Patents

Literature

219results about How to "Improve aerodynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

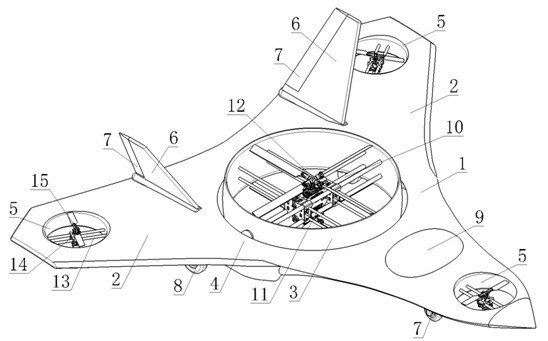

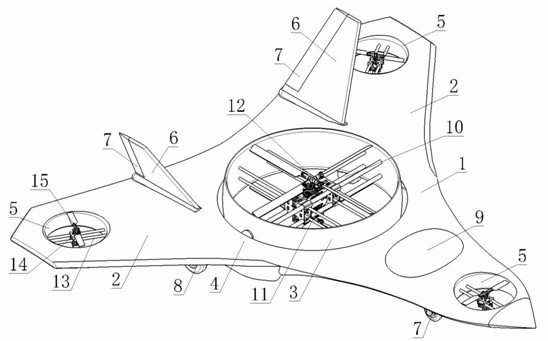

Tilt ducted unmanned aerial vehicle

InactiveCN102120489AExcellent air deceleration performanceWith hover performancePropellersActuated automaticallyAttitude controlUncrewed vehicle

The invention discloses a tilt ducted unmanned aerial vehicle. A central duct is arranged in an inner cavity of a center of a body, and is connected with the body through a tilting axis; the part of the body connected with the tilting axis is provided with a duct tiling mechanism; wings are symmetrically arranged on two sides of the body; a nose and wingtips of the wings are provided with posture control ducts; the lateral rear of the body is provided with extraverted double vertical tails; the rear of the extraverted double vertical tails is provided with a rudder; the lower side of the body is provided with a front three-point wheel landing gear; and the central duct, the duct tilting mechanism, the posture control duct and the rubber are respectively connected with a flight control system. The tilt ducted unmanned aerial vehicle has the advantages that: 1, a tail-free and large-triangle wing fusion layout is adopted, and the pneumatic property is good; 2, a unique tilt central duct design is adopted; 3, a unique three-duct posture control design is adopted; and 4, a duct rotor wing design is adopted, namely all paddles are embedded in the ducts, and the flight safety in an complex environment is effectively improved.

Owner:NANCHANG HANGKONG UNIVERSITY

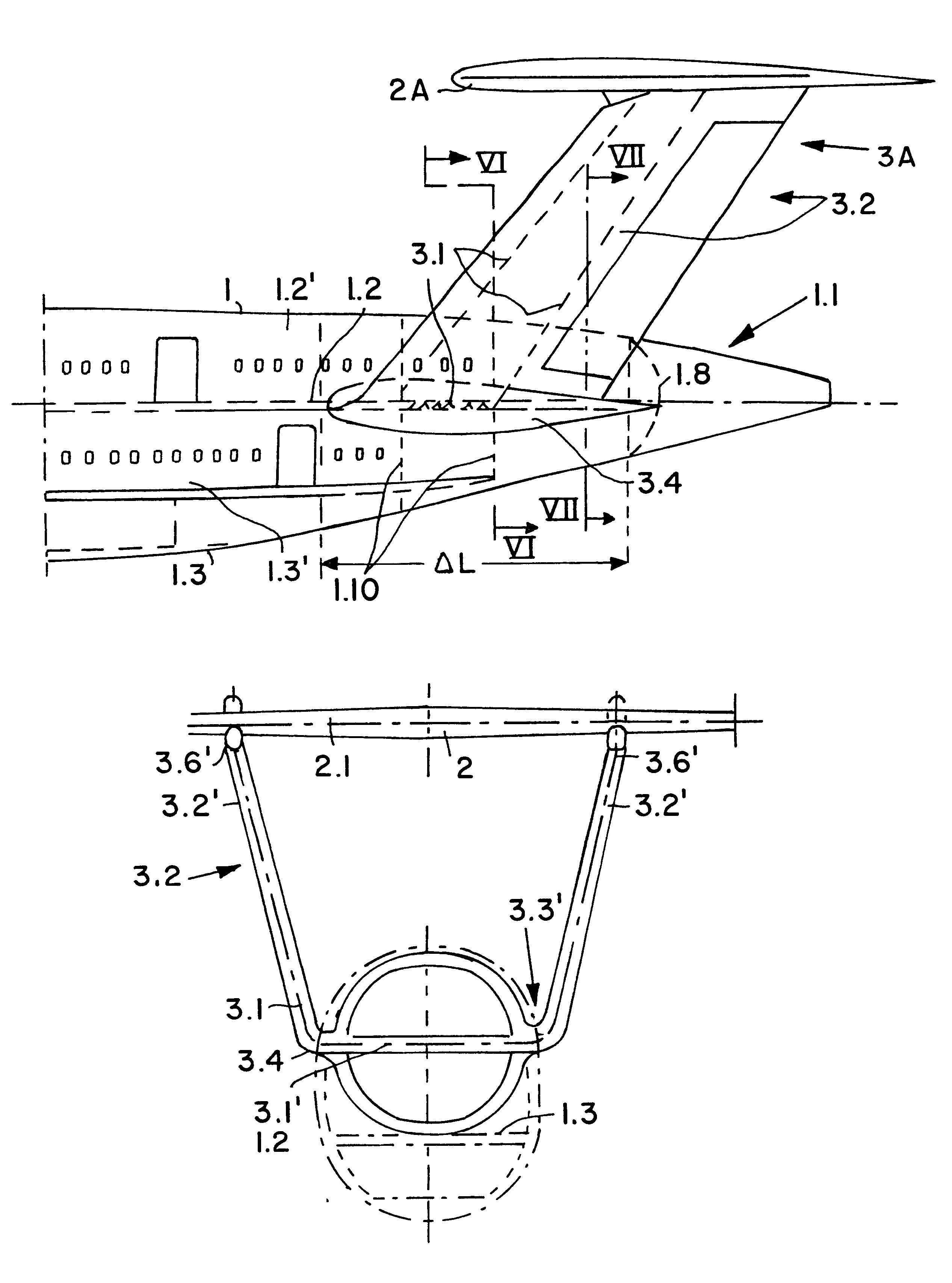

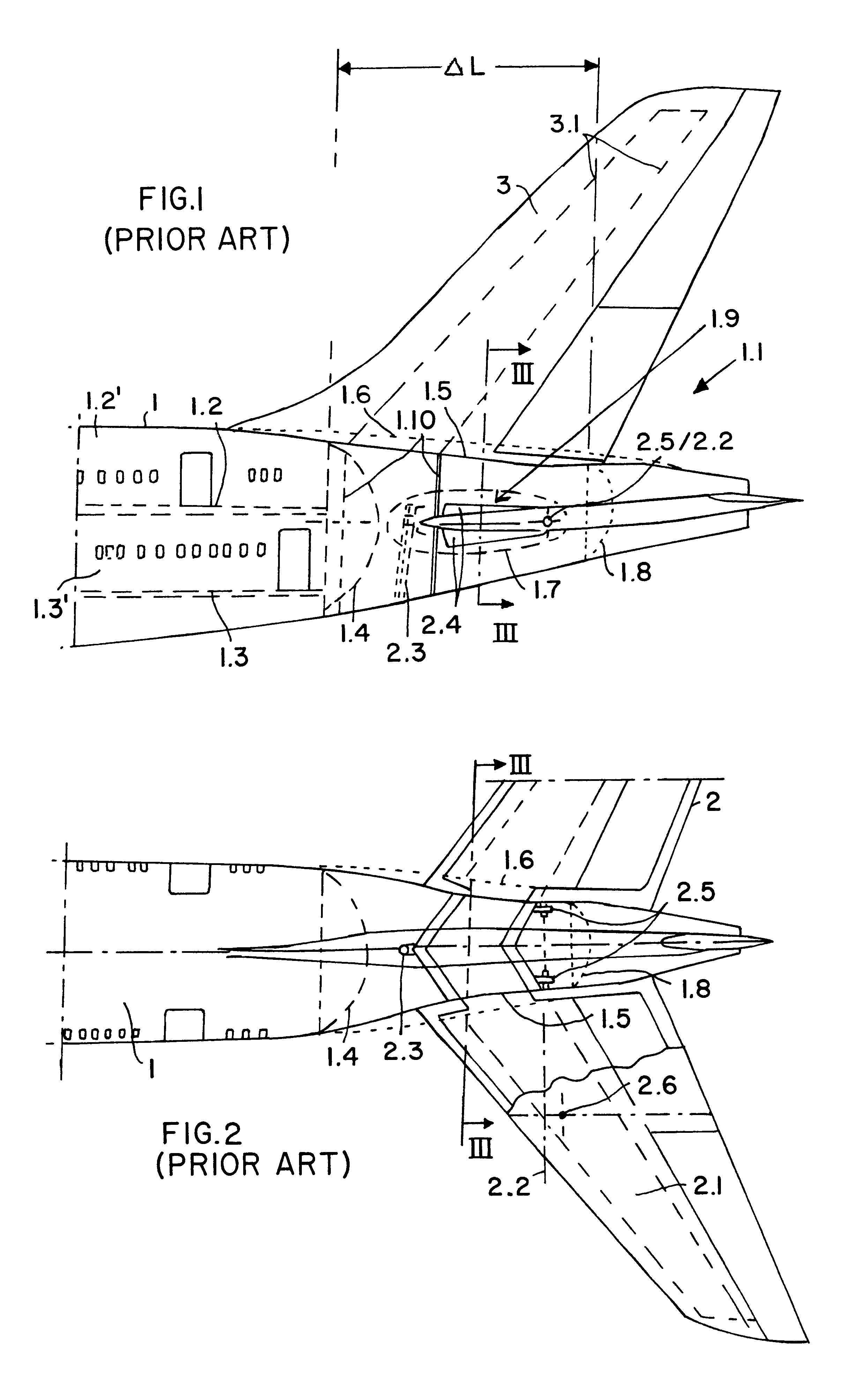

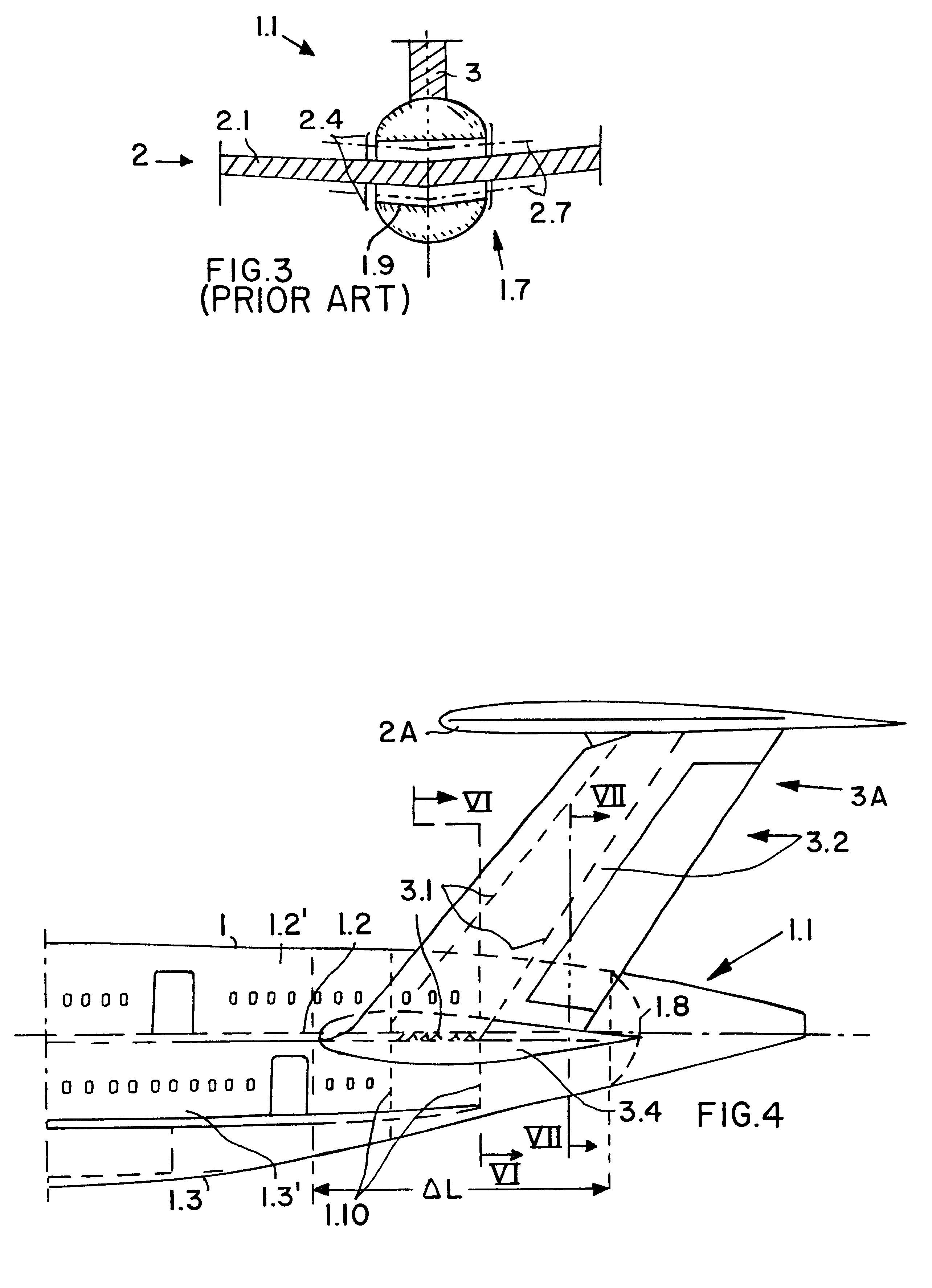

Aircraft with a double-T tail assembly

InactiveUS6273363B1Great available interior spaceEasy to manufactureAircraft stabilisationActuated automaticallyRudderAirplane

An aircraft, preferably a large capacity passenger aircraft with two passenger decks, has a double-T tail assembly arranged on its tail section. The double-T tail assembly includes a double fin and rudder assembly and a tailplane and elevator assembly, and provides a significant increase in the usable passenger cabin space in the tail section of the aircraft. The double fin and rudder assembly has a U-shaped structure and comprises two upright stabilizer fins connected to each other by a horizontal torsion box that fixedly extends crosswise through the fuselage tail section within the floor of a cabin deck. The tailplane and elevator assembly is pivotably mounted on the upper tips of the two upright stabilizer fins in a double-T arrangement.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

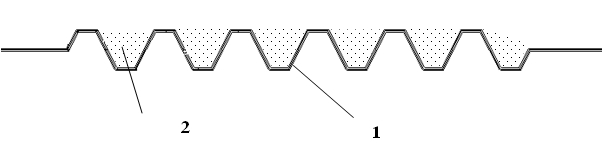

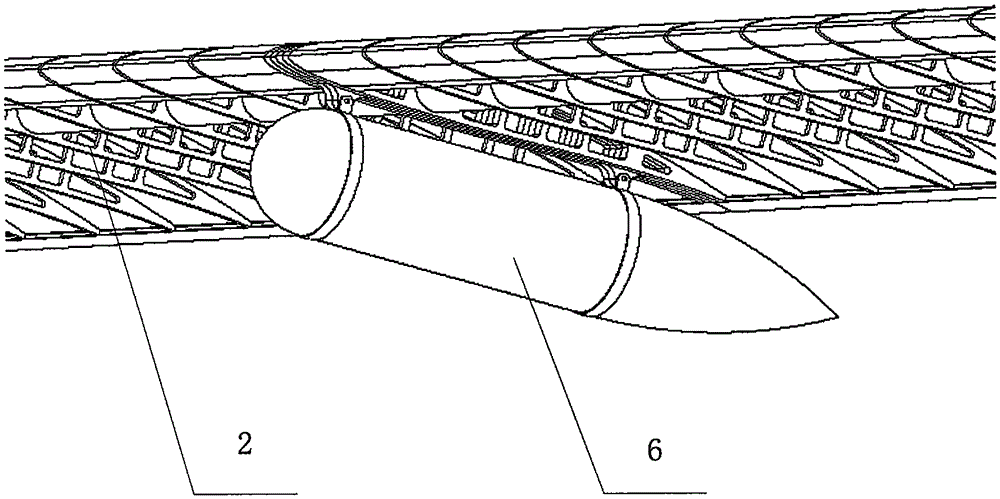

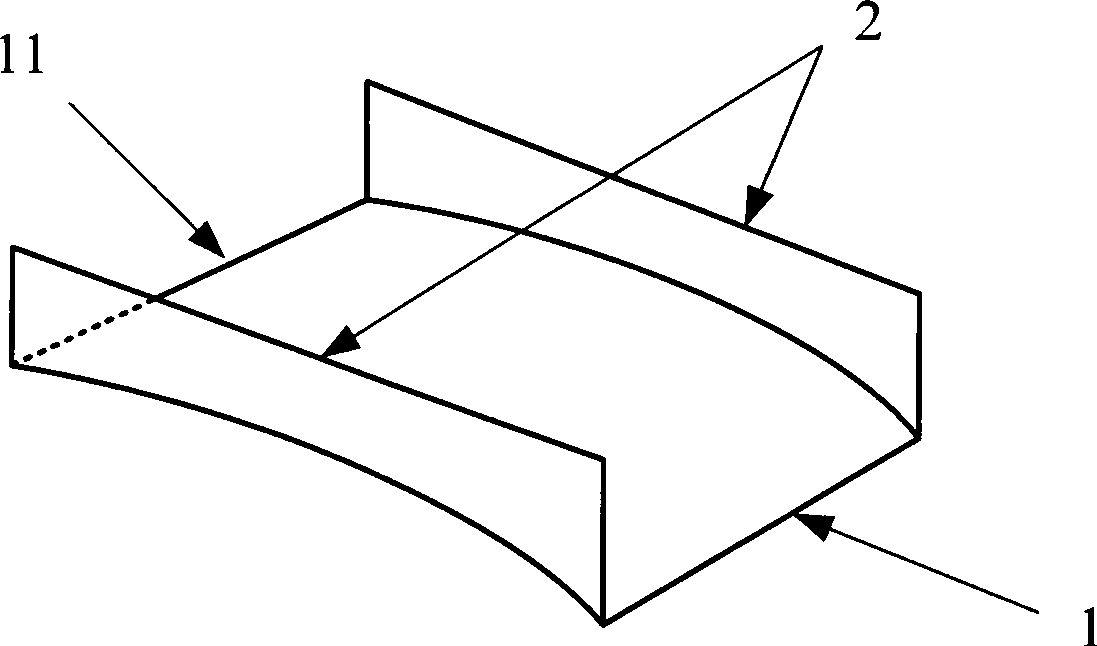

Skin for morphing wings

InactiveCN102060101AGuaranteed to be smoothRealize health monitoringWingsIsosceles trapezoidVibration control

The invention discloses a skin for morphing wings, belonging to the technical field of design of morphing aircrafts. The skin for the morphing wings is made from fibre reinforced composites, and the cross section of the skin is in an isosceles trapezoid ripple structure. The invention also carries out analysis aiming at the chordwise and spanwise equivalent elastic modulus and flexural modulus ofthe skin structure with isosceles trapezoid ripples, provides a corresponding mathematical model and can further optimize the skin structure according to the mathematical model. The invention meets the requirements of the skin of the morphing wings of the morphing aircrafts for large deformation aerodynamic load bearing, can realize the design optimization of the skin structure under different load operating conditions according to the mathematical analysis model of the equivalent elastic modulus and the flexural modulus in two different directions of the skin structure, also has structure health monitoring and self-adapting deformation capability and can realize optimal aerodynamic characteristics by controlling the shape and the vibration of the skin.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

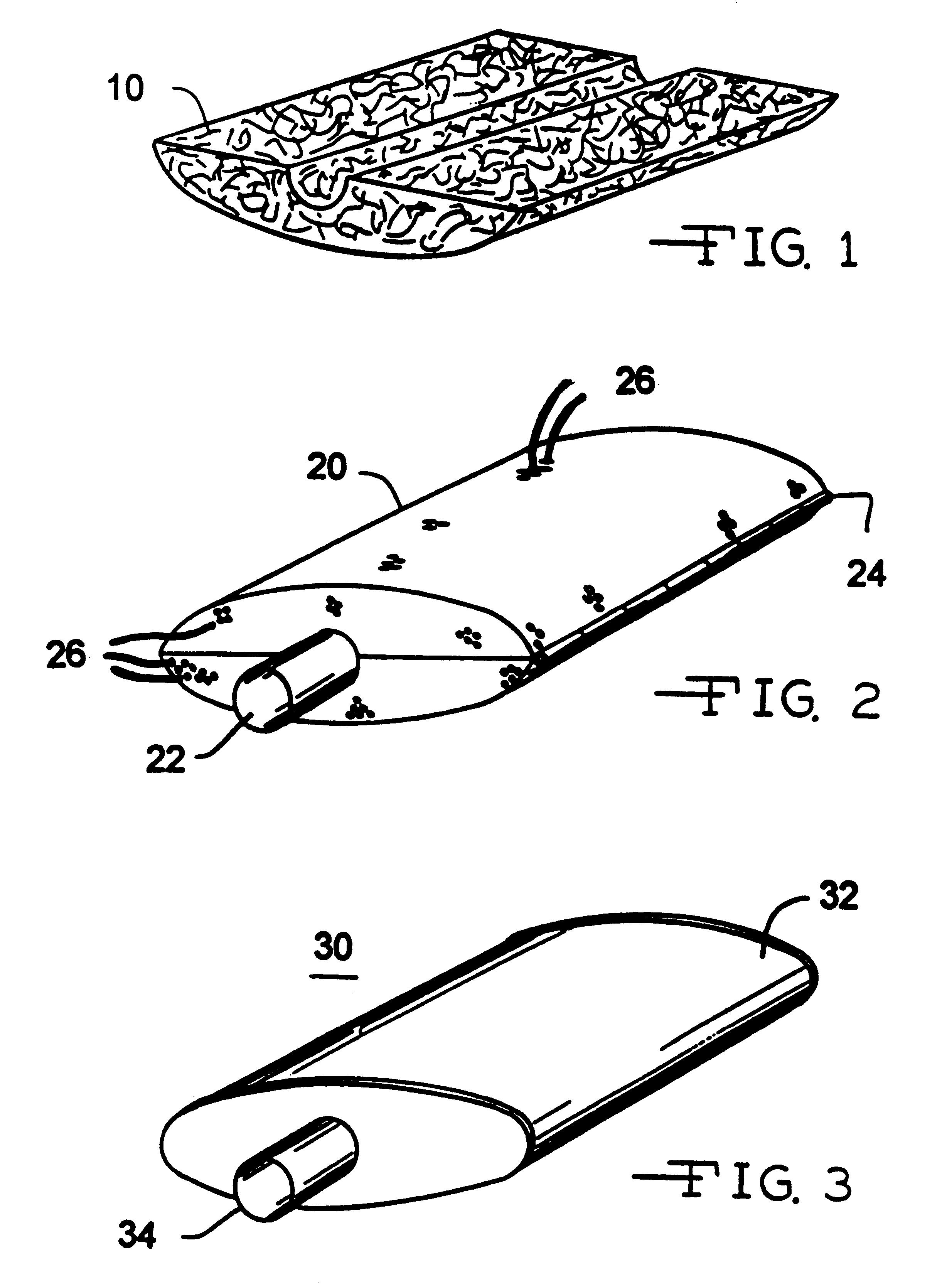

Preformed sound absorbing material for engine exhaust muffler

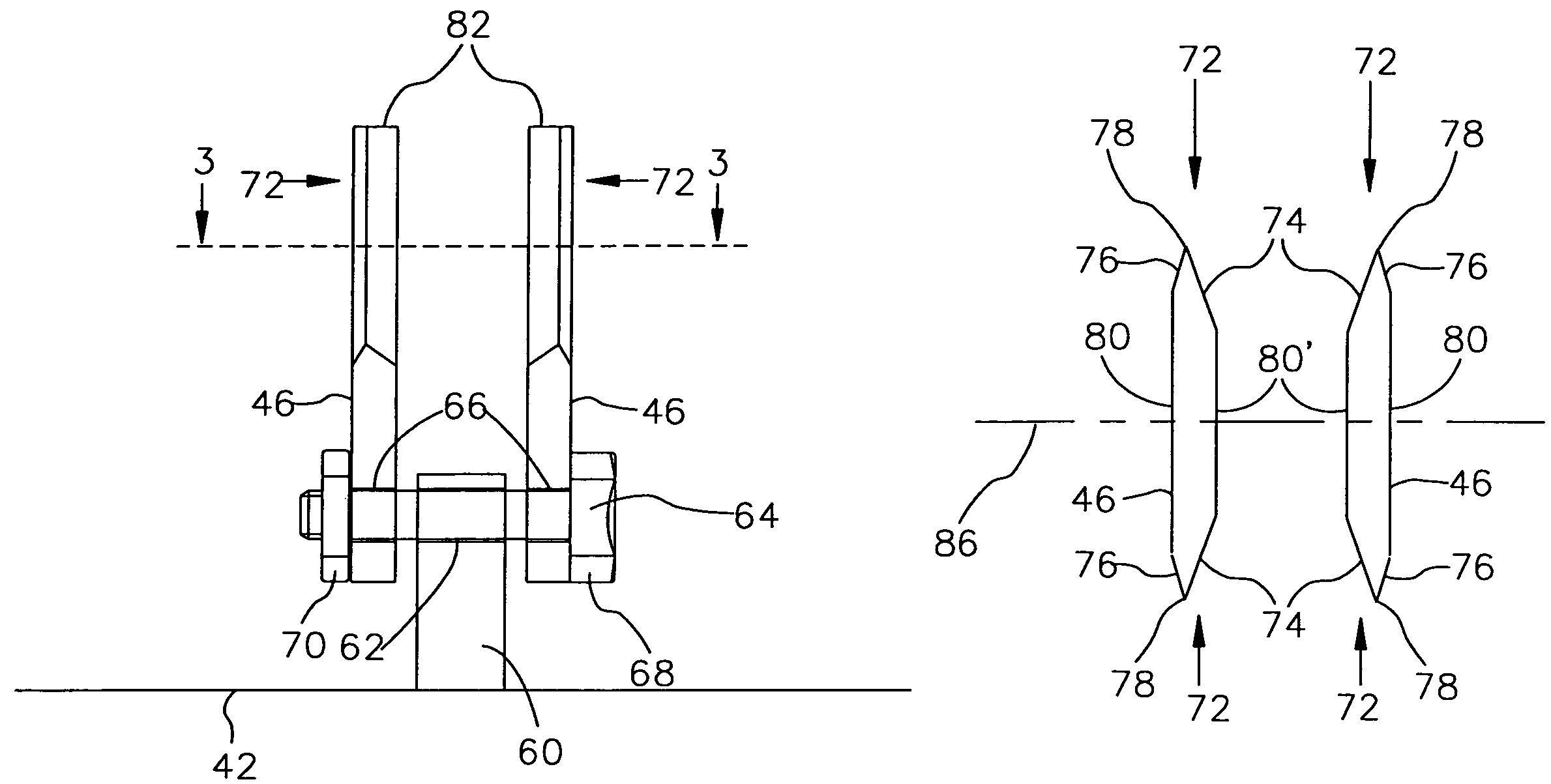

InactiveUS20010011780A1Improve aerodynamicsProduced in volumeMovable spraying apparatusLaminationGlass fiberFiber

This invention provides preforms of continuous glass fiber strands for use as the sound absorbing material in an engine exhaust muffler. Preferably, the material is made of glass fibers of E glass compositions. With this invention, the strands are fluffed up, not directly in the muffler, but in a cavity that is made of a perforated shell matching the muffler shape. During this operation, a powder binder also is blown in with the fibers. This blowing operation is completed by forcing hot air through the preform which melts or cures the binder and allows it to bond the fibers together.

Owner:O C FIBERGLAS SWEDEN +1

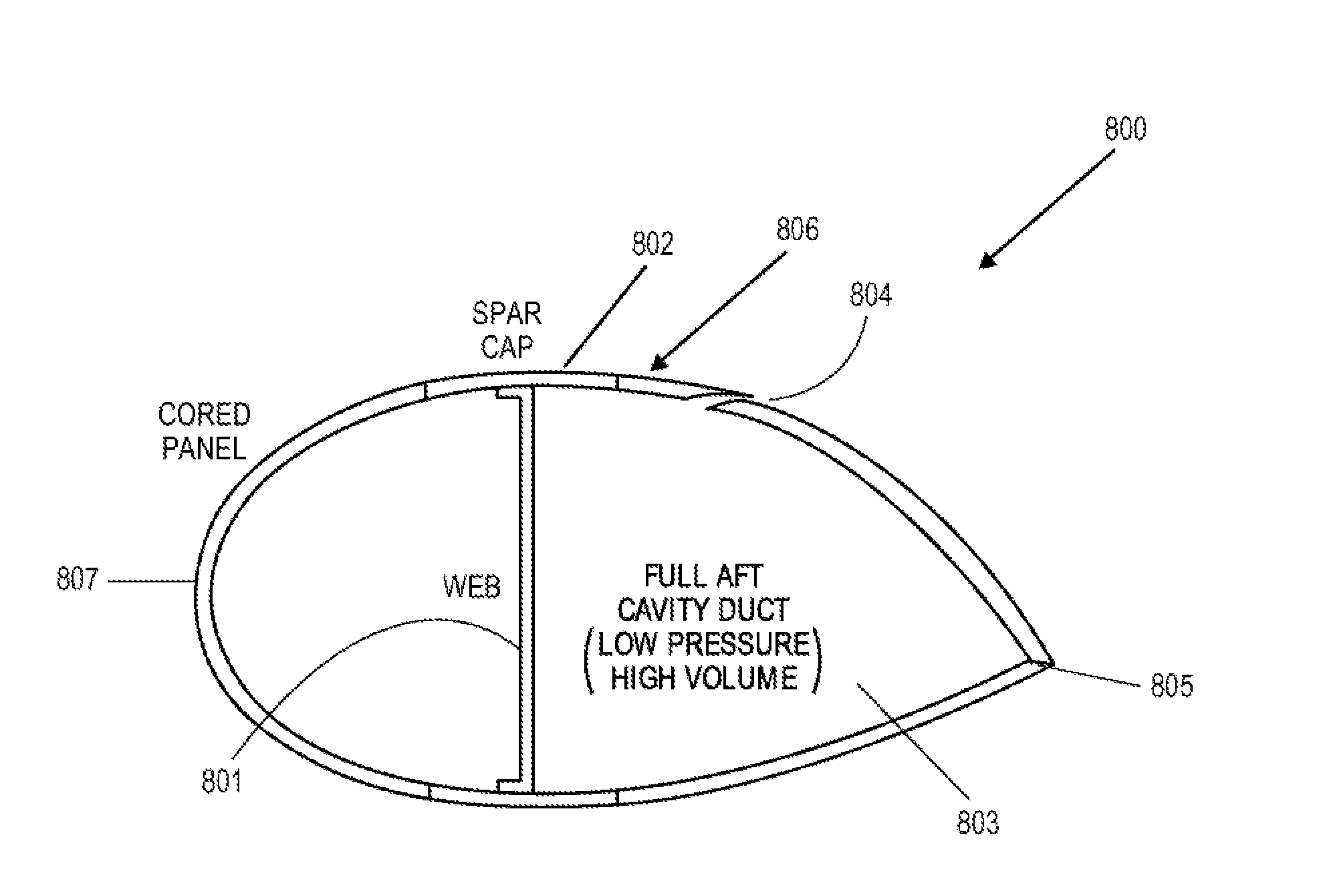

Turbine blades, systems and methods

InactiveUS20120020803A1Energy efficiencyImprove efficiencyPropellersWind motor controlLeading edgeTurbine blade

A blade for use in a wind turbine comprises a pressure side and suction side meeting at a trailing edge and leading edge, the pressure side having a pressure side surface and the suction side having a suction side surface, the pressure side surface and suction side surface for providing lift to the turbine blade upon the flow of air from the leading edge to the trailing edge and over the pressure side and suction side surfaces, the pressure side and suction side extending from a root portion to a tip portion of the turbine blade. In some situations, the root portion is non-aerodynamic. The aerodynamics of such a blade is improved with the aid of pneumatic blowing through one or more blown passages for providing pressurized air (or other fluid) to a suction side and / or pressure side of the blade.

Owner:PAUL LEES DBA MACH 2 WIND +2

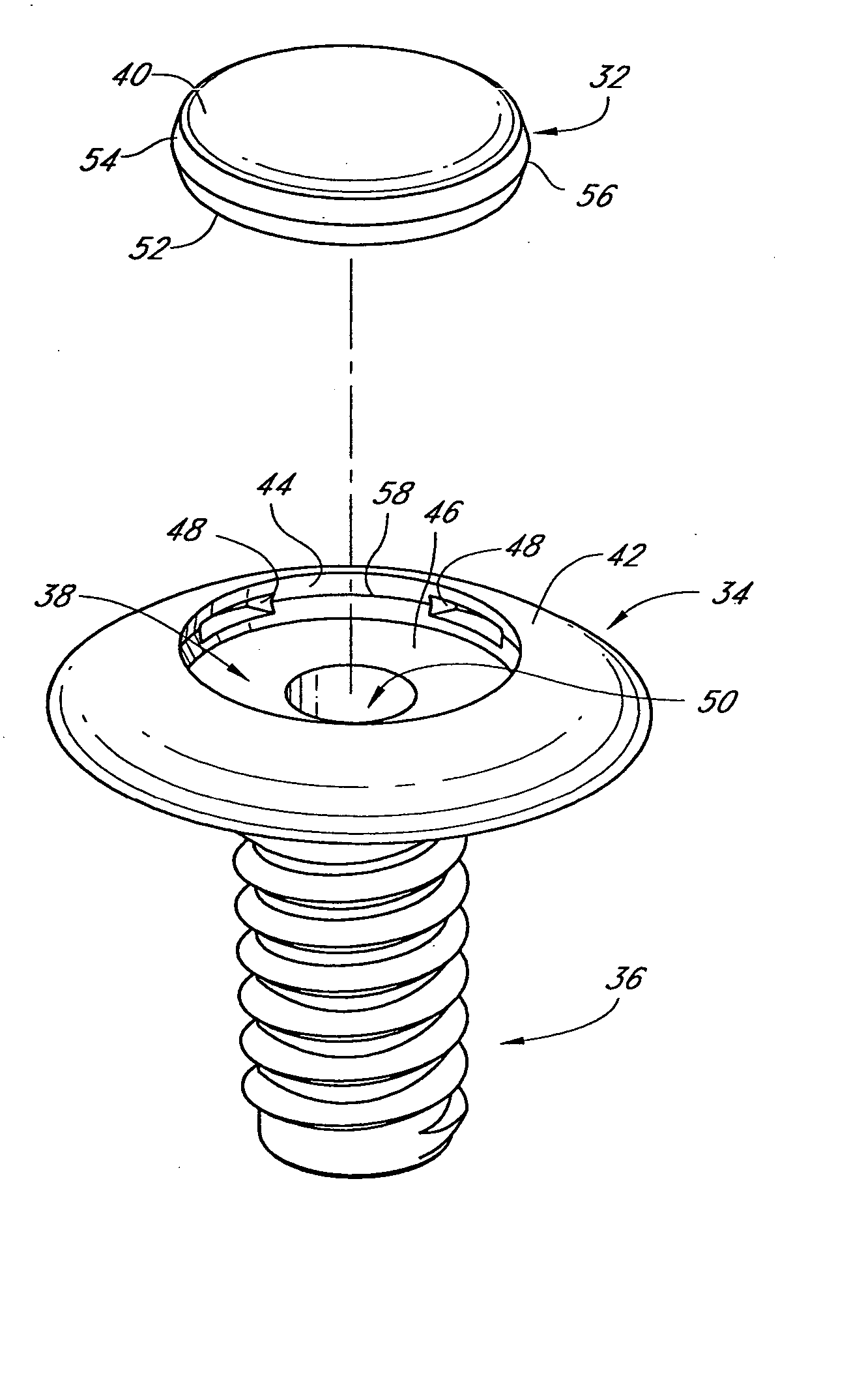

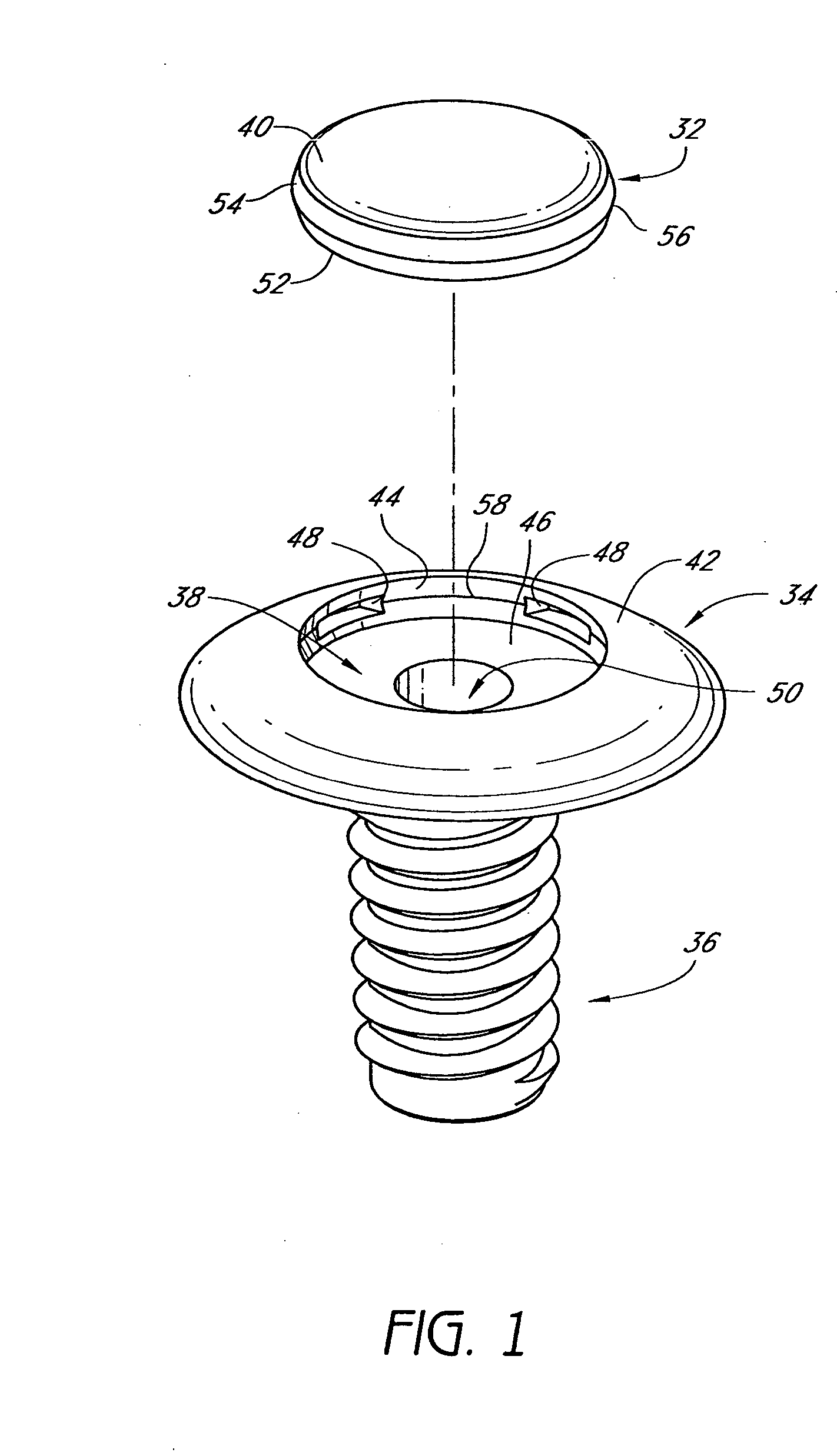

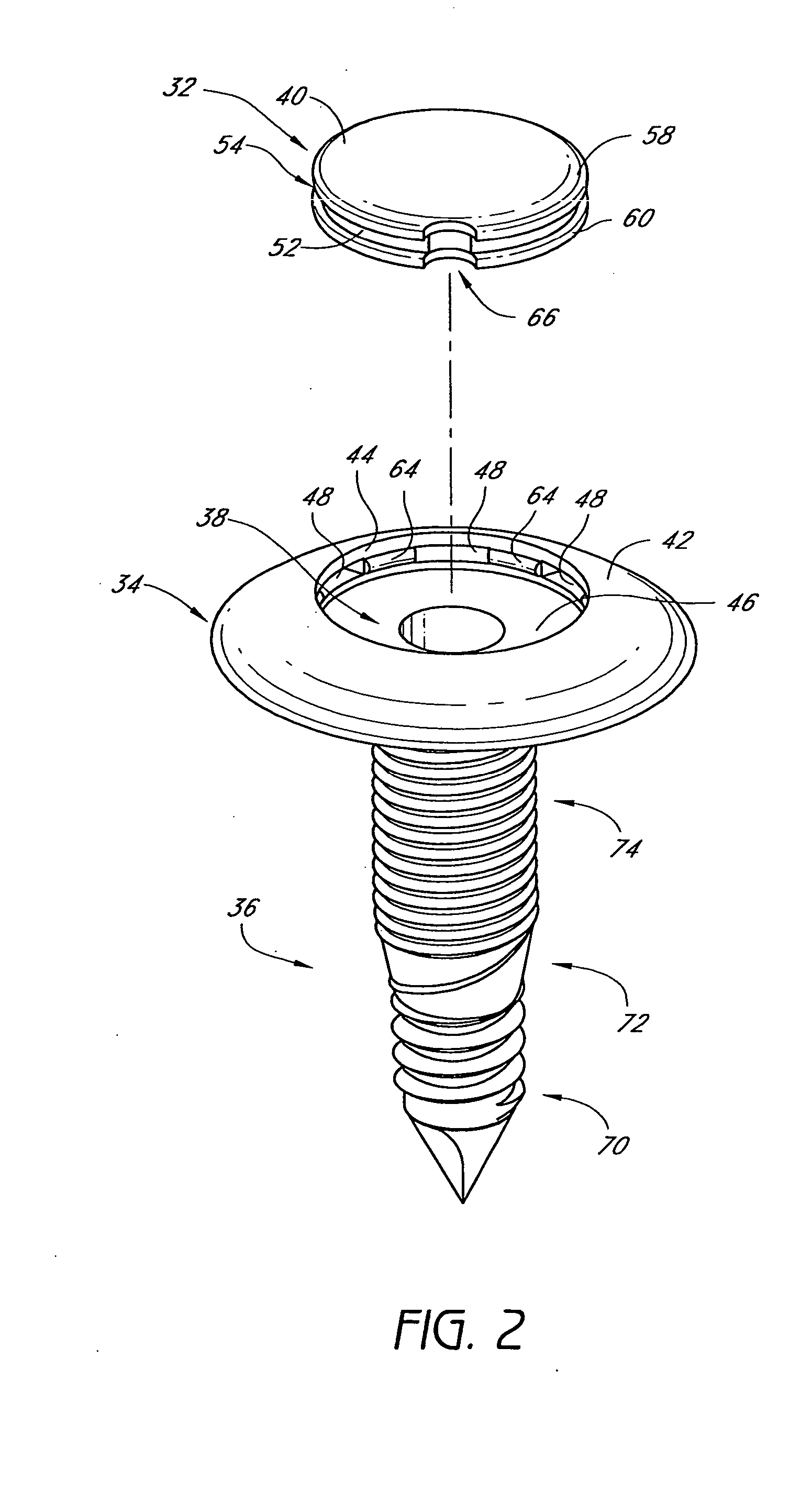

Low profile fastening system

Described herein are embodiments of fastening systems that can provide easily removed and reapplied fasteners and that provide a hindrance to those that might tamper with the fasteners. In some embodiments, fasteners are also described that are configured to reduce the accumulation of dust and dirt inside the fasteners. In further embodiments, fasteners are provided for improving the aerodynamics of the fastener, and some embodiments describe provision of commercial advertising or other messages on the fastener.

Owner:MONDAY JOHN S +1

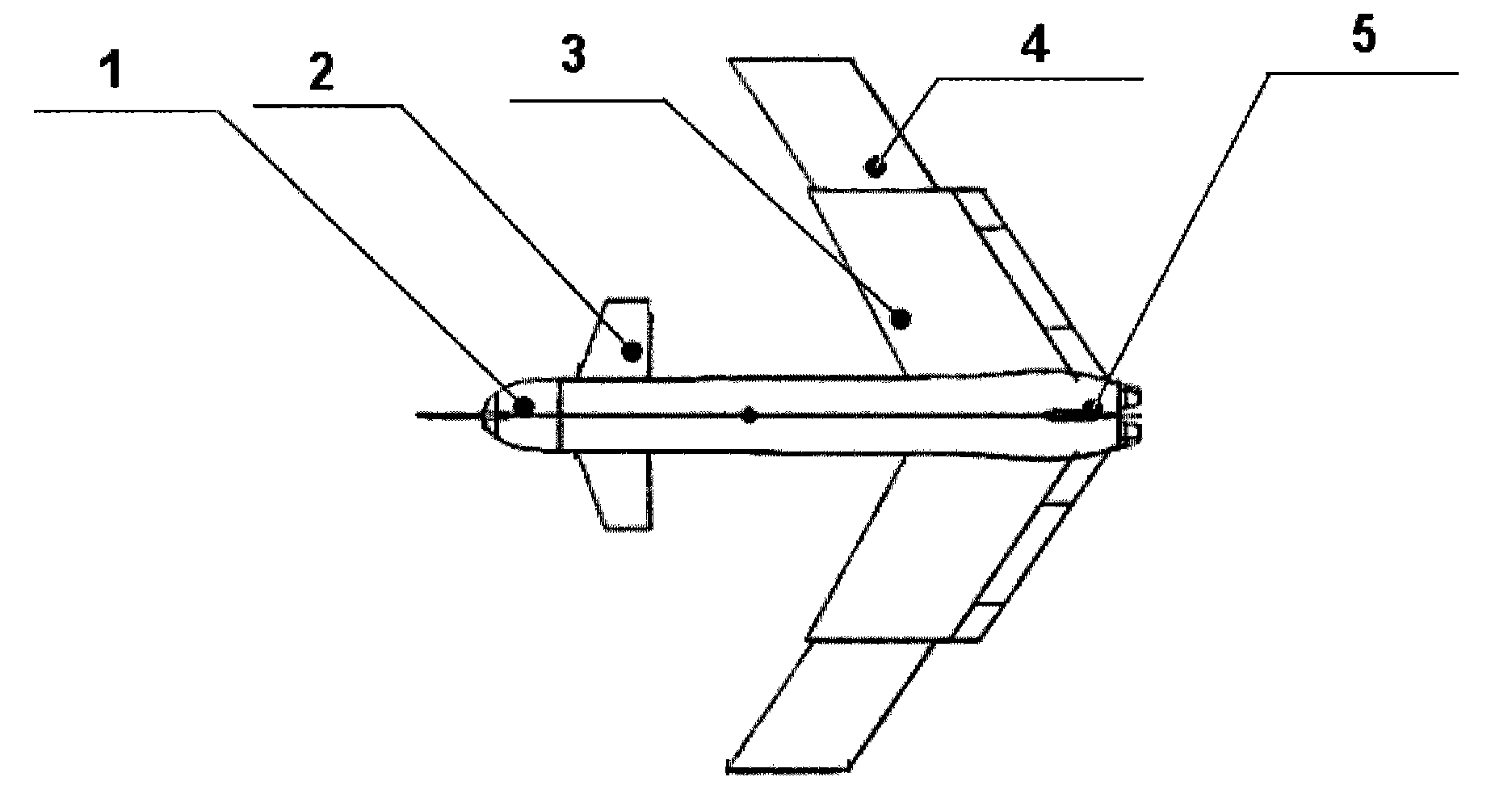

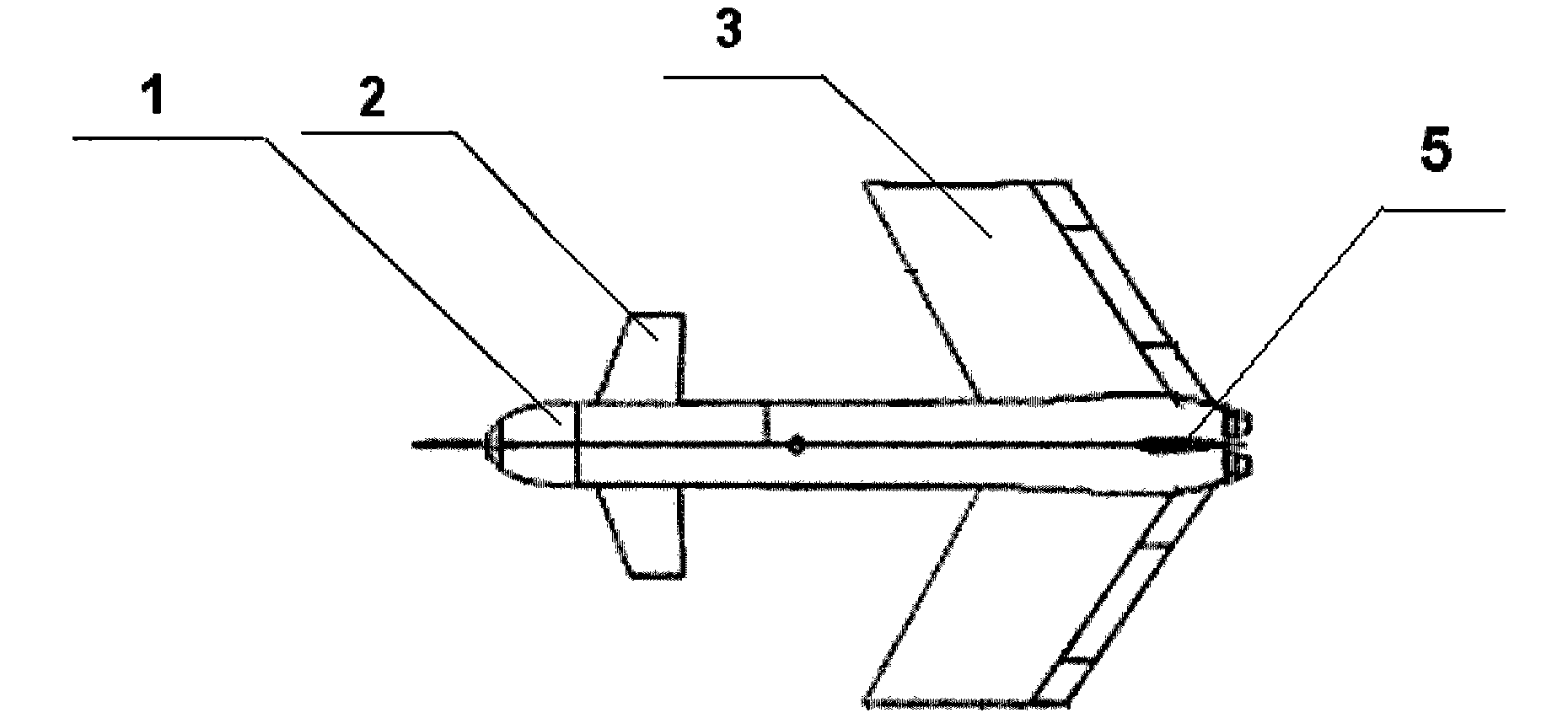

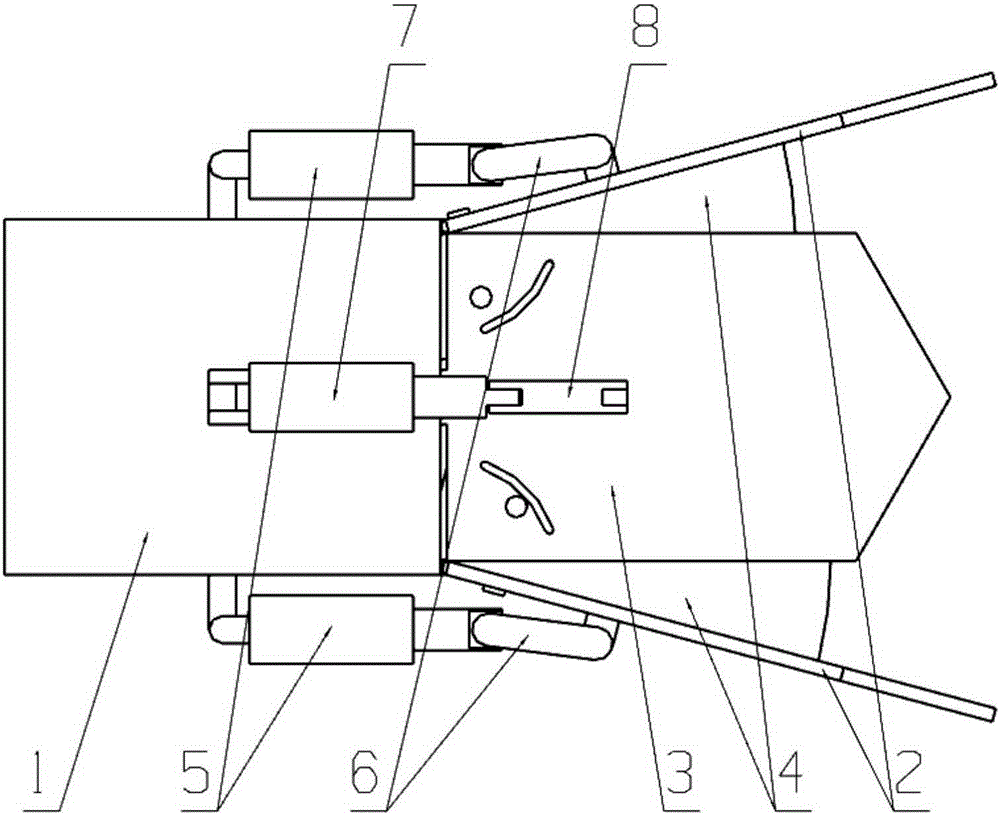

Aerodynamic layout of a canard-swept forward-swept telescoping wing with variable wing area

ActiveCN102267557AImprove aerodynamicsImprove mobilityWing adjustmentsFuselagesLow speedWing configuration

The invention relates to a canard forward-sweep telescoping wing aerodynamic configuration with variable span wing area. The canard forward-sweep telescoping wing aerodynamic configuration comprises a fuselage, canards, wings, and a vertical fin; the wings comprise forward-sweep inner wings and forward-sweep telescopic outer wings having internal connections with the forward-sweep inner wings by a telescoping mechanism; and the telescoping mechanism extends to allow the forward-sweep telescopic outer wings to extend to the outside of the forward-sweep inner wings when the mach number (Ma) of an unmanned aerial vehicle is 0.2, and the telescoping mechanism contracts to allow the forward-sweep telescopic outer wings to contract to the inside of the forward-sweep inner wings when the Ma of the unmanned aerial vehicle is 0.4, wherein the area ratio of the forward-sweep telescopic outer wings to the forward-sweep inner wings is 0.25-0.45. The telescoping wing configuration with variable span wing area adopted in the invention allows the unmanned aerial vehicle to have good aerodynamic performances in scopes of different spatial domains and different speeds and the mobility and the flexibility of the unmanned aerial vehicle to be improved. According to the canard forward-sweep telescoping wing aerodynamic configuration of the invention, when Ma is equal to 0.2 or 0.4, the cruise lift-to-drag ratio of the high aspect ratio aerodynamic configuration is over 20% higher than the cruise lift-to-drag ratio of the low aspect ratio aerodynamic configuration when the unmanned aerial vehicle flies at a low speed, and the cruise lift-to-drag ratio of the low aspect ratio aerodynamic configuration is about 15% higher than the cruise lift-to-drag ratio of the high aspect ratio aerodynamic configuration when the unmanned aerial vehicle flies at a high speed, so the capacities of the cruise flight with the Ma of 0.2 and 0.4 are possessed.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

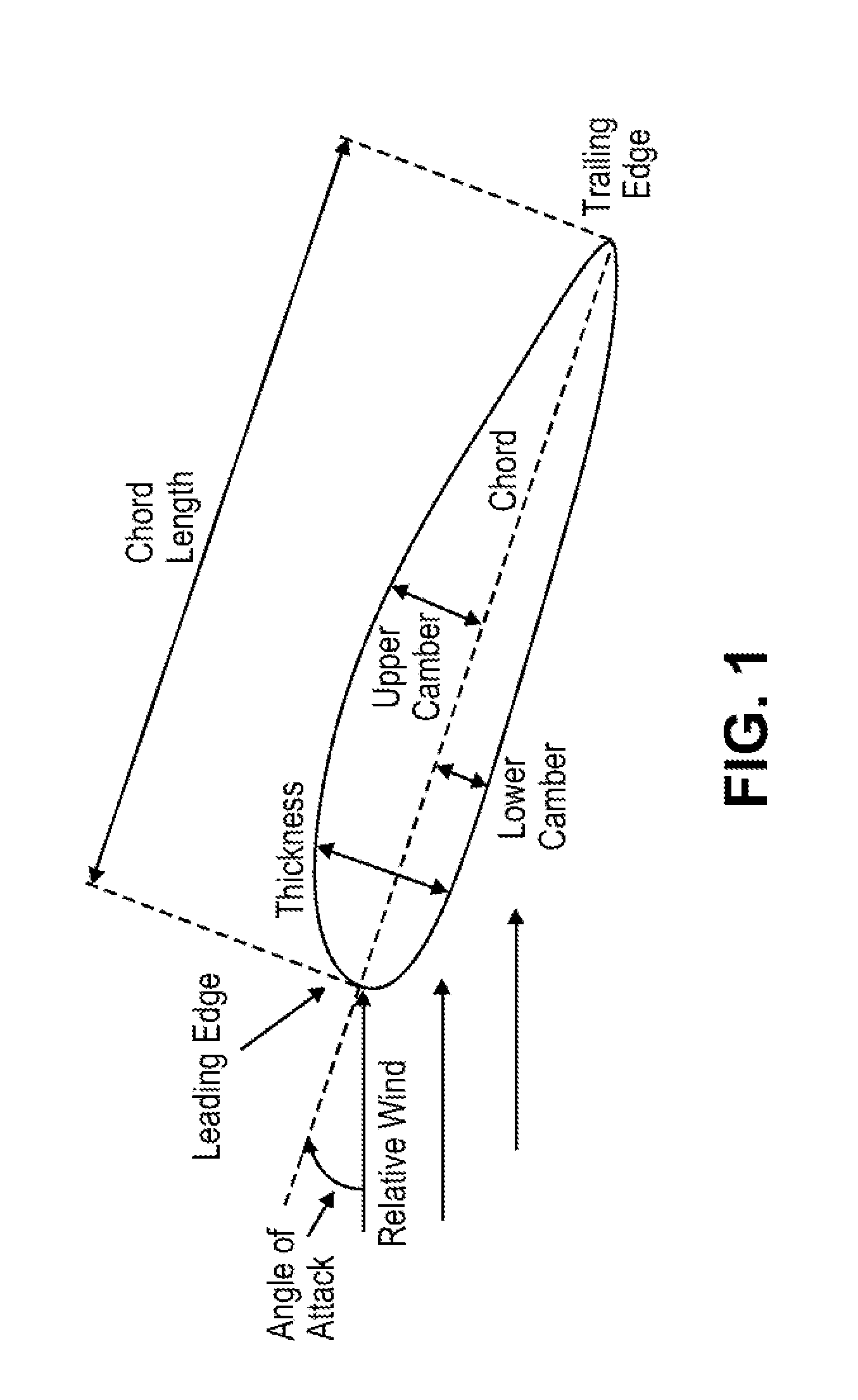

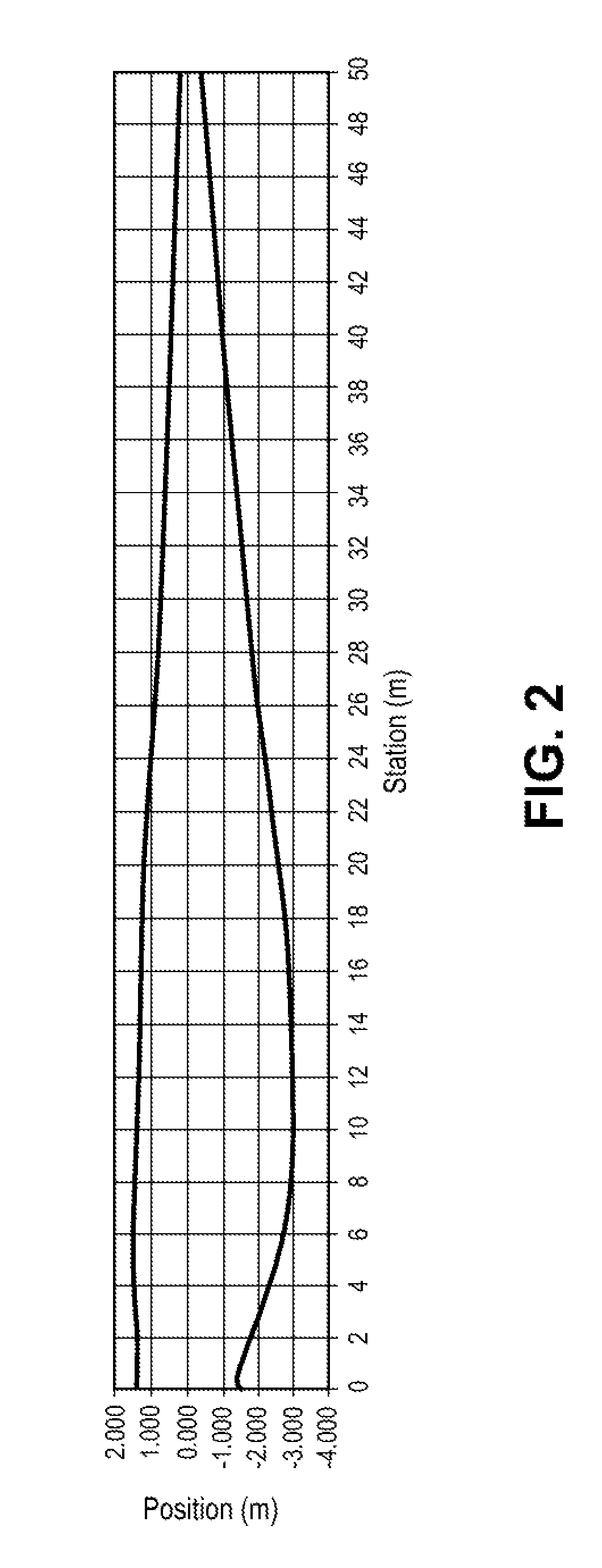

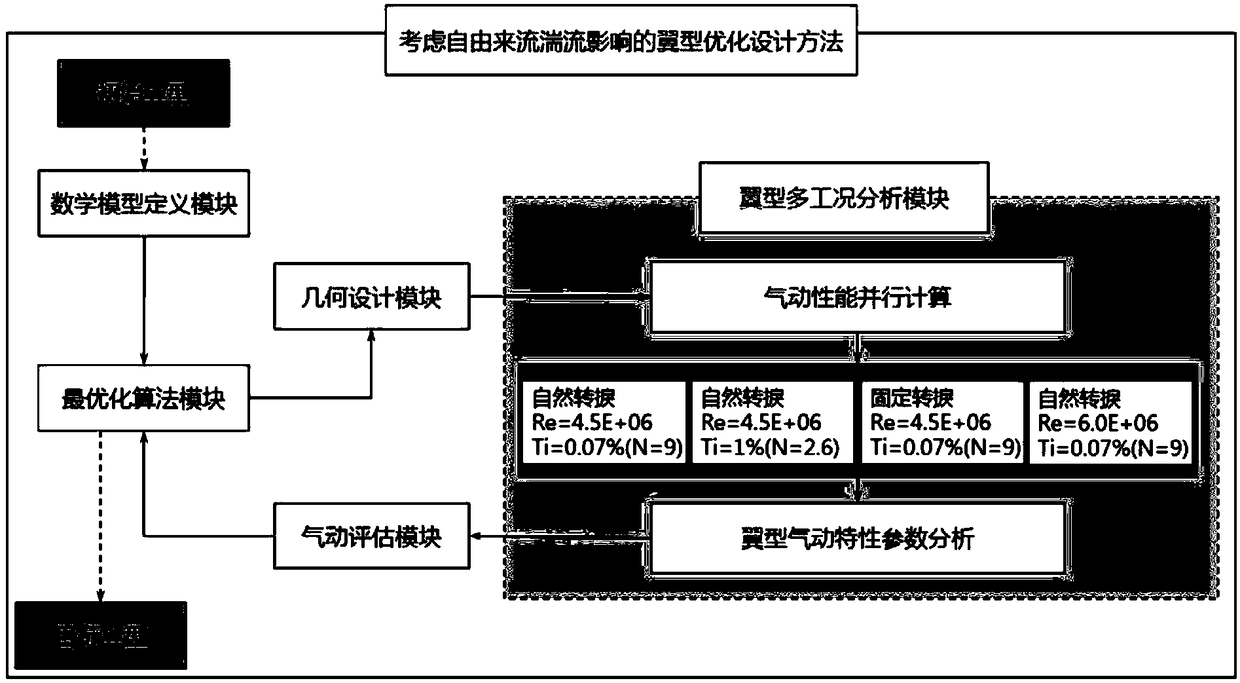

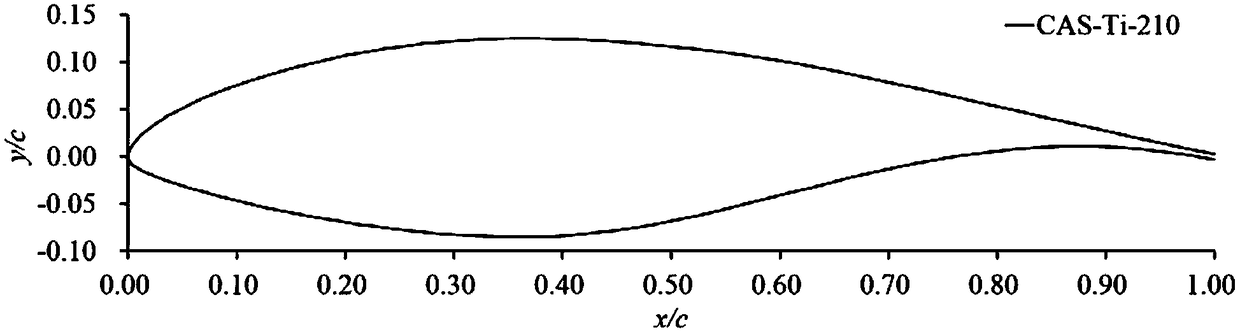

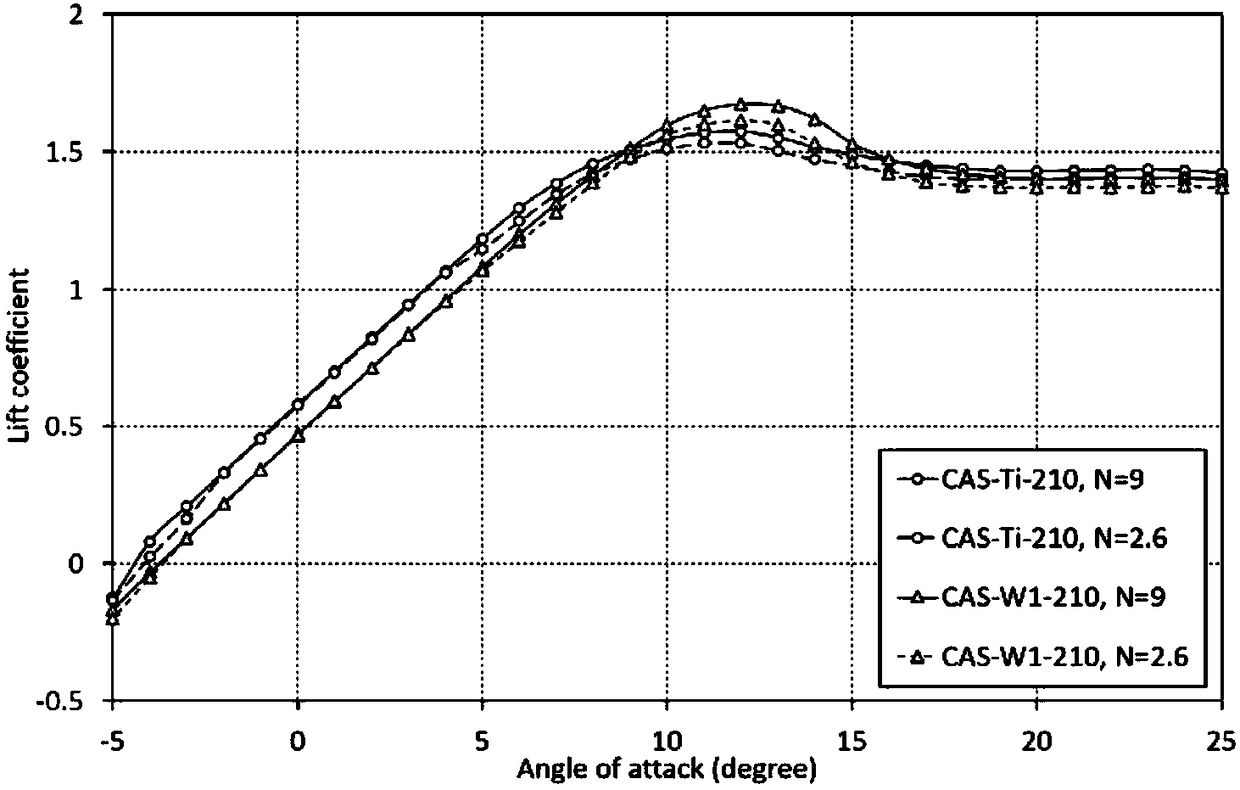

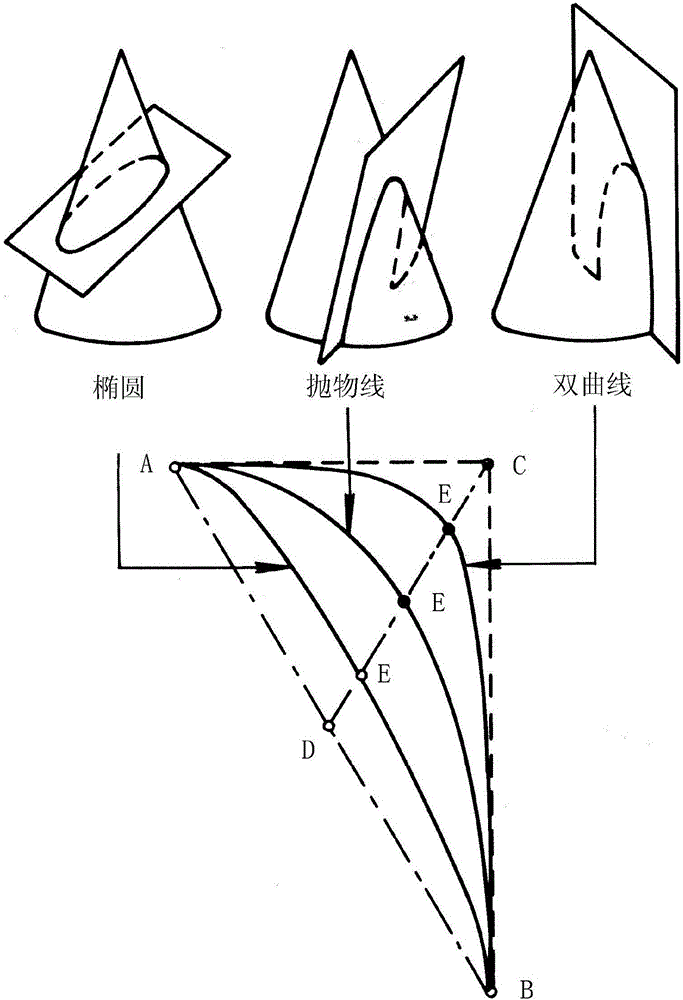

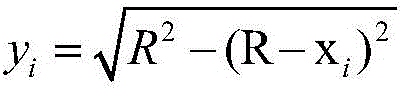

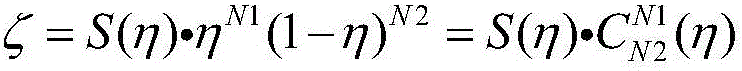

An aerodynamic optimization method for wind turbine airfoil profile considering a high turbulence free flow effect\

ActiveCN109190283AImprove aerodynamicsImprove stabilityGeometric CADDesign optimisation/simulationWeight coefficientSurface roughness

The invention discloses an aerodynamic optimization method of a wind turbine airfoil profile considering a high turbulence free flow effect. Based on the high turbulence characteristics of incoming flow from a blade airfoil in an actual wind field, the effect of inflow turbulence intensity on the airfoil profile aerodynamic efficiency and load are parameterized and the sensitivity parameters of the maximum lift-drag ratio and the maximum lift coefficient are established, and then the aerodynamic optimization model of the airfoil is formed by combining the objective parameters of airfoil efficiency and load, surface roughness sensitivity and Reynolds number effect with the weight coefficient method, and the aerodynamic optimization method of the airfoil is constructed by combining the genetic algorithm. As shown by the numerical simulation and evaluation, the aerofoil profile aerodynamic optimization method provided by the invention not only maintains a high design lift coefficient andimprove the maximum lift-drag ratio, but also remarkably reduces the sensitive parameters of the aerofoil aerodynamic performance varying with the turbulence intensity of the free flow; in addition, the maximum lift coefficient of the airfoil is effectively limited, and the stall process is more smooth.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

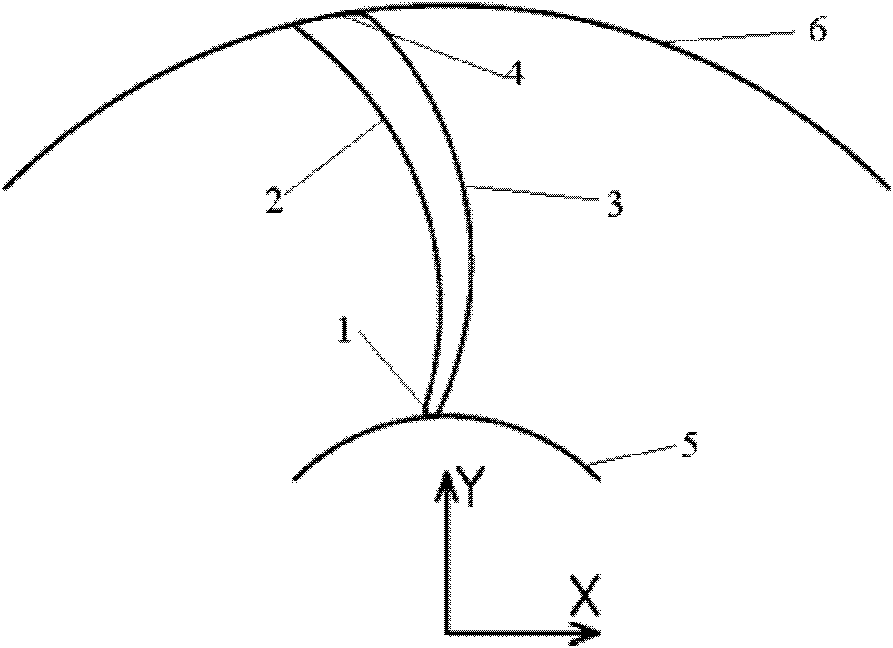

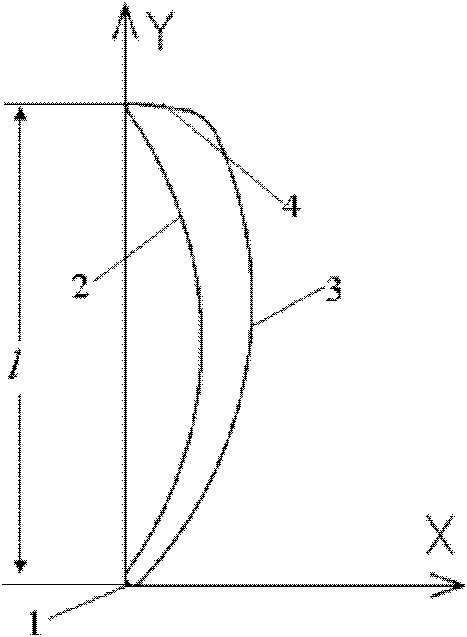

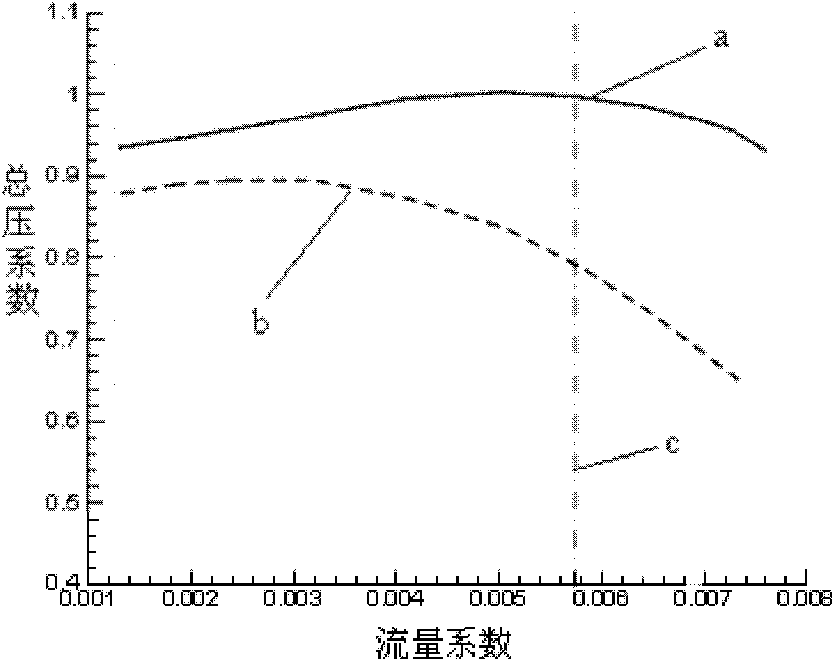

Centrifugal fan blade

InactiveCN101769266AReduces airflow separation and energy lossGood aerodynamic performancePump componentsPumpsTrailing edgeForward bending

The invention relates to a centrifugal fan blade, belonging to the technical field of fluid machinery. The blade comprises a front edge, a pressure surface, a suction surface and a rear edge, wherein the front edge is tangent to the inner diameter of a fan; the rear edge is positioned on the outer diameter of the fan; one end of the pressure surface and one end of the suction surface are respectively connected with the two ends of the front edge, and the other ends of the pressure surface and the suction surface are respectively connected with the two ends of the rear edge; and the blade is formed by the area surrounded by the front edge, the pressure surface, the suction surface and the rear edge. The blade adopts variable thickness forward bending structure, and the pressure surface and the suction surface of blade are controlled by high-order bezier curve, so that higher pressure rise and working efficiency can be ensured under the condition of low flow rate, the situation of a flow channel is improved, and the energy loss is reduced.

Owner:SHANGHAI JIAO TONG UNIV

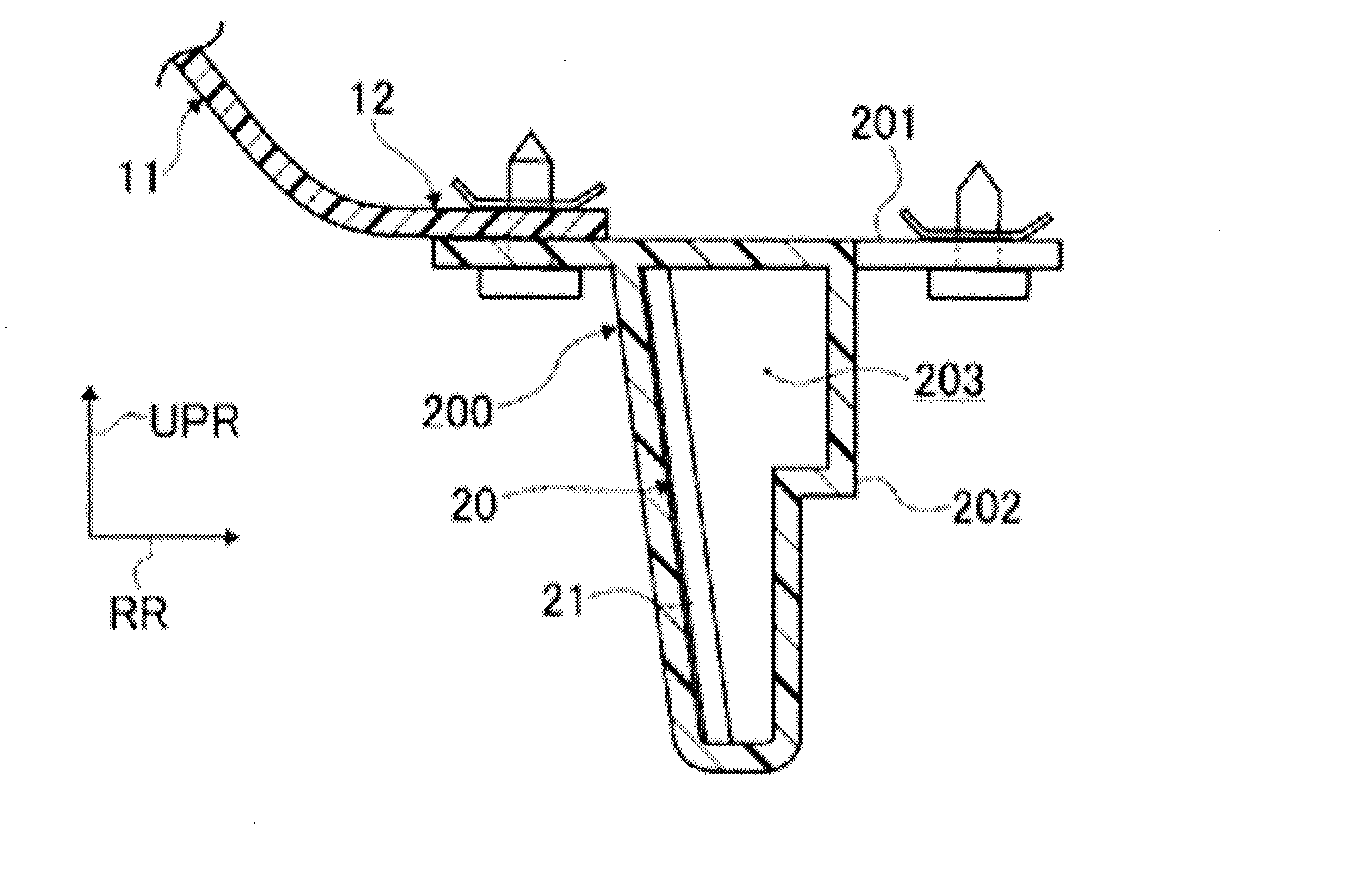

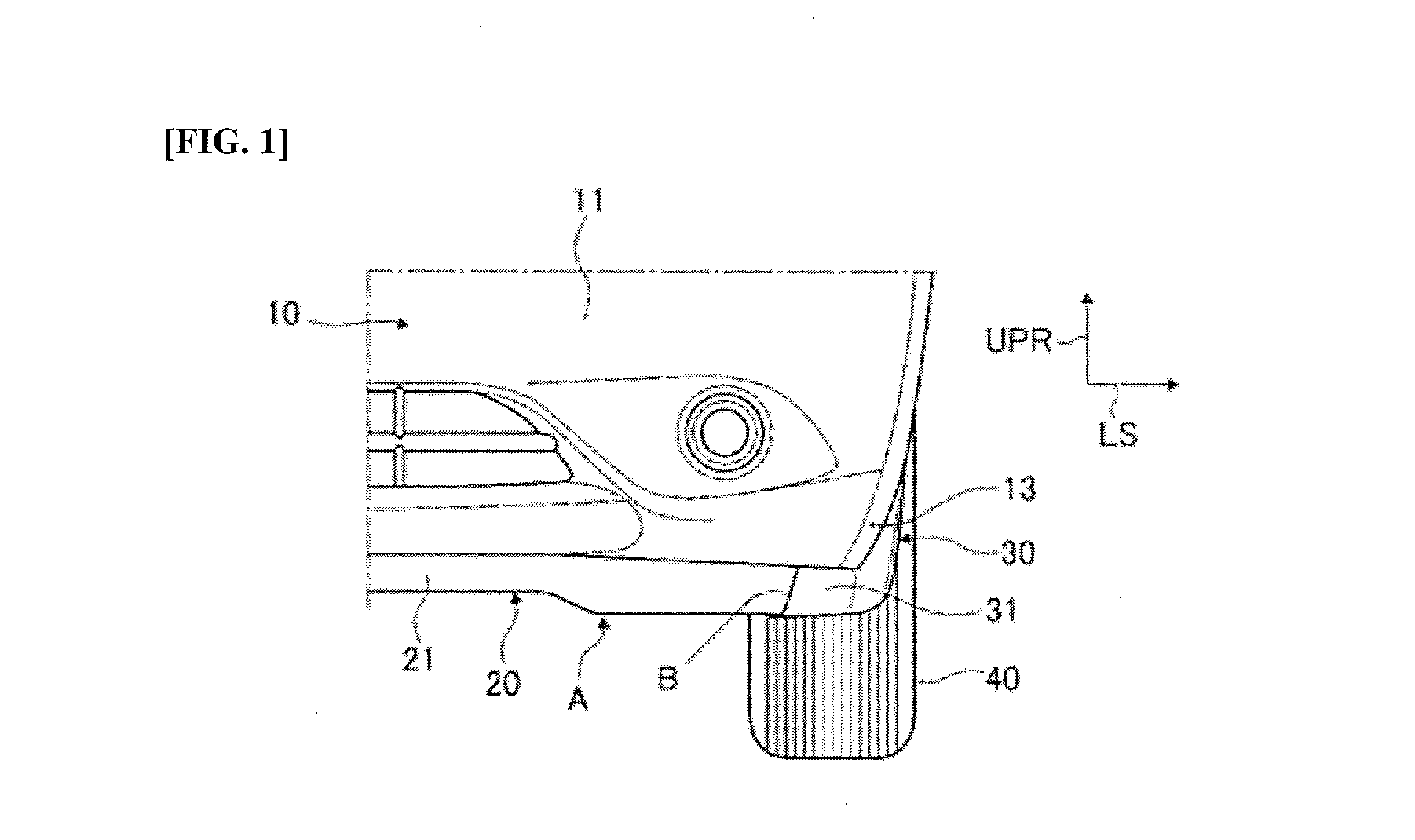

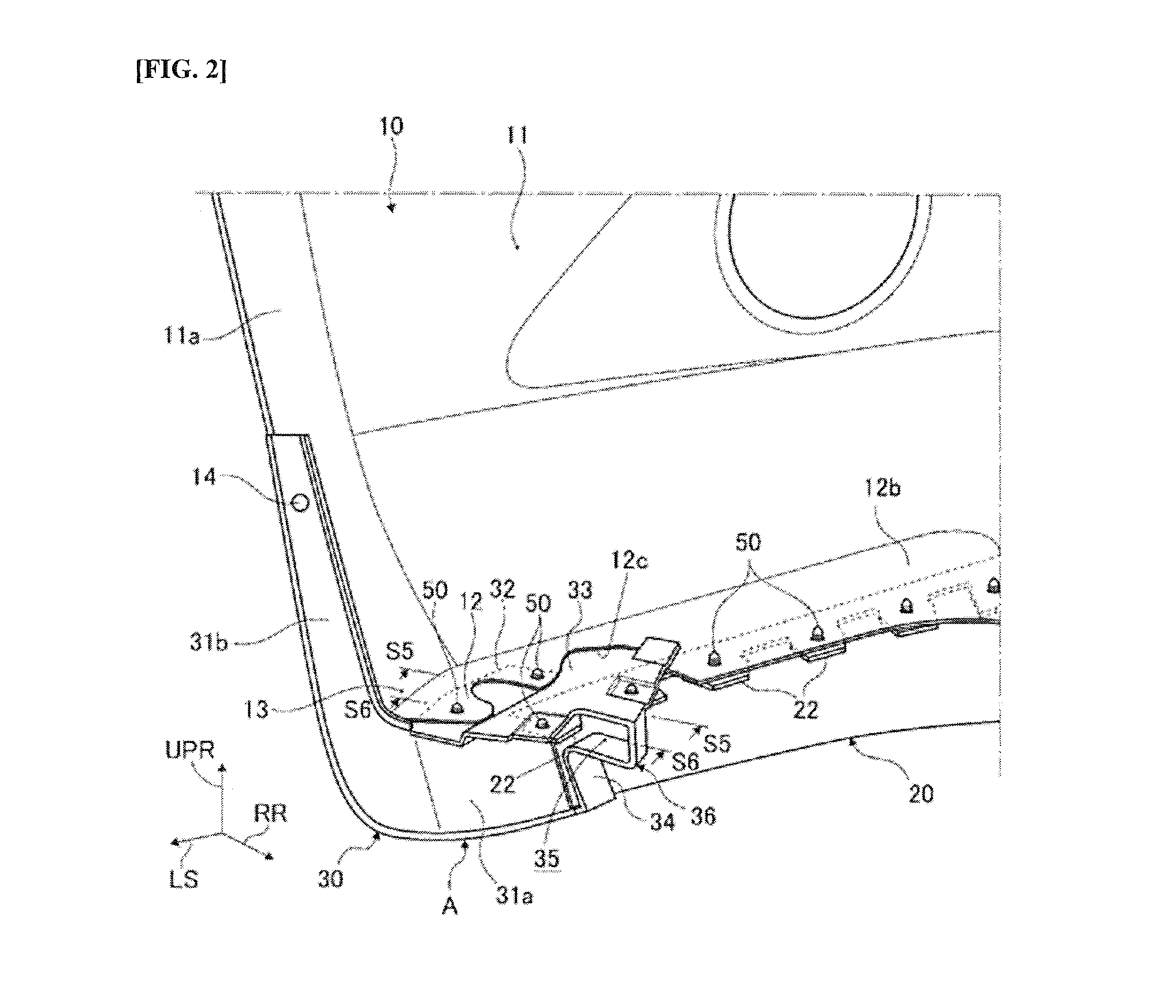

Front spoiler device

ActiveUS20150210324A1Improve aerodynamicsControl appearance qualityVehicle seatsWindowsFlangeAerospace engineering

A front spoiler device configured to be installed on a vehicle having a vehicle width direction, a vehicle upward direction, a vehicle downward direction, a vehicle forward direction, and vehicle rearward direction, has a front bumper, a bumper fascia that forms an outer surface of the front bumper, a spoiler supporting flange portion extending in the vehicle rearward direction from a lower end of the bumper fascia, a spoiler body extending along the lower end of the bumper fascia in the vehicle width direction, the spoiler body being provided with a vertical wall portion facing the vehicle forward direction, and two diffuser portions, each of which is connected to each lateral end of the spoiler body, each of which extends in the vehicle downward direction and in the vehicle width direction along a corner portion of each lateral end on the lower end of the bumper fascia.

Owner:NISSAN MOTOR CO LTD

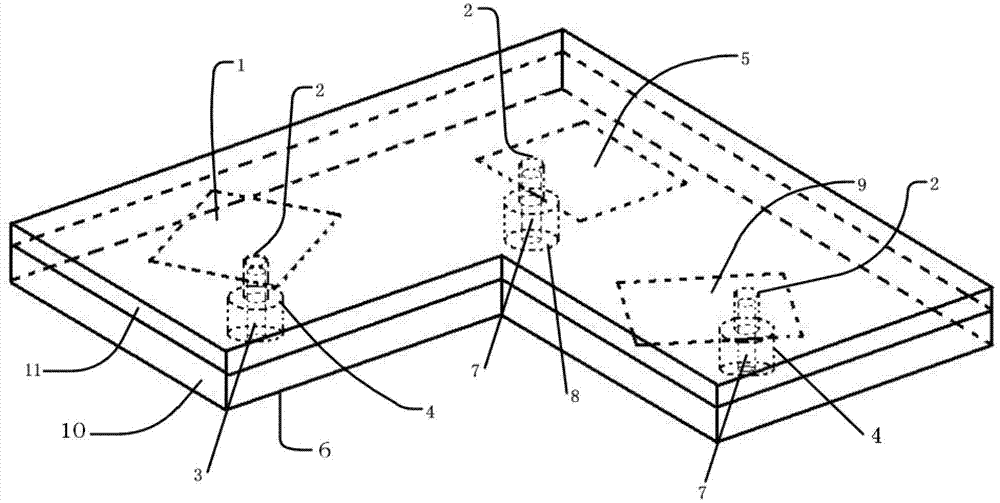

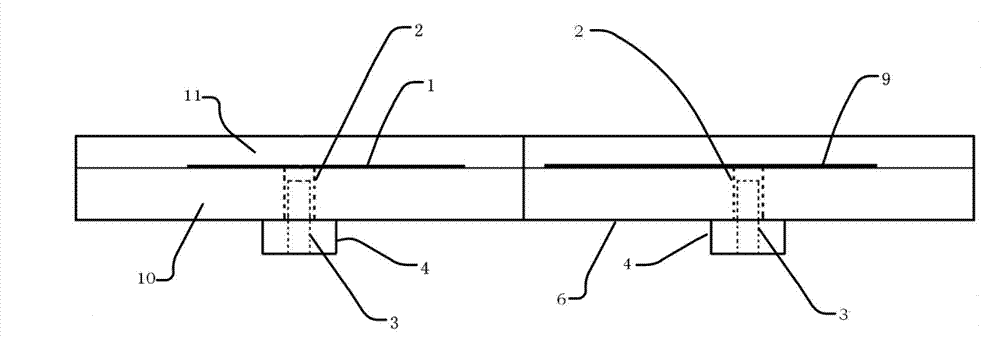

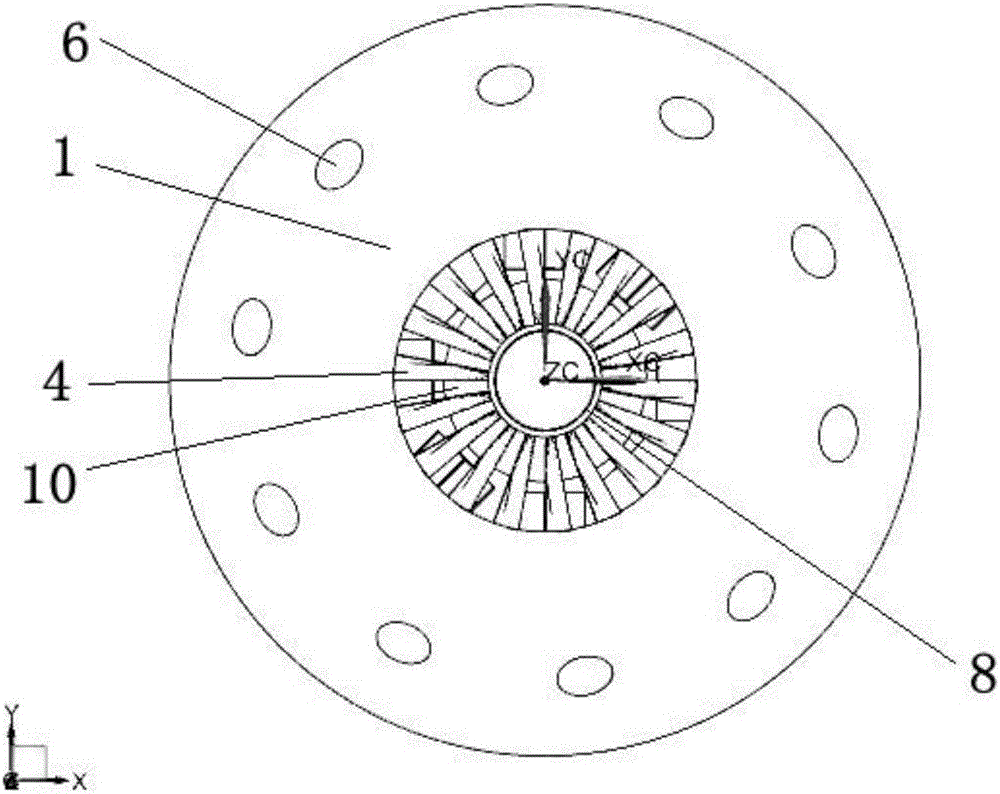

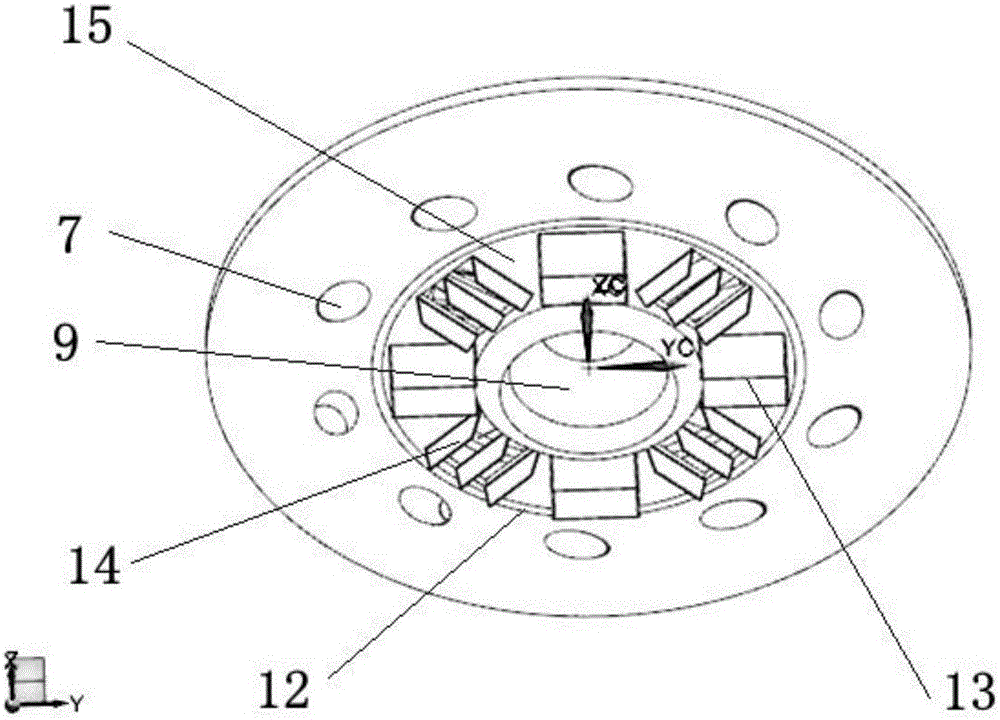

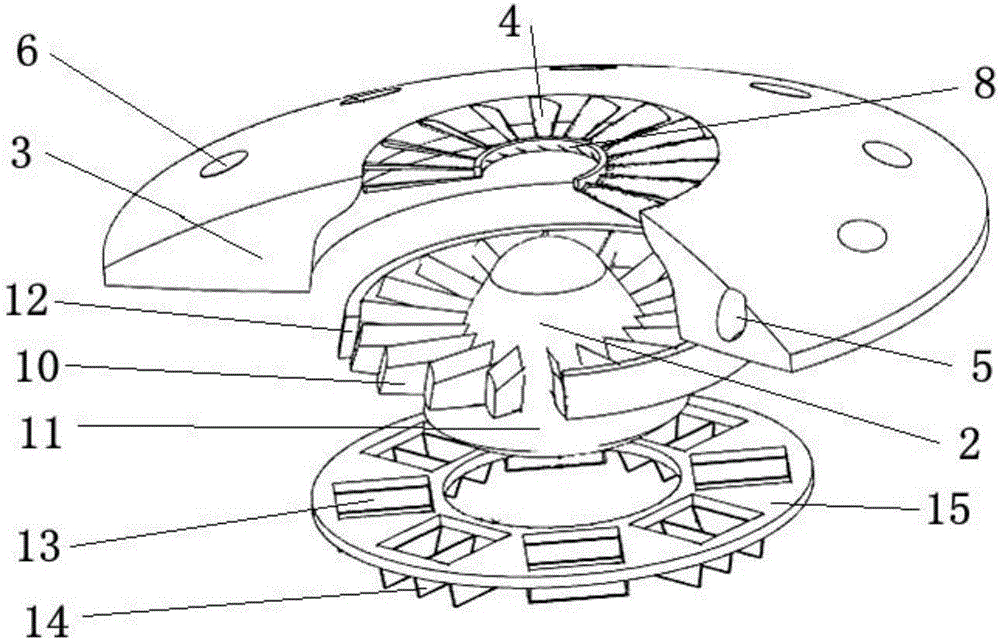

Phased-array antenna subarray for circularly polarized wide-angle scanning

InactiveCN103247845AAxle ratio is betterLarge Angle Gain BoostAntenna arraysAntenna adaptation in movable bodiesPhysicsPhase compensation

The invention provides a phased-array antenna subarray for circularly polarized wide-angle scanning, and aims at providing a phased-array antenna subarray which has a good wide-angle scanning gain characteristic and a good wide-angle scanning circular polarization characteristic, and can avoid derotation properly. The phased-array antenna subarray is achieved by the technical scheme as follows: three circularly polarized microstrip antenna radiation patches are distributed on a microstrip antenna dielectric plate (10) in a ternary rotary inversion subarray form; a metal layer (6) at the lower part of the microstrip antenna dielectric plate serves as a metal place for three microstrip antenna units; each coaxial joint inner core (3) and each coaxial joint outer core (4) form a coaxial feeding port; each coaxial outer core is connected with the metal place; each coaxial joint inner core is connected with the corresponding radiation patch located in the microstrip antenna dielectric plate in blind-inserting and non-contact manners; and the coaxial feeding ports perform electromagnetic coupling feeding and implement phase compensation on the microstrip antenna units to obtain a subarray radiating left-hand circular polarization electromagnetic waves or a subarray radiating right-hand circular polarization electromagnetic waves.

Owner:10TH RES INST OF CETC

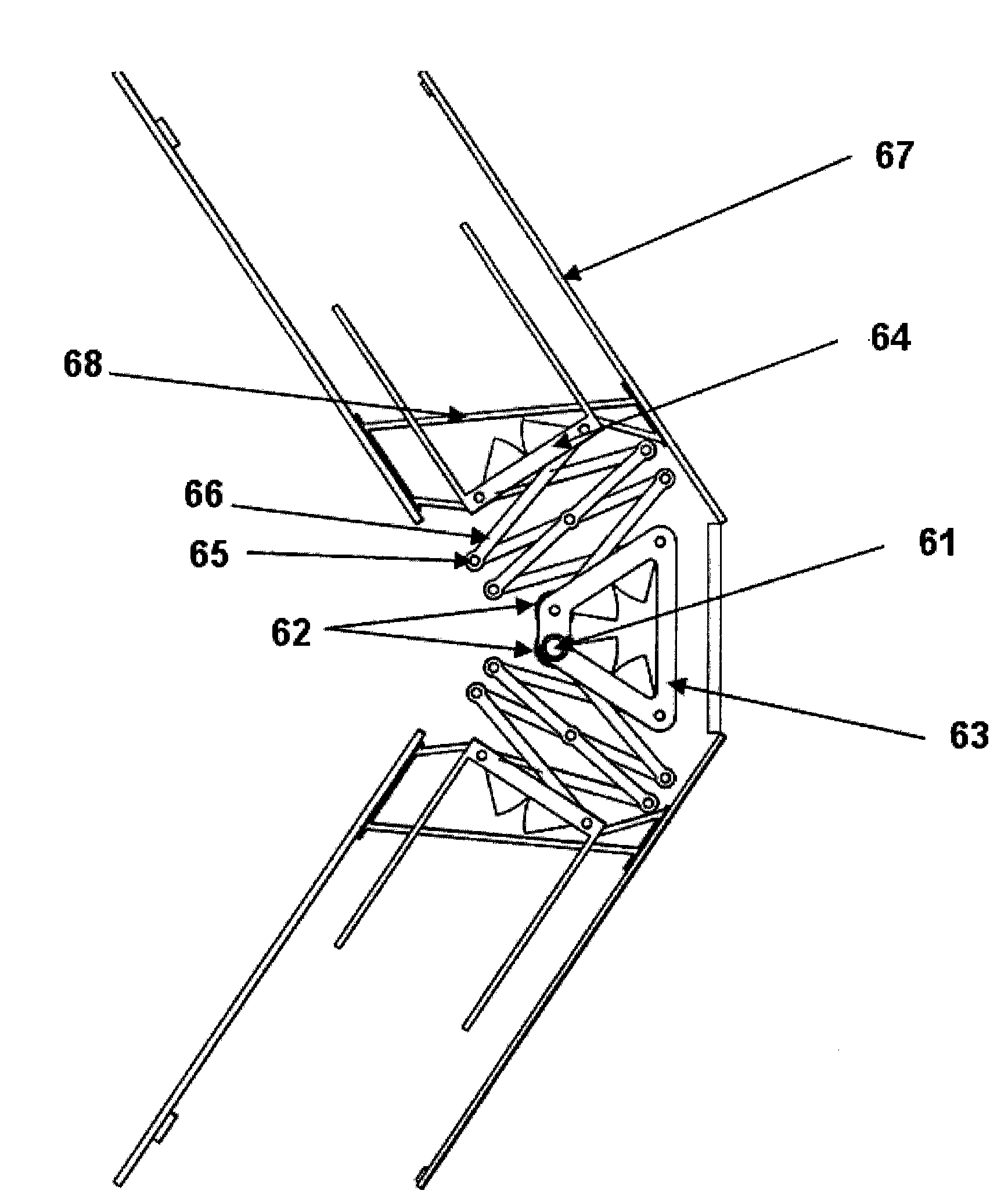

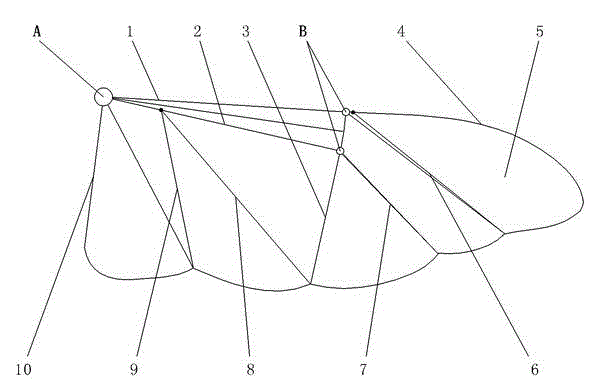

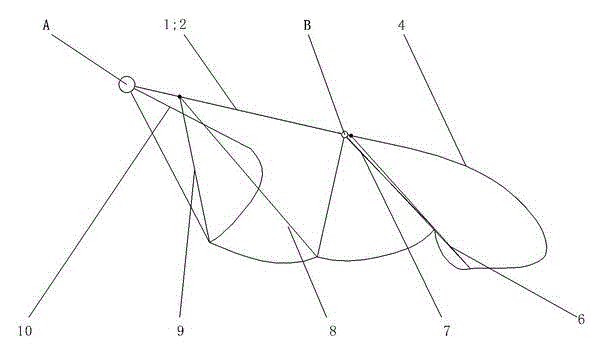

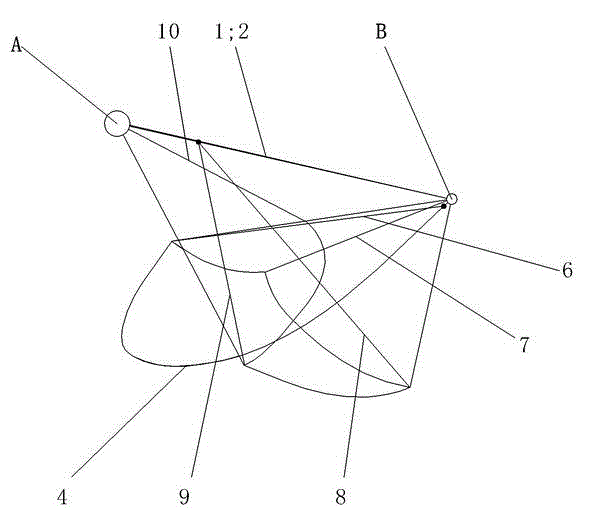

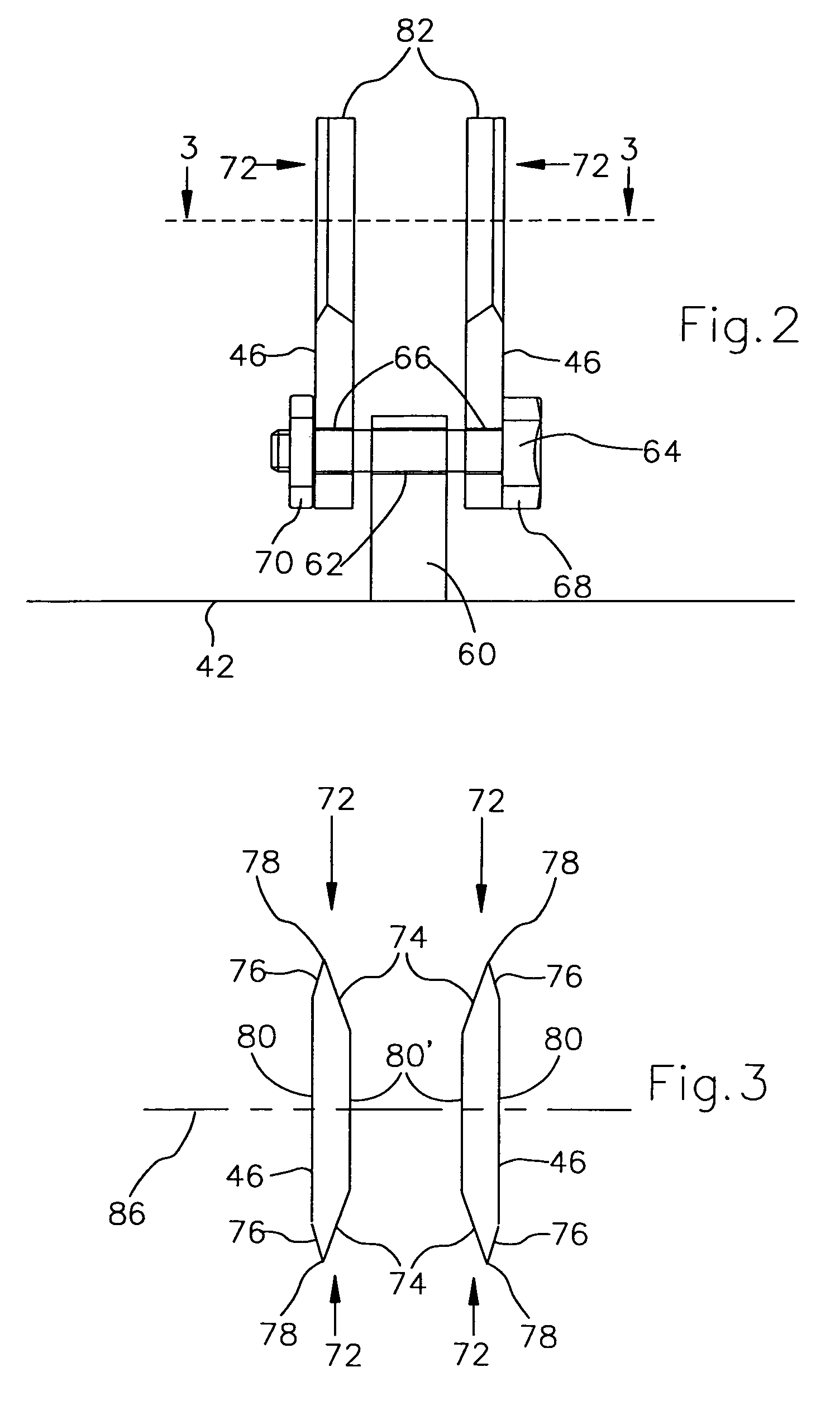

Flapping wing capable of automatically folding and unfolding for flapping wing type micro aerial vehicle

The invention discloses a flapping wing capable of automatically folding and unfolding for a flapping wing type micro aerial vehicle. The flapping wing consists of a power device, two hydraulic pipes, a plurality of creases, a plurality of supporting rods, a wing membrane and two folding devices, and the folding and unfolding of the flapping wing are realized by adopting a hydraulic principle. According to the flapping wing, the two hydraulic pipes and the plurality of supporting rods form wing veins of a bionic flapping wing, and the wing membrane is adhered to the bionic wing veins to form a wing surface. The flapping wing pumps liquid into different liquid chambers by virtue of a micro flow pump to generate a pressure so as to drive the flapping wing to fold up or unfold. The flapping wing disclosed by the invention has the beneficial effects of reducing the transverse size of flapping wing type micro aerial vehicle when the flapping wing type micro aerial vehicle does not fly, reducing the spaces required for carrying, transportation and storage, reducing transportation requirements, conveniently protecting the flapping wing of the aerial vehicle from being damaged, favorably replacing a damaged flapping wing to improve the service life of the micro aerial vehicle.

Owner:JILIN UNIV

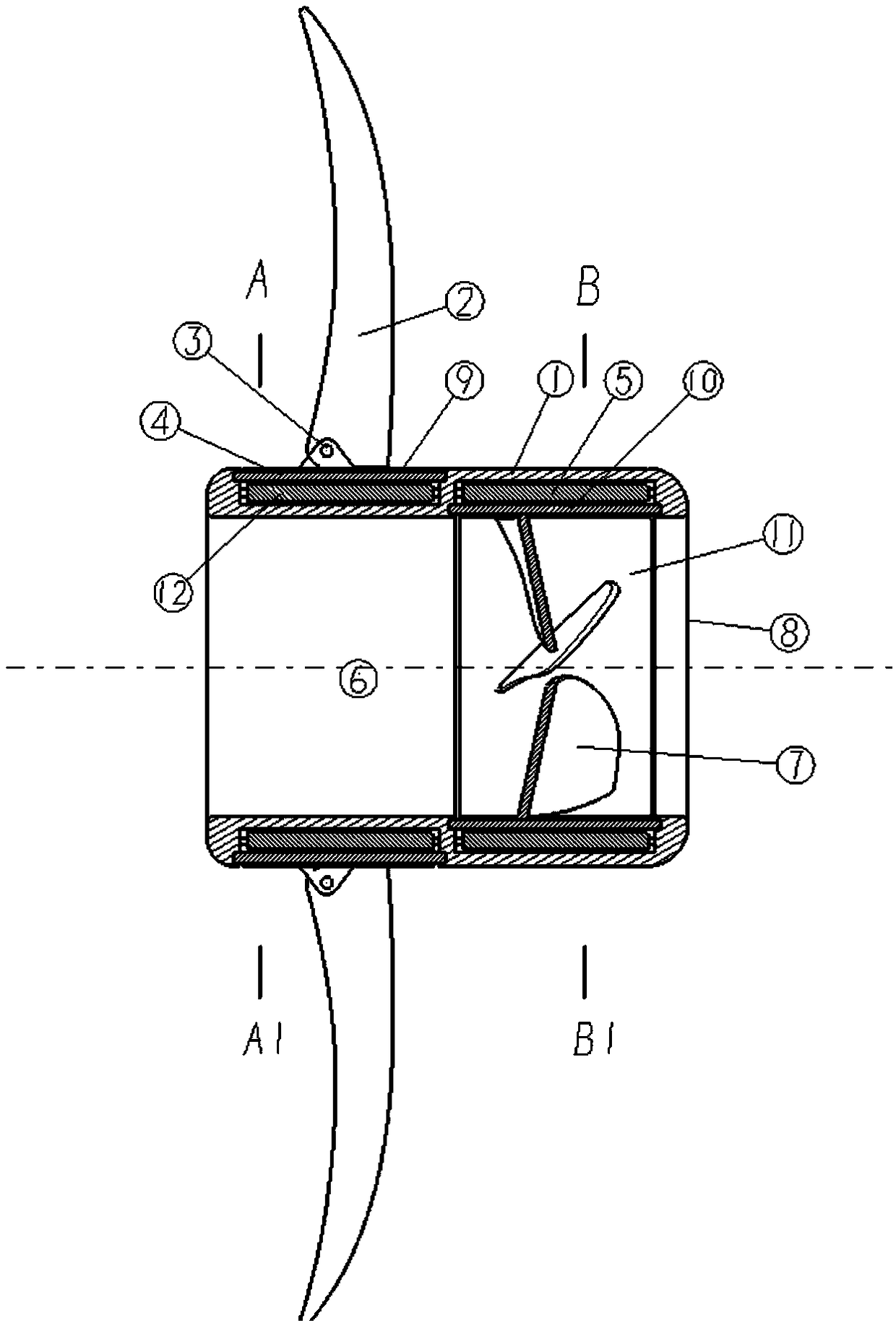

Jet self-rotation disc type aircraft capable of realizing vertical take-off and landing and working method

ActiveCN106379537AImprove stabilityImprove aerodynamicsAircraft navigation controlFlying saucersJet engineFuselage

The invention discloses a jet self-rotation disc type aircraft capable of realizing vertical take-off and landing and a working method. The jet self-rotation disc type aircraft is formed by two parts of a disc type machine body and a stator machine body which can be used for bearing cargos, and mainly comprises a rotary disc machine body, a lift fan, jet engines, air inlets of the jet engines, air outlets of the jet engines, a lift fan hub, a gyrorotor type cargo compartment, a stator blade bar, a stator blade bar hub, an outer cartridge receiver of the stator blade bar, vector nozzles, flow deflectors and the like. According to the jet self-rotation disc type aircraft capable of realizing the vertical take-off and landing, designed by the invention, the jet self-rotation disc type aircraft adopts pneumatic layout with a blended wing body, not only has good pneumatic performance, but also has no need to consider limiting factors of place space during a take-off and landing process, is capable of freely taking off and landing, hovering and climbing, and has good stability under a high-speed self-rotation flying state.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

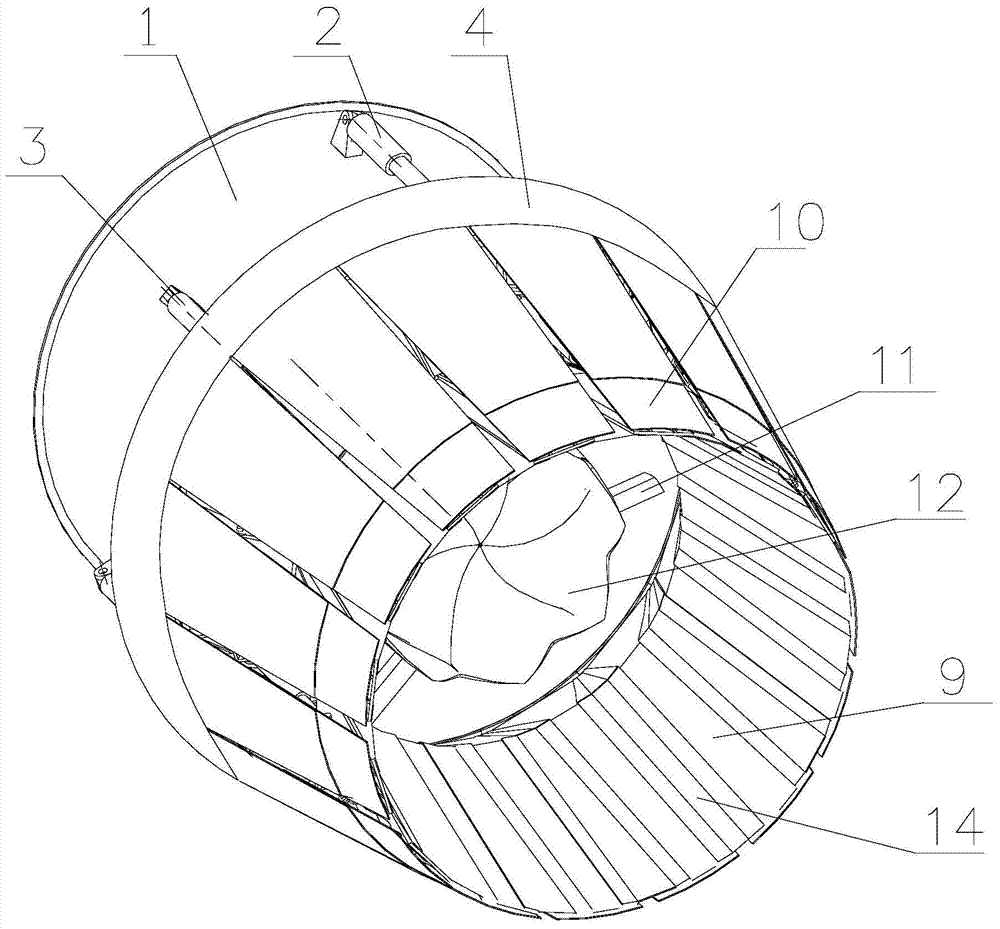

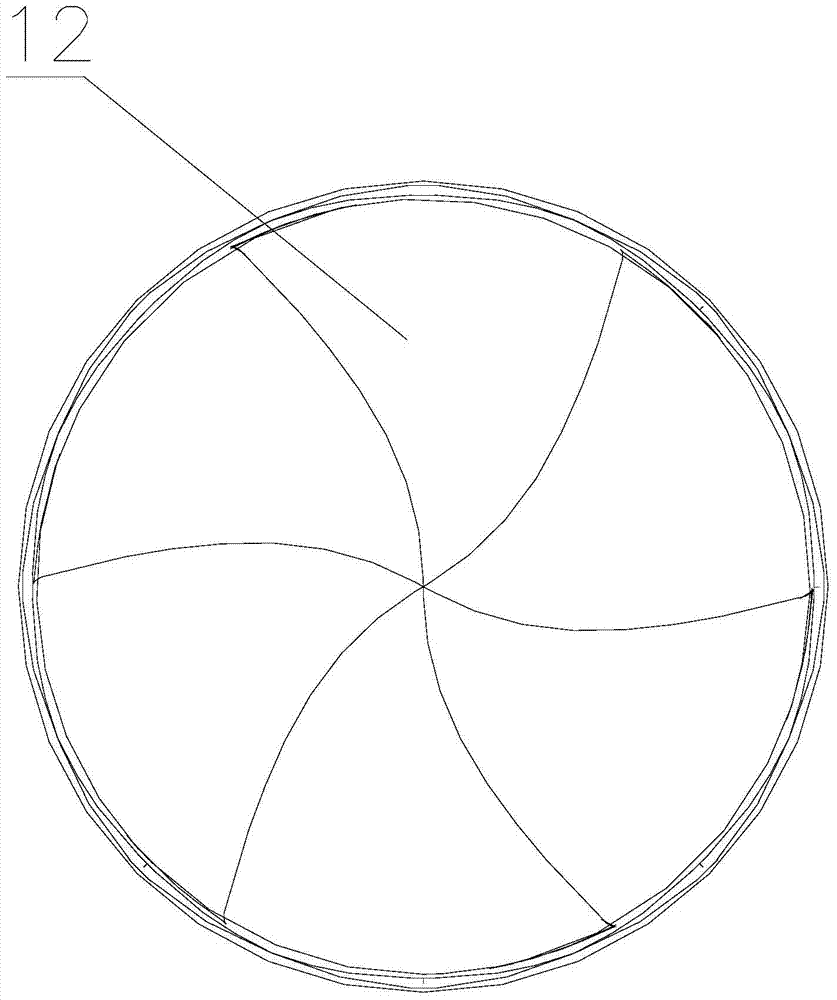

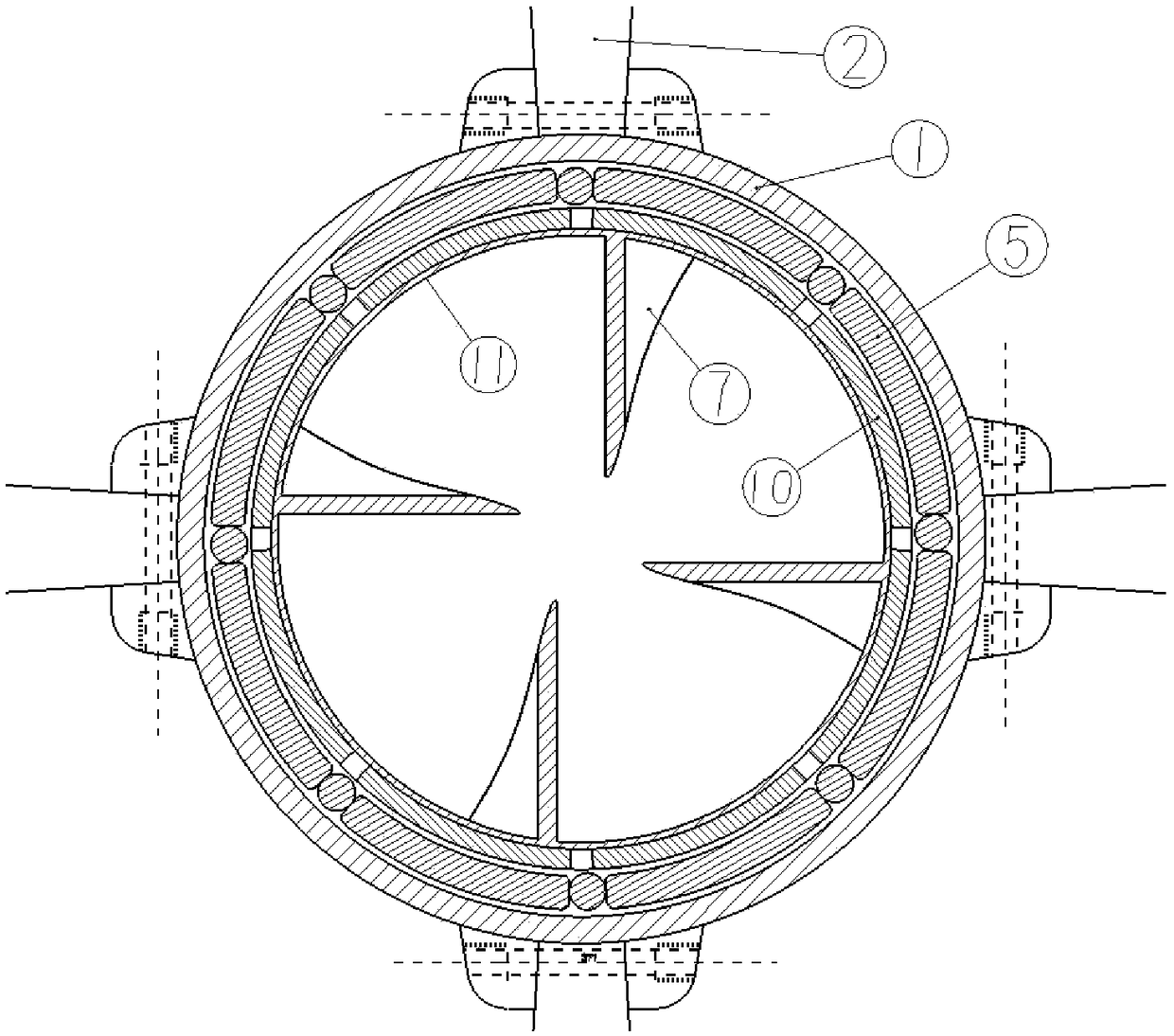

Axisymmetric vectoring nozzle with good stealth function

ActiveCN103696873AImprove aerodynamicsDoes not affect the area adjustment rangeJet propulsion plantsEngineeringActuator

An axisymmetric vectoring nozzle with a good stealth function is characterized in that the axisymmetric vectoring nozzle comprises a barrel, a divergent section adjustment mechanism, a throat adjustment mechanism, a sealing component, a central shielding component and a shroud component; specifically, the front end of the barrel is connected with an engine, and the divergent section adjustment mechanism mainly comprises vectoring actuator cylinders, vector-adjusting rings, pull rods and divergence-adjusting plates; the vectoring actuator cylinders are arranged along the circumference of the nozzle, the front ends of the vectoring actuator cylinders are mechanically connected with the external wall of the barrel, and the rear ends of the vectoring actuator cylinders are connected with the vector-adjusting rings; the rear ends of the vector-adjusting rings are connected with the pull rods through revolute pairs and connected with the barrel through centering mechanisms, so that the radial displacement of the vector-adjusting rings is limited; the pull rods are evenly distributed along the circumference of the nozzle, and the other ends of the pull rods are connected with the outsides of the divergence-adjusting plates through revolute pairs. The axisymmetric vectoring nozzle has the advantages that the axisymmetric vectoring nozzle has good stealth capability, so that the defect in the stealth function of conventional axisymmetric vectoring nozzles is made up for, and meanwhile, the axisymmetric vectoring nozzle has the advantages of simple structure and high reliability.

Owner:AECC SHENYANG ENGINE RES INST

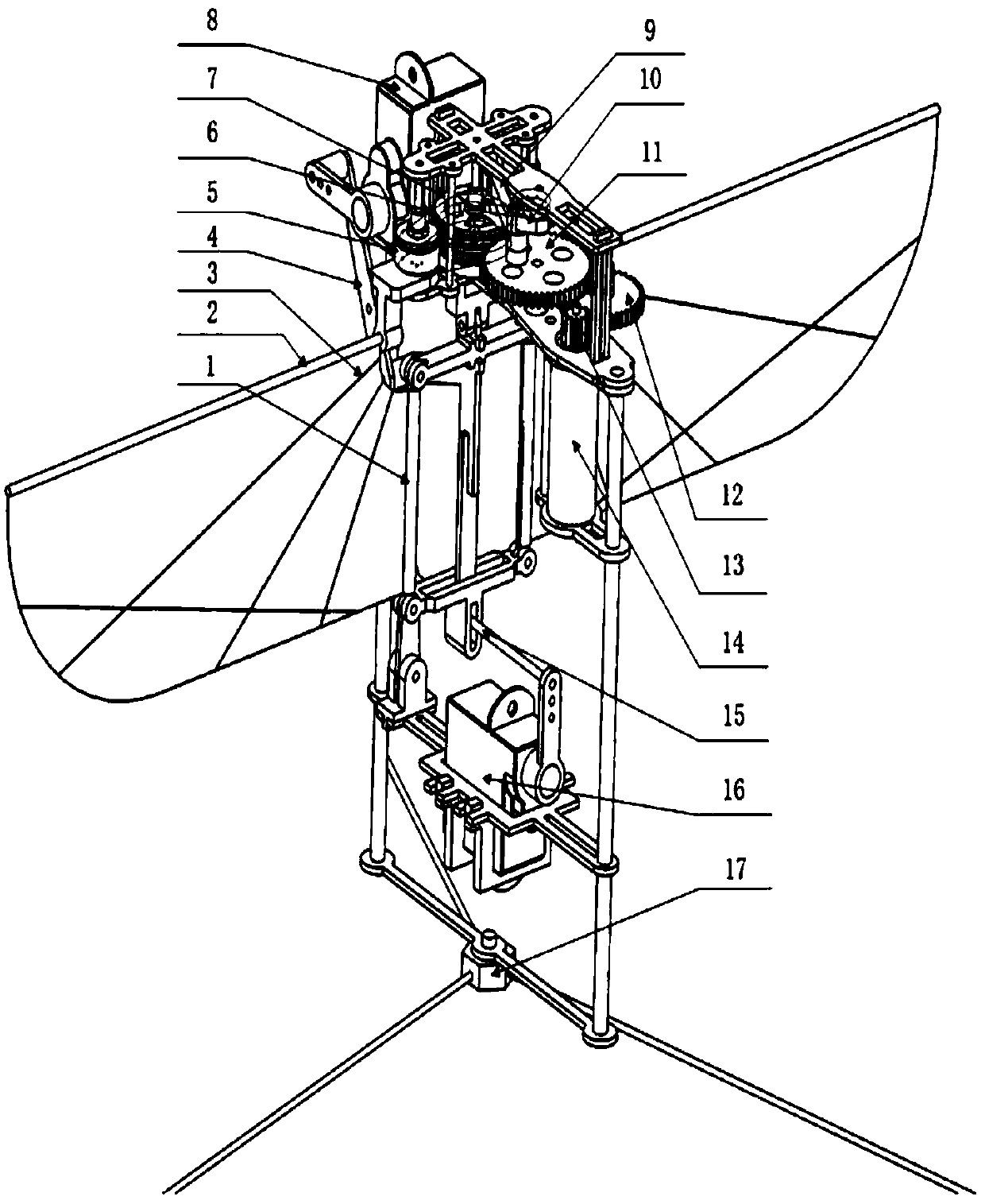

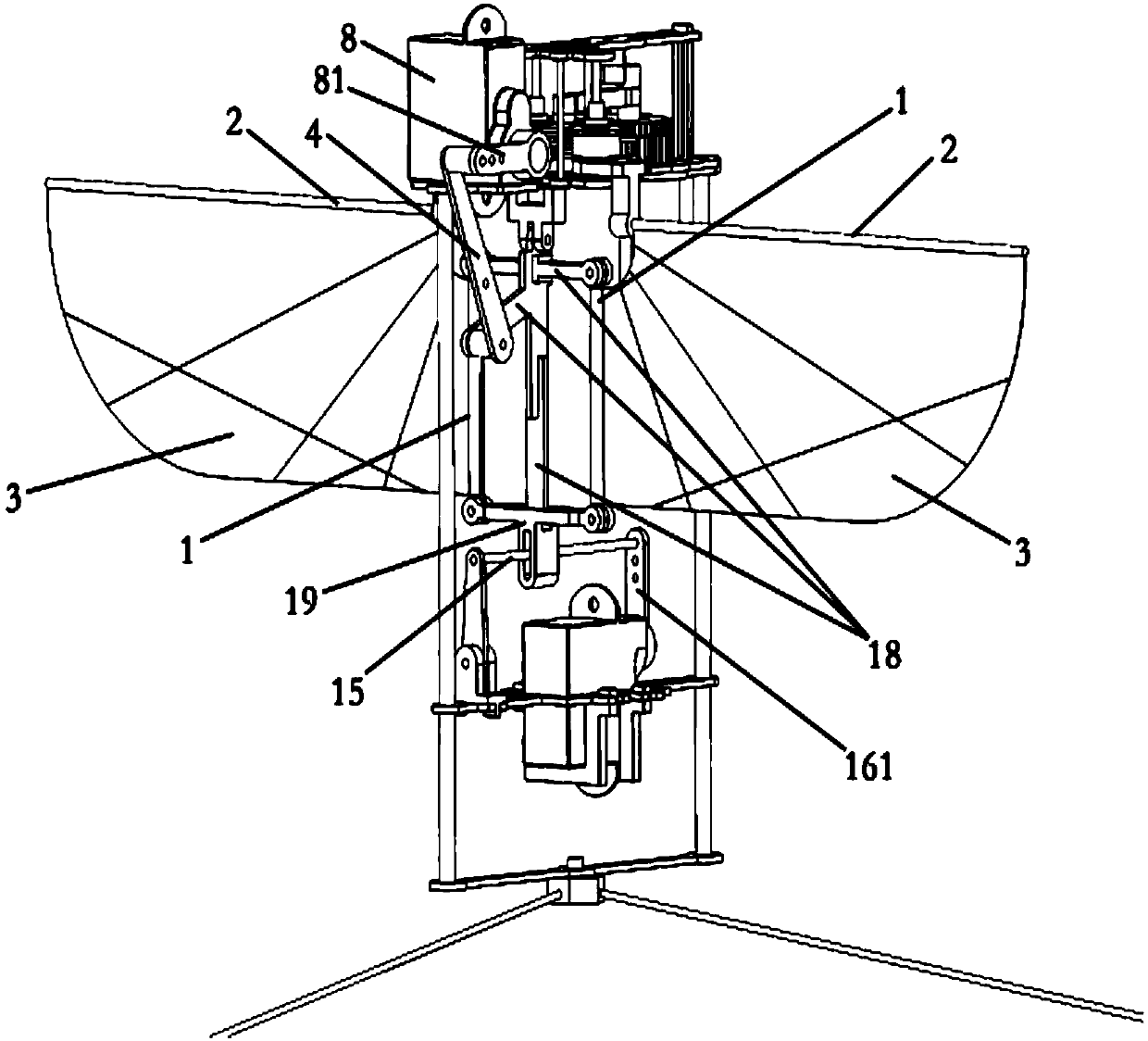

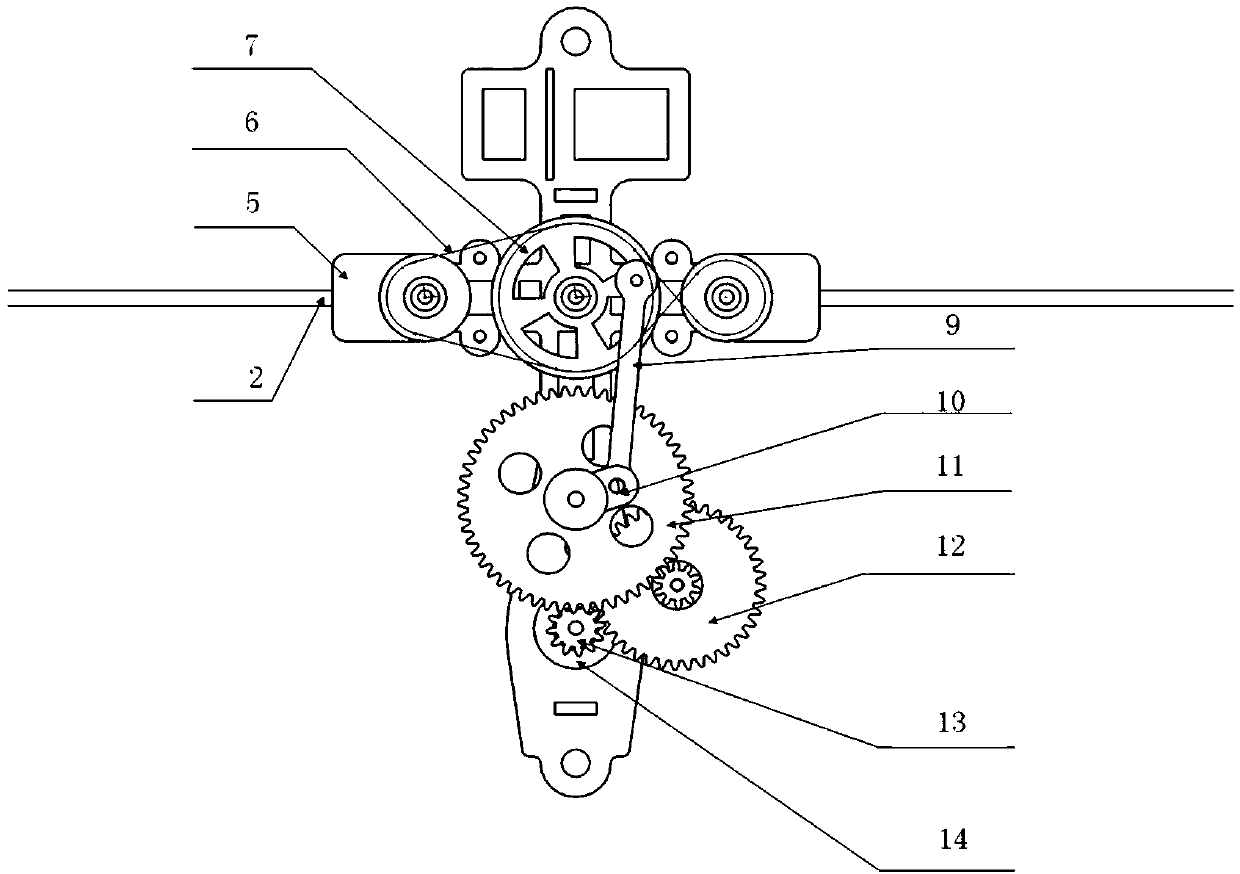

Insect-imitating miniature ornithopter

The invention provides an insect-imitating miniature ornithopter which comprises a first drive mechanism, a crank and rocker mechanism, a pulley mechanism and two wings. The pulley mechanism comprisesa large pulley, two small pulleys and two transmission belts, the two small pulleys are located on the two sides of the large pulley, the large pulley is connected with one small pulley through one transmission belt and connected with the other small pulley after being reversed at 180 degrees through the other transmission belt, the two small pulleys are connected with the two wings, and the wings are driven to flutter through rotation of the small pulleys. The insect-imitating miniature ornithopter has the beneficial effects that the ornithopter is simple in structure, convenient to manufacture and low in cost; the crank and rocker mechanism and the pulley mechanism are combined to achieve large-amplitude flutters of the insect-imitating miniature ornithopter, and the aerodynamic performance is good; and the insect-imitating miniature ornithopter can conduct hovering flight, wing fluttering parameters can be changed in the flight process, so that the flight attitude of the insect-imitating miniature ornithopter is changed, and hovering flight is achieved.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

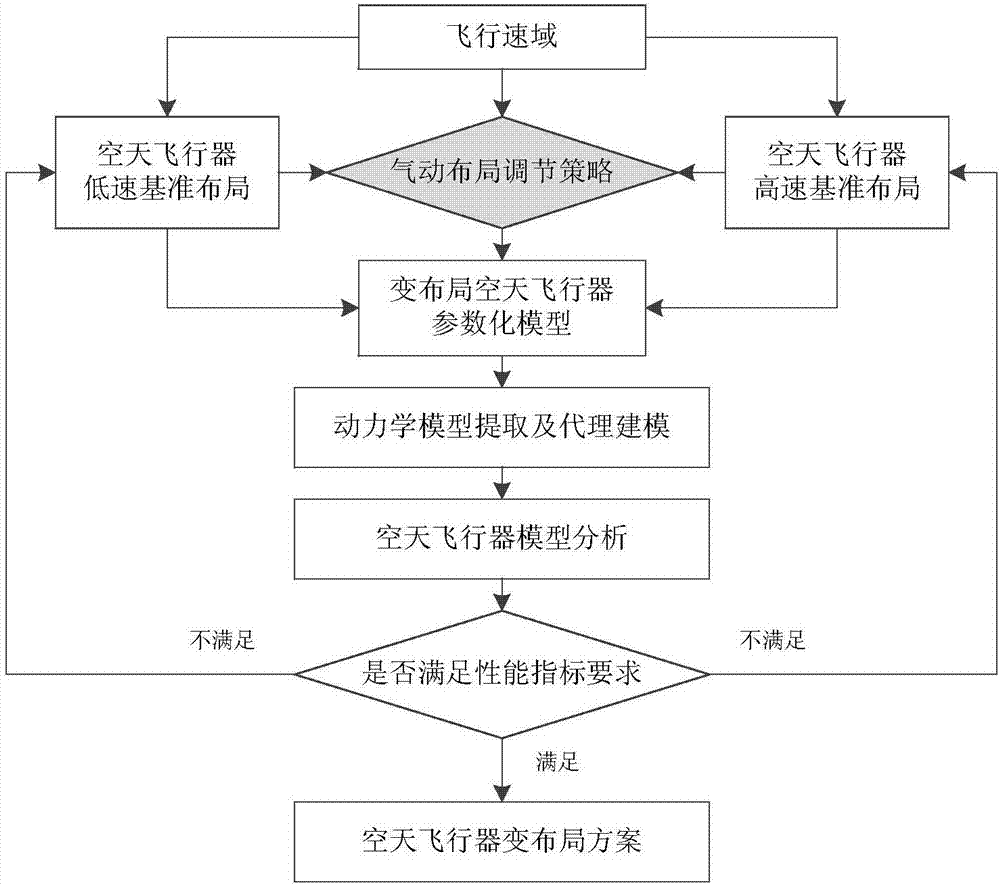

Aerodynamic layout design method based on variable-configuration aerospace vehicle

ActiveCN107985626AGood aerodynamic performanceEnsure system stability and maneuverabilityGround installationsFlight vehicleAutomotive engineering

The invention discloses an aerodynamic layout design method based on a variable-configuration aerospace vehicle. The aerodynamic layout design method comprises the steps that the low-speed datum layout and the high-speed datum layout of the variable-configuration aerospace vehicle are determined correspondingly; the geometrical shape of the variable-configuration aerospace vehicle is described ina parameterization mode through a state-type function method; a corresponding parameterization kinetic model is established through an engineering estimation method, models of different speed domainsare integrated based on the similarity criterion, and a corresponding agent model is established; the influence of the flight condition and aerodynamic layout change on the performance of a flight control system is determined through a sensitivity analysis method, and the stability boundary and system requirements of the variable-configuration aerospace vehicle are determined; and through full-speed-domain performance matching analysis, a variable-layout scheme of the variable-configuration aerospace vehicle is determined. By properly changing the wing configuration of the aerospace vehicle, it is guaranteed that the aerospace vehicle has the optimal aerodynamic layout at each mission stage, large envelope continuous flight under the minimum energy consumption is achieved, and the need ofintegrated design of the aerospace vehicle is met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

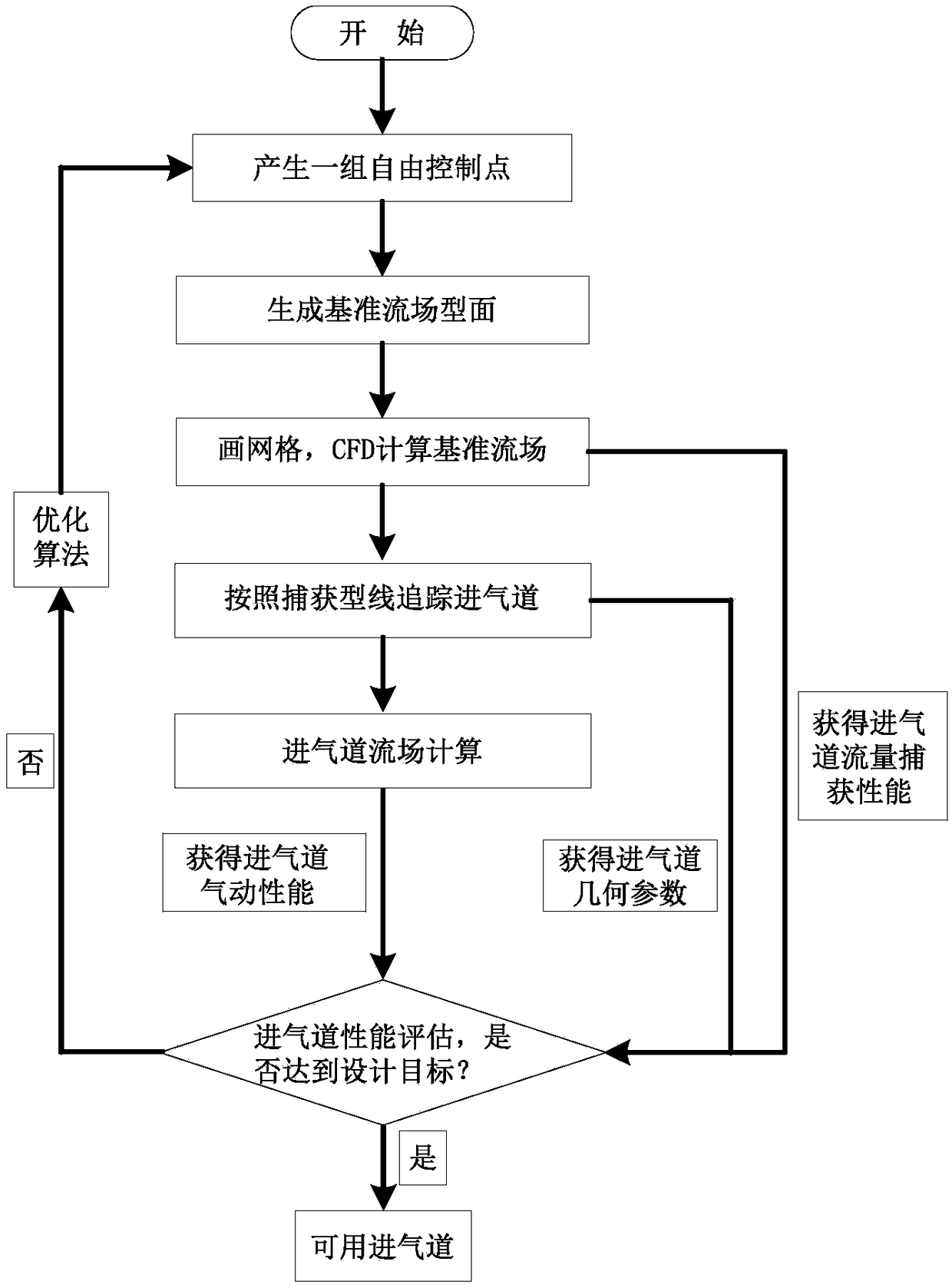

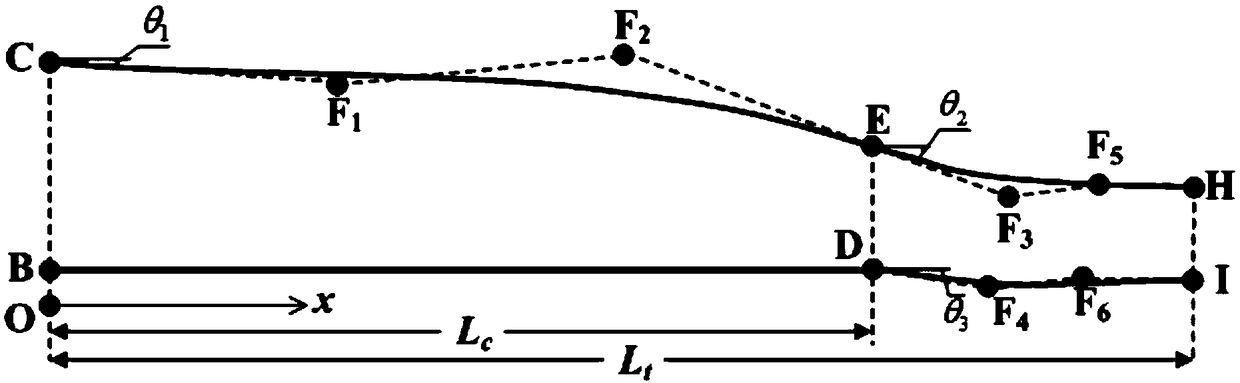

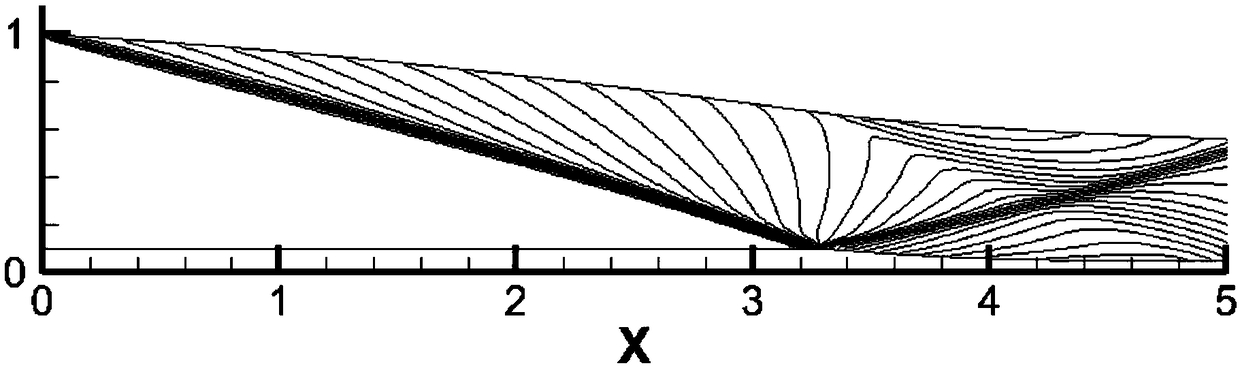

Supersonic flow channel design method and apparatus

ActiveCN108846224AMeet pre-determined requirementsImprove aerodynamicsGeometric CADDesign optimisation/simulationInlet channelEngineering

The invention relates to a supersonic flow channel design method and apparatus. The method comprises the following steps: step S1, generating a reference flow field molded surface; step S2, calculating the reference flow field obtained in the step S1; step S3, generating a three-dimensional internal steering air inlet channel by using a streamline tracing method; step S4, calculating the flow field of the three-dimensional internal steering air inlet channel obtained in the step S3; and step S5, repeatedly iterating step S1 to step S5 by using an optimization algorithm to obtain a three-dimensional internal steering air inlet channel meeting traffic capture performance, geometric parameters and aerodynamic performance. Compared with the prior art, the method has the advantages of being able to solve the problems that the traditional air inlet channel design does not directly aim at the aerodynamic performance of the air inlet channel and starts from the reference flow field performance, such that it is difficult to ensure the same performance of the air inlet channel, the experience is too high to ensure the optimal value of the performance of the air inlet channel and that the total shrinkage ratio and the internal shrinkage ratio of the internal steering air inlet channel are uncontrollable.

Owner:NAT UNIV OF DEFENSE TECH

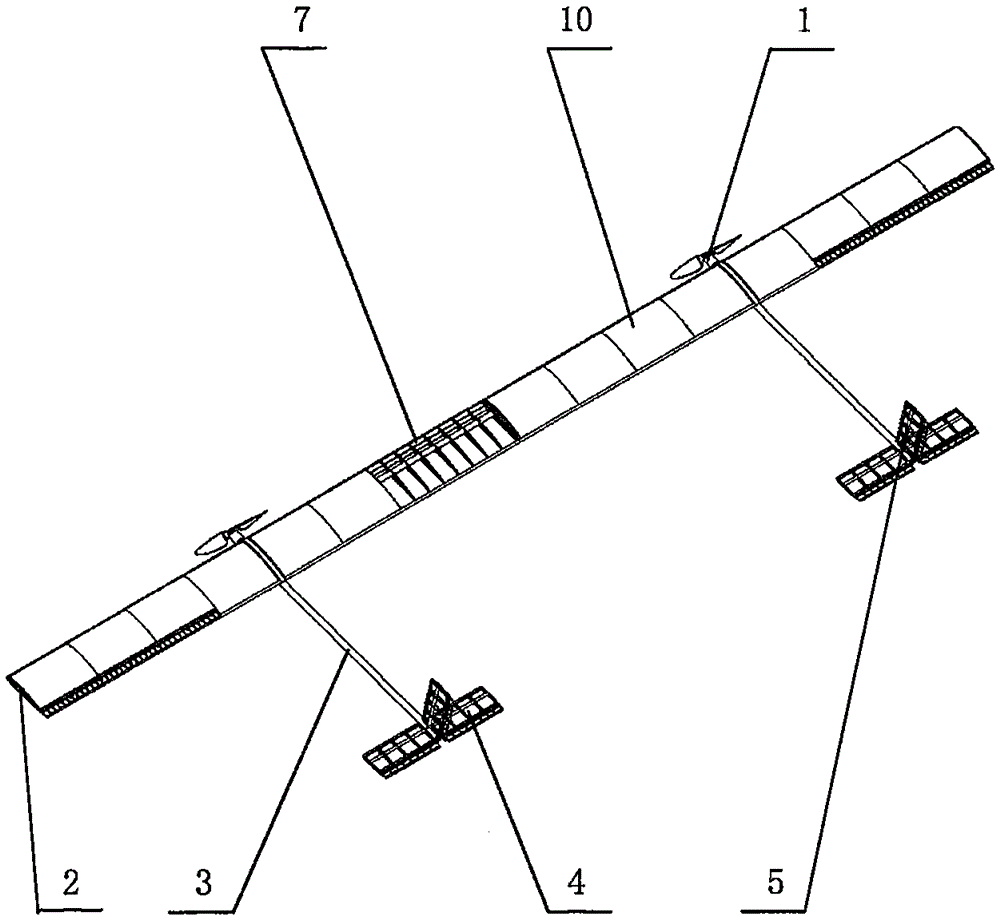

Solar aircraft

InactiveCN105398561ARealize long-term high-altitude reconnaissance and surveillanceGood aerodynamic performanceEfficient propulsion technologiesSpars/stringersFlight vehicleSurveillance and monitoring

The invention belongs to the field of overall design of aviation aircrafts and particularly relates to a solar aircraft. The solar aircraft comprises a wing which is a rectangular wing. An energy storage battery is fixedly distributed in the wing. Solar cells are laid on the upper surface of the wing. Two aircraft bodies are fixed to the positions 1 / 4 and 3 / 4 of the wing in the tangential direction. Flat tails are parallel to the wing, perpendicular tails are perpendicular to the flat tails, and the flat tails and the perpendicular tails are fixed to the rear ends of the aircraft bodies. Two power systems are fixed to the front ends of the two aircraft bodies respectively. By the adoption of the solar aircraft, the arrangement of the two aircraft bodies is adopted and the energy storage battery is distributed in the wing, so that loads are evenly distributed, lifting weight balance and thrust and resistance balance are considered, energy balance needs to be further considered, it is guaranteed that the energy consumed for maintaining lifting force of the aircraft is equivalent to the energy obtained by the solar cells, and long-time high-altitude surveillance and monitoring can be achieved; and meanwhile, the solar aircraft of the structure has the good aerodynamic performance and is convenient to install.

Owner:NAT UNIV OF DEFENSE TECH

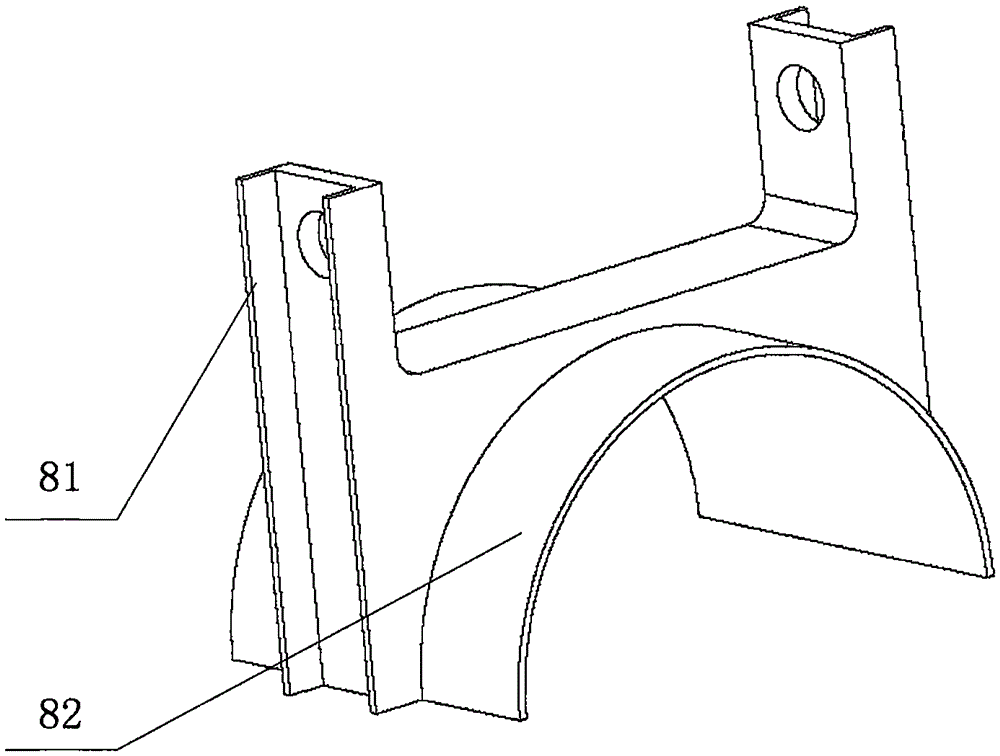

Chopper knife for a straw chopper

Owner:DEERE & CO

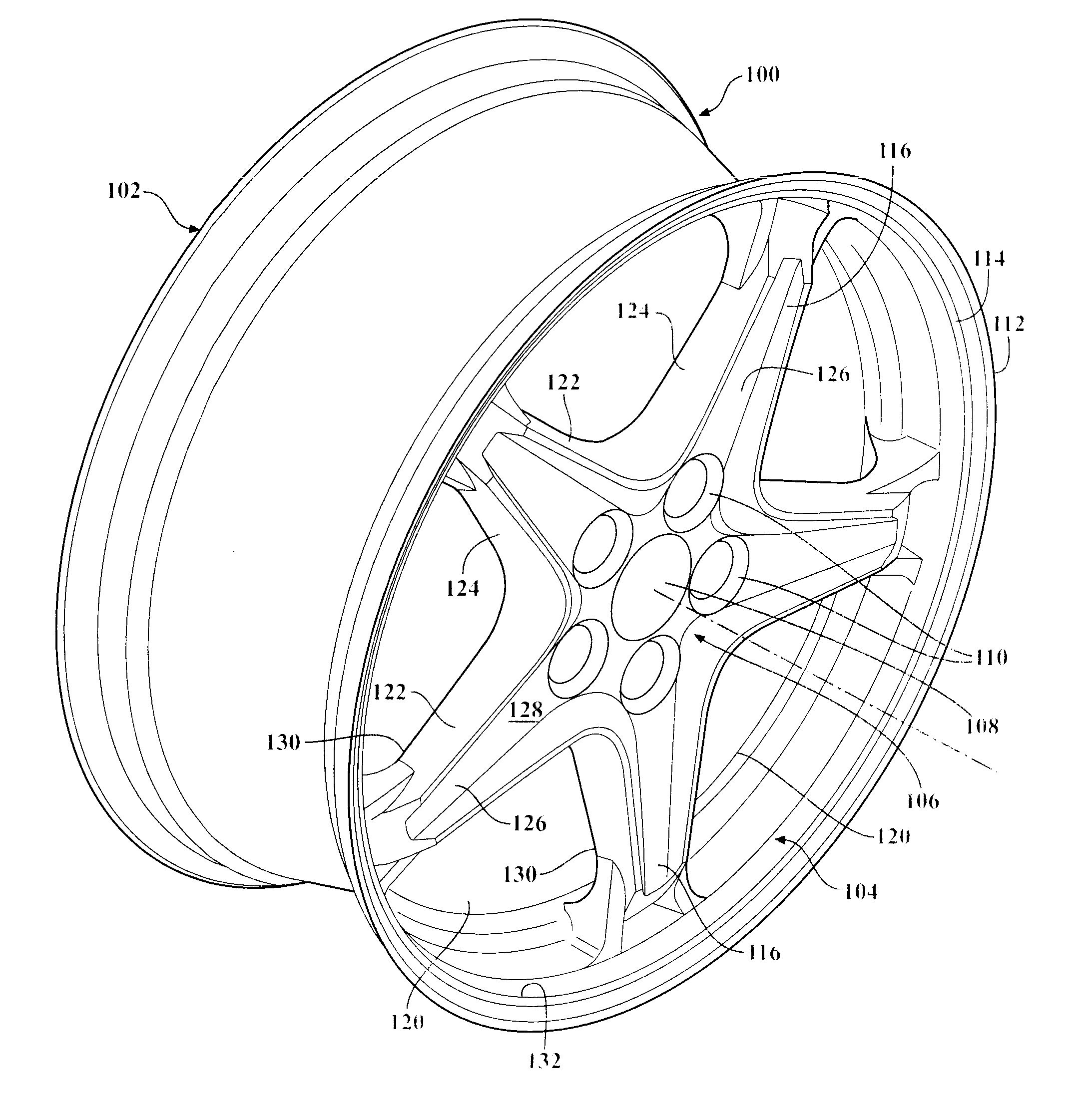

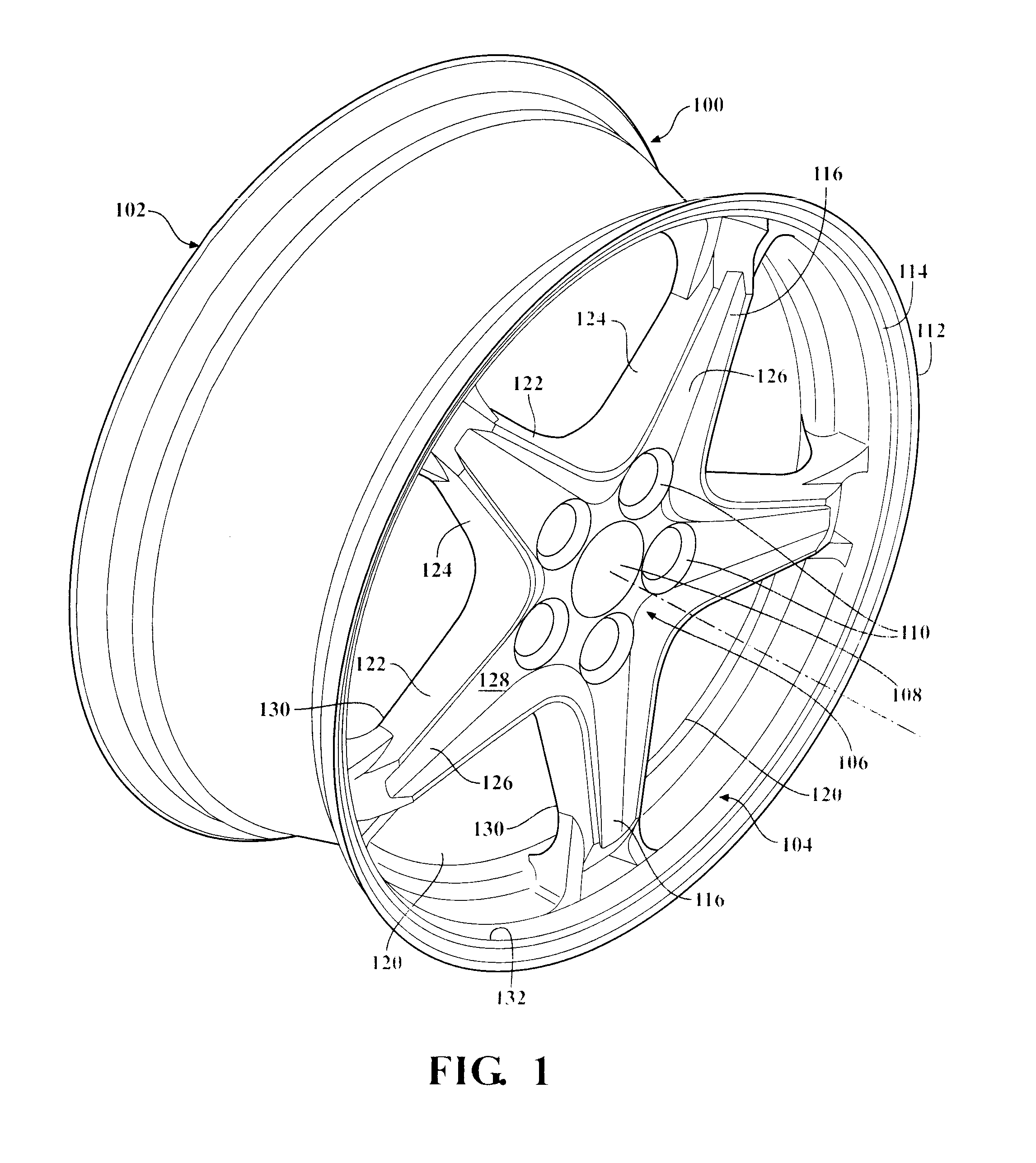

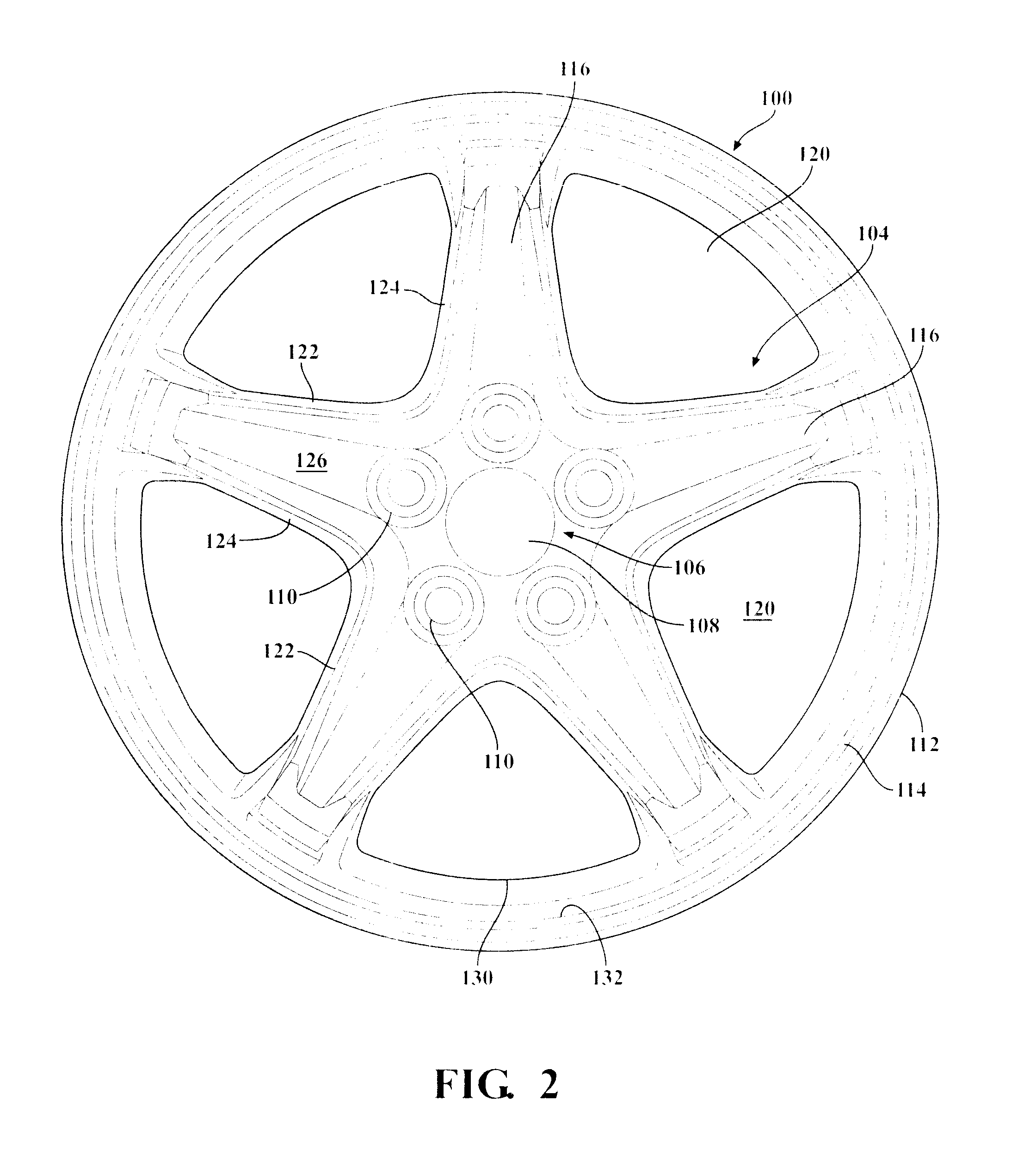

Aerodynamically efficient spoke design for a vehicle wheel

ActiveUS20140265534A1Improve aerodynamicsImprove aerodynamic performanceWheel protectionSpoked wheelsAerodynamicsTurbine

A wheel for a vehicle includes an inner hub portion that is configured to receive an axle therethrough and which defines an axis of rotation at a center thereof. The wheel includes an outer rim portion. A plurality of wheel spoke portions extend generally between the inner hub portion and the outer rim portion. The inner hub portion, the outer rim portion, and the plurality of spoke portions cooperate to form a wheel outer surface having a plurality of turbine openings. The outer surface of the wheel defines a wheel reference plane that is oriented generally perpendicular to the axis of rotation. The wheel outer surface is the side that face away from a vehicle. Each of the plurality of wheel spoke portions has an outer side adjacent the wheel outer surface, an inner side opposite the outer side, a leading side surface and a trailing side surface. The inner side of each of the plurality of spoke portions has a first edge adjacent the leading side surface that is spaced a first distance apart from the wheel reference plane and a second edge adjacent the trailing side surface that is spaced a second distance apart from the wheel reference plane. The inner side of the spoke is configured such that the first distance is less than the second distance.

Owner:LACKS ENTERPRISES

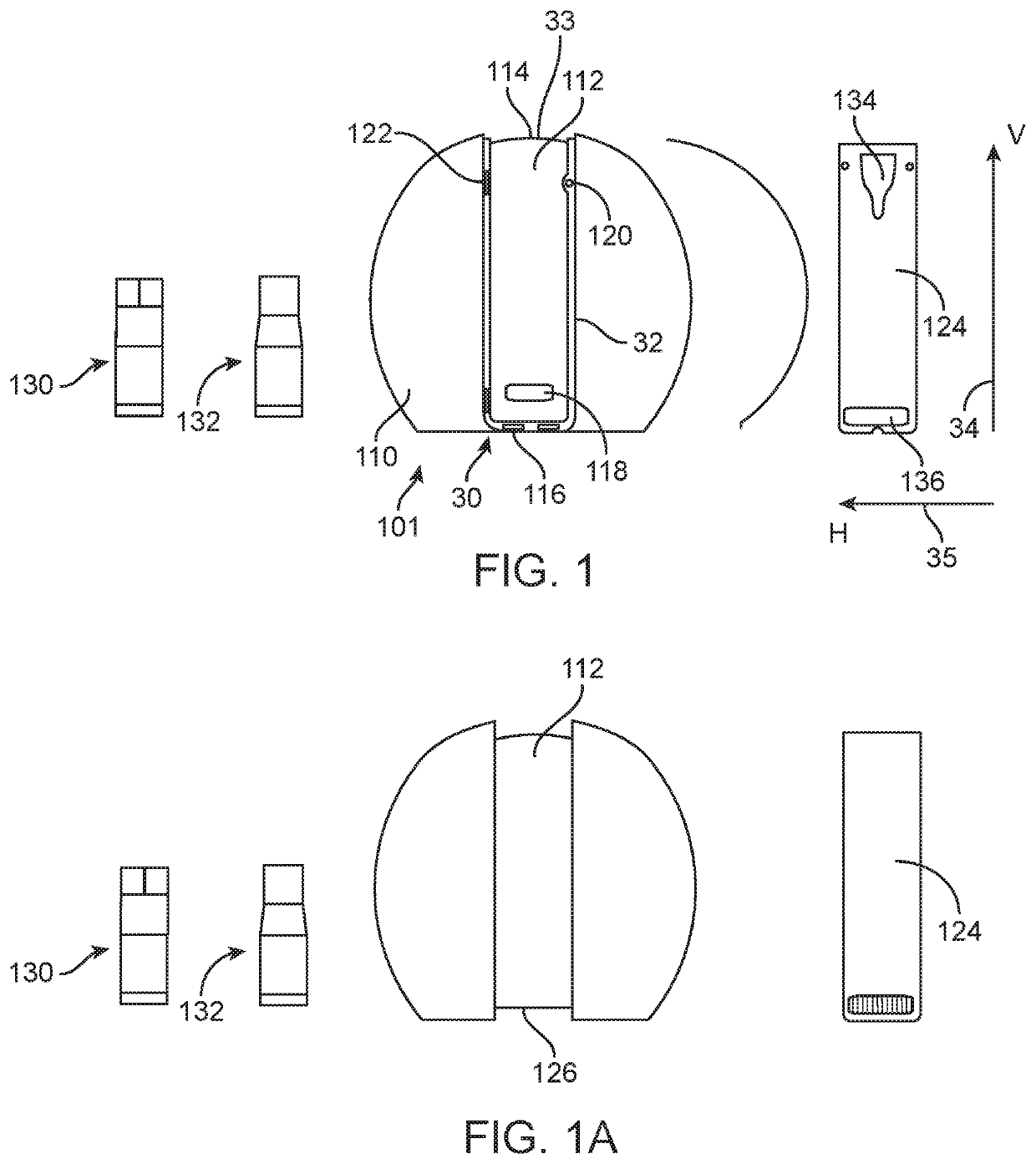

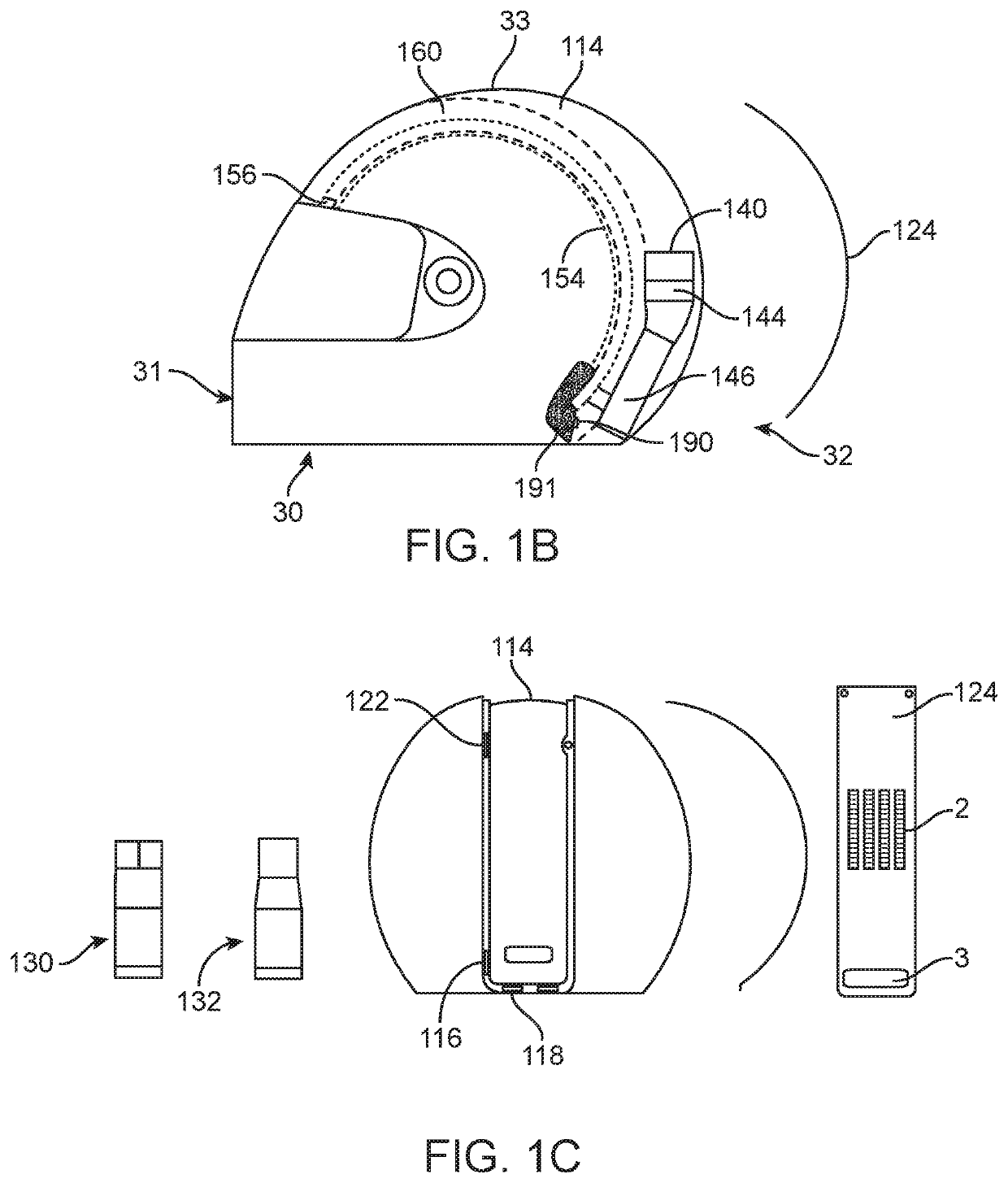

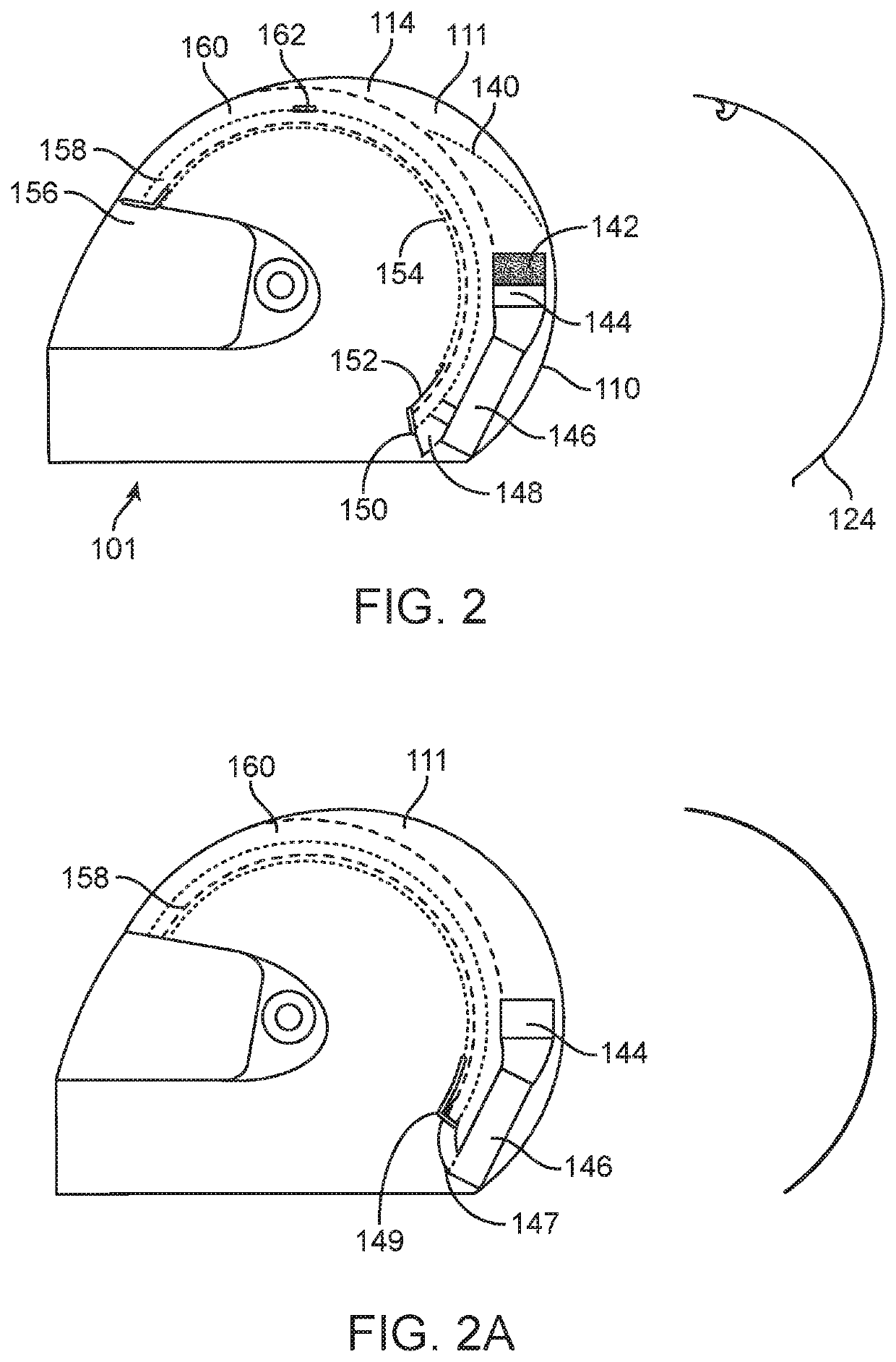

Climate controlled headgear apparatus

InactiveUS20200229530A1Reduce rotational traumaSmooth integrationHelmetsHelmet coversPhysicsFresh air

A headgear apparatus for delivering temperature conditioned air including passively or actively cooled, heated, or ventilated air to the interior of a shell is disclosed. A device housing which enshrouds a device for providing temperature conditioned air is placed on a rear portion of the shell. The device housing has air inlets and air rejector vents for delivering fresh air to and removing heated air from the device, and is configured to reduce the heated air from re-entering the device through the air inlets. The headgear apparatus is designed to withstand impact forces without injuring the wearer.

Owner:FEHER STEVE

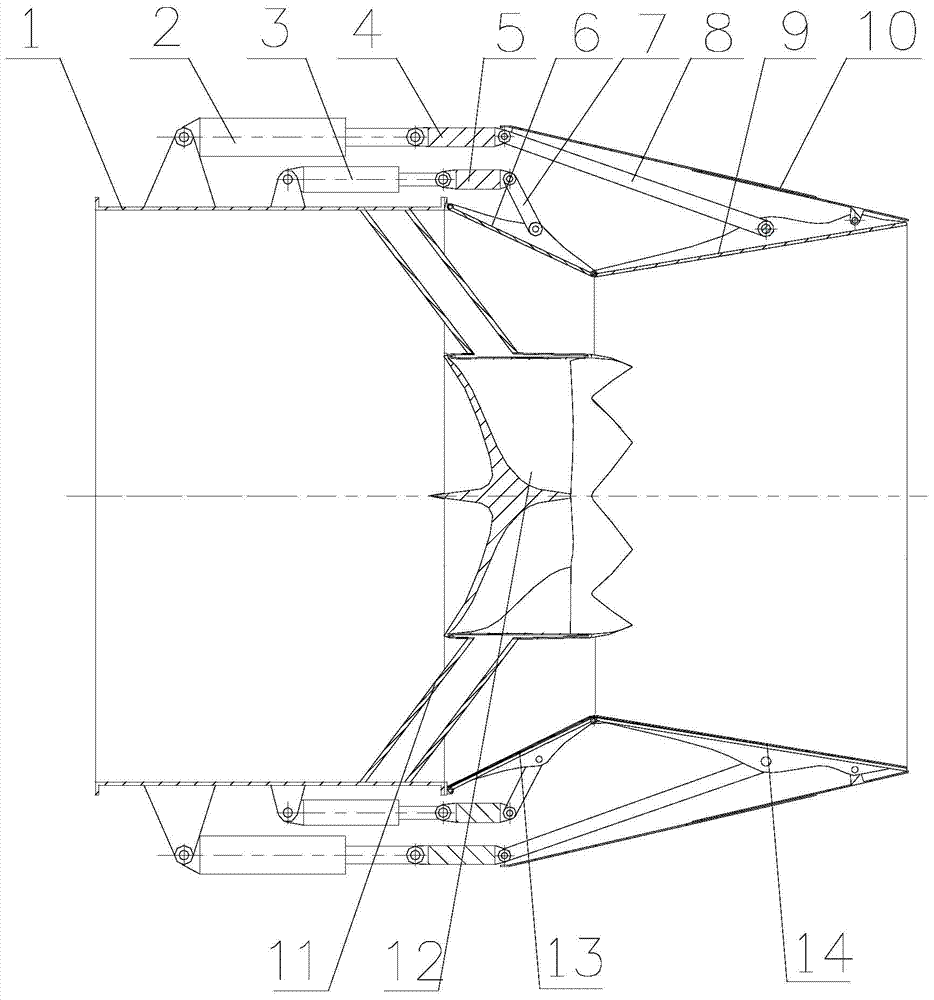

Two-dimensional vector convergent-divergent nozzle capable of achieving pitching and yawing

The invention relates to the field of aero-engine nozzles, in particular to a two-dimensional vector convergent-divergent nozzle capable of achieving pitching and yawing. The two-dimensional vector convergent-divergent nozzle comprises a barrel, two pitching adjusting sheets, two yawing adjusting sheets, four sealing sheets, first actuating cylinders, first pulling rods, second actuating cylinders and second pulling rods. The outer side face of each pitching adjusting sheet is connected with the corresponding first pulling rod and the corresponding first actuating cylinder so that the pitching adjusting sheet can rotate in the pitching direction. The outer side face of each yawing adjusting sheet is connected with the corresponding second pulling rod and the corresponding second actuating cylinder so that the yawing adjusting sheet can rotate in the yawing direction. Sealing sheets are located between the pitching adjusting sheets and the yawing adjusting sheets. The two-dimensional vector convergent-divergent nozzle capable of achieving pitching and yawing is simple in structure; deflecting, converging and diverging in the pitching and yawing directions are achieved through deformation combination of the adjusting sheets on the four sides; good aerodynamic performance is also achieved, the control law is simple, and the reliability is high.

Owner:AECC SHENYANG ENGINE RES INST

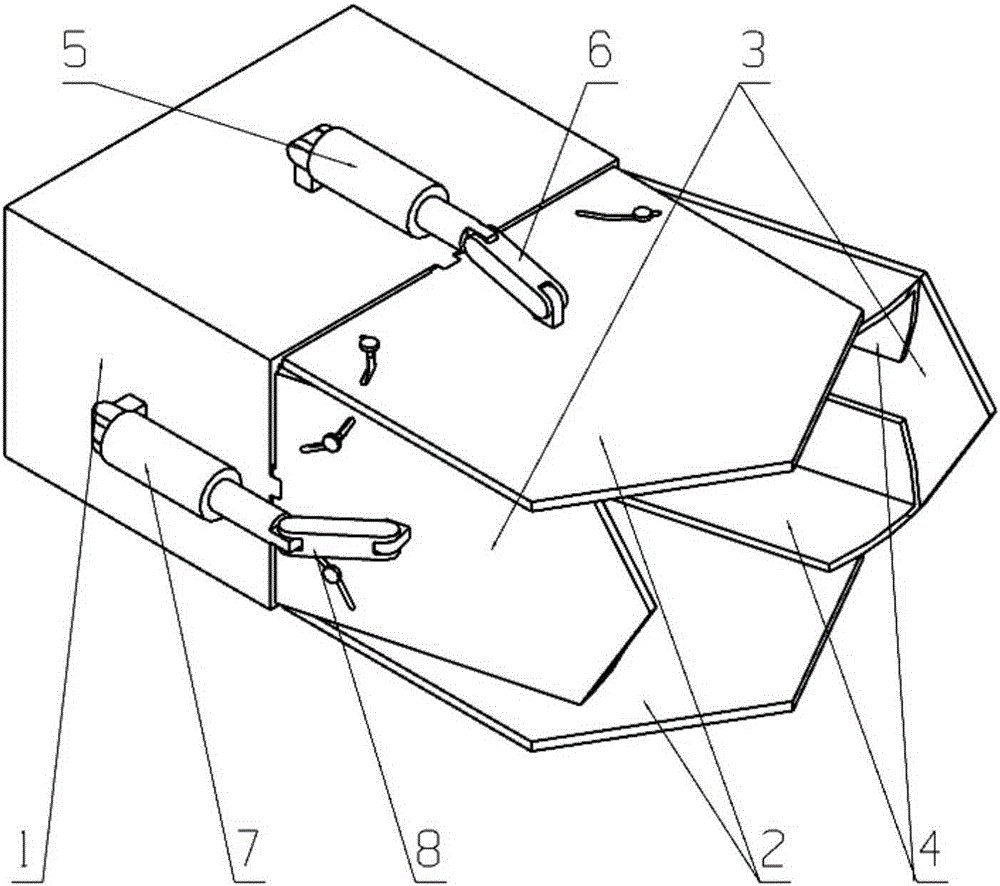

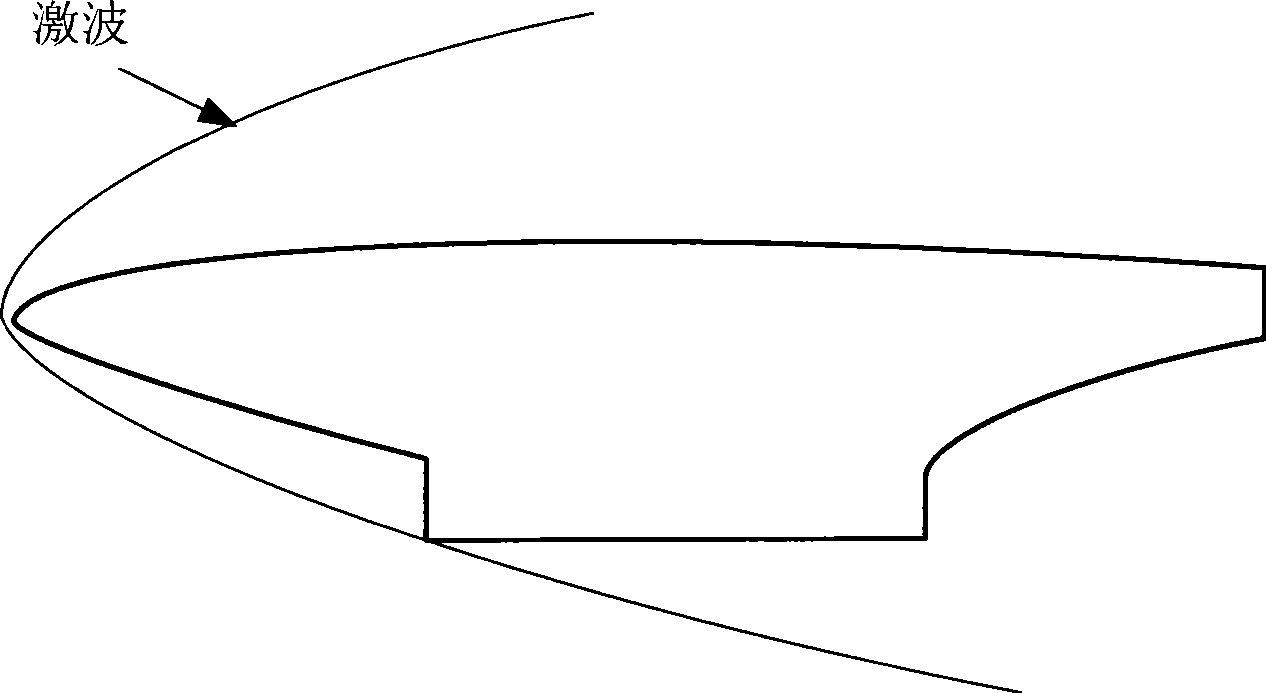

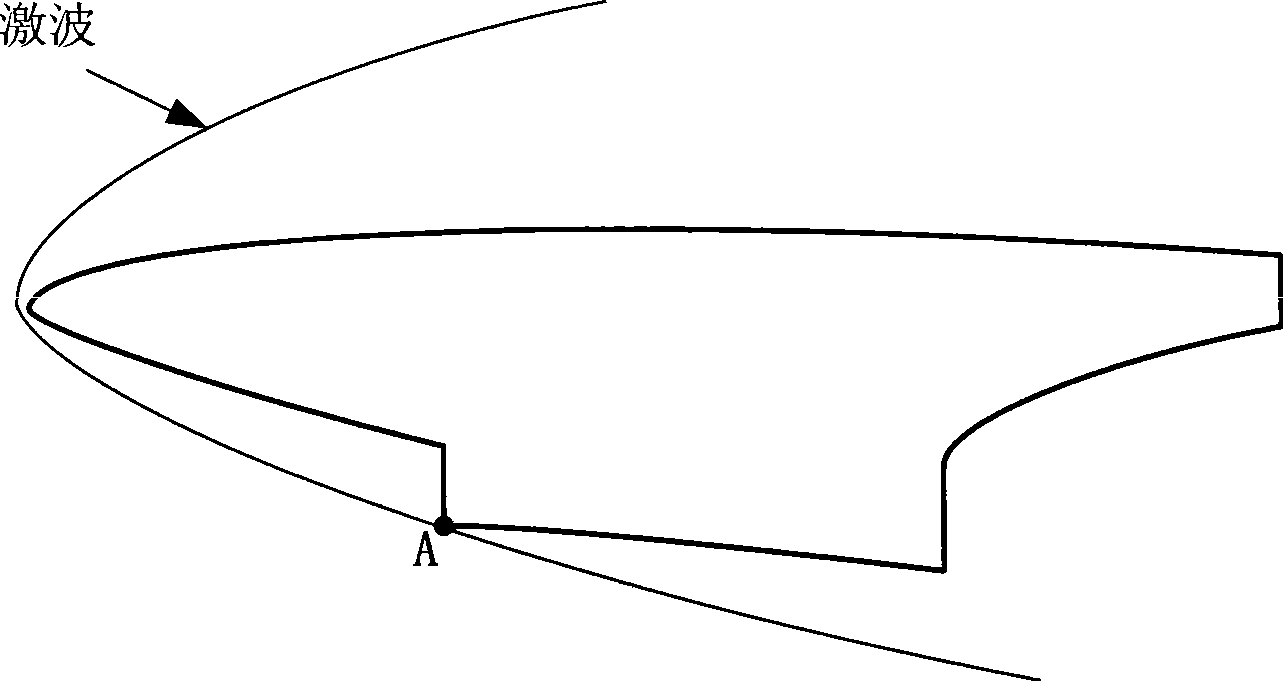

External cowling of scramjet engine and design method thereof

InactiveCN101497372AReduce the windward areaReduce resistanceAircraft power plant componentsFlight vehicleShock wave

The invention discloses an outer rectifying cover of a scramjet engine and a method for designing the same. The main design thought comprises the following steps: firstly carrying out non-adhesion numerical analysis on a flow field generated on a front body of a hypersonic speed aerocraft; then designing the lower wall face shape of the outer rectifying cover in the flow field in a flown line tracing mode, and adopting a plane vertical to the lower wall on the side wall of the outer rectifying cover; and deflecting the outer rectifying cover by certain angle to obtain the outer rectifying cover of the scramjet engine according to the information such as flight attack angle, flight mach number and the like of the aerocraft by taking the lip opening position of the outer rectifying cover asa rotating point. The outer rectifying cover of the scramjet engine adopts the design principle of a waverider body, makes full use of a high pressure area after shocking waves to generate additionallift force, and reduces incident flow area and pressure difference resistance by deflecting the rectifying cover to make the whole aerodynamic performance of the aerocraft obviously improved. The outer rectifying cover can be directly applied to designing the hypersonic speed aerocraft taking various scramjet engines as power.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

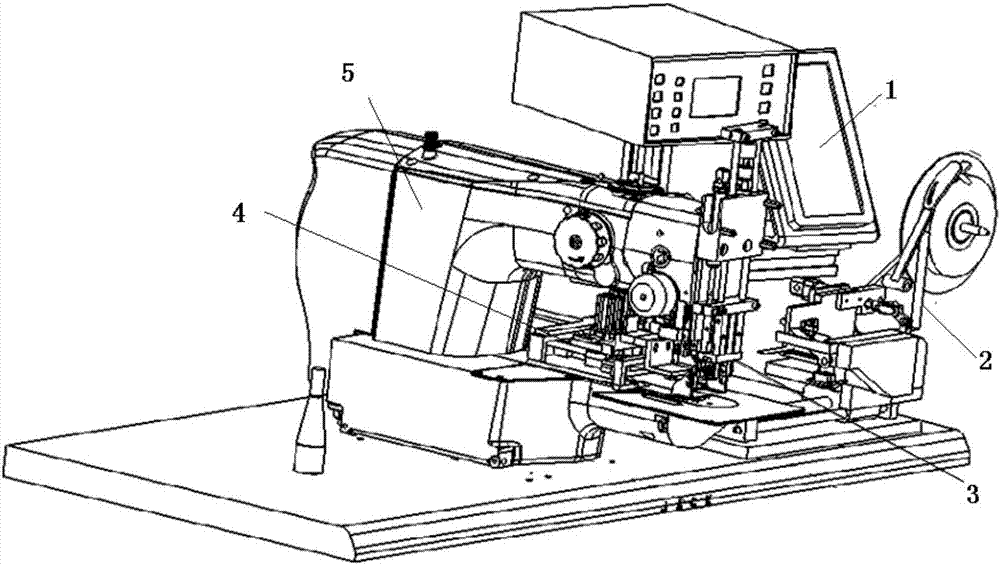

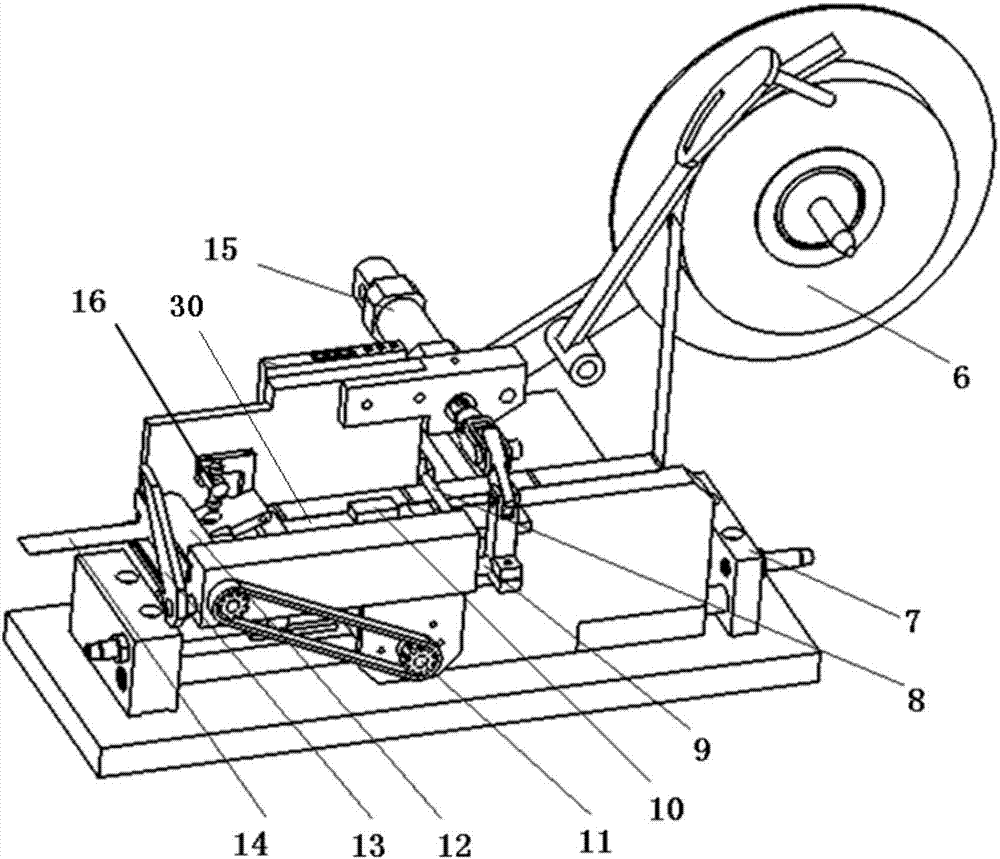

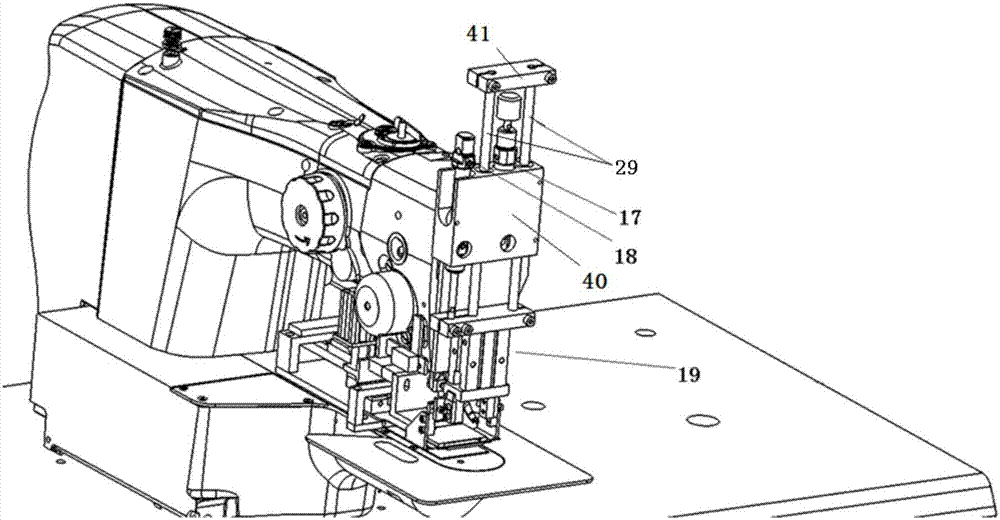

Automatic garment label sewing equipment

ActiveCN107503047AImprove aerodynamicsIncrease electric controlWork-feeding meansControl systemElectric control

The invention provides automatic garment label sewing equipment. The automatic garment label sewing equipment has the advantages that a label sewing bar tacking machine, pneumatic and electric control systems and related mechanical mechanisms are combined with one another, accordingly, labels can be automatically conveyed and folded and can be automatically accurately placed, the production efficiency of label sewing work can be improved, the labor cost can be reduced, and the integral automatic level of the garment label sewing work can be upgraded.

Owner:JACK SEWING MASCH CO LTD

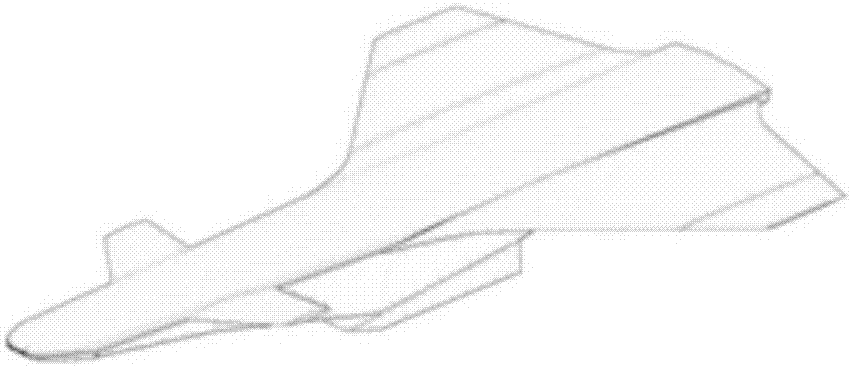

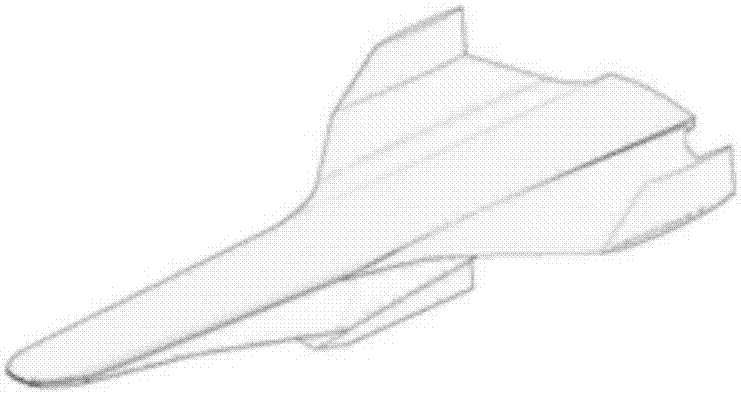

Design method for reusable sky-earth aircraft configuration

ActiveCN107180134AImprove aerodynamicsGood heat protectionGeometric CADSustainable transportationState of artSky

The invention discloses a design method for reusable sky-earth aircraft configuration. According to the method, an up-down contour control line and a left-right width contour line of a fuselage are determined, a quadratic curve and a CST method based on a type function and a shape function are adopted to generate a corresponding section shape, and therefore a key stance shape of the whole fuselage is obtained; the shape of the whole fuselage is obtained through a surface lofting technology; a numerical computation method is adopted to compute a flow field; matching design is performed on a control plane; and aerodynamic configuration is optimized. Compared with the prior art, the method has the advantages that high supersonic velocity lift-to-drag ratio characteristics and sub-cross-ultralow velocity entrance characteristics are comprehensively considered, the reusable sky-earth aircraft configuration with all velocity domains meeting design demands is designed, and an aircraft obtained through optimization has excellent aerodynamic performance and good heat resistance as well as good practicability.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

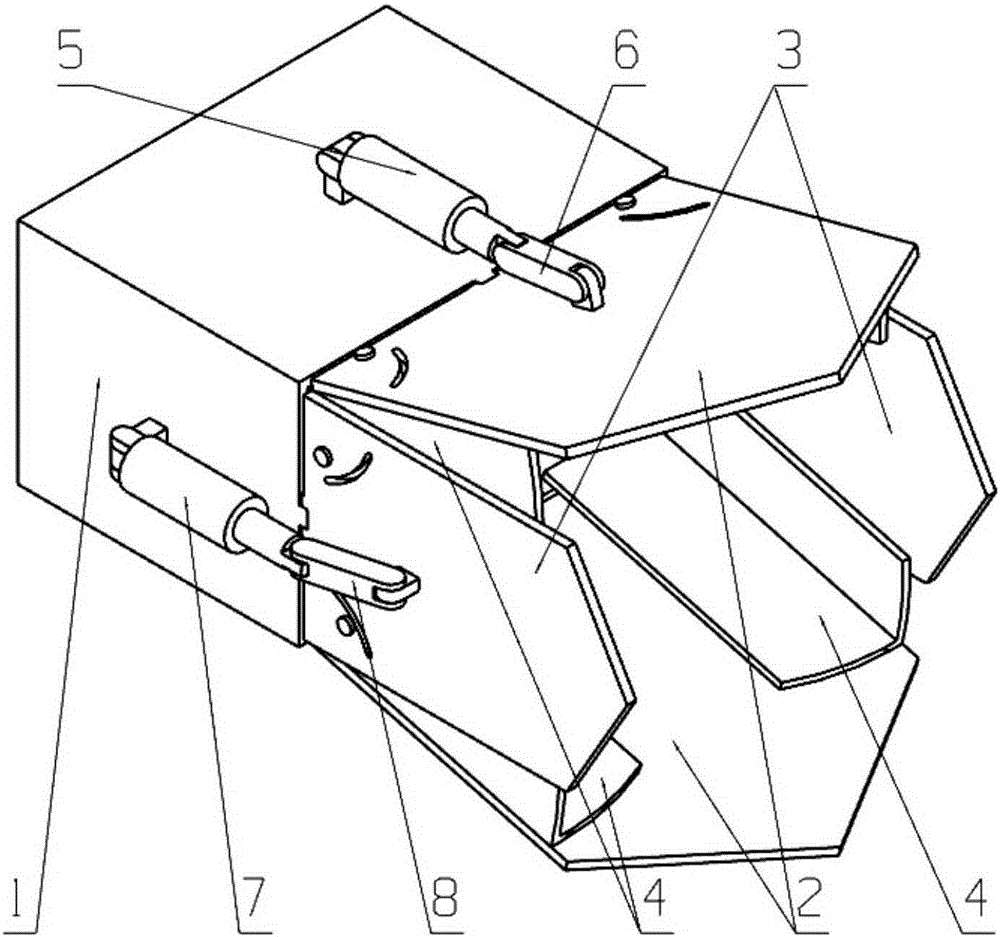

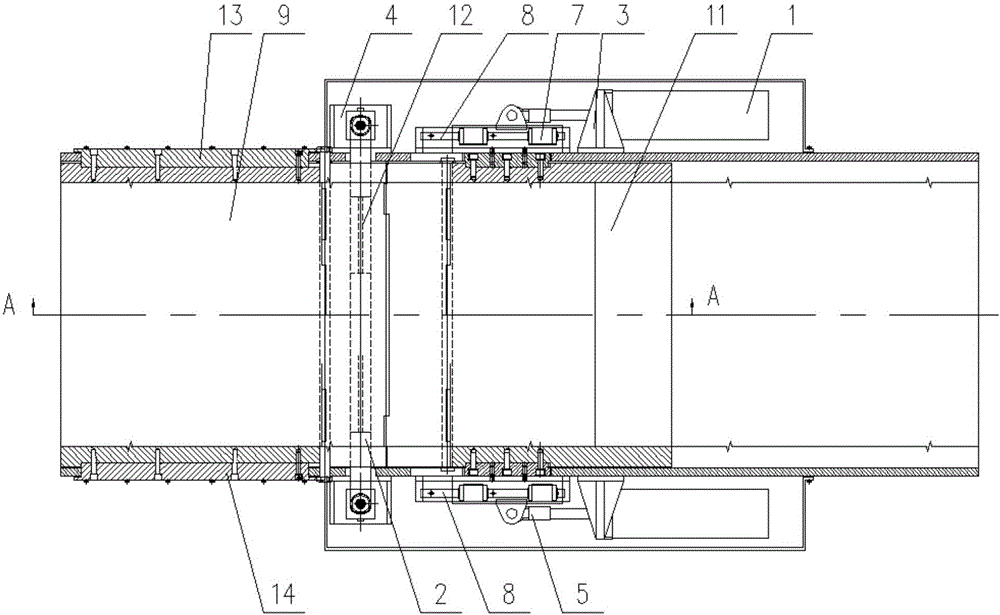

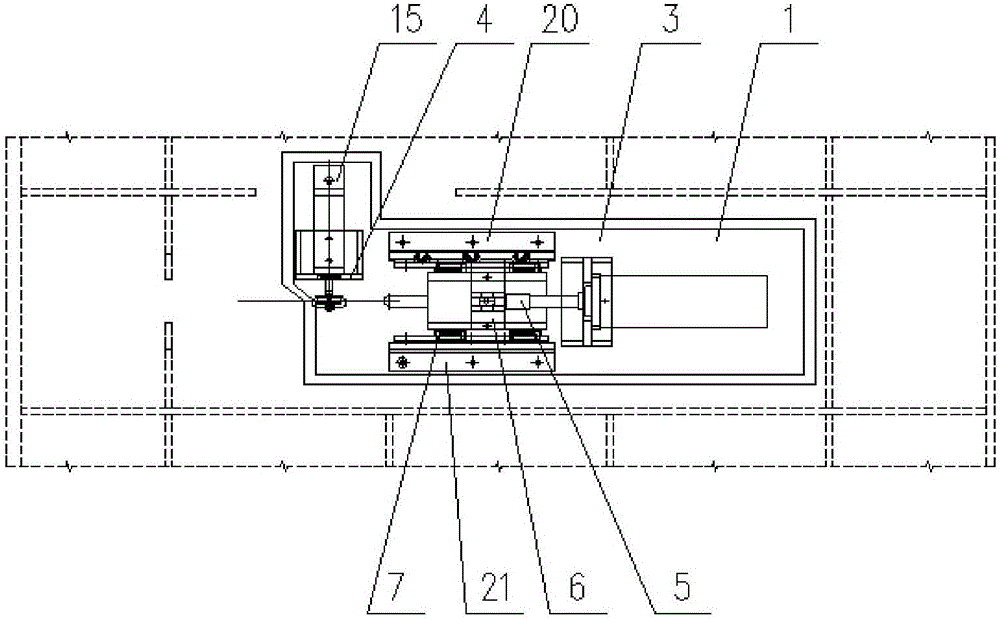

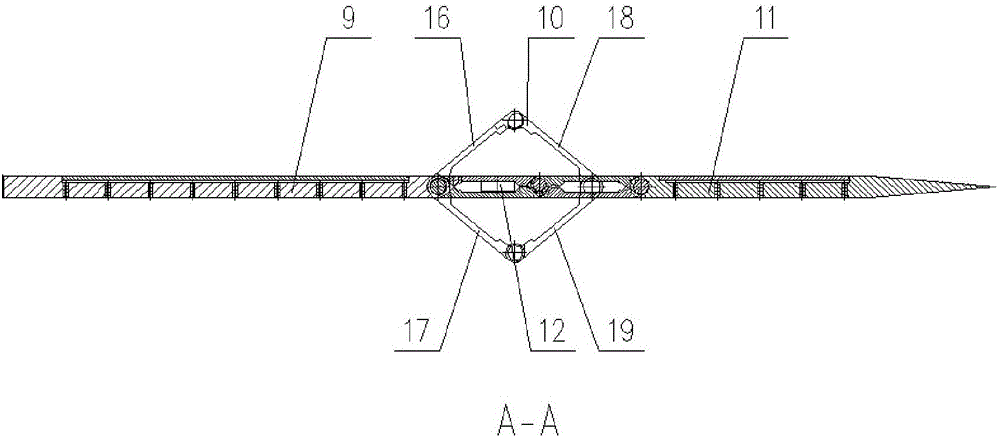

Mach number adjusting mechanism suitable for trans-supersonic wind tunnel

A Mach number adjusting mechanism suitable for a trans-supersonic wind tunnel belongs to the technical field of aviation aerodynamic force wind tunnel test, and aims at solving the problem that a present Mach number adjusting mechanism is high in the adjusting obstruction degree of an air flow cross section. The adjusting mechanism comprises a front tail plate, a rhombic adjusting sheet and a rear tail plate, the front tail plate and the rear tail plate are mounted in a cavity formed by an upper double-throat wallboard and a lower double-throat wallboard, the rhombic adjusting sheet is hinged between the front tail plate and the rear tail plate, an auxiliary adjusting mechanism is arranged in a rhombic frame of the rhombic adjusting sheet, a main electric cylinder drives the rear tail plate to slide in a slide rail soleplate, and the rear tail plate is pulled to adjust opening and closing of the rhombic adjusting sheet. The Mach number adjusting mechanism uses the rhombic adjusting sheet, the rhombic adjusting sheet is continuous with and has no order difference from an air flow profile formed by the front and rear tail plates, and can be folded completely, the mechanism is low in obstruction degree, and a pneumatic performance is high.

Owner:AVIC SHENYANG AERODYNAMICS RES INST

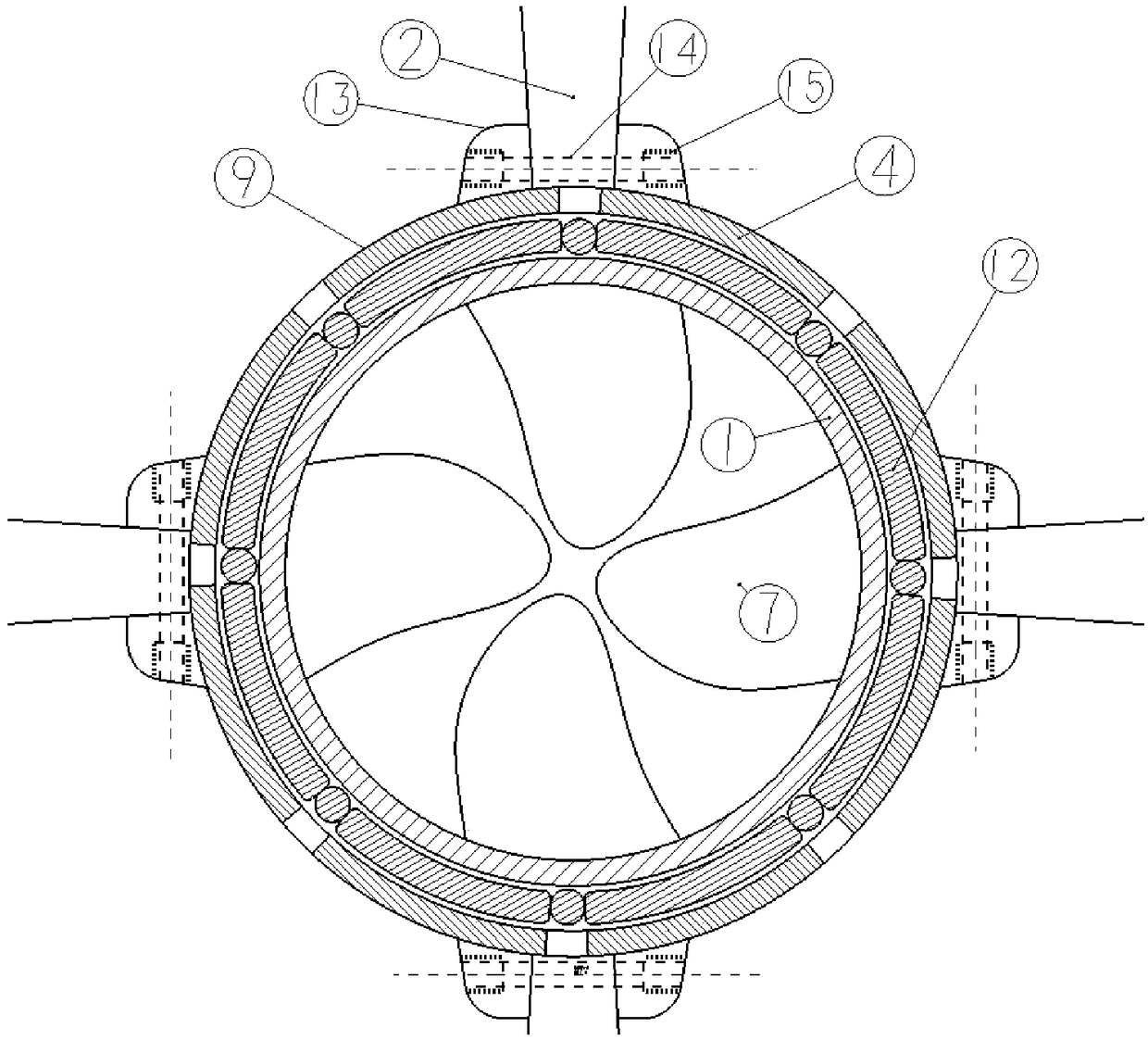

Sea and air amphibious propeller

ActiveCN108839800AImprove propulsion performanceSwitch freelyPropellersPropulsion power plantsDucted propellerAerospace engineering

The invention provides a sea and air amphibious propeller. The propeller comprises a ducted propeller stator, air propellers, air propeller rotors, ducted propellers and ducted propeller rotors, wherein a group of magnets is fixed on the air propeller rotors and the ducted propeller rotors respectively, the air propeller rotors and the ducted propeller rotors rotate coaxially and are nested to thesame ducted propeller stator, and two coils corresponding to the air propeller rotors and the ducted rotors respectively are embedded into the ducted propeller stator. The air propellers are used foraerial propulsion, water propellers are used for underwater propulsion, and the both can work independently. During underwater propulsion, the air propellers are folded back and rotated at a lower speed to eliminate the resistance to the air propellers, and the shaftless ducted propellers work to generate propulsion. In the air, the air propellers are unfolded and rotate to generate propulsion, and the ducted propellers assist the operation. The shaftless ducted propellers have good propulsion performance under water, the air propellers are suitable for working in the air, and the air propellers are combined with the shaftless ducted propellers to realize efficient propulsion and free switching under water and in the air.

Owner:HARBIN ENG UNIV

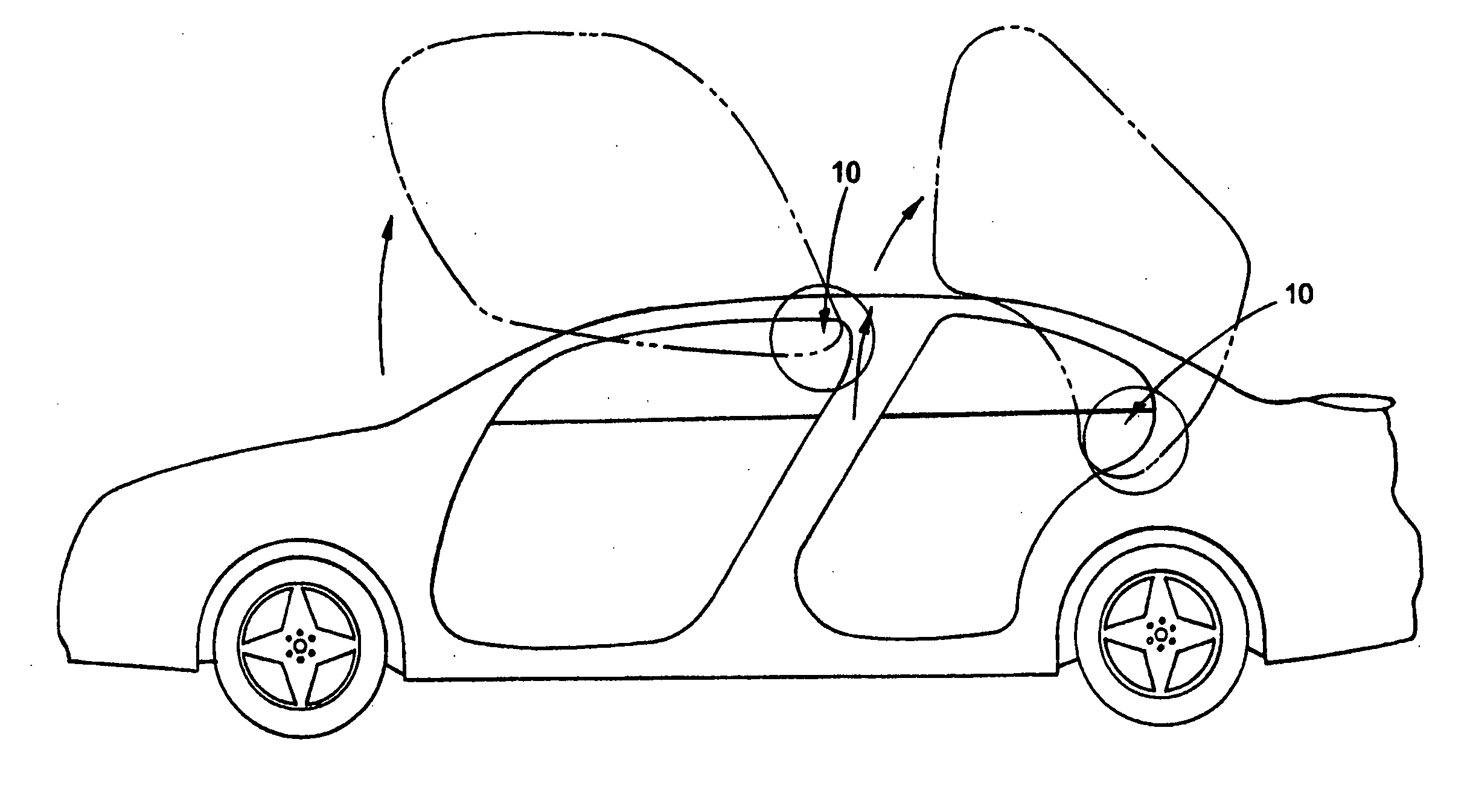

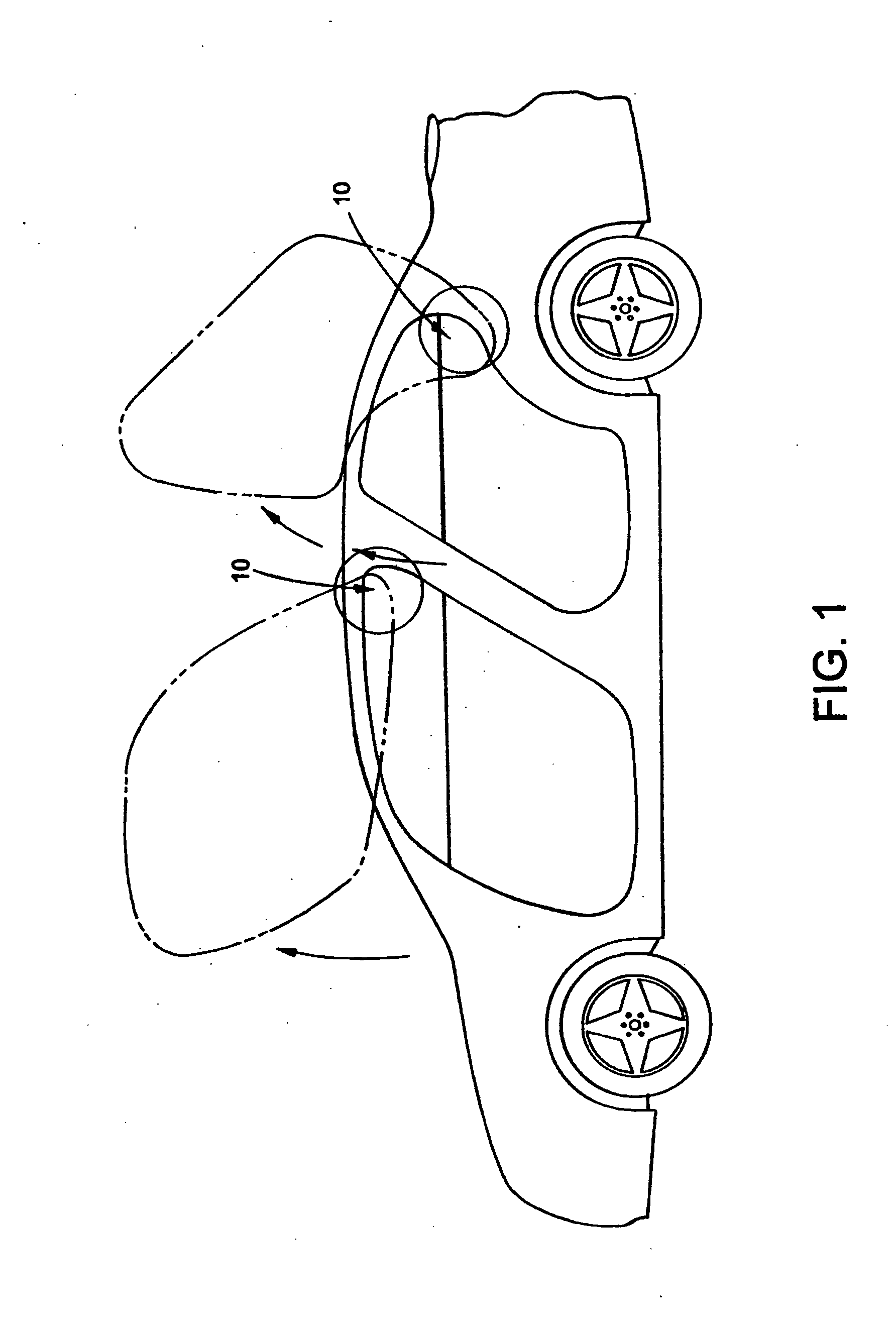

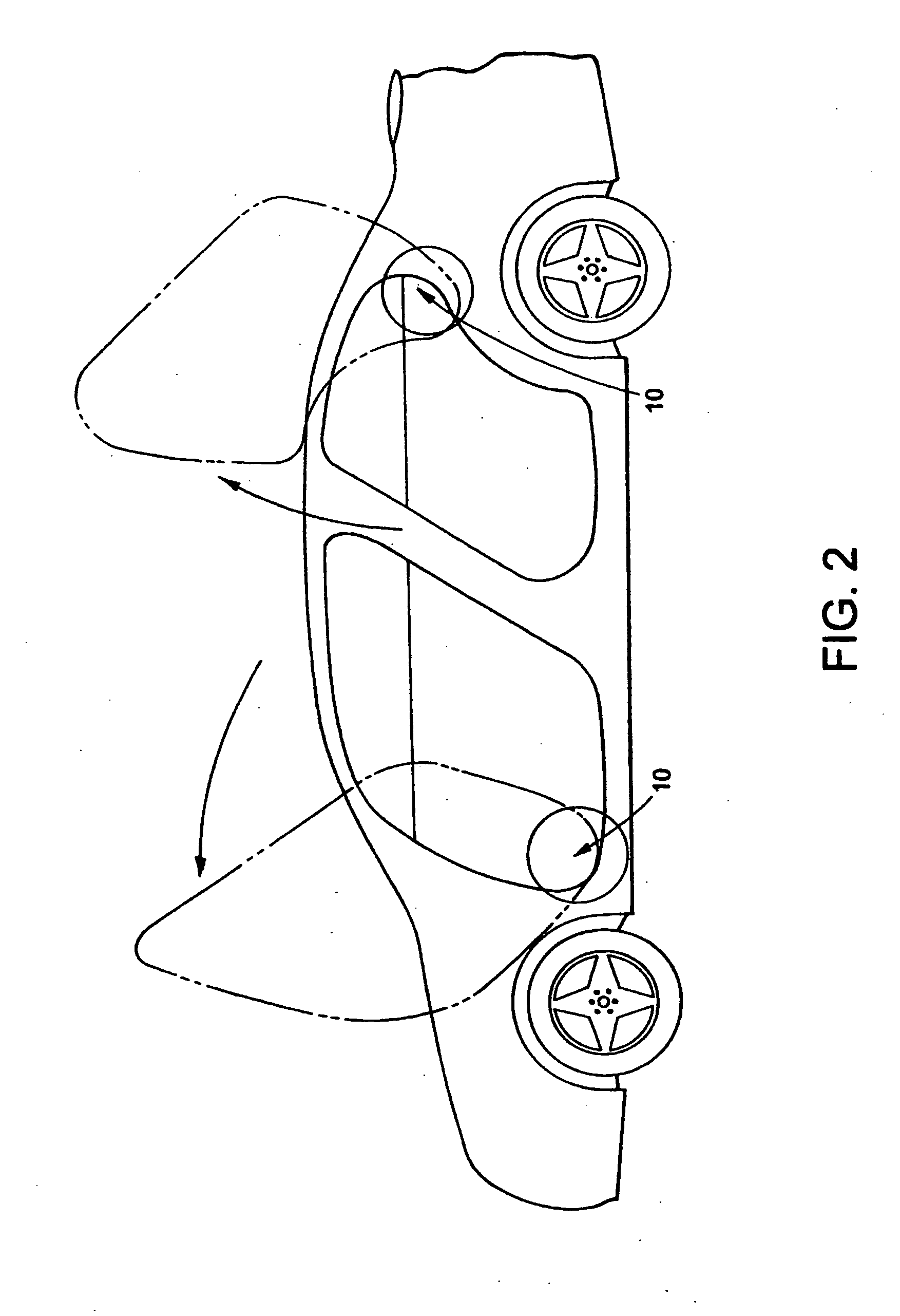

Scissor style pivoting vehicle door

InactiveUS20100276966A1Improve aerodynamicsMore aesthetically pleasing profileMonocoque constructionsVehicle bodiesPick-up truckCar door

A vehicle door that opens from a point of rotation in a scissors like motion is provided. When the door is unlatched, it moves away from the side of the vehicle and swivels upward in a scissors like motion traveling along an arcuate path which parallels the curvature of the vehicle. It is suitable for use with any vehicles including four door sedan, two door coupe, two or four door convertible, pick-up truck, van, minivan and minibus.

Owner:GOJCAJ SIMON

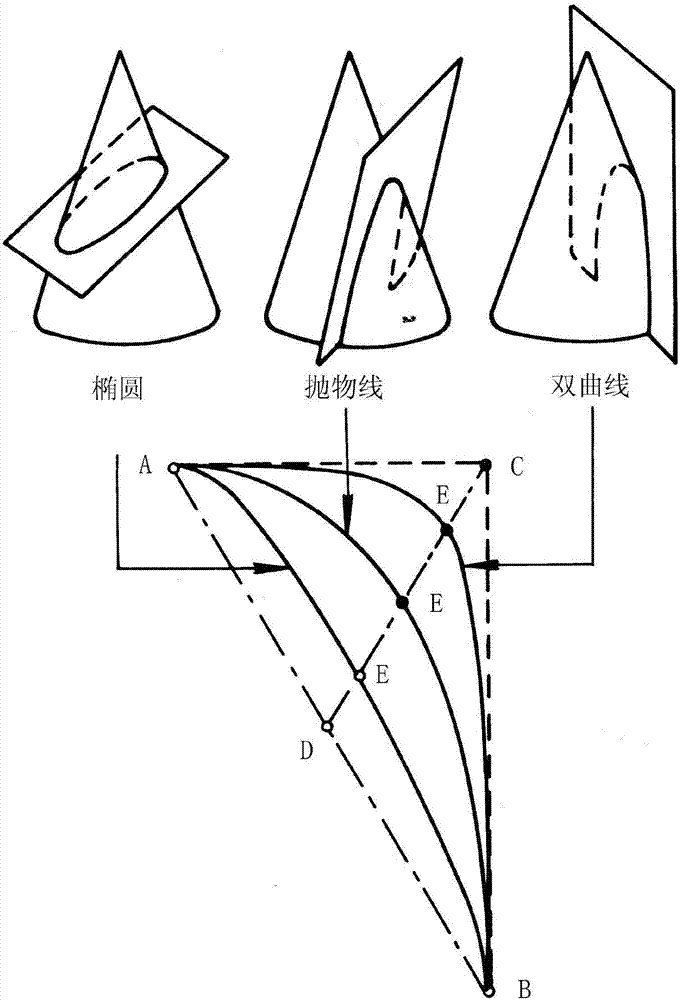

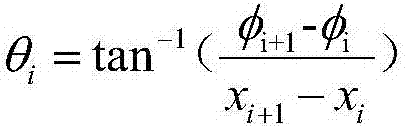

Wave rider concept gliding aircraft profile design method satisfying filling demand

ActiveCN107140230AImprove aerodynamicsImprove practicalityGeometric CADDesign optimisation/simulationFlight vehicleControl line

The invention discloses a wave rider concept gliding aircraft profile design method satisfying filling demands; the method comprises the following steps: determining fuselage up and down contour control lines according to dimension constraints of the fuselage length and different cross sections, wherein the contour lines are spliced by linear segments; calculating an airflow deflection angle, calculating a two dimension tangent wedge flow field pressure, and calculating a FCT arc curve radius; determining an arc curve according to the FCT arc curve radius, and using the two dimension tangent wedge flow field to form a lower surface wave rider surface; using a secondary curve to form a leeside cross section shape; carrying out shrink ratio design for the lower surface wave rider surface according to the fuselage width and height dimension constraints and the upper surface shape, thus obtaining the whole fuselage shape; designing a passivation rounding with the radius of 15mm on the head and the wave rider tip leaning edge; match-designing a control surface. The aircraft has excellent pneumatic performance, and is high in practicality.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

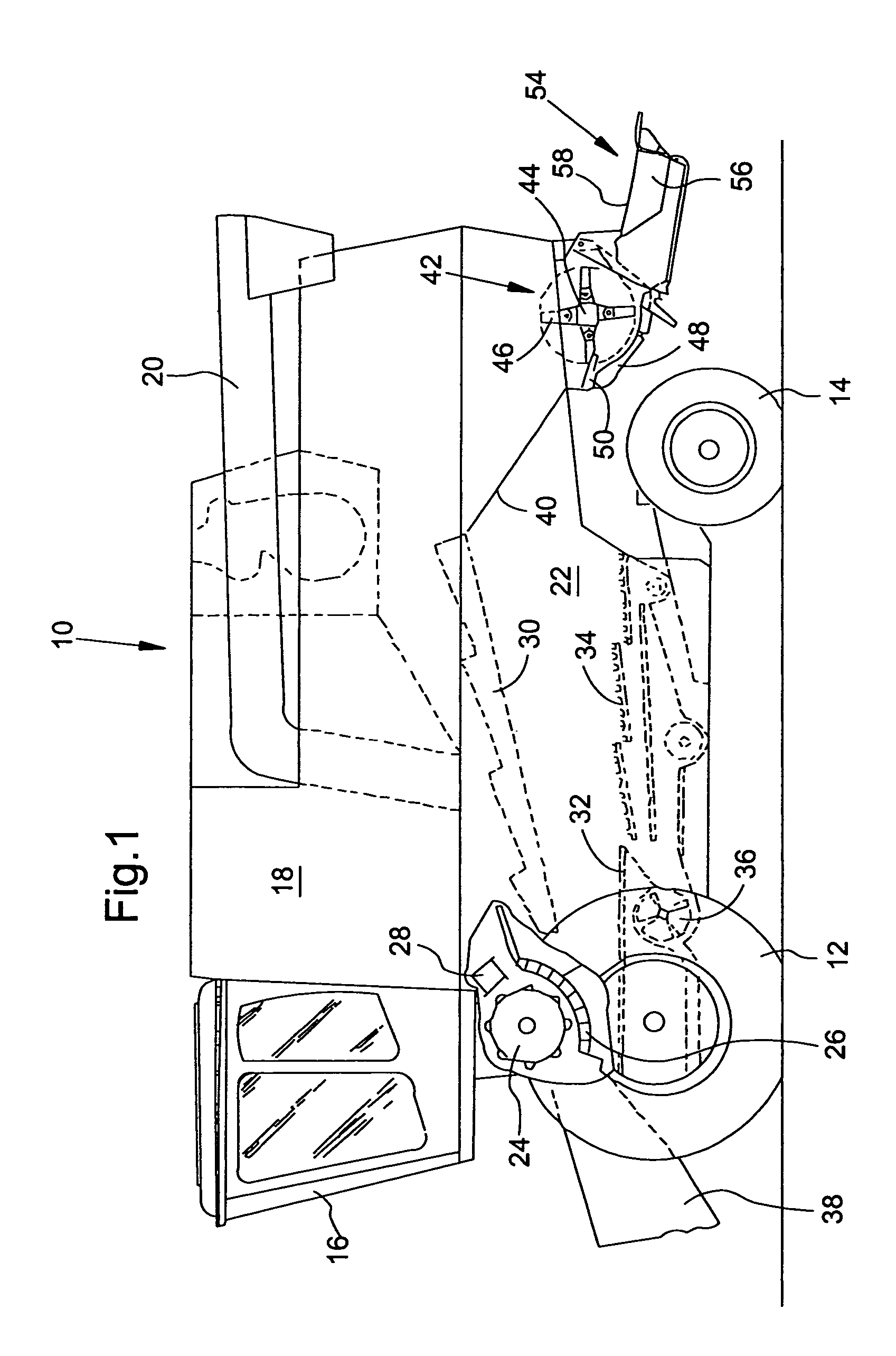

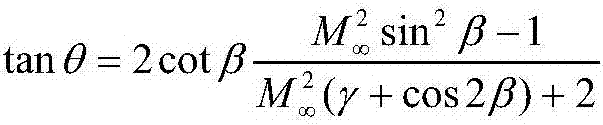

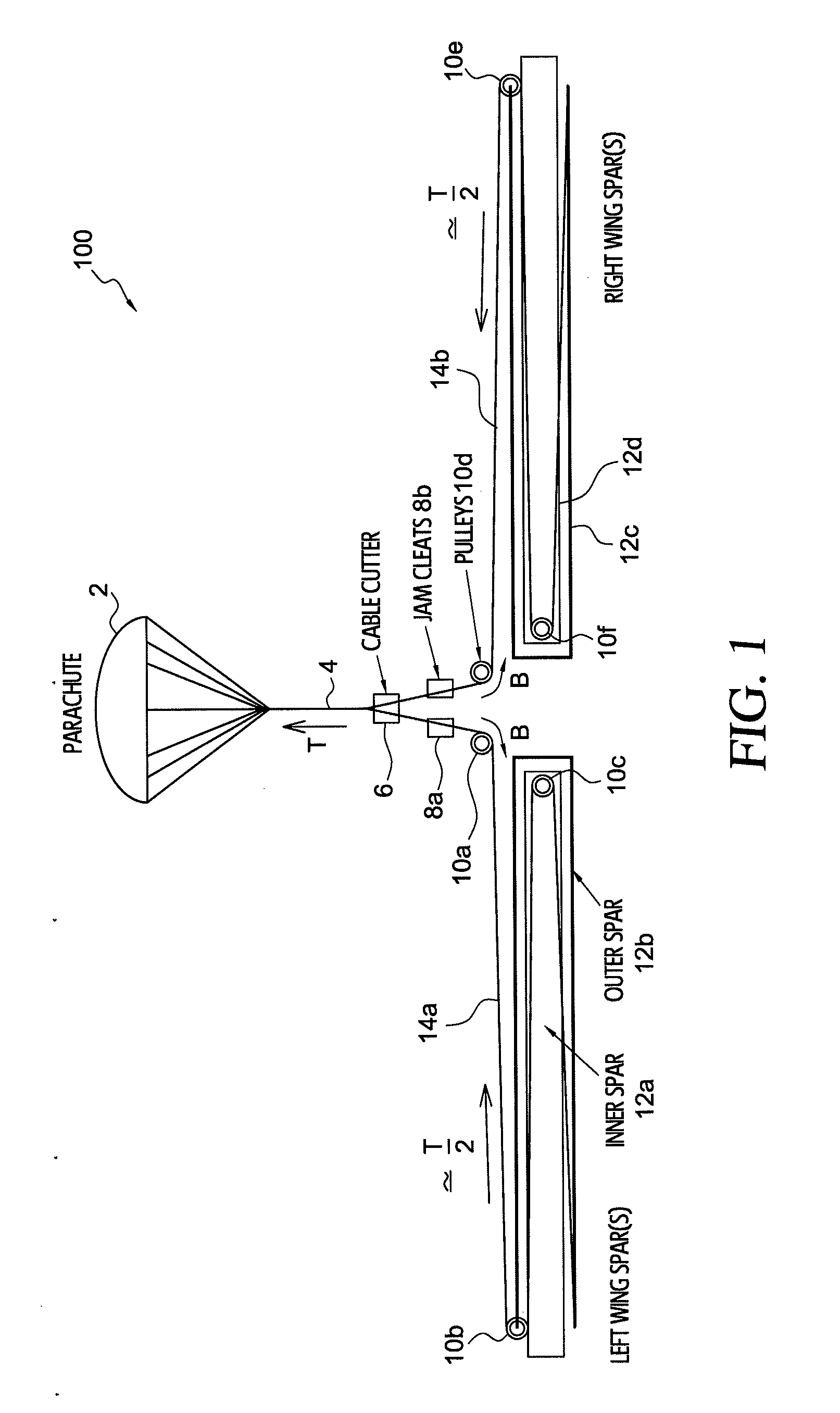

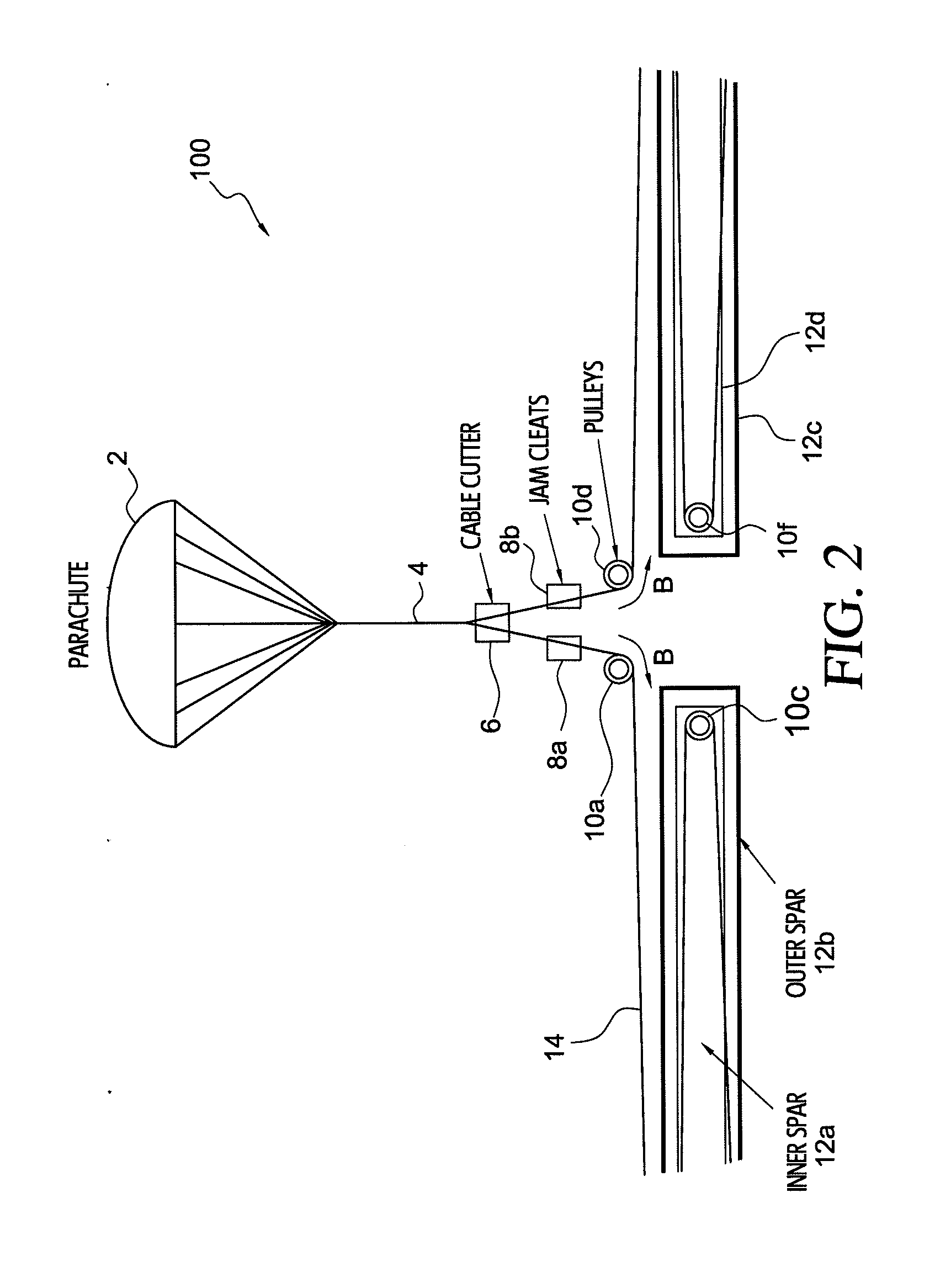

Deployment of telescoping aircraft structures by drogue parachute riser tension

InactiveUS20090314886A1Reducing ratePrevent and reduce damageSnap fastenersRemote controlled aircraftDrogue parachuteAirplane

A system for deploying a deployable structure in an aircraft, comprising a drogue parachute, at least one deployable structure, a riser line attached to the drogue parachute and the at least one deployable structure, wherein when the drogue parachute is deployed, a tension is applied to the riser line, and a parachute deployment system, wherein the parachute deployment system is configured to utilize the applied tension to deploy the at least one deployable structure.

Owner:AURORA FLIGHT SCI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com