Permanent magnet generator with forward and negative rotors

A permanent magnet generator and dual rotor technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of restricting the development prospect of low-speed power generation, less electricity, and low rotor speed, so as to achieve a wide range of applications and improve power generation efficiency. , the effect of relative speed increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

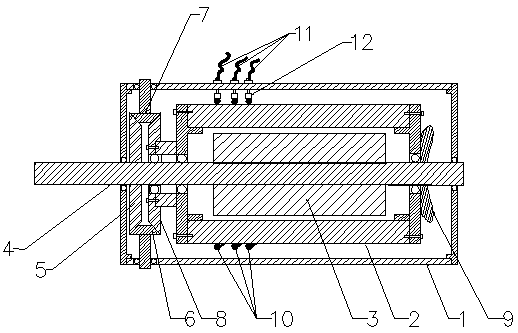

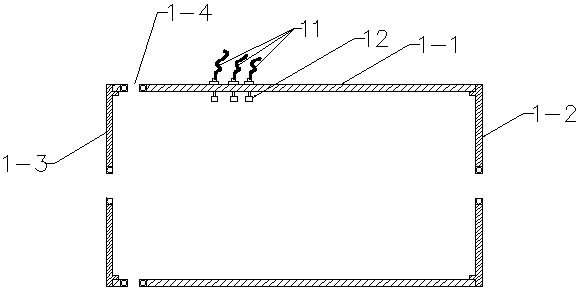

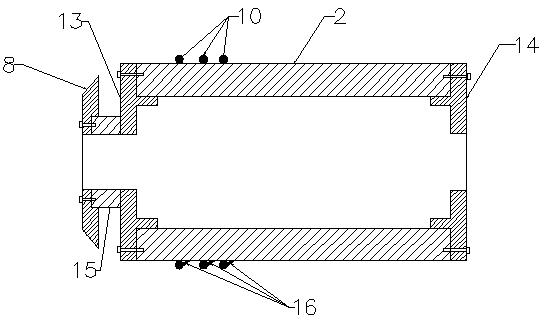

[0019] Such as figure 1 As shown, a permanent magnet generator with forward and reverse double rotors includes a casing 1, an outer rotor 2, an inner rotor 3, a central shaft 4, a driving wheel 5, a driven wheel 8, a transmission wheel 6-7 and a cooling fan 9. There is an outer rotor 2 inside the casing 1, and an inner rotor 3 is arranged inside the outer rotor 2. The inner rotor 3 is fixed on the central shaft 4 and rotates with the rotation of the central shaft 4. The outer casing 1 and the outer rotor 2 are respectively installed through bearings. On the central rotating shaft 4 , the outer rotor 2 rotates around the central rotating shaft 4 , and the rotating direction of the outer rotor 2 is opposite to that of the inner rotor 3 . A driven wheel 8 is fixedly mounted on the front end of the outer rotor 2 . A driving wheel 5 is fixedly installed on the central rotating shaft 4 in front of the driven wheel 8, and along with the central rotating shaft 4 rotates, the driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com