Flexible assembly technology of low-voltage motor and assembly line thereof

A technology for flexible assembly and low-voltage motors, applied in electromechanical devices, manufacturing motor generators, electrical components, etc. Control and other issues to achieve the effect of improving appearance quality, reducing labor intensity of workers, ensuring production efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

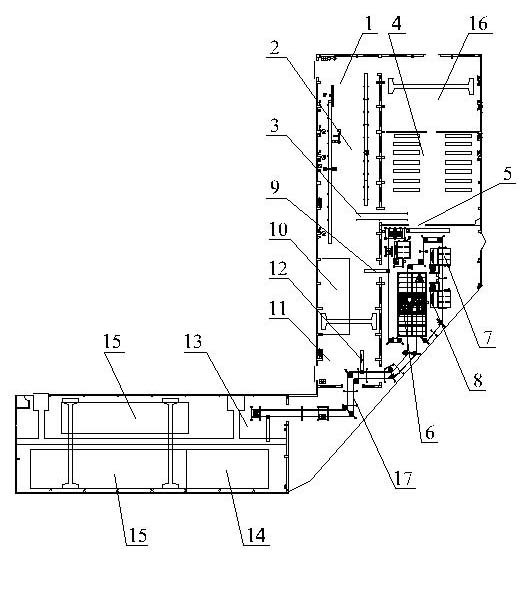

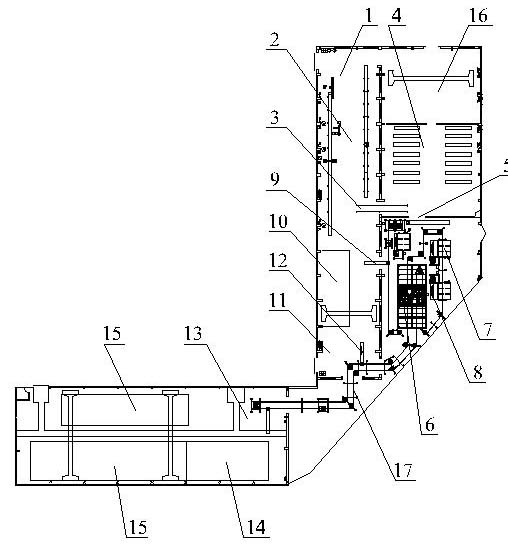

[0014] refer to figure 1 , the present invention provides a flexible assembly process for low-voltage motors, which includes the steps: a. The stator goes online from the upper part area 1 and enters the assembly area 2, and starts the motor assembly, that is: inserting the rotor into the stator, hanging the inner cover and the end cover , press-fit the bearing, install the outer cover and other components, improve and oil the motor that has completed the above assembly work, and use the online automatic quantitative grease injection technology for oil filling; b, go offline from the first offline area 3 and enter the pretreatment area 4; c, Pretreatment is carried out in the pretreatment area 4, that is, the appearance of the motor is finely treated to improve the appearance quality of the motor; d, from the first-time on-line area 5 to the first-time painting area 6, the end caps are sprayed and dried. Drying is connected by transmission device 17, and motor is sent to dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com