Polyethylene film with easy straight-line tearing and preparation method for polyethylene film

A polyethylene film, polyethylene technology, applied in chemical instruments and methods, flexible coverings, lamination, etc., can solve problems such as poor linear tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

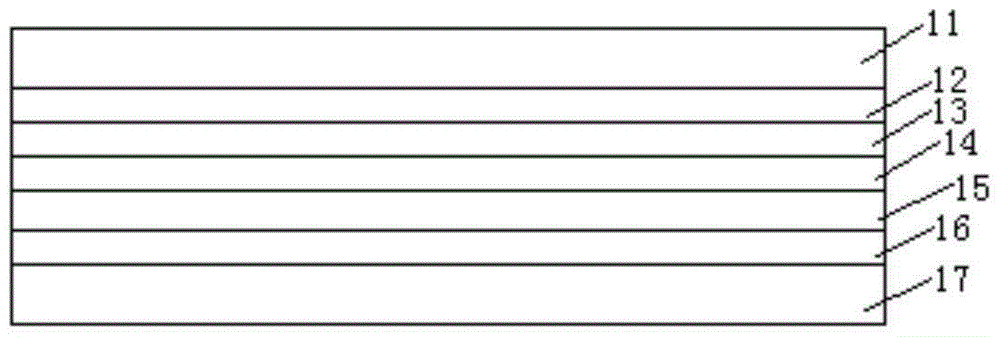

[0052] The present invention also provides a kind of preparation method of the polyethylene film described in above-mentioned technical scheme, comprises the following steps:

[0053] The composite layer, the first middle layer, the second middle layer, the third middle layer, the fourth middle layer and the raw materials of the heat-sealing layer are co-extruded to obtain the composite layer, the first middle layer, the second middle layer which are sequentially in contact with each other. layer, the third middle layer, the fourth middle layer and heat-sealed heat-melt pipe;

[0054] The hot-melt pipe is sequentially blown into a film and cooled to shape;

[0055] The composite layer of the film after cooling and setting is subjected to corona treatment to obtain a polyethylene film.

[0056] In the present invention, the types and amounts of the raw materials of the composite layer, the first middle layer, the second middle layer, the third middle layer, the fourth middle l...

Embodiment 1

[0072] Add the raw materials for the composite layer, the raw materials for the first middle layer, the raw materials for the fifth middle layer, the raw materials for the sixth middle layer, the raw materials for the third middle layer, the raw materials for the fourth middle layer, respectively, into the seven barrels of the extruder machine. The raw materials of raw materials and heat-sealing layer, each raw material formula is as follows:

[0073] Composite layer: 75kg grade is the linear low density polyethylene LLDPE of 7042 and 25kg grade is the low density polyethylene LDPE of L420;

[0074] The first intermediate layer: 50kg of low-density polyethylene LDPE of L420 grade and 50kg of high-density polyethylene HDPE of HTA108 grade;

[0075] The fifth middle layer: 100kg of high-density polyethylene HDPE with the grade of HTA108;

[0076] The sixth middle layer: 100kg of high-density polyethylene HDPE with the grade of HTA108;

[0077] The third intermediate layer: the...

Embodiment 2

[0088] Add the raw materials for the composite layer, the raw materials for the first middle layer, the raw materials for the fifth middle layer, the raw materials for the sixth middle layer, the raw materials for the third middle layer, the raw materials for the fourth middle layer, respectively, into the seven barrels of the extruder machine. The raw materials of raw materials and heat-sealing layer, each raw material formula is as follows:

[0089] Composite layer: the 75kg grade is the linear low density polyethylene LLDPE of 7042 and the grade of 25kg Shanghai Petrochemical is the low density polyethylene LDPE of Q281;

[0090] The first intermediate layer: low-density polyethylene LDPE of Q281 produced by Shanghai Petrochemical and 50kg of high-density polyethylene HDPE of HTA108;

[0091] The fifth middle layer: 100kg of high-density polyethylene with the grade of HTA108;

[0092] The sixth middle layer: 100kg of high-density polyethylene with grade HTA108;

[0093] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com