Patents

Literature

615results about How to "Guarantee the appearance quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

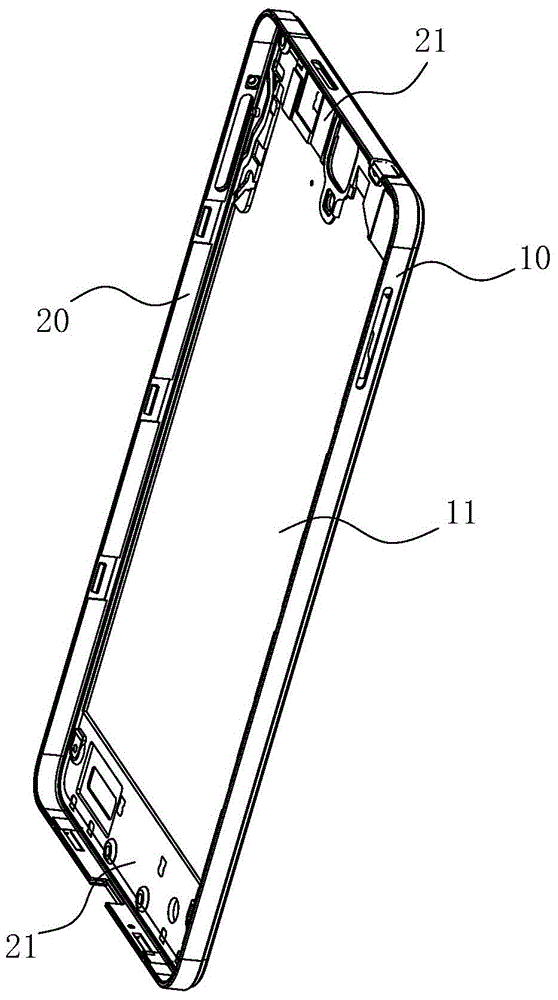

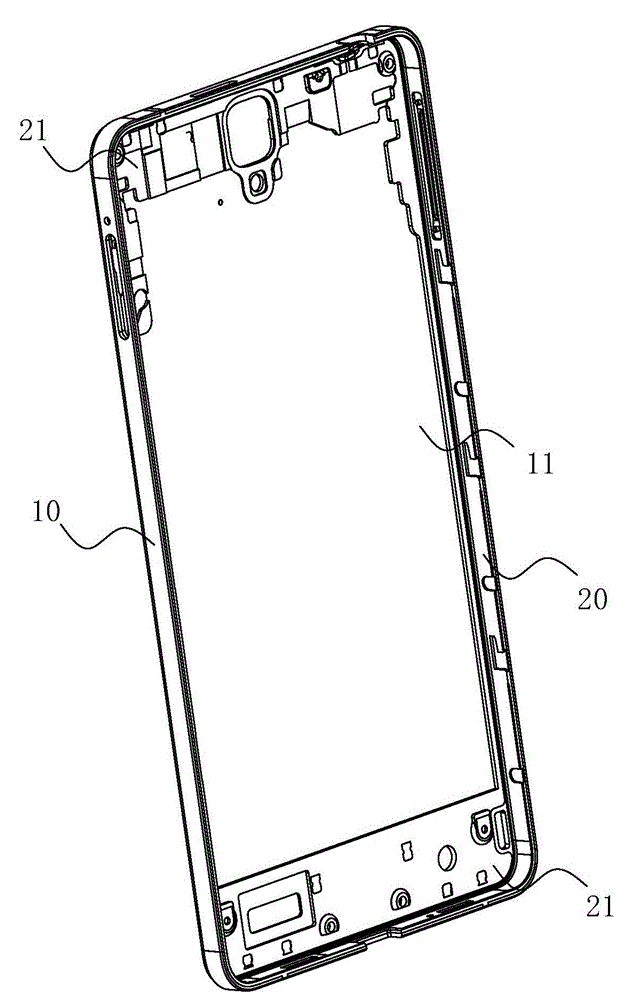

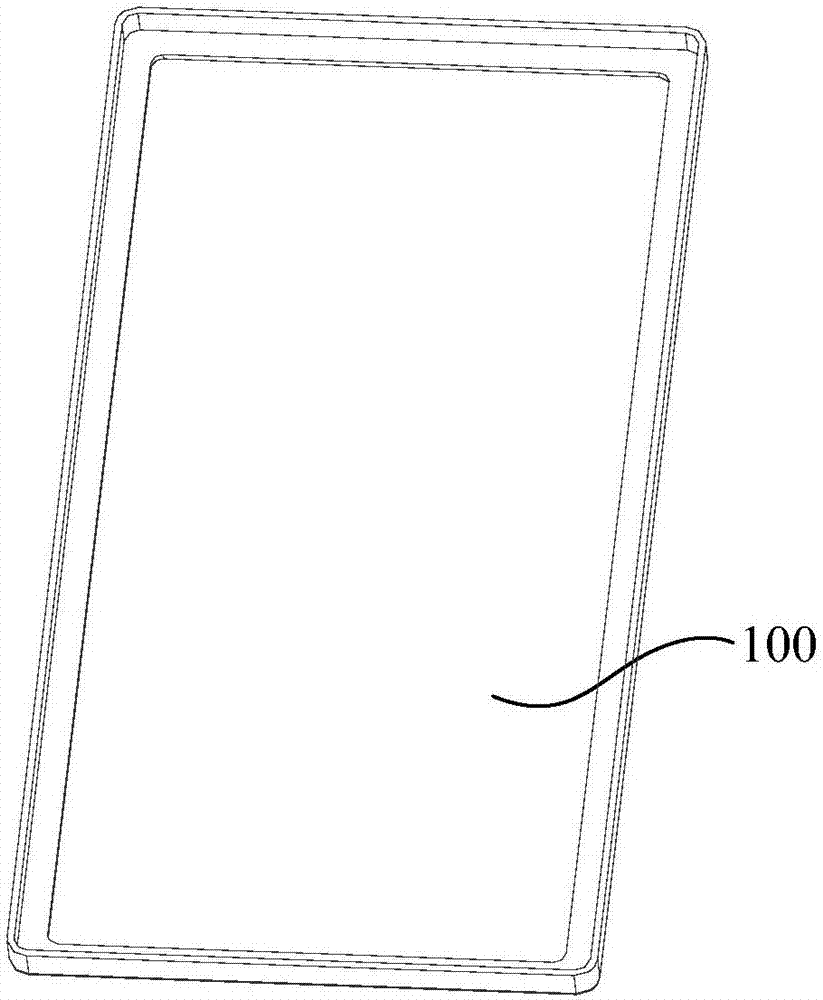

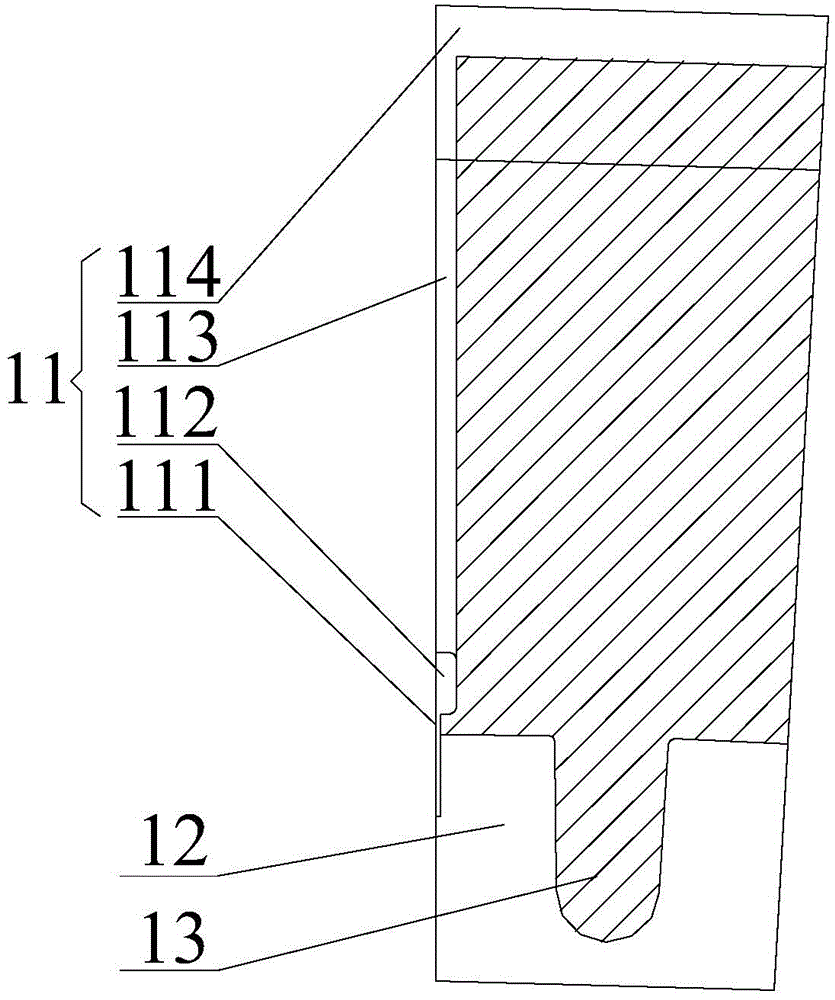

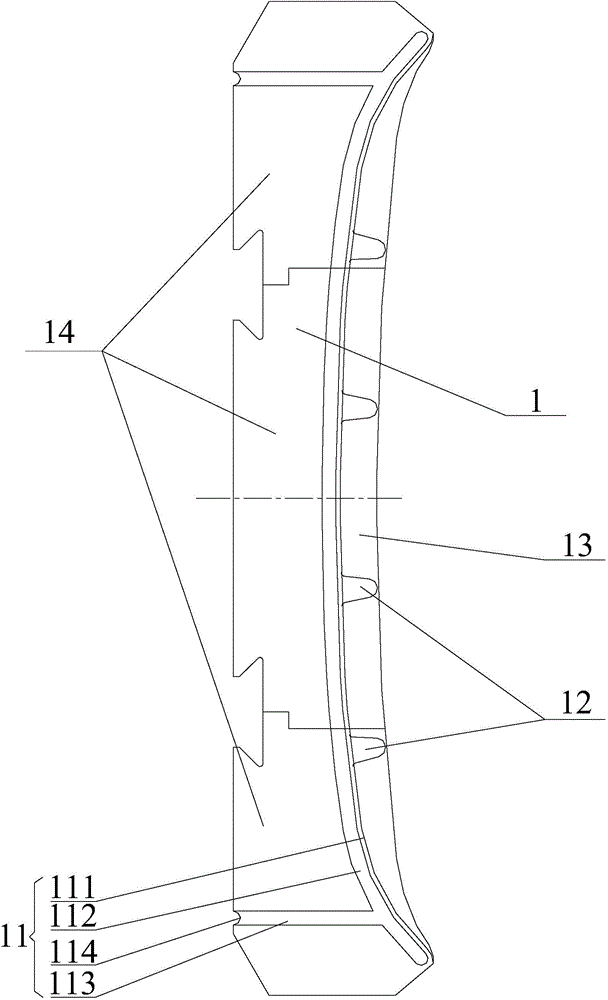

Mobile phone battery case and forming process thereof

InactiveCN104539753ARetain toughnessReduce processing timeTelephone set constructionsElectrical batteryMobile phone

The invention discloses a mobile phone battery case. The mobile phone battery case comprises a metal case and plastic parts fixedly connected to the metal case, wherein the metal case comprises a metal frame and a metal cover board, the metal cover board and the metal frame form an integrated structure, and a partial hollow structure is formed at a position where the metal cover board is connected with the metal frame; the plastic parts consist of a plastic frame and a plastic filling part, the plastic frame and the plastic filling part form an integrated structure, the plastic frame is in tight contact with the metal frame at the inner side of the metal frame, and the hollow structure is filled with the plastic filling part. The invention also discloses a forming process of the mobile phone battery case. By adopting the mobile phone battery case, the appearance expression of the mobile phone product is guaranteed, the structure of the metal case is simplified, the thickness of the metal case is reduced, the processing difficulty and the product cost are reduced, and the product productivity is improved; by adopting the process, the production efficiency is improved while the production quality of the product is guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

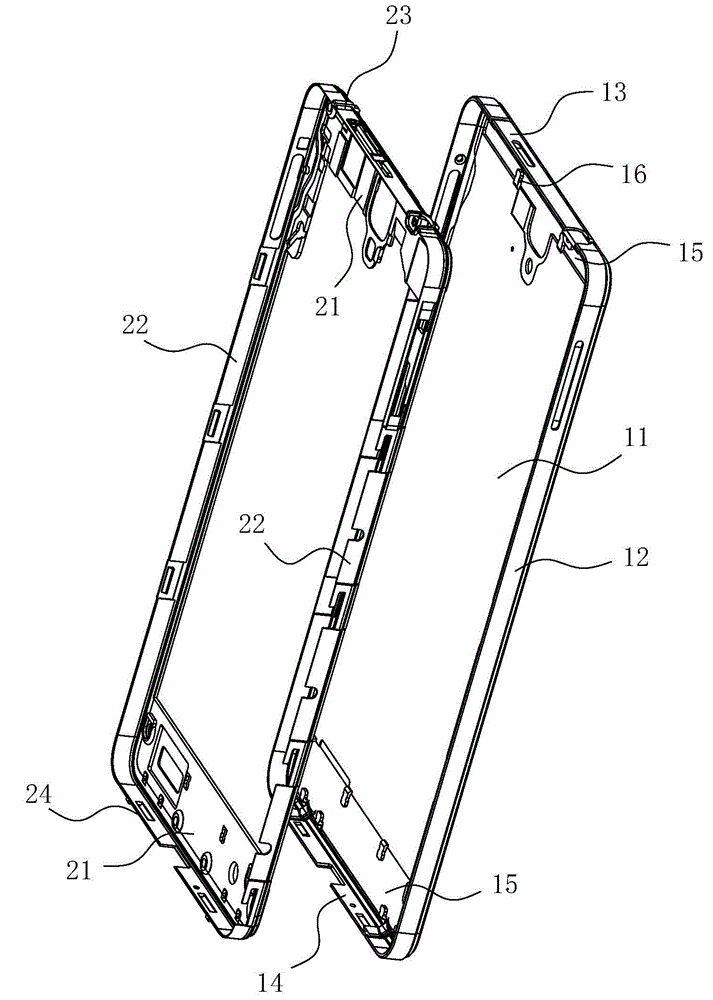

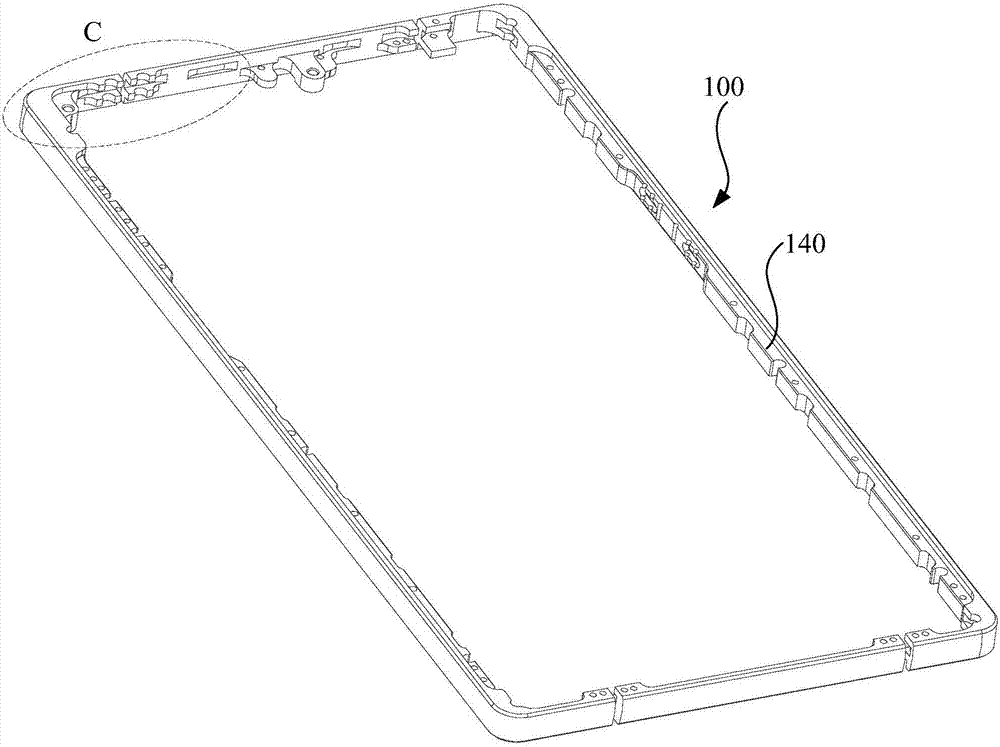

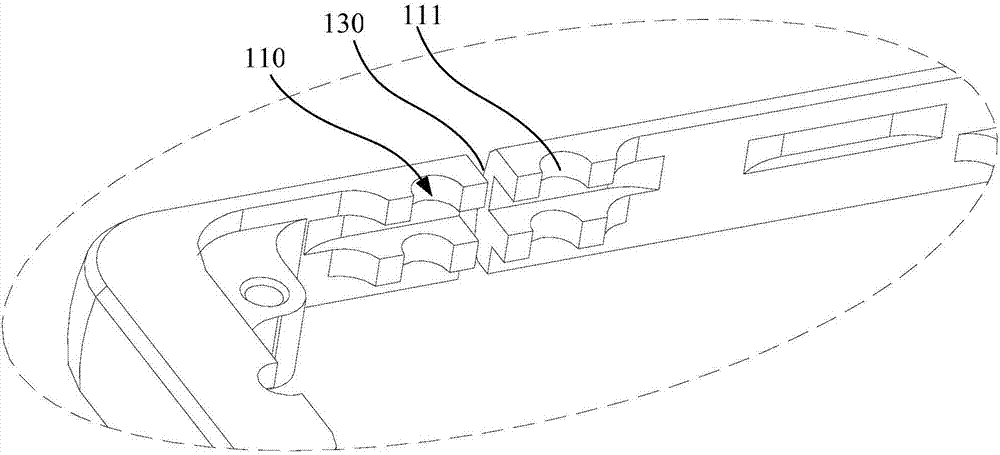

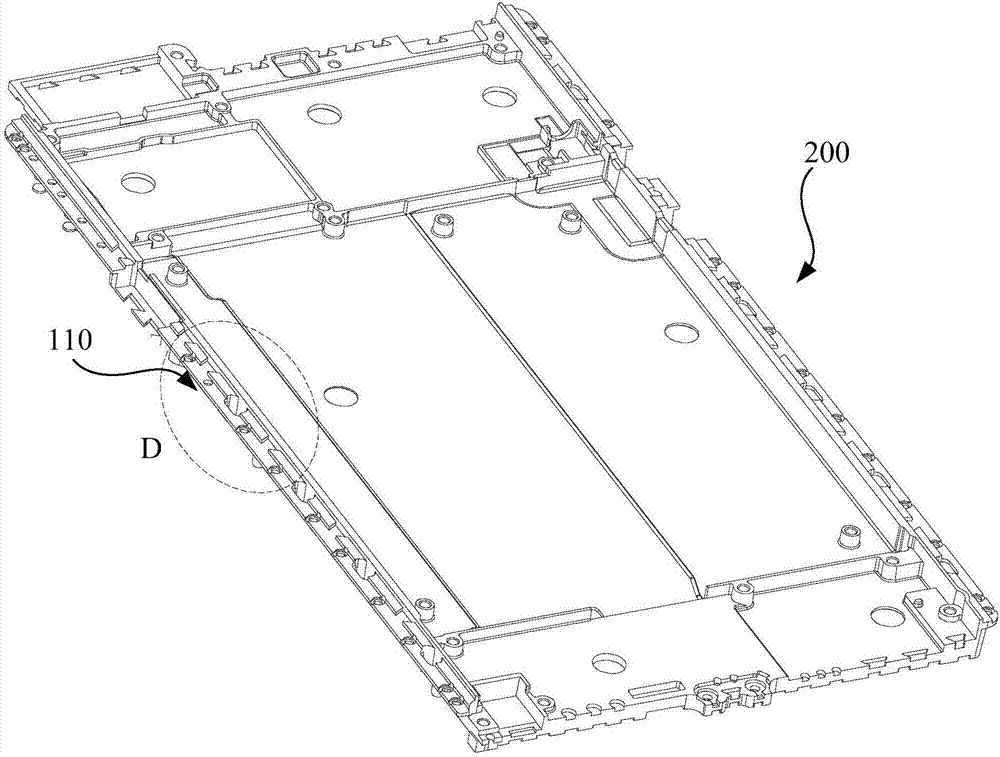

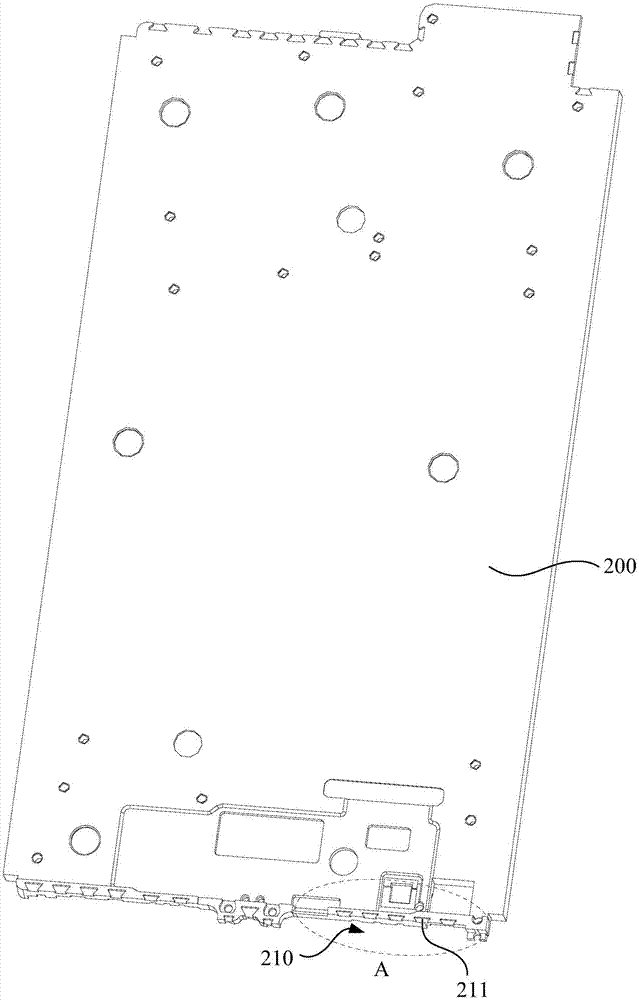

Metal middle frame processing technique, metal middle frame and electronic device

InactiveCN107087363AGuarantee the appearance qualityReduce manufacturing costCasings/cabinets/drawers detailsDomestic articlesInterference fitBiochemical engineering

The invention relates to a metal middle frame processing technique, a metal middle frame and an electronic device. The metal middle frame comprises a frame, a middle plate and a rubber piece. A groove or a protrusion which extends circumferentially is arranged on the inner surface of the frame. A protrusion or a groove which is in interference fit with the groove or the protrusion is arranged in the edge of the middle plate. The rubber piece is moulded between the frame and the middle plate in an injection manner. The metal middle frame processing technique comprises following steps of through squeezing technique and CNC technique, processing and moulding the frame with the groove or the protrusion; using the die-casting technique to process and mould the middle plate with the protrusion or the groove; heating the groove or cooling the protrusion, matching the protrusion or the groove and recovering the temperature of the protrusion or the groove to the initial temperature; injecting fused rubber in a slit between the middle plate and the frame; and carrying out cooling and surface processing on the moulded metal middle frame. In this way, processing quantity of the CNC technique is reduced; processing time in the whole metal middle frame is reduced; and manufacturing cost of the metal middle frame is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

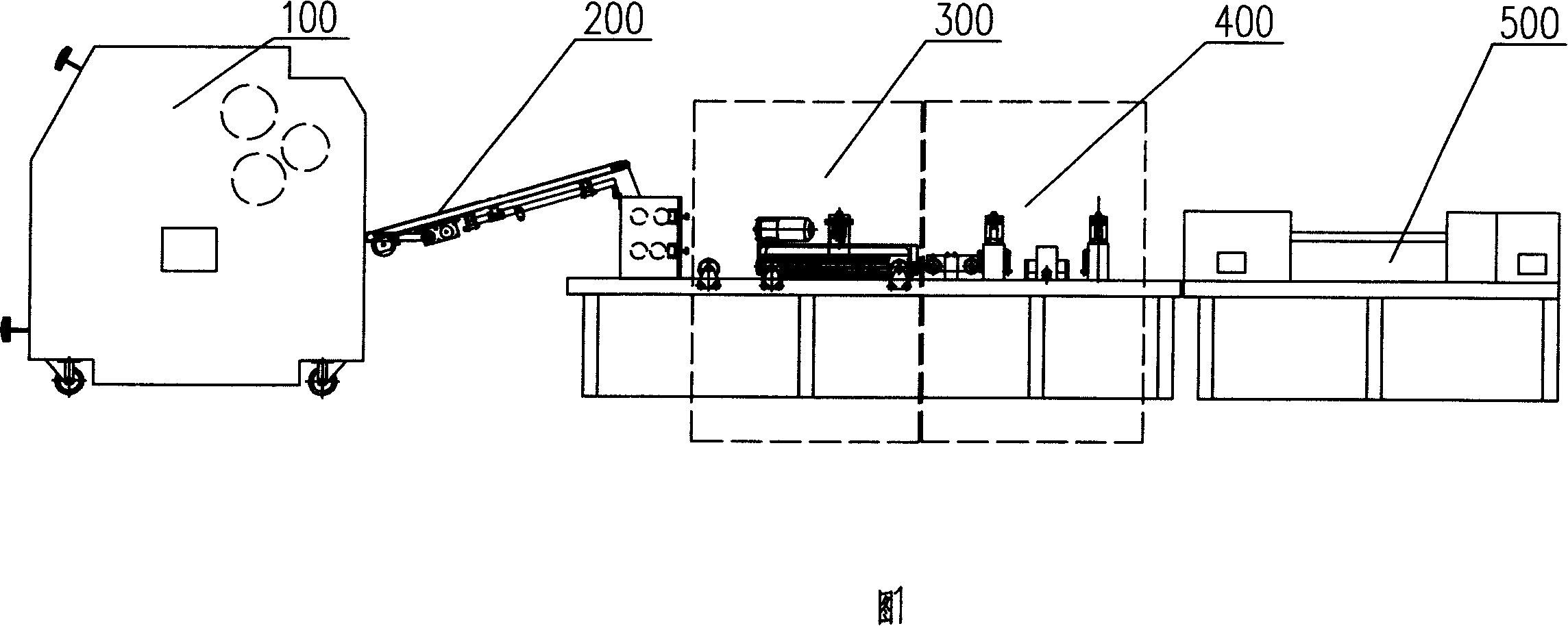

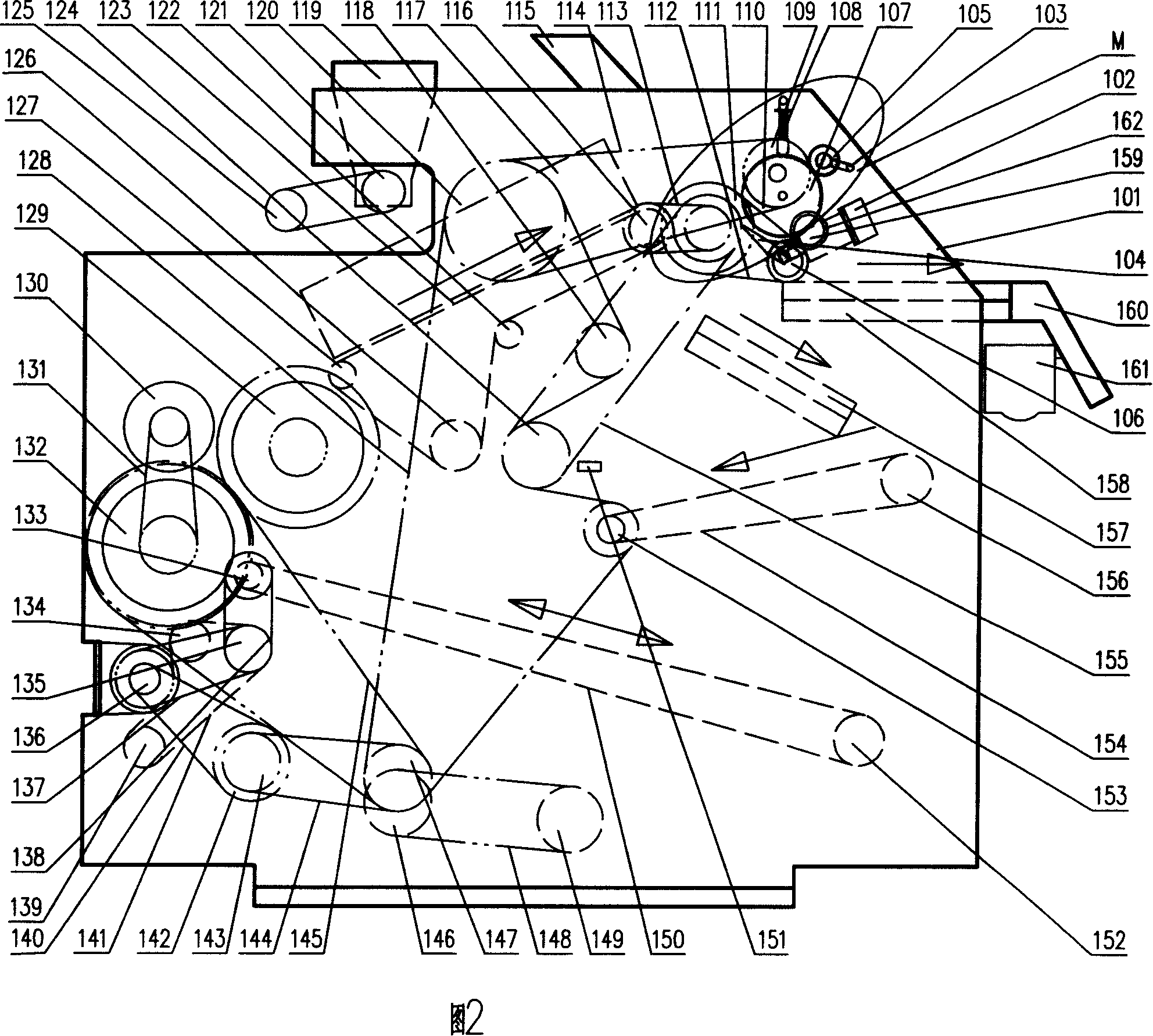

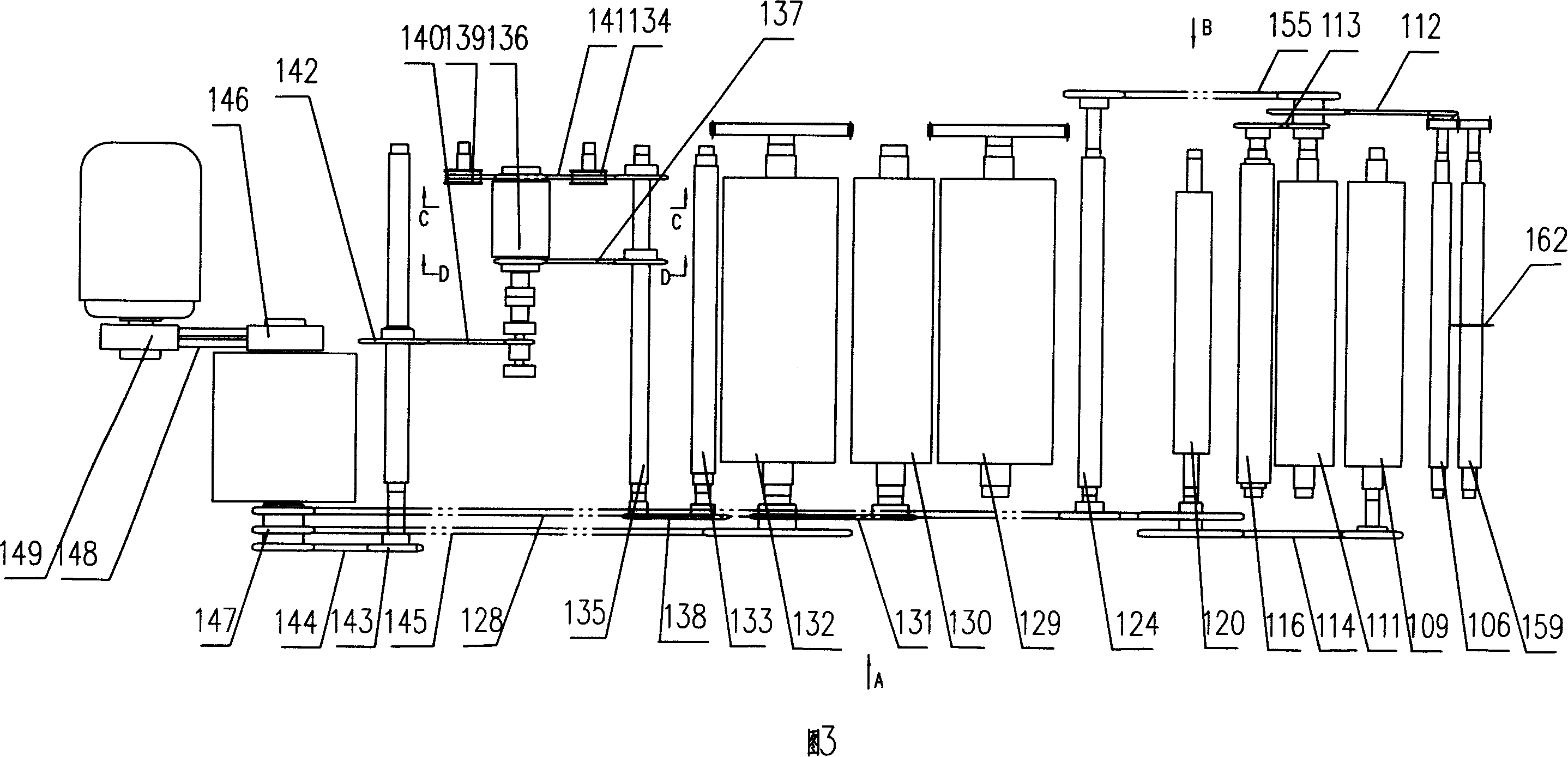

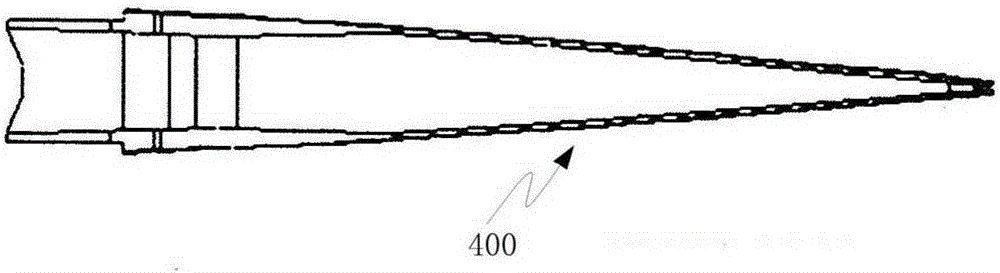

Equipment for producing round steamed bread

ActiveCN101112202AImprove skin brightnessClear internal structureDough-sheeters/rolling-machines/rolling-pinsForming processesFood products

The invention pertains to the technical field of food machinery and relates to producing equipment of round steamed bread. The equipment is provided with the following settings from front to back in sequence: a squash device (100), an incline plane transportation device (200), a winding device (300), a cutting device (400) and a molding device (500). Each device is connected by conveying belt. The squash, winding and cutting devices are added before the molding process. The process steps are as follows: paste is squashed into dough sheet; dough roll is made of the dough sheet through the winding device; then the dough roll is cut, molded to form a clear inner structure layer and improve the brightness of the steamed bread surface and enable the steamed bread to be tasted puckering. The molding process of the invention simulates manual entwisting molding process, which enables the steamed bread inner structure to be difficult to be torn and broken, maintains the sourdough network completely and evenly, has high molding efficiency, and at the same time improves the appearance quality of the dough.

Owner:郑州多福多食品有限公司

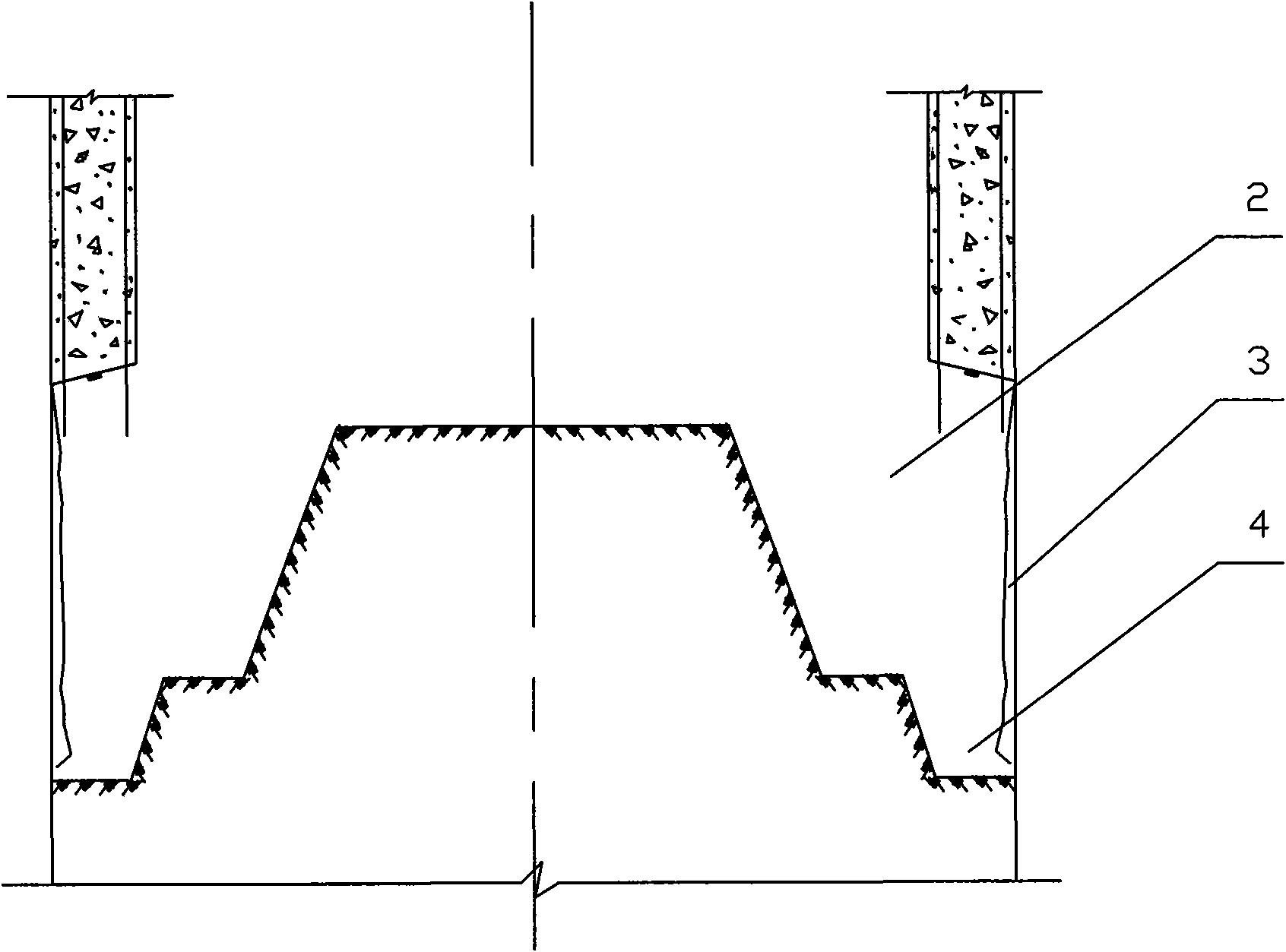

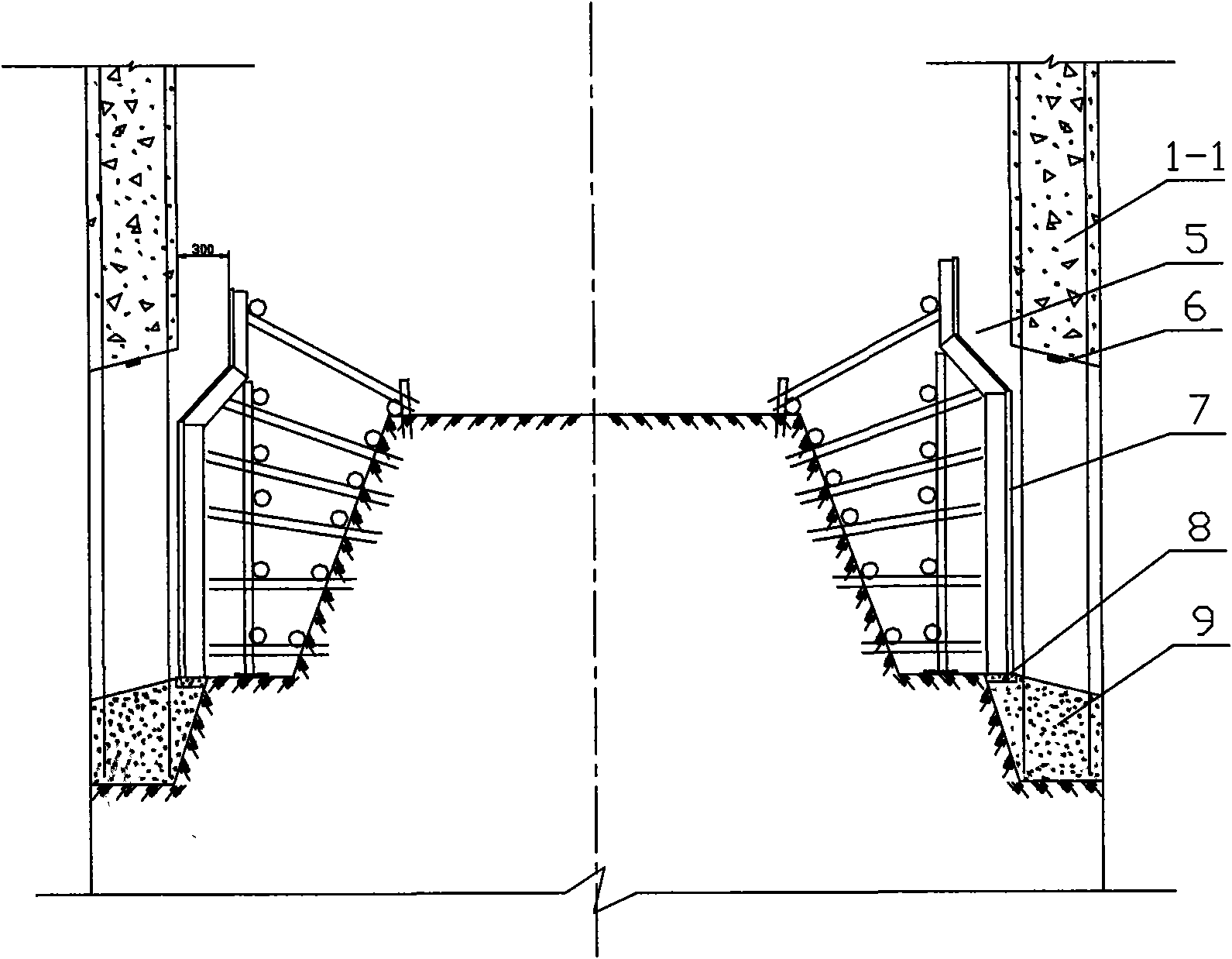

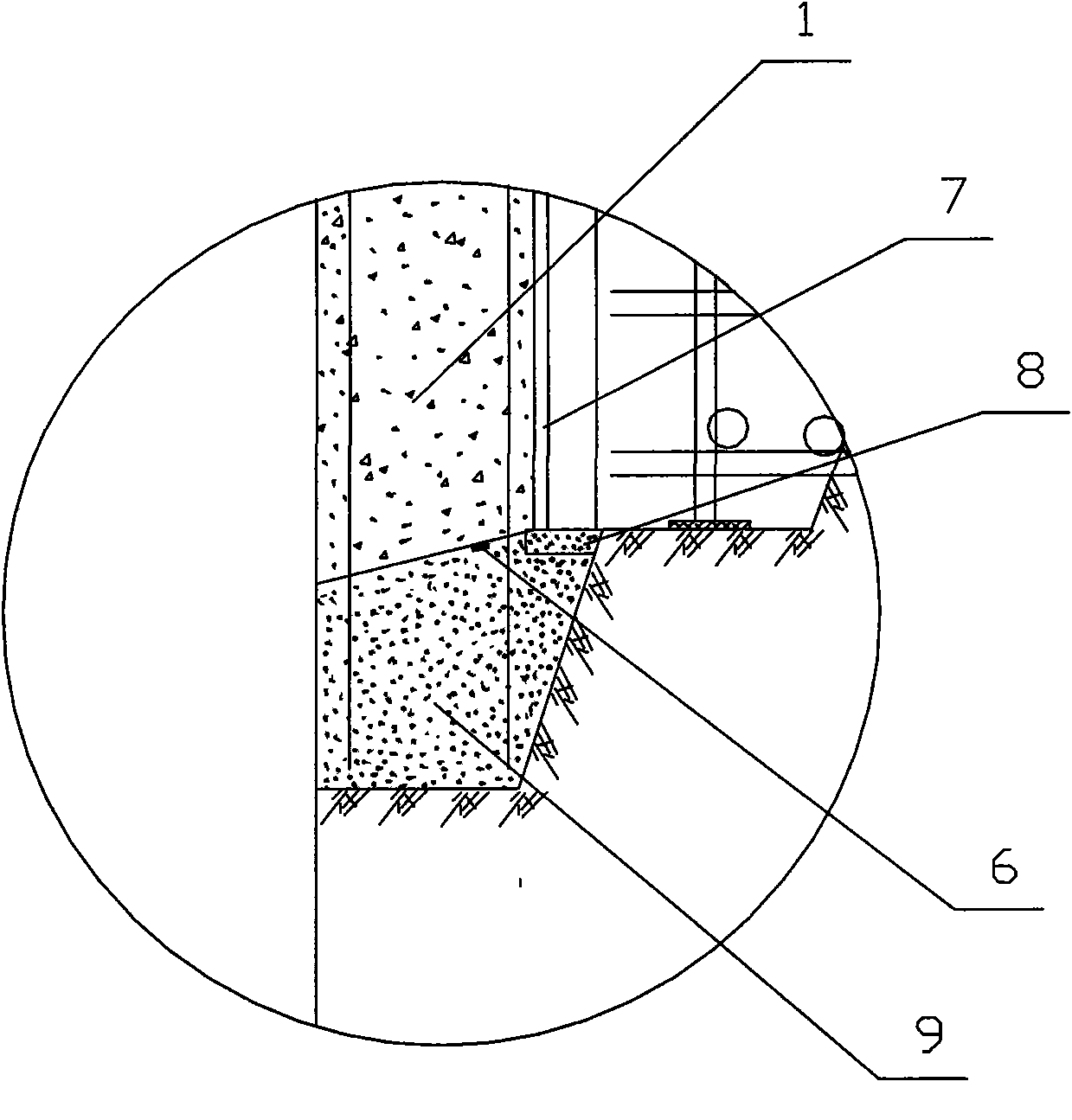

Top-down construction method of large underground structure outer wall

InactiveCN101672041AImprove ergonomicsGuarantee molding qualityArtificial islandsUnderwater structuresEngineeringRebar

The invention discloses a top-down construction method of a large underground structure outer wall, comprising the following steps: constructing a supporting pile; borrowing earth; binding a first section of outer wall and ring beam reinforcing steel bars, wherein the ring beam reinforcing steel bars are respectively fixedly connected with reinforcing steel bars in the first section of outer walland the reinforcing steel bars in the supporting piles; raising templates; pouring concrete, wherein the first section of outer wall, the ring beam and the supporting piles are integrated as a whole;and repeating the construction of borrowing earth, binding reinforcing steel bars, raising templates, pouring concrete until the bottom surface of the last section of outer wall reaches the designed elevation. The adoption of a pile hanging technique in the invention ensures safe construction, the adoption of a double anti-leakage technique ensures no leakage inside the outer wall, the adoption ofa fast molding technique accelerates the program progress, and the application of sizing steel templates ensures the appearance quality of the concrete thereby achieving a good effect.

Owner:TIANJIN 20 CONSTR

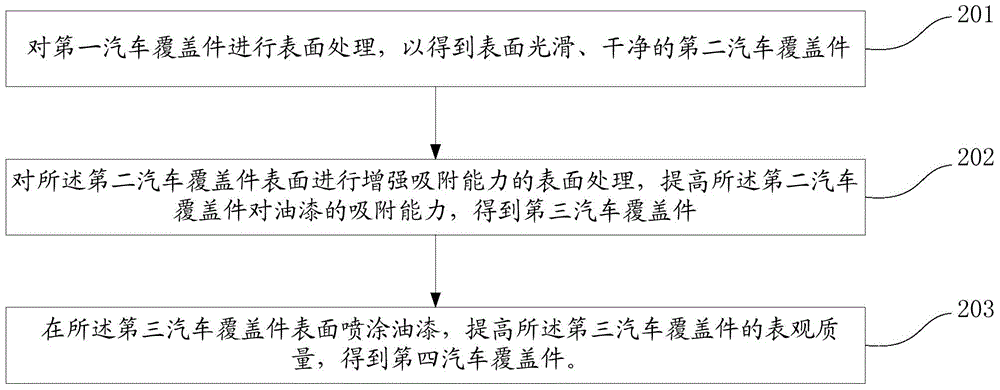

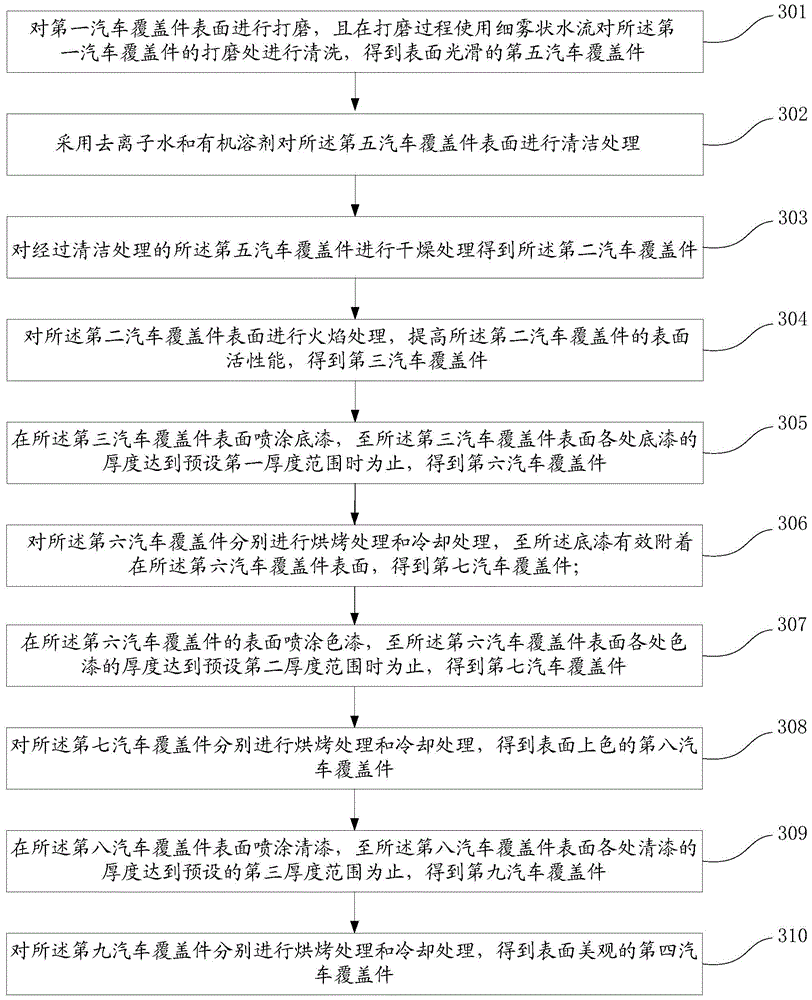

Automobile covering element spray coating method

ActiveCN104826784AGuarantee the appearance qualityMeet the needs of mass productionPretreated surfacesSpecial surfacesSpray coatingEngineering

The invention discloses an automobile covering element spray coating method, and belongs to the field of automobile part manufacturing. The method comprises the following steps that a first automobile covering element is subjected to surface treatment to obtain a second automobile covering element with the smooth and clean surface; the surface of the second automobile covering element is subjected to surface treatment for enhancing the adsorption capability, the adsorption capability of the second automobile covering element on the paint is improved, and a third automobile covering element is obtained; the paint is sprayed and coated on the surface of the third automobile covering element to obtain a fourth automobile covering element. The automobile covering element spray coating method has the advantages that the second automobile covering element is subjected to the surface treatment for enhancing the adsorption capability, so that on the basis that the paint can be effectively adsorbed onto the surface of the third automobile covering element, the surface depression of the third automobile covering element can be filled through increasing the thickness of the paint, the puttying or the lime scraping is avoided, the spray coating schedule is accelerated, and the whole spray coating operation period is shortened, so that the method can be applied to large-scale automobile spray coating processing, and the current automobile large-scale production requirements are met.

Owner:CHERY AUTOMOBILE CO LTD

Manufacturing method of relief silverware

ActiveCN102922936AImprove appearance qualityGuarantee the appearance qualitySpecial ornamental structuresSilver plateAdhesive

The invention relates to the field of processing of silverware and specifically relates to a manufacturing method of relief silverware, which can solve the problems of low work efficiency, low degree of mechanization, poor appearance quality and the like of conventional manual manufacturing of the silverware. The manufacturing method comprises the following steps: melting silver water; casting a silver blank; forging and pressing the silver blank into a thin silver plate with the thickness being 0.3-1mm on a forging and pressing machine; stamping the thin silver plate to form the basic contour of all parts of the silverware on a rotary stretch forming machine; welding all the parts by adopting welding materials according to the shape requirements of the silverware, and forming a matrix of the silverware; casting a filling adhesive into the matrix of the silverware, cooling and then forming a plastic support; carving flowers or patterns; removing the plastic support; washing; and grinding and polishing. The manufacturing method disclosed by the invention can not only inherit a quantity of traditional processes of old folk silversmiths, but also integrate with modernized devices and processes; and during the manufacturing process, the forging and pressing machine and a stretch forming machine are utilized, the structure is simple, the design is reasonable, the operation is simple and convenient, the mechanized operation of forging, pressing and forming of a silver plate can be realized, the operation is time-saving and labor-saving, the efficiency is high, and high-efficiency and fine manufacturing requirements in manufacturing of the silverware can be met.

Owner:繁峙县星河银业有限公司

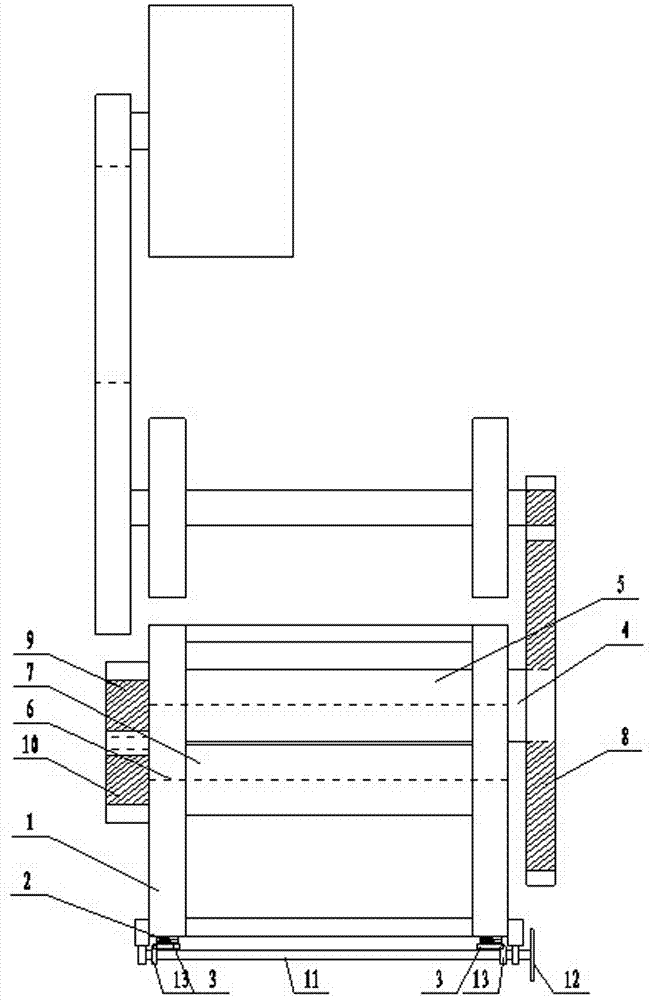

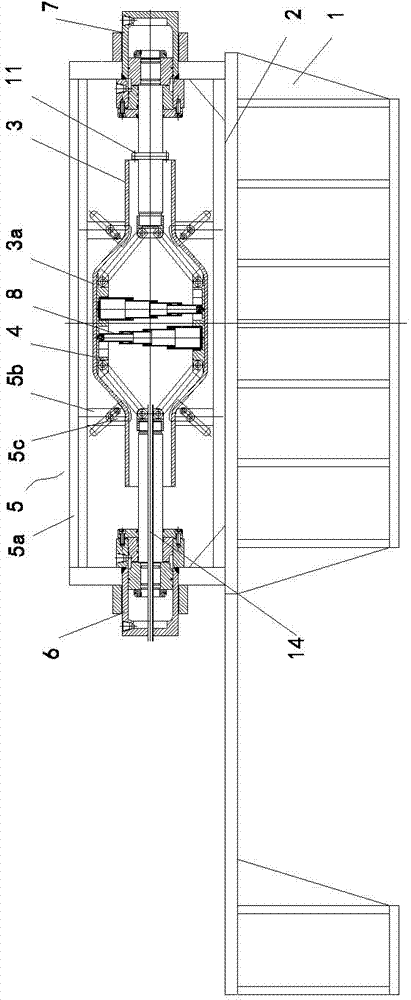

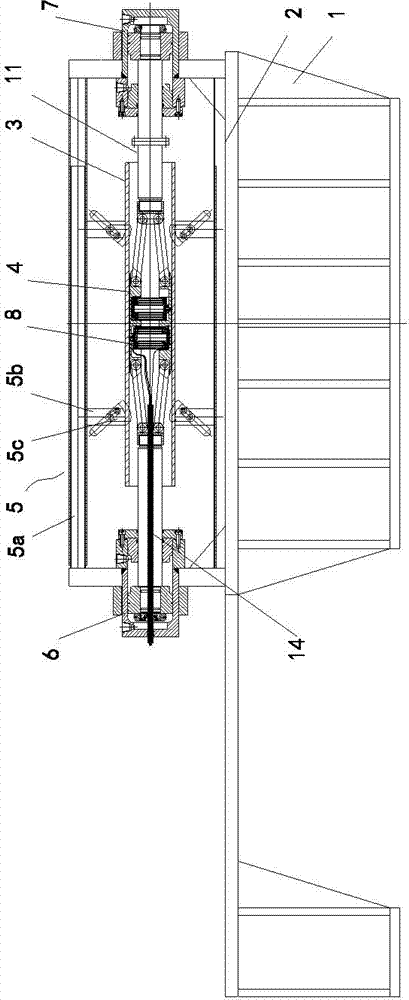

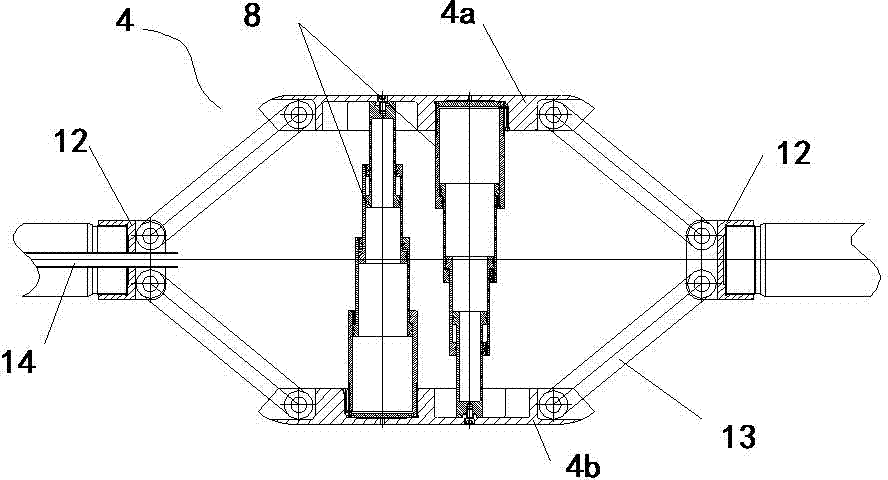

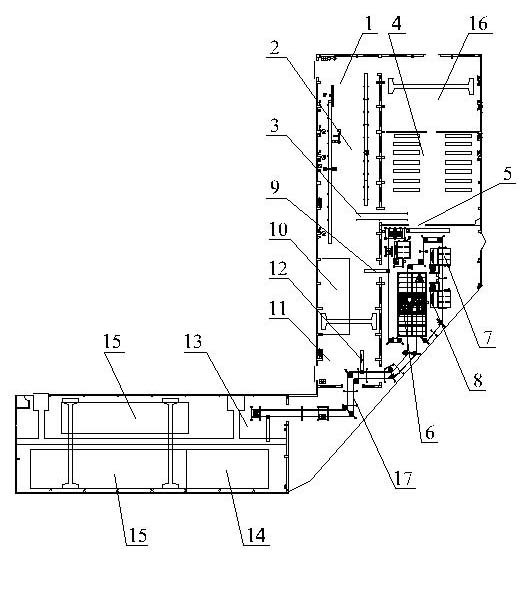

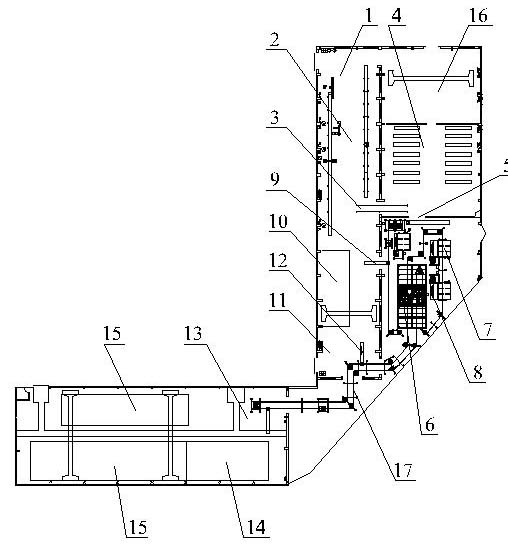

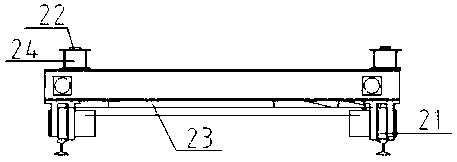

Hydraulic press special for integral compound bulging of automatic driving axle

InactiveCN102886463ALimited deformation areaGuarantee the appearance qualityShaping toolsFluid-pressure actuatorsHydraulic cylinderStructural engineering

The invention discloses a hydraulic press special for the integral compound bulging of an automatic driving axle. The hydraulic press comprises a hydraulic press body and a hydraulic bulging system. The hydraulic press body comprises a rack with a workbench. An internal bulging die and an external bulging die are arranged on the workbench. The internal bulging die comprises an upper module and a lower module. The external bulging die comprises a rack. A support structure is arranged on the rack, and comprises support rods and support heads. A left thrust hydraulic cylinder and a right thrust hydraulic cylinder are arranged at the two ends of the workbench respectively. The two ends of the upper and lower modules are hinged with piston rods of the left and right thrust hydraulic cylinders through link mechanisms respectively. At least one multi-stage hydraulic cylinder is arranged between the upper and lower modules. A quick disassembly connecting structure is arranged on the piston rod of the left or right thrust hydraulic cylinder. Hydraulic pressure required by the integral compound bulging production of the automotive driving axle can be provided, the whole continuous bulging process of the automotive driving axle can be well controlled, and the bulging production requirements of the automotive driving axle can be met.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

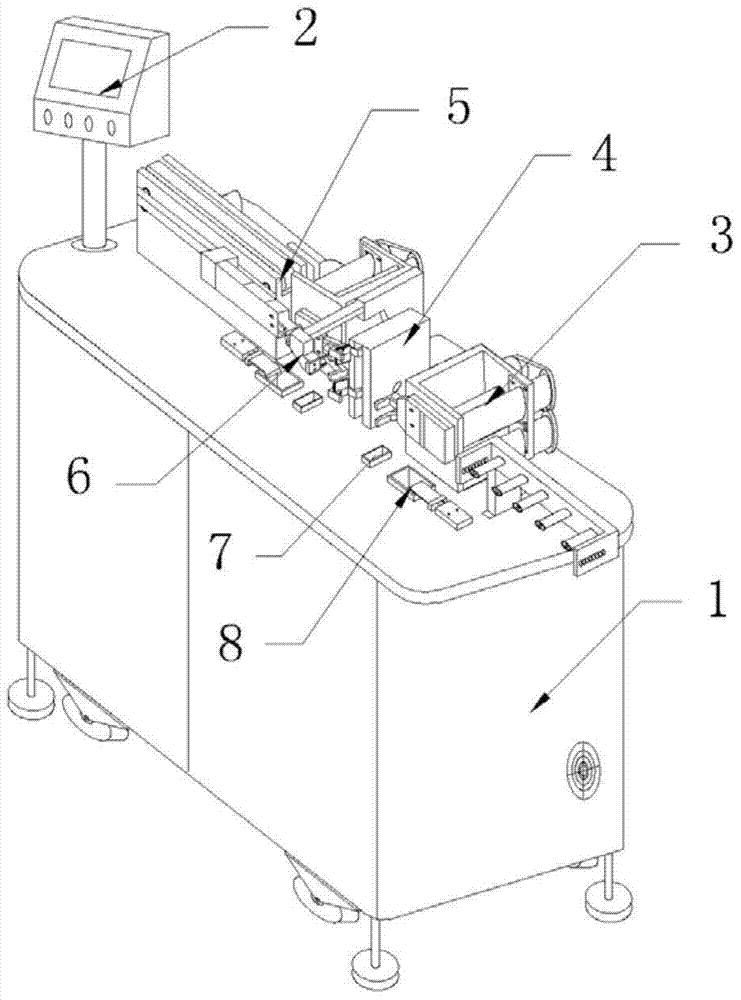

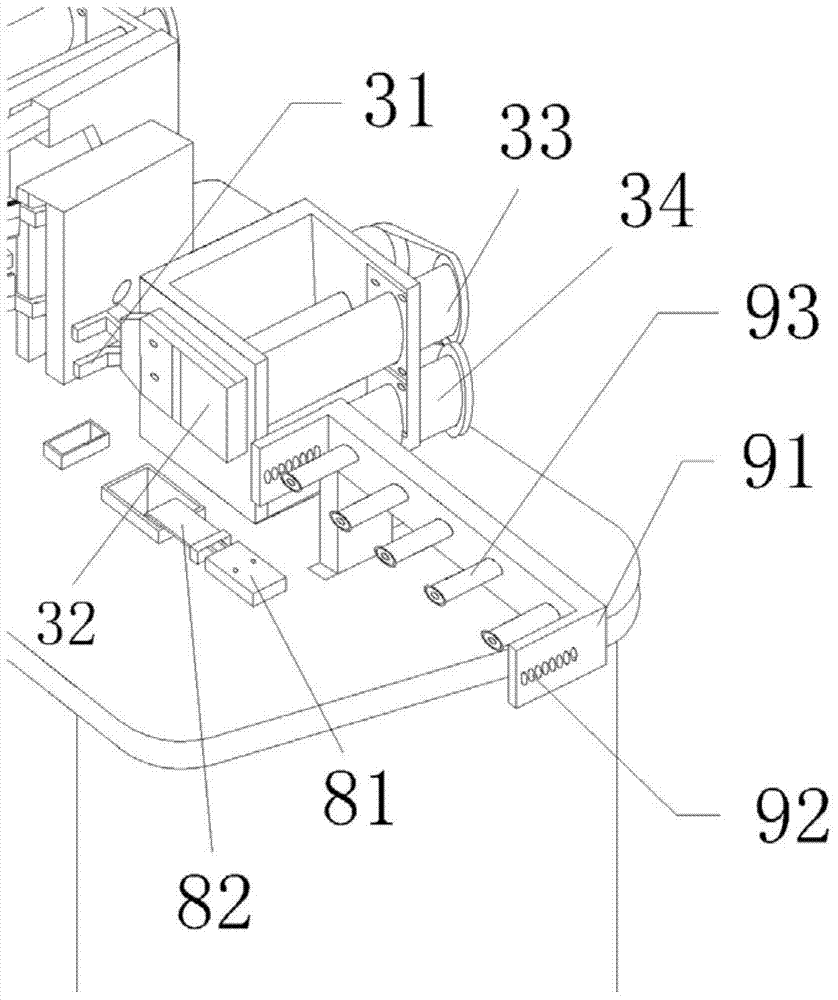

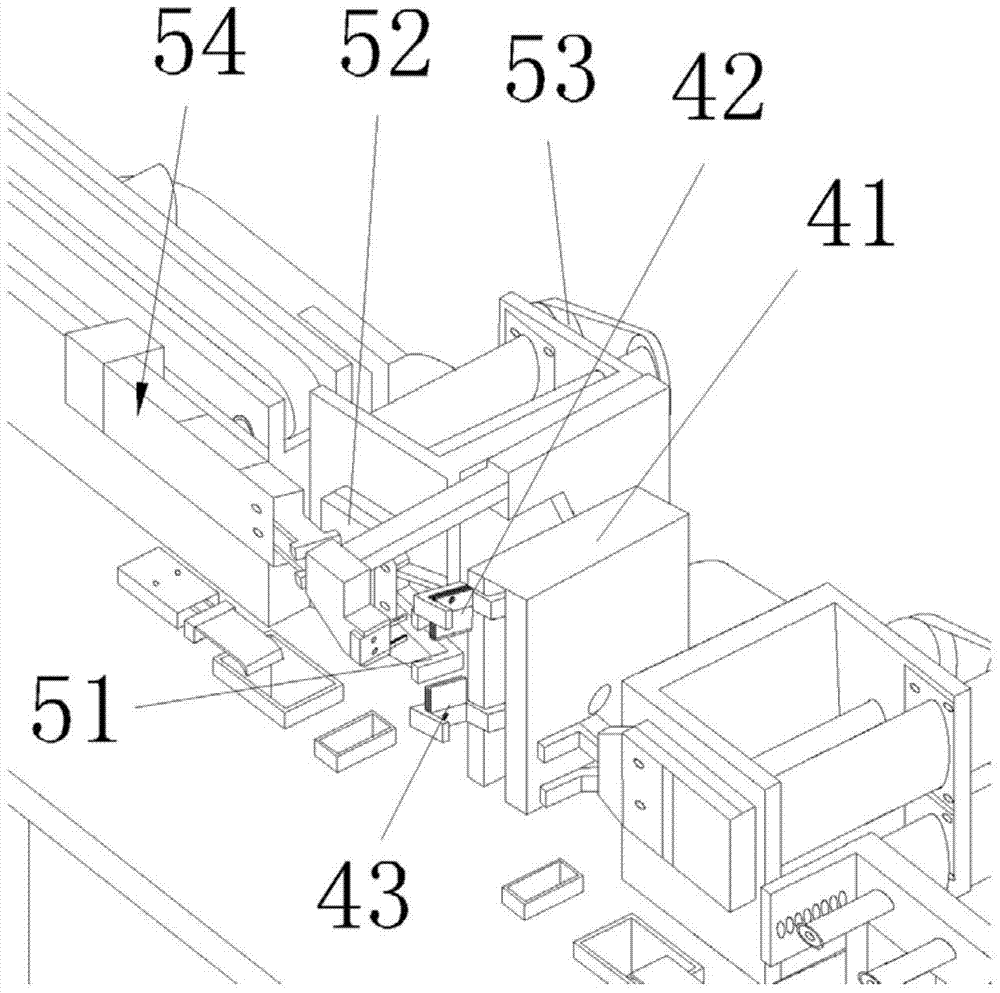

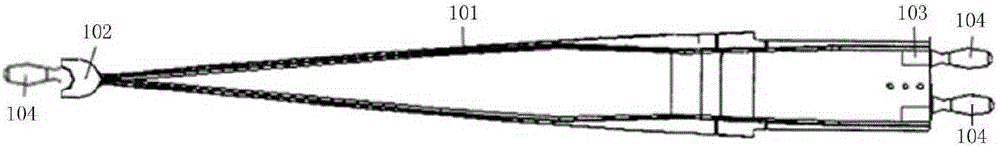

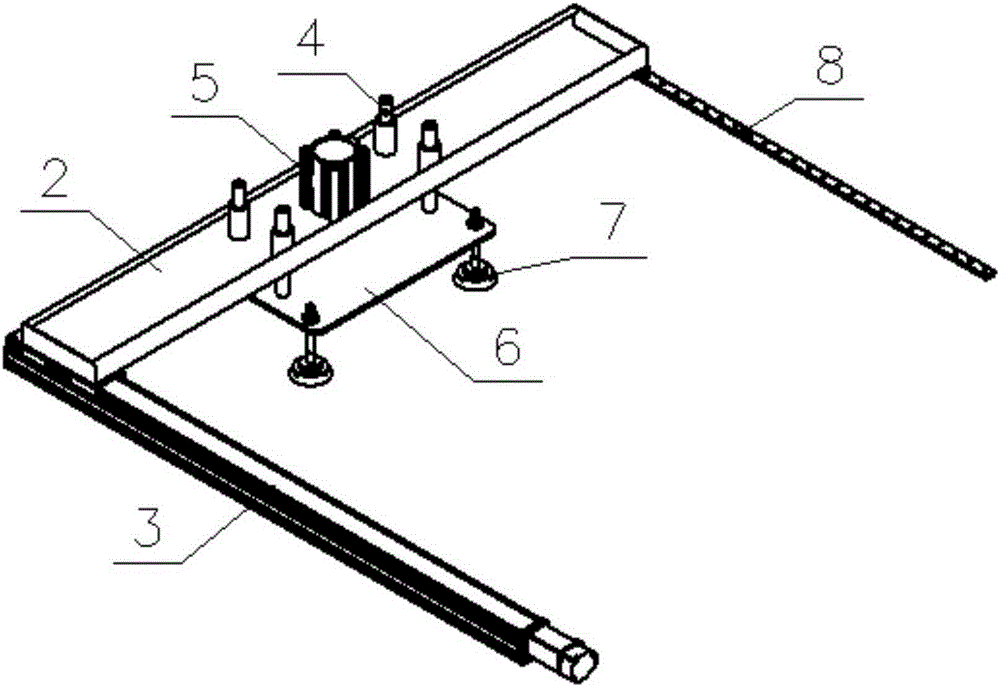

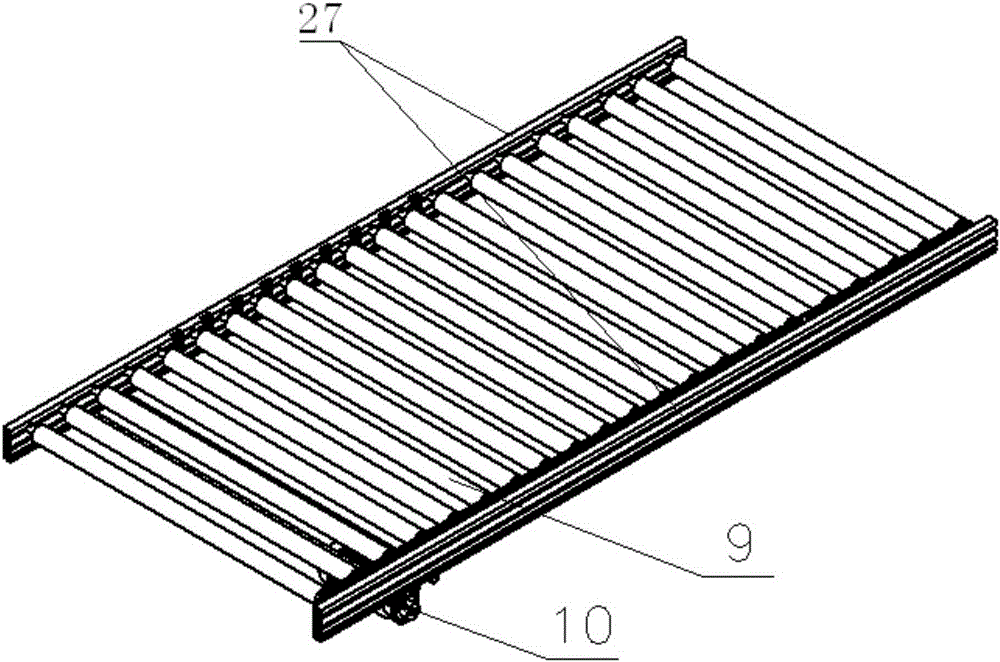

Full automatic wire cutting and peeling double-headed tin adhering machine and use method thereof

ActiveCN103692049ADouble-ended tinningRealize single-head tin dippingMetal working apparatusSolder feeding devicesElectricityWire cutting

The invention relates to the technical field of tin adhering equipment, in particular to a full automatic wire cutting and peeling double-headed tin adhering machine, comprising a machine case, wherein the machine case is provided with a controller, the machine case is provided with a first tin adhering mechanism, a wire cutting and peeling mechanism and a second tin adhering mechanism in sequence along the conveying direction of wires, the machine case is also provided with a reclaiming mechanism, the first tin adhering mechanism, the wire cutting and peeling mechanism, the second tin adhering mechanism and the reclaiming mechanism are respectively and electrically connected with the controller, and soldering flux grooves and tin water grooves are arranged below the first tin adhering mechanism and the second tin adhering mechanism respectively. The tin adhering machine is simple in structure and operation, easy to produce, low in production cost, high in tin adhering efficiency, high in tin adhering precision, good in tin adhering quality and high in economic benefit, and has functions of wire cutting, peeling, soldering flux adhering and tin adhering which are integrally completed.

Owner:黄雷

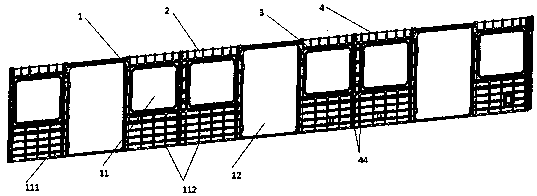

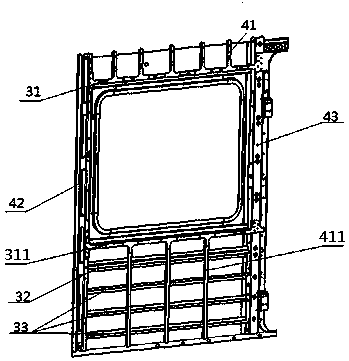

Novel stainless steel side wall structure and mounting method of novel stainless steel side wall

InactiveCN107901932AReduce welding processGuarantee the appearance qualityAxle-box lubricationRailway bodiesStructural engineeringEngineering

The invention provides a novel stainless steel side wall structure and a mounting method of a novel stainless steel side wall. The novel stainless steel side wall structure comprises a side wall skeleton. The side wall skeleton is formed by connecting a plurality of cross beams and a plurality of vertical columns in a mutually-crossing mode, and the cross beams and the vertical columns are fixed through mutual inserting; end vertical columns are arranged on the left and right sides of the side wall skeleton correspondingly; door vertical columns are arranged on the left and right sides of doorframes correspondingly; a window upper cross beam is arranged on the upper portion of each window frame, and a window lower cross beam is arranged on the lower portion of each window frame; a waist cross beam is arranged below each window lower cross beam; three lower cross beams are arranged below each waist cross beam; a window upper vertical column is connected to each window upper cross beam;skeleton connecting plates are welded inside the connecting positions of the window upper cross beams and the window upper vertical columns in the side wall skeleton; window lower vertical columns are connected among each window lower cross beam, the corresponding waist cross beam and the three corresponding lower cross beams; and skeleton connecting plates are welded inside the connecting positions of the window lower cross beams and the window lower vertical columns in the side wall skeleton. The cross beams and the vertical columns of the novel stainless steel side wall structure are fixedthrough mutual inserting connection, the deformation problem caused by welding of a skeleton is solved, the production cost is saved, and the assembly production efficiency is improved.

Owner:CRRC NANJING PUZHEN CO LTD

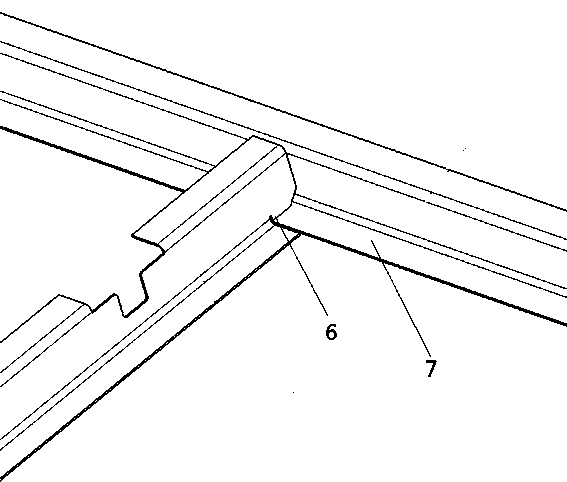

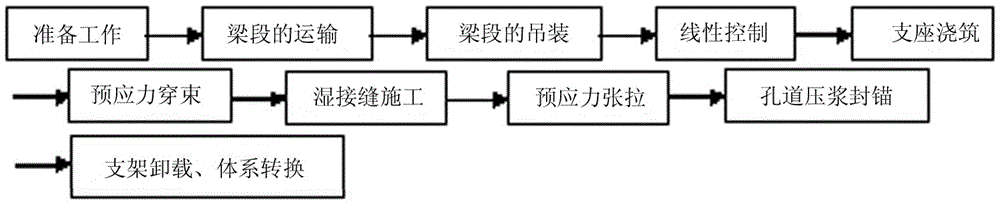

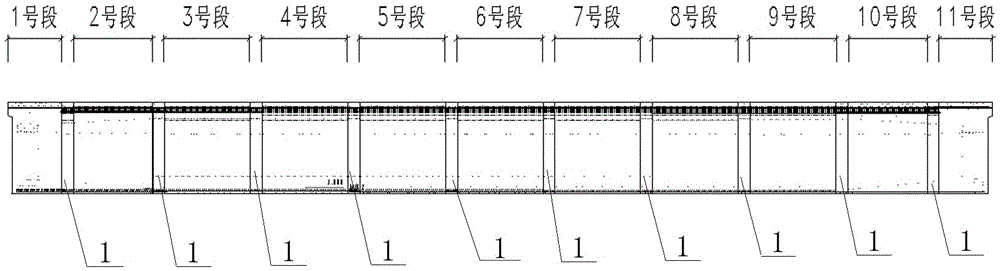

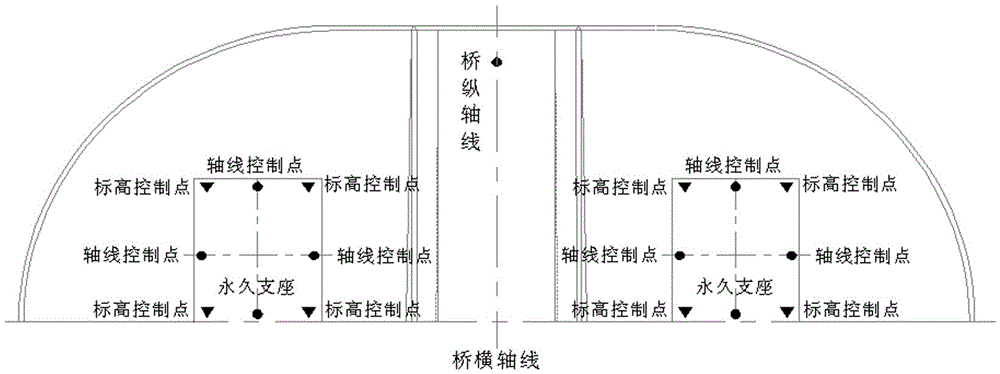

Construction method for 48m sectional beam of passenger railway based on BIM technology

InactiveCN105625188ACollision does not existImprove construction efficiencyBridge erection/assemblyPre stressPre stressing

The invention belongs to the technical field of sectional beam construction of railways, roads, municipal engineering and intercity rail transits. In order to solve the problems such as slow construction progress, high cost, difficulty-to-guarantee construction quality and the like of a large-span beam, the invention provides a construction method for a 48m sectional beam of passenger railway based on a BIM technology. The construction method is characterized being a construction process of dividing a beam body into a plurality of beam sections, and jointing each beam section into a bridge by applying pre-stress; the assembly construction process of the beam sections comprises prefabrication of beam sections, transportation and lifting of the beam sections, strand pulling by pre-stress, wed joint construction, pre-stress tensioning, duct grouting for sealing anchor as well as bracket unloading and system conversion; and each construction process is pre-simulated by adopting the BIM technology. Compared with the conventional construction method, the construction method can effectively guarantee that in a reinforcement binding process, reinforcement does not have collision and can effectively guarantee precision of a corrugated pipe reserved position and the like by utilizing functions such as three-dimensional modeling, visualization and the like of the BIM technology, and has the advantages of high construction efficiency, high construction precision, a short construction period, a high safety coefficient and the like.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

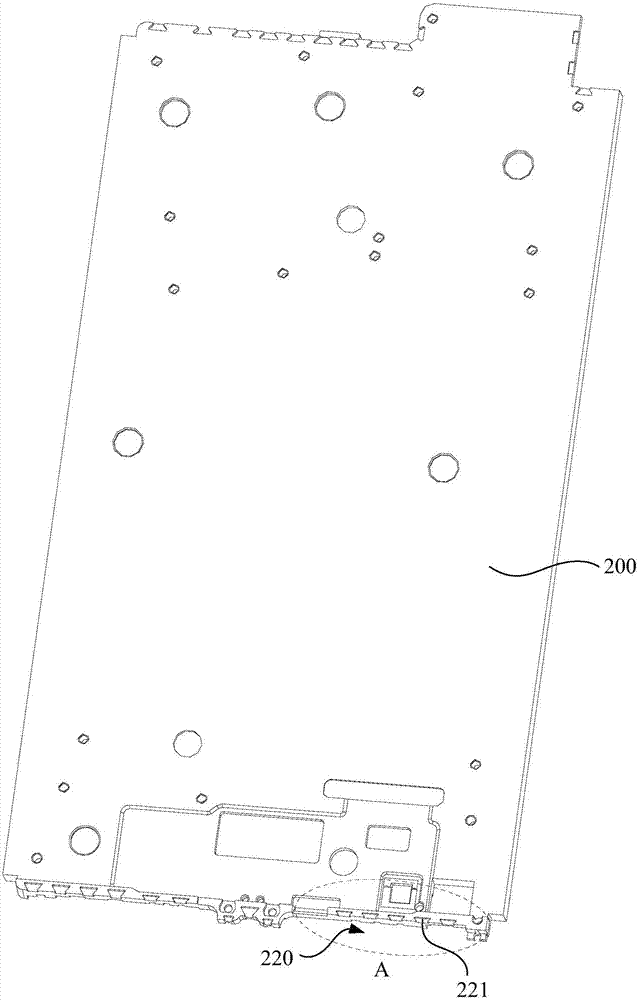

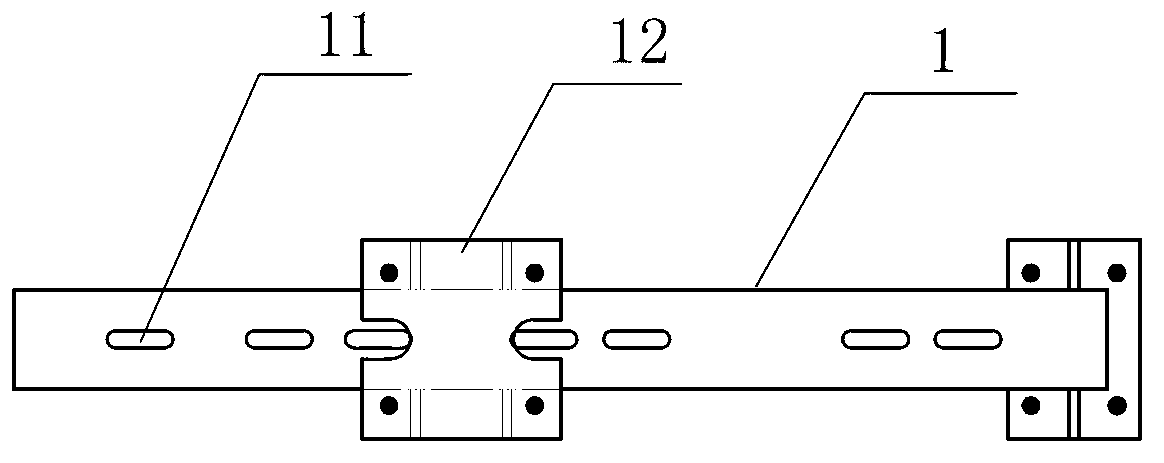

Metal middle frame processing technique, metal middle frame and electronic device

InactiveCN107087364ALow manufacturing costGuarantee the appearance qualityCasings/cabinets/drawers detailsDomestic articlesEngineeringMachining time

The invention relates to a metal middle frame processing technique, a metal middle frame and an electronic device with the metal middle frame. The metal middle frame comprises a middle plate, a frame and a rubber piece. The frame is arranged around the middle plate and is connected to the edge of the middle plate through overlapping welding. The rubber piece is moulded in a slit between the middle plate and the frame in an injection manner. The metal middle frame processing technique comprises following steps of through squeezing technique and CNC technique, processing and moulding the frame; using the die-casting technique to mould the middle plate; connecting the middle plate into the frame through the overlapping welding; injecting fused rubber in a slit between the middle plate and the frame; and carrying out cooling and surface processing on the moulded metal middle frame. In this way, stable and reliable connection between the middle plate and the frame is achieved; processing quantity of the CNC technique is reduced; processing time in the whole metal middle frame is reduced; manufacturing cost of the metal middle frame is reduced; and meanwhile, improving of surface processing quality of the metal middle frame is facilitated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

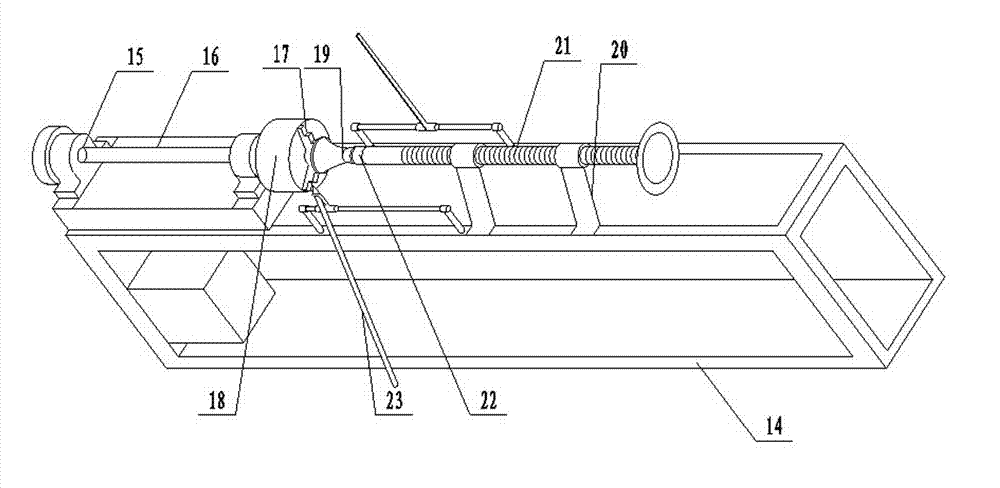

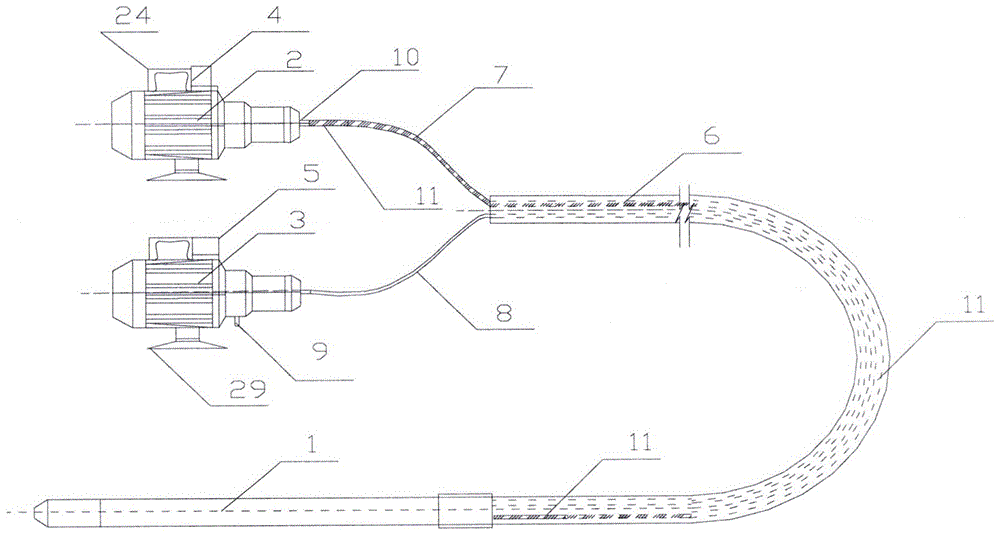

Insert type concrete vibrorammer combining vacuum air exhaust and water suction and principles thereof

ActiveCN105781114ASimple structureEasy to operateBuilding material handlingReinforced concreteCement paste

The invention discloses an insert type concrete vibrorammer combining vacuum air exhaust and water suction and principles thereof, and belongs to the technical field of construction engineering machines. The vibrorammer solves the problems that microbubbles and free water in concrete and bubbles attached to a template are difficult to eliminate through existing insert type vibrorammers by means of vibration waves, the number of bubbles on the surface of the concrete is large, the appearance quality of the concrete is poor, outside air and water invade steel from air holes in the surface of the concrete and rust the steel, and reinforced concrete component concrete protection layers fall off, so that the service life of structures and buildings is shortened, and the effects that set cement and cement paste in the concrete are forced to be more compact and the segregation phenomenon of the concrete in the vibration process is avoided are achieved. The strength of the concrete is improved, the bearing capacity of the structures and the buildings is improved, and the service life of reinforced concrete components is prolonged. An insert type concrete vibrorammer nanoscale micropore shell bar body connects a motor and a vacuum pump through double-pore-channel hoses into a system combining vibration, air exhaust and water suction.

Owner:刘思广

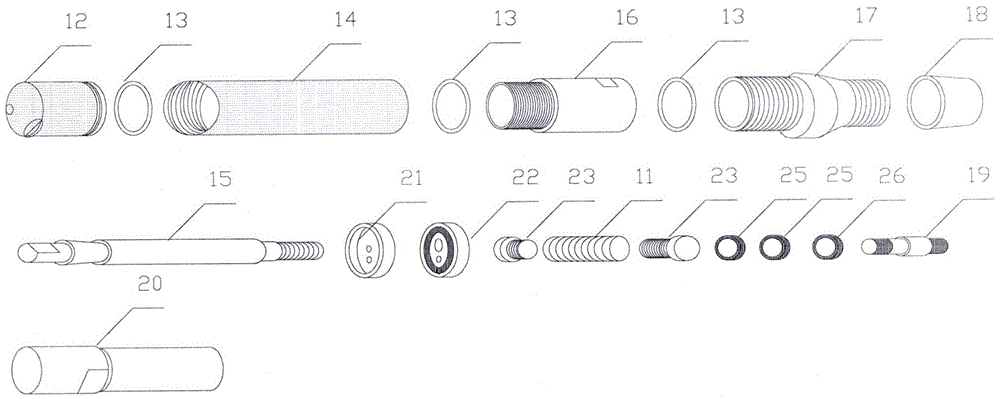

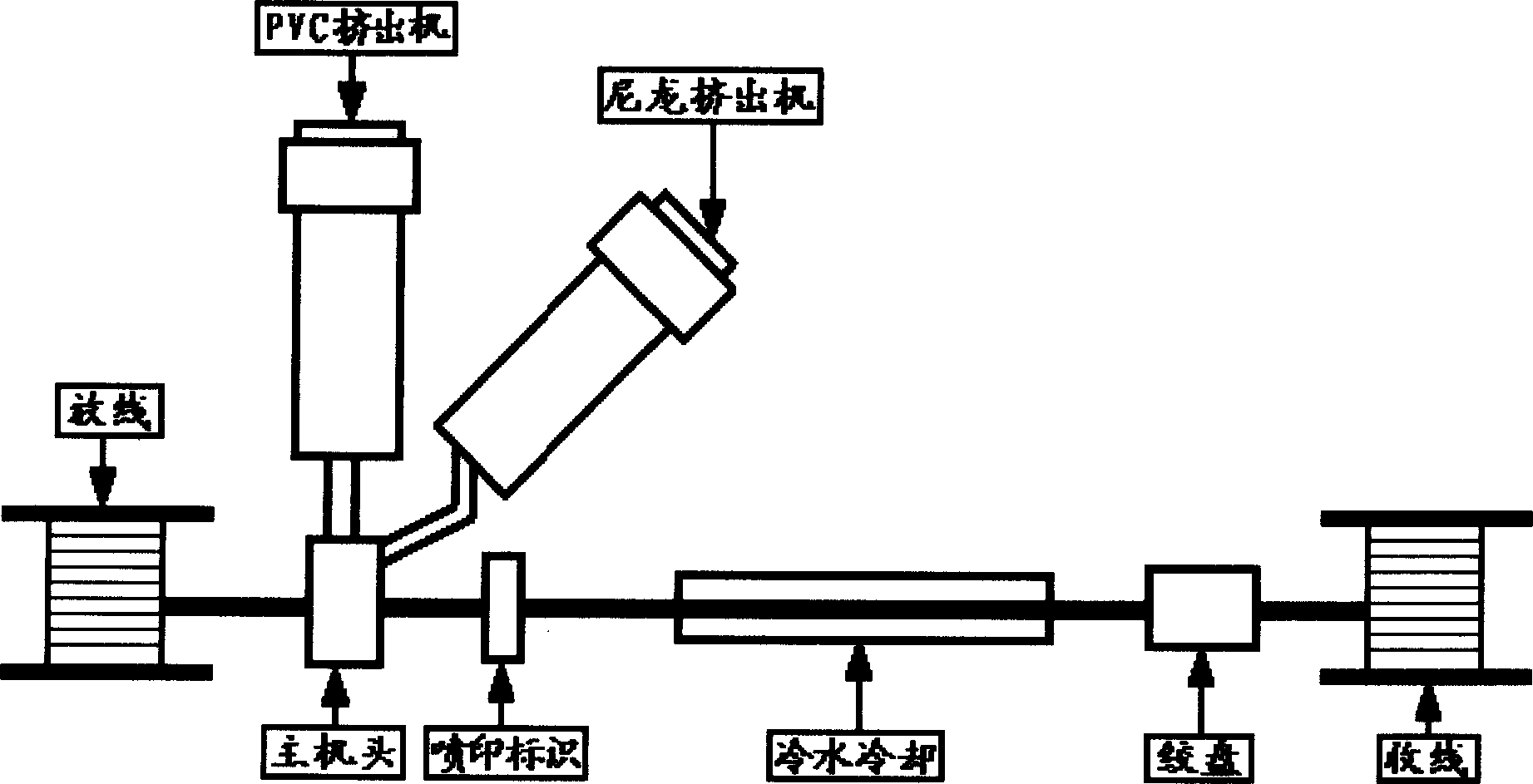

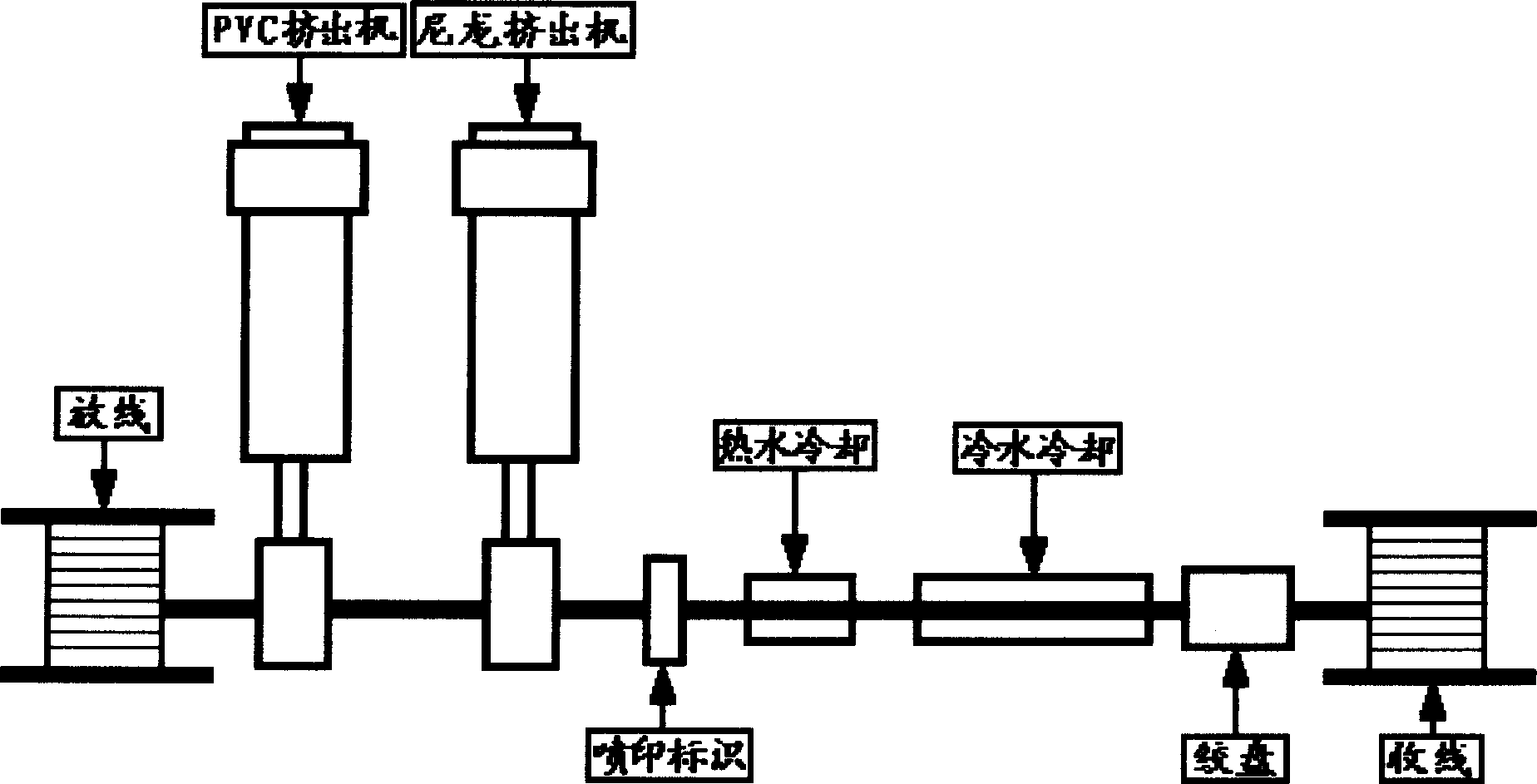

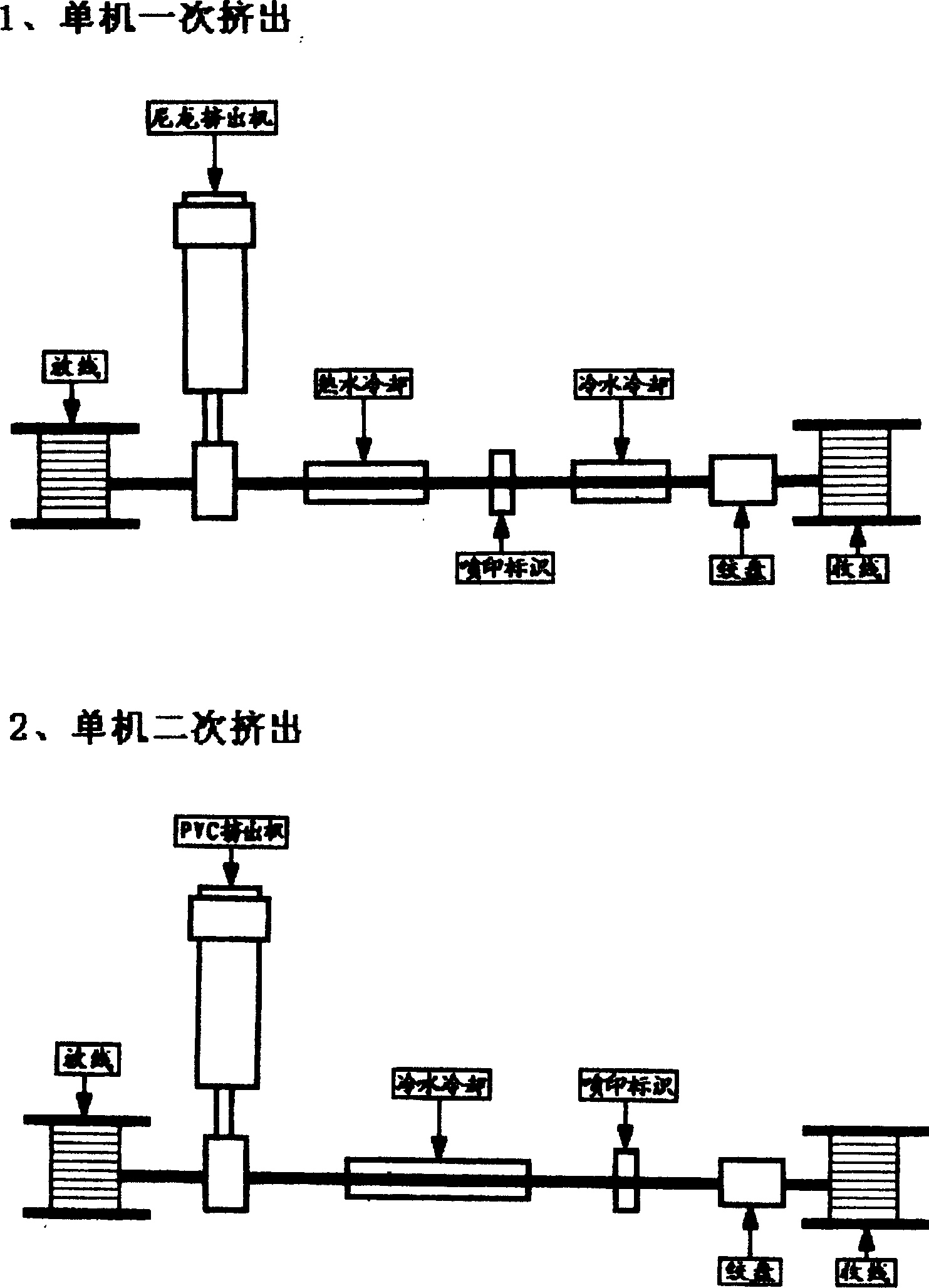

Technology for producing PVC insulated nylon flexible wire using double machine extruding method

InactiveCN1595547AAccelerated agingAvoid stayingInsulated cablesCable/conductor manufactureProduction linePolyvinyl chloride

Disclosed is a technique using dual-machine extrusion method to produce polyvinyl chloride insulating nylon jacket electric wire. Make nylon and polyvinyl chloride separately melt by nylon extruding machine and PVC extruding machine, which are separately injected into different ingates and channels of shunt in prime machinery head, firstly polyvinyl chloride is extruded and then nylon to form tightly connected insulating layer of polyvinyl chloride and nylon jacket layer covered on it. Polyvinyl chloride insulating nylon jacket electric wire is formed through word sprinkling, cooling and taking up of capstan. It has the advantages of increased smoothness and mechanical performance of electric wire surface, simplified technique, shortened production line, prolonged wire service life and excellent safety and reliability.

Owner:湖北红旗电缆有限责任公司

Metal middle frame processing process, metal middle frame and electronic device

InactiveCN106973536ALow manufacturing costGuarantee the appearance qualityCasings/cabinets/drawers detailsDomestic articlesEngineeringMachining time

The invention relates to a metal middle frame, a metal middle frame processing process and an electronic device provided with the metal middle frame. The metal middle frame comprises a middle plate, a border arranged around the middle plate and connected with the edge of the middle plate through butt welding, and a plastic piece in the gap between the middle plate and the border through injection molding. The metal middle frame processing process comprises the following steps: the border is processed and formed through an extrusion process and a CNC process; a die casting process is adopted to form the middle plate; the middle plate is connected in the border through butt welding; the melted plastic is injected to the gap between the middle plate and the border; and after cooling, the formed metal middle frame is subjected to surface processing. Thus, stable and reliable connection between the middle plate and the border can be realized, the processing amount of the CNC process can be saved, the whole metal middle frame processing time is reduced, and the metal middle frame manufacturing cost is further reduced and besides, the metal middle frame surface processing quality is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Flexible assembly technology of low-voltage motor and assembly line thereof

ActiveCN101951082AEasy to assemblePlay a transitional roleManufacturing dynamo-electric machinesLow voltageEngineering

The invention discloses a flexible assembly technology of a low voltage motor and an assembly line thereof. The assembly process comprises the following steps in sequence: a stator enters an assembly area from the top line of a piece feeding area to start motor assembly, and then enters a pretreatment area from the underline of a primary underline area; the appearance of the motor is subjected to fine treatment in the pretreatment area; the motor enters a primary painting area to paint and dry an end cover from the top line of a primary top line area, and then a fan and an end shield are assembled on line; the motor enters an experimental area from the underline of a secondary underline area; a motor experiment is carried out in a test area, and then the motor enters a perfect area after test permission to be perfectly assembled in the perfect area; the motor enters a secondary painting area to be painted and dried from the top line of a secondary top line area, and then is packaged at the underline of a package area; and after packaging, the motor enters a finished motor storage area to be stored. The time and beat of each assembly link can be flexibly regulated and controlled so as to realize flexible assembly, thus not only reserving the advantage of the assembly line facilitating line production but also meeting the production requirements of various species, small batch and multiple specifications.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

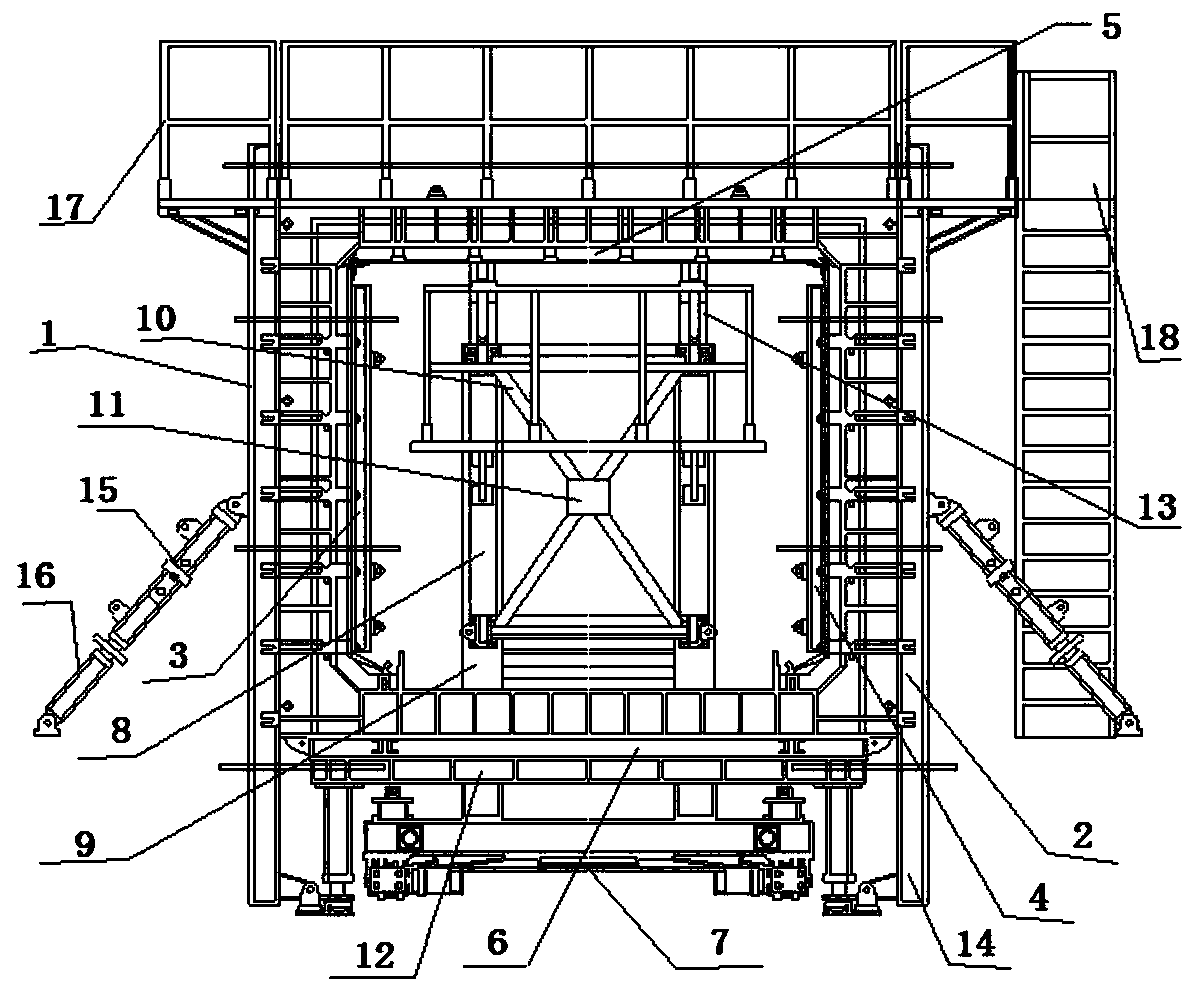

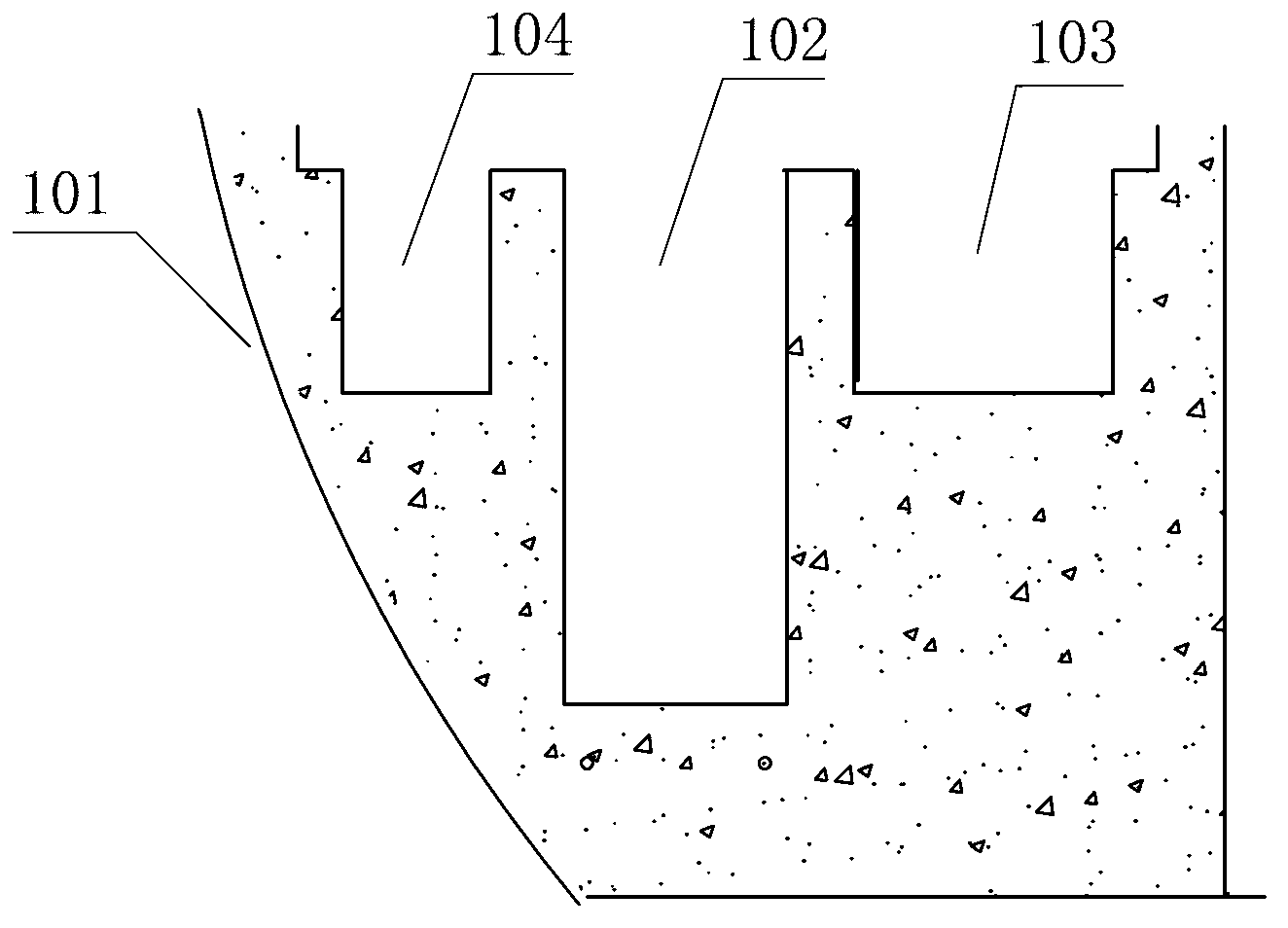

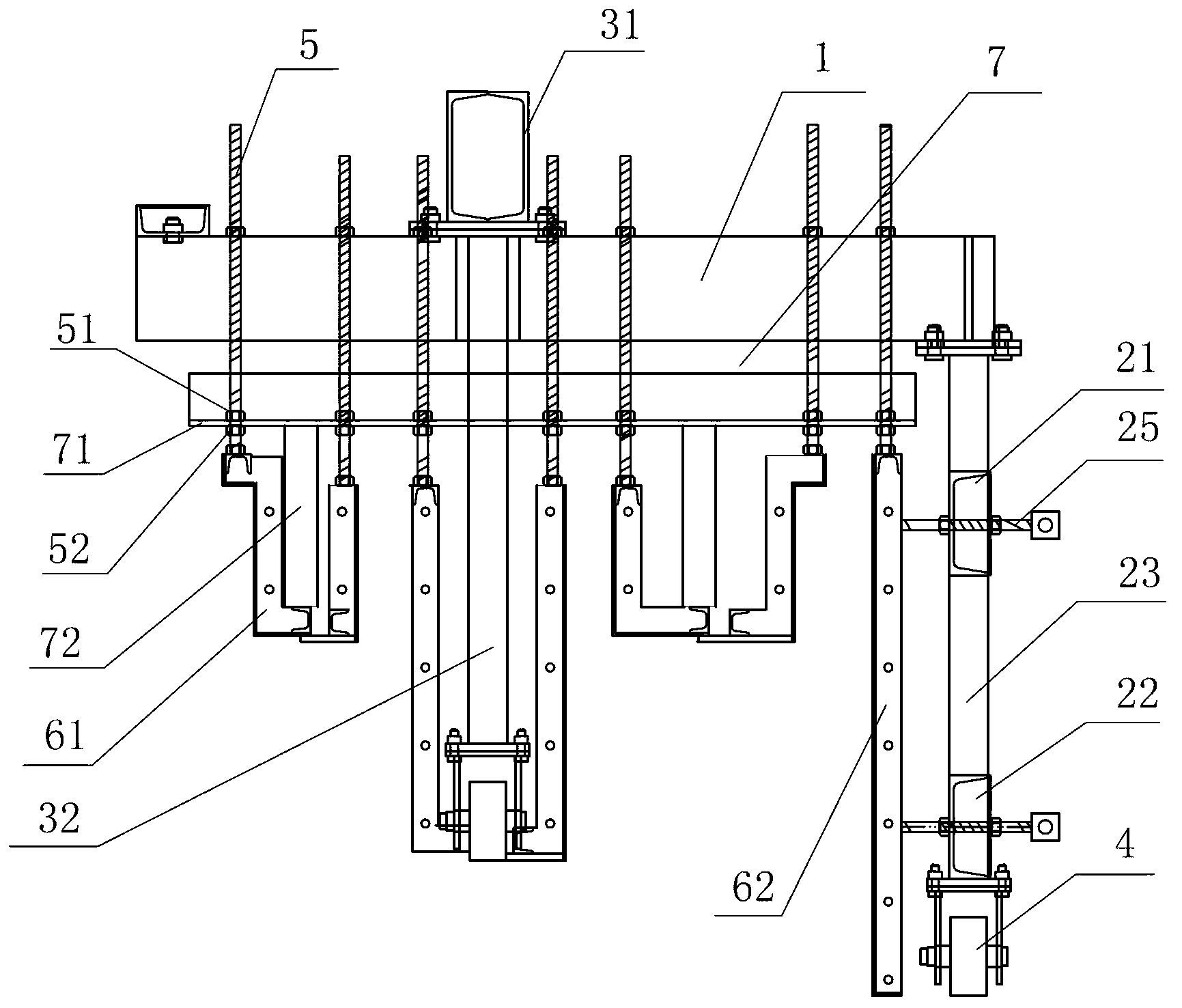

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

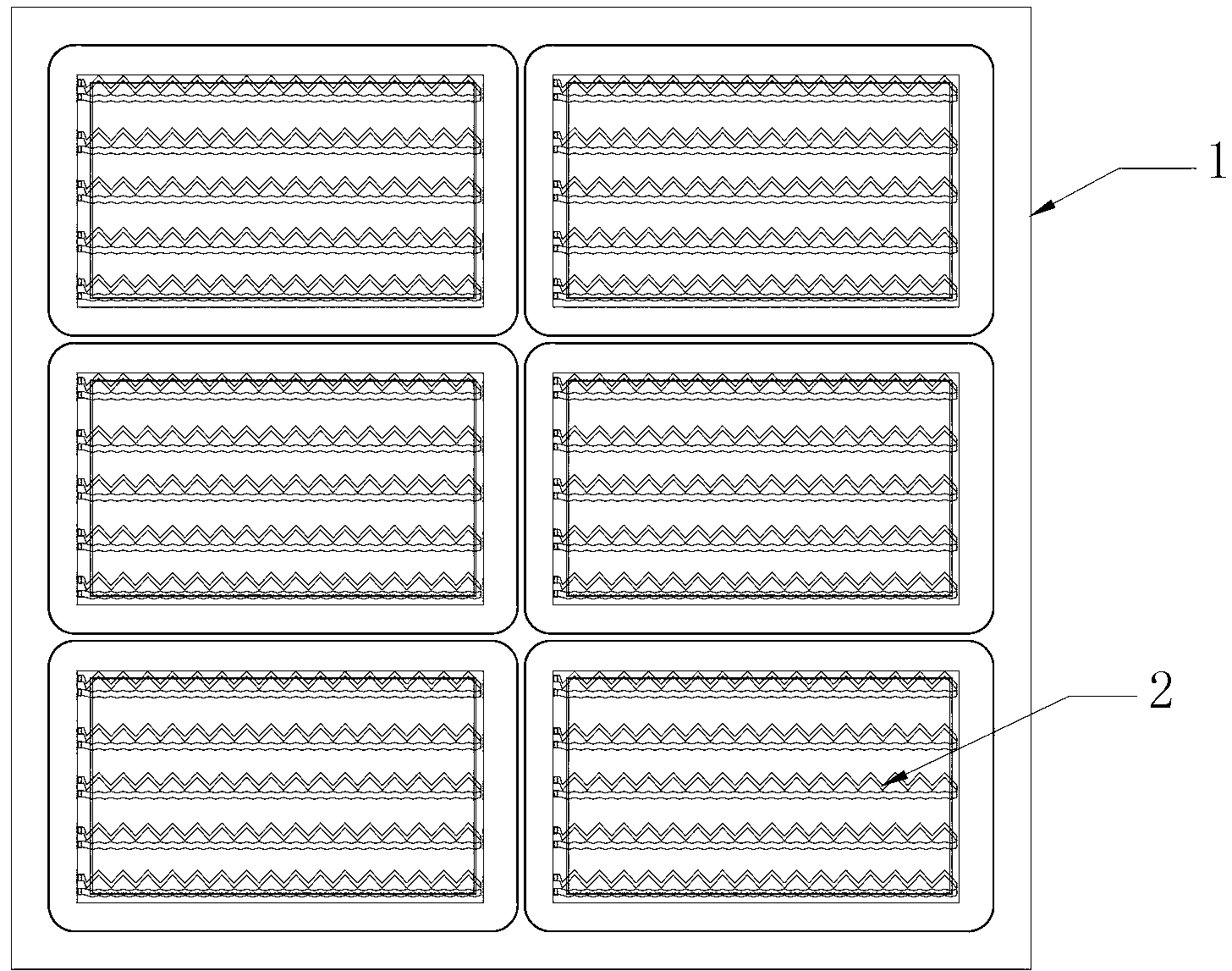

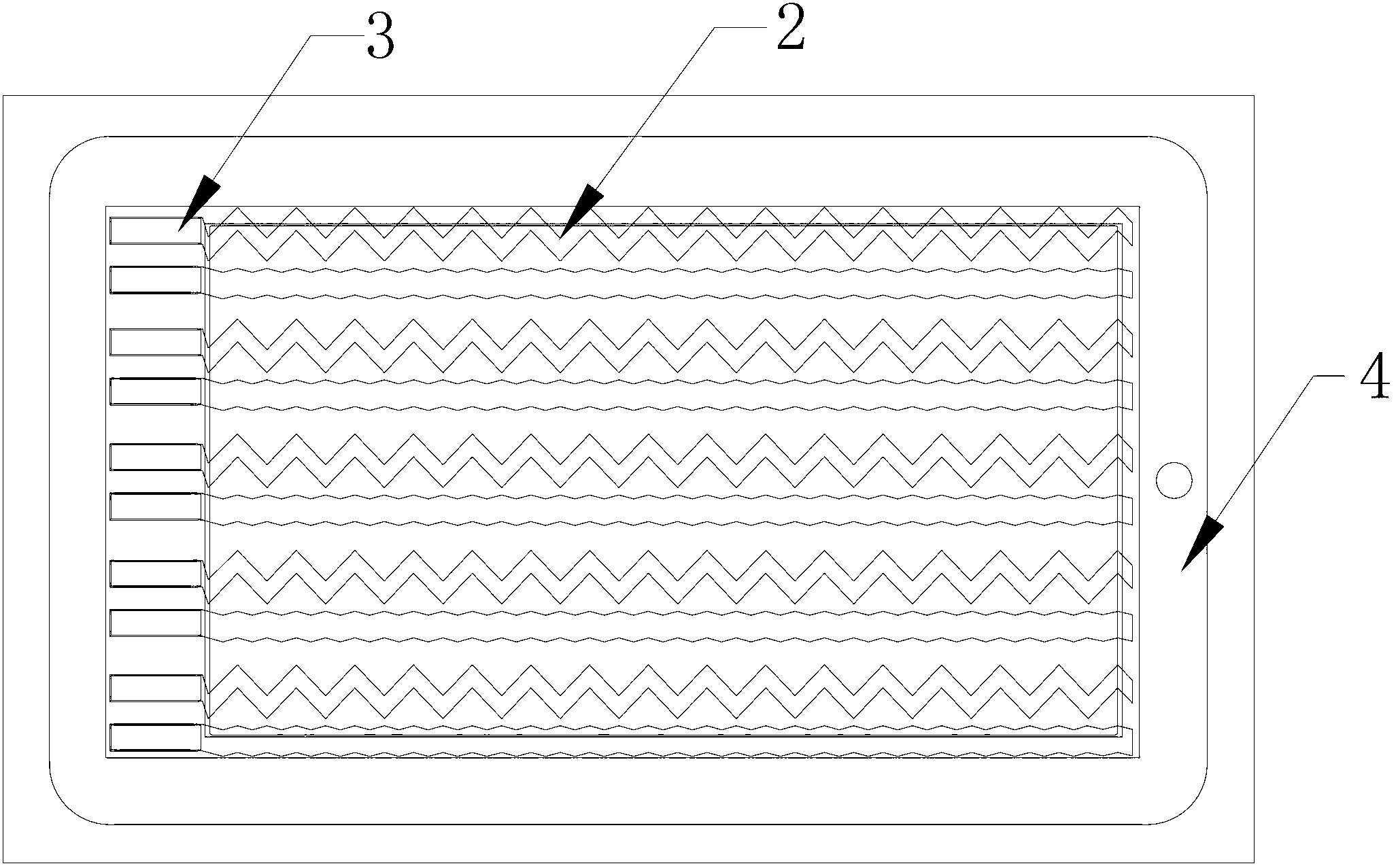

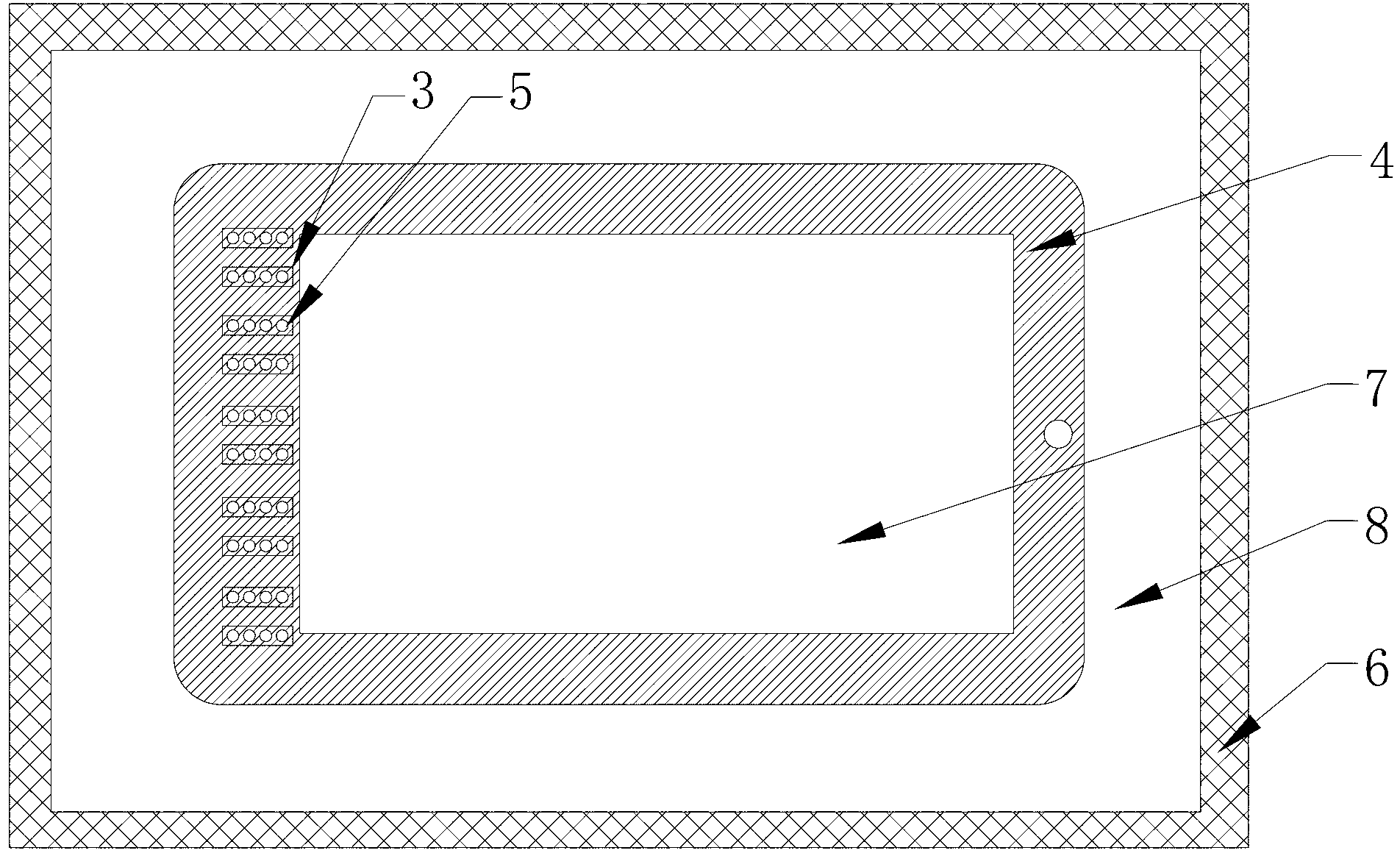

OGS (one glass solution) capacitive touch screen and method for manufacturing same

InactiveCN103294313ASufficient and secure connection conductionMeet the appearance qualityInput/output processes for data processingSilver pasteScreen printing

The invention discloses an OGS (one glass solution) capacitive touch screen and a method for manufacturing the same. The method for manufacturing the OGS capacitive touch screen includes chemically strengthening the surfaces of a glass substrate, and then coating a transparent conducting film layer on one surface of the glass substrate; etching a circuit on the transparent conducting film layer to obtain a conducting glass substrate with distributed conducting film layer patterns; performing screen printing on positions, except for small conducting holes, of a frame by insulating printing ink, curing the printing ink and forming a black insulating film layer; performing screen printing on the small conducting holes by conducting printing ink and nano-silver paste; adhering the nano-silver paste with a flexible printed circuit to obtain the touch screen. The frame is arranged on the surface, which is coated with the transparent conducting film layer, of the glass substrate. A viewing area is arranged inside the frame. The OGS capacitive touch screen and the method have the advantages that requirements on the appearance quality (namely, coloring of the frame of the touch screen) and the functional quality (in other words, edge electrodes of the touch screen are sufficiently and firmly connected and conducted with the flexible printed circuit) of the OGS capacitive touch screen can be met simultaneously, the bonding strength of the small conducting holes and the flexible printed circuit is improved, accordingly, the conductivity of the OGS capacitive touch screen is improved, the product yield is increased, and the production cost is reduced.

Owner:城步新鼎盛电子科技有限公司

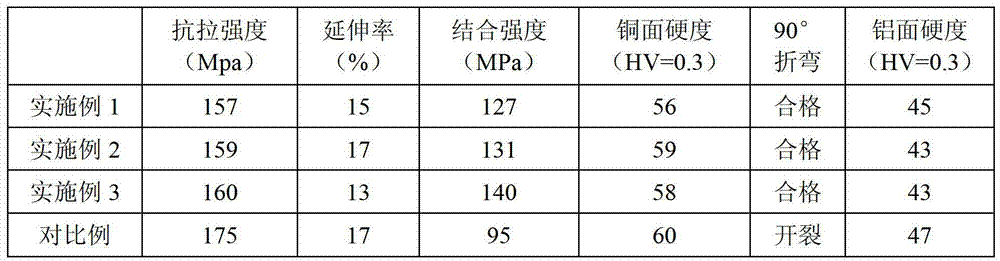

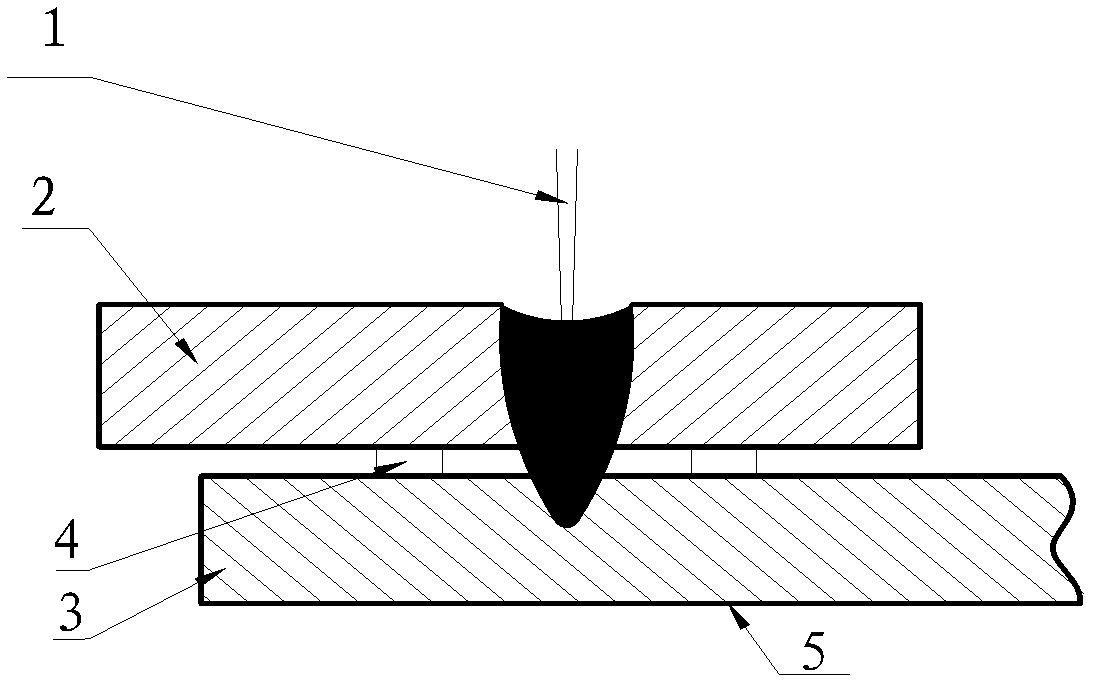

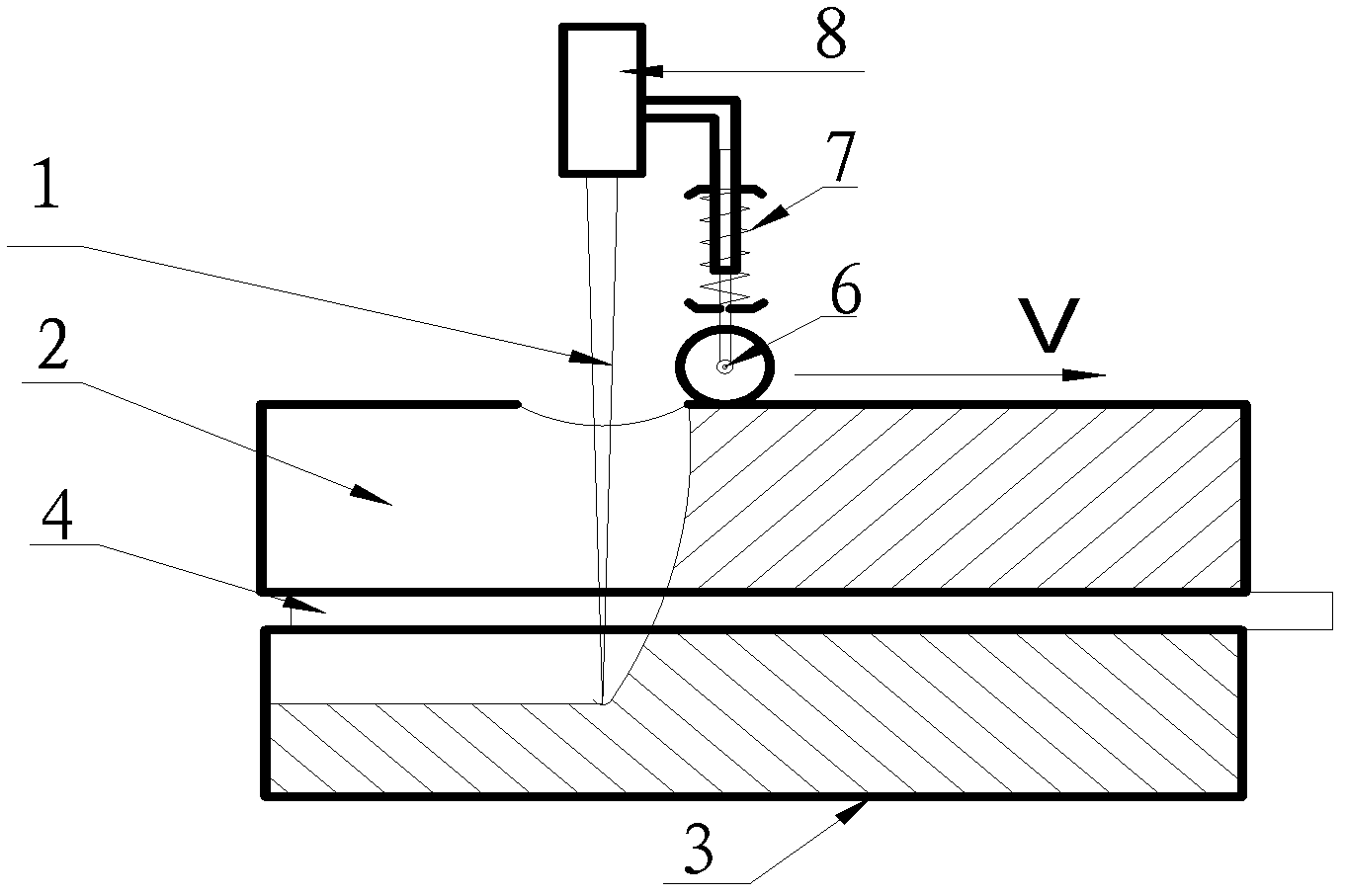

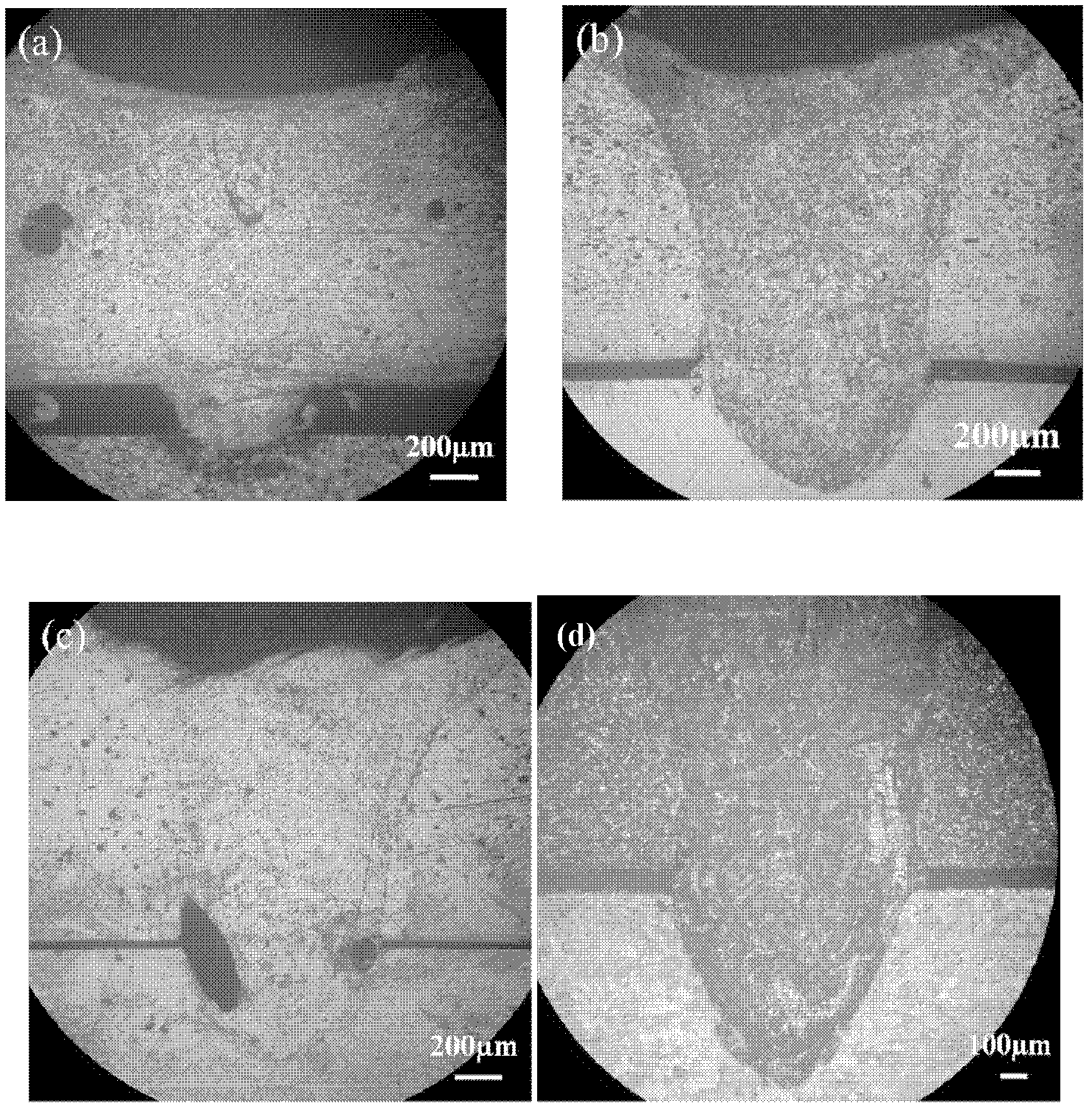

Aluminum substrate layer material of copper-aluminum composite metal strip, strip and machining method thereof

ActiveCN103029377AEasy to controlSuppress exceptionTension/compression control deviceMetal rolling arrangementsMetal stripsAluminum substrate

The invention discloses an aluminum substrate layer material of a copper-aluminum composite metal strip, a strip and a machining method of the strip. According to the invention, the aluminum substrate layer material of the copper-aluminum composite metal strip is formed by adding the elements of Si, Fe, Cu, Mn and Ti into an aluminum substrate layer material, so that the machining property of an aluminum substrate layer is improved effectively, the machinability of the aluminum substrate layer can accord with that of a copper covering layer. According to the invention, a copper covering layer material with the shop sign of TU2 and the state of TM is adopted by the copper-aluminum composite metal strip as the copper covering layer, so that the machining property of the aluminum substrate layer can further accord with that of the copper covering layer. The strip adopts multi-pass rolling, reduces single-pass machining rate, and adopts sectional type annealing, so that the reliability of annealing is improved, and the abnormality of copper and aluminum caused by the difference of properties is restrained. The copper-aluminum composite metal strip manufactured through the machining method has the advantages that the bonding strength is high, and the strip cannot easily crack because of bend.

Owner:LUOYANG TONGYI METAL MATERIAL DEV

Production technology of double-sided PCB

ActiveCN105555046AThe mass concentration is reasonableImprove air tightnessConductive material chemical/electrolytical removalCircuit precursor manufactureResistMetallurgy

The invention relates to the technical field of PCBs, in particular to a production technology of a double-sided PCB. The technology sequentially comprises the following steps: double-sided copper foil substrate pretreatment, line coating and exposure treatment, line development, etching, de-inking treatment, solder resist pretreatment, solder resist development, lettering treatment, molding treatment, testing and antioxidant treatment. A copper foil substrate is subjected to surface polish-brush treatment through a polish-brush; a photosensitive ink layer and a solder resist ink layer coat the surface of the copper foil substrate; relatively high adsorption force is provided among the photosensitive ink layer, the solder resist ink layer and the copper foil substrate; the photosensitive ink layer and the solder resist ink layer are good in quality; and the produced PCB is good in quality. Cutting treatment is carried out on the copper foil substrate by a V-Cut technology; and the minimum thickness of the formed substrate corresponding to a V-shaped plate-dividing groove is controlled at 0.4-0.5mm, so that subsequent plate division is facilitated; and no burr is left.

Owner:湖北碧辰科技股份有限公司 +1

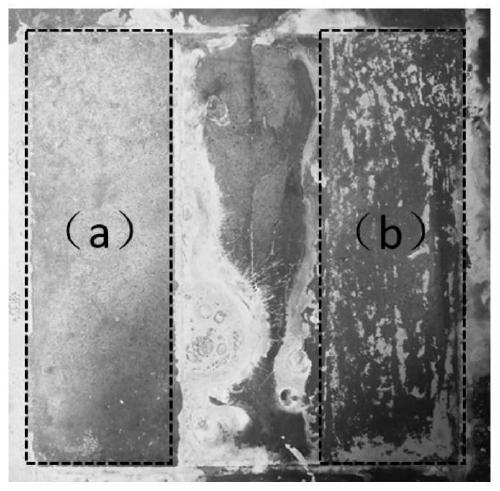

Single-surface traceless welding method for stainless steel composite panel of elevator

ActiveCN102248297AHigh strengthGuarantee the appearance qualityLaser beam welding apparatusSheet steelShielding gas

The invention discloses a single-surface traceless welding method for a stainless steel composite panel of an elevator, comprising the following steps of: (1) eliminating oil stains on respective surfaces to be welded of a cold (hot) rolled steel plate and a stainless steel surface plate; (2) placing the stainless steel surface plate on a work table, respectively placing a separation bar at two sides of a position to be welded and 5-10 mm away from the position to be welded, and then placing the cold (hot) rolled steel plate on the separation bar so that a gap of 0.08-0.12mm is reserved between the cold (hot) rolled steel plate and the stainless steel surface plate; (3) carrying out laser welding on the cold (hot) rolled steel plate and the stainless steel surface plate with a mixed gas of oxygen gas and inert gas as a protective gas to ensure that a welding seam penetrates through the cold (hot) rolled steel plate and the depth of the welding seam on the stainless steel surface plate is controlled to be 1 / 3-1 / 2 of the thickness of the stainless steel surface plate; and ensuring that the stainless steel surface plate, the cold (hot) rolled steel plate and the separation bar are clamped tightly in a welding process. The method provided by the invention has the characteristics of no trace on a single stainless steel panel surface, high welding seam quality and high strength of a combination structure.

Owner:ZHEJIANG UNIV OF TECH +1

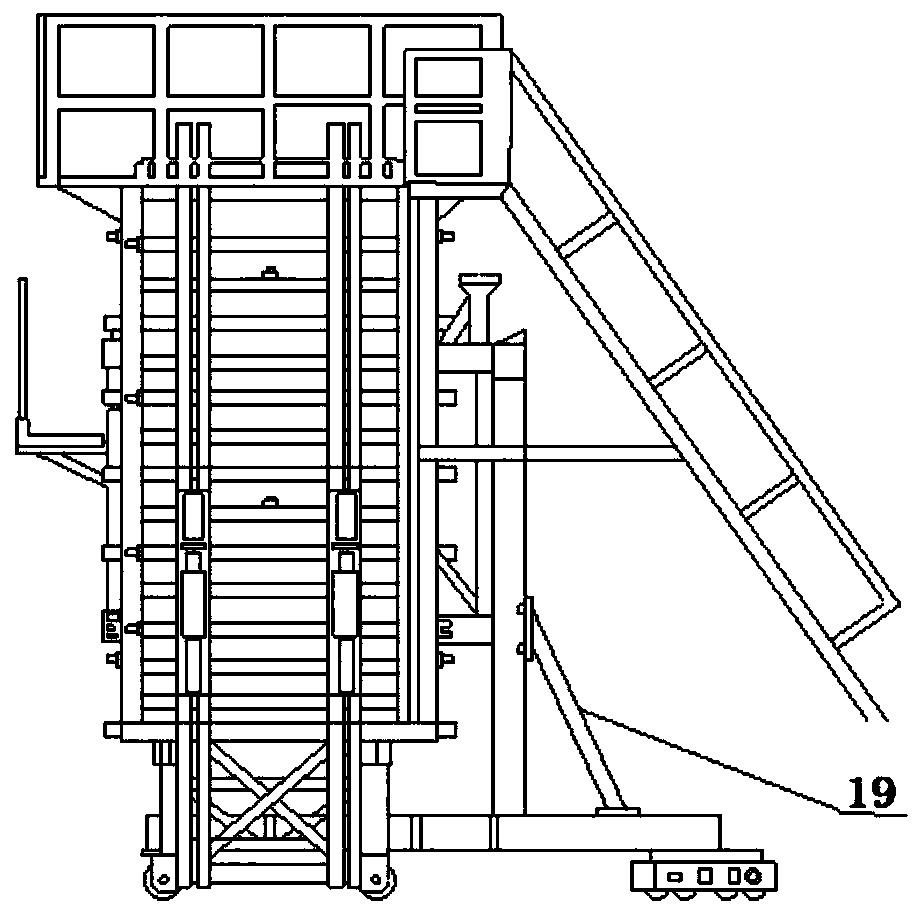

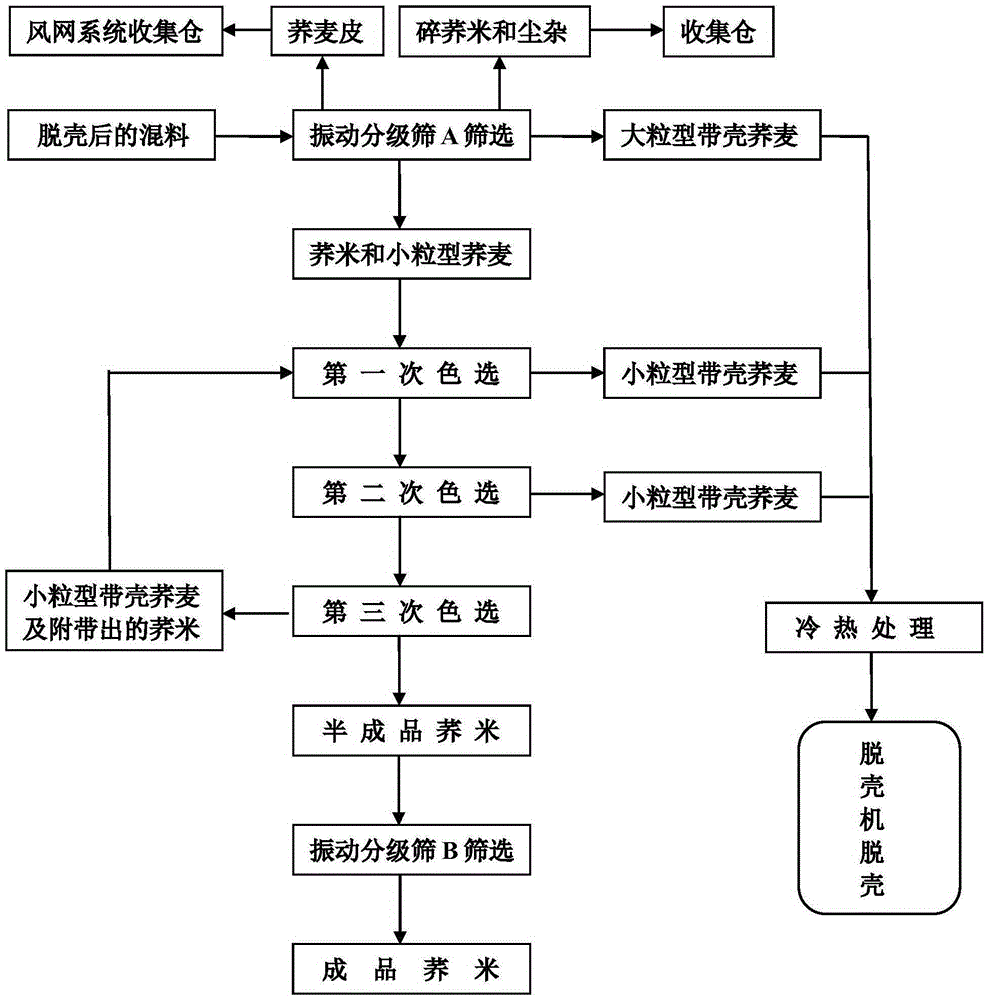

Material grain separation technology used after shelling shells during processing of buckwheat

InactiveCN105414028AFacilitate strippingSecond shelling is convenientSievingGas current separationHuskSeparation technology

The invention discloses a material grain separation technology used after shelling shells during processing of buckwheat. The technology comprises the steps that 1, after the shells of the buckwheat are separated, a mixed material containing a small part of buckwheat husks, buckwheat grains and the buckwheat with the shells is screened through a vibration grading screen at first, oversize products on lower layer screen cloth enter a color sorter through an elevator and the colors of the oversize products are sorted and separated, color sorting is conducted three times sequentially, separated semi-finished buckwheat grains are screened and graded through the vibration grading screen, and high-quality finished buckwheat grains are obtained; 2, small-grain-type buckwheat with the colors being sorted for the first time and the second time is uniformly mixed with large-grain-type buckwheat intercepted by upper layer screen cloth, wherein the small-grain-type buckwheat and the large-grain-type buckwheat are provided with the shells, and after cooling-heating treatment is conducted, the buckwheat enters a huller in batches for secondary shelling; and 3, the final material grain separation rate reaches 99.9%, the secondary shelling rate reaches 95%, the purity of the buckwheat grains can reach 99.9%, the imperfect grain mass is 1% or less, impurities account for 0.10% or less, broken grains account for 1% or less, the surface of the buckwheat is bright and clean, and the buckwheat has obvious buckwheat fragrance. The purpose of large-scale material grain separation with high quality, high efficiency and high yield is achieved for the buckwheat grains with the shells being separated.

Owner:NINGXIA JIADAO HALAL FOOD

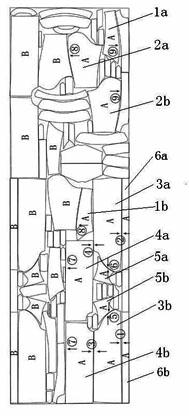

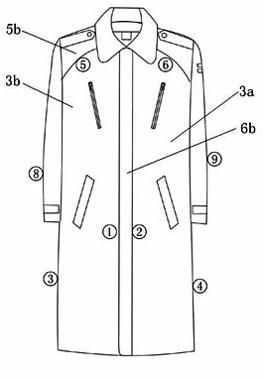

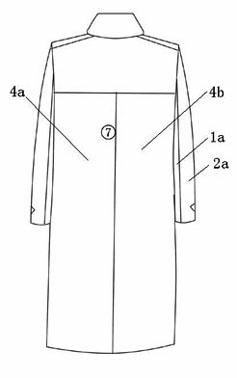

Garment layout tailoring method

The invention relates to a garment layout tailoring method. The method comprises the following steps of laying out according to the size of the fabric and the specifications of each pieces of cloth of the ready-made garment and by utilizing garment CAD software; printing layout drawing into a slab; placing the slab on the placed fabric; tailoring according to the slab; and placing the exposed obvious combined part on warps as same as or similar to the fabric during layout. The layout is optimized, so that the exposed obvious combined part is positioned on the warps as same as the fabric or near the warp direction, the defect caused by the color difference of the fabric is overcome, the color difference of the combined part of the two pieces of cloth is reduced and eliminated, the impression of the ready-made garment is improved, and the grade of the garment product is improved. The method is applicable to effective utilization of the degraded fabric caused by printing and dyeing color difference. By adopting the method, the economic loss of enterprises caused by the dyeing quality is reduced and the economic benefit is increased.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

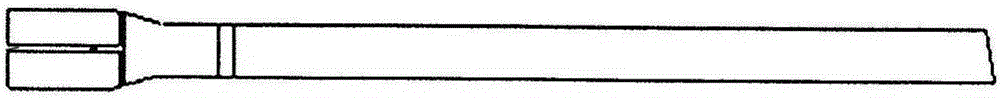

Tool and production method for producing variable cross-section type I-shaped composite part

The invention relate to a tool and production method for producing a variable cross-section type I-shaped composite part. According to the technical scheme, the tool is composed of an upper male die, a lower male die, a middle spacer plate and composite even pressing plates on the two sides. The production method comprises the steps that firstly, the composite even pressing plates are made; then, carbon fiber prepregs cut into fixed sizes are laid on a forming tool; finally all parts of the carbon fiber prepregs laid well are transferred from the forming tool to an assembly solidification tool for integral assembly, and packaged in a vacuum bag; the fully sealed prepreg blank is subjected to solidification forming under the conditions of 120-180 DEG C and 0.3-0.8 mpa for 1-3 hours; and after cooling, the composite even pressing plates, the middle spacer plate, the upper male die and the lower male die are detached to obtain the variable cross-section type I-shaped composite part. According to the production process, the pressure transmission efficiency of the part in the solidification process can be improved; generation of the structure defect of the part is reduced; the shape and the internal quality of the part are ensured.

Owner:SHENYANG AIRCRAFT CORP

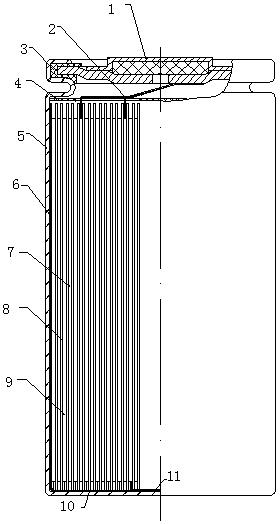

Nickel-zinc secondary seal cylindrical alkaline battery with shell as cathode and manufacturing method for nickel-zinc secondary seal cylindrical alkaline battery

InactiveCN102664242AExtend your lifeImprove performanceElectrode carriers/collectorsCell component detailsNickel zincMaterials science

The invention discloses a nickel-zinc secondary seal cylindrical alkaline battery with a shell as a cathode. The battery comprises a battery shell, a nickel plated cover, tin and copper plated tab anode plates, diaphragms, nickel plated tab cathode plates and a protective film, and is characterized in that the battery shell is the nickel-plated steel shell; each anode plate is prepared by coating an anode material on a tin-plated brass screen; each anode plate trough is formed by removing the anode material from the anode plate; an tin-plated copper tab which is arranged in each anode plate trough is welded with each tin-plated brass screen; the surface and the other side of each tin-plated copper tab positioned in each anode plate trough are pasted with an anode alkali-resisting tape; an anode tin-plated copper gasket, the tin-plated copper tabs and the bottom of the battery shell are sequentially welded; the cathode plates are welded with 1 to 3 nickel tabs; the surface and the other side of each nickel tab positioned in each cathode plate trough or rib with the nickel tab cathode plate are pasted with a cathode alkali-resisting tape; and the nickel tabs are welded with the nickel-plated cover. The invention also provides a method for manufacturing the battery. The battery has the advantages of rational structure, good electrical property, long service life and the like.

Owner:JILIN ZHUOER TECH

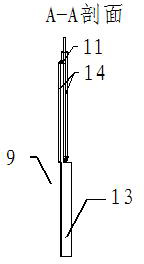

Corn straw particle board and manufacturing method thereof

The invention belongs to the category of cropper straw wood based panel. A maize straw grain plate comprises maize straw broken material and isocyanate adhesive. The invention is characterized in that the maize straw broken material is the grain of the skin of the marrow-removed maize straw; the weight percentage of the grain composition can be seen in the table; the content of the isocyanate is 3.2% to 3.7% times of the weight of the maize straw broken material. The manufacturing method of the maize straw grain plate is that the skin and marrow of the maize straw are removed; the peeled skin of the maize straw is cut off, crushed, screened, glued, paved, pre-pressed, hot pressed under the temperature ranging from 170 DEG C to 175 DEG C and edge cut. The invention solves the technical problems of improving the strength of maize straw crushed grain plate, simplifying gluing and glue mixing process, raising hot pressing temperature and shortening hot pressing time.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Pore-free tire segmental mould and pattern block thereof

ActiveCN104626409AGood exhaust performanceGuarantee the appearance qualityTyresEngineeringRubber material

The invention provides a pore-free tire segmental mould and a pattern block thereof. The pattern block comprises a plurality of pattern pieces and a pattern piece shell, wherein the pattern pieces are circumferentially arranged and assembled to form an annular structure capable of accommodating a rubber blank for tire molding, and the pattern piece shell sleeves the outer side of the annular structure; exhaust ducts are arranged inside the annular structure and are communicated with the inner side and the outer side of the annular structure, and each exhaust duct comprises an exhaust gap which is positioned between every two adjacent pattern pieces, is arranged along the axial direction of the annular structure, and is capable of preventing the rubber blank from overflowing the annular structure; the exhaust gap is close to the inner side of the annular structure. The mould provided by the invention comprises the pattern block. The pore-free tire segmental mould and the pattern block thereof provided by the invention have a good exhaust performance, and the effects of only exhausting and no rubber leaking are achieved, so that the tread of the finally molded tire has no rubber hair, the appearance quality of the tire is ensured, the unnecessary waste of a rubber material is avoided, and the production cost is ensured.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

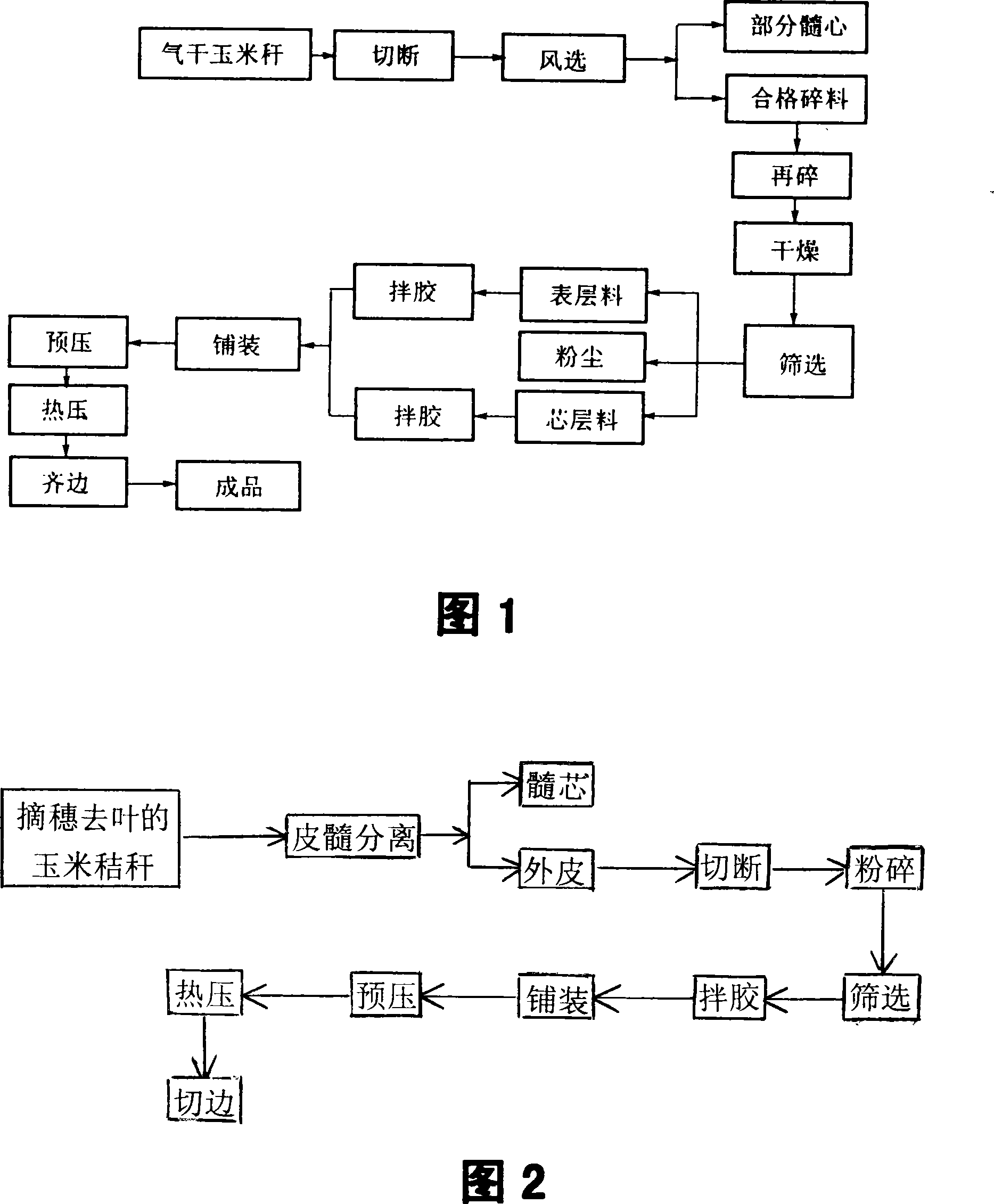

Integrated quick moving formwork for tunnel multi-longitudinal cable trough construction

InactiveCN103266900AImprove integrityGuarantee the appearance qualityUnderground chambersTunnel liningEngineeringBuilding construction

Owner:ROAD & BRIDGE INT +1

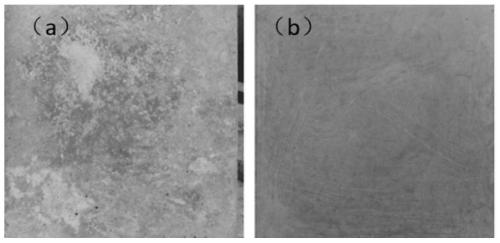

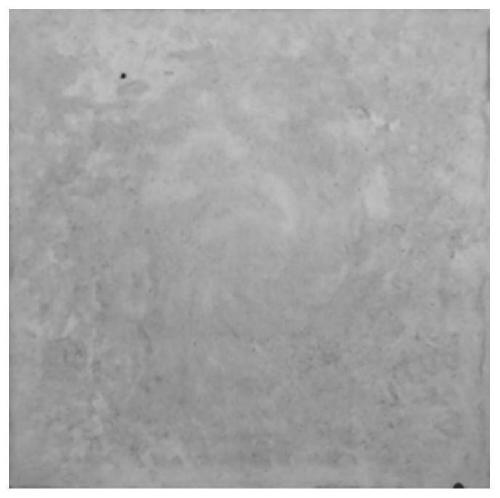

Environment-friendly release agent for fair-faced concrete and preparation method thereof

InactiveCN111394165ALow viscosityLow spread uniformityCeramic shaping apparatusLubricant compositionPhysical chemistryEnvironmental engineering

The invention discloses an environment-friendly release agent for fair-faced concrete and a preparation method thereof. The release agent is prepared from the following raw materials in percentage byweight: 35-45% of palm oil, 5-10% of an emulsifier, 0.2% of an antirust agent, 0.1% of a stabilizer, 0-8% of nano titanium dioxide and the balance of water. The preparation method of the release agentcomprises the following steps: 1) respectively mixing and uniformly stirring the emulsifier, the water and the palm oil to obtain two mixed solutions according to the emulsifying property of the emulsifier; and 2) uniformly mixing the two mixed solutions prepared in the step 1), sequentially adding an antirust agent, a stabilizer and nano titanium dioxide, stirring for 40-50 minutes at the temperature of 10-60 DEG C, and cooling to obtain the release agent. The release agent has the properties of low viscosity, good spreading uniformity, isolation lubrication and the like and can effectivelyeliminate bubbles on the surface of fair-faced concrete and stably and effectively ensure the appearance quality of the fair-faced concrete, and the fair-faced concrete after release has the advantages of good apparent quality, smooth appearance, small apparent pore size, small quantity, uniform color and small color difference.

Owner:SOUTHEAST UNIV +2

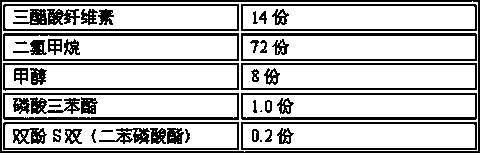

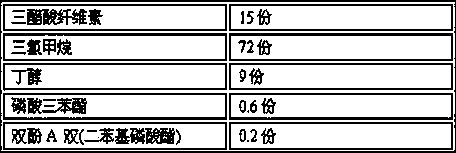

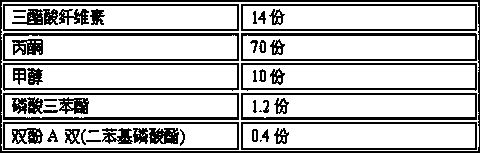

Cellulose triacetate membrane

InactiveCN103467779AAvoid apparent illsGuarantee the apparent qualityComposite materialPolymer chemistry

The invention discloses a cellulose triacetate membrane which is prepared from a solution containing cellulose triacetate, a solvent and a plasticizer by using a solution curtain-casting method. The cellulose triacetate membrane is characterized in that the dosage of the plasticizer is 3-15% of weight of the cellulose triacetate; the plasticizer is prepared from a triphenyl phosphate primary plasticizer and an aryl diphosphate coplasticizer; the weight ratio of aryl diphosphate to triphenyl phosphate is 1 / 6 to 4 / 5. By adopting the cellulose triacetate membrane, precipitation of the plasticizer caused by fluctuation of a production process condition in a membrane production process is solved; apparent defects of the membrane caused by precipitation of the plasticizer are avoided; the apparent mass, the optical property and the physical and mechanical properties of the membrane are ensured; meanwhile, the cellulose triacetate membrane accords with the environment-friendly emission requirements.

Owner:CHINA LUCKY FILM CORP

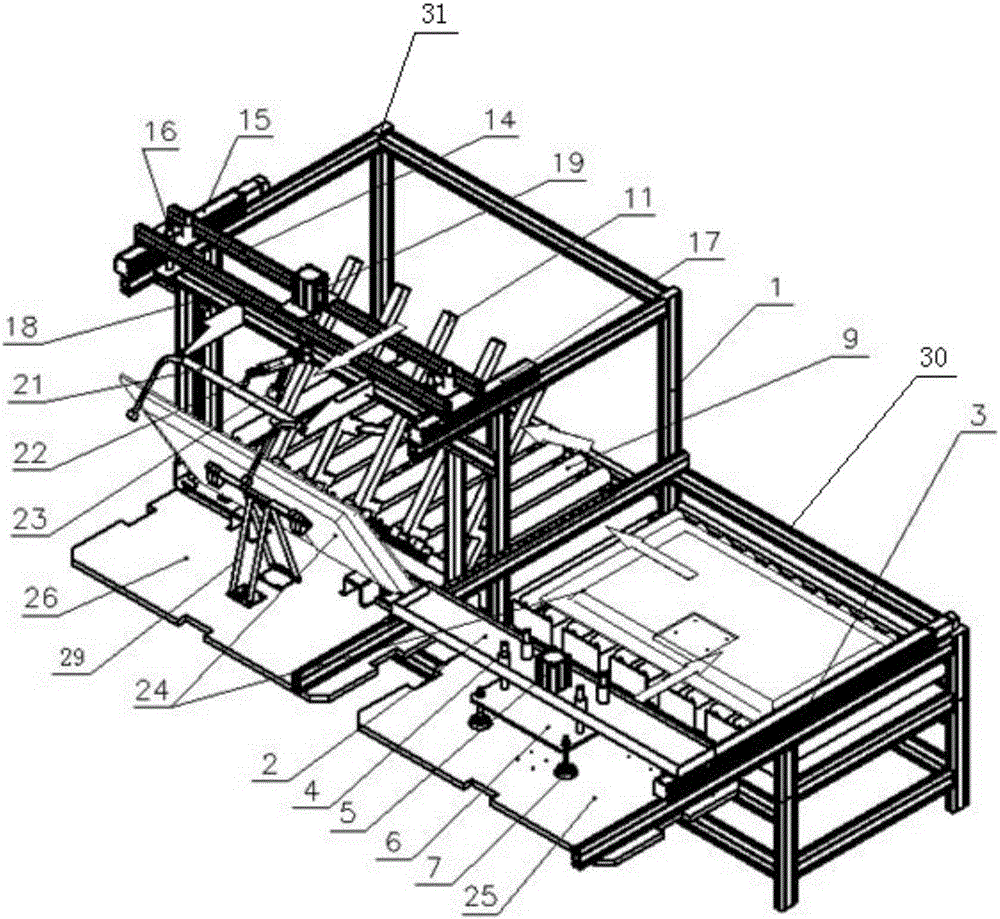

Equipment for transferring, overturning and leaning panel television set

The invention discloses equipment for transferring, overturning and leaning a panel television set. The equipment comprises a rack. The rack is composed of a first rectangular frame and a second rectangular frame. The second rectangular frame is installed on the first rectangular frame. A horizontal tool plate and a leaning tool plate are sequentially arranged on the same side of the first rectangular frame. The leaning tool plate is located below the second rectangular frame. An adsorption transferring mechanism is arranged above the horizontal tool plate. The leaning tool plate is sequentially provided with an overturning mechanism and a leaning transferring mechanism from bottom to top. The leaning transferring mechanism is connected with the upper end of the second rectangular frame. A conveying mechanism is arranged on the surface of the first rectangular frame. The equipment has the beneficial effects that it can be guaranteed that the panel television set can be smoothly transferred, overturned and leaned, manpower can be replaced, the production manner of multiple types, flexibility and easy switching is met, and meanwhile efficiency and product quality are improved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com