Patents

Literature

530results about How to "Guaranteed to be smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antibacterial enamel and preparation method thereof

The invention discloses an antibiotic enamel, wherein the glaze-making base formulation includes SiO2 30-50%, Al2O3 5-10%, B2O3 5-20%, Na2O 2-20%, K2O 2-10%, CaO 0-5%, MgO 0-5%, TiO2 0-20%, Zr02 0-10%, ZnO 0-5%, BaO 0-5%, F 1-10%, NiO 0-2%, MnO 20-4%, Fe2O3 0-4%, CuO 0-2%, the added antibacterial agents being Cu, Ag, Sn, Zr, rare earth, Ca, Zn, B, Ba, Ti and their compounds, salts or oxide compounds, the total content being 1-5%.

Owner:丁文战

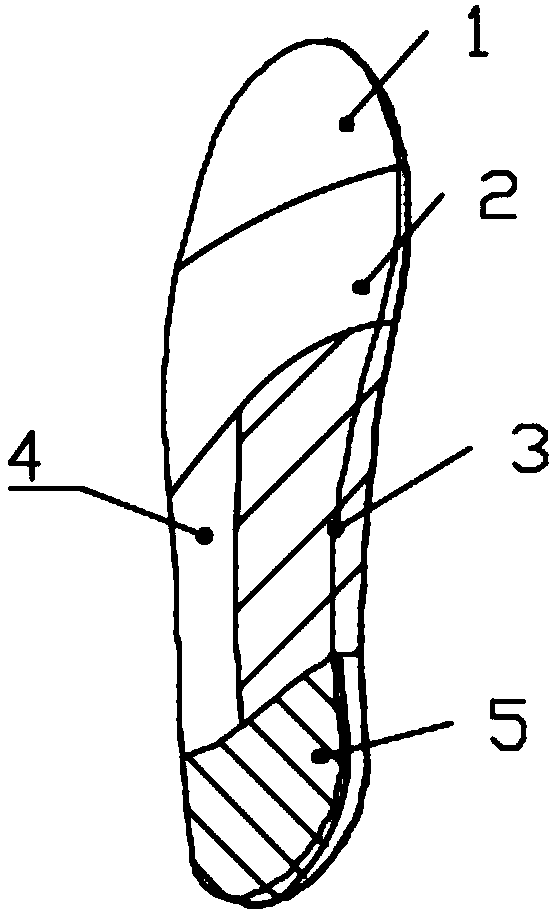

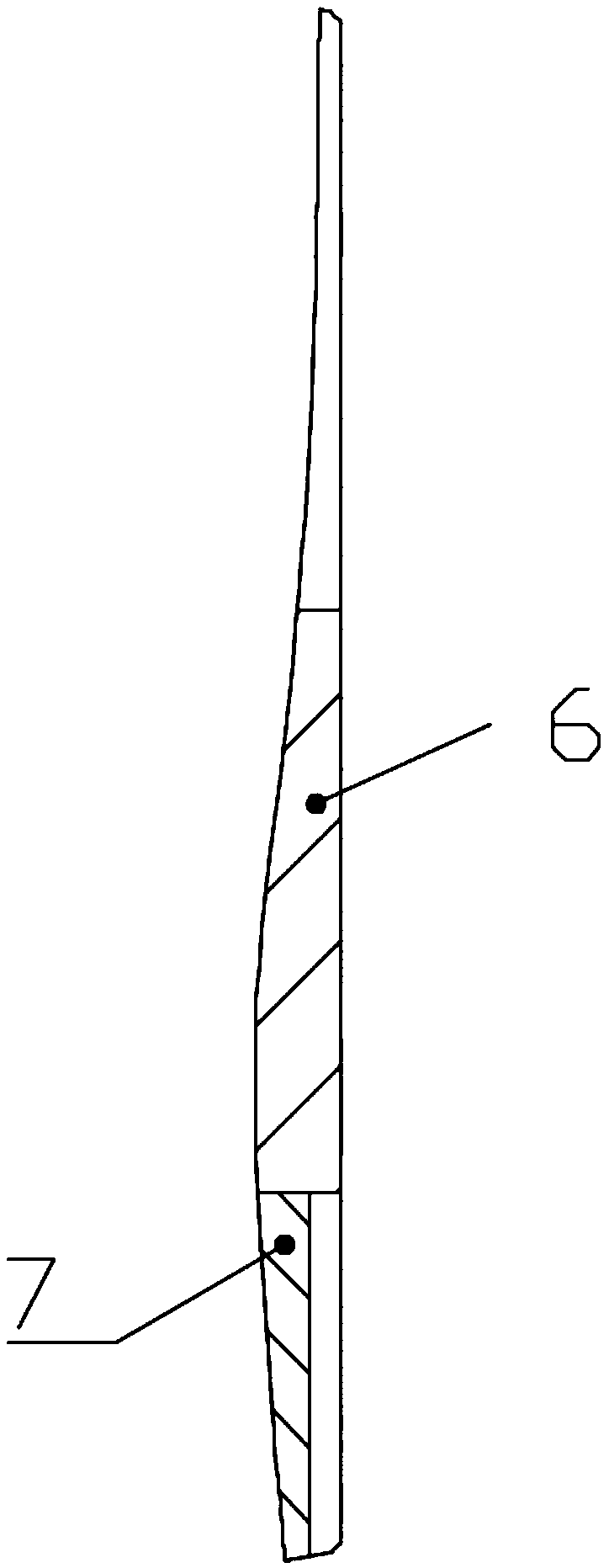

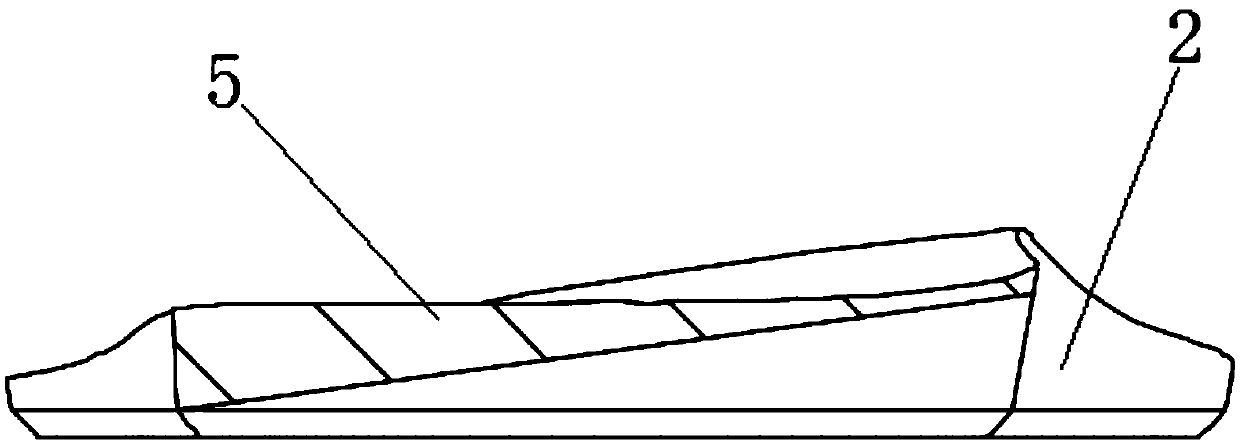

Skin for morphing wings

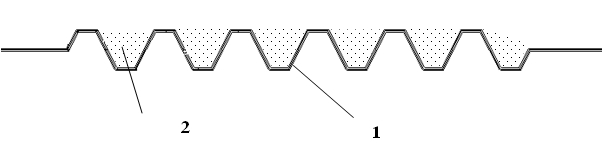

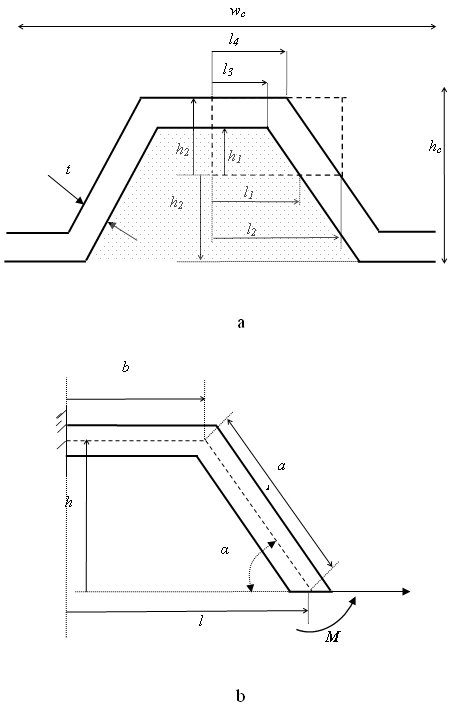

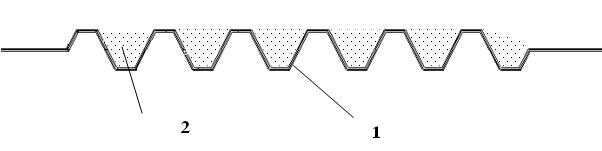

InactiveCN102060101AGuaranteed to be smoothRealize health monitoringWingsIsosceles trapezoidVibration control

The invention discloses a skin for morphing wings, belonging to the technical field of design of morphing aircrafts. The skin for the morphing wings is made from fibre reinforced composites, and the cross section of the skin is in an isosceles trapezoid ripple structure. The invention also carries out analysis aiming at the chordwise and spanwise equivalent elastic modulus and flexural modulus ofthe skin structure with isosceles trapezoid ripples, provides a corresponding mathematical model and can further optimize the skin structure according to the mathematical model. The invention meets the requirements of the skin of the morphing wings of the morphing aircrafts for large deformation aerodynamic load bearing, can realize the design optimization of the skin structure under different load operating conditions according to the mathematical analysis model of the equivalent elastic modulus and the flexural modulus in two different directions of the skin structure, also has structure health monitoring and self-adapting deformation capability and can realize optimal aerodynamic characteristics by controlling the shape and the vibration of the skin.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Nano-silica/polyacrylate organic and inorganic hybrid water-dispersible resin and preparation method thereof

InactiveCN105061700AGood storage stabilityInhibit aggregationAntifouling/underwater paintsPaints with biocidesWater dispersibleIn situ polymerization

The invention discloses nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin and a preparation method thereof. According to the method, a silane coupling agent is adopted to modify a methyl methacrylate dispersion liquid of silica at first, and then in-situ polymerization of the modified methyl methacrylate dispersion liquid of silica and acrylate monomers is carried out in a solvent. The nano-silica / polyacrylate organic and inorganic hybrid water-dispersible resin comprises the following ingredients in parts by mass: 20-40 parts of a solvent, 10-40 parts of a modified methyl methacrylate dispersion liquid of silica, 8-14 parts of acrylate monomers, 2-6 parts of acrylic acid, 0.15-0.5 part of an initiator, 1.5-5.5 parts of a pH regulator and 10-30 parts of deionized water. The water-dispersible resin is a pale yellow or pale yellow and slightly-blue semitransparent liquid, is favorable in storage stability, high in coating transparency and good in stain resistance and water resistance, the hardness can be 4H or above and the adhesion can be 1 grade.

Owner:SOUTH CHINA UNIV OF TECH

High-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage

ActiveCN101717624AEnhanced inhibitory effectImprove rheologyDrilling compositionWater basedInorganic salts

The invention discloses a high-efficient water-based well drilling fluid with fast absorption, strong inhibition and low damage, which comprises the following components: 100 parts of seawater or fresh water, 2-5 parts of inorganic salt, 0.2-0.8 part of coating inhibitor, 1.5-3.5 parts of fluid loss additive, 2-4 parts of strong inhibitor, 2-4 parts of lubricant, 0.1-0.5 part of shear strength improving agent and 30-150 parts of weighting agent. The well drilling fluid has strong inhibition and has good rheological property and stable system performance during the whole well drilling process,even a large quantity of highly easily hydrated and dispersed cuttings exist for invasion of sewage, the viscosity of the well drilling fluid is basically controlled to be about 50s.

Owner:CHINA NAT OFFSHORE OIL CORP +1

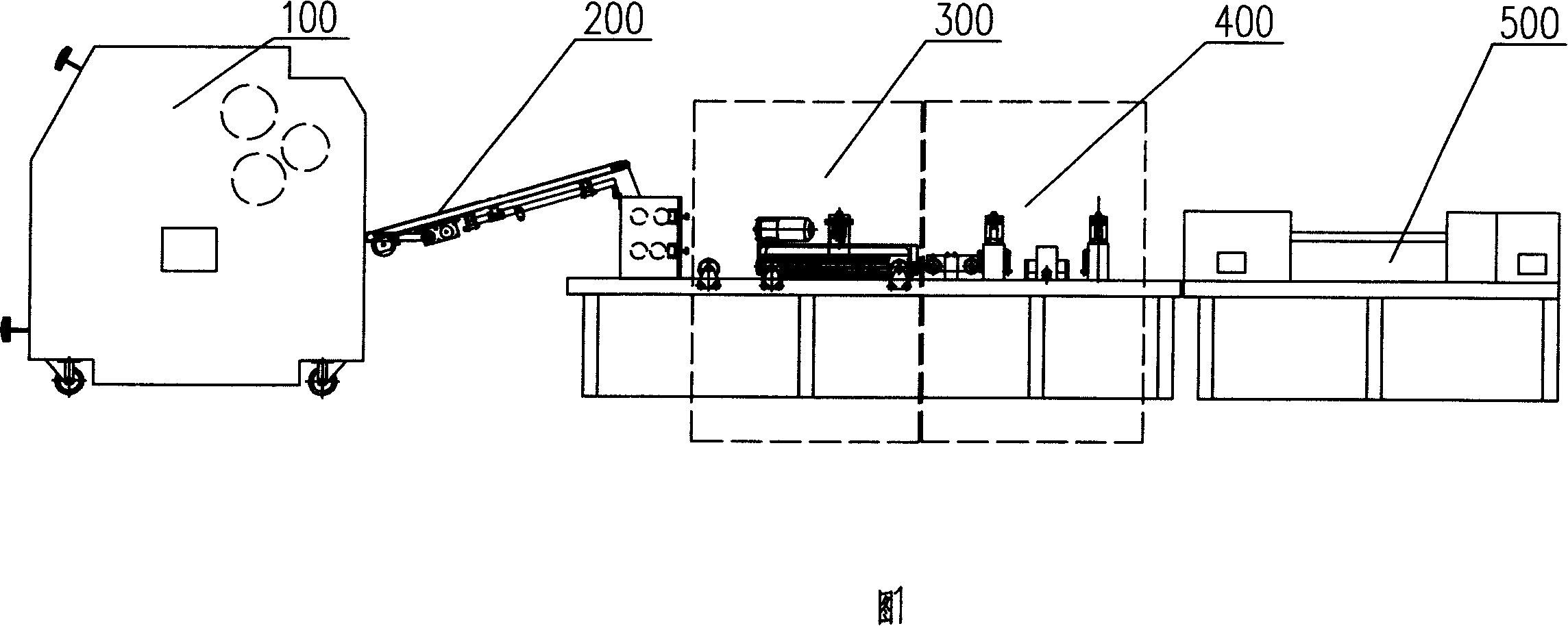

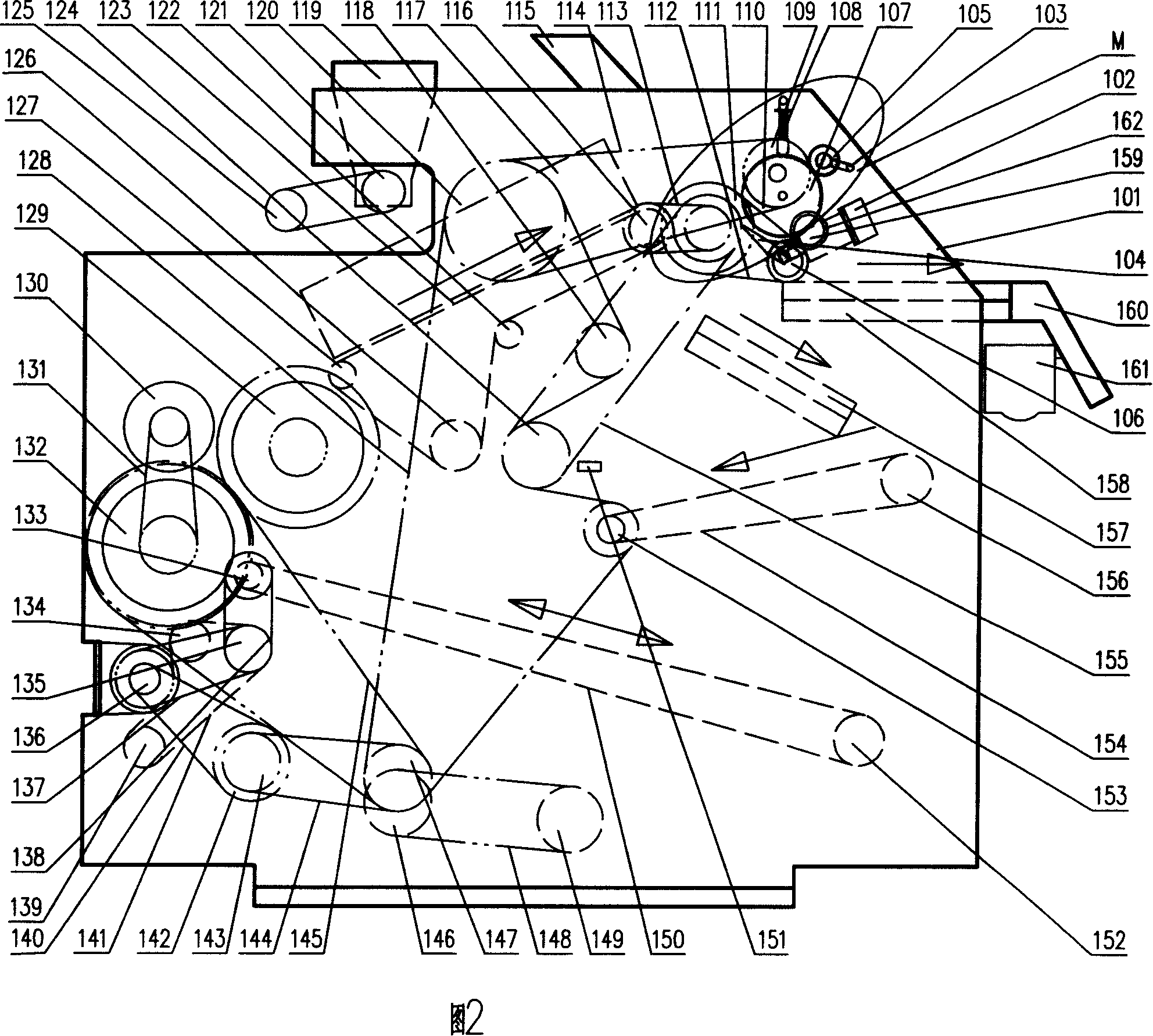

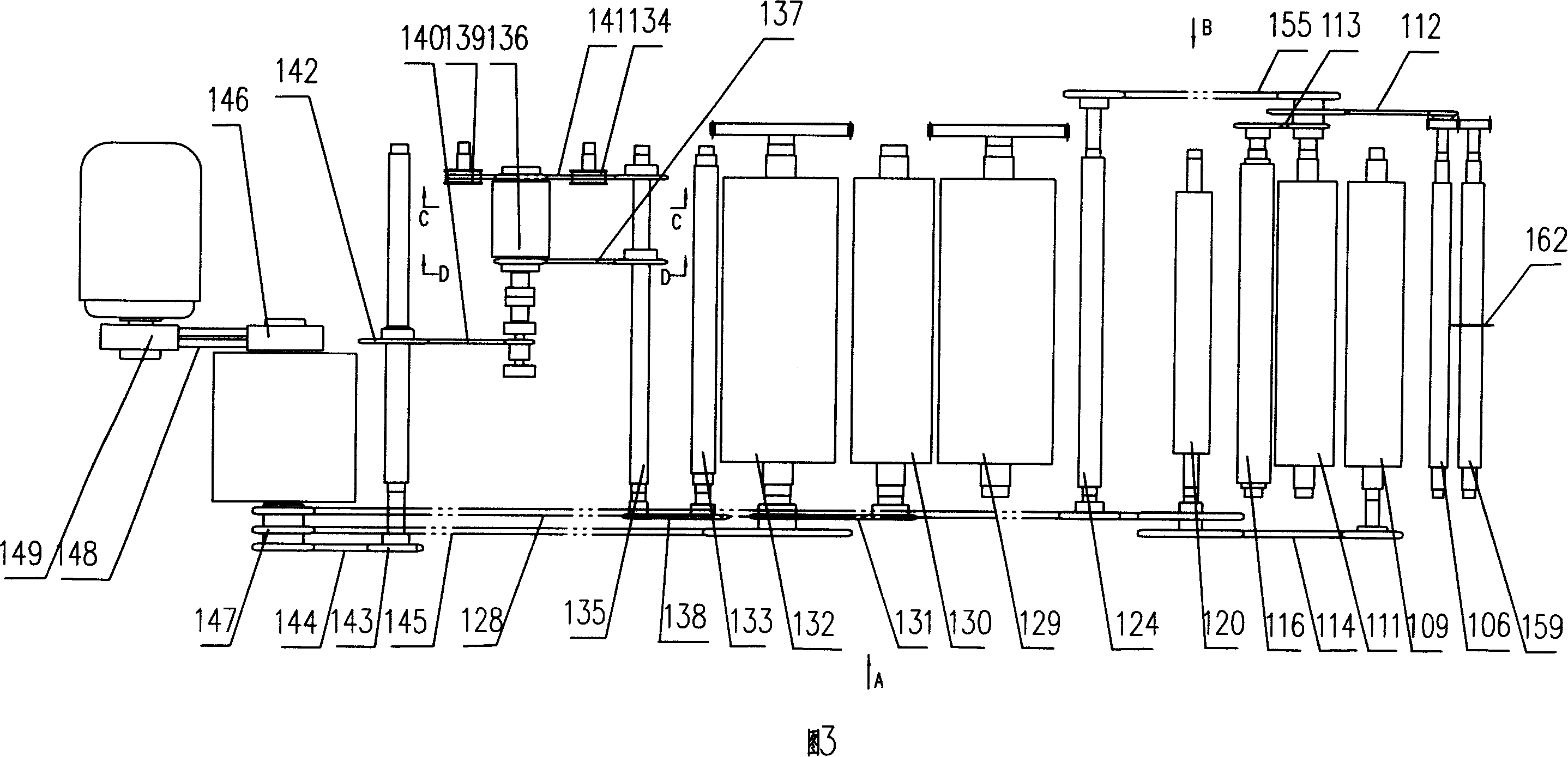

Equipment for producing round steamed bread

ActiveCN101112202AImprove skin brightnessClear internal structureDough-sheeters/rolling-machines/rolling-pinsForming processesFood products

The invention pertains to the technical field of food machinery and relates to producing equipment of round steamed bread. The equipment is provided with the following settings from front to back in sequence: a squash device (100), an incline plane transportation device (200), a winding device (300), a cutting device (400) and a molding device (500). Each device is connected by conveying belt. The squash, winding and cutting devices are added before the molding process. The process steps are as follows: paste is squashed into dough sheet; dough roll is made of the dough sheet through the winding device; then the dough roll is cut, molded to form a clear inner structure layer and improve the brightness of the steamed bread surface and enable the steamed bread to be tasted puckering. The molding process of the invention simulates manual entwisting molding process, which enables the steamed bread inner structure to be difficult to be torn and broken, maintains the sourdough network completely and evenly, has high molding efficiency, and at the same time improves the appearance quality of the dough.

Owner:郑州多福多食品有限公司

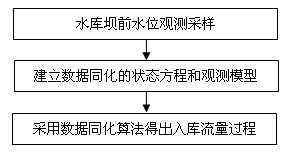

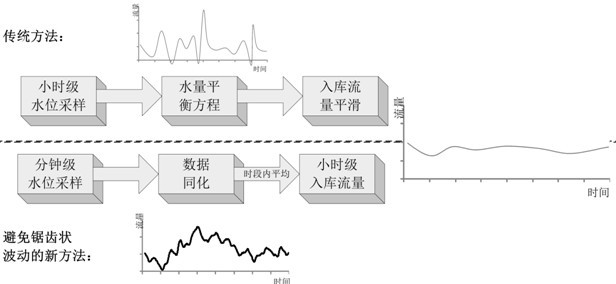

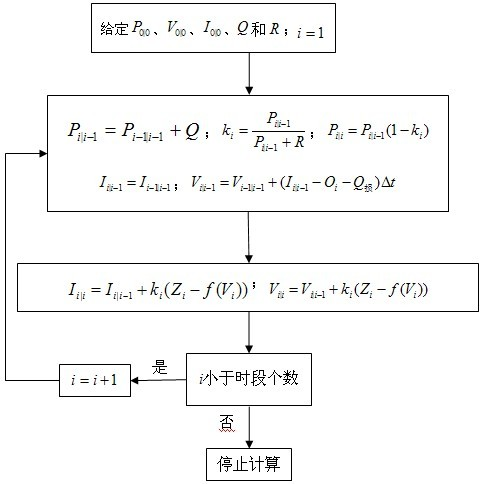

Measuring method for inversing reservoir feeding flow procedures

The invention discloses a measuring method for inversing reservoir feeding flow procedure, comprising the steps: step I, performing observation and sampling to obtain the information of reservoir water level and discharging flow via a water level in front of the reservoir dam; step II, building a data assimilative state model and an observation model according to the information obtained in the step I; and step III, ascertaining the reservoir feeding flow procedures by a data assimilation algorithm according to the state model and the observation model obtained in the step II. The method disclosed by the invention can be used for ascertaining the reservoir feeding flow; compared with the prior art, the method disclosed by the invention can ensure smooth reservoir feeding flow, and avoid exceptional data like negative values and the like of the flow; the method also can supply the reservoir feeding flow procedure of minute time step, so as to reflect the flood peak information more truthfully; in addition, the method disclosed by the invention has low precision requirement to the water level gauge on the reservoir dam, so that the building and management costs of water level measurement stations are saved.

Owner:WUHAN UNIV

Hand cream and preparation process thereof

InactiveCN102451144ANutritional diversitySuitable for useCosmetic preparationsToilet preparationsCetyl alcoholShea butter

The invention discloses hand cream. The hand cream consists of the following components in part by weight: 40 to 50 parts of natural Chinese herbal medicinal extract, 5 to 10 parts of shea butter, 5 to 10 parts of beewax, 2 to 5 parts of palmitic acid, 2 to 5 parts of cetyl alcohol, 1 to 3 parts of cod-liver oil, 1 to 3 parts of honey, 10 to 20 parts of hyaluronic acid, and 10 to 20 parts of medical vaseline. A preparation method comprises the following steps of: mixing all the components, heating to 50 to 60 DEG C, uniformly mixing, and cooling to room temperature to obtain the hand cream. The hand cream has the effects of moisturizing and maintaining skin, delaying senility, eliminating hard stratum corneum, and the like, and all components are low in cost, and the hand cream is suitable for common crowds.

Owner:蚌埠勤勉信息科技有限公司

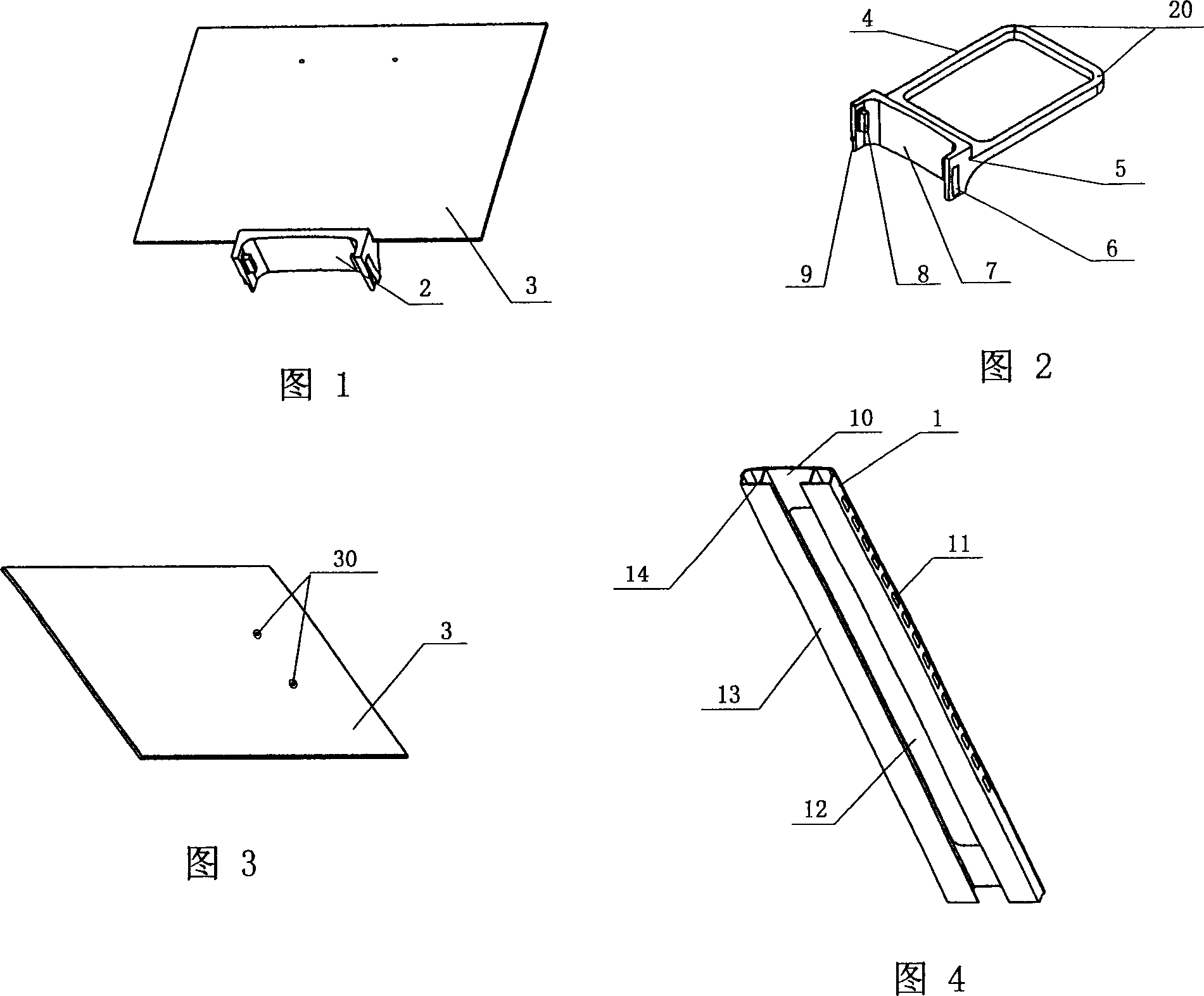

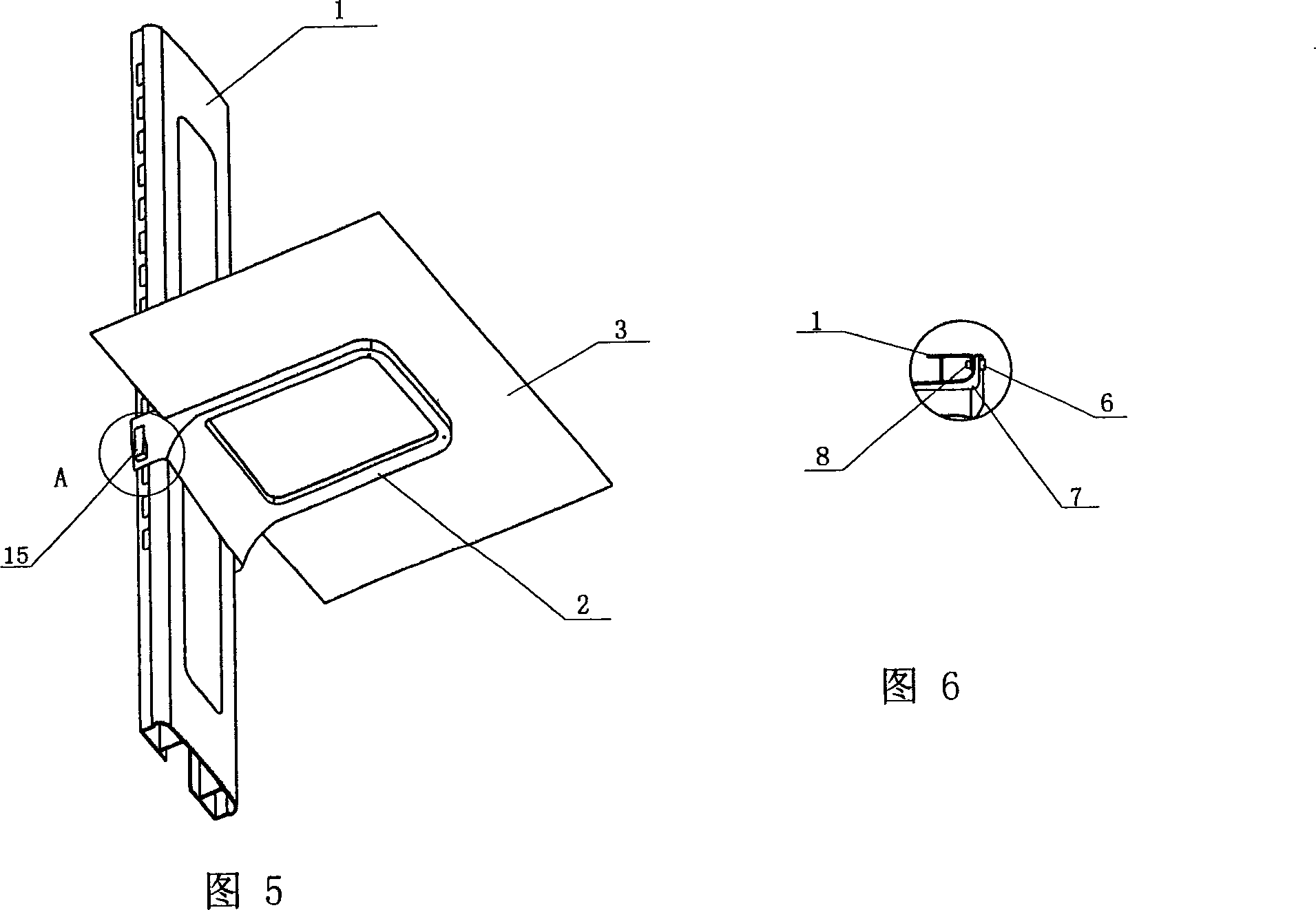

Refrigerator shelf assembly

InactiveCN101071031AEasy to cleanGuaranteed to be smoothLighting and heating apparatusSupportEngineeringGlass sheet

The invention involves a refrigerator dormant rack assembly, the dormant rack assembly including supporting skeleton and dormant rack, rack set aside by a fixed support bracket glass structure, built in the rack cards to support the skeleton exact. The invention of the dormant rack assembly, supported by a skeleton support dormant rack, minus the interior biliary tendons support, the relatively low production costs, and can guarantee that on both sides of the interior refrigerator smooth, easy interior cleaning, and through the support frame on the exact number of the structure can be built rack in a wide range of arbitrary regulation to meet the individual needs of users, in addition, put aside rack and support skeleton key part of the structure connecting the design allows built-in support of the skeleton is very fast and easy loading and unloading.

Owner:HAIER GRP CORP +1

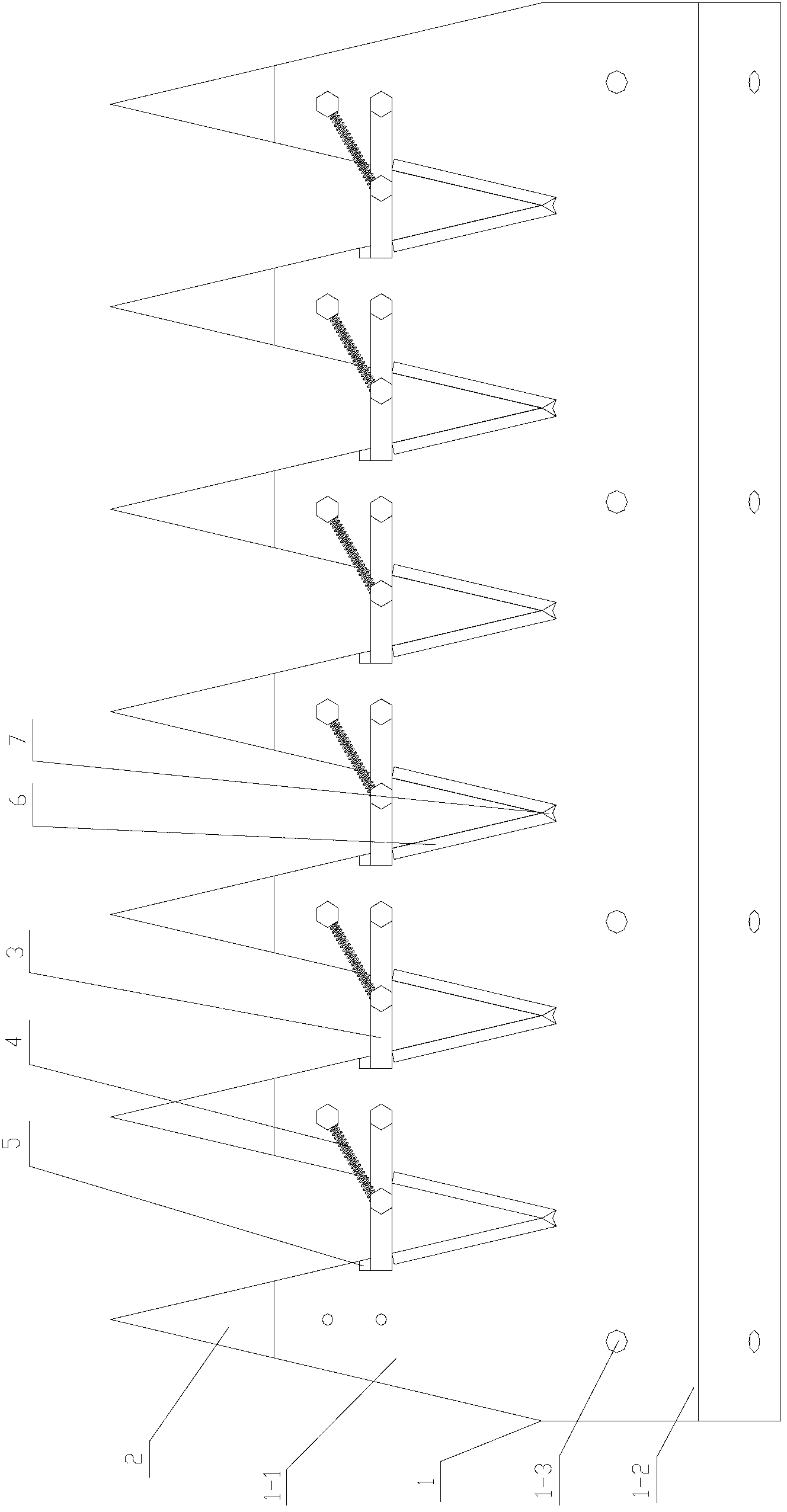

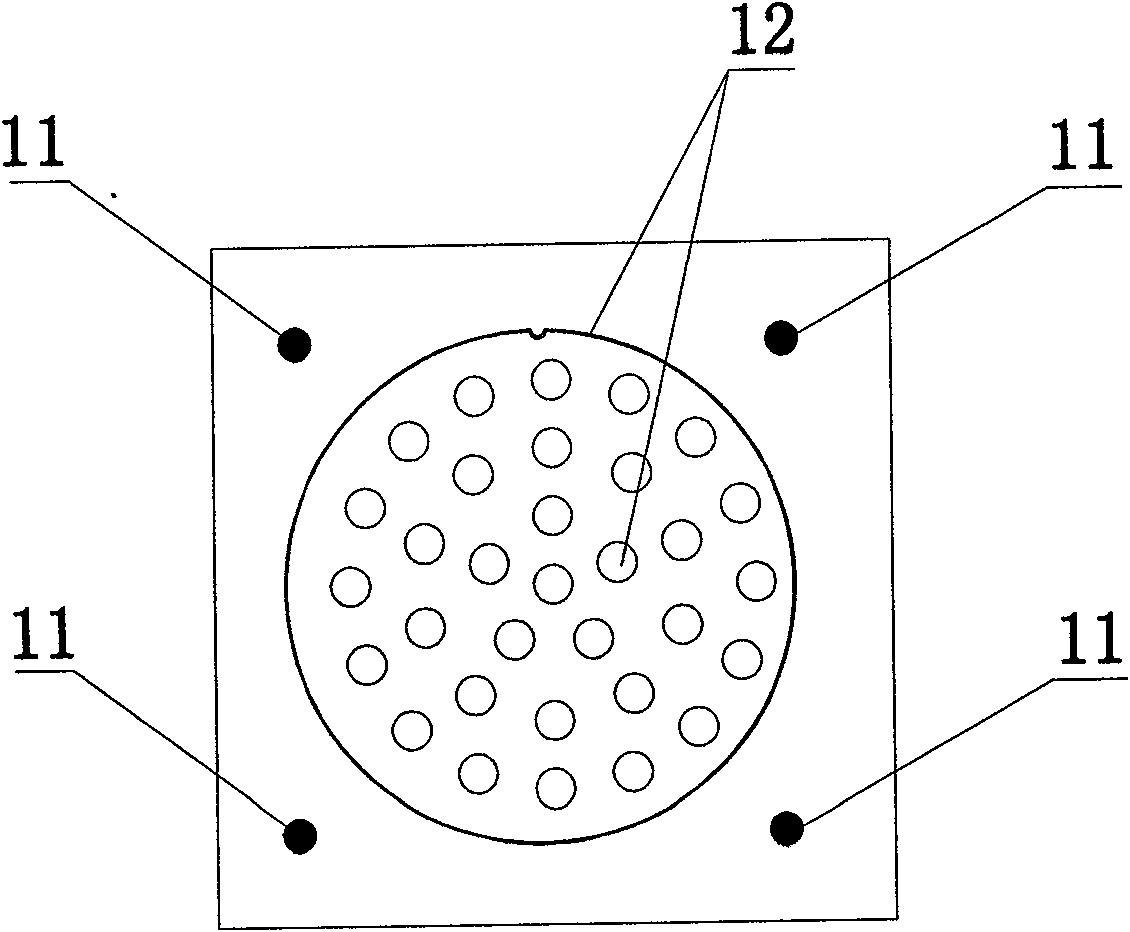

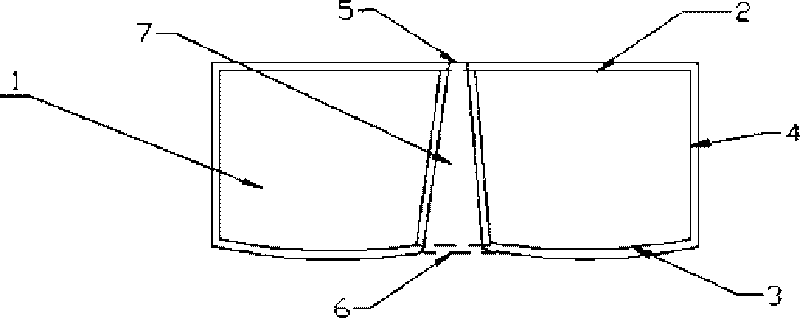

Light component for cast-in-situ hollow floor

InactiveCN101457562AGuaranteed stabilityImprove stabilitySolid waste managementFloorsEngineeringSuspending Agents

The invention relates to a building apparatus, in particular to a filling component used for a cast-in-situ hollow floor. The component is box-shaped and is formed by mixing expanding material and water in a mould to be directly expanded. The component comprises a bottom surface, a top surface, a frame body and a hollow channel, wherein, the bottom surface includes at least two arch preiections which are convex outwards, and an opening at the lower end of the hollow channel is positioned at the joint between an underside arch and an arch. The expanding material contains the components with the weight percentage: 4-15% of sulphate aluminium cement, 50-65% of portland cement, 18-35% of pulverized fuel ash and 2-10% of modifying agent, wherein, the modifying agent includes early strength admixture, water reducing agent, suspending agent, diffusant, expanding foam solution and foam stabilizer, and the mixed water and expanding material has the weight percentage of 45-72%. The technical proposal can ensure stableness of the structure of the cast-in-situ hollow floor, and improve the shock resistant and anti-cracking effects of the building. The component formed by solidifying the expanding material has lighter weight, more particularly, the light weight component formed by expanding and solidifying the expanding solution has better performances of heat preservation and sound insulation. The invention is in accordance with the principle of energy-saving and land-saving building promoted by China.

Owner:HUNAN BDF ENERGY SAVING TECH

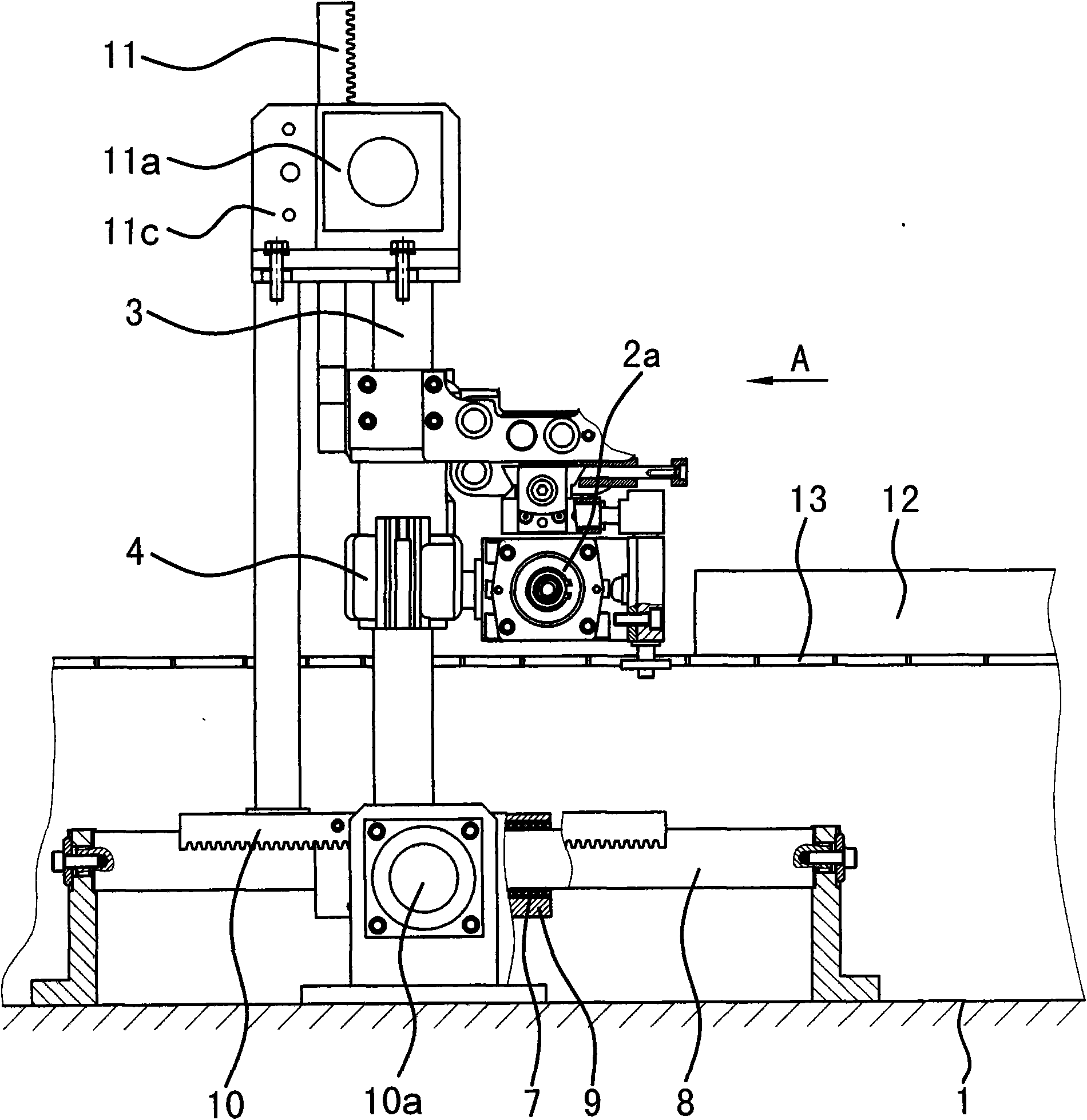

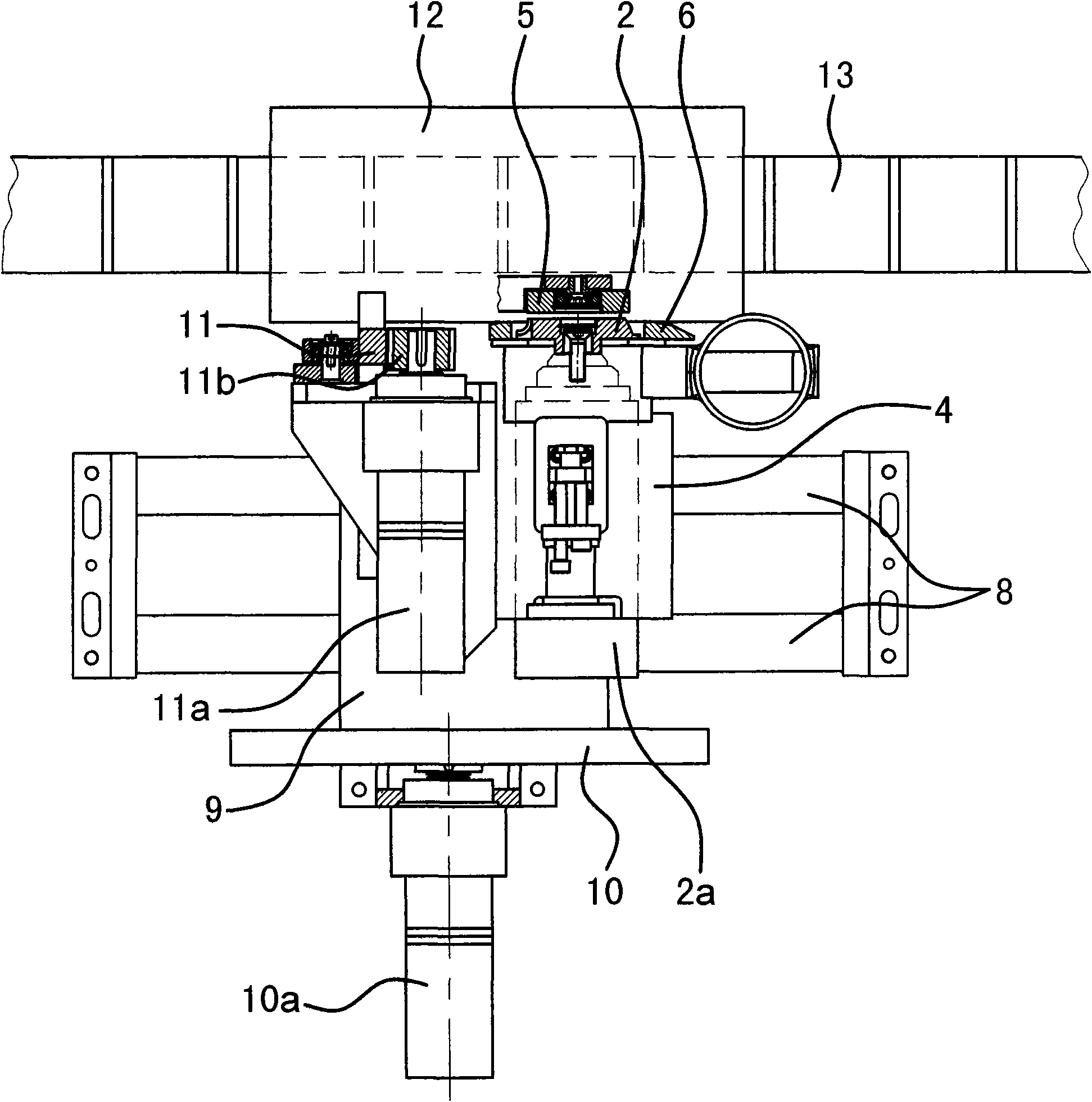

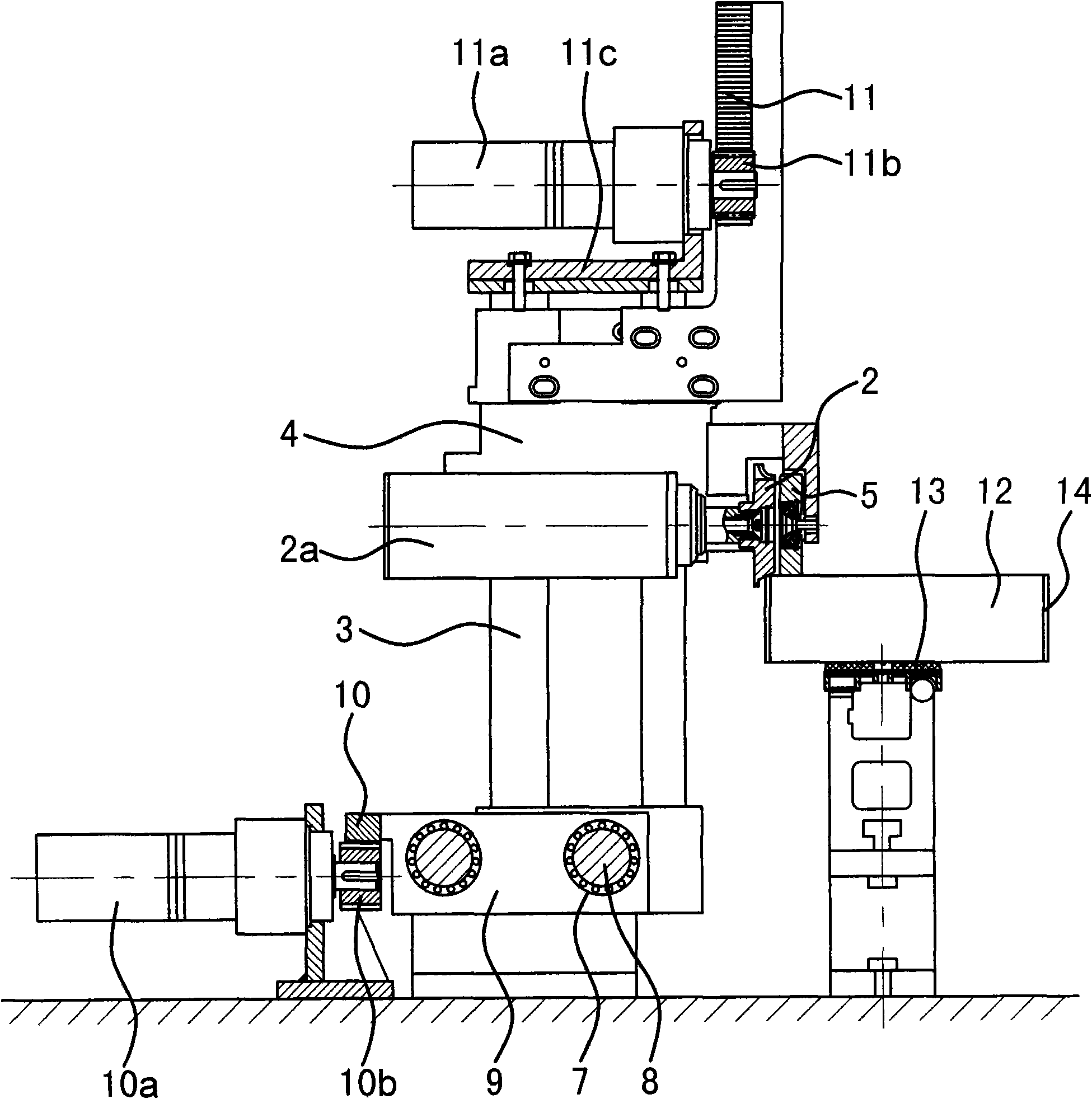

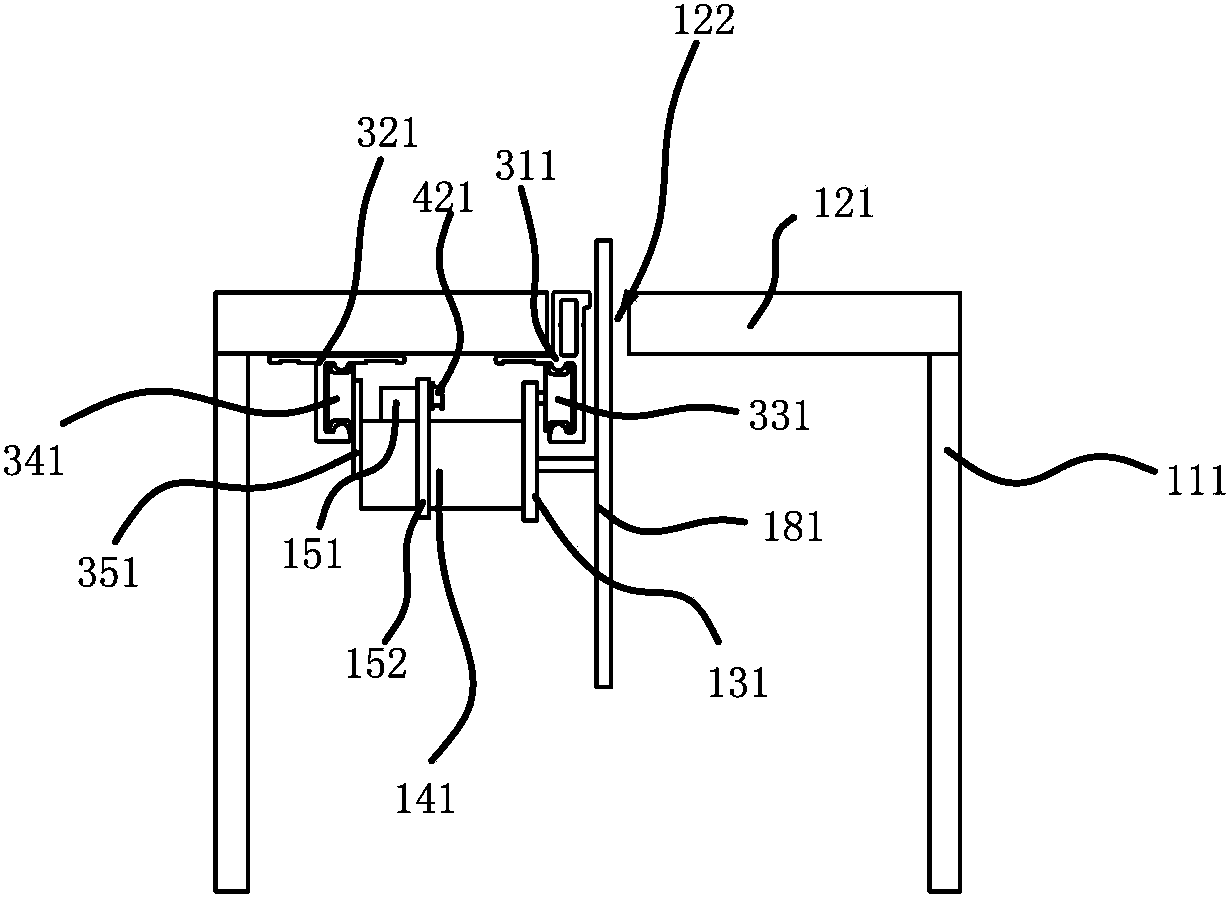

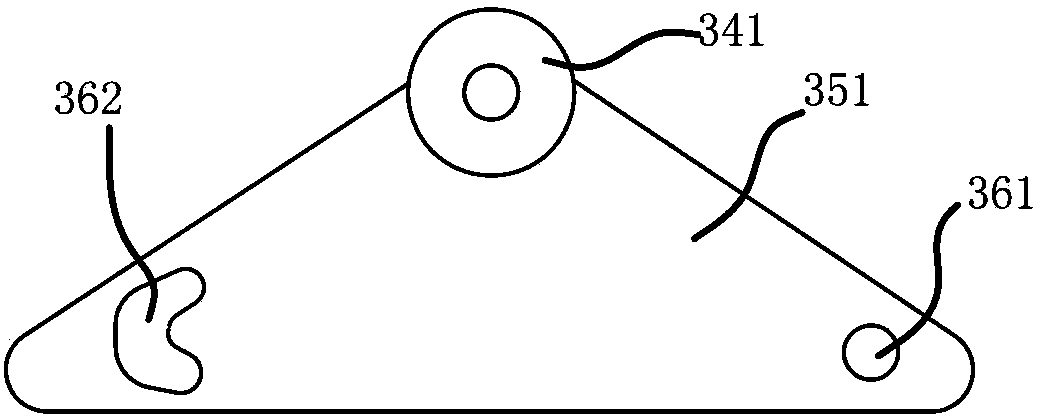

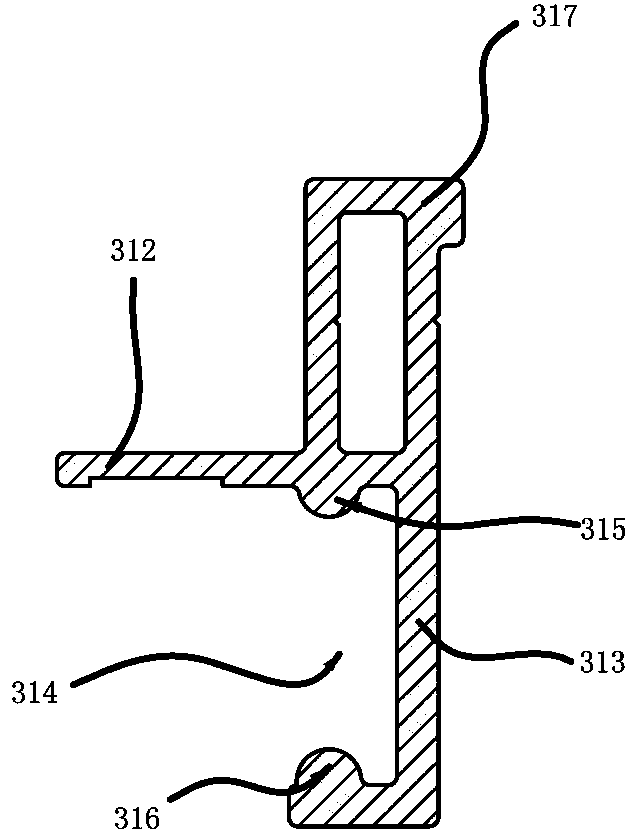

Tracking and trimming means of automatic edge sealing machine

InactiveCN101549509ASimple structureReduce volumeWood working apparatusDomestic articlesMilling cutterKinematic pair

The invention provides a tracking and trimming means of automatic edge sealing machine, belongs to the carpentry machinery field, solves the problems of complex construction, instable gravity center, easily damage to cylinder, asynchronous motions of patterning wheel, patterning plate and milling cutter driven by different cylinders, and poor cutting precision existing in current trimming devices. The tracking and trimming means of automatic edge sealing machine comprises a base, a tracking mechanism capable of causing the edge of the milling cutter mounted on the base to move along the edge of the edge sealing band pasted on the plate side; the milling cutter is driven by a motor. The invention is characterized in: The tracking mechanism comprises a vertical shaft and a lifting slide carriage disposed out of the vertical shaft; the vertical shaft is connected with a translation mechanism capable of driving it to move levelly; and the motor is levelly fixed on the lifting slide carriage. The invention realizes milling cutter tracking simply by combining two linear kinematic pair: a level kinematic pair and a vertical kinematic pair, has a simple construction and stable gravity center.

Owner:TAIZHOU EVOK MASCH CO LTD

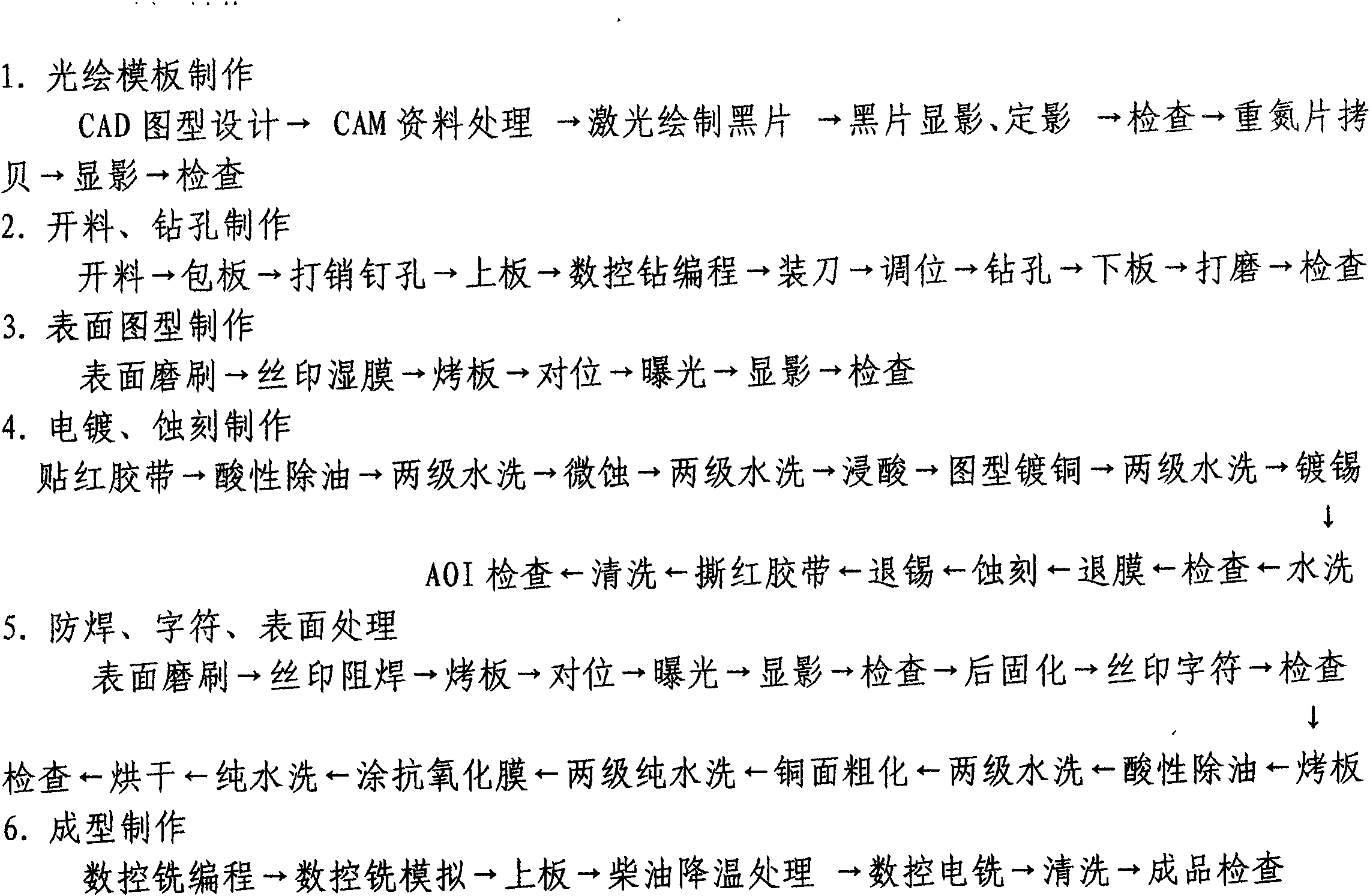

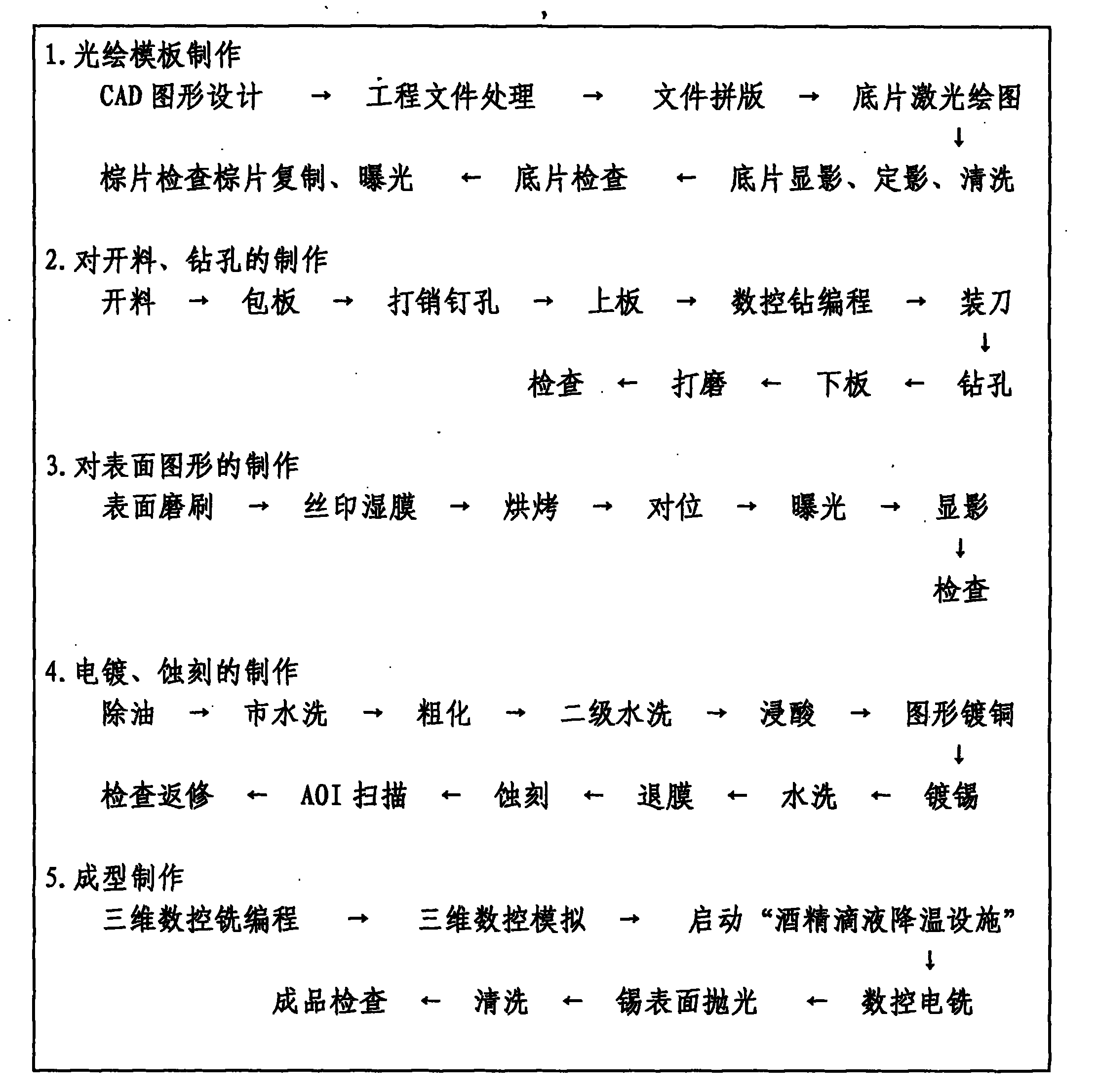

Method for making high-frequency aluminium-based circuit board

ActiveCN102159029AAvoid glitchesImprove performancePrinted circuit manufactureCircuit susbtrate materialsSurface patternElectrical and Electronics engineering

The invention discloses a method for making a high-frequency aluminium-based circuit board. The method comprises the following steps of: 1, making a photo-plotted template; 2, cutting and drilling holes; 3, making surface patterns; 4, electroplating and etching; 5, carrying out welding preventing and character and surface weldable processing; and 6, molding to make the high-frequency aluminium-based circuit board. The making accuracy of the method is high, the product quality and the work efficiency are effectively improved, and the performance of the made high-frequency aluminium-based circuit board is stable.

Owner:TAIZHOU JINDING ELECTRONICS

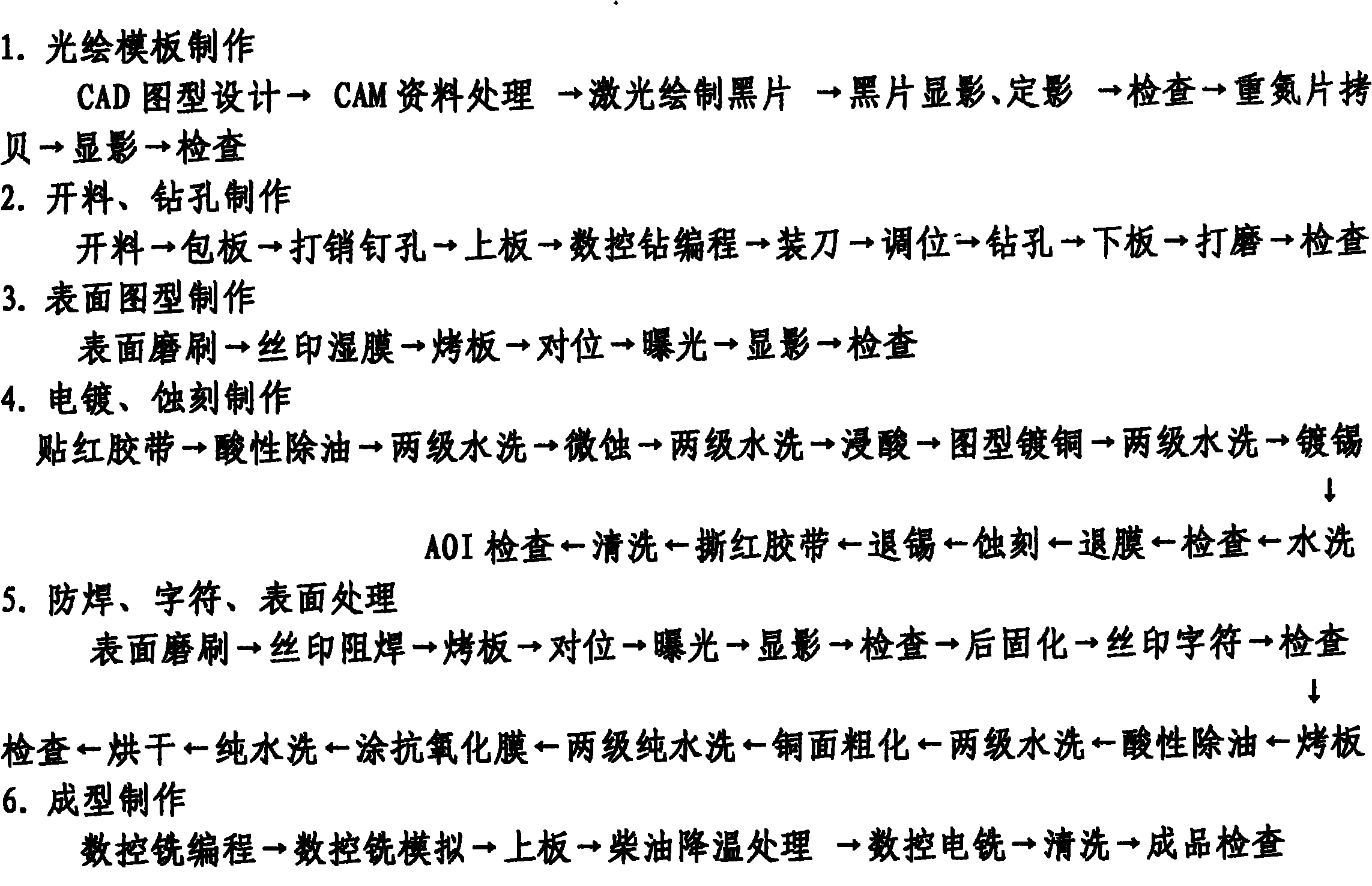

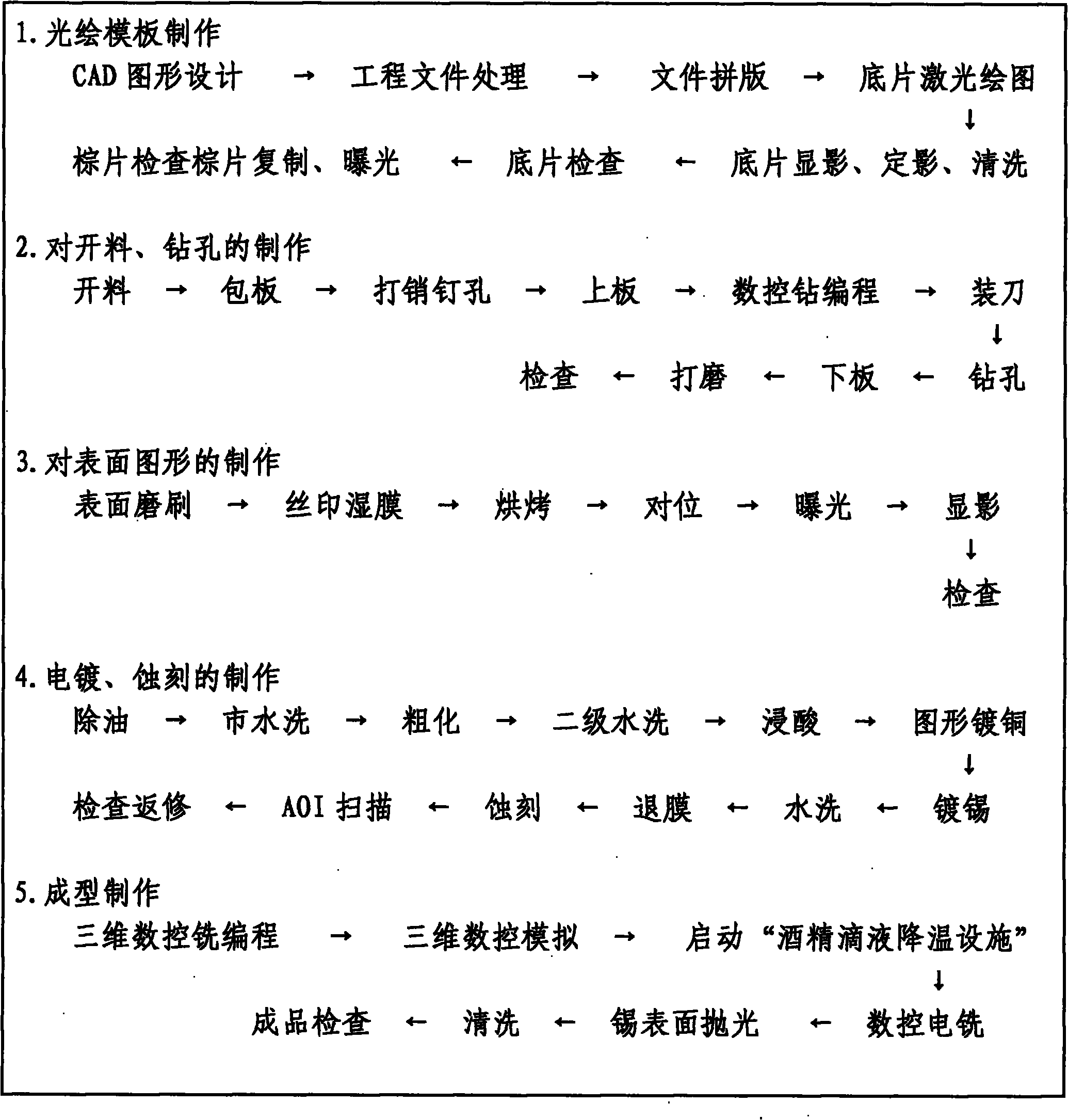

Manufacturing method for microwave high frequency metal base circuit board

InactiveCN101784162ASolve the blackeningSolve the roughness of the hole wallDrilling/boring measurement devicesTransportation and packagingMicrowaveCopper

The invention discloses a manufacturing method for a microwave high frequency metal base circuit board, which comprises the following steps: step one, manufacturing an optical drawing template; step two, manufacturing a split material and a bore hole; step three, manufacturing the surface graph of a composition board of a metal base copper-clad plate; step four, electroplating and etching; and step five, molding. Not only the manufacturing method has high manufacturing precision and effectively increases the product quality and working efficiency, but also the manufactured microwave high frequency metal base circuit board has stable performance.

Owner:施吉连

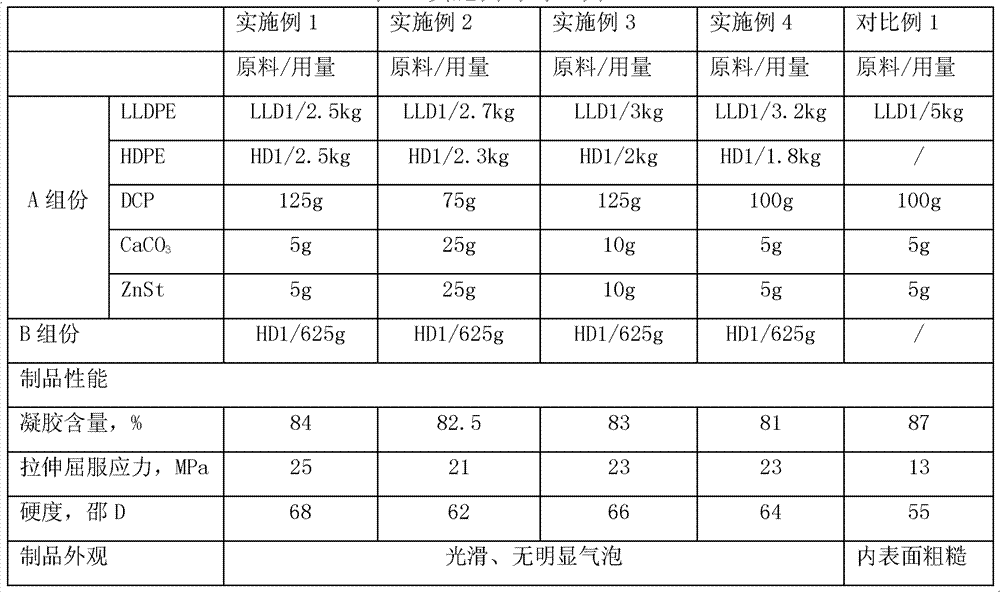

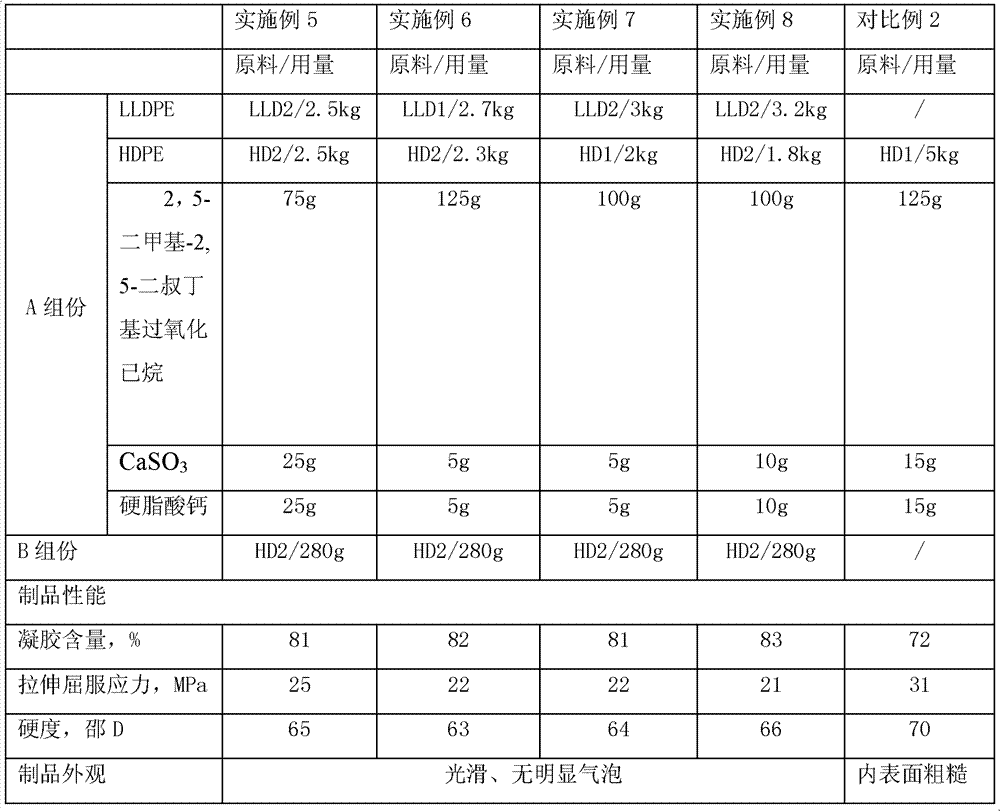

Cross-linked polyolefin composition for rotational molding and preparation method thereof

The invention relates to a cross-linked polyolefin composition for rotational molding and a preparation method thereof, belonging to the field of cross-linked polyolefin composition for rotational molding. The cross-linked polyolefin composition comprises a component A and a component B, wherein the component A comprises 100 weight parts of linear low density polyethylene (LLDPE), 50-100 weight parts of high density polyethylene (HDPE), 2-5 weight parts of cross-linking agent, 0.2-1.0 weight parts of nucleating agent, and 0.2-1.0 weight parts of lubricant; and the component B is high density polyethylene, and the ratio of the component A to the component B is 90:10-95:5. According to the invention, optimum crosslinking degree is achieved and high hardness and difficulty in warpage are guaranteed by selecting the basic resin, and the addition of the nucleating agent is beneficial for reducing product bubbles; products produced by using the composition of the invention has smooth internal and external surface, easiness in mold stripping, high crosslinking degree, and good comprehensive properties.

Owner:CHINA PETROLEUM & CHEM CORP

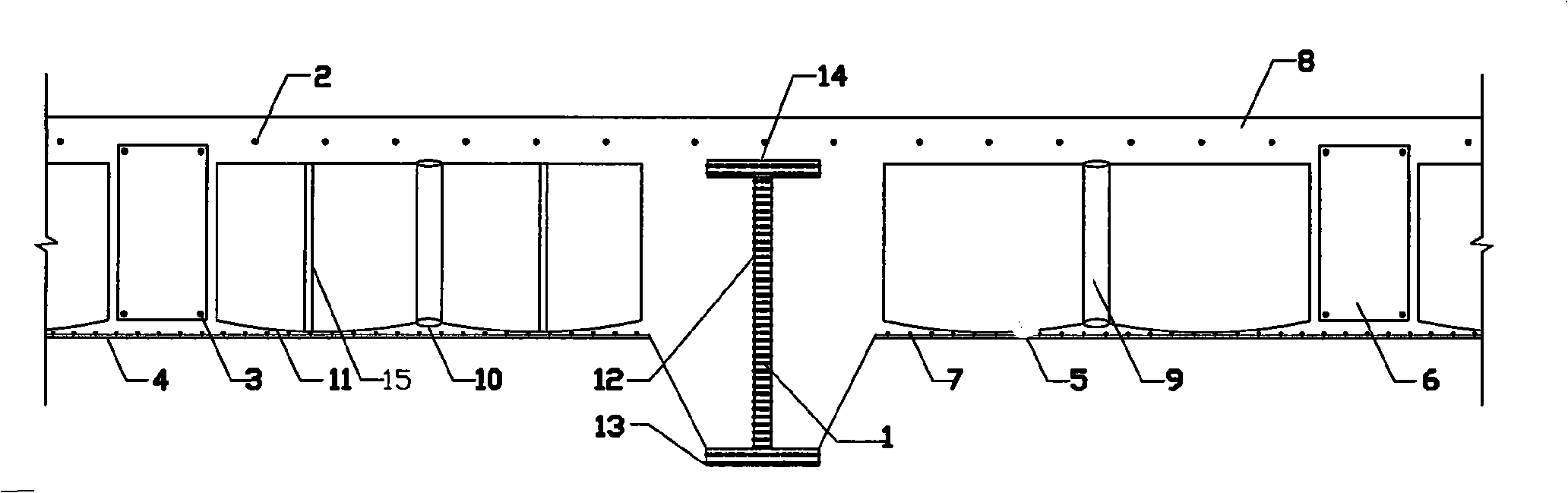

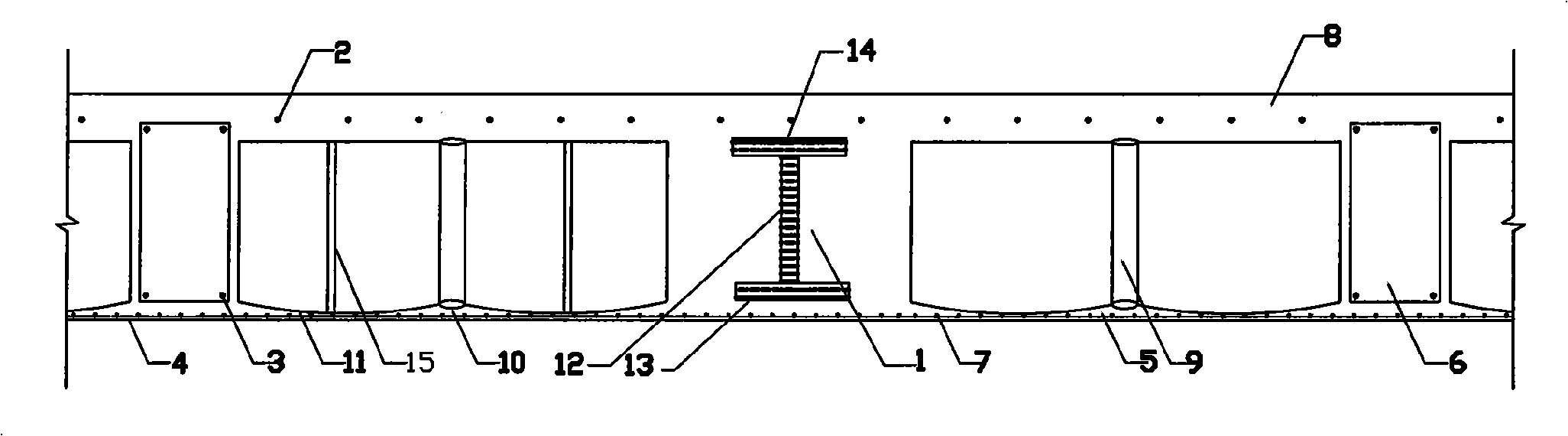

Cast-in-situ section steel concrete cavity building roof

InactiveCN101314970AImprove rigidityReduce difficultyFloorsForms/shuttering/falseworksReinforced concreteRebar

The invention relates to a structure of a hollow floor system of cast-in-site steel-concrete in architectural engineering. The structure adopts the technical proposal that a special communicating hole for a common rib at the bottom part of a ribbon strip is manufactured in a web of section steel; the reinforcing steel bar at the bottom part of the ribbon strip penetrates through the communicating hole of the web of the section steel; the upper part penetrates through the upper flange of the section steel; a grid with the size of a crisscrossed prefabricated hollow body is formed; a hollowed hollow body is placed into the grid; and then concrete and mortar are poured into the hollow body, thereby the upper flange and the web of the section steel form into a whole with the entire floor system. By adopting the proposal, the reinforced concrete can be in close contact with the section steel, ans the bearing effect of the floor system is better. A plurality of raised arcs are formed on the bottom surface of the hollow body in the proposal, therefore, during the process of pouring the concrete and the mortar, the mortar can enter the bottom surface of the hollow body, the lower flange plate of the floor system forms a smooth surface after being solidified, and the problem that the secondary processing is still required to be performed to the bottom surface in the prior art can be overcome.

Owner:王本淼

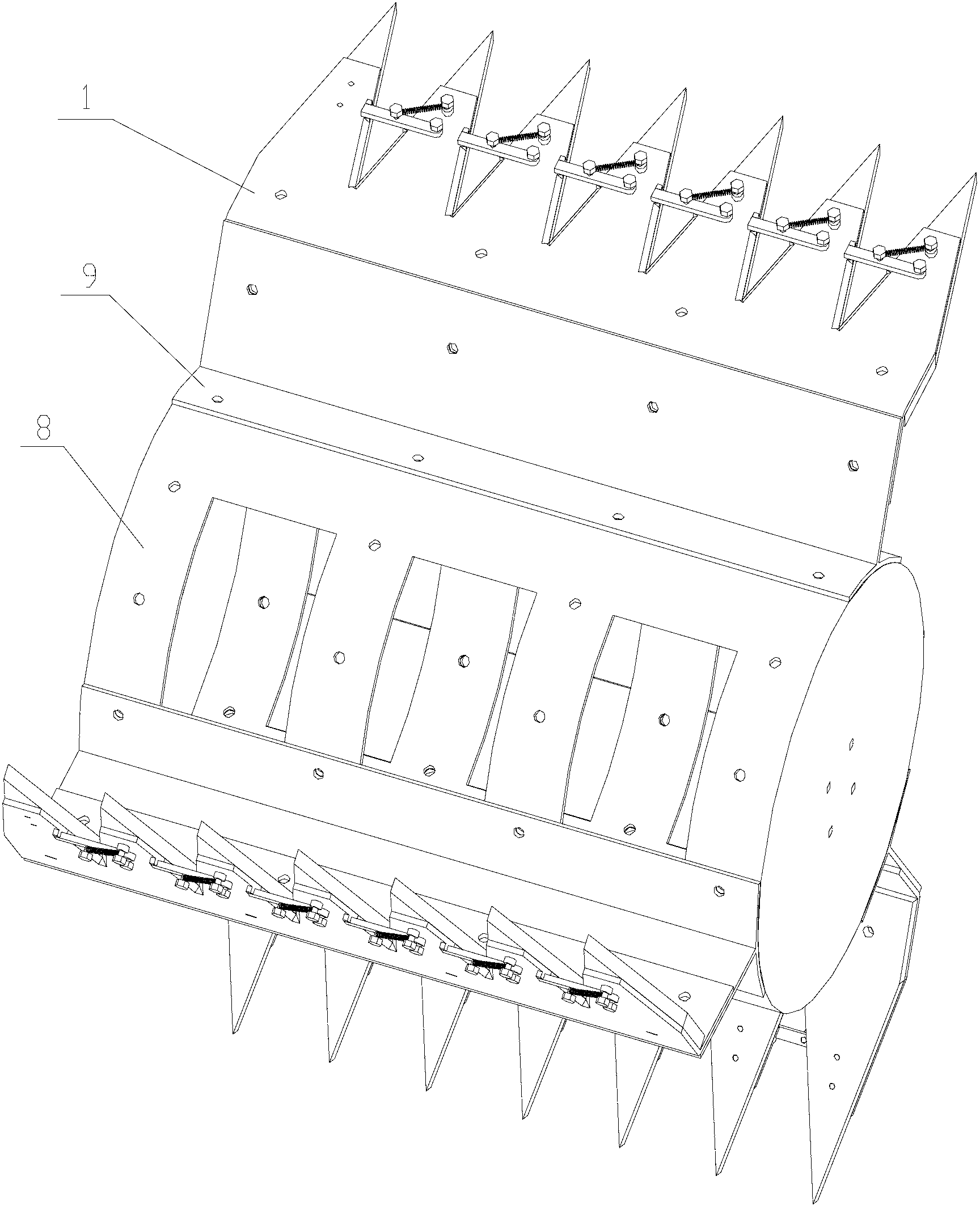

Litchi picking flexible combing-shearing mechanism and rolling combing-shearing device

InactiveCN103262711AImprove accuracy and effectivenessReduce stickingPicking devicesEngineeringMechanical engineering

The invention discloses a litchi picking flexible combing-shearing mechanism and a rolling combing-shearing device. The flexible combing-shearing mechanism comprises a tooth-shaped plate, branch separating components, a sorting component and cutting components, wherein the branching components comprise a plurality of tapered rubber blocks, all the tapered rubber blocks are arranged at the tail ends of all teeth on the tooth-shaped plate respectively, a sorting component is arranged in the middle of a tooth gap between any two adjacent teeth on the tooth-shaped plate, and a cutting component is arranged at a tooth root position of any two adjacent teeth on the tooth-shaped plate. The rolling combing-shearing device is provided with the litchi picking flexible combing-shearing mechanism. According to the litchi picking flexible combing-shearing mechanism and the rolling combing-shearing device, braches with fruits and branches without fruits of litchis can be separated, and effective shear can only be carried out on the branches with the fruits.

Owner:SOUTH CHINA AGRI UNIV

Woodworking sawing machine

ActiveCN103358360AQuick cutImprove cutting efficiencyPortable power driven sawsBark-zones/chip/dust/waste removalIndustrial AccidentEngineering

The invention provides a woodworking sawing machine, and belongs to the technical field of woodworking machines. The technical problems that industrial accidents can occur easily when an existing woodworking sawing machine is operated, and thus personal safety is seriously affected are solved. The woodworking sawing machine comprises a machine frame, an electric saw and a workbench which is fixed on the machine frame. The electric saw comprises a driving motor and a saw blade which is fixed on an output shaft of the driving motor. The workbench is provided with a bar-shaped channel which allows the saw blade to pass through, and the driving motor is placed below the workbench and can slide in the direction of the channel. The upper end of the saw blade passes through the channel and is placed above the workbench. A driving structure which can drive the driving motor to move is arranged between the driving motor and the machine frame. The woodworking sawing machine has the advantages of being capable of reducing the contacting probability of the saw blade and workers and improving the safety.

Owner:颜夏根

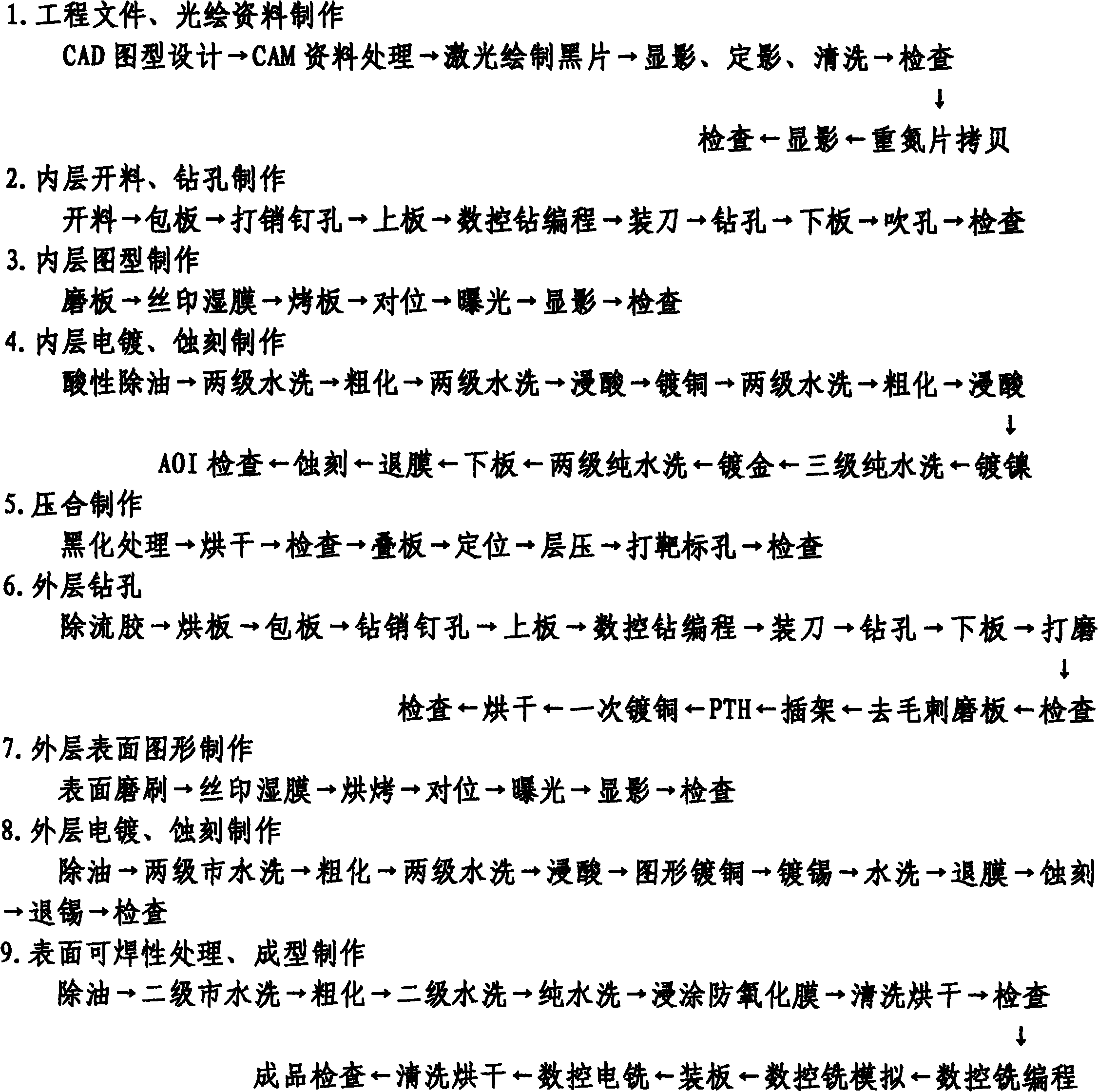

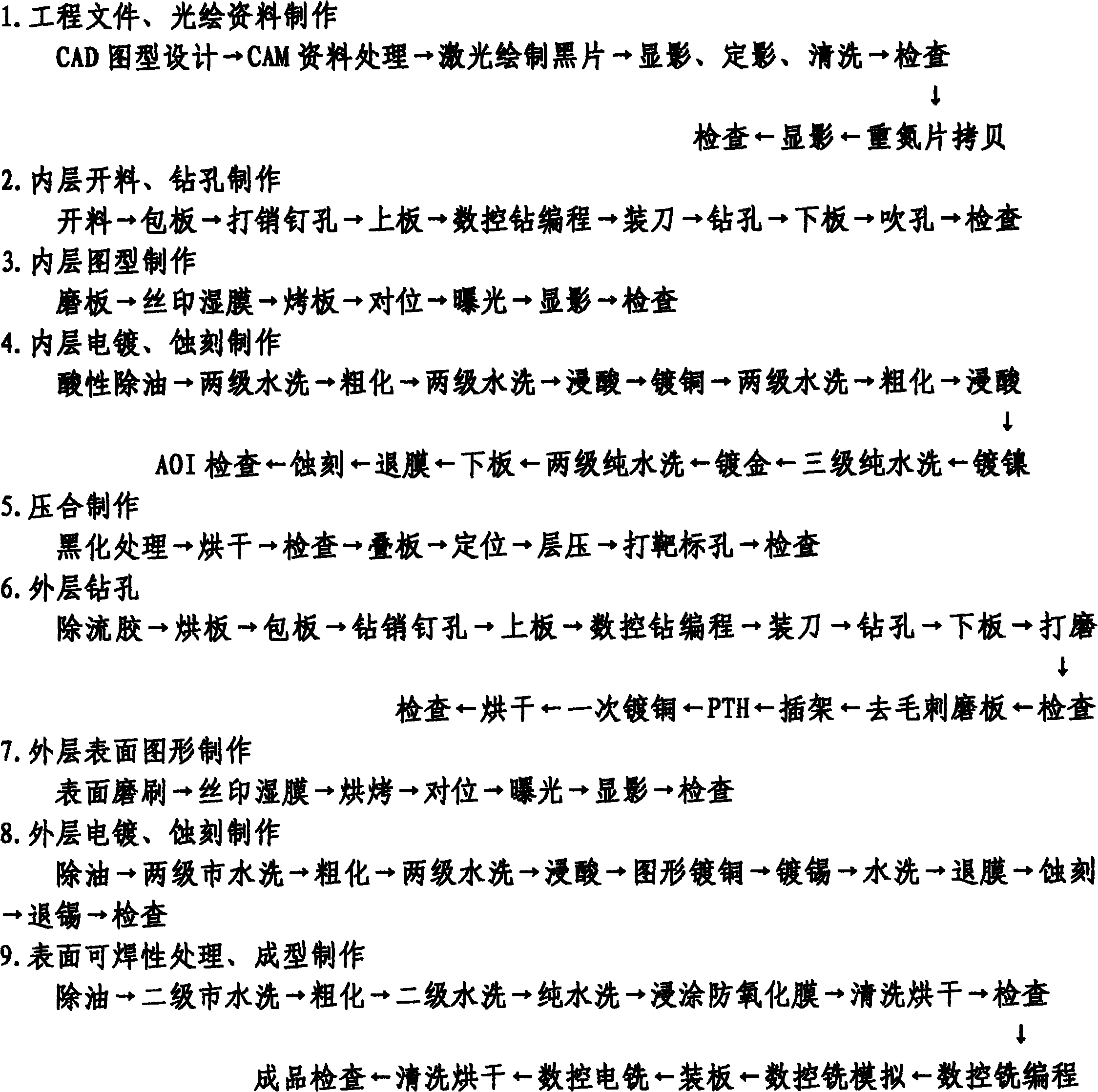

Production method of high-frequency four-layer circuit board

ActiveCN102137551ASolve the edge burr phenomenonImprove performanceMultilayer circuit manufactureSurface patternEngineering

The invention discloses a production method of a high-frequency four-layer circuit board, comprising the following steps of: 1, producing engineering and plotting information; 2, cutting the board and drilling; 3, producing L2 and L3 layer patterns; 4, electroplating and etching; 5, stitching; 6, drilling at an outer layer; 7, producing the surface pattern of the high-frequency four-layer circuit board; 8, electroplating and etching on the outer layer; and 9, performing a surface solderable process and molding. The production method of the high-frequency four-layer circuit board, provided by the invention, can be used producing the circuit board with high accuracy; and the high-frequency four-layer circuit board produced by the method has stable performance.

Owner:TAIZHOU JINDING ELECTRONICS

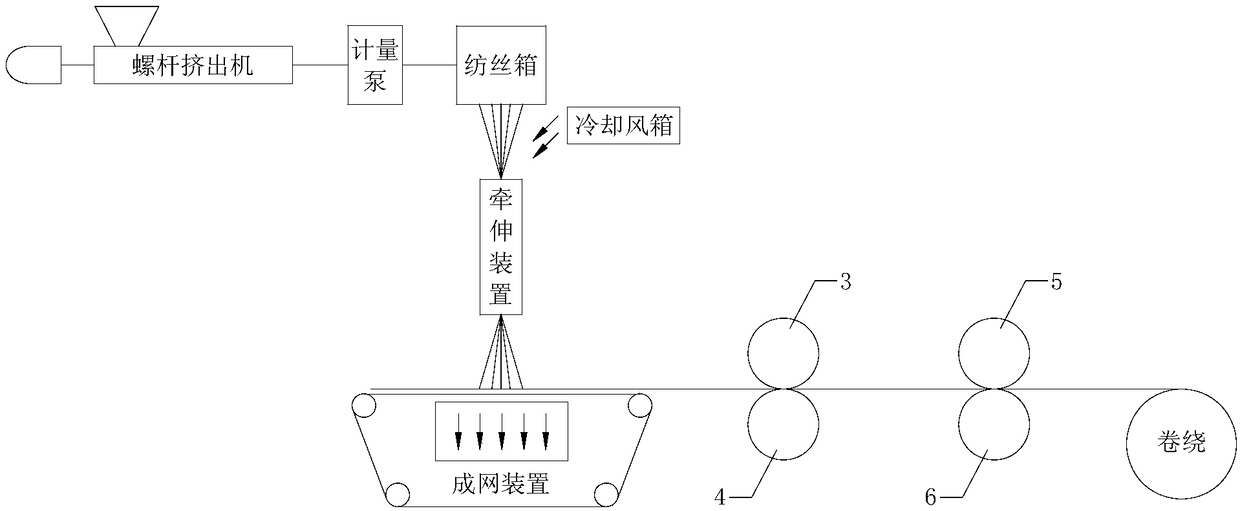

Extremely soft non-woven fabric and production process thereof

PendingCN108532130AImprove rednessHigh tensile strengthFilament forming substance formingPattern makingSmooth surfacePolypropylene

The invention discloses an extremely soft non-woven fabric. The non-woven fabric comprises a milky white extremely soft spun-bonding non-woven fabric, and the milky white extremely soft spun-bonding non-woven fabric is densely covered with rolling points. The non-woven fabric can be better applied to a diaper base film and a waistline, the milky white extremely soft spun-bonding non-woven fabric blended by a propylene-based elastic material, a milky white master batch, a soft master batch and polypropylene is adopted, the softness is better than ordinary products, the problems of redness and swelling, itching and the like caused by friction between the skin and a non-woven fabric are solved, the non-woven fabric has an effective protective effect, the milky white extremely soft spun-bonding non-woven fabric is densely covered with the rolling points in diamond arrangement, the tensile strength of the non-woven fabric is improved, the fluffing phenomenon can be prevented, and the non-woven fabric has smooth surface and is softer during use.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

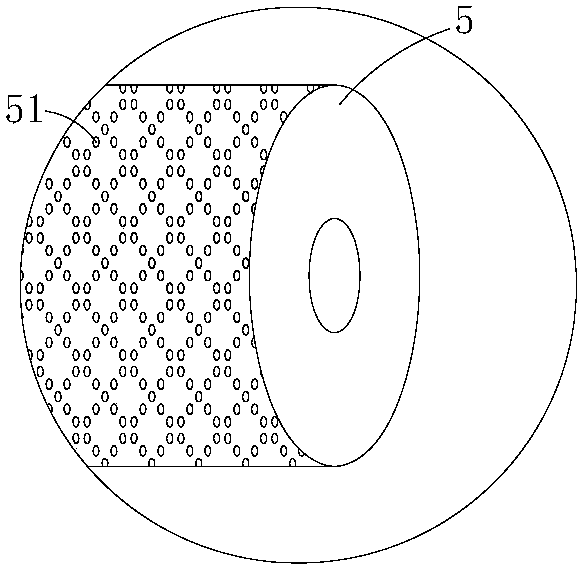

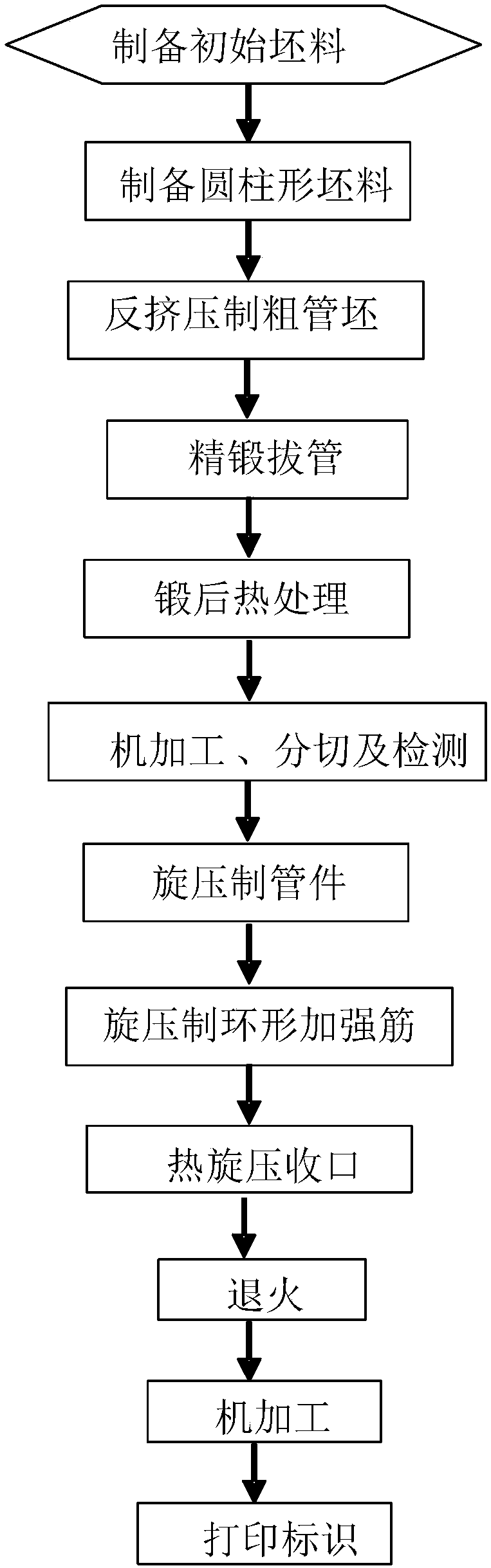

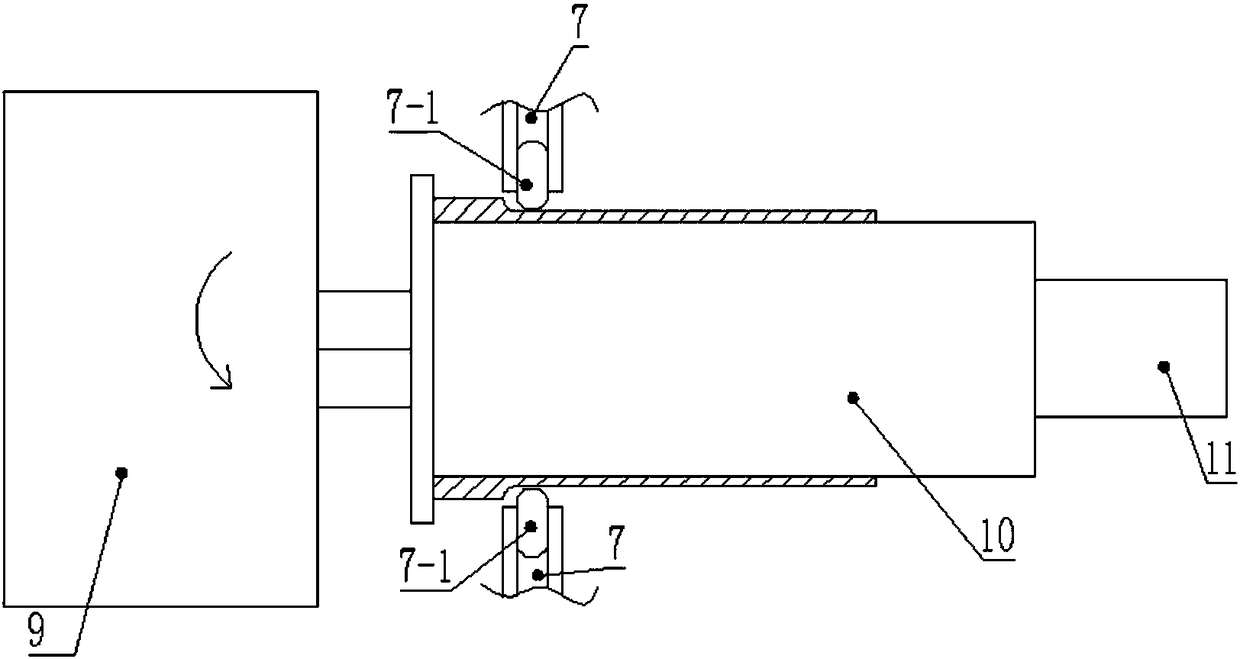

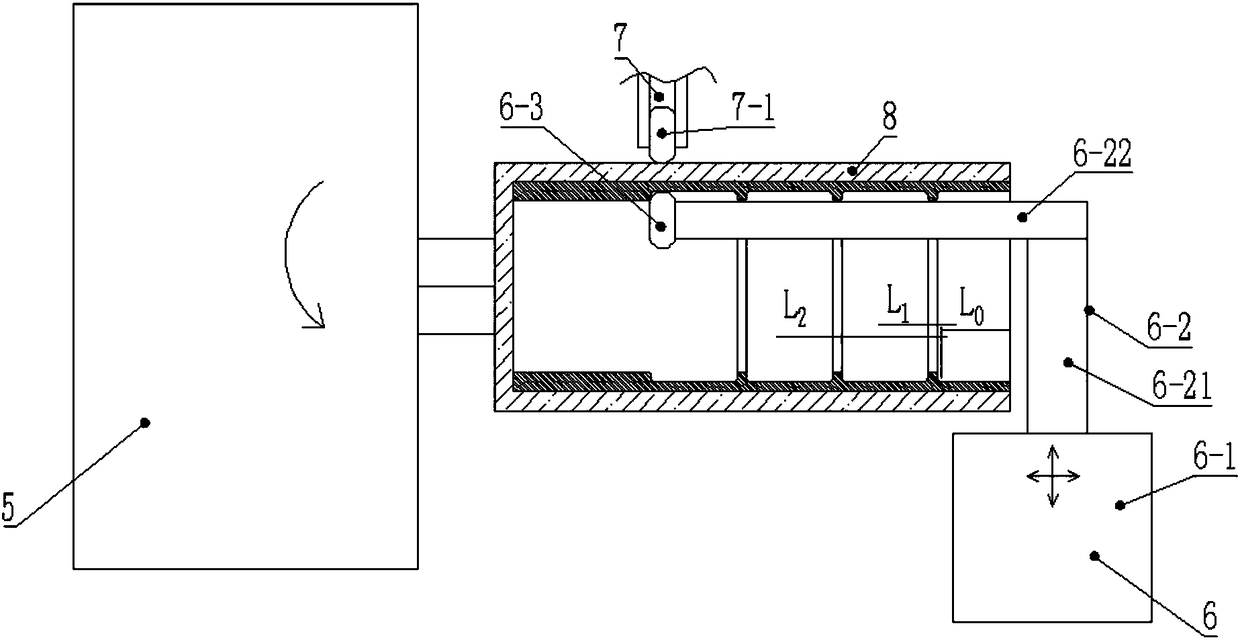

Preparation method of seamless high-pressure gas cylinder and gas cylinder

ActiveCN108188301ASimple processGood surface qualityPressure vesselsHollow articlesTube drawingHigh pressure

The invention relates to a preparation method of a seamless high-pressure gas cylinder. The preparation method comprises the following steps of 1, preparing a blank; 2, extruding the blank reversely to machine a rough tube blank; 3, carrying out precision forging and tube drawing to form a precision forging tube blank; 4, carrying out heat treatment on the precision forging tube blank; 5, carryingout spinning to prepare a tube, reducting the thickness of the tube blank subjected to precision forging to a required thickness by thickness reduction spinning equipment, forming the tube, and preparing annular reinforcing ribs integrally formed with the tube on the inner wall of the tube through spinning; and 6, sealing the opening by hot spinning, and preparing the gas cylinder. The inventionfurther relates to the seamless high-pressure gas cylinder prepared by the method, the inner wall of the gas cylinder is provided with the integrally-formed annular reinforcing ribs, so that the pressure-bearing capacity of the tube is improved, and the tube is attractive in appearance and easy to install; and materials are saved, the cost is low.

Owner:烟台台海材料科技有限公司

Flexible orthopedic shoe pad and preparation method thereof

ActiveCN109674144APrecise modulus designCorrectly designedFoot measurement devicesAdditive manufacturing apparatusStrength of materialsData acquisition

The invention discloses a flexible orthopedic shoe pad and a preparation method thereof. The method comprises the following steps: establishing a shoe pad model having foot bottom morphology accordingto foot data; by acquiring foot evaluation index data, foot bottom pressure distribution data and foot appearance scanning data, by using a corresponding optimization relation between key shoe-pad appearance parameters and the foot evaluation indexes and a corresponding relation between material performance distribution of the shoe pad and foot bottom pressure distribution, adjusting the outer contour model of the orthopedic shoe pad and the mechanical property of the material; and preparing the flexible orthopedic shoe pad by adopting a 3D printing process. The shoe pad is filled by virtue of a porous structure with adjustable mechanical property of the material, and finally the personalized porous shoe pad model is printed, so that the shoe pad can bring the optimal comfort level to a wearer and is convenient and rapid.

Owner:XI AN JIAOTONG UNIV

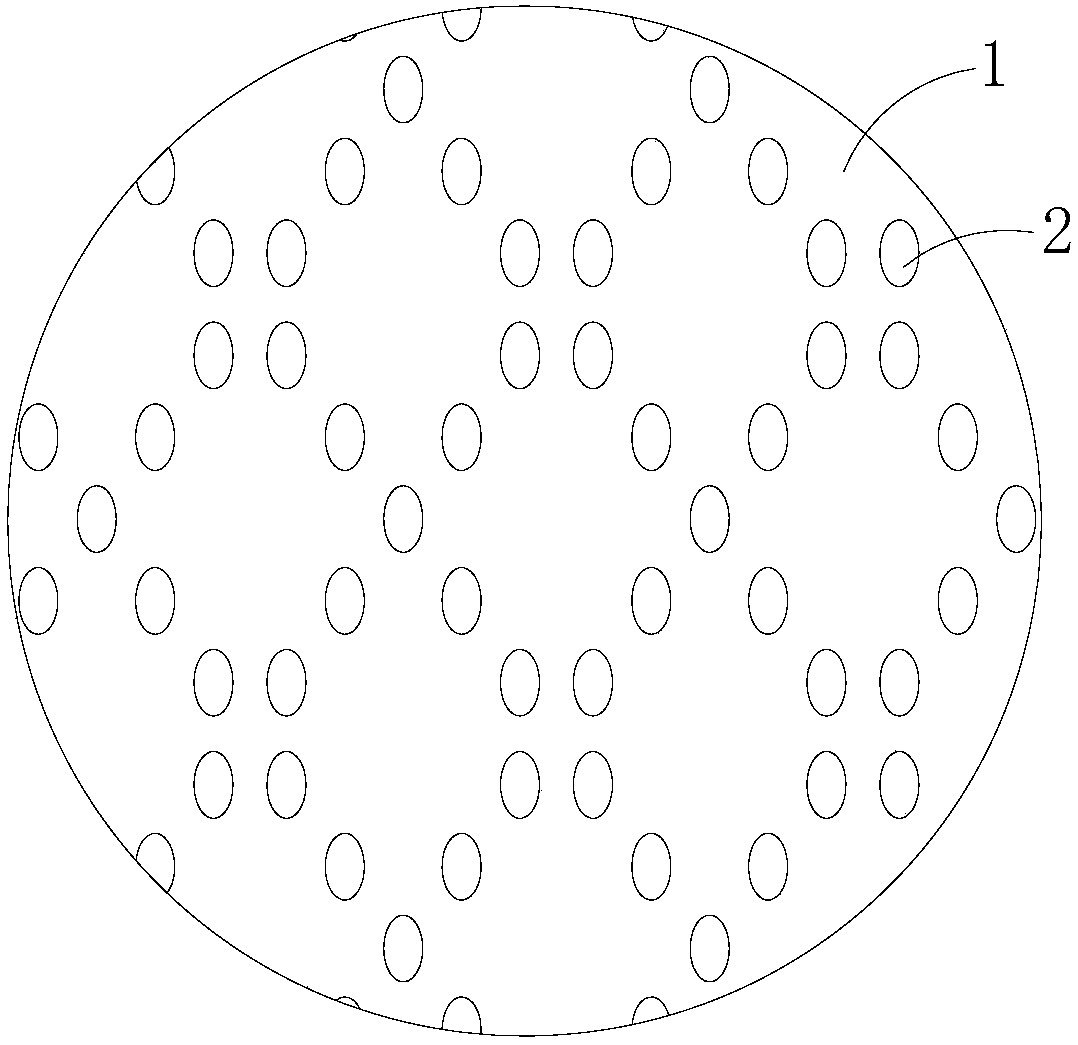

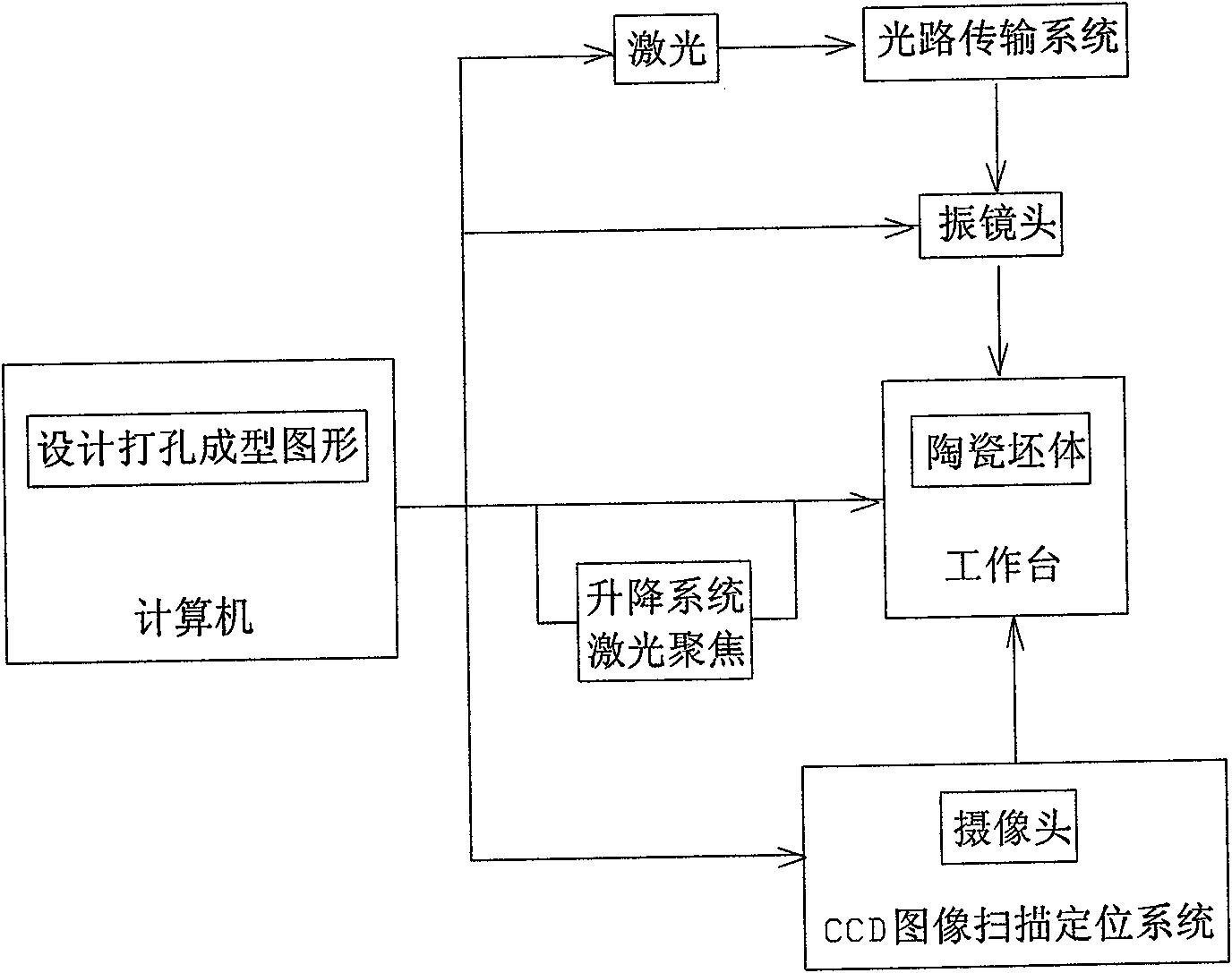

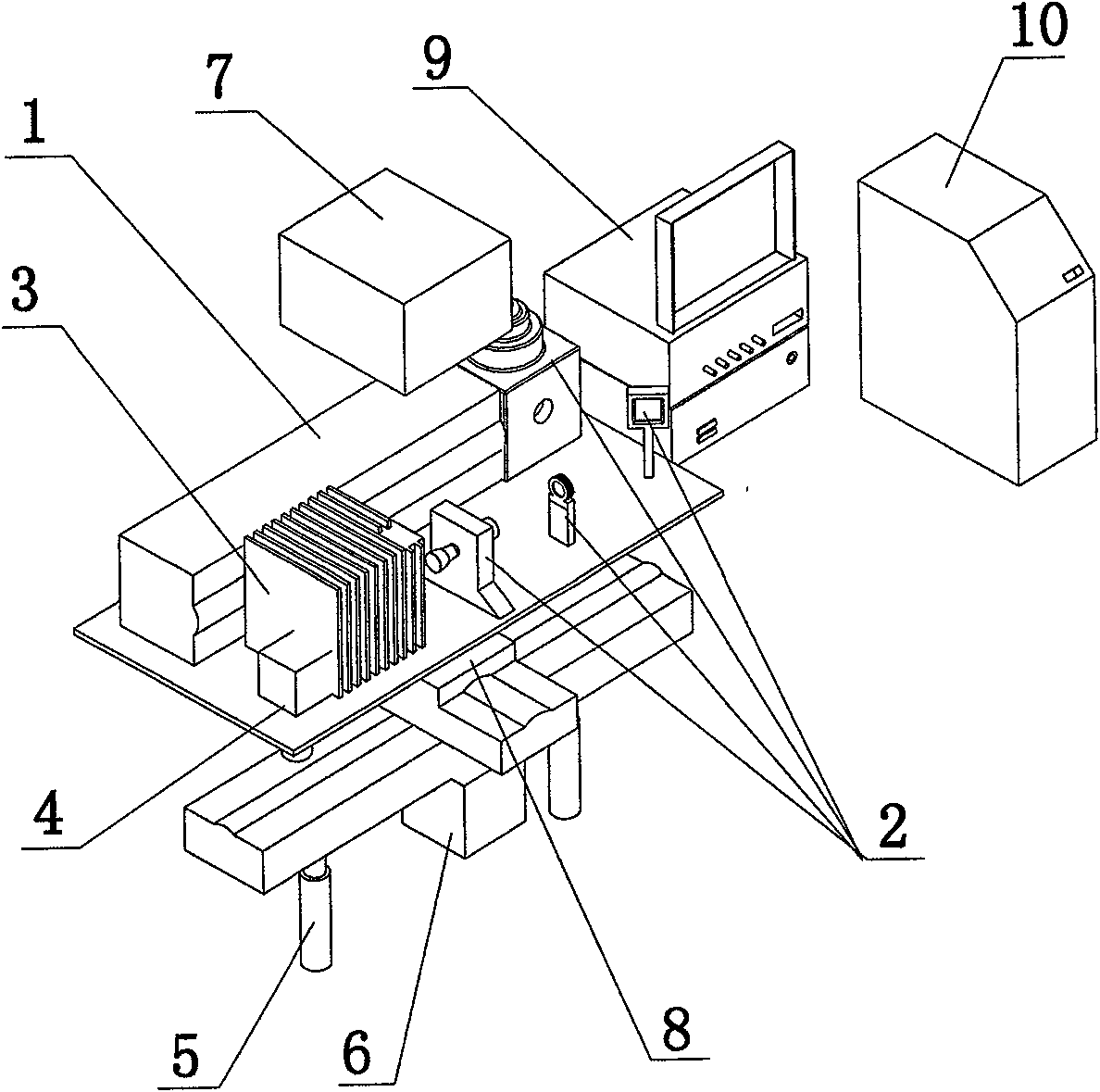

Method for molding multi-layer plate-type array-structure ceramic filter

InactiveCN101673868AAvoid strainLong solution cycleImpedence networksWaveguide type devicesPunchingLight energy

The invention discloses a method for molding a multi-layer plate-type array-structure ceramic filter, relating to a processing and molding method of an electronic element, and comprising the followingmain steps: putting a ceramic body printed with positioning points on a working bench; loading the designed pattern for punching and molding by a computer, and setting parameters for the punching andcutting processes; setting the size of the light energy of a laser light source; controlling a machine vision system to scan the printed pattern on the ceramic body by the computer so as to automatically capture and recognize the positioning points, driving the working bench to move the ceramic body to a cutting position below the laser beam according to the positioning points, controlling a vibrating lens to move according to the position of the positioning points based on the designed pattern for punching and molding by the computer so as to carry out laser punching and cutting, and punching and cutting the inner hole and the outer profile of the ceramic body to mold the ceramic filter. The method for molding a multi-layer plate-type array-structure ceramic filter utilizes the laser toautomatically capture and cut, so that the cutting precision is high, the speed is high, and the damage on the surface of the filter is small. The method for molding a multi-layer plate-type array-structure ceramic filter is applicable to filters with requirements such as small space, high precision, large capacity, ultra-large thickness and diversity, and improves the production efficiency and the qualification rate of the filter products.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

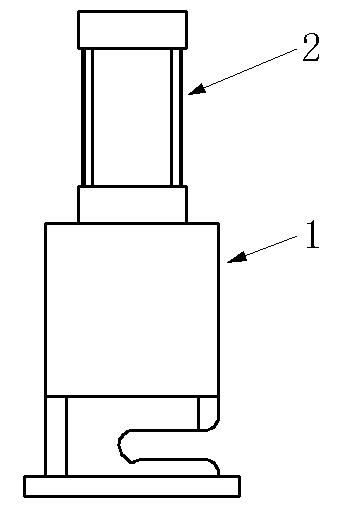

Nylon tube feeder and using method thereof

InactiveCN102794783AMeet the requirementsGuaranteed stabilityMetal working apparatusEngineeringPiston rod

The invention discloses a nylon tube feeder and a using method thereof, and belongs to enginery. The nylon tube feeder mainly comprises a feeder framework, a motive power air cylinder, a nylon tube cutter component, an auxiliary calibrated scale assembly for measuring the cutting length and a pneumatic control device for implementing cutting operation; the feeder framework is a metal support structure of the device; the motive power air cylinder for providing cutting motive power is fixed on the upper part of the feeder framework; a nylon tube cutter is installed on the lower part of the motive power air cylinder; the motive power air cylinder provides cutting motive power for the nylon tube cutter; a left fixed block and a right fixed block which are fixed on the base at the bottom of the feeder framework form a containing space, and the containing space is provided with a matched clearance for containing the vertical cutting motion of a cutter body of the nylon tube cutter; the motive power air cylinder comprises an air cylinder body and a piston rod; the nylon tube cutter comprises the cutter body and a sliding block; and the nylon tube cutter and the piston rod are fixedly connected. The nylon tube feeder is small in volume and simple in structure, and when the nylon tube is cut, the cutting quality is ensured because of the extrusion effect of the nylon tube cutter.

Owner:CHANGCHUN CHINAUST AUTOMOBILE PARTS

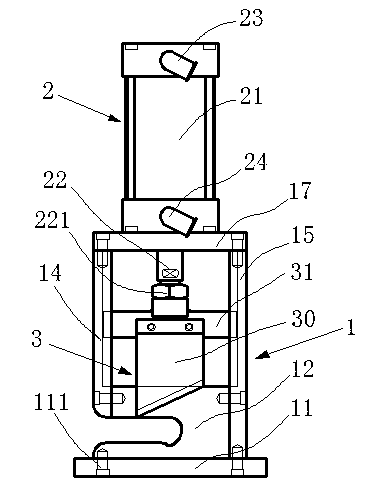

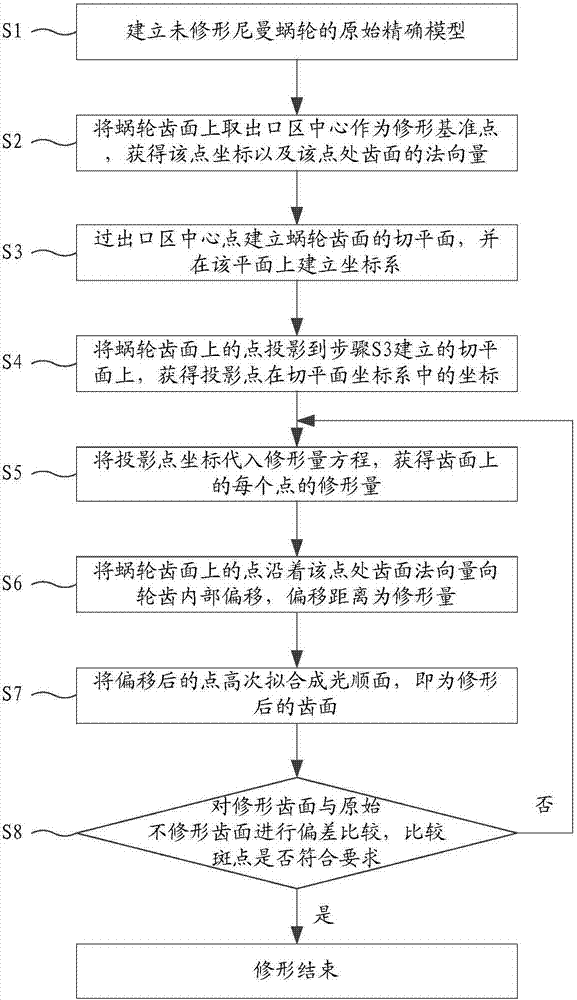

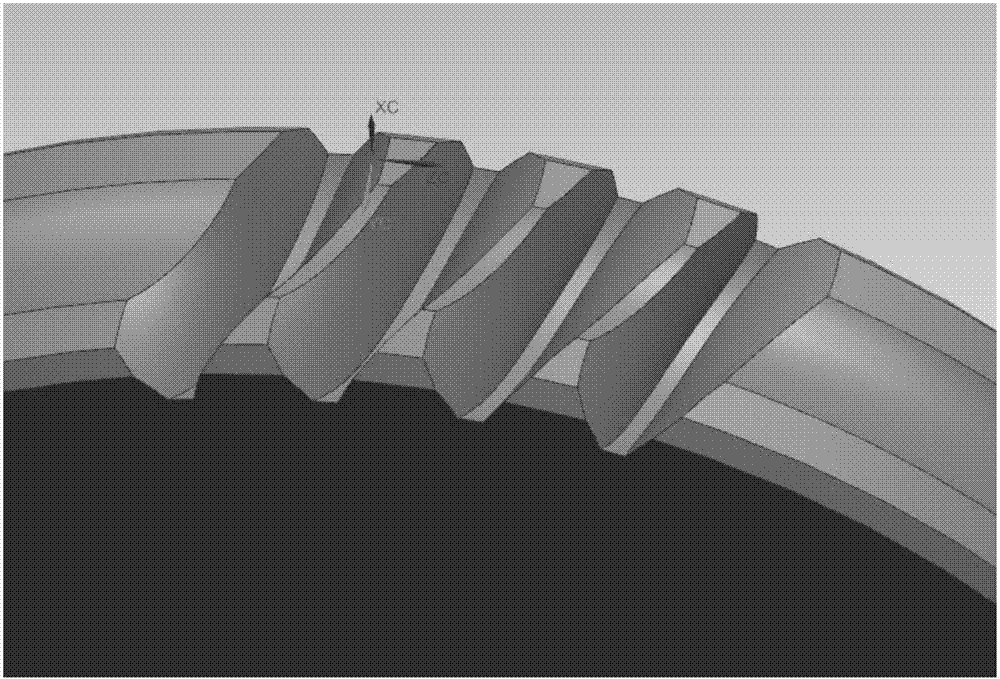

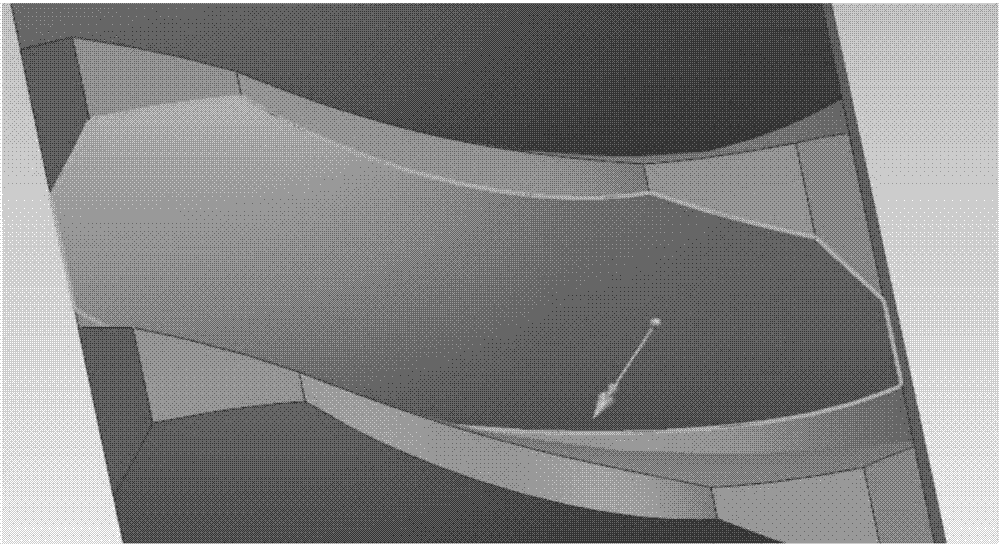

Point contact shape correcting method of Niemain worm gear

ActiveCN107269801AGuaranteed to be smoothRealize controllablePortable liftingGearing elementsStress concentrationNoise level

The invention discloses a point contact shape correcting method of a Niemain worm gear. The method includes the steps that S1, an original precise model is established; S2, coordinates of a central point of an exit region and the normal vector of the tooth surface of the point are acquired; S3, a tangent plane of the tooth surface of the worm gear is established by passing the central point of the exit region, and a coordinate system is established on the plane; S4, points on the tooth surface of the worm gear are projected on the tangent plane; S5, projection point coordinates are substituted into a shape correcting amount equation to obtain the shape correcting amount of projected points; S6, the points on the tooth surface of the worm gear deviate into gear teeth along the normal vectors of the tooth surfaces of the points; S7, the deviating points are fit into a smooth surface, namely a shape-corrected tooth surface in a high order mode; S8, the shape-corrected tooth surface and the original tooth surface are subjected to deviation comparison in three-dimensional software, if spots meet requirements, the operation is completed, or else, shape correcting amount equation coefficients in S5 are adjusted, and S5 to S8 are repeated. The method has the advantages that the sensitivity of the tooth surface of the Niemain worm gear to errors and tooth surface contact stress concentration are effectively improved, drive precision is improved, and the vibration and noise level of engagement is reduced.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

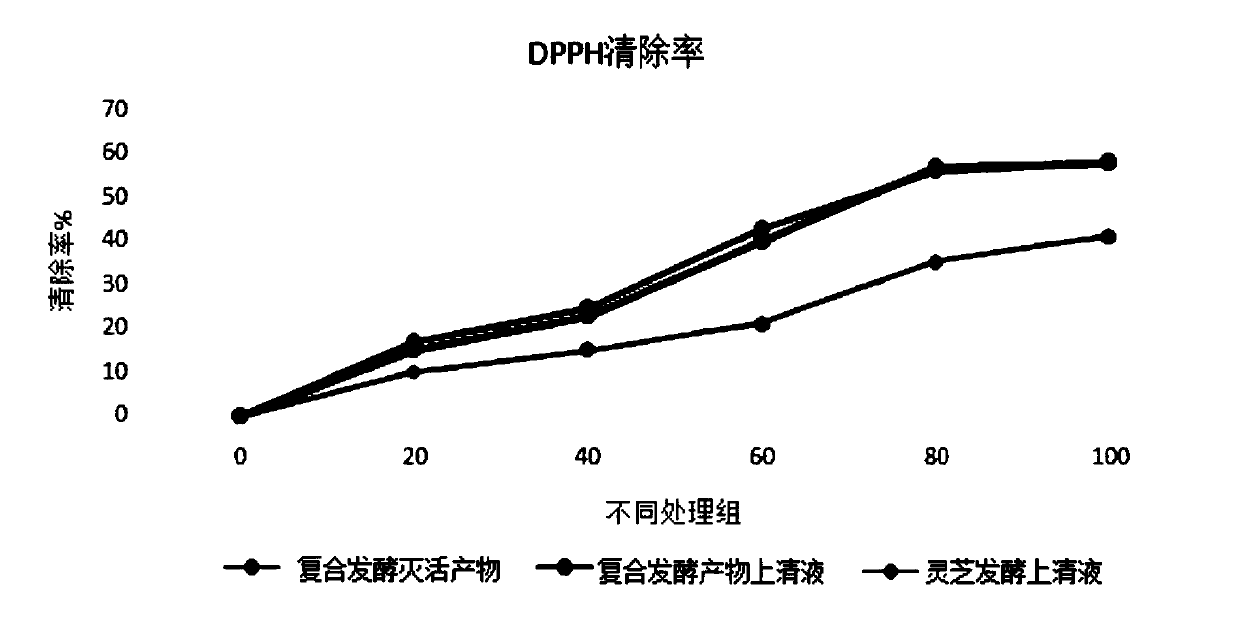

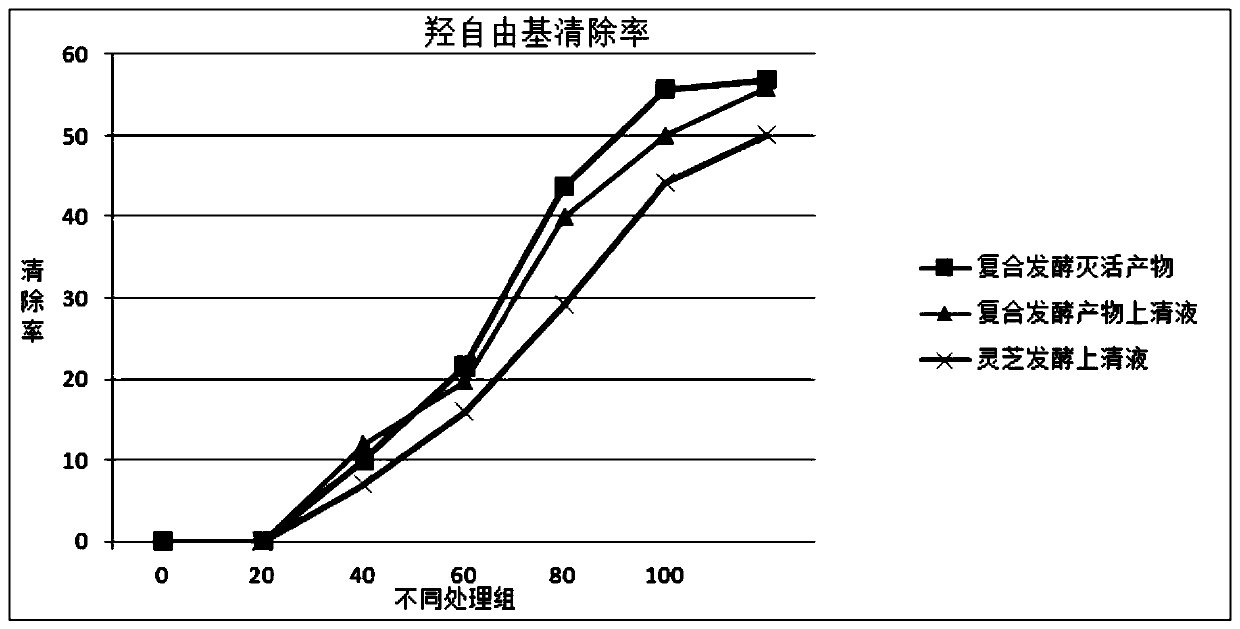

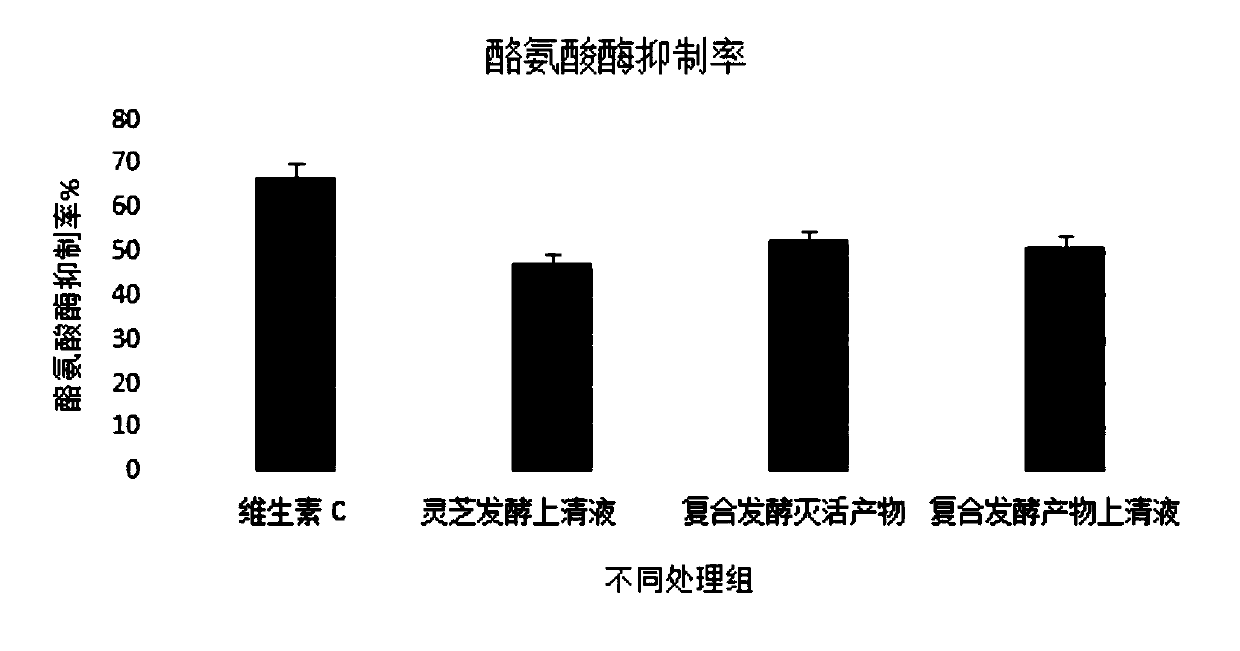

Lucid ganoderma-probiotic composite fermentation product, and preparation method and application thereof

InactiveCN111053711AImprove antioxidant capacityFast absorptionCosmetic preparationsToilet preparationsBiotechnologyCentrifugation

The invention discloses a lucid ganoderma-probiotic composite fermentation product and a preparation method and application thereof. The lucid ganoderma-probiotic composite fermentation product comprises a lucid ganoderma fermentation supernatant, a probiotic fermentation liquid and functional nutritional ingredients. The preparation method comprises the following steps: fermenting lucidum ganoderma mycelia, carrying out centrifuging, taking the supernatant, and mixing the supernatant with the functional nutritional ingredients; then adding the probiotic fermentation liquid into a mixture obtained in the previous step, and carrying out fermentation; and finally, subjecting a fermentation product to inactivation or centrifugation to obtain the composite fermentation product. The composite fermentation product contains rich nutritional ingredients such as polysaccharides, polypeptides and organic acids and is easily and fully absorbed by the skin, and the composite fermentation product contains ingredients such as microelements which can promote repair and recovery of injured skin, so the composite fermentation product has a good skin care effect. The composite fermentation product is beneficial for skin health and is not polluted by enzymes, chemicals and the like; the whole fermentation system is mild in conditions; and the preparation method is simple to operate and controllable in cost, and is beneficial for large-scale production.

Owner:山东凤凰生物科技股份有限公司

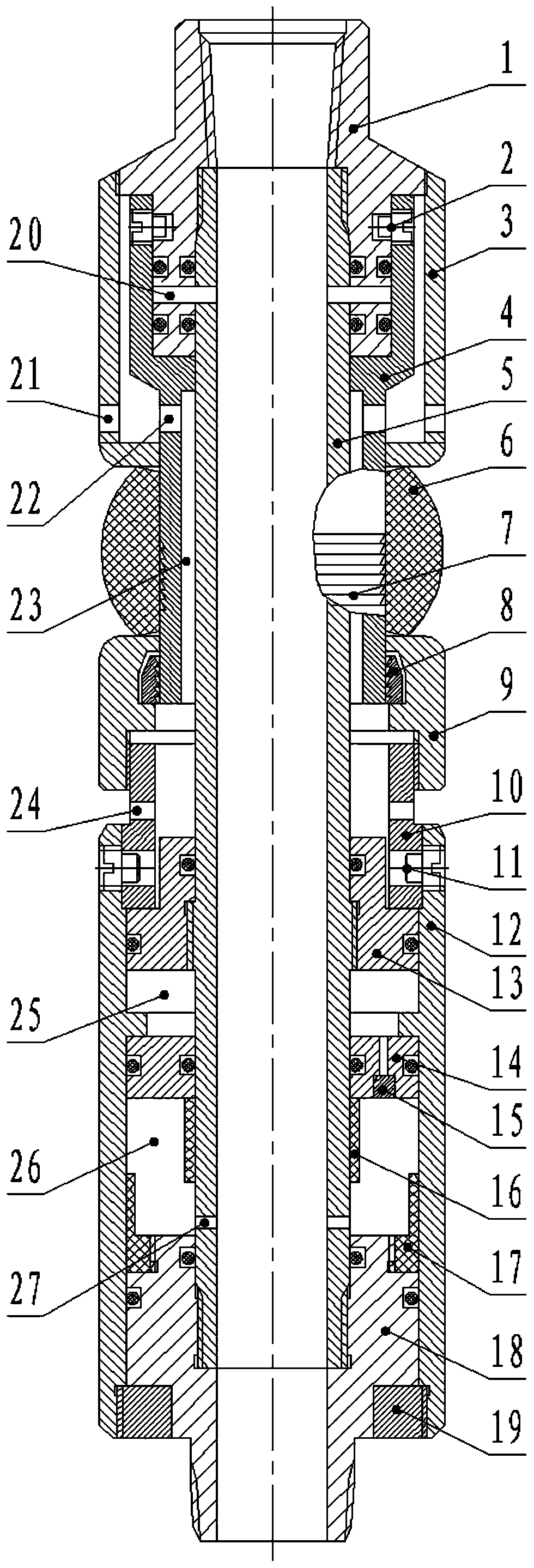

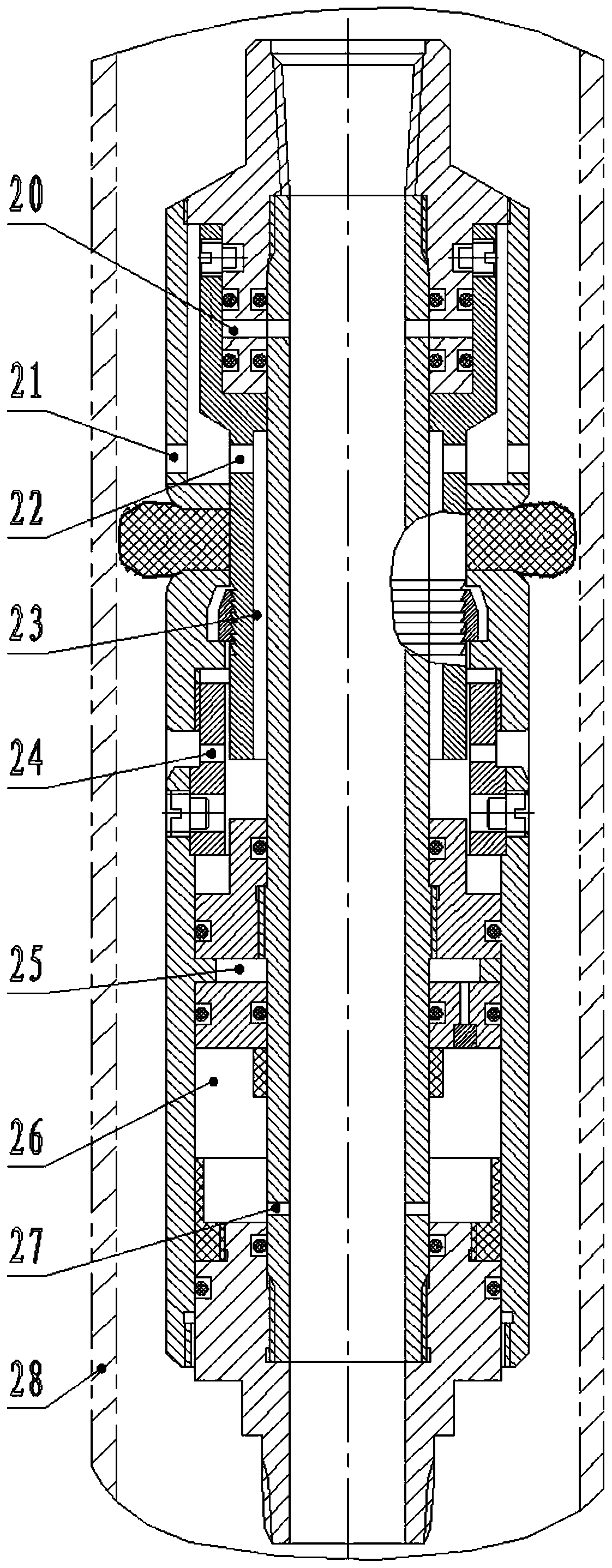

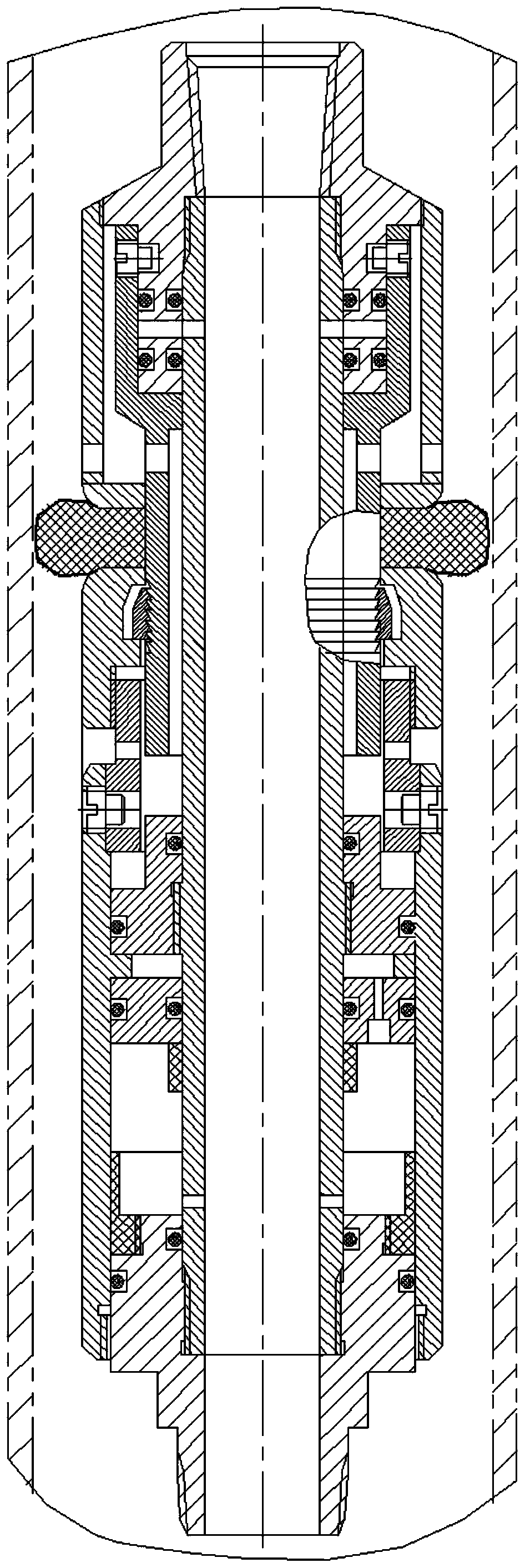

Self-expanding automatic oil drain device

InactiveCN109854207AAchieve continuous tightening functionRealize the self-righting functionDrilling rodsWell/borehole valve arrangementsUpper jointEngineering

The invention belongs to the field of downhole tools for oil field production, and particularly relates to a self-expanding automatic oil drain device. The self-expanding automatic oil drain device comprises an upper joint, a central pipe, a lower joint, an outer central pipe, a shear pin, an upper outer sleeve, an elastic damping ring assembly, a clamp spring carrier, a clamp spring and a lower outer sleeve; the upper end of the central pipe is connected with the upper joint in a threaded mode, and oil drain holes are formed in the side wall, under the positions of the threaded connection, ofthe central pipe and the side wall, corresponding to the threaded connecting positions, of the upper joint; the outer central pipe sleeves the outer part of the central pipe and a ring cavity for liquid passing is reserved between the central pipe and the outer central pipe, and the ring cavity is called a liquid passing passage; the upper end of the outer central pipe sleeves the upper joint andthe oil drain holes are blocked; and the outer central pipe is connected with the upper joint through the shear pin, and the upper outer sleeve sleeves the outer part of the outer central pipe, and aring cavity is reserved between the upper outer sleeve and the outer central pipe. According to the self-expanding automatic oil drain device, the problems of tedious processes of pressing, repeatedly lifting and releasing a pipe string, throwing weights and the like of a conventional oil drainer are solved; and the automatic oil drain can be realized with the linkage of the pipe string, and theoperation efficiency is greatly improved.

Owner:大庆吉庆雨科技开发有限公司

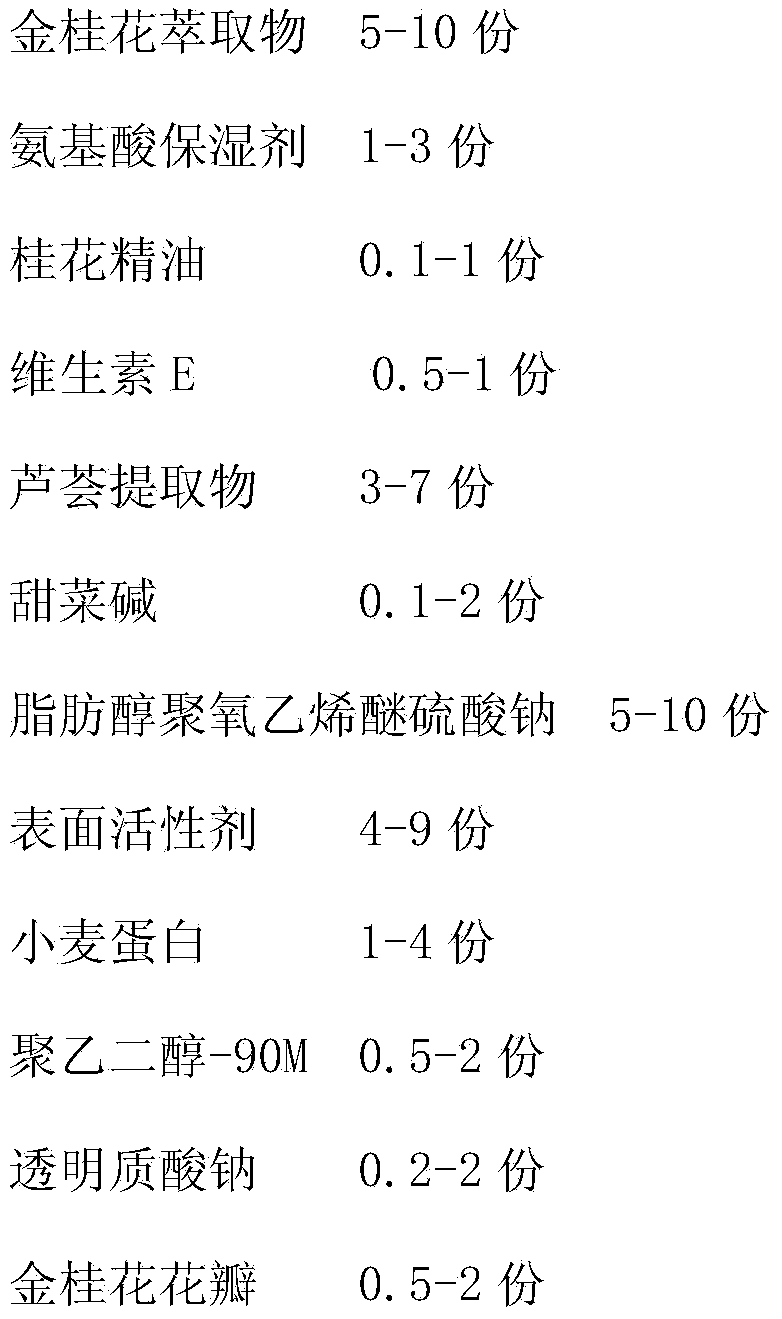

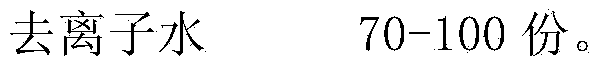

Shower gel

ActiveCN103637940AFast absorptionHigh activityCosmetic preparationsToilet preparationsBetaineShower gel

The invention discloses shower gel. The shower gel comprises the following components in weight ratio: 5-10 parts of osmanthus extract, 1-3 parts of ammonic acid humectants, 0.1-1 part of sweet-scented osmanthus essential oil, 0.5-1 part of vitamin E, 3-7 parts of aloe extract, 0.1-2 parts of glycine betaine, 5-10 parts of fatty alcohol polyoxyethylene ether sodium sulfate, 4-9 parts of surface active agents, 1-4 parts of wheat protein, 0.5-2 parts of polyethylene glycol-90M, 0.2-2 parts of sodium hyaluronate, 0.5-2 parts of osmanthus petals and 70-100 parts of deionized water. The shower gel is rich and fine in foam, moderate in detersive power, has no stimulation to hair, skin and eyes, is smooth in skin after bathing, and especially enables people to feel cool and comfortable.

Owner:广东龙泰实业有限公司

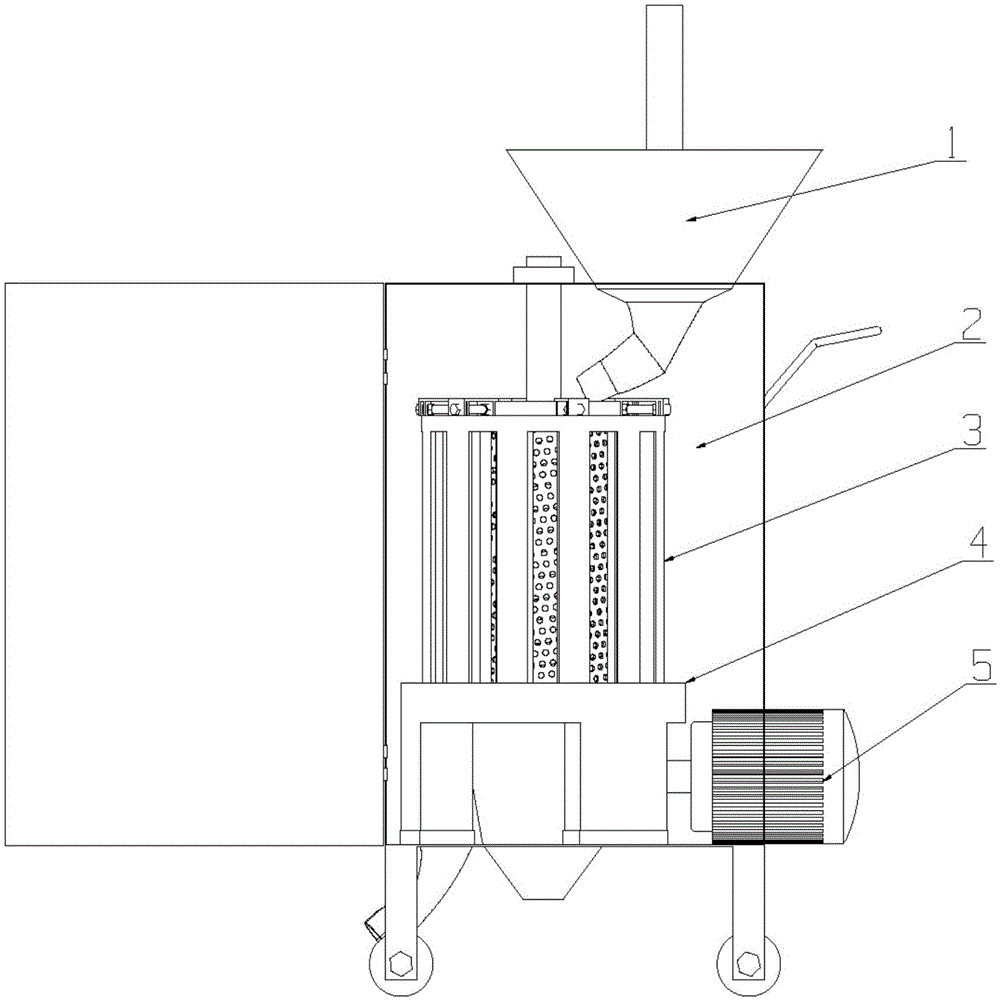

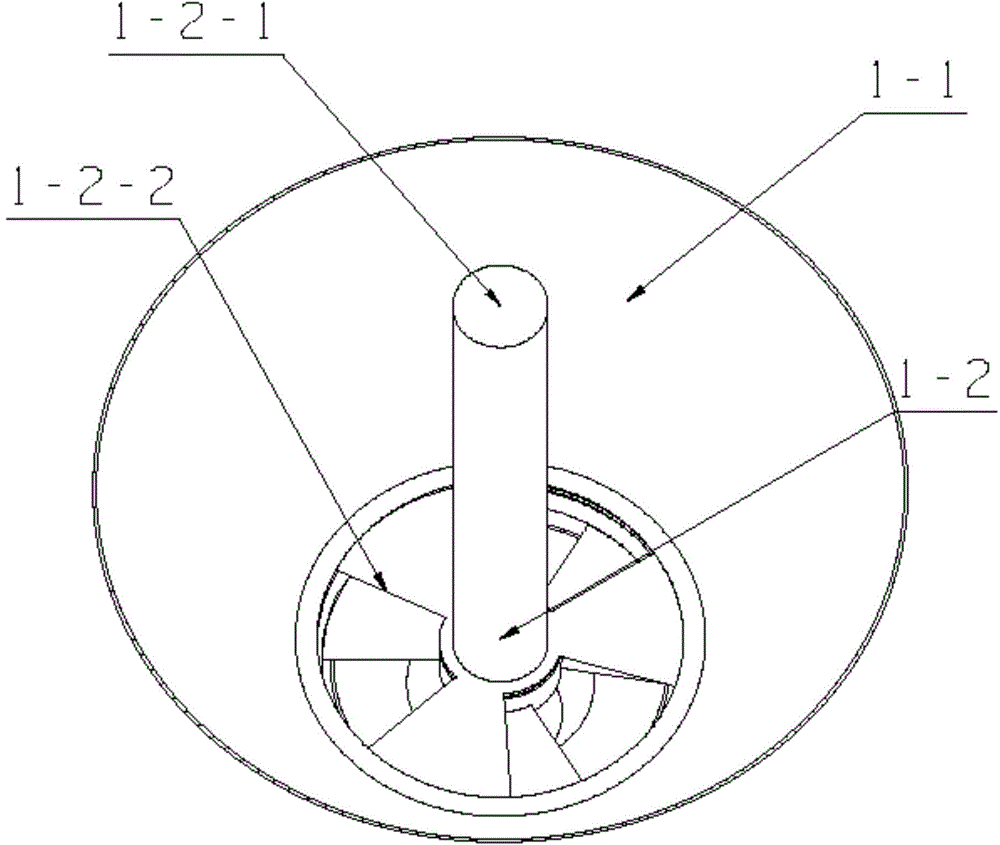

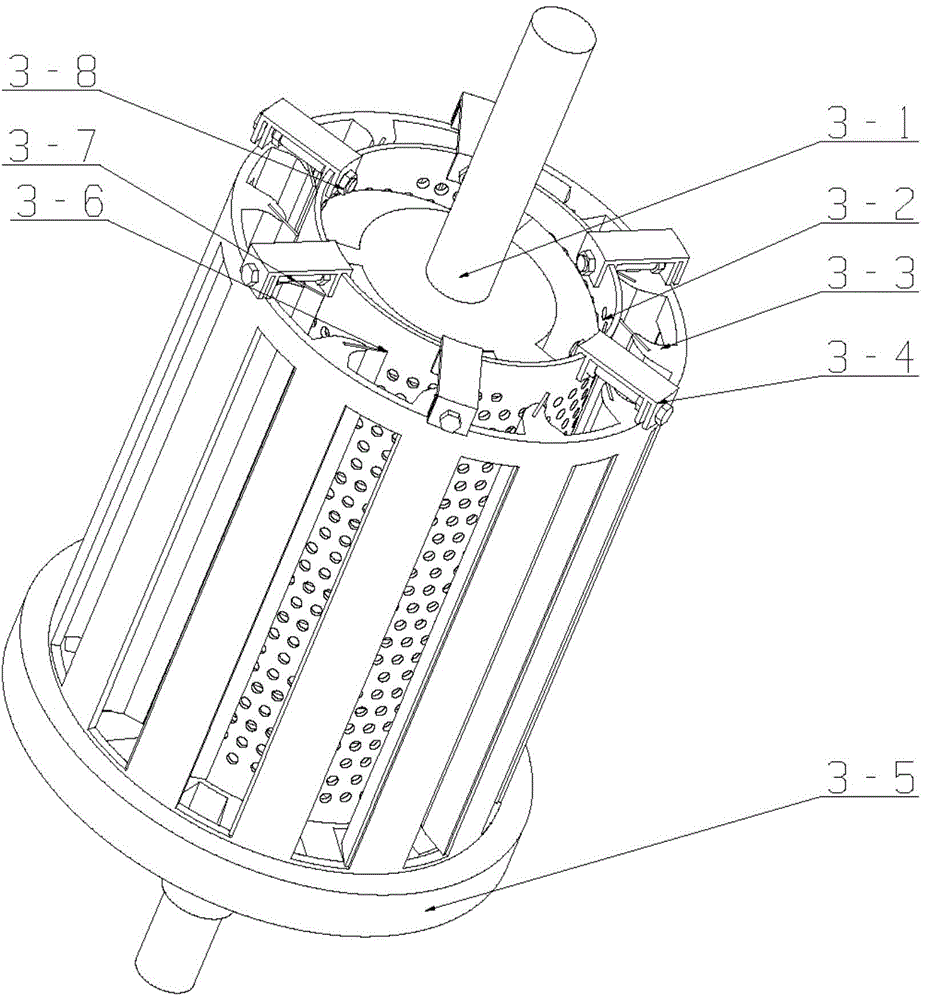

Equipment for deep processing of spiral shells

InactiveCN104886223AIncrease the relative speedQuality improvementShellfish processingPore diameterEngineering

The invention discloses equipment for deep processing of spiral shells, comprising a machine body. A feeding device, a tail cutting device, a discharge device and a transmission device are arranged on the machine body. The tail cutting device comprises a spiral revolving shaft which is vertically arranged and provided with spiral orbits on the outer wall, a tail embedding cylinder sleeved outside the spiral revolving shaft, and a rotating cylinder sleeved outside the tail embedding cylinder. The two ends of the spiral revolving shaft are connected to the machine body in a rotating mode through bearings and bearing pedestals. The protruded part of each spiral orbit, which is in contact with the tail embedding cylinder, is provided with flexible scrapers. A plurality of pores are densely distributed on the wall of the tail embedding cylinder, and the outer bore diameter of each pore is less than the inner pore diameter. Cutters at the outer side of the pores are fixed on the inner wall of the rotating cylinder. The transmission device drives the spiral revolving shaft and the rotating cylinder to rotate in opposite directions. With the adoption of the equipment disclosed in the invention, the tail shells of the spiral shells can be processed more conveniently, omission in cutting can be avoided, and the survival rate of the spiral shells is improved.

Owner:全椒县赤镇龙虾经济专业合作社

Method for drilling hole with plastic clay for protecting wall of hole

InactiveCN101545357AImprove drilling efficiencyReduce drilling costsDrilling machines and methodsDrill holeDrill bit

The invention discloses a method for drilling a hole with plastic clay for protecting the wall of the hole, which relates to a drilling method. The invention aims to provide the method for drilling the hole with the plastic clay for protecting the wall of the hole, which can effectively prevent drill hole wall from collapsing and jamming of a drilling tool, and can improve the hole quality and charging conditions as well as the blasting effect. The aim of the invention is achieved through the following technical proposal: the method for drilling the hole with the plastic clay for protecting the wall of the hole comprises the following steps: (1) adding water to clay and blending the mixture into a plastic state; (2) in the process of drilling a bore hole, when a rock land lot is crushed, forming the hole preliminarily first, then pulling out the drilling tool, putting the plastic clay into the bore hole, putting the drilling tool into the hole again, and moving a drill bit up and down while rotating so that the drill bit drags and extrudes the plastic clay; and (3) blocking the orifice of the bore hole after the hole is formed, and waiting for charging. The method is mainly applicable for drilling holes in blasting engineering.

Owner:CHINA RAILWAY HI TECH IND CORP LTD +1

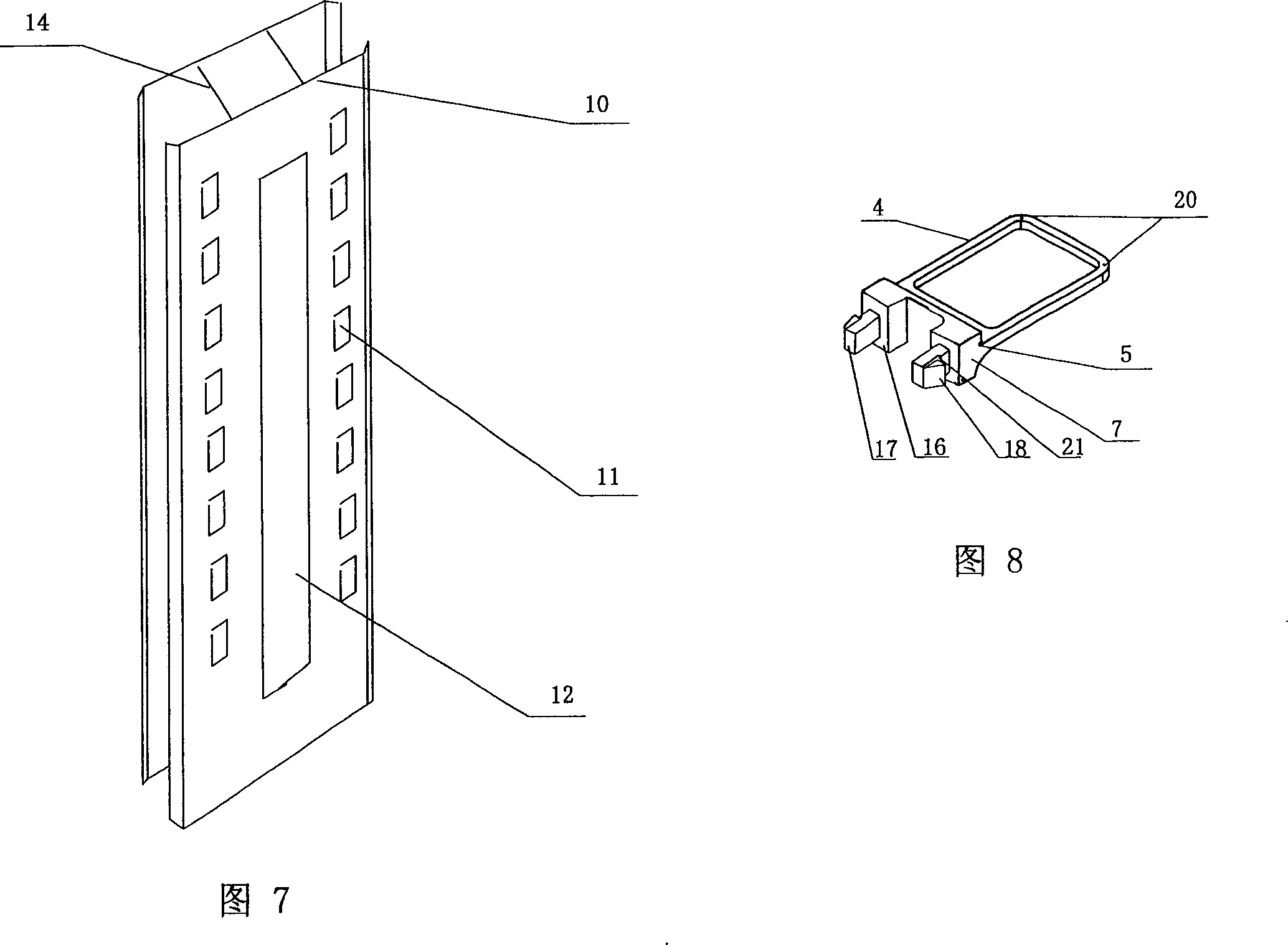

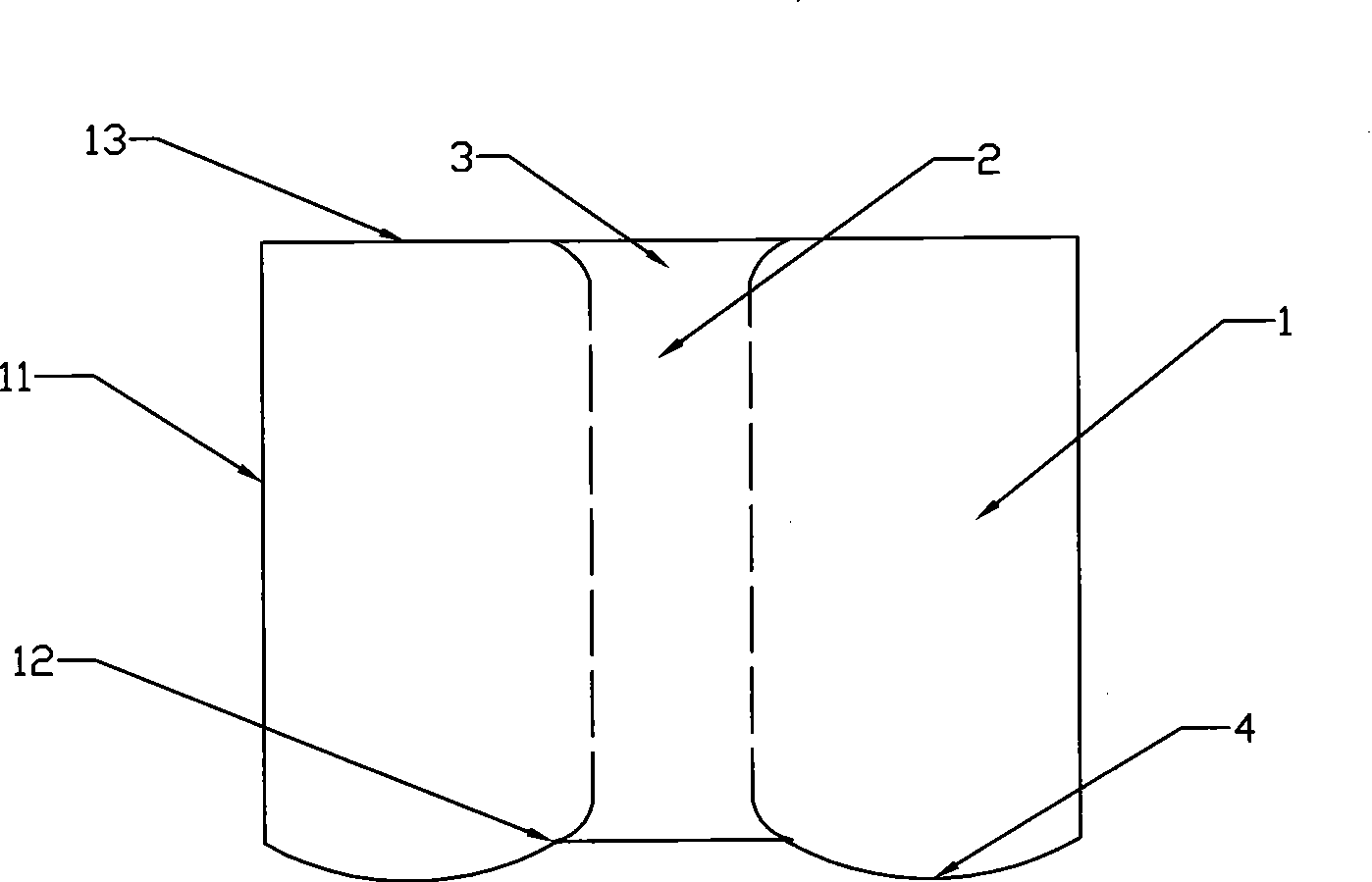

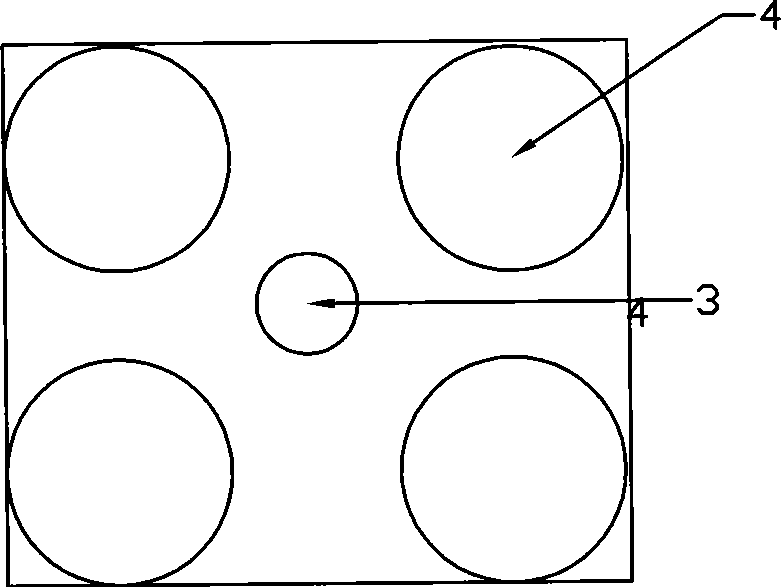

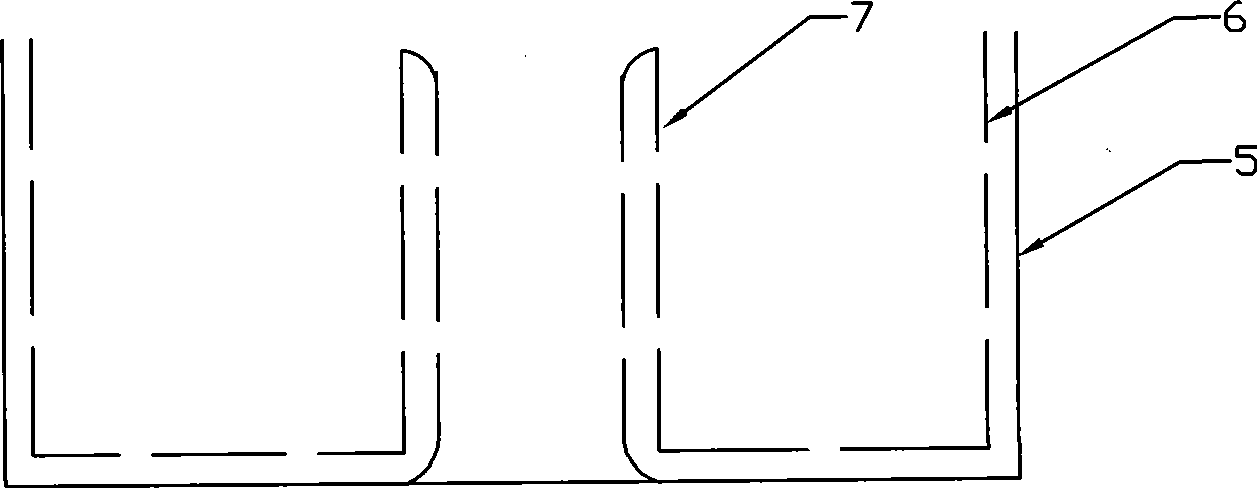

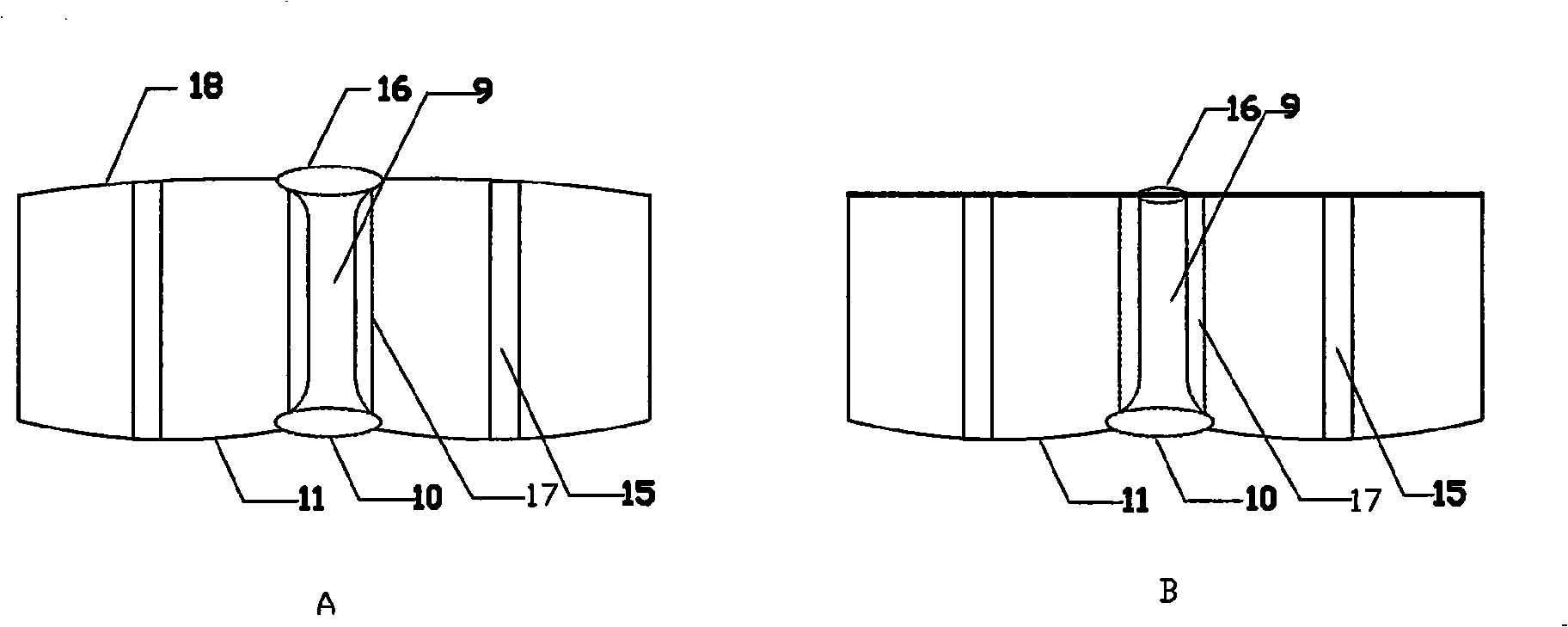

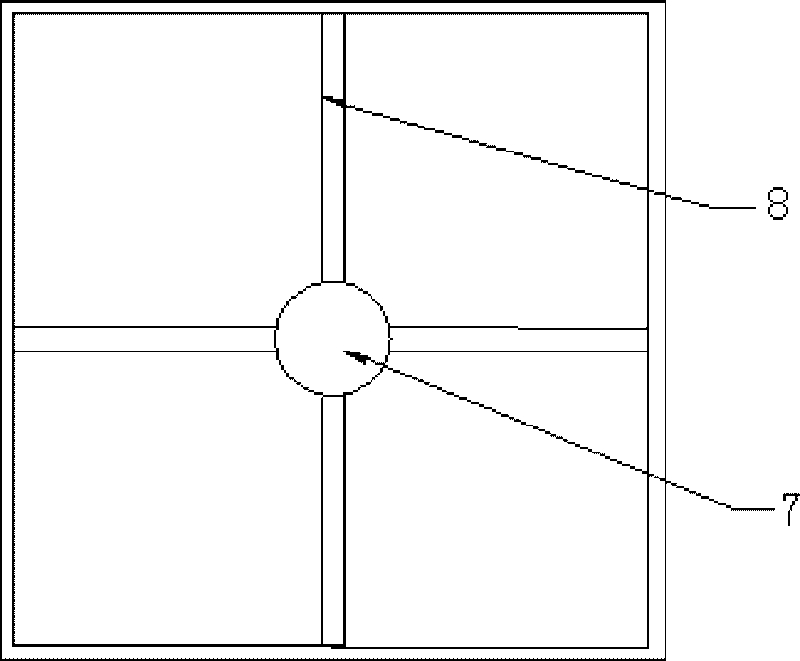

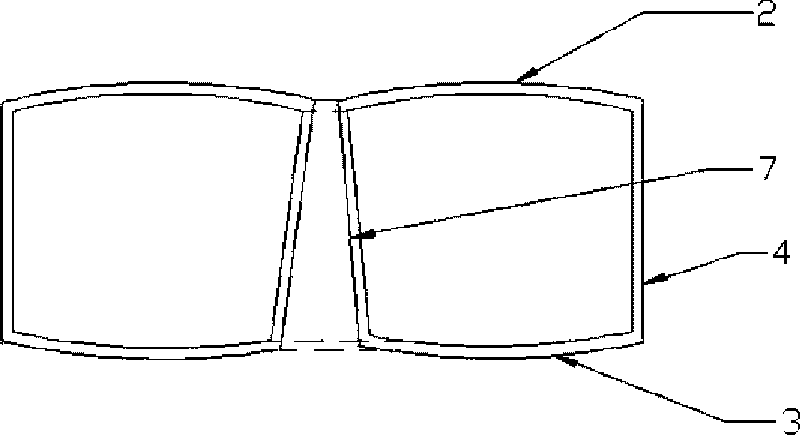

Hollow body of cast-in-situ hollow superstructure

InactiveCN101761161AImprove the anti-seismic and anti-crack effectImproved resistance to top and side pressureFloorsForms/shuttering/falseworksHardnessMechanical engineering

The invention relates to a hollow body of a cast-in-situ hollow superstructure, which comprises a bottom board (3), a frame body (4) and a top cover (2). The hollow body of the cast-in-situ hollow superstructure is characterized in that the outer surface of the bottom board (3) is provided with at least two arc-shaped bulges, holes (5) and (6) are respectively arranged on the bottom board and the top cover, and the holes of the bottom board and the top cover are connected by a sealed penetration passage (7); the penetration passage (7) is in a horn shape from top to bottom; the hollow body is integrally sealed, and the penetration passage (7) and the frame body (4) are in a sealed state; and a supporter is arranged between the bottom board (3) and the top cover (2). The superstructure adopting the hollow body has the characteristics of light weight, large hardness, crushing resistance, crack prevention, vibration resistance and the like.

Owner:王本淼

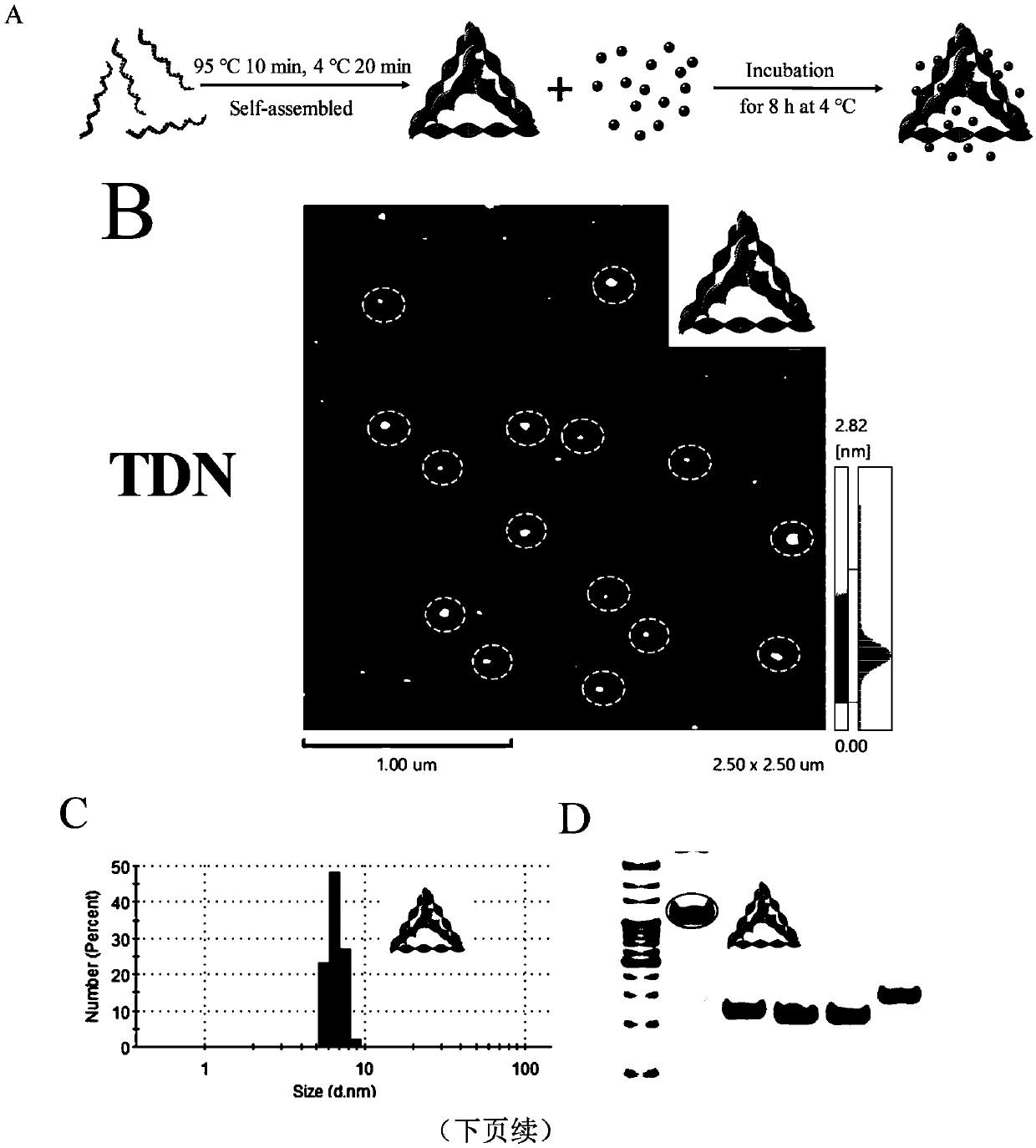

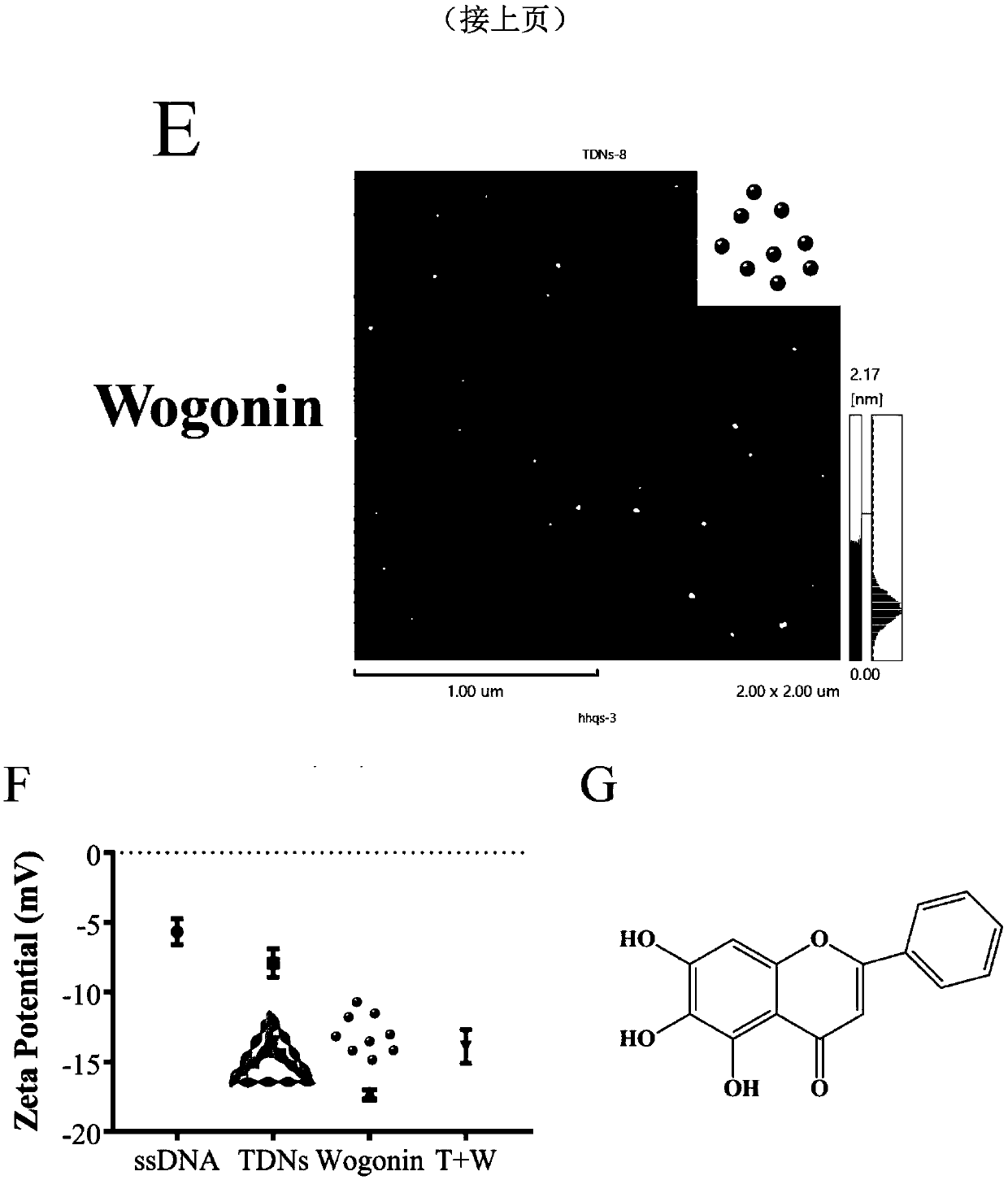

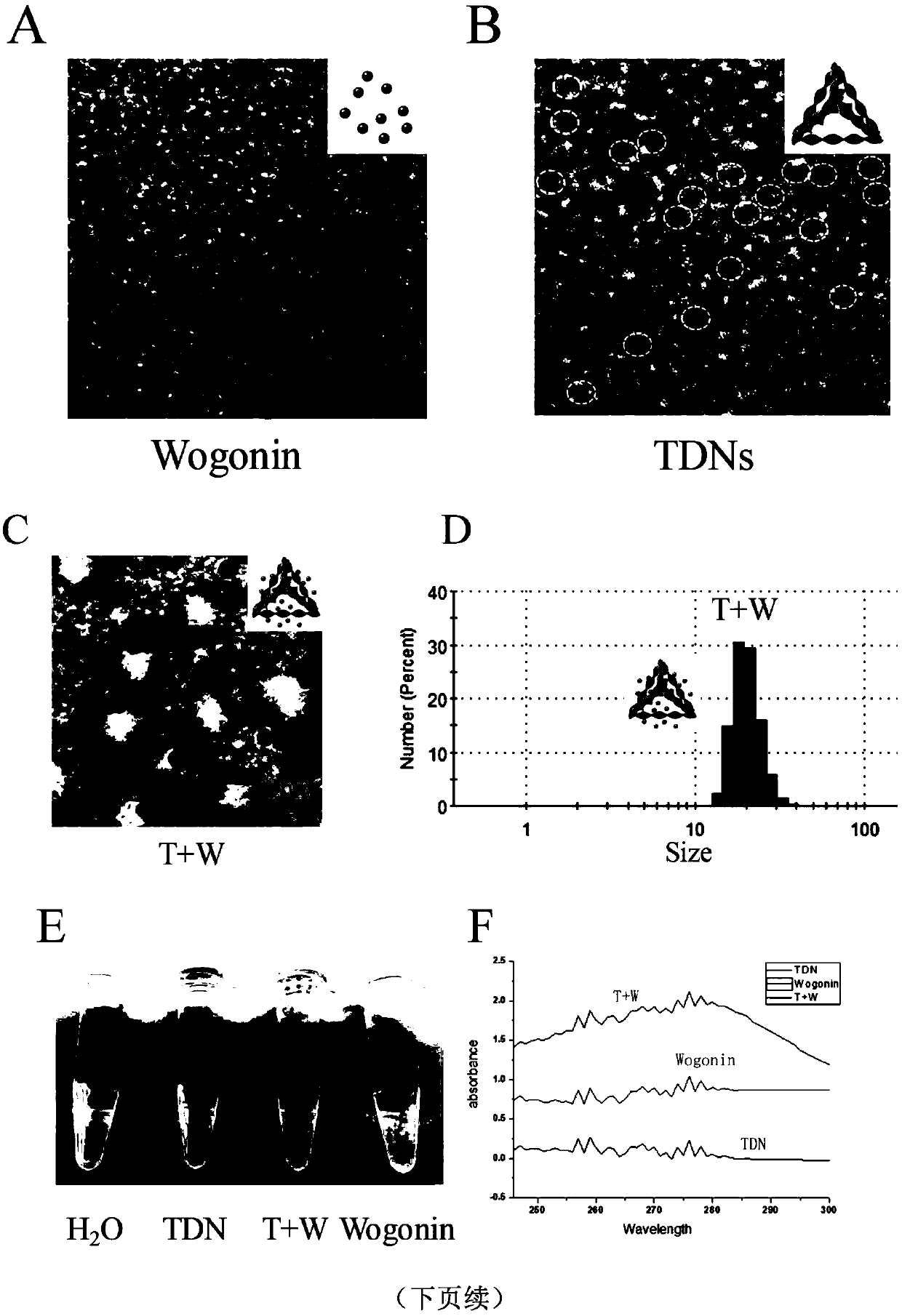

DNA tetrahedron-wogonin compound and preparation method and application thereof

ActiveCN109620959AInhibit the inflammatory responseImprove bone damageOrganic active ingredientsAntipyreticDrugSingle use

The invention provides a nano molecule drug-carrying compound, which is formed by encapsulating a DNA tetrahedron and wogonin according to a molar ratio of 1: (40-200). The invention also provides a preparation method of the compound. The invention also provides the application of the compound in a medicament for the treatment of osteoarthritis. Compared with the single use of DNA tetrahedron andwogonin, the compound has better effect in the aspects of inhibiting inflammatory reaction and improving bone injury, and the compound has good industrialization prospect when being used for preparingmedicaments for treating osteoarthritis.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com