Equipment for deep processing of spiral shells

A snail and equipment technology, applied in the field of snail deep processing equipment, can solve the problems of time-consuming and labor-intensive, high manpower requirements, and inability to process in large quantities, and achieve the effects of easy manufacturing, fast processing, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to the conditions of the specific construction unit, and the unspecified implementation conditions are usually the conditions in routine experiments.

[0029] Specific embodiment mode:

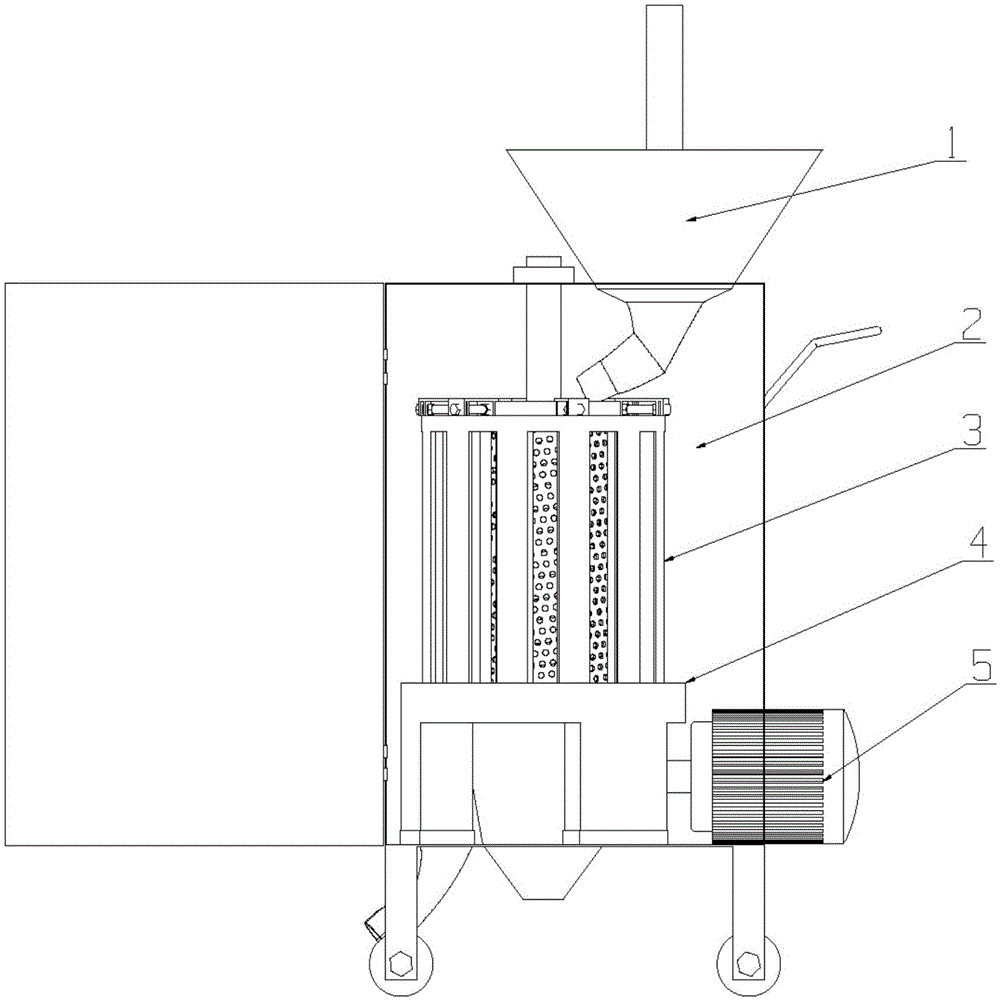

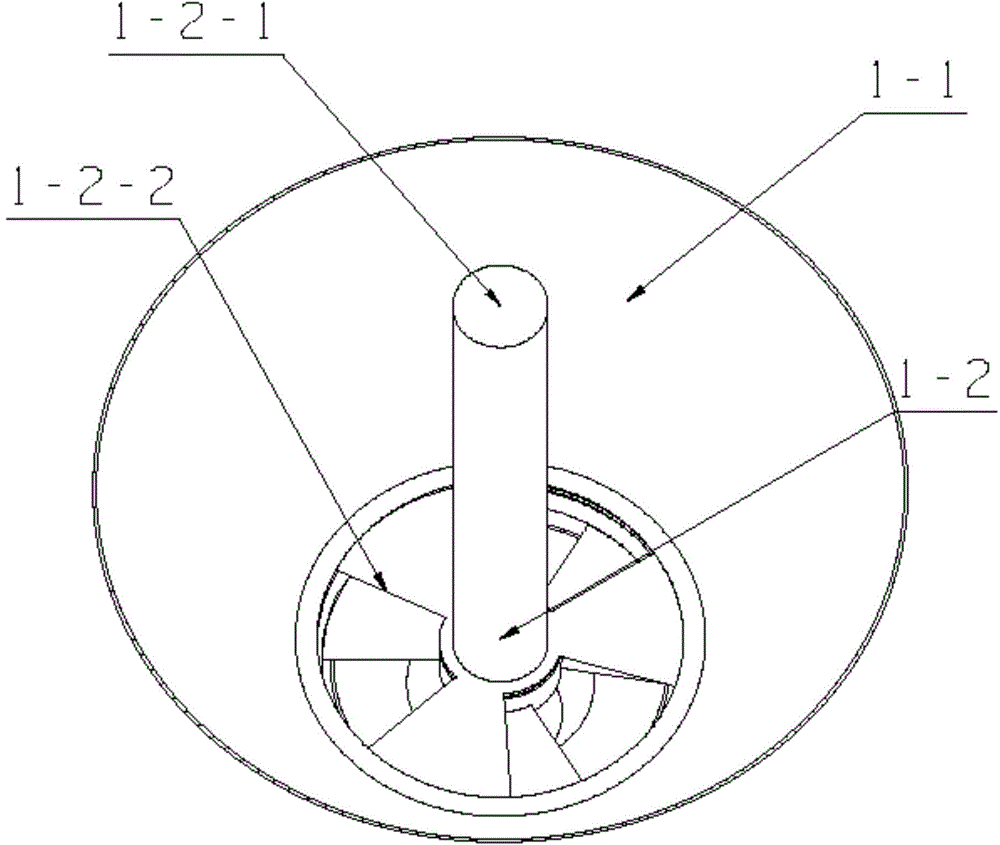

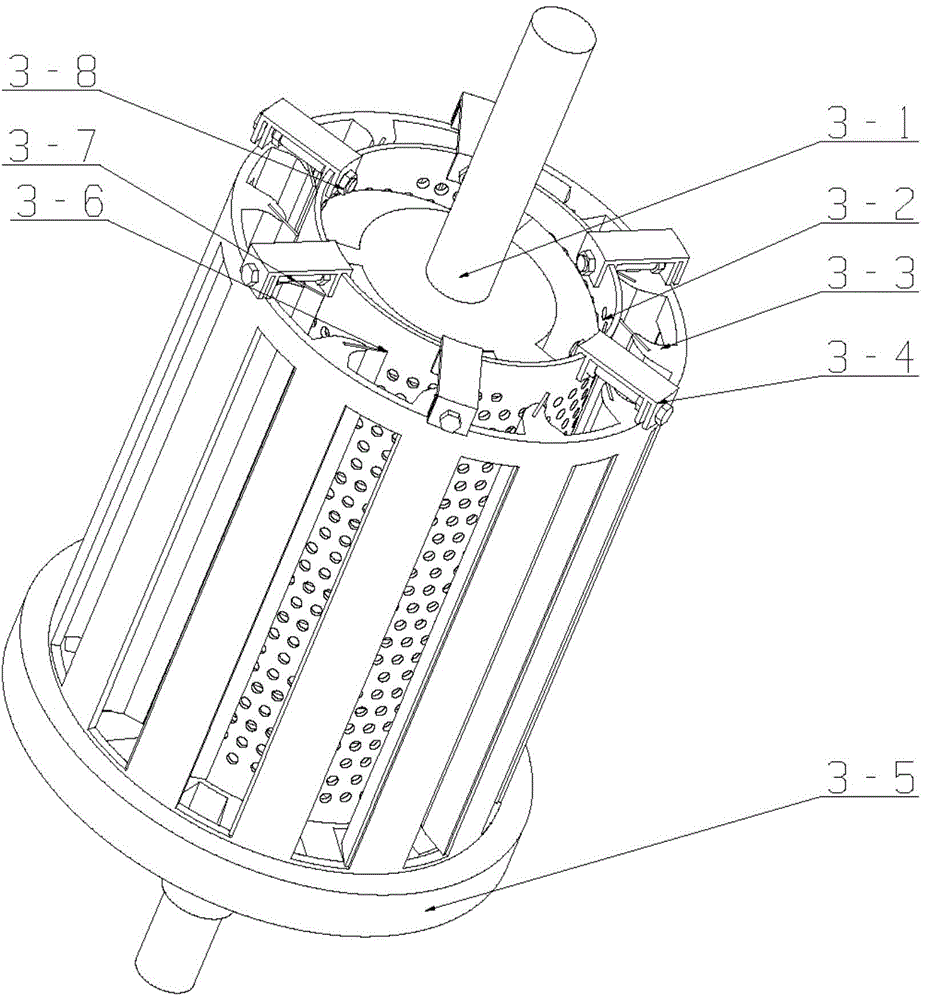

[0030] Figure 1 to Figure 5 Shown is a specific embodiment of this snail deep processing equipment of the present invention, and this equipment comprises fuselage 2, is provided with the feeding device 1 that provides snail to be processed on described fuselage 2, carries out tail-cutting process to described snail The tail cutting device 3, the discharge device 4 that separately discharges the tail shell waste obtained after processing and the finished snail, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com