Patents

Literature

430 results about "Lofting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lofting is a drafting technique (sometimes using mathematical tables) whereby curved lines are generated, to be used in plans for streamlined objects such as aircraft and boats. The lines may be drawn on wood and the wood then cut for advanced woodworking. The technique can be as simple as bending a flexible object, such as a long strip of thin wood or thin plastic, so that it passes over three non-linear points, and scribing the resultant curved line; or as elaborate as plotting the line using computers or mathematical tables.

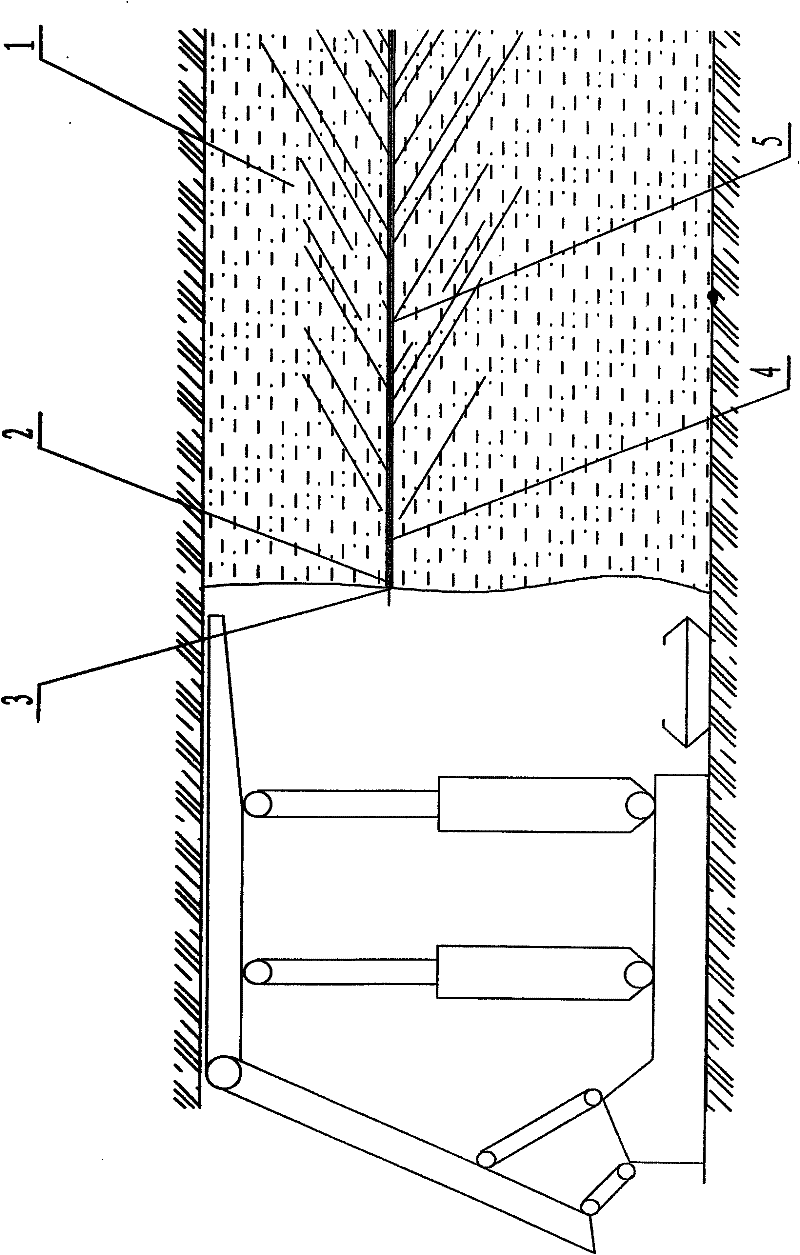

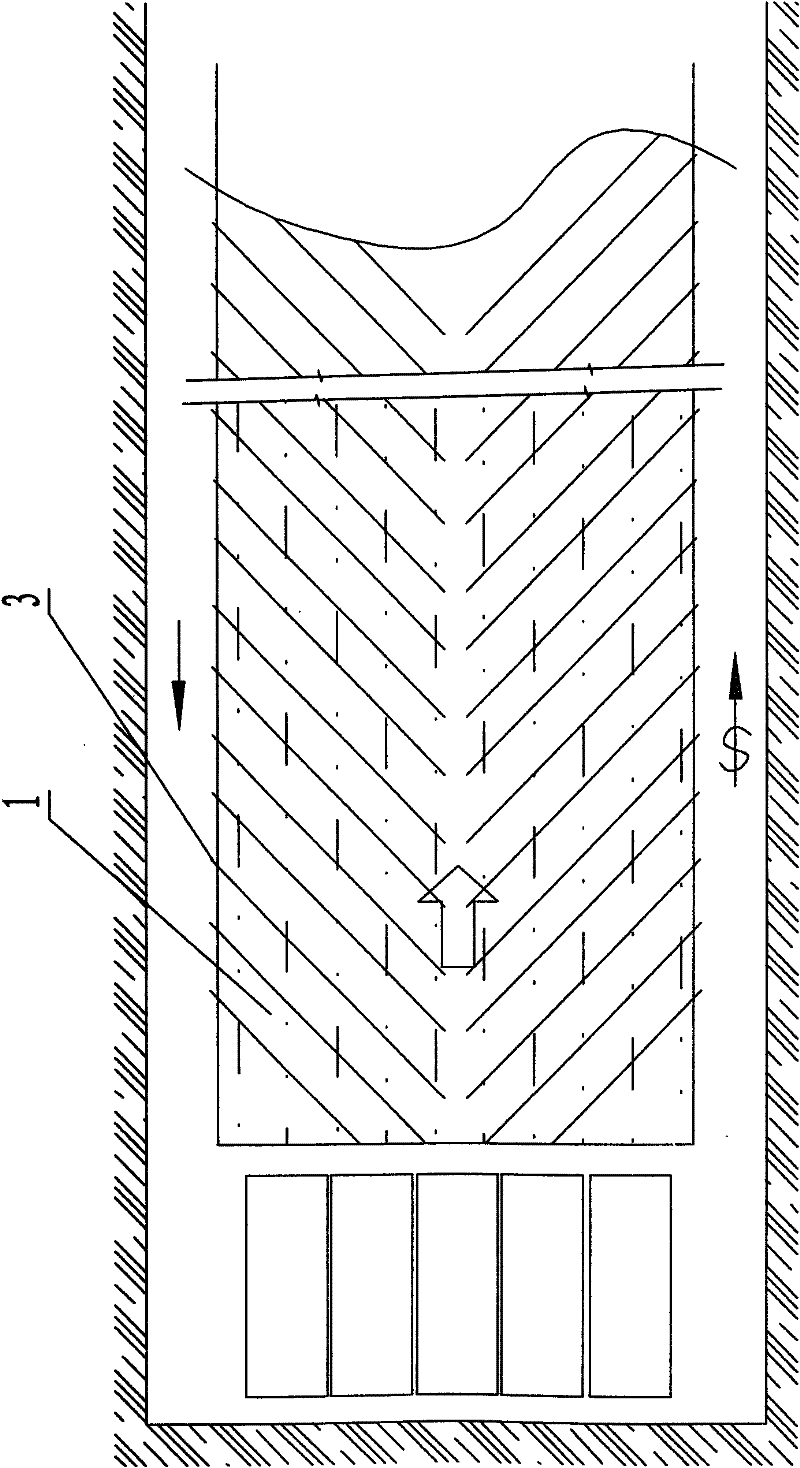

High ground stress soft rock stress-relief construction method

InactiveCN101644160AMature technologyGood effectUnderground chambersTunnel liningShotcretePolystyrene

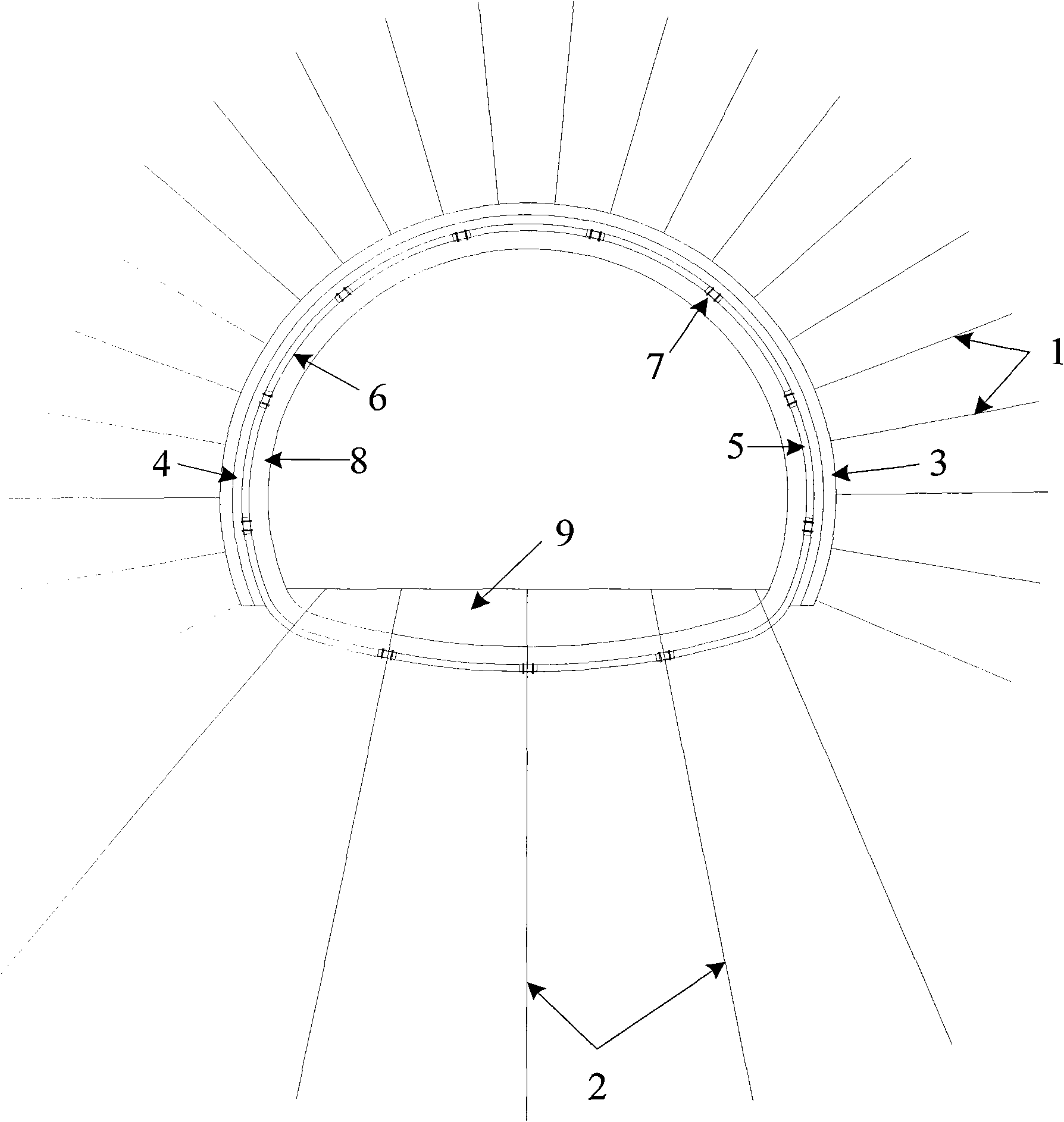

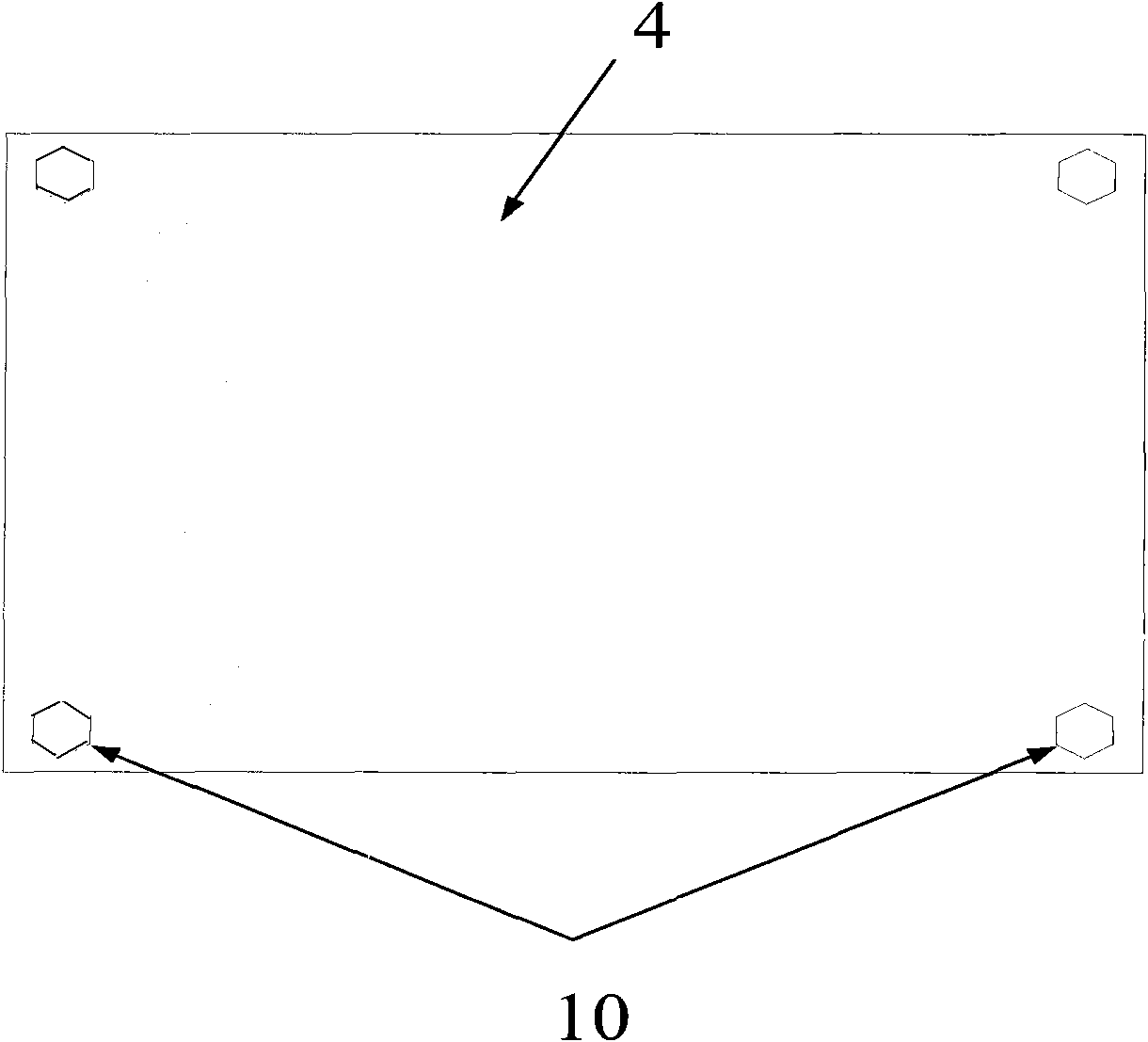

The invention discloses a high ground stress soft rock stress-relief construction method which comprises the following steps: A. anchor shotcreting constructing, tagging the anchor shotcreting constructing with heading, and eliminating dangerous rock; B. cystosepiment hanging, carrying out hanging construction on polystyrene cystosepiment; C. inverted arch excavating and U shape steel spanning, lining tunnel to a ring, and carrying out re-spraying with shotcrete on clearance of steel racks; D. inverted arch backfilling, carrying out construction of a waterproof barrier layer after completing spanning of the U shape steel so as to conserve concrete; E. waterproof barrier layer constructing, carrying out waterproof barrier layer constructing when the convergence rate of tunnel is stabilized;F. secondary lining constructing, carrying out secondary lining constructing when the waterproof barrier layer constructing is completed; and G. prestress anchor line constructing, determining a holesite of an anchor line and the drilling direction through field lofting, and clearing the location of the hole site. The construction method has obvious effect for controlling large deformation of the soft rock with the high ground stress, is simple and convenient, and has the advantages of simple operation, obvious effect and relatively low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Production process method of pipe whip restraint steel structure of main power house of nuclear power station conventional island

ActiveCN101862942AImprove perforation rateReduce distortionArc welding apparatusBoring/drilling machinesNumerical controlGusset plate

The invention belongs to the technical field of pipe whip restraint steel structures of main power houses of nuclear power station conventional islands, in particular to a production process method of the pipe whip restraint steel structure of the main power house of the nuclear power station conventional island, which comprises the lofting process, the marking-off and scribing process, the cutting processing process, the bevel processing process, the hole-making process, the correction process, the polishing surface, the material splicing process, the pre-splicing process of a steel member, the assembly process, the processing process of a friction surface, the welding process of the steel structure and the anti-slip test of the friction surface of the steel member before leaving a factory, sandblasting, derusting and coating of a base coat are carried out in the factory, and the production of the steel structure is divided into the production processing of a welded H-shaped steel column, the production of a steel beam, the assembly and the welding of a support part, the production of a combined steel beam, the assembly and the welding of a girder box body and an inclined support below the girder box body, and the assembly and the welding of a pipe whip restraint key. The production process method can improve the drilling precision, utilize a numerical control planar drilling machine to complete the drilling on a gusset plate, determine a variety of processing processes and welding process parameters, and ensure the dimension of the member after the assembly and the smooth proceeding of field installation.

Owner:EAST STEEL STRUCTURE BRIDGE

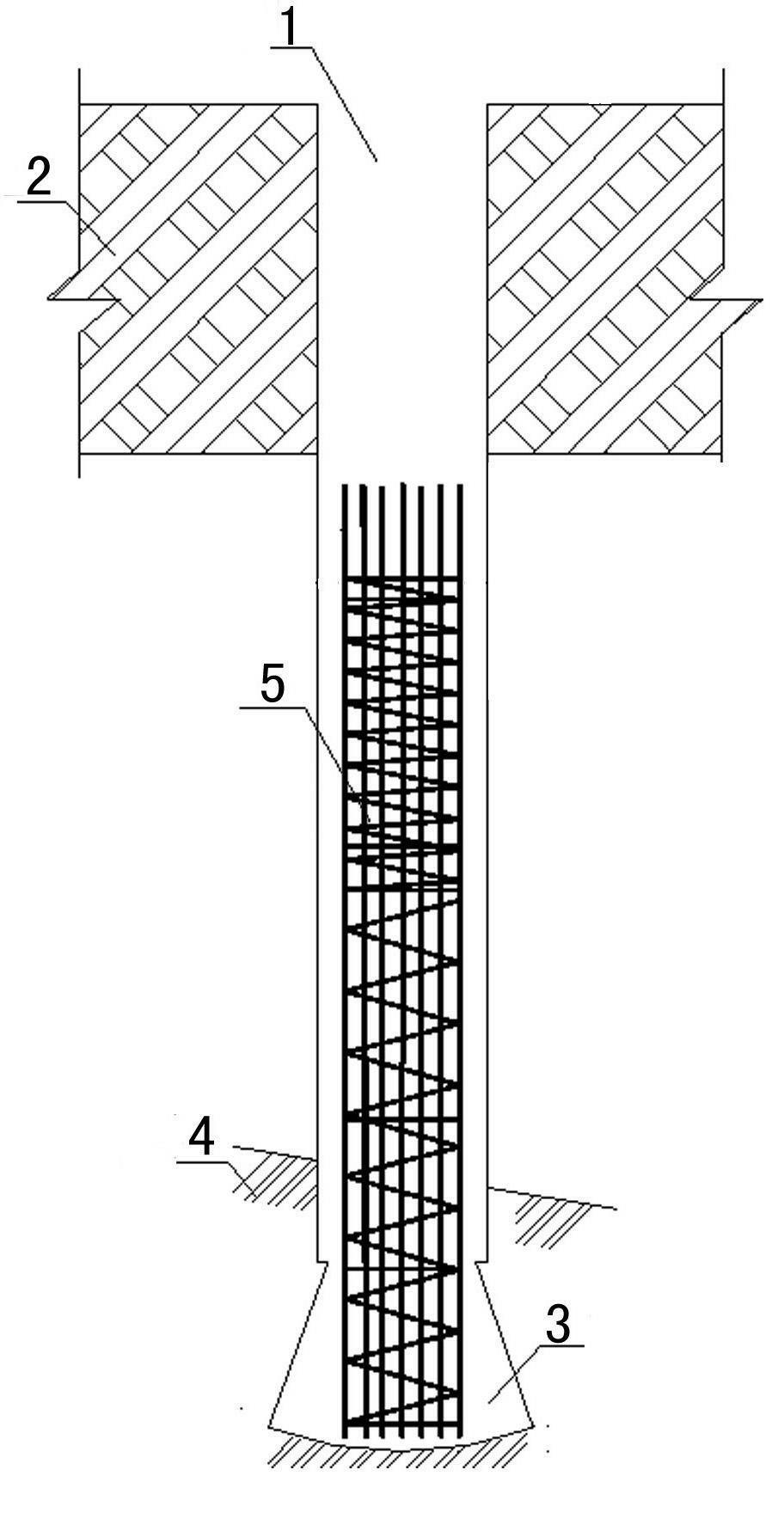

Method for constructing engineering pile by combining rotary drilling rig with manual pile base chambering

InactiveCN102425160AGuarantee the construction qualityImprove construction qualityBulkheads/pilesRebarDrill

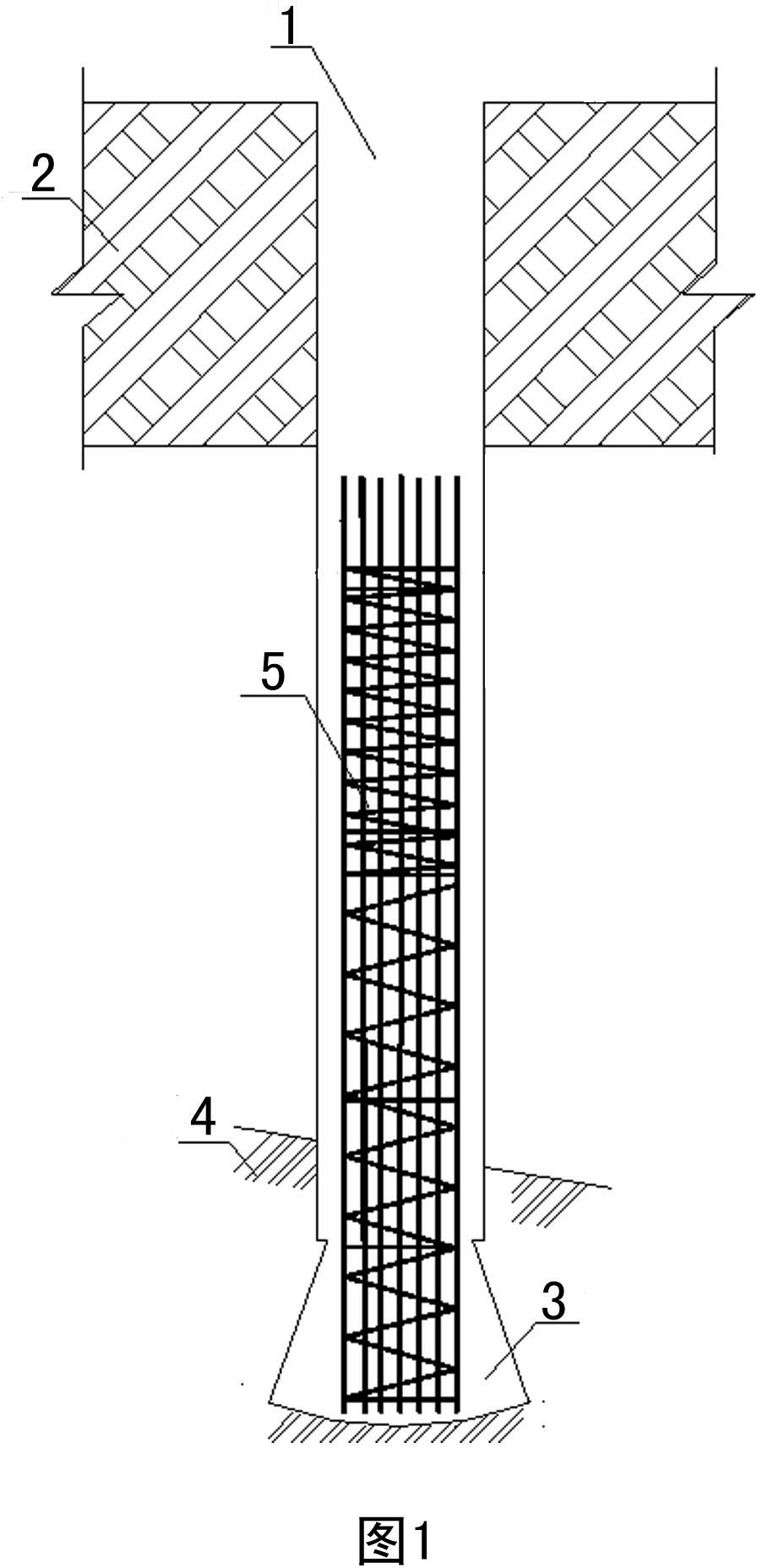

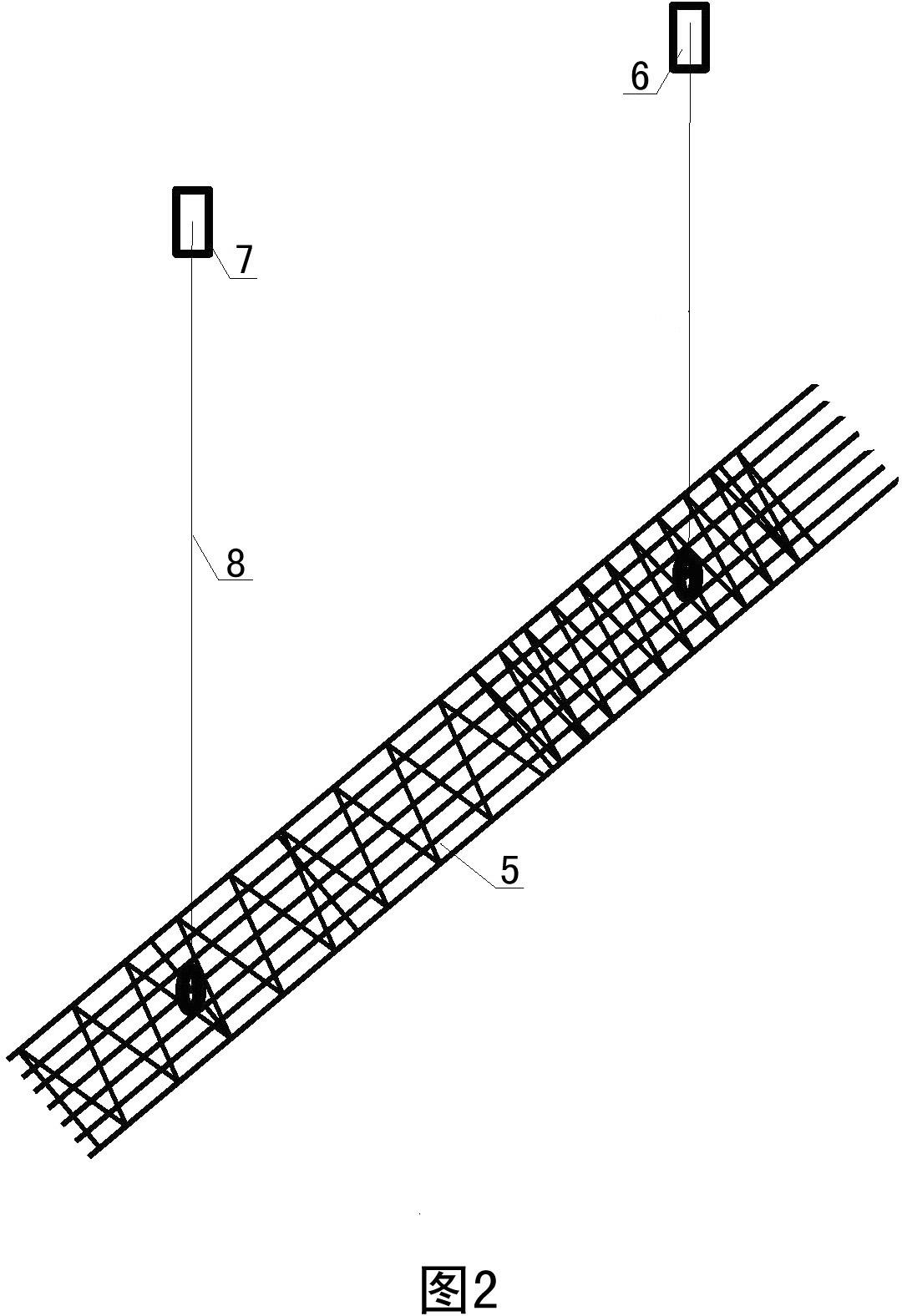

The invention relates to a method for constructing an engineering pile by combining a rotary drilling rig with manual pile base chambering, which comprises the following steps: (1) preparation work before construction, including field leveling; (2) pile lofting; (3) pile casing embedding; (4) rig installation and rotary drilling; (5) manual pile base chambering; (6) rotary drilling drill quality detection; (7) reinforcement cage manufacturing; (8) reinforcement cage installation; (9) preparation before casting, mainly including hole cleaning, final hole acceptance check, and pump concrete casting quality safeguard measure; and (10) concrete casting, mainly including guide pipe installation, concrete casting and sampling for test and pile forming. In the method for constructing the engineering pile by combining the rotary drilling rig with the manual pile base chambering, the high efficiency of the rotary drilling rig is fully utilized, and the manual pile base chambering is utilized, the advantages of the rotary drilling rig and the manual pile base chambering are combined to make up the defects of the rotary drilling rig and the manual pile base chambering. The construction steps are detailed; the process flow is clear and definite; the construction quality of the engineering pile is ensured through an effective detail measure; the construction process of the rotary drilling rig and the process step of the manual pile base chambering are combined as a whole to realize the effective allocation of a construction field, a construction machine and construction time; and when the construction quality is ensured, the construction efficiency of a digging pile is greatly increased, thereby, the construction time of the engineering pile can be greatly saved, and the construction period requirement of the project is met.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

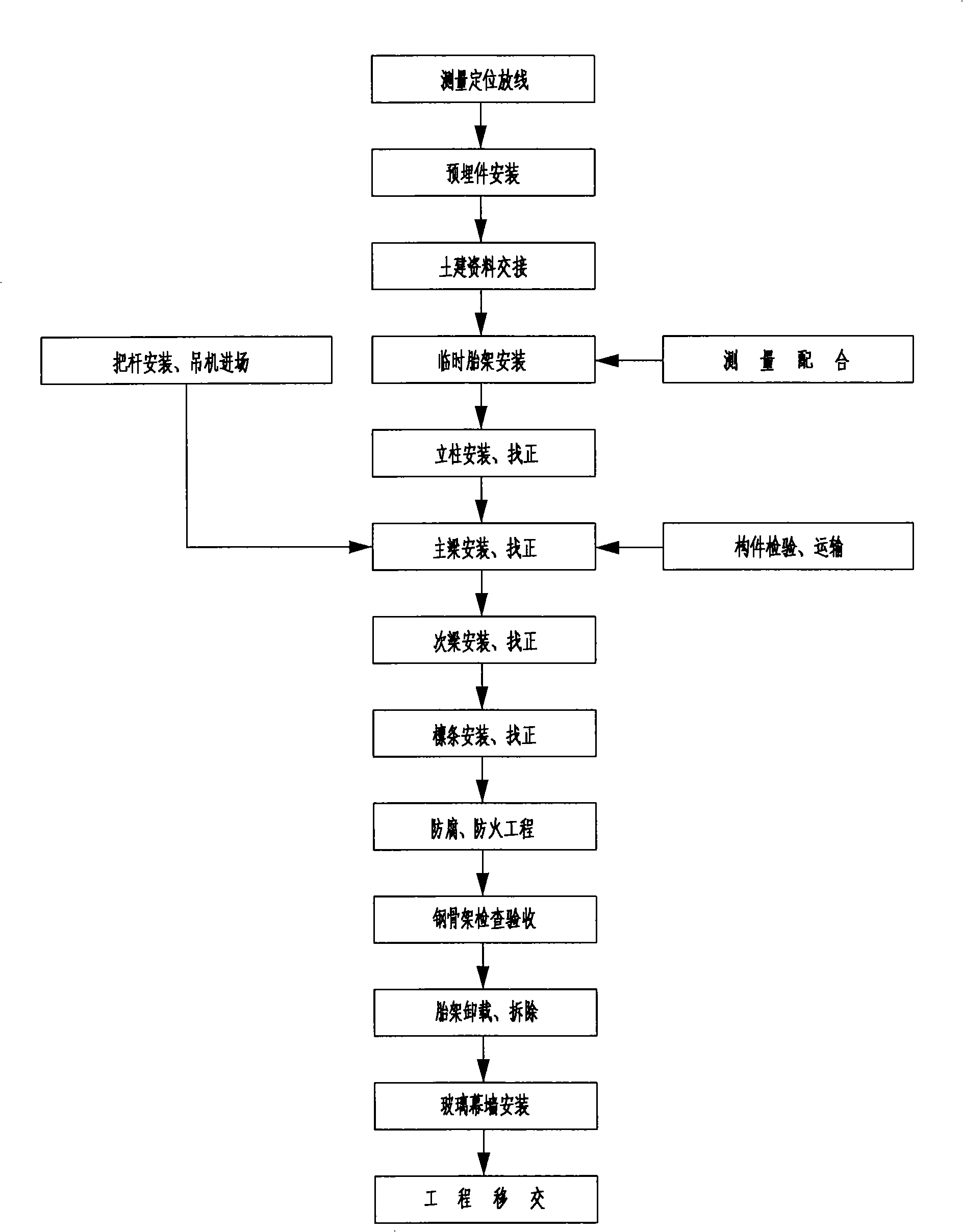

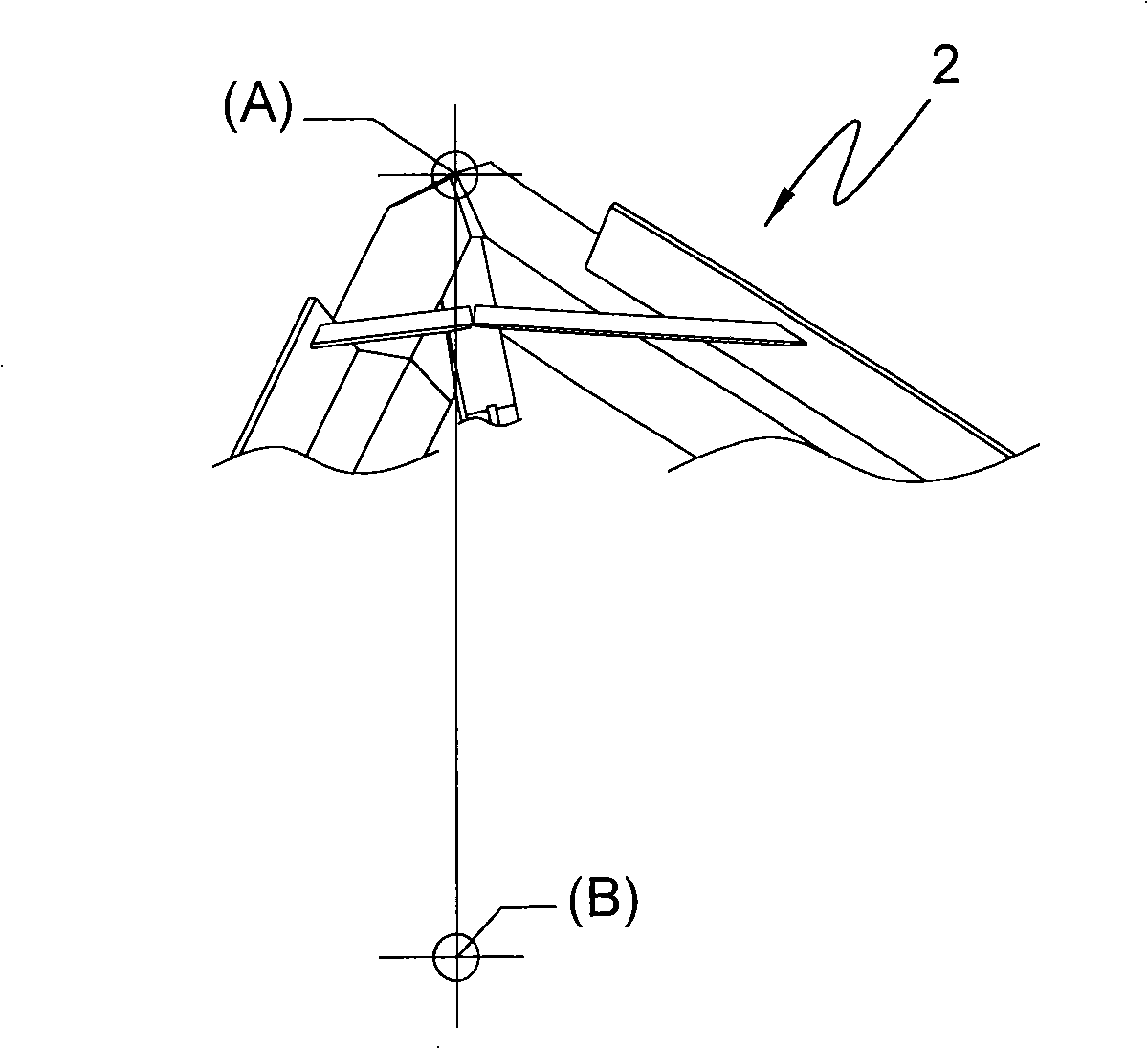

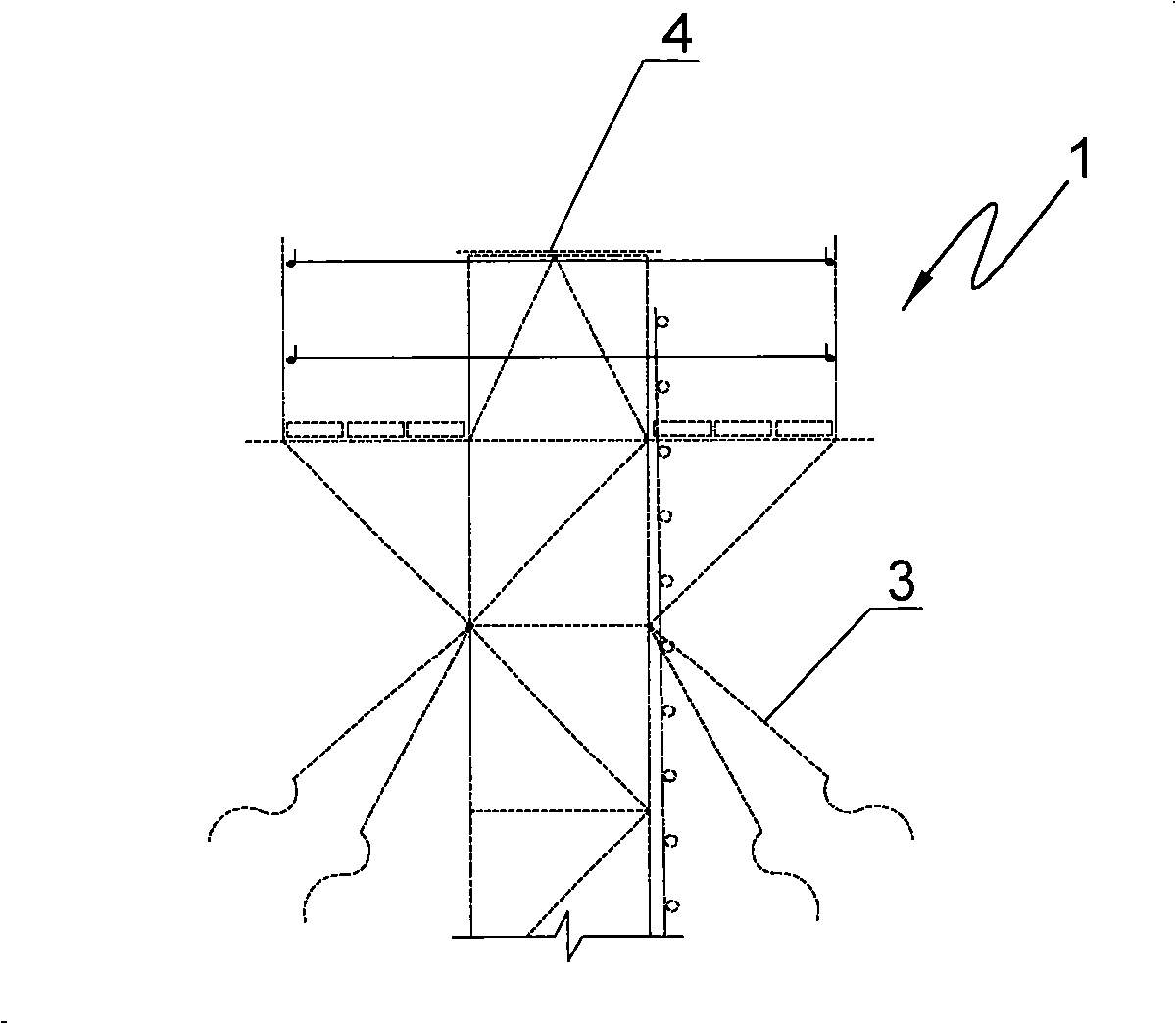

Steel structure high altitude mounting method

InactiveCN101328746AGuaranteed manufacturing accuracyAccurate modelingBuilding roofsBuilding material handlingEngineeringWelding

The invention provides a method for installing an overhead steel structure high, which belongs to a method for constructing a fixed structure. The prior installation method has defects that precise positioning is hard to realize and installation precision is hard to guarantee. The method comprises the following steps of: accurately modeling and correctly lofting and cutting, correctly paying off and accurately positioning; installing embedded parts, a temporary assembly jig and an upright post according to the paying-off position; positioning and fixing a joint on the temporary assembly jig; orderly lifting a main girder, a secondary girder and a purline; and unloading and dismounting the temporary assembly jig. The method is easy to guarantee manufacture precision of each component and installation precisions of the embedded parts, the temporary assembly jig, and the joint; the on-site lofting and cutting is unnecessary to undergo, and the on-site lifting and connection (welding) of each component are convenient.

Owner:ZHEJIANG ZHANCHENG CONSTR GROUP

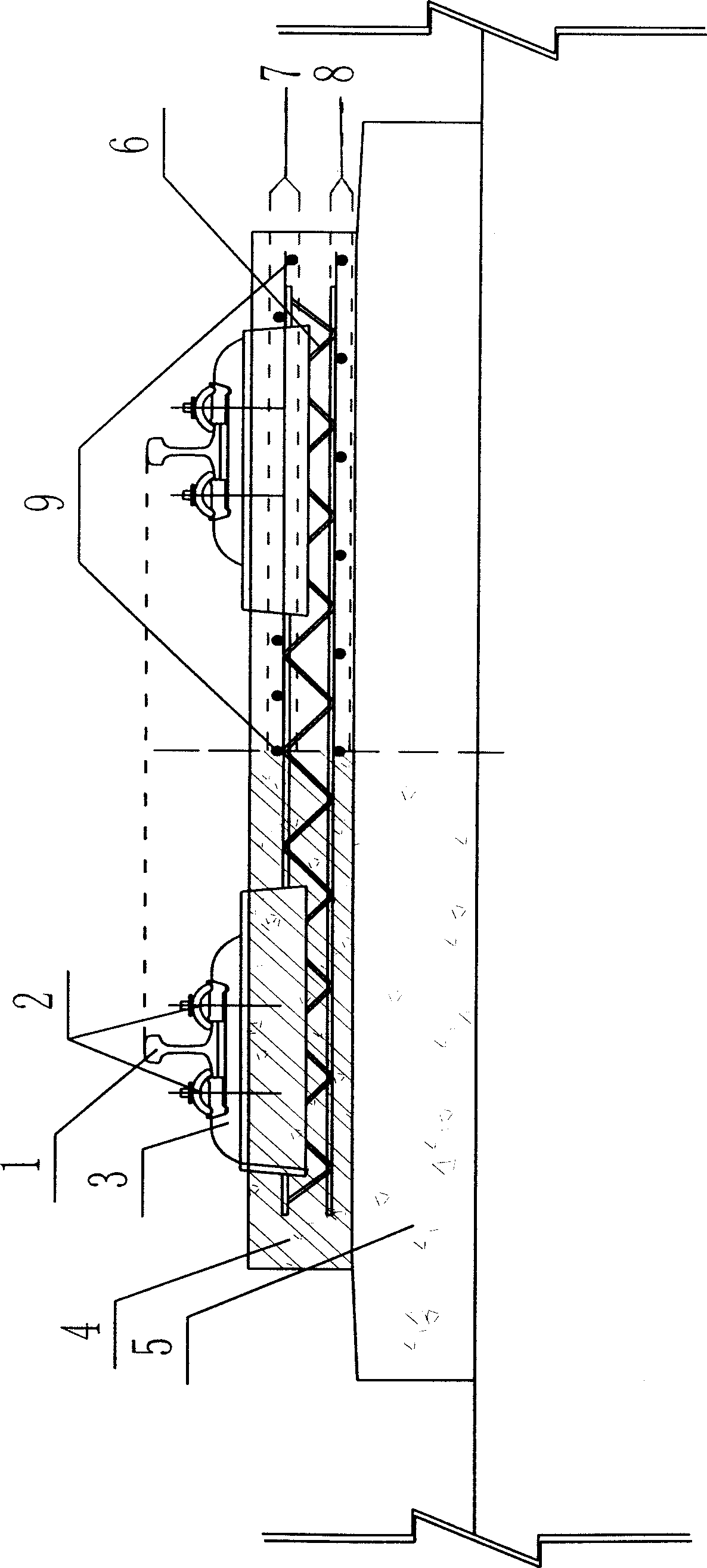

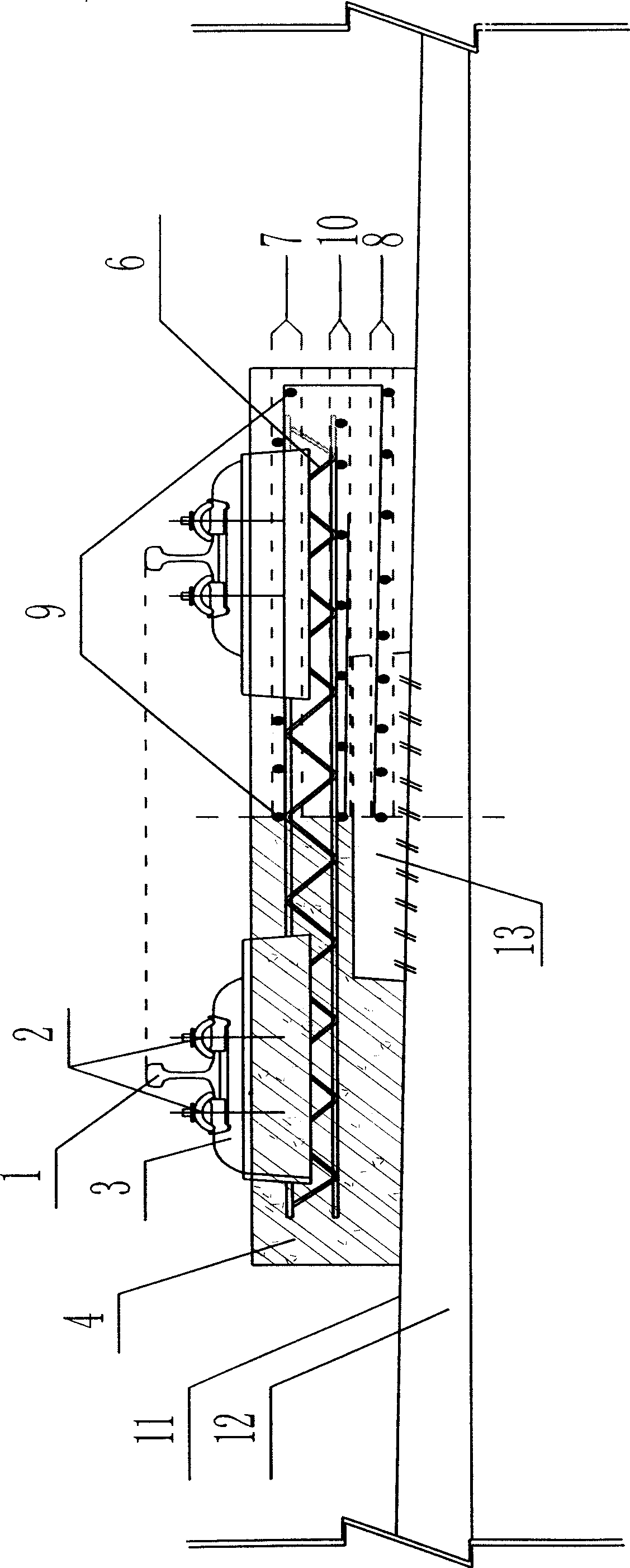

Construction method for two-block unballasted track bed board

InactiveCN101503870AAchieve precise positioningTooling system is simpleRailway track constructionEngineeringRebar

The invention relates to a construction method for a double-block-type ballastless track bed slab, which comprises the following steps: 1, clearing a base surface and performing construction lofting; 2, placing a bottom layer of reinforcing steel bars, and laying sleepers; 3, mounting a tool track and adjusting the sleepers; 4, assembling track panels; 5, coarsely adjusting the track panels; 6, binding the reinforcing steel bars and performing earthing welding; 7, mounting templates and finely adjusting the track; 8, casting concrete into the track bed slab; 9, loosening adjusting devices and fasteners, and curing the concrete; and 10, relocking the tool track and completing the measurement. The construction method has the advantages that: the tool track is adopted as a detection standard, so the precise positioning of the track is realized; a frock system is simple, is easy to process and manufacture, has wide commonality, and is not only suitable for construction of the track bed slab in a subgrade section but also suitable for construction of the track bed slab in a bridge section; the construction process is simple and quick, and various working procedures are easily carried out by flow construction; and the construction cost is low, so the construction investment is effectively saved.

Owner:THE 8TH GRP OF CHINA RAILWAY 1ST ENG CO LTD

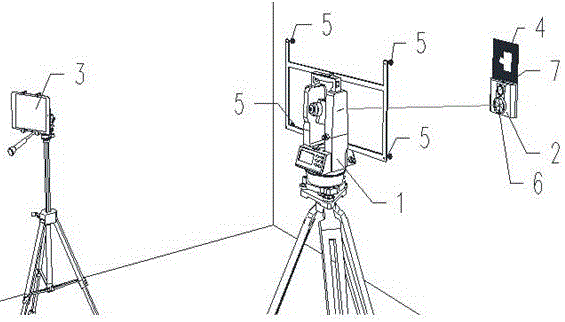

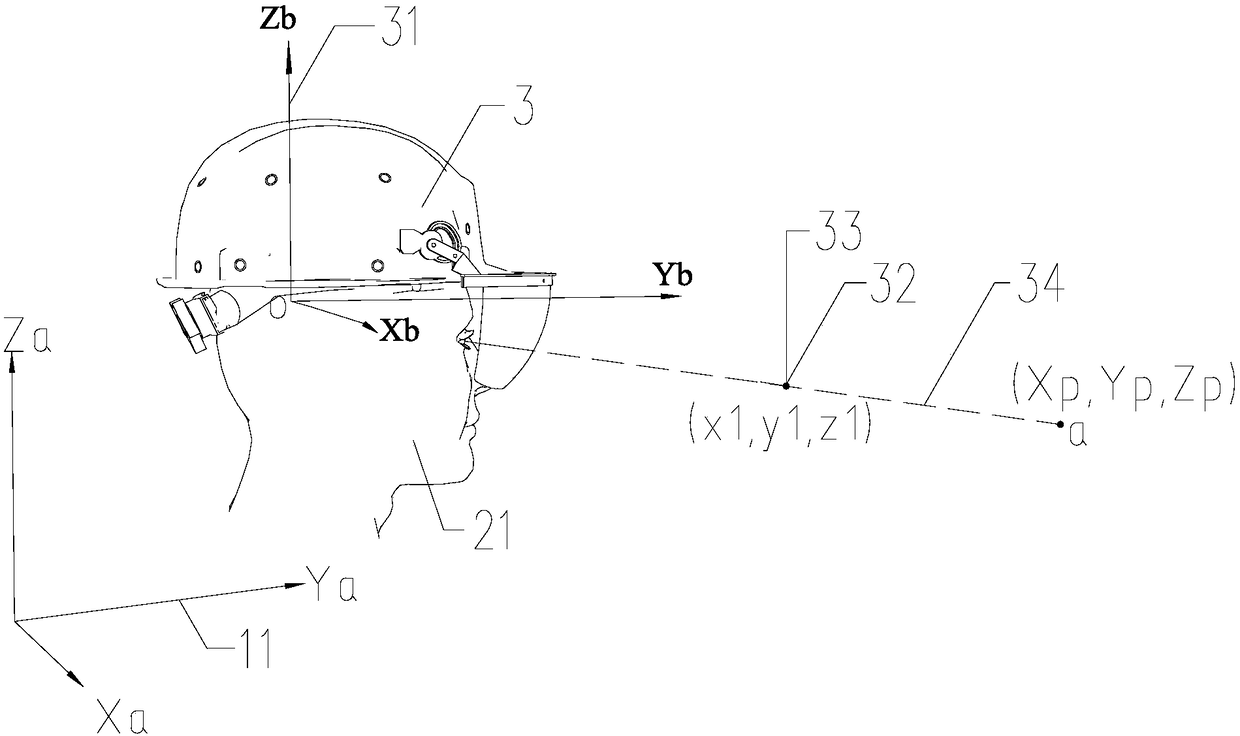

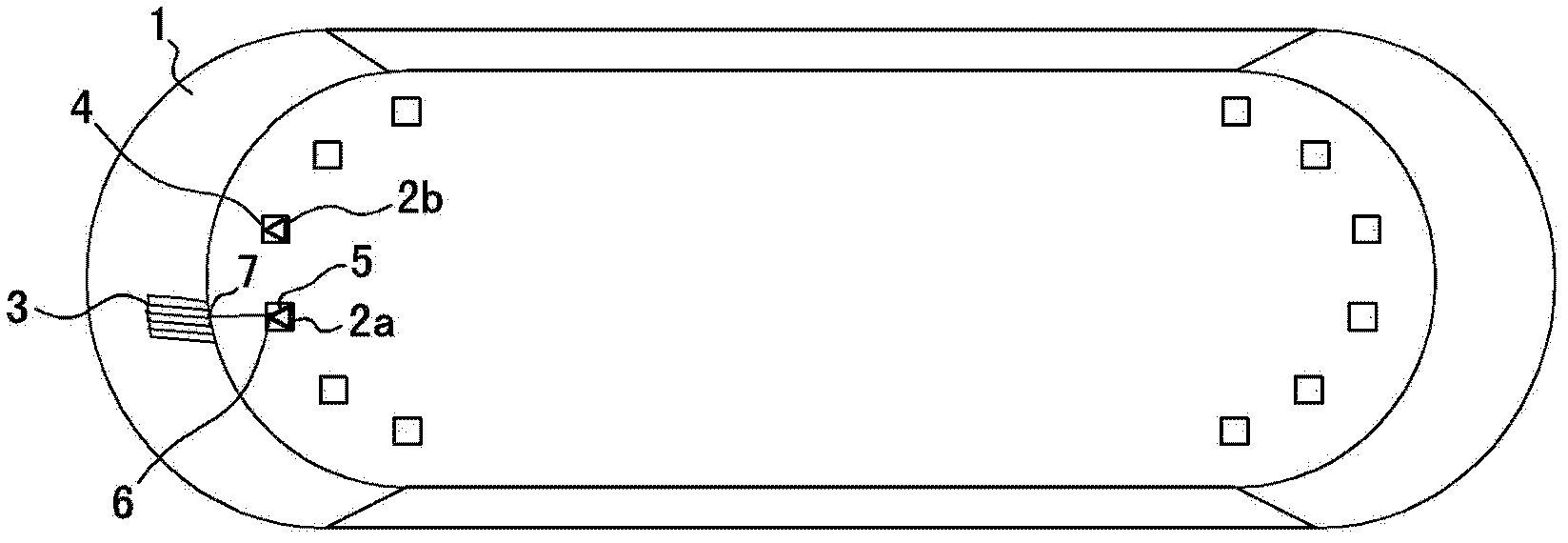

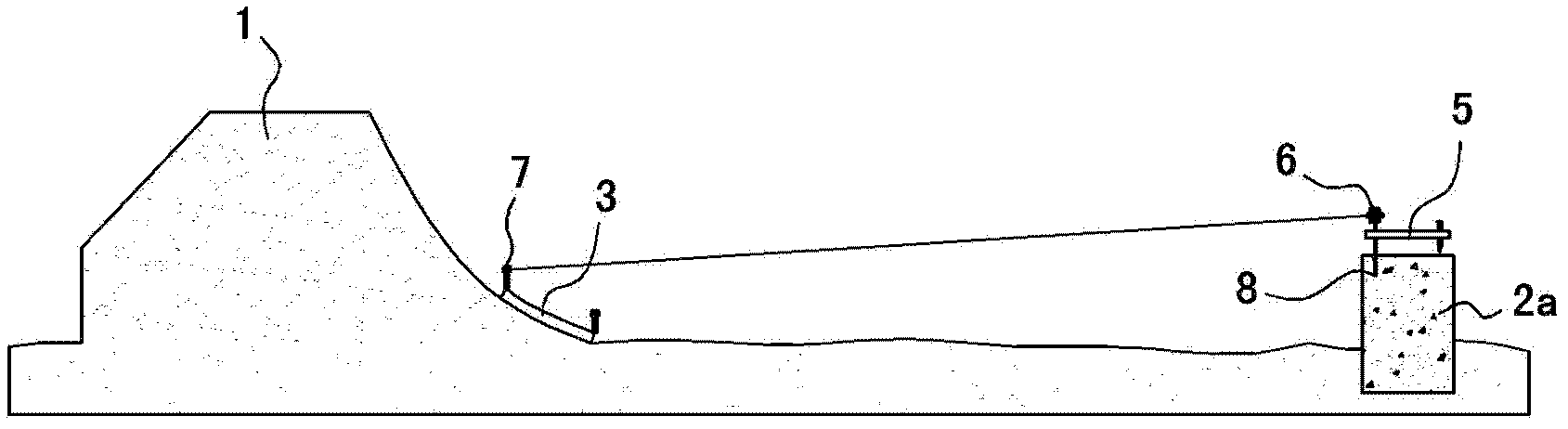

Building information modeling (BIM) augmented reality lofting system based on electronic total station and photogrammetric technology

ActiveCN106017436AQuick measurement stakeoutFull mapActive open surveying meansTotal stationAugmented reality

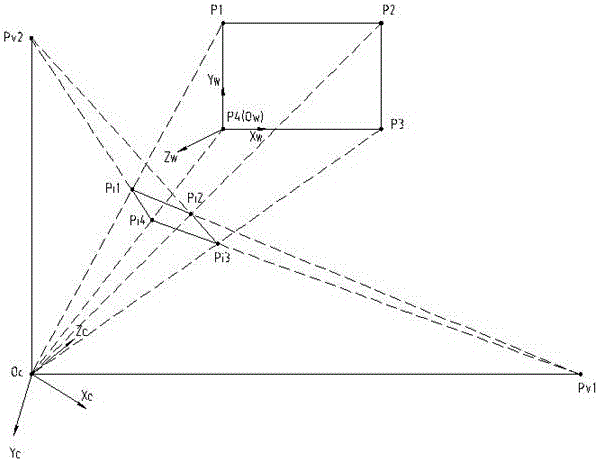

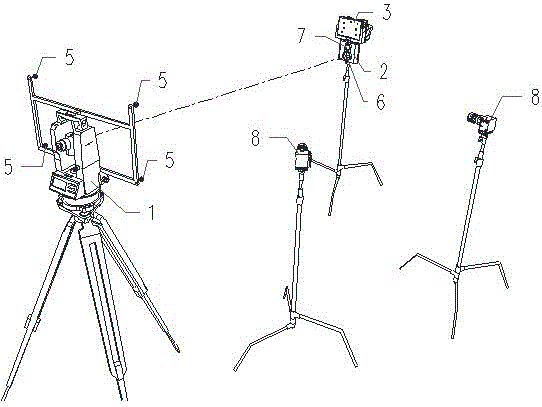

The invention relates to a measuring technology, and discloses a building information modeling (BIM) augmented reality lofting system based on an electronic total station and a photogrammetric technology. The BIM augmented reality lofting system comprises an augmented reality device, the electronic total station, a positioning device and a to-be-measured marker, wherein the to-be-measured marker or the augmented reality device is fixed with the positioning device; at least four optical identification points are arranged on on the electronic total station; the positioning device comprises a camera; the camera is used for acquiring images of the optical identification points, arranged on the electronic total station, in the camera, calculating the relative attitudes of the optical identification points and the positioning device, and calculating the attitude of the positioning device in an engineering measurement coordinate system according to the relative attitudes of the optical identification points and the positioning device; the electronic total station is used for acquiring coordinates of the positioning device; the augmented reality device is used for calculating the coordinates, elevation and attitude of the to-be-measured marker or the augmented reality device in the engineering measurement coordinate system according to the relative distance and attitude of the to-be-measured marker or the augmented reality device and the positioning device, thus realizing fusion of coordinates.

Owner:廖卫东

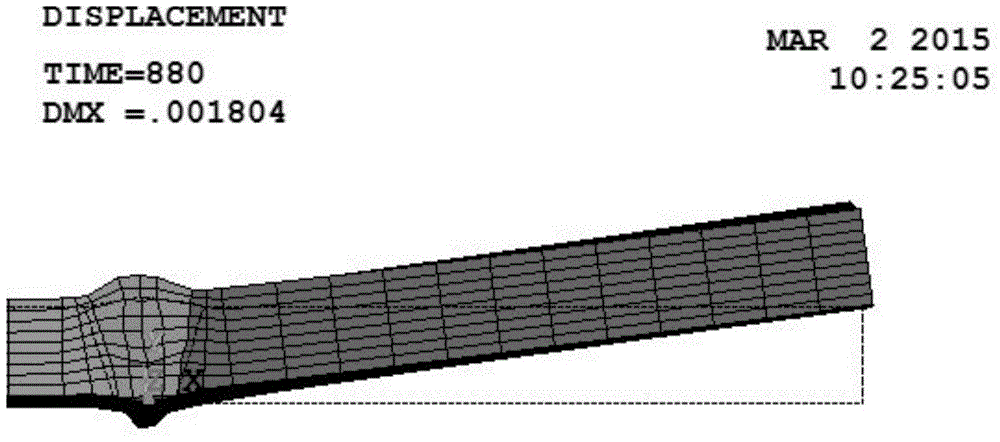

ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method

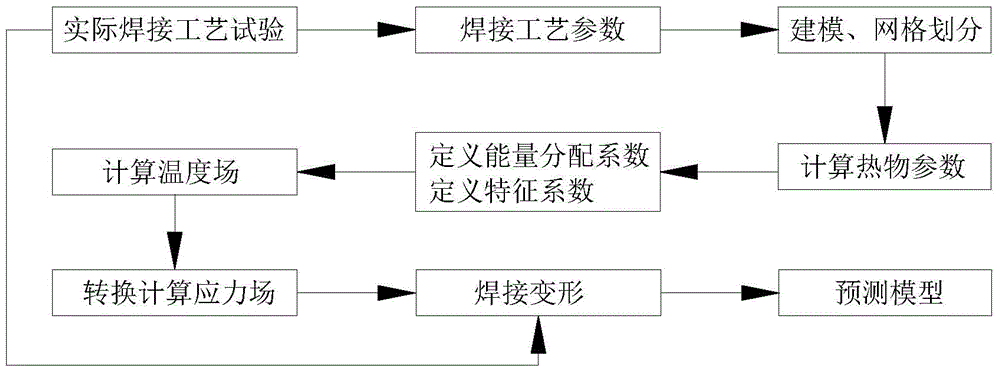

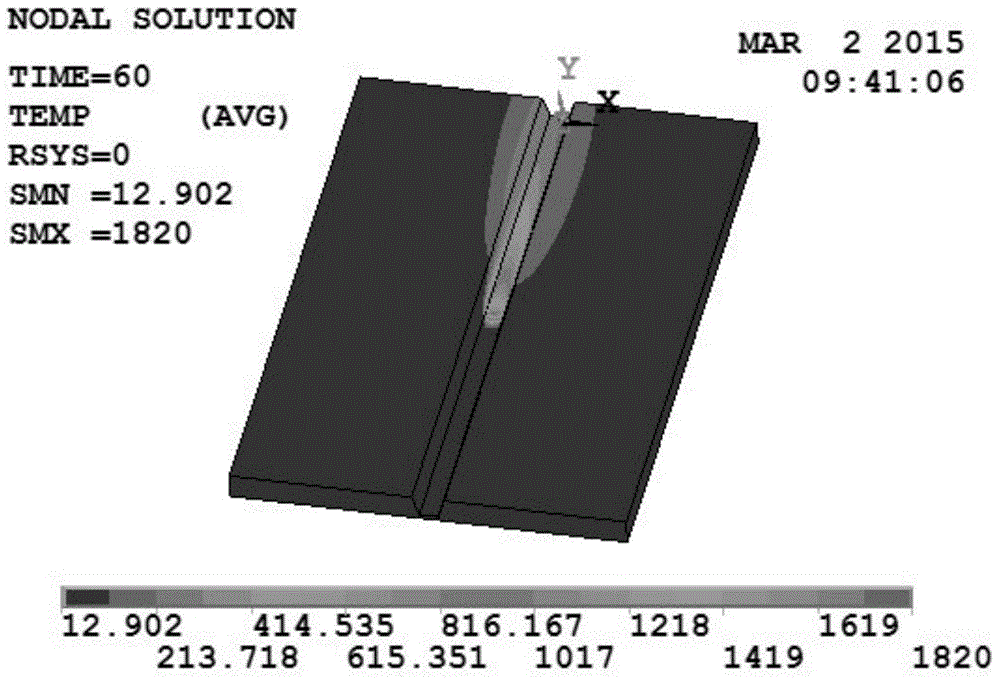

InactiveCN104809291AReduce the number of welding procedure testsSave manpower and material resourcesWelding/cutting auxillary devicesAuxillary welding devicesElement modelWorkload

The invention provides an ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method. The method comprises the following steps: (1) determining welding process parameters; (2) establishing a finite element model and carrying out grid partitioning; (3) determining thermal physical parameters of a welding material; (4) determining a heat source model; (5) calculating a temperature field; (6) calculating a stress field, and calculating welding deformation of duplex stainless steel and dissimilar steel. Compared with the prior art, the ANSYS-based duplex stainless steel and dissimilar steel welding deformation prediction method has the advantages that the deformation after welding of SAF2507 super duplex stainless steel and Q235 low-carbon dissimilar steel is successfully predicted; a thermal treatment scheme after welding is formulated according to a prediction result; the quantity of experiments for a welding process is reduced; manpower and materials are saved; a technical specification is provided for working procedures of previous lofting and feeding in a product manufacturing process; the workload of a working procedure of later machining is reduced.

Owner:JIN TONG LING TECH GRP CO LTD

Method for repairing damaged precision part of turbine

The invention discloses a method for repairing a damaged precision part of a turbine. According to the method, the micro-plasma welding repair technique characterized in low heat input, low deformation and precise welding forming is adopted, the original profile data of the precision part of the turbine are measured through optical three-dimensional scanning and taken as a model for repairing and postwelding precise finishing of the profile of the precision part of the turbine, and then precise repair of the profile of the precision part of the turbine is achieved. The method has the advantages that welding precision is high, repair of complicated parts can be achieved, cost is low, part size is not limited, equipment is simple, small in size and high in automation degree, and the difference between sizes of a workpiece before and after repair is small. Blade lofting is not needed, precise repair can still be conducted without three-dimensional models of complicated parts such as a blade, and the method can be used for in-plant repair or on-site repair.

Owner:DONGFANG TURBINE CO LTD

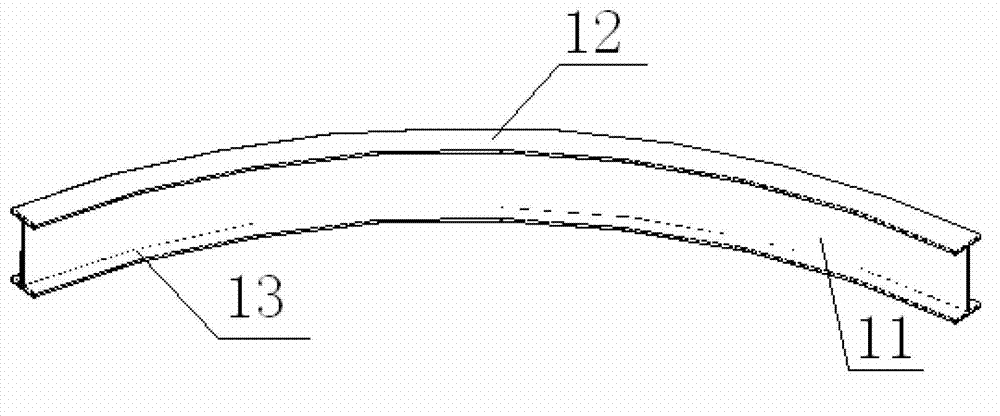

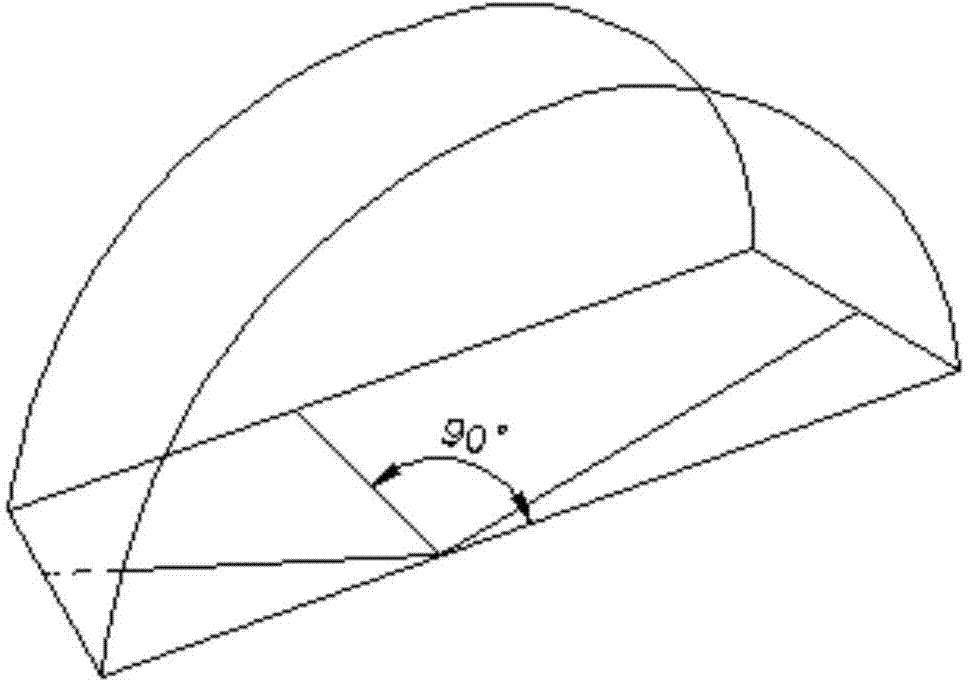

Manufacture method for double-curve H-shaped steel

The invention discloses a manufacture method for double-curve H-shaped steel. The manufacture method comprises the following steps of: 1) reviewing the material quality of a supplied horizontal plate, flattening the horizontal plate, and pre-processing; 2) three-dimensional lofting by a computer, and spreading in a plane; 3) cutting and blanking on a numeric control cutting machine; 4) opening a groove on an H-shaped steel web, and carrying out the butt welding; 5) marking a bending line and an assembly line on the web and a flange plate; 6) manufacturing a bending jig frame according to three-dimensional coordinates; 7) bending the web and the flange plate via the method of flame rectification assisting cold bending formation; 8) manufacturing a assembly jig frame; 9) combining position welding and spot-welding on an upper flange plate and a lower flange plate respectively assembled on an assembly jig frame group; 10) welding the soldering seam between the web and the lower flange plate; 11) lifting the component from the jig frame, and turning over the component to weld the soldering seam between the web and the upper flange plate; and 12) returning the jig for a repeated inspection, and carrying out the three-dimensional coordinates detection through a total-station instrument. According to the manufacture method, used equipment is simple, and efficiencies on manufacture and production are improved.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

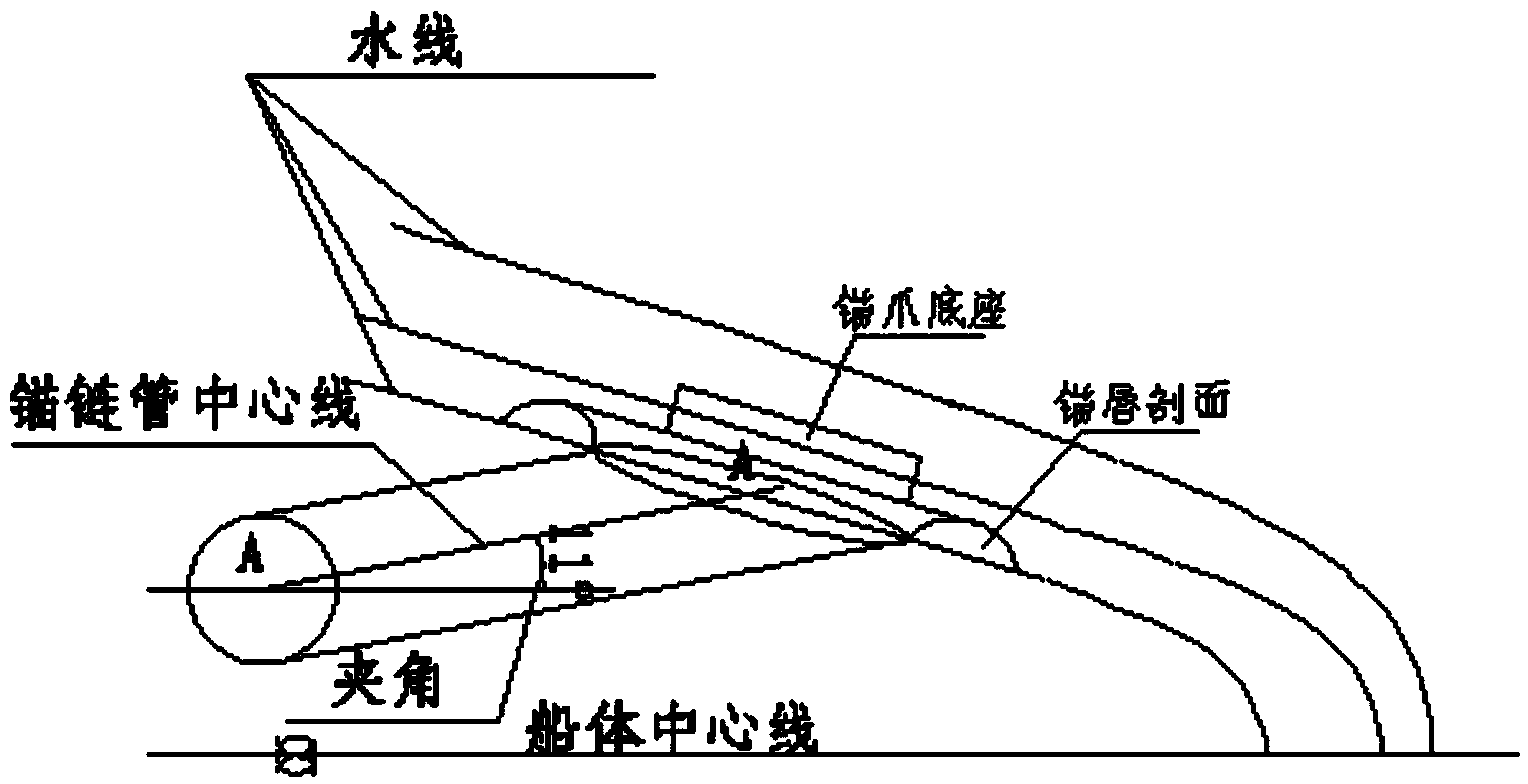

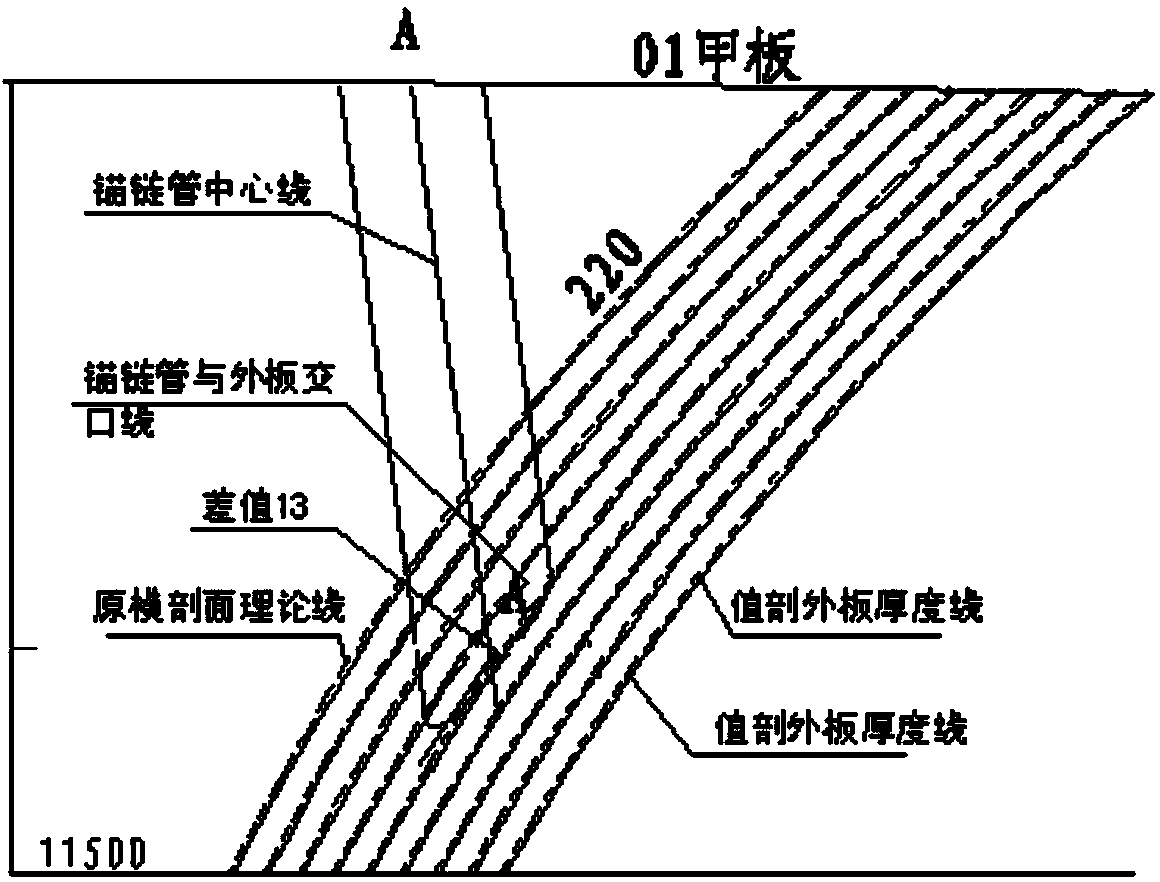

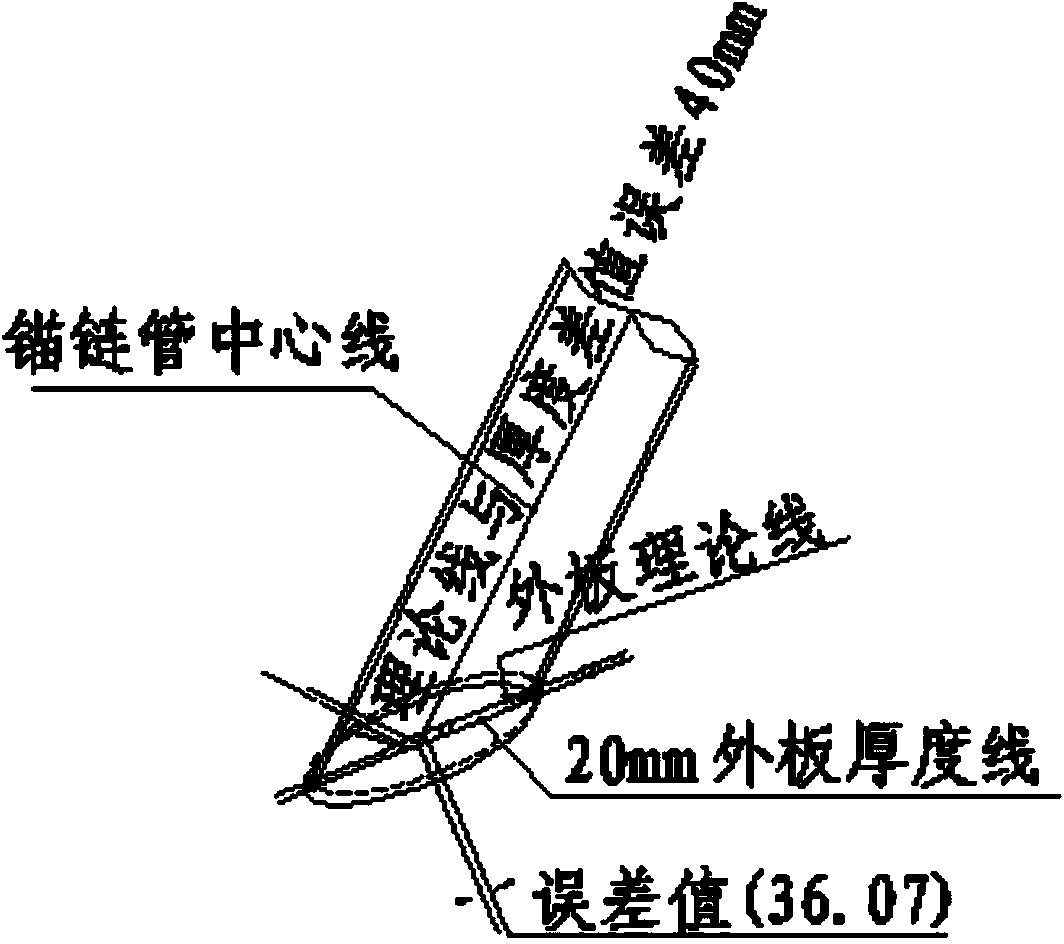

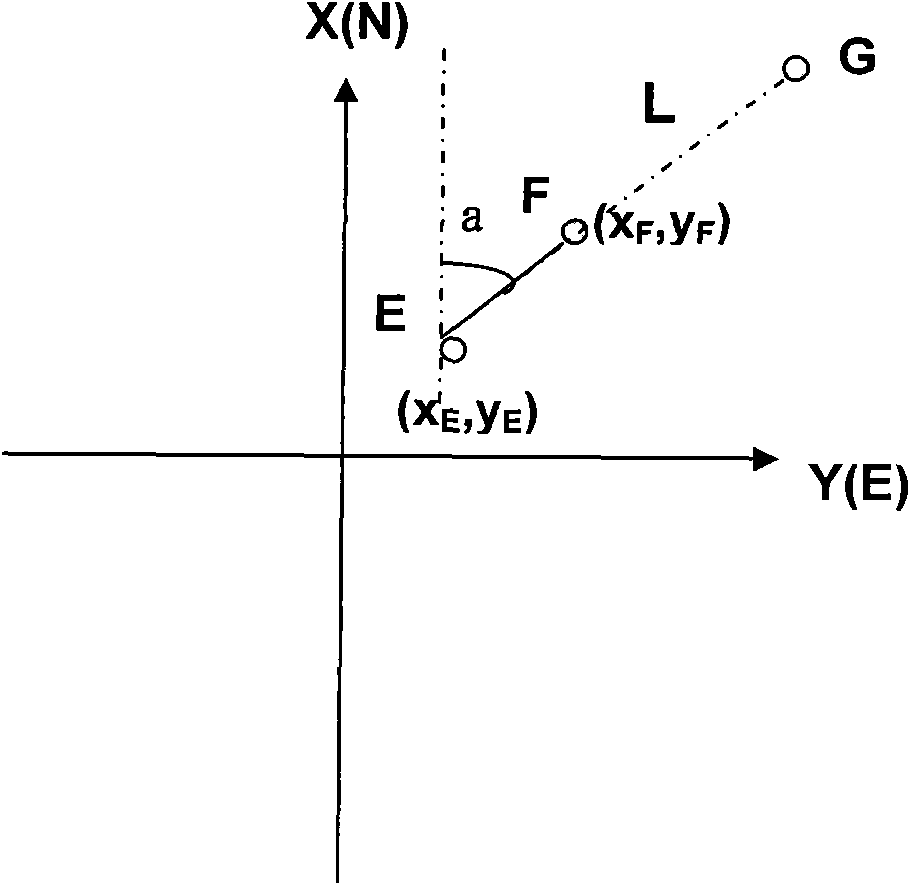

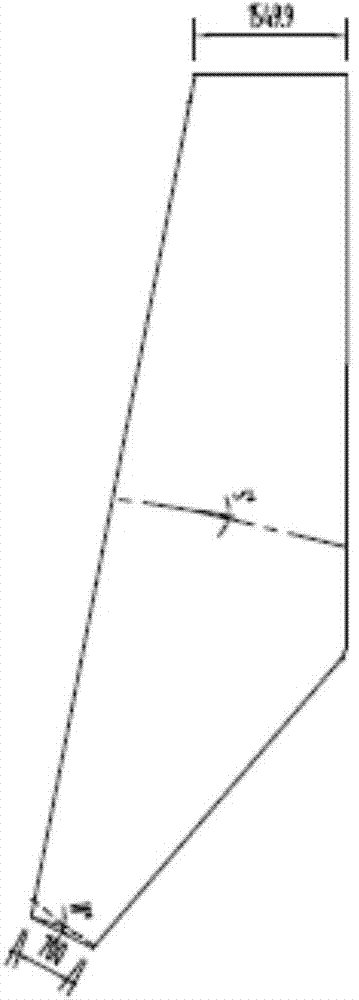

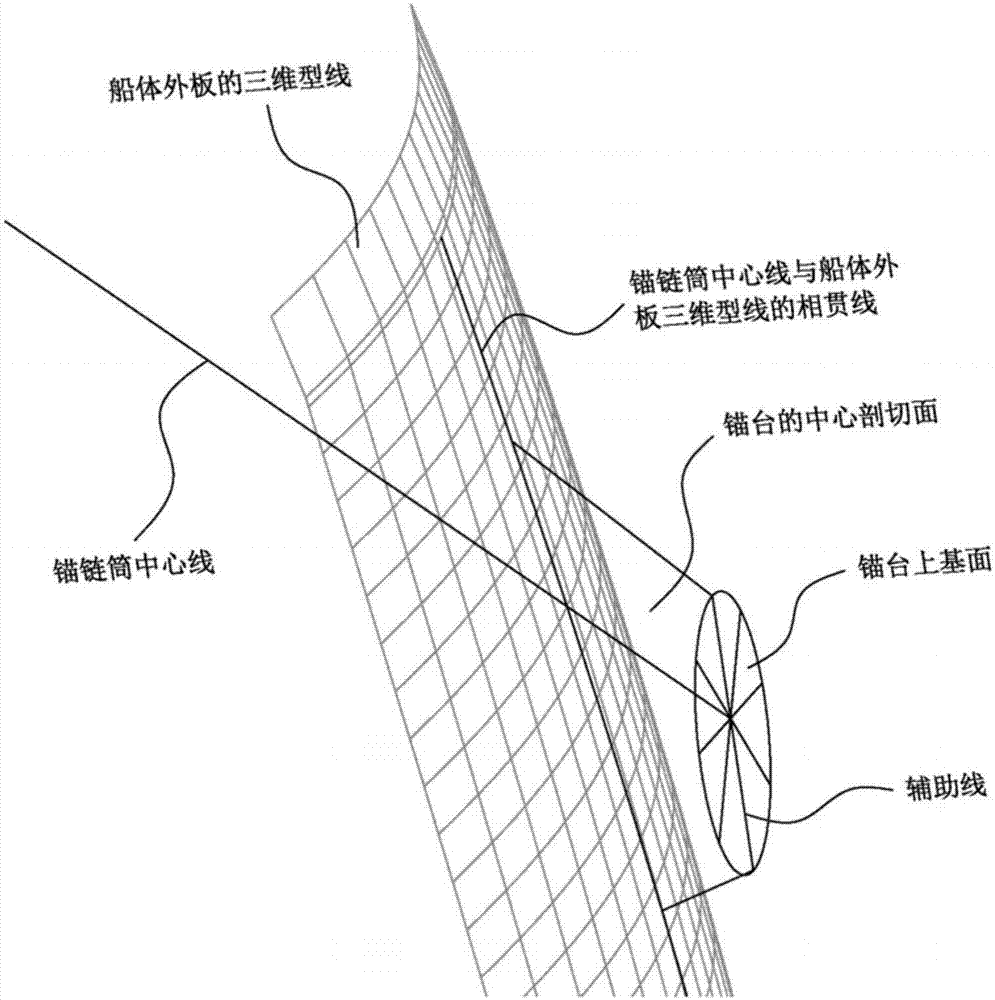

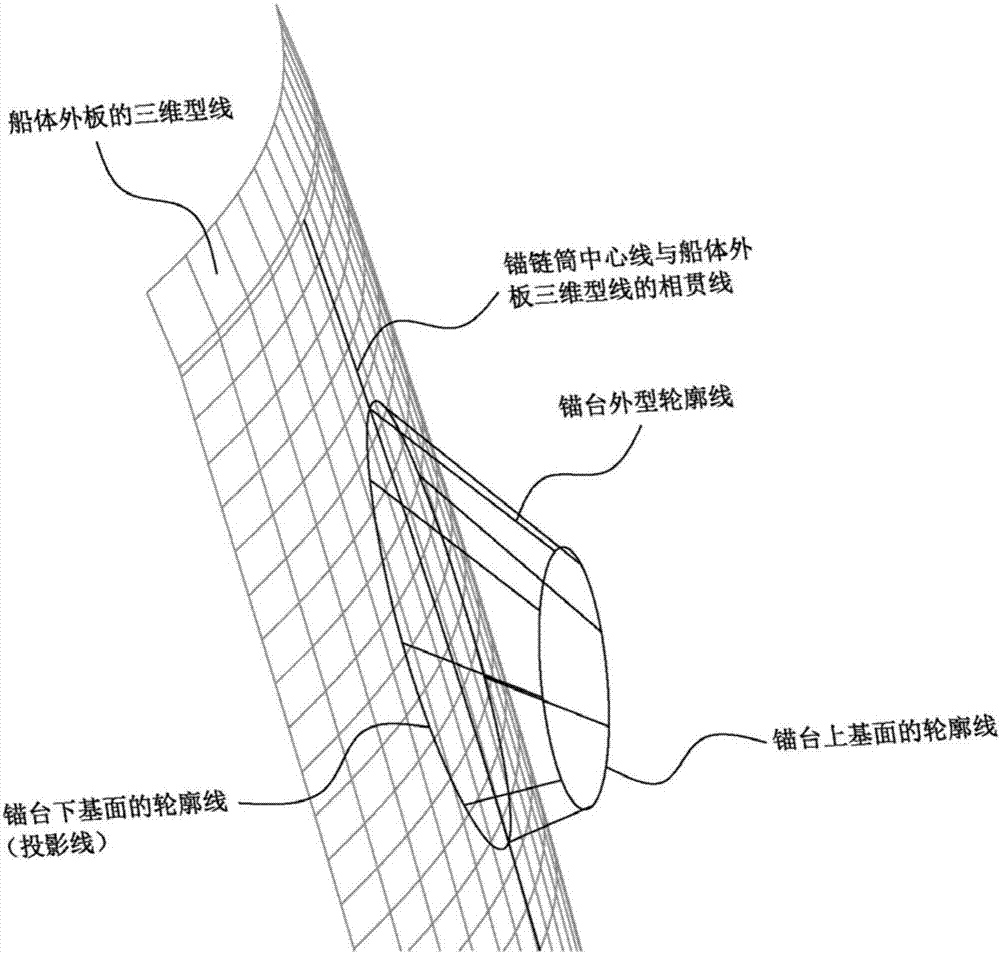

Lofting production method of anchor recess of planking thickness line of hull

ActiveCN103625603AImprove accuracyIncrease success rateVessel partsQuality by DesignStructural engineering

The invention discloses a lofting production method of an anchor recess of a planking thickness line of a hull. The lofting production method comprises the following steps: (1) line type lofting of an anchor recess region adopts a method of deducting the planking thickness line of the hull; (2) the line type of the anchor recess takes an A-A section of a center line of a hawse pipe as a reference, and projection is carried out on a three-directional line type deducting the planking thickness; (3) the protection of a section of an anchor mouth takes a 7# section and a 3# section of the center line of an anchor pipe as reference, and an origin of the outlet of the anchor pipe is a constant value; (4) the center line of the anchor pipe and a rib position of a water line are marked on a tapping sample; (5) the anchor mouth is located on the outlet point of the anchor pipe of the planking of the hull; (6) values are reasonably corrected by a cat anchor test; (7) the anchor recess is installed. According to the lofting production method, the validity and the success rate of the cat anchor test are improved, the design quality is improved, the production cost is reduced, the production cycle is shortened, the production design is matched with a production method of a production department, so that anchor release, anchor raise and mooring of a ship can be successfully carried out after the anchor recess is installed.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

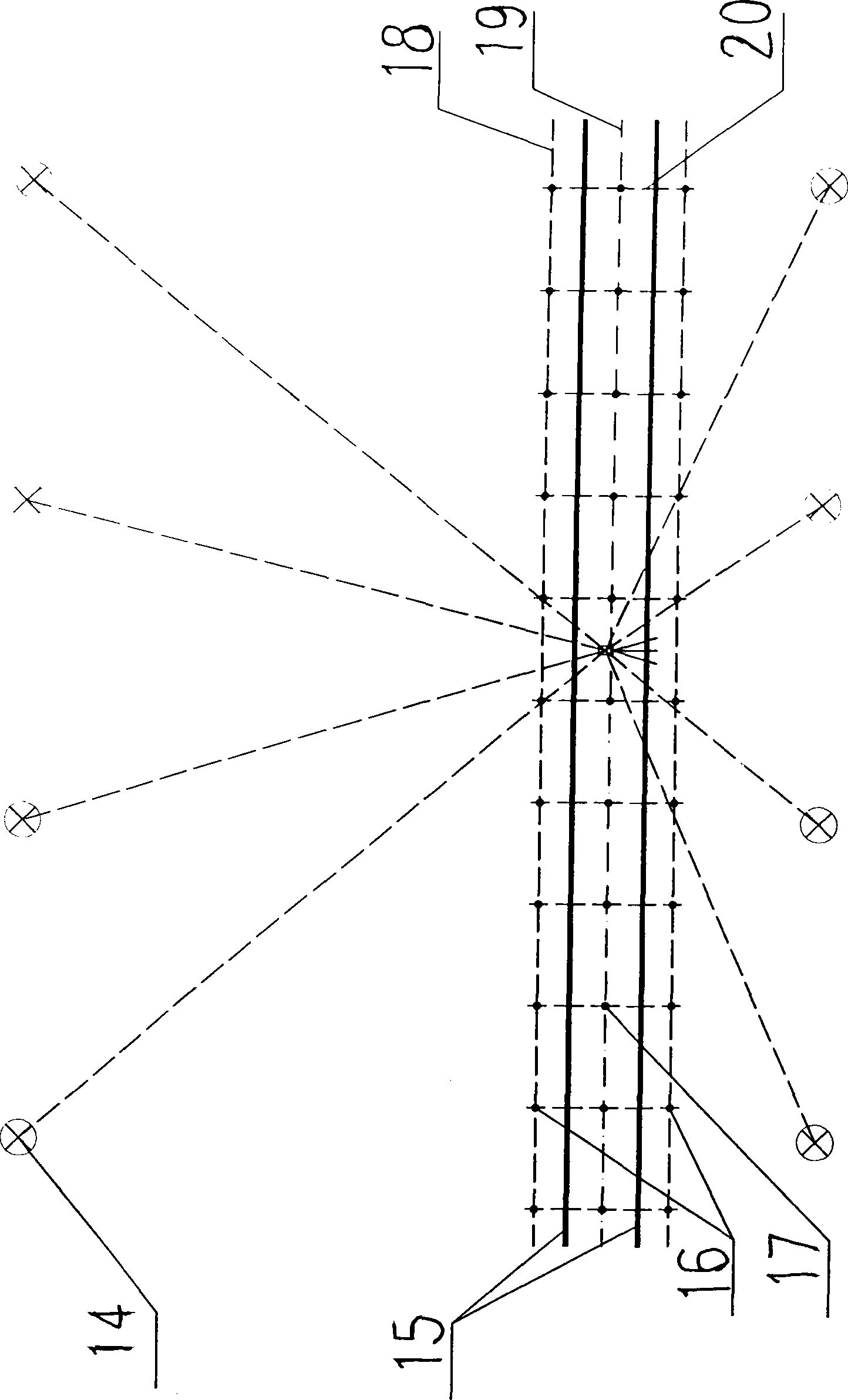

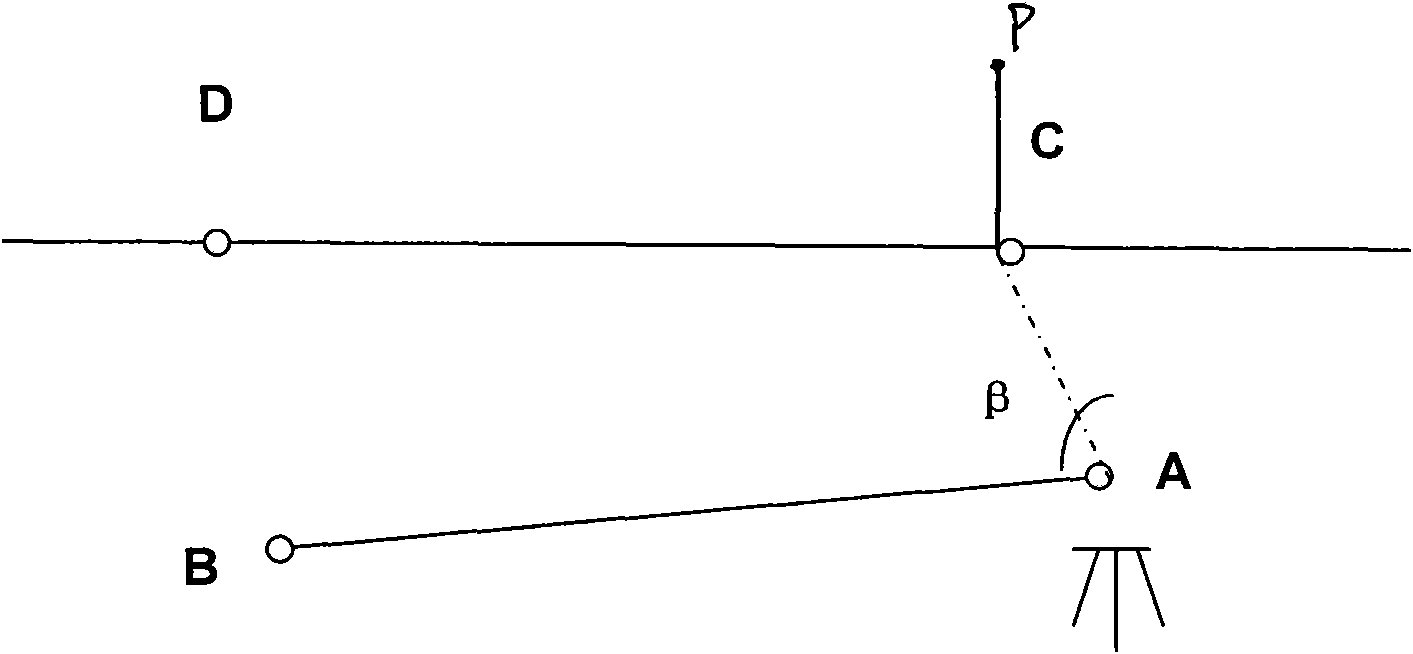

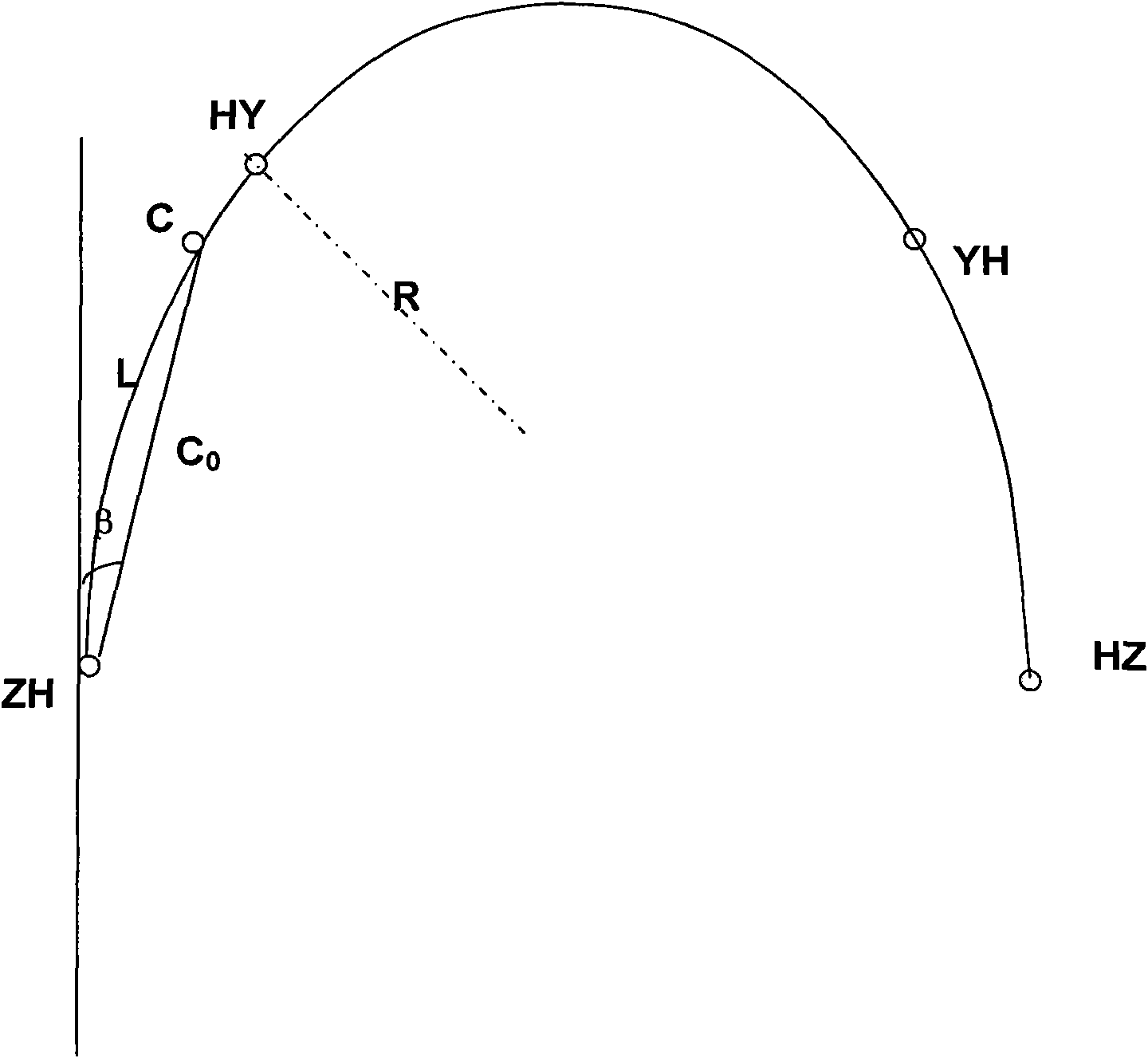

Method for determining strut positions of contact network of special railway line for passenger traffic

ActiveCN102147252AFast measurementHigh measurement accuracyMeasuring points markingHeight/levelling measurementContact networkEngineering

The invention discloses a method for determining strut positions of a contact network of a special railway line for passenger traffic, solving the problem of low accuracy in the prior art for surveying and lofting the strut positions of the contact network. The method comprises the following steps of: obtaining the coordinates of all CPIII points to serve as survey datum for railway line and related line parameters under a coordinate system of a foundation pile control network CPIII; when a central point C of the railway line is located in a linear, smooth curved and round curved railway lines, respectively calculating the coordinates of the central point C of the railway line; and lofting the coordinates, measuring a distance between the point C to a strut P to serve as a strut side face limit value by using a steel measure tape on a CP linear direction vertical to a railway central line, so as to determine the specific position of the strut P, wherein a rail surface elevation H, calculated in the second step, of the central point C of the railway line is taken as a reference in survey and lofting. By adopting a CPIII coordinate measurement construction method, the advantages of greatly accelerating measurement speed, improving measurement precision and saving cost are achieved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

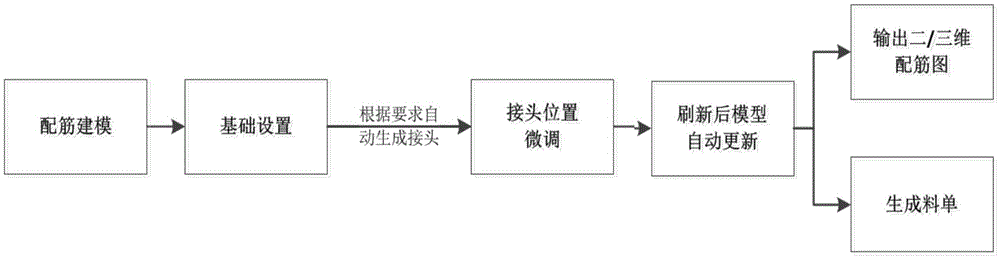

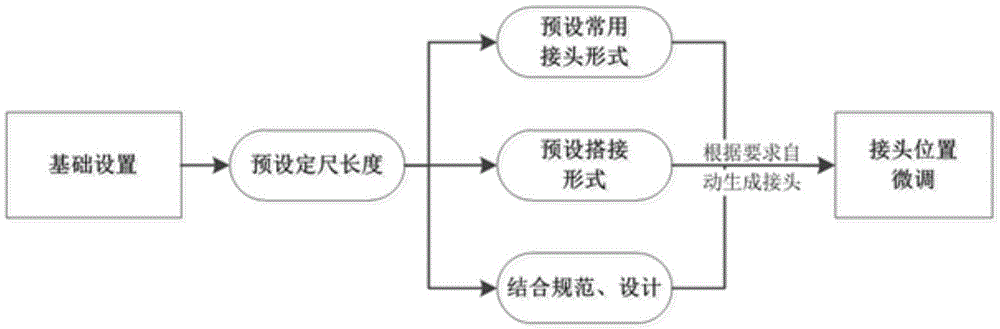

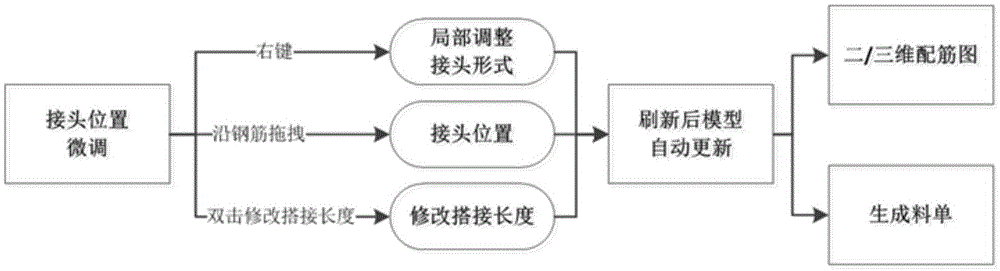

Three-dimensional reinforcing steel bar lofting method

ActiveCN105488301AEasy to understandDeepening time shortenedGeometric CADSpecial data processing applicationsEngineeringDimensional modeling

The invention relates to a three-dimensional reinforcing steel bar lofting method. The three-dimensional reinforcing steel bar lofting method includes the specific steps that 1, a concrete member solid model is generated through three-dimensional modeling software, 2, the types and the lap joint lengths of reinforcing steel bar connectors are preset according to the design and standard requirements for reinforcing steel bars; 3, the types and the number of the connectors are automatically calculated according to the positions of the reinforcing steel bars and the selected types of the connectors, and corresponding connector type models are generated at the lap joint positions of the reinforcing steel bars; 4, after the positions of the connectors are partially adjusted, the related positions of the connectors and the whole model are automatically updated through refreshing; meanwhile, generation of three-dimensional or two-dimensional material lists are supported, and the statistics of the quantity of reinforcing steel bars is carried out in real time. By means of the three-dimensional reinforcing steel bar lofting method, blanking in the three-dimensional model mode can be achieved; as for complex members, observation can be carried out in any direction, any sectioning can be carried out, and a reinforcing steel bar arrangement person can conveniently learn drawings; due to consideration of the positions of the reinforcing steel bar connectors, calculation of the construction quantity can be sufficiently achieved, project cost is saved, and workloads are reduced.

Owner:SHANGHAI FOUND ENG GRP

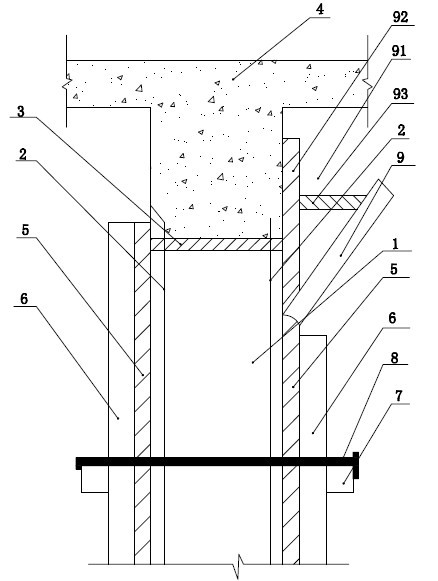

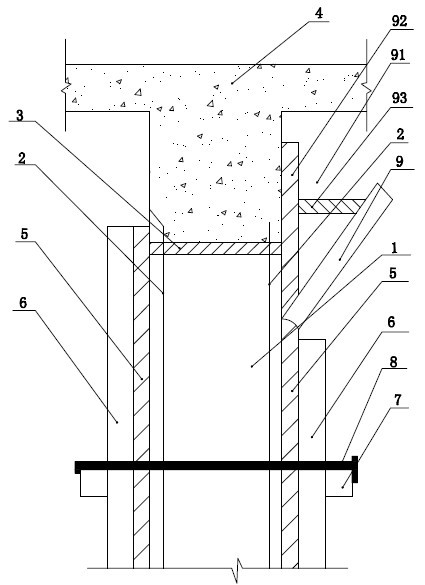

Construction method and pouring device for framework masonry infill wall structure

ActiveCN102003069AForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSteel barInfill wall

The invention relates to a construction method and a pouring device for a framework masonry infill wall structure. The construction method comprises the following steps of: 1, performing lofting of construction; 2, planting ribs on the end part; 3, spreading and attaching flexible materials on the end part; 4, binding steel bars; 5, constructing the wall; 6, arranging the pouring device; 7, pouring concrete; 8, removing the pouring device; and 9, curing. The technical scheme has the advantages of shortening the construction period, saving manpower and effectively ensuring construction quality.

Owner:温州城建集团股份有限公司

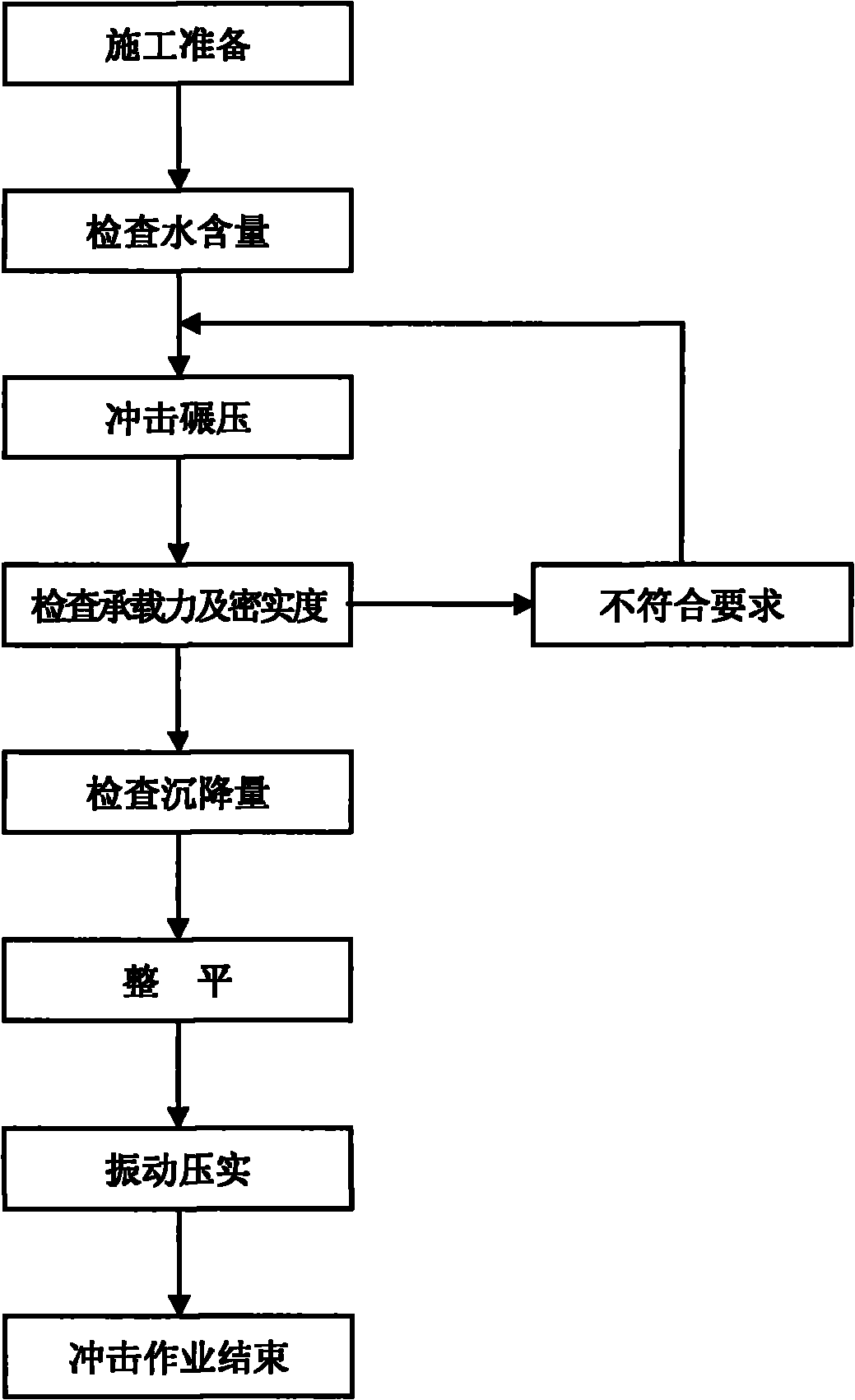

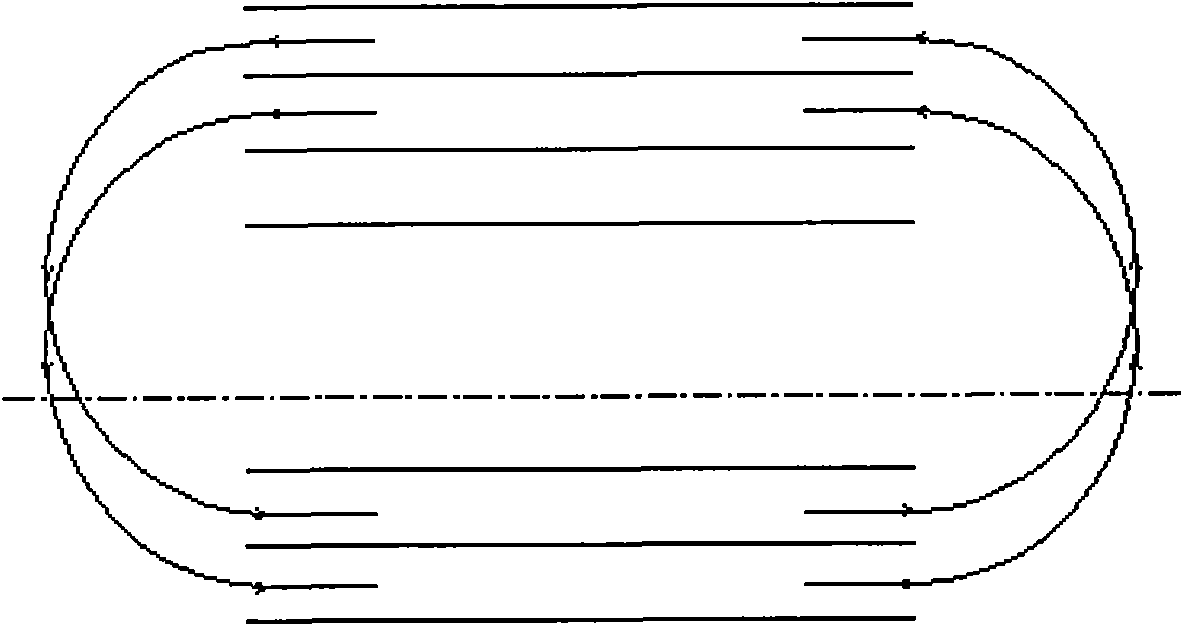

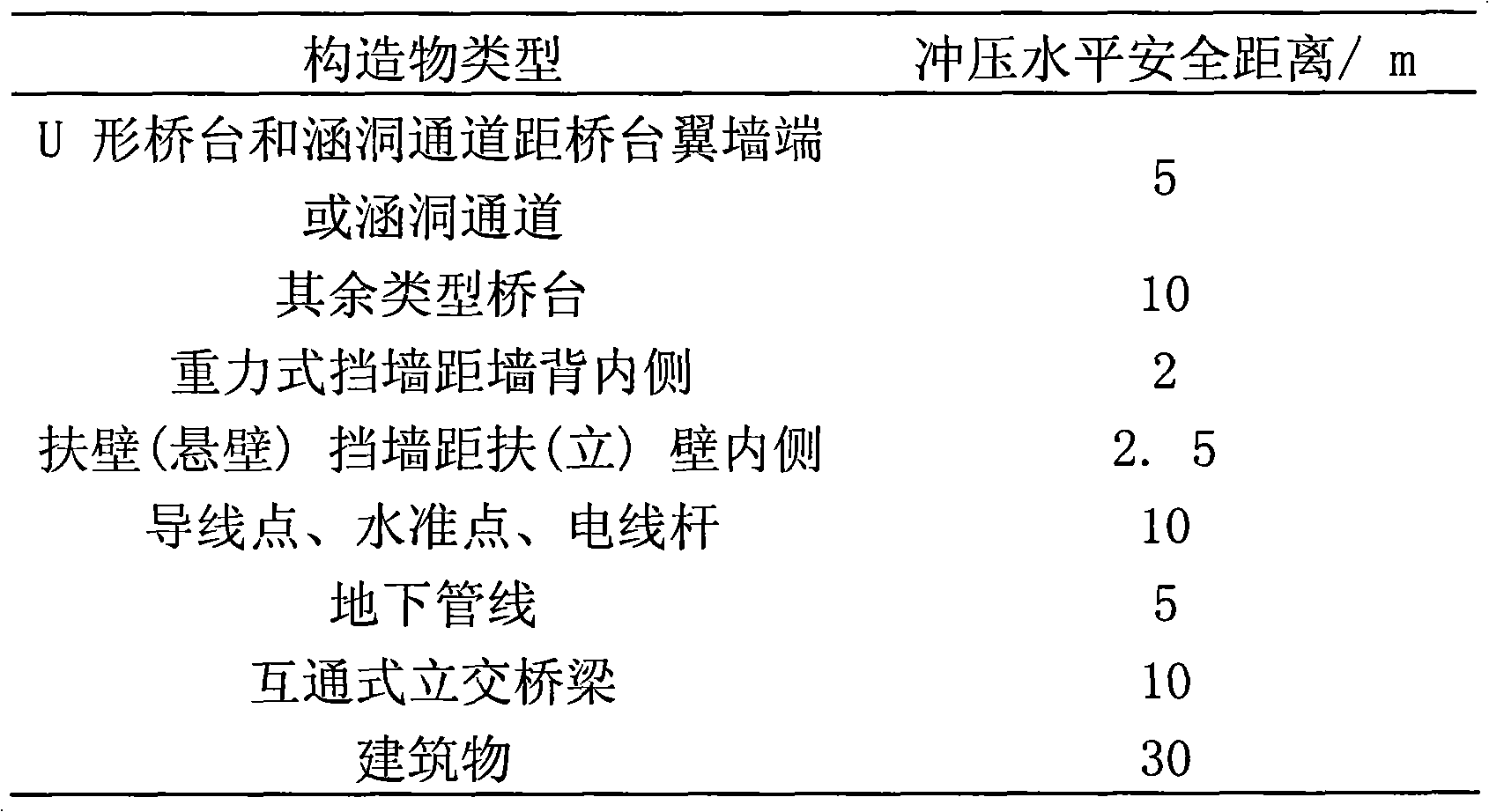

Construction method for processing aeolian sand roadbed base through impacting and grinding

ActiveCN101962928AImpact rolling is easy and fastImpact rolling saves labor and timeRoads maintainenceReplacement methodMoisture

The invention discloses a construction method for processing an aeolian sand roadbed base through impacting and grinding, which is characterized by comprising the following steps of: (1) preparing construction, i.e. carrying out measurement lofting, list clearing and levelling on an impacting and grinding segment; (2) checking moisture content; (3) impacting and grinding the roadbed base, i.e. controlling the longitudinal and horizontal movement of an impact-type road roller by an impact-type compactor which travels at constant speed; (4) checking the bearing capacity and the compactness of the roadbed base, i.e. detecting the compactness of a soil body by adopting two indexes, i.e. a compacting factor and a foundation factor, and using a sand replacement method; (5) checking the settlement amount of the roadbed base; (6) levelling the grinding surface of the roadbed base; and (7) carrying out vibrating compacting on the roadbed base. The invention applies the processing method impacting and grinding a roadbed to the construction of the aeolian sand roadbed base with large post-construction settlement amount caused by difficult compaction of the traditional construction process; and in addition, compared with the traditional processing method, i.e. a replacement method, a heavy-tamping method, and the like, the impacting and grinding method has the advantages of simpleness, convenience, fastness, labor and time saving, engineering cost reduction, and the like.

Owner:NO 1 ENG CO LTD OF CHINA RAILWAY 22ND CONSTR BUREAU +1

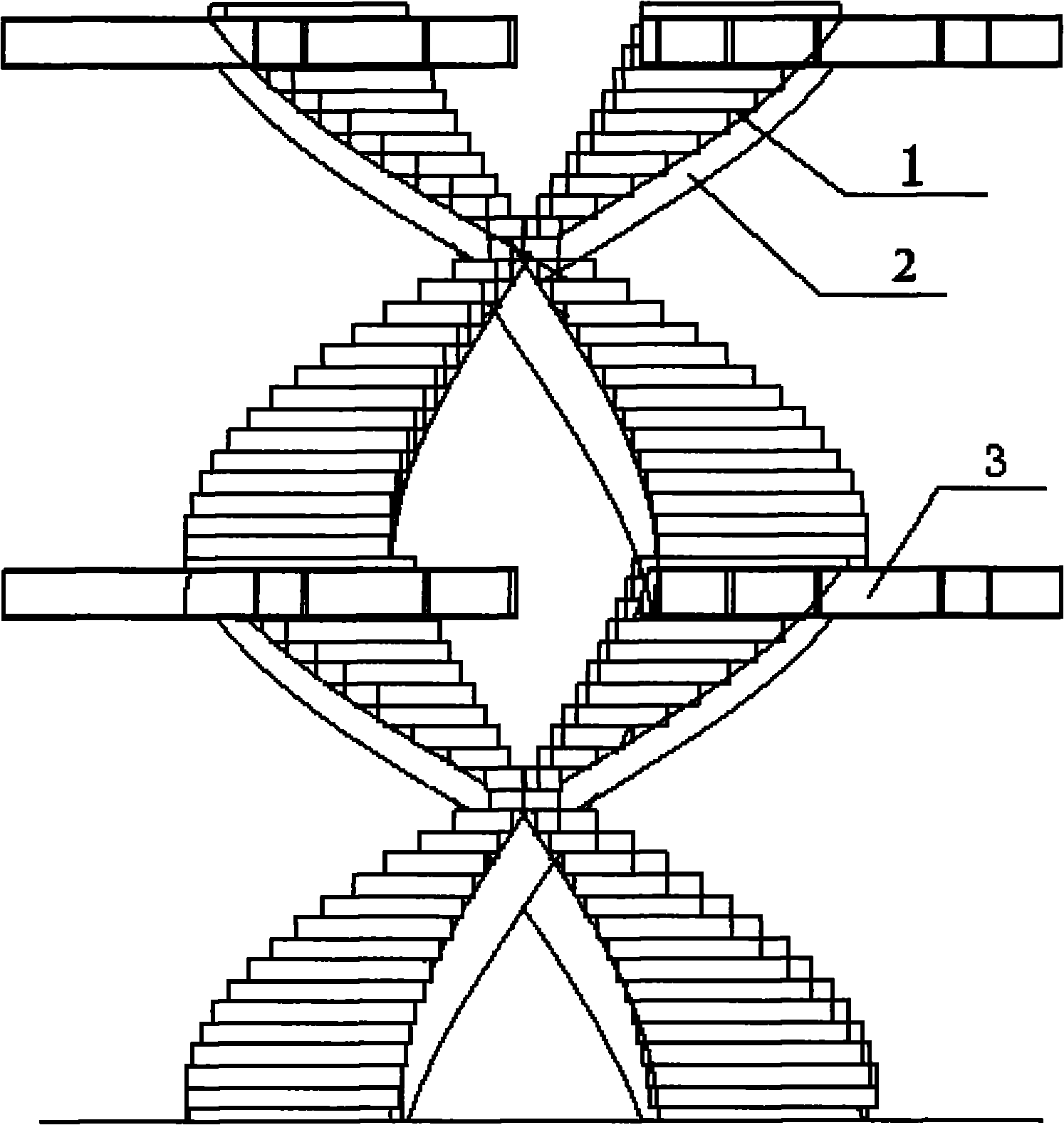

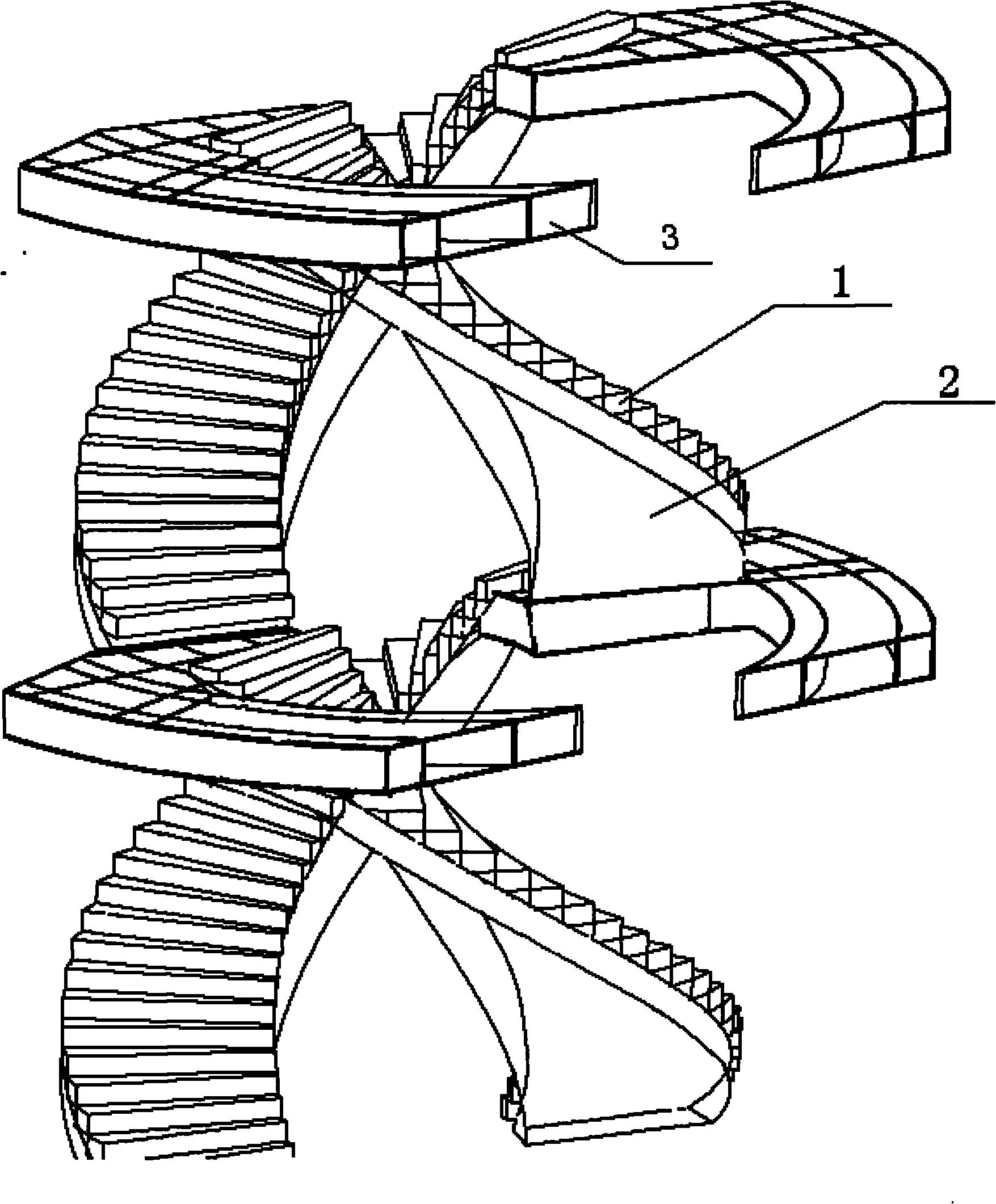

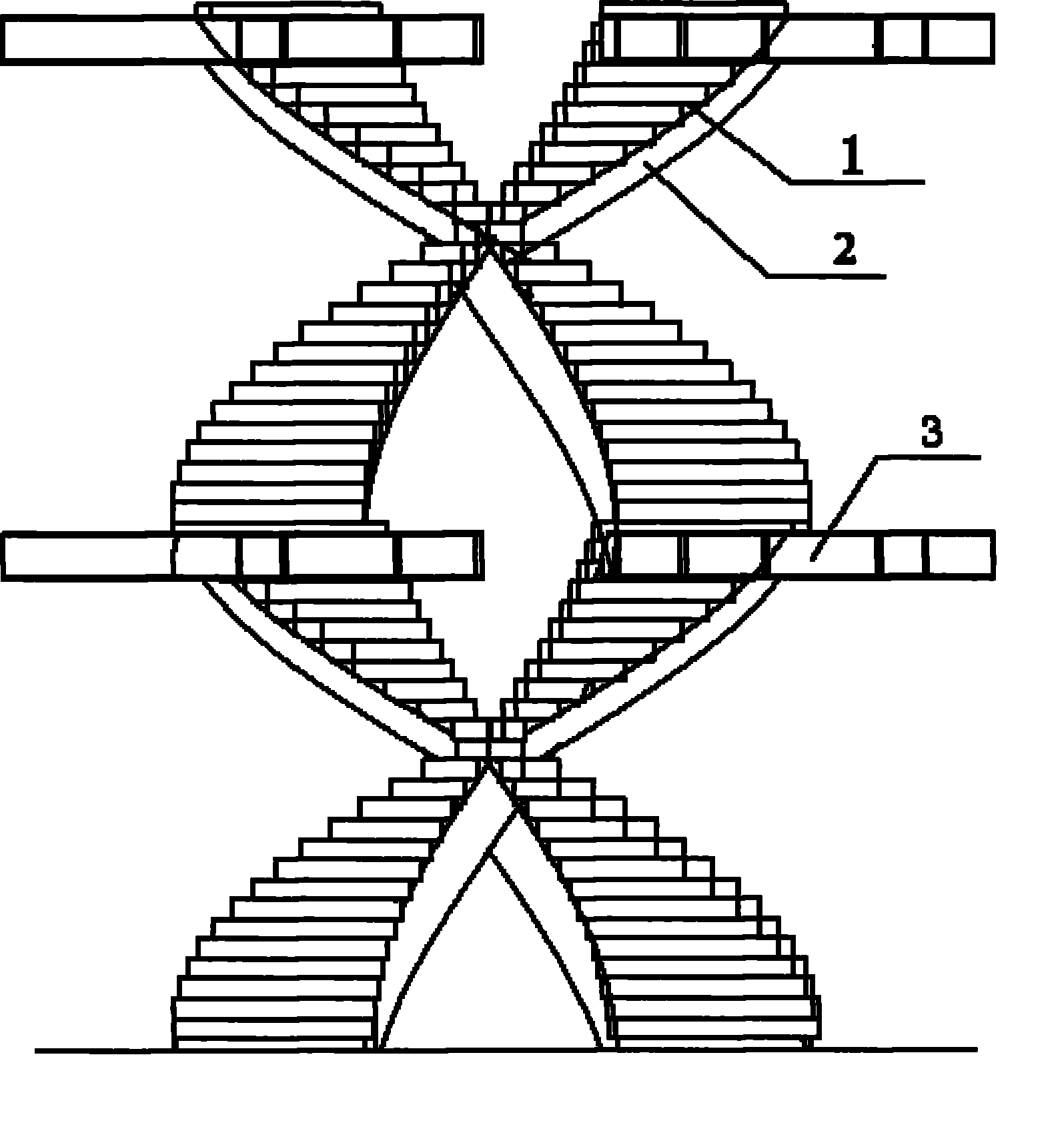

Method for manufacturing double-spiral steel staircase without middle standing pillar

The invention discloses a method for manufacturing a double-spiral steel staircase without a middle standing pillar. The staircase is formed by welding stairs, stair fixing layers and a staircase platform. The method comprises the following steps: carrying out the three-dimensional lofting by using a computer, so as to decompose the staircase into bent plate components; calculating the length, width, bending radius and planar cutting line position of each bent plate component; feeding and cutting materials by a numerical-control cutting machine; manufacturing the bent plate components; checking the bent plate components; manufacturing a jig; lifting the bent plate components onto the assembly jig, to check and locate the bent plate components, and welding the bent plate components into box-type components; lifting the stair fixing layers onto the assembly jig, so as to locate the stair fixing layers, then, lifting the staircase platform onto the stair fixing layers to mount and fix the staircase platform, and carrying out the integrity acceptance; numbering the stairs, the stair fixing layers and the staircase platform, then lifting the stairs, the stair fixing layers and the staircase platform off the assembly rig, sand-washing and coating; and carrying out the integral installation. By using the method for 'breaking up the whole into parts', the invention increases the accuracy of the single component, ensures the integrity of the double-spiral steel staircase and guarantees the overall quality.

Owner:JIANGSU HUNING STEEL MECHANISM

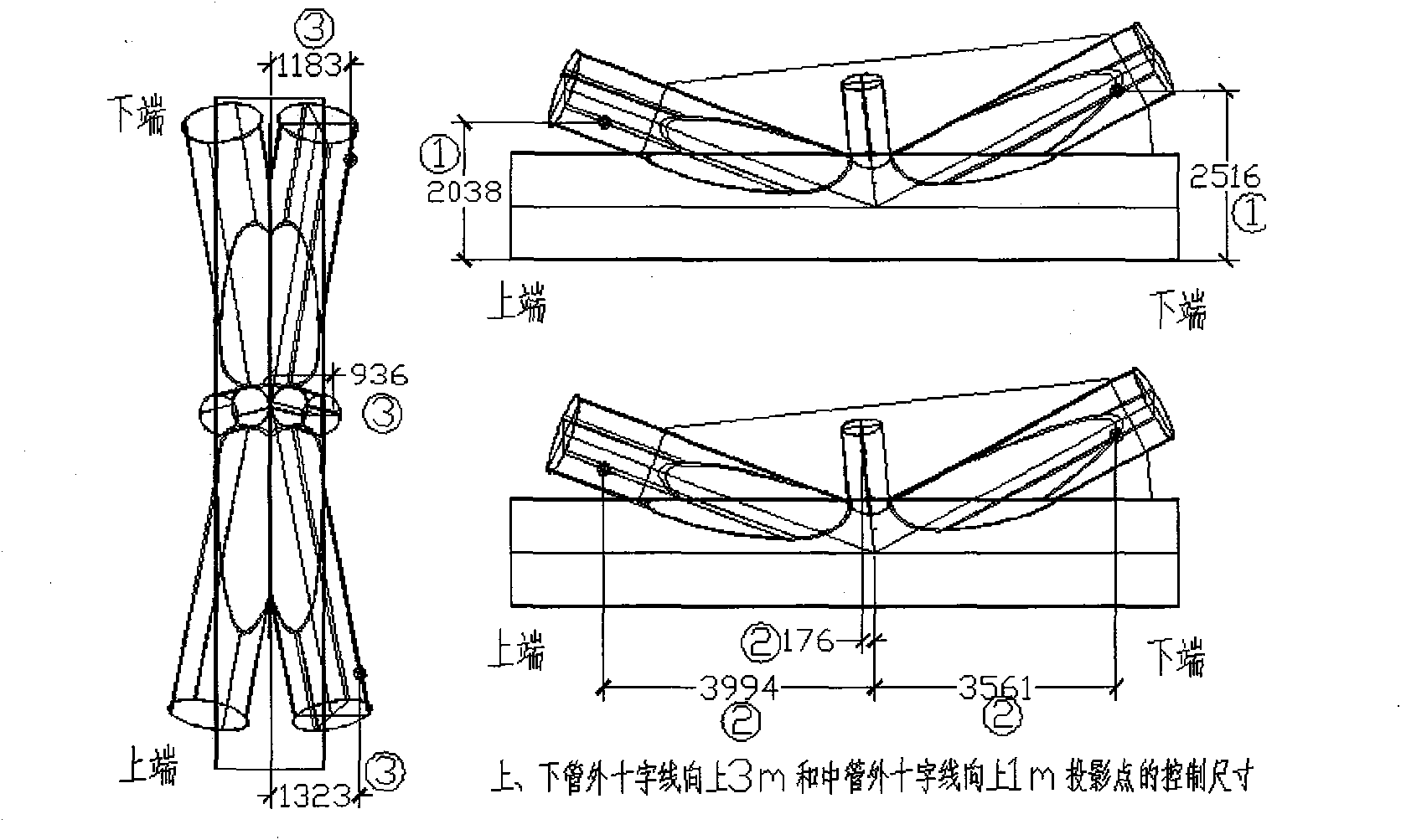

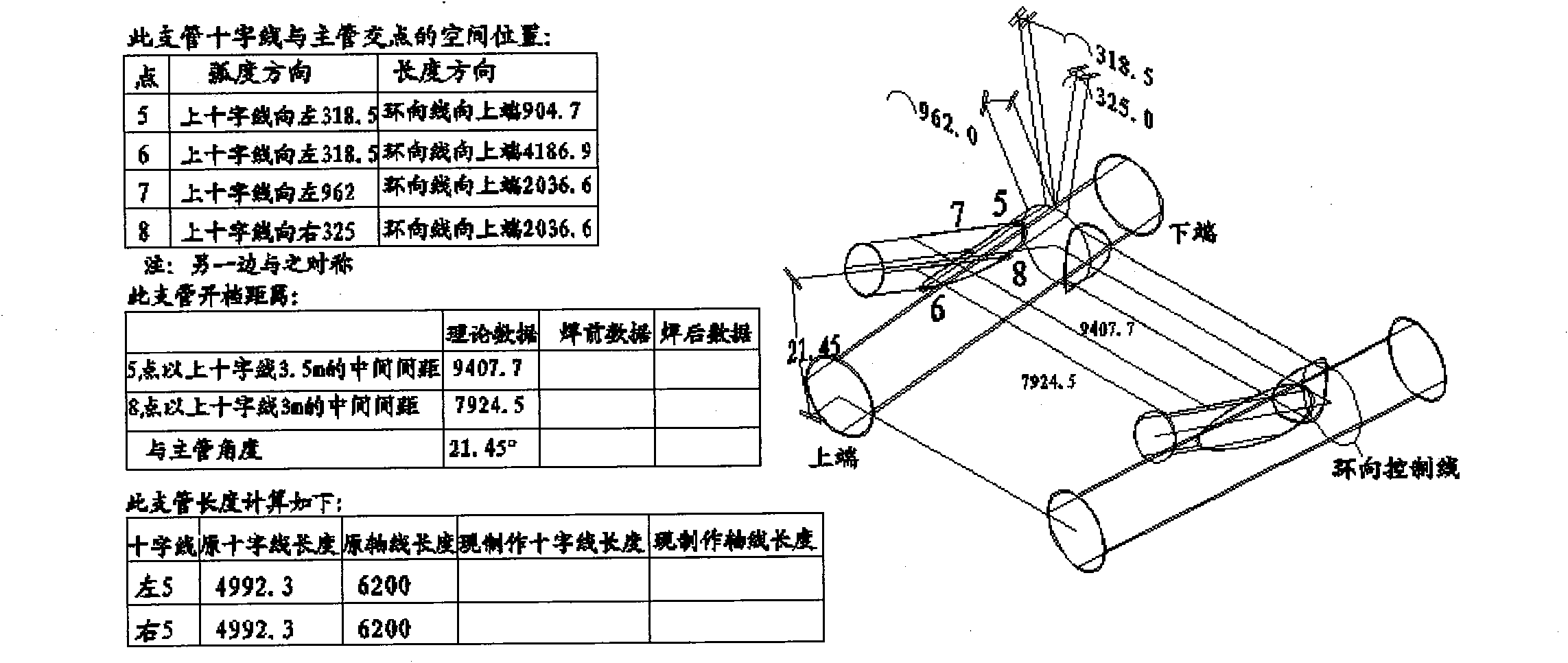

Construction method for manufacturing multi-pipe intersecting steel pipe component

InactiveCN101961810AImprove construction efficiencyEasy to weldPlasma welding apparatusGas flame welding apparatusSheet steelWeld line

The invention relates to a construction method for manufacturing a multi-pipe intersecting steel pipe component and belongs to the technical field of steel structure manufacturing. The construction method is characterized in that: 1) intersecting lines are drawn by adopting three-dimensional AutoCAD modeling and circumference bisecting tessellation line methods, thereby filling the blank that most intersecting line software in markets cannot solve the problems of complicated intersecting line forms that the axes of multi-pipe intersecting and intersecting steel pipes are not intersected on one point, the steep pipe is intersected with a steel plate and the like; 2) a sample figure is printed in a ratio of 1 to 1 instead of a conventional manual lofting method ; 3) relative space relations among cross lines of a main pipe and branch pipes are found out by a computer, a method combining projection, space angles and characteristic points and lines is used as a method for positioning manufacturing spaces, so that a great amount of investment in high-precision measurement instruments is saved, and the method is the low-cost, high-efficiency and high-precision method for measuring and positioning the spaces; and 4) a welding method is adopted for welding lines of large-diameter and small-angle intersecting lines by combining internal and external groove welding and internal and external welding, so the problem that the welding lines of the roots of the intersecting lines cannot be fully welded is solved.

Owner:王正怡 +2

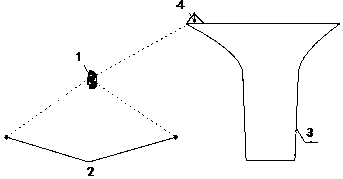

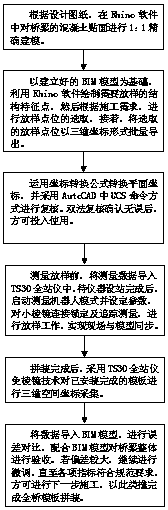

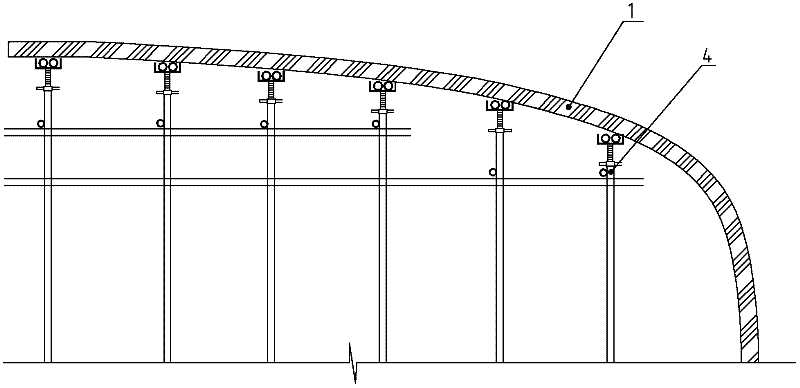

BIM technology-based three-dimensional bridge template assembling measurement method

PendingCN108363860AImprove assembly measurement accuracyImprove assembly efficiencyGeometric CADSpecial data processing applicationsData acquisitionWork content

The invention relates to a BIM technology-based three-dimensional bridge template assembling measurement method, and belongs to the technical field of engineering measurement. The method comprises thefollowing steps of: establishing a BIM model; exporting three-dimensional lofting data; converting a plane coordinate; carrying out site lifting by a measurement robot; carrying out data acquisition;and importing the data into the model to carry out recheck. The method has the benefits of saving the measurement data calculation time and error rate, improving the three-dimensional special-shapedbridge template assembling measurement precision, enabling site piece and dislocation to be lower than standard requirements, saving a lot of construction cost, simplifying the measurement work content and improving the template assembling efficiency.

Owner:NO 2 ENG CO LTD OF CCCC FIRST HIGHWAY ENG +1

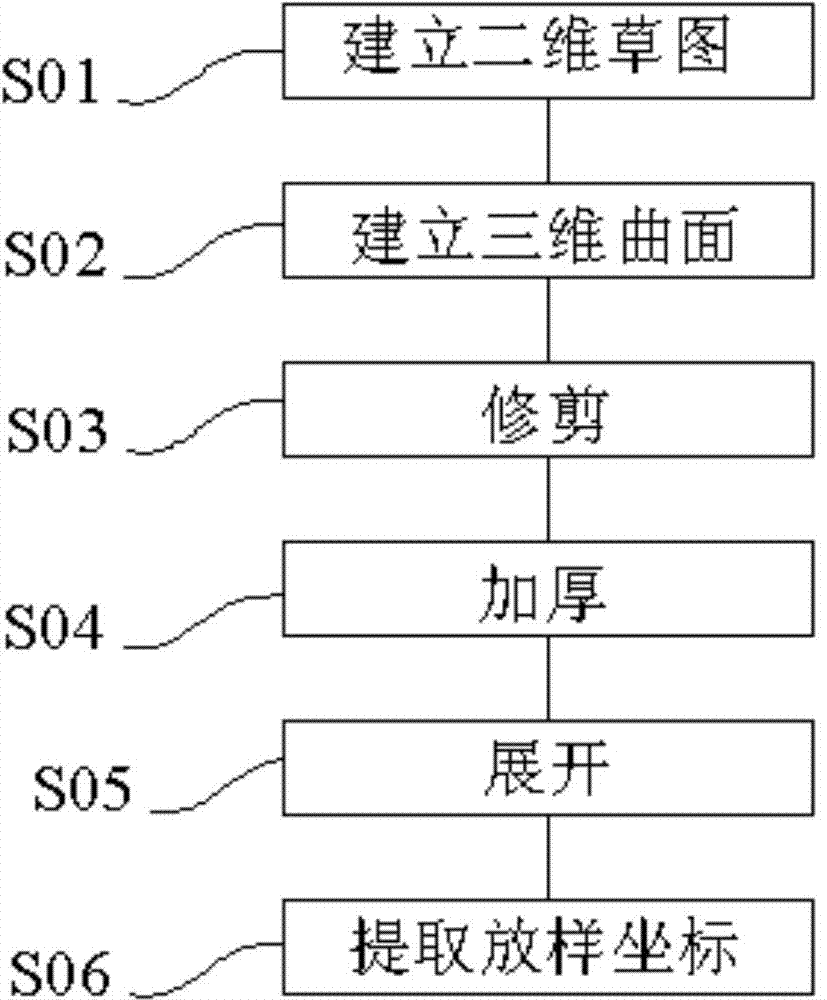

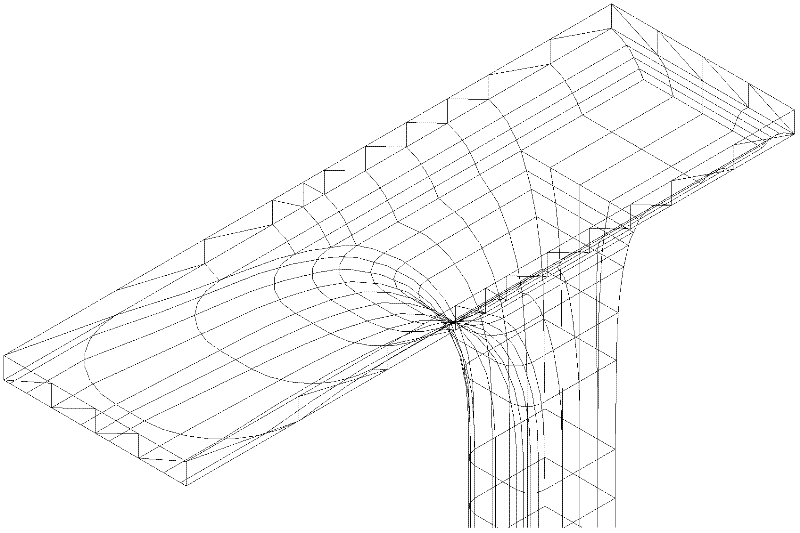

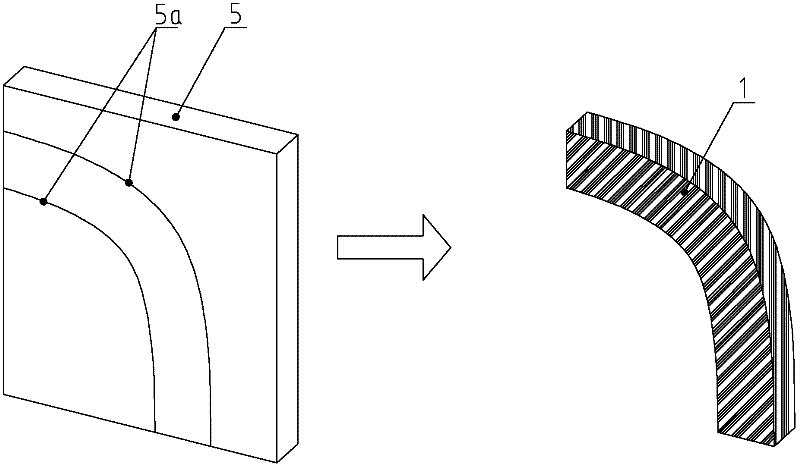

Operation method of three-dimensional modeling expansion and lofting coordinate generation based on Autodesk inventor software

ActiveCN104765936AReduce duplicationFully automatedSpecial data processing applicationsEconomic benefitsDimensional modeling

The invention relates to an operation method of three-dimensional modeling expansion and lofting coordinate generation based on Autodesk inventor software. The method at least comprises the following steps that S01, a two-dimensional rough draft is built; S02, a three-dimensional curved surface is built; S03, trimming is performed; S04, thickening is performed; S05, expansion is performed; S06, lofting coordinates are extracted. The method has the advantages that the expanded view repeated drawing and lofting procedures are reduced after the operation method is adopted, automation of the discharging process of a numerically controlled cutting machine is achieved, the manufacturing precision is high, product performance is stable, the cost is reduced, economic benefits are improved, and the labor cost is reduced by 3% based on manual lofting time cost.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD

Method for making spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood

The invention discloses a method for making a spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood. The method comprises the following steps of: (1) establishing a three-dimensional model of a spatial multi-curved-surface as-cast finish concrete structure; (2) simulating concrete force analysis in a computer, computing a back lining keel distance, and arranging a bottom framework; (3) introducing three-dimensional coordinate data of the three-dimensional model into an electronic total station for field lofting, and lofting an arc-shaped locus intersecting with a spatial curved surface; (4) lofting a wood back lining keel according to curves at different height sections of a building drawing; (5) paving curved plywood on the back lining keel for serving as a bottom framework; and (6) paving thin plywood on an opposite surface between the bottom framework and as-cast finish concrete for serving as a panel. The method for making the spatial multi-curved-surface as-cast finish concrete stay in place formwork by using plywood provided by the invention has the advantages of low manufacturing cost, convenience and rapidness for constructing, flat, smooth, attractive surface of the made as-cast finish concrete structure and the like, and has remarkable economic benefit and social benefit.

Owner:广州市第三建筑工程有限公司

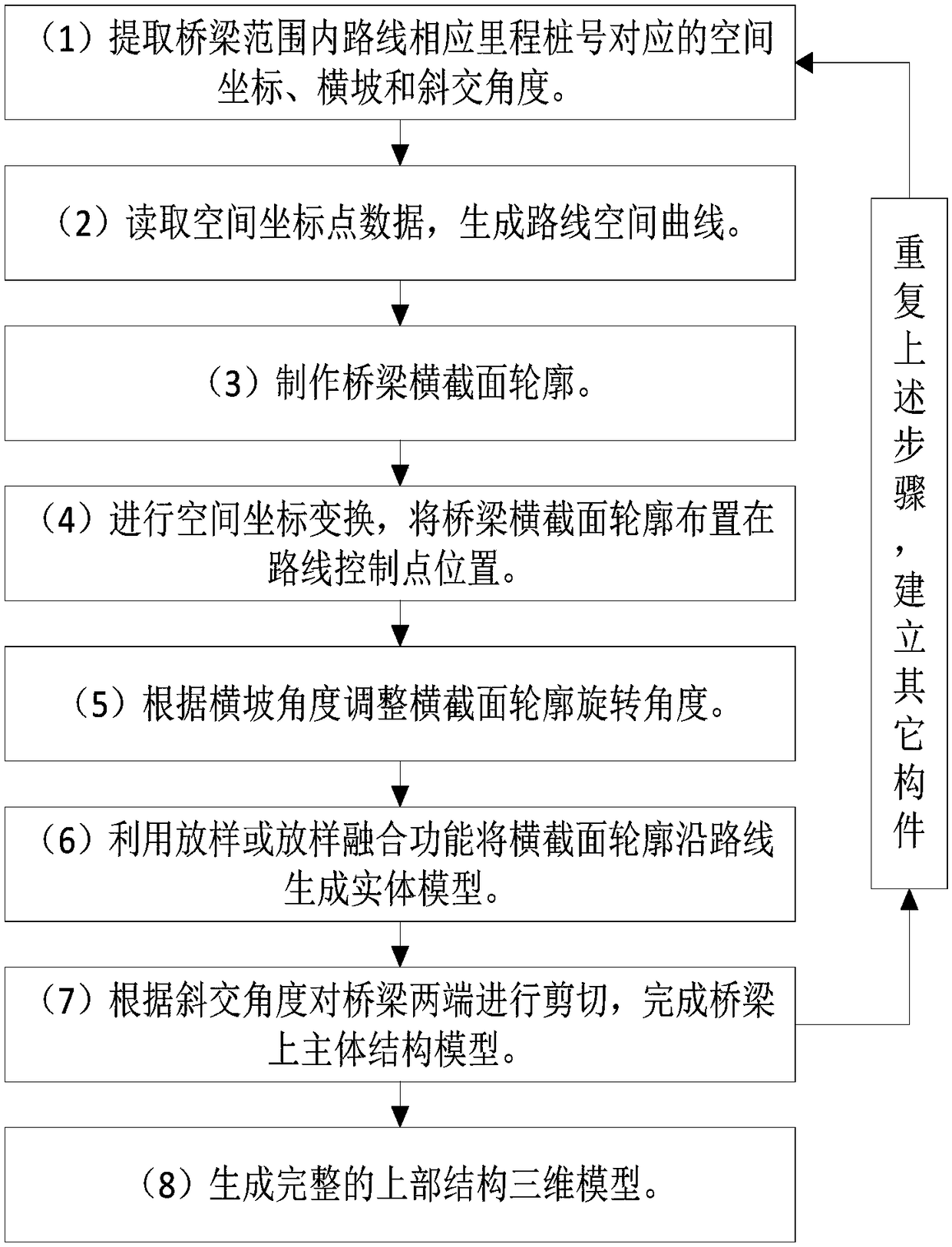

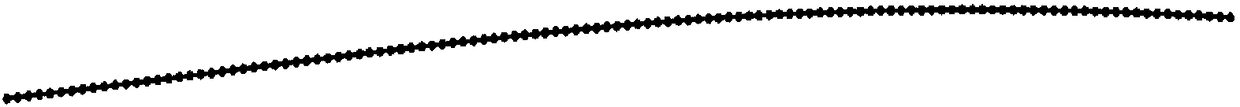

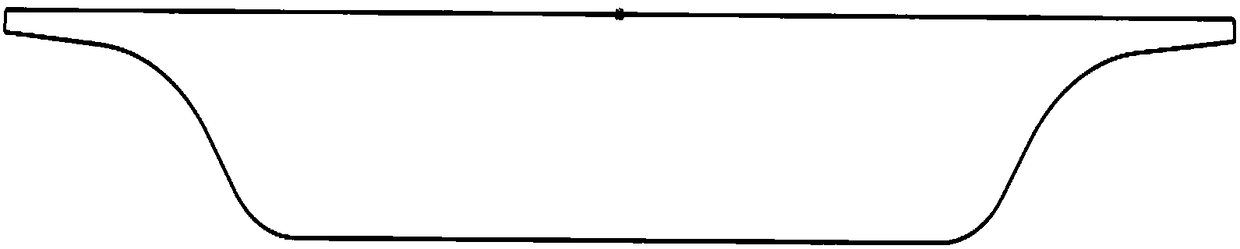

BIM parametric design method for bridge superstructures

PendingCN108304631AMake up for the inability to build such a complex spatial structure modelClear thinkingGeometric CADDesign optimisation/simulationBridge engineeringOffset distance

The invention discloses a BIM parametric design method for bridge superstructures, and relates to the field of bridge engineering design, construction and detection. The method comprises the followingsteps of: (1) extracting a space coordinate, a cross slope angle and an oblique crossing angle corresponding to a mileage stake mark corresponding to a path in a bridge range; (2) reading space coordinate point data and generating a path space curve; (3) making a bridge cross section profile; (4) carrying out space coordinate transformation, and arranging the bridge cross section profile at a path control point position; (5) adjusting a rotation angle of the cross section profile according to the cross slope angle; (6) generating the cross section profile into an entity model along the path by utilizing a lofting or lofting fusion function; (7) shearing two ends of the bridge according to the oblique crossing angle so as to complete a bridge upper major structure model; and (8) repeatingthe steps (1) to (7) according to offset distances between components such as a bridge deck system and the like and a road axis so as to generate a complete model. According to the method, the difficulty of establishing three-dimensional models of bridge special-shaped space structures is solved, and parameterization is realized by utilizing data reading and visual programming, so that the precision and efficiency are greatly improved.

Owner:北京市政路桥锐诚科技有限公司

Method for detecting test pile stress and strain of PHC (Prestressed High-Strength Concrete) pipe pile

The invention discloses a method for detecting a test pile stress and strain of a PHC (Prestressed High-Strength Concrete) pipe pile, and the method comprises the following specific steps of: 1) lofting: marking the positions of each detection point and routing on the surface of the PHC pipe pile; 2) grooving: grooving the PHC pipe pile along the lofting; 3) connecting line: connecting optical fiber grating sensors arranged according to the predetermined order by an optical fiber to form a detection line; 4) paying-off and testing: putting the detection line in the marked position in the groove and testing whether the optical fiber grating sensors work normally; 5) fixed routing: putting the detection line in the groove in a position which should be at least 5 mm lower than the surface of the PHC pipe pile; 6) glue preparation: pouring glue in the groove, and pasting the optical fiber grating sensors, thereby fixing the sensors; 7) detection: performing stress and strain detection by means of the optical fiber grating sensors and sending out the detection data through the optical fiber. According to the method, the advantages of the optical fiber grating sensors are utilized and combined with the characteristics of the armored optical fiber and a detection line is formed integrally, and the method has the advantages of simplicity, feasibility, high efficiency and the like.

Owner:北京和理监测技术有限公司

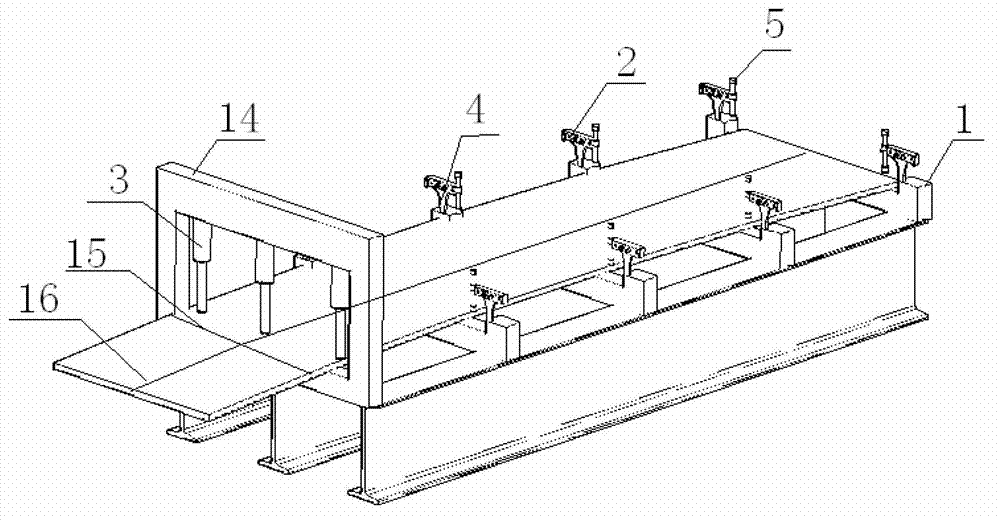

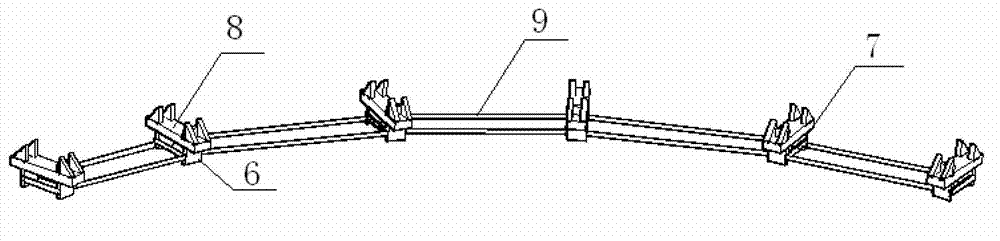

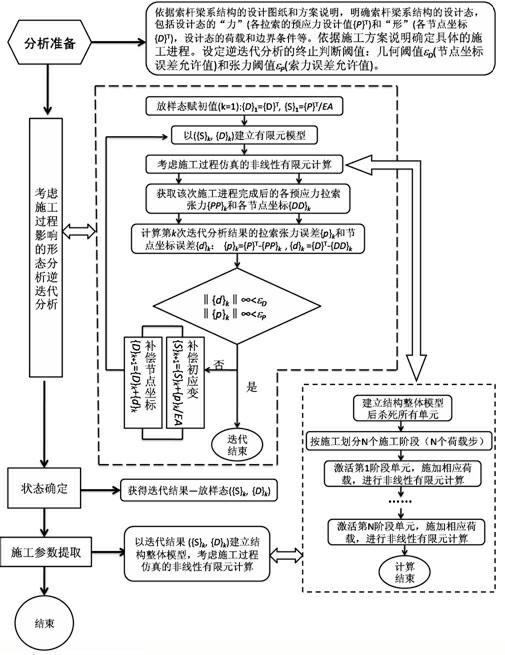

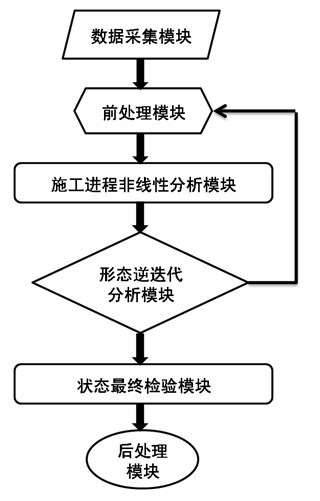

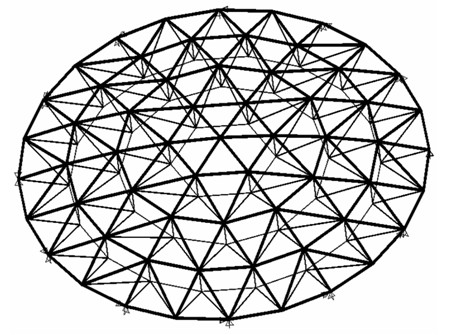

Morphological analysis inverse iteration method for determining space structural lofting states of cable-strut-beam system

InactiveCN102622485ASolving Morphological Analysis ProblemsGuaranteed accuracySpecial data processing applicationsSpatial structureEngineering

The invention provides a morphological analysis inverse iteration method for determining space structural lofting states of a cable-strut-beam system. The method includes: using a nonlinear finite element inverse iteration method with construction process considered, using an inactivating-activating unit method to positively simulate construction process influences based on assumption of the lofting similar state, using a morphological compensation method to inversely correct a lofting state geometrical configuration and pretension scheme, gradually astringing a positive tension analysis result of a lofting similar state to a preset design state through positive-inverse loop iteration, and finally obtaining a precise lofting state geometrical configuration and pretension control scheme.

Owner:SOUTHEAST UNIV

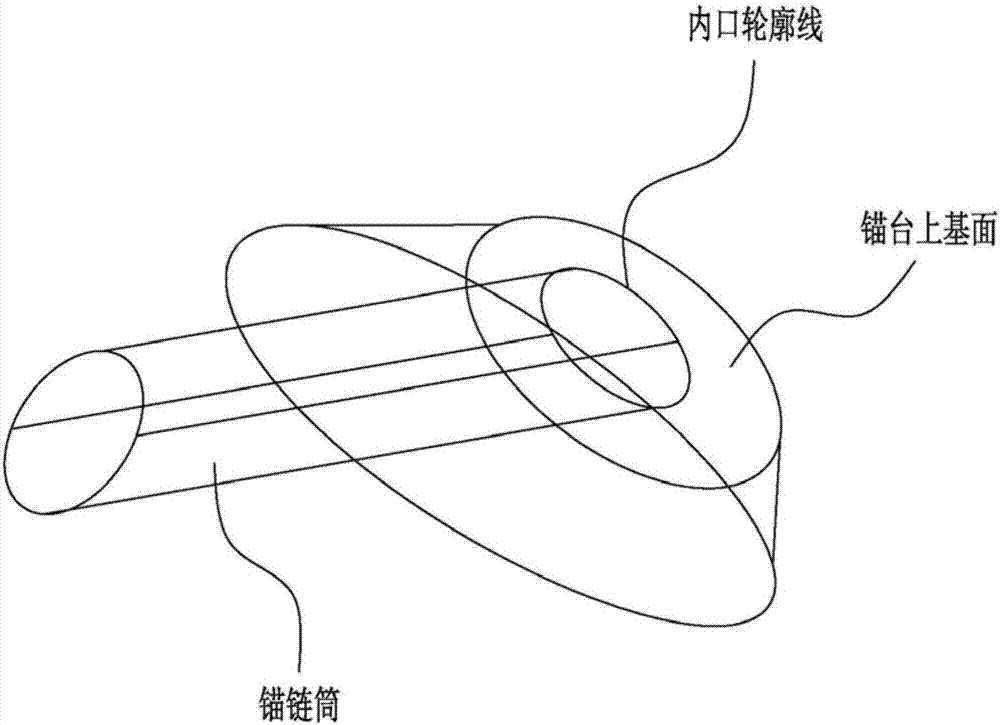

Large-scale anchor chock and anchor mouth lofting design method

ActiveCN108001614ASolve efficiency problemsSolve the accuracy problemVessel designingThree-dimensional spaceDimensional modeling

The invention provides a large-scale anchor chock and anchor mouth lofting design method. According to the lofting design method, a three-dimensional space lofting principle is used for completing theoretical model construction, and a specific three-dimensional projection lofting method is adopted to complete the lofting of an intersecting line of the anchor chock and a ship hull plate and a contour line of an anchor chock upper basal plane; and at the same time, a tangency included angle of the anchor mouth and the anchor chock and a hawse pipe is obtained, a contour line of the anchor mouthis drawn, a three-dimensional shaded surface of the anchor chock and anchor mouth is constructed, and three-dimensional modeling work of the hawse pipe, the anchor chock and the anchor mouth is finished. The large-scale anchor chock and the anchor mouth lofting design method solves the problem that the lofting of anchor chocks and anchor mouths of various types of ships is low in efficiency and poor in precision, precision data of feeding, machining, and assembly locating are provided for a site, the work of field proofing and adjustment is simplified, and the installation efficiency and precision of the anchor chocks and the anchor mouths are enhanced.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Method for reinforcing working surface of loose and soft coal bed by utilizing nonmetal grouting anchor cable

The invention discloses a method for reinforcing a working surface of a loose and soft coal bed by utilizing a nonmetal grouting anchor cable. The grouting anchor cable is made of a high-strength composite material carbon fiber / glass fiber. The reinforcement of the working surface of the loose and soft coal bed is realized through the processes of surveying and lofting, drilling holes in a coal body, manufacturing and arranging the grouting anchor cable, sealing an anchor cable hole, and grouting chemical grout in the hole and the like. As the grouting anchor cable is made of nonmetal materials, no sparks are generated when a coal-winning machine cuts, and the grouting anchor cable has the characteristics of flame retardancy, anti-static electricity, safety and reliability in use and hightensile strength, higher breaking force, light weight, and capability of being bent and coiled, and is higher than steel and convenient in transportation; and by utilizing the method, deep hole reinforcement and support on the working face can be carried out under the condition that the coal face can not be supported by using a metal anchor cable, the grouting support operation can be carried outon the working surface on site by combining a chemical grouting method, and the coal body of the working surface can be reinforced at the upper and lower tunnels of the working face by combining the chemical grouting in advance.

Owner:HEBEI TONGCHENG MINING TECH

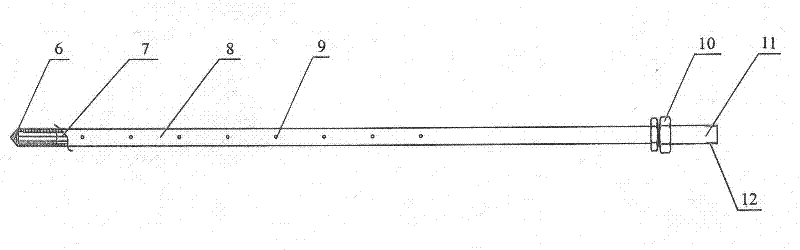

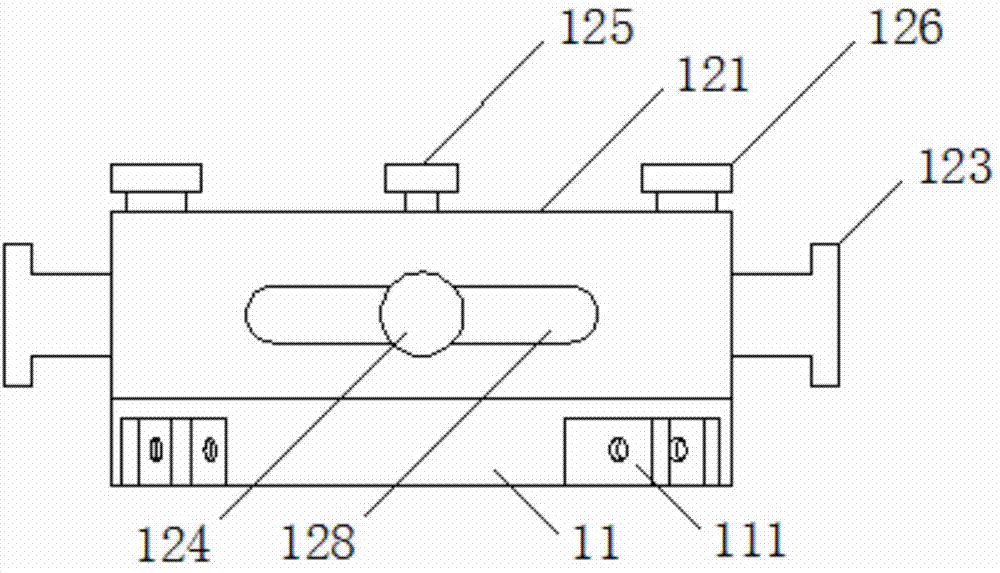

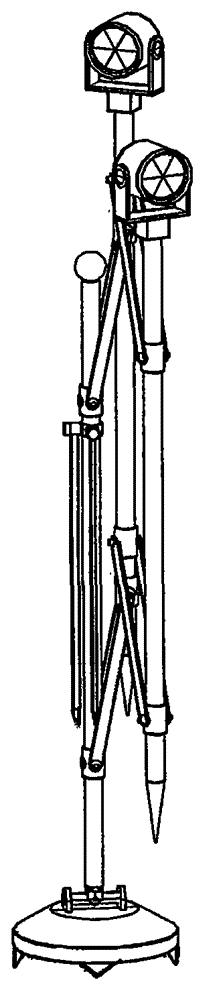

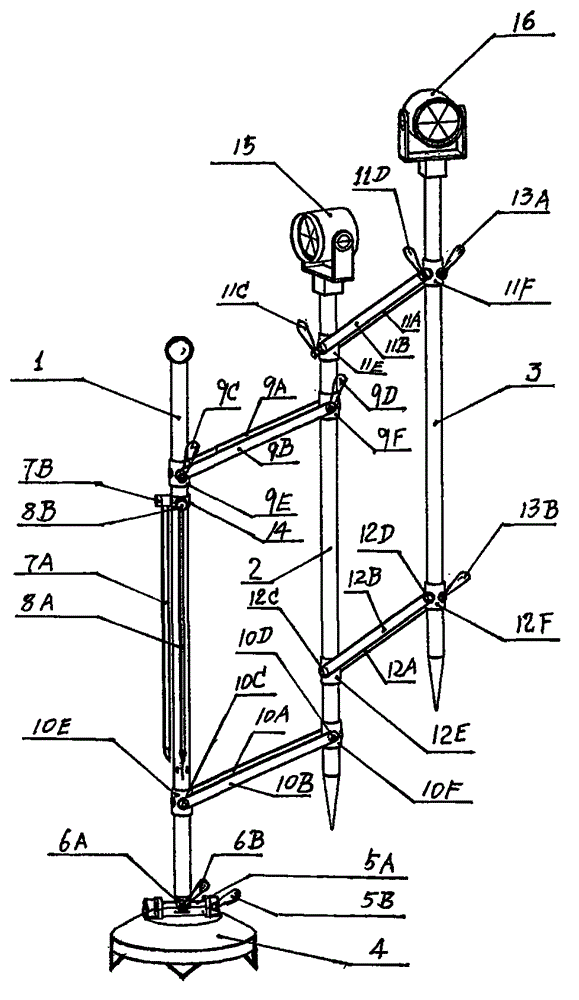

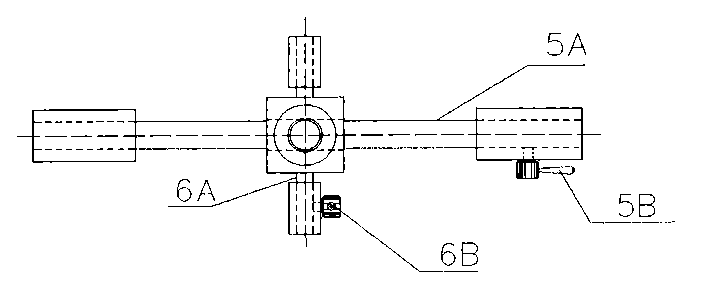

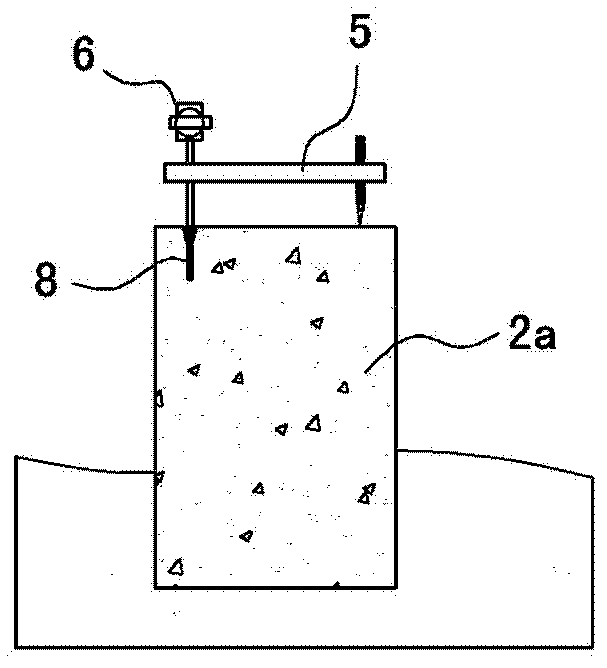

Adjustable precise lofting device

InactiveCN103528573AShorten the timeImprove comfortMeasuring points markingMeasurement pointDeformation monitoring

The invention discloses an adjustable measurement point aligning and lofting device, i.e. an adjustable precise lofting device. The adjustable precise lofting device consists of a substrate, upright tubes, a connecting sleeve, a connecting rod, a plurality of regulating and braking handles and connection bolts. The device adopts an original combined structure of a cross-shaped linkage shaft and a dangling pointer to realize the quick alignment of each upright tube, and the upright tubes can be freely regulated between left and right, between front and back and between top and bottom. As a point aligning tool, the device can be used for lightly, visually and stably aligning the point. As a lofting tool, the device can be cooperated with a total station to quickly and accurately position a surveying point, and also can be cooperated with a satellite positioning receiver to serve as a moving station, so as to realize GPS-RTK (global positioning system- real time kinematic) quick lofting. The adjustable precise lofting device has the advantages of convenience in carrying, flexibility in operation, visual point alignment and high lofting speed, can be widely applied to the fields such as the control measurement, the construction lofting and deformation monitoring of industrial and civil buildings, urban mass transit engineering, high speed railways and the municipal engineering, the labor intensity is lightened, and the lofting measurement efficiency and precision can be improved.

Owner:刘晓梅

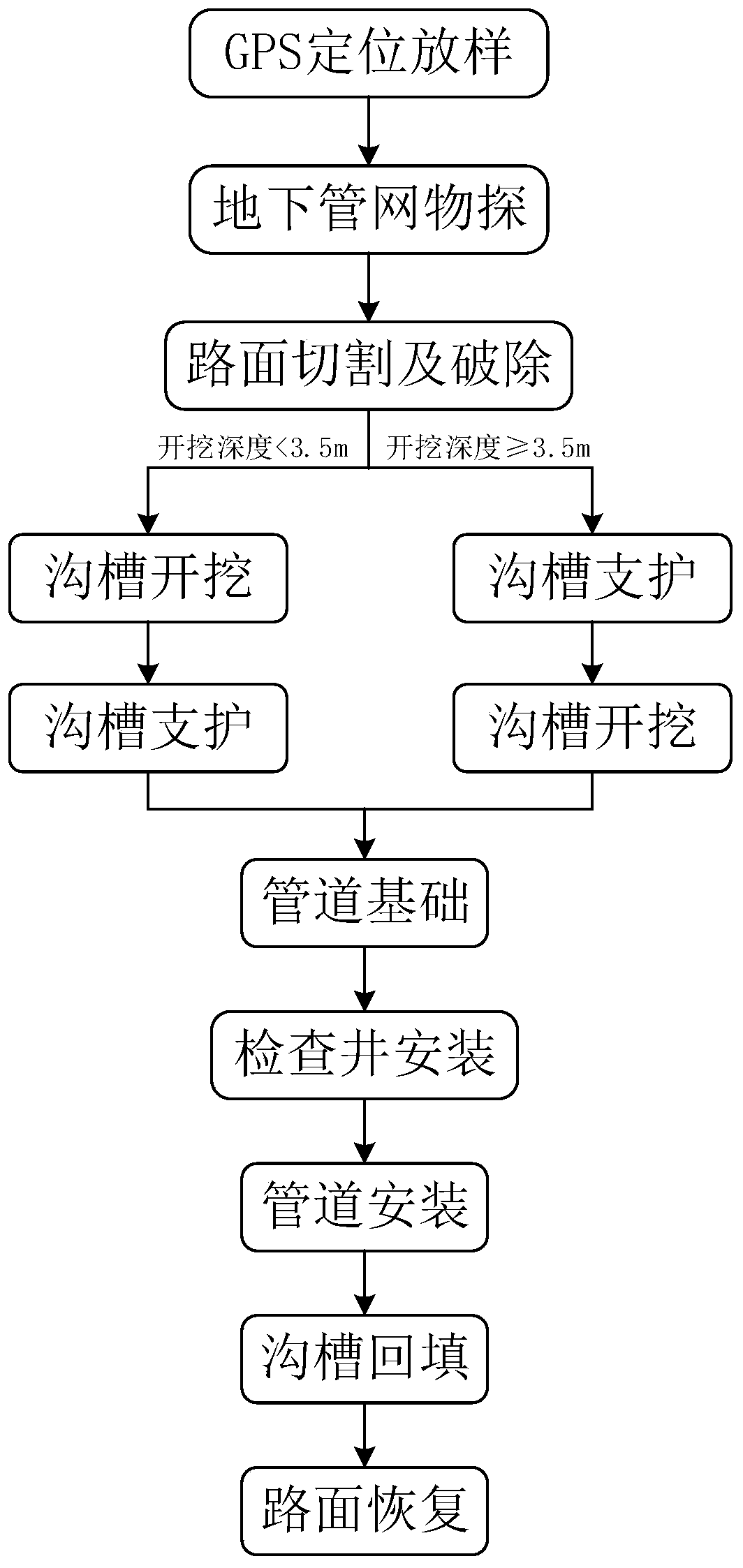

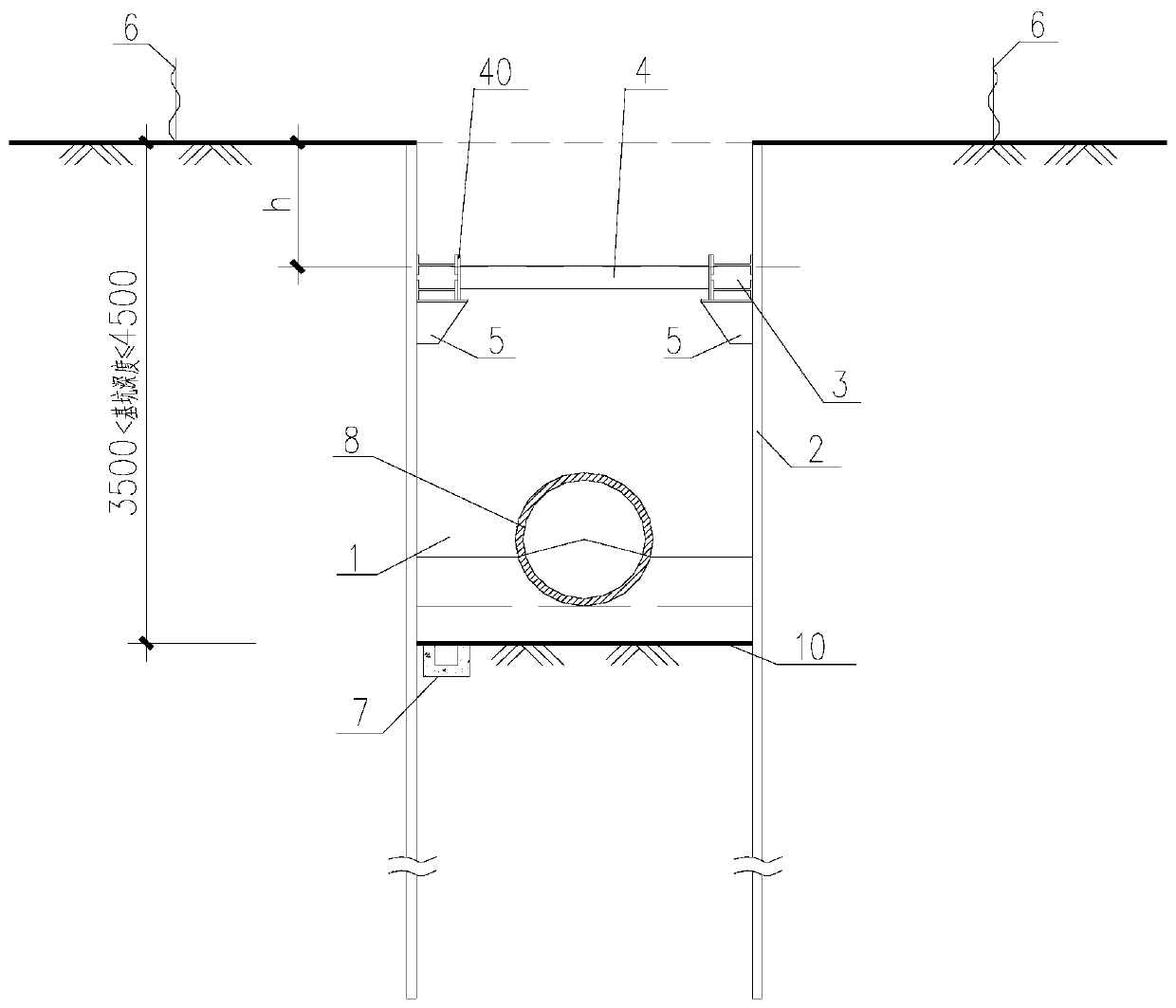

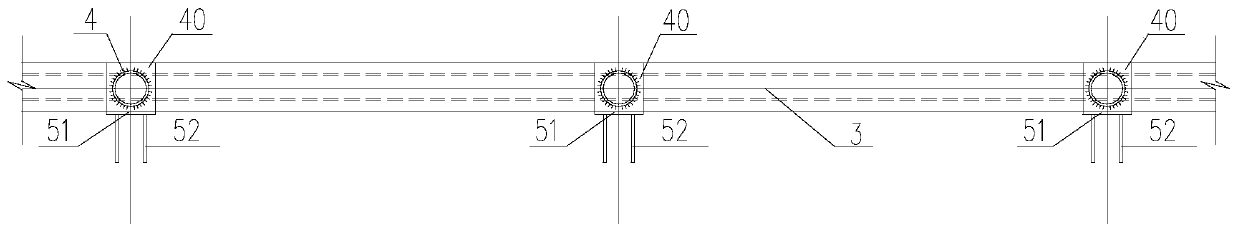

Construction method of sewage pipeline

ActiveCN110306616AReduce damageEnsure construction efficiencyArtificial islandsSoil-shifting machines/dredgersLine tubingRoad surface

The invention discloses a construction method of a sewage pipeline. The construction method comprises the following processes of GPS positioning and lofting, pavement cutting and breaking, pipeline groove supporting and excavation, pipeline foundation construction, inspection well mounting, pipeline mounting, pipeline groove backfilling, and pavement recovery. The pavement cutting and breaking process comprises the following steps of pipeline axis measuring and lofting, pavement cutting edge line marking, pavement cutting, and pavement breaking. When the pipeline groove supporting and excavation process is carried out, steel plate pile supporting is adopted when the depth is larger than 3.5 m. The pipeline foundation construction process comprises the following steps of foundation levelingand compacting, cushion layer paving, manual primary leveling, cushion layer compacting, and compactness detecting. The inspection well mounting process comprises the following steps of well bottom elevation rechecking, well bottom foundation checking, well chamber hoisting and splicing, and inspection well and pipeline connecting. The pipeline mounting process comprises the following steps of pipeline hoisting and manual mounting, pipeline axis positioning, pipeline joint cleaning, cutting, elevation and positioning retesting, and pipeline hot-melt welding or socket welding. According to theconstruction method, the construction period is greatly shortened, and the engineering efficiency is improved.

Owner:CCCC SHANGHAI DREDGING

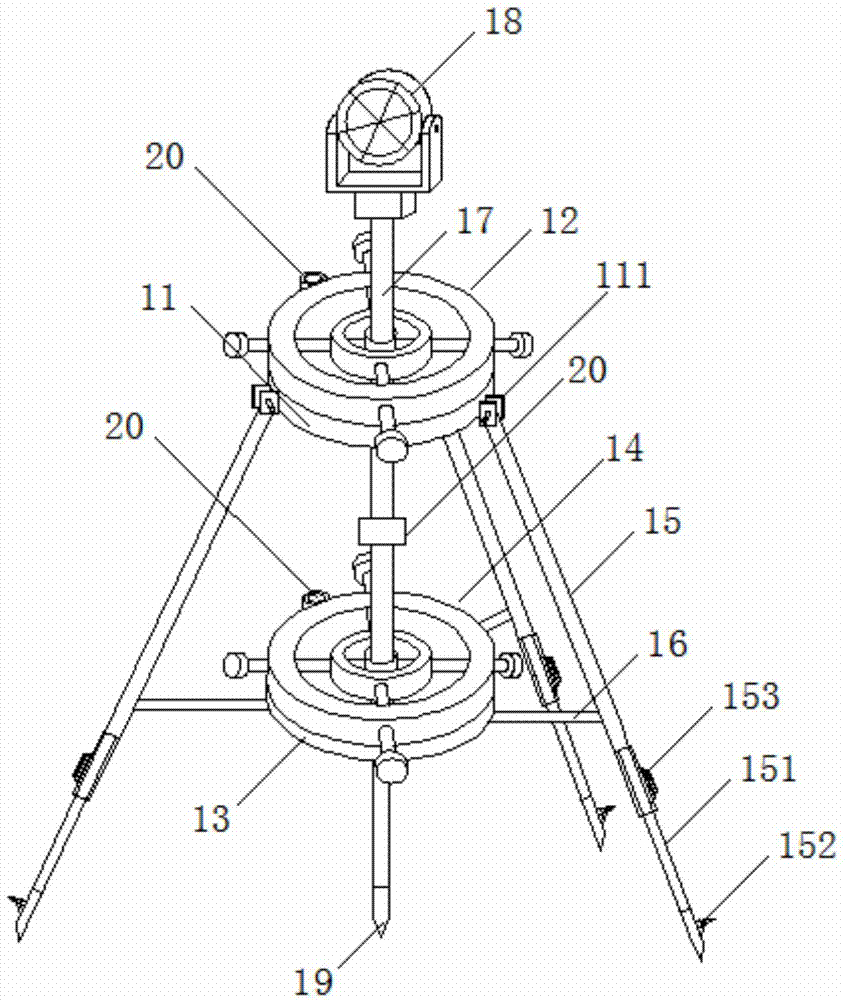

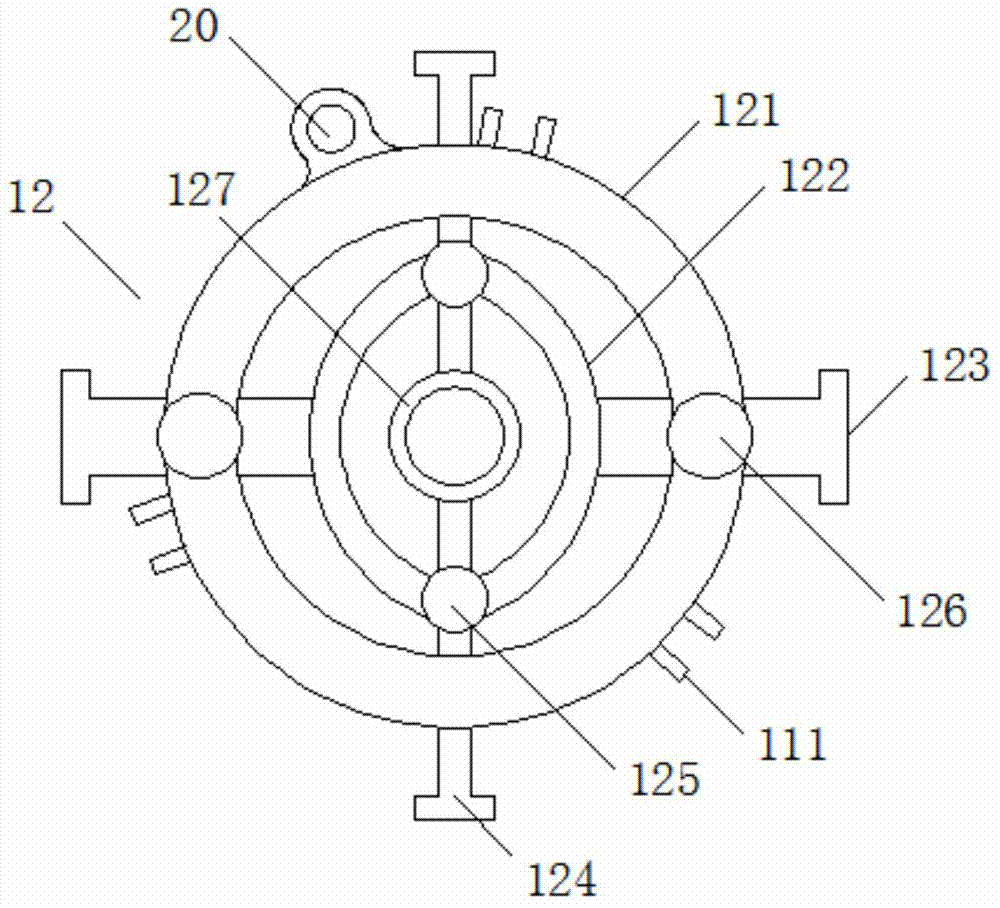

Adjustable precise lofting device

InactiveCN102944228AQuick 2DRapid 3D LoftingMeasuring points markingMeasurement pointDeformation monitoring

The invention discloses an adjustable measurement point aligning and lofting device, i.e. an adjustable precise lofting device. The adjustable precise lofting device consists of a substrate, upright tubes, a connecting sleeve, a connecting rod, a plurality of regulating and braking handles and connection bolts. The device adopts an original combined structure of a cross-shaped linkage shaft and a dangling pointer to realize the quick alignment of each upright tube, and the upright tubes can be freely regulated between left and right, between front and back and between top and bottom. As a point aligning tool, the device can be used for lightly, visually and stably aligning the point. As a lofting tool, the device can be cooperated with a total station to quickly and accurately position a surveying point, and also can be cooperated with a satellite positioning receiver to serve as a moving station, so as to realize GPS-RTK (global positioning system- real time kinematic) quick lofting. The adjustable precise lofting device has the advantages of convenience in carrying, flexibility in operation, visual point alignment and high lofting speed, can be widely applied to the fields such as the control measurement, the construction lofting and deformation monitoring of industrial and civil buildings, urban mass transit engineering, high speed railways and the municipal engineering, the labor intensity is lightened, and the lofting measurement efficiency and precision can be improved.

Owner:北京中土凯林勘测设计有限公司

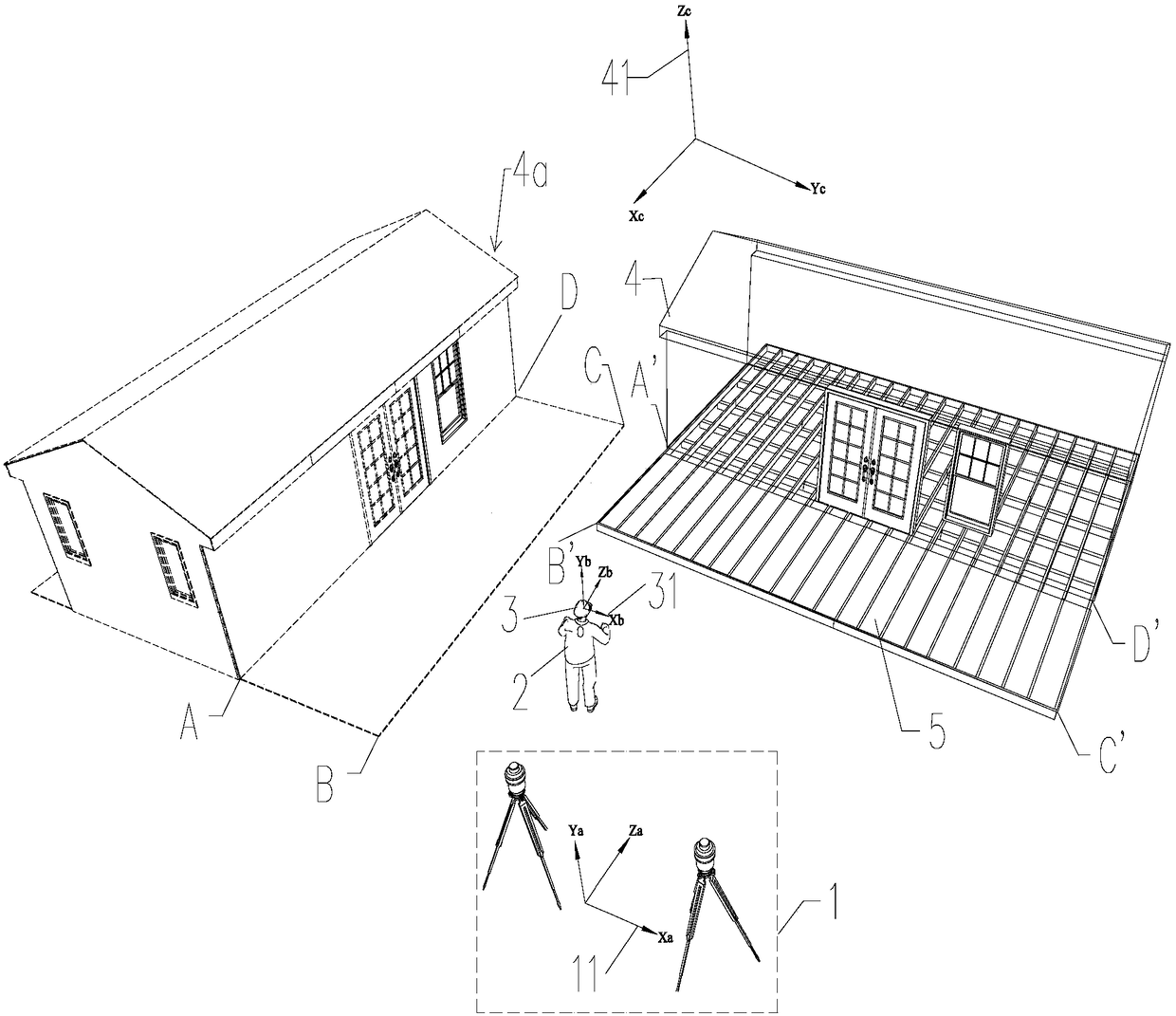

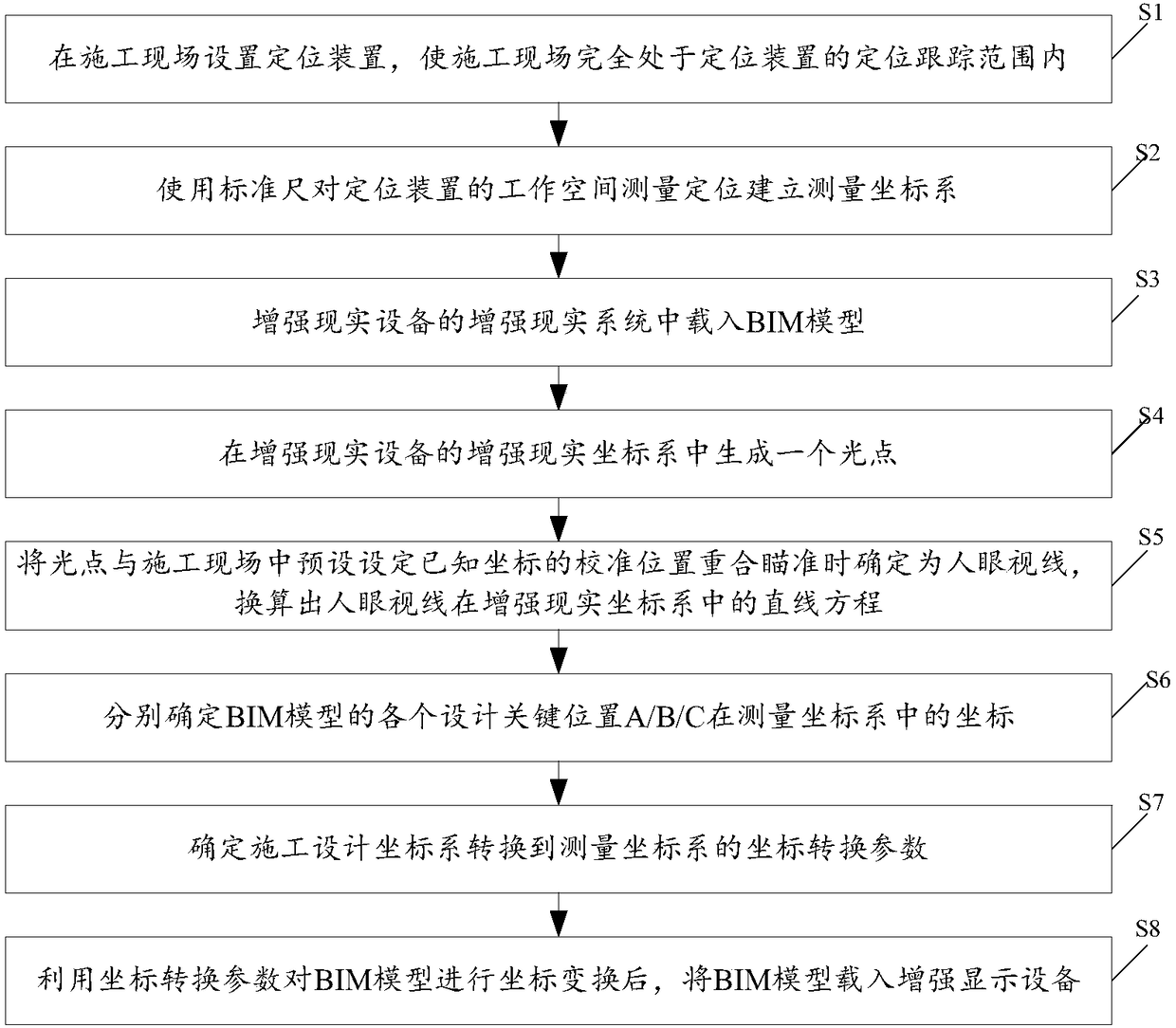

Augmented reality lofting system and implementation method based on BIM technology

ActiveCN108227929AEasy to superviseAvoid misunderstandingInput/output for user-computer interactionData processing applicationsTransformation parameterCritical position

The invention discloses an augmented reality lofting system and method based on a BIM technology. The method comprises the steps that a construction site is located in a positioning and tracking rangeof a positioning device, and a standard ruler is used for measuring and positioning the working space of the positioning device and establishing a measurement coordinate system; coordinates of key design positions A / B / C in the measurement coordinate system are determined respectively; coordinate transformation parameters of a construction design coordinate system which is converted to the measurement coordinate system are determined; the coordinate conversion parameters are utilized to conduct coordinate transformation on a BIM model, then the BIM model after subjected to coordinate transformation is loaded into augmented reality equipment, and when a user wears the augmented reality equipment on the head to observe the construction site, the BIM model is displayed in the construction site and all the key design positions of the BIM model overlap with all key construction positions of the construction site one to one respectively. By means of the method, the mapping relationship of the construction site and the BIM model can be accurately determined so that a BIM three-dimensional design result of a design unit can be accurately superimposed on the construction site by using an augmented reality technology.

Owner:廖卫东 +2

Process for manufacturing ship hatch cover of ten-thousand-tonnage container ship

ActiveCN102756790AIncrease productivityReduce energy consumptionWatercraft hull designVessel hatches/hatchwaysFillet weldIndustrial engineering

A process for manufacturing a ship hatch cover of a ten-thousand-tonnage container ship belongs to the shipbuilding field and comprises the following steps of: manufacturing an assembly jig; calibrating the levelness of the assembly jig before building and dividing the assembly jig rationally according to the product; lofting and blanking, detailing shrinkage allowance to each part of the hatch cover, and elaborately setting the shrinkage allowance; fabricating parts: dividing the hatch cover into three major assembly areas, requiring that all structures of the part areas are connected through flat fillet weld or butt weld; assembling the structure of the hatch cover, and then checking and meeting various accuracy requirements; mounting a container foot; performing tracking, supervision and measurement by using QC from container seat marking, before welding of the container seats and after welding of the container seats, repairing the unaccepted container seat immediately, and finally performing a container hoisting test to perfectly guarantee the accuracy of the container foot. With the abovementioned process research and improvement, the production efficiency can be improved to a large extent; and compared with the traditional building way, about 8% of energy can be saved for each set and the building period can be shorted by about three weeks.

Owner:浙江扬帆通用机械制造有限公司

Pavement construction lofting method for high-speed loop in skid pad

The invention discloses a pavement construction lofting method for a high-speed loop in a skid pad. The method is characterized by comprising the following steps of: arranging basic control network points on the inner side of a loop curve section subgrade to establish a basic control network; and fixing the height of an instrument in the lofting process, and performing planar and height lofting simultaneously, wherein the height of an intelligent total station instrument and the height of a reflecting prism are not required to be measured during planar lofting, a balance level is not required additionally during height lofting, automatic locking, and automatic aiming and three-dimensional coordinate synchronous lofting are realized by using a TCRP1201 intelligent total station instrument, so that the working efficiency of construction lofting for the high-speed loop in the skid pad can be greatly increased.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com