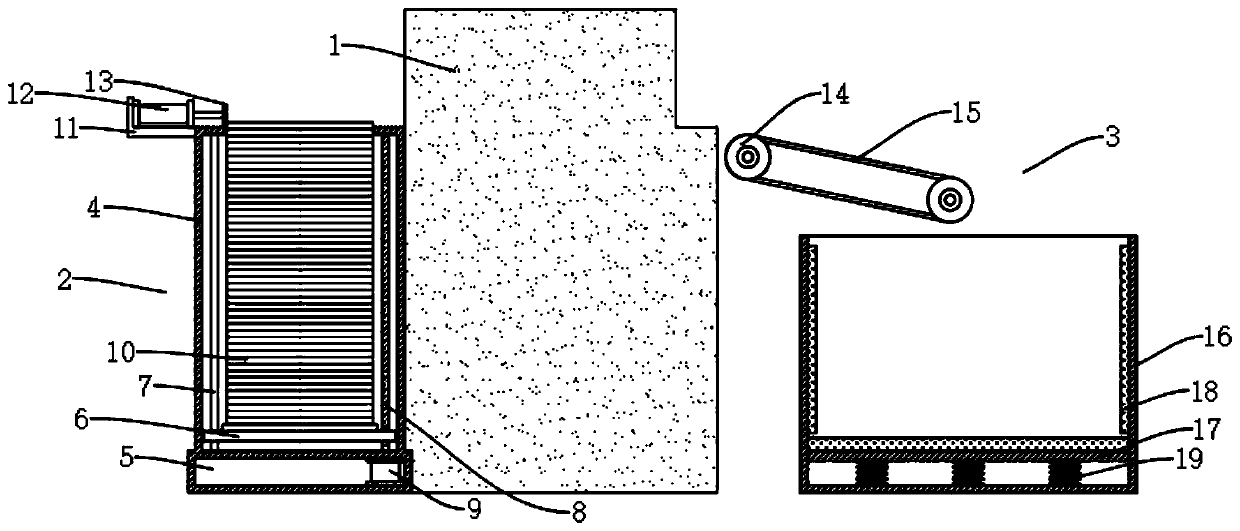

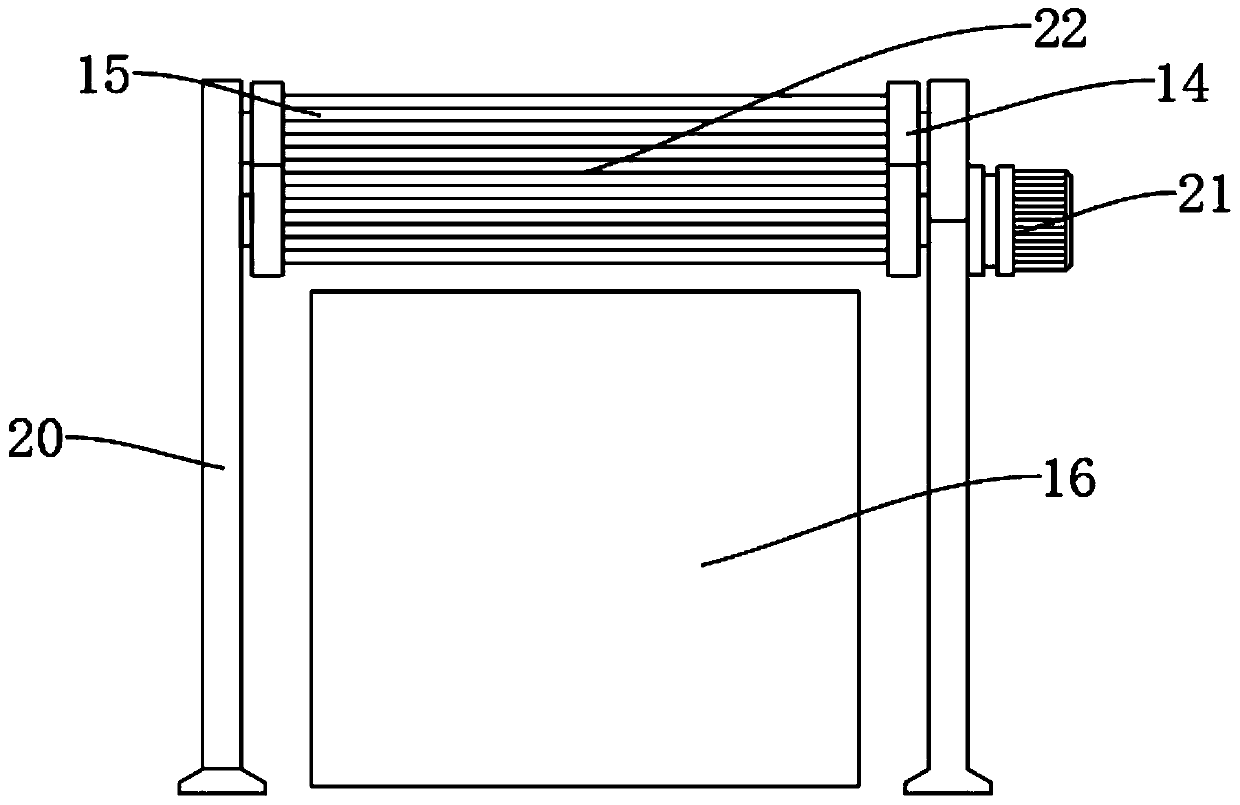

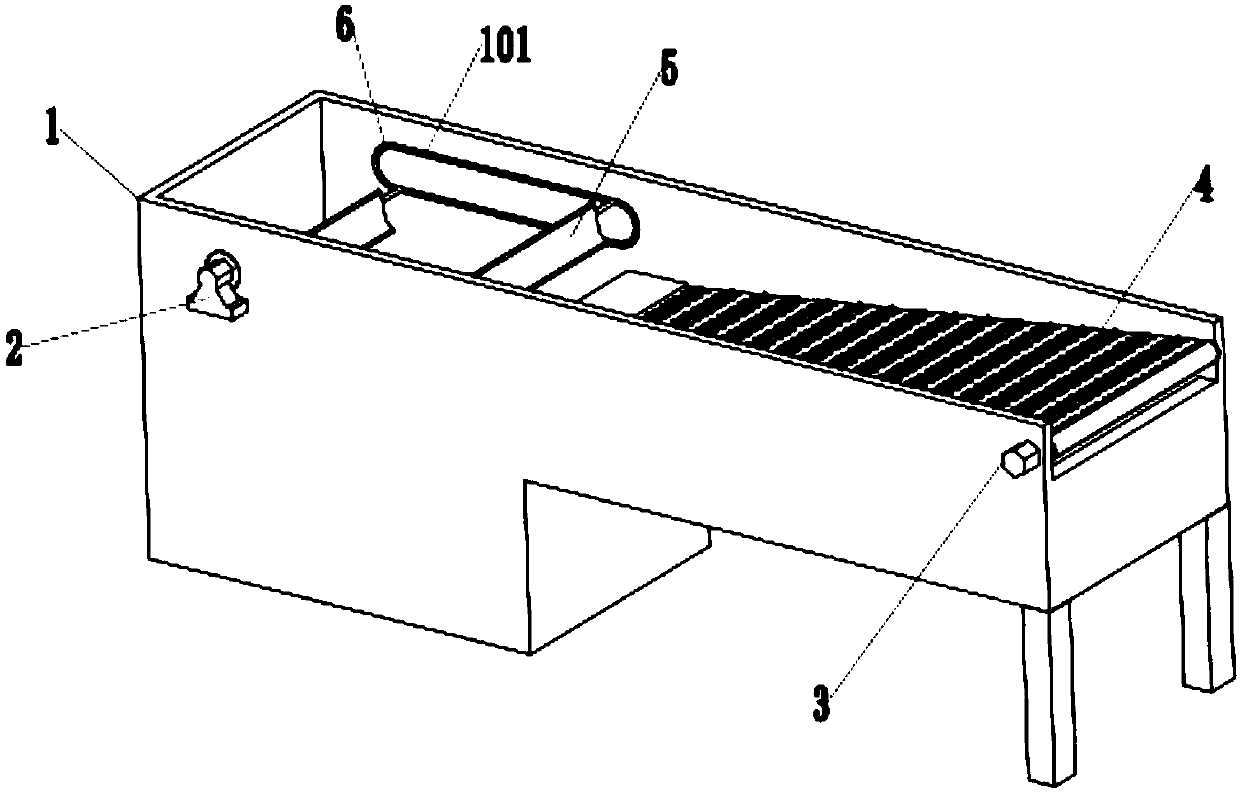

Winding device

ActiveCN108975055AIncrease wrap angleIncrease contact areaFilament handlingWebs handlingEngineeringAxial distance

The invention discloses a winding device. The winding device includes a roll-up device, a pressing wheel device, a tension adjusting device and a machine table; the roll-up device, the pressing wheeldevice and the tension adjusting device are sequentially arranged on the machine table, andafter passing through the tension adjusting device and then passing through the pressing wheel device, a wound wire is wound through the roll-up device; a large pressing wheel is arranged between a small pressing wheel and a roll-up disc to play a role of transition, therefore, the small pressing wheel getsaway from limit of the roll-up disc, the small pressing wheel does reciprocating movement on the surface of the large pressing wheel and can move to the very edge of the large pressing wheel, meanwhile, the axial distance of the large pressing wheel is the same as that of thecore of the roll-up disc so that the wound wire can be directly guided to the edge of the roll-up disc through cooperation of the small pressing wheel and the large pressing wheel, the problem of edge wire winding is solved, the end face is flat, the wound wire has the sense of layering, the accuracy of products is greatlyimproved, and the qualification rate of the products is greatly increased.

Owner:TAICANG HONGHAI PRECISION MACHINERY CO LTD

Material guiding device for stamping parts

PendingCN110883258ARealize automatic feeding actionNo manual feedingMetal-working feeding devicesShaping safety devicesElectric machineryStructural engineering

The invention discloses a material guiding device for stamping parts, and relates to the technical field of the stamping parts. The material guiding device for the stamping parts aims to solve the existing problem of being time-consuming and labor-intensive due to the fact that manual feeding and collection of the stamping parts are required in the stamping process. A first material guiding mechanism is arranged on one side of a press machine, and a second material guiding mechanism is arranged on the other side of the press machine. The first material guiding mechanism includes a material storage box, and a bottom box is installed at the lower end of the material storage box. A steel plate placing table is installed in the material storage box, and a plurality of steel plate bodies are placed at the upper end of the steel plate placing table. A guiding rod is installed on one side in the steel plate placing table, and a screw rod is installed on the other side in the steel plate placing table. A stepper motor is installed at the lower end of the screw rod, and the upper end of the screw rod is connected with the material storage box through a bearing. The stepper motor is locatedin the bottom box, and the bottom box is connected with the stepper motor through a screw. A fixing plate is installed above one side of the outer part of the material storage box.

Owner:苏州苏宏模具有限公司

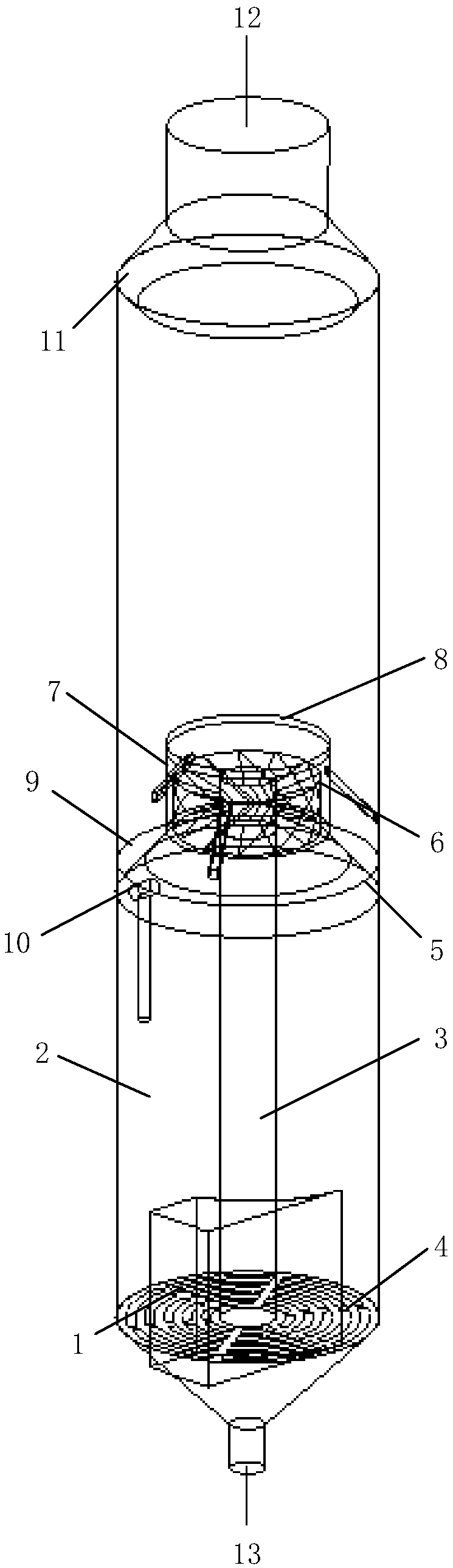

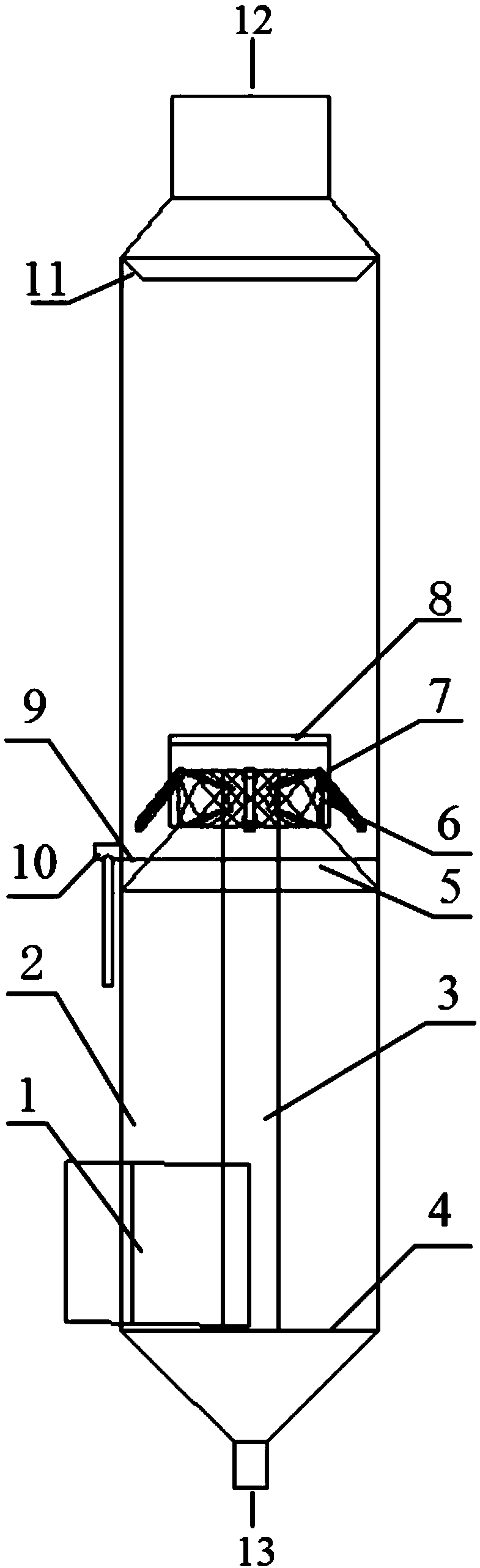

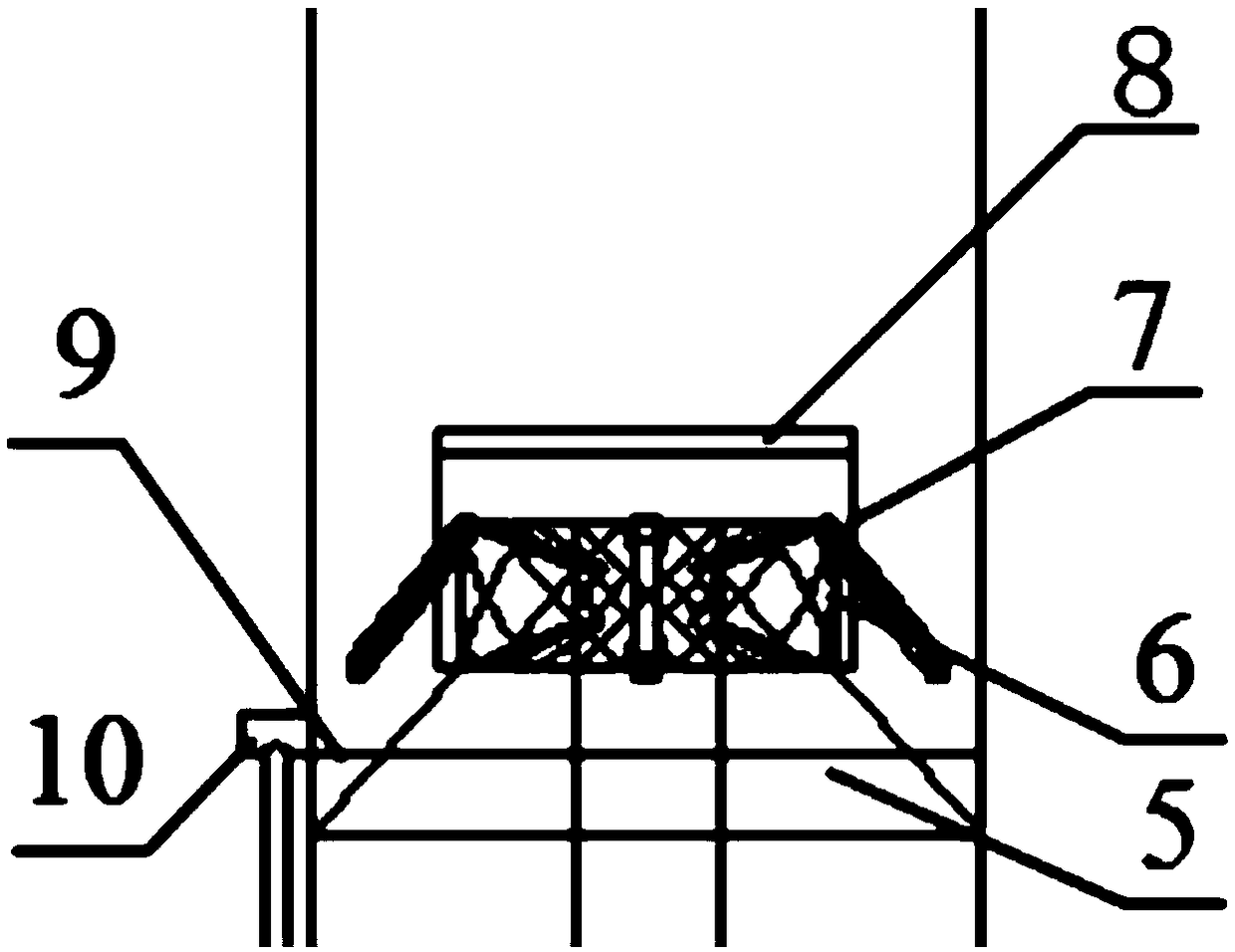

Efficient revolving furnace gas rotational flow dewatering device and dewatering method thereof

PendingCN108772213AImprove dehydration effectPrevent the situation of being easily entrained by the flue gasReversed direction vortexIncreasing energy efficiencyCycloneEngineering

The invention discloses an efficient revolving furnace gas rotational flow dewatering device and a dewatering method thereof and belongs to the technical field of steel dust removal. The efficient revolving furnace gas rotational flow dewatering device comprises an outer barrel wall, a gas guiding pillar, an overflow plate, a contracting pipe and a cyclone. The overflow plate is arranged at the bottom of the outer barrel wall. The gas guiding pillar is arranged on the upper portion of the overflow plate and located at the central axis of the outer barrel wall. The gas guiding pillar extends toan inlet of the cyclone in the height direction. The bottom end of the cyclone is connected with the contracting pipe. An inner barrel wall is arranged outside the cyclone in a sleeving manner and fixed to the outer barrel wall. The overflow plate is provided with an annular overflow gap. By means of the efficient revolving furnace gas rotational flow dewatering device and the dewatering method thereof, under the conditions that the structure of an outer barrel body is not changed and the resistance is not increased obviously, structural optimization is conducted on a rotational flow dewaterer; dewatering efficiency can be improved, thus, the gas recycling quality is improved, and the gas recycling rate is increased; the application effect of a fan is improved, and the cleaning cycle of the fan is prolonged; and the problem that the inner side of the outer barrel body is corroded can be solved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Punching device for printing and bookbinding of printed matter

InactiveCN108818739AConvenience to workPlay a transitional roleMetal working apparatusPunchingEngineering

The invention discloses a punching device for printing and bookbinding of printed matter. The punching device comprises a machine base, a punching motor and a pin; a worktable is arranged on the upperportion of the machine base, a fixing block is mounted on the upper portion of the worktable, a transverse pressing plate is arranged on the upper portion of the fixing block, a bracket is arranged on the right side of the transverse pressing plate, and the bracket penetrates into a sliding block; and a lifting air cylinder is mounted on the upper portion of the bracket, a connecting rod is arranged on the left side of the sliding block, a control box is mounted on the left side of the connecting rod, a pressing block is arranged on the lower portion of the control box, and an operation tableis arranged on the right side of the bracket. The punching device for printing and bookbinding of the printed matter can move up and down on the bracket through the sliding block, when large and heavy paper leather products are mounted on the specified position of the worktable, the sliding block moves to the proper position through a sliding groove in the bracket, thus the pressing block and a punching head work together, the connecting rod extends and retracts freely, and after work is finished, the sliding block moves upwards on the bracket.

Owner:姜来娟

Apple floating and feeding device

Owner:INST OF S&T INFORMATION SHANDONG ACADEMY OFAGRI SCI

Tool special for wire drawing installation of electric transmission line guyed tower and wire drawing method

ActiveCN105089282APlay a transitional roleAvoid damageTowersBuilding material handlingTerrainEngineering

The invention discloses a tool special for wire drawing installation of an electric transmission line guyed tower and a wire drawing method. The tool structurally comprises a clamping plate part, two lug plates and two fasteners. The clamping plate part is formed by buckling two clamping plates of the same structure. Each clamping plate is provided with a channel used for clamping a wire drawing hardware fitting. The portions, on the two sides of the channels, of the clamping plates are provided with grooves. The two lug plates of the same structure are installed in the grooves respectively. Bolt holes used for being fixedly connected with the clamping plates are formed in the lower portions of the lug plates. Reamed holes are formed in the upper portions of the lug plates. The two fasteners are located on the upper sides of the clamping plates. In a forest or a tower place with the complex terrain, large-tonnage autocranes cannot enter the place due to road and geological conditions, and the construction way of guyed tower erection through subsection hoisting is achieved by using the tool special for wire drawing installation, and environment damage caused by deforestation and the like is reduced.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

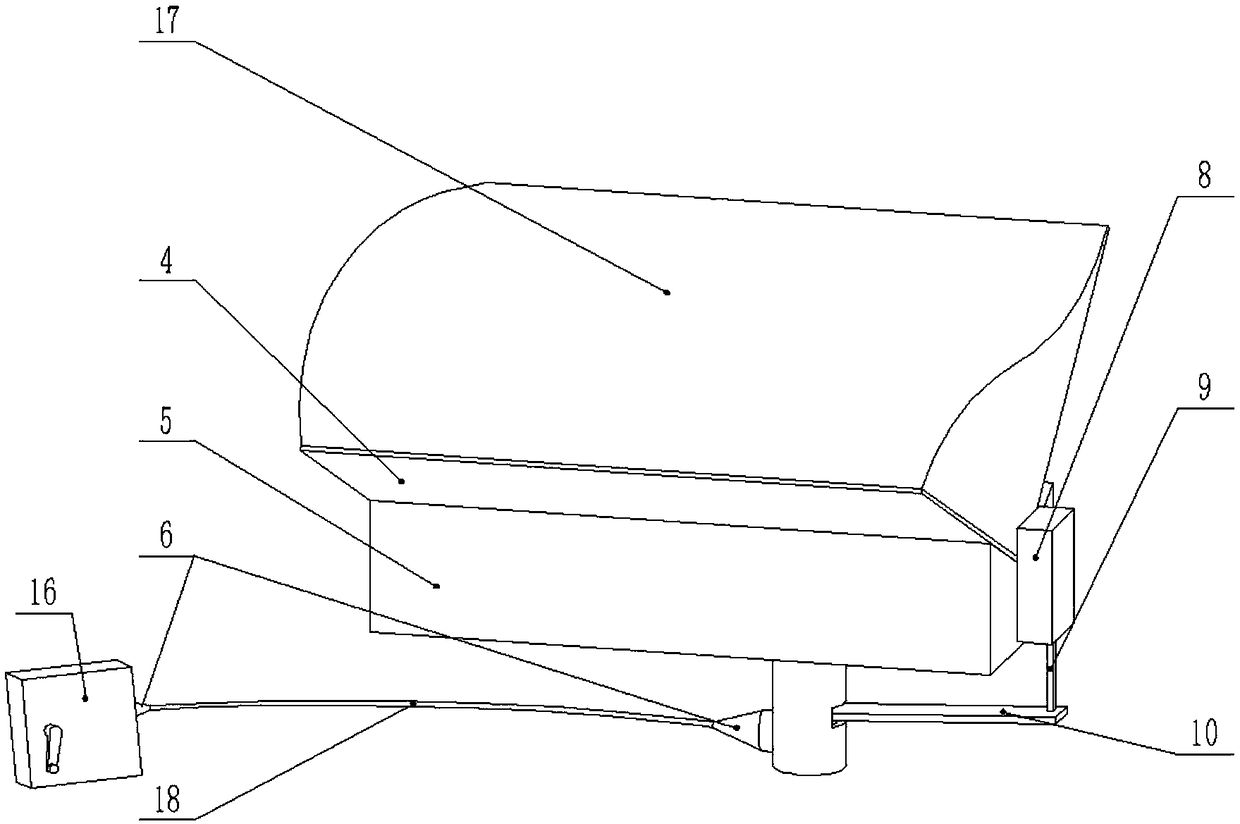

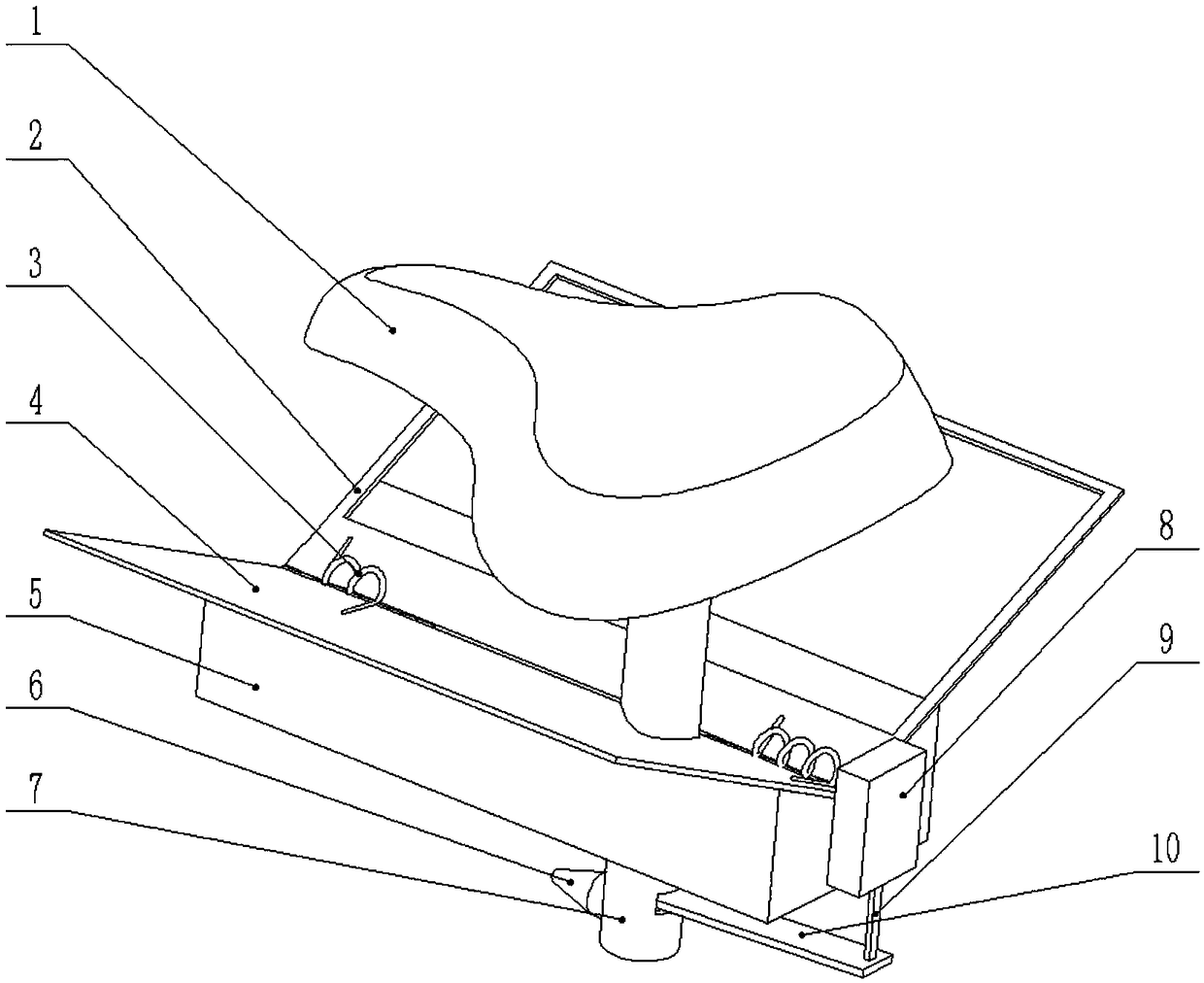

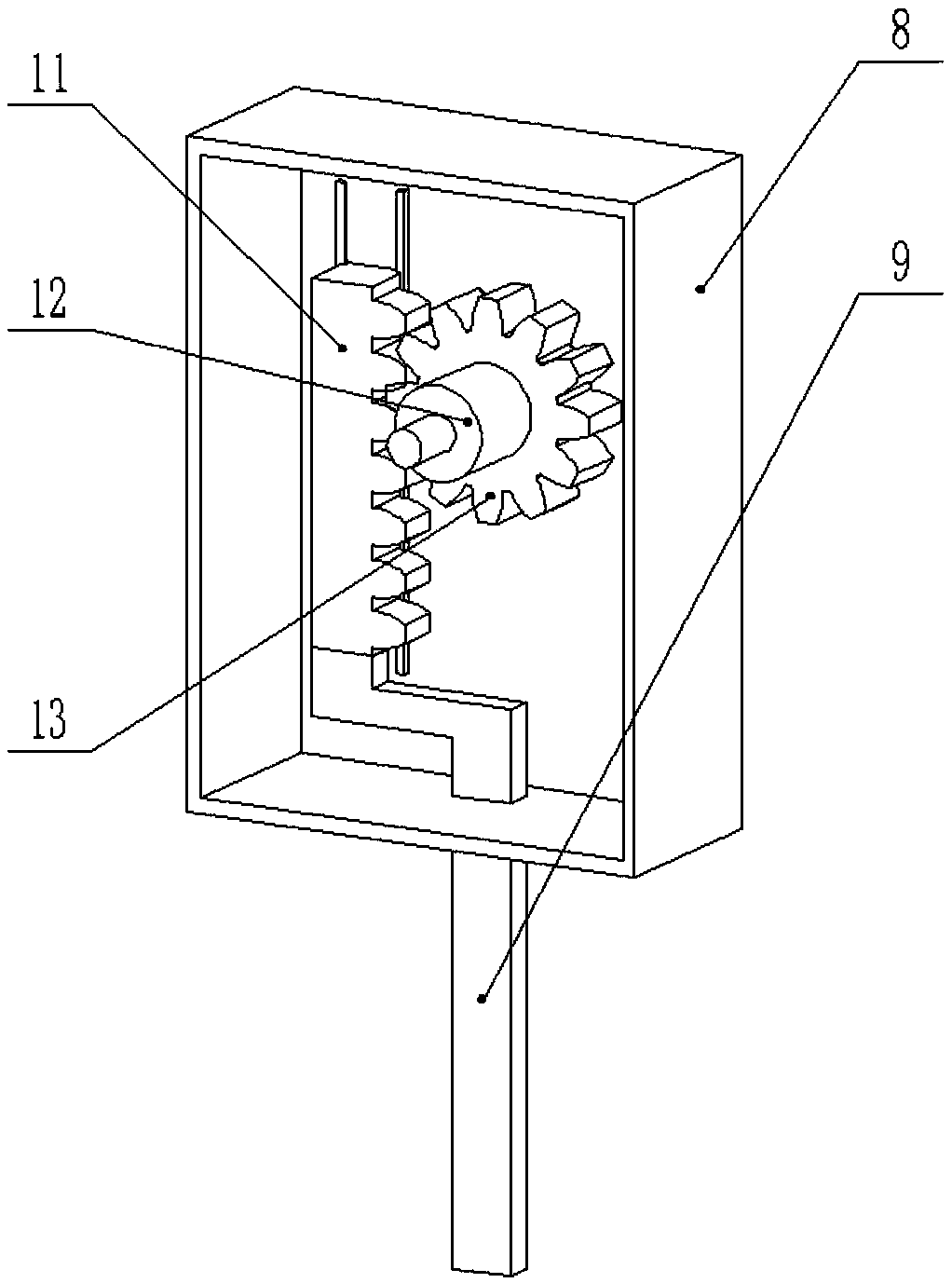

A rain-and-snow-proof device for bicycle

The utility model relates to a bicycle rain-and-snow-proof device, belonging to the field of bicycle accessories. The rain-and-snow-proof device is composed of seat, right plate, torsion spring, leftplate, base, rope head seat, seat shaft, protective housing, push rod, lever, rack, wheel shaft, gear, spring, ejector rod, hand crank case, stopper cloth and steel wire rope. By adding a protective layer on the surface of the vehicle seat, the invention can realize the purpose of preventing rain and snow in rainy and snowy weather, and also has the functions of dust prevention and dew prevention.Blocking cloth is made of grey waterproof cloth, on the one hand waterproof, on the other hand can block the sun on the car seat in the summer isolation. The two ends of the steel wire rope are provided with rope head seats, which can provide the mechanical support for the tension of the steel wire rope, and the rope head seats are cast with rounded corners, which can play a transitional role forthe tension of the steel wire rope, reduce the friction between the steel wire rope and the vehicle seat shaft and the hand crank box, and prolong the service life of the steel wire rope. The steel wire rope between the two rope sockets is coated with a protective layer, which can prolong the service life of the steel wire rope.

Owner:张熙翔

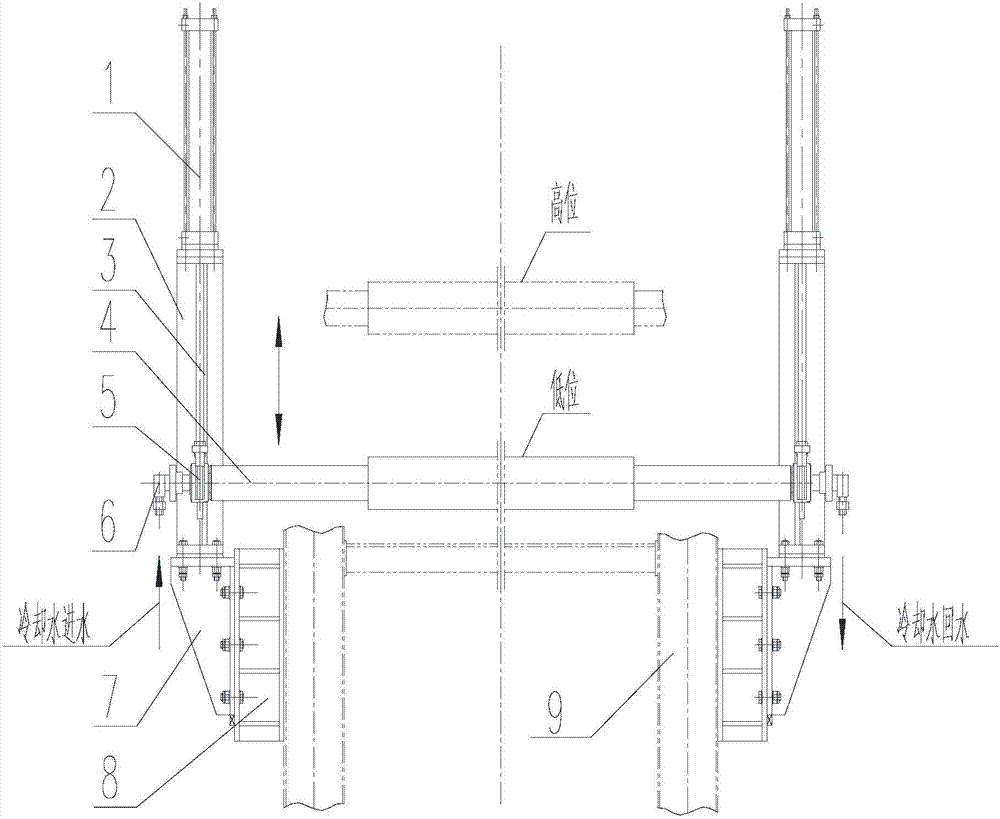

Conveying device of roller hearth furnace

PendingCN107883771AAvoid defectsNovel structureCharge manipulationFurnace coolingMechanical engineeringEngineering

The invention provides a conveying device of a roller hearth furnace. A furnace inner roller and a furnace outer roller are arranged at the bottom of the roller bottom furnace. The conveying device ofthe roller hearth furnace comprises a bracket, a guide rail, a supporting roller, and a driving roller, wherein the bracket is arranged outside the furnace of the roller hearth furnace. The guide rail is vertically arranged on the bracket, the supporting roller is arranged outside the furnace of the roller hearth furnace and is disposed between an inner furnace roller and an outer furnace roller,the supporting roller can move up and down on the guide rail, the supporting roller is provided with a rotating shaft, the axial direction of the rotating shaft is disposed in the horizontal direction, and the axial direction of the rotating shaft is perpendicular to the moving direction of workpieces, and the workpieces are output from the roller bottom furnace. The driving device is connected with and drives the carrier roller. The device is novel in structure and ultra-high in cost performance, and overcomes the defects of a former roller hearth furnace and has extremely high market popularization value.

Owner:CERI PHOENIX INDAL FURNACE CO TD +1

Novel composite board

ActiveCN105082659APlay a protective effectHigh strengthWatercraft hull designHull partsComposite plateUltimate tensile strength

The invention relates to a novel composite board. The novel composite board is characterized by comprising a metal layer and an anti-corrosion and heat-preservation layer which is arranged at the outer side of the metal layer. The composite board disclosed by the invention is good in binding force, has good strength and mechanical property, further can achieve the effects of preserving the temperature, preventing corrosion and resisting impact, and is suitable for various ships such as business ships, yachts, tourist ships, working ships, steam ships and the like.

Owner:梁明森

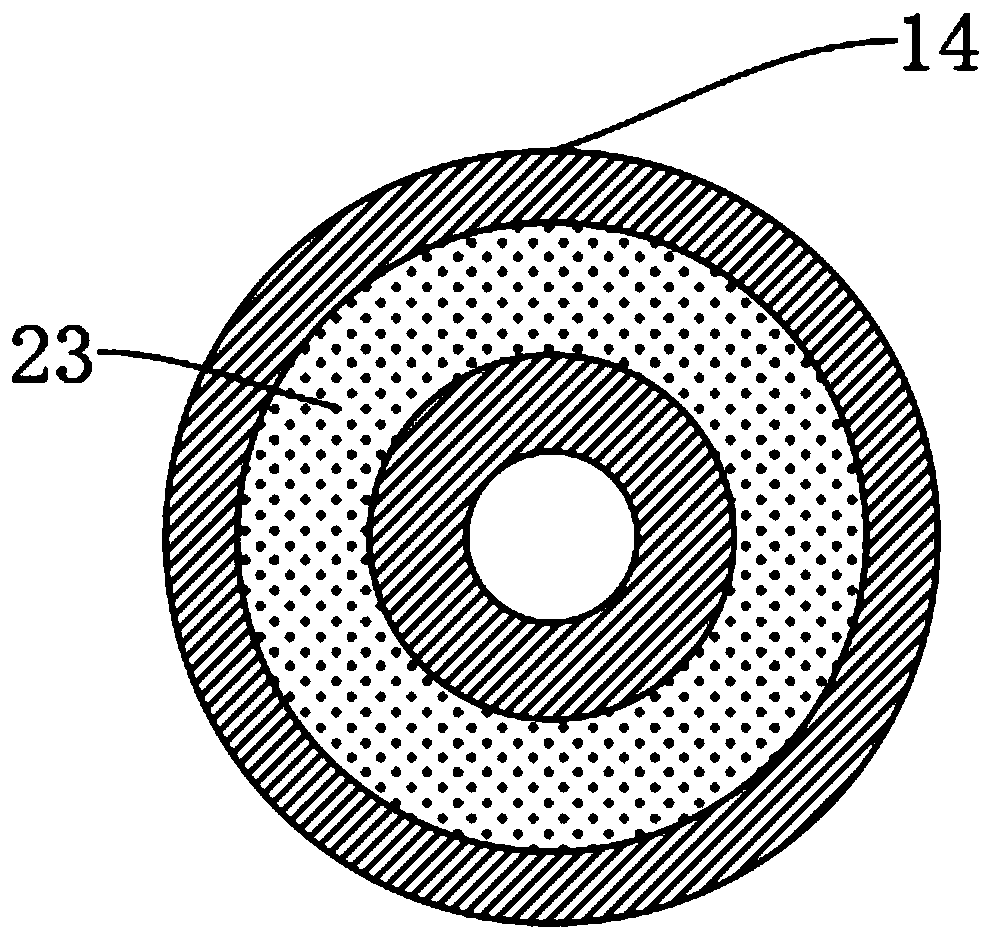

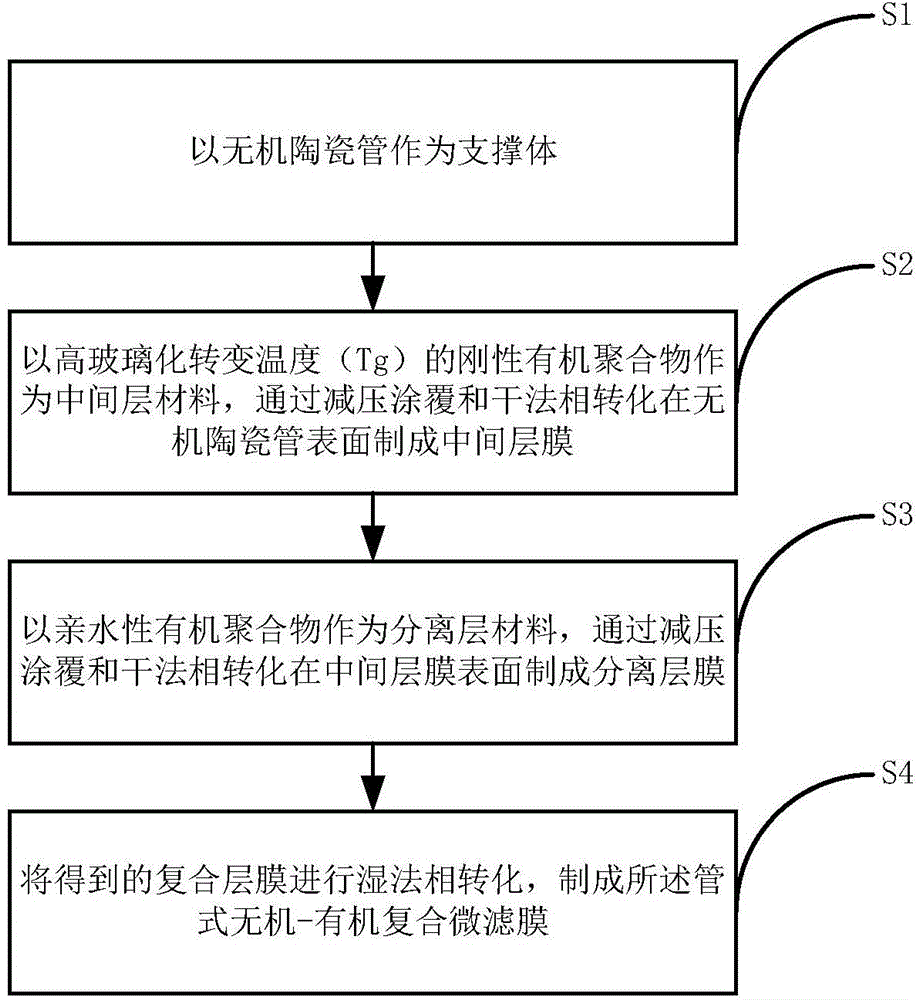

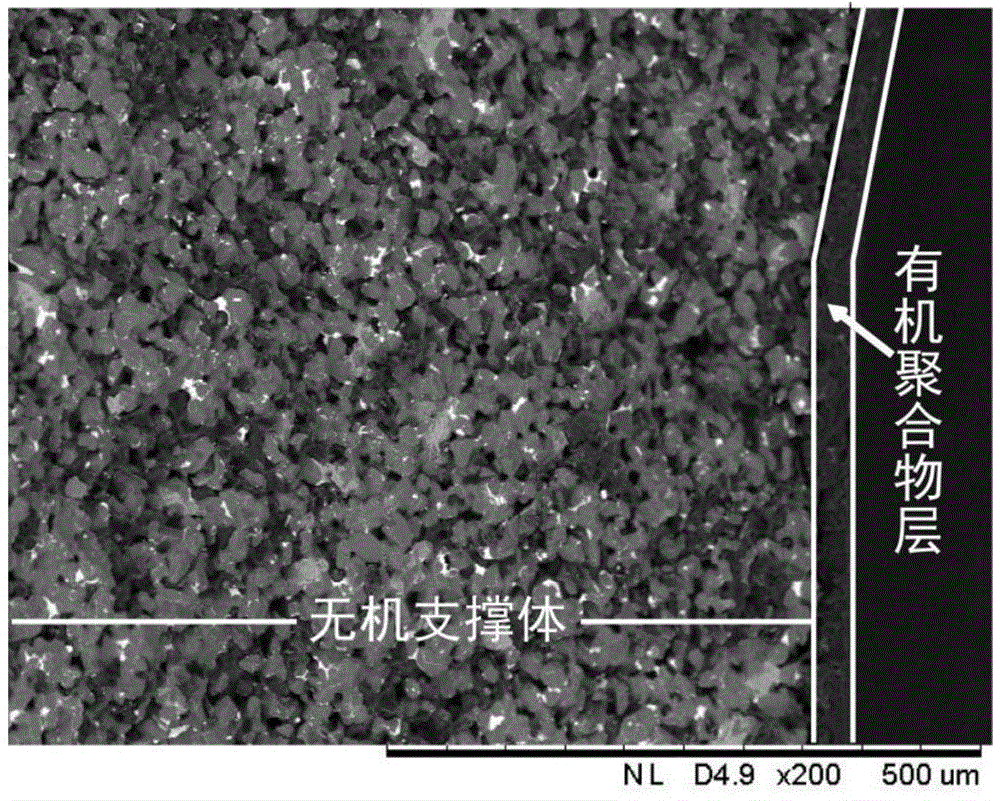

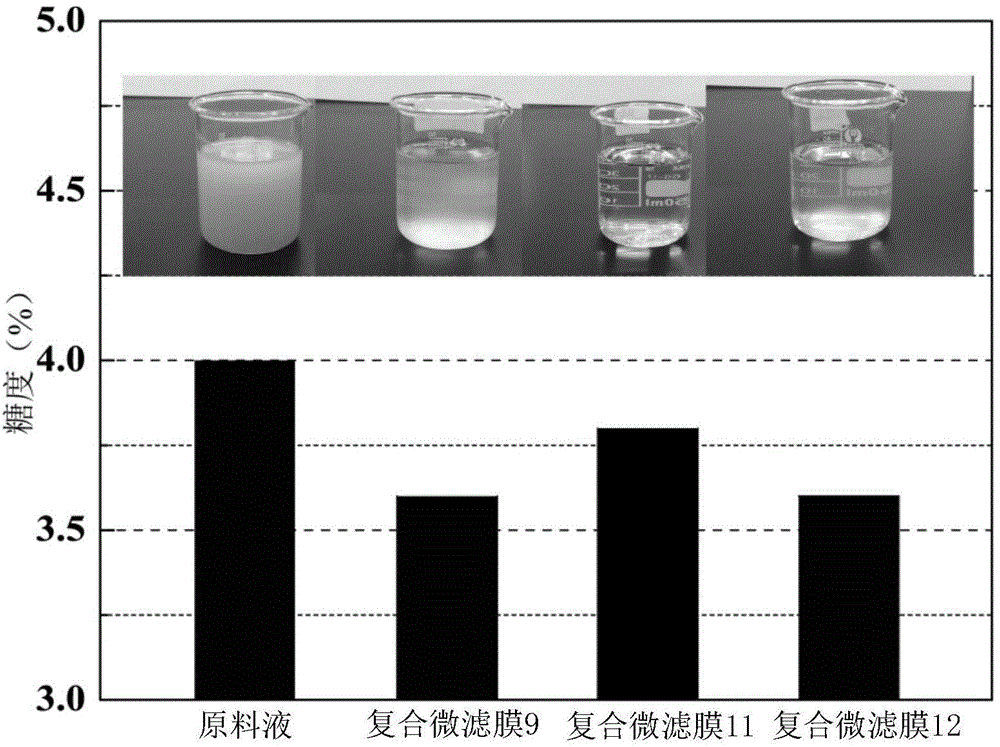

Preparation method of pipe type inorganic-organic compound micro-filtration membrane

The invention discloses a preparation method of a pipe type inorganic-organic compound micro-filtration membrane. The method comprises the flowing steps: forming a middle membrane on the surface of an inorganic ceramic pipe by decompression coating and dry phase converting, wherein the inorganic ceramic pipe is used as a supporting body, and a rigid organic polymer with high glass transition temperature (Tg) is used as a middle material; forming a separating layer membrane on the surface of the middle membrane by the decompression coating and the dry phase converting, wherein a hydrophilic organic polymer is used as a separating layer material so as to obtain a compound layer membrane; and performing wet phase converting on the obtained compound layer membrane to prepare the pipe type inorganic-organic compound micro-filtration membrane. In the method, the easy and fast preparation of the pipe type inorganic-organic compound micro-filtration membrane can be realized under a mild condition, the preparation cost of the ceramic micro-filtration membrane is reduced, and simultaneously the separation selection performance of the ceramic micro-filtration membrane is improved.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

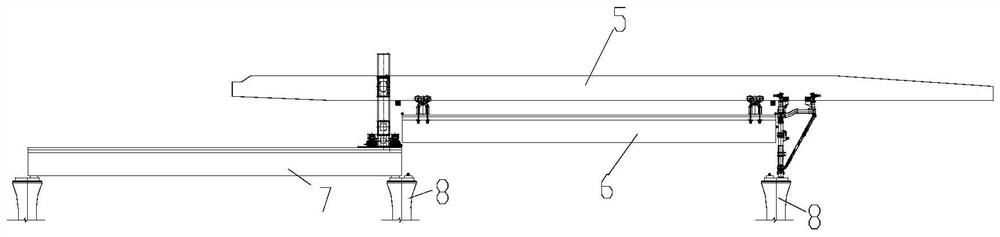

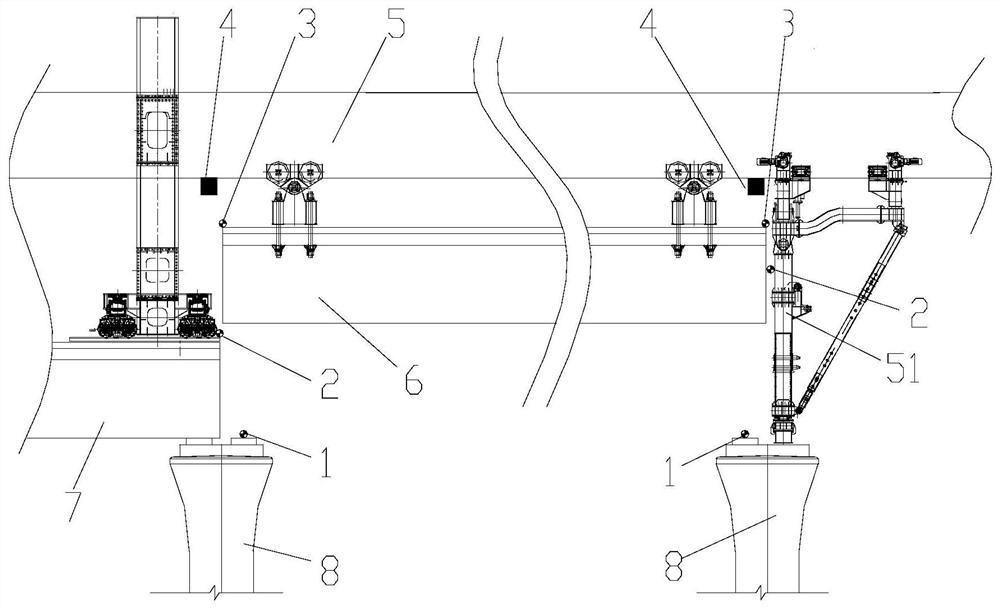

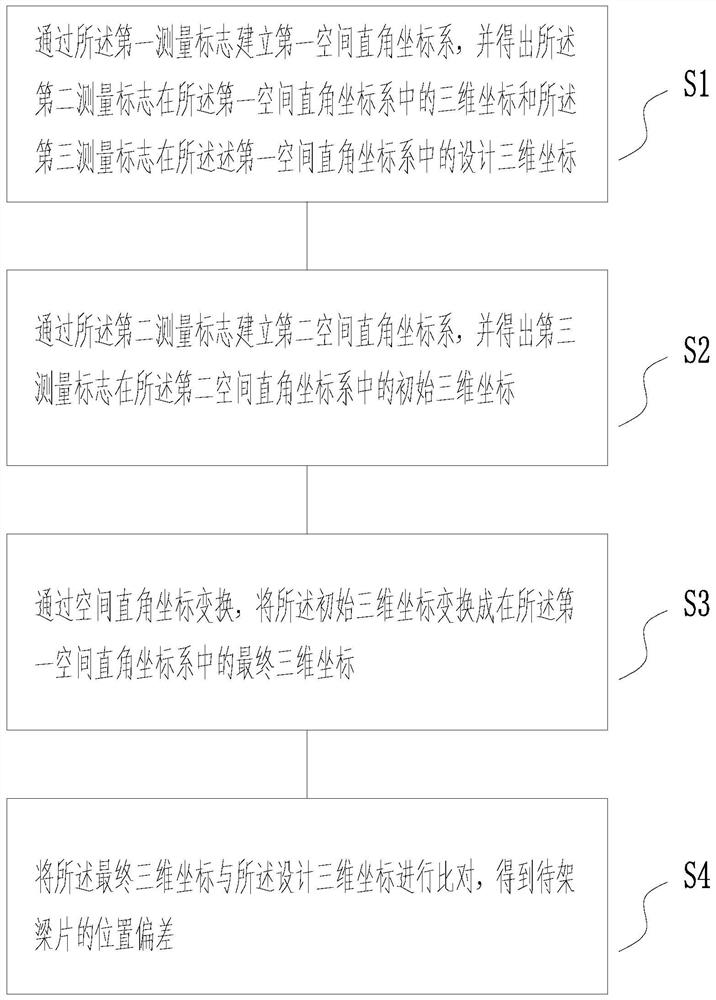

Bridge erecting machine beam falling deviation monitoring system and method

ActiveCN112146575APlay a transitional rolePlay a corrective roleUsing optical meansBridge erection/assemblyRectangular coordinatesMonitoring system

The invention relates to the technical field of bridge erecting, and particularly relates to a bridge erecting machine beam falling deviation monitoring system. The bridge erecting machine beam falling deviation monitoring system comprises a first measuring mark, a second measuring mark, a third measuring mark, an industrial camera and a processor, wherein the processor is used for collecting testdata of the industrial camera, establishing a first space rectangular coordinate system through the first measuring mark and establishing a second space rectangular coordinate system through the second measuring mark according to the test data, converting initial three-dimensional coordinates of the third measuring mark in the second space rectangular coordinate system into final three-dimensional coordinates of the third measuring mark in the first space rectangular coordinate system, and comparing the final three-dimensional coordinates with a design value to obtain a deviation value. According to the bridge erecting machine beam falling deviation monitoring system, the second measuring mark is arranged and can play a transition role when the first measuring mark is shielded by a to-be-erected beam sheet, the three-dimensional coordinates of the third measuring mark in the first space rectangular coordinate system are obtained, meanwhile, the deviation rectifying effect is achieved,the measuring error caused by deviation of the industrial camera can be effectively eliminated, and therefore accurate beam falling is achieved.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

Incoming mechanism of feeding unit

InactiveCN104493695AGuaranteed work efficiency and reliabilityPrecise dockingGrinding feedersEngineeringElectrical and Electronics engineering

The invention provides an incoming mechanism of a feeding unit and belongs to the technical field of machinery. The incoming mechanism comprises a frame, an incoming passage and an ejection component disposed at an outlet of the incoming passage. The incoming passage is provided over the frame and used for conveying workpieces horizontally placed. The ejection mechanism comprises a receiving plate, at least one retaining plate and a first driver; the receiving plate horizontally arranged is used for receiving the workpieces from the incoming passage, the retaining plates are fixedly connected to the receiving plate and the first driver is disposed below the receiving plate; the first driver can drive the receiving plate and the retaining plates to slide up and down along the vertical direction in the same time; when the first driver drives the retaining plates to move up, the retaining plates seal the outlet of the incoming passage and stop the workpieces from continually entering the receiving plate. The incoming mechanism has the advantages of reasonableness in layout and high automation level.

Owner:NINGBO MEIDE ROBOT

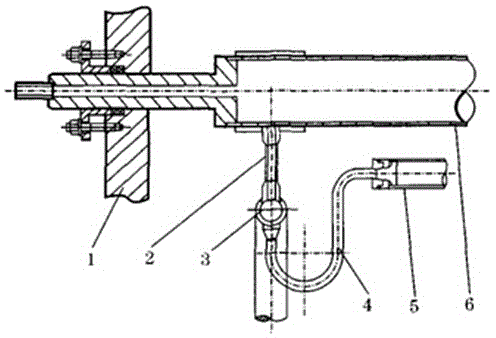

Steam-pipe rotatory dryer

The invention relates to the field of washing powder equipment, in particular to a steam-pipe rotatory dryer. The steam-pipe rotatory dryer comprises an end plate which is connected with a middle circle heat exchange pipe. The lower side face of the middle circle heat exchange pipe is connected with a connecting pipe which is connected with a ring pipe. The ring pipe is connected with an arc-shaped pipe which is connected with an inner circle heat exchange pipe. The inner circle heat exchange pipe is connected with the arc-shaped pipe, and the ring pipe plays a transition role, so that cracks caused by gas expansion are prevented; furthermore, the inner circle heat exchange pipe is gathered through the connecting pipe to be connected to the middle circle heat exchange pipe, and therefore fatigue damage to the connecting part of a non-condensable gas exhaust part and the middle circle heat exchange pipe is avoided, and in the operation process of the dryer, stress of a welding line part connected with the middle circle heat exchange pipe is reduced.

Owner:天津市天亨洗涤剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com