Polyethylene film, packaging composite film, and making method of packaging composite film

A polyethylene film, polyethylene technology, applied in the field of packaging materials, can solve problems such as poor linear tearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

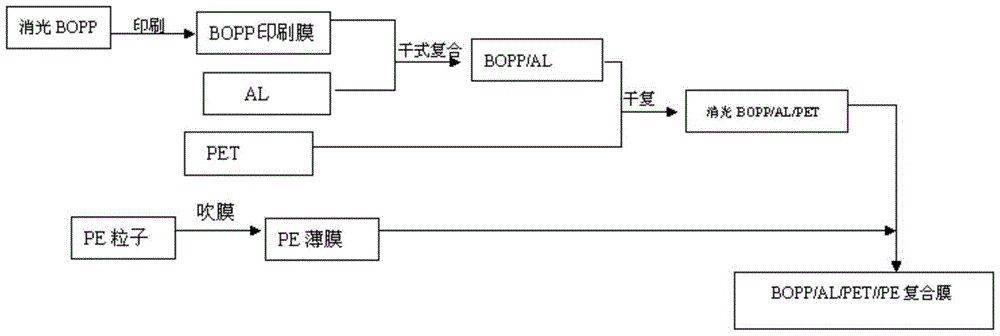

[0054] The present invention also provides a method for preparing the packaging composite film described in the above technical solution, comprising the following steps:

[0055] The polypropylene film, the aluminum foil layer and the polyester film are sequentially compounded to obtain a composite film intermediate;

[0056] Composite the composite film intermediate with a polyethylene film to obtain a packaging composite film;

[0057] The polyester film is in contact with the corona layer of the polyethylene film.

[0058] see figure 1 , figure 1 The production process flow chart of the packaging composite film provided by the embodiment of the present invention.

[0059] In the invention, the polypropylene film, the aluminum foil layer and the polyester film are compounded to obtain a composite film intermediate. In the present invention, the compounding method is preferably dry compounding. In the present invention, the polypropylene film and the aluminum foil layer ...

Embodiment 1

[0074] Add the raw materials of the corona layer, the middle layer and the heat-sealing layer respectively into the three barrels of the extruder machine, and the formulas of each raw material are as follows:

[0075] Corona layer: 50kg of linear low-density polyethylene LLDPE manufactured by Yangzi Petrochemical with the brand number 7042 and 25kg of low-density polyethylene LDPE manufactured by Qilu Petrochemical Company with the brand name of 2102TN00;

[0076] Middle layer: 50kg Yangzi Petrochemical's LLDPE grade 7042 and 20kg COC8007F-04 cycloolefin copolymer Topas Advanced Polymers,

[0077] The above-mentioned cyclic olefin copolymer has the following structure:

[0078]

[0079] Heat-sealing layer: 50kg of 100AC low-density polyethylene LDPE, 25kg of SP1520 metallocene linear low-density polyethylene mLLDPE, 0.5kg of 10090-K slip agent and 0.8kg of AB-20LD opening agent.

[0080] Set the first-stage heating temperature of each barrel to 120°C, the second-stage hea...

Embodiment 2

[0091] Add the raw materials of the corona layer, the middle layer and the heat-sealing layer respectively into the three barrels of the extruder machine, and the formulas of each raw material are as follows:

[0092] Corona layer: 55kg of linear low-density polyethylene LLDPE manufactured by Yangzi Petrochemical with the brand name of 7042 and 20kg of low-density polyethylene LDPE manufactured by Qilu Petrochemical Company with the brand name of 2102TN00;

[0093] Middle layer: 45kg of LLDPE manufactured by Yangzi Petrochemical Company with the brand name of 7042 and 25kg of cycloolefin copolymer manufactured by Topas Advanced Polymers Company with the brand name of COC8007F-04;

[0094] The above-mentioned cyclic olefin copolymer has the following structure:

[0095]

[0096] Heat-sealing layer: 55kg of 100AC low-density polyethylene LDPE, 20kg of SP1520 metallocene linear low-density polyethylene mLLDPE, 0.4kg of 10090-K slip agent and 1.0kg of AB-20LD opening agent.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com